Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "Alpha-naphthylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

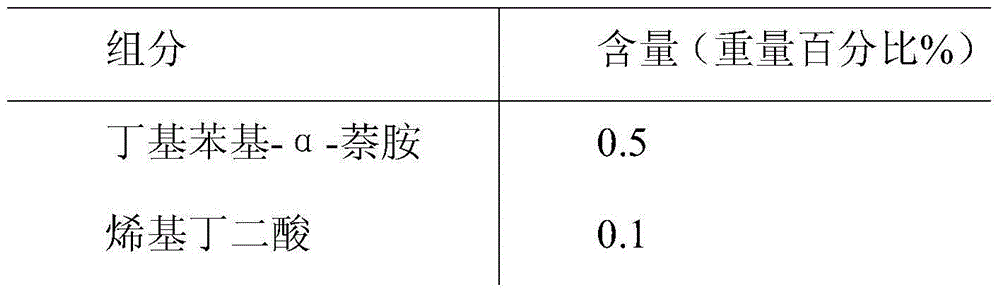

Lubricant and functional fluid additive package, and lubricants and functional fluids containing same

InactiveUS20120088704A1Stable storageLow lubricantOther chemical processesAdditivesPolyolefinAntioxidant

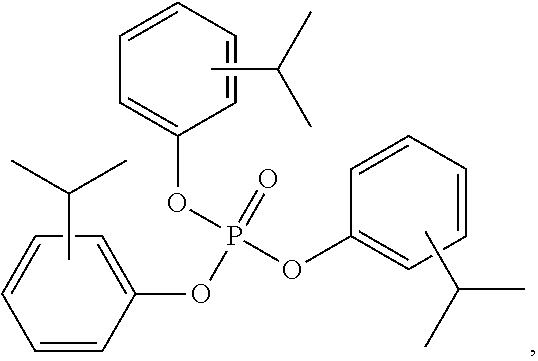

The present invention is a lubricant or functional fluid additive for a polyolefin oil blend, comprising a mixture of: (a) an anti-wear component consisting essentially of 95% isopropylated triarylphosphate and 5% dodecyl phosphate, the dodecyl phosphate being only partially esterified, the anti-wear component present in the polyolefin oil blend in a range of from about 0.75 percent to about 2.00 percent by weight; (b) an antioxidant component selected from the group consisting of alkylated phenyl-alpha-naphthylamine, phenyl-alpha-naphthylamine and mixtures thereof, and present in the polyolefin oil blend in a range of from about 0.75 percent to about 2.00 percent by weight; (c) an anti-rust component comprising an alkylated succinic acid ester anti-rust agent, and present in the polyolefin oil blend in a range of from about 0.050 percent to about 0.125 percent by weight; and (d) a metal deactivator component comprising a tolytriazole derivative, and present in the polyolefin oil blend in a range of from about 0.050 percent to about 0.125 percent by weight.

Owner:MATERIALS ENG & TECHN SUPPORT SERVICES CORP METABS CORP

Special lubricating oil for fuel gas engine of public transport automobile

ActiveCN104342266AAntioxidant time is longImprove protectionLubricant compositionThiadiazolesPolyisobutylene succinimide

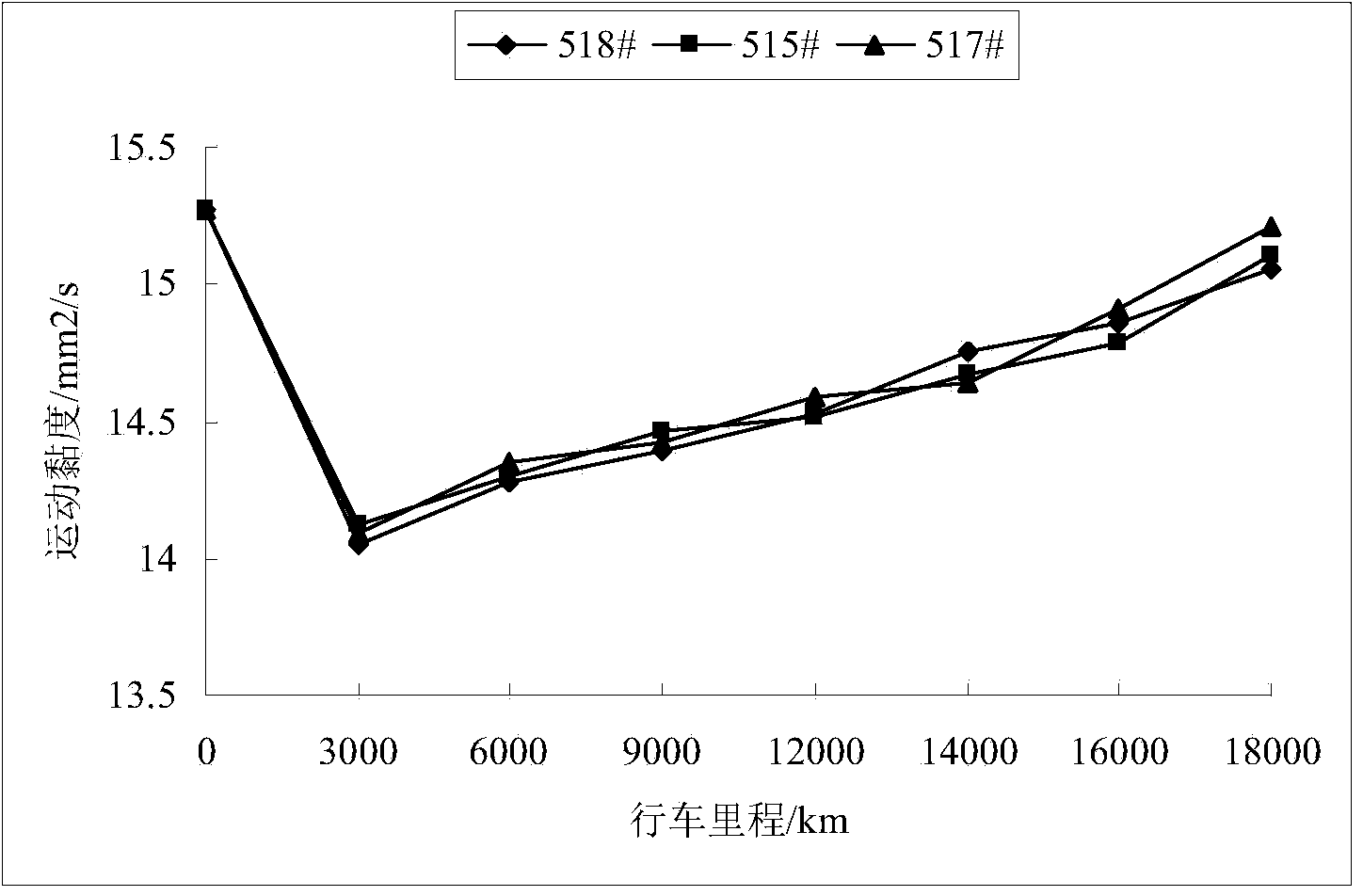

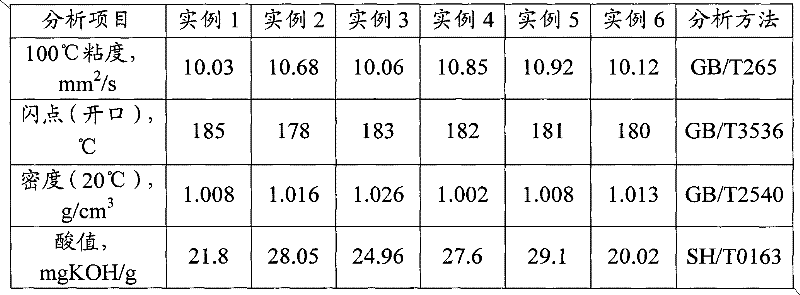

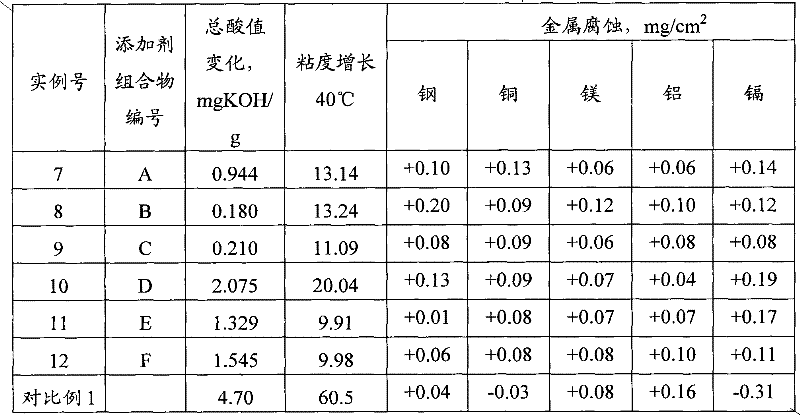

The invention discloses special lubricating oil for a fuel gas engine of a public transport automobile. The special lubricating oil is prepared from blended base oil, binary ethylene-propylene rubber, polymethacrylate, alkylphenol calcium sulfide, high-base-number calcium alkylbenzenesulfonate, polyisobutylene succinimide, boronated polyisobutylene succinimide, alkylated phenyl-alpha-naphthylamine, p,p'-dioctyl diphenylamine, a hindered phenol type antioxidant, dialkyl molybdenum dithiocarbamate, copper nanoparticle anti-wear additives, methyl silicone oil and thiadiazole polysulfide. According to the lubricating oil composition oil product, the sulfate ash content is lower than 0.5%, the content of phosphorus is lower than 0.03%, and the base number is 3-8mgKOH / g. According to the special lubricating oil for the fuel gas engine of the public transport automobile, aiming at the special requirements of the public transport automobile on engine oil, different additive varieties and charging sequences are adopted, so that physical and chemical indicators and use performance of the special lubricating oil are better than natural gas engine lubricating oil of the same grade, and the special lubricating oil has excellent cleaning and dispersion properties, lubricating property, abrasion resistance and oxidation resistance.

Owner:陕西通用润滑科技有限公司

Metal processing oil for tapping

InactiveCN101880571AImprove the lubrication effectImprove extreme pressure performanceAdditivesAntioxidantHigh carbon

The invention provides metal processing oil for tapping and a preparation method thereof. The metal processing oil contains base oil, extreme-pressure agent, oiliness agent, viscosity regulator, anti-rusting agent and antioxidant, wherein the extreme-pressure agent contains chlorine, sulfur and phosphorus; the oiliness agent is vulcanizing grease; the viscosity regulator is ethylene-propylene copolymer or polyisobutene; the anti-rusting agent is dodecenyl succinic acid; and the antioxidant is one or mixture of 2,6-di-tert-butyl-methyl phenol, phenyl-alpha-naphthylamine, benzotriazole and derivatives thereof. The metal processing oil for tapping has excellent lubricating property, high extreme pressure and high cooling property, has a simple preparation method, and can be used for drillingand tapping of stainless steel, alloy steel and high carbon steel.

Owner:广东垠星科技发展有限公司

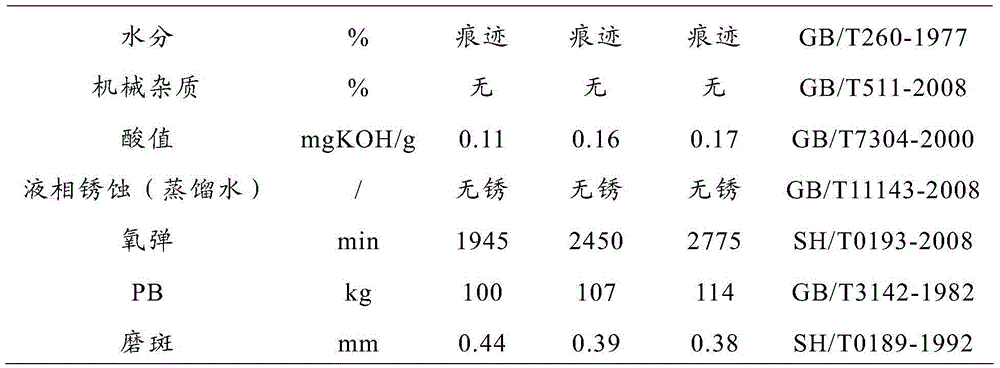

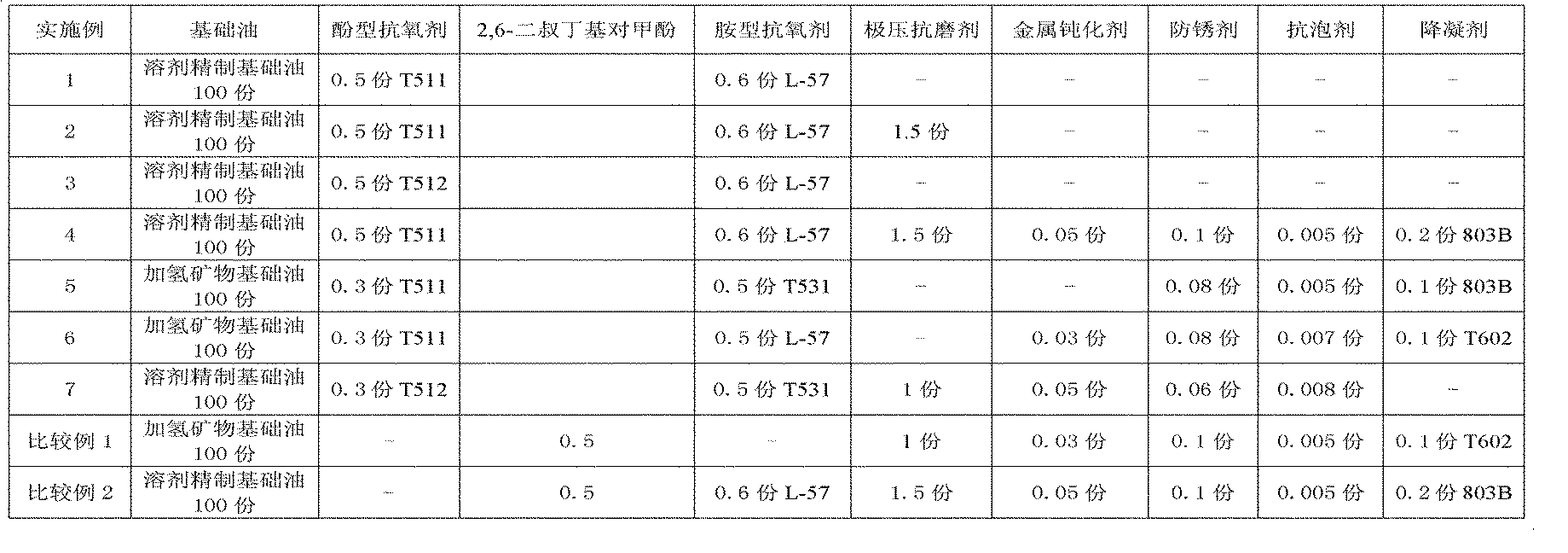

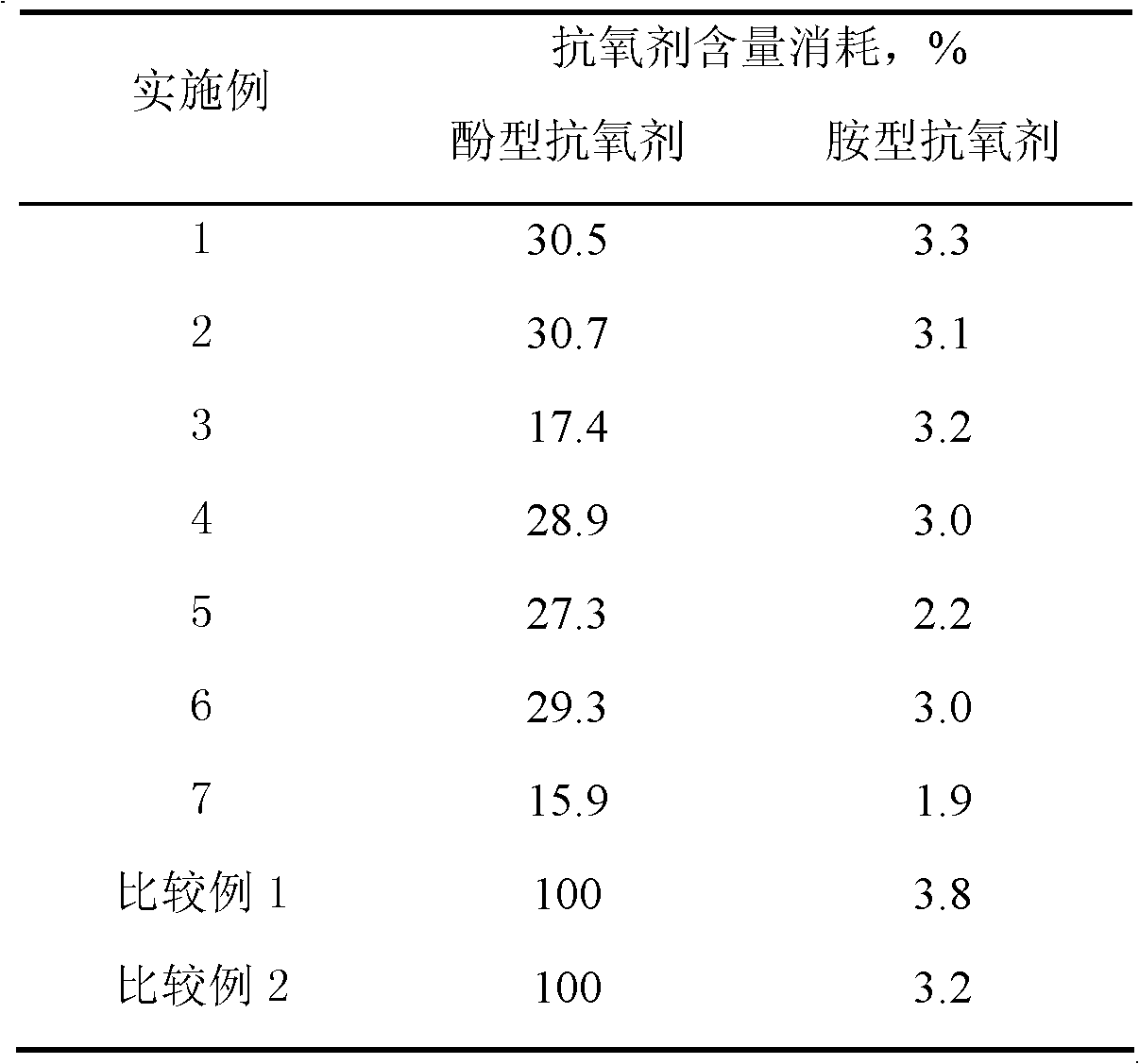

Turbine oil additive composition

ActiveCN102344849AImprove performanceSmall amount of corrosionAdditivesOil additivePhenolic antioxidant

The invention discloses a turbine oil additive composition, which comprises the following components in percent by mass: 8-30 percent of C4 / C8 alkyl substituted diphenylamine, 6-12 percent of phenyl-alpha-naphthylamine, 15-25 percent of phenolic antioxidant, 13-25 percent of methyl ester dibutyl dithiocarbamicacid, 8-10 percent of metal passivator, 5-25 percent of extreme-pressure anti-wear additive, 3-20 percent of anti-rusting agent and 0.5-5 percent of demulsifying agent. The additive composition does not contain diluent oil, is mixed into turbine oil with basic oil, and has superior oxidation stability, high-temperature stability, liquid phase rust-preventing characteristic and water separating performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

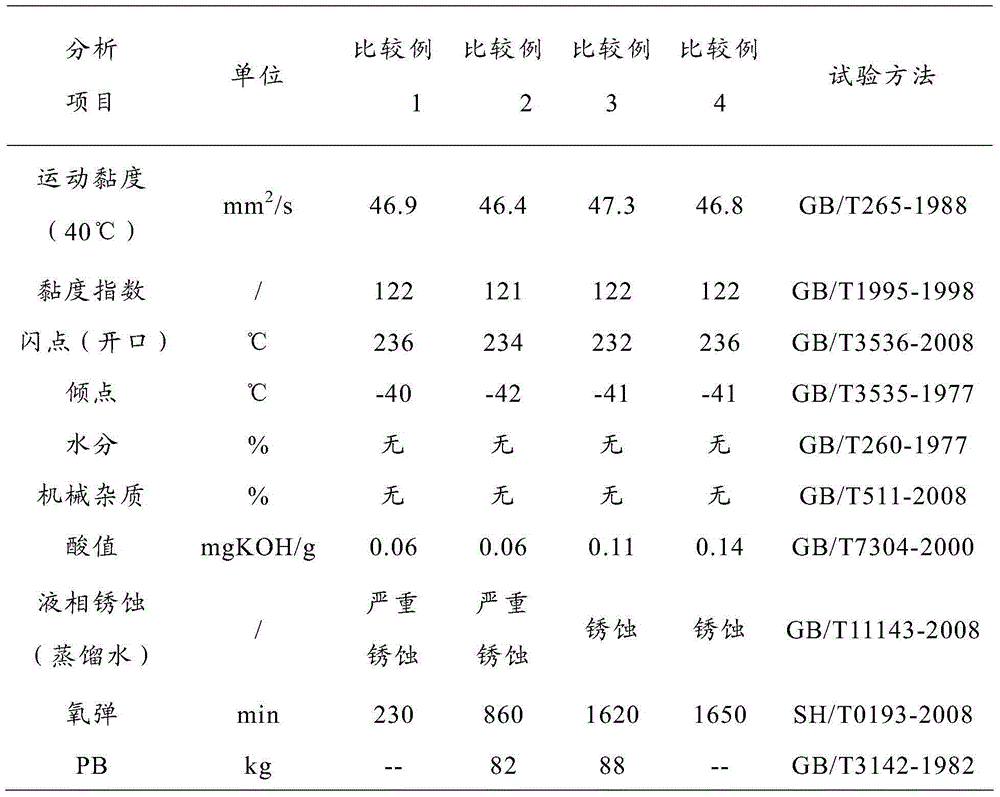

Lubricating oil composition used in rotary screw rod air compressor and preparation method thereof

ActiveCN103981005AImprove protectionImprove antioxidant capacityLubricant compositionBenzoic acidButylated hydroxytoluene

The invention provides a lubricating oil composition used in a rotary screw rod air compressor. The lubricating oil composition comprises the following components in percentage by mass: 0.1-3.0% of antioxidant, 0.01-1.5% of metal antirust agent, 0.01-1.5% of metal deactivating agent, 0.5-3.0% of anti-wear reagent at extreme pressure, 0.1-2.0% of pour point depressant, 10-500ppm of defoaming agent and the balance of hydrofined mineral oil, wherein the antioxidant is one or more of 2,6-ditertiary butyl p-cresol, phenyl-alpha-naphthylamine, dialkyl diphenylamine, butyl octyl diphenylamine and 3,5-ditertbutyl-4-hydroxy hydroxyl acetic acid ester; the metal deactivating agent is one or more of benzotriazole, a derivative of benzotriazole, thiadiazole and a derivative of thiadiazole; the metal antirust agent is one or more of long-chain carboxylic acid, alkyl benzoic acid, oleamide, oleoyl amino acid, benzotriazole and derivative of benzotriazole. The invention further provides a preparation method of the lubricating oil composition.

Owner:KASONG SCI & TECH

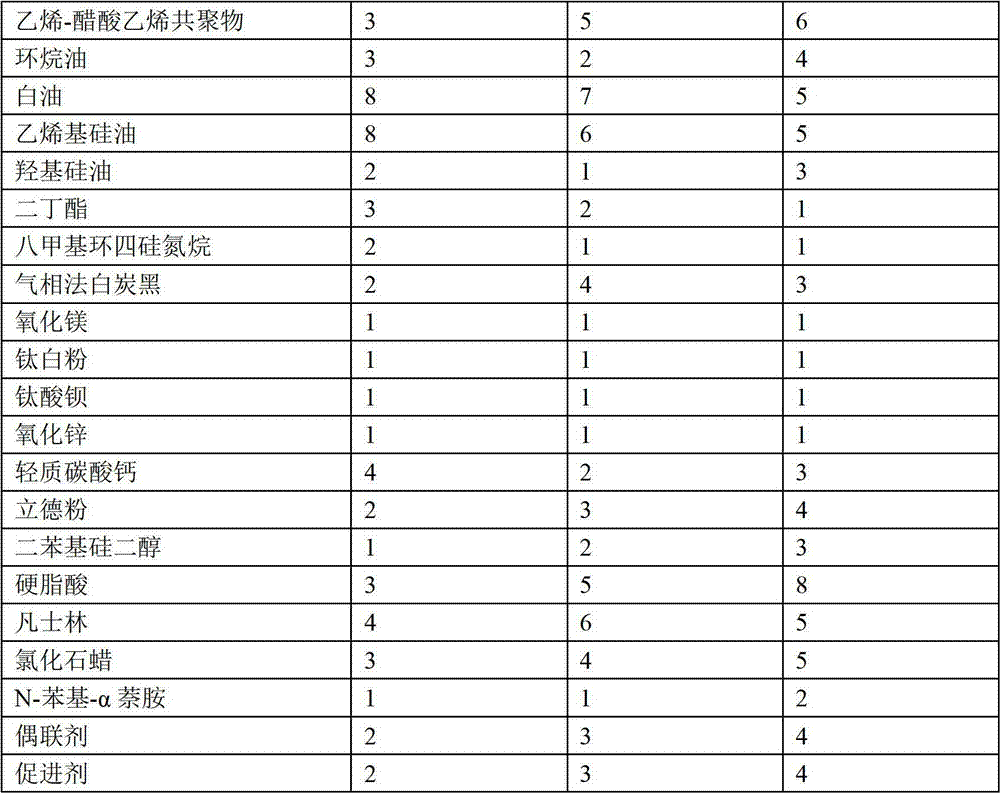

Tearing-resistant silicone rubber composition

The invention discloses a tearing-resistant silicone rubber composition, falling into the technical field of polymer material. The composition comprises the following materials by weight: 30-50 parts of vinyl silicone rubber, 5-10 parts of polyethylene, 5-10 parts of polyolefin resin, 3-6 parts of ethylene-vinyl acetate (EVA) copolymer, 2-4 parts of naphthene oil, 5-8 parts of white oil, 5-8 parts of vinyl silicone oil, 1-3 parts of hydroxyl silicone oil, 1-3 parts of dibutyl ester, 1-2 parts of octamethylcyclotetrasilazane, 2-4 parts of fumed silica, 1 part of magnesia, 1 part of titanium dioxide, 1 part of barium titanate, 1 part of zinc oxide, 2-4 parts of light calcium carbonate, 2-4 parts of lithopone powder, 1-3 parts of diphenylsilanediol, 3-8 parts of stearic acid, 4-6 parts of vaseline, 3-5 parts of chlorinated paraffin, 1-2 parts of N-phenyl-alpha-naphthylamine, 2-4 parts of a coupling agent, and 2-4 parts of accelerator. The silicone rubber composition has excellent mechanical properties, especially tearing-resistant property.

Owner:汕头市科源有机硅材料有限公司

Liquid ashless antioxidant additive for lubricating compositions

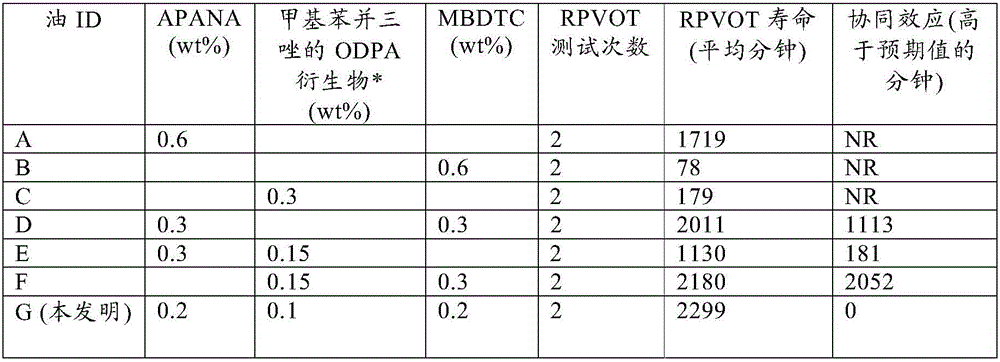

A lubricating composition comprising at least 90% by weight of a base oil, and an antioxidant composition comprising the components, set forth as weight % of the lubricating compostion: (1) solid alkylated-phenyl-alpha-naphthylamine at 0.01-0.3%, (2) an alkylated diphenylamine derivative of triazole, tolutriazole or benzotriazole, at 0.01-0.3%, and (3) methylenebis(di-n-butyldithiocarbamate), at 0.01-0.4%.

Owner:VANDERBILT CHEM LLC

Lubricating oil compound additive for compressed natural gas engine

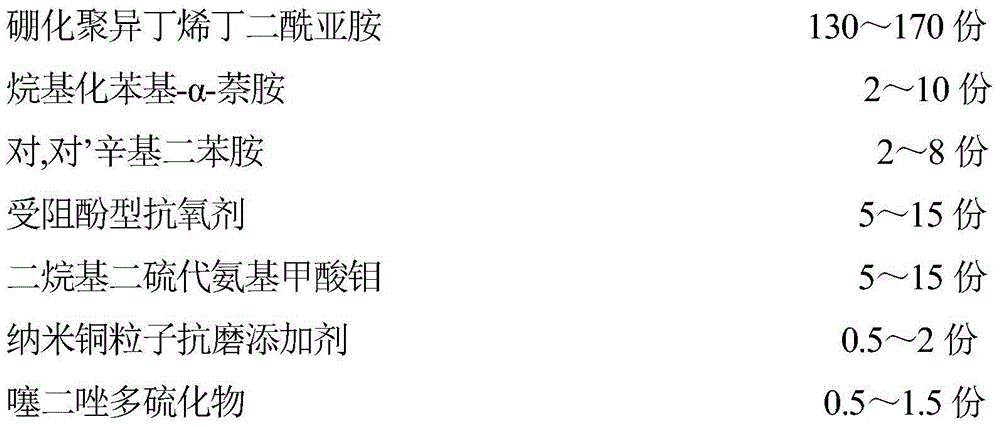

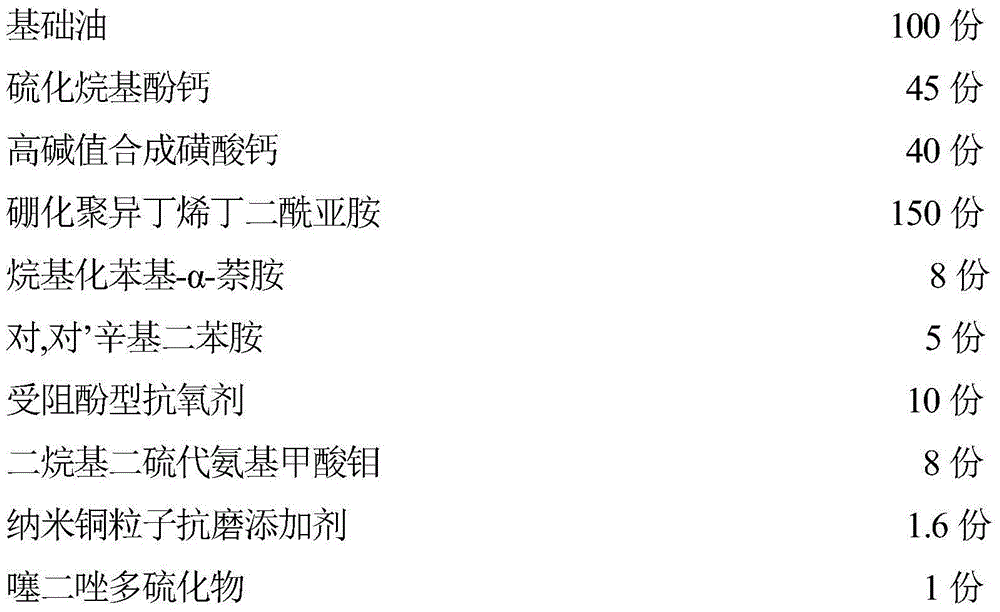

The invention discloses a lubricating oil compound additive for a compressed natural gas engine. The lubricating oil compound additive consists of the following components in parts by weight: 100 parts of base oil, 30-70 parts of sulfurized calcium alkyl phenate, 20-50 parts of high alkali value synthesized calcium sulfonate, 130-170 parts of borated polyisobutylene succinimide, 2-10 parts of alkylated phenyl-alpha-naphthylamine, 2-8 parts of p,p'-octyl diphenylamine, 5-15 parts of a hindered phenol-type antioxidant, 5-15 parts of molybdenum dialkyldithiocarbamate, 0.5-2 parts of a nano-copper particle antiwear additive, and 0.5-1.5 parts of thiadiazole polysulfide. The lubricating oil compound additive can be used for blending compressed natural gas engine oil of various quality grades, and can be particularly used for blending a special lubricating oil for a heavy-load compressed natural gas engine of a bus, the product blended by use of the lubricating oil compound additive is excellent in product performance, and has longer oil exchange period as well as relatively excellent lustration dispersivity, lubricating performance, abrasion resistance and oxidation resistance, and the additive dose is 6.0%-7.2%, and is lower than the average addition level of the industry.

Owner:陕西通用润滑科技有限公司

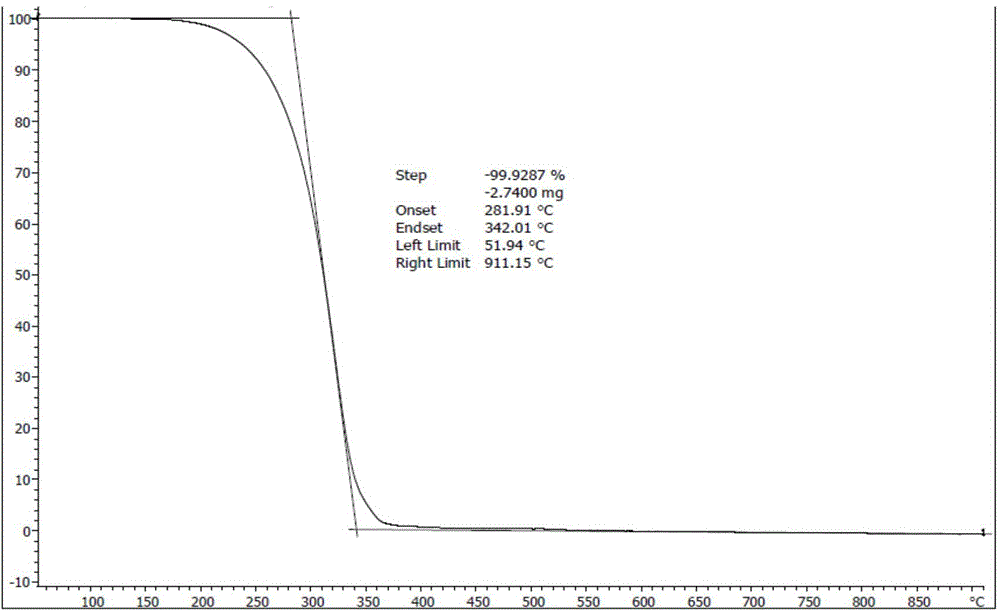

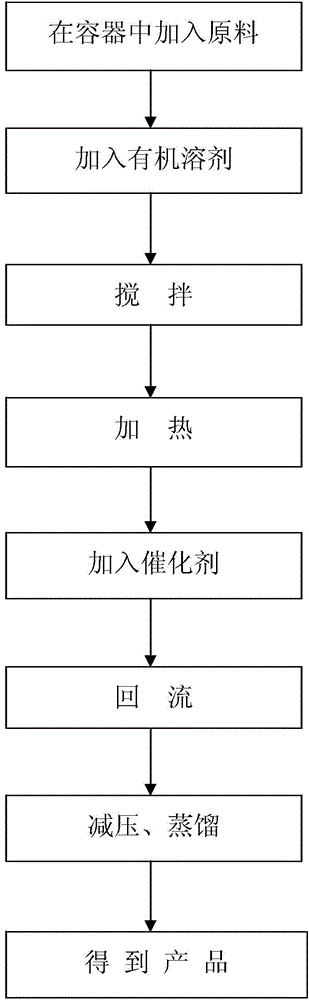

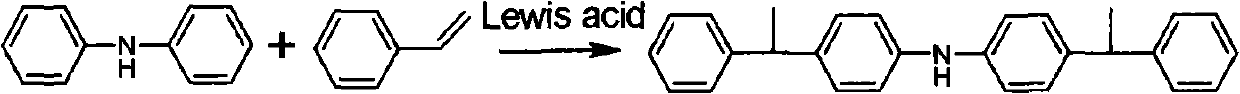

Amine oligomer anti-oxidant and preparation method thereof

InactiveCN105733740AHigh thermal decomposition temperatureImprove thermal stabilityAdditivesDistillationReaction temperature

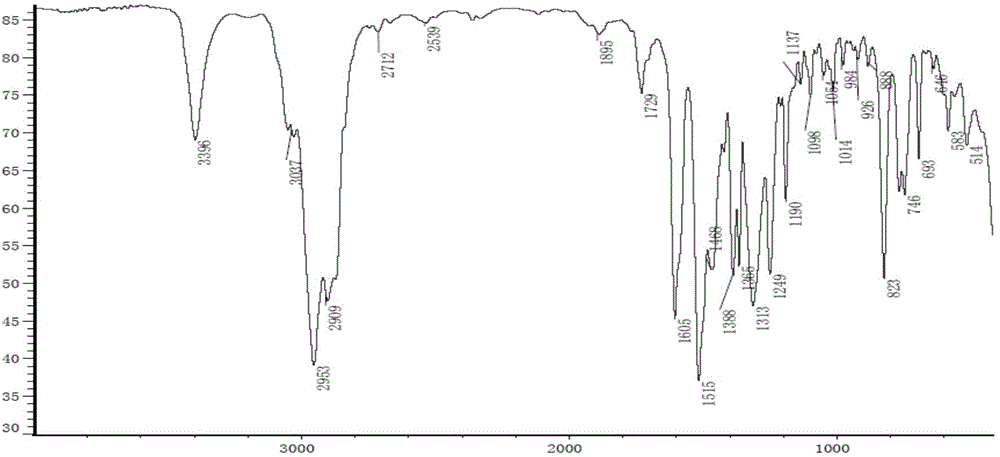

The invention belongs to the technical field of organic polymer compounds and discloses an amine oligomer anti-oxidant and a preparation method thereof. The amine oligomer anti-oxidant is prepared from an alkylated diphenylamine compound and an N-phenyl-alpha-naphthylamine compound through a reaction. The preparation method comprises 1, adding the alkylated diphenylamine compound and the N-phenyl-alpha-naphthylamine compound into a container, 2, adding an organic solvent into the container and carrying out stirring, 3, carrying out a reaction process at a reaction temperature of 40-160 DEG C, 4, adding an oxidation coupling catalyst into the reaction system along with stirring, 5, carrying out a backflow reaction process for 2-10h, and 6, after the reaction, diluting the product through a diluent, carrying out water washing until pH is 7 and carrying out reduced pressure distillation to obtain a taupe solid product. The amine oligomer anti-oxidant has a high thermolysis temperature, provides excellent oxidation resistance for a lubricant and can be individually used as an anti-oxidant or be combined with other additives.

Owner:PETROCHINA CO LTD

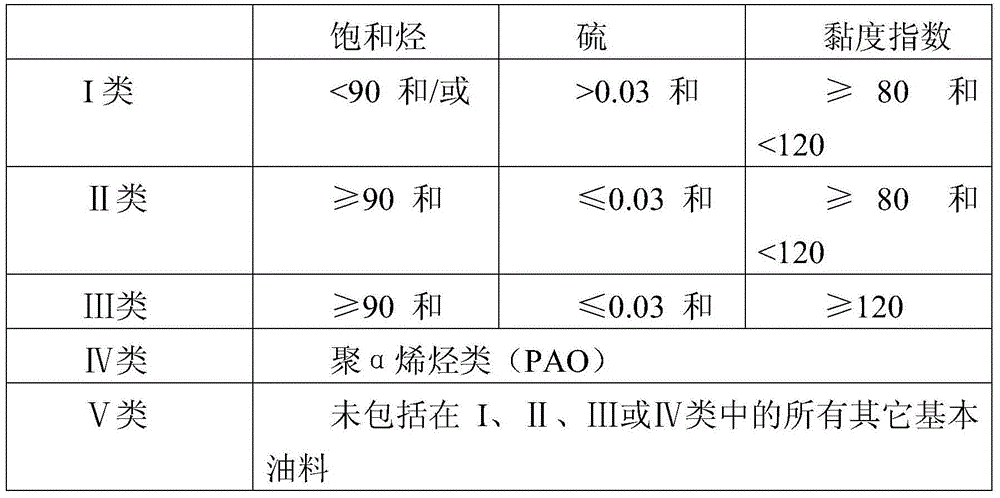

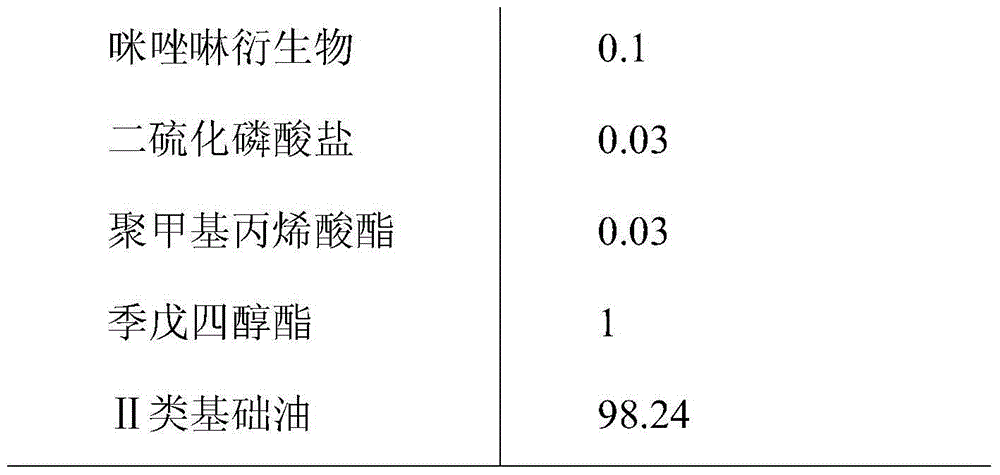

Steam turbine lubricating oil composition

InactiveCN105733761AGood high temperature resistance and oxidation resistanceStrong extreme pressureLubricant compositionImidazoline derivativesCarboxylic acid

The invention relates to a steam turbine lubricating oil composition which comprises the following components: 0.03-1.5 wt% of an anti-oxidant; 0.03-0.2 wt% of an antirust agent, 0.001-0.1 wt% of an anti-foaming agent, 0.03-1 wt% of an antiwear agent, 1-20 wt% of polyol ester, and balance base oil, wherein the anti-oxidant is alkyl diphenylamine and / or alkyl phenyl-alpha-naphthylamine; the antirust agent is a complex mixture of carboxylic acid derivatives and imidazoline derivatives; the anti-foaming agent is polymethacrylate or methyl siloxane; the antiwear agent is a compound containing sulfur, phosphor, and nitrogen; the polyol ester is pentaerythritol ester or diol ester; and the base oil is II type or III type base oil with the saturated hydrocarbon content more than 90% and the sulfur content less than 0.03%. The steam turbine lubricating oil composition has the advantages of the excellent high temperature resistance and antioxidation performances, tiny greasy filth generation trend, excellent extreme pressure performance, antirust performance, hydrodissection performance, air separation performance, filterability and extreme low acid value.

Owner:PETROCHINA CO LTD

Screw-type ammonia compressor oil composite

InactiveCN103031188AImprove Oxidation StabilityGood viscosity and temperatureAdditivesPropanoic acidTert butyl phenol

The invention relates to a screw-type ammonia compressor oil composite, which mainly solves the technical problems of poor resistance to oxidation and short oil product service life of the screw-type ammonia compressor oil composite under the condition that cuprammonia is mixed with ammonia in the prior art. The screw-type ammonia compressor oil composite comprises the following ingredients in parts by weight: 100 parts of mineral base oil and 0.01-2 parts of antioxygen, wherein the antioxygen consists of phenol-type antioxygen and ammonia-type antioxygen; the phenol-type antioxygen is selected from at least one of 4,4-methylenebis (2,6- di-tert-butyl phenol), 3,5-di-tert-butyl-4-hydroxy phenyl acrylic ester or quadri[beta(3,5-di-tert-butyl-4-hydroxy phenyl) propionic acid] pentaerythritol ester; and the ammonia-type antioxygen is selected from at least one of phenyl-alpha-naphthylamine, alkylating phenyl-alpha-naphthylamine and octyl butyl diphenylamine or alkylating diphenylamine. According to the technical scheme, the problem is favorably solved, and the technical scheme can be used for the industrial production of the screw-type ammonia compressor oil composite.

Owner:CHINA PETROLEUM & CHEM CORP

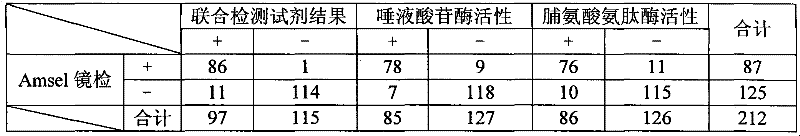

Joint detection reagent for bacterial vaginosis

InactiveCN101748188AAvoid missing detectionHigh sensitivityMicrobiological testing/measurementMicroorganism based processesBacterial vaginosisP-Nitroaniline

The invention relates to a joint detection reagent for bacterial vaginosis, which comprises a sialidase activity detection reagent and a praline aminopeptidase activity detection reagent, wherein the sialidase activity detection reagent consists of the following substances: 0.5-2.5g / l enzyme substrate A, 30-60g / l carbohydrate and 1-2g / l citric acid; the enzyme substrate A is 5-bromine-4-chlorine-3-indol-N-acetyl-alpha-sialic acid glycosides, nitrobenzene-N-acetyl-alpha-sialic acid glycosides or naphthol-N-acetyl-alpha-sialic acid glycosides; the praline aminopeptidase activity detection reagent consists of the following substances: 2-5g / l enzyme substrate B, 0.1-0.3mol / l Tris-hydrochloric acid buffer solution and 10-20g / l N-glycylglycine; and the enzyme substrate B is L-proline-paranitroaniline, L-proline-alpha-naphthylamine or L-proline-beta-naphthylamine. The reagent is used conveniently, special devices such as a microscope and the like are not required in detection, the detection speed is high, the sensitivity and the specificity are high, BV detection miss caused by merely detecting the activity of one enzyme is effectively avoided, and the reagent is popularized easily.

Owner:AUTOBIO DIAGNOSTICS CO LTD

Coke inhibitor of high-temperature refining equipment

InactiveCN1712494AAvoid corrosionApplicable temperature rangeThermal non-catalytic crackingKeroseneDistillation

A coking inhibitor of high-temperature for petroleum refining consists of thiophosphoric acid alkyl benzene monosulfonic acid bisamine salt 75í½98wt%, antioxidant 1í½15wt%, polymerization inhibitor 1í½10wt% and organic solvent 20wt%. Antioxidant is hydroquinone or 4,4-di-2-ethylhexylphosphine oxide or 2,6-di-tert.-butyl-p-cresol or N, N,-di-secondary-ursol or phenyl-alpha-naphthylamine, polymerization inhibitor is benzoquinone or p-tert-butyloxophenic acid, and organic solvent is xylene or diesel or kerosene or solvent oil. Its advantages include simple process, and good coke-inhibiting effect and stability. It can be used for crude oil distillation, catalytic crack and inhibition delay coking heater.

Owner:张喜文

Formula of flame retardant ABS (Acrylonitrile Butadiene Styrene)

InactiveCN102675812AImprove flame retardant performanceImprove mechanical propertiesPolymer scienceAntioxidant

The invention discloses a formula of flame retardant ABS (Acrylonitrile Butadiene Styrene), which comprises ABS, a flame retardant, a compatible agent, an additive, an antioxidant as well as a dispersing agent, wherein the ABS is 121HABS; the flame retardant is magnesium hydroxide and melamine sodium phosphate; the compatible agent is chlorinated polyethylene; the additive is silicon oxide; the antioxidant is N-phenyl-alpha naphthylamine; and the dispersing agent is polyethylene wax. The formula of the flame retardant ABS enables the flame retardant ABS to have the efficacies of flame retardance, good mechanical property, good gloss, good stability, oxidation resistance, corrosion resistance, wide using range and the like.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

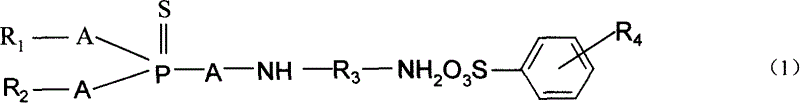

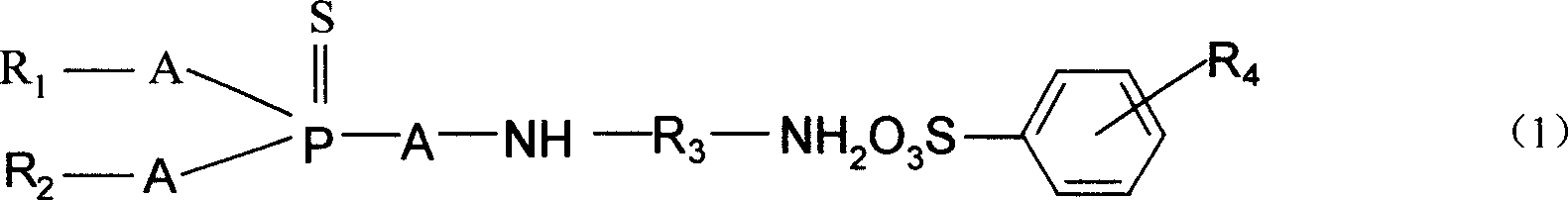

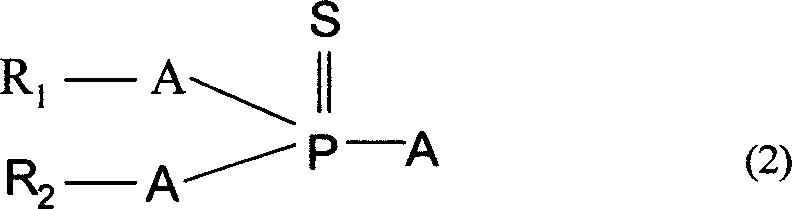

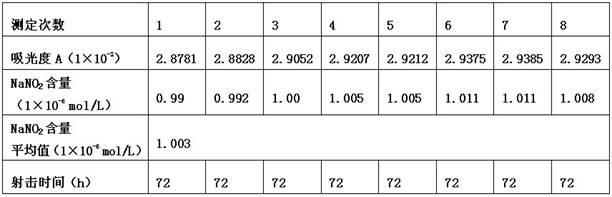

Measuring method for gun shooting time

InactiveCN102519955AReduced redox propertiesImprove detection efficiencyMaterial analysis by observing effect on chemical indicatorSulfanilic acidAcetic acid

Provided is a measuring method for gun shooting time. On the condition of acetic acid (HAC), nitrite and sulfanilic acid (SN) have a diazo reaction and then couple with alpha-naphthylamine (NC) for coloration. Based on the light absorption characteristic of the product, spectrophotometry is adopted to measure the content of nitrite in shooting residue. The residue in a gun barrel obtained at different time after shooting is extracted for analysis, a relation curve of the content of nitrite and shooting time is obtained, and thus gun shooting time is determined. The measuring method for gun shooting time is capable of providing an effective method for detection of gun shooting time, causes no damage to a gun on the premise of guaranteeing extraction effect, has the advantages of being accurate, fast, high in sensitivity, good in stability, reliable in results and the like, and meets the requirements for detection and scientific research of gun shooting time.

Owner:GANSU INST OF POLITICAL SCI & LAW

Volatile stamping and cutting oil

The invention provides volatile stamping and cutting oil which is suitable for the metal stamping and cutting processing of laminar plate materials and contains the following components: 85 to 98 percent of aromatic hydrocarbon removal solvent, 1 to 10 percent of synthetic ester monoester, 0.01 to 2 percent of metal corrosion inhibitor and 0.05 to 5 percent of antioxidant, wherein the metal corrosion inhibitor is benzotriazole, and the antioxidant is the mixture of one or several selected from 2,6-di-tert-butyl-p-cresol, phenyl-alpha-naphthylamine, benzotriazole and derivatives thereof. The volatile stamping and cutting oil is suitable for the metal stamping and cutting processing of the laminar plate materials and has light viscosity and excellent volatilization performance and anti-rustperformance, a workpiece after the processing is finished can be free from washing, the deformation of the processed and molded workpiece is avoided, the time of a processing process is greatly saved, and the efficiency is enhanced.

Owner:广东恒昌科技润滑油有限公司

Super-thick soft rubber and preparation method thereof

The invention relates to the field of rubber industry and discloses super-thick soft rubber and the preparation method thereof. The super-thick soft rubber comprises the following components by weight portion: 100 portions of natural rubber 1#, 5-40 portions of carbon black N33, 1-4 portions of stearic acid, 0.75-2.5 portions of N-phenyl-alpha-naphthylamine, 1-4 portions of N-isopropyl-N'-steephenyl-para-phenylene diamine, 1-4 portions of paraffin 58#, 5-40 portions of talcum powder, 1.5-5 portions of brenstone, 2.5-7 portions of magnesium oxide, 4-11 portions of zinc oxide, 0.75-2.5 portions of accelerating agent D, 1-4 portions of solid coumarone, 10-60 portions of barium sulfate, 4-12 portions of dibutyl sebacate and 1.5-4 portions of pine tar. The preparation method comprises the following steps: plasticating the natural rubber 1# until the plasticity of the natural rubber 1# ranges from 0.6 to 0.65, adding other materials, mixing, forming rubber sheets, and molding and vulcanizing the rubber sheets, wherein . The assisting step of partial qualitative die clamping is carried out before vulcanization so as to obtain the super-thick soft rubber through one-step stable molding. The product is not easily deformed during vulcanization and can still maintain the dimensional stability and accuracy in the molding process.

Owner:SHANGHAI GUIGANG RUBBER PRODS

Aviation lubricating oil composition

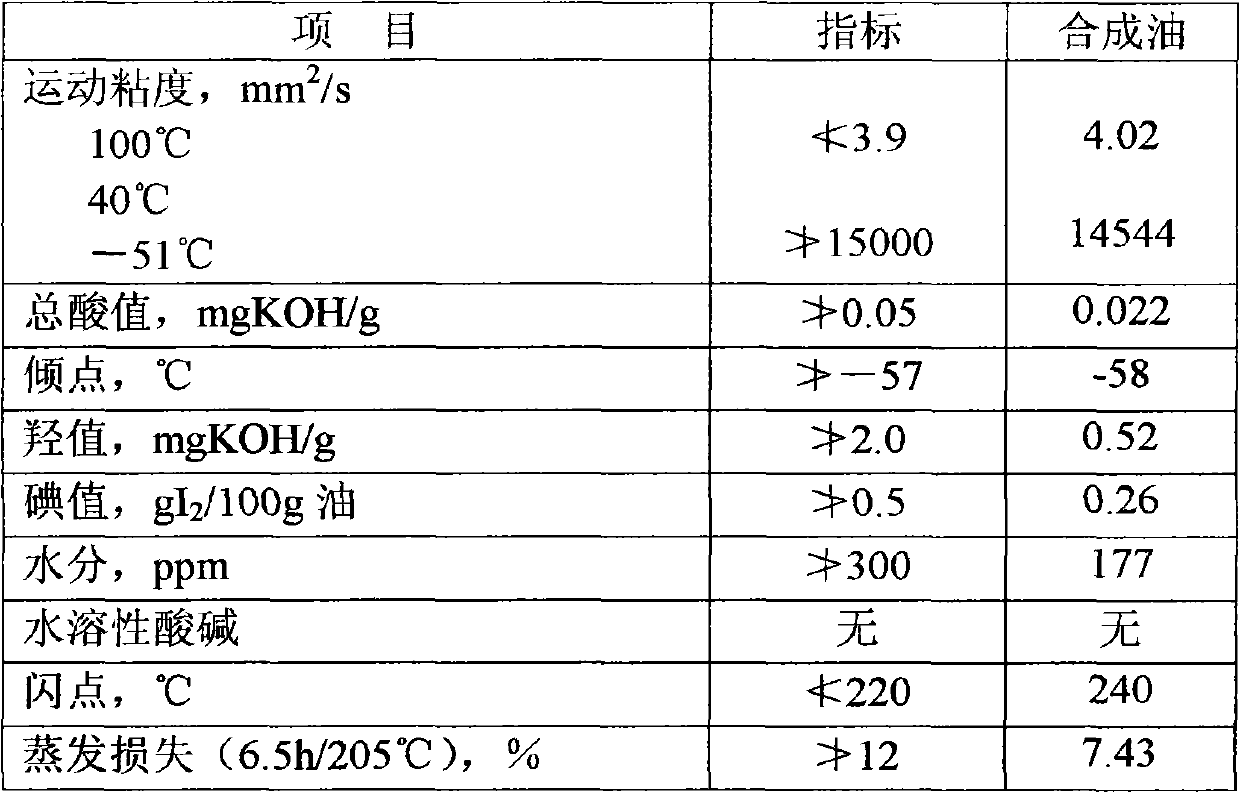

The invention relates to the field of lubricating oil, in particular to a four-centisthene synthetic aviation lubricating oil composition. The composition consists of the following components in percentage by weight: 1.4-3.3 percent of antioxidant mixture, 2-4 percent of triorthocresol phosphate, 0.05-0.1 percent of benzotriazol, 10-100 ppm of non-silicon antifoaming agent and the balance synthetic basic oil, wherein the antioxidant mixture consists of 0.2-0.8 percent by weight of styrenated amine antioxidant NHA11, 0.5-1.0 percent by weight of para,para-di-iso-octyldiphenylamine, 0.2-0.5 percent by weight of N-phenyl-alpha-naphthylamine and 0.5-1.0 percent by weight of sterically hindered phenol antioxidant. The four-centisthene synthetic aviation lubricating oil composition disclosed bythe invention is suitable to be used at high and low temperatures, and has high oxidation resistance and high wear resistance.

Owner:PLA AIR FORCE OIL MATERIAL RES INST

Biochemical detection liquid for nitrite in urine

InactiveCN1570636AQuick Self-Test MethodFit closelyMaterial analysis by observing effect on chemical indicatorBiological testingAcetic acidSulfanilic acid

This is a biochemistry detection liquid of urine nitrate comprising 0.35-0.45w / v percents sulfanilic acid, 0.2-0.3mgw / v percents alpha-naphthylamine, 20-40v / v percents glacial acetic acid, 1 -2v / v percents carbinol and distilled water. This invention offers biochemistry detection liquid and self-checking method of urine nitrate for the mass scoutting and checking dynamically. Through the recording curve diagram in accordance with series detecting color result one can self-estimate something: 1, warning signal of health and pathogenic factor; 2, forepart detectable rate of bacterial urine; 3, the synchronous tracking monitoring of curative effect during the treating course. The above liquid offer the likelihood of carrying out all this function.

Owner:赵青华

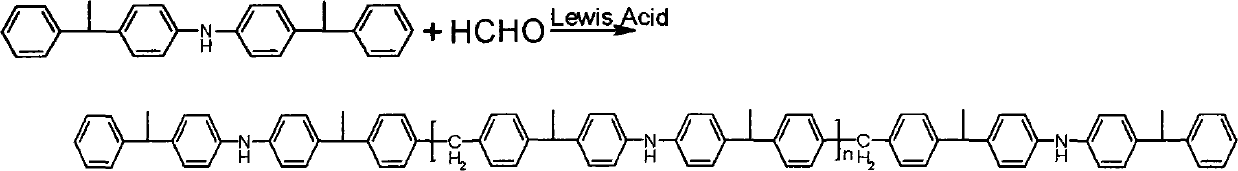

Special visco-elasticity adhesive for damping and construction method thereof

InactiveCN101463232ANon-macromolecular adhesive additivesMacromolecular adhesive additivesSolubilityEngineering

The invention discloses an adhesive special for viscoelastic damping, having a formulation composed of: neoprene-240, duprene B-30, magnesia, zinc oxide, resins (giving specific names of the resins) and carbon black, N-phenyl-alpha-naphthylamine (an anti-aging agent A). A manufacturing method thereof comprises the steps: using a mill, adding enough cooling water, regulating the roller spacing to the minimum thereof, putting in crude rubbers, plasticating the rubbers over 10 times, widening the roller spacing to 2-4 mm, adding a variety of accessory ingredients, plasticating inversely for three times, regulating the roller spacing to about 1mm, packing 3-6 triangle bags, putting 1-2mm heavy-gage rubber sheets for backup; preventing the rubber sheets from adhesive bonding, cutting the rubber sheets into rubber strips and immersing the rubber strips in a solvent for over 24 hours, stirring the solvent until sufficient dissolution thereof is realized, wherein, the concentration of the solution is 20-25%; acquiring the adhesive special for viscoelastic damping. The body materials have similar solubility parameters and high cohesive strength, are resistant to seawater, oil and flame and possess high mutual viscosity and adhesion strength with the adhered materials like a steel plate, besides, the initial viscosity of the adhesive is excellent.

Owner:天津市振海橡胶科技发展有限公司

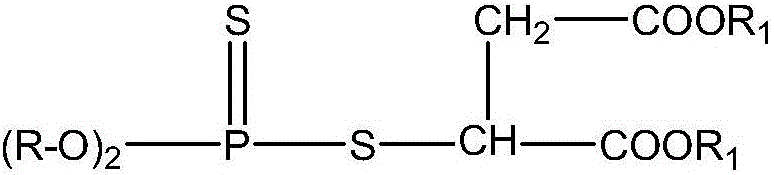

Octylated Phenyl-Alpha-Naphthylamine Product Mixtures And Production Of Such Mixtures Having A High Content Of Octylated Phenyl-Alpha-Naphthylamine

InactiveUS20110124538A1Less-costly to produceWell mixedAmino preparation from aminesLiquid carbonaceous fuelsAlkyl transferAntioxidant

Process technology is described for producing a reaction-derived product mixture containing a high yield of octylated phenyl-alpha-naphthylamine by catalytic alkylation of phenyl-alpha-naphthylamine with diisobutylene. New reaction-derived product mixtures are produced. Also provided are novel reaction-derived octylated phenyl-alpha-naphthylamine reaction product mixtures from which catalyst residues and excess olefin components have been removed. These reaction product mixtures are effective as antioxidants for various oxygen-sensitive substrate materials such as oils and lubricants. Also described are new octylated phenyl-alpha-naphthylamine product mixtures and their use in forming clear, stable, liquid antioxidant compositions for addition to a wide variety of substrates.

Owner:ALBEMARLE CORP

Oxidation inhibitors for alcohol fuel engine lubricating oil and preparation method thereof

The invention discloses oxidation inhibitors of different proportions for alcohol fuel engine lubricating oil and a preparation method thereof. The oxidation inhibitors are a group of composite additives composed of 5 to 45% of N-phenyl-alpha-naphthylamine, 3 to 35% of 2,5-mercaptothiadiazole, 10 to 60% of aminoborate, 15 to 40% of modified low-base number petroleum calcium sulfonate and 5 to 10% of dilution oil. The preparation method comprises the following steps: heating dilution oil to 55 to 65 DEG C; then successively adding N-phenyl-alpha-naphthylamine, 2,5-mercaptothiadiazole, aminoborate and modified low-base number petroleum calcium sulfonate; and carrying out stirring at a constant temperature of 45 to 50 DEG C for no less than 45 min so as to obtain the oxidation inhibitors. 3.5 to 5% of the oxidation inhibitors are added into in-use internal combustion engine oil, so oxidation and decay of alcohol fuel engine lubricating oil can be effectively inhibited, the service life of engine lubricating oil is prolonged, and carbon formation in an engine is reduced. The oxidation inhibitors are convenient to use.

Owner:HARBIN UNIV OF COMMERCE

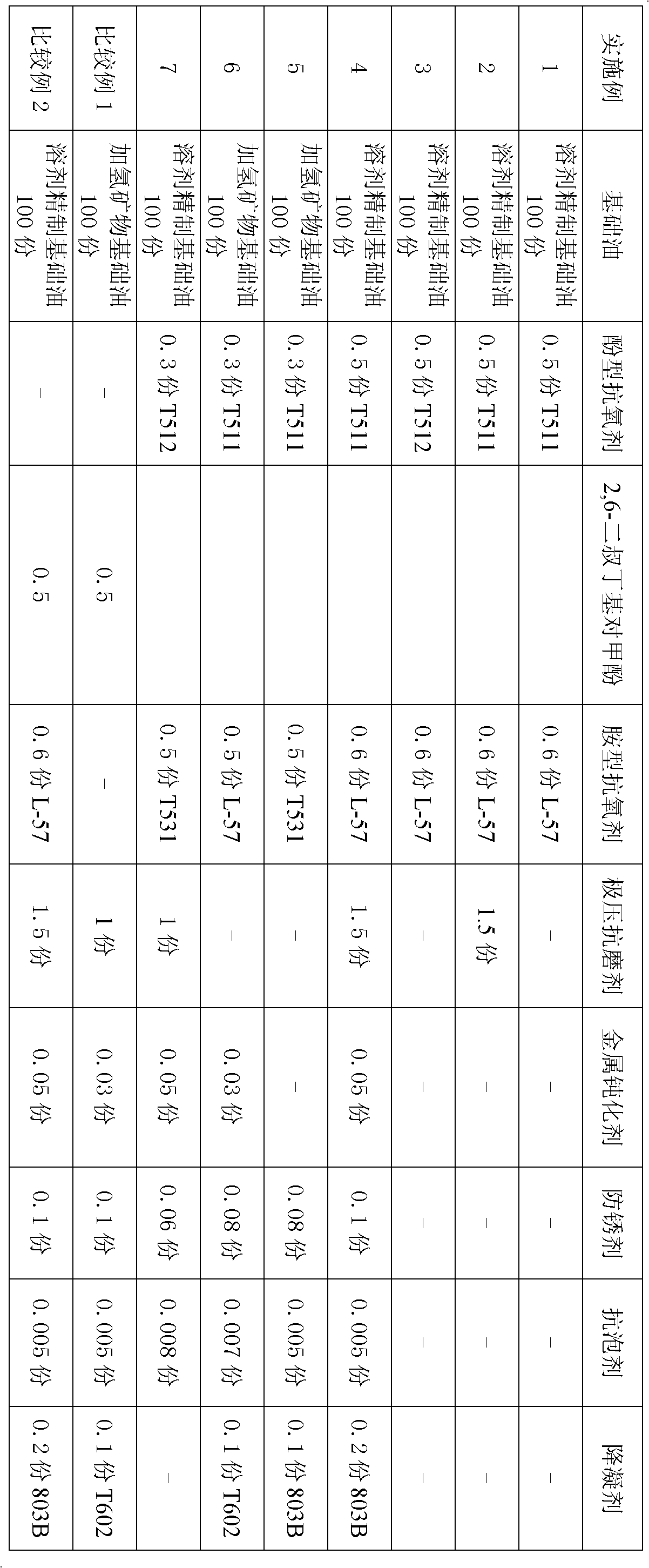

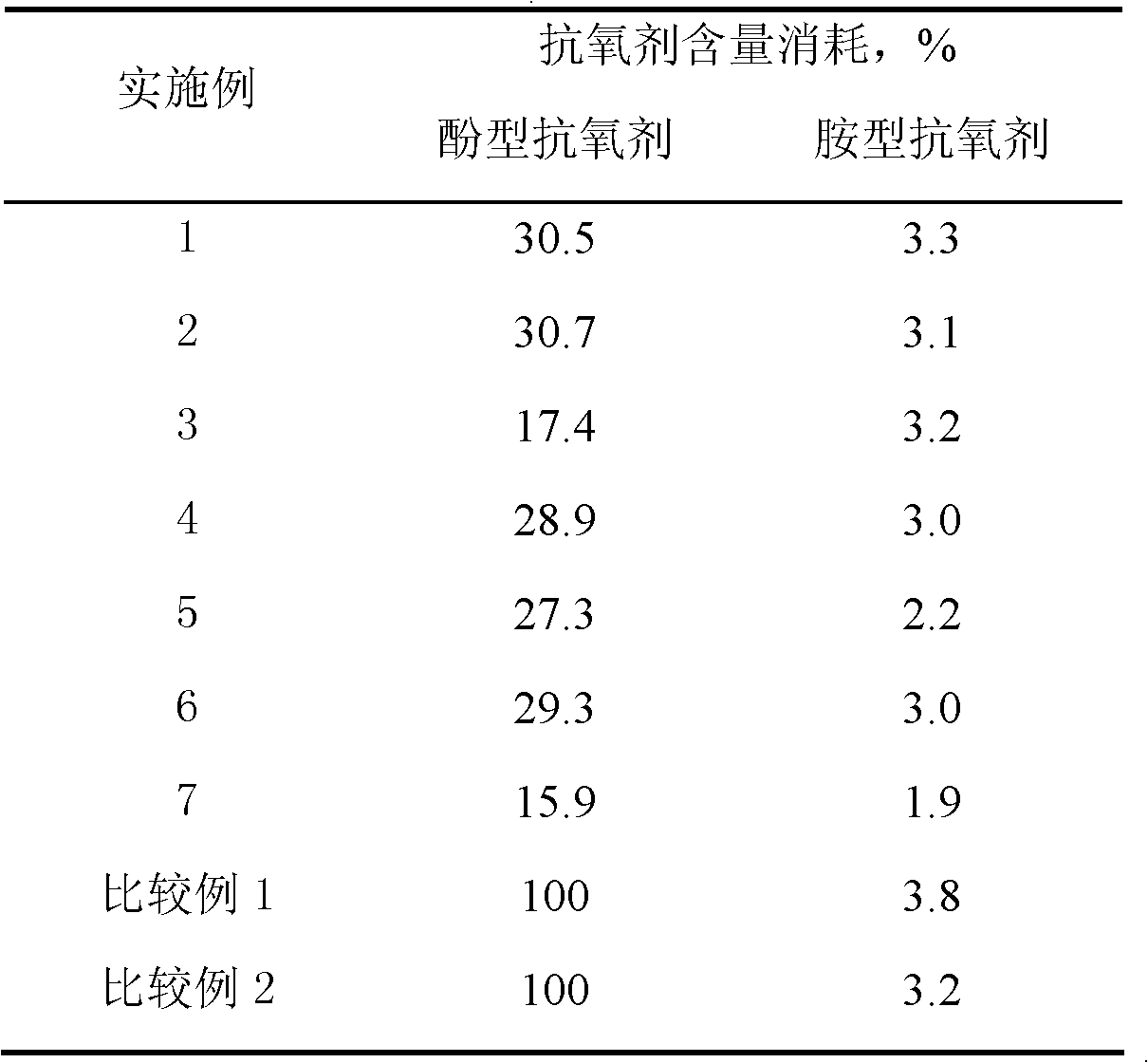

Method for improving inoxidizability of cuprammonia-containing ammonia compressor oil

InactiveCN103031186AImprove Oxidation StabilityGood viscosity and temperatureAdditivesTert butyl phenolTert butyl

The invention relates to a method for improving the inoxidizability of cuprammonia-containing ammonia compressor oil, and mainly solves the problems of the prior art that under the condition that cuprammonia is mixed with ammonia gas, the inoxidizability of a screw type ammonia compressor oil composite is poor, and the service life of an oil product is short. The method disclosed by the invention has the technical scheme that the ammonia compressor oil and cuprammonia mixed liquor are fully contacted for 1-10 hours under the conditions that the temperature is 40-60 DEG C and the gage pressure is 10-30MPa; the weight ratio of the ammonia compressor oil to the cuprammonia is 1-3, wherein the ammonia compressor oil comprises the following components in parts by weight: 100 parts of mineral base oil and 0.01-2 parts of antioxygen, and the antioxygen consists of phenolic antioxidant and amine antioxidant; and the phenolic antioxidant is selected from at least one of 4,4-methylenebis (2,6-di-tert-butyl phenol), 3,5-di-tert-butyl-4-hydroxy phenylacrylic acid and pentaerythritol tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate], and the amine antioxidant is selected from at least one of phenyl-alpha-naphthylamine, alkylate phenyl-alpha-naphthylamine, octyl butyl diphenylamine and alkylated diphenylamine, so that the problem is better solved. The method can be used in the industrial production for improving the inoxidizability of the cuprammonia-containing ammonia compressor oil.

Owner:CHINA PETROLEUM & CHEM CORP

Sealing ring and preparation method thereof

InactiveCN107200935AExtended service lifeImprove aging resistanceMetallic material coating processesSulfurSulfenamide

The invention discloses a sealing ring and a preparation method thereof. The sealing ring comprises a framework and a rubber strip, wherein the rubber strip is prepared from the following ingredients in parts by weight: 80 to 120 parts of ethylene propylene diene rubber, 1 to 5 parts of N-phenyl-alpha-naphthylamine, 1 to 3 parts of sulfur, 2 to 5 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1 to 3 parts of zinc stearate, 5 to 8 parts of softening agents, 20 to 25 parts of reinforcing agents and 15 to 20 parts of filling agents. The sealing ring has the beneficial effects that when the sealing ring is applied to a wheel hub, the sealing ring is in the air and sunlight contact state; the anti-aging performance is realized; the service life is long.

Owner:浙江哈楠业科技有限公司

Formula of inner ply compound of microwave-vulcanized double-compound rubber tube

InactiveCN101781414ASolve the problem of microporousSimple processFlexible pipesPolymer scienceStearic acid

The invention relates to a formula of an inner play compound of a microwave-vulcanized double-compound rubber tube, which comprises the following components in part by mass: 100 parts of nitrile rubber, 80 to 100 parts of fast extruding furnace black, 20 to 30 parts of dioctyl phthalate, 20 to 30 parts of dehumidification antifoaming agent, 4 to 6 parts of zinc oxide, 1 to 2 parts of stearic acid, 1 to 2 parts of N-phenyl-alpha-naphthylamine, 2 to 3 parts of N-isopropyl-N-ditolyl p-phenylene diamine, 5 to 15 parts of coumarone indene resin, 0.6 to 1 part of 2-mercaptobenzothiazole, 1.4 to 1.8 parts of dibenzothiazyl disulfide, 0.8 to 1.2 parts of dialkyl zinc phosphate disulfide, and 1.6 to 2.0 parts of sulfur. Due to the addition of TP / S and the dehumidification antifoaming agent, the problem of micropores after microwave vulcanization of the inner ply compound is solved. Compared with the traditional rubber tube vulcanized by the vulcanizing tanks, the rubber tube of the invention has the advantages of simple process, manual labor conservation, improvement of production efficiency by one time, reduction of production cost by 50 percent, and same material performance as the traditional rubber tube vulcanized by the vulcanizing tanks.

Owner:TIANJIN PENGYI GRP CO LTD

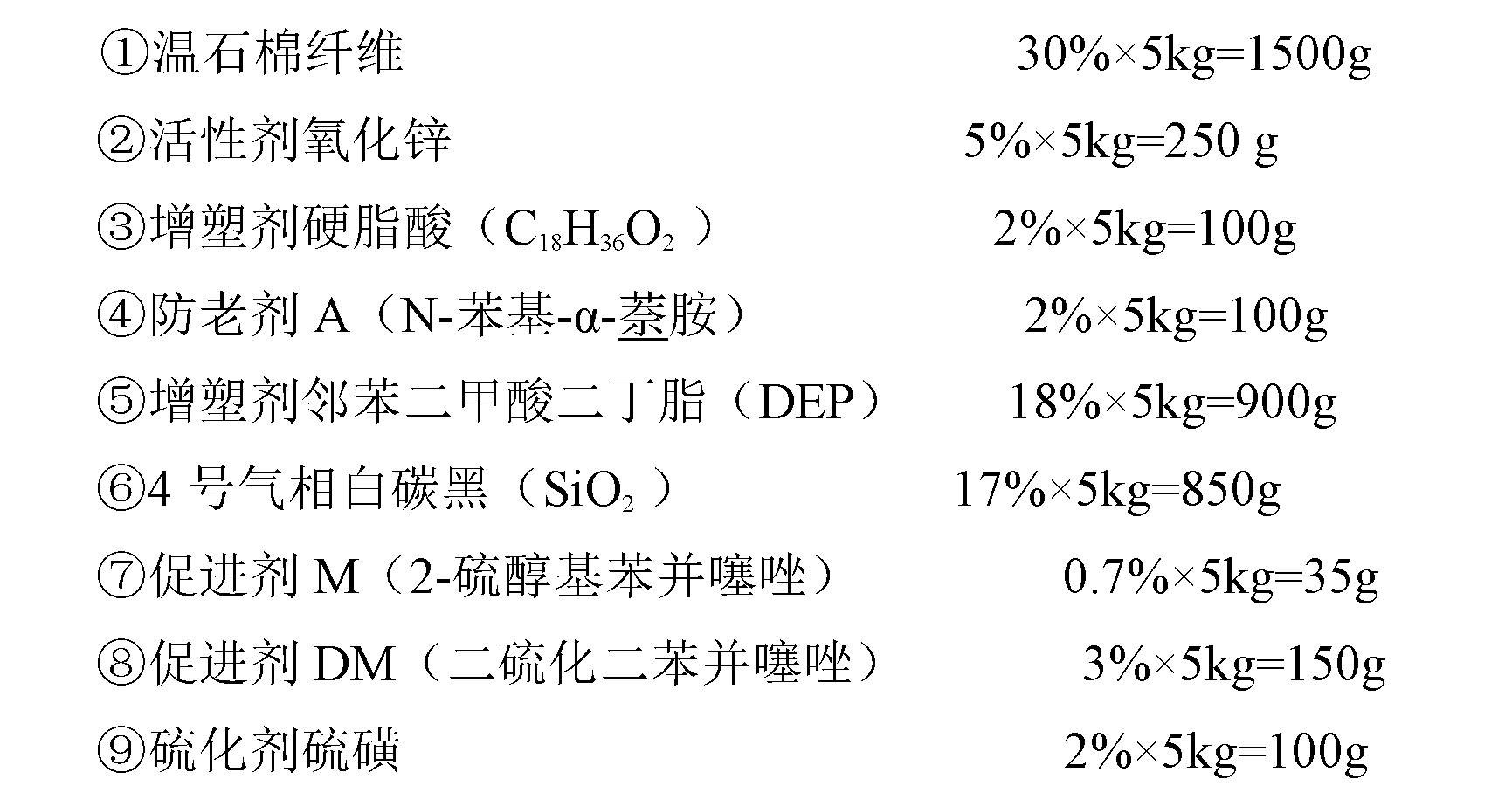

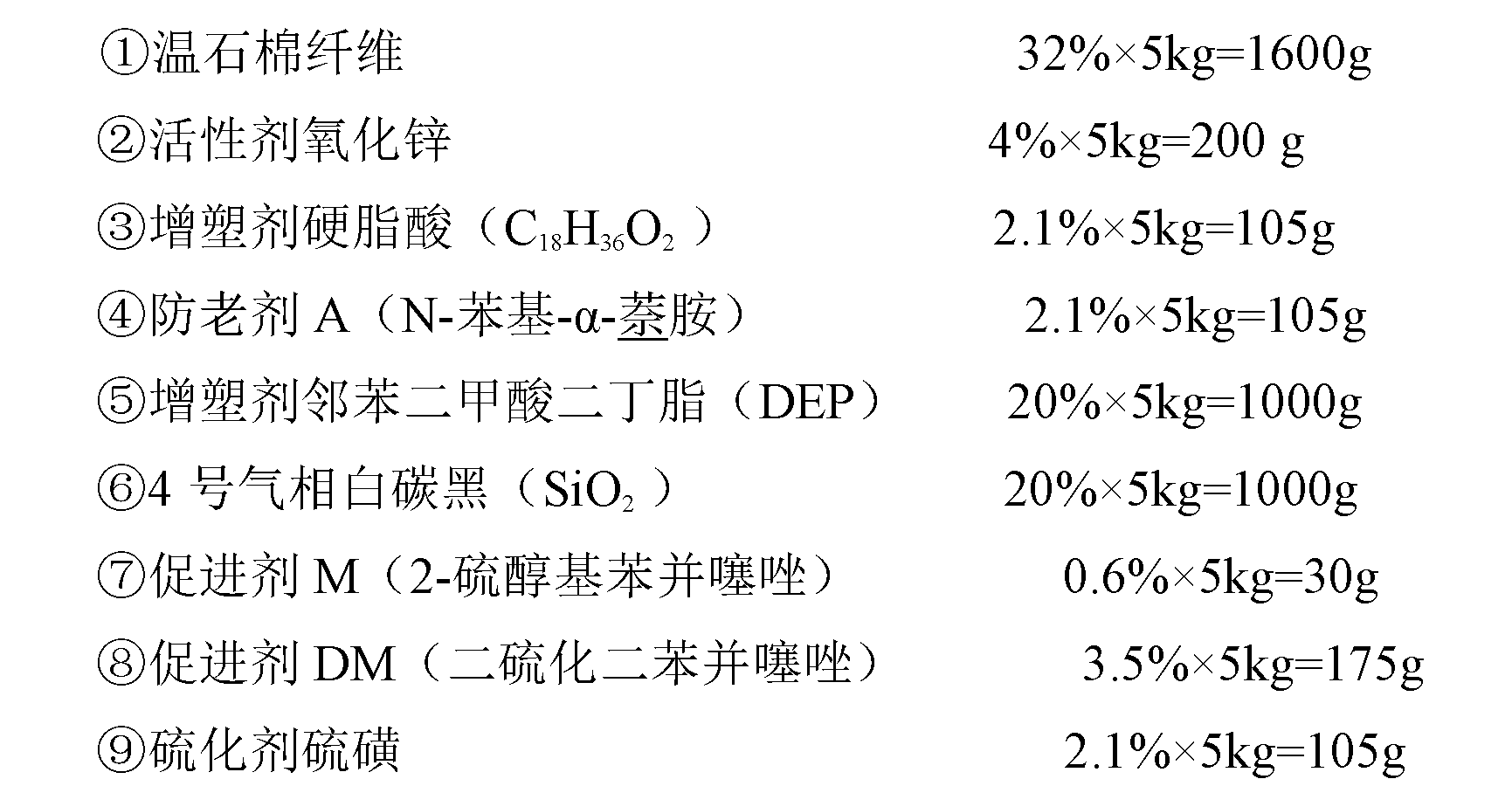

Styrene-butadiene asbestos heat-resisting composite rubber and preparation method thereof

The invention discloses styrene-butadiene asbestos heat-resisting composite rubber and a preparation method thereof. The styrene-butadiene asbestos heat-resisting composite rubber is prepared by styrene-butadiene rubber, chrysotile fiber and compounding agent as raw materials, wherein when the styrene-butadiene rubber is computed according to the mass m, the chrysotile fiber is 25-32%m; and the compounding agent comprises 4-6%m of zinc oxide, 1.8-2.2%m of stearic acid, 16-20%m of dibutyl phthalate, 1.8-2.2%m of N-phenyl-alpha-naphthylamine, 15-20m% of fumed silica, 0.6-0.8%m of 2- mercaptobenzothiazole, 2.5-3.5%m of dibenzothiazyl disulfide and 1.9-2.1%m of sulphur. The styrene-butadiene asbestos heat-releasing compound rubber can be obtained after plastifying, mixing and the like. The rubber has excellent aging resistance, ablation resistance and mechanical property; meanwhile, the preparation method is simple in operation so as to be suitable for mass production.

Owner:航天科工火箭技术有限公司

Formula of modified polystyrene

The invention discloses a formula of modified polystyrene, which comprises polystyrene, an antioxidant, a filler, a foaming agent, a photostabilizer and an antistatic agent, wherein the antioxidant is N-phenyl-alpha-naphthylamine, the filler is talcum powder, the foaming agent is sodium lauryl sulfate, the photostabilizer is 2-hydroxy-methoxydiphenyl ketone, and the antistatic agent is polyoxyethylene sorbitan monostearate. According to the formula, the modified polystyrene has the advantages of antistatic property, aging resistance, low cost, favorable mechanical properties and the like.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

Synthetic plant type insulation oil and preparation method thereof

InactiveCN108456589AImprove low temperature fluidityLubricant compositionN-Octadecanoic acidMass ratio

The invention provides synthetic plant type insulation oil and a preparation method thereof. The insulation oil is prepared from an esterification product and additives, wherein the esterification product is prepared by reacting mixed straight-chain fatty acid and polyols under a catalyst according to a mass ratio of (2-6) to 1; the mixed straight-chain fatty acids are selected from any two or more of n-capric acid, n-hexadecanoic acid, n-octadecanoic acid, oleic acid, linoleic acid and linolenic acid; the polyols are selected from one or more of mono-pentaerythritol, dipentaerythritol, glycerinum and neopentyl glycol; the additives are selected from one or more of tert-butyl p-diphenylamine, di-iso-octyldiphenylamine, octylphenyl-alpha-naphthylamine, 2,6-di-tert-butyl-p-cresol, tetra(beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate) pentaerythritol ester, di-iso-octyldiphenylamine polymer, benzotriazole, 2,5-di(tert-dodecyldithio)-1,3,4-thiadiazole and benzotriazole polymer. The synthetic plant type insulation oil has good low-temperature property, electrical property and oxidation stability.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating oil

The invention relates to lubricating oil. The lubricating oil consists of phosphate, dialkyl zinc dithiophosphate, succinimide, salicylate, polymethacrylate, an antioxidant alpha-naphthylamine, N,N-bisec-butyl p-phenylenediamine, chlorinated paraffin, a rust remover and a demulsifying agent. The lubricating oil disclosed by the invention is good in using effect in a relatively wide temperature range, applicable to be used as the lubricating oil for a diesel engine, small in viscosity in use, capable of commendably saving energy and reducing oil consumption, and also not too large in viscosity during low-temperature start in order to prevent the problem of difficulty in start.

Owner:全椒县新华机械有限责任公司

Top sealing ring of plastic thermos bottle stopper

The invention provides a top sealing ring of a plastic thermos bottle stopper. A material for making the top sealing ring is formed by compositing raw materials in parts by weight as follows: 30 parts of polyethylene, 1.5 parts of glass fibers, 0.08 parts of phenyl-alpha-naphthylamine, 0.1 parts of triphenyl phosphate, 21.8 parts of polyester, 19.9 parts of epoxy resin, 1.9 parts of a rubber accelerator, 23.5 parts of barium carbonate, 2.5 parts of 6,000-mesh superfine barium, 1.5 parts of titanium dioxide, 0.65 parts of a leveling agent, 0.2 parts of copper gold powder, 0.01 parts of graphene, 0.3 parts of talc and 0.5 parts of modified zeolite powder. The top sealing ring has better ageing resistance in the high-temperature environment, has better flexibility at the temperature of subzero 35-150 DEG C, is high in elasticity and good in shape restoration performance and cannot stick to other objects after long-term sealing.

Owner:蚌埠市万达塑料制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com