Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

183results about How to "Improve toughness and plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

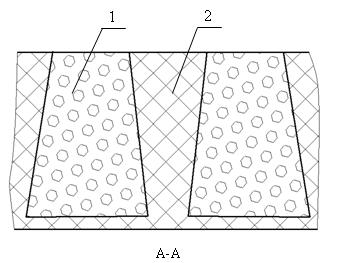

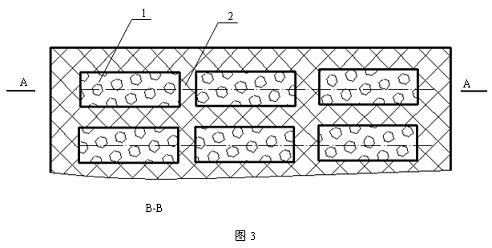

Abrasion resistant material featuring ceramic embedded in metal and preparation method thereof

InactiveCN101598261ANot easy to fall offImprove reliabilityShrinkage connectionsSheets/panelsAdhesiveMetallurgy

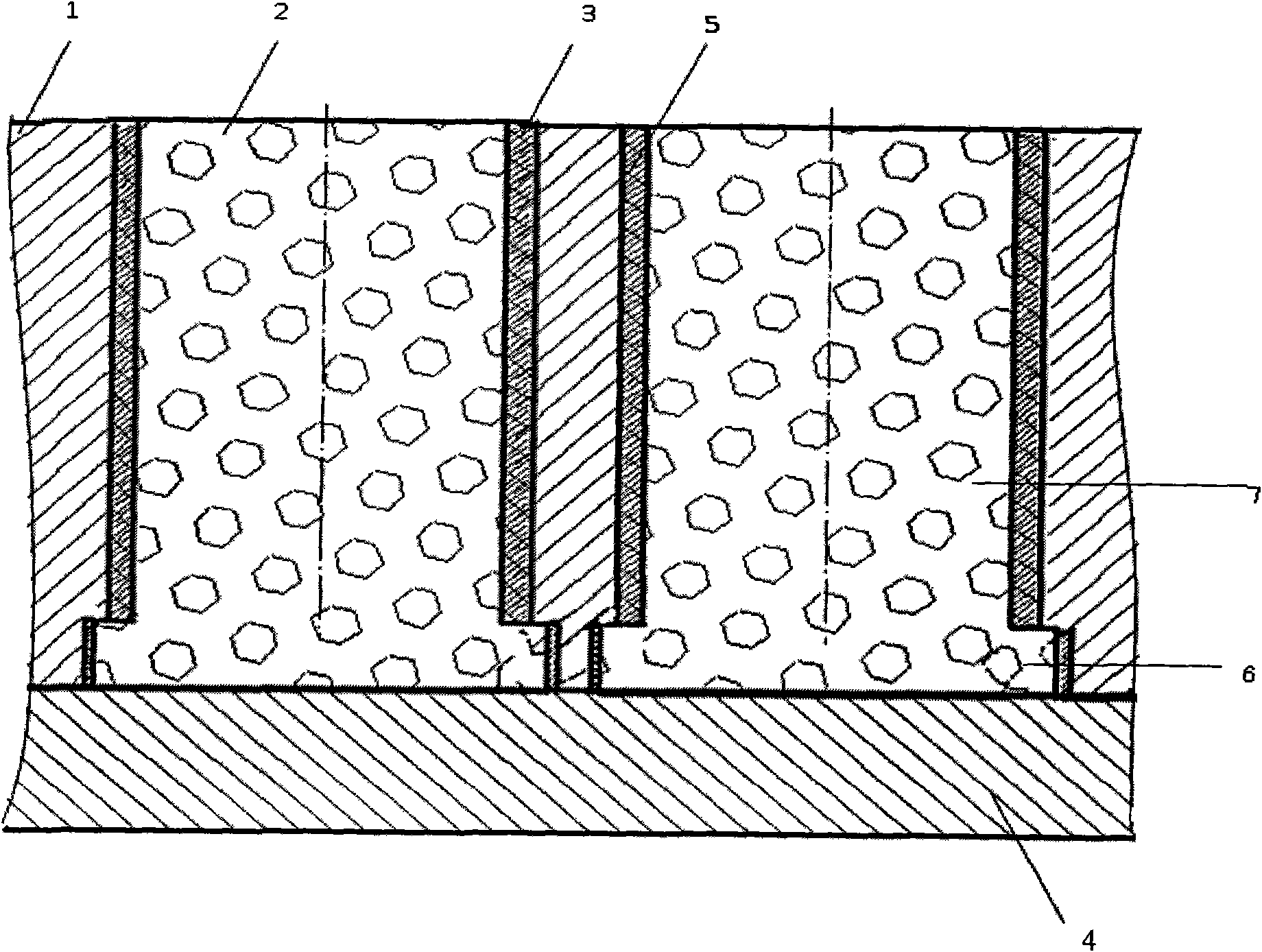

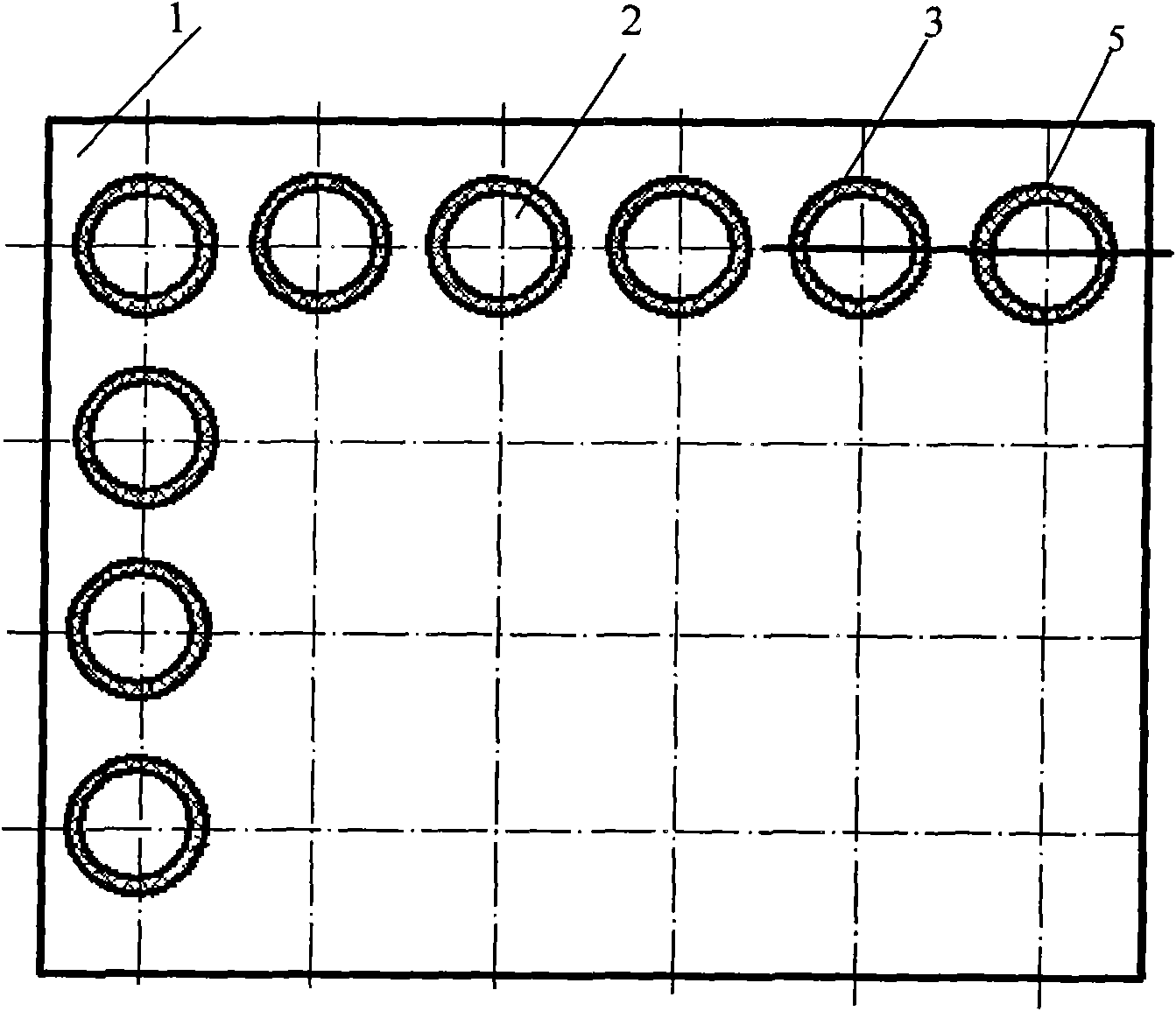

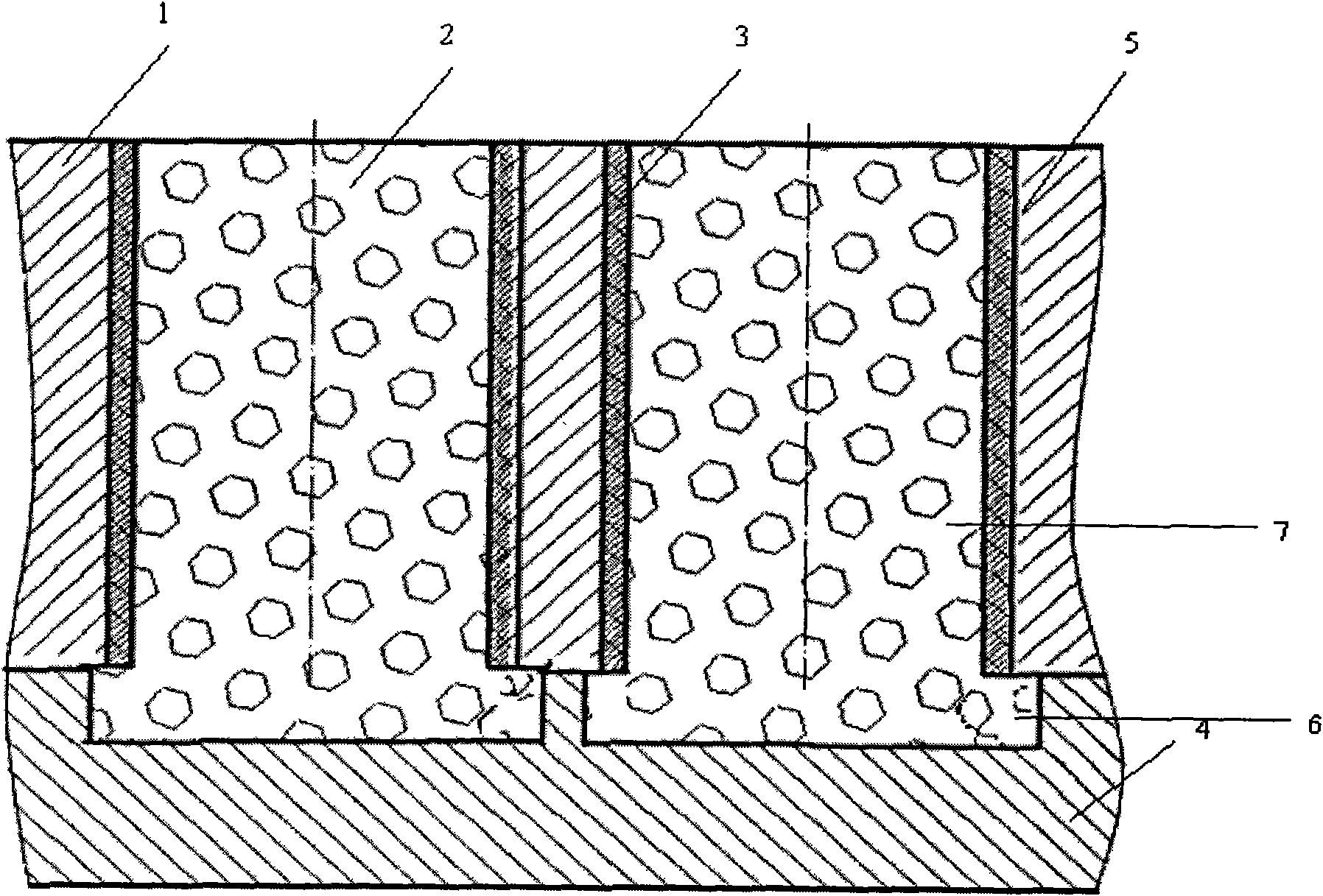

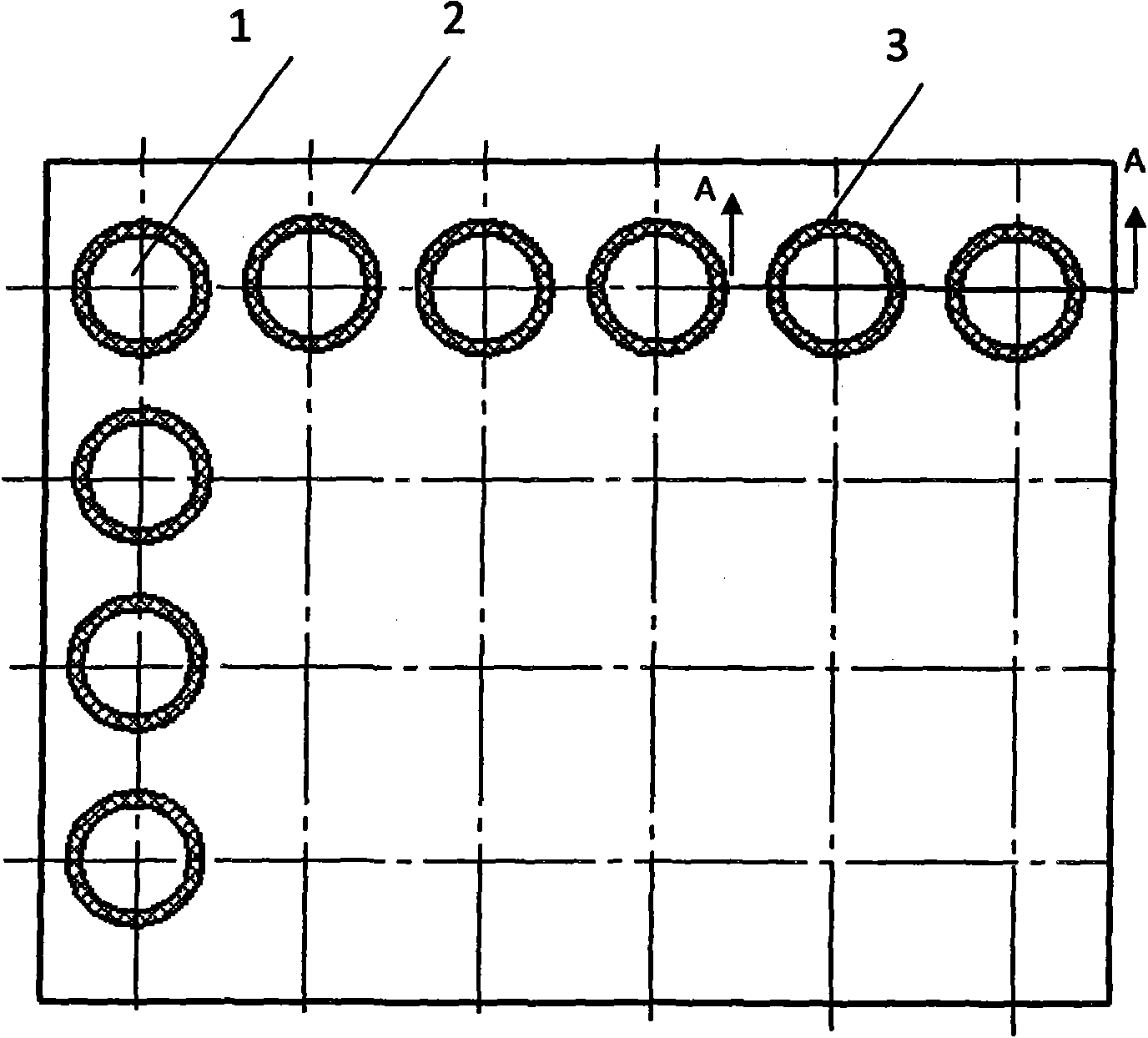

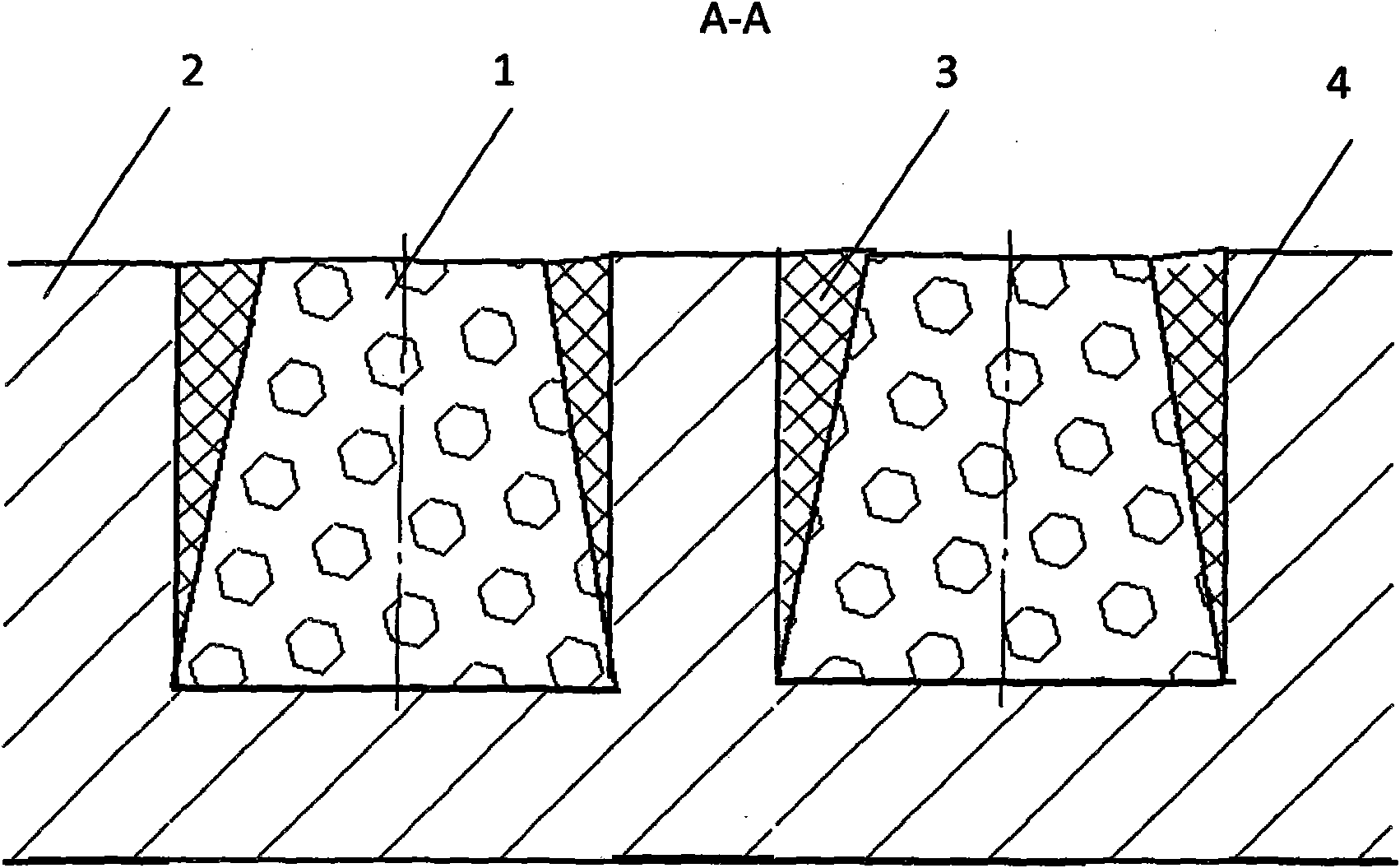

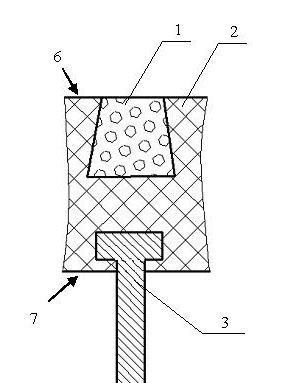

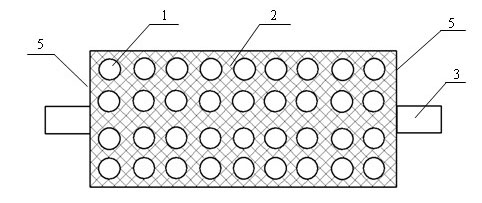

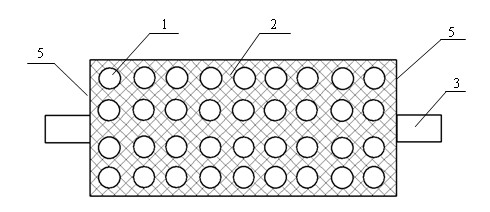

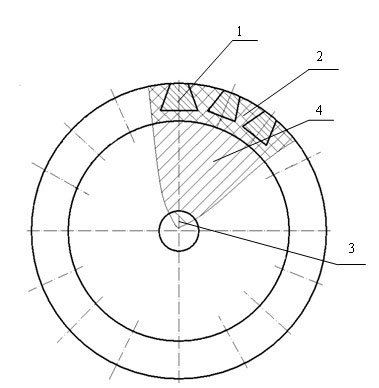

The invention discloses an abrasion resistant material featuring ceramic embedded in metal and a preparation method thereof. The abrasion resistant material comprises an abrasion resistant ceramic block, a base plate and a substrate with a through hole; the abrasion resistant ceramic block is embedded in the through hole of the substrate, the substrate is mounted on the base plate, the abrasion resistant ceramic block comprises a working section and a positioning section with identical cross section shape and the cross section area of the positioning section is larger than that of the working section, the abrasion resistant ceramic block is connected with the substrate by the positioning section, the through hole of the substrate is matched with the working section and the positioning section of the abrasion resistant ceramic block, or the through hole of the substrate is only matched with the working section of the abrasion resistant ceramic block. The material adopts the abrasion resistant ceramic block designed with a variable cross section structure, overcomes the defect of easy peeling off as the original metal ceramic abrasion composite material is only fixed by adhesive; at the same time, the abrasion resistant ceramic block is embedded in the metal through hole by the hot mounting method, thus overcoming easy ageing of the adhesive and easy peeling off of the abrasion resistant ceramic block caused by using adhesive.

Owner:SHANDONG UNIV

Metal ceramic composite wear-resistant material and preparation method thereof

InactiveCN101566271AHigh bonding strengthOvercome the disadvantages of easy agingArc welding apparatusSheets/panelsAdhesiveWear resistant

The invention discloses a metal ceramic composite wear-resistant material and a preparation method thereof. The method solves the problems that in the prior metal ceramic composite wear-resistant material, the bonding strength of metal and ceramic is low, an adhesive is easy to age, and a wear-resistant ceramic is easy to fall off and is not suitable for high temperature operating conditions. Themethod has the advantages that the metal and the ceramic are welded firmly to improve the wear resistance of the composite material, reduce the use cost, meet production requirements and the like. Thestructure of the metal ceramic composite wear-resistant material comprises a substrate which is provided with a plurality of blind holes, and wear-resistant ceramic blocks matched with the blind holes are arranged in the blind holes and are connected with the blind holes by welding.

Owner:SHANDONG UNIV

Method for controlling non-metallic impurities in structural alloy steel

ActiveCN101519710AAvoid it happening againFully float to removeProcess efficiency improvementFatigue loadingNon-metallic inclusions

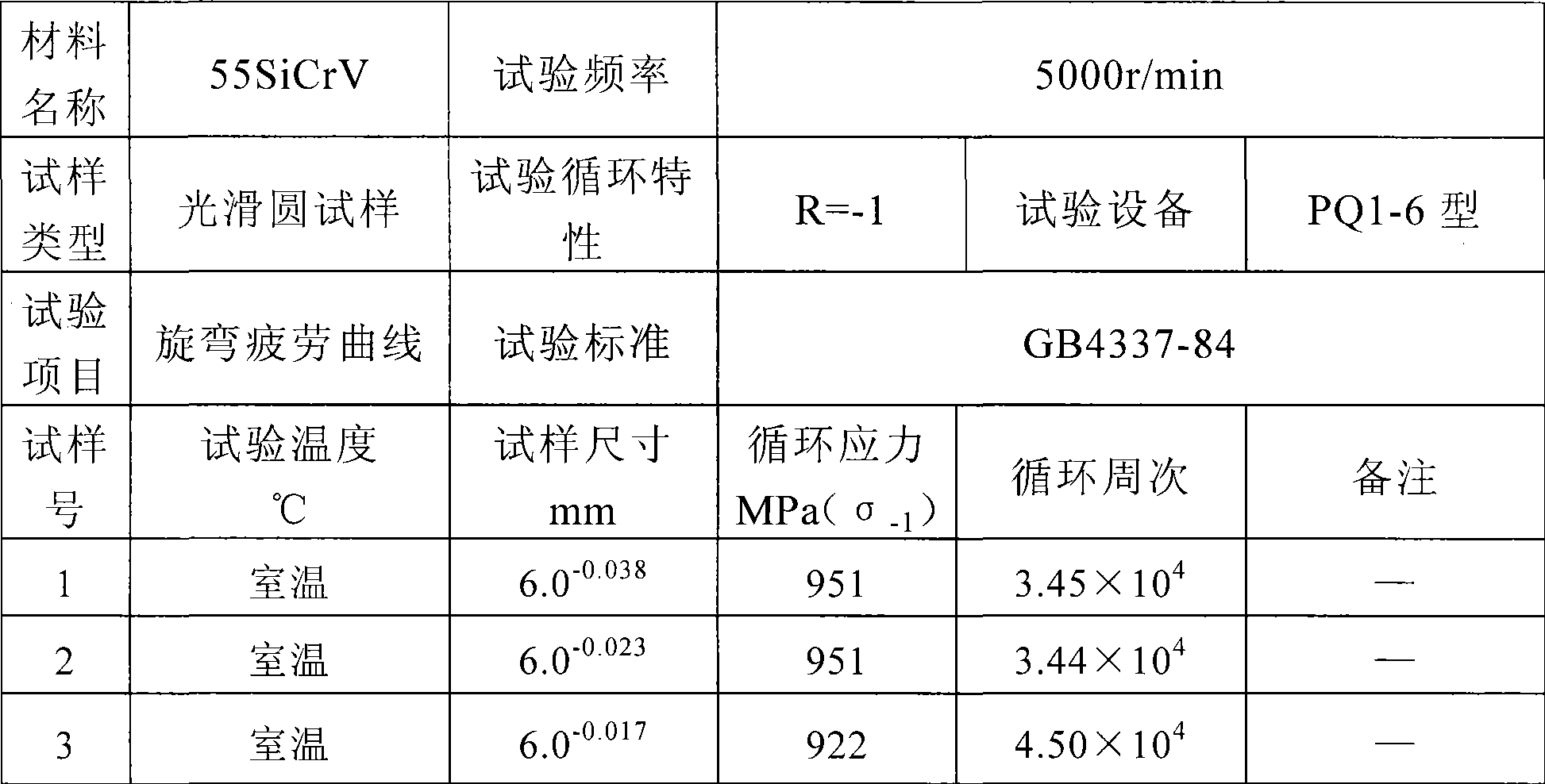

A method for controlling non-metallic impurities in structural alloy steel includes the following steps of: step one: pre-smelting molten steel: (1) batching; (2) slagging in advance in the melting stage; (3) tapping, tapping conditions: (P) is less than or equal to 0.005 percent; (S) is less than or equal to 0.005 percent; and tapping temperature is 1640 DEG C to 1660 DEG C; step two: external refining: at the time of one third of the tapping of a primary smelting furnace, fluxing medium is added into ladles; the heating station of an external refining furnace adopts Si-Fe powder and SiC powder to conduct diffusive deoxidation; oxygen is determined before the ladles enter vacuum degassing, and deoxidizing agent is added; step three: vacuum refining: the vacuum process is kept for longer than or equal to 20min under less than or equal to 66.7Pa; the post-vacuum soft argon blowing time is longer than or equal to 15min; the soft argon blowing intensity is less than or equal to 0.10Mpa; and the post-vacuum crane ladle temperature is 1530 DEG C to 1540 DEG C; and step four: continuous casting. The method improves the purity of steel by improving the composition and size of the non-metallic impurities in steel so as to further meet the requirement on pure steel under high dynamic stress and high cycle fatigue loading.

Owner:宝武特种冶金有限公司

Spring steel and manufacturing and thermal treatment method thereof

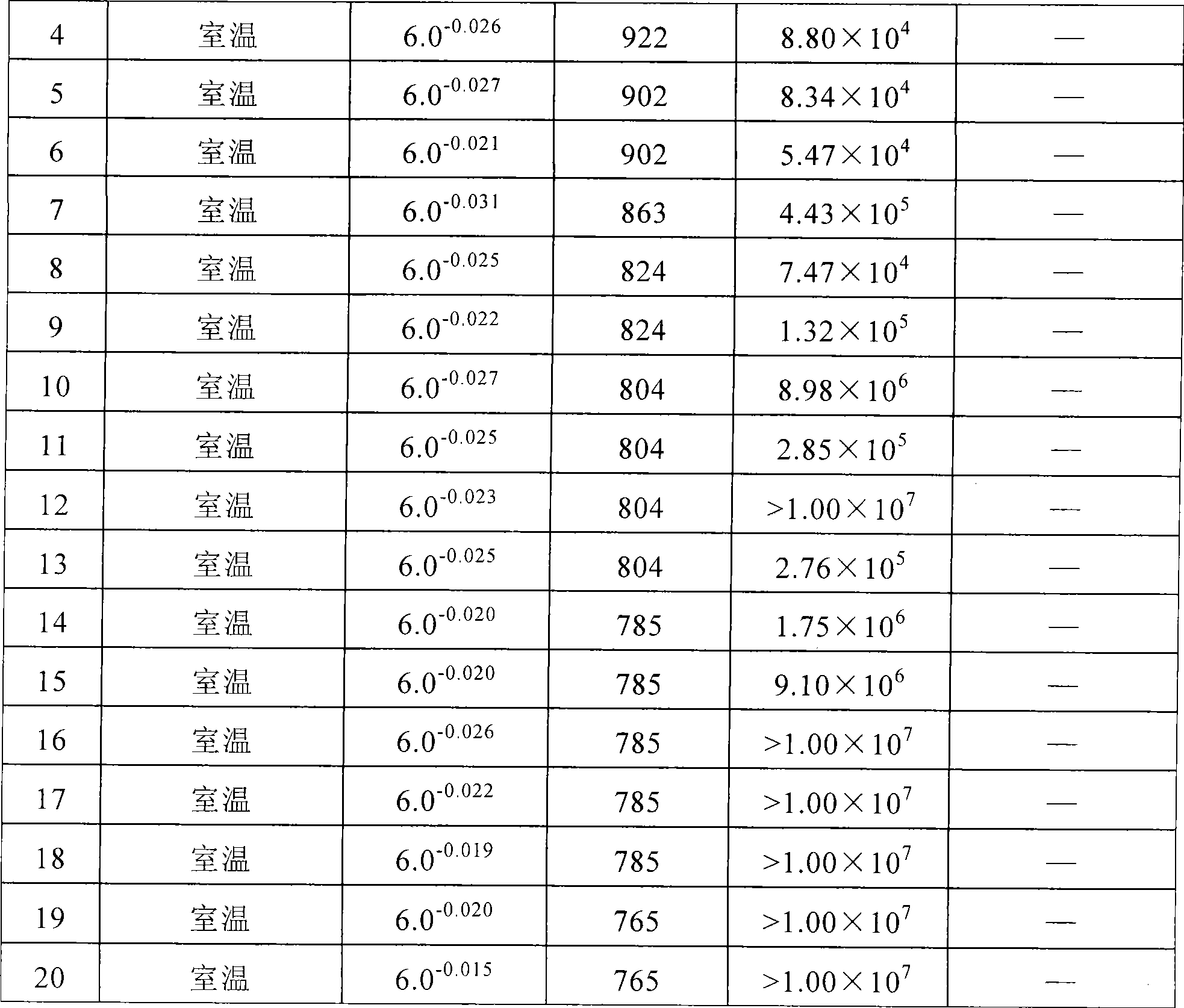

InactiveCN102162068AStrong cold forming abilityReduce processTemperature control deviceProcess efficiency improvementShrinkage rateSpring steel

The invention discloses a spring steel, which comprises the following components in percentage by mass: 0.3 to 0.5 percent of C, 1.0 to 2.5 percent of Si, 0.3 to 1.5 percent of Mn, 0.1 to 1.0 percent of Cr, 0.01 to 0.30 percent of Ni, less than or equal to 0.15 percent of Cu, less than or equal to 0.010 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities, wherein the spring steel can be manufactured into high-speed railway rail buckles by a processing method of cold forming. The invention also discloses a manufacturing and thermal treatment method of the spring steel. By the method, the yield strength (Rm) of the spring steel is more than or equal to 1,000MPa, the tensile strength (Rp0.2) is more than or equal to 1,200MPa, the elongationrate (A) is more than or equal to 6 percent, the section shrinkage rate (Z) is more than or equal to 30 percent, and the buckle requirements of high-speed railway rails are met.

Owner:宝钢特钢有限公司

High-strength corrosion-resistant spring steel and manufacturing method thereof

ActiveCN105886930AGood resistance to corrosion and crackingImprove toughness and plasticityChemical elementSpring steel

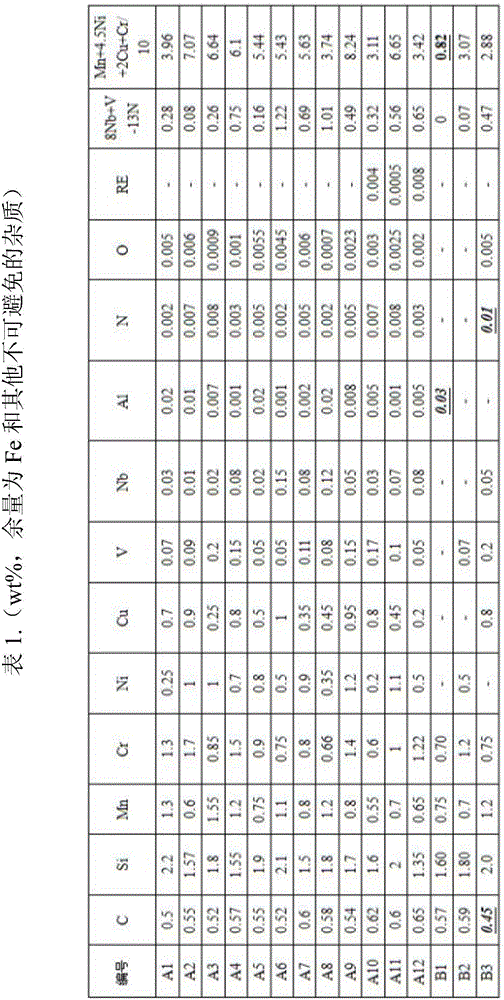

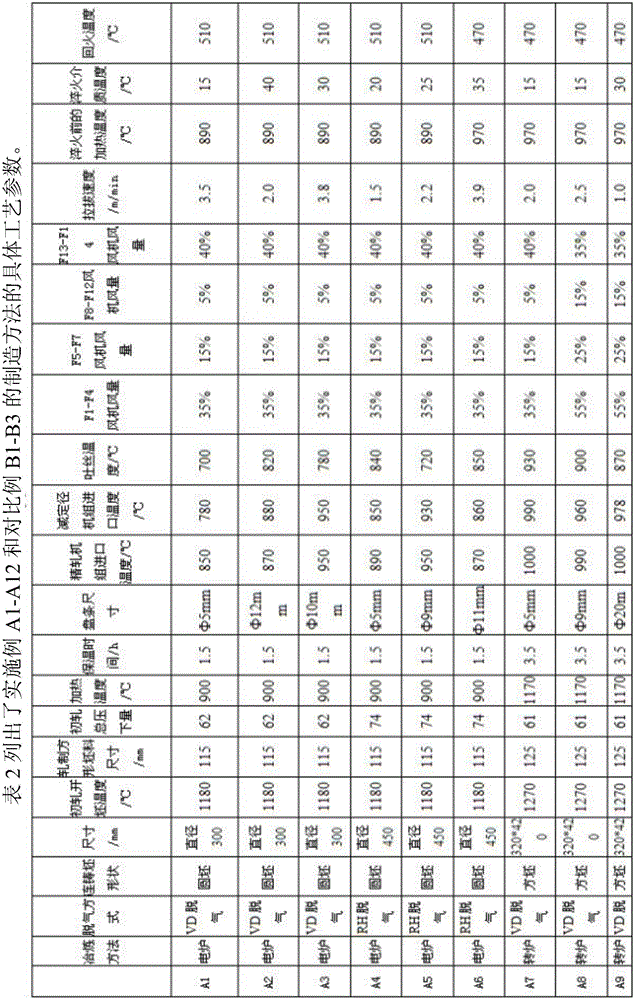

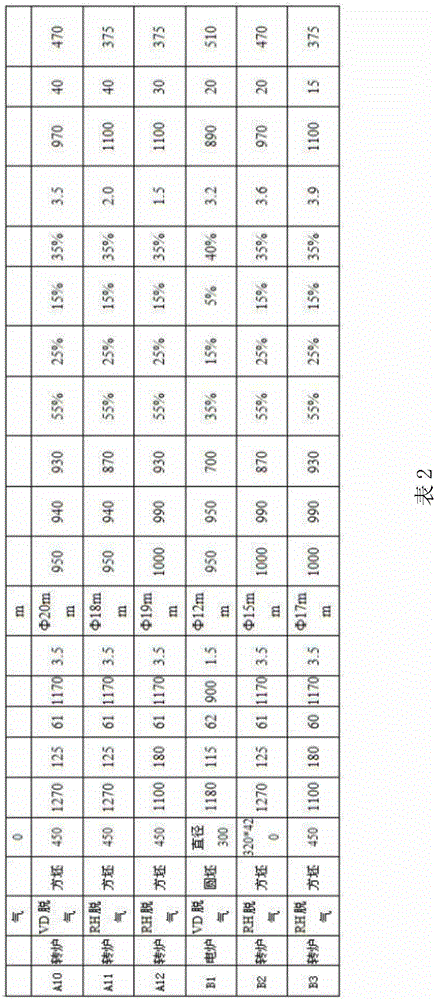

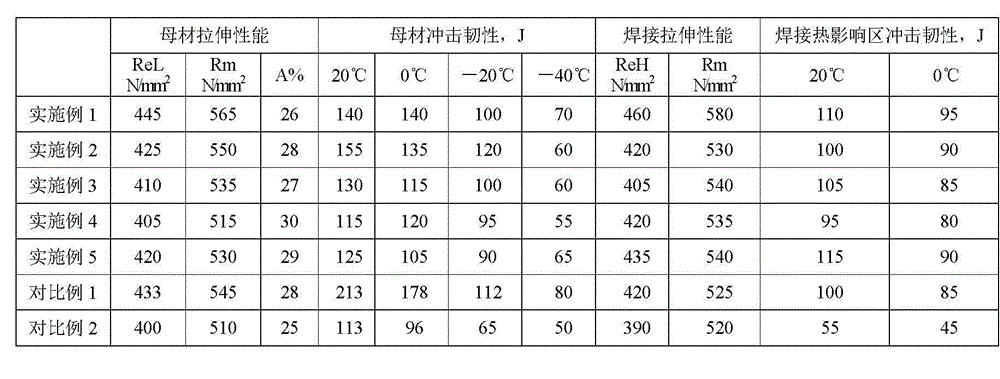

The invention discloses high-strength corrosion-resistant spring steel. The high-strength corrosion-resistant spring steel is manufactured from the following chemical elements in percentage by weight: 0.50-0.65% of C, 1.35-2.20% of Si, 0.55-1.55% of Mn, 0.60-1.70% of Cr, 0.20-1.2% of Ni, 0.20-1.0% of Cu, 0.05-0.20% of V, 0.01-0.15% of Nb, 0.001-0.020% of Al, 0.002-0.008% of N, 0.0007-0.006% of O, and the balance being Fe and other inevitable impurities. Accordingly, the invention further provides a manufacturing method of the high-strength corrosion-resistant spring steel. The tensile strength of the high-strength corrosion-resistant spring steel disclosed by the invention can reach 2000MPa or above, and besides, the high-strength corrosion-resistant spring steel has good corrosion resistant property and fracture resistant property, so that development requirements of automobile trade can be met.

Owner:BAOSHAN IRON & STEEL CO LTD

390MPa-grade low-cost hot rolling structural steel plate and manufacture method thereof

The invention provides a 390MPa-grade low-cost hot rolling structural steel plate and a manufacture method of the 390MPa-grade low-cost hot rolling structural steel plate. The 390MPa-grade low-cost hot rolling structural steel plate is prepared from the following components in percentage by weight: 0.15 to 0.20% of C, 0.05 to 0.20% of Si, 0.1 to 0.5% of Mn, 0.0005 to 0.004% of B, not greater than 0.0060% of N, 0.02 to 0.05% of Al, 0.015 to 0.025% of Ti, 0.0025 to 0.0060% of Ca, 0.12 to 0.2% of Ca / Al, and the balance of Fe. The manufacture method comprises steps as follows: melting by a converter; refining outside the converter; continuously casting; and rolling; Al is added to remove oxygen during refining, and Ti is added for fixing nitrogen, so that O is not greater than 0.002%, and N is not greater than 0.006%; boron is added for alloying before ending the refining, and an Si-Ca line is fed; a temperature in hot-charging of a continuous casting blank is more than 840 DEG C; a slab blank is processed by heating to reach the temperature of 1100 to 1180 DEG C, maintaining the temperature for 2 to 3 hours, roughly rolling at the temperature of 1020 to 1100 DEG C, wherein an intermediate blank / finished product is in thickness of 5; refining at the temperature of 950 to 1000 DEG C, wherein accumulation deformation is more than 50%; finally rolling at the temperature of 850 to 900 DEG C, cooling to reach the temperature of 500 to 600 DEG C at 6 to 20 DEG C per second after rolling, and coiling, and then cooling by air. The manufacture method is simple in technology and low in cost; and the product is high in toughness and plasticity and high in welding performance.

Owner:ANGANG STEEL CO LTD

Method for producing thin-specification and high-strength atmosphere corrosion resistance structural steel plate

InactiveCN105256246AHigh strengthImprove toughness and plasticityLaminar coolingUltimate tensile strength

The invention discloses a method for producing a thin-specification and high-strength atmosphere corrosion resistance structural steel plate. The heating temperature of a continuous casting before rolling ranges from 1,150 DEG C to 1,250 DEG C; the finishing temperature of rough rolling ranges from 1,020 DEG C to 1,080 DEG C, and the accumulated rolling reduction of rough rolling is larger than or equal to 60%; the thickness of a hold-temperature blank is larger than or equal to 3.0 h, the fine rolling finishing temperature is larger than or equal to 830 DEG C, and the reduction rate of fine rolling tail pass is smaller than or equal to 12.5%; after fine rolling is finished, high-speed steel throwing is carried out, the steel throwing speed is 4 m / s, and it is guaranteed that the water entry temperature of a rolled piece is larger than or equal to 770 DEG C; and laminar cooling is carried out, the finished cooling temperature ranges from 550 DEG C to 650 DEG C, and the cooling speed ranges from 5 DEG C / s to 30 DEG C / s. The steel is delivered in the hot rolling state; and by means of the low-carbon and alloy components, it is guaranteed that the atmosphere corrosion resistance index I of the steel is larger than or equal to 6.5, the yield strength of the steel is larger than or equal to 450 MPa, the tensile strength of the steel is larger than or equal to 550 MPa, the yield ratio of the steel is smaller than or equal to 0.85, the ductility of the steel is larger than or equal to 20%, and the ballistic work of the steel at the temperature being minus 60 DEG C is larger than or equal to 100 J.

Owner:NANJING IRON & STEEL CO LTD

Heat treatment method for down-the-hole drill bit of high-wind pressure drilling tool, and drill bit

ActiveCN102703911AImprove toughness and plasticityHigh surface hardnessSolid state diffusion coatingFurnace typesNumerical controlHardness

The invention relates to a heat treatment method for a down-the-hole drill bit of a high-wind pressure drilling tool. The method comprises the following steps: heating the original down-the-hole drill bit to 750-850 DEG C for forging and beating, forming and die forging, conducting air cooling after heating at 900-950 DEG C for four hours to five hours, conducting furnace cooling to be lower than 200 DEG C after heating at 650-700 DEG C for four hours to five hours, carrying out numerical control machining according to size requirement, conducting carburization treatment at 900-950 DEG C, then conducting high-temperature tempering to the carburization treatment, machining, and conducting isothermal quenching at 850-900 DEG C. The invention further relates to a down-the-hole drill bit of the high-wind pressure drilling tool, which is manufactured by the heat treatment method. The down-the-hole drill bit is subjected to mechanical treatment after being heated and cooled for many times, so that the toughness and plasticity of the down-the-hole drill bit can be greatly improved, the surface hardness and compression stress of the down-the-hole drill bit can also be enhanced, and the fatigue resistance strength and the wear resistance of threads can be improved.

Owner:CHANGSHA HEIJINGANG IND CO LTD

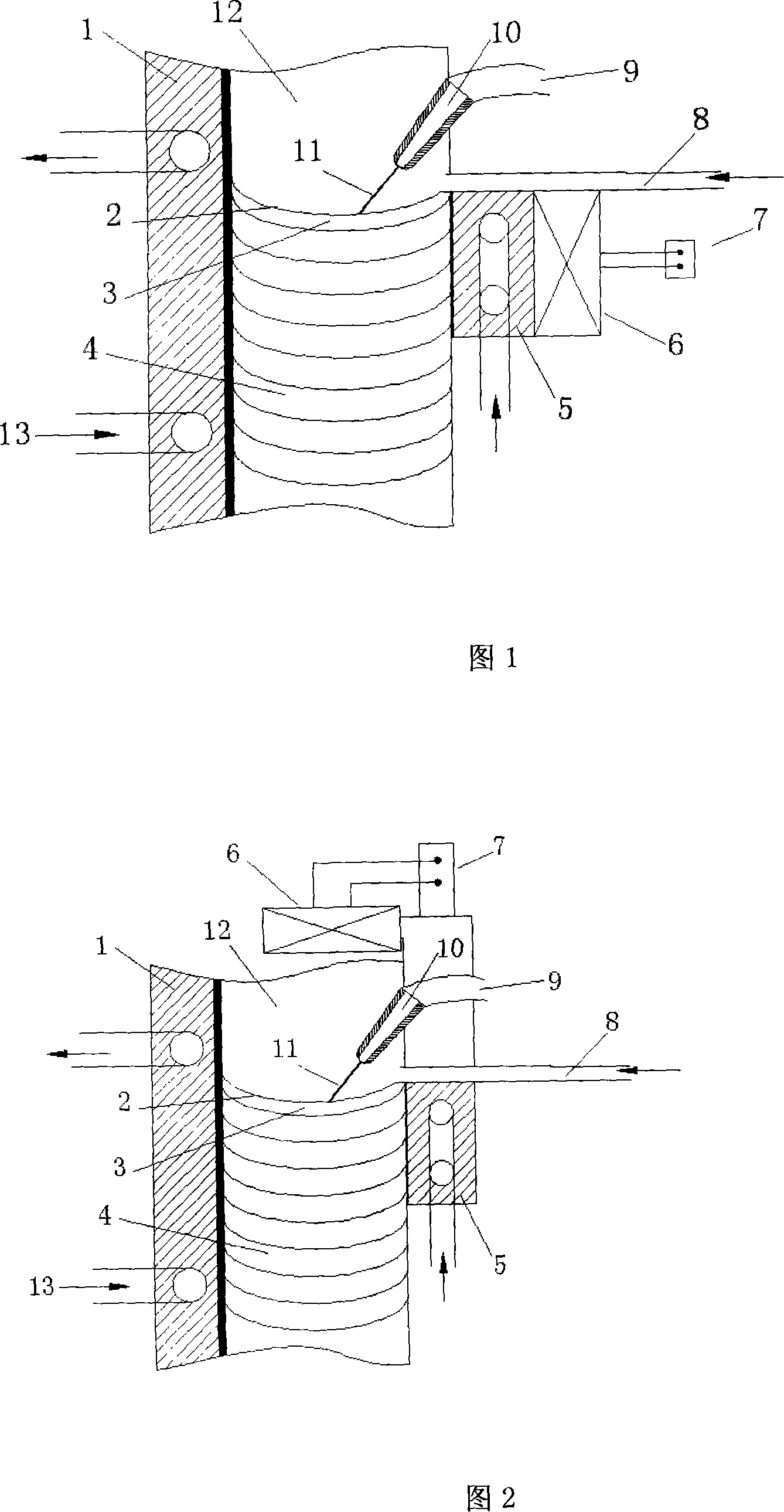

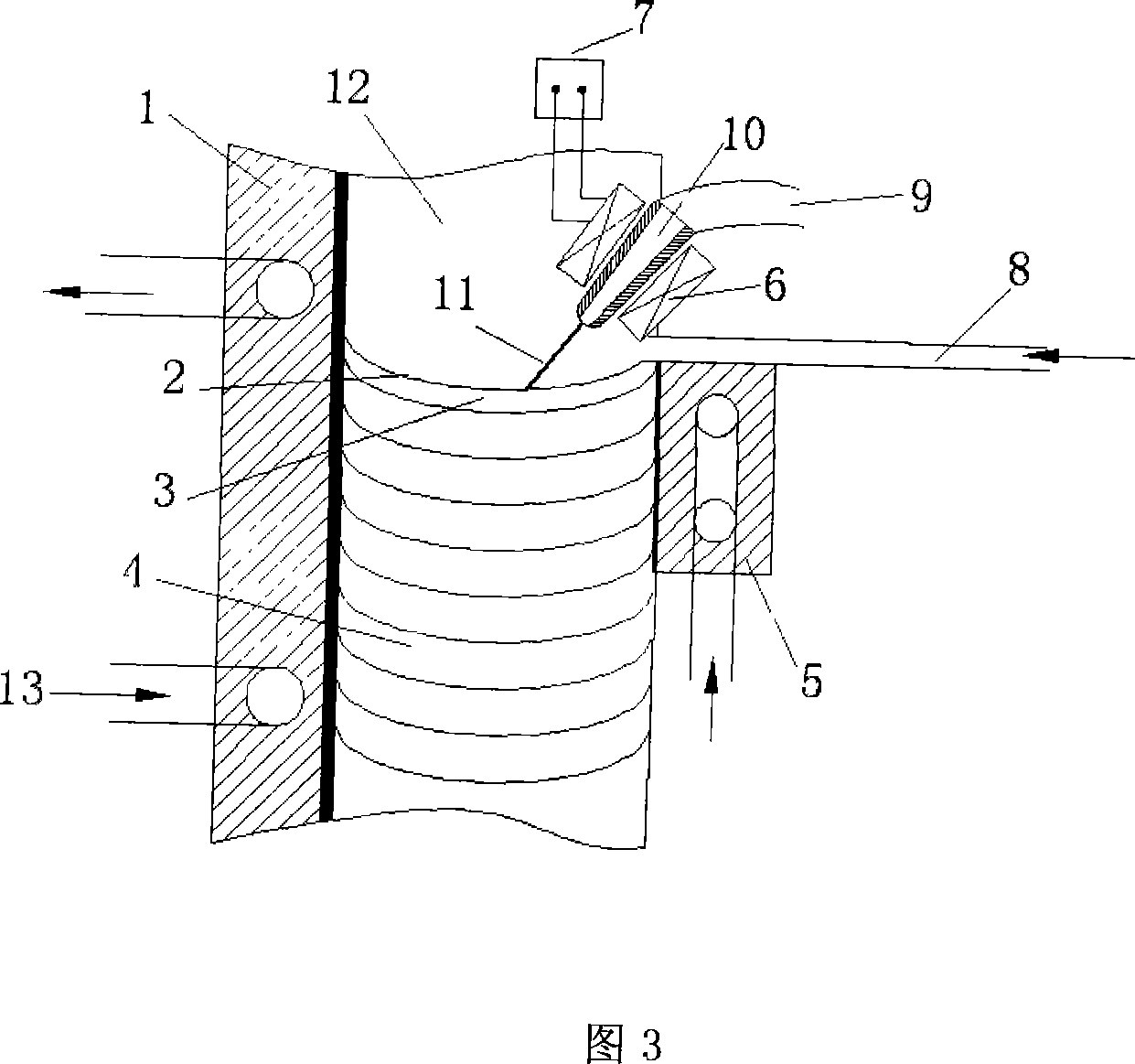

Electromagnetic control electro-gas welding method and equipment thereof

InactiveCN101172312AStir wellImprove crystallizationArc welding apparatusEngineeringElectromagnetic shielding

The invention relates to an electromagnetically controlled gas-electric vertical welding (EMS-EGW) method, which is to set an external magnetic field above or / and near the side of the gas-electric vertical welding (EGW) molten pool (3), such as an excitation coil that provides an excitation current by an excitation power supply , produce time-varying or constant electromagnetic stirring and external magnetic field to produce electromagnetic stirring effect; the electromagnetic field promotes the forced movement of the metal fluid in the gas-electric vertical welding pool, and comprehensively controls the solidification process of the weld metal. With the cooperation of gas protection, the method of electromagnetically controlled gas-electric vertical welding (EMS-EGW) is realized on the workpiece. The electromagnetic control gas-electric vertical welding (EMS-EGW) device of the present invention adds excitation equipment on the existing basis, and the excitation equipment is composed of an excitation coil and an excitation power supply that provides excitation current for the excitation coil. The invention breaks through the traditional gas-electric vertical welding method, and provides a new idea for improving gas-electric vertical welding; reduces welding defects, reduces welding costs, improves welding quality and production efficiency, and ensures product reliability; The appearance is well formed; the equipment is simple and easy to popularize and apply.

Owner:CHONGQING UNIV

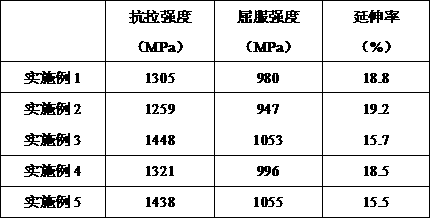

Process for producing super high carbon steel

The super high carbon steel has the alloy composition of: C 1.0-1.8 wt%, Si 0.5-3.0 wt%, Cr 0.5-2.0 wt% and Mn 0.2-0.7 wt% except Fe. The jet formed super high carbon steel is produced through one deformation and heat treatment combining production process, in which, the jet formed super high carbon steel is maintained inside furnace at 1000 deg.c before taking out for rolling in the single gate reducing degree of 60 %, and the rolled steel is set quickly into heat treatment furnace already reaching the required heat treating temperature and maintained for 150 min before being taken out. The super high carbon steel obtained through the combined production process has special metallurgical structure with pearlite and nodulized structure in proper ratio, tensile strength as high as 1300 MPa, and specific elongation of 18.5 %. The present invention has simple technological process, low power consumption and low production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

High-performance stainless steel surfacing nickel-based special welding wire and preparation method thereof

InactiveCN108406164AHigh tensile strengthImprove intergranular corrosion resistanceWelding/cutting media/materialsSoldering mediaRare-earth elementCrack resistance

The invention belongs to the field of welding materials and particularly relates to a high-performance stainless steel surfacing nickel-based special welding wire and a preparation method thereof. Thewelding wire comprises chemical elements including, by mass, not greater than 0.04% of C, 0.1-0.5% of Mn, not greater than 0.001% of P, not greater than 0.001% of S, 0.05-0.1% of Si, 20-25% of Cr, 8-12% of Mo, 2-6% of Nb, 0.2-0.5% of Ti, not greater than 0.001% of Cu, 0.1-0.3% of Al, not greater than 1% of Fe, 0.03-0.08% of Co, 0.05-0.1% of the rare earth element RE, 30-80 ppm of N and the balance Ni and inevitable impurity elements. The preparation method comprises the steps of (1) vacuum electric-furnace smelting; (2) VOD external refining; (3) horizontal continuous casting; (4) tandem rolling; and (5) tandem drawing. The welding wire provided by the invention has the good properties of active gas resistance and reducing acid medium corrosion resistance, the electric arc stability and slag stripping performance are excellent during welding, and welding metal with high strength, good tenacity, flaw resistance, high temperature cracking resistance and corrosion resistance is obtained;and the preparation technology is simple, the raw material and manufacturing cost is low, environmental friendliness is achieved, no pollution is generated, and the welding wire and the preparation method are suitable for industrial volume production and remarkable in economic benefit.

Owner:DANYANG HUALONG SUPERIOR STEEL

Manufacture technology for improving toughness of non-quenched and tempered steel forging

InactiveCN102586558AImprove toughness and plasticityImprove impact toughnessManufacturing technologyRoom temperature

The invenmtion relates to a manufacture technology of a forging, in particular to a manufacture technology for improving the toughness of a non-quenched and tempered steel forging, which comprises the following working procedures of: blanking-induction heating-dummying-finish forging-trimming-controlled cooling-cooling in heap in a charging box-shot blasting-magnetically inspecting-machining; the working procedure of controlled cooling comprises the following steps of: trimming workpieces, immediately arranging the workpieces on a transmission band which moves at a certain speed in a dispersing way, and under the cooling condition of compulsory aerating or water mist spraying, cooling the workpieces to some temperature within 520 DEG C-650 DEG C at the cooling speed of 2.0 DEG C / s-50.0 DEG C / s, and then cooling the workpieces in heap in the charging box; and the working procedure of cooling in heap in the charging box comprises the following step of slowly cooling the workpieces to room temperature at the cooling speed which is less than 5 DEG C / min. According to the manufacture technology, the precipitation of an eutectoid ferrite at an original austenitic crystal boundary in the form of net and the appearance of the bainite tissue can be eliminated or avoided, more intra-granular ferrite can be obtained, and the toughness and the plasticity of parts can be improved.

Owner:NANJING INST OF TECH +1

Wear-resistant composite material with ceramic embedded in rubber and preparation method thereof

InactiveCN101806388AImprove toughness and plasticityHigh hardnessSheets/panelsFastening meansRubber materialVulcanization

The invention discloses a wear-resistant composite material with ceramic embedded in rubber and a preparation method thereof. The wear-resistant composite material comprises a rubber substrate, the rubber substrate is provided with a plurality of blind holes, wear-resistant ceramic blocks with the sizes matched with the sizes of the blind holes are embedded in the blind holes, and the rubber substrate and the wear-resistant ceramic blocks are tightly matched with each other or bonded with each other. During rubber vulcanization, the pre-treated wear-resistant ceramic blocks are embedded in the rubber, and the rubber and the wear-resistant ceramic blocks are tightly matched with each other or bonded with each other. The composite material of the invention not only has the advantages of the rubber material such as good plasticity and impact resistance, but also has the advantages that the ceramic material has high hardness and excellent wear resistance. Therefore, the composite material can bear the working condition with large impact loads, and overcomes the defect that the highly wear-resistant ceramic material has no impact resistance.

Owner:SHANDONG UNIV

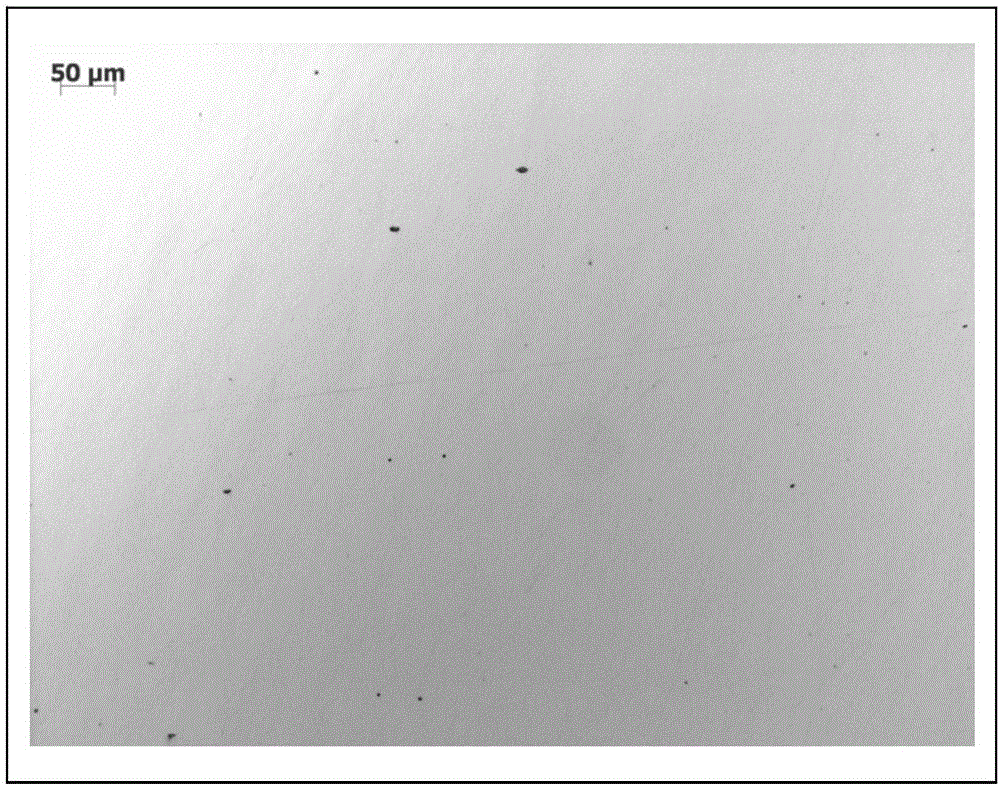

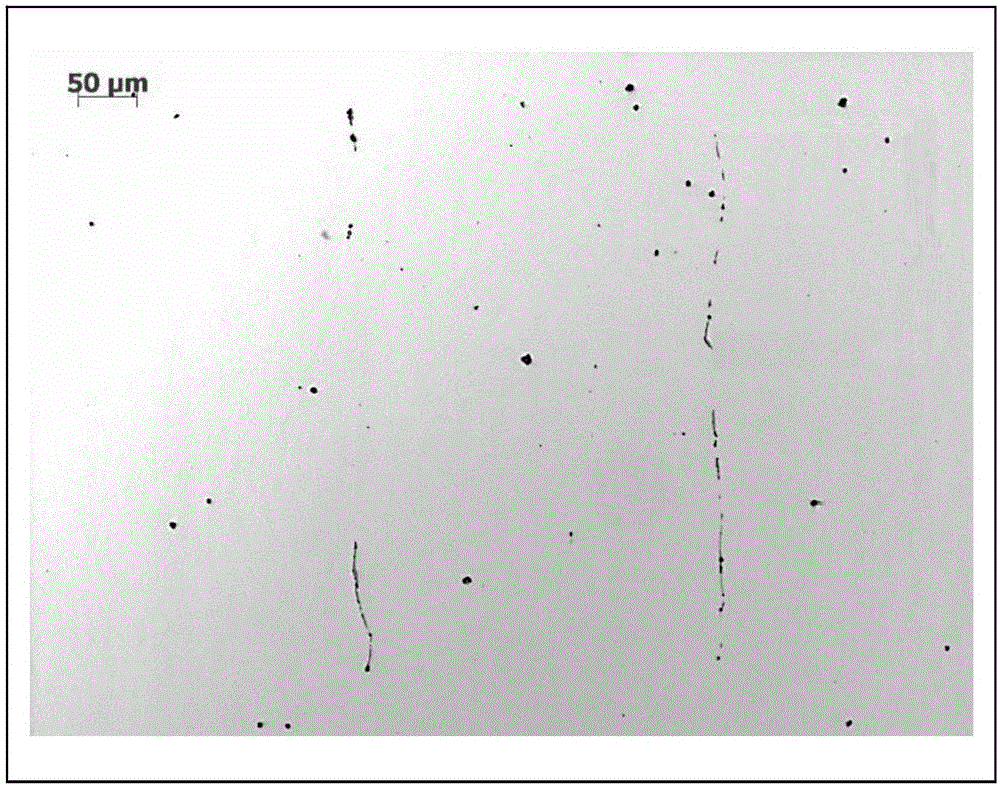

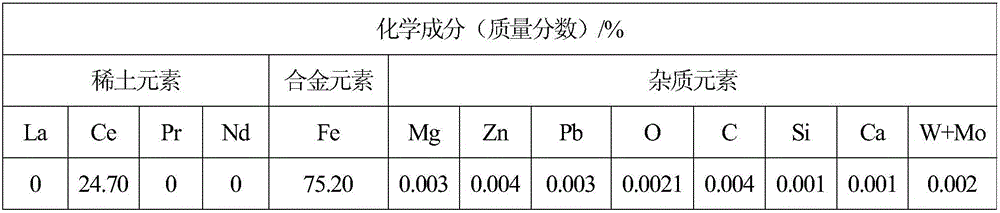

Extra-low oxygen rare earth alloy and use

InactiveCN106636880AImprove performanceSpecial chemical compositionGas emission reductionMetallic materialsCerium

The invention relates to the technical field of the sound metal material manufacture and in particular to extra-low oxygen rare earth alloy and use. The rare earth metal content is 5%-95%, and the oxygen content O is less than or equal to 0.010% (weight percentage). The rare earth metal in the rare earth alloy is the single metal of lanthanum, cerium, praseodymium and neodymium or an arbitrarily-proportional mixture of more than two metals. The rare earth alloy is a metal mixture of the rare earth metal with one or more of iron, silicon, magnesium and aluminum. The extra-low oxygen rare earth alloy is capable of providing an additive to sound metal materials of equipment manufacture, such as steel, aluminum, magnesium alloy, and magnet, stably improving the performance of the metal material for equipment manufacture, and avoiding the negative effects of the rare earth additive generated in the materials, such as large occluded foreign substance and deterioration performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Layered Ti-Ni shape memory composite material and preparation method thereof

ActiveCN105058914AHigh specific strengthImprove toughness and plasticityMetal rolling arrangementsMetal layered productsBiocompatibility TestingTitanium

The invention discloses a layered Ti-Ni shape memory composite material and a preparation method thereof and belongs to the technical field of preparation of functional composite materials. Pure titanium and pure nickel are used as initial raw materials, a titanium plate and a nickel plate are subjected to surface pretreatment, accumulative composite rolling and diffusion annealing, controlled cooling is adopted, and the multi-phase and multi-layer structure shape memory composite material with a Ti layer serving as the outmost layer and a Ti-Ni layer and an Ni layer coated with the Ti layer is prepared. The shape memory composite material prepared with the method has the characteristics that the material is high in specific strength, good in plasticity and toughness, high in fatigue strength, high in interface bonding, excellent in conductivity, free of magnesium and toxicity, high in corrosion resistance, good in biocompatibility and the like. The preparation method has the advantages of simple process and convenience in operation.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

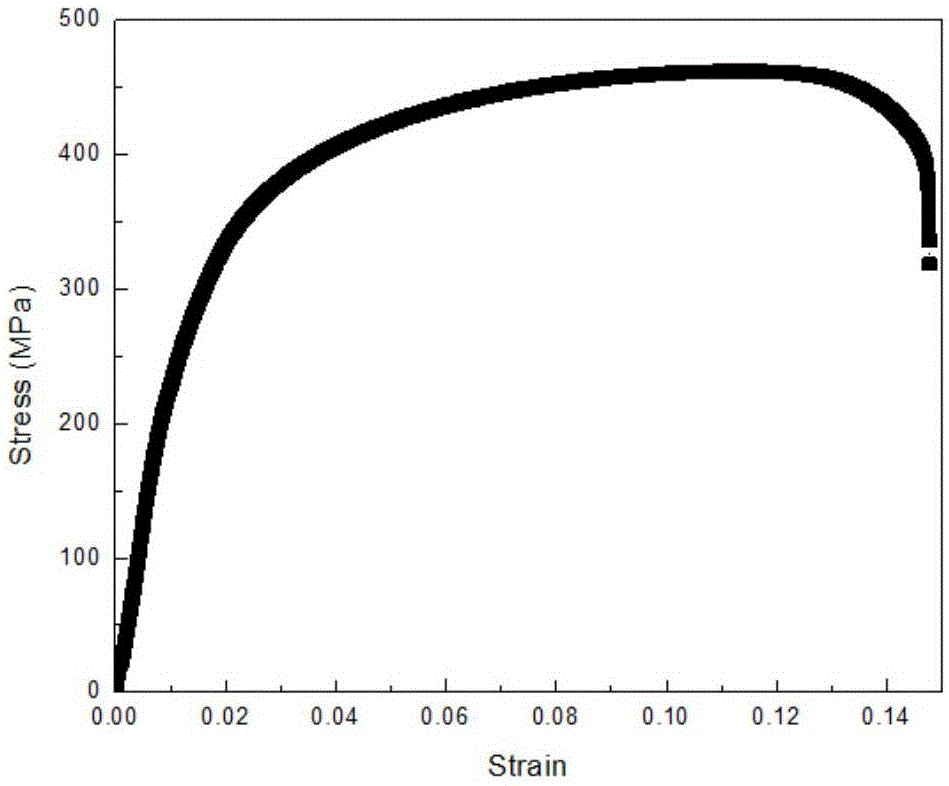

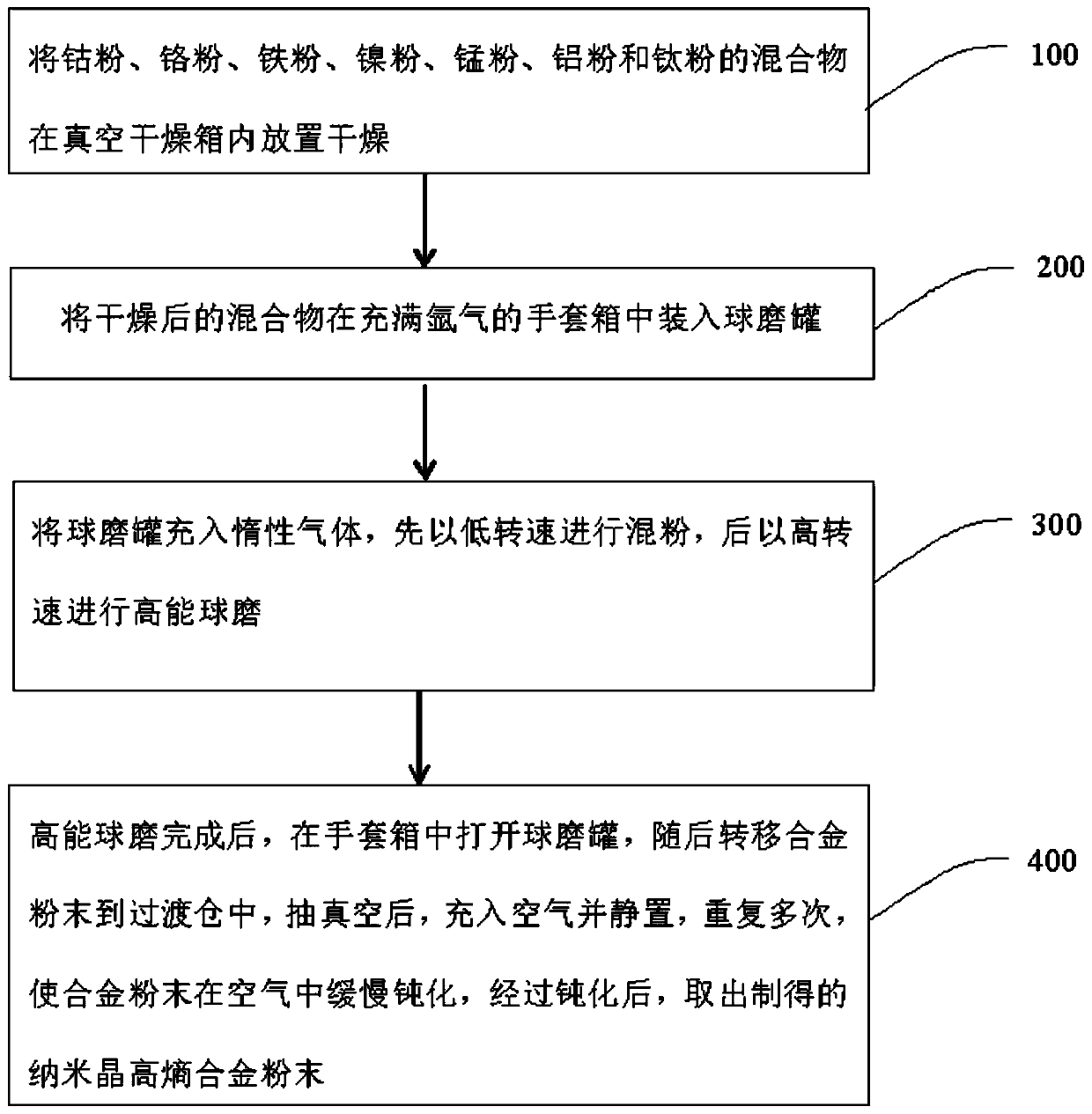

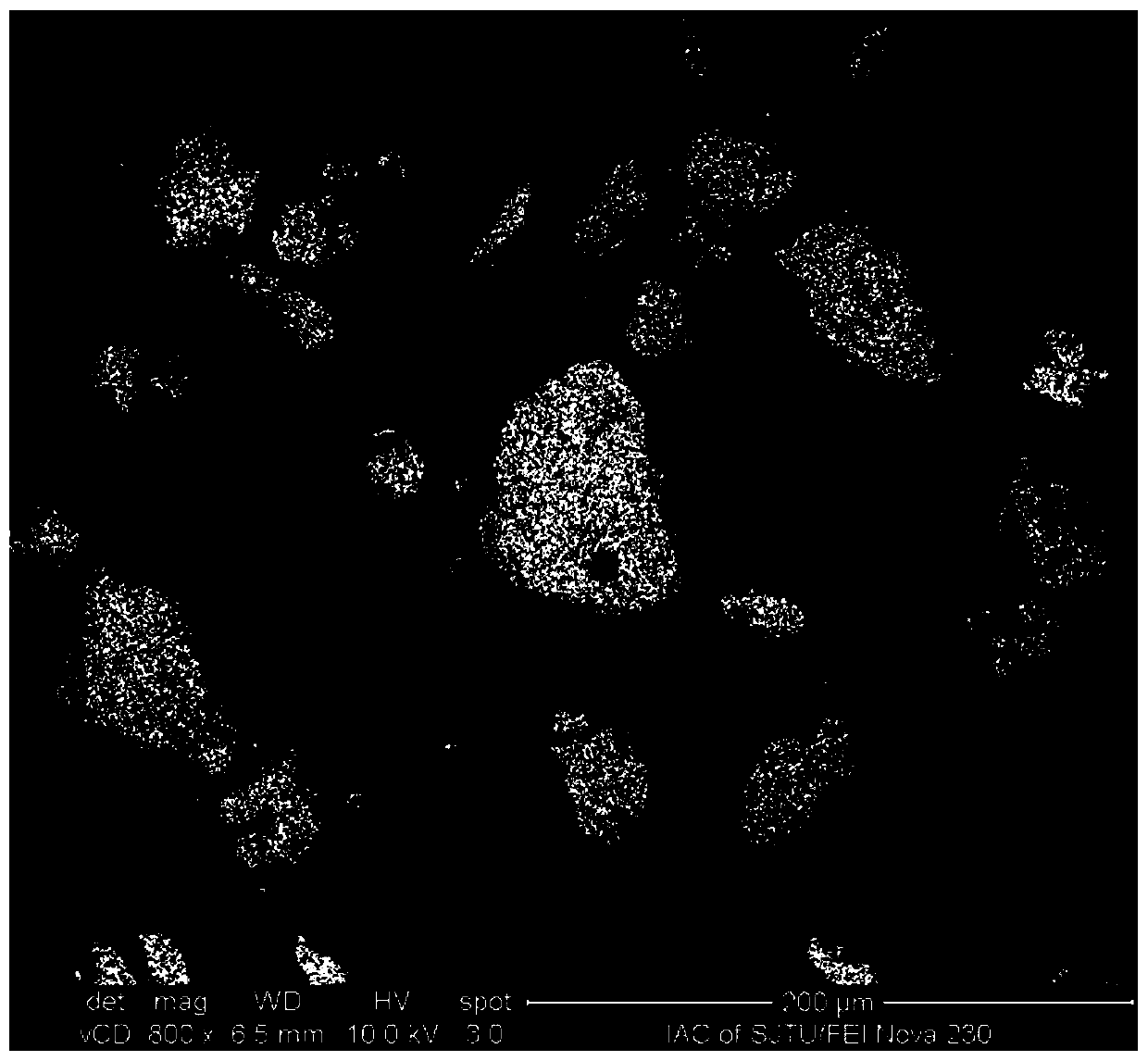

Nanocrystalline high-entropy alloy powder and preparation method thereof

InactiveCN110576185AOvercome high energy consumptionLower the activation energy of the reactionHigh entropy alloysPowder metallurgy

The invention discloses nanocrystalline high-entropy alloy powder and a preparation method thereof, and relates to the technical field of powder metallurgy. The invention involves the nanocrystallinehigh-entropy alloy powder and the preparation method of the nanocrystalline high-entropy alloy powder, wherein the nanocrystalline high-entropy alloy powder comprises cobalt powder, chromium powder, iron powder, nickel powder, manganese powder, aluminum powder and titanium powder; and the metal element powder is directly mixed through a high-energy mechanical ball milling method by the preparationmethod of the nanocrystalline high-entropy alloy powder, and the nanocrystalline high-entropy alloy powder is prepared according to the specific steps. According to the nanocrystalline high-entropy alloy powder and the preparation method, through high-speed impact and grinding of grinding medium, reaction activation energy is reduced, powder activity is improved, solid diffusion among element powder is promoted, low-temperature chemical reaction is induced, and finally, the alloy powder with uniform composition and structure distribution is obtained, so that the problems of element volatilization and non-uniform components of the powdering after smelting is conducted are solved. The technical is simple in equipment, the procedure is simplified compared with a traditional method, the manufacturing cost is reduced, and the nanocrystalline high-entropy alloy powder powder the preparation method thereof are suitable for industrial large-scale preparation.

Owner:SHANGHAI JIAO TONG UNIV

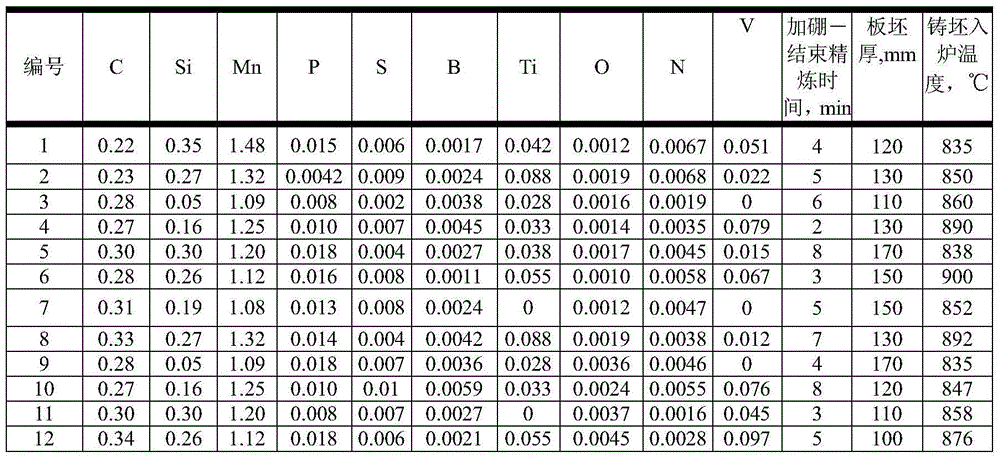

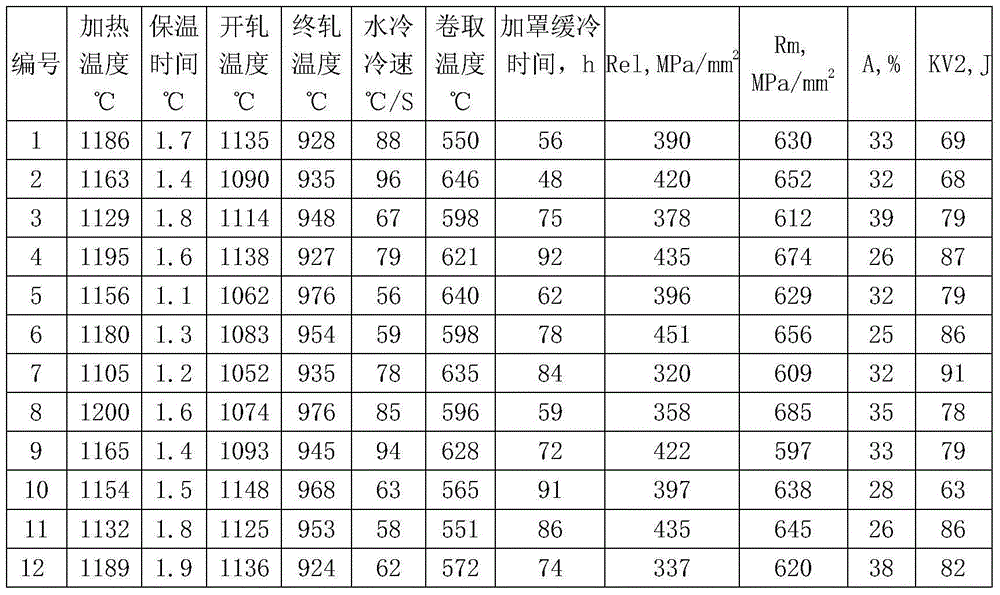

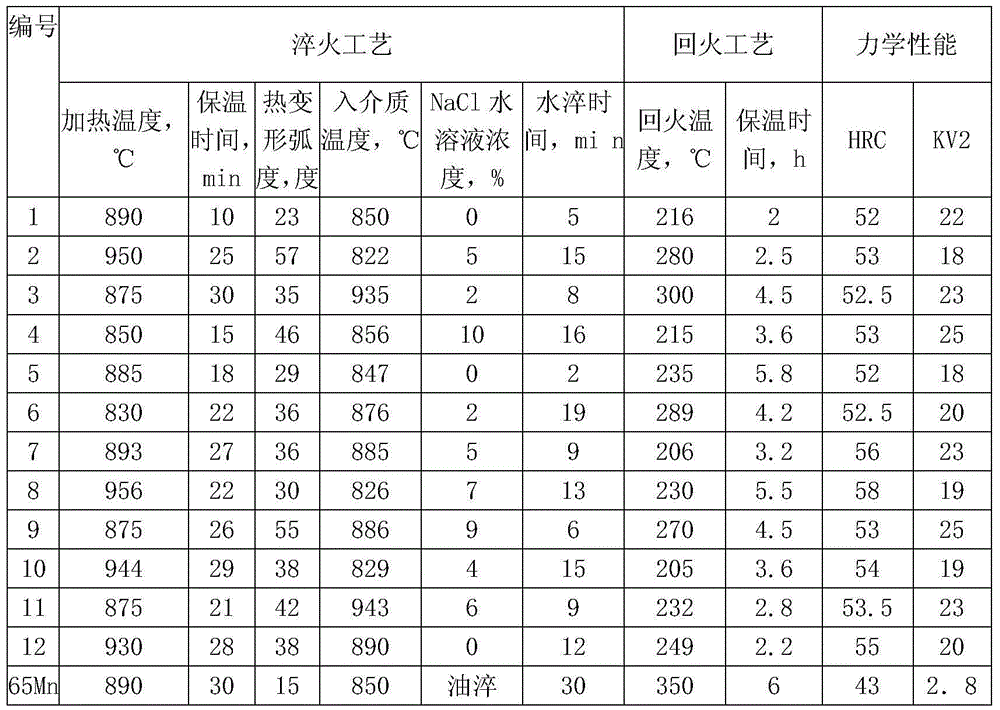

Hot-rolling strip-steel harrow disk suitable for water quenching and manufacture method thereof

ActiveCN105274431AReduce pollutionImprove toughness and plasticityFurnace typesQuenching agentsChemical compositionHardness

The invention discloses a hot-rolling strip-steel harrow disk suitable for water quenching and a manufacture method thereof. The harrow disk comprises the following chemical compositions in percent by weight: 0.22%-0.34% of C, 0.1%-0.40% of Si, 1.0%-1.5% of Mn, 0.0070% or less of N, 0.1% or less of Ti, 0.001 %-0.006 % of B, 0.1 % or less of V, 0.020% or less of impurity element P, 0.010% or less of impurity element S, and the balance Fe and unavoidable impurities. The technology comprises a hot-rolling strip steel production technology and a harrow-disk heat treatment technology. The whole technology comprises smelting by a converter, refining by an electric furnace, continuously casting and rolling a slab and performing ultra-rapid cooling, slowly cooling after reeling, performing stamping forming on the harrow disk, quenching, and annealing. The harrow disk is reduced in C and Mn composition content, and thus the steel can be subjected to water quenching, and after water quenching, the textile is fine M. After heat treatment, the hardness reaches 52 HRC or more, the impact energy reaches 18 J or more, the wear resistance and the toughness and plasticity are excellent, the service life is obviously higher than that of a 65Mn-mateiral harrow disk. Also, the water quenching technology is small in environment pollution and accords with environment protection requirement.

Owner:ANGANG STEEL CO LTD

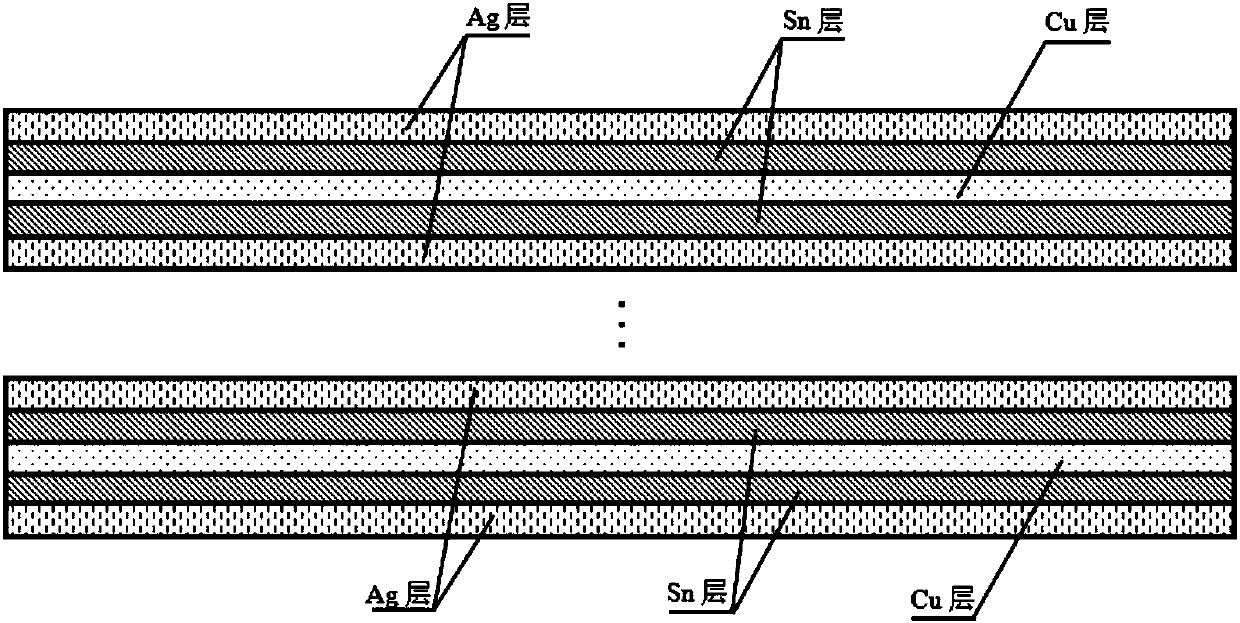

Ag-based composite brazing foil and preparing method thereof

ActiveCN107695559AImprove toughness and plasticityEnergy saving and environmental protection in the preparation processWelding/cutting media/materialsSoldering mediaPre compressionCopper

The invention discloses Ag-based composite brazing foil and a preparing method thereof, which is used for brazing electric vacuum components. The thickness of the Ag-based composite brazing foil is 0.05-1mm, the Sn content is 19-21%, the Cu content is 21-23%, and the rest is Ag. The preparing method of the Ag-based composite brazing foil comprises the following steps: orderly stacking Ag layers, Cu layers and Sn layers which are the same in size and 0.05-0.5mm in thickness according to the structure mode of Ag / Sn / Cu / Sn / Ag / ... / Ag / Sn / Cu / Sn / Ag; making an Ag-Cu-Sn multi-layer composite blank of which the total layer number is 5-30 through pre-compression; then carrying out rolling to make Ag-Cu-Sn foil of which the thickness is 0.05-1mm; and after the following heat treatment, obtaining the Ag-based composite brazing foil. The prepared foil product has great tenacity and ductility, can be made into various sizes of premolding soldering lugs through cold blanking, and has great wetting property and welding property on base materials, such as copper, nickel, high-temperature alloy and kovar alloy.

Owner:SINO PLATINUM METALS CO LTD

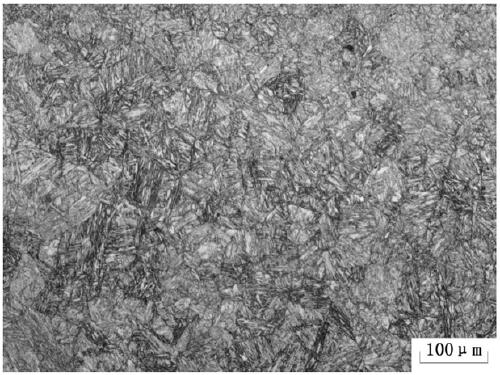

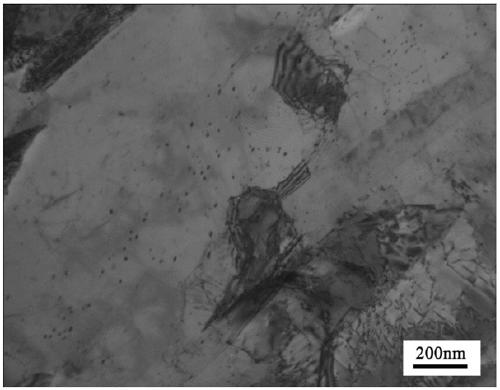

High-toughness anti-fatigue nano precipitation enhancing martensite-austenite multiphase steel and preparation method thereof

ActiveCN109609848AImprove hardenabilityImprove toughness and plasticityCorrosion resistant alloyChemical composition

The invention discloses high-toughness anti-fatigue nano precipitation enhancing martensite-austenite multiphase steel and a preparation method thereof, and belongs to the technical field of alloy steel. The martensite-austenite stainless steel comprises chemical components of, by mass percentage, 0.06-0.20% of C, 0.05 -0.20% of Si, less than or equal to 0.01% of P, less than or equal to 0.01% ofS, 2.50 -5.00% of Mn, less than or equal to 1.00% of Cu, less than or equal to 2.00% of Ni, 0.20-0.50% of Mo, 1.00-1.50% of Cr, 0.10-0.80% of V, and the balance Fe and inevitable impurities. The microstructure structure of the steel comprises tempered martensite, reverted austenite and nano-sized vanadium carbide precipitate attached to the tempered martensite. The preparation method comprises thefollowing steps of smelting and secondary refining to obtain a casting blank in the design range of target components, and forging, hot rolling and thermal refining to obtain the martensite-austenitic multiphase steel. In a martensite-austenite multiphase steel plate, the toughening and anti-fatigue effect of the martensite-austenite and the strengthening effect of a large amount of nano precipitation phase are utilized to achieve high-strength and toughness matching of the steel, and the corrosion resistance of material is greatly improved by combining with the corrosion-resistant alloy design.

Owner:CENT IRON & STEEL RES INST

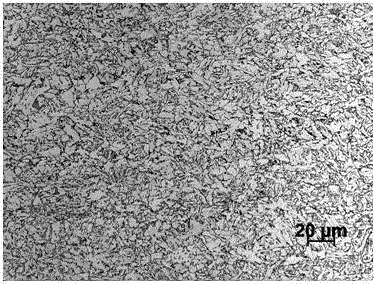

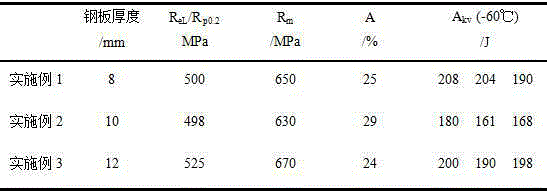

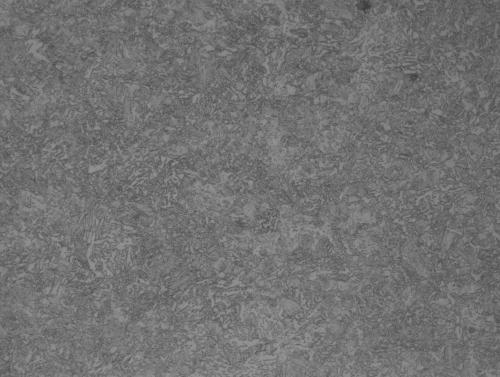

Low-yield-ratio high-intensity hardened and tempered steel for coal mine hydraulic support frame and manufacturing method of low-yield-ratio high-intensity hardened and tempered steel

ActiveCN109266812ALow yield ratioHigh strengthFurnace typesMetal rolling arrangementsHigh intensityQuenching

The invention provides low-yield-ratio high-intensity hardened and tempered steel for a coal mine hydraulic support frame. The hardened and tempered steel is prepared from the following raw materialsin percentage by weight: 0.10 to 0.14 percent of C, 1.35 to 1.50 percent of Mn, 0.10 to 0.40 percent of Si, less than or equal to 0.015 percent of S, less than or equal to 0.020 percent of P, 0.015 to0.030 percent of Nb, 0.20 to 0.30 percent of Mo, 0.30 to 0.40 percent of Cr, 0.020 to 0.040 percent of Al, less than or equal to 0.0050 percent of N, 0.0010 to 0.0020 percent of B and the balance ofFe and unavoidable impurities. Meanwhile, the invention also discloses a manufacturing method of the low-yield-ratio high-intensity hardened and tempered steel for the coal mine hydraulic support frame. The method comprises the steps of top and bottom combined blown converter treatment, LF refining, VD degassing, wide plate blank continuous casting, furnace roll mill rolling, two-phase interval quenching, and tempering. The hardened and tempered steel has a low yield ratio and can be applied to the coal mine hydraulic support frame industry.

Owner:ANYANG IRON & STEEL

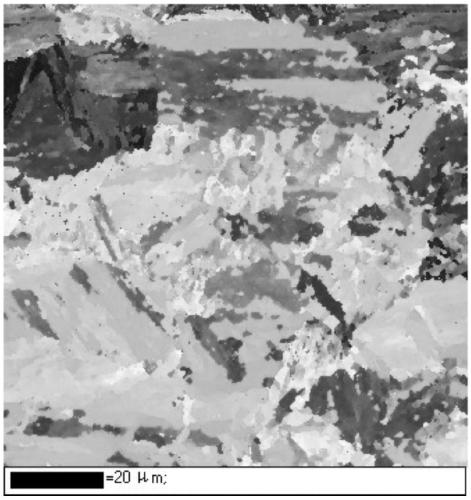

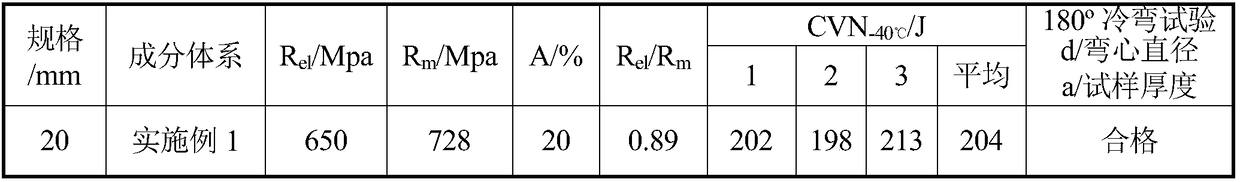

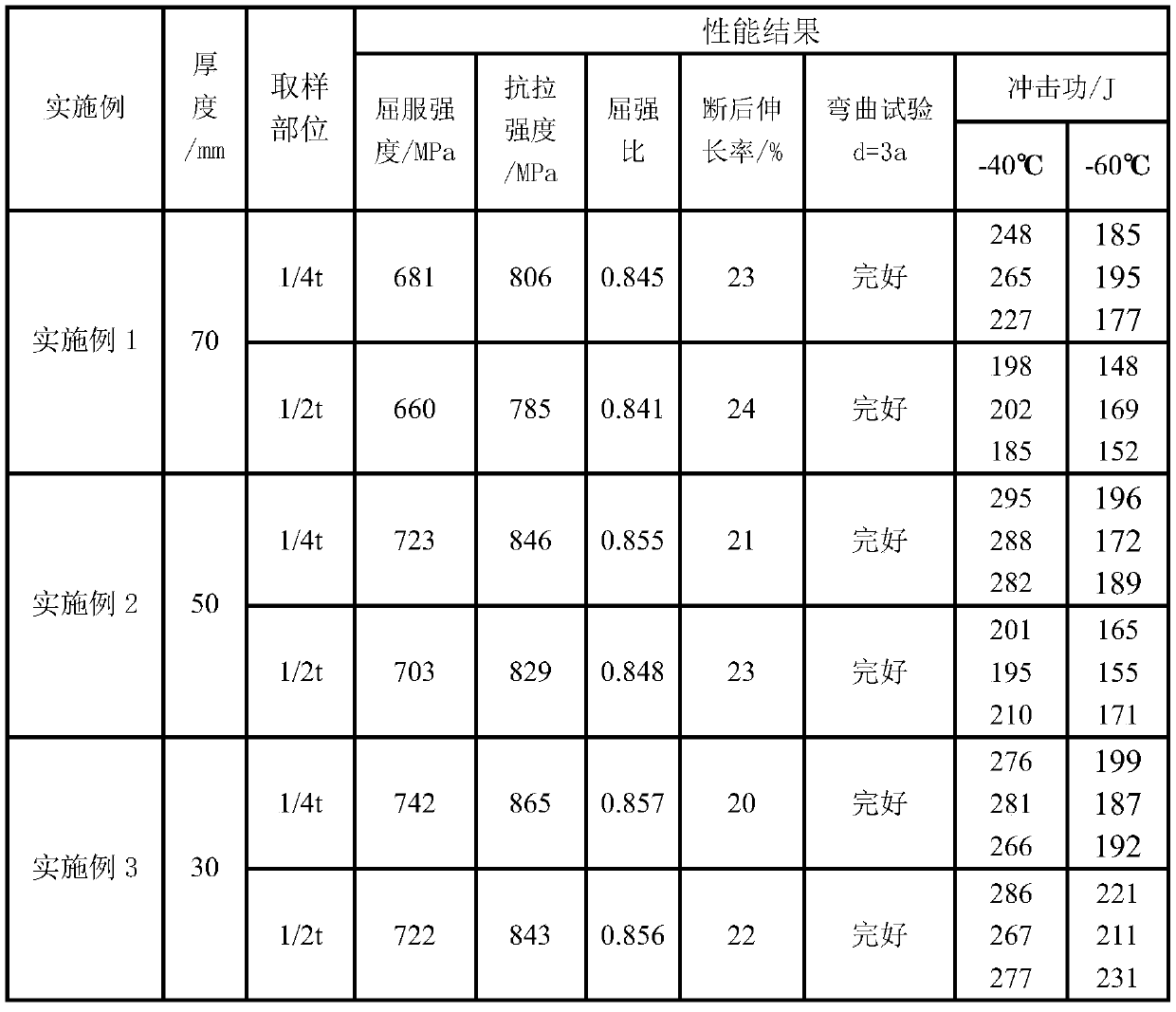

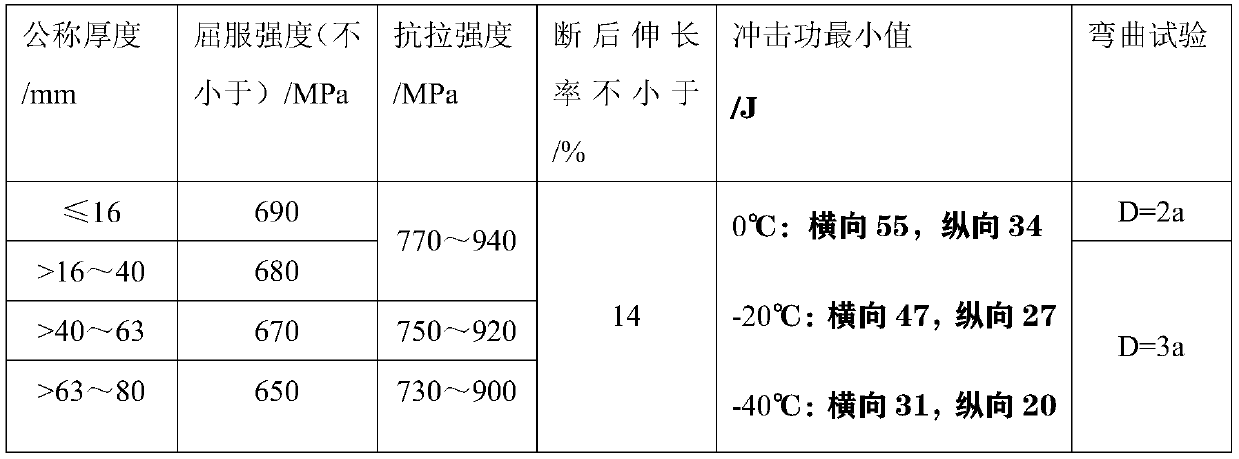

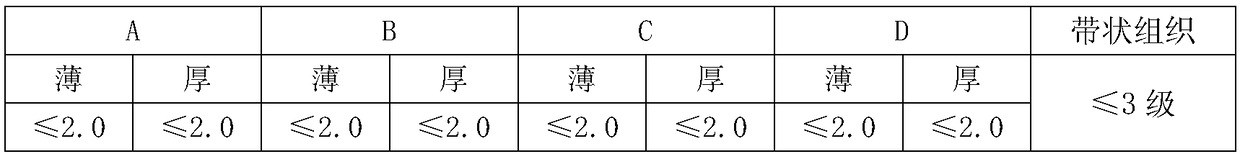

690 MPa grade high-strength low-yield-ratio medium-manganese steel medium-thickness steel and manufacturing method

The invention discloses 690 MPa grade high-strength low-yield-ratio medium-manganese steel medium-thickness steel and a manufacturing method, and relates to the technical field of steel smelting. Thesteel comprises the following chemical components of, in percentage by mass, 0.05%-0.10% of C, 4.1%-4.7% of Mn, 0.15%-0.4% of Si, less than or equal to 0.010% of P, less than or equal to 0.003% of S,0.01%-0.05% of Ti, less than or equal to 0.6% of Ni + Cr + Mo, and the balance Fe and inevitable impurities. The requirements of ultra-high strength steel safety performance and construction cost in acomplex environment in the field of engineering machinery can be met.

Owner:NANJING IRON & STEEL CO LTD

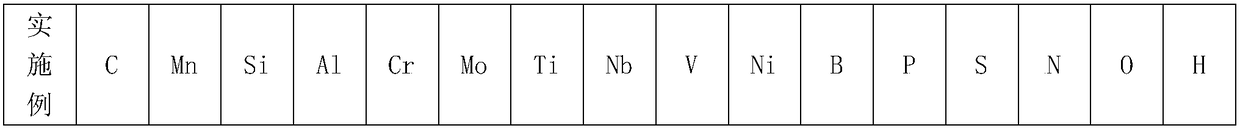

Acid-corrosion-resistant X70MS pipeline steel hot rolled coil and manufacturing method thereof

The invention provides an acid-corrosion-resistant X70MS pipeline steel hot rolled coil and a manufacturing method thereof. The acid-corrosion-resistant X70MS pipeline steel hot rolled coil comprisesthe following components including, by mass, 0.03% to 0.10% of C, 1.10% to 1.40% of Mn, 0.10% to 0.20% of Si, 0.010% to 0.030% of Al, 0.15% to 0.55% of Cr, 0.15% to 0.45% of Mo, 0.005% to 0.025% of Ti, 0.050% to 0.080% of Nb, 0.020% to 0.040% of V, 0.15% to 0.30% of Ni, not larger than 0.0002% of B, not larger than 0.012% of P, not larger than 0.0020% of S, not larger than 0.0060% of N, not largerthan 0.0018% of O, not larger than 0.0005% of H and the balance Fe and inevitable inclusions. Compositions and mechanical property of the acid-corrosion-resistant pipeline steel X70MS products meet the API 5L standard, the acid corrosion resistance performance meets international HIC resistant and SSCC resistant related standard requirements, the good welding technology performance is obtained, and the requirements for producing materials for oil and gas pipelines are met.

Owner:BENGANG STEEL PLATES

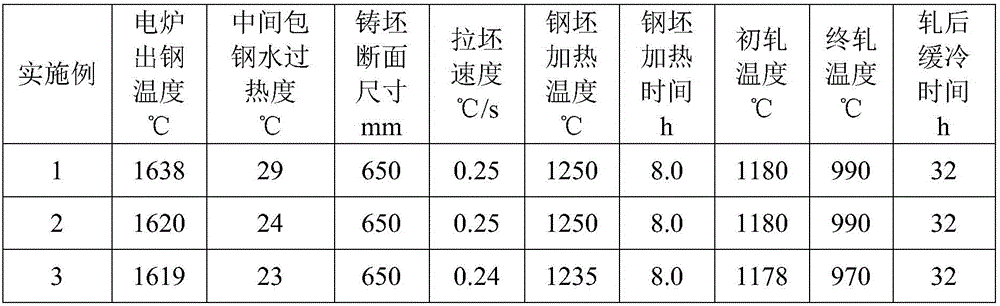

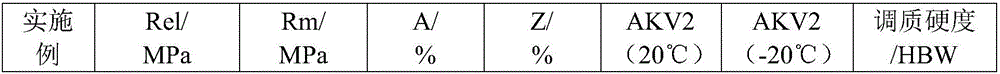

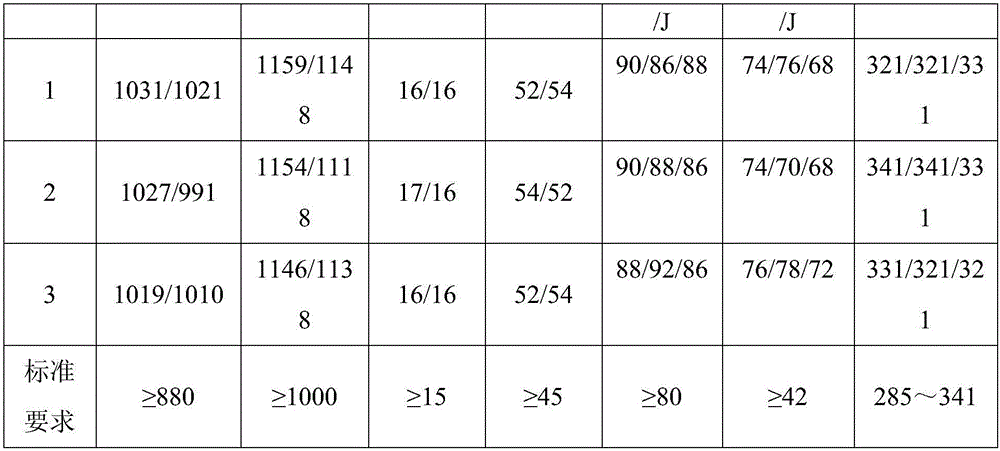

Ni micro-alloyed steel for petroleum drill collar and preparation method thereof

The invention discloses a Ni micro-alloyed steel for a petroleum drill collar and a preparation method of the Ni micro-alloyed steel. The Ni micro-alloyed steel for the petroleum drill collar comprises, by mass, 0.40%-0.48% of C, 0.15%-0.35% of Si, 1.00%-1.20% of Mn, 1.05%-1.30% of Cr, 0.20%-0.35% of Mo, 0.20%-0.40% of Ni, no more than 0.015% of P, no more than 0.010% of S and the balance iron and inevitable impurity elements. The preparation method of the Ni micro-alloyed steel comprises the procedures of smelting conducted through an electric furnace, external refining conducted through a ladle furnace, vacuum treatment conducted through a vacuum degassing furnace, continuous casting and rolling. The Ni micro-alloyed steel for the petroleum drill collar has good comprehensive mechanical performance and stable hardenability, and heat treatment stability is guaranteed. Because micro-alloying is achieved through the added Ni, the low-temperature impact toughness of the Ni micro-alloyed steel is improved.

Owner:SHANDONG IRON & STEEL CO LTD

Reversal austenite toughened martensitic stainless steel and manufacturing method thereof

ActiveCN108251759AImprove toughness and plasticityHigh thermodynamic stabilityMartensitic stainless steelHeat stability

The invention discloses reversal austenite toughened martensitic stainless steel and a manufacturing method thereof. The stainless steel comprises, by mass percent, 0.001 to 0.40% of C, 11.0 to 22.0%of Cr, 1.0 to 12.0% of Ni, 0 to 3.0% of Mo, 0.07 to 1.50% of Ti, 0.05 to 1.50% of Al, 0.10 to 2.0% of Si and the balance Fe and inevitable impurities. The manufacturing method of the stainless steel comprises the steps that firstly, an electric furnace is used for smelting, and an AOD furnace is used for refining and casting to form a steel ingot; hot rolling or hot forging treatment is carried out; austenitizing is carried out, and air cooling quenching is carried out; deep cooling treatment is carried out; tempering is carried out. The thermodynamics condition formed by the reversal austenite and the martensite transformation principle serve as the reference, the fine dispersion nucleation position is created for the reversal austenite, the austenite heat stability is improved, a large amount of thin long strip reversal austenite is formed between martensite strips, and toughness plasticity of the martensite stainless steel can be obviously improved.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of submicrocrystal ultra high strength aluminium alloy

InactiveCN1459512AGood toughness and plasticityShorten the aging timeHigh strength aluminiumNonferrous metal

A process for preparing ultrahigh-strength submicron-crystal aluminium alloy 2000 or 7000 includes such steps as annealing Al alloy, squeezing by equal pathway angle 2-6 times, solid dissolving at 450-500 deg.C, squeezing by equal pathway angle 2-4 times, and natural ageing. An another process is also disclosed. Its advantages are high tension strength 100-150 MPa, better toughness, and super plasticity.

Owner:曾梅光

High-resistance electrophoretic aluminum profile being resistant to cracking caused by bending and preparation method of aluminum profile

InactiveCN109536794AImprove plasticityImprove toughness and plasticityAnodisationElectrophoretic coatingsAnodic oxidationHigh resistance

The invention discloses a high-resistance electrophoretic aluminum profile being resistant to cracking caused by bending and a preparation method of the aluminum profile, and relates to the technicalfield of aluminum alloy materials. A substrate material of the aluminum profile comprises the following elements in percentage by weight: 0.46-0.55% of Si, 0.68-0.78% of Mg, 0.25-0.33% of Fe, 0.12-0.18% of Mo, 0.22-0.30% of Mn, no more than 0.05% of Cr, no more than 0 .05% of Cu, no more than 0.10% of Zn, and the balance Al and inevitable impurities, wherein the content of a single impurity is lower than or equal to 0.05%, the total content of the impurities is lower than or equal to 0.15%, and the ratio of Mg to Si in the substrate material is higher than or equal to 1.43 and lower than or equal to 1.60. The preparation method comprises the following steps: smelting, homogenization treatment, primary extrusion, secondary extrusion, aging treatment, anodic oxidation treatment and electrophoretic painting. Through the interaction among all the alloying elements, the aluminum profile disclosed by the invention is high in toughness and plasticity; during the preparation process, crystal grains become finer and more uniform through two extrusion forming operations, the strengthening effect is good, both the mechanical properties and the processing properties of such an alloy are obviously improved, and the possibility of cracking and other phenomena during the bending deformation processing process is low; and accordingly, the aluminum profile is resistant to cracking caused by bending and high in resistance.

Owner:ANHUI XIN FA ALUMINUM PROD

Rubber-coating roll with composite rubber-coating layer and method for preparing same

InactiveCN101811379AHigh hardnessImprove wear resistanceMetal layered productsRubber materialWear resistant

The invention discloses a rubber-coating roll with a composite rubber-coating layer. The rubber-coating roll comprises a cylindrical rotary body made of a metallic material; the rubber composite material layer is coated on the rotary body; and the rubber composite material layer is made of a composite material formed by embedding wear resistant alloy blocks in rubber. The rubber-coating roll has the advantages of high toughness and plasticity and impact resistance of rubber materials and high hardness and wear resistance of wearing resistant alloy; and the rubber-coating roll can be used under working conditions of bearing a bigger impact load, and overcomes the defect that the impact resistance of the wearing resistant alloy materials is low.

Owner:SHANDONG UNIV

Controlled-rolling and controlled-cooling high-strength pearlitic steel rail and production method thereof

InactiveCN112501512AHigh strengthHigh hardnessTemperature control deviceFurnace typesPearliteUltimate tensile strength

The invention discloses a controlled-rolling and controlled-cooling high-strength pearlitic steel rail and a production method thereof. The controlled-rolling and controlled-cooling high-strength pearlitic steel rail comprises the following chemical components in percentage by mass: 0.71-0.85% of C, 0.45-0.70% of Si, 0.35-0.70% of Mn, 0.2-1.0% of Cr, 0.05-0.1% of V, 0.005-0.08% of Nb, 0-0.025% ofP, 0-0.015% of S and the balance of Fe and inevitable impurities; and the tensile strength of the steel rail is larger than or equal to 1360 MPa, the ductility is larger than or equal to 12%, the railhead tread hardness is larger than or equal to 390 HB, the hardened layer depth is larger than or equal to 30 mm, the structure is thin-sheet pearlite, and the pearlite lamellar spacing away from theposition 30 mm deep away from the surface of the steel rail is smaller than or equal to 90 nm. The strength and hardness of the steel rail are improved, and meanwhile good toughness and plasticity are kept.

Owner:武汉钢铁有限公司

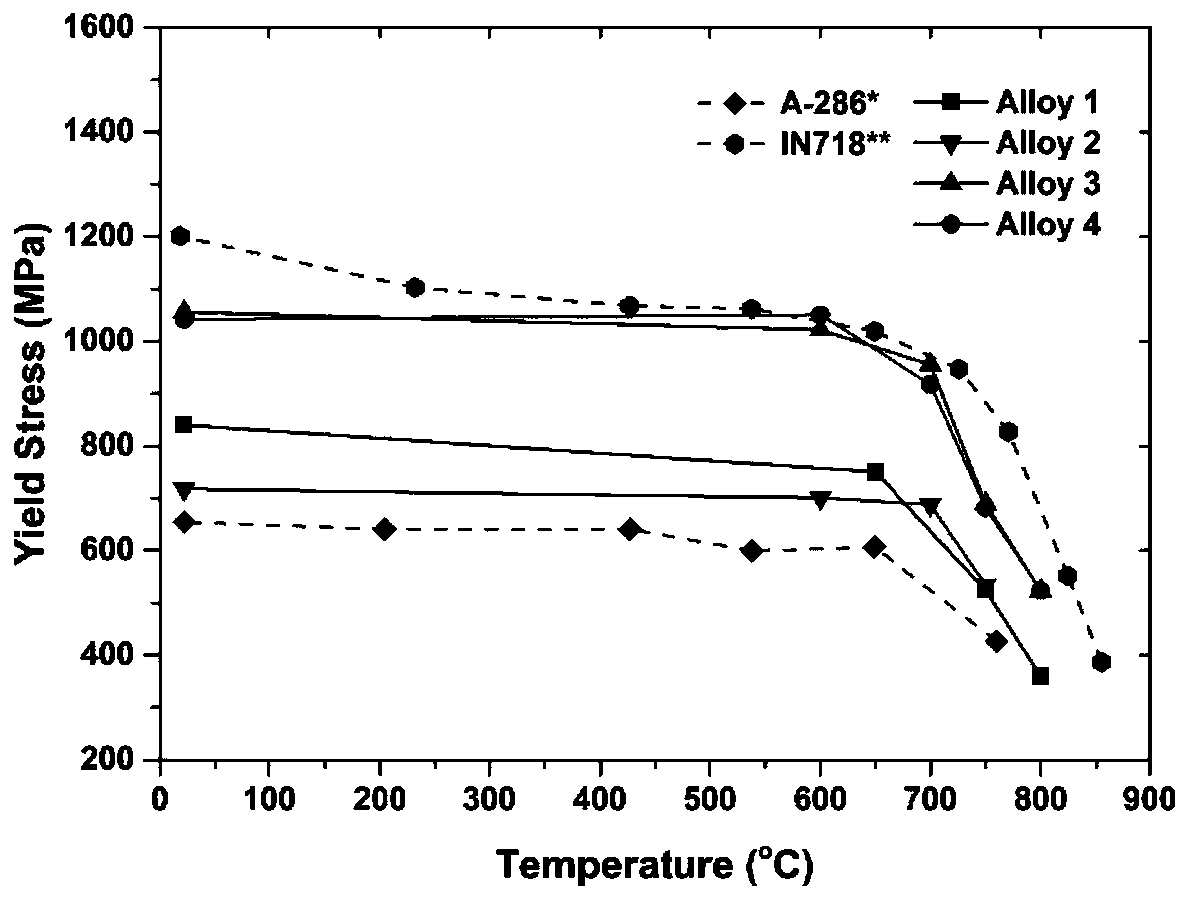

Super steel reinforced by precipitation of nano intermetallic compound, and preparation method for same

The invention discloses super steel reinforced by precipitation of a Ni3(Al, Ti) nano intermetallic compound, and a preparation method for the same. The super steel contains, by mass, the ingredient elements including 2%-6% of Al, 25%-35% of Ni, 4%-14% of Cr, 0.1%-3% of Ti, 2%-12% of at least one among elements of Ta, Nb, Mo and W, 0.2% of C0, 0.1% of B0 and the balance being Fe. The super steel disclosed by the invention is an iron-based high temperature alloy with high strength and high ductility, oxidation resistance and good comprehensive properties under high temperatures.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com