Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

582results about How to "High viscosity index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

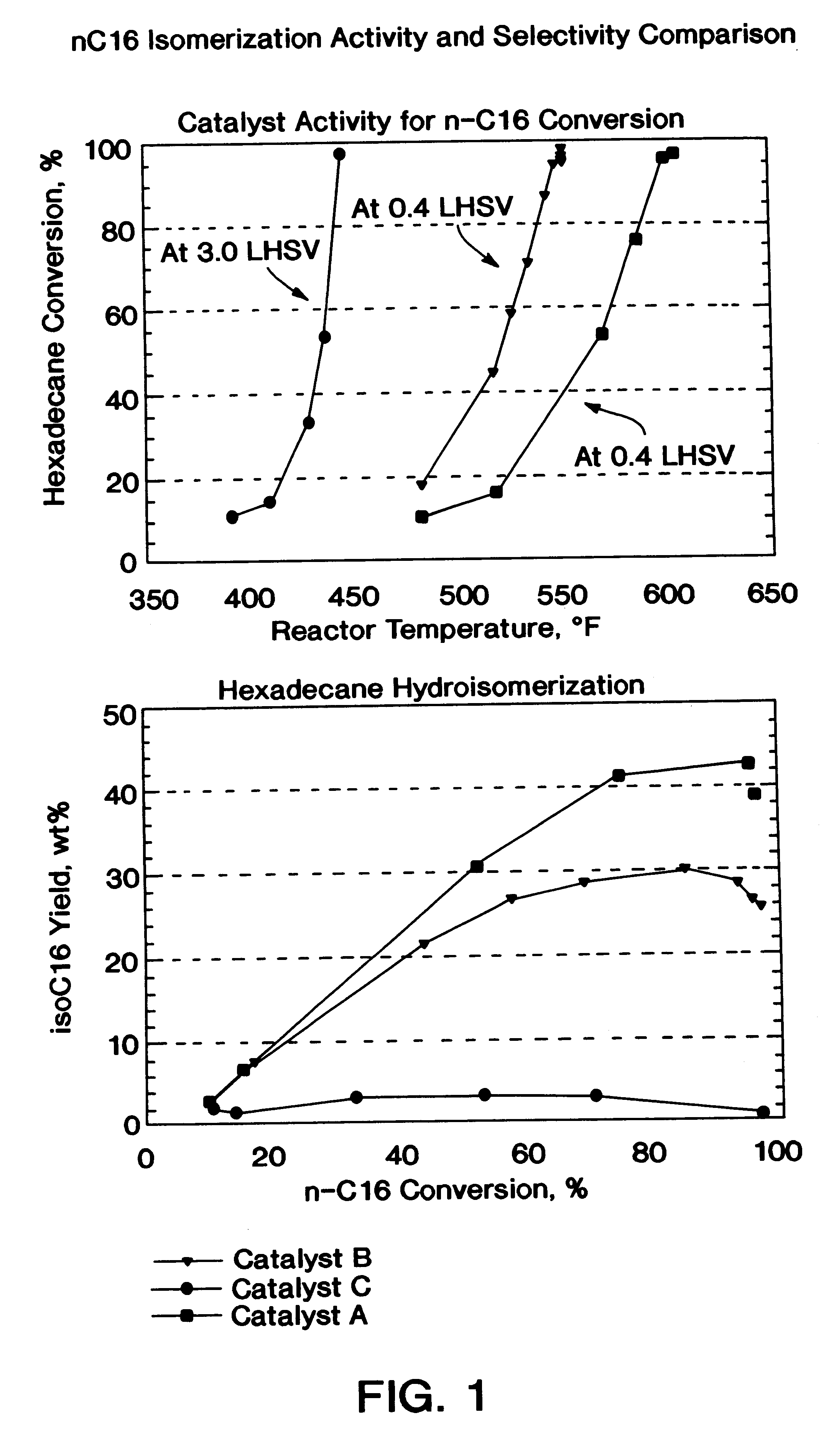

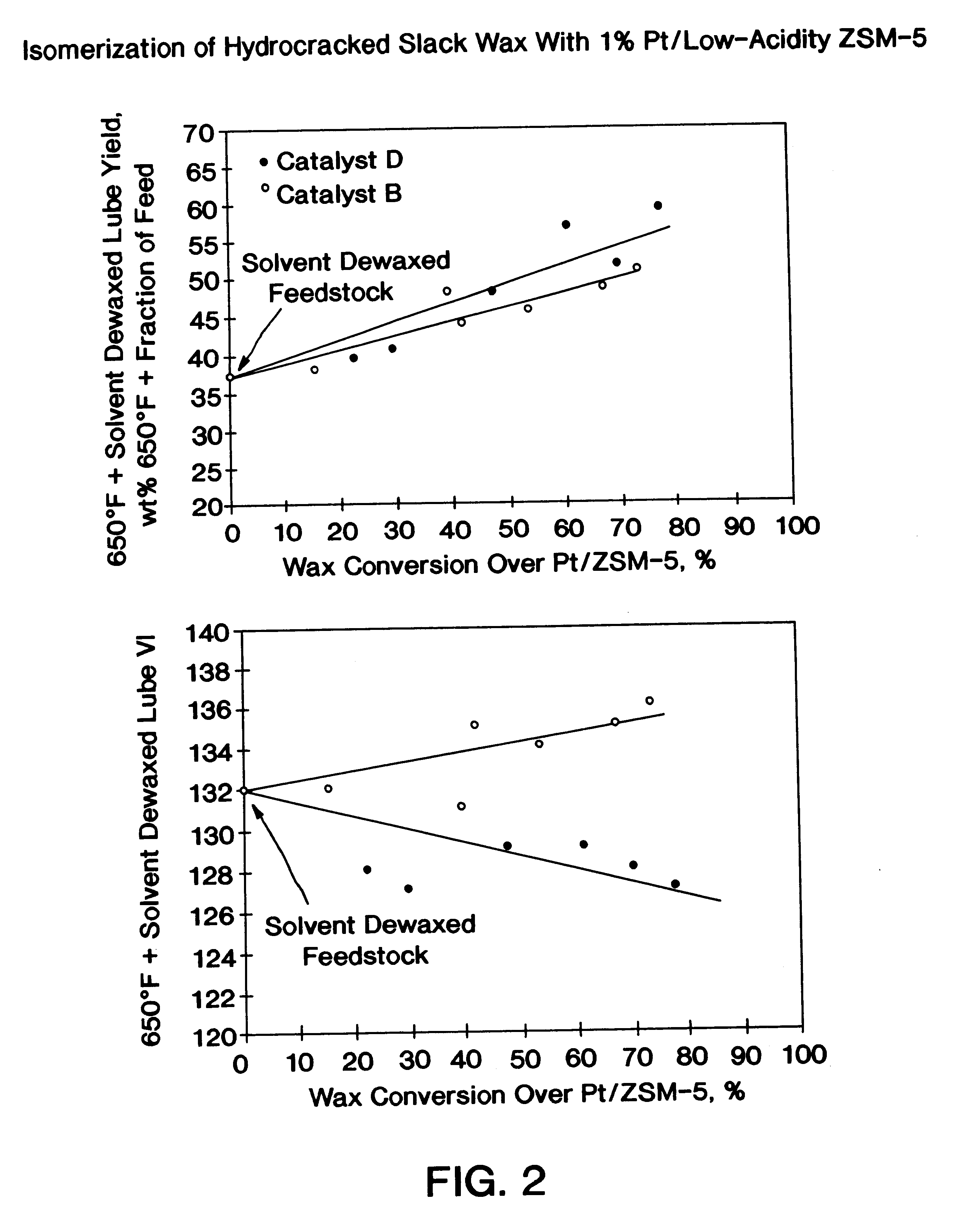

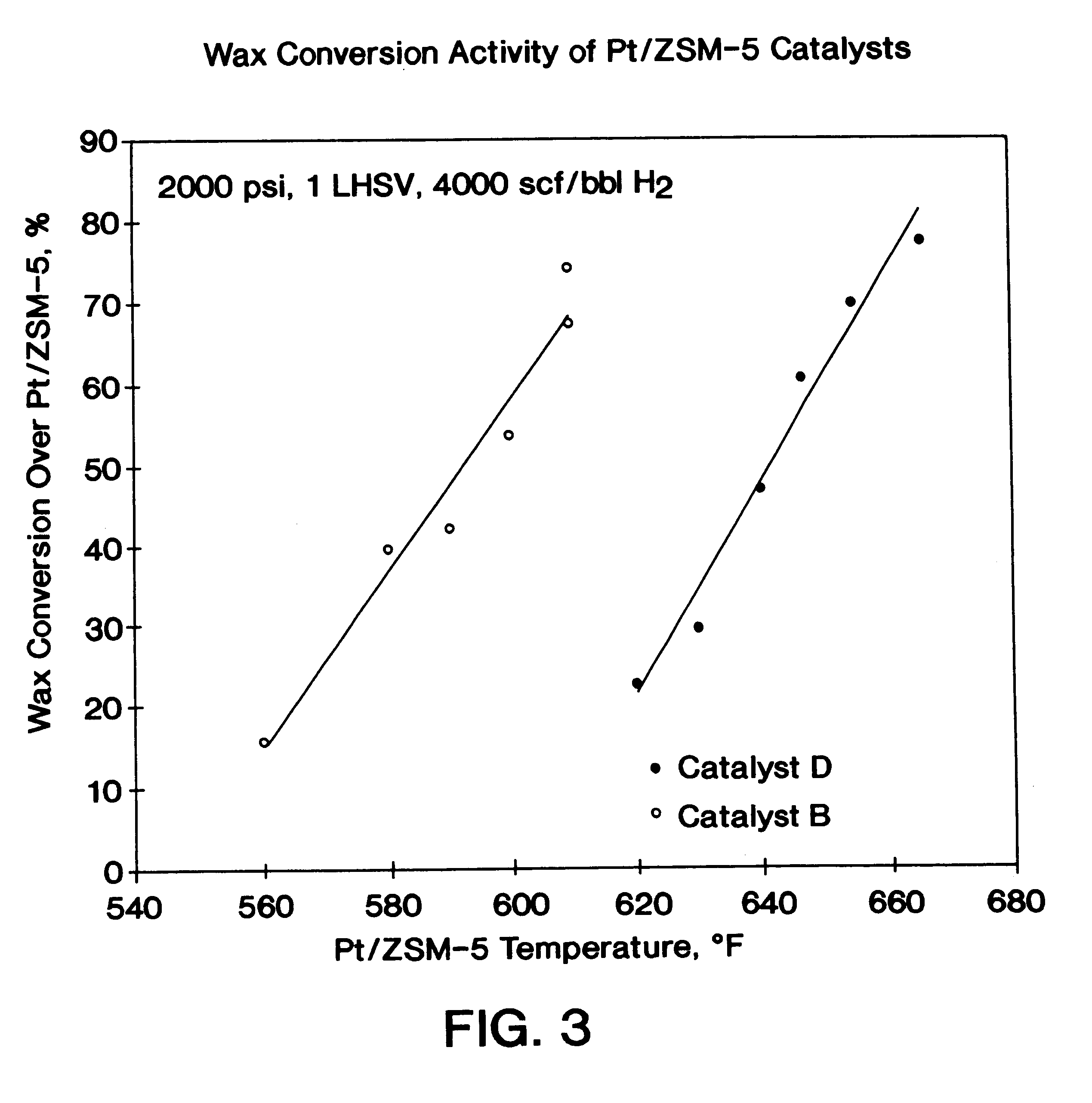

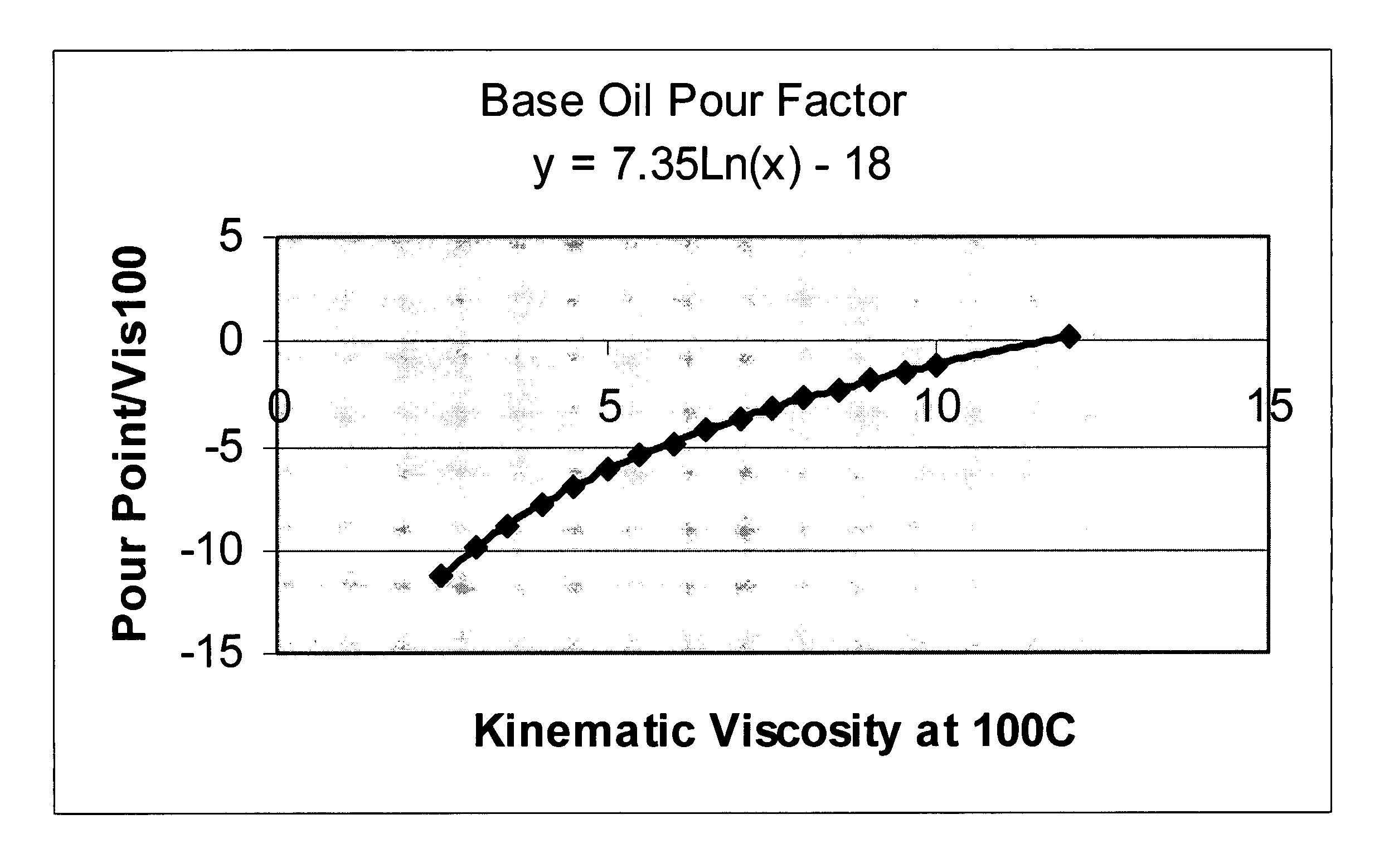

Production of high viscosity lubricating oil stock with improved ZSM-5 catalyst

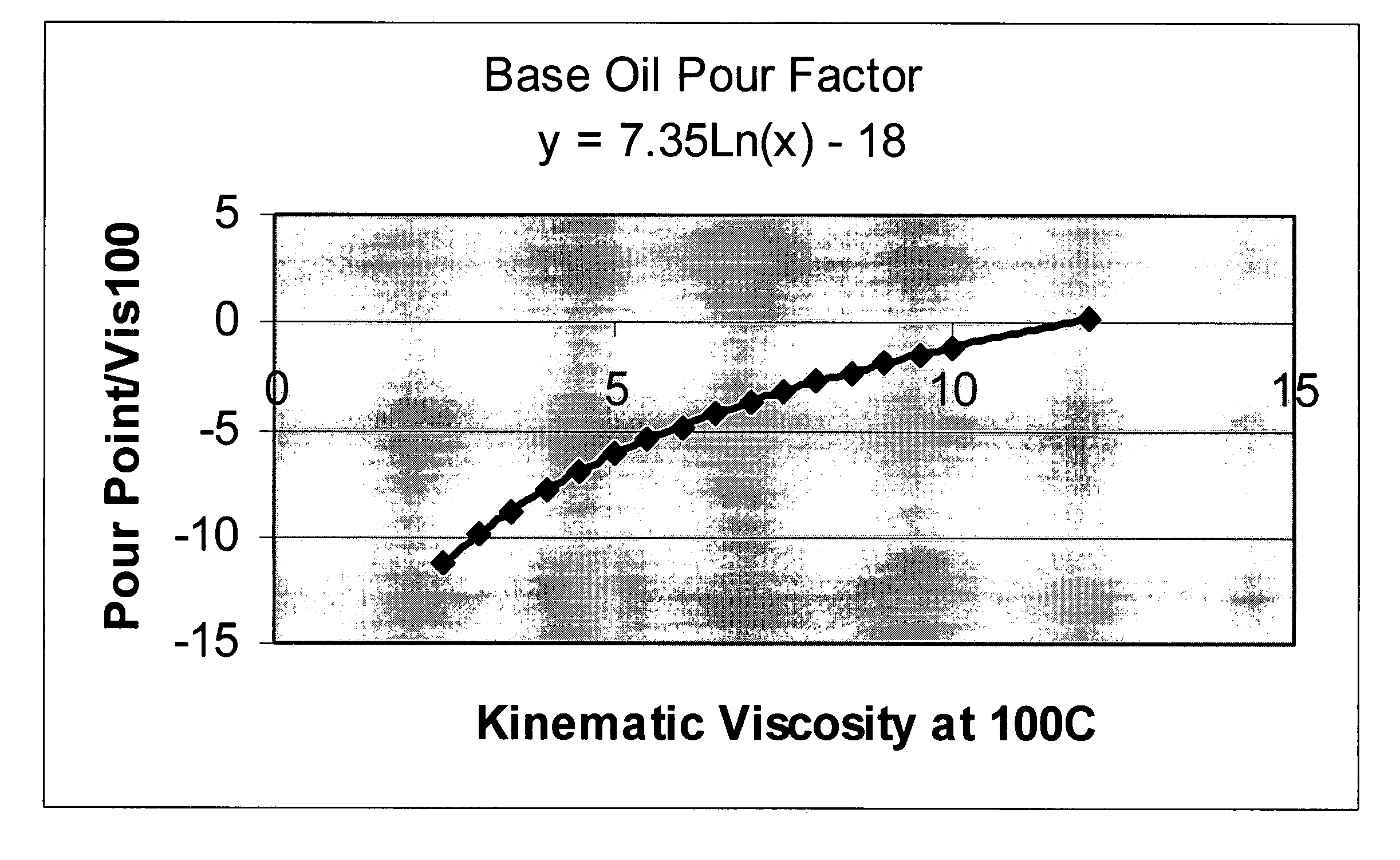

InactiveUS6294077B1Low pour pointHigh viscosity indexMolecular sieve catalystsRefining to change hydrocarbon structural skeletonHydrogenParaffin oils

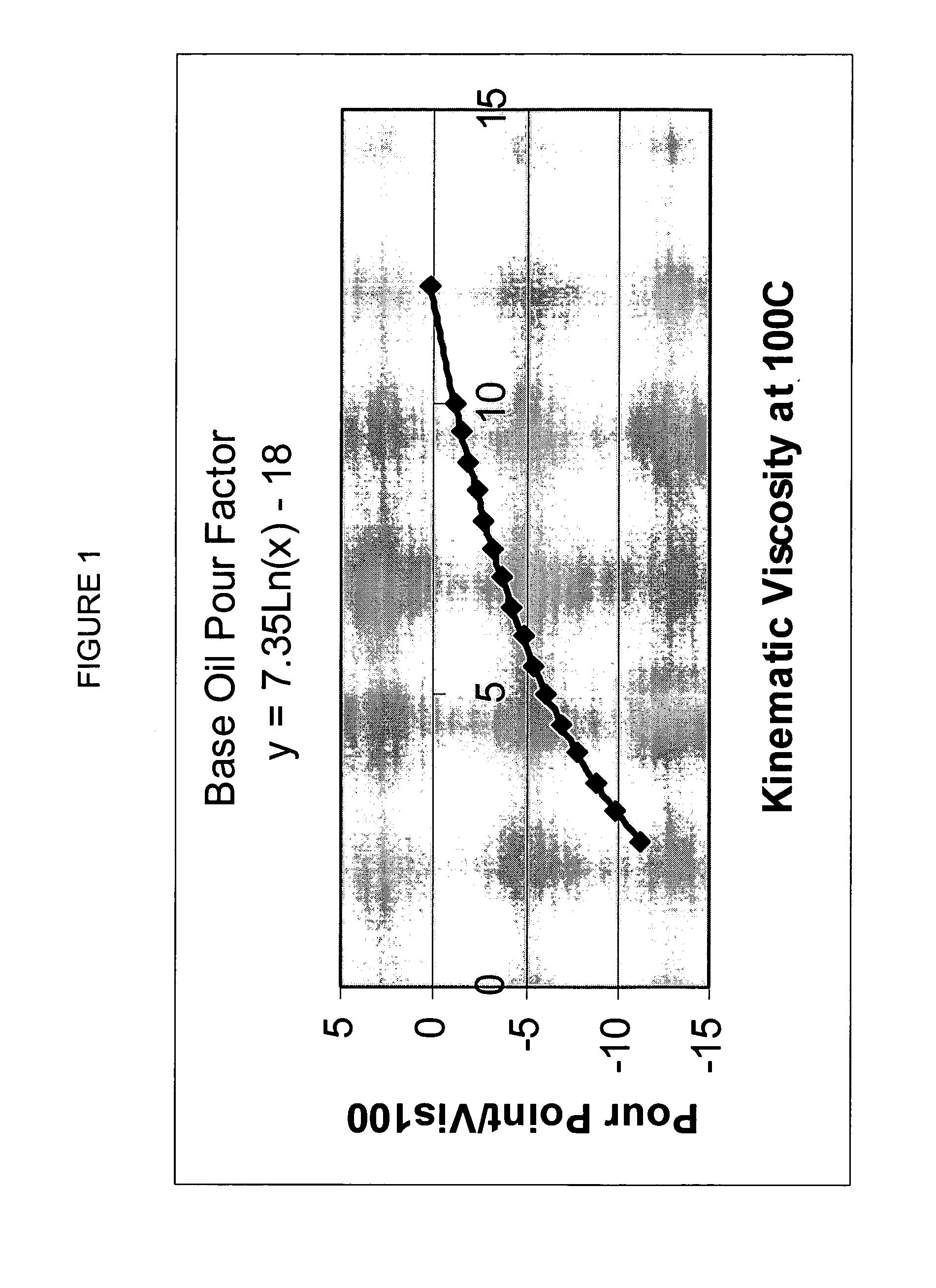

The present invention is a process for producing a high viscosity index and low pour point lubricating oil base stock which comprises catalytically converting a hydrotreated hydrocarbon lube oil feedstock containing waxy paraffins in the presence of hydrogen and in the presence of a low acidity ZSM-5 catalyst having a highly dispersed noble metal component. The ZSM-5 catalyst is subjected to controlled acidity reduction to an alpha value below 15 prior to incorporation of the noble metal component.

Owner:MOBIL OIL CORP

Composition of lubricating base oil with high monocycloparaffins and low multicycloparaffins

ActiveUS7083713B2Improve Oxidation StabilityHigh viscosity indexRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationCycloparaffinsBase oil

A composition of lubricating base oil having a weight percent of all molecules with at least one aromatic function less than 0.30, a weight percent of all molecules with at least one cycloparaffin function greater than 10, and a ratio of weight percent of molecules with monocycloparaffins to weight percent of molecules with multicycloparaffins greater than 15.

Owner:CHEVROU USA INC

Composition of lubricating base oil with high monocycloparaffins and low multicycloparaffins

ActiveUS20050133408A1Improve Oxidation StabilityHigh viscosity indexHydrocarbon purification/separationLiquid hydrocarbon mixture productionCycloparaffinsBase oil

A composition of lubricating base oil having a weight percent of all molecules with at least one aromatic function less than 0.30, a weight percent of all molecules with at least one cycloparaffin function greater than 10, and a ratio of weight percent of molecules with monocycloparaffins to weight percent of molecules with multicycloparaffins greater than 15.

Owner:CHEVROU USA INC

Food-grade-lubricant

InactiveUS20040241309A1Increase varietyExtend compassBase-materialsFood preparationGeneral purposePolyolefin

The present invention discloses an improved food-grade-lubricant useful as hydraulic oil, circulating oil, drip oil, general purpose oil, grease base oil, cable oil, chain oil, spindle oil, gear oil, and compressor oil for equipment in the food service industry. The lubricant comprises at least one vegetable oil, at least one polyalphaolefin, and at least one antioxidant. The lubricant has improved properties when subjected to thermal and mechanical stress.

Owner:RENEWABLE LUBRICANTS INC

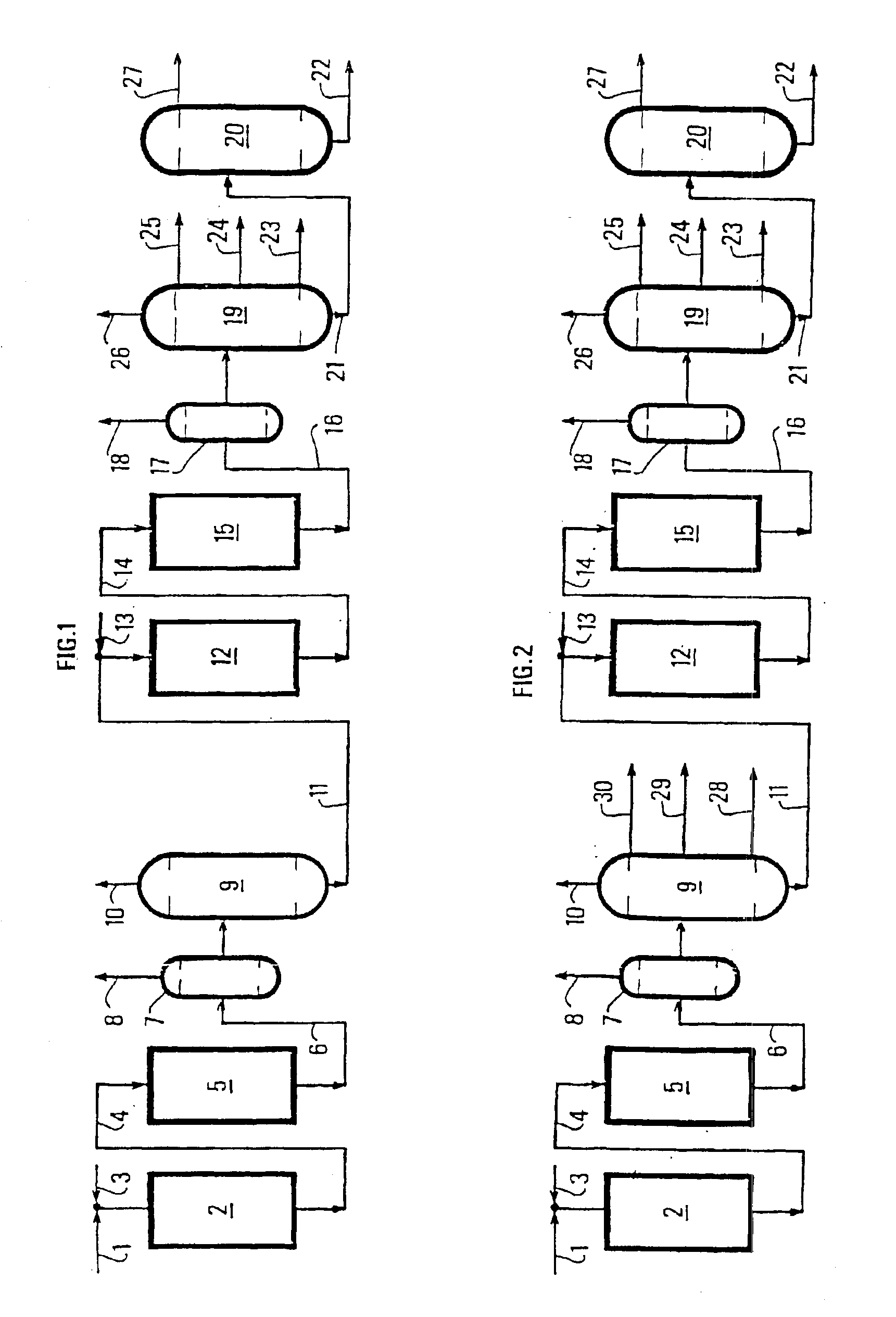

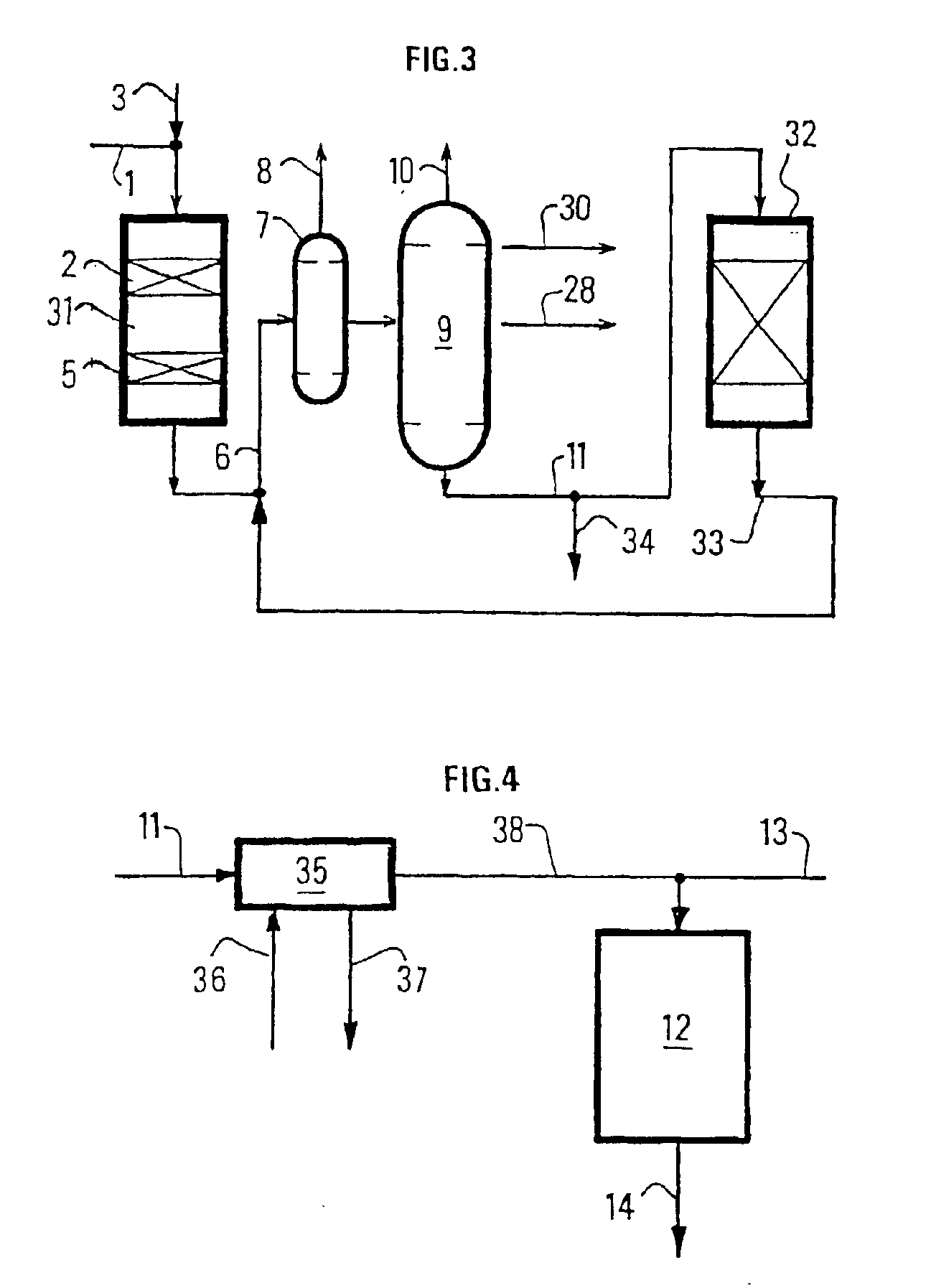

Hydro-isomerization catalyst for paraffine, and its preparing method and application

InactiveCN1792451ASuitable for acidityHigh yieldHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveAlkane

A catalyst for the hydroisomerizing reaction of paraffin is composed of the active component (0.05-5.0 Wt%) chosen from Pt, Pd and Ir, and the composite molecular sieve ZSM-22 / ZSM-23 (or ZSM-23 / ZSM-22). It has high catalytic activity and selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Flexible method for producing oil bases with a ZSM-48 zeolite

InactiveUS6884339B2Reduce contentImproves UV stabilityTreatment with plural serial cracking stages onlyCoke ovensBase oilAzeotropic distillation

A process for the production of very high quality base oils optionally with simultaneous production of high quality middle distillates comprises the stages for hydrotreatment, preferably hydrocracking, on Y or beta zeolite, and atmospheric distillation. The effluent is subjected to a catalytic dewaxing on the ZSM-48 catalyst. The process then comprises a hydrofinishing stage for hydrogenating the aromatic compounds, preferably on a catalyst that comprises at least one noble metal of group VIII, chlorine and fluorine, and the stages of atmospheric and vacuum distillation. The hydrofinishing stage is conducted at a temperature lower by 20-200° C. than the catalytic dewaxing stage.

Owner:INST FR DU PETROLE

Invert emulsion based completion and displacement fluid and method of use

InactiveUS20060223714A1Easy to placeHigh viscosity indexFluid removalFlushingOrganic acidOrganic solvent

A method of cleaning a wellbore prior to the production of oil or gas, wherein the wellbore has been drilled with an invert emulsion drilling mud that forms an invert emulsion filter cake is disclosed. The method may include circulating a breaker fluid into the wellbore, where the breaker fluid includes a non-oleaginous internal phase and an oleaginous external phase, where the non-oleaginous phase includes a water soluble polar organic solvent, a hydrolysable ester of a carboxylic acid, and a weighting agent, and the oleaginous external phase includes an oleaginous fluid and an emulsifier, and where the hydrolysable ester is selected so that upon hydrolysis an organic acid is released and the invert emulsion of the filter cake breaks.

Owner:MI

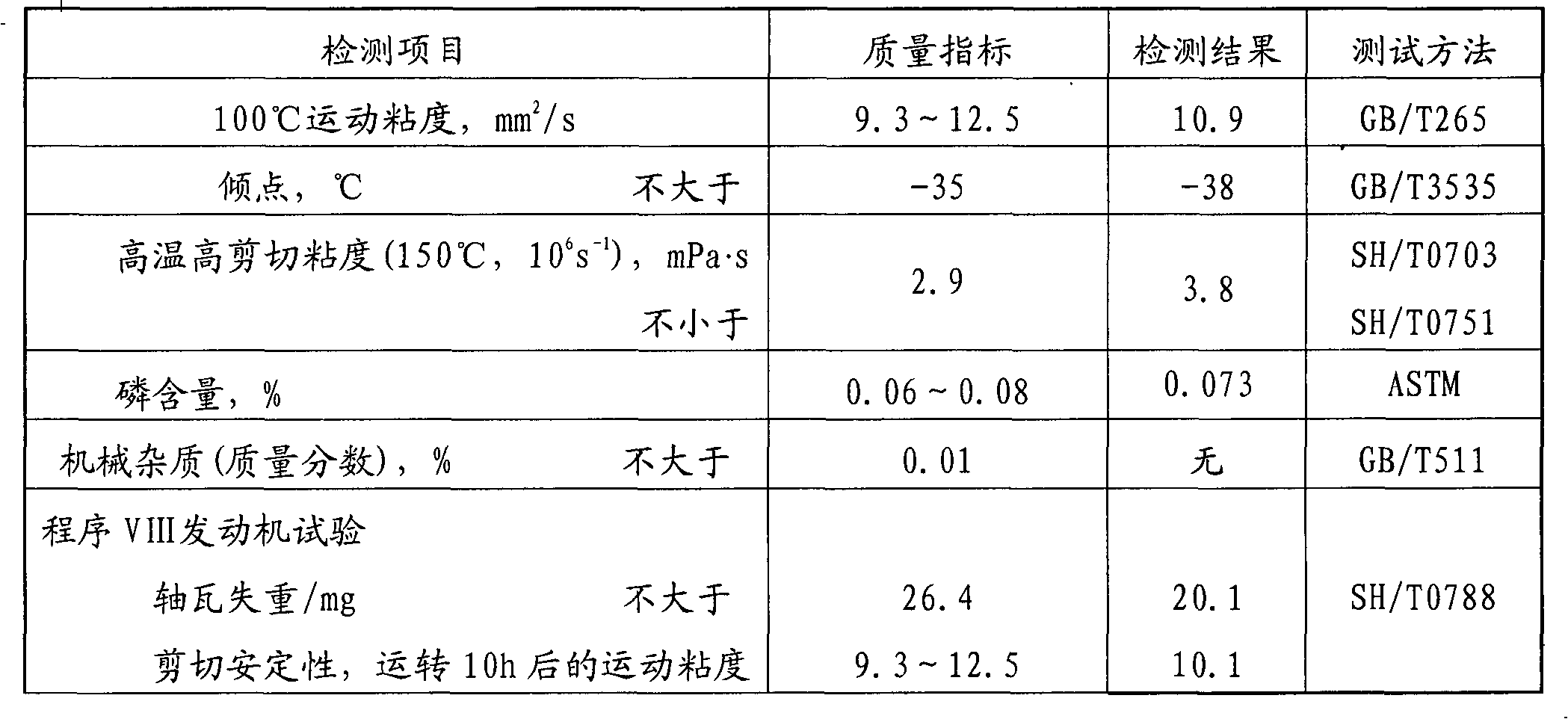

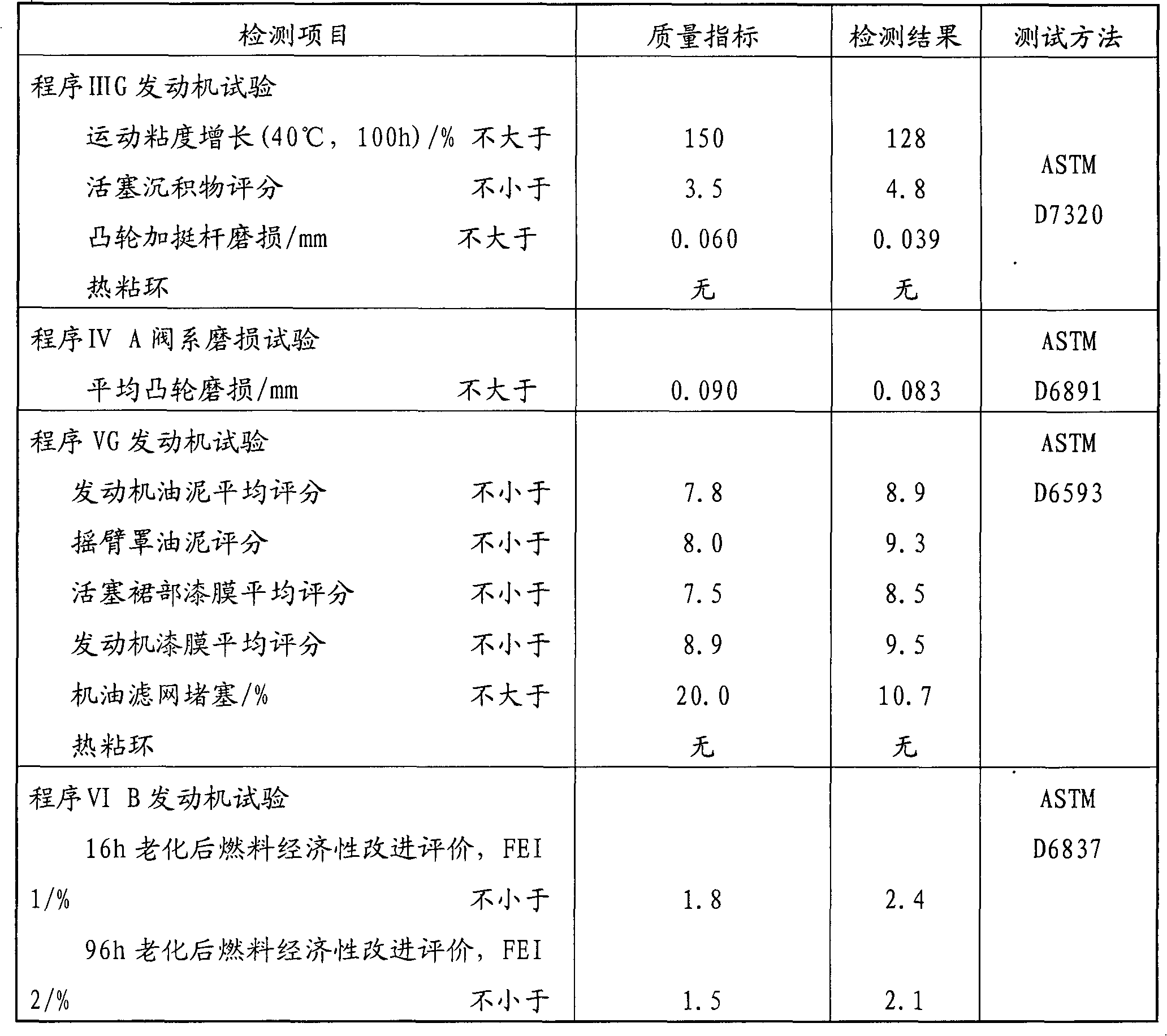

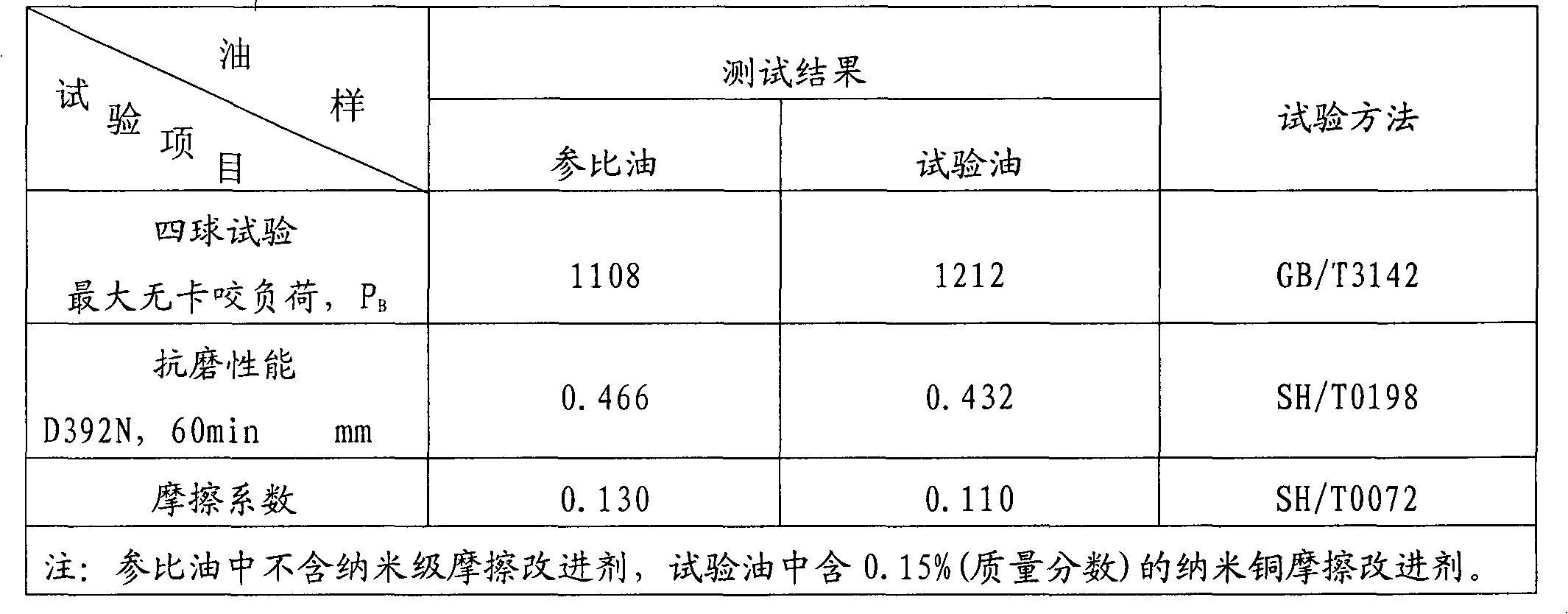

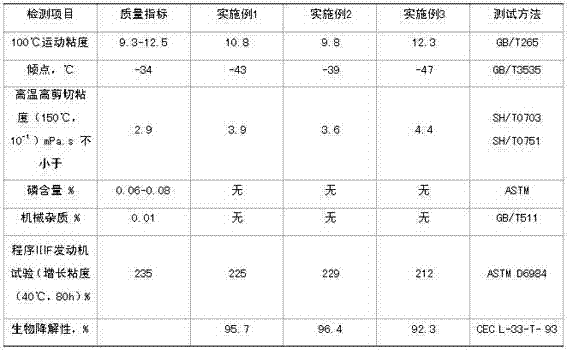

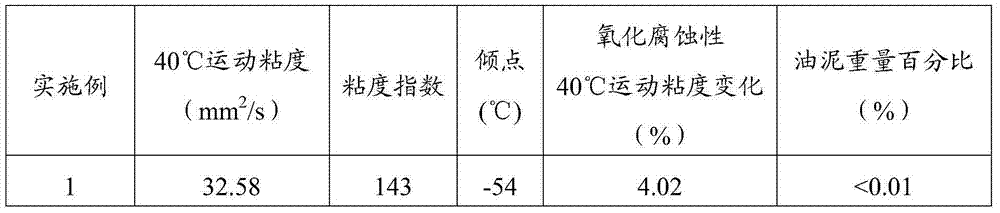

Energy-efficient long-life gasoline engine oil

InactiveCN101982534AReduce sulfur and phosphorus contentImprove carrying capacityLubricant compositionEcological environmentOil sludge

The invention discloses energy-efficient long-life gasoline engine oil prepared from the following components: synthetic base oil, a composite antioxygen, a metal cleaning agent, an ashless dispersant, a nano-level friction improver, a viscosity improver and a pour point reducer. The gasoline engine oil provided by the invention has the following advantages: requirements of API SM, ILSAC GF-4 and SAEJ300 are met and the service life is long; the complete synthetic base oil features low pour point, high viscosity index, good economy of fuel, degradability and reduced harm to the ecological environment; the phenol type antioxygen is combined with ZDDP, the anti-oxygen and antifriction properties are good and the catalyst poisoning in a tail gas processing unit is prevented; the acid neutralization capacity is good, the cleaning dispersibility is good and the oil sludge and carbon deposit are prevented from being generated; and the nano-level friction improver is added, the frictional factor is low, and the oil film features high carrying capacity and can automatically repair abraded surface and lengthen the service life of the engine.

Owner:GUANGDONG SANVO CHEM IND TECH

Water based completion and displacement fluid and method of use

ActiveUS20060223715A1Easy to placeHigh viscosity indexCleaning apparatusFluid removalWater basedOrganic acid

A method of cleaning a wellbore prior to the production of oil or gas is disclosed, wherein the wellbore has been drilled with an invert emulsion drilling mud that forms an invert emulsion filter cake. The method may include the steps of circulating a breaker fluid into the wellbore, where the breaker fluid includes an aqueous fluid, a water soluble polar organic solvent, a hydrolysable ester of a carboxylic acid, and a weighting age, and where the hydrolysable ester is selected so that upon hydrolysis an organic acid is released and the invert emulsion of the filter cake breaks.

Owner:MI

Finished lubricating comprising lubricating base oil with high monocycloparaffins and low multicycloparaffins

InactiveUS7195706B2Improve Oxidation StabilityReduce wearRefining to change hydrocarbon structural skeletonLiquid hydrocarbon mixture productionAlkaneSyngas

A process for manufacturing a finished lubricant by: a) performing Fischer-Tropsch synthesis on syngas to provide a product stream; b) isolating from said product stream a substantially paraffinic wax feed having less than about 30 ppm total nitrogen and sulfur, and less than about 1 wt % oxygen; c) dewaxing said feed by hydroisomerization dewaxing using a shape selective intermediate pore size molecular sieve comprising a noble metal hydrogenation component, wherein the hydroisomerization temperature is between about 600° F. (315° C.) and about 750° F. (399° C.), to produce an isomerized oil; and d) hydrofinishing said isomerized oil, whereby a lubricating base oil is produced having specific desired properties; and e) blending the lubricating base oil with at least one lubricant additive.

Owner:CHEVROU USA INC

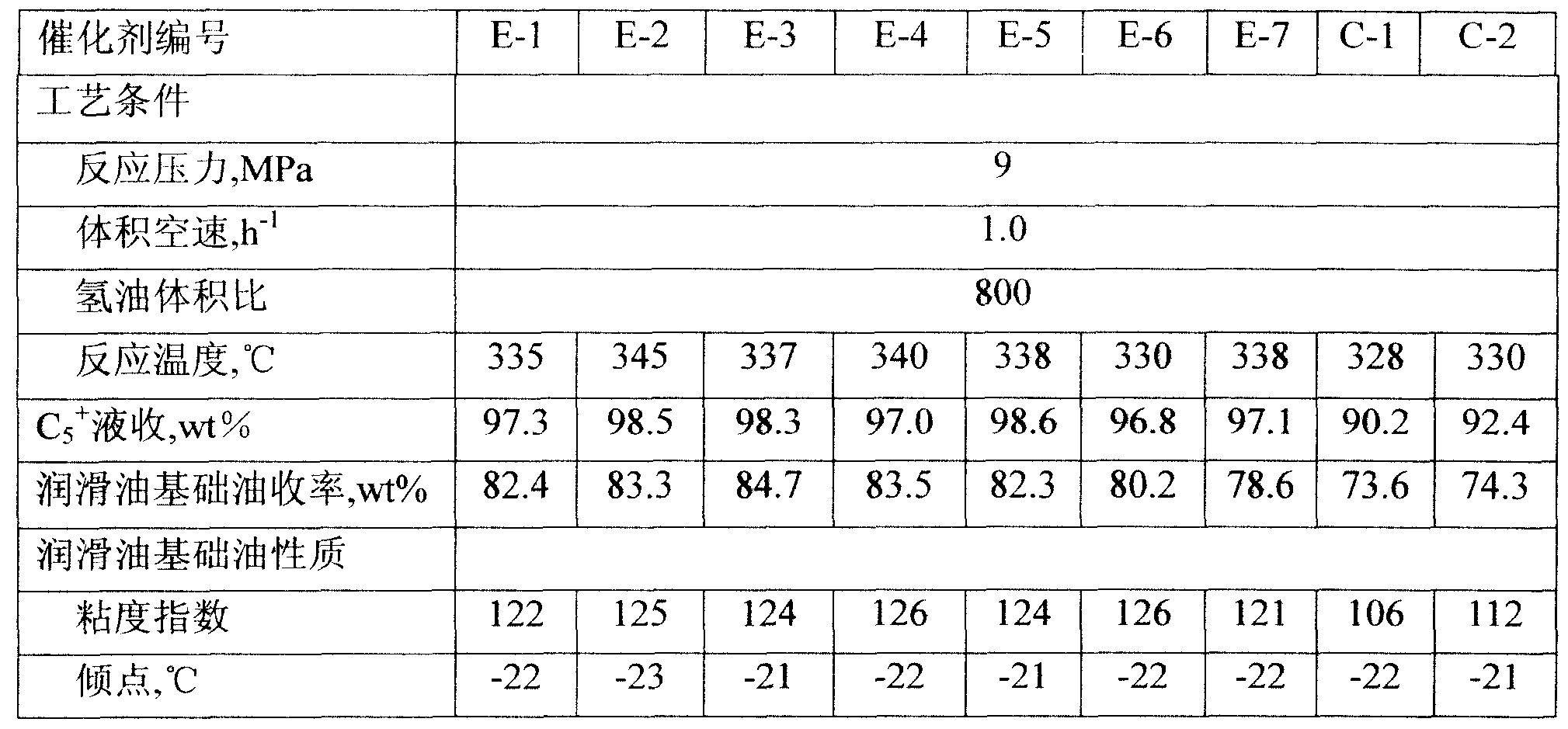

Preparation method of lube base oil

ActiveCN107286978AHigh yieldHigh viscosity indexMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveViscosity index

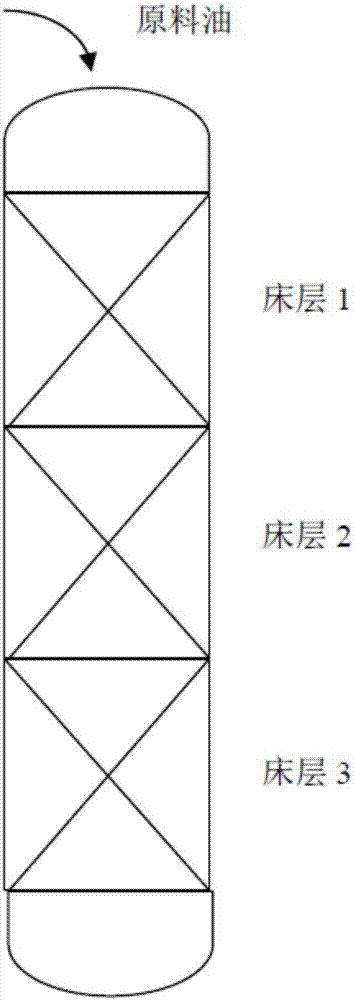

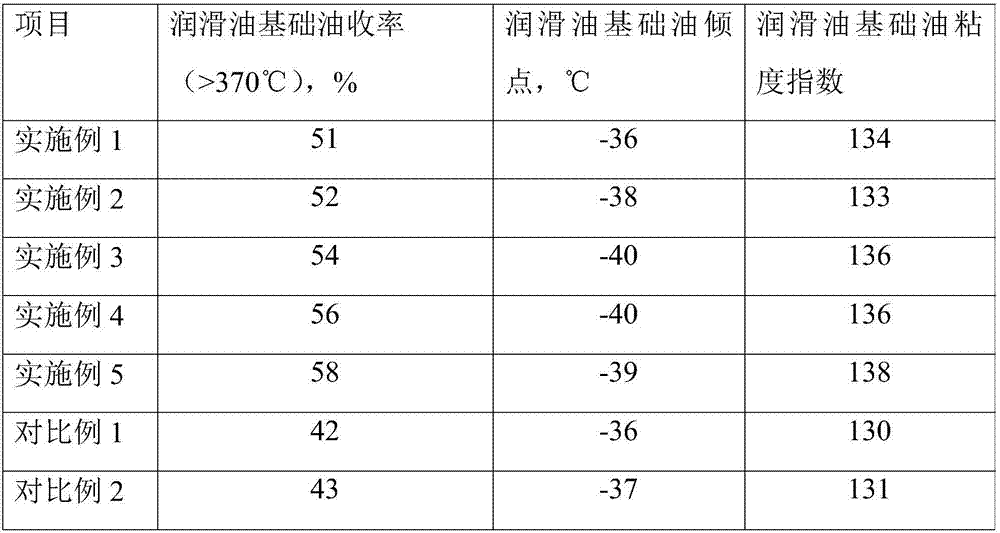

The invention discloses a preparation method of lube base oil. The preparation method comprises the following steps: enabling raw material oil to be in contact with at least two isomerization catalysts respectively comprising a molecular sieve and VIII family noble metal in a reactor and performing hydroisomerization reaction to obtain the lube base oil; according to the flowing direction of the raw material oil, the at least two isomerization catalysts in the reactor are set as that the diameter of the isomerization catalyst positioned at the downstream is greater than that of the isomerization catalyst positioned at the upstream. The preparation method disclosed by the invention is adopted for preparing the lube base oil, so that the yield of the lube base oil can be improved; meanwhile, the pour point of the lube base oil is reduced, and the viscosity index of the lube base oil is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly and energy-saving gasoline engine oil and preparation method thereof

The invention discloses environment-friendly and energy-saving gasoline engine oil and a preparation method thereof. The environment-friendly and energy-saving gasoline engine oil is prepared from the following raw materials in parts by weight: 70-85 parts of environment-friendly base oil, 0.8-3.0 parts of a complex antioxidant, 3.7-6.7 parts of a metal detergent, 5.8-7.8 parts of an ashless dispersant, 0.7-1.5 parts of a nanoscale friction modifier, 4.0-10.0 parts of a viscosity index improver and 0.2-1.0 part of a pour-point depressant. The preparation method comprises the following steps: feeding the environment-friendly base oil to an adjustable dehydrator; sequentially feeding the pour-point depressant, the viscosity index improver, the complex antioxidant, the metal detergent and the ashless dispersant when stirring at 58-65 DEG C, and stirring evenly; and feeding the nanoscale friction modifier, keeping at 58-65 DEG C, further stirring for 1.5 hours, and standing for 0.5 hour, so as to obtain the environment-friendly and energy-saving gasoline engine oil which meets the API SN / GF-5 requirements and is long in service life.

Owner:SHANGHAI INST OF TECH +1

Air compressor oil and preparation method thereof

InactiveCN104263481AGuaranteed safe operationAvoid cloggingLubricant compositionGas compressorAntioxidant

The invention provides air compressor oil which comprises the following components in parts by weight: 75-94 parts of synthetic hydrocarbon base oil, 5-20 parts of synthetic ester base oil and 1-5 parts of functional additive, wherein the functional additive comprises a purification dispersant, an antiwear agent, a metal deactivator, an antirust agent, an antioxidant, a pour point depressant, a demulsifying agent and an anti-foaming agent. The invention provides a preparation method of the air compressor oil. The preparation method comprises the step of mixing the synthetic hydrocarbon base oil, the synthetic ester base oil and the functional additive at the temperature of 60-80DEG C to obtain the air compressor oil. According to the air compressor oil provided by the invention, the synthetic oil is used as the base oil and the compound type functional additive is added, so that the air compressor oil provided by the invention has low oil sludge property. In addition, the air compressor oil provided by the invention also has the advantages of better thermal oxidation stability, low-temperature fluidity and higher viscosity index, and the use requirement of an air compressor is met.

Owner:CHINA PETROLEUM & CHEM CORP

Process for the preparation of high activity carbon monoxide hydrogenation catalysts; the catalyst compositions, use of the catalysts for conducting such reactions, and the products of such reactions

InactiveUS20020028745A1High viscosity indexReduce pointsHydrocarbon from carbon oxidesOrganic compound preparationMagnesium saltHigh activity

A process for the preparation of a catalyst useful for conducting carbon monoxide hydrogenation reactions, particularly Fischer-Tropsch reactions; the catalyst compositions, use of the catalyst compositions for conducting such reactions, and the products of these reactions. The steps of the process for producing the catalyst comprise mixing together in solution (a) a compound, or salt of a Group VIII metal, e.g., Co(NO3)2; (b) a compound, or salt of magnesium, e.g., Mg(NO3)2; (c) a compound, salt, or powdered oxide of a Group IVB metal, e.g., zirconia; (d) a refractory inorganic oxide, e.g., kieselguhr; and (e) an ammonium or alkali metal salt precipitating agent, e.g., Na2CO3, to produce a precipitated solids mass, or catalyst precursor, and then reducing the precipitated solids mass, or catalyst precursor, to form a catalyst, e.g., (100 Co:6 MgO:10 ZrO2:200 kieselguhr). The precipitated solids mass, or catalyst precursor, is shaped and brought to a critical level of moisture, and reduced. A catalyst formed from the precursor in this manner has greater activity, and selectivity in the production of high melting waxes in conducting Fischer-Tropsch reactions, and gas make is lower, than in the use of catalysts made conventionally, i.e., from precursors of similar composition at differing moisture levels.

Owner:EXXON RES & ENG CO

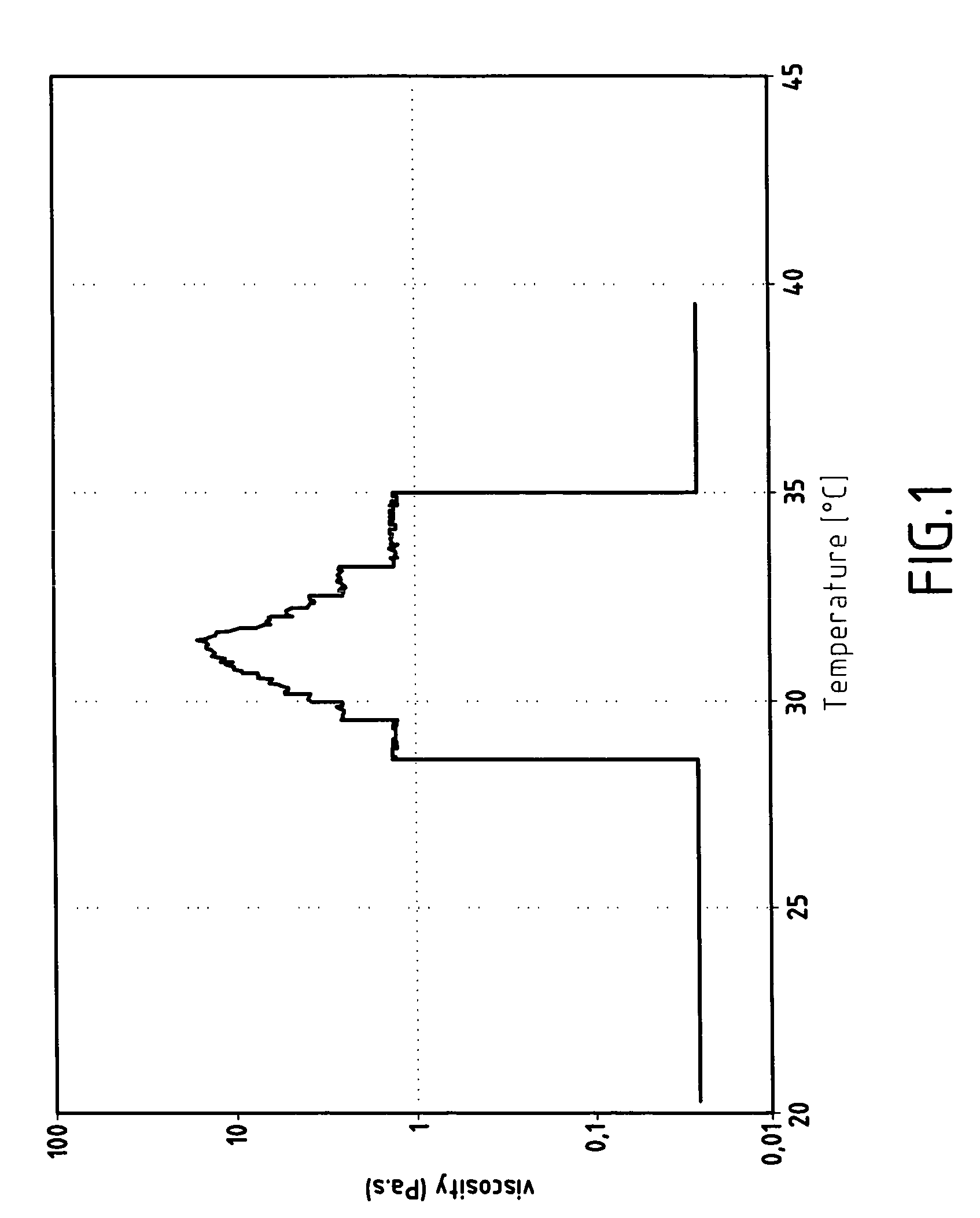

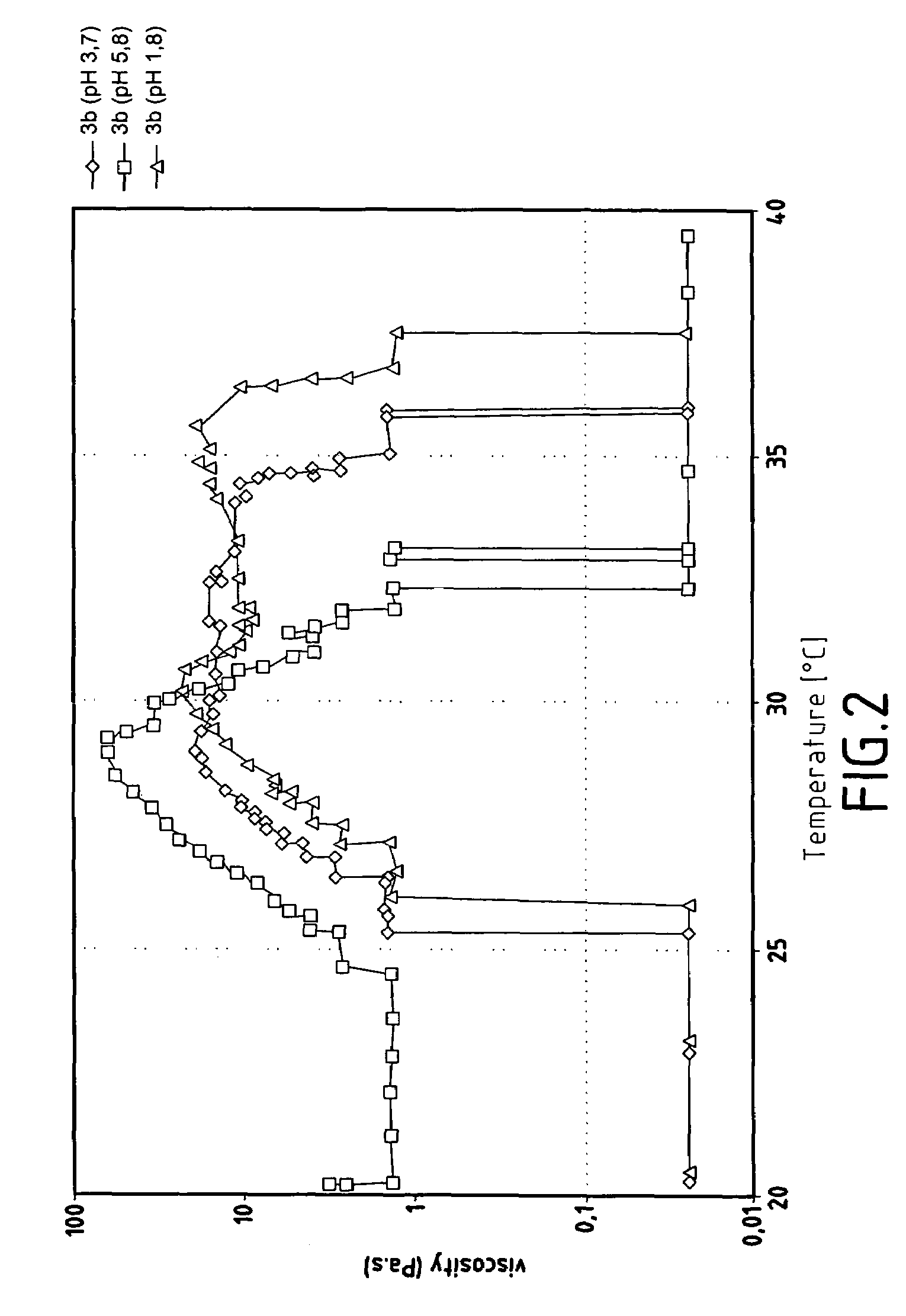

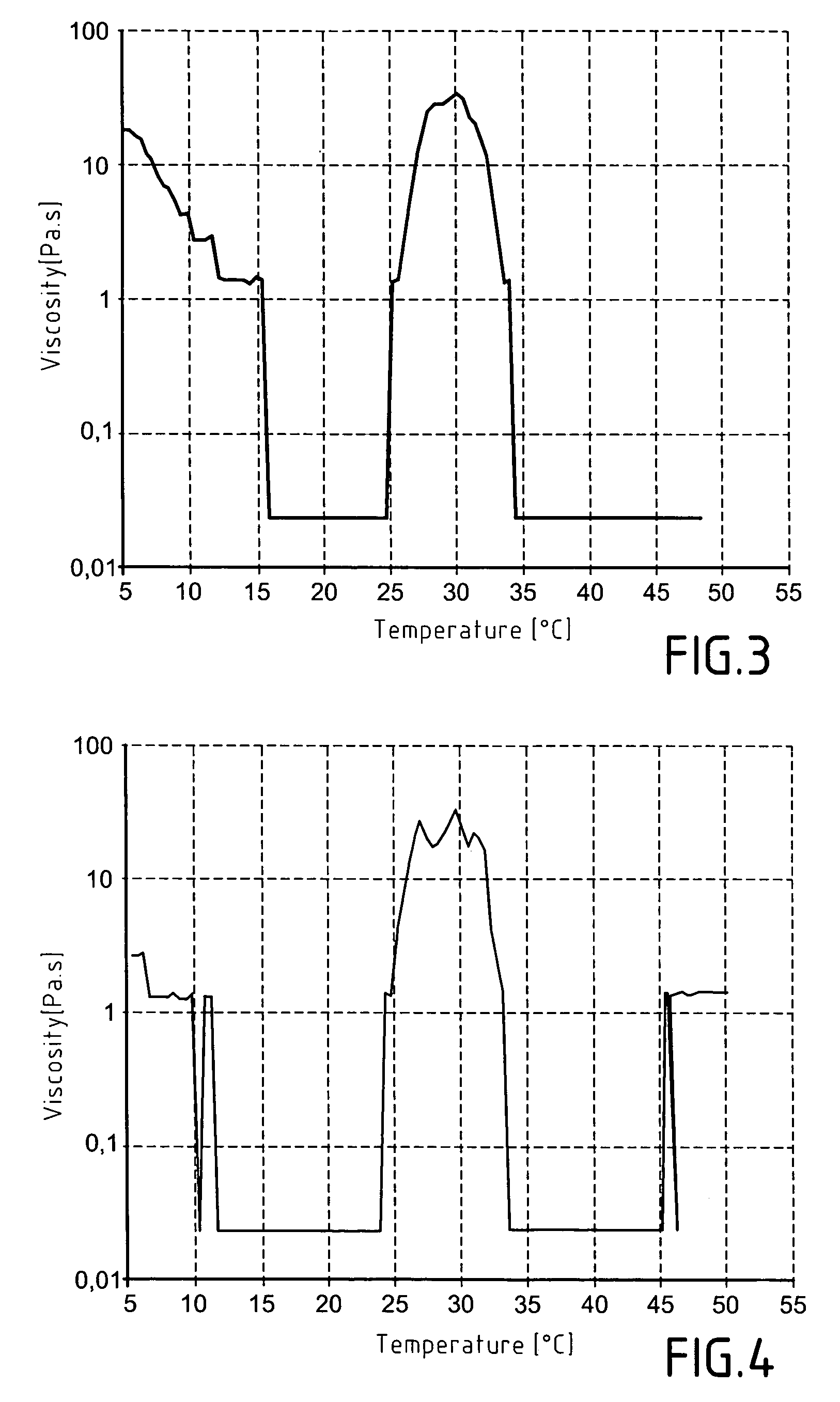

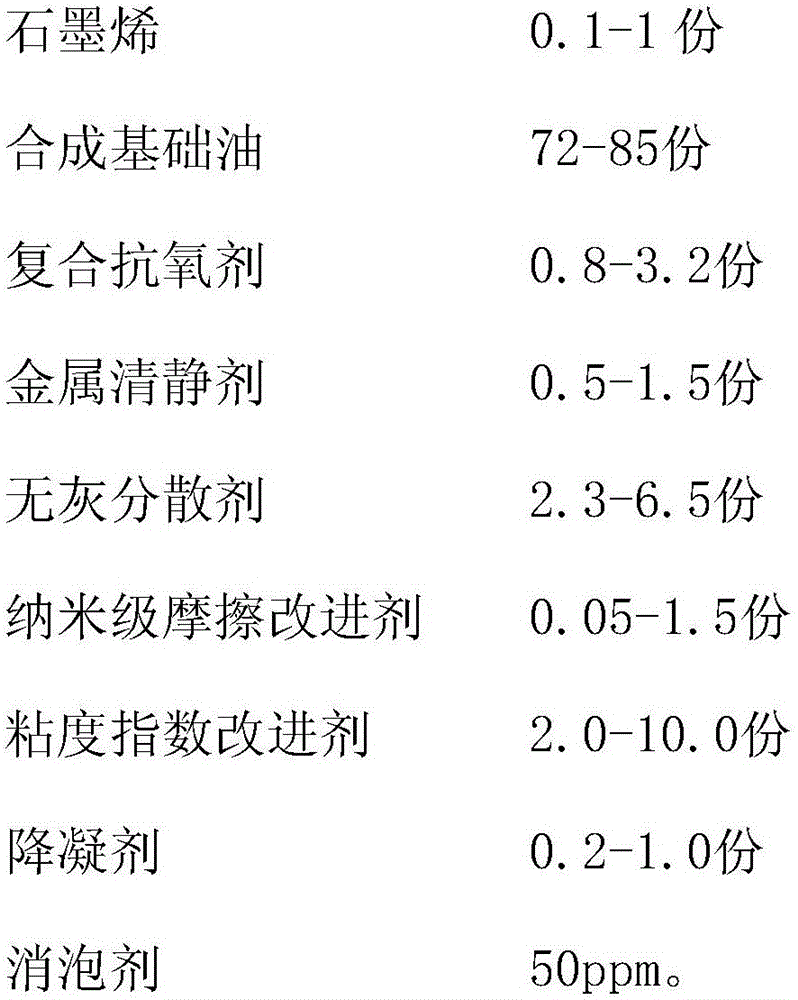

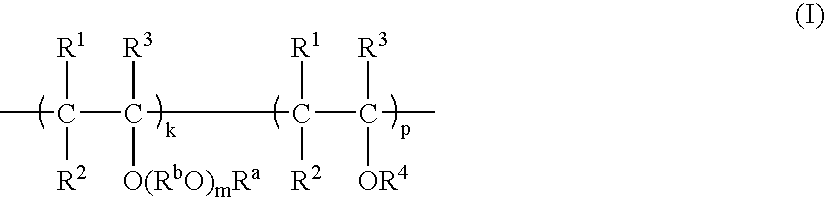

Thermosensitive polymers and thermoreversible gels obtained from these polymers

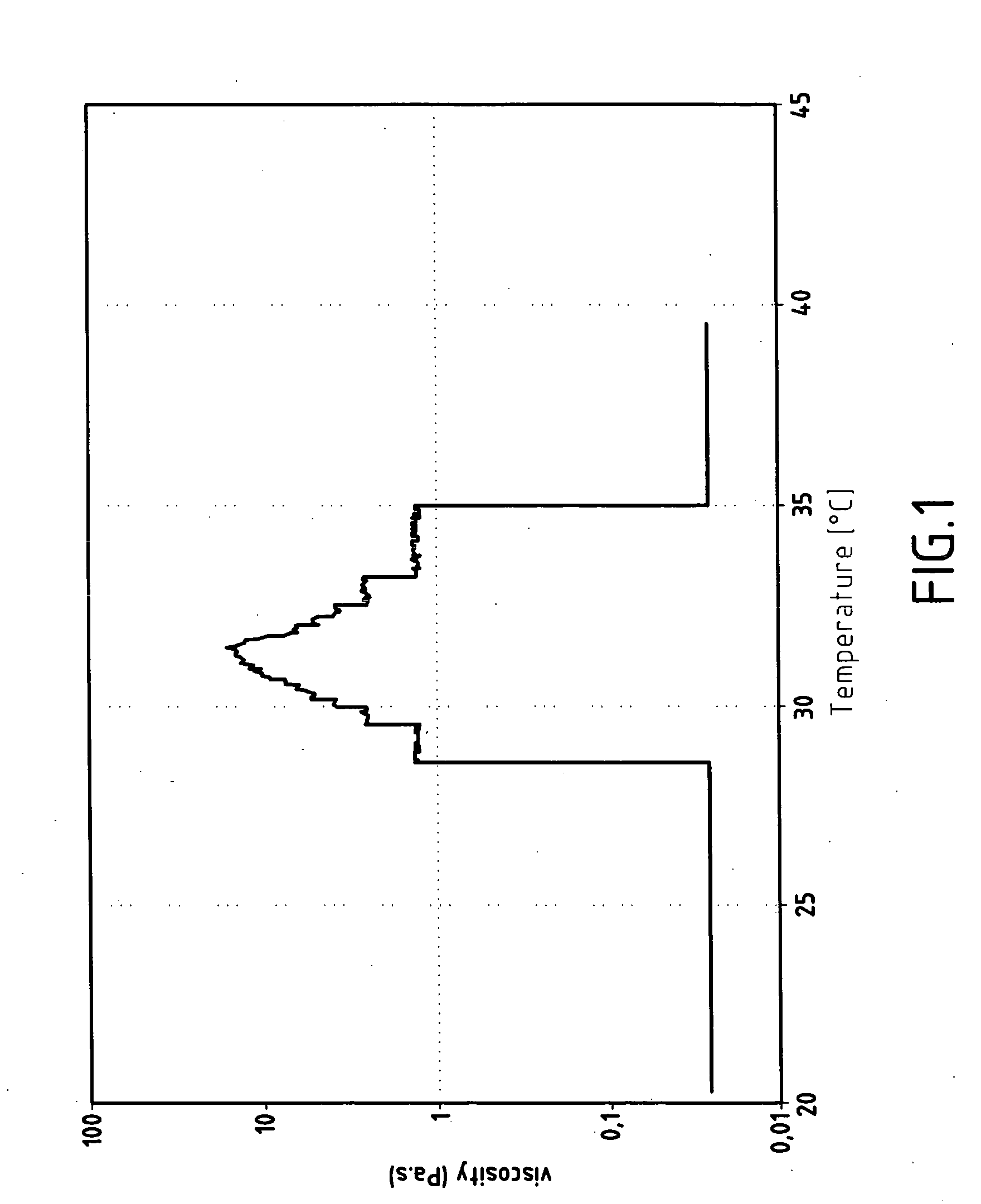

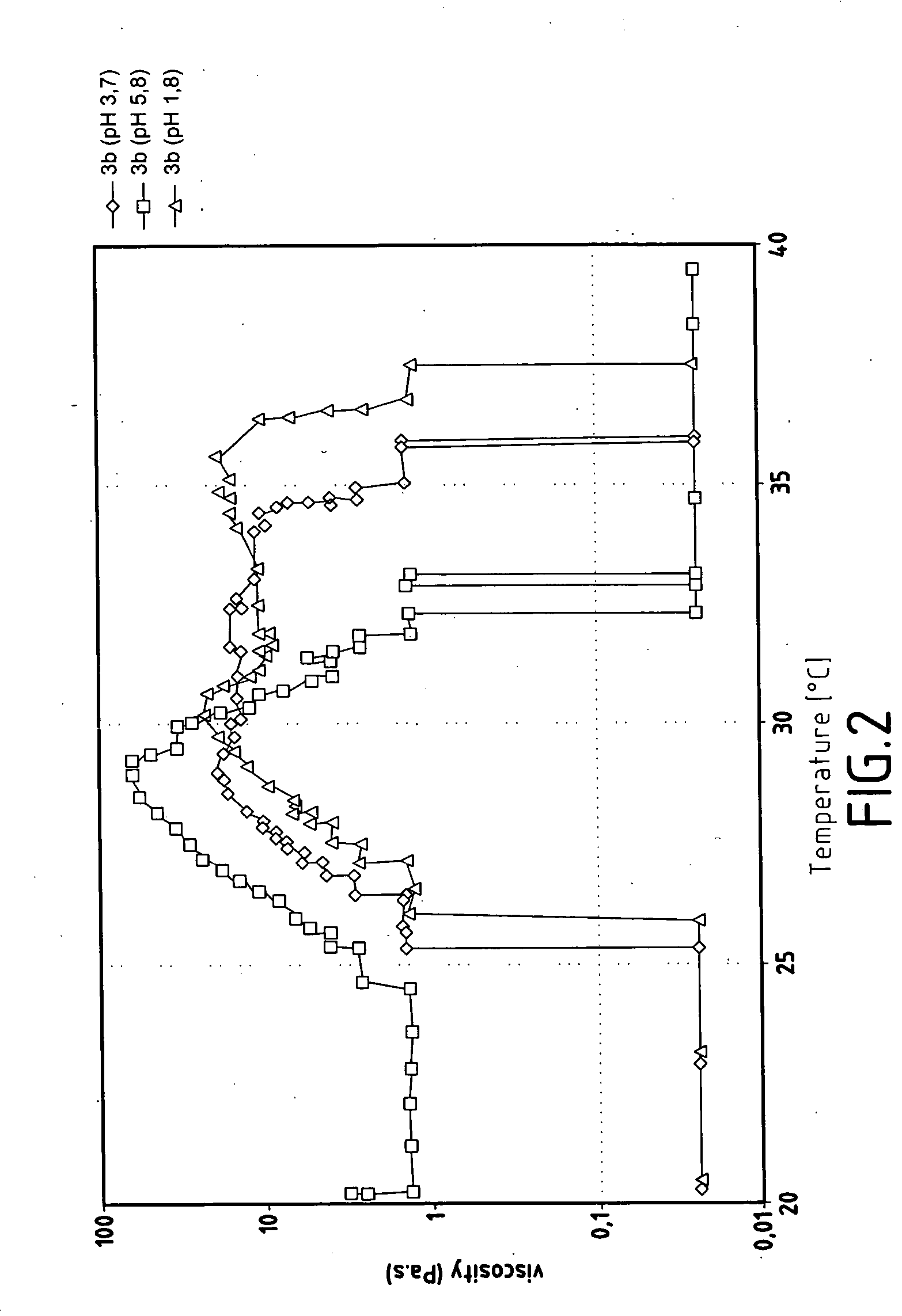

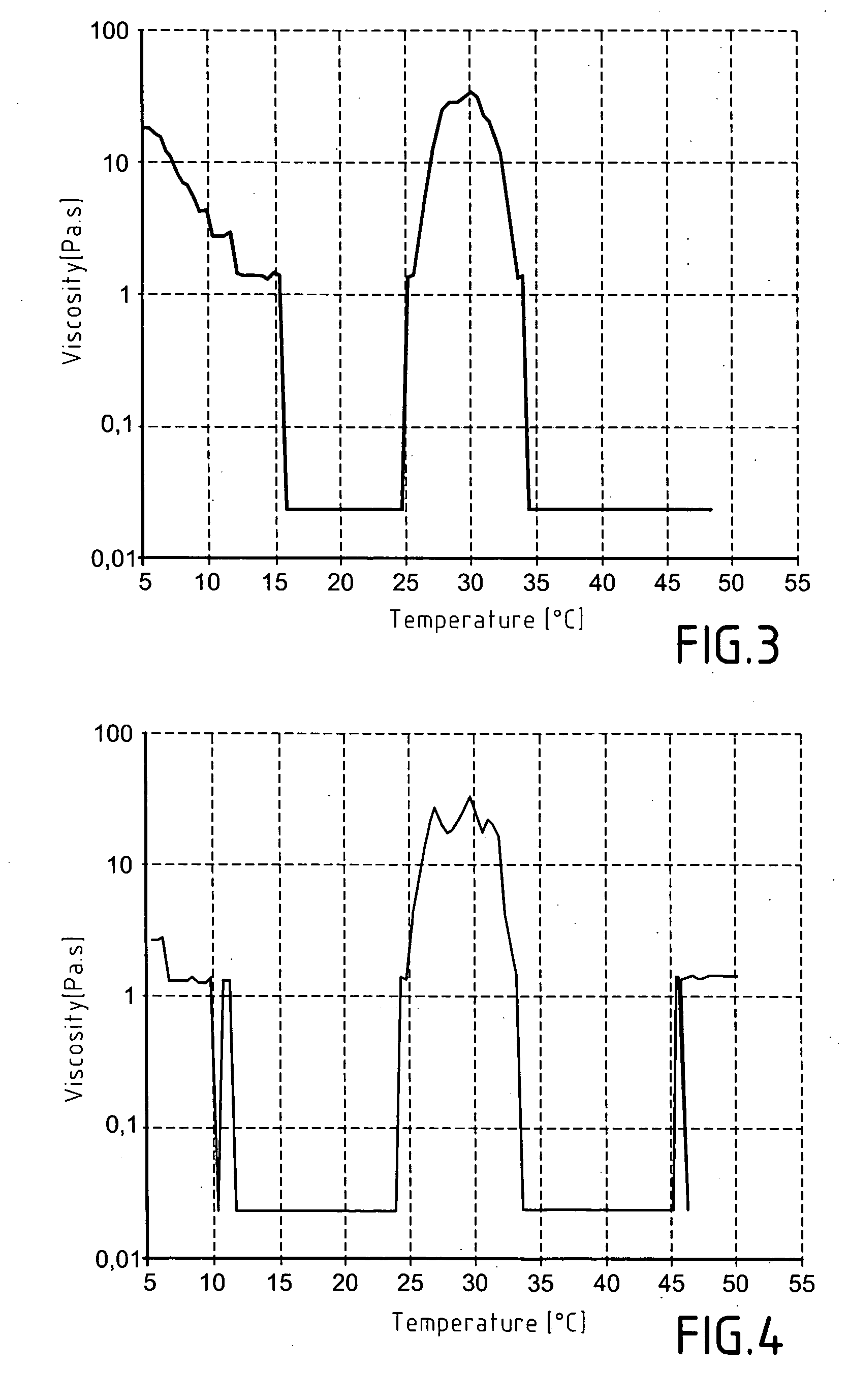

InactiveUS7339013B2High viscosity indexEffective compositionCosmetic preparationsSenses disorderAllophaneThermosensitive polymer

Polymers which comprise polymer chains of terpolymer type which are constituted by poly(ethylene oxide) (PEO) and poly(propylene oxide) (PPO) of PEO-PPO-PEO form, which are modified at their termini by groups which can essentially be other chains of PEO-PPO-PEO, acid segments, amine groups or PEOs, these chains being linked to the terpolymer chains via chemical bridges which are constituted by urethane bridges, urea bridges, allophanate bridges and biuret bridges, and which comprise more than 80% by weight of said PEO-PPO-PEO.Thermoreversible physical gels of high viscosification index, which contain these polymers, and their uses.Preparation of these polymers and of these gels.

Owner:POLYMEREXPERT

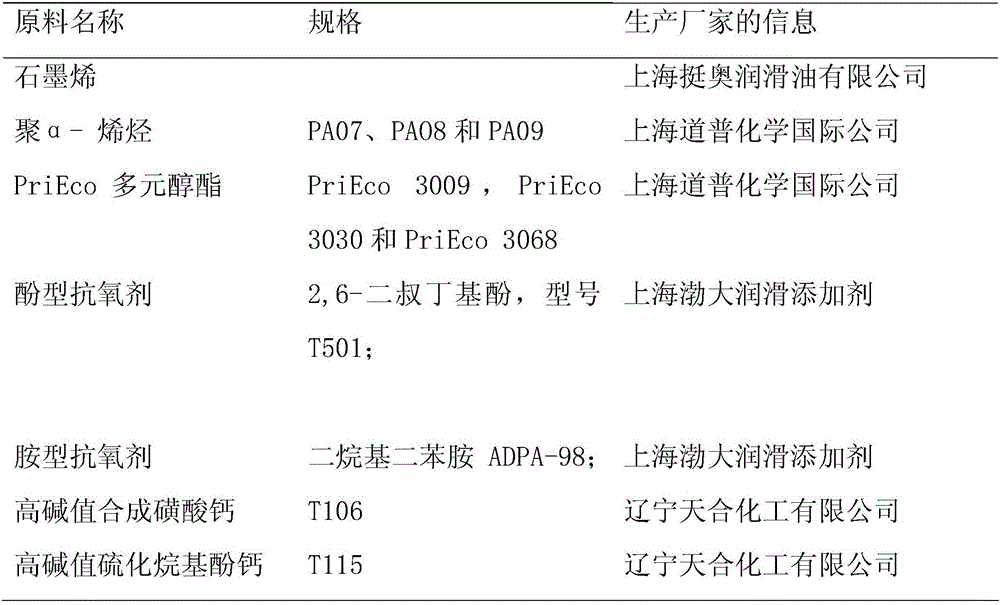

Graphene-containing lubricating oil and preparation method thereof

The invention relates to a graphene-containing lubricating oil and a preparation method thereof. The graphene-containing lubricating oil comprises the following components by weight: 0.1-1 part of graphene, 72-85 parts of synthetic base oil, 0.8-3.2 parts of a composite antioxidant, 0.5-1.5 parts of a metal detergent, 2.3-6.5 parts of an ashless dispersant, 0.05-1.5 parts of a nanoscale friction modifier, 2.0-10.0 parts of a viscosity index improver, 0.2-1.0 part of a pour point reducer, and 50ppm of a defoamer. The preparation method includes: putting the synthetic base oil into a blending kettle, performing stirring, then adding the pour point reducer, the viscosity index improver, the composite antioxidant, the metal detergent, the ashless dispersant, and the nanoscale friction modifier, stirring the substances evenly, adding graphene and the defoamer, maintaining the original temperature, stirring the materials evenly, and performing standing. The graphene-containing lubricating oil provided by the invention solves the problems of corrosion and selectivity in traditional lubricating oil additives, at the same time the process is improved, and the ultrasonic dispersion link of graphene is eliminated.

Owner:SHANGHAI INST OF TECH

Paraffinic hydrocarbon shape selecting isomerization catalyst and method for producing the same

ActiveCN101173193AHigh yieldHigh viscosity indexMolecular sieve catalystsPetroleum wax recoveryRare-earth elementMolecular sieve

The invention discloses a paraffin hydrocarbon shape-selective isomerization catalyst and a preparation method thereof. The catalyst contains TON molecular sieves, inorganic refractory oxides and noble metal components, wherein the TON molecular sieves contain rare earth elements, and the weight content in the molecular sieves is 1%-20% in terms of oxides. In the preparation process of the catalyst, the rare earth element is first loaded on the molecular sieve to obtain the rare earth-containing molecular sieve, and then prepared into a catalyst. The catalyst is especially suitable for the hydrotreating process of lubricating oil fractions, and has the characteristics of high yield of target product, low pour point and high viscosity index.

Owner:CHINA PETROLEUM & CHEM CORP +1

Transmission liquid composition for stepless speed gear

ActiveCN101007982AHigh viscosity indexHigh traction coefficientAdditivesAlkaline earth metalAlicyclic Hydrocarbons

The invention provides a stepless variable device transmission fluide compound. It comprises following components with their percentage on base oil weight: (1) bicyclo alicyclic hydrocarbon base oil, (2) alkali metal salt detersive, 0.05- 3%, (3) ashless dispersant 1- 15%, (4) phenol or amine anti- oxidant, 0.01- 1%, (5) antiwear agent, 0.05- 2%, (6) friction improver. 0.05- 3%, (7) viscosity index improver, 0-20%, (8) antifoam agent, 0- 1000ppm. The transmission fluide is characterized by good viscosity-temperature characteristic and low- temperature flowability, high drag coefficient at normal temperature, good comprehensive performance, and satification for CVT use requirement.

Owner:CHINA PETROLEUM & CHEM CORP +1

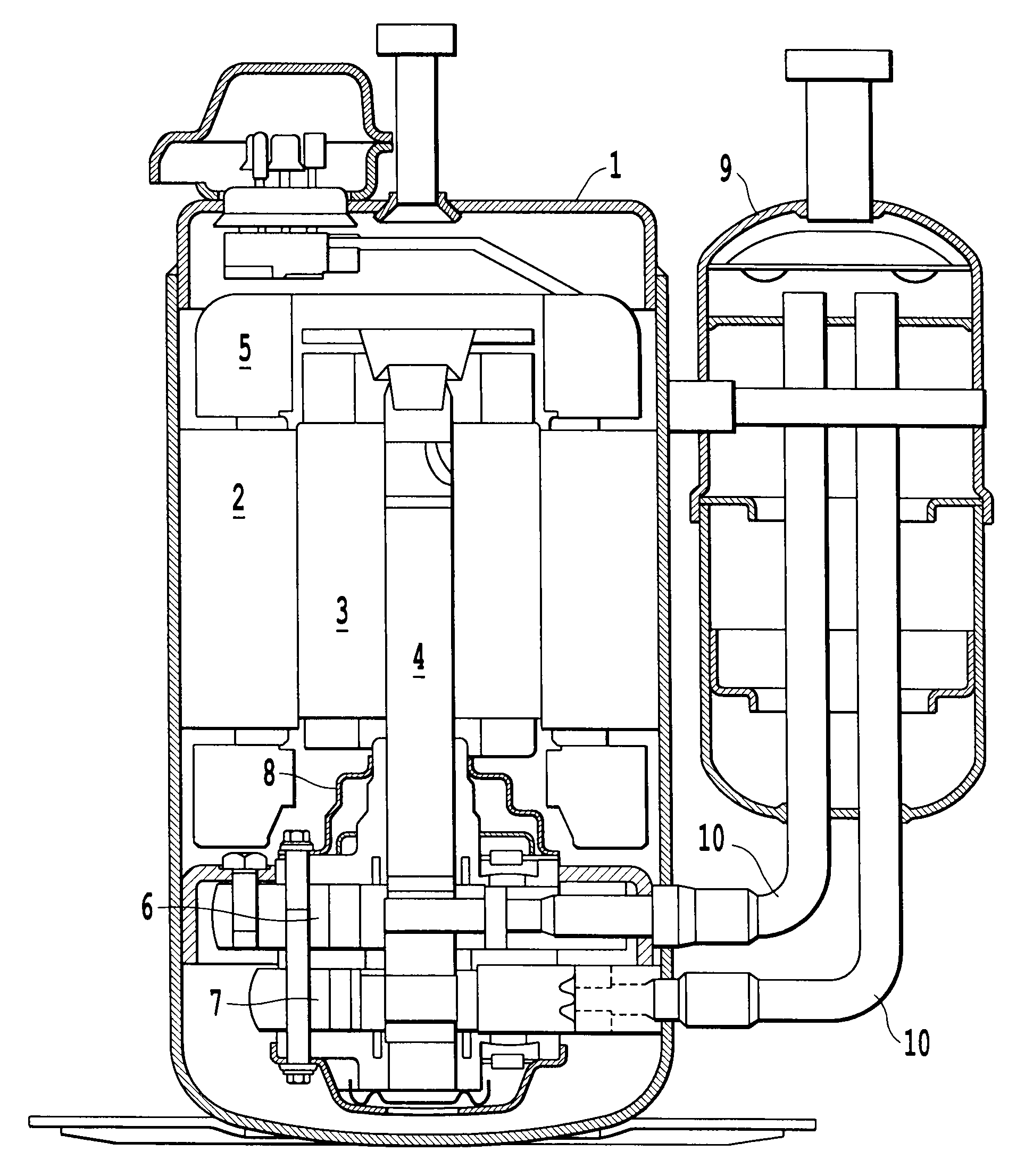

Lubricant for compression type refrigerating machine and refrigerating device using same

InactiveUS20090000331A1Improve compatibilityHigh viscosity indexCompression machines with non-reversible cycleHeat-exchange elementsVinyl etherEther

The present invention provides lubricating oil for a compression refrigerator, characterized by including an alkylene glycol or polyoxy alkylene glycol unit and a vinyl ether unit in a molecule and containing a polyvinyl ether compound having a molecular weight of 300 to 3,000. The lubricating oil for a compression refrigerator has a high viscosity index and excellent compatibility under a natural refrigerant atmosphere such as carbon dioxide.

Owner:IDEMITSU KOSAN CO LTD

Lubricating base oil with high monocycloparaffins and low multicycloparaffins

InactiveCN1906277AImprove solubilityGood Elastomer CompatibilityRefining to change hydrocarbon structural skeletonLiquid hydrocarbon mixture productionPolymer scienceCycloparaffins

A composition of lubricating base oil having a weight percent of all molecules with at least one aromatic function less than 0.30, a weight percent of all molecules with at least one cycloparaffin function greater than 10, and a ratio of weight percent of molecules with monocycloparaffins to weight percent of molecules with multicycloparaffins greater than 15.

Owner:CHEVROU USA INC

Refrigerating machine oil combination and preparation method thereof

ActiveCN101177643AImprove solubilityGood fluidity at low temperatureLiquid hydrocarbon mixtures productionBase-materialsAlkaneSolubility

The invention relates to a refrigerant machine oil composition, comprising a mixed Alpha olefin polymer oil which is adopted as base oil and additive, wherein, a viscosity of the mixed Alpha olefin polymer oil at 40 DEG C ranges from 3 square millimeter per second to less than 6 square millimeter per second; the mixed Alpha olefin polymer oil is C15-C22 mixed isoolefine, C15-C22 mixed isoparaffin or the mixture of C15-C22 mixed isoolefine and C15-C22 mixed isoparaffin. The refrigerant machine oil composition provided by the invention has the advantages that: (1) good solubility with R600A refrigerating fluid, and floc point being lowered to minus 70 DEG C; (2) excellent fluidity in low temperature, with a pour point lowering to minus 70 DEG C, and a kinematic coefficient of the viscosity being less than 500 square millimeter per second at minus 40 DEG C; (3) comparatively apparent energy saving effect which is respectively higher than the refrigerant machine oil with a viscosity of 22 and 10 square millimeter per second by 14 percent and 4 percent at 40 DEG C.

Owner:BEIJING FRIENDLINK PETROCHEM T&D CO LTD

Thermosensitive polymers and thermoreversible gels obtained from these polymers

InactiveUS20050175573A1Improve propertiesHigh viscosity indexCosmetic preparationsSenses disorderAllophanePolymer science

Polymers which comprise polymer chains of terpolymer type which are constituted by poly(ethylene oxide) (PEO) and poly(propylene oxide) (PPO) of PEO-PPO-PEO form, which are modified at their termini by groups which can essentially be other chains of PEO-PPO-PEO, acid segments, amine groups or PEOs, these chains being linked to the terpolymer chains via chemical bridges which are constituted by urethane bridges, urea bridges, allophanate bridges and biuret bridges, and which comprise more than 80% by weight of said PEO-PPO-PEO. Thermoreversible physical gels of high viscosification index, which contain these polymers, and their uses. Preparation of these polymers and of these gels.

Owner:POLYMEREXPERT

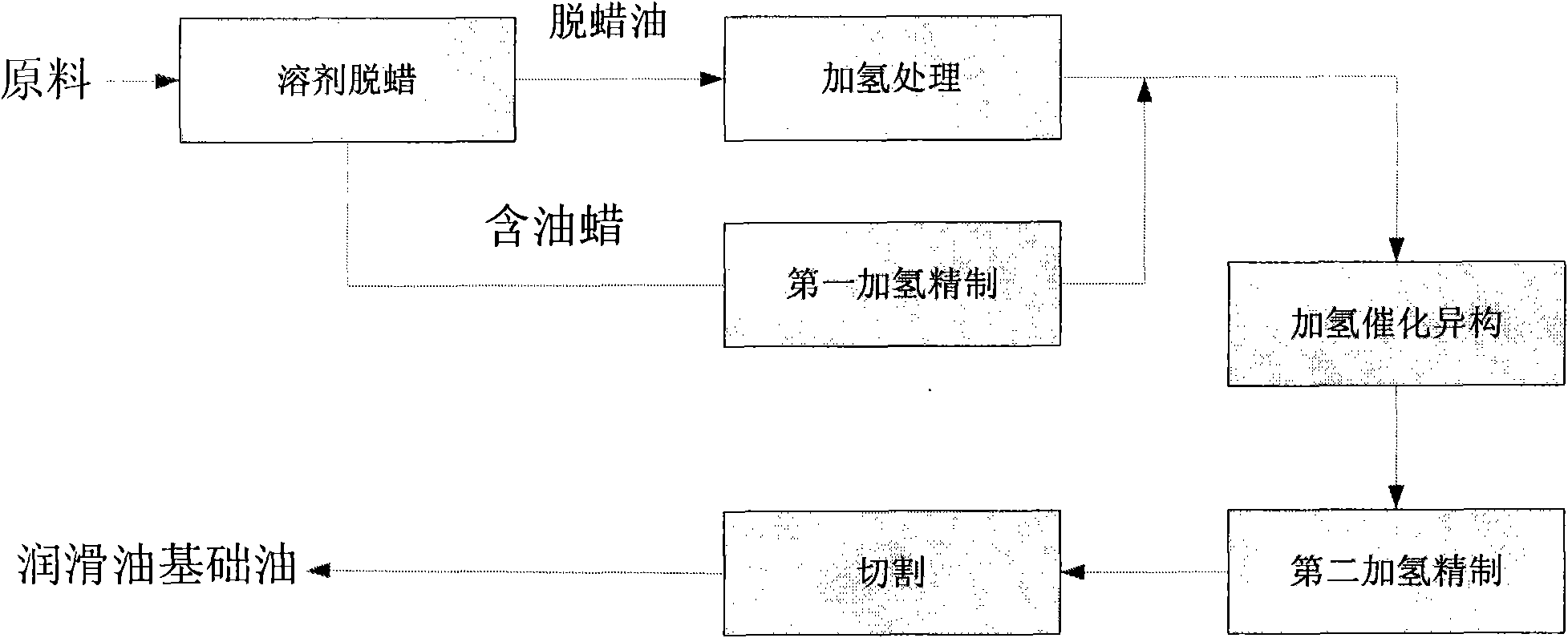

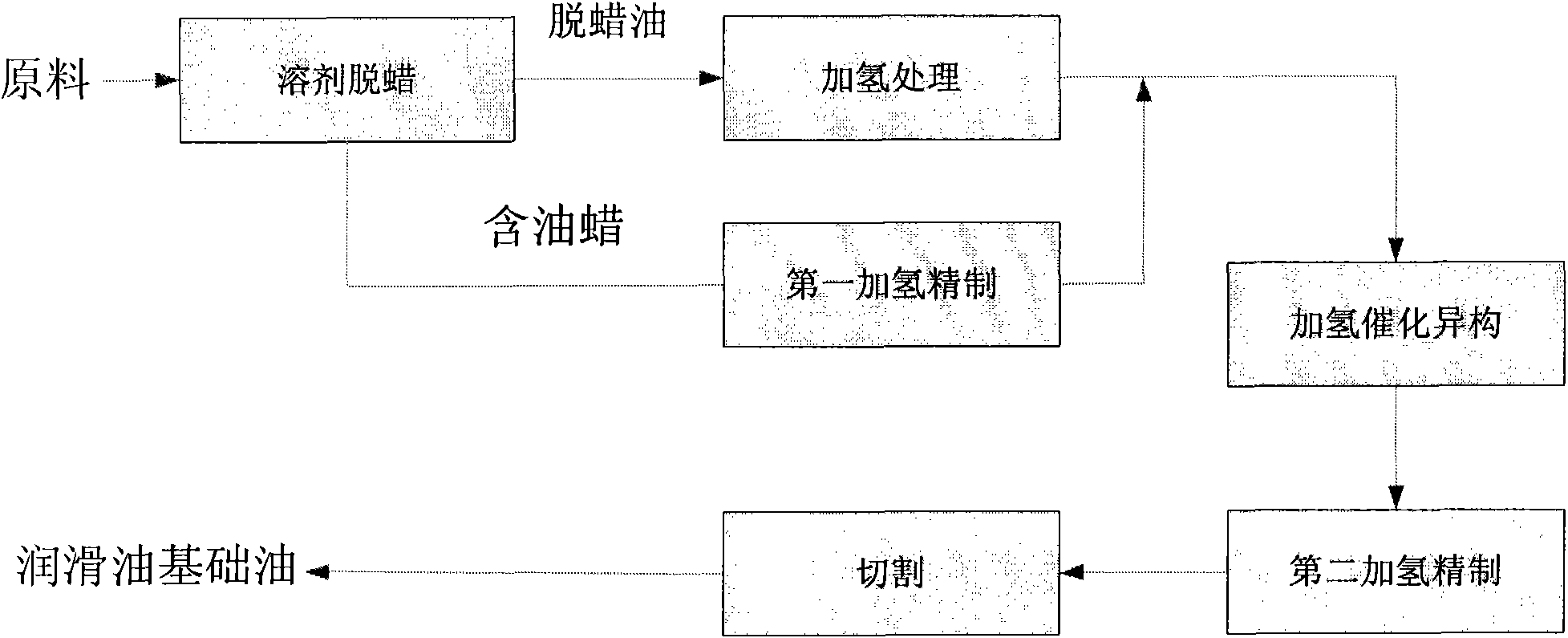

Preparation method of high-viscosity-index lubricating oil base oil

ActiveCN102051220AHigh viscosity indexLower quality requirementsTreatment with hydrotreatment processesBase-materialsWaxHydrogen

The invention relates to a preparation method of high-viscosity-index lubricating oil base oil, which is characterized by comprising the following steps of, firstly, contacting raw materials with to a dewaxing solvent to obtain dewaxed oil and oil-bearing wax, wherein the raw materials are vacuum gas oil and / or light deasphalting oil; secondly, contacting the dewaxed oil with a hydrotreating catalyst in the presence of hydrogen to obtain a hydrotreating product; thirdly, contacting the oil-bearing wax with a first hydrofining catalyst in the presence of the hydrogen to obtain a first hydrofining product; fourthly, mixing the first hydrofining product and the hydrotreating product, and sequentially contacting the mixture to a hydroisomerization catalyst and a second hydrofining catalyst in the presence of the hydrogen to obtain a second hydrofining product; and fifthly, cutting the second hydrofining product to obtain a lubricating oil base oil product. In the preparation method of the lubricating oil base oil, intermediate base raw materials with low wax content can be adopted to produce the lubricating oil base oil which has the viscosity index up to above 120 and the high yield of 60-70 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

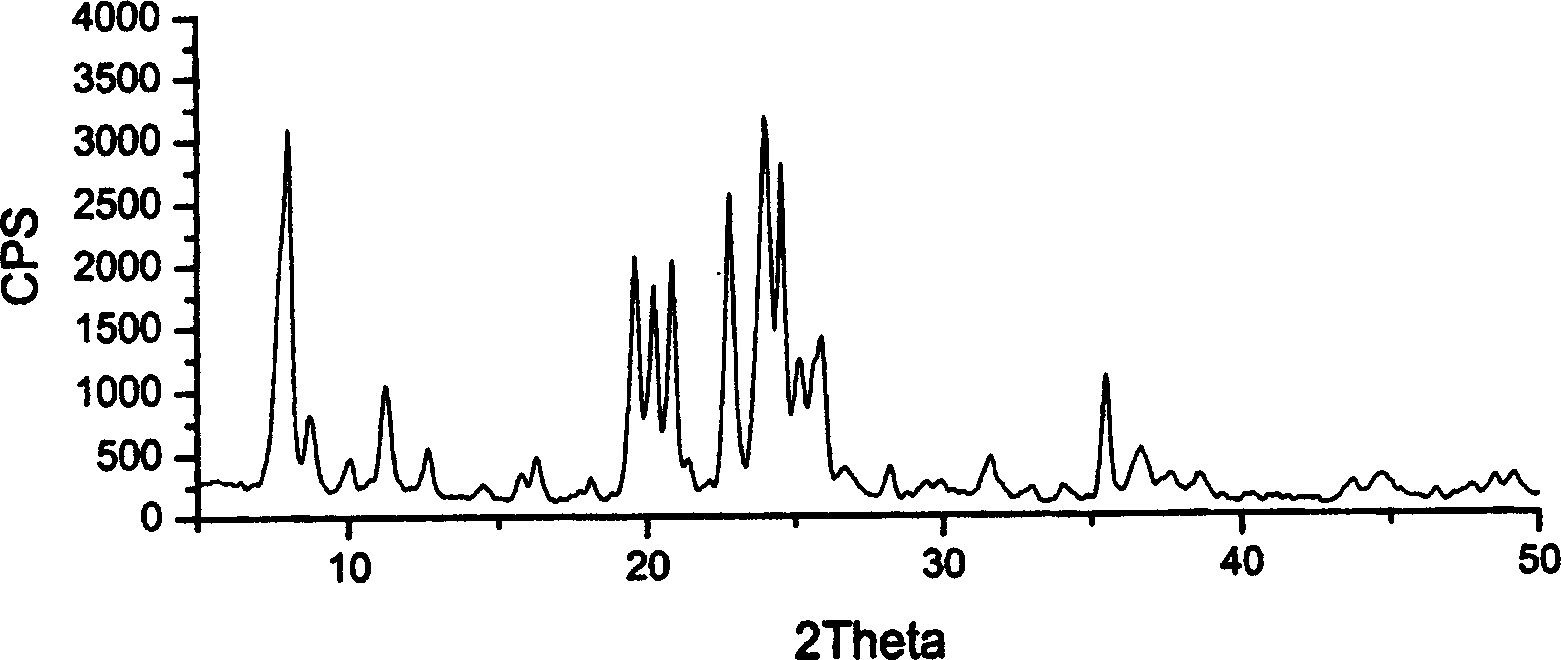

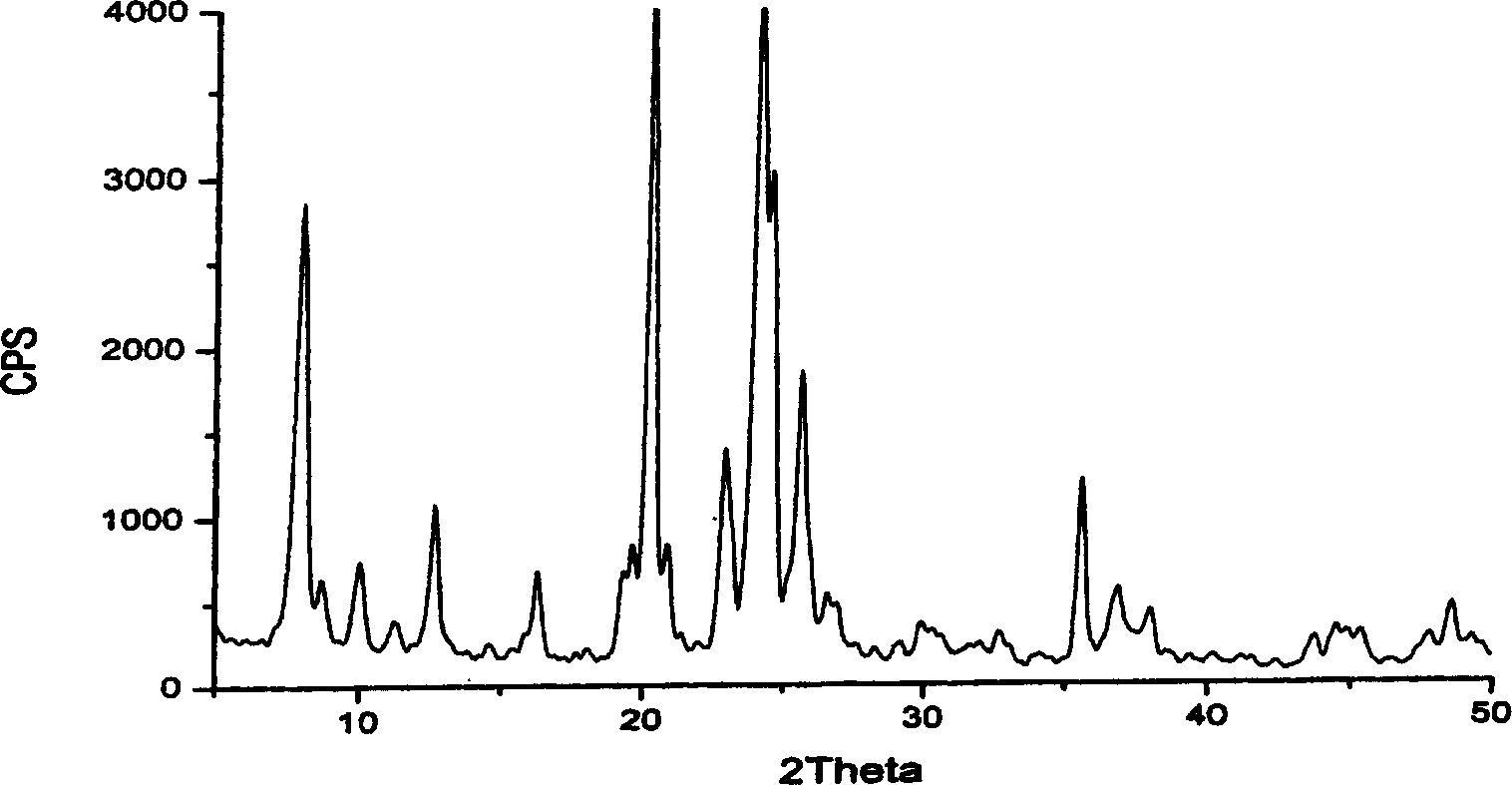

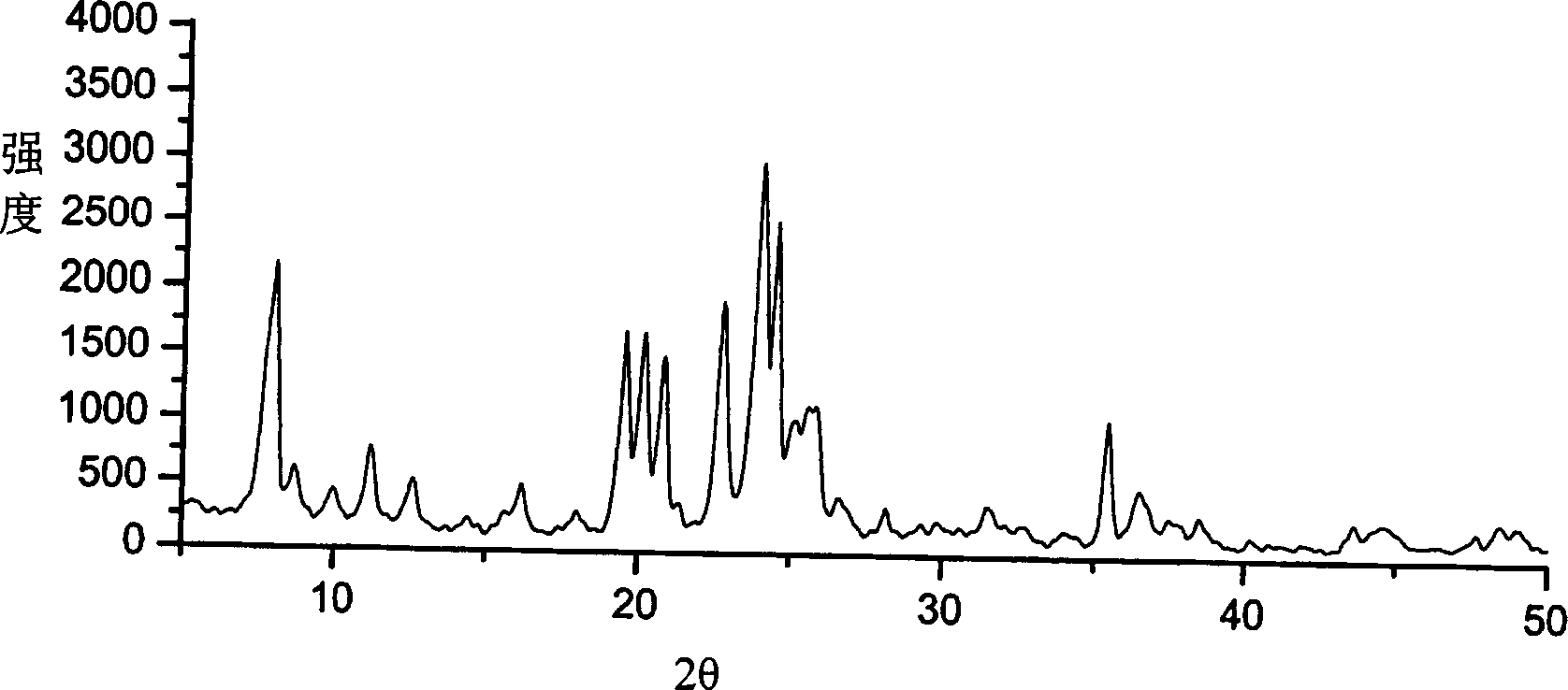

ZSM-22/ZSM-23 composite molecular screen and its preparation method

InactiveCN1769173AHigh yieldHigh viscosity indexCrystalline aluminosilicate zeolitesMolecular sieveCarbon source

The invention relates to a ZSM-22 / ZSM-23 composite molecular sieve and a method for synthesis it, which contains: mixing ZSM-22 molecular sieve with alumina silica colloid prepared by mixing carbon source, aluminum source, inorganic base, water with template agent, and adjusting the acid-base quality of the solution with inorganic acid to prepare initial colloid, the mole composition of the colloid being: SiO2 / Al2O3= 60-300, R / SiO2= 0.05-3, OH- / SiO2= 0.05-0.5, M / SiO2=0.1-0.5, H2O / SiO2= 10-65, the usage of ZSM-22 molecular sieve being 1-60% of silica dioxide by weight, and the temperature agent being one or more of pyrrolidine, isopropyl amine or isobutylamine. The ZSM-22 / ZSM-23 composite molecular sieve is prepared by hydrothermal crystallization of initial colloid.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

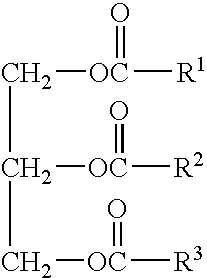

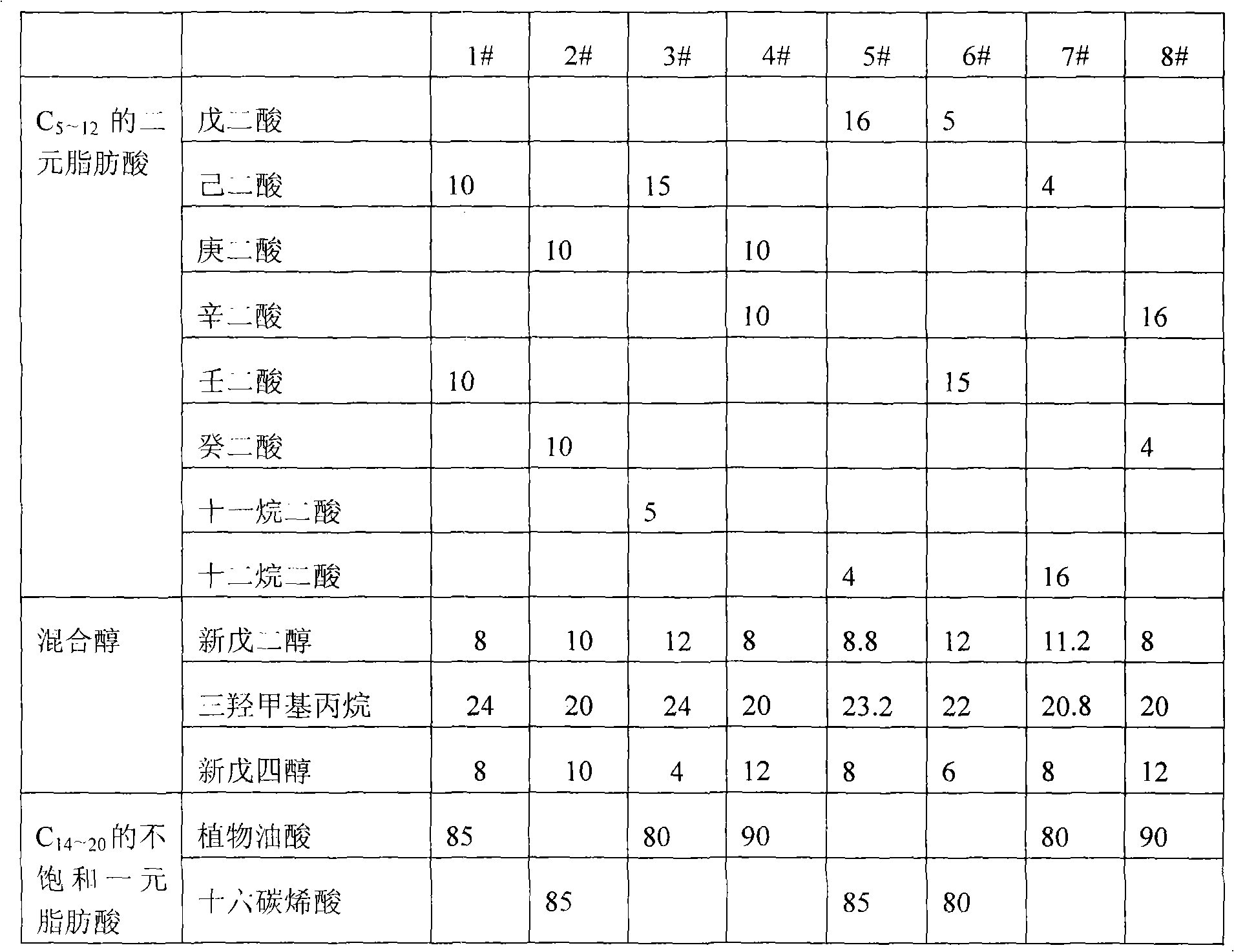

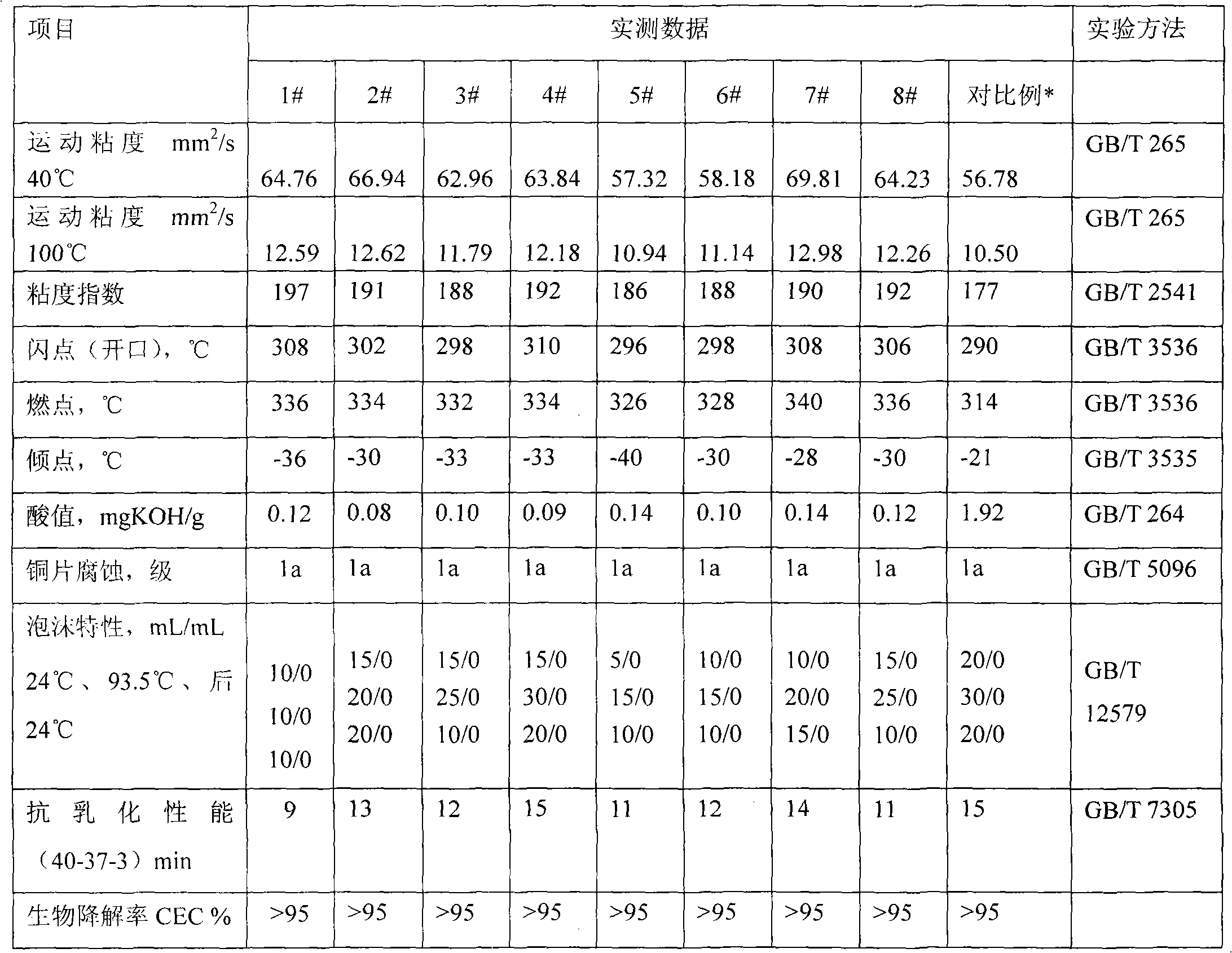

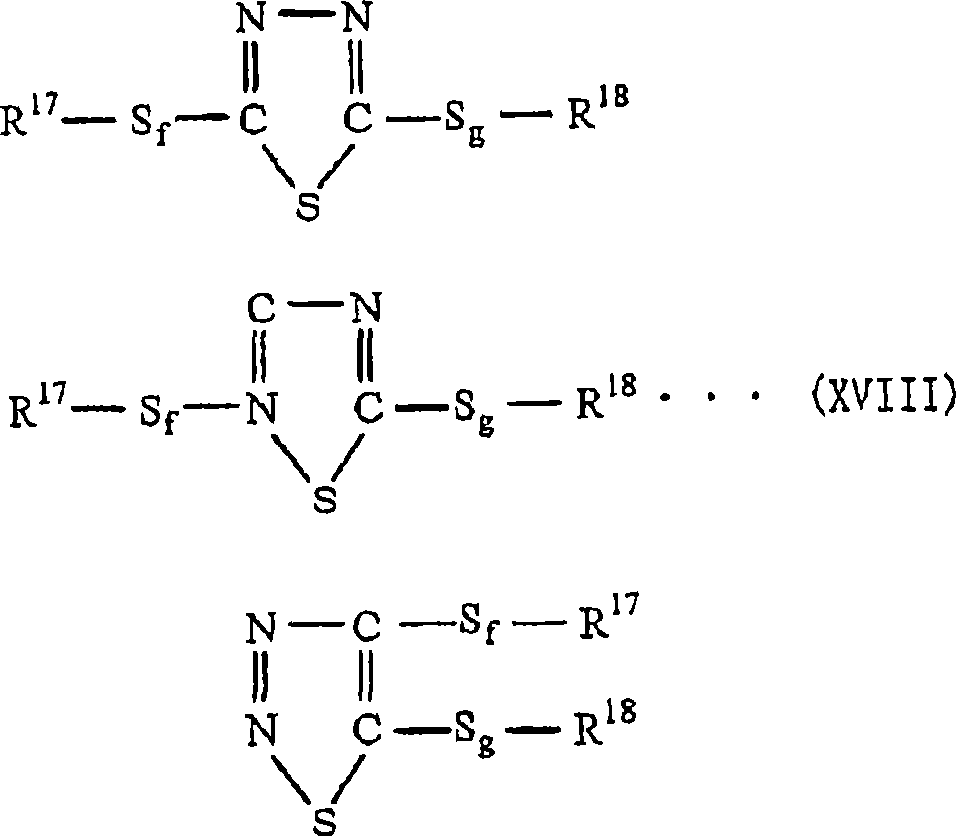

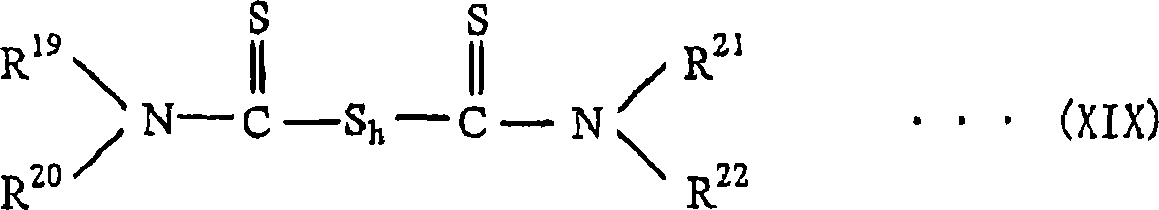

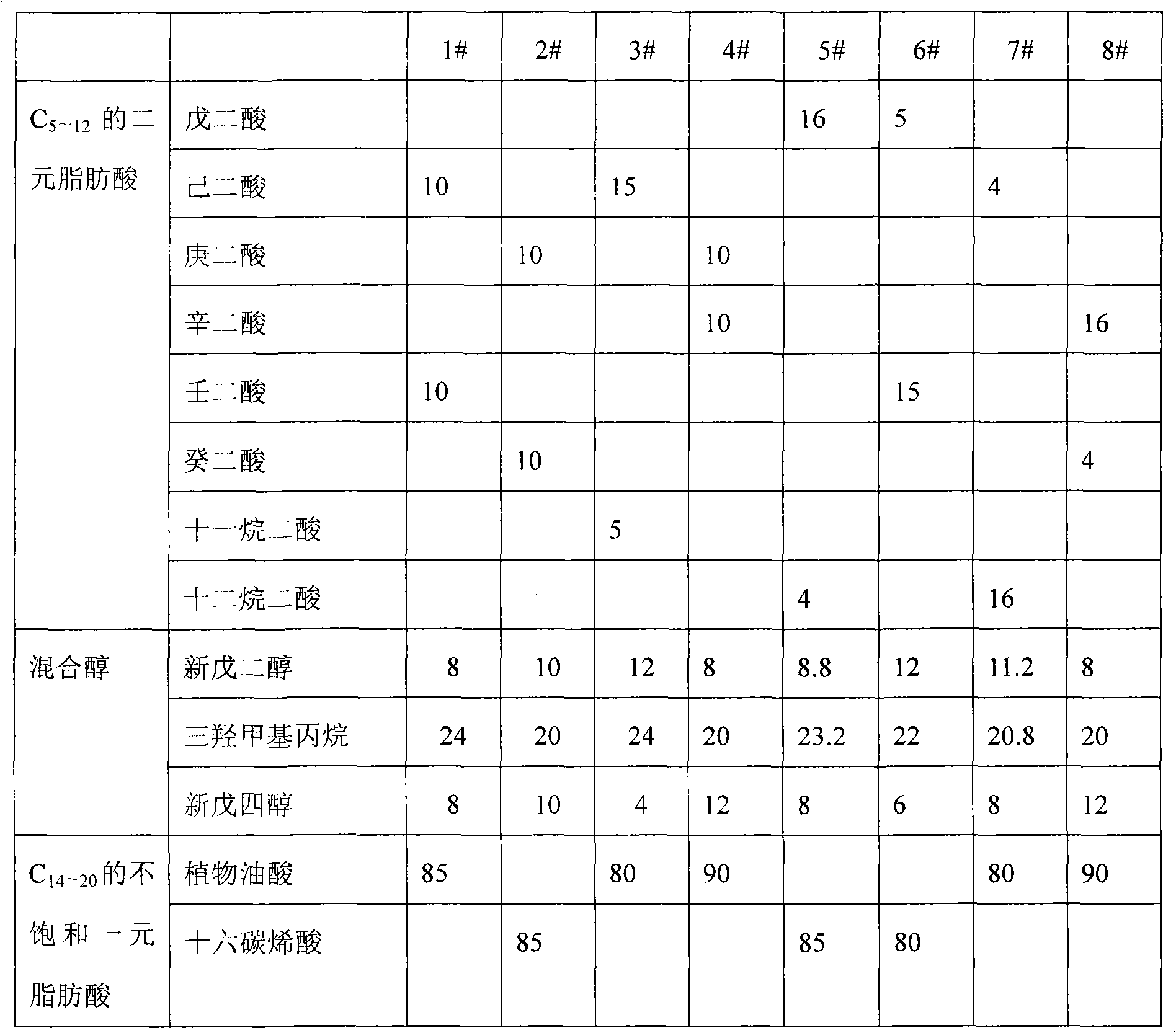

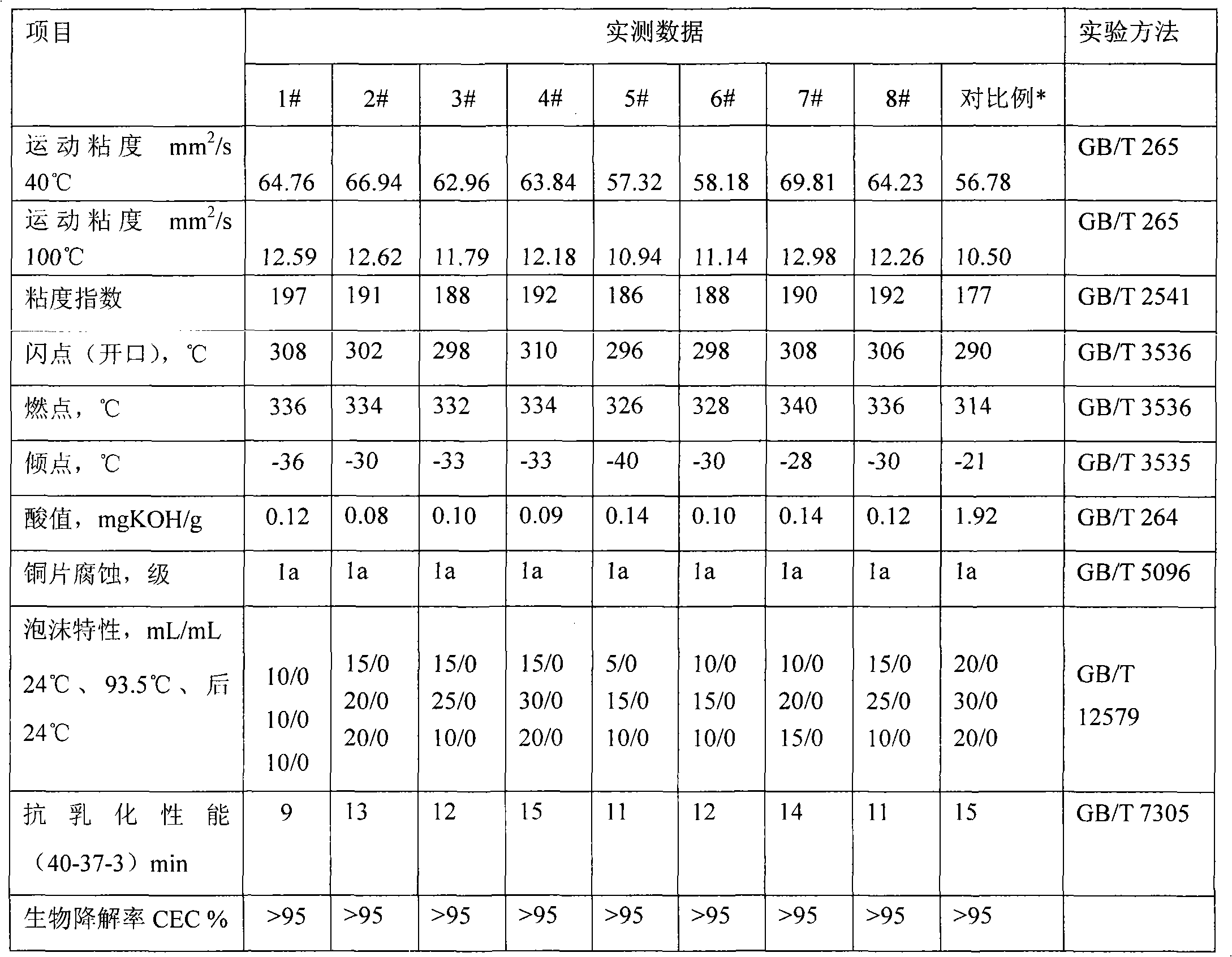

Flame-retardant hydraulic oil and preparation and application thereof

ActiveCN101831346AImprove long-term high-temperature anti-oxidation stabilitySatisfy flame resistanceLubricant compositionAntioxidantHigh pressure

The invention provides flame-retardant hydraulic oil, which comprises the following components in percentage by weight: 1.9 to 4.5 percent of antioxidant, 1.5 to 3.5 percent of extreme-pressure abrasion resistant agent, 5 to 50ppm of antifoaming agent, 0.1 to 0.4 percent of anti-rusting agent and 92 to 97 percent of base oil, wherein the base oil is neopentyl polyol diacid composite ester which is prepared by fully esterifying carboxyl of aliphatic dibasic acid of C5-12 with mixed alcohol consisting of neopentyl glycol, trimethylolpropane and pentaerythritol and terminating the esterified product with unsaturated unitary fatty acid of C14-20. The flame-retardant hydraulic oil provided by the invention can be applied to various high-temperature and high-pressure hydraulic systems easy to contact naked flame. Compared with mineral-based (compressor) hydraulic oil, the flame-retardant hydraulic oil has the advantages of energy conservation, reduced oil consumption, reduced environmental pollution and prolonged service life, and can fully meet the working requirements of the high-temperature and high-pressure hydraulic systems easy to contact naked flame.

Owner:上海海都化学科技有限公司 +1

Highly branched oily alkane polymer, and preparation method and application thereof

ActiveCN103360517AHigh viscosity indexIncrease the degree of branchingLiquid hydrocarbon mixtures productionBase-materialsAlkaneProcedure Agents

The invention discloses a highly branched oily alkane polymer, and a preparation method and application thereof. The highly branched oily alkane polymer provided by the invention has the following characteristics that (a) the viscosity index ranges from 100 to 300, (b) the pour point ranges from minus 50 DEG C to minus 10 DEG C, (c) the molecular weight ranges from 300 to 500,000 g / mol, and (d) the number of methyls corresponding to every 1000 methylenes ranges from 100 to 500. The invention also discloses a preparation method and application of the highly branched oily alkane polymer, and a lubricating oil prepared from the highly branched oily alkane polymer. The highly branched oily alkane polymer provided by the invention is high in viscosity index and high in branching degree, and thus can be used as a base oil or a processing assistant for an advanced lubricating oil.

Owner:NANJING CHEMRUN CO LTD +1

ZSM-22/ZSM-23 composite molecular sieve and preparation method

InactiveCN1686800AHigh yieldHigh viscosity indexCrystalline aluminosilicate zeolitesMolecular sieveSynthesis methods

The present invention relates to a ZSM-22 / ZSM-23 compound molecular sieve and its synthesis method. The aluminosiica colloid obtained by mixing silicon source, aluminium source, inorganic alkali, water and template agent and ZSM-22 molcular sieve are mixed, then molar composition of said aluminosilica colloid includes SiO2 / Al2O3=60-300, R / SiO2=0.05-3, OH- / SiO2=0.05-0.5 and H2O / SiO2=10-65, and the added quantity of ZSM-22 molecular sieve is 0.01-0.6 of weight of silicon dioxide, and the template agent can be one of pyrrolidine, isopropyl amine and isobutyl amine or several kinds of them, and the obtained reaction mixture is undergone the process of hydrothermal crystallization so as to obtain the invented compound molecular sieve.

Owner:PETROCHINA CO LTD +1

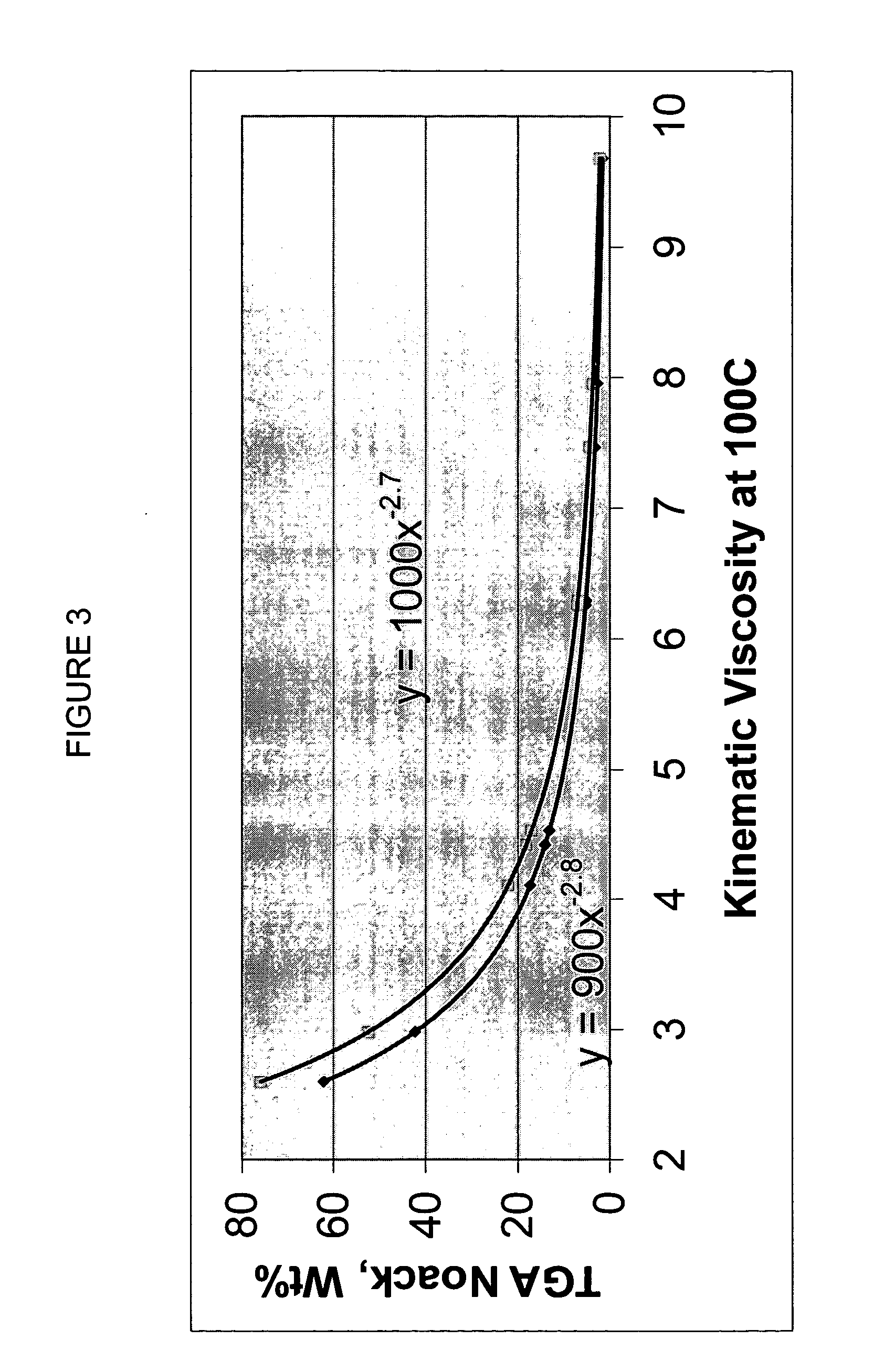

Lubricant composition for fluid dynamic bearing

InactiveCN101006164ALow viscosityReduce evaporationAdditivesBase-materialsPolymer scienceHeat resistance

Disclosed is a lubricant composition for fluid dynamic bearings which contains, as a base oil, 50-100% by mass of an ether compound having at least one ether bond and 11-34 carbon atoms, and has a kinematic viscosity at 100 DEG C of not less than 2.2 mm2 / s. Such a lubricant composition for fluid dynamic bearings has good low-temperature fluidity and such excellent viscosity characteristics that viscosity decrease is small even in the high temperature range. The lubricant composition further has low evaporativity, energy saving properties and heat resistance stability, and is thus suitable for compact fluid dynamic bearings which are rotated at high speed.

Owner:IDEMITSU KOSAN CO LTD

Lubricating oil and grease base oil, and preparation method and applications thereof

ActiveCN101812349AImprove long-term high-temperature anti-oxidation stabilitySatisfy flame resistanceBase-materialsOil and greaseEvaporation

The invention provides base oil, in particular to a neopentyl polyalcohol dibasic acid complex ester. The neopentyl polyalcohol dibasic acid complex ester is prepared in a way that: completely esterifying C5-12 binary fatty acid carboxyl with the mixture of neopentyl glycol, trimethylolpropane and pentaerythritol, and blocking with C14-20 unsaturated monobasic fatty acid. The base oil provided bythe invention has the characteristics of high flash point, high flammability point, low pour point, high viscosity index, low evaporation loss, high thermal oxidation stability and high biodegradation rate. The invention can be used as syntholube and grease base oil, especially syntholube base oil used under the conditions of high temperature and high pressure. The invention is especially suitable to be used in fire resistant hydraulic fluid, high-temperature chain oil, high-temperature grease and the like in severe working spaces at which naked flame can is accessible under the conditions ofhigh temperature and high pressure.

Owner:上海海都化学科技有限公司 +1

Special-purpose lubricating agent

InactiveCN101104830ANo pollutionImprove extreme pressure performanceThickenersAdditivesAntioxidantCrusher

The invention relates to a special lubricant named as HP800 Special Lubricant which is used for the open gear and support roller that are oiled by injection method. The lubricant takes composite calcium sulphonate and composite aluminium as the thickener; the base oil of the lubricant is synthetic oil; and in addition tackifier, extreme pressure agent and antioxidant are also added in. Wherein the weight-portion of each component are: the base oil: 50-64, the thickener: 20, the tackifier :5-10, the extreme pressure agent: 10-25,and the antioxidant: 1. The invention is suitable for lubrication of the open gear, the support roller of all kinds of umbrella ball mill, mixer, rotary kiln, imported umbrella excavator, crusher, and coal grinding machine; and has very high extreme-pressure performance, excellent viscosity and protection performance, thereby the invention can substitute import products of the same kind and has the advantages of thick oil-film, non-oil-swinging and environmental-protection.

Owner:辽宁海华科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com