Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3211 results about "Non aqueous electrolytes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

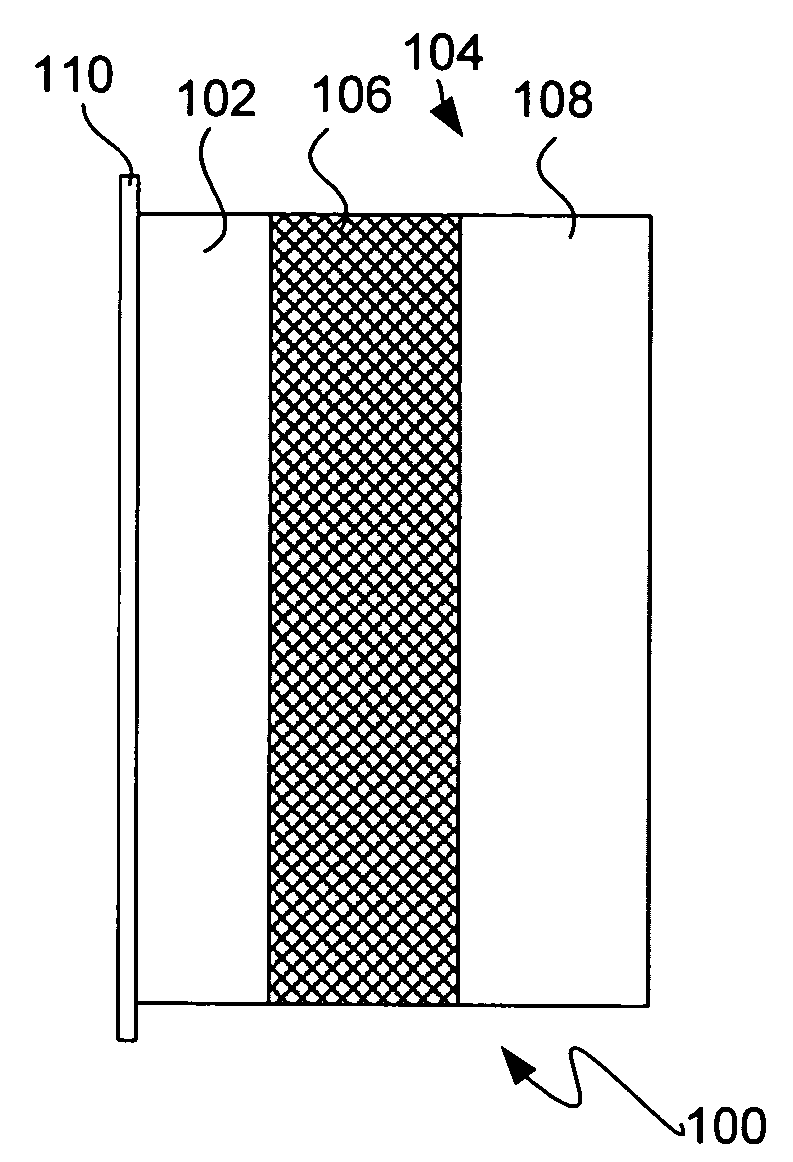

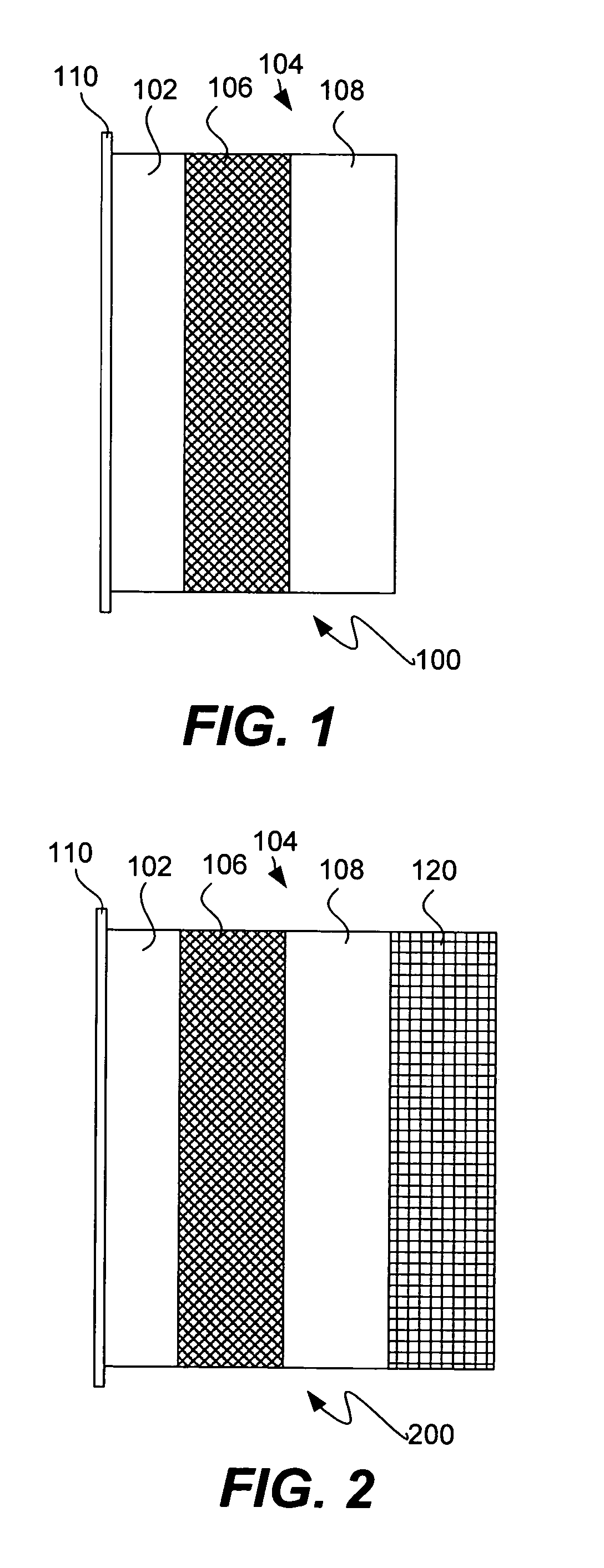

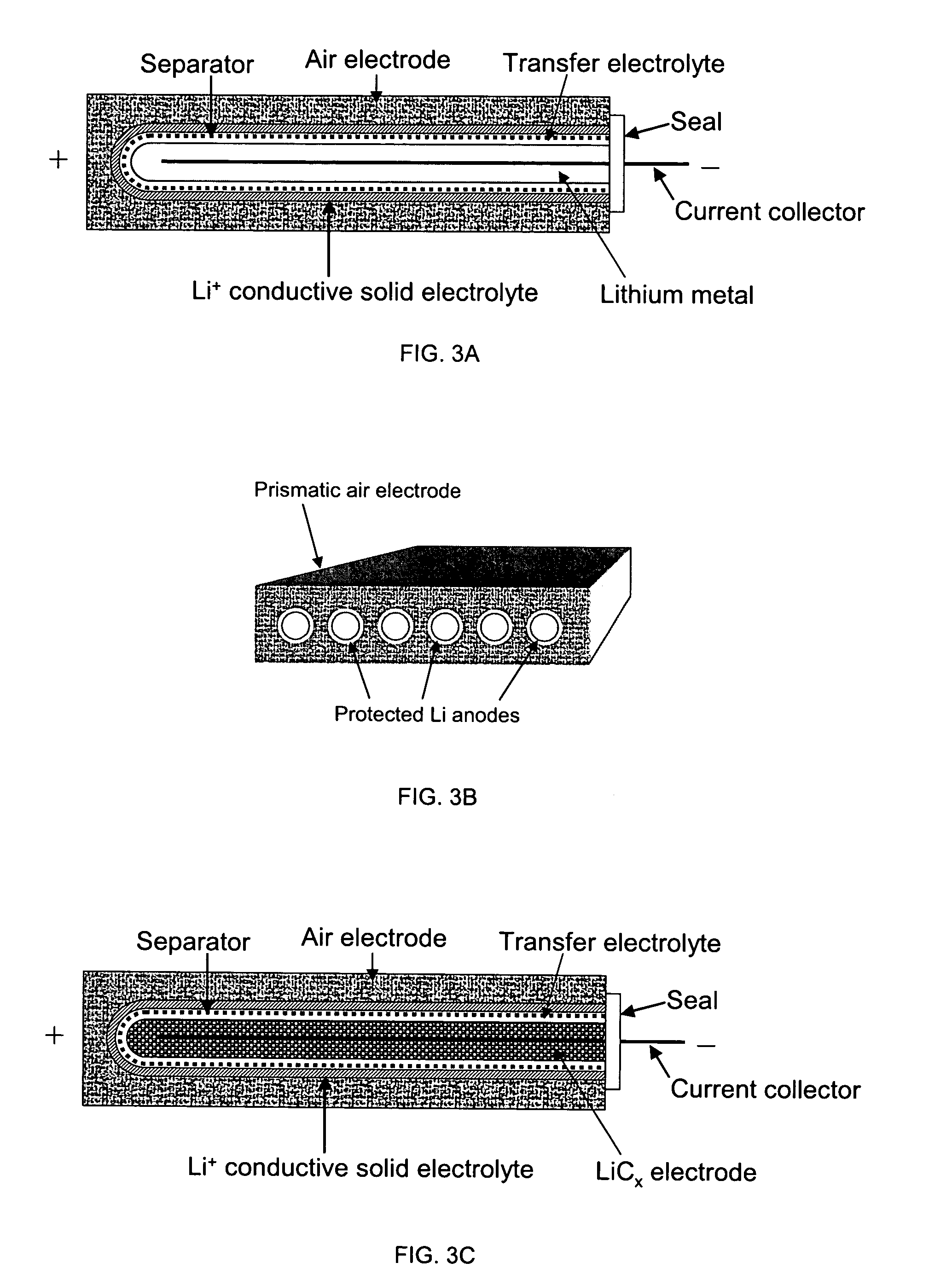

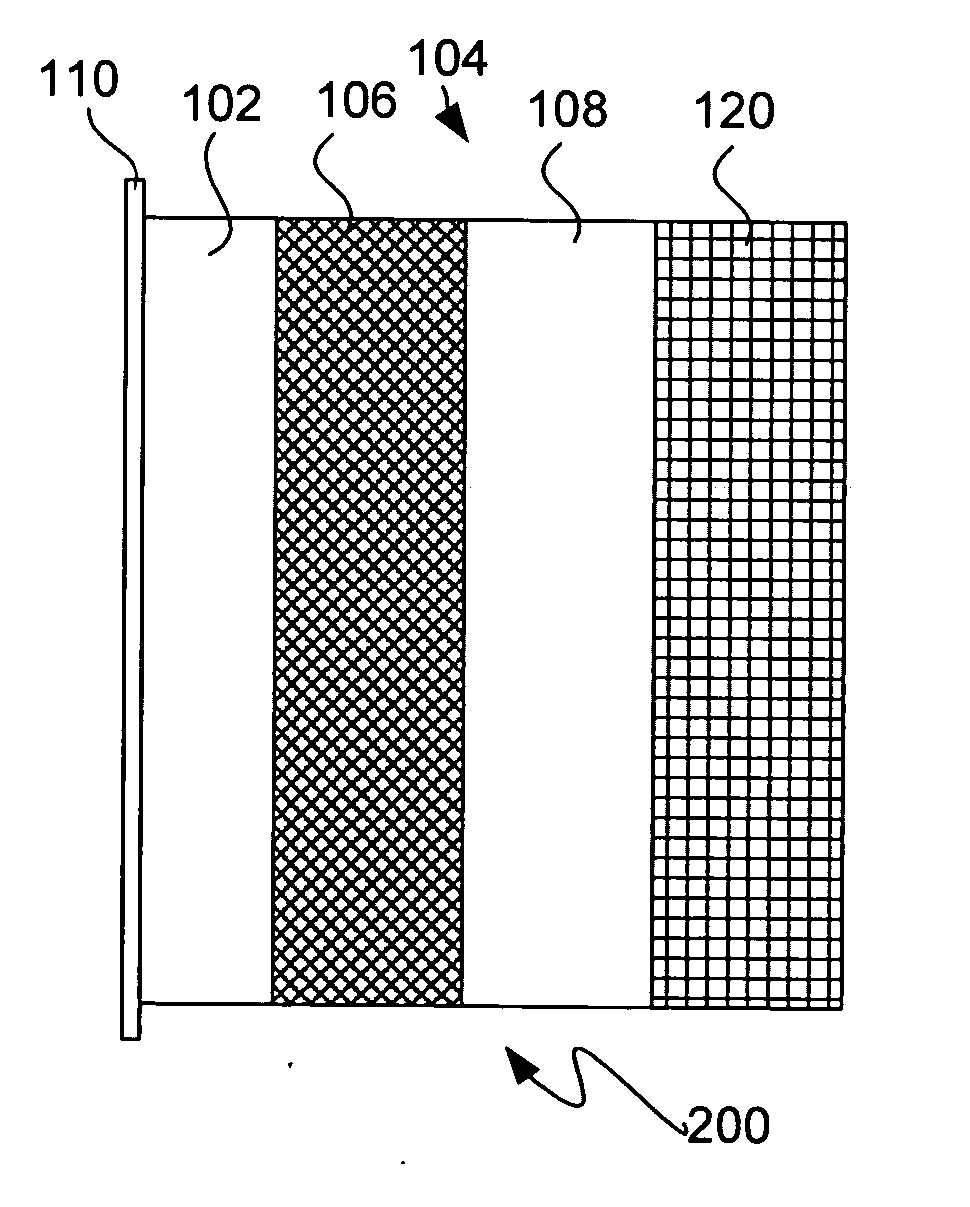

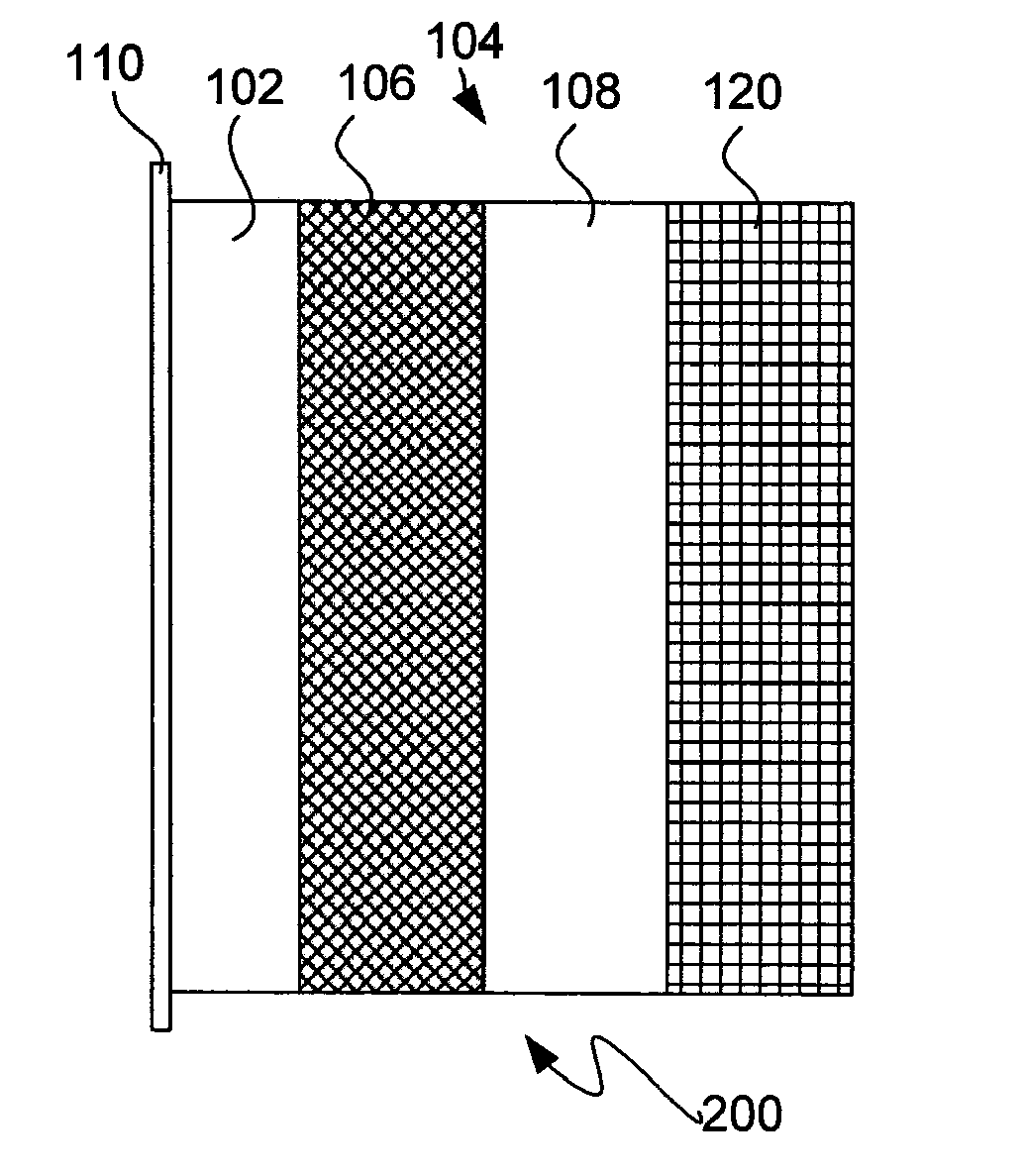

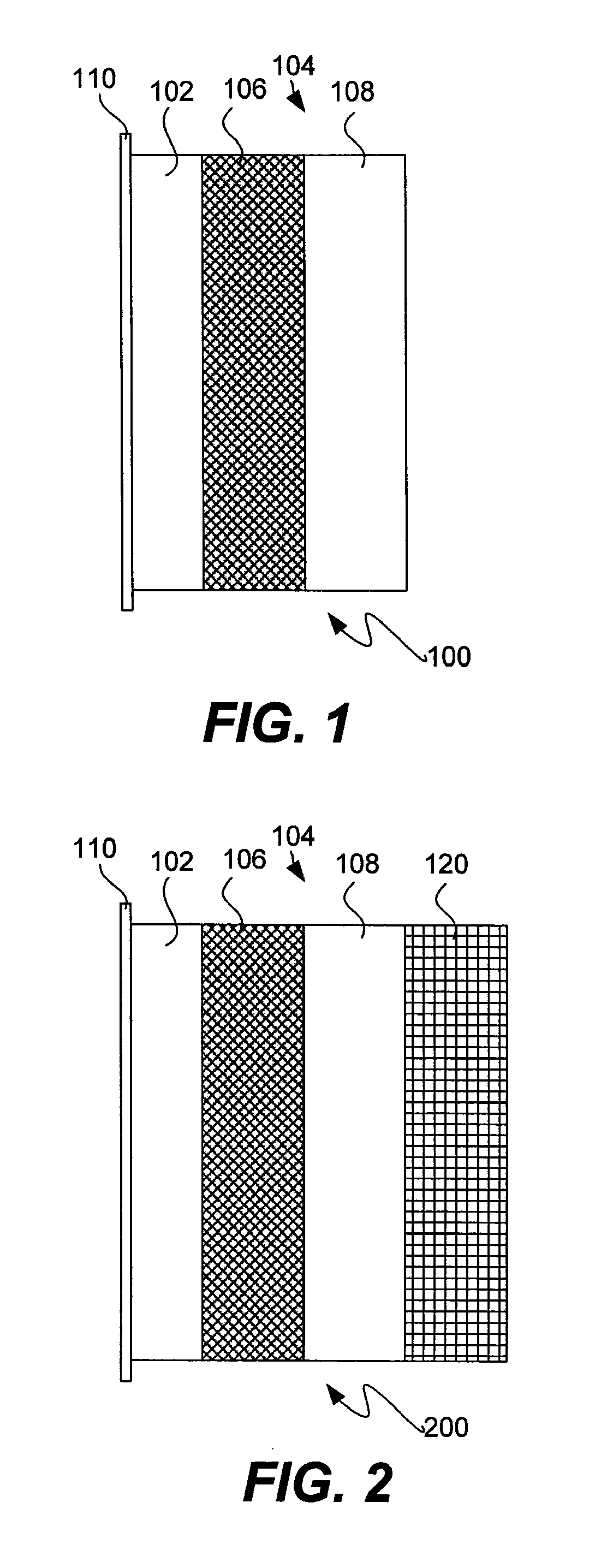

Protected active metal electrode and battery cell structures with non-aqueous interlayer architecture

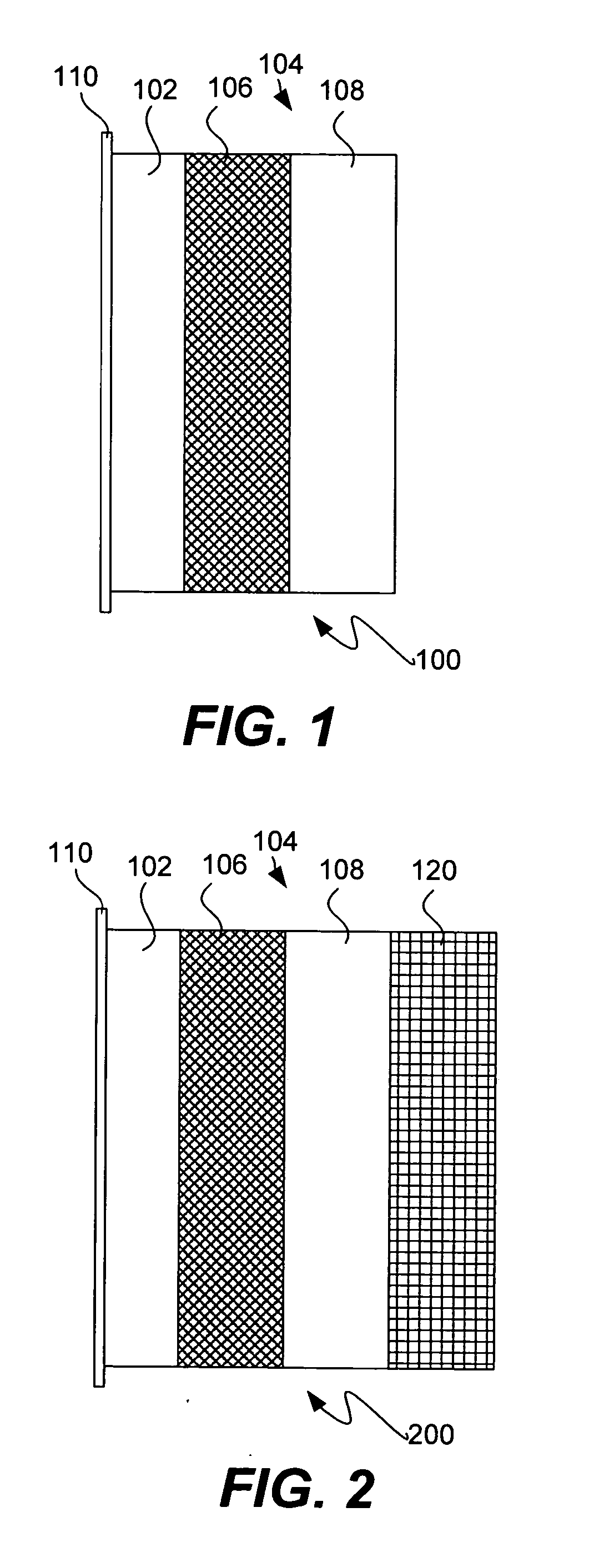

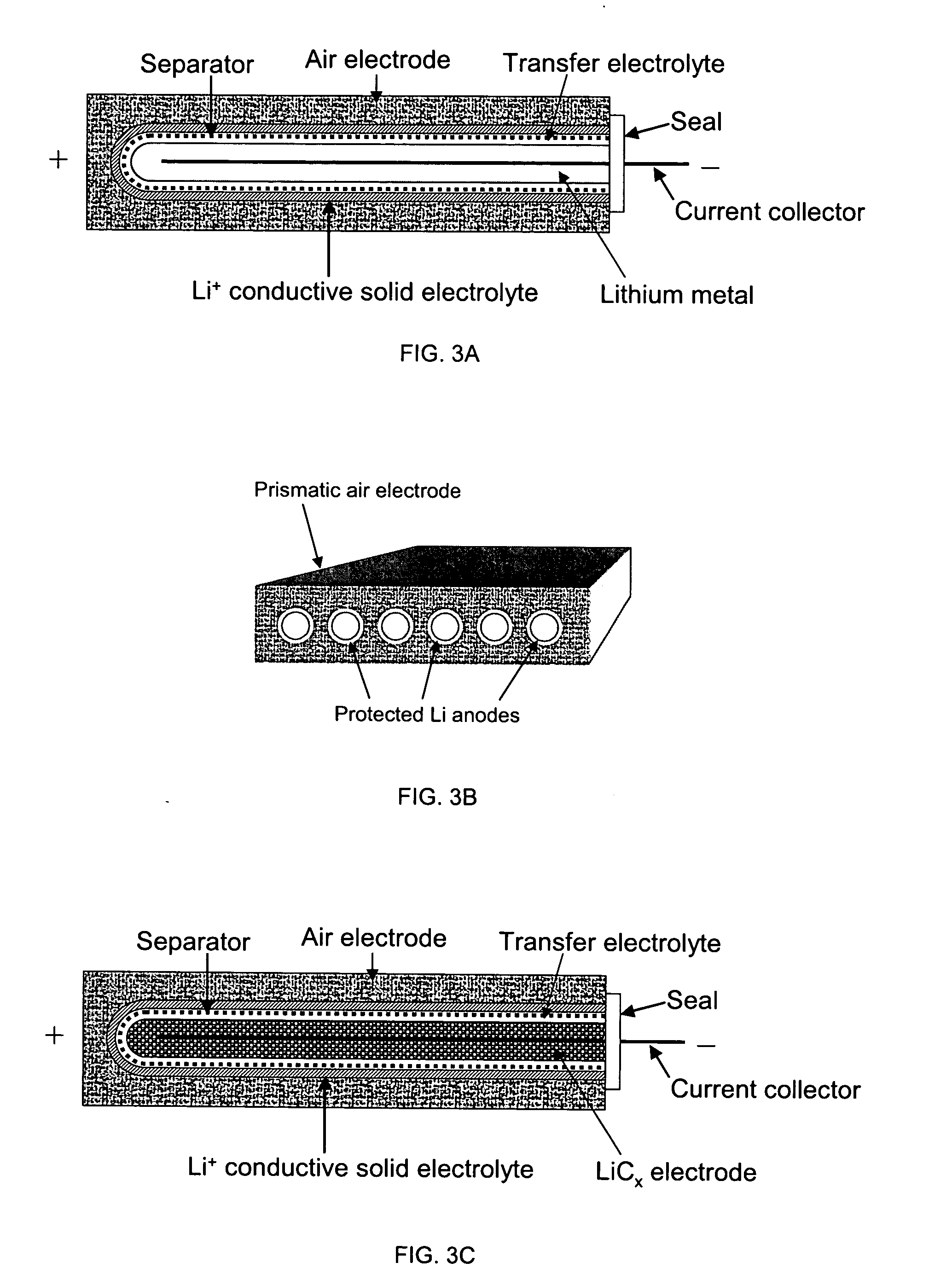

ActiveUS7282295B2Avoid harmful reactionsFinal product manufactureElectrode carriers/collectorsMetal electrodesBattery cell

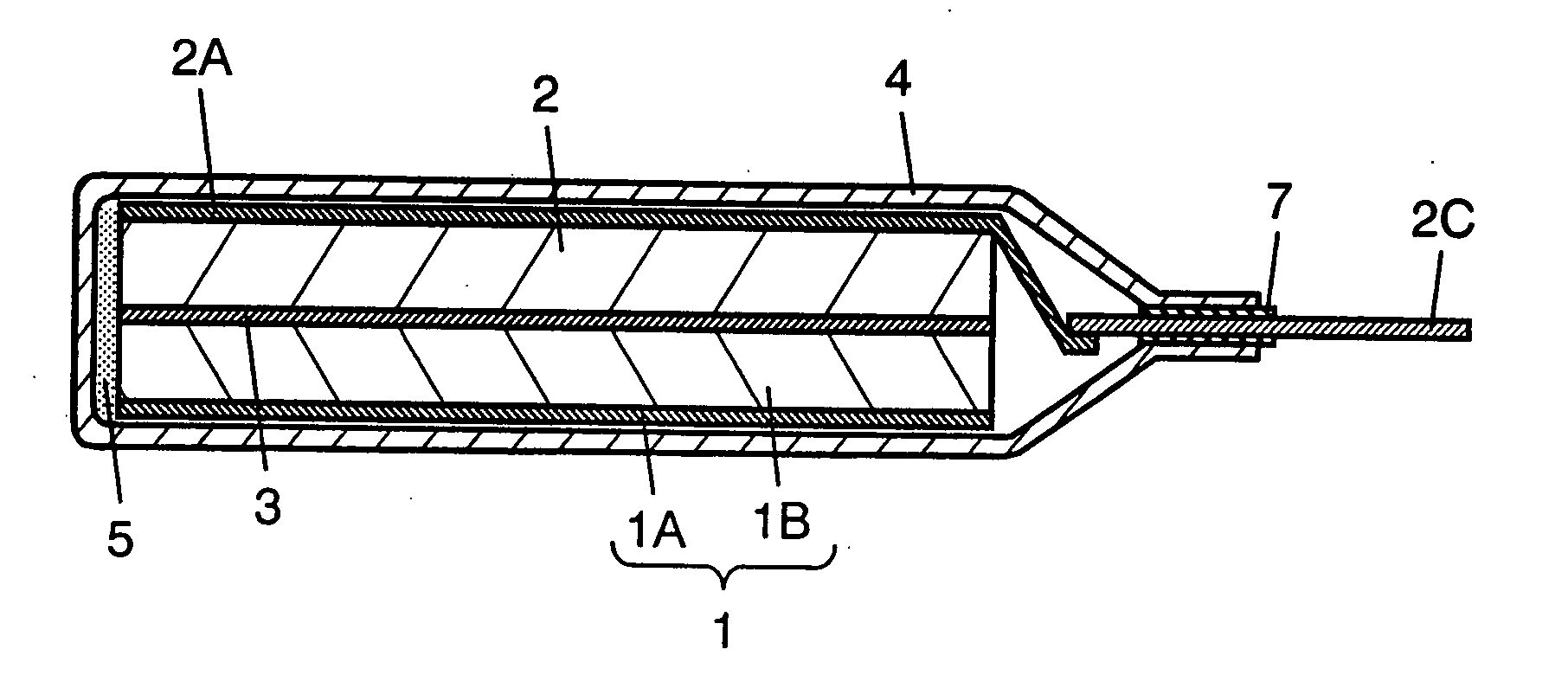

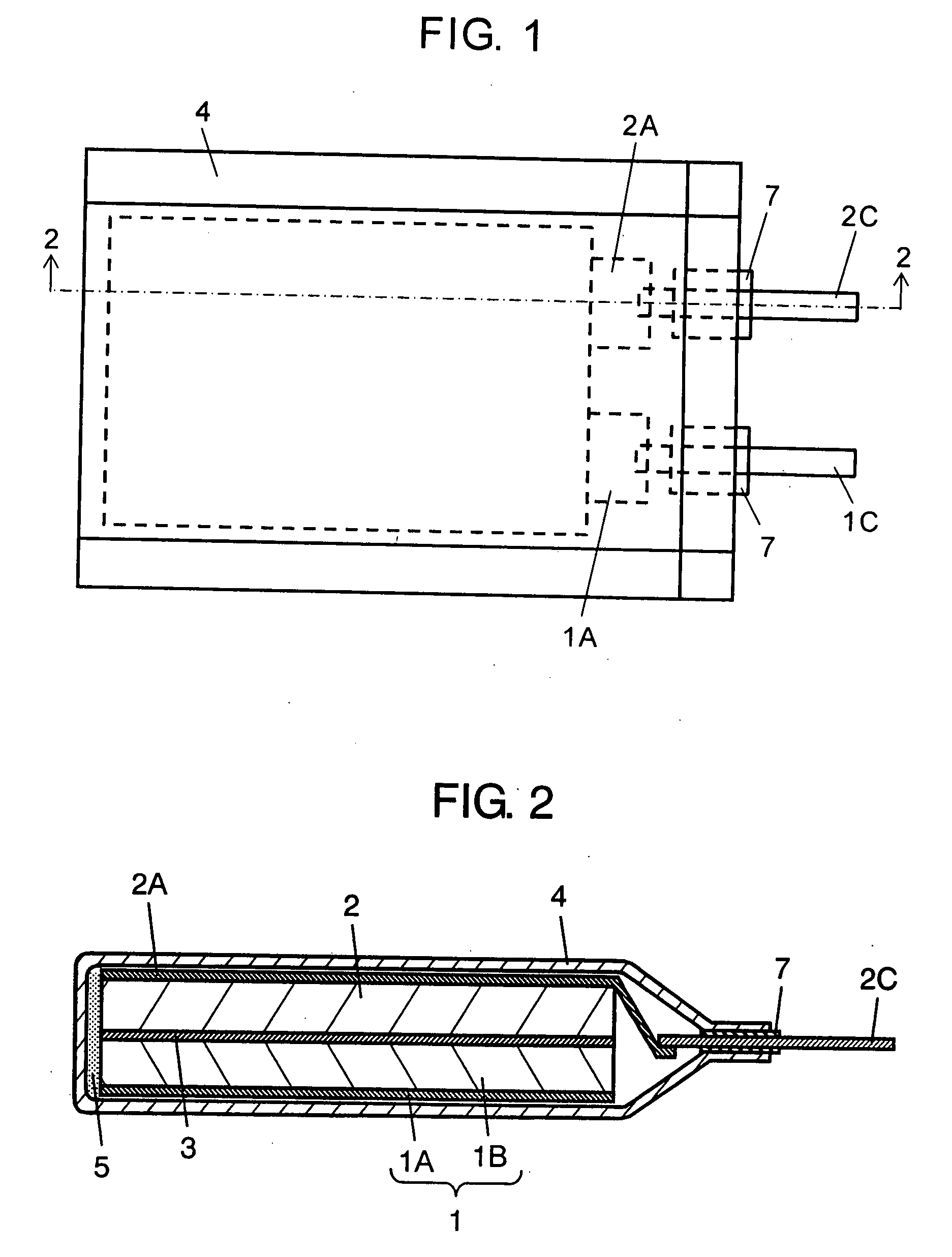

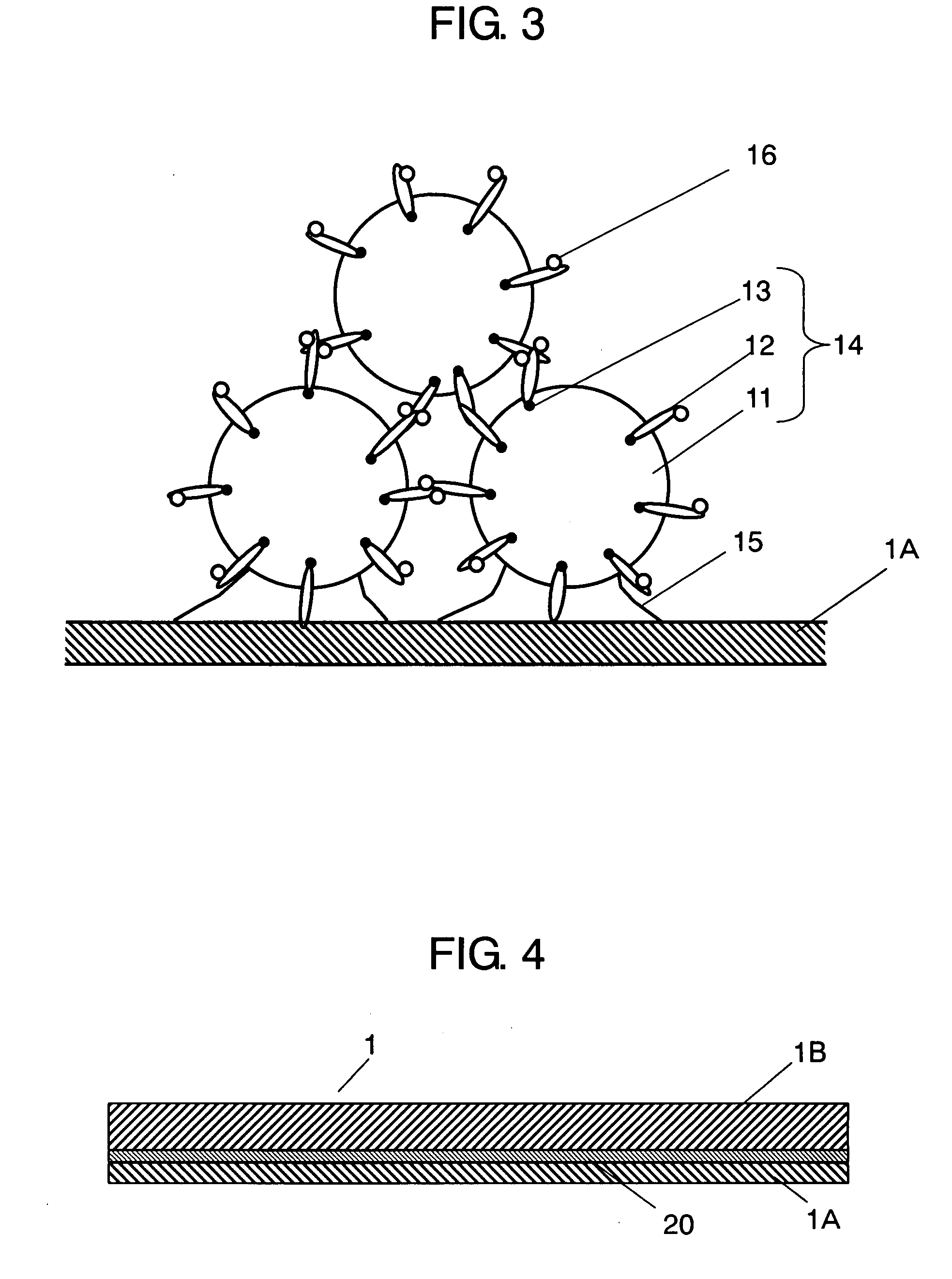

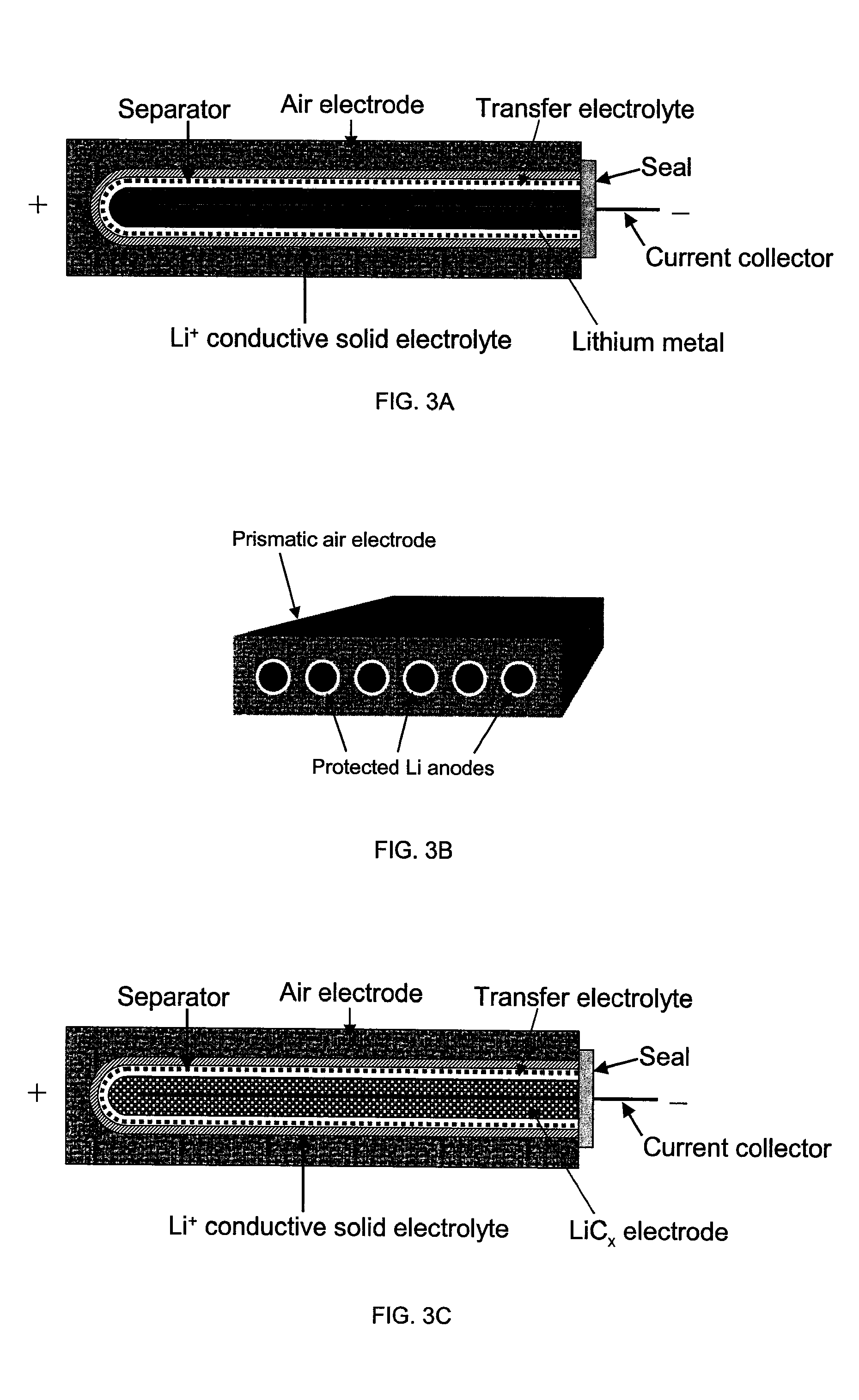

Active metal and active metal intercalation electrode structures and battery cells having ionically conductive protective architecture including an active metal (e.g., lithium) conductive impervious layer separated from the electrode (anode) by a porous separator impregnated with a non-aqueous electrolyte (anolyte). This protective architecture prevents the active metal from deleterious reaction with the environment on the other (cathode) side of the impervious layer, which may include aqueous or non-aqueous liquid electrolytes (catholytes) and / or a variety electrochemically active materials, including liquid, solid and gaseous oxidizers. Safety additives and designs that facilitate manufacture are also provided.

Owner:POLYPLUS BATTERY CO INC

Protected active metal electrode and battery cell structures with non-aqueous interlayer architecture

ActiveUS20050175894A1Avoid harmful reactionsHybrid capacitor separatorsHybrid capacitor electrolytesMetal electrodesBattery cell

Active metal and active metal intercalation electrode structures and battery cells having ionically conductive protective architecture including an active metal (e.g., lithium) conductive impervious layer separated from the electrode (anode) by a porous separator impregnated with a non-aqueous electrolyte (anolyte). This protective architecture prevents the active metal from deleterious reaction with the environment on the other (cathode) side of the impervious layer, which may include aqueous or non-aqueous liquid electrolytes (catholytes) and / or a variety electrochemically active materials, including liquid, solid and gaseous oxidizers. Safety additives and designs that facilitate manufacture are also provided.

Owner:POLYPLUS BATTERY CO INC

Non-aqueous electrolyte battery separator

InactiveUS6447958B1Improve securityHigh short-circuit temperatureFinal product manufactureLi-accumulatorsNitrogenPolymer

A non-aqueous electrolyte battery separator comprising a heat-resistant nitrogen-containing aromatic polymer and a ceramic powder.

Owner:SUMITOMO CHEM CO LTD

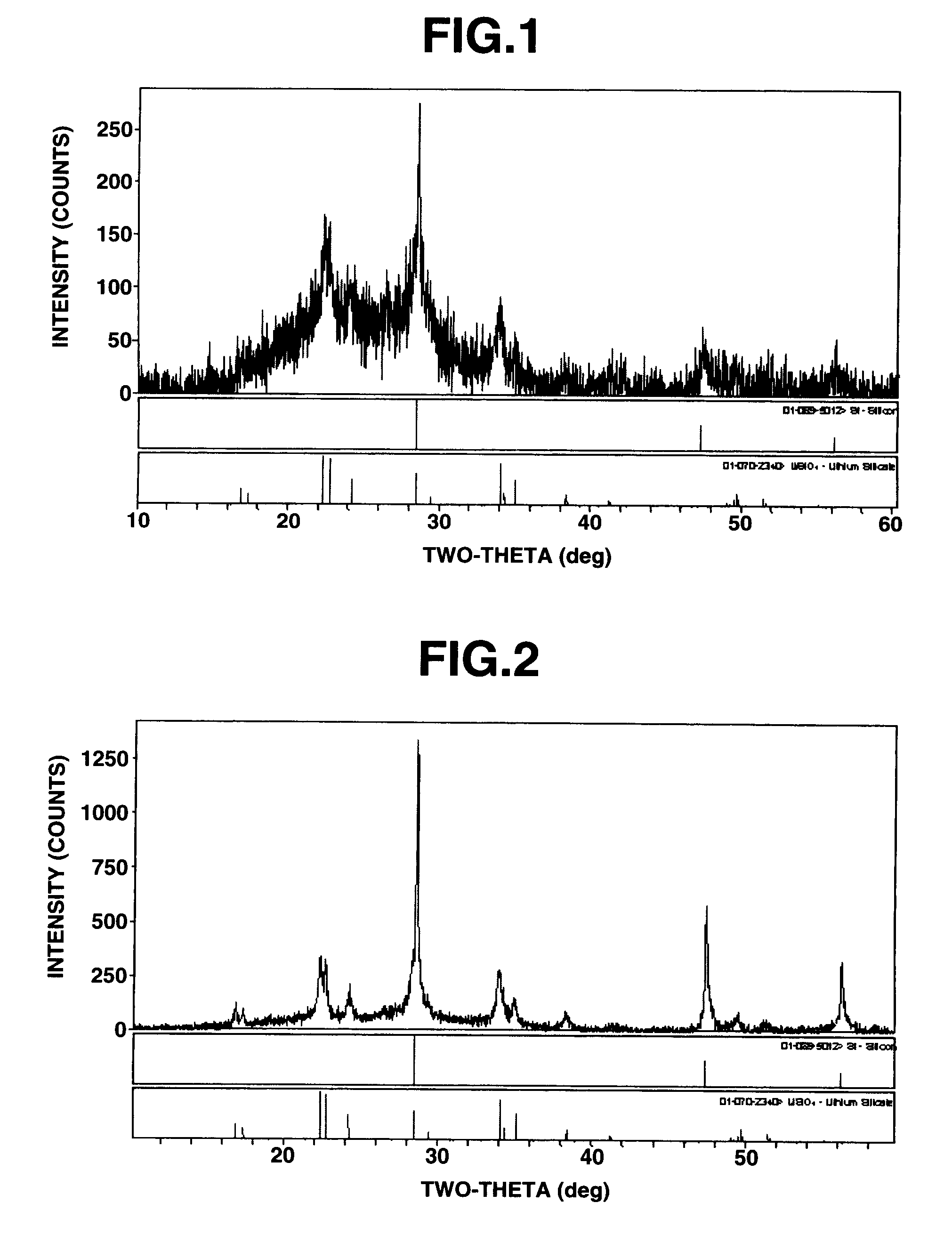

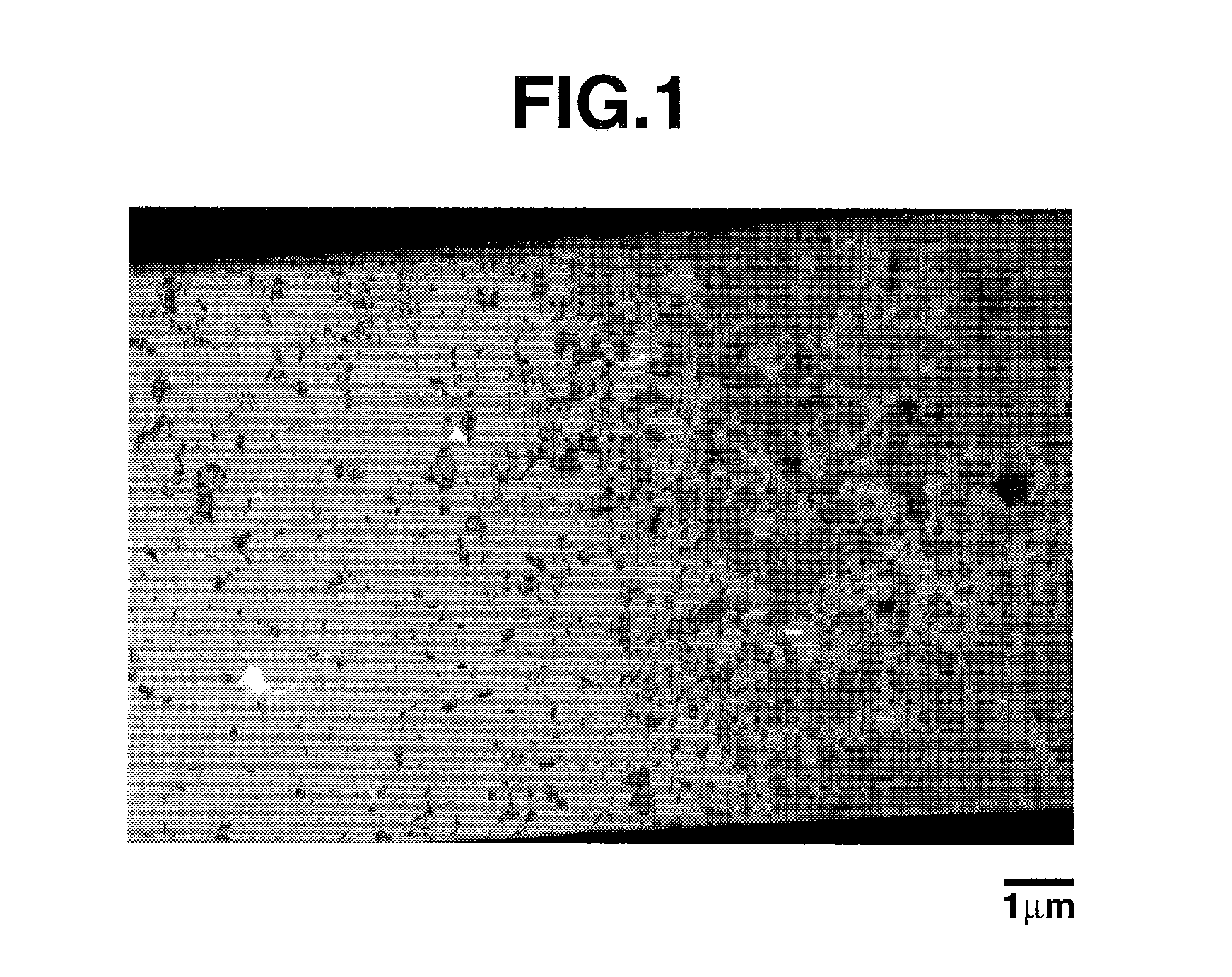

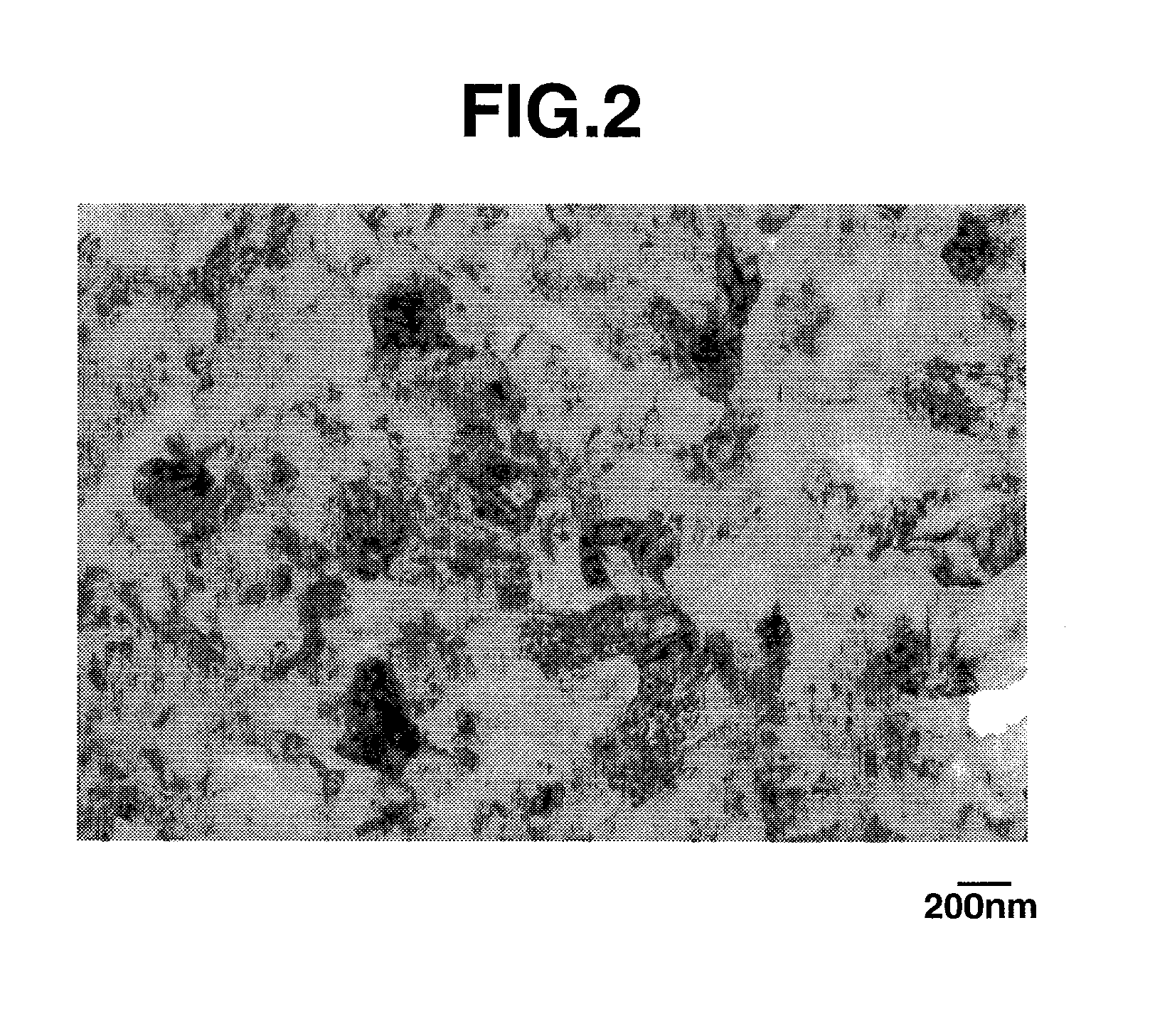

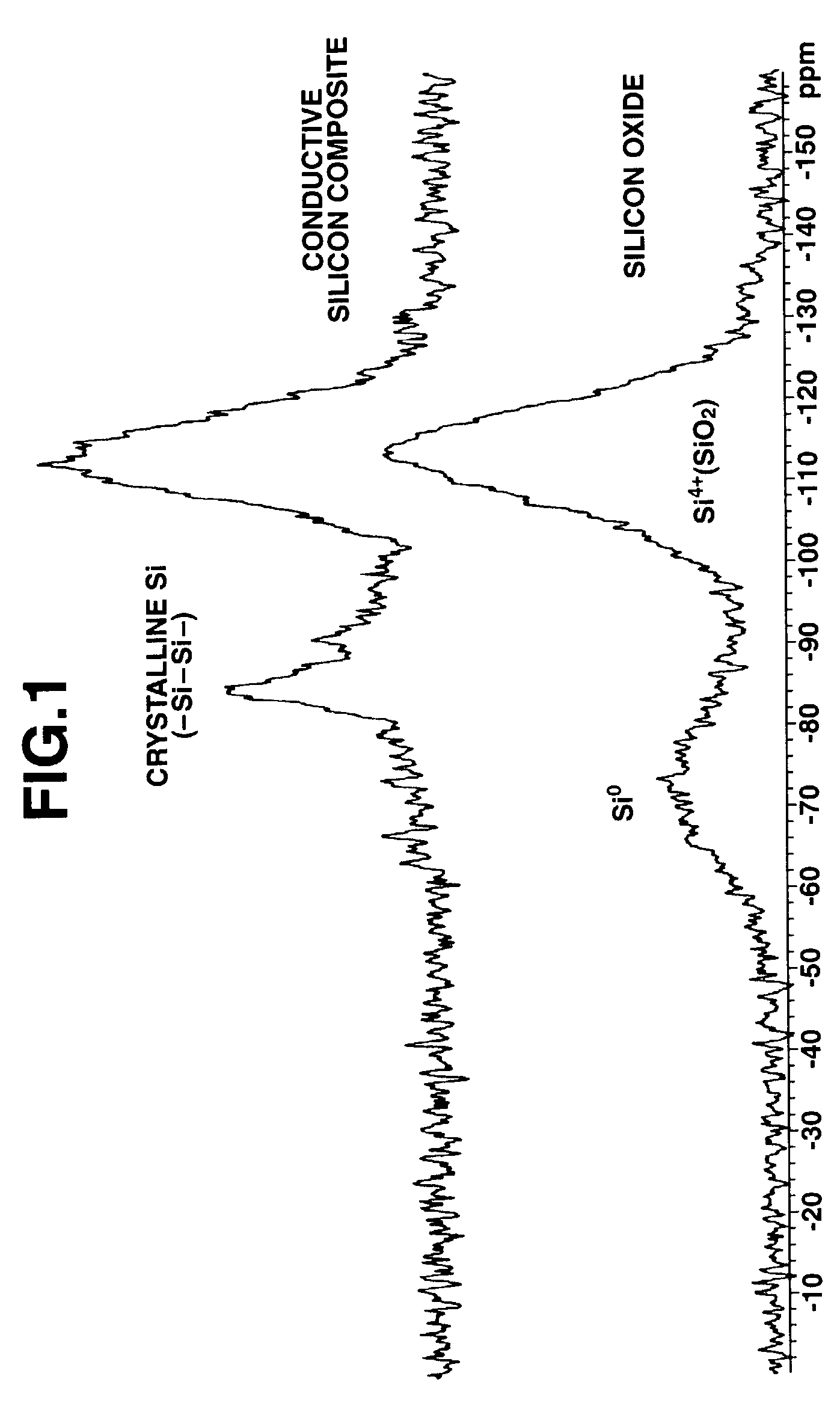

Silicon-silicon oxide-lithium composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

ActiveUS20070224508A1Improve initial efficiencyImprove cycle performanceSecondary cellsNegative electrodesOxide compositeSilicon oxide

A silicon-silicon oxide-lithium composite comprises a silicon-silicon oxide composite having such a structure that silicon grains having a size of 0.5-50 nm are dispersed in silicon oxide, the silicon-silicon oxide composite being doped with lithium. Using the silicon-silicon oxide-lithium composite as a negative electrode material, a lithium ion secondary cell having a high initial efficiency and improved cycle performance can be constructed.

Owner:SHIN ETSU CHEM IND CO LTD

Non-aqueous electrolyte secondary battery, negative electrode material, and making method

ActiveUS20090239151A1Improve cycle performanceImprove efficiencyNon-aqueous electrolyte accumulatorsActive material electrodesSilicon oxideSilicon particle

A negative electrode material comprising an active material and 1-20 wt % of a polyimide resin binder is suitable for use in non-aqueous electrolyte secondary batteries. The active material comprises silicon oxide particles and 1-50 wt % of silicon particles. The negative electrode exhibits improved cycle performance while maintaining the high battery capacity and low volume expansion of silicon oxide. The non-aqueous electrolyte secondary battery has a high initial efficiency and maintains improved performance and efficiency over repeated charge / discharge cycles by virtue of mitigated volumetric changes during charge / discharge cycles.

Owner:SHIN ETSU CHEM IND CO LTD

Negative electrode and non-aqueous electrolyte secondary battery using the same

InactiveUS20080096110A1Good charge and discharge cycle performanceImprove cycle performanceNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsPorous substrateConductive materials

The negative electrode for a non-aqueous electrolyte secondary battery of the present invention includes a conductive porous substrate, and a conductive material and an active material filled in pores of the porous substrate. The active material contains at least one of a metal element and a semi-metal element capable of reversibly absorbing and desorbing lithium.

Owner:PANASONIC CORP

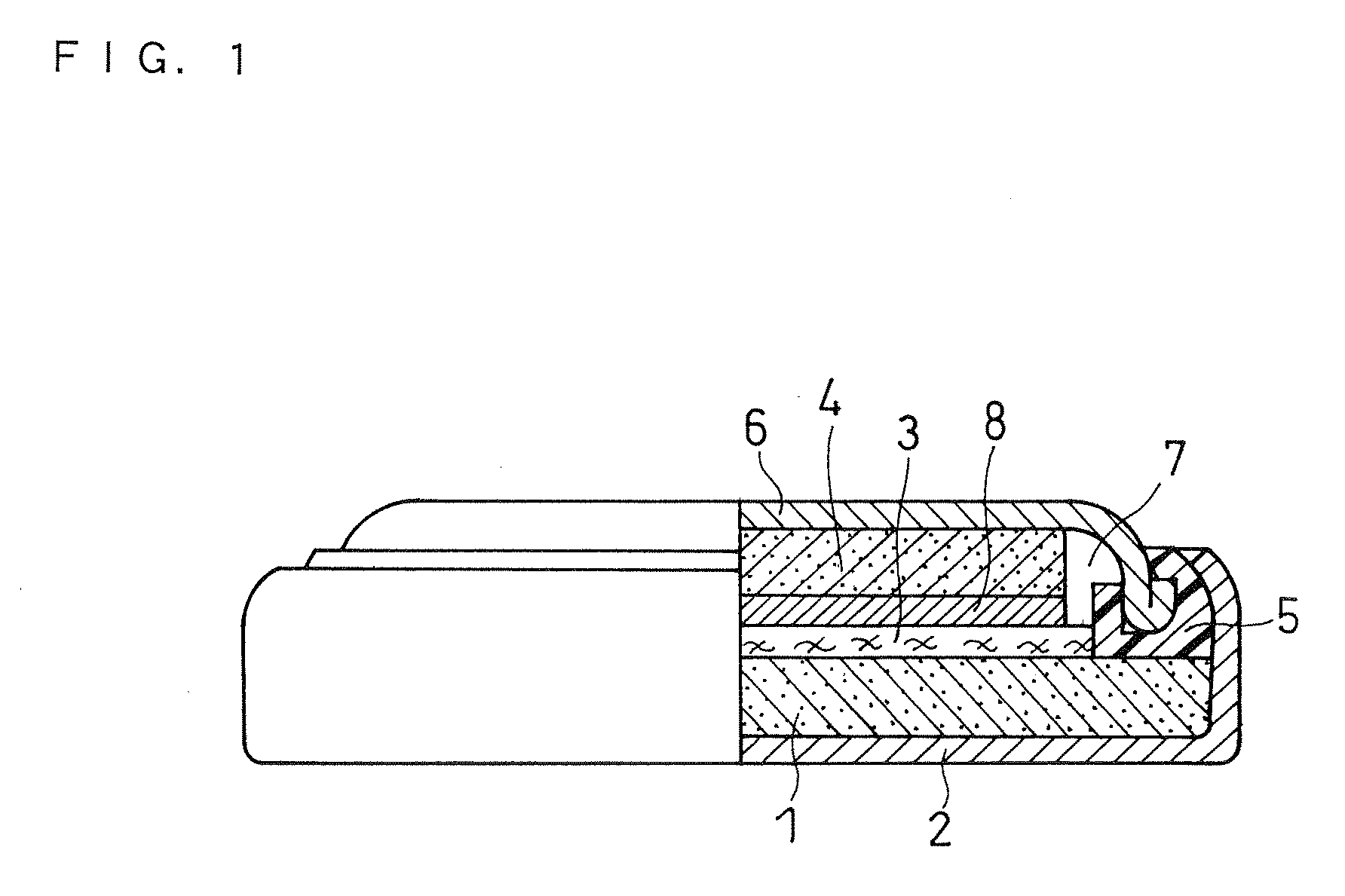

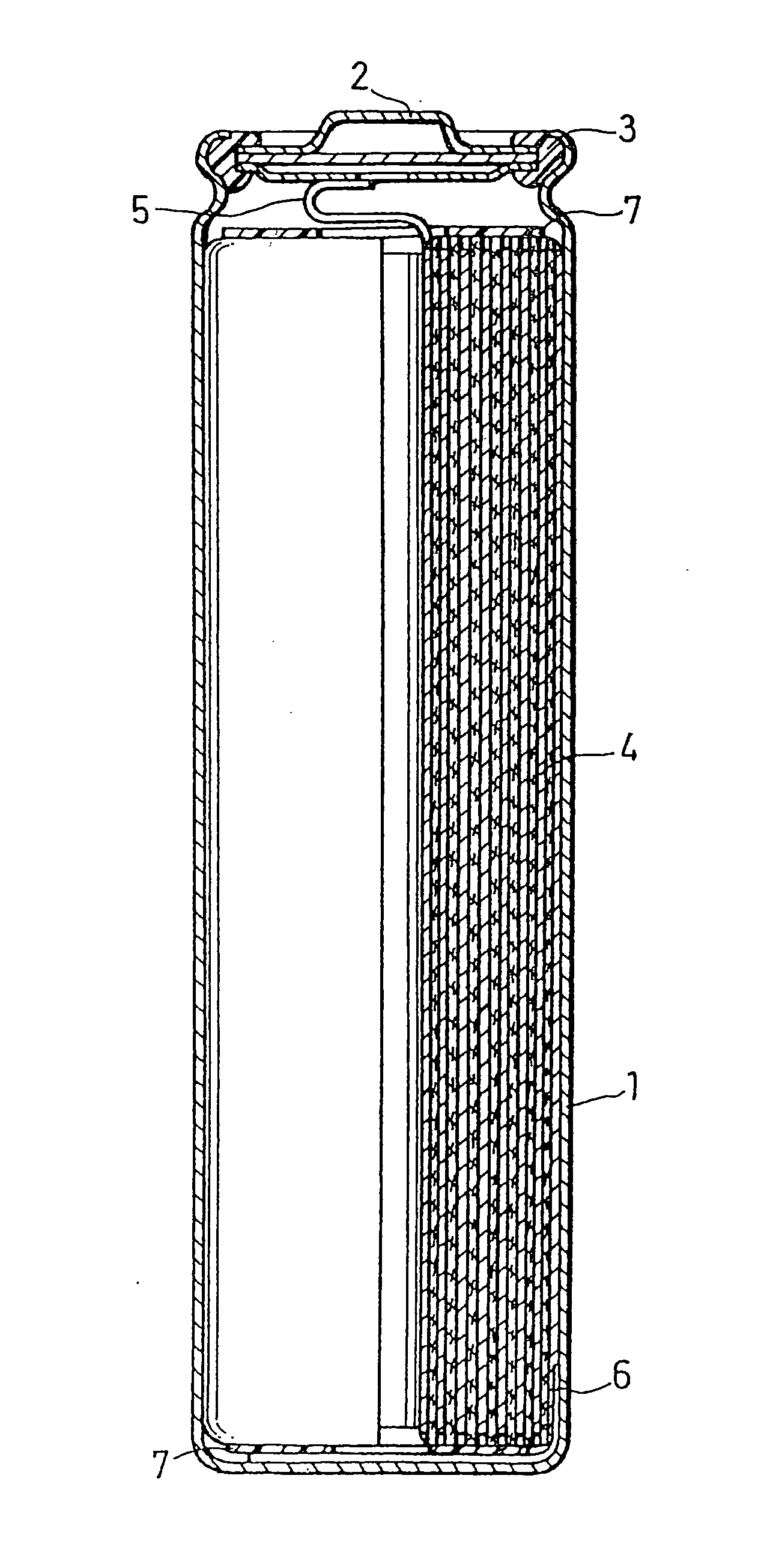

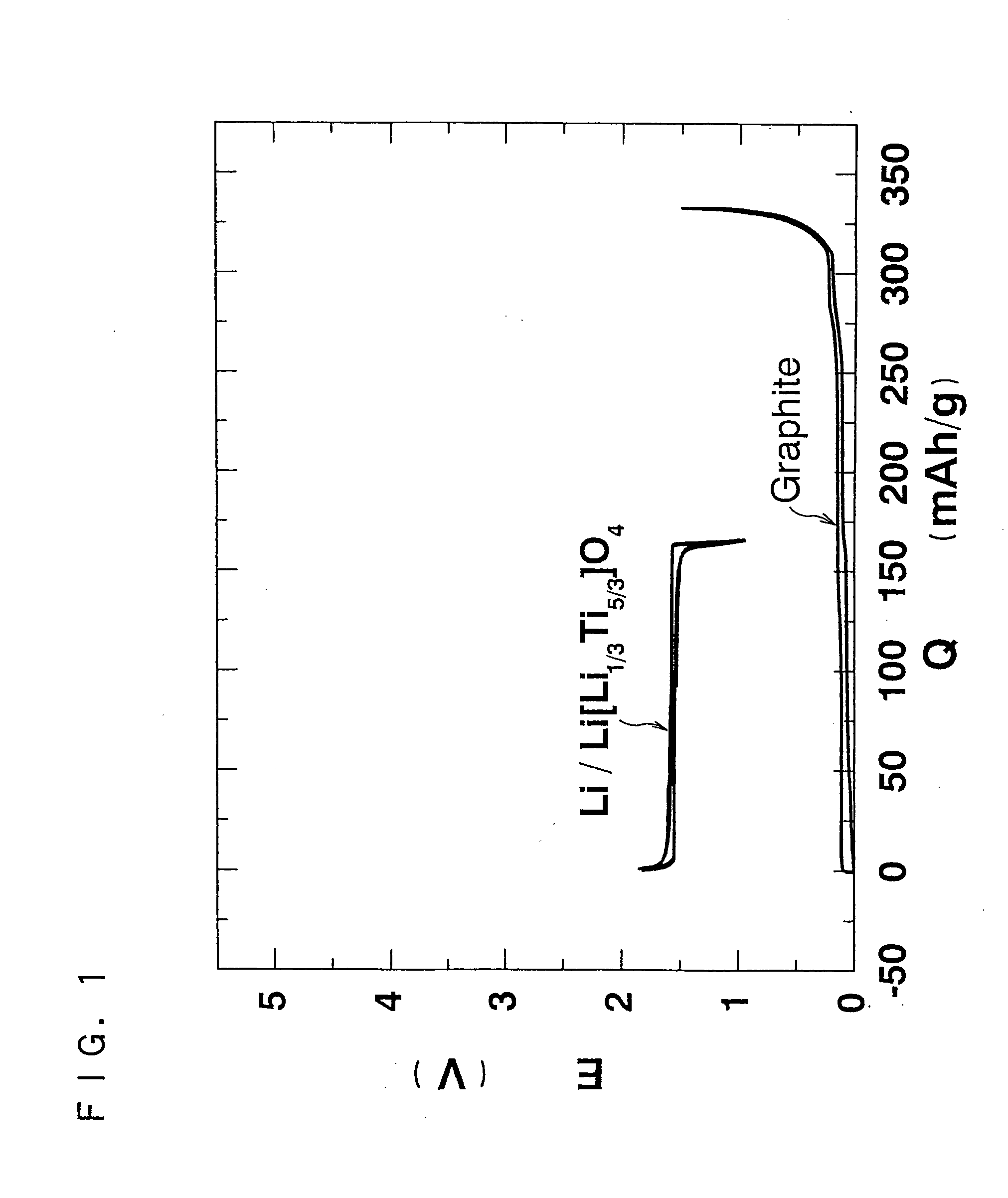

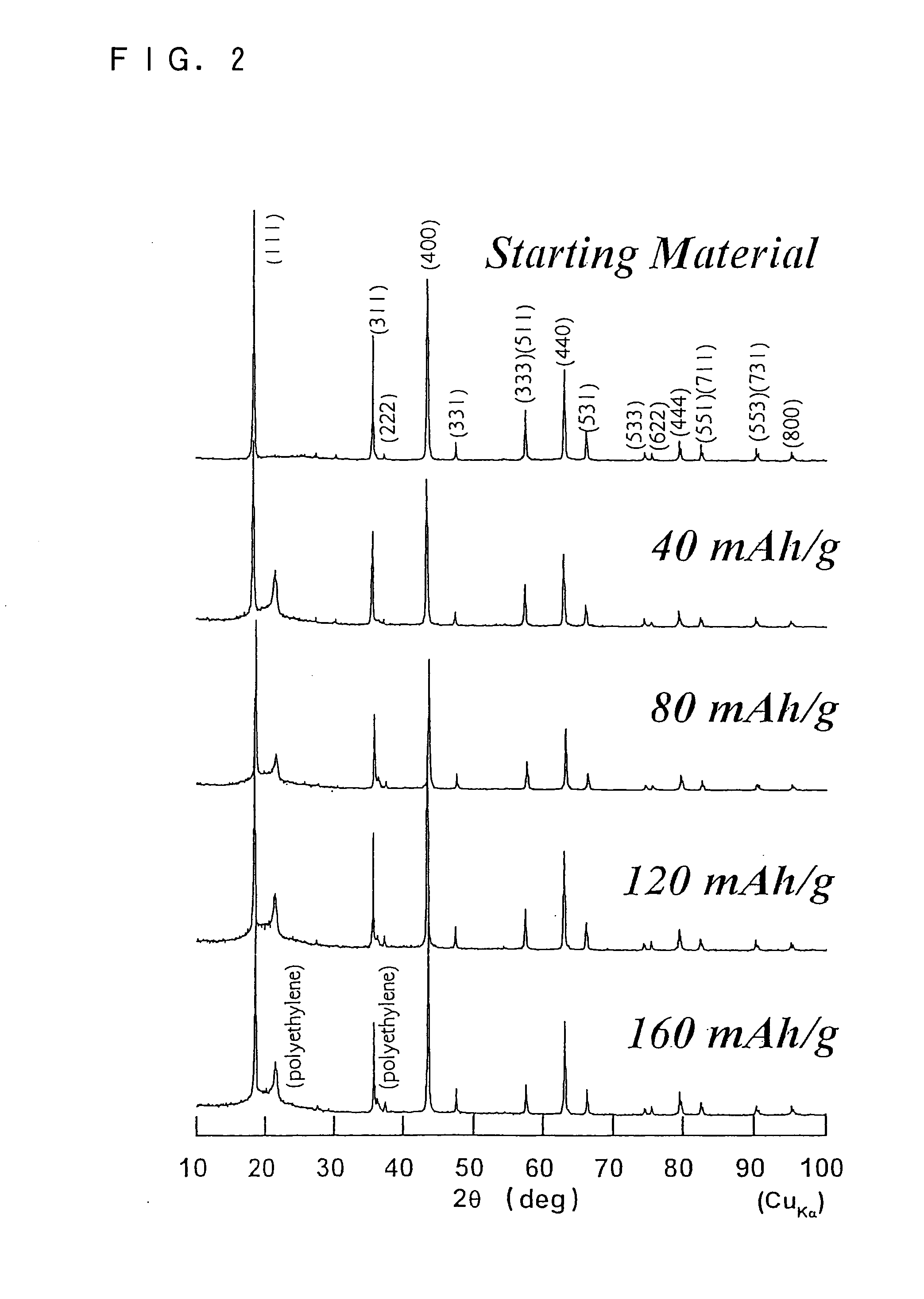

Non-aqueous electrolyte secondary battery

ActiveUS20050147889A1Reduce the possibilityIncrease resistanceFinal product manufactureElectrode carriers/collectorsHigh rateCobalt

As an alternative technique to lead-acid batteries, the present invention provides an inexpensive 2 V non-aqueous electrolyte secondary battery having excellent cycle life at a high rate by preventing volume change during charge and discharge. The non-aqueous electrolyte secondary battery uses: a positive electrode active material having a layered structure, being represented by chemical formula Li1±α[Me]O2, where 0≦α<0.2, and Me is a transition metal including Ni and at least one selected from the group consisting of Mn, Fe, Co, Ti and Cu, and including elemental nickel and elemental cobalt in substantially the same ratio; and a negative electrode active material including Li4Ti5O12(Li[Li1 / 3Ti5 / 3]O4).

Owner:OSAKA CITY UNIV +1

Silicon composite particles, preparation thereof, and negative electrode material for non-aqueous electrolyte secondary cell

ActiveUS20050214644A1Improve cycle performanceMinimize changesSilicaNitrogen compoundsSilicon alloyInorganic compound

Silicon composite particles are prepared by sintering primary fine particles of silicon, silicon alloy or silicon oxide together with an organosilicon compound. Sintering of the organosilicon compound results in a silicon-base inorganic compound which serves as a binder. Each particle has the structure that silicon or silicon alloy fine particles are dispersed in the silicon-base inorganic compound binder, and voids are present within the particle.

Owner:SHIN ETSU CHEM IND CO LTD

Lithium secondary battery

InactiveUS20090087731A1Improve charge-discharge cycle performanceCell electrodesSecondary cellsSilicon alloyComposite oxide

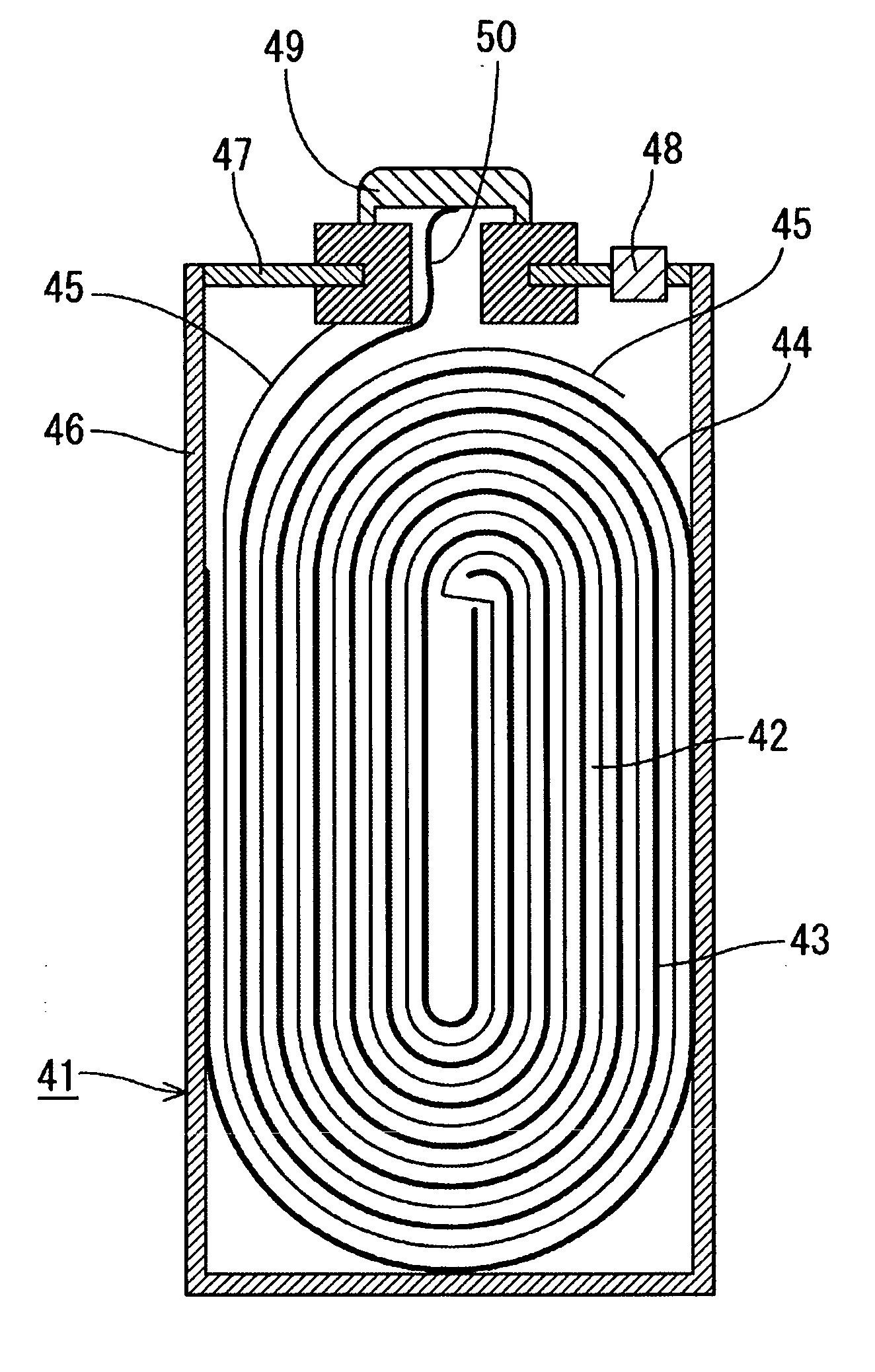

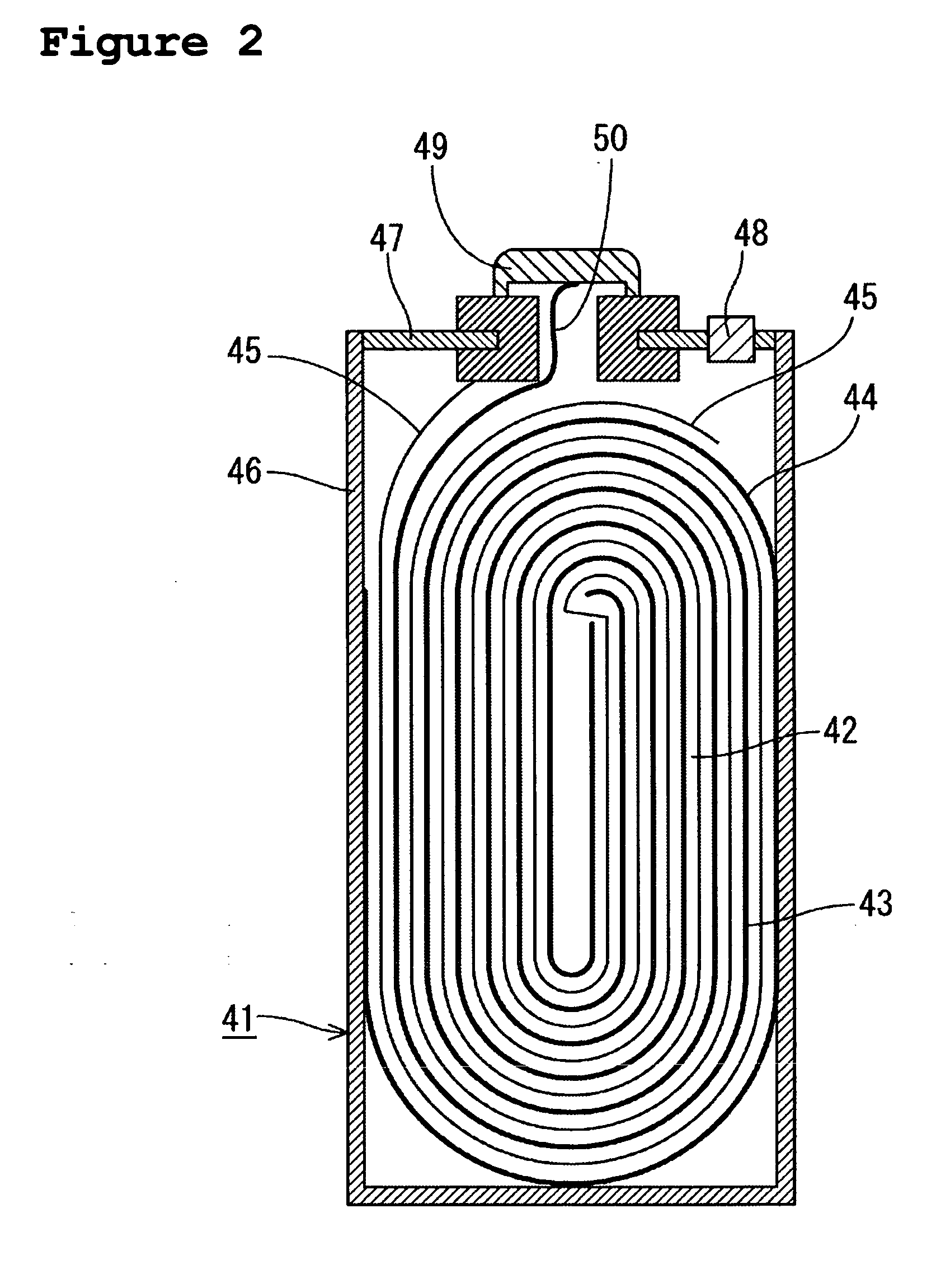

A lithium secondary battery includes: a positive electrode having a positive electrode active material layer disposed on a positive electrode current collector, the positive electrode active material layer containing a positive electrode binder and a positive electrode active material containing a layered lithium-transition metal composite oxide; a negative electrode having a negative electrode current collector and a negative electrode active material layer disposed on the negative electrode current collector, the negative electrode active material layer containing a negative electrode binder and a negative electrode active material containing particles of silicon and / or a silicon alloy; and a non-aqueous electrolyte. Al2O3 particles are firmly adhered to a surface of the lithium-transition metal composite oxide so that a BET specific surface area of the positive electrode active material after the adherence of the Al2O3 particles is from 1.5 times to 8 times greater than that before the adherence of the Al2O3 particles

Owner:SANYO ELECTRIC CO LTD

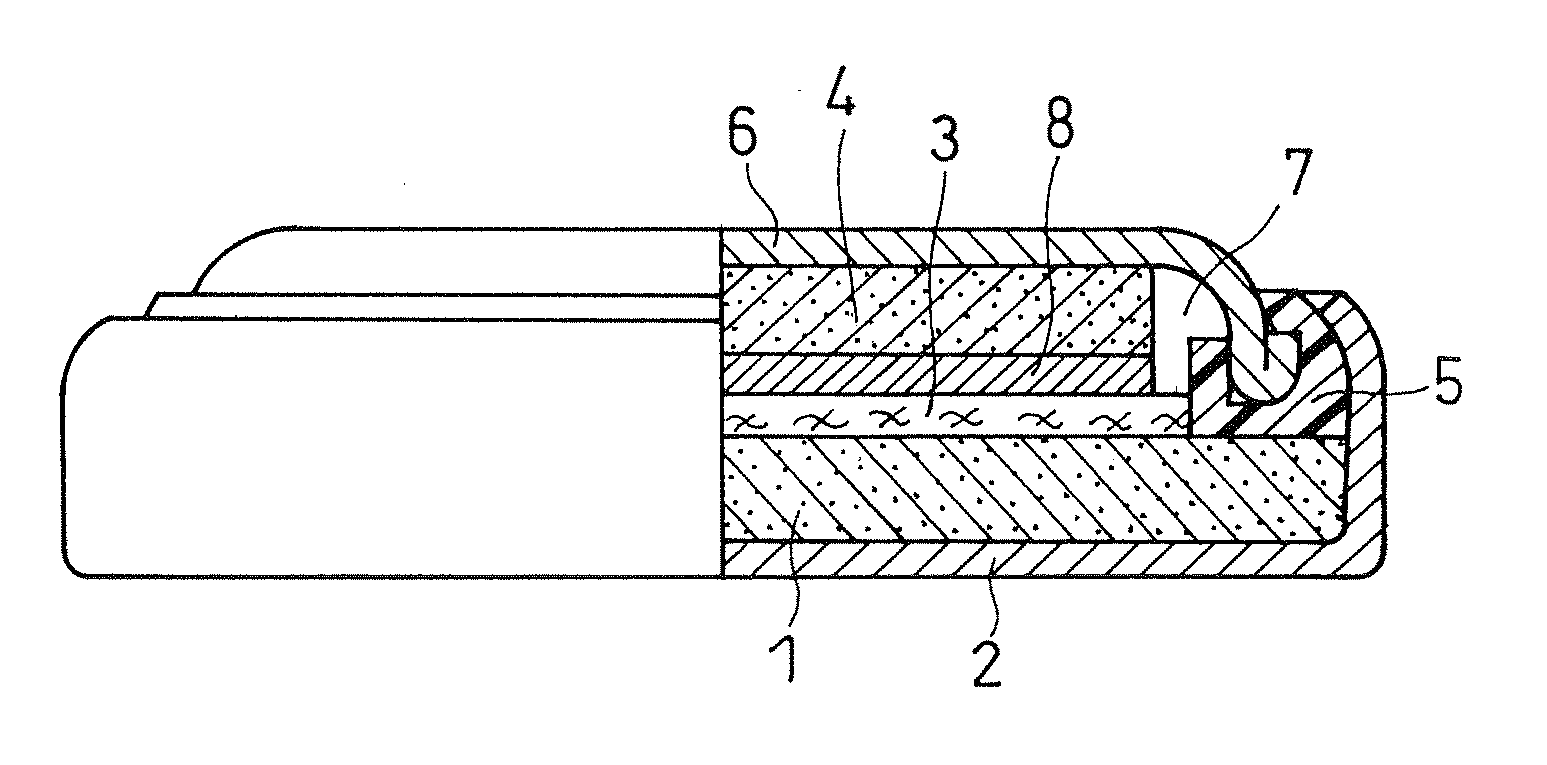

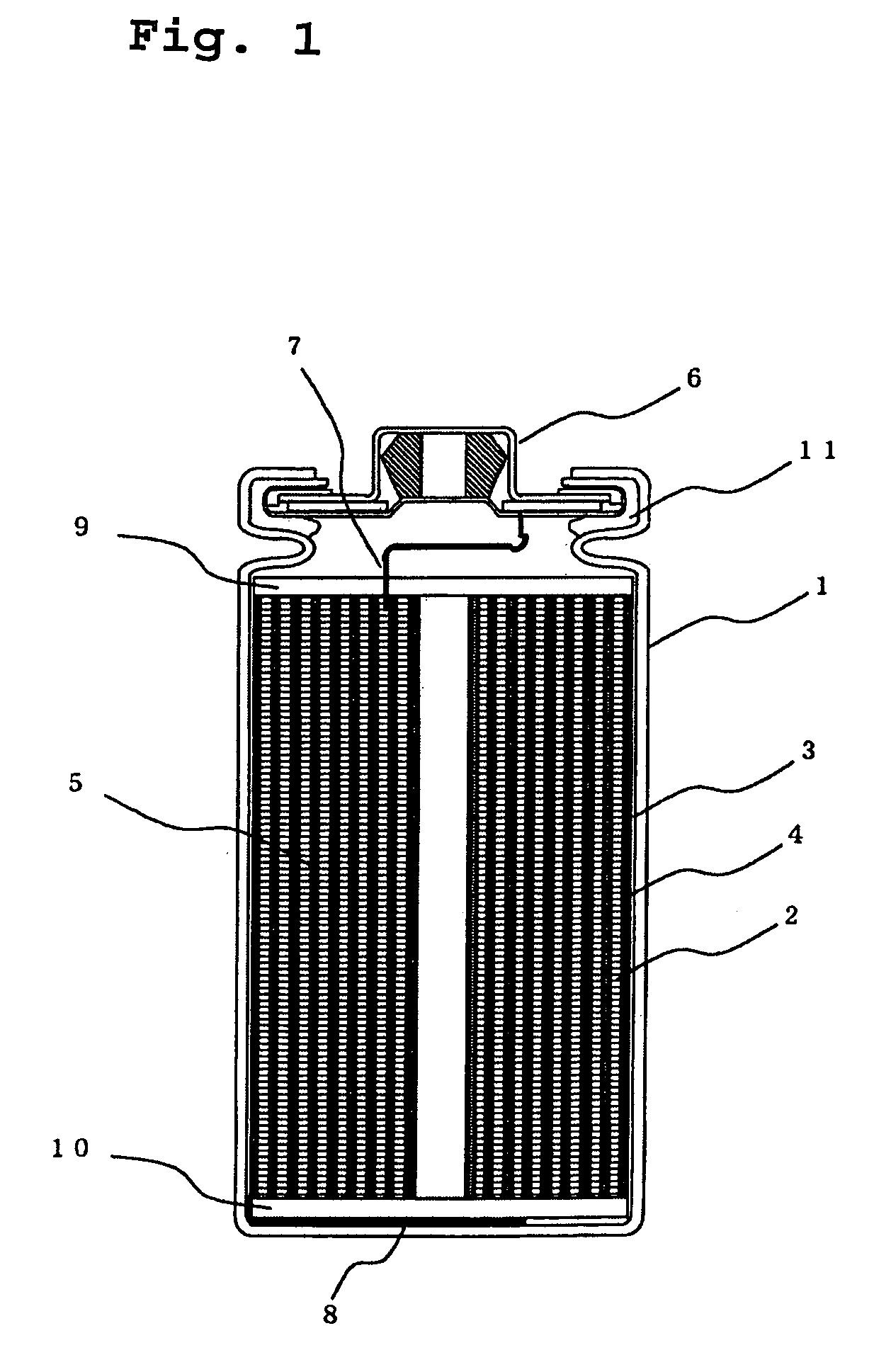

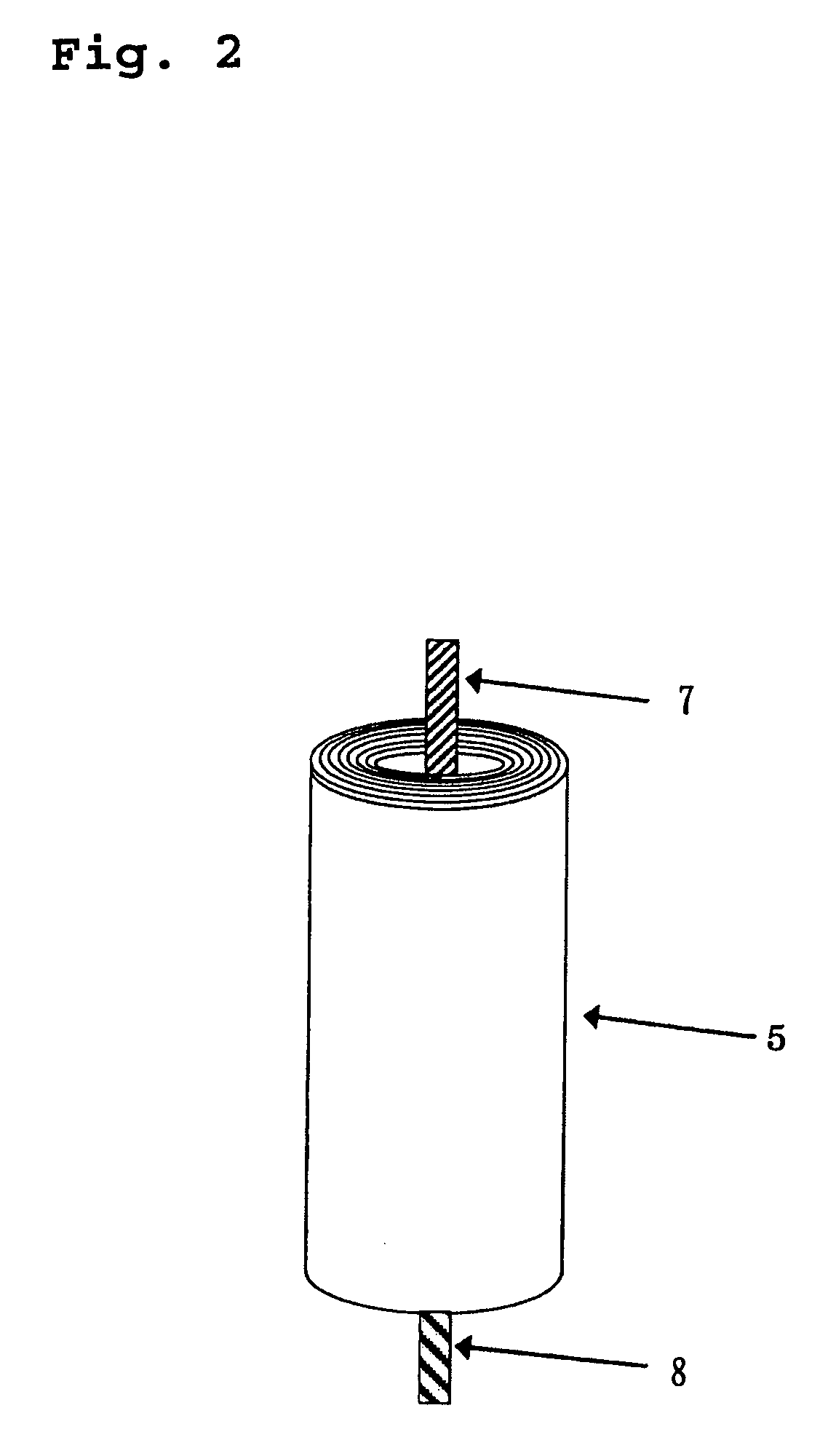

Battery and non-aqueous electrolyte secondary battery using the same

InactiveUS20050064291A1Increase energy densityExcellent cycle characteristicsElectrode carriers/collectorsNegative electrodesEngineeringNon aqueous electrolytes

A negative electrode for a non-aqueous electrolyte secondary battery including a current collector, and an electrode material layer including an electrode material capable of reversibly absorbing and desorbing Li ions is provided. The electrode material includes at least one element selected from the group consisting of Si, Sn and Al; the surface of the current collector is provided with protrusions; the electrode material layer is disposed on the surfaces of the current collector and the protrusions; and the protrusion has a portion facing the surface of the current collector other than a portion that is brought into contact with the current collector. Thus, a negative electrode for a non-aqueous electrolyte battery having high properties such as an energy density, charging / discharging cycle property, and the like, and a non-aqueous electrolyte secondary battery can be provided.

Owner:PANASONIC CORP

Separator for nonaqueous electrolyte batteries, nonaqueous electrolyte battery using it, and method for manufacturing separator for nonaqueous electrolyte batteries

InactiveUS6511774B1High tear strengthEnhanced penetration strengthNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersHigh energyEngineering

The present invention provides a separator for non-aqueous electrolyte batteries which neither breaks nor slips off at the time of fabrication of battery, gives excellent battery fabricability, causes no internal short-circuit caused by contact between electrodes even if the electrodes are externally short-circuited, can inhibit ignition of battery and produces high energy density and excellent cycle life, and further provides a non-aqueous electrolyte battery using the separator and a method for manufacturing the separator. That is, the present invention relates to a separator for non-aqueous electrolyte batteries which comprises a porous base containing at least one member selected from a porous film, a woven fabric or nonwoven fabric containing an organic fiber and a paper and an organometallic compound applied to the porous base; a method for the manufacture of the separator for non-aqueous electrolyte batteries which comprises allowing said porous base to contact with a solution of organometallic compound by impregnation, coating or spraying, followed by drying or curing with heating to apply the organometallic compound to the porous base; and a non-aqueous electrolyte battery using the separator.

Owner:MITSUBISHI PAPER MILLS LTD

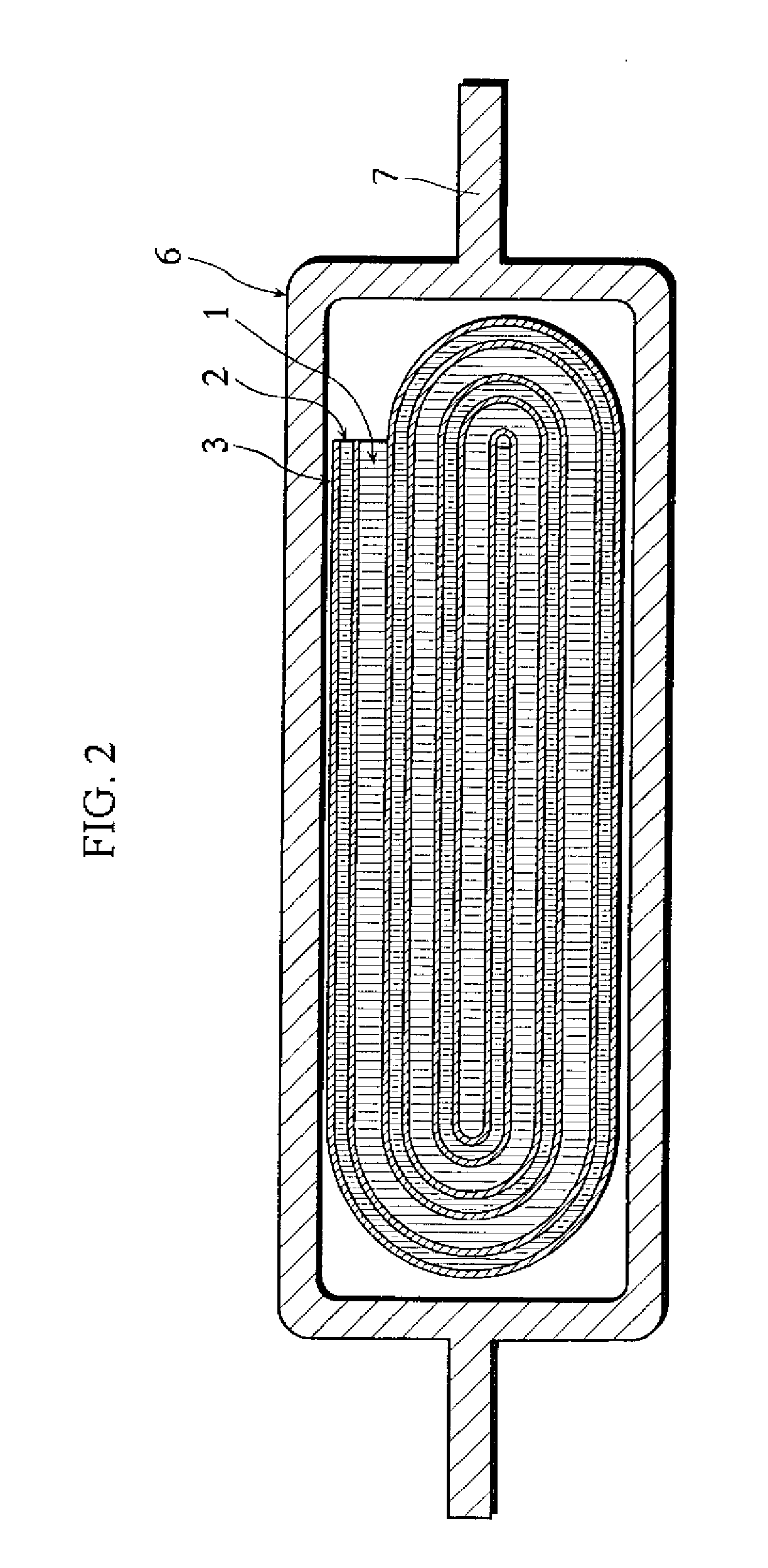

Nonaqueous electrolyte secondary cell

ActiveUS20060166098A1Improve cycle performanceImprove cycle lifeSecondary cellsNegative electrodesSiliconMaterials science

The present invention provides a non-aqueous electrolyte secondary battery comprising a positive electrode, a negative electrode having a negative active material, and a non-aqueous electrolyte; characterized in that said negative active material contains composite particle (C), which has silicon-containing particle (A) and electronic conductive additive (B), and carbon material (D), wherein the weight of said electronic conductive additive (B) falls within the range of 0.5 wt. % to 60 wt. % to the weight of said composite particle (C). The negative active material contains silicon which is capable of performing high discharge capacity, so that a non-aqueous electrolyte secondary battery having a large discharge capacity can be obtained. In addition, since the negative active material contains the electronic conductive additive (B) and the carbon material (D), the contact conductivity between the silicon-containing particle (A) or between the negative active material improves and, as a result, a non-aqueous electrolyte secondary battery having satisfactory cycle performance can be attained.

Owner:GS YUASA INT LTD

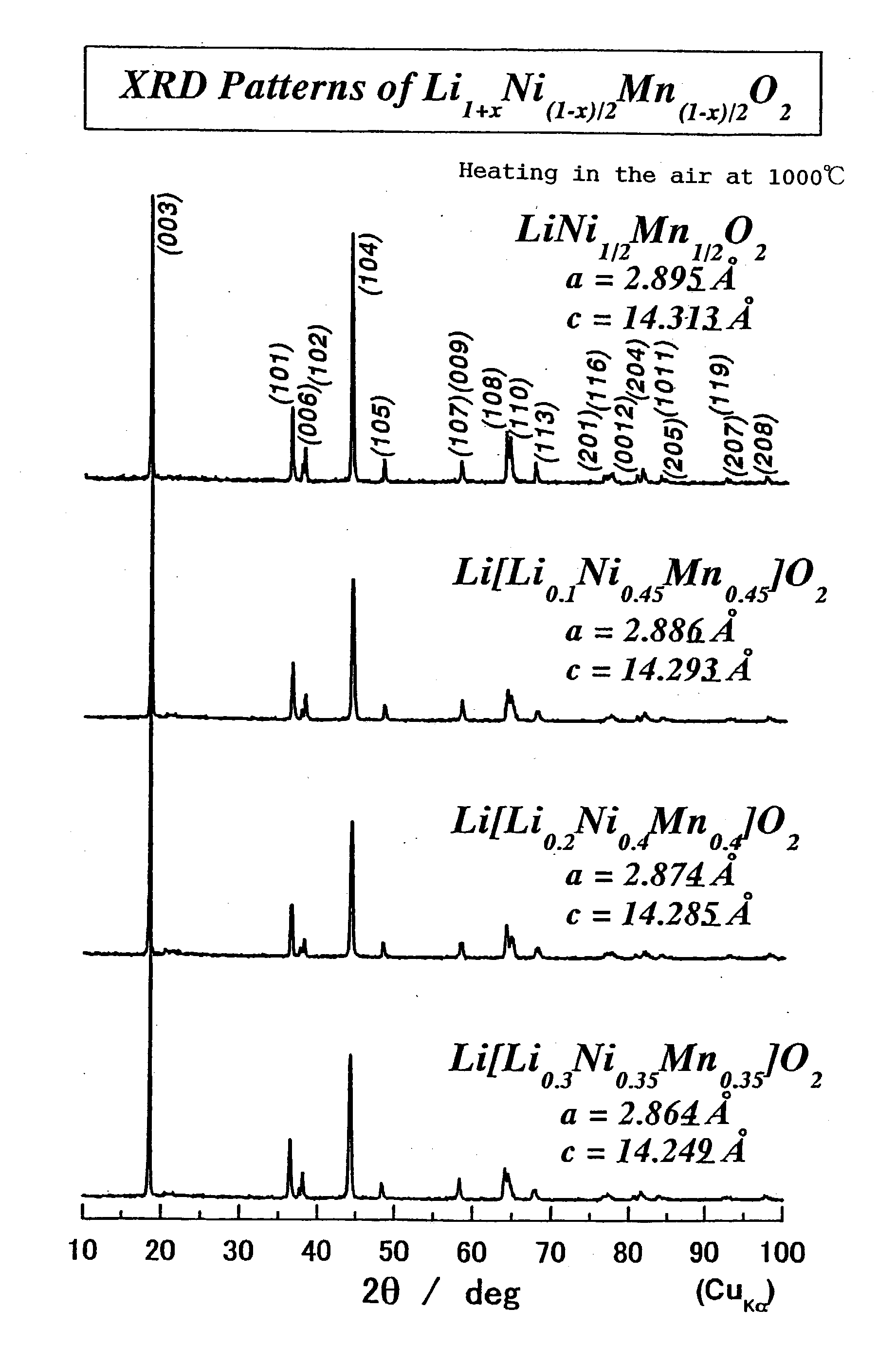

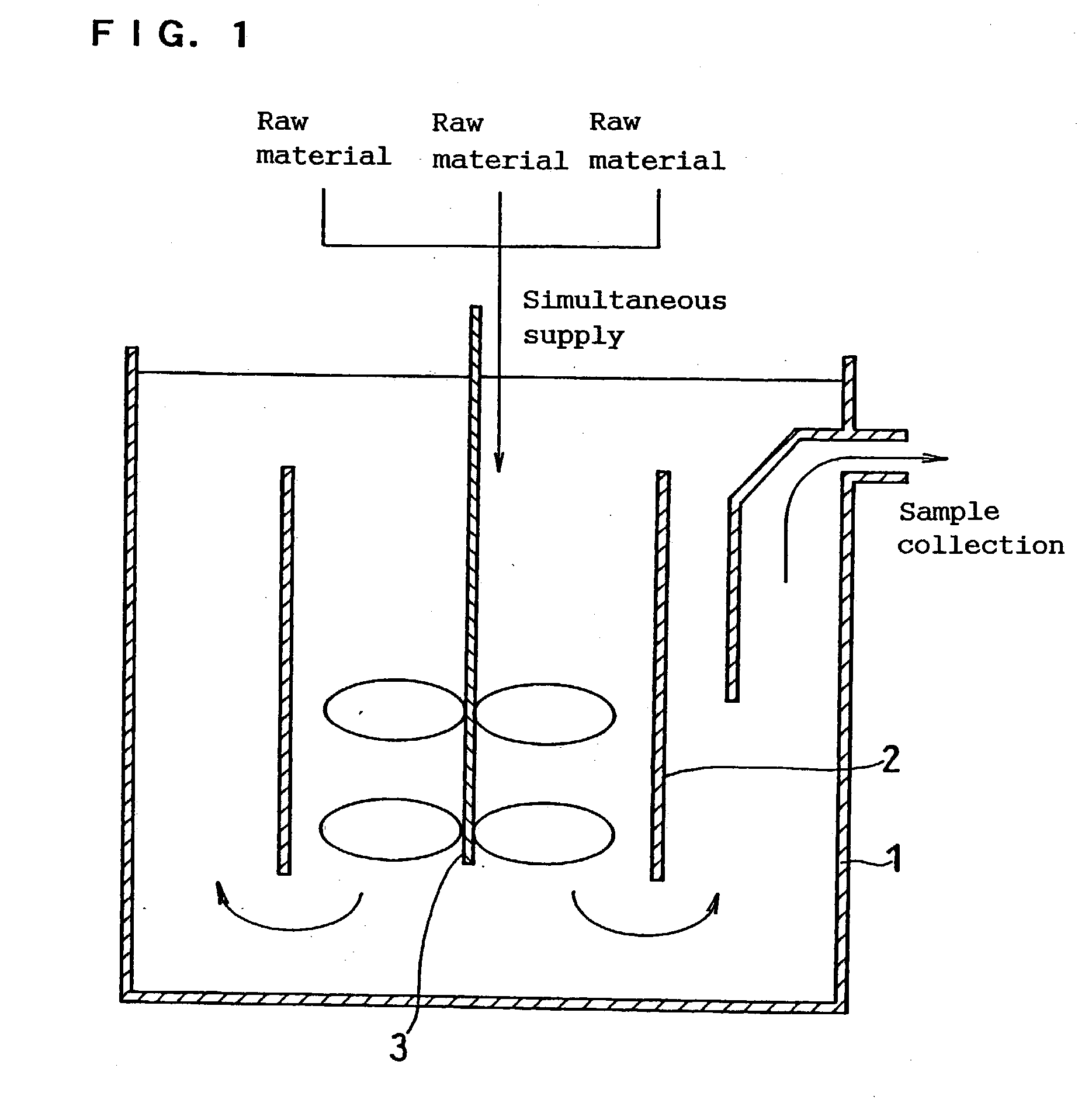

Positive-electrode active material and nonaqueous-electrolyte secondary battery containing the same

InactiveUS20030170540A1Improve the immunityLarge ion permeabilityIron oxides/hydroxidesElectrode thermal treatmentCrystal structureOxygen

The present invention provides a high-capacity and low-cost non-aqueous electrolyte secondary battery, comprising: a negative electrode containing, as a negative electrode active material, a ssubstance capable of absorbing / desorbing lithium ions and / or metal lithium; a separator; a positive electrode; and an electrolyte, wherein the positive electrode active material contained in the positive electrode is composed of crystalline particles of an oxide containing two kinds of transition metal elements, the crystalline particles having a layered crystal structure, and oxygen atoms constituting the oxide forming a cubic closest packing structure.

Owner:PANASONIC CORP +1

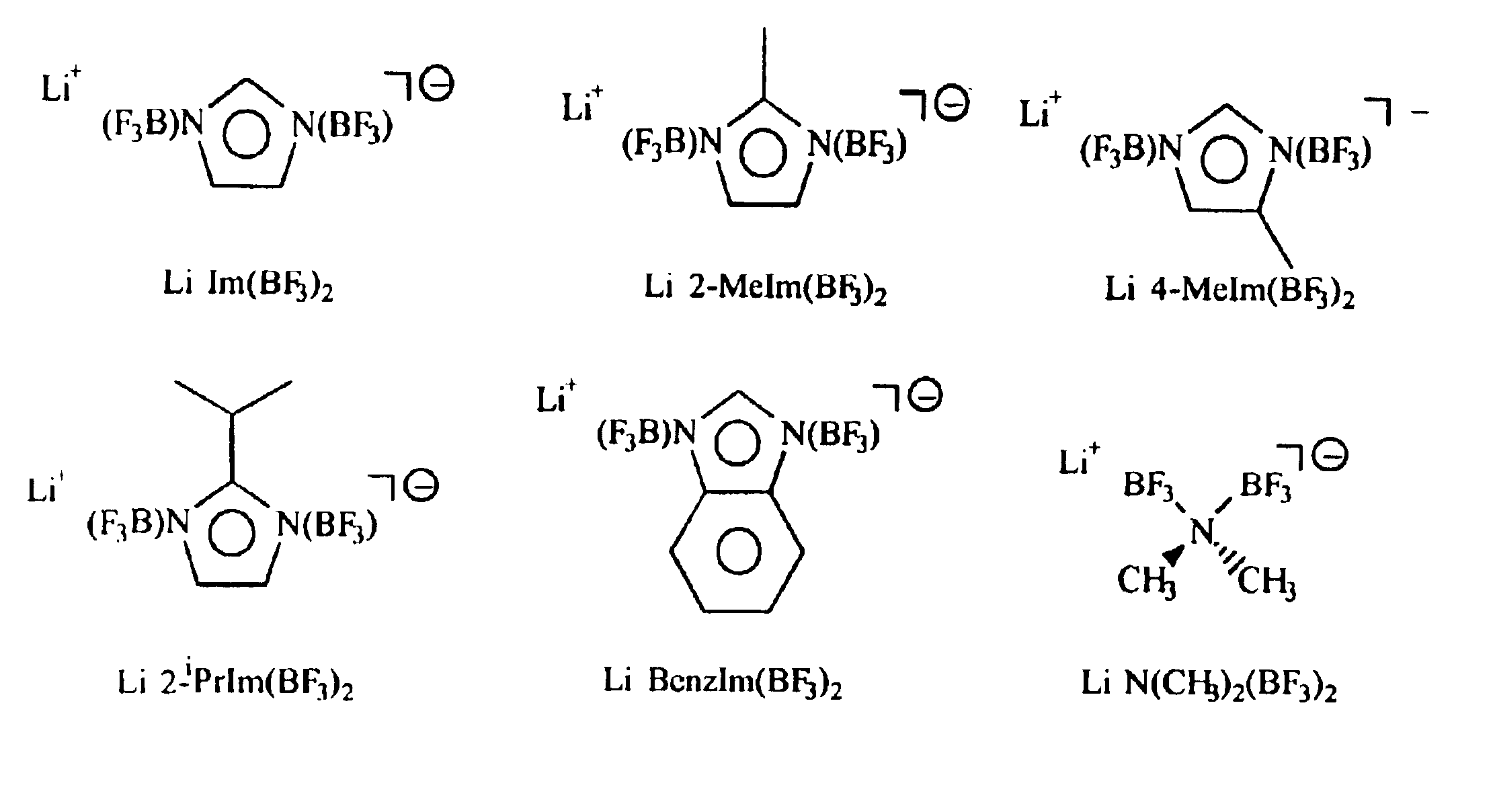

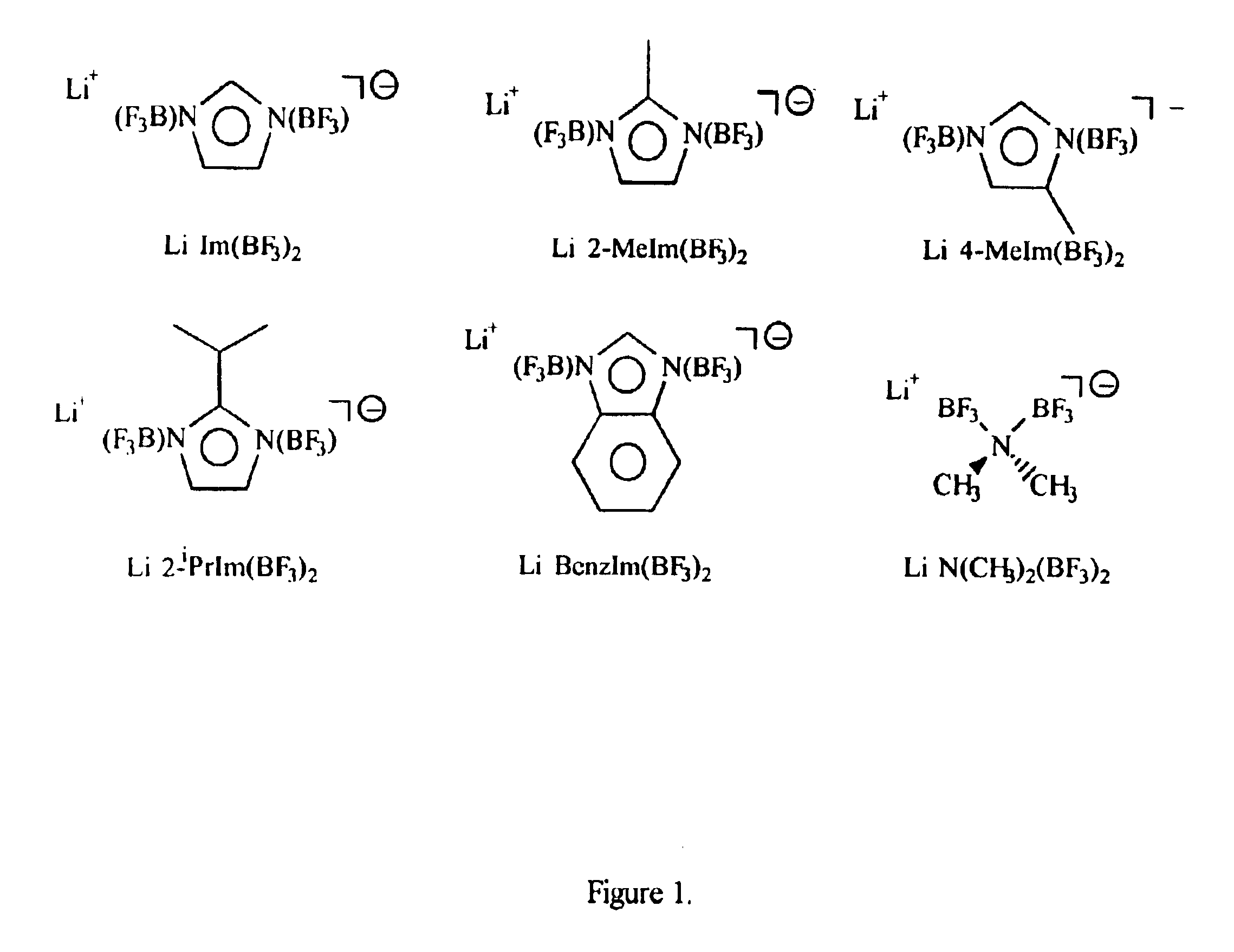

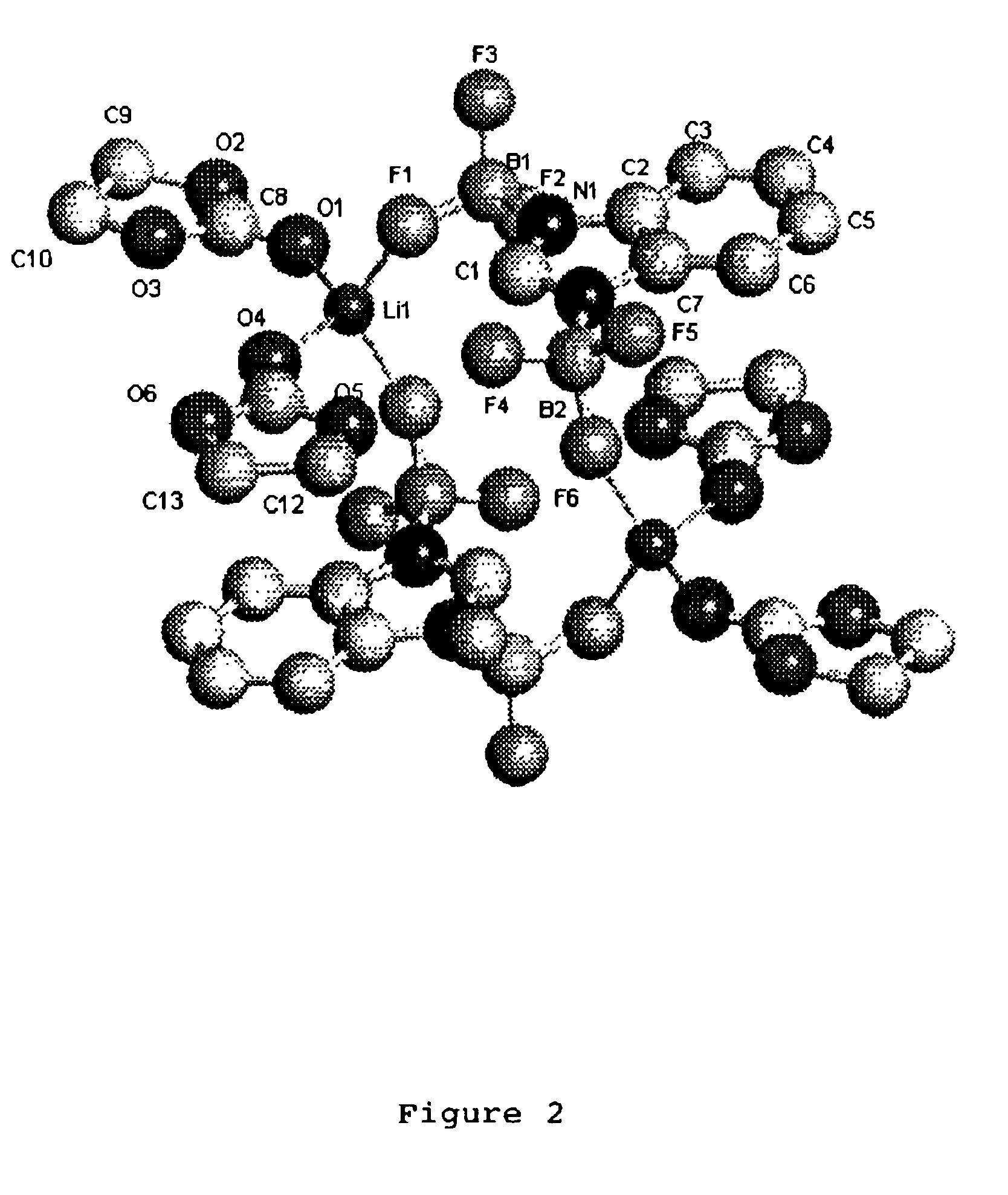

Non-aqueous electrolytes for lithium electrochemical cells

InactiveUS6852446B2Improve conductivityImprove stabilityAlkaline accumulatorsOrganic electrolyte cellsHydrogen atomHydrogen

A non-aqueous electric current producing electrochemical cell is provided comprising an anode and a cathode, an ionically permeable separator interposed between the anode and the cathode, and a non-aqueous electrolyte, the electrolyte comprising an ionically conducting salt in a non-aqueous medium, the ionically conducting salt corresponding to the formula:M+(Z*(J*)j(X*)x)−, wherein:M is a lithium atom,Z* is an anion group containing two or more Lewis basic sites and comprising less than 50 atoms not including hydrogen atoms,J* independently each occurance is a Lewis acid coordinated to at least one Lewis basic site of Z*, and optionally two or more such J* groups may be joined together in a moiety having multiple Lewis acidic functionality,X* independently each occurrence is selected from the group consisting of H, C1-C4 alkyl, alkoxide, halide and mixtures thereof,j is an integer from 2 to 12, andx is an integer from 0 to 4.

Owner:EAGLE PICHER TECH LLC

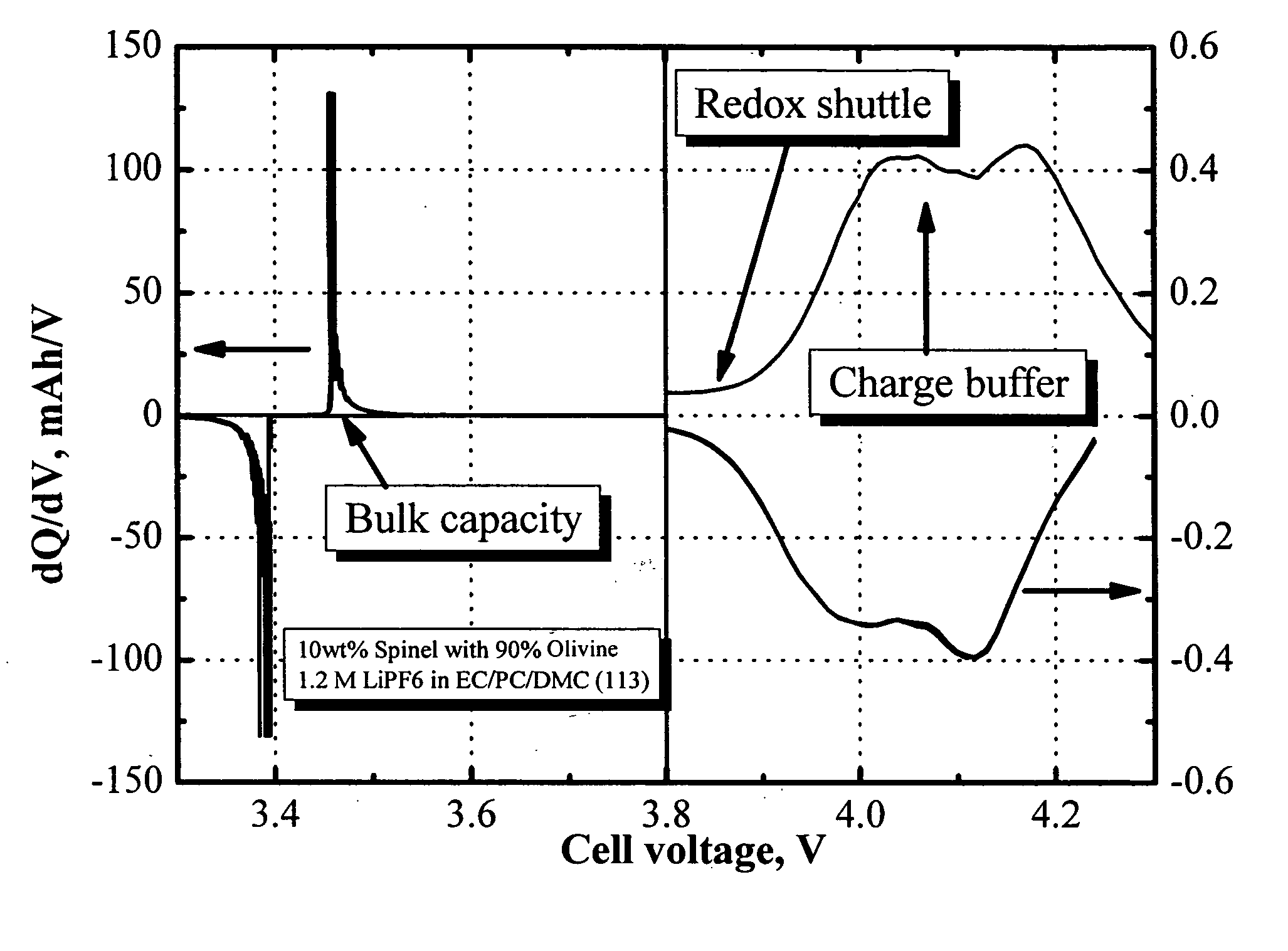

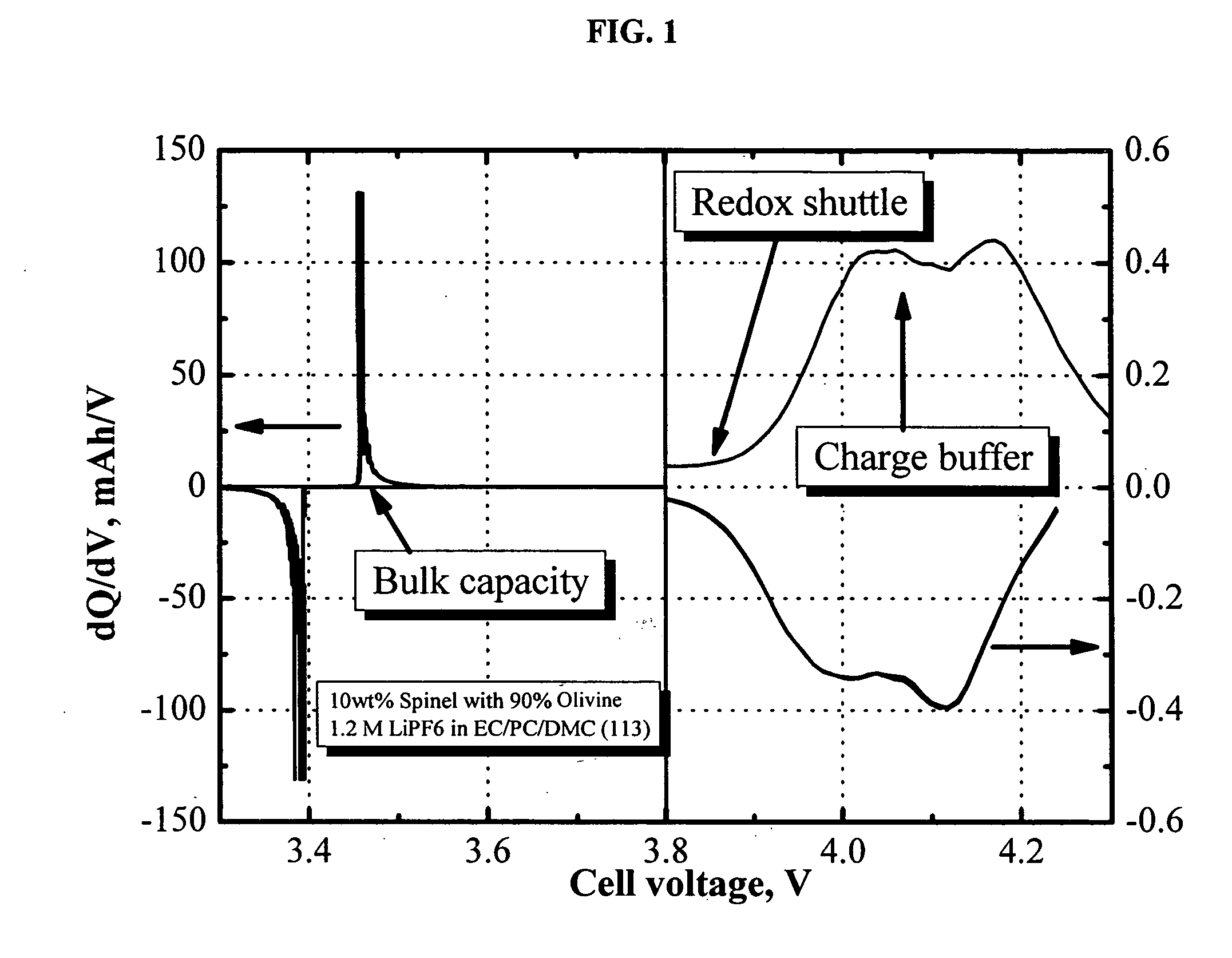

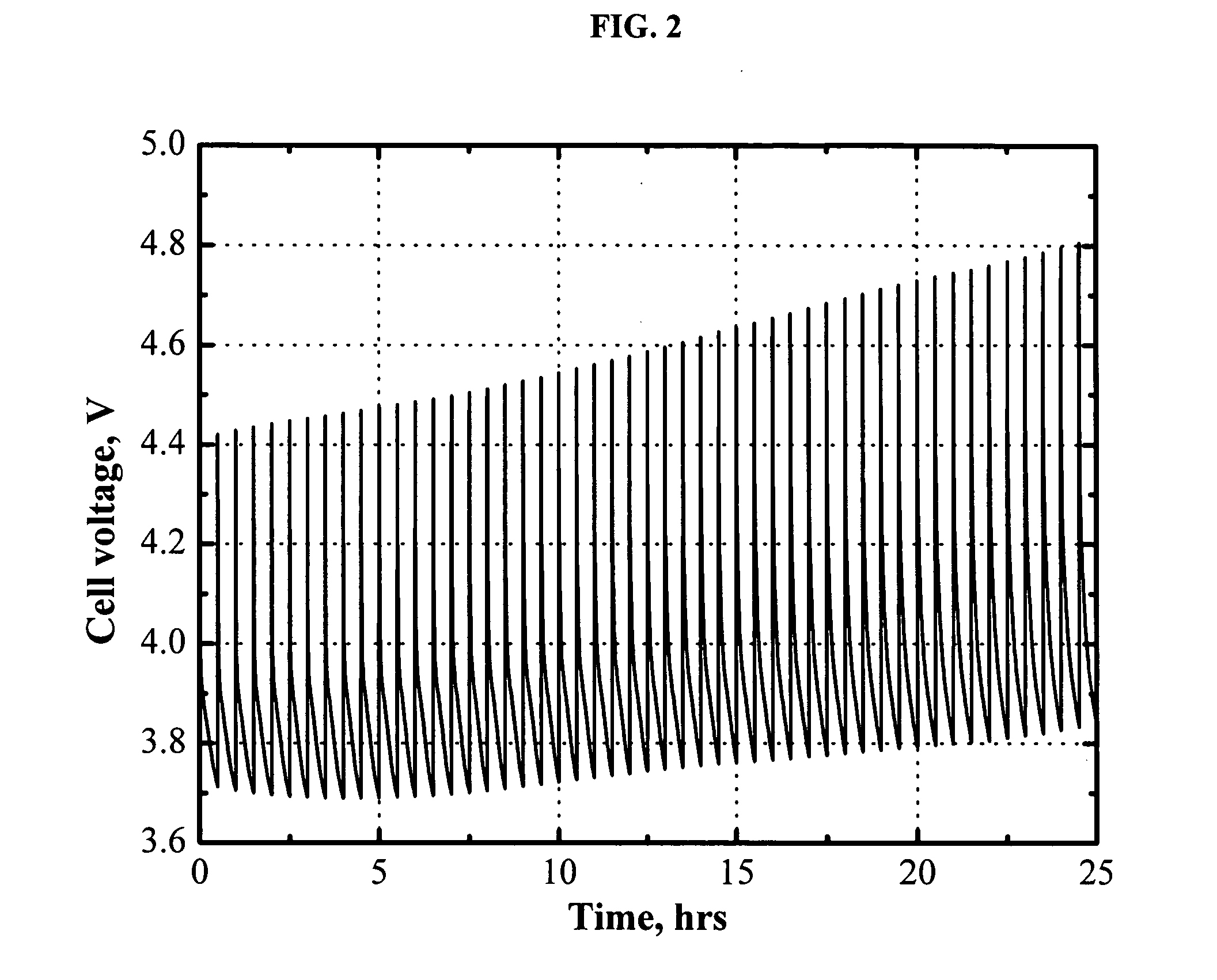

Lithium-ion batteries with intrinsic pulse overcharge protection

The present invention relates in general to the field of lithium rechargeable batteries, and more particularly relates to the positive electrode design of lithium-ion batteries with improved high-rate pulse overcharge protection. Thus the present invention provides electrochemical devices containing a cathode comprising at least one primary positive material and at least one secondary positive material; an anode; and a non-aqueous electrolyte comprising a redox shuttle additive; wherein the redox potential of the redox shuttle additive is greater than the redox potential of the primary positive material; the redox potential of the redox shuttle additive is lower than the redox potential of the secondary positive material; and the redox shuttle additive is stable at least up to the redox potential of the secondary positive material.

Owner:UCHICAGO ARGONNE LLC

Negative Electrode for Non-Aqueous Electrolyte Secondary Batteries, and Non-Aqueous Electrolyte Secondary Battery Having the Same

InactiveUS20090004566A1Excellent cycle characteristicsImproving impedanceFinal product manufactureElectrode carriers/collectorsCarbon nanofiberSilicon

A negative electrode for non-aqueous electrolyte secondary batteries has a mixture layer disposed on a current collector. The mixture layer includes a composite negative electrode active material, a first binder containing an acryl-group-containing polymer, and a second binder containing adhesive rubber particles. The composite negative electrode active material contains carbon nanofibers, a catalyst element, and silicon-containing particles capable of charging and discharging at least lithium ions. The first binder binds the silicon-containing particles to the current collector, and the second binder binds the carbon nanofibers together.

Owner:GK BRIDGE 1

Anode active material, manufacturing method thereof, and non-aqueous electrolyte secondary battery

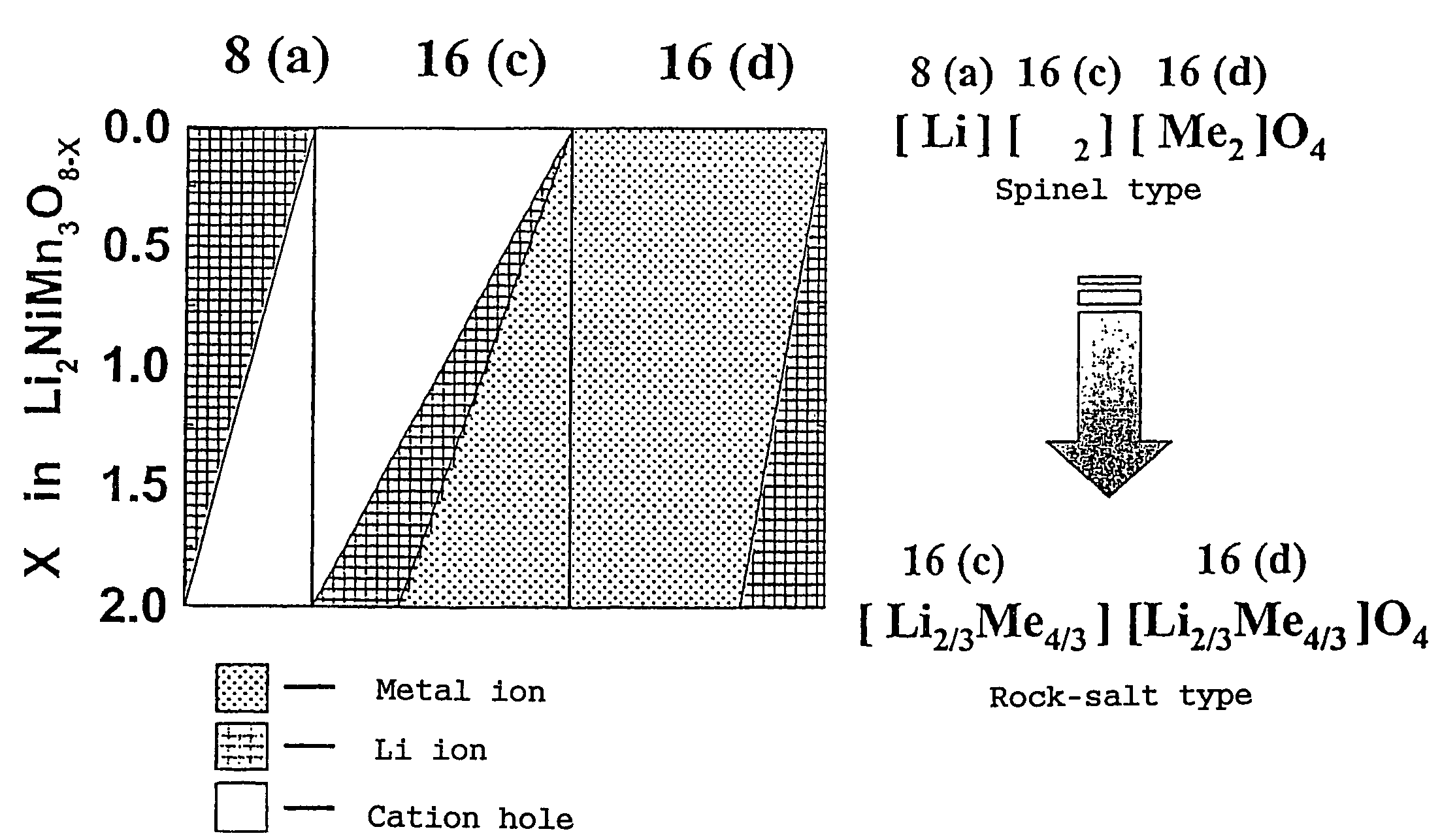

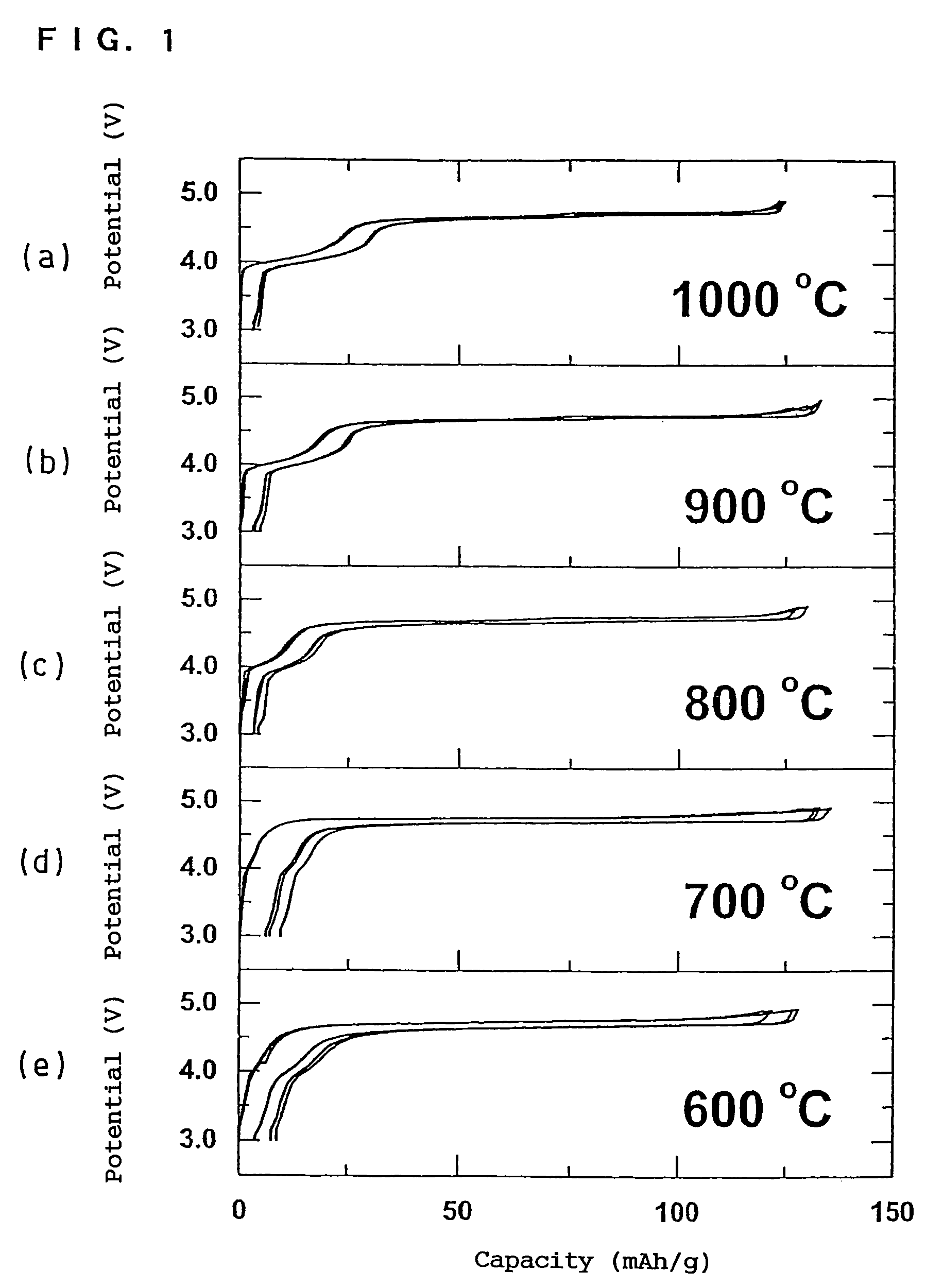

In order to provide a 3V level non-aqueous electrolyte secondary battery with a flat voltage and excellent cycle life at a high rate with low cost, the present invention provides a positive electrode represented by the formula: Li2±α[Me]4O8−x, wherein 0≦α<0.4, 0≦x<2, and Me is a transition metal containing Mn and at least one selected from the group consisting of Ni, Cr, Fe, Co and Cu, said active material exhibiting topotactic two-phase reactions during charge and discharge.

Owner:OSAKA CITY UNIV +1

Lithium secondary battery and method of manufacturing the same

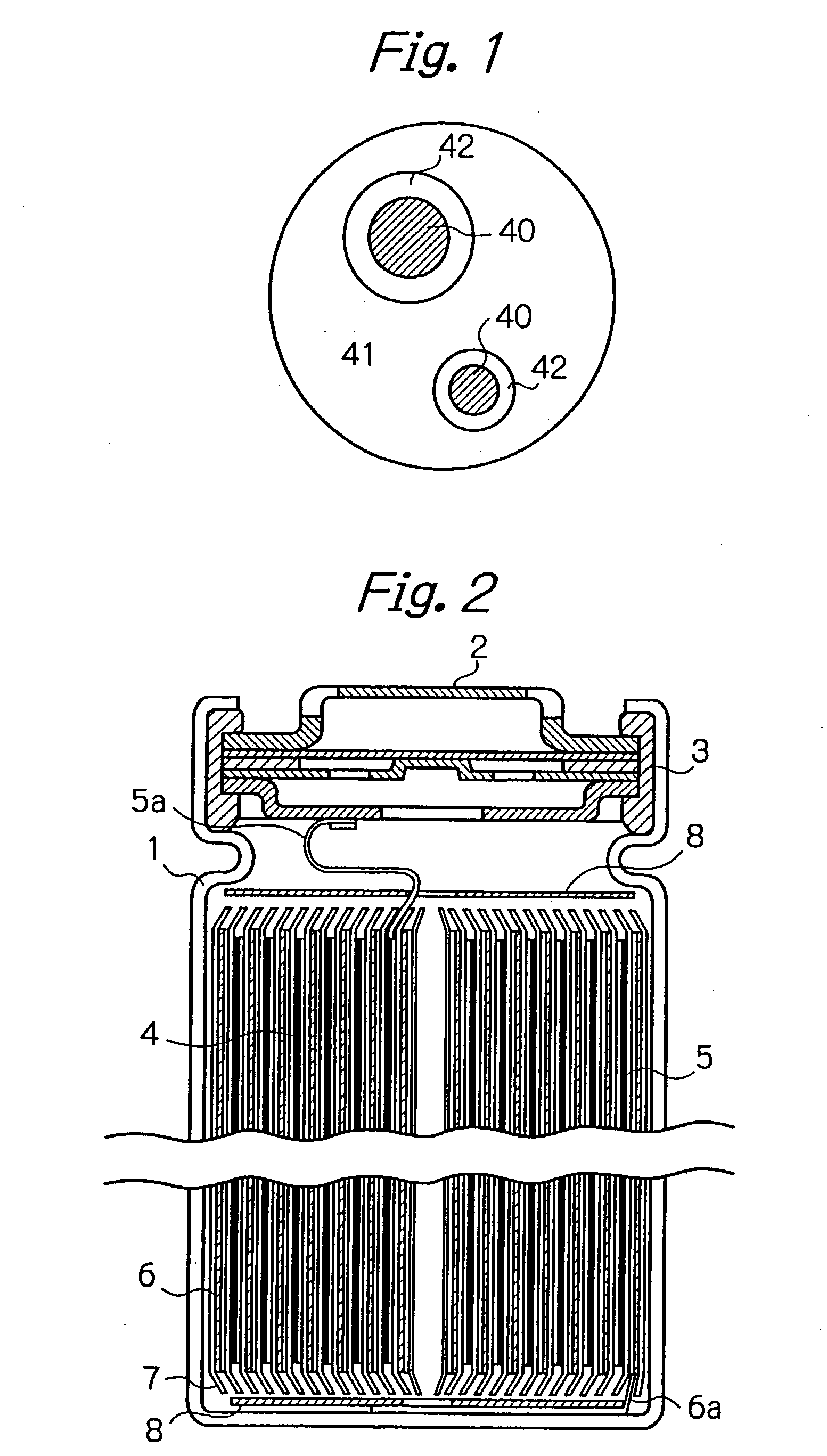

ActiveUS20080124631A1Avoid fracturesImprove cycle performanceElectrode carriers/collectorsNegative electrodesSilicon alloyMaterials science

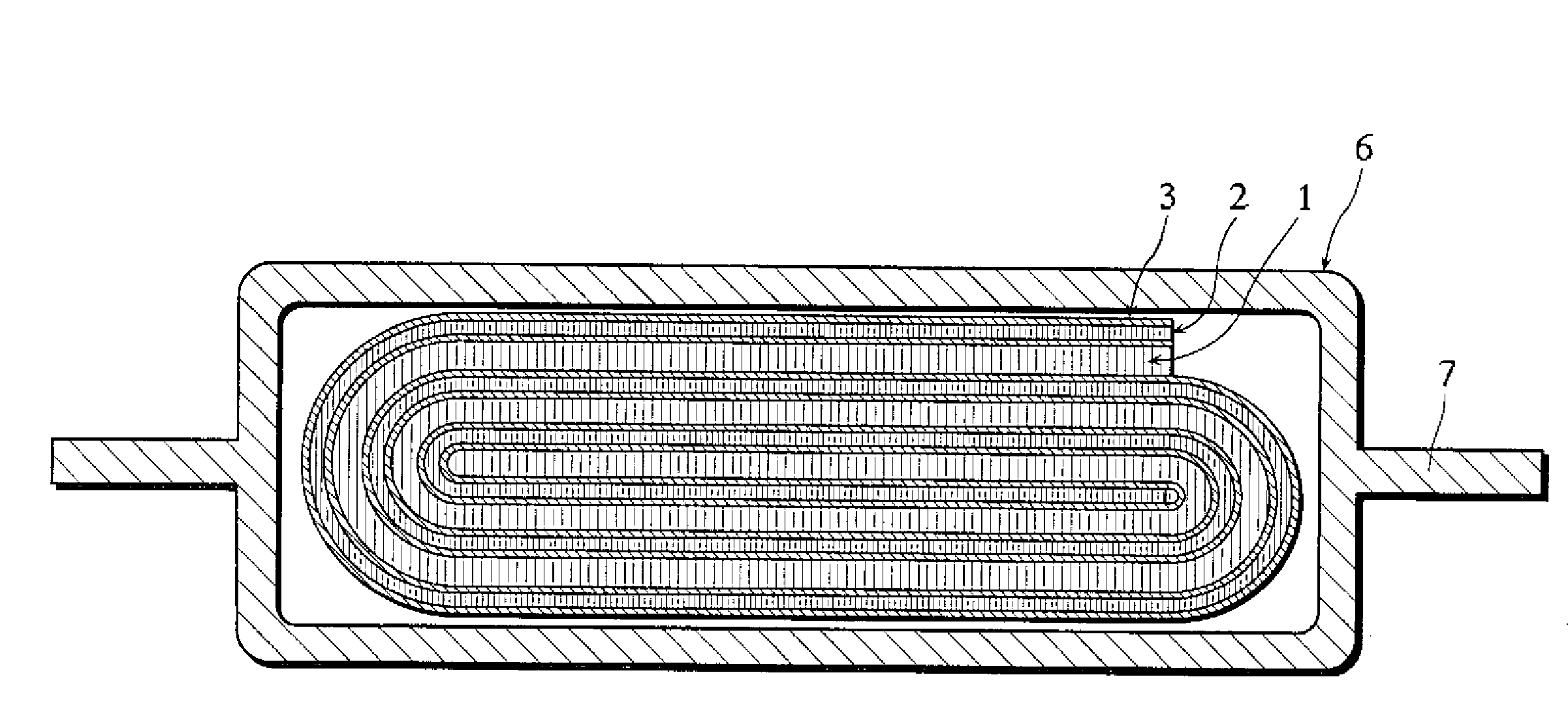

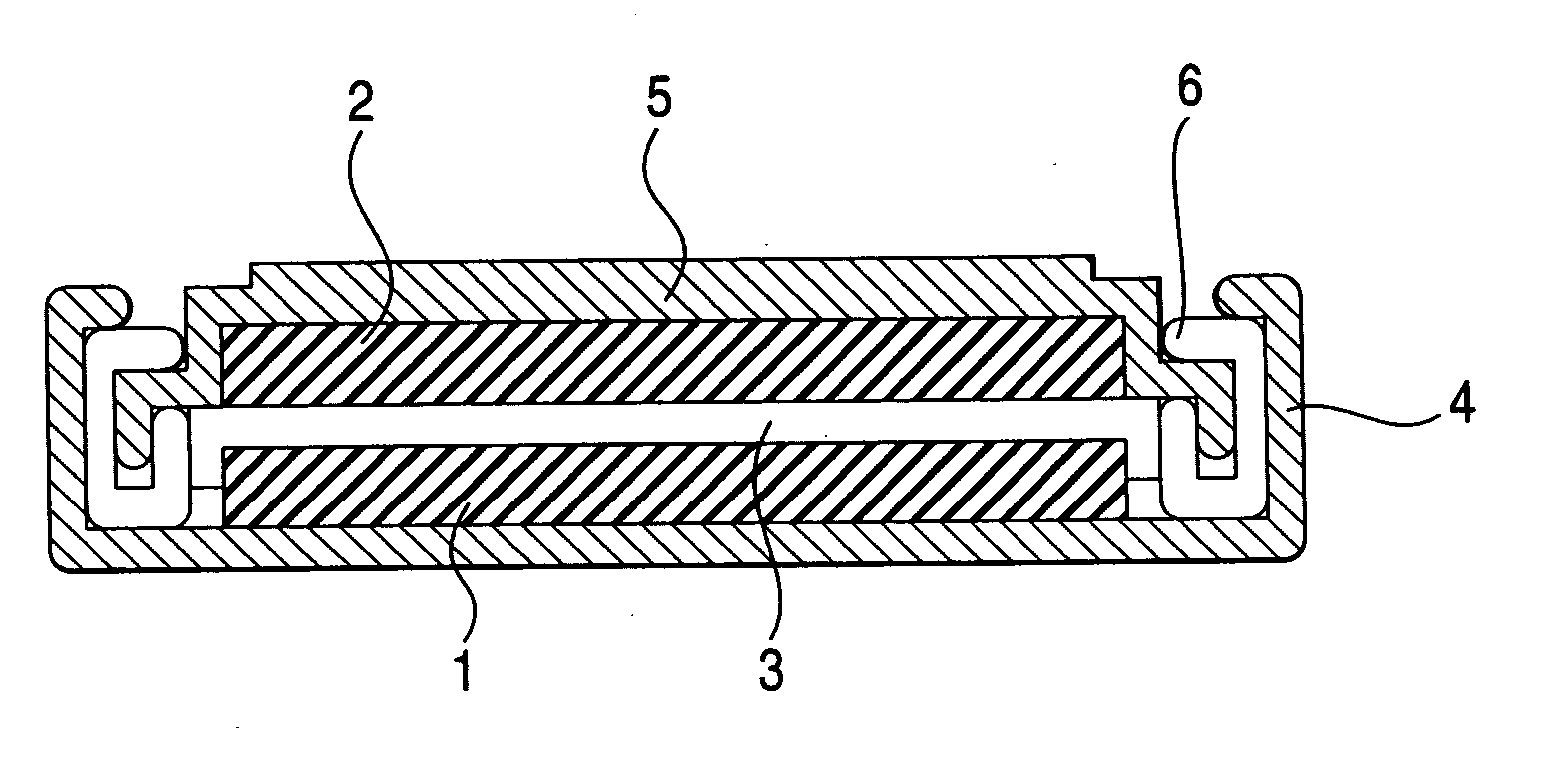

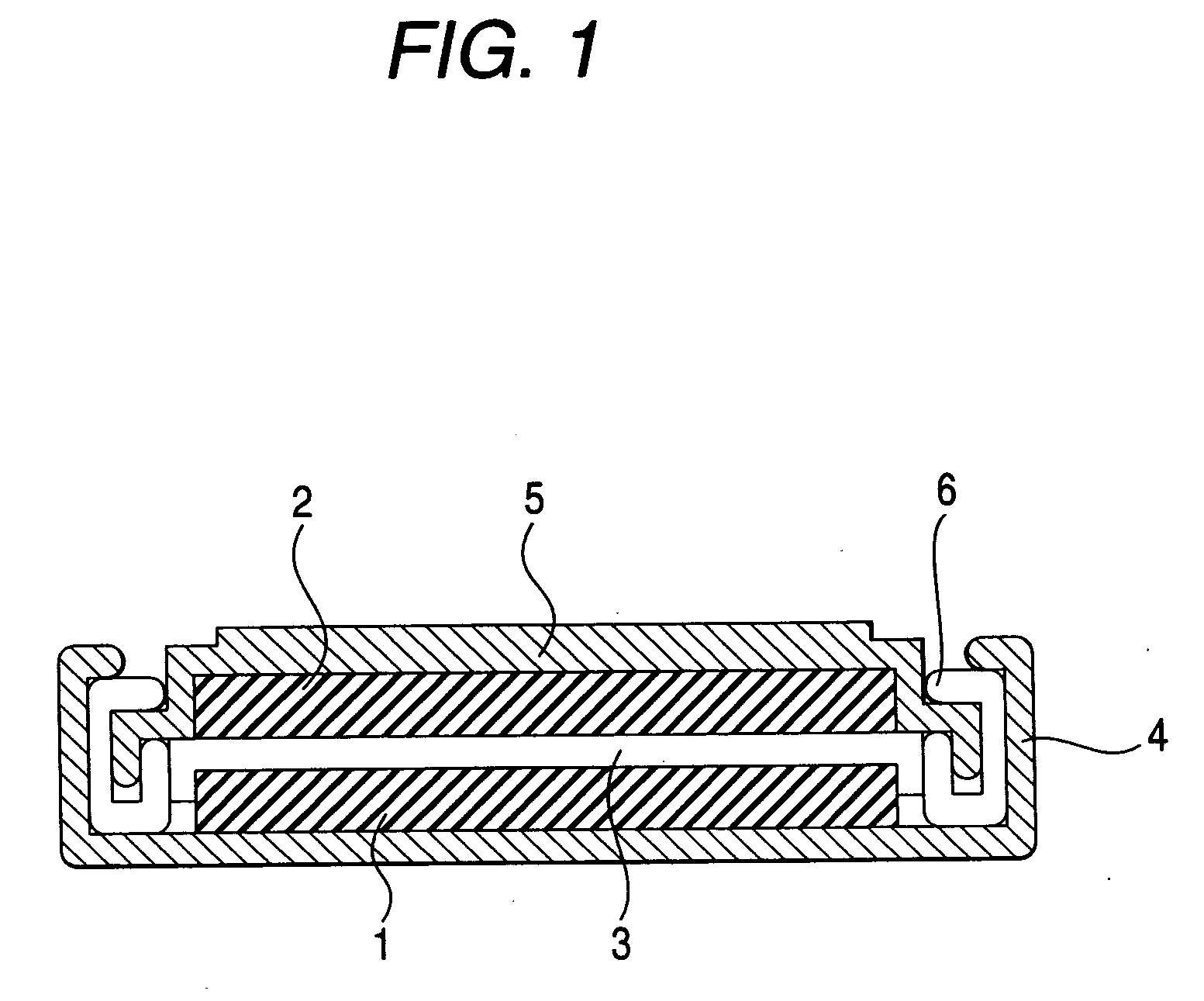

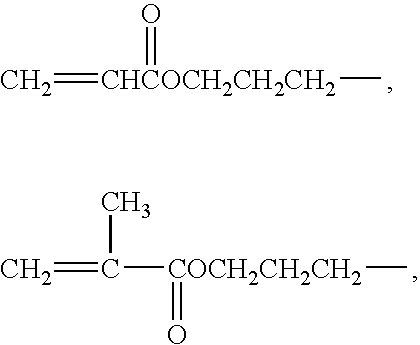

A lithium secondary battery includes an electrode assembly having a positive electrode (1), a negative electrode (2) having a negative electrode current collector and a negative electrode active material layer formed on a surface of the negative electrode current collector and composed of a binder and negative electrode active material particles containing silicon and / or a silicon alloy, and a separator (3) interposed between the electrodes. The electrode assembly is impregnated with a non-aqueous electrolyte. The binder contains a polyimide resin represented by the following chemical formula (1):where R contains at least a benzene ring, and n is within the range of from 10 to 100,000, and the negative electrode active material particles have an average particle size of 5 μm or greater.

Owner:SANYO ELECTRIC CO LTD

Nonwoven fabric for separator of non-aqueous electrolyte battery and non-aqueous electrolyte battery using the same

InactiveUS6200706B1Uniform and efficient productionImprove various performanceOrganic electrolyte cellsPaper/cardboardSurface roughnessEngineering

The object of the present invention is to provide a nonwoven fabric for separators of non-aqueous electrolyte batteries which is superior in adhesion to electrodes, causes no breakage of the separator and neither slippage nor space between electrode and the separator at the time of fabrication of battery, provides superior battery processability such as rollability with electrodes, causes no internal short-circuit due to contact between electrodes caused by shrinking or burning of the nonwoven fabric even when electrodes generate heat owing to external short-circuit, whereby ignition of the battery can be inhibited, has no pin holes and is superior in retention of electrolyte and penetration of electrolyte, and which can give non-aqueous electrolyte batteries superior in capacity, battery characteristics and battery storage characteristics. Specifically, the nonwoven fabric for separators of non-aqueous electrolyte batteries according to the present invention has a thickness non-uniformity index (Rpy) of 1000 mV or less or a center surface average roughness SRa of 6 mum or less in whole wavelength region as measured using a tracer method three-dimensional surface roughness meter.

Owner:MITSUBISHI PAPER MILLS LTD

Protected lithium electrodes having a porous electrolyte interlayer and associated battery cells

ActiveUS20140170465A1Avoid harmful reactionsHybrid capacitor separatorsHybrid capacitor electrolytesBattery cellMetal

Active metal and active metal intercalation electrode structures and battery cells having ionically conductive protective architecture including an active metal (e.g., lithium) conductive impervious layer separated from the electrode (anode) by a porous separator impregnated with a non-aqueous electrolyte (anolyte). This protective architecture prevents the active metal from deleterious reaction with the environment on the other (cathode) side of the impervious layer, which may include aqueous or non-aqueous liquid electrolytes (catholytes) and / or a variety electrochemically active materials, including liquid, solid and gaseous oxidizers. Safety additives and designs that facilitate manufacture are also provided.

Owner:POLYPLUS BATTERY CO INC

Non-aqueous electrolyte battery

InactiveUS20060068282A1Improve output performanceImprove cycle performanceNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersMolten saltNon aqueous electrolytes

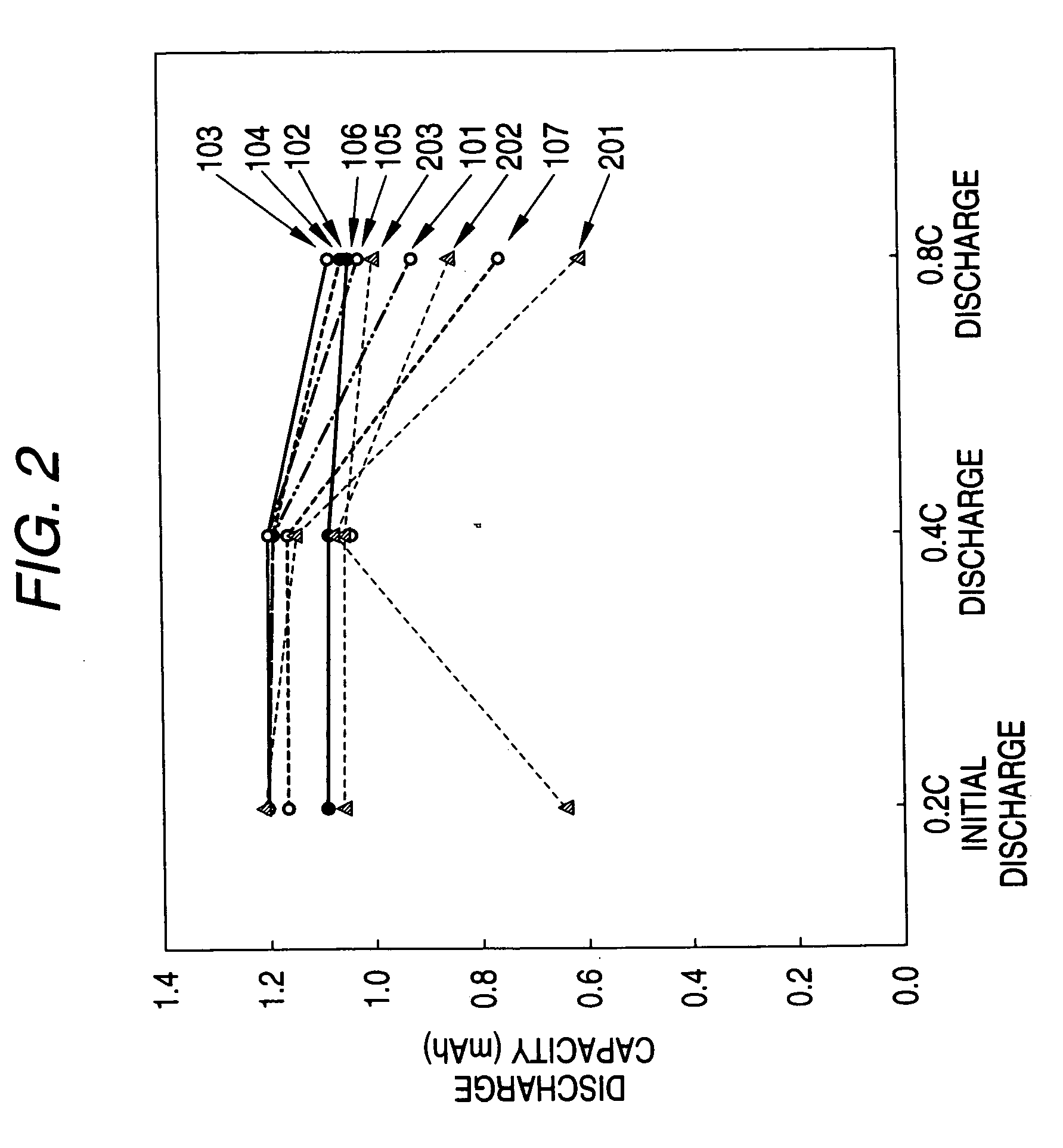

A non-aqueous electrolyte battery that contains a molten salt electrolyte and has the enhanced output performances and cycle performances can be provided. The electrolyte has a molar ratio of lithium salt to molten salt of from 0.3 to 0.5, and the non-aqueous electrolyte battery has a positive electrode having a discharge capacity of 1.05 or more times that of a negative electrode thereof.

Owner:KK TOSHIBA

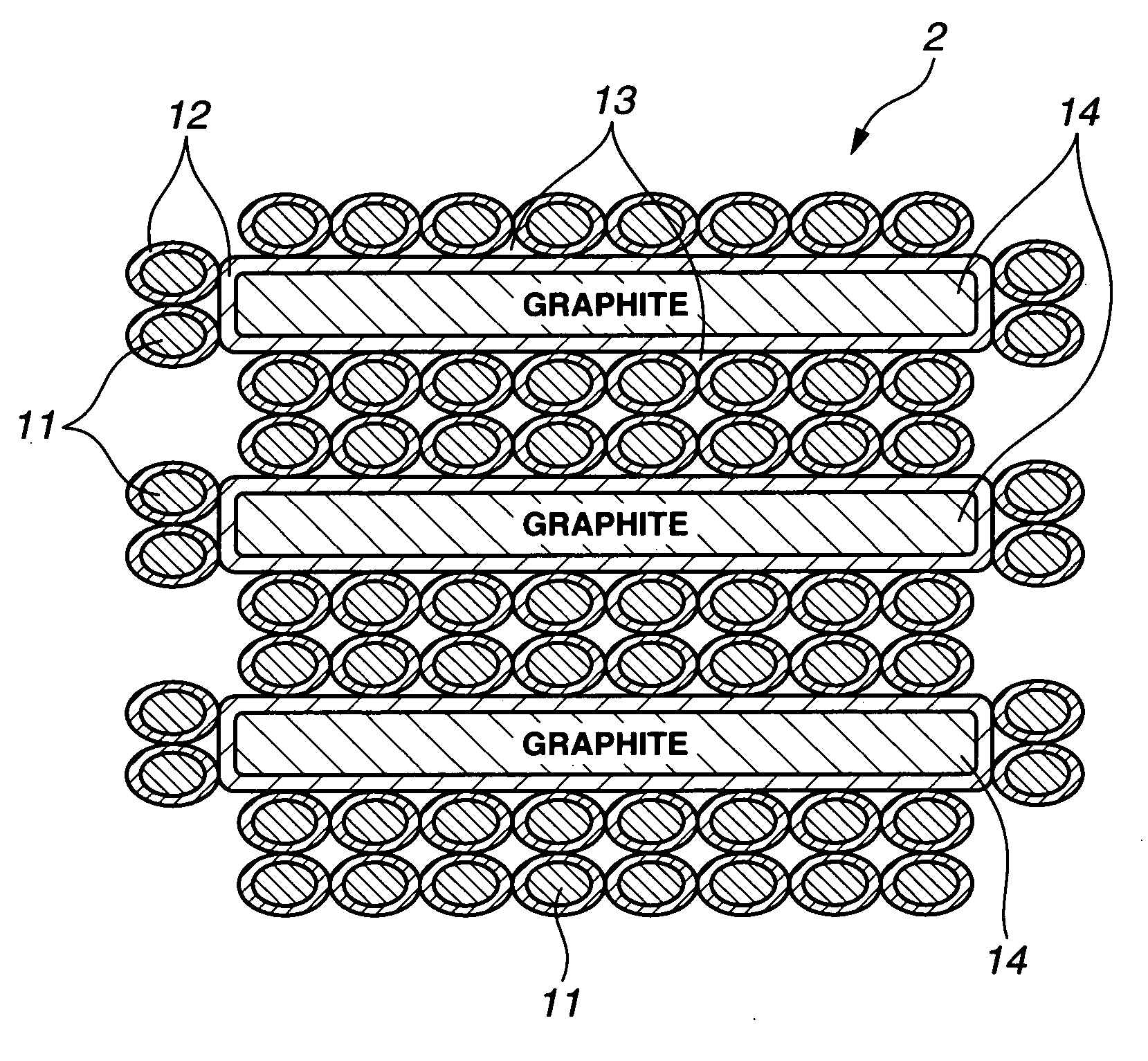

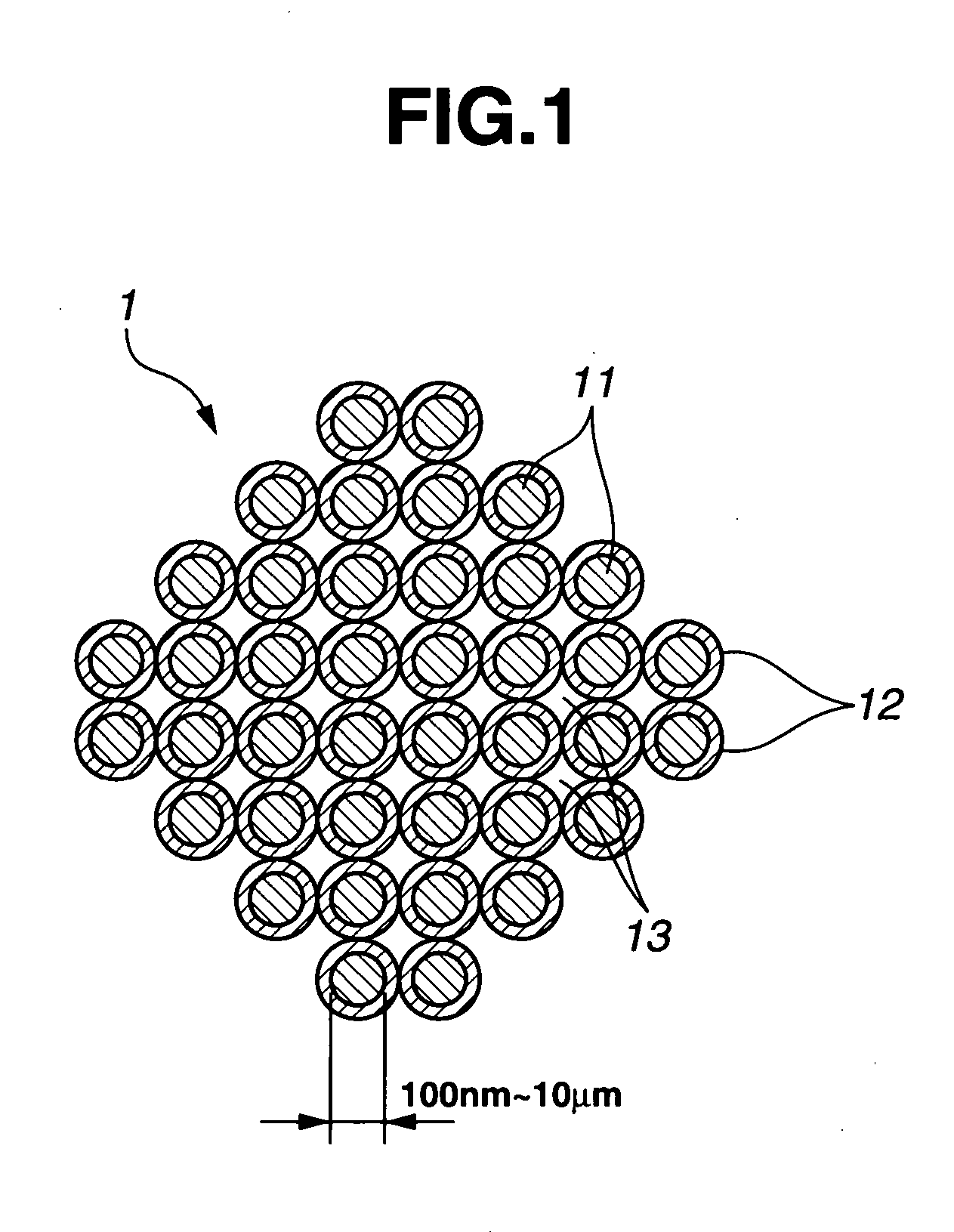

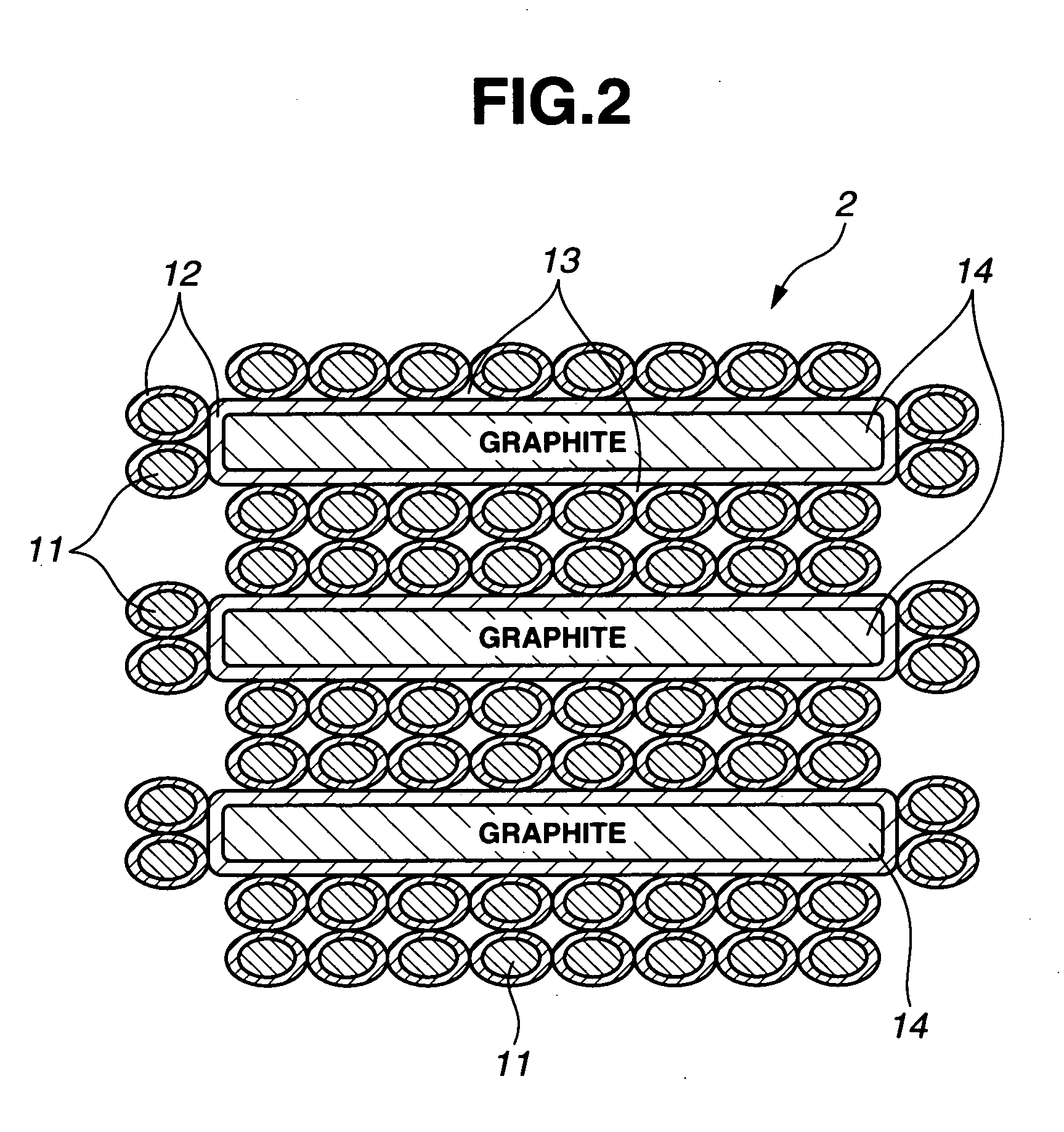

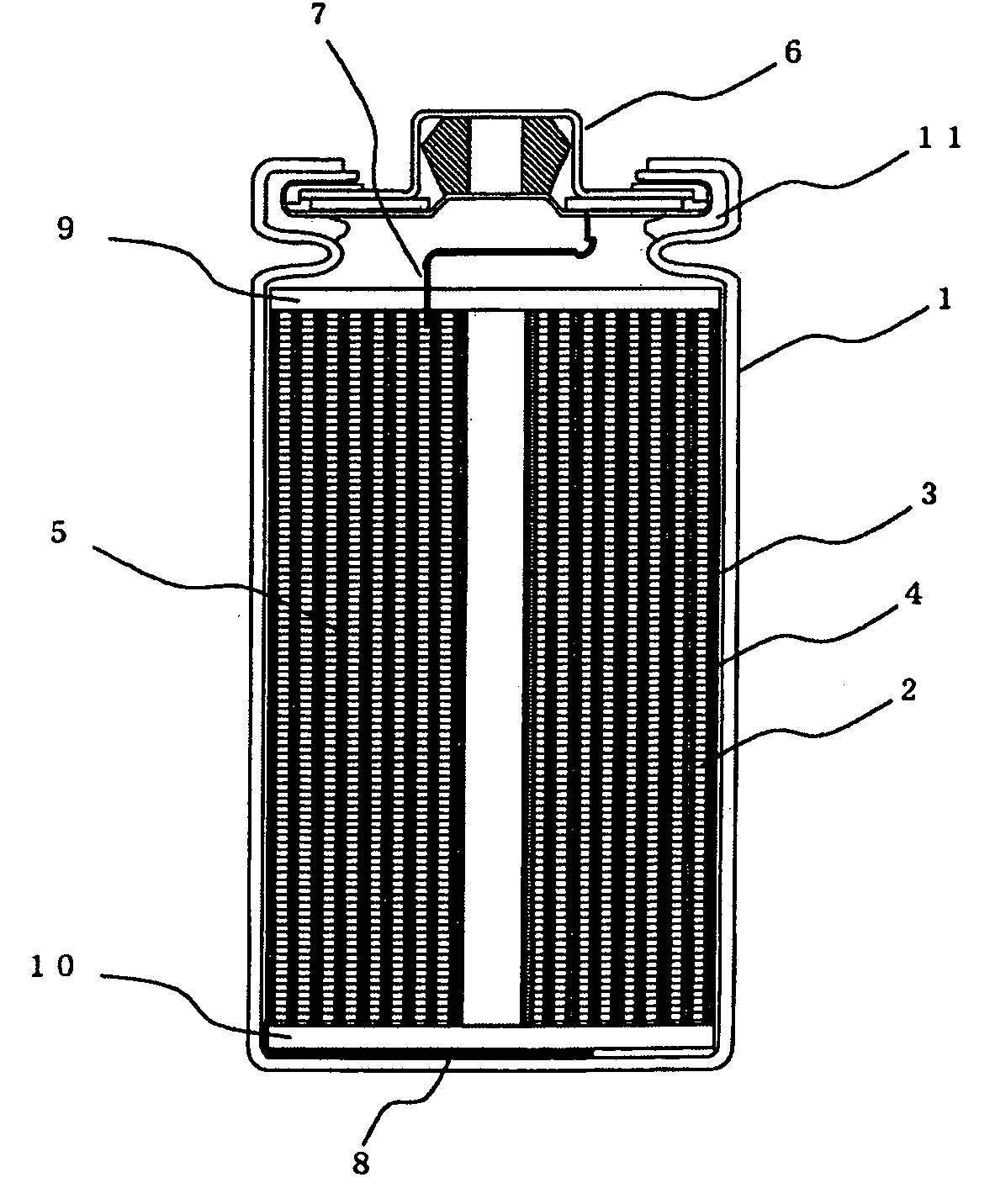

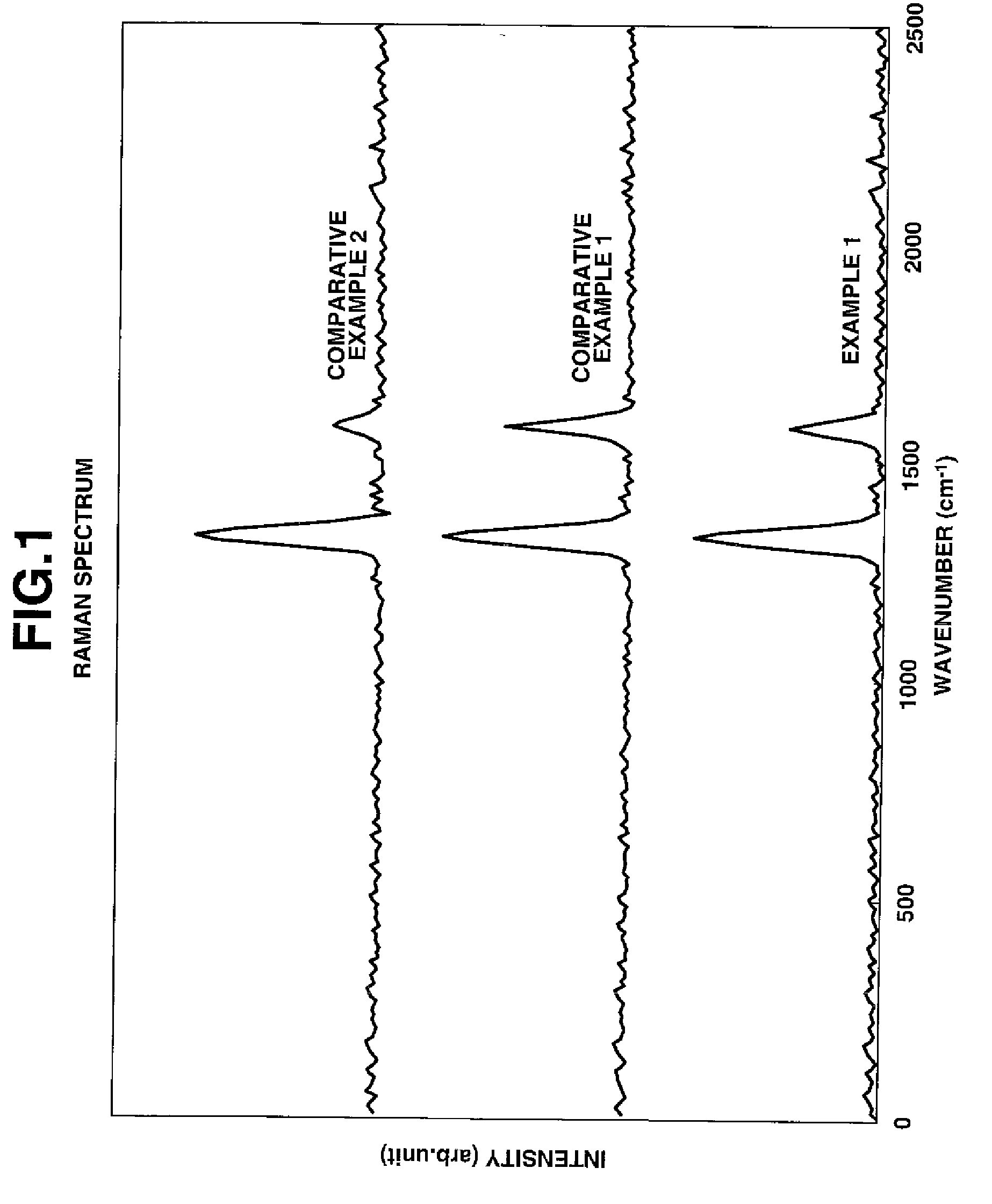

Non-aqueous electrolyte secondary battery negative electrode material, making method, lithium ion secondary battery, and electrochemical capacitor

InactiveUS20090202911A1Improve cycle performanceLarge capacityHybrid capacitor electrodesLiquid electrolytic capacitorsGraphiteCapacitor

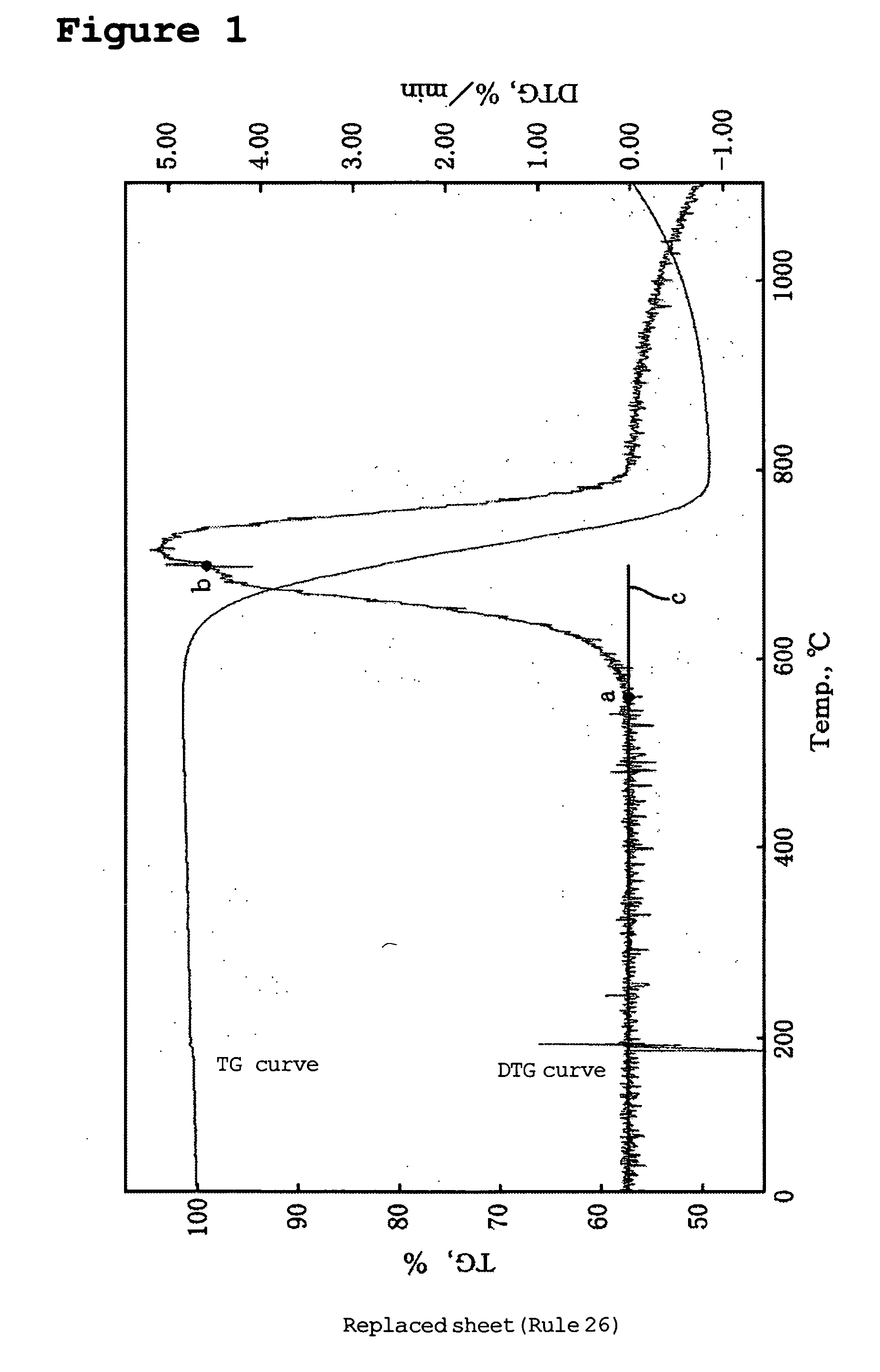

A negative electrode material comprises a conductive powder of particles of a lithium ion-occluding and releasing material coated on their surface with a graphite coating. The graphite coating, on Raman spectroscopy analysis, develops broad peaks having an intensity I1330 and I1580 at 1330 cm−1 and 1580 cm−1 Raman shift, an intensity ratio I1330 / I1580 being 1.5<I1330 / I1580<3.0. Using the negative electrode material, a lithium ion secondary battery having a high capacity and improved cycle performance can be manufactured.

Owner:SHIN ETSU CHEM IND CO LTD

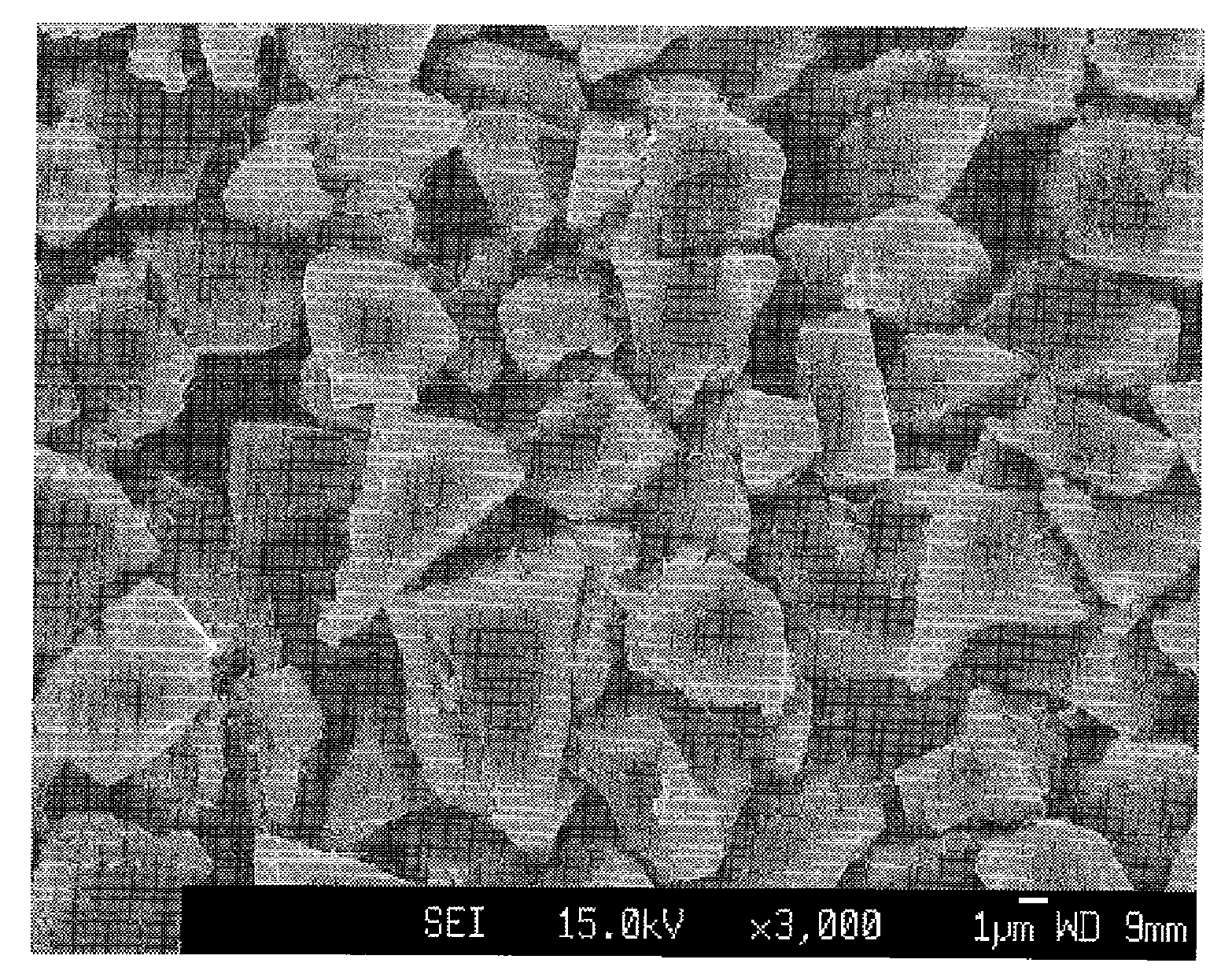

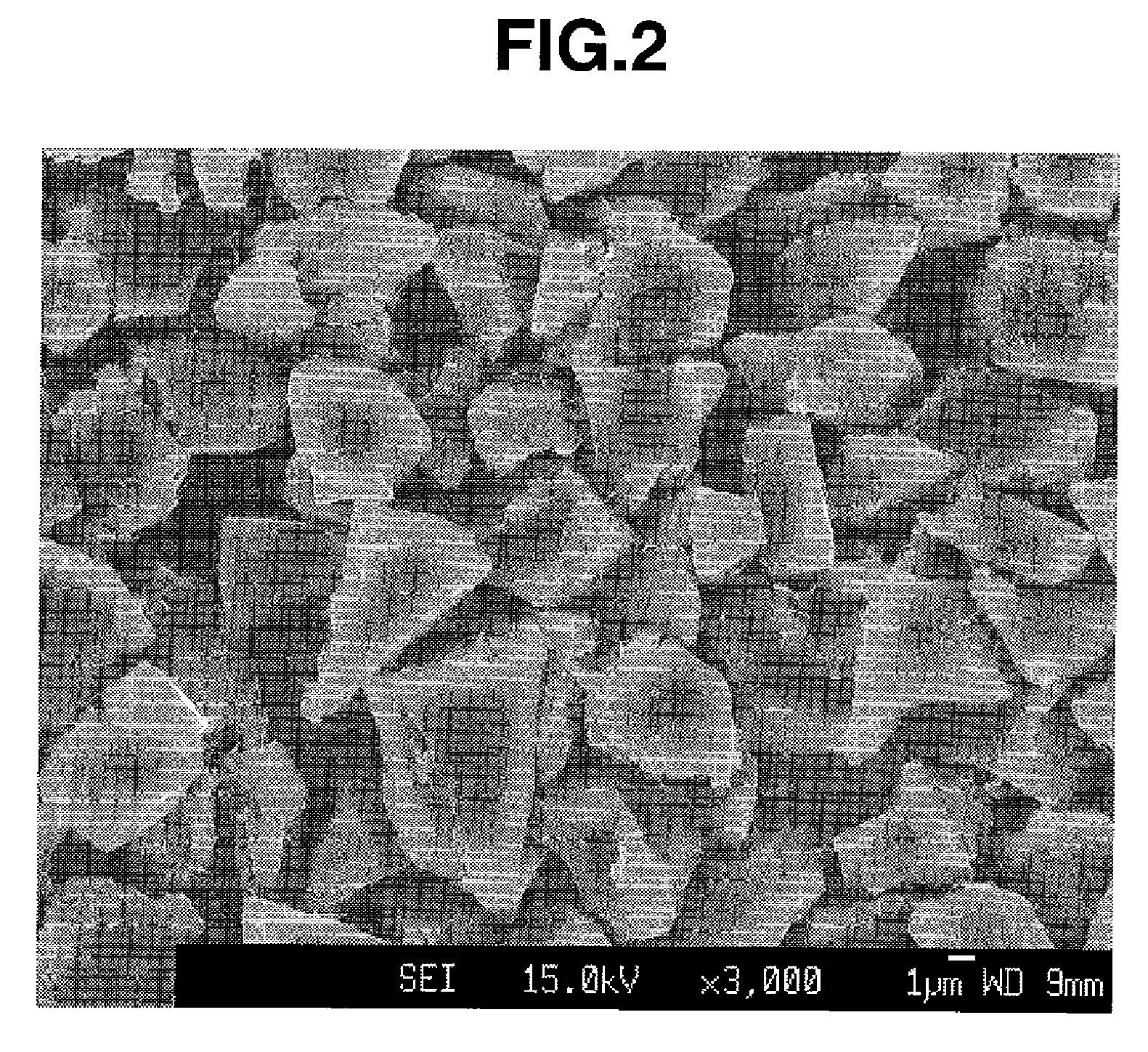

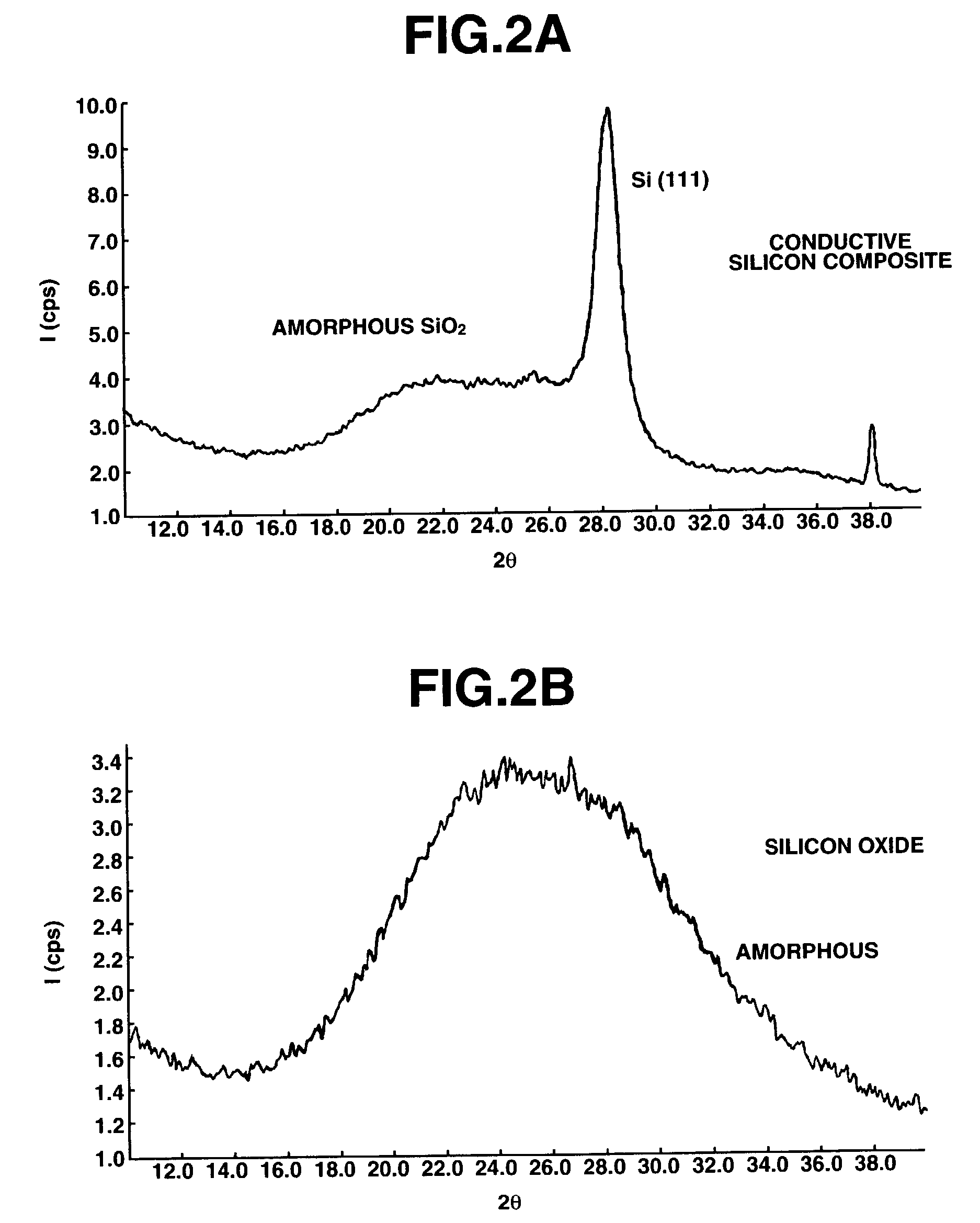

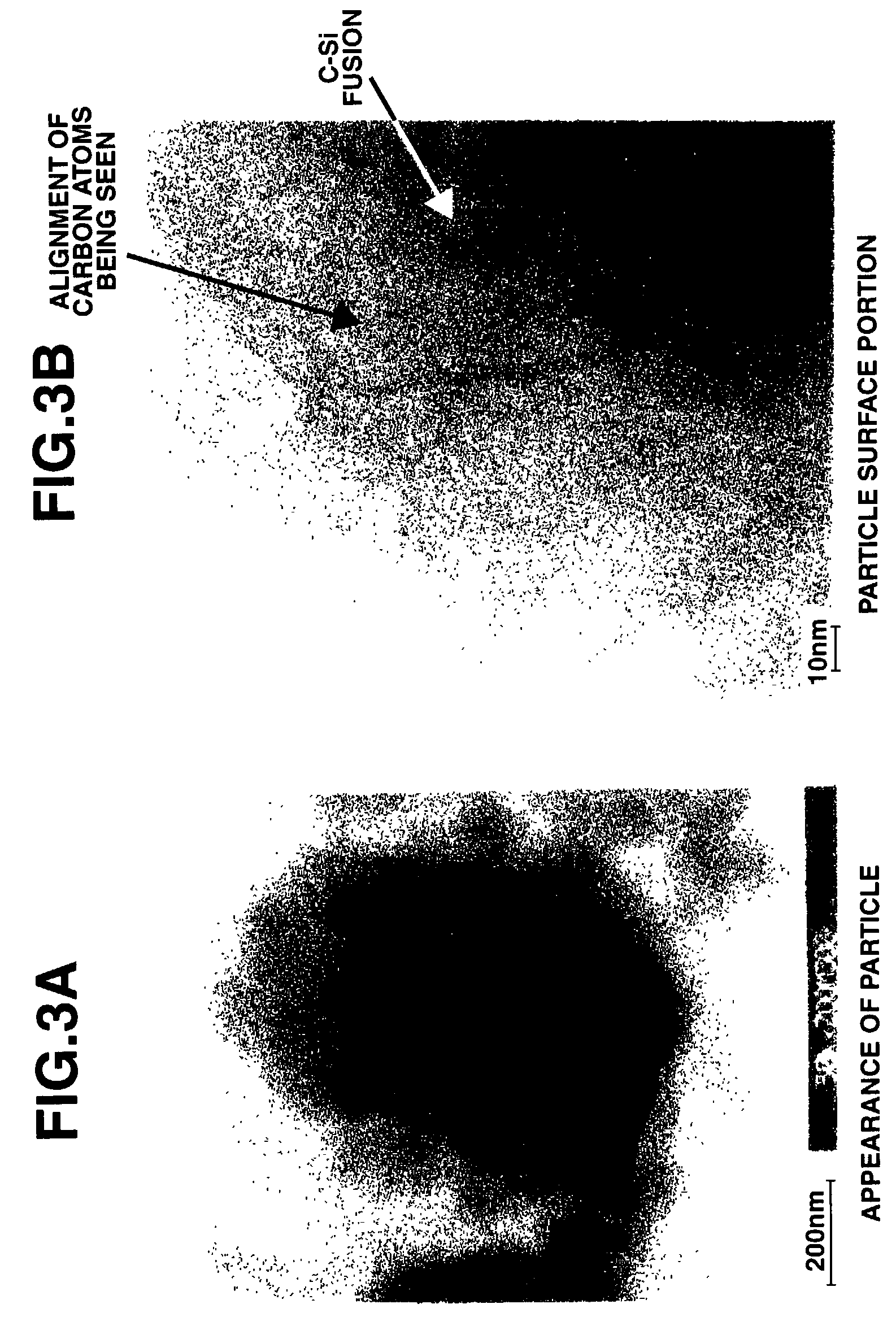

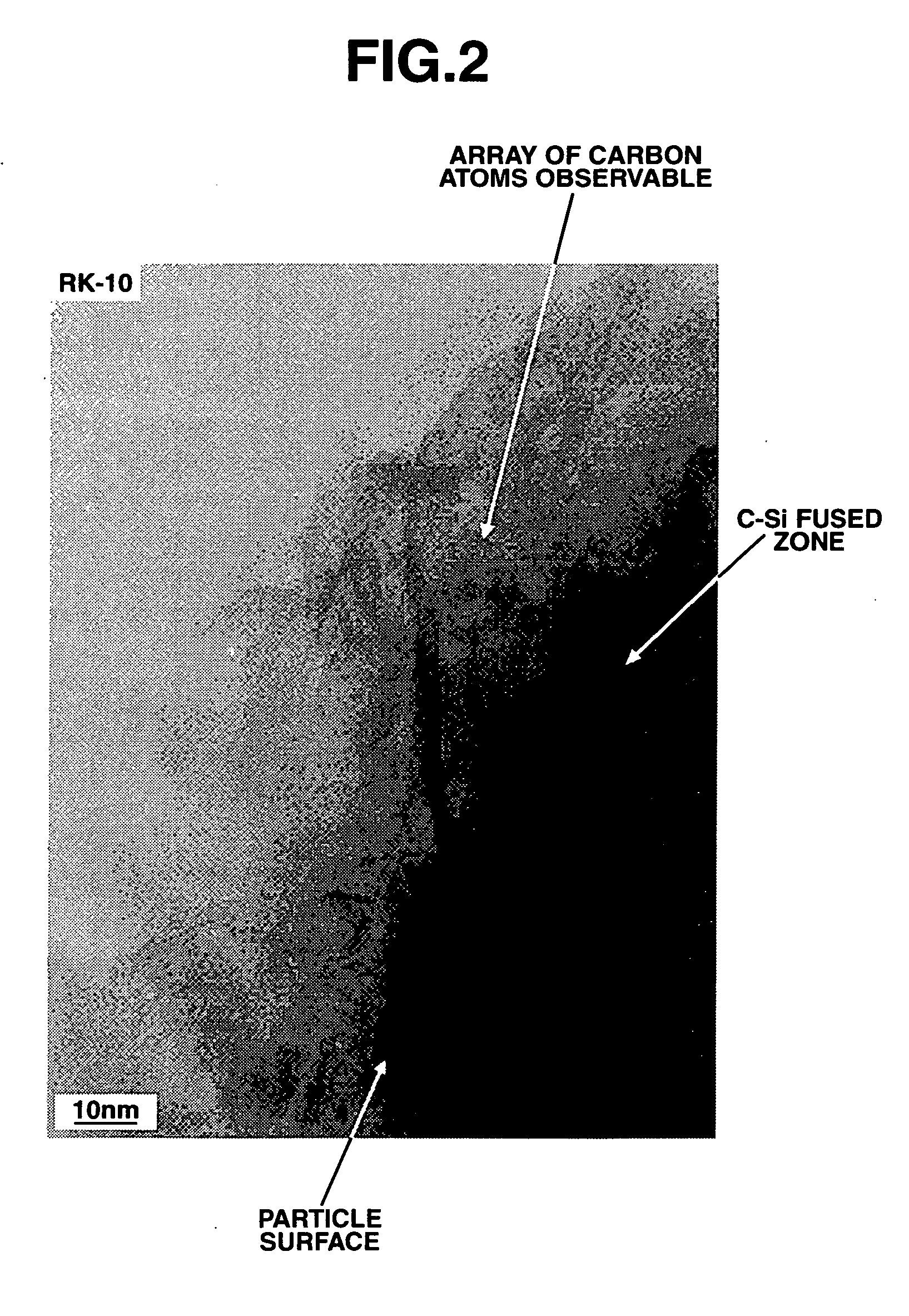

Conductive silicon composite, preparation thereof, and negative electrode material for non-aqueous electrolyte secondary cell

ActiveUS7037581B2Improve cycle performanceReduce conductivityMaterial nanotechnologyPigmenting treatmentSilicon dioxideSilicon

Owner:SHIN ETSU CHEM IND CO LTD

Separator and Non-Aqueous Electrolyte Secondary Battery Using Same

InactiveUS20080070107A1Improve securityImprove performanceNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersFine particulateMaterials science

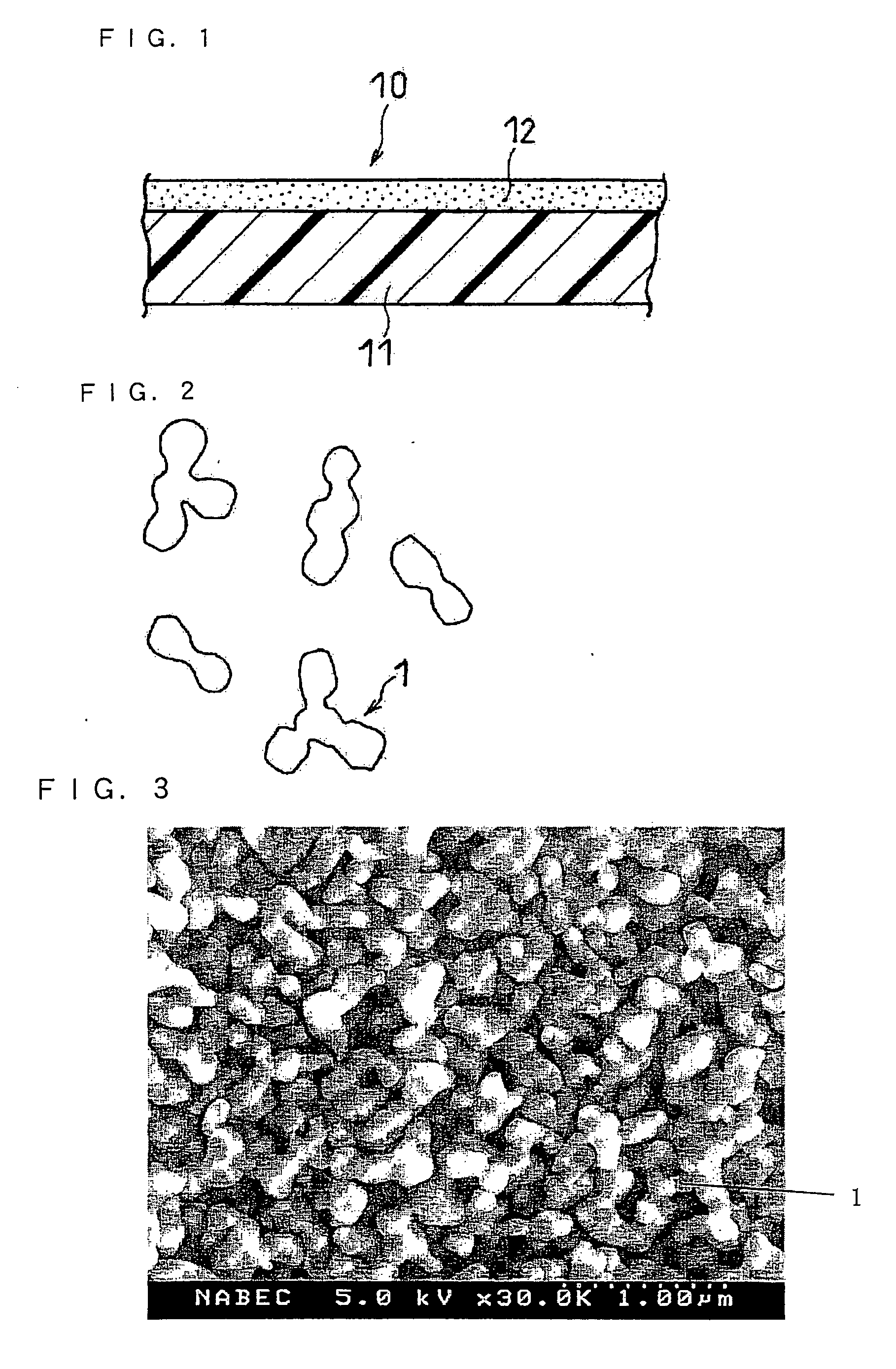

A separator including at least a layer containing a fine particulate filler and a shutdown layer. The fine particulate filler includes a joined-particle filler that is in the form of a plurality of primary particles joined and bonded to one another. A non-aqueous electrolyte secondary battery including this separator exhibits improved safety, high performance and large current discharge capability particularly at low temperatures.

Owner:PANASONIC CORP

Non-aqueous electrolyte secondary battery negative electrode material, making method, and lithium ion secondary battery

ActiveUS20040106040A1Large capacityImprove cycle performanceNon-aqueous electrolyte accumulatorsNegative electrodesConductive coatingMaterials science

A non-aqueous electrolyte secondary battery negative electrode material is provided wherein a negative electrode active material containing a lithium ion-occluding and releasing material which has been treated with an organosilicon base surface treating agent is surface coated with a conductive coating. Using the negative electrode material, a lithium ion secondary battery having a high capacity and improved cycle performance is obtainable.

Owner:SHIN ETSU CHEM IND CO LTD

Non-aqueous electrolyte secondary cell negative electrode material and metallic silicon power therefor

InactiveUS20060051670A1Improve cycle performanceLow costSiliconSynthetic resin layered productsImpuritySilicon

A metallic silicon powder is prepared by effecting chemical reduction on silica stone, metallurgical refinement, and metallurgical and / or chemical purification to reduce the content of impurities. The powder is best suited as a negative electrode material for non-aqueous electrolyte secondary cells, affording better cycle performance.

Owner:SHIN ETSU CHEM IND CO LTD

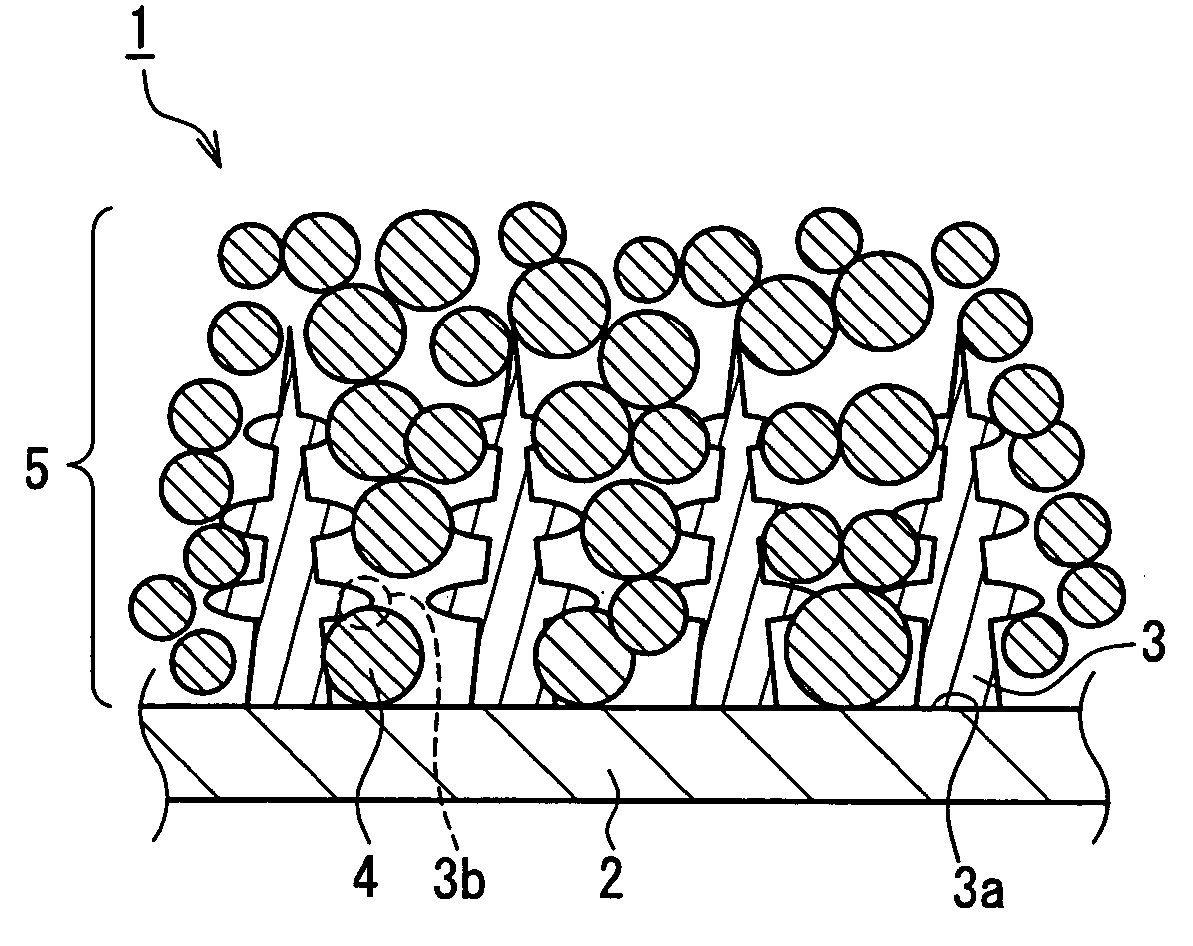

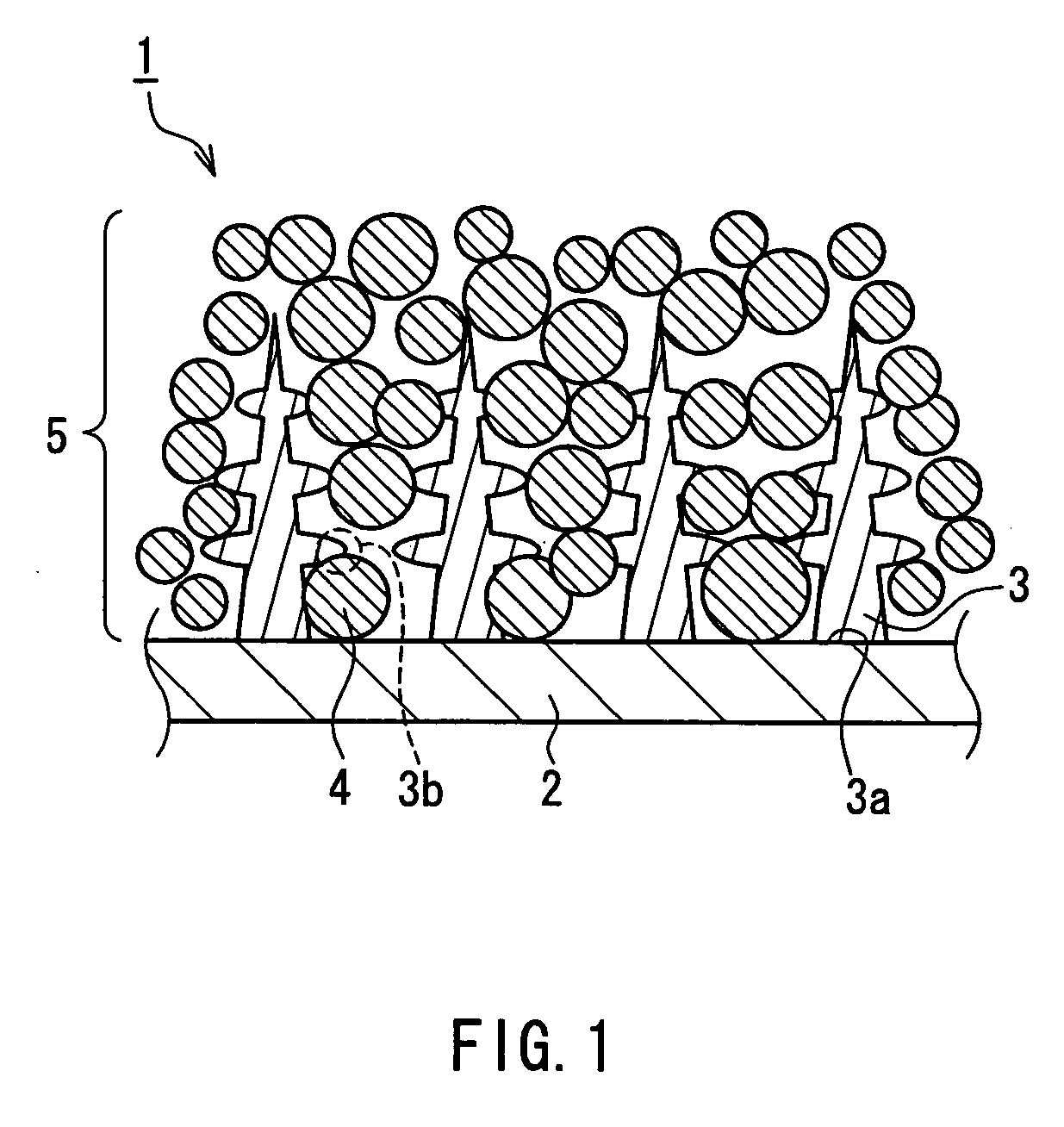

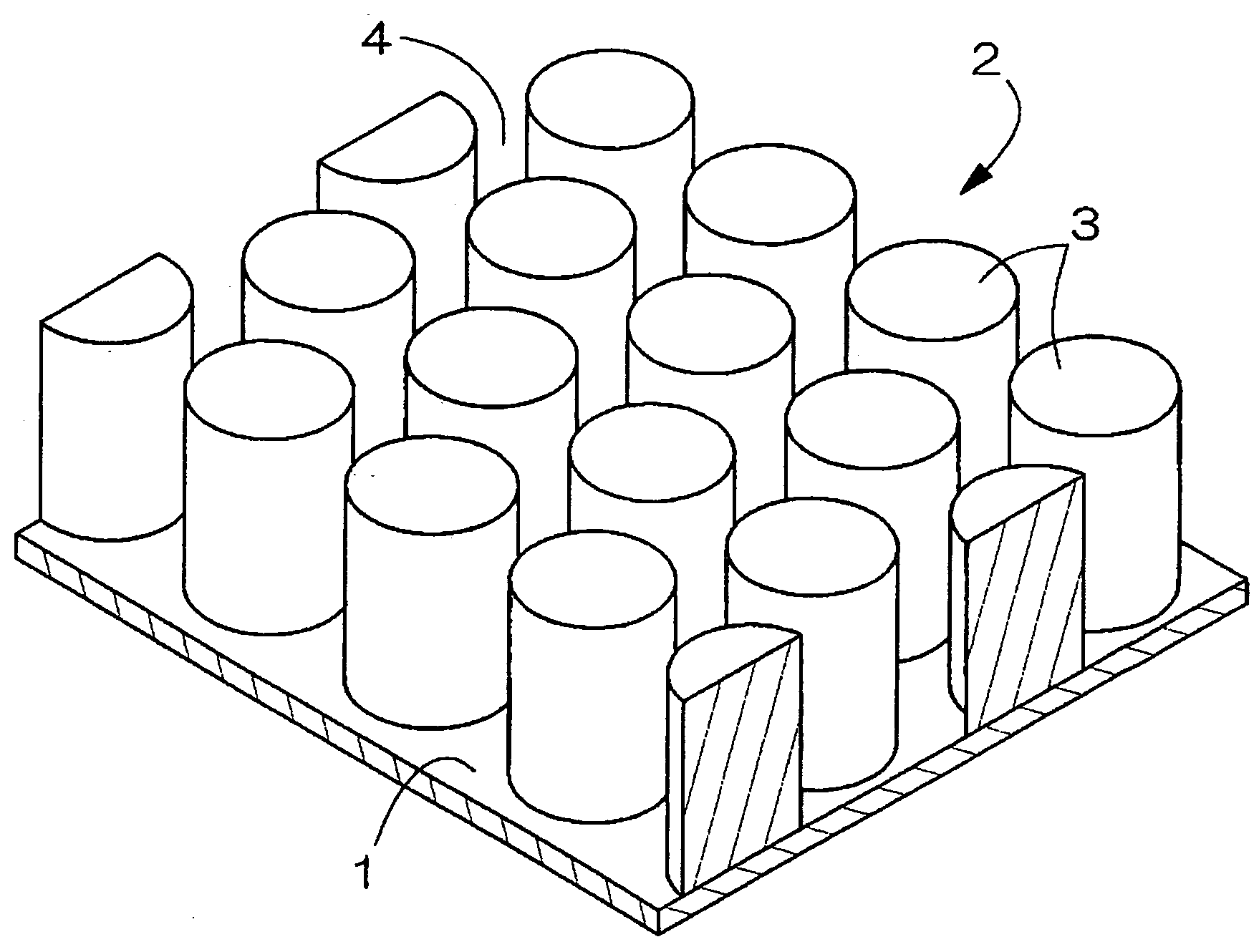

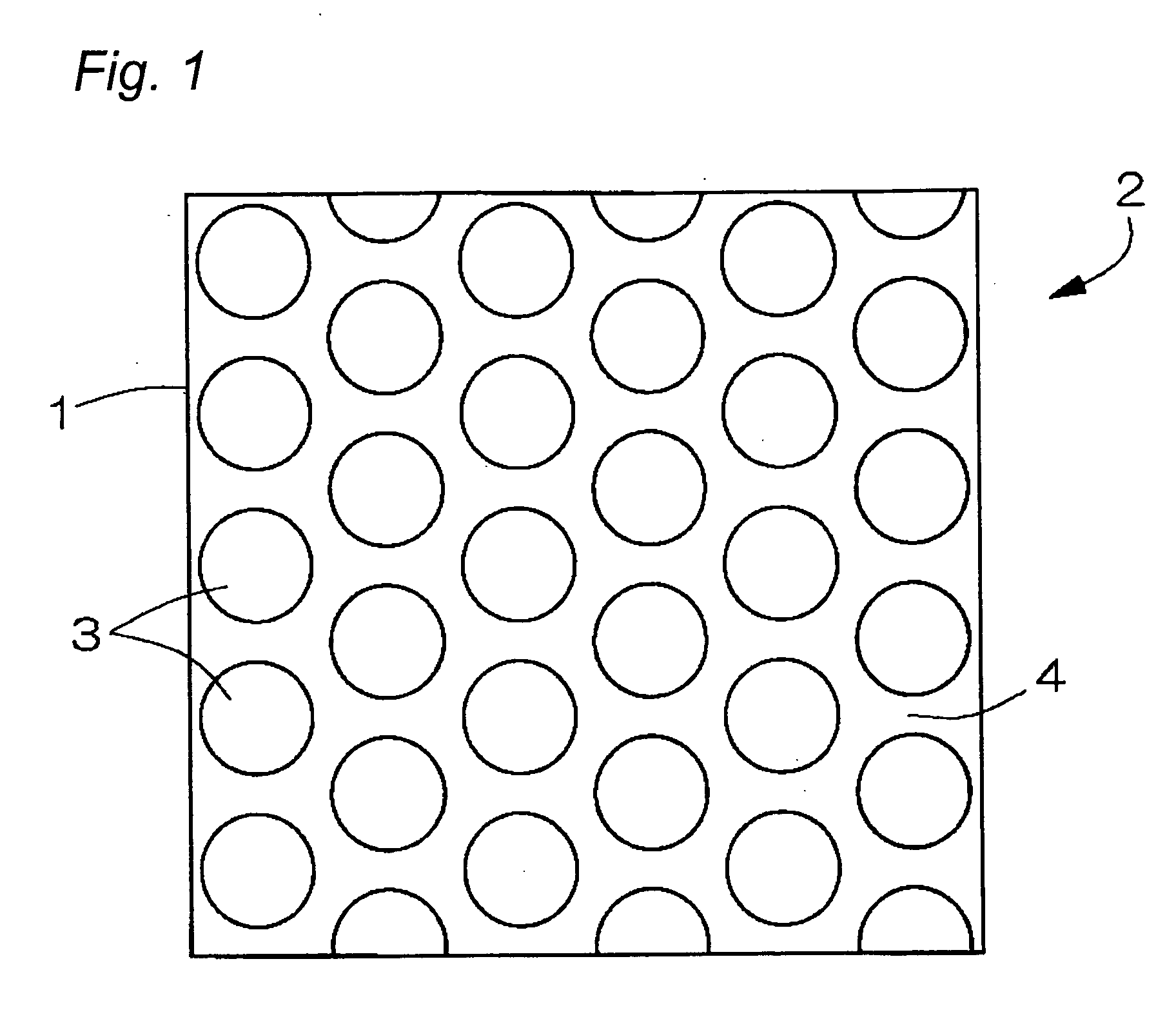

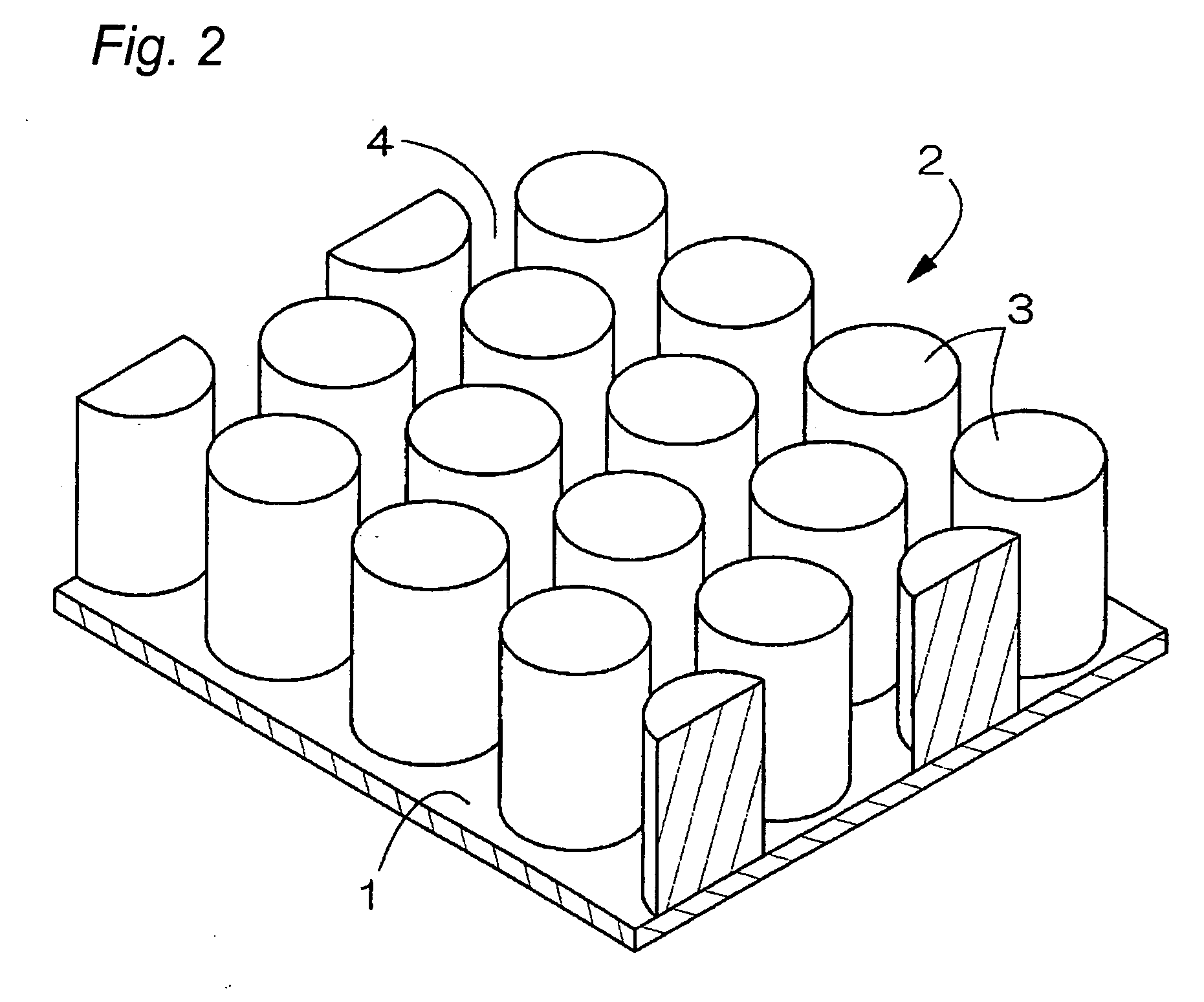

Electrode used for a non-aqueous electrolyte secondary battery and a non-aqueous electrolyte secondary battery using the same for a negative electrode

InactiveUS20050074671A1Increase capacityInsufficient releaseElectrode carriers/collectorsLi-accumulatorsPorosityMetallic materials

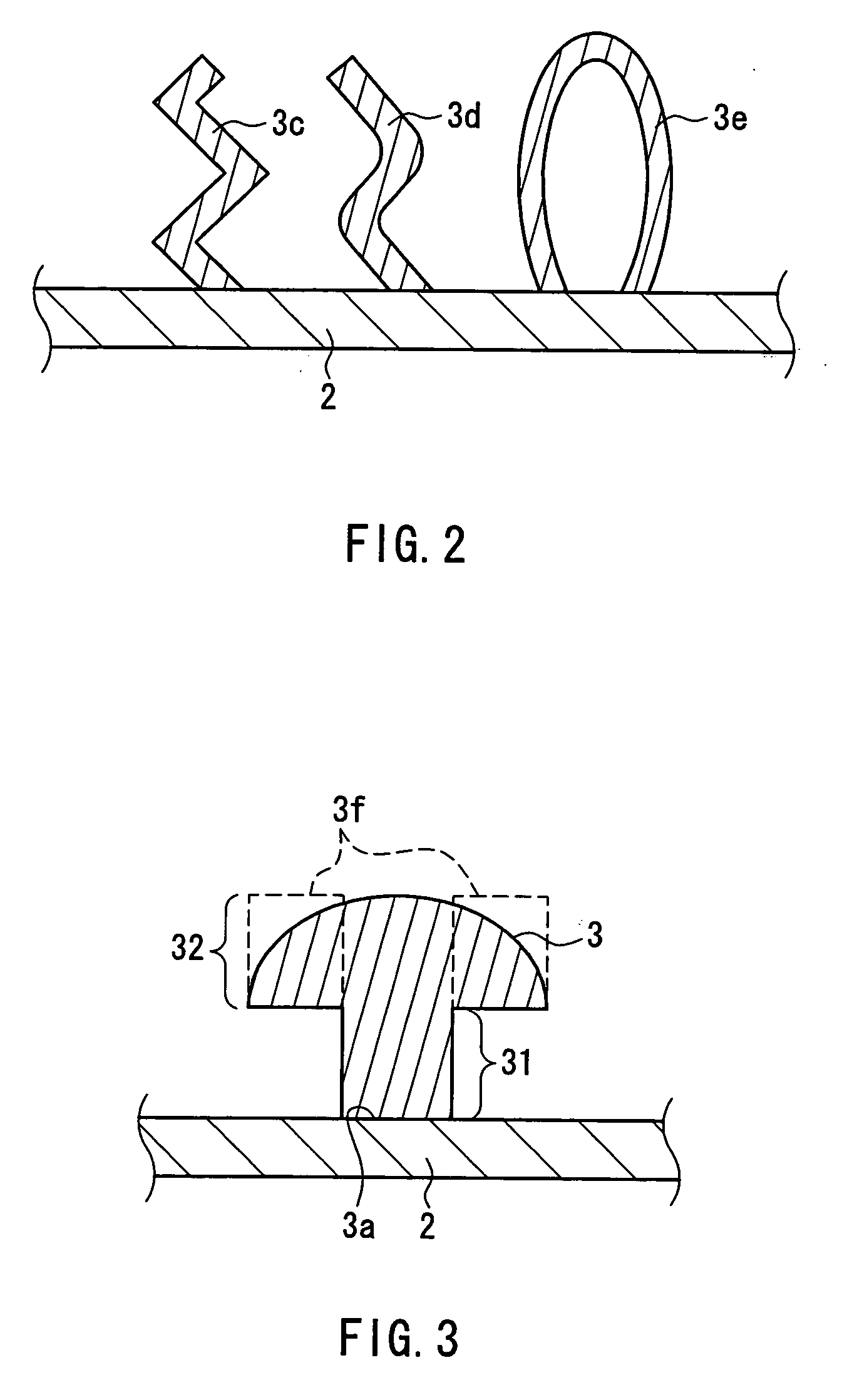

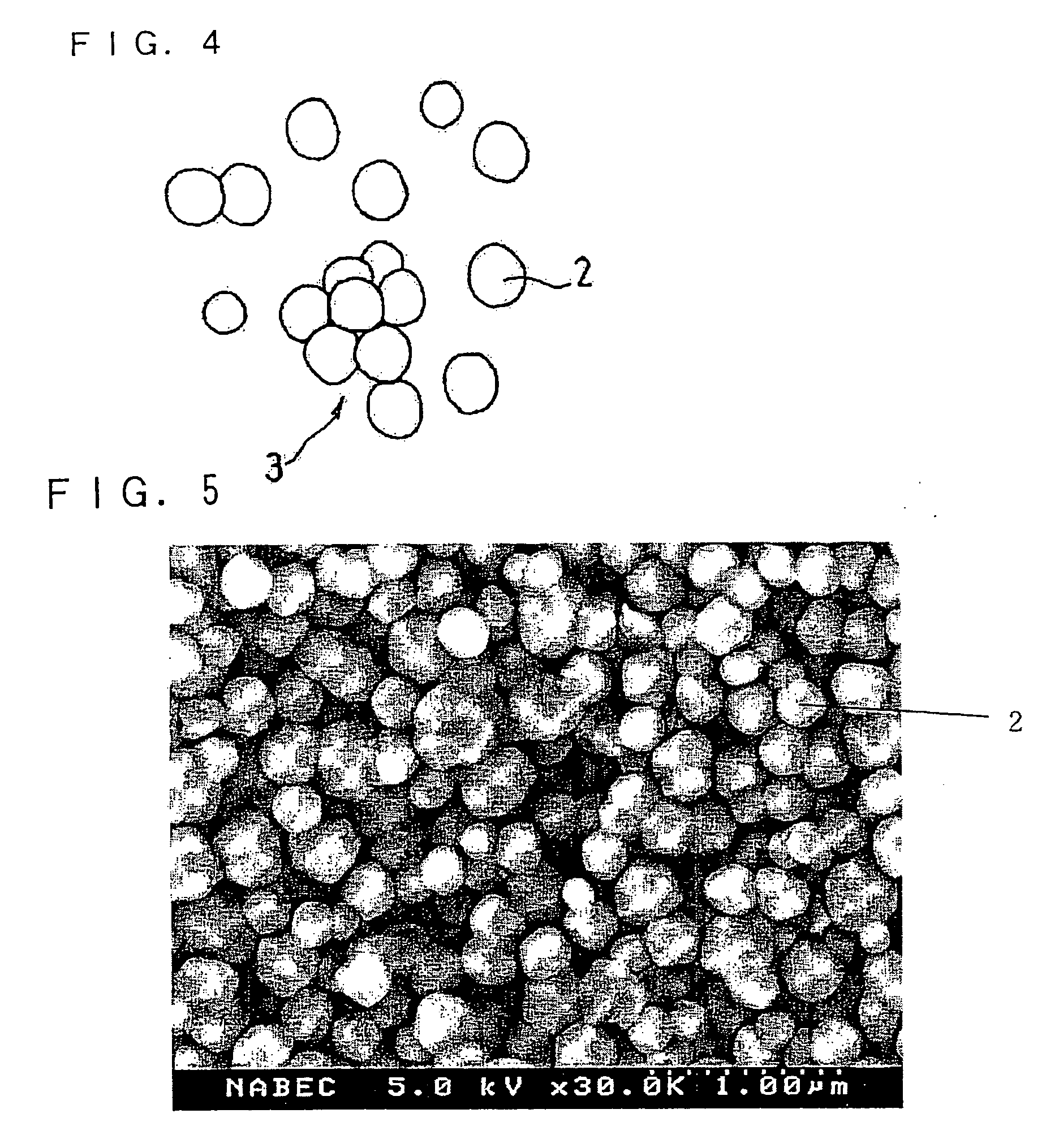

An electrode according to the invention can provide a non-aqueous electrolyte secondary battery having an ability to release a volume expansion at the time of charge and discharge as well as the time of a cycle. The electrode comprises a current collector made of a material which is not alloyed with Li, and a dot pattern 2 of a metallic material able to be alloyed with Li formed on the current collector. At the time of charge, since the volume expansion of each dot 3 is carried out so as to bury adjoining crevices 4 between the dots, a stress generated is released, thereby degradation of an electrode being avoided. Each dot may also be made into porosity.

Owner:HITACHI MAXELL ENERGY LTD

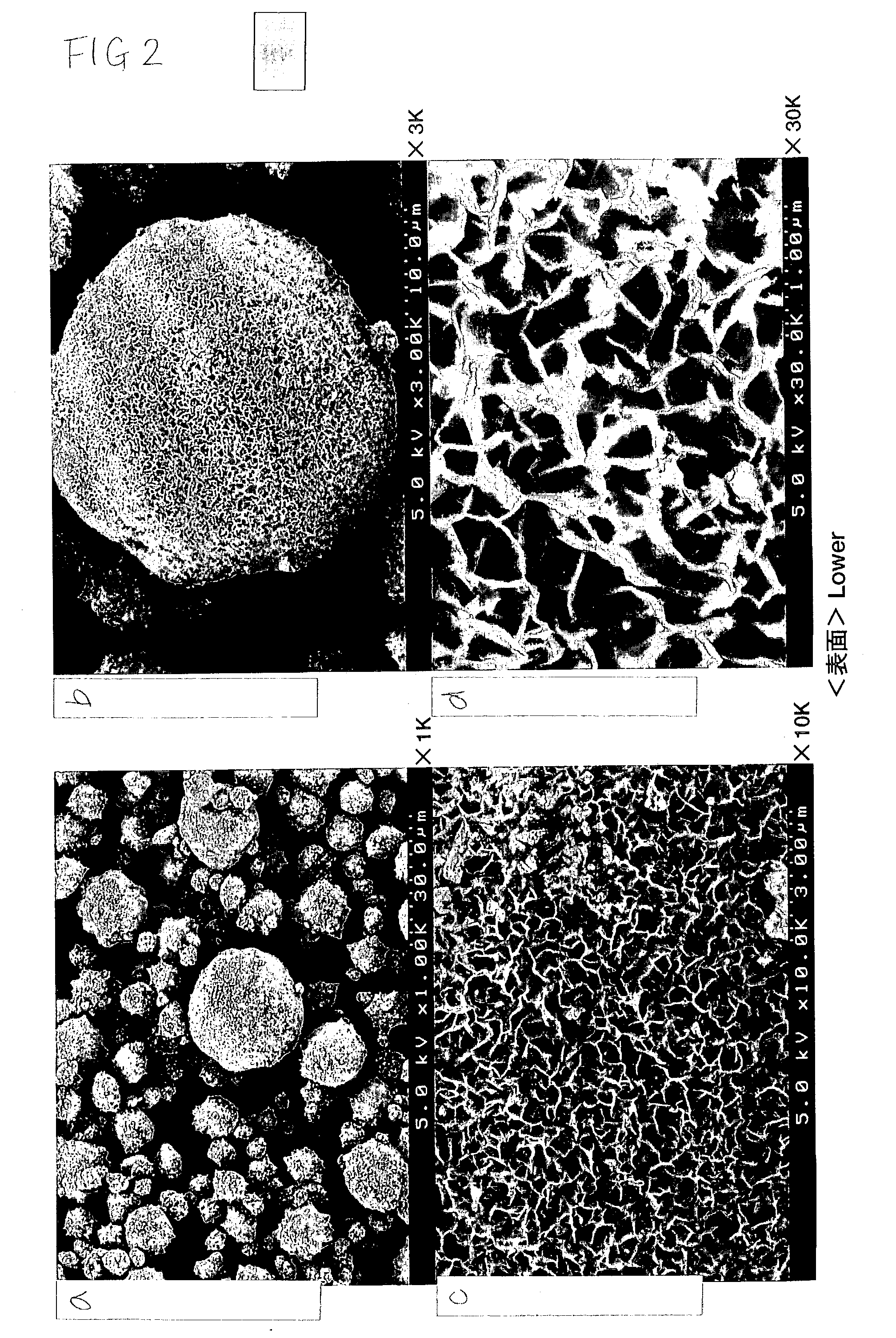

Positive electrode material for lithium ion battery with nonaqueous electrolyte, and battery using the same

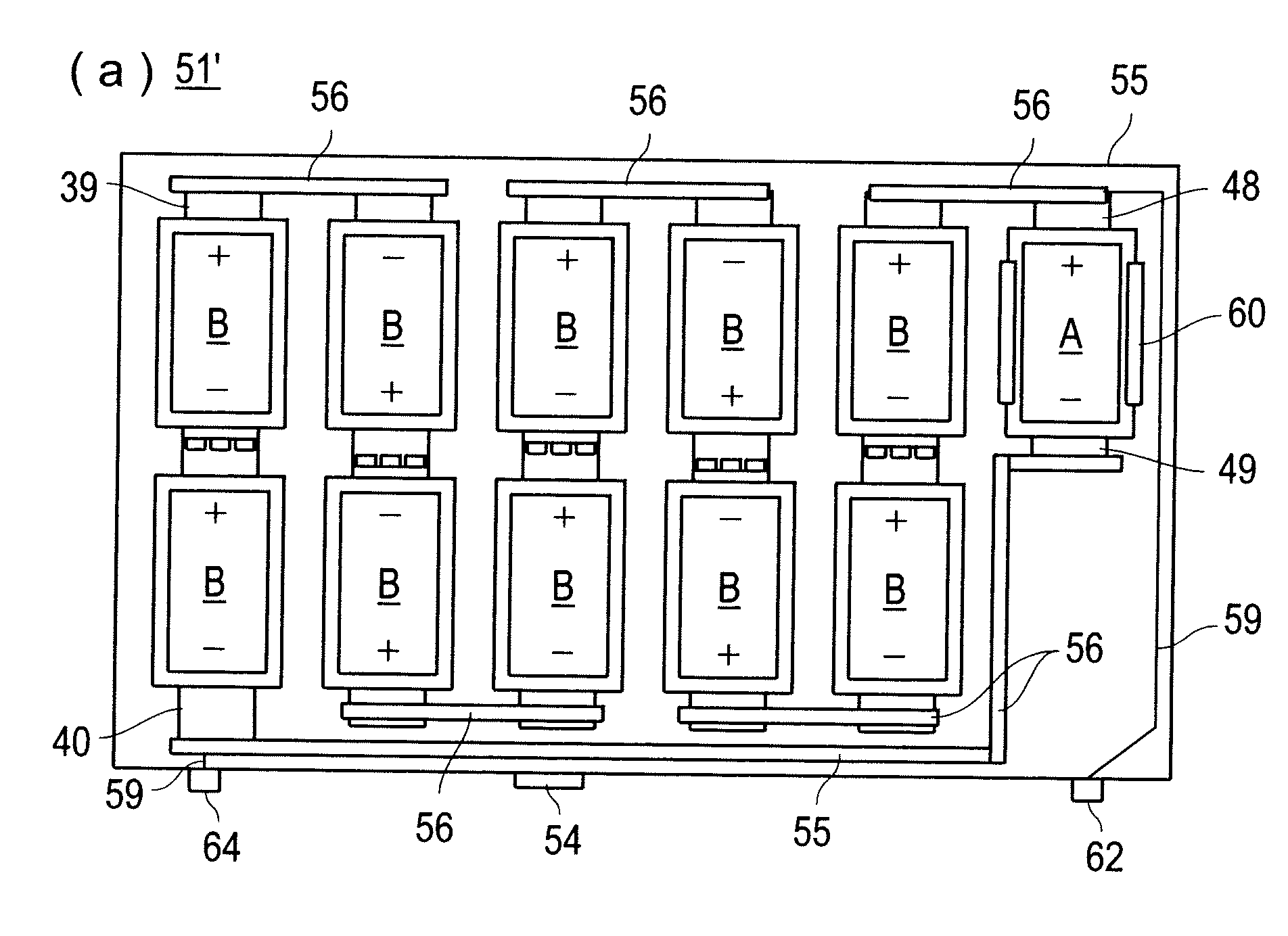

ActiveUS20090029253A1Increase output powerAvoid crackingSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsLithium-ion batteryComposite oxide

An object of the present invention is to provide a positive electrode material for non-aqueous electrolyte lithium-ion battery which capable of discharging high output power and inhibiting cracking of secondary particle in the cyclic endurance at a high temperature. The above object can be attained by a positive electrode material for non-aqueous electrolyte lithium-ion battery of the present invention, characterized in that said material comprises secondary particles composed of primary particles of lithium nickel composite oxide containing the primary particles having different aspect ratios, and that at least a part of said primary particles having different aspect ratios are arranged so as to make the longitudinal direction (the long side direction) thereof oriented toward the center of the secondary particle.

Owner:ENVISION AESC JAPAN LTD +1

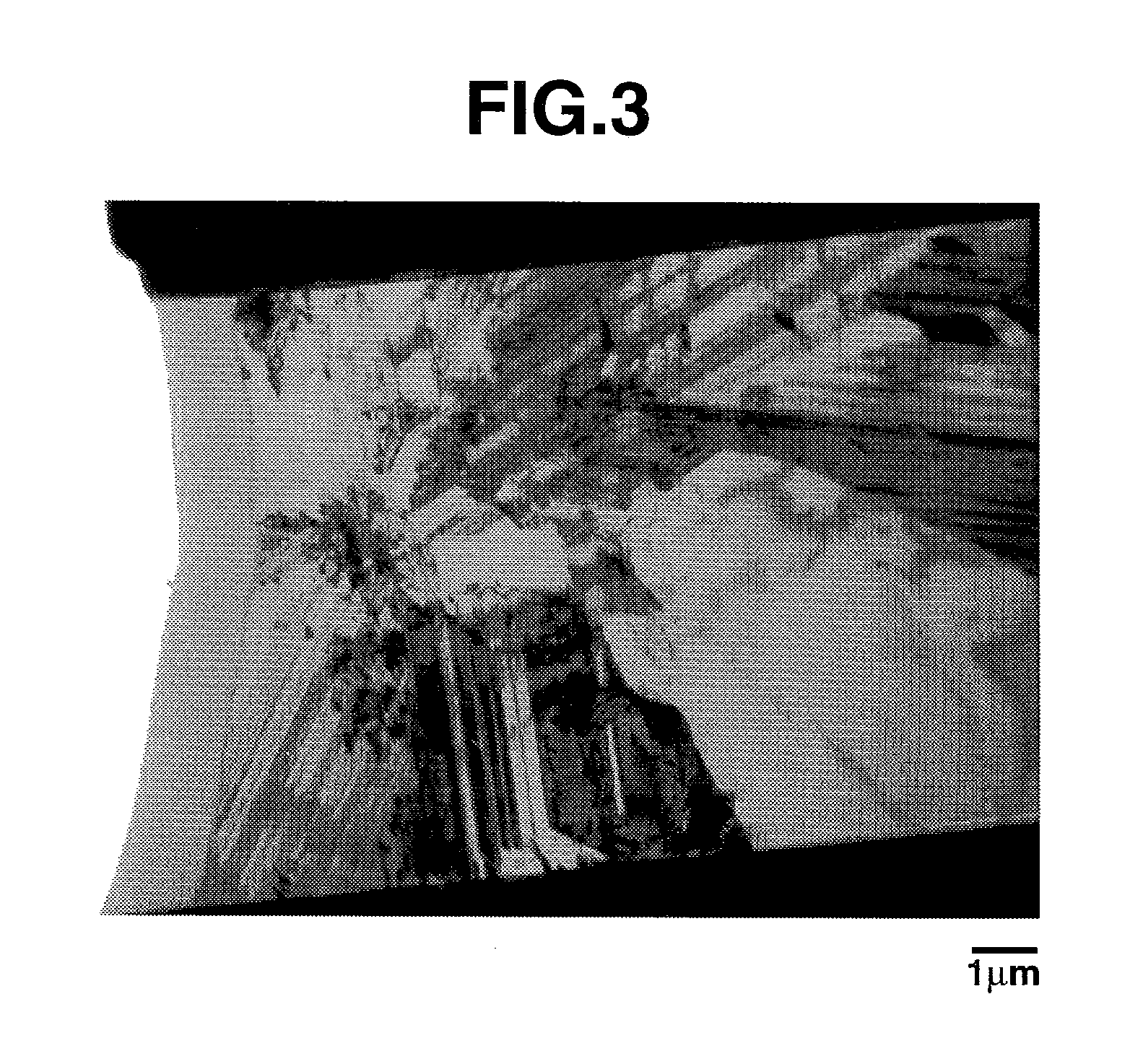

Process for manufacture of negative electrode material for a non-aqueous electrolyte secondary battery

InactiveUS20030175589A1Maintain good propertiesReduce battery sizeSolid electrolytesElectrode manufacturing processesAlloySolid solution

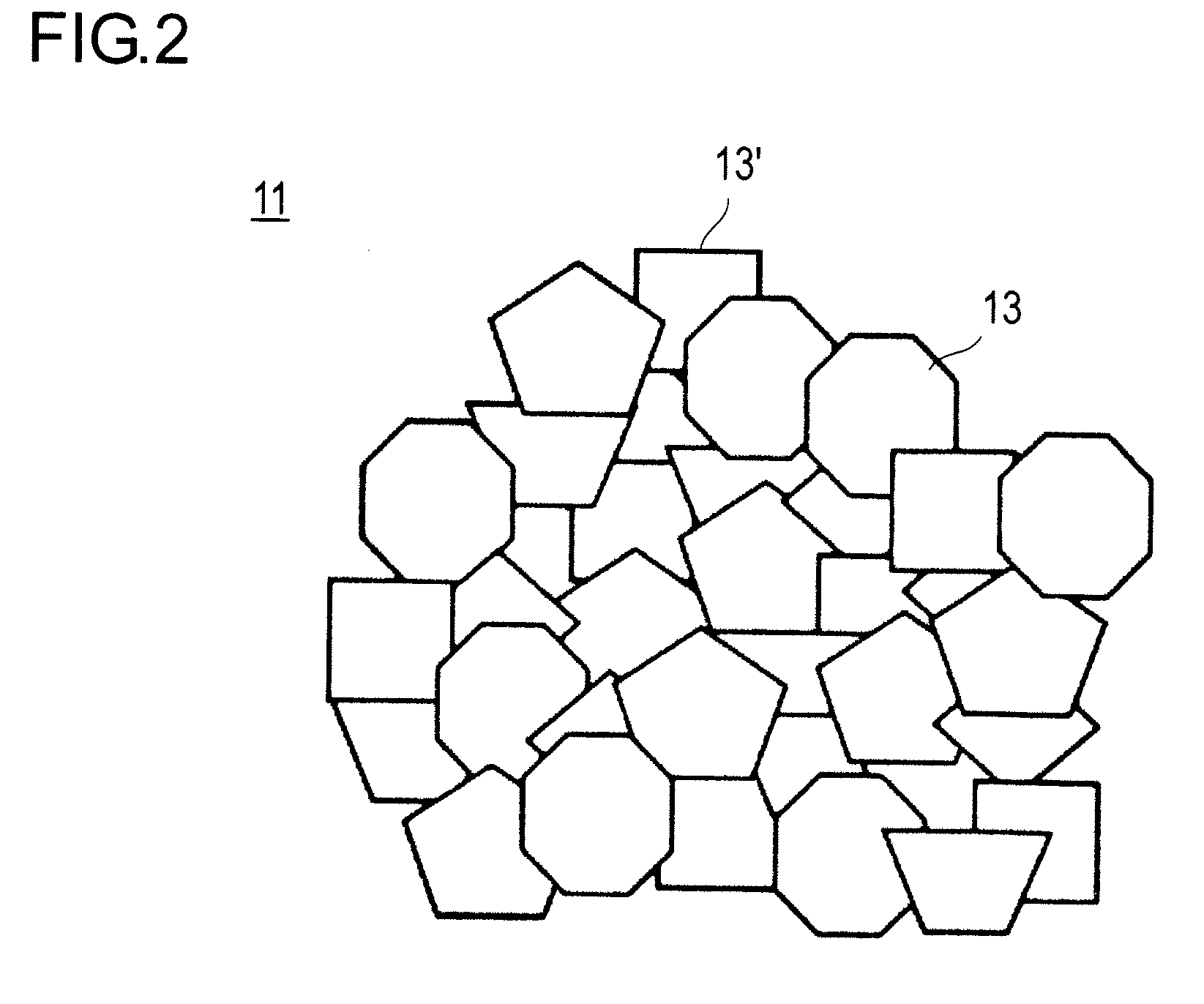

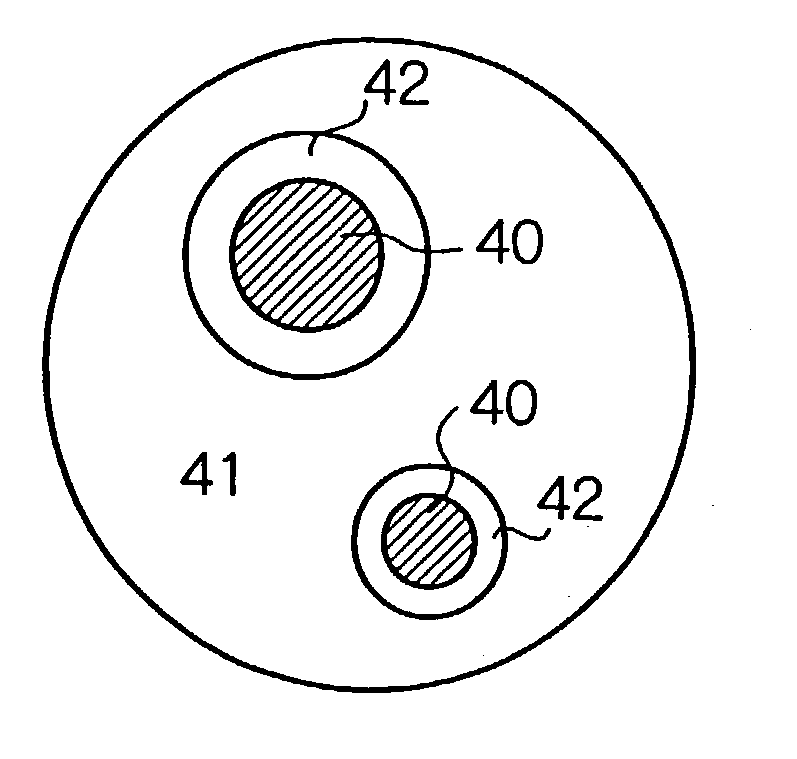

A negative electrode material for a nonaqueous electrolyte secondary battery having a high discharge capacity and a good cycle life is made from alloy particles having an average particle diameter of 0.1-50 mum and including Si phase grains 40 and a phase of a solid solution or an intermetallic compound of Si and other element selected from Group 2A elements, transition elements, Group 3B elements, and Group 4B elements from the long form periodic table (for example, an NiSi2 phase 42 and an [NiSi2+NiSi] phase 41) at least partially enveloping the Si phase grains. 5-99 wt % of this material is Si phase grains. The alloy particles can be manufactured by rapid solidification (such as atomization or roller quenching) of a melt including Si and the other element, or by adhering the other element to Si powder by electroless plating or mechanical alloying and then performing heat treatment. Even if rapid solidification is carried out, a negative electrode material having a good discharge capacity and cycle life is obtained without heat treatment.

Owner:CHUO DENKI KOGYO CO LTD

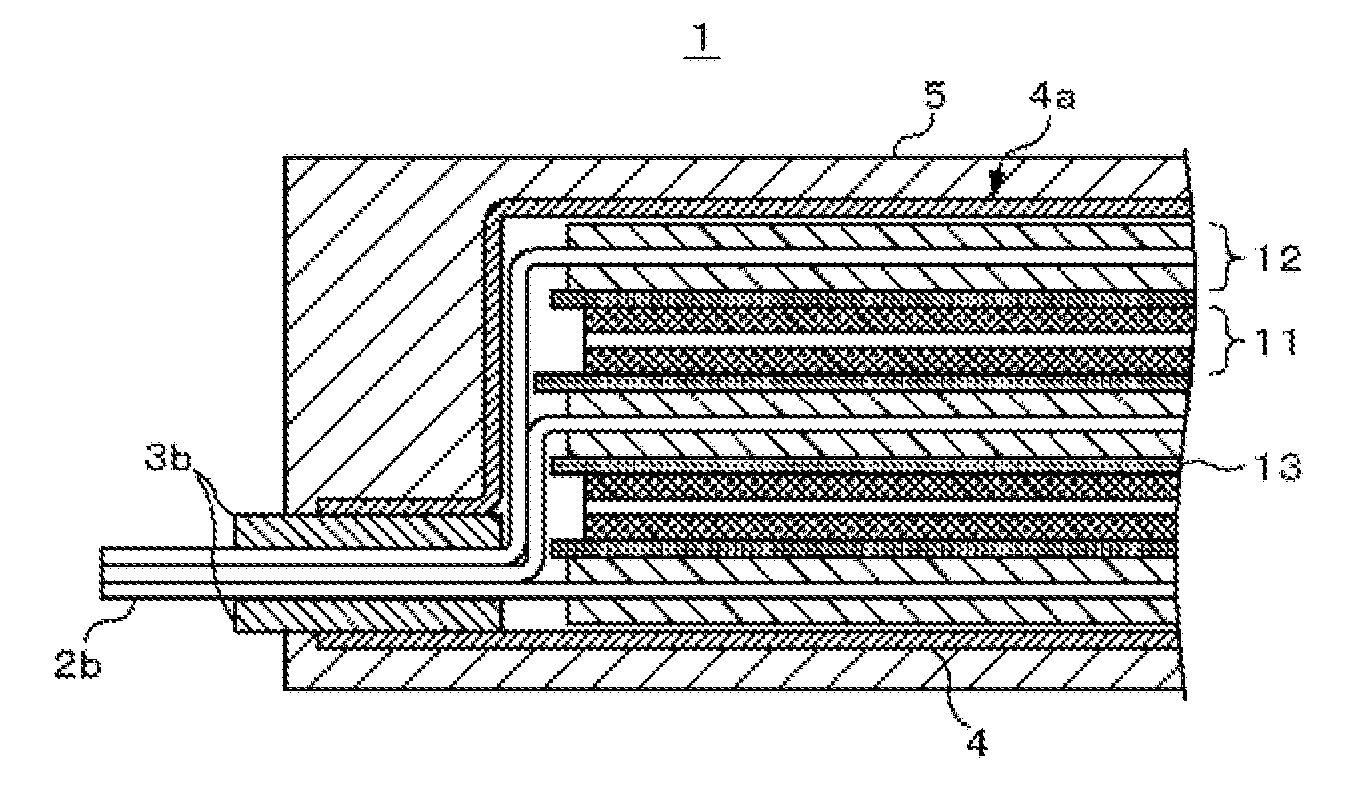

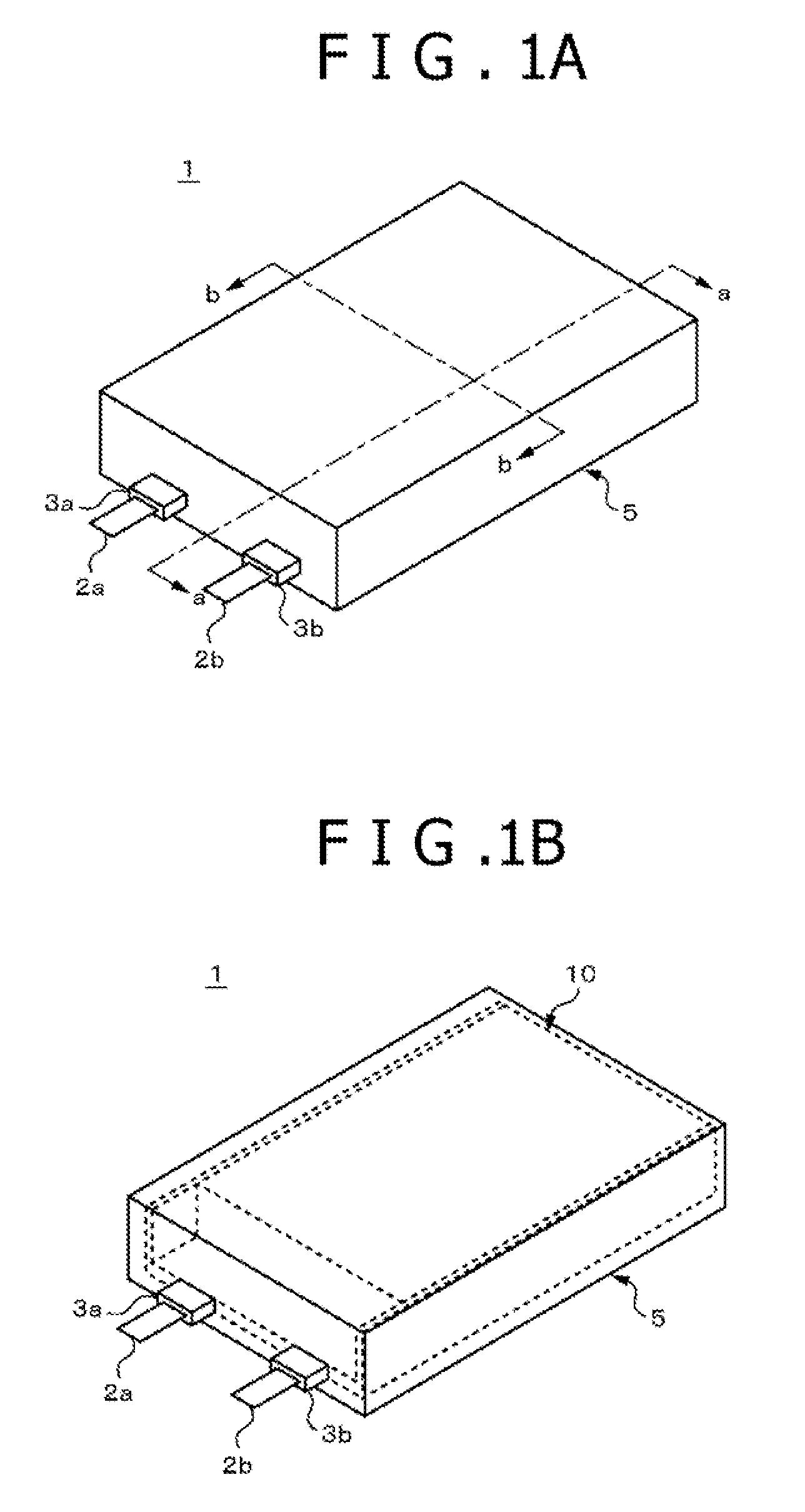

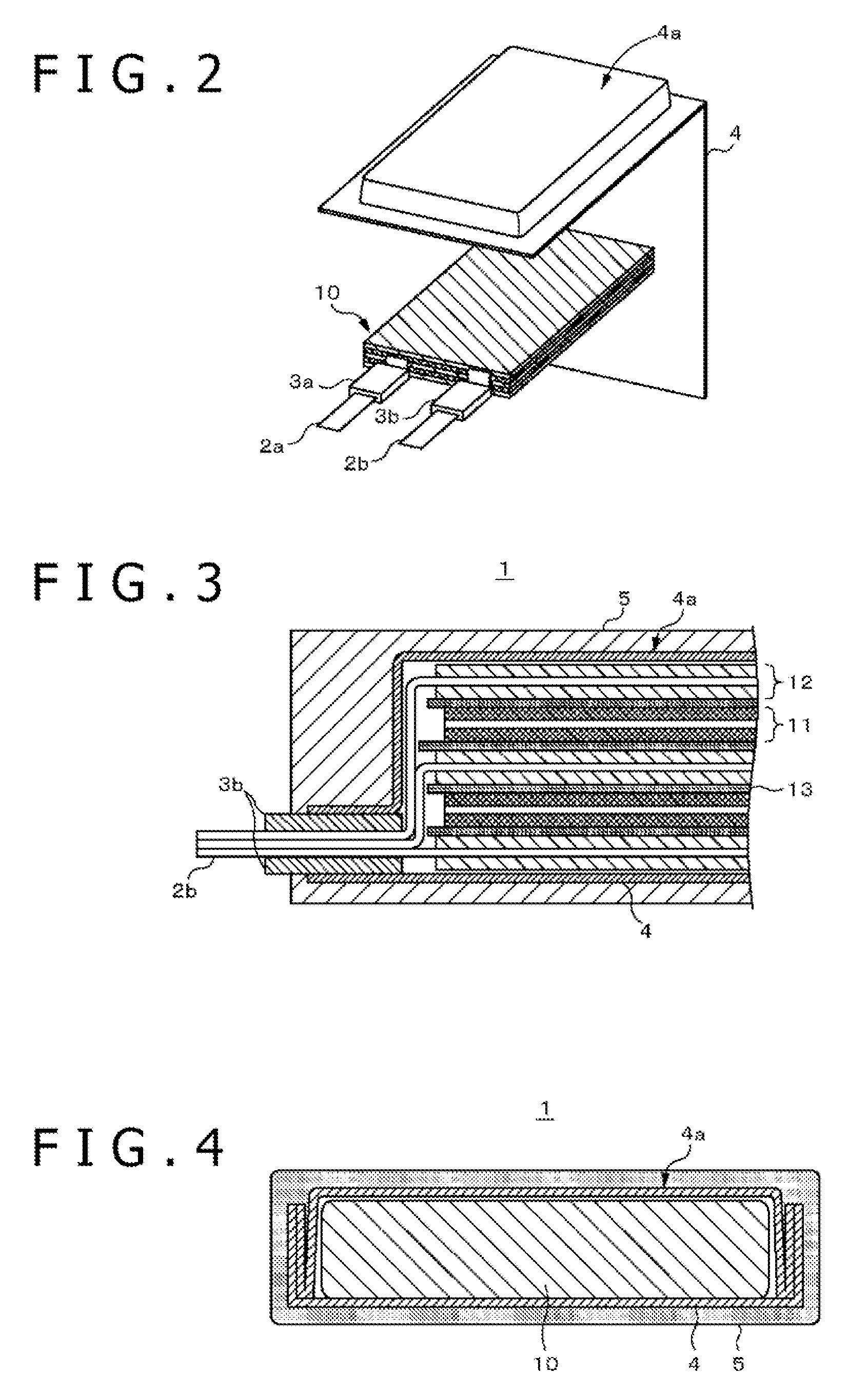

Non-aqueous electrolyte battery and method for producing the same

ActiveUS20090186270A1Improving battery strengthHigh strengthFinal product manufacturePrimary cellsEngineeringNon aqueous electrolytes

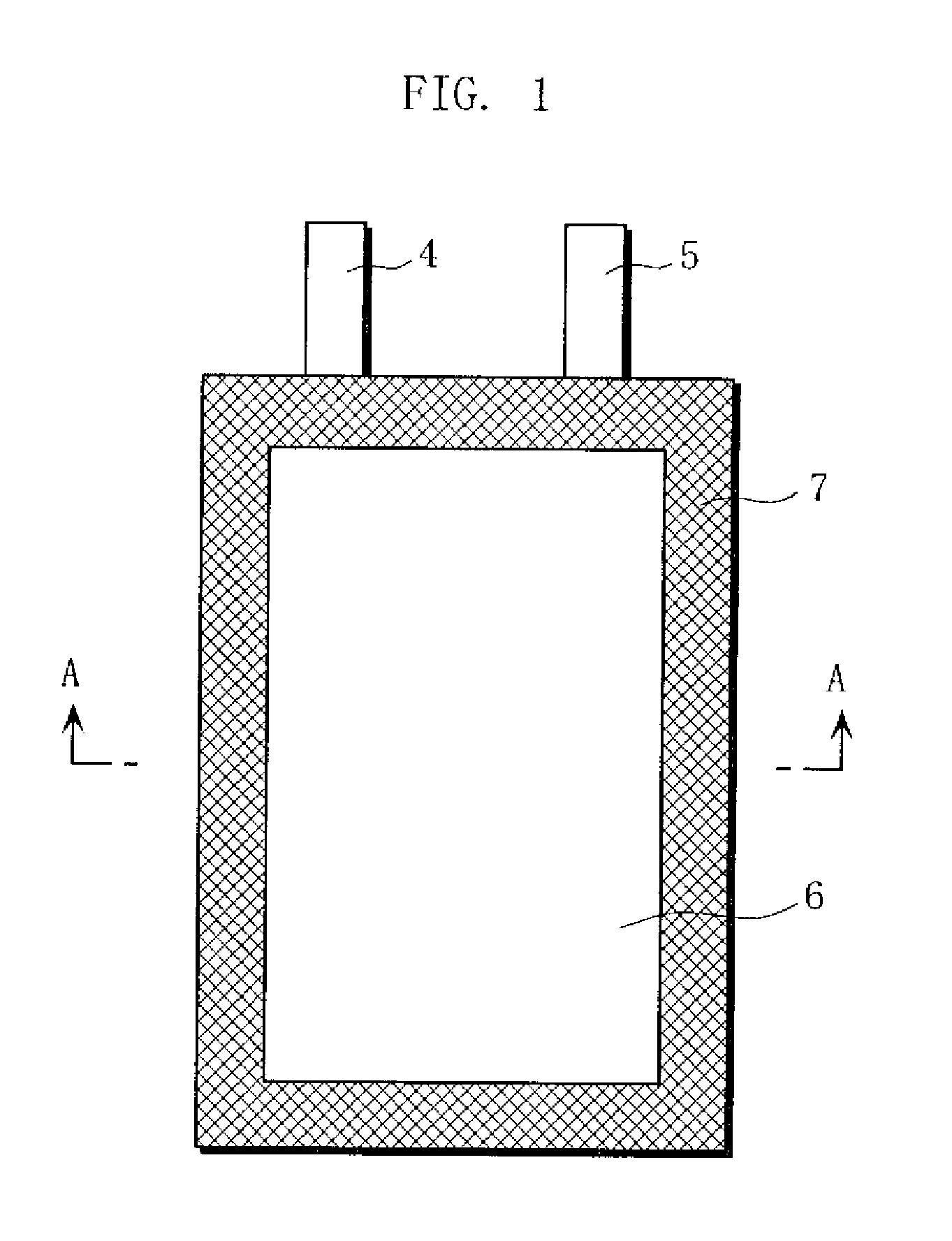

A non-aqueous electrolyte battery includes a battery element, a film-form casing member, and a resin protective layer. The battery element includes a positive electrode, a negative electrode, and a separator disposed between the positive electrode and the negative electrode. The film-form casing member contains the battery element and an electrolyte in an enclosed space thereof. The resin protective layer is formed along the surface of the film-form casing member and has a substantially uniform thickness.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com