Biodegradable stent with groove and preparation method thereof

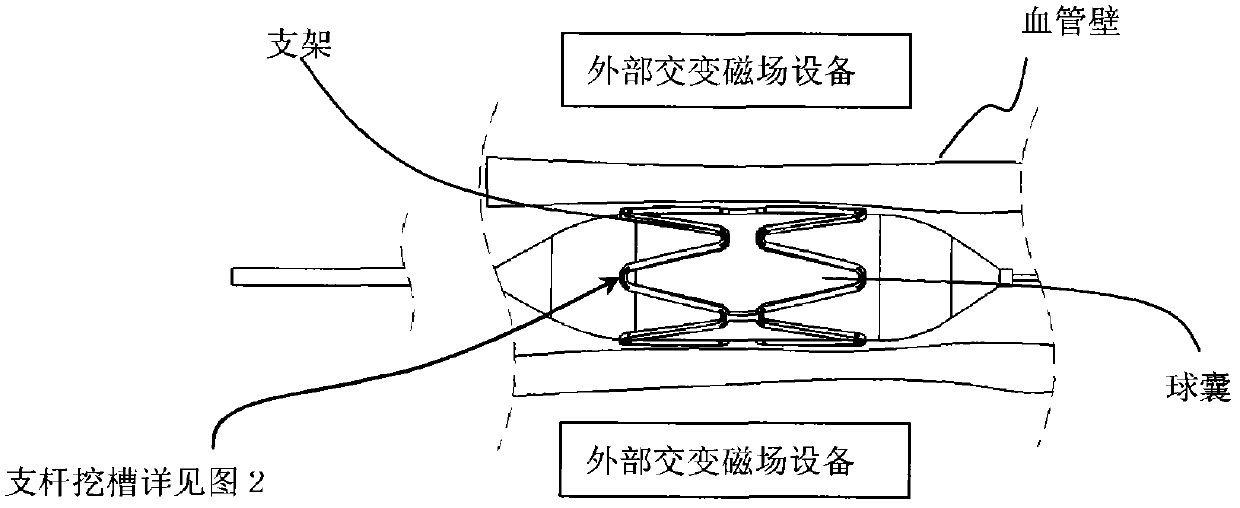

A biodegradable material technology, applied in the field of biodegradable stents with grooves and its preparation, can solve the problems of smooth muscle cell proliferation, arterial wall necrosis, stent stenosis, etc., and achieve short heating time, controllable temperature and safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

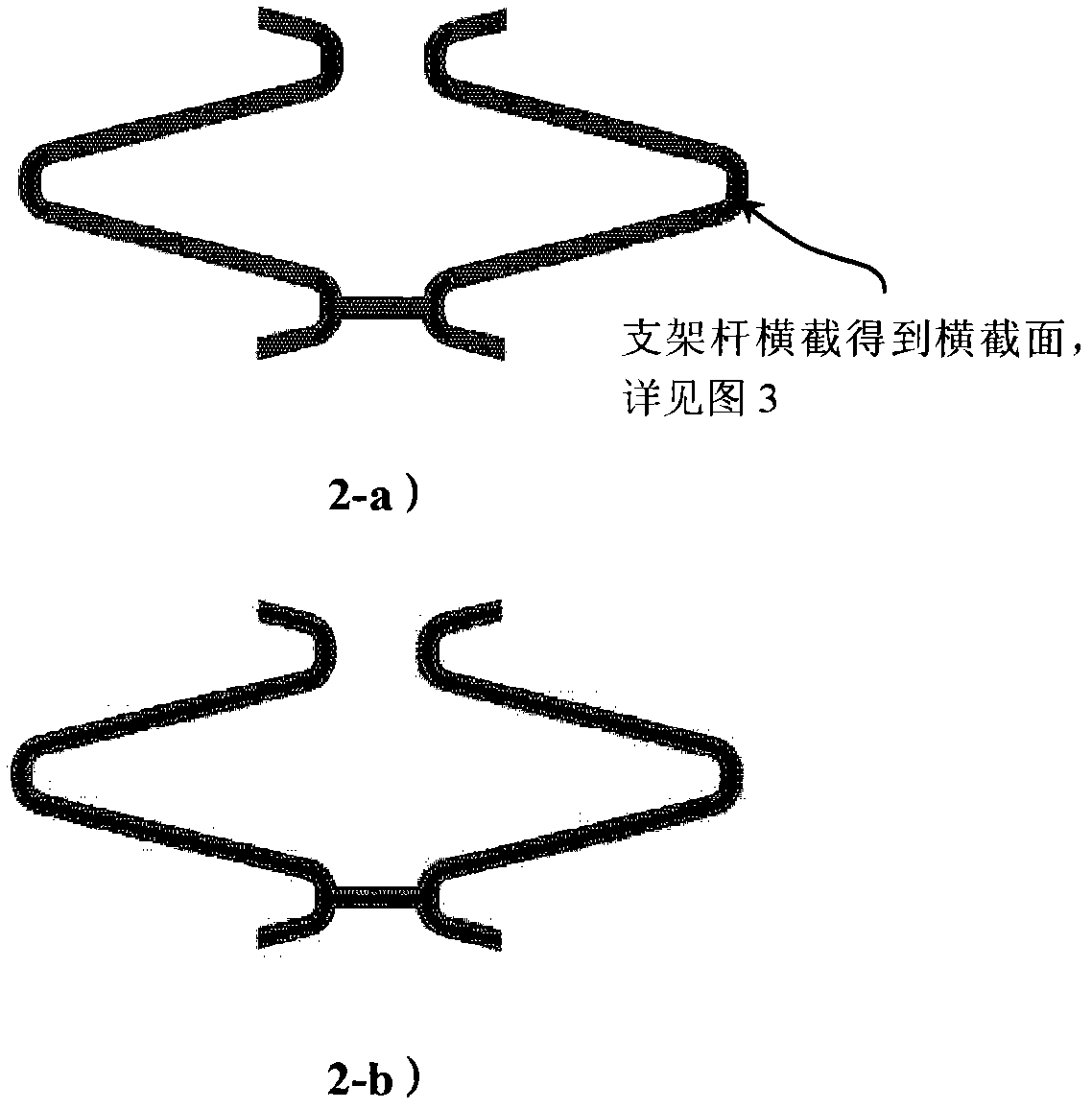

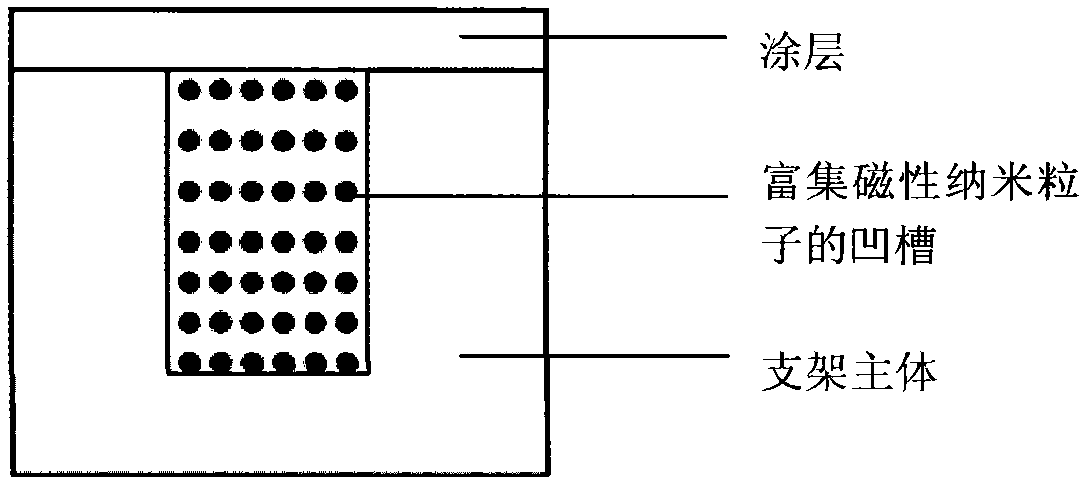

[0027] See attached figure 2-a), Extrude the L-lactic acid-caprolactone copolymer (PLCA) material to obtain a pipe with an outer diameter of 2.5mm, and then process it into a stent by laser engraving technology to obtain the stent main body; dig 150 μm deep at the reinforcement ring of the stent main body , a groove with a width of 150 μm; the γ-Fe with a particle size of 80 nm 2 o 3 The magnetic nanoparticles are made into a magnetic fluid with anhydrous ethanol solvent, which is added dropwise into the aforementioned groove, and the mass of the nanoparticles accounts for 1 / 20 of the weight of the stent; after the solvent is completely evaporated, the outer surface of the main body of the stent is sprayed with rapamycin (Rapamycin) and its derivatives polymeso-lactic acid (PDLLA) material forms the outer coating of the stent. The cross section of the bracket is as image 3 Shown, reflecting the structure of the scaffold. The stent includes a main body structure, grooves ...

Embodiment 2

[0030] See attached figure 2 -b), using a laser cutting machine to process the main body of the stent on a poly-L-lactic acid (PLLA) tube with an outer diameter of 3.0mm; The MnFeO magnetic nanoparticles and PLLA are dissolved in the solvent tetrahydrofuran, and the solution is sprayed into the groove of the stent. After the solvent volatilizes completely, the weight of the nanoparticles in the stent accounts for 1 / 10 of the weight of the stent; the outer surface of the stent body is sprayed with Rapa The L-lactic acid and glycolide copolymer (PLGA) material of Rapamycin forms the outer coating of the stent. The cross section of the bracket is as image 3 Shown, reflecting the structure of the scaffold. The stent includes a main structure, grooves enriched with magnetic nanoparticles and an outer coating; the grooves are distributed in all parts of the stent including the deformed parts.

[0031] The stent is crimped onto the delivery system and packaged for sterilization....

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com