Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1421results about "Faujasite aluminosilicate zeolite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High silicon aluminium ratio small crystal NaY molecular sieve

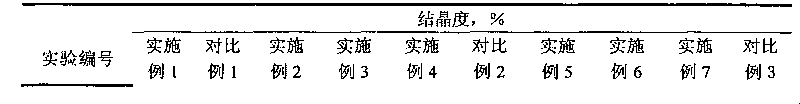

ActiveCN1785807ALow costReduce manufacturing costFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

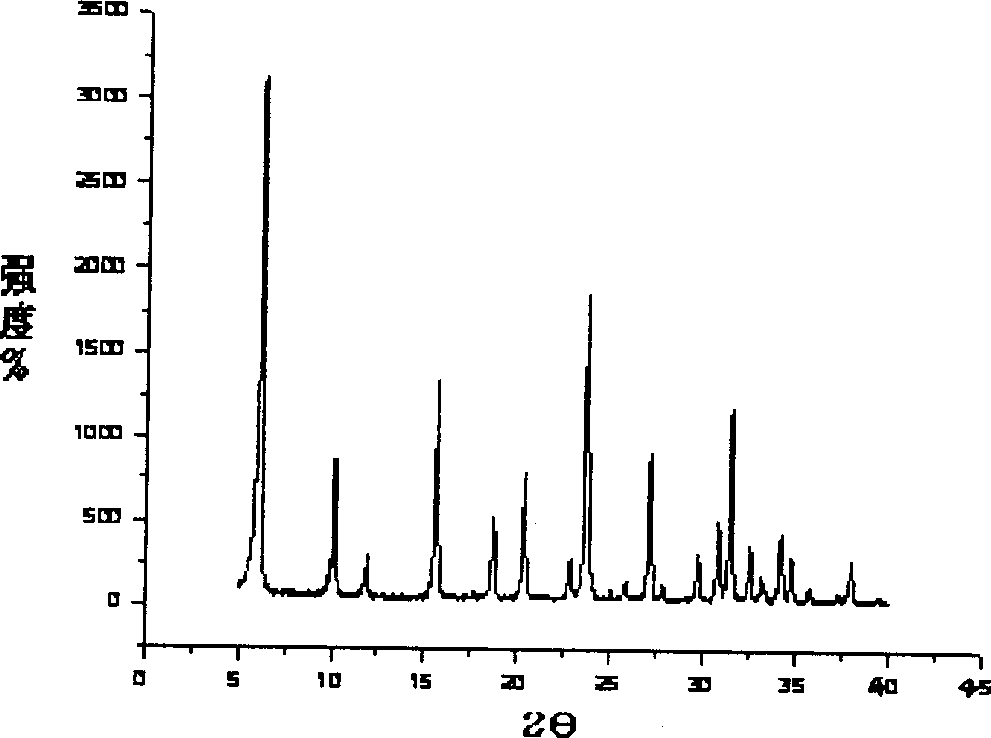

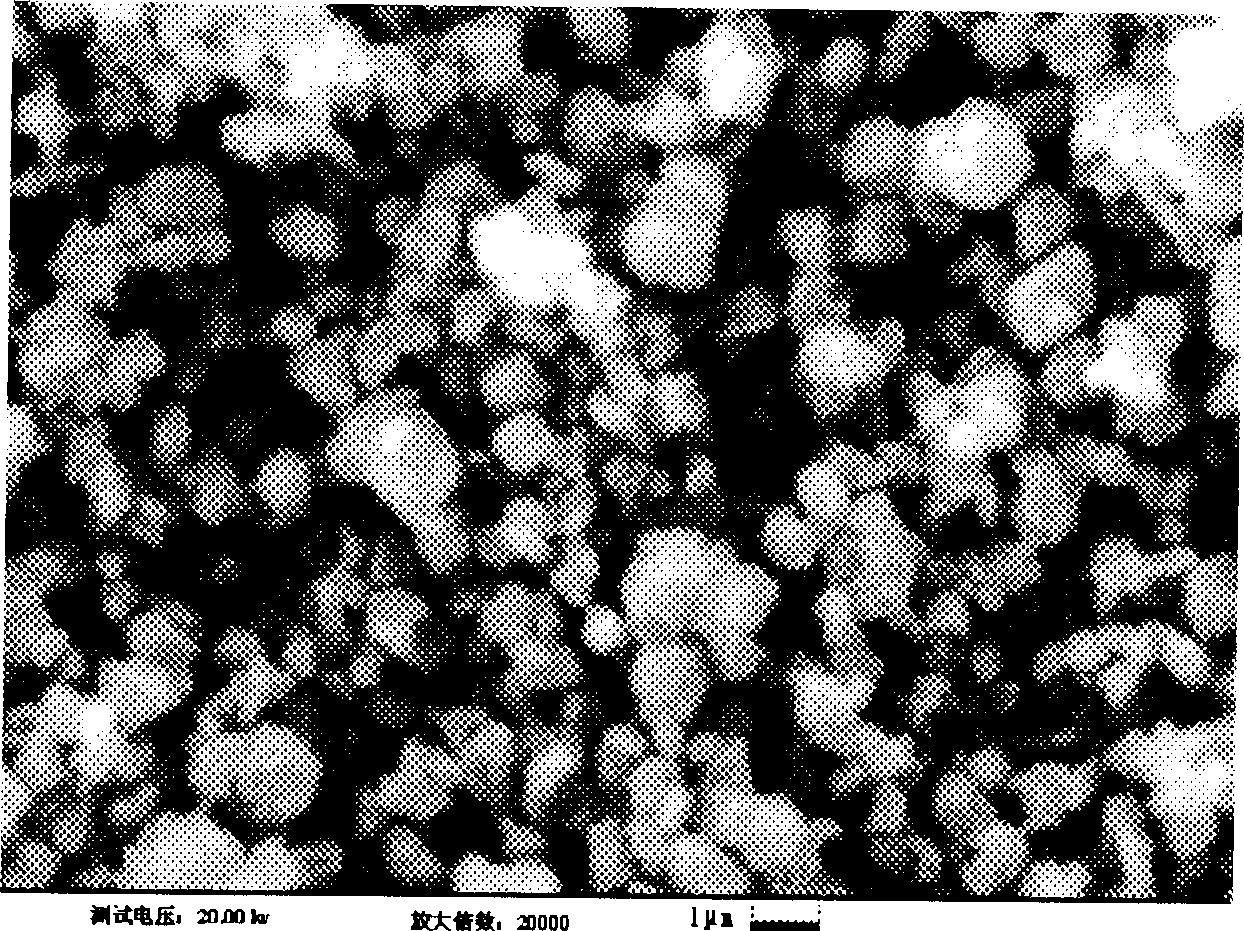

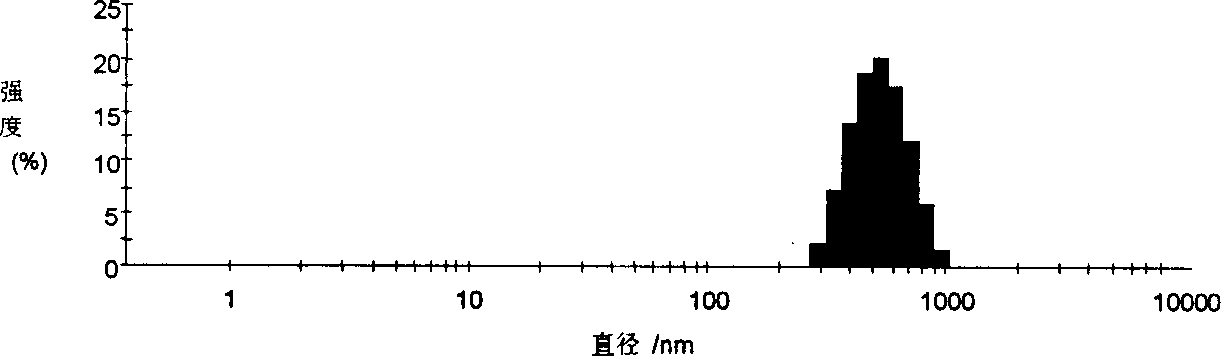

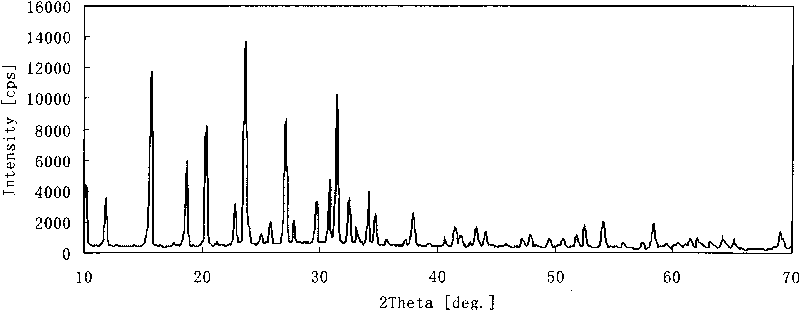

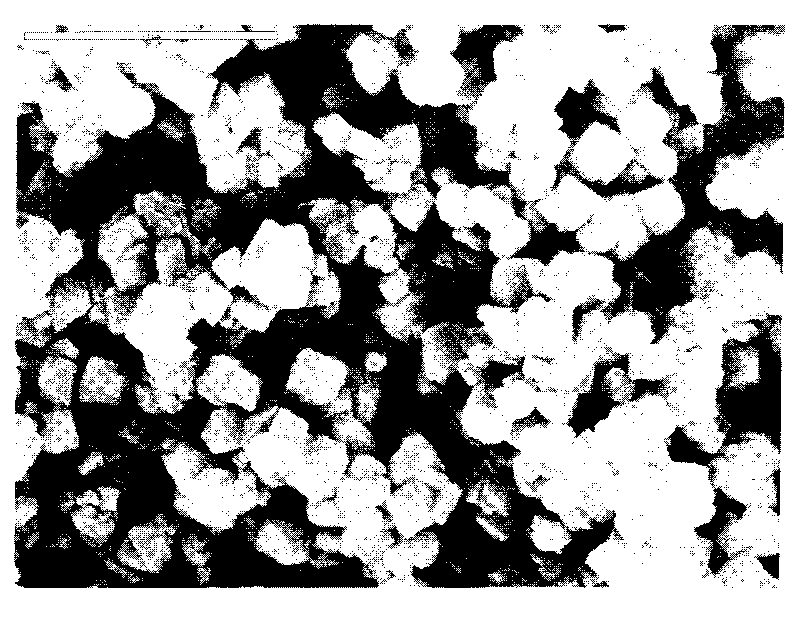

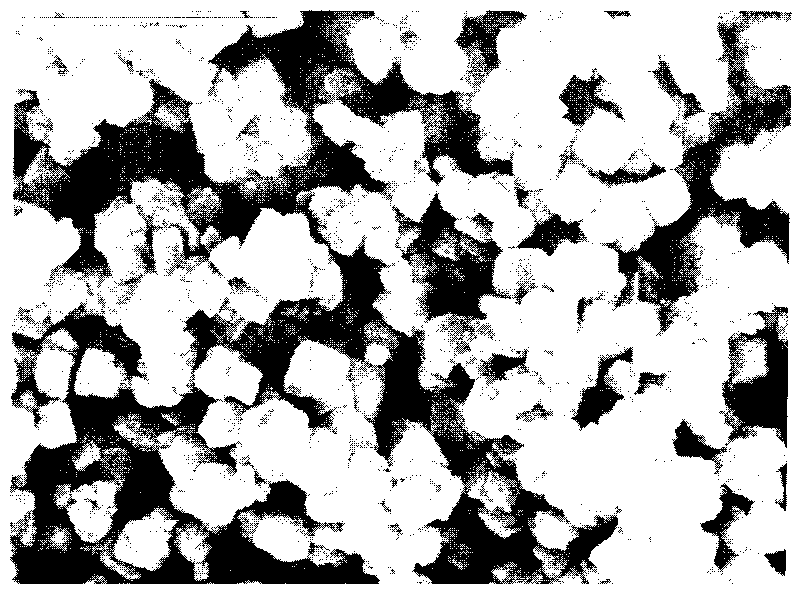

The present invention provides a high silica-alumina ratio small crystal grain NaY molecular sieve. The skeleton silica-alumina ratio of NaY molecular sieve, namely. SiO2 / Al2O3 mole ratio is 6.0-7.0, and the average grain size is 300-800 nm. It can be made up by adopting non-template agent direct synthesis process. Its preparation method includes the following steps: firstly, stirring and ageing for 0.5-48 hr at 15-60deg.C to obtain crystallization guide agent, then mixing said guide agent, water, silicon source and aluminium source to obtain reaction mixture, then crystallizing said mixture at twice, first steps is dynamic crystallization and second step is static crystallization, finally, filtering, washing and drying so as to obtain the invented high silica-alumina ratio small crystal grain NaY molecular sieve whose relative crystallinity is greater than 80%.

Owner:PETROCHINA CO LTD +1

Modified octahedral zeolite and hydrocarbon cracking catalyst containing the octahedral zeolite

InactiveCN1436727ASimple processReduce manufacturing costCatalytic crackingFaujasite aluminosilicate zeoliteAmmonium compoundsRare earth

The modified octahedral zeolite is prepared through the once exchange reaction of octahedral zeolite, phosphorus compound and ammonium compound, the further reaction inside exchange slurry with introduced RE solution, filtering, washing and roasting in vapor. The catalyst contains the modified octahedral zeolite 5-45 wt%, clay 15-85 wt% and heat resistant inorganic oxide 15-85 wt%. The catalyst is prepared through mixing the zeolite component, clay and the precursor of the heat resistant inorganic oxide, spraying to form and washing. The catalyst has high activity stability, high gasoline yield, low coke yield, strong heavy oil cracking capacity and high heavy metal pollution resistance.

Owner:PETROCHINA CO LTD

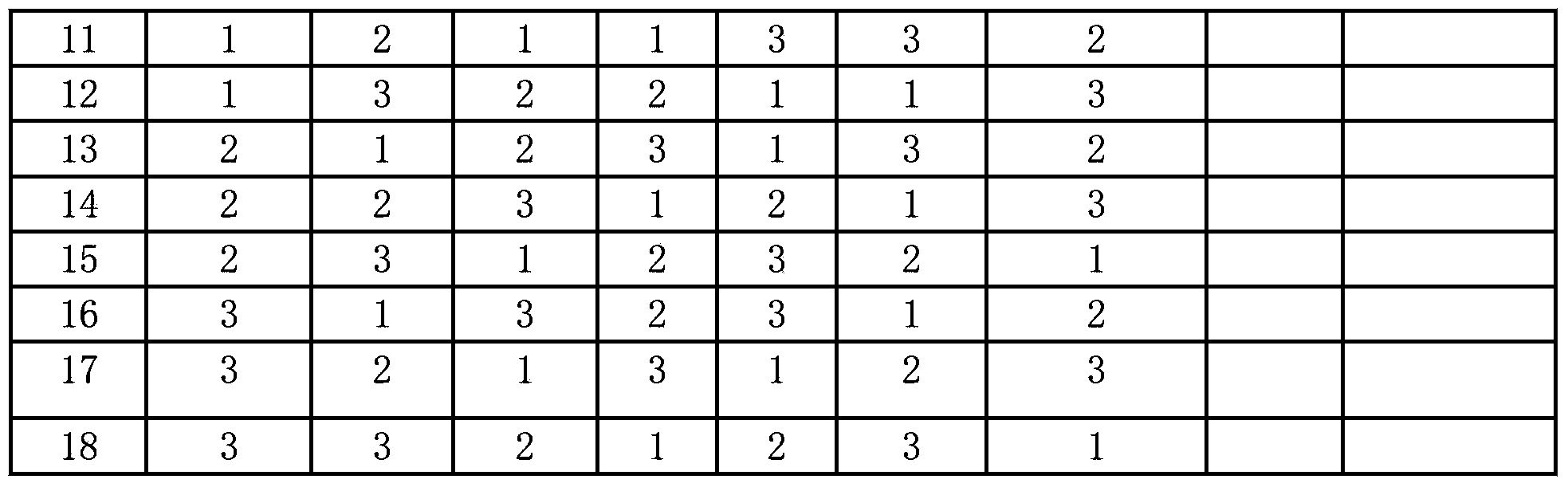

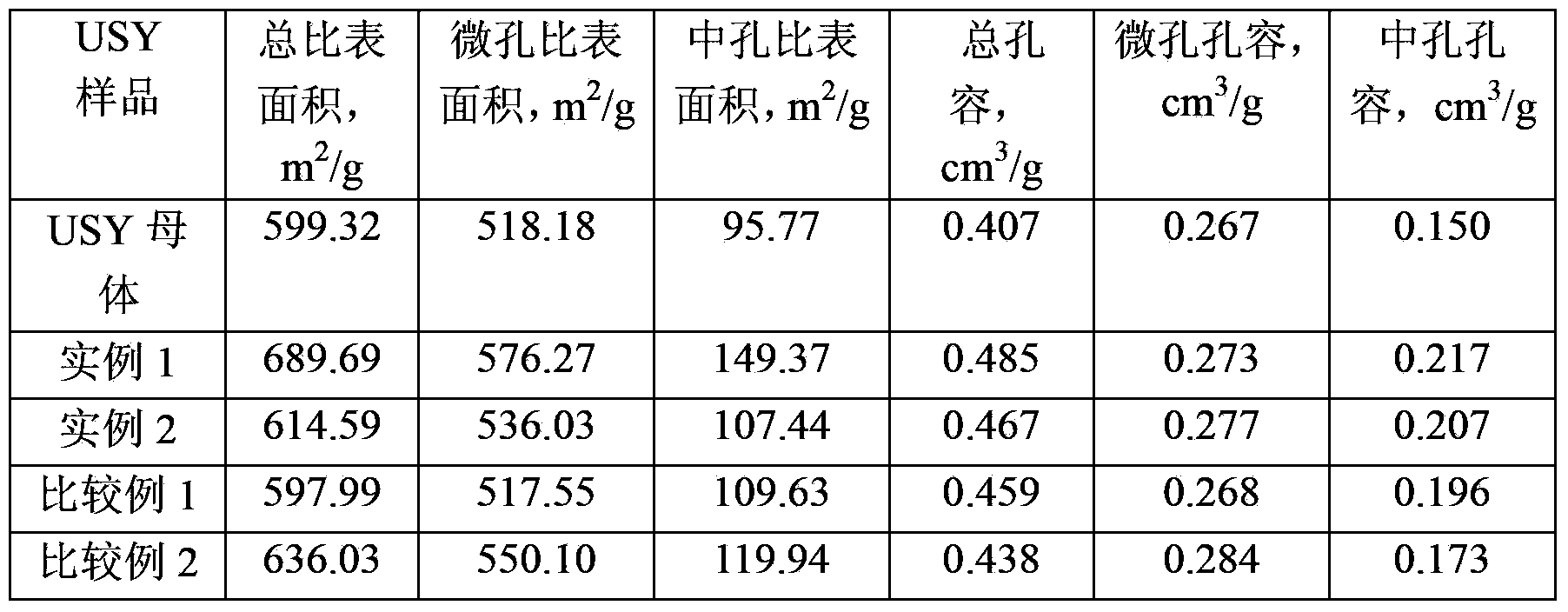

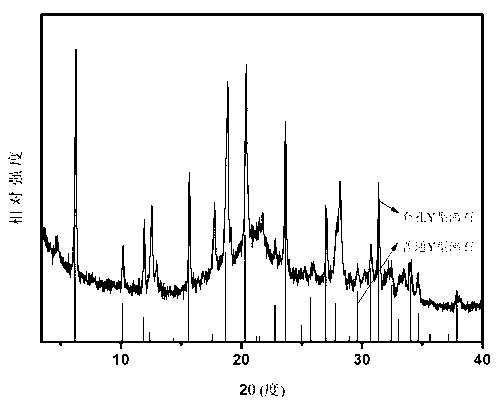

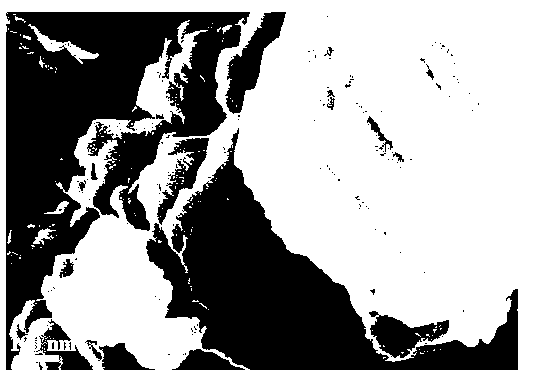

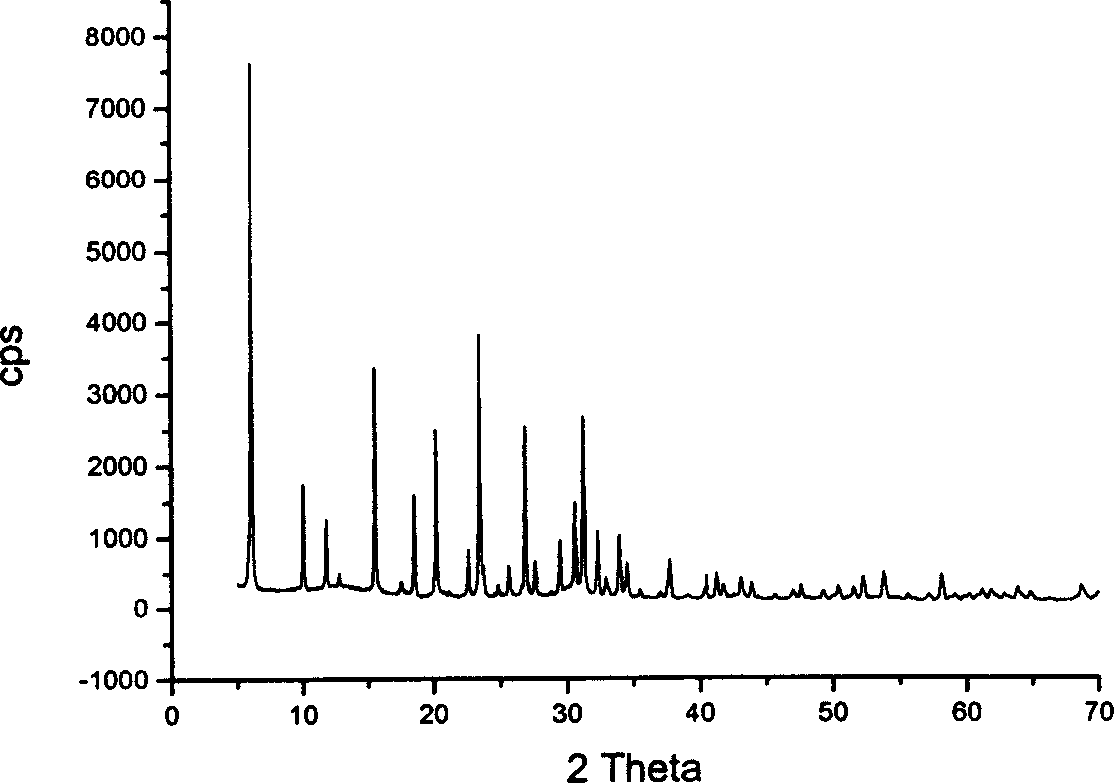

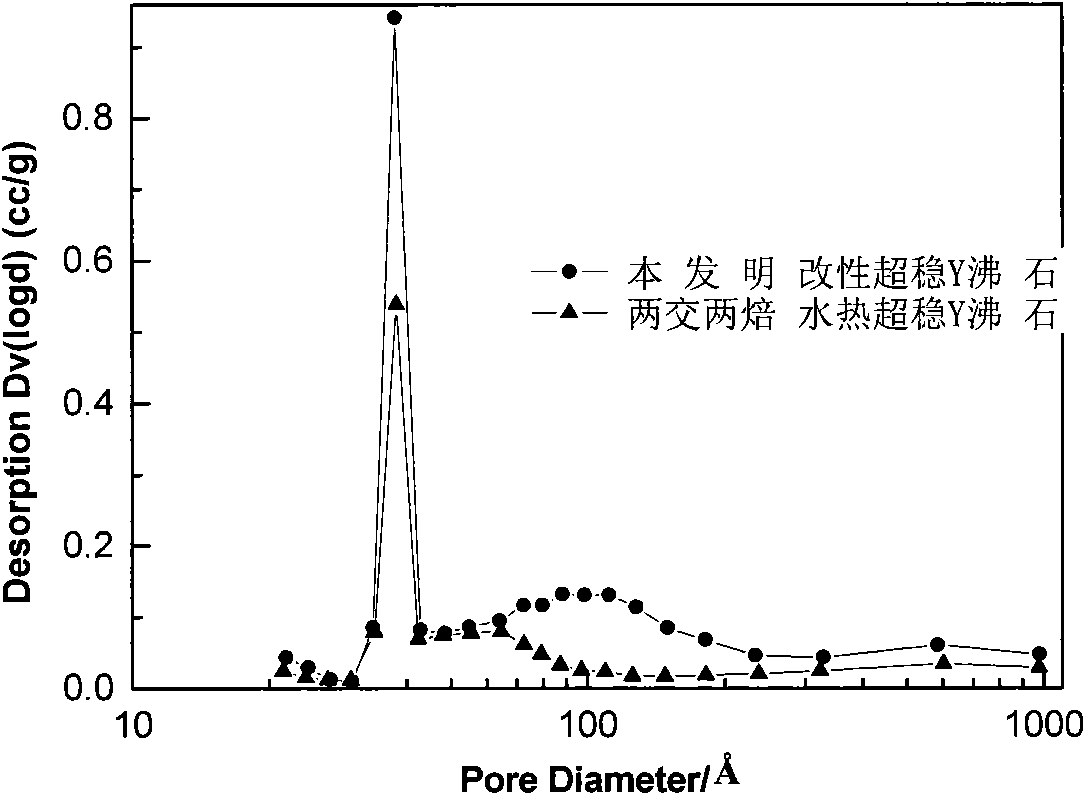

Method for modifying mesoporous-rich USY (Ultra-Stable Y) molecular sieve in combined manner

InactiveCN104229823ASmall cell constantIncreased secondary pore contentFaujasite aluminosilicate zeoliteInorganic saltsMolecular sieve

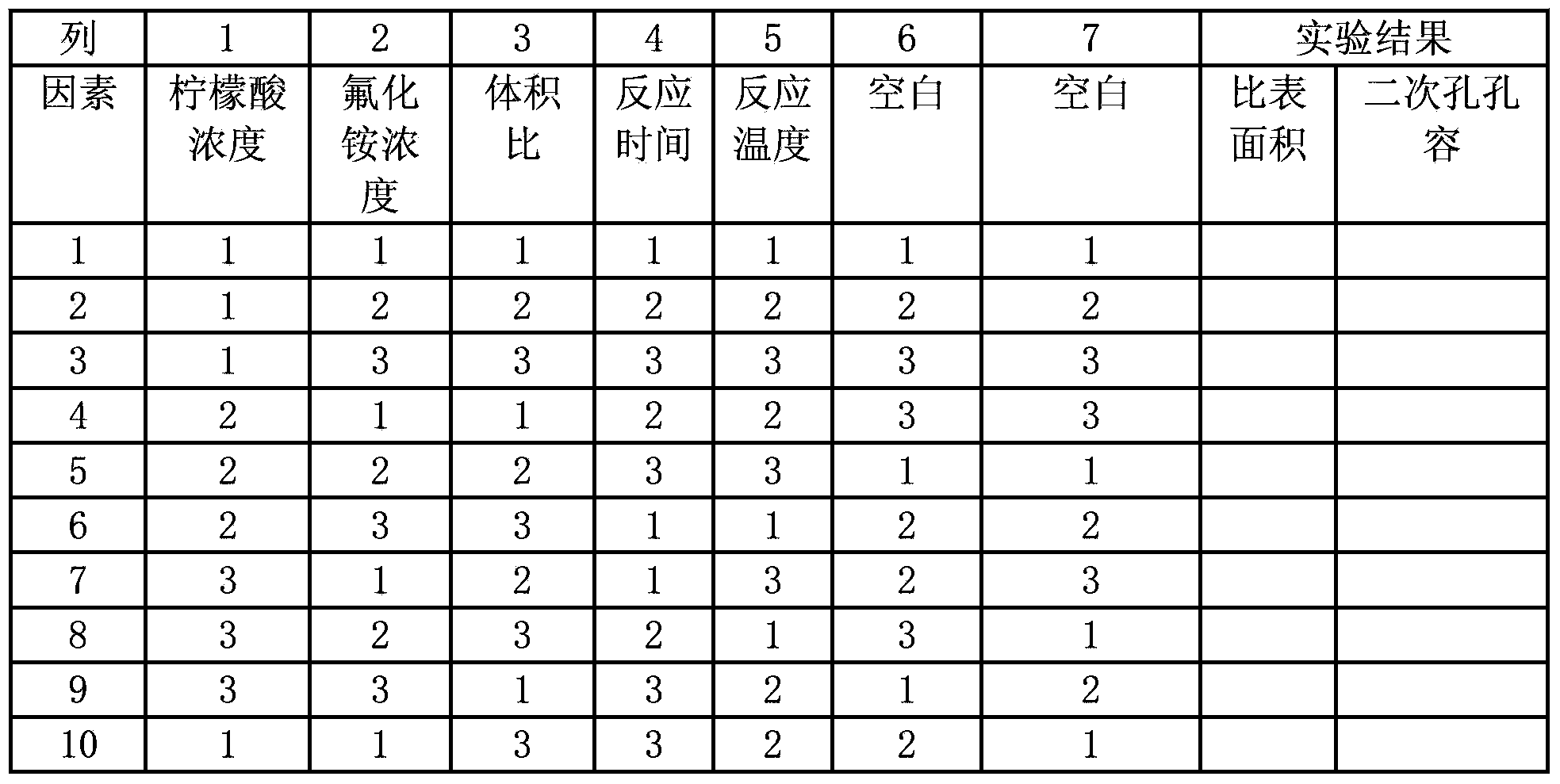

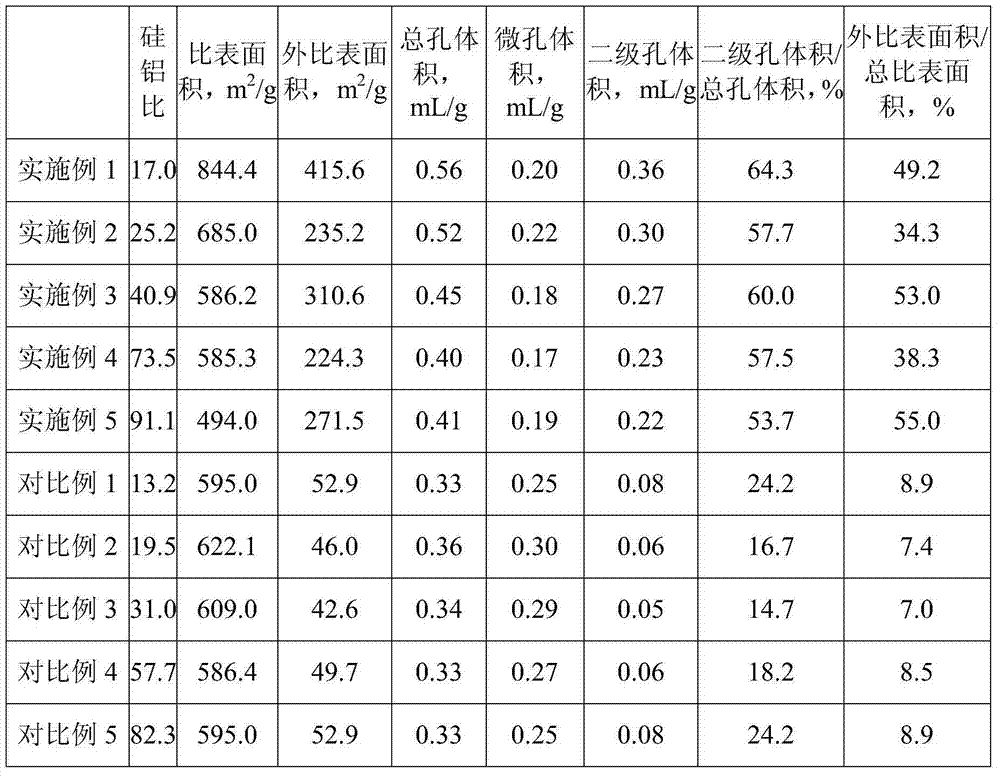

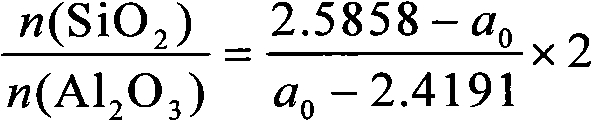

The invention relates to a method for modifying a USY (Ultra-Stable Y) molecular sieve. The method is characterized in that organic acid and an inorganic salt dealuminizing reagent are simultaneously added in a modifying process for organic acid-inorganic salt combined modification, and optimum process conditions, namely optimum concentration, volume ratio, reaction time, reaction temperature and the like, of an organic acid and an inorganic salt solution are determined by virtue of an orthogonal test. Compared with an industrial USY molecular sieve, the USY molecular sieve obtained by adopting the method disclosed by the invention is obviously increased in secondary pore content, can be kept at higher crystallinity and is enhanced in silica-alumina ratio, reduced in lattice constant and suitable for high-medium oil type hydrocracking catalyst carriers.

Owner:PETROCHINA CO LTD +1

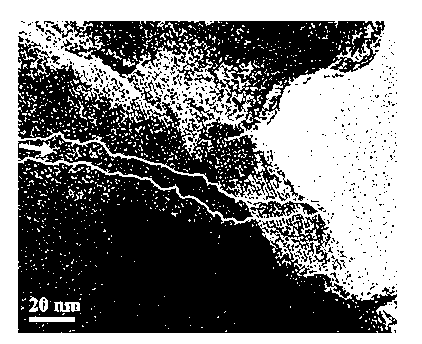

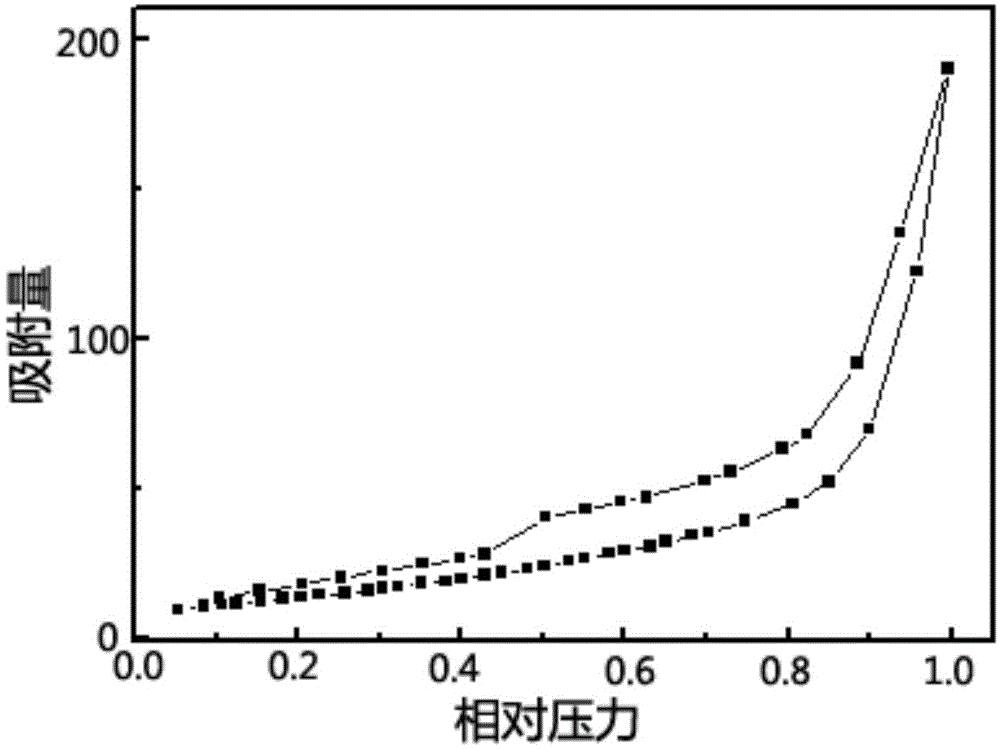

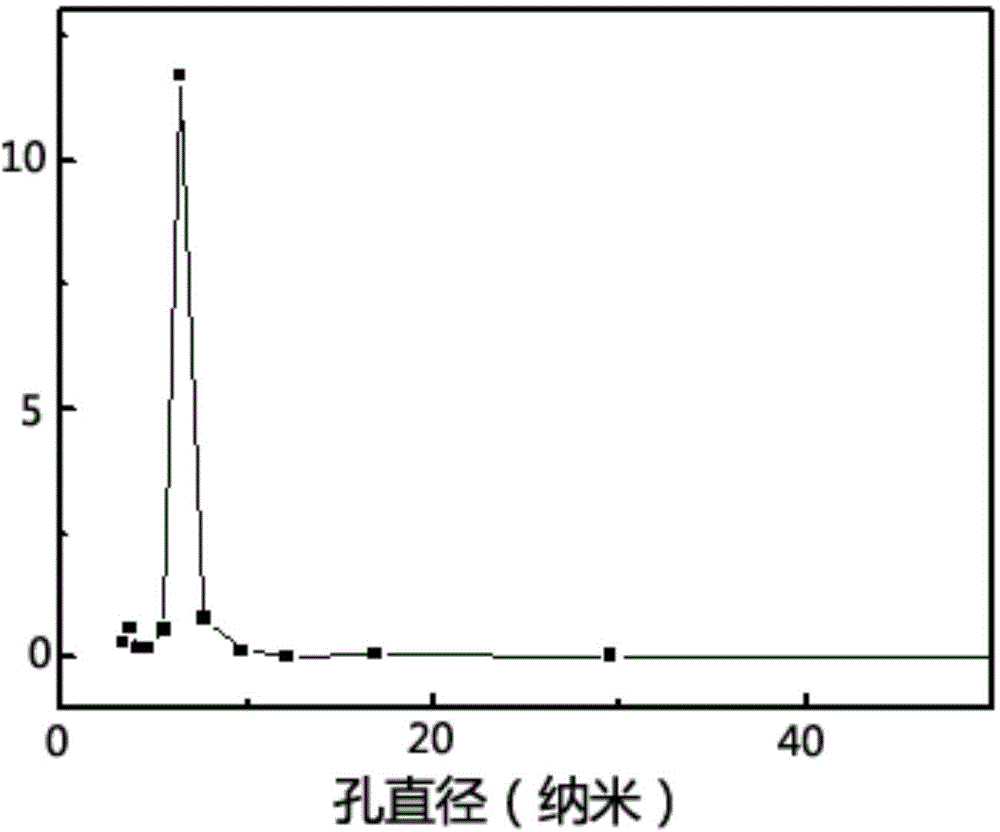

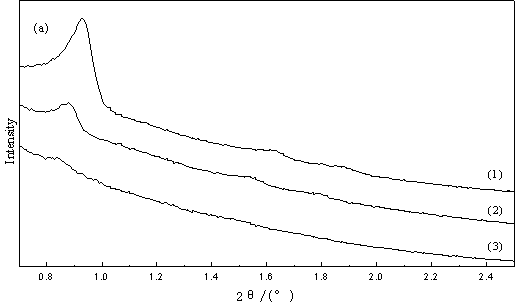

Mesoporous Y-type zeolite molecular sieve and preparation method thereof

InactiveCN103214003APlay a structural roleLow costFaujasite aluminosilicate zeoliteMolecular sieveSilanes

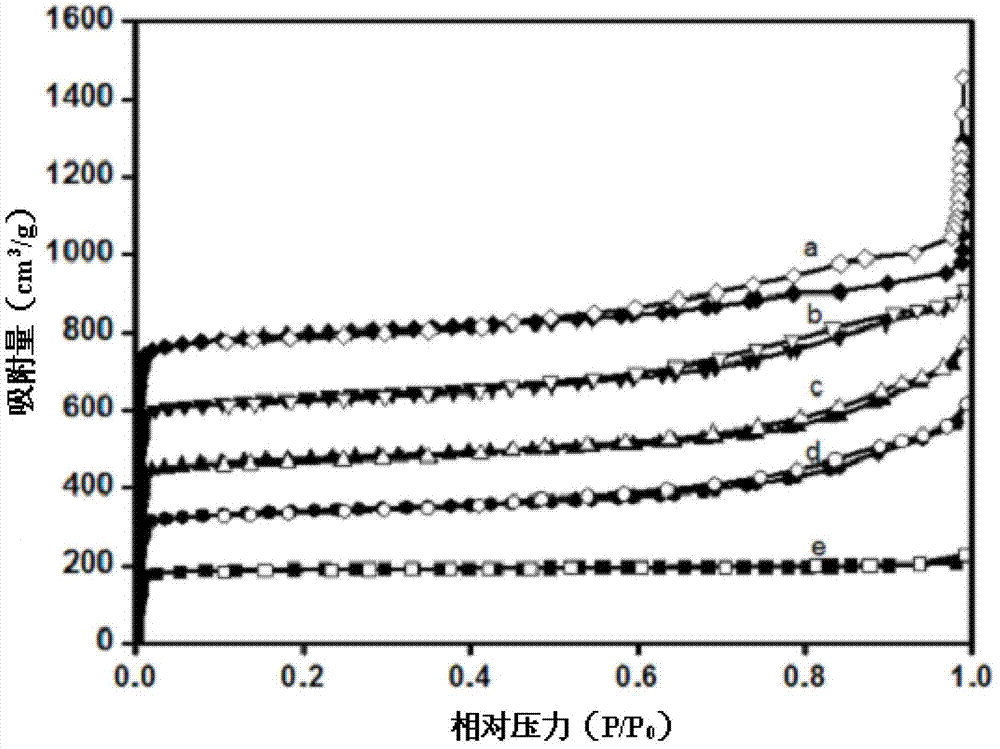

The invention discloses a mesoporous Y-type zeolite molecular sieve and a preparation method thereof. The preparation method comprises the following steps of: firstly preparing a Y-type zeolite guiding agent; and then guiding synthesis of the mesoporous Y-type zeolite molecular sieve by using amphiphilic organosilane N,N-dimethyl-N-[3-(trimethoxysilane)propyl]octadecyl ammonium chloride (TPOAC) as a mesoporous template, wherein siloxane group at the organosilane terminal is firstly hydrolyzed into silicon hydroxyl; then the silicon hydroxyl is linked to a skeleton on the zeolite surface through chemical bonds; and other alkyl terminals are polymerized and then participate in pore expansion. According to the method disclosed by the invention, mesoporous zeolites can be synthesized by using a one-step hydrothermal process; the method is simple in preparation process, easy to operate and low in cost and good in connectivity between mesopores and micropores, and facilitates macromolecular diffusion. As the prepared mesoporous zeolite molecular sieve has the mesopores and the micropores, the defect of a single pore structure is avoided; and the mesoporous Y-type zeolite molecular sieve has broad application prospect in the catalytic field, in particular in macromolecular diffusion-limited reaction.

Owner:SOUTH CHINA UNIV OF TECH

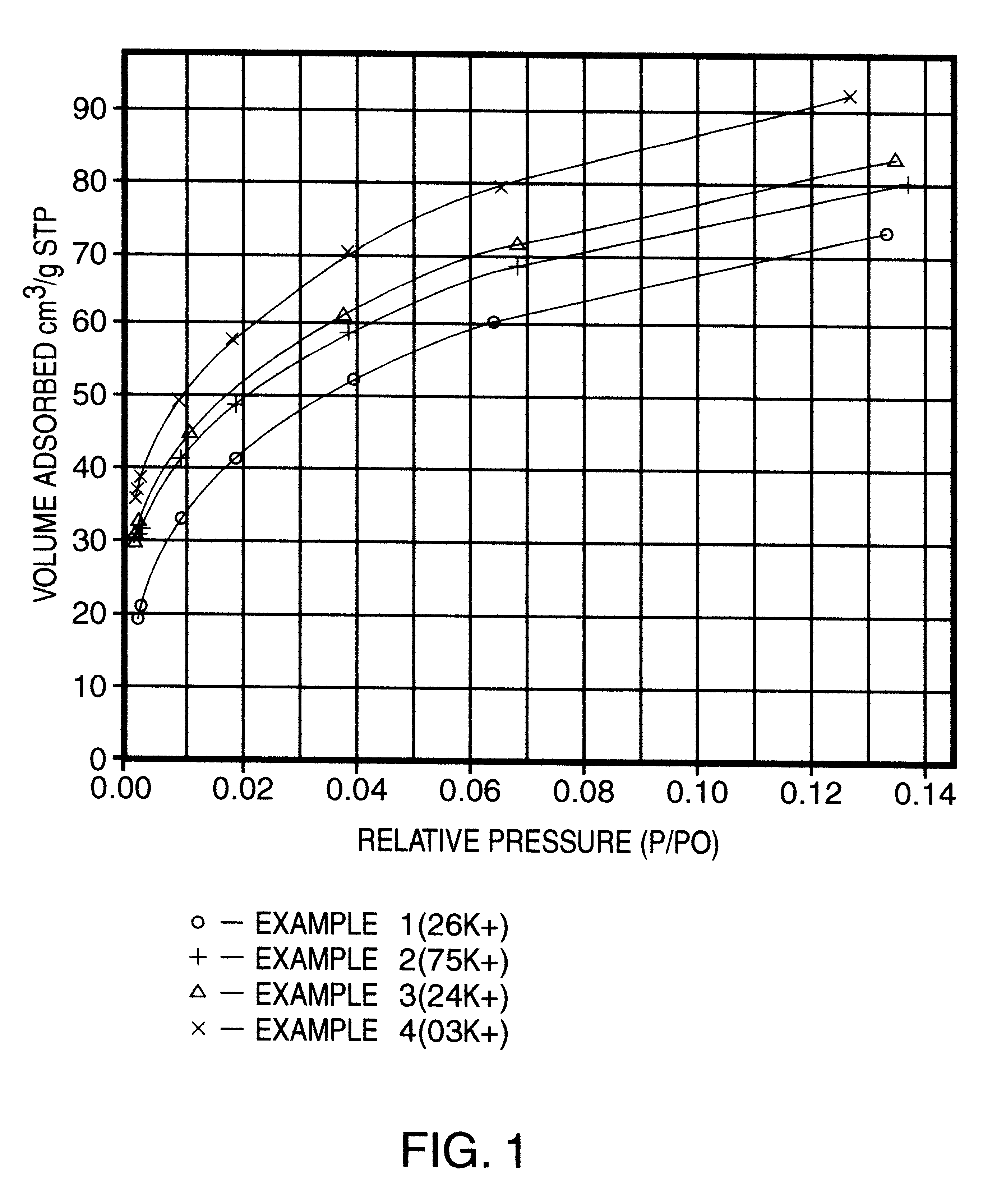

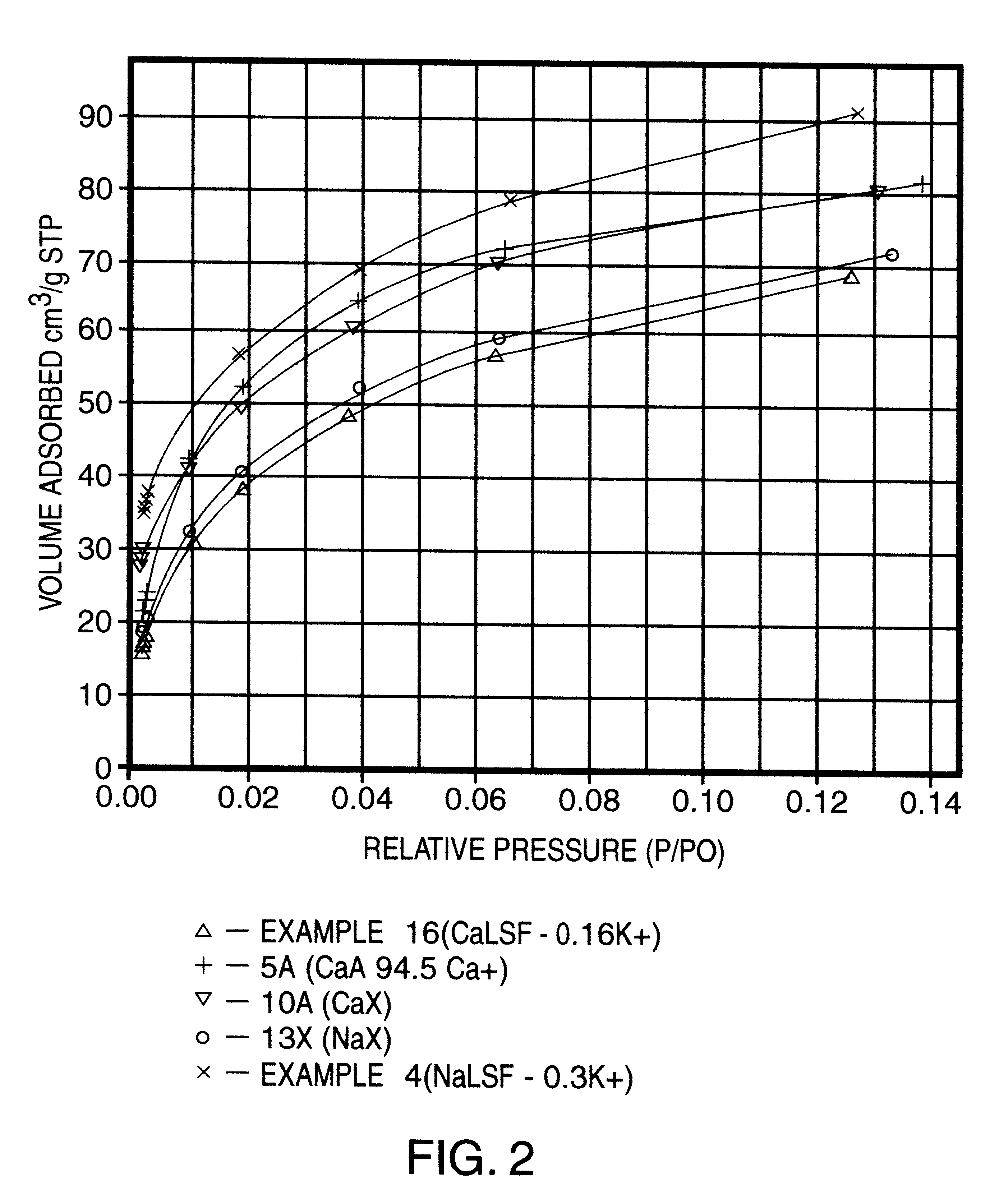

Molecular sieve adsorbent for gas purification and preparation thereof

InactiveUS6183539B1Reduce resistanceImprove adsorption capacityMolecular sieve catalystsOther chemical processesMolecular sieveWater vapor

A molecular sieve adsorbent for the purification of gas streams containing water vapor and carbon dioxide and a process for its preparation. The adsorbent is a sodium form of a low-silica faujasite having a silica to alumina ratio of about 1.8:1 to about 2.2:1, a residual content of potassium ions less than about 8.0 percent (equiv.), a low content of crystalline and amorphous admixtures and crystal sizes generally within the range of 1-4 mum, blended with a binder.

Owner:ZEOCHEM LLC

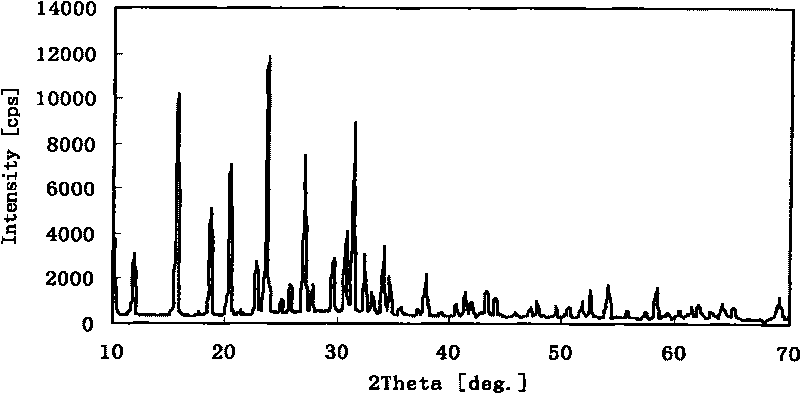

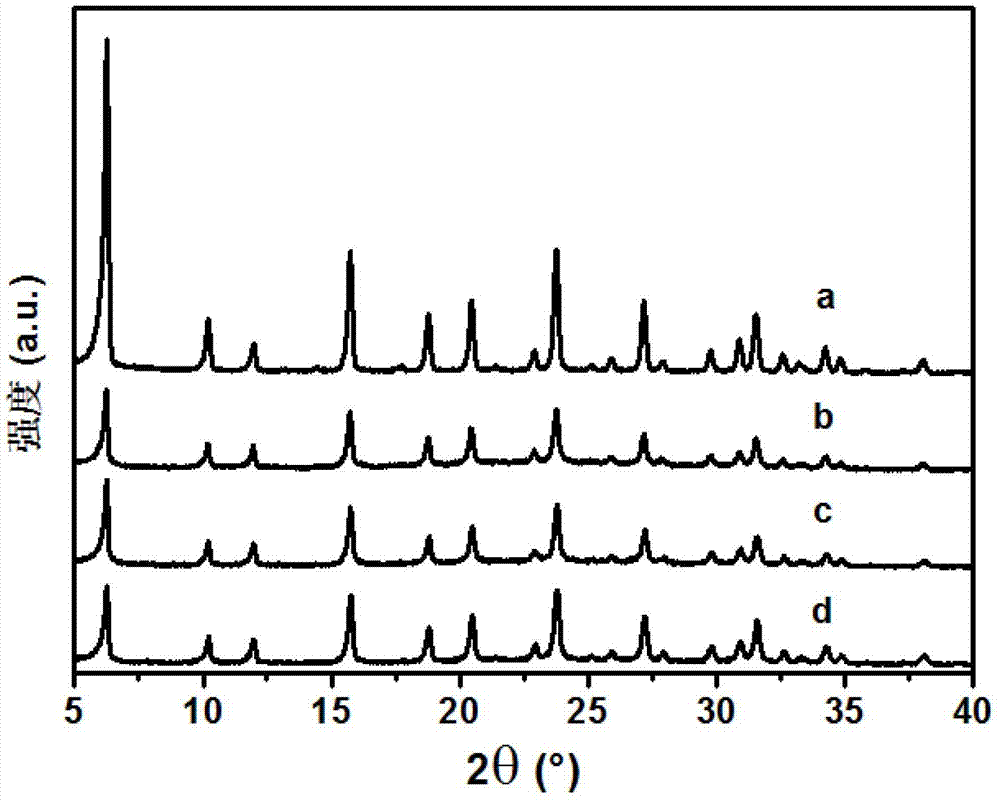

NaY-type molecular sieves and preparation method thereof

ActiveCN101722023AOrderly formationOrderly and stableMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveThermal stability

The invention discloses microcrystal NaY-type molecular sieves and a preparation method thereof. In the microcrystal NaY-type molecular sieves, the molar ratio of SiO2 to Al2O3 is 4.0 to 6.0, and the average particle size is 100 to 700 nanometers. The microcrystal NaY-type molecular sieves are prepared by a method combining low-temperature synthesis directing agent, low-temperature synthesis gel and two-stage variable-temperature dynamic crystallization. The NaY-type molecular sieves have a relative crystallinity of over 80 percent after being roasted in the air at 600 DEG C for 3 hours or after undergoing hydrothermal treatment with vapor at 650 DEG C for 1 hour, as well as high thermostability and hydrothermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

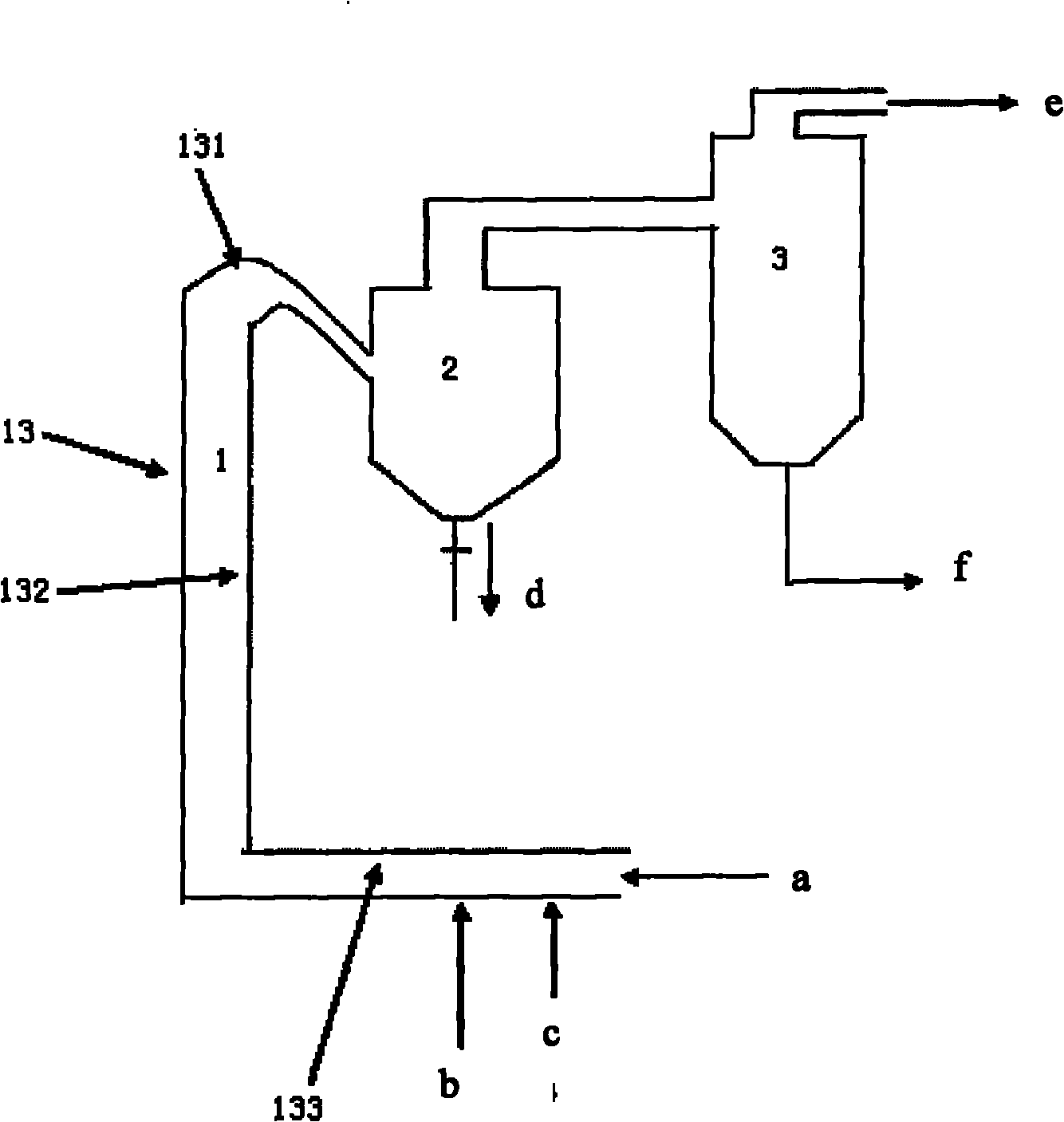

Prepn process of hyperastable Y-type RE molecular sieve

InactiveCN1436728AExcellent anti-vanadium effectMolecular sieve catalystsFaujasite aluminosilicate zeoliteRare earthHigh activity

The present invention relates to the preparation of hyperstable Y-type RE molecular sieve for the catalytic cracking of heavy oil and containnig vanadium resisting component. The preparation uses NaY-type molecular sieve as main material and chemical aluminum-eliminating complex containing oxalic acid and / or oxalate and its mixture and through introducing RE ion in the late stage of chemical aluminum elimination reaction to from RE precipitate and hydrothermal treatment to realize hyperstabilizing and introduce RE ion and independent phase Re oxide. The formed precipitate RE precursor includes RE oxalate. Compared with conventional REY, REHY and REUSY, the molecular sieve preparing process is simple and high in RE utilization, and has homogeneously distributed aluminum, more secondary pores high hydrothermal stability, high activity and high vanadium contamination resisting capacity.

Owner:PETROCHINA CO LTD

Small crystal particle Y-shaped molecular sieve and preparation method thereof

ActiveCN101759198AReduce pollutionEasy to makeFaujasite aluminosilicate zeoliteAmmonium fluorosilicateOxygen

The invention discloses a small crystal particle Y-shaped molecular sieve and a preparation method thereof. The property of the small crystal particle Y-shaped molecular sieve is as follows: the molar ratio of Si, O2 / Al2O3 is 10.0-120.0, the cell parameters are 2.420-2.445 nm, the crystallization retention is larger than 95 percent, and B acid / L acid is above 7.0. Due to higher raw material thermal and hydrothermal stability, higher silicon-aluminum ratio, good stability and uniform framework silicon-aluminum structure, the small crystal particle NaY molecular sieve can ensure the framework continuity of the molecular sieve, reduce the collapse possibility of the framework structure and maximally keep the integrity of a silicon-aluminum-oxygen structure in the modification, namely in the ammonia exchange, ammonium fluorosilicate dealumination and silicon reinsertion, hydro-thermal treatment, aluminum salt and acid mixed water solution treatment process, thereby having high crystallization retention. The Y-shaped molecular sieve can be taken as an active component of a hydrocracking catalyst, thereby improving the activity of the catalyst, the selectivity of the molecular sieve and the product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

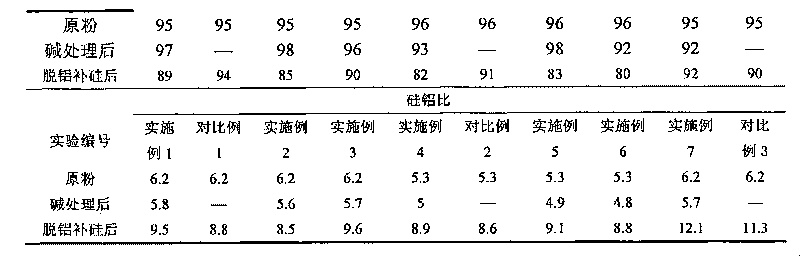

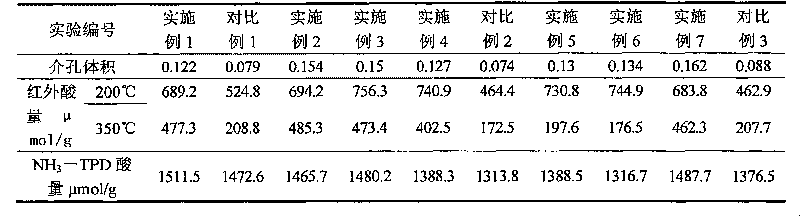

Preparation method of skeleton silicon-rich Y-shaped molecular sieve

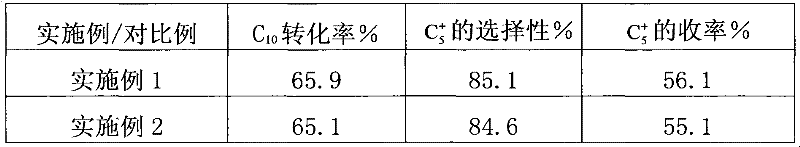

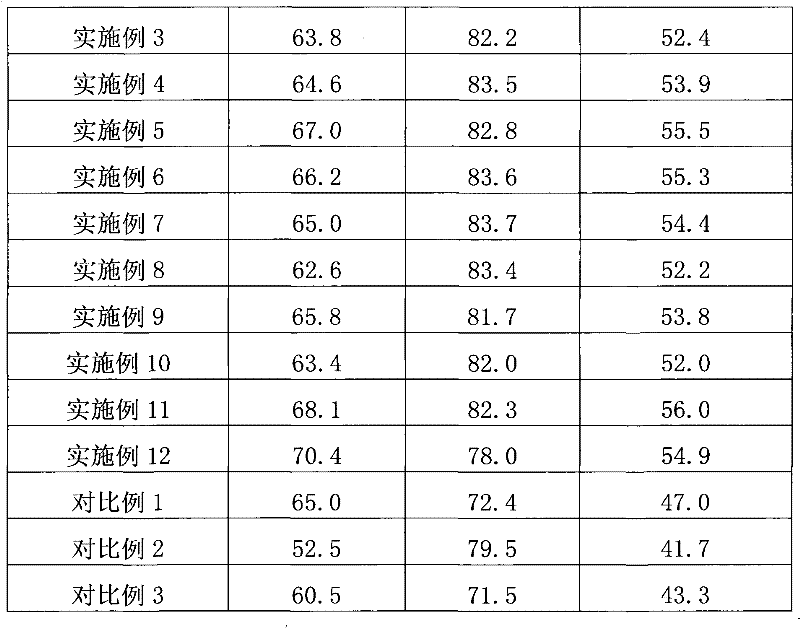

ActiveCN101723399AImprove effective apertureIncreased secondary pore contentFaujasite aluminosilicate zeoliteMolecular sieveActive component

The invention discloses a preparation method of a skeleton silicon-rich Y-shaped molecular sieve, comprising the following steps of: firstly, carrying out desiliconizing pretreatment on a NaY molecular sieve with alkali lye and secondly carrying out ammonium exchange and dealumination and silicon reinsertion on the molecular sieve treated with alkali. The alkali treatment condition is to pulp and evenly mix the NaY molecular sieve and an alkali liquor in the mass ratio of NaY (dry basis): alkali: H2O being (0.1-2): (0.05-2): (4-15) and carry out alkali treatment at 0-120 DEG C for 0.1-24h. Compared with a product obtained by carrying out ammonium exchange and silicon-rich treatment on the NaY molecular sieve, the skeleton silicon-rich Y-shaped molecular sieve subject to the desiliconizing pretreatment has higher infrared acid quantity, B acid quantity and secondary pore content. A catalyst prepared from an active component which is the skeleton silicon-rich Y-shaped molecular sieve prepared by the method has stronger heavy oil transformation capability and higher light oil recovery rate when being used for a heavy oil cracking reaction.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

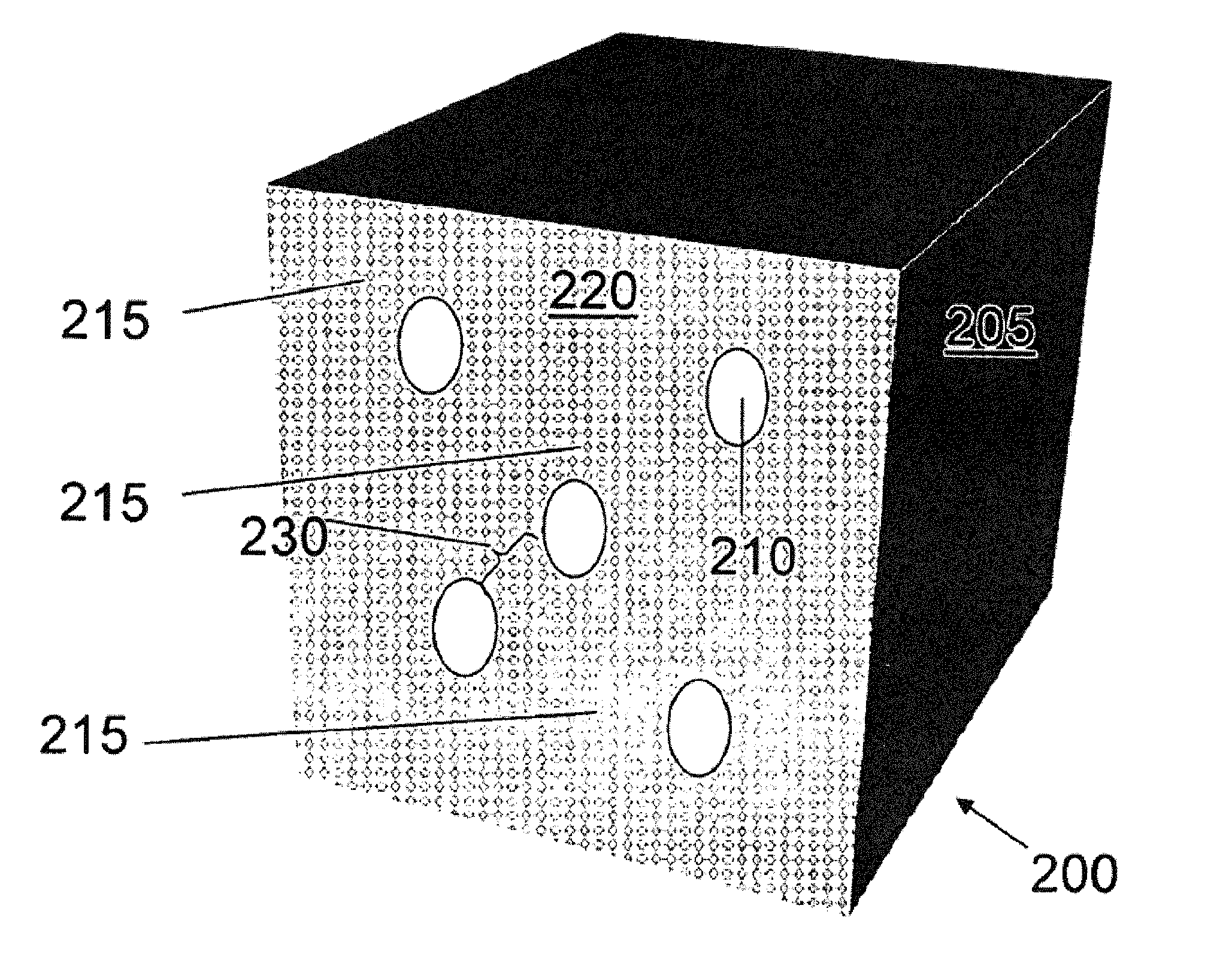

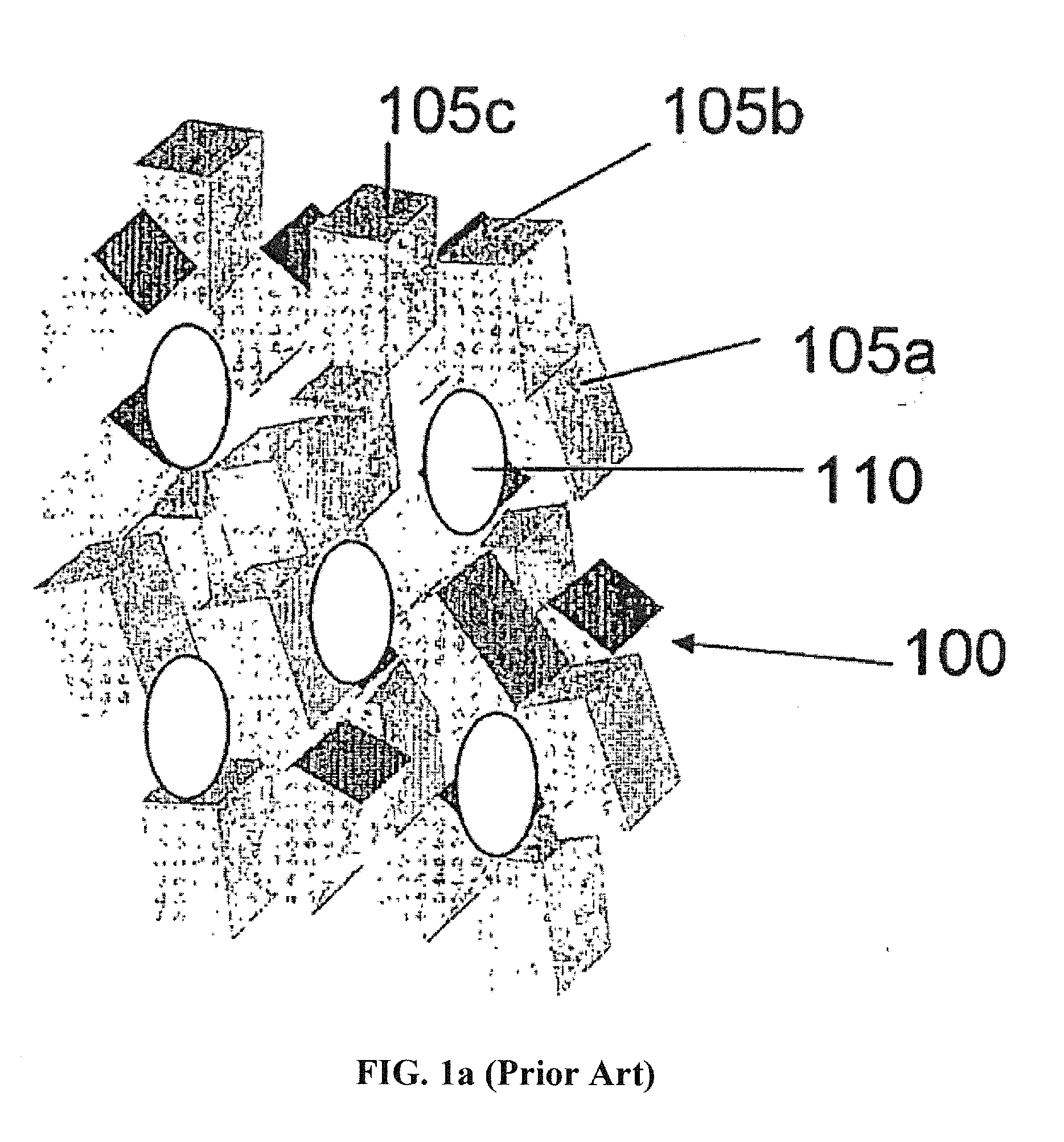

Compositions and methods for making stabilized mesoporous materials

InactiveUS20110171121A1Aluminium compoundsFaujasite aluminosilicate zeoliteMesoporous materialAmmonia

Compositions and methods for making stabilized mesoporous materials. Surfactant-treated mesoporous precursor materials can be heat-treated in the presence of steam and / or ammonia in a heat-treating environment. The steam and / or ammonia can be introduced into the heat-treating environment via in situ and / or ex situ sources. Such stabilized mesoporous materials can have increased structural stability.

Owner:RIVE TECH

Binderless zeolitic adsorbents, methods for producing binderless zeolitic adsorbents, and processes for adsorptive separation of para-xylene from mixed xylenes using the binderless zeolitic adsorbents

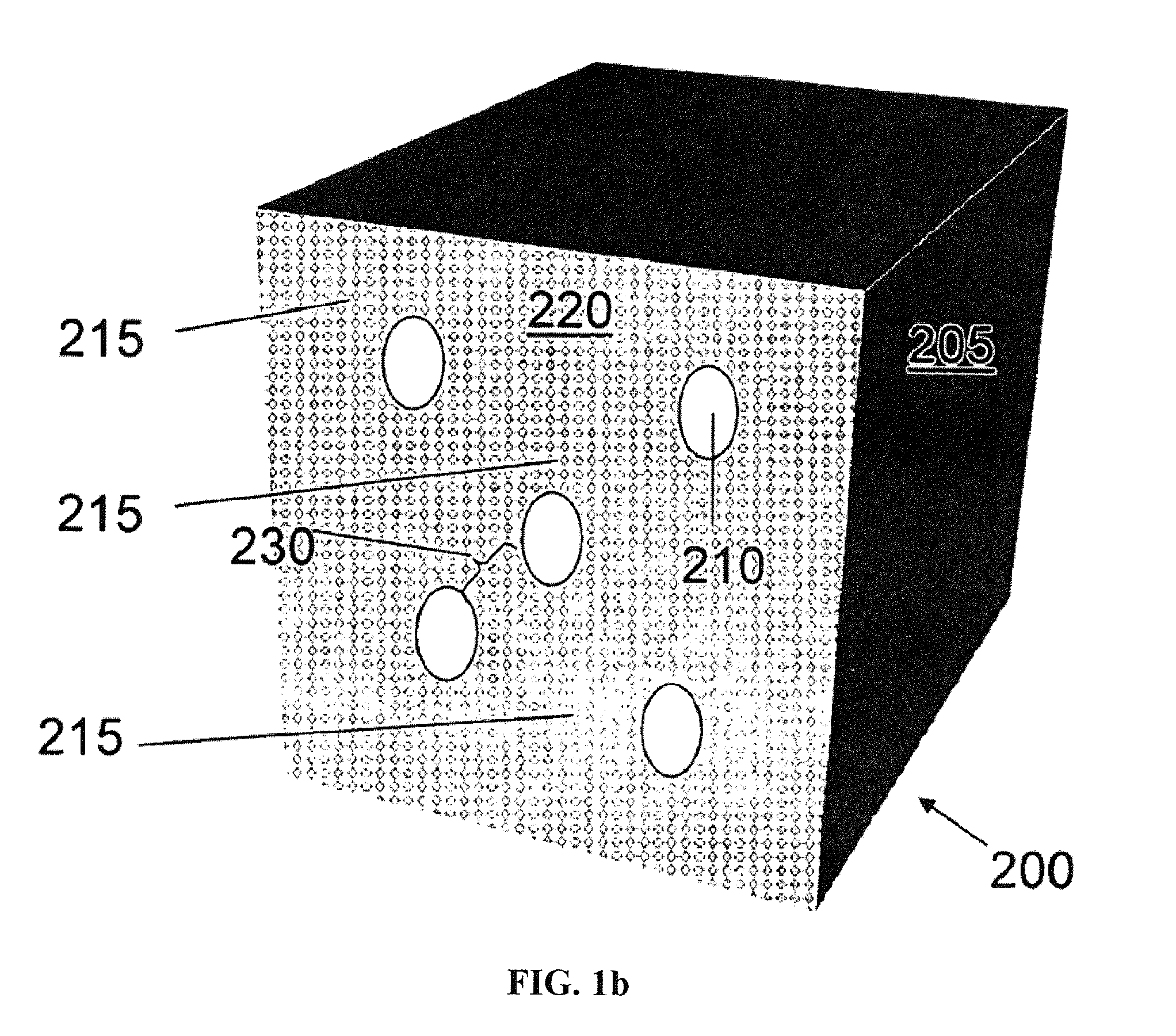

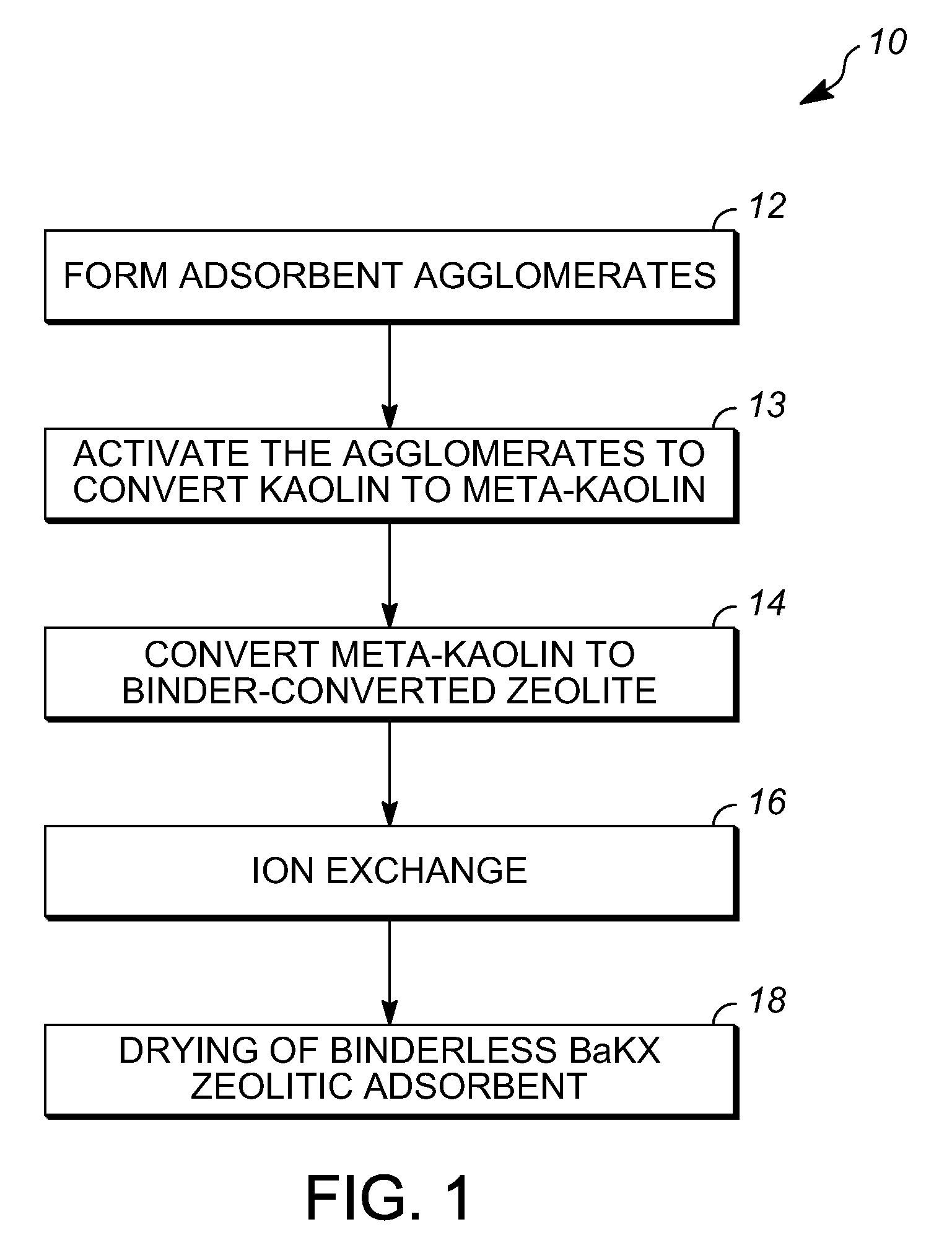

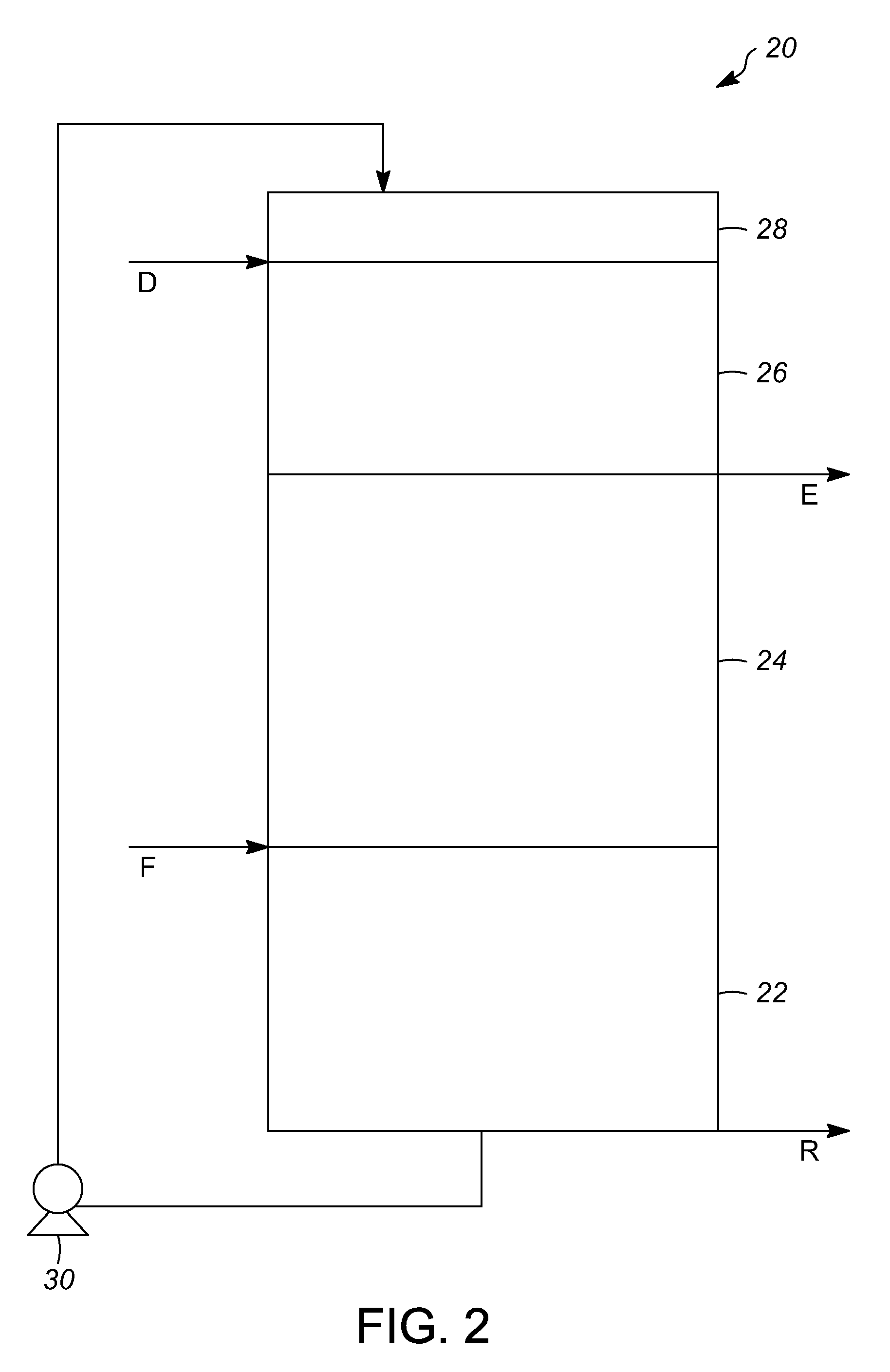

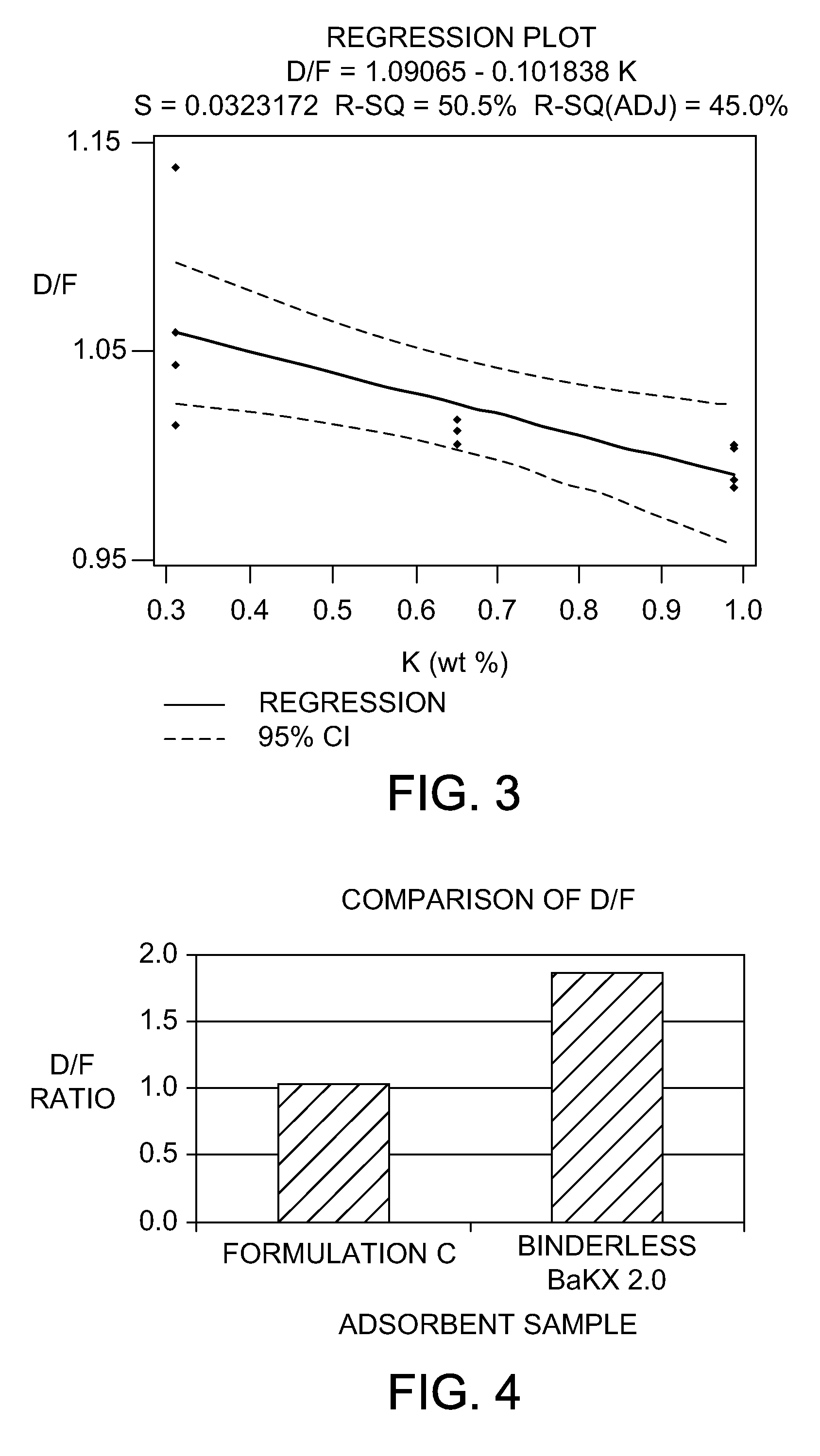

Binderless BaKX zeolitic adsorbents, methods for their production, and processes for their use in a liquid phase adsorptive separation process are provided. An adsorbent includes a binder-converted zeolite portion formed from x wt % kaolin clay binder and (100-x) wt % unconverted Zeolite X with a silica:alumina molar ratio of about 2.5. The kaolin clay binder is in the range of about 10 to about 20 wt %. Ba and K occupy cationic exchangeable sites within the adsorbent. K is in the range of about 0.25 to about 0.9% by weight and Ba is greater than about 31.6% by weight of the binderless BaKX zeolitic adsorbent. Cornstarch may be added to the Zeolite X and kaolin clay binder to increase adsorbent macro-porosity and pore volume. Productivity of the adsorbent is improved decreasing process operating costs. The mechanical strength of the adsorbent is also improved.

Owner:UOP LLC

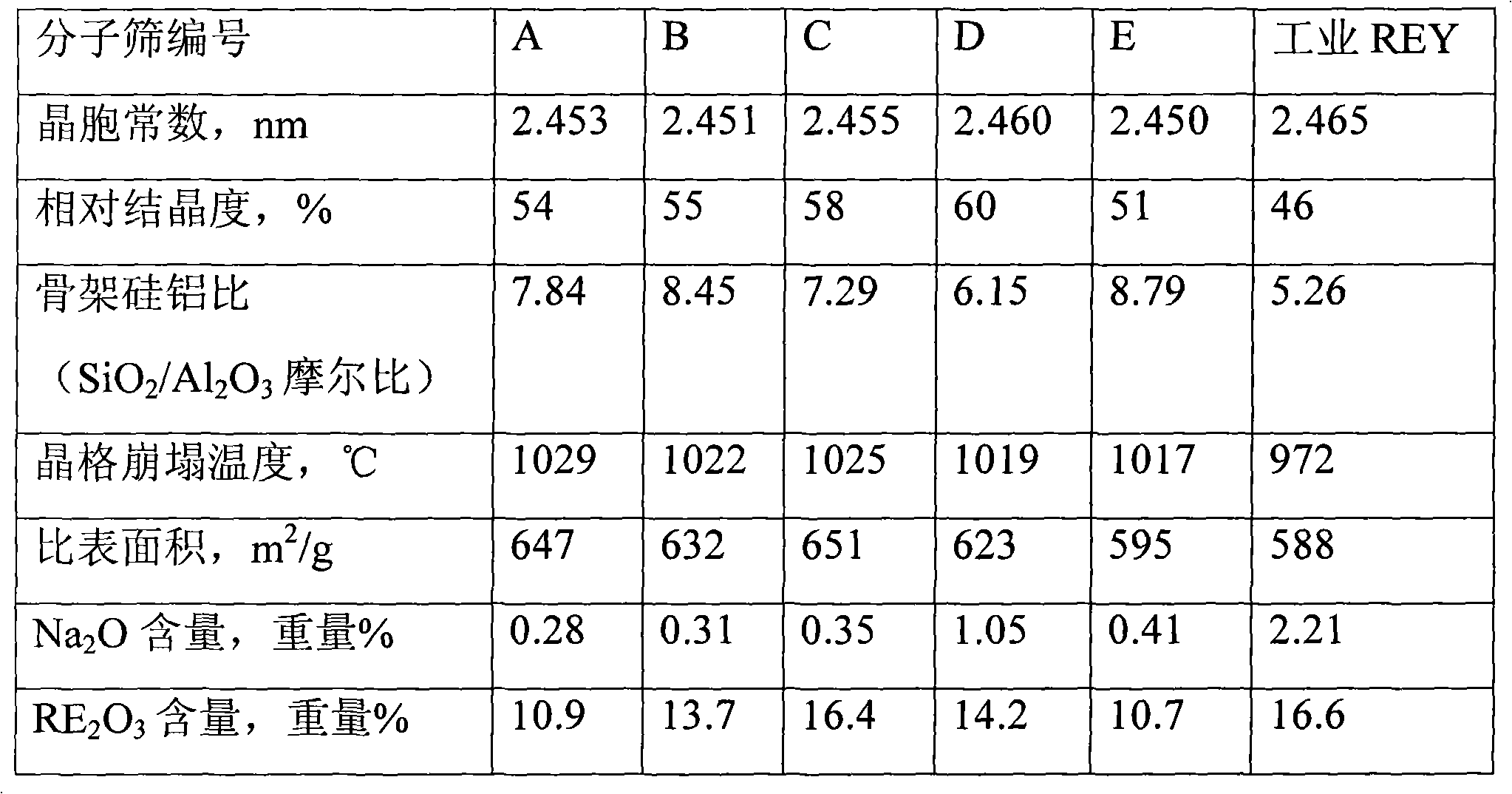

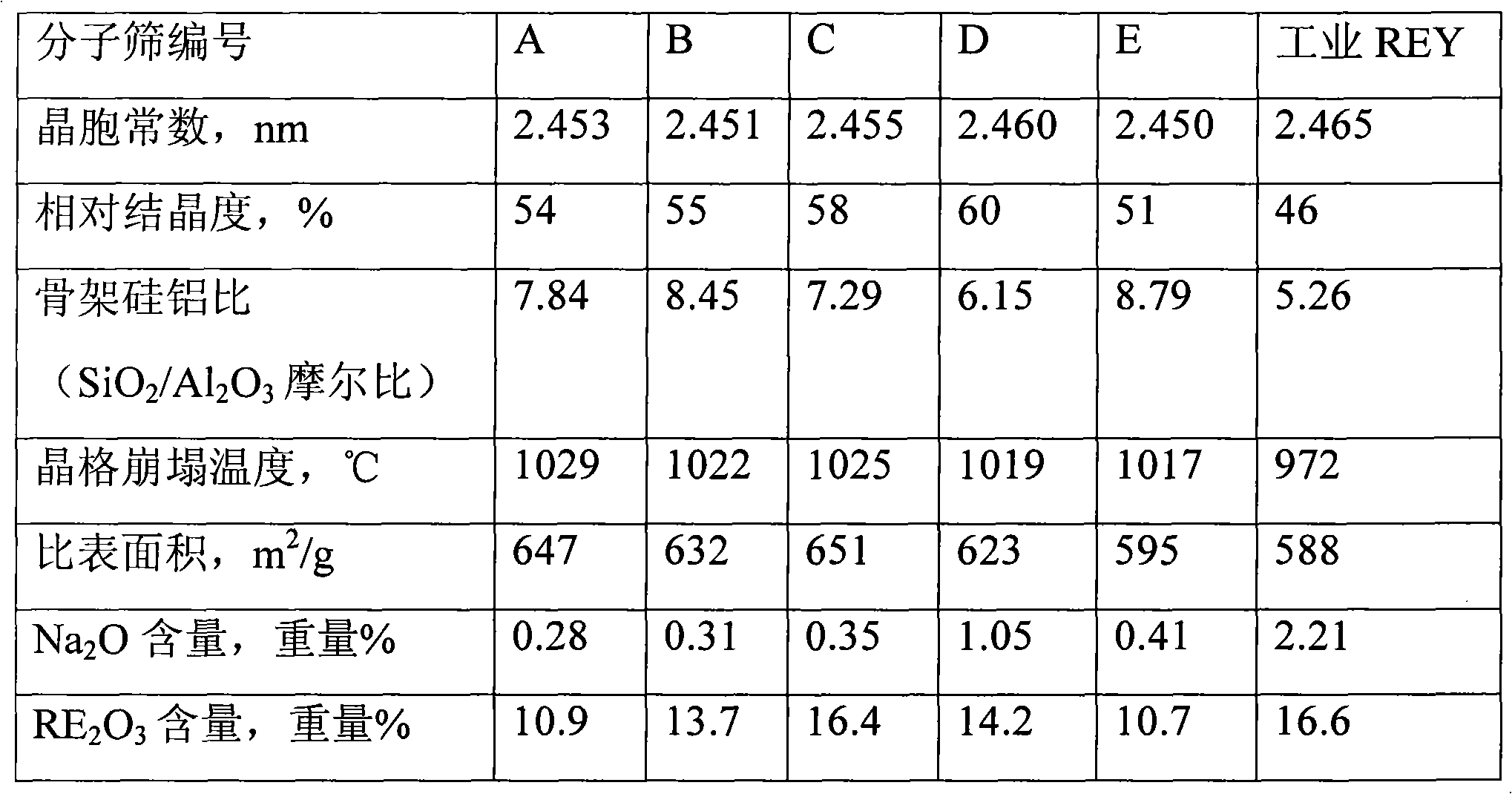

High silicon Y-type zeolite containing rare-earth and its preparing method

ActiveCN1281493CThe initial unit cell constant is smallThe equilibrium cell constant is largeFaujasite aluminosilicate zeoliteGasolineRare earth

A rare-earth-containing high-silicon Y-type zeolite, the zeolite contains rare earths, is characterized in that the silicon-aluminum ratio of the zeolite is 5-30, the initial unit cell constant is 2.430-2.465 nanometers, and the balance unit cell constant and the initial unit cell constant The ratio is at least 0.985. The zeolite has the characteristics of small initial unit cell constant and large equilibrium unit cell constant. It has high structural stability and hydrothermal stability. The cracking catalyst containing this zeolite is not easy to deactivate. The choice of gasoline, diesel oil, dry gas and coke Good sex.

Owner:CHINA PETROLEUM & CHEM CORP +1

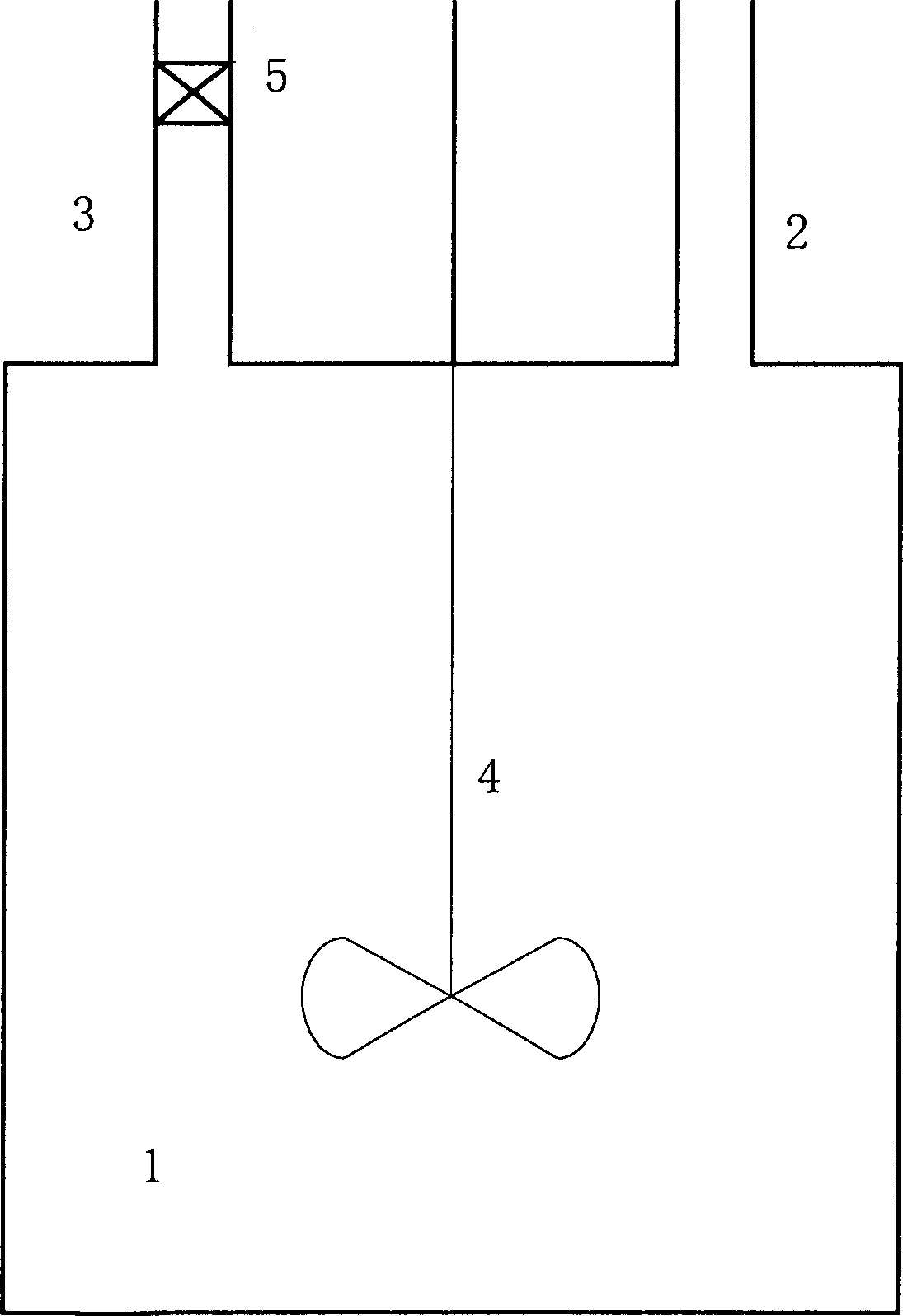

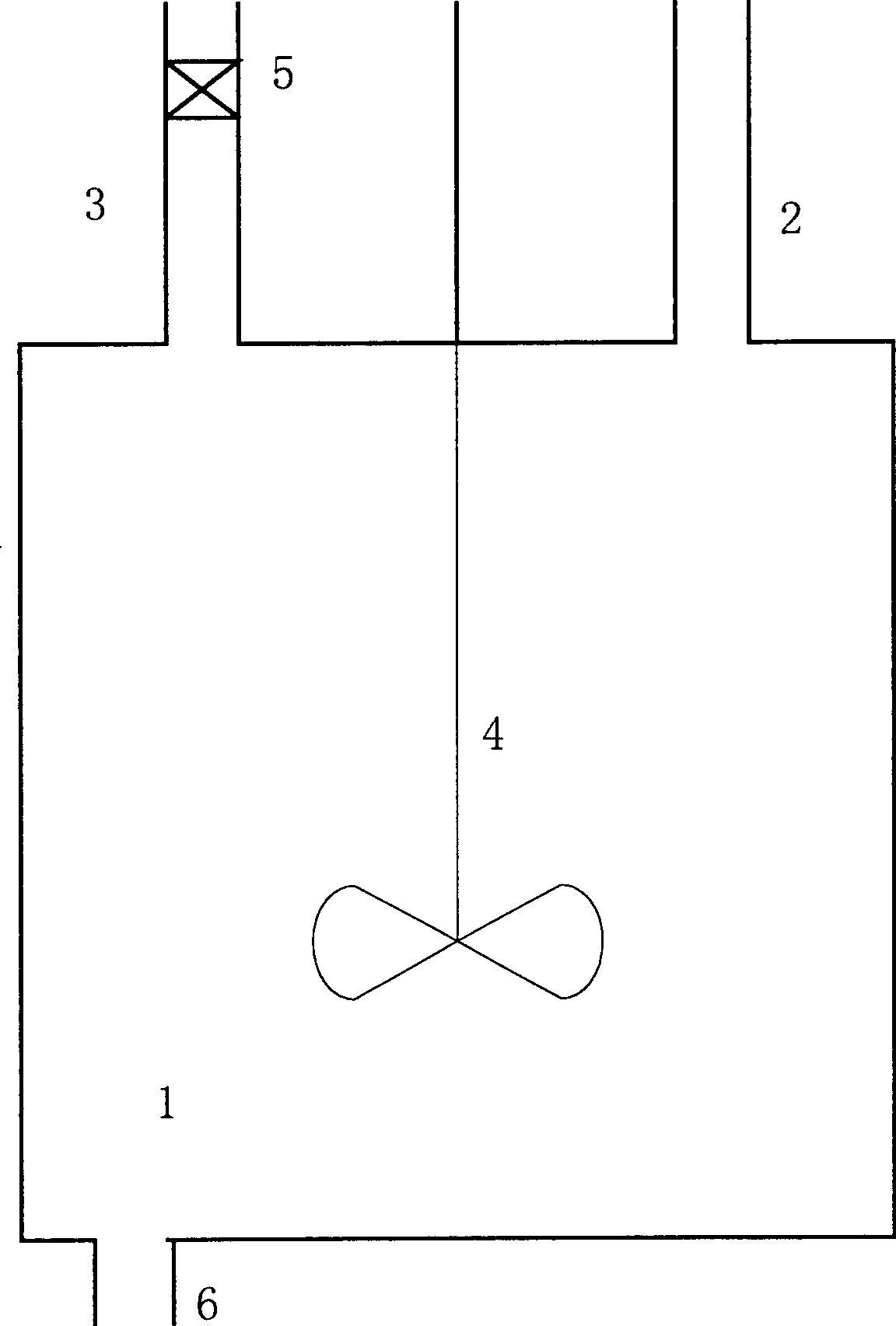

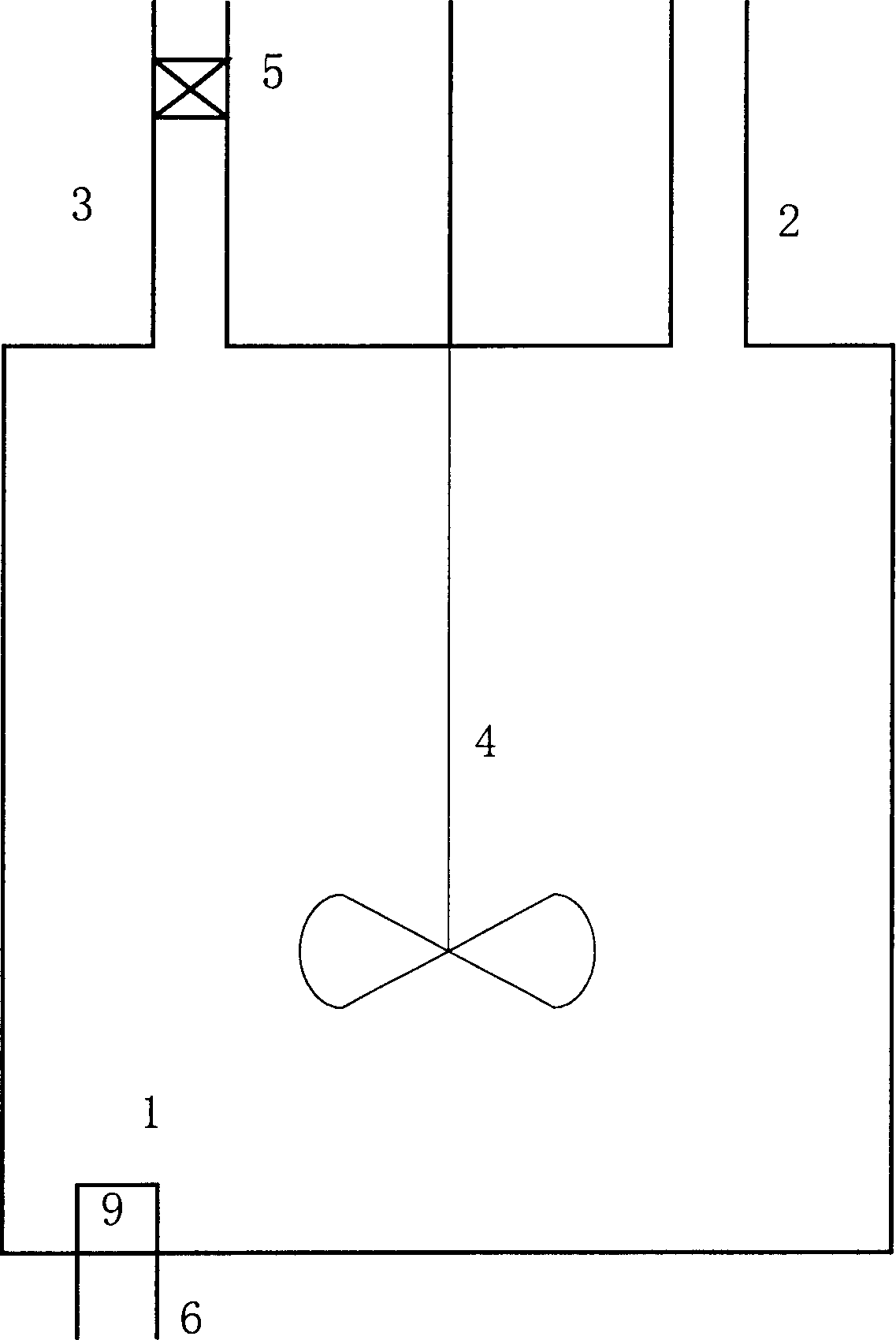

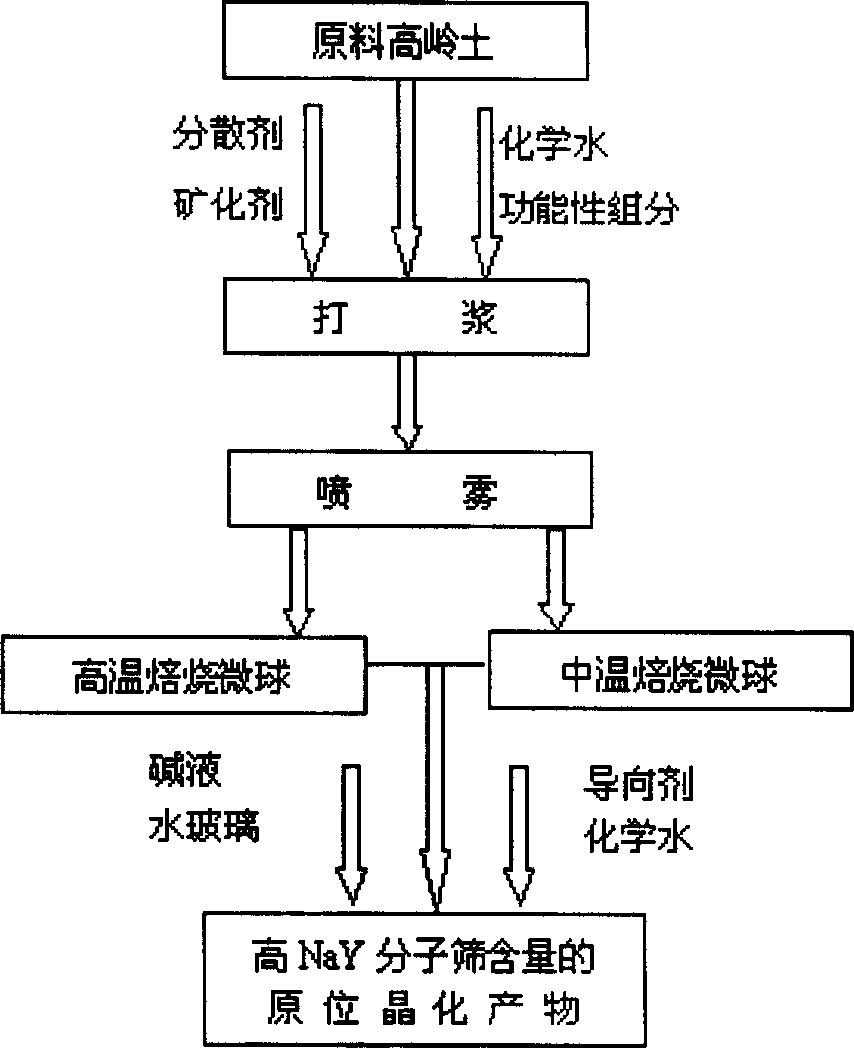

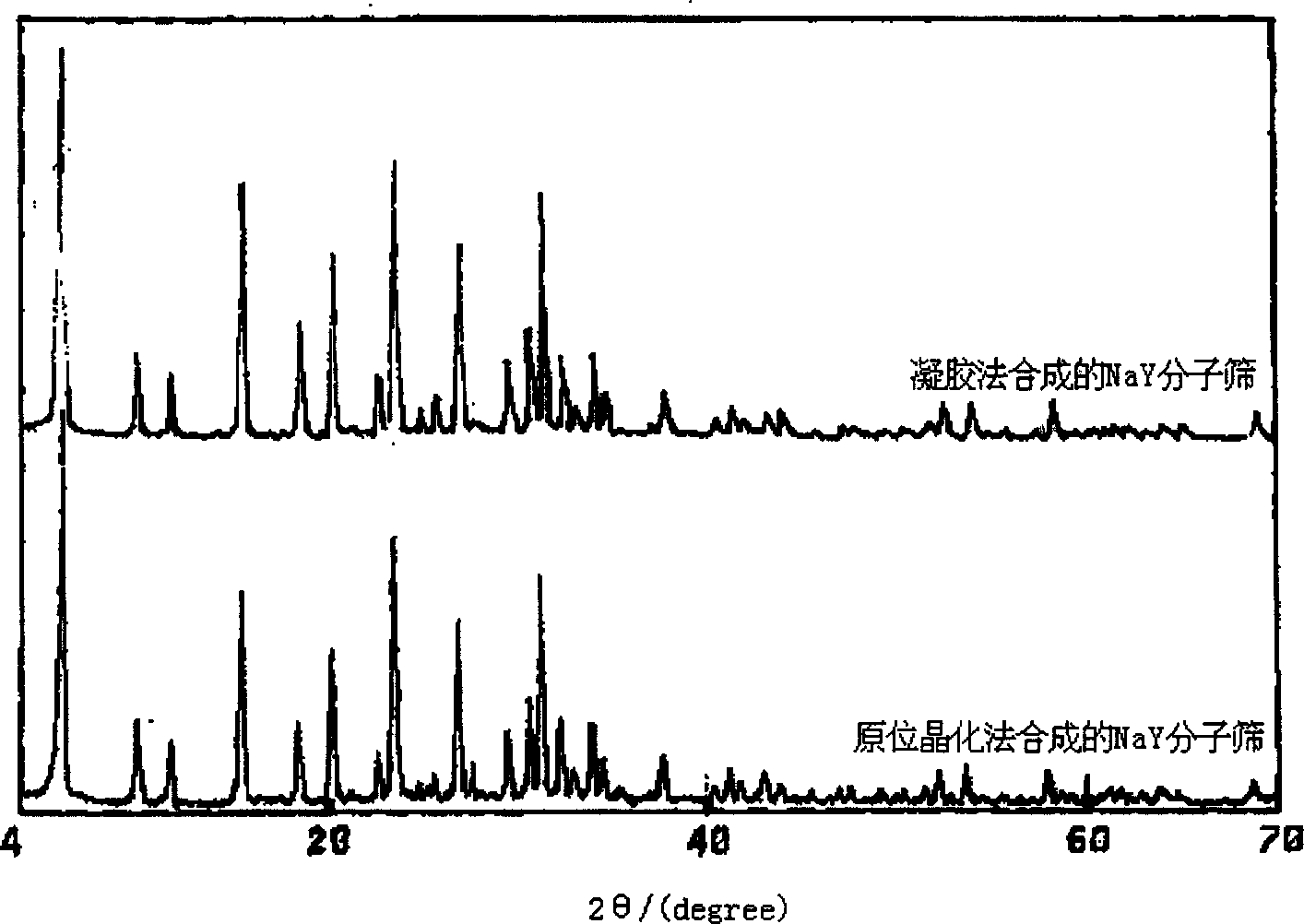

Production for synthesizing high-content NaY molecular sieve from kaolin atomized microball

InactiveCN1778676AMolecular sieve catalystsCatalyst activation/preparationMolecular sieveMicrosphere

Synthesis of high-content NaY molecular sieve from kaolin spray micro-sphere is carried out by taking kaolin as raw materials, adding into functional components, removing ion water to obtain mixed size, spray drying to obtain kaolin micro-sphere, calcining at 700í½1000íÒC, mixed crystallizing by guiding agent, washing and drying by filter cake, or high-temperature baking one part of spray micro-sphere with 20í½110ª–m to obtain high-temperature calcined clay, baking another part of micro-sphere at low temperature to obtain biskaolin, mixing the two baked kaolin, and crystallization reacting under hydrothermal condition to obtain crystallized product containing NaY molecular sieve in proportion of NaY=46í½60% and silicon:aluminium=3.5í½5.5.

Owner:PETROCHINA CO LTD

Small crystal grain molecular sieve preparation method

The invention discloses a method for preparing the NaY molecular screen of high alumina silica ratio and fine grain, firstly synthesizing NaY molecular screen guilding agent according to current technology, then producing gel with sodium silicate, guilding agent, acid aluminium salt and sodium metaaluminate, blooming the gei under the temperature of 50-100 Deg C for 0-70 hours, adding some silicon, then blooming continuously under temperature of 90-120 Deg C for 0.5-50 hours, finally filtering, washing and drying. The NaY molecular screen with the alumina silica ratio being 5.2-7.0, and fine grain being 100-400 nm can be prepared by using the method in this invention.

Owner:CHINA PETROLEUM & CHEM CORP +1

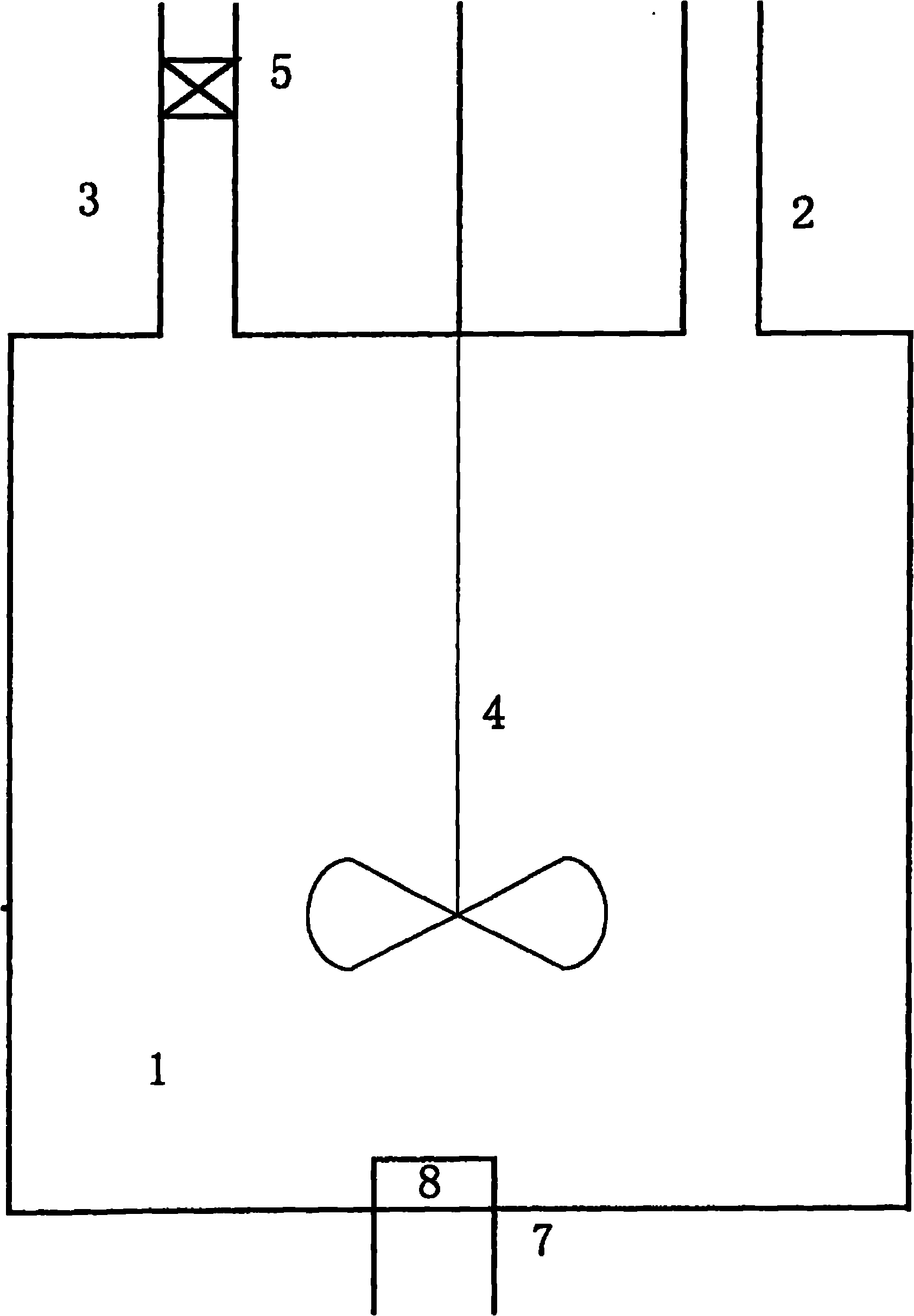

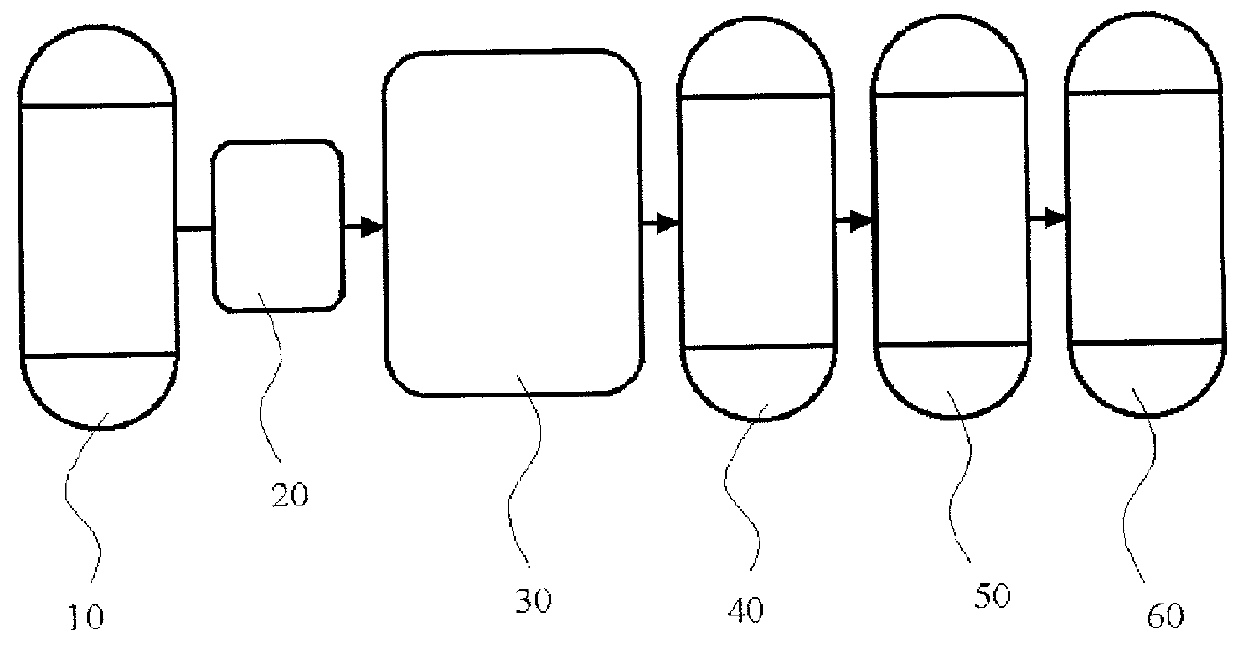

Method for preparing high silicon molecular sieve

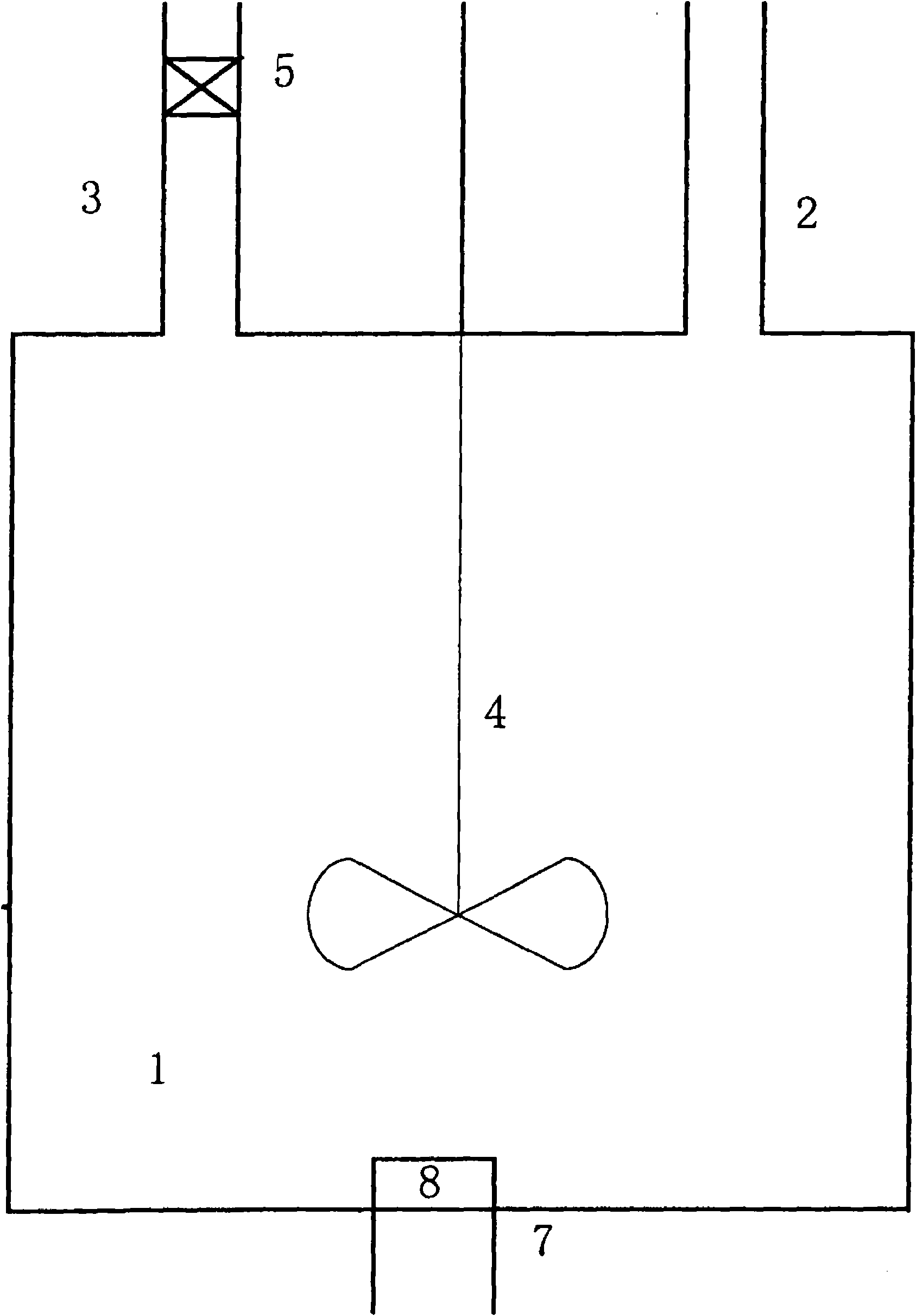

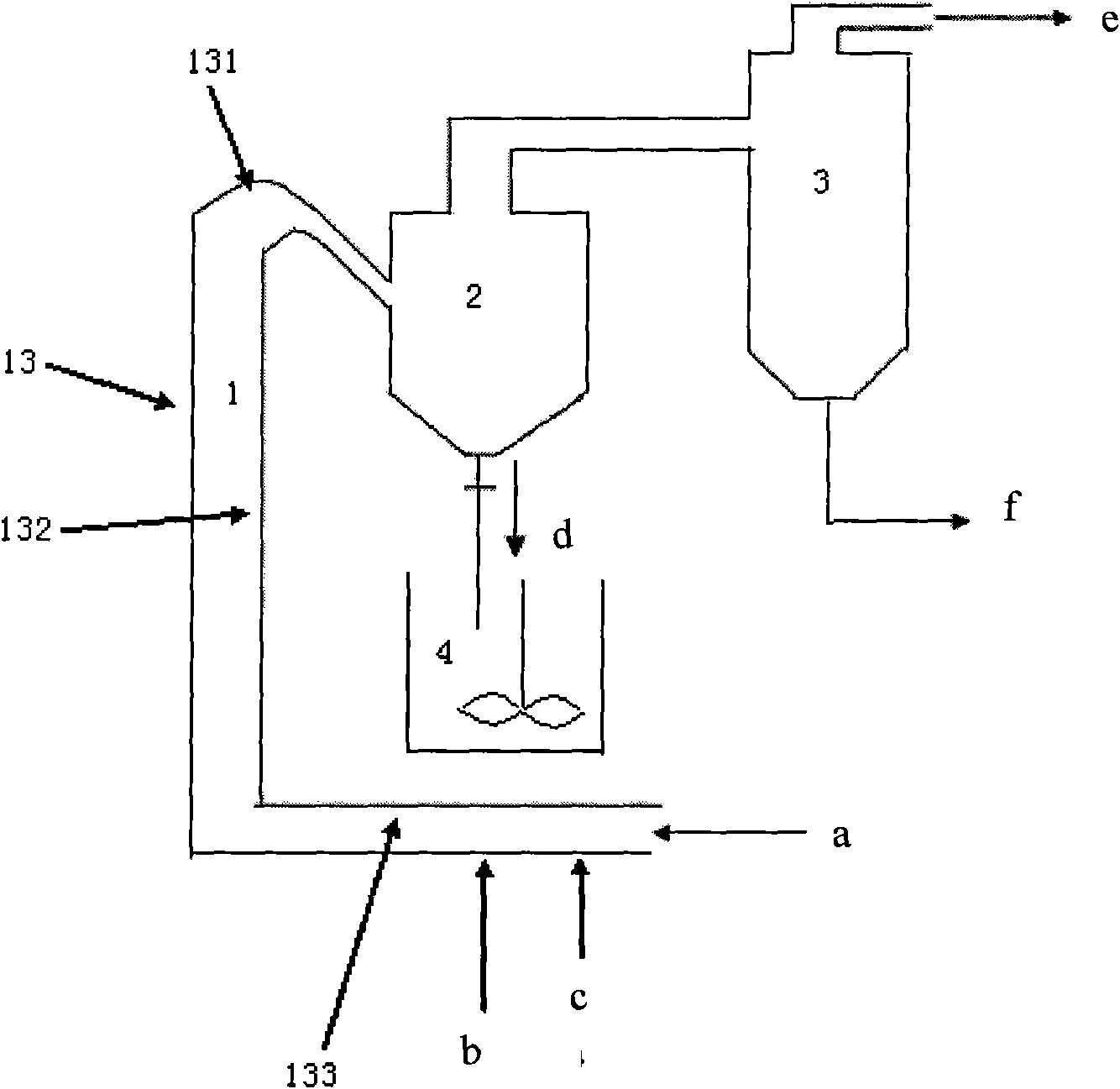

ActiveCN102050459AAdequate contact responseContinuous contact reactionFaujasite aluminosilicate zeoliteMolecular-sieve compoundsMolecular sieveGas phase

The invention relates to a method for preparing a high silicon molecular sieve. The method comprises the following steps: circulating a molecular sieve along with inert carrier air under the carrying of inert carrier air flow and contacting the molecular sieve with gas-phase SiCl4 in a flowing sate, wherein the contact time of the molecular sieve and the gas-phase SiCl4 is from 10 seconds to 100 minutes. By using the method for preparing the high silicon molecular sieve in the invention, the continuous contact reaction of the molecular sieve and the SiCl4 can be achieved, and the contact time of the molecular sieve and the SiCl4 can be controlled through controlling the flow speed of the carrier air and the length of a tubular reactor, thus the contact reaction of the molecular sieve and the SiCl4 can be fully carried out in the tubular reactor.

Owner:CHINA PETROLEUM & CHEM CORP

Method for improving Y-shaped molecular sieve water heat stability by employing cage heteroatom

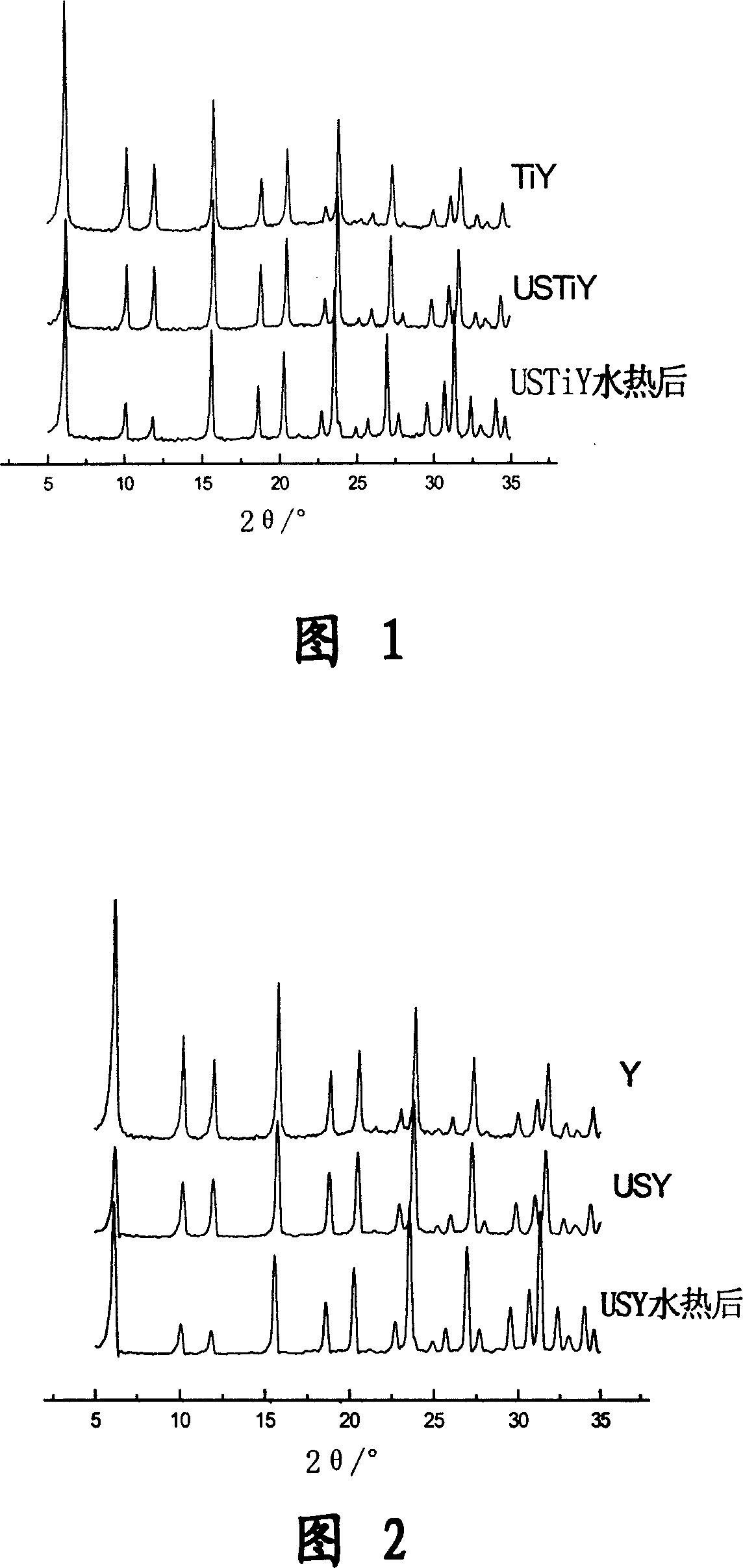

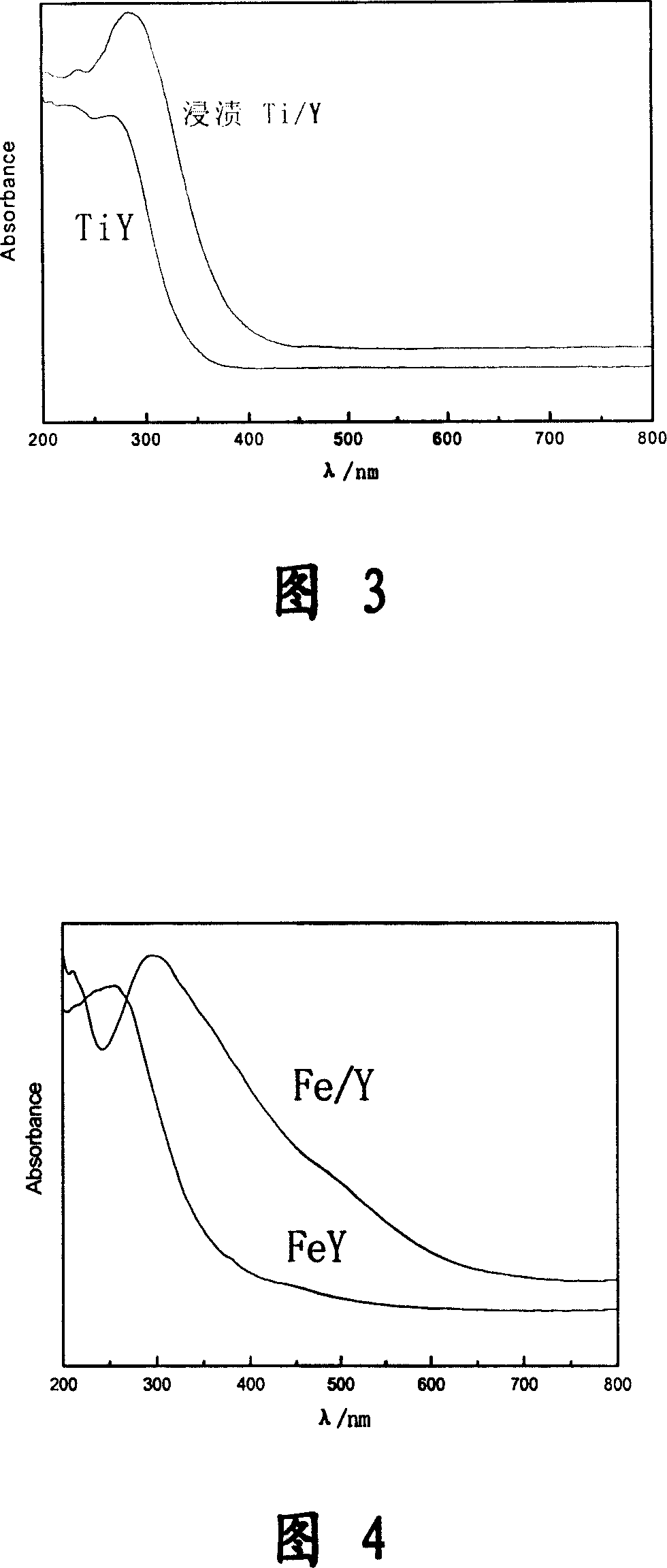

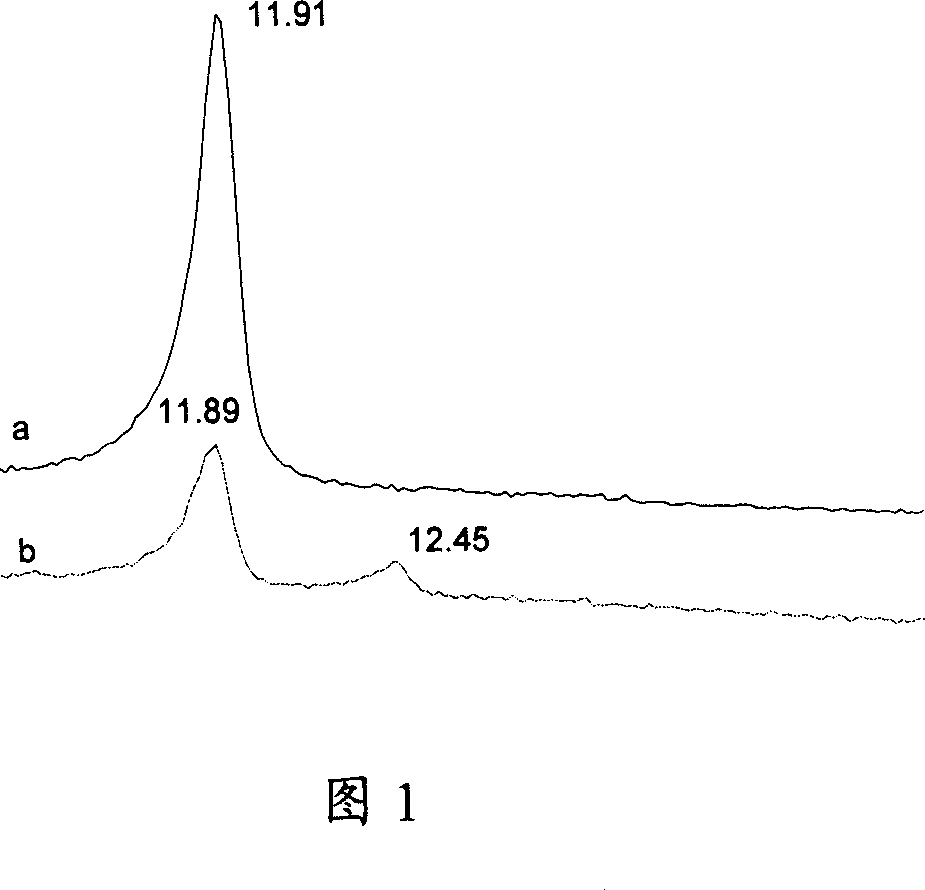

InactiveCN101134576AImprove catalytic performanceImprove skeletal stabilityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveIon exchange

The present invention provides process of selecting proper hetero atom to modify the skeleton of Y-type molecular sieve and to raise the heat stability and hydrothermal stability of Y-type molecular sieve. The process includes direct hydrothermal crystallizing, adding proper amount of hetero atom to prepare MY-type molecular sieve containing skeleton hetero atom, performing the secondary ion exchange and secondary roasting of MY-type molecular sieve after adding small amount of hetero atom in the same kind to obtain USMY type molecular sieve with very high heat stability and hydrothermal stability. The molecular sieve with very high heat stability and hydrothermal stability is applied in the catalysts for catalytic cracking, hydrogenation cracking, etc of hydrocarbons.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for raising content of rare earth of ultra stable Y type zeolite

ActiveCN1958452AHigh cracking activityStrong ability to convert heavy oilFaujasite aluminosilicate zeoliteRare earth ionsActive component

This invention discloses a method for raising rare earth content in super-stable Y-type zeolite. The method comprises: mixing super-stable Y-type zeolite and 0.01-2 N acid solution at a liquid / solid ratio of 4-20 at 20-100 deg.C, treating for 10-300 min, washing, filtering, adding rare earth salt solution for rare earth ion exchange, washing, filtering, and drying to obtain rare earth reinforced super-stable Y-type zeolite. The obtained rare earth reinforced super-stable Y-type zeolite has through pores without any blockage, and has obviously raised rare earth content. Cracking catalyst containing the rare earth reinforced super-stable Y-type zeolite as the active component has high heavy oil conversion ability.

Owner:CHINA PETROLEUM & CHEM CORP +1

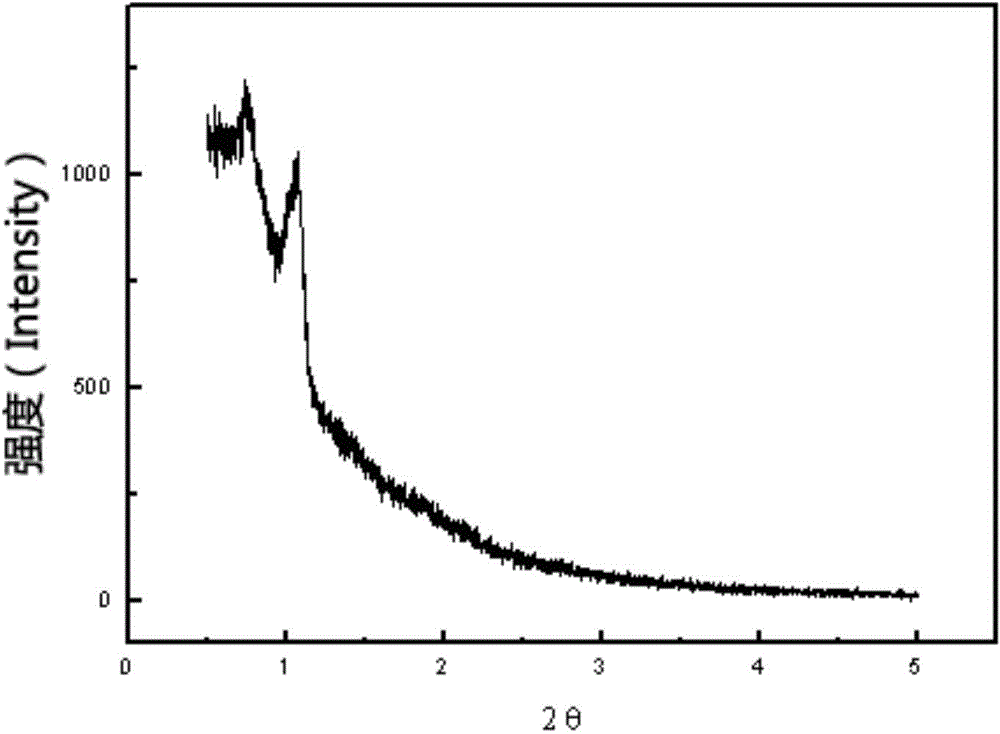

Microwave method for synthesizing nanometer silicate basic hole material

InactiveCN1730391AFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteMolecular sieveMicrowave method

The invention relates to a microwave synthesizing process for nano-size silicate based poromeric material, which consists of dissolving aluminium source into water, charging silicon source while agitating, continuously agitating, carrying out microwave processing directly for 3-180 minutes to the reaction solution, microwave heating 3-30 minutes, crystallizing 1-8 days at 60-100 deg C, centrifugally separating, filtering, scouring, dry scouring to neutral, thus obtaining nano-size molecular sieve with adjustable particle size.

Owner:朱广山

Y molecular sieve modification method

ActiveCN1803612ASmall cell constantHigh crystal retentionCatalyst carriersMolecular sieve catalystsMolecular sieveDistilled oil

The invention relates to a modifying method for Y molecular sieve, which comprises: using industrial NaY molecular sieve as material for ammonium exchange, baking deeply; then, adding surfactant during dealumination with acid. This invention obtains HY molecular sieve with high SiO2 / Al2O3(9~15) and crystallinity, improves secondary pores and acid structure compared with the industrial NaY, and fits to be carrier for hydrotreating catalyst for heavy distilled oil.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Modified Y zeolite and its preparation method

ActiveCN1951814ALarge specific surface areaHigh crystallinityFaujasite aluminosilicate zeoliteCapacitanceAmmonia

The invention discloses a modified Y-zeolite and preparing method with molar rate of SiO2 / Al2O3 at 7.0-30, wherein the specific area of Y-zeolite is 700-900m2 / g with cell constant at 2.425-2.445nm; the relative crystallizing degree is not less than 80% with Na2O content not more than 0.25%; the 1.7-10nm second hole is over 45% in the total hole capacitance; the non-frame aluminium is over 30% in the whole aluminium with infrared acid degree at 0.15-0.55mmol / g; the preparing method adopts NaY as raw material to produce the modified Y-zeolite through ammonia exchanging, hydrothermal disposal, non-frame aluminium stripping, hole expanding and secondary hydrothermal disposal.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high-stability mesoporous molecular sieve

ActiveCN104891526APolycrystallineActs as a templating agentFaujasite aluminosilicate zeoliteMolecular sieveMicroreactor

The invention provides a method for preparing a high-hydrothermal-stability mesoporous molecular sieve. The method includes the following steps: (1) preparation of a first Y-type molecular sieve precursor; and (2) crystallization: adding a seed crystal to the first Y-type molecular sieve precursor, adjusting the pH value to 0.5-5, stirring for 10 h-24 h at the temperature of 20 DEG C-50 DEG C, then aging for 2 h-24 h at the temperature of 20 DEG C-50 DEG C, to obtain an assembled product, transferring the assembled product into a microreactor with a polytetrafluoroethylene lining, then transferring together with the reactor into a high-pressure reaction kettle, crystallizing for 10 h-48 h at the temperature of 100 DEG C-200 DEG C, filtering, washing, drying, and thus obtaining the high-stability mesoporous molecular sieve. Firstly, the microporous molecular sieve precursor is prepared, a mesoporous-microporous molecular sieve as the seed crystal is used for preparation of the mesoporous molecular sieve, the molecular sieve precursor assembly method and the seed crystal method are combined, and the high-stability mesoporous molecular sieve is obtained under the condition without use of an organic template agent. Not only is the preparation cost of the molecular sieve reduced greatly, but also the process of calcination of the template agent is omitted so as to reduce the energy consumption.

Owner:PETROCHINA CO LTD +1

Preparation method of mesoporous-containing Y-shaped molecular sieve

ActiveCN103172082AMicroporosity unchangedGood hydrothermal stabilityFaujasite aluminosilicate zeoliteMolecular sieveOrganic acid

The invention relates to a preparation method of a mesoporous-containing Y-shaped molecular sieve, and relates to a preparation method of a Y-shaped molecular sieve. The preparation method aims to solve the problems of small pore diameter and pore volume of the Y-shaped molecular sieve prepared through the traditional method. The preparation method comprises the following steps of: 1, preparing a sodium type Y-shaped molecular sieve; 2, preparing an ammonium type Y-shaped molecular sieve; 3, processing through an organic acid water solution; 4, processing through NaOH; and 5, processing through an ammonium nitrate water solution so as to obtain the mesoporous-containing Y-shaped molecular sieve. The mesoporous-containing Y-shaped molecular sieve is synthesized through a simple and effective method under a moderate condition, contains abundant mesoporous, is unchanged in microporosity, achieves the volume of the mesoporous at 0.5-1.5 mL / g, greatly promotes the macromolecule to approach a catalytic active center and is favorable for reaction mass transfer through more concentrated pore diameter distribution, has the advantages of adjustable ratio of silicon and aluminum contained in a framework and good hydrothermal stability and can be used as a catalyst carrier or directly used as a catalyst. The preparation method disclosed by the invention can be used for preparing the mesoporous-containing Y-shaped molecular sieve.

Owner:HARBIN INST OF TECH

Preparation method of mesoporous-microporous composite molecular sieve

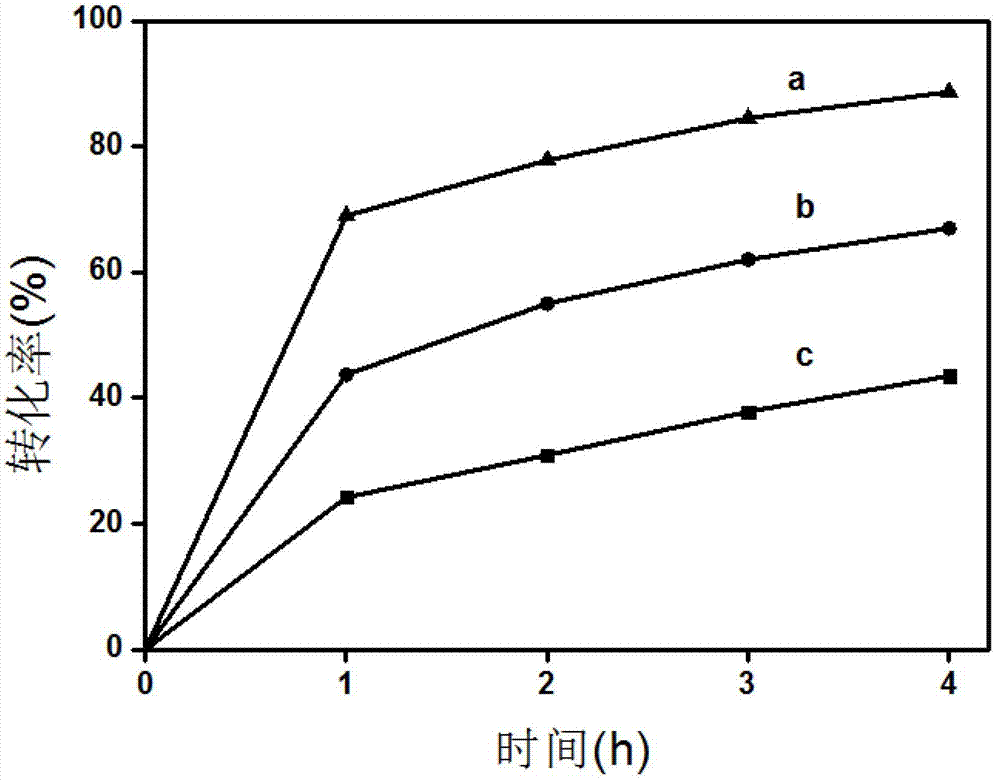

ActiveCN103100399ALarge hole volumeLarge specific surface areaMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveFiltration

The invention discloses a preparation method of a mesoporous-microporous composite molecular sieve. The preparation method comprises the following steps of adding a microporous molecular sieve subjected to hydrothermal treatment into a mixed system of a silicon source, an acid solution and a surfactant, then carrying out crystallization, filtration and washing, and then carrying out drying and calcination to obtain the mesoporous-microporous composite molecular sieve. The preparation method fully utilizes non-framework aluminum falling from the microporous molecular sieve, avoids an aluminum source used by the conventional molecular sieve preparation technology, is conducive to improvement of a silica-alumina ratio of the mesoporous-microporous composite molecular sieve, realizes a high degree of crystallization, and improves hydrothermal stability and thermostability of the mesoporous-microporous composite molecular sieve. The mesoporous-microporous composite molecular sieve is suitable for the field of macromolecule catalysis, is conducive to improvement of a reaction conversion ratio and reaction selectivity, and is especially suitable for being used in a cracking catalyst for maximum-degree production of middle distillate from heavy oil as a raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Continuous process and apparatus for preparing inorganic materials employing microwave

This invention relates to a continuous microwave synthesis process of inorganic materials and its apparatus and more particularly, to the process of synthesizing inorganic materials prepared in a manner such that after preparing a mixed solution of precursor materials for various inorganic materials such as porous molecular sieve, layered compounds and ceramics, this mixed solution is continuously added to a tube-type microwave reactor using a slurry pump for the synthesis and crystallization of inorganic materials. Thus the manufacturing process of this invention has the following advantages: (1) the reaction time is further shortened by several to tens of minutes for crystallization, compared to the conventional hydrothermal reaction requiring a prolonged time, (2) the continuous manufacturing and collection processes of this invention can give access to mass-scale production of inorganic materials with relatively small facility, compared to the conventional batch hydrothermal or microwave synthesis, and (3) less amount of organic templating agent can be required during the manufacture of porous molecular sieve.

Owner:KOREA RES INST OF CHEM TECH

Small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN101723400AGuaranteed skeleton continuityReduce collapseFaujasite aluminosilicate zeoliteOxygenFluosilicates

The invention discloses a small crystal grain Y-shaped molecular sieve and a preparation method thereof. The small crystal grain Y-shaped molecular sieve has the following properties that: the molar ratio of SiO2 / Al2O3 is 5.0-20.0; the average diameter of crystal grains is 100 to 700nm; the crystallization reservation degree is over 95 percent; and the weight percentage of sodium oxide is less than or equal to 0.1 percent. The small crystal grain Y-shaped molecular sieve takes a small crystal grain NaY molecular sieve with good thermal stability and hydrothermal stability as a raw material, has a high silicon-aluminum ratio, good stability and a uniform framework, namely a silicon-aluminum structure, can uniformly remove aluminum and supplement silica in an ammonium exchanging and ammonium fluosilicate dealuminizing and silica-supplementing process, guarantees the framework continuity of the molecular sieve product, decreases the probability of framework structure collapse, and furthest reserves the integrity of the product, namely the silicon-aluminum-oxygen structure so that the product has very high crystallization reservation degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing catalytic cracking catalyst

ActiveCN102049315AAdequate contact responseContinuous contact reactionCatalytic crackingMolecular sieve catalystsMolecular sieveContact time

The invention relates to a method for preparing a catalytic cracking catalyst. The method comprises the following steps: a molecular sieve flows along with inert carrier gas under the condition of being carried by the inert carrier gas flow, and is in contact with gas phase SiCl4 under the flow state; the contact time between the molecular sieve and the gas phase SiCl4 is 10 seconds to 100 minutes; and then the molecular sieve in contact with the gas phase SiCl4 is mixed with a binding agent, clay and water for pulping and pelleting to obtain the catalytic cracking catalyst. The provided preparation method for the catalytic cracking catalyst can realize the continuous contact reaction between the molecular sieve and the gas phase SiCl4 and can control the contact time between the molecular sieve and the gas phase SiCl4 by controlling the flow velocity of the carrier gas and the length of the tubular reactor, so that the contact reaction between the molecular sieve and the gas phase SiCl4 can be fully carried out in the tubular reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Y-type molecular sieve with ultra-high mesoporous content and preparation method of Y-type molecular sieve

ActiveCN104760973AMolar ratio of silicon to aluminum is adjustableImprove thermal and hydrothermal stabilityFaujasite aluminosilicate zeoliteMolecular sievePre treatment

The invention provides a Y-type molecular sieve with an ultra-high mesoporous content and a preparation method of the Y-type molecular sieve. The method comprises the following steps: pre-treating Y-type zeolites for 1-5 hours at 300-600 DEG C; cooling to 200-600 DEG C; in an anhydrous drying environment, introducing dry gas saturated by a dealuminating silicon-reinforcing agent into the pre-treated Y-type zeolites and carrying out reaction for 0.5-7 hours to obtain a coarse product; or in the anhydrous dry environment, raising the temperature at a constant speed to 250-700 DEG C, introducing dry gas saturated by the dealuminating silicon-reinforcing agent into the pre-treated Y-type zeolites simultaneously and carrying out reaction for 0.5-7 hours to obtain a coarse product, wherein the introducing speed of the dry gas saturated by the dealuminating silicon-reinforcing agent is 50mL / minute; carrying out acid treatment on the coarse product; and carrying out alkaline treatment on the coarse product after acid treatment to obtain the Y-type molecular sieve. The invention further provides the Y-type molecular sieve with the ultra-high mesoporous content by virtue of the method. The sieve is the Y-type molecular sieve which is high in silica-alumina ratio, wide in range and high in mesoporous content; and the preparation method is simple to operate and low in raw material cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method for nano-Y-shaped molecular sieve/amorphous silicon-aluminum composite material

ActiveCN102451740AHigh yieldEasy to operateMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveAmorphous silicon

The invention relates to a preparation method for a nano-Y-shaped molecular sieve / amorphous silicon-aluminum composite material. According to the method, a guiding agent is synthesized, and a surfactant is added during the guiding agent synthesizing process; a surfactant is added during a preparation and synthesis process of gel of the Y-shaped molecular sieve, and a hydrothermal crystallization method is adopted to synthesize the nano-Y-shaped molecular sieve; an aqueous solution of a mixture is added to the slurry containing the nano-Y-shaped molecular sieve, wherein the mixture comprises water glass and an aluminum source; an acid is added to adjust the pH value to 7-9.5 to form the gel; the gel is washed, dried and baked to obtain the composite material. According to the present invention, the grain of the Y-shaped molecular sieve in the composite material prepared by the method of the present invention is maintained to less than 100 nm, and the composite material of the present invention is suitable for catalytic cracking reactions and hydrocracking reactions of heavy oil macromolecules.

Owner:PETROCHINA CO LTD +1

Nano-grade Y type zeolite synthesized from kaolin and its preparation metod

InactiveCN1533982ASpecial nest structureSmall grainCatalytic crackingMolecular sieve catalystsKaoliniteFuel oil

A nano-class Y zeolite prepared from raw kaolinite powder through crystallizing has 30-85 wt.% for NaY content. Its primary particles can be rod-shaped, flaky or block crystal. Its secondary particle is the nest-type sphere. It can be made into HY, REY, or REHY and used as the catalyst for catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Super-stable Y zeolite, preparation method and application thereof

ActiveCN102020289AHigh crystallinityIncrease the areaCatalytic crackingMolecular sieve catalystsOrganic acidGasoline

The present invention provides a super-stable Y zeolite and the preparation method thereof. The ratio of silicate to aluminum in the super-stable Y zeolite is 6-11. The lattice constant of the zeolite is 2.446 to 2.458 nanometers. The percentage of non-skeleton aluminum in total aluminum in the zeolite is not higher than 30% by weight. The diameter of secondary pores with diameter of 2 to 100 nanometers in the zeolite shows a double probable distribution. The most probable diameter of the secondary pores with comparatively large diameter is 6-15 nanometers. The proportion of secondary pores with diameter between 8 to 100 nanometers in total secondary pores is 35% to 60%. The preparation method of the zeolite includes the step of making the super-stable Y zeolite come into contact with a solution containing organic acids and inorganic acids in the atmosphere of inert gases and / or nitrogen. The modified super-stable Y zeolite provided in the invention is applied to catalytic cracking; therefore the following effects can be realized: the cracking ability of heavy oil is strong, the selectivity of gasoline is high, and the selectivity of dry gas and carbon coke is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com