Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

503 results about "Diffractometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A diffractometer (pronunciation: di-"frak-'tä-m&-t&r) is a measuring instrument for analyzing the structure of a material from the scattering pattern produced when a beam of radiation or particles (such as X-rays or neutrons) interacts with it.

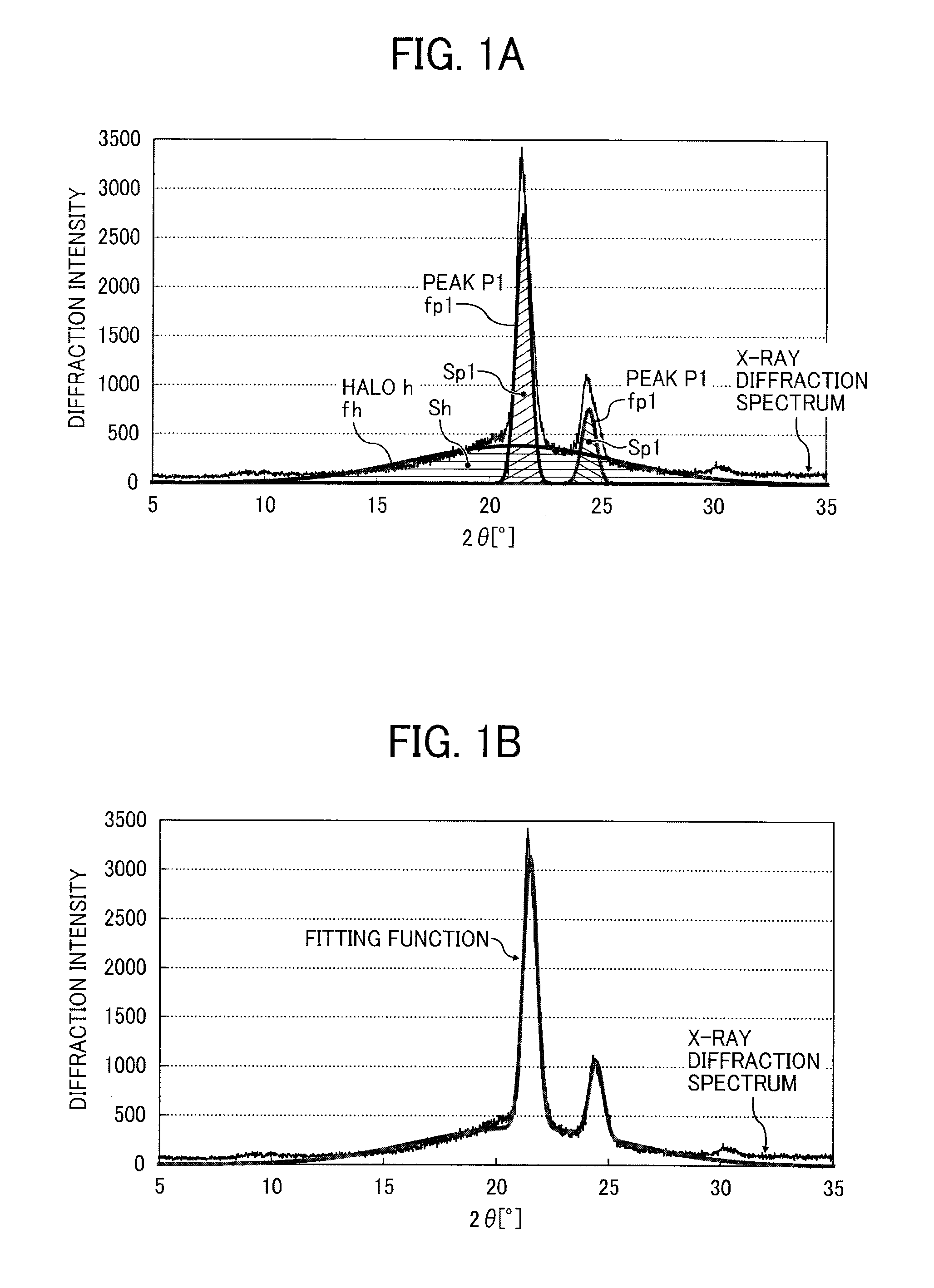

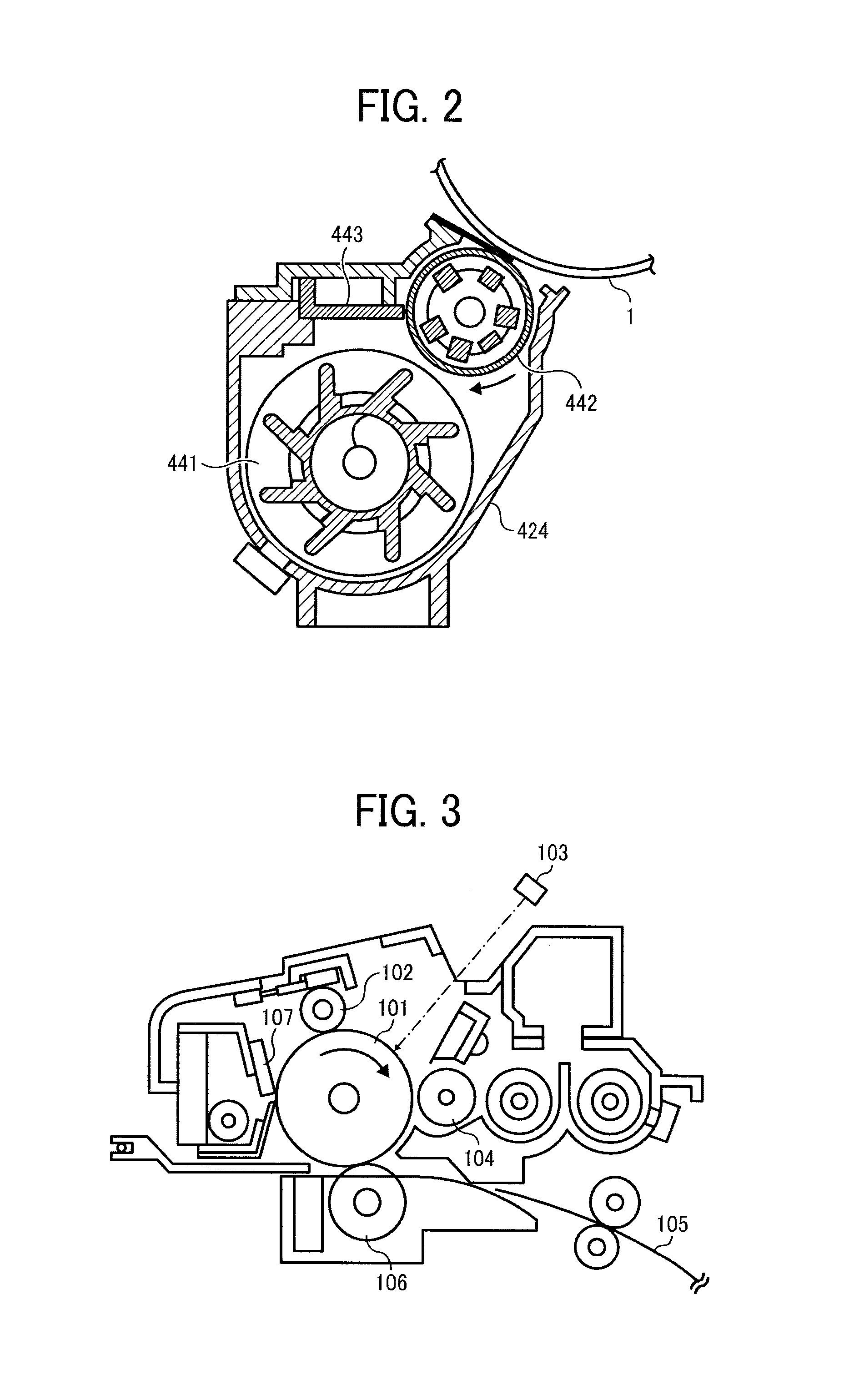

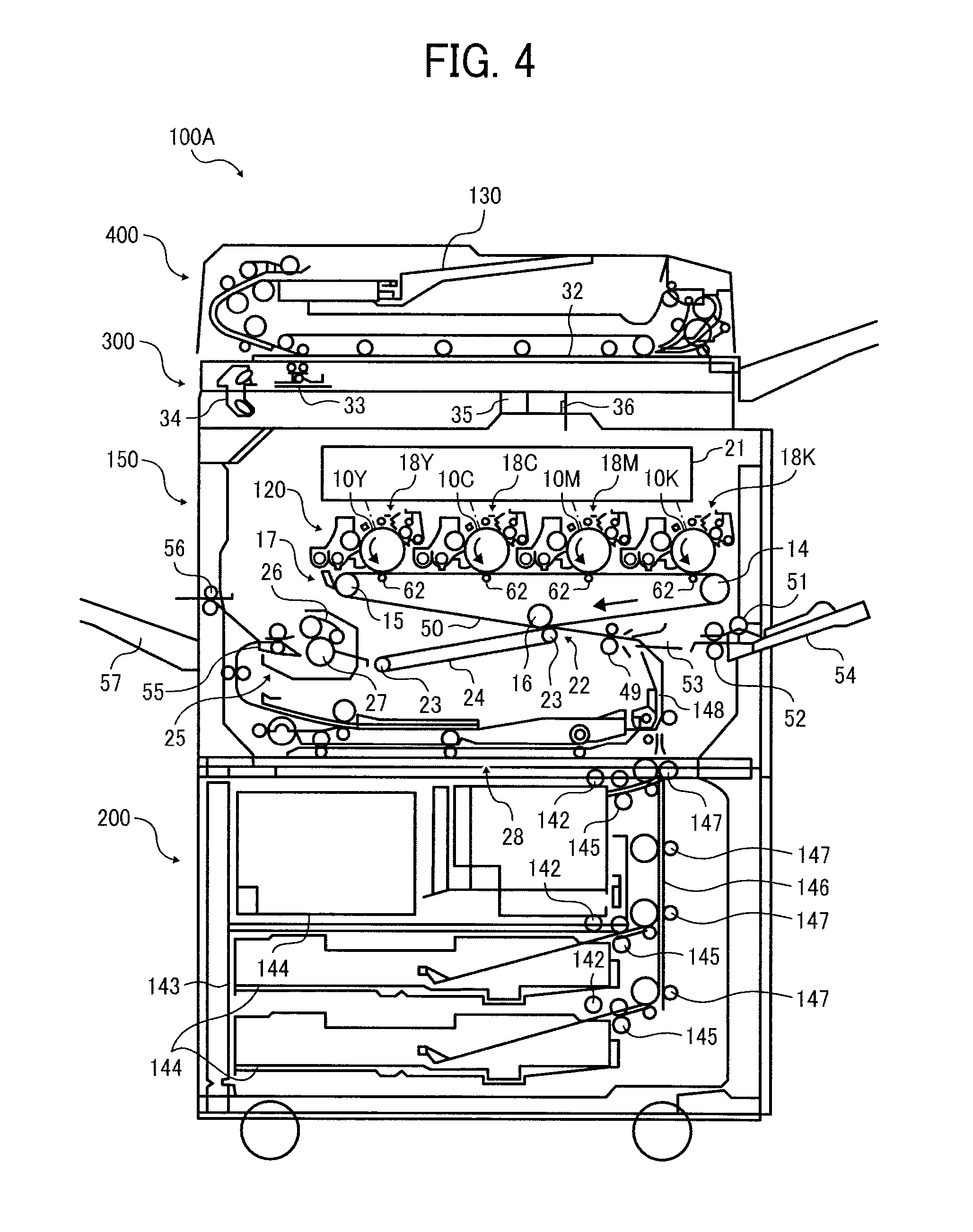

Toner, development agent, image forming apparatus, and process cartridge

Toner contains a binder resin containing a crystalline resin having a urethane and / or urea bonding; and a colorant, wherein in a diffraction spectrum of the toner as measured by an X-ray diffraction instrument, a ratio {C / (C+A)} of an integral intensity C of the spectrum derived from the crystalline structure to an integral intensity A of the spectrum derived from the non-crystalline structure is 0.12 or greater, wherein the toner satisfies the following relation 1: T1−T2≦30° C. (Relation 1), where T1 represents the maximum endothermic peak in the first temperature rising from 0° C. to 100° C. at the temperature rising rate of 10° C. / min and T2 represents the maximum exothermic peak in the first temperature falling from 100° C. to 0° C. at the temperature falling rate of 10° C. / min as T1 and T2 are measured by diffraction scanning calorimetry (DSC).

Owner:RICOH KK

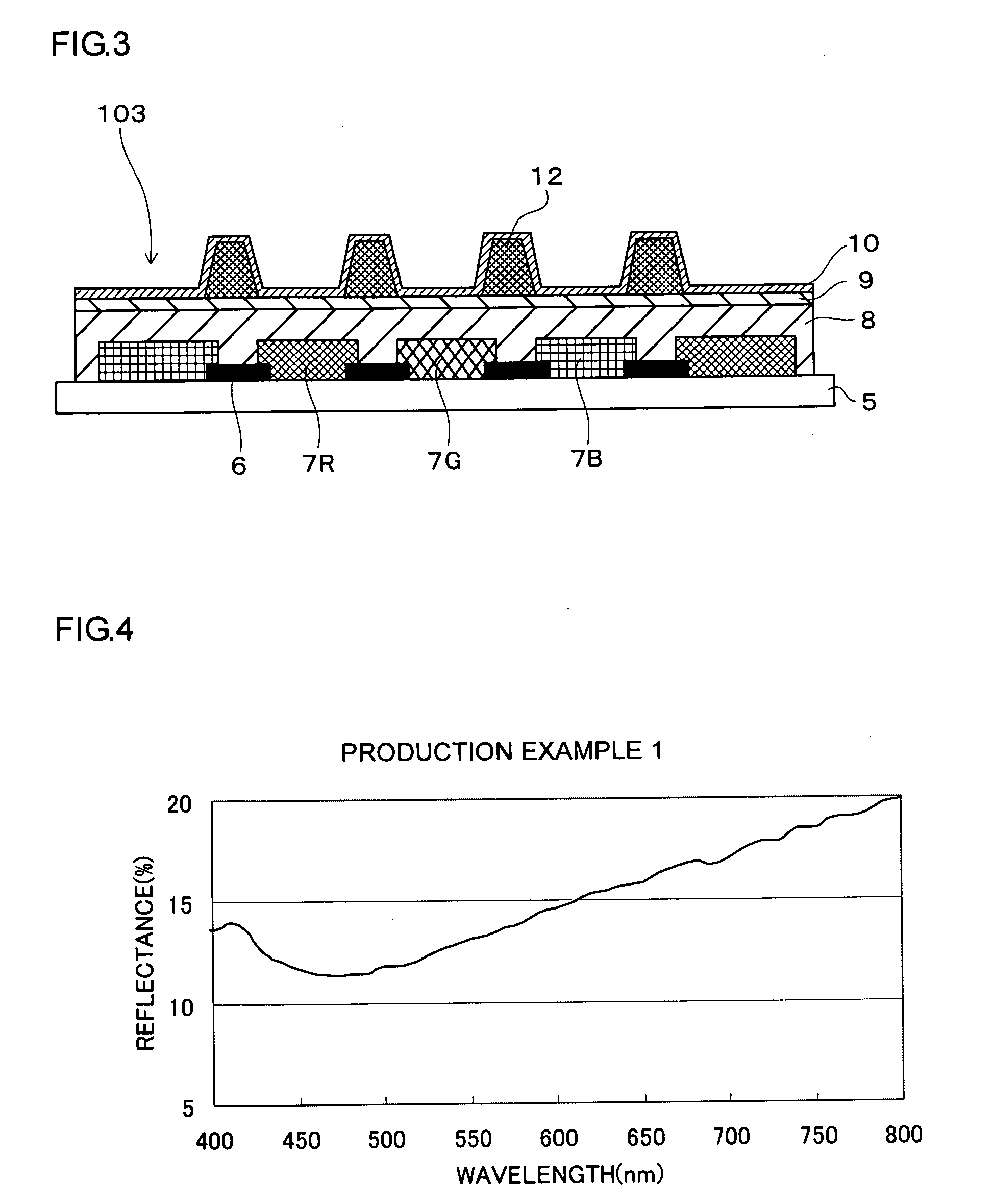

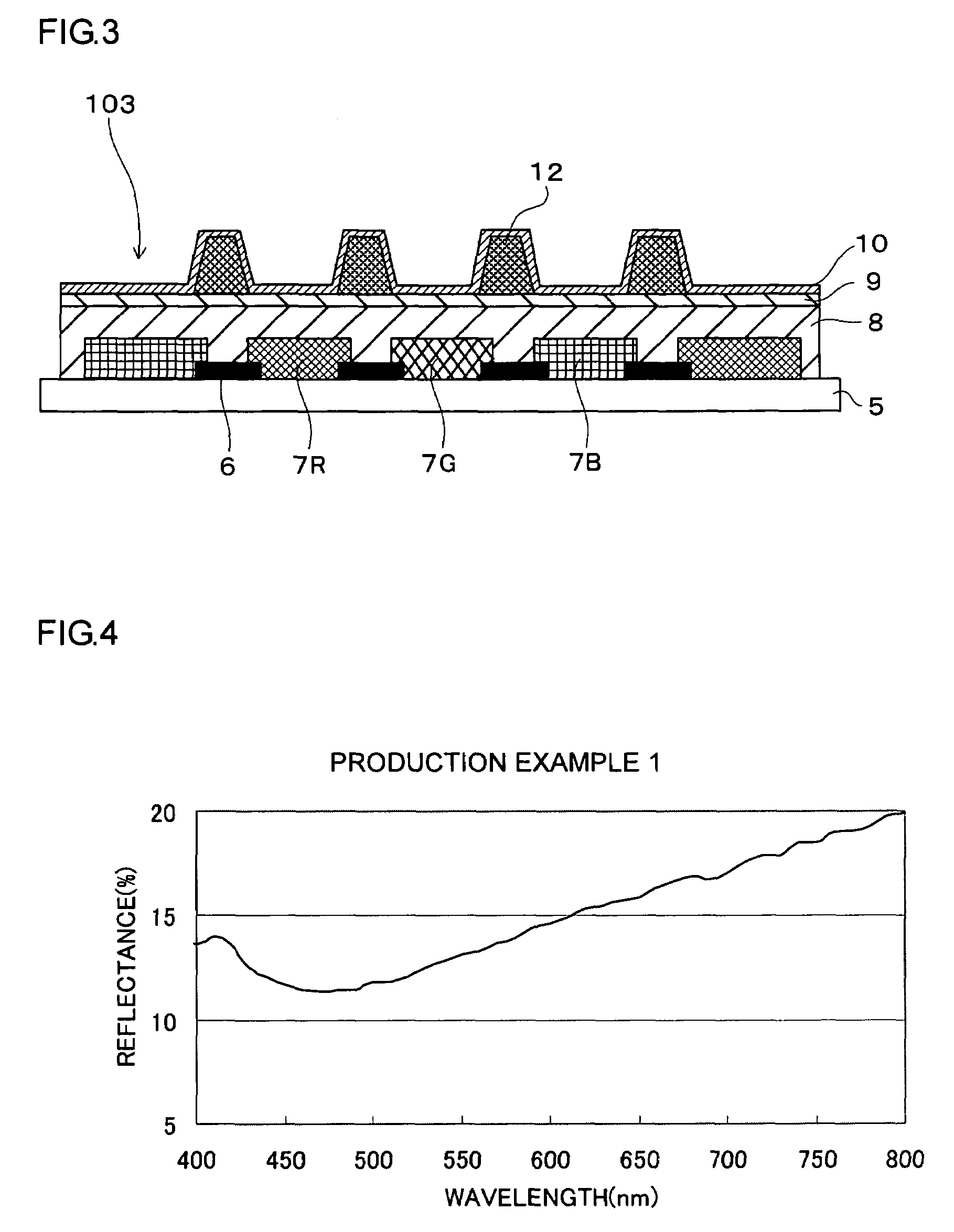

Black Resin Composition for Display Device, and Member for Display Device

InactiveUS20080318018A1High optical densitySufficient optical densitySynthetic resin layered productsConductive materialDisplay deviceX-ray

A black resin composition for a display device, which can achieve a high optical density even when its light-blocking agent content is relatively low and can achieve a high optical density even when it is formed into a thin film, and a member for display device which can reduce unevenness of display caused by a level difference in a pixel part resulting from the film thickness of the black resin composition. The black resin composition for a display device has a black titanium oxynitride represented by composition formula: TiNxOy-nSiO2 (wherein x and y each are a real number of larger than 0 but less than 2, and n is a real number within the range of 0≦n≦0.05), containing a nitrogen atom represented by N in an amount of 17 wt % or more but less than 23 wt %, and having a specific surface area of 5 to 30 m2 / g and a crystalline size as measured with an X-ray diffractometer of 17 to 25 nm, and a curable binder system. Also, a member for display device having a light-blocking layer formed using the said black resin composition for display device.

Owner:ISHIHARA SANGYO KAISHA LTD +1

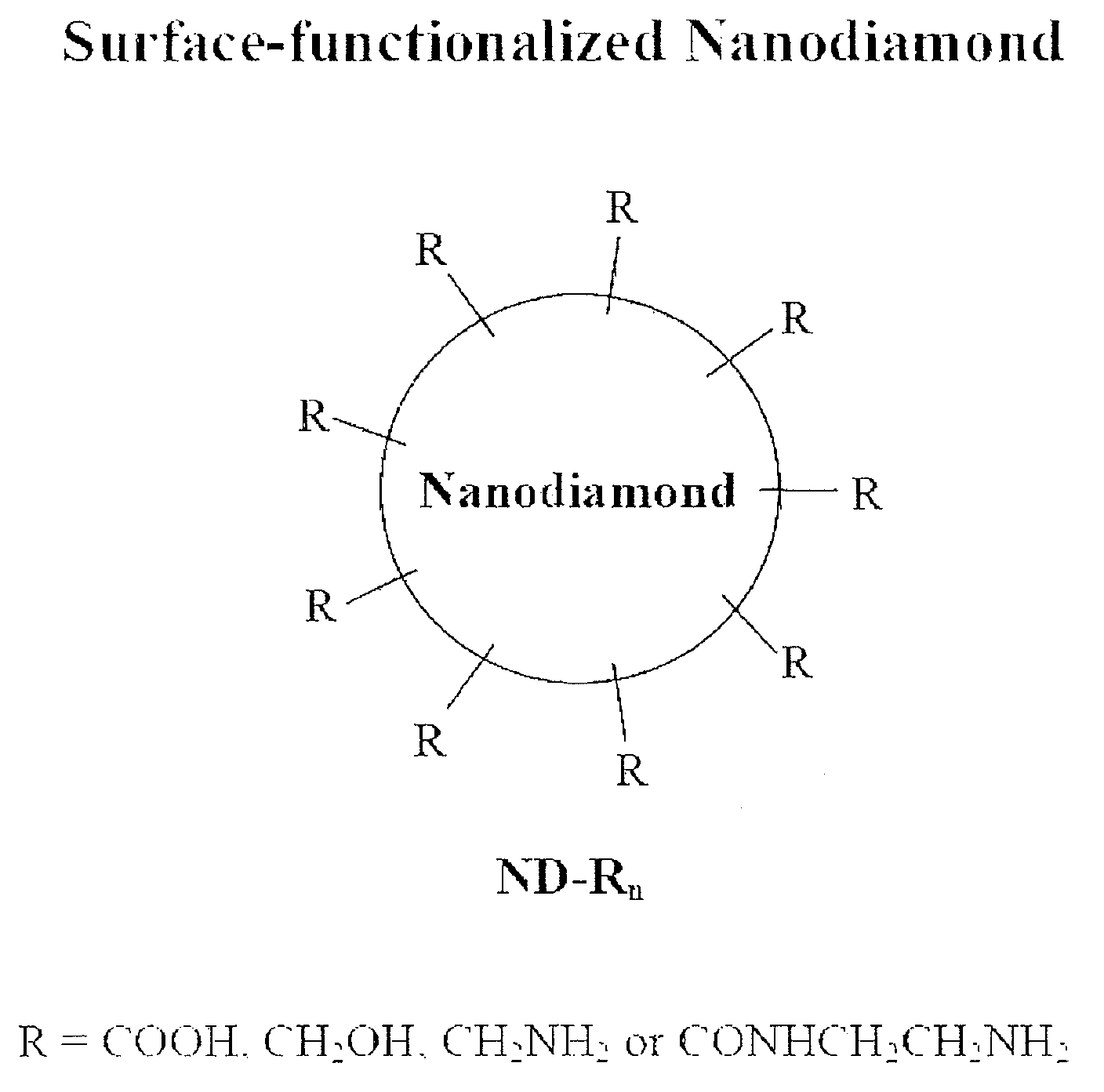

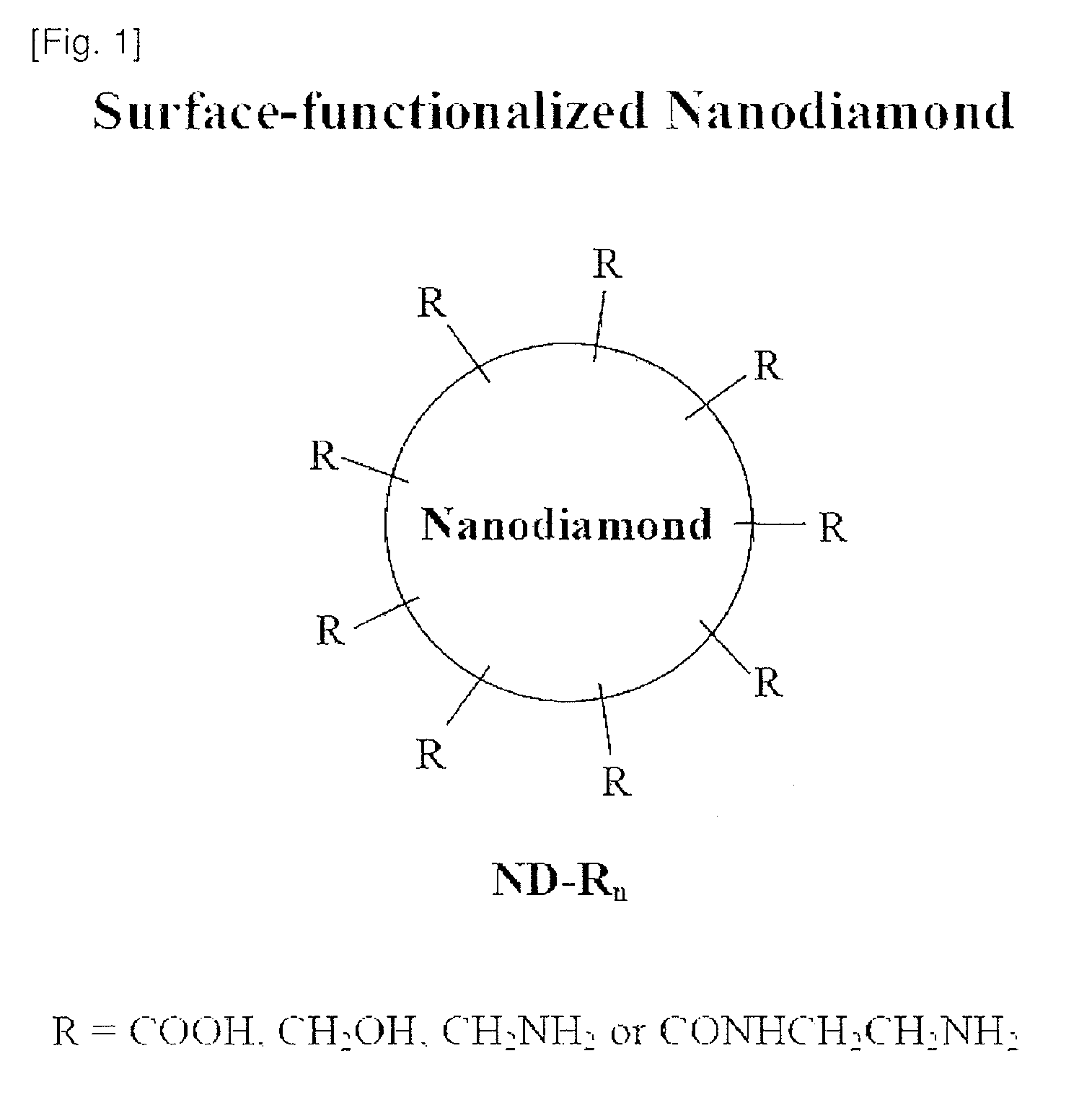

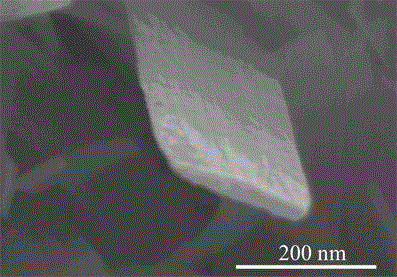

Nanodiamond compounds synthesized by surface functionalization

InactiveUS20100298600A1Improve solubilityMaterial nanotechnologyOxygen-containing compound preparationSolubilityStrong acids

Disclosed herein is a method for chemically attaching carboxyl, alcohol, amine or amide groups to the surface of nanodiamond (ND) in a liquid phase. Also disclosed herein are a functional ND compound obtained by the method and use thereof. The method includes treating synthetic ND with a size of 1 nm-1OO nm with sonication and a strong acid to provide ND-(COOH)n. The ND-(COOH)n compound is used as a starting material to provide ND compounds having alcohol, amine or amide groups attached to the surfaces thereof. The surface-functionalized ND compounds are characterized by using an X-ray diffractometer, FTIR, AFM, particle size analyzer and zeta sizer. The ND compounds show functionalities as well as high solubility to provide stable ND solutions in a liquid phase. Therefore, the ND compounds may be used as diamond coating agents. The powder of the ND compounds may be used as materials for producing composites of polymers, plastics, synthetic fibers, ceramics, etc., or as additives for toothpaste, shampoos, soap and cosmetic compositions.

Owner:NANODIAMOND

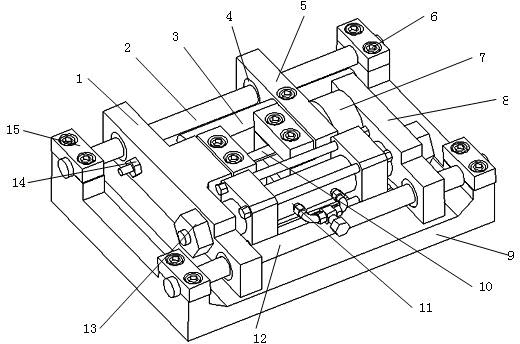

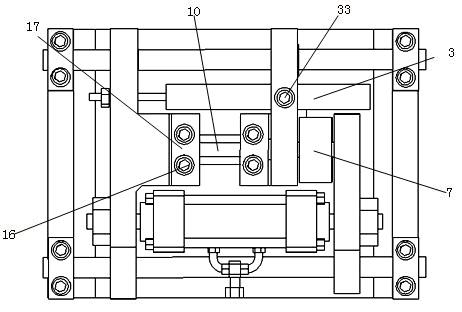

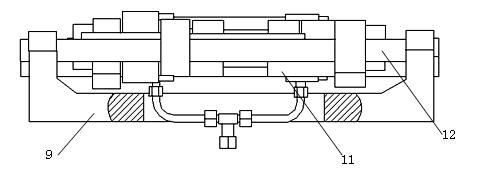

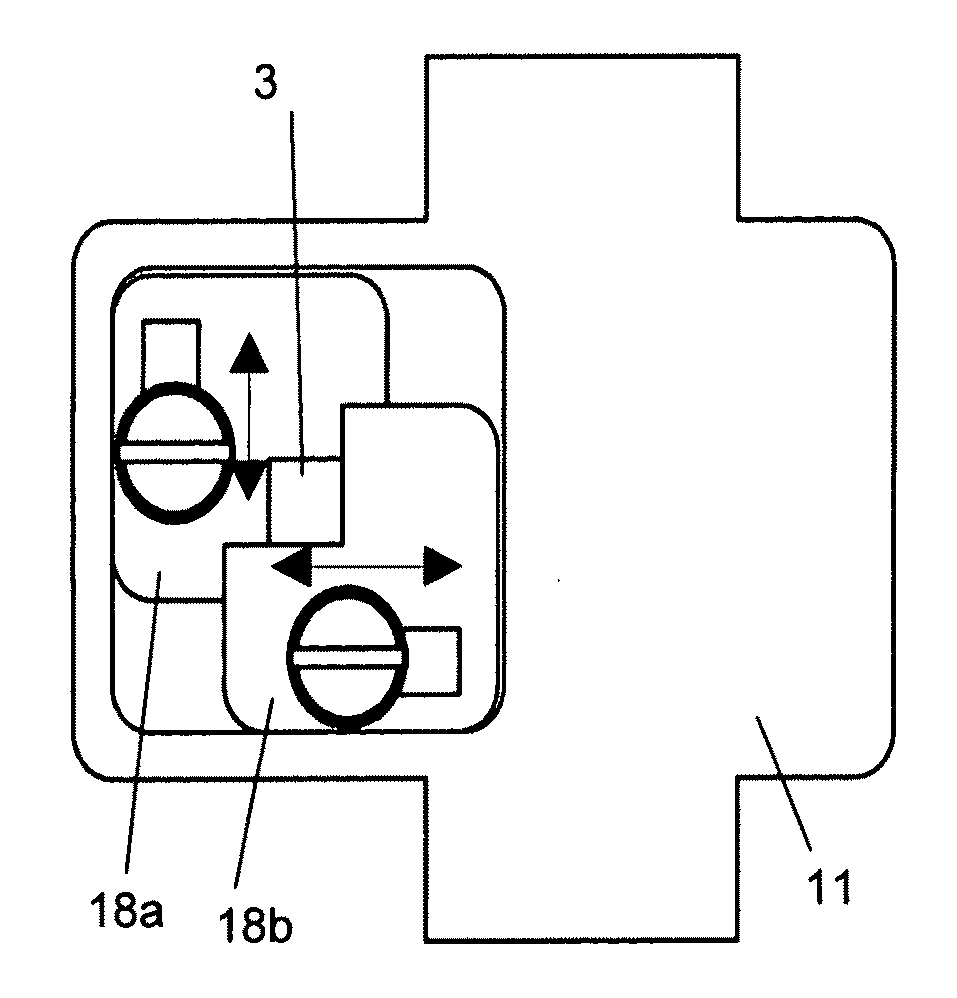

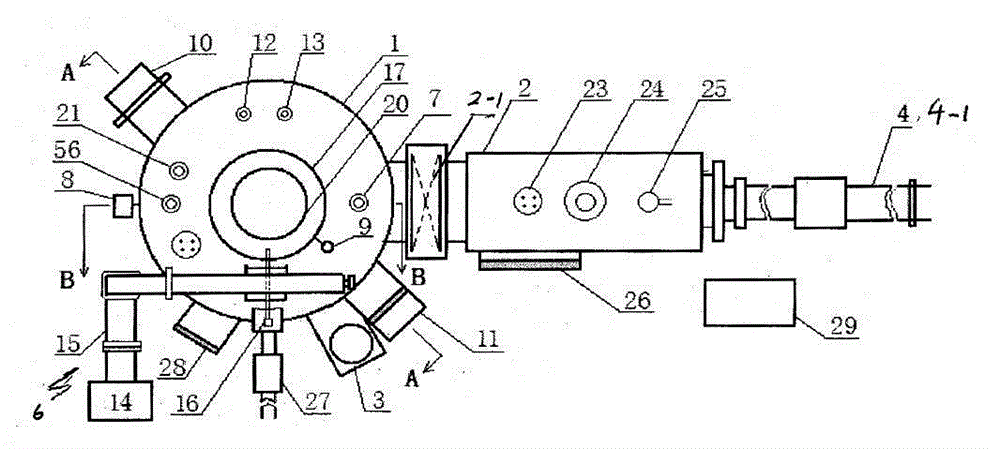

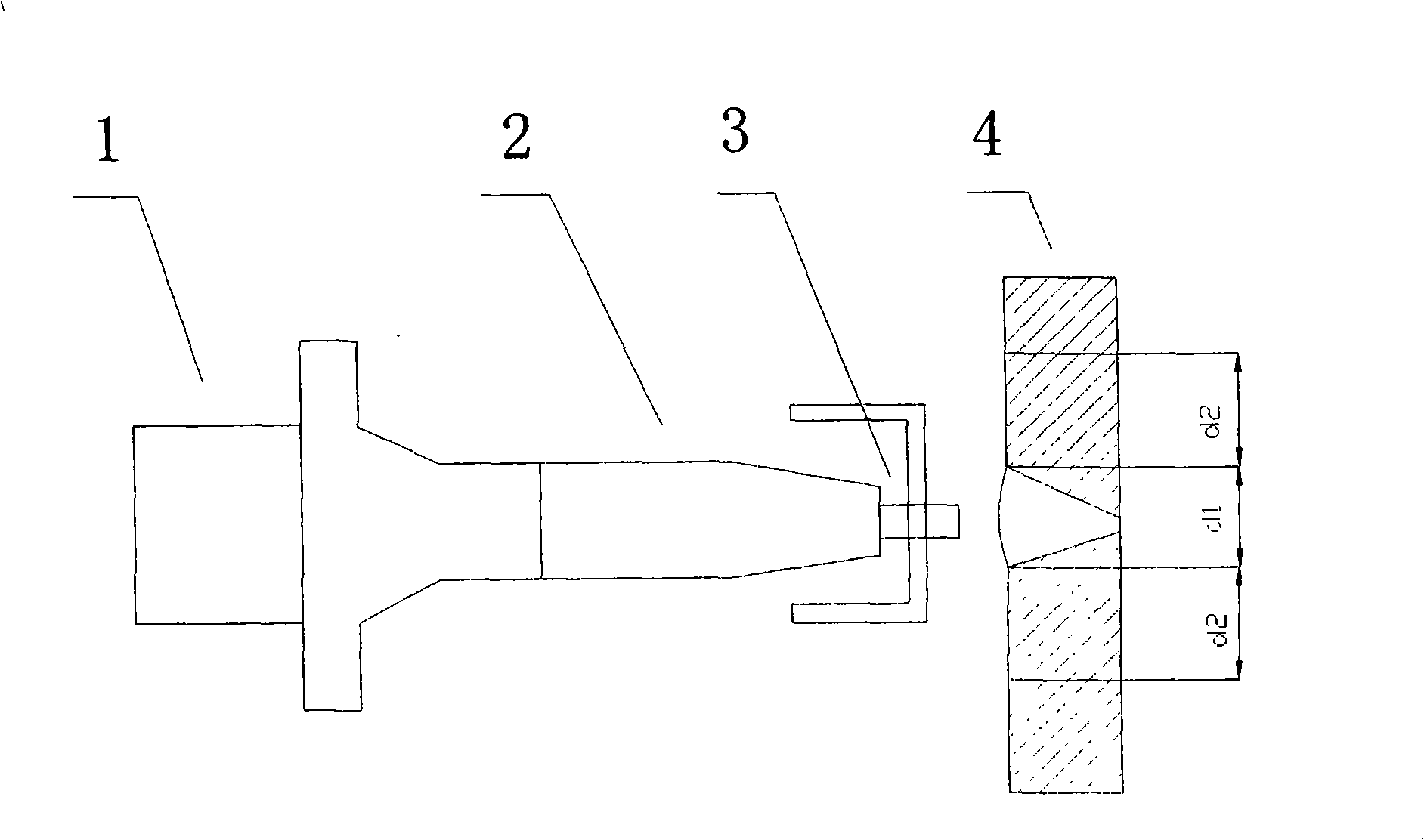

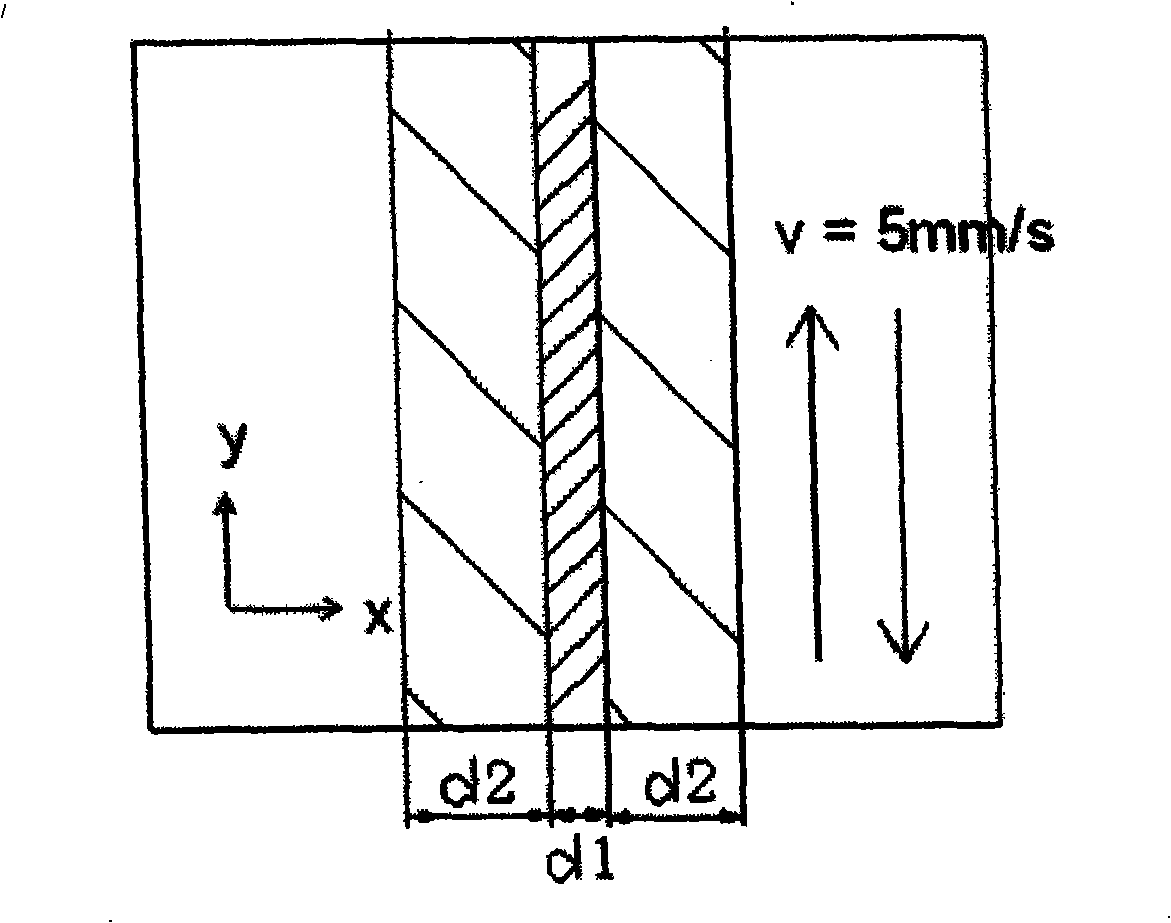

Hydraulic-driving mode based in situ tensile/compression testing platform under scanning electron microscope

InactiveCN102435493AGood structural compatibilityImprove compatibilityStrength propertiesElectromechanicsScanning tunneling microscope

The invention relates to a hydraulic-driving mode based in-situ tensile / compression testing platform under a scanning electron microscope, and belongs to the field of electromechanics. The hydraulic-driving mode based in-situ tensile / compression testing platform under the scanning electron microscope comprises a hydraulic driving unit consisting of a hydraulic cylinder, an oil tank, an oil filter, a motor, a hydraulic pump, an overflow valve, a throttle valve and an electro-hydraulic servo valve, a load / displacement signal detection and control unit consisting of a displacement sensor and a pull and pressure sensor, and a clamping and supporting unit consisting of light bars, fixture body supporting racks, base linear bearings, pressure plates, a force sensor supporting rack and a specimen. The hydraulic-driving mode based in-situ tensile / compression testing platform under the scanning electron microscope has the advantages of small volume, compact structure, large output load, continuously variable transmission loading, and good structural compatibility with a microscopic imaging system with an open space structure, such as an optical microscope, a Raman spectrometer and an X-ray diffractometer and the like, and also can used for deep study on the micro-mechanical behavior and the deformation and damage mechanism of the specimen with a centimeter-level characteristic size under the action of tensile / compression loads by combination with the instruments.

Owner:JILIN UNIV

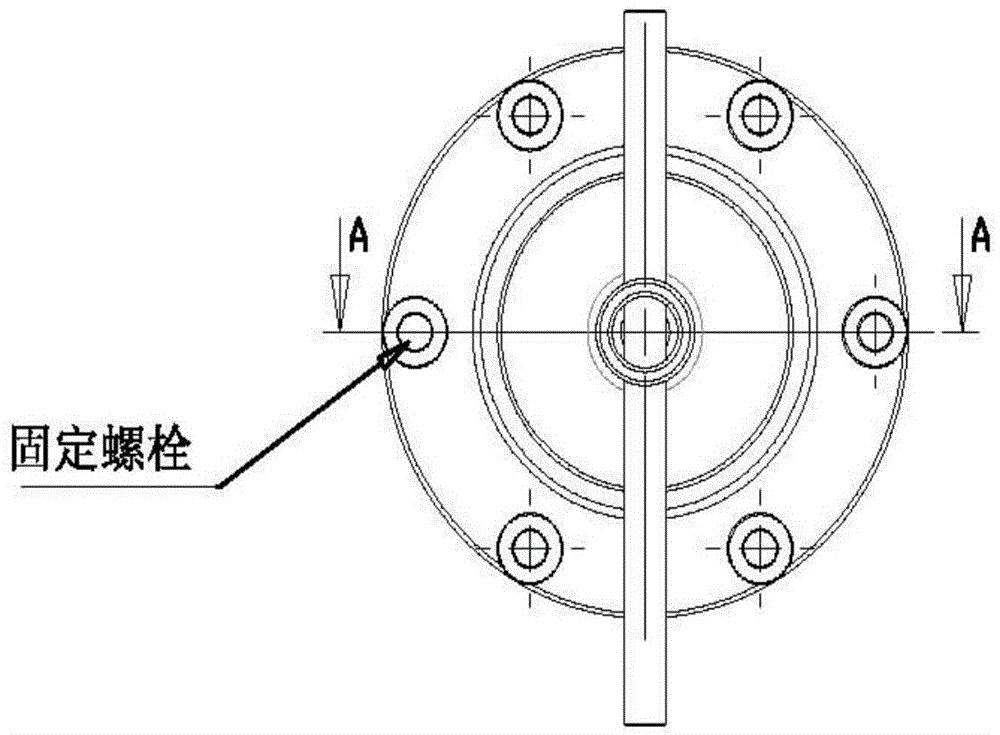

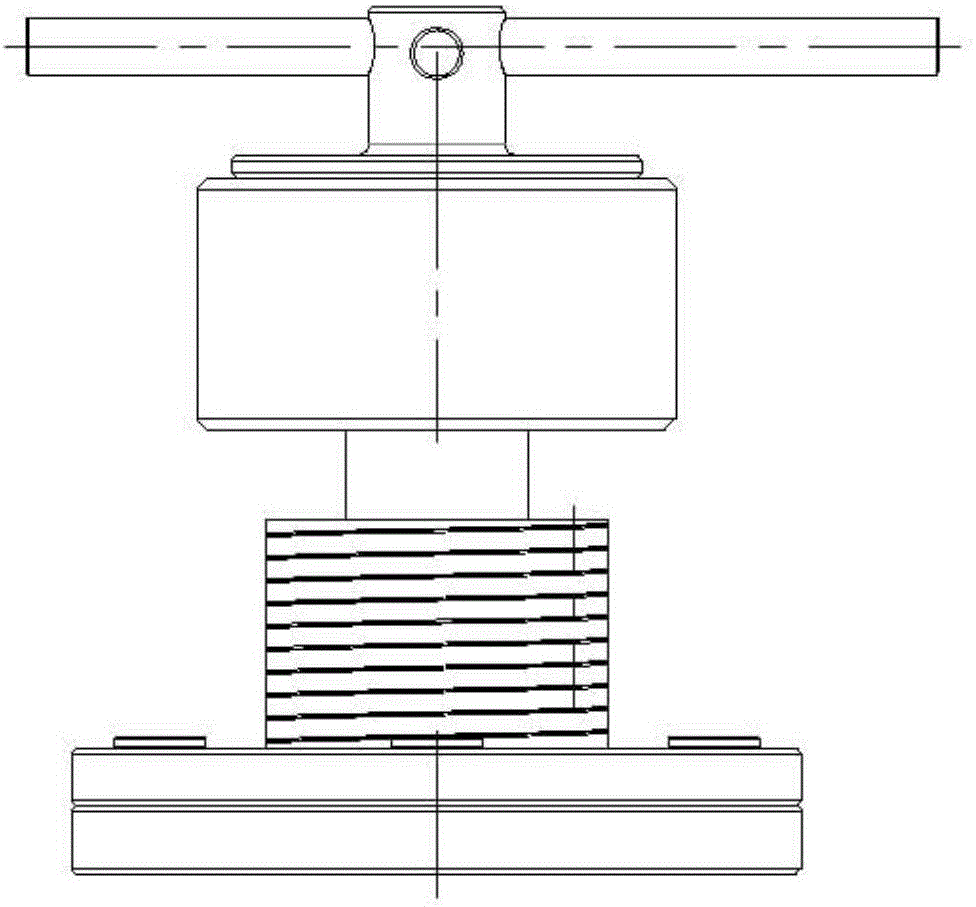

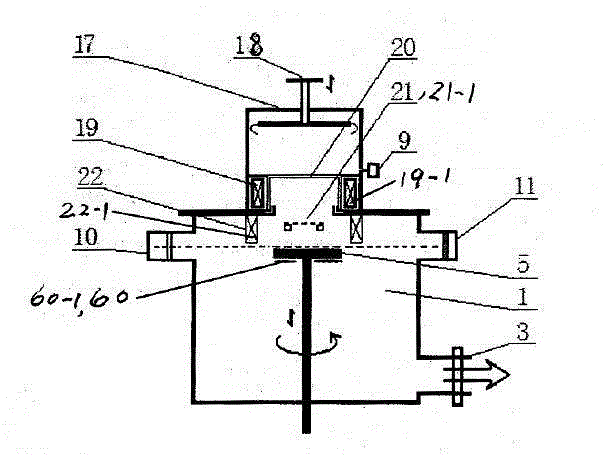

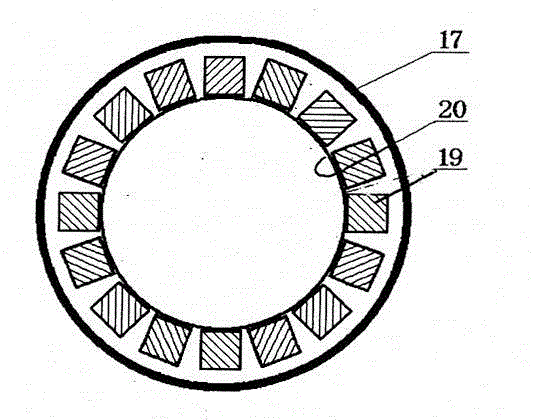

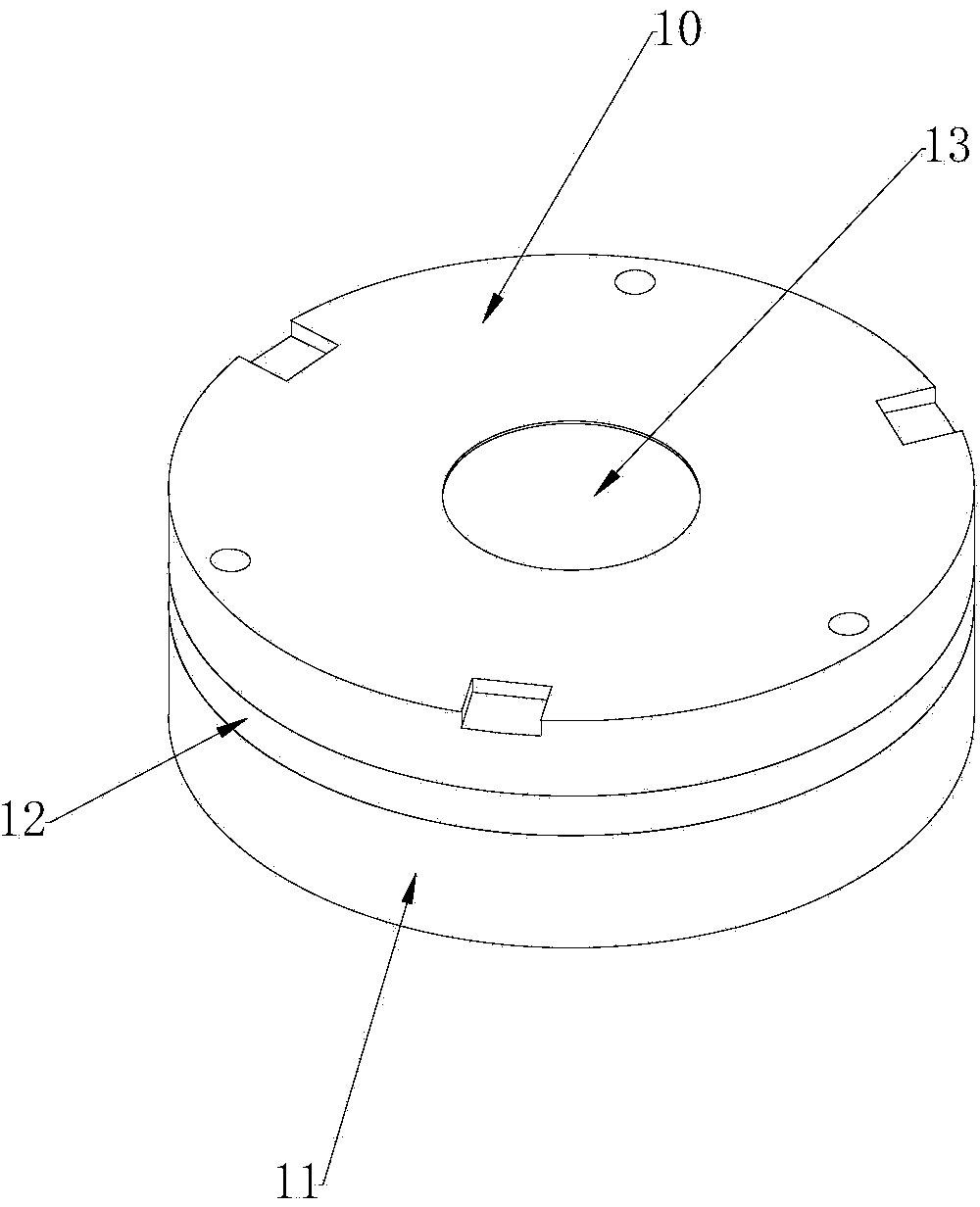

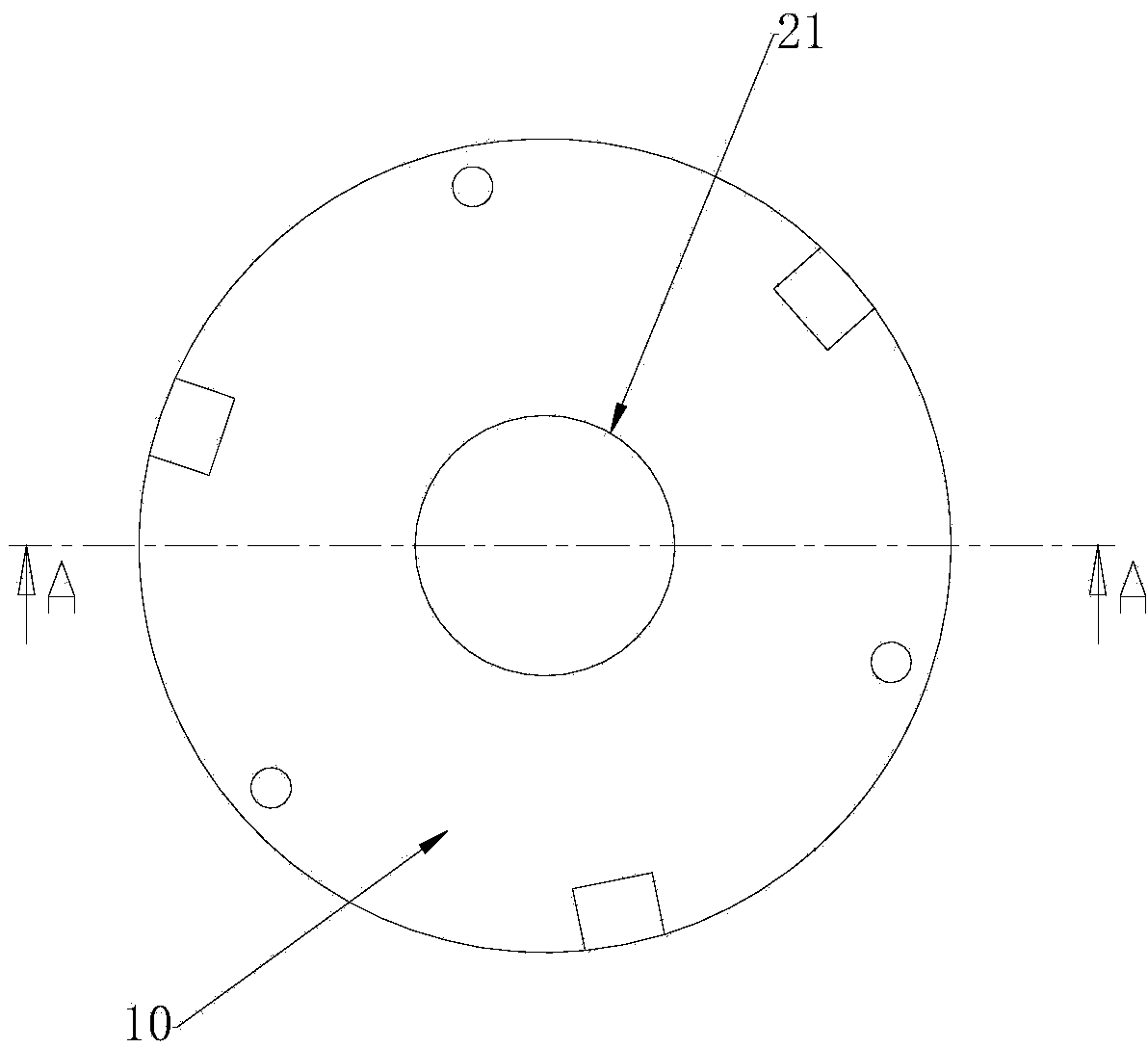

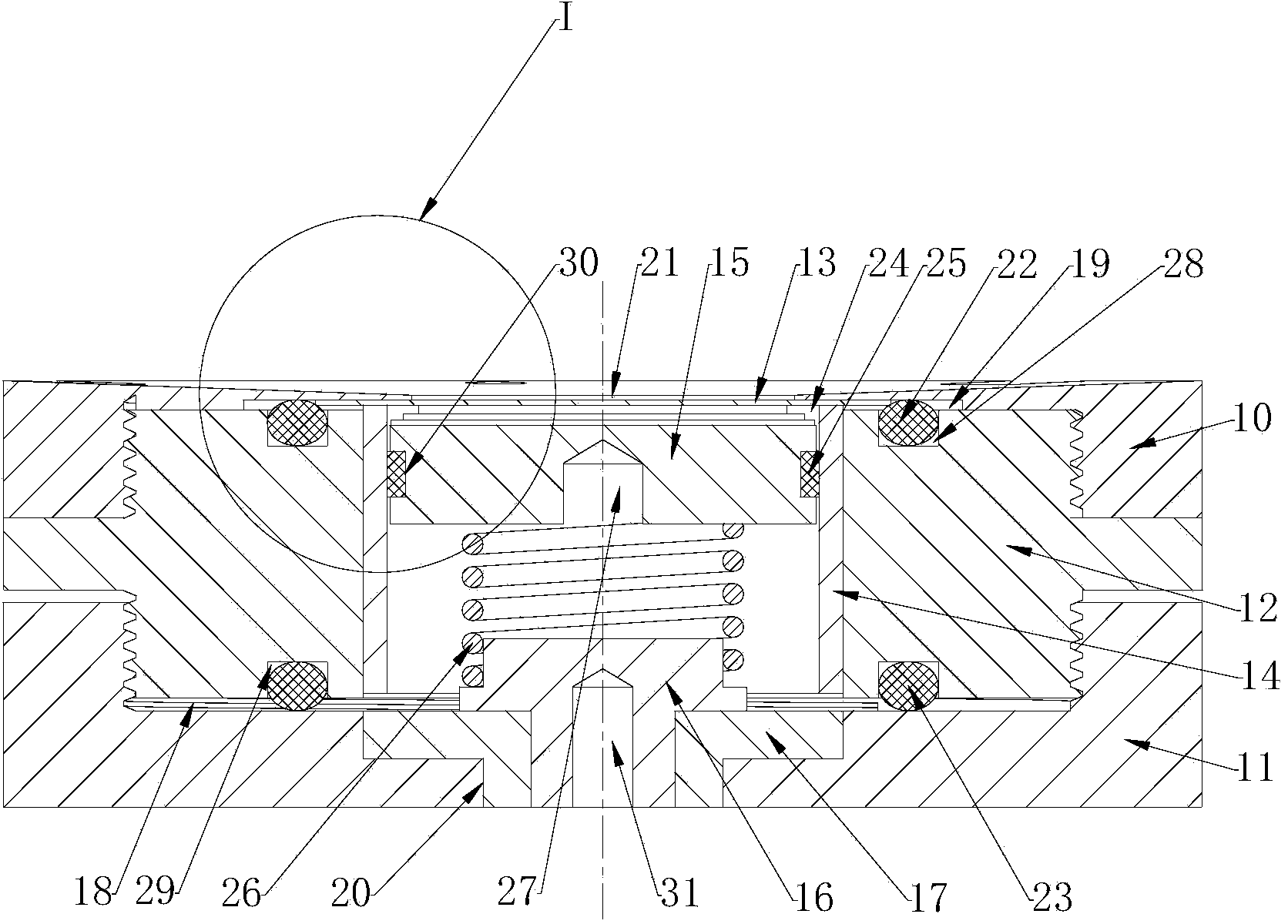

Electrochemical analysis in-situ cell for X-ray diffraction and testing method

InactiveCN104597064AIncrease signal strengthAirtightElectrical testingMaterial analysis using radiation diffractionSoft x rayBattery charge

The invention relates to an electrochemical analysis in-situ cell for X-ray diffraction and a testing method. The combination of an X-ray diffractometer and a battery charging / discharging tester can be realized. The in-situ cell comprises an upper flange and a lower flange which are fixedly connected together, a cavity formed in the middle of the lower flange, a counter electrode column extending into the cavity, and a positioning device connected with the counter electrode column; a hole is formed in the middle of the upper flange; a beryllium sheet covers the hole to form a beryllium window; an electrode slice, a diaphragm and a counter electrode slice are arranged in the cavity; the upper flange is connected with an electrode lead; the counter electrode column is connected with a counter electrode lead. According to the electrochemical analysis in-situ cell, the X-beam generated by the X-ray diffractometer passes through the beryllium window to detect and analyze the crystal structure of a positive electrode material in real time, and therefore, the problem of difficult real-time detection on the change of the crystal structure in the charging and discharging process of the battery material is effectively solved; the electrochemical analysis in-situ cell is ingenious in design, simple to operate, and low in cost.

Owner:PULEAD TECH IND

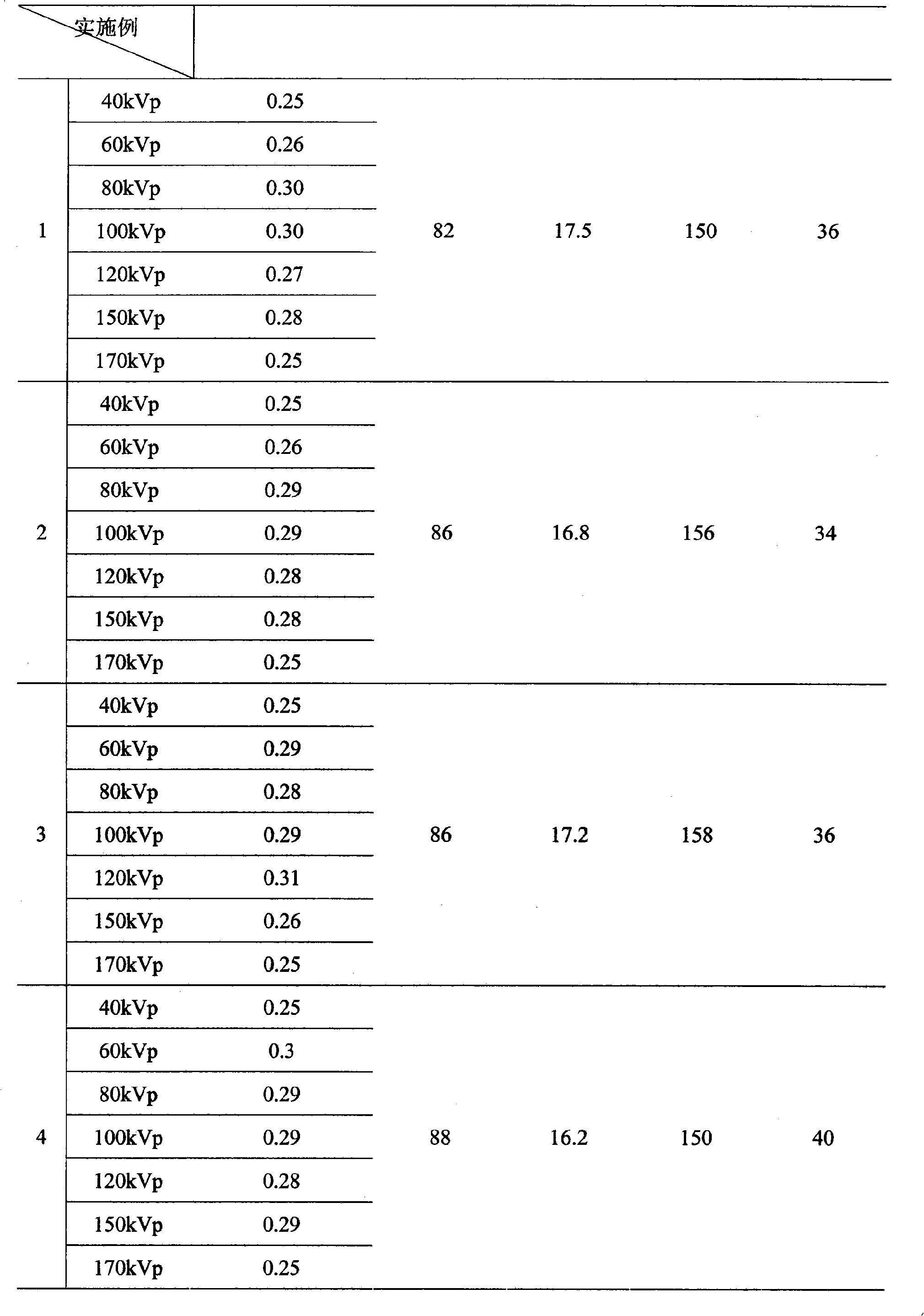

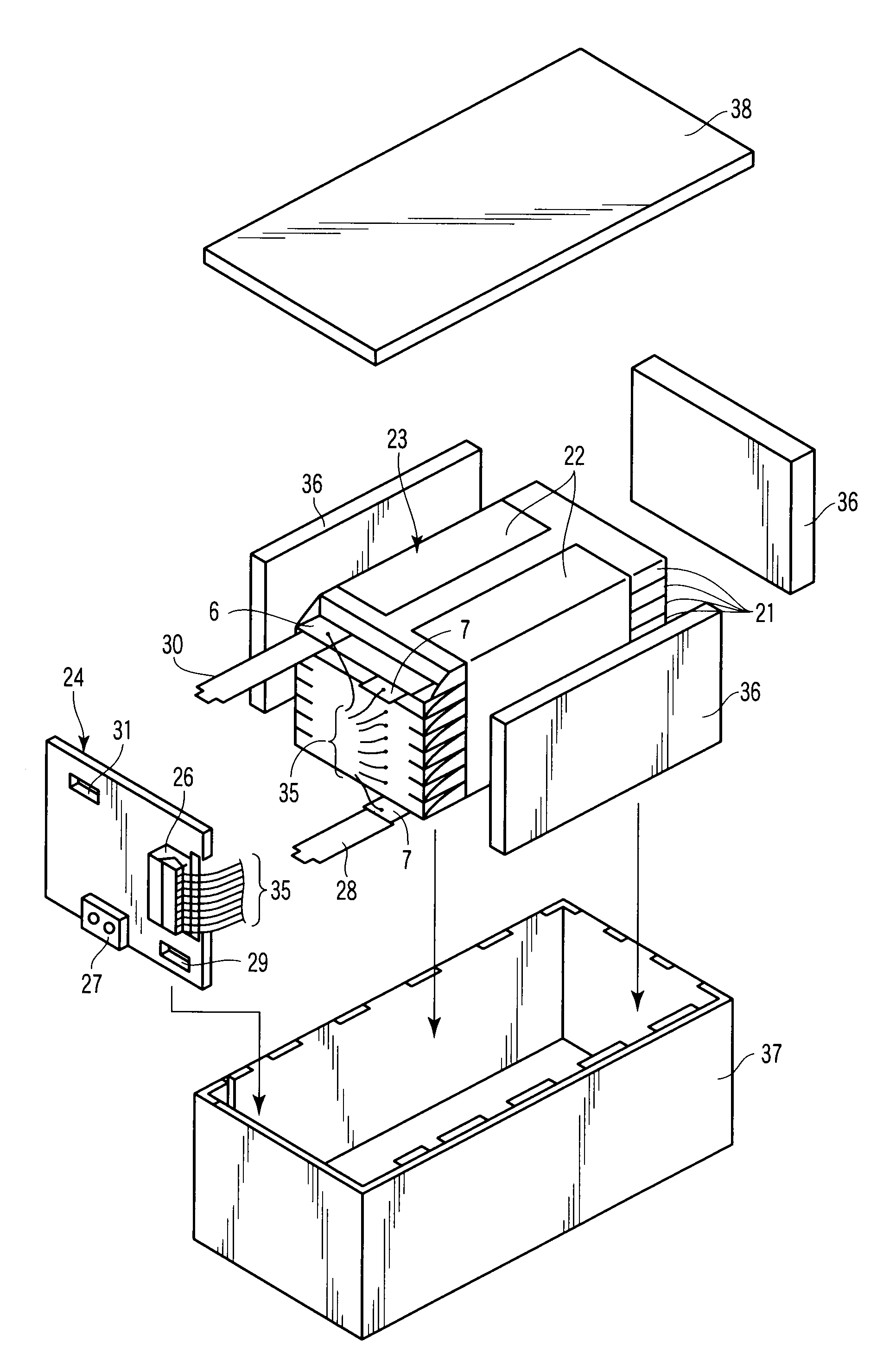

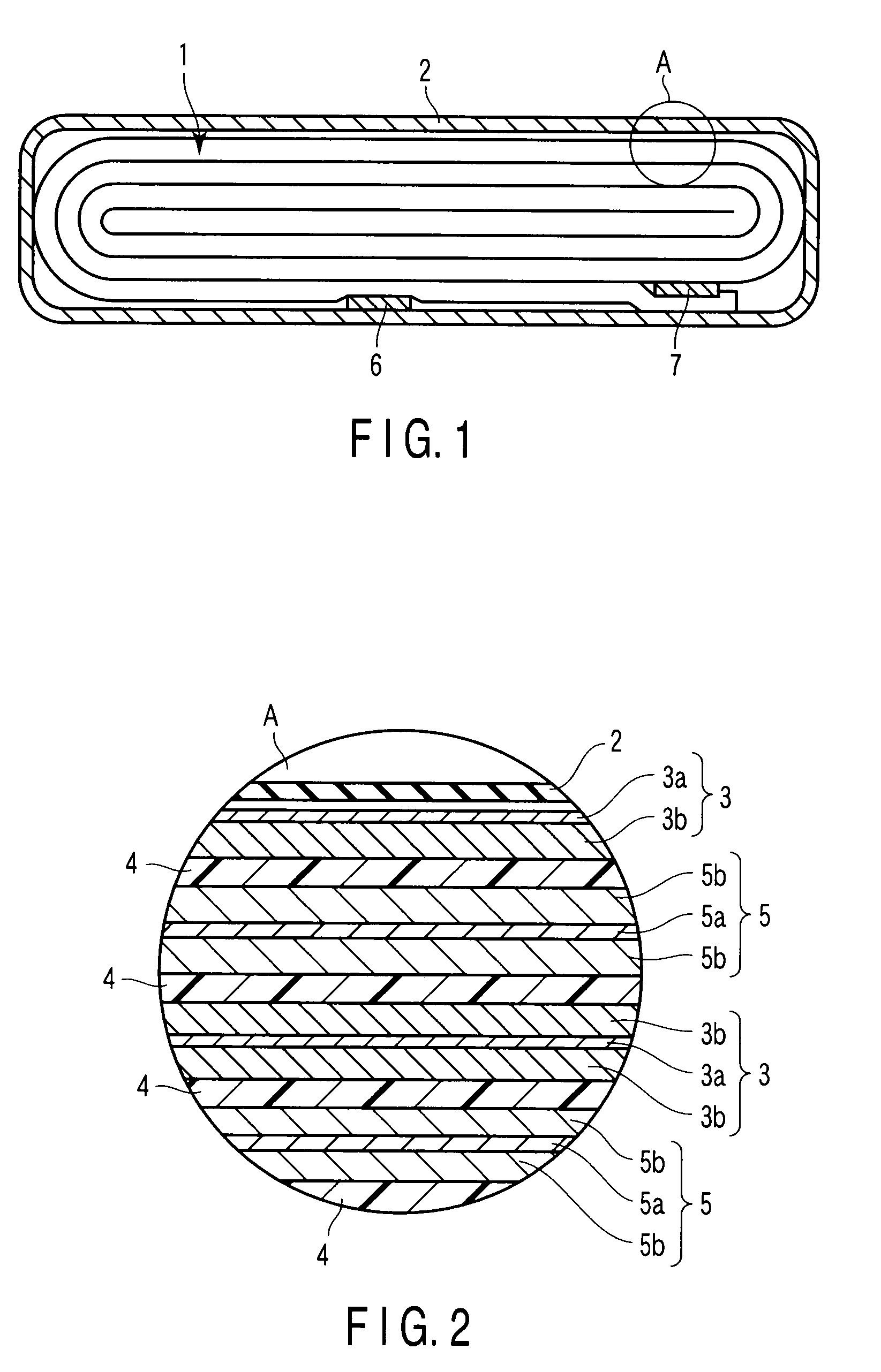

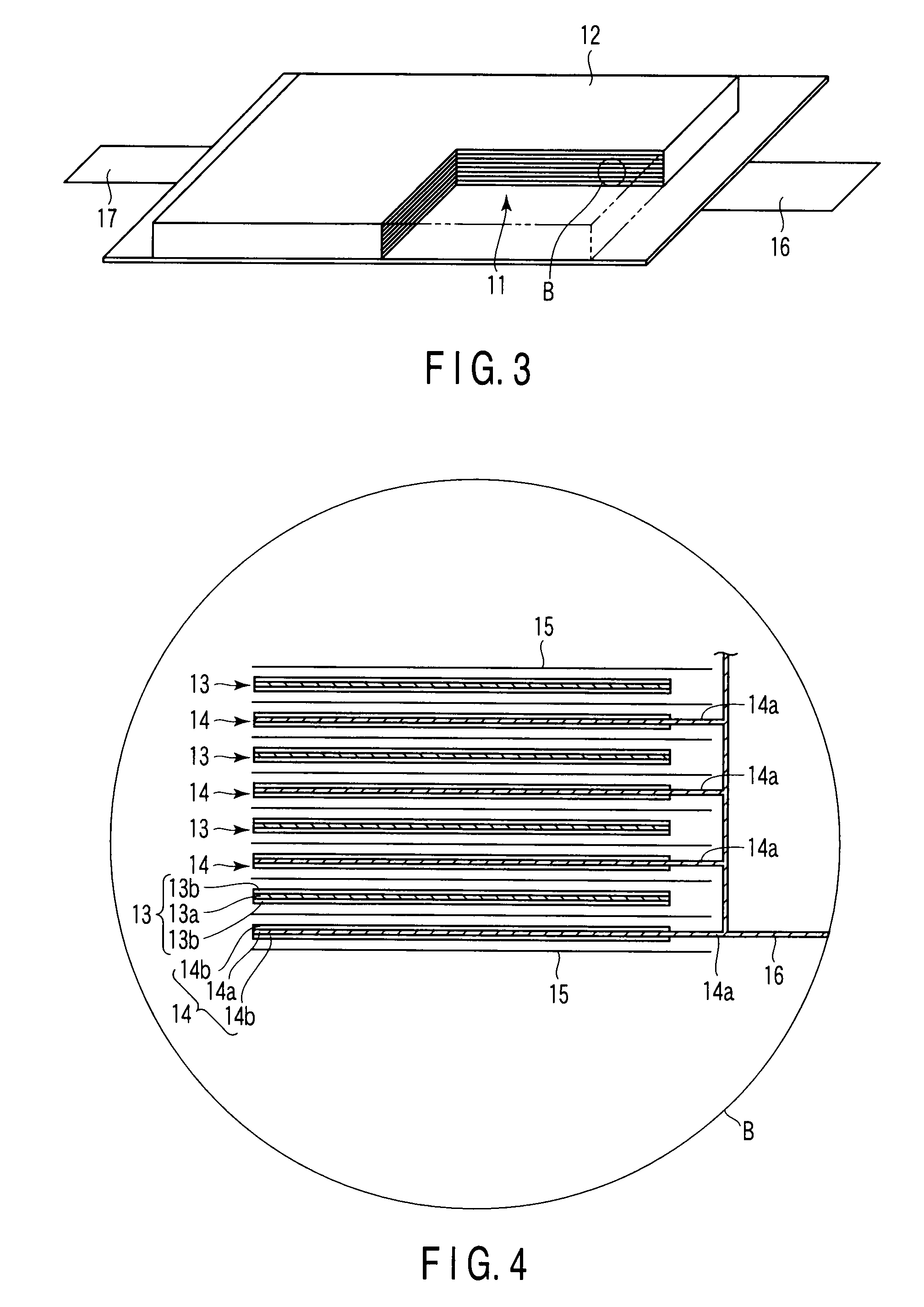

Overall lead-free X-ray shielding plastic compound material

InactiveCN101572129AEvenly distributedExcellent conventional physical and mechanical propertiesShieldingCoatingsX-ray shieldInorganic compound

The invention relates to an overall lead-free X-ray shielding plastic compound material. The overall lead-free X-ray shielding plastic compound material uses rare earth mixture to replace lead, simultaneously adds metal tin and compounds thereof, metal tungsten and the compounds thereof and bismuth and the compounds thereof as shielding main materials and is further compounded with plastic to prepare the compound material which can realize the overall shielding and the complete lead-free property within the energy range of 40-170kVp. When in use of rare earth and bismuth materials, the way of combined use of the two metal element inorganic compounds and unsaturated organic complexes is adopted, and the in-situ reaction and the compounding with a polymer matrix are carried out, thereby leading the shielding element disperse phase to form nano-micro-level dispersed particles. The prepared material combines the X-ray shielding performance of shielding elements and the good conventional physical mechanical performance of matrix polymer material and can be widely used in medical diagnostic X-ray machines, X-ray diffraction instruments and occasions accompanied with X-ray generation for ray protection for working staff.

Owner:BEIJING UNIV OF CHEM TECH

Active material of negative electrode for non-aqueous electrolyte battery, method of manufacturing active material of negative electrode for non-aqueous electrolyte battery and non-aqueous electrolyte battery

There is disclosed a negative electrode active material for a non-aqueous electrolyte battery, which comprises lithium titanium composite oxide represented by a general formula of: Li2+xTi4O9 (wherein x is 0≦x≦4). The lithium titanium composite oxide is exhibited a highest intensity peak of (002) crystal face at 2θ=10°±2°, a peak of (402) crystal face at 2θ=30°±2° and a peak of (020) crystal face at 2θ=48°±2° as measured by a powder X-ray diffractometer using Cu—Kα-ray source. A half band width of the highest intensity peak is 0.5° / 2θ to 3° / 2θ.

Owner:KK TOSHIBA

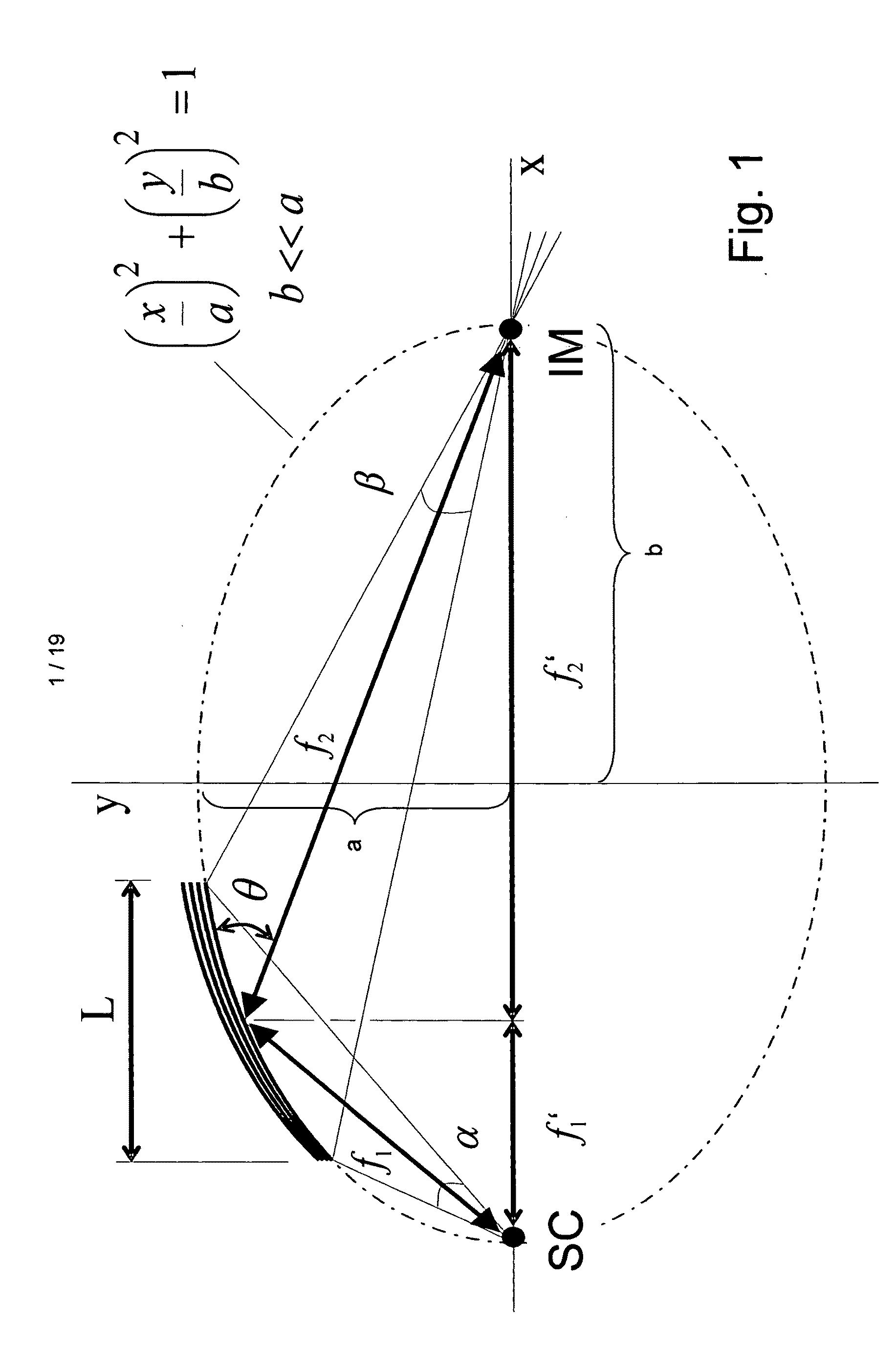

X-ray analysis instrument with adjustable aperture window

ActiveUS20100086104A1Avoid difficult choicesEasy to controlHandling using diaphragms/collimetersMaterial analysis using radiation diffractionDiffractometerLight beam

An X-ray analysis instrument, in particular, an X-ray diffractometer (21), has an X-ray source (22; SC) that emits an X-ray beam (23), an X-ray optics (24), in particular a multi-layer X-ray mirror, and a collimator mechanism (BM), wherein the collimator mechanism (BM) forms an aperture window (2, 2′) with an aperture opening (3, 3′) through which at least part (26) of the X-ray beam (23) passes. The collimator mechanism (BM) comprises means for gradual movement of the aperture window (2, 2′) in at least one direction (A / B, x,y) transversely to the X-ray beam (23), the aperture opening (3, 3′) is at least as large as the cross-section (32) of the X-ray beam (23) at the location of the aperture window (2, 2′), and the path of movement (VWx, VWy) of the aperture window (2, 2′), which is accessible by the collimator mechanism (BM), in the at least one direction (A / B, x, y) is at least twice as large as the extension (RSx, RSy) of the X-ray beam (23) at the location of the aperture window (2, 2′) in this direction (A / B, x, y). The X-ray analysis instrument offers a wider scope of beam conditioning possibilities.

Owner:INCOATEC

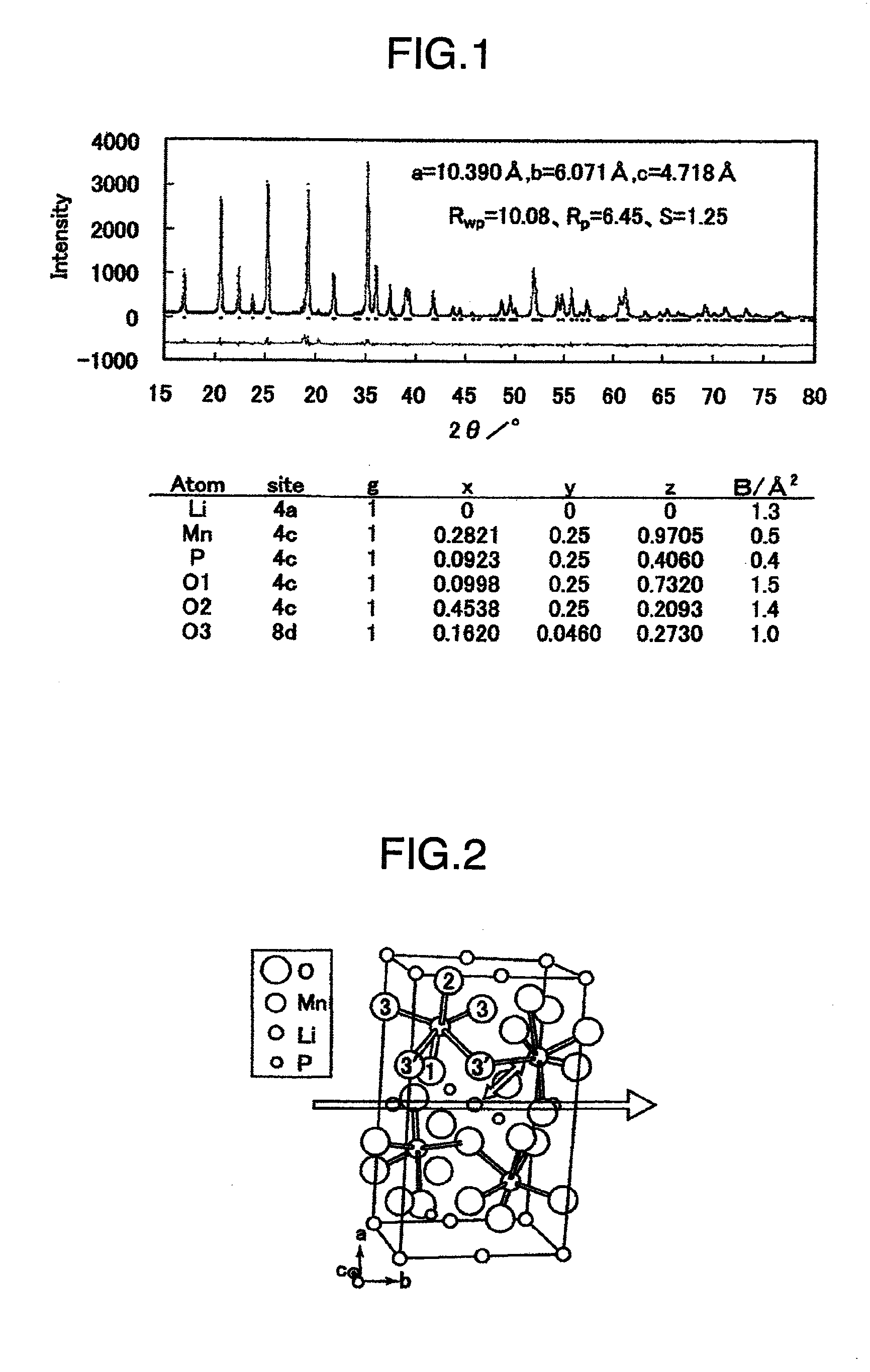

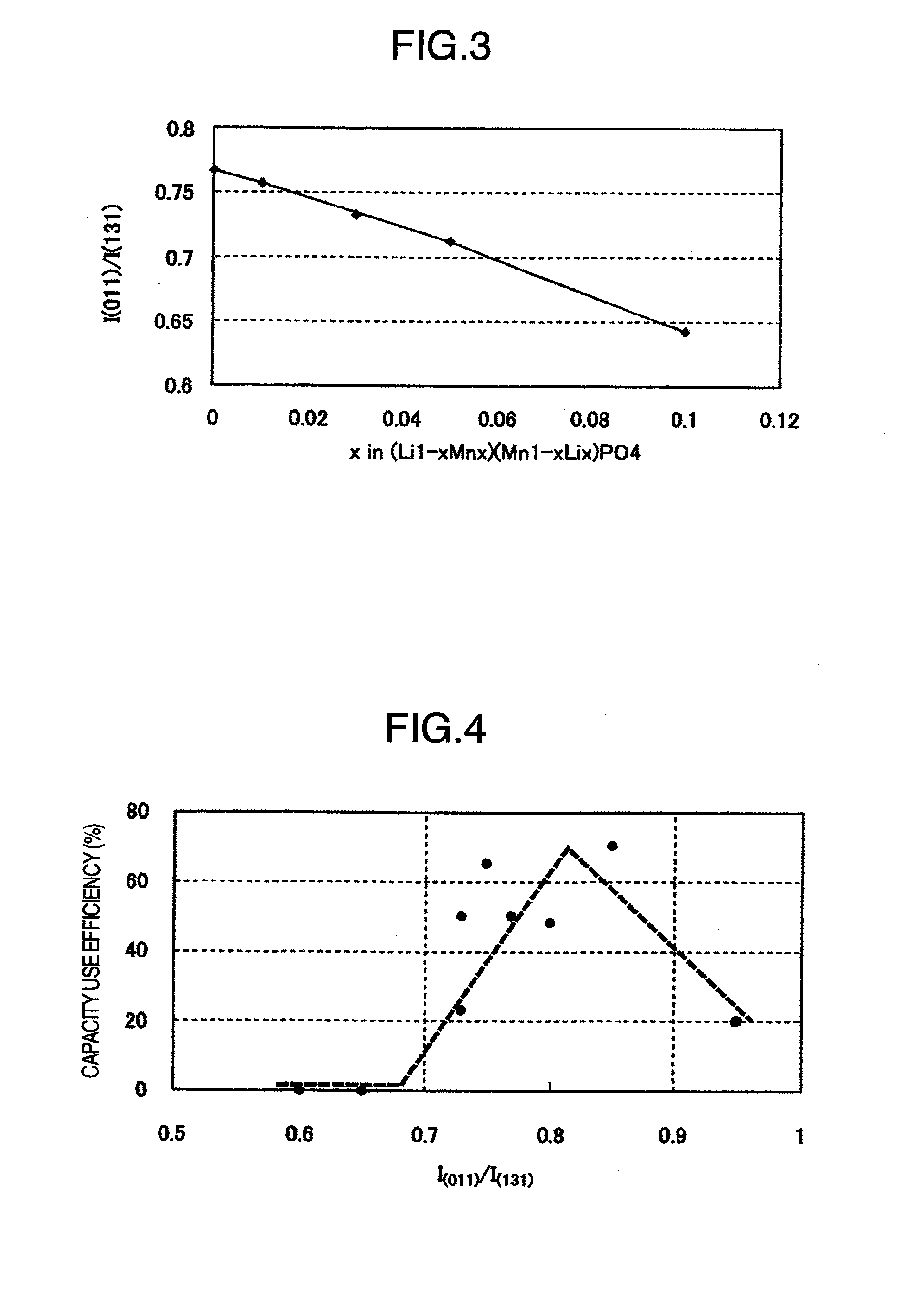

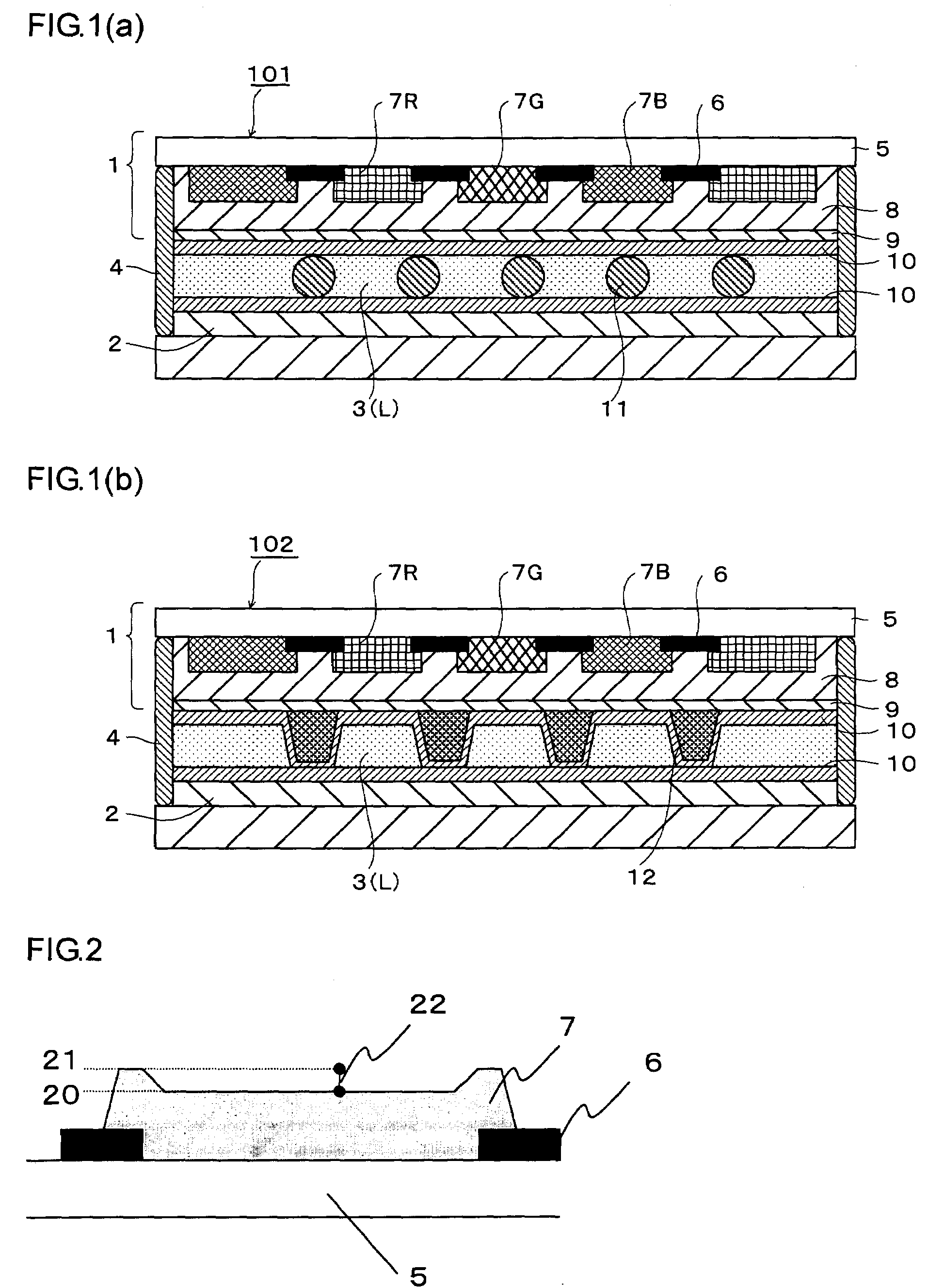

Nonaqueous Electrolyte Secondary Batteries

InactiveUS20100028777A1Improve load characteristicsImprove thermal stabilitySecondary cellsNon-aqueous electrolyte accumulator electrodesDiffractometerX-ray

The present invention is intended to improve load characteristics at the time of charging or discharging by assuring a lithium ion transport pathway in the crystal structure of olivine lithium-containing manganese phosphate. There is used a positive electrode active material which is a composite material comprising a material having an olivine structure and represented by Li1-y[Mn1-xMx]PzO4 (0<x≦0.3, −0.05≦y<1, 0.99≦z≦1.03, and M includes at least one of Li, Mg, Ti, Co, Ni, Zr, Nb, Mo or W) and a carbon material, and which shows an average half width of 0.17 or more, and an intensity ratio between a diffraction line near 20° and a diffraction line near 35° of not less than 0.7 and not more than 1.0, in powder X-ray diffractometry.

Owner:HITACHI LTD

Facility for manufacturing vertical GaN-based LED chips by metal substrates

ActiveCN102751399AHigh densityImprove uniformityElectric discharge tubesChemical vapor deposition coatingElectron probe microanalysisGas phase

The invention discloses a facility for manufacturing vertical GaN-based LED chips by metal substrates. The facility comprises a computer information acquisition controller, a reaction room, a metal substrate feeding room, a gaseous-phase metal organism supply device, a nitrogen and / or hydrogen and / or ammonia supply device, an ECR (electron cyclotron resonance) plasma resource supply device, a vacuum degree meter and an imaging display formed relatively by a reflection high-energy electron diffractometer and a fluorescent screen, and is mainly characterized by further comprising a magnetic field coil support cylinder, a photoelectric alarm, a Faraday cylinder, an electronic probe and a direct-current bias voltage. The facility is reasonable in structure, high in film-coating quality and working efficiency, low in chip manufacture cost and the like.

Owner:GAOYOU INST CO LTD DALIAN UNIV OF TECH

Thermographic recording material with improved image tone and/or stability upon thermal development

InactiveUS6096486AImprove wear resistanceAvoid local deformationX-ray/infra-red processesOrganic compound preparationOrganic solventDiffractometer

A recording material comprising a support and a thermosensitive element containing silver behenate, an organic reducing agent therefor in thermal working relationship therewith and a binder, wherein the silver behenate is not associated with mercury and / or lead ions and when the recording material is irradiated with a copper K alpha 1 X-ray source the ratio, normalized to a quantity of silver in the recording material of 1 g per m2 thereof, of the sum of the peak heights of the X-ray diffraction lines attributable to silver behenate at Bragg angles, 2 THETA , of 6.01 DEG , 7.56 DEG , 9.12 DEG , 10.66 DEG , 12.12 DEG and 13.62 DEG to the sum of the peak heights of the X-ray diffraction lines at Bragg angles, 2 THETA , of 25.60 DEG , 35.16 DEG and 43.40 DEG of NIST standard 1976, rhombohedral Al2O3, determined with the same X-ray diffractometer in the same state of adjustment, is greater than 0.85; production processes for particles of substantially light-insensitive organic silver salt comprising silver behenate with these X-ray characteristics in the presence and substantial absence of organic solvent.

Owner:AGFA HEALTHCARE NV

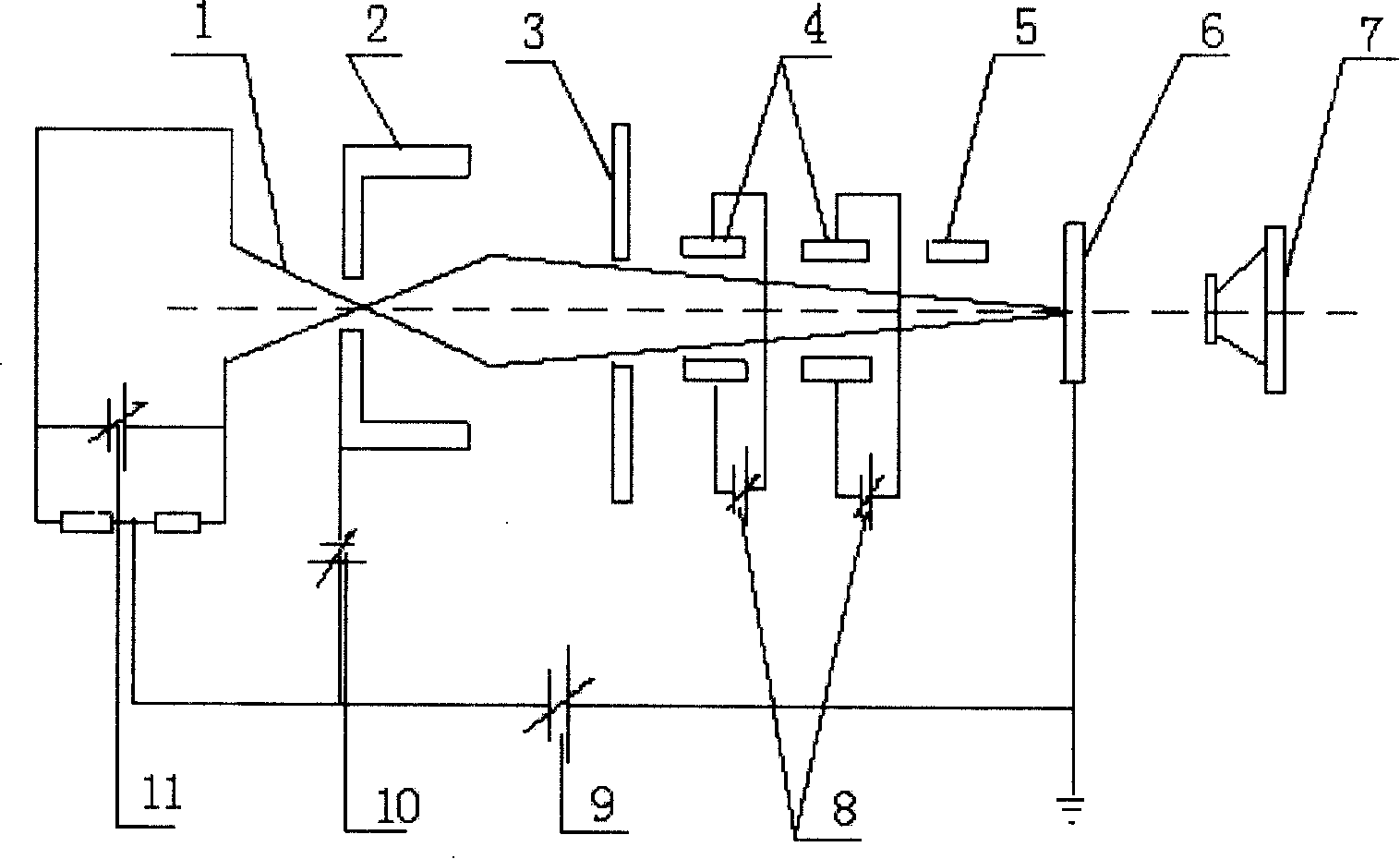

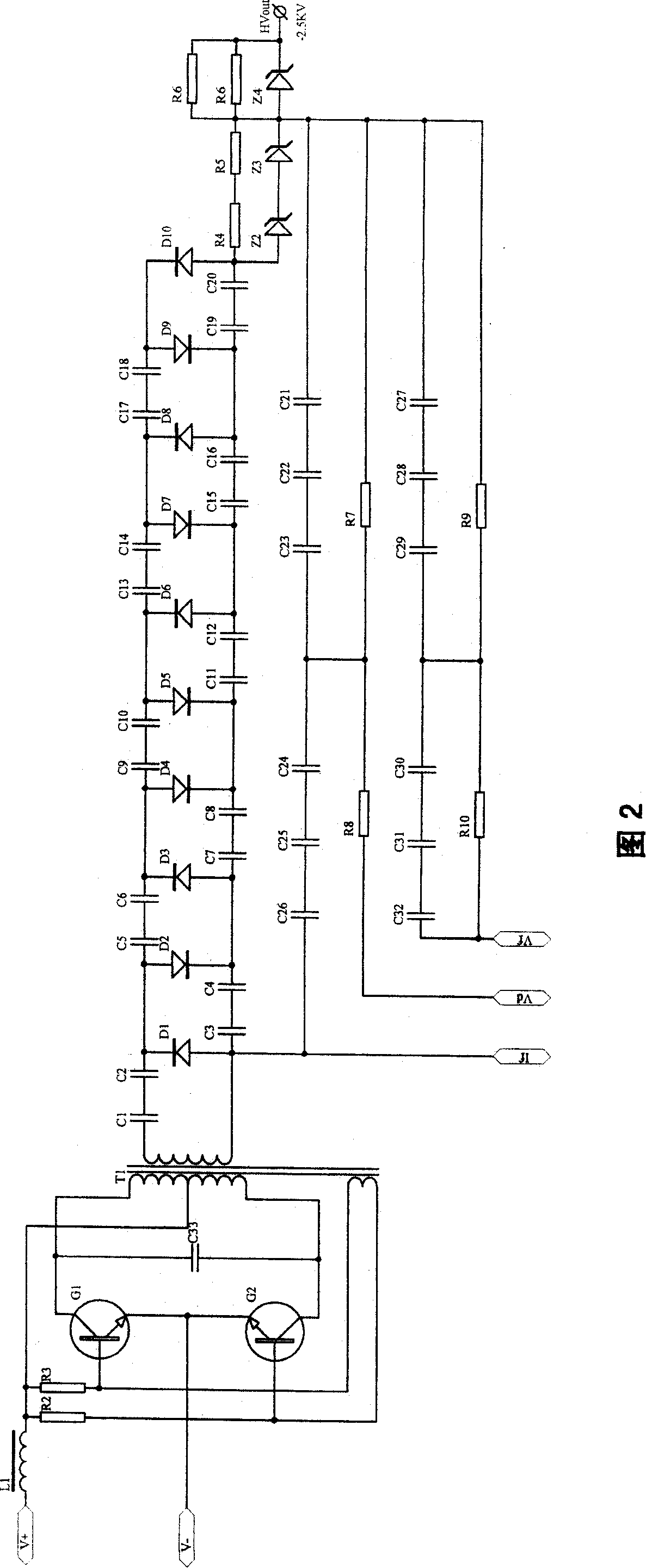

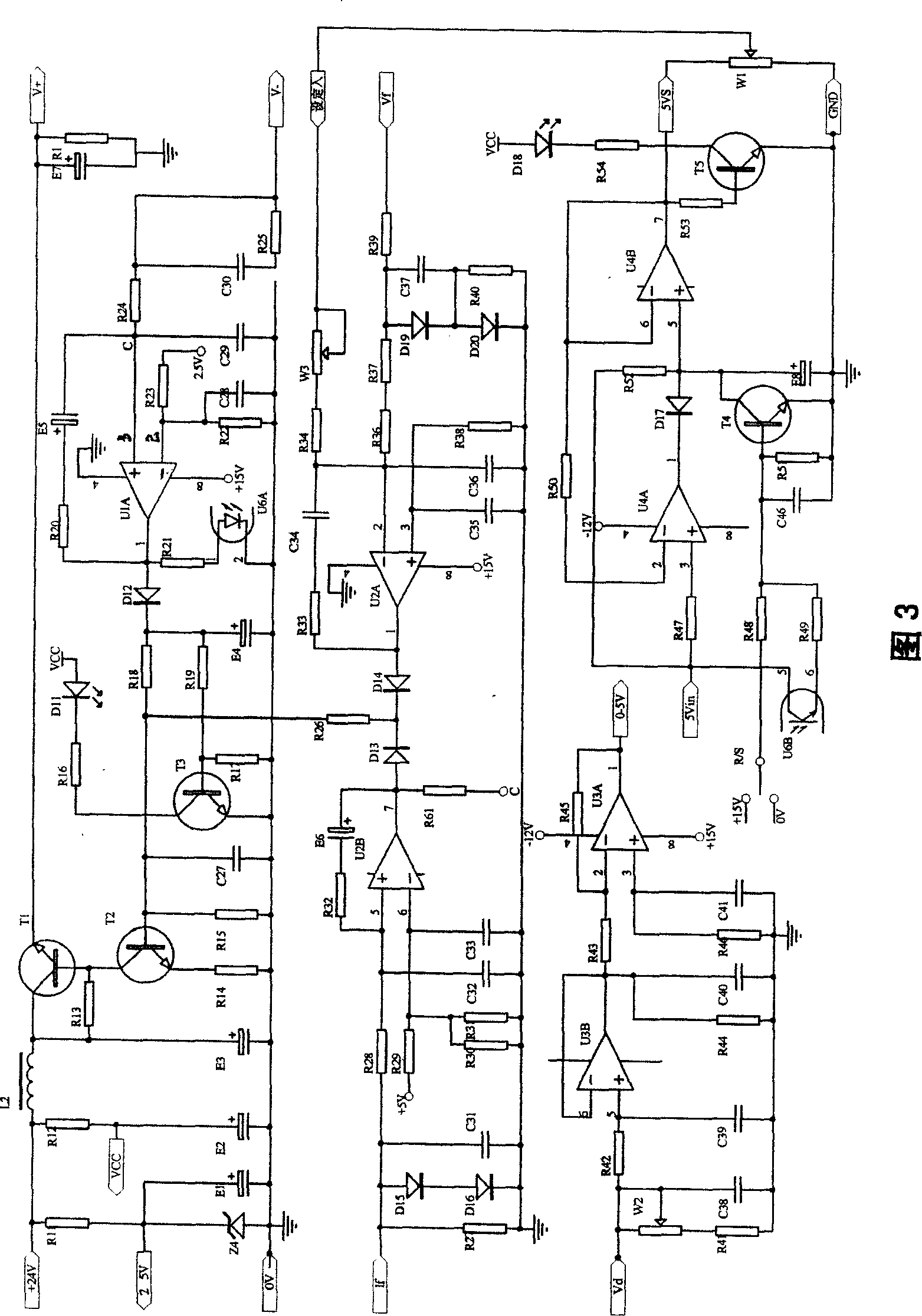

Electronic gun power supply for reflected high energy electron diffraction instrument

ActiveCN101178371AImprove reliabilityReduce volumeAc-dc conversion without reversalEfficient power electronics conversionHigh energyLow voltage

The invention discloses a power supply of an electron gun for a reflection high-energy electron diffractometer, wherein, the high-voltage power supply which consists of a high-voltage part and a low-voltage adjusting part is minus 25 KV,, the output of a resonance circuit of the high-voltage part is connected on a lamp wire of the electron gun and a grid by generating the high voltage of minus 25KV by a 10-time rectifier filter; the low-voltage adjusting part is connected with the high-voltage part and a second driving tube by an adjusting tube, an input signal which is connected with the second driving tube comes from the high-voltage part and an overflow protection and fault alarm circuit of a current sampling amplifying circuit, a slow starting circuit is connected with the overflow protection and fault alarm circuit and a voltage sampling amplifying circuit; the input of a high-voltage measurement display circuit is the high-voltage part, the output thereof is connected with a display; a deflection power supply includes a low-voltage signal circuit and a high-voltage amplifying circuit, the low-voltage signal circuit provides the voltage signals with two reverse polarities andis connected with the high-voltage amplifying circuit and is finally connected with a deflection plate. The invention has reliable work and simple structure.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

Hydroxyapatite, composite, processes for producing these, and use of these

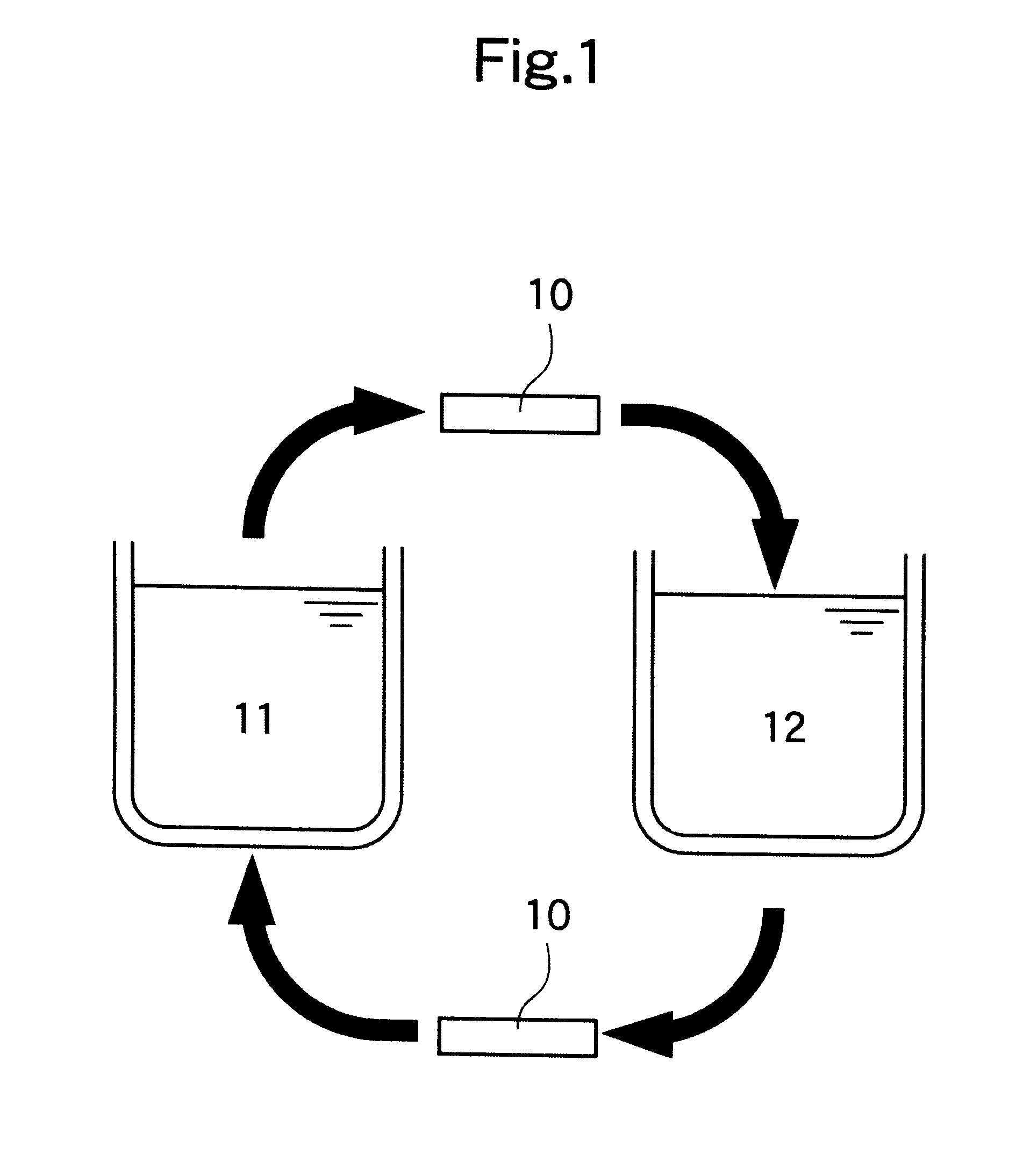

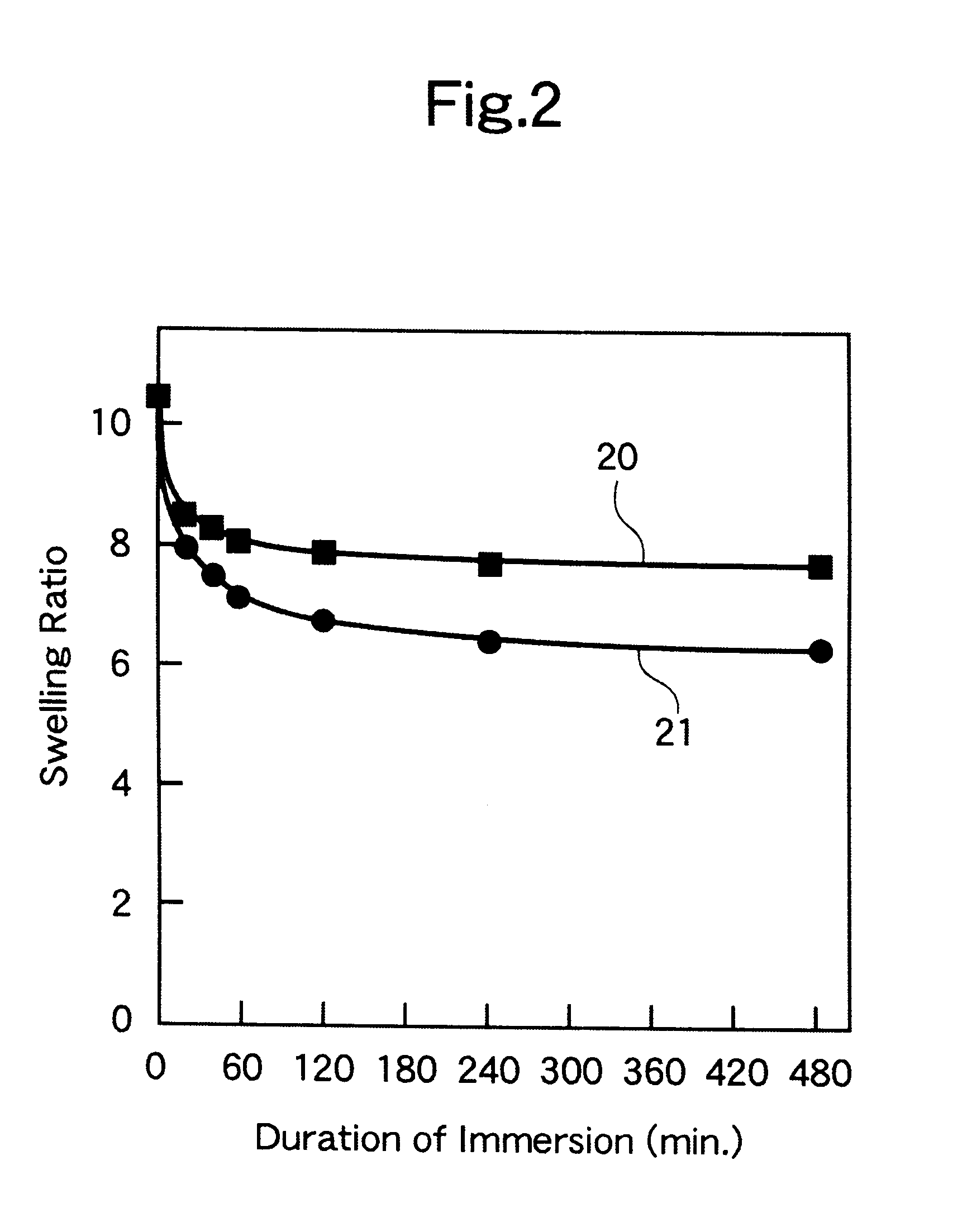

A hydroxyapatite consisting substantially of Ca10(PO4)6(OH)2, and having a crystal structure which has at least two diffraction peaks at 31-32 degrees and 26 degrees in X-ray diffractometry; and a process for producing a hydroxyapatite which comprises the step (A) of immersing a substrate in a first aqueous solution containing calcium ions and a second solution containing PO4 ions to generate the hydroxyapatite at least on the surface of the substrate and the step (B) of recovering the hydroxyapatite from the substrate.

Owner:NOF CORP

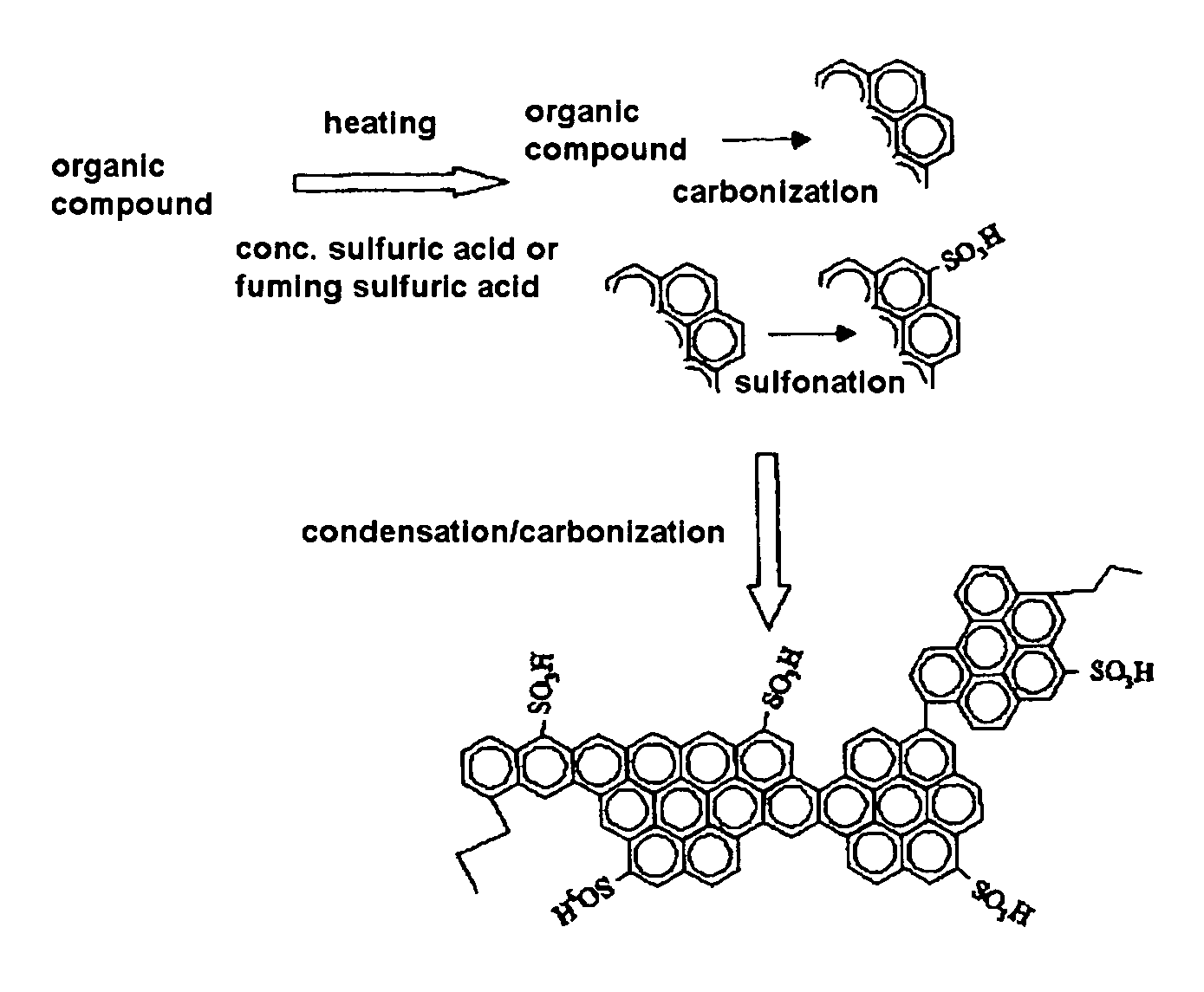

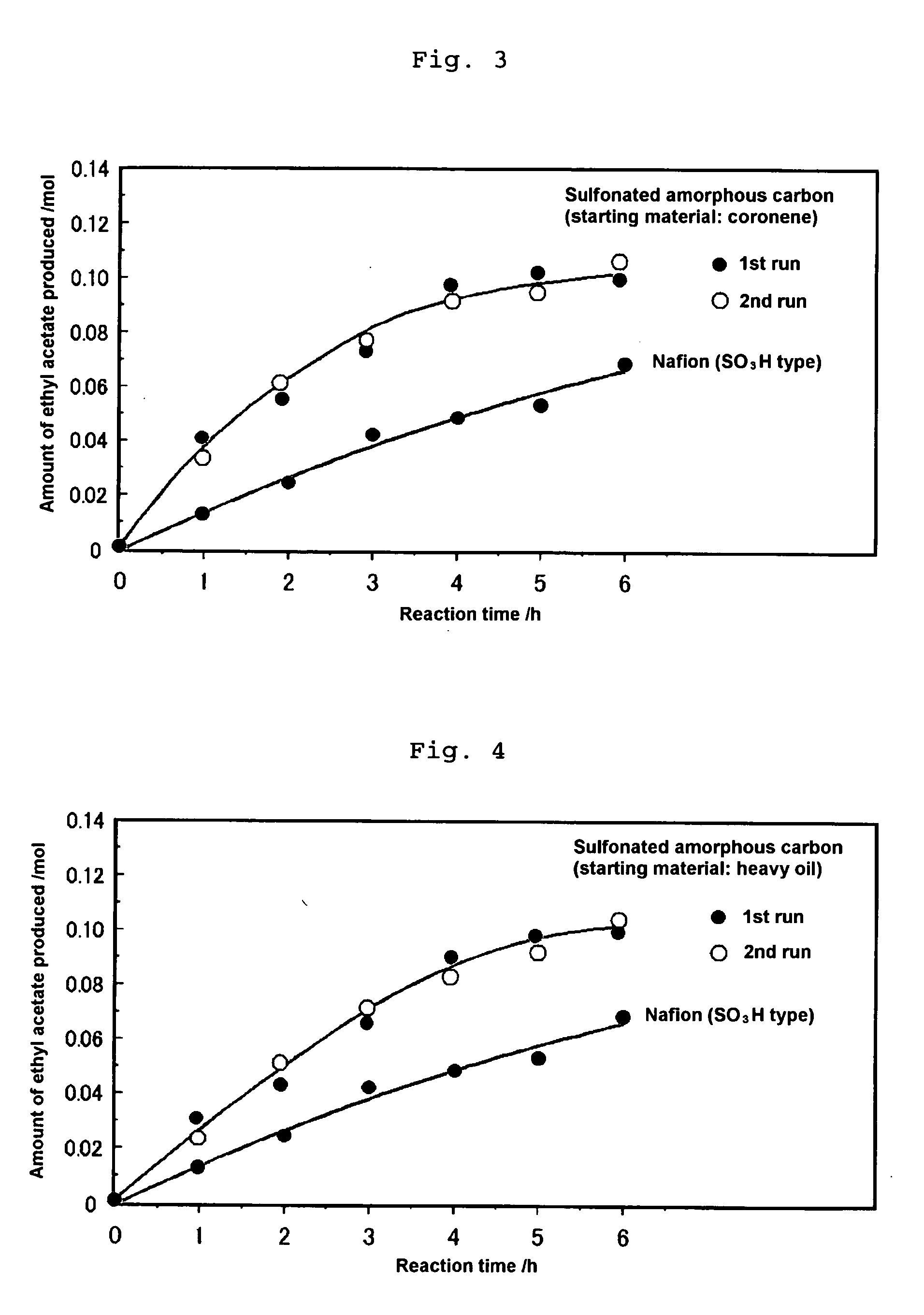

Sulfonated Amorphous Carbon, Process for Producing the Same and Use Thereof

InactiveUS20080227996A1Low costHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsElectrical conductorSolid acid

An amorphous carbon having sulfonate group introduced therein is provided which is characterized in that chemical shifts of a condensed aromatic carbon 6-membered ring and a condensed aromatic carbon 6-membered ring having sulfonate group bonded thereto are detected in a 13C nuclear magnetic resonance spectrum and that at least a diffraction peak of carbon (002) face whose half-value width (2θ) is in the range of 5 to 30° is detected in powder X-ray diffractometry, and which exhibits proton conductivity. This sulfonated amorphous carbon is very useful as a proton conductor material or solid acid catalyst because it excels in proton conductivity, acid catalytic activity, thermal stability and chemical stability and can be produced at low cost.

Owner:TOKYO INST OF TECH

Preparation method for manganese dioxide hollow sphere

InactiveCN101624213AMild reaction conditionsThe process steps are simpleCapacitor electrodesManganese oxides/hydroxidesScanning tunneling microscopeX-ray

The invention relates to a preparation method for a manganese dioxide hollow sphere, which is as follows: manganese sulfate, potassium permanganate and soluble ferric salt are weighed and added into a hydrothermal reactor; deionized water is added till manganese sulfate, potassium permanganate and soluble ferric salt are dissolved; the mixed liquor is fully mixed and added with sulfuric acid; the molar ratio of manganese sulfate, potassium permanganate, soluble ferric salt and sulfuric acid are 1:6:0.04-1:36.8; the hydrothermal reactor is put in a baking oven, hydrothermally reacted for 10 to 1440 minutes in the constant temperature of 130 to 180 DEG C and naturally cools to the room temperature; the prepared product is washed for five times by deionized water, and dried in the 50 DEG C of the air of the drying oven to prepare manganese dioxide hollow sphere. The prepared manganese dioxide hollow sphere is tested by an x-ray diffraction instrument, a scanning electron microscope and a transmission electron microscope, has spherical appearance, big cavity, about 3mu m p grain size distribution, big specific surface area, and can be used as electrode material and battery material of a super capacitor.

Owner:SHAANXI NORMAL UNIV

Thermographic recording material with improved image tone and/or stability upon thermal development

InactiveUS6159667AImproved archivabilityImprove stabilityX-ray/infra-red processesOrganic compound preparationOrganic solventDiffractometer

A recording material comprising a support and a thermosensitive element containing silver behenate, an organic reducing agent therefor in thermal working relationship therewith and a binder, wherein the silver behenate is not associated with mercury and / or lead ions and when the recording material is irradiated with a copper K alpha 1 X-ray source the ratio, normalized to a quantity of silver in the recording material of 1 g per m2 thereof, of the sum of the peak heights of the X-ray diffraction lines attributable to silver behenate at Bragg angles, 2 THETA , of 6.01 DEG , 7.56 DEG , 9.12 DEG , 10.66 DEG , 12.12 DEG and 13.62 DEG to the sum of the peak heights of the X-ray diffraction lines at Bragg angles, 2 THETA , of 25.60 DEG , 35.16 DEG and 43.40 DEG of NIST standard 1976, rhombohedral Al2O3, determined with the same X-ray diffractometer in the same state of adjustment, is greater than 0.85; production processes for particles of substantially light-insensitive organic silver salt comprising silver behenate with these X-ray characteristics in the presence and substantial absence of organic solvent.

Owner:AGFA HEALTHCARE NV

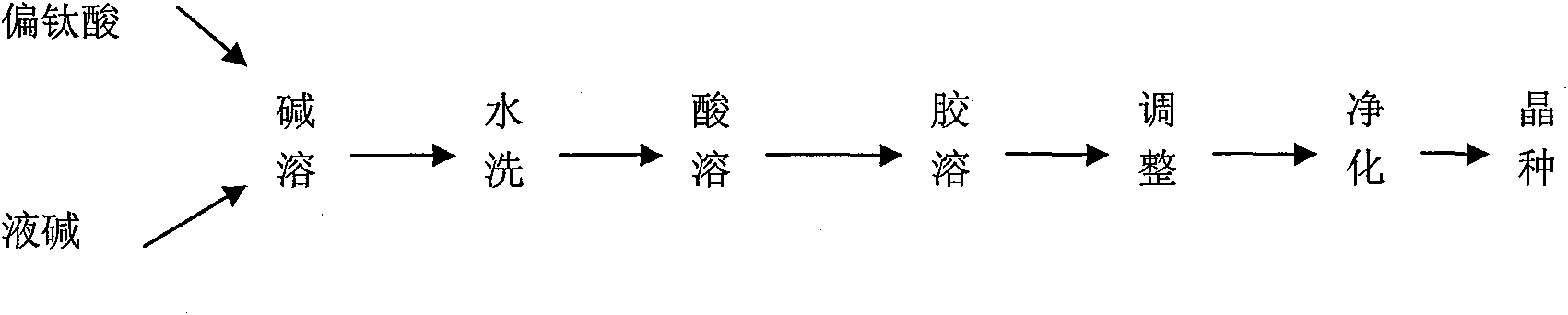

Preparation of white titanium pigment double action crystal seed from metatitanic acid

ActiveCN101565201AFast phase changeSimplify operating proceduresPigmenting treatmentTitanium dioxideX-raySodium sulfate

The invention relates to a preparation of white titanium pigment double action crystal seed from metatitanic acid, which is characterized in the process of (1) alkali dissolving, boiling the metatitanic acid purified by water washing with thermokalite; (2) water washing, removing residue sodium hydroxide and generated sodium sulfate thereby; (3) neutralizing and acid dissolving, neutralizing by hydrochloric acid and acid solution; (4) peptizing to generate a seed suspension, evaporating the suspension at a temperature from 105 to 300 DEG C., grinding, measuring the rutile microcrystalline with weight percentage over 90-98% by a X-ray diffractometer. The preparation uses metatitanic acid produced during sulphuric acid production process as raw material, adopts sol-gel process, with the produced rutile microcrystalline is safe and non-toxic, simple and easy to get raw material, low in cost, thus capable of evidently improving quality of product, enhancing stability of product quality and market competitiveness.

Owner:江西添光钛业有限公司

Method of preparing manganese oxide hollow nano-sphere with large-specific surface area

InactiveCN101343081AThe process steps are simpleReduce manufacturing costManganese oxides/hydroxidesFourier transform on finite groupsX-ray

Disclosed is a preparation method of a hollow manganese oxide nanosphere of large specific surface area, comprising steps of preparing a silicon dioxide nanosphere, preparing a silicon dioxide composite nanosphere covered by manganese dioxide and preparing hollow manganese oxide nanosphere. Because the preparation method adopts the process steps, which are simple, the production cost is low; the prepared hollow manganese oxide nanosphere is tested by an X-ray diffraction instrument, a scanning electron microscope, a transmission electron microscope, a Fourier transform infrared spectrometer and a physisorption instrument; the hollow manganese oxide nanosphere belongs to natrium-manganese crystal phase and is characterized by spherical morphology, having particle sizes ranging from 300 to 450nm and large specific surface area, and can be used as electrode materials to produce electrochemical capacitors.

Owner:SHAANXI NORMAL UNIV

X-ray diffractometer in situ battery accessory, heating device, cooling device and measuring method

ActiveCN104393223AGood air tightnessSimple designCurrent conducting connectionsSecondary cellsDiffractometerElectrical battery

The invention discloses an X-ray diffractometer in situ battery accessory which comprises an upper top cover, a lower top cover, a center bolt, a beryllium window, a center cavity insulating part, a cathode conductive sealing part, a center electrode and a center insulator, wherein the upper end of the center bolt is mounted in a second threaded hole; the beryllium window is mounted at the bottom of the second threaded hole; the beryllium window seals the second threaded hole; the center cavity insulating part is mounted in a through hole of the center bolt; the upper end of the center cavity insulating part is in contact with the beryllium window; the cathode conductive sealing part is mounted in the inner chamber of the center cavity insulating part; the center insulator is fixedly mounted in a first through hole; the center electrode is fixedly mounted in a through hole of the center insulator; the upper end of the center electrode is connected with the cathode conductive sealing part. The device is simple in design, convenient to use, and good in air sealing property. The invention also discloses a heating device and a cooling device for the X-ray diffractometer in situ battery accessory as well as a method for measuring a lithium battery material by using the X-ray diffractometer in situ battery accessory.

Owner:苏州亿凡星仪器科技有限公司

Rare earth modified full non-lead X-ray screen rubber

InactiveCN1787117AIdeal X-ray shielding performanceImprove mechanical propertiesShieldingX-rayRare earth

The invention relates to a rare-earth modified all lead-free X-ray screening rubber, making surface modification processing on a part of the organic rare-earth and making organization reaction processing on the other part to prepare organic rare-earth salt, then adding them both to rubber in a certain proportion, so as to obtain the modified all lead-free X-ray screening rubber, making the screening property and mechanical property of the material achieve the desired effects. It can be widely applied to medical diagnosis X-ray machines, X-ray diffraction meters, and emitters of electron microscopes as well as the protection of working personnel on the occasions of generating X-rays.

Owner:BEIJING UNIV OF CHEM TECH

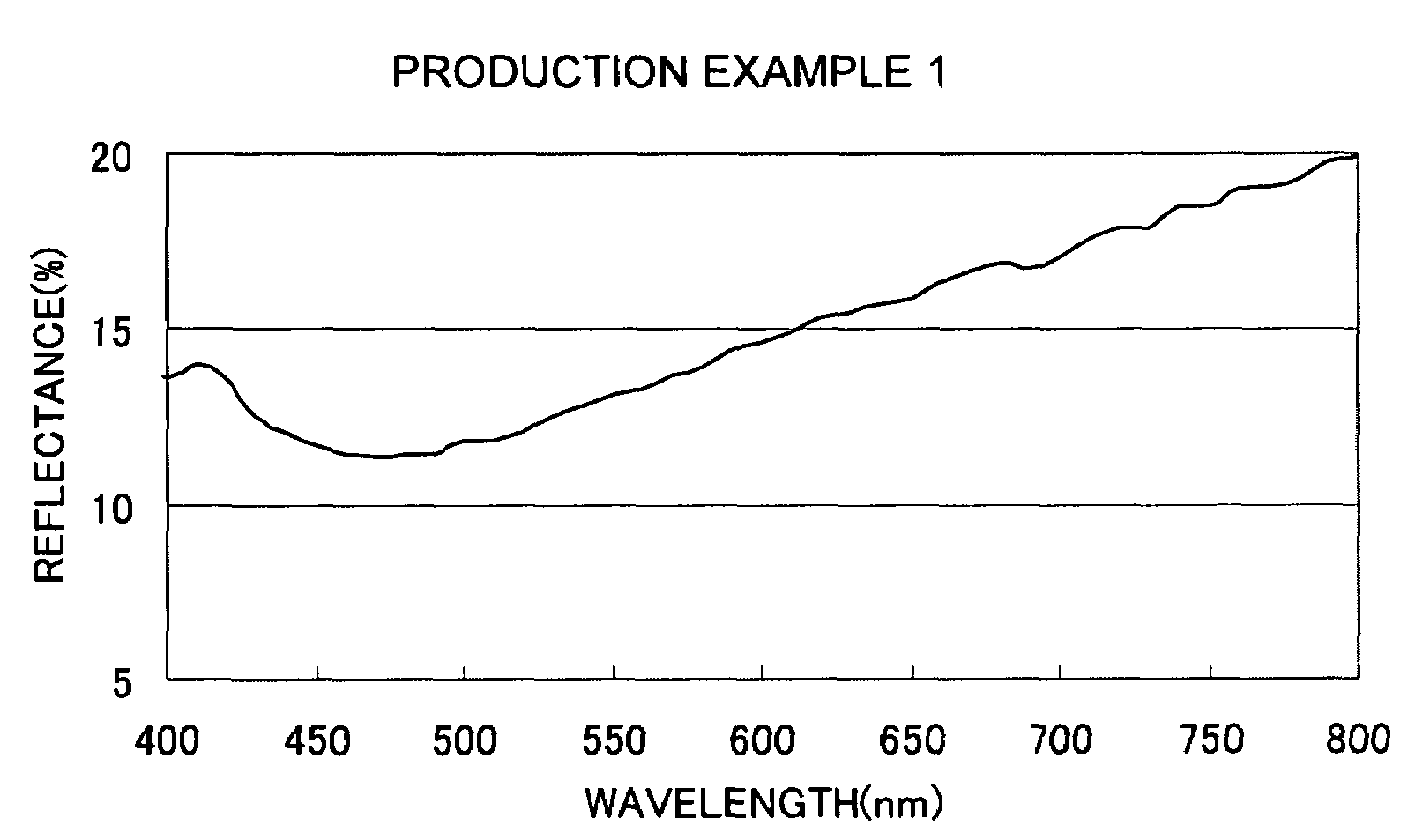

Black resin composition for display device, and member for display device

InactiveUS7785501B2Solve the lack of densityHigh optical densityNon-metal conductorsOptical filtersDiffractometerDisplay device

A black resin composition for a display device, which can achieve a high optical density even when its light-blocking agent content is relatively low and can achieve a high optical density even when it is formed into a thin film, and a member for display device which can reduce unevenness of display caused by a level difference in a pixel part resulting from the film thickness of the black resin composition. The black resin composition for a display device has a black titanium oxynitride represented by composition formula: TiNxOy-nSiO2 (wherein x and y each are a real number of larger than 0 but less than 2, and n is a real number within the range of 0 less than or equal to n less than or equal to 0.05), containing a nitrogen atom represented by N in an amount of 17 wt % or more but less than 23 wt %, and having a specific surface area of 5 to 30 m2 / g and a crystalline size as measured with an X-ray diffractometer of 17 to 25 nm, and a curable binder system. Also, a member for display device having a light-blocking layer formed using the said black resin composition for display device.

Owner:ISHIHARA SANGYO KAISHA LTD +1

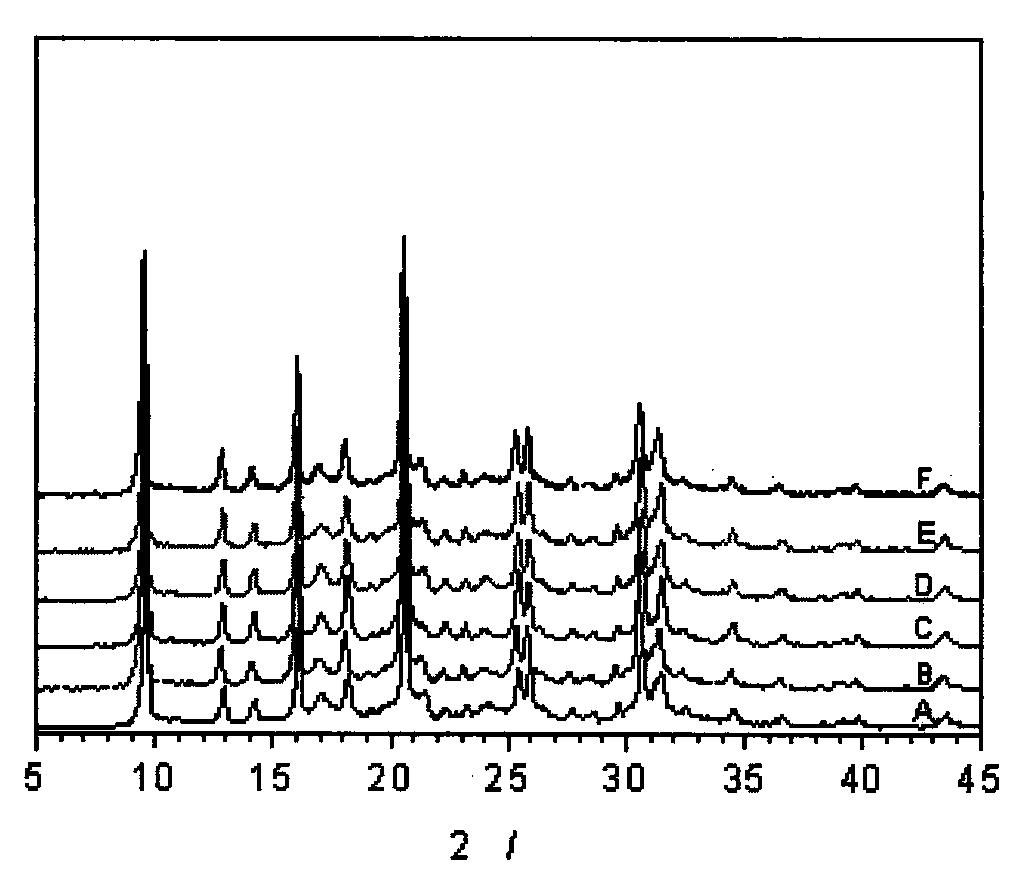

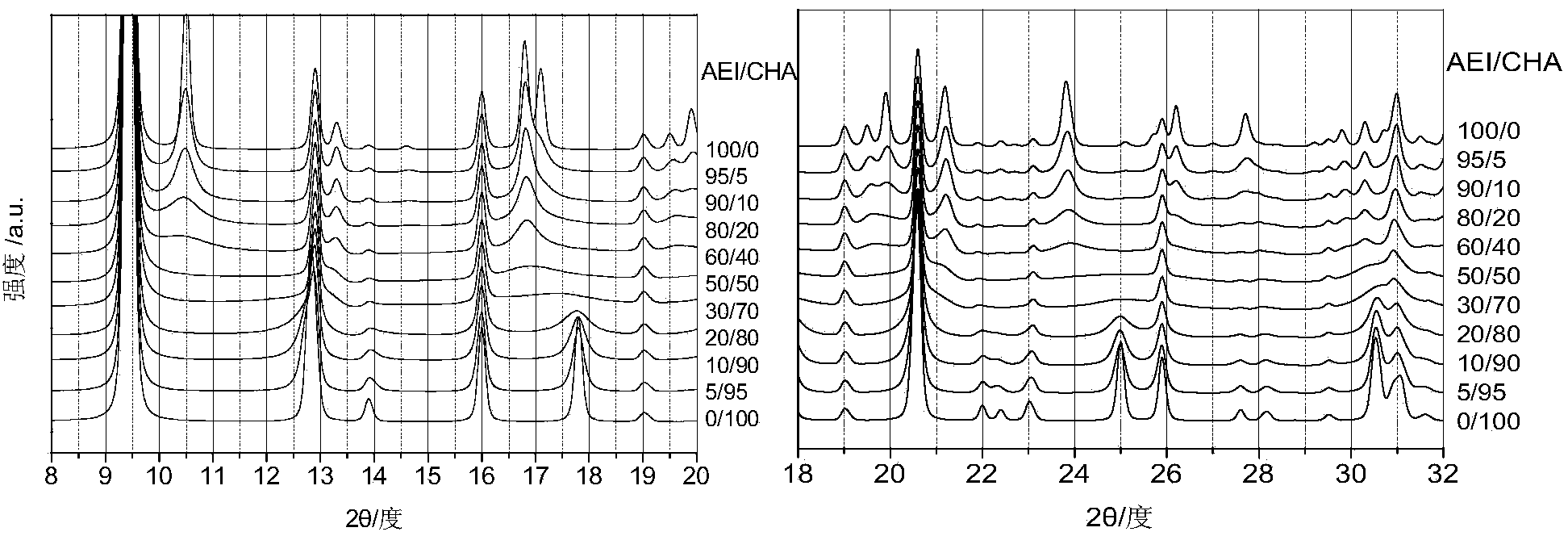

Method for synthesizing small grain SAPO-18/SAPO-34 eutectic molecular sieve

ActiveCN103878018ASmall grainEasy to operateMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveDiffractometer

The invention discloses a method for synthesizing a small grain SAPO-18 / SAPO-34 eutectic molecular sieve. The method is mainly characterized in that a single-template agent or a double-template agent is adopted, a crystal growth inhibitor is added in the synthetic process, and the synthesis parameters are adjusted to carry out crystallization under high-speed stirring. The specific method comprises the following steps: forming a mixed solution A through an aluminum source and water; forming a mixed solution B through a phosphorus source and water; uniformly mixing the solution B with the solution A in a stirring state; sequentially adding the template agent and a silicon source in the stirring state; adding the crystal growth inhibitor, performing hydrothermal crystallization under high-temperature stirring, separating, washing and drying to obtain the molecular sieve. The obtained molecular sieve is characterized by using a powder X-ray diffractometer, and a ratio of AEI / CHA in the eutectic molecular sieve is calculated to be about 50 / 50-70 / 30 through DIFFaX. The obtained molecular sieve is small in grain and large in specific surface area and has high activity, selectivity and stability in an olefin preparation reaction through a catalyst methanol.

Owner:淄博齐创新材料科技有限公司

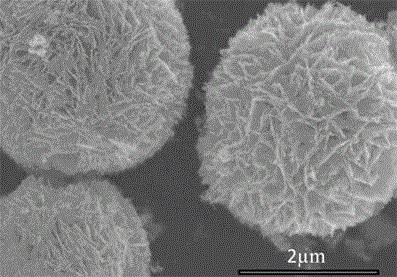

Sea-urchin-shaped nanometer nickel silicate hollow sphere and preparation method thereof

InactiveCN105129809APerfect control of size and shapeArbitrary control of morphologyMaterial nanotechnologySilicon compoundsNickel saltSilicic acid

The invention discloses a sea-urchin-shaped nanometer nickel silicate hollow sphere and a preparation method thereof. An appropriate quantity of silicon dioxide spherules and an appropriate amount of urea, soluble nickel salt and deionized water are added into a hydrothermal reaction kettle core, react for certain time inside a drying oven at the constant temperature of 80-150 DEG C and then are naturally cooled to indoor temperature; the prepared product is subjected to centrifugal washing and drying, an appropriate quantity of NaOH solutions and the product are together added into a hydrothermal reaction kettle and placed at the constant temperature of 100-200 DEG C to be subjected to hydrothermal reaction for certain time, and the product is subjected to centrifugal washing and drying and then calcined at certain temperature to prepare the sea-urchin-shaped nanometer nickel silicate hollow sphere. The prepared nickel silicate hollow sphere is tested by an X-ray diffractometer, a scanning electron microscope and a transmission electron microscope and is in a sea urchin shape, the wall of the sphere is quite thin, the specific surface area is large, particle size distribution is even, and the nickel silicate hollow sphere can serve as a material for manufacturing an electrochromic device and an electrode material for manufacturing a super capacitor.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

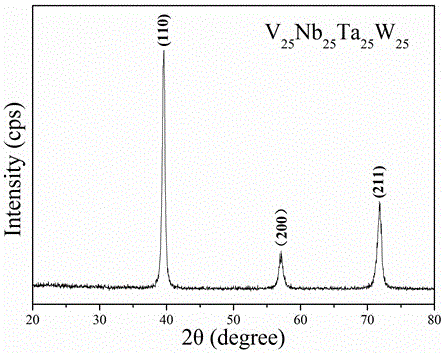

High-temperature-resistant high-entropy alloy material and preparation method thereof

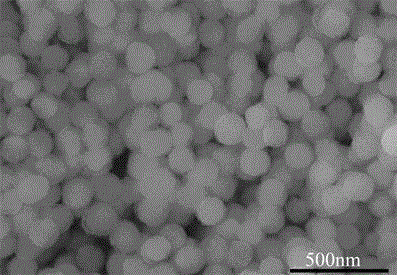

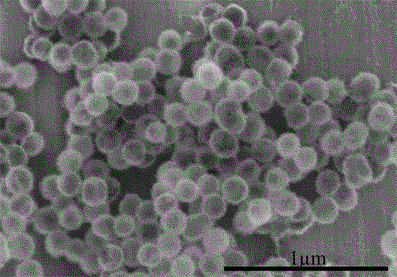

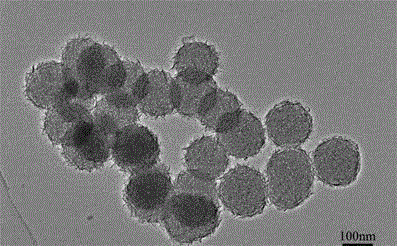

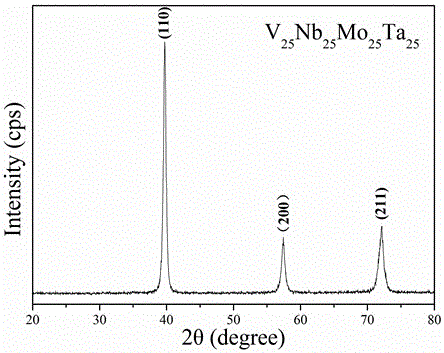

ActiveCN105112759AHigh temperature fatigue resistanceHas the ability to resist high temperature softeningStatic compressionHigh entropy alloys

The invention discloses a high-temperature-resistant high-entropy alloy material and a preparation method thereof, and belongs to the technical field of the alloy materials. The preparation method comprises the steps that four of Ti, V, Nb, Mo, Ta and W are adopted as raw materials; the raw materials are smelted into mother alloy button ingots by a high-vacuum nonconsumable arc melting furnace under high-purity argon shielding; the four button ingots are mounted to be samples in the sizes of phi 20mmx10mm by a metallurgical phase mounting press; the surfaces of the samples are smoothed by 100#, 240#, 400#, 600#, 800#, 1000#, 1200# and 1500# metallurgical phase abrasive paper; then the samples are subjected to mechanical polishing; a crystal structure is determined by an X-ray diffractometer; a scanning electron microscope is used to observe the morphology of a microstructure; a room temperature quasi-static compression performance test is carried out; and the obtained four alloys have higher yield strength and work hardening capacity.

Owner:TAIYUAN UNIV OF TECH

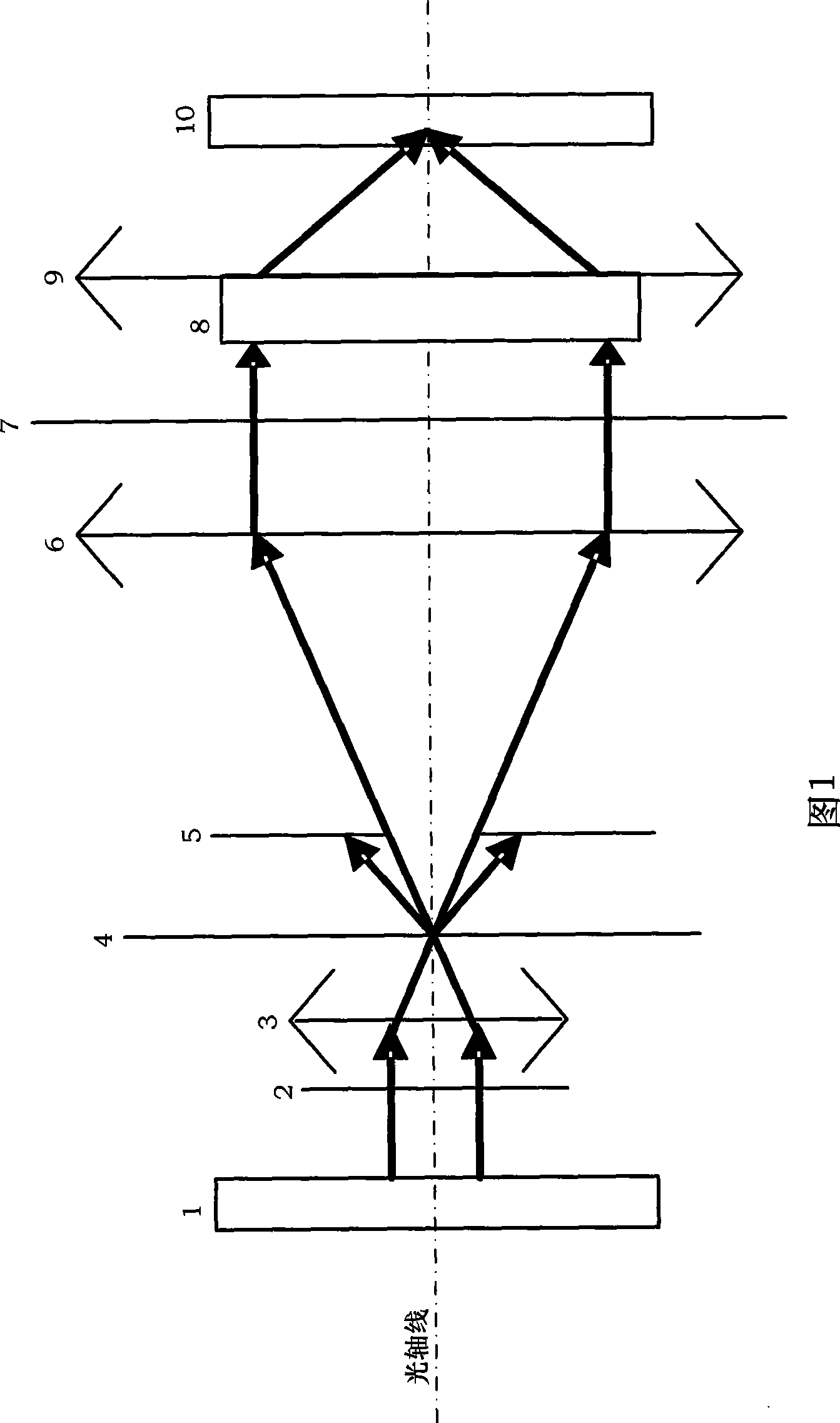

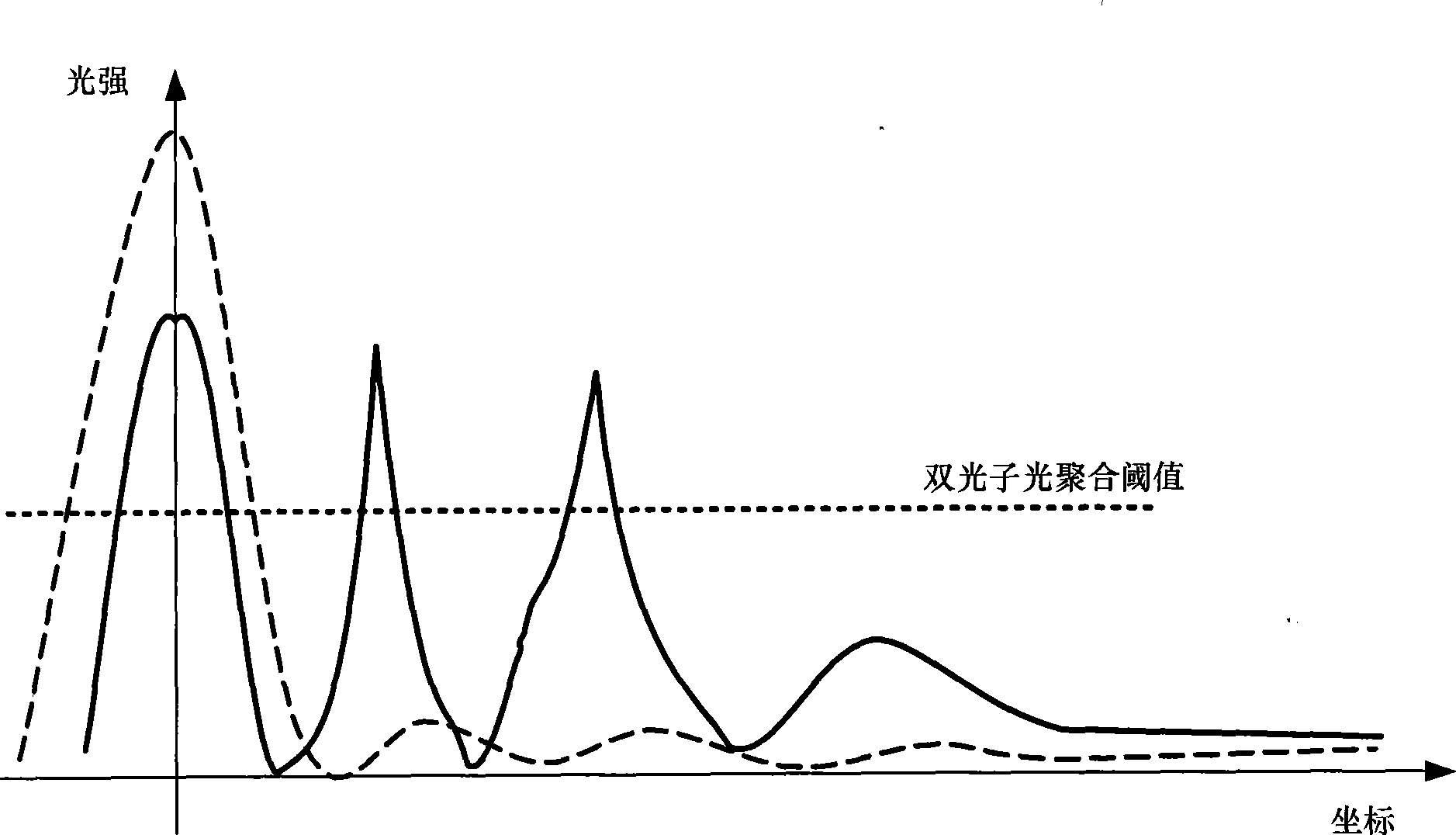

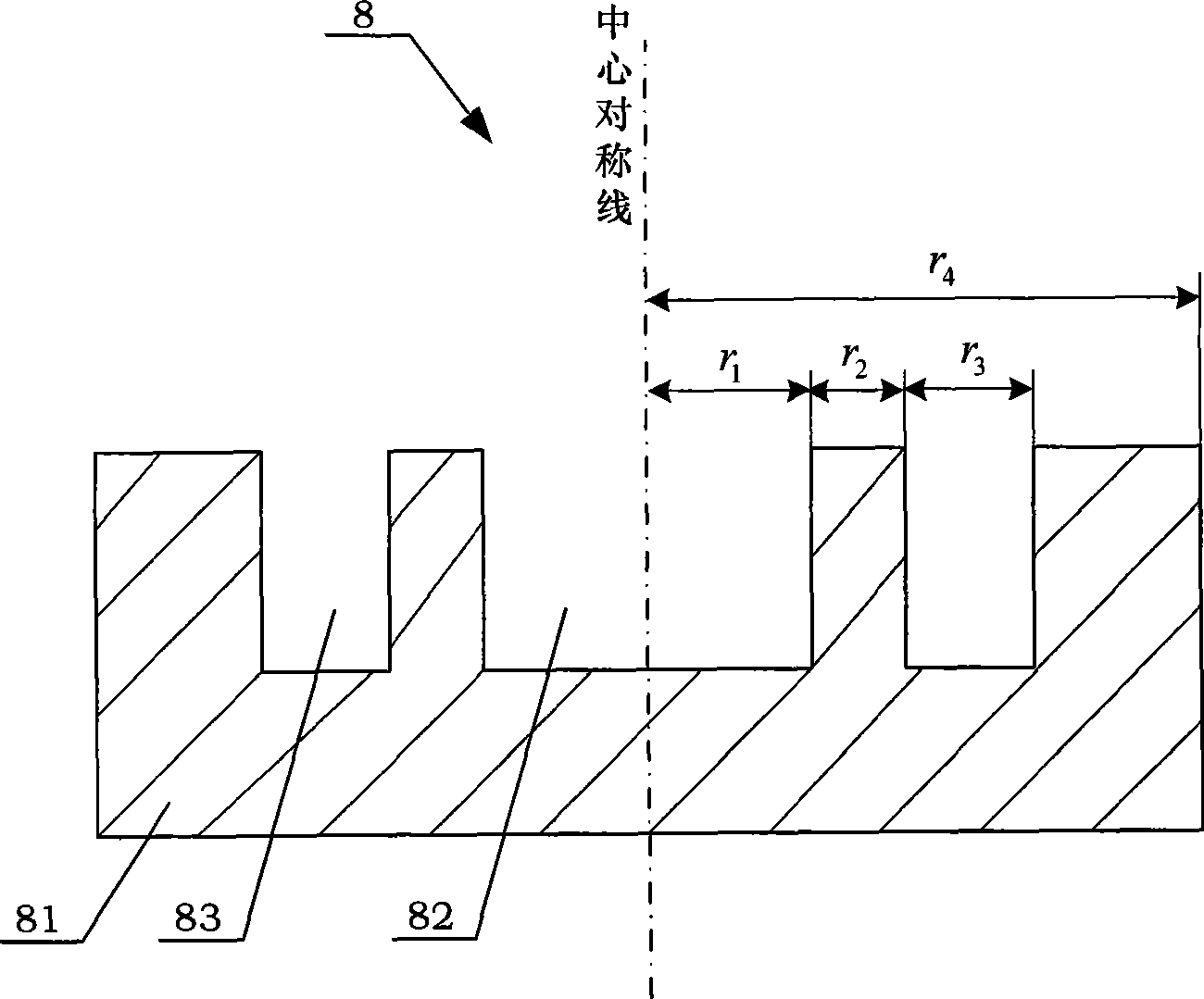

Light path structure suitable for femtosecond laser two-photon mirco-nano processing system

InactiveCN101458451AHas the effect of filtering clutterLight intensity sharpeningPhotomechanical apparatusNon-linear opticsMicro nanoProcess systems

The invention discloses a light path structure suitable for a femto-second laser two-photon micro-nano processing system. The light path structure consists of a femto-second two-photon laser, a light gradient attenuator, a filtering convex lens, a pinhole filter, an intercepting diaphragm, a collimating lens, an aperture diaphragm, a super resolution diffractometer and an oil immersion objective. The light gradient attenuator, the filtering convex lens, the pinhole filter, the intercepting diaphragm, the collimating lens, the aperture diaphragm, the super resolution diffractometer and the oil immersion objective are arranged between the femto-second two-photon laser and photosensitive resin in sequence by using an optical axes as the center. The super resolution diffractometer is arranged on the oil immersion objective. The light path structure changes power distribution of femto-second laser in a focus local area by the super resolution diffractometer, so that the light intensity of a side lobe is larger than a two-photon converged power threshold value, thus achieving multi-point processing in two-photon micro-nano processing.

Owner:BEIHANG UNIV

Stress corrosion dehiscence resistant ultrasonic impact treatment process

ActiveCN101492759AEnhanced resistance to stress corrosion crackingImprove fatigue performanceFurnace typesHeat treatment furnacesHeat-affected zoneDiffractometer

The invention relates to an ultrasonic impacting processing technique for resisting stress corrosion cracking, comprising steps of cleaning the surface of a workpiece to be processed to remove all the dust, scales and coating; aligning an ultrasonic impacting gun to the area to be processed including a welding line and heat-affected zones at the two sides of the welding line, wherein the width of the heat-affected zones is 2 to 3 times that of the welding line; converting electrical energy into mechanical energy by a transducer, wherein ultrasonic impacting frequency is 20kHz, leading the ultrasonic impacting gun vertical to the surface of the workpiece to be processed, using a pinhead to impact a determined welding line processing zone at a high speed, wherein coverage percentage of the impact is over 50%; using an X-ray diffractometer to detect the surface of the workpiece, wherein residual stress on the surface of the welded workpiece is compressive stress the value of which is far less than a threshold value causing stress corrosion cracking of the workpiece, and a solidified layer with certain thickness is formed on the surface of the workpiece, thus the processing is finished.

Owner:NANJING UNIV OF TECH

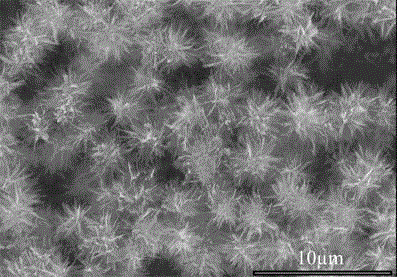

Flower-shaped tungsten oxide nanometer material and preparing method thereof

InactiveCN105129857AUniform shapeEasy to makeTungsten oxides/hydroxidesNanotechnologyDiffractometerSolar cell

The invention discloses a flower-shaped tungsten oxide nanometer material and a preparing method thereof. The preparing method includes the steps that tungsten salt powder with a certain mass, organic acid and a certain amount of absolute ethyl alcohol are mixed and dissolved, and ultrasonic oscillation is carried out; then the solution is added into a reaction kettle, and reacting is carried out for 2 h to 8 h at the temperature of 150 DEG C to 230 DEG C; after reacting is finished, the mixture is naturally cooled to the indoor temperature, an obtained product is centrifugally dried, and the flower-shaped tungsten oxide nanometer material is obtained. Testing through an X-ray diffractometer, a scanning electron microscope and the like shows that the flower-shaped tungsten oxide nanometer material is a spherical flower-shaped (NH4)xWO3 mixed type material and is uniform in shape, a sphere is even, flower-shaped sheets are small in thickness, and the flower-shaped tungsten oxide nanometer material and the preparing method can be applied to the fields of dye-sensitized solar cells, electrochromism and the like.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

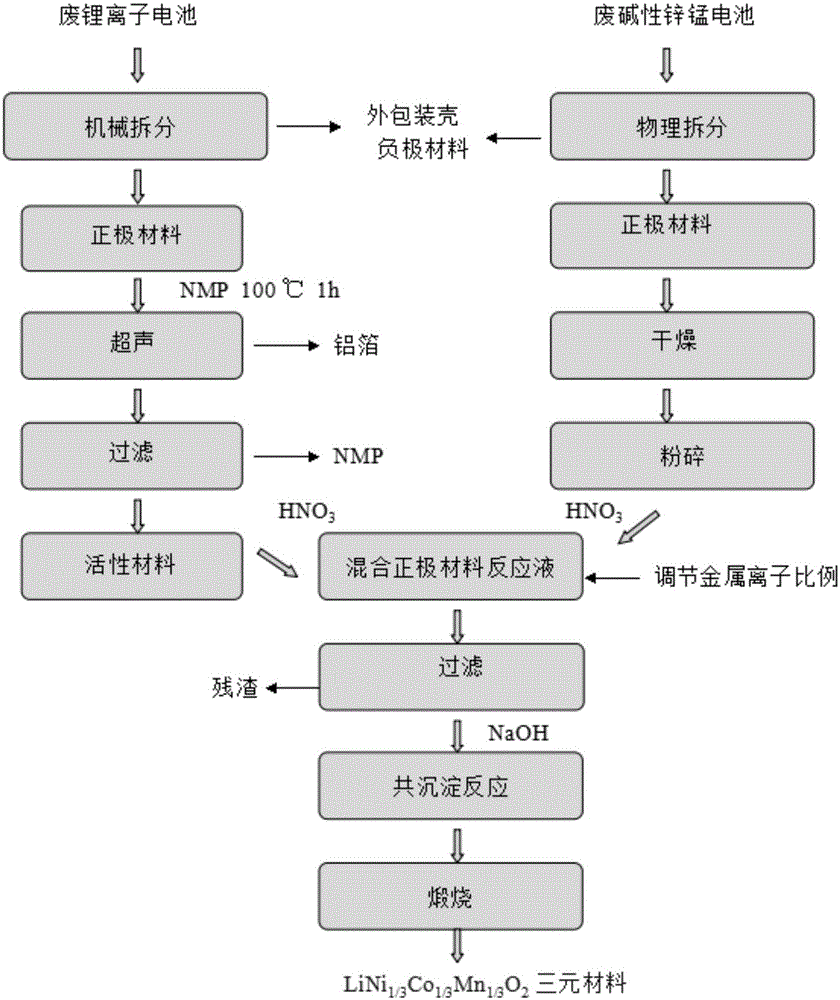

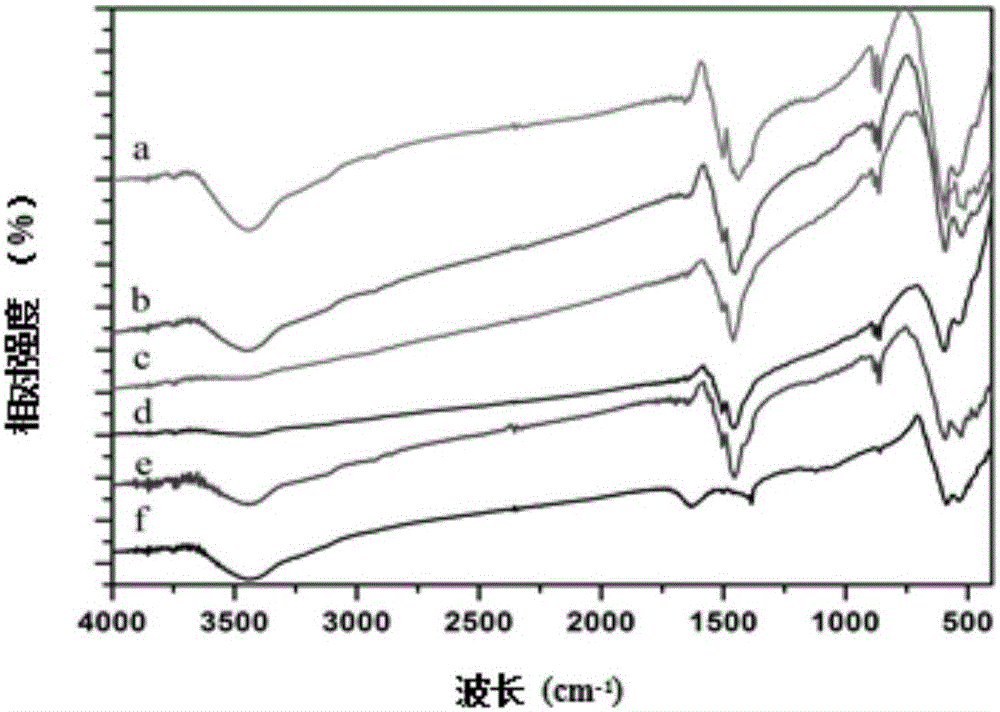

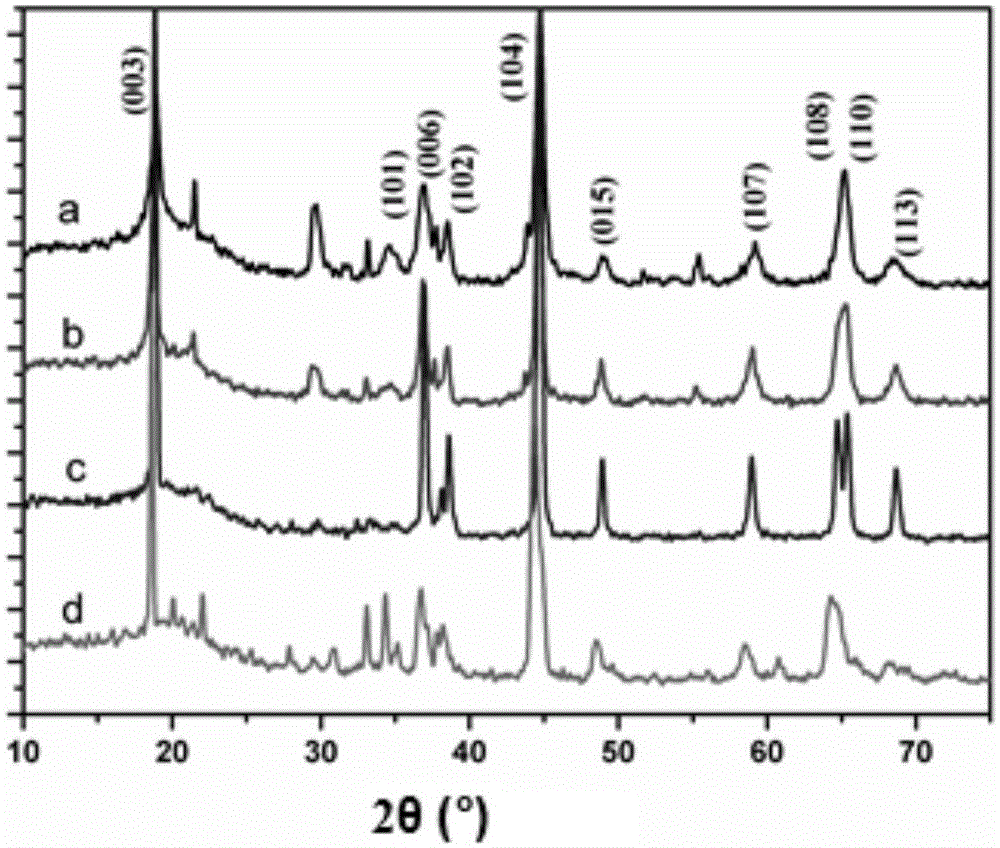

Method for preparing cathode material of lithium ion battery from mixed waste alkaline batteries

InactiveCN105070970AImprove performanceLow costCell electrodesWaste accumulators reclaimingElectrical batteryManganese

A method for preparing a cathode material of a lithium ion battery from mixed waste alkaline batteries comprises the following steps of: using cathode materials of waste alkaline zinc-manganese batteries and cathode materials of waste lithium ion batteries as raw materials, dissolving the cathode materials with nitric acid with a certain concentration, and adding corresponding nitrate into a dissolution liquid to regulate proportions of metal cobalt, nickel and manganese ions; taking sodium hydroxide as a precipitant, preparing a nickel-cobalt-manganese hydroxide precursor by a co-precipitation method, carrying out filtering and drying, mixing the precursor with a certain amount of lithium carbonate, and placing the mixture in a muffle furnace for calcination to obtain a ternary cathode material LiNi<1 / 3>Co<1 / 3>Mn<1 / 3>O2. Morphology and structural characterization of an obtained product are carried out by means of a spectrograph, an X-ray diffractometer, a scanning electron microscope and an energy disperse spectroscopy, the product is used to produce a button cell, and characterization is carried out on the electrochemical performance of the button cell by means of a LAND tester. A result shows that the initial discharging capacity of the prepared new battery is 158.3mAHg<-1> when pH is controlled to be 8, the calcination temperature is 850 DEG C and the calcination time is 10 hours during the precipitation reaction. According to the research, various models of waste alkaline batteries can be simultaneously recycled, the production cost of the battery cathode material is reduced, and the method has high economical and social benefits.

Owner:HENAN INST OF SCI & TECH

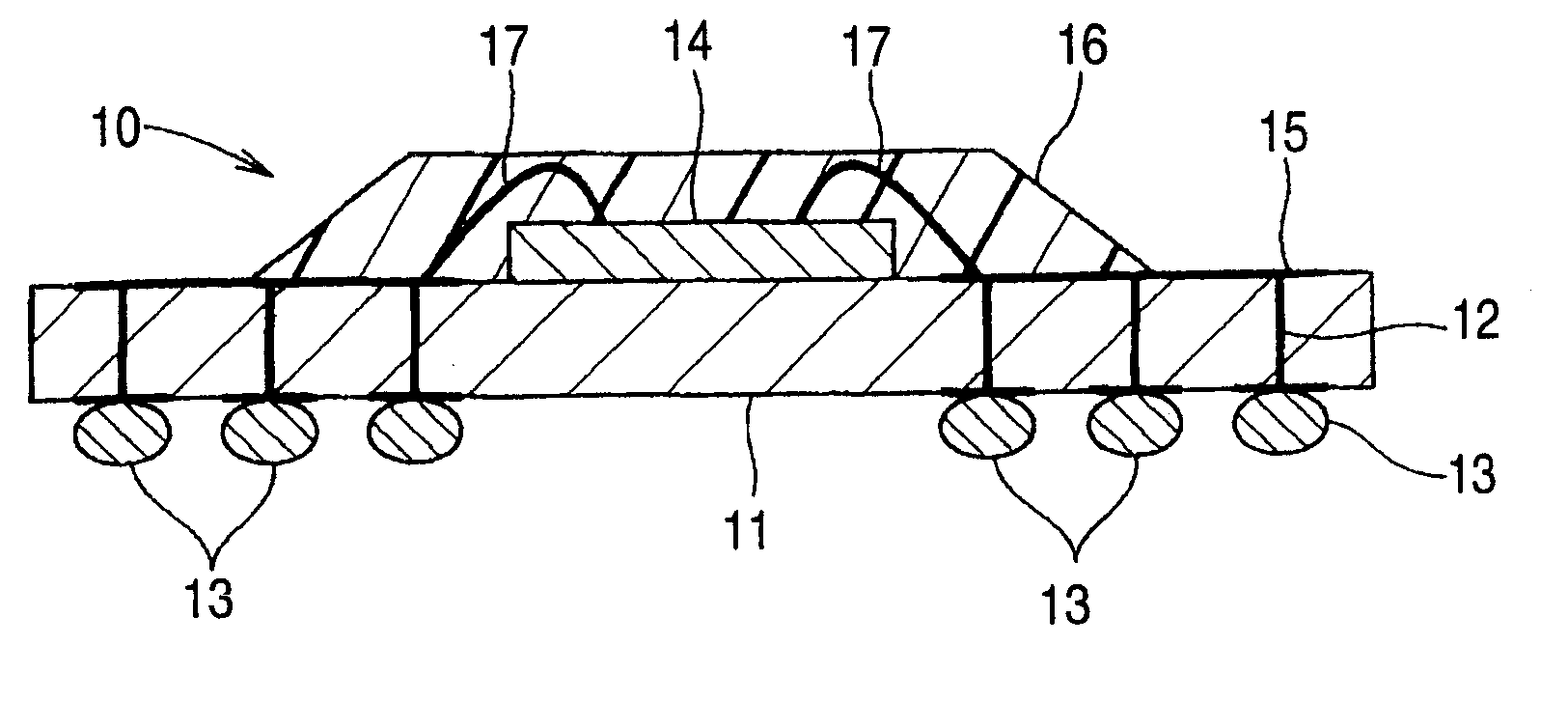

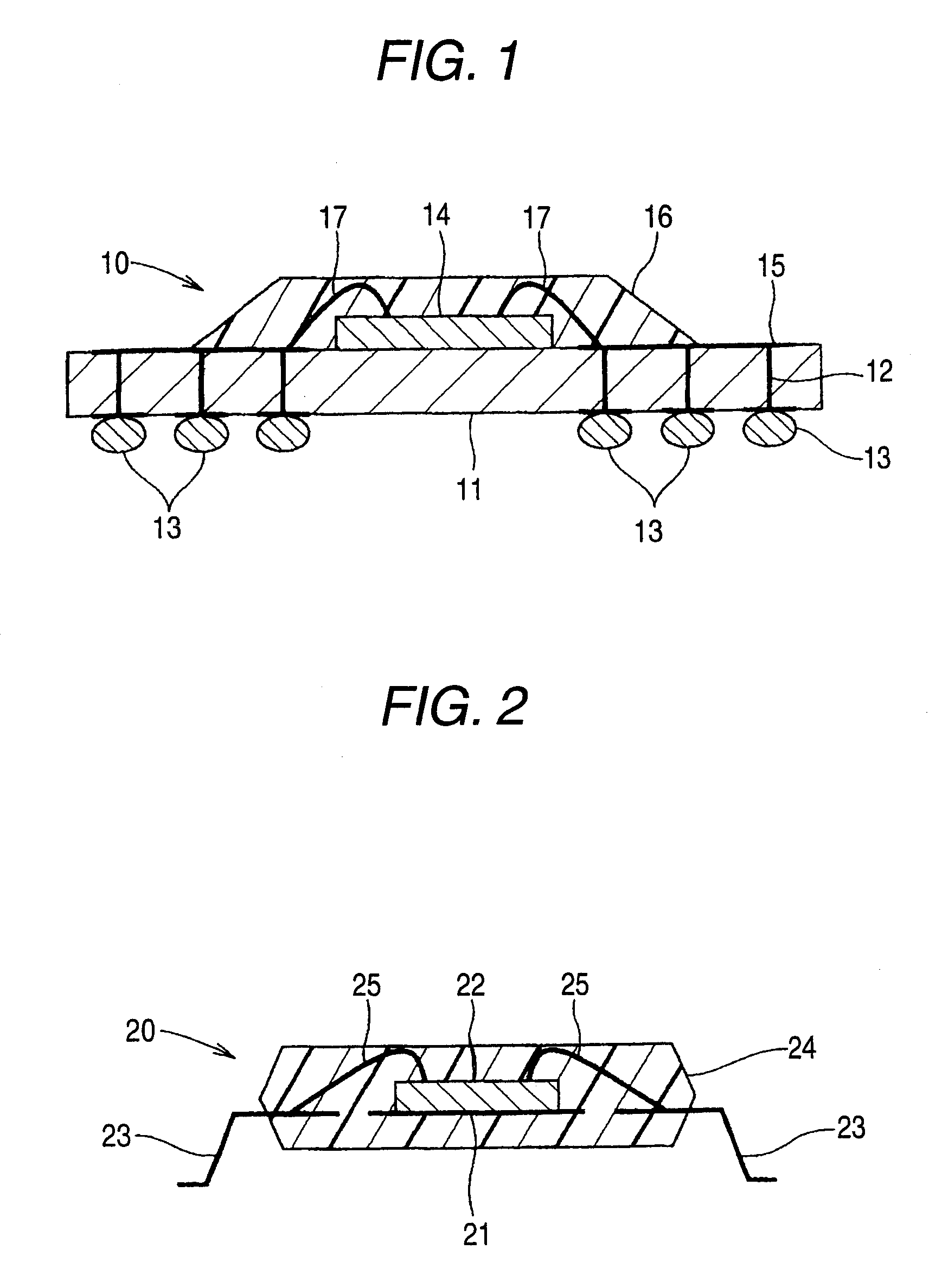

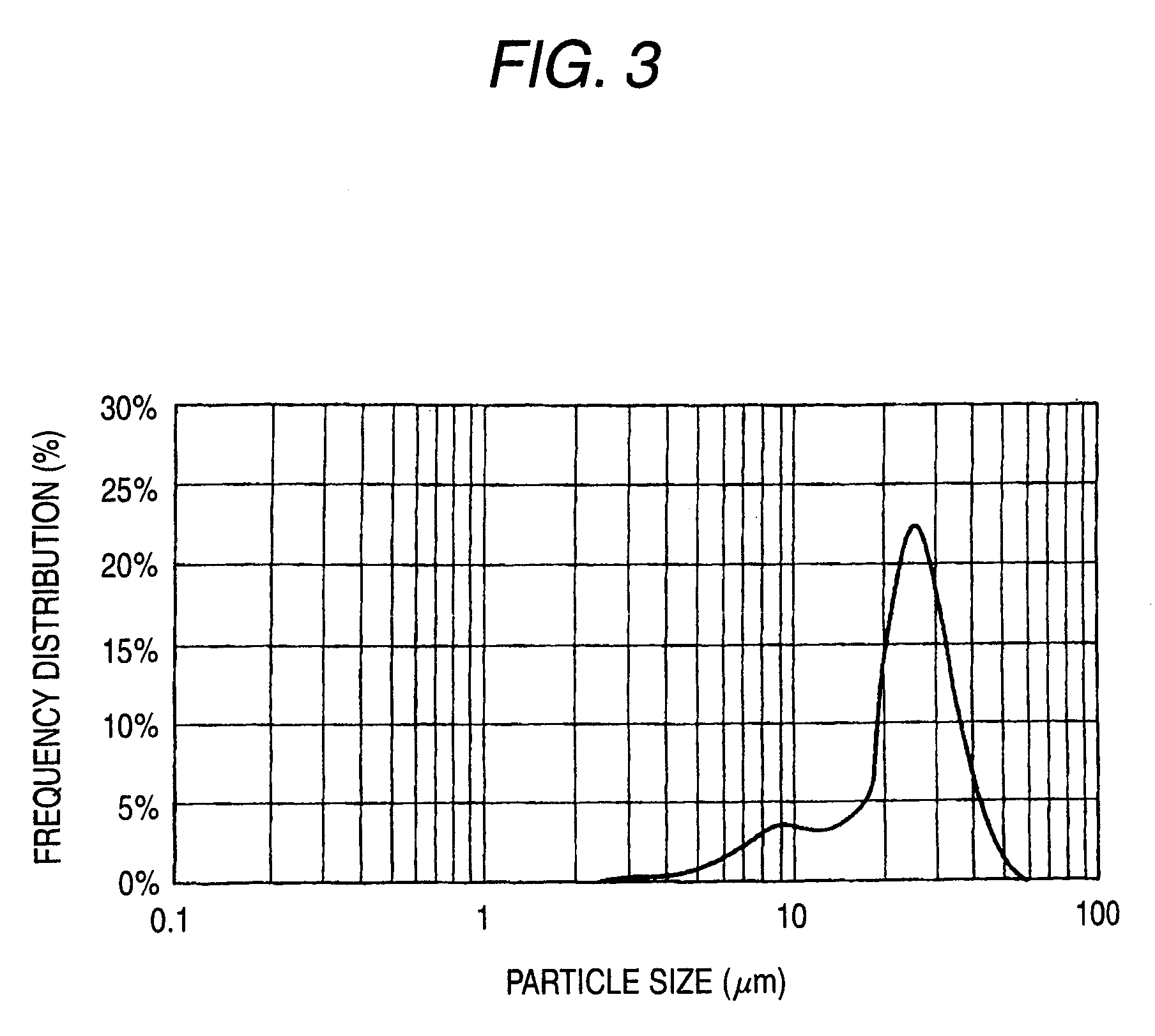

Spherical sintered ferrite particles, resin composition for semiconductor encapsulation comprising them and semiconductor devices produced by using the same

InactiveUS20100193972A1Low viscosityImprove liquidityPigmenting treatmentSemiconductor/solid-state device detailsIon contentDiffractometer

A resin composition for semiconductor encapsulation having good moldability, of which the cured product has effective electromagnetic wave shieldability, is provided. A resin composition for semiconductor encapsulation, containing spherical sintered ferrite particles having the following properties (a) to (c) : (a) the soluble ion content of the particles is at most 5 ppm; (b) the mean particle size of the particles is from 10 to 50 μm; (c) the crystal structure of the particles by X-ray diffractiometry is a spinel structure.

Owner:NITTO DENKO CORP +1

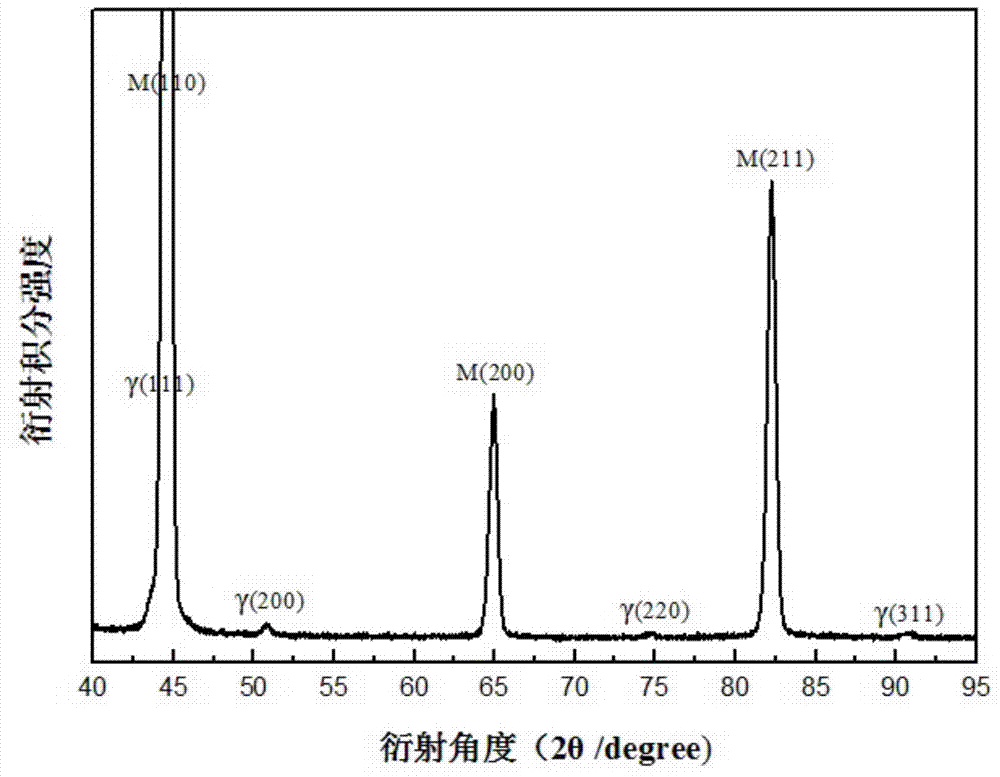

Method for measuring austenite content in steel by using X-ray diffraction technology

ActiveCN103808743AEliminate the effects of measurement resultsThe test result is accurateMaterial analysis using radiation diffractionSoft x rayTest sample

The invention discloses a method for measuring austenite content in steel by using an X-ray diffraction technology. The method comprises the following steps: firstly, scanning a steel test sample by using an X-ray diffractometer to obtain an XDR (External Data Representation) graph; revising martensite and austenite by using the XDR graph and calculating the diffraction strength of each crystal face; and finally, measuring the content of the austenite in the steel test sample. With the adoption of the designed method for measuring the content of the austenite in the steel by using the X-ray diffraction technology, the measurement accuracy of the content of the austenite in the steel is improved under the condition that the test sample has a texture.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com