Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152results about How to "Strong extreme pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combination circulation steam turbine lubricating oil composition

ActiveCN101240212AExcellent high temperature oxidation resistanceMeet lubrication needsAdditivesAntioxidantRust

The invention relates to a combined-cycle gas turbine lubricant combination which is suitable to be used in a large-scale gas steam combined-cycle gas turbine, and the composition and content of the combined-cycle gas turbine lubricant combination by weight percentage of antioxidant of 0.1 to 2 percent, anti-wear agent of 0.01 to 1 percent, no gray rust-proof agent of 0.01 to 1 percent, metal deactivating agent of 0.01 to 1 percent, anti-foam agent of 0.001 to 1 percent, the allowance is based oil, which is Class II or Class III paraffin-based oil, and the sulfur content is less than 0.03 percent, the lubricant combination of the invention has an extremely long induction period of oxidation and excellent performance of high temperature oxidation, excellent extreme pressure antifriction property and corrosion, good water separation, air separation and filterability, and can well meet the lubricating demand of large-scale combined cycle gas turbine.

Owner:PETROCHINA CO LTD

Ship steam turbine lubricating oil composition

InactiveCN102676279AImprove rust resistanceAnti-emulsification time is smallLubricant compositionAntioxidantWear resistant

The invention relates to a ship steam turbine lubricating oil composition. The ship steam turbine lubricating oil composition is characterized by comprising the following components in weight percent: 0.3-1.5% of antioxidant, 0.03-0.2% of rust inhibitor, 0.03-1% of wear-resistant agent, 0.003-0.1% of demulsifier, 0.001-0.1% of anti-foaming agent, 0.02-0.1% of metal deactivator and base oil in balancing amount. Through a direct liquid rustiness test (synthetic seawater, 24 h), the ship steam turbine lubricating oil composition is rustless; after distilled water is added at 90 DEG C and stirred for half an hour, the direct liquid rustiness test (synthetic seawater, 24 h) is further performed on a separated oil layer, and the ship steam turbine lubricating oil composition is still rustless; the anti-emulsification time in a steam method is less than 180 s; the FZG invalid level is greater than 12; the viscosity level is ISOVG68, anti-foaming performance is less than 65-65-65 / 0 (mL / mL); air is released for less than 8min; and the TOST oxidation life is longer than 10,000 h.

Owner:PETROCHINA CO LTD

Lubricating grease for hub bearing of heavy load truck and preparation method thereof

InactiveCN103450978AEliminates tendency to overflowSlow dehydration stepThickenersThiocarbamateChemical industry

The invention relates to a lubricating grease and a preparation method thereof, particularly relates to a lubricating grease for a hub bearing of a heavy load truck and a preparation method thereof, and belongs to the technical field of a chemical industry. The lubricating grease is prepared from the following raw materials: (A) base oil which accounts for 60-85% of total weight of the lubricating grease, (B) a thickening agent, which is C12-C22 unitary organic acid which accounts for 7-12% of total weight of the lubricating grease, 0.5-3% of sebacic acid, 0.2-1% of boric acid, and 3-5% of lithium hydroxide oil solution, (C) an additive, which is thiocarbamate which accounts for 0.5-3% of total weight of the lubricating grease, 2-5% of sulfide olefin cottonseed oil, 2-4% of dialkyl dithiocarbamate salt, 0.5-2.5% of molybdenum dialkyl dithiophosphate, 0.3-2% of antirust agent and 0.3-1% of antioxidant. The lubricating grease has the beneficial effects that the production time is shortened; the lubricating grease is more controllable in process, stable in product quality, less in seepage loss of a high-temperature bearing, and prominent in extreme pressure property; lubricating protection can be better provided for hubs of the heavy load truck; the lubricating requirements of the hub bearing of the heavy load truck under various working conditions can be met; the grease exchange period of the hub bearing is prolonged.

Owner:JIANGSU LOPALTECH

Lubricating grease combination and preparing method of lubricating grease combination

ActiveCN104140867ASmall operating torque at low temperatureReduce coefficient of frictionLubricant compositionMetal deactivatorMetal

The invention provides a preparing method of a lubricating grease combination. The preparing method includes the steps that 40wt% to 50wt% of base grease, 2wt% to 10wt% of thickening agents and 35wt% to 40wt% of solid lubricants are mixed to be homogenized to obtain a lubricating grease combination precursor; the lubricating grease combination precursor is mixed with 0.05wt% to 0.50wt% of structure stabilizers, 0.5wt% to 2.0wt% of metal deactivators, 2wt% to 8wt% of extreme-pressure anti-wear agents and 0.2wt% to 2.0wt% of antioxidants to obtain the lubricating grease combination. By means of the preparing method, the base grease, the thickening agents and the solid lubricants are homogenized and then mixed with the structure stabilizers, the metal deactivators, the extreme-pressure anti-wear agents and the antioxidants; due to homogenizing, the components are evenly dispersed, solid-liquid phases are not separated, the lubricating grease combination of the good colloid structure is obtained, and the steel-net separated grease amount of the lubricating grease combination is small.

Owner:CHINA PETROLEUM & CHEM CORP

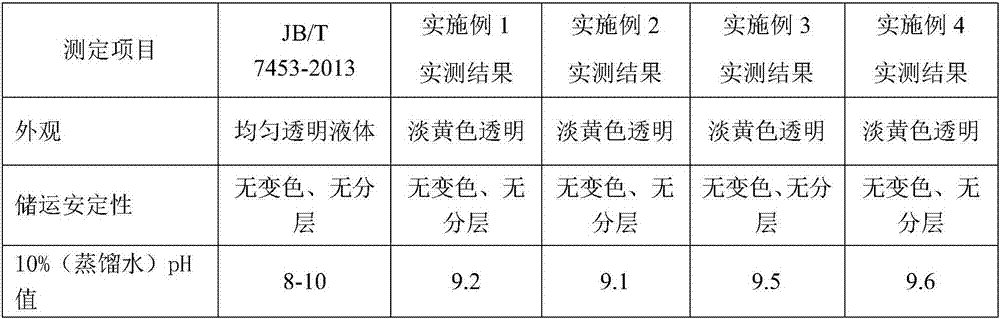

Multifunctional extreme-pressure antiwear cutting fluid and preparation method thereof

InactiveCN103666733AStrong extreme pressureImprove wear resistanceLubricant compositionRapeseedSebacic acid

A multifunctional extreme-pressure antiwear cutting fluid is prepared form the following raw materials: by weight, 1-2 parts of diethanolamine, 3-4 parts of boric acid ester, 2-3 parts of borax, 4-5 parts of sebacic acid, 1-2 parts of petroleum sodium sulfonate, 2-3 parts of molybdenum disulfide, 2-3 parts of methylparaben, 1-2 parts of sodium metaborate, 0.8-1.2 parts of fatty alcohol polyoxyethylene ether, 0.05-0.1 part of lanthanum acetate, 12-14 parts of rapeseed oil, 6-8 parts of an additive and 200 parts of water; the multifunctional extreme-pressure antiwear cutting fluid, by use of the boric acid ester, the molybdenum disulfide, the lanthanum acetate and the rapeseed oil, has good extreme pressure property, wear resistance and lubricity, the service life of the cutting fluid and a machine tool is prolonged, and the multifunctional extreme-pressure antiwear cutting fluid has good rust resistance to ferrous metals and copper and other non-ferrous metals, is wide in use, is a multifunctional cutting fluid, and at the same time has strong inhibitory effects on bacteria and mould.

Owner:MAANSHAN HENGYI MACHINERY MFG

Lubricating oil containing sheet magnetic nanometer Fe3O4 particles and preparation method of lubricating oil

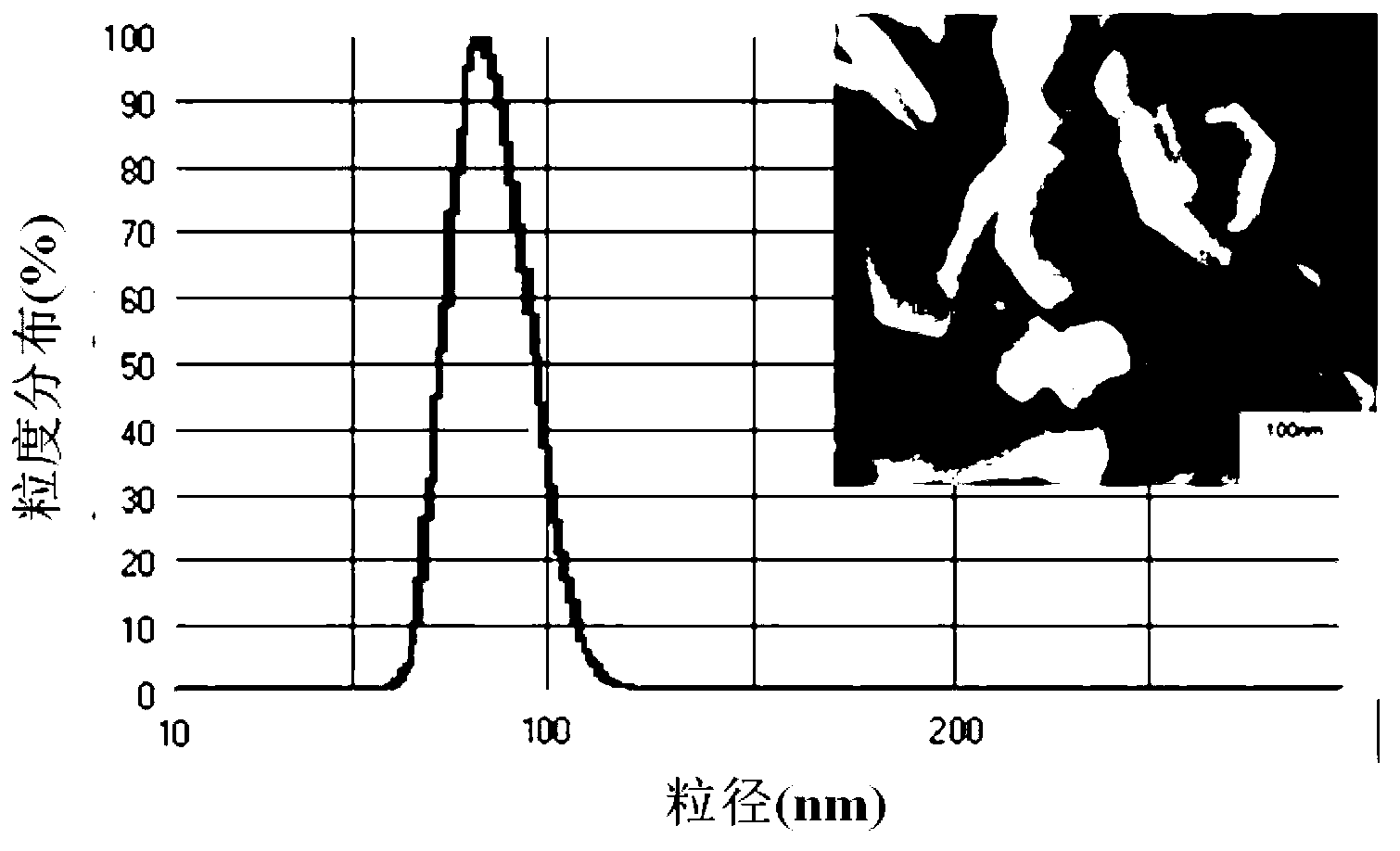

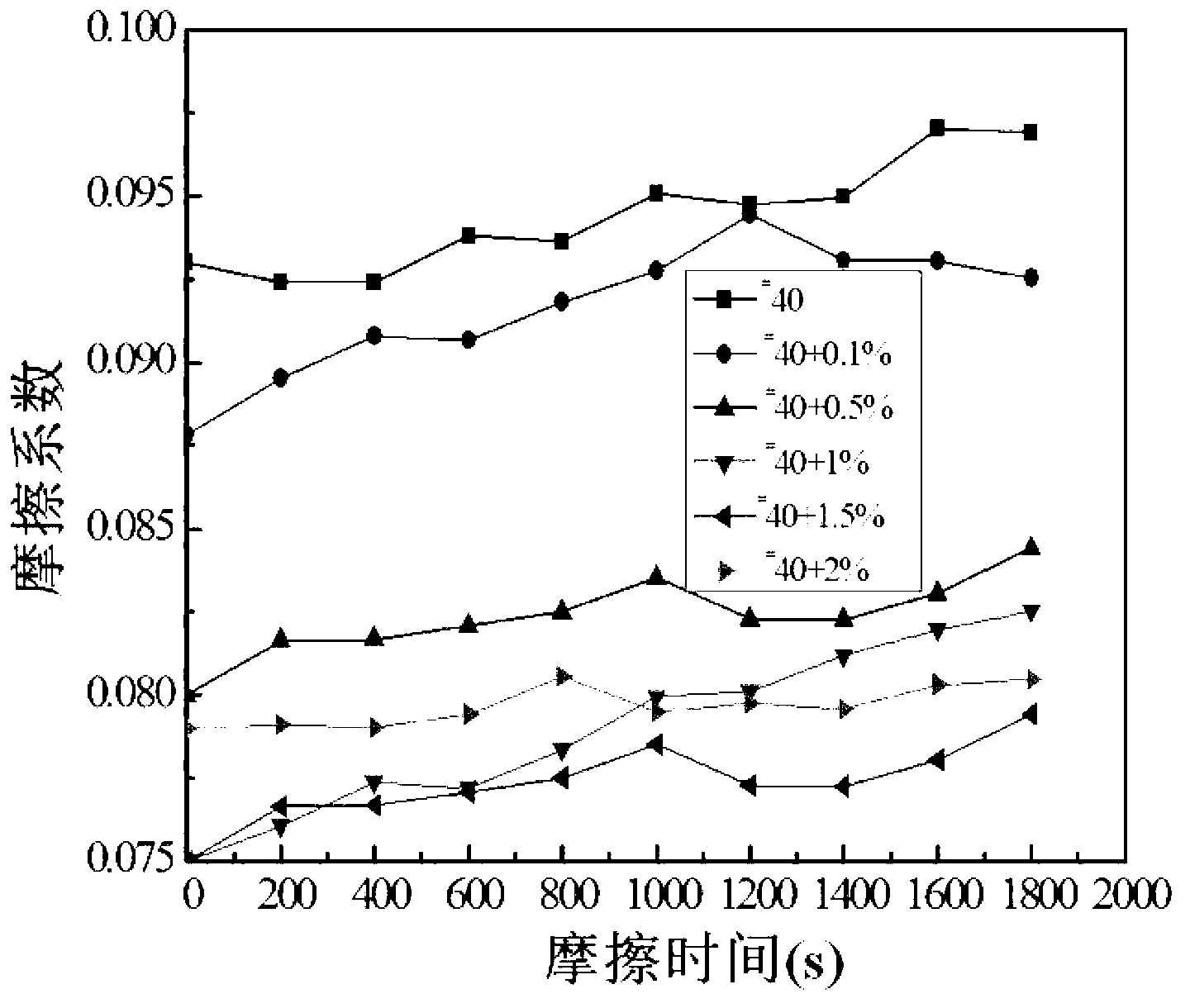

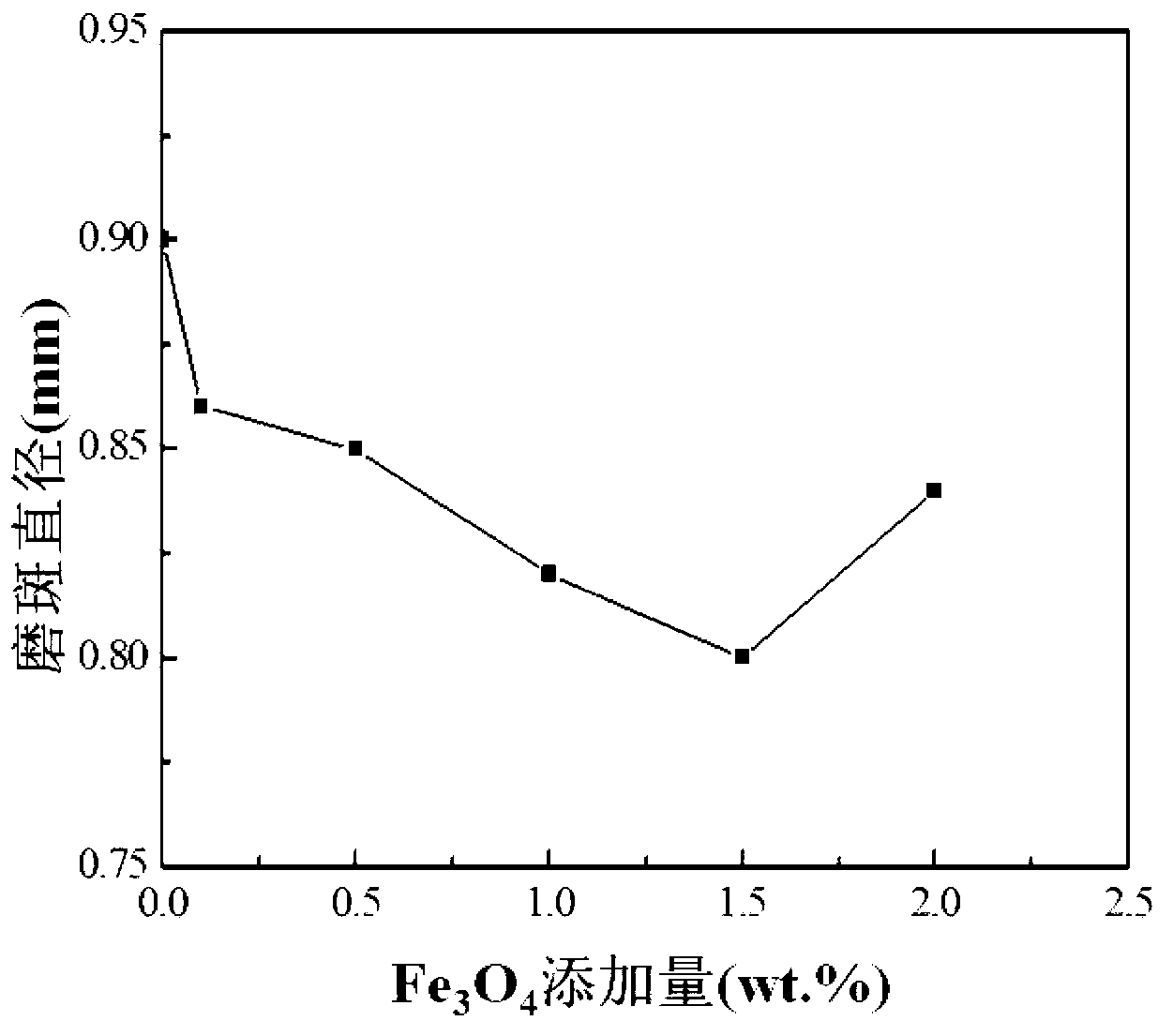

InactiveCN103254971AExtended service lifeUniform and stable dispersionAdditivesCarrying capacityBase oil

The invention discloses lubricating oil containing sheet magnetic nanometer Fe3O4 particles and a preparation method of the lubricating oil. The preparation method of the lubricating oil comprises the following steps of: (1), using oleic acid to clad sheet magnetic nanometer Fe3O4 particles to carry out surface modification to obtain modified Fe3O4 particles; (2), mixing the modified Fe3O4 particles with III base oil, wherein mass fraction of the modified Fe3O4 particles is 0.1%-2.0wt%, and preparing the lubricating oil containing sheet magnetic nanometer Fe3O4 particles through ultrasonic dispersion and high-speed shearing dispersion. The lubricating oil prepared by the preparation method disclosed by the invention has extremely good friction resistance and abrasion resistance, and high carrying capacity. Moreover, the prepared lubricating oil has the advantages of being stable in characteristics, capable of being stored for a long time without precipitation. Besides, the lubricating oil can be extensively applied to mechanical lubricating, can be used for saving energy consumption and prolonging service lives of mechanical parts, and therefore, the application prospect is extensive.

Owner:SOUTH CHINA UNIV OF TECH

Special environment-friendly complete-synthesis cutting fluid for drilling stainless steel and preparation method thereof

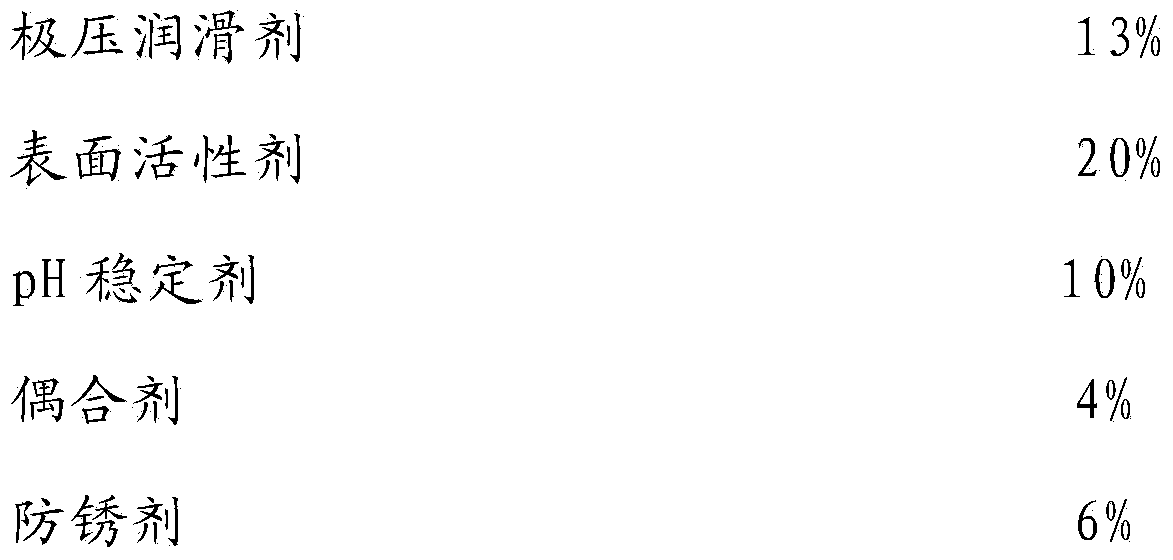

ActiveCN103805329AImprove stabilityStrong rust resistanceLubricant compositionSurface-active agentsMIXTURE COMPONENT

The invention discloses a special environment-friendly complete-synthesis cutting fluid for drilling stainless steel and a preparation method thereof. The preparation method comprises the following steps: mixing and stirring 10 to 15 percent of extreme-pressure lubricant, 3 to 5 percent of hydroxylation sulfonation castor oil borate and water for 10 minutes to 1 hour at the temperature of 30 to 80 DEG C to obtain a mixed component A; mixing and stirring 5 to 15 percent of pH stabilizer, 5 to 8 percent of antirust agent and water for 10 minutes to 1 hour at the temperature of 30 to 80 DEG C to obtain a mixed component B; uniformly mixing and stirring 15 to 25 percent of surface active agent and 3 to 5 percent of coupling agent at the normal temperature and normal pressure to obtain a mixture component C; adding the mixed component A, the mixed component B and the mixed component C into a reaction kettle and stirring and mixing for 10 minutes to 1 hour at the temperature of 30 to 80 DEG C to obtain the product. The prepared product is good in lubricating property, washing property, antirust property and cooling property, long in service life and environment-friendly.

Owner:GUANGZHOU LANDNOK CHEM TECH

Water-based lubricating agent for titanium alloy hot extrusion forming

ActiveCN107653051AImprove the lubrication effectImproved cleaning performance and economic performanceLiquid surface applicatorsCoatingsDodecylsulfonic acidAdhesive

The invention discloses a water-based lubricating agent for titanium alloy hot extrusion forming, and a preparation method of the water-based lubricating agent. The water-based lubricating agent for titanium alloy hot extrusion forming comprises the following components in parts by weight: 28 to 35 parts by weight of lubricating main agent, 45 to 55 parts of water, 5 to 10 parts of a dispersing agent and 4 to 6 parts of an adhesive, wherein the lubricating main agent comprises graphite, molybdenum disulfide and silicon dioxide; the dispersing agent is industrial alcohol and / or polyethylene glycol, lauryl sodium sulfate or sodium dodecyl sulfate. The water-based lubricating agent for titanium alloy hot extrusion forming has the characteristics of a good lubricating effect, a wide applicabletemperature range, simplicity in operation, easiness in removal, environmental friendliness, avoidance of oxidation in the high-temperature processing process of a workpiece and the like.

Owner:TSINGHUA UNIV

Chloride-free extreme pressure microemulsion cutting fluid and preparation method therefor

InactiveCN103710121AImprove the lubrication effectOvercoming perishable and smellyLubricant compositionHazardous substanceKerosene

Provided is a chloride-free extreme pressure microemulsion cutting fluid. The cutting fluid is prepared from the following raw materials, by weight, 4-5 parts of boric acid, 1-2 benzotriazole, 1-2 parts of octyl decanoic acid, 1-2 parts of lauryl sodium sulfate, 3-4 parts of polyacrylamide, 2-3 parts of urea, 0.8-1.2 parts of span 40, 0.5-1 part of lanthanum nitrate, 12-15 parts of kerosene, 6-8 parts of auxiliary agents and 200 parts of water. The cutting fluid contains no harmful substances of sodium nitrite, phenol, chlorine, mercury and the like, and is safe and environmentally friendly. Through application of boric acid and lanthanum nitrate, the cutting fluid has excellent extreme pressure performances, and workpieces are not easy to damage. The cutting fluid is advantaged by stable emulsification, no delamination, no coacervation, long service time and low cost. The cutting fluid is suitable for processing of a plurality of materials such as cast iron, steel, aluminum, copper, magnesium alloy and the like, and can meet a plurality of processing technology requirements of turning, drilling, grinding, center processing and the like.

Owner:MAANSHAN HENGYI MACHINERY MFG

Preparation method of environment-friendly water-based metal cutting fluid

The invention discloses a preparation method of an environment-friendly water-based metal cutting fluid. The preparation method comprises the steps that: (1) 1 / 3 of a total amount of water is heated to a temperature of 40-50 DEG C; triethanolamine, polyethylene glycol, isopropanol, sodium molybdate, ethylene disodium tetraacetate, sodium silicate, and methyl benzotriazole are sequentially added into the water; the mixture is mixed by stirring for 20-30min, such that a mixture is prepared; (2) sodium benzoate and monoethanolamine benzoate are added into the mixture, and the mixture is stirred for 20-30min; (2) 1 / 3 of a total amount of water is heated to a temperature of 70-80 DEG C; glycerin and water-soluble borate are added to the water, and the mixture is stirred for 10-20min; (4) the solution obtained in the step (3) is mixed with the mixture obtained in the step (2), and the mixture is mixed by stirring for 30-40min under a temperature of 50-60 DEG C; and (5) nano-grade silica is added into the mixed solution obtained in the step (4); and the mixture is stirred for 2-4h, such that the cutting fluid is obtained.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Lubricating grease composition and preparation method thereof

ActiveCN104087396AImprove high temperature performanceSlow cokingLubricant compositionGas phaseBase oil

The invention provides a lubricating grease composition which comprises 40-50 wt% of poly-alpha-olefin, 30-40 wt% of polyisobutylene, 2.5-5 wt% of silanediol, 5-10 wt% of gas-phase silicon dioxide, 1-2 wt% of anti-aging agent and 5-10 wt% of solid lubricant. The poly-alpha-olefin and polyisobutylene are used as base oil, the silanediol and gas-phase silicon dioxide are used as the thickeners, the anti-aging agent and solid lubricant are used as the additives, and the component contents are controlled within the respective range, so that the lubricating grease composition has excellent high temperature property, and thus, can slowly cake at high temperature; and therefore, the coke residue is fewer after use. Besides the lubricating grease composition provided by the invention has favorable extreme pressure performance.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating oil for aluminum alloy sawing and preparation method of lubricating oil

ActiveCN102787008ASatisfies the requirements of minimum quantity lubrication with less oilThe effect is positive and obviousLubricant compositionPolyesterPhosphate

The invention discloses lubricating oil for aluminum alloy sawing and a preparation method of the lubricating oil, wherein the lubricating oil is prepared from synthetic ester, poly alpha-olefin, sulfurized fatty acid ester, phosphate, calcium alkyl sulfonate and macromolecular polyester tackifier; the mass percentage of the synthetic ester in the lubricating oil is 10-50%, the mass percentage ofthe poly alpha-olefin in the lubricating oil is 10-50%, the mass percentage of the sulfurized fatty acid ester in the lubricating oil is 1-10%, the mass percentage of the phosphate in the lubricatingoil is 1-5%, the mass percentage of the calcium alkyl sulfonate in the lubricating oil is 1-3%, and the mass percentage of the macromolecular polyester tackifier in the lubricating oil is 1-5%. At constant pressure, the synthetic ester, the poly alpha-olefin, the sulfurized fatty acid ester, the phosphate, the calcium alkyl sulfonate and the macromolecular polyester tackifier are added into a kettle to stir and heat up to 60-80 DEG C; the stirring is carried out for 30-50min till the product is mixed uniformly; and then the material is discharged, filtered and packaged. The lubricating oil ismixed with compressed air to achieve purposes of satisfying a sawing process, recycling sawdust, saving energy and protecting environment.

Owner:SHANGHAI TIANLAN BIOTECH

Aqueous cutting fluid and preparation method thereof

ActiveCN103666729AGood viscosity and temperatureImprove the lubrication effectLubricant compositionPolyethylene glycolAlkylphenol

The invention discloses an aqueous cutting fluid, which is prepared from the following raw materials in parts by weight: 10-12 parts of polyethylene glycol, 2-3 parts of triethanolamine, 6-9 parts of dibutyl phosphate, 19-22 parts of castor oil, 1-2 parts of calcium sulfide alkylphenol, 1-2 parts of sorbic monostearate, 6-8 parts of assistant and 200 parts of water. The aqueous cutting fluid disclosed by the invention has excellent viscosity-temperature performance, lubricity, extreme pressure property and biodegradability, fast cooling speed, and good corrosion inhibition property, is long in service cycle in comparison with the traditional cutting fluid, small in abrasion on a tool, and high in yield, and has good protection roles on nonferrous metals and black metal, and the processed work-piece is bright.

Owner:广州南星润滑科技股份有限公司

Environment-friendly composite multisoap base self-repairing bearing grease and preparation method thereof

ActiveCN102604724AImprove performanceOvercoming the lack of extreme pressure wear resistanceLubricant compositionMaximum levelWear resistant

The invention relates to environment-friendly composite multisoap base self-repairing bearing grease and a preparation method of the bearing grease. The bearing grease is prepared from composite base liquid, a composite calcium soap thickening agent, an oxidation and corrosion resistant additive, a tungsten disulfide extreme pressure additive, a metal deactivator, a polarization graphite wear resistant additive, a self-repairing additive and a structure improving agent. According to the bearing grease provided by the invention, an additive containing non-heavy metal elements is used to replace the originally used additive containing heavy metal elements. Because base liquid, a thickening agent and an additive are all optimized, the bearing grease provided by the invention is more excellent in combination property and highlighted in abrasion resistance, maintains an excellent level in extreme pressure property, can fully meet the requirements of the bit bearing extreme pressure, the high temperature, a deep well with high temperature, the high-impact load and the abrasion resistance, meanwhile, can effectively supplement the defect that silver coating is not sufficiently brushed onthe bearing axial diameter plane, and acts a function of repairing an abrasion resistant layer on a metal seal and a rubber seal of a bit bearing, so that the service life of the bearing is prolongedat a maximum level.

Owner:KINGDREAM PLC CO +2

Lubricating oil compositions

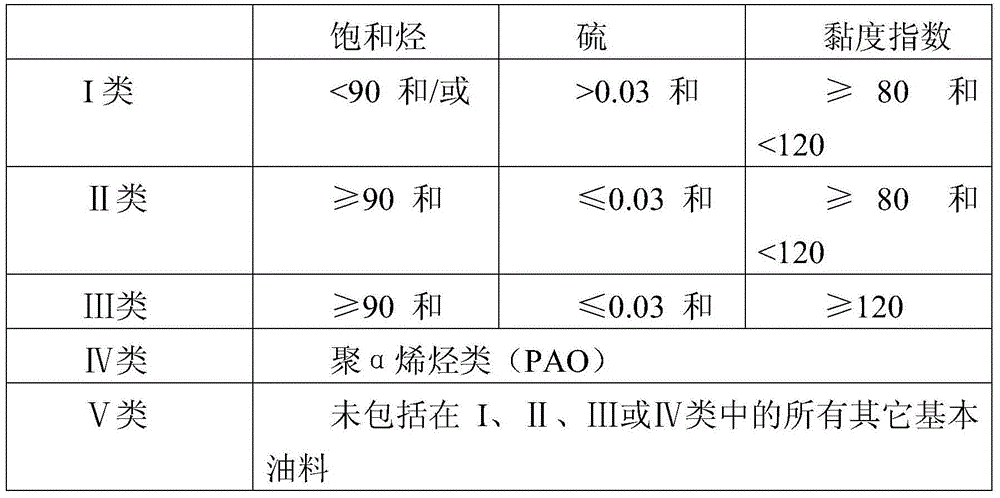

InactiveCN1685036AStrong extreme pressureImprove wear resistanceAdditivesBase-materialsPhosphoric Acid EstersChemical composition

A lubricating oil composition is disclosed which comprises a lubricating base oil, (A) at least one type of compound selected from specific phosphoric acid esters and salts thereof or in combination with (B) at least one type of compound selected from specific metal salts of specific phosphoric acid esters, with excellent oxidation stability, base number retention properties, anti-wear properties, extreme pressure properties and anti-corrosion properties and thus can be suitably used, in particular, as a lubricating oil for an internal combustion engine.

Owner:NIPPON OIL CO LTD

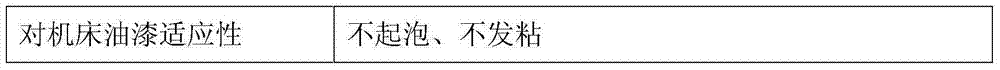

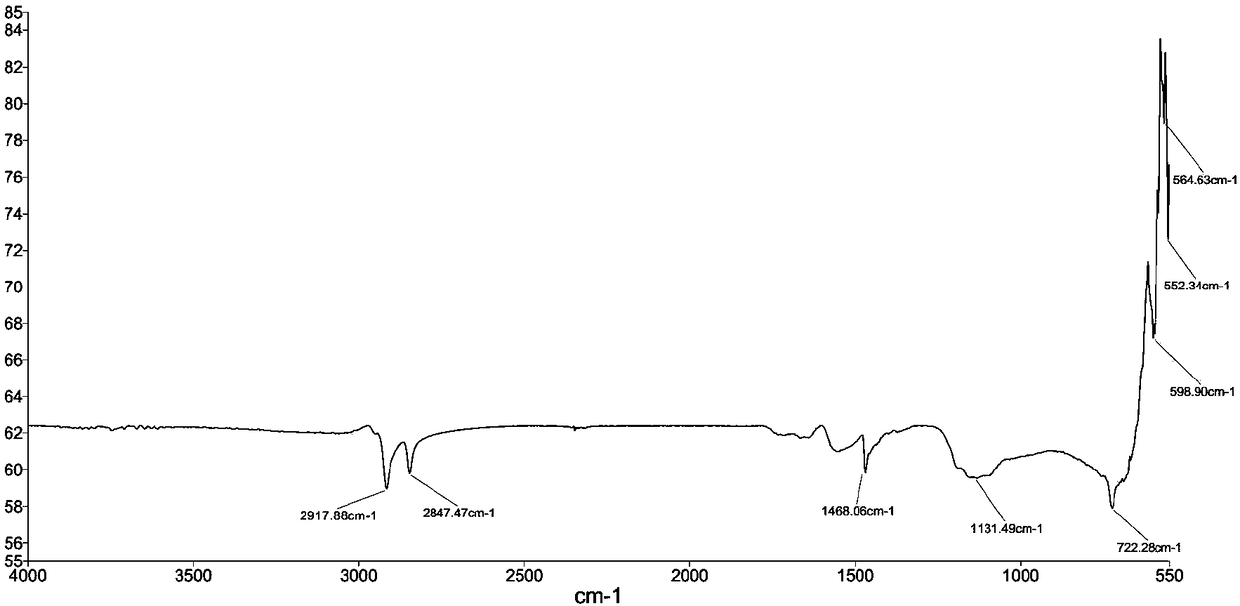

Oil-soluble graphene compound and preparation method and application thereof

The invention provides an oil-soluble graphene compound. The structural formula of the compound is gamma(CONHCmH2m+1)x(CH2COOCnH2n+1)y or gamma(CONHCmH2m+1)x[Si(OCH3)zCpH2p+1]y, wherein gamma represents graphene oxide, n is equal to or greater than 1 and equal to or smaller than 18, m is equal to or greater than 1 and equal to or smaller than 18, p is equal to or greater than 1 and equal to or smaller than 18, x is equal to or greater than 1 and equal to or smaller than 100, y is equal to or greater than 1 and equal to or smaller than 100, and z is 1 or 2. Molecules of the compound comprise straight-chain paraffin, and radicals in graphene oxide basically not include active hydroxide radicals, and therefore the compound has high oil solubility; moreover, since the compound contains a graphene structure, the compound has great wearproof performance and an excellent extreme pressure property. Meanwhile, the molecular structure of the compound does not contain elements harmful to the environment, such as sulfur, phosphorus and chlorine, so that the compound serving as a wearproof agent is environmentally friendly and can be applied to lubricating oil, lubricating grease, food and other aspects.

Owner:CHINA PETROLEUM & CHEM CORP

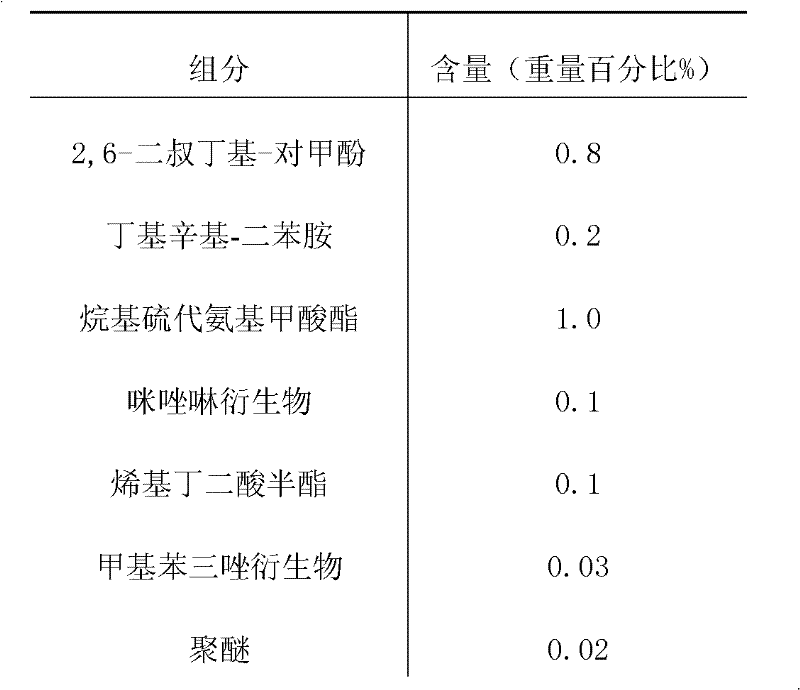

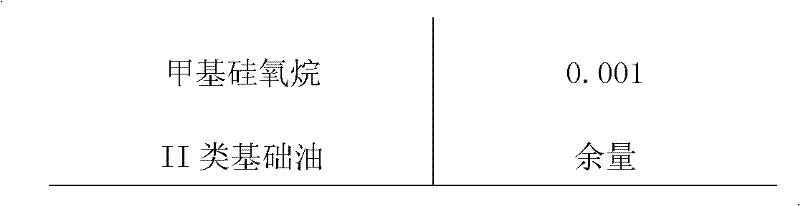

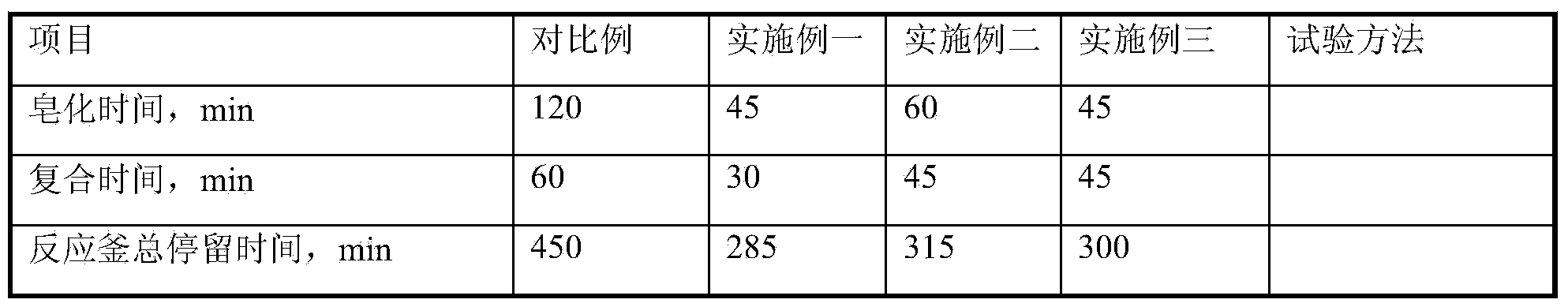

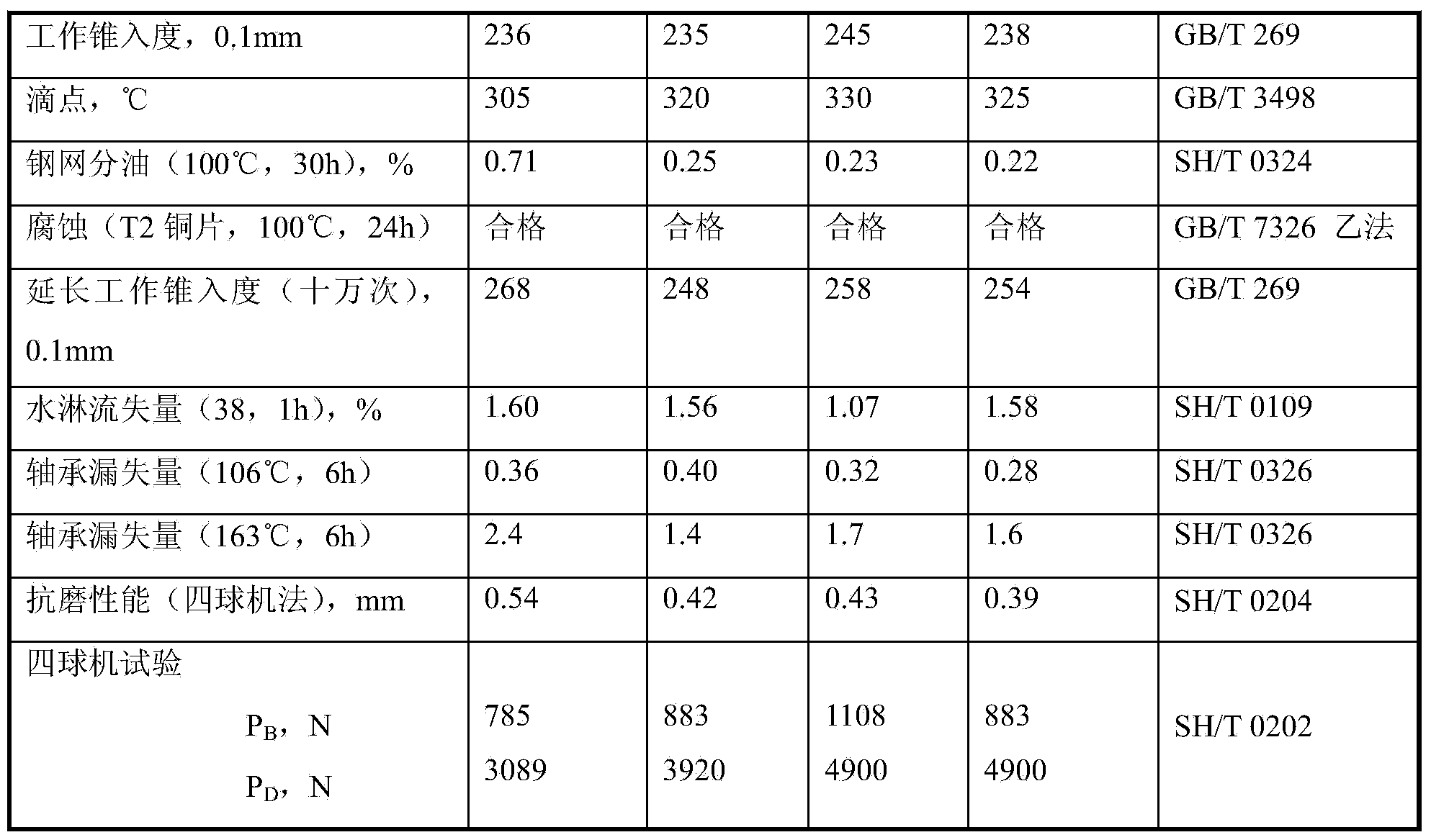

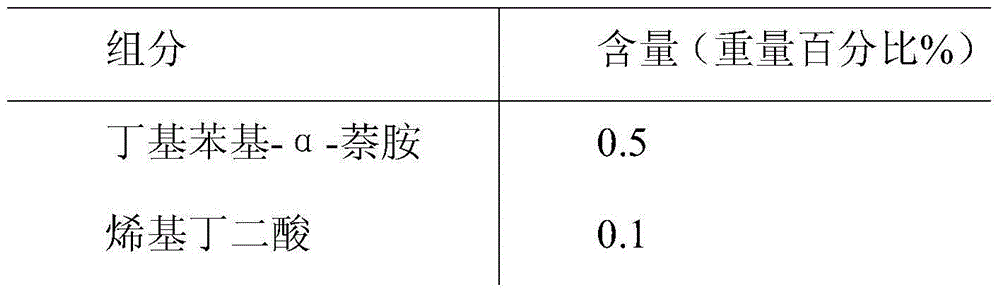

Steam turbine lubricating oil composition

InactiveCN105733761AGood high temperature resistance and oxidation resistanceStrong extreme pressureLubricant compositionImidazoline derivativesCarboxylic acid

The invention relates to a steam turbine lubricating oil composition which comprises the following components: 0.03-1.5 wt% of an anti-oxidant; 0.03-0.2 wt% of an antirust agent, 0.001-0.1 wt% of an anti-foaming agent, 0.03-1 wt% of an antiwear agent, 1-20 wt% of polyol ester, and balance base oil, wherein the anti-oxidant is alkyl diphenylamine and / or alkyl phenyl-alpha-naphthylamine; the antirust agent is a complex mixture of carboxylic acid derivatives and imidazoline derivatives; the anti-foaming agent is polymethacrylate or methyl siloxane; the antiwear agent is a compound containing sulfur, phosphor, and nitrogen; the polyol ester is pentaerythritol ester or diol ester; and the base oil is II type or III type base oil with the saturated hydrocarbon content more than 90% and the sulfur content less than 0.03%. The steam turbine lubricating oil composition has the advantages of the excellent high temperature resistance and antioxidation performances, tiny greasy filth generation trend, excellent extreme pressure performance, antirust performance, hydrodissection performance, air separation performance, filterability and extreme low acid value.

Owner:PETROCHINA CO LTD

Lubricating grease for robot and application of lubricating grease

ActiveCN110724577AGood thermal stabilityImprove Oxidation StabilityLubricant compositionPhysical chemistryMechanical stability

The invention relates to lubricating grease and application of the lubricating grease to a robot harmonic reducer. The lubricating grease comprises, by mass, 78-86% of base oil, 5-8% of a thickening agent, 1-3% of an antioxidant, 2.3-4% of an extreme pressure anti-wear agent, 1-3% of a solid lubricant and 4-8% of calcium sulfonate complex grease, wherein the base oil is a mixture of mineral oil, PAO synthetic oil and ester oil in the mass ratio of 2-6:6:1-2. The lubricating grease has good mechanical stability, extreme pressure wear resistance, high-temperature stability, oxidation stability,low-temperature resistance and fretting wear resistance.

Owner:清研高装科技(天津)有限公司

High-efficiency wear-resistant energy-saving lubricating oil composition and preparation method thereof

InactiveCN108690698AHigh affinityReduce friction and wearLubricant compositionPolyesterWear resistant

The invention discloses a high-efficiency wear-resistant energy-saving lubricating oil composition and a preparation method thereof. The high-efficiency wear-resistant energy-saving lubricating oil composition is prepared from the following raw materials in parts by weight: 40-60 parts of polyester base oil, 10-20 parts of pentaerythritol ester base oil, 5-10 parts of modified nano graphite, 0.5-1.5 parts of emulsifying agent, 1.5-3.5 parts of friction modifier, 2.5-4.5 parts of petroleum calcium sulfonate, 1-3 parts of octadecylamine, 0.4-0.6 part of composite antioxidant, 0.7-0.9 part of extreme-pressure antiwear agent, 0.6-0.8 part of preservative and 0.6-0.9 part of anti-foaming agent. The high-efficiency wear-resistant energy-saving lubricating oil composition has better wear-resistant and wear-reducing properties, and can repair and reduce wear; meanwhile, due to addition of the preservative, rusting of metal parts can be prevented and the service life of a car is prolonged.

Owner:薛士军

A composition used for food-grade gear oil, a preparing method thereof, gear oil including the composition and a preparing method of the gear oil including the composition

InactiveCN106947575ACaused by pollutionMeet hygiene requirementsLubricant compositionMicro pittingEngineering

The invention relates to the field of lubricating oil, and particularly discloses a composition used for food-grade gear oil, a preparing method thereof, gear oil including the composition and a preparing method of the gear oil including the composition. The composition includes, by weight, 5-10 parts of a food-grade antioxidant, 10-25 parts of a food-grade antiwear agent, 0.5-1.5 parts of a food-grade metal deactivator, 1.0-2.5 parts of a food-grade antirust agent, 0.5-1.5 parts of a food-grade corrosion inhibitor, 0.2-1.0 part of a food-grade oiliness agent, 0.1-0.5 part of a food-grade anti-emulsification agent and 0.01-0.3 part of a food-grade defoamer, with the balance being food-grade base oil A and the total weight parts being 100 parts. The composition and the gear oil including the composition have excellent waterproofness, oxidation resistance, wear resistance, extreme pressure properties, micro pitting resistance, rust resistance, emulsification resistance and foam resistance, can effectively meet requirements on heavy duty, extreme pressure properties, wear resistance, emulsification resistance, rust resistance, micro pitting resistance, and the like of gear systems in a food processing process, are nontoxic and harmless and do not contaminate foods.

Owner:TEXAS PETROCHEM YANTAI

Special grinding fluid for grinding of silicon carbide ceramic by diamond grinding wheels and preparation method of special grinding fluid

ActiveCN105586142AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsDimethyl siloxaneMachining process

The invention relates to a special grinding fluid for grinding of silicon carbide ceramic by diamond grinding wheels. The special grinding fluid comprises 4.8%-6.2% of fatty acid methyl ester polyoxyethylene ether, 2.5%-2.9% of an alkyl synthol alkoxy compound, 2.2%-2.5% of tungsten disulfide, 4.2%-4.4% of cyclopentasiloxane, 3.5%-3.7% of an anti-wear reagent at extreme pressure, 2.3%-3% of a corrosion inhibitor, 2.5%-3.5% of a friction modifier and the balance of deionized water. The special grinding fluid for grinding of the silicon carbide ceramic by the diamond grinding wheels has excellent lubricating, cooling and cleaning effects, has the long service cycle and can substantially reduce the grinding temperature, the normal grinding force and the tangential grinding force in the machining process of the silicon carbide ceramic, reduce abrasions of the grinding wheels, effectively improve surface quality and precision of ground surfaces of the silicon carbide engineering ceramic and the like.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

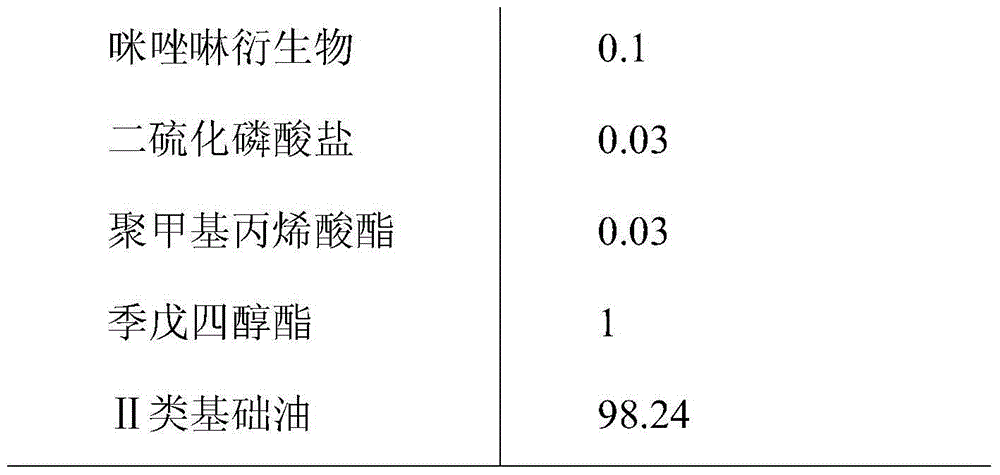

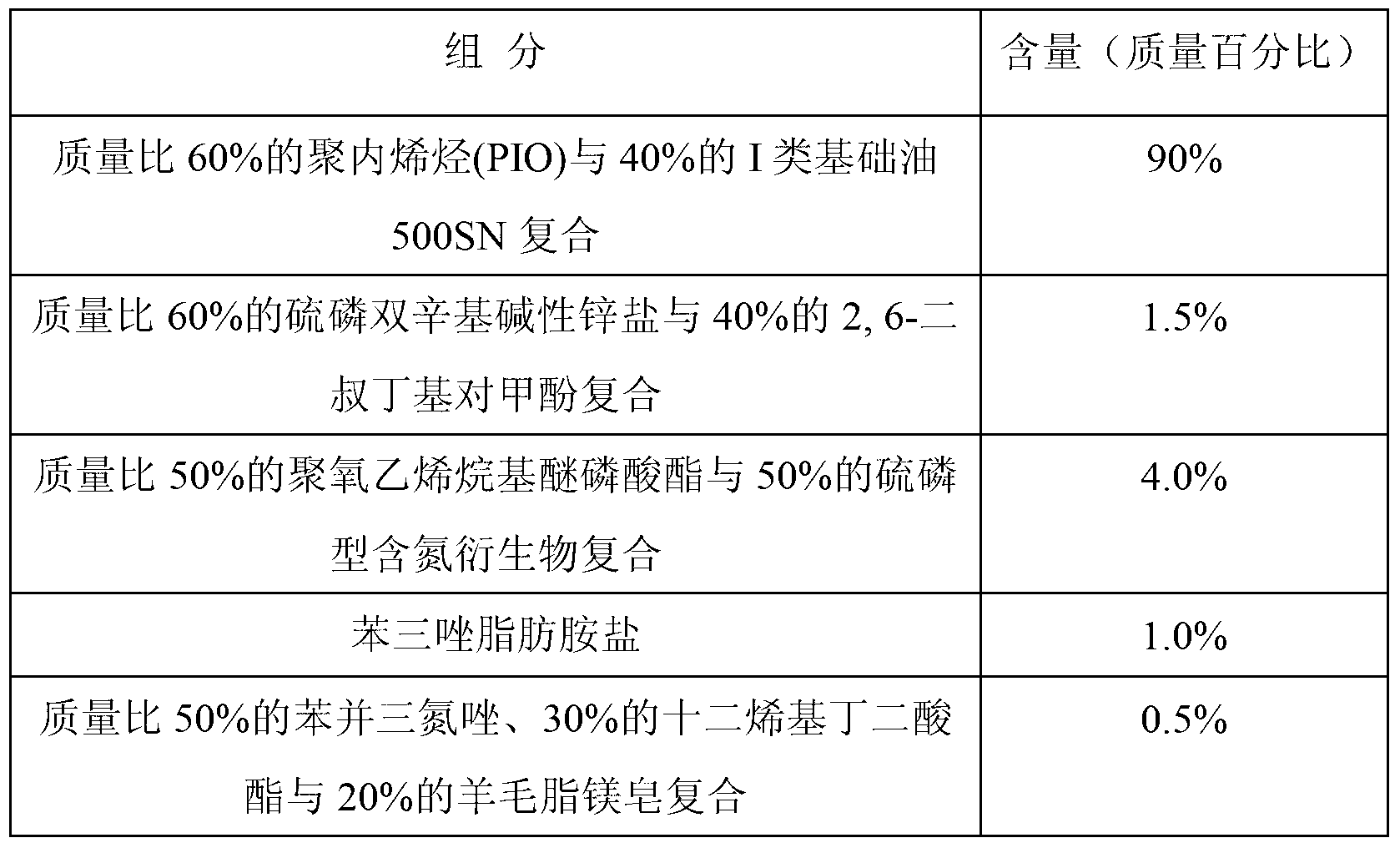

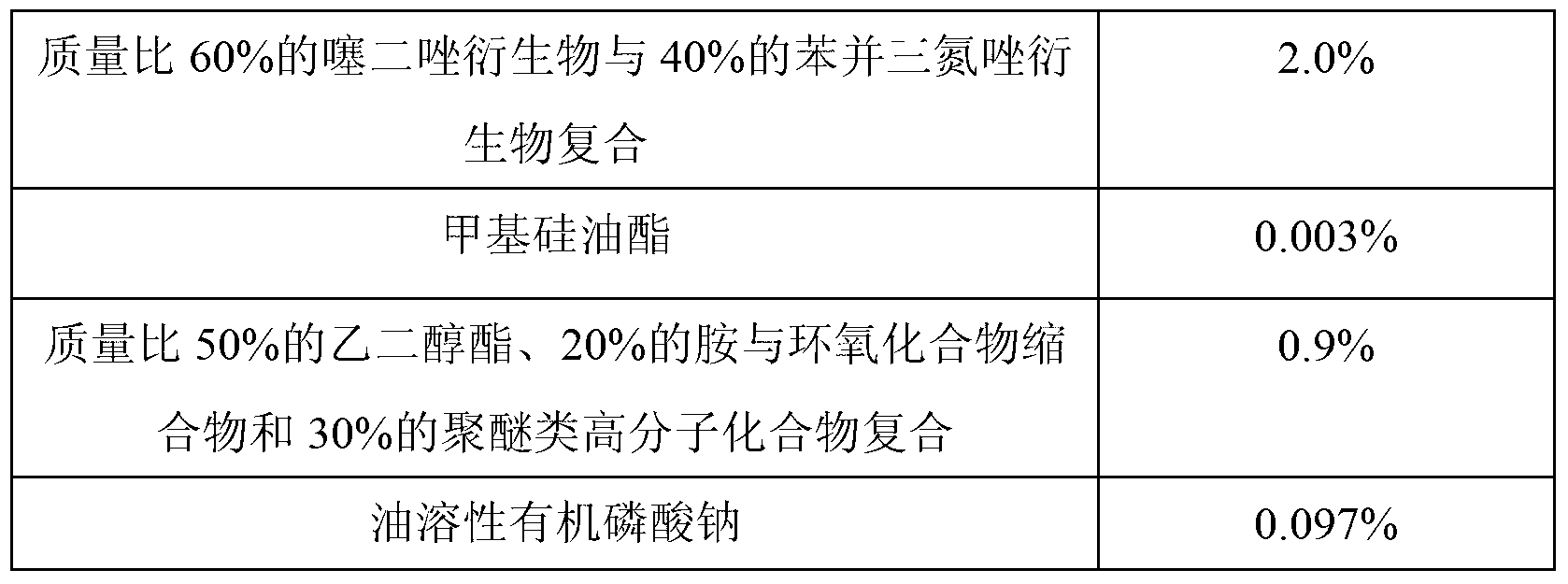

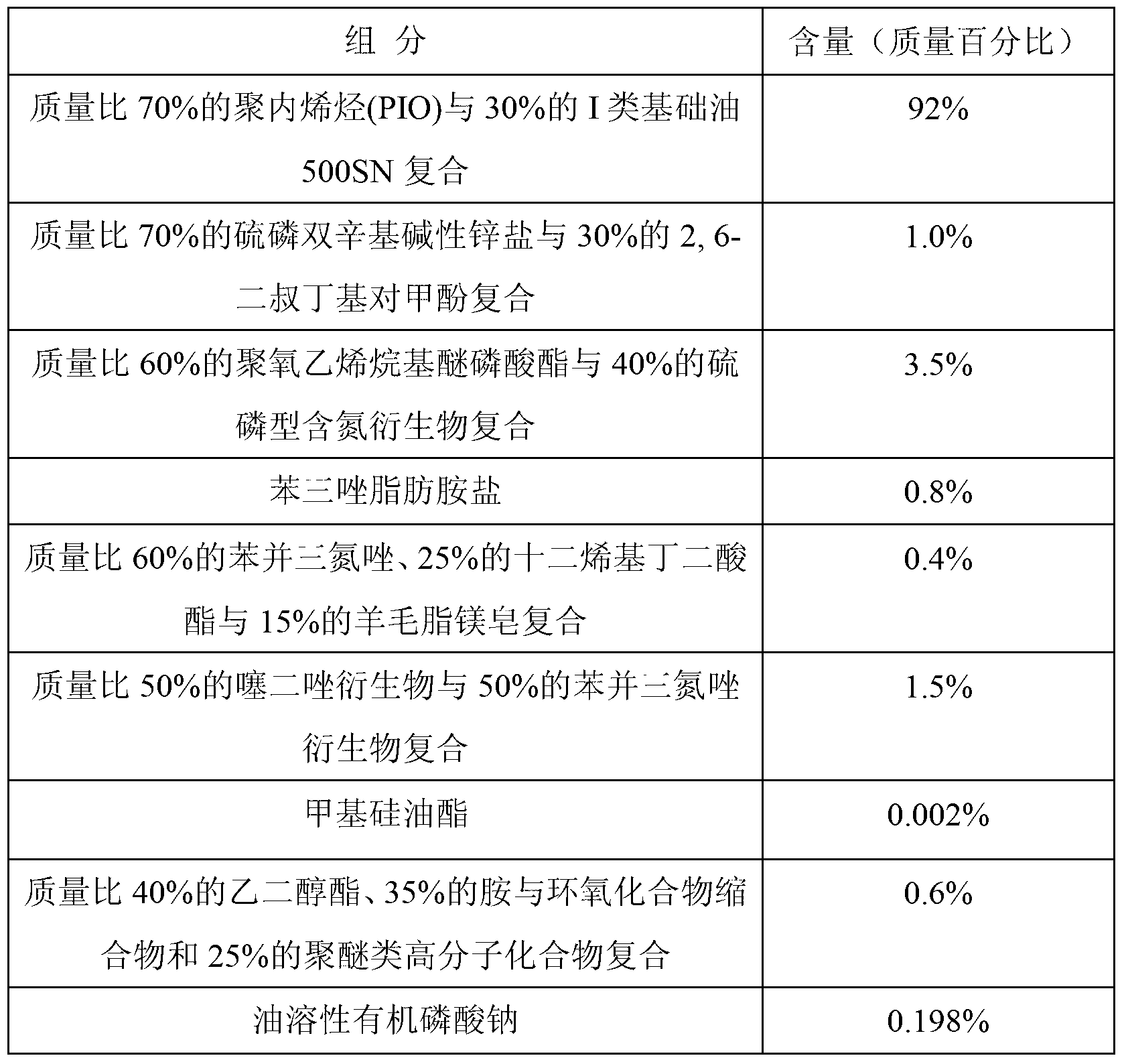

High water resistance type heavy load industrial gear oil

The invention discloses a high water resistance type heavy load industrial gear oil, which comprises the following ingredients in percentage by mass: 90-94% of base oil and 10-6% of other additives. PIO (Poly Internal Olefin) and I-type base oil 500SN are combined to serve as the base oil. The high water resistance type heavy load industrial gear oil has the remarkable advantages that the comprehensive property is good, and the use requirements on various performance indexes are met. The gear oil has good thermal oxidation stability, extreme pressure property, abrasion resistance, anti-rust resistance, foam resistance and outstanding high-temperature demulsibility; the gear face abrasion and scratching or even sintering are effectively reduced, the gear transmission efficiency is improved, and the use requirements of industrial gears in extreme severe rugged environments such as high temperature, high humidity, dust, impact load and strong vibration are met. Products of the industrial gear oil can meet the performance requirements on the viscosity grades N150, N220 and N320 of the GB5903-2011 heavy load industrial gear oil.

Owner:GUANGXI UNIV

Cutting oil

InactiveCN101724497AImprove adsorption capacityInhibit wearAdditivesBase-materialsParaffin waxBenzotriazole

The invention discloses cutting oil, which comprises the following components in percentage by mass: 40 to 60 percent of liquid paraffin, 20 to 50 percent of oiliness improver, 4 to 18 percent of extreme-pressure additive and 0.1 to 2 percent of benzotriazole, wherein the oiliness improver is a mixture of 30 to 90 percent of tricaprylin and 10 to 70 percent of glycol ethyl ether. The invention provides the cutting oil which has good effects of lubricating, cooling, rust protection and cleaning and has good environment-friendly performance.

Owner:SHAANXI UNIV OF SCI & TECH

High-temperature grease and preparation method thereof

InactiveCN103805323AGood oil solubilityStrong extreme pressureLubricant compositionOrganic sulfide compoundAntioxidant

The invention relates to a high-temperature grease and a preparation method thereof. The high-temperature grease comprises the following raw materials in parts by weight: 60-90 parts of base oil, 6-35 parts of thickening agent, 0.5-4 parts of organic sulfide, 0.1-8 parts of rust-inhibiting additive and 0.5-2 parts of antioxidant. The organic sulfide has favorable oil dissolving property, extreme pressure property, oxidation resistance and capability of lowering friction coefficient, does not lose efficacy under high temperature, and effectively avoids great reduction of extrusion property of grease caused by high temperature.

Owner:WUXI FEITIAN GREASE

Layered zirconium phosphate and molybdenum disulfide compound extreme pressure grease and preparation method thereof

InactiveCN107384527AImprove bearing capacity and wear resistanceGood anti-wear performanceAdditivesAntioxidantMolybdenum disulfide

The invention discloses a layered zirconium phosphate and molybdenum disulfide compound extreme pressure grease and a preparation method thereof. The grease comprises the following components by weight percent: 90-96% of base grease, 2.0-7.0% of alpha-layered zirconium phosphate and molybdenum disulfide mixed powder, 1.0-3.0% of an extreme pressure agent and 1.0-2.0% of an antioxidant. The preparation method comprises the following steps: adding 2.0-7.0% of alpha-layered zirconium phosphate and molybdenum disulfide mixed powder, 1.0-3.0% of an extreme pressure agent and 1.0-2.0% of an antioxidant into 90-96% of base grease and then rolling and grinding for 3 times by using a three-roller grinder, thereby acquiring a grease product. The grease disclosed by the invention is capable of promoting the bearing capacity and anti-grinding capacity of the grease. After the grease is mixed with the extreme pressure agent, the grease can meet the rigorous working conditions, such as high impact load.

Owner:TAIYUAN UNIV OF TECH

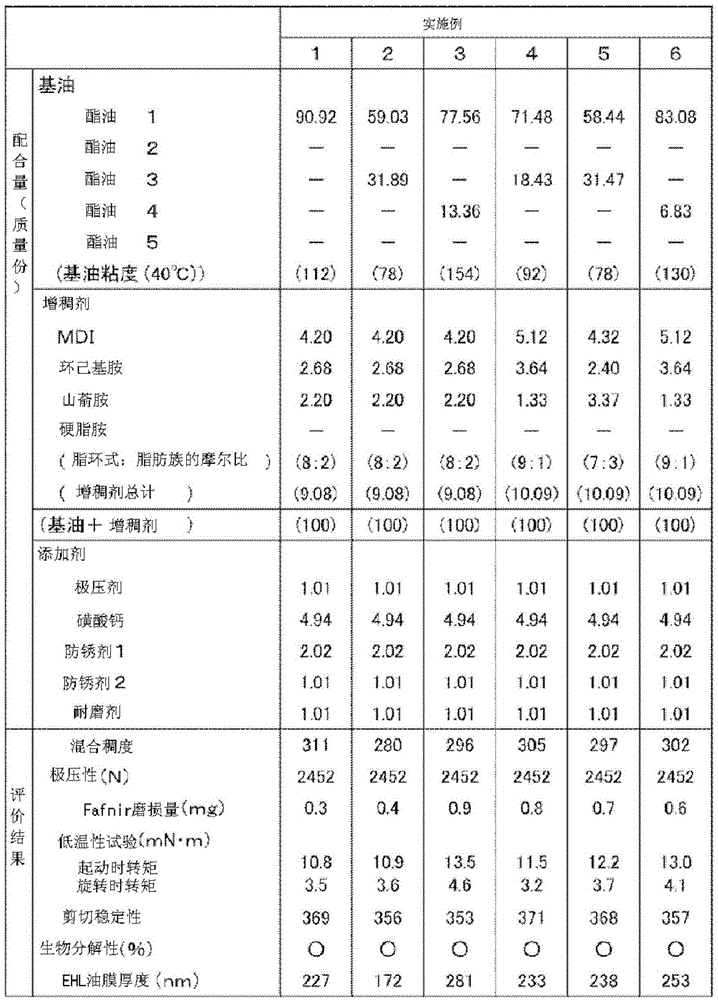

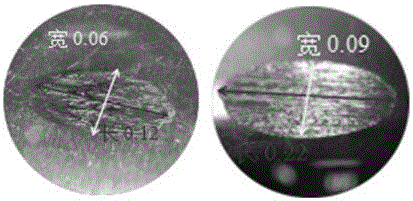

Biodegradable grease composition for aerogenerator

ActiveCN105567386AImprove biodegradabilityReduce the impactLubricant compositionBase oilOrganic chemistry

The invention provides a biodegradable grease composition for an aerogenerator. An object of the present invention is to provide a biodegradable grease composition which is excellent in fretting resistance, extreme pressure property, low temperature property, and biodegradability as well, and has a small effect on the environment even if released to a natural environment. The grease composition comprises a base oil composed of an ester oil having a kinematic viscosity at 40 DEG C of 60 to 160 mm 2 / s and a thickener composed of a diurea compound obtained by allowing an amine mixture comprising a 4-8C alicyclic monoamine and a 20-24C aliphatic monoamine to react with a diisocyanate compound, wherein a content molar ratio of the alicyclic monoamine and the aliphatic monoamine in the amine mixture is 7:3 to 9:1, the content of the thickener in a total amount of the base oil and the thickener is 7 to 11 % by mass and a penetration is 265 to 340.

Owner:NIPPON GREASE

Lubricating oil containing oleic acid-modified superparamagnetic nanometer hollow beads and preparation method thereof

InactiveCN106590817AImprove wear resistanceImprove carrying capacityAdditivesSuperparamagnetismBase oil

The invention specifically relates to a lubricating oil containing oleic acid-modified superparamagnetic nanometer hollow beads and a preparation method thereof, belonging to the technical field of lubricating oil. The lubricating oil comprises the following components: 1, 0.1 to 2 wt% of superparamagnetic nanometer hollow Fe3O4 beads grafted with oleic acid function groups; and 2, 98 to 99.9 wt% of three kinds of base oil. The preparation method comprises the following steps: 1, synthesizing the superparamagnetic nanometer hollow Fe3O4 beads in one step by using a solvothermal synthesis method and grafting the oleic acid function groups onto the surfaces of the superparamagnetic nanometer hollow Fe3O4 beads at the same time; 2, mixing the hollow Fe3O4 beads grafted with the oleic acid function groups and the three kinds of base oil; 3, subjecting a product obtained after previous mixing to ultrasonic dispersion; 4, carrying out high-speed shearing and dispersion on the product having undergone ultrasonic dispersion; and 5, preparing the finished lubricating oil containing the oleic acid-modified superparamagnetic nanometer hollow beads. The lubricating oil containing the oleic acid-modified superparamagnetic nanometer hollow beads have excellent resistance to friction and abrasion, high bearing capability and stable quality and produce no precipitation after long-term storage.

Owner:JINLING INST OF TECH

Environment-friendly micro-emulsified cutting fluid and preparation method thereof

ActiveCN107057818AExtended storage timePrevent deterioration and odorLubricant compositionSURFACTANT BLENDCutting fluid

The invention provides an environment-friendly micro-emulsified cutting fluid. The cutting fluid is prepared from, in percentage by weight, 30%-40% of narrow-fraction naphthenic oil, 15%-20% of an oiliness agent, 15%-20% of water, 3%-5% of an antirust agent, 8%-10% of a pH value regulator, 6%-10% of a surfactant, 6%-8% of a bactericide and 0.1%-0.5% of an antifoaming agent. The cutting fluid is safe, environment-friendly and harmless to the human body.

Owner:上海中孚油品集团有限公司

Polyurea thickening agent, lubricating grease prepared from polyurea thickening agent and preparation method of lubricating grease

The invention provides a polyurea thickening agent, lubricating grease prepared from the polyurea thickening agent and a preparation method of the lubricating grease, belonging to the technical fieldof lubricating materials. The polyurea lubricating grease comprises the following components in percentage by weight: 69.2 to 89.8% of base oil, 10 to 25% of a polyurea thickening agent, 0 to 5% of anantioxidant and 0.2 to 0.8% of an antirust agent, wherein the polyurea thickening agent is synthesized from diphenylmethane-4,4'-diisocyanate and 2-amino-6-methoxybenzothiazole or mixed amine, the mixed amine is a mixture of 2-amino-6-methoxybenzothiazole and a compound with a structural formula of R-NH2, and R is an alkyl or cycloalkyl group with a carbon atom number of 8-22. Compared with existing polyurea lubricating grease technology, the polyurea lubricating grease prepared by the invention adopts the novel polyurea thickening agent with extreme pressure property, does not need to add anextreme pressure agent, has good extreme pressure property, reduces the variety and dosage of additives, and can be widely applied to the field of bearing lubrication.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Carbon steel warm-forging lubricant composition

InactiveCN104450078AImprove liquidityImprove diffusivityLubricant compositionAntioxidantFriction modifier

The invention discloses a carbon steel warm-forging lubricant composition which adopts No.680 cylinder oil as basic oil and is matched with multiple composite additives which include an antioxidant, an antiwear additive, an oiliness agent, a metal passivator, a friction improver, a reinforcing agent, a corrosion inhibitor and a preservative agent. The carbon steel warm-forging lubricant composition disclosed by the invention is preferable in flowability and high in diffusion capacity, is capable of forming a layer of uniform and continuous oil film between a forge piece and a mould, has the advantages of good antiwear property and viscosity-temperature property, high extreme pressure property, stability in oil film thickness, good pressure-resistant property, good lubricating property, stability in component, no toxicity and no pungent smell and can be used for protecting a material from being cracked in a forging process, preventing the mould from being damaged and prolonging the service life of the mould.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com