Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Equivalent low" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

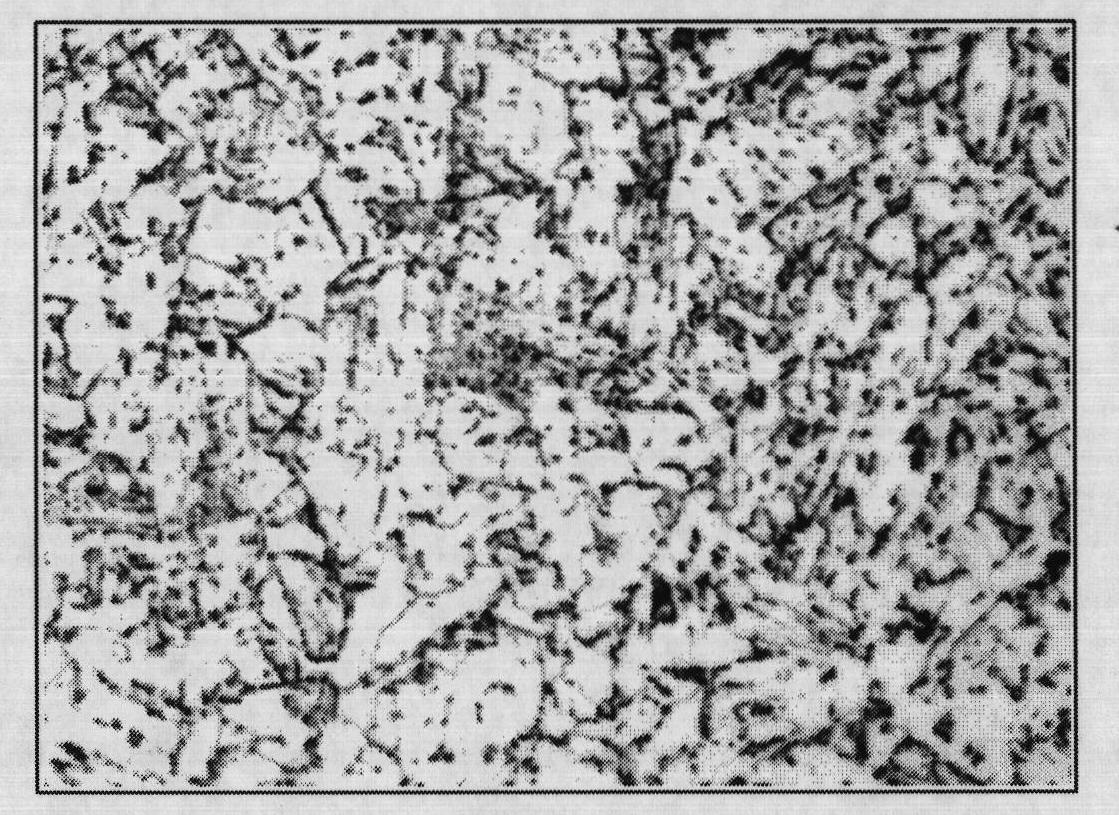

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

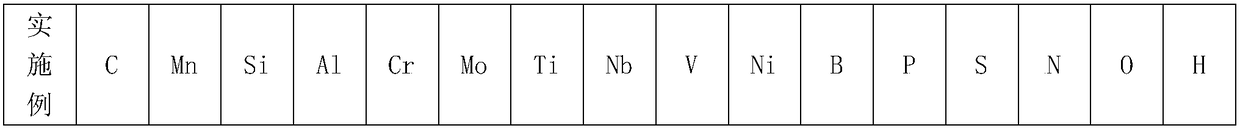

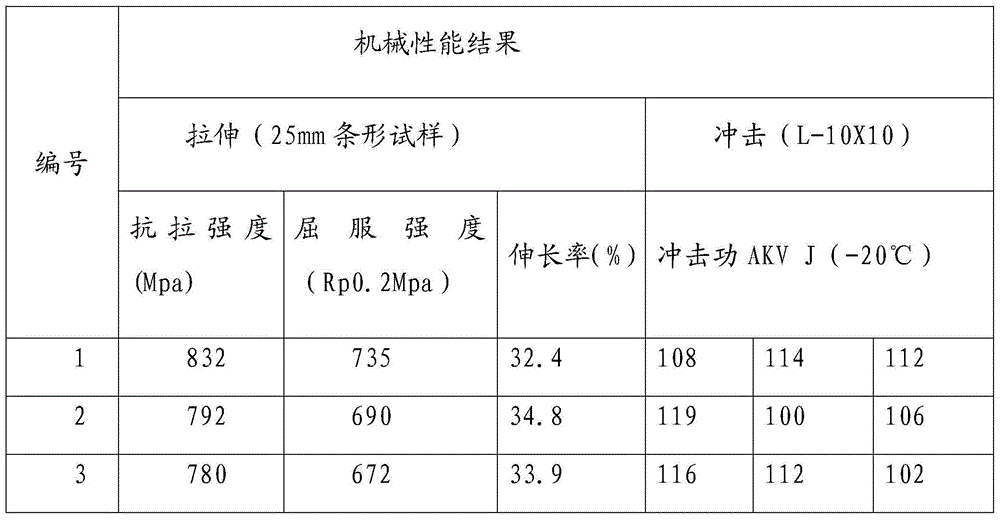

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

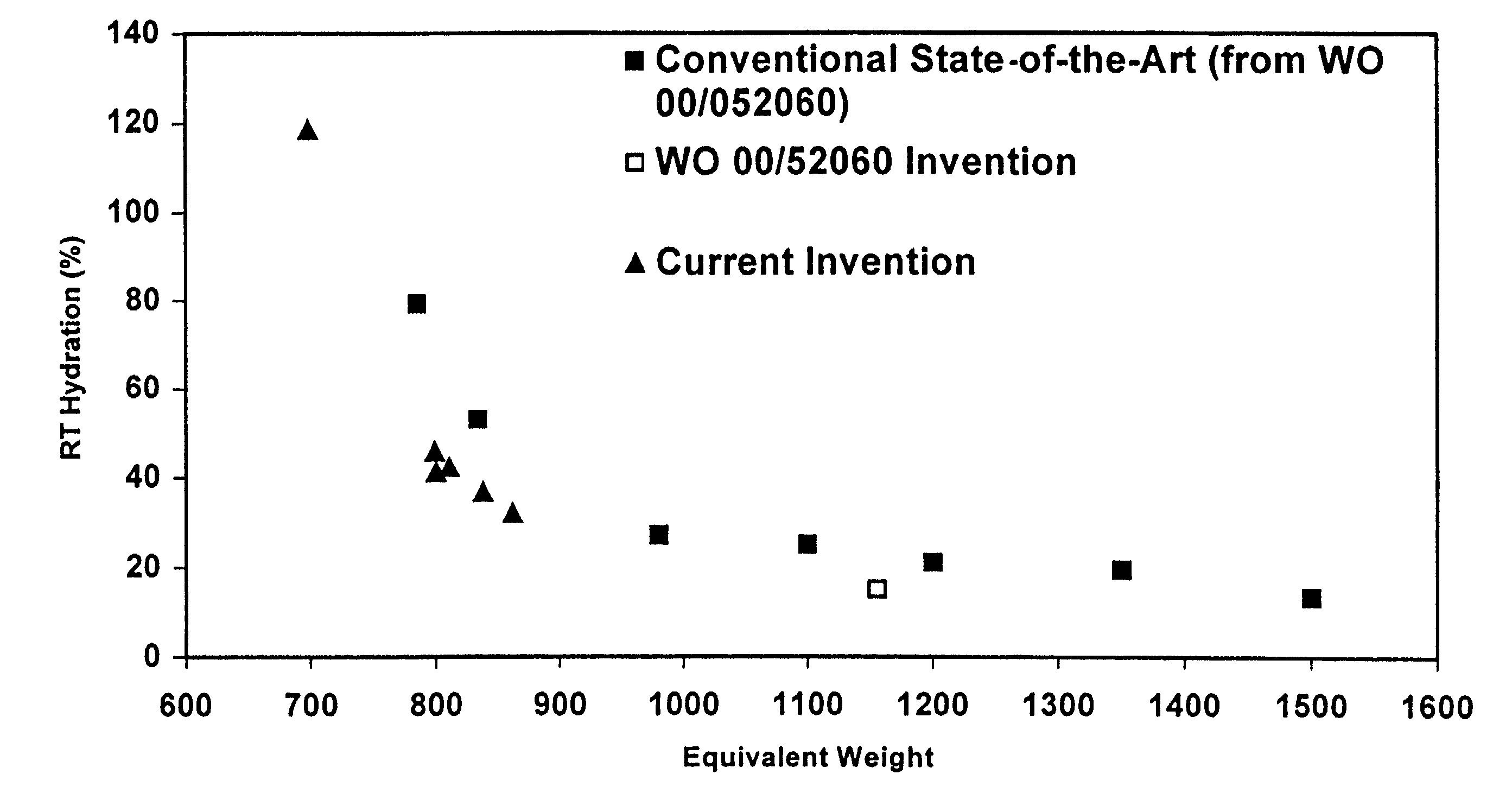

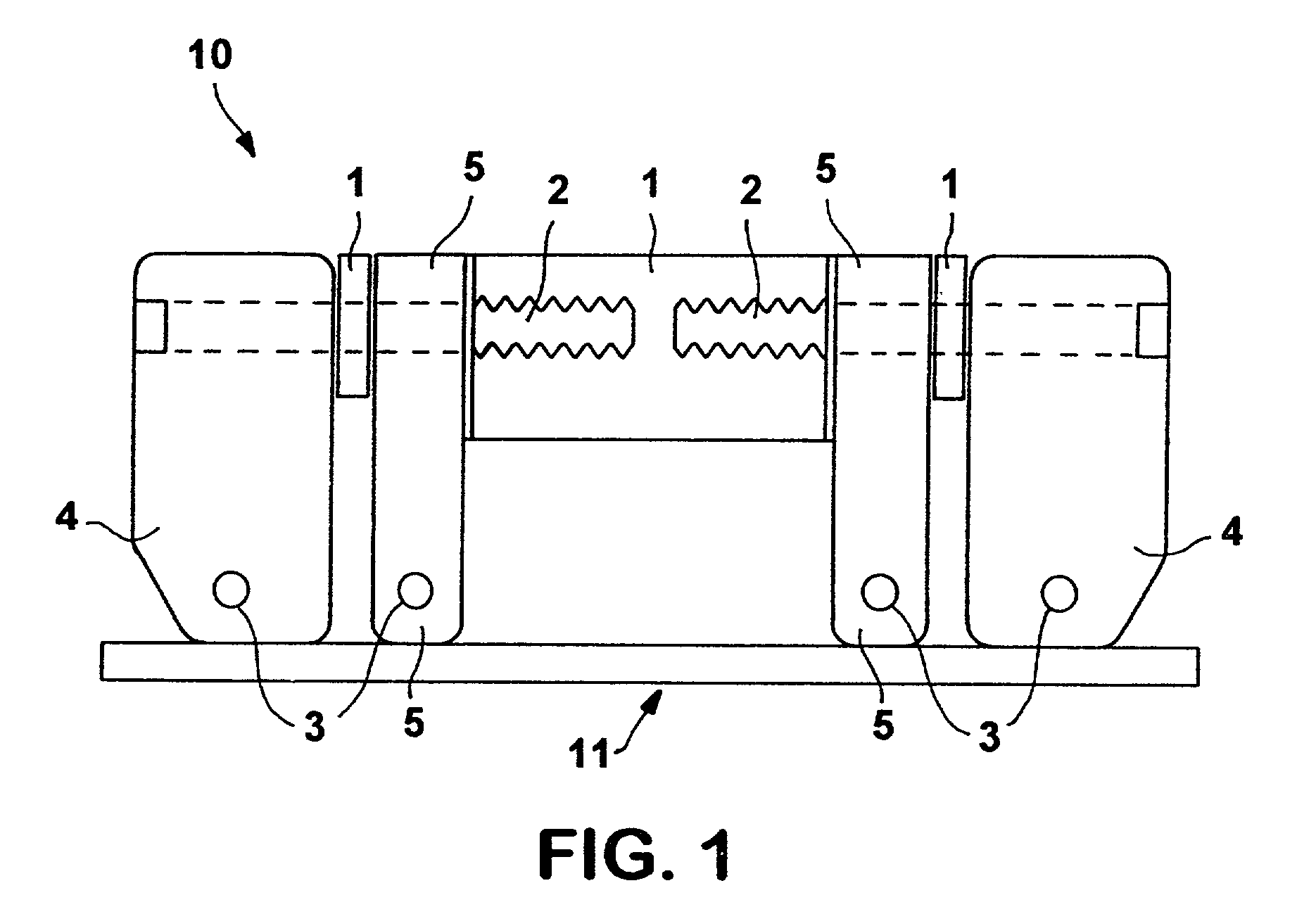

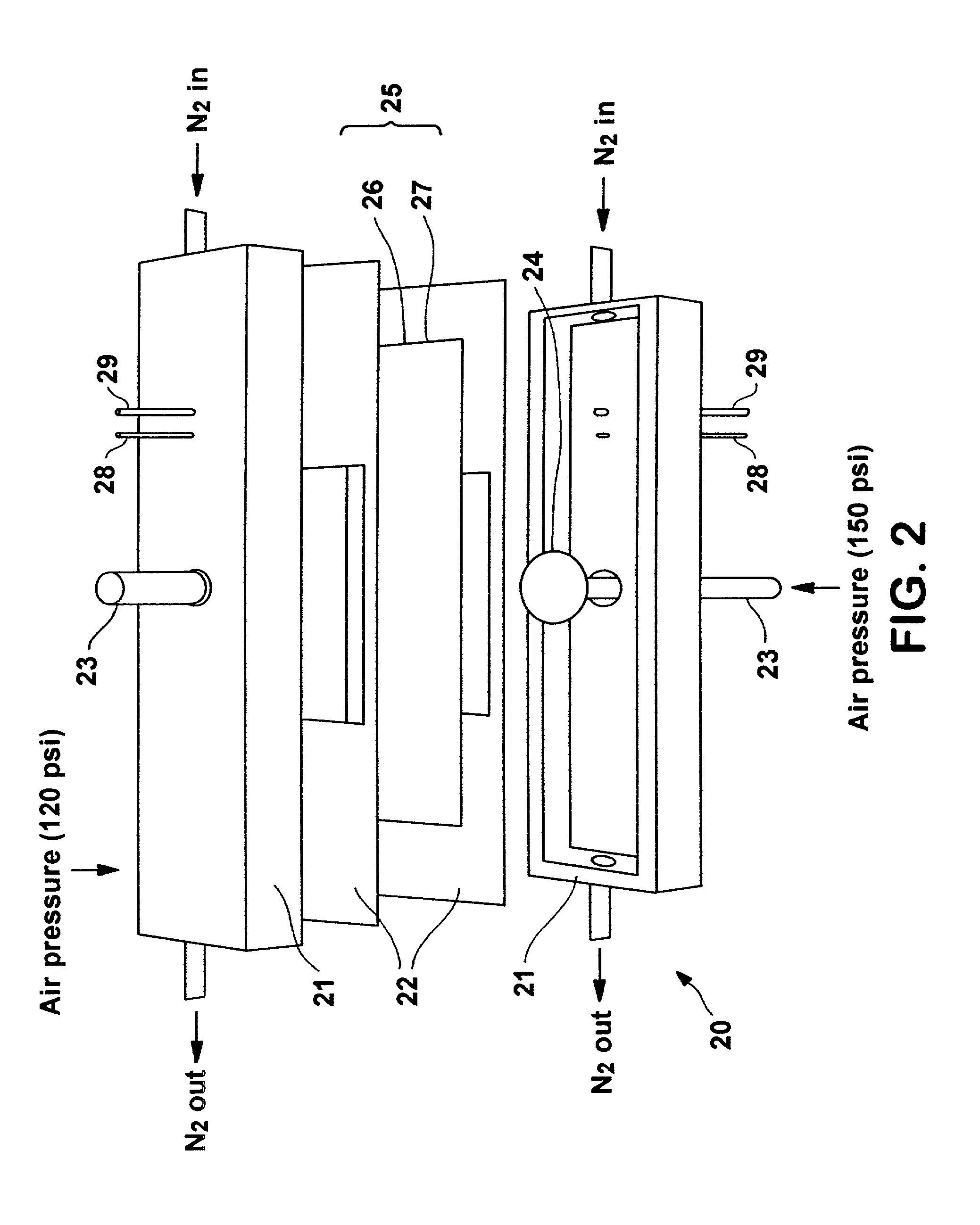

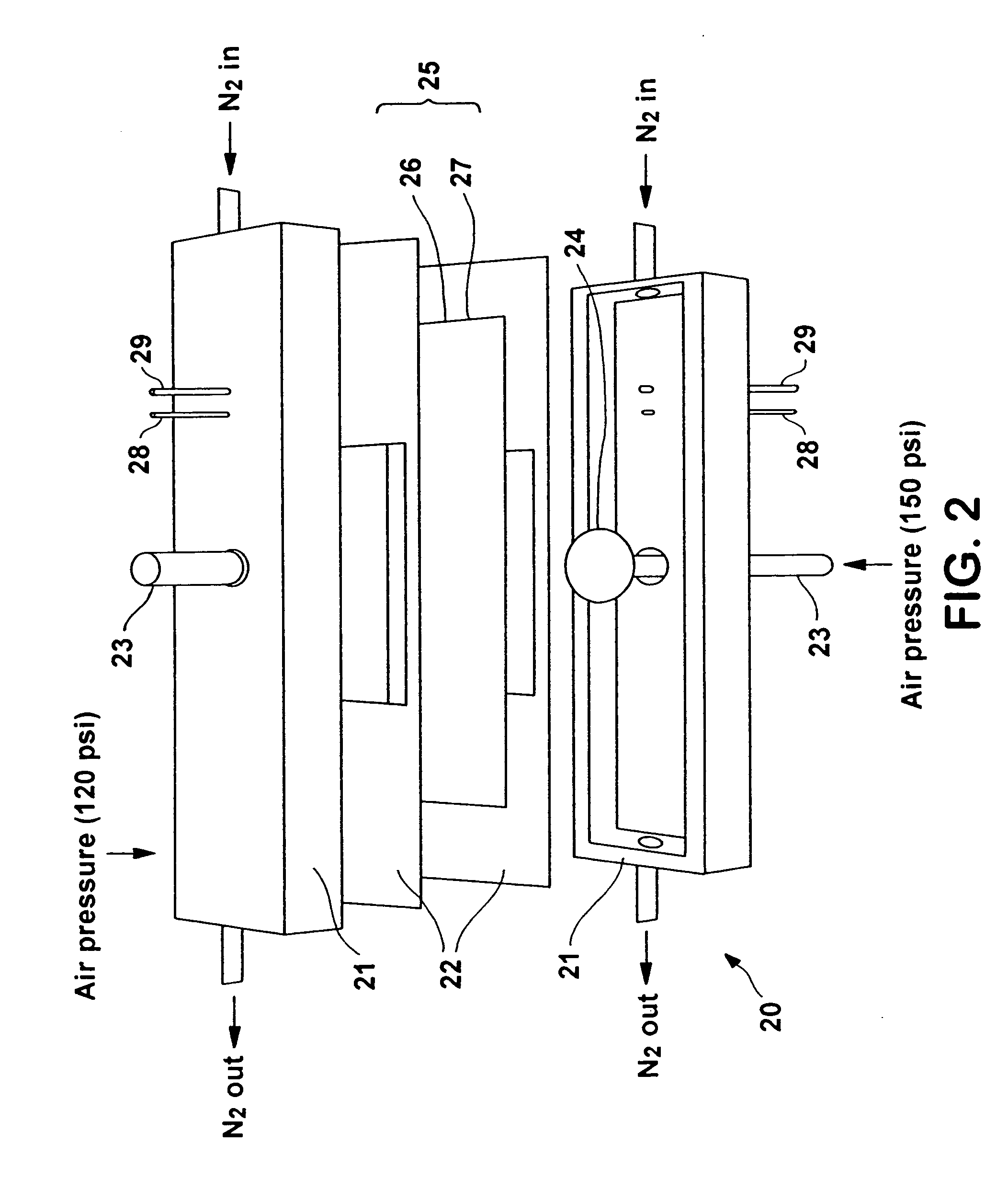

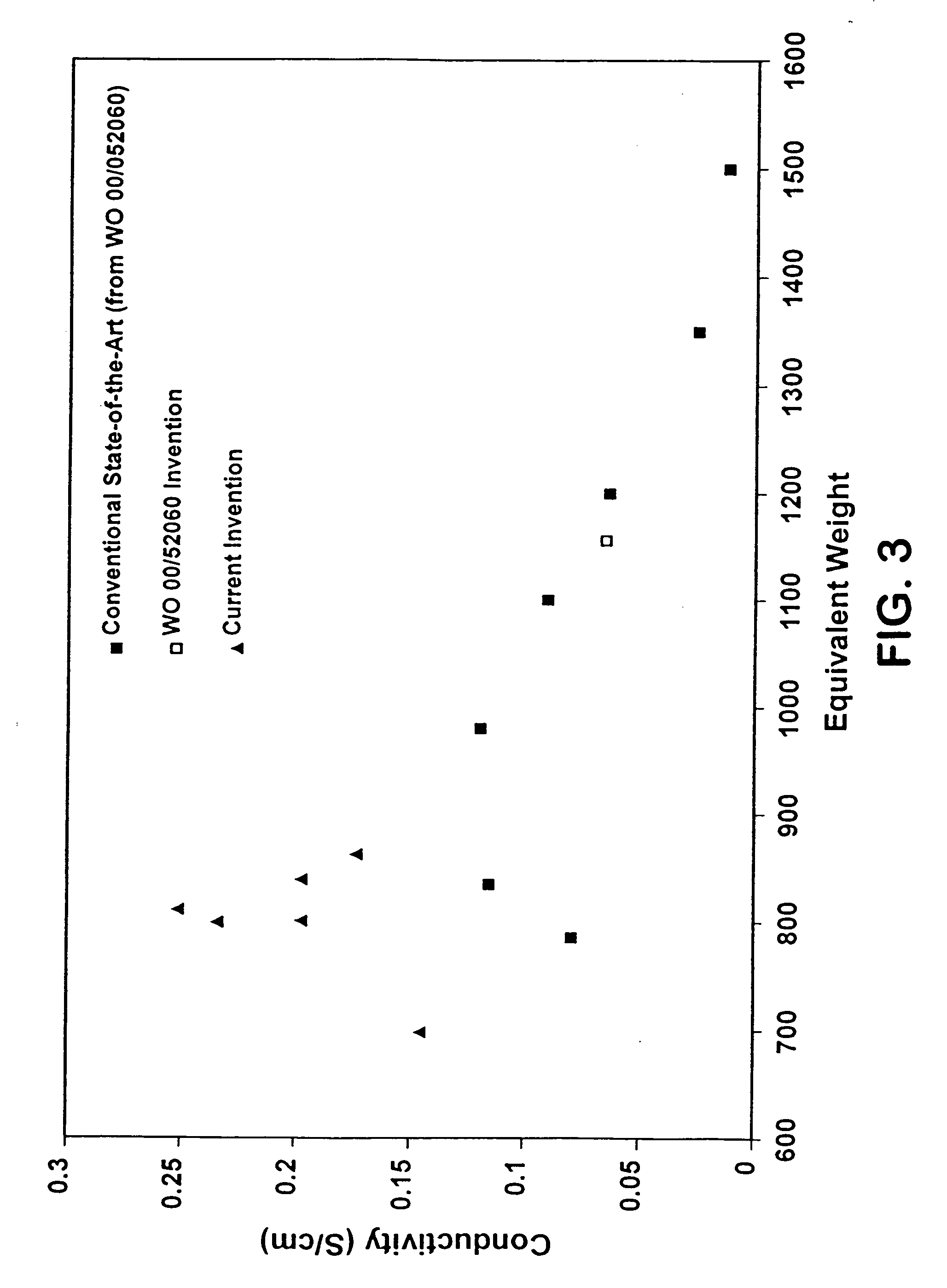

Low equivalent weight ionomer

An ionomer and a process for forming the ionomer such that the ionomer has (1) low equivalent weight (below 950, preferably between 625 and 850, and most preferably between 675 and 800) and (2) high conductivity (greater than 0.13 S / cm). In another embodiment, the invention is an ionomer having (1) low equivalent weight (below 950, preferably between 625 and 850, and most preferably between 675 and 800) and (2) acceptably low hydration (less than about 120 weight percent). These ionomers are capable of being processed into thin film and are extremely well-suited for low humidity or high temperature fuel cell applications.

Owner:WL GORE & ASSOC INC

390 MPa class low-temperature hull steel having excellent toughness and manufacturing method thereof

ActiveCN103882297ALow elemental contentReduce contentTemperature control deviceReduction rateNiobium

The invention discloses 390 MPa class low-temperature hull steel having excellent toughness and a manufacturing method thereof. The hull steel comprises, by weight, 0.05-0.12% of carbon, 0.08-0.30% of silicon, 1.0-1.40% of manganese, not more than 0.01% of phosphorus, not more than 0.01% of sulphur, 0.01-0.05% of aluminum, 0.02-0.04% of niobium, 0.005-0.020% of titanium with the balance being ferrum and unavoidable impurities. A first stage rolling temperature is 1050-1100 DEG C, a total reduction rate is not less than 60% and a finish rolling temperature is 900-940 DEG C; a second stage rolling temperature is 850-900 DEG C, the total reduction rate is not less than 60% and the finish rolling temperature is 790-880 DEG C. The steel is the steel is subjected to ultra-rapid cooling at a cooling speed of larger than 30 DEG C per second and is cooled at a cooling speed of larger than 10 DEG C per second in a manner of laminar flow; a self-tempering temperature of the steel ranges from 580-640 DEG C and the final cooling temperature of the steel ranges from 500-630 DEG C; and the steel is air cooled to the room temperature.

Owner:ANGANG STEEL CO LTD

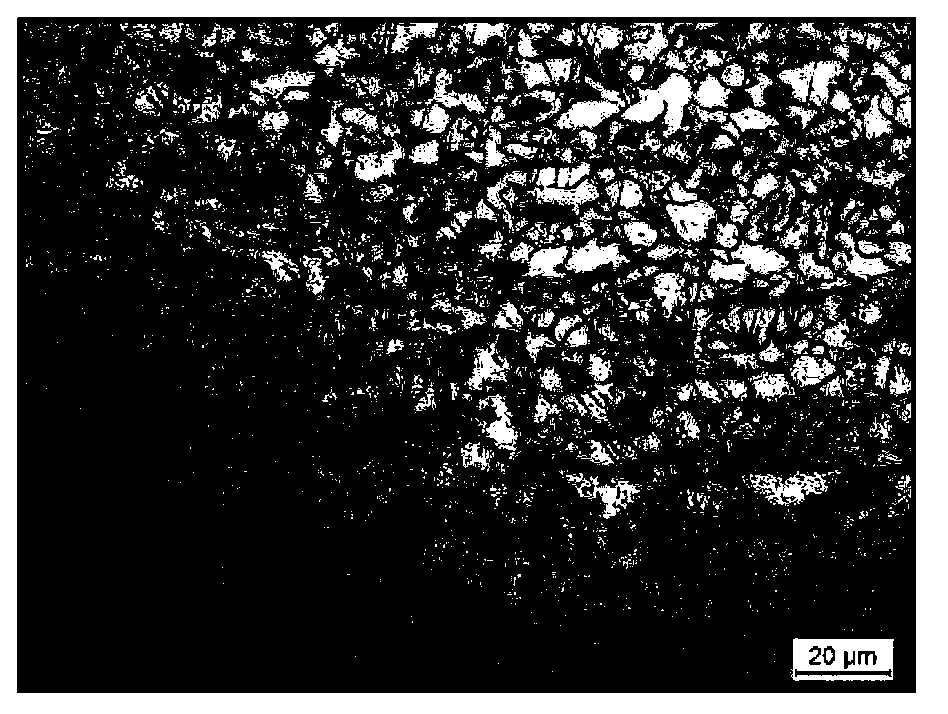

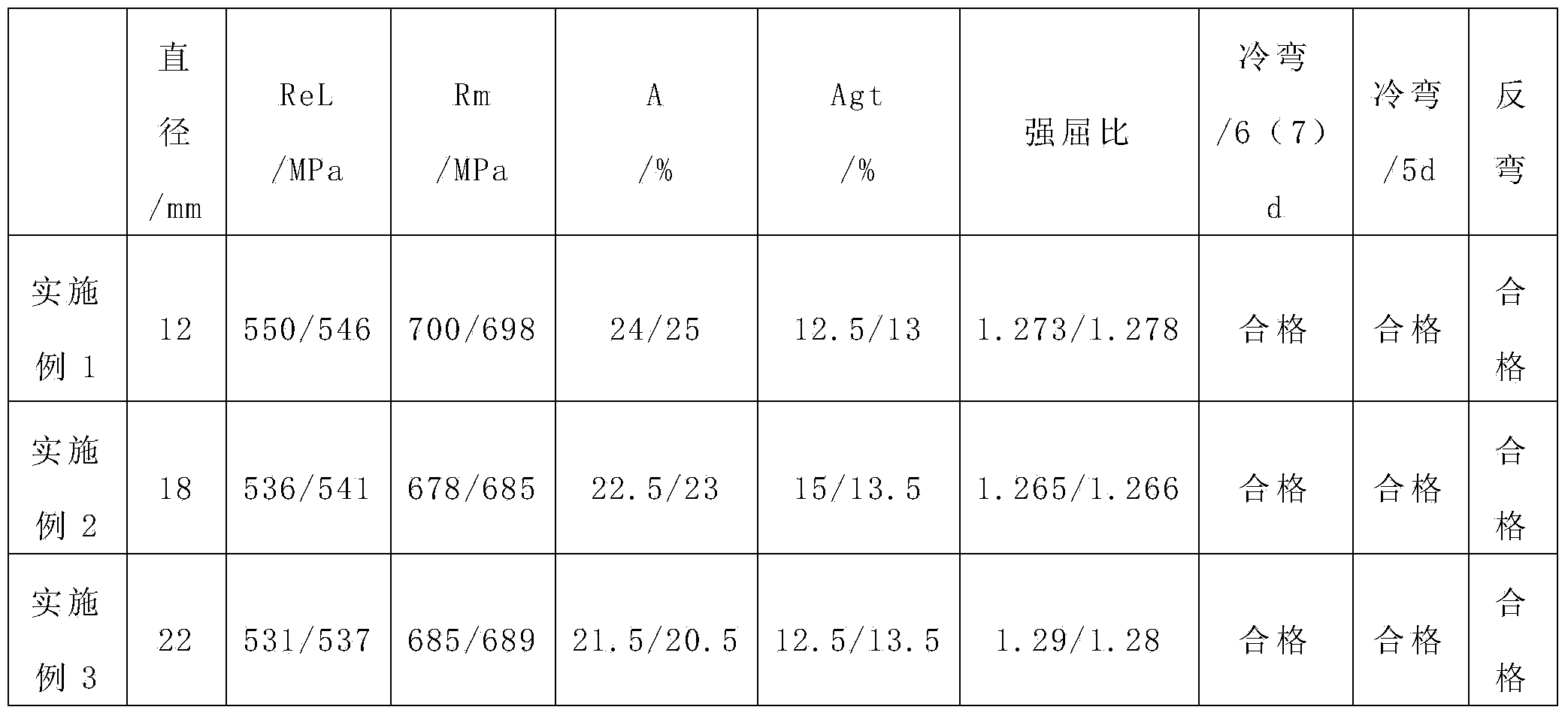

HRB500 hot-rolled belt rib antiseismic steel bar and preparation method thereof

The invention discloses an HRB500 hot-rolled belt rib antiseismic steel bar and a preparation method thereof. The steel comprises the following chemical components in percentage by weight: 0.17-0.25% of C, 0.4-0.8% of Si, 1.2-1.5% of Mn, at most 0.045% of P, at most 0.045% of S, 0.028-0.045% of V, 0.008-0.014% of N, and the balance of Fe and inevitable impurity elements. The preparation method comprises the following steps: molten iron desulfurization, converter smelting, argon blowing, continuous casting, square billet heating, rolling, controlled cooling after rolling, and cooling bed air cooling. The steel has the advantages of high strength, high toughness and low manufacturing cost. The preparation technique has the advantages of simple process and low production cost.

Owner:武汉钢铁有限公司

Ultra high strength ship plate steel and production method thereof

The invention discloses ultra high strength ship plate steel and a production method thereof. A plate blank comprises the following components in percentage by weight: 0.02-0.09 percent of C, 0.1-0.4 percent of Si, 0.5-1.6 percent of Mn, 0.01-0.04 percent of Alt, 0.02-0.05 percent of Nb, 0.008-0.02 percent of Ti, 0.3-0.7 percent of Cr, 0.2-0.5 percent of Mo, 0.5-1 percent of Ni, 0.2-1 percent of Cu, less than 0.013 percent of P, less than 0.005 percent of S, less than 0.0012 percent of O, less than 0.0045 percent of N, less than 0.00015 percent of H and the balance of Fe and inevitable impurities. The production method comprises the following steps of heating the plate blank with the thickness of 220-300 mm before rolling at the temperature of 1250 DEG C; starting rough rolling at the starting temperature of not less than 1100 DEG C; starting finish rolling at the temperature of not more than 910 DEG C, and stopping finish rolling at the temperature of 870-890 DEG C; rolling a steel plate with the thickness of 10-60 mm; rapidly entering ACC to control cooling at the cooling speed of 8-12 DEG C / s after finish rolling; returning red at the temperature of 650-680 DEG C; and tempering for 90-180min at the temperature of 500-680 DEG C. The product has good comprehensive mechanical property.

Owner:NANJING IRON & STEEL CO LTD

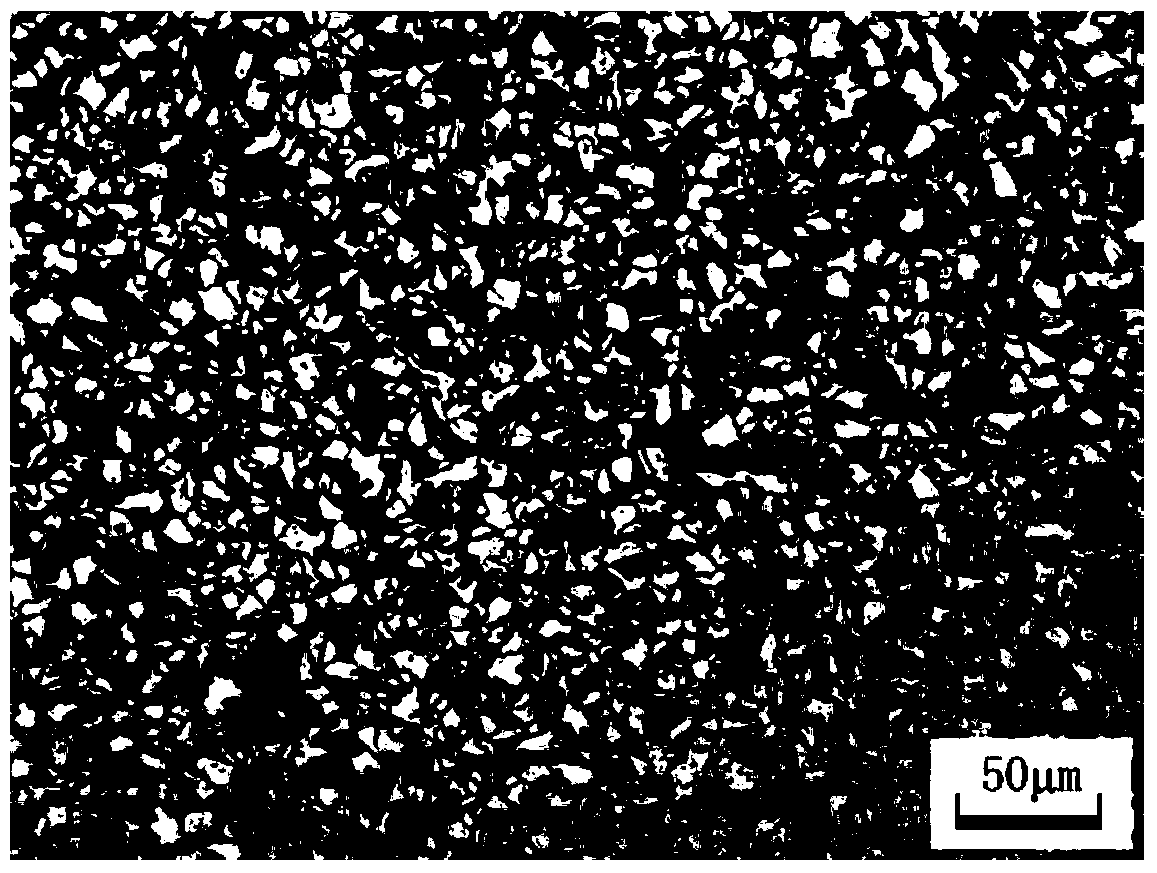

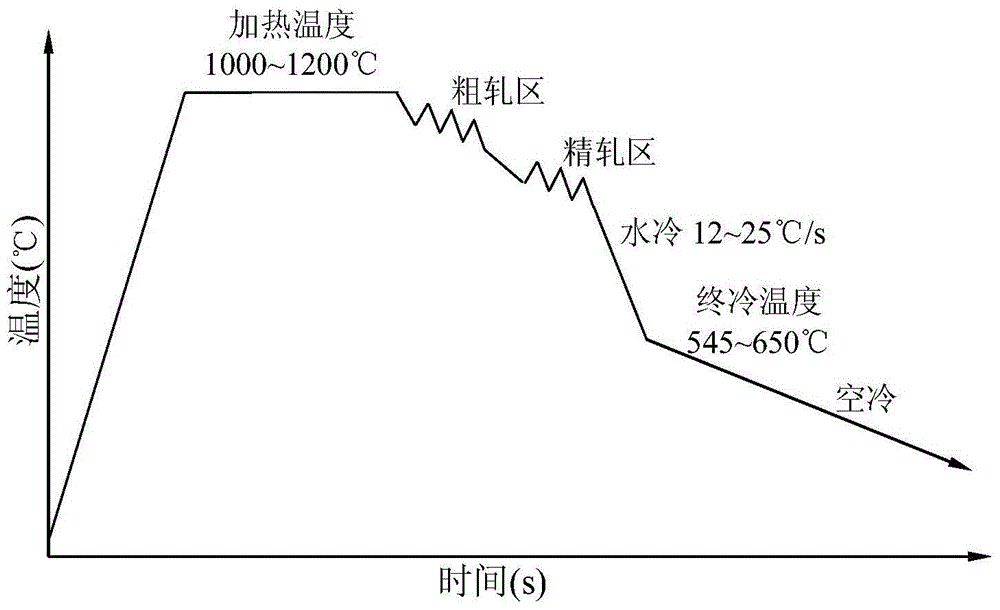

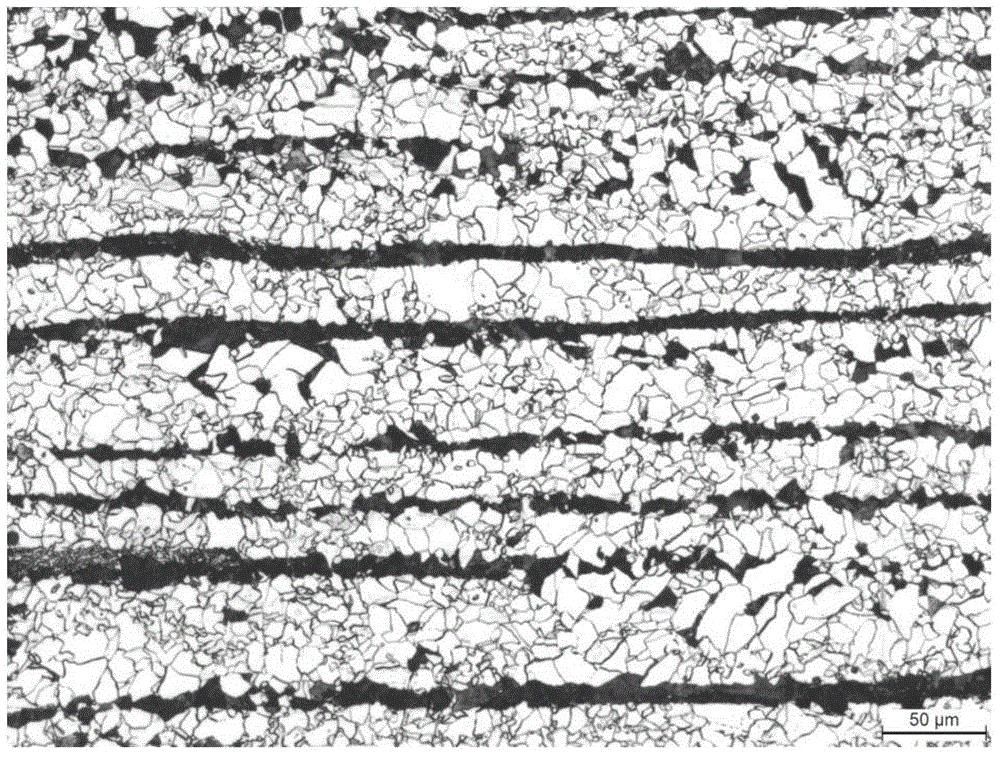

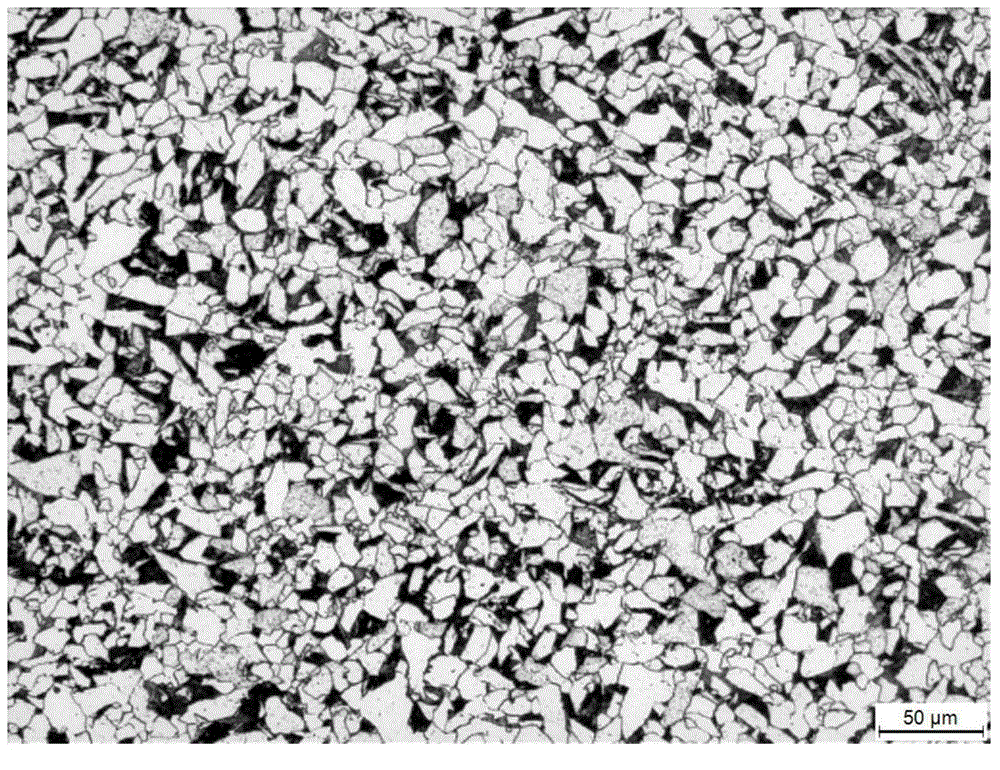

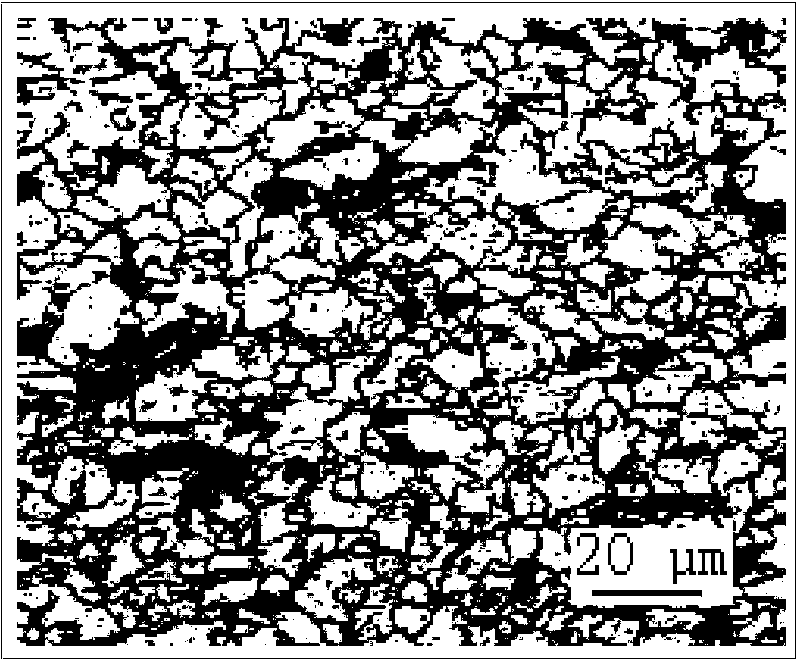

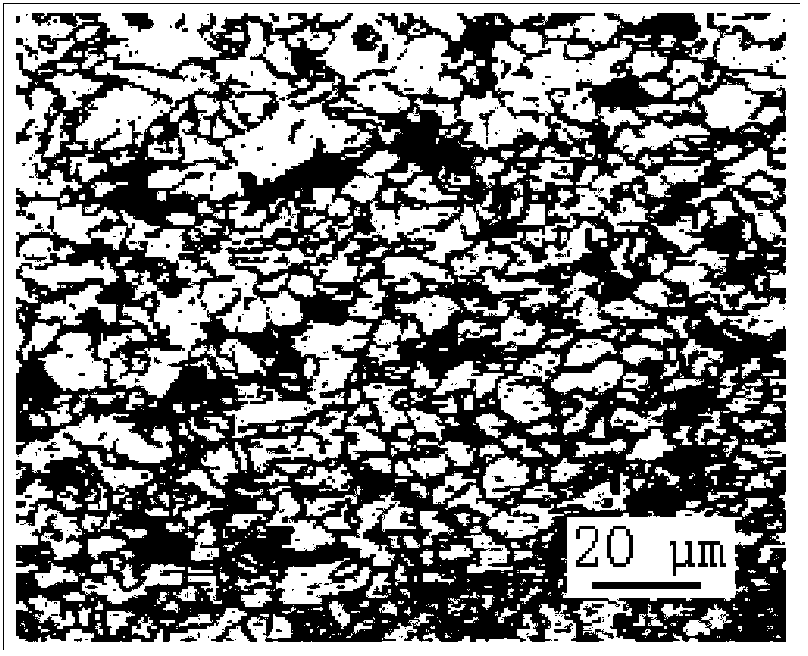

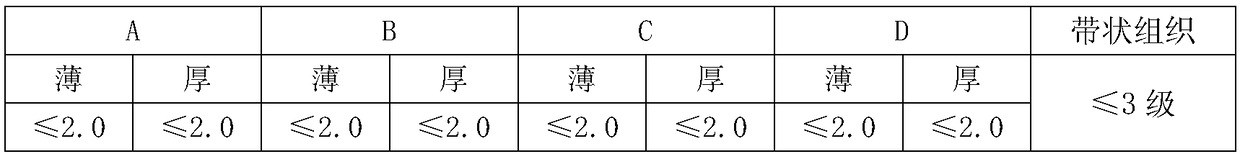

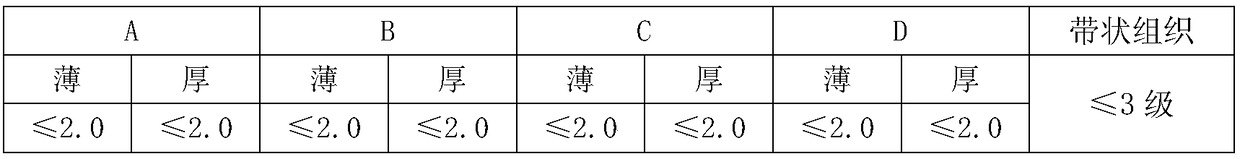

V-N microalloyed Q550 grade medium plate and preparation method thereof

The invention aims at providing a V-N microalloyed Q550 grade medium plate and a preparation method thereof which are specific to the condition that in the prior art, the Q550 grade medium plate expensive alloy is in large consumption and the preparation process is complex. The chemical constitutions of the steel are as follows by weight percentage: 0.06 to 0.12 percent of C, 1.20 to 2.00 percent of Mn, 0.10 to 0.50 percent of Si, 0.002 to 0.01 percent of S, 0.003 to 0.01 percent of P, 0.01 to 0.05 percent of Al, 0.06 to 0.15 percent of V, 0.01 to 0.02 percent of N and the balance of Fe and other unavoidable impurities; the preparation method comprises the steps of heating a steel billet to 1000 to 1200 DEG C along with a furnace and performing heat preservation for 3 to 4 hours, and further carrying out hot rolling on the steel billet to form a hot rolled plate being 20 to 50mm in thickness, wherein the beginning temperature and the finishing temperature in a rough rolling stage are respectively 1030 to 1150 DEG C and 980 to 1020 DEG C, and the beginning temperature and the finishing temperature in a finish rolling stage are respectively 908 to 925 DEG C and 820 to 845 DEG C; cooling the plate by water to 545 to 650 DEG C after the hot rolling, and then cooling by air to room temperature. The plate is a high-toughness ultra-low-carbon medium-manganese medium plate, and the metallographic structure of the plate is a fine crystalline ferrite, a pearlite and an acicular ferrite; the method is simple in operation process, has no need of quenching and tempering treatment, and is easy to realize industrial production.

Owner:NORTHEASTERN UNIV LIAONING

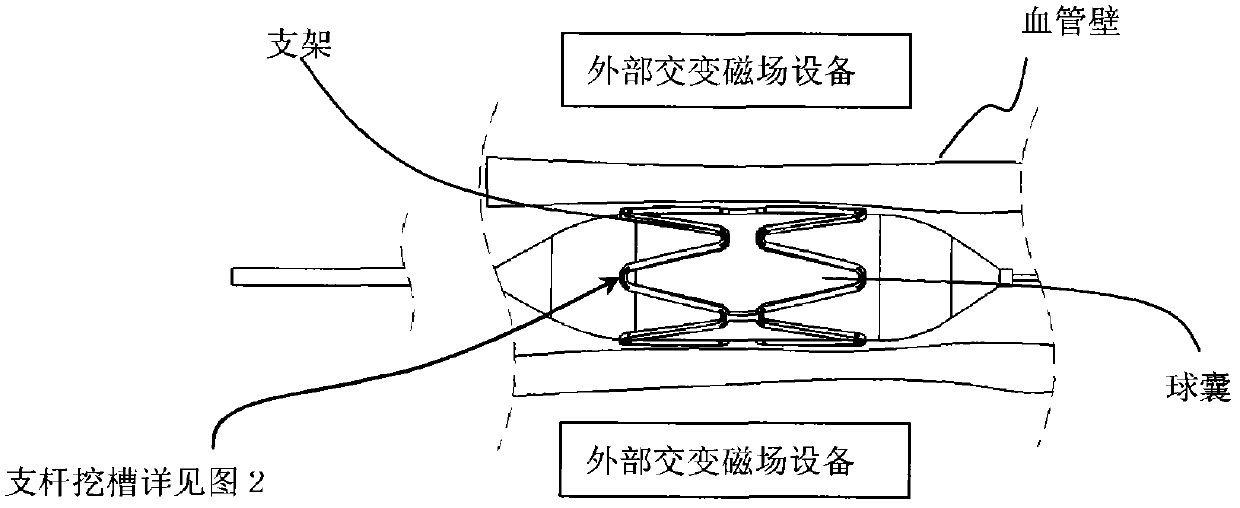

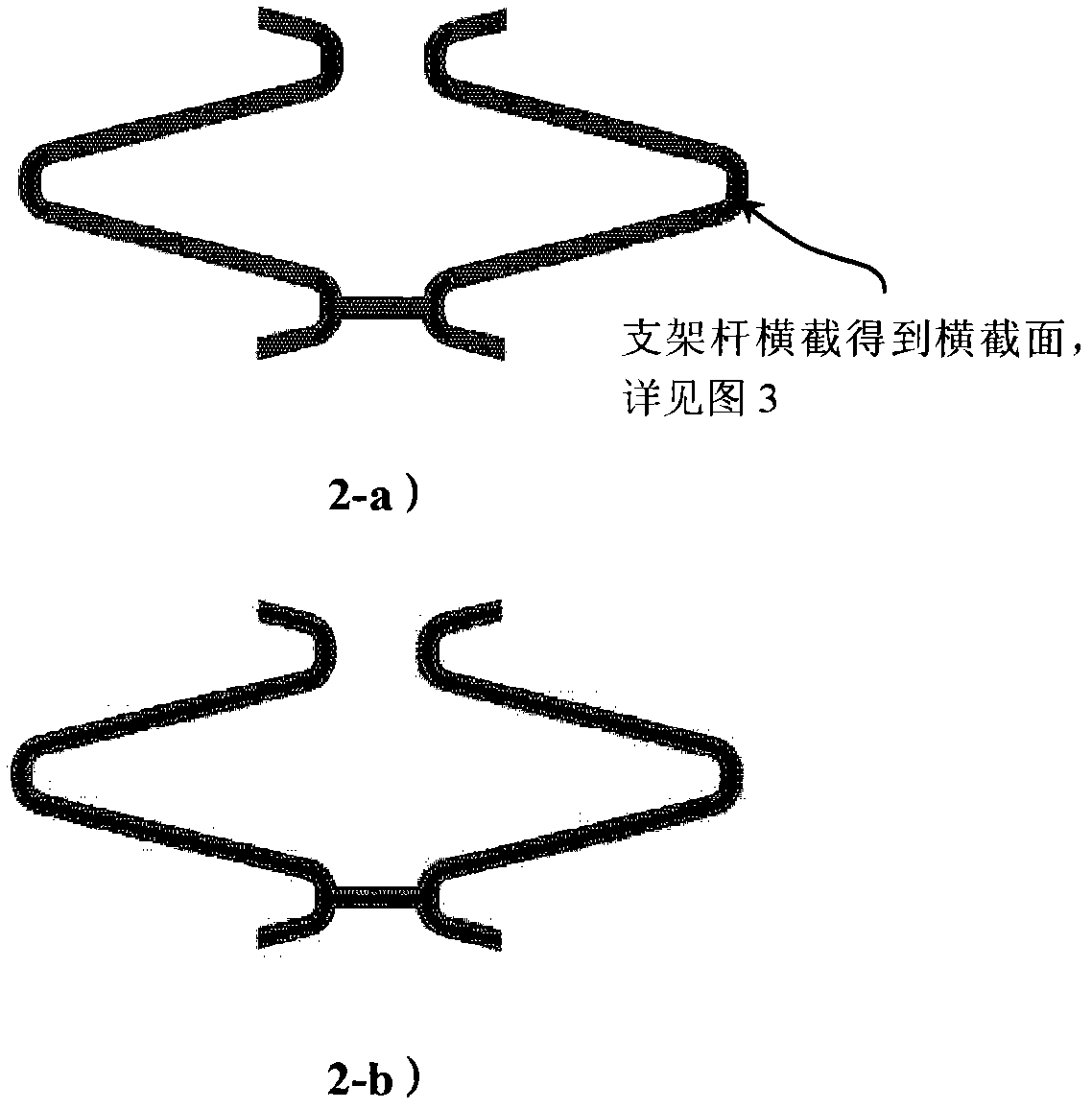

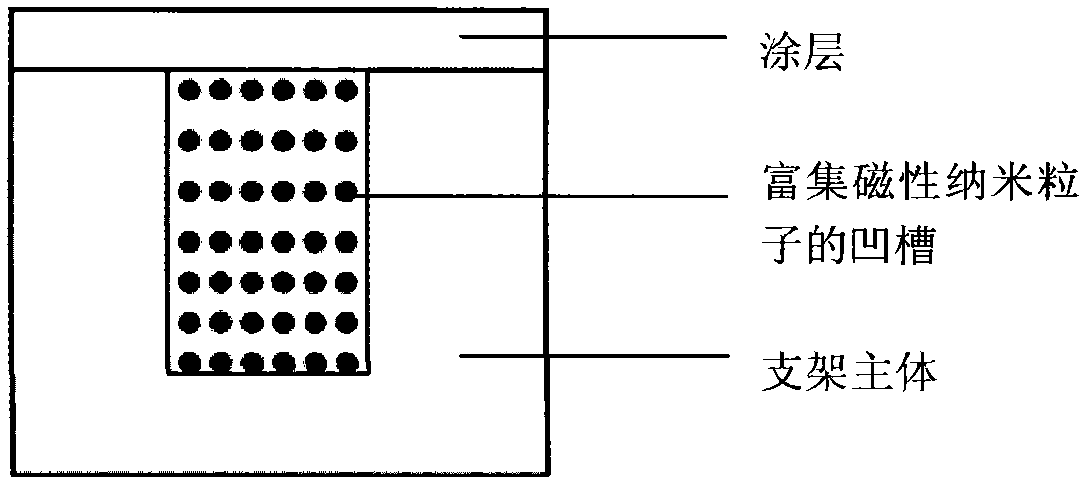

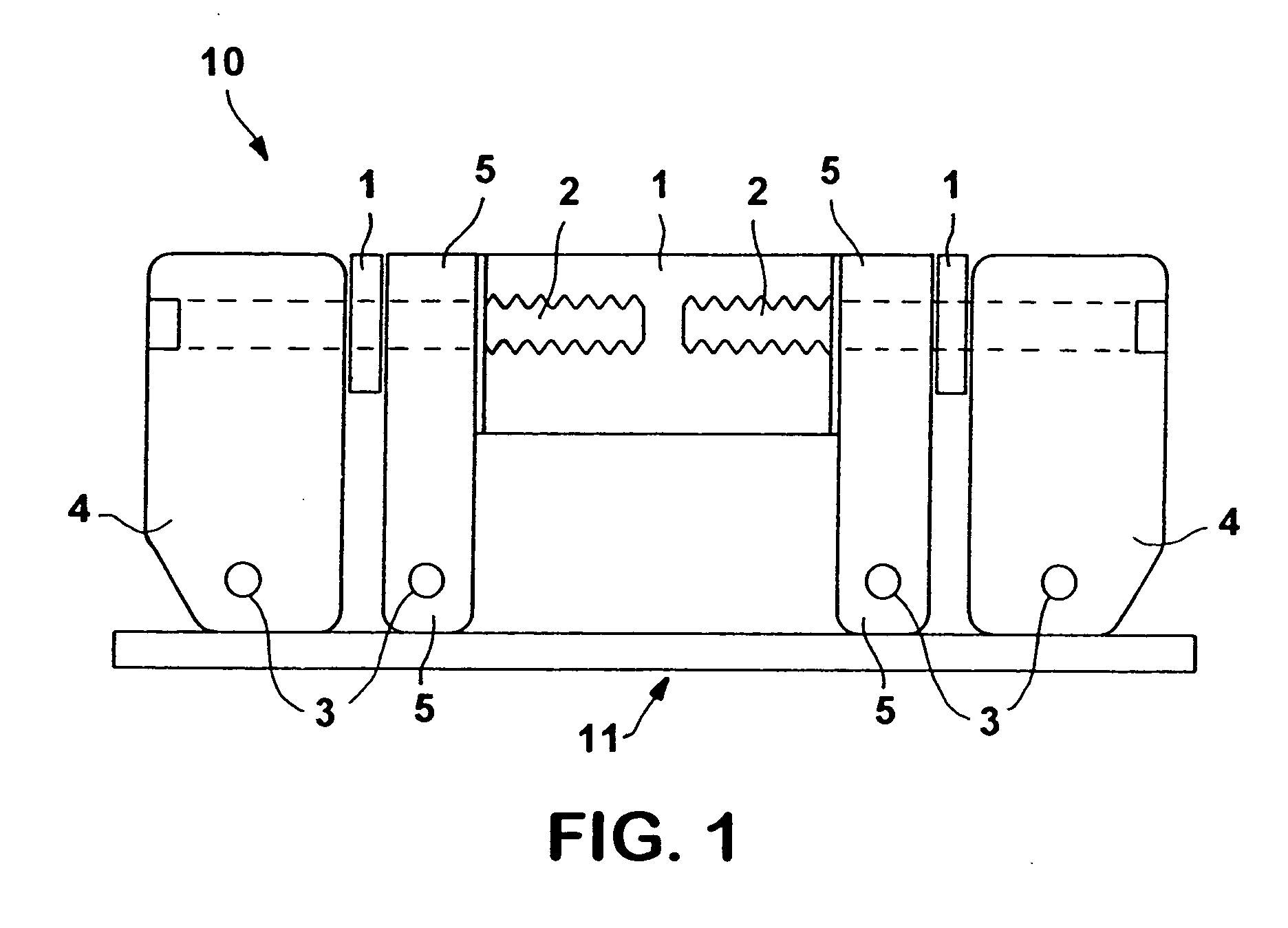

Biodegradable stent with groove and preparation method thereof

ActiveCN102379762AReduced expansion and retractionEquivalent lowStentsSurgeryBiodegradable polymerBlood vessel

The invention relates to the field of medical apparatuses, in particular to a biodegradable polymer stent with grooves and a preparation method thereof. The biodegradable polymer stent comprises a stent main body, magnetic nano particles and a coating layer, wherein the grooves are excavated at parts bearing stent deformation or all parts of the stent main body, and the magnetic nano particles are arranged in the grooves. The temperature of the magnetic nano particles is increased through an external alternating magnetic field to heat the stent. After the stent is heated and expanded, the stent is cooled, fixed and formed in a body, the retraction rate can be decreased to less than 10 percent, and the consequences such as collapse, displacement and the like are avoided. At the same time, by heating the stent through the magnetic nano particles, the thermal damages to the wall of a blood vessel can be minimized.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

DQ-T method for 1000 MPa stage water and electricity steel plate with thickness not larger than 60 mm

ActiveCN108359879AReduce manufacturing costReduce carbon equivalent and weld cold crack susceptibility indexSteel platesQuenching

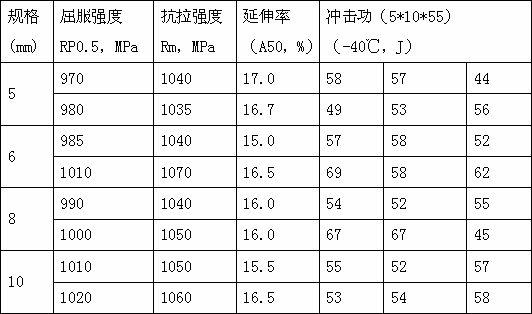

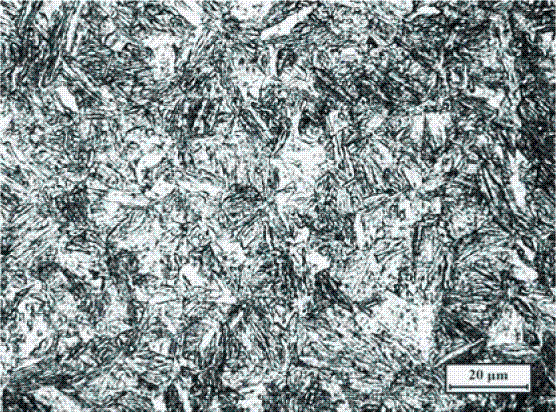

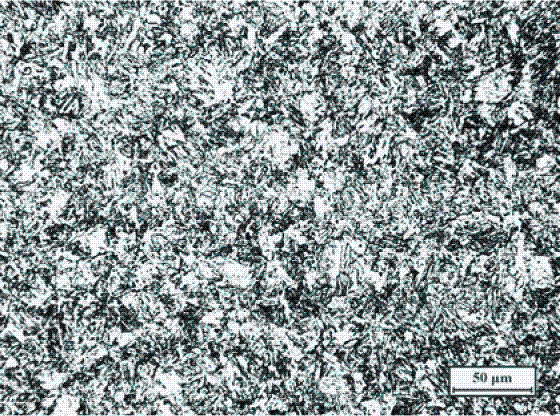

The invention discloses a DQ-T method for a 1000 MPa stage water and electricity steel plate with the thickness not larger than 60 mm. The steel plate comprises chemical components including 0.09%-0.18% of C, 0.80%-1.60% of Mn, not larger than 0.01% of P, not larger than 0.002% of S, not larger than 0.40% of Si, 0.9%-2.6% of Ni, not larger than 0.75% of Cr, not larger than 0.20% of Cu, not largerthan 0.10% of Alt, not larger than 0.06% of Nb, 0.3%-0.65% of Mo, not larger than 0.12% of V, not larger than 0.06% of Ti, not larger than 0.003% of B and the balance Fe. Smelting is carried out according to set components, two-stage rolling is carried out, direct quenching is carried out after rolling, off-line tempering is finally carried out to obtain a microscopic structure with tempered sorbite and a small quantity of tempered martensite, the strength, plasticity and low temperature impact toughness are excellent and matched, the good welding performance is achieved, and the welding coldcrack sensitive index Pcm is smaller than or equal to 0.29%.

Owner:NORTHEASTERN UNIV +1

Low temperature curing powder coating for producing reduced gloss, weatherable coatings

InactiveUS6407181B1Reduce glossEliminate fading, chalking and/or yellowingSynthetic resin layered productsPretreated surfacesPolyesterMeth-

A coating powder, based on glycidyl (meth)acrylate copolymer / carboxylic acid functional polyester chemistry, provides a smooth, weatherable, reduced gloss coating for use on heat sensitive substrates, such as wood. The glycidyl (meth)acrylate copolymer has an epoxy equivalent weight of 250 to 400 and the carboxylic acid functional polyester has a viscosity of 2500 cps or less at 200 C.

Owner:ROHM & HAAS CO

Ultra-large linear energy input welding high-strength steel and production method thereof

InactiveCN101818304AImprove mechanical propertiesImprove toughnessRoll mill control devicesMetal rolling arrangementsSheet steelChemical composition

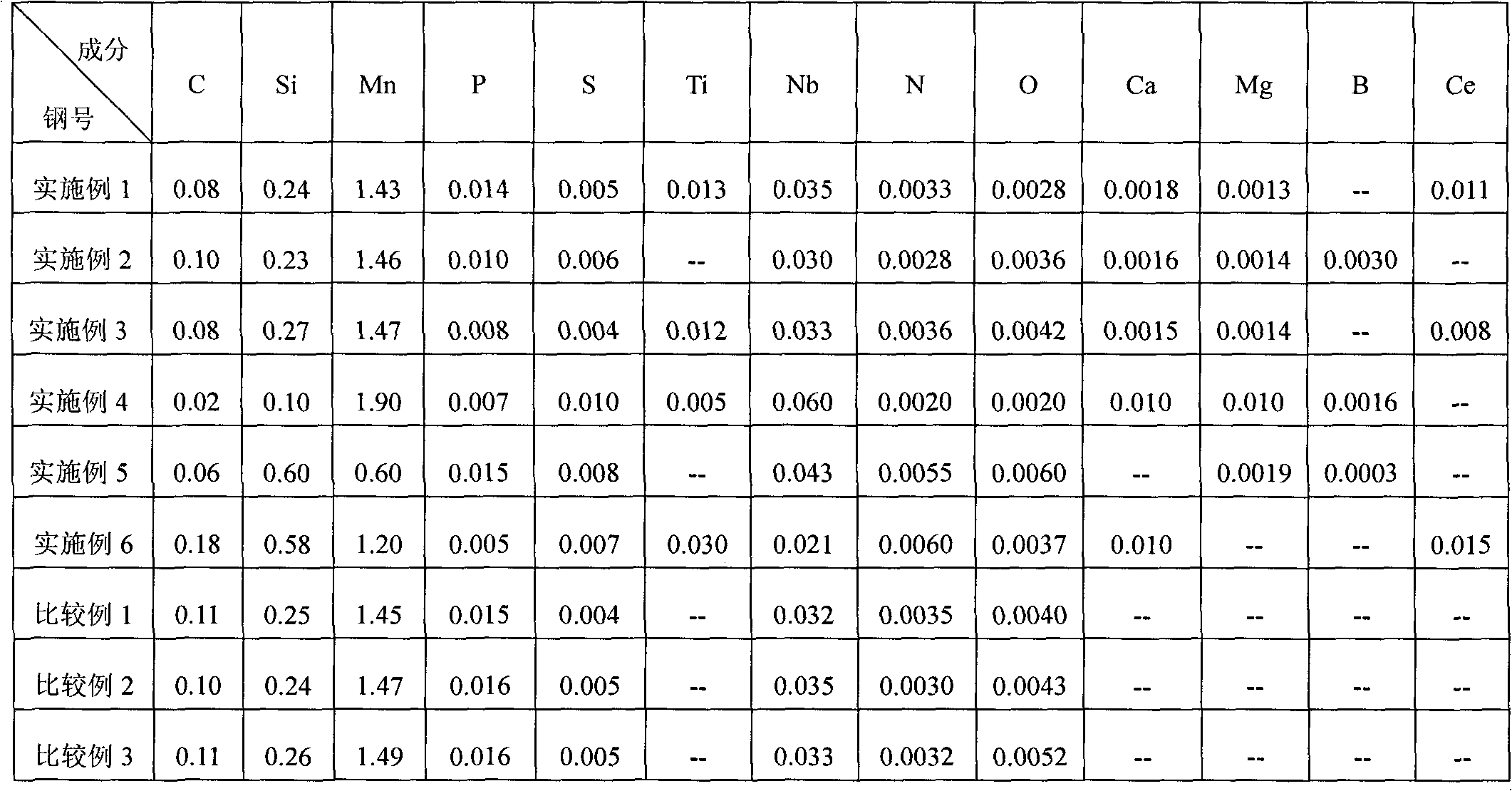

The invention discloses ultra-large linear energy input welding high-strength steel and a production method thereof, and solves the problems of high alloying cost, poor welding performance of steel plates and low HAZ impact toughness of the conventional large linear energy input welding high-strength steel. The steel comprises the following chemical compositions in percentage by weight: 0.02 to 0.18 percent of C, 0.10 to 0.60 percent of Si, 0.60 to 1.90 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.060 percent of Nb, 0.0020 to 0.0060 percent of N, 0.0020 to 0.0060 percent of O, and at least two of 0.005 to 0.030 percent of Ti, less than or equal to 0.010 percent of Ca, less than or equal to 0.010 percent of Mg, 0.0003 to 0.003 percent of B, and 0.008 to 0.015 percent of Ce, and the balance of Fe and inevitable impurities. In addition, the chemical compositions meet the following conditions: (1) 4.0C+Mn is less than or equal to 2.1; (2) the carbon equivalent CE is equal to C+Si / 24+Mn / 6+Ni / 40+Cr / 5+Mo / 4+V / 14 and is less than or equal to 0.39. A casting blank with the compositions is prepared through hot metal desulphurization, converter top and bottom blowing, vacuum deep treatment and fine adjustment of the compositions, the casting blank subjected to controlled rolling is air-cooled to room temperature, and the high-strength strong-toughness and excellent-match steel is obtained. The steel has the advantages of high strength, excellent low temperature toughness, and high Z-direction performance, and can bear ultra-large linear energy input (more than or equal to 500kJ / cm) welding.

Owner:武钢集团有限公司

Barrier laminate, gas barrier film and device using the same

InactiveUS20090324942A1Improve barrier propertiesIncrease stickinessElectrical apparatusElectroluminescent light sourcesMethacrylateMeth-

Disclosed is a barrier laminate comprising at least one organic layer and at least one inorganic layer, wherein the organic layer has a thickness of 300 nm to 900 nm and is formed by curing a polymerizable composition comprising an aromatic (meth)acrylate and a multifunctional (meth)acrylate having an acryl equivalent weight of not more than 200.

Owner:FUJIFILM CORP

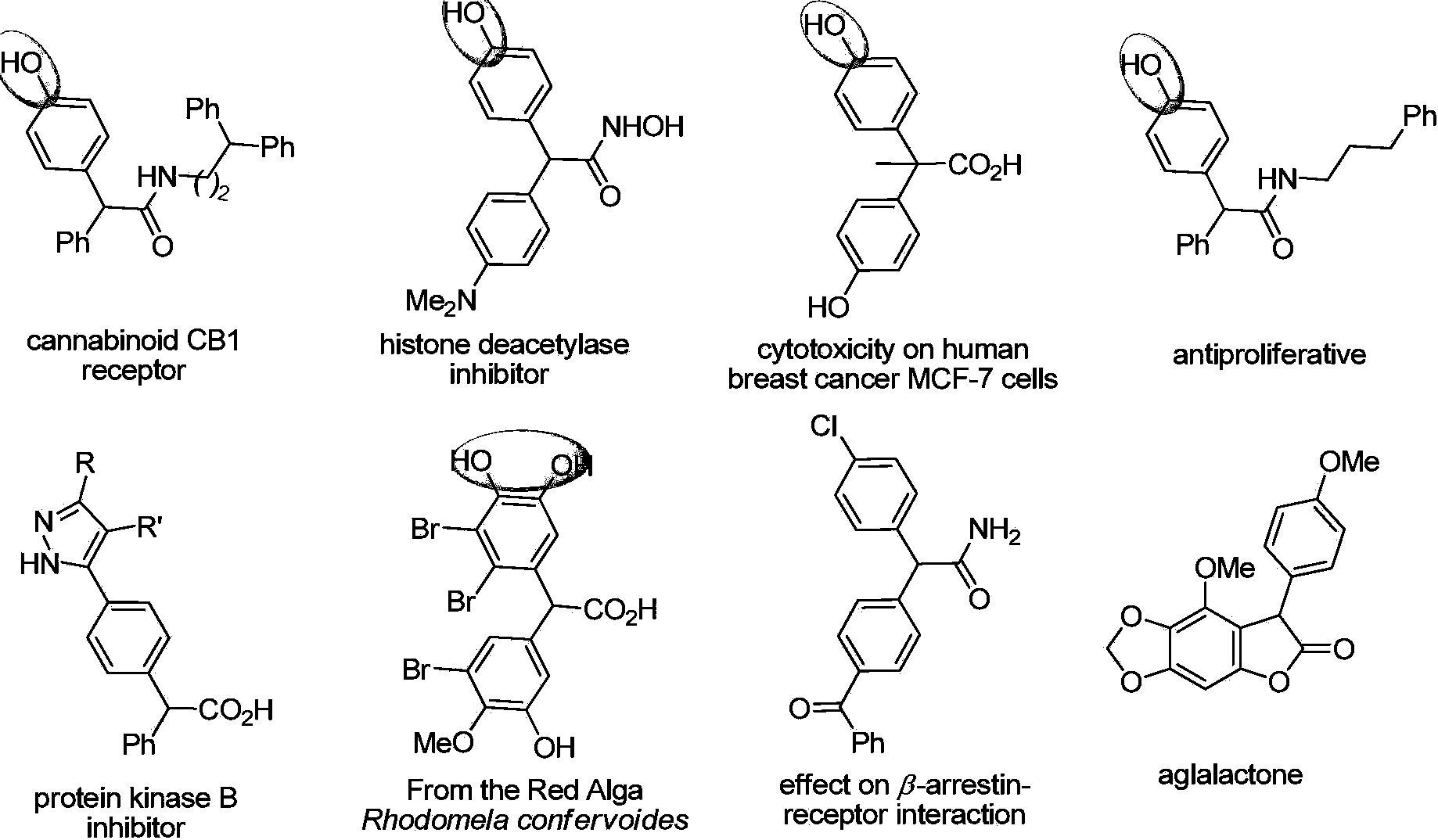

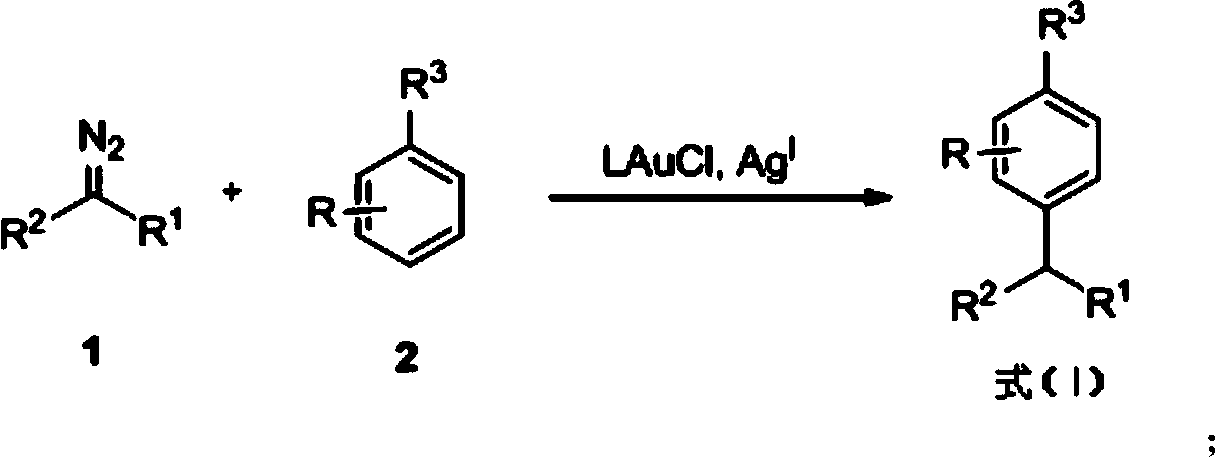

Method for performing gold-catalyzed selective C-H bond functionalization on phenol and aniline

ActiveCN103936537AEfficient synthesisReduce dosageCarbamic acid derivatives preparationCarboxylic acid nitrile preparationEstroneOrtho position

The invention provides a method for performing gold-catalyzed selective C-H bond functionalization on phenol and aniline, which comprises the following steps: by taking phenol and aniline compounds as raw materials and taking phosphine ligand or carbene as ligand, in organic solvent, reacting with a diazo compound in the presence of a gold catalyst and a silver salt, performing carbon-hydrogen bond insertion at the para-position or ortho-position of the phenol or aniline structure. The method provided by the invention has the characteristics of low catalyst consumption, mild conditions, wide substrate application range and the like; the method can be used for quickly and efficiently synthesizing methyl acetate derivatives containing the phenol or aniline structure; and meanwhile, the method can be used for performing later modification on natural products or drug molecules (such as estrone), or be used for synthesizing some molecules having biological activity, thus having favorable application prospects.

Owner:EAST CHINA NORMAL UNIV

Q420E steel plate with low carbon equivalent and high toughness and production method of Q420E steel plate

The invention discloses a Q420E steel plate with low carbon equivalent and high toughness. The steel plate comprises the following chemical components in percentage by weight: 0.06-0.08% of C, 0.35-0.45% of Si, 1.3-1.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.005% of S, 0.025-0.035% of Nb, 0.0015-0.003% of Ca, 0.017-0.03% of Als and the balance of iron and impurities. The invention also discloses a production method of the Q420E steel plate with low carbon equivalent and high toughness. The Q420E steel plate disclosed by the invention is simple in preparation process, low in production cost and good in surface quality; the Q420E steel plate with low carbon equivalent, high toughness and good surface quality can be obtained by adding a trace amount of Nb on the basis of a conventional C-Mn steel by virtue of appropriate heating, controlled rolling and controlled cooling processes.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Acid-corrosion-resistant X70MS pipeline steel hot rolled coil and manufacturing method thereof

The invention provides an acid-corrosion-resistant X70MS pipeline steel hot rolled coil and a manufacturing method thereof. The acid-corrosion-resistant X70MS pipeline steel hot rolled coil comprisesthe following components including, by mass, 0.03% to 0.10% of C, 1.10% to 1.40% of Mn, 0.10% to 0.20% of Si, 0.010% to 0.030% of Al, 0.15% to 0.55% of Cr, 0.15% to 0.45% of Mo, 0.005% to 0.025% of Ti, 0.050% to 0.080% of Nb, 0.020% to 0.040% of V, 0.15% to 0.30% of Ni, not larger than 0.0002% of B, not larger than 0.012% of P, not larger than 0.0020% of S, not larger than 0.0060% of N, not largerthan 0.0018% of O, not larger than 0.0005% of H and the balance Fe and inevitable inclusions. Compositions and mechanical property of the acid-corrosion-resistant pipeline steel X70MS products meet the API 5L standard, the acid corrosion resistance performance meets international HIC resistant and SSCC resistant related standard requirements, the good welding technology performance is obtained, and the requirements for producing materials for oil and gas pipelines are met.

Owner:BENGANG STEEL PLATES

The manufacturing method of high-strength plate q960 produced by the steel coil rolling mill

InactiveCN102286687ALow yield ratioImprove low temperature toughnessChemical compositionSmelting process

The invention discloses a method for manufacturing high-strength plate Q960 produced by a coil rolling mill. In terms of smelting technology, converter steelmaking is adopted, and top-lower compound blowing is used for deep decarburization; RH vacuum treatment is used for further decarburization and microalloying. Obtain a steel billet that meets the requirements; the chemical composition weight percentage of the steel billet is: C0.12~0.20%, Mn0.80~1.60%, Si0.02~0.40, P≤0.015, S≤0.005, B0.001~0.003, and add Appropriate amount of Cr, Mo, V, Ni alloy elements, and satisfy carbon equivalent Ceq=+Mn / 6+Cr / 5+Mo / 4+V / 14+Ni / 40+Si / 24≤0.60; in terms of rolling process , controlled rolling is carried out by a steckel rolling mill, and the heating temperature of the steel billet before rolling is 1150-1250 °C; the invention has the characteristics of low carbon equivalent, excellent low-temperature toughness, smooth plate shape, and good welding performance, and is suitable for construction machinery, mining equipment, ports, etc. Machinery and other fields.

Owner:NANJING IRON & STEEL CO LTD

High-strength steel sheet with yield strength of 1100MPa and manufacturing method thereof

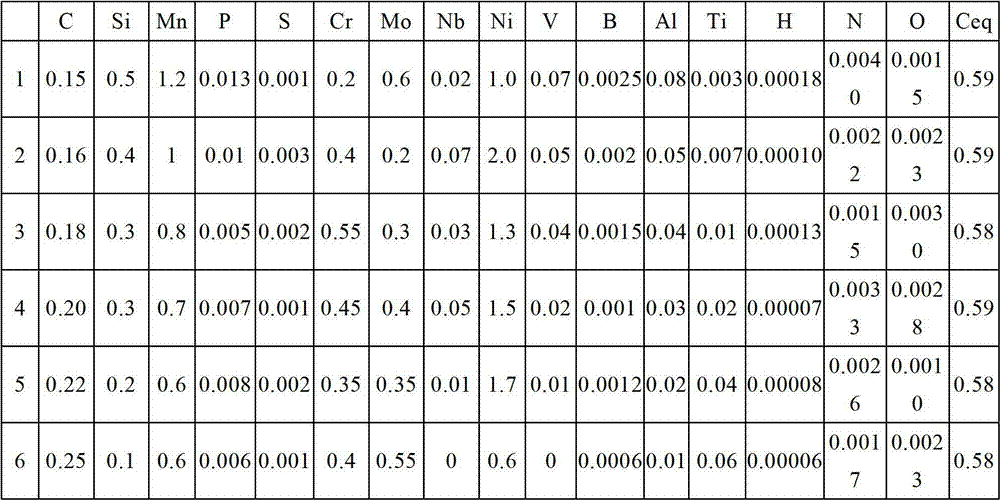

A high-strength steel sheet with yield strength of 1100MPa and a manufacturing method thereof. The high-strength steel sheet comprises, based on the weight percentage, 0.15-0.25% of C, 0.10-0.50% of Si, 0.60-1.20% of Mn, no more than 0.013% of P, no more than 0.003% of S, 0.20-0.55% of Cr, 0.20-0.70% of Mo, 0.60-2% of Ni, 0-0.07% of Nb, 0-0.07% of V, 0.0006-0.0025% of B, 0.01-0.08% of Al, 0.003-0.06% of Ti, no more than 0.00018% of H, no more than 0.0040% of N, no more than 0.0030% of O, and the balance of Fe and inevitable impurities; and the carbon equivalent CEQ is no more than 0.60%. A quenching and a tempering heat treatment are employed to obtain a tempered martensite tissue. The steel provided by the present invention has yield strength no less than 1100MPa, tensile strength no less than 1250MPa, Charpy ballistic work Akv (-40 DEG C) no less than 50J, and good strength and toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

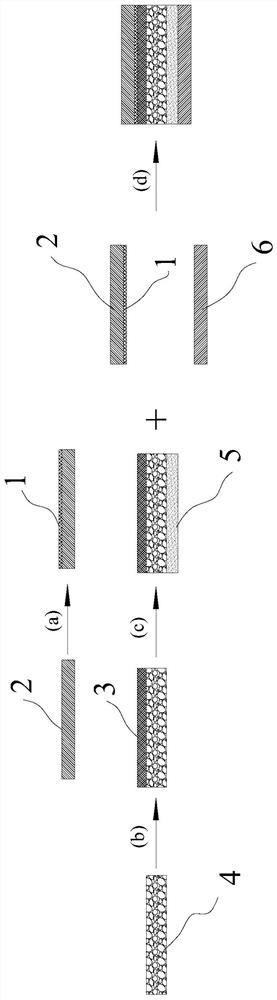

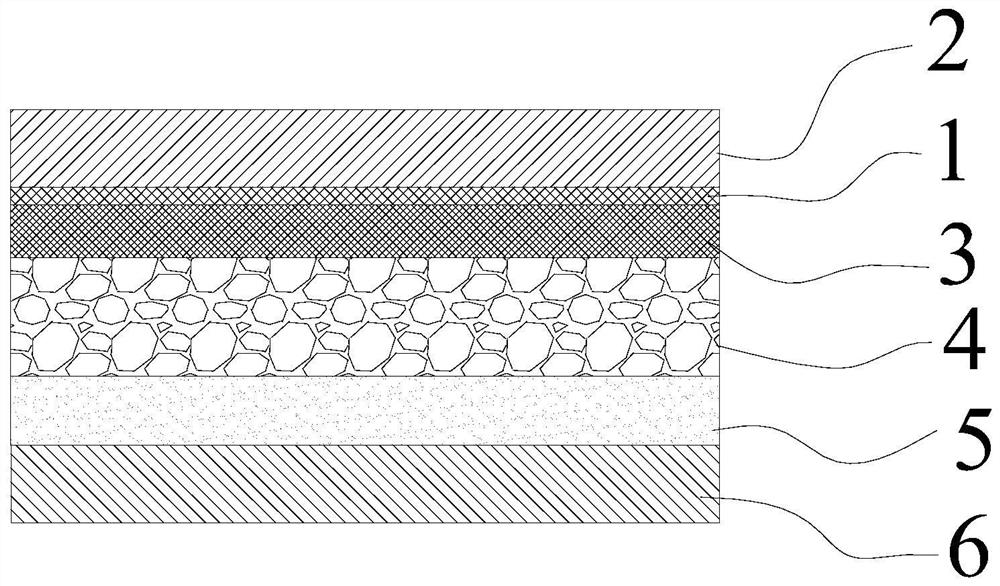

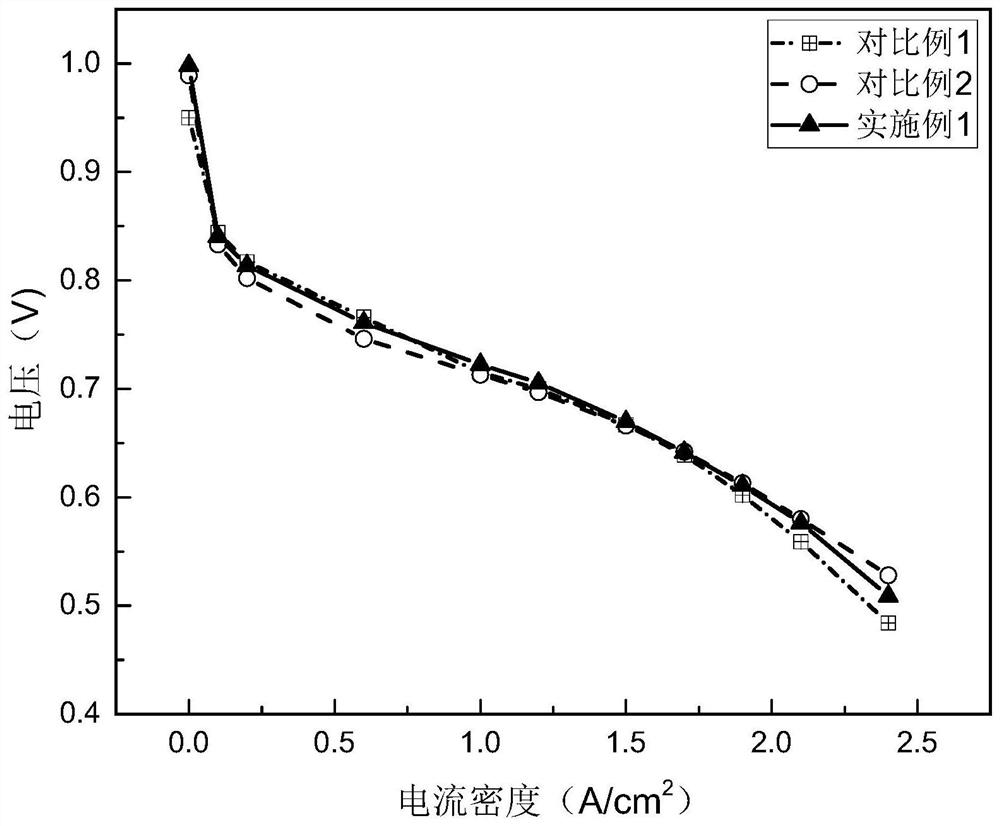

Membrane electrode and preparation method thereof

InactiveCN111900448AEquivalent lowEquivalent highCell electrodesFuel cellsPerfluorosulfonic acidCathode catalyst

The invention relates to the technical field of fuel cells. The invention particularly relates to a membrane electrode. The membrane electrode comprises an anode gas diffusion layer, an anode catalystlayer, a proton exchange membrane, a cathode catalyst layer and a cathode gas diffusion layer which are arranged in sequence, wherein the cathode catalyst layer is mainly prepared from perfluorosulfonic acid resin and a catalyst, the cathode catalyst layer comprises at least two cathode catalyst sub-layers, and the equivalent weight of the perfluorosulfonic acid resin in the sub-layer close to the proton exchange membrane is smaller than that of the perfluorosulfonic acid resin in the sub-layer close to the cathode gas diffusion layer. According to the membrane electrode, the cathode catalystlayer has certain water content to ensure proton transfer, and oxygen transfer is not influenced by excessive water content. The invention also provides a preparation method of the membrane electrode.

Owner:SINOHYKEY TECH CO LTD

Manufacturing method of seamless steel pipe

The invention discloses a manufacturing method of a seamless steel pipe. The manufacturing method comprises the following steps of making steel: feeding a SiCaBa alloy core wire after slagging molten steel in a steel ladle, and expanding slag to form foamed slag; adjusting the amount, the alkalinity and the fluidity of the slag according to slag conditions, and adding SiC powder, silicon calcium (barium), silicon iron and calcium carbide so as to reduce refined slag to form white slag; adding 0.13-0.20% of carbon, 0.25-0.50% of silicon, 0.9-1.3% of manganese, less than or equal to 0.030% of phosphorus, less than or equal to 0.030% of sulphur, 0.03-0.10% of vanadium, 0.015-0.040% of aluminium, less than or equal to 0.20% of chromium, less than or equal to 0.10% of nickel, less than or equal to 0.10% of molybdenum, less than or equal to 0.10% of titanium, and less than or equal to 0.20% of copper; pouring out a part of the refined slag, and retaining a slag layer, the molten steel surface layer of which is less than or equal to 100 mm; stirring in vacuum; feeding an aluminium wire with the diameter of 12 mm after breaking vacuum; feeding a pure calcium wire for modifying inclusions; blowing by using argon so that the molten steel is uniform; continuously casting; rolling; thermally treating; straightening; and detecting flaws. The seamless steel pipe prepared by the invention has high strength, high toughness, low carbon equivalent and good welding property, and therefore, the use reliability and the safety are increased.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

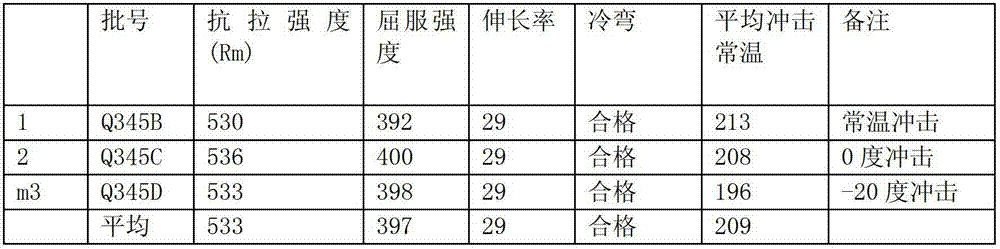

Production method for controlling fault detection defect of medium thick plate Q345 steel

InactiveCN103031490AImprove the qualified rate of flaw detectionImproving the pass rate of strong flaw detection of steelThick plateSlag

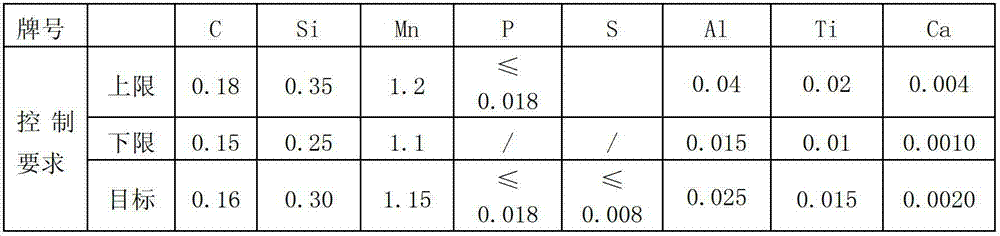

The invention provides a production method for controlling fault detection defect of medium thick plate Q345 steel. The composition design is: 0.15-0.18% of C, 0.25-0.35% of Si, 1.1-1.2% of Mn, equal to or less than 0.018% of P, equal to or less than 0.008% of S, 0.025-0.04% of Al, 0.015-0.02% of Ti, and 0.002-0.004% of Ca; an Al-Ca refining agent is added during LF refining, the Al-Ca reining agent is began to feed into a steel ladle when the temperature reaches 1530 DEG C, and the addition amount is 0.5-1.0kg / t steel; the S content of the pretreated molten iron is 0.001-0.002%, and the tapping temperature of a converter is kept at 1620 DEG C to 1630 DEG C; the Al2O3 content of refined slag of an LF refining furnace is 30-35%, the delivery of current is 10min to 15min, and the final molten steel nitrogen content is 0.002-0.004%; and the molten steel liquid level of a casting pot is controlled to be 500mm to 550mm, and the steel ladle long nozzle is protected by argon seal, thus the nitrogen content of the continuous casting molten steel is enhanced by 0.0003-0.0008%, and the molten steel continuous casting temperature is 1525 DEG C to 1535 DEG C.

Owner:宝钢集团八一钢铁股份有限公司

Low equivalent weight ionomer

InactiveUS20060241261A1Equivalent lowImprove conductivityCellsElectrolyte holding meansIonomerFuel cells

Owner:WL GORE & ASSOC INC

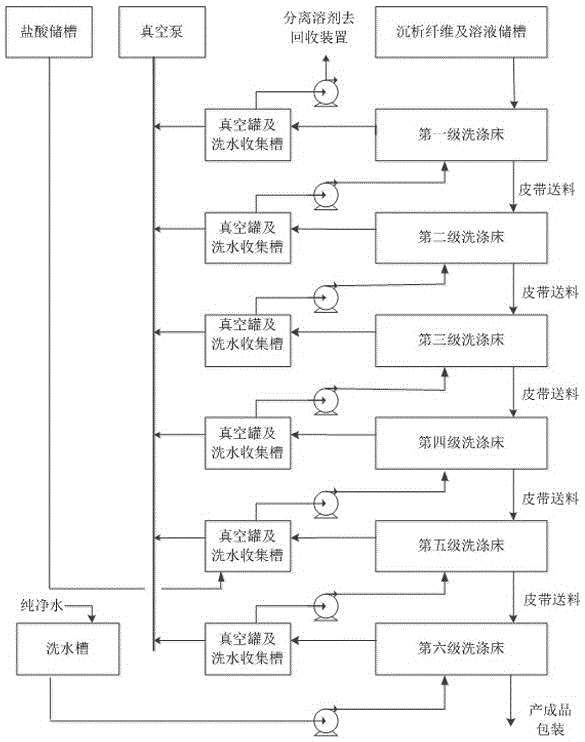

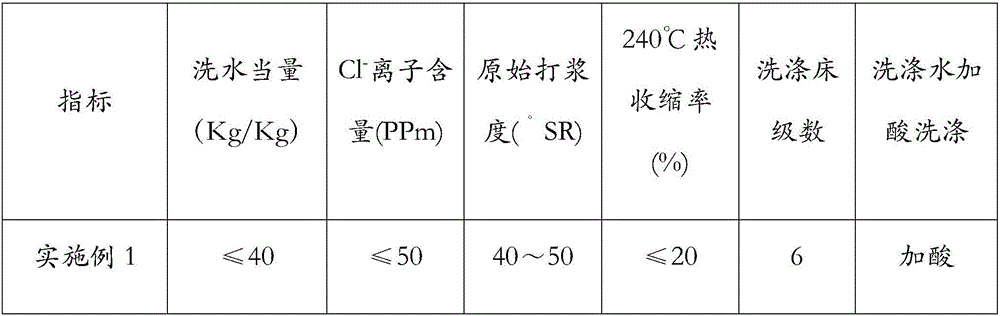

Method for washing meta-aramid fibrid

ActiveCN106367827AIncrease penetration rateAccelerated Diffusion DissolutionArtificial filament washing/dryingOligomerHydrolysate

The invention relates to the technical field of special synthesized fiber manufacturing, and in particular to a method for washing meta-aramid fibrid. The method comprises the following steps: performing continuous washing for six stages in sequence, from the sixth time of washing, performing countercurrent washing with pure water, recycling separated washing water for a former washing stage, and adding acid into washing water of the fourth stage to the first stage so as to acidify the fiber in an acid washing solution, so that the caked surface of the fiber is loosed, the infiltration rate of the washing water is increased, and diffusion dissolution of Cl- and chlorizated salts in the washing water in the fiber is accelerated; meanwhile, oligomers in the acid washing solution can be subjected to acidolysis and can be decomposed into acid hydrolysate which can be dissolved in the washing water, so that the product quality can be improved. By adopting the method, the content of Cl- ions of a fibrid product obtained by using the method can be less than or equal to 50PPm, the original beating degree of the fibrid product can be 35-50 DEG SR, the thermal shrinkage rate of the fibrid product at 240 DEG C is less than or equal to 20%, and the washing water equivalent of the fibrid product on a dry basis Kg is less than or equal to 40Kg.

Owner:四川辉腾科技股份有限公司

Low-cost quenched and tempered 690MPa-grade steel plate for engineering machinery and production method

The invention relates to a low-cost quenched and tempered 690MPa-grade steel plate for engineering machinery and a production method, and belongs to the technical field of steel production. The steelplate comprises the following chemical components in percentage by mass: 0.10-0.25% of C, 0.20-0.60% of Si, 1.00-1.50% of Mn, less than or equal to 0.020% of P, less than or equal to 0.007% of S, 0.20-0.50% of Cr, 0.20-0.50% of Mo, 0.03-0.06% of V, 0.01-0.03% of Ti, 0.001-0.003% of B, and the balance of Fe and inevitable impurities. The production method comprises the processes of smelting, heating, rolling and heat treatment, wherein the rolling process adopts a two-stage controlled rolling process, and the heat treatment process adopts a quenching and tempering process. The steel plate provided by the invention reduces the content of precious metals and has a low production cost; the steel plate has excellent mechanical properties by adopting a process of 'controlled rolling and off-linequenching and tempering heat treatment'.

Owner:HEBEI IRON AND STEEL

Preparation method of anti-dezincification lead-free bismuth arsenic brass pipe

The invention relates to the field of copper alloys for toilet and kitchen industries, and provides a preparation method of an anti-dezincification lead-free bismuth arsenic brass pipe. The preparation method comprises the steps of casting as a copper ingot-extrusion as a copper pipe blank-stretching-annealing-inspection of a finished copper pipe-warehousing of the finished copper pipe after smelting of the following raw materials in percentage by mass: 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, Pb not more than 0.1%, and the balance of Zn and impuritieswith a total amount not more than 0.25%.

Owner:龙岩市鸿航金属科技有限公司

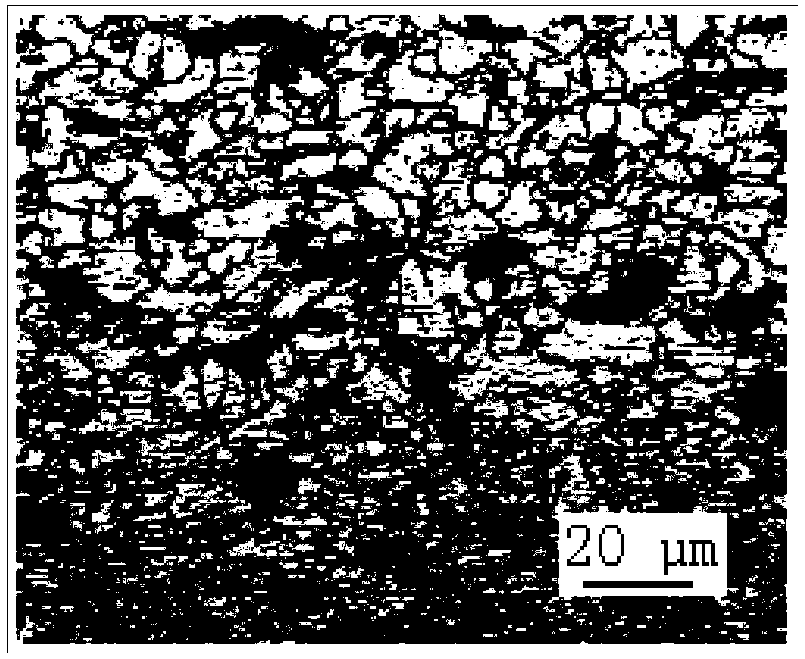

Welding method of non-preheating before welding and non-heat-treatment after welding of V-N microalloying Q550D medium plate

ActiveCN106216817AImprove toughnessIncrease productivityArc welding apparatusWorkpiece edge portionsHeat-affected zoneThick plate

The invention belongs to the technical field of welding, and particularly relates to a welding method of non-preheating before welding and non-heat-treatment after welding of a V-N microalloying Q550D medium plate. Through selection of reasonable welding wires and optimization of welding parameters, the welding technology of non-preheating before welding and non-heat-treatment after welding is developed; a VN precipitated phase in austenite of V-N microalloying steel is used for promoting the acicular ferrite nucleation action, the toughness performance of a welding heat affected zone is improved, and the welding technology has the important significance in applying and popularizing of the V-N steel.

Owner:NORTHEASTERN UNIV

Preparation method of welding steel plate with large energy input

The invention discloses a preparation method of a welding steel plate with large energy input. The steel plate comprises C, Mn, Si, Ni, Cr, V, Ti, P, S, O, Als, Ca and Fe. The preparation method comprises following steps of: desulfurizing molten steel, smelting in a converter or an electric furnace, blowing bottom argon to a steel ladle or a ladle furnace to perform refining, performing continuous casting and rolling to obtain a plate, wherein ferrovanadium, ferronickel and ferrotitanium are added together with waste steel at first during the smelting step in the converter or the electric furnace; ferrochromium and calcium wires are added during the refining step so that chemical components in the steel satisfy requirements of components of the steel plate; the temperature of the molten steel added into a crystallizer during the continuous casting step is controlled to be 1530-1550 DEG C; and in the rolling step, the starting rolling temperature is 1200-1220 DEG C, the accumulated reduction rate of last three controlled rolling steps is not less than 42%, and the finish rolling temperature is 880-900 DEG C.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

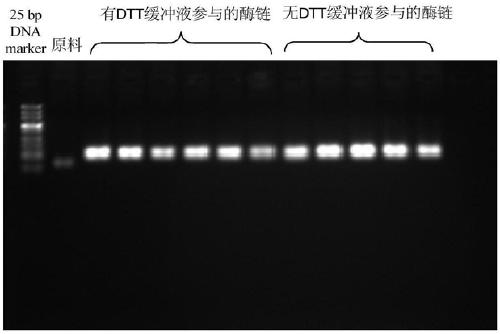

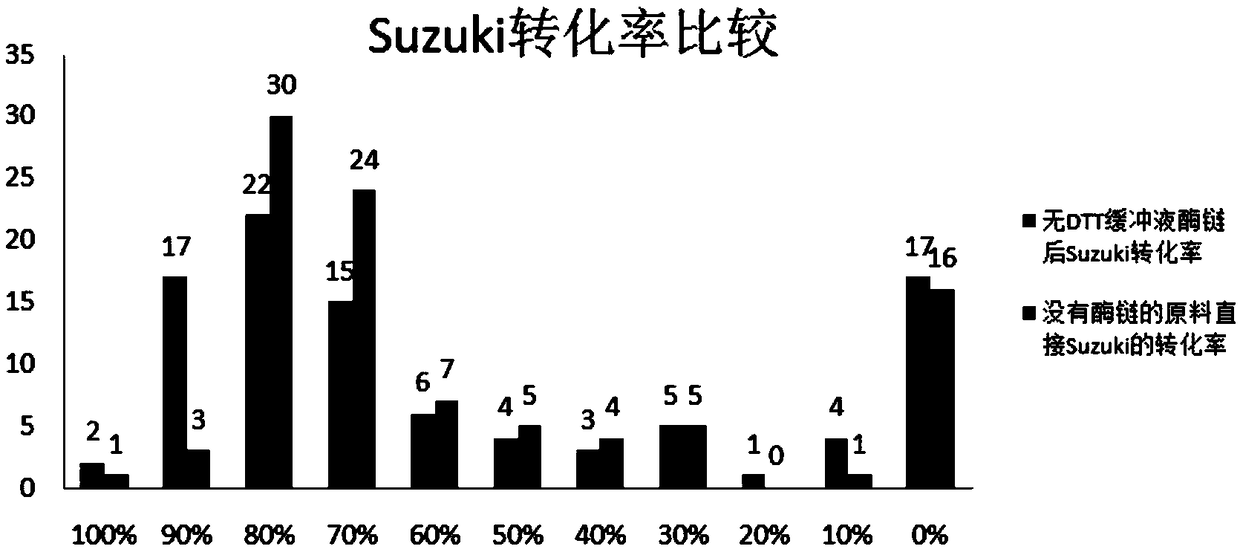

T4 DNA ligase buffer solution for polymerase chain reaction in DNA coding compound library synthesis and application of T4 DNA ligase buffer solution

ActiveCN109439710AReduce synthesis cycleImprove conversion efficiencyFermentationChemical reactionPropanediol

The invention discloses three types of T4 DNA ligase buffer solutions for DNA coding compound library construction. The T4 DNA ligase buffer solutions include 1) DTT-free 10X T4 DNA ligase buffer solution in pH of 6.0-10.0 and prepared from 10-1000mM of Tris-HCl, 10-500mM of MgCl2 and 1-50mM of ATP, 2) Tris-free 2X T4 DNA ligase buffer solution in pH of 6.0-10.0 and prepared from 1-200mM of a sulfonic acid agent, 1-400mM of MgCl2, 0.1-5.0mM of ATP, 1-20% of 1,3-propanediol and 0.1-5.0mM of DTT and 3) Tris-free and DTT-free 2X T4 DNA ligase buffer solution in pH of 6.0-10.0 and prepared from 1-200mM of a sulfonic acid agent, 1-400mM of MgCl2, 0.1-5.0mM of ATP and 1-20% of 1,3-propanediol. The invention further discloses application of the three types of T4 DNA ligase buffer solutions. By the buffer solutions and application thereof, the defect of adverse effect, caused by residual components after existing buffer solution polymerase chain reaction, on next chemical reaction is overcome,and a DNA coding compound library synthesis period is shortened.

Owner:上海药明康德新药开发有限公司 +1

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101BEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsChemical compositionPower station

Owner:WUYANG IRON & STEEL

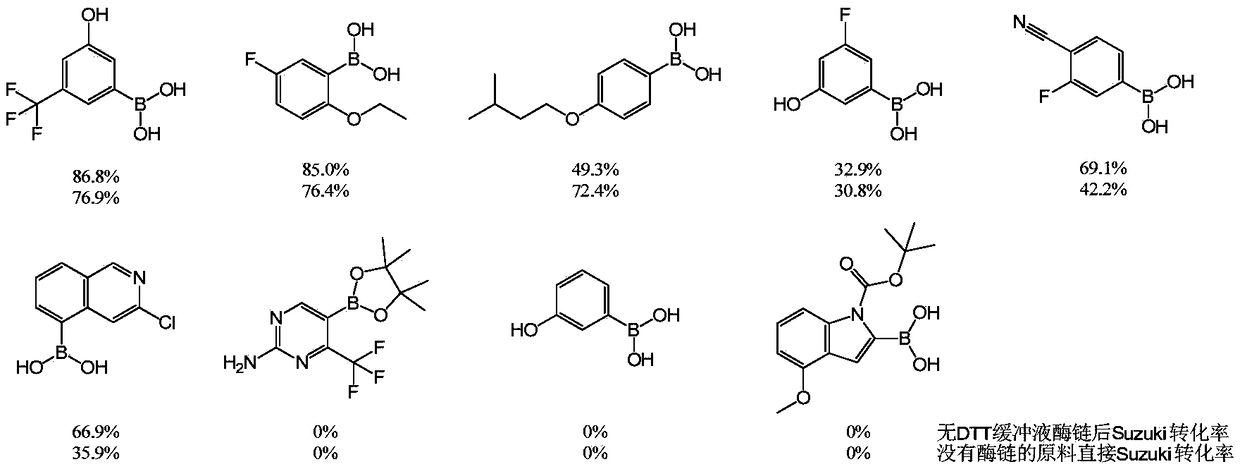

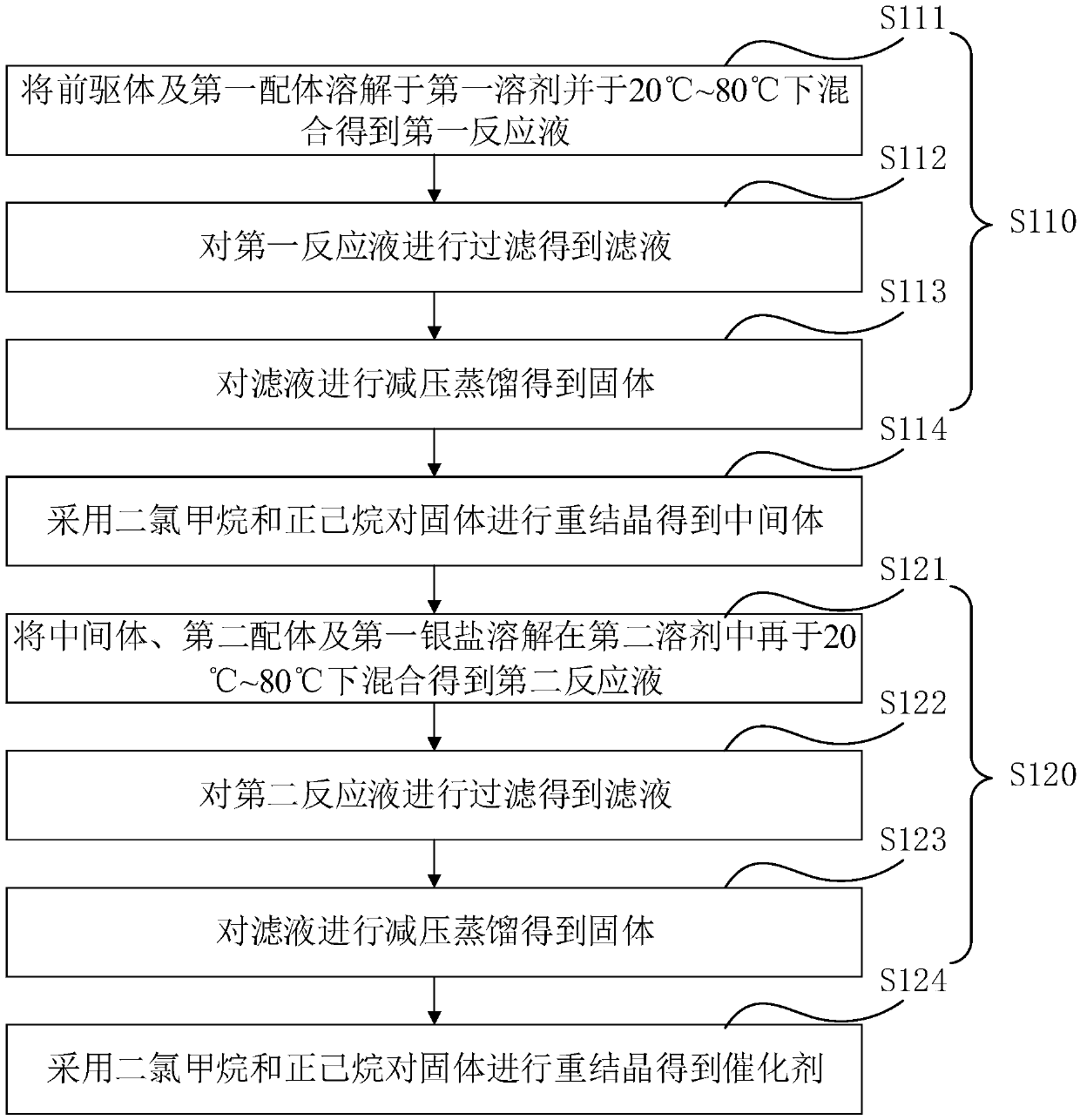

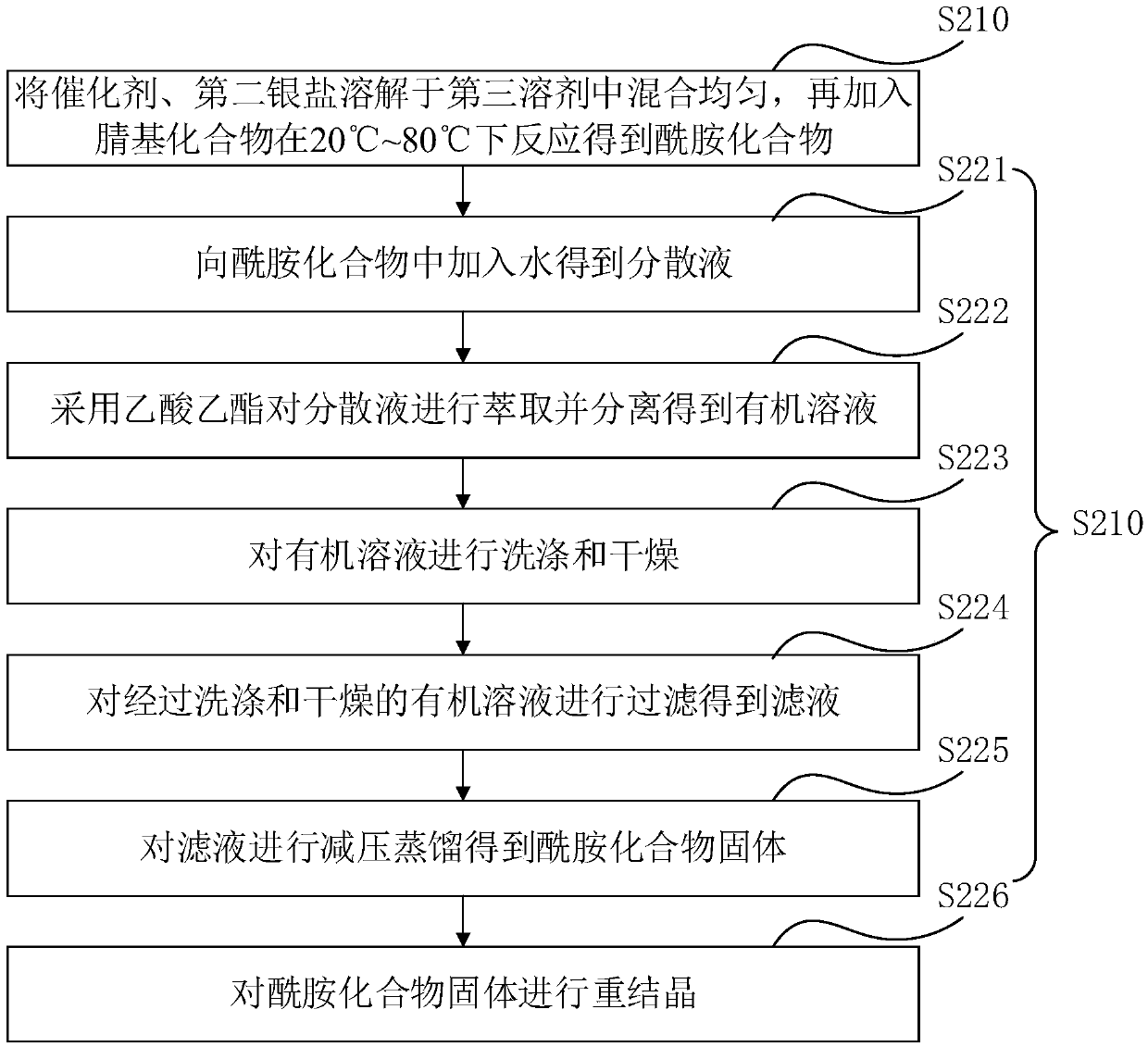

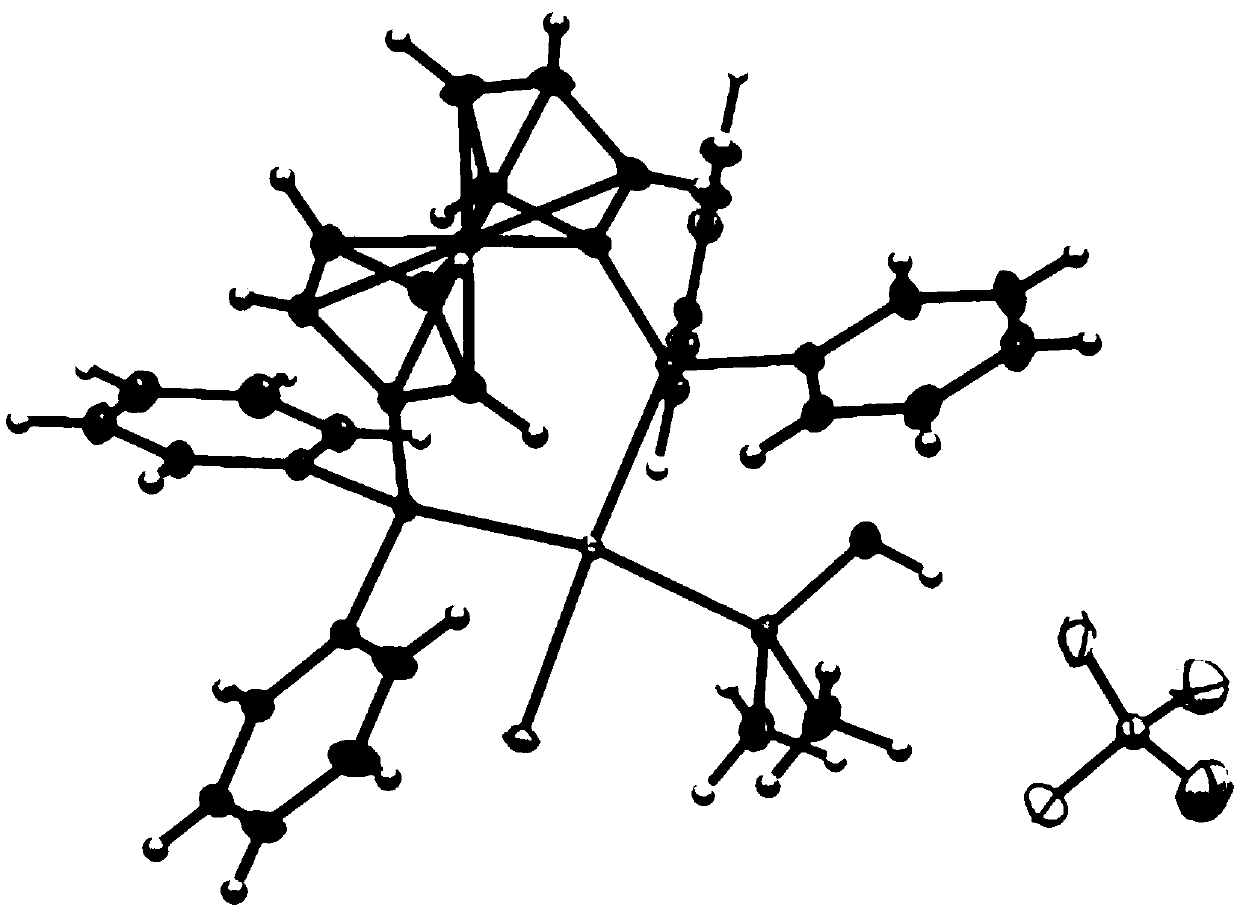

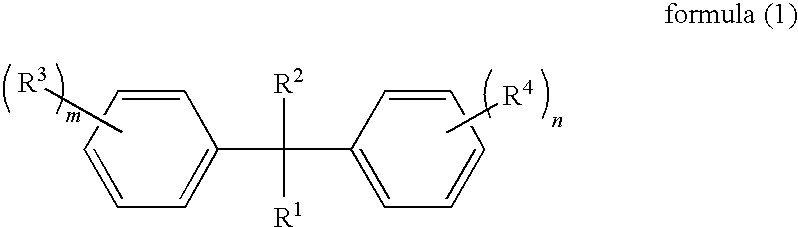

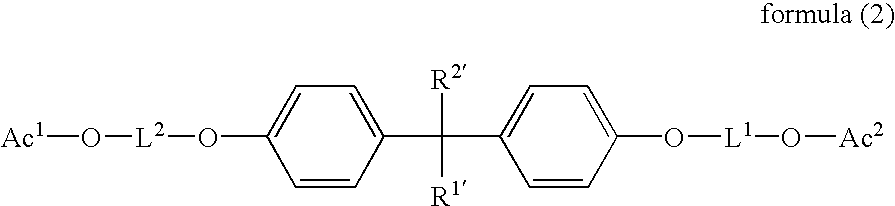

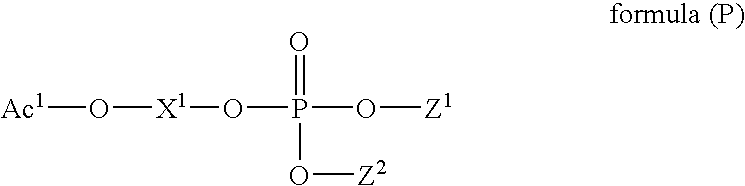

Catalyst, preparation method thereof and preparation method of amide compound

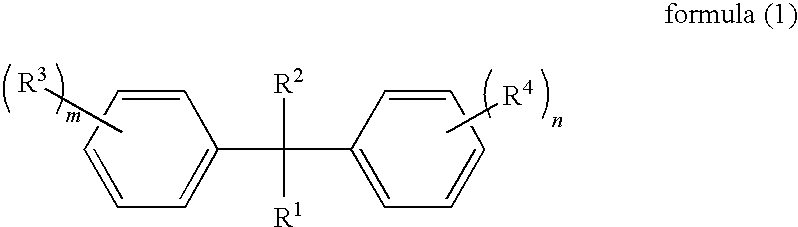

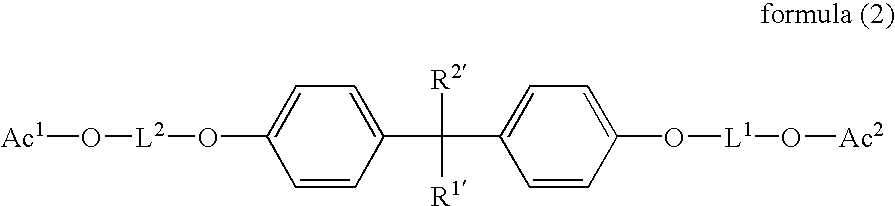

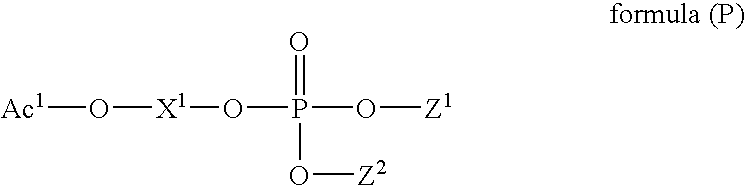

ActiveCN110642895AEquivalent lowImprove conversion rateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlkanePolymer science

The invention relates to a catalyst, a preparation method thereof, and a preparation method for hydrating nitrile groups into amides. The catalyst is used for catalyzing nitrile groups to be hydratedinto amides, and the structural general formula of the catalyst is shown in the specification. In the formula, a plurality of R<1> are respectively and independently ones selected from aromatic groups, heteroaromatic groups and non-aromatic ring groups; a plurality of R<2> are ones respectively and independently selected from linear alkyl groups and alkane aromatic groups; X is one selected from Cl and Br; and L is one selected from OTf, BF4, PF6 and SbF6. The catalyst can catalyze nitrile groups to be hydrated into amides, and the nitrile groups can be catalyzed to be hydrated into amides even at a low temperature (20-80 DEG C); besides, compared with existing common catalysts for catalyzing nitrile groups to be hydrated into amides, the catalyst has the advantages that the equivalent weight of the catalyst can be obviously reduced, and nitrile groups can reach a relatively high conversion rate when the equivalent weight of the catalyst is only 0.01 mol%-0.5 mol%; and meanwhile, the catalyst is wider in application range and can catalyze various nitrile compounds to be hydrated into amide compounds.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Barrier laminate, gas barrier film and device using the same

InactiveUS8637147B2Improve barrier propertiesEquivalent lowElectrical apparatusElectroluminescent light sourcesMethacrylatePolymer science

Disclosed is a barrier laminate comprising at least one organic layer and at least one inorganic layer, wherein the organic layer has a thickness of 300 nm to 900 nm and is formed by curing a polymerizable composition comprising an aromatic (meth)acrylate and a multifunctional (meth)acrylate having an acryl equivalent weight of not more than 200.

Owner:FUJIFILM CORP

Preparing method for anti-dezincification leadless bismuth arsenic extruded brass rod

The invention relates to the field of copper alloys for the bathroom and kitchen industry and provides a preparing method for an anti-dezincification leadless bismuth arsenic extruded brass rod. The preparing method comprises the step of smelting 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, smaller than 0.1% of Pb, the balance Zn and smaller than or equal to 0.25% of impurities to obtain the solid brass rod by the processes of lead casting and extruding.

Owner:龙岩市鸿航金属科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com