Methanol gasoline

A technology of methanol gasoline and gasoline, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc. It can solve the problems of affecting product quality, rising vapor pressure, insufficient power, etc., and achieves good corrosion resistance, fast starting speed, and sufficient power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A methanol gasoline, including the following components in weight fraction:

[0027] Weight percentage: gasoline 60% methanol 20% additive 20%

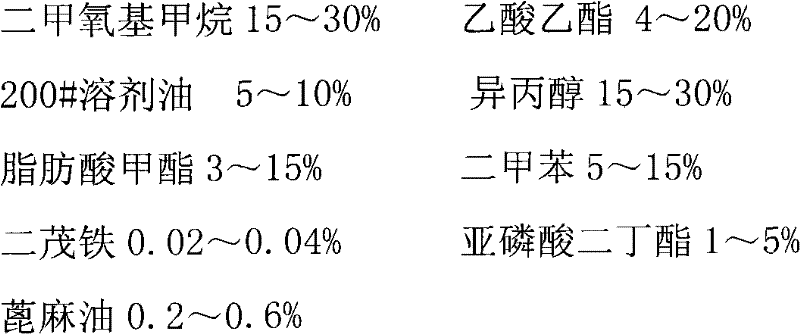

[0028] The additive composition and weight percentage are:

[0029]

[0030] The above-mentioned raw materials are uniformly mixed in a pressure vessel according to a ratio, pressed into a normal temperature and normal pressure oil tank, and matured for 24 hours to obtain additives.

[0031] Then the gasoline, methanol, and additives are fed into the synthesis tank at the same time in proportion, and after the mixing is successful, they are injected into the finished product tank, and the product is obtained after the sample is passed and tested.

Embodiment 2

[0033] A methanol gasoline, including the following components in weight fraction:

[0034] Weight percentage: gasoline 70% methanol 12% additive 18%

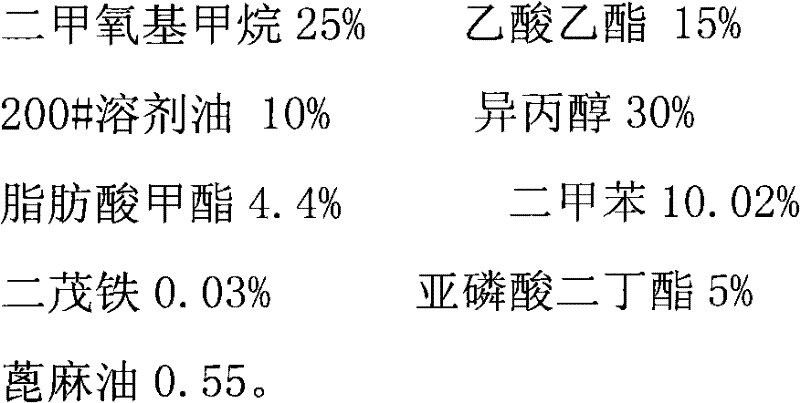

[0035] The additive composition and weight percentage are:

[0036]

[0037] The above-mentioned raw materials are uniformly mixed in a pressure vessel according to a ratio, pressed into a normal temperature and normal pressure oil tank, and matured for 24 hours to obtain additives.

[0038] Then the gasoline, methanol, and additives are fed into the synthesis tank at the same time in proportion, and then injected into the finished tank after the mixing is successful, and the product is obtained after a small sample is taken and passed the inspection.

Embodiment 3

[0040] A methanol gasoline, including the following components in weight fraction:

[0041] Weight percentage: gasoline 58% methanol 30% additive 12%

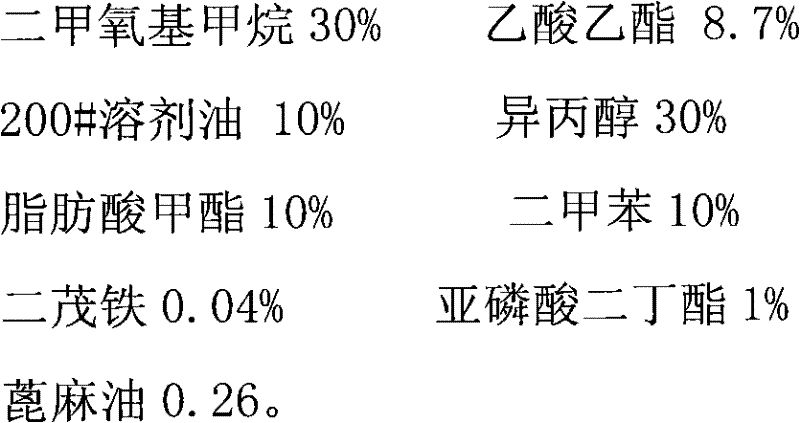

[0042] The additive composition and weight percentage are:

[0043]

[0044]

[0045] The above-mentioned raw materials are uniformly mixed in a pressure vessel according to a ratio, pressed into a normal temperature and normal pressure oil tank, and matured for 24 hours to obtain additives.

[0046] Then the gasoline, methanol, and additives are fed into the synthesis tank at the same time in proportion, and then injected into the finished tank after the mixing is successful, and the product is obtained after a small sample is taken and passed the inspection.

[0047] Take 200mL of the methanol gasoline and place it in a 250mL graduated cylinder with a stopper, add 3mL of distilled water and shake for 5min. After placing it at room temperature for 48 hours, the methanol gasoline is still clear and transparent without phase separation, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com