Air compressor oil and preparation method thereof

An air compressor oil and base oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of short oil life, air compressor failure, etc., achieve low sludge, avoid oil circuit blockage, and good thermal oxidation stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

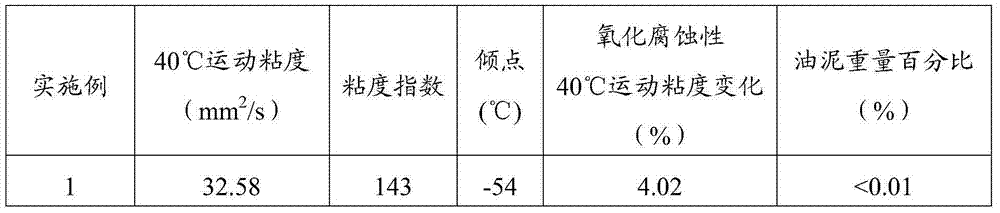

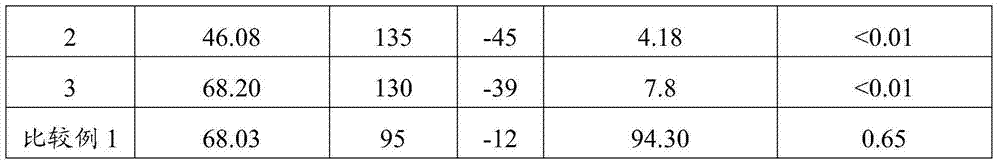

Examples

preparation example Construction

[0049] The invention provides a kind of preparation method of air compressor oil, comprising:

[0050] Mixing synthetic hydrocarbon base oil, synthetic ester base oil and functional additives to obtain air compressor oil, the mixing temperature is 60°C to 80°C; the functional additives include detergent and dispersant, anti-wear agent, metal deactivator, rust inhibitor, antioxidant, pour point depressant, anti-emulsifier and anti-foaming agent.

[0051] The air compressor oil prepared by the method provided by the invention has low sludge property. In addition, the air compressor oil prepared by the method provided by the invention also has better thermal oxidation stability, low-temperature fluidity, and higher viscosity index, which meets the use requirements of air compressors.

[0052] The present invention mixes synthetic hydrocarbon base oil, synthetic ester base oil and functional additives to obtain air compressor oil; preferably, functional additives are added to syn...

Embodiment 1

[0062] 64.87g of PAO 6 type base oil provided by ExxonMobil, 29g of PAO 8 type base oil provided by ExxonMobil, and 5g of fatty alcohol sebacic acid esters were heated to 120°C to remove moisture to obtain mixture;

[0063] The mixture is cooled to 60°C, and the T109 type detergent and dispersant provided by 0.2g of Lubrizol Land Refining Co., Ltd., the Irgalube232 type anti-wear agent provided by 0.25g of BASF (BASF) company, and 0.25g are added to the mixture. T306 type anti-wear agent provided by Zibo Huihua Company, 0.05g T551 metal deactivator provided by Lubrizol Orchid Refining Company, 0.05g T746 type antirust agent provided by Dalian Guanghui Chemical Co., Ltd., 0.15g The T531 type antioxidant provided by Tianjin Kemai Chemical Co., Ltd. of g, the T501 type antioxidant provided by Shanghai Huayuan Co., Ltd. of 0.15 g, the T1001 type anti-emulsifier provided by Danyang Tianyu Petroleum Additive Factory of 0.02 g and 0.01 g of T921 antifoaming agent provided by Shangha...

Embodiment 2

[0066] Heat 52.72g of PAO 8 type base oil provided by INEOS, 30g of Korean Ssangyong No. 8 hydrogenated base oil, and 15g of fatty alcohol phthalate to 120°C to remove water to obtain a mixture;

[0067] The mixture was cooled to 80° C., and 0.5 g of LZL156 detergent and dispersant provided by Lubrizol Land Refining Co., Ltd., 0.5 g of T362 antiwear agent provided by Qingdao Libao Oil Additive Co., Ltd. were added to the mixture. 0.5g of T323 anti-wear agent provided by Changsha Wangcheng Petrochemical Company, 0.05g of T561 metal deactivator provided by Changsha Wangcheng Petrochemical Company, 0.1g of POUPC3001 antirust agent provided by Pacific United Beijing Petrochemical Co., Ltd. , 0.5g of T508 type antioxidant provided by Liaoning Fine Chemical Co., Ltd., 0.1g of LZL803B type pour point depressant provided by Lubrizol Land Refining Co., Ltd., 0.02g of T1001 type anti-emulsification agent provided by Danyang Tianyu Petroleum Additive Factory The T921 type antifoam agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com