Non-aqueous electrolyte for high-voltage lithium ion batteries

A non-aqueous electrolyte and lithium-ion battery technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of low inflation rate, achieve high performance, increase decomposition voltage, and improve cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

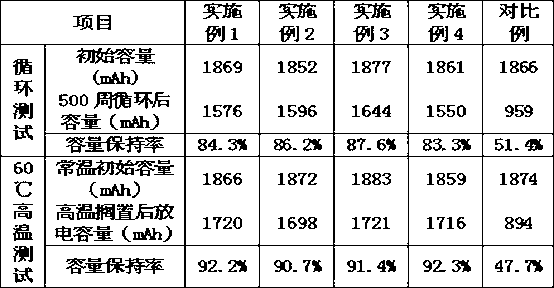

Examples

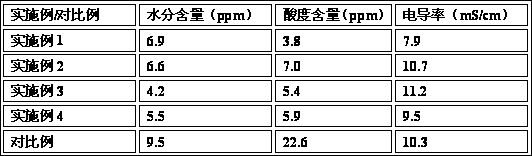

Embodiment 1

[0044] Preparation of non-aqueous electrolyte: at room temperature, in a glove box with dry air (moisture <20PPM), accurately weigh 31.76 grams of ethylene carbonate, 37.70 grams of diethyl carbonate, and 7.94 grams of ethyl methyl carbonate with an electronic balance , vinylene carbonate 1.50 g, 1,3-propane sultone 2.50 g, fluoroethylene carbonate 4.00 g, succinonitrile: 1.00 g, lithium tetrafluoroborate: 1.00 g, hexamethyldisilazane 0.02 grams, 0.08 grams of trimethyl phosphite and 12.50 grams of lithium hexafluorophosphate; then add the above-mentioned various raw materials into a conical flask with a ground mouth, and stir until lithium hexafluorophosphate is completely dissolved, and the organic solvents are mixed uniformly to obtain 100 grams of non-aqueous electrolyte.

Embodiment 2

[0046] The preparation method of this example is the same as Example 1, except that the raw materials used are 30.26 grams of ethylene carbonate, 23.82 grams of dimethyl carbonate, 23.82 grams of ethyl methyl carbonate, 1.00 grams of vinyl vinylene carbonate, 1,4-butane Sultone 2.00 g, adiponitrile: 3.00 g, difluoroethylene carbonate: 2.00 g, lithium bisoxalate borate 1.5 g, heptamethyldisilazane 0.04 g, trimethyl phosphite 0.06 g and lithium hexafluorophosphate 12.50 gram.

Embodiment 3

[0048] The preparation method of this example is the same as Example 1, except that the raw materials used are 15.68 grams of ethylene carbonate, 45.54 grams of dimethyl carbonate, 15.68 grams of propylene carbonate, 2.00 grams of vinylene carbonate, 1,4-butane sultone 2.00 g, succinonitrile 2.00 g, difluoroethylene carbonate: 3.00 g, lithium difluorooxalate borate 1.5 g, heptamethyldisilazane 0.03 g, triphenyl phosphite 0.07 g and lithium hexafluorophosphate 12.50 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com