Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6664 results about "Solid solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A solid solution is a solid-state solution of one or more solutes in a solvent. Such a multi-component system is considered a solution rather than a compound when the crystal structure of the solvent remains unchanged by addition of the solutes, and when the chemical components remain in a single homogeneous phase. This often happens when the two elements (generally metals) involved are close together on the periodic table; conversely, a chemical compound generally results when two metals involved are not near each other on the periodic table.

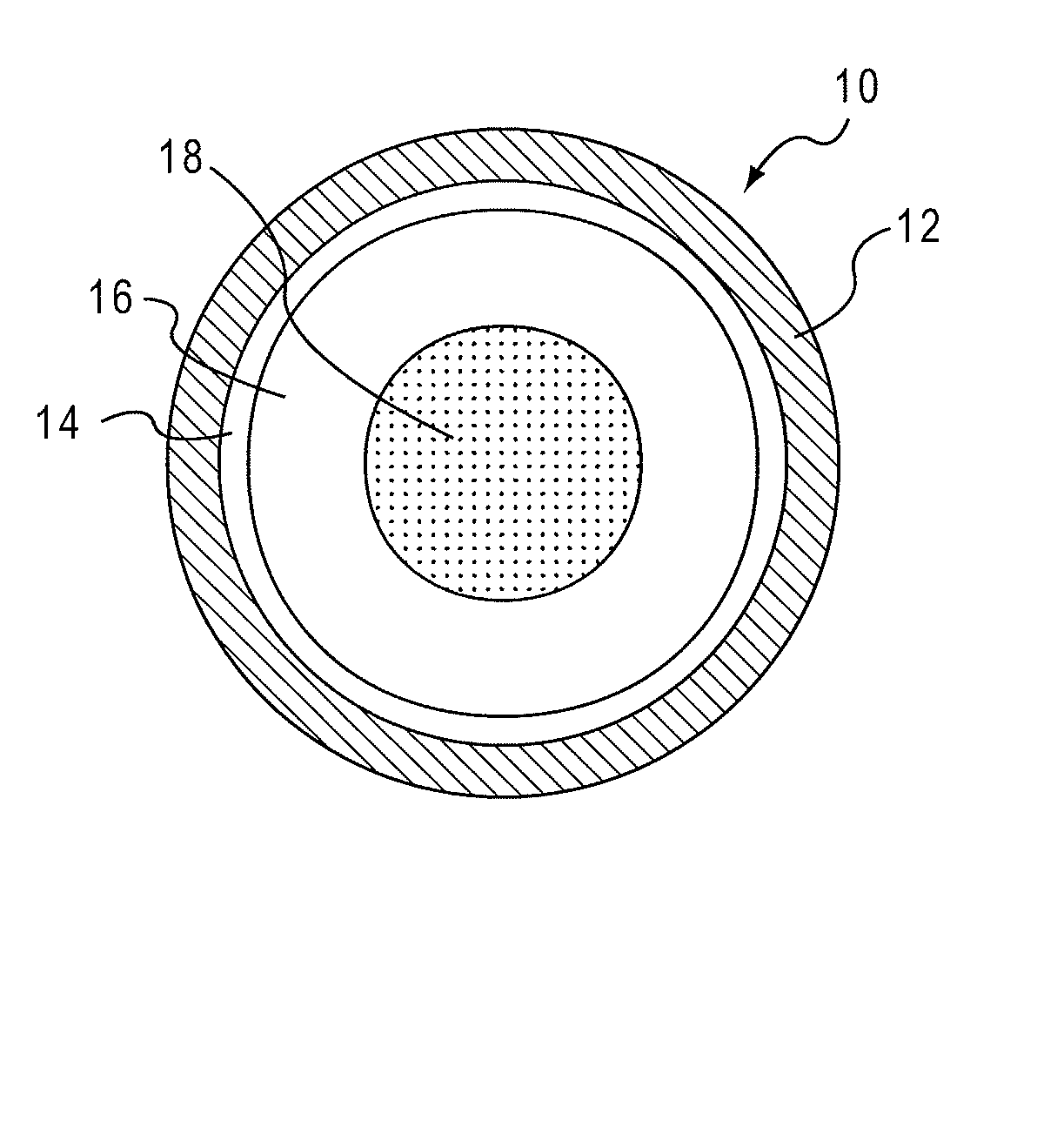

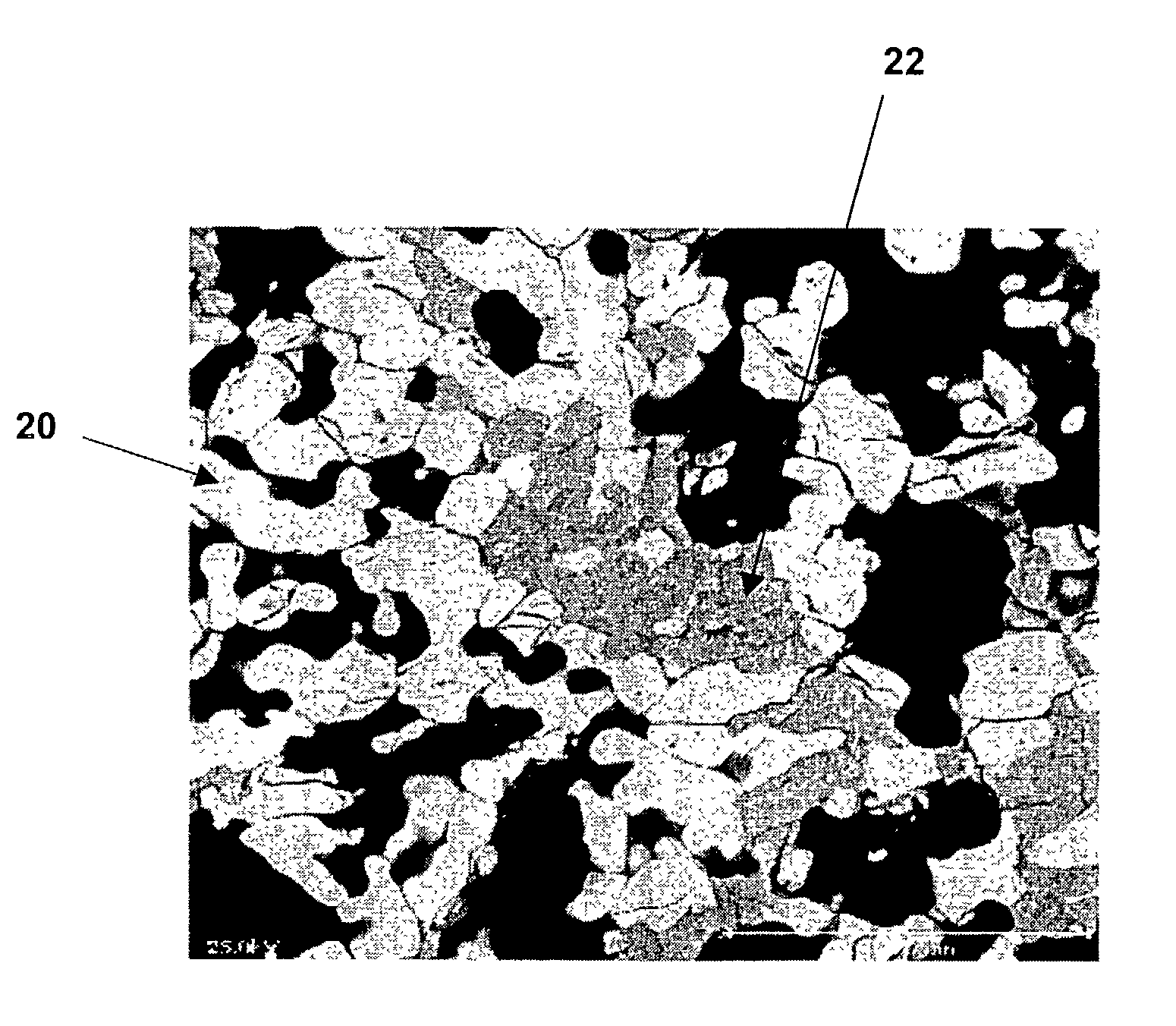

Oral transmucosal drug dosage using solid solution

InactiveUS6264981B1High dissolution rateEasy to usePharmaceutical non-active ingredientsPill deliverySolid solutionPharmaceutical formulation

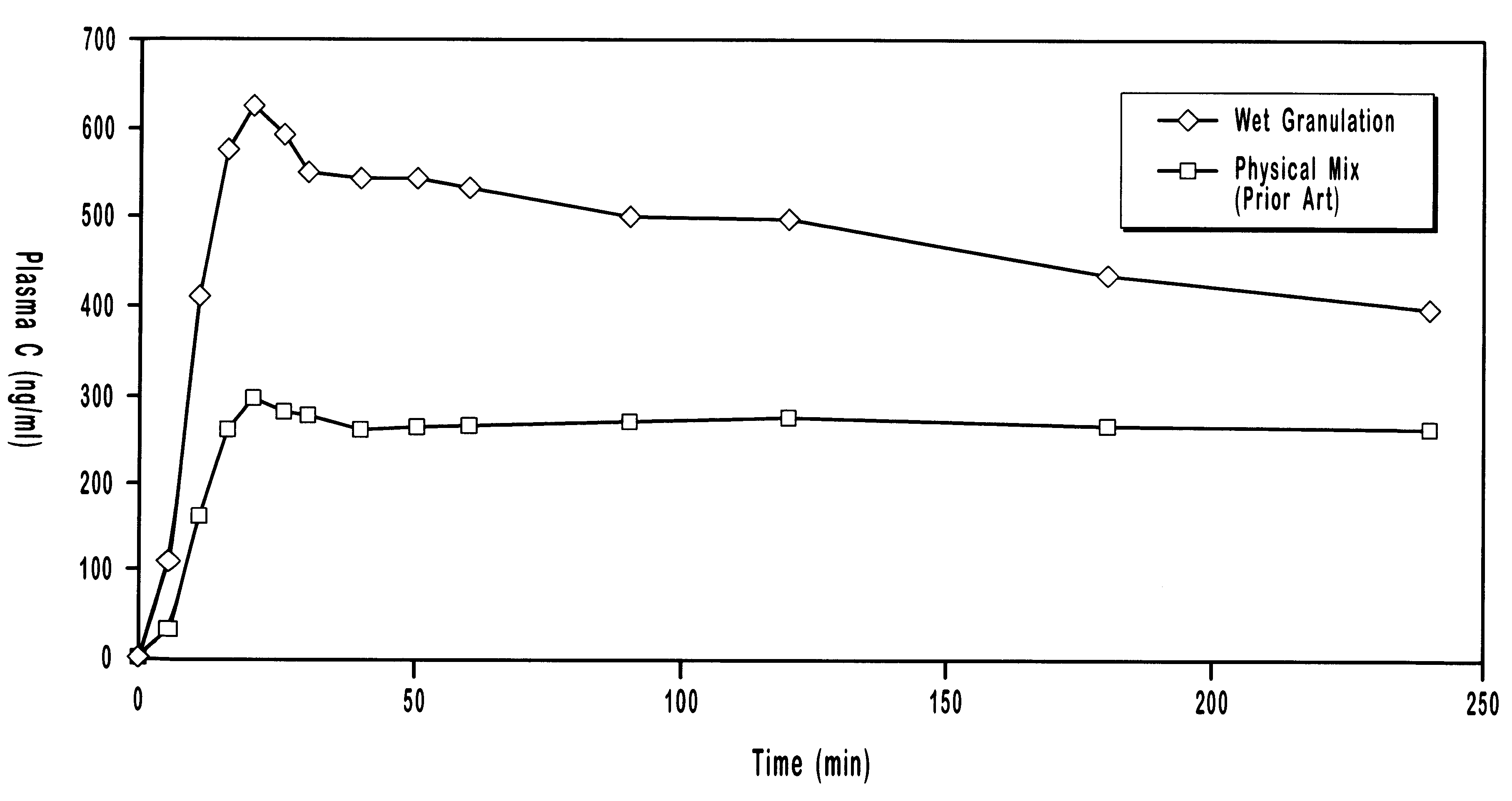

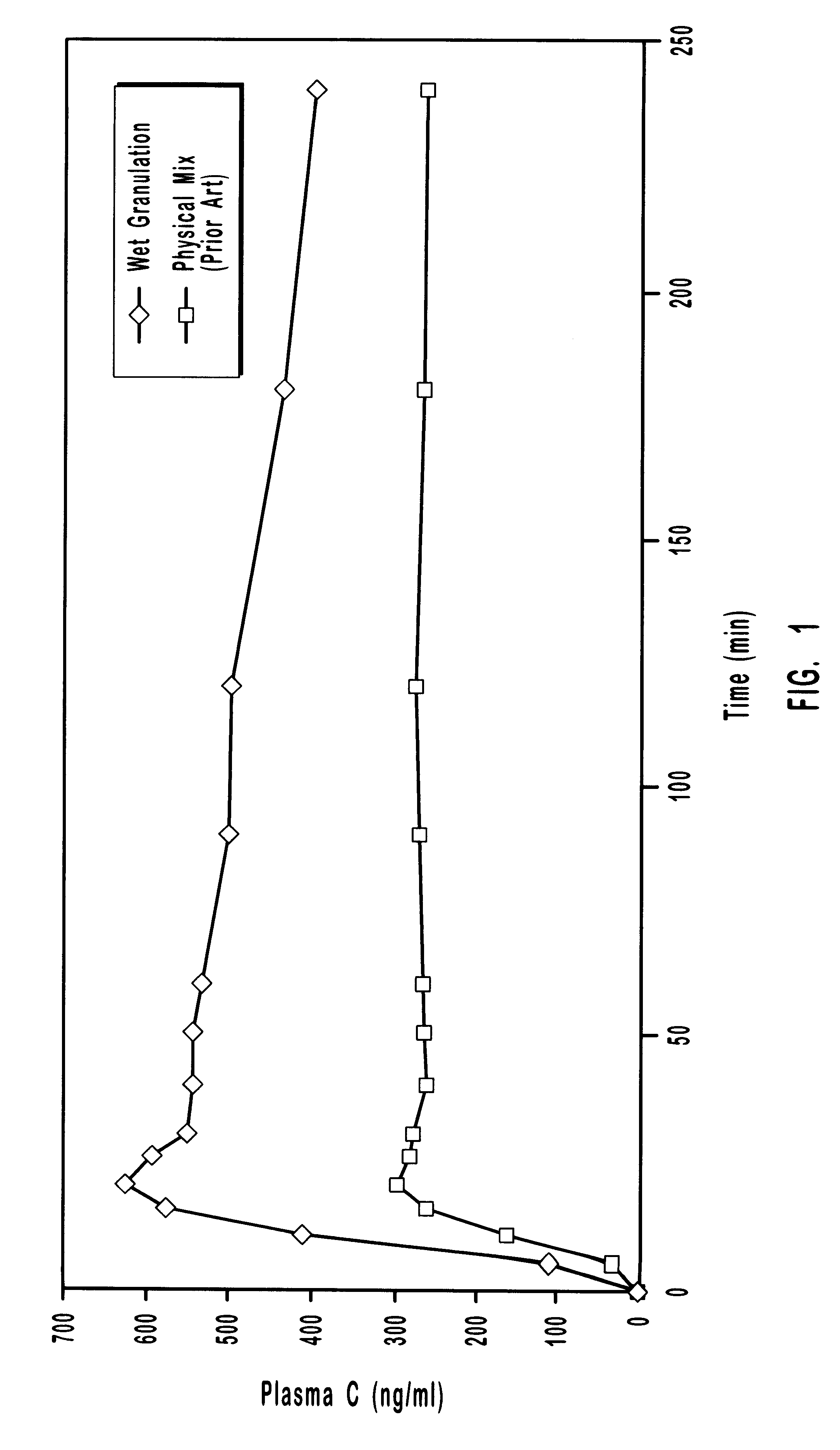

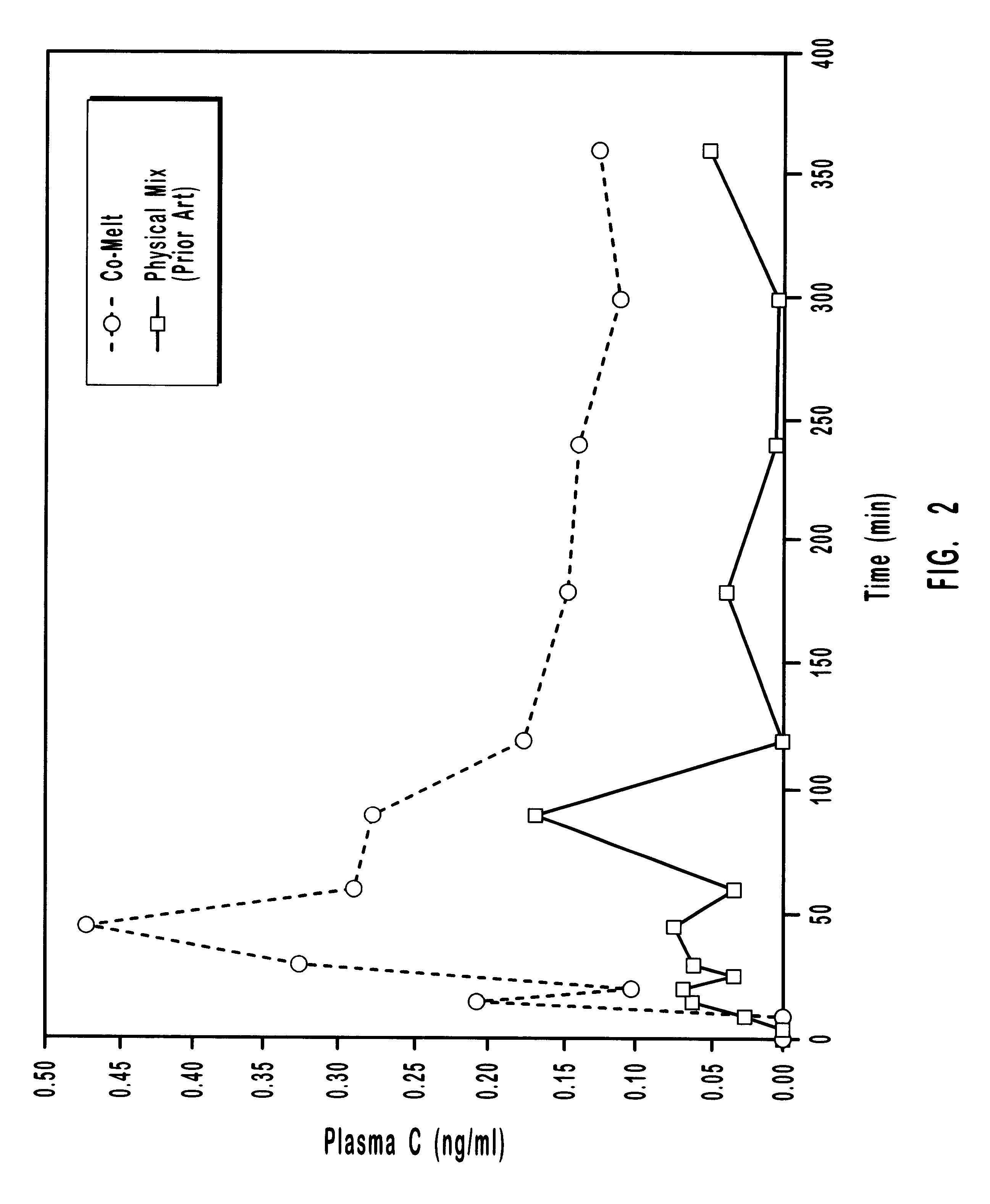

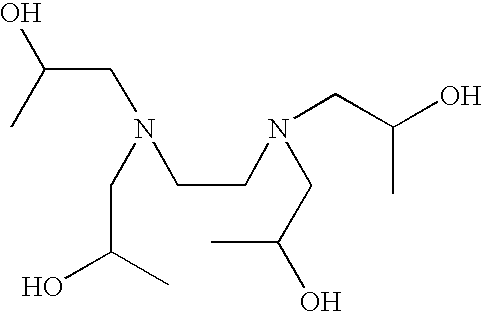

The present invention is directed toward formulation and method for oral transmucosal delivery of a pharmaceutical. The invention provides a drug formulation comprising a solid pharmaceutical agent in solid solution with a dissolution agent. The formulation is administered into a patient's oral cavity, delivering the pharmaceutical agent by absorption through a patient's oral mucosal tissue. The formulation and method provide for improved oral mucosal delivery of the pharmaceutical agent.

Owner:CEPHALON INC

Targeted delivery of active/bioactive and perfuming compositions

Described are controlled, time-release microparticulate active and bioactive compositions (including perfuming compositions) for targeted delivery to surfaces such as skin, hair and fabric and the environment proximate thereto, where the active and bioactive materials have a calculated log10P values of between 1 and 8 (P being the n-octanol-water partition coefficient). Such compositions include the active or bioactive material in single phase, solid solution in a wax or polymer matrix also having coated thereon and / or containing a compatible surfactant. Also described are processes and apparatus for preparing such compositions and processes for using same. Furthermore, certain component(s) of the aforementioned compositions in combination with one another are novel, and other components have novel uses in increasing fragrance substantivity, particularly in hair care preparations such as hair gels and shampoos.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

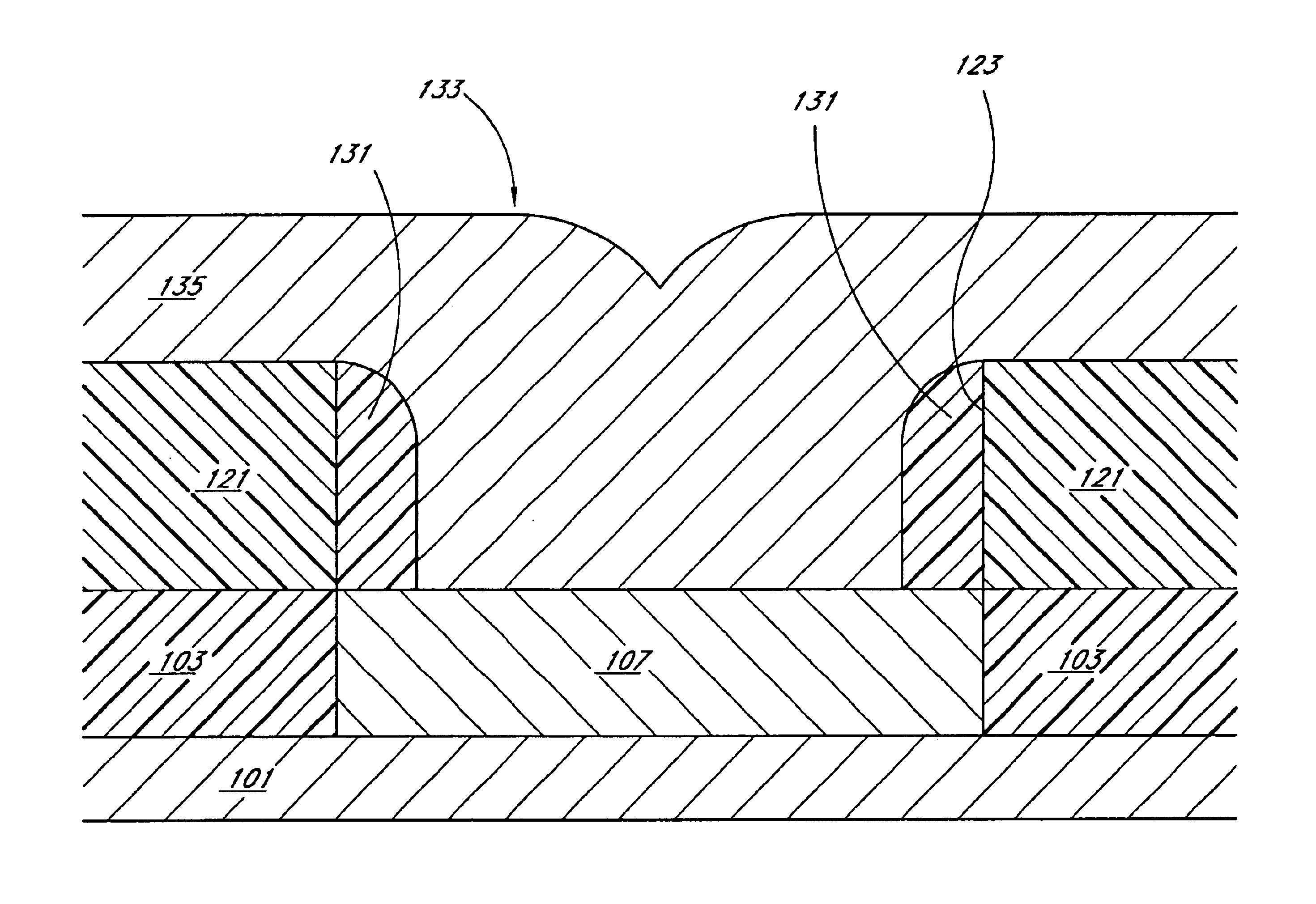

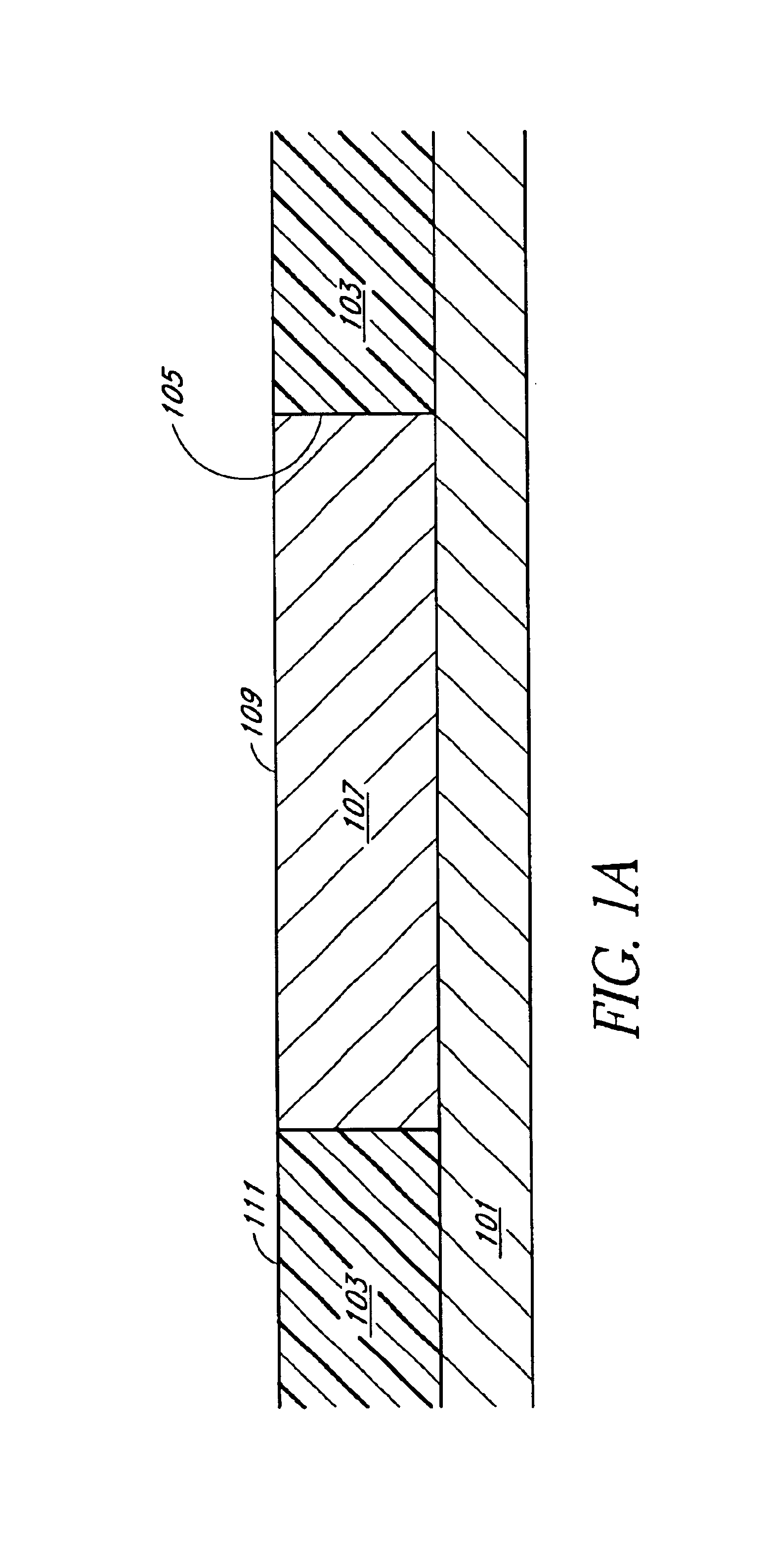

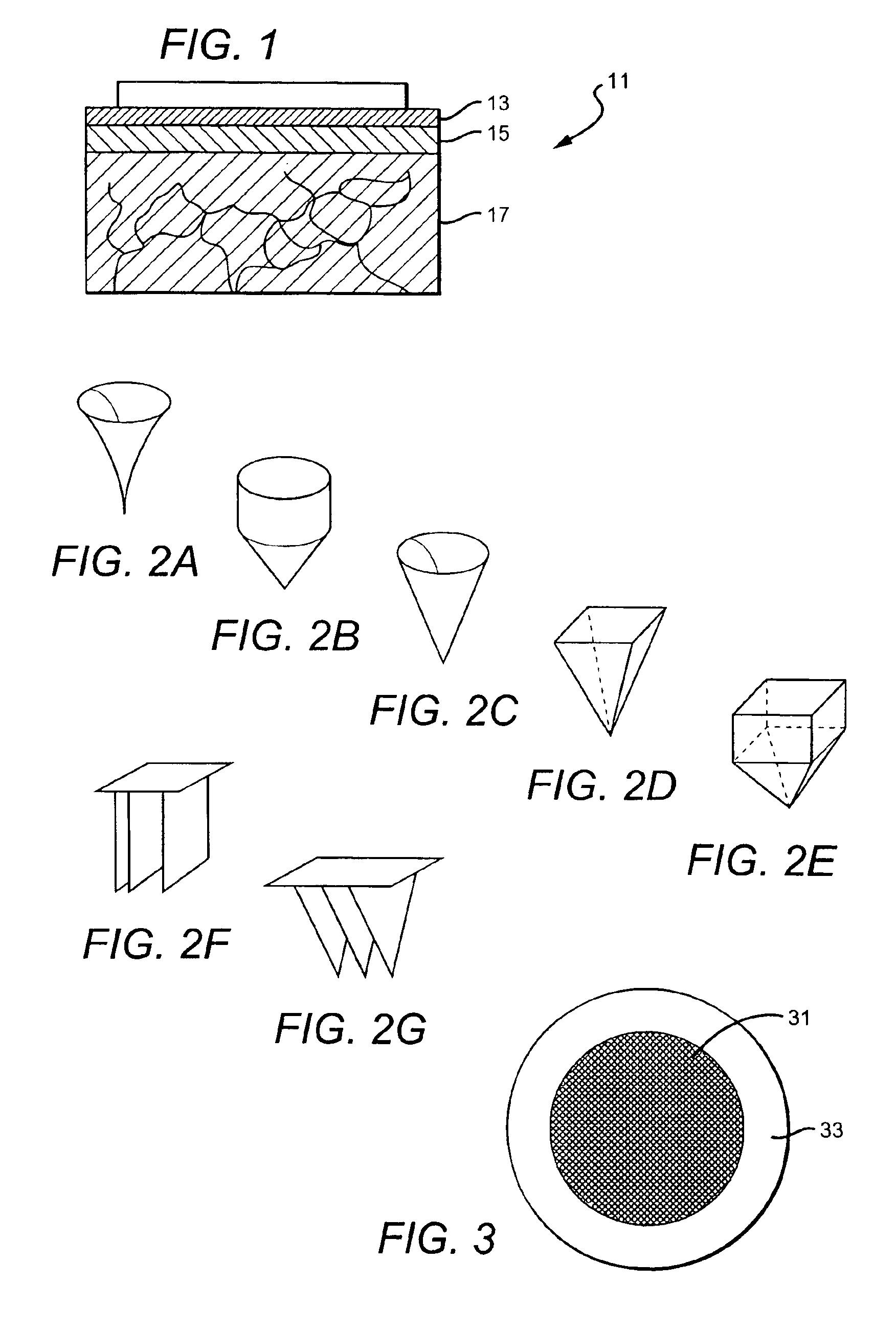

Programmable conductor memory cell structure

In programmable conductor memory cells, metal ions precipitate out of a glass electrolyte element in response to an applied electric field in one direction only, causing a conductive pathway to grow from cathode to anode. The amount of conductive pathway growth, and therefore the programming, depends, in part, on the availability of metal ions. It is important that the metal ions come only from the solid solution of the memory cell body. If additional metal ions are supplied from other sources, such as the sidewall edge at the anode interface, the amount of metal ions may not be directly related to the strength of the electric field, and the programming will not respond consistently from cell to cell. The embodiments described herein provide new and novel structures that block interface diffusion paths for metal ions, leaving diffusion from the bulk glass electrolyte as the only supply of metal ions for conductive pathway formation.

Owner:OVONYX MEMORY TECH LLC

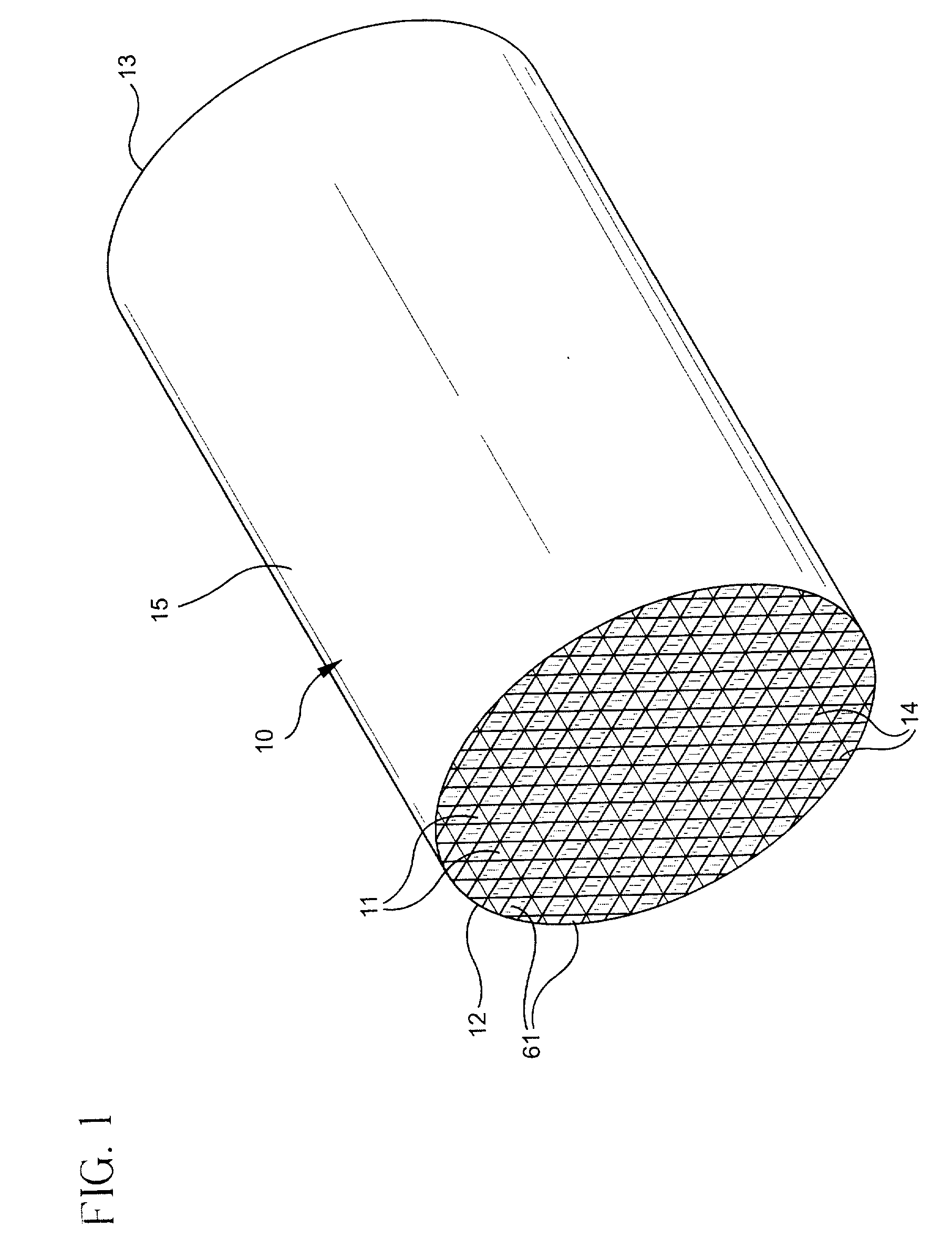

Apparatus for preparing a solid phase microparticulate composition

InactiveUS6042792ALow costImproved substantivityCosmetic preparationsComponent separationWaxMicroparticle

Described are controlled, time-release microparticulate active and bioactive compositions (including perfuming compositions) for targeted delivery to services such as skin, hair and fabric and the environment proximate thereto, where the active and bioactive materials have a calculated log10P values of between 1 and 8 (P being the n-octanol-water partition coefficient). Such compositions include the active or bioactive material in single phase, solid solution in a wax or polymer matrix also having coated thereon and / or containing a compatible surfactant. Also described are processes and apparatus for preparing such compositions and processes for using same. Furthermore, certain component(s) of the aforementioned compositions in combination with one another are novel, and other components have novel uses in increasing fragrance substantivity.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

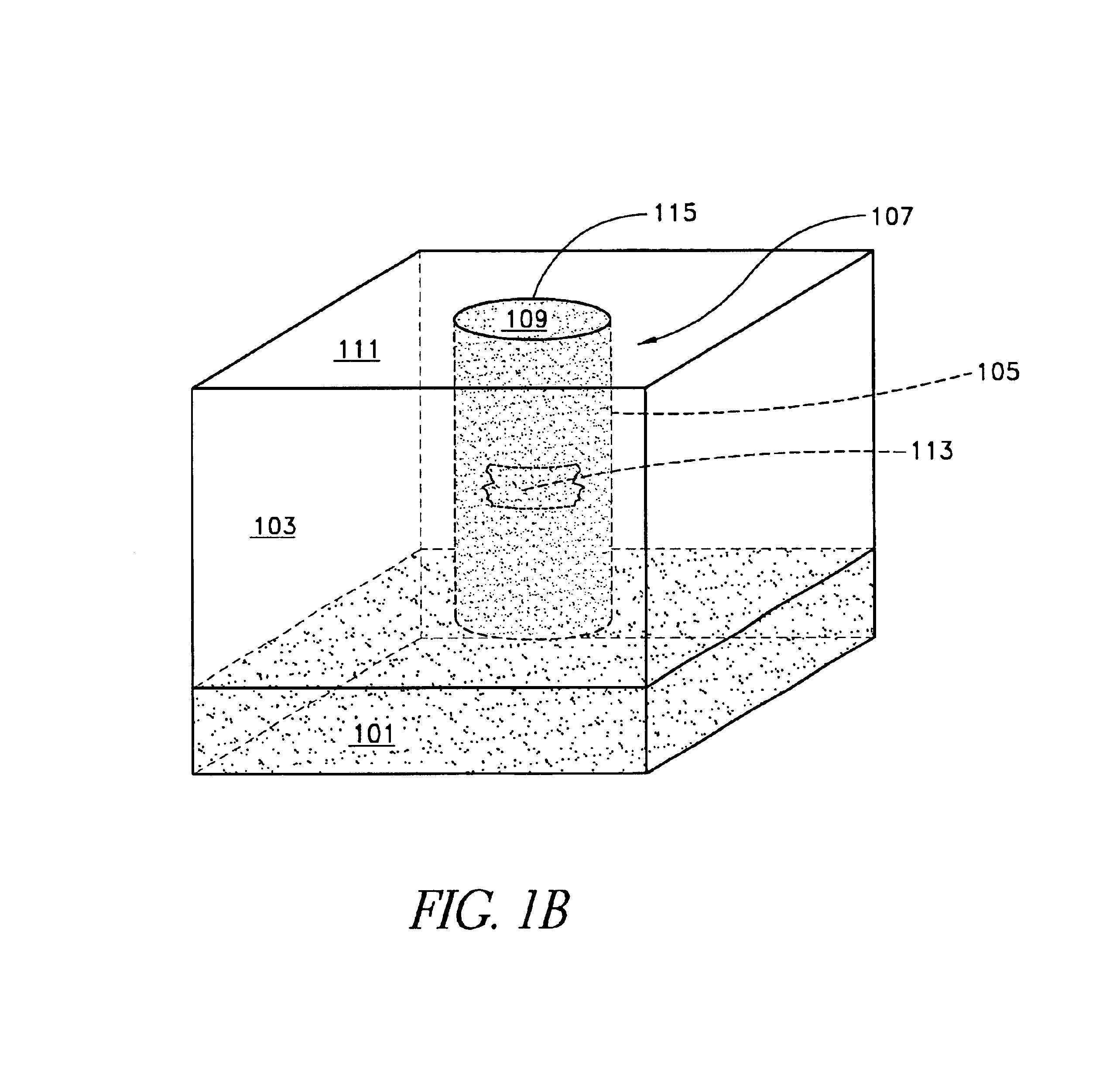

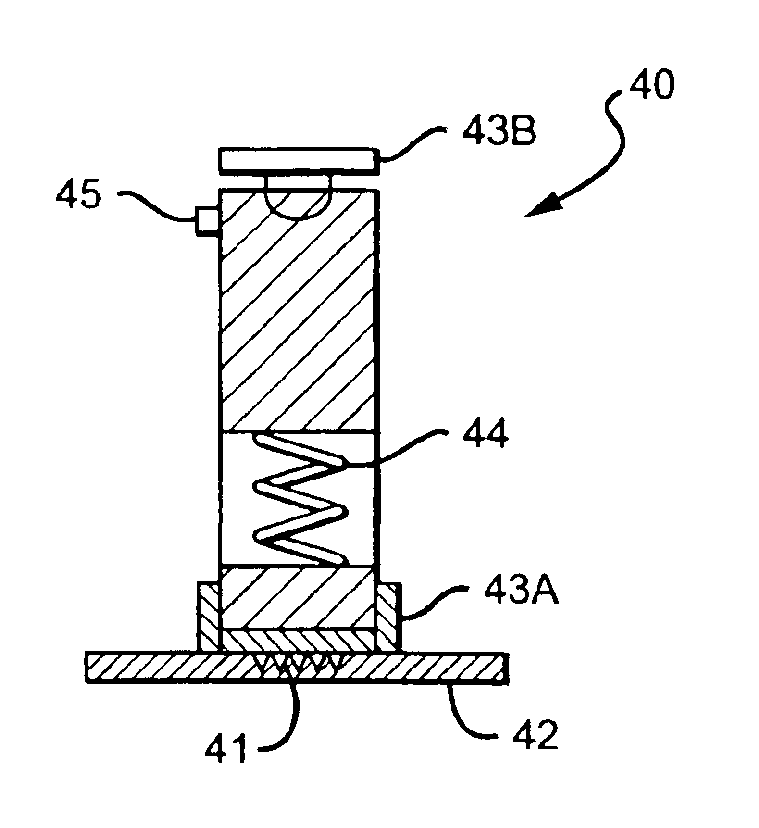

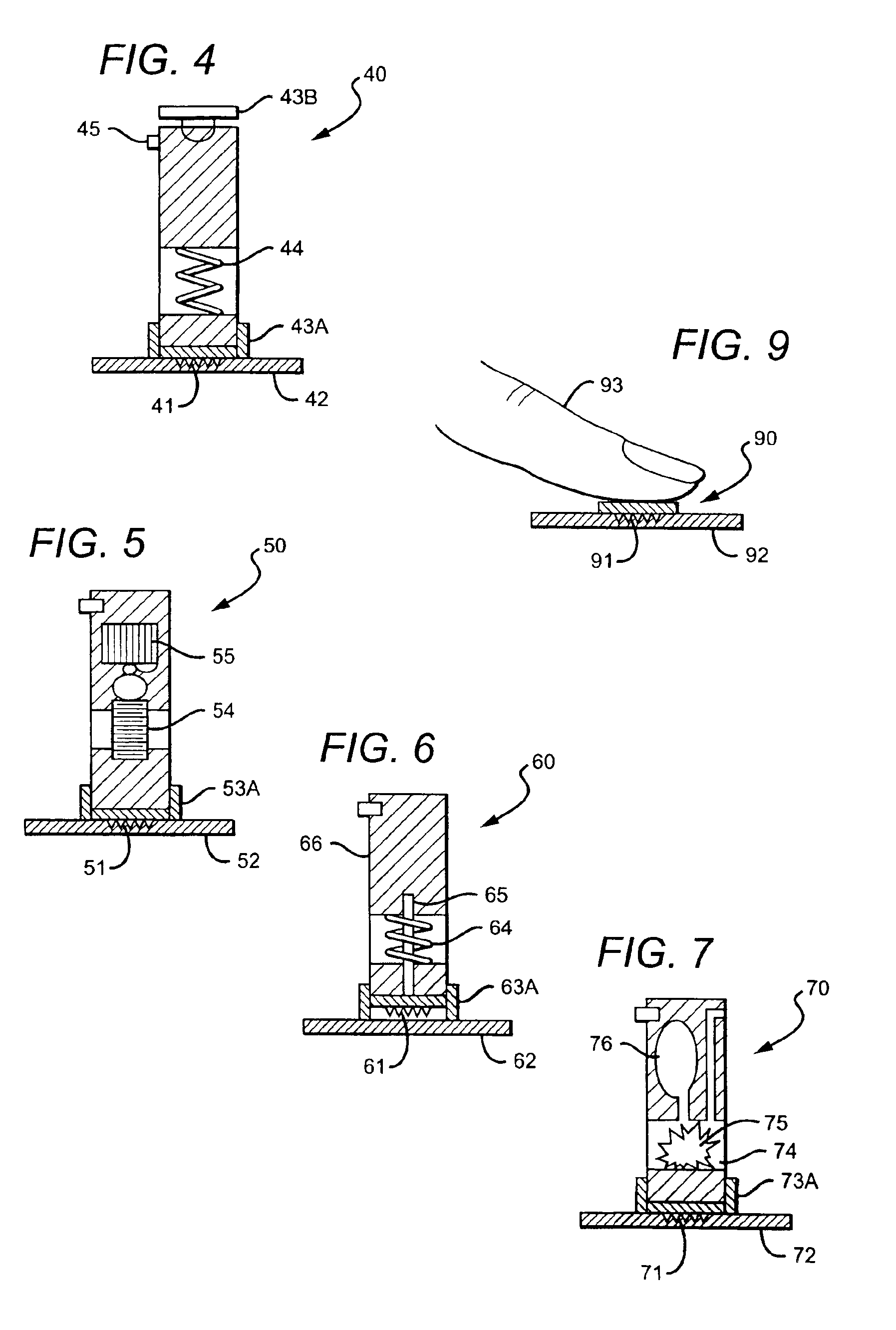

Solid solution perforator for drug delivery and other applications

InactiveUS6945952B2Fast biodegradationBarrier property can be diminished and controlledSurgeryMicroneedlesDrug reservoirDrugs solution

A solid drug solution perforator (SSP) system and an associated drug reservoir are provided for delivering therapeutic, prophylactic and / or cosmetic compounds, for nutrient delivery and for drug targeting. For drug delivery, the SSP system includes an active drug ingredient and a matrix of perforator material that biodegrades or dissolves quickly upon contact with a patient's body. The SSP system provides a skin barrier perforator and a controller for prompt initiation and cut-off drug delivery. In a preferred method of transdermal drug delivery, an SSP system containing a selected drug penetrates into an epidermis or dermis, and the drug is promptly released from the (dissolving) SSP system perforator. An additional drug is optionally delivered from a patch reservoir through skin pores created by insertion of the perforator. Formulation and fabrication procedures for the SSP and associated reservoir are also provided. An SSP system can be fabricated with variety of shapes and dimensions.

Owner:THERAJECT INC.

Phosphor and light-emitting equipment using phosphor

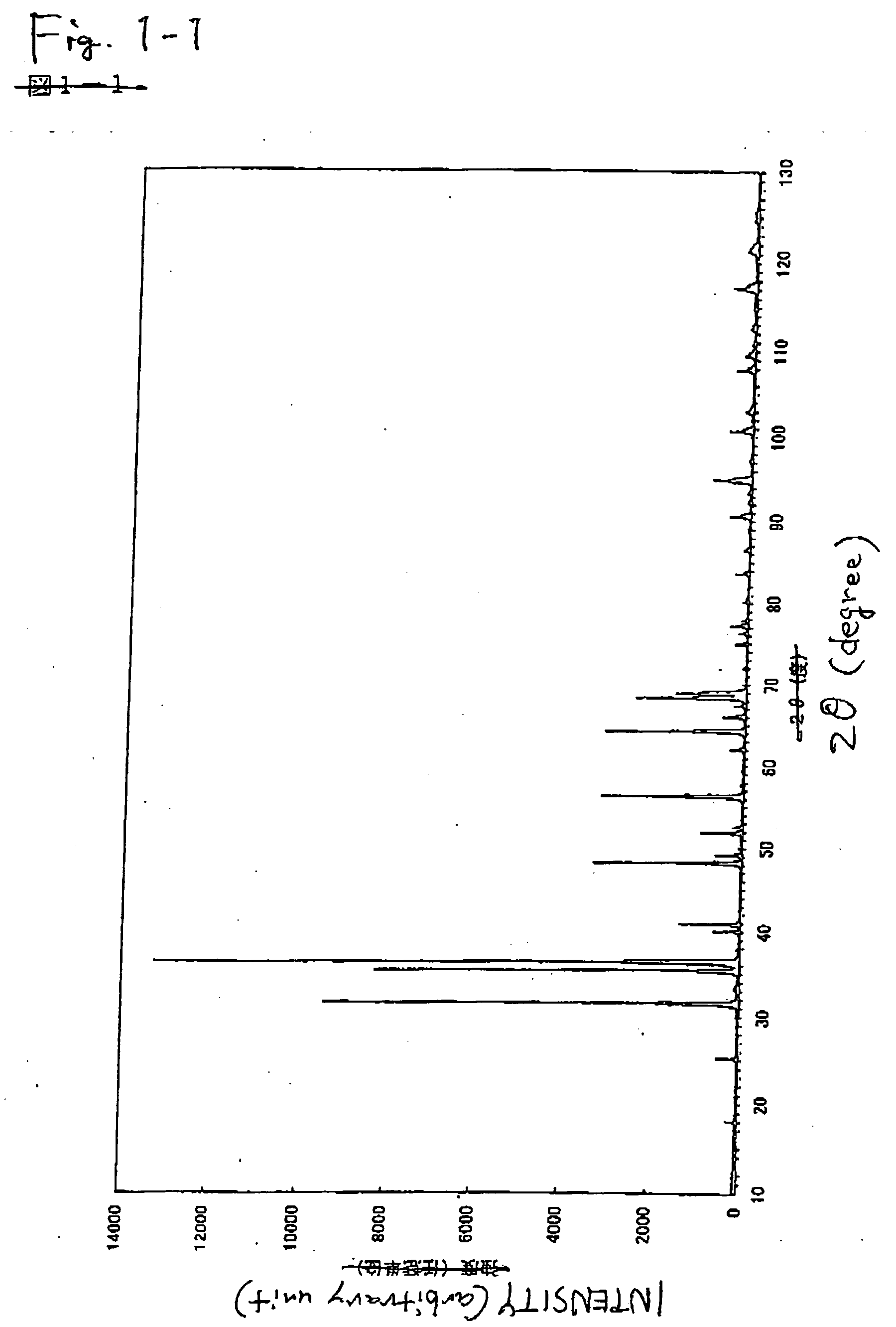

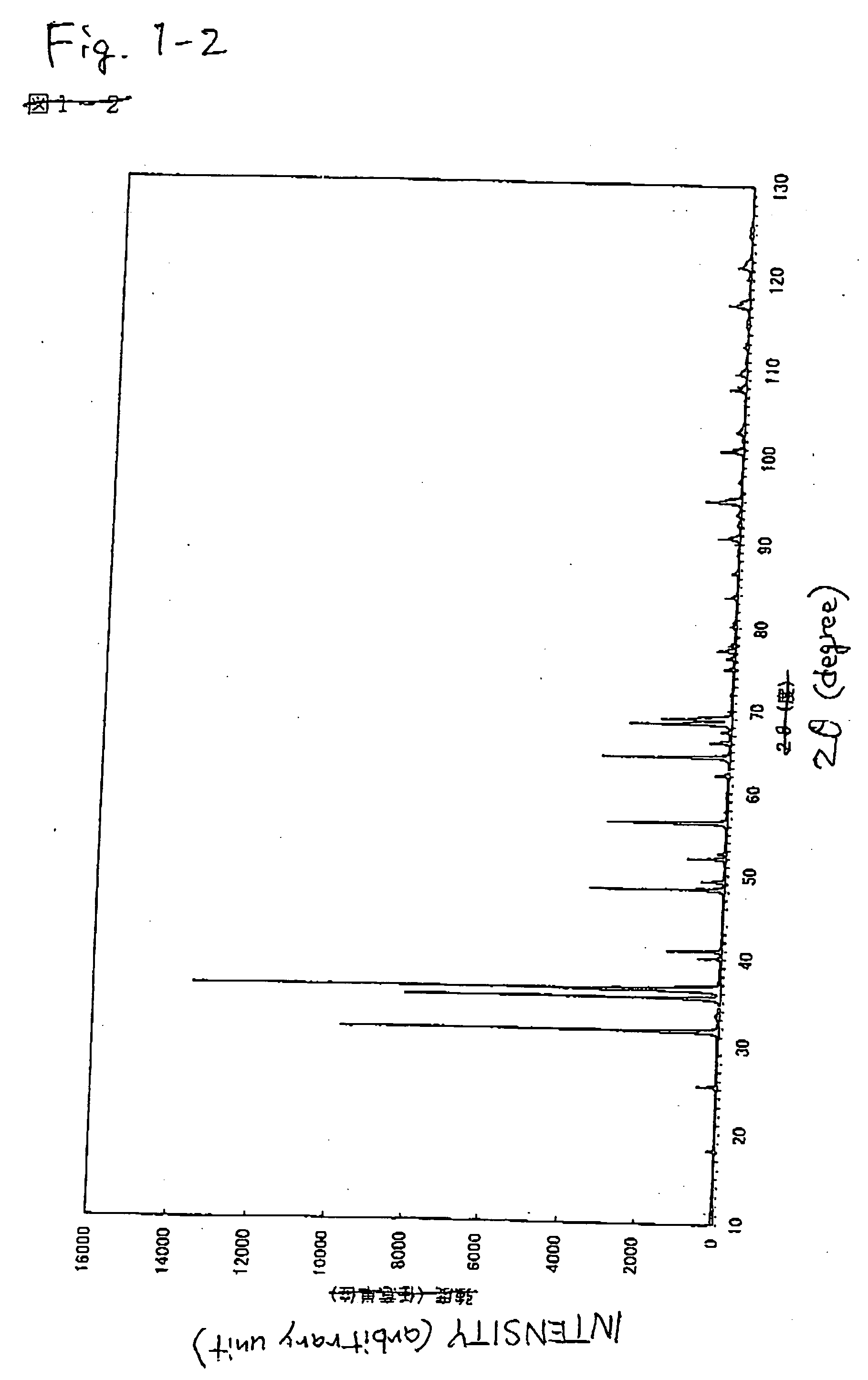

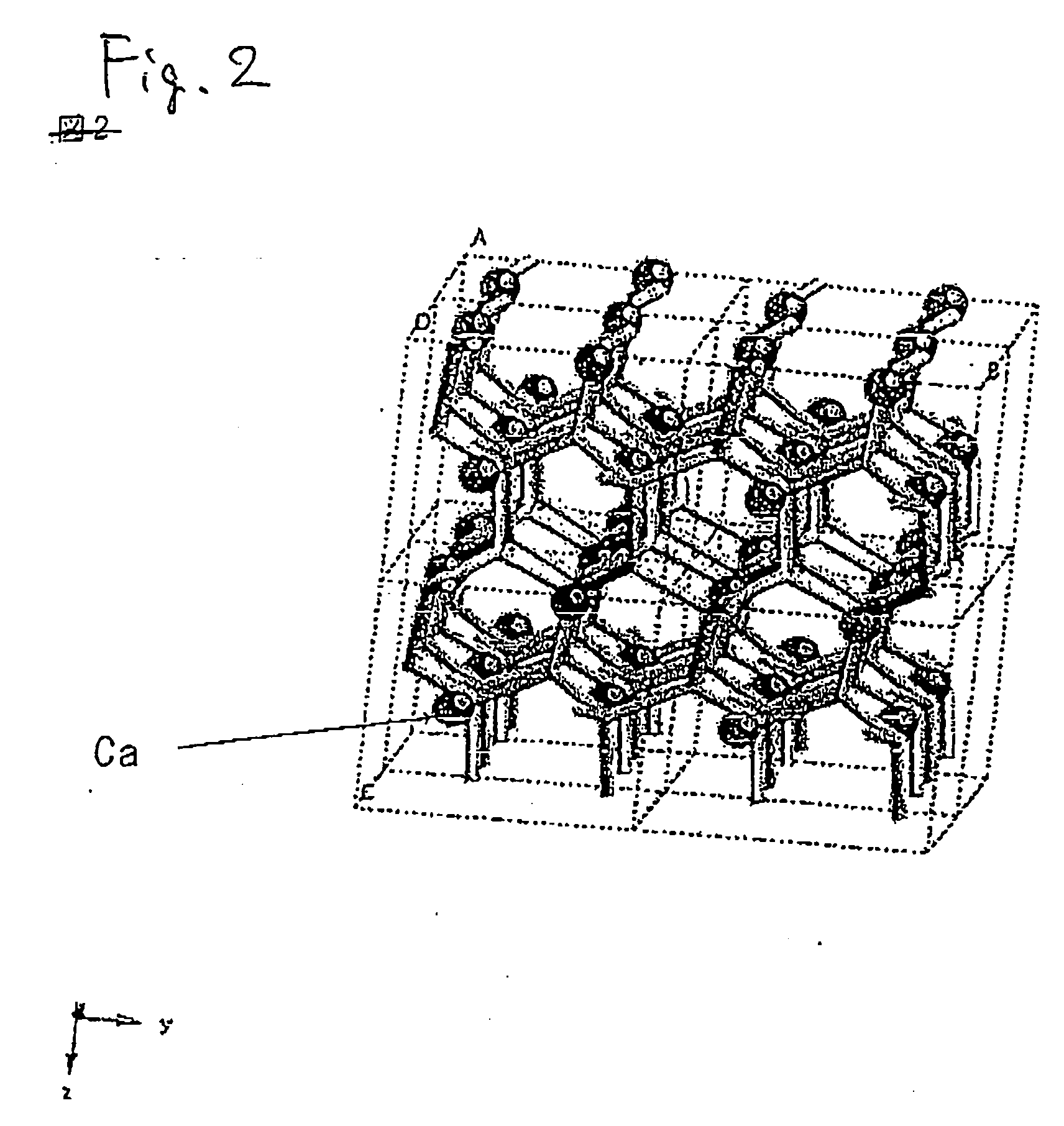

ActiveUS20070007494A1Increase brightnessGood colorOther chemical processesNitrogen-metal/silicon/boron binary compoundsFluorescenceRare earth

An object of the present invention is to provide an inorganic phosphor having fluorescence properties emitting an orange or red light which has a longer wavelength as compared with the cases of conventional sialon phosphors activated with a rare earth. The invention relates to a design of white light-emitting diode rich in a red component and having good color-rendering properties by employing a solid solution crystal phase phosphor which uses as a host crystal an inorganic compound having the same crystal structure as that of a CaSiAlN3 crystal phase and to which M Element (wherein M Element is one or two or more elements selected from the group consisting of Mn, Ce, Pr, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm, and Yb) is added as an emission center.

Owner:NICHIA CORP +1

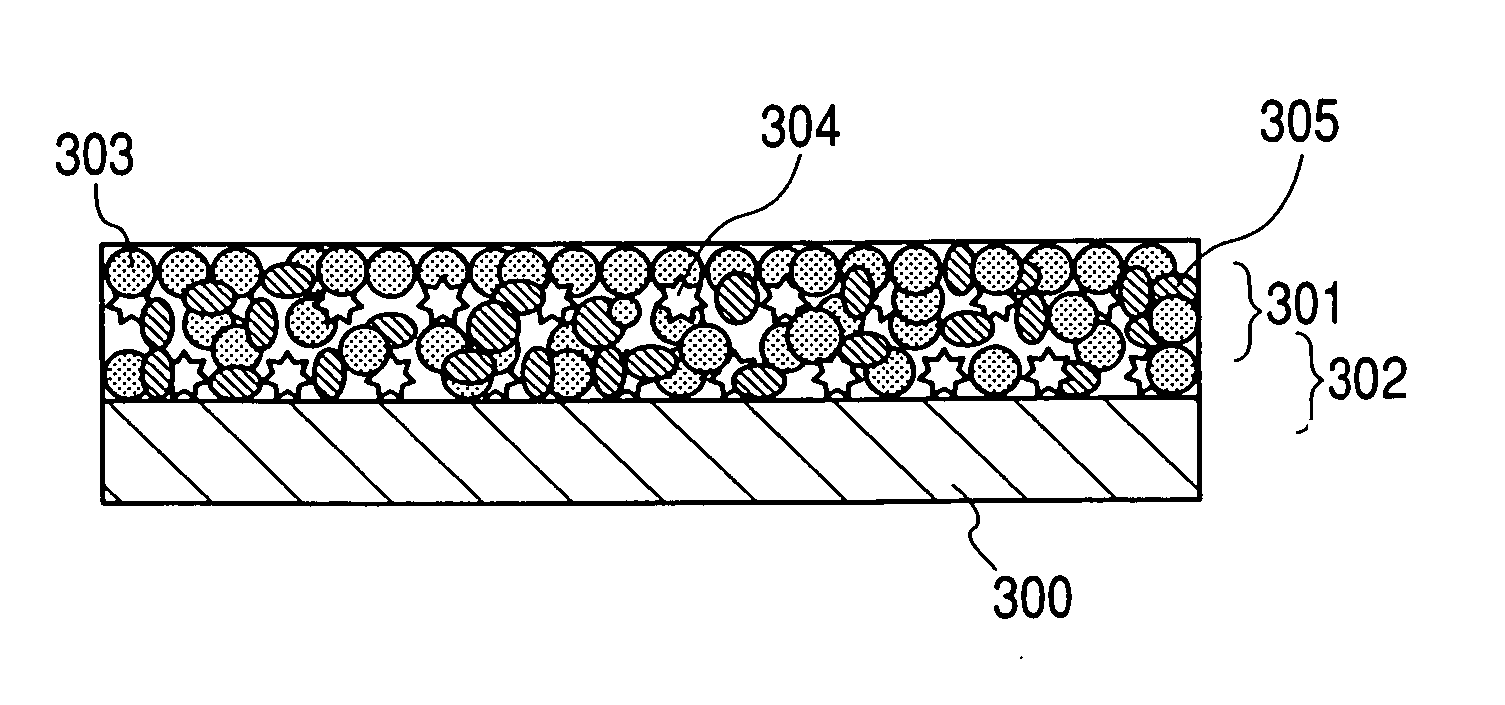

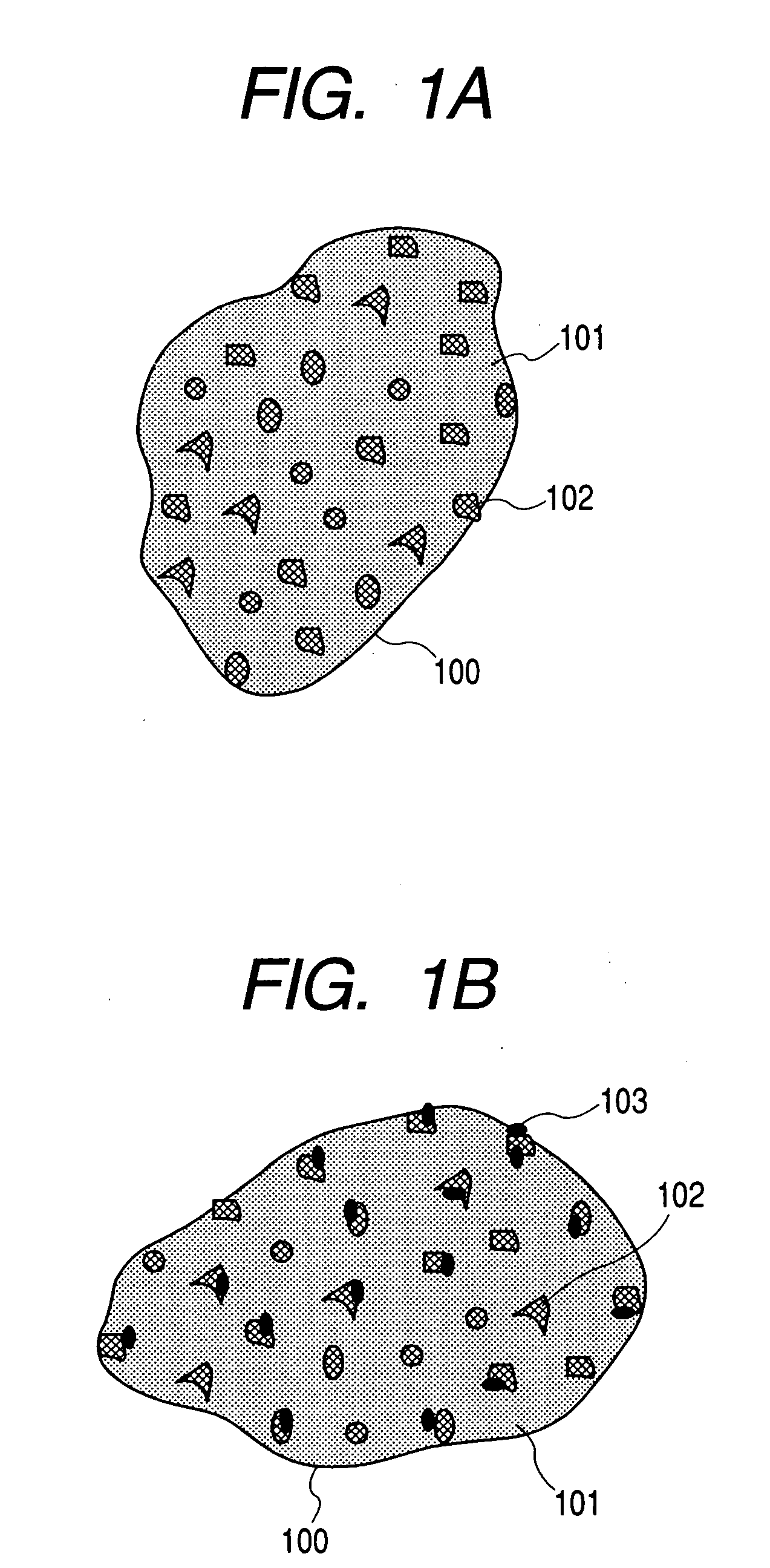

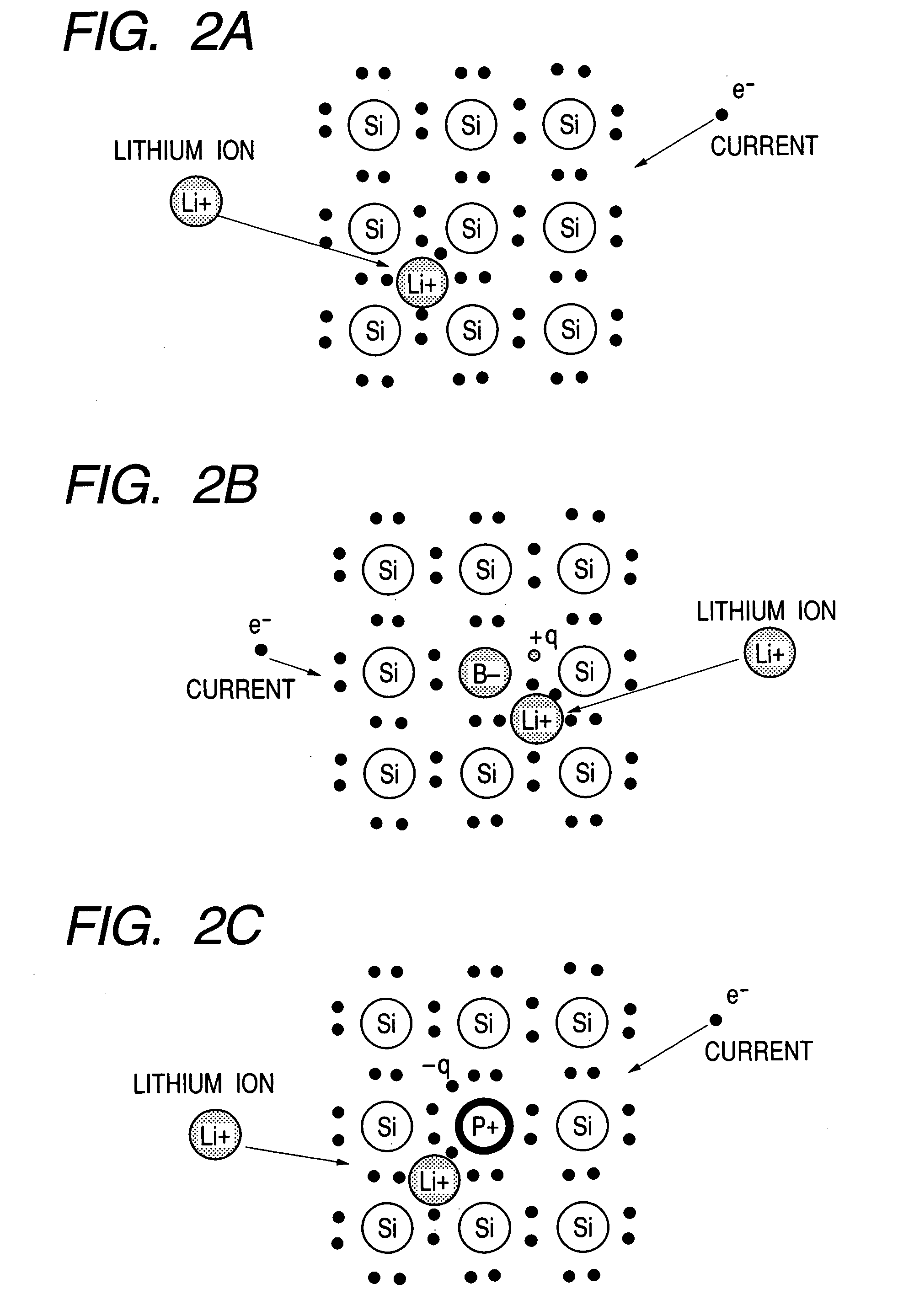

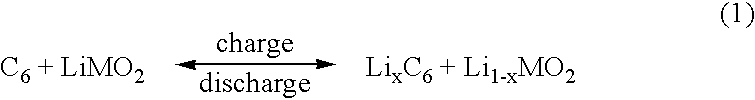

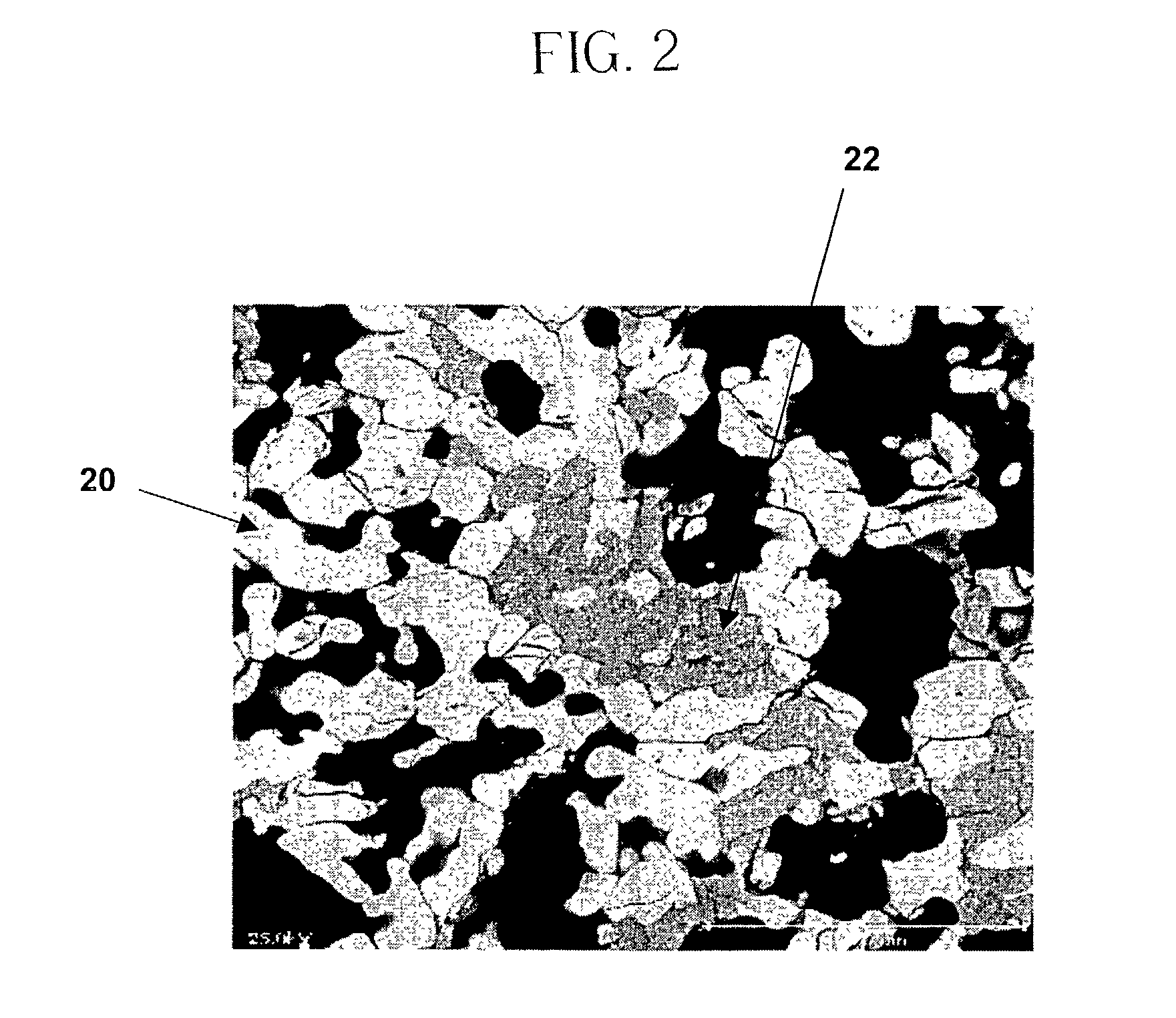

Electrode material for lithium secondary battery and electrode structure having the electrode material

InactiveUS20060040182A1Reduce conductivityImprove conductivityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithiumLiquid state

The electrode material for a lithium secondary battery according to the present invention includes particles of a solid state alloy having silicon as a main component, wherein the particles of the solid state alloy have a microcrystal or amorphous material including an element other than silicon, dispersed in microcrystalline silicon or amorphized silicon. The solid state alloy preferably contains a pure metal or a solid solution. The composition of the alloy preferably has an element composition in which the alloy is completely mixed in a melted liquid state, whereby the alloy has a single phase in a melted liquid state without presence of two or more phases. The element composition can be determined by the kind of elements constituting the alloy and an atomic ratio of the elements.

Owner:CANON KK

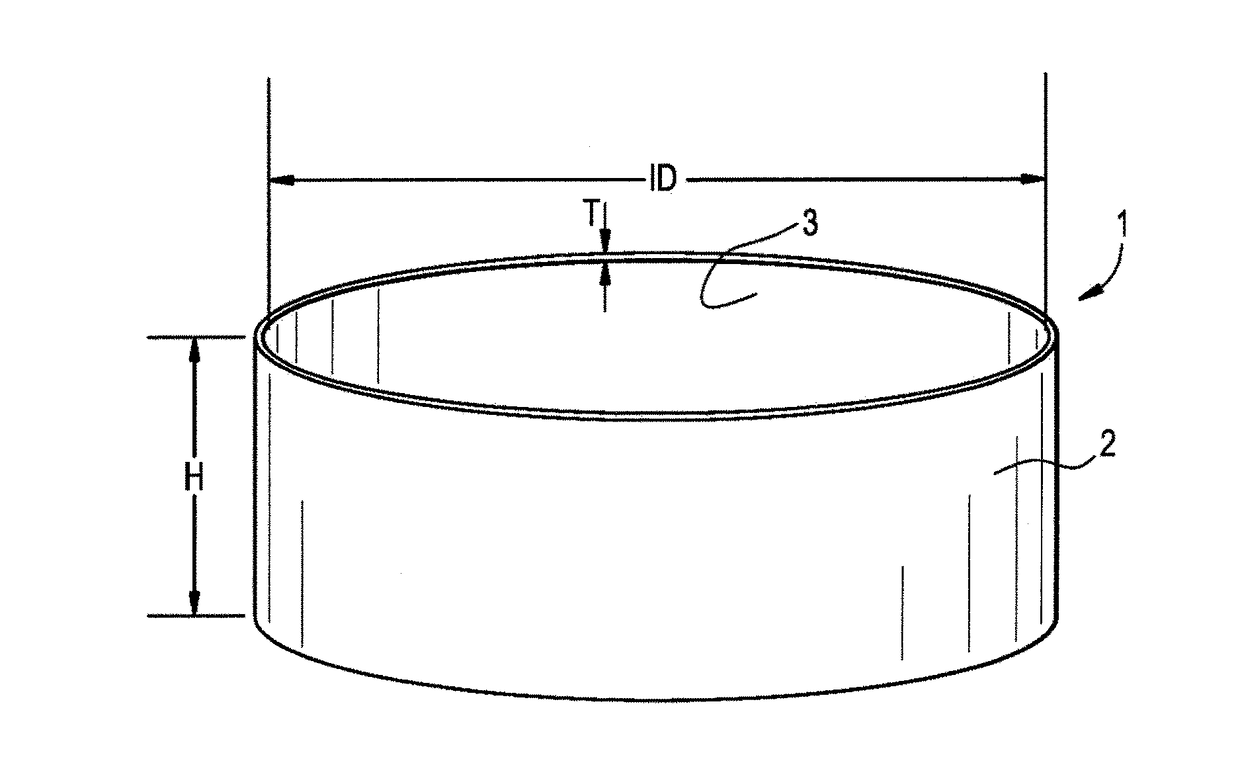

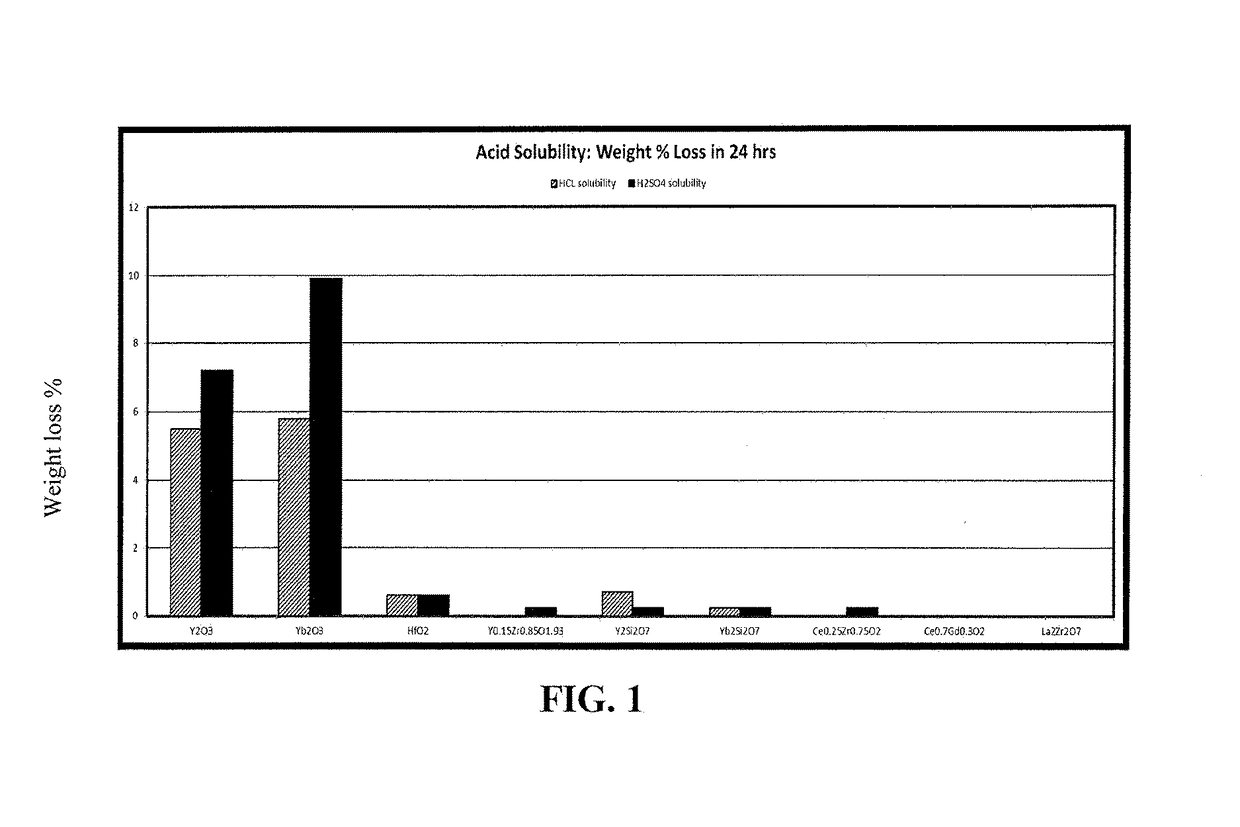

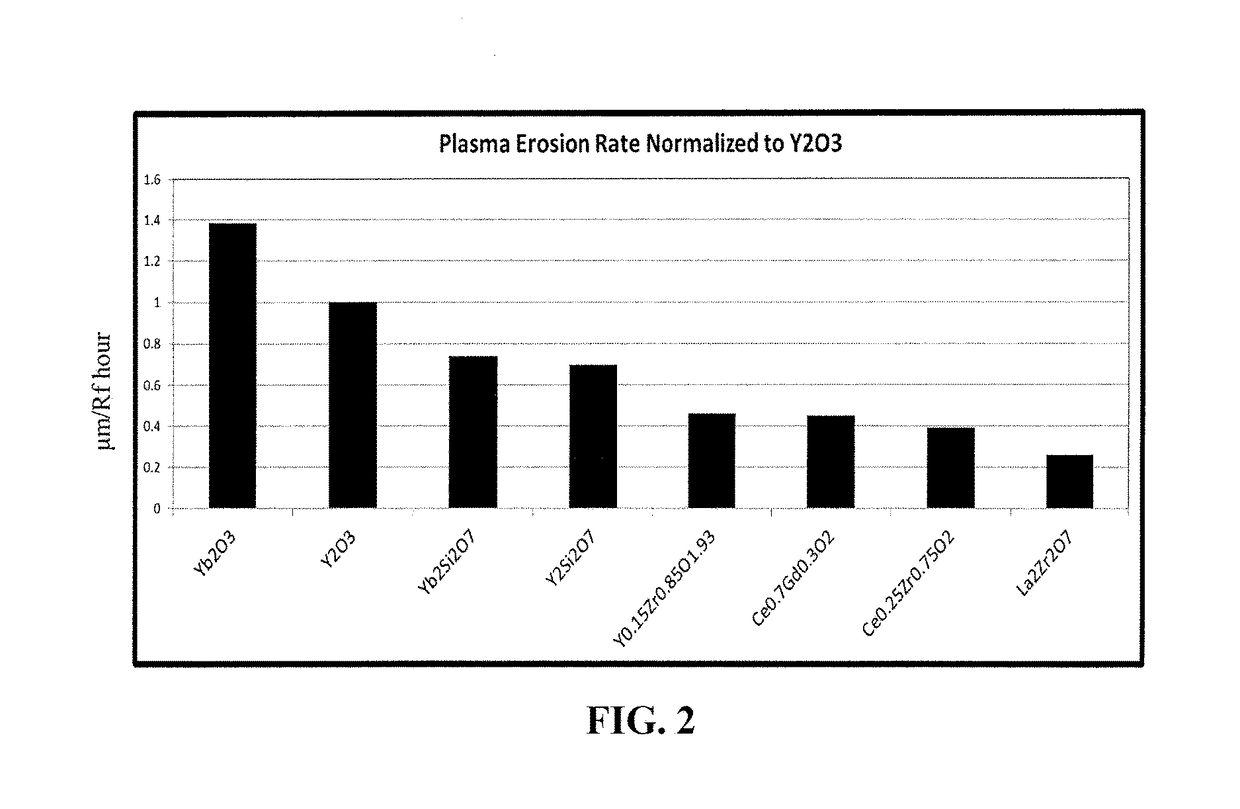

Coated semiconductor processing members having chlorine and fluorine plasma erosion resistance and complex oxide coatings therefor

ActiveUS20170301519A1High tensile bond strengthReduce pollutionMolten spray coatingElectric discharge tubesSolid solutionPlasma sprayed

A semiconductor processing member is provided, including a body and a plasma spray coating provided on the body. The coating is an ABO or ABCO complex oxide solid solution composition, where A, B and C are selected from the group consisting of La, Zr, Ce, Gd, Y, Yb and Si, and O is an oxide. The coating imparts both chlorine and fluorine plasma erosion resistance, reduces particle generation during plasma etching, and prevents spalling of the coating during wet cleaning of the semiconductor processing member.

Owner:FM INDS

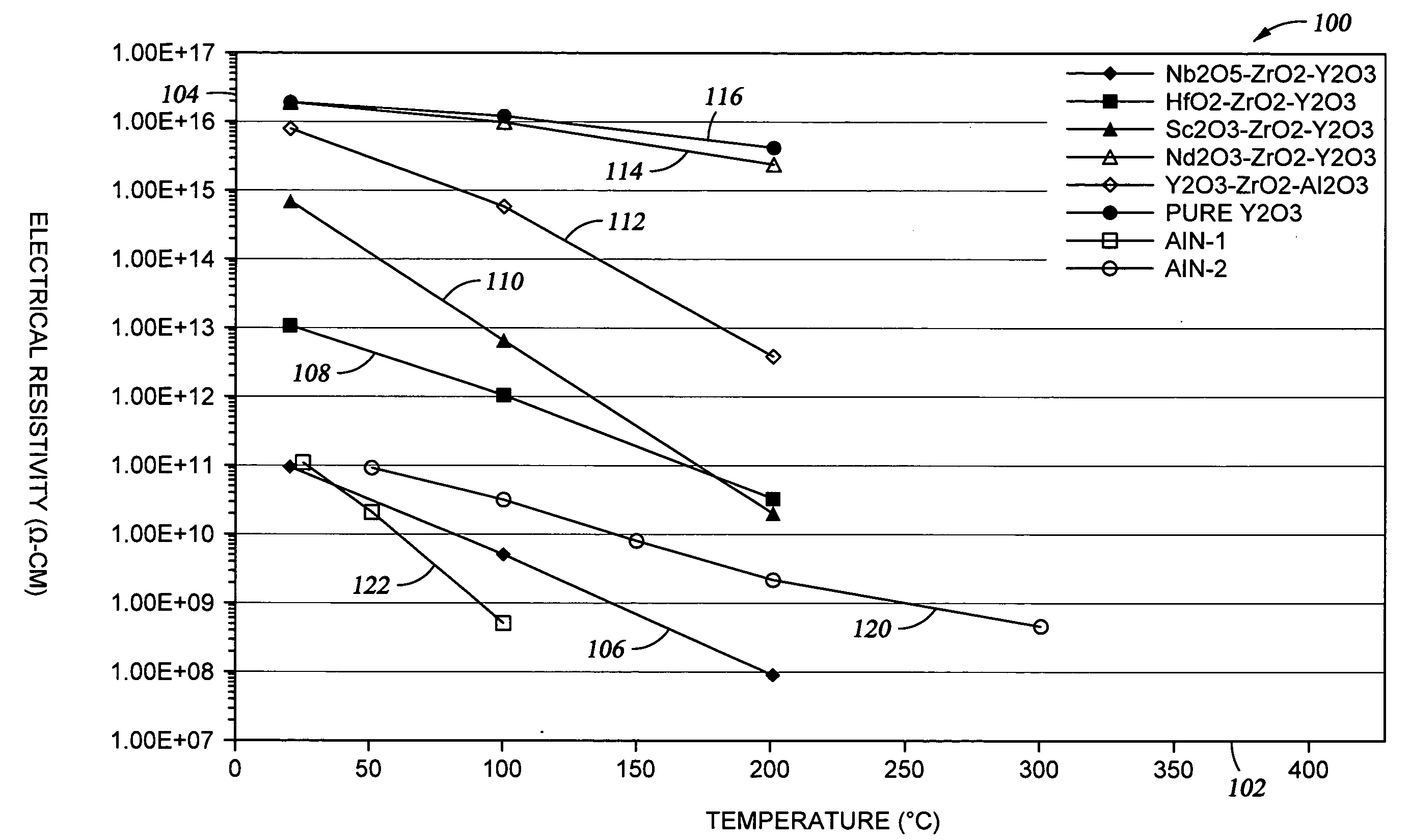

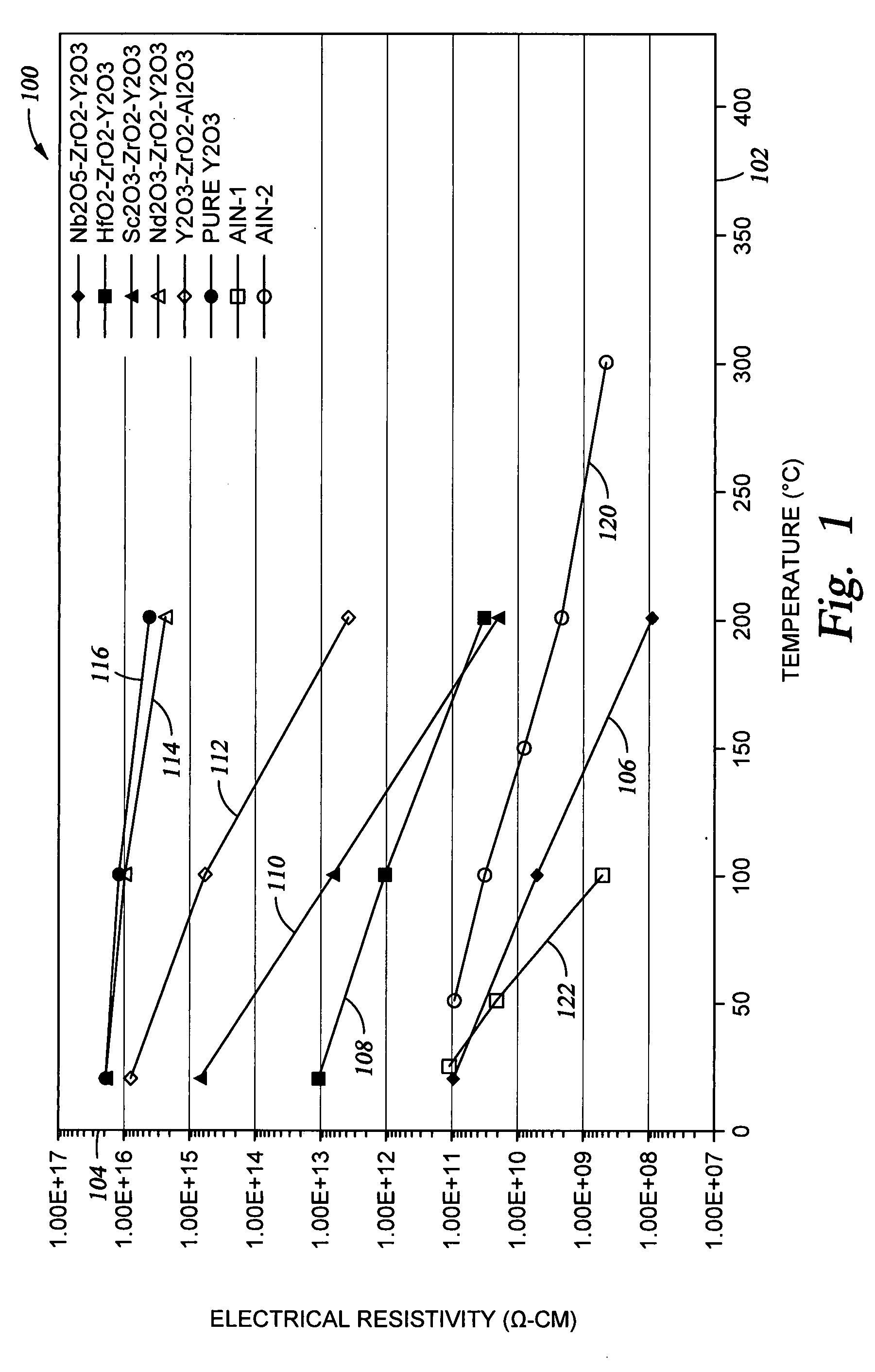

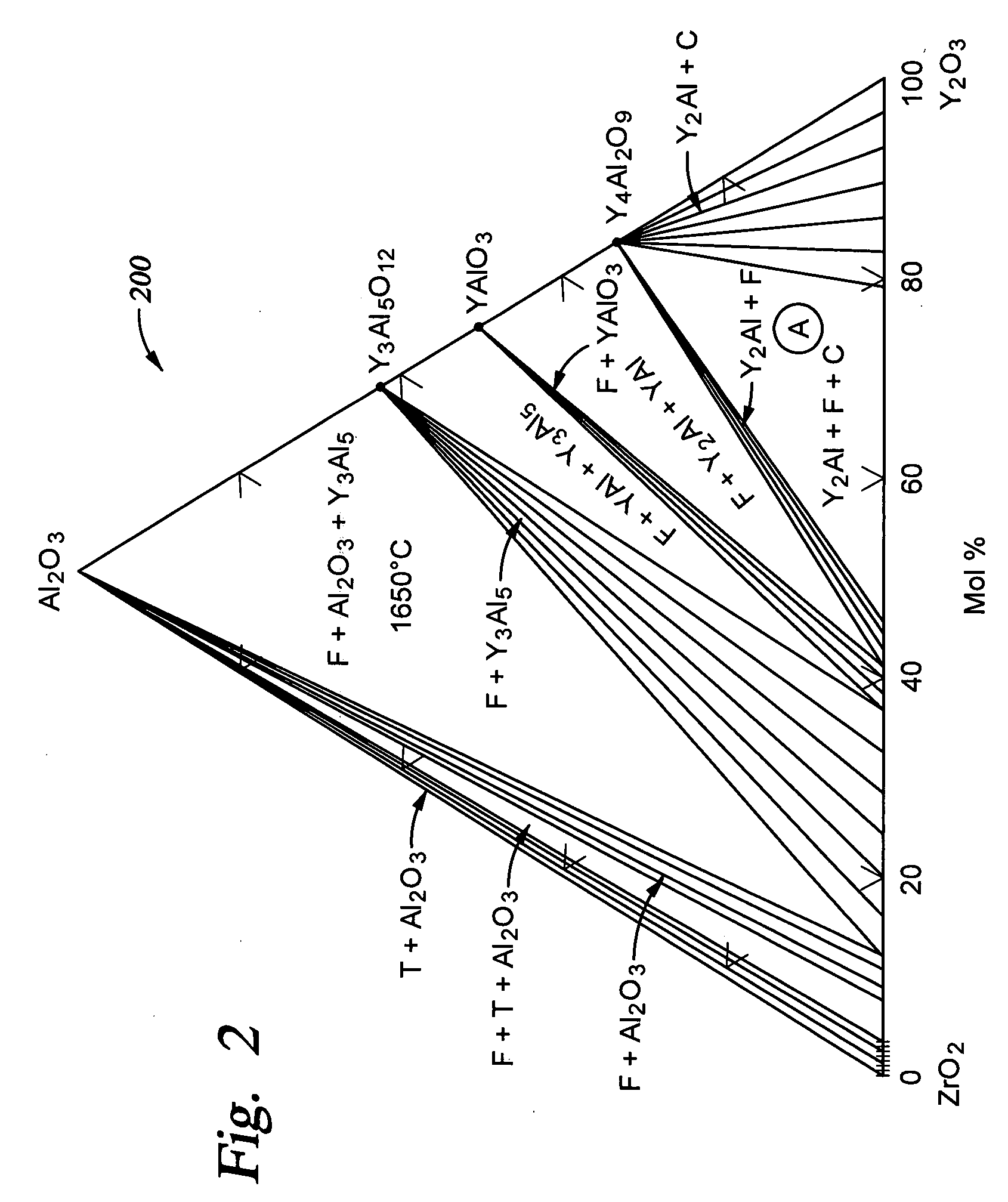

Method of coating semiconductor processing apparatus with protective yttrium-containing coatings

InactiveUS20080213496A1Improve plasma resistanceTailored mechanical propertiesMolten spray coatingVacuum evaporation coatingSolid solutionYttrium

Methods of applying specialty ceramic materials to semiconductor processing apparatus, where the specialty ceramic materials are resistant to halogen-comprising plasmas. The specialty ceramic materials contain at least one yttrium oxide-comprising solid solution. Some embodiments of the specialty ceramic materials have been modified to provide a resistivity which reduces the possibility of arcing within a semiconductor processing chamber.

Owner:APPLIED MATERIALS INC

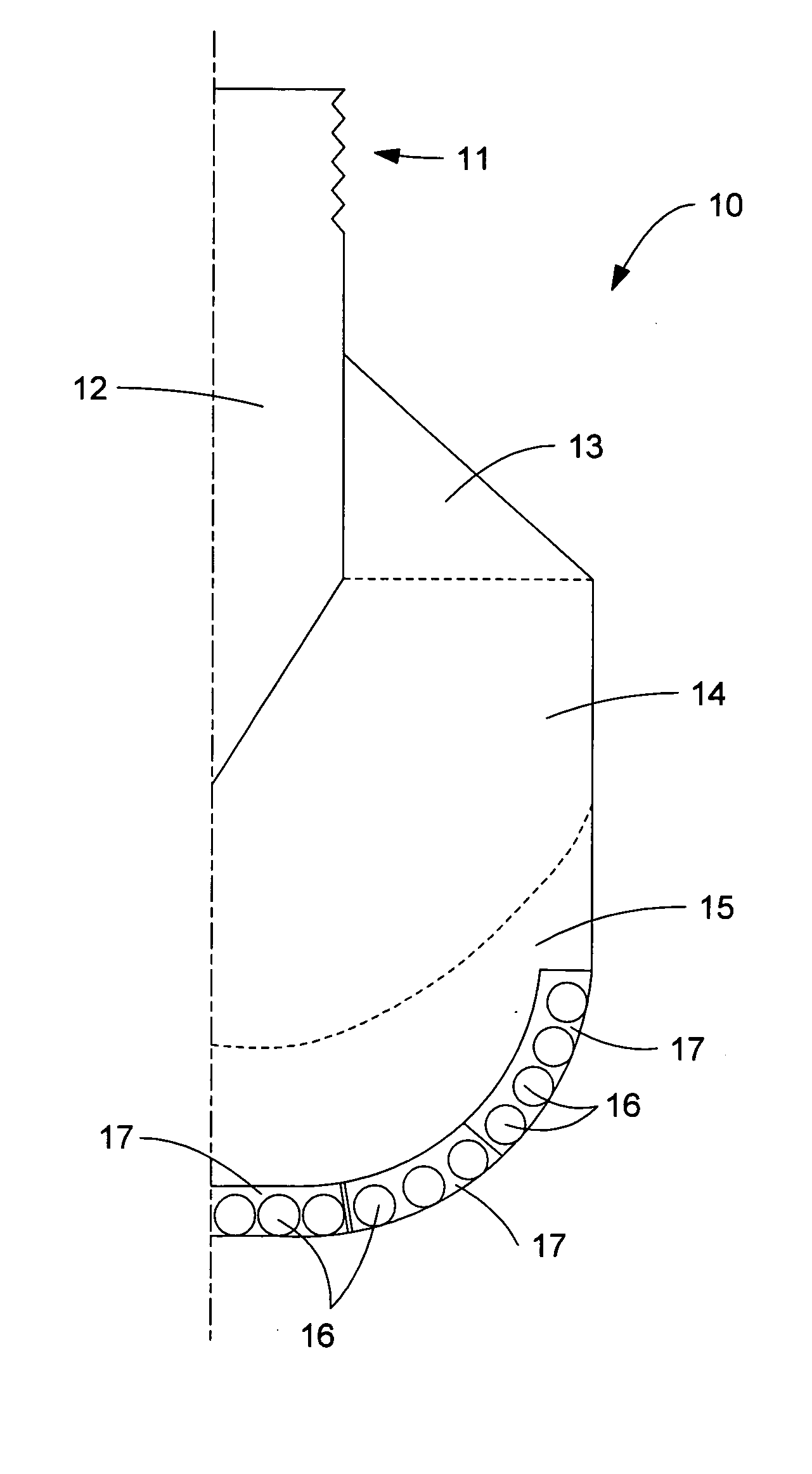

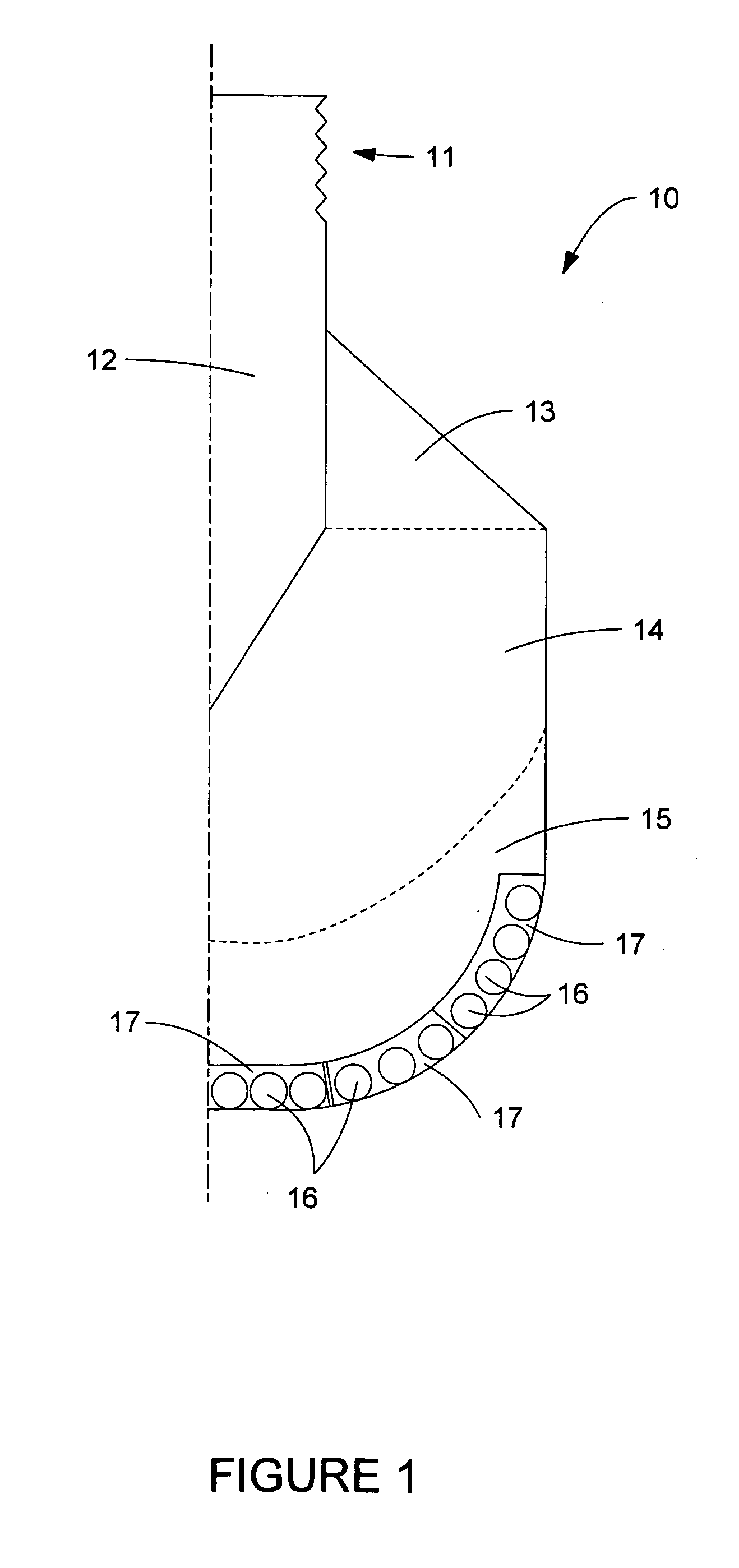

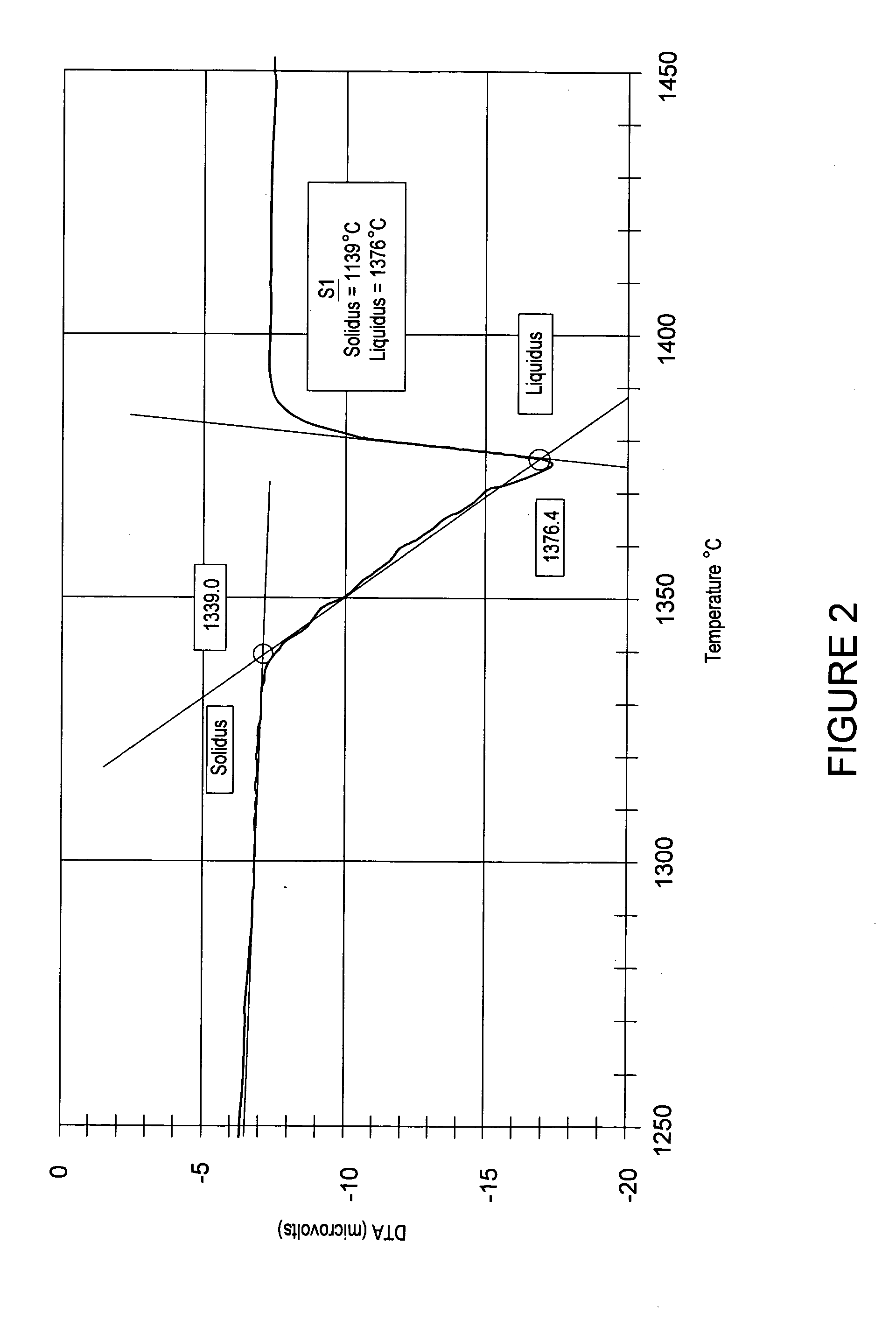

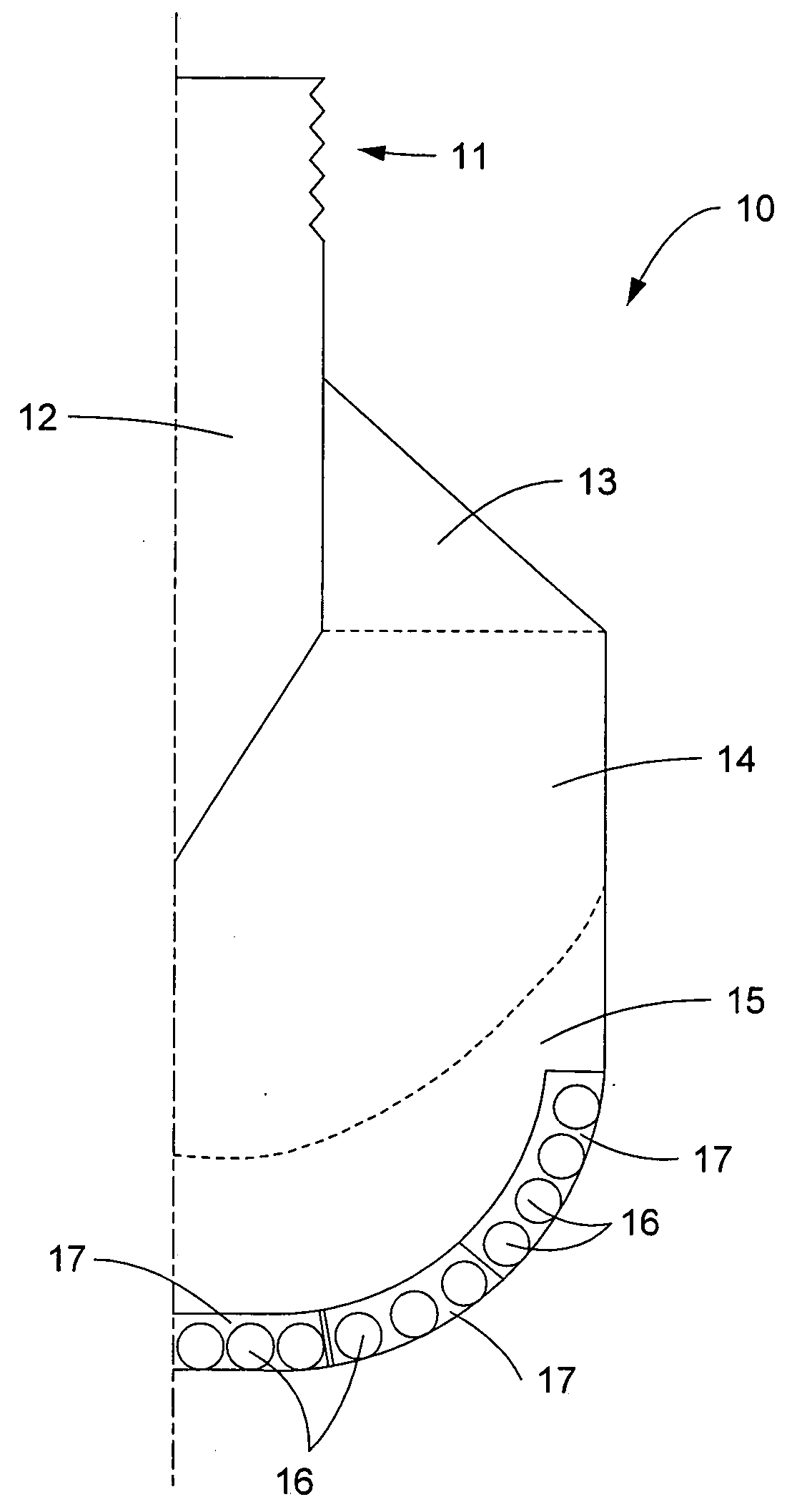

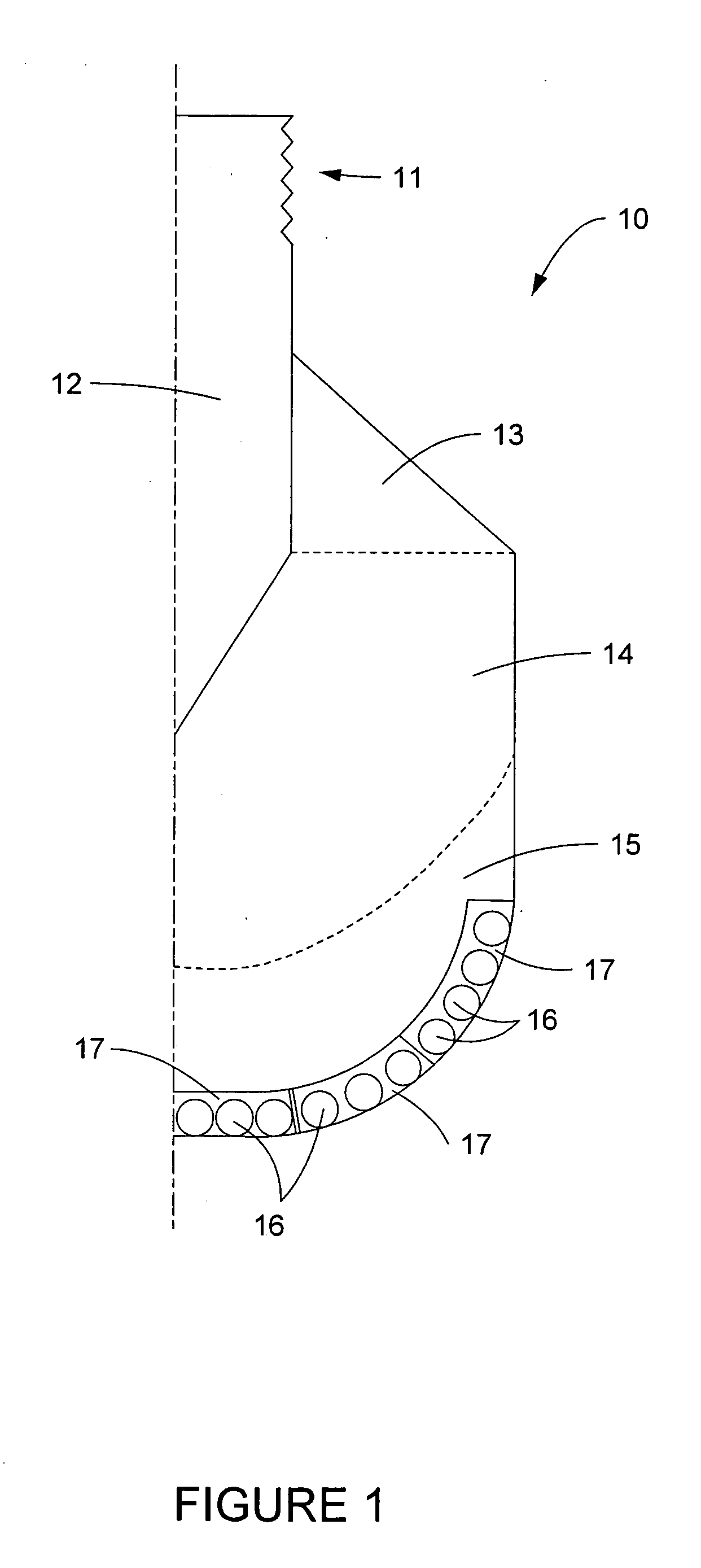

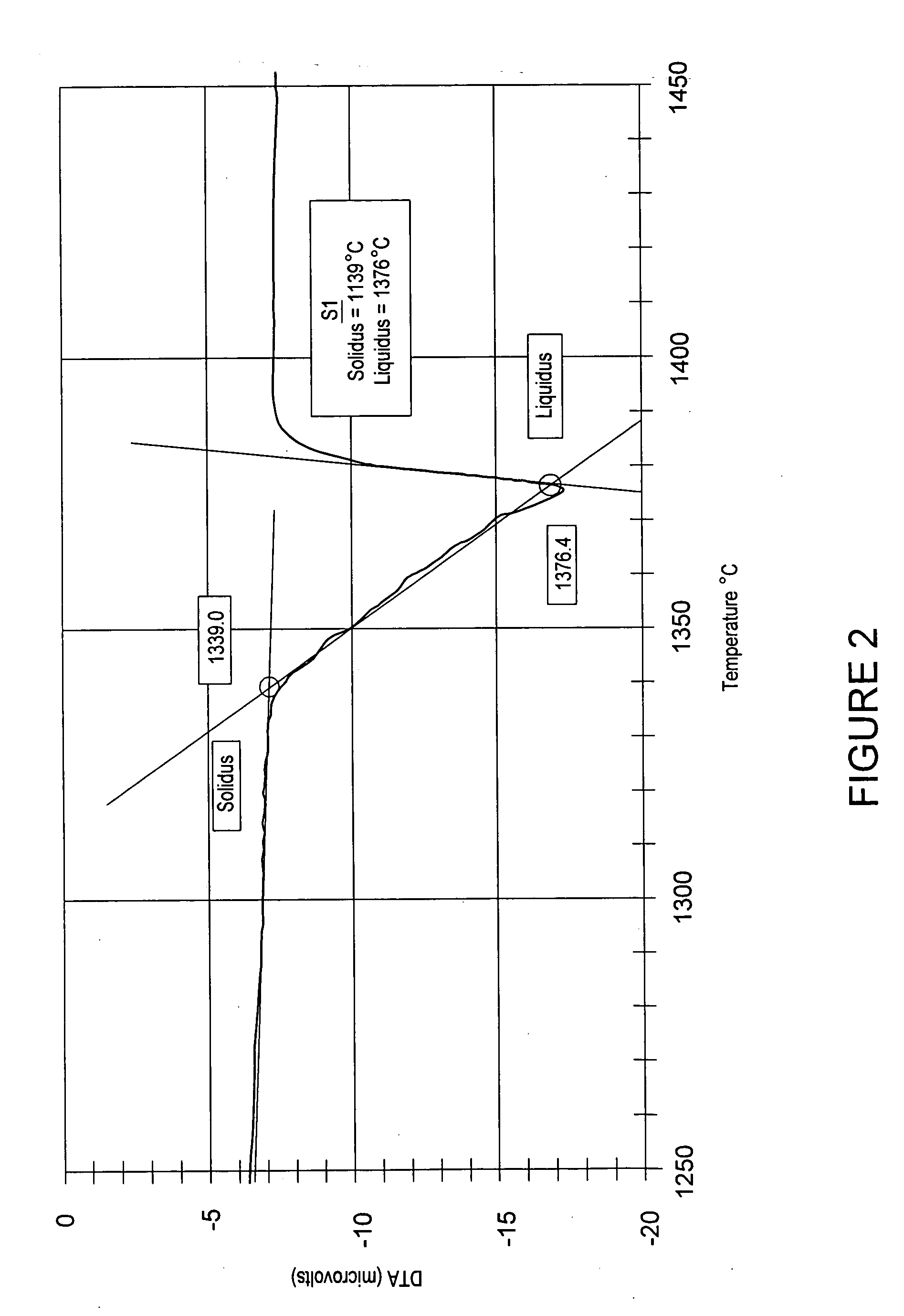

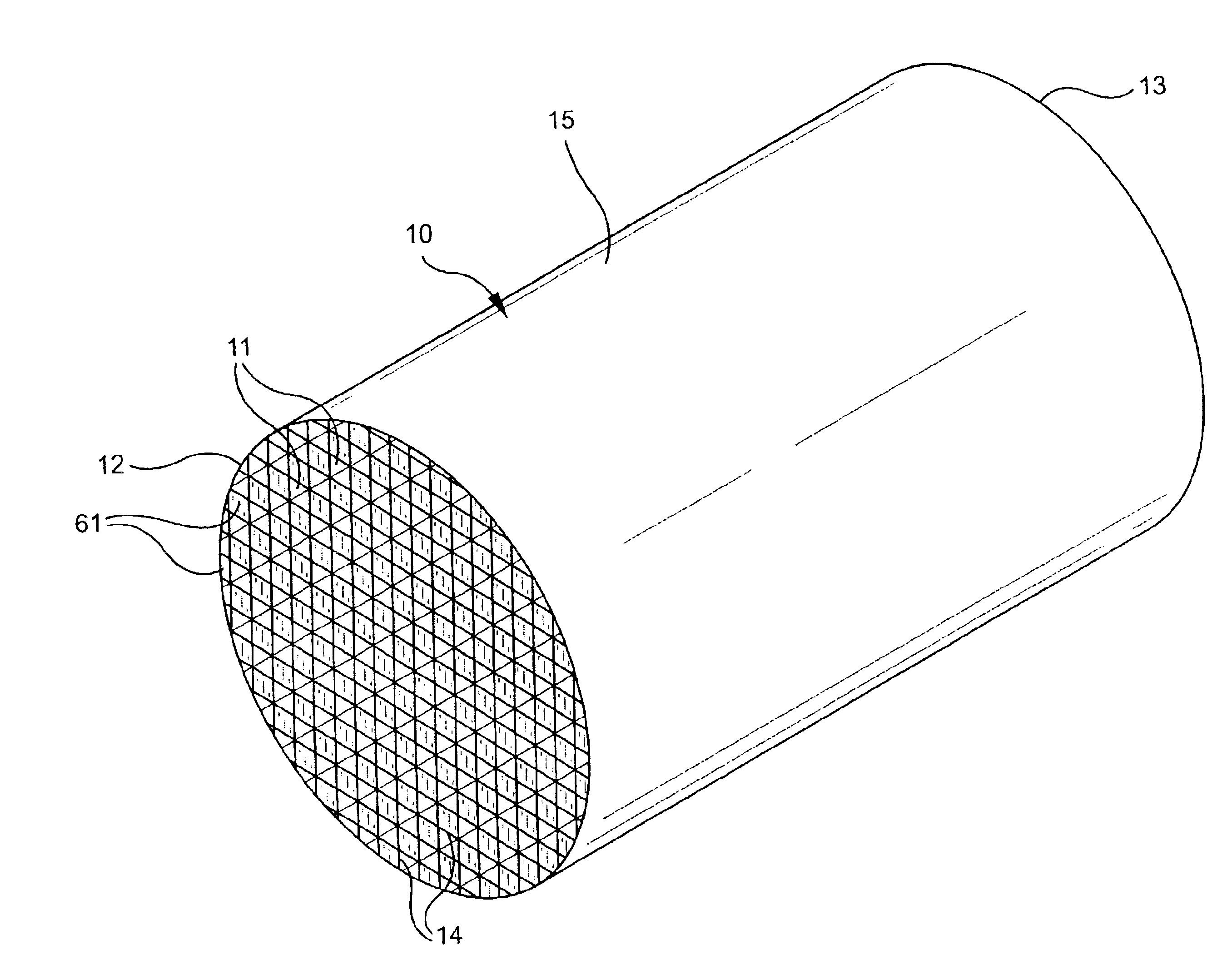

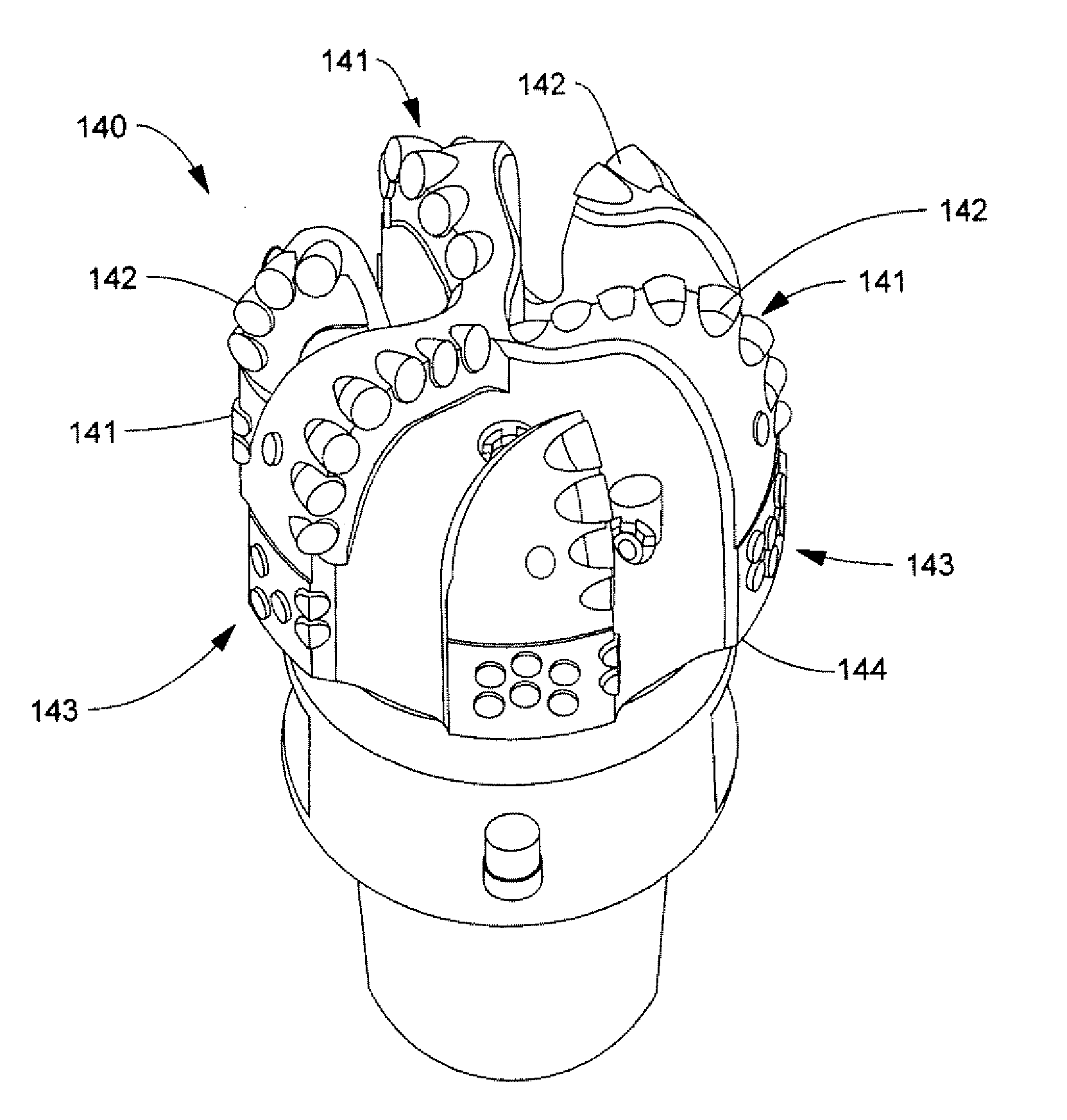

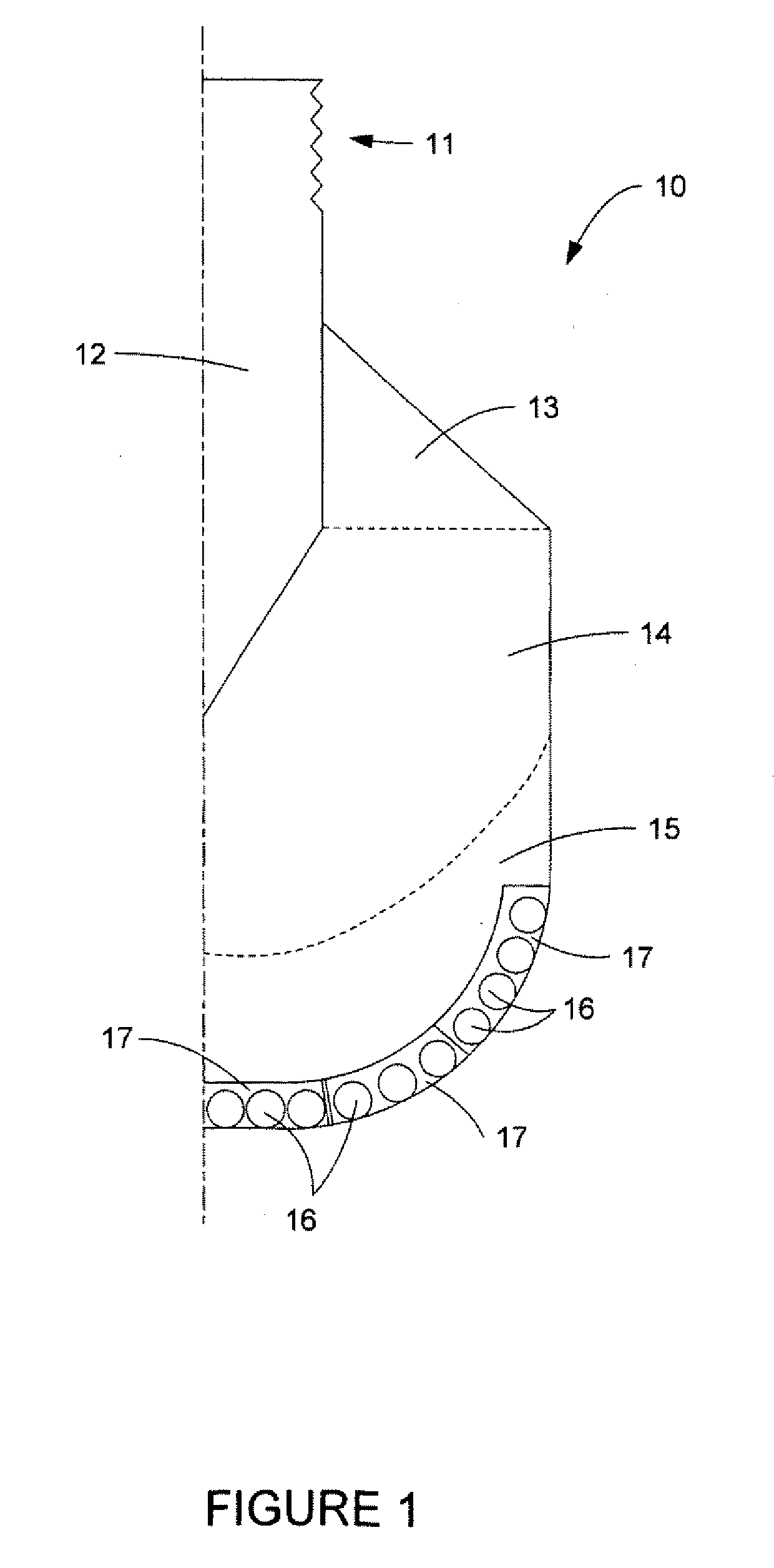

Earth-boring bits

ActiveUS20050247491A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsCutting machinesBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and, optionally, at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:BAKER HUGHES INC +1

Earth-boring bits

InactiveUS20050211475A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsMetal-working drilling toolsBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:ATI PROPERTIES +1

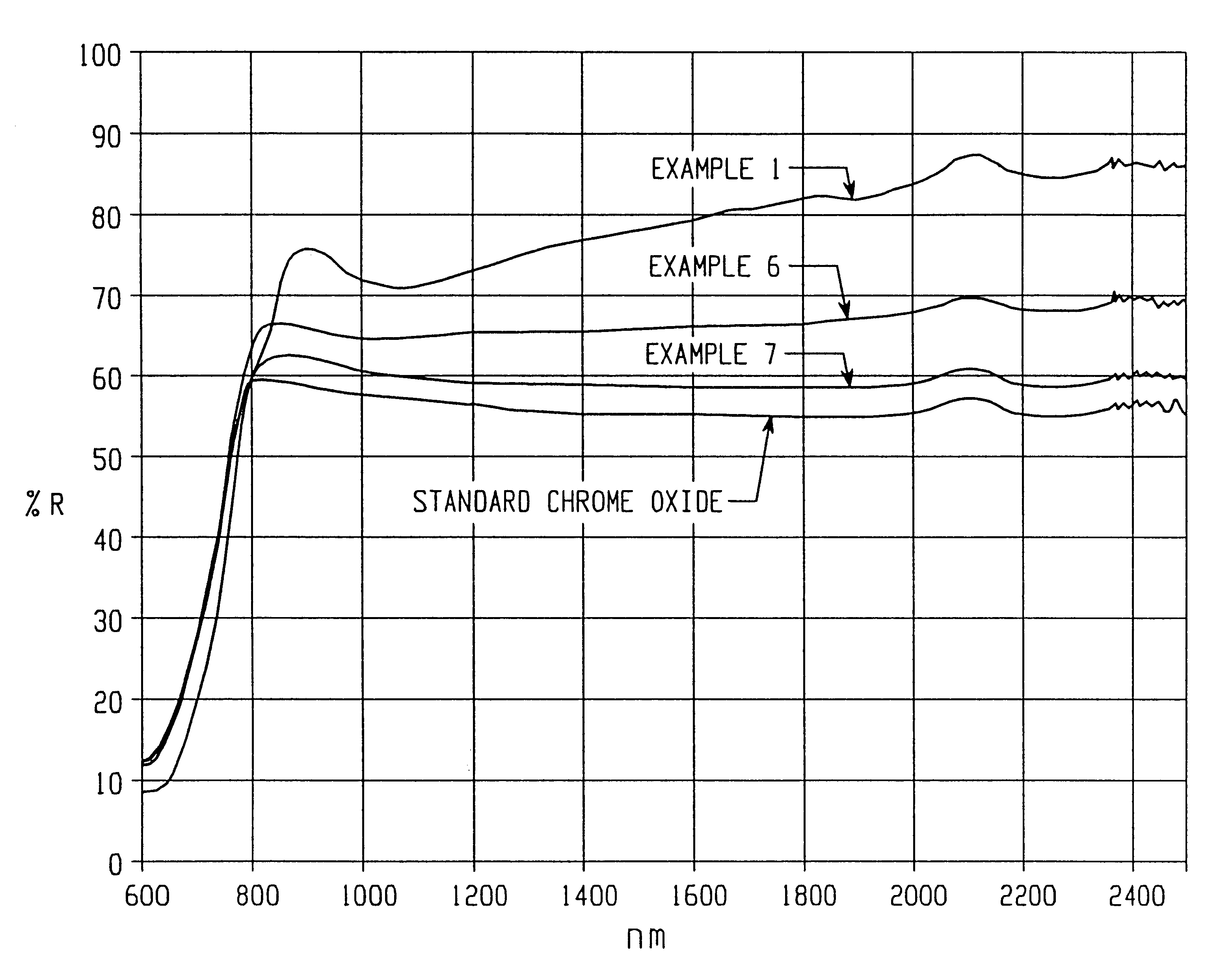

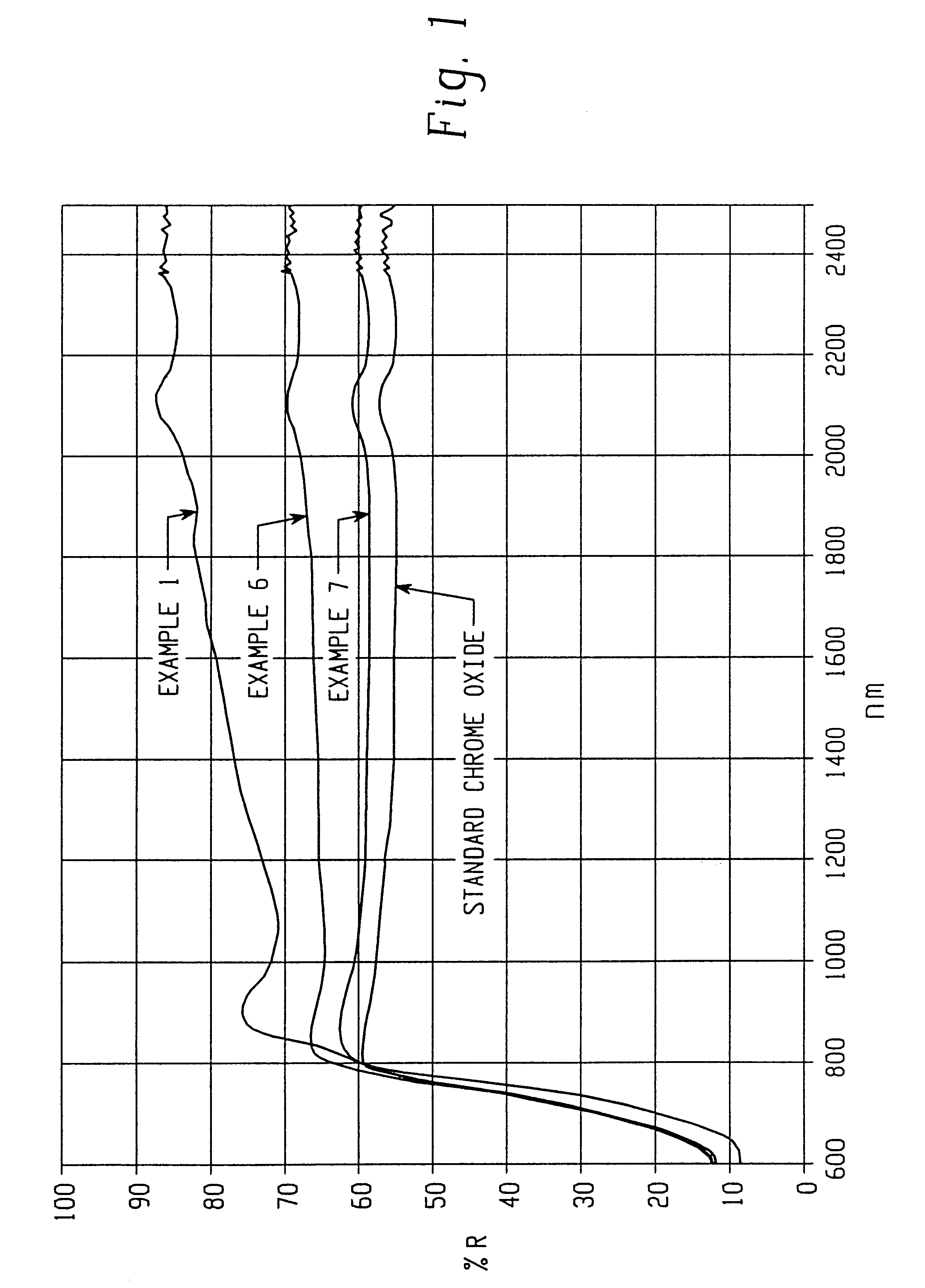

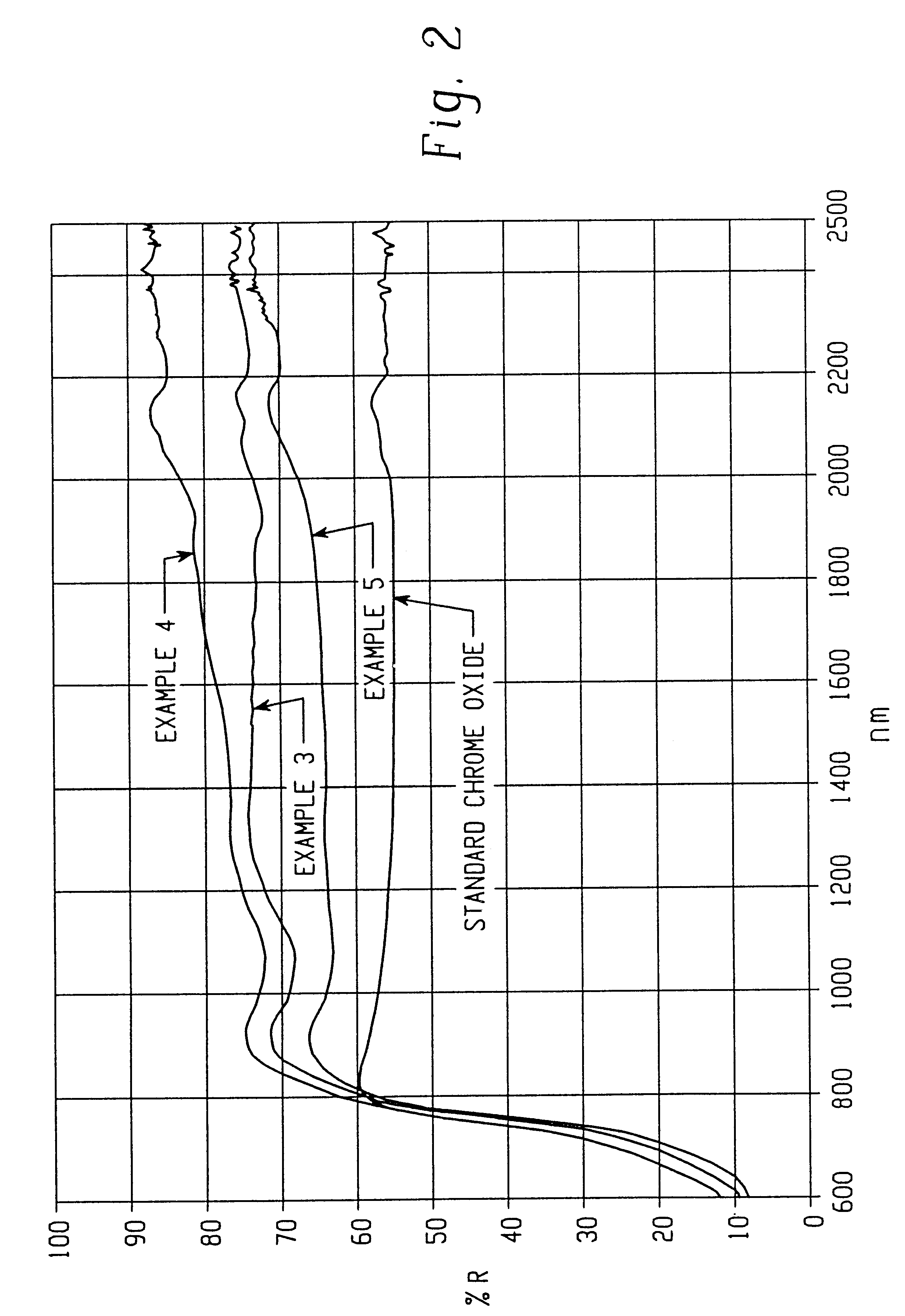

Infrared reflective color pigment

InactiveUS6454848B2Reduce heat buildupReduce energy costsInorganic pigment treatmentCoatingsIndiumCobalt

The present invention provides new solid solutions having a corundum-hematite crystalline structure which are useful as inorganic color pigments. Solid solutions according to the present invention include a host component having a corundum-hematite crystalline structure which contains as guest components one or more elements from the group consisting of aluminum, antimony, bismuth, boron, chrome, cobalt, gallium, indium, iron, lanthanum, lithium, magnesium, manganese, molybdenum, neodymium, nickel, niobium, silicon, tin, titanium, vanadium, and zinc. Solid solutions according to the present invention are formed by thoroughly mixing compounds, usually metal oxides or precursors thereof, which contain the host and guest components and then calcining the compounds to form the solid solutions having the corundum-hematite crystalline structure. Some of the new solid solutions according to the present invention exhibit relatively low Y CIE tri-stimulus values and relatively high near infrared reflectance.

Owner:FERRO CORP

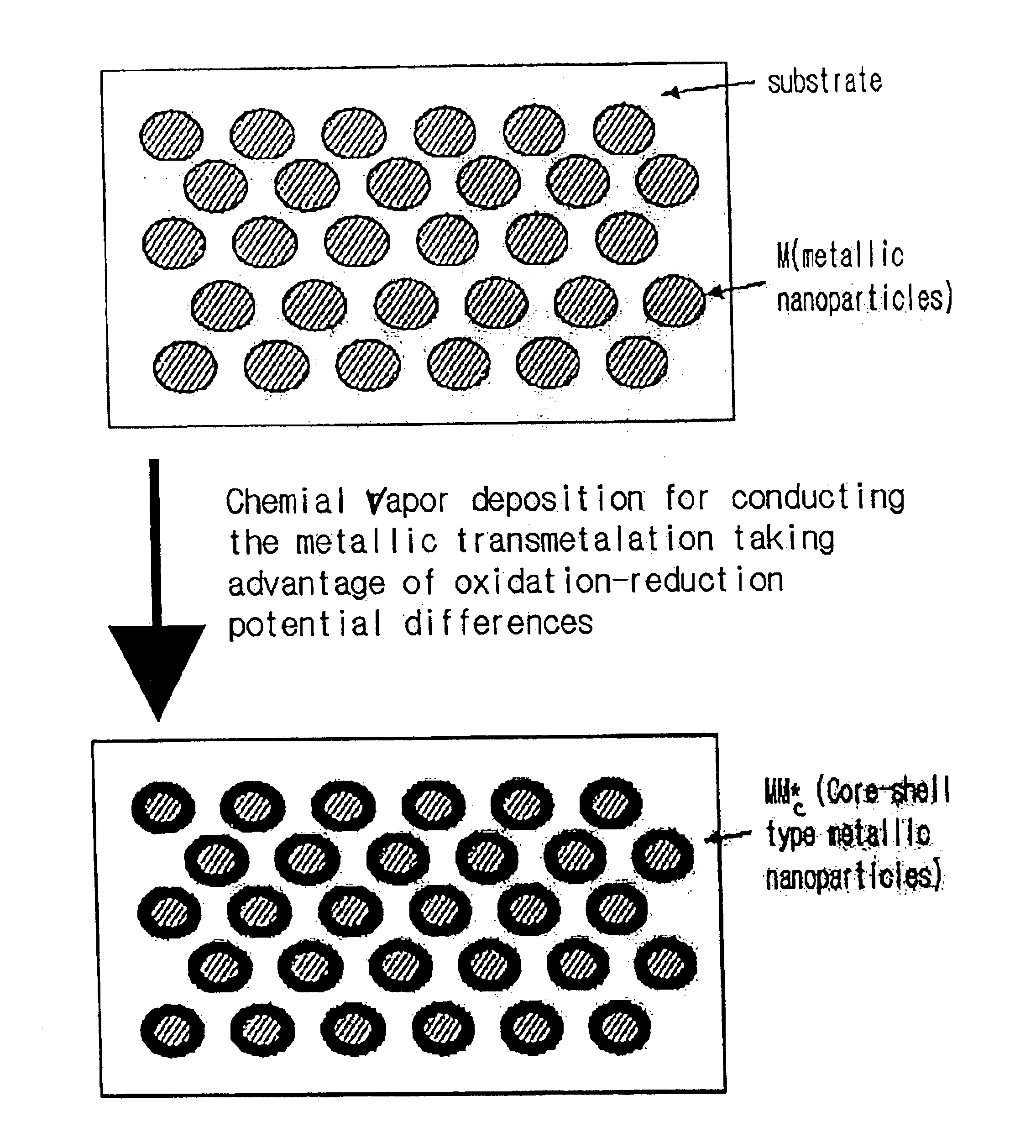

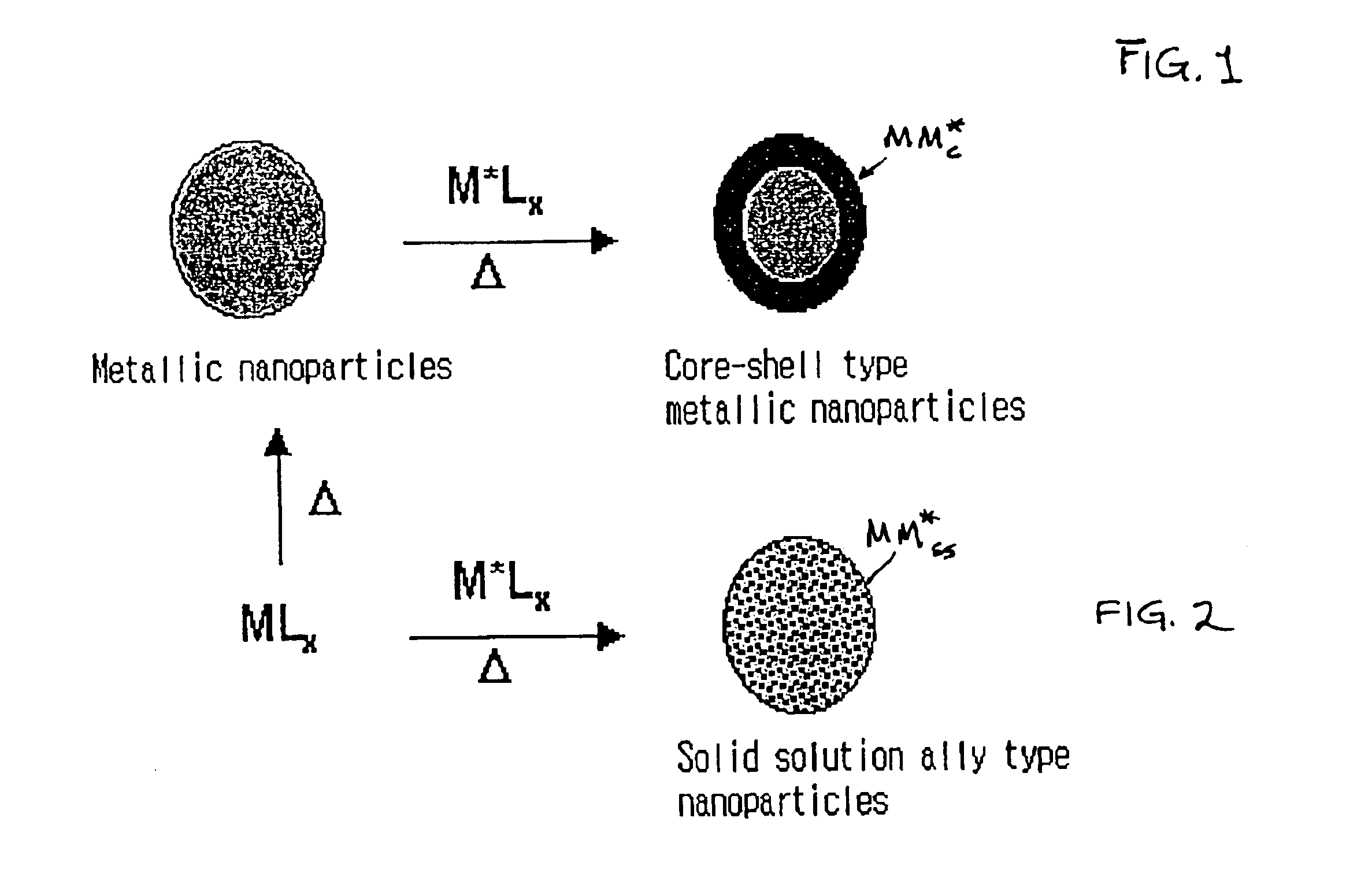

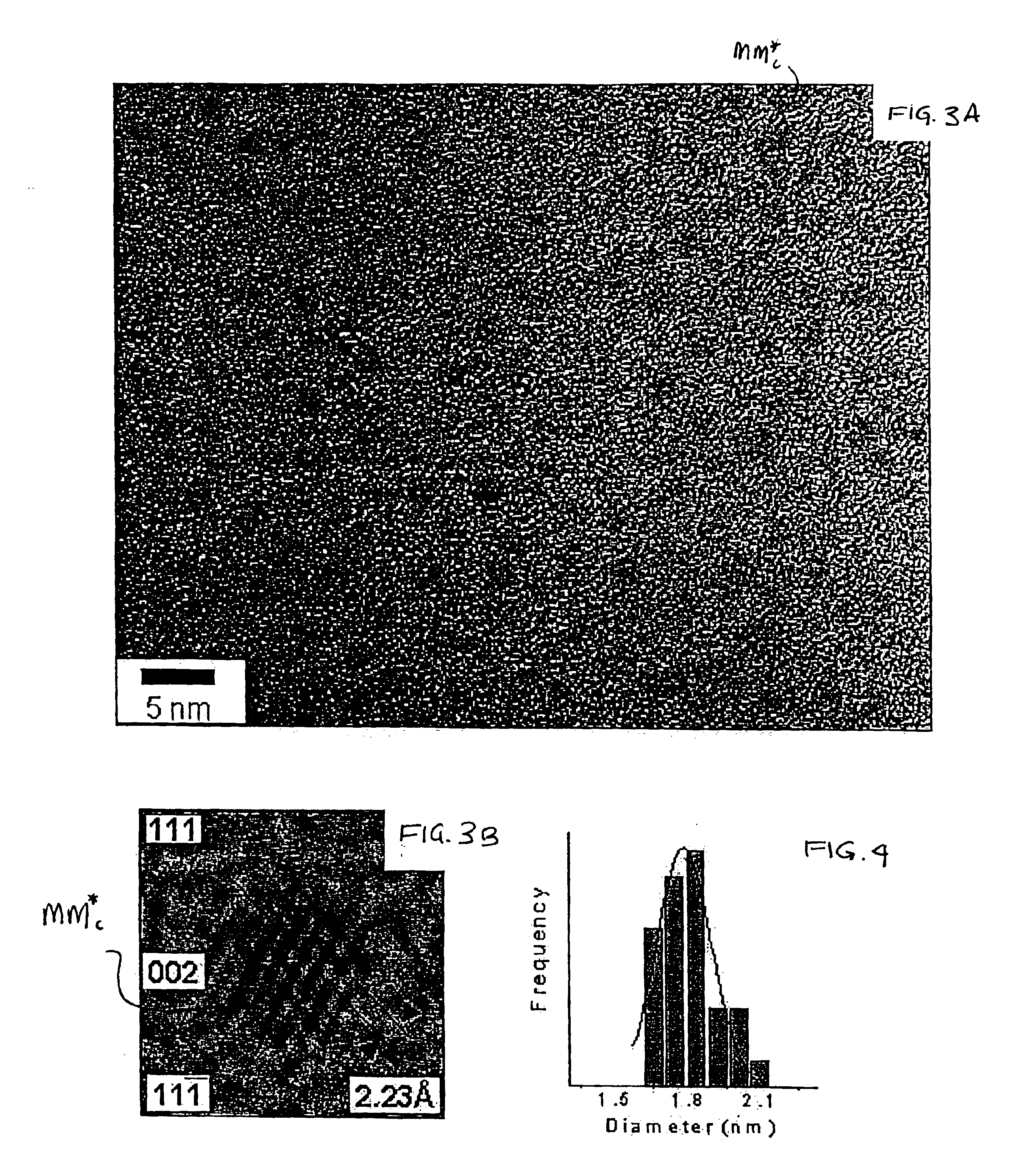

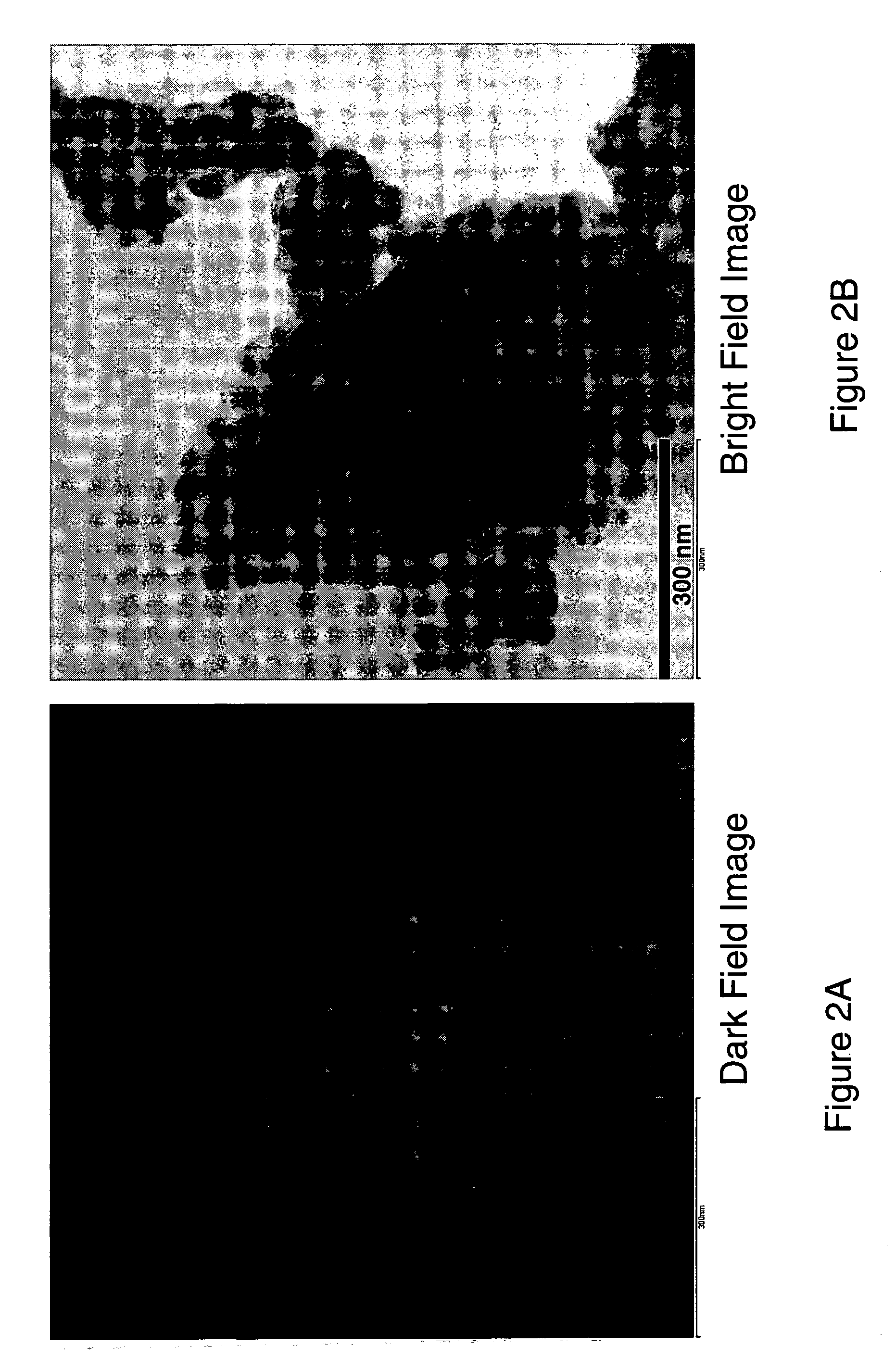

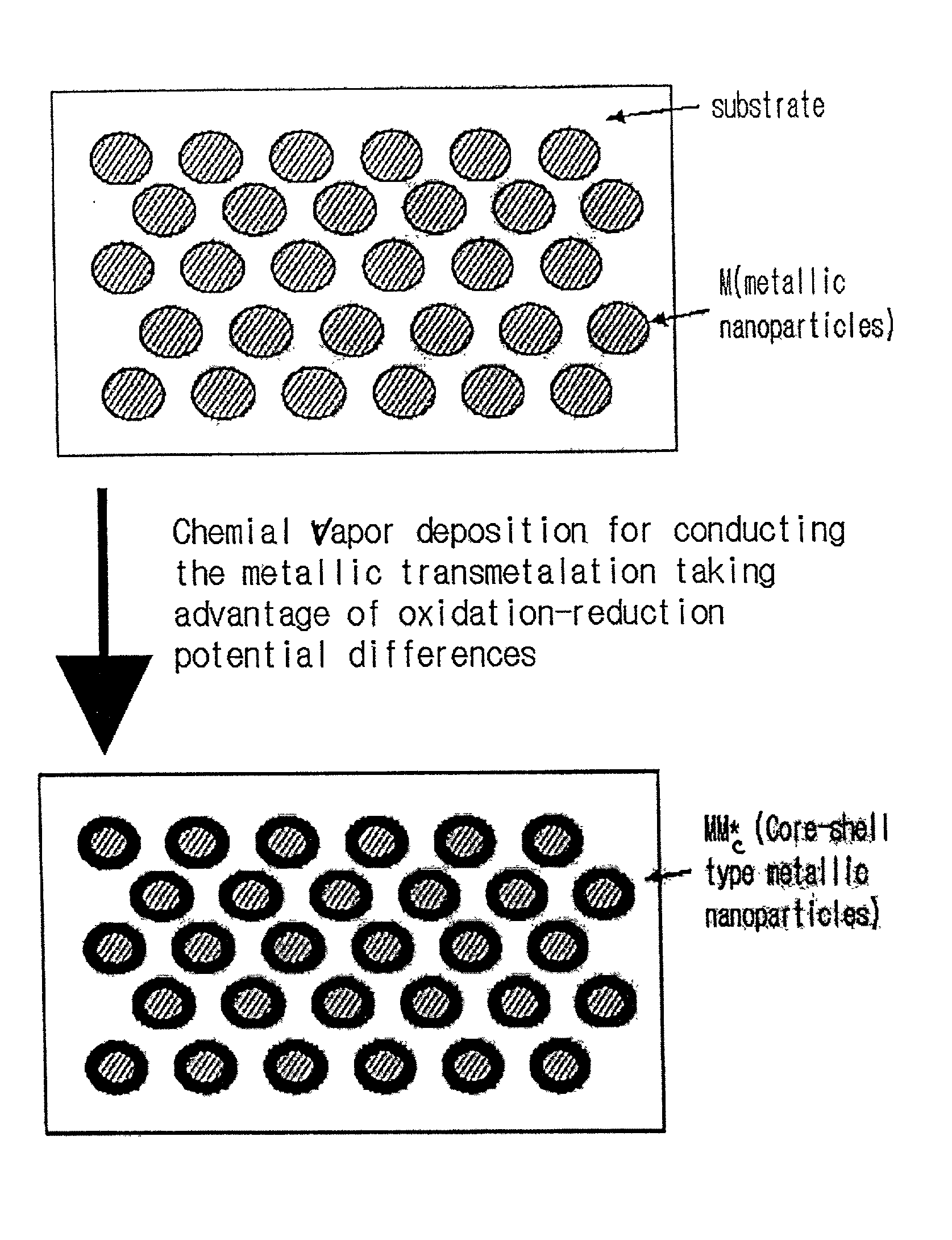

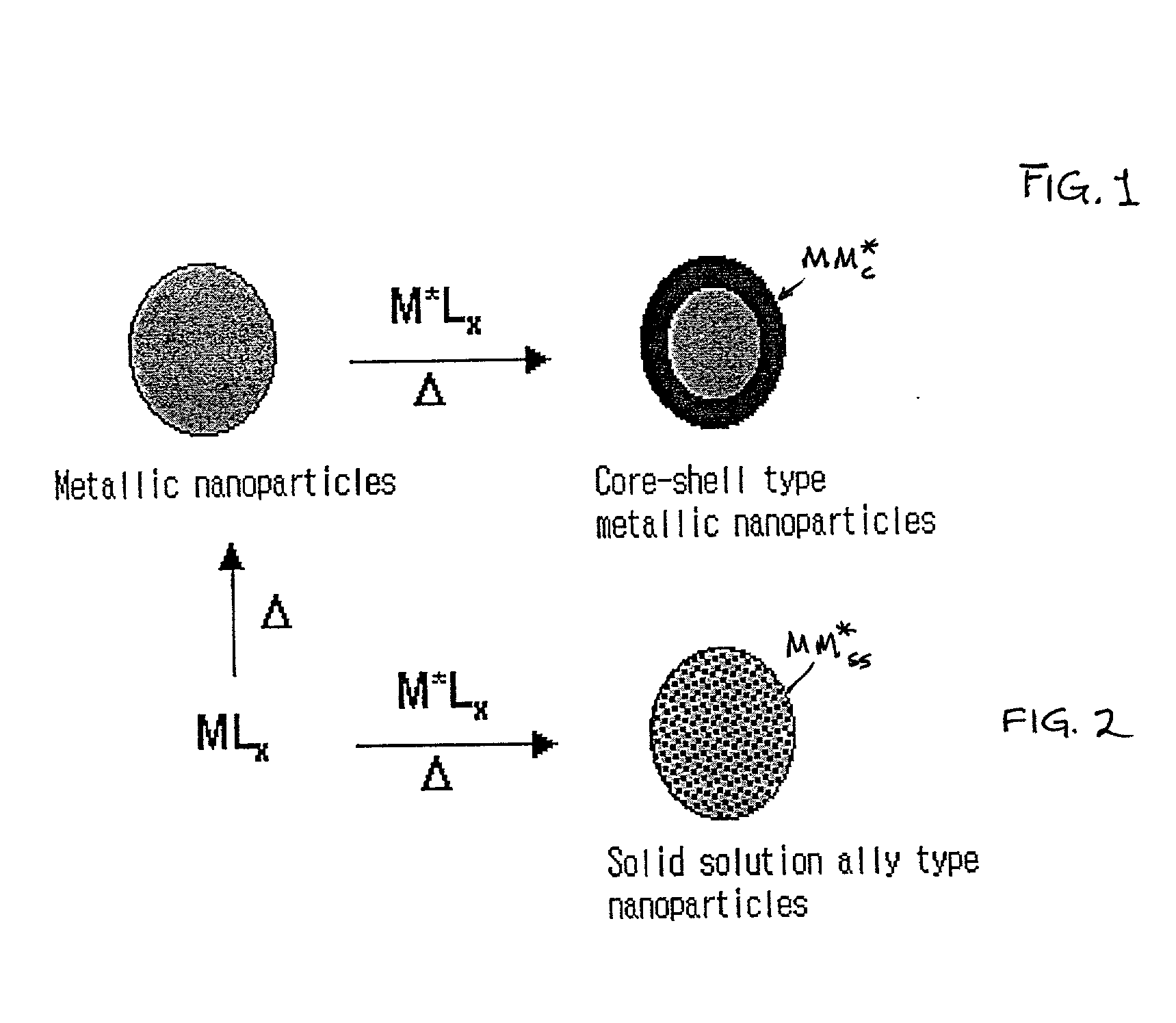

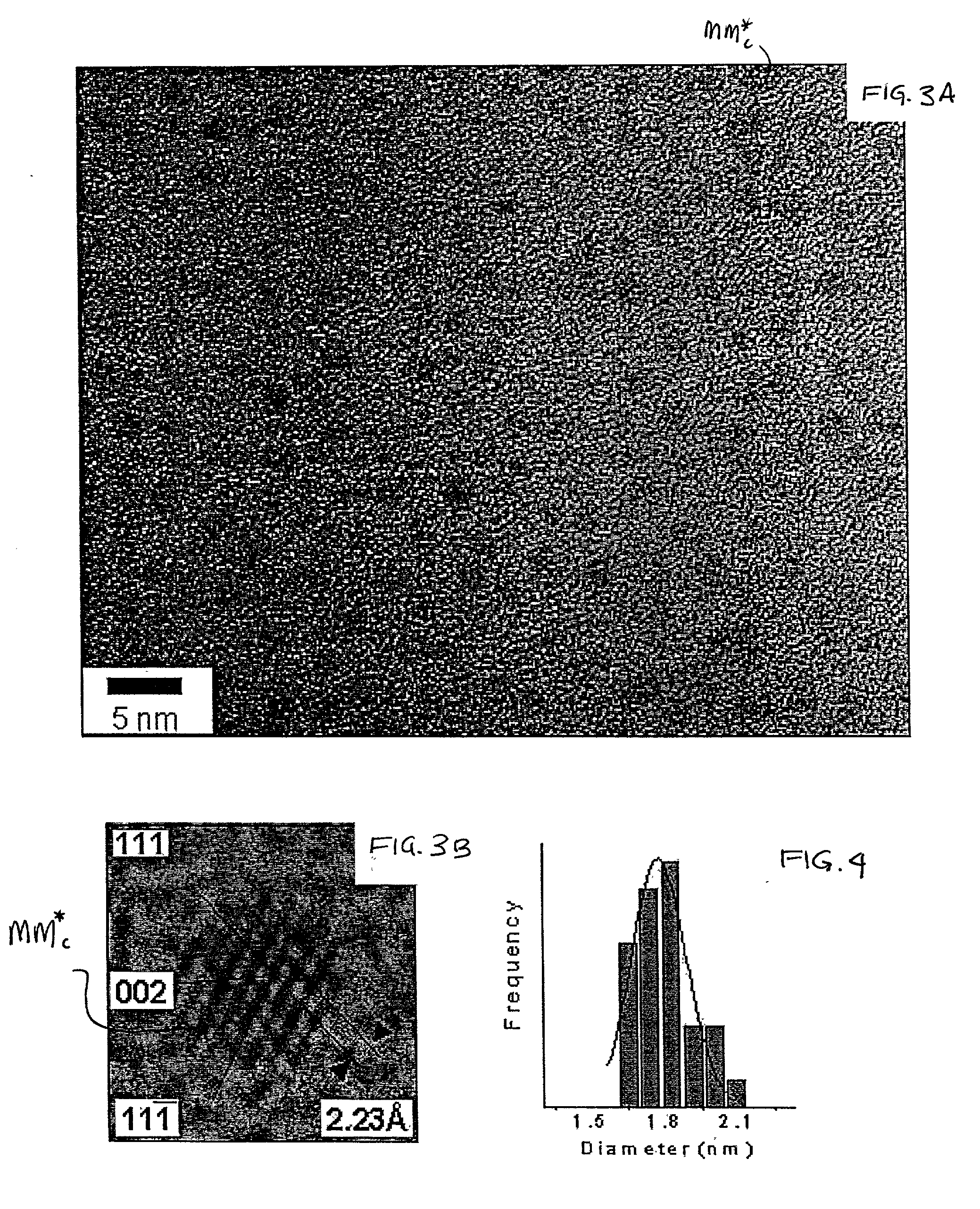

Method for synthesis of core-shell type and solid solution alloy type metallic nanoparticles via transmetalation reactions and applications of same

Disclosed is a method for producing core-shell type metallic nanoparticles involving (i) providing a dispersion of a first metal as nanoparticles in an appropriate organic solvent; (ii) providing a solution of a metallic precursor containing a second metal in an appropriate organic solvent, in which the second metal has a reduction potential higher than that of the first metal; and (iii) combining the dispersion from (i) and the solution from (ii) together to carry out the transmetalation reaction of the first and second metals, thereby forming core-shell type metallic nanoparticles.

Owner:KOREA ADVANCED INST OF SCI & TECH

Cemented carbide inserts for earth-boring bits

This invention relates to cutting inserts for earth boring bits comprising a cutting zone, wherein the cutting zone comprises first cemented hard particles and a body zone, wherein the body zone comprises second cemented hard particles. The first cemented hard particles may differ in at least one property from the second cemented hard particles. As used herein, the cemented hard particles means a material comprising hard particles in a binder. The hard particles may be at least one of a carbide, a nitride, a boride, a silicide, an oxide, and solid solutions thereof and the binder may be at least one metal selected from cobalt, nickel, iron and alloys of cobalt, nickel or iron.

Owner:KENNAMETAL INC

Mullite-aluminum titanate diesel exhaust filter

InactiveUS6849181B2High porosityLarge apertureIron oxides/hydroxidesExhaust apparatusFiltrationMullite

The invention is directed at a mullite-aluminum titanate porous diesel particulate filter constituting a porous ceramic body containing, expressed in terms of weight percent of the total body, of 60-90%, preferably 70-80%, most preferably 70% iron-aluminum titanate solid solution having a stoichiometry of Al2(1−x)Fe2xTiO5, where x is 0-0.1, and 10-40%, preferably 20-30%, most preferably 30% mullite (3Al2O3.2SiO2), and consists essentially, expressed in terms of weigh percent on the oxide basis, of 3 to 15% SiO2, 55 to 65% Al2O3, 22 to 40% TiO2, and 0 to 10% Fe2O3, and being useful for filtration of diesel exhaust. The inventive diesel particulate filter exhibits high interconnected open porosity and large median pore size, in combination with high permeability when fired to a temperature of between 1650° to 1700° C., along with high thermal shock resistance and good filtration capability.

Owner:CORNING INC

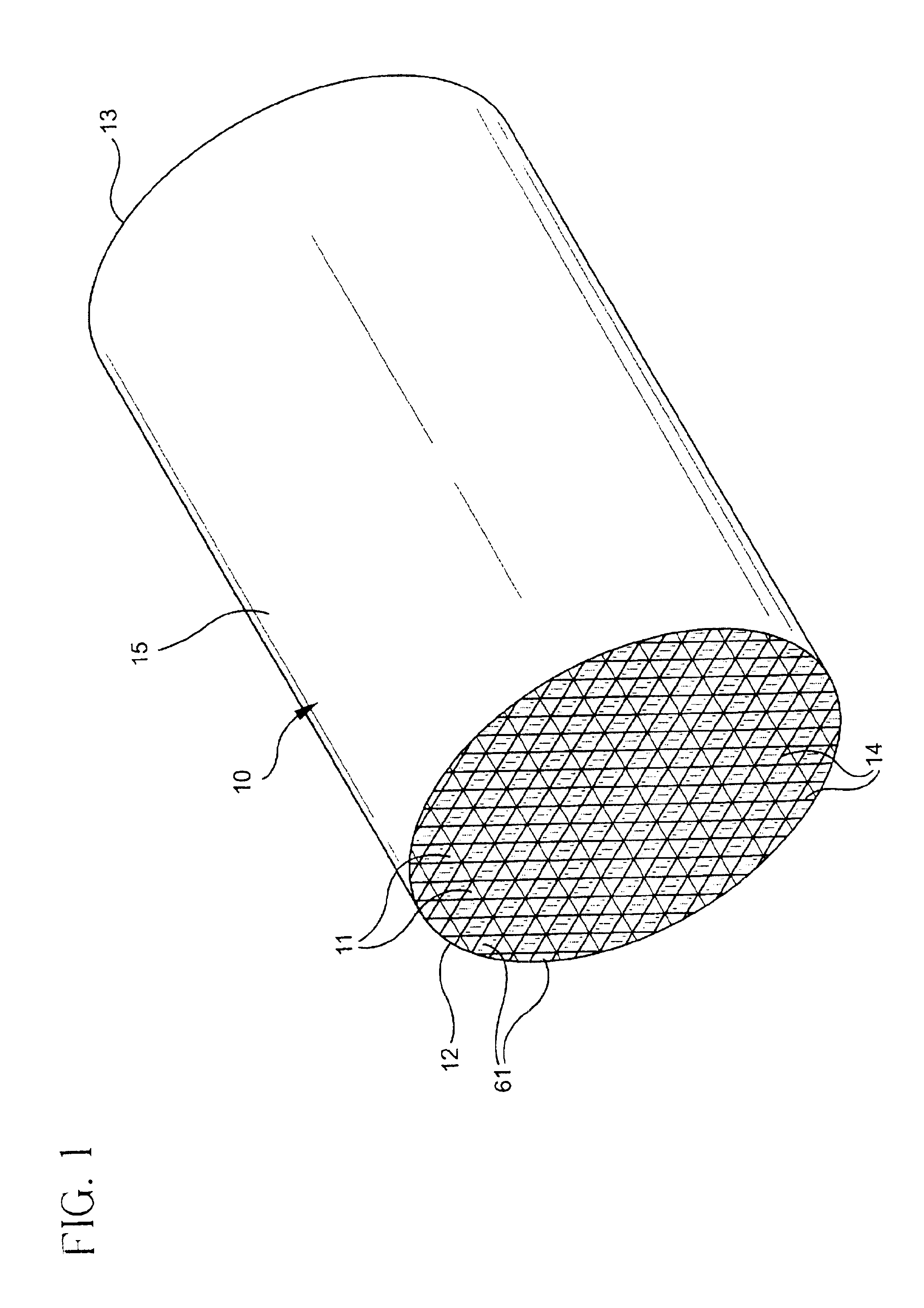

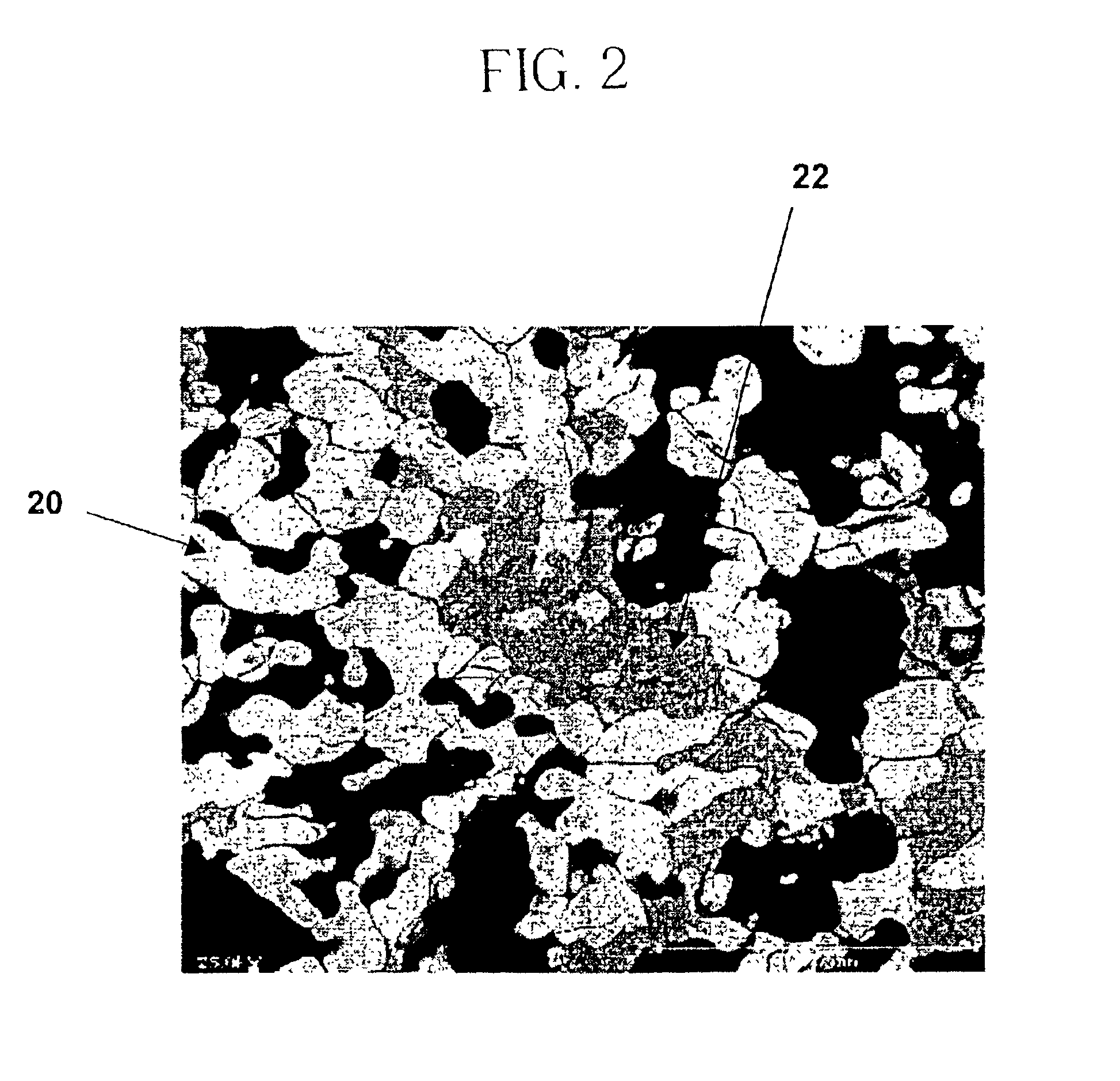

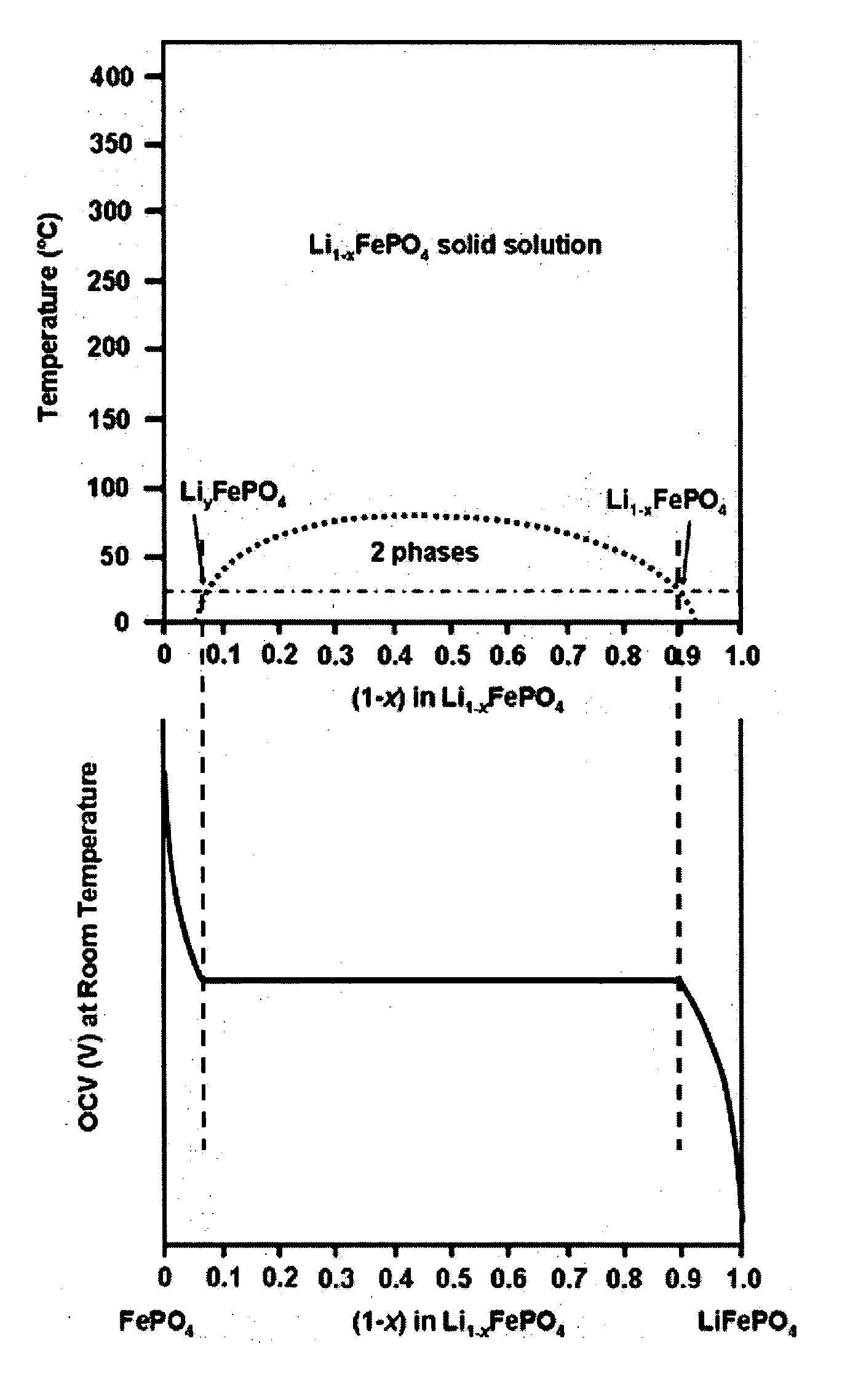

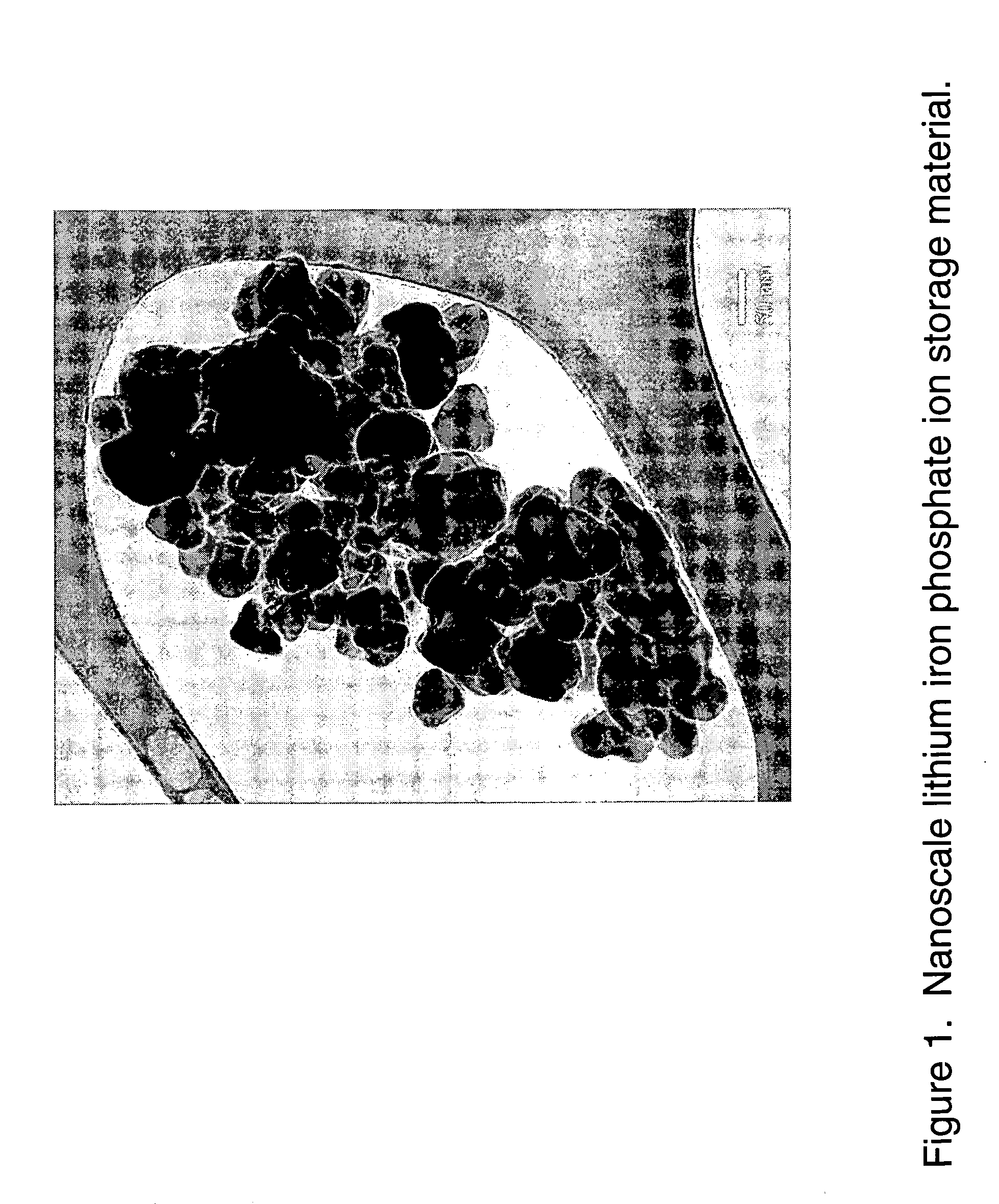

Nanoscale ion storage materials

ActiveUS20070031732A1Improve electronic conductivityImproved electromechanical stabilityMaterial nanotechnologyPhosphatesHigh ratePhosphate

Nanoscale ion storage materials are provided that exhibit unique properties measurably distinct from their larger scale counterparts. For example, the nanoscale materials can exhibit increased electronic conductivity, improved electromechanical stability, increased rate of intercalation, and / or an extended range of solid solution. Useful nanoscale materials include alkaline transition metal phosphates, such as LiMPO4, where M is one or more transition metals. The nanoscale ion storage materials are useful for producing devices such as high energy and high power storage batteries, battery-capacitor hybrid devices, and high rate electrochromic devices.

Owner:RIL USA INC +1

Method for synthesis of core-shell type and solid solution alloy type metallic nanoparticles via transmetalation reactions and applications of same

Disclosed is a method for producing core-shell type metallic nanoparticles involving (i) providing a dispersion of a first metal as nanoparticles in an appropriate organic solvent; (ii) providing a solution of a metallic precursor containing a second metal in an appropriate organic solvent, in which the second metal has a reduction potential higher than that of the first metal; and (iii) combining the dispersion from (i) and the solution from (ii) together to carry out the transmetalation reaction of the first and second metals, thereby forming core-shell type metallic nanoparticles.

Owner:KOREA ADVANCED INST OF SCI & TECH

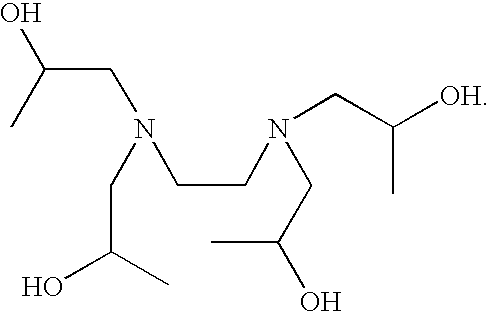

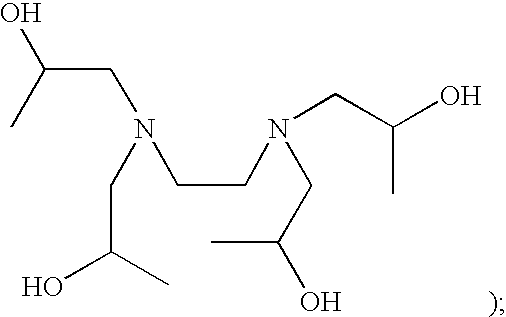

Lithium ion polymer electrolytes

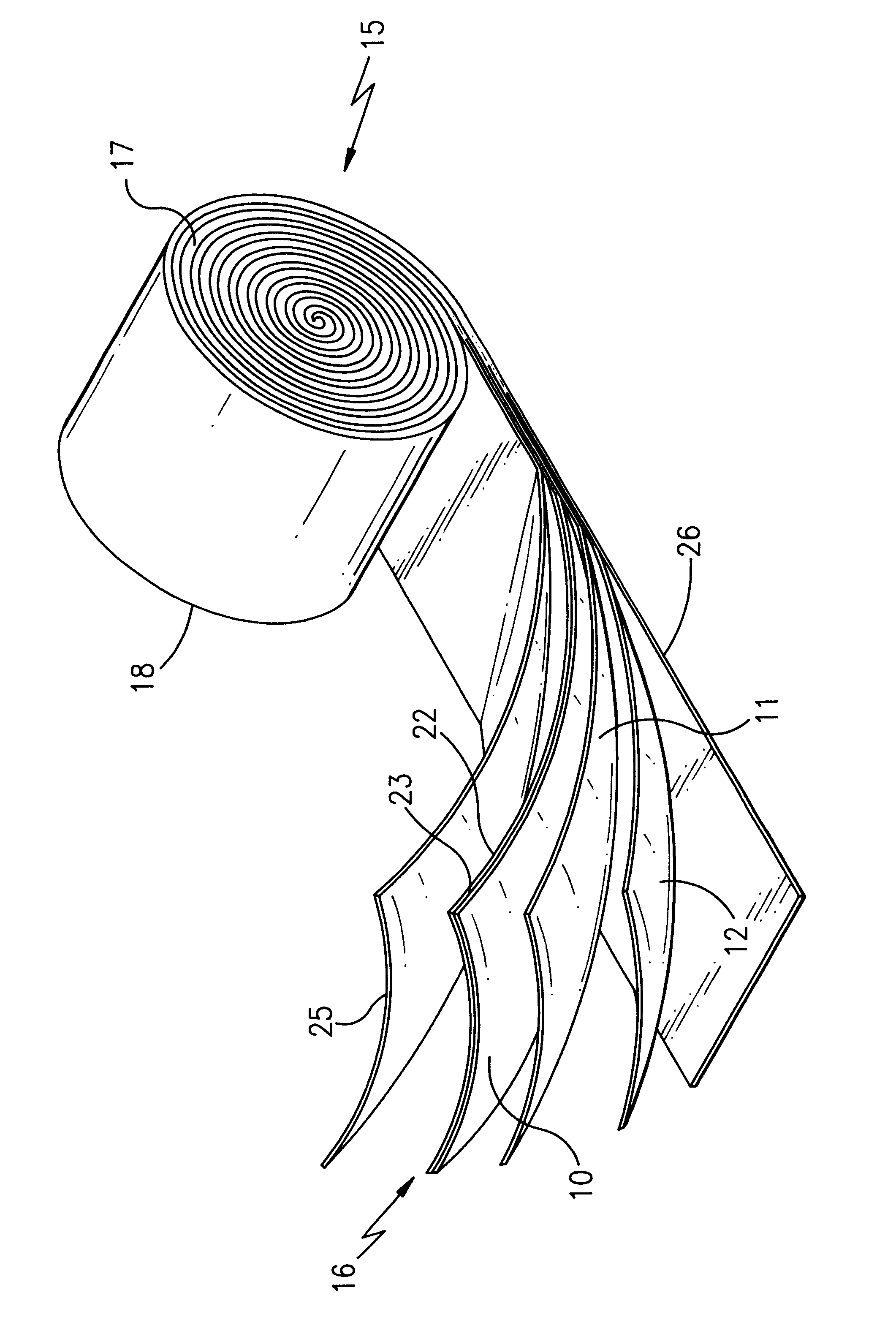

InactiveUS6413676B1Prevent kinkingAvoid deformationElectrode manufacturing processesFinal product manufacturePorosityCross-link

A dimensionally stable, highly resilient, hybrid copolymer solid-solution electrolyte-retention film for use in a lithium ion battery in one preferred embodiment has a predominantly amorphous structure and mechanical strength despite contact with liquid solvent electrolyte. The film is a thinned (stretched), cast film of a homogeneous blend of two or more polymers, one of which is selected for its pronounced solvent retention properties. A very high surface area inorganic filler dispersed in the blend during formation thereof serves to increase the porosity of the film and thereby enhance electrolyte retention. The film is soaked in a solution of liquid polymer with liquid organic solvent electrolyte and lithium salt, for absorption thereof. Use of a cross-linked liquid polymer enhances trapping of molecules of the electrolyte into pores of the film. The electrolyte film is sandwiched between flexible active anode and cathode layers to form the lithium ion battery. Novel methods are provided for forming the electrodes, the polymer substrate, and other elements of the battery.

Owner:LITHIUM POWER TECH

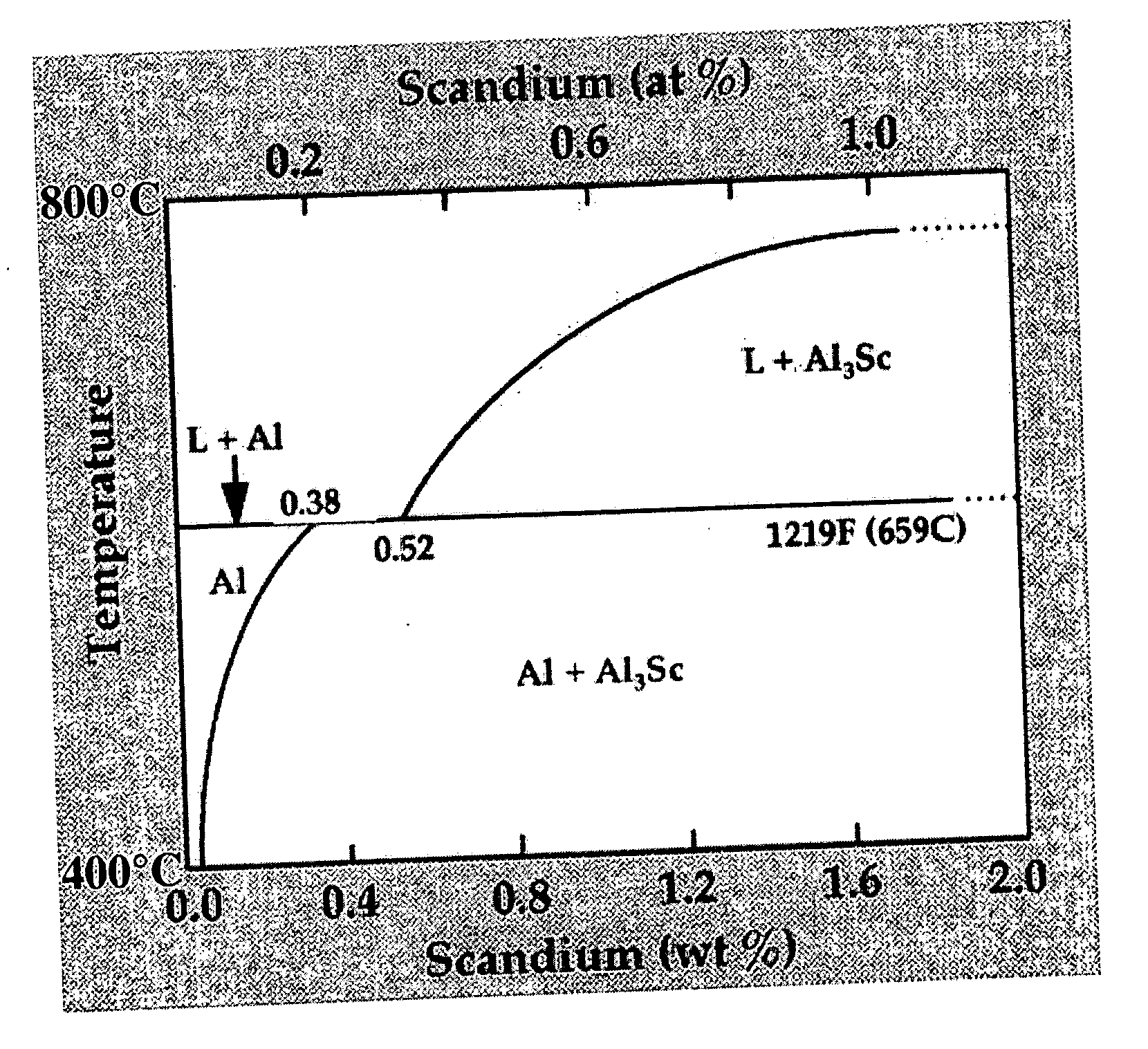

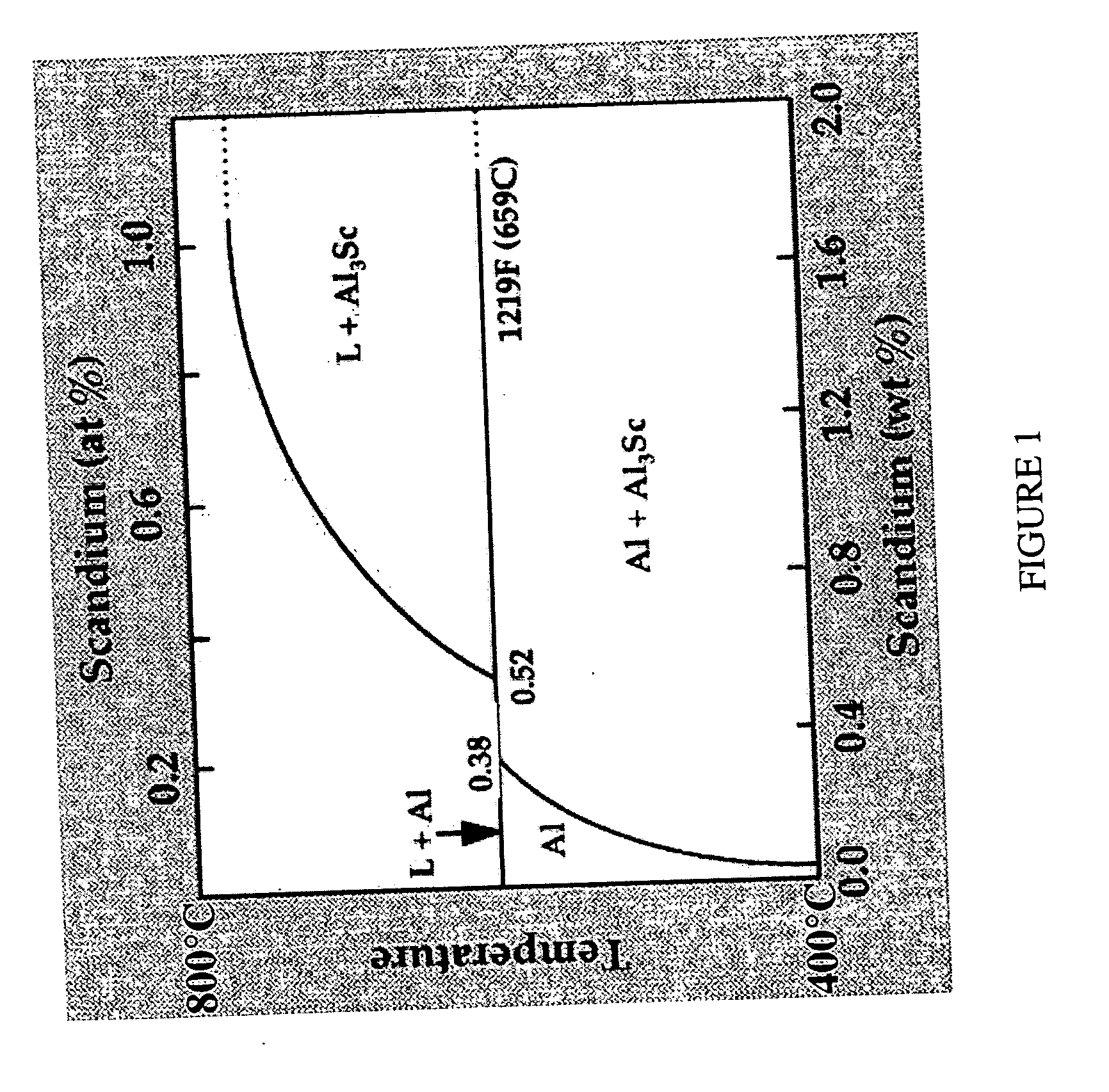

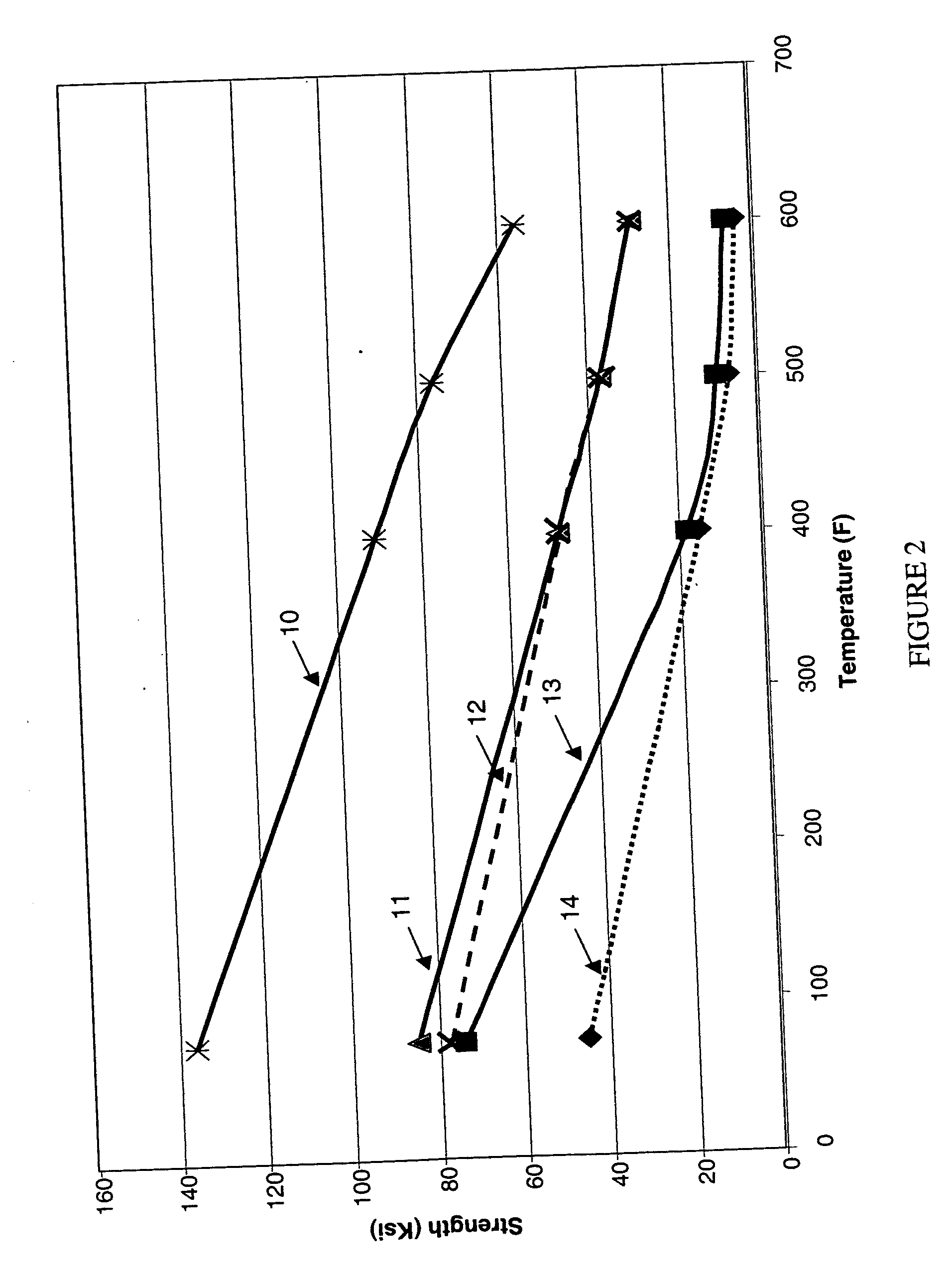

High temperature aluminum alloys

High temperature aluminum alloys that can be used at temperatures from about −420° F. (−251° C.) up to about 650° F. (343° C.) are described herein. These alloys comprise aluminum; scandium; at least one of nickel, iron, chromium, manganese and cobalt; and at least one of zirconium, gadolinium, hafnium, yttrium, niobium and vanadiuim. These alloys comprise an aluminum solid solution matrix and a mixture of various dispersoids. These alloys are substantially free of magnesium.

Owner:RTX CORP

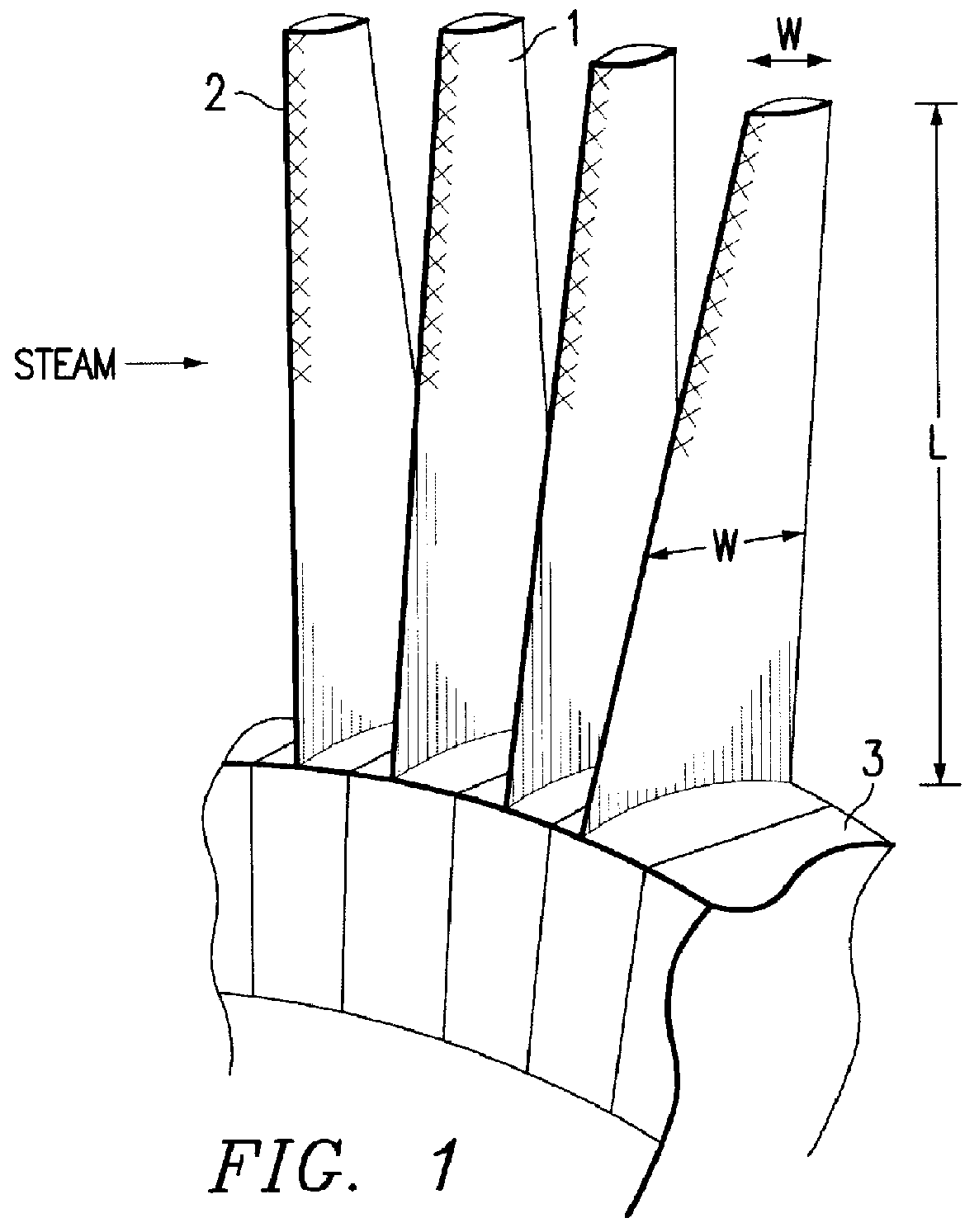

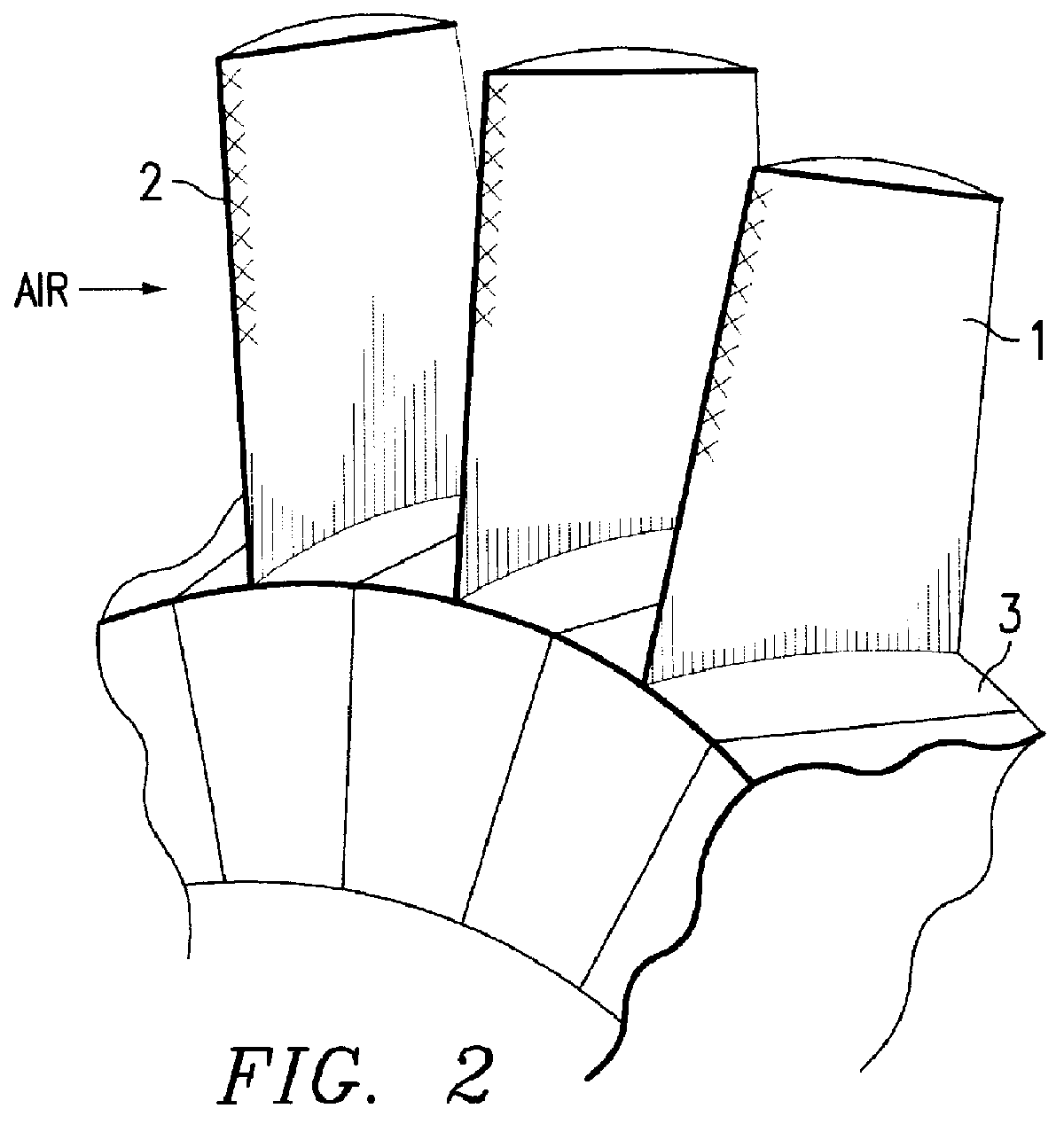

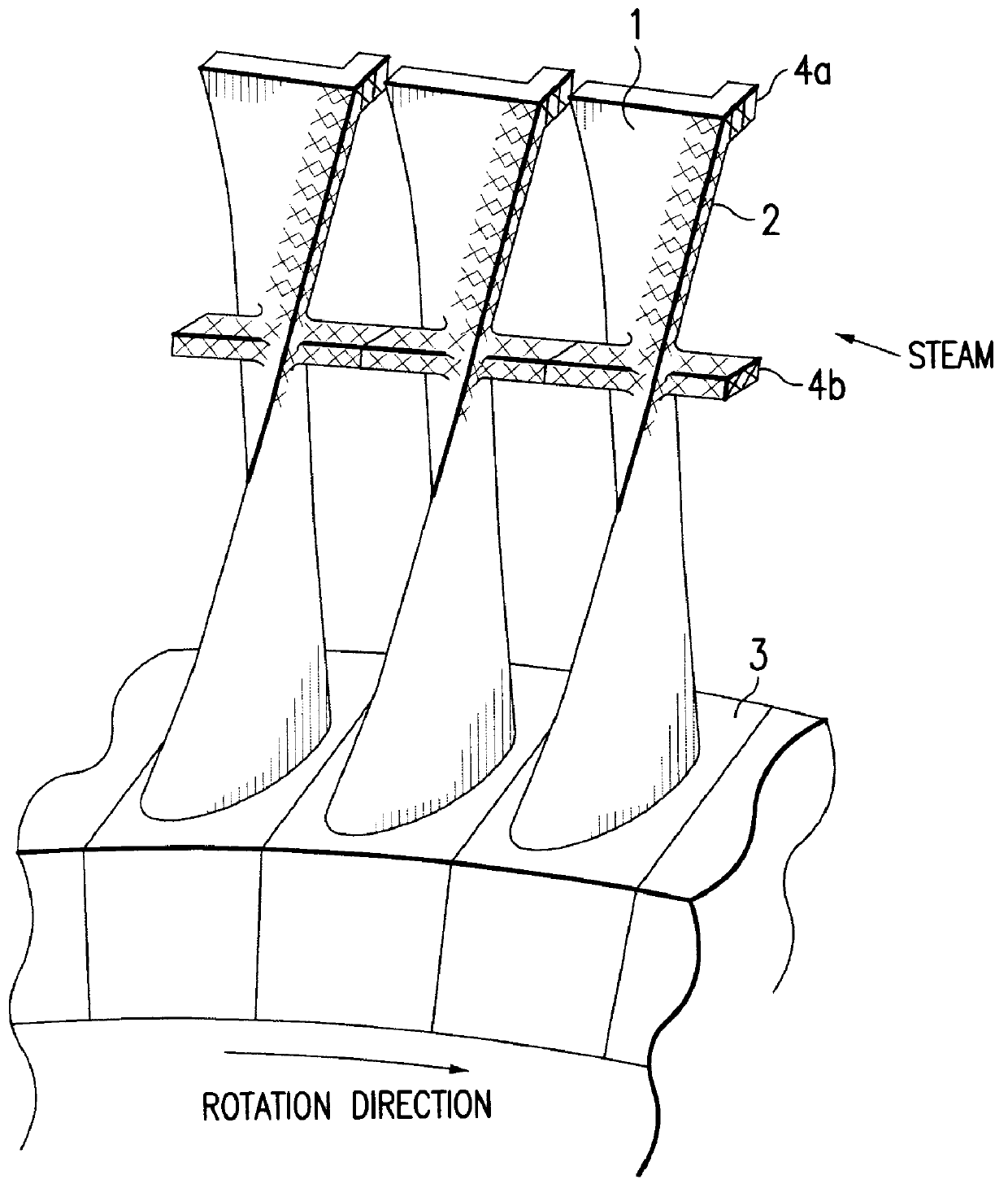

Method for producing titanium alloy turbine blades and titanium alloy turbine blades

InactiveUS6127044ALess abrasionSuperior in water droplet erosion resistancePropellersEngine manufactureLeading edgeTurbine blade

PCT No. PCT / JP95 / 01817 Sec. 371 Date Jun. 2, 1998 Sec. 102(e) Date Jun. 2, 1998 PCT Filed Sep. 13, 1995 PCT Pub. No. WO97 / 10066 PCT Pub. Date Mar. 20, 1997A method for producing titanium alloy turbine blades comprising the steps of (a) forming turbine blades of titanium alloy through hot forging or machining, (b) cooling leading edges on tip portions of the turbine blades including covers thereof formed through hot forging or machining faster than blade main body after final hot forging or solid solution treatment, and (c) heat treating the cooled turbine blades. With this method, it is possible to manufacture titanium turbine blades in an economical fashion and obtain titanium alloy turbine blades superior in reliability by preventing erosion.

Owner:KK TOSHIBA +1

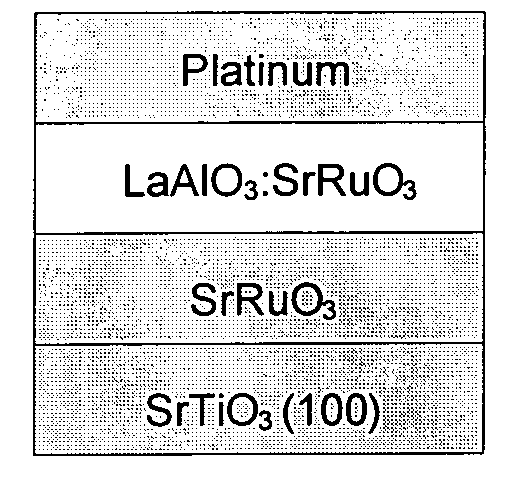

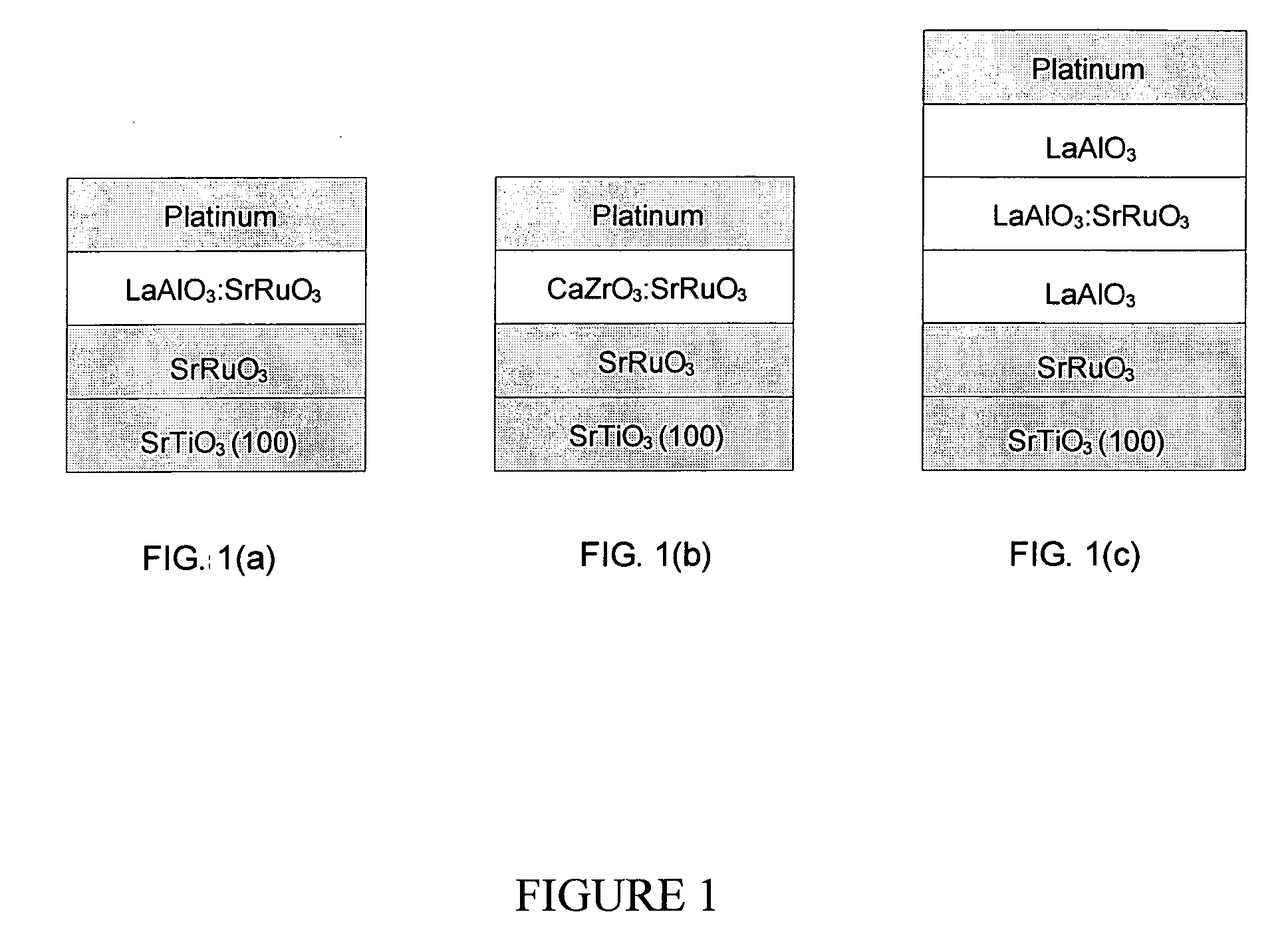

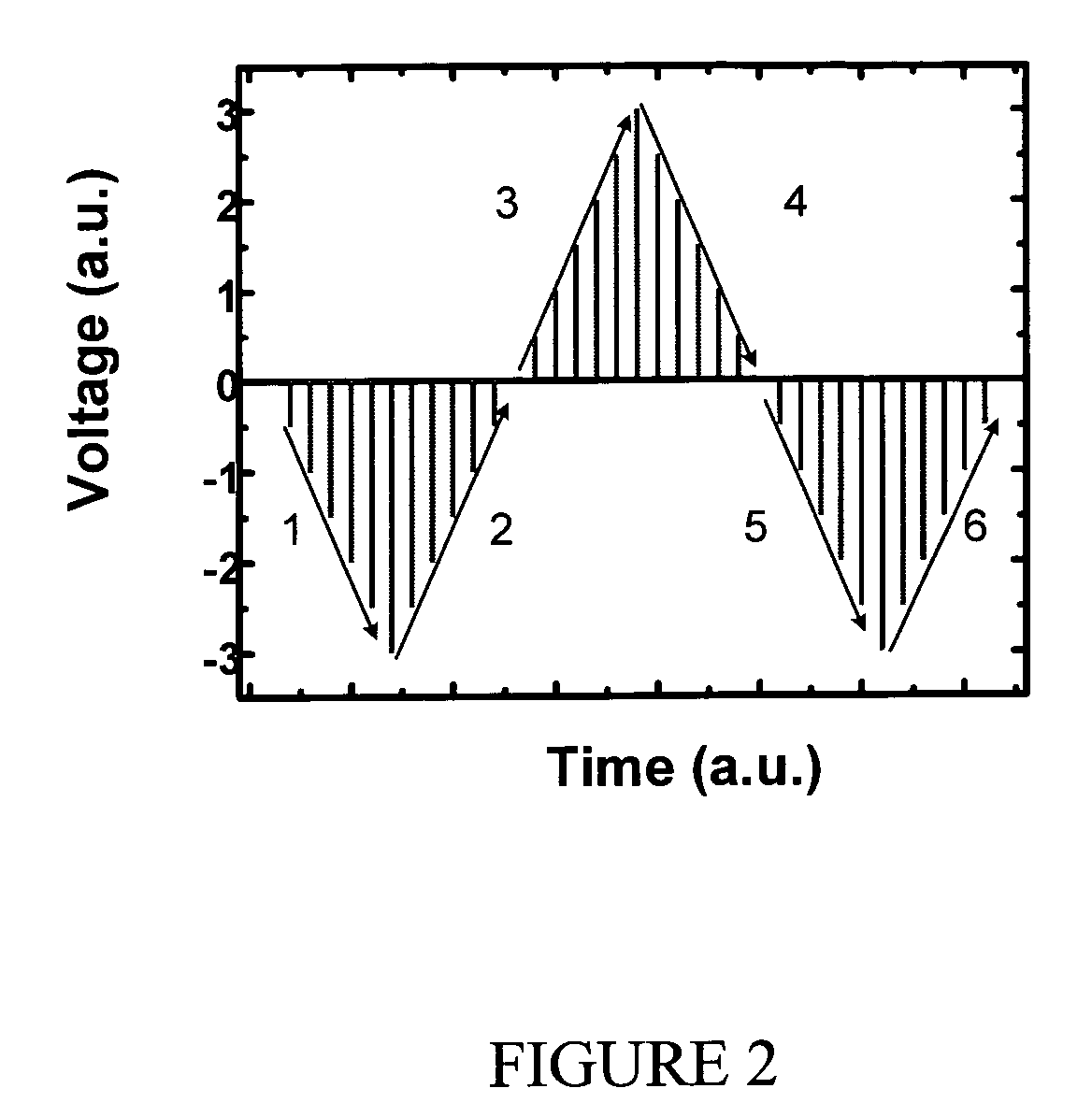

Resistance-switching oxide thin film devices

Resistance-switching oxide films, and devices therewith, are disclosed. Resistance-switching oxide films, according to certain preferred aspects of the present invention, include at least about 75 atomic percent of an insulator oxide matrix having a conducting material dopant in an amount up to about 25 atomic percent. The matrix and dopant are preferably in solid solution. The insulator oxide matrix may also preferably include about 6 to about 12 atomic percent of a conducting material dopant. According to certain aspects of the present invention, the insulator oxide matrix, the conducting material dopant, or both, may have a perovskite crystal structure. The insulator oxide matrix may preferably include at least one of LaAlO3 and CaZrO3. Preferred conducting material dopants include SrRuO3, CaRuO3, or combinations thereof.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

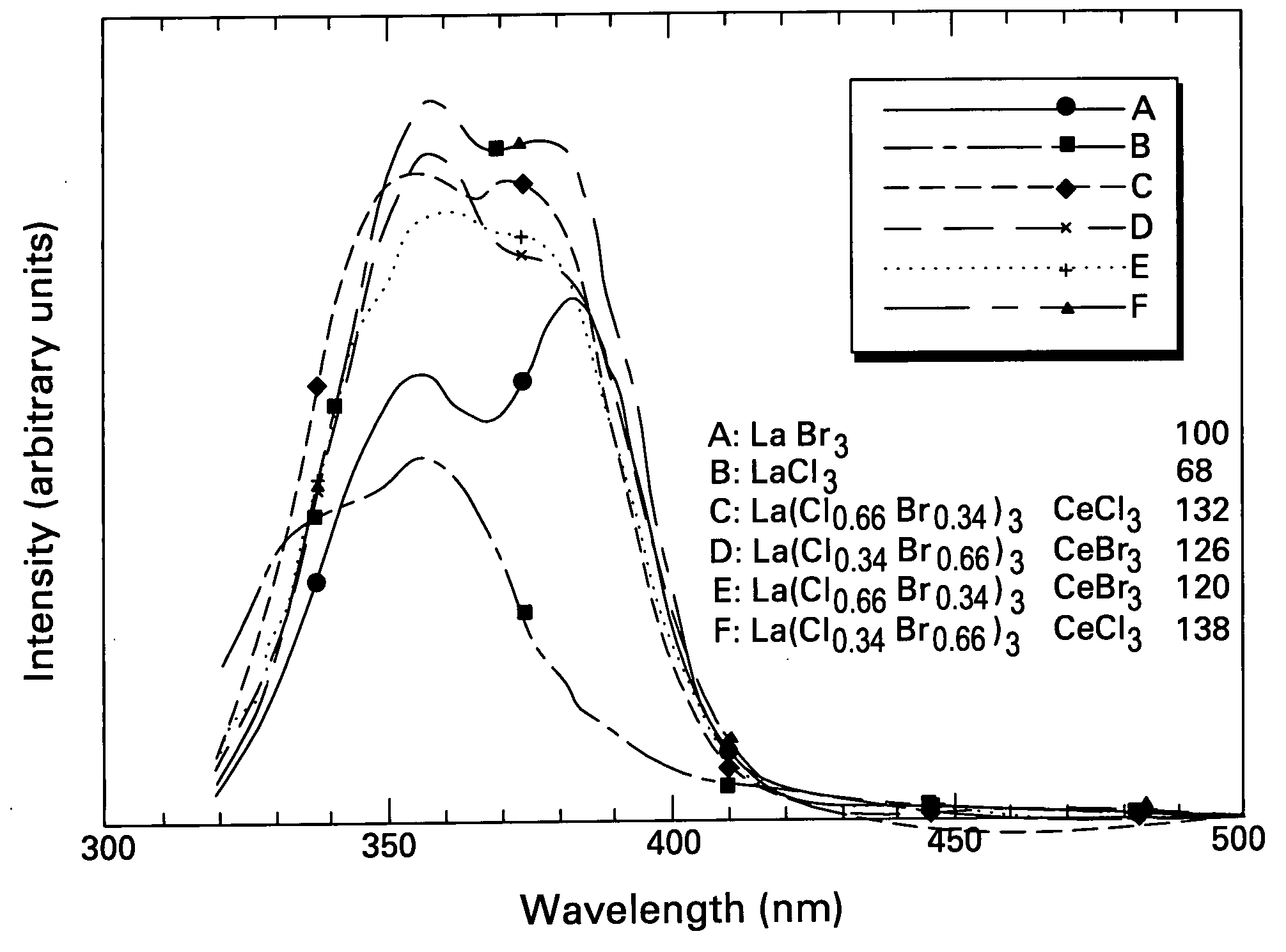

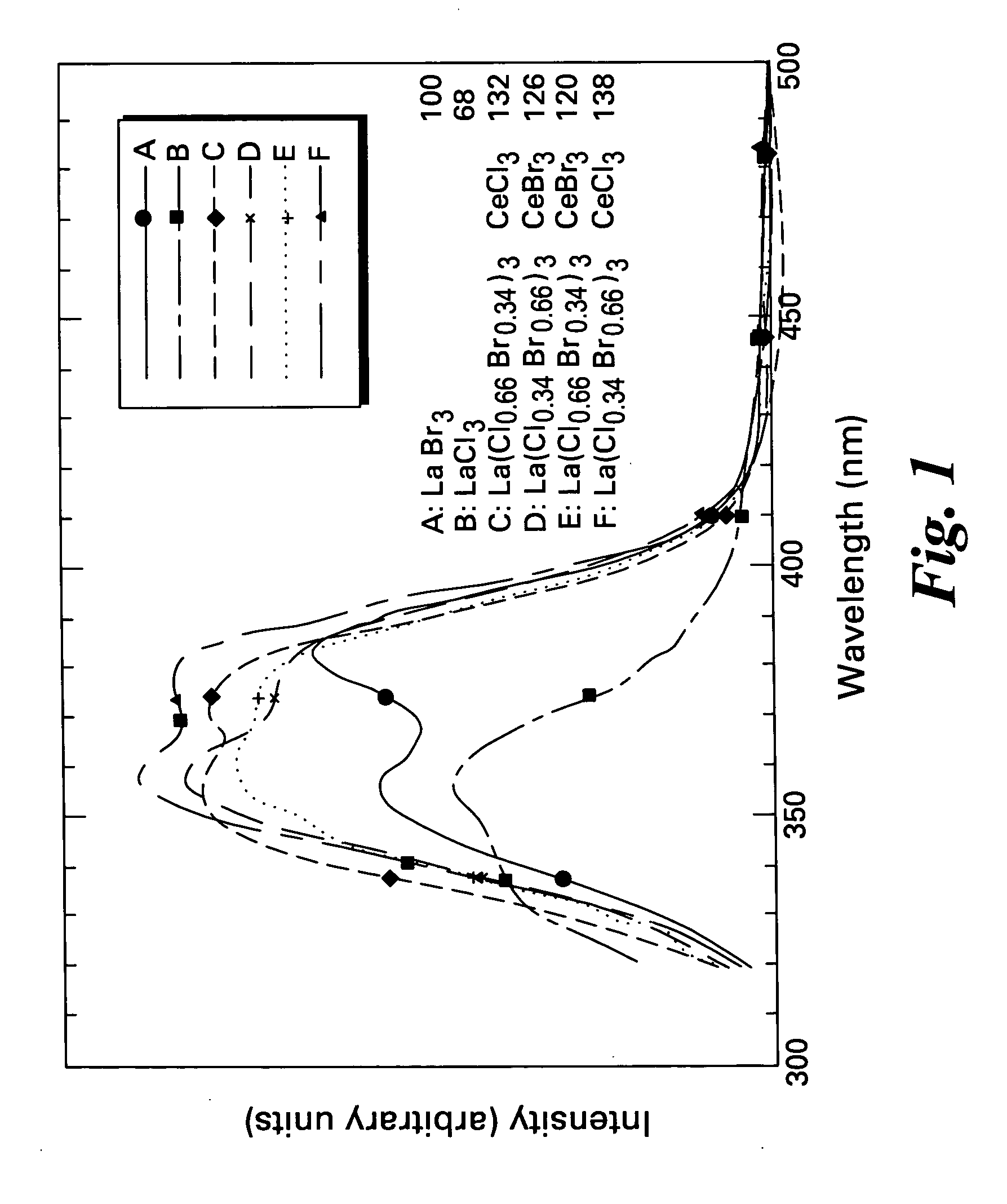

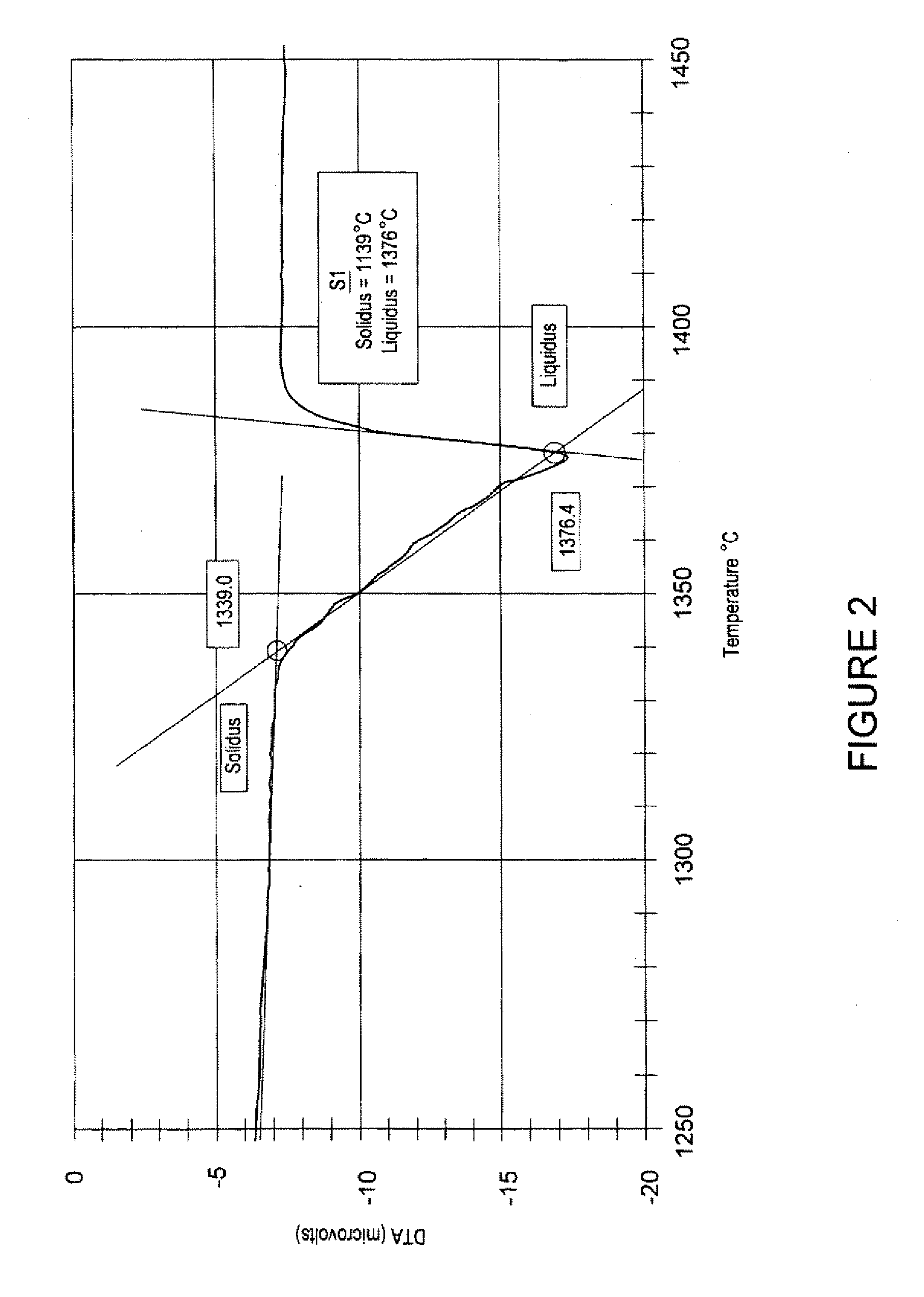

Scintillator compositions, and related processes and articles of manufacture

ActiveUS20050082484A1Improve performanceExcellent and reproducible scintillation responseMaterial analysis by optical meansLuminescent compositionsIodideHigh energy

Scintillator materials based on certain types of halide-lanthanide matrix materials are described. In one embodiment, the matrix material contains a mixture of lanthanide halides, i.e., a solid solution of at least two of the halides, such as lanthanum chloride and lanthanum bromide. In another embodiment, the matrix material is based on lanthanum iodide alone, which must be substantially free of lanthanum oxyiodide. The scintillator materials, which can be in monocrystalline or polycrystalline form, also include an activator for the matrix material, e.g., cerium. Radiation detectors that use the scintillators are also described, as are related methods for detecting high-energy radiation.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

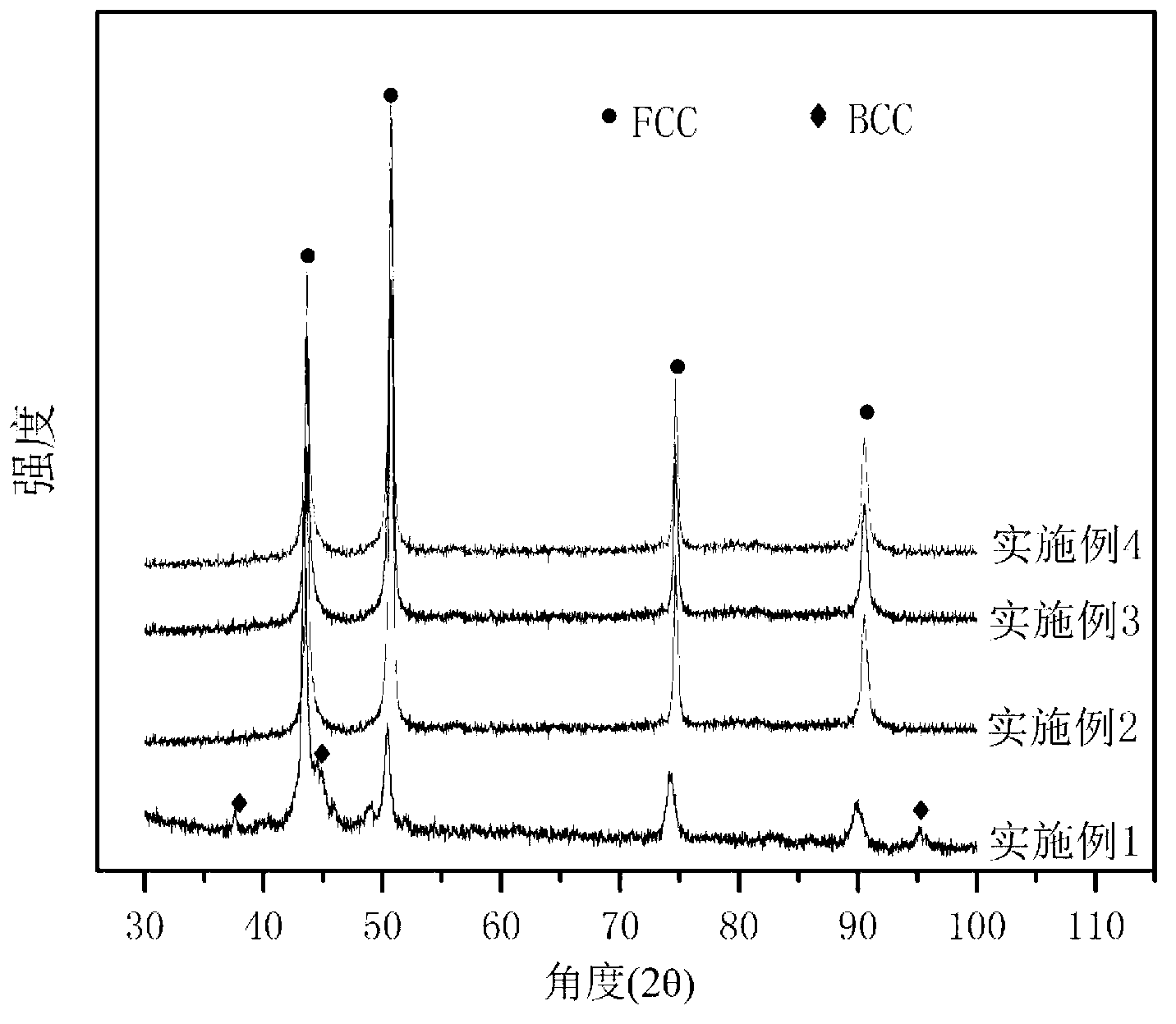

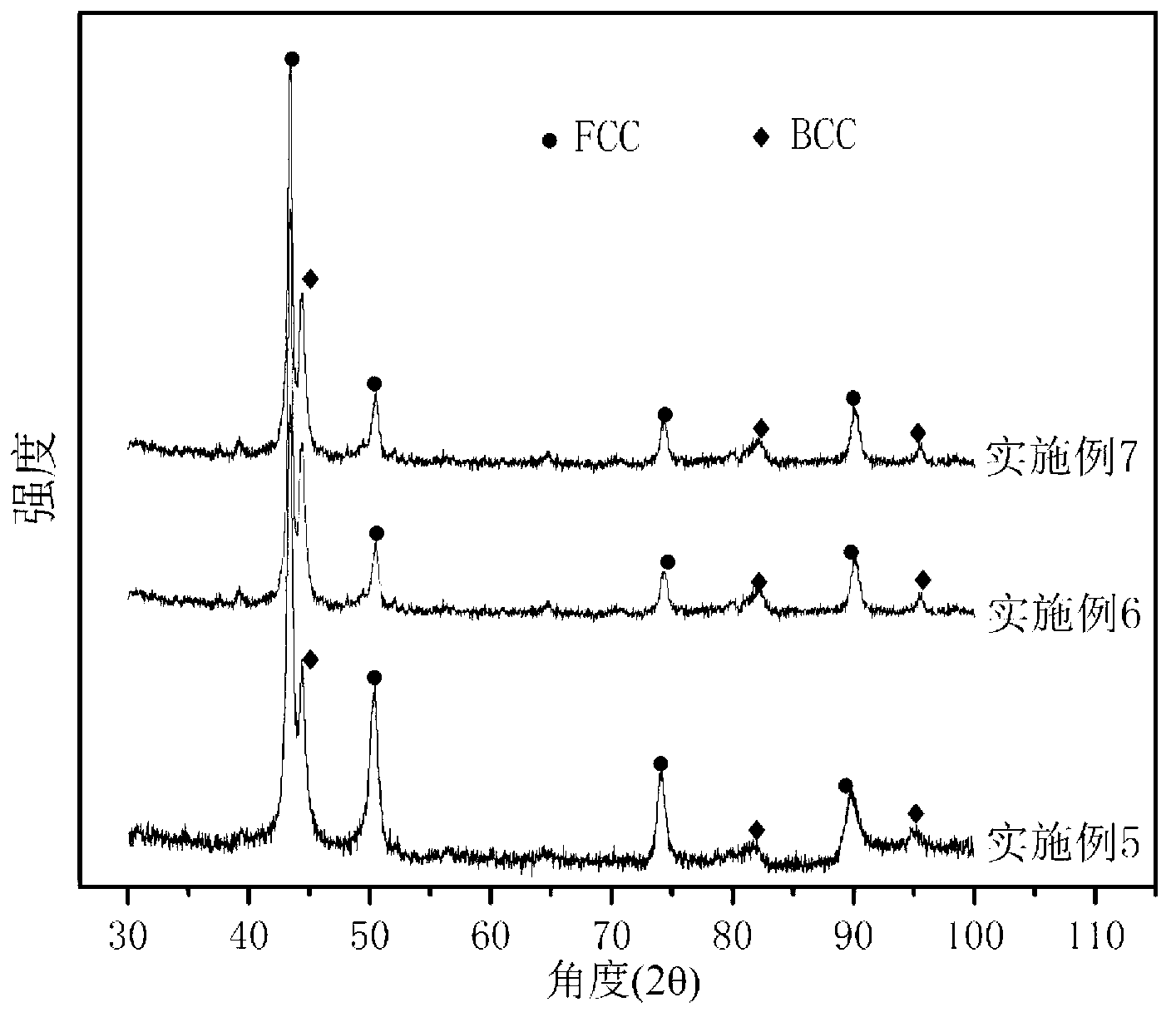

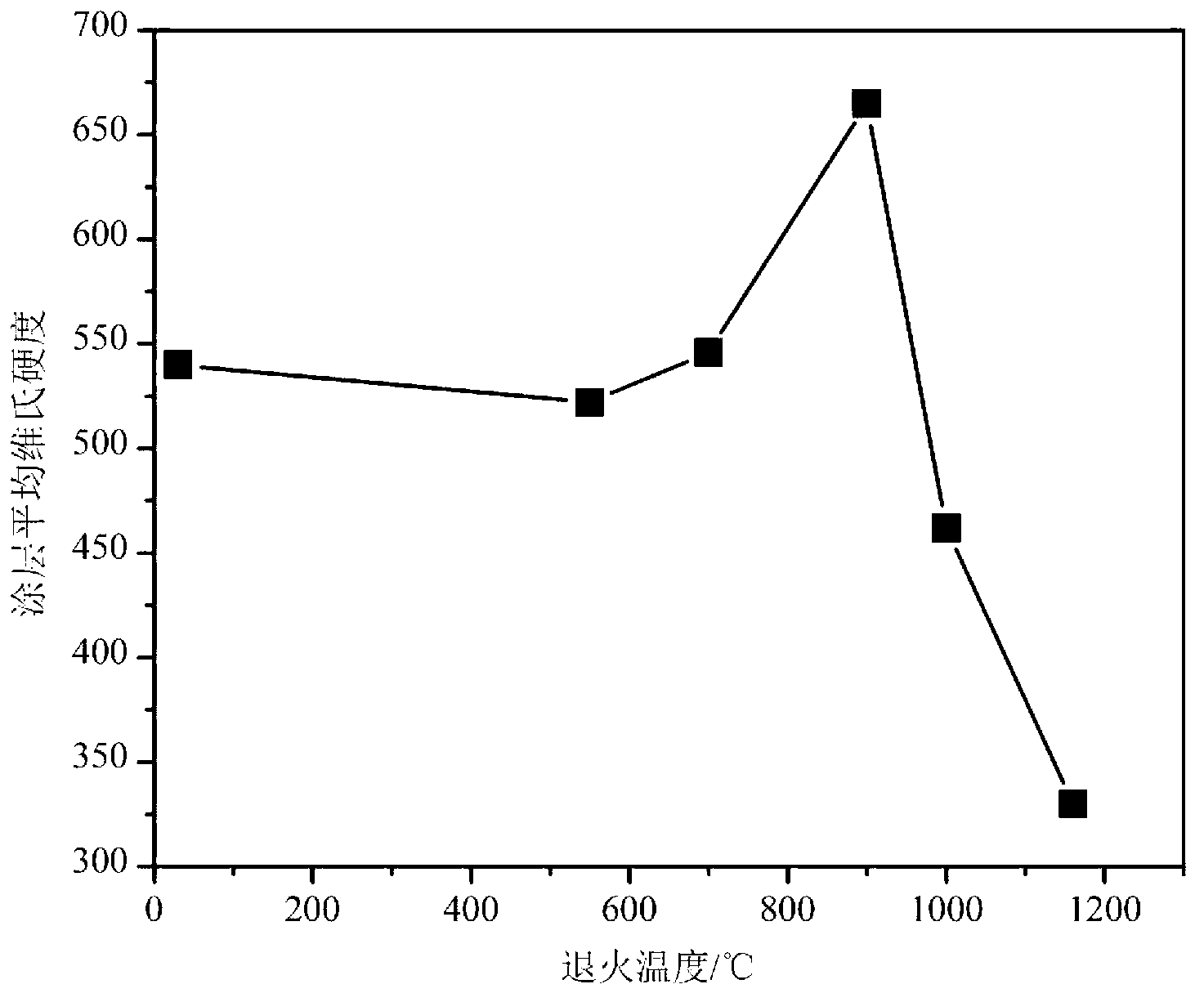

Laser-cladding high-entropy alloy powder and preparation method of high-entropy alloy coating

ActiveCN103290404AImprove coating qualityHigh hardnessMetallic material coating processesHigh entropy alloysOperability

The invention discloses laser-cladding high-entropy alloy powder. The laser-cladding high-entropy alloy powder comprises the following elements in percentage by weight: 10%-15% of Fe, 14%-17% of Cr, 22%-25% of Ni, 22%-24% of Co, 22%-24% of Mn, 0%-4% of Si and 0%-4% of B. The invention further discloses a scheme of adding another element Al based on the gradients of the scheme, and a method for preparing a high-entropy alloy coating by using the laser-cladding high-entropy alloy powder. According to the technical scheme, after laser cladding, good coating quality is realized; a phase structure of the coating retains peculiar solid solution structure of high-entropy alloy, and the atomic percent of each main metal element in the cladding coating satisfies nominal category of the high-entropy alloy; the coating has a plurality of excellent performances of high rigidity, high temperature resistance, wear resistance, corrosion resistance and the like; the technical repeatability and operability are both greatly improved, so that the high-entropy alloy is popularized and applied in surface modification of laser materials.

Owner:ZHEJIANG UNIV OF TECH +1

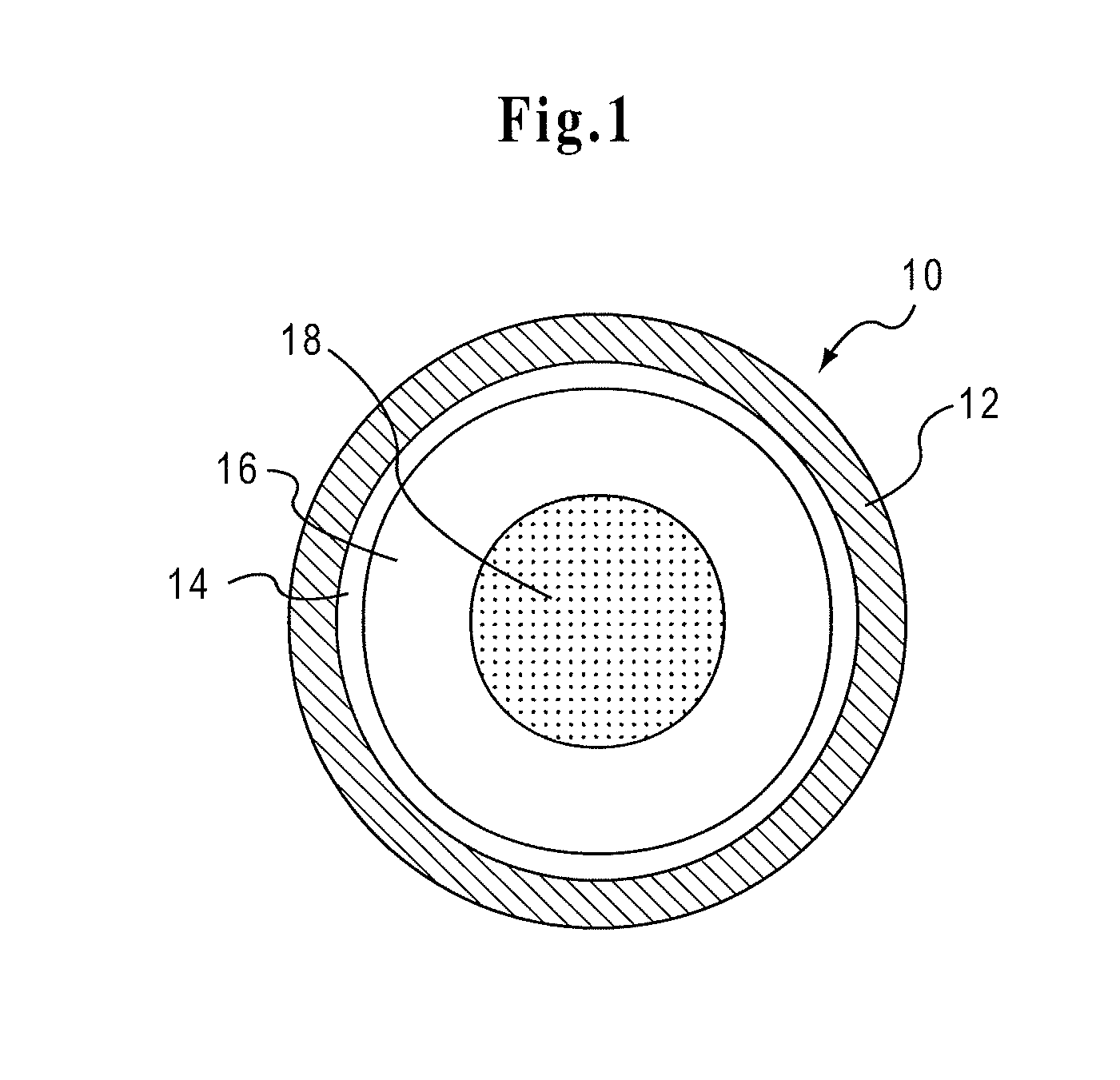

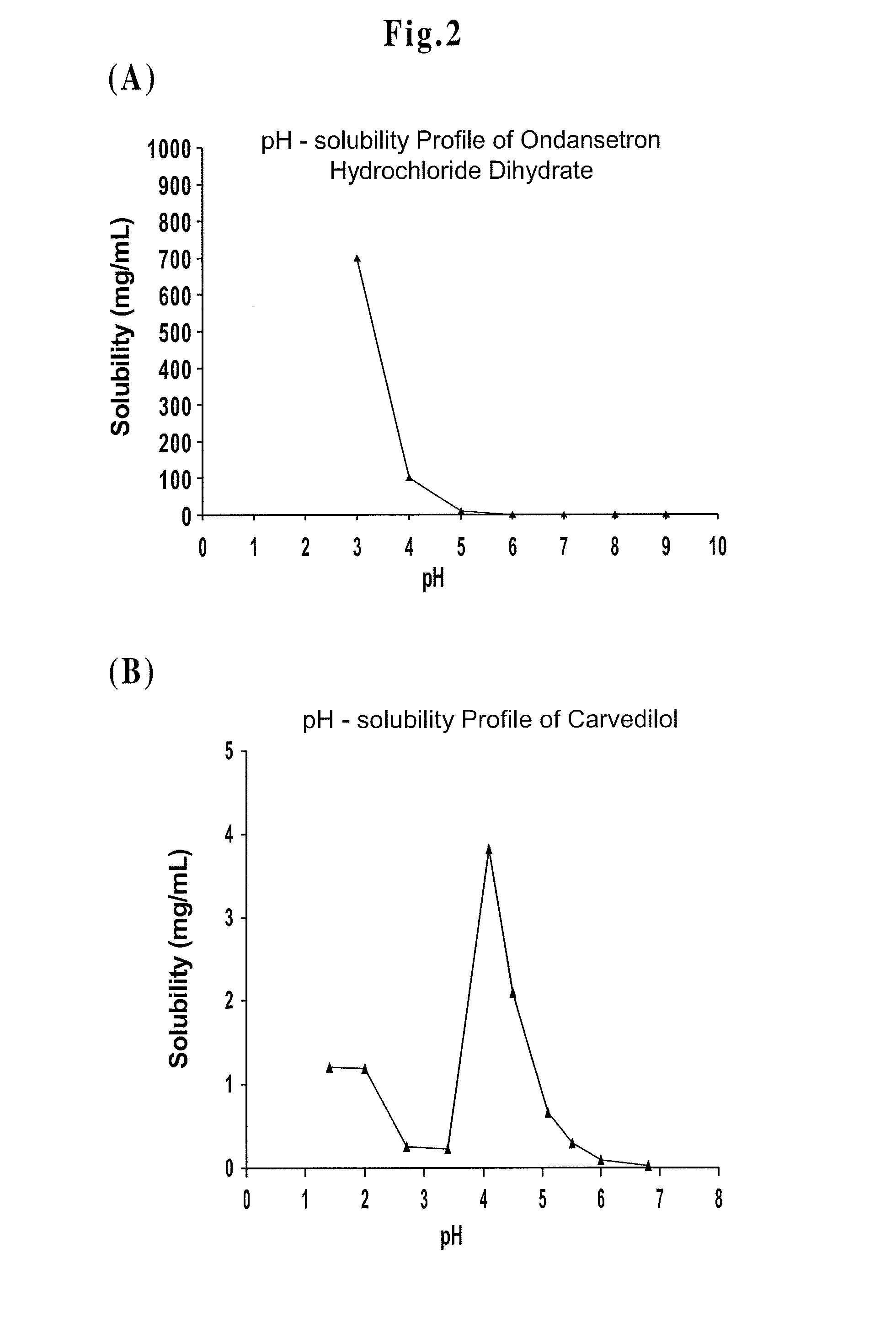

Drug Delivery Systems Comprising Solid Solutions of Weakly Basic Drugs

The present invention is directed to pharmaceutical compositions and dosage forms comprising TPR beads, wherein said TPR beads comprise a solid dispersion of at least one active pharmaceutical ingredient in at least one solubility-enhancing polymer, and a TPR coating comprising a water insoluble polymer and an enteric polymer, wherein the active pharmaceutical ingredient comprises a weakly basic active pharmaceutical ingredient having a solubility of not more than 100 μg / mL at pH 6.8.

Owner:APTALIS PHARMATECH

Mullite-aluminum titanate diesel exhaust filter

InactiveUS20040020846A1High interconnected porosityReduce back pressureIron oxides/hydroxidesExhaust apparatusFiltrationWhole body

The invention is directed at a mullite-aluminum titanate porous diesel particulate filter constituting a porous ceramic body containing, expressed in terms of weight percent of the total body, of 60-90%, preferably 70-80%, most preferably 70% iron-aluminum titanate solid solution having a stoichiometry of Al2(1-x)Fe2xTiO5, where x is 0-0.1, and 10-40%, preferably 20-30%, most preferably 30% mullite (3Al2O3.2SiO2), and consists essentially, expressed in terms of weigh percent on the oxide basis, of 3 to 15% SiO2, 55 to 65% Al2O3, 22 to 40% TiO2, and 0 to 10% Fe2O3, and being useful for filtration of diesel exhaust. The inventive diesel particulate filter exhibits high interconnected open porosity and large median pore size, in combination with high permeability when fired to a temperature of between 1650° to 1700° C., along with high thermal shock resistance and good filtration capability.

Owner:CORNING INC

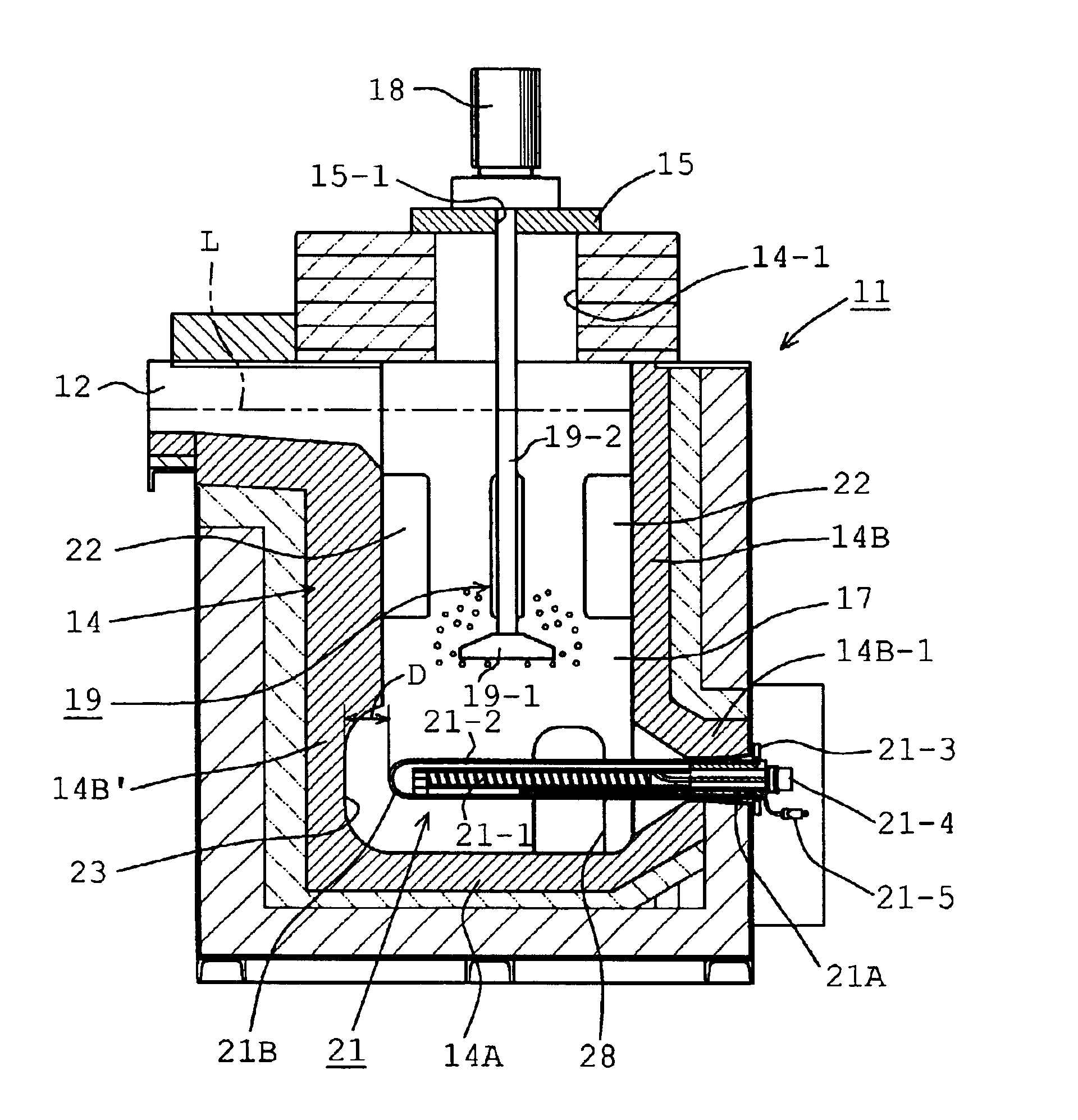

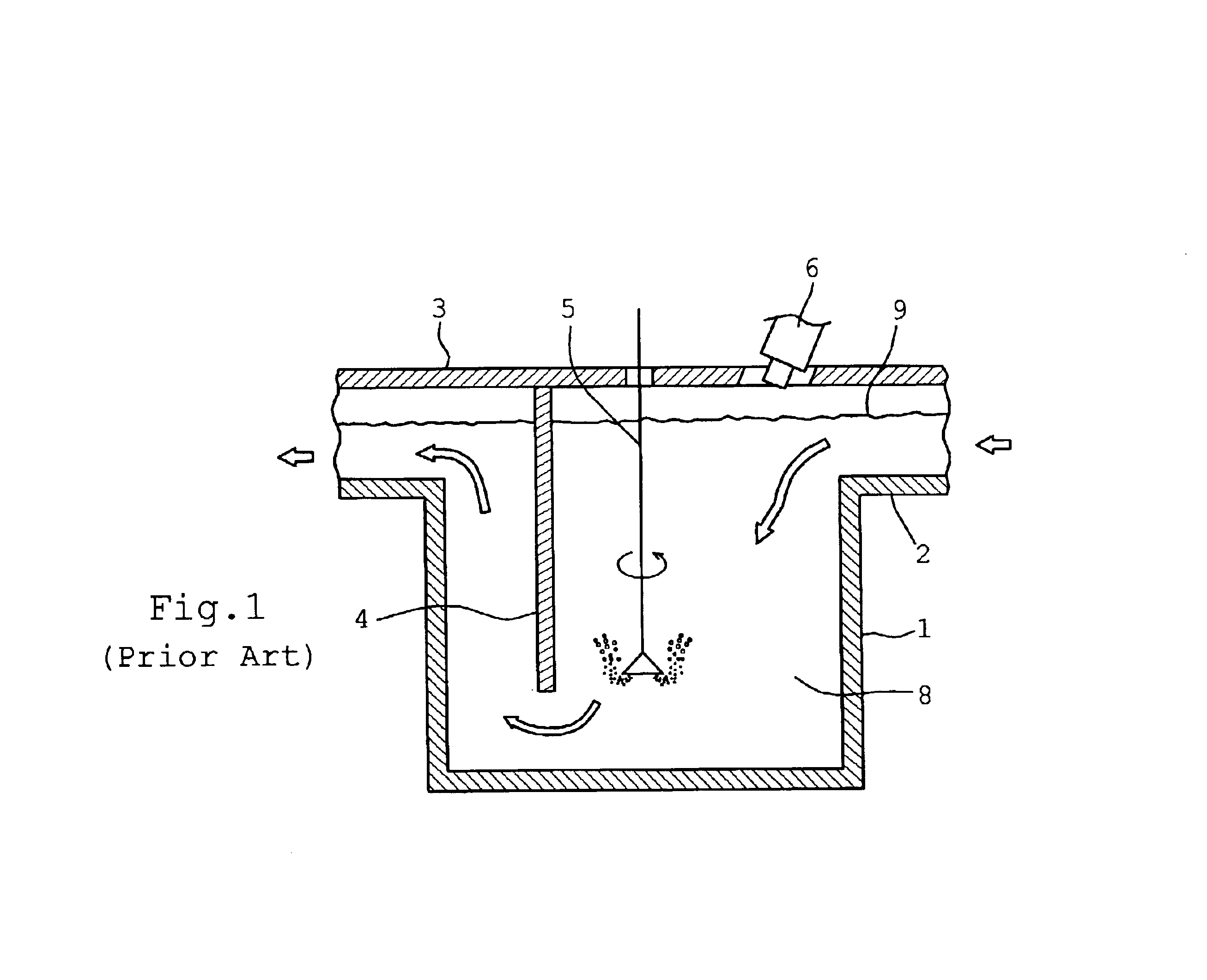

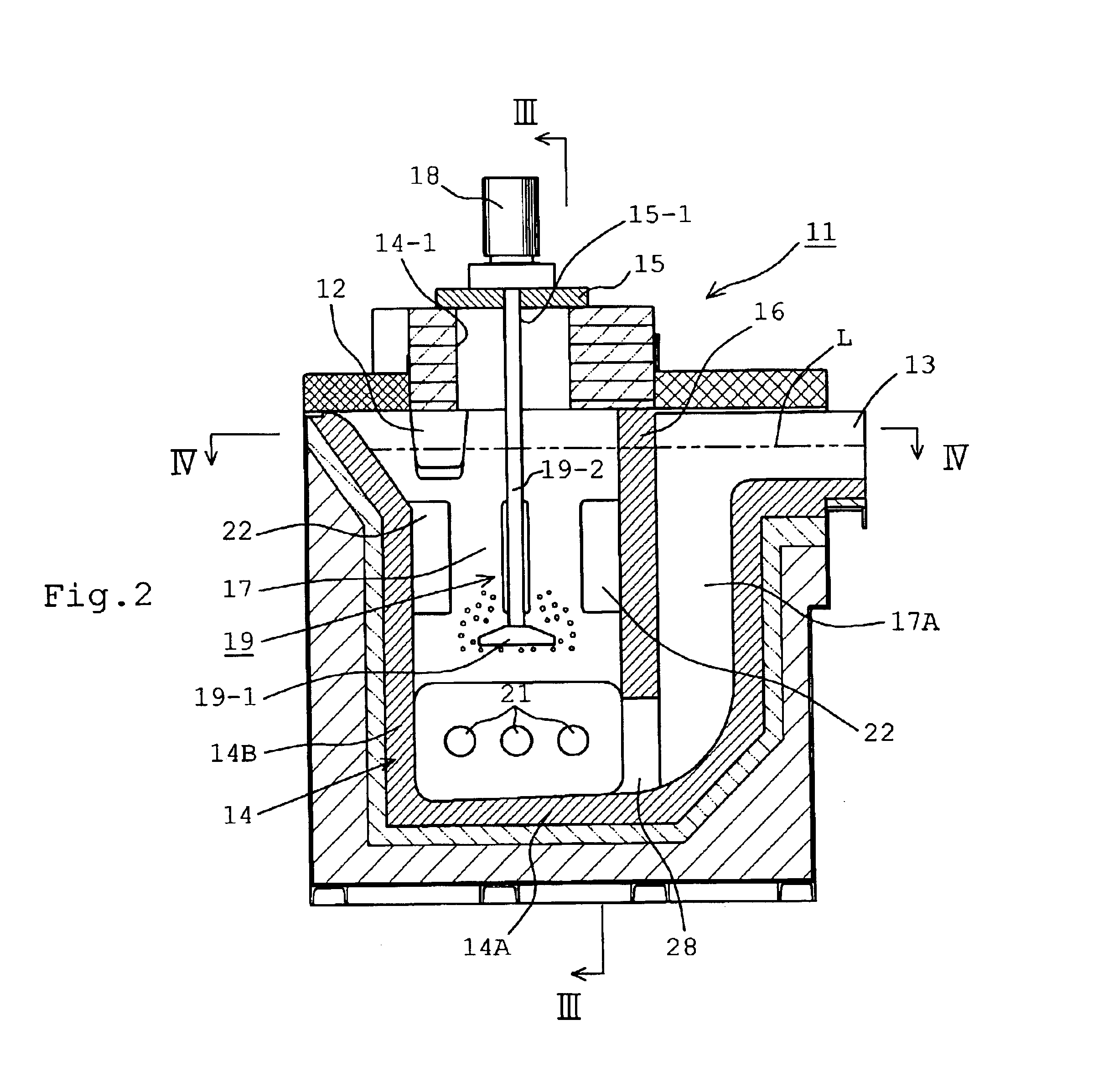

Inline degassing apparatus

InactiveUS6887424B2Reduce the amount requiredSmall volumeMelt-holding vesselsMechanical apparatusNon-metallic inclusionsSolid solution

An inline degassing apparatus for removing solid solution gases as well as nonmetallic inclusions from molten metal in a degassing container, to which the molten metal is continuously introduced for degassing operation and from which the degassed molten metal is continuously removed. A rotary diffusing device is arranged in the degassing container for generating bubbles of inert gas diffused into the molten metal, thereby entrapping solid solution gases as well as nonmetallic inclusions into the bubbles, which are then floated and separated. Heaters are provided, which extend, in a cantilever fashion, from a side wall of container at a position adjacent the bottom wall of the container substantially parallel to the bottom wall.

Owner:PYROTEK JAPAN +1

Sintered bodies for earth-boring rotary drill bits and methods of forming the same

InactiveUS20080101977A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and, optionally, at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:EASON JIMMY W +2

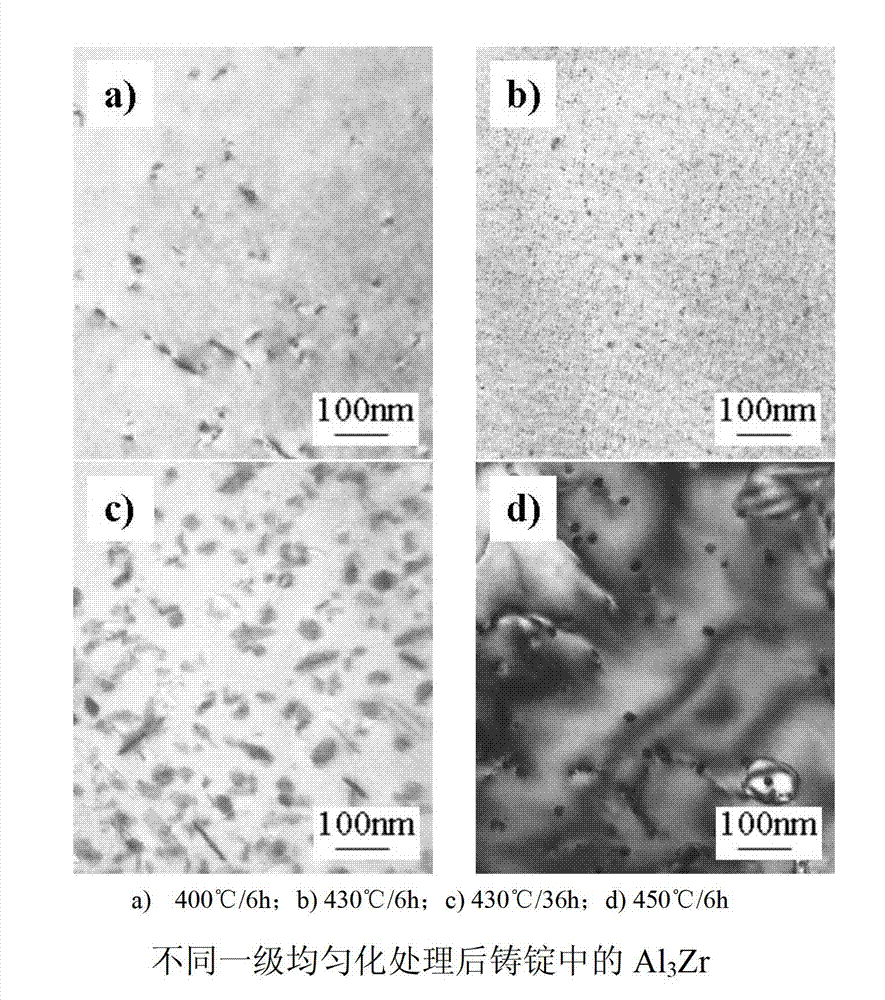

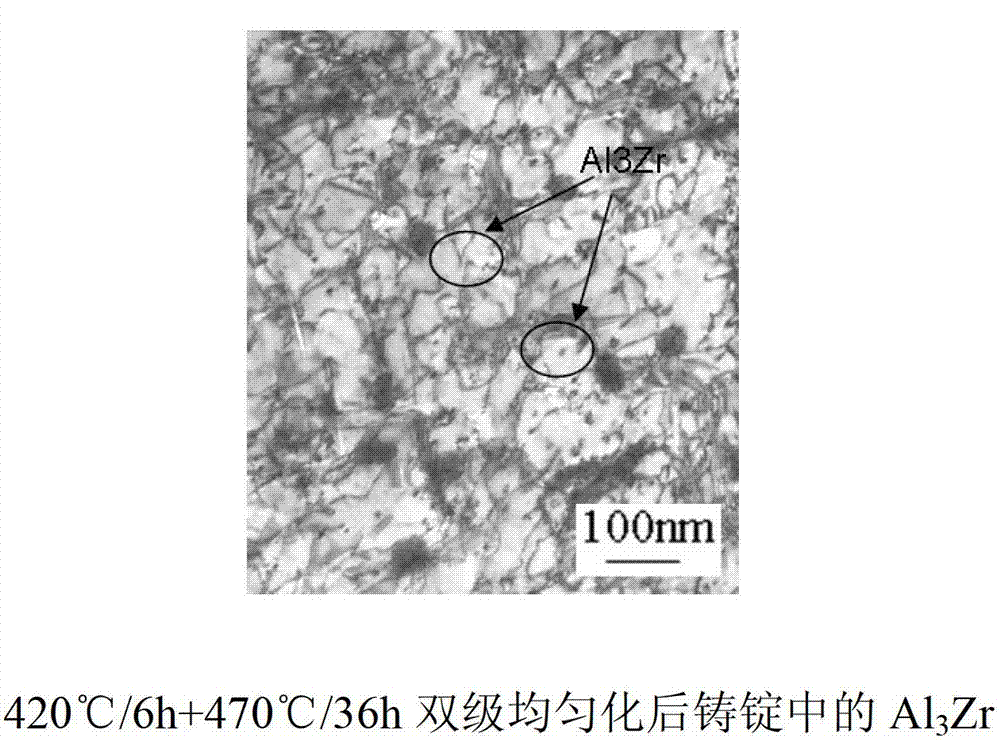

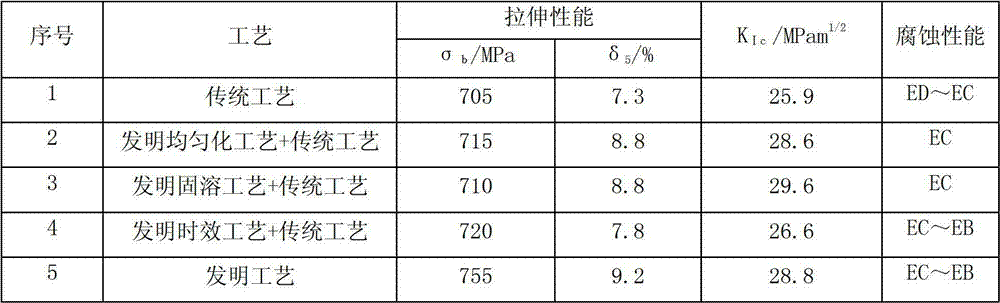

7000 series aluminum alloy material and preparation method thereof

The invention relates to a 7000 series aluminum alloy material and a preparation method thereof. The aluminum alloy material has alloy components of, by weight: 7.6-11.0% of Zn, 1.2-3.0% of Mg, 1.3-2.6% of Cu, 0.04-0.30% of Zr, 0.10-0.60% of Cr, no more than 0.08% of Si, no more than 0.10% of Fe, no more than 0.10% of Ti, no more than 0.15% of total other impurities (wherein the content of single other impurity is no more than 0.05%), and balance of Al. The alloy elements Zr and Cr can be added optionally or simultaneously. The materials are prepared according to the alloy composition; the raw materials are molten; in-furnace refining and standing are carried out; and the material is cast into alloy ingots with required specifications. The alloy ingots are subjected to a preferable graded uniformization process, and is forged or extruded, such that the alloy ingots are molded; the molded materials are subjected to graded solid solution treatment, and are quenched; and artificial forced aging is carried out, such that the material can be processed into parts. The microstructures of the material are uniform, and the property of the material is stable. The ultimate tensile strength of the material can be more than 750MPa. The extensibility of the material is higher than 10%. The T-L direction KIc of the material reaches 28MPam1 / 2.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

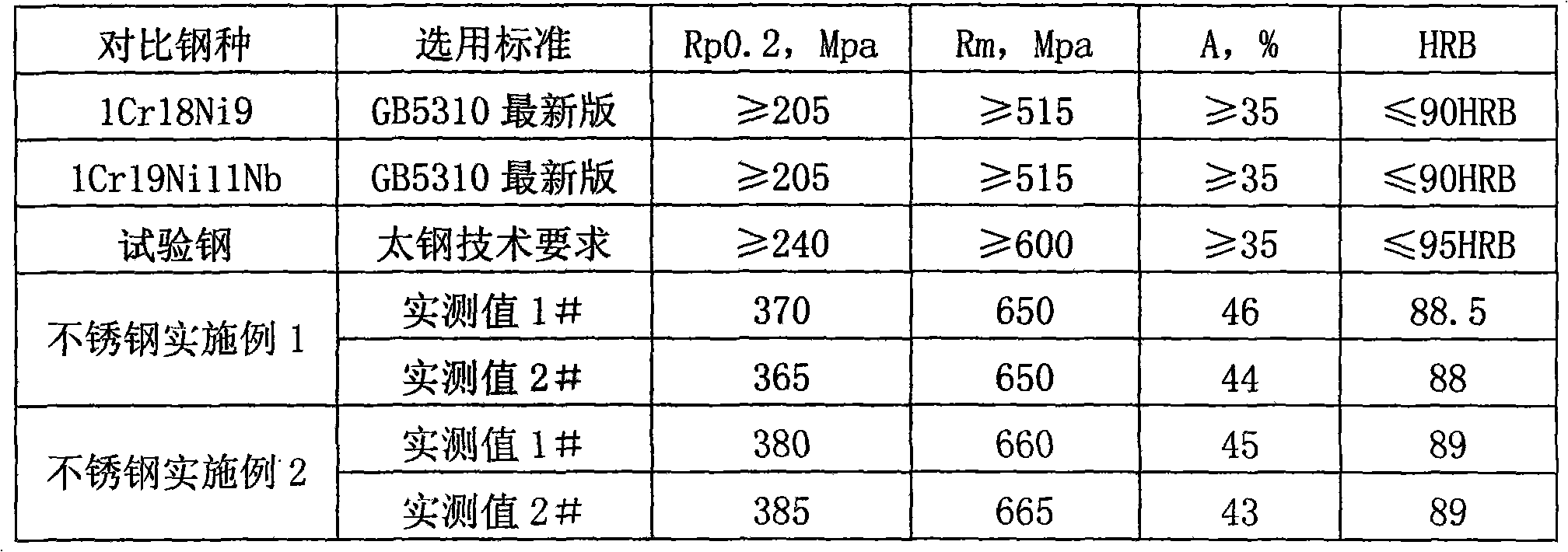

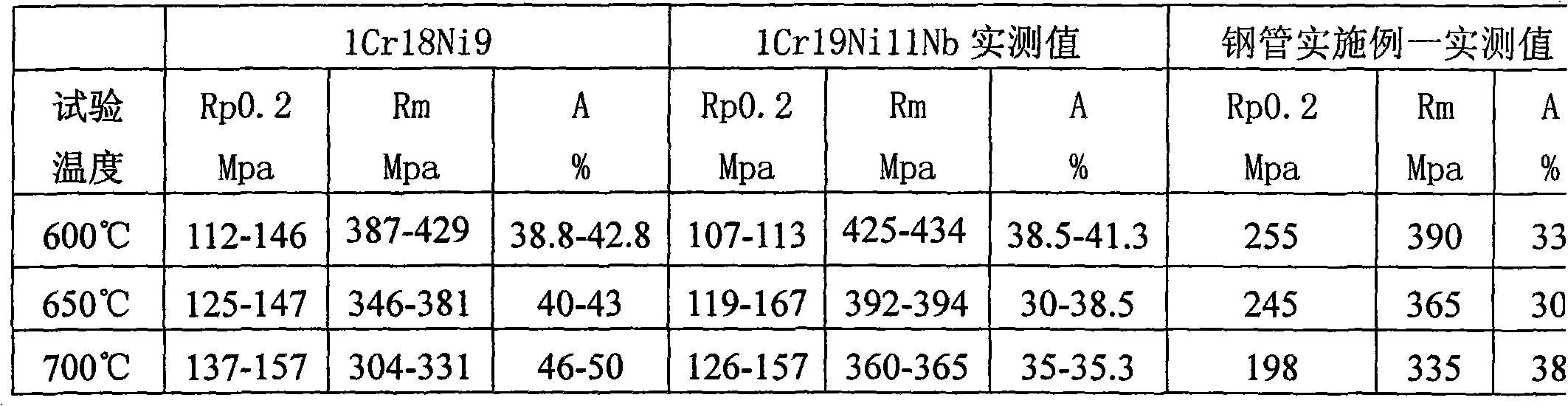

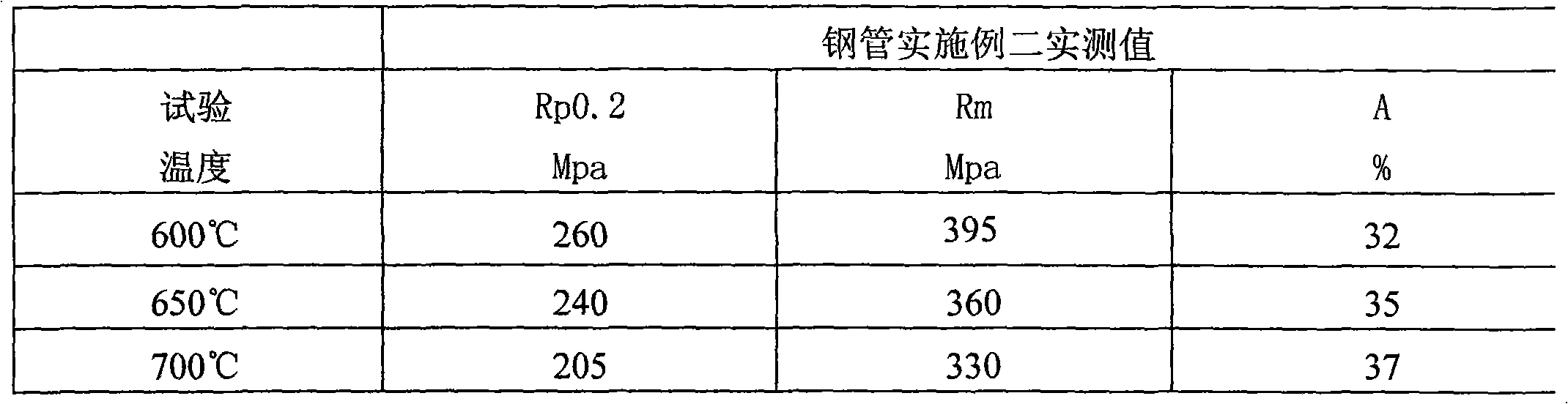

Austenitic stainless steel, steel tube thereof and manufacturing method thereof

ActiveCN101633999AImprove high temperature creep resistanceExcellent resistance to high temperature steam corrosionTemperature control deviceManufacturing convertersSS - Stainless steelIngot

The invention relates to an austenitic stainless steel, a steel tube thereof and a manufacturing method thereof, wherein the austenitic stainless steel and the stainless steel tube comprise the components by mass percent: 0.060-0.14% of C, more than 0 and less than or equal to 0.50% of Si, more than 0 and less than or equal to 1.00% of Mn, less than 0.040% of P, less than 0.015% of S, 17.00-20.00% of Cr, 8.00-11.00% of Ni, 2.50-4.00% of Cu, 0.30-0.60% of Nb, 0.15-0.50% of Mo, 0.15-0.50% of Co, 0.05-0.14% of N, 0.001-0.01% of B, the rest of Fe and unavoidable impurity. The manufacturing method of the steel tube comprises: smelting and pouring to form steel ingots or continuously cast bloom, processing bar material, preparing tubular billet and further processing the steel tube; the method comprises the steps: the heating temperature of processing the bar material is 1250-1270 DEG C, heating temperature of preparing the tubular billet is 1100-1220 DEG C, and the finished product solid solution temperature is 1120-1190 DEG C. The austenitic stainless steel tube has high temperature creep strength and corrosion resisting performance at the high temperature.

Owner:SHANXI TAIGANG ENG TECH +1

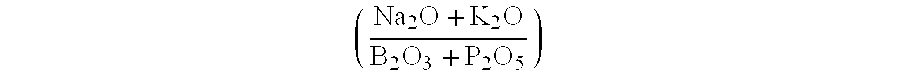

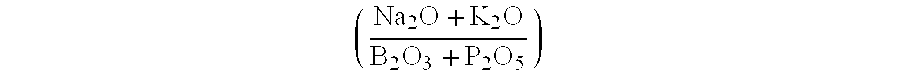

Beta-spodumene glass-ceramic materials and process for making the same

InactiveUS7476633B2Increase brightnessReduce the temperatureGlass tempering apparatusSolid solutionGlass-ceramic

The present invention relates to glass-ceramic materials, processes for making the same and articles comprising the same. The glass-ceramic material has a composition, by weight of the total composition, comprising 55-68% SiO2; 18-24% Al2O3; 3.3-4.1% Li2O; 1.5-4.0% ZnO; 1.5-5.0% MgO; 2-5% TiO2; 0-2% ZrO2; 0-5% B2O3; 0-8% P2O5; 0-2% Na2O, 0-2% K2O; and at least one component resulting from an effective amount of at least one fining agent; wherein: the total of B2O3 and P2O5 is at least 1.5% by weight, the total of MgO and ZnO is at least about 3.5% by weight, the total of Na2O and K2O is less than about 3.0% by weight, the total of P2O5, B2O3, Na2O and K2O is less than about 11% by weight, the weight ratio of the sum total of Na2O+K2O to the sum total of P2O5+B2O3 (Na2O+K2OB2O3+P2O5)is less than about 0.5; advantageously the total of P2O5, B2O3, Na2O and K2O is less than about 9% by weight and the total of Na2O ad K2O is less than about 2% by weight; and more advantageously the total of P2O5, B2O3, Na2O and K2O is less than about 7% by weight and the total of Na2O ad K2O is less than about 1% by weight. The glass-ceramic material comprises β-spodumene solid solution as the predominant crystalline phase.

Owner:EUROKERA SOC & NOM COLLECTIF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com