Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3974 results about "Solution treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solution treatment is a broad term in heat treating used to refer to the heating of a material to temperatures sufficient for the dissolution of its soluble phases. It is then held for a time until it is quenched, causing the material to retain the properties of the solution.

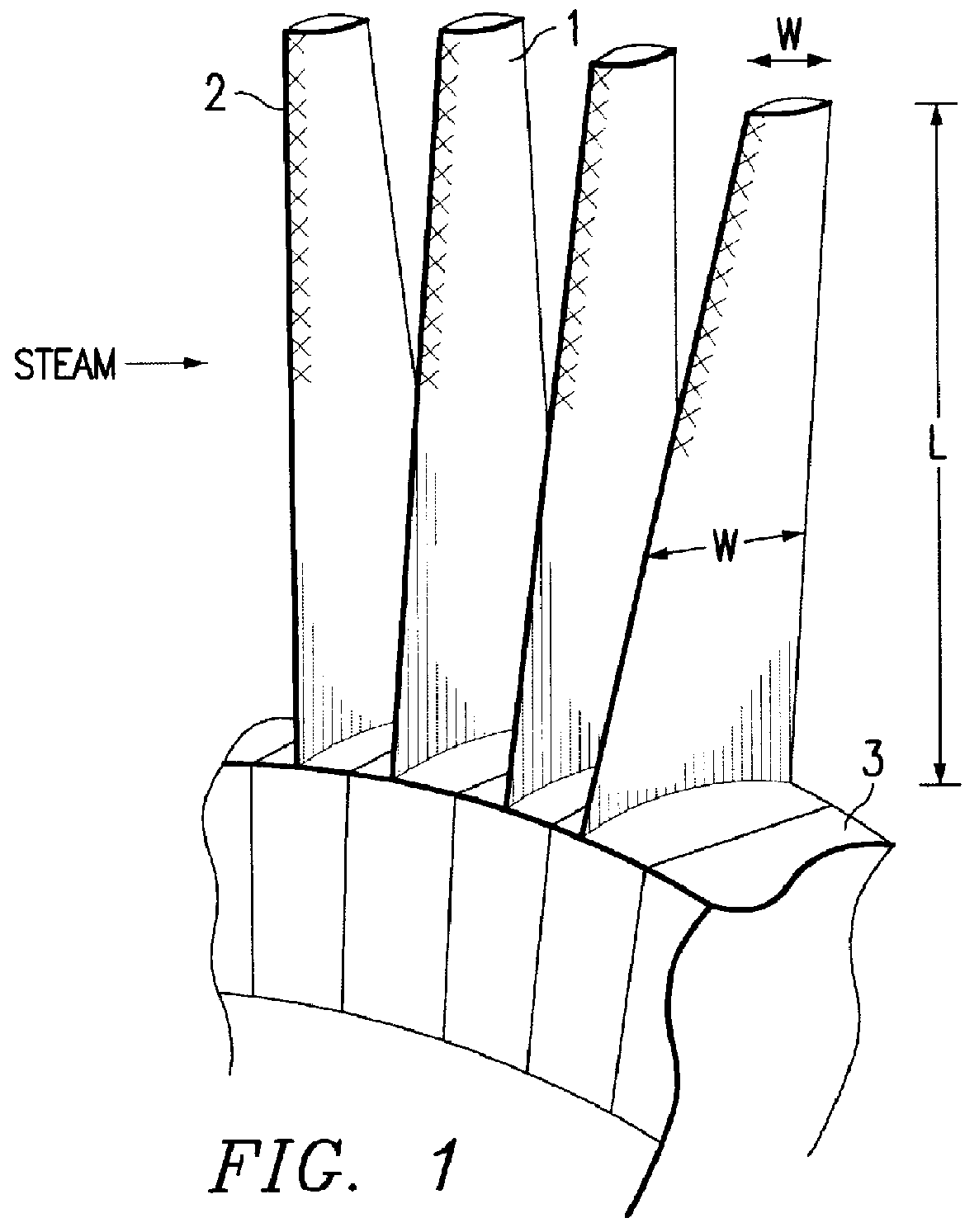

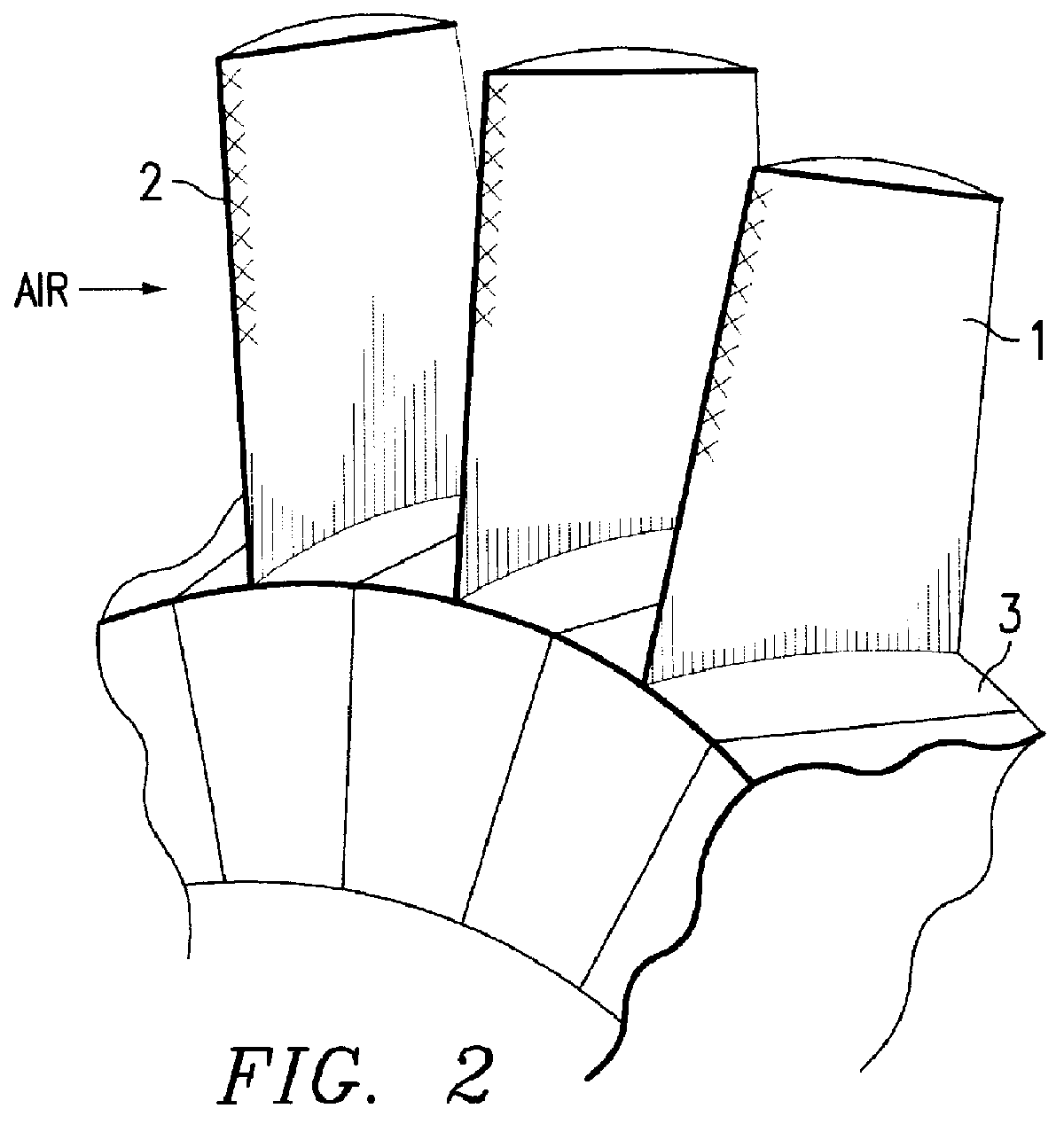

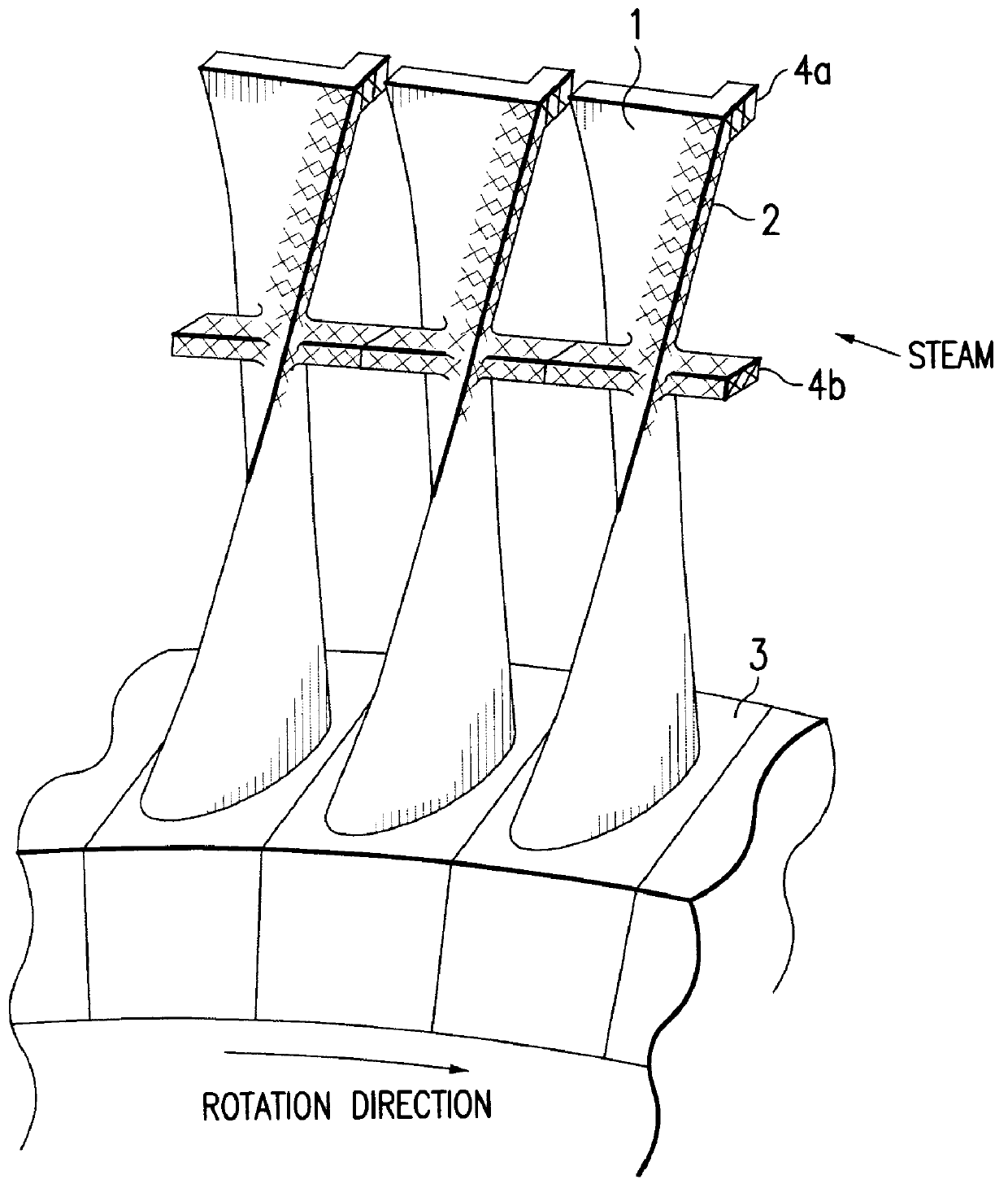

Method for producing titanium alloy turbine blades and titanium alloy turbine blades

InactiveUS6127044ALess abrasionSuperior in water droplet erosion resistancePropellersEngine manufactureLeading edgeTurbine blade

PCT No. PCT / JP95 / 01817 Sec. 371 Date Jun. 2, 1998 Sec. 102(e) Date Jun. 2, 1998 PCT Filed Sep. 13, 1995 PCT Pub. No. WO97 / 10066 PCT Pub. Date Mar. 20, 1997A method for producing titanium alloy turbine blades comprising the steps of (a) forming turbine blades of titanium alloy through hot forging or machining, (b) cooling leading edges on tip portions of the turbine blades including covers thereof formed through hot forging or machining faster than blade main body after final hot forging or solid solution treatment, and (c) heat treating the cooled turbine blades. With this method, it is possible to manufacture titanium turbine blades in an economical fashion and obtain titanium alloy turbine blades superior in reliability by preventing erosion.

Owner:KK TOSHIBA +1

High-strength heat-resisting magnesium alloy and its preparing method

This invention is a high-intensive heat-fast magnesium alloy and its preparation method, and the magnesium alloy has the following components with their weight percentages: 6-15%Gd, 1-6%Y, 0.35-0.8%Zr, 0-1.5%Ca, and impurity elements Si, Fe, Cu and Ni with their gross less than 0.02%, and the rest percentage is Mg. while melting, add Gd, Y, Zr in the Mg melt in Mg-Gd, Mg-Y, Mg-Zr forms, then carry out solution treatment to the magnesium alloy under 450-500deg.C for 6-12 hours, squeeze in in 350-450deg.C, treat in time the squeezing stick for 10-16 hours in 225deg.C to improve its strength.

Owner:SHANGHAI JIAO TONG UNIV

Small crystal particle Y-shaped molecular sieve and preparation method thereof

ActiveCN101759198AReduce pollutionEasy to makeFaujasite aluminosilicate zeoliteAmmonium fluorosilicateOxygen

The invention discloses a small crystal particle Y-shaped molecular sieve and a preparation method thereof. The property of the small crystal particle Y-shaped molecular sieve is as follows: the molar ratio of Si, O2 / Al2O3 is 10.0-120.0, the cell parameters are 2.420-2.445 nm, the crystallization retention is larger than 95 percent, and B acid / L acid is above 7.0. Due to higher raw material thermal and hydrothermal stability, higher silicon-aluminum ratio, good stability and uniform framework silicon-aluminum structure, the small crystal particle NaY molecular sieve can ensure the framework continuity of the molecular sieve, reduce the collapse possibility of the framework structure and maximally keep the integrity of a silicon-aluminum-oxygen structure in the modification, namely in the ammonia exchange, ammonium fluorosilicate dealumination and silicon reinsertion, hydro-thermal treatment, aluminum salt and acid mixed water solution treatment process, thereby having high crystallization retention. The Y-shaped molecular sieve can be taken as an active component of a hydrocracking catalyst, thereby improving the activity of the catalyst, the selectivity of the molecular sieve and the product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

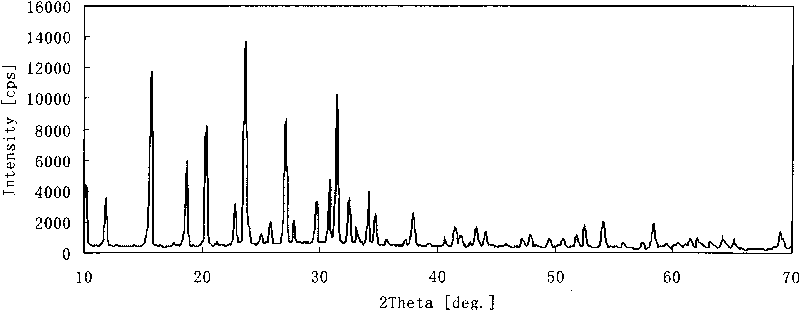

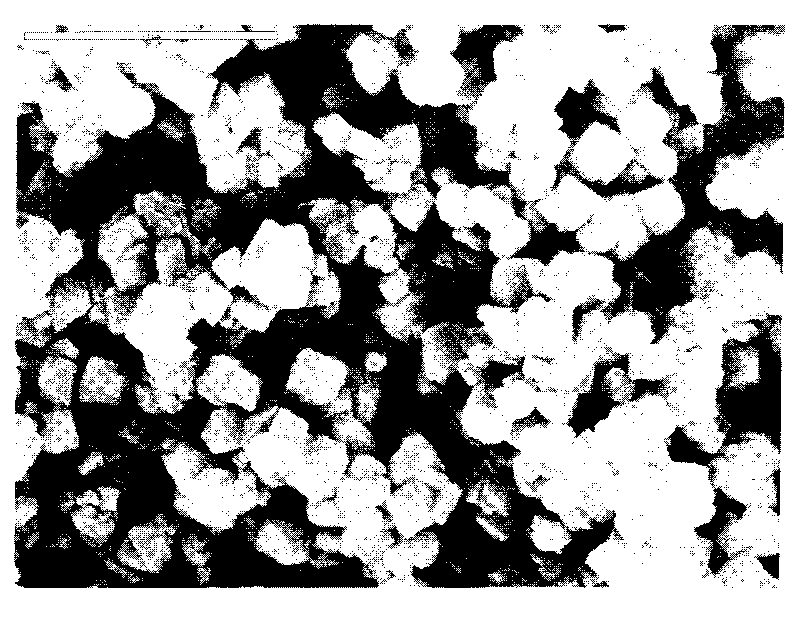

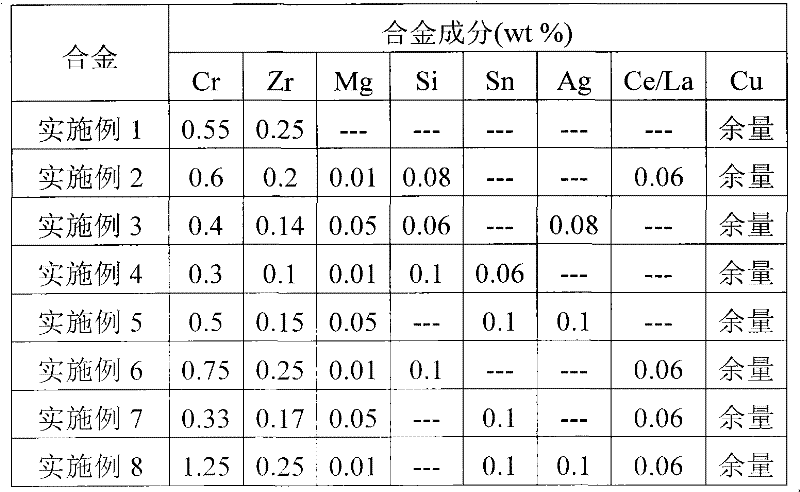

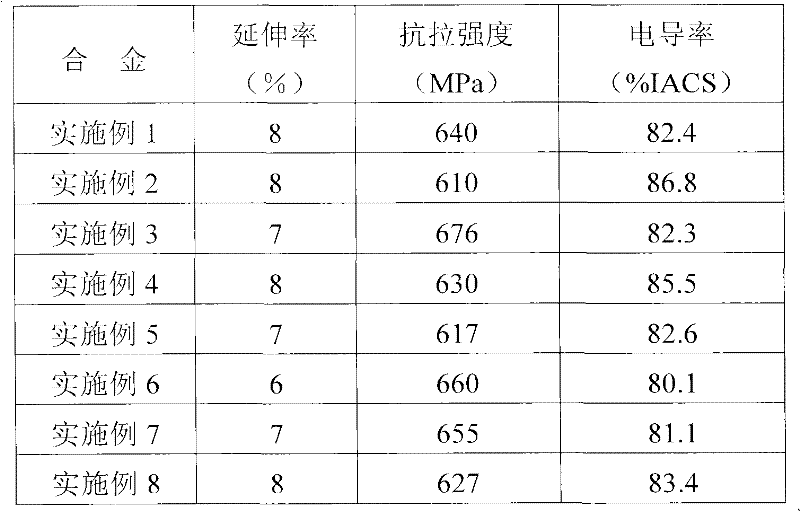

CuCrZr alloy with high strength and high conductivity, and preparation and processing method thereof

The invention relates to a CuCrZr alloy with high strength and high conductivity, and a preparation and processing method thereof. The alloy comprises the basic ingredients in percentage by mass: 0.3 percent to 1.4 percent of Cr, 0.02 percent to 0.25 percent of Zr and the balance Cu, wherein the ingredients in the CuCrZr alloy are needed to meet the following requirements: (a) Cr / Zr is less than or equal to 5 and is greater than or equal to 1.9; and (b) Cr+Zr is less than or equal to 1.5 percent and is greater than or equal to 0.4 percent. The preparation and processing method comprises the following steps of: a, compounding, feeding, smelting and casting according to mass percent; b, surface milling; c, hot rolling; d, solution treatment; e, primary cold rolling; f, primary aging; g, secondary cold rolling; and h, secondary aging. The CuCrZr alloy has the tensile strength sigma b being 600-700 MPa, the plasticity elongation rate delta being 4-10 percent, and the conductivity being greater than 80 percent of IACS (International Annealed Copper Standard), can be widely applied to occasions with high strength and high conductivity for preparing resistance welding electrodes, liners of crystallizers of continuous casting machines, integrated circuit lead frame and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Rolling apparatus

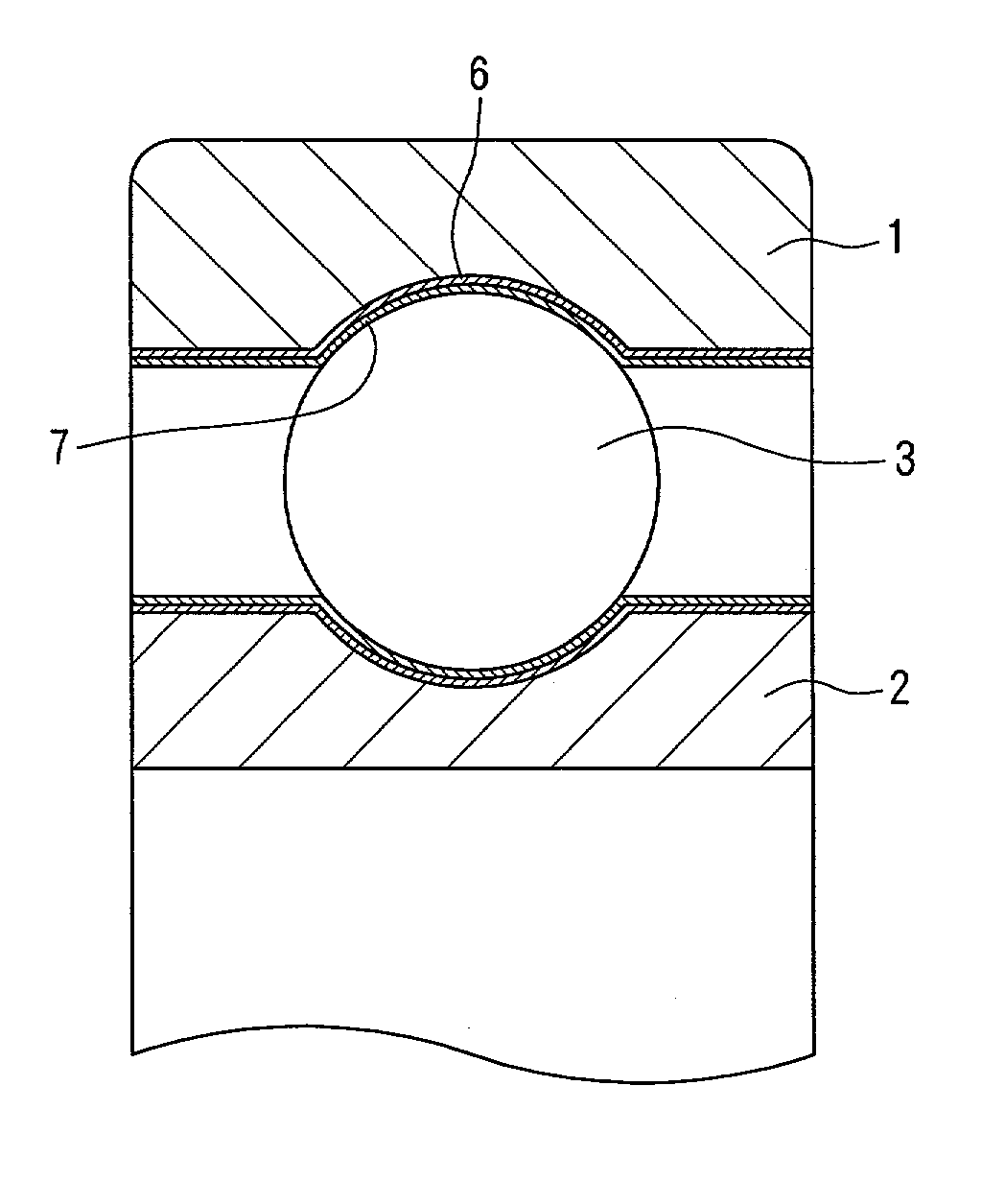

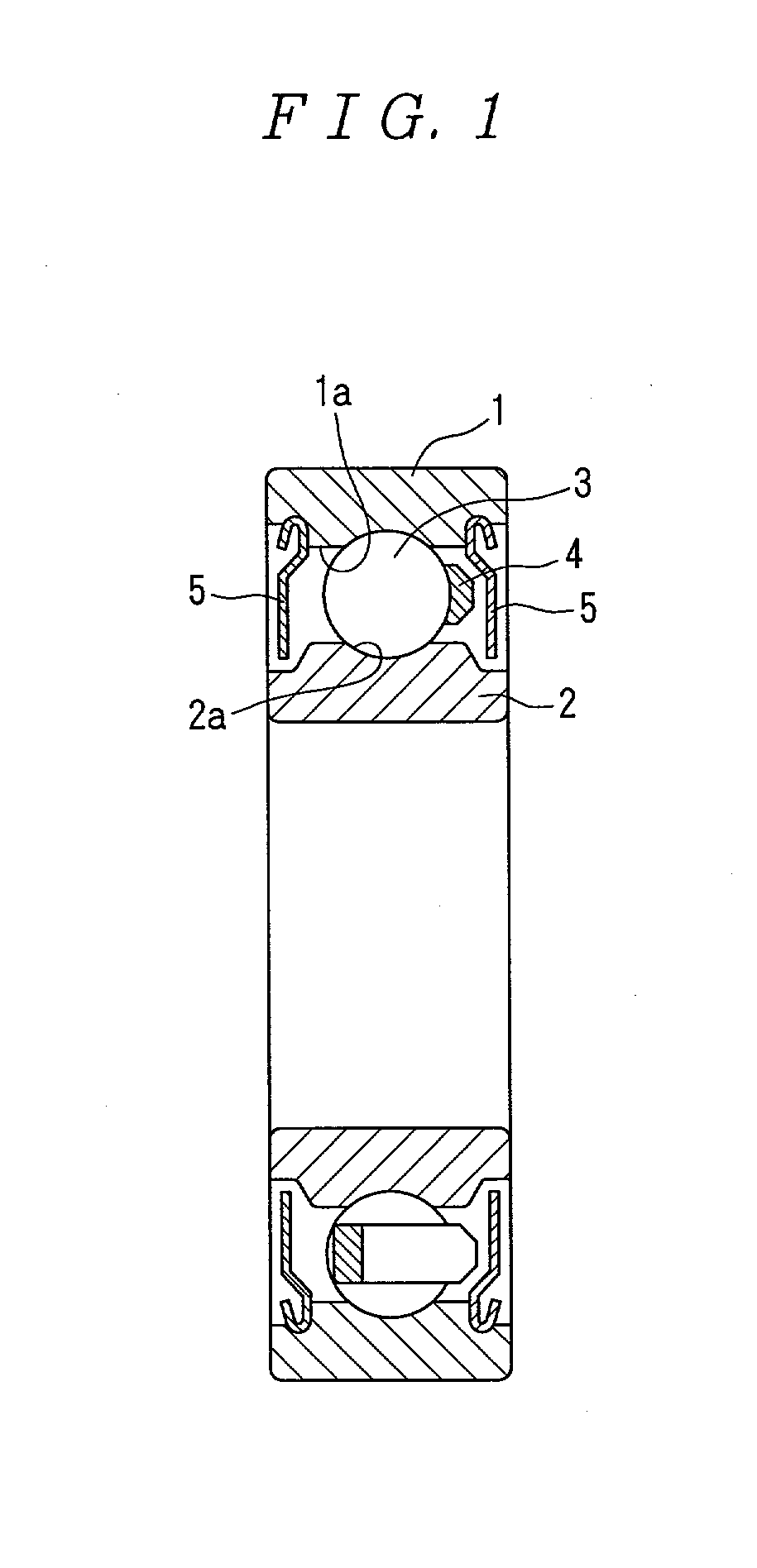

The bearing rings 1 and 2 of a rolling bearing is formed of one kind of titanium alloys of beta type titanium alloys, near beta type titanium alloys and alpha+beta type titanium alloys. The titanium alloy has a surface hardness of Hv 400 or more and less than Hv 600 for increasing the corrosion resistance and wear resistance of the bearing ring. Spherical rolling elements 3 rolling on the raceway surfaces 1a and 2a of the bearing rings 1 and 2 are formed of ceramics such as silicon nitride. When beta type titanium alloys or alpha+beta type titanium alloys after a solution treatment and applied with an oxidation treatment at a low temperature of 400 to 600° C. are used as the material for the bearing ring, a bearing ring made of titanium alloy suitable to use under a circumstance requiring corrosion resistance is obtained.

Owner:NSK LTD

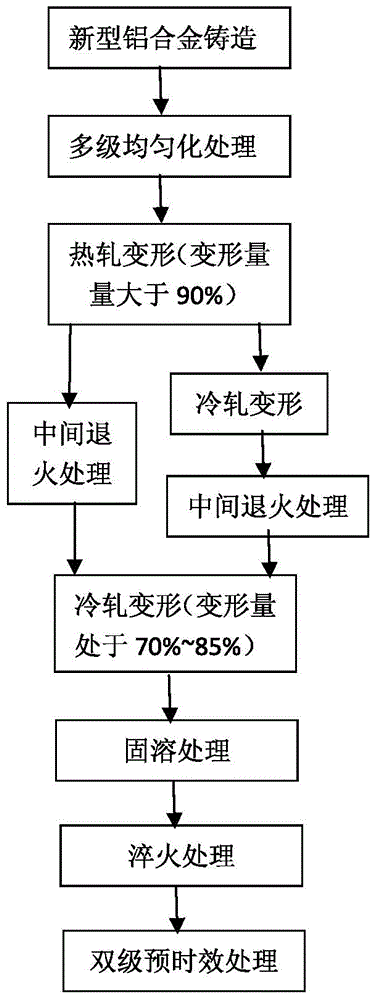

Automotive high-formability aluminum alloy material and preparation method thereof

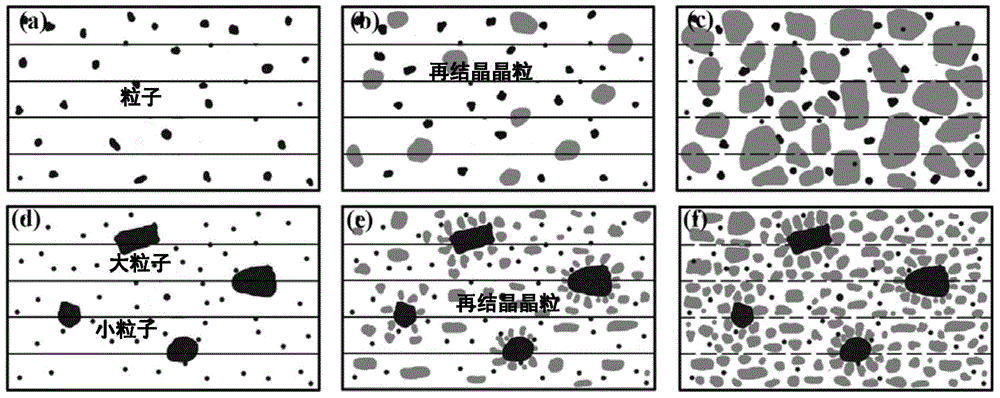

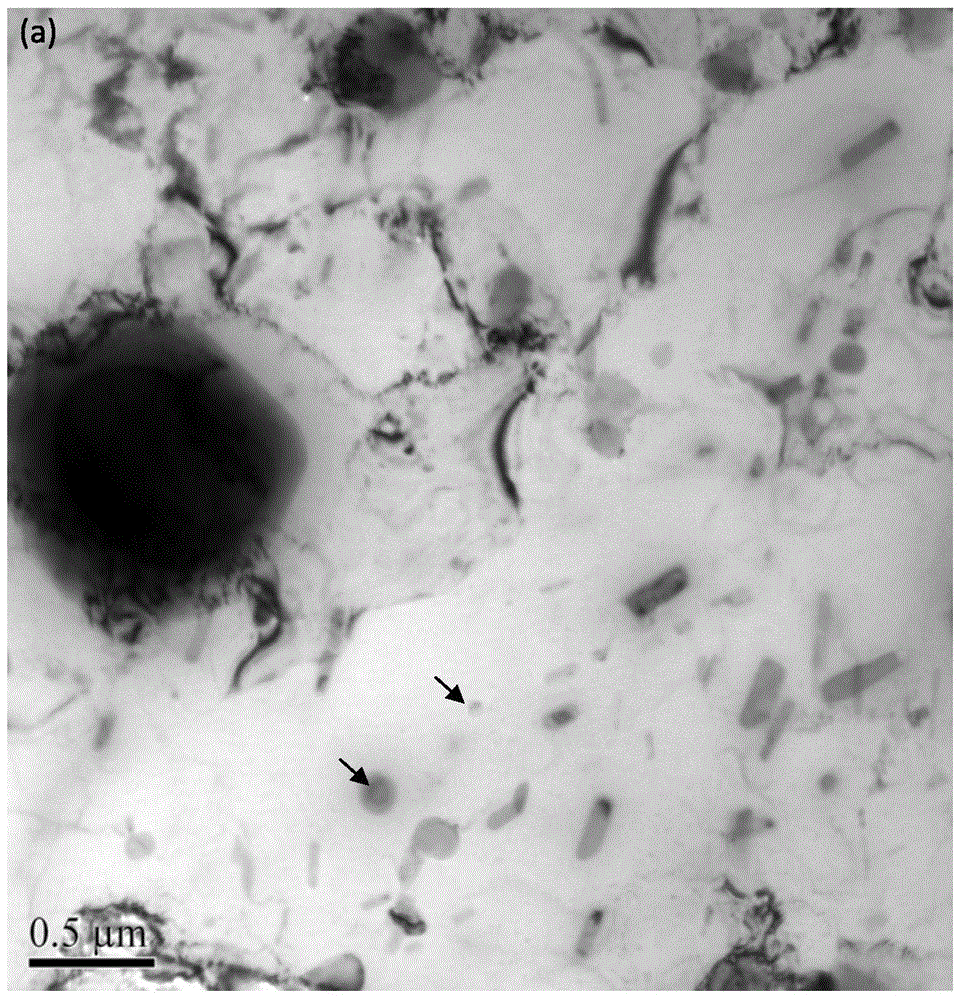

The invention provides an automotive high-formability aluminum alloy material and a preparation method thereof. The preparation method comprises the steps of selection of novel aluminum alloy components, alloy preparation and melting-casting, homogenization, hot rolling deformation, intermediate annealing or cold rolling deformation and intermediate annealing, intermediate annealing, solution treatment, quenching and multistage pre-ageing treatment. By using the double effects that a certain quantity of multi-scale particles can be formed among different solute elements in the alloy material and then oversize particles are stimulated, re-crystallized and nucleated while fine particles block the growth of the re-crystallized grains in the high-temperature heat treatment process, so that the structure of an alloy plate is formed by the fine and uniformly distributed re-crystallized grains, the anisotropy of the alloy plate is well controlled, and the stamping forming performance is relatively excellent. Meanwhile, the novel aluminum alloy with high formability and high baking varnish hardening increment is very suitable for manufacturing of automotive body outer plates, particularly manufacturing of parts having relatively high requirements for stamping formability and baking varnish hardening increment and having complex shapes.

Owner:UNIV OF SCI & TECH BEIJING

Ultra pure electroslag remelting method for high-performance corrosion resistant alloy

ActiveCN102912151AImprove performanceImprove organizationIncreasing energy efficiencyCorrosion resistant alloySolution treatment

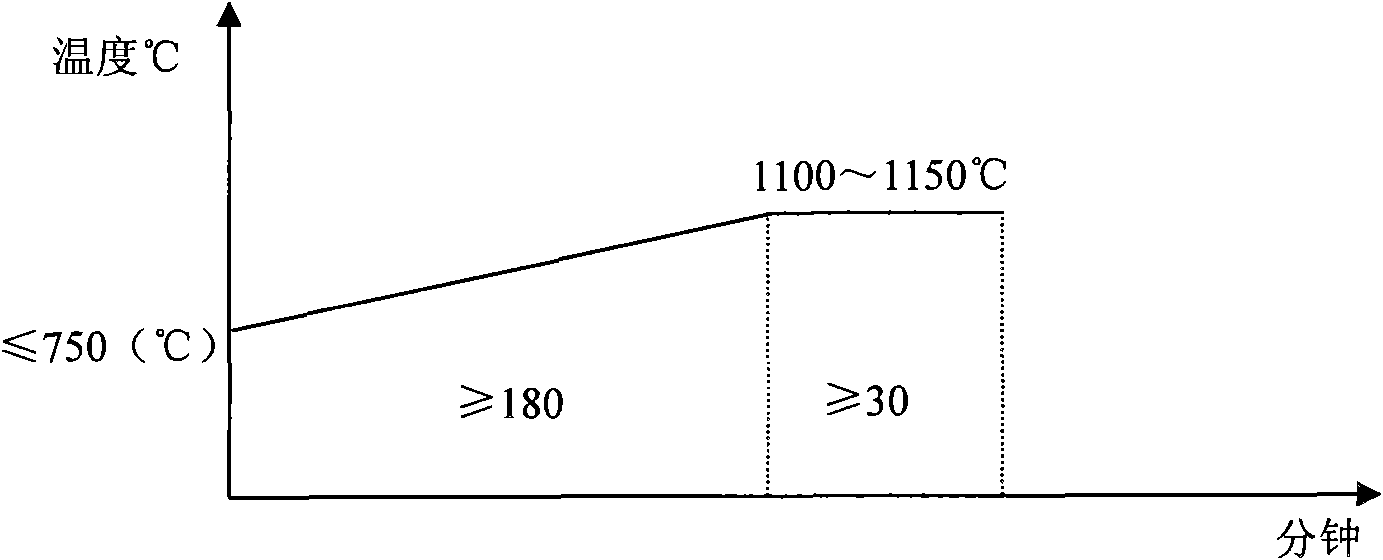

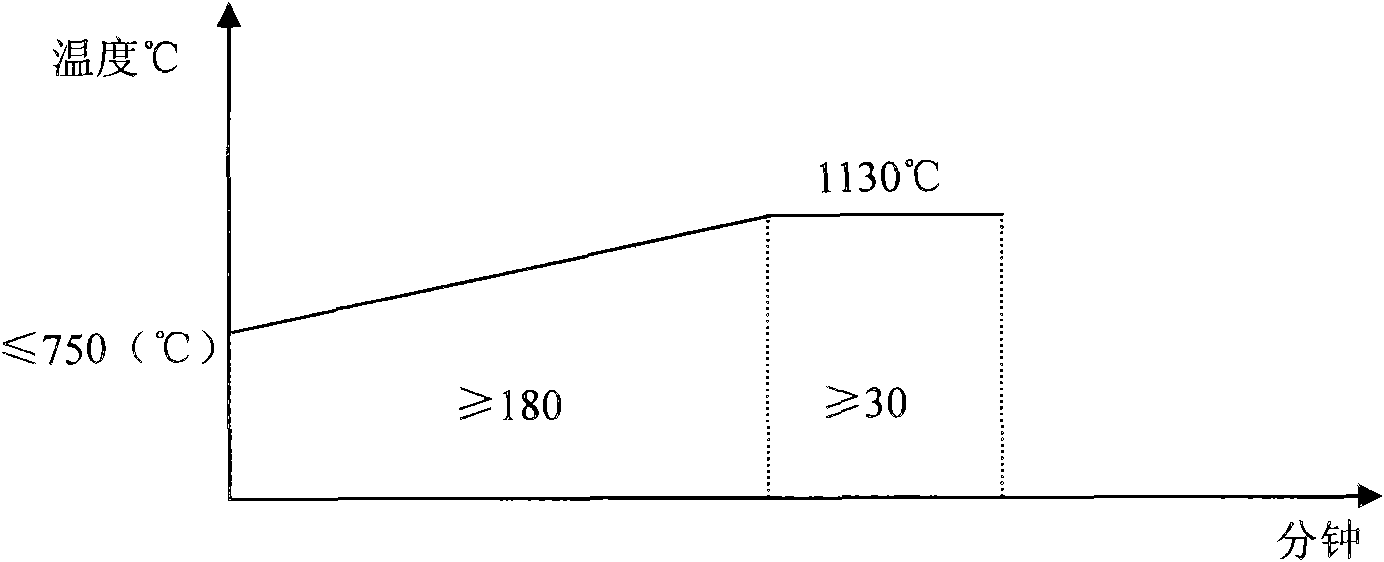

The invention relates to an ultra pure electroslag remelting method for a high-performance corrosion resistant alloy, and the method comprises the following steps of: preparing the following ingredient components of a self-fluxing electrode bar in parts by weight: 25-34 parts of Ni, 25-29 parts of Cr, 2.5-4.5 parts of Mo and 30-45 parts of Fe, and carrying out vacuum induction melting, so as to obtain the self-fluxing electrode bar; slowly melting the self-fluxing electrode bar in melted electroslag remelting slag charge comprising the following components in parts by weight: 55-80 parts of CaF2, 5-25 parts of CaO, 5-15 parts of Al2O3 and 5-10 parts of MgO, purifying, and recrystallizing in a crystallizer, so as to obtain an electroslag ingot; and forging the electroslag ingot into a bar material at the temperature of 1130+ / -5 DEG C, and carrying out solution treatment, so that the high-performance corrosion resistant alloy is obtained. By utilizing the ultra pure electroslag remelting method provided by the invention, the content of harmful elements such as sulphur and phosphorus in the alloy can be reduced, the impurity distribution of the alloy is improved, fining of structure can be facilitated, and the hot workability and yield of the alloy can be improved.

Owner:CHONGQING MATERIALS RES INST

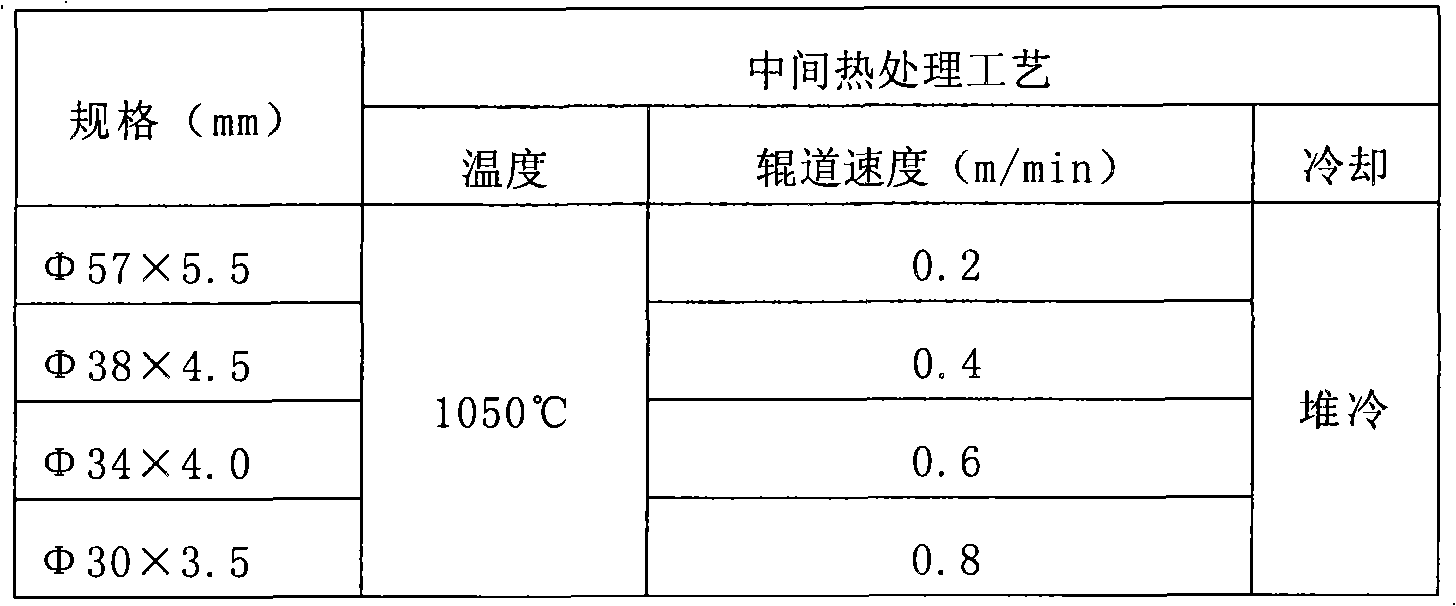

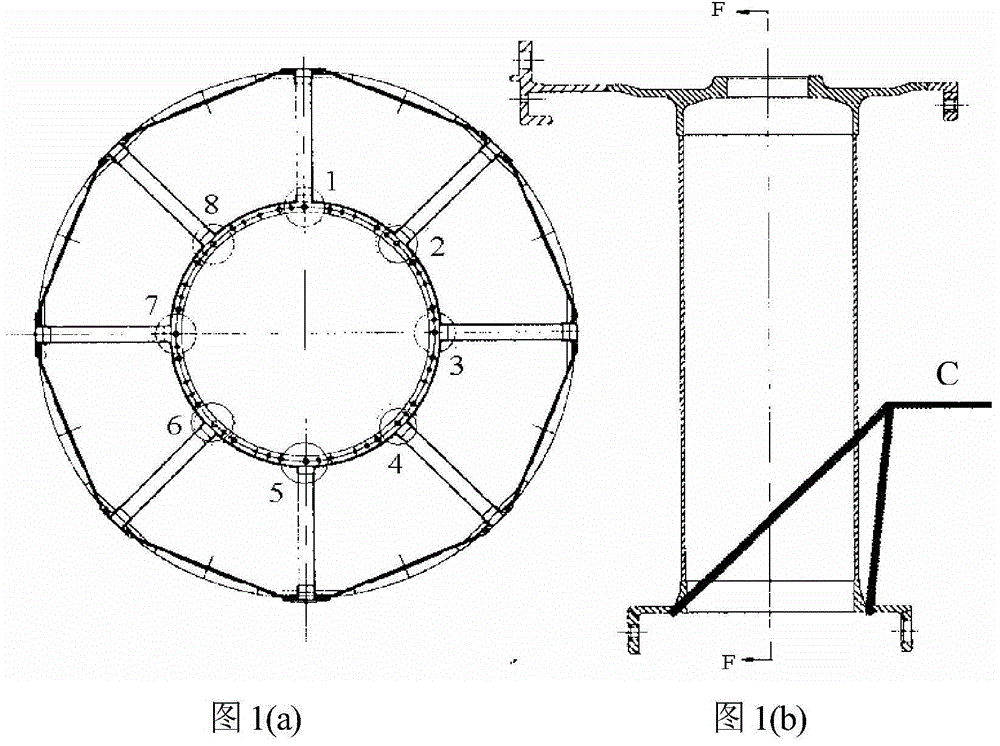

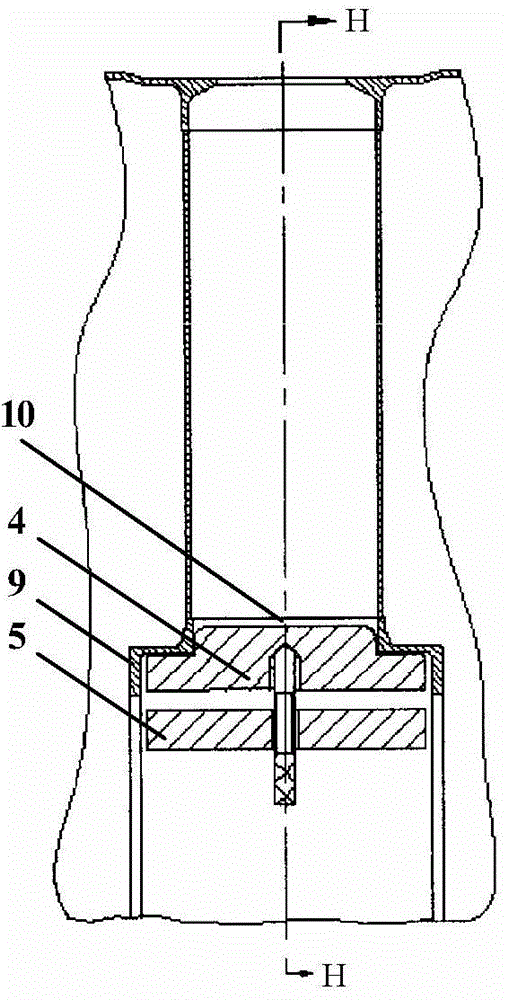

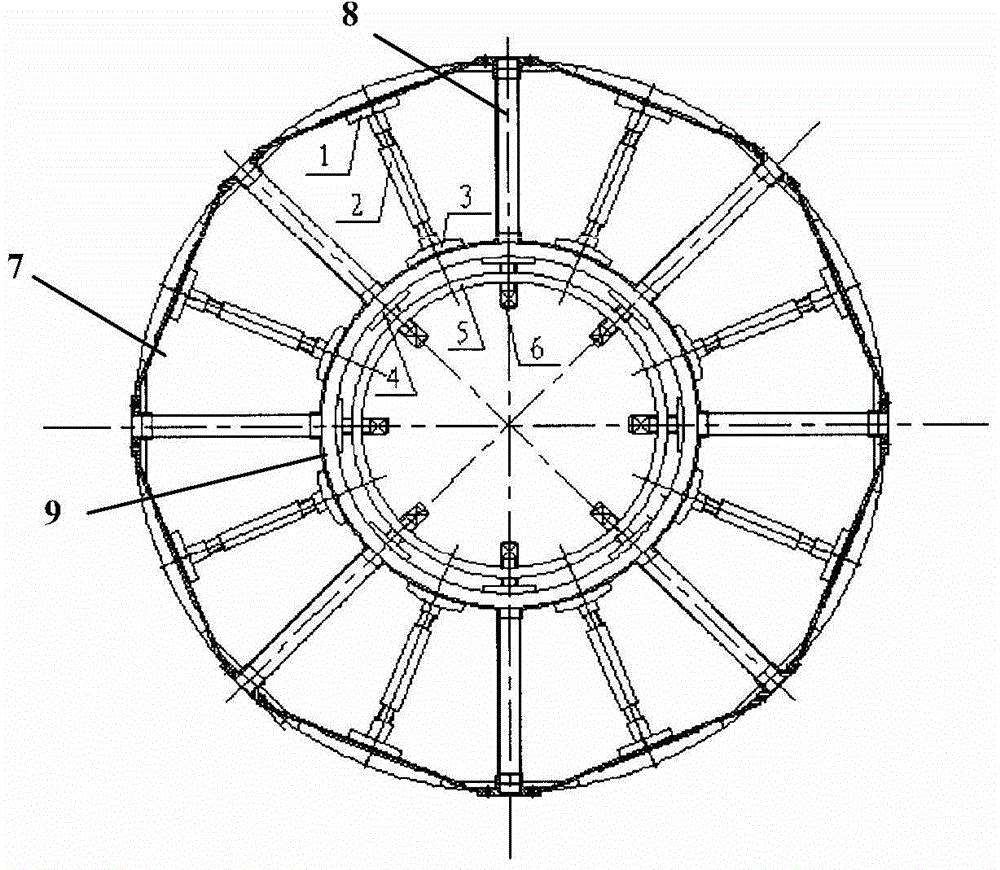

Method for preparing seamless steel tubes made of martensite precipitation hardening stainless steel

InactiveCN101612700AAvoid Surface Quality IssuesReduce lossFurnace typesMetal rolling arrangementsSolution treatmentProduct inspection

The invention discloses a method for preparing seamless steel tubes made of martensite precipitation hardening stainless steel, which comprises the following steps of billets, peeling, blanking, heating, hot punching, cooling, finishing, acid cleaning, lubricating, degreasing, heat treatment, straightening, tube cutting, acid cleaning, inspection, and packaging and warehousing. Compared with the prior art, the method has the following advantages that: pierced billets after hot punching are cooled in a pile so as to reduce working procedures and cost; the intermediate heat treatment adopts solution treatment, has short time and high efficiency, and improves surface quality; the tubes all adopt cold rolling process to improve yield; and vacuum aging treatment is adopted to improve the comprehensive mechanical property, the finished product inspection qualified rate reach 95 percent, and the yield from the billets to the finished products reach 51.31 percent.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Production process of precise stainless steel band for vehicle sealing pad

InactiveCN101716594AImprove quality requirementsThickness tolerance fluctuations are smallBell type furnacesTension/compression control deviceSolution treatmentStress relieving

The invention relates to a production process of a precise stainless steel band for a vehicle sealing pad. The production process comprises the following working procedures of: first cold rolling, solid solution, second cold rolling, spraying and degreasing, hot water spraying, hot wind drying, pre-bending straightening, stress relieving annealing, final bending straightening, finished product cutting, and the like. The production process adopts a 20-roller sendzimir mill and a unique rolling process to carry out cold rolling. Through the processes of degreasing, solid solution treatment, bending straightening, stress relieving annealing, and the like, the thickness tolerance undulation of a product is small, mechanical properties are stable, the plate flatness is good, the product is not easy to generate cracks and secondary deformation during stamping, and the quality of the product is obviously improved, thus the production process is suitable for industrial production and can meet the requirement for high quality of the vehicle part industry.

Owner:YONGXIN PRECISION MATERIAL WUXI

Electric wire conductor and a method of producing the same

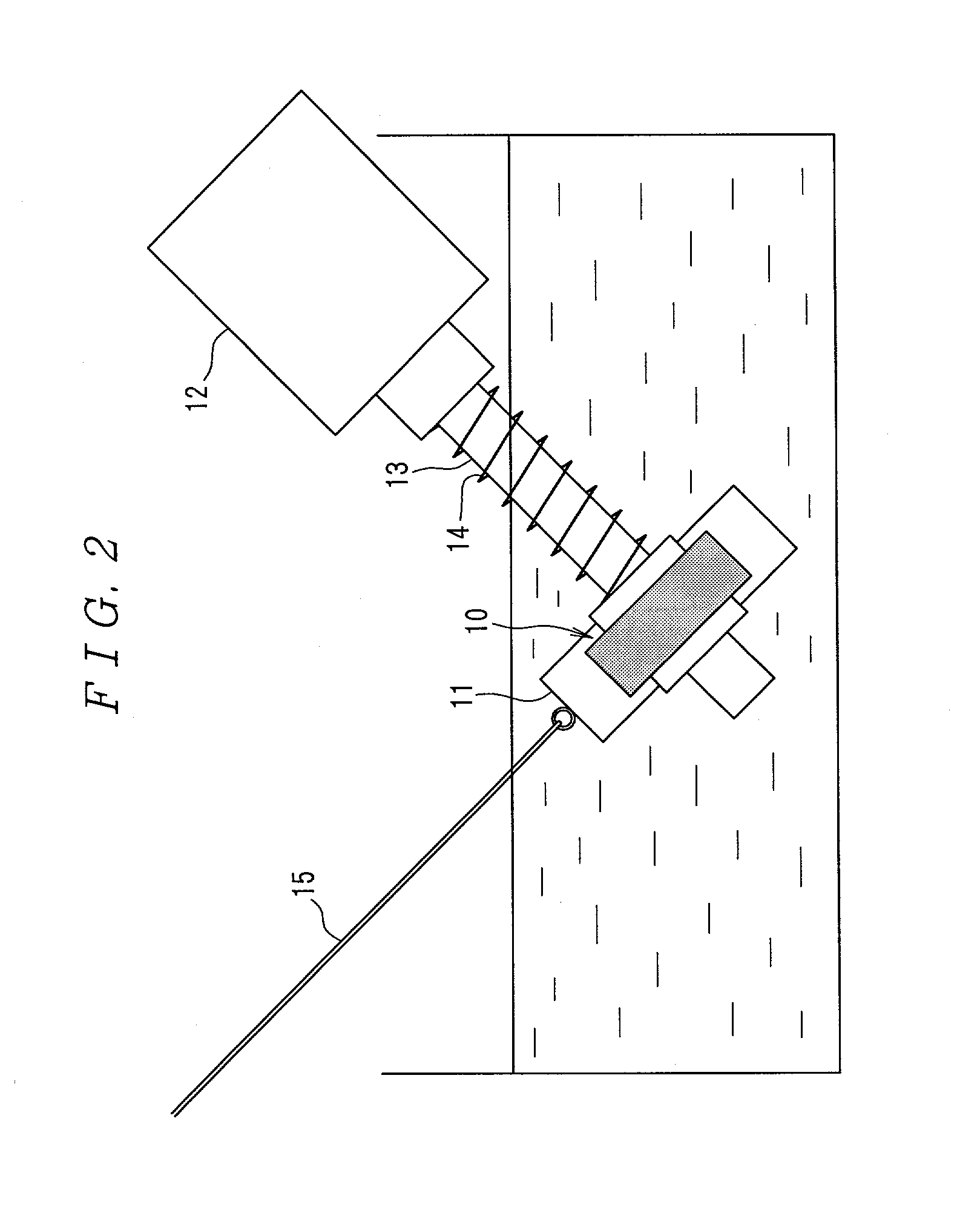

ActiveUS20100071933A1High elongationHigh strengthNon-insulated conductorsConductive materialElectrical conductorQuenching

A conductor excellent in tensile strength, breaking elongation, impact resistance, electrical conductivity, and fatigue resistance, and a production method thereof. The conductor includes elemental wires made from an aluminum alloy containing Si whose content is 0.3-1.2 mass %, Mg whose content makes an Mg / Si weight ratio in a range from 0.8 to 1.8, and a remainder essentially including Al and an unavoidable impurity. The conductor has tensile strength of 240 MPa or more, breaking elongation of 10% or more, impact absorption energy of 8 J / m or more, and electrical conductivity of 40% IACS or more. The production method includes the step of preparing a strand by bunching elemental wires with the above composition, and the step of subjecting the wire to solution treatment, quenching, and aging heat treatment. Solution treatment temperature is 500-580° C., and aging heat treatment temperature is 150-220° C. Heating in solution treatment is high frequency induction heating.

Owner:AUTONETWORKS TECH LTD +2

Copper alloy materials with high-strength and conducting performances and production thereof

InactiveCN1818109AHigh temperature strengthImprove plasticityHigh intensityUltimate tensile strength

The invention opened a high strength and conductance aldary material which includes: Cr 0.05%-0.10wt%; Zr 0.05%-0.50%; Mg 0.05-0.20wt%; (Ce+Y)<=0.20%; The residue is Cu. The process is : water quench for 1h in 900-960DEG C->30%-45% of cold-drawing deformation->aging treatment for 0.5-4h in 440-520 ->formed by cold-drawing. The strength can reach above 550-600MPa and the specific conductivity can keep above 80% IACS, and the life is improved to 3-5 times, the sintering can reach 550DEG C; the slip is less than 10% in the 300DEG C, the elongation percentage is above 5%, also the alloy has the performance of resistance to elevated temperatures and stand wear and tear.

Owner:HENAN UNIV OF SCI & TECH

Low pressure casting process for aluminum alloy cylinder part

The invention discloses a low pressure casting process for an aluminum alloy cylinder part. The aluminum alloy used by the method comprises the following materials in percentage by mass: 6.0 to 7.0 percent of Si, 0.3 to 0.5 percent of Mg, 0.1 to 0.2 percent of Ti, 0.05 to 0.15 percent of Fe and the balance of Al. After melting, thining, modification, and refining, the materials are subjected to low pressure casting and pouring; and after low pressure casting process of liquid lifting, filling, pressure maintaining and pressure releasing, the materials form a cast in a die cavity; and after a cast blank is subjected to solution treatment, and heat treatment of incomplete artificial aging, the cast has the advantages that: the texture is compact, casting defects such as pores, shrinkage porosity, shrinkage cavity, slag inclusion, and the like are avoided, the quality of the cast is improved; meanwhile, the working allowance of the cast is less, so the material utilization is improved and the production cost is reduced.

Owner:王宏波

Method and tooling for controlling deformation of nickel-based ageing-strengthening high-temperature alloy casing welding assembly

ActiveCN103551770AAvoid fatigue crackingMeet reliabilityWelding/cutting auxillary devicesAuxillary welding devicesWelding residual stressElectron

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

High-strength corrosion-resisting nickel base alloy and manufacturing method thereof

InactiveCN102628127AWill not affect the comprehensive application performanceNo destabilizationRare-earth elementNiobium

The invention relates to a high-strength corrosion-resisting nickel base alloy and a manufacturing method thereof. The high-strength corrosion-resisting nickel base alloy comprises the following chemical components by weight percent: not more than 0.04% of carbon (C), about 20.0%-26.0% of chromium (Cr), about 6.0%-10.0% of cobalt (Co), about 4.0%-8.0% of tungsten (W), not more than 1.0% of molybdenum (Mo), not more than 1.0% of Ferrum (Fe), not more than 0.5% of silicon (Si), not more than 0.5% of manganese (Mn), about 0.8%-1.3% of niobium (Nb), about 0.3%-0.7% of titanium (Ti), about 0.6%-1.0% of aluminum (Al), about 0.1%-0.4% of zirconium (Zr), not more than 0.003% of boron (B), tiny lanthanum (La) or rare-earth element (Re), and the balance of nickel (Ni) and inevitable impurity element. Vacuum melting and electroslag remelting are adopted, and then solution treatment and ageing treatment are performed.

Owner:丹阳恒庆复合材料科技有限公司

Regeneration method of titanium silicalite molecular sieve catalyst

InactiveCN101602011AEasy to operateEasy to controlMolecular sieve catalystsCatalyst regeneration/reactivationMolecular sieveSolution treatment

The invention discloses a regeneration method of titanium silicalite molecular sieve catalyst, and the deactivated titanium silicalite molecular sieve is Ti-MWW molecular sieve which is from the epoxidation reaction of alkene and the ammonia oximation reaction of ketone. The method comprises the following steps: carrying out an acid compound solution treatment and an alkaline compound solution treatment on the deactivated titanium silicalite molecular sieve, then filtering, washing, drying and baking the Ti-MWW molecular sieve, thus obtaining the regenerative titanium silicalite molecular sieve. The invention has the advantages of simple operation, and easy-controlled process and the regenerative titanium silicalite molecular sieve catalytic activity can restore to the level of a fresh agent.

Owner:EAST CHINA NORMAL UNIV

Austenic stainless steel strip and manufacturing method thereof

ActiveCN101481778AReduce dosageReduce the amount of ferriteTemperature control deviceMetal rolling arrangementsSolution treatmentStrip steel

The invention discloses an austenitic stainless steel belt and a manufacturing method thereof. The invention is characterized by comprising the following chemical elements in terms of weight percentage: 0.04 to 0.12 percent of C, 0.4 to 1. percent of Si, 0.8 to 2 percent of Mn, less than or equal to 0.04 percent of P, less than or equal to 0.03 percent of S, 17 to 19 percent of Cr, 7 to 10 percent of Ni, 0.25 to 0.5 percent of Cu and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: smelting; continuous casting with thin belts; control of cooling and winding; acid pickling, direct cold rolling and annealing; acid pickling again and cold rolling to achieve the thickness of a finished product; annealing after achieving the thickness of the finished belt steel, acid pickling, leveling, and length cutting into a finished coil. By utilizing the element of Cu, the invention reduces the use amount of Ni in the steel, reduces the production cost, simultaneously reduces the content of the residual ferrite in the steel, improves the wearing resistance of the steel, adopts direct cold rolling to match the high-temperature annealing procedure, and saves the procedures of hot rolling and solution treatment so as to lead the production process to be simple and stable.

Owner:BAOSHAN IRON & STEEL CO LTD

Micro-alloy chemical die steel and thermal treatment method thereof

InactiveCN101798657AEmission reductionSimple heat treatment processSolution treatmentChemical composition

The invention discloses a micro-alloy chemical die steel and a thermal treatment method thereof. The chemical die steel comprises the following chemical components in percent by weight: 0.7 to 0.9 percent of C, 0.15 to 0.25 percent of V or Nb, 1.0 to 2.0 percent of Cr, Mn, Si and Mo, common steel with more than or equal to 50ppm of O, N, S and P, and less than 50ppm clean steel. The thermal treatment method for the steel comprises the following steps: heating the steel to between 1,050 and 1,150 DEG C after hot rolling to perform solution treatment, quickly cooling the steel to 600 DEG C, transferring the steel to a 400 to 700 DEG C furnace to perform isothermal transformation, heating the steel to between 900 and 950 DEG C after machining, quenching the steel by oil, and finally tempering the steel at the temperature of between 150 and 200 DEG C. The invention discloses the high-quality chemical die steel with low alloy element content, advantages of saving sources and reducing carbon emission and wide application prospect in die and bearing industries.

Owner:戚正风 +1

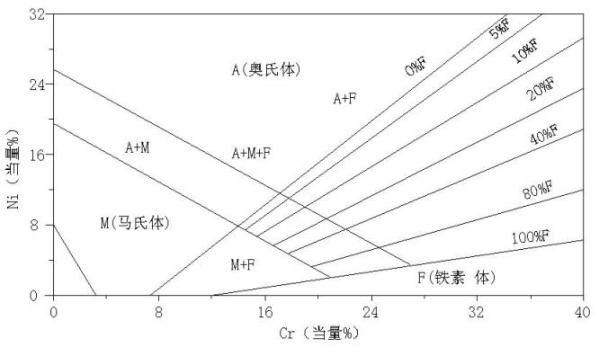

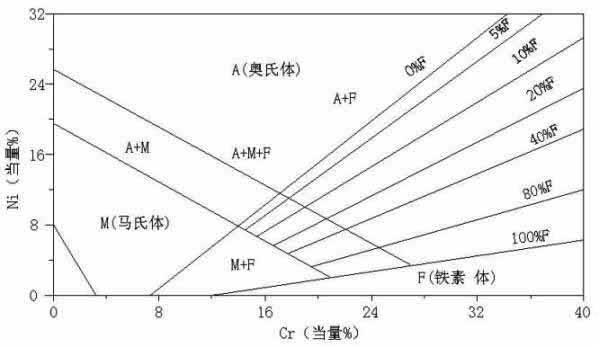

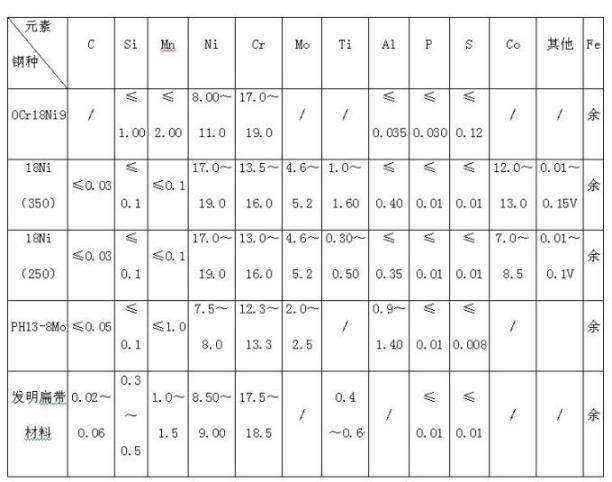

Martensite stainless steel and preparation method for flat strip of martensite stainless steel

ActiveCN102251191AHigh strengthHigh hardnessIncreasing energy efficiencySolution treatmentMartensitic stainless steel

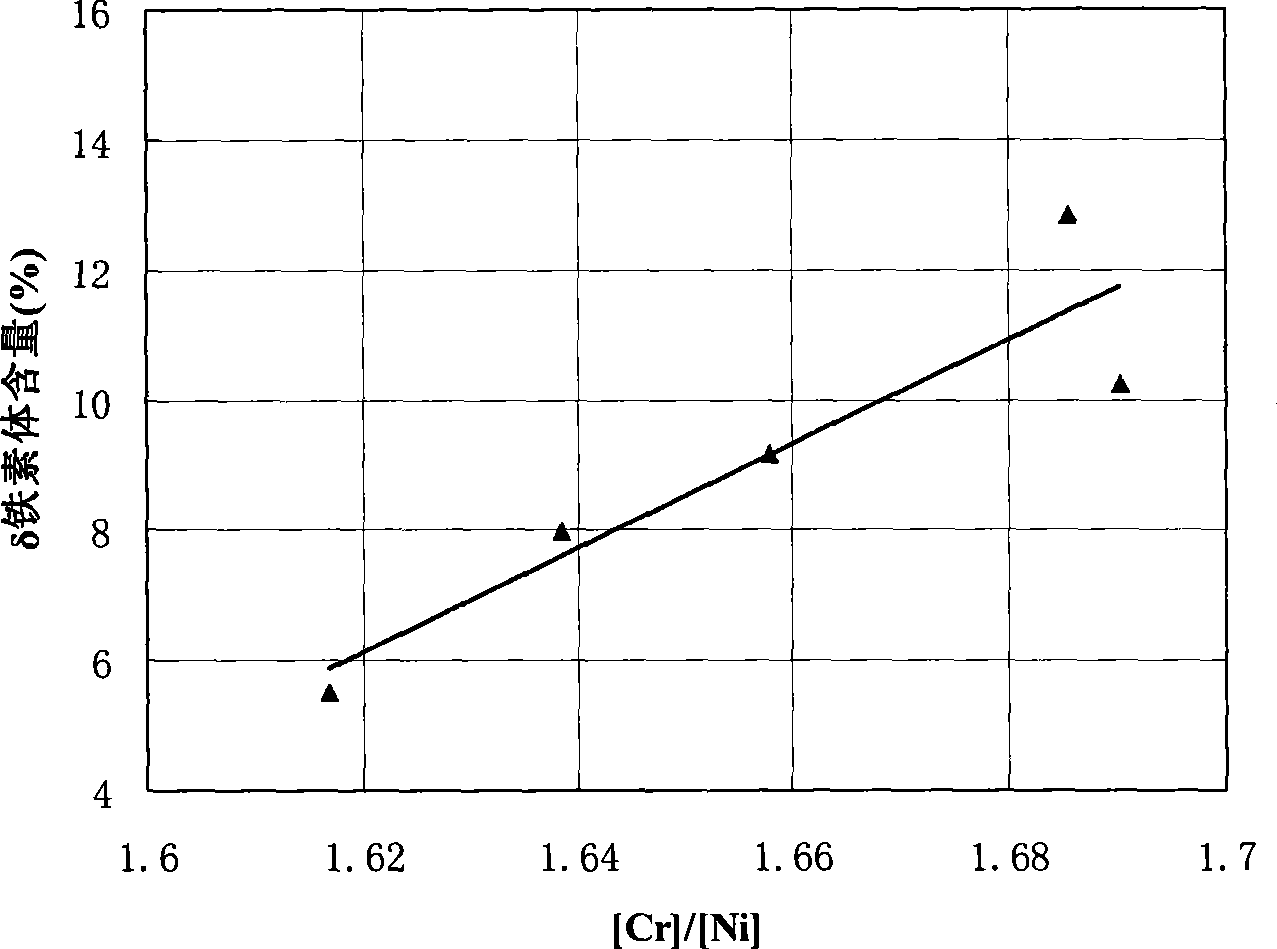

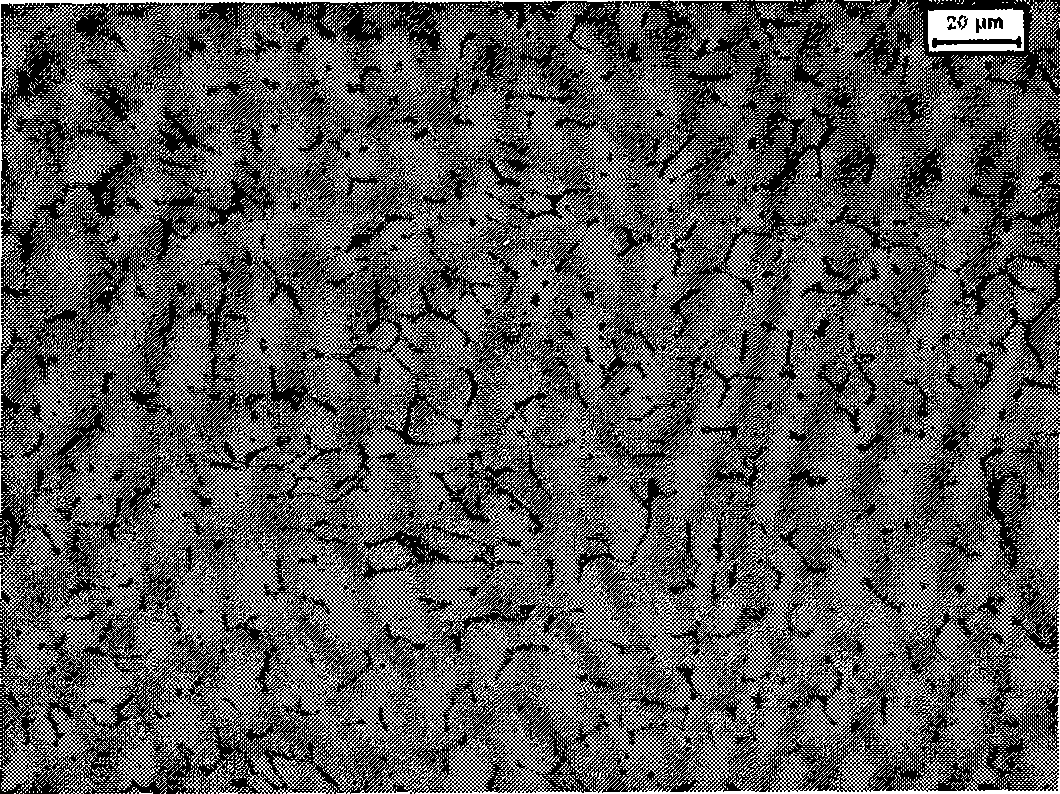

The invention discloses martensite stainless steel and preparation method for flat strips of martensite stainless steel. The martensite stainless steel comprises following chemical components by weight percentage: C 0.02 to 0.06%, Si 0.3 to 0.5%, Mn 1.0 to 1.5%, Ni 8.5 to 9.0%, Cr 17.5 to 18.5%, Ti 0.4 to 0.6%, P no more than 0.009% and S no more than 0.009%, with the balance being Fe. The preparation method for flat strips of the martensite stainless steel comprises the following steps: a) weighing above-mentioned chemical components at desired weight percentage; b) carrying out vacuum induction melting; c) carrying out casting to obtain remelt electrode bars; d) carrying out electroslag remelting to obtain steel ingots; e) forging steel ingots into billets; f) processing billets into round strips; g) carrying out solid solution treatment; h) drawing treated blanks into wires; i) preparing flat strips. According to the invention, equivalents of nickel and chromium are strictly controlled, the ratio of C to Ti and alloy elements are optimized, EVR smelting is carried out and such alloying elements as C, Si, Mn and Ti are added, thereby enabling formation of a metastable austenite structure; a predeformed phase-changed martensite wire material is obtained by wire drawing; and the ultra high strength deformed flat strips of martensite stainless steel are obtained by flat strip rolling.

Owner:CHONGQING MATERIALS RES INST

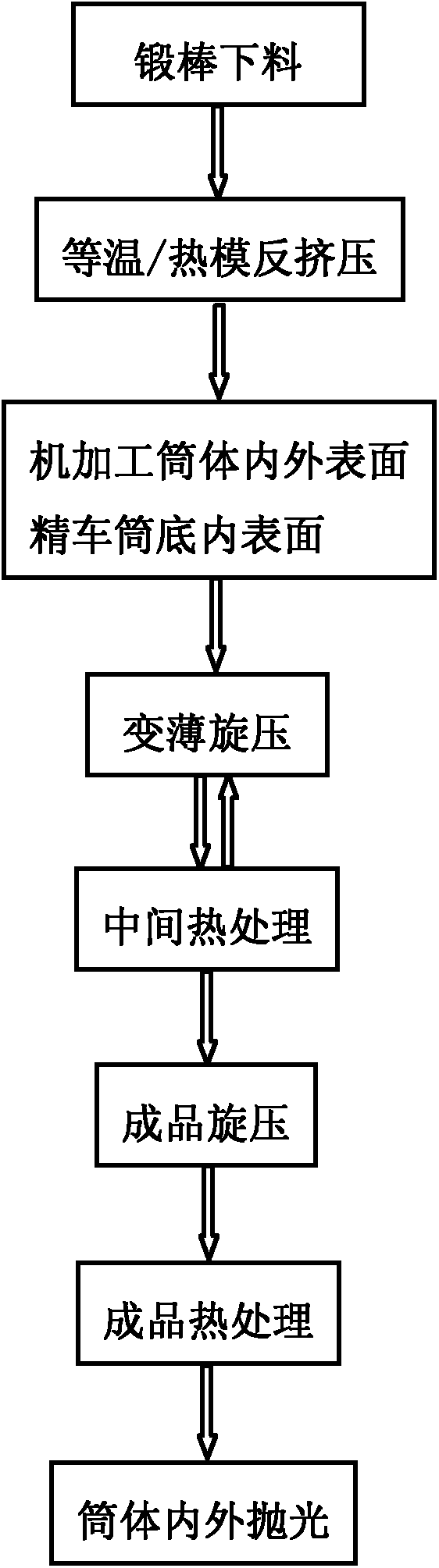

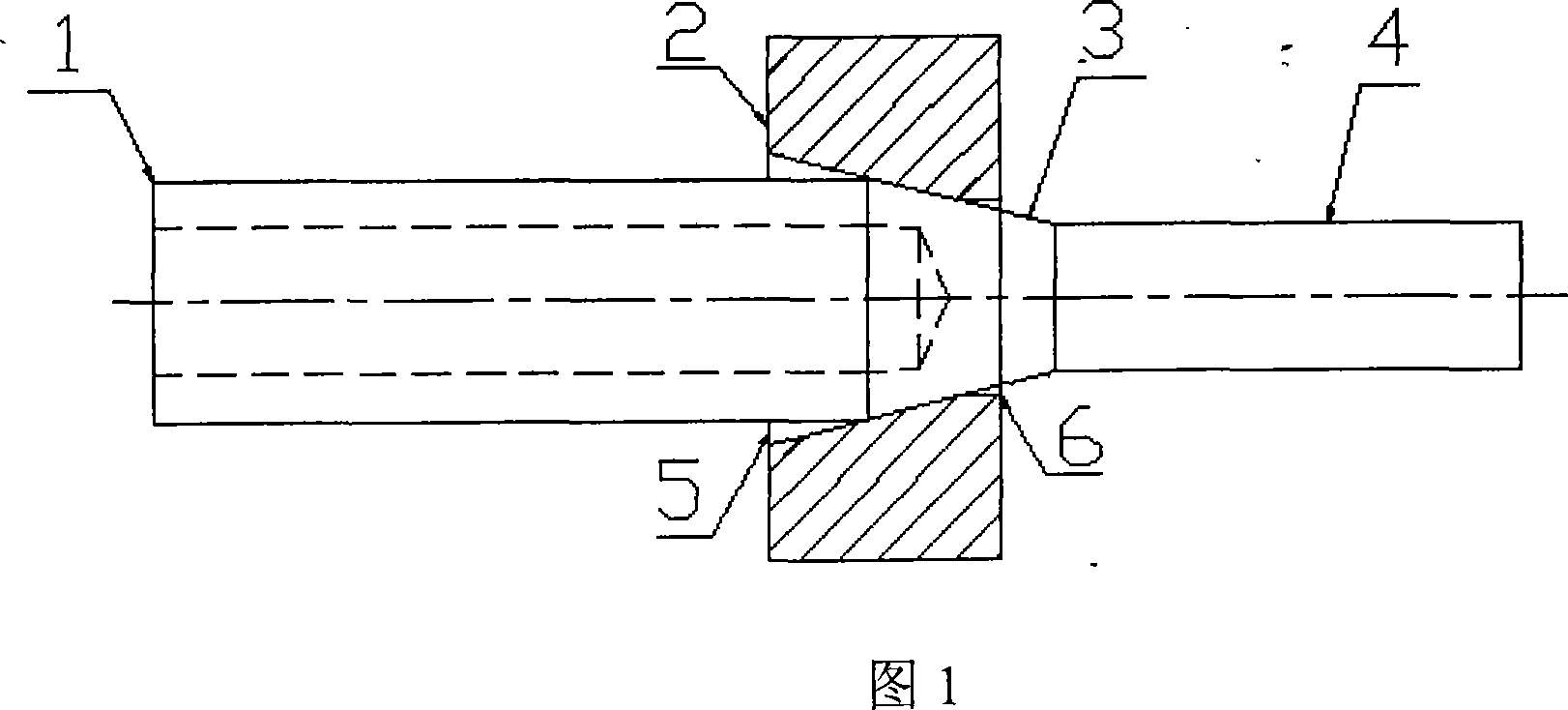

Machining method of high-quality large-diameter thin-wall metal barrel body

The invention relates to a machining method of a high-quality large-diameter thin-wall barrel body. The machining method comprises the following steps. Firstly, isothermy or hot die anti-extrusion technology is utilized, and anti-extrusion is performed on an alloy forging rod. Secondly, machining is performed on the inner and outer surfaces of a spinning barrel billet, and finish turning is performed on the inner surface of the barrel bottom of the barrel billet. Thirdly, multi-pass brute force thinning spinning is performed on the machined spinning barrel billet, and the spinning is hot spinning or cold spinning. Fourthly, intermediate heat treatment is performed on a spinning semi-finished product, and the intermediate heat treatment is annealing or solution treatment. Fifthly, the third step and the fourth step are performed repeatedly and alternatively so that finished product spinning is performed. Sixthly, scouring and cleaning are performed on the barrel body, and finished product heat treatment is performed. Seventhly, polishing of the inner and outer surfaces of the barrel body after heat treatment in the sixth step is performed, and a finished product barrel body is obtained. By adoption of the machining method of the high-quality large-diameter thin-wall barrel body to machine a large-diameter thin-wall metal barrel body without welding lines, organization is even and fine, comprehensive performance is high, the process is short, product additional values are high, and good application and popularizing prospects and certain economic and social benefits are achieved.

Owner:有研金属复材技术有限公司

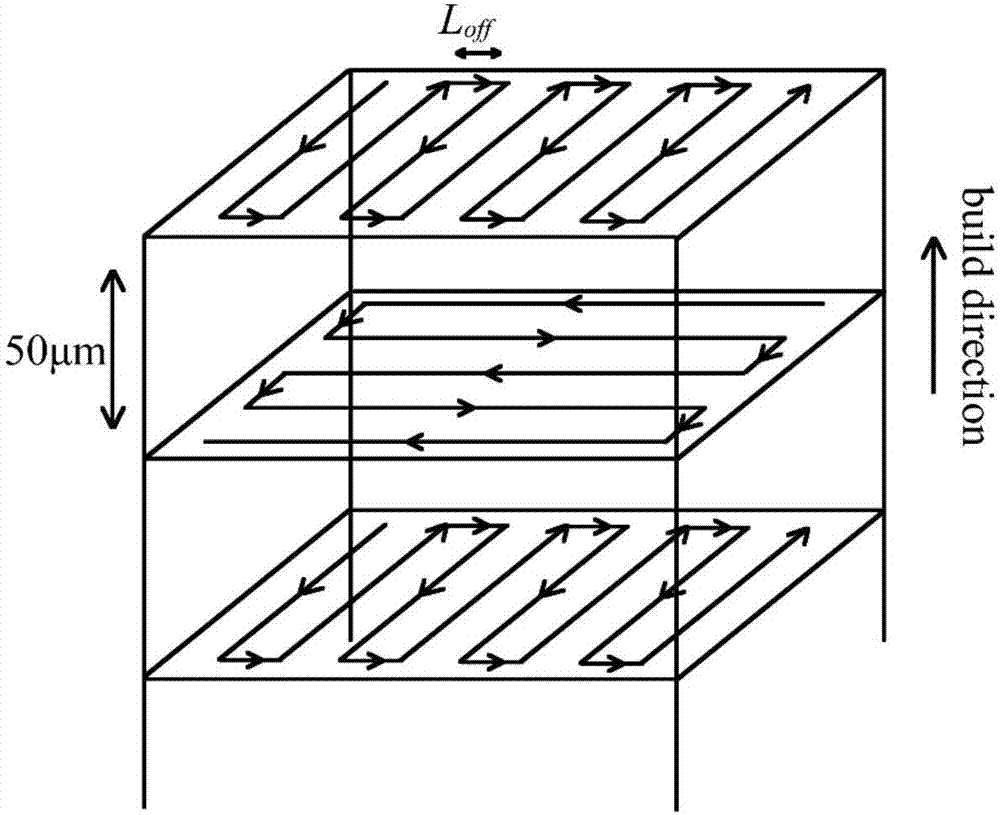

Method for removing microcracks from additive manufacturing nickel-base high-temperature alloy components manufactured by electron beam selective melting

InactiveCN107971491ASimple structureImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySolution treatmentSolid solution

The invention discloses a method for removing microcracks from additive manufacturing nickel-base high-temperature alloy components manufactured by electron beam selective melting, and belongs to thetechnical field of high-temperature alloy and additive manufacturing. According to the method disclosed by the invention, additive manufacturing nickel-base high-temperature alloy is treated with heattreatment technologies, including hot isostatic pressing treatment, solid solution treatment and aging treatment in sequence, and compact additive manufacturing nickel-base high-temperature alloy materials without the microcracks can be prepared with the heat treatment technologies, and have excellent microstructure and mechanical properties.

Owner:BEIHANG UNIV

Beta titanium alloy and preparation method thereof

The invention discloses a beta titanium alloy and a preparation method thereof, relates to a titanium alloy, and provides a beta titanium alloy with excellent combination property and a preparation method thereof. The beta titanium alloy comprises the following components by mass percent: 6-10% of vanadium, 2-4% of aluminum, 2-4% of chromium, 0-13% of niobium, 0-3% of tin, 0-5% of zirconium, 0-4% of molybdenum, 0-0.05% of boron and the balance titanium. The preparation method comprises the following steps: putting the titanium and zirconium in a sponge state into an arc furnace; vacuumizing and then charging argon for smelting; smelting the smelted titanium and zirconium with vanadium, aluminum, chromium, niobium, tin, molybdenum and boron to obtain a beta titanium alloy pig material; carrying out homogenizing heat treatment on the beta titanium alloy pig material, and cooling along with the furnace; rolling the beta titanium alloy pig material after the heat treatment into a schistose alloy material; slicing the obtained schistose alloy material into a sample; and quenching with icy water after the solution treatment, and then carrying out aging to obtain the beta titanium alloy.

Owner:XIAMEN UNIV

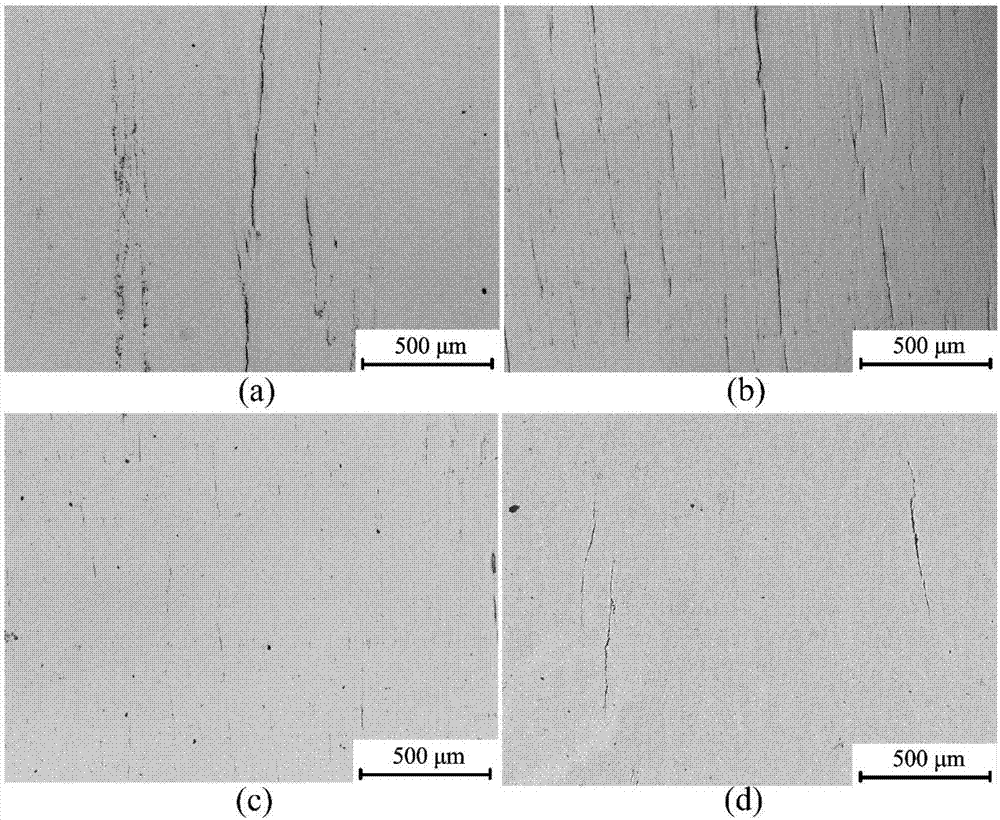

Process for forming magnesium alloy ultra-fine thin-wall tube used for degradable blood vessel bracket

The invention provides a figuration technology of superfine magnesium alloy thin-walled tube for degradable vascular bracket. The characteristics of its major technique is adding yttrium to pure magnesium, mixing RE, Al, Ca, Mn, Sb, Zn, and Zr, smelting through gas shield smelting + reduction iron solvent refining method to obtain ingot casting of magnesium alloy, performing hot extrusion, distortion and solution treatment, intercepting certain length as workpiece for subsequent processing, processing one end to tubular form and the other end to clubbed form, heating the pipe end, and tugging through multiple tracks to obtain superfine thin-walled tube with diameter of 2-10mm, wall thickness of 0.20-1mm.Its advantage is overcoming limitation of figuration technology such as pressing, has low cost, uniform wall thickness and tissue, and good mechanical property.

Owner:SHENYANG POLYTECHNIC UNIV

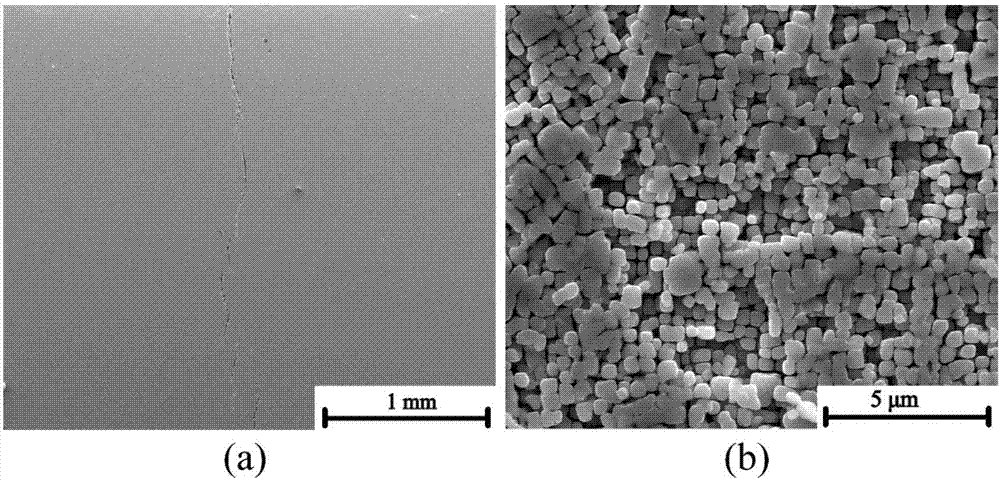

Preparation method of micro/nano-structure ultrahigh-strength plastic stainless steel containing Nb

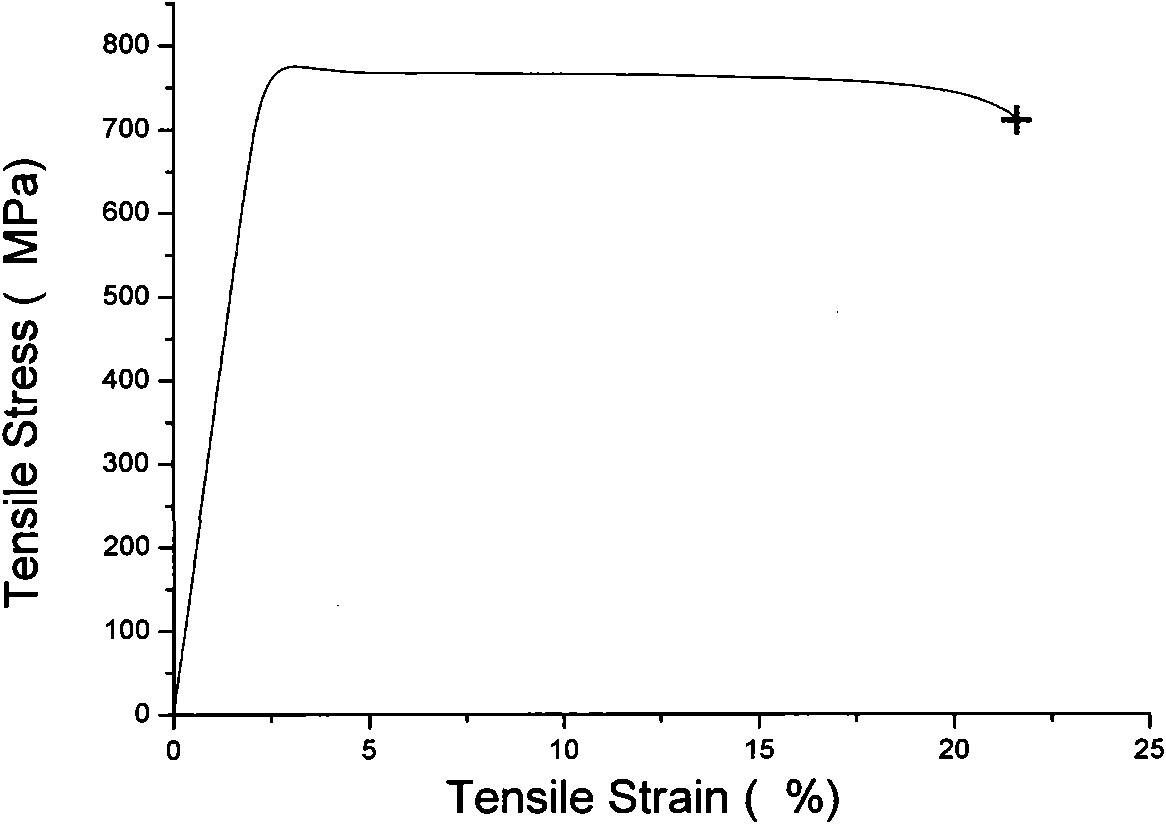

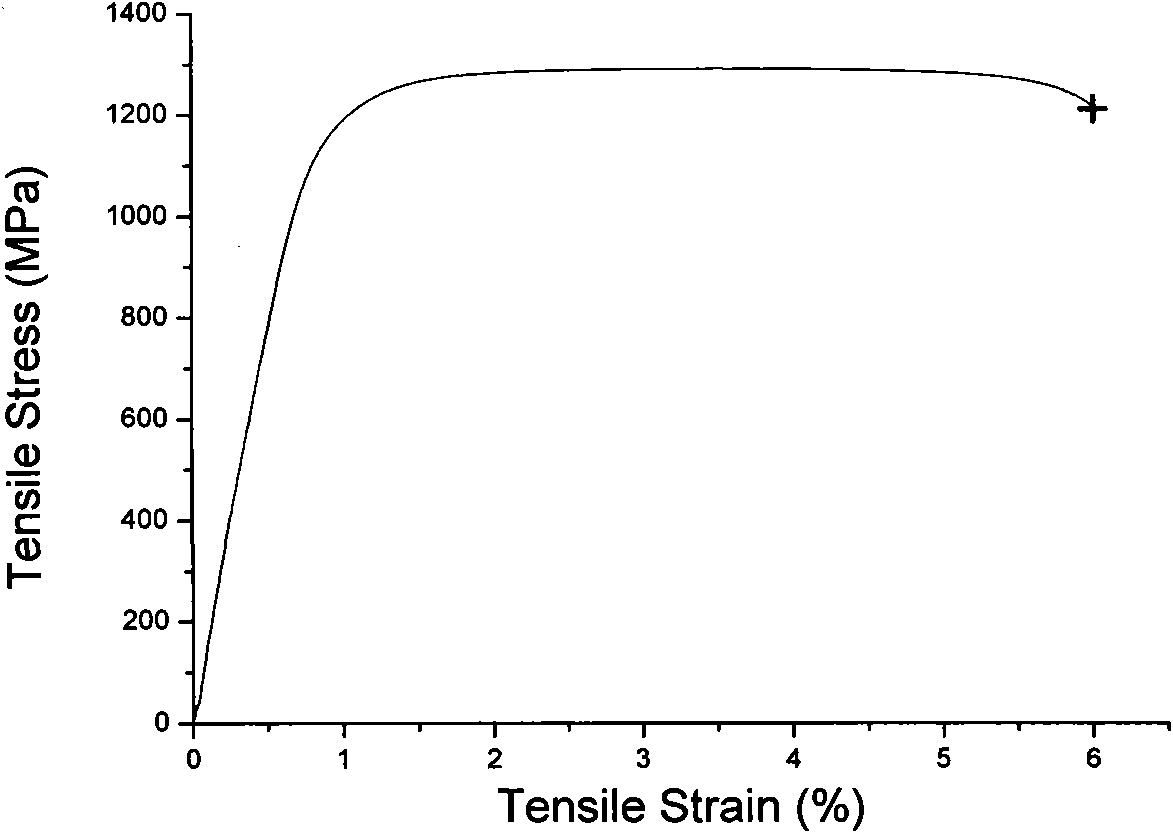

The invention belongs to the field of production of ultrahigh-strength plastic alloy steel, and relates to a preparation method of micro / nano-structure ultrahigh-strength plastic stainless steel containing Nb. The preparation method comprises the steps of: firstly preparing materials according to a composition proportion, adding 0.05-0.15% of Nb element on the basis of 316L austenitic stainless steel, then carrying out vacuum induction furnace smelting, casting blank forging, forged piece hot rolling and solution treatment, carrying out cold deformation on the steel plate which undergoes the solution treatment with deformations of 40%, 60%, 80% and 90% and with single reduction in pass controlled within 3-10% to prepare steel plate with different cold deformations, annealing the steel plate which undergoes the cold deformation with heating rate controlled at 50-200 DEG C / s, with heating temperature within 750-950 DEG C and with heat preservation time within 5-100s, and cooling to the room temperature at a cooling rate of 50-400 DEG C / s to obtain a superfine austenite structure with micro-nano scale. The obdurability of the material is synchronously improved. The yield strength of the final product can be up to 750-800MPa, the strength of extension is up to 1100-1200MPa and the percentage of elongation is 35-45%.

Owner:UNIV OF SCI & TECH BEIJING

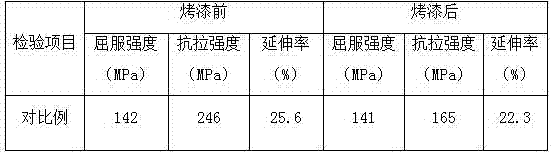

Aluminum alloy panel for automobile body lightweight and preparing method of aluminum alloy panel

InactiveCN106917016AHigh bake hardening propertiesImprove stamping formabilitySolution treatmentImpurity

The invention relates to an aluminum alloy panel for automobile body lightweight and a preparing method of the aluminum alloy panel. The aluminum alloy panel is characterized by comprising chemical components including, by mass percent, 1.2%-2.2% of Mg, 0.8%-1.5% of Si, 0.1%-0.3% of Fe, 0.2%-0.8% of Mn, 0.2%-0.5% of Cu, 0.05%-0.2% of Zr, 0.01%-0.5% of Cr, 0.05%-0.2% of La, smaller than or equal to 0.2% of Zn, smaller than or equal to 0.1% of Ti, smaller than or equal to 0.05% of each of the other impurity elements, and the balance Al, wherein the total content of the other impurity elements is smaller than or equal to 0.15%. According to the preparing method of the aluminum alloy panel for automobile body lightweight, the aluminum alloy panel is obtained through smelting, refining, casting, homogenizing, head cutting and face milling, hot rolling, intermediate annealing, cold rolling and solution treatment. The aluminum alloy panel for automobile body lightweight has high baking hardening performance and good forming performance, and the aluminum alloy panel has good comprehensive performance through reasonable optimization of the content of the elements in the alloy and the heat treatment technology.

Owner:GUILIN UNIV OF AEROSPACE TECH

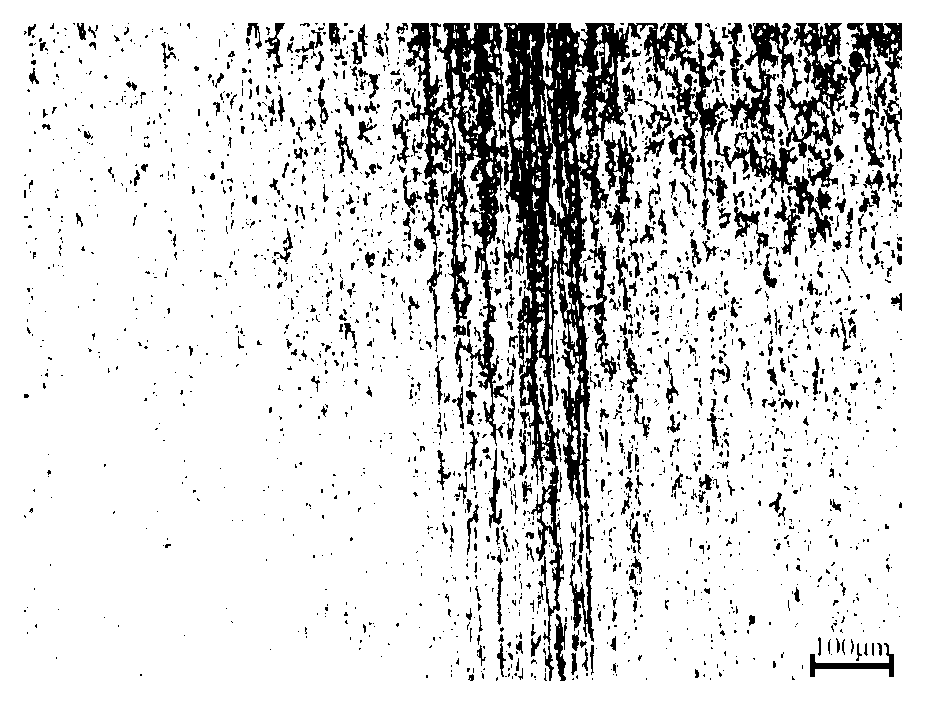

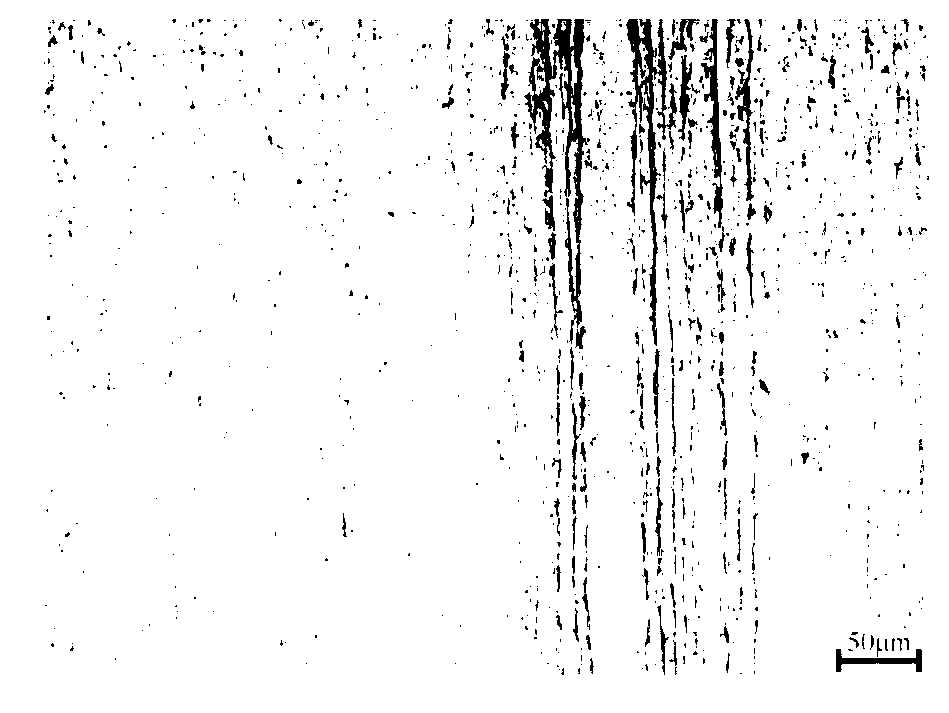

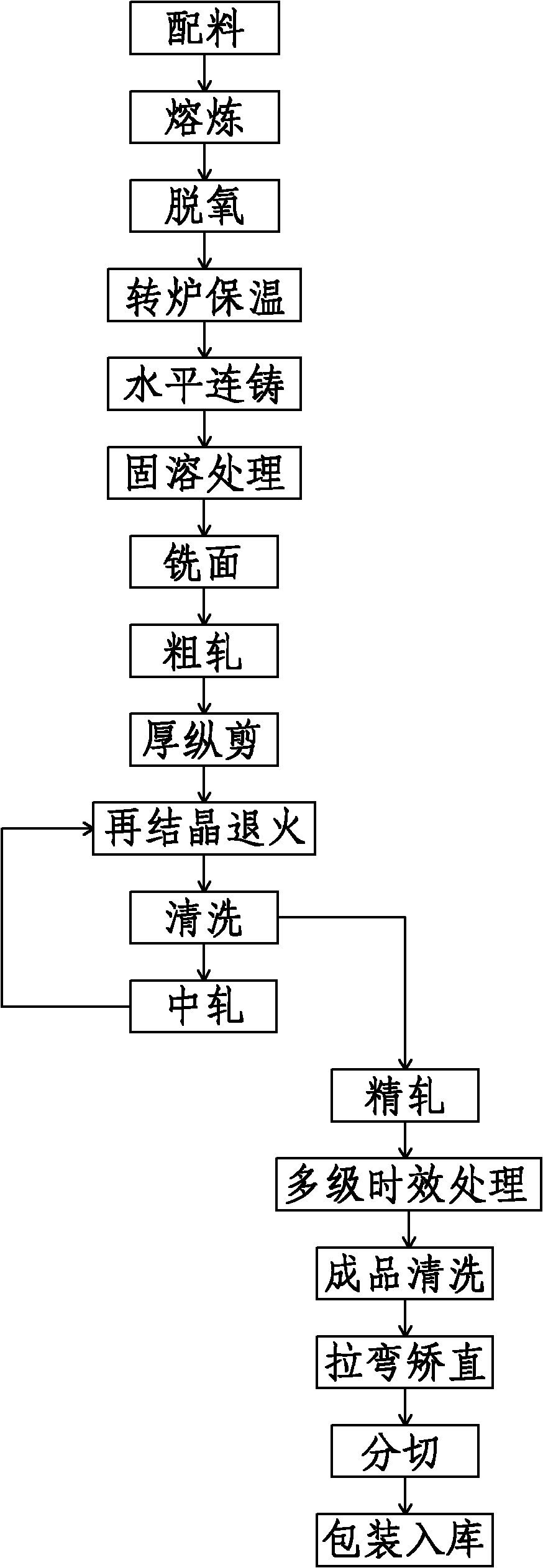

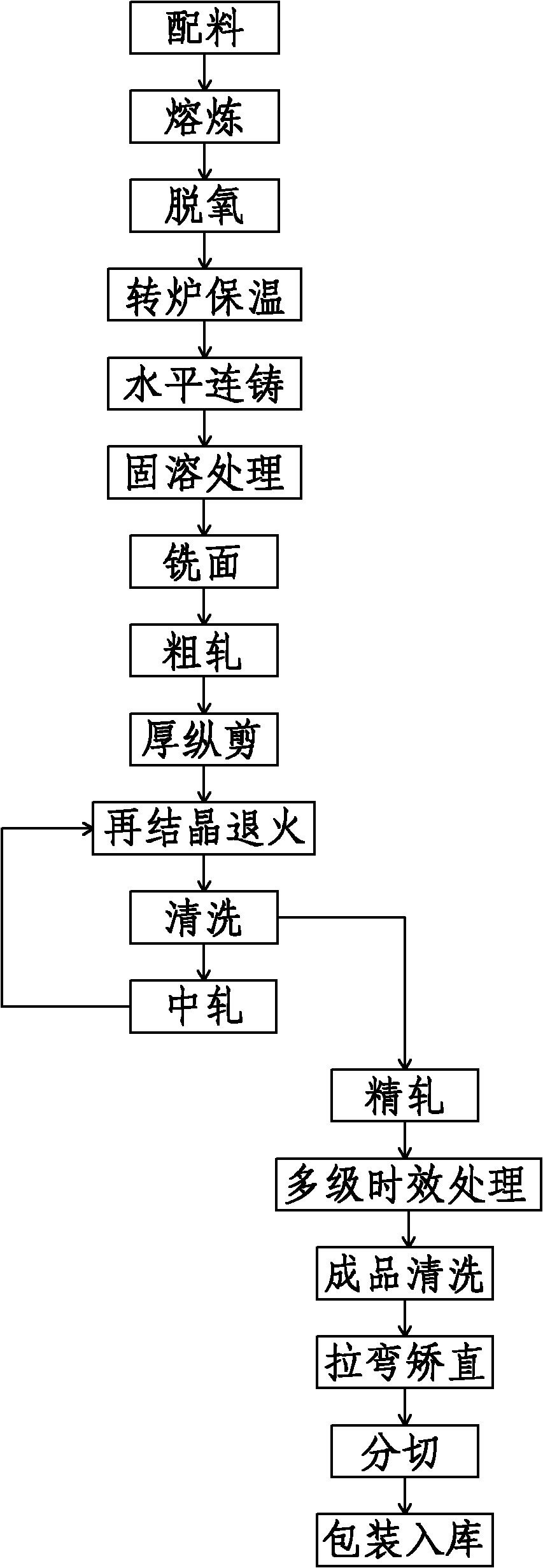

Formula of copper nickel tin alloy strip and production process

The invention discloses a formula of a copper nickel tin alloy strip and a production process. The formula of the alloy strip comprises the following components in percentage by weight: 19.0 to 21.0 percent of Ni, 4.0 to 6.0 percent of Sn, 0.01 to 0.05 percent of Zr and the balance of Cu. The production process comprises the following steps of: proportioning, smelting, bath analysis, deoxidation, converter heat preservation, horizontal continuous casting, solution treatment, surface milling, rough rolling, thickness longitudinal shearing, strong convection bright annealing, cleaning, precision rolling, multistage ageing, bending, straightening and slitting. The production process has no pollution, the production flow is short, the alloy strip blank has small specification size and high quality, cold rolling is directly performed, a hot rolling process is saved, and the production efficiency is improved; the obtained copper nickel tin alloy has the properties of high strength, high elongation, high hardness, high elasticity, stress corrosion resistance and the like, the performance of the copper nickel tin alloy is close to that of beryllium bronze, and the copper nickel tin alloy can partially replace the beryllium bronze to manufacture elastic elements.

Owner:江苏富威科技股份有限公司

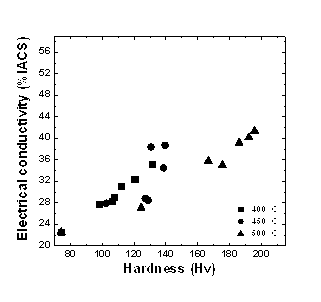

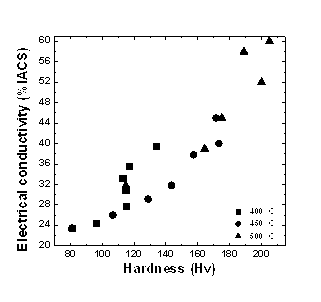

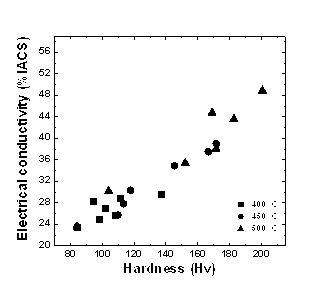

Cu-Ni-Si-based alloy and preparation method thereof

The invention belongs to the technical field of copper alloy material, and discloses Cu-Ni-Si-based alloy with high strength and high conductivity, and a preparation method thereof. The Cu-Ni-Si-based alloy is characterized in that the Cu-Ni-Si-V alloy comprises the following components in weight percent: 95.5-97.5% of Cu, 2.0-3.0% of Ni, 0.5-1.2% of Si, and 0-0.3% of V; and the method comprises specific steps as follows: smelting pure copper, pure silicon, pure nickel and pure vanadium in an induction furnace according to the proportion, casting in a metal die to obtain a blank, and performing ageing and solution treatment for the blank after hot rolling and cold rolling deformation treatment. As shown by experimental results, the added alloy V has the remarkable grain refinement function on the CU-Ni-Si alloy; and appropriately-added V (0.086 weight percent) can significantly improve the conductivity of the alloy, at the same time, the combination properties of the alloy are improved to the conductivity of 60% IACS and the hardness number of 205 Hv from the conductivity of 41.4% IACS and the hardness number of 195.7 Hv only with slight reduction in hardness; and the alloy with 0.086 weight percent V can separate out second phase with a volume fraction twice of that of the alloy before adding V.

Owner:TAIYUAN UNIV OF TECH

High-strength and high-Gd-content deformed magnesium alloy and preparing method thereof

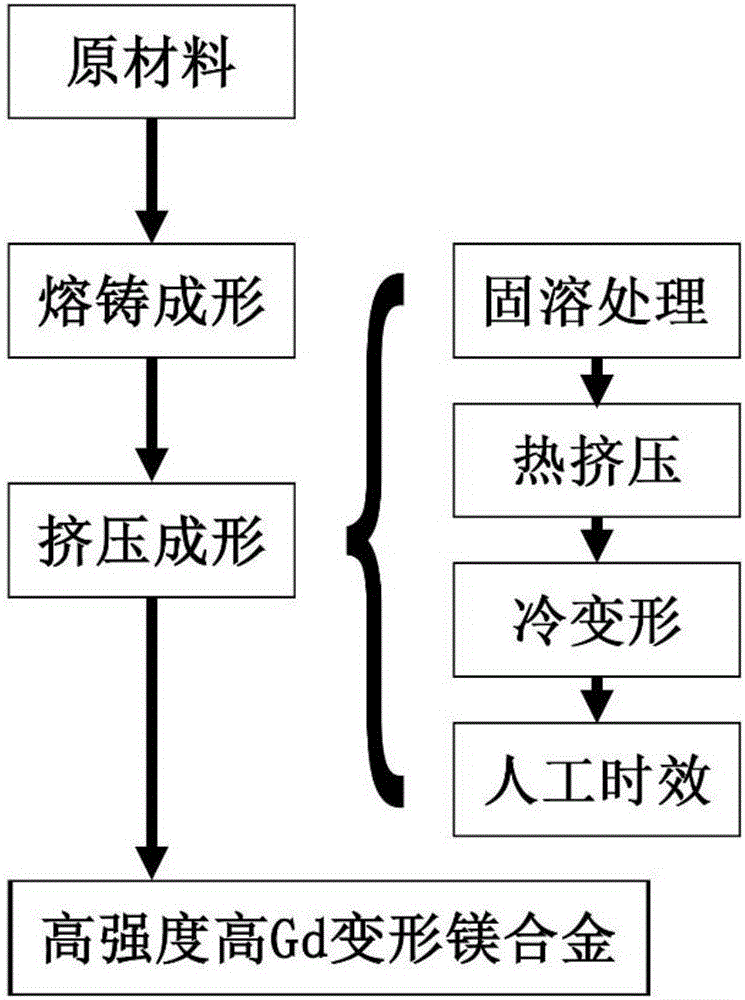

The invention provides a high-strength and high-Gd-content deformed magnesium alloy and a preparing method thereof. The magnesium alloy comprises the following elements of Mg, Gd, Zn and one or more kinds of Y, Zr and Mn. The preparing method includes the following steps that a magnesium alloy cast ingot high in Gd content is prepared; after the magnesium alloy cast ingot is subjected to two steps of T4 solution treatment, quenching is conducted at the temperature ranging from 80 DEG C to 100 DEG C, and a T4-state magnesium alloy cast ingot is obtained; the T4-state magnesium alloy cast ingot is subjected to different-temperature extrusion forming and is then quenched at the temperature ranging from 15 DEG C to 30 DEG C, and a bar or plate is obtained; and the bar or plate is subjected to cold rolling and cold drawing deformation at the room temperature, then artificial aging is conducted, and a T10-state deformed magnesium alloy, namely the high-strength and high-Gd-content deformed magnesium alloy is obtained. According to the high-strength and high-Gd-content deformed magnesium alloy and the preparing method thereof, the preparing technology is simple, the performance is stable, the success rate is high, the production efficiency is high, and the high-strength and high-Gd-content deformed magnesium alloy and the preparing method thereof are easily applied to industrial production.

Owner:SHANGHAI JIAO TONG UNIV

High-strength, high-conductivity and high-extensibility rare earth copper alloy and preparation method thereof

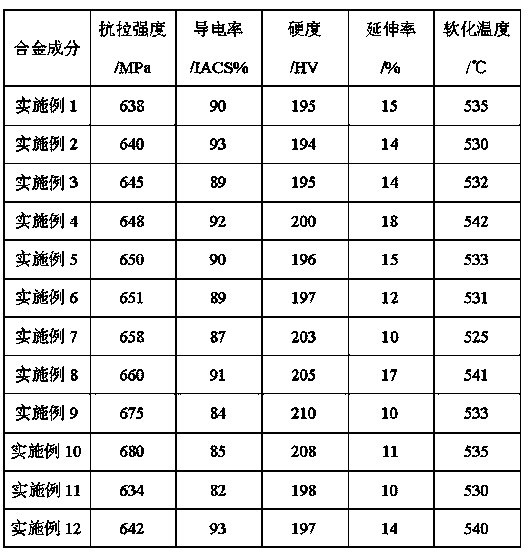

A high-strength, high-conductivity and high-extensibility rare earth copper alloy and a preparation method thereof are disclosed. The alloy is composed of following components in percentage by weight: 0.5 to 1.5% of chromium, 0.3 to 0.5% of zirconium, 0.1 to 0.3% of nickel, 0.2 to 0.5% of titanium, 0.2 to 0.4% of manganese, 0.02 to 0.15% of rare earth elements and the balance of copper and inevitable impurity elements, wherein the rare earth elements are one or two elements of erbium and lanthanum. The preparation method comprises following steps: preparing intermediate alloy, smelting, moulding, casting, treating solid solution, drawing to deform, performing an aging treatment, and a cold rolling treatment. The components and the ratio of the components are limited to let each component have a combined action, thus the comprehensive properties of the alloy material are prominently improved: the extension strength is larger than 630 MPa, the hardness is larger than 190 HV, the ductility is larger than 10%, the conductivity is larger than 80%IACS, and the softening temperature is larger than 520 DEG C; and the rare earth copper alloy can satisfy the requirements of materials in the electronic industry such as lead frame on copper alloy performances.

Owner:HENAN UNIV OF SCI & TECH

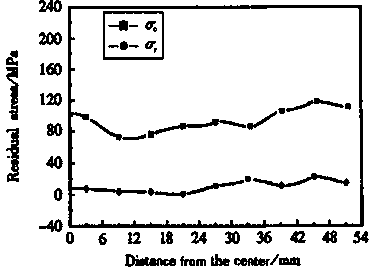

New method for eliminating aluminium alloy workpiece residual stress

The invention provides a new method for eliminating aluminium alloy workpiece residual stress, mainly aims at defects existing in a conventional residual stress eliminating method that the cost is high, the operation is complex, the requirement is high, the workpiece mechanical property is reduced, the workpiece surface is damaged, and the use is limited, and achieves double effects of eliminating residual stress and refining crystal grains through the organic combination of subzero treatment, the uphill quenching technology and conventional heat treatment. The new method has the specific operating steps of solution treatment, subzero treatment, uphill quenching and aging treatment, and has the characteristics that the technology method is simple, the environment is protected, the operation cost is low, the effect is superior to that of the conventional residual stress eliminating method, the residual stress is eliminated, meanwhile, the workpiece comprehensive mechanical property can be improved, and industrialized scale production can be realized.

Owner:葛鹏

Method for preparing high nitrogen and nickel-less austenitic stainless steel

The invention provides a method for smelting and manufacturing a high-nitrogen nickel-free austenitic stainless steel under normal pressure. The method comprises the following: a step of rapidly adding high-nitrogen alloy before or when the refined Cr-Mn base steel to be poured is poured; a step of stirring the mixture rapidly; a step of quickly casting the steel liquid which is not or little dissolved in the high-nitrogen alloy to make blank material; a step of dealing with the blank material through thermal deformation process and solution treatment to obtain the single phase austenitic stainless steel with 0.6-1.2 weight percent of nitrogen. The method can be carried out under the normal pressure without being smelted at high pressure. Moreover, the method has the advantages of low cost, high efficiency, simple process and accurate control of N, can produce various profiles and is suitable for the mass production.

Owner:上海莅辰企业管理中心(有限合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com