Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

129 results about "Dibutyl phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Down feather composite fiber modified by polypropylene fiber and preparation method of down feather composite fiber

InactiveCN104195664AThe ratio is scientific and reasonableDelicate feelMonocomponent protein artificial filamentArtifical filament manufactureSucrosePhosphoric acid

The invention discloses a down feather composite fiber modified by polypropylene fiber. The down feather composite fiber modified by polypropylene fiber is prepared from the following raw materials in parts by weight: 18-20 parts of superfine duck down powder, 25-30 parts of puffed goose feather powder, 12-15 parts of polypropylene fiber, 3-5 parts of kaolin, 0.3-0.6 part of calcium saccharate, 1-2 parts of wolfberry fruit, 2-4 parts of fruit of Chinese magnoliavine, 1-3 parts of radix rehmanniae, 3-5 parts of cucumber juice, 0.1-0.3 part of ammonium dihydrogen phosphate, 120-130 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 110-140 parts of 1-ethyl-3-diethyl methyl imidazole phosphoric acid, 2-4 parts of additives and a proper amount of water. According to the down feather composite fiber modified by polypropylene fiber, the components such as the polypropylene fiber, the wolfberry fruit, the fruit of Chinese magnoliavine and the radix rehmanniae are added; the prepared product is soft and smooth in hand feeling, has the characteristics of the down feather, also has the characteristics of being light, soft, warm, breathable, moisture permeable, mildew-proof, mothproof and washable, and is wide in application prospect and further and more competitive in the market.

Owner:ANHUI LION GOOSE PROD

Water-washable silk composite fiber and preparation method thereof

InactiveCN104213247AUV resistantAntistaticConjugated cellulose/protein artificial filamentsArtifical filament manufacturePolyesterFiber

Disclosed water-washable silk composite fiber is characterized by being prepared from the following raw materials in parts by weight: 18-22 parts of silk, 11-13 parts of wool, 4-7 parts of cuprammonium rayon, 6-8 parts of polyester fiber, 8-10 parts of newdal fiber, 10-12 parts of bast fiber, 0.6-1.1 parts of nanometer TiO2, 6-9 parts of aloe viscose fiber, 0.7-0.9 parts of hydroxypropyl methyl cellulose, 0.8-1.4 parts of polypropylenglycol diglycidyl ether, 100-110 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 110-120 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 1-3 parts of radix aucklandiae, 2-4 parts of cortex moutan, 3-5 parts of an auxiliary agent, and proper amount of water. By adding cuprammonium rayon and nanometer TiO2, the silk composite fiber has performances of resisting ultraviolet, resisting static electricity, resisting water washing and the like; and additionally by adding aloe viscose fiber, the Chinese herbal medicines and other compositions, the prepared silk composite fiber has the characteristics of resisting bacteria, diminishing inflammation, light and soft texture, excellent air permeability, high strength and high elasticity, and thus the silk composite fiber is repeatedly cleanable and keeps comfortableness, and is not flat or sunk after being used for a long time.

Owner:TONGCHENG SHUANGLONG SILK

Down feather composite fiber compounded by waste down feather fiber and acrylic staple fiber and preparation method of down feather composite fiber

ActiveCN104195665AEfficient use ofPrevent mildew and insectsMonocomponent protein artificial filamentSpinning solutions preparationPerilla frutescensMaterials science

The invention discloses a down feather composite fiber compounded by waste down feather fiber and acrylic staple fiber. The down feather composite fiber compounded by the waste down feather fiber and the acrylic staple fiber is prepared from the following raw materials in parts by weight: 10-15 parts of superfine goose down powder, 20-25 parts of waste down feather fiber, 25-30 parts of nano goose feather powder, 18-20 parts of acrylic staple fiber, 14-17 parts of collagen fiber, 7-9 parts of nano bamboo charcoal powder, 17-21 parts of coconut shell, 0.3-0.6 part of magnesium oxide, 1-3 parts of perilla frutescens bark, 2-4 parts of rhizoma smilacis glabrae, 13-15 parts of rice straw pulp fiber, 100-120 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 120-140 parts of 1,3-dimethyl imidazole dimethyl phosphate, 2-4 parts of additives and a proper amount of water. According to the down feather composite fiber compounded by the waste down feather fiber and the acrylic staple fiber, the waste down feather fiber is effectively used; the cost is reduced; meanwhile, perilla frutescens bark and rhizoma smilacis glabrae are added in the down feather composite fiber, so that the mildew and moth of the down feather composite fiber during the storage, transportation and utilization of the down feather composite fiber can be effectively avoided; especially, after the down feather composite fiber is used as a filler and made into articles of daily use, due to the bacteria resistance and bacteriostasis of the down feather composite fiber, the corresponding products have the obvious antibacterial, anti-inflammatory, deodorant, mildew-proof, anit-pruritic and astringent functions, have no stimulation to the skin and are well received by consumers.

Owner:ANHUI LION GOOSE PROD

Antibacterial and mothproof silk composite fibers and manufacturing method thereof

InactiveCN104233505AIncrease elasticityHigh strengthConjugated artificial filamentsArtifical filament manufactureDiethyl phosphateMoisture

The invention discloses antibacterial and mothproof silk composite fibers. The antibacterial and mothproof silk composite fibers are characterized by comprising the following materials in parts by weight: 17-20 parts of mulberry silk, 10-13 parts of tencel, 12-15 parts of chicken feather down fibers, 4-7 parts of acrylic fibers, 6-9 parts of aloe fiber, 7-10 parts of kawo kawo fiber, 1.2-3.2 parts of chitin fibers, 2-3 parts of epoxidized soybean oil, 0.3-0.5 part of calcium carbonate, 0.1-0.3 part of sodium sec-alkyl sulfonate, 1-3 parts of mica powder, 100-110 parts of 1-butyl-3-methylimidazole dibutyl phosphate, 120-125 parts of 1-ethyl-3-methylimidazole diethyl phosphate, 1.2-3.2 parts of folium cortex eucommiae, 1-3 parts of rhizoma corydalis, 2-4 parts of radix rubiae, 2-5 parts of additives and a proper amount of water. Due to addition of the multiple plant fibers and Chinese herbal medicines, the silk composite fibers have good antibacterial, mothproof, breathable, moisture-absorbing and heat-preserving functions, and the prepared silk composite fibers are also high in elasticity, strength and washing durability.

Owner:TONGCHENG SHUANGLONG SILK

Environmentally friendly cutting fluid containing graphene and preparation method therefor

InactiveCN103710123AImprove the lubrication effectImprove anti-wear performanceLubricant compositionSolventMonomer

Provided is a environmentally friendly cutting fluid containing graphene. The cutting fluid is prepared from the following raw materials, by weight, 2-3 parts of graphene, 1-2 parts of silane coupling agent KH-550, 3-4 parts of vinyl acetate, 4-5 parts of dibutyl phosphate, 10-12 parts of drainage oil, 13-15 parts of propylene glycol, 2-3 parts of zirconium fluoride, 3-4 parts of ricinoleic acid, 1-2 parts of polyoxyethylene octylphenol ether, 1-2 parts of sodium butylnaphthalenesulfonate, 6-8 parts of auxiliary agents and 200 parts of water. Through application of graphene and zirconium fluoride, the lubricating property and abrasion resistance of the cutting fluid are enhanced greatly, and the service life of the cutting fluid is prolonged. Through application of drainage oil, the lubricating property is raised, and the cutting fluid is beneficial for environmental protection. Through application of surfactants, high-molecular monomers, solvents and coupling agents, the cutting fluid is advantaged by stable emulsification and no sedimentation.

Owner:MAANSHAN HENGYI MACHINERY MFG

Moisture-absorbing air-permeable silk composite fiber and preparation method thereof

InactiveCN104213248AAntibacterialWith deodorizing adsorptionConjugated cellulose/protein artificial filamentsArtifical filament manufacturePyrophosphatePolyphenol

Disclosed moisture-absorbing air-permeable silk composite fiber is characterized by being prepared from the following raw materials in parts by weight: 16-19 parts of silk, 13-15 parts of camel hair, 7-9 parts of coral fleece, 10-12 parts of ramie fiber, 8-11 parts of PTT short fiber, 5-7 parts of soybean fiber, 2.3-4.7 parts of milk protein fiber, 0.4-0.8 parts of tea polyphenol, 1.2-3.2 parts of plastic starch, 0.3-0.6 parts of sodium pyrophosphate, 1.2-2.4 parts of cocounut oil essence, 100-110 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 110-120 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 1-2 parts of frankincense, 0.5-0.9 parts of sediment of human urine, 0.6-0.8 part of flos lonicerae, 2-4 parts of an auxiliary agent, and proper amount of water. By adding ramie fiber, the silk composite fiber has functions of resisting bacteria, inhibiting bacteria, eliminating and adsorbing odor, absorbing moisture and breathing, and the like, and by adding tea polyphenol, the improved silk composite fiber also has effects of resisting radiation, being smooth and light, keeping warm and resisting static electricity.

Owner:TONGCHENG SHUANGLONG SILK

Mothproof down feather composite fiber and preparation method thereof

InactiveCN104264277AAntibacterial and mothproofLightweight and high strengthConjugated cellulose/protein artificial filamentsArtifical filament manufactureAluminium silicateGluconates

The invention discloses a mothproof down feather composite fiber. The mothproof down feather composite fiber is characterized by being prepared from the following raw materials in parts by weight: 16-18 parts of duck's down, 15-19 parts of chicken feather, 11-13 parts of mercerized wool fibers, 12-14 parts of mercerization cotton fibers, 4-7 parts of copper ammonia fibers, 15-19 parts of straw stalk, 4-6 parts of closed cell perlite powder, 1-3 parts of angelica sinensis, 2-4 parts of gastrodia elata, 2-3 parts of ligusticum wallichii, 0.2-0.4 part of zinc gluconate, 0.3-0.6 part of aluminium silicate, 100-105 parts of 1-butyl-3-methyl imidazole acetate, 110-115 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 2-4 parts of additives and a proper amount of water. The down feather composite fiber prepared by the invention has the advantages of sterilization, moth prevention, light weight, high intensity, thermal preservation, flame retardance and the like.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Waterborne cutting liquid suitable for various metals and preparation method of cutting liquid

InactiveCN104120009AImprove the lubrication effectEasy to cleanLubricant compositionDispersityBetaine

The invention discloses waterborne cutting liquid suitable for various metals. The cutting liquid is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of erucic acid, 5-7 parts of white oil, 4-6 parts of dodecyl dimethyl betaine, 2-3 parts of magnesium stearate, 3-4 parts of polyethylene glycol, 2-3 parts of sodium alginate, 0.7-1.5 parts of paraphthaloyl chloride, 4-6 parts of dibutyl phosphate, 5-7 parts of an assistant and 200 parts of de-ionized water. The cutting liquid has good wear resistance, dispersity, lubricity and film-forming property due to the addition of the assistant; a layer of protection film can be formed on the metal surface to prevent the metal surface from being corroded by air; a surfactant used in the lubricating cutting liquid has excellent lubricating, cleaning and anti-rust performances; after processing, the surface smoothness of a workpiece is improved and the wear of a cutter is reduced; the cutting liquid is suitable for processing the various metals.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

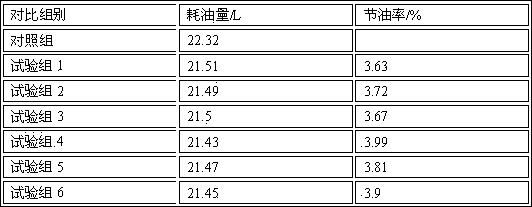

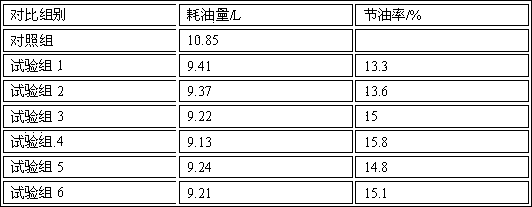

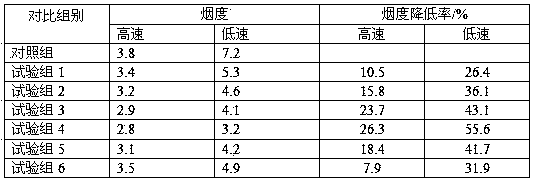

Energy-saving environmental-friendly curing agent for diesel oil

InactiveCN103382406AReduce consumptionImprove combustionLiquid carbonaceous fuelsFuel additivesFuel oilEngineering

The invention relates to an energy-saving environmental-friendly curing agent for diesel oil. The energy-saving environmental-friendly curing agent comprises following effective raw materials, by weight: 3 to 8 portions of ethylhexylnitrate, 1 to 4 portions of dibutyl phosphate, 5 to 13 portions of ethyl lactate, 5 to 13 portions of ethyl acetate, 25 to 45 portions of dimethyl carbonate, 25 to 45 portions of a purification dispersant and 2 to 6 portions of dimethyl oxalate. The energy-saving environmental-friendly curing agent is capable of improving combustion conditions of fuel oil, increasing the power of engines, reducing diesel oil consumption and harmful gas emission load. The fuel oil containing the curing agent is capable of lubricating parts which can contact with the fuel oil in the engines, and lubricating gaps which can be permeated with the fuel oil; a thin protection film is formed; the protection film is capable of preventing rust, resisting abrasion, and reducing noise, so that the inner parts of the engines are protected, service life of the engines is prolonged. In addition the preparation technology of the curing agent is simple; the intermiscibility of the curing agent and diesel oil is excellent; and the curing agent is simple and convenient to use, and is safe and stable.

Owner:山东国弘能源科技有限公司

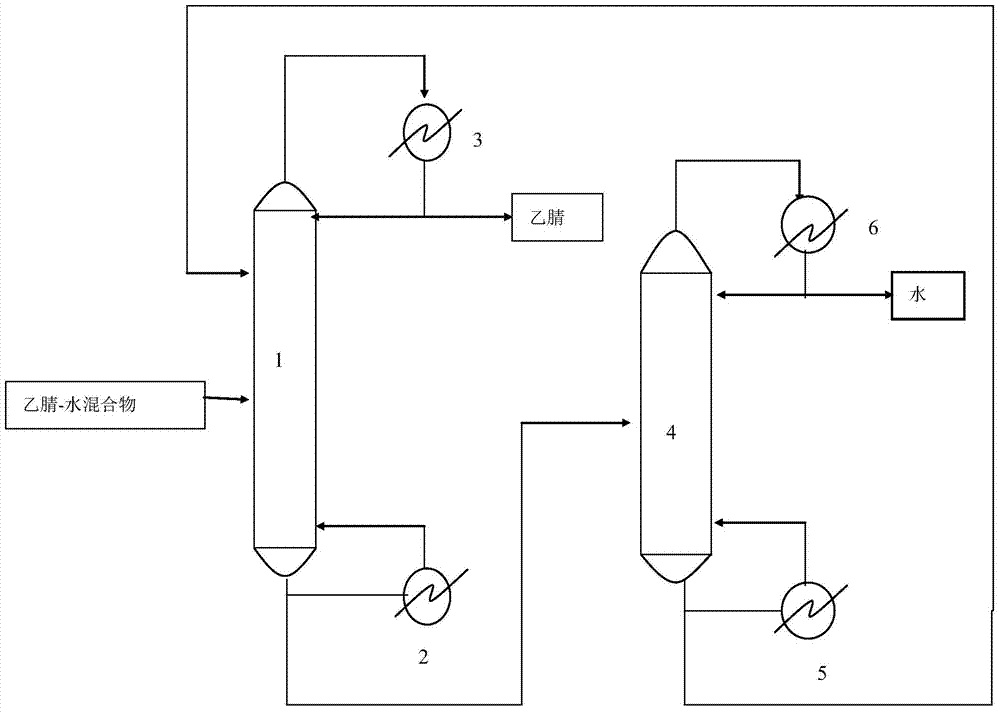

Process for separating acetonitrile-water azeotrope system by adopting ionic liquid extraction distillation

ActiveCN103922963AIncrease relative volatilityGood miscibilityExtractive distillationCarboxylic acid nitrile purification/separationTriflic acidSolvent

Owner:HEBEI UNIV OF TECH

Waterproof down feather composite fiber and preparation method thereof

InactiveCN104264275AWaterproofAntibacterialConjugated cellulose/protein artificial filamentsArtifical filament manufactureEpoxyFiber

The invention discloses a waterproof down feather composite fiber. The waterproof down feather composite fiber is characterized by being prepared from the following raw materials in parts by weight: 10-15 parts of duck's down, 16-21 parts of rabbit hair, 15-17 parts of merino super fine wool, 8-10 parts of gabardine fibers, 3-5 parts of acetate fibers, 0.1-0.3 part of zinc oxide, 0.4-0.8 part of methyl sodium silicate, 2-4 parts of kieselguhr, 1.2-2.3 parts of polystyrene foam particles, 1-3 parts of gastrodia elata, 0.6-0.9 part of prunella vulgaris, 0.8-1.3 parts of mint, 3-5 parts of melon vine, 4-7 parts of epoxy butyl oleate, 100-115 parts of 1-butyl-3-methyl imidazole acetate, 105-115 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 2-4 parts of additives and a proper amount of water. Polystyrene foam particles, methyl sodium, gastrodia elata, prunella vulgaris, mint and other ingredients are added; the technology is simple, convenient and feasible, and is low in production cost; the prepared down feather composite fiber has the advantages of water prevention, bacteria resistance, bacteriostasis, mildew and moth prevention and the like, so that the down feather composite fiber has no odor in using, and is clean and sanitary.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Aqueous cutting fluid and preparation method thereof

ActiveCN103666729AGood viscosity and temperatureImprove the lubrication effectLubricant compositionPolyethylene glycolAlkylphenol

The invention discloses an aqueous cutting fluid, which is prepared from the following raw materials in parts by weight: 10-12 parts of polyethylene glycol, 2-3 parts of triethanolamine, 6-9 parts of dibutyl phosphate, 19-22 parts of castor oil, 1-2 parts of calcium sulfide alkylphenol, 1-2 parts of sorbic monostearate, 6-8 parts of assistant and 200 parts of water. The aqueous cutting fluid disclosed by the invention has excellent viscosity-temperature performance, lubricity, extreme pressure property and biodegradability, fast cooling speed, and good corrosion inhibition property, is long in service cycle in comparison with the traditional cutting fluid, small in abrasion on a tool, and high in yield, and has good protection roles on nonferrous metals and black metal, and the processed work-piece is bright.

Owner:广州南星润滑科技股份有限公司

Simulated low-emission organic waste liquid pyrolysis incineration suspending liquid formula and preparation method thereof

ActiveCN105161154AImprove stabilityReduce the amount of sedimentIncinerator apparatusRadioactive decontaminationLiquid wasteActive agent

The invention relates to a simulated low-emission organic waste liquid pyrolysis incineration suspending liquid formula and a preparation method thereof and relates to the field of low-emission waste liquid treatment. The formula comprises a component A, a component B and a component C, wherein the component A is simulated low-emission organic waste liquid and comprises, according to volume ratio, 20-30% of tributyl phosphate, 70-78% of aviation hydrogenated kerosene and 0-2% of dibutyl phosphate; the component B is calcium hydroxide suspending liquid and comprises, according to mass ratio, 25-30% of phosphorus fixation agent calcium hydroxide, 32-40% of active agent and 30-40% of deionized water; and the component C is an additive which is analytical pure magnesium carbonate. According to the formula, the shortcomings in the prior art are overcome, the suspending liquid prepared according to the formula is good in stability, small in precipitation capacity, low in viscosity and easy to convey; the active agent and the phosphorus fixation agent in the formula are domestic, and the barrier problem of introducing a foreign technology is solved.

Owner:SICHUAN ENVIRONMENTAL PROTECTION ENG CO LTD CNNC

Novel extreme-pressure (EP) gear oil

InactiveCN102041145AReduce frictionImprove energy savingLubricant compositionIndustrial equipmentOctanol

The invention discloses novel extreme-pressure (EP) gear oil, which comprises the following components in parts by weight: 30 to 45 parts of 100# mechanical oil, 40 to 50 parts of 38# cylinder oil, 0.1 to 1.0 part of BHT (butylated hydroxytoluene) antioxidant, 0.1 to 0.7 part of dibutyl phosphate, 1.0 to 2.0 parts of sulfur-phosphorous butyl octanol zinc salt, 0.2 to 0.8 part of alkenyl dibutyric acid, 0.2 to 0.9 part of demulsifying agent, 1.5 to 3.5 parts of dibenzyl disulphide, 10*10 to 6 parts of methyl silicone oil and 0.5 to 1.0 part of alkyl naphthalene. The EP gear oil has the advantages of the energy-conservation effect superior to the conventional product can be reached by fully reducing the friction; the EP gear oil has no toxin or harm to a human body and can reach the safety and environment protection requirements at high standards; the EP gear oil has good thermal oxidative stability and excellent rust protection and corrosion protection action; the service life of gears can be effectively prolonged; strong load or large load impact can be stood; the abrasion or the sintering of the gears can be prevented; and the EP gear oil is used for various industrial equipment working under the severe conditions of the heavy load or the impact load and high temperature.

Owner:薛淑芳

Methanol gasoline

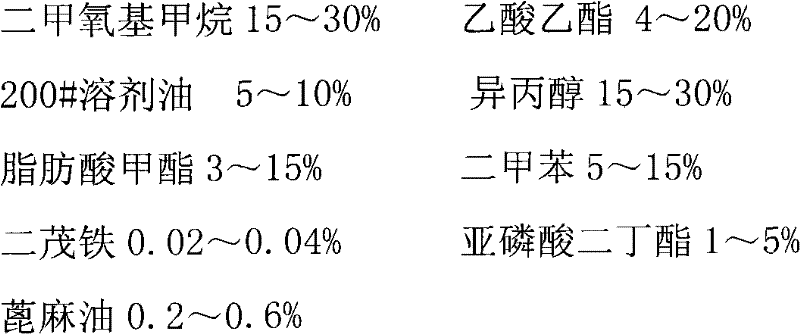

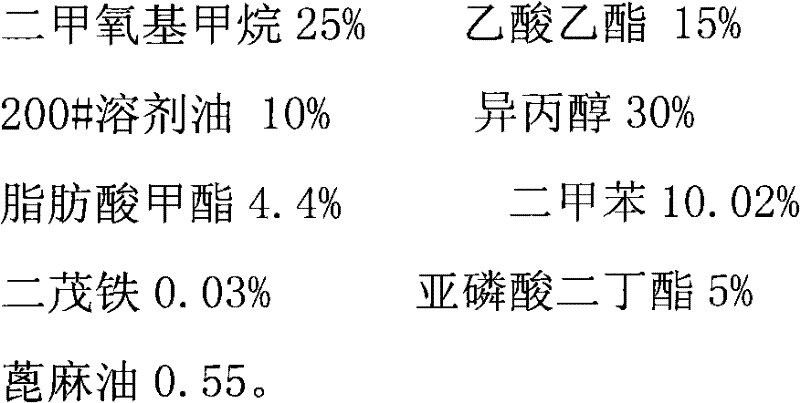

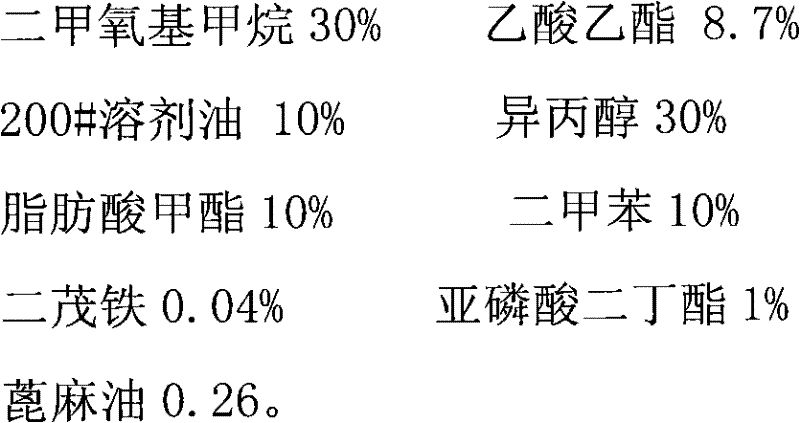

The invention discloses a methanol gasoline. The methanol gasoline comprises the following elements in percentage by weight: 50-70% of gasoline, 10-30% of methanol and 12-25% of additive, wherein the additive comprises the following elements in percentage by weight: 15-30% of dimethoxymethane, 4-20% of ethyl acetate, 5-10% of 200# solvent oil, 15-30% of isopropyl alcohol, 3-15% of fatty acid methyl ester, 5-15% of dimethylbenzene, 0.02-0.04% of ferrocene, 1-5% of dibutyl phosphate, and 0.2-0.6% of caster oil. The methanol gasoline disclosed by the invention is not layered and emulsified when being naturally arranged, can still keep stable at low temperature of below 40 DEG C, and has excellent corrosion resistance and ultrastrong waterproof performance.

Owner:胡显坤 +4

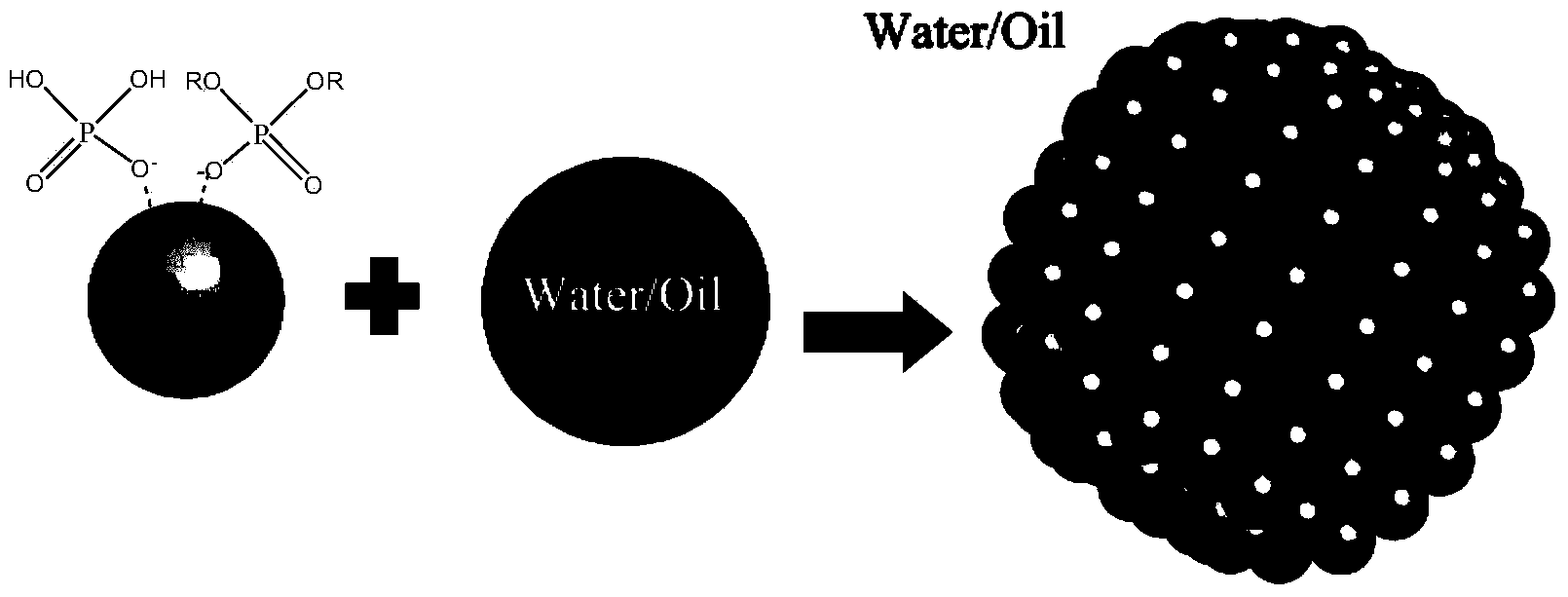

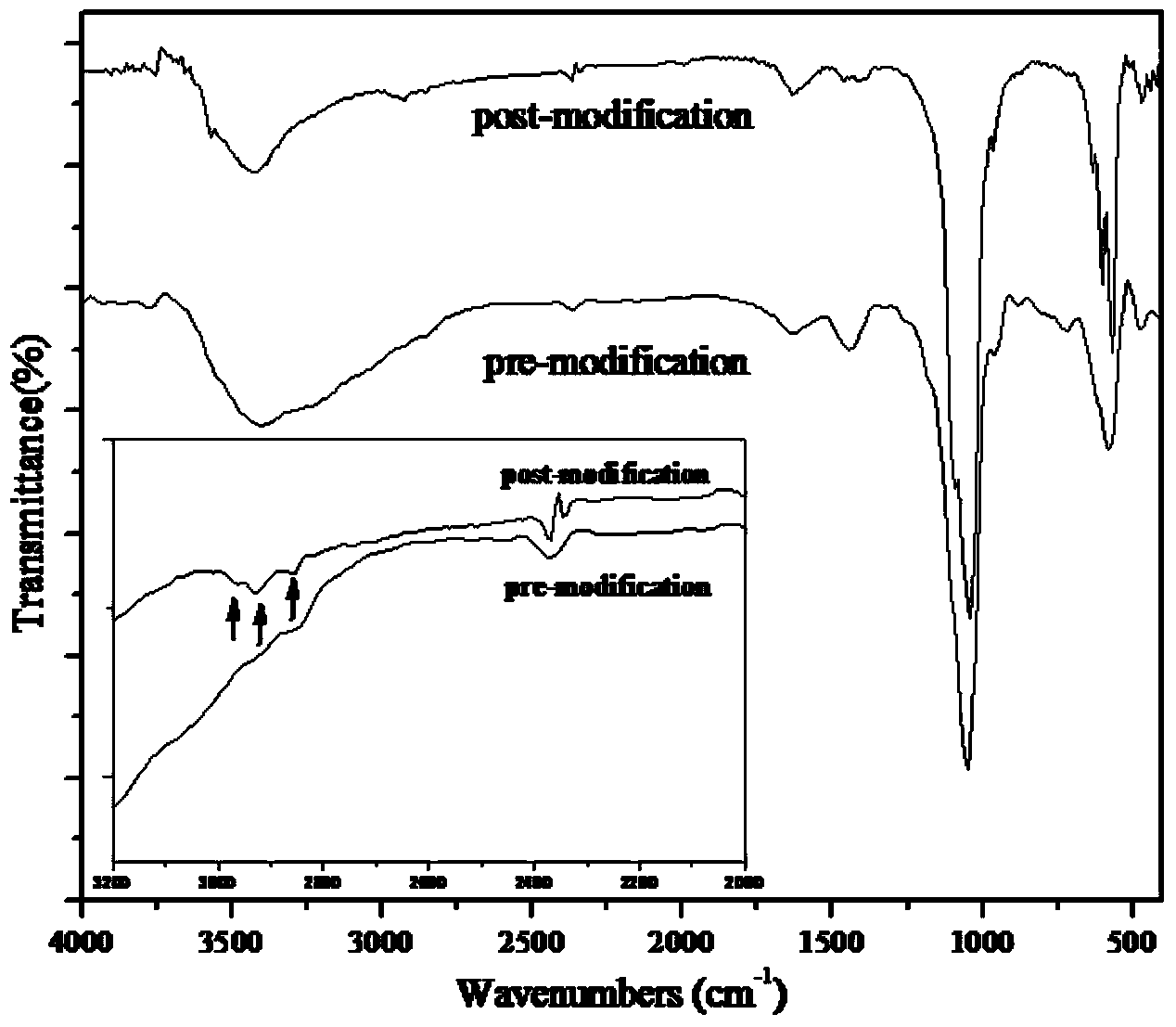

Preparation method and application of modified hydroxyapatite microcapsule biological material carrier

ActiveCN104069499AEasy to prepareLow costPharmaceutical delivery mechanismPharmaceutical non-active ingredientsOil phaseBiological materials

The invention belongs to the technical field of preparation and application of biocompatibility carrier materials and specifically discloses a preparation method and application of a modified hydroxyapatite microcapsule biological material carrier. The preparation method of the modified hydroxyapatite microcapsule biological material carrier comprises the following steps: adding hydroxyapatite nano-particles and dibutyl phosphate in acetone, modifying the surfaces of the nano-particles by using n-butyl, simultaneously generating hydroxyl groups and n-butyl groups on the surfaces of the nano-particles so as to obtain nano-particles with hydrophilcity / hydrophobicity and the modified surfaces; adding the nano-particles in a water phase or an oil phase, then adding the oil phase or the water phase to be used as a core material, violently shaking and carrying out self-assembling to obtain the microcapsule material which takes the nano-particles with modified surfaces as membrane materials and has water / oil interface stability. The microcapsule material has a relatively large loading rate, the function of isolating effective components and has the specific release capability and the like; by dissolving single water-soluble or fat-soluble biological material in the core material, the microcapsule carrier material can be conveniently taken as an efficient carrier of the biological material for practical application.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Long-acting slow-release fragrant silk composite fiber and preparation method thereof

InactiveCN104213245AFresh and long-lasting fragranceFeel goodConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsStearic acidLemon juice

Disclosed long-acting slow-release fragrant silk composite fiber is characterized by being prepared from the following raw materials in parts by weight: 16-23 parts of silk, 5-8 parts of white eider, 8-10 parts of acrylic fiber, 4-7 parts of basalt fiber, 6-8 parts of pearl fiber, 9-12 parts of kendir fiber, 7-9 parts of aloe viscose fiber, 1.2-2.5 parts of matricaria chamomilla extraction liquid, 1.1-2.3 parts of lemon juice, 0.4-0.7 parts of zinc acetate, 1-2 parts of talcum powder, 0.7-0.9 parts of stearic acid, 100-110 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 105-110 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 2-4 parts of wild chrysanthemum flower, 1-3 parts of scutellaria baicalensis, 3-5 parts of an auxiliary agent, and proper amount of water. The original taste of conventional silk is changed, and the prepared silk composite fiber has the characteristics of durable refreshing fragrance, resistance to worm damaging, good handfeel, high elasticity and the like, gives people refreshing feeling and does not generate yellowing phenomenon.

Owner:TONGCHENG SHUANGLONG SILK

Down feather composite fibers with jasmine fragrance and preparation method thereof

InactiveCN104294399AAnti-staticAntibacterialConjugated cellulose/protein artificial filamentsArtifical filament manufactureFiberNicotiana langsdorffii

The invention discloses down feather composite fibers with a jasmine fragrance, and is characterized in that the down feather composite fibers comprise the following raw materials in parts by weight: 13-16 parts of goose down, 16-21 parts of ox hair, 8-10 parts of glass fibers, 5-8 parts of polynosic, 3-6 parts of conductive fibers, 3-6 parts of jasmine, 1-3 parts of fructus toosendan, 2-4 parts of radix paeoniae rubra, 6-9 parts of mineral wool fibers, 18-22 parts of tobacco straws, 1.2-3.1 parts of triethyl acetyl citrate, 2.1-3.2 parts of propyl acetate, 0.2-0.5 parts of triethyl citrate, 0.6-1.4 parts of a nano pearl powder, 100-110 parts of 1-butyl-3-methylimidazolium acetate, 110-130 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 3-5 parts of an auxiliary agent, and a proper amount of water. With addition of jasmine, fructus toosendan, radix paeoniae rubra and other components, the down feather composite fibers not only have the jasmine fragrance, but also can effectively remove dirt on the feather composite fibers, and have better conditioning and nursing effects on down feather; and the prepared down feather composite fibers have the advantages of static electricity resistance, large elasticity, good filling power, bacteria resistance, bacteriostasis, wash durability and the like.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Silk composite fiber with anticancer function and preparation method thereof

InactiveCN104213246AInhibition of divisionPrevent proliferationConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberYarn

Disclosed silk composite fiber with the anticancer function is characterized by being prepared from the following raw materials in parts by weight: 17-21 parts of tussah silk, 10-13 parts of waste eider down, 7-9 parts of cashmere fiber, 11-13 parts of rose fiber, 8-10 parts of alga fiber, 5-8 parts of taxus chinensis fiber, 4-7 parts of far-infrared ceramic fiber, 5.3-6.8 parts of nylon yarn fiber, 20-30 parts of rice washing water, 2-4 parts of dimethyl siloxane, 0.2-0.4 part of soda ash, 3-5 parts of acetyl tributyl citrate, 1.2-3.5 parts of kaolin, 95-105 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 100-120 parts of 1-ethyl-3-methylimidazolium diethylphosphate, and 3-6 parts of an auxiliary agent. By adding taxus chinensis fiber, once the inside-contained paclitaxel smell forms microcirculation in human body capillary micropores, cancer cell division is effectively inhibiting and cance cell propagation is prevented. Additionally, a plurality of other beneficial compositions are added, and the prepared silk composite fiber is rich in elasticity, bulkiness and flexibility, and the added Chinese herbal medicines are pleasant in smell, are capable of promoting sleep and are free of toxic and side effects.

Owner:TONGCHENG SHUANGLONG SILK

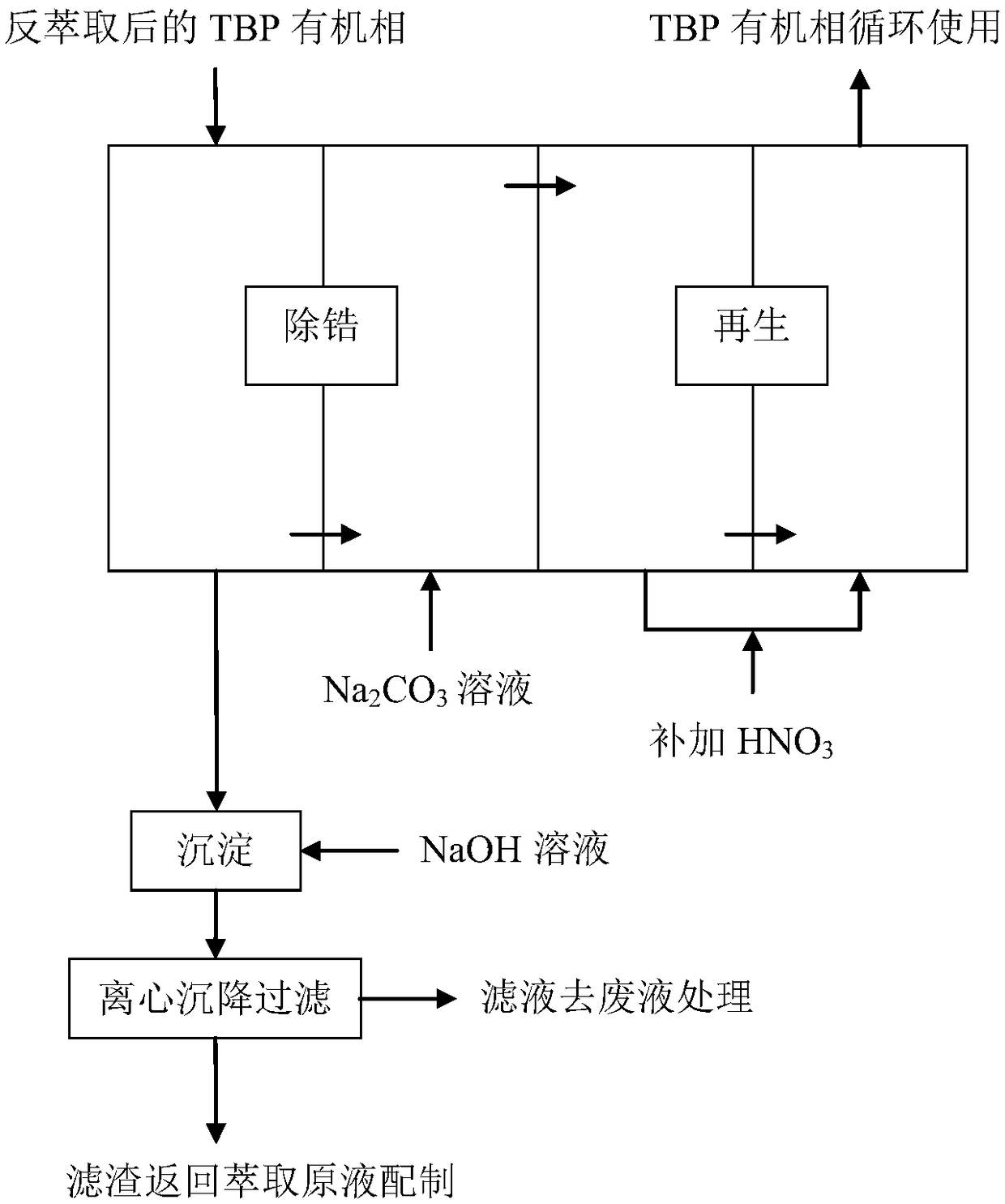

Tributyl phosphate organic phase regeneration treatment method

InactiveCN109355500AComply with recycling requirementsNo wasteProcess efficiency improvementDibutyl phosphateAcid washing

The invention belongs to the technical field of treatment methods of zirconium (hafnium) removal from a zirconium hafnium separation and extraction organic phase, and particularly relates to a tributyl phosphate organic phase regeneration treatment method. The method comprises the following steps that the organic phase is subjected to alkali washing to remove zirconium; alkali washing is carried out on residual liquid to recover zirconium; the organic phase is subjected to acid washing for regeneration; acid washing is carried out on the residual liquid for recycling; and the organic phase isused in a circulated manner. The method can completely remove zirconium (hafnium) and degradation products in the TBP organic phase obtained after back extraction treatment, and the zirconium (hafnium) content of the regenerated TBP organic phase is 30 mg / L or below, dibutyl phosphate is not detected, the requirement for recycling is met, and all the removed zirconium (hafnium) can be recovered, and no loss of products exists.

Owner:中核二七二铀业有限责任公司

Flux

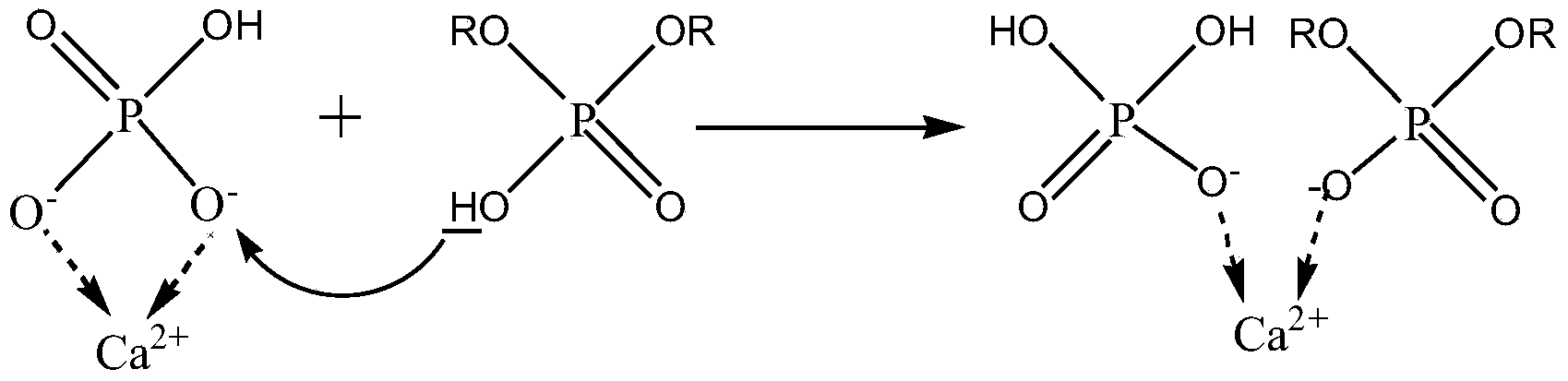

InactiveCN103402697AInhibition of attachmentInhibit migrationWelding/cutting media/materialsSoldering mediaDibutyl phosphatePhosphoric acid

Provided is a flux that allows the occurrence of migration to be reliably suppressed in a soldered part where a flux residue is formed. The flux is mixed with a solder powder to produce a solder paste, wherein the flux includes a phosphate ester in an amount at which the ester is adsorbed on the surface of a soldered part during soldering and forms a hydrophobic coating. The phosphate ester is preferably added in an amount of from at least 1 mass% to less than 30 mass%. The phosphate ester is preferably 2-ethylhexyl phosphate, monoisodecyl phosphate, monobutyl phosphate, dibutyl phosphate, monolauryl phosphate, monostearyl phosphate, monooleyl phosphate, tetracosyl phosphate, or bis(2-ethylhexyl)phosphate.

Owner:SENJU METAL IND CO LTD

Silk composite fibers applicable to allergic constitution and manufacturing method thereof

InactiveCN104233506AAbsorbs odorMoisture-proofConjugated cellulose/protein artificial filamentsArtifical filament manufactureDiethyl phosphateFiber

The invention discloses silk composite fibers applicable to allergic constitution. The silk composite fibers are characterized by comprising the following materials in parts by weight: 15-20 parts of mulberry silk, 12-14 parts of down feather, 9-11 parts of camel wool, 5-8 parts of aloe fiber, 7-9 parts of banana stem fiber, 6-8 parts of Lycra fibers, 5.6-7.8 parts of coconut-carbon fibers, 1.2-3.1 parts of fatty acid methyl ester ethoxylate, 0.6-1.2 parts of cinnamomum camphora essential oil, 0.8-1.4 parts of calcium alginate, 100-110 parts of 1-butyl-3-methylimidazole dibutyl phosphate, 110-120 parts of 1-ethyl-3-methylimidazole diethyl phosphate, 2-4 parts of liquorice, 1-3 parts of bitter almond kernel, 0.5-0.8 part of sophora alopecuroides, 2-3 parts of folium artemisiae argyi, 3-5 parts of additives and a proper amount of water. Due to addition of the coconut-carbon fibers, the silk composite fibers contain coconut-carbon particles and achieve health effects of activating cells, purifying blood, eliminating fatigue, changing allergic constitution and the like to a human body, and simultaneously, due to addition of other plant fibers, Chinese herbal medicines and other animal protein fibers, the prepared silk composite fibers have health functions of adsorbing odor, resisting moisture, removing odor, resisting ultraviolet rays and the like.

Owner:TONGCHENG SHUANGLONG SILK

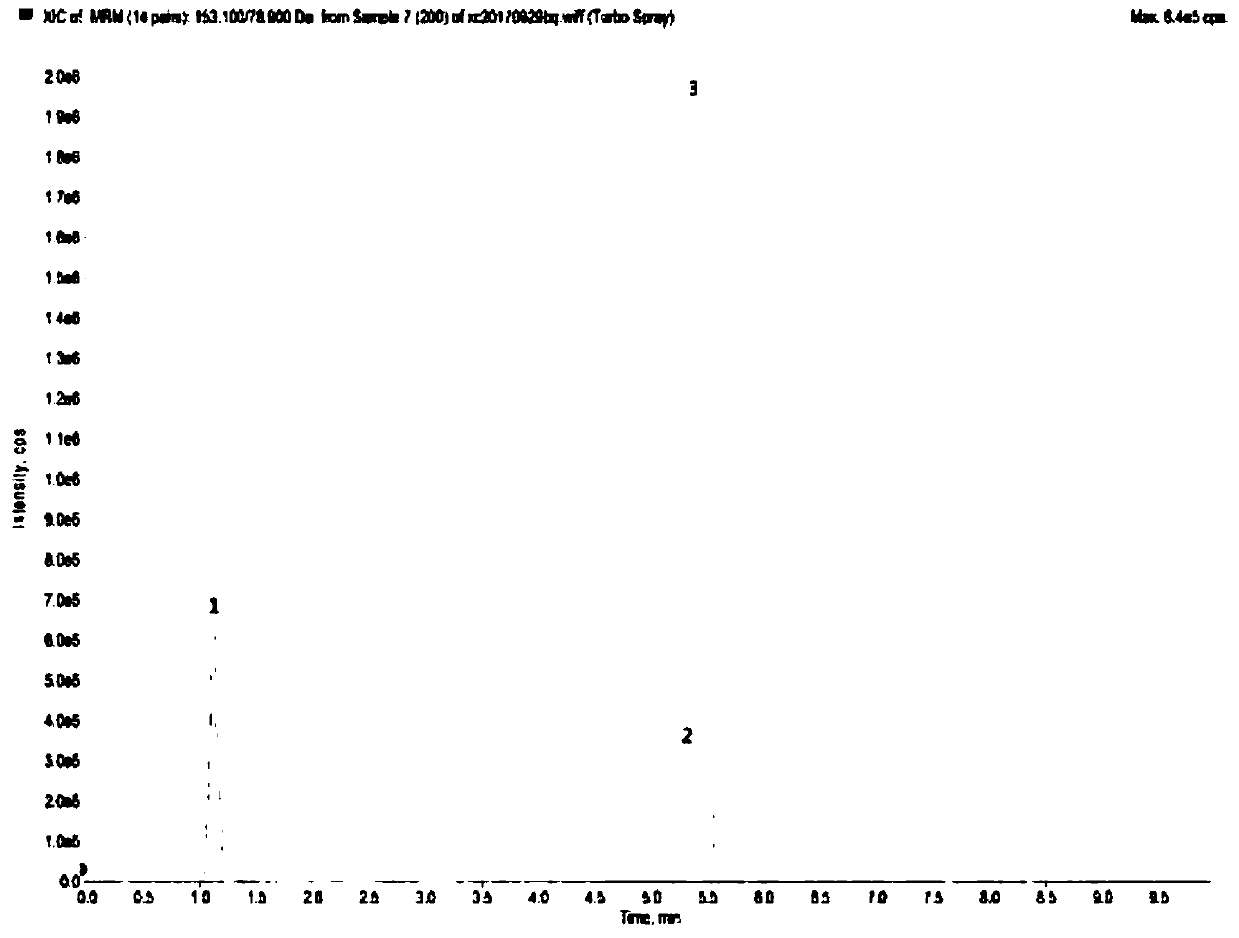

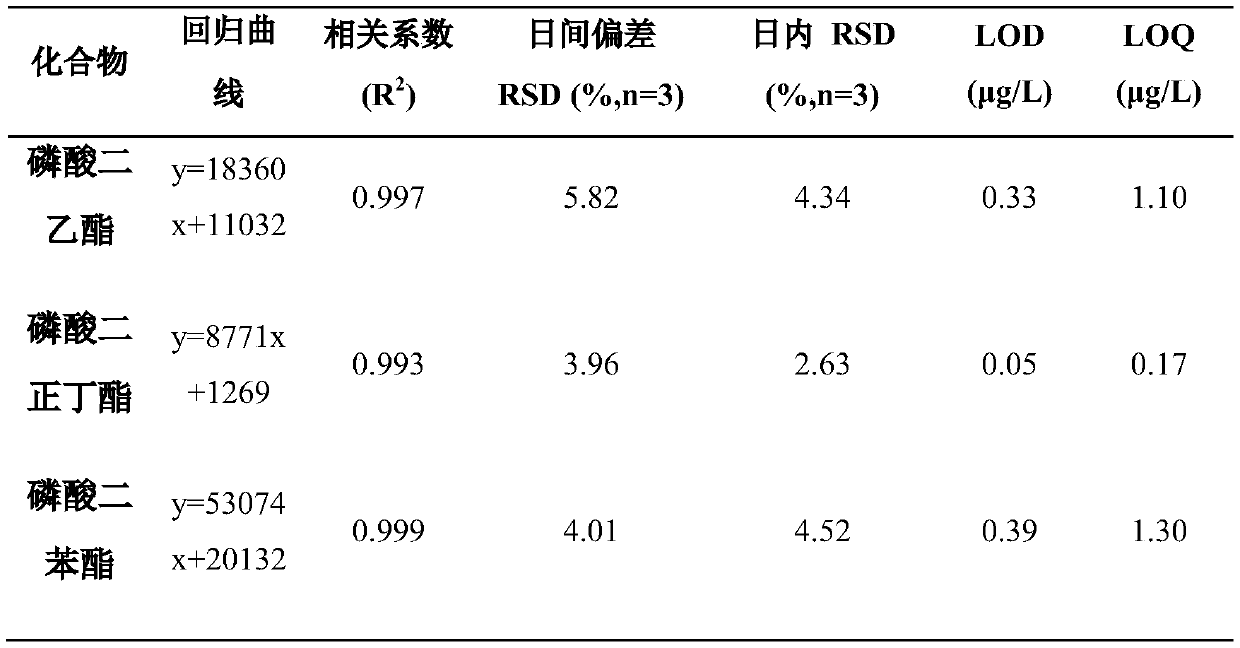

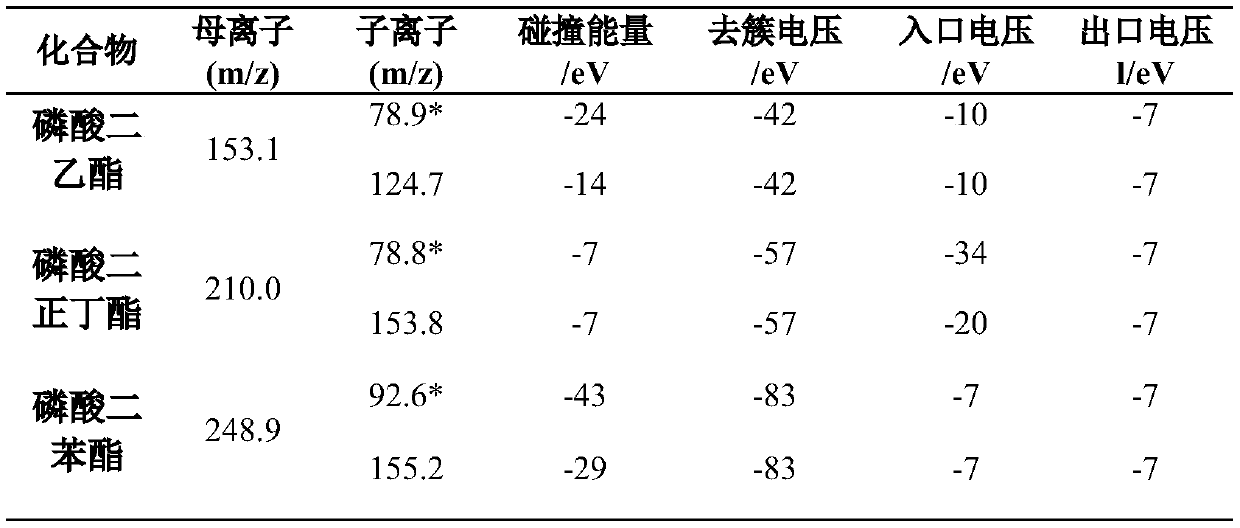

Method for determining contents of phosphodiester metabolites of organophosphorus esters (OPEs) in plasma

ActiveCN110806451AMeet the testing requirementsReduce extraction timeComponent separationDiethyl phosphatePhosphoric Acid Esters

The invention relates to the technical field of determination of contaminants in plasma, particularly to a method for determining the contents of phosphodiester metabolites of organophosphorus esters(OPEs) in the plasma. The method is characterized in that the high-performance liquid chromatography-ion trap-triple quadrupole mass spectrometry technology is combined with liquid-liquid extraction and extraction through a self-made solid-phase column for detection of the contents of diethyl phosphate, dibutyl phosphate and diphenyl phosphate in the plasma; and plasma samples are purified throughthe liquid-liquid extraction and the solid-phase extraction, analysis is carried out through an ion monitoring mode of a high-performance liquid chromatograph-mass spectrometer MRM, and quantification is carried out through the external standard method. The method provided by the invention has the advantages of low detection limit, high stability, high recovery rate and high detection sensitivity, is applicable to the determination of the contents of the diethyl phosphate, the dibutyl phosphate and the diphenyl phosphate in the human plasma, and can meet detection requirements for residues oftarget substances in the human plasma.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Ultraviolet-proof cotton fiber and preparation method thereof

InactiveCN104357933AGood moisture absorption and air permeabilityGood drapabilityMonocomponent cellulose artificial filamentCellulose/protein filament chemical after-treatmentAcetic anhydrideKapok fiber

The invention discloses ultraviolet-proof cotton fiber. The ultraviolet-proof cotton fiber is characterized by being prepared by raw materials in parts by weight as follows: 18-24 parts of cotton fiber, 6-8 parts of acrylic fiber, 7-9 parts of kapok fiber, 12-14 parts of milkweed fiber, 10-12 parts of silk worm protein fiber, 1.3-2.7 parts of hydroxyethyl cellulose, 2.1-4.5 parts of hollow glass beads, 4-6 parts of aloe vera gel, 2-4 parts of lonicera japonica, 3-5 parts of chrysanthemum, 1-3 parts of rose, 0.6-1.1 parts of calcium fluoride, 1.6-2.8 parts of cationic polyacrylamide, 3.1-4.7 parts of N-methyl pyrrolidone, 15-18 parts of acetic anhydride, 16-19 parts of triphenyl phosphite, 100-115 parts of 1-butyl-3-ethylimidazolium dibutyl phosphate, 115-120 parts of 1-butyl-3-methylimidazole acetate, 4-8 parts of an auxiliary and appropriate amount of water. Ultraviolet light can be absorbed by the added triphenyl phosphite; the cotton fiber has the advantages of good breathability and hygroscopicity, excellent drapability, comfortable hand feeling and the like by means of the added silk worm protein fiber; and meanwhile, by means of other added effective ingredients, the prepared cotton fiber further has the advantages of light mass, warm keeping, good elasticity, antibacterial and mouldproof performance, avoidance of fuzzing and pilling and the like.

Owner:安徽颍元农业科技股份有限公司

High-performance extreme pressure antiwear emulsified cutting oil and preparation method thereof

The invention discloses a high-performance extreme pressure antiwear emulsified cutting oil, and is characterized in that the emulsified cutting oil is prepared from the following raw materials in parts by weight: 19-24 parts of liquid paraffin, 30-40 parts of light oil, 13-15 parts of furfural extract oil, 8-10 parts of span-80, 2-3 parts of N,N'-bis(salicylidene)propanediamine, 2-4 parts of sebacic acid, 3-5 parts of dodecylene, 5-8 parts of sodium borate, 2-3 parts of dibutyl phosphite, 2.5-3.5 parts of a copper powder, 2-3 parts of petroleum sodium sulfonate, 2-2.5 parts of butyl carbitol, and 9-11 parts of modified waste engine oil. The sodium borate, dibutyl phosphate and other extreme pressure additives are added, and N,N'-bis(salicylidene)propanediamine and other metal surface passivation agents are added; with addition of the modified waste engine oil, resources are fully utilized, the cost is reduced, the lubricity is enhanced, the antirust passivation effect and the film-forming property are improved, and a metal section is prevented from being oxidized; and the cutting oil has good antiwear effect, can be used after being diluted by adding water, has extremely low oil mist, has no irritating smell, and is wide in use range and high in performance.

Owner:ANHUI RONGDA VALVE

Washable light down feather composite fiber and preparation method thereof

InactiveCN104278355AIncrease profitLow costConjugated cellulose/protein artificial filamentsArtifical filament manufactureRhizomeMaterials science

The invention discloses a washable light down feather composite fiber. The washable light down feather composite fiber is characterized by being prepared from the following raw materials in parts by weight: 12-14 parts of goose down, 15-20 parts of pig hair, 14-17 parts of camel hair, 6-8 parts of plumetis fibers, 10-12 parts of tencel fibers, 7-9 parts of cheviot fibers, 2.1-3.3 parts of sorbitol, 1.2-3.4 parts of glycerol monolaurate, 10-13 parts of grapevine, 1.2-3.1 parts of citric acid, 2-4 parts of phellodendron amurense, 1-3 parts of white atractylodes rhizome, 2-3 parts of the root bark of white mulberry, 0.3-0.5 part of magnesium chloride, 3-5 parts of oxidized castor oil, 100-120 parts of 1-butyl-3-methylimidazolium acetate, 110-130 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 1-3 parts of assistants and an appropriate amount of water. According to the washable light down feather composite fiber, the pig hairs and the camel hairs are added, and therefore, the feather utilization rate is increased and the cost is reduced; and the phellodendron amurense, the white atractylodes rhizome, the root bark of white mulberry and other Chinese herbal medicines are added, so that the washable light down feather composite fiber has the advantages of health keeping, sterilization, excellent breathability, washing durability and the like.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Special oil for automatic gearbox of AMT (automatic manual transmission)

InactiveCN102676282AHigh viscosityImprove the lubrication effectLubricant compositionThio-Phosphoric acid

The invention discloses special oil for an automatic gearbox of an AMT (automatic manual transmission), which is prepared from the following materials in parts by weight: 10-90 parts of base oil, 10-90 parts of polymerized alpha olefin, 1-8 parts of polyisobutene, 1-8 parts of ethylene propylene rubber, 0-2 parts of dibutyl phosphate, 0-2 parts of sulfur and phosphorus double-nitrogen derivative,0-2 parts of thio-phosphoric acid compound amine salt, 0.5-2 parts of sulfurized isobutylene and 0.1-0.5 parts of polymethylmethacrylate. The special oil for the automatic gearbox of the AMT disclosed by the invention has the following advantages of excellent extreme-pressure anti-wear property, small corrosion to copper, good low-temperature fluidity, good high-temperature antioxidant property, strong adhesive power and excellent oil film protection to a gear surface, and can resist the low temperature of 45 DEG C below zero. The special oil for the automatic gearbox of the AMT disclosed by the invention has small viscosity, good lubricating property and small flow resistance at the room temperature, and is energy-saving and environment-friendly special oil for the automatic gearbox of the AMT with quick instruction response to an electric actuator and excellent fuel economy.

Owner:东昊石油集团有限公司

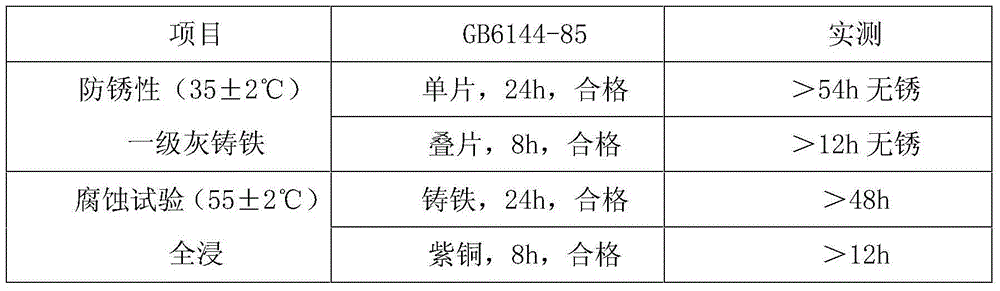

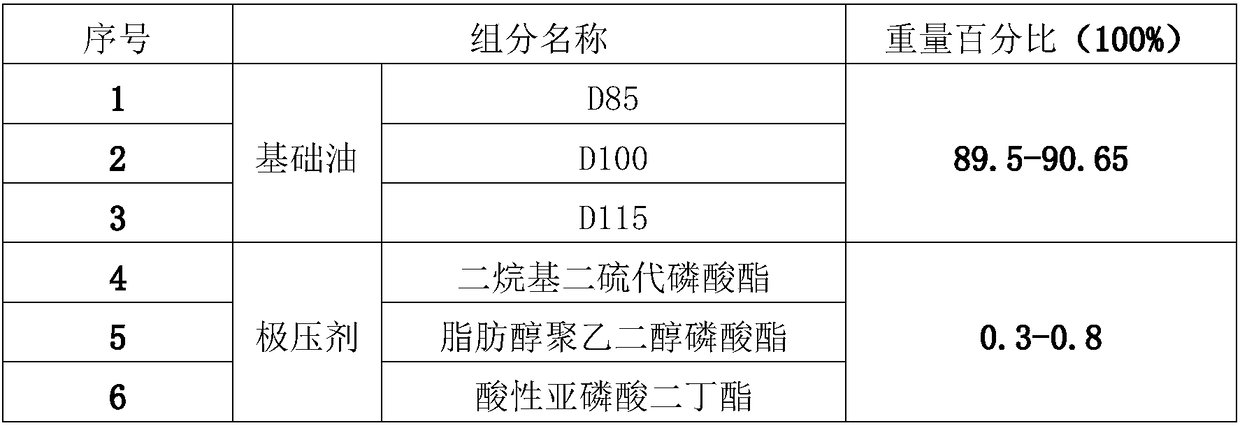

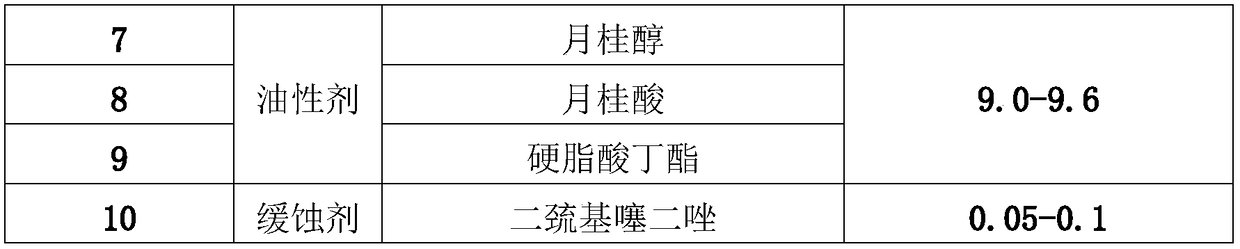

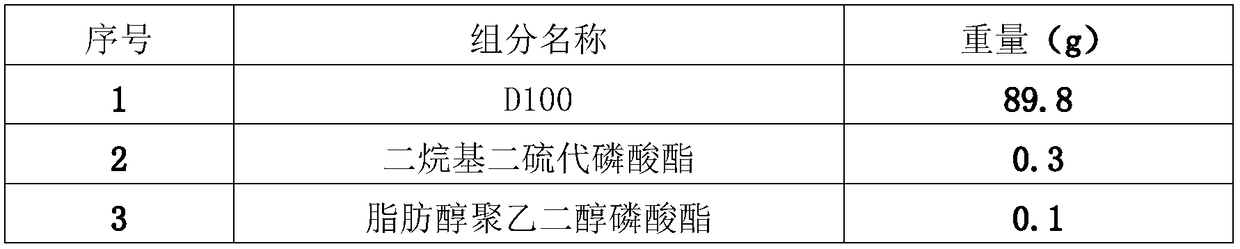

Cleaning type copper-aluminum composite board cold-rolled rolling oil and preparation method thereof

ActiveCN108251200AReduce coefficient of frictionGuaranteed cleanlinessLubricant compositionFriction reductionSurface cleaning

The invention provides cleaning type copper-aluminum composite board cold-rolled rolling oil and a preparation method thereof and belongs to the technical field of technological lubrication. A lubricant is prepared from the following components in percentage by weight: 89.5 percent to 90.65 percent of basic oil containing mineral oil D85, D100 and D115, 0.3 percent to 0.8 percent of extreme-pressure agent containing dialkylphosphorodithiloate, fatty alcohol polyethylene glycol ester and acidic dibutyl phosphite, 9.0 percent to 9.6 percent of oily agent containing lauric acid, lauryl alcohol and butyl stearate and 0.05 percent to 0.1 percent of corrosion inhibitor dimercaptothiodiazole. According to the cleaning type copper-aluminum composite board cold-rolled rolling oil, common aluminum rolling oil is adopted, and phosphorus and alcohol ester type extreme-pressure anti-wearing agents are added, so that the strength of an oil film of the rolling oil can be effectively improved; the lauric acid, the lauryl alcohol and the butyl stearate are used as the compound oily agent, so that the stability of a friction reduction capability of the rolling oil is effectively ensured; meanwhile,less dimercaptothiodiazole is added and used as the corrosion inhibitor and is used for preventing the surface of a copper substrate from being oxidized. The prepared rolling oil has extreme-pressureanti-wearing performance, corrosion resistance and surface cleaning performance.

Owner:UNIV OF SCI & TECH BEIJING

Warm-keeping air-permeable silk composite fiber and preparation method thereof

InactiveCN104213244AHeat storageBreathable and moisture-absorbingConjugated artificial filamentsArtifical filament manufactureCarbon fibersHemin

Disclosed warm-keeping air-permeable silk composite fiber is characterized by being prepared from the following raw materials in parts by weight: 15-20 parts of mulberry silk, 11-13 parts of rex rabbit hair, 5-7 parts of polypropylene fiber, 7-9 parts of soybean protein fiber, 6-8 parts of space cotton, 9-11 parts of silk floss, 4-7 parts of coffee carbon fiber, 0.2-0.4 parts of hemin, 1.2-3.2 parts of palm oil, 0.4-0.7 parts of alumina silicate, 100-110 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 105-110 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 1-3 parts of spica prunellae, 2-4 parts of folium artemisiae argyi, 3-6 parts of an auxiliary agent, and proper amount of water. Coffee carbon fiber is subjected to modification processing and then is added into raw materials, and the prepared silk composite fiber has the effects of storing heat, keeping warm, making air through, retaining moisture, emitting negative ions, resisting ultraviolet and the like. A negative-oxygen-ion silk quilt prepared from the silk composite fiber is capable of adjusting the body state of a user in sleep to an optimum state, enabling the user to rapidly enter a deep sleep state, improving the self immunity of the user and realizing the efficacy of prolonging life span.

Owner:TONGCHENG SHUANGLONG SILK

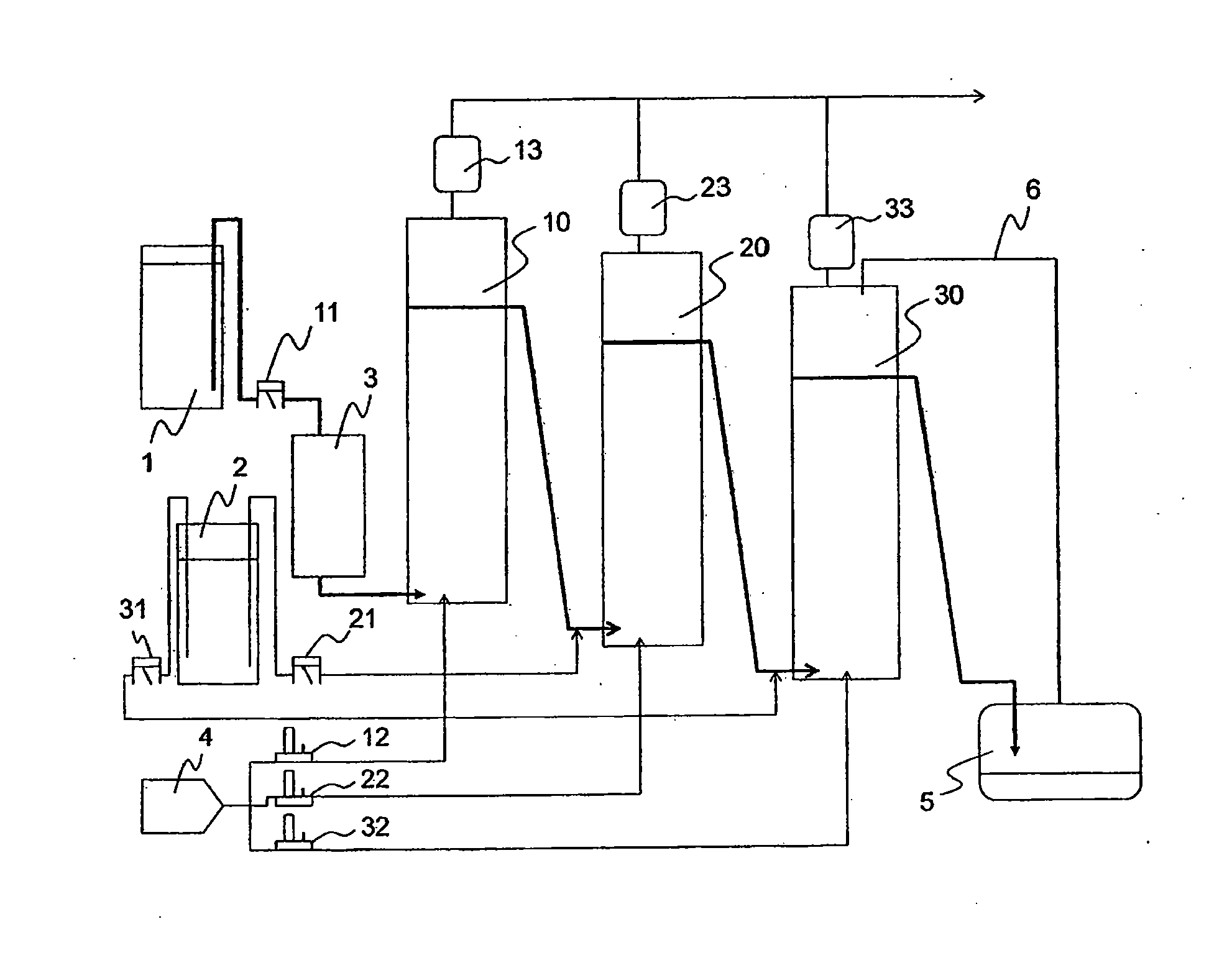

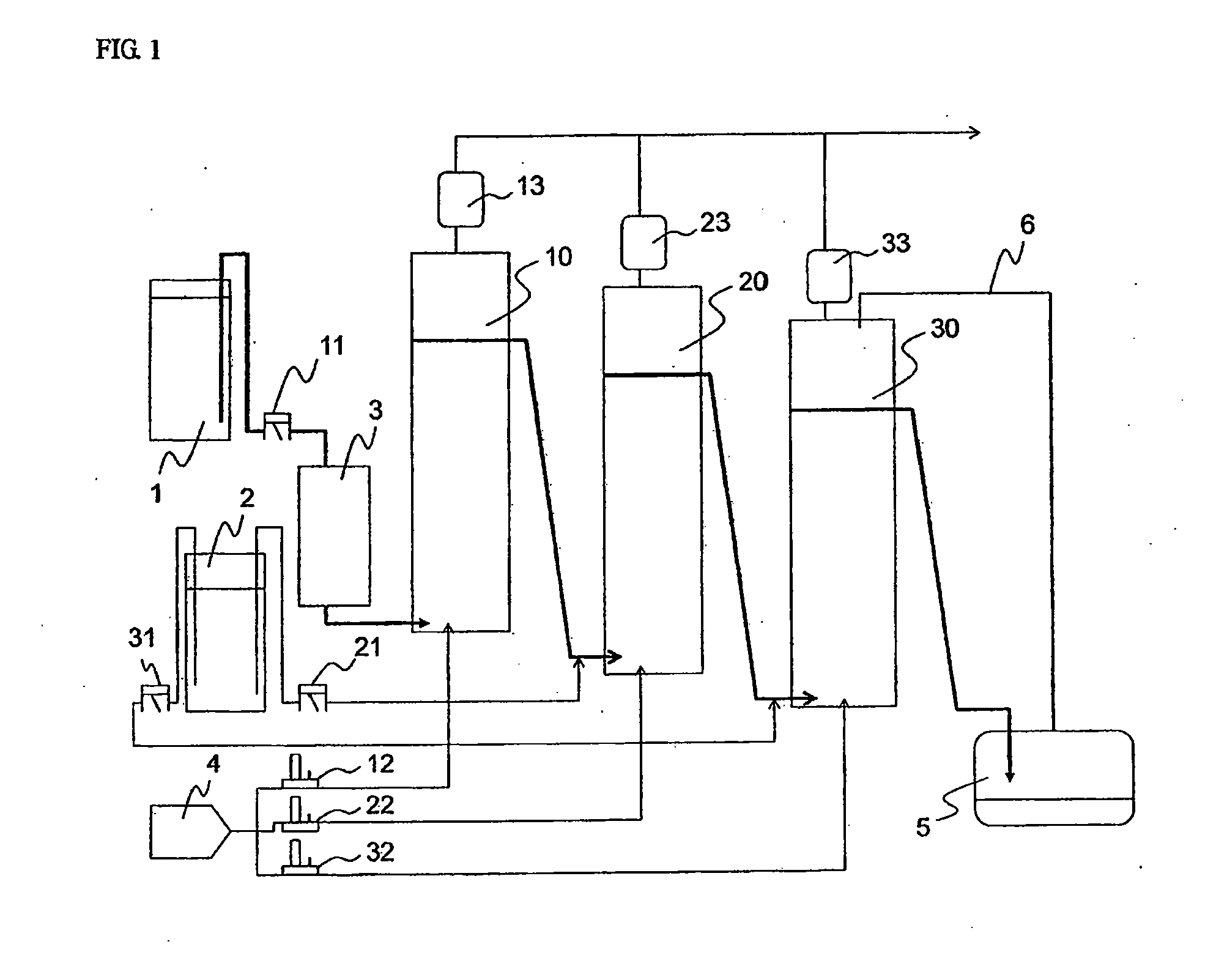

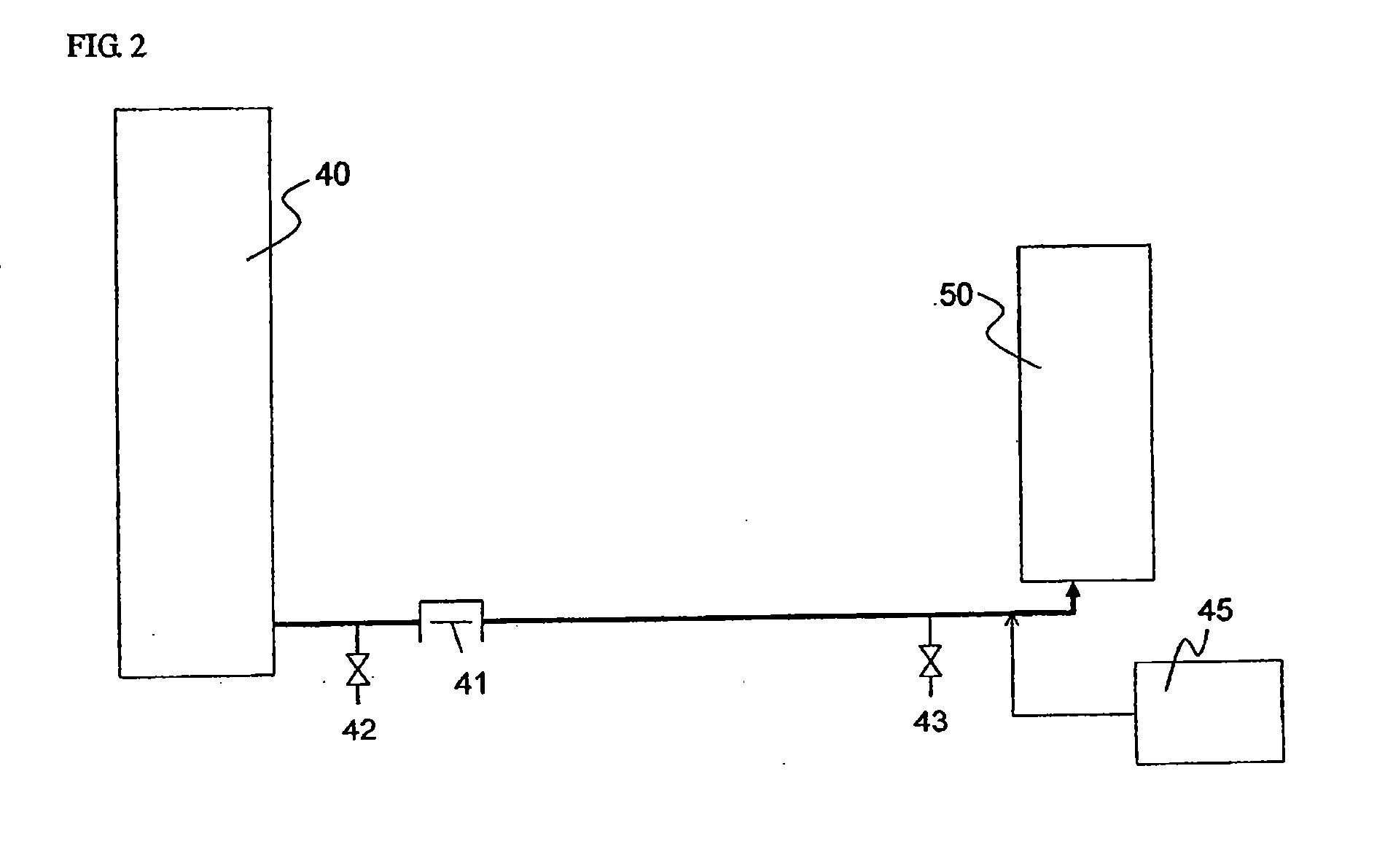

Oxidation Catalyst for Hydrocarbon Compound, and Method and Apparatus for Producing Oxide of Hydrocarbon Compound Using Same

InactiveUS20130184494A1High yieldImprove productivityPreparation by oxidation reactionsOrganic compound preparationDibutyl phosphateAlcohol

According to the first embodiment of the present invention, an oxide of a hydrocarbon compound can be produced with high yield and high productivity by oxidizing the hydrocarbon compound with molecular oxygen in the co-presence of an N-hydroxy compound, such as methyl ethyl ketone or N-hydroxysuccinimide, and a phosphate ester, such as dibutyl phosphate. According to another embodiment of the present invention, an oxide of a hydrocarbon compound can be produced with high yield by using an oxidation catalyst that comprises an oxime compound, such as methyl ethyl ketone. According to another embodiment of the present invention, an alcohol and / or a ketone can be produced with high yield by oxidizing the hydrocarbon compound at a temperature of 160° C. or less, and by decomposing the resulting hydroperoxide, for example, in a unit having an inner surface formed by a material from which no transition metal ion is generated.

Owner:UBE IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com