High-temperature-resistant high-entropy alloy material and preparation method thereof

A high-entropy alloy and high-temperature-resistant technology, which is applied in the field of alloy materials to achieve good toughness and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

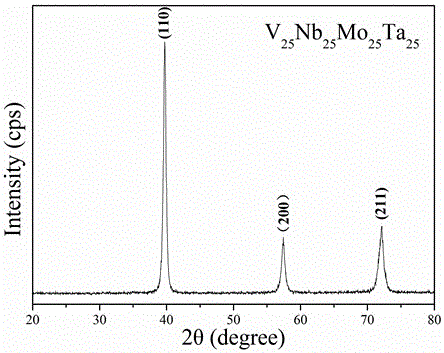

[0053] Example 1: Alloy V 25 Nb 25 Mo 25 Ta 25 preparation method

[0054] Include the following steps:

[0055] 1. Select V, Nb, Mo, Ta with a purity higher than 99.9% (wt.) as raw materials, according to V 25 Nb 25 Mo 25 Ta 25 The ingredients are proportioned;

[0056] 2. Using a high-vacuum non-consumable arc melting furnace, and under the protection of 99.999% high-purity argon, the raw materials are smelted into master alloy button ingots, and the button ingots are turned over for 6 to 8 times during each smelting to ensure that the alloy Uniform melting;

[0057] 3. Use the metallographic inlay prototype to inlay the four button ingots into sizes of the sample;

[0058] 4. Use 100#, 240#, 400#, 600#, 800#, 1000#, 1200# and 1500# metallographic sandpaper to smooth the surface of the sample, and then mechanically polish the sample to obtain an alloy material.

Embodiment 2

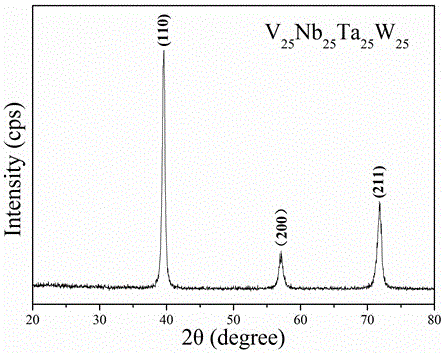

[0059] Example 2: Alloy V 25 Nb 25 Ta 25 W 25 preparation method

[0060] Select V, Nb, Ta and W with a purity higher than 99.9% (wt.) as raw materials, according to V 25 Nb 25 Ta 25 W 25 The ingredients are proportioned;

[0061] Subsequent steps are the same as in Example 1.

Embodiment 3

[0062] Example 3: Ti 20 V 20 Nb 20 Mo 20 Ta 20 preparation method

[0063] Select Ti, V, Nb, Mo, Ta with a purity higher than 99.9% (wt.) as raw materials, according to Ti 20 V 20 Nb 20 Mo 20 Ta 20 The ingredients are proportioned;

[0064] Subsequent steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com