Oil field oil sludge drying treatment combined device and oil sludge drying treatment technique

A combined device and treatment process technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of immature treatment process, large arable land, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

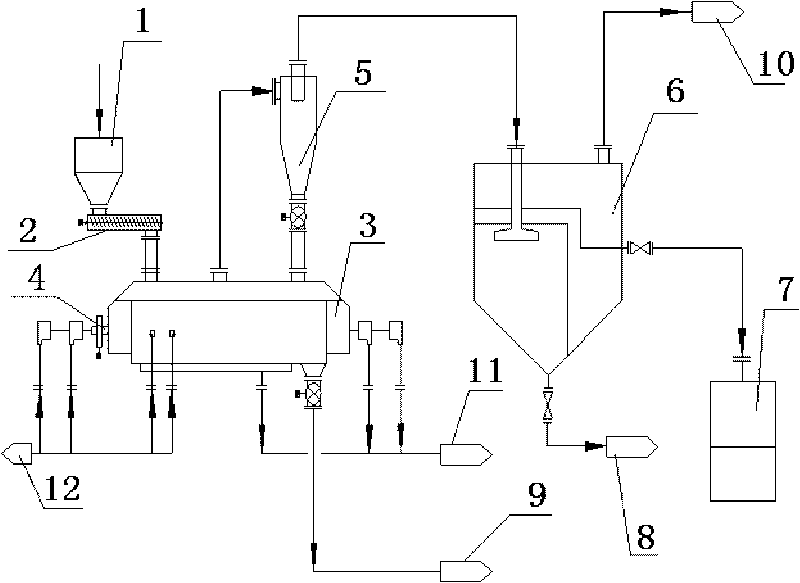

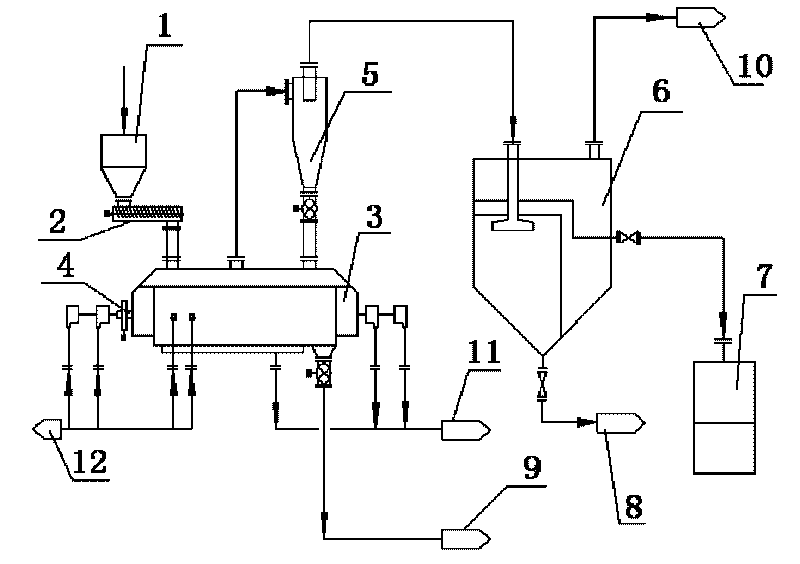

[0024] Such as figure 1 As shown, the oily sludge with a moisture content of about 80% is first added into the sludge hopper 1 from the oily sludge inlet, the lower end of the sludge hopper 1 is connected to the screw conveyor 2, and the sludge hopper 1 passes through the lower screw conveyor 2 continuously and evenly The wet sludge is sent into the paddle dryer 3 connected to the pipeline at the lower end of the screw conveyor 2. The hollow shaft of the paddle dryer 3 and the hollow blades on the shaft, and the honeycomb jacket 4 are connected with the high-temperature heating medium 12 (saturated steam or superheated steam, high-temperature heat-conducting oil or high-temperature waste heat flue gas, etc.), and the high-temperature heating medium 12 The hollow shaft and the hollow blade on the shaft, and the walls of the honeycomb jacket 4 are used to dry the sludge entering the paddle dryer 3, so as to evaporate the moisture in the oily sludge. With the rotation and agitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com