Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23759 results about "Ethyl ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl esters are produced by reacting crude fish oil in a free fatty acid form with ethanol (and industrial alcohol) to form a synthetic substrate. Under a vacuum, the mix is then heat distilled and the resulting condensate is a concentrated omega-3 ethyl ester solution.

Ethylene production from acetic acid utilizing dual reaction zone process

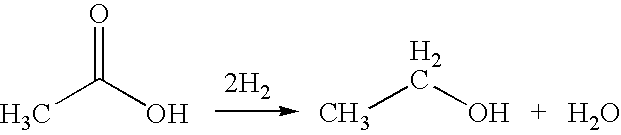

A process for selective formation of ethylene from acetic acid includes contacting a feed stream containing acetic acid and hydrogen at an elevated temperature with a first catalytic composition including a suitable hydrogenating catalyst in a first reaction zone to form an intermediate mixture including ethanol and ethyl acetate; and subsequently reacting the intermediate mixture over a suitable dehydrating and / or cracking catalyst in a second reaction zone to form ethylene. Selectivities of ethylene of over 80% are achieved.

Owner:CELANESE INT CORP

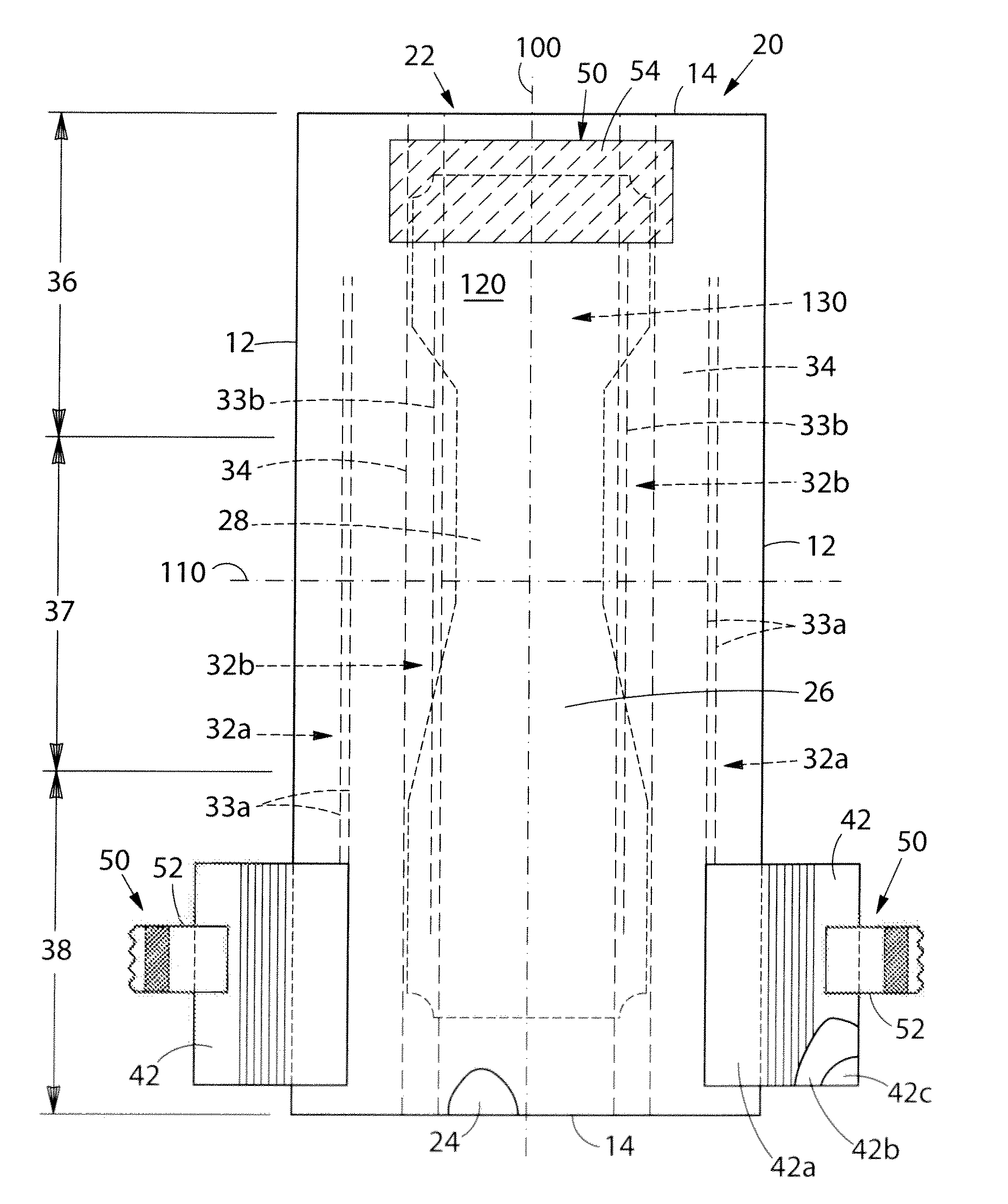

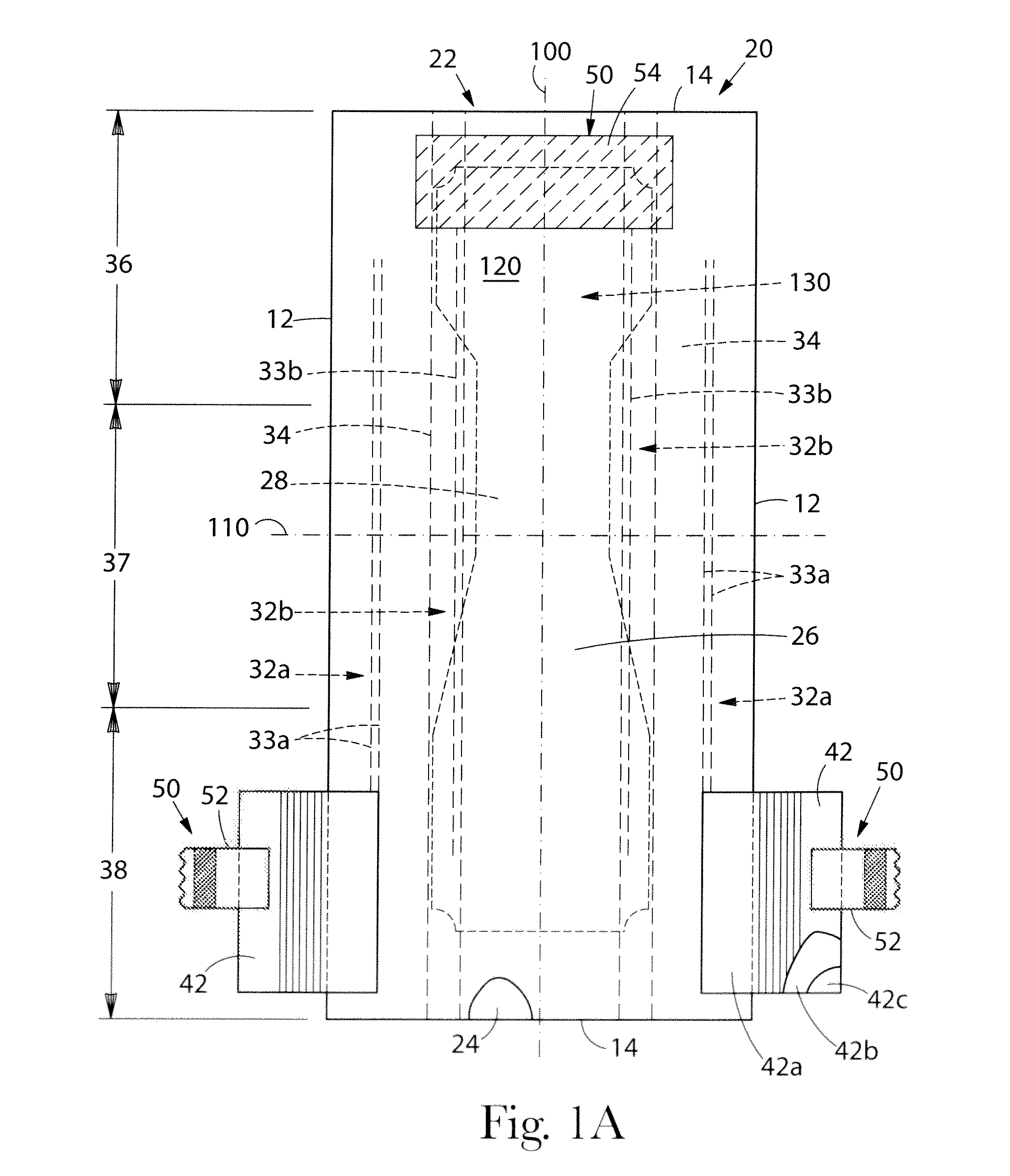

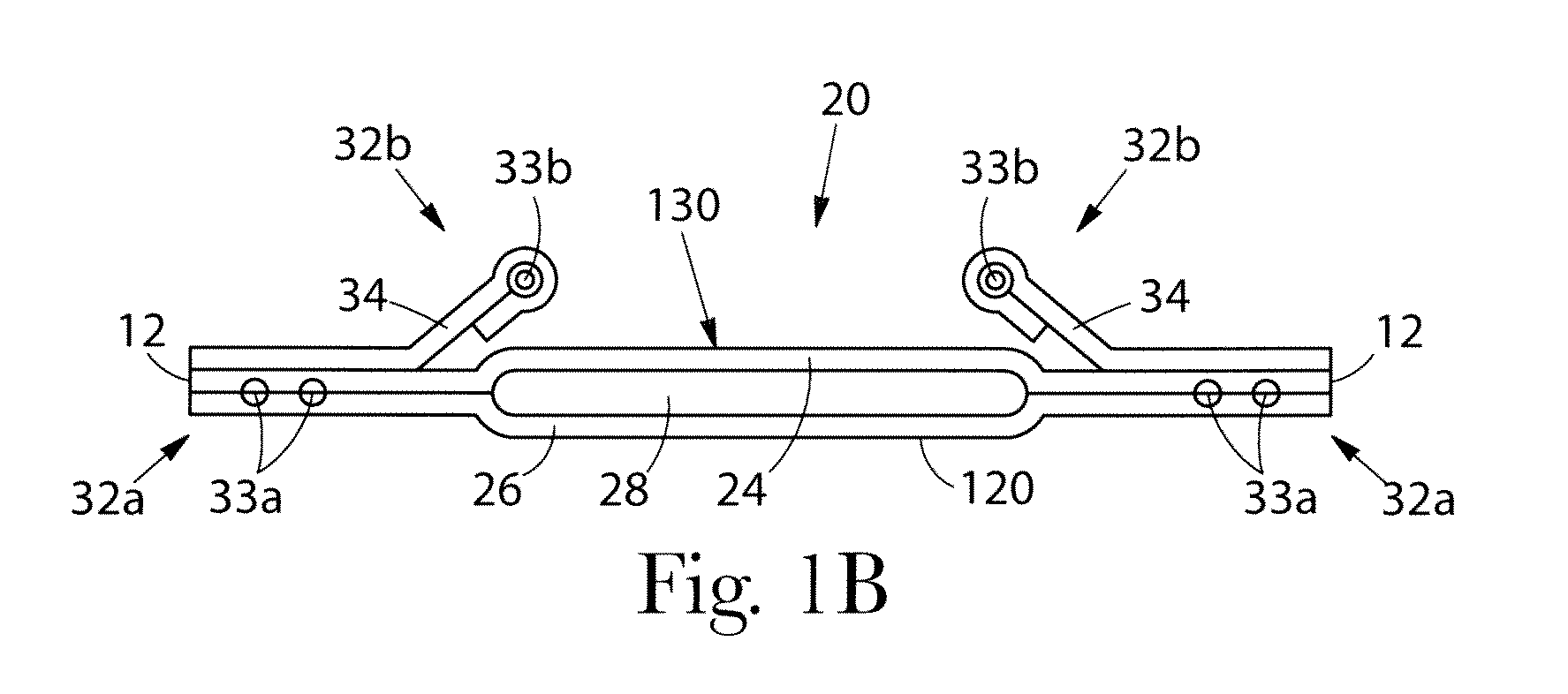

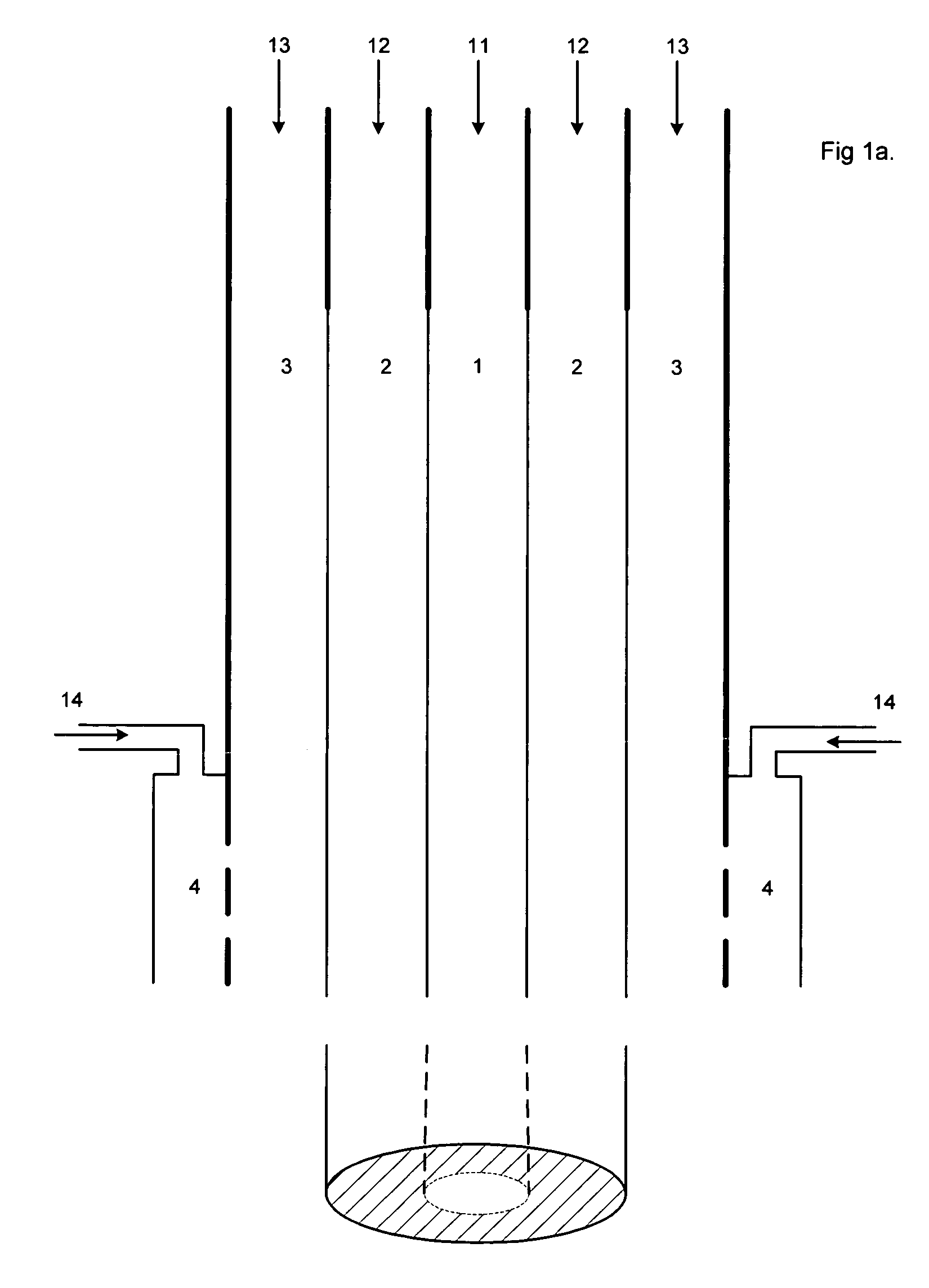

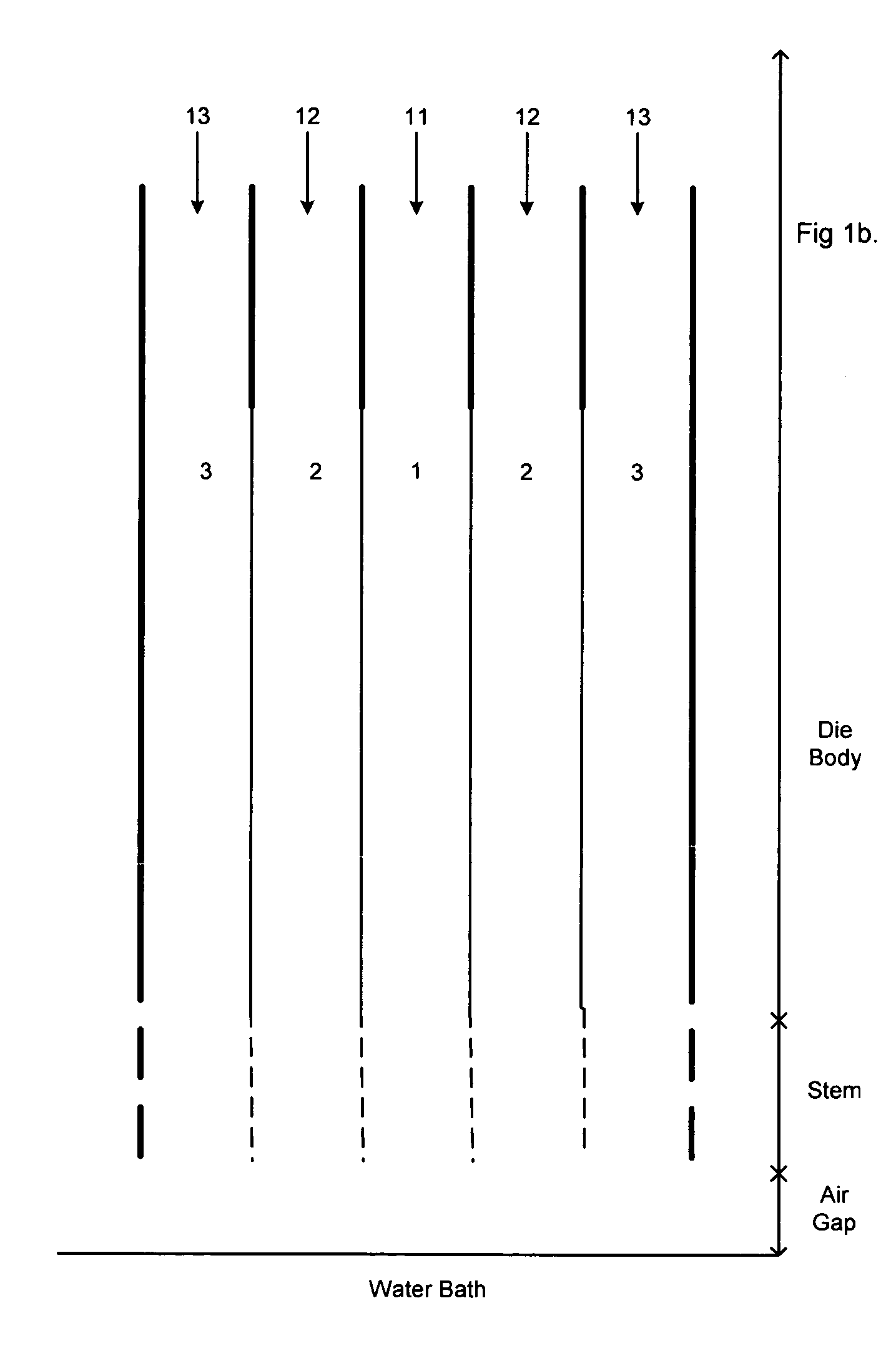

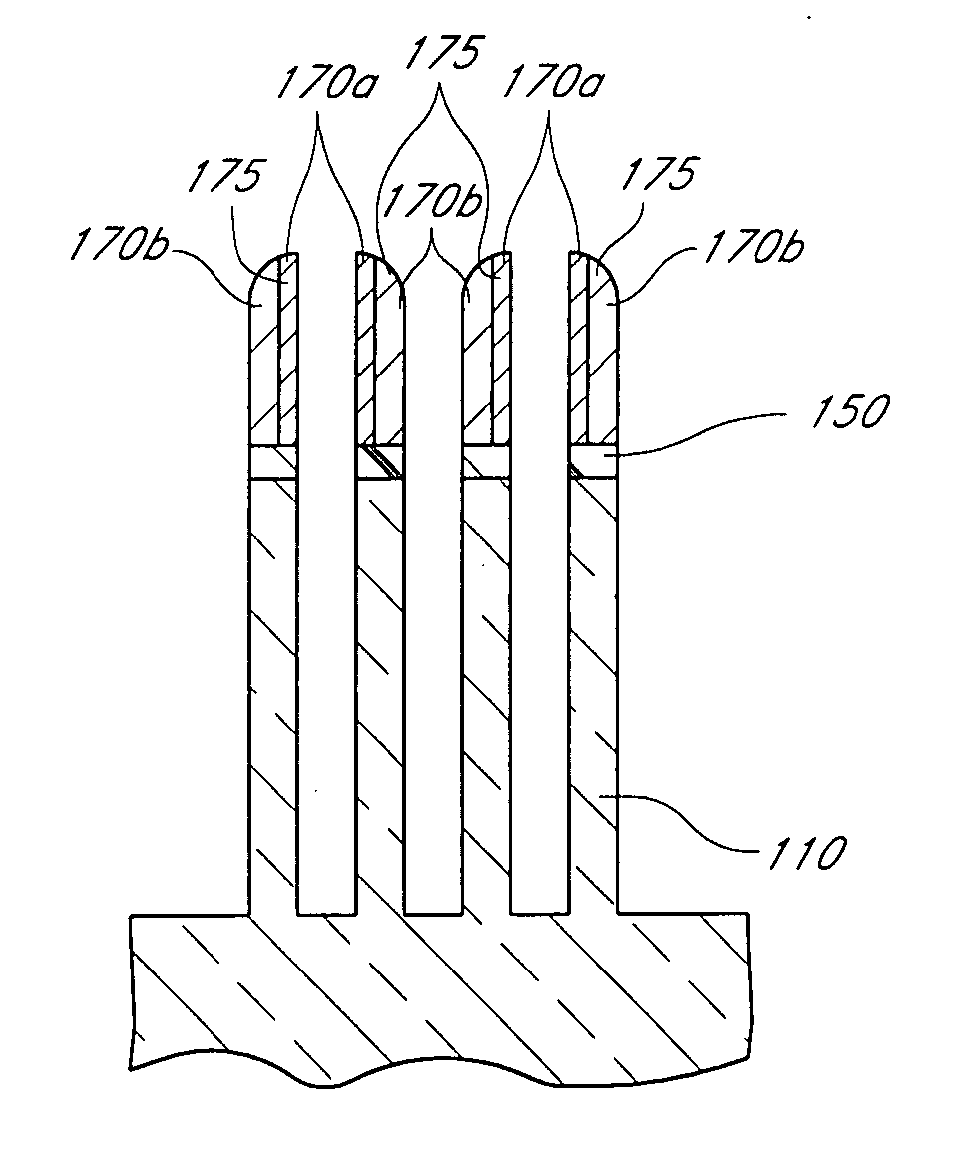

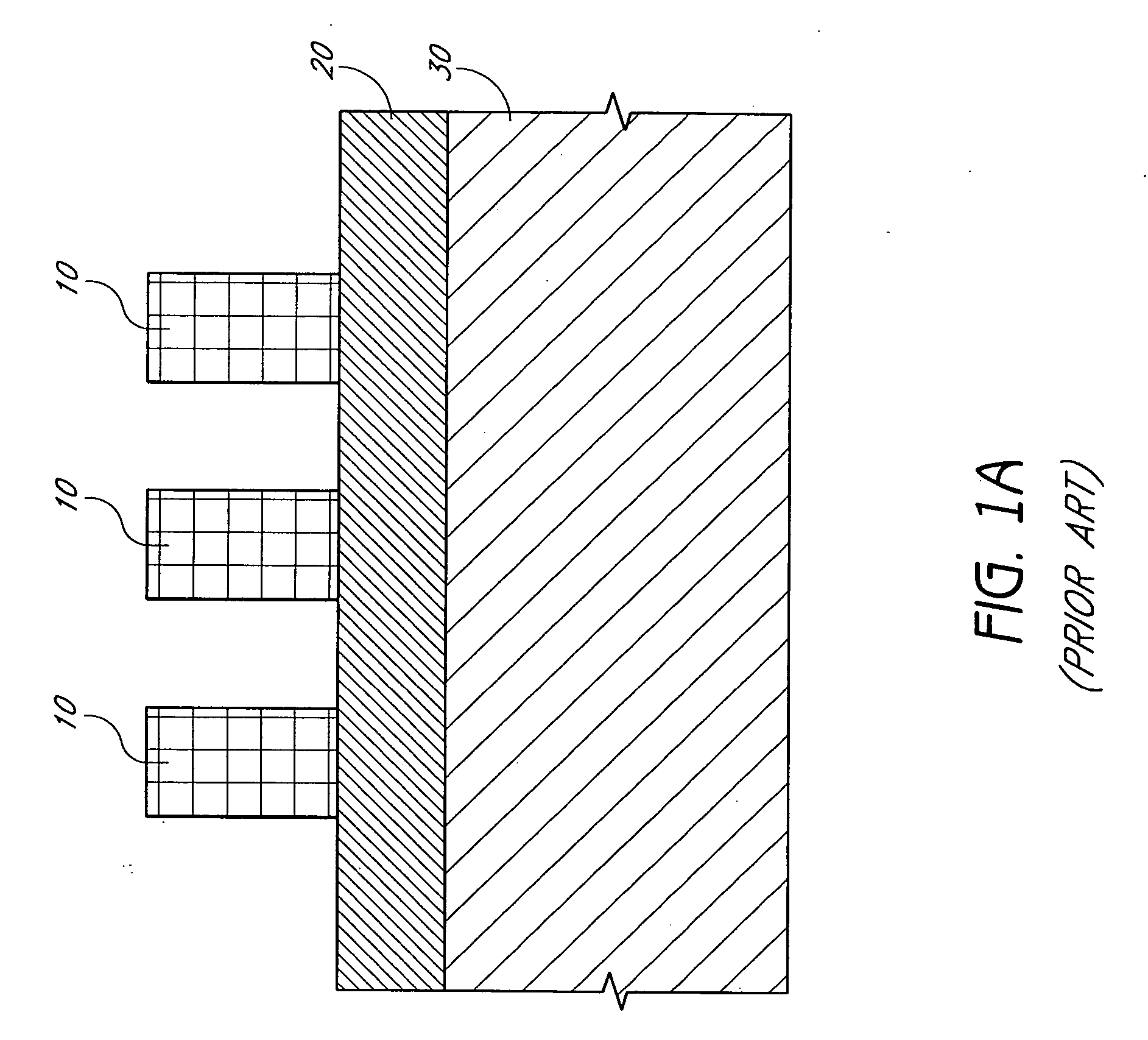

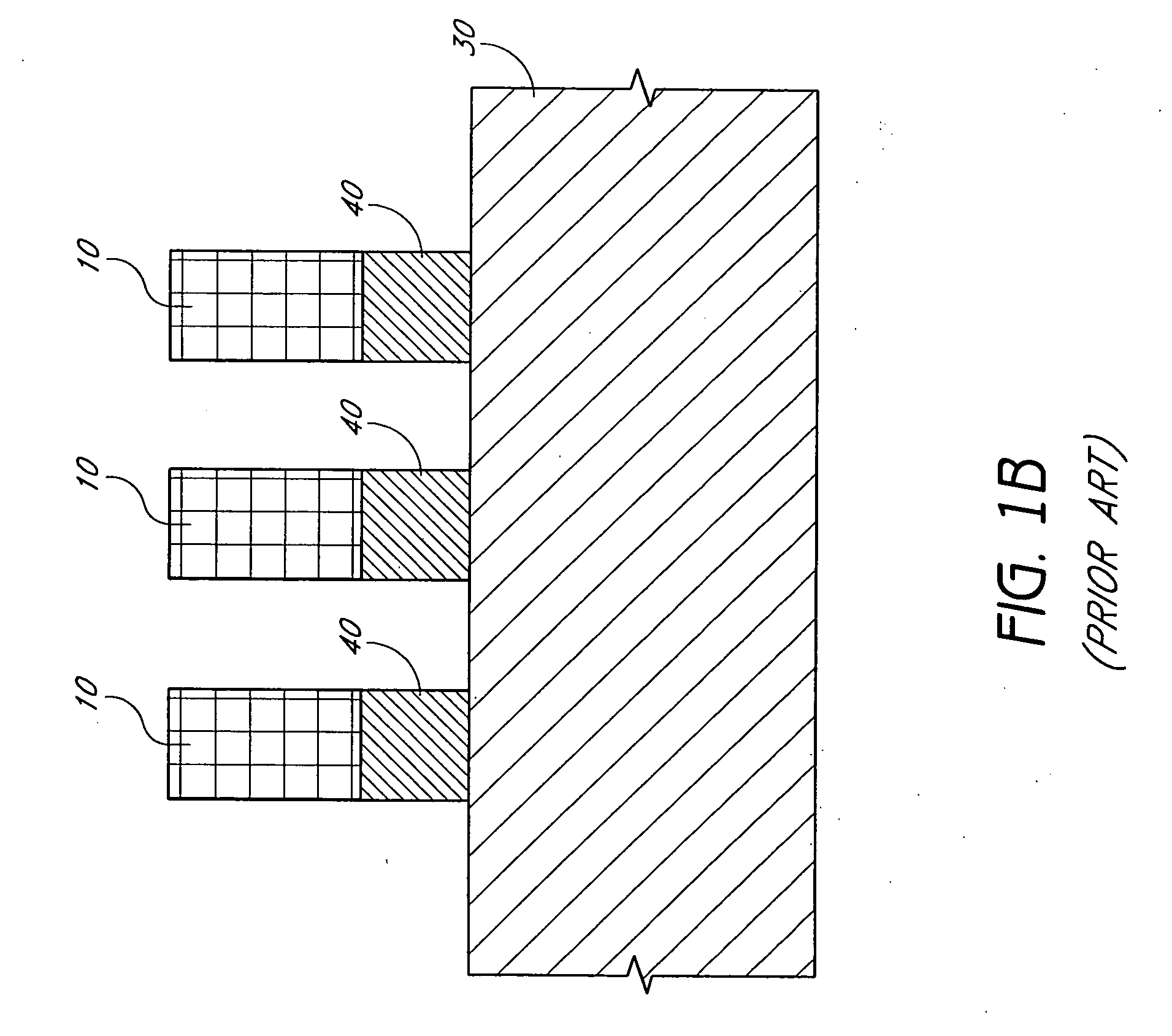

Multiple deposition for integration of spacers in pitch multiplication process

InactiveUS20070049040A1Decorative surface effectsSemiconductor/solid-state device manufacturingChemical reactionGas phase

Pitch multiplication is performed using a two step process to deposit spacer material on mandrels. The precursors of the first step react minimally with the mandrels, forming a barrier layer against chemical reactions for the deposition process of the second step, which uses precursors more reactive with the mandrels. Where the mandrels are formed of amorphous carbon and the spacer material is silicon oxide, the silicon oxide is first deposited by a plasma enhanced deposition process and then by a thermal chemical vapor deposition process. Oxygen gas and plasma-enhanced tetraethylorthosilicate (TEOS) are used as reactants in the plasma enhanced process, while ozone and TEOS are used as reactants in the thermal chemical vapor deposition process. The oxygen gas is less reactive with the amorphous carbon than ozone, thereby minimizing deformation of the mandrels caused by oxidation of the amorphous carbon.

Owner:ROUND ROCK RES LLC

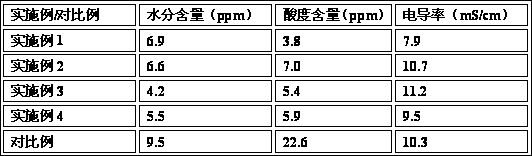

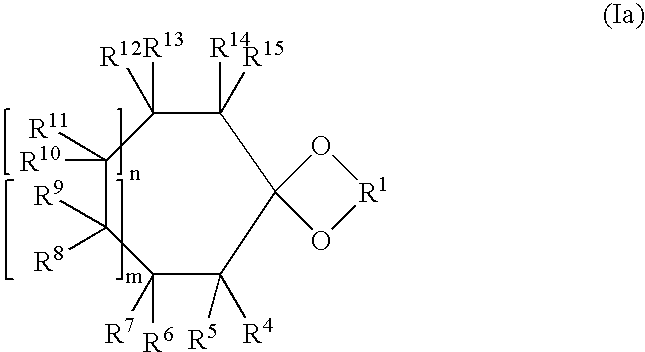

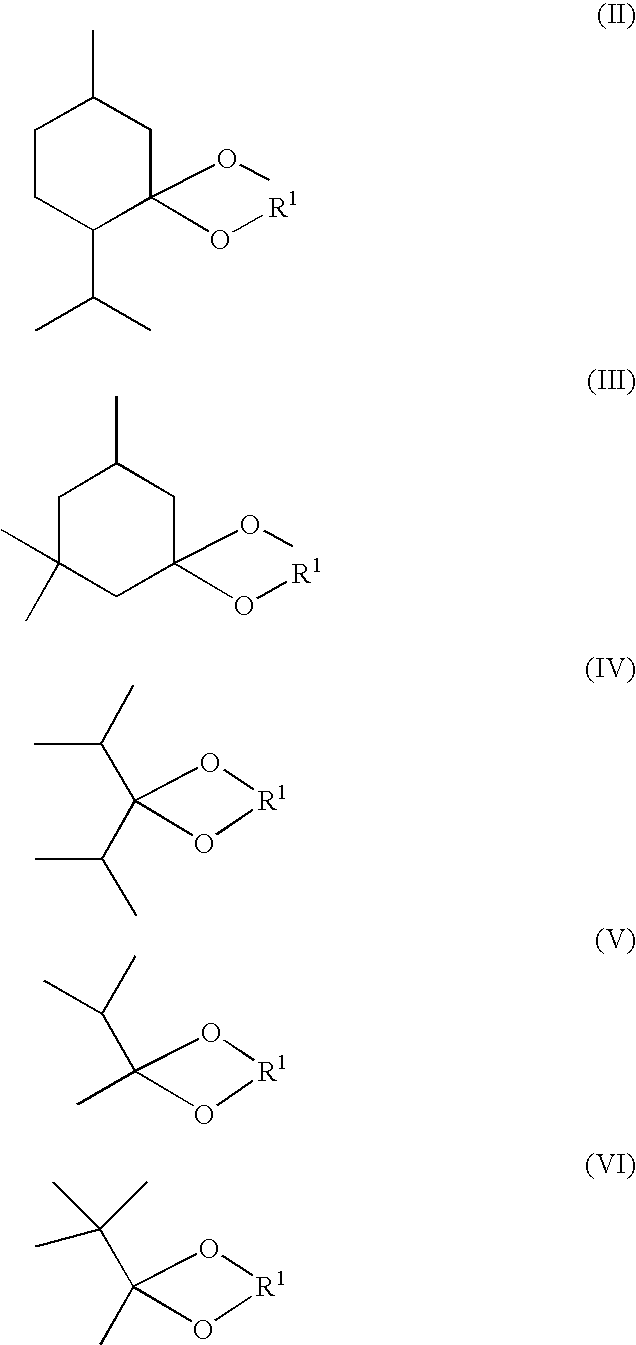

Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl) cyclohexyl] carbonyl]glycine

The present invention provides, in one aspect, a substantially pure ethyl ester of N-[[5-methyl-2-(1-methylethyl)cyclohexyl]carbonyl]glycine. In another aspect, disclosed is a method for producing substantially pure ethyl ester of N-[[5-methyl-2-(1-methylethyl)cyclohexyl]carbonyl]glycine. In still another aspect, disclosed are various consumer products comprising the substantially pure ethyl ester of N-[[5-methyl-2-(1-methylethyl)cyclohexyl]carbonyl]glycine disclosed herein.

Owner:RENESSENZ

Novel Polymers

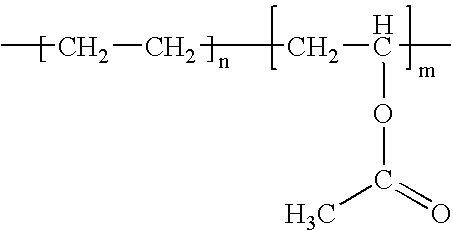

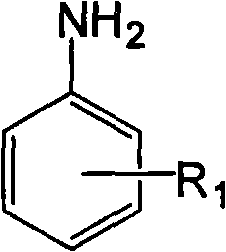

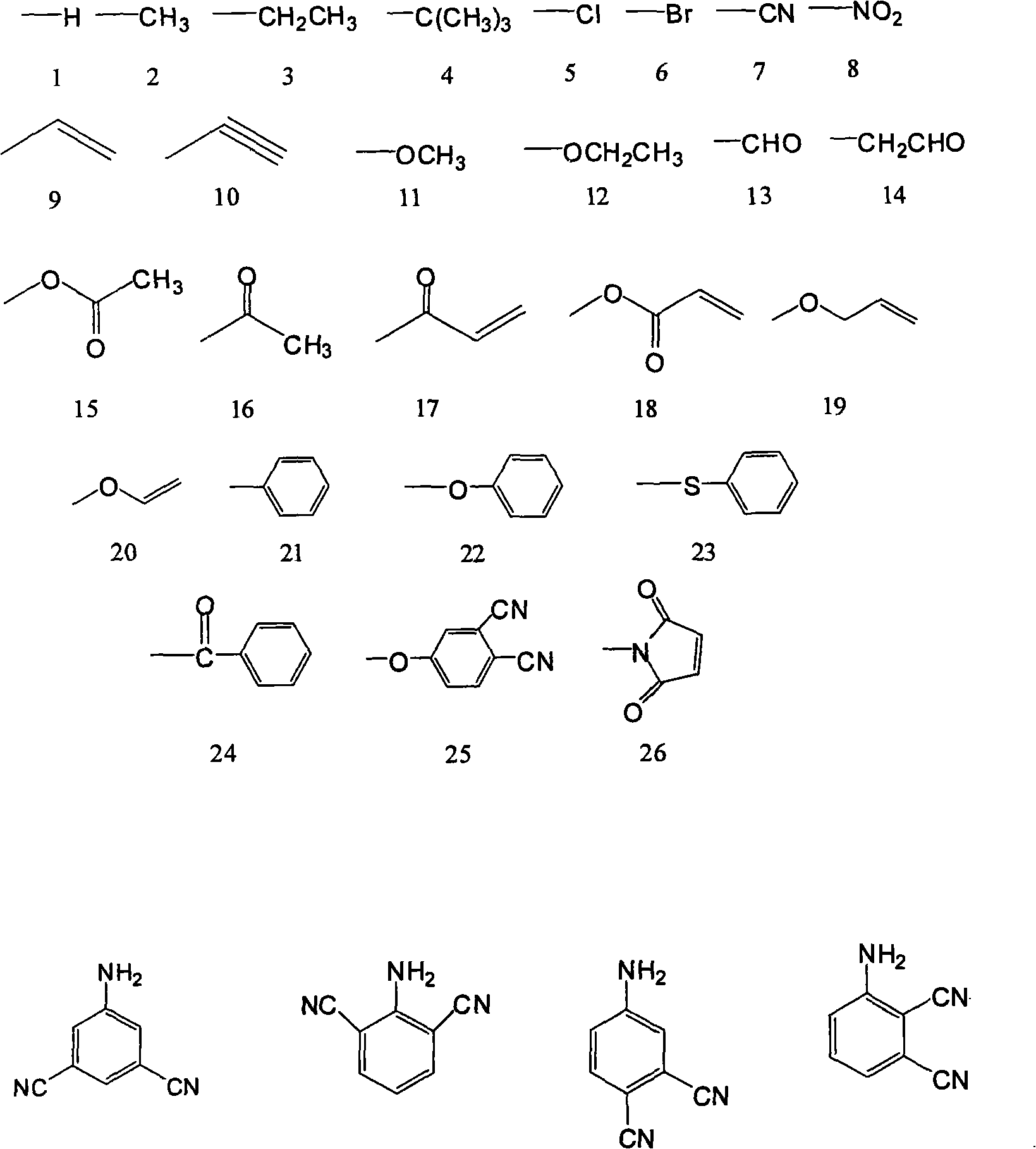

ActiveUS20080015315A1Sufficient amountReduce the amount requiredOrganic compound preparationCarboxylic acid esters preparationHydrophilic monomerPolymer science

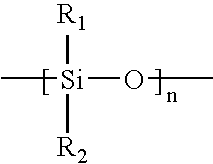

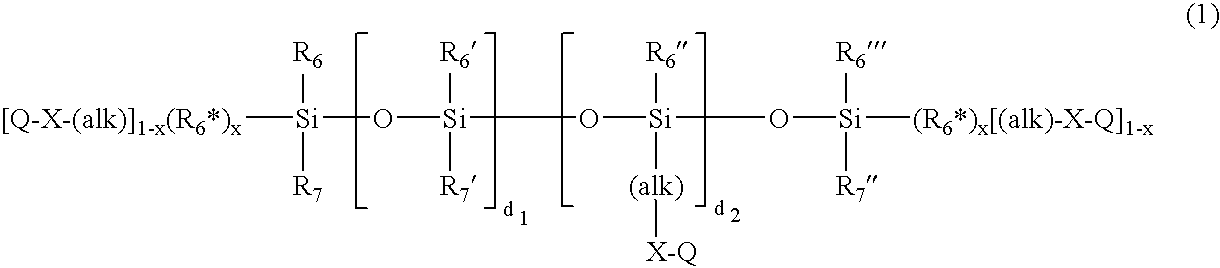

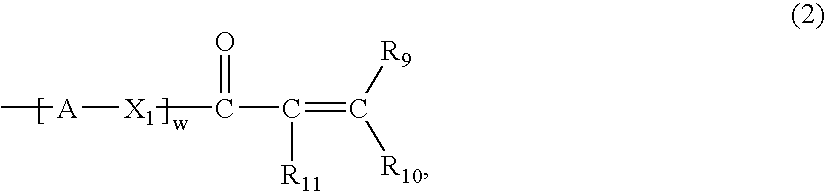

The invention relates to novel crosslinkable copolymers which are obtainable by (a) copolymerizing at least two different hydrophilic monomers selected from the group consisting of N,N-dimethyl acrylamide (DMA), 2-hydroxyethyl acrylate (HEA), glycidyl methacrylate (GMA), N-vinylpyrrolidone (NVP), acrylic acid (AA) and a C1-C4-alkoxy polyethylene glycol (meth)acrylate having a weight average molecular weight of from 200 to 1500, and at least one crosslinker comprising two or more ethylenically unsaturated double bonds in the presence of a chain transfer agent having a functional group; and (b) reacting one or more functional groups of the resulting copolymer with an organic compound having an ethylenically unsaturated group.

Owner:ALCON INC

Spontaneous emulsions containing cyclosporine

A pharmaceutical composition contains cyclosporine as the active ingredient. More specifically, the composition is an orally administered pharmaceutical formulation in the form of a spontaneous emulsion comprising cyclosporine, ethanol ethyl oleate and polyoxyethylene glycerol trioleate. A method for preparing an orally administered pharmaceutical composition involves first dissolving cyclosporine in ethanol. Polyoxyethylene glycerol trioleate and an oil component are then added, mixed and diluted in an aqueous media to form a spontaneous emulsion.

Owner:WOCKHARDT EU OPERATIONS SWISS

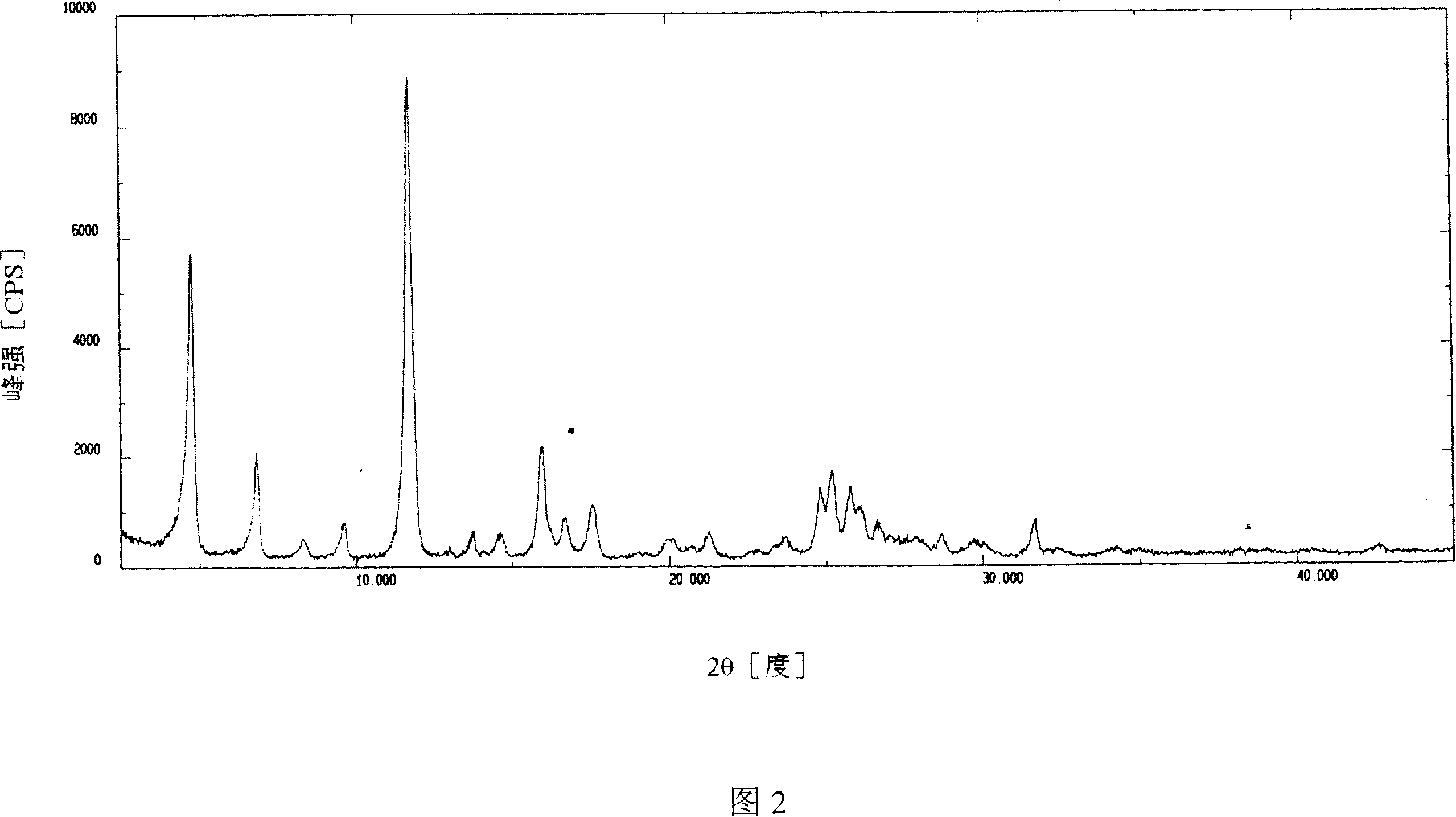

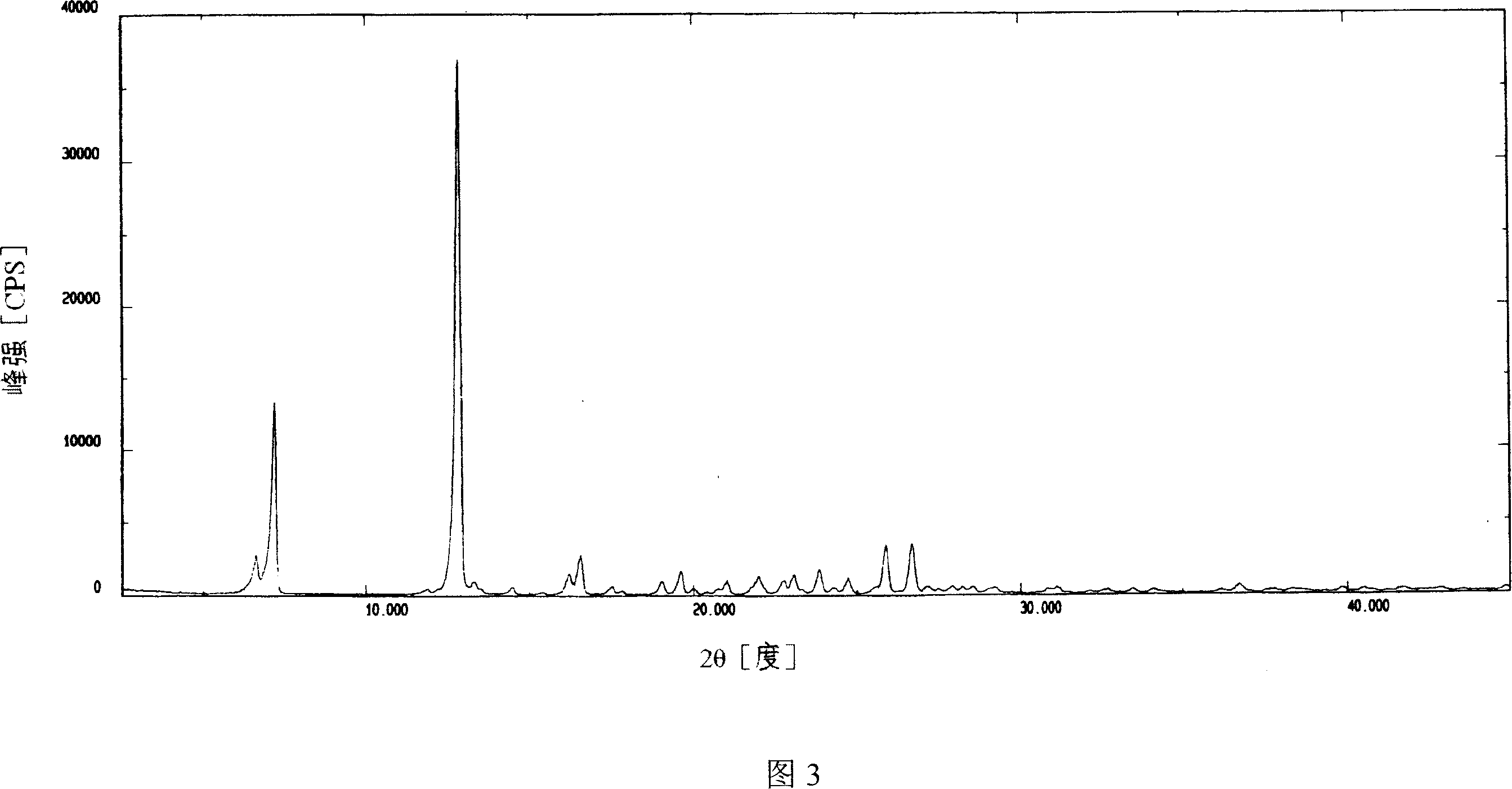

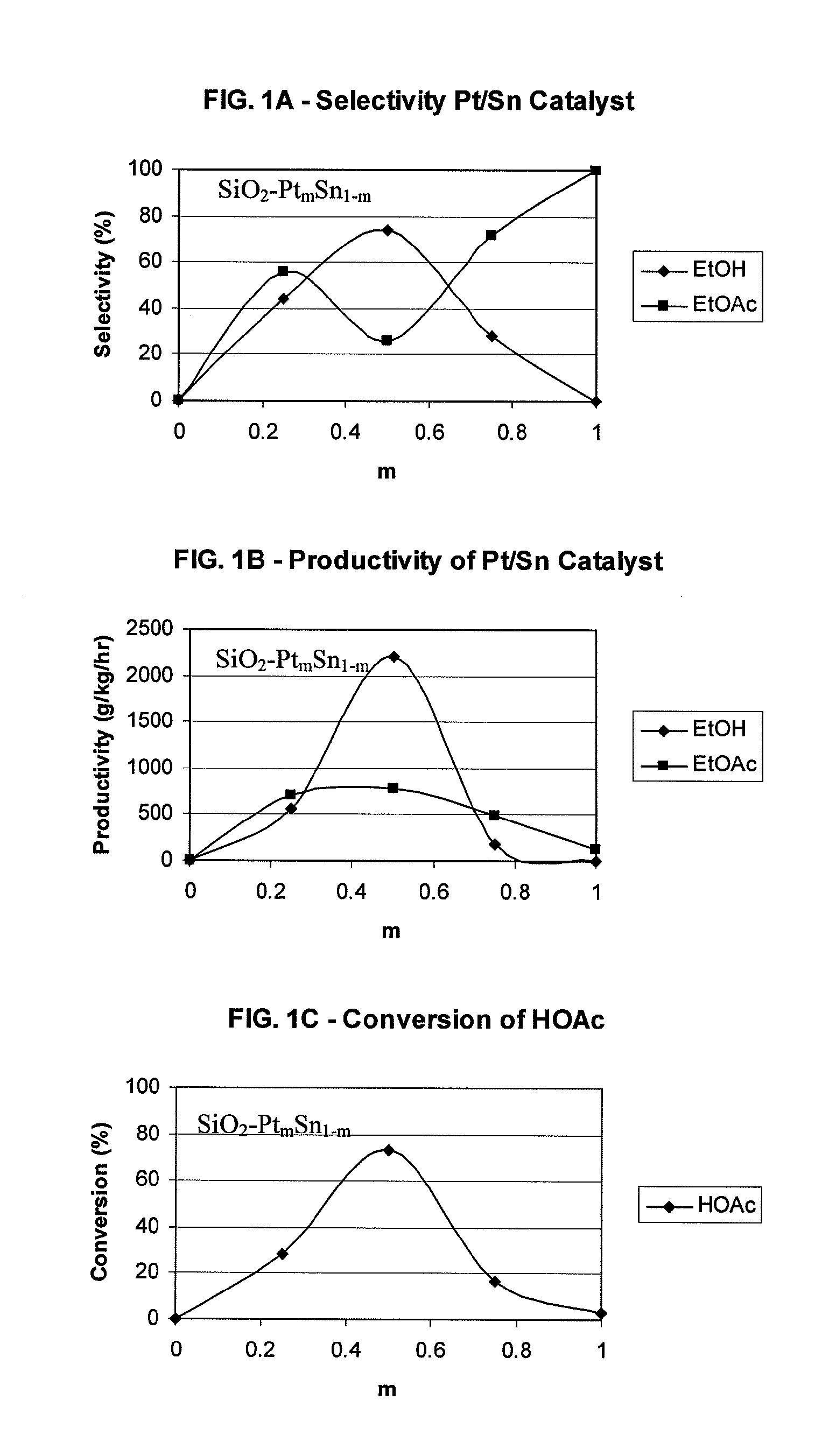

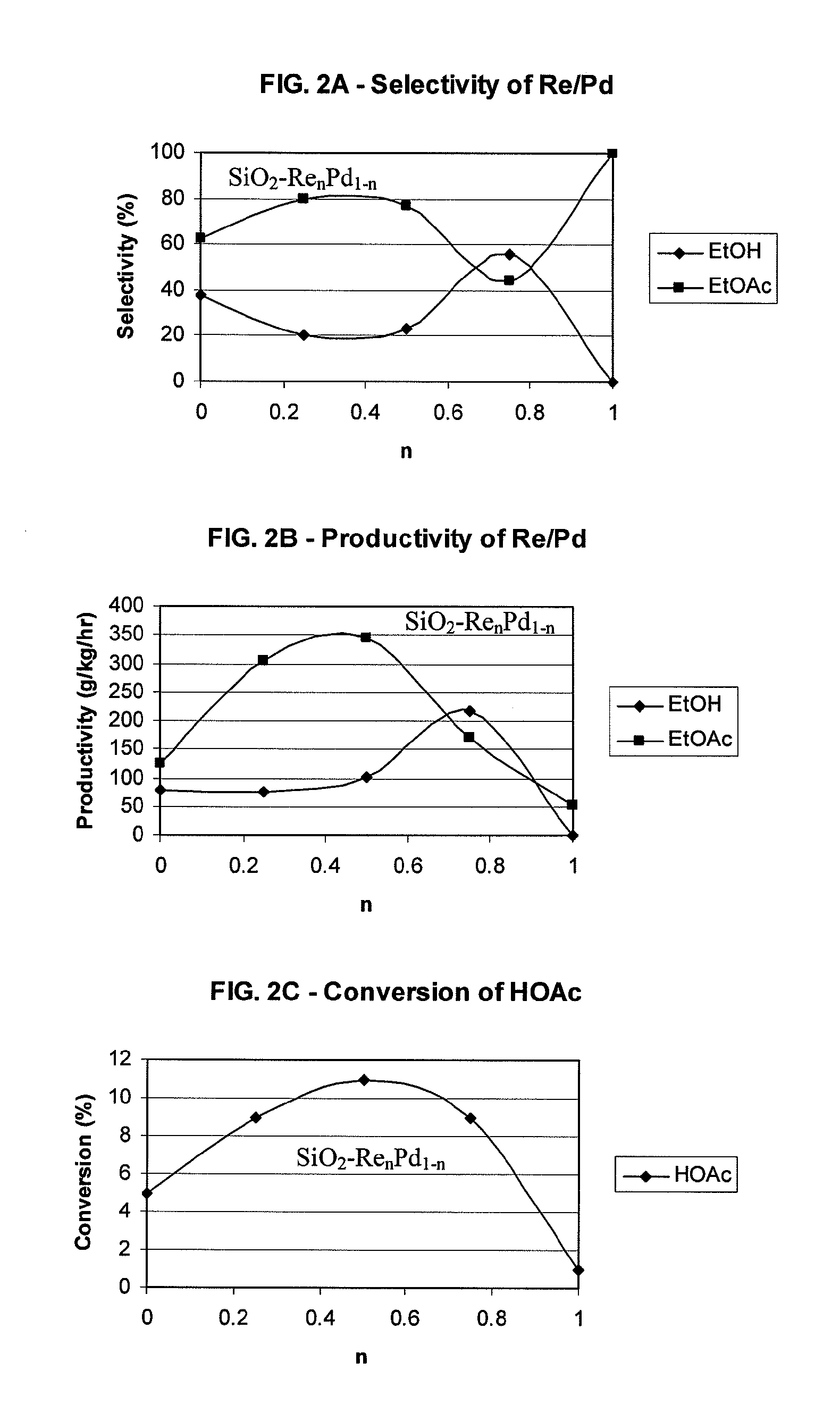

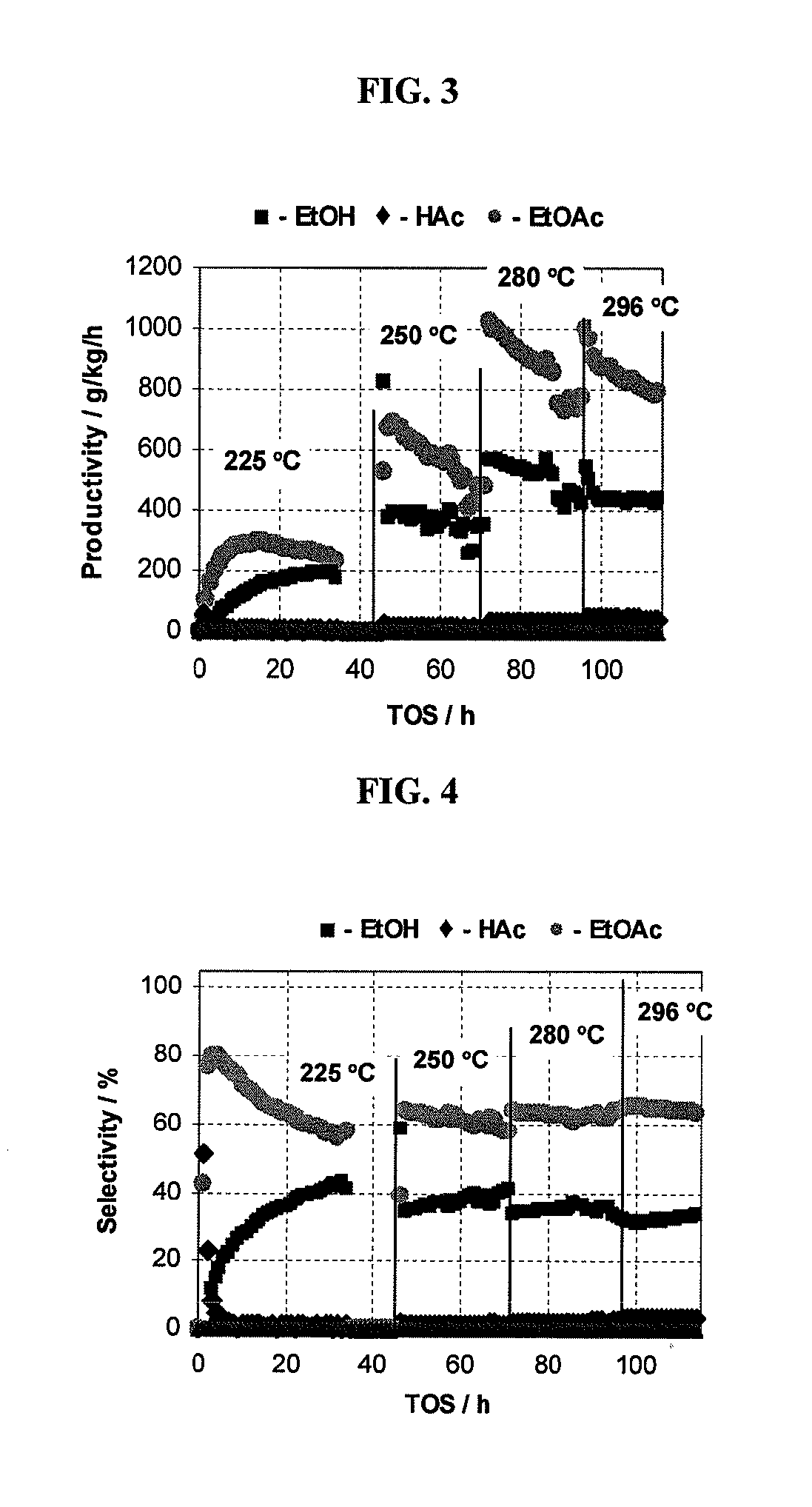

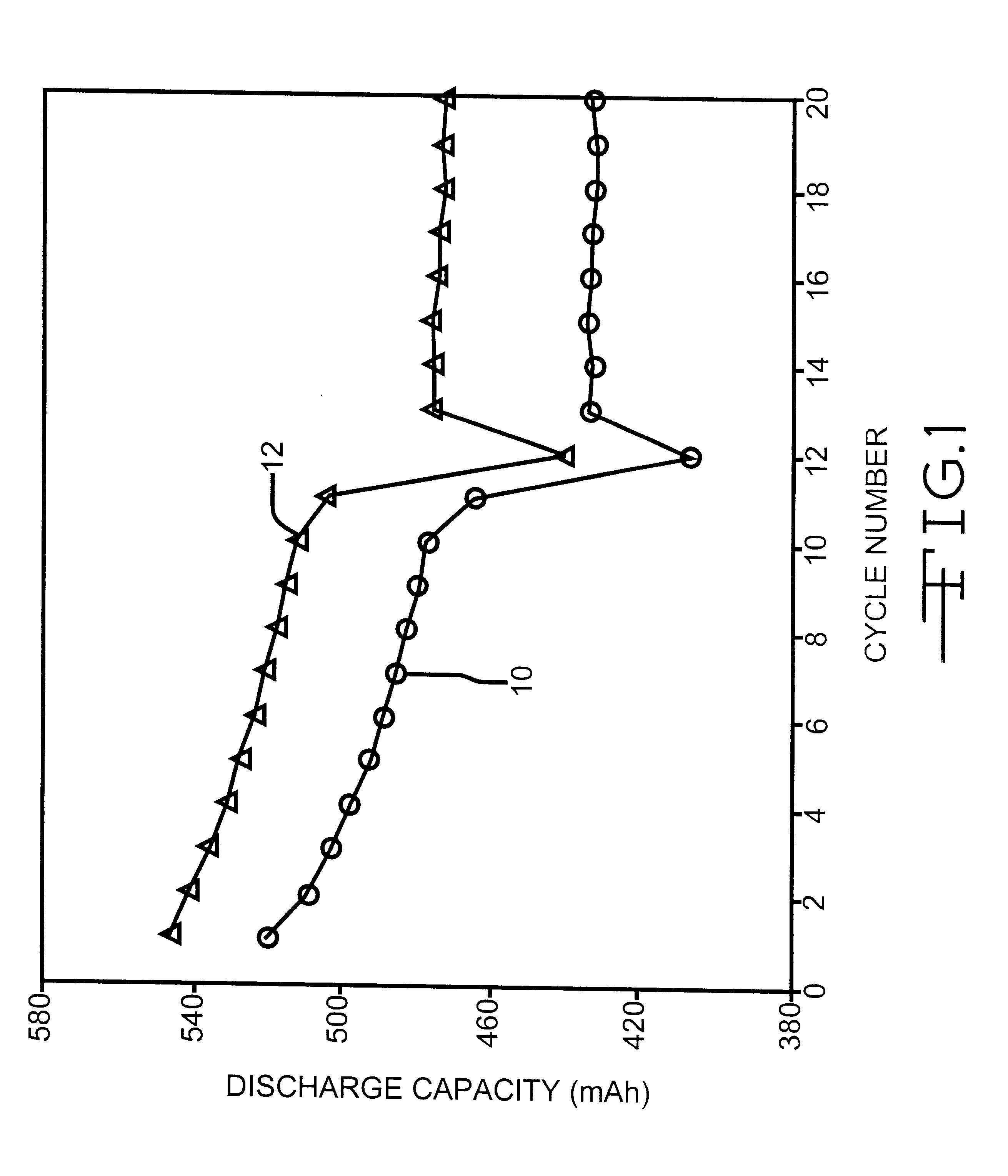

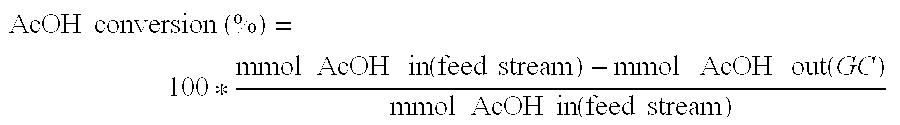

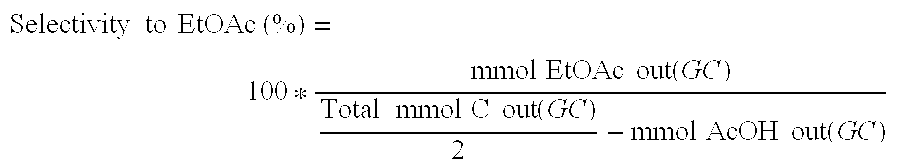

Direct and selective production of ethyl acetate from acetic acid utilizing a bimetal supported catalyst

InactiveUS20100029980A1High selectivityHigh yieldMolecular sieve catalystsOrganic compound preparationChemistryEthyl ester

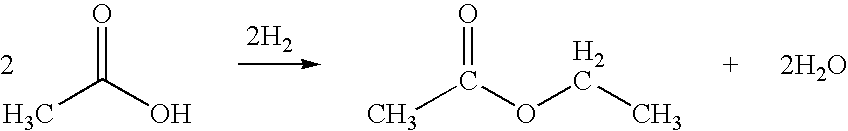

A process for the selective production of ethyl acetate by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethyl acetate is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and copper supported on silica selectively produces ethyl acetate in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

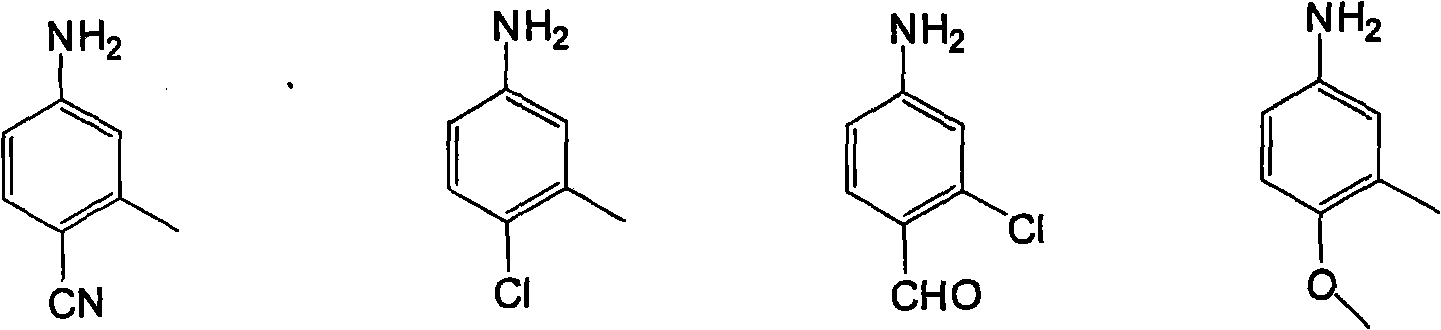

Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl)cyclohexyl] carbonyl]glycine

ActiveUS20050222256A1Reduce volatilitySuitable for useAntibacterial agentsCosmetic preparationsGlycineEthyl ester

The present invention provides, in one aspect, a substantially pure ethyl ester of N-[[5-methyl-2-(1-methylethyl)cyclohexyl]carbonyl]glycine. In another aspect, disclosed is a method for producing substantially pure ethyl ester of N-[[5-methyl-2-(1-methylethyl)cyclohexyl]carbonyl]glycine. In still another aspect, disclosed are various consumer products comprising the substantially pure ethyl ester of N-[[5-methyl-2-(1-methylethyl)cyclohexyl]carbonyl]glycine disclosed herein.

Owner:RENESSENZ

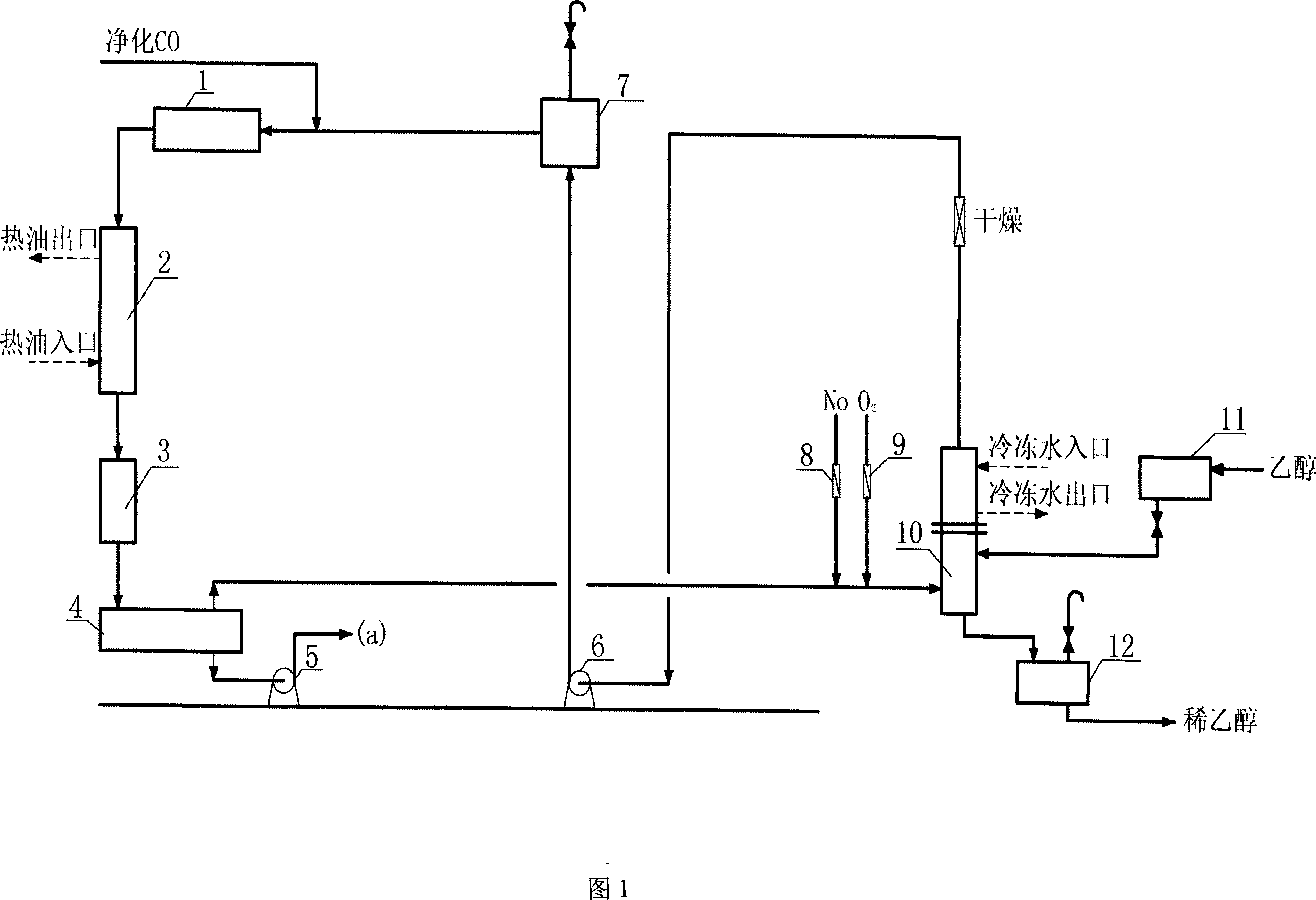

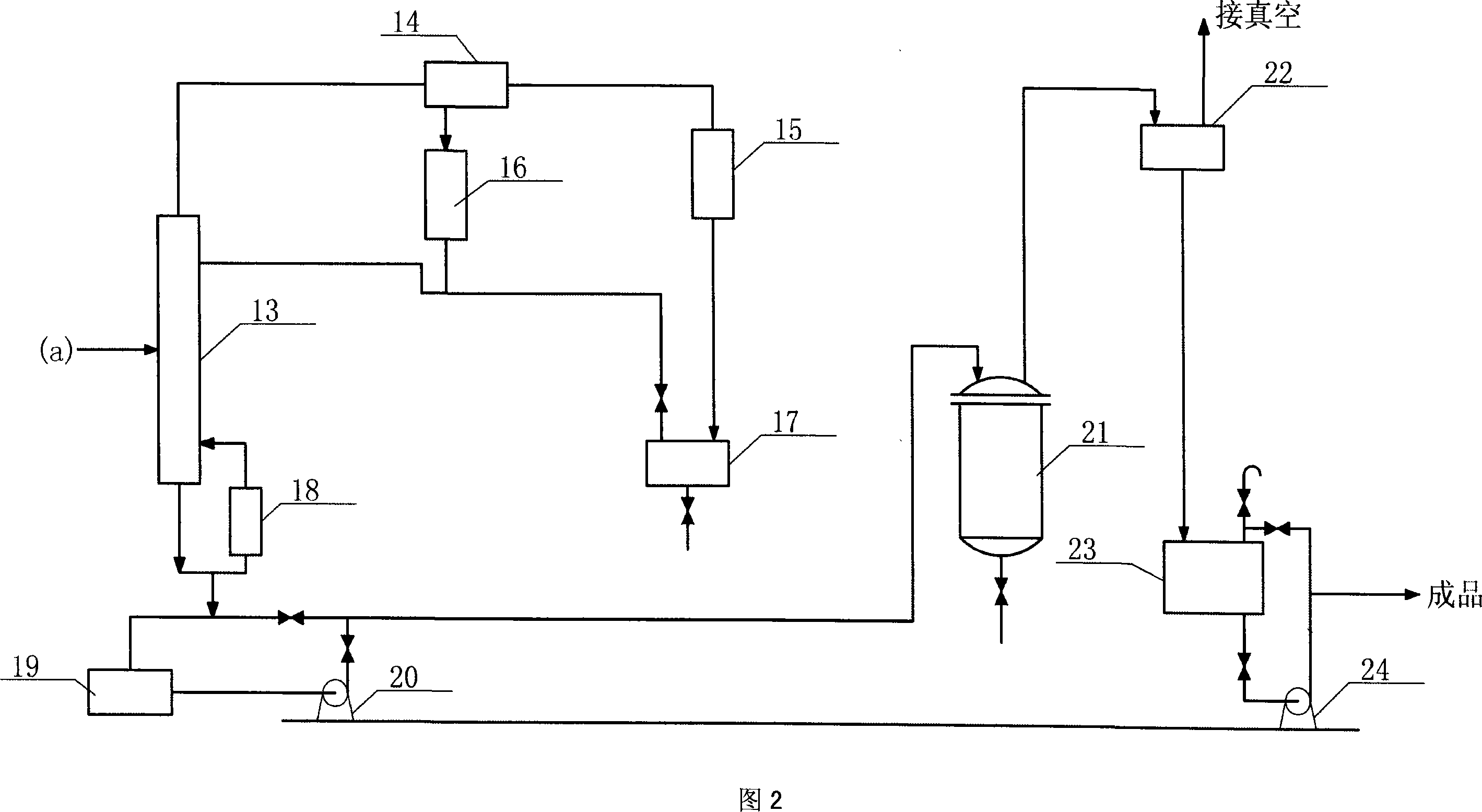

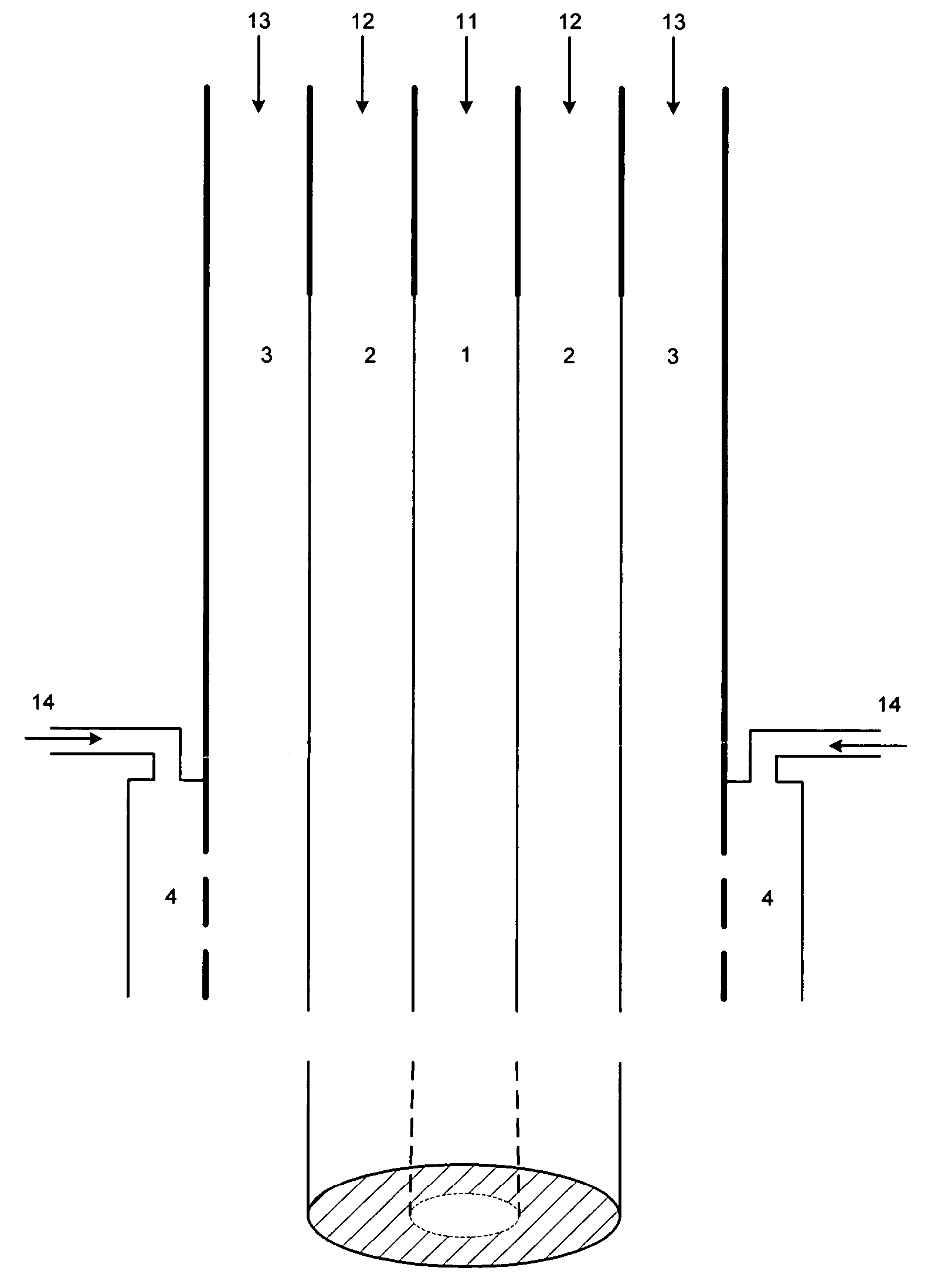

Method for preparing diethyl oxalate by coupling CO

ActiveCN101143821ANo pollution in the processImprove efficiencyPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsCyclic processContinuous use

The invention discloses a method for preparing diethyl oxalate by CO coupling reaction. By applying a gas phase method, CO is coordinated with ethyl nitrite and is catalyzed by bimetallic supported catalyzer to couplingly generate crude diethyl oxalate, the reaction is a self-sealing circulation process, the CO gas mixed with the ethyl nitrite coming from a regeneration reactor is preheated and then enters into a coupling reactor, after the reaction, the gas is separated by condensation, so that the colorless and transparent condensed diethyl oxalate liquid is produced, and the uncondensed gas containing NO enters into the regeneration reactor to react with ethanol and oxygen in order to generate ethyl nitrite which is again circulated back to the coupling reactor for continuous use. The invention is carried out on the basis of previous laboratory research and under the background of industrial production and fulfils the continuous run examination of the bench scale test and pilot magnification under the condition of industrial operation, the temperature of the coupling reaction is low, and the concentration of products is increased. The method has the advantages of more energy saving, no pollution and high benefit. The total conversion rate of the CO generated by reaction is one hundred percent, and the selectivity of diethyl oxalate is over ninety six percent.

Owner:TIANJIN UNIV

Method of producing ethyl acetate

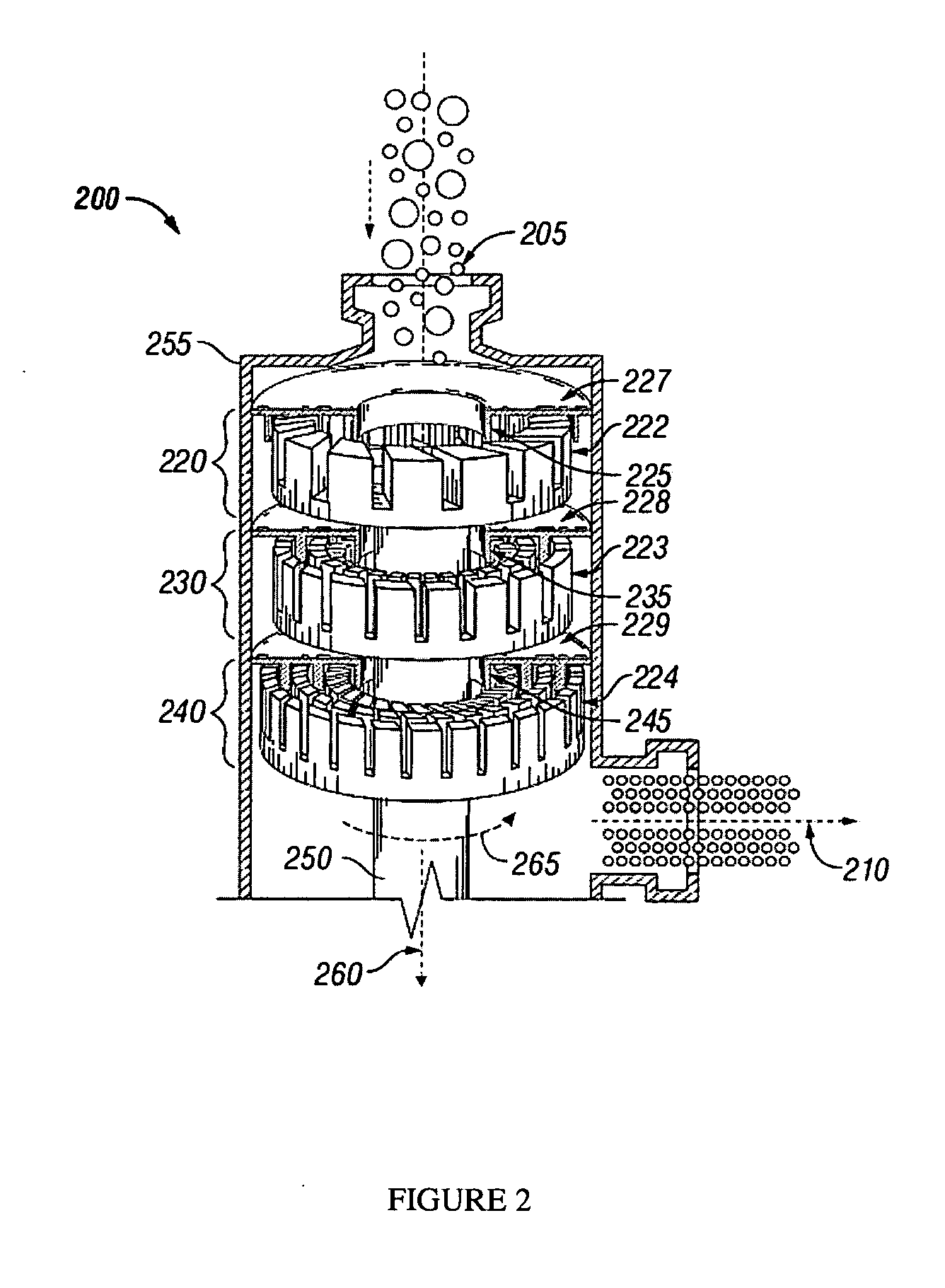

InactiveUS20090005588A1Good dispersionWell mixedOrganic compound preparationRotary stirring mixersAcetic acidReaction temperature

Methods and systems for the production of ethyl acetate are described herein. The methods and systems incorporate the novel use of a high shear device to promote dispersion and mixing of a carbonyl co-reactant (e.g. acetic acid, acetaldehyde) with ethanol. The high shear device may allow for lower reaction temperatures and pressures and may also reduce reaction time with existing catalysts.

Owner:HRD CORP

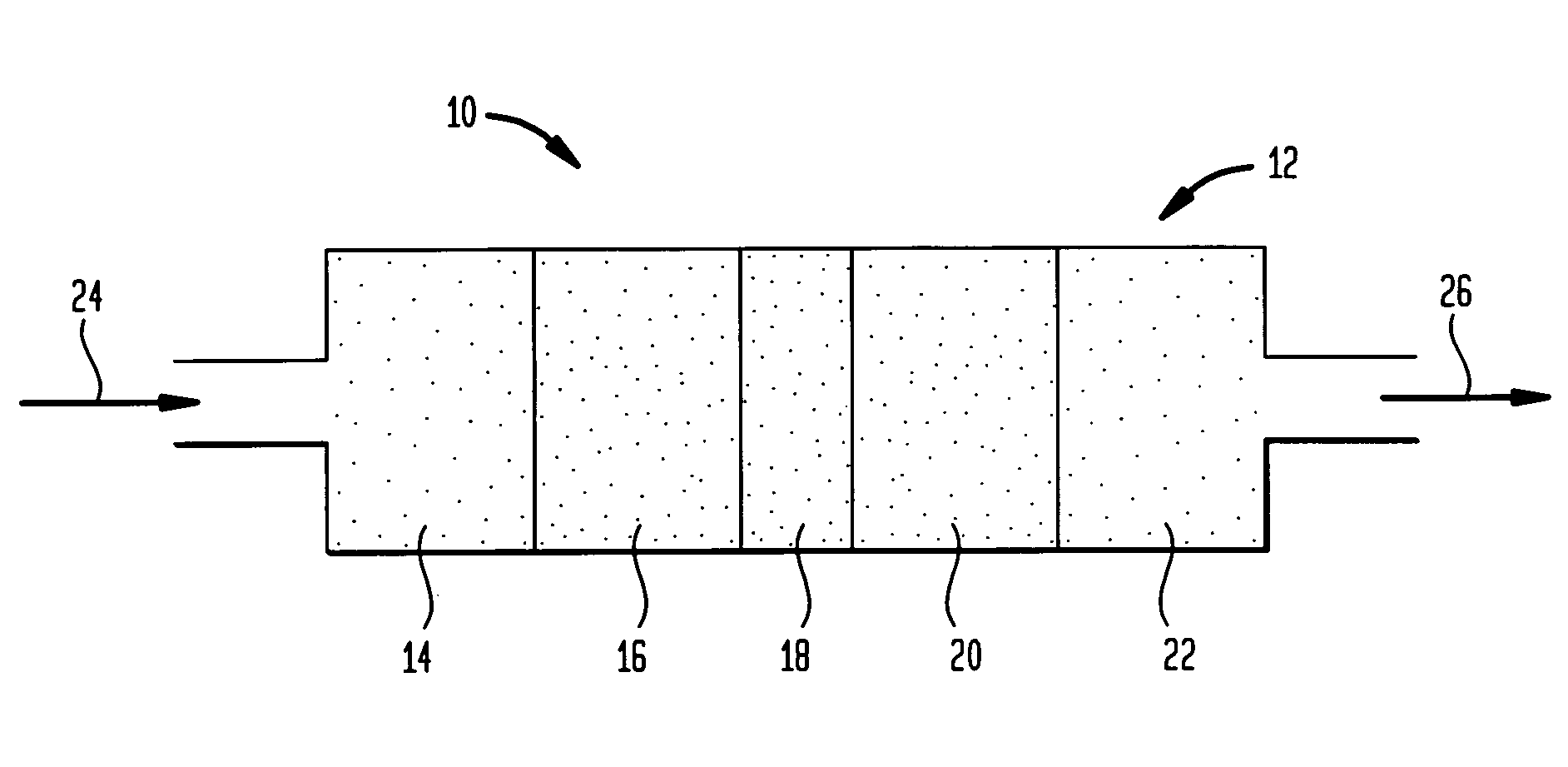

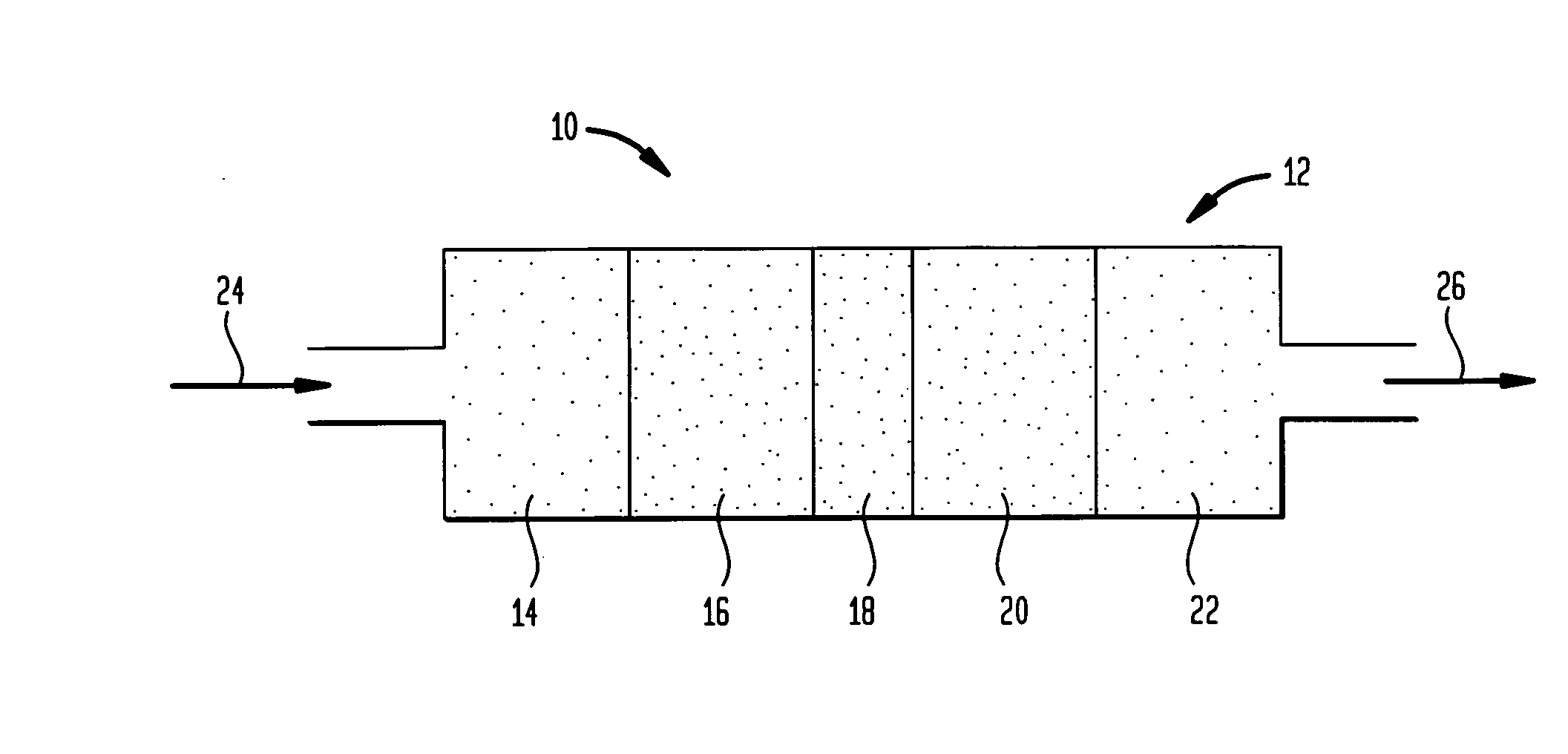

Poly(ethylene chlorotrifluoroethylene) membranes

InactiveUS7247238B2Improve permeabilityImprove integrityMembranesSemi-permeable membranesFiberGlycerol

Porous polymeric membranes including Halar (poly (ethylene chlorotrifluoroethylene)) and related compounds and the methods of production thereof which avoid the use of toxic solvents. Preferred solvents, coating agents and pore forming agents are citric acid ethyl ester or glycerol triacetate. The membranes may be in the form of a hollow fiber or flat sheet, and may include other agents to modify the properties of the membrane, such as the hydrophilic / hydrophobic balance. Leachable agents may also be incorporated into the membranes.

Owner:EVOQUA WATER TECH LLC

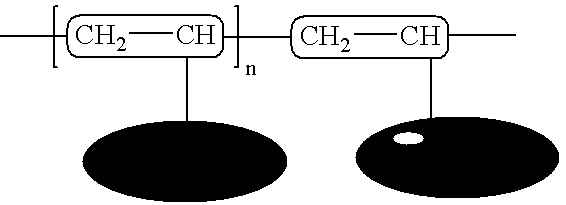

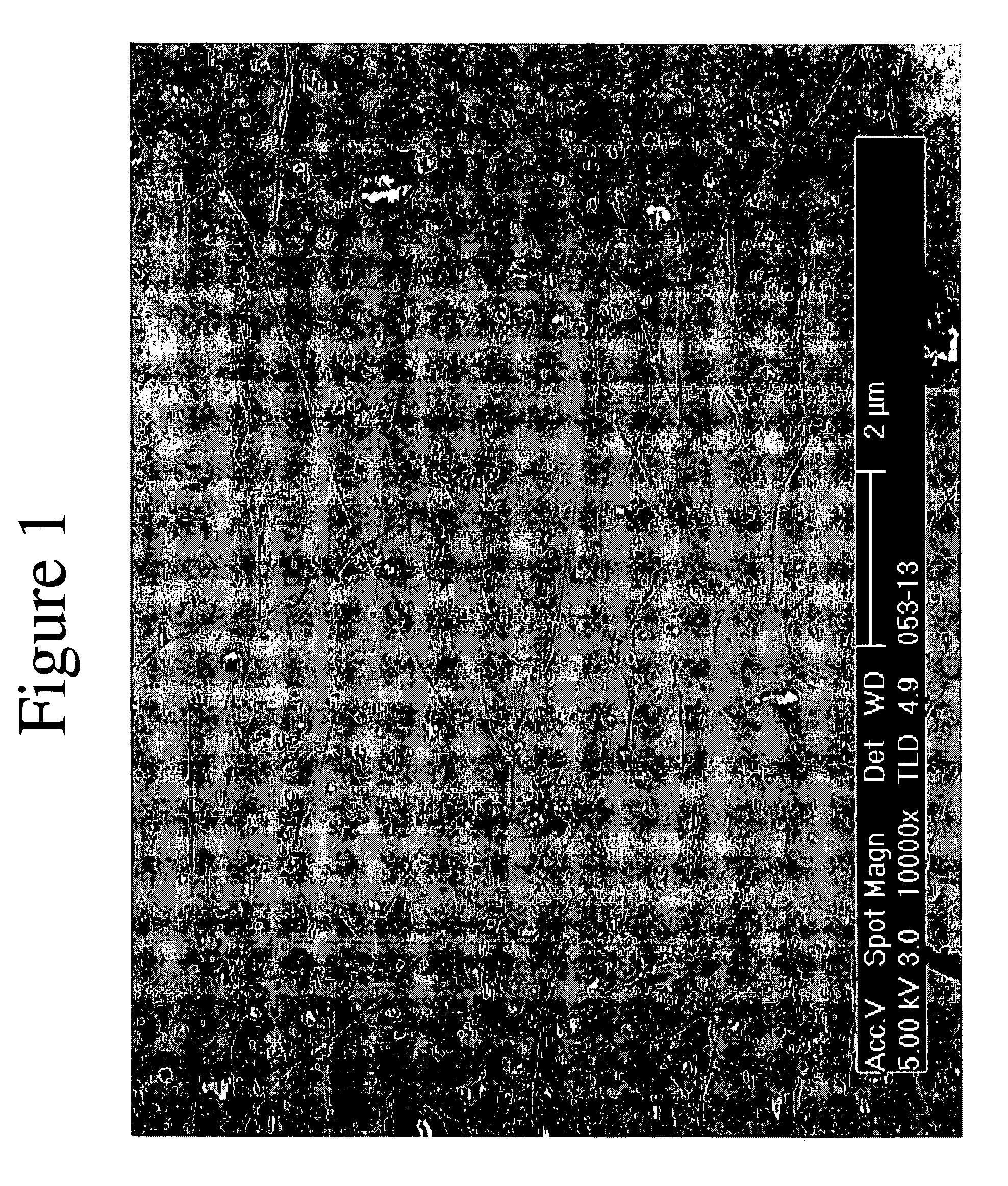

Compositions comprising carbon nanotubes and articles formed therefrom

InactiveUS20050186378A1Easy injectionImprove the immunityMaterial nanotechnologyCell electrodesFiberPolymer science

Improved compositions comprise a polymer and carbon fibers, such as nanotubes. In some embodiments, the carbon fibers, e.g., nanotubes, can be mechanically blended or incorporated into the polymer, while in some embodiments carbon nanotubes also may be covalently bonded to the polymer to form corresponding covalent materials. In particular, the polymer can be covalently bonded to the side walls of the carbon nanotubes to form a composite with particularly desirable mechanical properties. Specifically, the bonding of the polymer to the nanotube sidewall can provide desirable mechanical properties of the composite due to the orientation relative to other types of association between the nanotubes and the polymer. The processing of the nanotubes can be facilitated by the dispersion of the nanotubes in an aqueous solution comprising a hydrophylic polymer, such as ethyl vinyl acetate. A dispersion of nanotubes can be combined with a polymer in an extrusion process to blend the materials under high shear, such as in an extruder. In general, various articles can be formed that take advantage of the properties of the composite materials incorporating a polymer and carbon fibers, such as carbon nanotubes.

Owner:ENTEGRIS INC

Film coating composition for whitening teeth

PCT No. PCT / CN97 / 00004 Sec. 371 Date Sep. 17, 1998 Sec. 102(e) Date Sep. 17, 1998 PCT Filed Jan. 20, 1997 PCT Pub. No. WO97 / 25968 PCT Pub. Date Jul. 24, 1997The invention relates to a tooth-whitening varnish composition, comprising 6-20% of carbamide peroxide, 2-9% of film forming agent and 77-88% of volatile organic solvent, based on the total weight of the composition. The volatile organic solvent is selected from ether, ethylacetate, ethyl alcohol, or acetone. The film forming agent is artificial or natural material selected from cellulose, polyvinyl, butyral, coumarone resin or shellac. The composition can rapidly form films on dry tooth surfaces, and a remarkable tooth-whitening effect can be obtained.

Owner:IVOCLAR VIVADENT INC

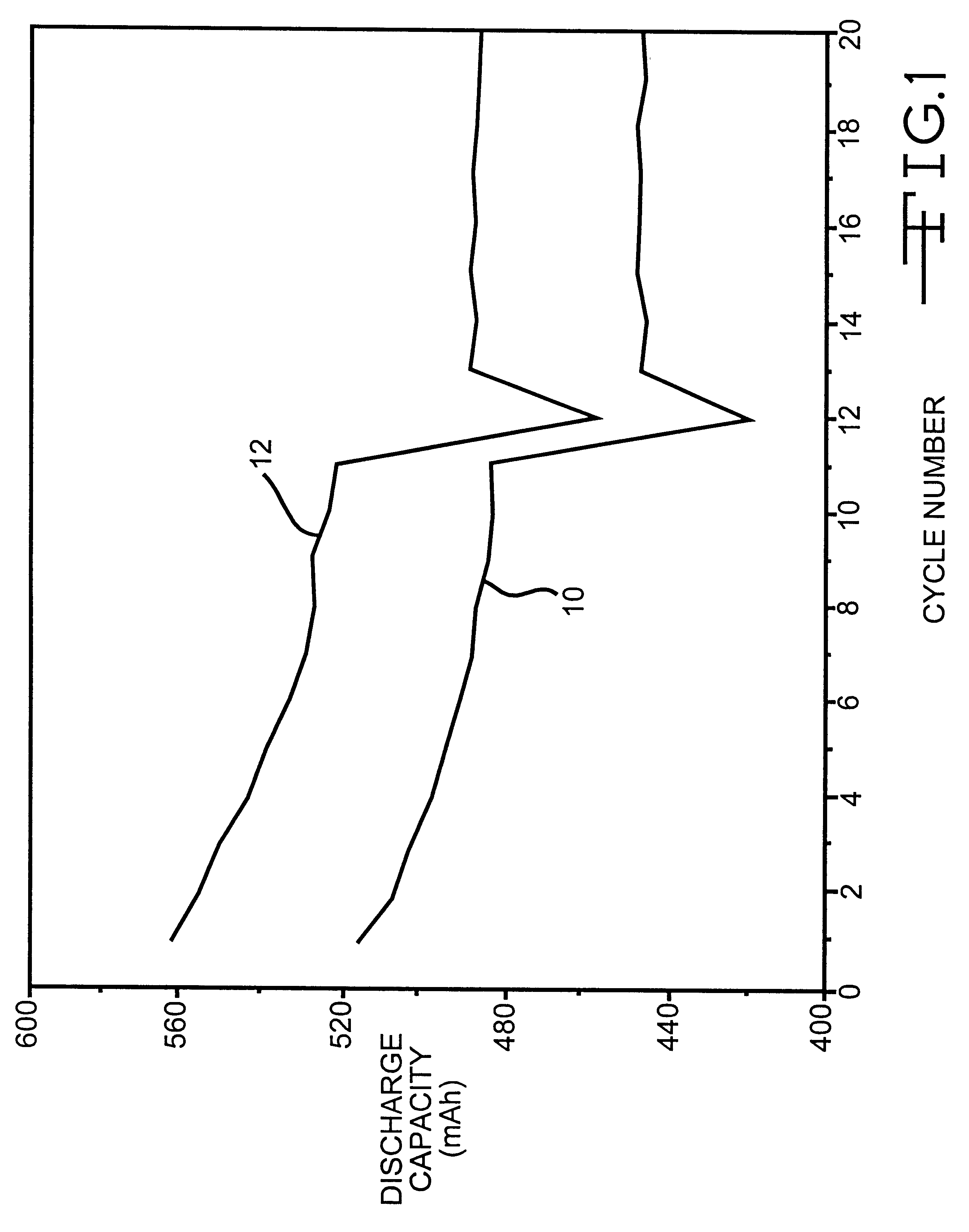

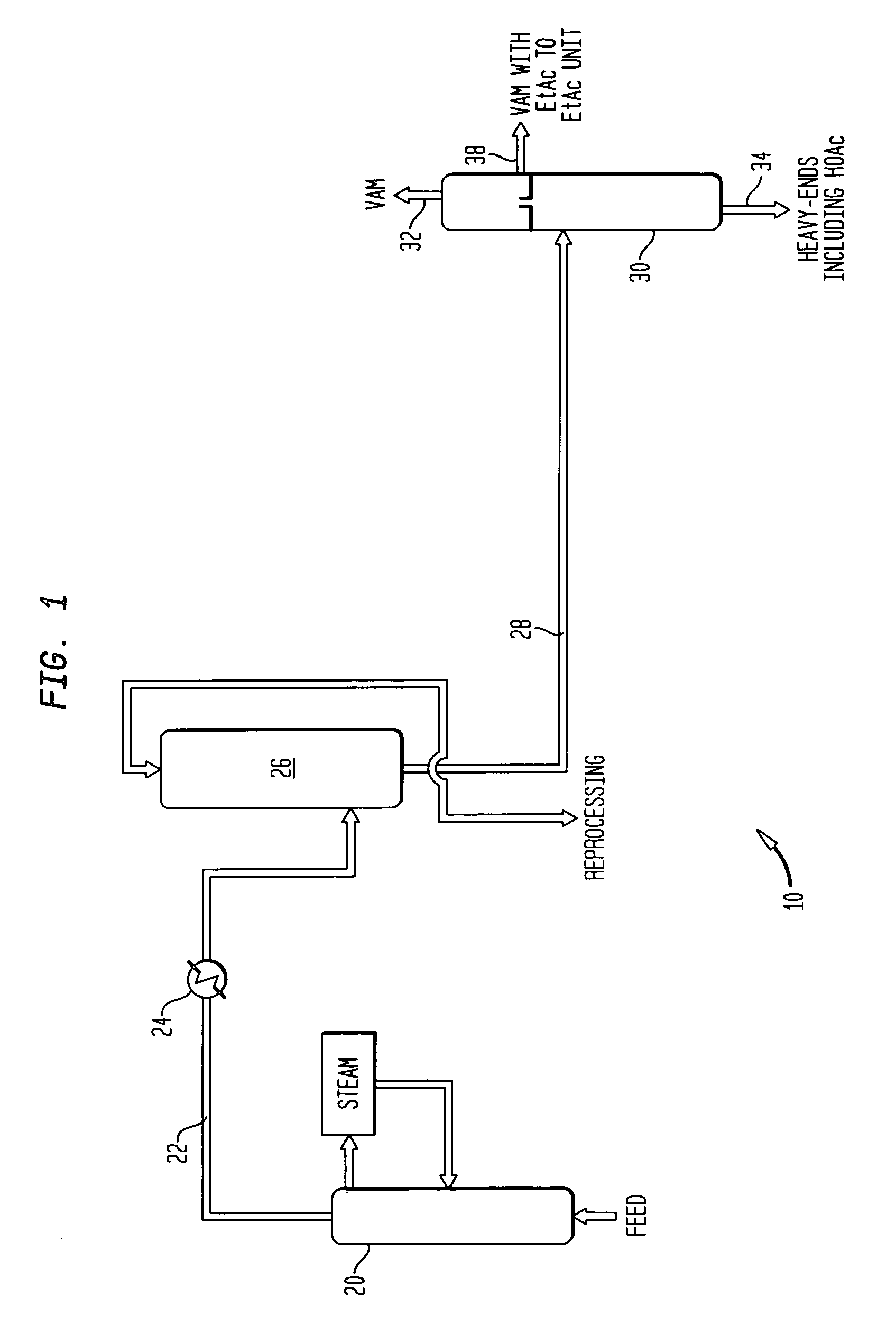

Phosphate additives for nonaqueous electrolyte rechargeable electrochemical cells

InactiveUS6203942B1Improve oxidation stabilityImprove dynamic stabilityPrimary cell maintainance/servicingOrganic electrolyte cellsAlkylphosphateSolvent

A lithium ion electrochemical cell having high charge / discharge capacity, long cycle life and exhibiting a reduced first cycle irreversible capacity, is described. The stated benefits are realized by the addition of at least one phosphate additive to an electrolyte comprising an alkali metal salt dissolved in a solvent mixture that includes ethylene carbonate, dimethyl carbonate, ethylmethyl carbonate and diethyl carbonate. The preferred additive is an alkyl phosphate compound.

Owner:WILSON GREATBATCH LTD

Method of treating an oil or gas well with biodegradable low toxicity fluid system

InactiveUS7231976B2Well remediationIncrease stimulationCleaning apparatusFluid removalMETHYL SOYATEFluid system

A method of treating a well consists of introducing into the wellbore a biodegradable fluid system containing a blend of lactic acid ester, such as ethyl lactate, and a fatty acid ester, such as methyl soyate. The fluid system may be further in the form of a microemulsion that is formed by combining a blend with one or more emulsifiers, an alcohol, and water. The fluid system may be used in displacement, well remediation and stimulation as well as additional, alternative applications such as the cleaning of surface and / or downhole equipment.

Owner:BAKER HUGHES HLDG LLC

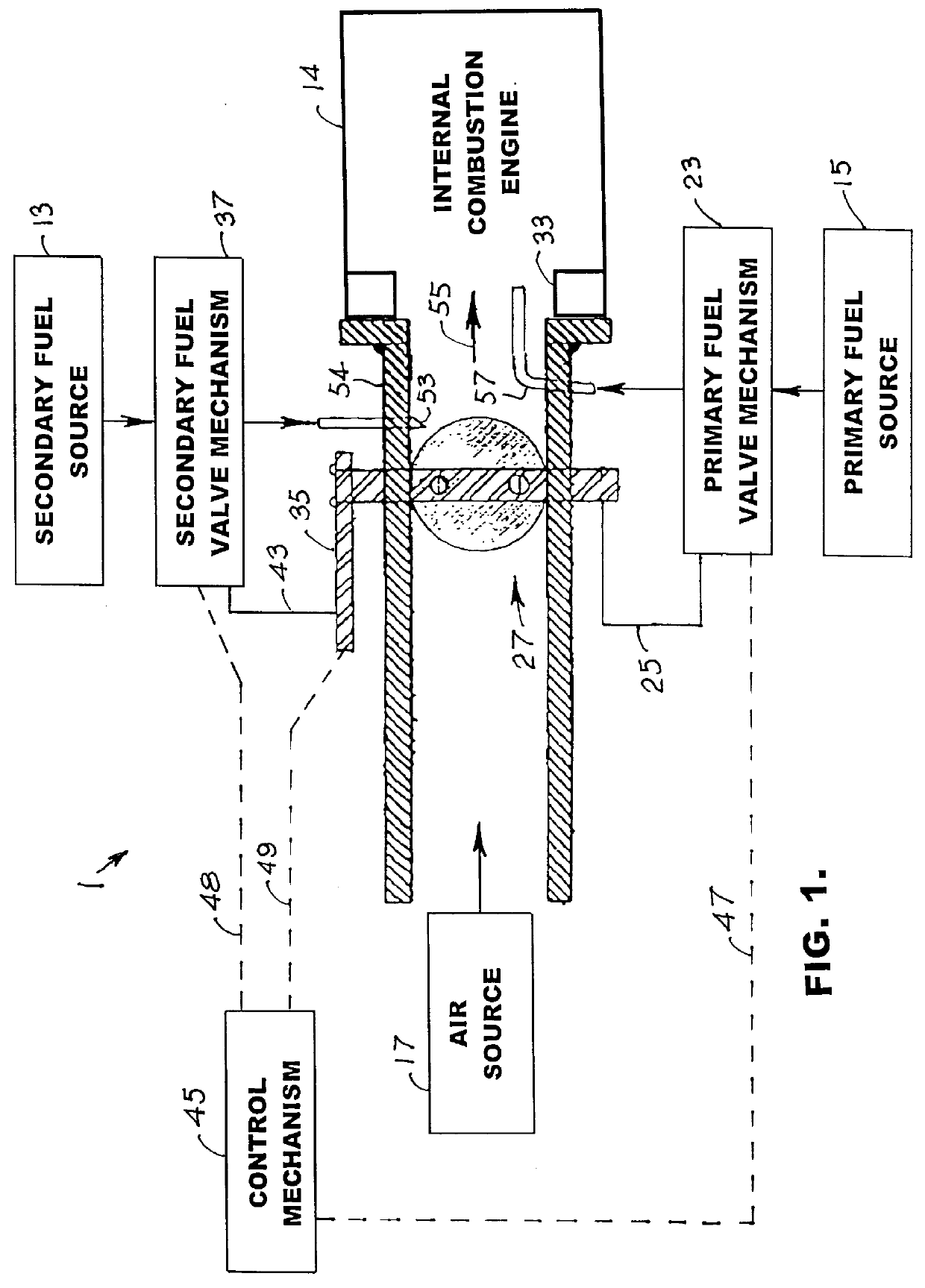

Internal combustion system using acetylene fuel

InactiveUS6076487AInternal combustion piston enginesNon-fuel substance addition to fuelCarbon chainInternal combustion engine

An environmentally clean dual fuel for an internal combustion engine, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C20 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel. The dual fuel, internal combustion system, which generally utilizes a two-stage process for start-up and operation and can be operated with air- or liquid-cooling, is environmentally clean with hydrocarbon, CO, NOx, and SOx emissions substantially eliminated.

Owner:GOTEC

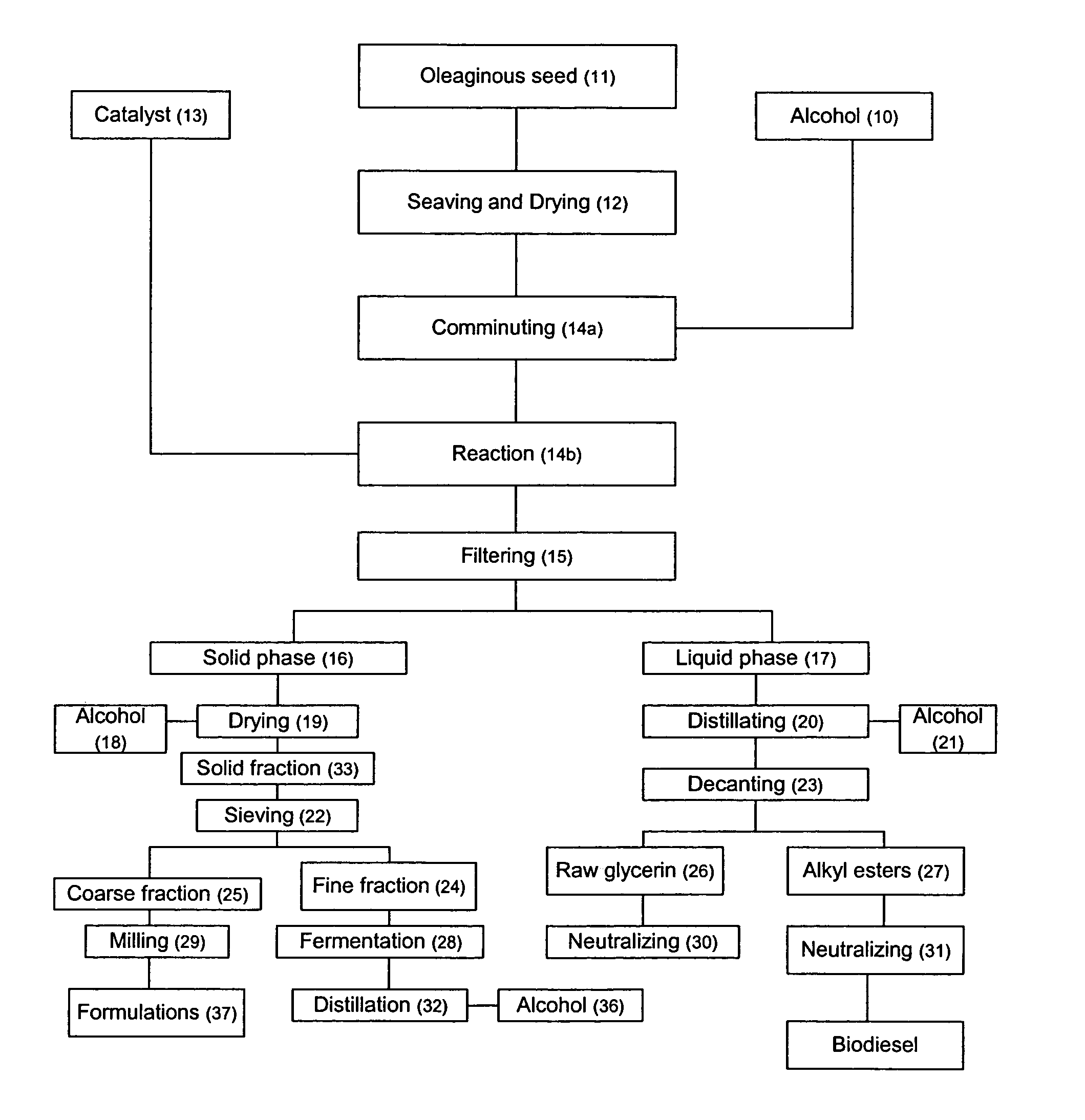

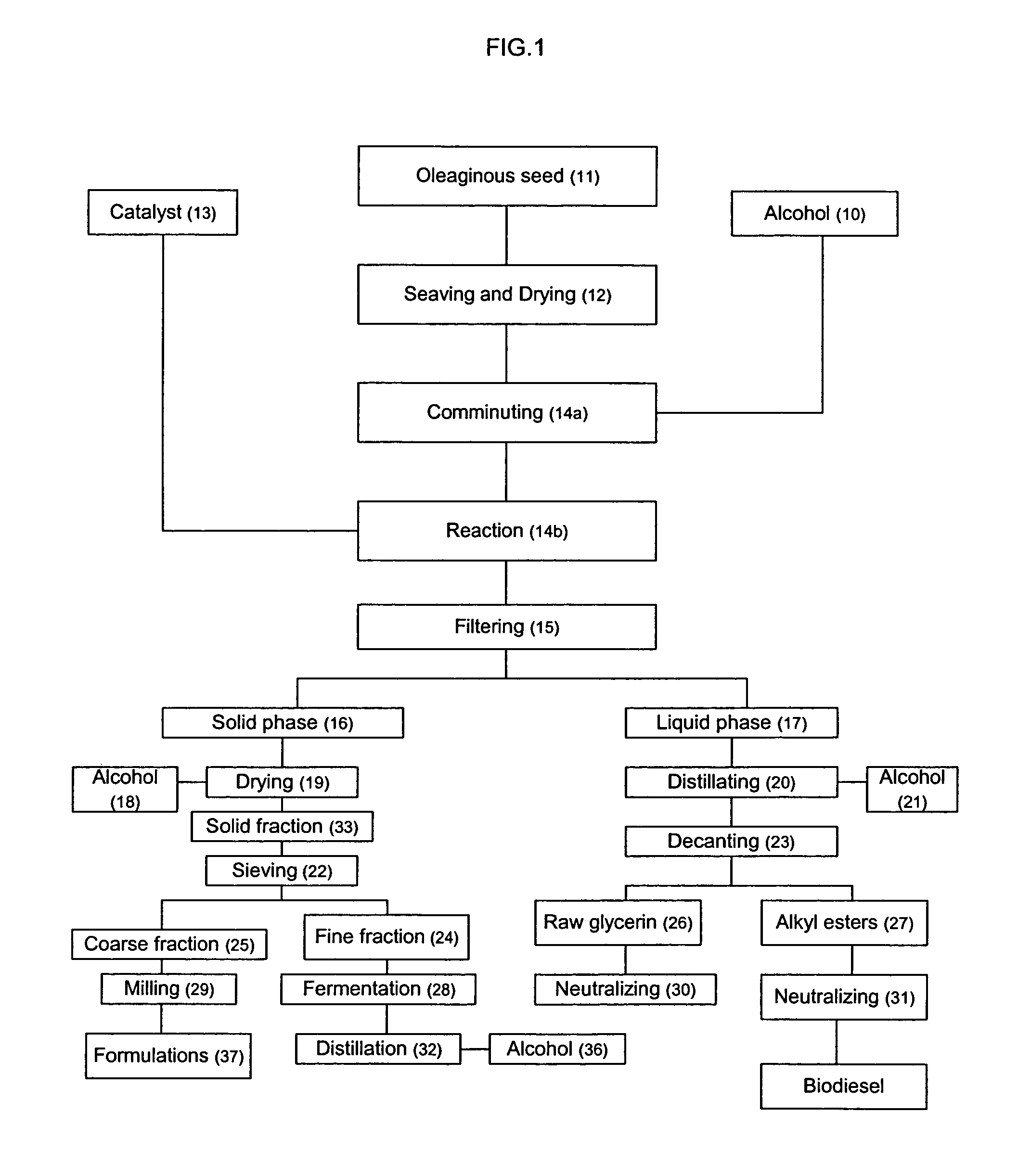

Process for producing biodiesel fuel using triglyceride-rich oleagineous seed directly in a transesterification reaction in the presence of an alkaline alkoxide catalyst

InactiveUS7112229B2Fatty oils/acids recovery from wasteFatty acid esterificationOil and greaseBiodiesel

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds. The inventive process includes a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

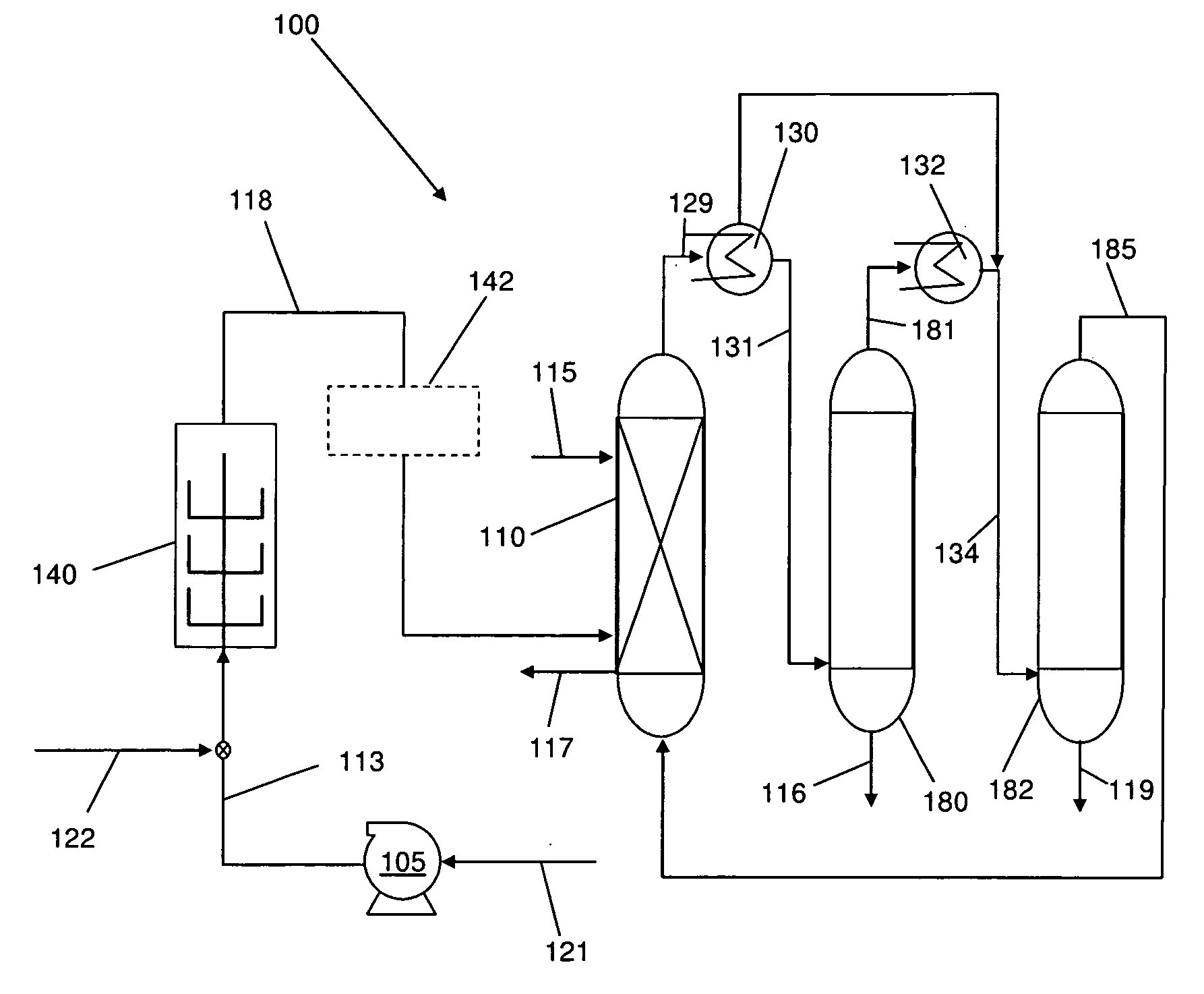

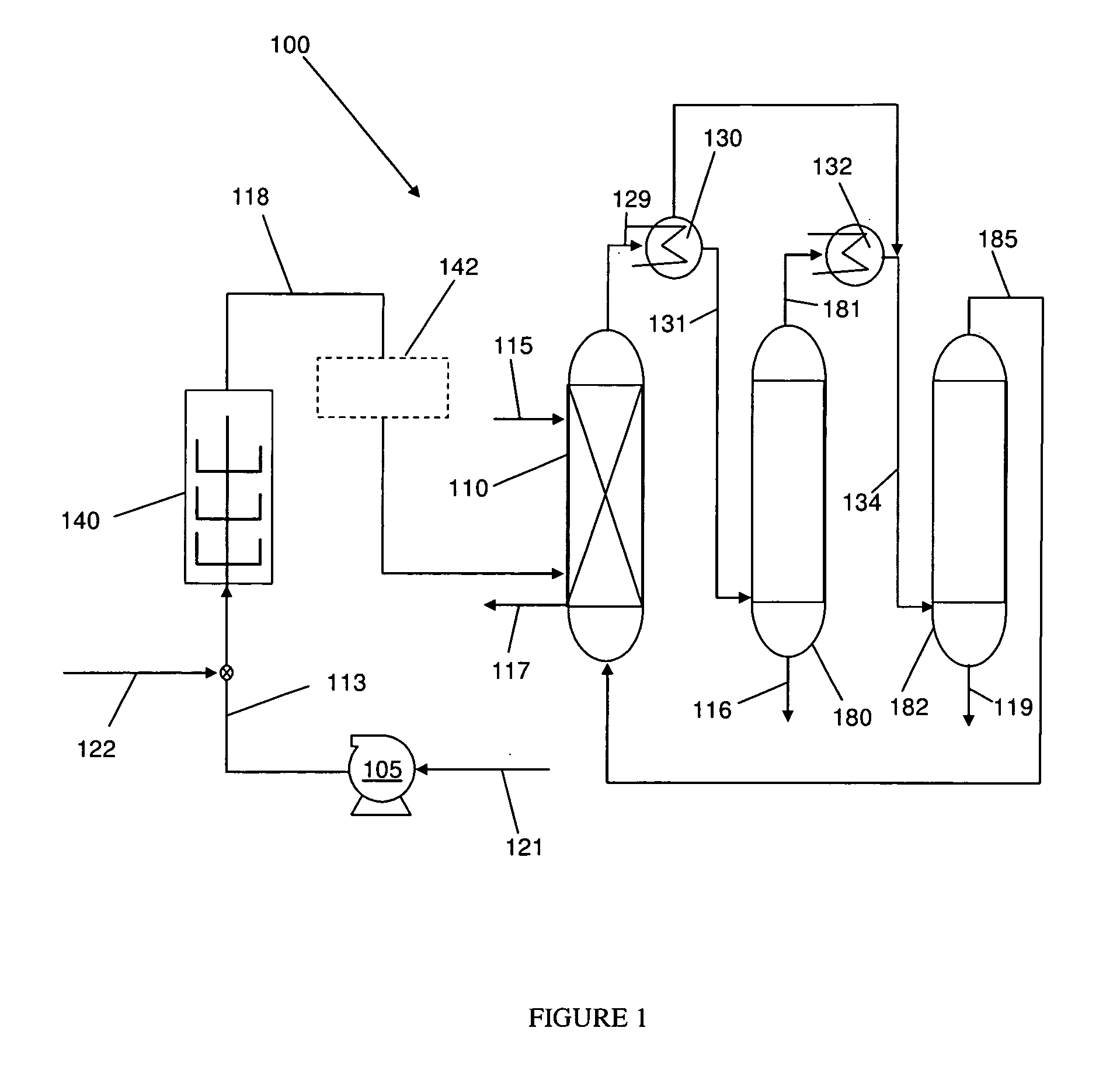

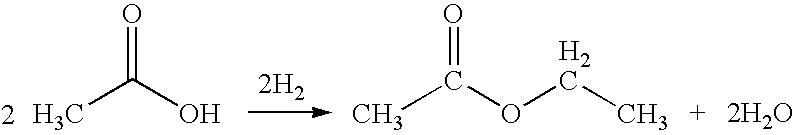

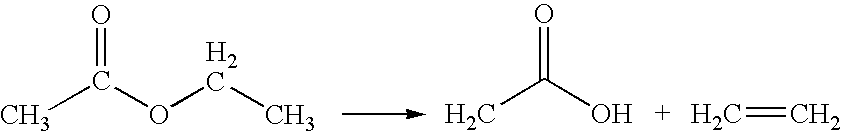

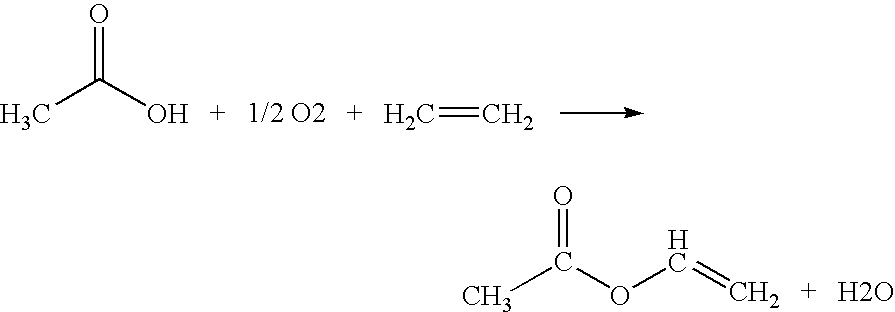

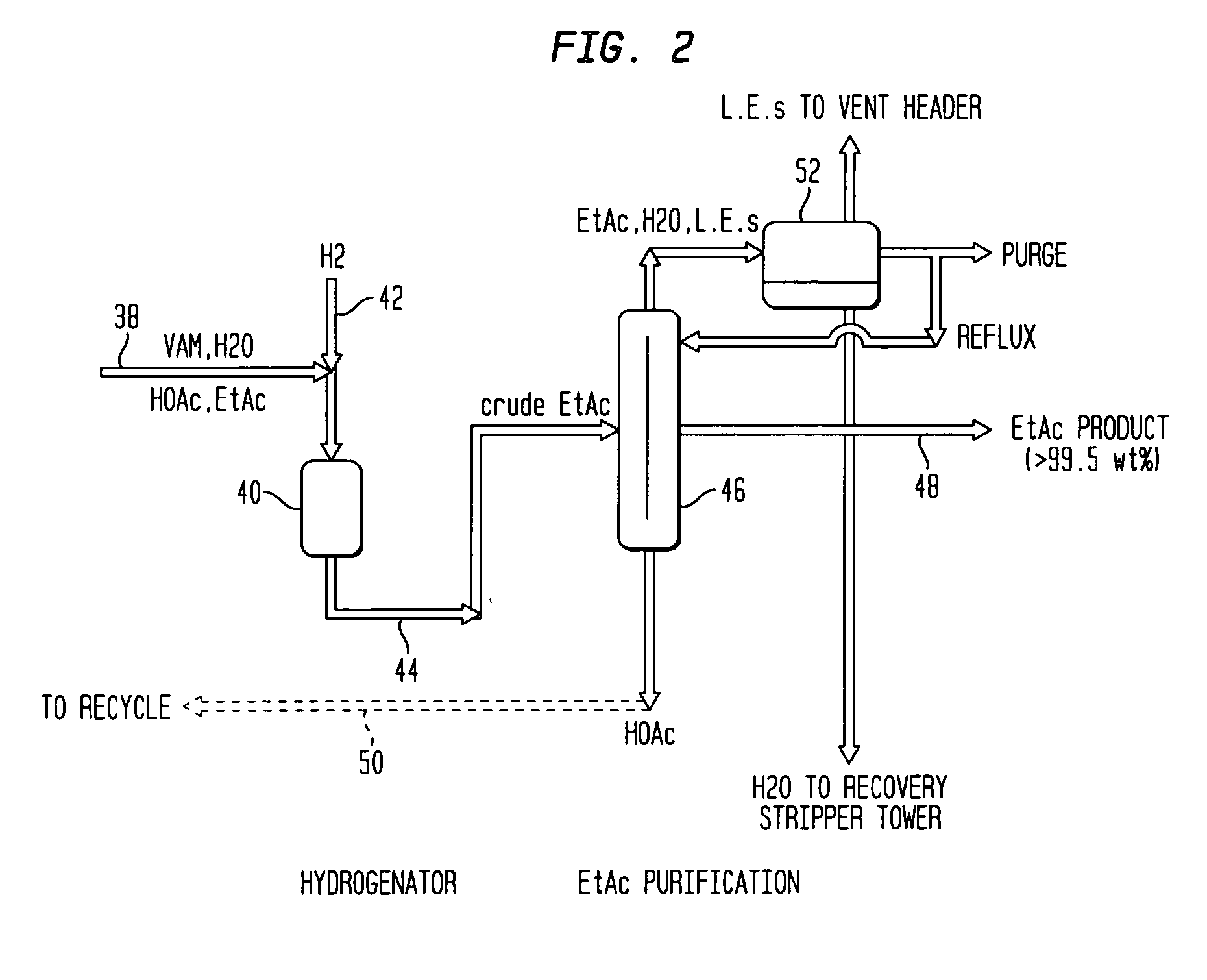

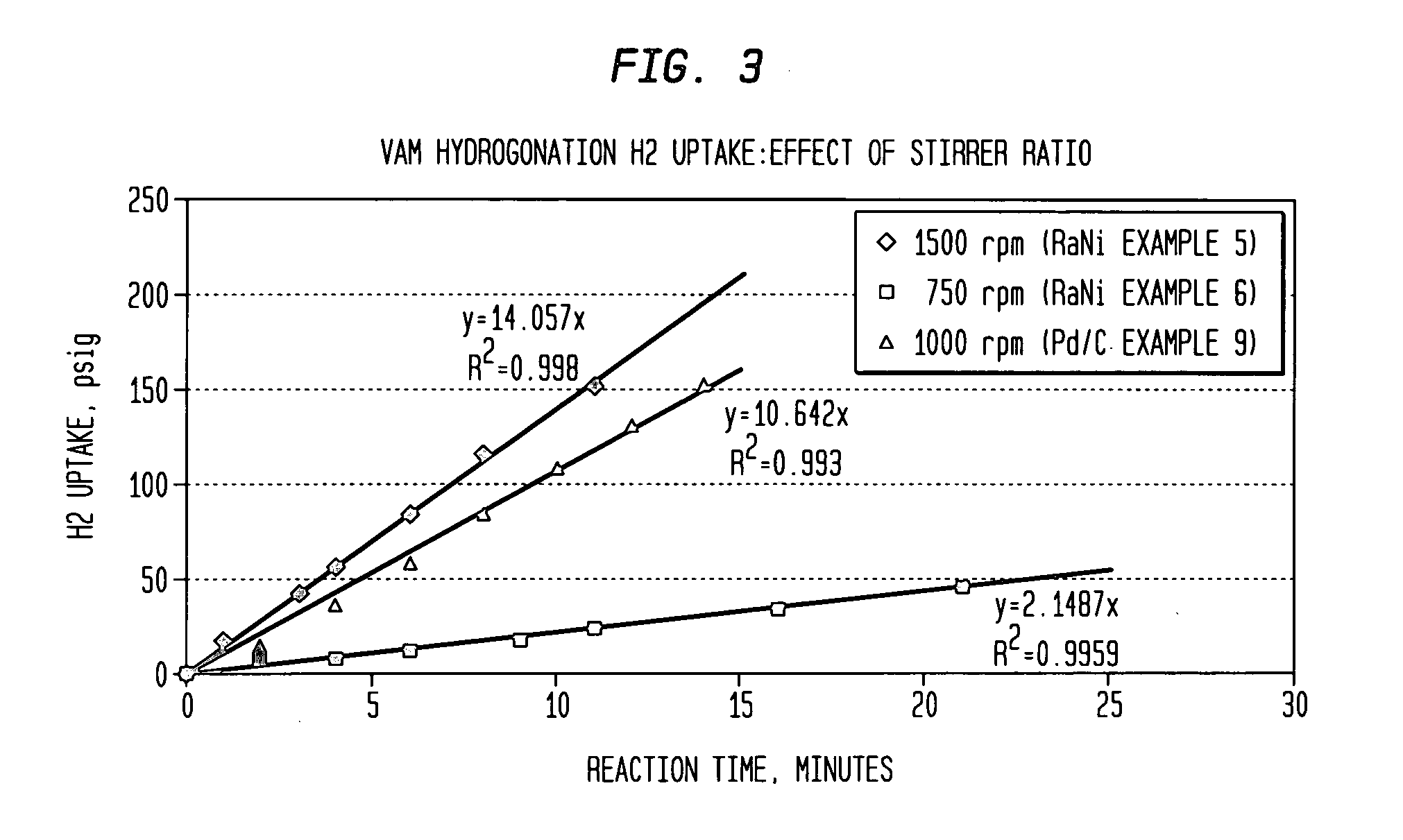

Integrated process for the production of viny acetate from acetic acid via ethy acetate

This invention provides an integrated three step economical process for the production of vinyl acetate monomer (VAM) from acetic acid in the vapor phase. First, acetic acid is selectively hydrogenated over a hydrogenating catalyst composition to form ethyl acetate which is cracked to form ethylene and acetic acid in the second step and in a subsequent step so formed ethylene and acetic acid is reacted with molecular oxygen over a suitable catalyst to form VAM. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and copper supported on silica selectively produces ethyl acetate in a vapor phase at a temperature of about 250° C., which is cracked over a NAFION catalyst to form ethylene and acetic acid at a temperature of about 185° C., which is mixed with molecular oxygen and reacted over a palladium / gold / potassium catalyst supported on titania to form VAM at a temperature of about 150° C. to 170° C.

Owner:CELANESE INT CORP

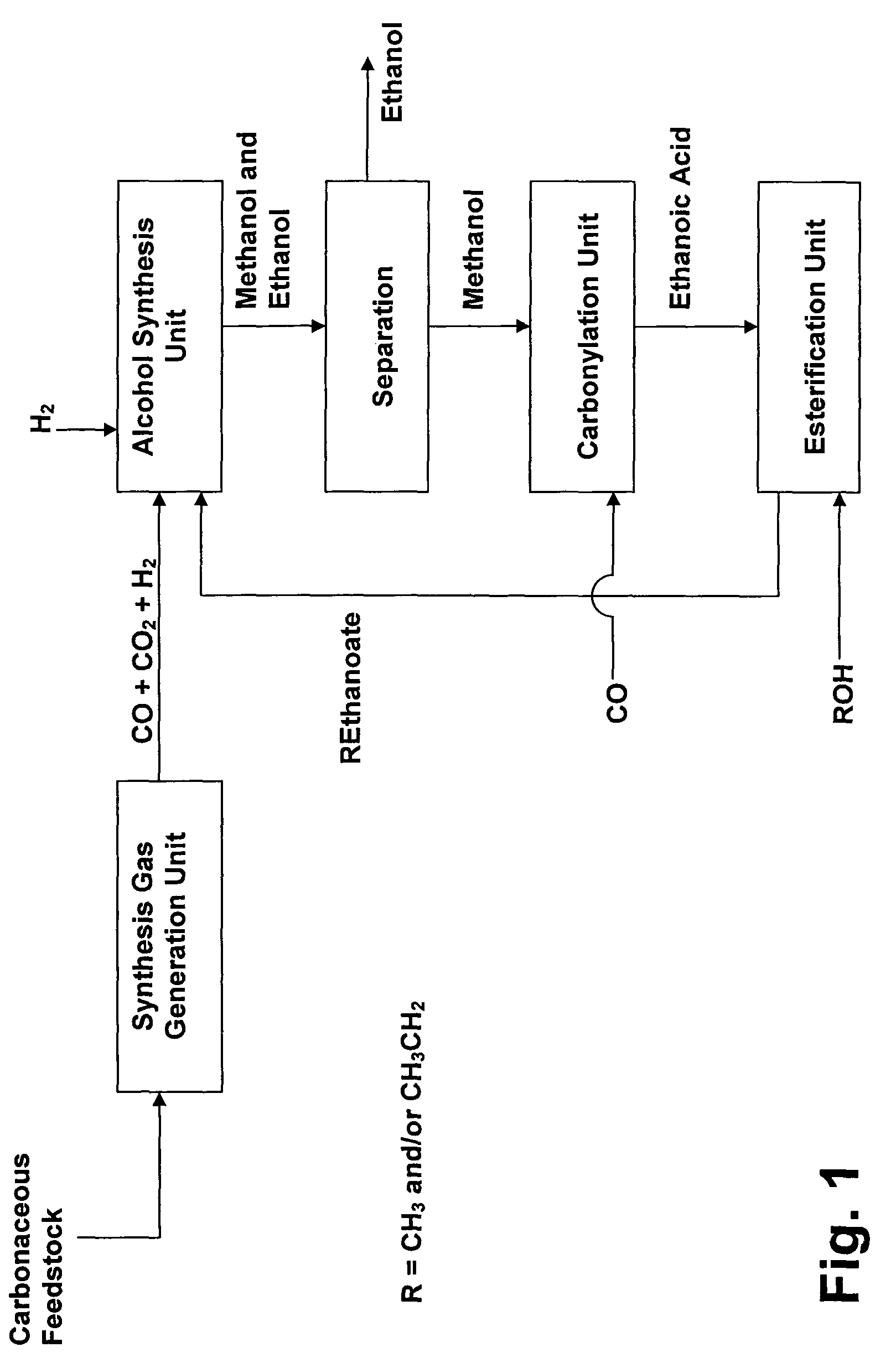

Process for the conversion of hydrocarbons into ethanol

ActiveUS7947746B2Increased formationIncreased purge stepOrganic compound preparationOxygen compounds preparation by reductionAcetic acidAlcohol

Process for converting synthesis gas to ethanol, including the steps of 1) introducing synthesis gas, together with methyl ethanoate and / or ethyl ethanoate, into an alcohol synthesis unit to produce methanol and ethanol, 2) separating the methanol from the ethanol of step 1, 3) introducing methanol, from step 2, together with CO, into a carbonylation unit in the presence of a methanol carbonylation catalyst, to produce ethanoic acid, and 4) introducing ethanoic acid, from step 3, together with methanol and / or ethanol, into an esterification unit to produce methyl ethanoate and / or ethyl ethanoate. In step 5), methyl ethanoate and / or ethyl ethanoate, produced in step 4, are fed into the alcohol synthesis unit of step 1, and in step 6) ethanol from step 2 is recovered.

Owner:INEOS ACETYLS UK LTD

Absorbent article comprising a synthetic polymer derived from a renewable resource and methods of producing said article

An element of an absorbent article is provided. The element has a bio-based content of at least about 50% based on the total weight of the element, and comprises a synthetic polymer derived from a renewable resource via a first intermediate compound selected from the group consisting of crotonic acid, propiolactone, ethylene oxide, i-propanol, butanol, butyric acid, propionic acid, 2-acetoxypropanoic acid, methyl 2-acetoxypropanoate, methyl lactate, ethyl lactate, polyhydroxybutyrate, and a polyhydroxyalkanoate comprising 3-hydroxypropionate monomers. An absorbent article comprising the element and a method of making an element for an absorbent article also are provided.

Owner:THE PROCTER & GAMBLE COMPANY

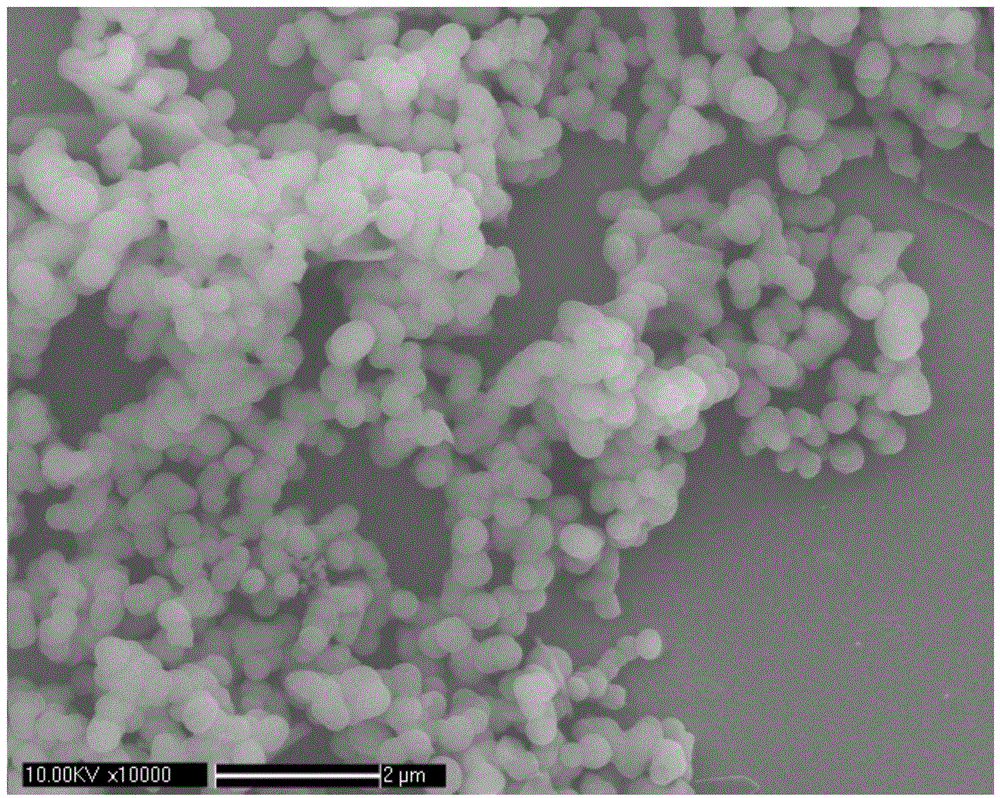

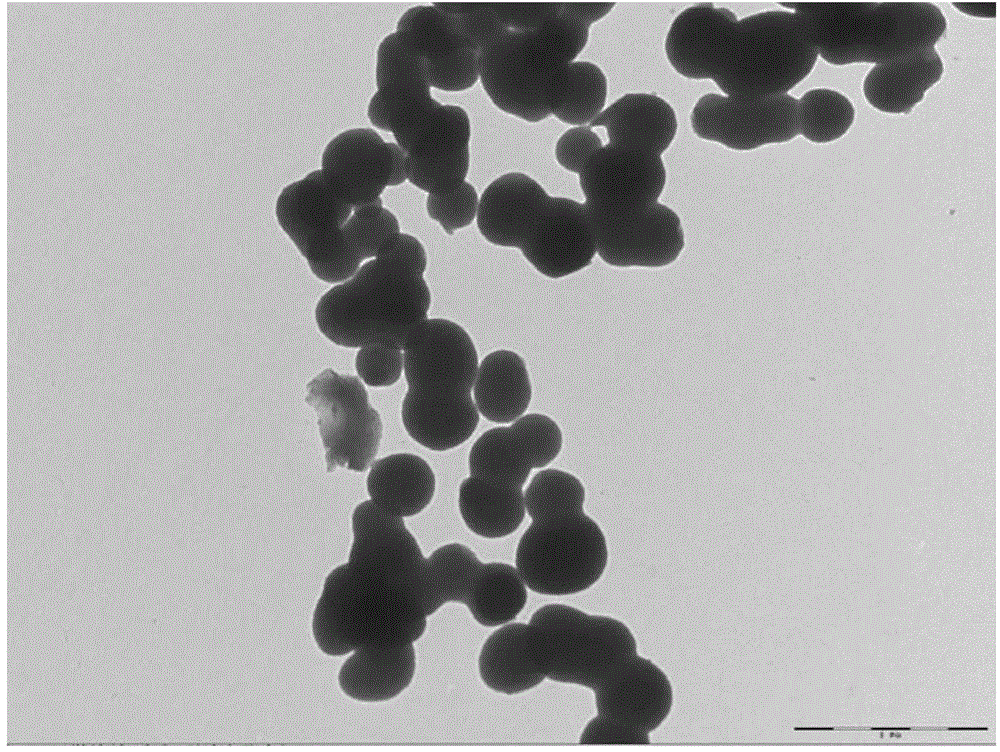

Phase-change energy-storage material nanocapsule and preparation method thereof

ActiveCN104449590ASmall sizeImprove stabilityHeat-exchange elementsMicroballoon preparationTetraethyl orthosilicateNanocapsules

The invention discloses a phase-change energy-storage material nanocapsule and a preparation method thereof and particularly relates to a phase-change energy-storage material capsule using an inorganic material as a shell layer and a preparation method of the capsule. By dispersing an oil phase formed by mixing the phase-change energy-storage material and tetraethyl orthosilicate in an aqueous phase formed by water and ethanol in a shape of nanoscale droplets, carrying out hydrolysis-condensation reaction on tetraethyl orthosilicate in the presence of a basic catalyst, and forming a silicon oxide shell layer on the surface of each of oil phase droplet to coat the phase-change energy-storage material, thus obtaining the phase-change energy-storage material nanocapsule of which the particle size is less than 1mu m. The nanocapsule has the advantages of uniform particle size distribution, large surface area and high enthalpy of phase change. The preparation method is simple and feasible, is high in preparation yield and is conductive to prepration of the phase-change energy-storage material having high heat storage / release efficiency in a large scale.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

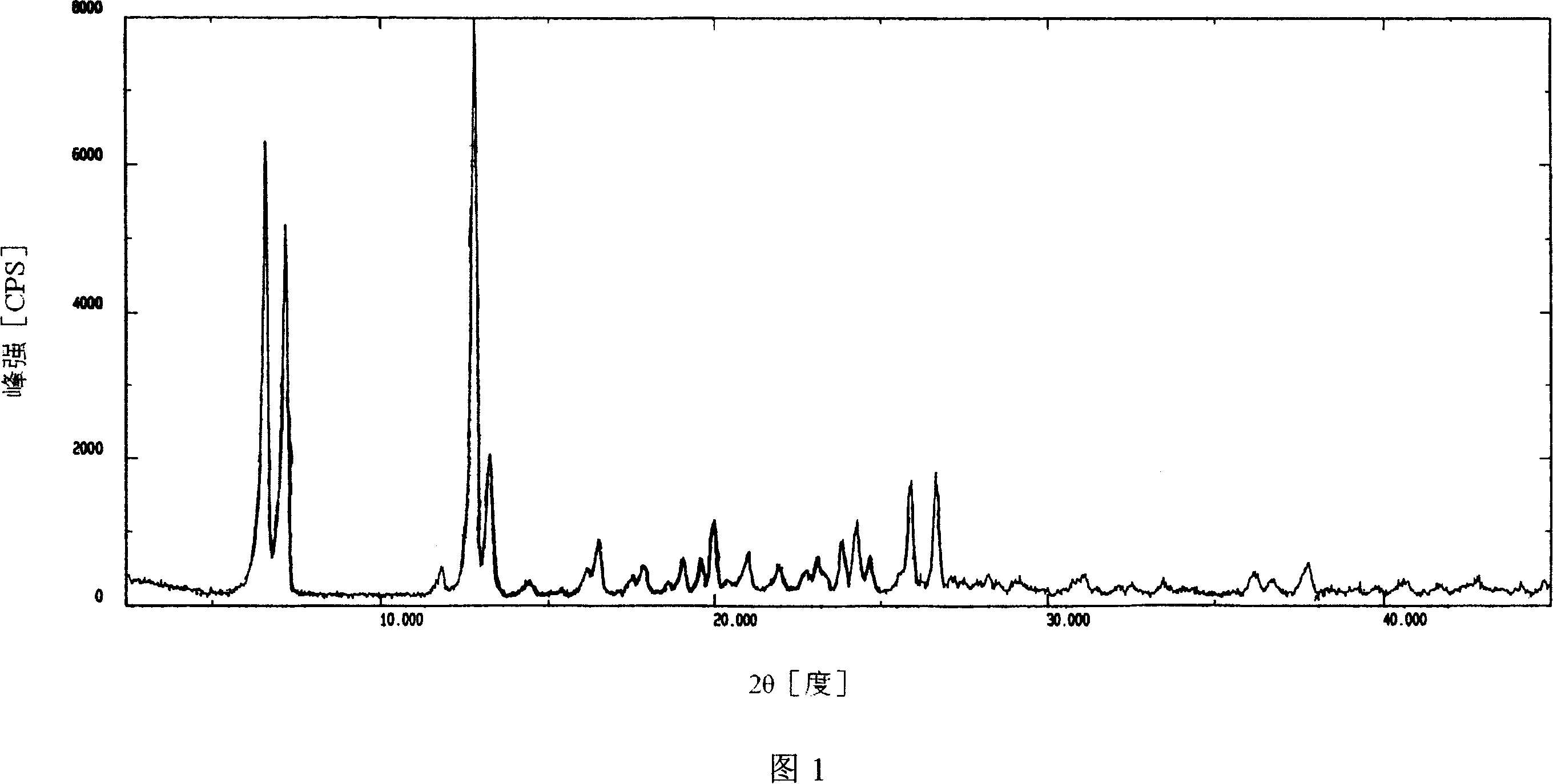

2-(3-cyano-4-isobuoxy phenyl)4-methyl-5-thiazole aminic acid crystal and preparation method thereof

The present invention discloses two crystal models and the preparation method of the anti-hyperuricemia drug 2-(3-ayano-4-isobuoxy phenyl)-4-methyl-5- thiazole acid. The preparation method of the crystal models commonly uses the low-toxicity ethanol, ethyl acetate or acetone as the solvent; the safety is relatively high. In addition, the hygroscopicity of the two crystal models is low in the high-humidity environment and the two crystal models are suitable for the steady pharmaceutical preparation.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

Processes for making ethyl acetate from acetic acid

InactiveUS20100197959A1High selectivityDecrease productivityOther chemical processesOrganic compound preparationAcetic acidEthyl ester

A process for hydrogenating acetic acid to form of ethyl acetate and mixtures of ethyl acetate and ethanol. The hydrogenation is done in the presence of catalyst, preferably on a support that optionally includes a support modifier.

Owner:CELANESE INT CORP

Nitrite additives for nonaqueous electrolyte rechargeable electrochemical cells

InactiveUS6210839B1Improve oxidation stabilityImprove dynamic stabilityOrganic electrolyte cellsSolid electrolyte cellsNitritePhysical chemistry

A lithium ion electrochemical cell having high charge / discharge capacity, long cycle life and exhibiting a reduced first cycle irreversible capacity, is described. The stated benefits are realized by the addition of at least one nitrite additive to an electrolyte comprising an alkali metal salt dissolved in a solvent mixture that includes ethylene carbonate, dimethyl carbonate, ethylmethyl carbonate and diethyl carbonate. The preferred additive is an alkyl nitrite compound.

Owner:WILSON GREATBATCH LTD

Co-production of vinyl acetate and ethyl acetate

InactiveUS20060106246A1Improve throughputReduce purification costsOrganic compound preparationCarboxylic acid esters preparationAcetic acidDistillation

A method of co-producing vinyl acetate and ethyl acetate includes: (a) reacting ethylene, acetic acid and oxygen to form vinyl acetate and at least a minor amount of ethyl acetate; (b) providing a crude product stream containing the vinyl acetate and ethyl acetate of step (a) and acetic acid to a distillation tower; (c) separating the crude product stream into: (i) a vinyl acetate product stream enriched in vinyl acetate with respect to the crude product stream; (ii) an acid recycle stream enriched in acetic acid with respect to the crude product stream; (iii) a mixed sidestream containing vinyl acetate and ethyl acetate, the mixed sidestream being enriched in ethyl acetate with respect to the vinyl acetate product stream; and (d) hydrogenating vinyl acetate in the mixed sidestream to provide an ethyl acetate product stream.

Owner:CELANESE INT CORP

High SPF transparent or translucent, cytoprotective, biodegradable, UV radiation resistant compositions

ActiveUS20080233060A1Protect the skinEliminating possible endocrine disruption responseCosmetic preparationsToilet preparationsCarrageenanPhospholipid

A composition comprising purified water using ozonation, ionization, or distillation or any combination thereof wherein alcohol may be substituted for, or combined with water at least one emollient including but not limited to chitosan, and aloe vera gel, individually or in any combination; an oil component with spf boosting agents including but not limited to; ethyl macadamiate, non-toxic silicone oil and essential oils, butter milk, waxes impregnated with inorganic sun-block or sunscreen agent and organic / inorganic micronized particles, wood powder and bentonite clay, keratin, either individually or in any combination; at least one inorganic sun-block or sunscreen agent including any metal oxide, glass microsphere, silica and silica compound, and optionally metal oxide pigments with particles that are micronized, submicronized, nanoparticle sized, or otherwise individually or in any combination that can be homogenized in either a water phase, a water-aloe phase, an oil phase or any phase of said composition; at least one emulsifier wherein said emulsifier includes but is not limited to a phospholipid and / or liposome or an aloe vera gel or an ester of coconut oil individually or in any combination, for emulsifying the water, water-aloe, or oil phase in combination with an homogenizer; where any of components are preferably mixed with an homogenizer and where an appropriate thickening agent including but not limited to xanthan gum, carageenan, either individually or in any combination is added as required.

Owner:GRUNE GUERRY L

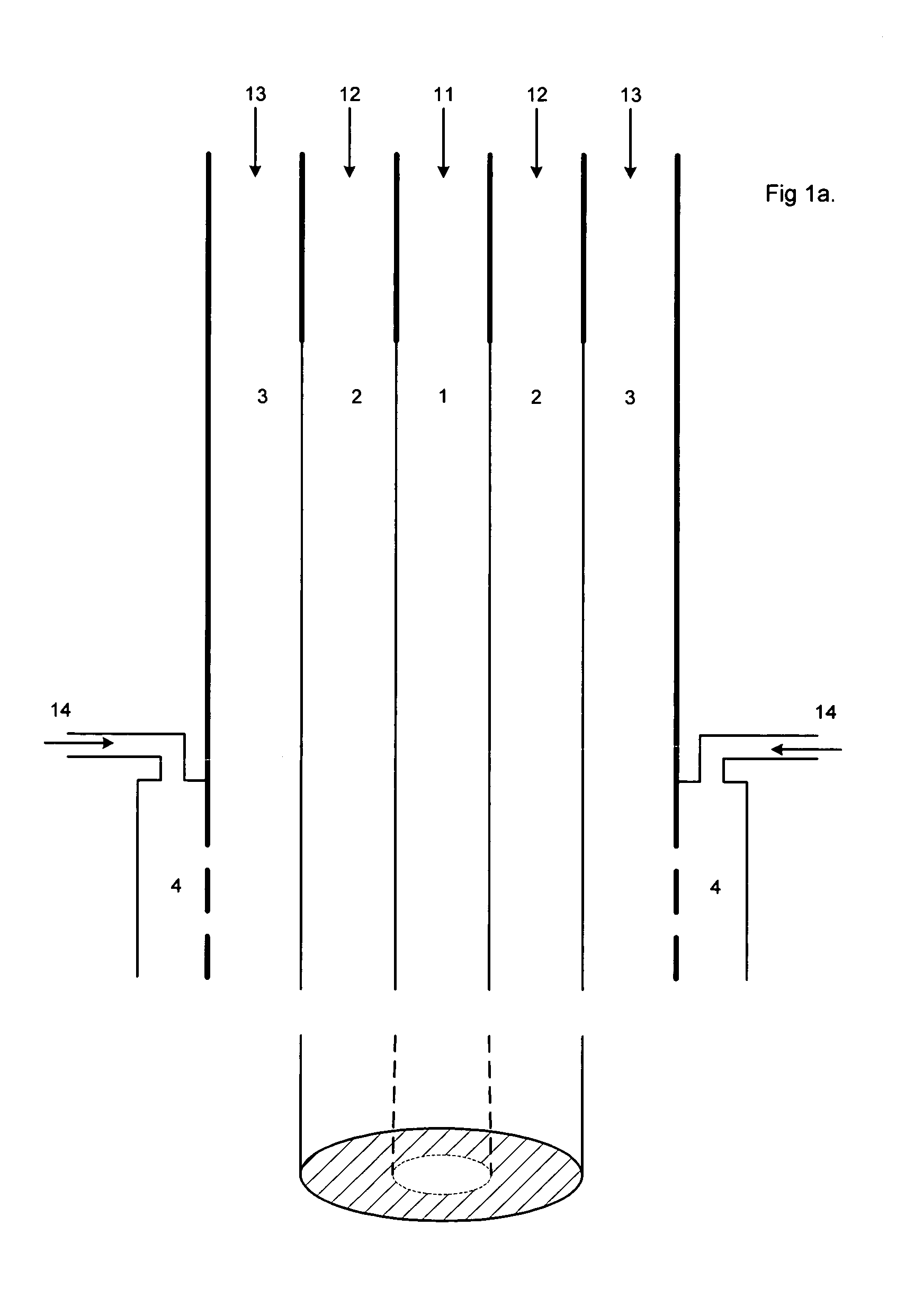

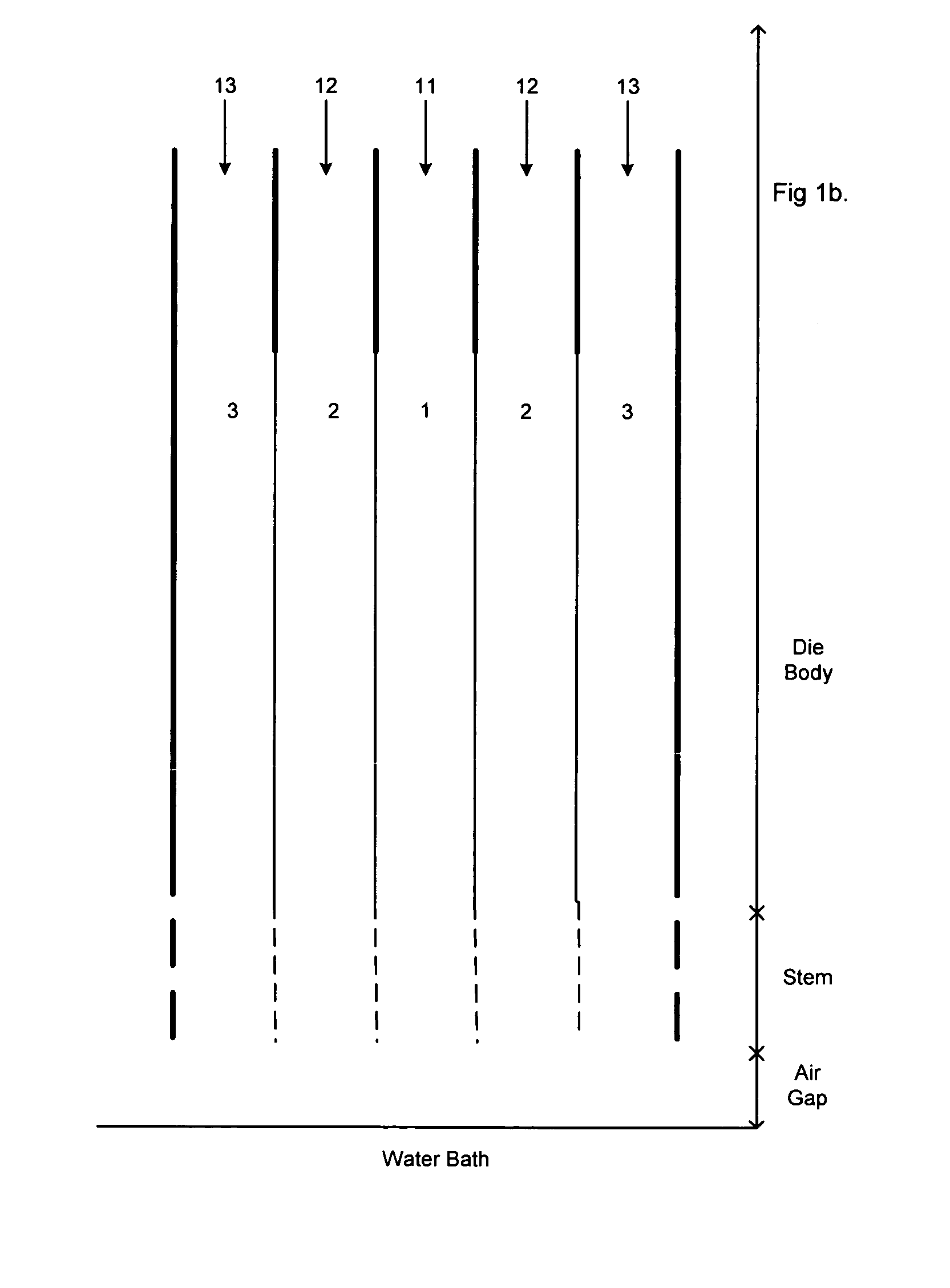

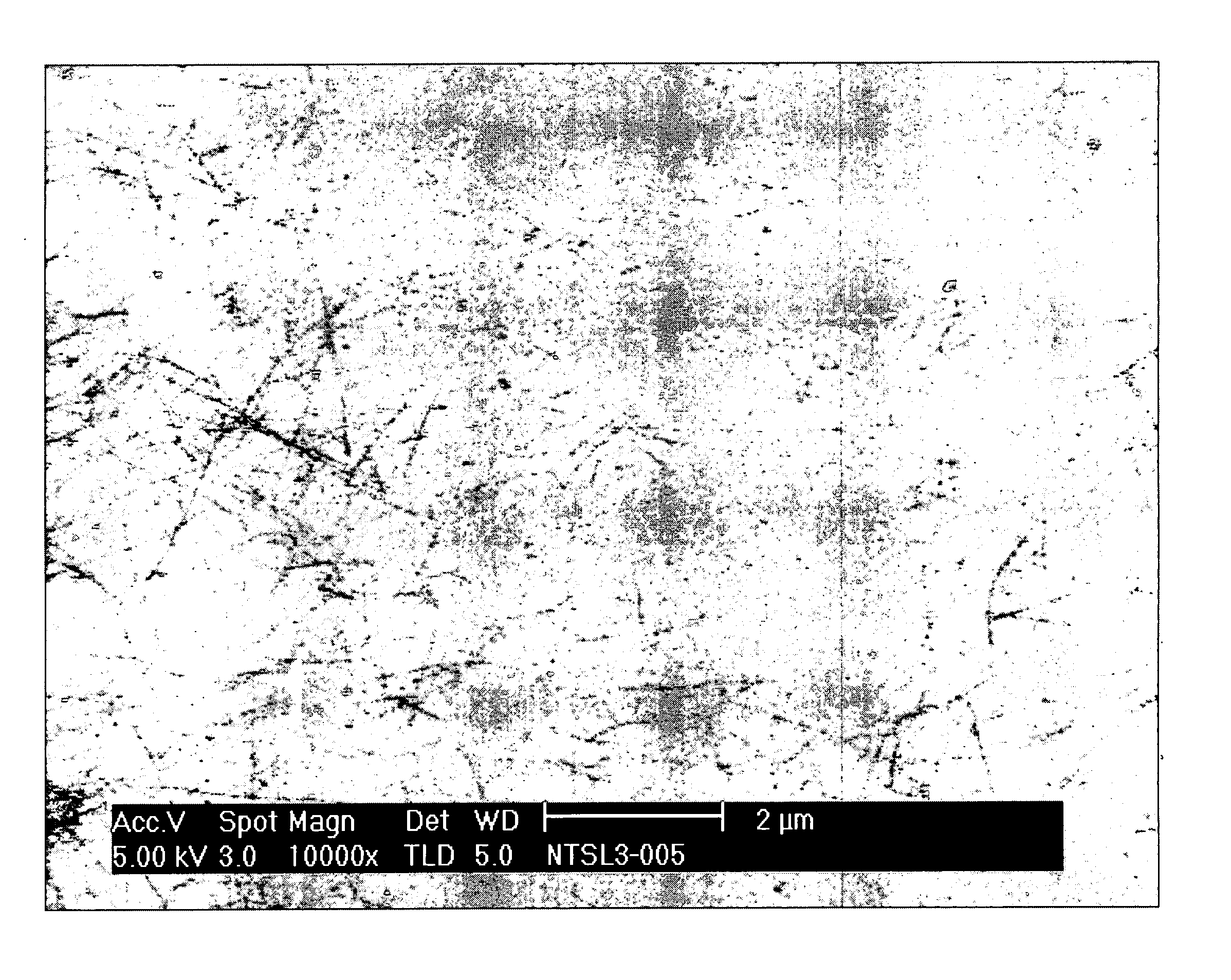

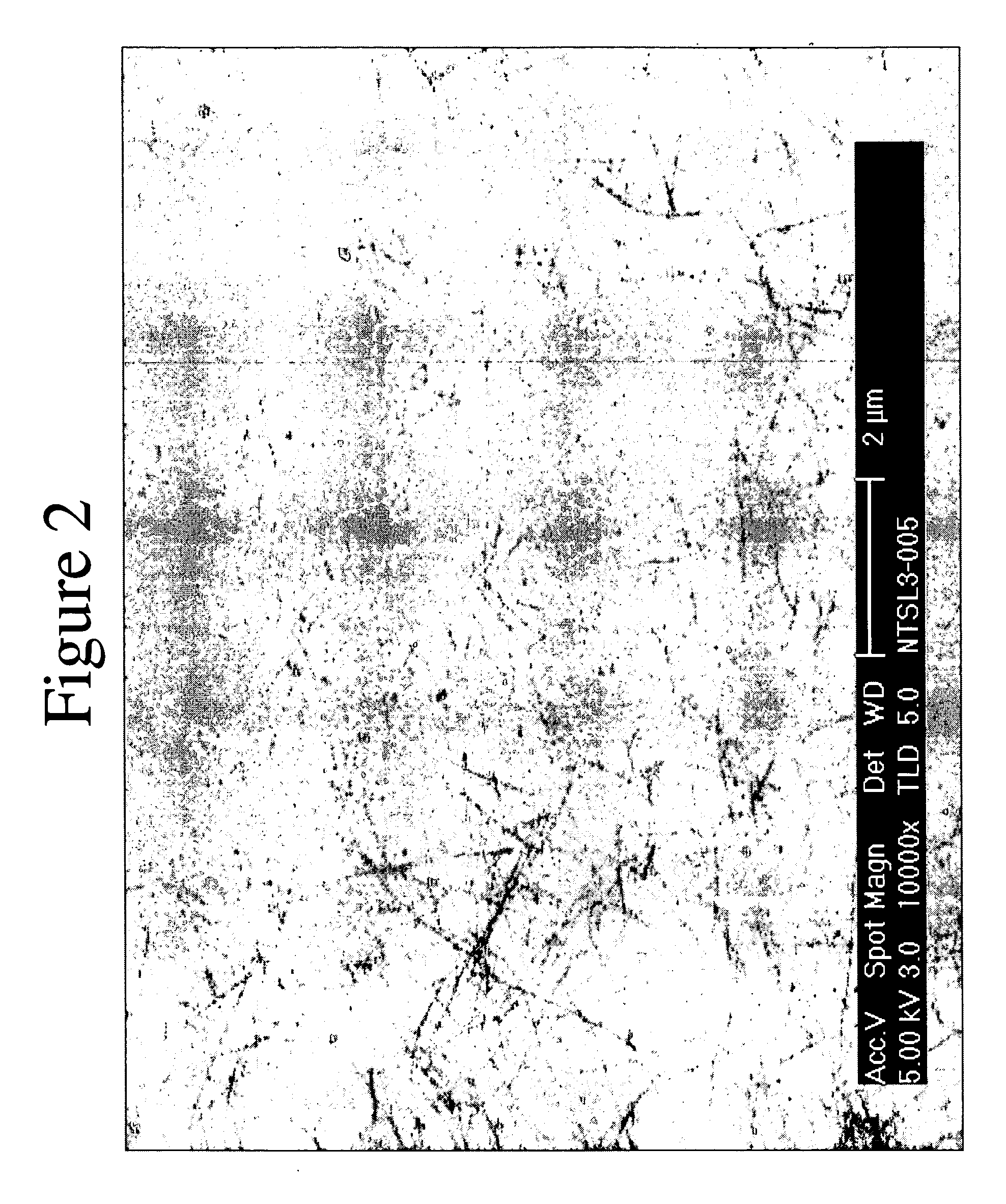

Applicator liquid containing ethyl lactate for preparation of nanotube films

ActiveUS20050269554A1High puritySuitable for useMaterial nanotechnologyNanoinformaticsEthyl esterNanotube membrane

Certain applicator liquids and application techniques are described, which can be used to form nanotube films or fabrics of controlled properties. An applicator liquid for preparation of a nanotube film or fabric includes a controlled concentration of nanotubes dispersed in ethyl lactate. The controlled concentration is sufficient to form a nanotube fabric or film of preselected density and uniformity.

Owner:ZEON CORP

Method for preparing benzoxazine intermediate containing triazine structure

The invention provides a preparation method of triazine structure containing benzoxazine intermediate, which sequentially includes: (1) performing synthetic reaction of aldehyde compound and amine compound at a molar ratio of at least 1:1 which includes adding aldehyde compound and solvent of at least one of clean water, methanol, ethanol, isopropanol, and ethyl acetate into a reactor at the room temperature under the normal pressure to obtain mixed solution with aldehyde mass concentration of no greater than 95%, adding amine compound while stirring, and reacting at 0-100 DEG C under the normal pressure for at least 15 minutes to obtain the reactant liquor; (2) pouring into the cleaning solution, stirring and cleaning, and filtering to collect solid substance, or directly filtering the reactant liquor to collect the solid substance; and (3) drying the solid substance obtained in step (2) at 30-100 DEG C.

Owner:SICHUAN UNIV

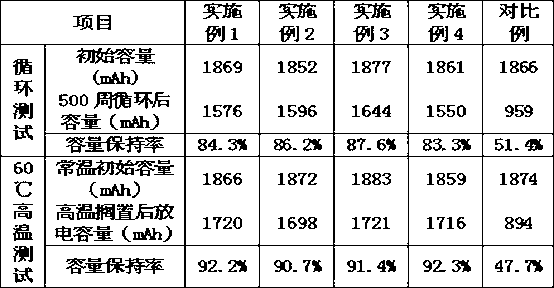

Non-aqueous electrolyte for high-voltage lithium ion batteries

ActiveCN103268956ASimple compositionPromote circulationSecondary cellsHigh voltage batteryPropylene carbonate

The invention relates to a non-aqueous electrolyte for high-voltage lithium ion batteries, which is prepared from the following raw materials in percentage by weight: 70-85% of carbonate, 3-20% of functional additive and 11-17% of lithium hexafluorophosphate. The carbonate is one or mixture of more of ethylene carbonate, propylene carbonate, butylene carbonate, dimethyl carbonate, diethyl carbonate, dipropyl carbonate, methylethyl carbonate, methyl propyl carbonate and methyl butyl carbonate; and the functional additive is one or mixture of more of 0.5-10% of negative pole film-forming additive, 0.5-10% of high-temperature additive, 0.5-10% of positive pole film-forming additive, 0.5-10% of high-voltage additive and 0.001-2% of stability additive. The invention solves the problem of adaptation of the lithium ion battery electrolyte to the 4.35V high-voltage battery positive / negative pole, and provides an electrolyte for high-voltage batteries, which has the advantages of high cycle life, low inflation rate and favorable high-temperature properties.

Owner:广东金光高科股份有限公司

Cooling compositons

The present invention relates to cooling compositions comprising a cooling agent (preferably menthyl lactate) together with an ester derivative (preferably tri-ethyl citrate). Such compositions deliver immediate and long lasting freshness sensation, while maintaining or even improving skin and / or mucosal membrane health to which they are contacted and deodorizing said skin and / or mucosal membrane.

Owner:THE PROCTER & GAMBLE COMPANY

Halar membranes

InactiveUS20050098494A1Low toxicityImprove permeabilityMembranesSemi-permeable membranesFiberGlycerol

Porous polymeric membranes including Halar (poly (ethylene chlorotrifluoroethylene)) and related compounds and the methods of production thereof which avoid the use of toxic solvents. Preferred solvents, coating agents and pore forming agents are citric acid ethyl ester or glycerol triacetate. The membranes may be in the form of a hollow fibre or flat sheet, and may include other agents to modify the properties of the membrane, such as the hydrophilic / hydrophobic balance. Leachable agents may also be incorporated into the membranes.

Owner:EVOQUA WATER TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl) cyclohexyl] carbonyl]glycine Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl) cyclohexyl] carbonyl]glycine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/adb4d26a-e9fc-49b3-bec1-672c98d419f4/US07189760-20070313-C00001.png)

![Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl) cyclohexyl] carbonyl]glycine Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl) cyclohexyl] carbonyl]glycine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/adb4d26a-e9fc-49b3-bec1-672c98d419f4/US07189760-20070313-C00002.png)

![Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl) cyclohexyl] carbonyl]glycine Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl) cyclohexyl] carbonyl]glycine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/adb4d26a-e9fc-49b3-bec1-672c98d419f4/US07189760-20070313-C00003.png)

![Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl)cyclohexyl] carbonyl]glycine Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl)cyclohexyl] carbonyl]glycine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/cff1f463-e31a-472e-a9ad-f8d2a848a23c/US20050222256A1-20051006-C00001.png)

![Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl)cyclohexyl] carbonyl]glycine Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl)cyclohexyl] carbonyl]glycine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/cff1f463-e31a-472e-a9ad-f8d2a848a23c/US20050222256A1-20051006-C00002.png)

![Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl)cyclohexyl] carbonyl]glycine Physiological cooling compositions containing highly purified ethyl ester of N-[[5-methyl-2-(1-methylethyl)cyclohexyl] carbonyl]glycine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/cff1f463-e31a-472e-a9ad-f8d2a848a23c/US20050222256A1-20051006-C00003.png)