Method for synthesizing small grain SAPO-18/SAPO-34 eutectic molecular sieve

A technology of SAPO-18 and SAPO-34, applied in the field of molecular sieves, can solve the problems of low catalytic activity and single pore size of molecular sieves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

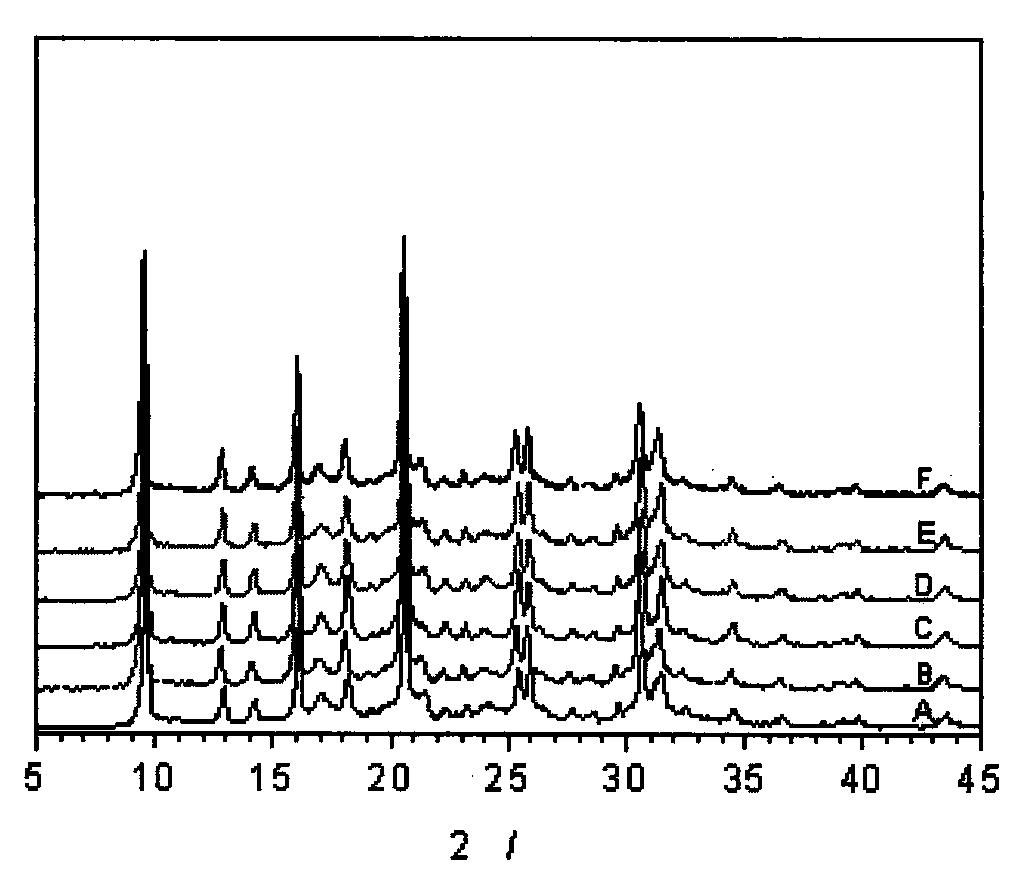

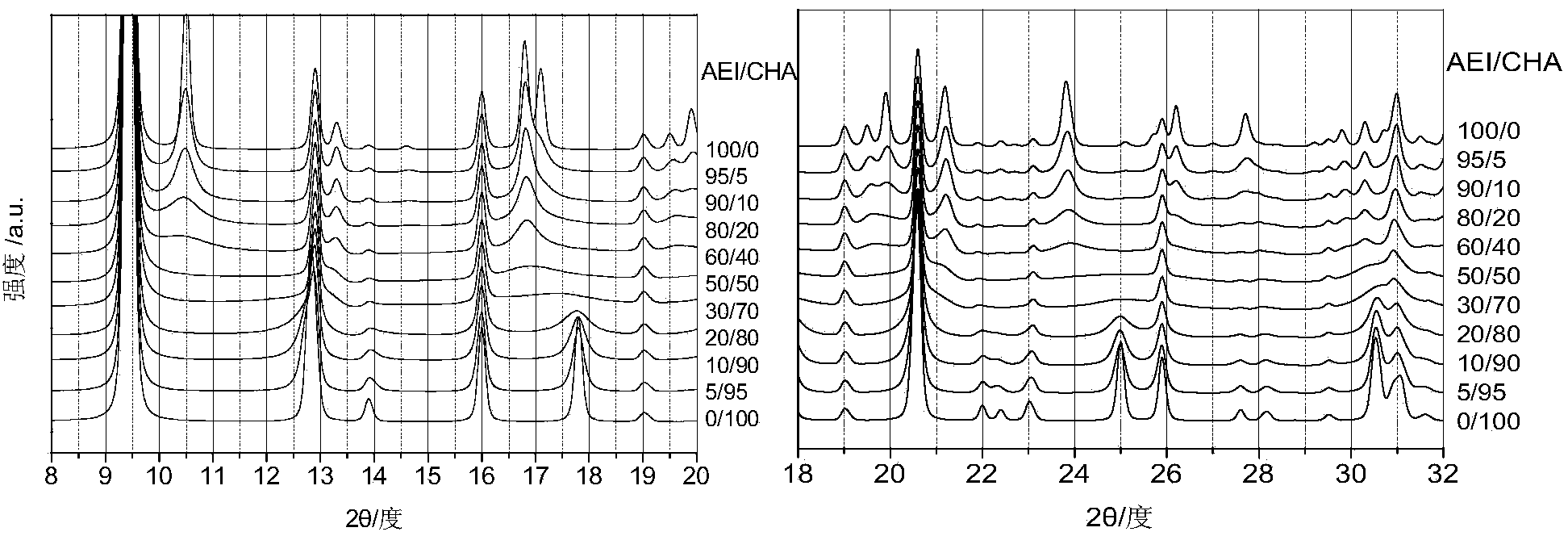

[0032] Example 1: 1) 12g pseudo-boehmite (Al 2 o 3 content is 65wt%) mixed with 12g water to form mixed solution A; 2) mixed 17.4g phosphoric acid with 4g water to form solution B; 3) mixed solution B and solution A evenly under stirring; 4) added 6.9 g triethylamine, 6 g tetraethylammonium hydroxide, and 0.4 g silica sol (41.1 wt%), and finally add 0.058 g polyethylene glycol, and stir evenly to obtain a molecular sieve synthetic liquid. 5) Transfer the prepared molecular sieve synthesis solution into a crystallization kettle, seal it and crystallize at 200°C for 2 days. After the crystallization is completed, the crystallization kettle is taken out, rapidly cooled, washed, and dried at 110°C to obtain a molecular sieve product. The XRD results show that the product is a SAPO-18 / SAPO-34 eutectic molecular sieve (such as figure 2 Shown by the middle line A), the AEI / CHA in the crystal is 67 / 33. SEM results show that the sample boundary is obvious, and the crystal size is ...

Embodiment 2

[0033] Example 2: 1) Mix 18g aluminum isopropoxide and 19.8g water to form mixed solution A; 2) Mix 5.22g phosphoric acid and 19.8g water to form solution B; 3) Mix B solution and A solution evenly under stirring 4) Add 2.28g of triethylamine, 1.8g of tetraethylammonium hydroxide and 4.86g of ethyl orthosilicate successively under stirring, add 0.055g of polyethylene glycol, and stir evenly to obtain a molecular sieve synthetic liquid. 5) Transfer the prepared molecular sieve synthesis solution into a crystallization kettle, seal it and crystallize at 200°C for 2 days. After the crystallization is completed, the crystallization kettle is taken out, rapidly cooled, washed, and dried at 110°C to obtain a molecular sieve product. The XRD results show that the product is a SAPO-18 / SAPO-34 eutectic molecular sieve (such as figure 2 Line B), the AEI / CHA in the crystal is 62 / 38. SEM results show that the sample boundary is obvious, and the crystal size is about 320-560nm (such as ...

Embodiment 3

[0034]Example 3: 1) 12g of pseudo-boehmite (Al2O3 content of 65wt%) was mixed with 18g of water to form a mixed solution A; 2) 8.8g of phosphoric acid was mixed with 18g of water to form a solution B; 3) under stirring, the B The solution was mixed evenly with liquid A; 4) 23g of triethylamine, 5g of diethylamine and 0.4g of silica sol (41.1wt%) were sequentially added under stirring, and 0.09g of polyethylene glycol was added, and stirred evenly to obtain a molecular sieve synthetic liquid. 5) Transfer the prepared molecular sieve synthesis solution into a crystallization kettle, seal it and crystallize at 200°C for 3 days. After the crystallization is completed, the crystallization kettle is taken out, rapidly cooled, washed, and dried at 110°C to obtain a molecular sieve product. The XRD results show that the product is a SAPO-18 / SAPO-34 eutectic molecular sieve (such as figure 2 Line C), the AEI / CHA in the crystal is 65 / 35. SEM results show that the sample boundary is o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com