Steam turbine lubricating oil composition

A lubricating oil composition, steam turbine technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of poor extreme pressure anti-wear performance, short high-temperature anti-oxidation life, no anti-wear agent, etc., and achieve excellent rust resistance , Excellent high temperature resistance and oxidation resistance, excellent extreme pressure performance

Inactive Publication Date: 2016-07-06

PETROCHINA CO LTD

View PDF7 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Antioxidants still use the compound of aromatic amine and hindered phenol, because hindered phenol is easy to volatilize at high temperature, its high temperature anti-oxidation life is short

Moreover, the composition has no anti-wear agent, and its extreme pressure anti-wear performance is very poor

Therefore, the composition also cannot meet the lubrication requirements of gas turbines and large gas-steam combined cycle units

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

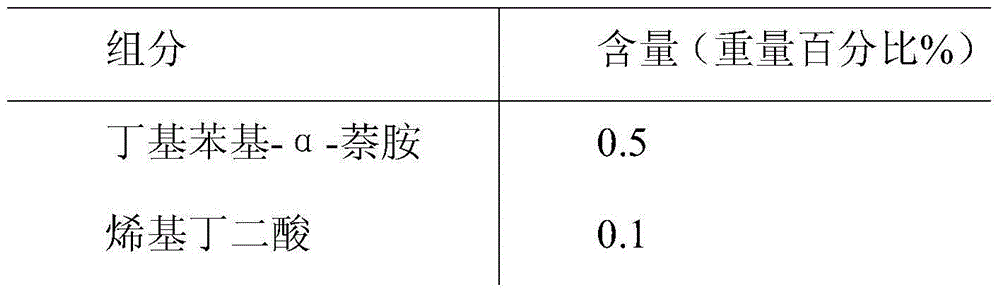

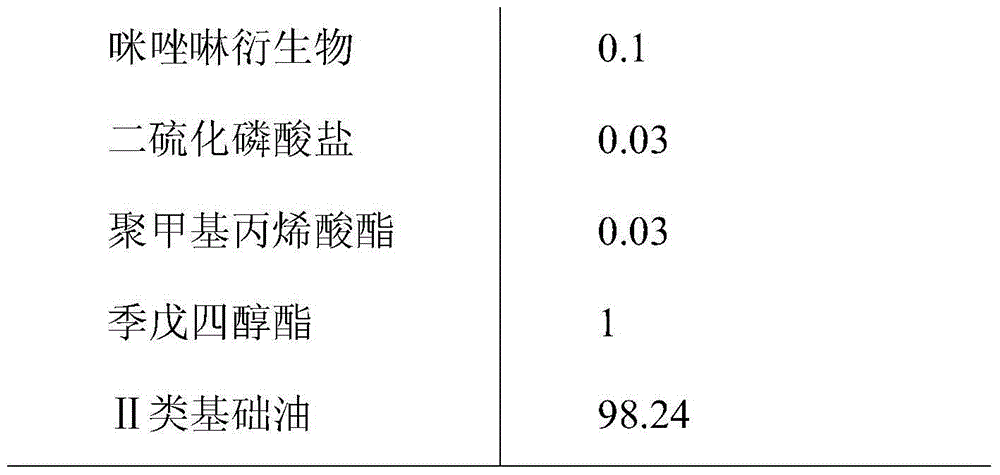

Embodiment 1

[0070]

[0071]

Embodiment 2

[0073]

Embodiment 3

[0075]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Login to View More

Abstract

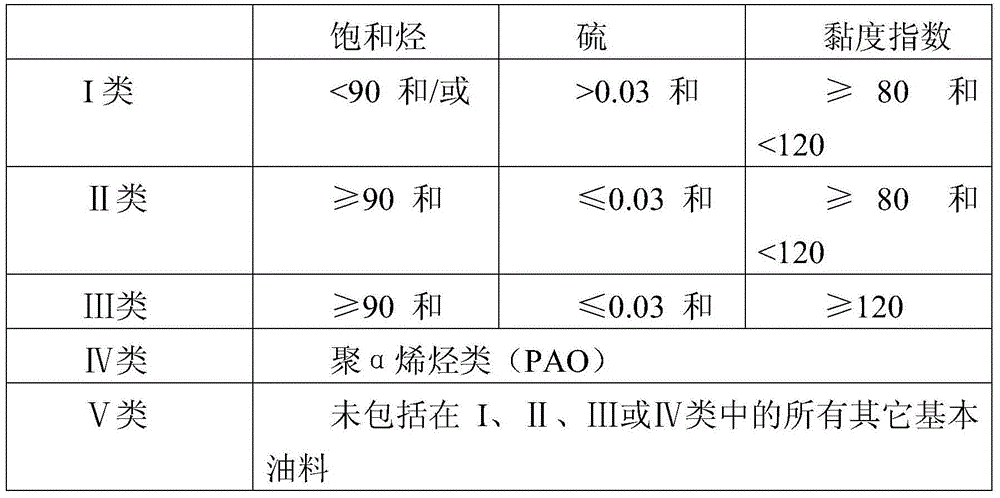

The invention relates to a steam turbine lubricating oil composition which comprises the following components: 0.03-1.5 wt% of an anti-oxidant; 0.03-0.2 wt% of an antirust agent, 0.001-0.1 wt% of an anti-foaming agent, 0.03-1 wt% of an antiwear agent, 1-20 wt% of polyol ester, and balance base oil, wherein the anti-oxidant is alkyl diphenylamine and / or alkyl phenyl-alpha-naphthylamine; the antirust agent is a complex mixture of carboxylic acid derivatives and imidazoline derivatives; the anti-foaming agent is polymethacrylate or methyl siloxane; the antiwear agent is a compound containing sulfur, phosphor, and nitrogen; the polyol ester is pentaerythritol ester or diol ester; and the base oil is II type or III type base oil with the saturated hydrocarbon content more than 90% and the sulfur content less than 0.03%. The steam turbine lubricating oil composition has the advantages of the excellent high temperature resistance and antioxidation performances, tiny greasy filth generation trend, excellent extreme pressure performance, antirust performance, hydrodissection performance, air separation performance, filterability and extreme low acid value.

Description

technical field [0001] The invention relates to a lubricating oil composition with extremely low sludge formation tendency, excellent high-temperature oxidation stability and anti-wear extreme pressure performance, which is especially suitable for the lubrication of gas-steam combined cycle units and gas turbines with gear connection. Background technique [0002] A turbine is a device used to generate electrical or mechanical work through the rotational motion of a shaft. In any combination, gas and steam turbines use the flow of hot combustion gases or steam to generate energy in the form of thrust and / or shaft power. For example, air flowing into a gas turbine is compressed in an air compressor and fed at high temperature and pressure into a combustor where fuel injection creates a fuel / compressed air mixture that ignites. The rapidly expanding gases resulting from this ignition exit the combustion chamber at high velocity, pass over the turbine blades and thus cause the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10N40/12C10N30/06C10N30/08C10N30/10C10N30/12

Inventor 孙大新王辉金琴华杨丽郑延波

Owner PETROCHINA CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com