Q420E steel plate with low carbon equivalent and high toughness and production method of Q420E steel plate

A production method and carbon equivalent technology, applied in the field of metal materials, can solve the problems of complex production process, low impact toughness and high production cost, and achieve the effects of simple production process, good toughness and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The thickness of the slab is 250mm, the temperature of the slab out of the furnace is 1220°C, the heating time of the slab is 290 minutes, and the chemical composition (percentage by weight) of the slab is: C0.08%, Si0.45%, Mn1.5%, P0 .02%, S0.002%, Nb0.035%, Als0.017%, Ca0.0015%, and the balance is Fe and unavoidable impurities. Rolled into a steel plate with a thickness of 10 mm, the detailed rolling and cold removal process is shown in Table 1, and its mechanical properties are shown in Table 2.

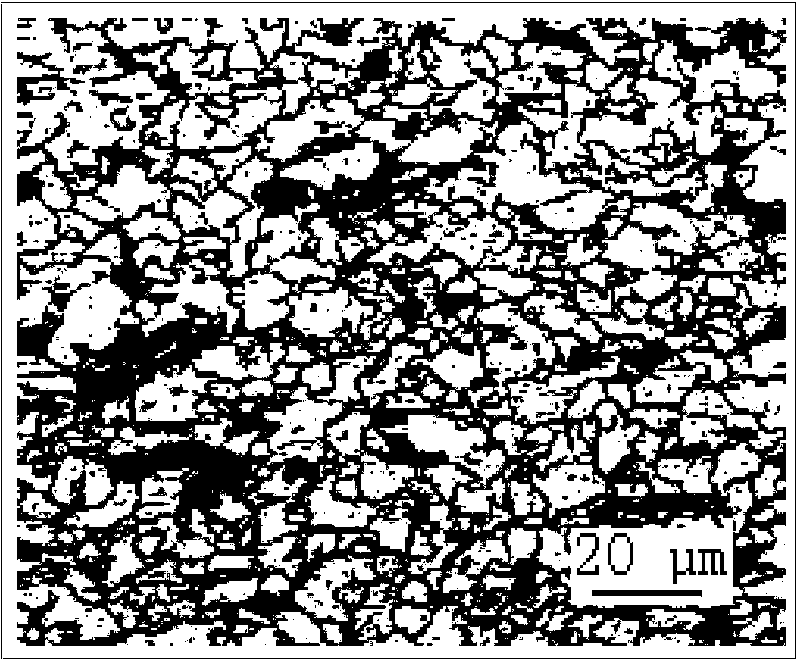

[0049] Such as figure 1 Shown is the metallographic structure diagram of the steel plate in Example 1 of the present invention. It can be seen from the metallographic diagram that the structure of the steel plate is mainly polygonal ferrite, and there are a small amount of acicular ferrite and pearlite, and the grains are fine. Since both polygonal ferrite and acicular ferrite have good plasticity and toughness, the steel plate with this structure has good toughness.

[...

Embodiment 2

[0055] Adopting thickness is 250mm slab, and slab furnace temperature is 1190 ℃, and slab heating time is 430 minutes, and the (weight percentage) chemical composition of slab is: C0.07%, Si0.35%, Mn1.3%, P0 .015%, S0.001%, Nb0.03%, Als0.03%, Ca0.003%, the balance is Fe and unavoidable impurities. Rolled into a steel plate with a thickness of 16 mm, the detailed rolling and cold removal process is shown in Table 3, and its mechanical properties are shown in Table 4.

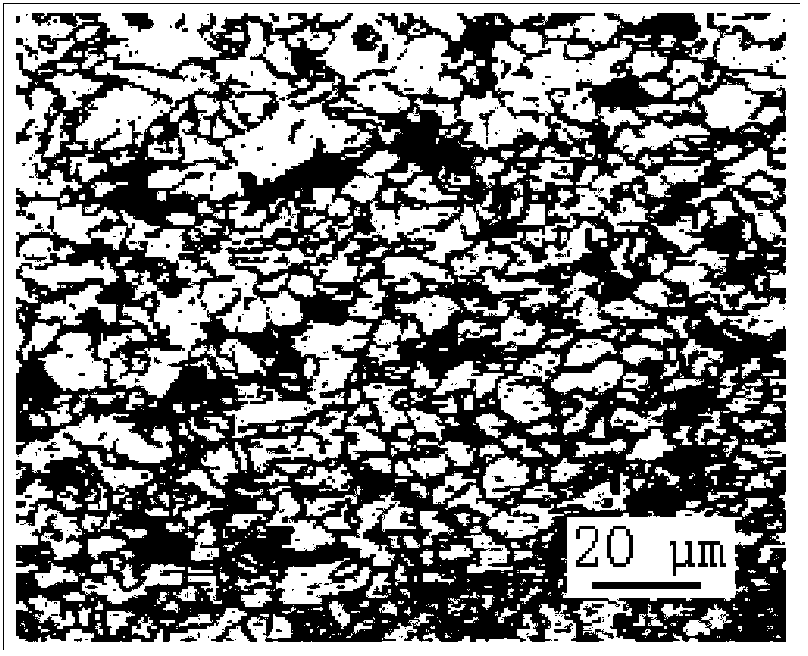

[0056] Such as figure 2 Shown is the metallographic structure diagram of the steel plate in Example 2 of the present invention. It can be seen from the metallographic diagram that the structure of the steel plate is mainly polygonal ferrite, and there are a small amount of acicular ferrite and pearlite, and the grains are fine. Since both polygonal ferrite and acicular ferrite have good plasticity and toughness, the steel plate with this structure has good toughness.

[0057] Table 3 Rolling and cooling proce...

Embodiment 3

[0062] Adopting thickness is 250mm slab, and slab furnace temperature is 1190 ℃, and slab heating time is 430 minutes, and the (weight percentage) chemical composition of slab is: C0.06%, Si0.42%, Mn1.41%, P0 .011%, S0.002%, Nb0.025%, Als0.021%, Ca0.0023%, the balance is Fe and unavoidable impurities. Rolled into a steel plate with a thickness of 12 mm, the detailed rolling and cold removal process is shown in Table 5, and its mechanical properties are shown in Table 6.

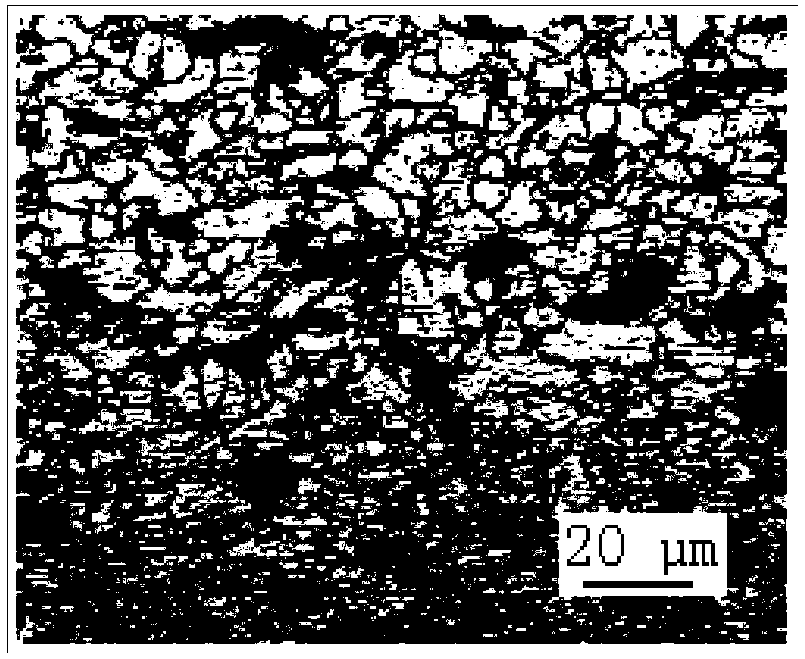

[0063] Such as image 3 Shown is the metallographic structure diagram of the steel plate in Example 3 of the present invention. It can be seen from the metallographic diagram that the structure of the steel plate is mainly polygonal ferrite, and there are a small amount of acicular ferrite and pearlite, and the grains are fine. Since both polygonal ferrite and acicular ferrite have good plasticity and toughness, the steel plate with this structure has good toughness.

[0064] Table 5 Rolling and cooling pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com