Small crystal particle Y-shaped molecular sieve and preparation method thereof

A molecular sieve, small-grain technology, applied in the direction of crystalline aluminosilicate zeolite, faux crystalline aluminosilicate zeolite, etc., can solve the problems affecting the distribution of B acid and L acid, poor thermal and hydrothermal stability, thermal and thermal stability. Problems such as poor hydrothermal stability, to achieve the effect of high crystal retention, good stability and high crystal retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

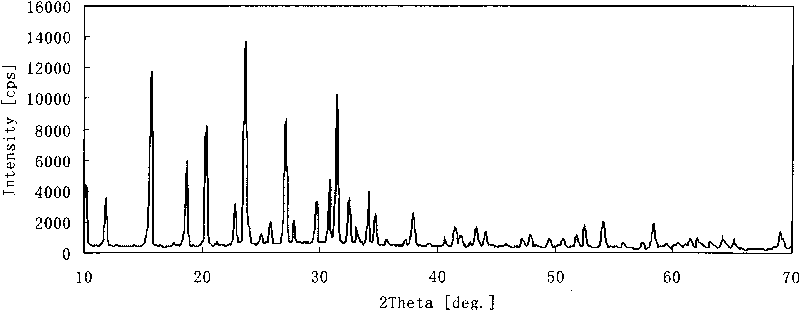

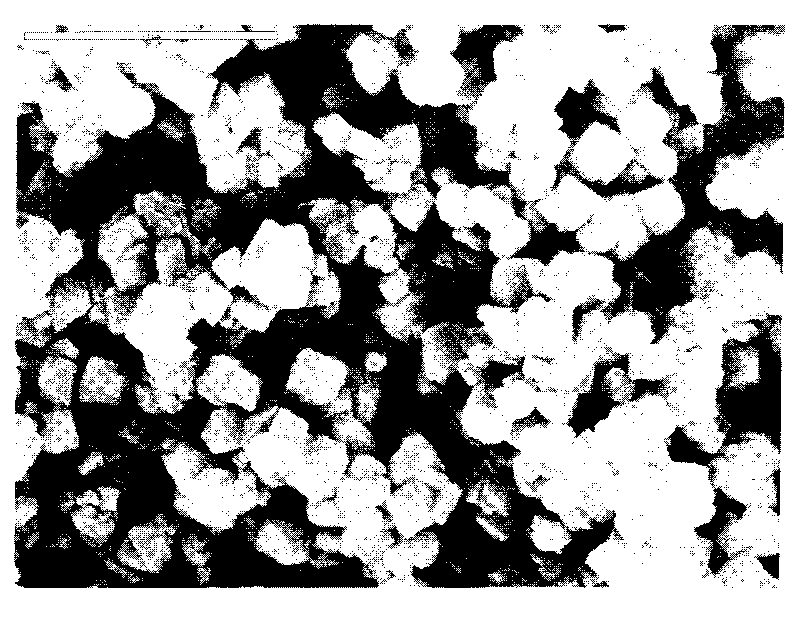

Image

Examples

preparation example Construction

[0033] The preparation method of the small crystal particle NaY type molecular sieve of the present invention specifically includes the following steps:

[0034] A. Preparation of directing agent at low temperature.

[0035] Follow Na 2 O: Al 2 O 3 : SiO 2 : H 2 O=10~20:1:10~20:300~400 molar ratio of feed, at a temperature above 0℃ and less than 15℃, preferably at a temperature of 0~10℃, the water glass is slowly stirred while stirring Add to the high-alkali sodium metaaluminate solution and mix uniformly, then stir at the above temperature at constant temperature and constant speed for 0.5 to 2 hours; then seal the mixed liquid in the synthesis kettle, static and constant temperature aging for 10 to 14 hours to prepare the directing agent ; The directing agent is best to add 20% to 40% of the directing agent weight of purified water before use.

[0036] B. Preparation of gel at low temperature.

[0037] Mix the water glass, aluminum sulfate solution, low-alkali sodium metaaluminate ...

Embodiment 1

[0051] This embodiment is to prepare the raw material small-crystalline NaY molecular sieve.

[0052] The properties of the raw materials used are as follows:

[0053] High alkali sodium metaaluminate: Na 2 O content 291g / L, Al 2 O 3 Content 42g / L; low alkali sodium metaaluminate: Na 2 O content 117g / L, Al 2 O 3 Content 77g / L; water glass: SiO 2 Content 250g / L, modulus 3.2; aluminum sulfate: Al 2 O 3 The content is 90g / L.

[0054] Preparation of LY-1:

[0055] A. Preparation of directing agent: slowly add 1200ml of water glass to 800ml of high-alkali sodium metaaluminate at a temperature of 10°C under stirring conditions. After the water glass is added, stir at constant temperature for 40 minutes. Stop stirring and seal the mixed solution in a container, and perform constant temperature aging treatment at 5°C for 12 hours. After the constant temperature is over, add 667ml of purified water to the mixed solution for use as a directing agent.

[0056] B. Preparation of gel: Under stirri...

Embodiment 2

[0063] Firstly, ammonium exchange was carried out on the small-crystalline NaY molecular sieve LY-1. The preparation concentration is 10 liters of 0.5mol / l ammonium nitrate aqueous solution. Weigh 2000 grams of small-crystalline NaY molecular sieve and dissolve it in 10 liters of prepared ammonium nitrate aqueous solution, stirring at 300 rpm, and stirring at a constant temperature of 90°C for 1 hour, then filter the molecular sieve and save a sample for analysis of Na 2 O content; repeat the above operation until Na in the molecular sieve 2 The O content reaches 2.5-5wt%, and the dried sample number is LNY-1.

[0064] Measure 1 liter of purified water and dissolve 1000 g of LNY-1 in the purified water, quickly raise the temperature and stir, the temperature is 95°C, and the stirring speed is 300 rpm. Within 2 hours, add ammonium hexafluorosilicate aqueous solution to the molecular sieve slurry at a constant speed, add 50 grams of ammonium hexafluorosilicate in total, then stir a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com