Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

564results about How to "Small grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous casting technique for aluminum alloy thin belt blank

InactiveCN101269406AImprove organizationComprehensive mechanical properties of high thin stripIngotMaterials science

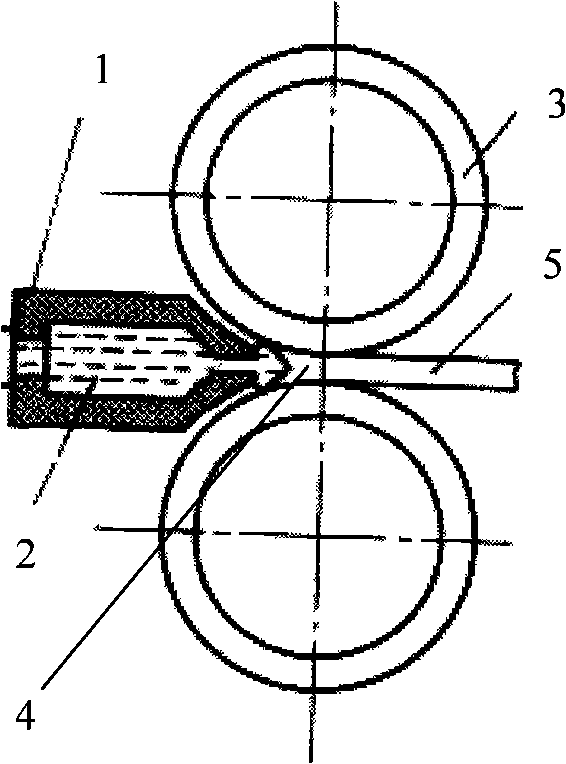

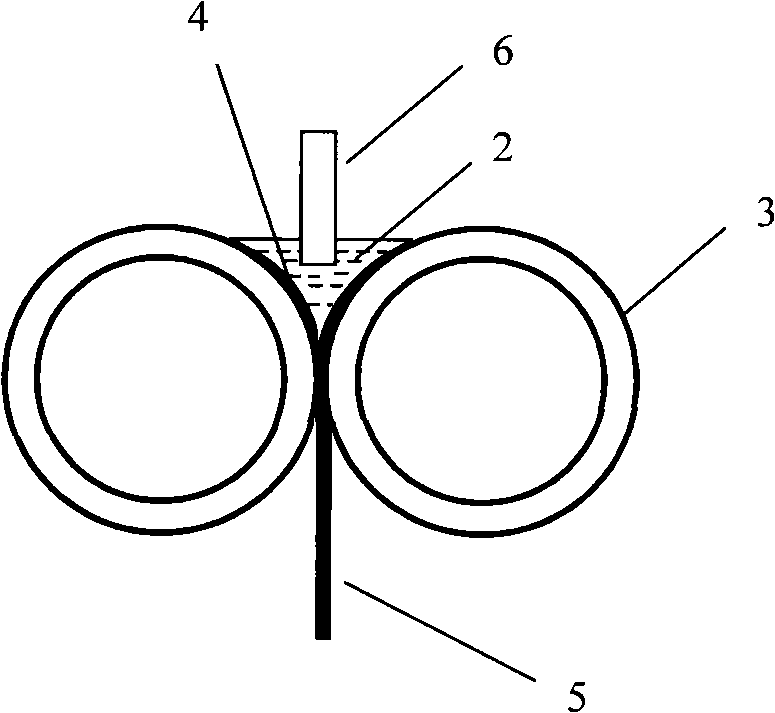

The invention discloses a continuous casting process of an aluminum thin billet, which is characterized in that the following steps are included: aluminum alloy ingots are preheated and are melted in a melting furnace in the role of a flux; before casting, a side closure system is preheated to 400-450 DEG C, when the temperature of a melting body ranges from 650 DEG C to 680 DEG C, the aluminum alloy ingots are arranged into a tundish for 15 to 30 minutes in the role of the flux, then through a flux distributing device, the aluminum alloy ingots flow into an equant vertical twin-roll thin strip billet continuous caster, with a left forging seam gap being 0 mm and maintaining the height of a melting pool between 90 mm and 340 mm, the casting is carried out in a sinking way; when in casting, the casting speed of the casting machine ranges from 20 to 120m / min, the thin strip blank is sent into a pinch roll after leaving a casting roller, and the forged aluminum alloy thin strip has a thickness between 1.0 mm and 3.5 mm. The continuous casting process can directly make aluminum alloy thin strip blank from the liquid aluminum alloy, the forged thin strip blank has good quality on the surface, and the internal organizational structure is uniform, thereby being conducive to succeeding rolling processes. The continuous casting process for an aluminum thin blank has short process and low cost.

Owner:CHONGQING UNIV

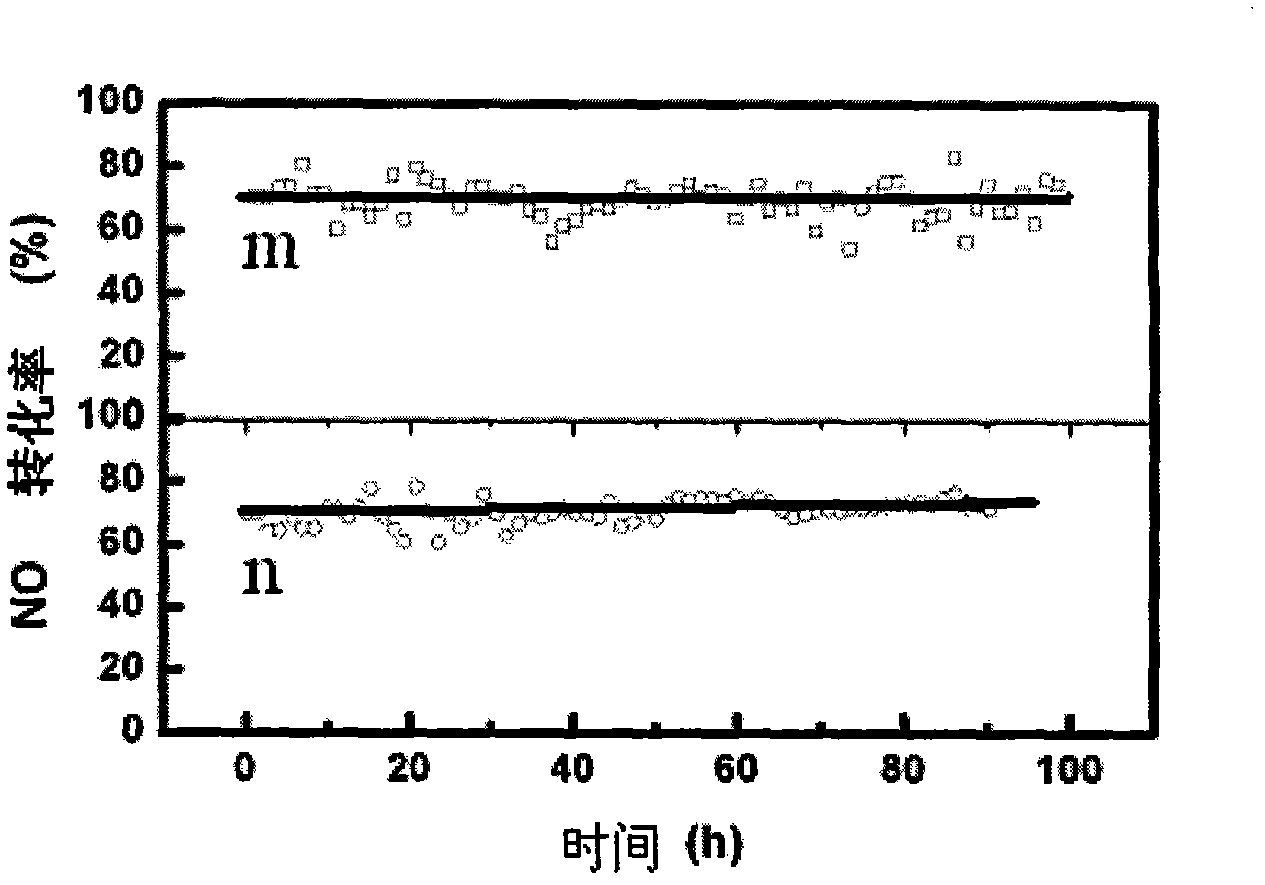

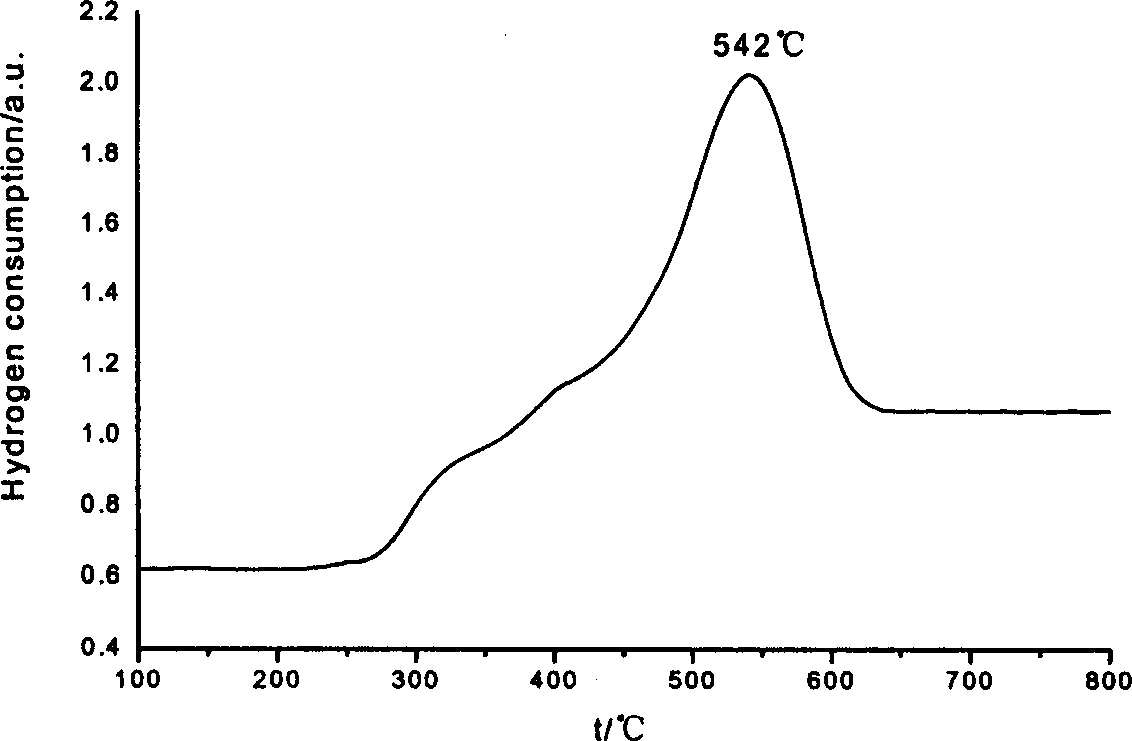

Preparation method of denitration catalyst

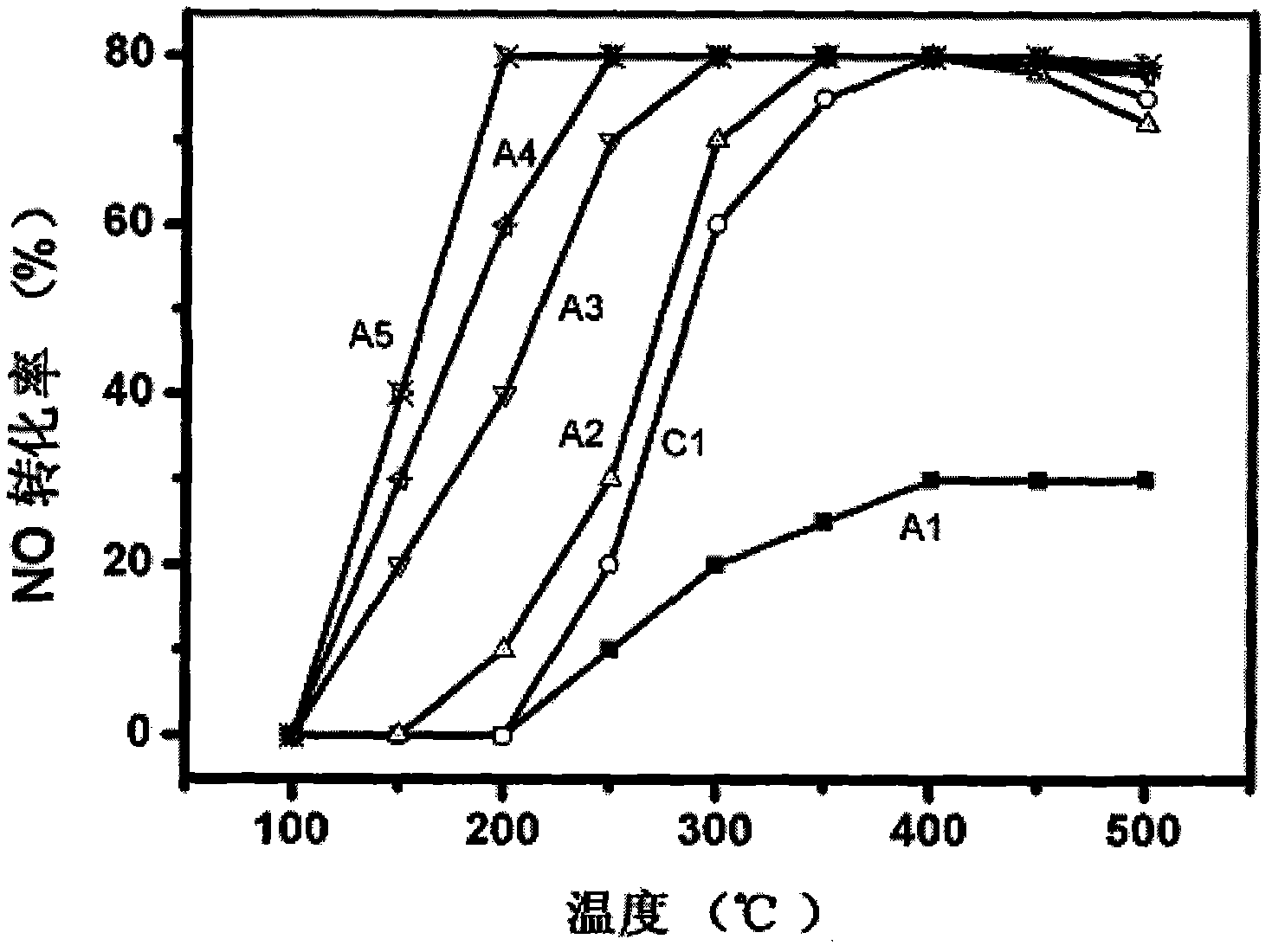

InactiveCN102463110ASmall grainReduce oxidationDispersed particle separationCatalyst activation/preparationSolventTungsten

The invention provides a preparation method of a denitration catalyst, comprising the following steps of: (1) dissolving or dispersing a titanium source precursor and a tungsten source precursor in water to obtain a precursor solution; (2) pouring the precursor solution into a solvent thermal autoclave with stirring for hydrothermal reaction; (3) filtering, washing and drying after the hydrothermal reaction so as to obtain the titanium-tungsten powdered denitration catalyst. According to the preparation method, the hydrothermal synthesis method is adopted to introduce an active component in the mode of in situ synthesis. As the active component is characterized by small crystal grain, low oxidizability and large specific surface, the component can maintain a monolayer dispersion state in a large range. By the titanium-tungsten powder hydrothermal synthesis technology provided by the invention, nationalization of key raw materials of the denitration catalyst can be realized, thus substantially reducing the manufacturing cost of present denitration catalysts.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Nano-grade Y type zeolite synthesized from kaolin and its preparation metod

InactiveCN1533982ASpecial nest structureSmall grainCatalytic crackingMolecular sieve catalystsKaoliniteFuel oil

A nano-class Y zeolite prepared from raw kaolinite powder through crystallizing has 30-85 wt.% for NaY content. Its primary particles can be rod-shaped, flaky or block crystal. Its secondary particle is the nest-type sphere. It can be made into HY, REY, or REHY and used as the catalyst for catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano Cerium-zirconium base compound oxide and preparation process thereof

InactiveCN1449863AAvoid reunionSmall grainDispersed particle separationCatalyst activation/preparationRare-earth elementCerium

The present invention discloses a nano cerium zirconium based compound oxide and its preparation method. Said invented cerium zirconium based compound oxide includes (wt%) 10-90% of CeO2 and 10-90% of ZrO2, and its crystal grain size is greater than or equal to 4 nm or less than or equal to 80 nm. Its preparation method includes the following steps: dissolving nitrates of Ce, Zr and one or more than one metal elements B (B is Ca or Sr or Ba or Mn or Al or Si or any one of rare earth elements except for Ce) in water to prepare solution (I); using hydrogen peroxide and ammonia water and dissolving them in the water to obtain solution (II); adding solution (I) and solution (II) into ammonia water solution, reacting, ageing, suction filtering, drying and roasting at 500-1000 deg.C so as to obtain the invented product with higher chemical activity and thermal stability.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing propene by catalytic cracking

InactiveCN102302945AInhibition of structuringHigh selectivityMolecular sieve catalystsBulk chemical productionPetrochemicalSide reaction

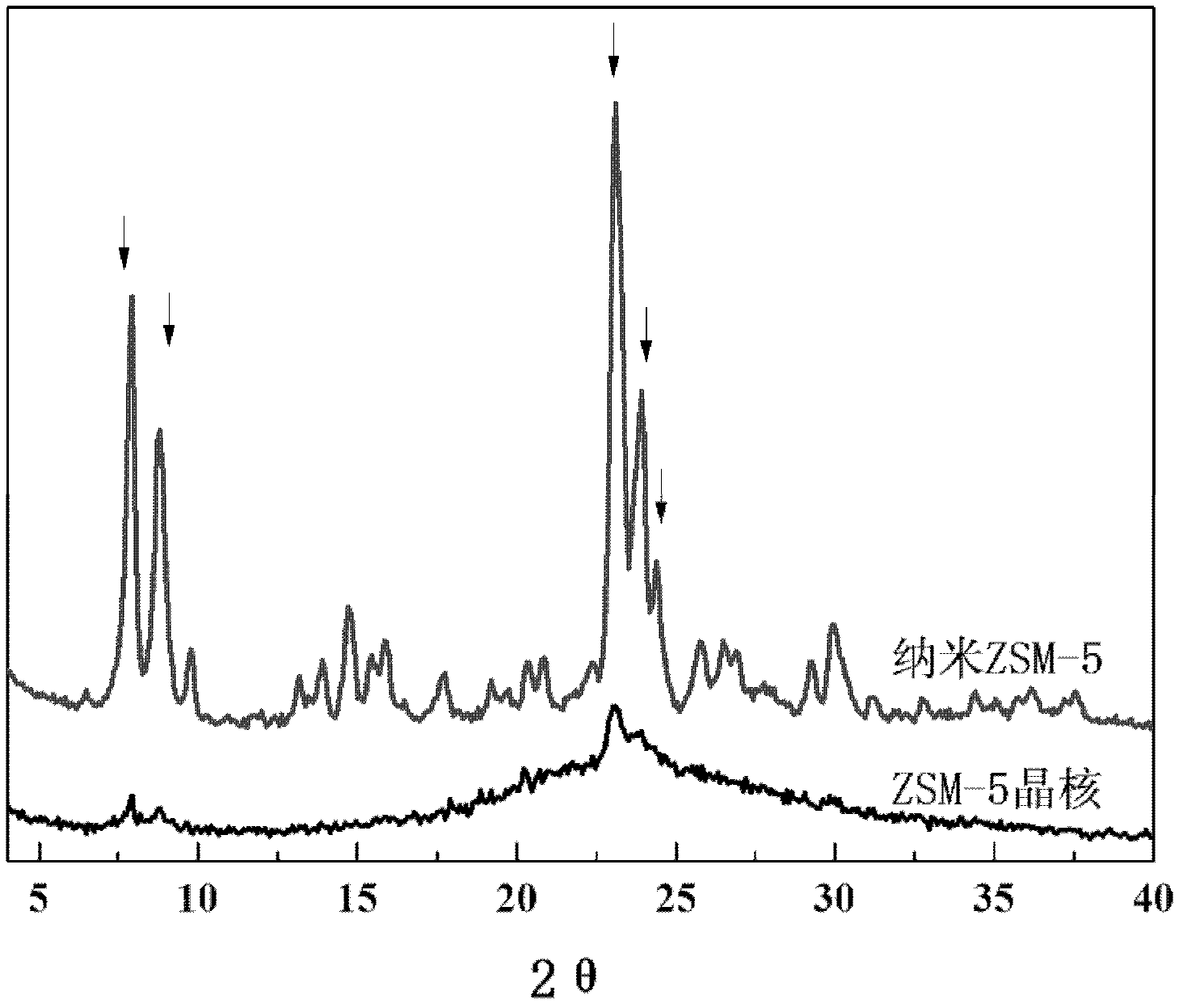

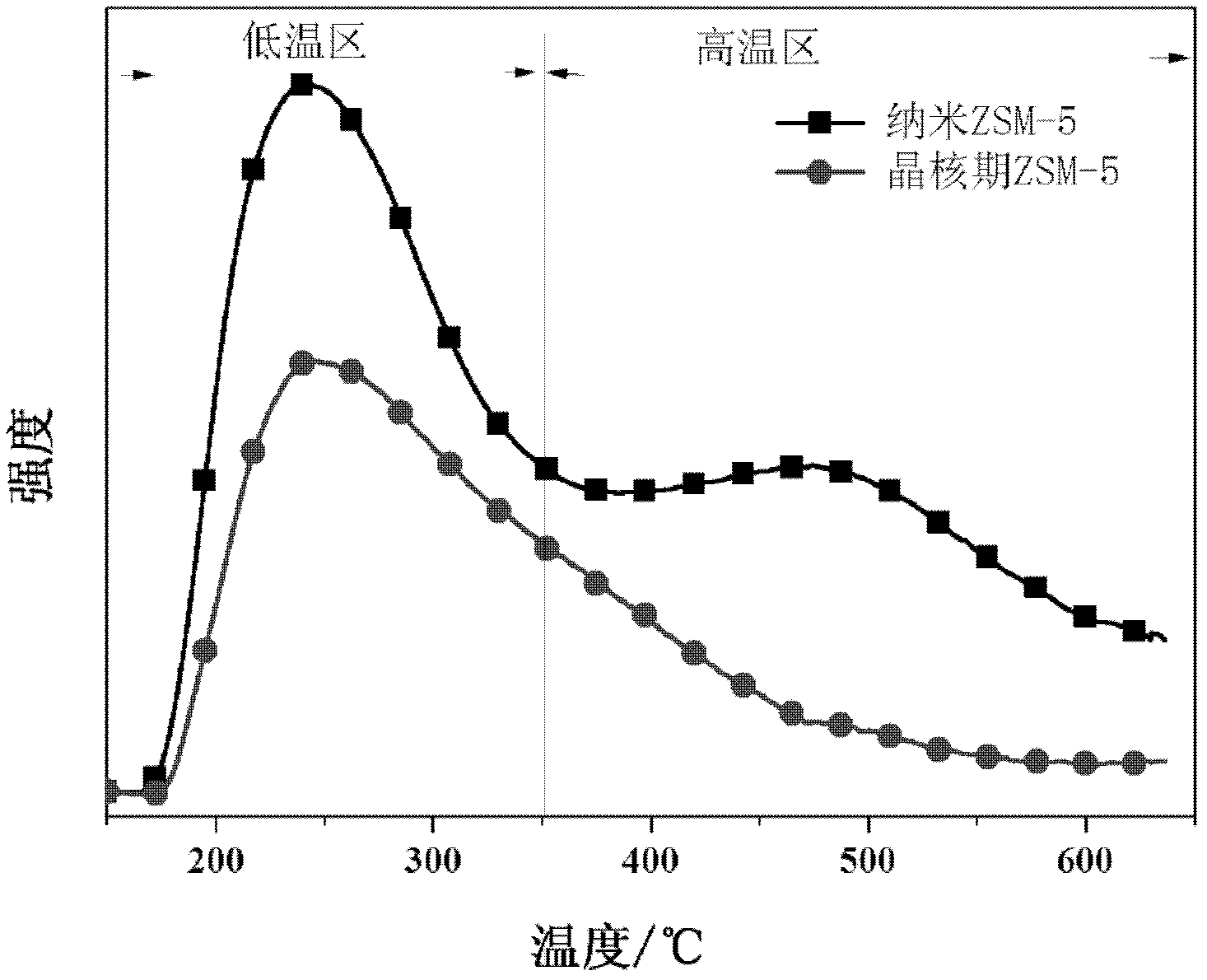

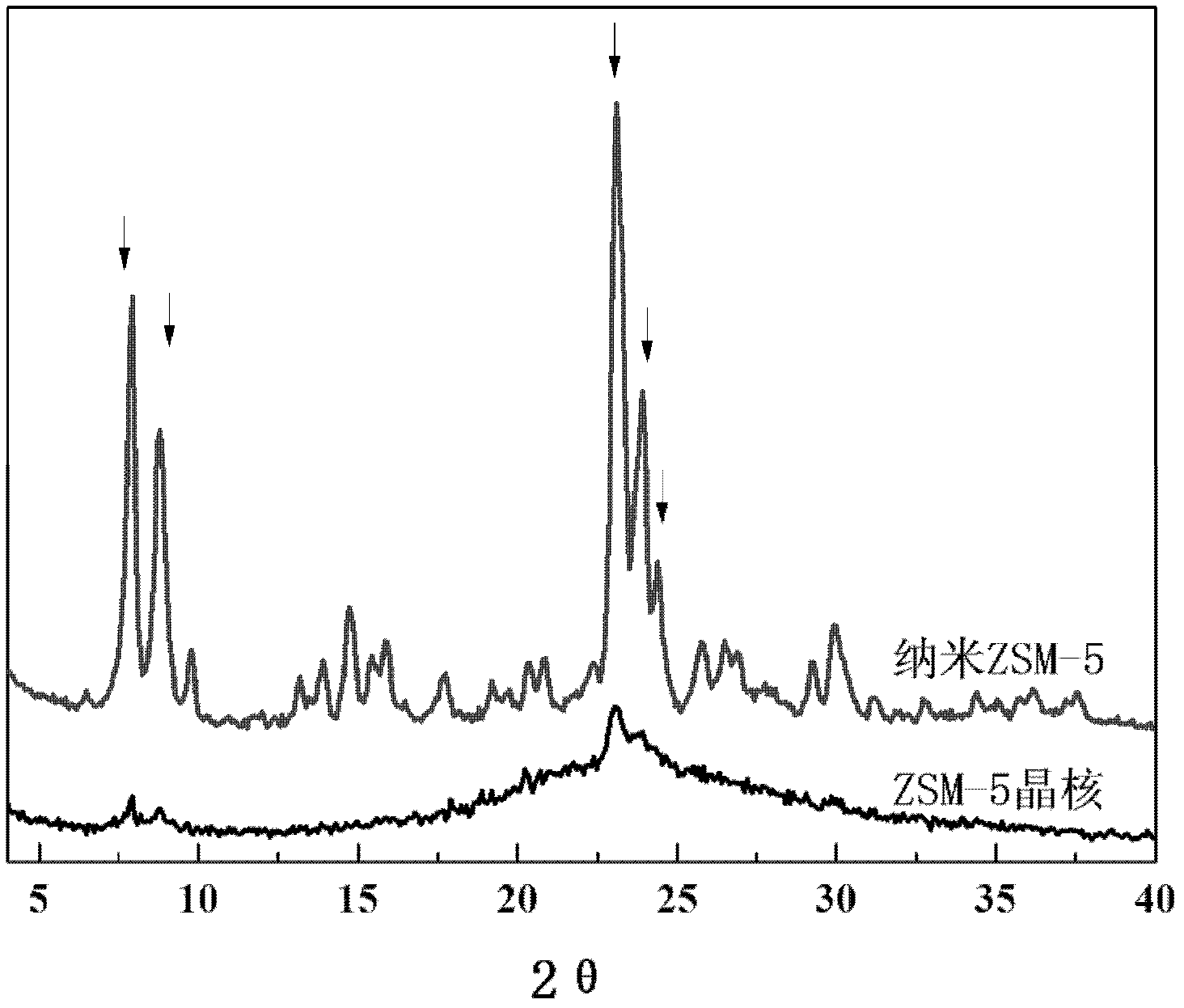

The invention belongs to the field of petrochemical industry, and relates to a method for preparing propene by catalytic cracking, which is characterized by comprising the following steps: firstly synthesizing molecular sieve ZSM-5 crystal nuclei, and preparing a silicon source, seed crystals, templating agent and deionized water into a colloidal liquid; preparing an aluminum source, inorganic acid or alkali and deionized water into a solution; while stirring, adding the solution into the colloidal liquid to prepare a uniform gel; carrying out hydrothermal crystallization on the gel, and stopping crystallization before the crystallization induction period finishes; and preparing the molecular sieve ZSM-5 crystal nuclei into a catalytic cracking catalyst which is used for preparing propylene and isobutylene by cracking olefins. The molecular sieve ZSM-5 crystal nuclei catalyst only has a weak acid center; the crystal grains are very tiny and do not need any modification treatment, and hydrogen transfer aromatization and other side reactions can be obviously inhibited without any negative pressure or diluent gas condition, thereby enhancing the selectivity of the target product, simplifying the catalytic cracking technique and lowering the catalyst cost.

Owner:DALIAN UNIV OF TECH

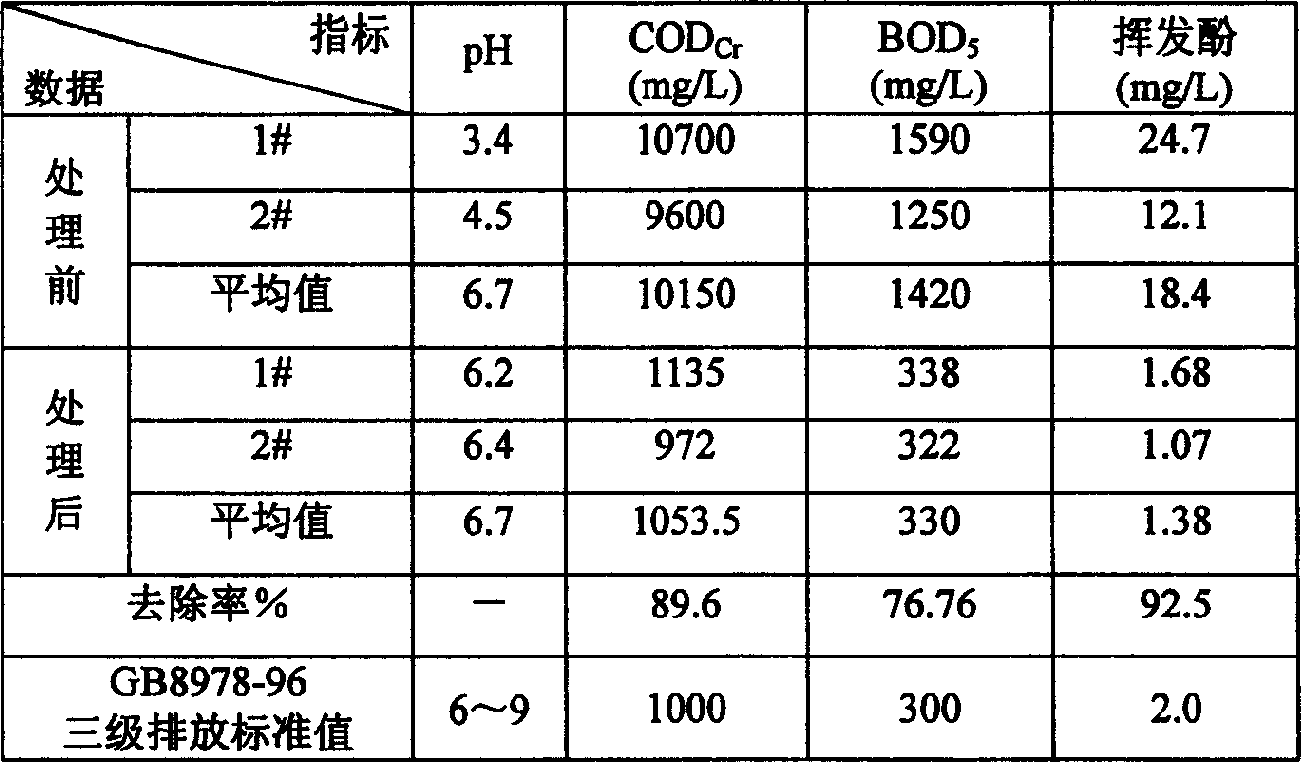

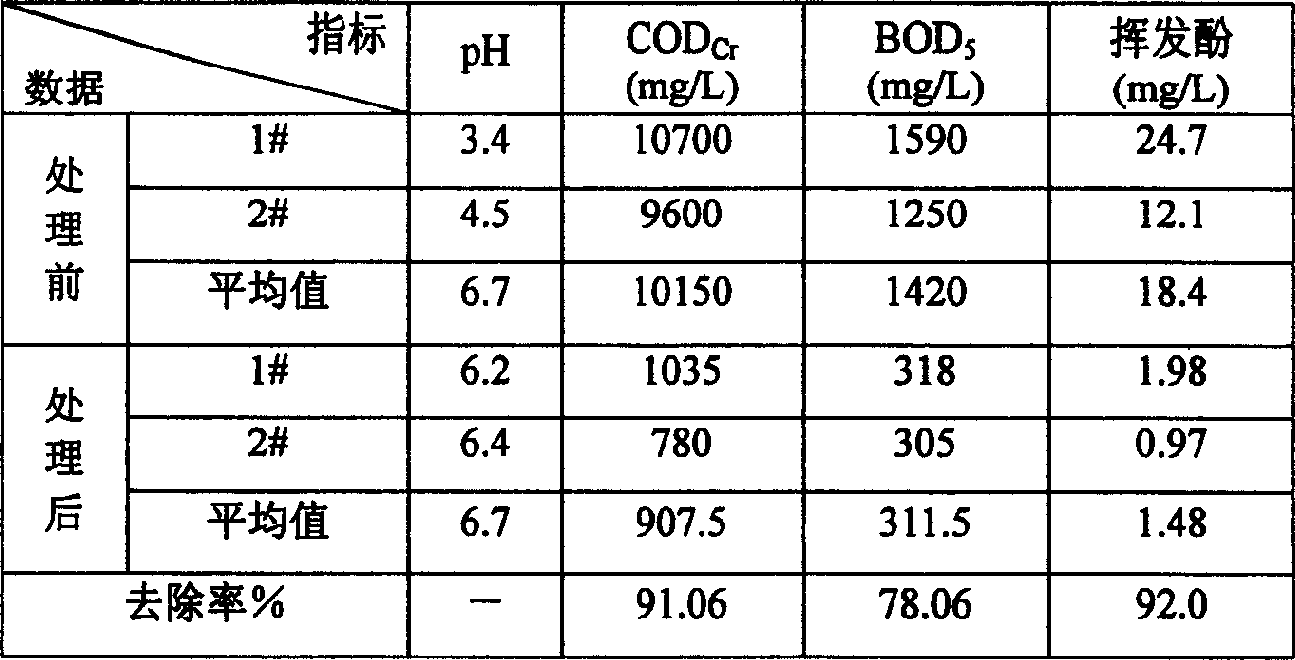

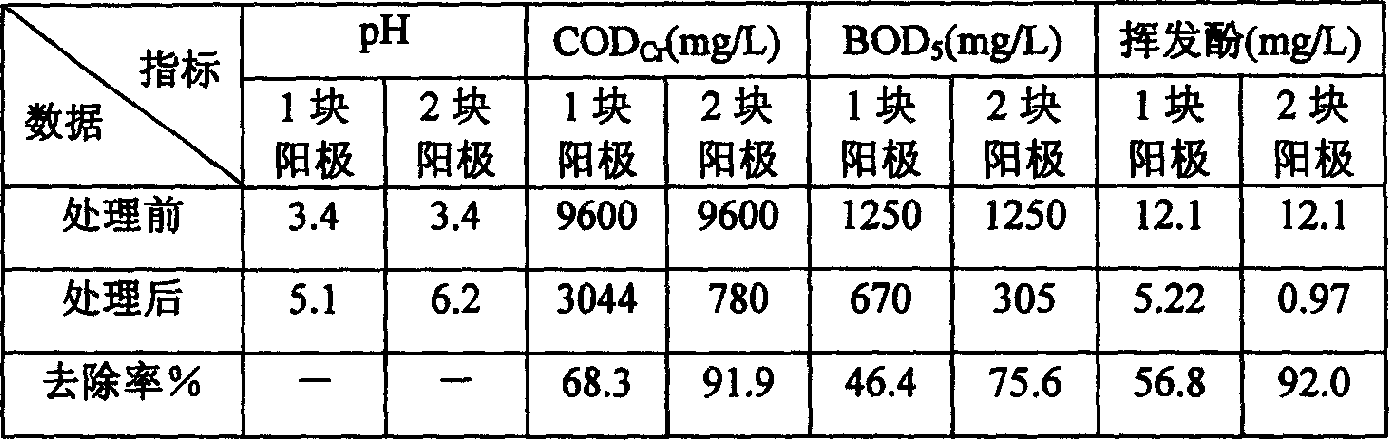

Technique of electrolytic oxidation for treating waste water of containing phenol

InactiveCN1600700AImprove performanceSmall grainWater/sewage treatment by oxidationOxideElectrochemistry

The invention relates to stirringless, internal circulating and double coordinating electrolyzing oxide treatment technology for organic waste water which is difficult to be degradated, particularly for the waste water containing phenol. Internal circulating plate frame electrolytic tank is used, Ti group PbO2 electrode is used as positive pole, stainless steel is negative pole, waste water containing phenol is used as electrolyte to discharge and generate strong oxide group-hydroxyl free radical on positive pole, negative pole get electron to form H2O2, negative and positive poles are coordinated action to realize deep oxide decomposing to phenol pollutant, and then to achieve the goal of treating waste water containing phenol.

Owner:ZHEJIANG UNIV OF TECH

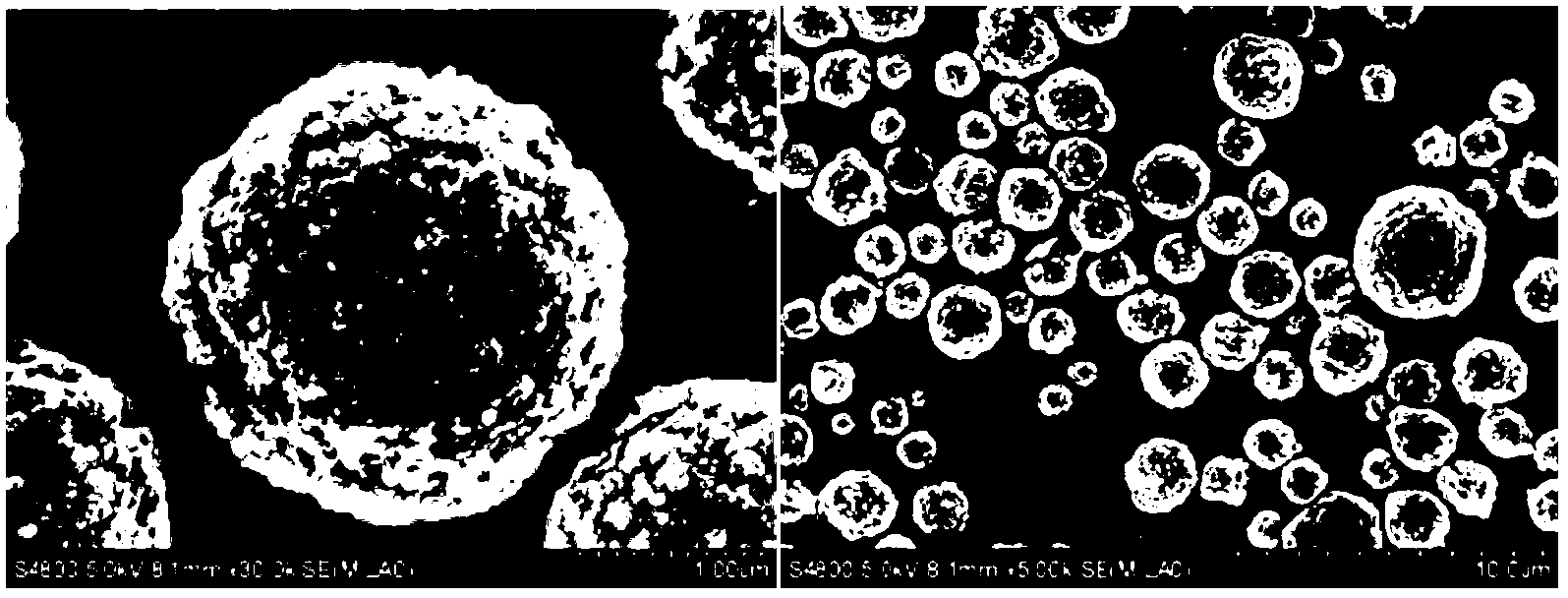

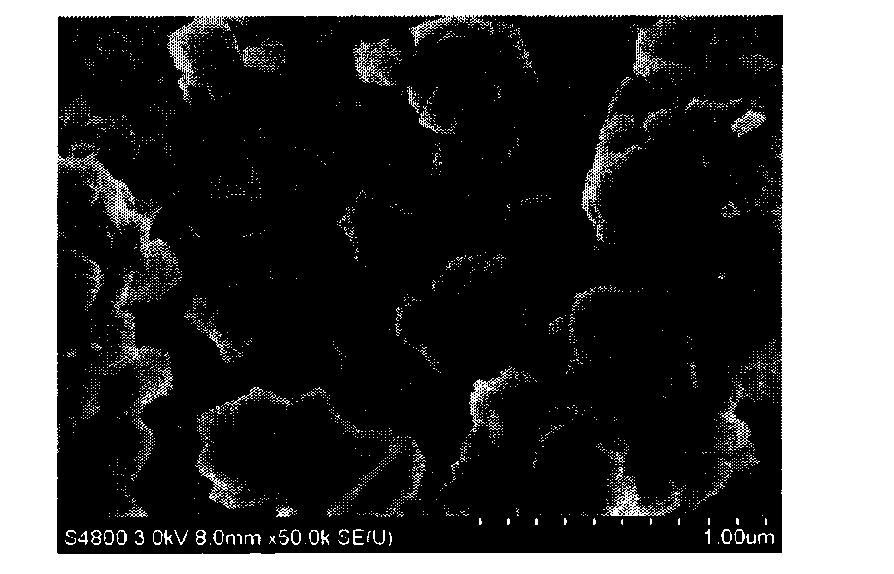

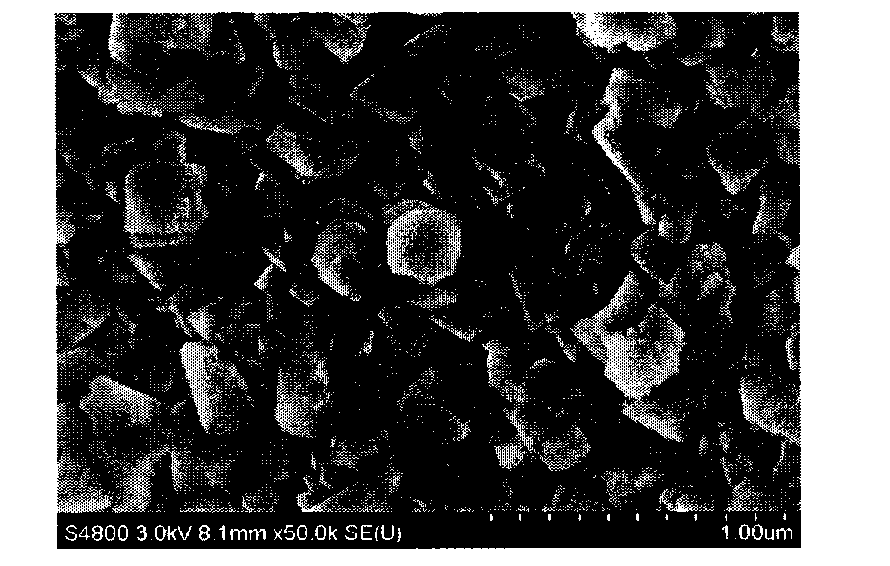

Oxide powder and preparation method thereof as well as catalyst and carrier thereof

InactiveCN103172030ALarge specific surface areaLow densityMaterial nanotechnologyCatalyst carriersMicrosphereSlurry

The invention discloses an oxide powder and a preparation method thereof as well as a catalyst and a carrier thereof. The powder comprises powder of hollow microballoon structure which is formed by converged nanocrystalline oxide, and the wall of the hollow microballoon is provided with a porous structure. The preparation method is the method for preparing the powder. Aqueous solution system slurry suitable for spray drying is prepared by a precipitation method, the target powder is obtained through roasting after spray drying, and the catalyst and the carrier thereof comprise the oxide powder. Compared with the prior art, the powder has the porous hollow microballoon structure, thus having high specific surface area and being beneficial to dispersing substances when being used as the catalyst or the carrier thereof; and the processes are simple, easy to operate and suitable for industrialized production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

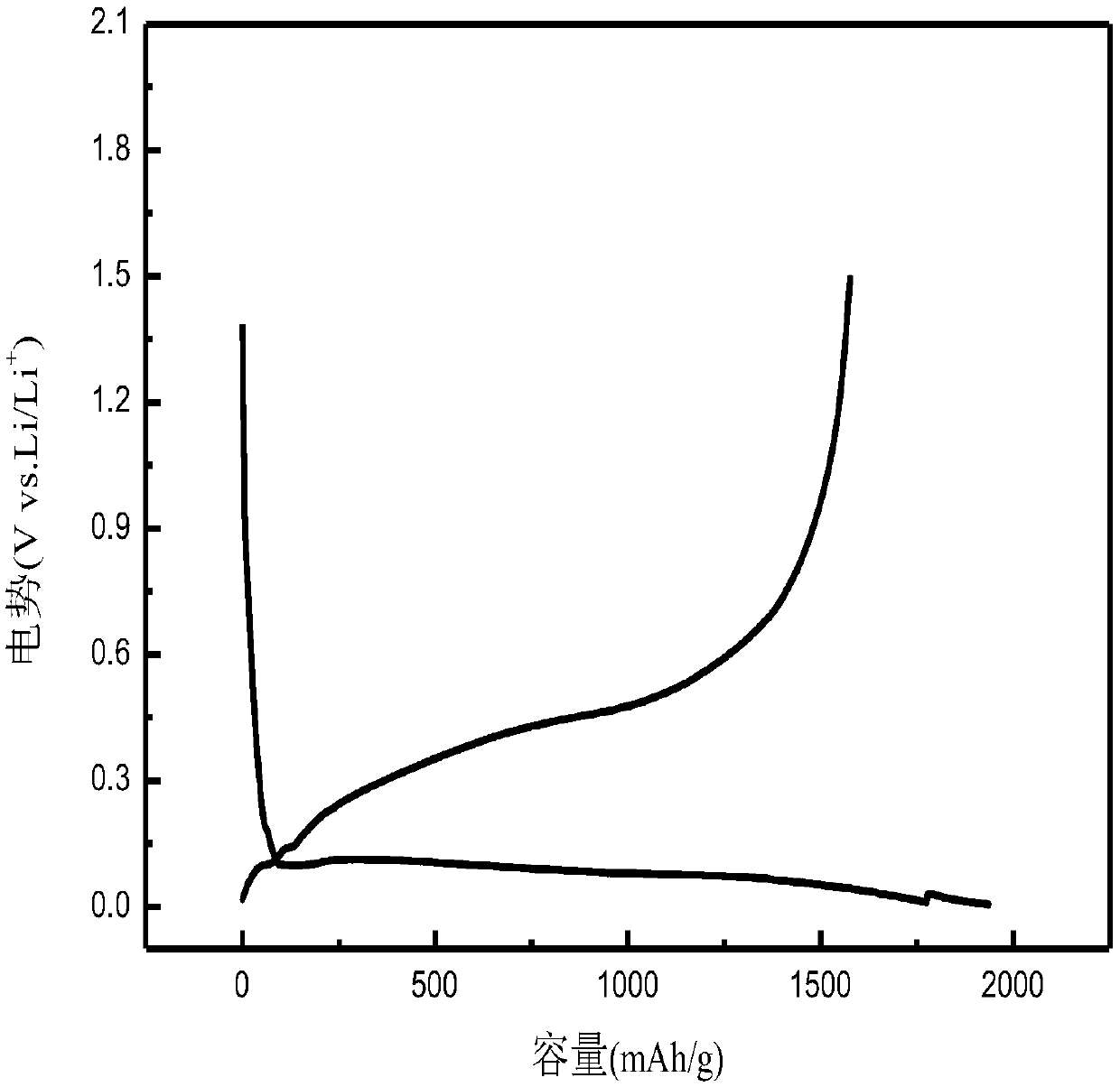

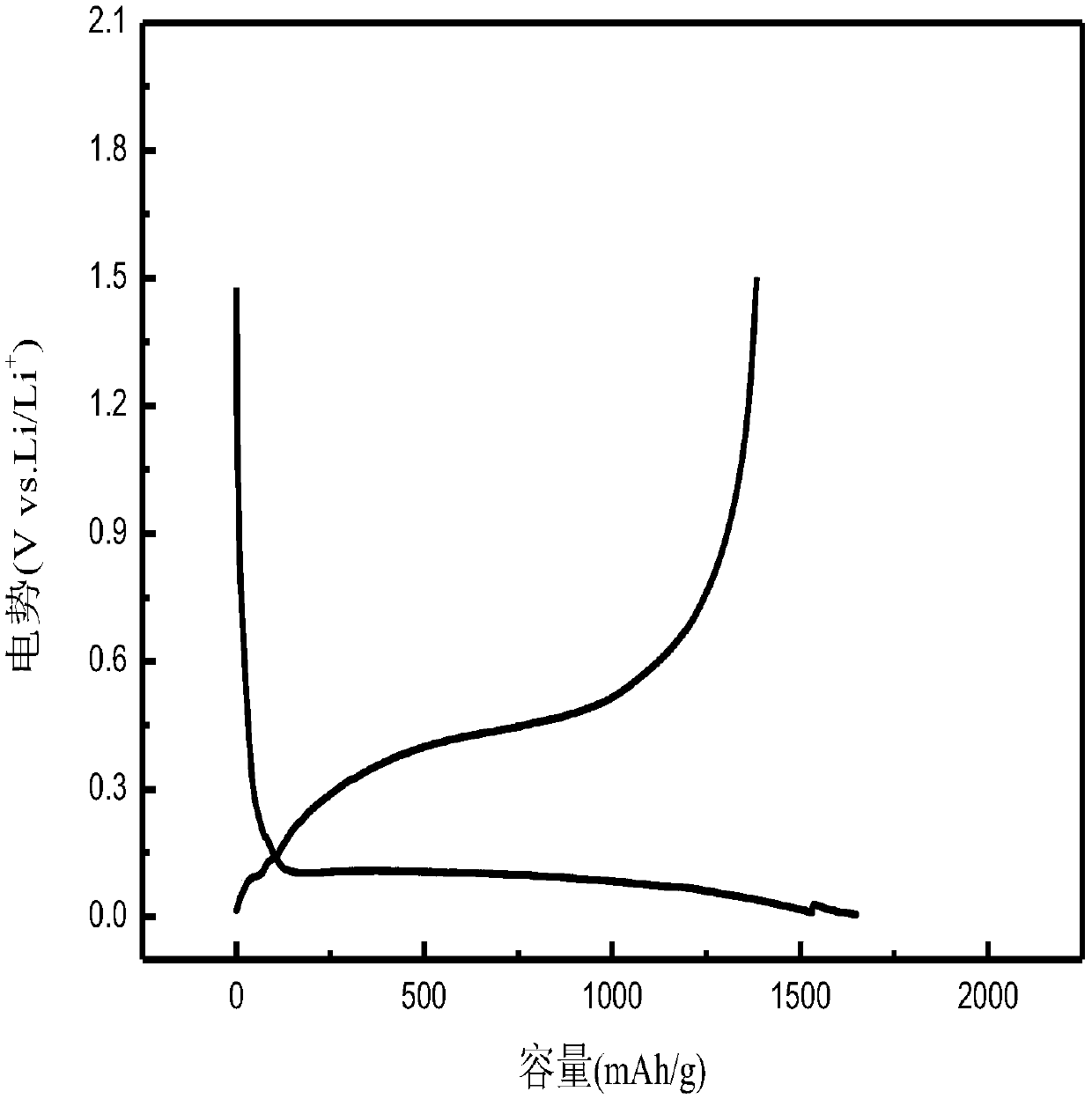

Silicon oxide composite negative electrode material for lithium ion battery and preparation method of silicon oxide composite negative electrode material

InactiveCN109524650AHigh reversible capacityImprove efficiencyCell electrodesSecondary cellsCarbon coatingElectrical battery

The invention discloses a preparation method of a silicon oxide composite negative electrode material. The preparation method comprises the following steps: mixing silicon oxide, a reactive metal anda fused salt to obtain a mixture; carrying out a roasting reaction in a protective atmosphere, cooling and pickling to remove impurities; mixing the obtained low-oxygen value silicon oxide material and a carbon coating material or adopting gas phase coating, roasting and carbonizing, cooling, crushing and screening, thereby obtaining the silicon oxide composite negative electrode material for thelithium ion battery. Compared with the prior art, the silicon oxide composite negative electrode material disclosed by the invention is prepared by taking the silicon oxide, the reactive metal, the carbon coating material and the fused salt as raw materials, mixing, performing metal hot reduction, pickling to remove impurities and grinding, the oxygen content of the finished material is low, and the first-cycle reversible capacity and efficiency of the lithium ion battery are obviously improved. Moreover, the negative electrode material is less in impurity, high in application value and smallin silicon grain size, cycle expansion of the material is effectively improved, and the cycle life of the material is obviously prolonged.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

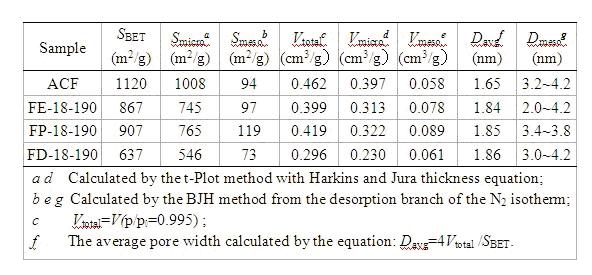

Magnetic separation type composite adsorbing material and preparation method thereof

InactiveCN101940910ASmall grainHigh degree of crystallinityOther chemical processesFiberActivated carbon

The invention relates to a magnetic separation type composite adsorbing material which is prepared from nano Fe3O4 and active carbon fiber. The ferriferous oxide nano composition fiber material is synthesized by using conventional organic solvent as the reaction medium under the control of a simple low temperature solvent thermal system. The magnetic separation type composite adsorbing material can be used as a magnetic separation type adsorbing material for adsorbing organic or inorganic pollutants to purify waste water.

Owner:FUZHOU UNIV

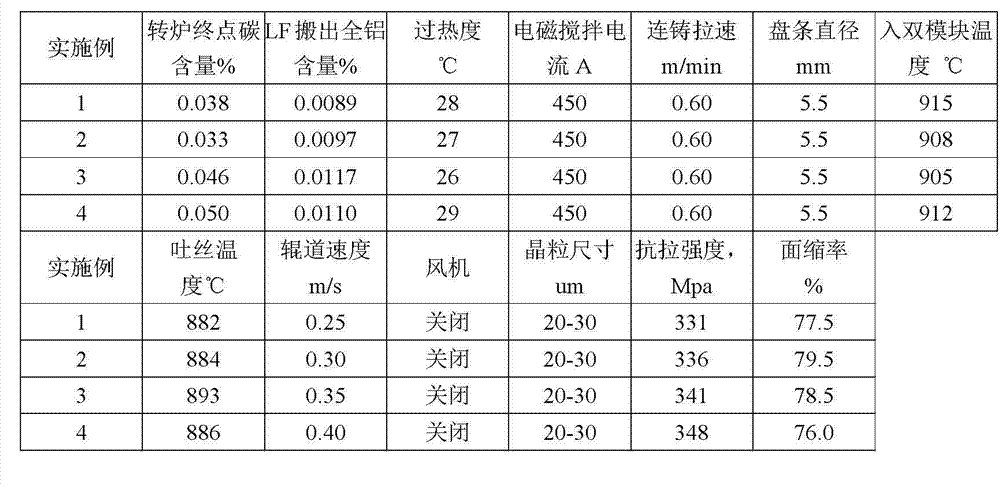

Annealing-free low-carbon steel coil rod and production method thereof

InactiveCN102899554AReduce intensity to create conditionsIncrease oxygen activityManufacturing convertersMetal rolling arrangementsChemical compositionCarbonization

The invention provides an annealing-free low-carbon steel coil rod and a production method thereof. The annealing-free low-carbon steel coil rod comprises the following chemical components: 0.04-0.10% of C, 0.01-0.10% of Si, 0.20-0.35% of Mn, at most 0.015% of P, at most 0.010% of S, at most 0.0060% of N, 0.0030-0.0060% of total oxygen, 0.0020-0.0080% of total aluminum, at most 0.1% of inevitable impurity and the balance of iron. The manufacturing method comprises the steps of converter smelting, LF (ladle furnace) refining, continuous casting and rolling, wherein incomplete deoxidation occurs at the tapping side of a converter, the aluminum content of molten steel is reduced by using the high oxygen activity of the molten steel, the carbonization of the molten steel in the refining process is inhibited, bloom protection casting is performed, the temperature for double module input is controlled at 900-920 DEG C, the loop laying temperature is 870-900 DEG C, the speed of a roller way is 0.2-0.4 m / s, and a blower is closed. Thus, the vacuum treatment procedure is omitted, the technical process is shortened, the production cost is lowered, and the requirement of users for canceling the annealing technique in the drawing process is satisfied. For the annealing-free low-carbon steel coil rod produced according to the components and the production method provided by the invention, the grain size is controlled at 20-30 um, the tensile strength is no more than 350 MPa, and the reduction of area is no less than 75%.

Owner:ANGANG STEEL CO LTD

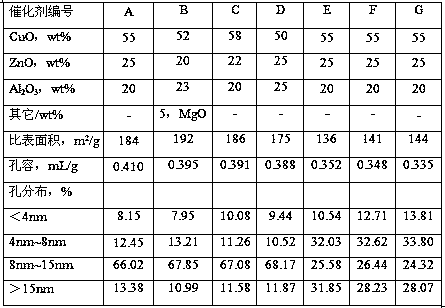

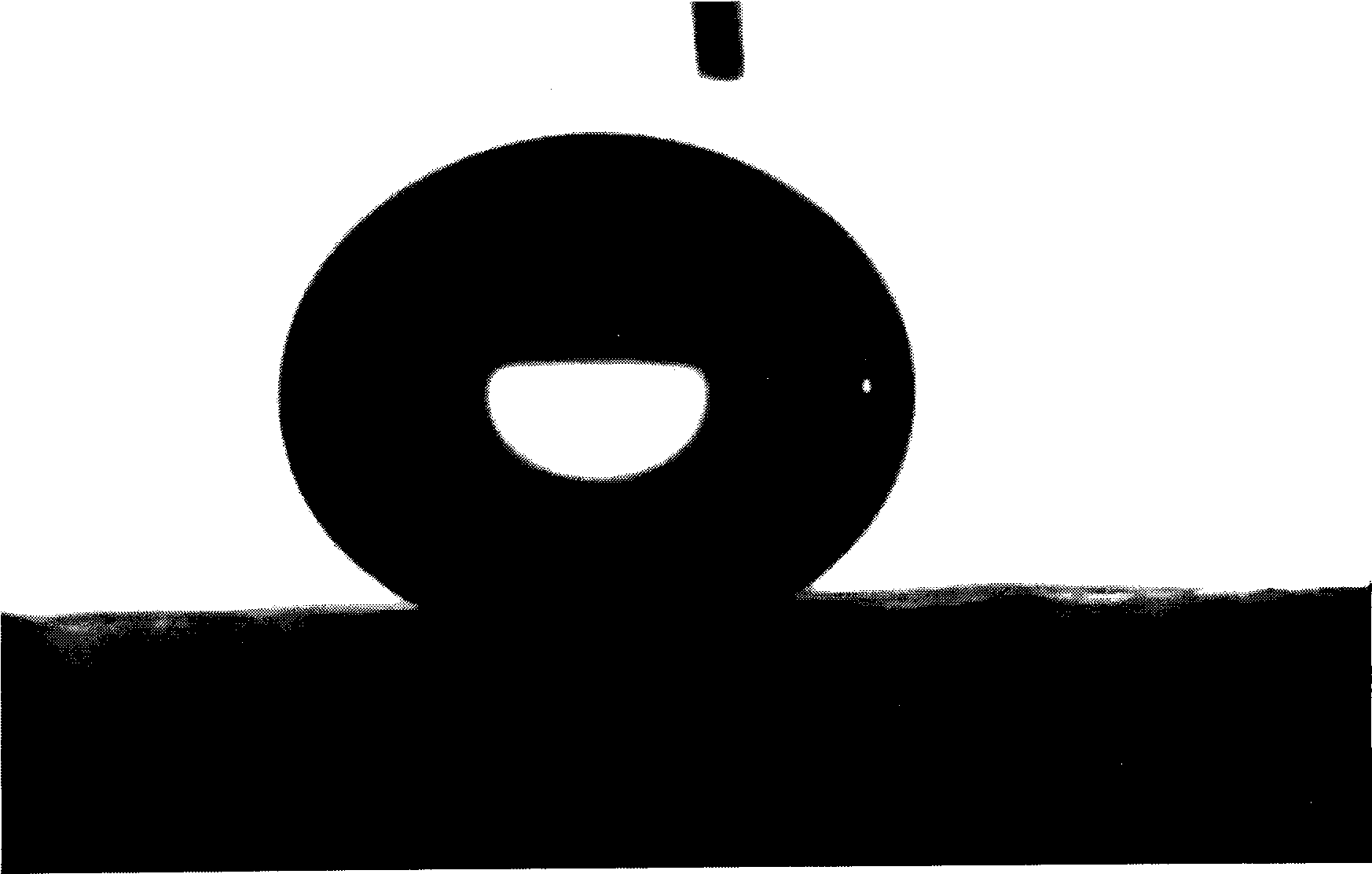

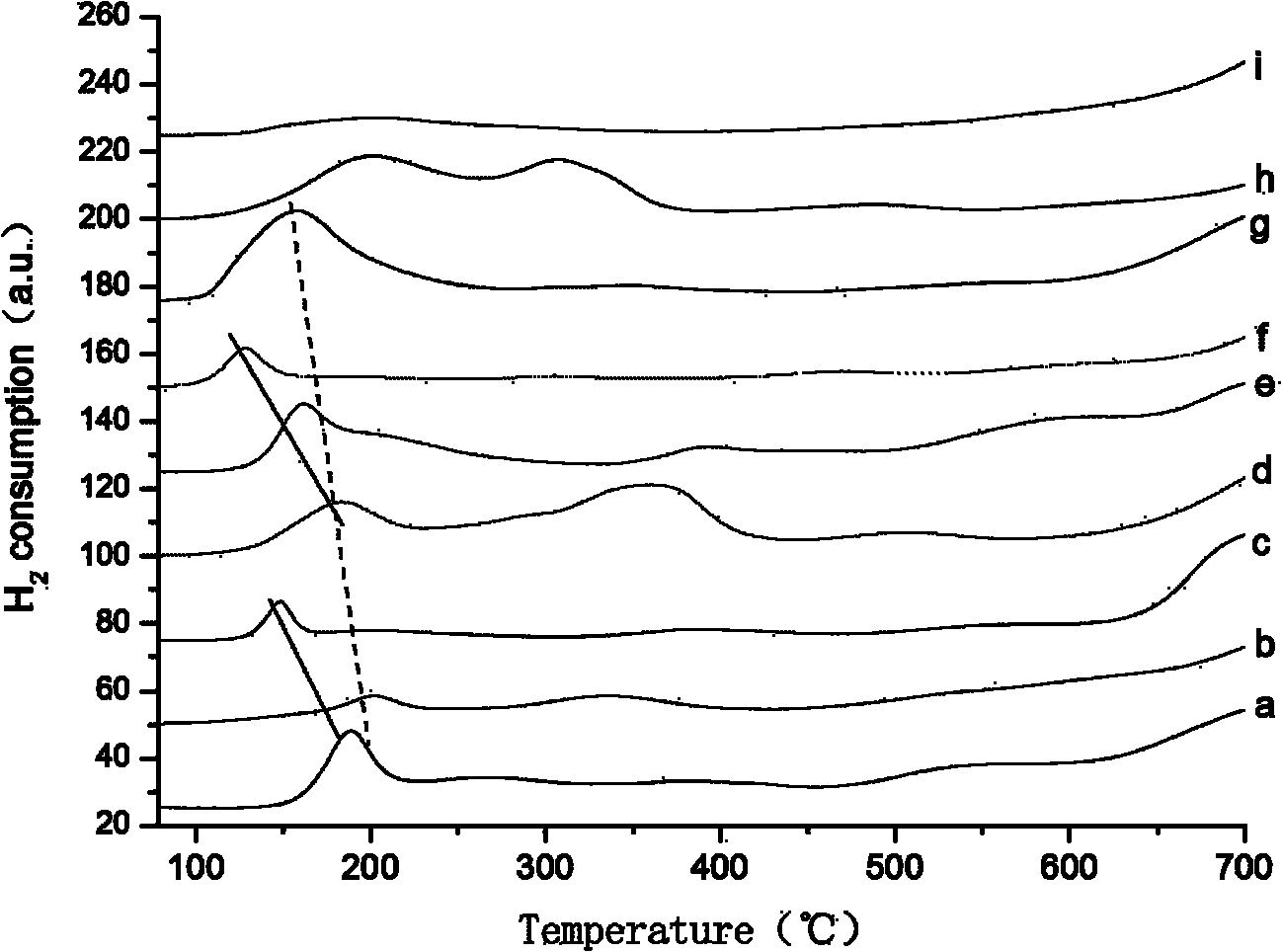

Preparation method for synthesizing methanol catalyst

ActiveCN107774263ALarge specific surface areaImprove coordinationOrganic compound preparationHeterogenous catalyst chemical elementsSurface phaseWater vapor

The invention discloses a preparation method for synthesizing a methanol catalyst. The preparation method comprises the following steps: (1) dissolving a soluble salt of Cu into water to prepare a solution A, adding a sodium metaaluminate alkaline solution and the solution A into a reaction tank with pure water to perform gelatinizing reaction in a parallel flow mode at the same time, thereby obtaining slurry I; (2) dissolving a soluble salt of Zn into water to prepare a solution B, dropwise adding the sodium metaaluminate alkaline solution into the solution B to perform gelatinizing reaction,thereby obtaining slurry II; (3) uniformly mixing the slurry I with the slurry II, aging under a stirring condition, filtering after ageing is ended, and performing hydro-thermal treatment on obtained materials through water vapor, wherein urea is added during hydro-thermal treatment; and (4) washing, filtering, drying, roasting, tabletting and forming, thereby obtaining the catalyst. A utilization rate of active metal copper in a surface phase of the catalyst prepared by the method is high, copper and zinc distribution is more uniform, the catalyst is reasonable in pore structure, activity,selectivity and thermal stability of the catalyst are improved, and the service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

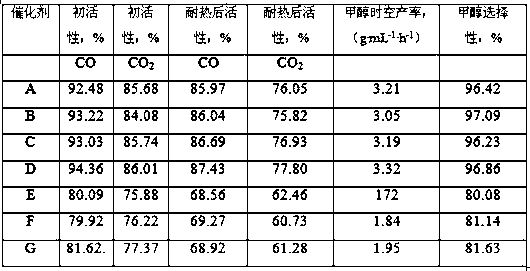

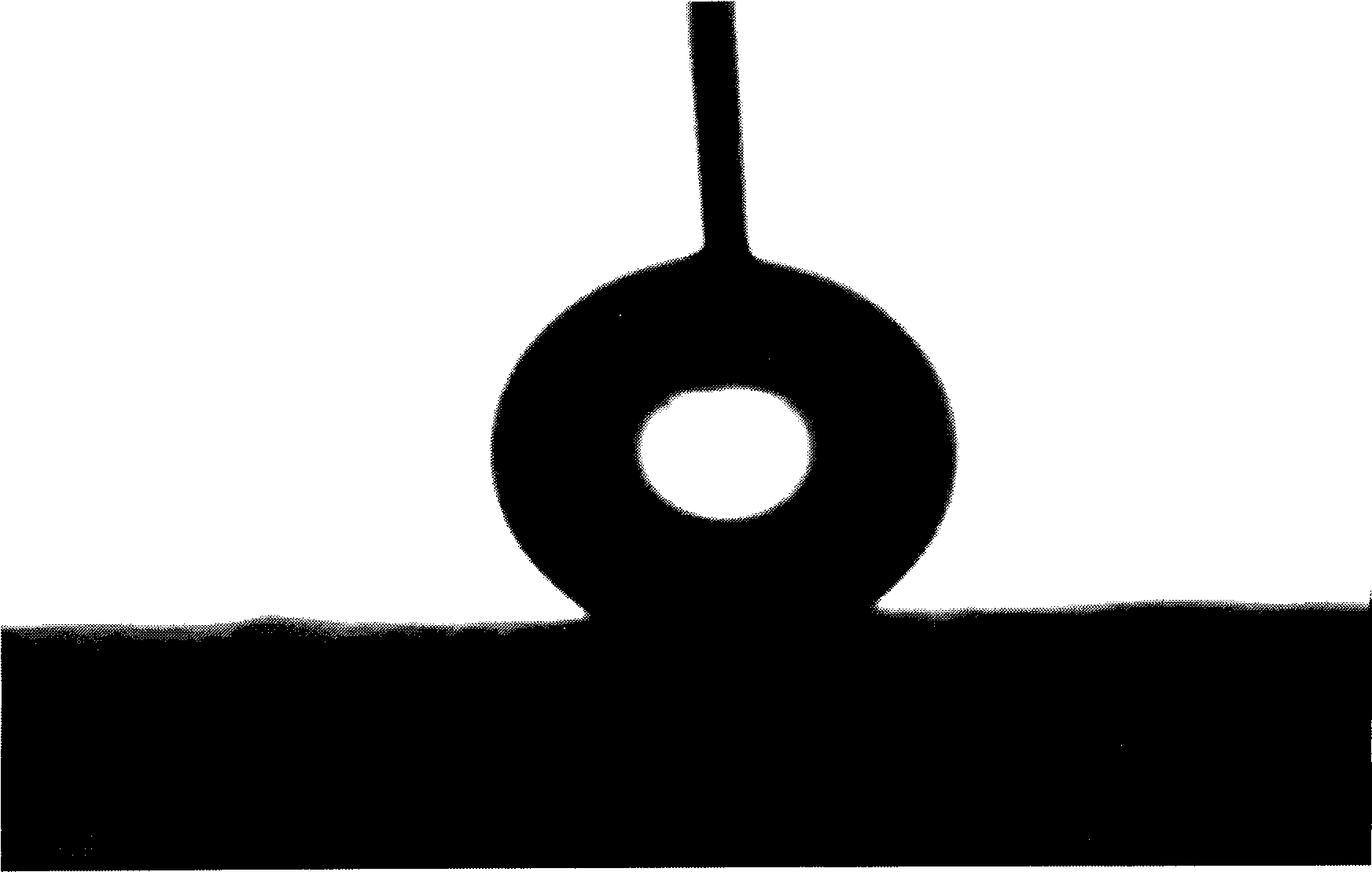

Super-hydrophobic polypropylene film and preparation method thereof

The invention discloses a super-hydrophobic polypropylene film and a preparation method thereof. The method comprises the following steps: firstly, weighing a definite amount of isotactic polypropylene granules and adding the granules into dimethyl benzene, rising the temperature to 130 DEG C, and stirring the solution by magnetic force to form 1 to 50mg / mL polypropylene solution; secondly, adding 20 to 60 percent of acetone by the volume of the solution into the polypropylene solution, and quickly stirring the solution; and finally, coating the polypropylene solution added with the acetone on a substrate by adopting a coating method, and drying the substrate for 3 to 12 hours at a temperature of between 20 and 70 DEG C to obtain a white film, namely the super-hydrophobic polypropylene film. The method has the advantages of simple operation, low cost and good controllability, does not need complex chemical treatment or expensive equipment, and is easy for industrialization. The obtained super-hydrophobic polypropylene film has the characteristics of better surface structure stability, weather-proof durability, chemical corrosion resistance and the like.

Owner:NANTONG RONGRUN AUTO PARTS

Hydrogenation catalyst carrier and production thereof

A carrier of hydrocatalyst for the hydrocracking of heavy oil, hydromodifying of poor diesel oil, etc is prepared from amorphour silicon aluminium, modified beta-molecular sieve and aluminium oxide. Its preparing process is also disclosed. Said catalyst has high catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

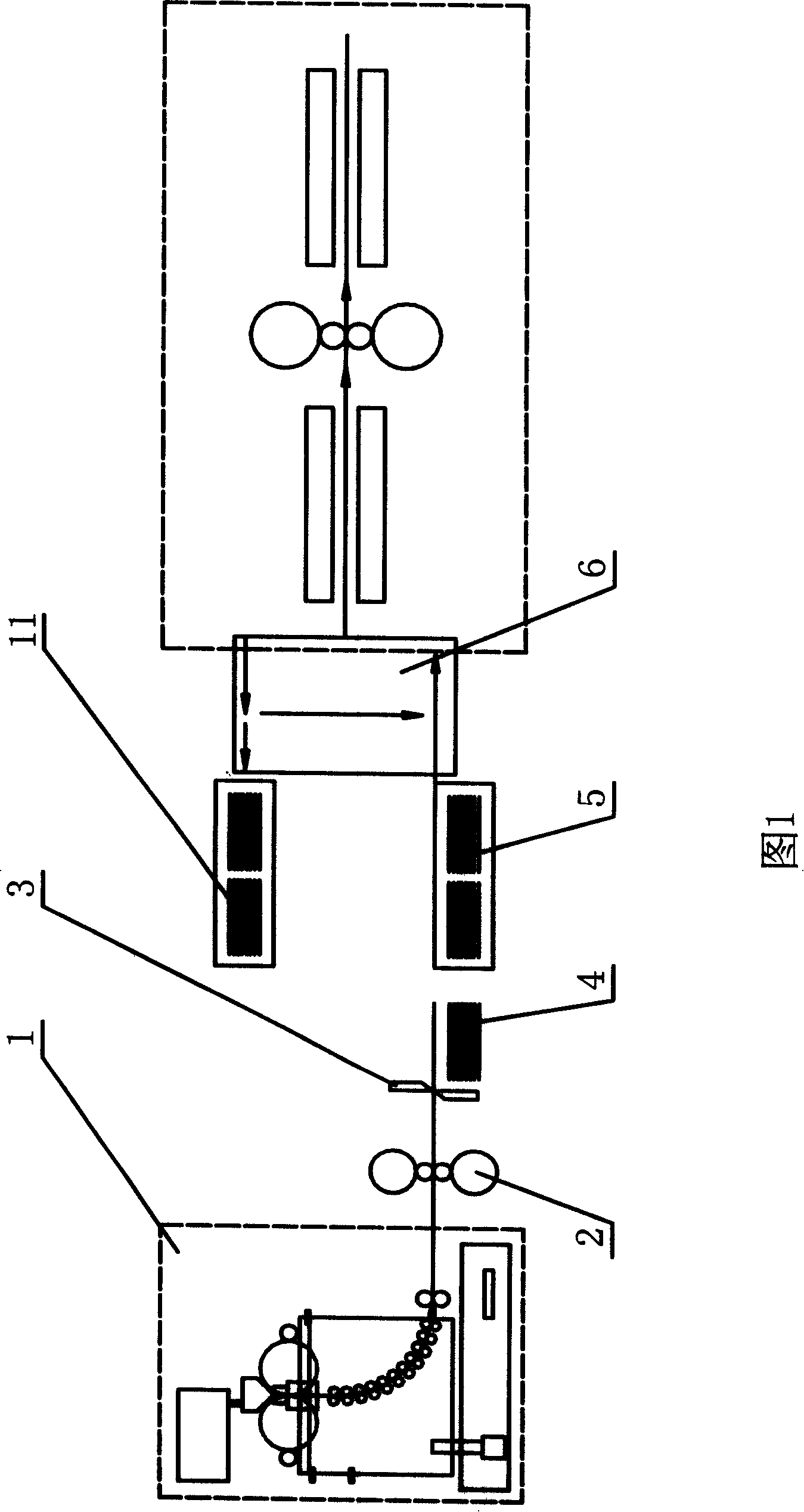

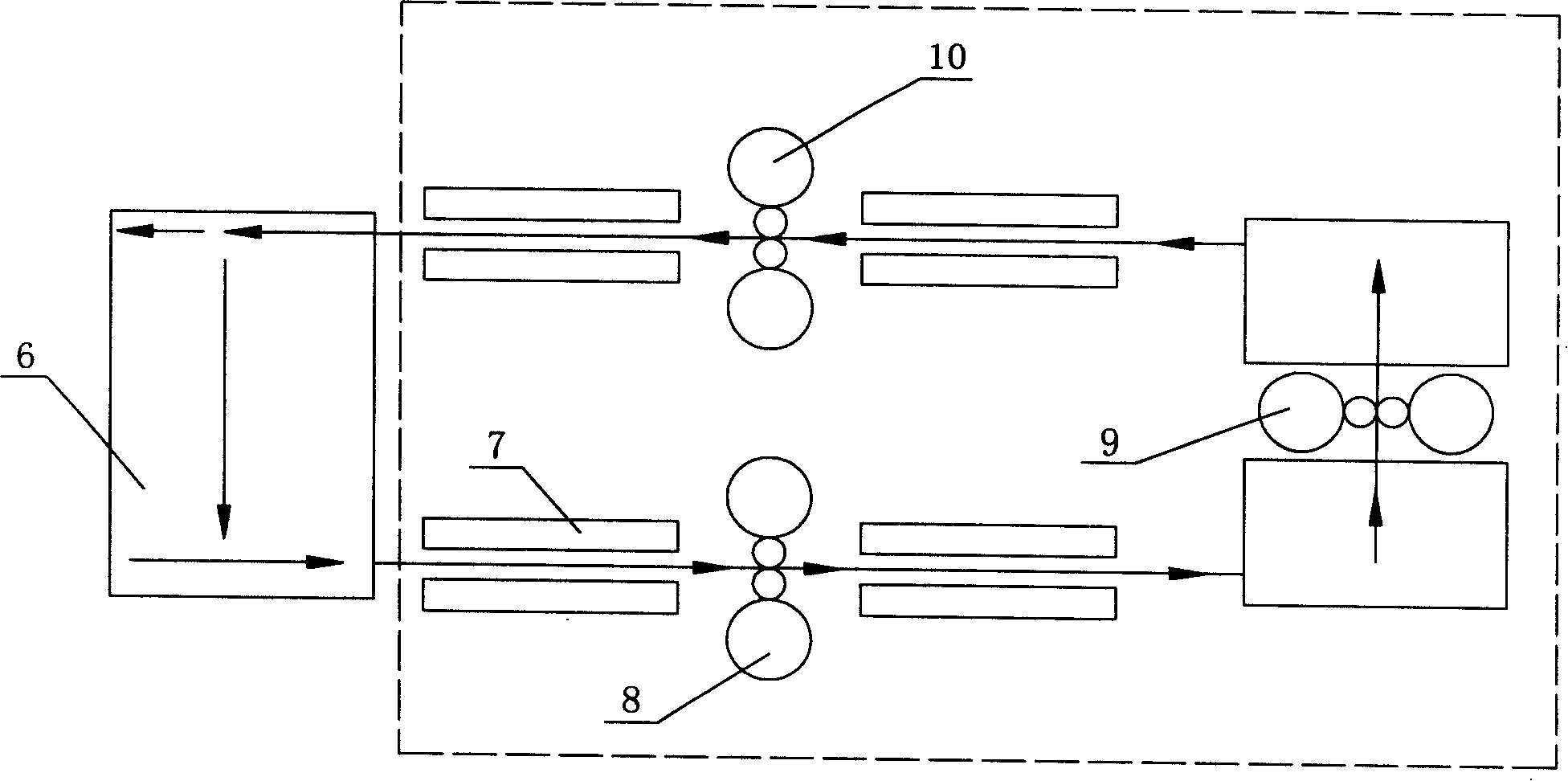

Rolling controlling method and device for double-roller continuous casting magnesium alloy sheet

InactiveCN101190491AImprove performanceGood molding effectRoll force/gap control deviceTemperature control deviceThin slabContinuous annealing

The invention discloses a dual-roll continuous casting magnesium alloy thin plate rolling control method and a device. The method comprises that magnesium alloy solution is formed in an integrated casting and rolling machine; the temperature of a casting plate out of a casting roll is 300 DEG C to 500 DEG C and casting and rolling speed is 10m / min to 90m / min; the casting and rolling plate is cooled in oil with control temperature of 200 DEG C to 400 DEG C and plate-out thickness is 1mm to 4mm; uniform annealing disposal is carried out before the hot rolling of the casting and rolling plate; the front and the rear of a rolling machine are provided with heat preservation rolls for heat supplementation; finished magnesium alloy plate of 0.2mm to 1mm can be rolled in an annealing period. The device comprises an integrated casting and rolling machine, a continuous annealing furnace behind the casting and rolling machine, three four-roll hot rolling machines arranged in 90 DEG and heat preservation rolls at the front and the rear, a flying shear and an edge-cutting shear. By adopting casting rolling and rolling methods to produce the magnesium alloy plate, the invention has the advantages of short flow, low production cost, uniform composition of products, good surface quality and uniform mechanical performance in all directions. The method and the device can be applied to the production of the magnesium alloy and aluminium alloy thin plates in all series.

Owner:UNIV OF SCI & TECH LIAONING +1

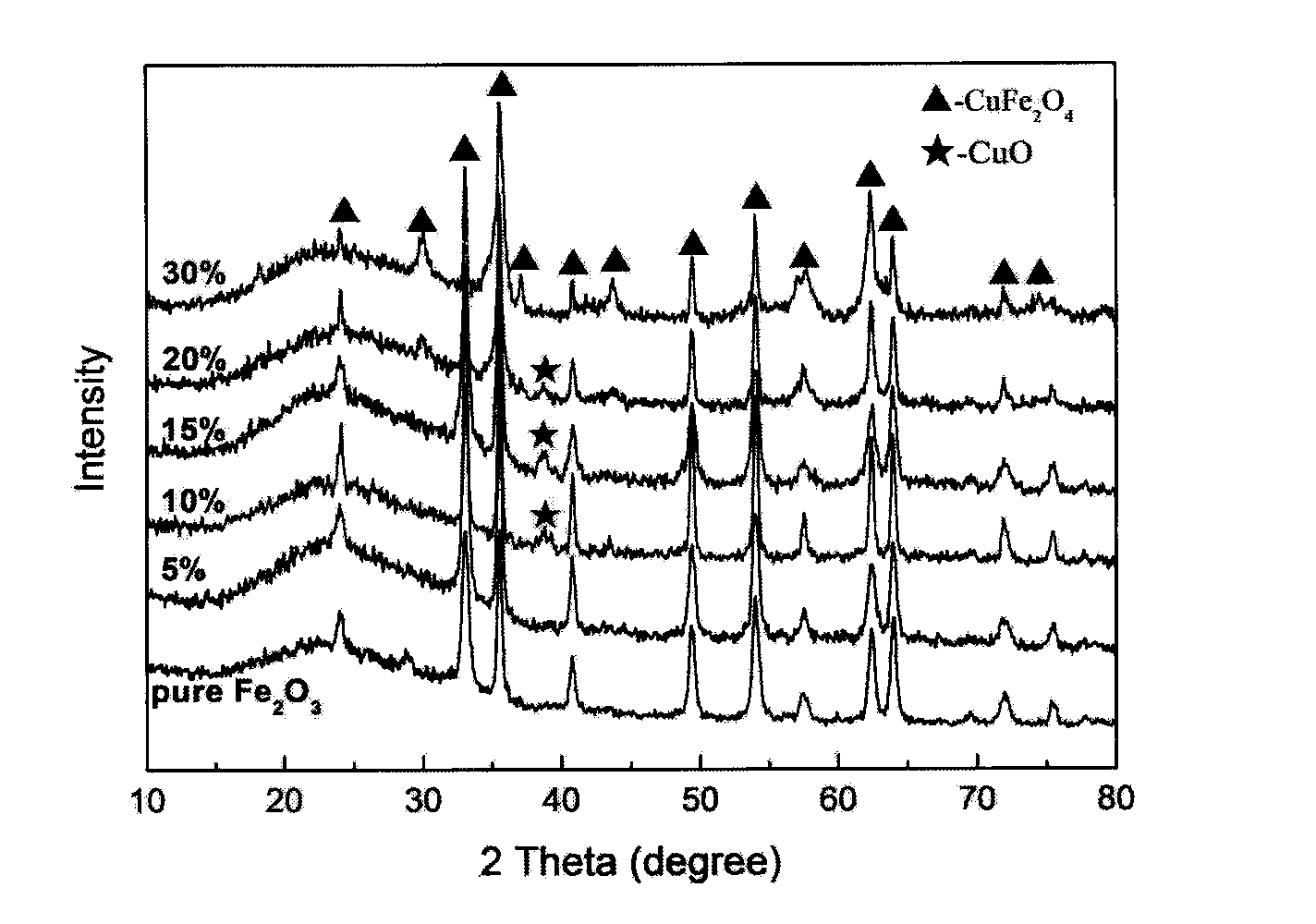

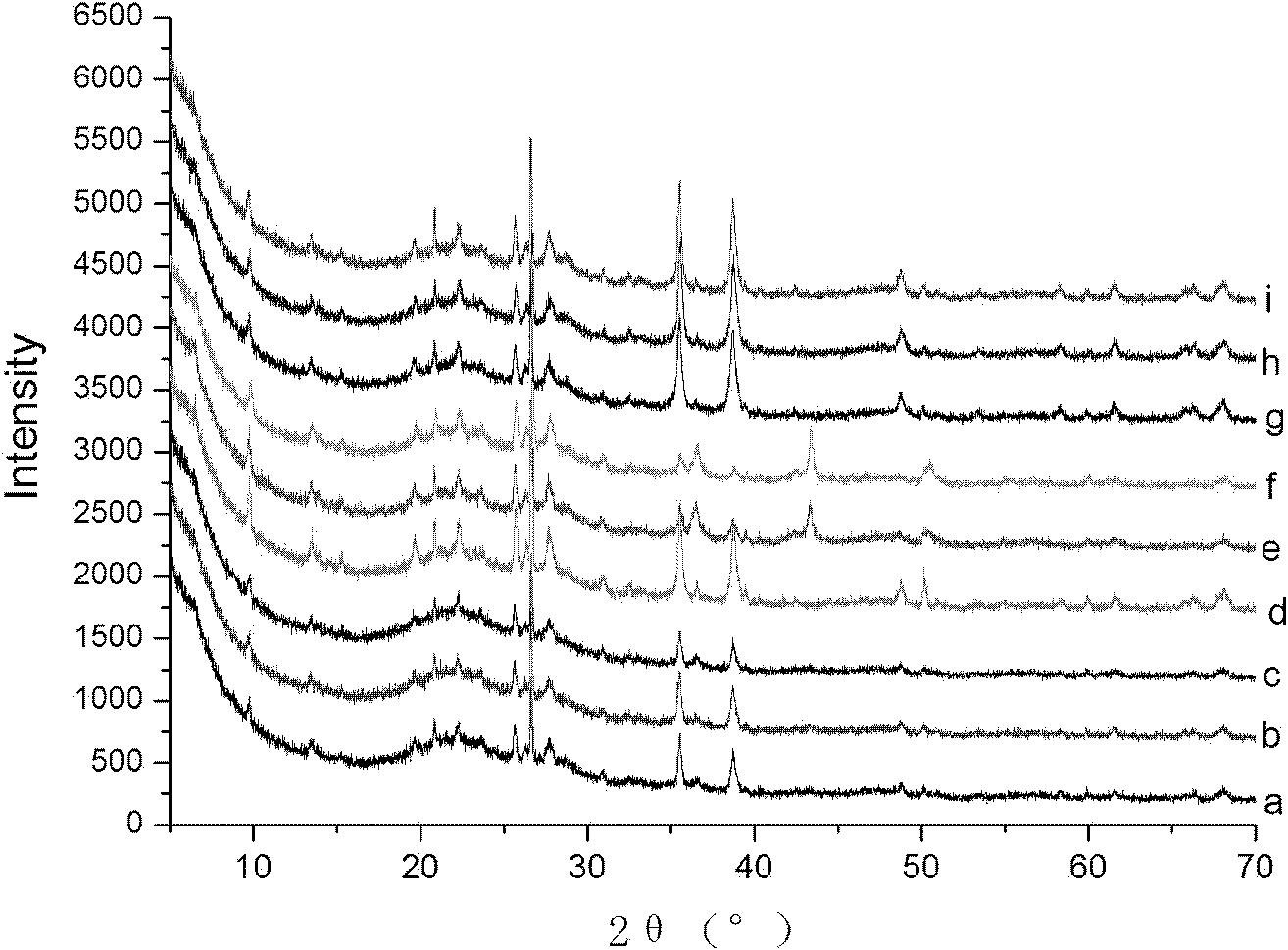

Preparation of p-n type nano CuO/alpha-Fe2O3 composite semiconductor material and application thereof as gas sensitive material

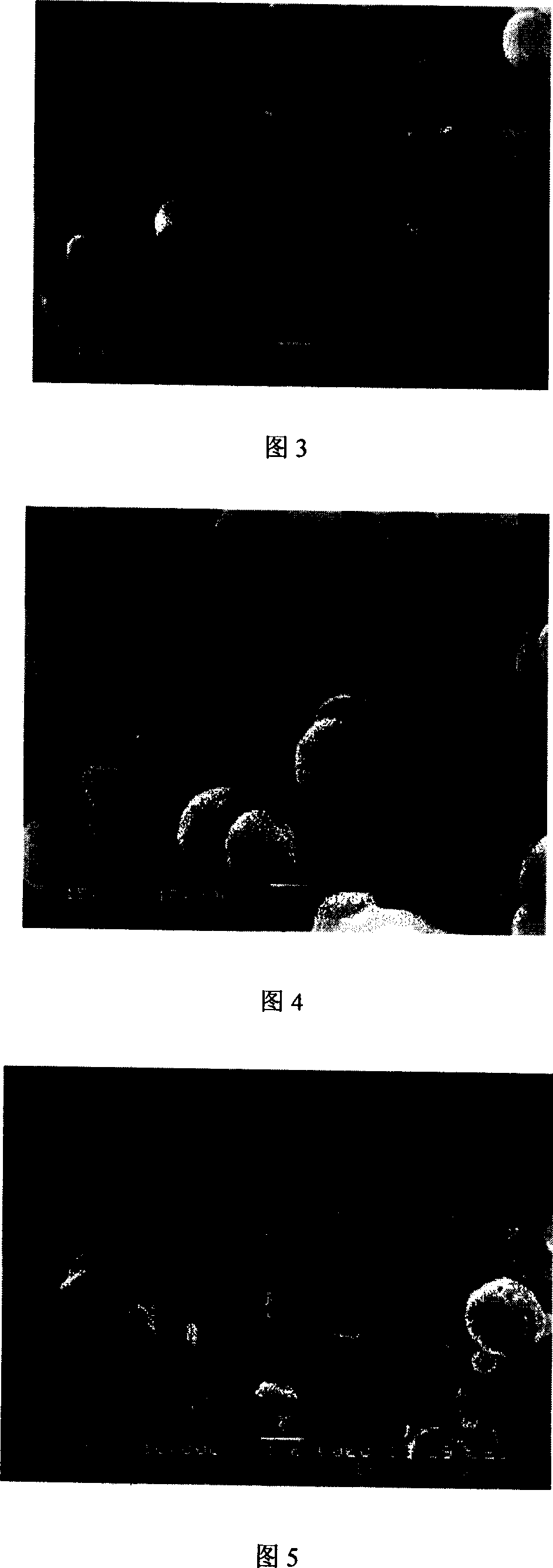

InactiveCN103257158AThe content is easy to controlLow costMaterial nanotechnologyMaterial resistanceDeposition precipitationSemiconductor materials

The invention relates to a preparation method of a p-n type nano CuO / alpha-Fe2O3 composite semiconductor material, and the material is applied to the field of gas sensors. Pure alpha-Fe2O3 is prepared by using a chemical precipitation method; and the nano CuO / alpha-Fe2O3 composite semiconductor material is further prepared by using a deposition-precipitation method. The CuO / alpha-Fe2O3 composite semiconductor gas sensitive material provided by the invention is simple in preparation technique, low in equipment requirement and low in cost; according to the prepared gas sensitive material, along with the increase of the CuO content, Cu atoms gradually enter alpha-Fe2O3 crystal phases, and the particle sizes of special grains range from 10nm to 20nm. By utilizing the prepared material, effective detection on hydrogen sulfide at room temperature is realized, and the material can rapidly respond to carbon monoxide at both 50 DEG C and 100 DEG C, so that the material has large application prospects.

Owner:HENAN POLYTECHNIC UNIV

Indium tin oxide (ITO) nano powder and preparation method thereof

The invention discloses nano indium tin oxide powder, which comprises an indium compound and a tin compound, wherein a mass ratio of indium oxide to tin oxide is 9:1; and the nano indium tin oxide powder is in an irregular elliptical spherical shape. The ITO nano powder obtained by a method for preparing the ITO nano powder is uniform in grain diameters and high in dispersibility, and the grain diameters are about 60 nanometers.

Owner:SUN YAT SEN UNIV

Compression casting heat-stable magnesium alloy

The invention discloses an Mg-Al based cast heatproof magnesium alloy, which comprises the following parts: 3.0-8.0 % Al, 0.30-0.60% Mn, 0.3-2.0% Y or Gd, 0.001-0.2% Ti, less than 0.005% Fe, less than 0.015%Cu, less than 0.002% Ni and Mg. The invention improves dynamic property of alloy, which reduces heat-cracking tendency of alloy.

Owner:鄂尔多斯市天旭轻合金有限责任公司

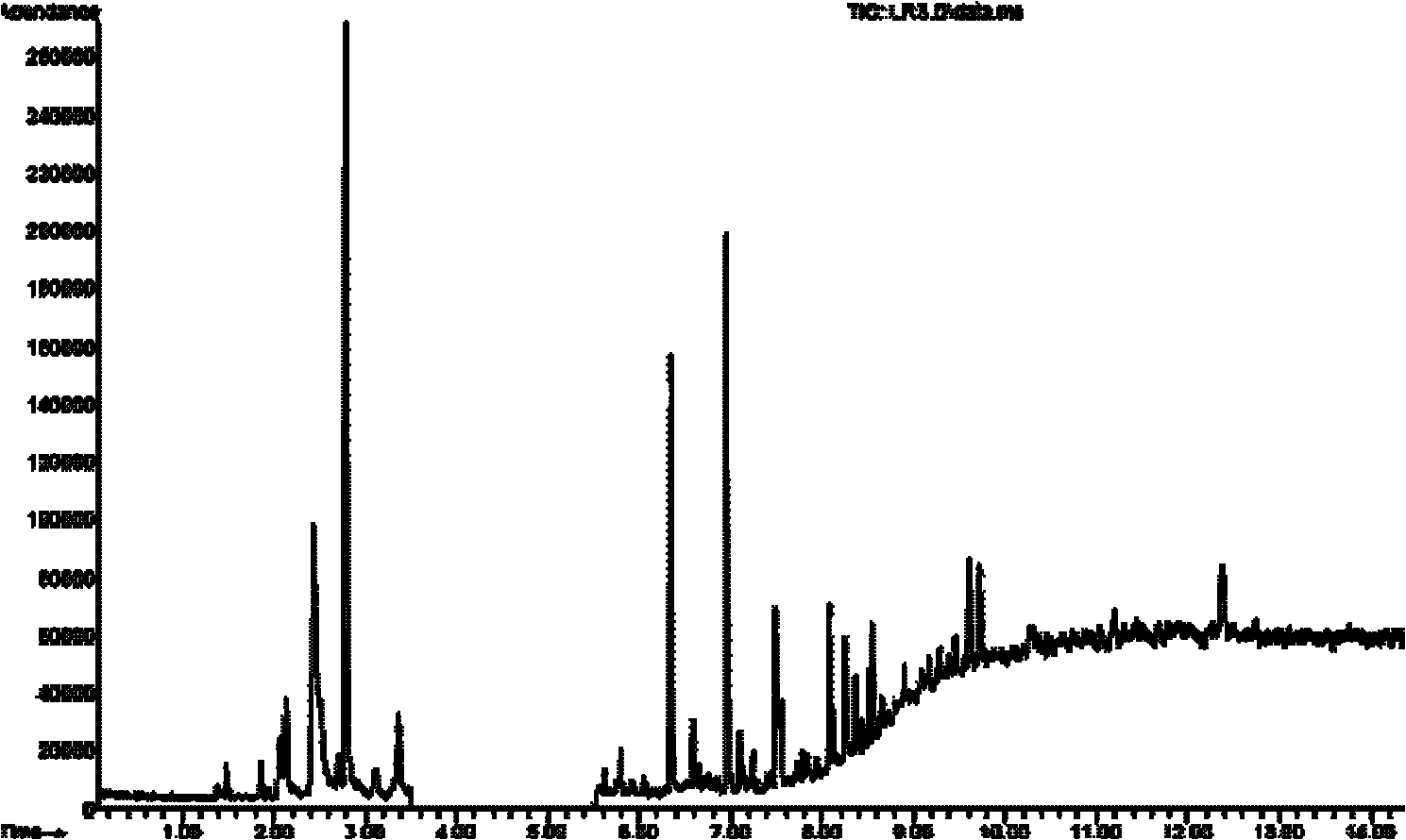

Composite carrier catalyst used for glycol and synthesized from hydrogenation of alkyl oxalate, and preparation method thereof

ActiveCN102225338AHigh activityGuaranteed thermal stabilityOrganic compound preparationHydroxy compound preparationOxalateActive component

The invention relates to a composite carrier catalyst used for glycol and synthesized from hydrogenation of alkyl oxalate, and a preparation method thereof. The chemical formula of the composite carrier catalyst is CuO / ROx-Moy. Wherein, CuO accounts for 5-60 mass percent, ROx accounts for 10-90 mass percent, and Moy accounts for 0.1-60 mass percent, x as 1 / 2 of the highest valency of R, y is 1 / 2 of the highest valency of M, R is one of Si, Al, Zr and Ti, and M is one of Si, Al, Cr, Zr, Ti, B, Zn, Mo, Ce, Bi, La. Compared with the prior art, in the invention a composite carrier is employed in the catalyst used for glycol and synthesized from hydrogenation of alkyl oxalate. The carrier can effectively disperse the active component copper so as to make the sintering of copper grains hard andextend the service life of the catalyst. Meanwhile, the composite carrier can effectively adjust the surface acidity and basicity, reduce the generation of by-products, and improve the selectivity ofglycol. The total conversion rate of oxalate can reach over 99.9%, while the selectivity of glycol is above 95%. Thus, the catalyst of the invention can be used in the industrial production of glycol.

Owner:PUJING CHEM IND SHA +1

Ca and heavy rare earth Gd-containing die-casting heat resisting magnesium alloy and preparation thereof

The invention relates to a die-casting heat resistant magnesium alloy containing Ca and heavy rare earth element Gd and a preparation method thereof, pertaining to the metal material technical field. The components and weight percentage thereof of the alloy are: 3.0 to 8.0 percent of Al, 0.1 to 3.0 percent of Ca, 0.1 to 3.0 percent of Gd, 0 to 0.5 percent of Mn, lower than 0.02 percent of impurity elements and the rest is Mg. The preparation method of the alloy comprises the following steps: the materials are weighed, and industrial pure Mg is heated under the protection of the mixed gas of N2 and 0.2 percent of SF6; after Mg is wholly melted, industrial pure Al, industrial pure Ca and Al-Mn interalloy are added at the temperature of 650 to 680 DEG C, Mg-Gd interalloy is added at the temperature of 660 to 680 DEG C, the temperature is increased to 740 to 760 DEG C, and when the Mg liquid is cooled to 670 to 690 DEG C, the mixture carries out die casting. The preparation method of the invention has the advantages of low cost and high production efficiency, obviously increases the tensile strength, the yield strength, the elongation percentage and the creep resistance of the alloy at room temperature, and has excellent die-casting performance.

Owner:SHANGHAI JIAO TONG UNIV

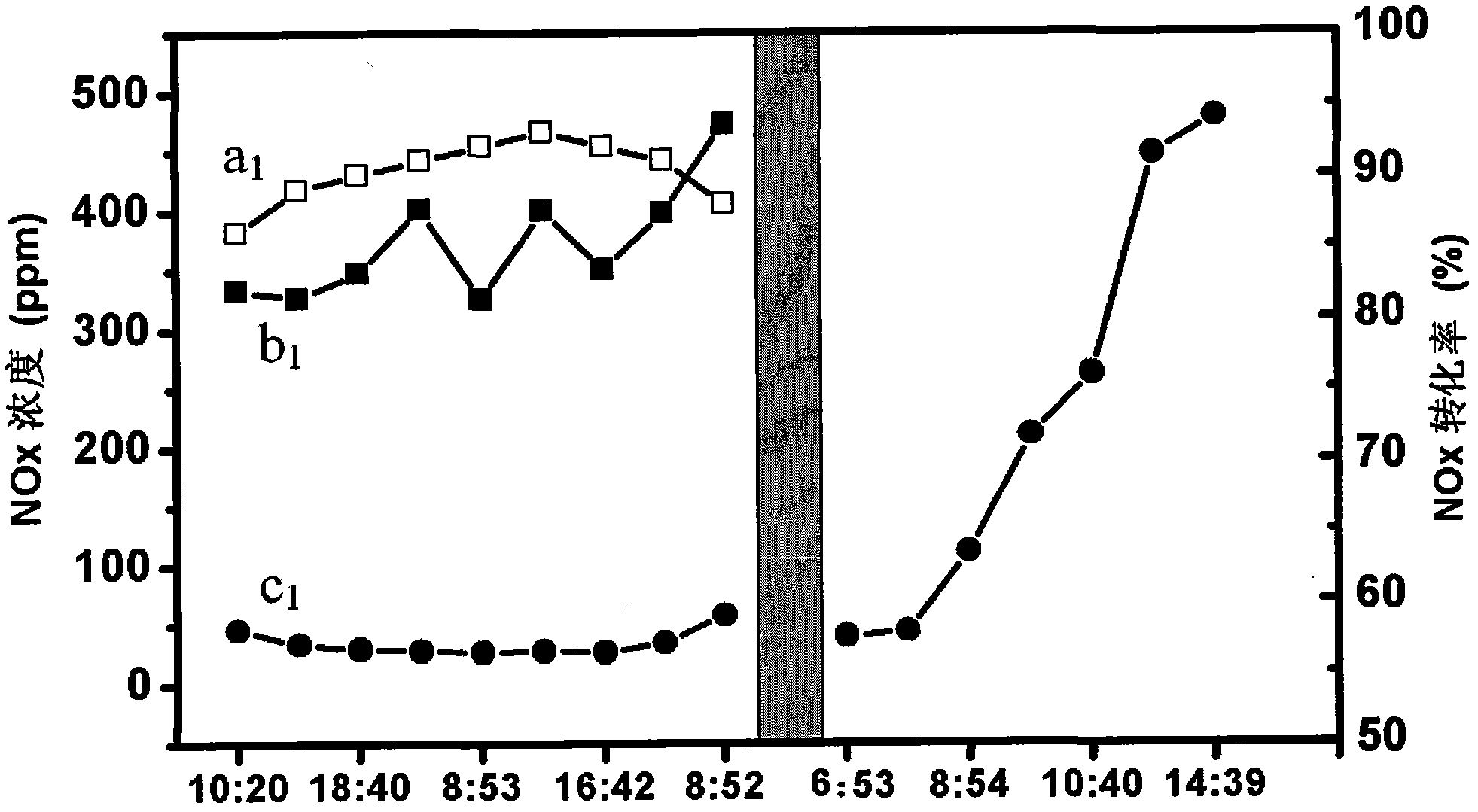

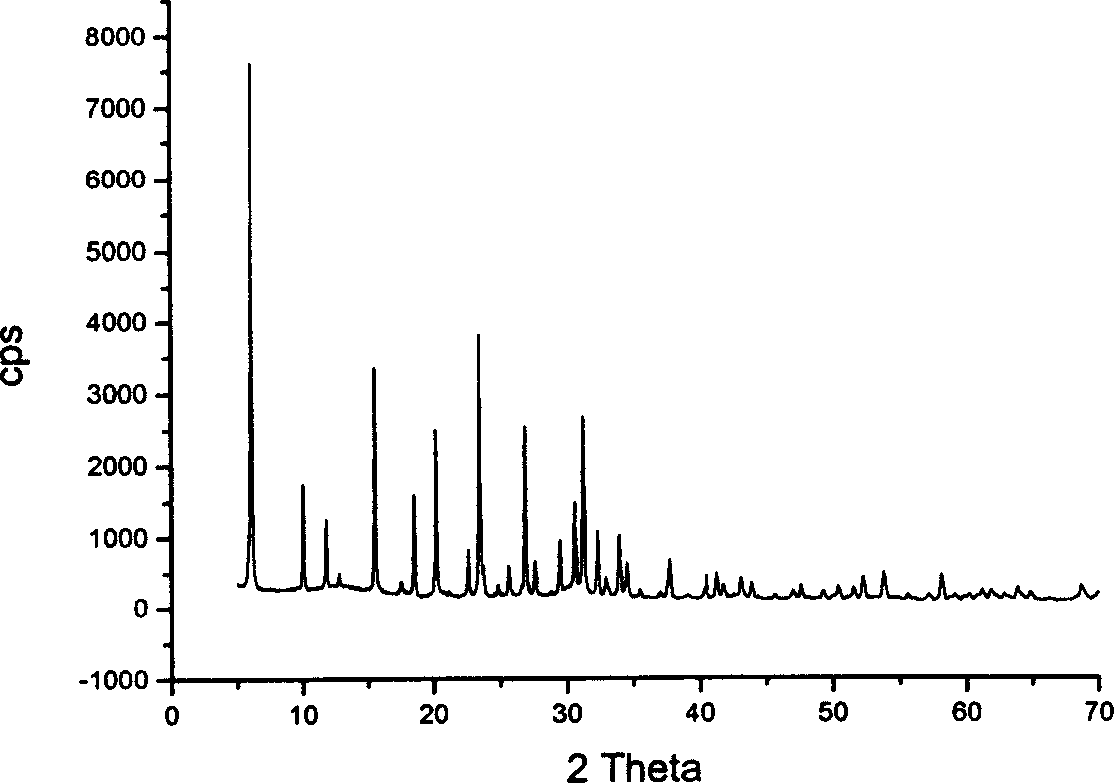

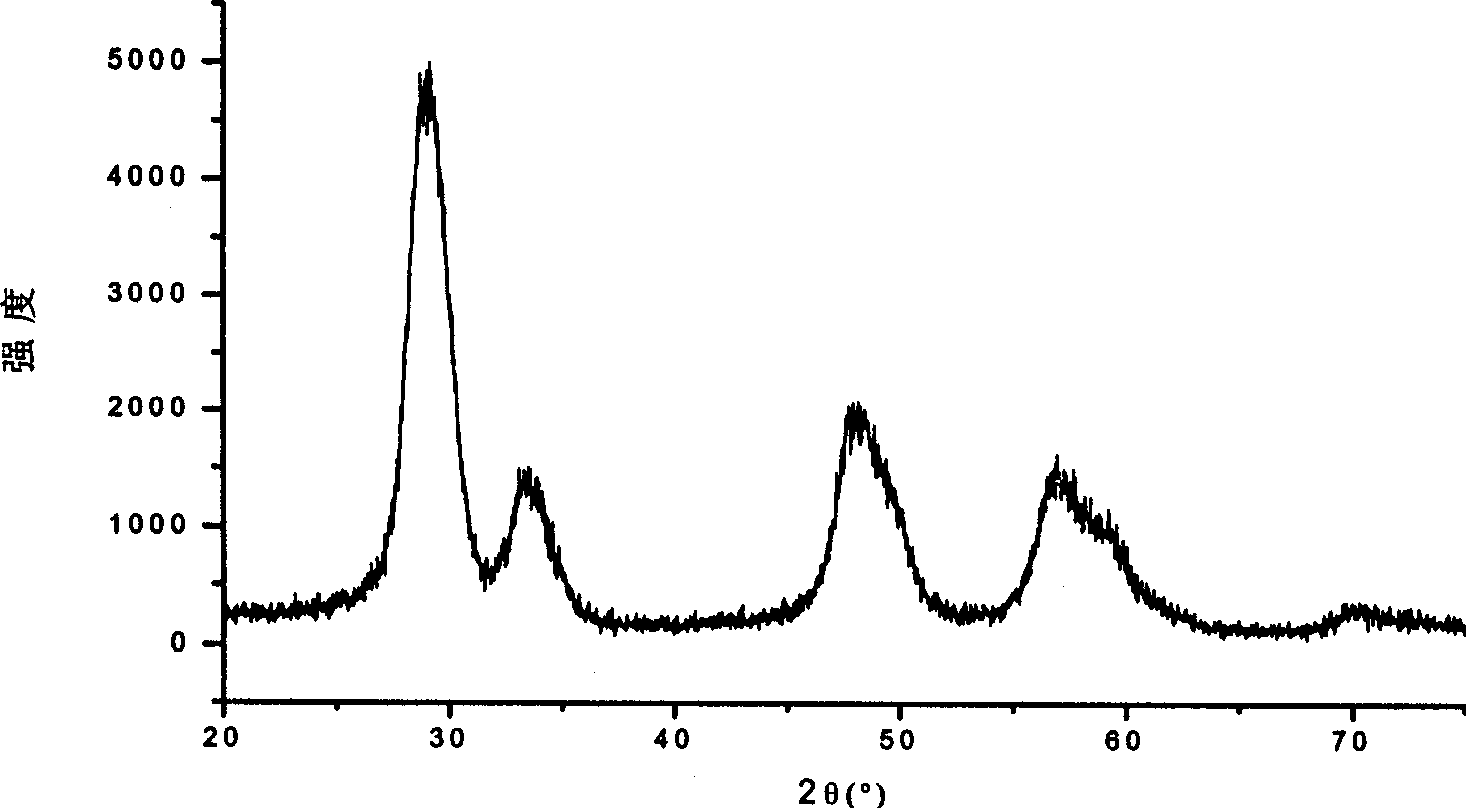

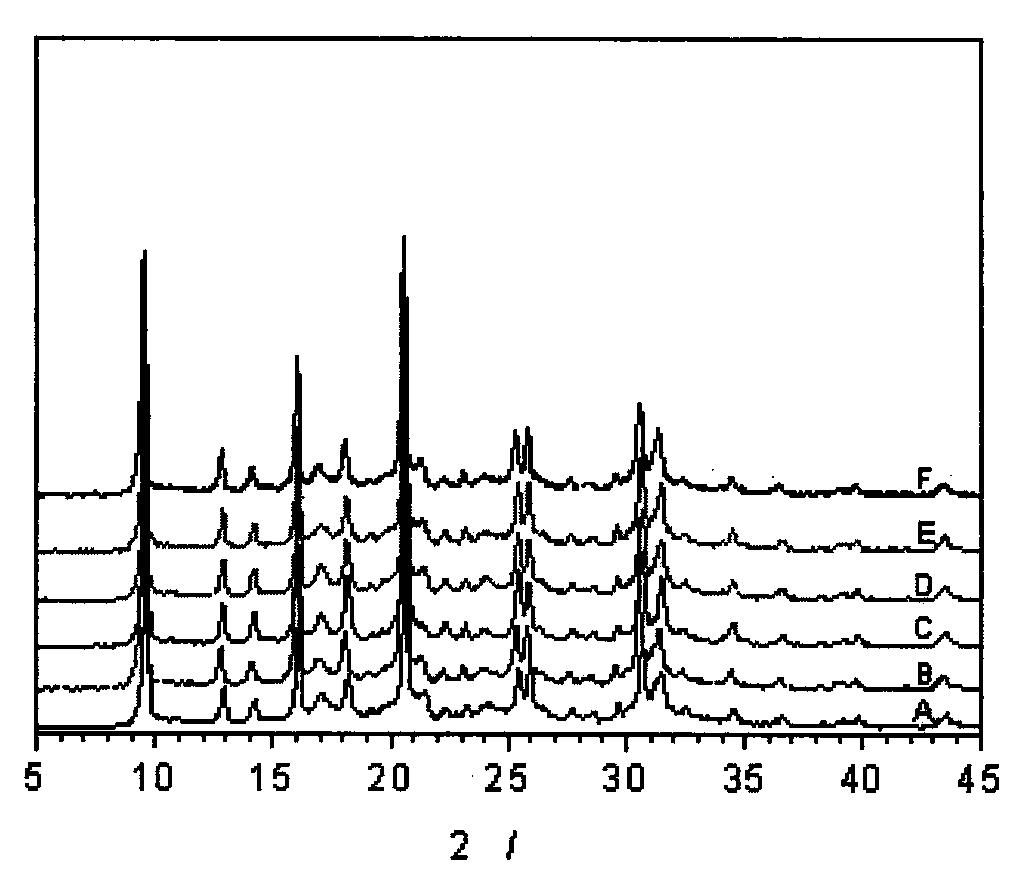

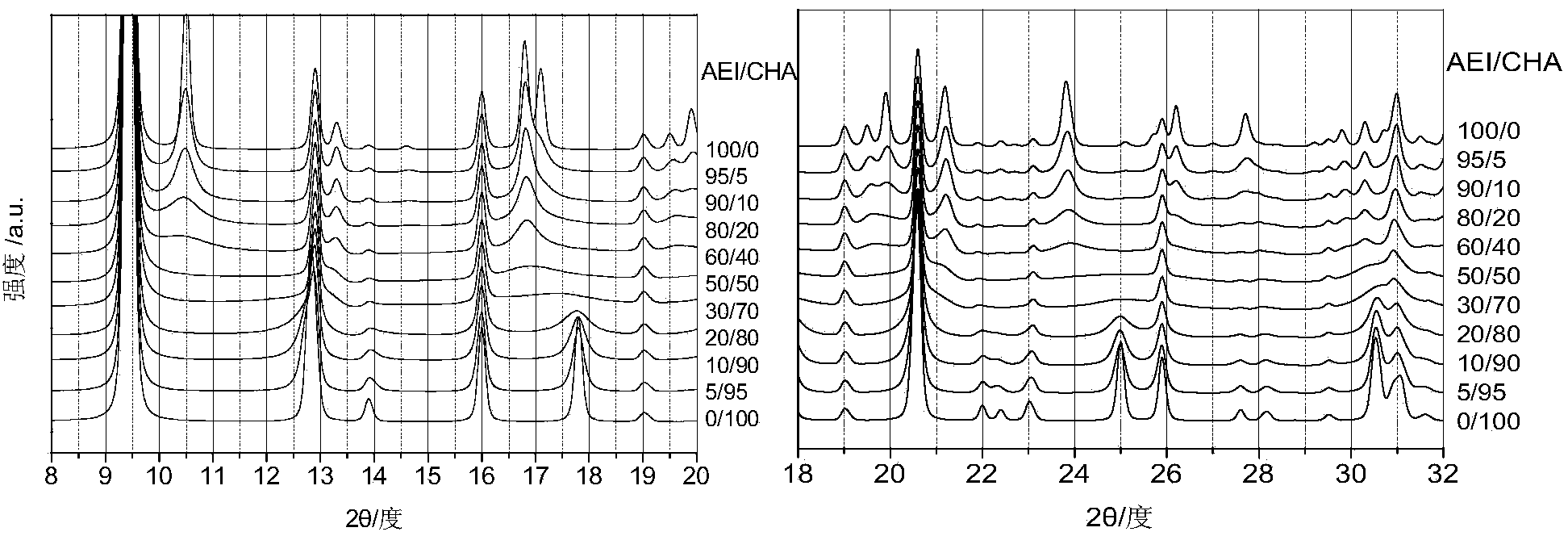

Method for synthesizing small grain SAPO-18/SAPO-34 eutectic molecular sieve

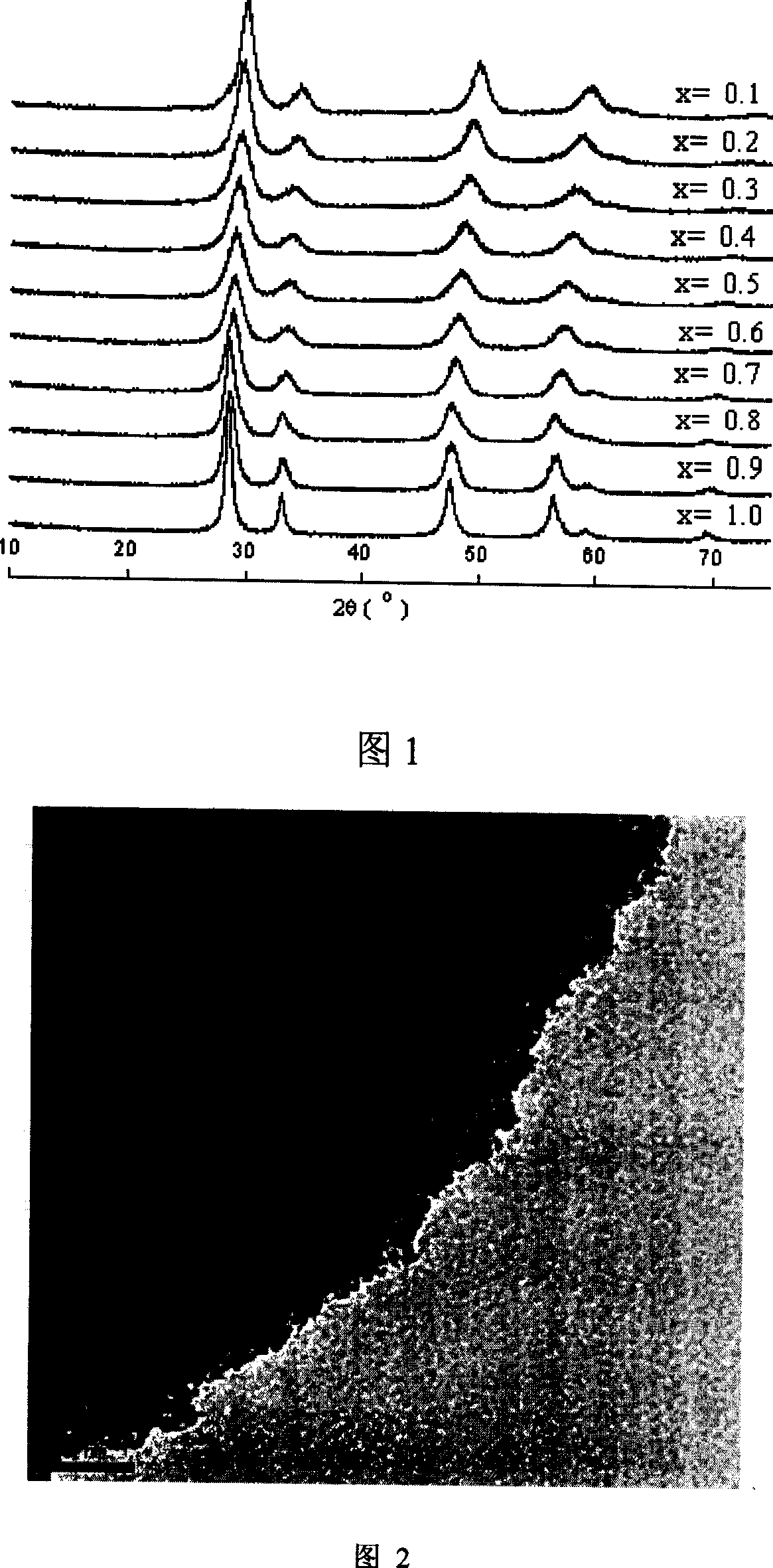

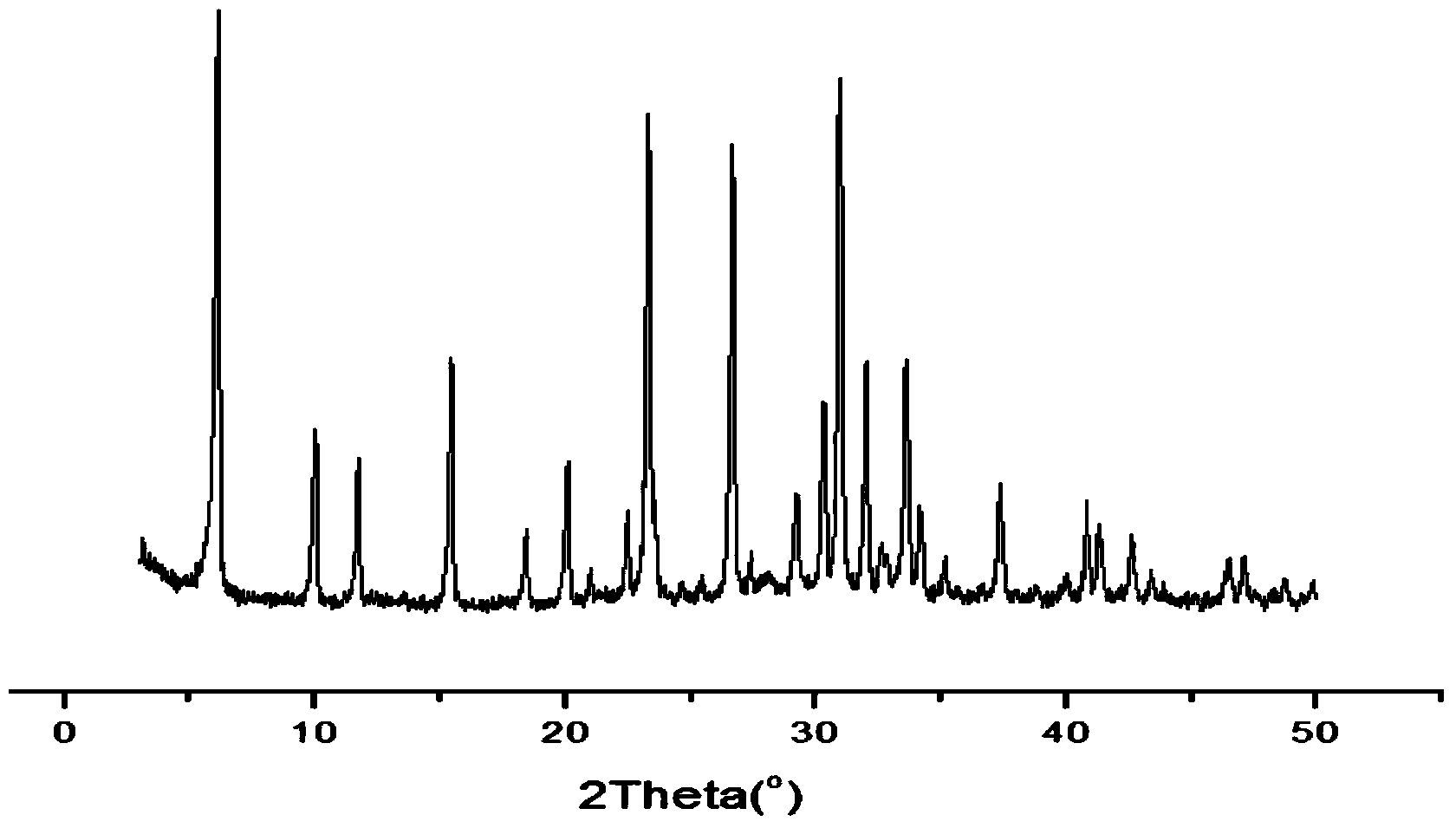

ActiveCN103878018ASmall grainEasy to operateMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveDiffractometer

The invention discloses a method for synthesizing a small grain SAPO-18 / SAPO-34 eutectic molecular sieve. The method is mainly characterized in that a single-template agent or a double-template agent is adopted, a crystal growth inhibitor is added in the synthetic process, and the synthesis parameters are adjusted to carry out crystallization under high-speed stirring. The specific method comprises the following steps: forming a mixed solution A through an aluminum source and water; forming a mixed solution B through a phosphorus source and water; uniformly mixing the solution B with the solution A in a stirring state; sequentially adding the template agent and a silicon source in the stirring state; adding the crystal growth inhibitor, performing hydrothermal crystallization under high-temperature stirring, separating, washing and drying to obtain the molecular sieve. The obtained molecular sieve is characterized by using a powder X-ray diffractometer, and a ratio of AEI / CHA in the eutectic molecular sieve is calculated to be about 50 / 50-70 / 30 through DIFFaX. The obtained molecular sieve is small in grain and large in specific surface area and has high activity, selectivity and stability in an olefin preparation reaction through a catalyst methanol.

Owner:淄博齐创新材料科技有限公司

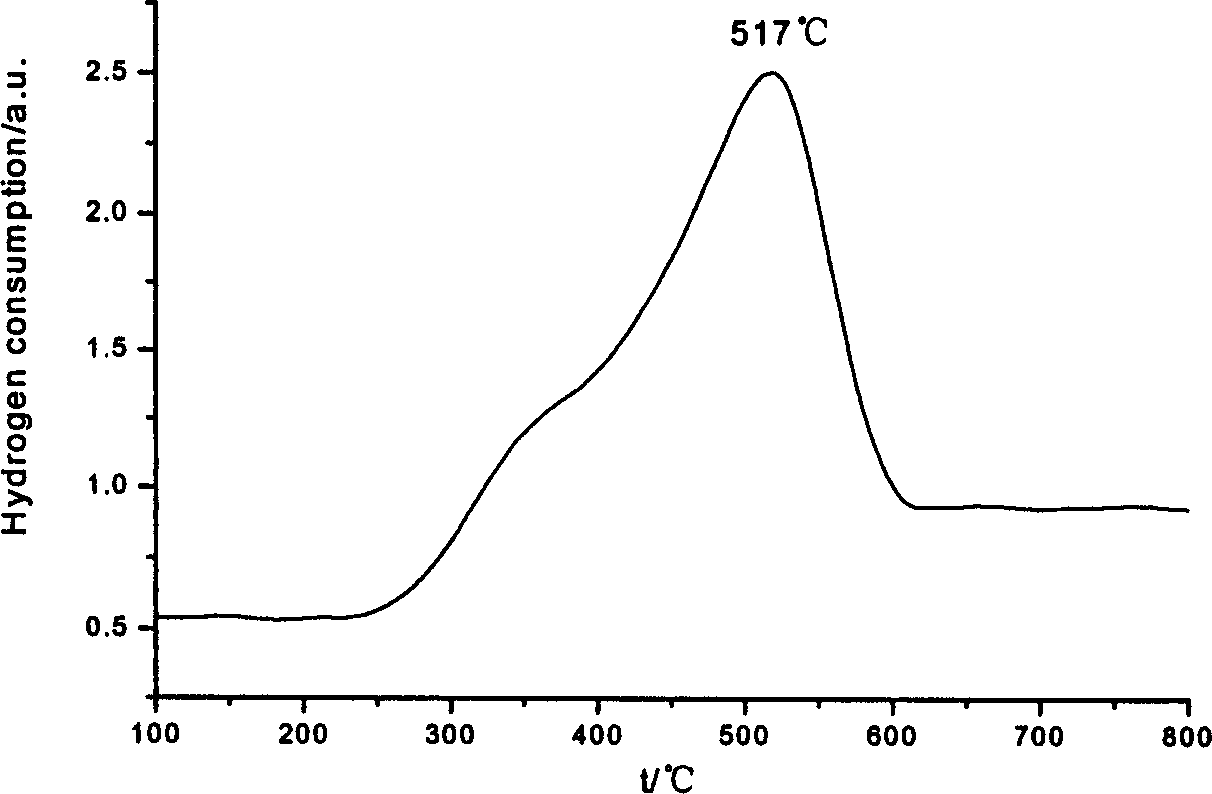

Method for preparing copper oxide hydrogenation catalyst loaded on silica gel-mordenite composite carrier

InactiveCN102247883AReduce the hydrogenation reduction temperatureHigh activityOrganic chemistryMolecular sieve catalystsPtru catalystMordenite

The invention relates to a method for preparing a copper oxide hydrogenation catalyst loaded on a silica gel-mordenite composite carrier. The method is characterized by comprising the following steps of: (1) activating natural mordenite; (2) dropwise adding a silica gel solution for adjusting a pH value to 2-3 into a mixed solution of copper salt, cerium salt and urea, wherein the copper salt, the cerium salt and the silica sol are CuO, CeO2 and SiO2 respectively based on weight, the molar ratio of CuO to SiO2 is 0.1-0.3, the molar ratio of CeO2 to SiO2 is 0.02-0.05, and the mass ratio of the urea to the copper salt is 0.16-0.21; continuously stirring in a water bath of 70-80 DEG C; adding the activated mordenite when a system is in a semi-gel state, wherein the mass ratio of the copper salt to the activated mordenite is 0.7-2; and continuously stirring to complete gelation, stopping stirring, and aging at room temperature to obtain gel; and (3) selecting the gel, washing until the pH value is 6.5-7.5, drying and roasting at the temperature of 450-600 DEG C to obtain the catalyst. The method has the advantages of high specific surface area, uniform distribution of copper oxide grains serving as a catalytic active component, small crystal grains and high activity.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for synthesizing kaolin microsphere in-situ crystallized product containing small crystal grain NaY molecular sieves

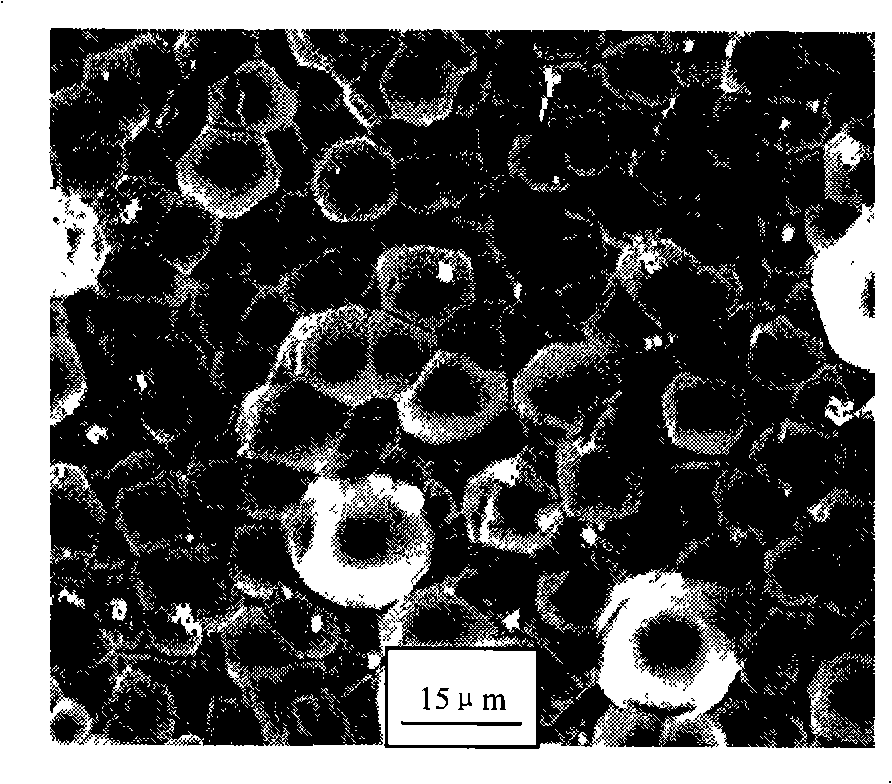

ActiveCN102019197APromote depolymerizationSmall grainMolecular sieve catalystsCatalyst activation/preparationMicrosphereSlurry

The invention relates to a method for synthesizing a kaolin microsphere in-situ crystallized product containing small crystal grain NaY molecular sieves. Kaolin is used as a raw material. The method comprises the following steps of: adding deionized water and sodium silicate or sodium pyrophosphate into the kaolin, mixing and slurrying, performing spray drying on the mixed slurry to prepare kaolin spray microspheres with particle diameters of 20 to 110 microns, roasting a part of the kaolin spray microspheres for 1 to 3 hours at the temperature of between 920 and 1,000 DEG C to obtain high-temperature roasted microspheres, and roasting the other part of the kaolin spray microspheres for 1 to 3 hours at the temperature of between 700 and 900 DEG C to obtain metakaolin microspheres; mixing the high-temperature roasted microspheres and the metakaolin microspheres in a mass ratio of 9:1-1:9, adding sodium silicate, directing agent, sodium hydroxide solution, deionized water and organic additive into the mixture, and crystallizing for 16 to 36 hours at the temperature of between 90 and 95 DEG C; and filtering, removing mother solution, and drying the filtrate to obtain the kaolin microsphere in-situ crystallized product containing NaY molecular sieve crystal grains of 200 to 400 nanometers.

Owner:PETROCHINA CO LTD +1

Spherical cerium-zirconium base composite oxide and its preparing method

InactiveCN1935359ASmall grainLarge specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsDecompositionComposite oxide

The present invention discloses a spherical cerium-zirconium base compound oxide and its preparation method. Said invention provides its structure general formula. Said invention adopts urea as precipitant, and utilizes the ammonia gas released by said urea when which is undergone the process of hydrothermal decomposition treatment at 125-135deg.C to make cerium, zirconium and nitrate produce uniform coprecipitation, so that it can make the obtained solid solution sample have the advantages of small grain size, large specific surface area, high oxygen-storing capacity and good thermal stability. Said compound oxide can be extensively used in various catalysts.

Owner:EAST CHINA UNIV OF SCI & TECH

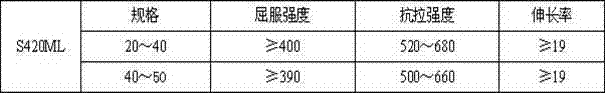

Structural steel S420ML medium and heavy plate and production method thereof

InactiveCN102345056AAvoid excessive grain growthGuaranteed purityRoll mill control devicesMetal rolling arrangementsHeating systemCooling speed

The invention discloses a structural steel S420ML medium and heavy plate comprising chemical components of, by weight: 0.12 to 0.15% of C, 0.25 to 0.40% of Si, 1.45 to 1.55% of Mn, no more than 0.017% of P, no more than 0.003% of S, 0.015 to 0.035% of Als, 0.030 to 0.040% of Nb, 0.010 to 0.020% of Ti, 0.010 to 0.020% of Ni, and balance of Fe and residual elements. The carbon equivalent is represented by that: [Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15]<=0.41. The production method of the plate comprises processes of KR hot metal pretreating, converter smelting, argon-blowing treating, LF refining, VD refining, continuous casting, heating, controlled rolling and controlled cooling, and stack cooling. During the processes, a TMCP rolling technology and a steel plate stacking and sustained-cooling technology are adopted. With the method provided by the invention, components in S420ML can be ensured; contents of harmful elements such as P and S can be strictly controlled; a heating system in the steel rolling process is strictly controlled; during a rolling process, a finishing temperature, a self-tempering temperature and a cooling speed are strictly controlled; and methods such as a steel plate stacking and sustained-cooling technology are adopted. Therefore, performance indexes of a 20-50mm hot-rolled weldable fine-grain structural steel S420ML medium and heavy plate can reach required standards.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Rapid synthesis method for small-crystal-grain molecular sieves and application of small-crystal-grain molecular sieves

ActiveCN109704365ASmall grainReduce manufacturing costFerrierite aluminosilicate zeoliteMolecular-sieve and base-exchange phosphatesSynthesis methodsCombinatorial chemistry

The invention belongs to the field of preparation of molecular sieves and particularly relates to a rapid synthesis method for small-crystal-grain molecular sieves and an application of the small-crystal-grain molecular sieves. The rapid synthesis of the small-crystal-grain molecular sieves is achieved through the procedures of firstly, preparing a precursor mixture, then, preparing gel and finally carrying out direct crystallization. The method is applied to the synthesis of the following molecular sieves, but not limited to: ZSM-5, ZSM-11, ZSM-22, ZSM-23, ZSM-35, SAPO-34, SAPO-11, SAPO-18, SSZ-13 and EU-1. Molecular sieve products synthesized by the method have the characteristics of small crystal grain, large specific surface area, high crystallinity and high yield. According to the method, the crystallization time can be shortened greatly, the production efficiency is increased, and the manufacturing cost of the molecular sieves is reduced.

Owner:SHANDONG QILU HUAXIN HIGH TECH

Synthesis method and application of submicron X-type molecular sieve

ActiveCN103523796ASuitable for deep purificationShort synthesis timeOther chemical processesFaujasite aluminosilicate zeoliteSynthesis methodsOxygen

The invention relates to a synthesis method and an application of a submicron X-type molecular sieve. The molecular sieve takes a silica solution as a silicon source to prepare a crystallization director, water glass and sodium metaaluminate or aluminum hydroxide and sodium hydroxide are used to prepare a molecular sieve synthesis mother solution, the director is added into the mother solution to age the mother solution for a certain period of time, then a weak-polarity water-soluble dispersing agent is added into the mixture, the mixture is stirred uniformly, and the submicron X-type molecular sieve is obtained through microwave assistance and hydrothermal crystallization in a closed container. The X-type molecular sieve prepared through the method is small in grain size, the synthesis time is greatly shortened, and the production cost is lowered. The molecular sieve is applied to separation and adsorption of hydrocarbon, and particularly has a technical characteristic of removing in depth the oxygen-bearing impurities during the purification of olefin in a MTO (Methanol To Olefin) process, and the molecular sieve prepared through the method has the characteristics of large adsorption capacity and easiness in regeneration, and the method is applicable to industrial production.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

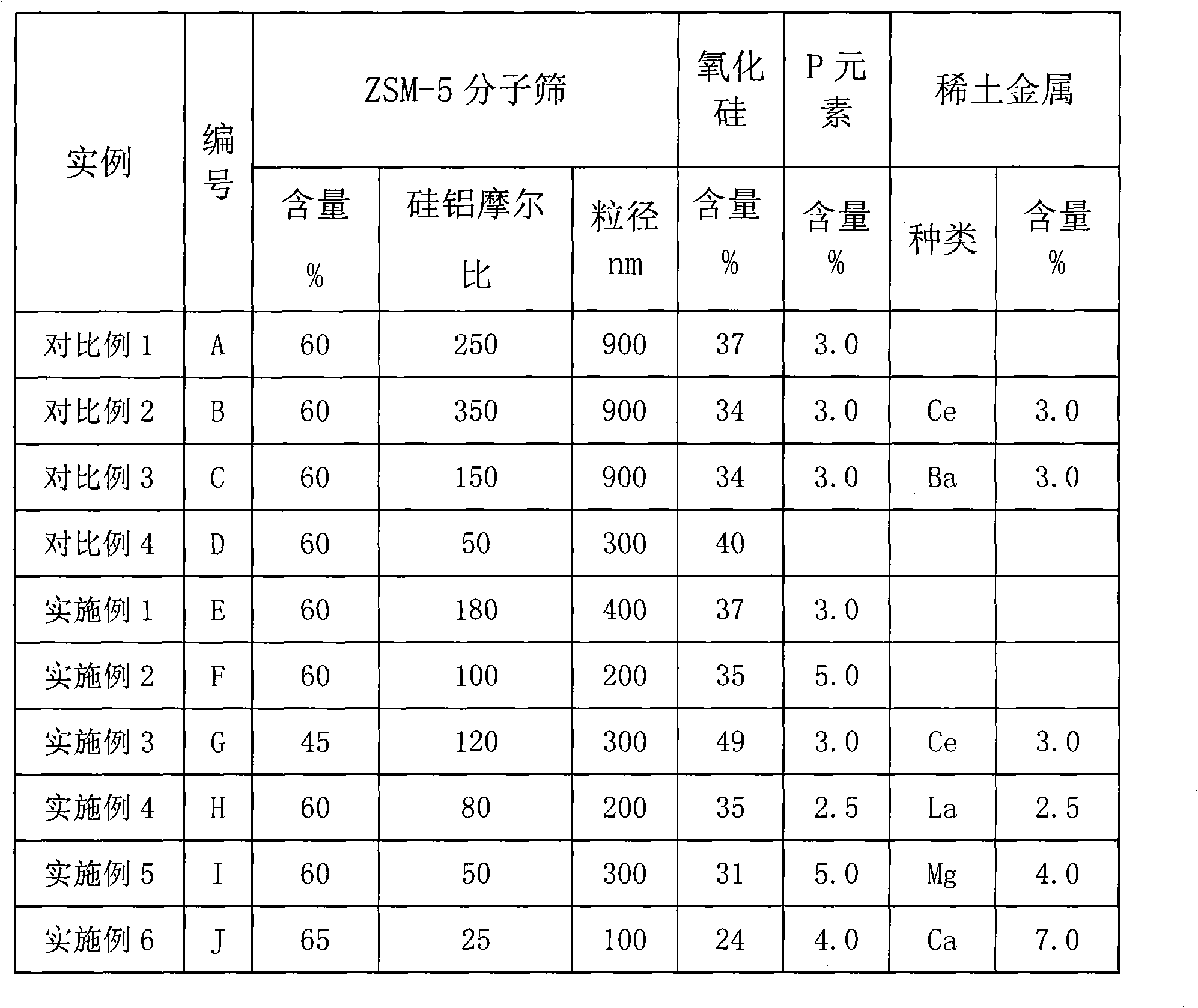

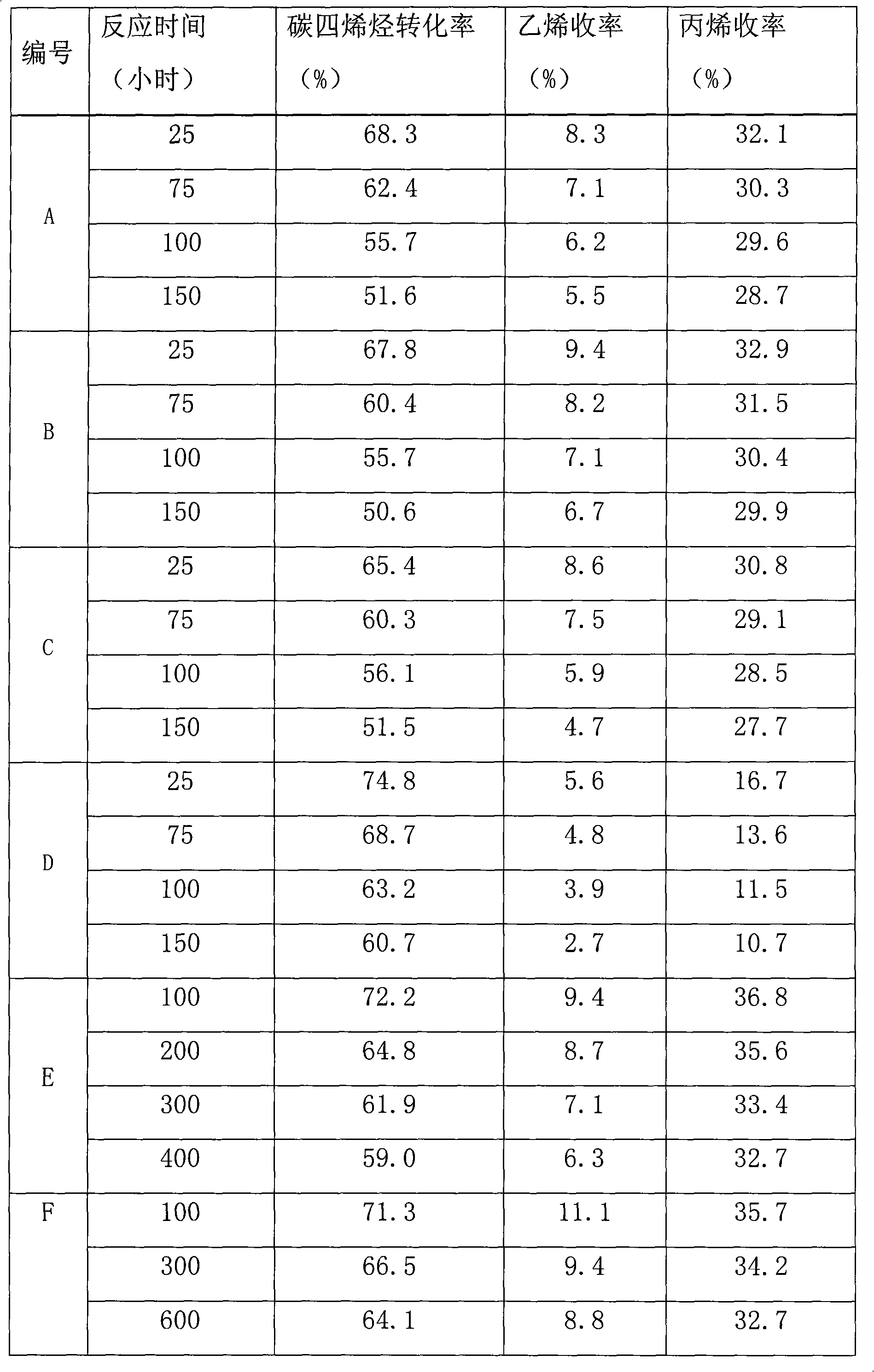

Method for producing propylene and ethylene through catalytic cracking of olefins

InactiveCN101684059AExtended service lifeMeet industrial productionCatalytic crackingMolecular sieve catalystsAdhesiveAlkane synthesis

The invention provides a novel method for producing propylene and ethylene through catalytic cracking of olefins, which comprises the steps of: taking C4-C12 olefins as raw materials; and performing acatalytic cracking reaction of the olefins on the raw materials through a catalyst bed to generate the propylene and the ethylene under the conditions that the reaction temperature is between 450 and650 DEG C, the reaction pressure is between 0 and 0.3MPa, the weight space velocity of the olefins is between 1 and 14 h<-1>, and the weight ratio of water to the olefins is 0.1-10, wherein a catalyst comprises a ZSM-5 molecular sieve, an adhesive and a phosphorus element supported on the catalyst, the silicon-aluminum molar ratio SiO2 / Al2O3 of the ZSM-5 molecular sieve is 10-300, and the grain diameter of crystal grains of the ZSM-5 molecular sieve is between 10 and 800nm. The method has longer reaction operation time while maintaining the high yield of the propylene and the ethylene, and can be used for industrialized production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Boron modified HZSM-5 molecular sieve, preparation method and application thereof

InactiveCN106745049ASmall grain sizeSimple method and operationMaterial nanotechnologyMolecular sieve catalystsIon exchangeSeed crystal

The invention discloses a method for preparing nanoscale boron modified HZSM-5 by seed crystal directing. The method comprises the steps as follows: (1) mixing an aluminum source, a silicon source, an alkali source, a boron source, ZSM-5 molecular sieve seed crystals and water, adjusting the pH of an obtained mixture to 10-12 and mixing the mixture uniformly to form gel; (2) crystallizing the gel in a reactor, and performing solid-liquid separation, washing and drying on a crystallized product to obtain a dried crystallized product; (3) adding the dried crystallized product in an ammonium salt solution for ion exchange to obtain an ammonia type ZSM-5 molecular sieve; (4) roasting the ammonia type ZSM-5 molecular sieve to obtain HZSM-5. The invention further discloses a molecular sieve prepared by the method and application of the molecular sieve in a reaction of methanol to propylene. The boron modified HZSM-5 requires no roasting of a template agent and is environment-friendly, the propylene yield and the service life are greatly increased, the selectivity of propylene reaches 44.0wt% or higher, and the service life reaches 500 h or longer.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

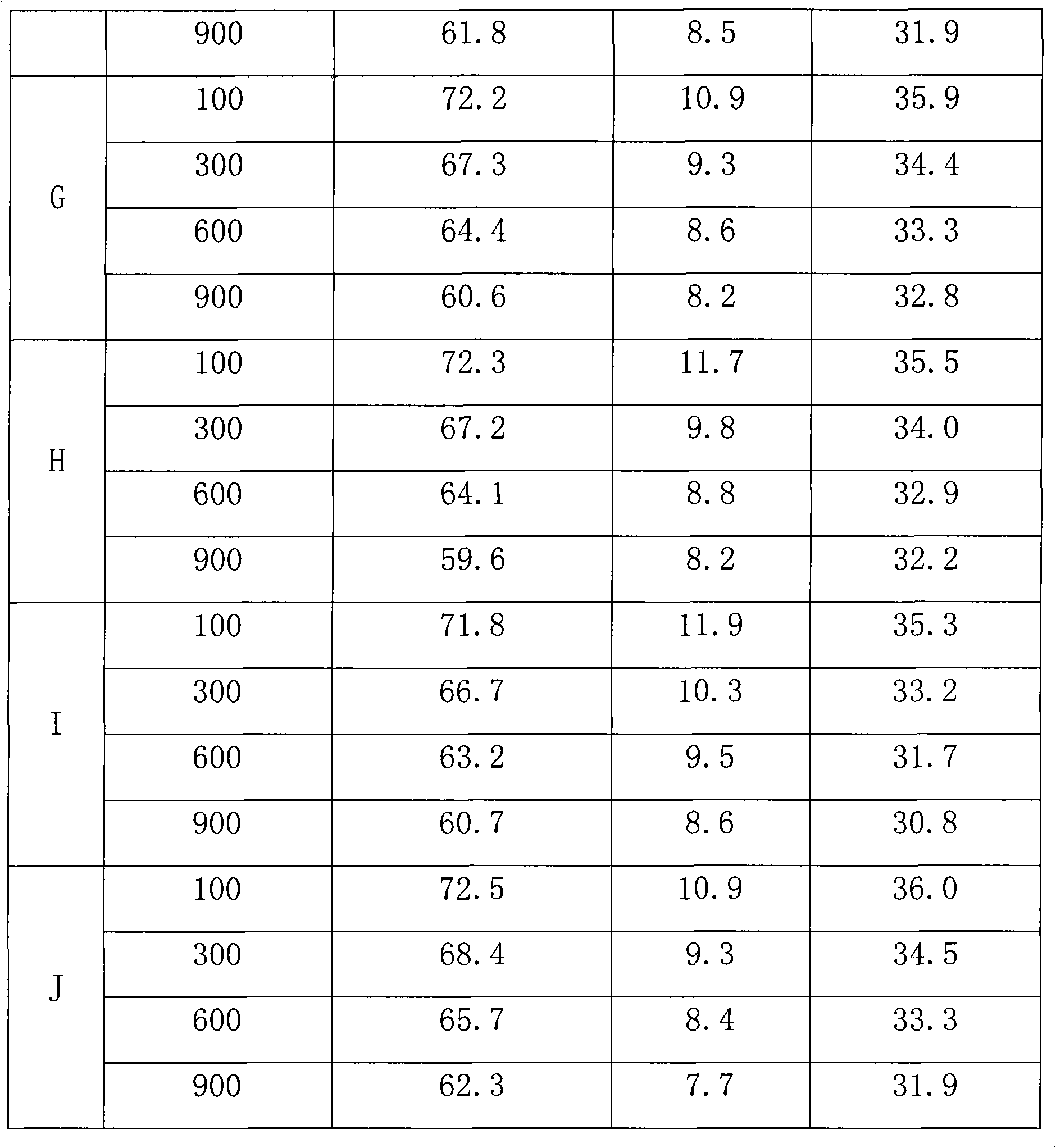

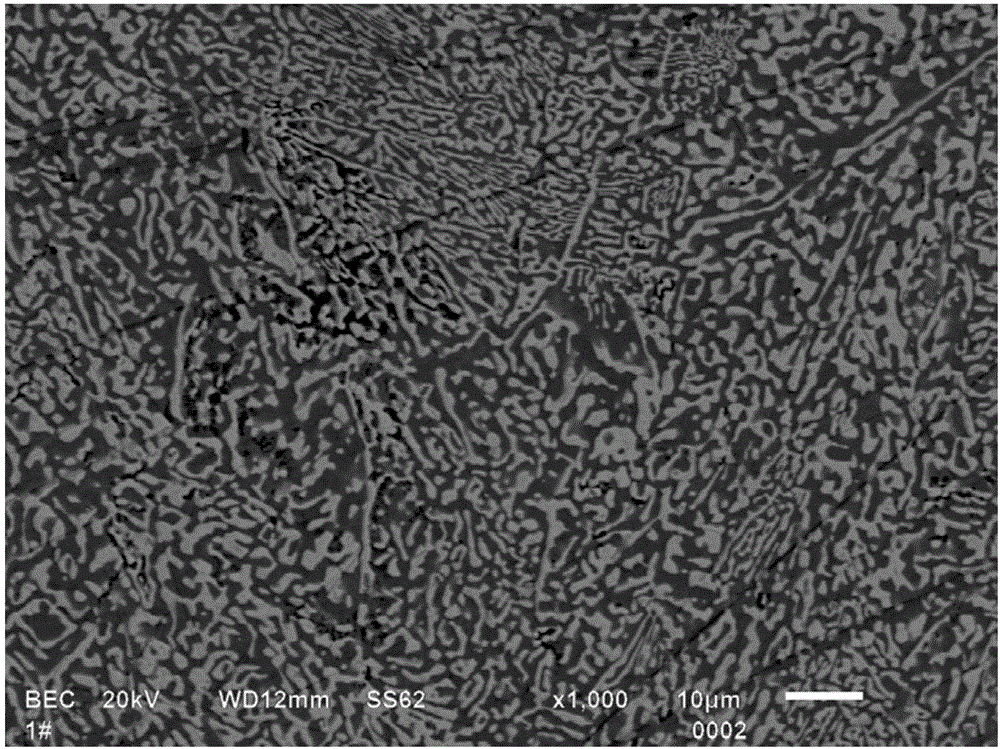

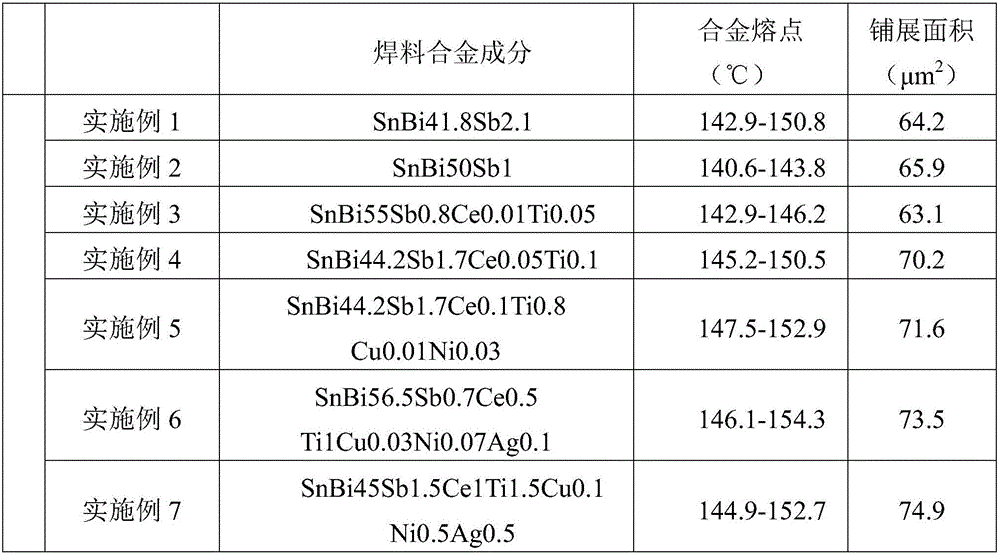

SnBiSb-series low-temperature lead-free solder and preparation method thereof

ActiveCN106216872AFine grainSmall grainWelding/cutting media/materialsSoldering mediaMechanical propertyMechanical properties of carbon nanotubes

The invention discloses SnBiSb-series low-temperature lead-free solder and a preparation method thereof, and belongs to the technical field of low-temperature soft solder. The SnBiSb-series low-temperature lead-free solder consists of the following components in percentage by weight: 32.8-56.5% of Bi, 0.7-2.2% of Sb, the balance Sn, wherein weight percentage of Bi and Sb meets a relation b=0.006 a<2>-0.0672a+19.61+c, a is weight percentage of Bi, b is weight percentage of Sb, and c is greater than or equal to c, and smaller than or equal to 1.85. The invention further discloses a preparation method for the lead-free solder. Solder alloy of the SnBiSb-series low-temperature lead-free solder is a ternary eutectic or near-elliptic eutectic structure, is low in melting point, has excellent mechanical property and reliability, and is suitable for the low-temperature solder field.

Owner:BEIJING COMPO ADVANCED TECH

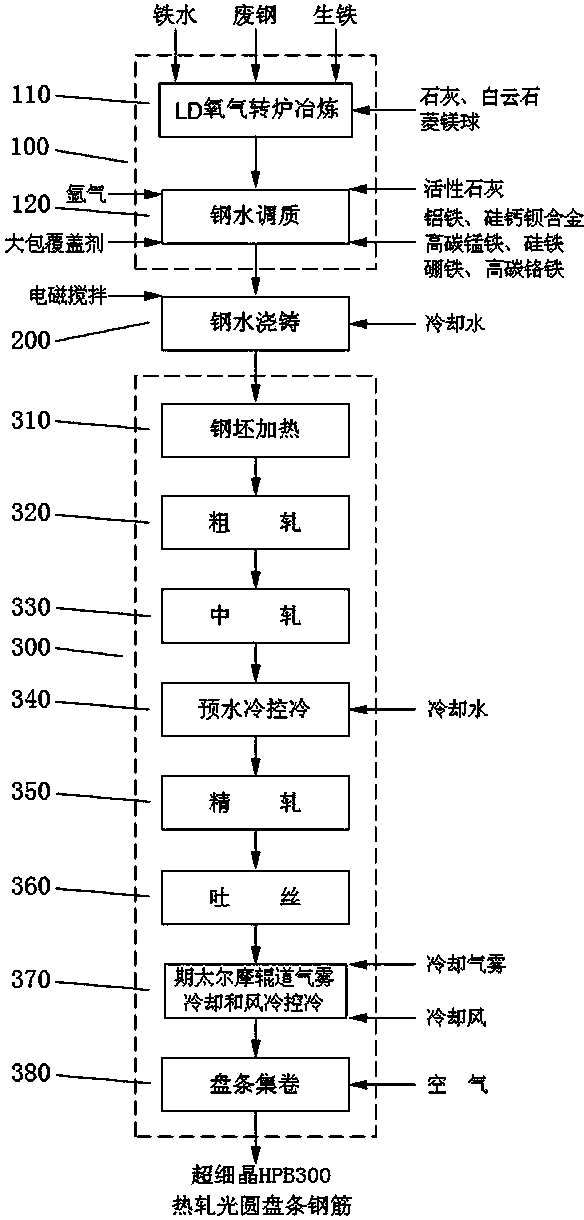

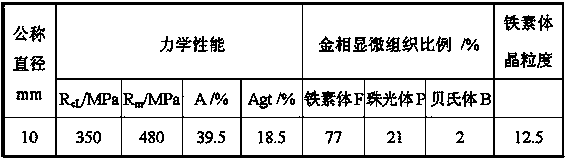

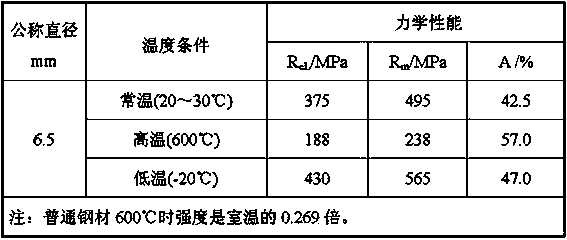

Ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar and preparation method thereof

The invention discloses an ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar and a preparation method thereof. The ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar comprises the following components in percentage by weight: 0.15-0.18% of C, 0.10-0.16% of Si, 0.16-0.28% of Mn, 0.080-0.120% of Cr, 0.0010-0.0020% of B, less than 0.030% of S, less than 0.045% of P and the balance of Fe. The reinforcing steel bar is prepared from molten iron, steel scrap and pig iron through steps of molten steel smelting, molten steel pouring and billet controlled rolling and controlled cooling. According to the reinforcing steel bar, a small amount of ferromanganese, ferroboron and high carbon ferro-chrome alloy into the steel-making step, so that the alloying cost is remarkably lowered. By adopting low-temperature controlled rolling before spinning and a stelmor roller aerial fog cooling process after spinning, the reinforcing steel bar has the advantages of low cost, good toughness, excellent high- and low-temperature performance, low stress time-validity and the like.

Owner:WUKUN STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com