Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1003 results about "Kaolinite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kaolinite (/ˈkeɪəlɪnaɪt/) is a clay mineral, part of the group of industrial minerals with the chemical composition Al₂Si₂O₅(OH)₄. It is a layered silicate mineral, with one tetrahedral sheet of silica (SiO4) linked through oxygen atoms to one octahedral sheet of alumina (AlO6) octahedra. Rocks that are rich in kaolinite are known as kaolin /ˈkeɪəlɪn/ or china clay.

Compositions and methods for removing mercury from mercury-containing fluids

InactiveUS20070140940A1Facilitate mercury removalThe material is lowGas treatmentDispersed particle filtrationSodium BentoniteSorbent

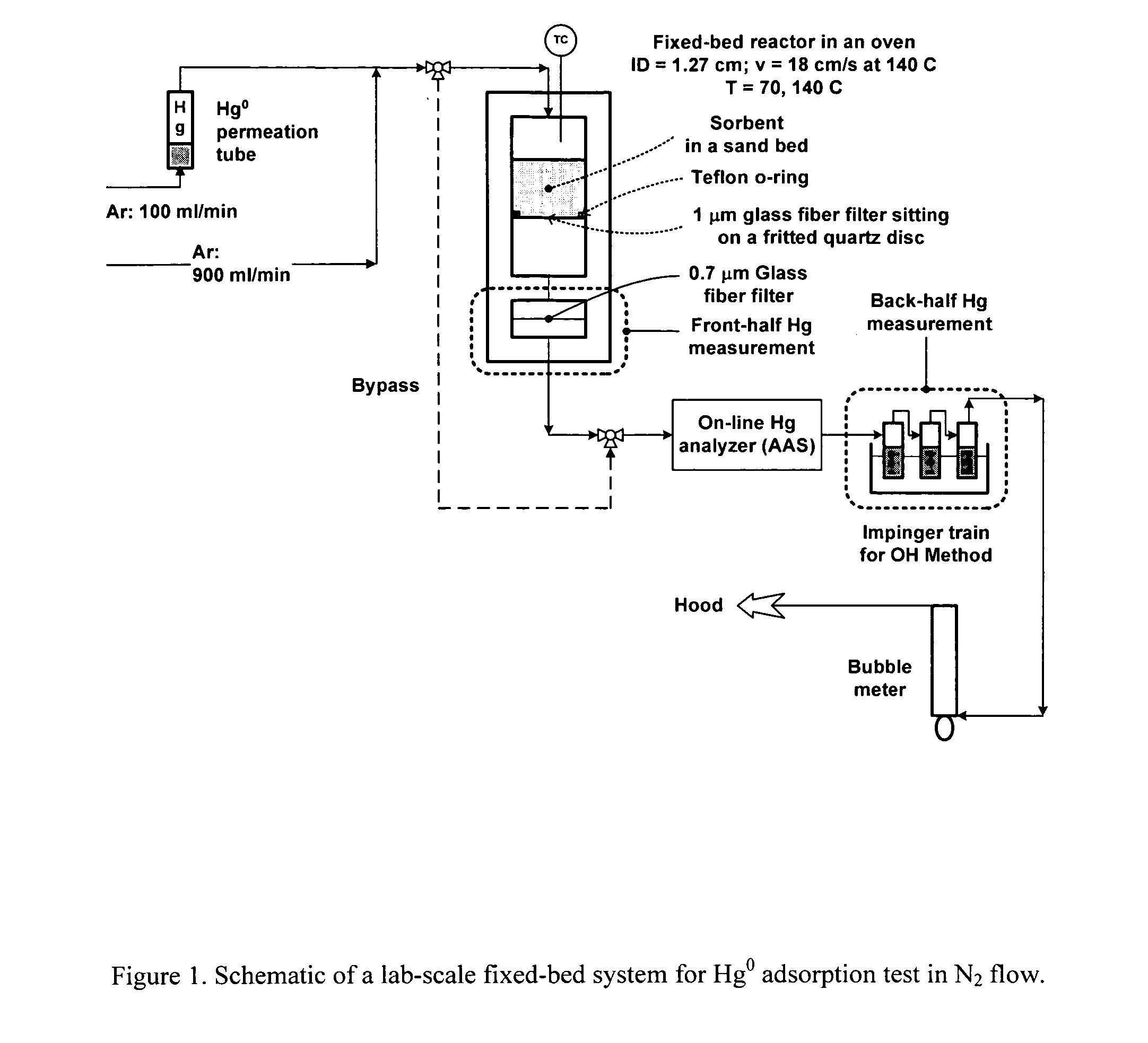

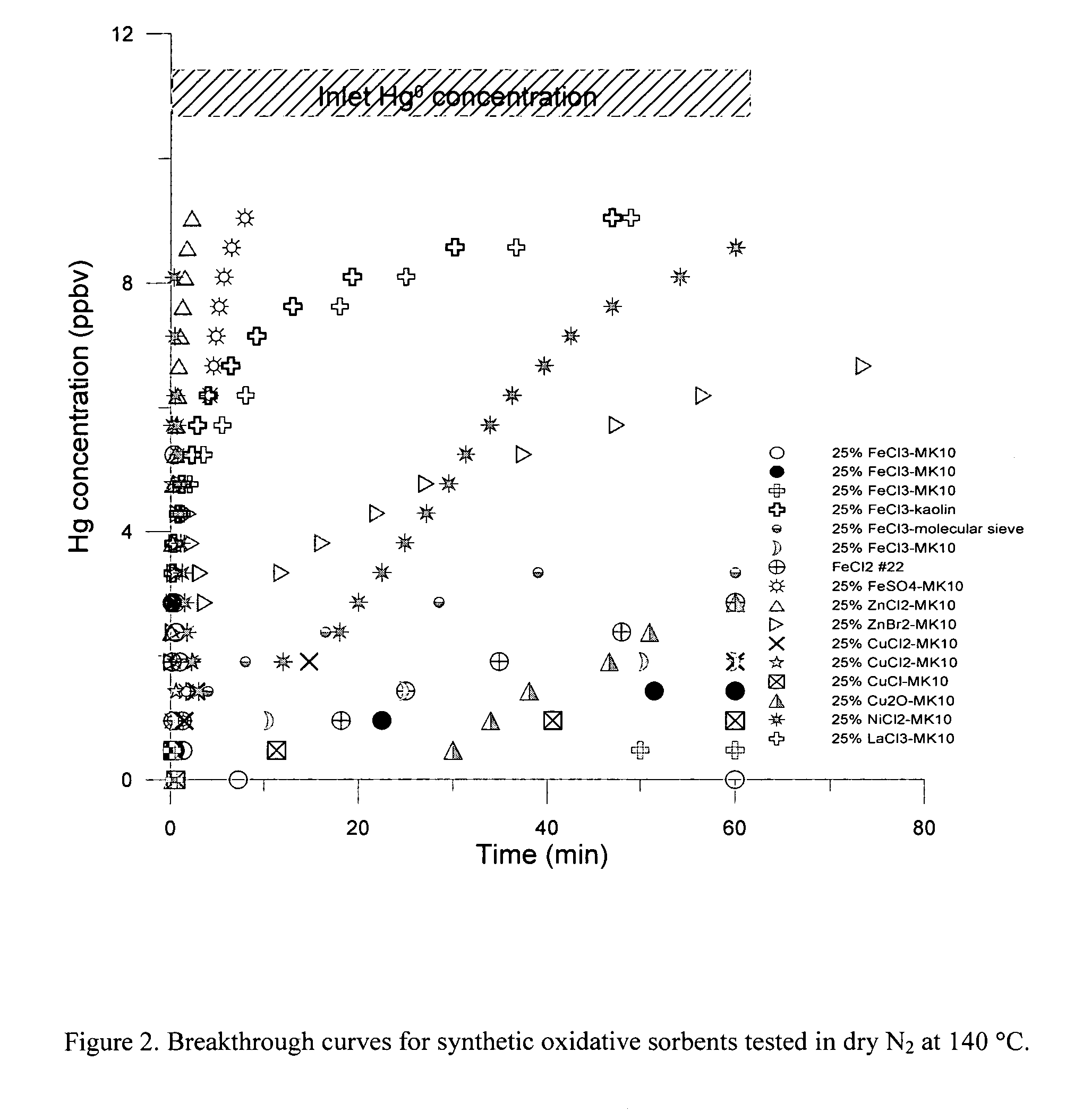

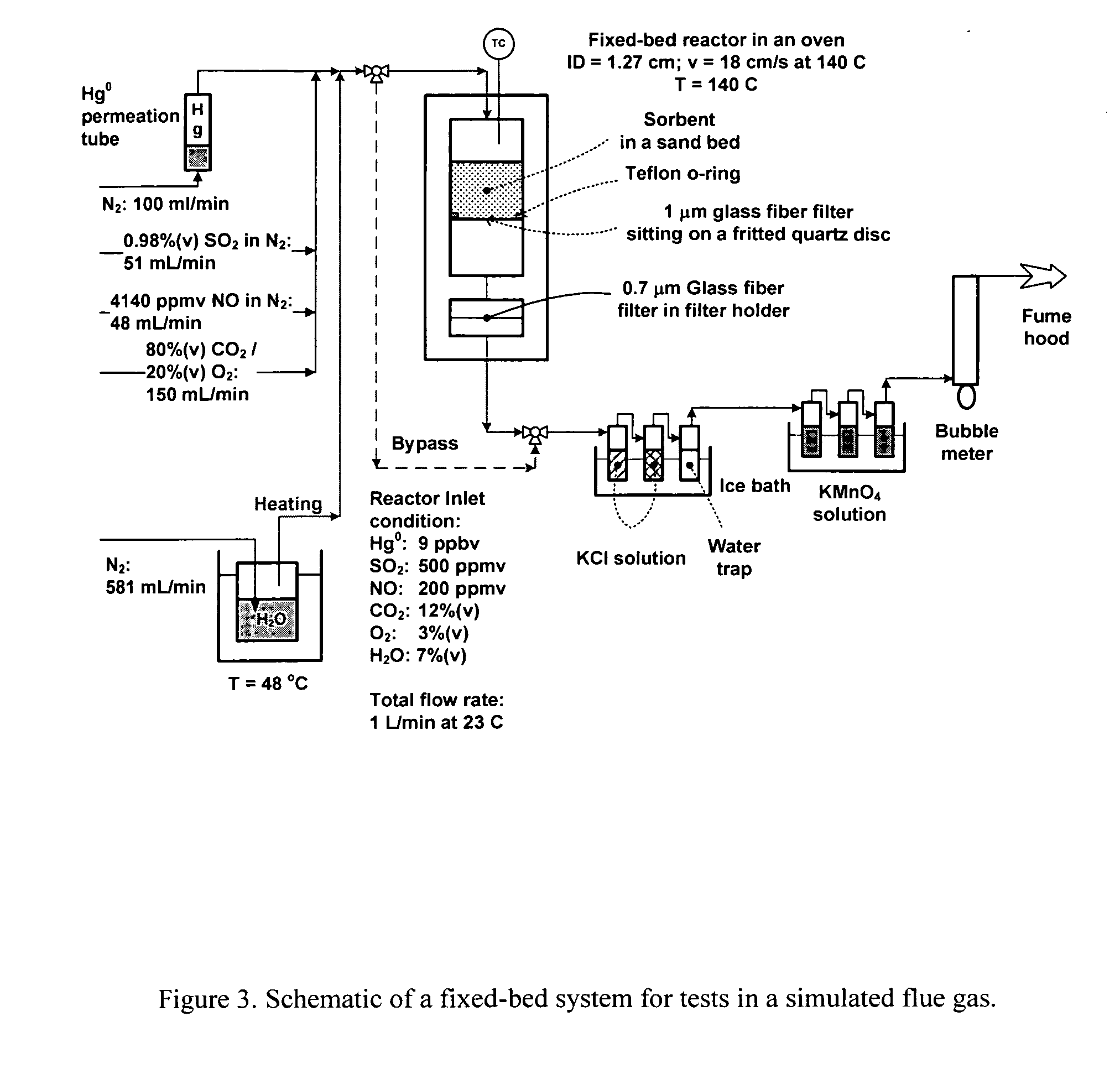

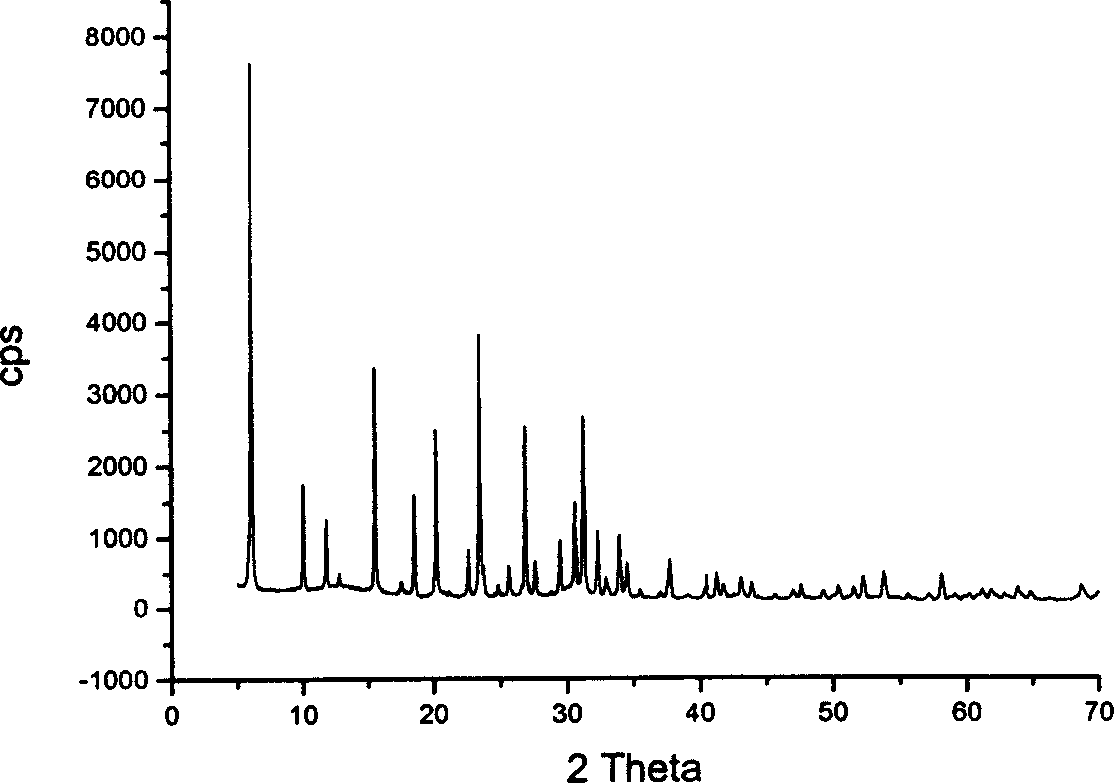

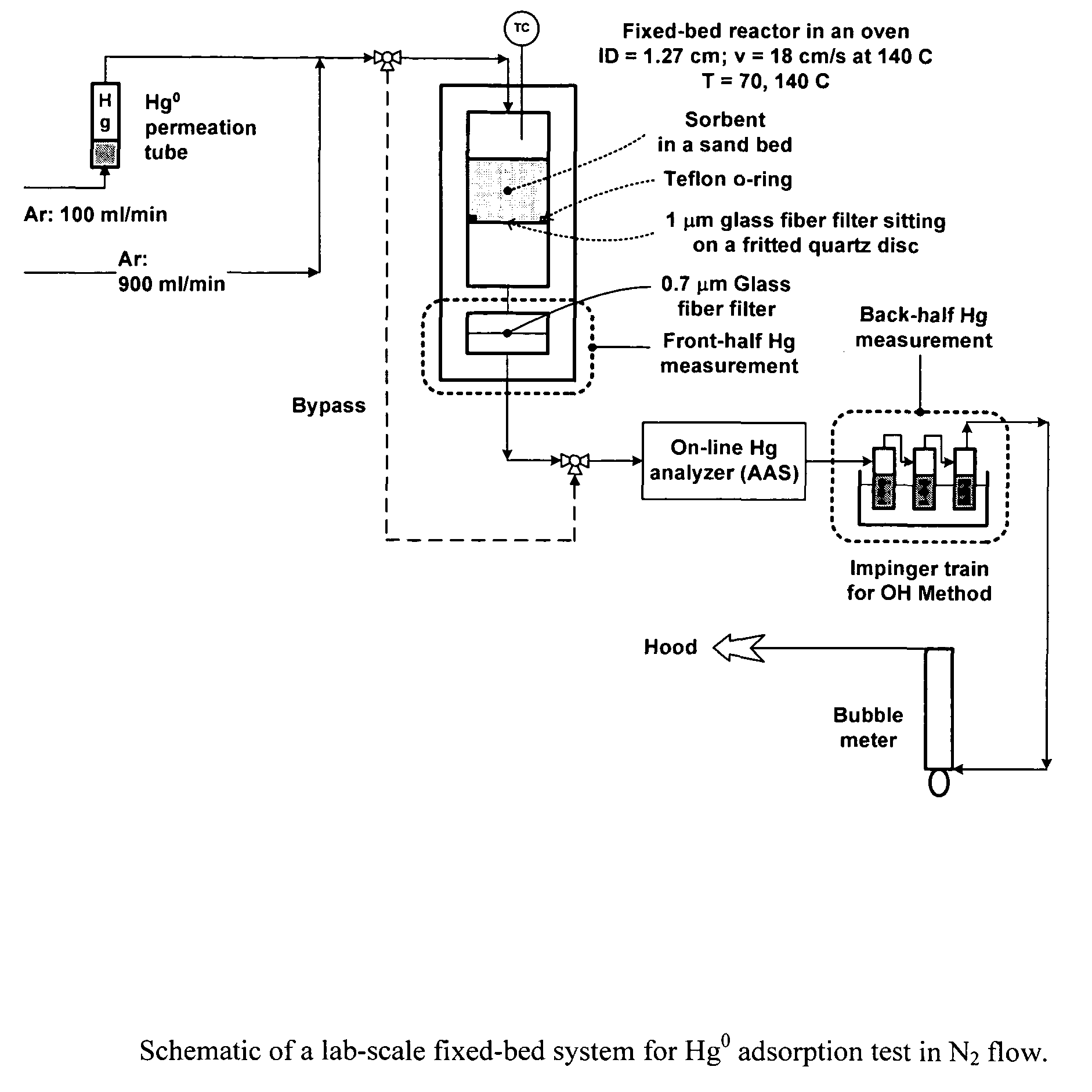

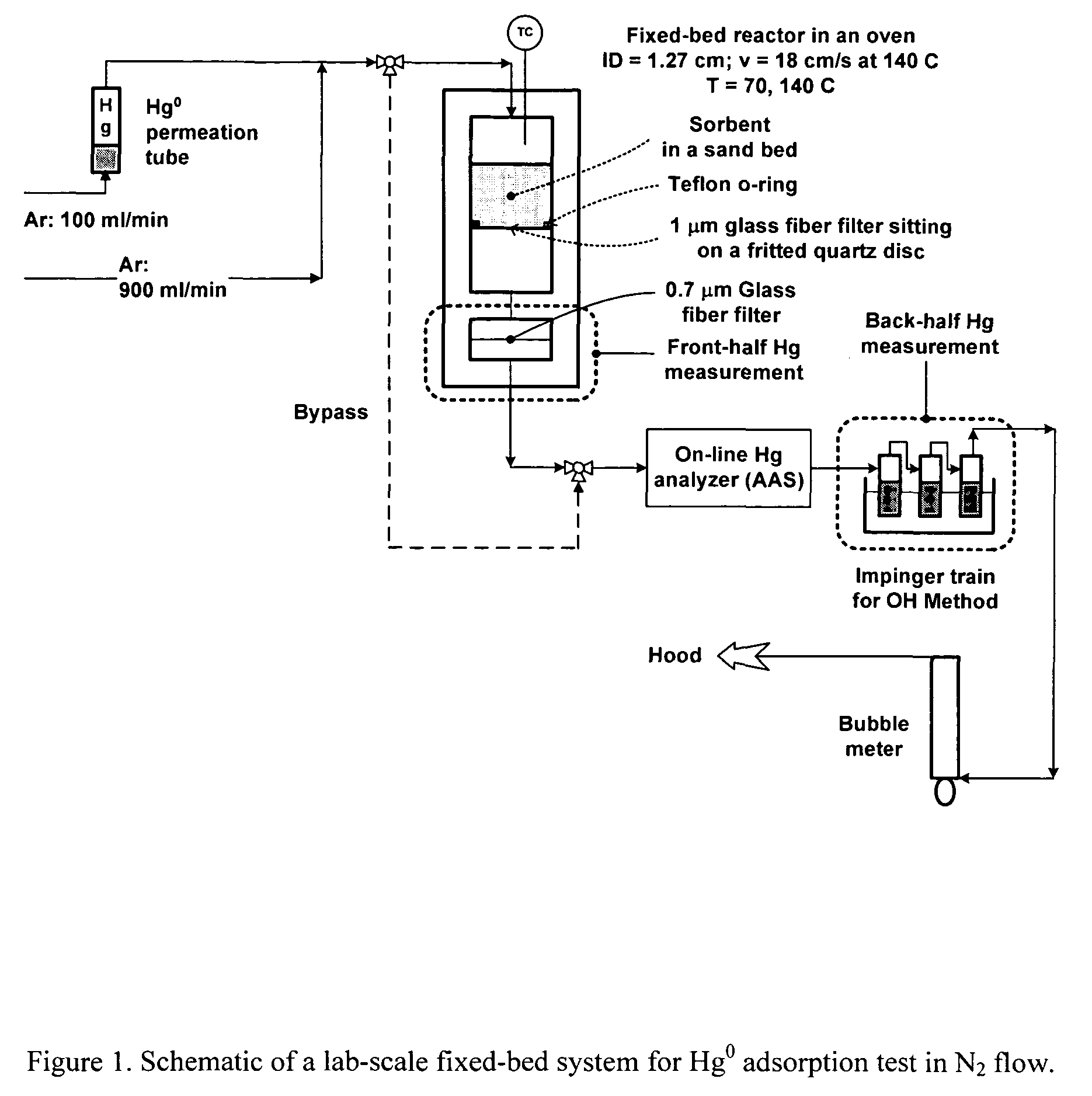

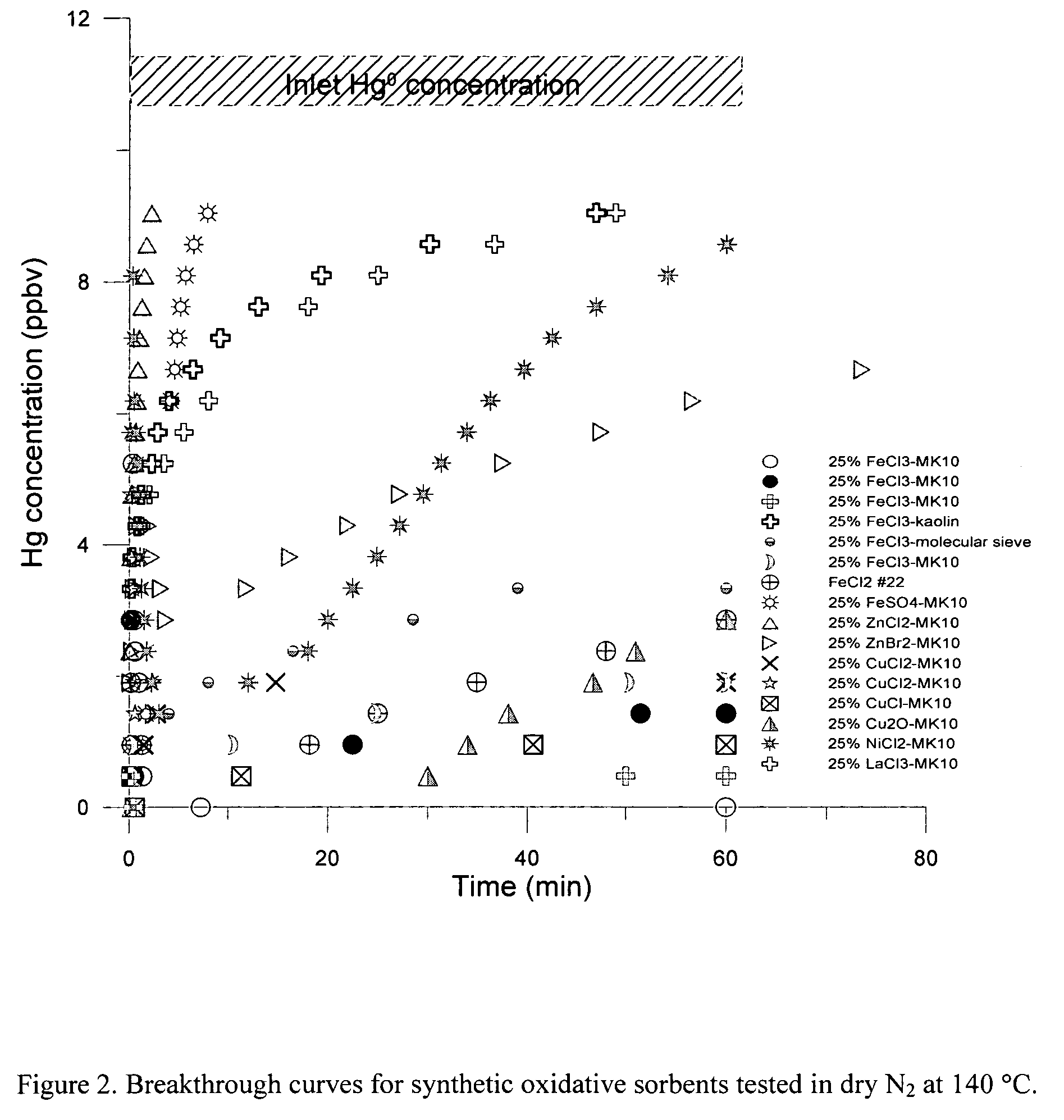

Oxidative sorbents are provided for adsorbing elemental or oxidized mercury from mercury-containing fluids such as flue gas from a coal-burning power utility or the like at a temperature range of about 50 to 350 ° C. The method of preparing and using the oxidative sorbents is also provided. The oxidative sorbent compositions include one or more silicates capable of cation exchange with a plurality of active metal cations and their counter anions. The silicates may include those selected from clays such as montmorillonite, laumonite, bentonite, Mica, vermiculite and kaolinite, and from silica gels, natural and synthetic molecular sieves, zeolites, and ashes from stoker- and pulverized coal-fired boilers. The one or more oxidative metal halides and / or sulfates may be selected from the group consisting of CuCl, CuBr, CuCl2, CuBr2, CuSO4, FeCl2, FeCl3, FeSO4, Fe2(SO4)3, ZnCl2, ZnBr2, NiCl2, and NiSO4. The oxidative sorbents may also include activated carbon.

Owner:U S ENVIRONMENTAL PROTECTION AGENCY UNITED STATES OF AMERICA THE AS REPRESENTED BY THE ADMINISTATOR

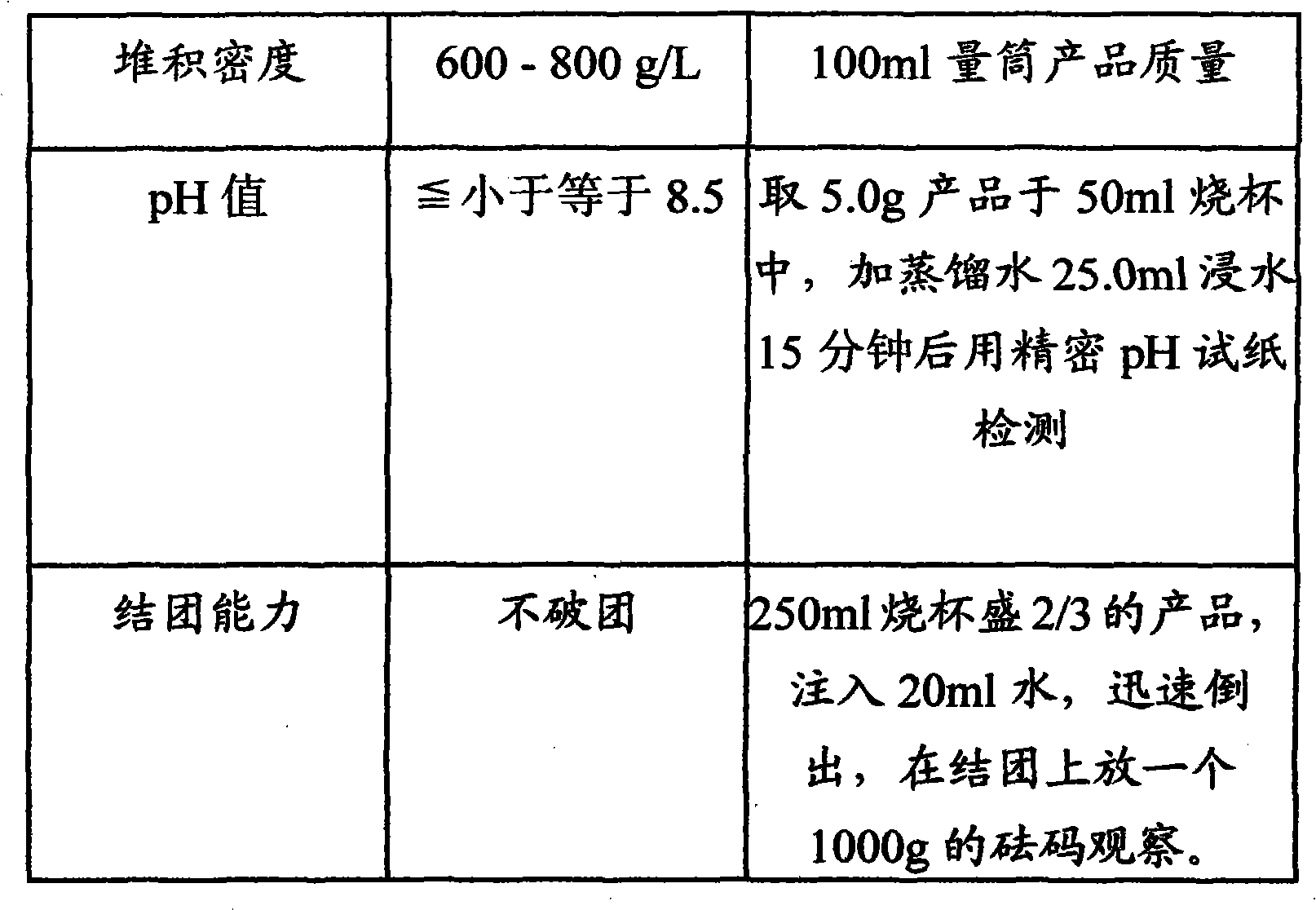

Cat litter and making method thereof

InactiveCN102150627AEnhanced adsorption and deodorization abilityImprove deodorization abilityAnimal housingSodium BentoniteSilica gel

The invention discloses cat litter comprising a composition prepared from the following components in percent by weight: 50-80% of inorganic clay, 5-15% of silica gel, 5-20% of organic substrate and 8-20% of mineral matter, wherein the inorganic clay is selected from one or a mixture of attapulgite, bentonite, kaolinite and sepiolite; the organic substrate is selected from one or a mixture of corncob, corn, wheat, clover, peanut hull, walnut shell, pine wood shavings and broadleaved tree wood shavings; and the mineral matter is selected from one or a mixture of perlite, diatomite, pumice and other low-density mineral matters. The cat litter disclosed by the invention has the following advantages of largely strengthened adsorption deodorization capacity due to the addition of the silica gel component, stronger deodorization capacity by utilizing the adsorbability of natural materials, natural fragrance, small weight and strong caking capability, in particular no dust and easiness for treatment; and the cat litter disclosed by the invention is 40% lighter than the traditional bentonite cat litter.

Owner:QINGDAO FRANK FINE CHEM

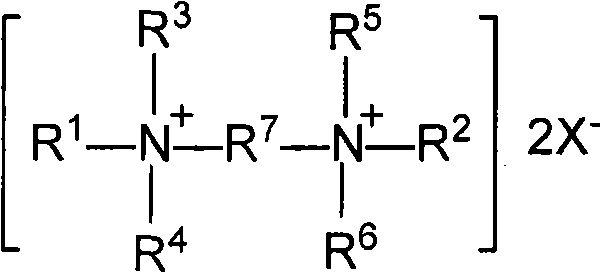

Use of quaternaries compound in floating silicate mineral

The invention relates to the field that biquaternary ammonium compounds are applied in silicate mineral flotation, and discloses a collector which applies the biquaternary ammonium compound with the constitutional formula shown as the formula I in bauxite or ironstone reverse flotation desiliconization. In the formula I, R<1> and R<2> are alkyls with 6-18 carbon atoms; R<3>, R<4>, R<5> and R<6> are respectively methyl, ethyl, -(CH2CH2O)nH, or -(CH(CH3)CH2O)nH, wherein, n is equal to 1-6; R<7> is alkylene with 2-6 carbon atoms; and X is Cl, Br or I. The collector of the invention has strong ability to collect quartz, kaolinite, illite and pyrophyllite, and is applicable to the silicate mineral separation from the bauxite or ironstone by reverse flotation, the suitable pH range of the flotation pulp is 5-13, and the dosage is equal to 50-500 g / t according to the content change of the silicate mineral in ores.

Owner:CENT SOUTH UNIV

Expendable pattern casting (EPC) molding shell paint for casting steel and preparation method thereof

InactiveCN102407275AHigh strengthImprove breathabilityFoundry mouldsFoundry coresFiberPolyvinyl alcohol

The invention relates to an expendable pattern casting (EPC) molding shell paint for casting steel, and the EPC molding shell paint comprises surface a layer fireproof paint and a back layer reinforcing paint, wherein the surface layer fireproof paint comprises the following components in parts by weight: 80-90 parts of high-chromium alundum powder, 10-20 parts of calcined kaolinite, 6-8 parts ofcalcium rectorite powder, 1-3 parts of sodium tripolyphosphate, 3-5 parts of polyvinyl formal solution, 0.3-0.5 part of ethoxylated alkyl sodium sulfate, 0.6-1.0 part of polyether type modified polydimethylsiloxane and 60-75 parts of water; and the back layer reinforcing paint comprises the following components in parts by weight: 75-85 parts of coal gangue sand, 15-25 parts of kaolinite, 3-6 parts of feldspar powder, 8-13 parts of calcium rectorite powder, 8-10 parts of sodium tripolyphosphate, 1.5-2.0 parts of wood fiber and 30-45 parts of water. A molding shell manufactured by the surface layer fireproof paint and the back layer reinforcing paint has the characteristics of high strength and refractoriness, good air permeability and the like.

Owner:HUBEI UNIV OF TECH

Nano-grade Y type zeolite synthesized from kaolin and its preparation metod

InactiveCN1533982ASpecial nest structureSmall grainCatalytic crackingMolecular sieve catalystsKaoliniteFuel oil

A nano-class Y zeolite prepared from raw kaolinite powder through crystallizing has 30-85 wt.% for NaY content. Its primary particles can be rod-shaped, flaky or block crystal. Its secondary particle is the nest-type sphere. It can be made into HY, REY, or REHY and used as the catalyst for catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oxygen-containing coal bed gas deoxidation catalyst and preparation thereof as well as applications

InactiveCN101322942ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsMordeniteAluminum silicate

The invention discloses a deoxidizing catalyst for a coal-seam gas containing oxygen and a preparation method as well as an application thereof. The deoxidizing catalyst of the invention consists of an active component, an active auxiliary and a porous carrier. The active component is the compound of Co; the active auxiliary is one or more compounds of Mn, Fe, Zn and Cu; the porous carrier is one or more of aluminum oxide, titanium oxide, zirconium oxide, magnesium oxide, calcium oxide, silicon oxide, a phosphor-aluminium molecular sieve, an A-typed molecular sieve, an X-typed molecular sieve, a Y-typed molecular sieve, a mordenite, a ZSM-5 zeolite, diatomaceous earth, kaolinite, natural clay, aluminum silicate and magnesium silicate; calculated by oxide, the weight percentage of the active component is 1 to 60 percent; the weight percentage of the active auxiliary is 1 to 50 percent; the rest is the carrier. The catalyst of the invention has certain sulfur-resistance performance, is applicable to the deoxidization treatment of coal-seam gas with an oxygen content of 3 to 6 percent (V / V) and is capable of causing the oxygen content in the coal-seam gas to be lower than 0.5 percent by deoxidization.

Owner:HAO HUA CHENGDU TECH

Treatment and production technique for calcining kaolin

A process for preparing the calcined kaolinite includes such steps as dressing ore, crushing, pulverizing by 325 meshes, mixing with water and disperser, pulverizing by 4500-6000 meshes, drying, pulverizing, calcining at 970-990 deg.C for 30-40 min while adding whitening agent, and breaking. Its features high whiteness and fineness.

Owner:SANBAO KAOLINIE CLAY INNER MONGOLIA

Compositions and methods for removing mercury from mercury-containing fluids

Oxidative sorbents are provided for adsorbing elemental or oxidized mercury from mercury-containing fluids such as flue gas from a coal-burning power utility or the like at a temperature range of about 50 to 350° C. The method of preparing and using the oxidative sorbents is also provided. The oxidative sorbent compositions include one or more silicates capable of cation exchange with a plurality of active metal cations and their counter anions. The silicates may include those selected from clays such as montmorillonite, laumonite, bentonite, Mica, vermiculite and kaolinite, and from silica gels, natural and synthetic molecular sieves, zeolites, and ashes from stoker- and pulverized coal-fired boilers. The one or more oxidative metal halides and / or sulfates may be selected from the group consisting of CuCl, CuBr, CuCl2, CuBr2, CuSO4, FeCl2, FeCl3, FeSO4, Fe2(SO4)3, ZnCl2, ZnBr2, NiCl2, and NiSO4. The oxidative sorbents may also include activated carbon.

Owner:U S ENVIRONMENTAL PROTECTION AGENCY UNITED STATES OF AMERICA THE AS REPRESENTED BY THE ADMINISTATOR

Method for making polyester for low-haze biaxial stretching polyester film

The invention discloses a method for preparing polyester for a low-haze biaxially oriented polyester film. The method takes dibasic acid and dihydric alcohol as the main materials to prepare low-haze biaxially oriented polyester film through direct esterification method by means of esterification and polycondensation. Agglomeration resistant agent and catalyzer are added during the esterification process and stabilizer is added during the polycondensation process; agglomeration resistant agent is steatite, calcium carbonate, barium sulfate or kaolinite. When taking the polyester prepared through the method of the invention to make films, no other agglomeration resistant agents are needed, the haze is more than 30%lower than normal like products and the agglomeration resistance is comparable with normal like products.

Owner:SINOPEC YIZHENG CHEM FIBER

Preparation method of low-cost high-alumina ceramic thin plate

The invention relates to a preparation method of a low-cost high-alumina ceramic thin plate. The preparation method of the low-cost high-alumina ceramic thin plate is characterized by including the steps: 1) raw material treatment; 2) raw material proportioning and mixing: weighing raw materials including, in weight percent, 10%-25% of coal series kaolinite, 10%-25% of calcined bauxite, 20%-30% ofcommon kaolinite, 15%-25% of feldspar, 0-5% of talcum and 18%-25% of quartz to obtain a blank; adding reinforcing agents equivalently accounting for 0.1%-0.25% of the total weight of the blank, performing ball milling for 12-18 hours and uniformly mixing the raw materials to obtain mixed materials; 3) pelleting and aging; 4) semi-dry pressing; 5) drying; 6) glazing; 7) sintering to obtain the low-cost high-alumina ceramic thin plate. The feldspar is formed by mixing potassium feldspar with soda feldspar, and the weight ratio of K2O to Na2O of the mixed feldspar chemical composition is 2:1. The sintering temperature of the high-alumina ceramic thin plate prepared by the method is only 1180 DEG C, so that the ceramic thin plate is low in cost and high in strength.

Owner:WUHAN UNIV OF TECH

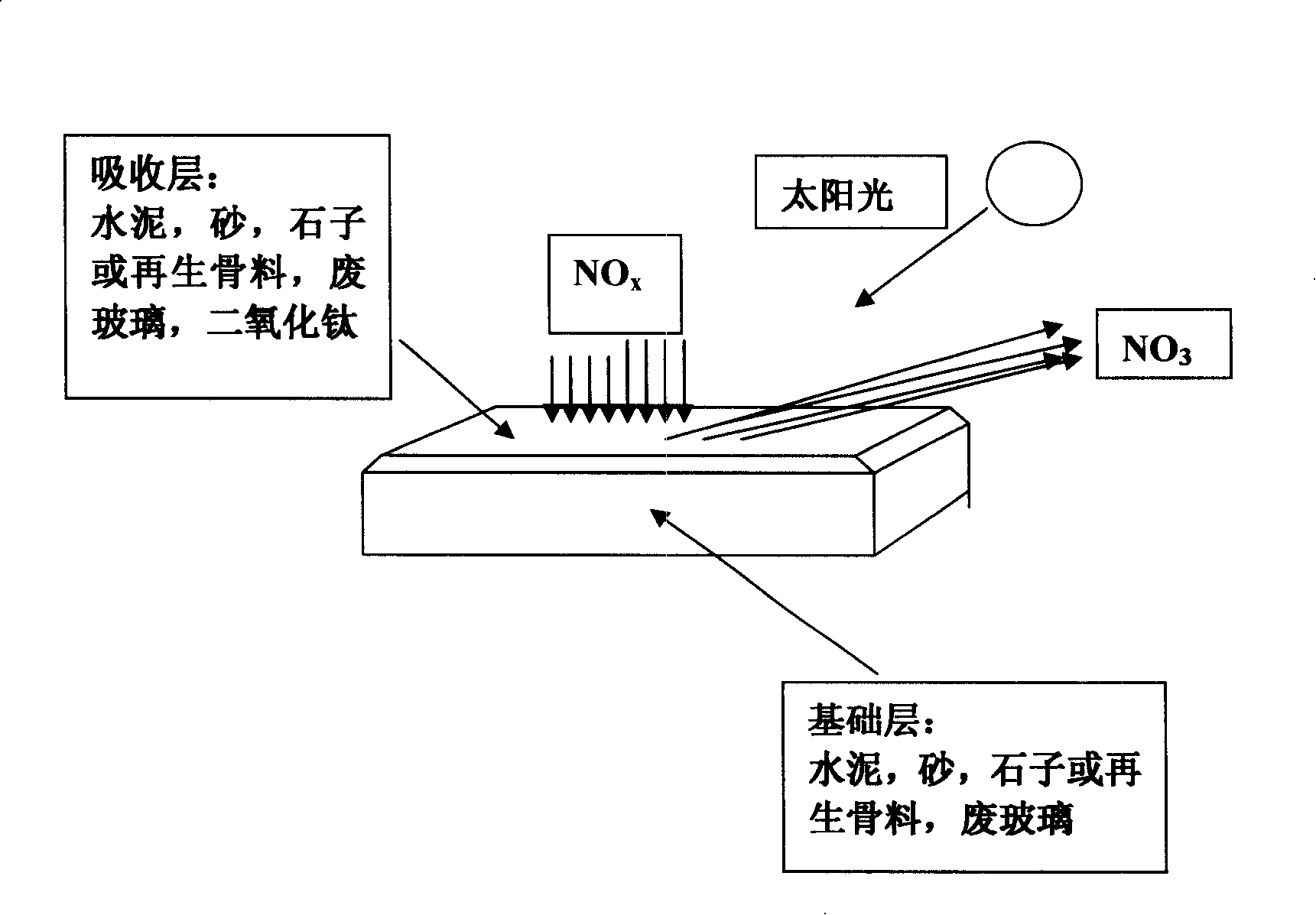

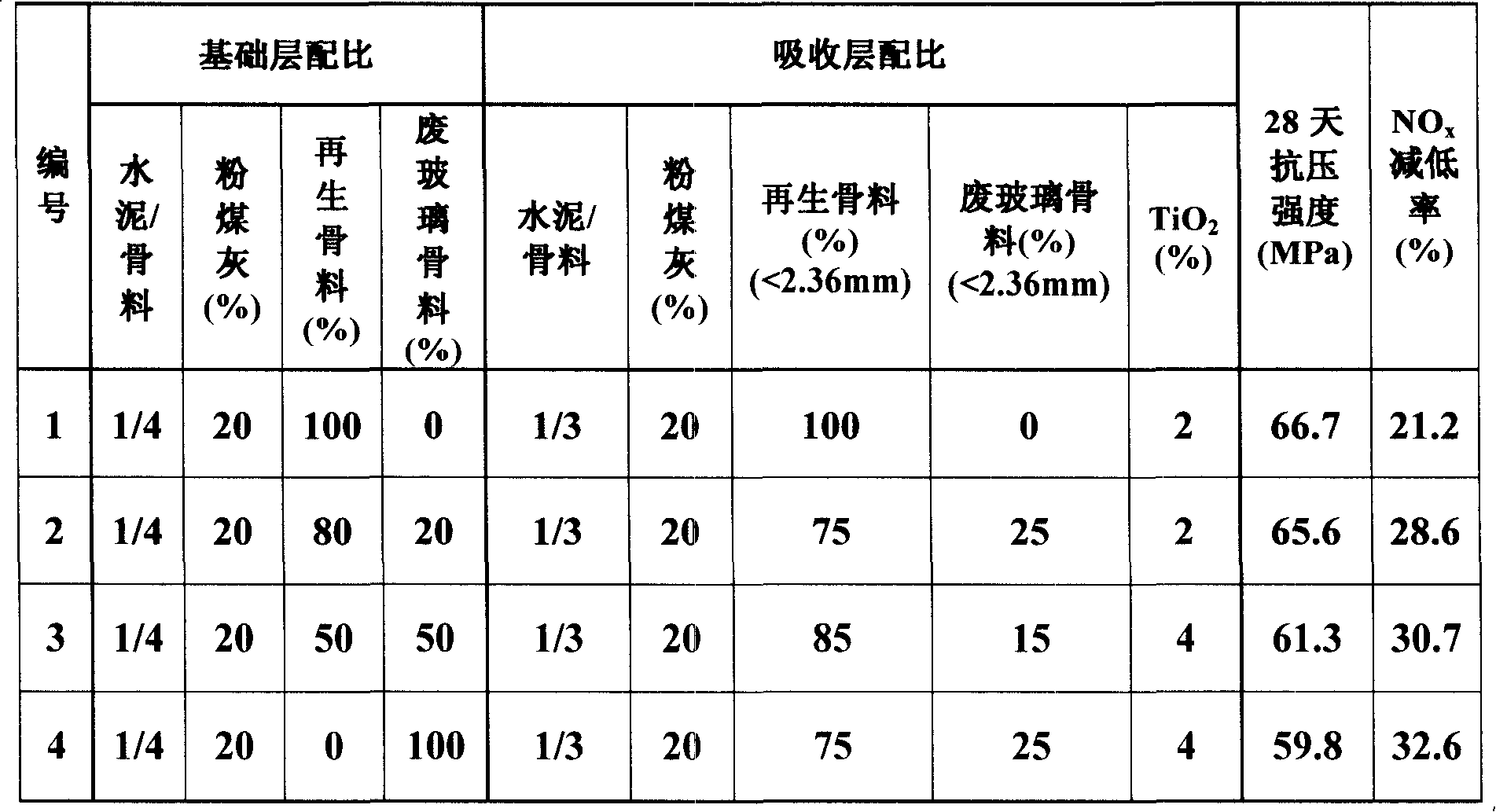

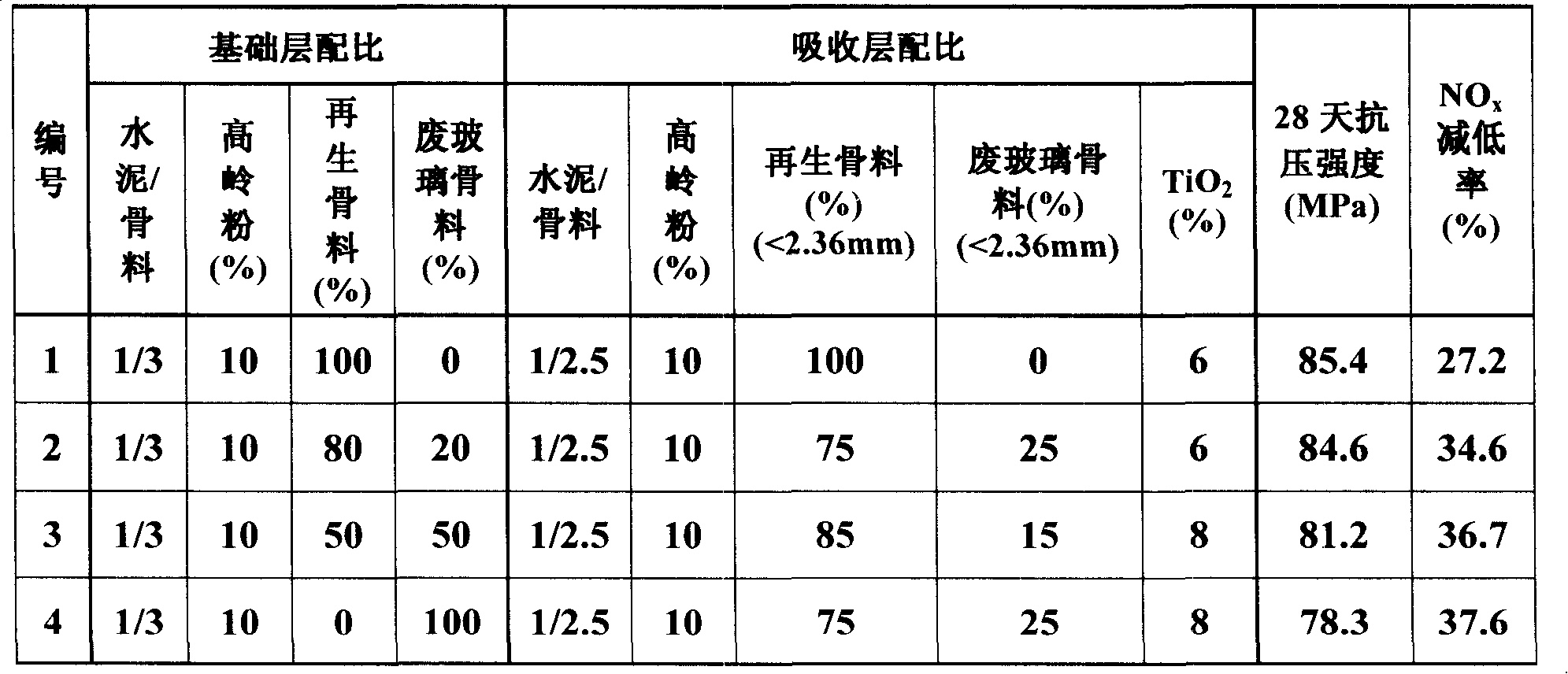

Concrete paving brick capable of purifying air and method for manufacturing the same

The invention provides a concrete paving brick capable of clarifying air produced by using building waste and recycled glass and the manufacturing method thereof. The paving brick comprises an absorption layer and a foundation layer, the absorption layer comprises cement, aggregate, titanium oxide and coal ash or kaolinite powder, the aggregate of the absorption layer comprises recycled aggregate, waste glass aggregate and sand or stones; the foundation layer comprises cement, aggregate and coal ash or kaolinite powder, the aggregate of the foundation layer comprises recycled aggregate, waste glass aggregate and sand or stones. The paving brick of the invention has good function of absorbing exhaust gas and good strength.

Owner:THE HONG KONG POLYTECHNIC UNIV

Methods for smoothing wrinkles and skin texture imperfections

InactiveUS20130189332A1Excellent initialExcellent lasting contractionCosmetic preparationsBiocideWrinkle skinKaolinite

A method for smoothing skin comprising applying a composition that has from about 0.5 to about 4% sodium silicate as measured by silica content (SiO2) and from about 0.1% to about 4.0% of a polyvalent silicate. The composition is provided in a carrier, for example, from about 10 to 98% water, and can be in the form of a water gel or oil-in-water emulsion. A second composition is applied before or after the first composition wherein the second composition is selected from the group consisting of an oil-in-water emulsion, water-in-oil emulsion, thickened water gel, thickened oil phase, encapsulated oil phase, solid oil phase, and mixtures thereof. The polyvalent silicate can be a silicate clay selected from the group consisting of bentonite, laponite, smectite, and kaolinite.

Owner:THE PROCTER & GAMBLE COMPANY

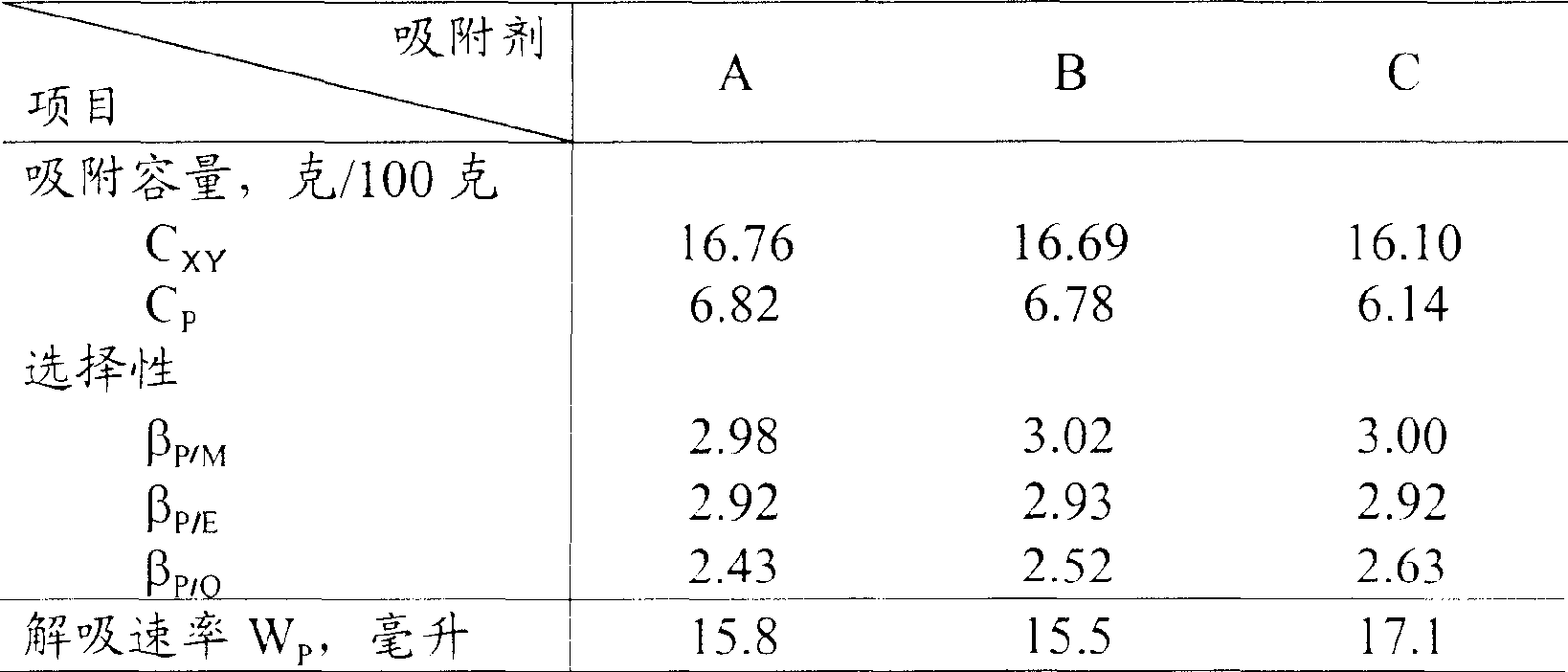

Paraxylene adsorbent and preparing method thereof

InactiveCN1552515AHigh bulk densityIncreased crush strengthOther chemical processesHydrocarbon oils refiningKaoliniteActive component

An adsorbent for adsorbing p-xylene from mixed C8 arylhydrocarbon is composed of the adsorptive active component chosen from Ba or Ba and K exchange X zeolite to Y zeolite (88-95 mass%) and the kaolinite. Its advantages are high adsorption capacity and high adsorption selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of kaolin type fluid catalytic cracking catalyst

InactiveCN1429882AHigh zeolite contentStrong resistance to heavy metalsCatalytic crackingHigh resistanceMicrosphere

A catalyst for catalytic cracking process is prepared from kaolinite, solid crystal seed, assistant, organic disperser and / or adhesive through spray drying, shaping microspheres, high-temp calcining,crystallizing reaction on sodium silicate and sodium hydroxide to obtain crystallized microspheres (content of NaY zeolite is 20-70%, ratio of zeolite silica-alumina is 4.0-6.0), calcining, and exchanging with NH4 and Re3 three times. Its advantages are high resistance to heavy metal, high activity and stability, and low cost.

Owner:QILU PETRO CHEM - SINOPEC

Preparation method of high activity fluid catalytic eracking catalyst

InactiveCN1429883AHigh zeolite contentStrong resistance to heavy metalsCatalytic crackingCatalyst activation/preparationHigh resistanceAdhesive

A high-activity catalyst for catalytic cracking process is prepared from kaolinite, solid seed, assistant, organic disperser and adhesive through spray drying, shaping, microspheres, high-temp calcining, crystallizing reaction on sodium silicate and sodium hydroxide to obtain crystallized microspheres content of zeolit is 20-70%, ratio of zeolit silica-alumina is 4.0-6.0), calcining, and exchanging with NH4 and Re3 three times. Its advantages are high resistance to heavy metal, high activity and stability, and low cost.

Owner:CHINA PETROLEUM & CHEM CORP

Method for modifying kaolinite

ActiveCN101045202ALarge specific surface areaLarge pore volumeCatalytic crackingPhysical/chemical process catalystsKaoliniteSlurry

A process for modifying kaolinite includes such steps as proportionally mixing kaolinite, dispersing modifier, acid solution and deionized water, beating, calcining, cooling, and washing with deionized water. The modified kaolinite has large specific surface area and pore volume, and high catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

High blending flyash porcelain brick and its making method

InactiveCN1410386AImprove adhesionImprove plasticizing effectSolid waste managementClaywaresBrickGranularity

A ceramic tile with high content is flyash is prepared from flyash (60-700 wt.%), superfine kaolinite (25-40) prepared by the nano intercalation technique, and feldspar (0-10) through pretreating rawmaterials, compounding, pulping, baking, grinding, adding water and granulating, ageing, die pressing, baking, sintering and cooling. Its advantages are low cost, low hydroscopicity (less than 0.5%),and high modulus of rupture (more than 35 MPa).

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Foundry water-soluble composite salt core material, salt core preparation method and prepared salt core

The invention relates to a foundry water-soluble composite salt core material, a salt core preparation method and a prepared salt core. The foundry water-soluble composite salt core material consists of 45 to 55 kilograms of water-soluble metal arsoniumsalt, 150 to 250 ml of bonding material and 120 to 250 grams of reinforcing agent, wherein the reinforcing agent may be kaolinite or talcpowder. The foundry water-soluble composite salt core material is prepared by mixing-molding and sintering the water-soluble metal arsoniumsalt, the bonding material and the reinforcing agent. The salt core material has low cost and production cost, high strength and low body shrinkage.

Owner:湖南江滨机器(集团)有限责任公司

High-performance variable-pressure adsorption 5A molecular sieve and preparing method thereof

InactiveCN1530167AReduce dosageHigh adsorption capacityOther chemical processesMolecular sieveKaolinite

A high-performance 5A molecular sieve with pressure-variable adsorption function is prepared through proportionally mixing the raw powder of 4A molecular sieve with kaolinite-type clay, adding plant fibres, granulating, sieving, baking, calcining at 200-1000 deg.C, immersing in the solution of sodium hydroxide, washing, Ca ion exchanging in CaCl2 solution, washing, baking, and calcining at 100-800 deg.C. Its advantages are high adsorption capacity, diffusing speed, and mechanical strength.

Owner:江苏洁欧康科技有限公司

Method for preparing sheet alumina using coal series kaolin rock or flyash as raw material

A process for preparing flaky aluminum oxide from coal kaolinite or powdered coal ash includes such steps as pulverizing, magnetic separation, high-temp calcining, extracting in acid to obtain Al salt, purifying, refining, crystallizing, shaping and pyrolyzing.

Owner:ZHEJIANG UNIV

Preparation method of metal-imitation glaze

The invention provides a production method for a colorful, color-stable imitated metallic luster glaze which can meet the requirements of low-temperature rapid firing process. The method includes: (1) first making the following raw materials into a frit by weight percentage of 10-20 per cent quartz, 40-60 per cent lepidolite, 10-20 per cent boric acid, 2-6 per cent barium carbonate, 3-10 per cent limestone, 3-12 per cent metal oxide and then evenly mixing the raw materials after melting at 1200-1350 DEG C and obtaining a color frit by water quenching. (2) making the glaze with the following materials by weight of 75-90 per cent color frit, 0-20 per cent high boron frit and 5-10 per cent kaolinite. The metallic luster glaze products is colorful and low in sintering temperature and is suitable for the characteristics and style of interior wall glazed tiles of twice low-temperature rapid firing and the frit is produced by sintering metal oxides, therefore the color is very stable.

Owner:冼金源 +1

Preparation method of porous silicon/graphite/carbon composite negative electrode material for lithium-ion secondary battery

ActiveCN108199030AAlleviate volume expansionEasy to makeNegative electrodesSecondary cellsCarbon compositesHigh energy

The invention relates to a preparation method of a porous silicon / graphite / carbon composite negative electrode material for a lithium-ion secondary battery. A silicon source of the composite materialis natural mineral soil: namely kaolinite, montmorillonite, mica powder, wollastonite, vermiculite powder, pumice powder and coal gangue. The silicon source is reduced into elemental silicon by usinga metal element or alloy powder and anhydrous metal chloride under a mild condition, and the reduced porous silicon, graphite and an organic carbon source are subjected to high-energy ball mill mixing. The reduction temperature is low, the inherent pore structure of the natural mineral soil is effectively reserved and the prepared silicon material has relatively high specific surface area and abundant pores and has excellent electrochemical properties. Volume expansion can be effectively relieved through the inherent pore characteristic of the natural mineral soil; and the prepared composite material has higher charge-discharge capacity and stability. Especially the kaolinite is wide in source and low in price, so that the preparation cost of the battery material is greatly reduced. The porous silicon / graphite / carbon composite negative electrode material is friendly to environment, simple in preparation method, instrument and equipment and suitable for industrial production.

Owner:NANKAI UNIV

Catalytic cracking auxiliary agent for increasing heavy oil conversion performance and preparation method thereof

The invention provides a catalytic cracking additive for improving the transformation ability of heavy oil and the preparation method. The catalytic cracking additive is produced by spray shaping, roasting, in-situ crystallization and composite elements modification after natural sepiolite is mixed with natural kaolinite mineral or with one or two roasting kaolinite mineral. Provided with high activity, high heavy metal resistance and good selectivity in cracking reaction, the additive can improve the transformation ability of heavy oil and reduce the olefin content and increase gasoline octane number.

Owner:姚华

Nano stripping method for coal series hard kaolinite

InactiveCN101121828AReduce energy consumptionReduce pollutionInorganic pigment treatmentSilicon compoundsCavitationKaolinite

The present invention discloses a coal hard kaolinite nano-stripping method. The hard kaolinite powder (the particle size of 10 to 20 microns) is used as the raw material; the water and dispersant are added to make the pulp; then the oxidant is added to remove the carbon for purification; then the mixture is put into the saturated solution of potassium acetate; the potassium acetate is used as the intercalation agent; the intercalation layer is made between the kaolinite layers to form the kaolinite-potassium acetate intercalation complex; the power ultrasonic acoustic cavitation is used to strip the intercalated kaolinite; then the surfactant is added to decorate the surface of the stripped kaolinite; finally, the materials are dried and broken to make the nano-kaolinite. The average thickness of the nano-kaolinite chip is between 20 and 60 nanometers; the average particle size of the chip is between 300 and 500 nanometers.

Owner:HEBEI UNIV OF ENG

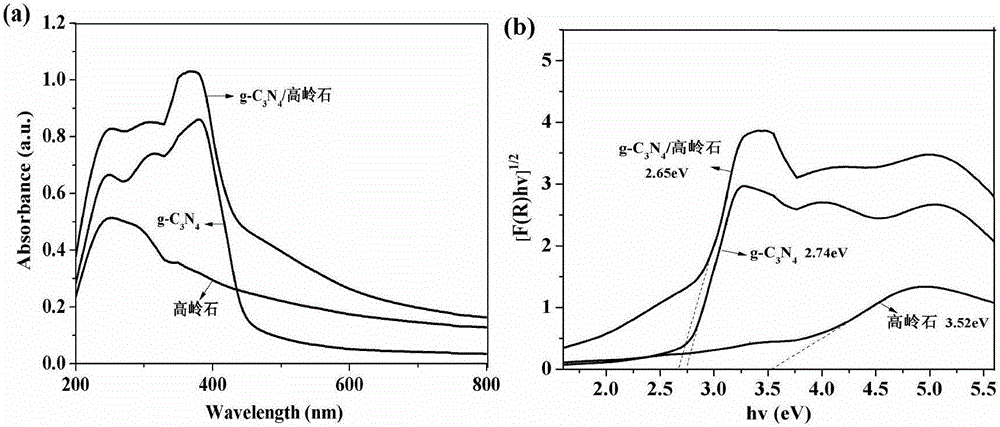

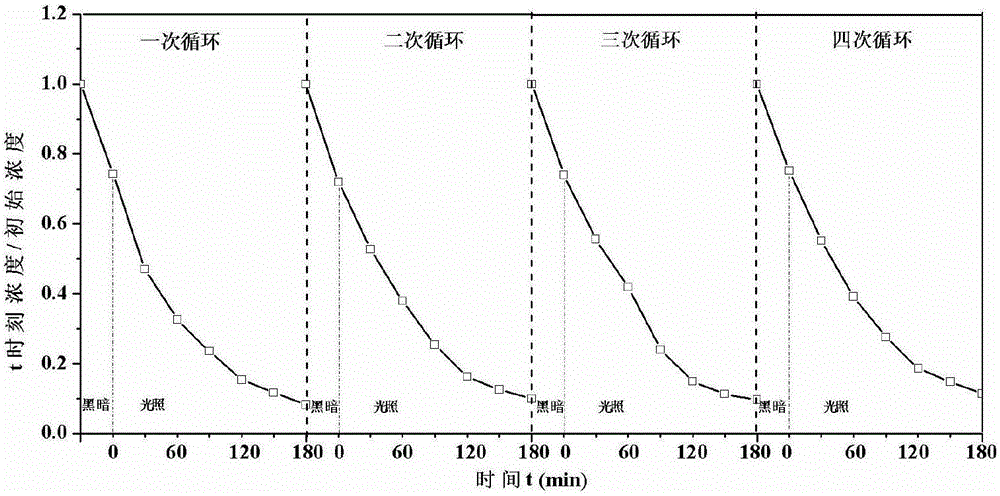

G-c3n4/kaolinite composite photocatalyst and preparation method thereof

InactiveCN106111174ALow application costIn situ assemblyPhysical/chemical process catalystsKaoliniteWastewater

The invention relates to a g-C3N4 / kaolinite photocatalyst and a preparation method thereof and belongs to the fields of nonmetallic mineral material deep-processing and environmental engineering. On the basis of a stratified structure and adsorption characteristics of kaolinite and chemical impregnation and calcination control technologies, piece-to-piece assembly of g-C3N4 and kaolinite is realized, and a kaolinite based composite photocatalytic material with high activity is prepared. With the adoption of the method, compositing of kaolinite and g-C3N4 is realized, g-C3N4 agglomeration and photon-generated carrier recombination are effectively inhibited, and pollutant adsorption and capture performance of the material and dispersibility of the catalyst are improved through a carrier effect of the kaolinite. The composite photocatalytic material has excellent photocatalytic activity under visible light, has low production cost, and is environment-friendly in a use process, thereby having great potential application value in the field of advanced treatment of organic wastewater.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Nanometer kaolinite powder and preparing method thereof

A nano-class kaolinite powder with 0.3-0.9 g / cu.m of bulk density and 400-800 nm of average diameter is prepared from the natural fine-particle kaolinite through removing impurities (Fe, Ti, etc) by magnetic separation and chemical reduction, and unique surface treating to prevent aggregation. It can be used for rubber, plastics, paper, ink and ceramics.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Phyllosilicate mineral depressor for sulfide ore floatation and preparation method thereof

The invention provides a phyllosilicate mineral depressor for sulfide ore floatation and a preparation method thereof. The phyllosilicate mineral depressor for the sulfide ore floatation is prepared from the following components in part by weight: 0 to 20 parts of modified corn starch, 8 to 30 parts of sodium alginate, 1 to 35 parts of carboxymethyl cellulose or polyanionic cellulose or methylenenapadisilate dinaphthalene sulfonate, and 5 to 55 parts of sodium hexametaphosphate. The preparation method comprises the following steps of: selecting the reagents according to types of depressed minerals; adding the reagents in a high-speed mixing granulator in the set ratio for granulation; and drying the obtained grains to obtain the phyllosilicate mineral depressor for the sulfide ore floatation. The product has the characteristics of small dosage, good depression selectivity, low toxicity, and the like. The specific depressor is mainly applied to depressing phyllosilicate minerals such as talcs, serpentines, chlorites, kaolinites and the like during the sulfide ore floatation, thus the specific depressor is favorable for improving floatation concentrate grade and metal recovery rate, and is particularly suitable for floating talc-containing molybdenites and nickel sulfide ores.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Process for recovery of silica followed by alumina from coal fly ash

A process for recovery of silica and alumina from fly ash, in which, Si is leached out from the fly ash in the form of Na2SiO3 using a NaOH solution of NaOH >40% (w / w), followed by separation to obtain a Na2SiO3 solution and a residue having Al—Si ratio ≧2; vaporizing the solution to obtain Na2SiO3 solutions of various concentrations, or producing silica by carbonation, and producing Al2O3 by prior art methods from residues obtained after alkali-leaching, ultimately producing filler or cement from the residue after the recovery of Al. The method permits recovery of Al2O3 directly from fly ash by removing Si before recovering the Al, which raises the Al—Si ratio of the residue after alkali-leaching and thus simplifies the recovery of Al2O3 and raises the rate of Al recovery from fly ash. The invention further includes calcining high Al coal gangue, kaolinite and middle-low-class bauxite at 900-1100° C.

Owner:PINGSHUO INDAL

Tunnel fire-proof slab and preparation method thereof

InactiveCN101344006AImprove flame retardant performanceLow toxicityUnderground chambersDust removalFiberAdditive ingredient

The invention discloses a tunnel fire-proof plate and a manufacture method thereof, relates to a fire-proof material and provides a fire-proof plate which is characterized by light weight, environment protection, high fire retardance, high intensity, low smoke formation and low toxicity, etc. and is applicable to the use of the tunnel and manufacture technique thereof; the tunnel fire-proof plate consists of base material, a modifying agent, reinforcing fiber and a bonding agent, wherein the base material comprises kaolinite, calcium carbonate, magnesium hydroxide and aluminium hydroxide; the modifying agent is expanded vermiculite and expanded perlite; the reinforcing fiber is the composition of inorganic fiber and polymer fiber; and the bonding agent is cement. All the ingredients are added into a high-speed disperser according to the proportion and dispersed uniformly; water is added and stirring is carried out so as to form paste; reverse mould is carried out; the obtained mixture is demoulded after being placed for one day at the room temperature, then dried after being cured for 20 to 28 days under the condition of 60 percent to 70 percent of relative humidity and the finished product is the tunnel fire-proof plate.

Owner:XIAMEN UNIV +1

Art for producing soyabean polypeptide powder without bitter taste

InactiveCN1461597AShorten the enzymatic digestion timeImprove utilization efficiencyProtein composition from vegetable seedsActivated carbonKaolinite

A soybean polypeptide powder without bitter taste is prepared through mixing soybean protein with distilled water, grinding, regulating pH value and temp. adding neutral proteinase, enzymolyzing, deactivating enzyme, regulating pH value and temp. adding pancreatin, enzymolyzing, deactivating enzyme, filter, adding kaolinite powder, adsorption, adding activated carbon powder, adsorption, and vacuum drying. Its advantages are no bitter taste and high quality.

Owner:瑞泰高直生物科技(武汉)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com