Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

695results about How to "Low yield ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

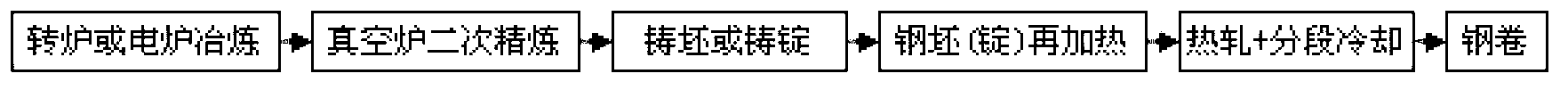

High strength steel plate for big thickness tall building structure and production method thereof

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

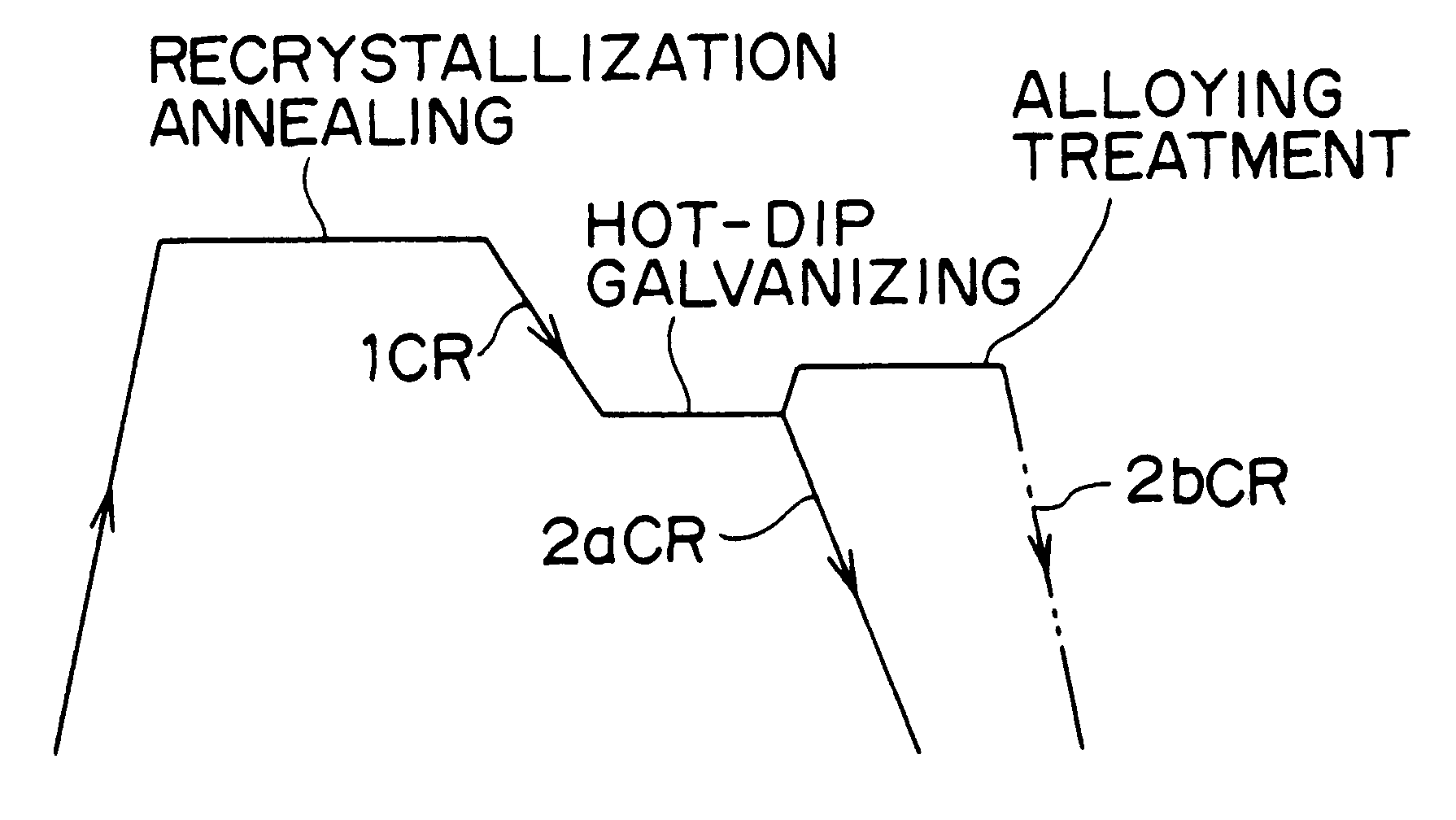

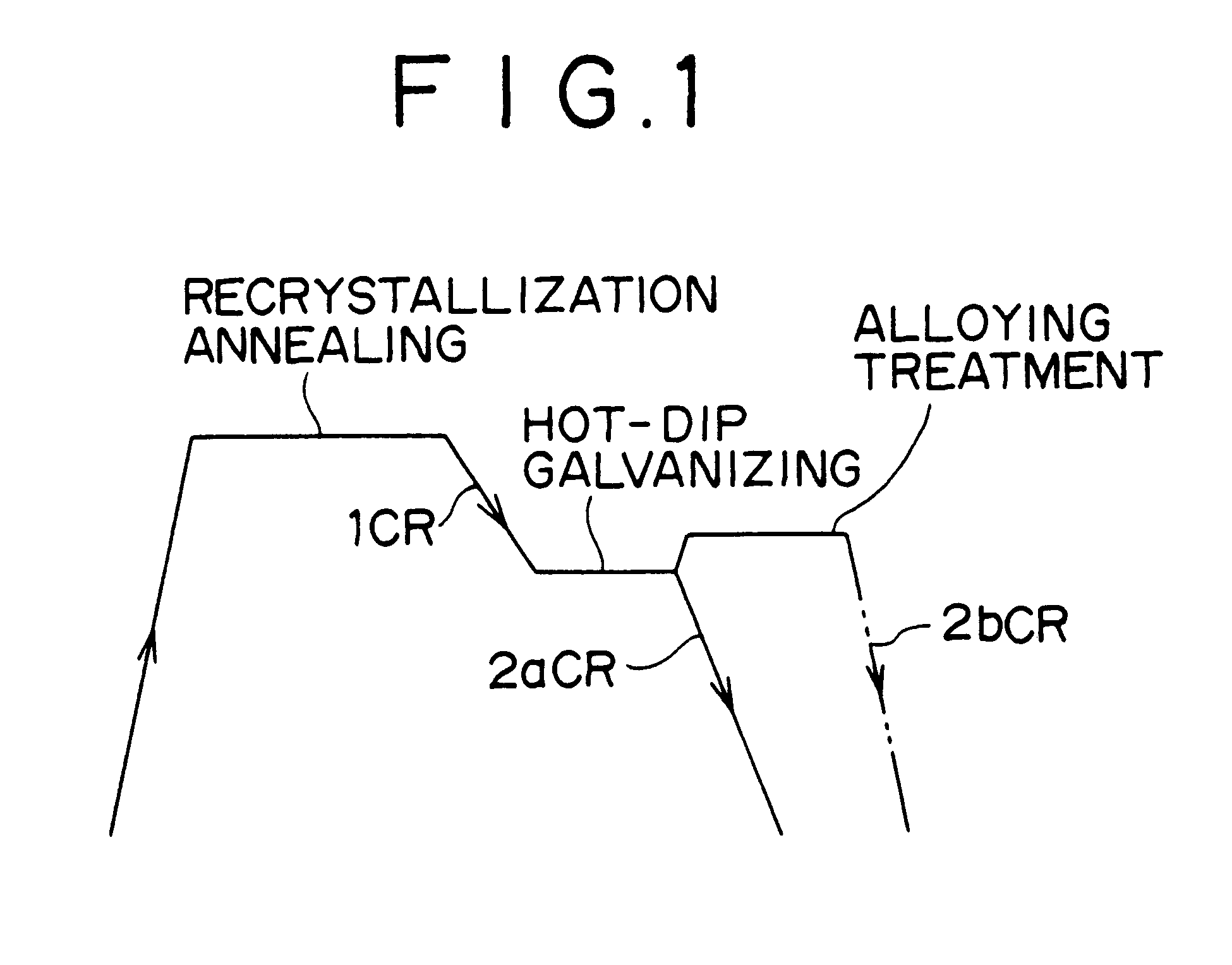

Hot-dip galvanized steel sheet and process for production thereof

InactiveUS6306527B1Ductility deterioratesImprove ductilityHot-dipping/immersion processesLiquid surface applicatorsHot-dip galvanizationDuctility

A hot-dip galvanized steel sheet which is produced from a cold-rolled steel sheet, as a base steel sheet, consisting essentially of C: 0.010-0.06 wt %, Si: no more than 0.5 wt %, Mn: no less than 0.5 wt % and less than 2.0 wt %, P: no more than 0.20 wt %, S: no more than 0.01 wt %, Al: 0.005-0.10 wt %, N: no more than 0.005 wt %, Cr: no more than 1.0 wt %, Mn+1.3Cr: 1.9-2.3 wt %, Fe: remainder, and having a structure composed of ferrite and a second phase containing martensite, said second phase in the structure accounting for no more than 20% in terms of area and martensite in the second phase accounting for no less than 50%, and which has a zinc-plated layer formed on the surface thereof by hot-dip galvanizing or hot-dip galvannealing. A process for production of said hot-dip galvanized steel sheet. This steel sheet has a composite structure containing martensite and yet it has a low strength (no higher than 500 MPa) and also has good strength-ductility balance.

Owner:KOBE STEEL LTD

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

700MPa high strength hot rolling Q&P steel and manufacturing method thereof

ActiveCN103215516AHigh strengthPrevent precipitationFurnace typesHeat treatment furnacesAustenite grainChemical composition

The invention relates to 700MPa high strength hot rolling Q&P steel and a manufacturing method thereof. The steel has the following chemical components in percentage by weight: 0.15-0.40% of C, 1.0-2.0% of Si, 1.5-3.0% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.3-1.0% of Al, less than or equal to 0.0065% of N, 0.005-0.015% of Ti and the balance of Fe. The yield strength is greater than or equal to 70MPa, the strength of extension is greater than or equal to 1300MPa, and the ductility is greater than 10%. According to the invention, through a reasonable compound design, based on common C-Mn steel components, austenite crystal is refined by micro Ti treatment by improving the content of Si to inhibit separation of cementite, so that the austenite transformation kinetics in the air cooling process is accelerated by improving the content of Al. Meanwhile, a hot continuous rolling process is matched with a sectional cooling process, so that proeutectoid ferrite+martensite+retained austenite tissues are obtained. The cost of the alloy is greatly lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

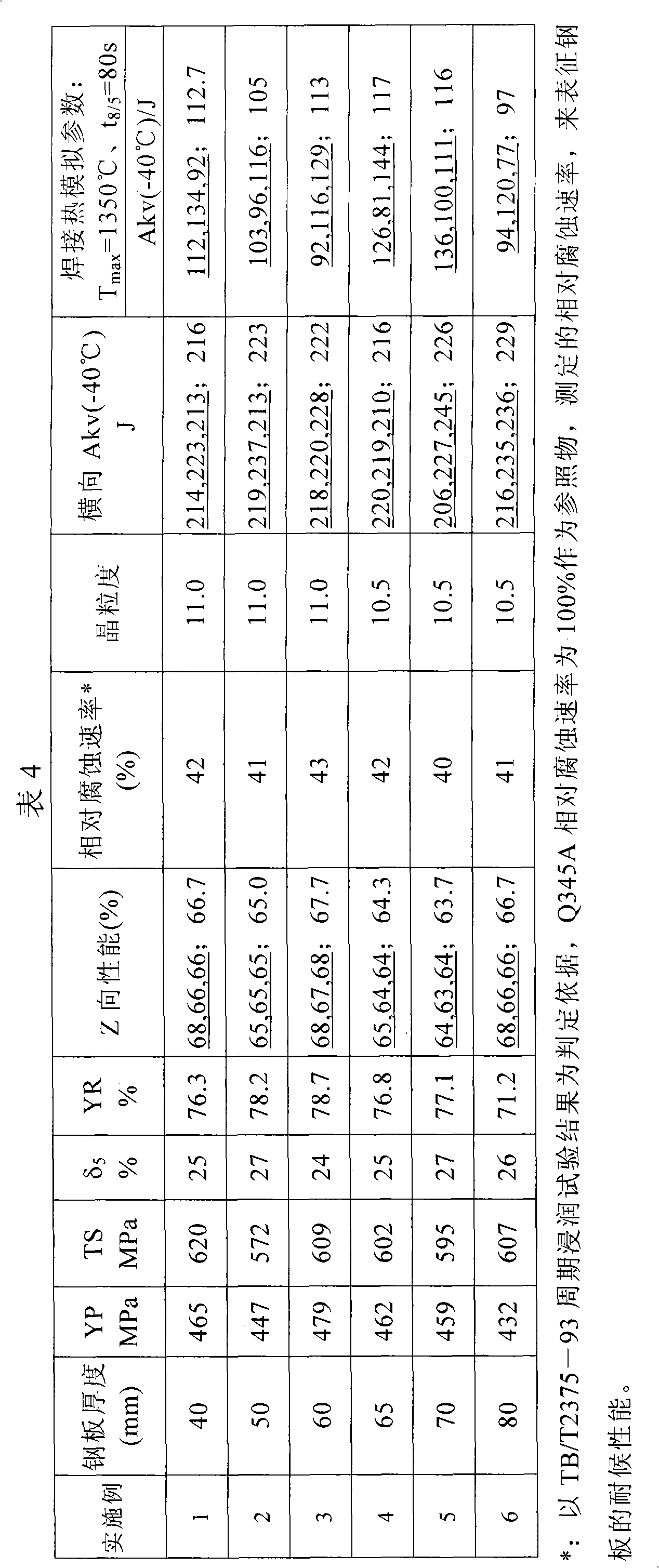

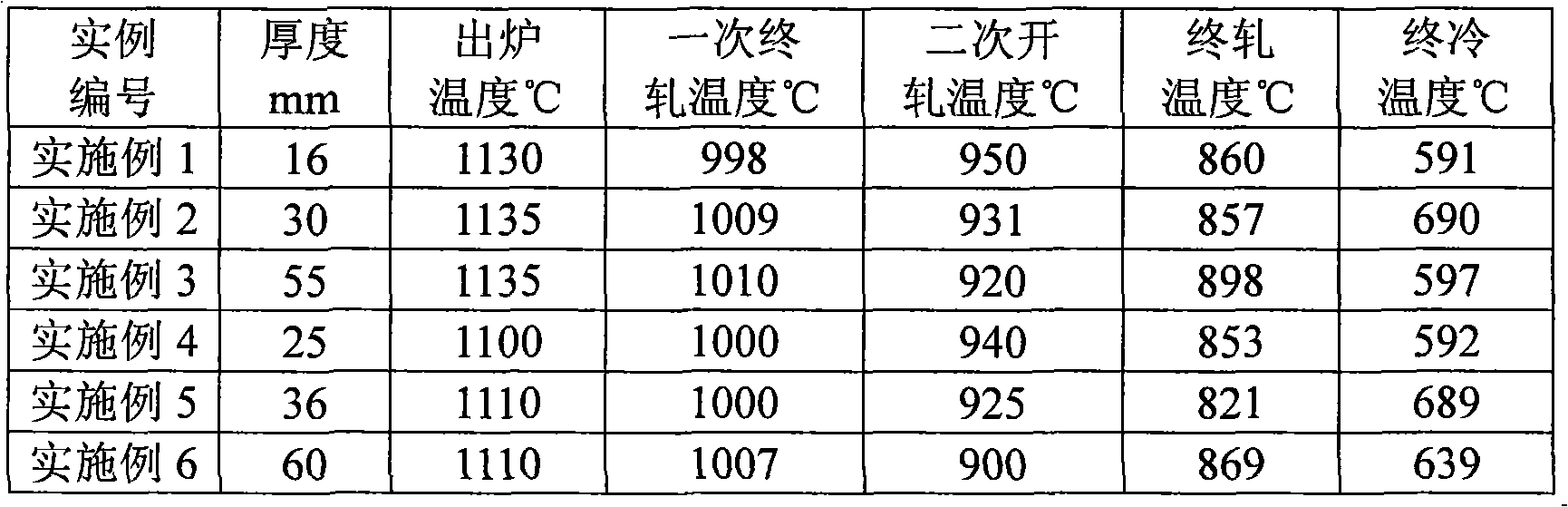

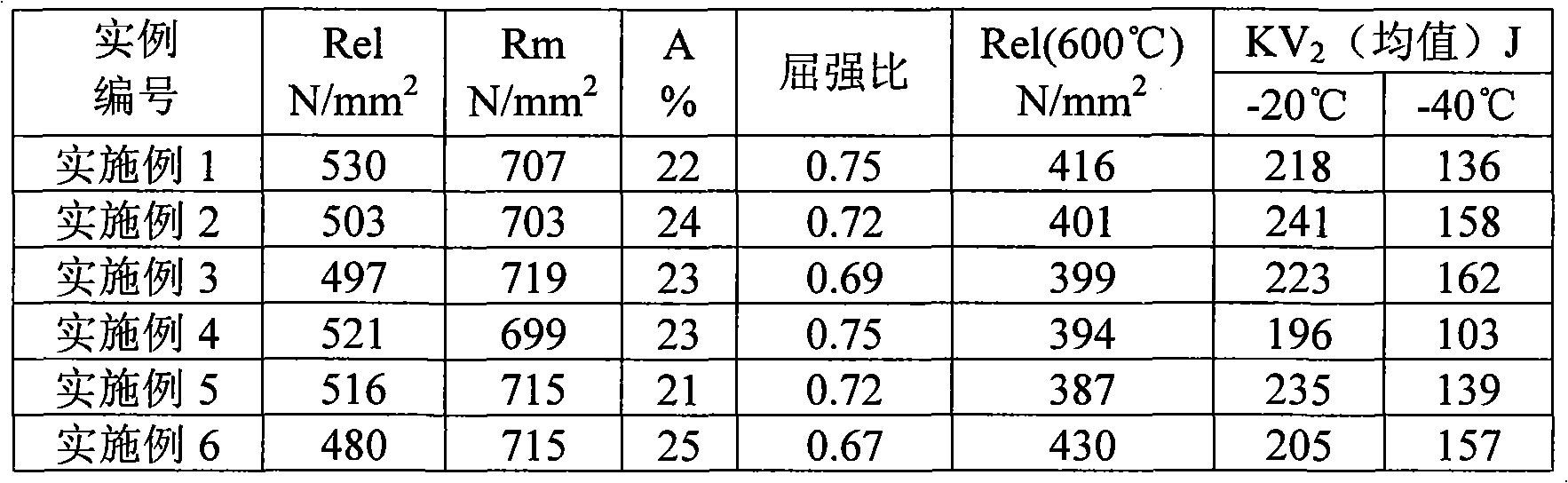

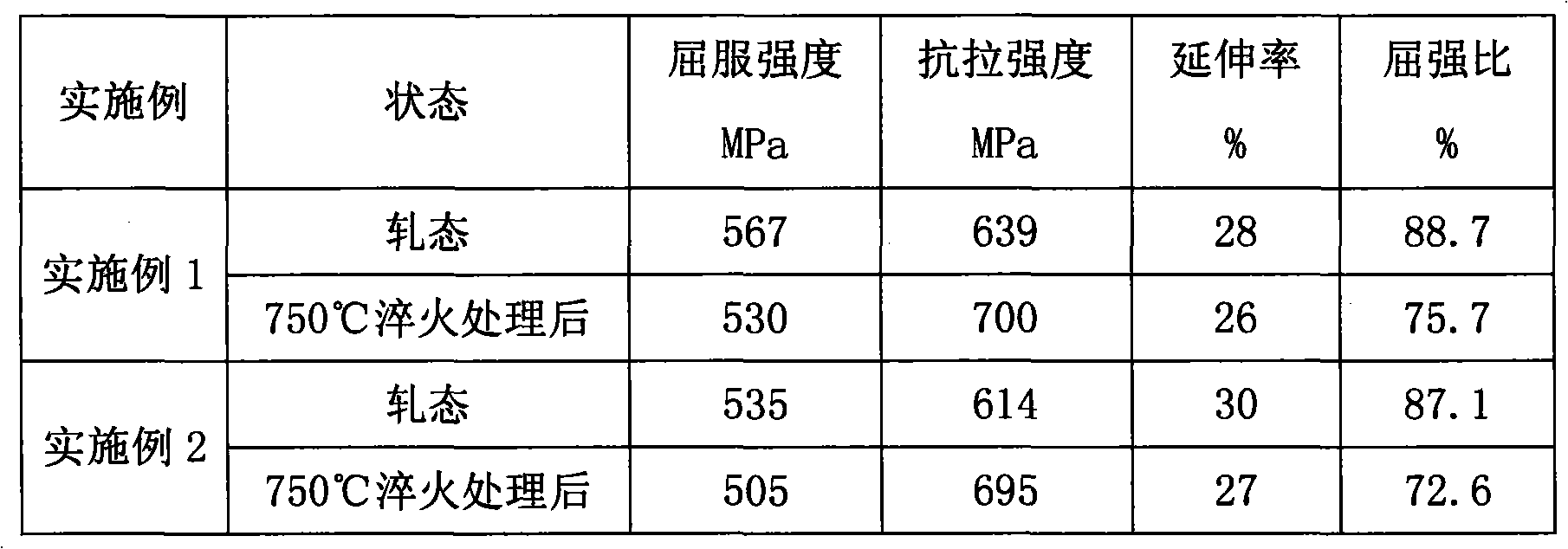

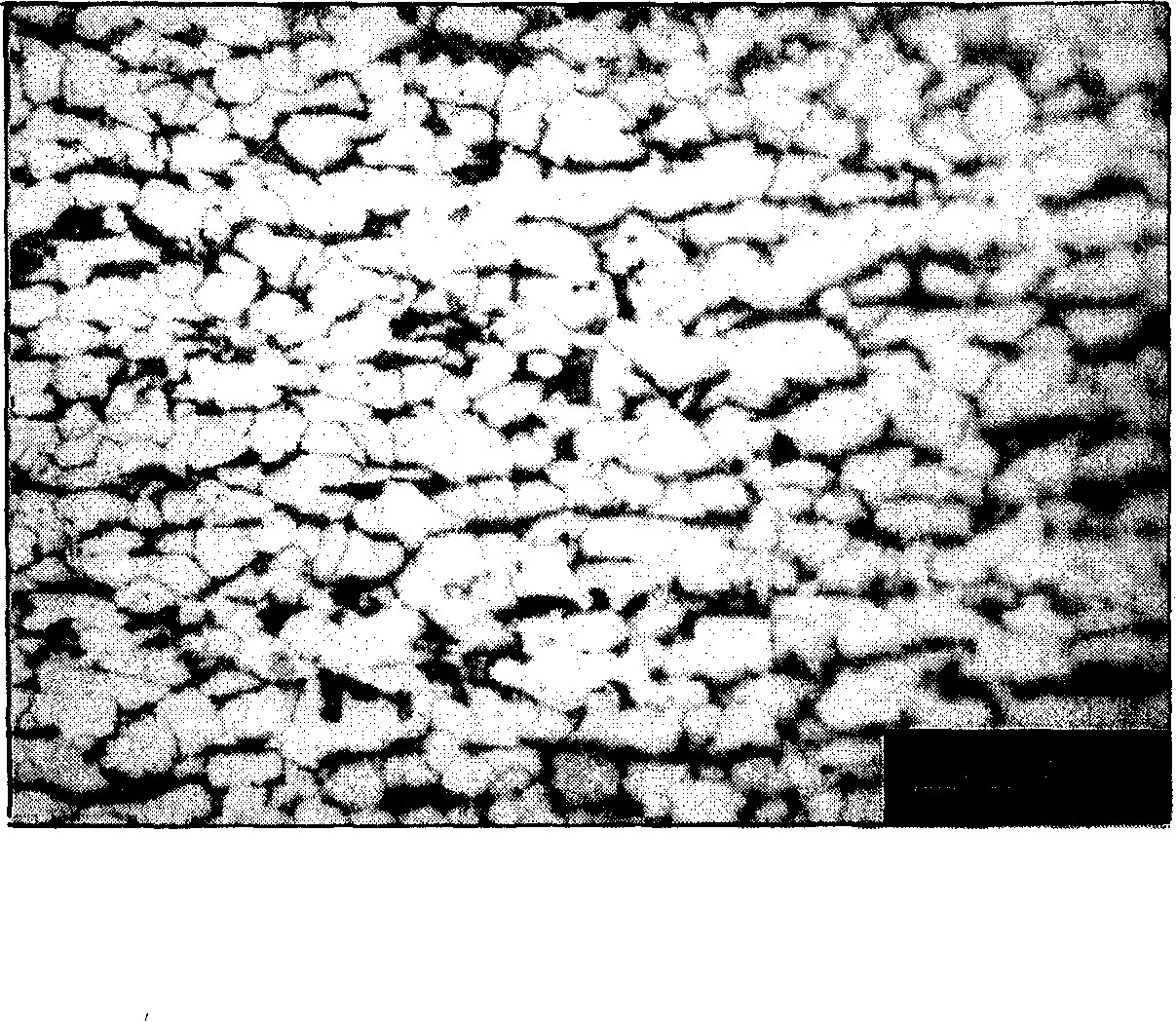

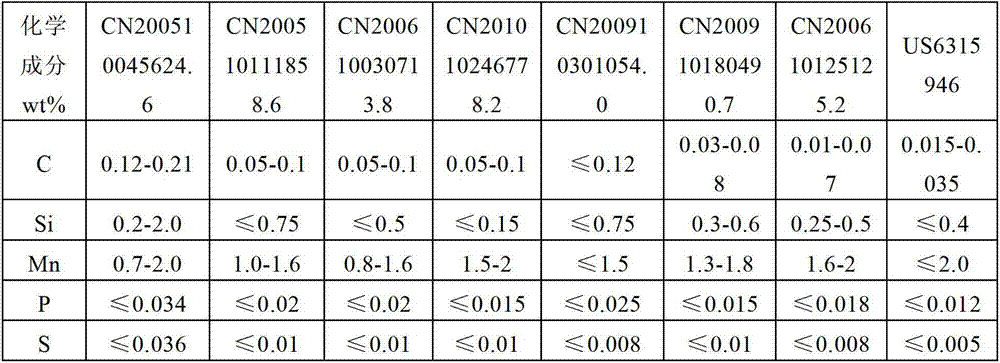

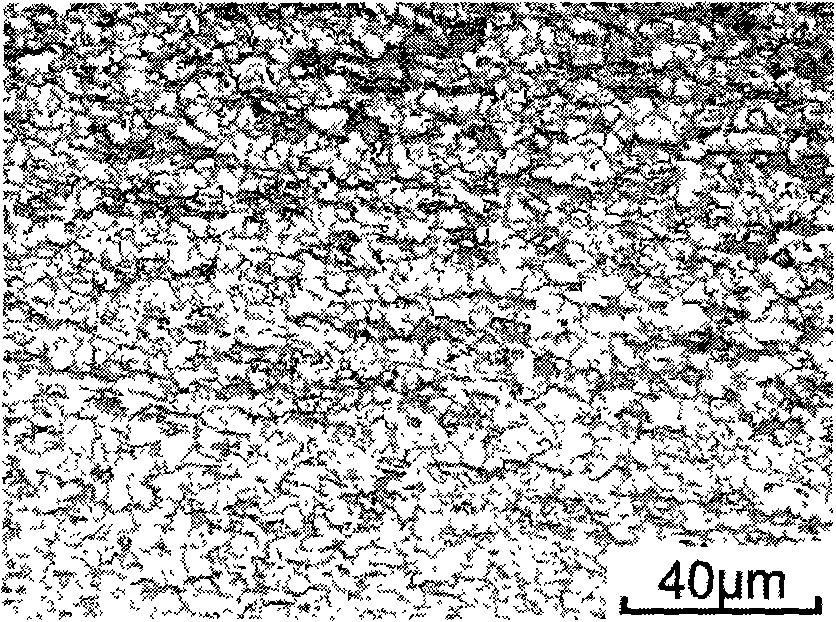

Super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and manufacturing method

The invention relates to a super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and a manufacturing method, which belongs to the technical field of high strength low alloy construction steel. The steel pipe comprises the following components by weight percent: 0.14 to 0.18 percent of C, 0.35 to 0.45 percent of Si, 1.40 to 1.50 percent of Mn, 0.025 to 0.035 percent of Nb, 0.040 to 0.050 percent of V, 0.010 to 0.020 percent of Ti, smaller than 0.020 percent of P, and the balance Fe. The rolling technology is as follows: the heating temperature is 1220 to 1250 DEG C, the tapping temperature is 1200 to 1230 DEG C, and two stages (ausrenitic recrystallization region and ausrenitic non-recrystailization region) are used for controlling rolling. The heat treatment technology is as follows: steel plates, the thickness of which is larger than or equal to 80 mm, are obtained after controlled rolling and cooling are carried out on continuously cast bloom, a two-phase region is heated up to 800 to 850 DEG C and insulated for 10 to 20 minutes, and then water quenching is adopted and the final cooling temperature is controlled to be less than or equal to 100 DEG C; 450 to 600 DEG C tempering treatment is carried out on the quenched steel plates, and finally the high strength low alloy construction steel plates are obtained. The steel plate not only has excellent comprehensive mechanical properties, but also lowers the cost and reduces the waste of resources.

Owner:SHOUGANG CORPORATION

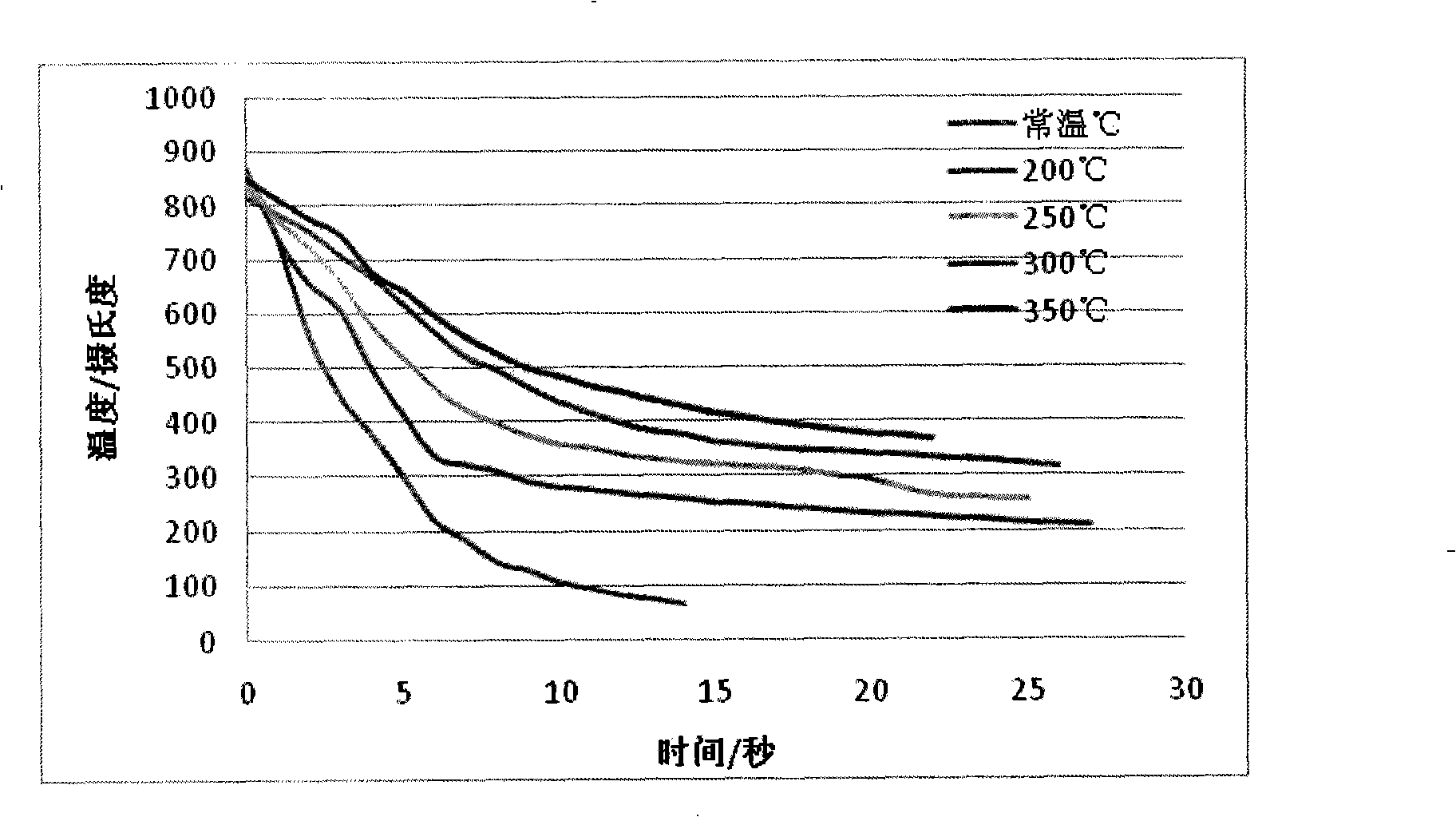

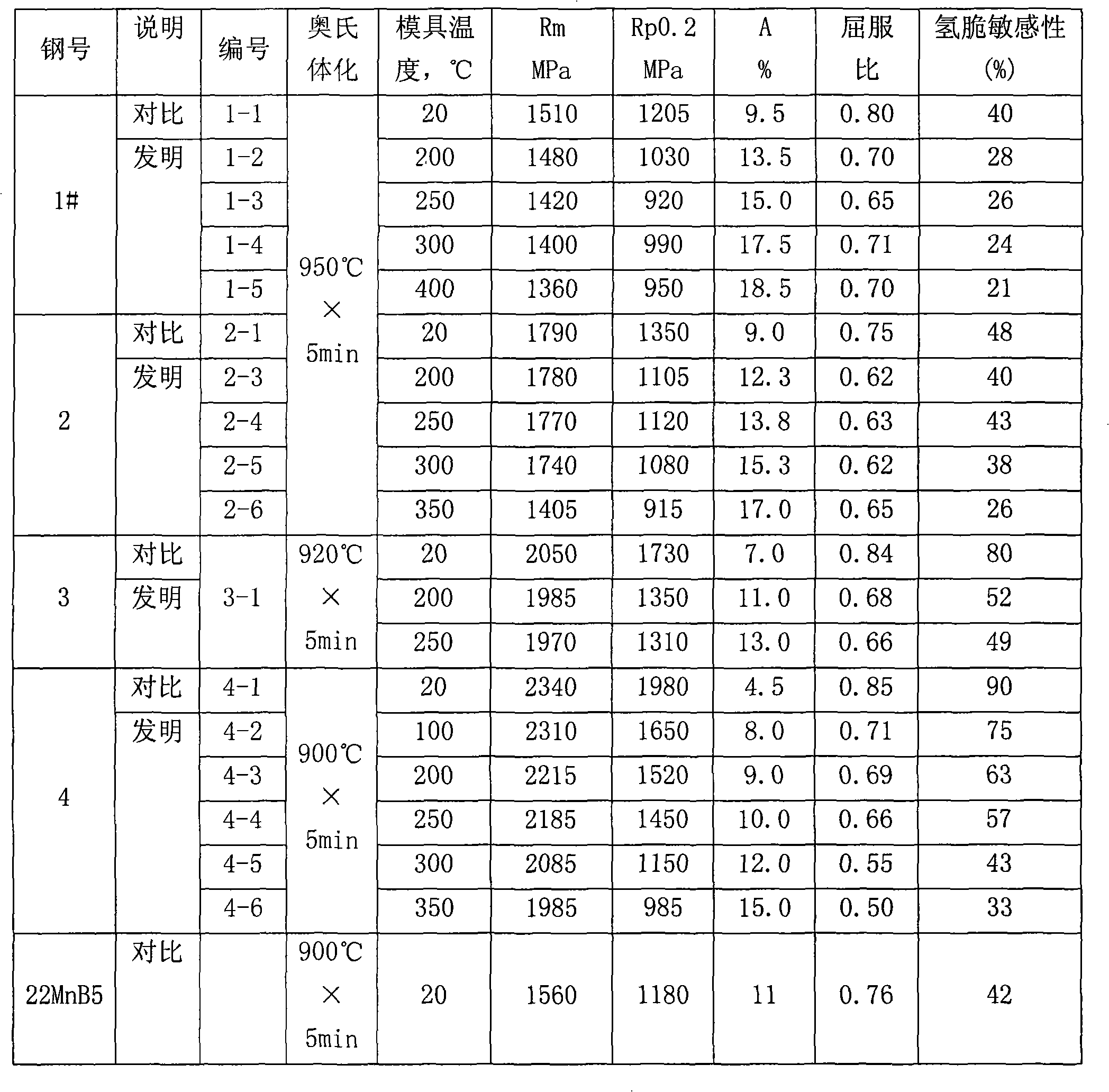

High-safe high-precision producing method of thermoforming martensitic steel parts

InactiveCN101280352AGuaranteed Hardenability RequirementsLow yield ratioShaping toolsHot stampingSheet steel

The invention provides a high security, high accuracy and thermal forming martensite steel part preparing method, which belongs to the field of obtaining controlling and cooling technology of the hot stamping forming part of the alloy steel plate, the martensite works as the matrix structure of the alloy steel plate. The method adopts the processes as follows: a steel plate is heated to 20 to 250 DEG C above the Ac3 temperature, therefore an austenite structure can be obtained, then the steel plate is transferred to the stamping die for forming by stamping; simultaneously, the temperature of the stamping die is controlled in a range of 100 to 400 DEG C, 5 to 60 seconds later after stamping forming, the formed component parts can be taken out of the stamping die. The method has the advantages that a well ductility and security can be obtained, and the anti-susceptibility of the steel can be greatly enhanced.

Owner:CENT IRON & STEEL RES INST

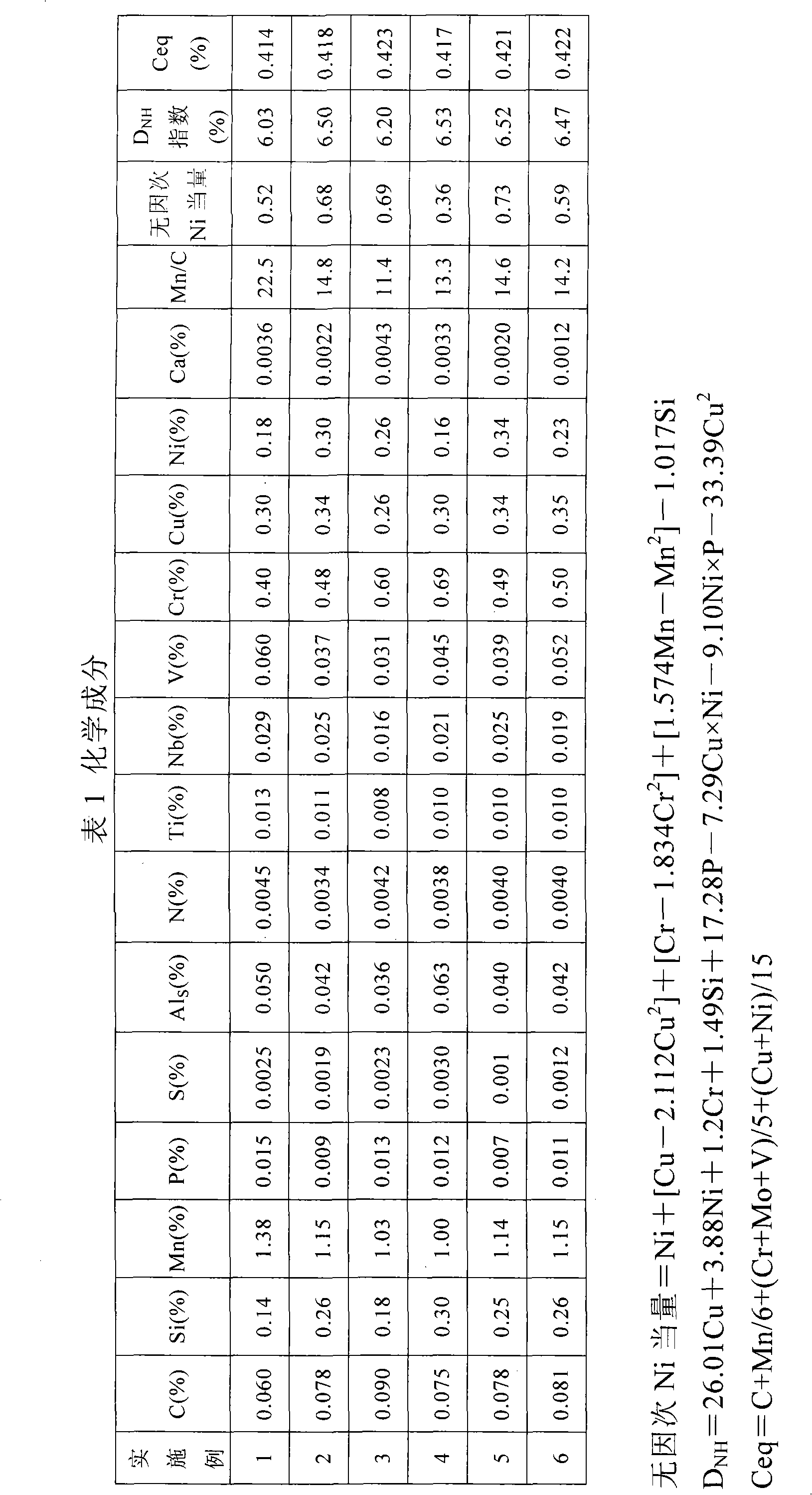

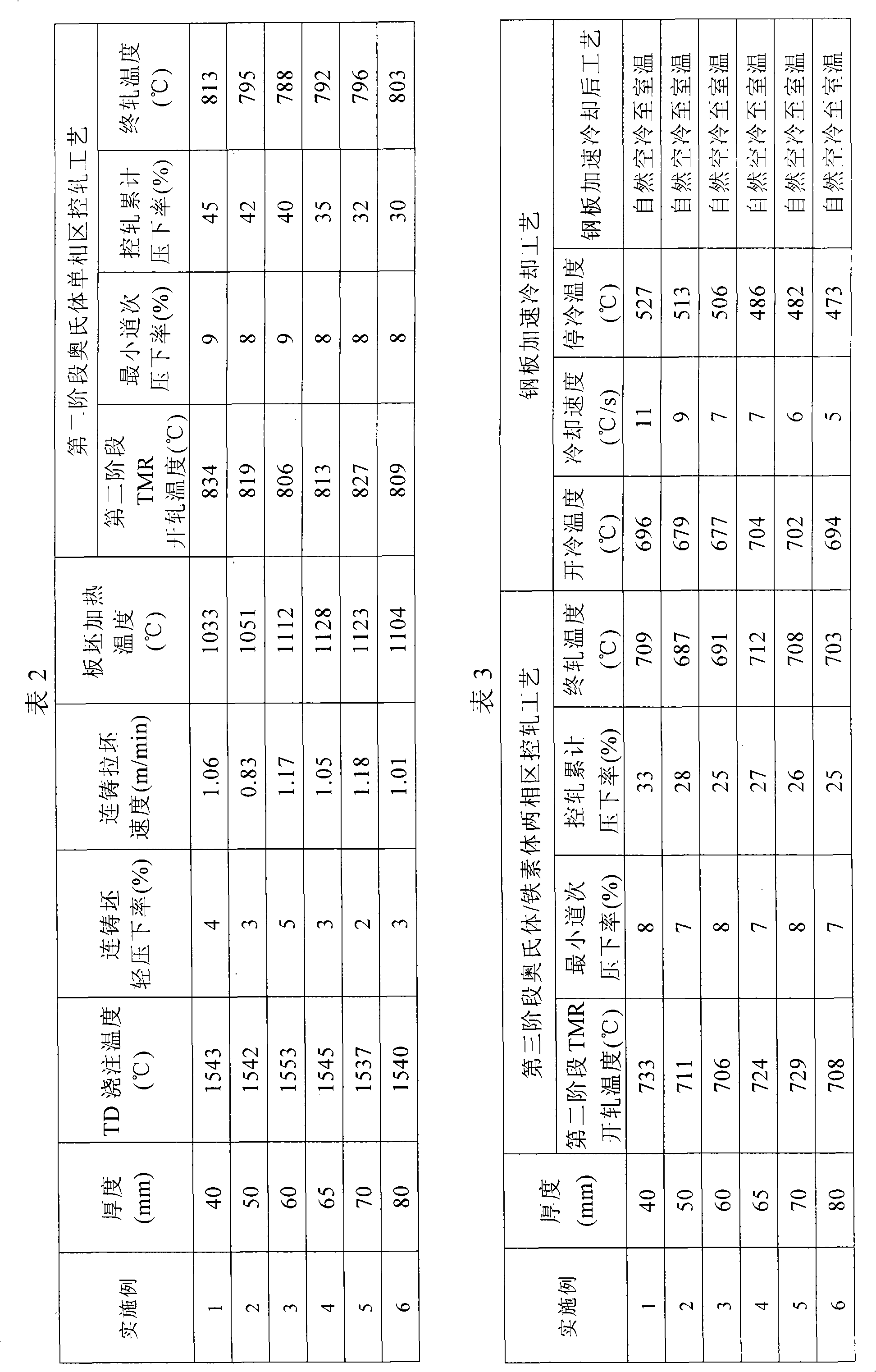

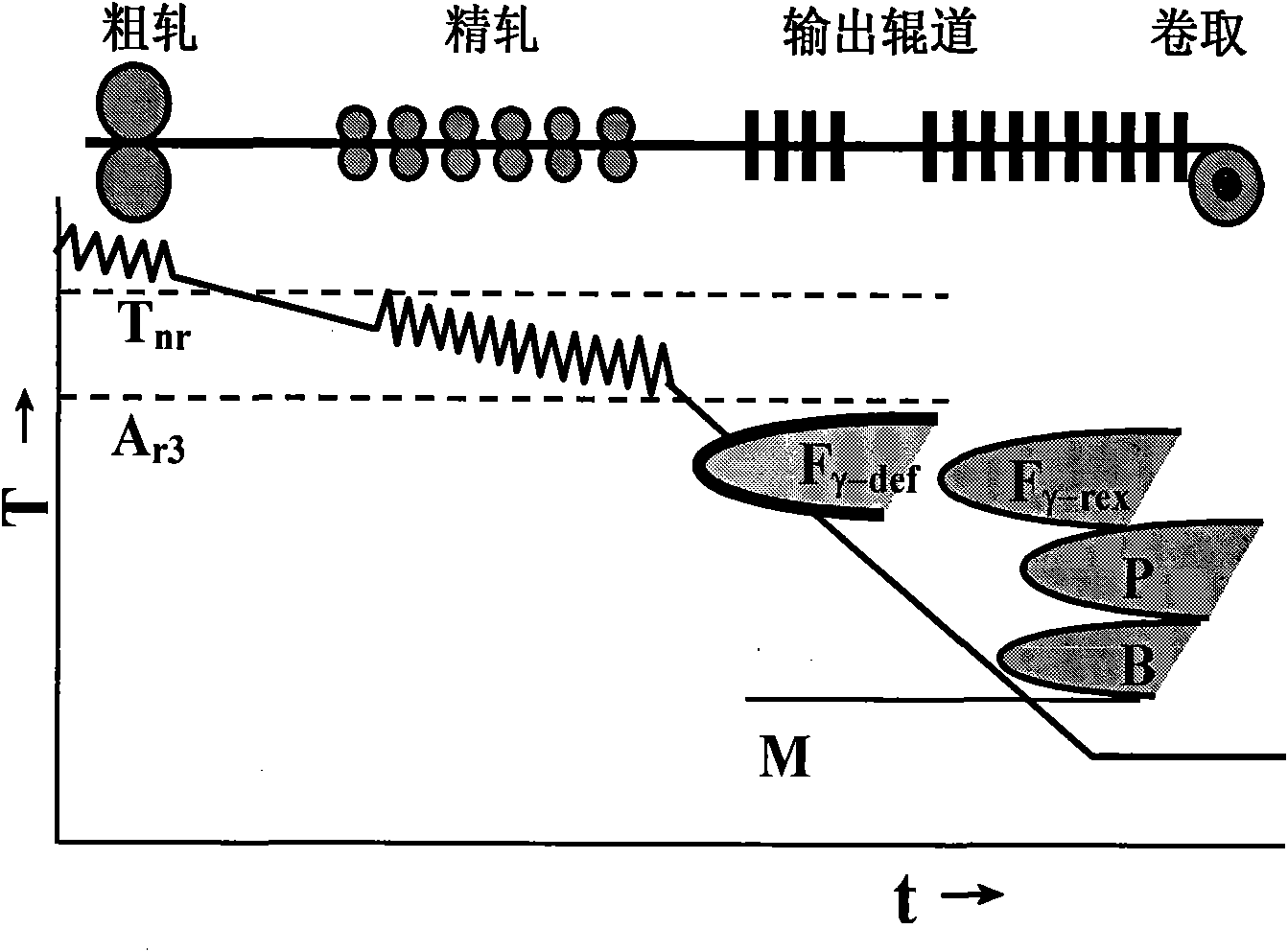

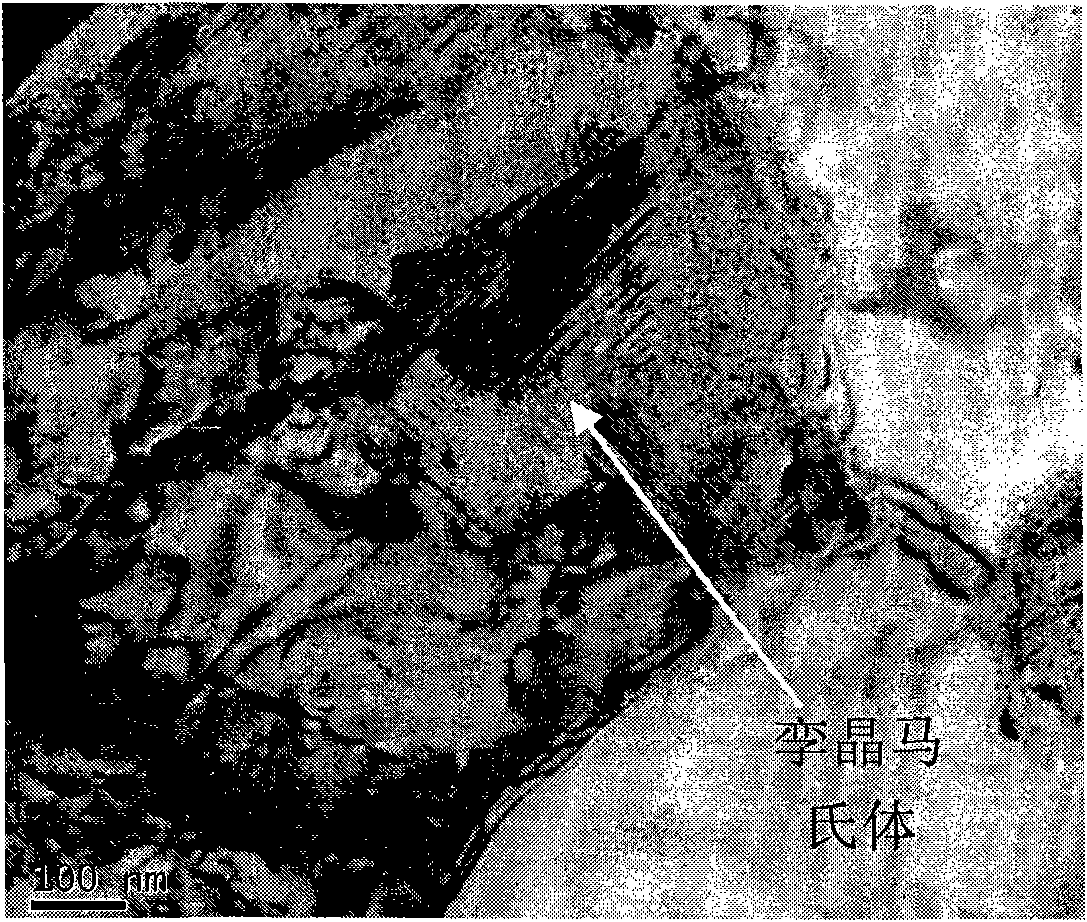

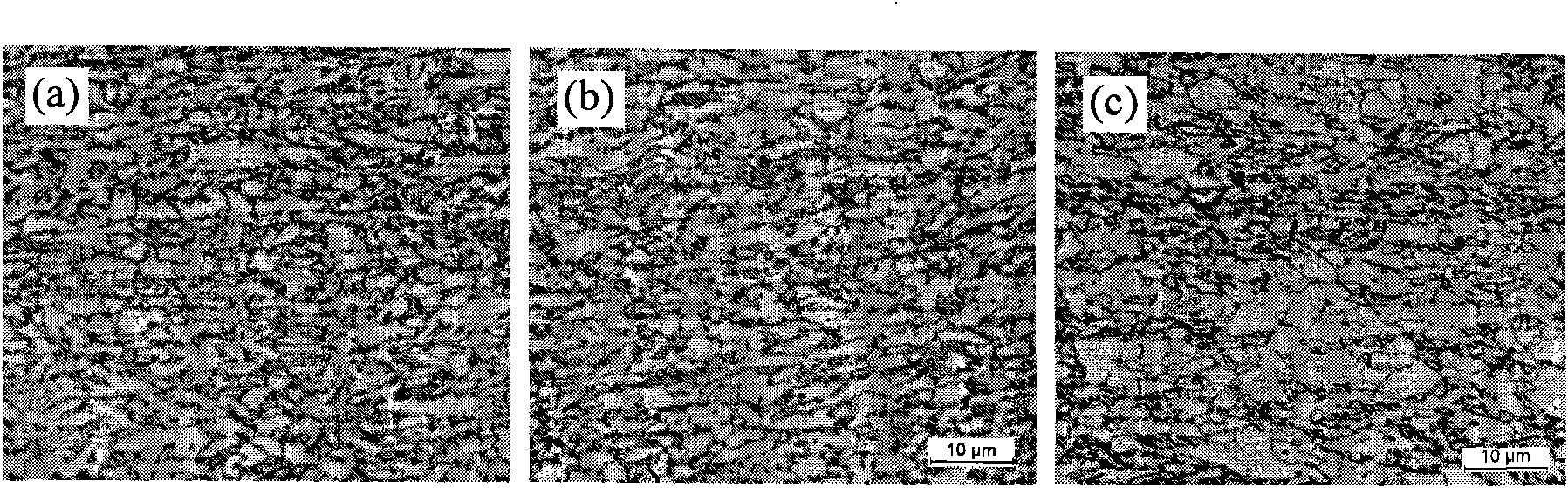

High-performance weather-proof building structural steel and manufacturing method thereof

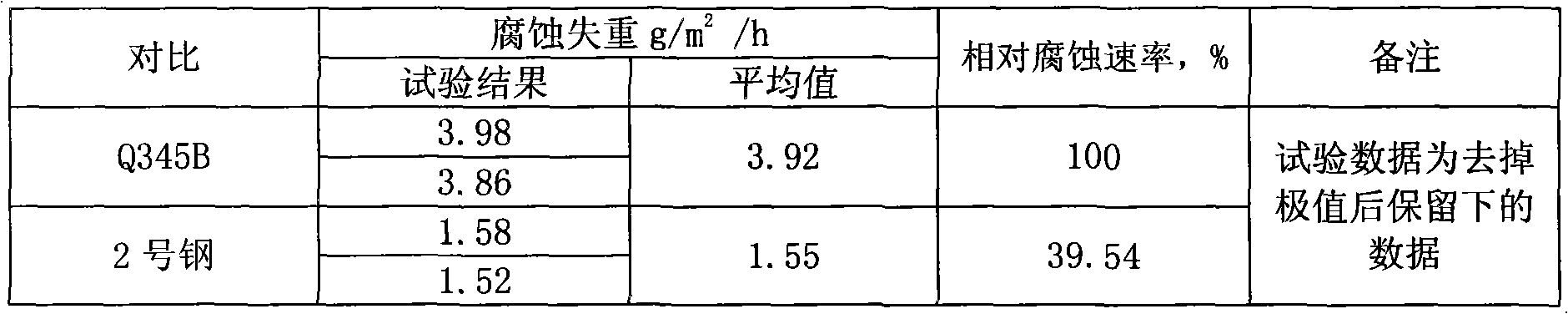

The invention relates to high-performance weather-proof building structural steel and a manufacturing method thereof. The composition system of low C-medium Mn-low N-micro Nb alloying-ultramicro Ti processing low content alloy weather-proof steel is taken as foundation, the acid solution Als content in the steel is increased properly, and the range of the acid solution Als content is controlled; the zero dimension Ni equivalent weight is controlled to be more than or equal to 0.35, the Ceq is less than or equal to 0.425%, and the Mn / C is more than or equal to 10; the weather-proof property index DNH is more than or equal to 6.0%; and the Ca is processed, the Ca / S is controlled within the range of 1.0-3.0, and Ca*S 0.28 is less than or equal to 1.0*10<-3>. By adopting a TMCP technique, a weather-proof steel plate with good toughness, strong plasticity matching, low yield ratio, atmosphere corrosion resistance, excellent weldability and anti-fatigue performance can be obtained, is especially suitable for non-coating high-rise building structure and bridge structure, and can realize stable batch industrialized production with low cost.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

Ultrafine grained hot rolled dual-phase steel with tensile strength of above 750MPa and manufacturing method of plate thereof

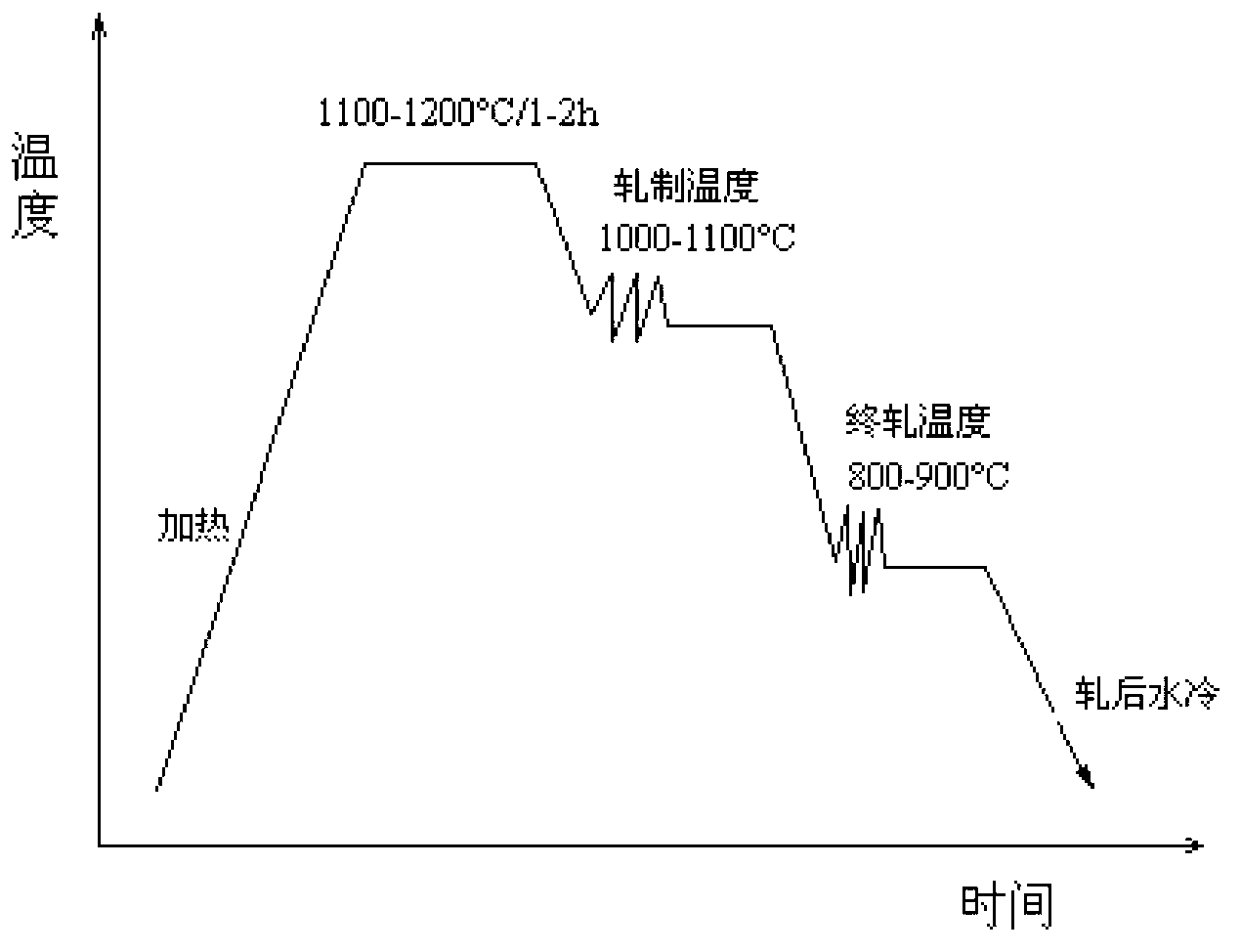

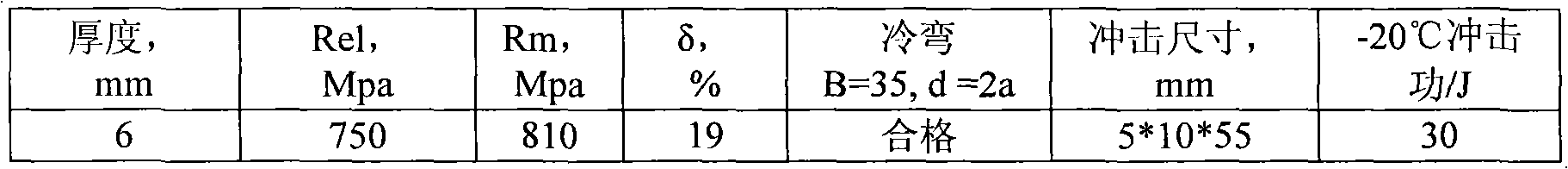

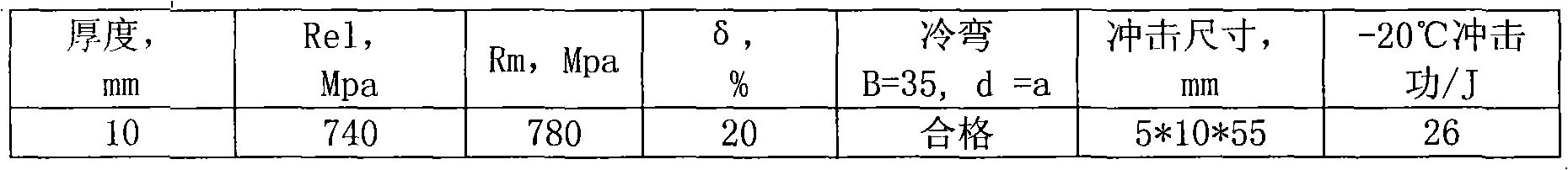

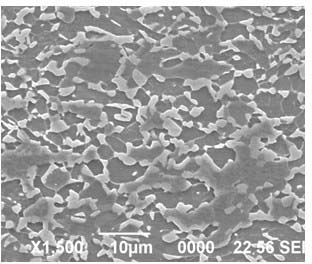

The invention relates to ultrafine grained hot rolled dual-phase steel with tensile strength of above 750MPa and a manufacturing method of a plate thereof, belonging to the technical field of steel rolling, and the dual-phase steel comprises the following chemical components by weight percentage: 0.06-0.16% of C, 0.10-0.50% of Si, 1.00-2.00% of Mn, 0.02-0.06% of Al, 0.01-0.08% of Nb, 0-0.03% of Ti, not more than 0.1 of P, not more than 0.05 of S and the balance of Fe. The manufacturing method of the dual-phase steel comprises the following steps: 1) heating, heating a plate blank with the thickness of not less than 60mm to 1100-1250 DEG C, and keeping the temperature for 1-4h; 2) rolling and adopting the two-stage controlled rolling, wherein the reduction rate in a recrystallization zone is larger than 60%, the reduction rate in a non-recrystallization zone is larger than 70%, the initial rolling temperature of the recrystallization zone is 1100-1150 DEG C, the initial rolling temperature of the non-recrystallization zone is 880-940 DEG C, and the final rolling temperature is 770-860 DEG C; and 3) cooling, and adopting the continuous cooling after final rolling, wherein the cooling rate is 30-40 DEG C / s, the coiling temperature is lower than 350 DEG C, and the thickness of a finished product is 2-10mm. The manufacturing method can obtain the high-performance steel plate with high strength, low yield-strength ratio and good extension property, and the steel plate can be suitable for forming processing of high-strength automobiles, other industrial mechanical parts and the like.

Owner:NORTHEASTERN UNIV

Low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa and manufacturing method thereof

InactiveCN101921965AAdd corrosion resistant elementsLow costUltimate tensile strengthContinuous rolling

The invention provides low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa for containers and a manufacturing method thereof. Based on the carbon manganese structural steel composition, the reinforcement effect is enhanced by adding a proper amount of micro-alloy elements such as Nb, Ti, Cu, Cr, Ni and the like, adopting a controlled rolling and controlled cooling technique, taking production characteristics of a normal hot continuous rolling machine into consideration and using a high-Ti component design. Meanwhile, Si content is reduced and high cold forming performance is ensured. The weathering steel for the containers comprises the following components in percentage by weight: 0.05 to 0.10 percent of C, less than or equal to 0.15 percent of Si, 1.5 to 2.0 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.01 percent of S, 0.3 to 0.8 percent o Cr, 0.2 to 0.4 percent of Cu, 0.15 to 0.4 percent of Ni, 0.09 to 0.15 percent of Ti, 0.02 to 0.08 percent of Nb, less than or equal to 0.005 percent of N, less than or equal to 0.002 percent of O and the balance of Fe and inevitable impurities. The yield strength is over 700MPa, the tensile strength is over 800MPa and the elongation is over 18 percent.

Owner:SHANDONG IRON & STEEL CO LTD

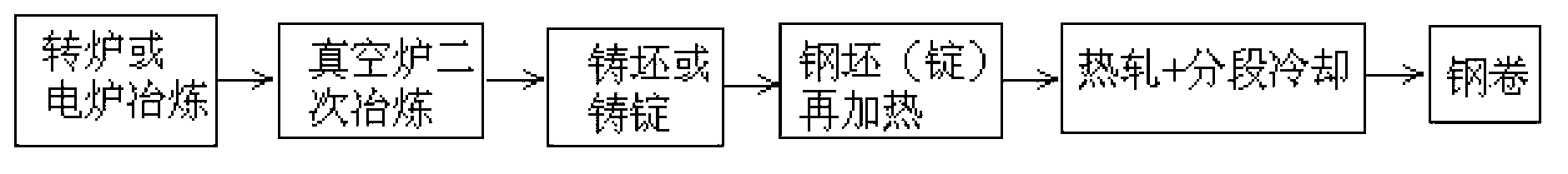

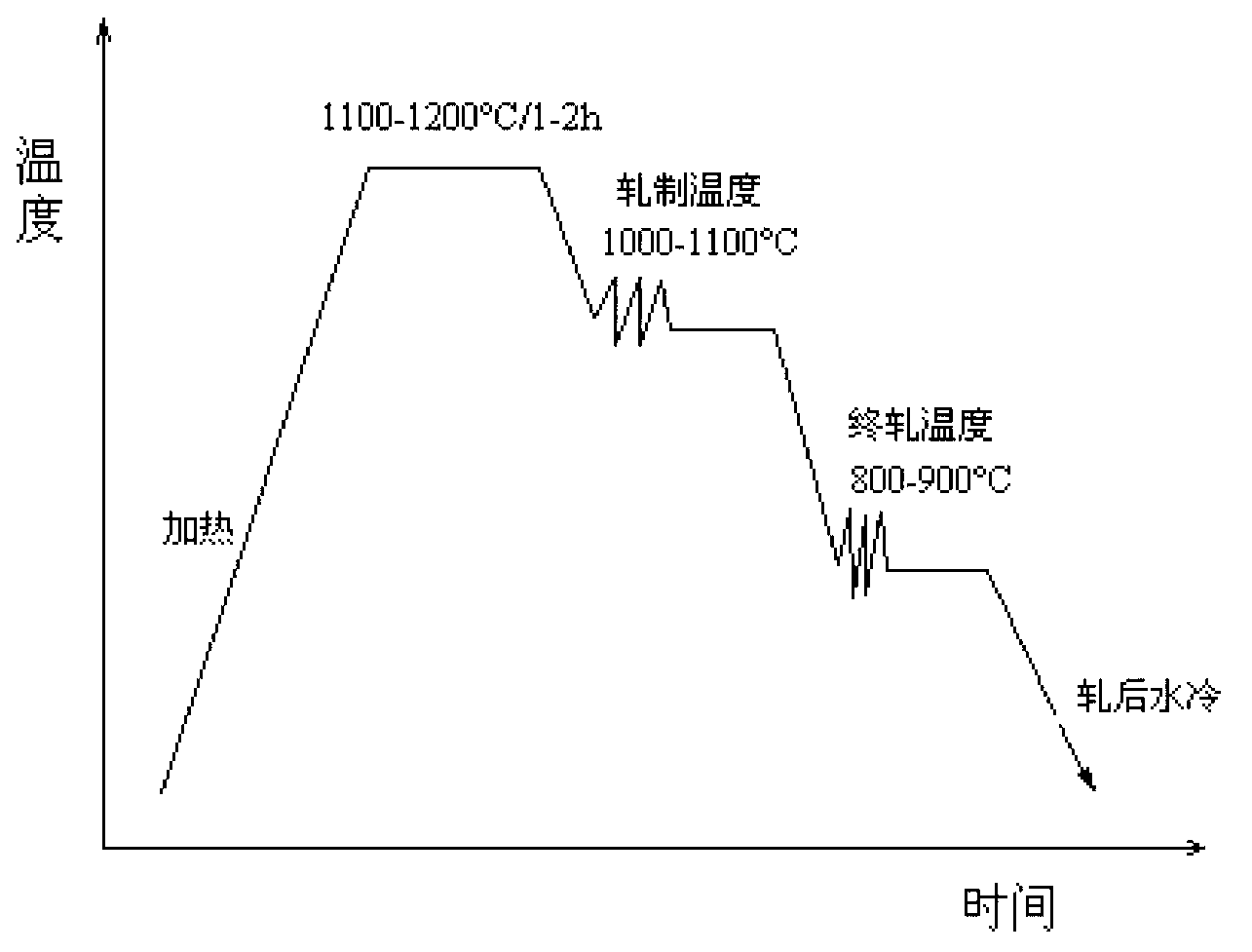

High-performance building structure refractory steel plates and manufacturing method thereof

ActiveCN101906585AMeet design needsMeet construction needsTemperature control deviceChemical compositionHeating time

The invention discloses high-performance building structure refractory steel plates and a manufacturing method thereof. The high-performance building structure refractory steel plate comprises the following chemical components in percentage by weight: 0.02 to 0.12 percent of C, 0.05 to 0.50 percent of Si, 0.08 to 1.50 percent of Mn, 0.010 to 0.050 percent of Nb, 0.010 to 0.040 percent of Ti, 0.010 to 0.050 percent of Als, 0.20 to 0.60 percent of Cr, 0.20 to 0.40 percent of Mo, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.0040 percent of N, less than or equal to 0.0020 percent of O and the balance of Fe and inevitable impurities. The production process of the high-performance building structure refractory steel plates is characterized in that: the steel blank heating temperature is 1,100 to 1,250 DEG C; the heating time is 60 to 110s / cm; two-stage controlled rolling is adopted; the final rolling temperature is kept between 800 and 900 DEG C; cooling is started 30 to 120 seconds later after final rolling; the final cooling temperature is kept between 500 and 750 DEG C; the steel plates are stacked quickly, cooled slowly and kept at a constant temperature; the stacking temperature is kept between 650 and 300 DEG C; and the temperature is kept for 10 to 24 hours. The plates have the characteristics of simple chemical components, low cost, and high refractability.

Owner:ANGANG STEEL CO LTD

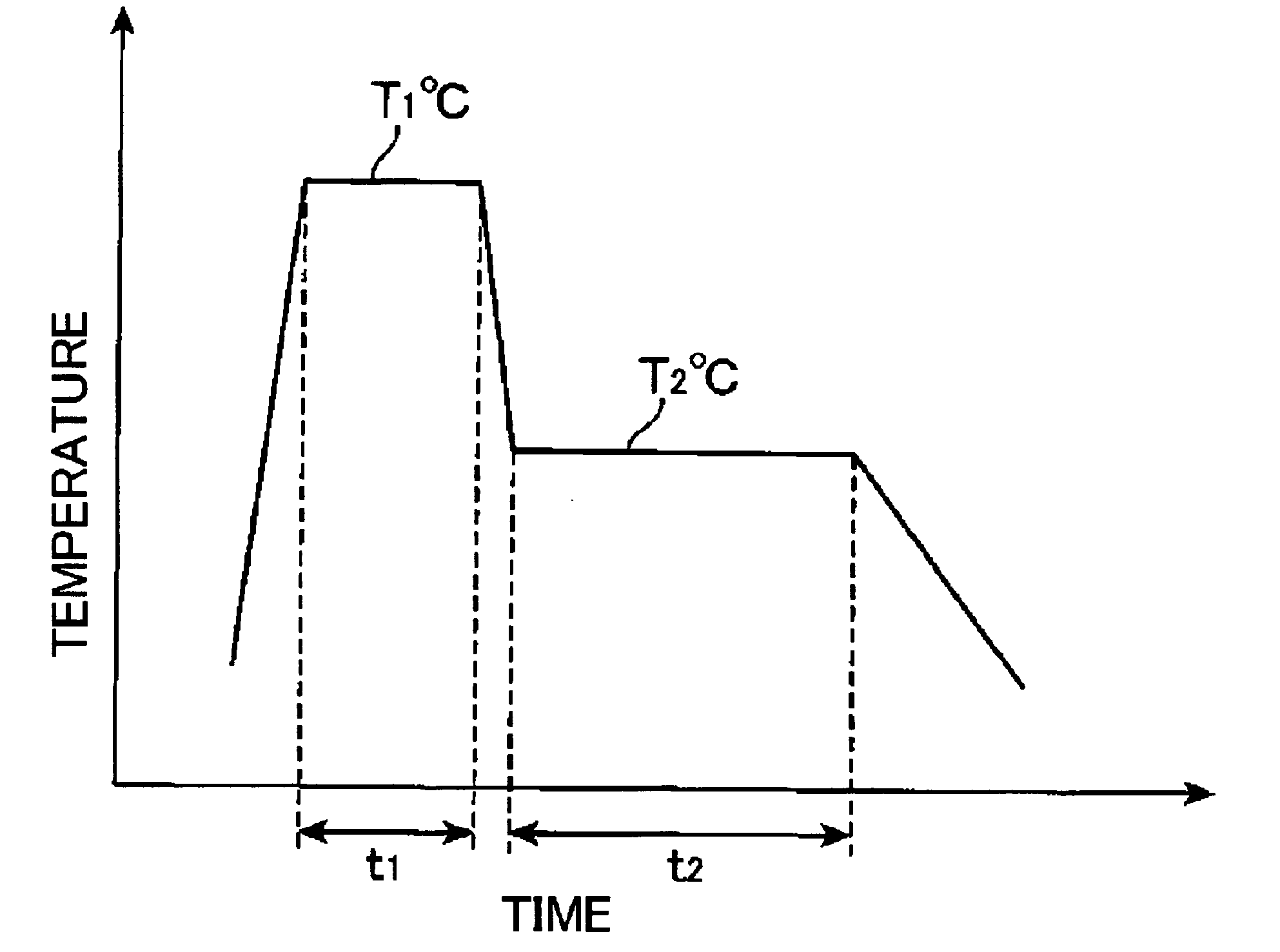

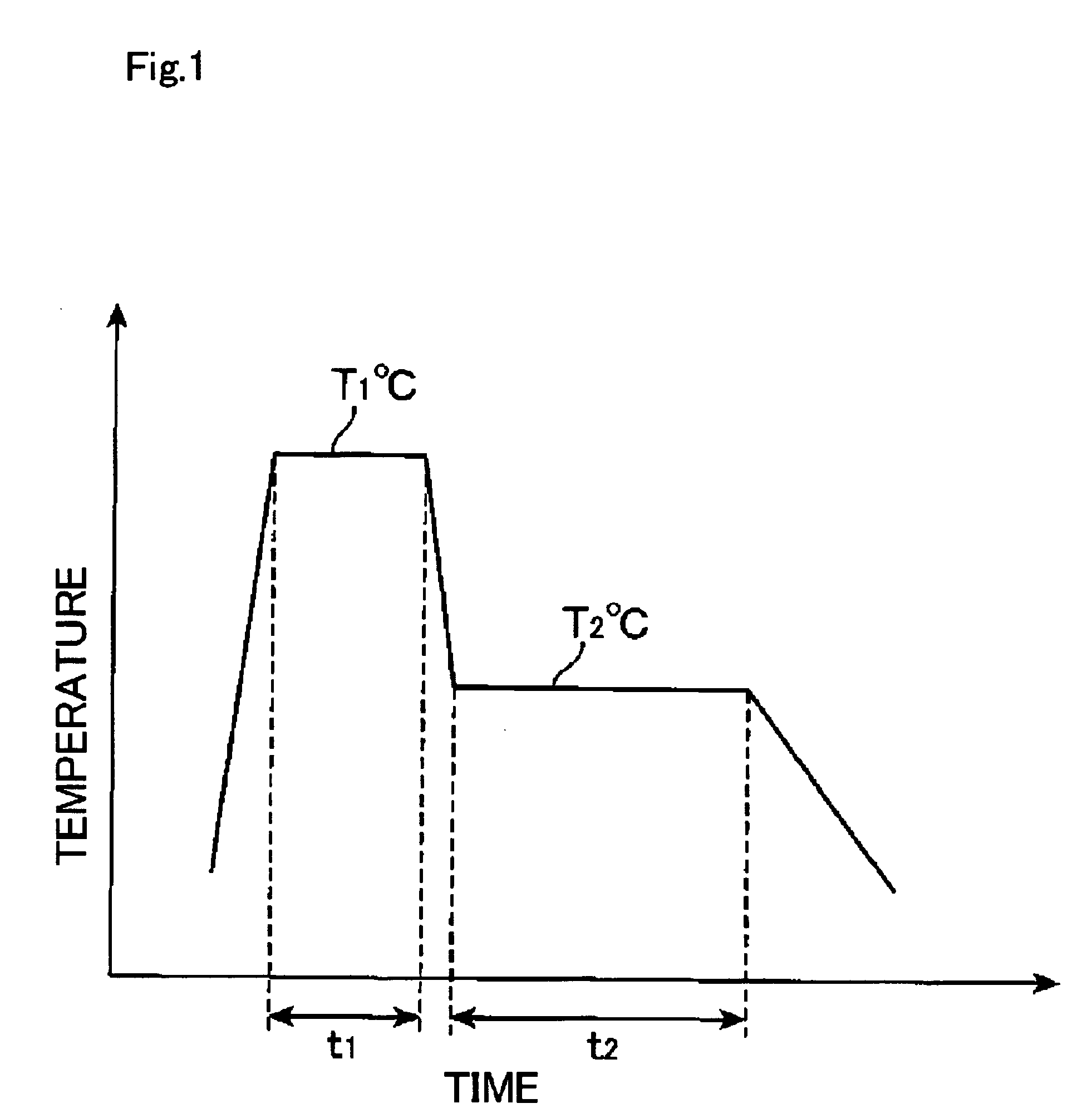

Low-yield-ratio high-strength hot-rolled Q&P steel and manufacturing method thereof

The invention relates to low-yield-ratio high-strength hot-rolled Q&P steel and a manufacturing method thereof. The steel comprises the chemical components of 0.20-0.40% of C, 1.0-2.0% of Si, 1.5-3.0% of Mn, no more than 0.015% of P, no more than 0.005% of S, 0.02-0.08% of Al, no more than 0.006% of N, 0.005-0.015% of Ti, and balance of Fe and unavoidable impurities. According to the invention, through low-cost component design, on a basis of common C-Mn steel, Si content is increased such that cementite precipitation is inhibited, and austenite grains are micronized through micro-Ti treatment. Also, with a combination of hot continuous rolling process and sectioned cooling process, a structure comprising proeutectoid ferrite, martensite, and residual austenite is obtained. The yield strength is lower than 700MPa, a tensile strength is higher than 1000MPa, a yield ratio is 0.50-0.60, and alloy cost is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

High strength and low yield ratio cold rolled steel sheet and method of manufacturing the same

ActiveUS20050161134A1High strengthLow yield ratioSolid state diffusion coatingFurnace typesHigh intensityUltimate tensile strength

To provide a high strength and low yield ratio cold rolled steel sheet having high elongation property and high flange drawing property, or a plated steel sheet made by plating the same. The high strength and low yield ratio cold rolled steel sheet or the plated steel sheet made by plating the same has such a constitution as 0.10 to 0.25% of C, 1.0 to 2.0% of Si and 1.5 to 3.0% of Mn, are contained in terms of weight percentage, while other elements are controlled such as Al within 0.2%, P within 0.15% and S within 0.02%, with residual austenite occupying at least 5%, bainitic ferrite occupying at least 60% (preferably 80% or more), and polygonal ferrite within 20% (containing 0%), so that a tensile strength is 980 MPa or higher, while an elongation (El in %), a flange drawing property (λ in %), a tensile strength (TS in MPa) and a yield strength (YP in MPa) satisfy the following inequality (1): [(El×λ×TS) / YP]≧645.

Owner:KOBE STEEL LTD

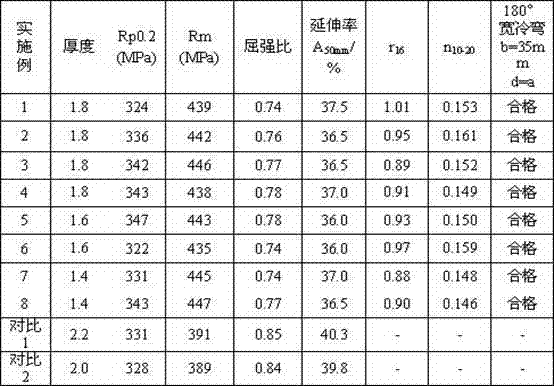

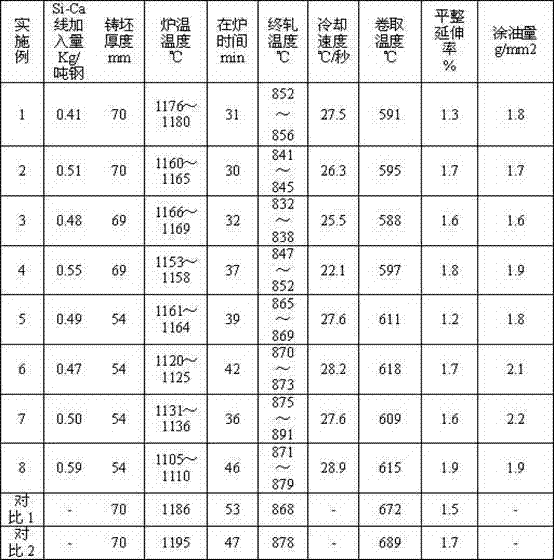

Sheet-billet produced hot-rolled pickled steel with thickness of 1.8mm or lower for automobile and production method thereof

InactiveCN102787273ALow yield ratioImprove surface qualityWork treatment devicesMetal rolling arrangementsCar manufacturingHigh pressure water

The invention relates to a sheet-billet produced hot-rolled pickled steel with thickness of 1.8mm or lower for an automobile, which comprises the following chemical components by weight: 0.04-0.07% of C, 0.10-0.30% of Si, 0.60-1.30% of Mn, 0.025% of P or less, 0.012% of S, 0.02-0.04% of Ti and 0.010-0.030% of Als. The preparation method of the sheet-billet produced hot-rolled pickled steel with thickness of 1.8mm or lower comprises the following steps: desulphurizing molten iron, smelting by a converter, alloying, treating by a ladle furnace, casting and rolling continuously, dephosphorizing high-pressure water by controlling the pressure at 25-35Mpa, controlling rolling, cooling by laminar flow, curling, pickling by acid, levelling by controlling the extension rate at 2% or lower, and finishing by adopting static oil removal. The produced thin hot-rolled pickled steel for the automobile, which has the tensile strength of 400MPa or higher and the thickness of 1.8 mm or lower, has the characteristics of low yield ratio, high surface quality, short production cycle and low cost, achieve the match of high strength and good stamping performance and can replace the cold-rolled high-strength steel to manufacture the automobile.

Owner:武钢集团有限公司

Low-cost steel plate for building structure and manufacturing method thereof

InactiveCN101705423ALow costGood welding performanceTemperature control deviceFurnace typesYield ratioHigh rise

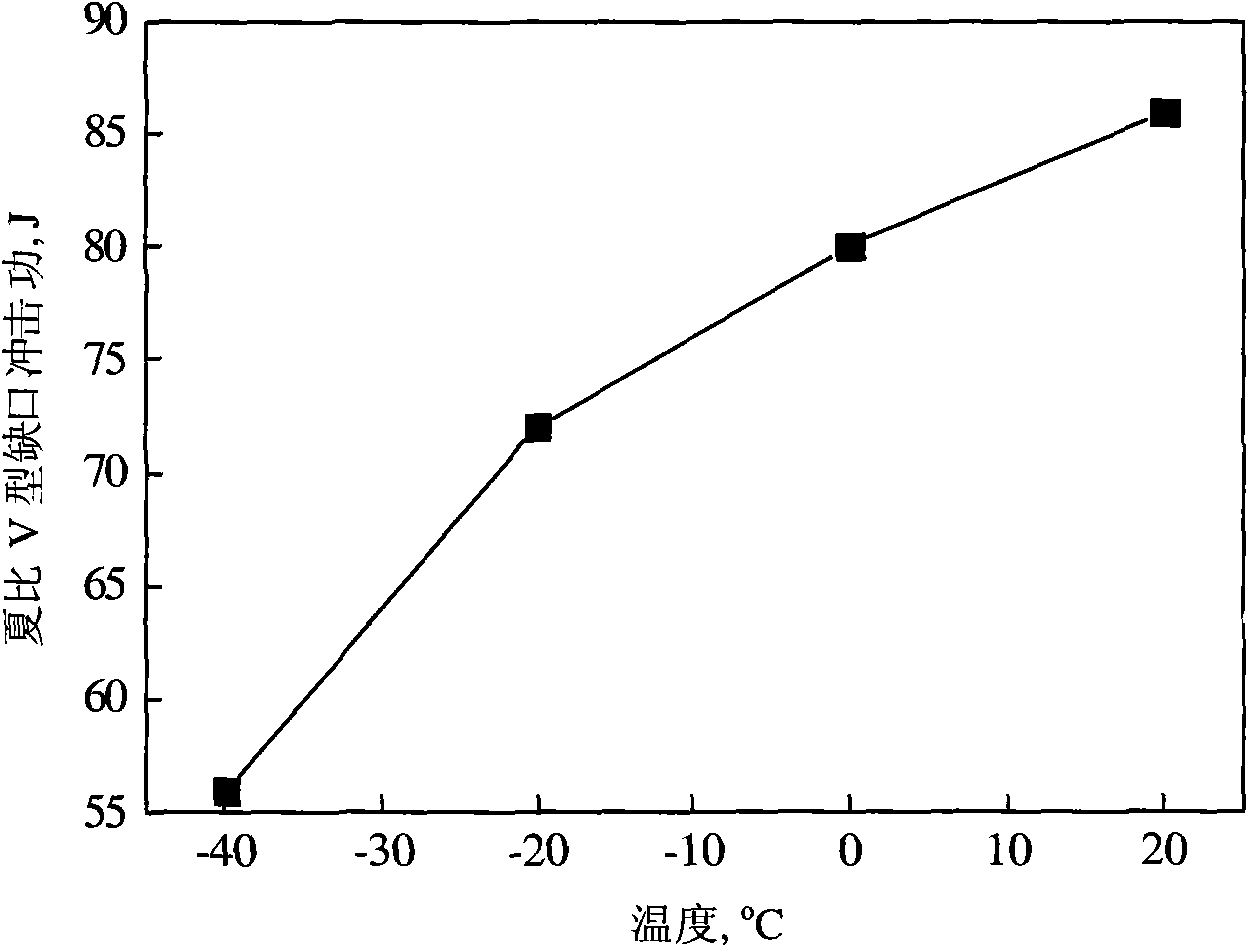

The invention discloses a low-cost steel plate for a building structure and a manufacturing method thereof. The steel plate comprises the following chemical components: C accounts for 0.14 percent to 0.17 percent, Si accounts for 0.20 percent to 0.50 percent, Mn accounts for 1.30 percent to 1.50 percent, P is equal to or less than 0.012 percent, S is equal to or less than 0.005 percent, Alt accounts for 0.020 percent to 0.060 percent, and the balances are Fe and unavoidable foreign impurities. (1) No noble metal elements such as Nb, V, Ti, Ni, Cr, Mo and the like, are added in the steel, the requirement of Q345GJ strength level is met completely though the chemical components C-Si-Mn-Al, and the cost is low; (2) the steel is purer, P is equal to or less than 0.012 percent, and S is equal to or less than 0.005 percent; (3) the impact toughness is good at the temperature of minus 40 DEG C, and the Charpy impact energy of a V-shaped notch is equal to or higher than 80 J; (4) the earthquake resistance is good, and the actual yield ratio is respectively smaller than 0.78; and (5) the lamellar tearing resistance is excellent, and the actual Z-direction section shrinkage ratio in the total-thickness direction is equal to or higher than 38 percent. The hot-rolling Q345GJEZ35 steel plate used for the building structure and provided with thickness of 20-90 mm can be produced, and the steel plate and the manufacturing method can be applied to the manufacture of the steel structure of the high-rise building, have good comprehensive performance and simple production process, can realize the batch production and have low cost.

Owner:SHOUGANG CORPORATION

High strength low yield ratio welding structure steel and production method thereof

The invention belongs to welded structural steel with high strength and low yield ratio and a production method thereof, aiming at solving the defects that a steel plate or a steel coil with the specification smaller than 25mm can only be produced, the process is long, and the like. The invention adopts the measures that the welded structural steel contains chemical components by weight that: 0.04-0.10 percent of C, 0.60-2.00 percent of Si, 1.50-2.50 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.010 percent of S, 0.20-0.50 percent of Cu, 0.40-0.80 percent of Cr, 0.35-0.80 percent of Ni, 0.0008-0.0030 percent of B, and at least three of the following components: less than or equal to 0.60 percent of Mo, 0.015-0.060 percent of Nb, 0.030-0.120 percent of V, less than or equal to 0.030 percent of Ti, less than or equal to 0.040 percent of Als and less than or equal to 0.010 percent of Zr, and the rest is Fe and unavoidable impurities; and meanwhile, Mn and Cr also need to satisfy the condition that Mn and Cr are equal to 2.20-2.80 percent, and the welding cold crack sensitivity coefficient Pcm is equal to C plus Si / 30 plus (Mn plus Cu plus Cr) / 20 plus Mo / 15 plus Ni / 60 plus V / 10 plus 5B and is less than or equal to 0.30 percent; the production method comprises the following steps of heating a steel billet, rough rolling, finishing rolling, relaxing and laminar cooling, and the laminar cooling comprises the following steps of slow cooling, quick cooling and natural cooling to room temperature.

Owner:武钢集团有限公司

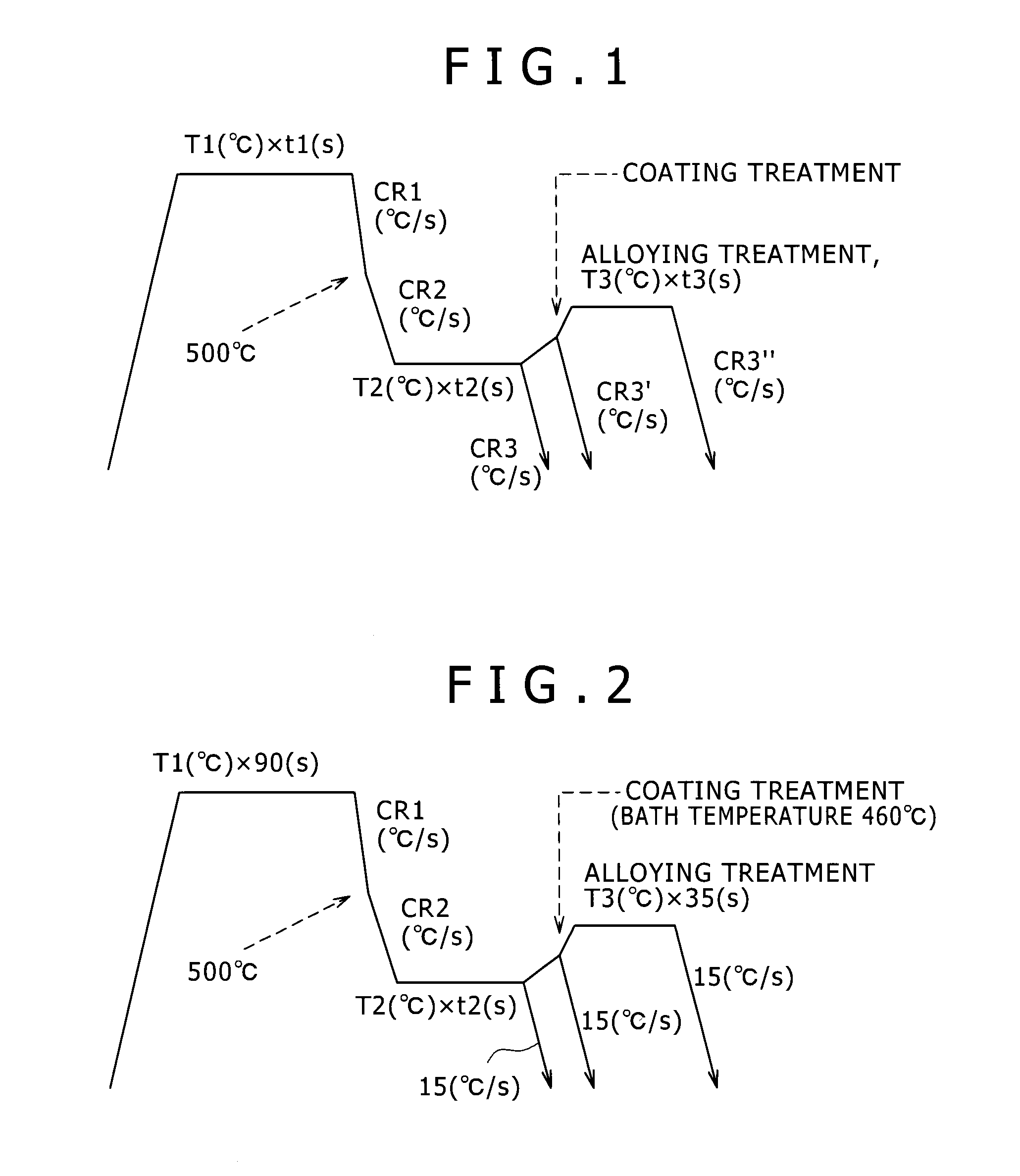

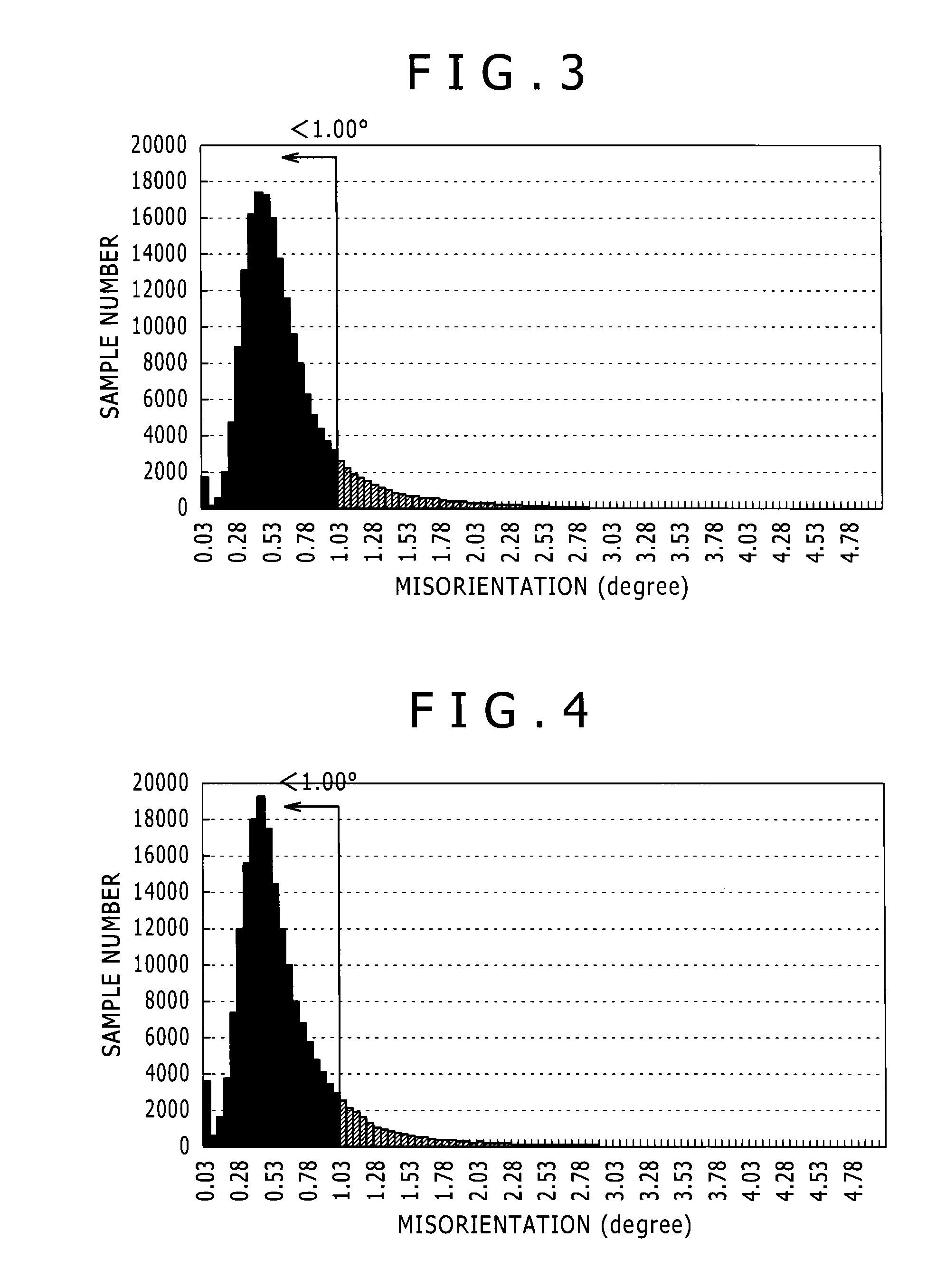

High-strength cold-rolled steel sheet, high-strength hot-dip galvanized steel sheet, and high-strength hot-dip galvannealed steel sheet excellent in formability and shape fixability, and methods for manufacturing them

InactiveUS20150086808A1Good formabilityEasy to shapeHot-dipping/immersion processesFurnace typesChemical compositionBainite

A high-strength cold-rolled steel sheet has a specific chemical composition and has a steel microstructure meeting conditions: a total content of bainitic ferrite (BF) and tempered martensite (TM) is 65% (in area percent, hereinafter the same for steel microstructure) or more; a fresh martensite (M) content is 3% to 18%; a retained austenite content is 5% or more; and a polygonal ferrite (F) content is 5% or less. The steel sheet has a specific average KAM<1.00° of 0.50° or more and has a tensile strength of 980 MPa or more. The high-strength cold-rolled steel sheet excels in formability and shape fixability.

Owner:KOBE STEEL LTD

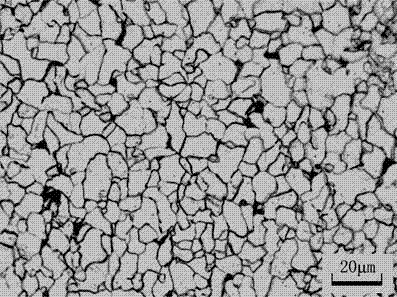

Pipeline steel plate with low yield ratio, fine grains and high strength and production method thereof

The invention discloses a pipeline steel plate with low yield ratio, fine grains and high strength and a manufacturing method thereof, and steel in the pipeline steel plate comprises the following chemical components by weight percent: 0.03-0.10% of C, 0.10-0.30% of Si, 1.20-1.80% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.040-0.060% of Nb, 0.006-0.020% of Ti, 0.10-0.40% of Cr, 0.10-0.30% of Ni, 0.010-0.050% of Al and the balance of Fe and inevitable impurities. The manufacturing method adopts a converter for smelting, adopts the TMCP (thermo mechanical control process) and the two-phase region subthermal quenching treatment at 720-750 DEG C, thereby obtaining the pipeline steel plate with low yield ratio, fine grains and high strength; and the manufacturing method has stable production process, strong operability, low cost and high performances.

Owner:NANJING IRON & STEEL CO LTD

Fine crystal strengthen carbon constructional steel and manufacture process for hot-rolling thin slab thereof

InactiveCN101153367AHigh strengthHigh elongationShaping toolsHeat treatment process controlChemical compositionThin slab

The invention relates to a manufacture process of carbon steel and carbon steel hot rolling plate, in particular to a manufacture process of fine grain reinforcement carbon structural steel and hot rolling sheet plate of the steel. The invention mainly solves the technical problem that hot rolling plate of higher strength can not be produced on common completely continuous hot continuous rolling mill by use of common carbon structural steel at present. The fine grain reinforcement carbon structural steel adopts the following chemical composition (weight percent): 0.14 percent to 0.20 percent of C, 0.10 percent to 0.40 percent of Si, 0.65 percent to 0.90 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S and the rest, Fe. The manufacture process of the hot rolling sheet plate is as follows: a continuous casting slab which meets the requirements of compositions is heated to 1,210 DEG C to 1,250 DEG C; a rough rolling stage comprises five-pass tandem rolling and the end temperature of the rough rolling stage is between 1,050 DEG C and 1,060 DEG C; in addition, the thickness of an intermediate slab ranges from 35 mm to 45 mm. When rough rolling is finished, the intermediate slab is curled through a hot coil box and then is unfolded for finish rolling; a finish rolling stage comprises six-pass tandem rolling with the start rolling temperature ranging between 920 DEG C and 940 DEG C and the end temperature ranging between 820 DEG C and 860 DEG C; after finish rolling, the thickness of a steel plate is between 2 mm to 8 mm; in addition, a laminar flow cooling stage adopts forepart intensive cooling with the coiling temperature ranging from 520 DEG C to 620 DEG C.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Cold rolled dual-phase sheet steel with 1000MPa grade tensile strength and preparation method thereof

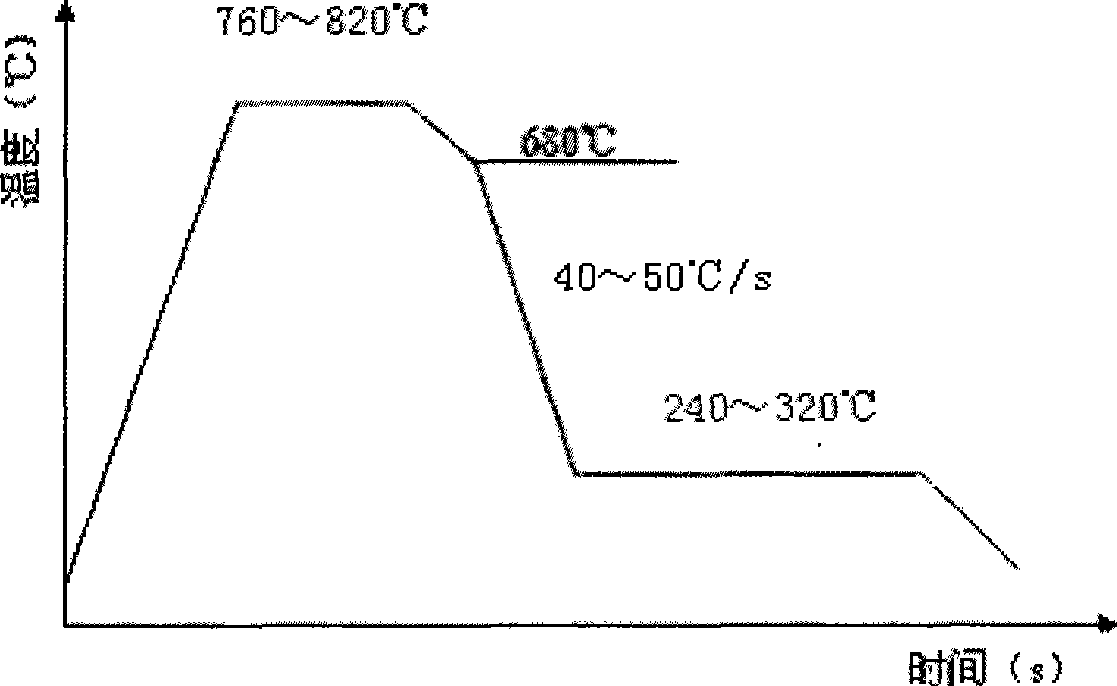

A cold-rolled biphase steel plate with 1000 MPa of tensile strength and a production method thereof belong to the technical field of high-intensity cold-rolled biphase steel. The steel plate comprises the following chemical components by mass percentages: 0.14%-0.21% of C, 0.40%-0.90% of Si, 1.5%-2.1% of Mn, 0.01%-0.05% of Nb, less than 0.02% of P, less than 0.01% of S, and Fe and inevitable impurities. The production method is as follows: a billet is treated by the conventional hot rolling, pickling, cold rolling and continuous annealing, the annealing temperature is 760-820 DEG C and is kept for 70-120s, the fast cooling speed is 40-50 DEG C per second, the aging temperature is 240-320 DEG C and the aging time is 180-300s. The cold-rolled biphase steel plate has the advantages of high tensile strength, low tensile ratio, high initial work hardening rate, no yield elongation which avoids wrinkles on the formed parts. The cold-rolled biphase steel plate has a biphase organization with fine grain ferrite and martensite, wherein, the volume fraction of the martensite is 30%-40% and the average grain size of the ferrite is 2mum.

Owner:UNIV OF SCI & TECH BEIJING +1

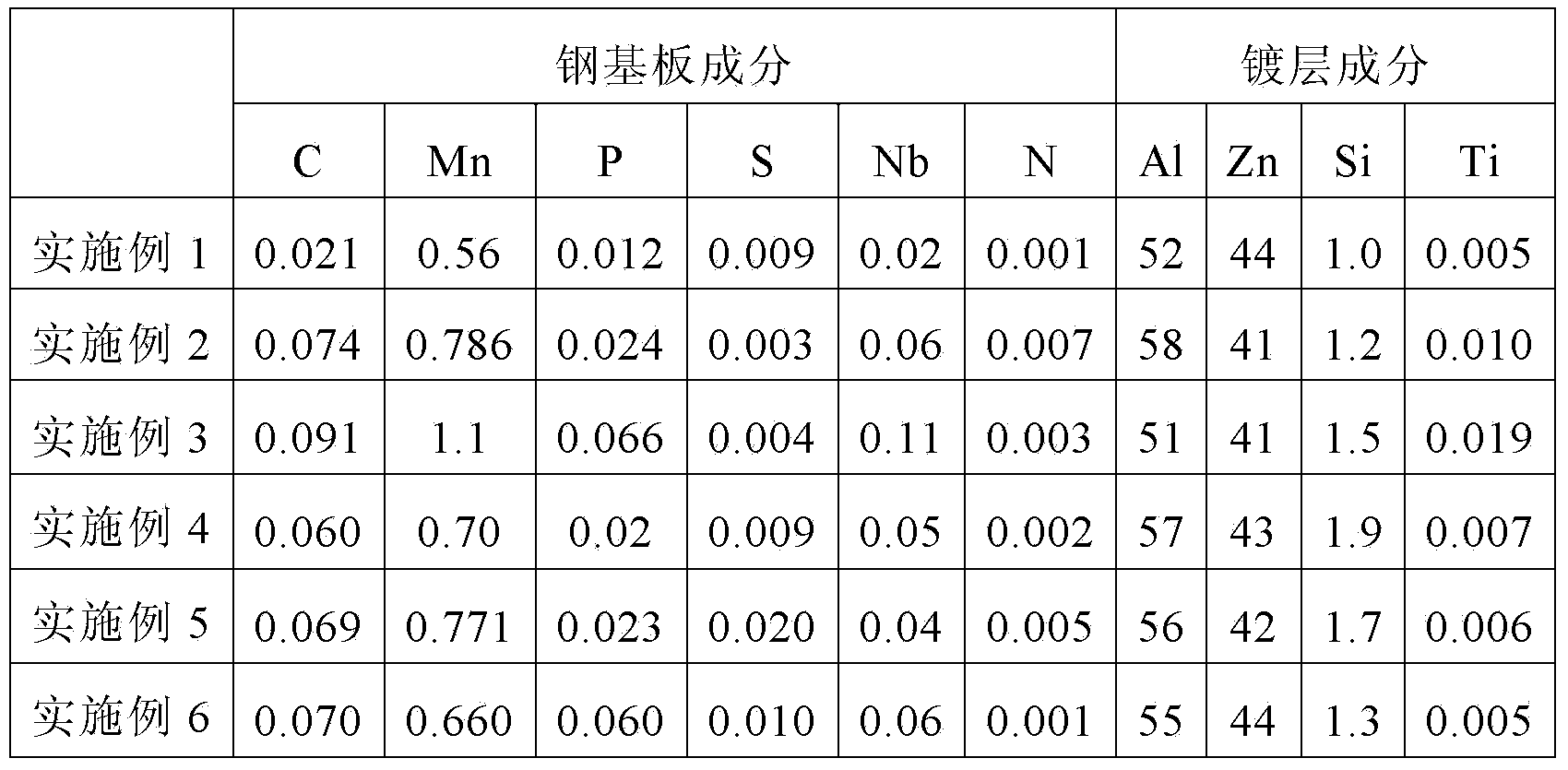

High-strength low-alloy hot-dip aluminized and galvanized steel strip and production method thereof

ActiveCN104264041AHigh strengthLow yield ratioHot-dipping/immersion processesAlloy coatingContinuous annealing

The invention relates to a high-strength low-alloy hot-dip aluminized and galvanized steel strip and a production method thereof. The hot-dip aluminized and galvanized steel strip comprises a steel base plate and an alloy coating, wherein the steel base plate comprises the following chemical components in percentage by weight: 0.02-0.10% of C, 0.5-1.2% of Mn, 0.01-0.07% of P, 0.01-0.12% of Nb, less than or equal to 0.0080% of N, less than or equal to 0.02% of S and the balance of Fe and inevitable impurities, wherein Nb-0.22C-1.1N is equal to or greater than 0.01% and less than or equal to 0.1% and Mn / 1.7S is equal to or greater than 8; the alloy coating comprises the following chemical components in percentage by weight: 50-58% of Al, 40-45% of Zn, 1.0-2.0% of Si, 0.005-0.020% of Ti and the balance of unavoidable impurities. According to the hot-dip aluminized and galvanized steel strip, by virtue of smelting, casting, carrying out hot rolling and cold rolling, continuously annealing and carrying out hot-dip aluminizing and galvanizing, the aluminum-zinc coating is evenly and densely adhered to the steel base plate, the obtained low-alloy hot-dip aluminized and galvanized steel strip has the yield strength of 410-570MPa, the tensile strength equal to or greater than 470MPa and elongation equal to or greater than 15% and has both good strength and toughness and excellent corrosion resistance. The production process is low in cost and high in steel plate yield.

Owner:BAOSHAN IRON & STEEL CO LTD

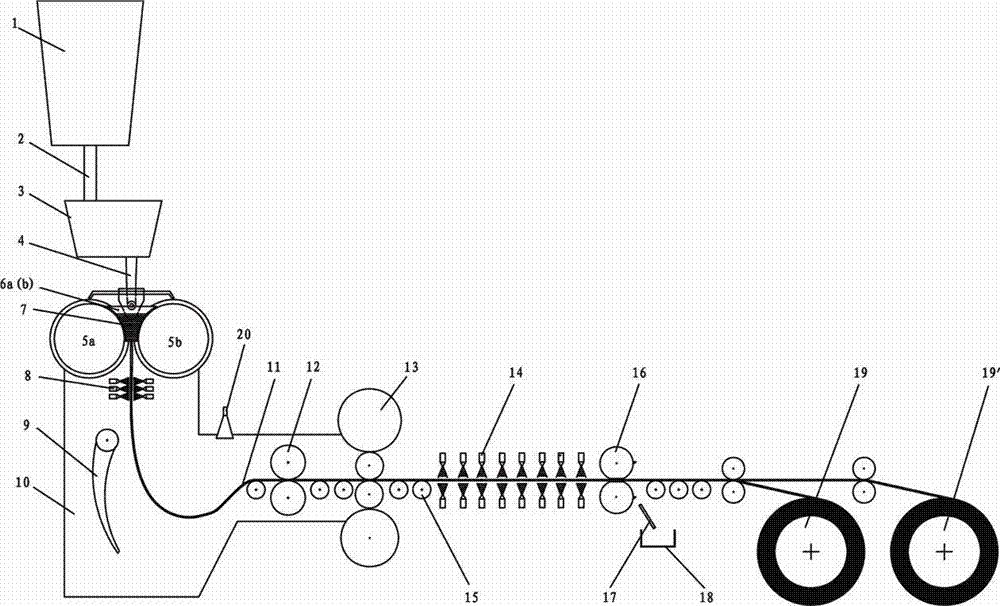

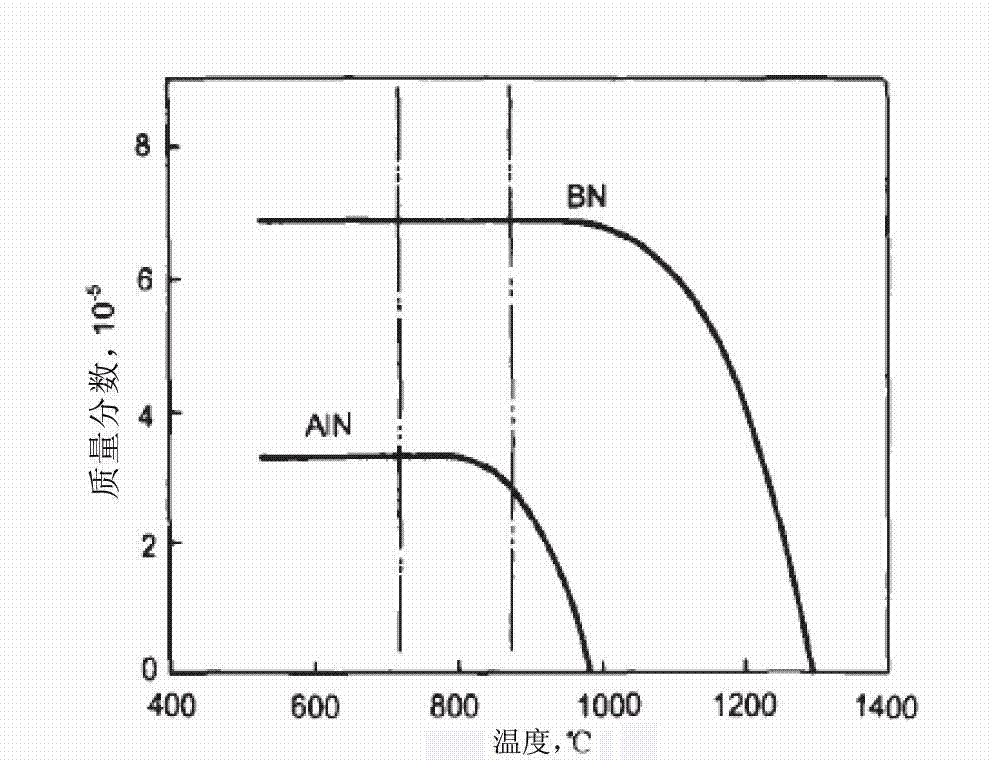

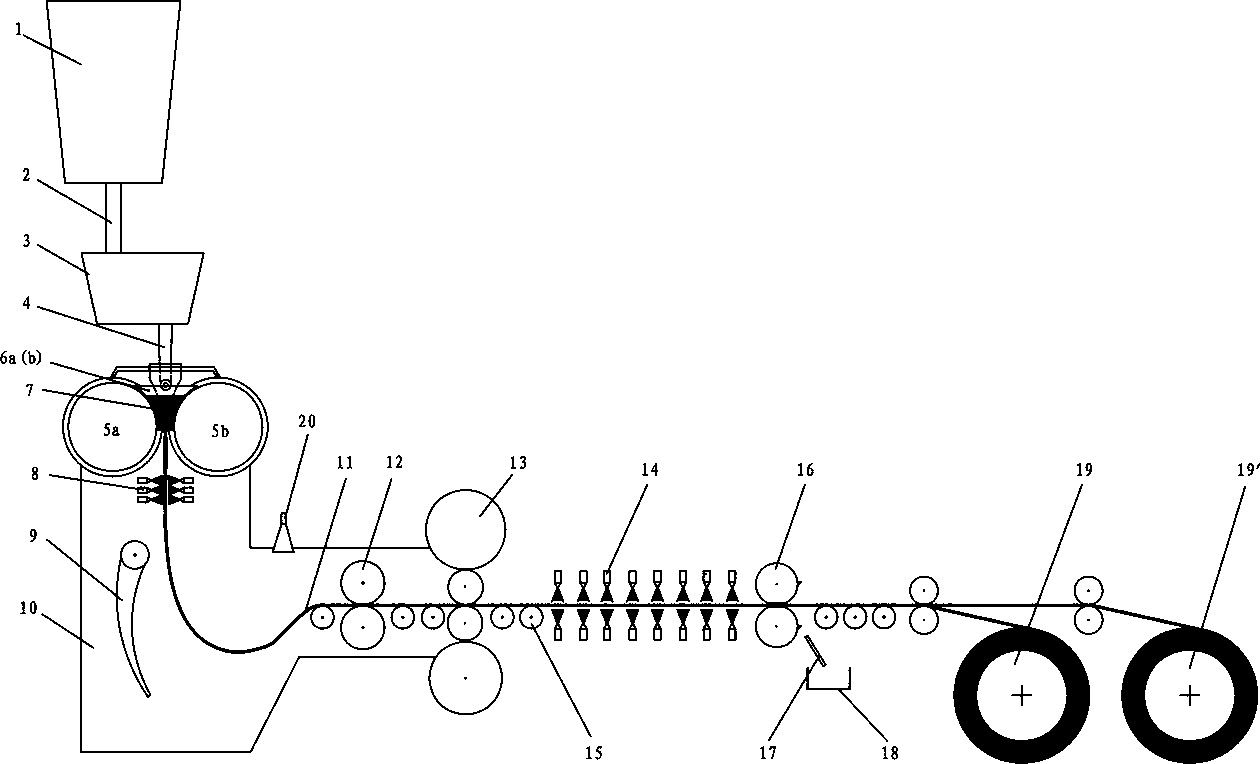

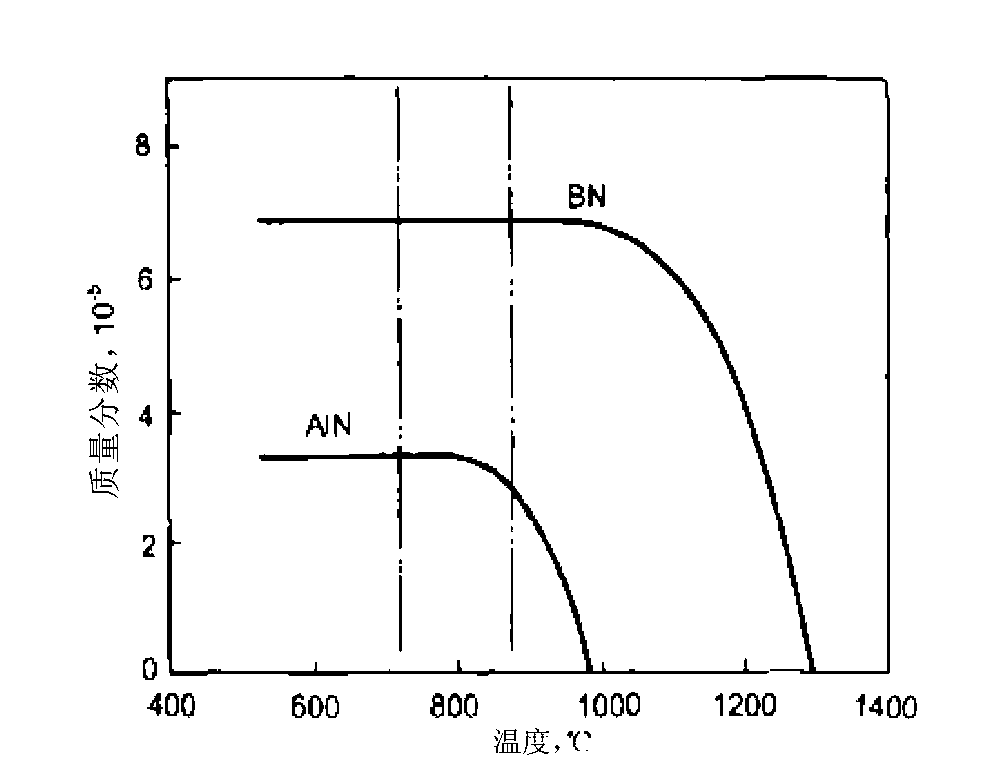

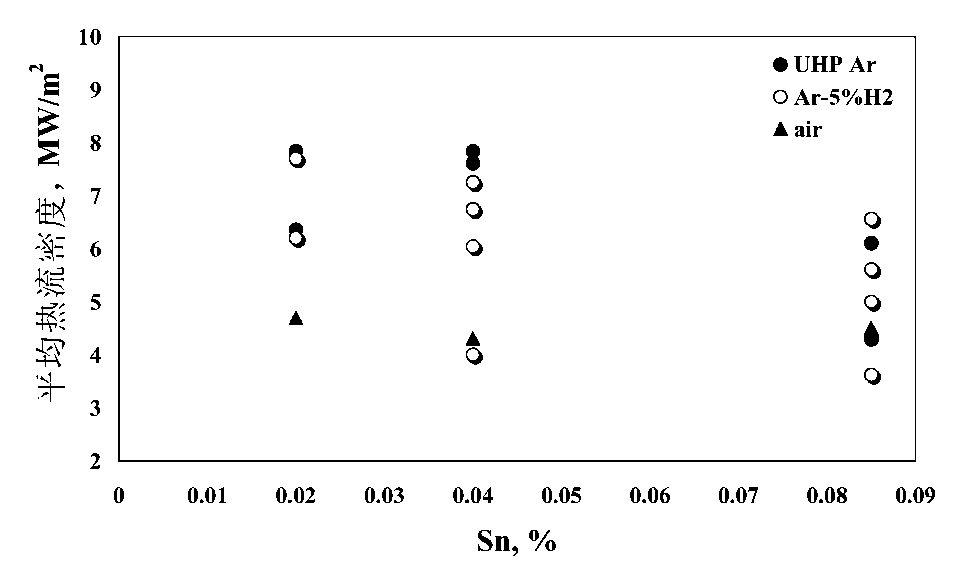

Boron-containing weather-proof thin strip steel and manufacturing method thereof

Provided are boron-containing weather-proof thin strip steel and a manufacturing method thereof. The manufacturing method comprises performing double roller thin strip continuous casting to produce boron-containing weather-proof steel; after a cast strip is processed through a crystallizing roller, adopting a mode of spraying dry ice to perform uniform strengthened cooling on the cast strip, rapidly cooling the cast strip to below 1,280 DEG C, and enabling the cooling speed to be 200-300 DEG C / s, so that precipitation of thick and large BN in the cooling mode is promoted, emergency of low-melting-point-phase B203 and precipitation of tiny AlN are avoided, and the aims of homogenizing austenite grains and reducing yield ratio are achieved; then performing austenite on-line recrystallization rolling; then performing anti-oxidizing rapid cooling to cool the strip steel undergoing hot rolling, and enabling the cooling temperature to be 80-200 DEG C / s; and enabling coiling temperature to be 500-600 DEG C. Steel with low yield ratio can be obtained through the manufacturing method, and the problems that steel produced by thin strip continuous casting are universally uneven in structure, high in yield ratio and difficult to form and cannot meet the requirements for cold rolling materials are effectively solved.

Owner:BAOSHAN IRON & STEEL CO LTD

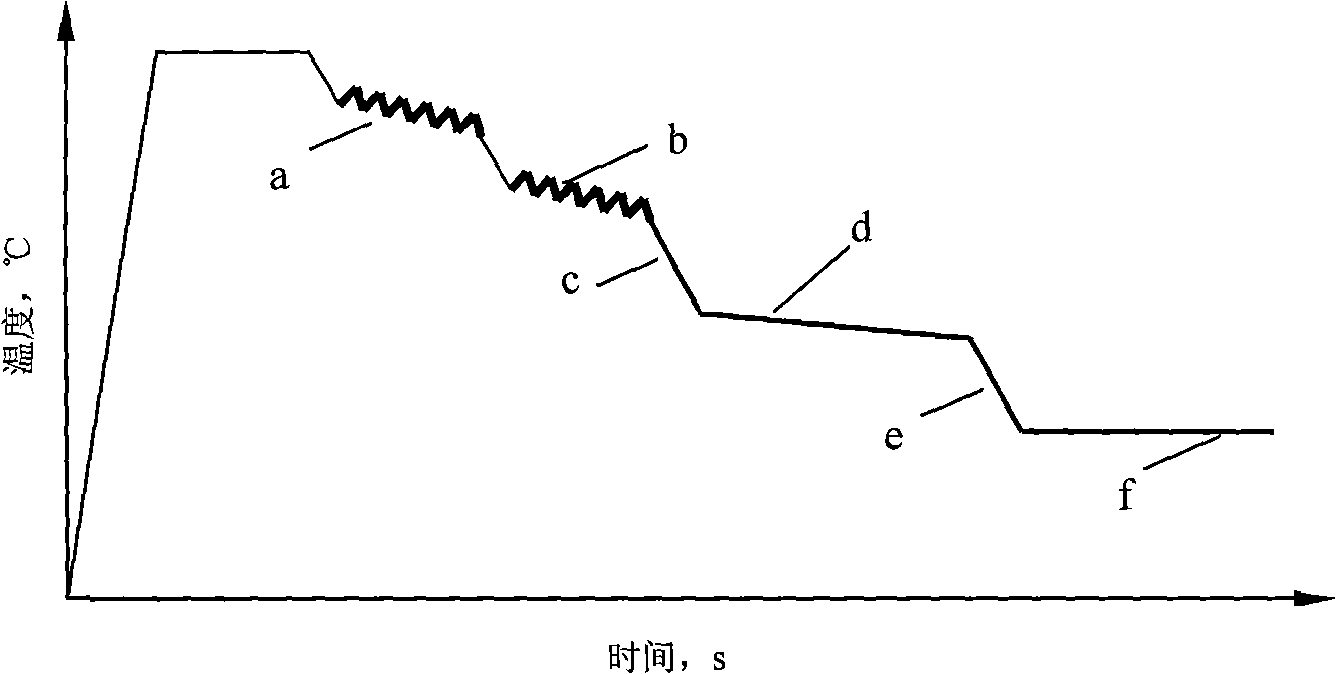

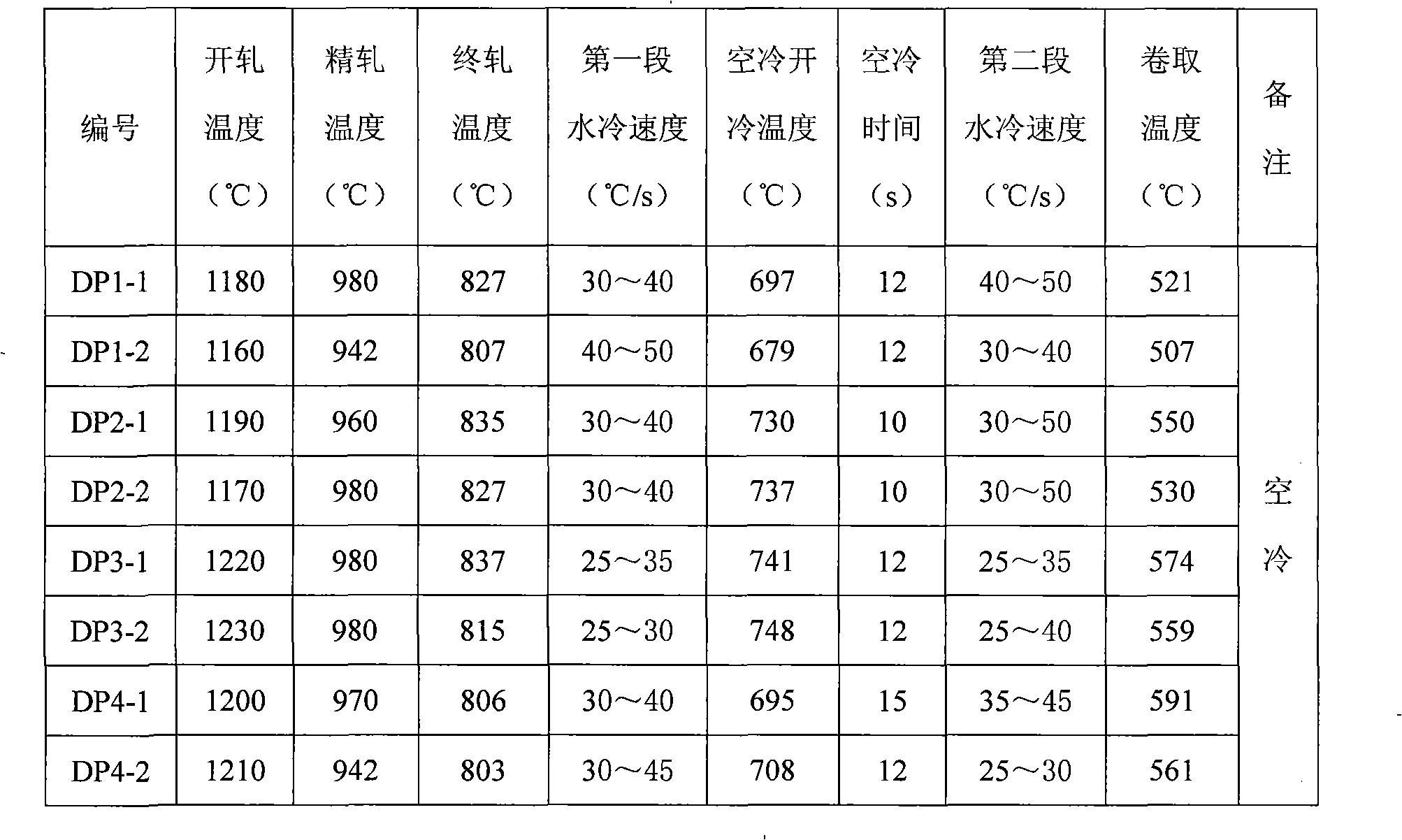

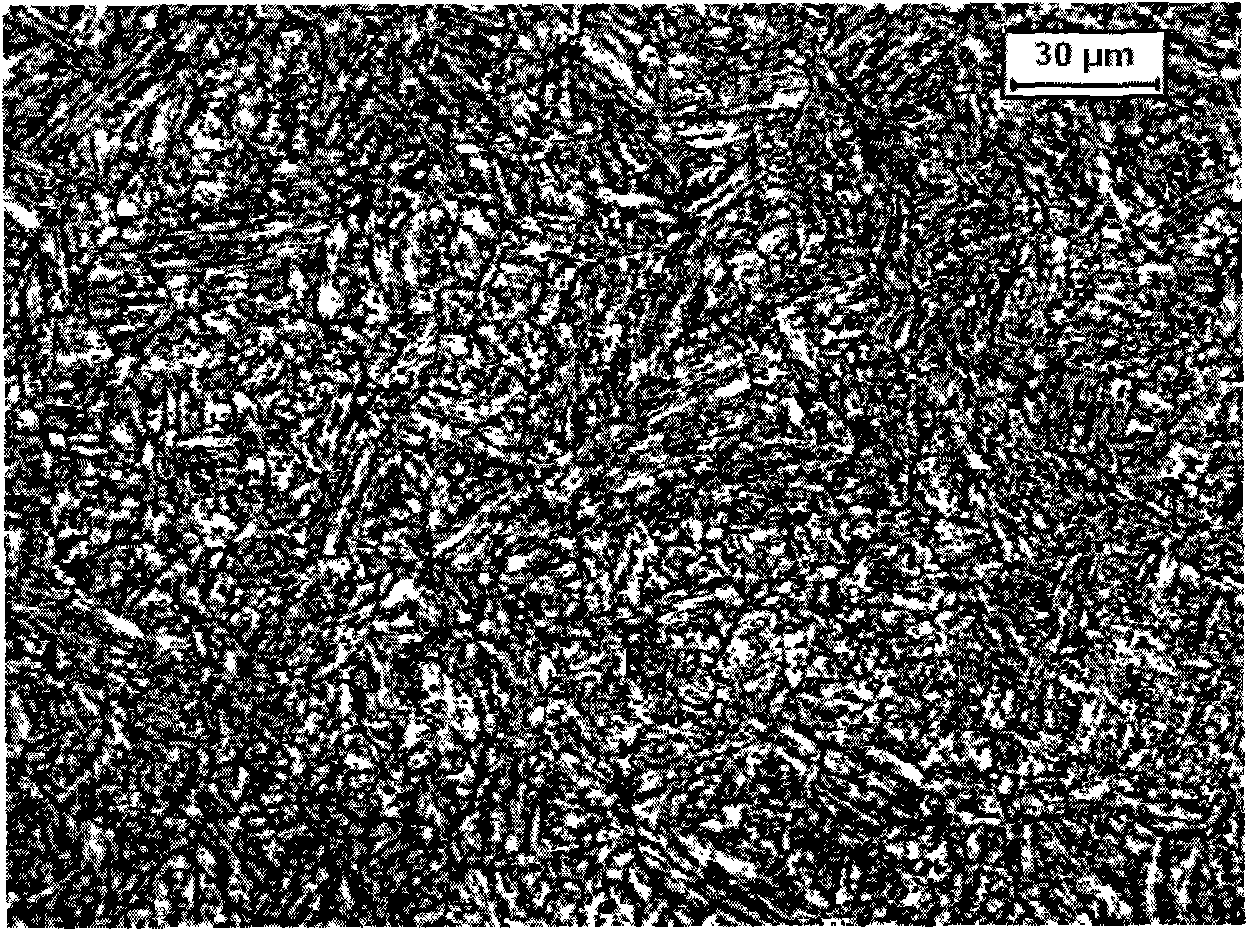

Method for producing hot rolling two-phase steel plate at 700MPa level of tensile strength

InactiveCN101279330AImprove mechanical propertiesLow costTemperature control deviceFurnace typesSheet steelChemical composition

The invention relates to a manufacture method for a thermal rolling double-phase steel plate with 700MPa of anti-tension intensity; the main chemical components of the invention calculated by weight percentage include: 0.03 to 0.08 percent of C, 0.50 to 0.70 percent of Si, 1.00 to 1.60 percent of Mn, 0 to 0.60 percent of Cr, 0 to 0.40 percent of Mo, and 0.02 to 0.05 percent of Nb, and the rest is Fe; the thickness specification of the invention is 3.0 to 4.0mm; the invention is provided with a polygonal ferrite and a martensite double-phase tissue; a few amount of grain bainites appear; wherein, the volume percent of the ferrite is 70 to 90 percent; the volume percent of the martensite is 30 to 10 percent; the average crystal grain dimension of the ferrite is 5Mum. The invention is rolled by a controlled rolling and controlled cooling technology; a beginning rolling temperature is controlled between 1250 to 1150 DEG C; the stopping rolling temperature is controlled between 800 to 850 DEG C; the cooling speed for a first section is controlled between 25 to 50 DEG C / s; after cooling the temperature is 680 to 750 DEG C; a second section controllable cooling is carried out after cooling the temperature between 670 to 700 DEG C by air; the cooling speed for a second section is controlled between 25 to 50 DEG C / s; the stopping cooling temperature, namely the coiling temperature is between 500 and 600 DEG C; then the steel plate is cooled to the room temperature by air.

Owner:UNIV OF SCI & TECH BEIJING

Steel plate with high strength and low yield ratio

The present invention provides a steel plate with high strength and low yield ratio, which comprises chemical components as follows: C: 0.15-0.20 wt%, Si: 1.0-2.0 wt%, Mn: 1.8-2.0 wt%, Al<=0.036 wt%,V: 0.05-0.1 wt%, P<=0.01 wt%, S<=0.005 wt%, Cr: 0.8-1.0 wt%, the residual is Fe and other unavoidable impurity. The hot-rolling steel plate with high strength and low yield ratio is obtained by adopting low alloyed processing and traditional TMCP rolling technique, which has a strength reaching to 1200-1500 MPa, simultaneously, has better low temperature impact toughness. The steel plate is suitable for the fields requiring high strength and low yield ratio, such as mechanical manufacture, fuel / gas delivery pipeline, building, bridge, steel rail and pressure vessel, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Impact stage low carbon steel hot-rolled sheet and mfg. method thereof

InactiveCN1752261ALower yield strengthLow yield ratioTemperature control deviceMetal rolling arrangementsAlloyConductor Coil

A hot-rolled low-carbon steel sheet for punching contains proportionally C, Mn, S, P, Si, Al, Fe, Cr, B, Ti and Nb. Its preparing process includes such steps as heating to 1100-1150 deg.C, primary rolling, water cooling, fine rolling, winding, recrystallizing at 600-700 deg.C and annealing. Its advantages are high deep punching performance, plasticity, tension strength, and elongation percentage, and low yield strength.

Owner:YANSHAN UNIV

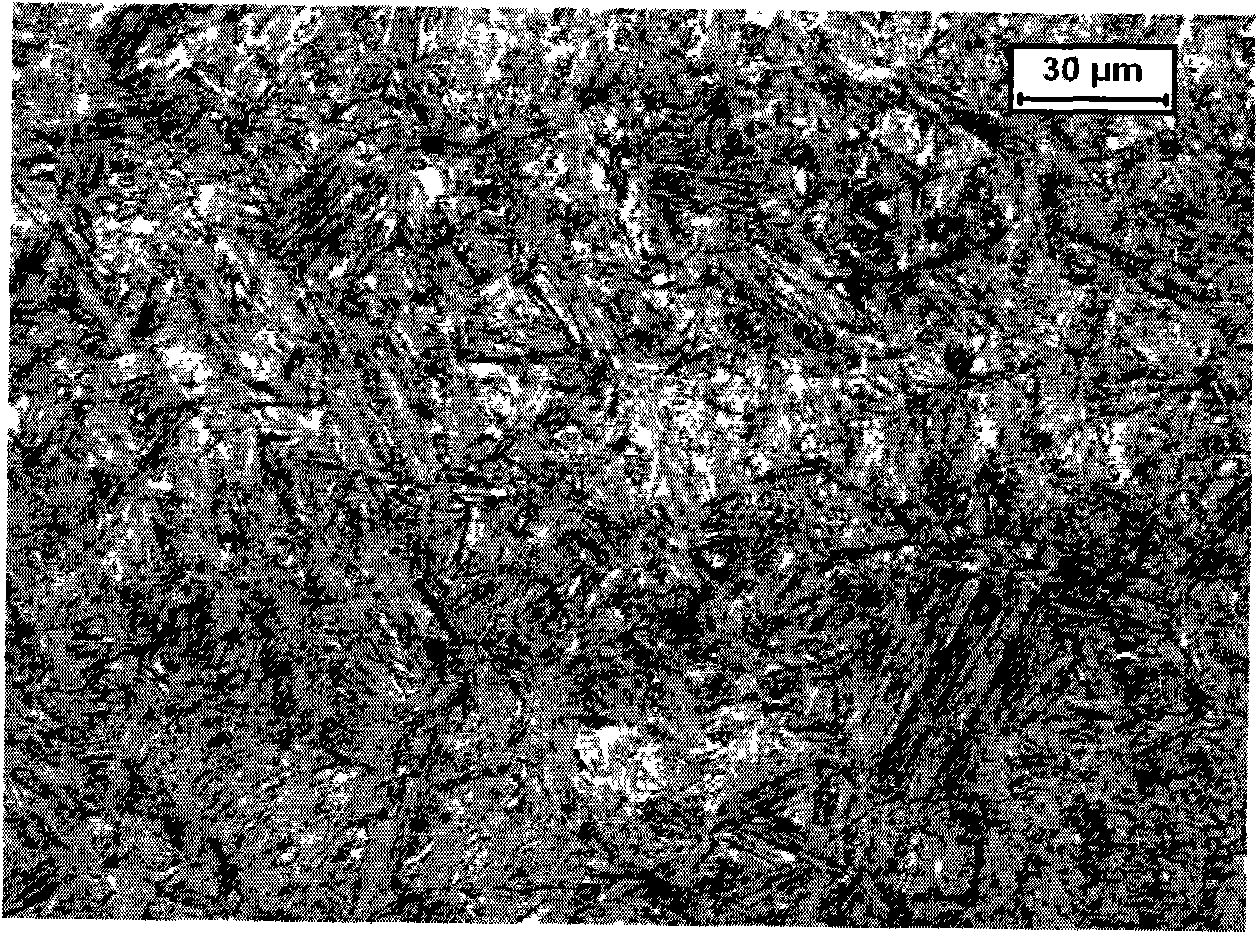

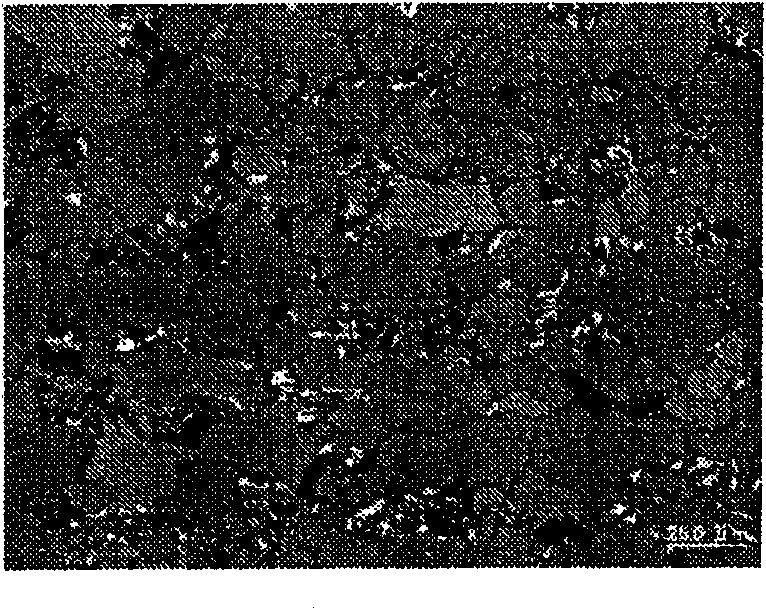

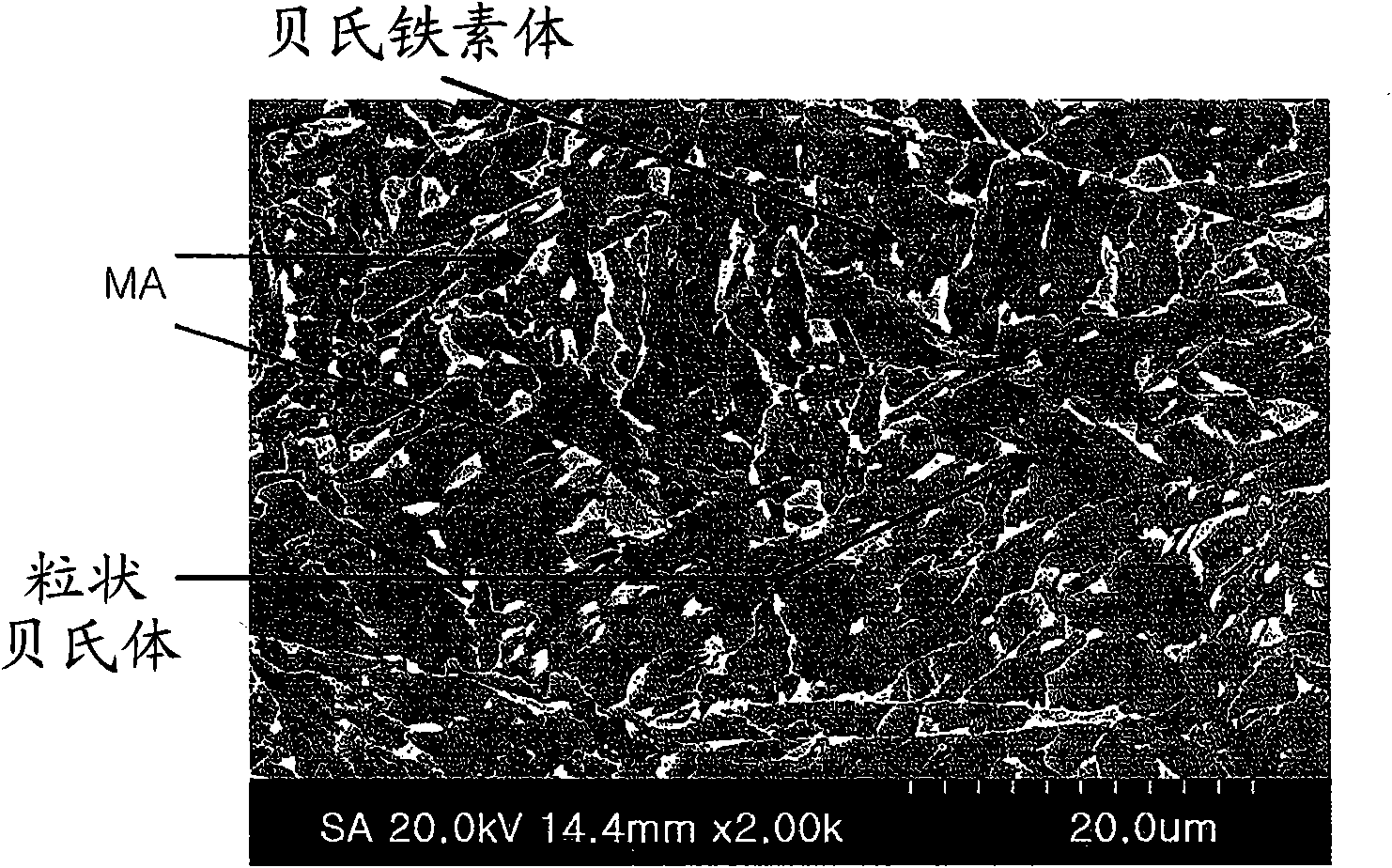

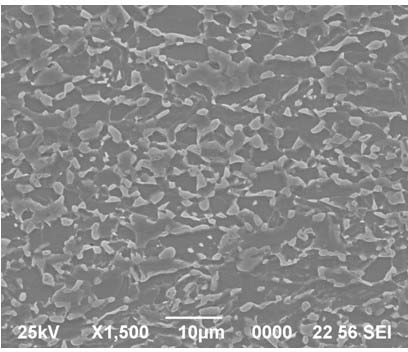

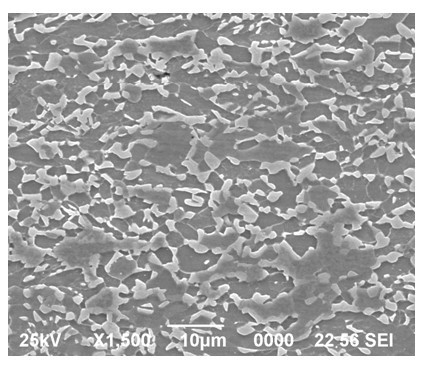

Thick steel board

The invention provides a thick steel board exhibiting low tensile ratio and high toughness, which contains following elements: 0.03-0.15 weight percent of C, less than 1.0 weight percent of Si (0 weight percent not included), 1.0-2.0 weight percent of Mn, less than 0.015 weight percent of P (0 weight percent not included), less than 0.010 weight percent of S (0 weight percent not included); 0.005-0.060 weight percent of Al, 0.008-0.030 weight percent of Ti; 0.0020-0.010 weight percent of N, and less than 0.010 weight percent of O (0 weight percent not included). The microscopic constitution at the t / 4 position of the steel board comprises mixed constitution of ferrite and bainite, wherein t represents thickness of the steel board. Island martensite is dispersed in the bainite, the average particle diameter of the ferrite is 10-50 mu m, and the island martesite in the bainite is 1-20 area percent of the total area.

Owner:KOBE STEEL LTD

High-strength thin band steel for cold forming and manufacturing method thereof

The invention relates to high-strength thin band steel for cold forming and a manufacturing method thereof. The method comprises the following steps: after discharging a cast band from a crystal roll, cooling the cast band forcibly and uniformly in a mode of spraying dry ice under high pressure; quickly cooling the cast band to be below 1,280 DEG C at the cooling speed of 200-300 DEG C / s; performing austenite on-line recrystallization rolling, wherein the rolling temperature is 1,050 to 1,200 DEG C and the rolling reduction is 20 to 50 percent; and quickly cooling the band steel subjected to hot rolling in an anti-oxidation mode, wherein the anti-oxidation quick cooling speed is 80 to 200 DEG C / s and the reeling temperature is 500 to 600 DEG C. By the method, the high-strength thin band steel for automobile cold forming and with low yield strength and excellent stamping performance can be obtained, can be directly used in a mode of substituting heat for cold, cancels the cold rolling procedure and greatly reduces the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

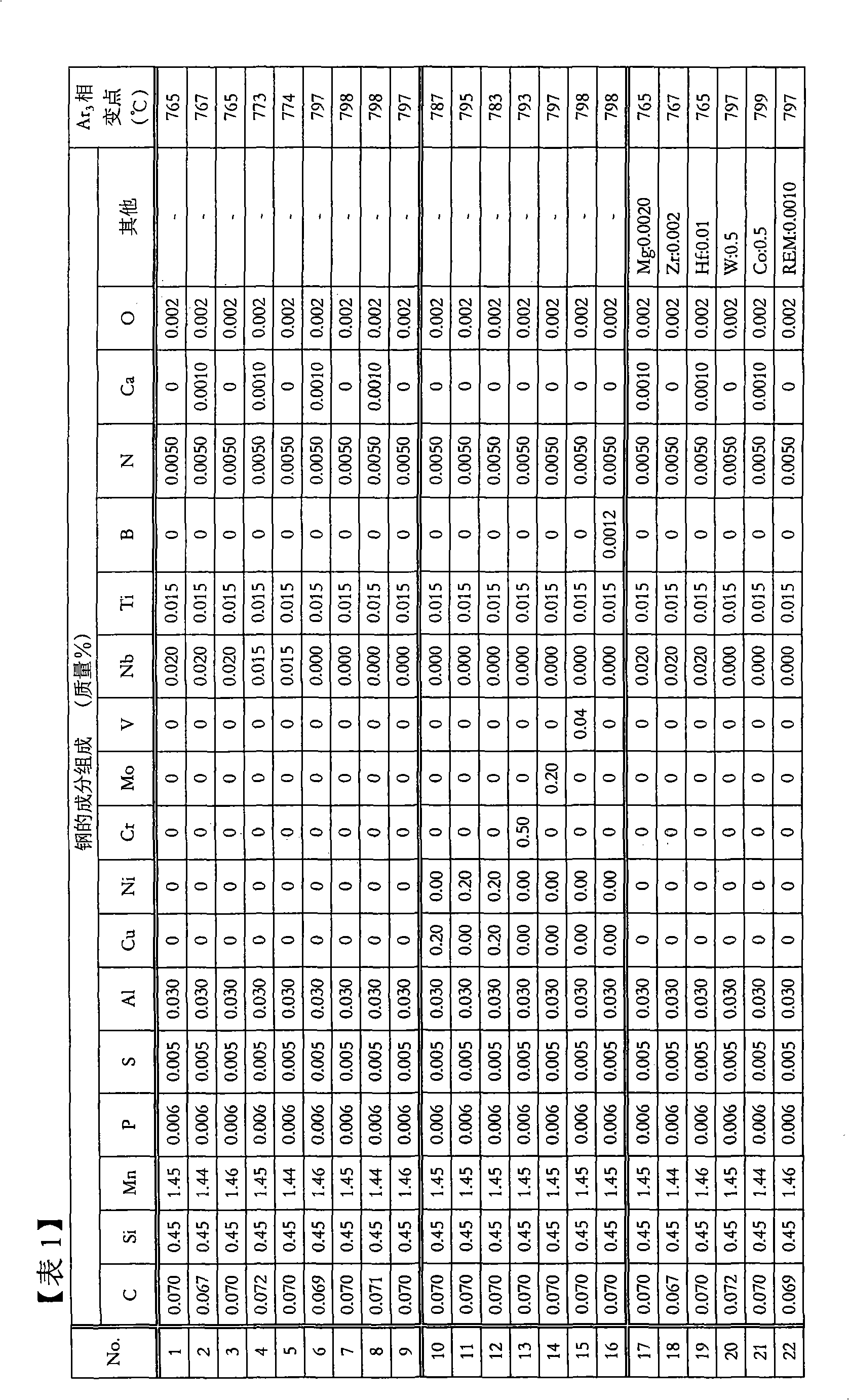

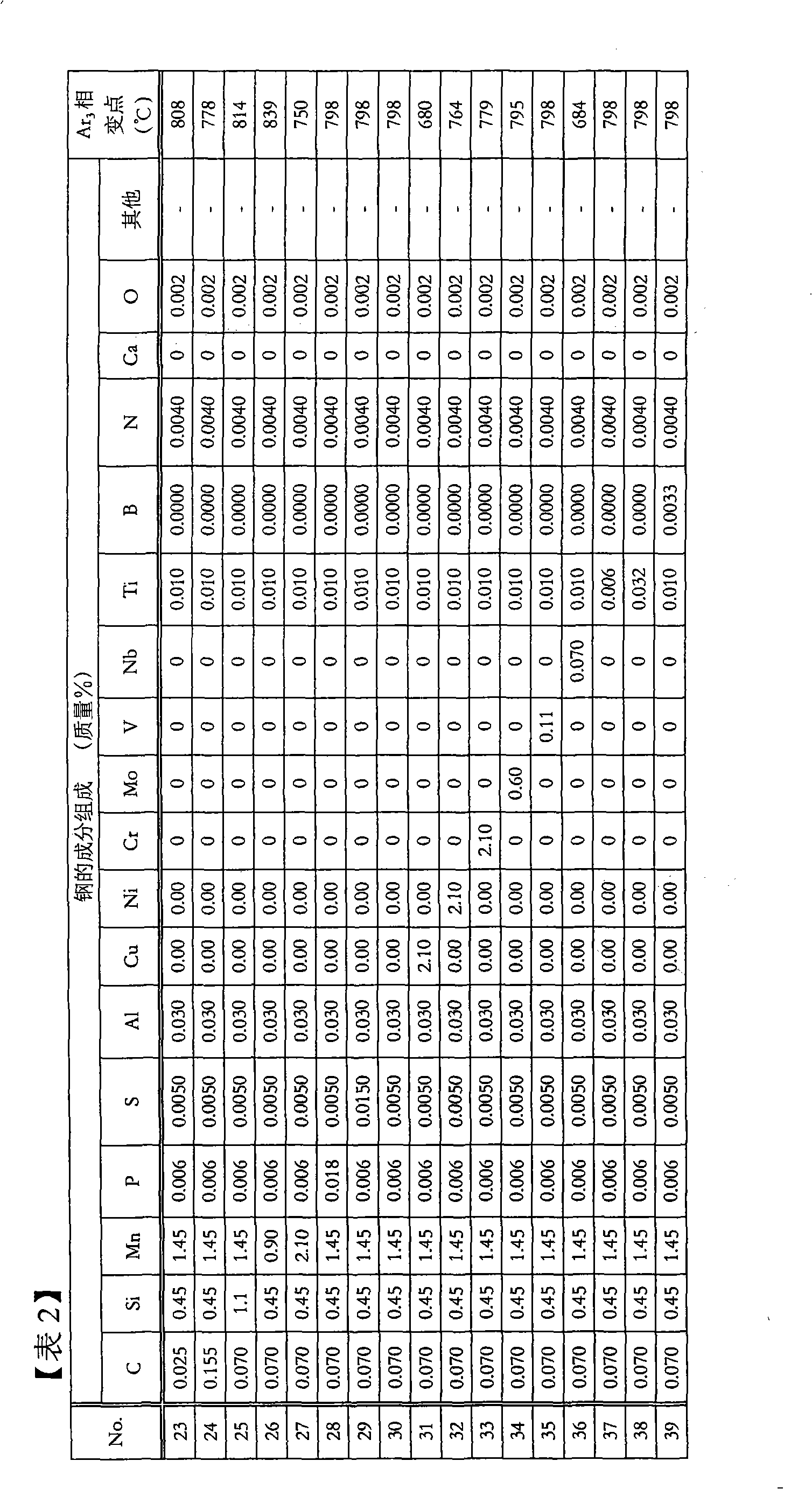

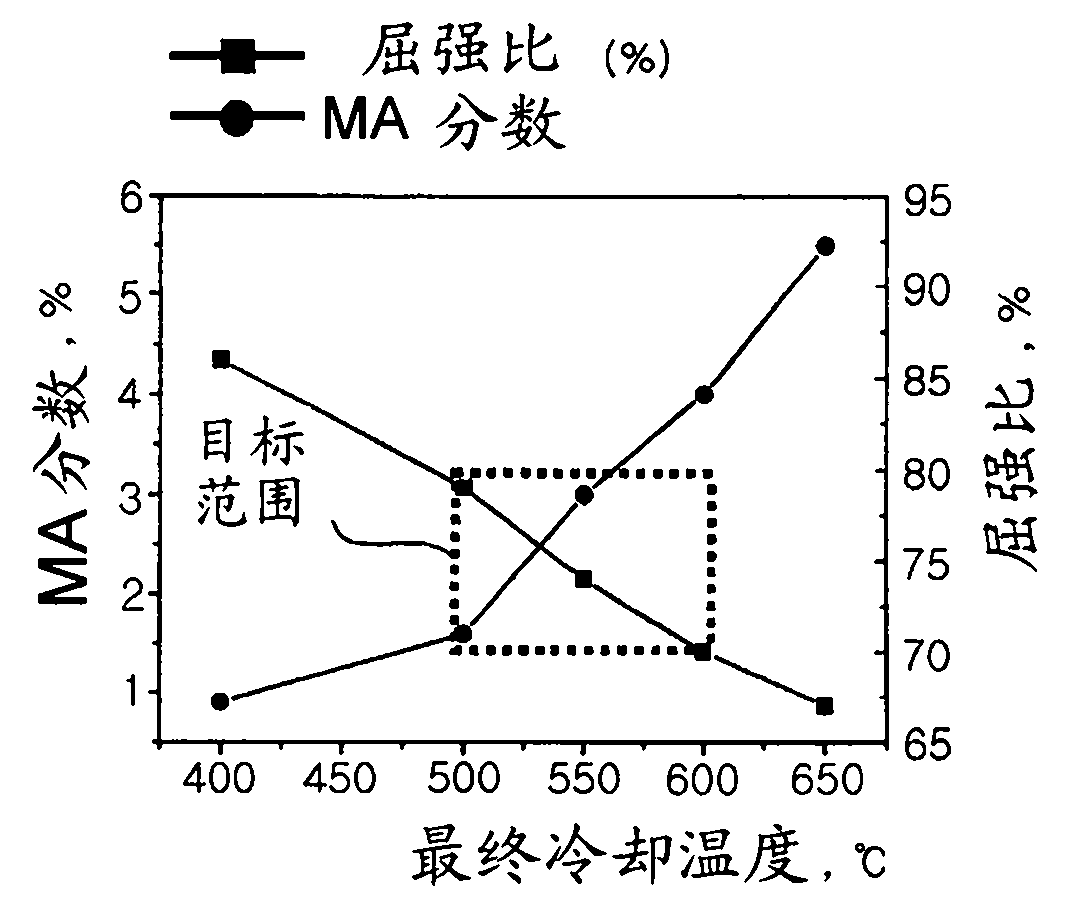

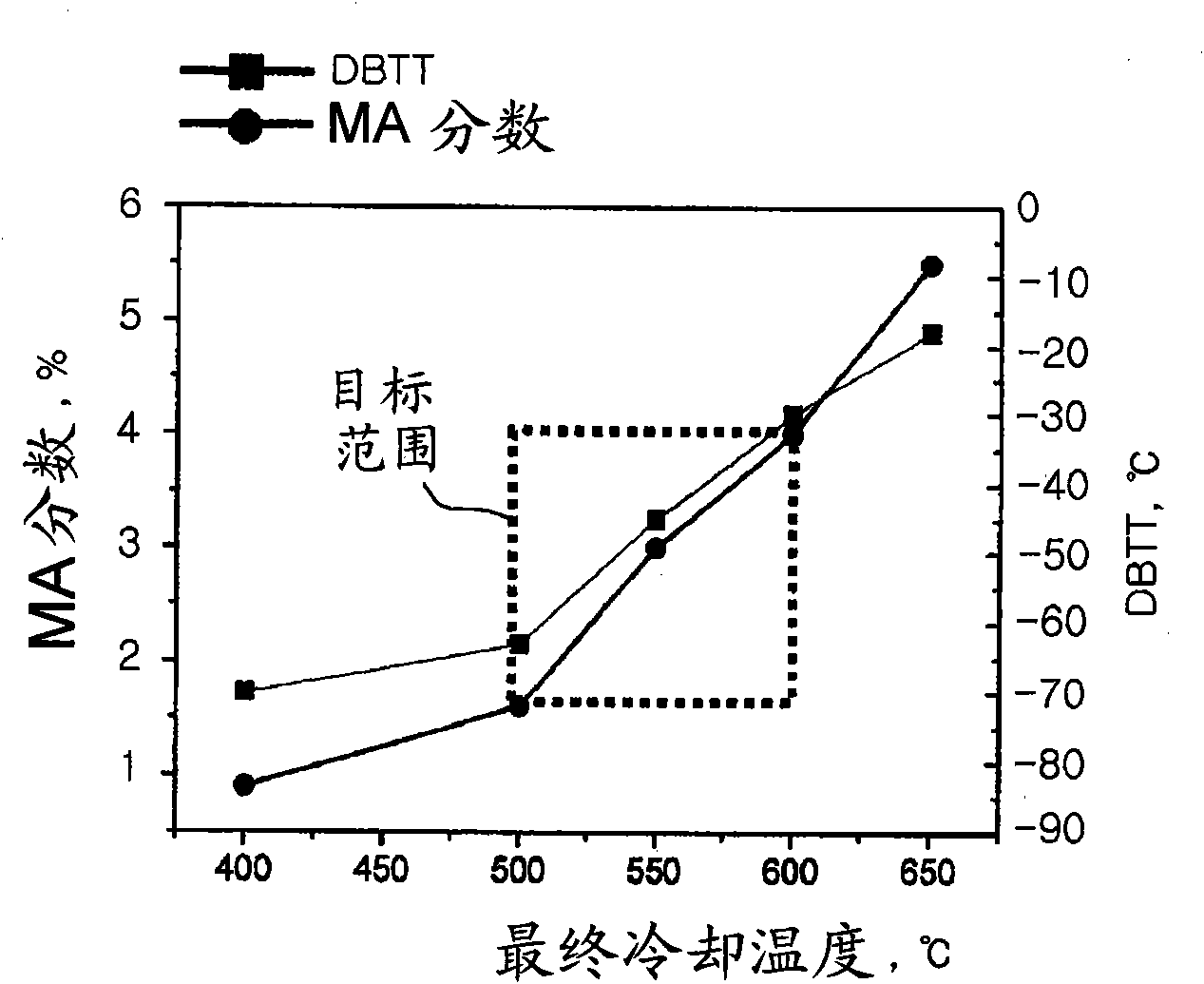

High strength and low yield ratio steel for structure having excellent low temperature toughness

There is provided a high strength and low yield ratio steel for structure that is used as steel for structures of buildings and has excellent characteristics such as low temperature toughness, a tensile strength of approximately 600 MPa or more and a low yield ratio of 80% or less. The high strength and low yield ratio steel includes, by weight percent: C: 0.02 to 0.12%, Si: 0.01 to 0.8%, Mn: 0.3 to 2.5%, P: 0.02% or less, S: 0.01% or less, Al: 0.005 to 0.5%, Nb: 0.005 to 0.10%, B: 3 to 50 ppm, Ti: 0.005 to 0.1%, N: 15 to 150 ppm, Ca: 60 ppm or less, and the balance of Fe and inevitable impurities, and further includes at least one component selected from the group consisting of, by weight percent: Cr: 0.05 to 1.0%, Mo: 0.01 to 1.0%, Ni: 0.01 to 2.0%, Cu: 0.01 to 1.0% and V: 0.005 to 0.3%, wherein a finish cooling temperature is limited to 500 to 600 DEG C after the finish-rolling process. The high strength and low yield ratio steel satisfying characteristics such as low temperature toughness, brittle crack arrestabi lity and low yield ratio, and the manufacturing method thereof may be provided.

Owner:浦项股份有限公司

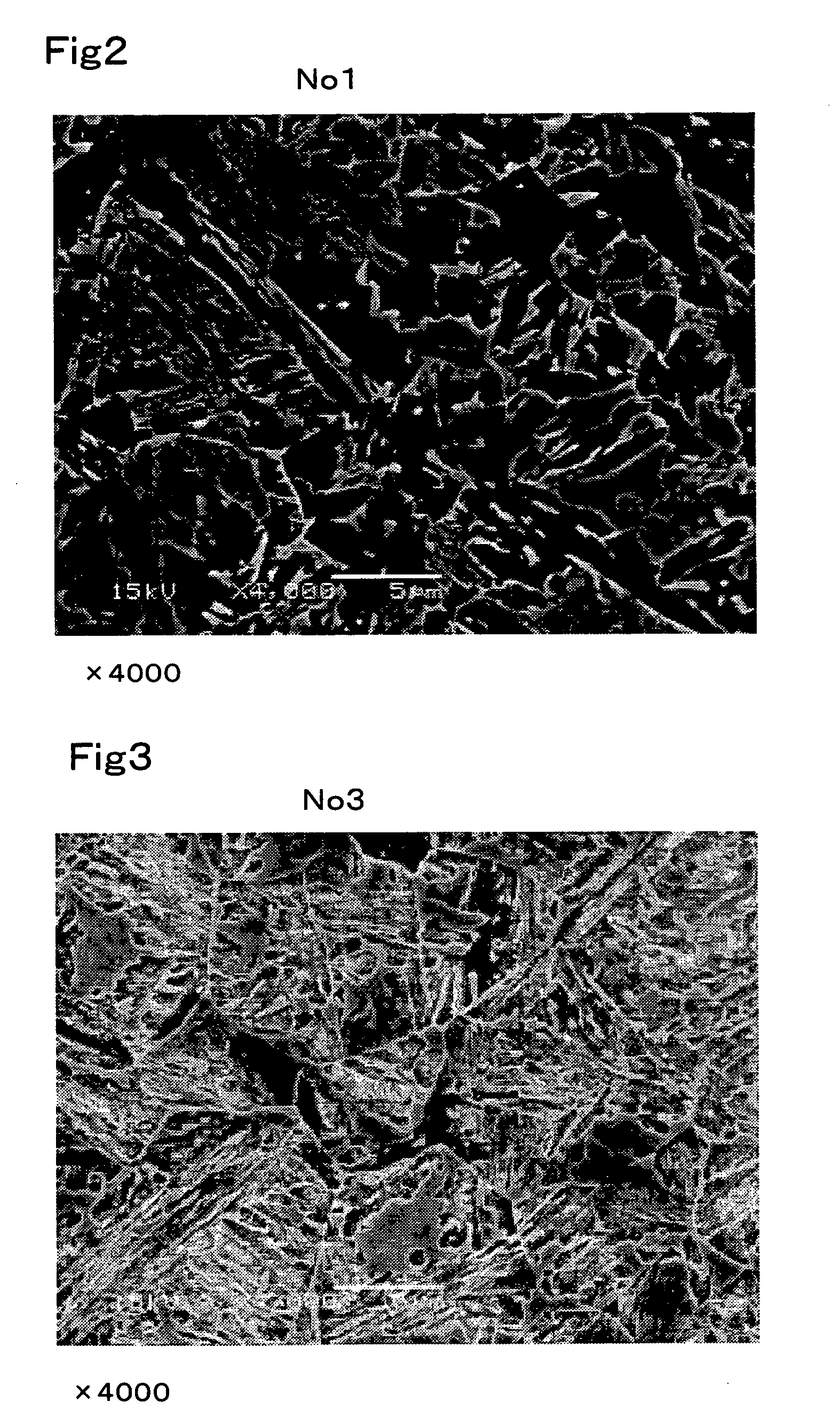

A kind of low yield ratio high plastic ultrafine grain high strength steel and its manufacturing method

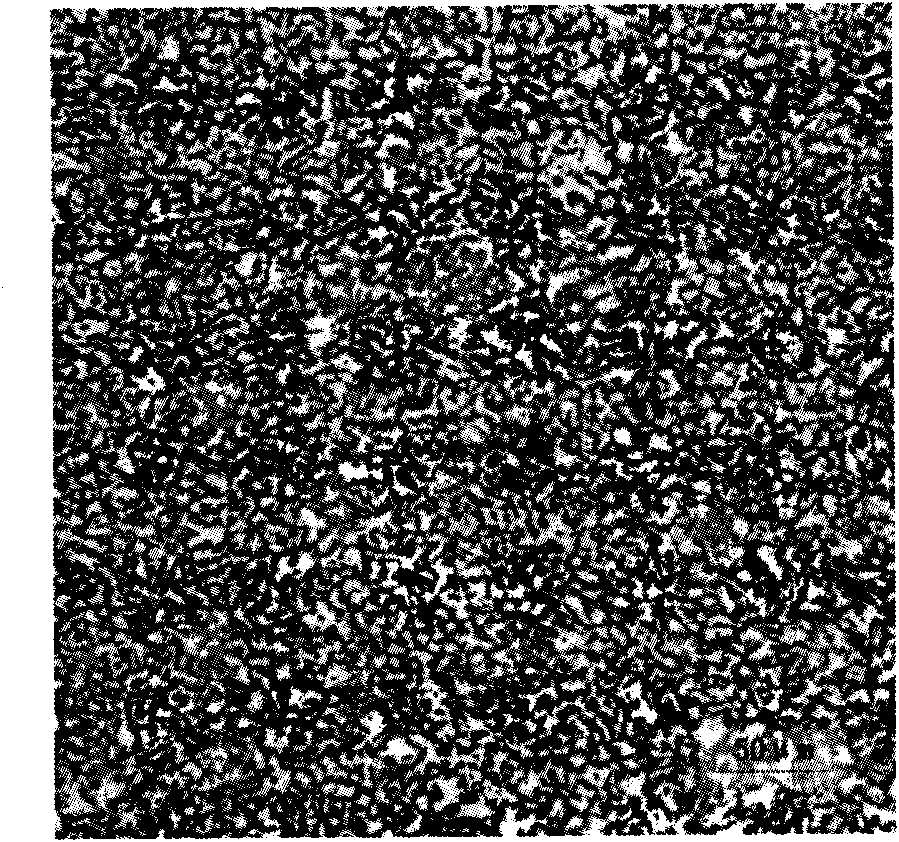

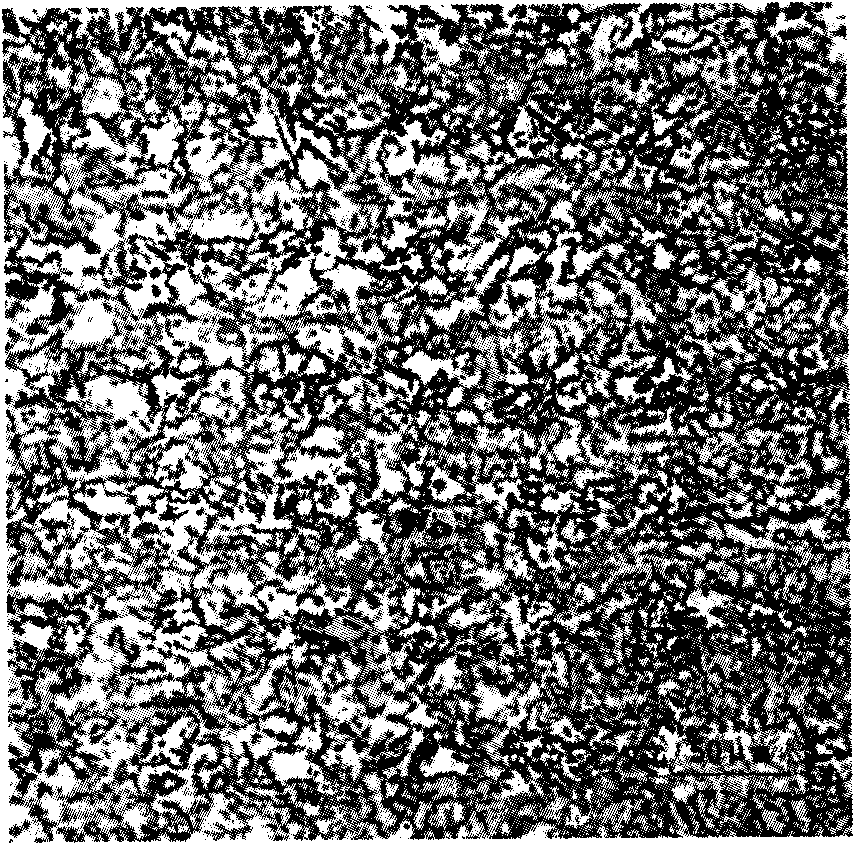

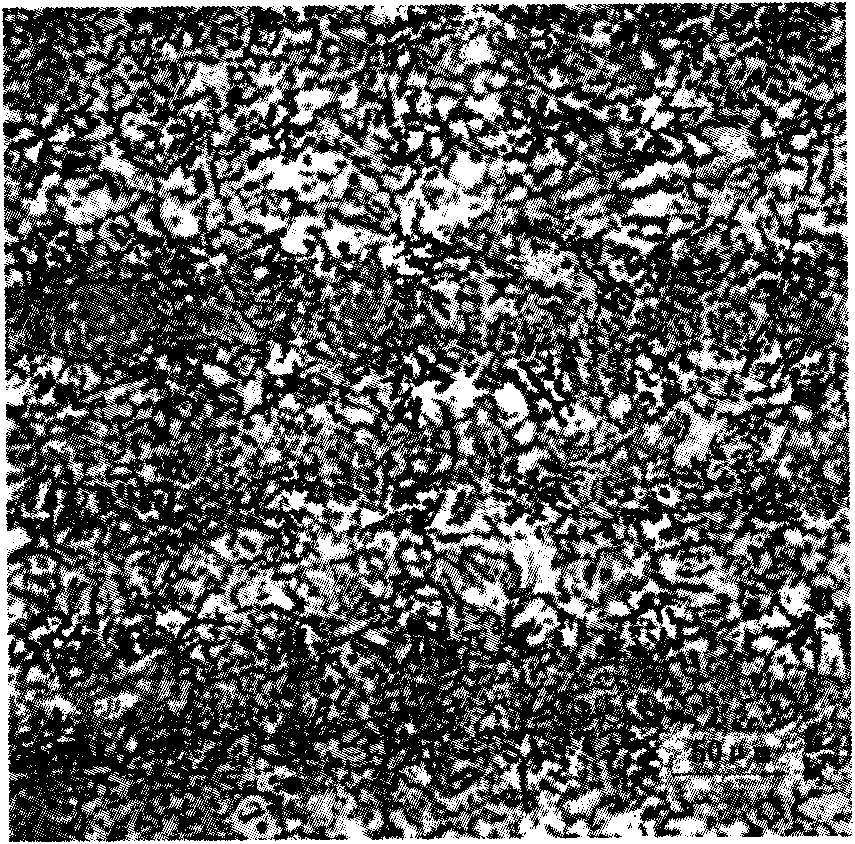

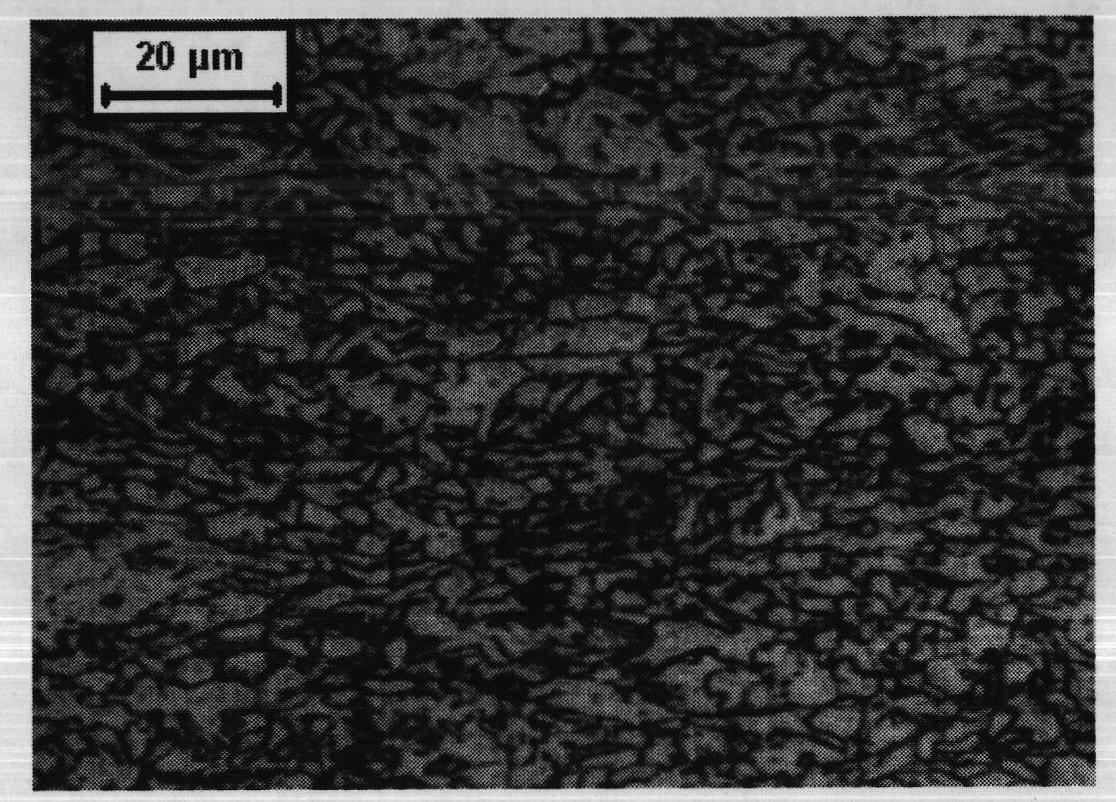

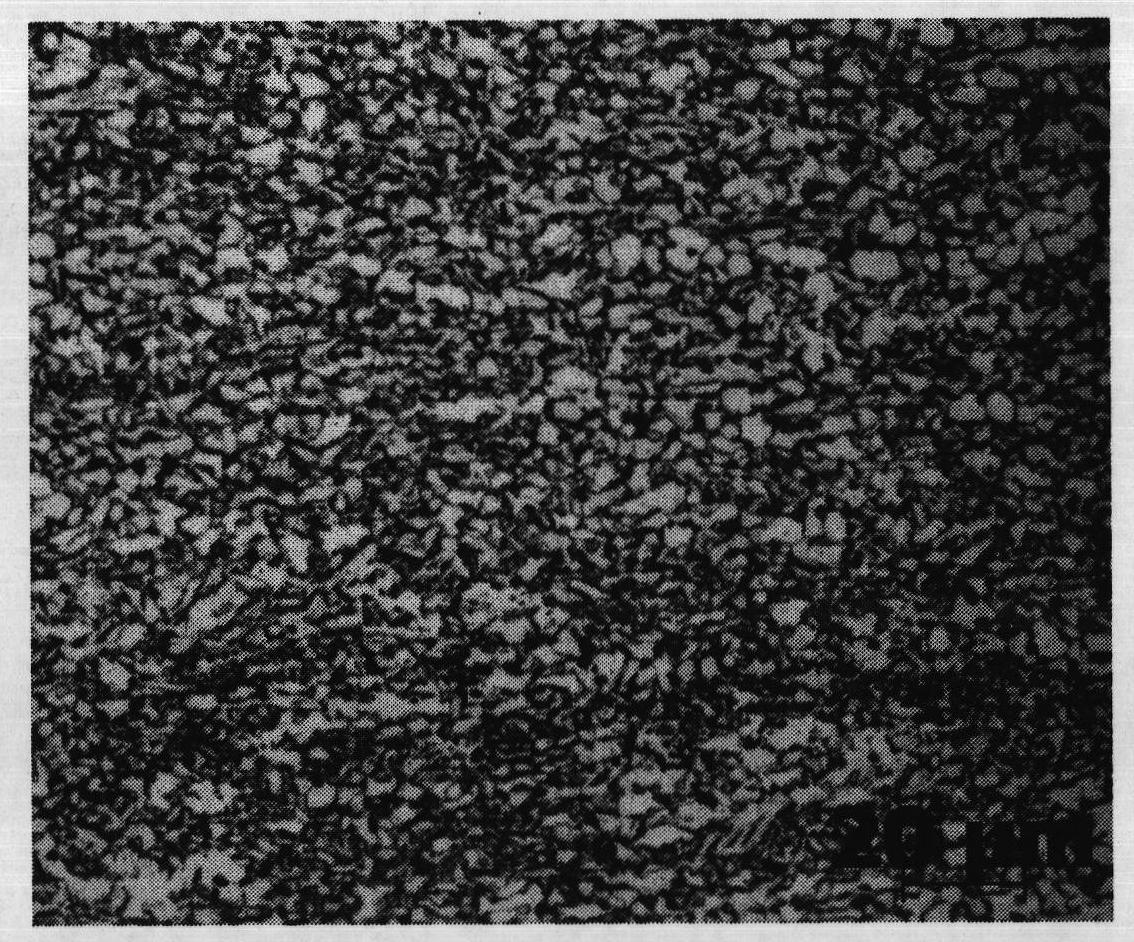

InactiveCN102277539AHigh yield strengthHigh tensile strengthRoll mill control devicesMetal rolling arrangementsChemical compositionGrain structure

The invention discloses a high-strength steel with low yield ratio, high plasticity and ultra-fine grain and a manufacturing method. The chemical composition weight percentage of steel is: C: 0.06~0.09%, Si: 0.15~0.25%, Mn: 1.20~1.50%, P: ≤0.015%, S: ≤0.005%, Nb: 0.020~0.040%, V: 0.010~0.030%, Ti: 0.008~0.015%, Cr: 0.10~0.30%, Ni: 0.10~0.30%, Cu: 0.10~0.30%, Al: 0.010~0.050%, and the balance is Fe and unavoidable impurities. The invention obtains the bainite structure by adopting the controlled rolling and controlled cooling process. Through the heat treatment process, an ultra-fine grain structure with bimodal distribution is obtained, which makes the material have characteristics such as low yield ratio, superplasticity, and high strength. The production process is stable, the operability is strong, the cost is low, and the comprehensive performance of the obtained material is excellent.

Owner:NANJING IRON & STEEL CO LTD

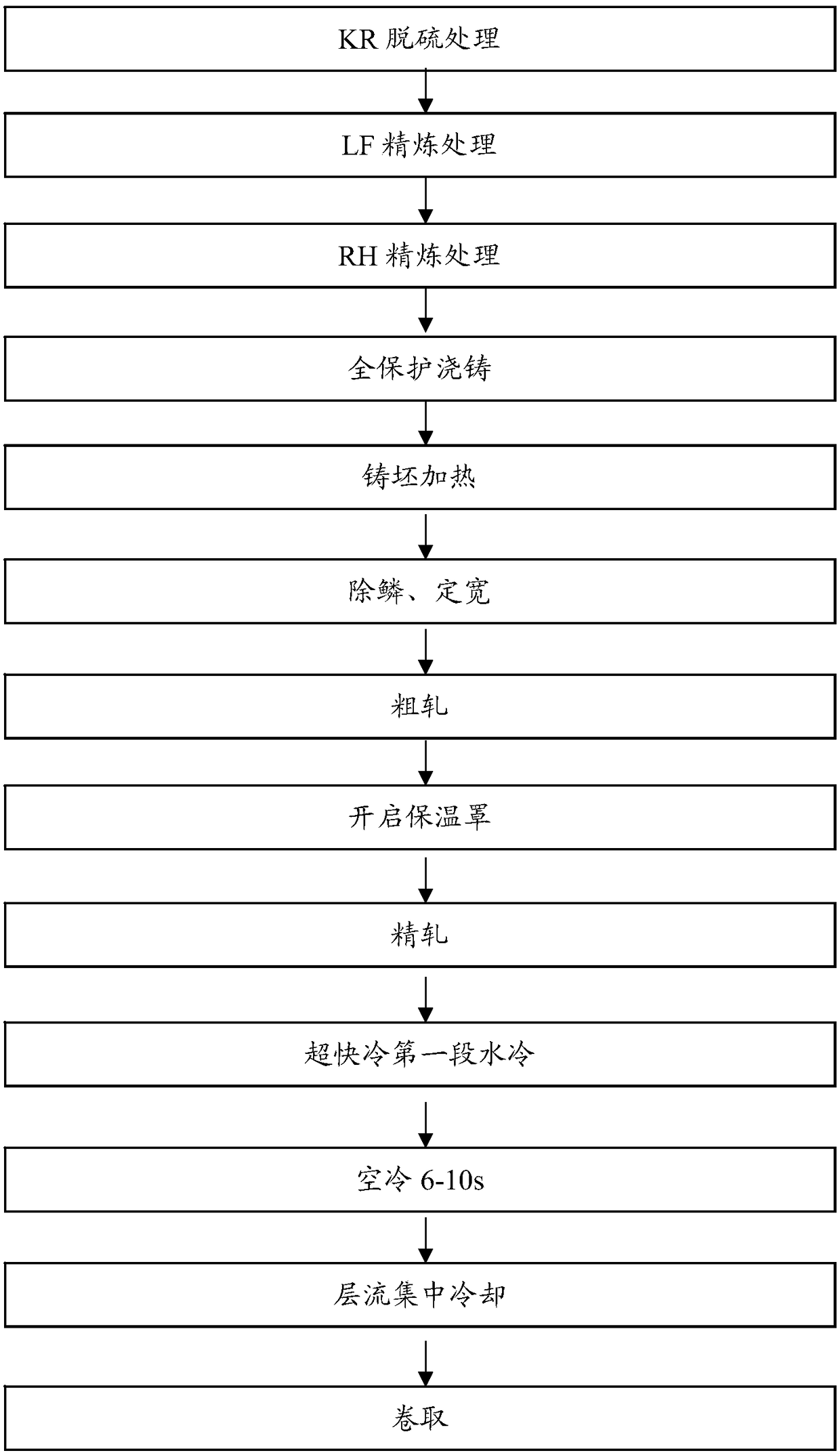

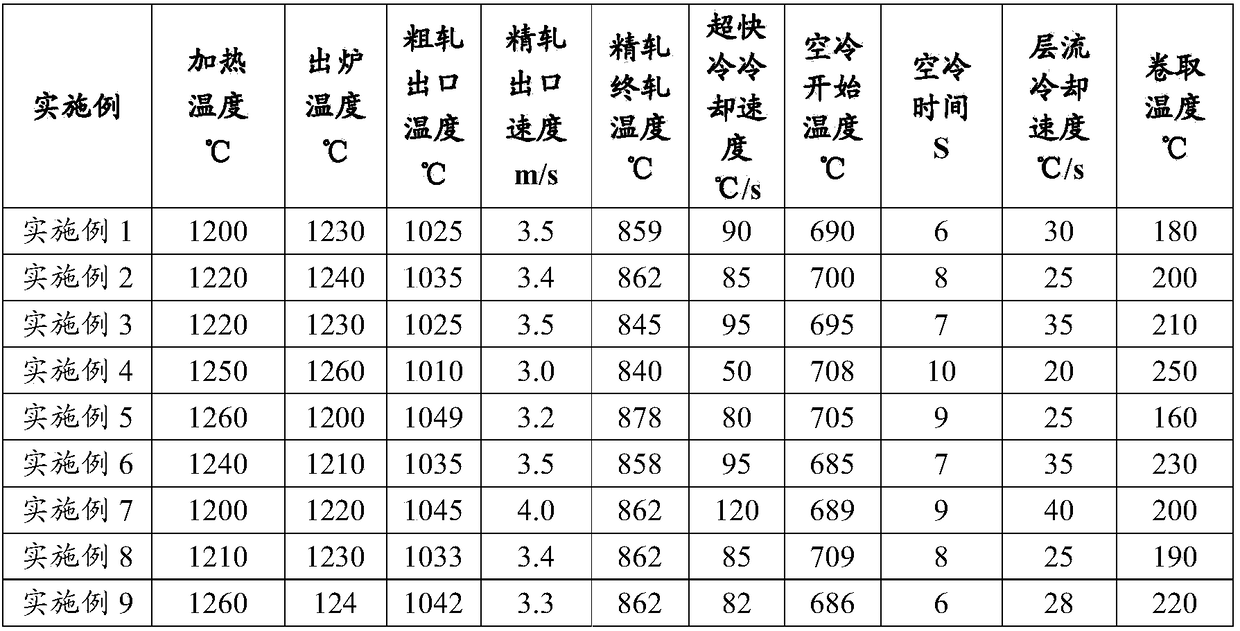

Steel for 690MPa grade hot rolled thick low-yield-ratio automobile spoke and preparation method thereof

The invention relates to steel for a 690MPa grade hot rolled thick low-yield-ratio automobile spoke. The steel comprises chemical compositions of, by weight, 0.06-0.10% of C, less than or equal to 0.20% of Si, 1.50-1.70% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.02-0.05% of Al, 0.15-0.25% of Cr, 0.02-0.04% of Nb, 0.01-0.03% of Ti, and the balance Fe and inevitable impurities. The invention further relates to a preparation method for the steel for the 690MPa grade hot rolled thick low-yield-ratio automobile spoke. The preparation method includes the steps ofmolten iron KR desulfurization, LF refining, RH refining, Ca treatment, continuous casting, and a hot rolling process. The preparation method adopts reasonable design of performance, specifications,compositions and the hot rolling process to produce the steel for the 690MPa grade hot rolled thick low-yield-ratio automobile spoke, the steel has high strength, low yield ratio, long fatigue life, high surface quality and stable performance, and meets the requirements of production and users.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com