Flame-retardant hydraulic oil and preparation and application thereof

A hydraulic oil and flame retardant technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as poor lubricity, limited application range, and failure to meet the long-life requirements of hydraulic systems, and achieve the effect of simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

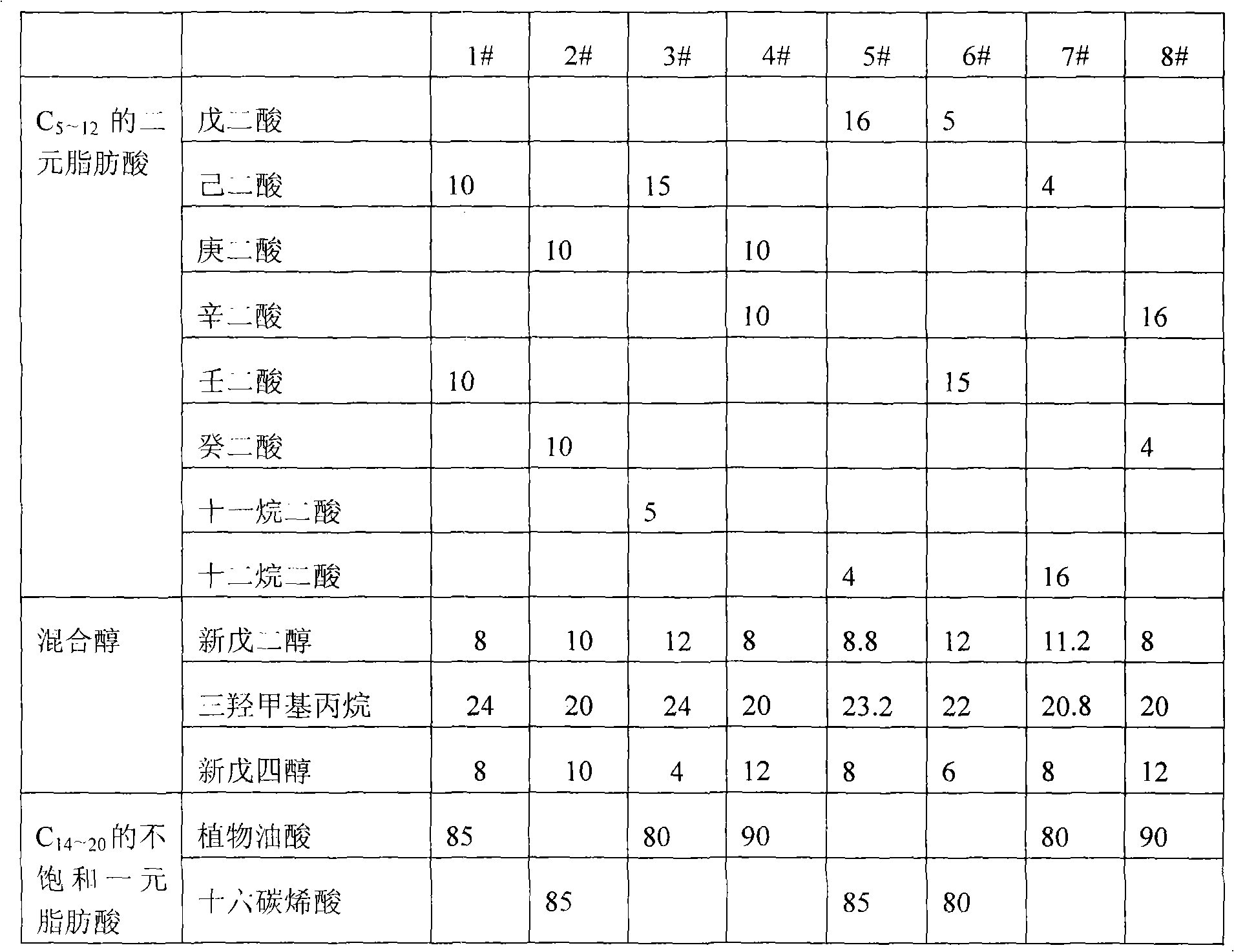

Embodiment 1

[0073] The preparation of embodiment 1 base oil

[0074] The preparation process is as follows:

[0075] 1. Select a dibasic acid with a carbon number of 5 to 12, add a mixed alcohol consisting of neopentyl glycol, trimethylolpropane and neopentylthritol in an amount twice the amount of the dibasic acid, and then add the substance The amount of the mixed dibasic acid is 0.95-1.05% tetraoctyl zirconate and 1.9-2.1% p-toluenesulfonic acid as a catalyst, and the reaction is stirred at a temperature of 160-180°C for 140-180 minutes to complete the first step Esterification reaction.

[0076] 2. The amount of the added substance is more than 4 times of the mixed dibasic acid, and the monobasic fatty acid with a carbon number of 14 to 20, (the monobasic fatty acid should be in excess, so that the second step of the esterification reaction is complete), at a temperature of 200-220 ° C Stir the reaction for 100 to 120 minutes to complete the second step of the esterification reactio...

Embodiment 2

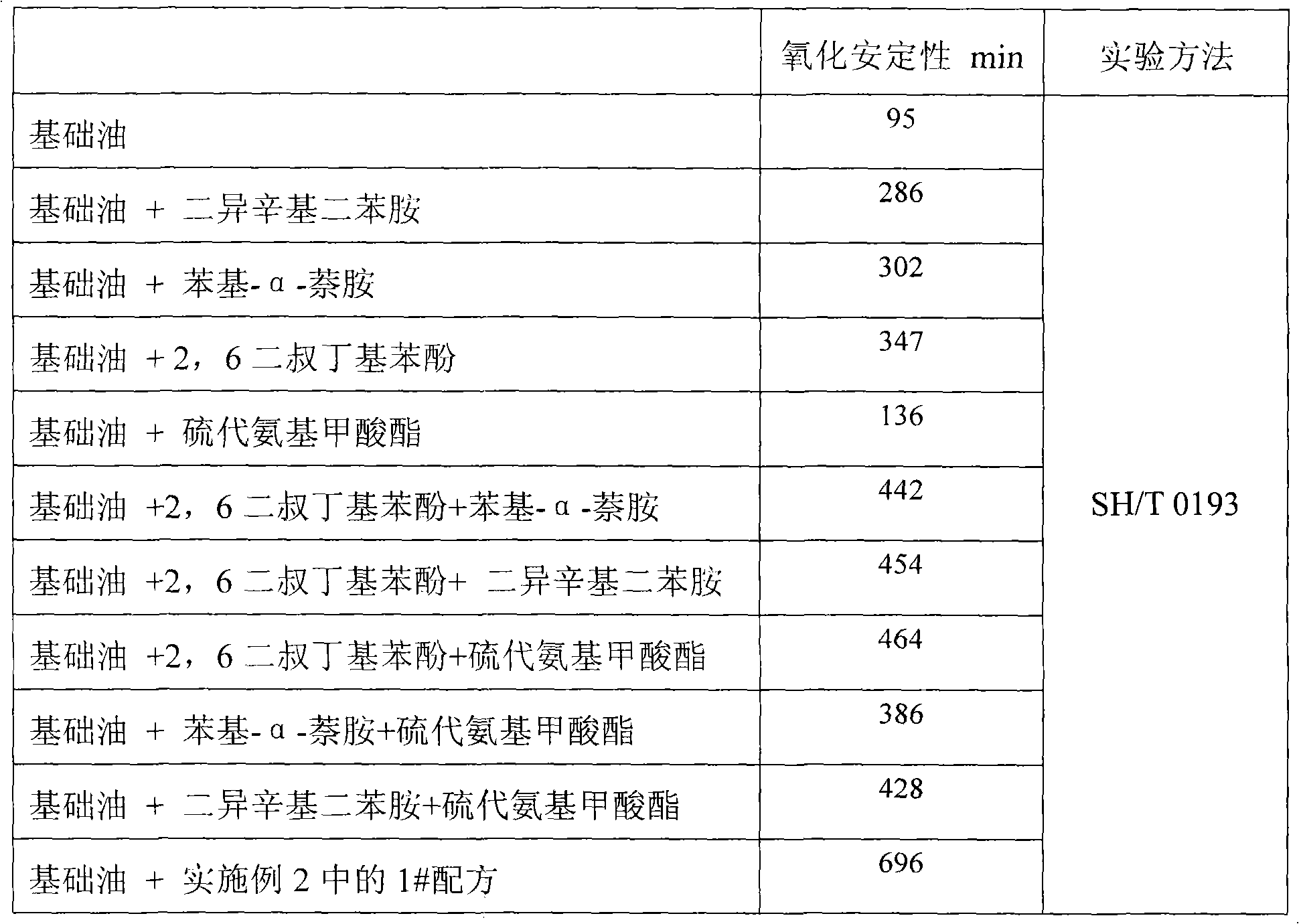

[0088] The preparation of embodiment 2 antioxidant

[0089] Antioxidant was prepared according to the formula in parts by weight in Table 3.

[0090] Preparation method: Mix the raw materials evenly according to the proportion.

[0091] table 3

[0092]

[0093] The structural formula of table 3 thiocarbamate is (C 4 h 9 ) 2 NCS 2 CS 2 CN(C 4 h 9 ) 2 .

Embodiment 3

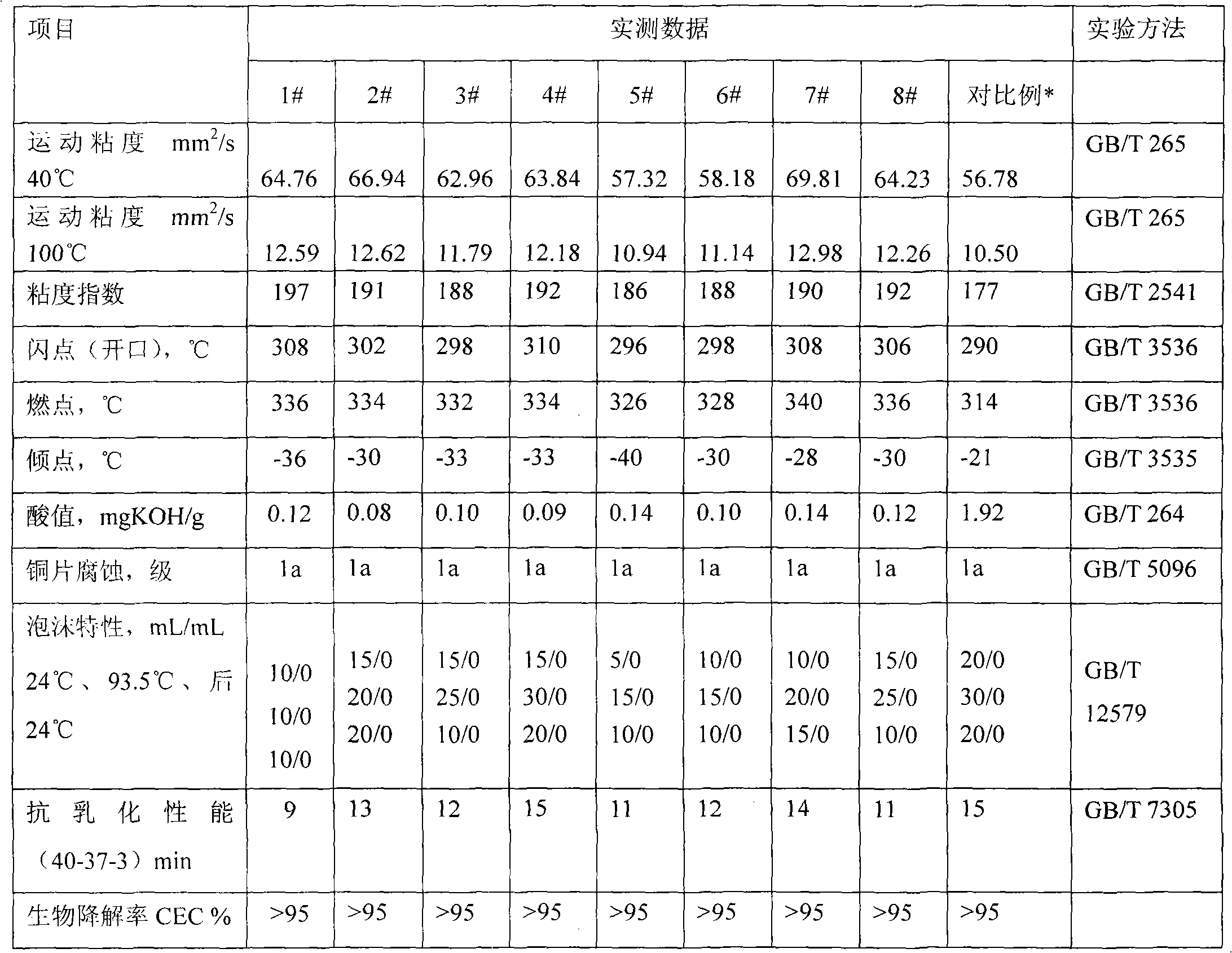

[0094] The performance of embodiment 3 antioxidants

[0095] The 4# formulation base oil in Example 1 was used to mix with various antioxidants in the following table, wherein the base oil accounted for 98wt%, and the total amount of antioxidants accounted for 2wt%. Mix the raw materials according to the ratio and stir evenly.

[0096] Table 4

[0097]

[0098] Note: the total amount of antioxidants is 2.0%; wherein, the structural formula of thiocarbamate is (C 4 h 9 ) 2 NCS 2 CS 2 CN(C 4 h 9 ) 2 .

[0099]As can be seen from the data in Table 4, the present invention selects the antioxidant compound compounded by diisooctyl diphenylamine, phenyl-α-naphthylamine, 2,6 di-tert-butylphenol and thiocarbamate. It achieves the complementary performance advantages of various antioxidants and greatly improves the long-term high-temperature anti-oxidation stability of oil products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com