Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3191results about "Roll mill control devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

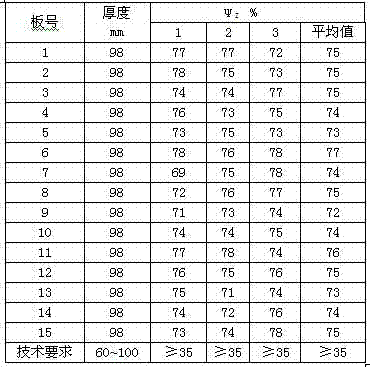

High strength steel plate for big thickness tall building structure and production method thereof

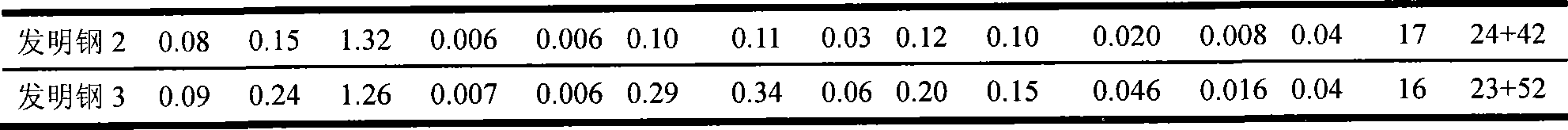

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

Method for controlling hot continuous rolling finish rolling process

InactiveCN102941232AHigh precisionAccurately predict the service lifeRoll mill control devicesMetal rolling arrangementsAutomatic controlControl system

The invention provides a method for controlling a hot continuous rolling finish rolling process, which belongs to the technical field of automatic steel rolling control. The method is that after the parallel data interface (PDI) data is obtained, according to the technological requirements which are established in a rolling plan, the thickness of a hot continuous rolling finish rolling target outlet and the target temperature of the finish rolling outlet are determined; the practical temperature of a hot continuous rolling finish rolling inlet is obtained; the load distribution of a rack is determined; rolling parameters including the roller linear velocity, inlet temperature, rolling force, roller gap position and motor power parameter of various racks are calculated; the rolling parameters are subjected to limit checking and are judged whether to meet the operation conditions of equipment or not, if yes, the rolling parameters are sent to a control system in a command mode, and the hot continuous rolling finish rolling process is controlled; and if not, calculation is carried out again. Through calculating the rolling force, the prediction precision and the thickness precision are improved, the service cycle of a roller is accurately predicted, based on a roller thermal expansion model, the rolling process has different rolling intervals, and good thickness controlling precision is obtained.

Owner:NORTHEASTERN UNIV

High-strength weathering steel and method of manufacturing same

InactiveCN1970818AReduce control requirementsUniform microstructureRoll mill control devicesHeat treatment process controlSolubilityMetallurgy

The invention discloses a high-strength weatherabile steel and manufacturing method in the low-alloy steel making domain, which is characterized by the following: adding low-carbon and Cu-Cr-Ni-Mo-Nb into two or more composite additives; controlling carbon content with maximum solubility in the alpha-Fe at 0.0218% under normal temperature; reducing carbon-permeating evolution; affirming main control tissue evenly.

Owner:武钢集团有限公司 +1

Hot rolled steel plate with excellent low-temperature toughness for thick submerged pipeline and production method of hot rolled steel plate

ActiveCN102409224AGuaranteed toughnessSuitable for solderabilityRoll mill control devicesMetal rolling arrangementsHydrogenChemical composition

The invention provides a hot rolled steel plate with excellent low-temperature toughness for a thick submerged pipeline and a production method of the hot rolled steel plate. The hot rolled steel plate comprises the following chemical components by weight percentage: 0.02%-0.07% of C, 0.15%-0.40% of Si, 1.0%-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.003% of S, less than or equal to 0.06% of Nb, less than or equal to 0.025% of Ti, less than or equal to 0.06% of V, less than or equal to 0.20% of Mo, less than or equal to 0.25% of Cu, 0.10%-0.30% of Ni, less than orequal to 0.25% of Cr, less than or equal to 0.008% of N, 0.010%-0.040% of Al, more than or equal to 2 of Al / N and the rest Fe and inevitable impurities. According to the steel for the submerged pipeline with the thickness being over 28mm, disclosed by the invention, the transversal and longitudinal bending strength can reach over 480MPa or 510MPa, the transversal and longitudinal tensile strengthcan reach over 560MPa or 600 MPa, the transversal impact toughness at the temperature of 60 DEG below zero is larger than or equal to 400 J, the transversal DWTT (Drop-Weight Tear Test) shearing areaat the temperature of 25 DEG C below zero is larger than or equal to 85%, simultaneously, the corrosion resistant of the steel plate is excellent, and the result of a 96-hour HIC (Hydrogen Induced Cracking) test conforms to the requirements of the standard 0284 of the NACE (National Association of Corrosion Engineers). The hot rolled steel plate is suitable to be as a raw material for manufacturing a pipeline for submerged oil and gas transmission.

Owner:ANGANG STEEL CO LTD

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

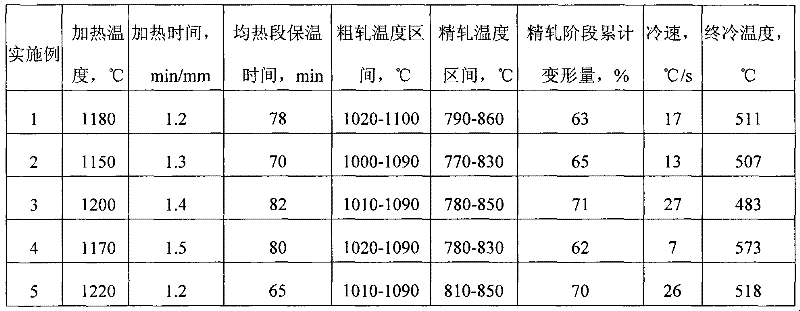

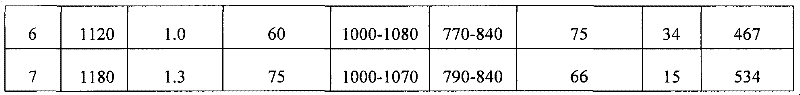

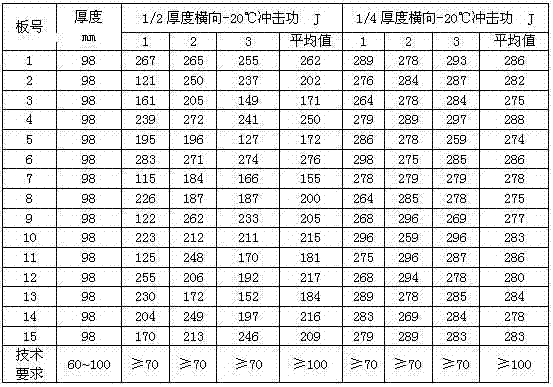

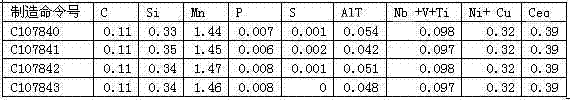

Method for producing super-thick steel plate

ActiveCN102409236AMeet manufacturing requirementsReduce manufacturing costRoll mill control devicesFurnace typesThick plateContinuous casting

The invention discloses a method for producing a super-thick steel plate. The method comprises the following production process steps of: performing pretreatment on molten iron; making steel by using a convertor; performing external refining; continuously casting; heating; rolling; cooling in an accelerated way; normalizing; controlling a cold condition; finishing; inspecting performance; and performing ultrasonic flaw detection. In the method, a low-C high-Mn component system is utilized, and Ni and Cu alloy elements are added into the steel in combination with micro-alloying treatment of Nb, V and Ti. The steel comprises the following chemical components in percentage by weight: less than or equal to 0.12 percent of C, 0.20 to 0.40 percent of Si, 1.20 to 1.50 percent of Mn, less than orequal to 0.008 percent of P, less than or equal to 0.003 percent of S, 0.03 to 0.06 percent of AlT, less than or equal to 0.10 percent of Nb, Ti and V, less than or equal to 0.80 percent of Cu and Ni, less than or equal to 0.40 percent of Ceq and the balance of Fe and inevitable impurities. By the method, a continuous casting blank is used for producing high-performance Q345R steel plates with the thickness of 60 to 100mm, so that production cost is reduced, and the requirement of manufacturing containers with high parameter pressure is met; the low-C high-Mn component system is used for a component design, so that the requirement that the material Ceq is less than or equal to 0.40 percent is met; and the continuous casting blank is used for producing a high-performance Q345R super-thick plate, so that the method has a simple process, the process is easy to realize, and the plate can be produced by a common wide and thick plate factory.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Steel plate for low temperature pressure container and producing method thereof

InactiveCN101144138AReduce dosageReduce usageRoll mill control devicesFurnace typesChemical industryChemical composition

The present invention relates to a steel plate used for a low temperature pressure vessel and the production method thereof. The steel plate has the main chemical composition content (wt percent) that C is 0.12-0.19 percent, Si is 0.15-0.45 percent, Mn is 1.2-1.6 percent, Nb is 0.015-0.050 percent, Ti is 0.01-0.03 percent, Ni is 0.10-0.35 percent, Al is 0.015-0.050 percent, and P is 0-0.015 percent; S is 0-0.01 percent, and the residual is Fe and inevitable impurity. The present invention uses a new process technology of hot billet steel furnace loading, intermediate billet water cooling, controlled rolling, controlled cooling accelerating, and normalizing, which is easy to be operated, reduces the dosage of the alloying element to the lowest, in particular, largely reduces the use of the precious metal Ni, the transverse impact power of the low temperature toughness 40 below zero is up to 164 J, transverse impact power of 30 below zero is up to 298 J, and CTOD is Delta 0.20 equal to 0.40 mm in the test condition that the temperature is 40 below zero. The cost of the steel type is relatively lower, the hourly output is high, the intensity is moderate, the plasticity is good, the low temperature toughness is high, the welding performance is extremely fine, and thereby the steel type can be widely applied to low temperature vessels for storing and delivering low temperature liquid in various industries and the petroleum and the chemical industry fields.

Owner:SHANDONG IRON & STEEL CO LTD

Ultra-high strength steel with excellent corrosion resistance and fatigue resistance and its making process

InactiveCN1888120ARaise Strength IndexMeet manufacturing requirementsRoll mill control devicesHeat treatment process controlHeat sensitiveUltimate tensile strength

The present invention discloses one kind of ultra-high strength steel with excellent corrosion resistance and fatigue resistance and its making process. The ultra-high strength steel consists of C 0.05-0.12 wt%, Si 0.05-0.50 wt%, Mn 1.10-1.70 wt%, P not more than 0.015 wt%, S not more than 0.010 wt%, Nb 0.025-0.070 wt%, V 0.005-0.080 wt%, Mo 0.20-0.50 wt%, Ni 0.30-0.80 wt%, Ti 0.005-0.025 wt%, Cu 0.25-0.80 wt%, B 0.0005-0.0020 wt%, and Cr 0.10-0.70 wt%, except Fe and inevitable impurities. It has carbon equivalent not lower than 0.65 % and heat sensitive coefficient not lower than 0.30 %. Its making process includes the steps of smelting, desulfurizing molten iron, combined blowing in converter, vacuum treatment, casting into plate blank, etc. It has yield strength not lower than 880 MPa, tensile strength not lower than 980 MPa and V-shaped notch Charpy absorbed-in-fracture energy at -20 deg.c not lower than 100J.

Owner:武钢集团有限公司

Low alloy high-strength steel plate capable of being welded in large energy input and method of producing the same

ActiveCN101153370AImprove toughnessSimple designRoll mill control devicesHeat treatment process controlHeat-affected zoneSheet steel

The invention provides a high strength low alloy steel plate suitable for high heat input welding and is characterized in that the chemical composition (wt percent) of steel comprises 0.04 percent to 0.16 percent of C, 0.10 percent to 0.50 percent of Si, 0.40 percent to 1.8 percent of Mn, 0.020 percent to 0.050 percent of Nb, 0.006 percent to 0.030 percent of Ti, 0.0030 percent to 0.010 percent of N, 0.015 percent to 0.060 percent of Al and the rest, Fe and other inevitable impurities; meanwhile, C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4+V / 14 is less than or equal to 0.45 percent and the total amount of Ti and the total amount of N are that [Ti percent]T is more than or equal to 2.667[N percent]T-0.004667 percent; moreover, Ti microalloying is adopted to ensure that the Ti / N ratio in the second sort of particle generated ranges between 2.4 and 3.2. The manufacture method of the steel plate adopts austenite recrystallization zone and austenite non-recrystallization zone rolling and forced water cooling after rolling; moreover, when the steel plate is under 50 KJ / cm to 150 KJ / cm high heat input welding, the welding heat affected zone has excellent toughness. The invention has the advantages of simple production process, low cost and wide applicability.

Owner:ANGANG STEEL CO LTD

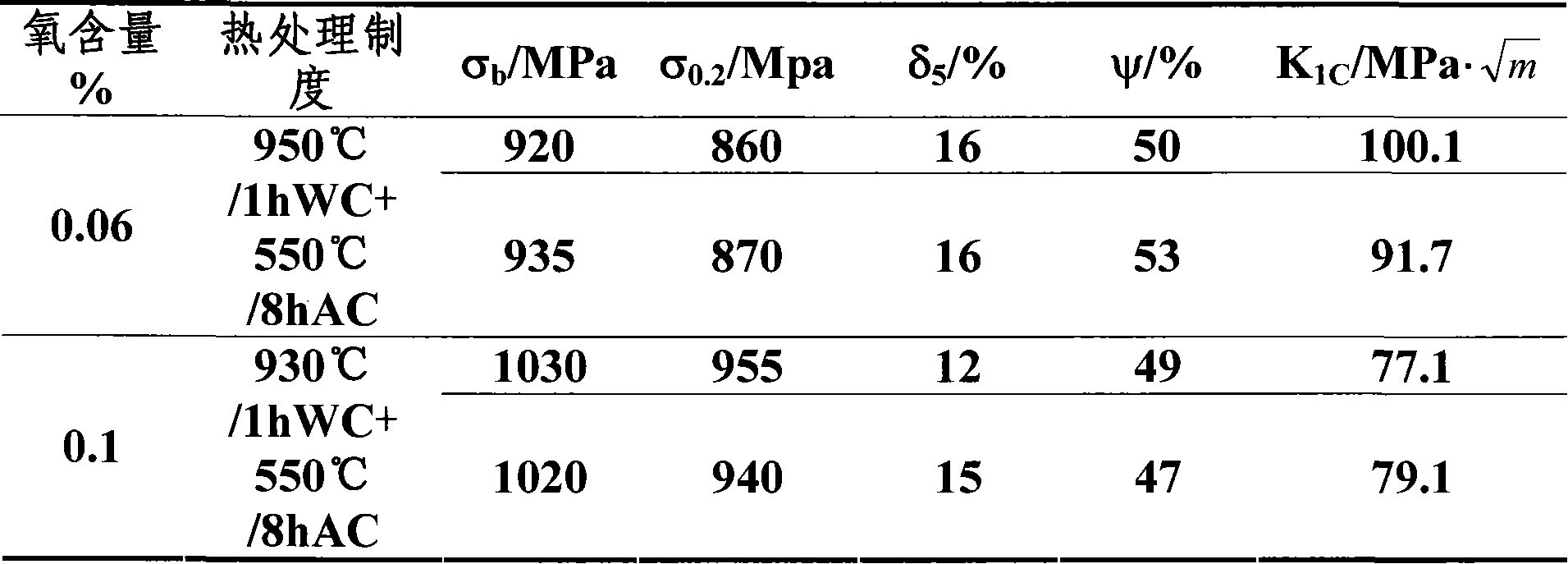

Technique for processing titanium alloy sheet material

ActiveCN101139670ATake full advantage of performanceHigh strengthRoll mill control devicesMetal rolling arrangementsTitaniumIngot

The invention discloses a processing process for a Ti-alloy sheet, which comprises such procedures as packing alloy on sponge titanium, industrial pure aluminum and Al-85V intermediate alloy, pressing and plasma welding the sponge titanium, the industrial pure aluminum and the Al-85V intermediate alloy, then smelting through a secondary vacuum self-consuming arc smelting method the sponge titanium, the industrial pure aluminum and the Al-85V intermediate alloy into cast ingots, cutting blanks from the cast ingots, blanketing the cut blanks into sheet blanks, forging freely on an air hammer into sheet blanks, rolling on a roller at temperature 900-1000 DEG C, holding the temperature for 50 minutes (deformation in each pass is 3-4 mm at initial rolling, rolling 2-5 passes, interrupting intermediately), finally rolling into Ti-alloy sheets, planing and cleaning surface, and getting finished product. The invention is of easy operation, high process controllability, enables TC4-DT alloy sheet to maintain good matching among strength, breakage toughness and plasticity, and improves the steadiness in performance of different sheet lots.

Owner:西安大富宇航科技有限公司

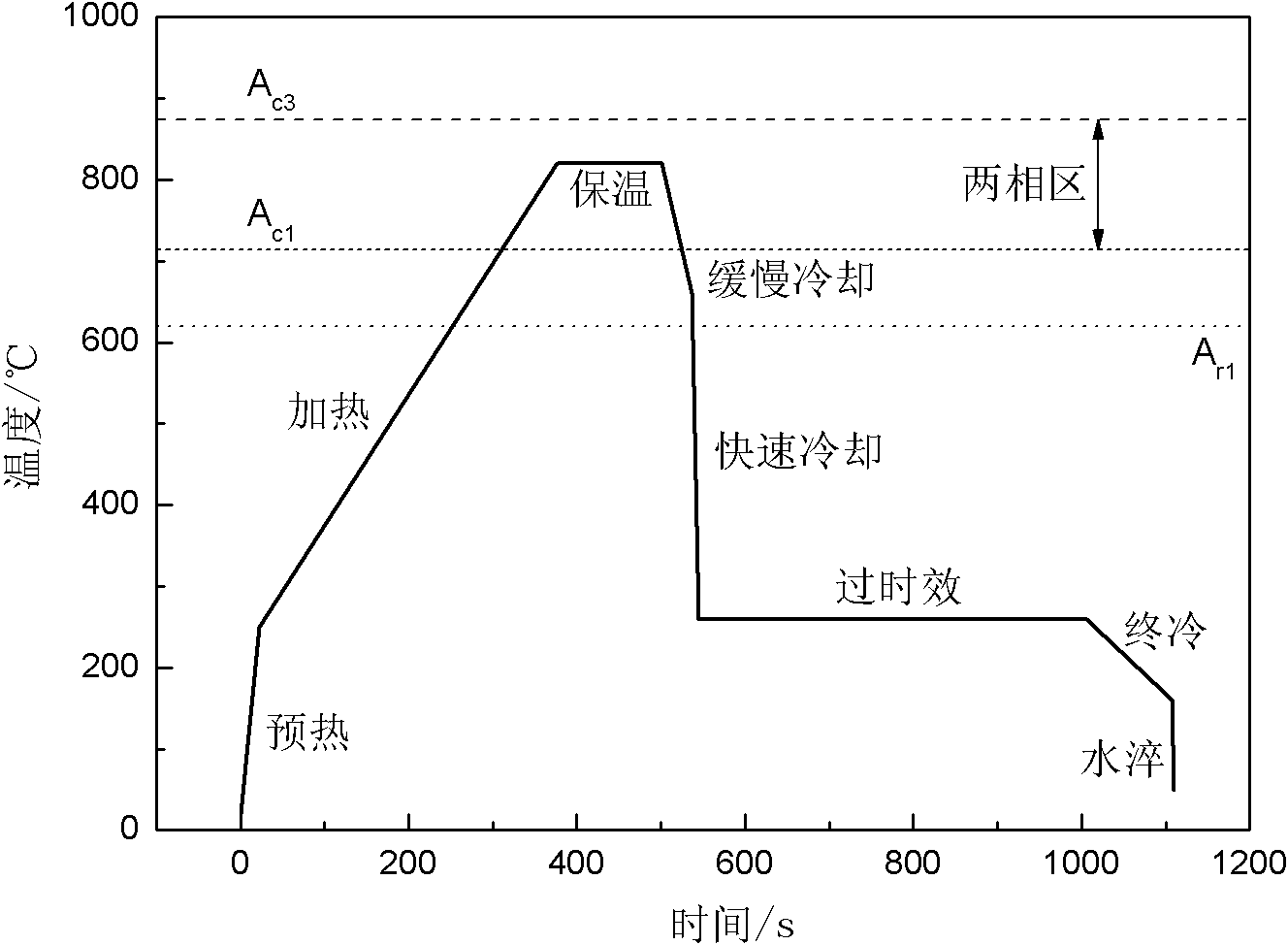

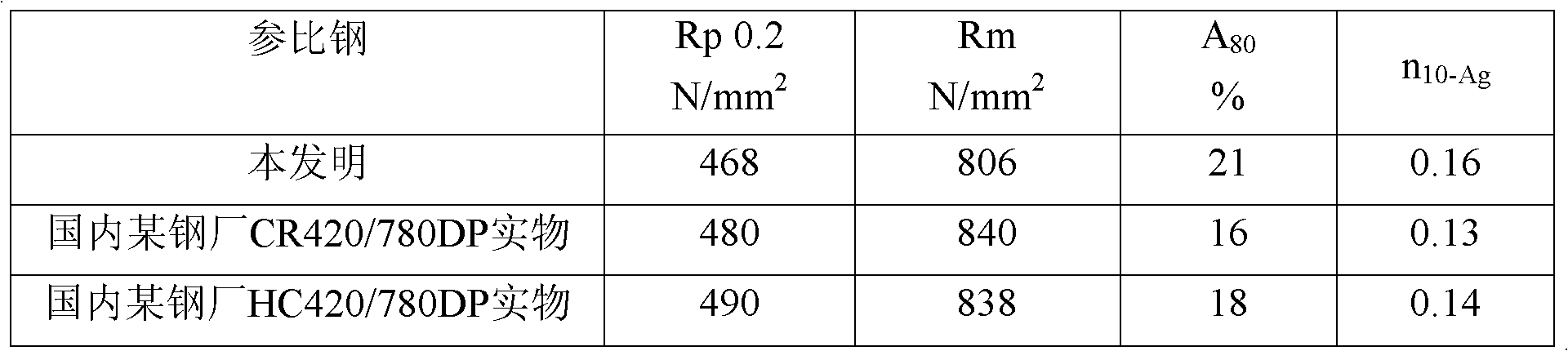

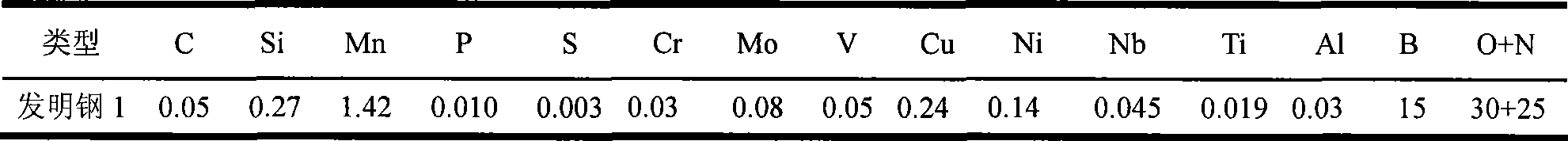

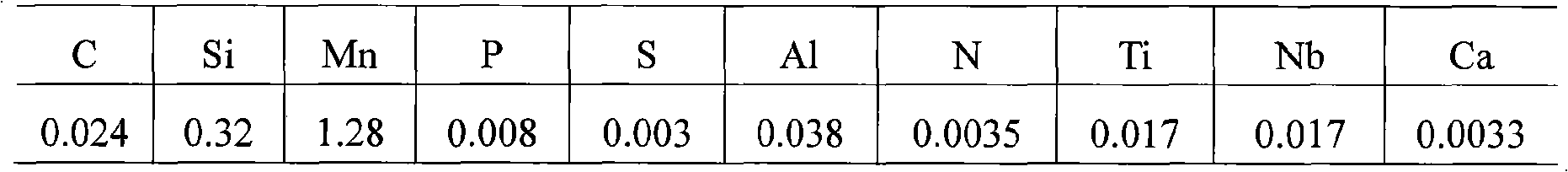

High-plasticity 780MPa-level cold rolled dual-phase steel and preparation method thereof

InactiveCN102212745ANominal C content decreasedGood welding performanceRoll mill control devicesHeat treatment process controlChemical compositionEconomic benefits

The invention discloses a high-plasticity 780MPa-level cold rolled dual-phase steel and a preparation method thereof. The steel comprises the following chemical components in percentage by weight: 0.06 to 0.08 percent of C, 1.0 to 1.3 percent of Si, 2.1 to 2.3 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.01 percent of S, 0.02 to 0.07 percent of Alt, less than or equal to 0.005 percent of N, and the balance of Fe and inevitable impurities. According to the hot rolling process parameters, the heating temperature of a continuously cast bloom is 1,250+ / -30 DEG C, the final rolling temperature is 890+ / -30 DEG C, the coiling temperature is 670+ / -30 DEG C, the cold rolling press-down rate is 50 to 70 percent, and the continuous annealing process is controlled. The invention has the advantages that: the C equivalent weight of the steel is effectively reduced by regulating the components of the alloy based on a conventional gas jet cooling and continuous annealing mode, the elongation of the steel is improved, and considerable economic benefit can be brought.

Owner:SHOUGANG CORPORATION

High grade cold rolling non-oriented silicon steel and method for manufacturing same

ActiveCN101139681ANo corrugated defectsGood electromagnetic performanceRoll mill control devicesMetal rolling arrangementsForeign matterMetallurgy

The invention provides a middle and high grade cold rolled no-orientation silicon steel and a manufacturing method for the no-orientation silicon steel, the components of which are C: 0.0015%-0.005% Si: 1.60%-3.30% Mn: 0.50-2.50% P<=0.050% S: 0.0010%-0.0050% Al: 0.15%-0.50% and N: 0.0010%-0.0050%, small amount of Sn, Sb, Cu can be added, total mount is <0.20%, the remainder are Fe and unavoidable foreign matters and Mn%=k is multiplied by |Si+2Al-2.05|%+0.28%, wherein, k=1.0-3.0. The manufacturing method is like follows: hot rolling, pickling, cold rolling and annealing the cast blanks of above components. The heating temperature for the cast blanks at hot rolling is 1050-1200 DEG C, the rolling passes are 3-5 no.s, the pressure-down rate is 20-40% for each pass; the temperature for fine and final rolling temperature is 800-900 DEG C, coiling temperature is 600-680 DEG C, and the annealing is done in a dry protective atmosphere. The method is of low process difficult, low cost and high product surface quality.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

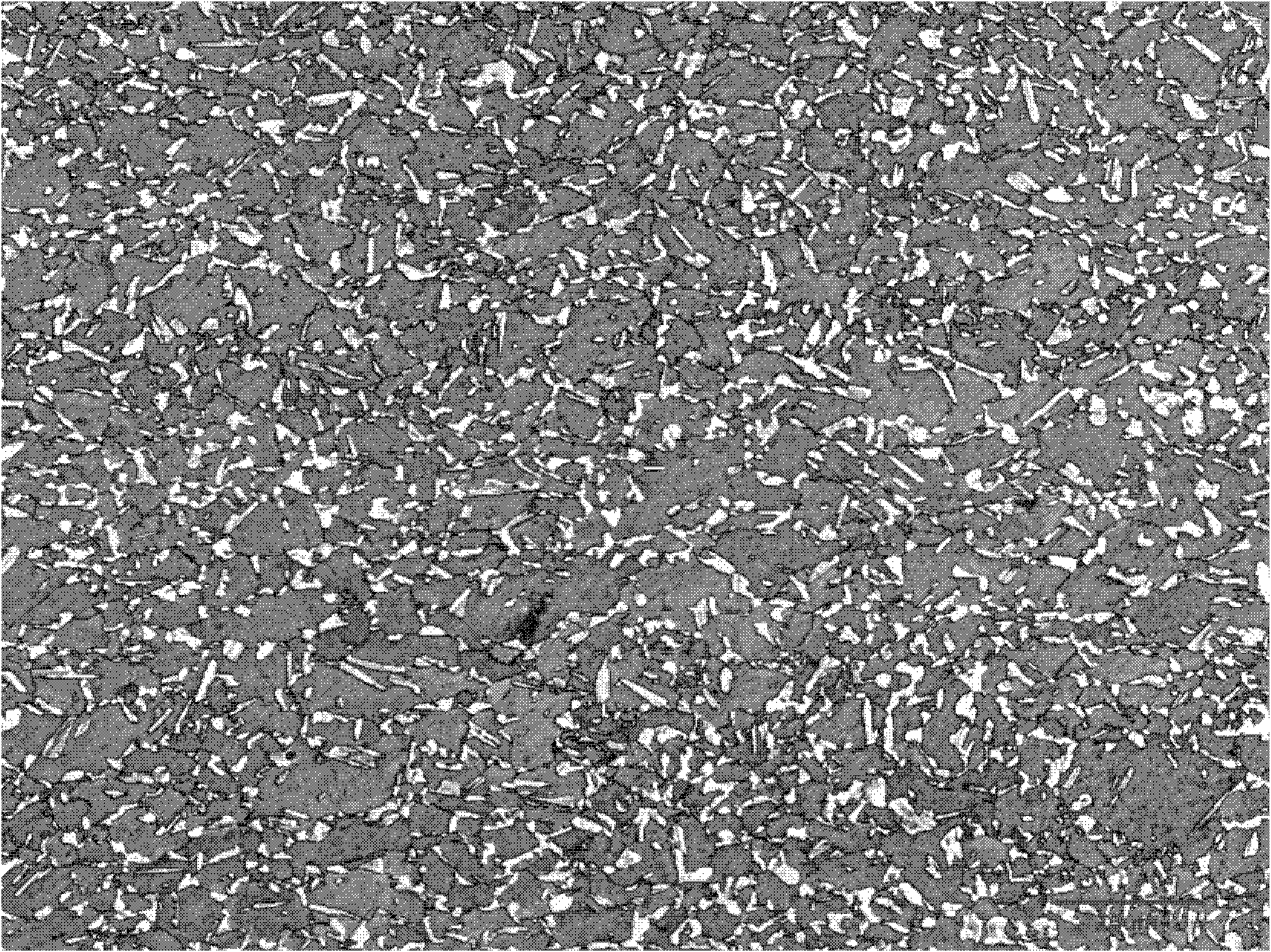

Easy-to-weld superfine austenite crystal steel with superhigh intensity and high tenacity and manufacturing method thereof

InactiveCN101481780ARoll mill control devicesProcess efficiency improvementAustenite grainChemical composition

The invention discloses an ultra-thin austenitic grained steel with ultrahigh strength, high toughness and easy welding and a manufacturing method thereof. The chemical compositions of the steel are as follows in terms of weigh percentage: 0.04 to 0.14 of C, 0.50 to 1.75 of Mn, 0.10 to 0.50 of Si, no more than 0.010 of S, no more than 0.012 of P, no more than 0.50 of Ni, no more than 1.00 of Cr, no more than 0,80 of Mo, no more than 0.10 of V, 0.10 to 0.30 of Cu, 0.010 to 0.050 of Al, 0.010 to 0.050 of Ti, no more than 0.050 of Nb, 0.0005 to 0.0020 of B, no more than 0.0090 of (O+N), no more than 0.15 of Pb+Sn+As+Sb+Bi and the balance of Fe and impurities. The equivalent carbon content CEQ (%) is no more than 0.60 and the crack sensitivity index PCM (%) is no more than 0.30. The manufacturing method comprises the following steps: low-temperature short-time tempering pretreatment, short-time heat preservation after extremely fast and integral heating to more than Ac3, then holding the temperature, and extremely fast quenching to the room temperature. The austenitic grain of the steel has the average size of less than or equal to 6.5Mum, the yield strength of more than or equal to 840MPa, the tensile strength of more than or equal to 945MPa and tough-brittle transition temperature of less than or equal to minus 60 DEG C. The method is particularly suitable for heat treatment of working pieces with thin specification.

Owner:YANSHAN UNIV

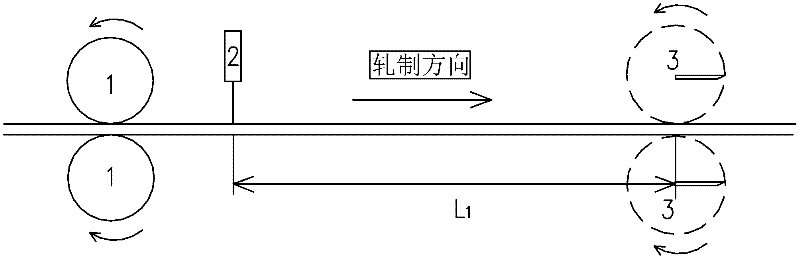

New method for controlling flying shears for bars and wires based on T400

InactiveCN102441569ASimple control structureImprove cut qualityRoll mill control devicesMetal rolling arrangementsWire rodStart stop

The invention provides a new method for controlling flying shears for bars and wires based on T400, which is an advanced electrical control method for start-stop type flying shears for bars and wires. The method comprises the steps of accurate shearing-blade position control, shearing length control and automatic shearing optimization, and the like; in the process of production, when an upstream rolling mill has an accident, or the quality of a section of a rolled piece is poor, a fragmentation function can be started on line so as to carry out partial fragmentation or complete fragmentation on the rolled piece, and the fragmentation and shearing speed is in step with the running speed of the rolled piece automatically; and when the fragmentation operation is stopped, a flying shear is automatically positioned to a start position and enters into a standby state of the normal shear mode. In the invention, the powerful computation function of the T400 is fully used, core control parts of the flying shear are completely integrated into the T400, and high-speed counters, shaft positioning modules and touch screens are not required, therefore, the cost is reduced, and high accuracy is obtained; and when the flying shear carries out double-length shearing at a speed of 21 m / s, the double-length error is basically within 75 mm, and partial double-length error can be within 30 mm.

Owner:WISDRI WUHAN AUTOMATION

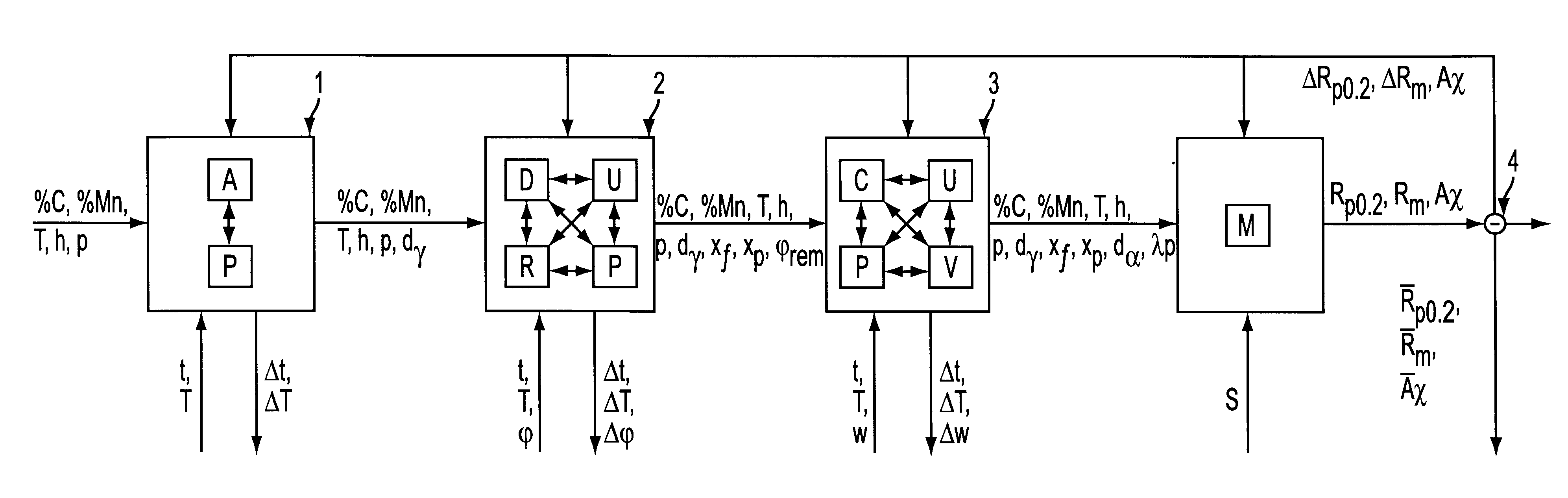

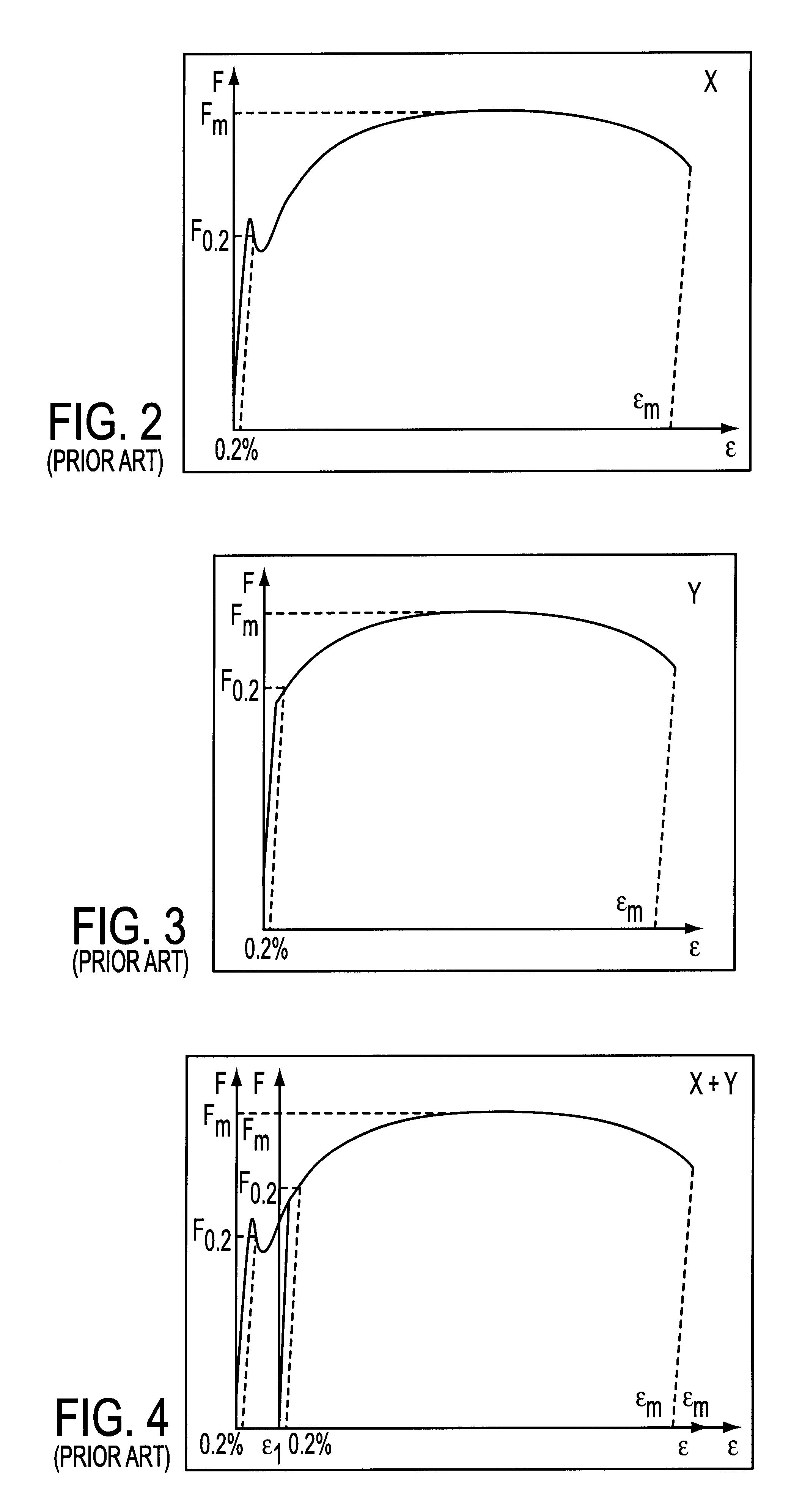

Process for monitoring and controlling the quality of rolled products from hot-rolling processes

InactiveUS6430461B1Simulator controlRoll mill control devicesPhysical metallurgyUltimate tensile strength

Owner:VOEST ALPINE AG

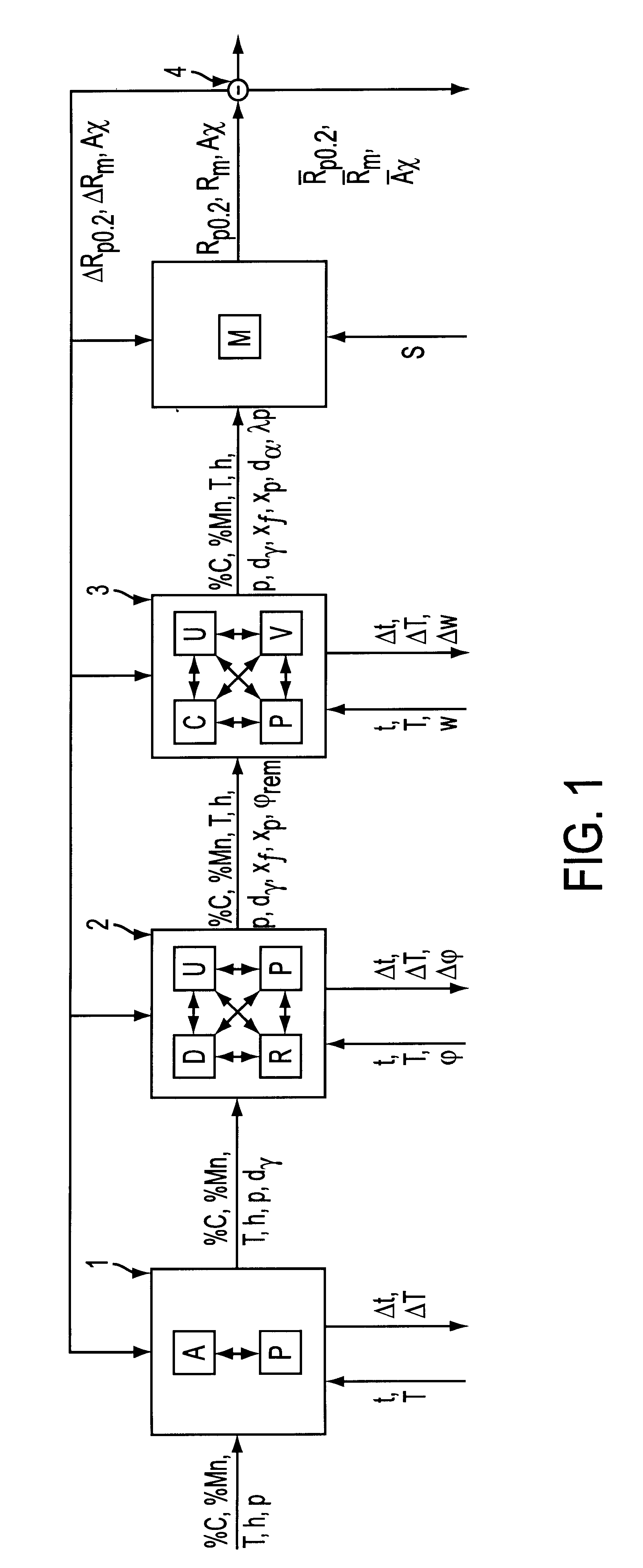

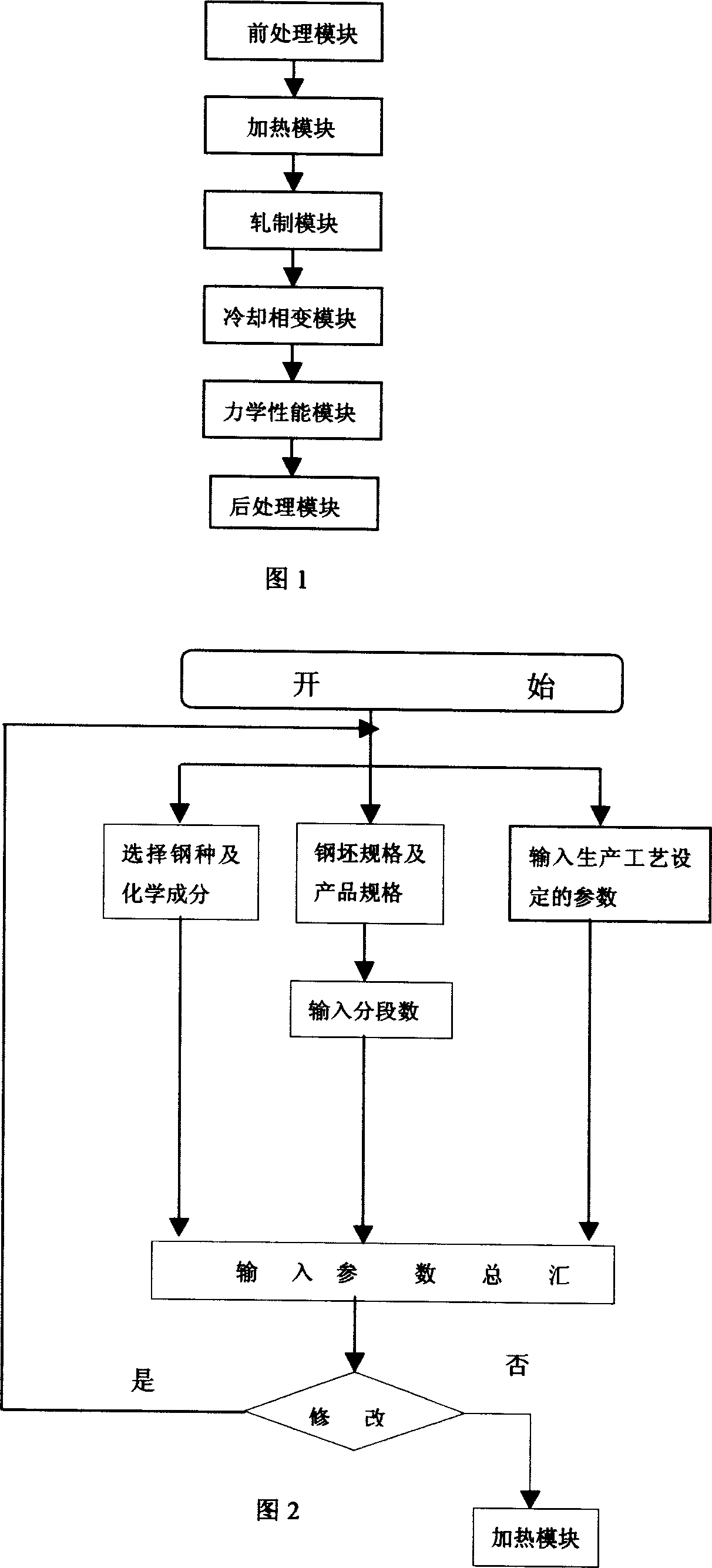

Method for predicting evolvement and performances of structure of strip steels in hot rolled proces

InactiveCN1431060AThe calculation result is accurateCalculations are reliableRoll mill control devicesMetal rolling arrangementsStrip steelPhase change

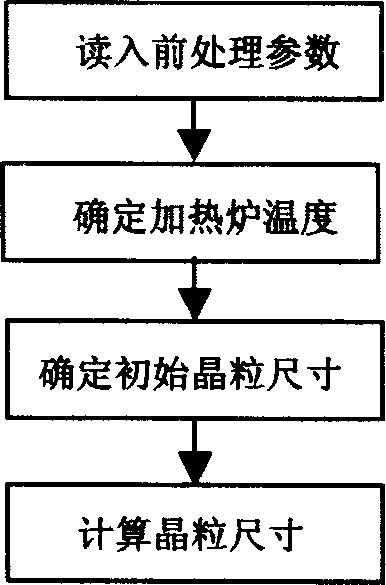

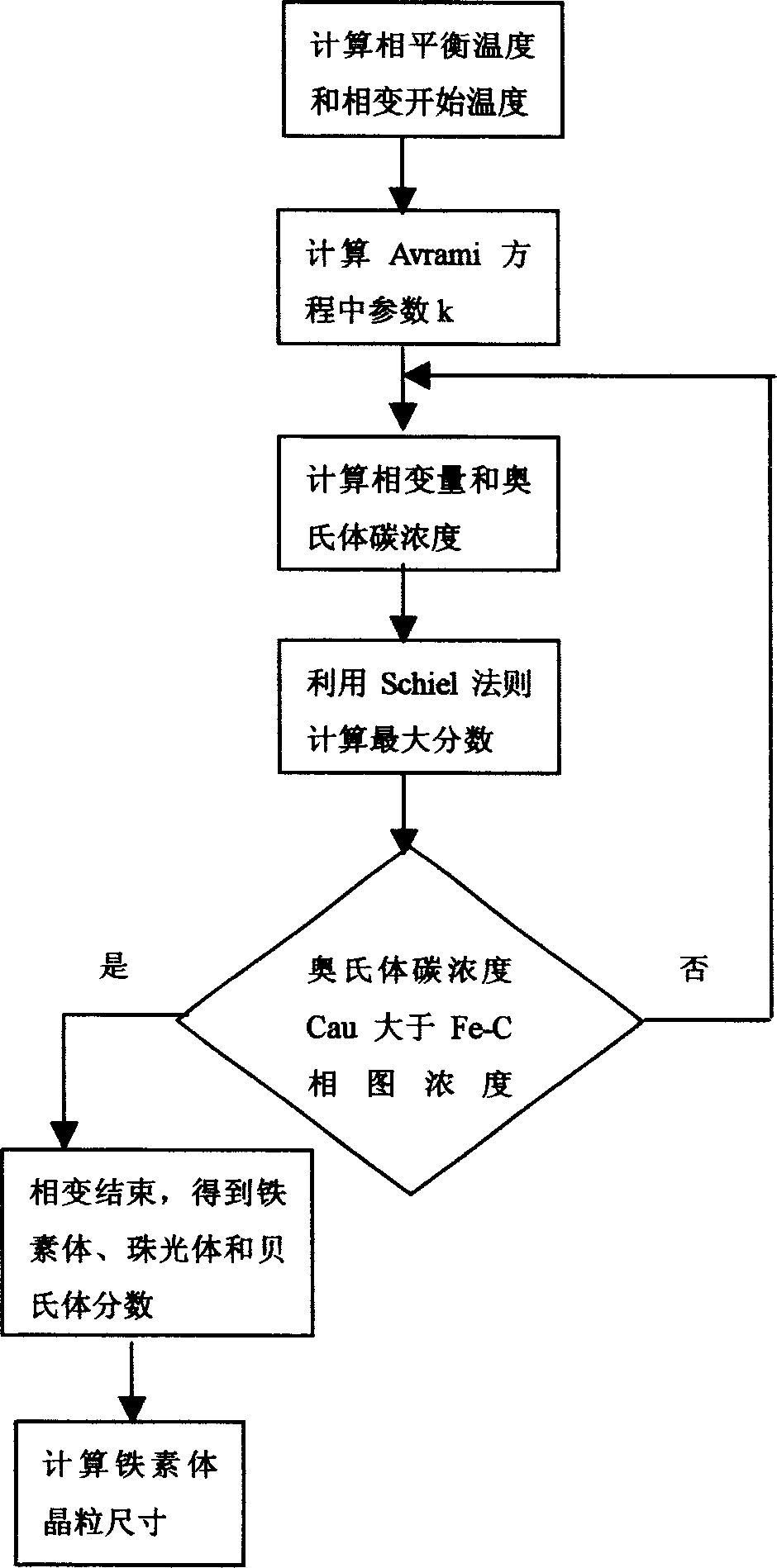

A method for predicting the structure variation and properties of band steel in hot rolling procedure features that its system is composed of the preprocessing module for reading the technological parameters needed by hot rolling from database, the heating module, rolling module, cooling phase-change module and mechanical performance module for simulating the hot rolling procedure and predicting the final structure performance, and the post-precessing module for displaying the final result.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Post-treating method for steel-back aluminium-based semisolid-state clad plate

InactiveCN101117696AIncreased interfacial shear strengthSimple methodRoll mill control devicesMetal rolling arrangementsReduction rateRoom temperature

The present invention discloses a post-processing method for steel-back aluminum-base semisolid composite plates and relates to the post-processing research field of interfacial mechanical characteristic of steel-back aluminum-base semisolid composite plates. At room temperature, a steel-back aluminum-base semisolid composite plate is rolled with the reduction rate of 0.5-1.6 percent on a precision rolling mill, and the difference between shrinkages of the aluminum-base coating and the steel base in the coagulating and cooling process of the composition is redeemed by the difference between the deformation of the aluminum-base coating and the steel base produced in the rolling process, thereby, reducing the additional interfacial stress of the composite plate, simply and conveniently improving the interfacial shear strength of the composite plate, and solving the technical problems of large energy consumption and small increase amplitude of interfacial shear strength in post-processing method of diffusion annealing of aluminum-base semisolid composite plates.

Owner:BEIJING JIAOTONG UNIV

Method for producing hot-rolled ferritic stainless steel strip steel

InactiveCN101245435AFree from common surface defectsNo surface defectsRoll mill control devicesHeat treatment process controlSurface finishChemical composition

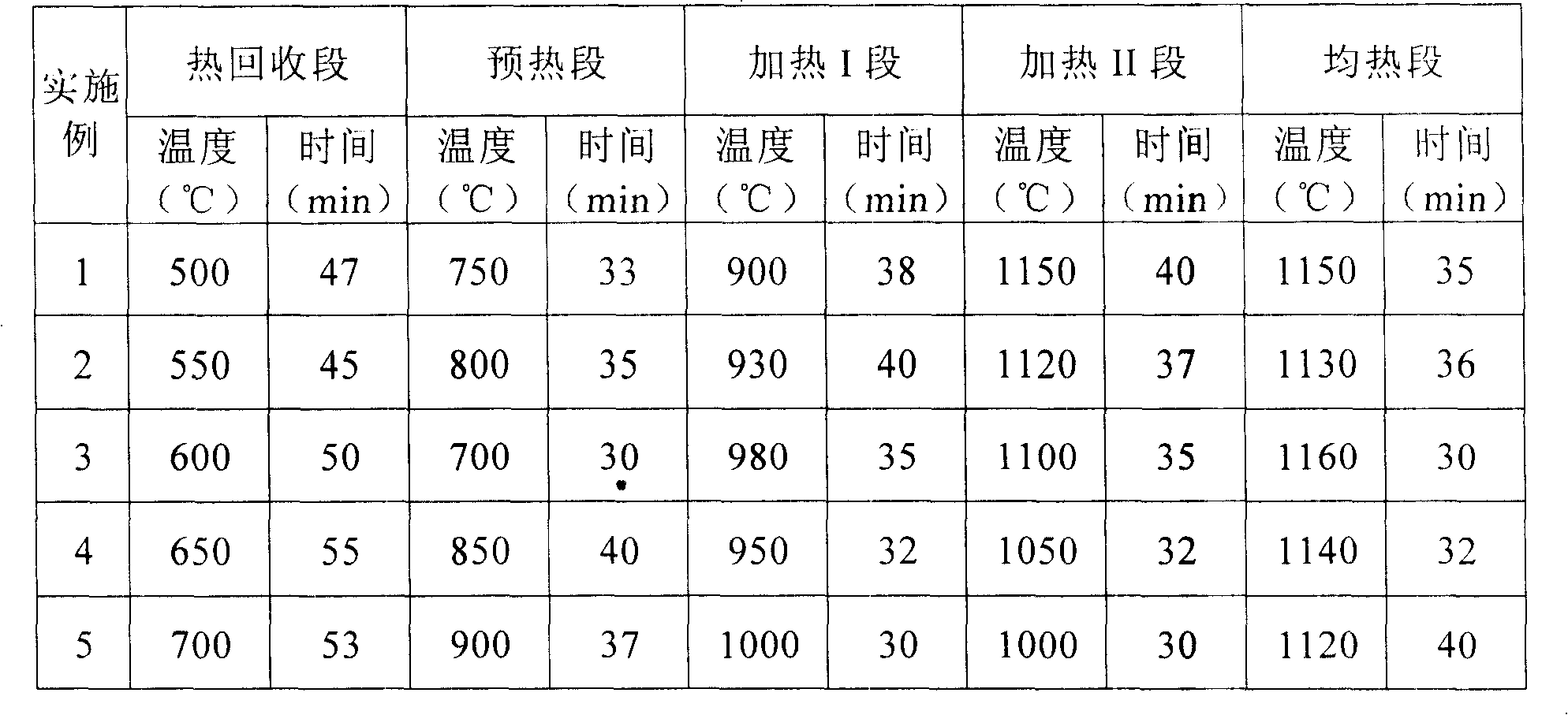

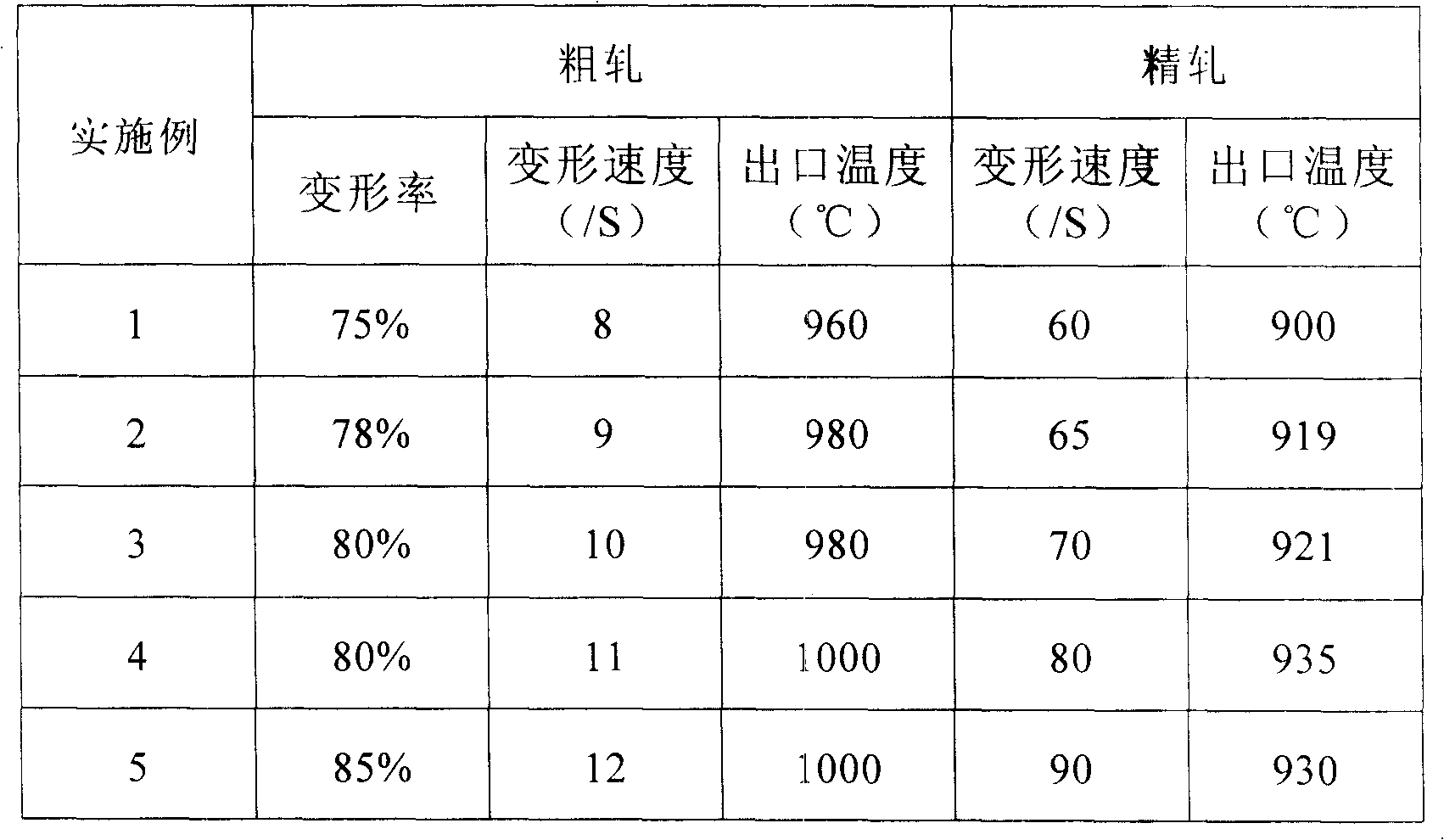

The invention discloses a method for producing a hot-rolled ferrite stainless strip steel, which comprises the following steps: 1) the chemical components by weight percentage are: 0.025-0.04 percent of C, less than or equal to 1.00 percent of Si, 0.25-0.4 percent of Mn, less than or equal to 0.030 percent of S, less than or equal to 0.035 of P, 12-12.5 percent of Cr and the rest is Fe; 2) a billet is formed by smelting and casting; 3) heating: the heating temperature zone for heating are divided into a heat recovery section, a preheating section, a I heating section, a II heating section and a holding section; furnace gas is controlled to be neutral atmosphere of non-oxidizing atmosphere; 4) when in heat rolling and rough rolling, the rolling temperature is 1,120 DEG C-1,160 DEG C, and the deforming speed during rolling is 10 / s-12 / s; 5) finish rolling: the deforming speed of the last pass rolling is 60 / s-90 / s, and the outlet temperature of the finish rolling is more than 900 DEG C; 6) cooling is carried out after rolling, and then reeling is carried out. The method of the invention has the advantages that the method guarantees not only the edge quality of the hot-rolled strip steel but also the stamping property of the cold-rolled strip steel, improves the surface finish quality and lowers the production cost, and has high production efficiency and rolling yield, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

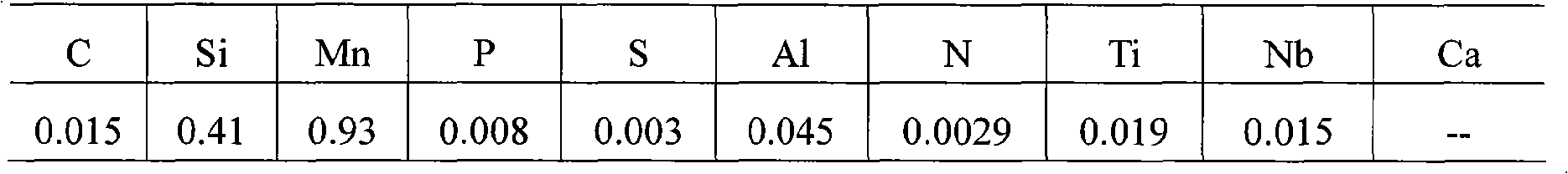

High-strength high-toughness low temperature steel for ship and manufacture method thereof

ActiveCN102851591AAchieve sex changeImprove purityRoll mill control devicesProcess efficiency improvementCrack resistanceHeat-affected zone

The invention discloses high-strength high-toughness low temperature steel for ship and manufacture method thereof. The steel is composed of (by wt%) C 0.04-0.12, Si 0.20-0.55, Mn 0.8-1.4, P 0.005-0.015, S less than or equal to 0.005, Als 0.02-0.07, N less than or equal to 0.005, Cu 0.05-0.40, Ni 0.05-0.50, and Fe and unavoidable impurity in balance, with Ni / Cu of 1.2-1.5; and one or more than two of Nb 0.005-0.03, Ti 0.005-0.02, Ca 0.001-0.006, and Mg 0.0005-0.002. The steel has advantages of low compression ratio, high strength, good low temperature impact energy, good texture uniformity, and good elongation, to ensure low hardenability and cold crack resistance of repair welding heat-affected zone even if under polar climate condition.

Owner:ANGANG STEEL CO LTD

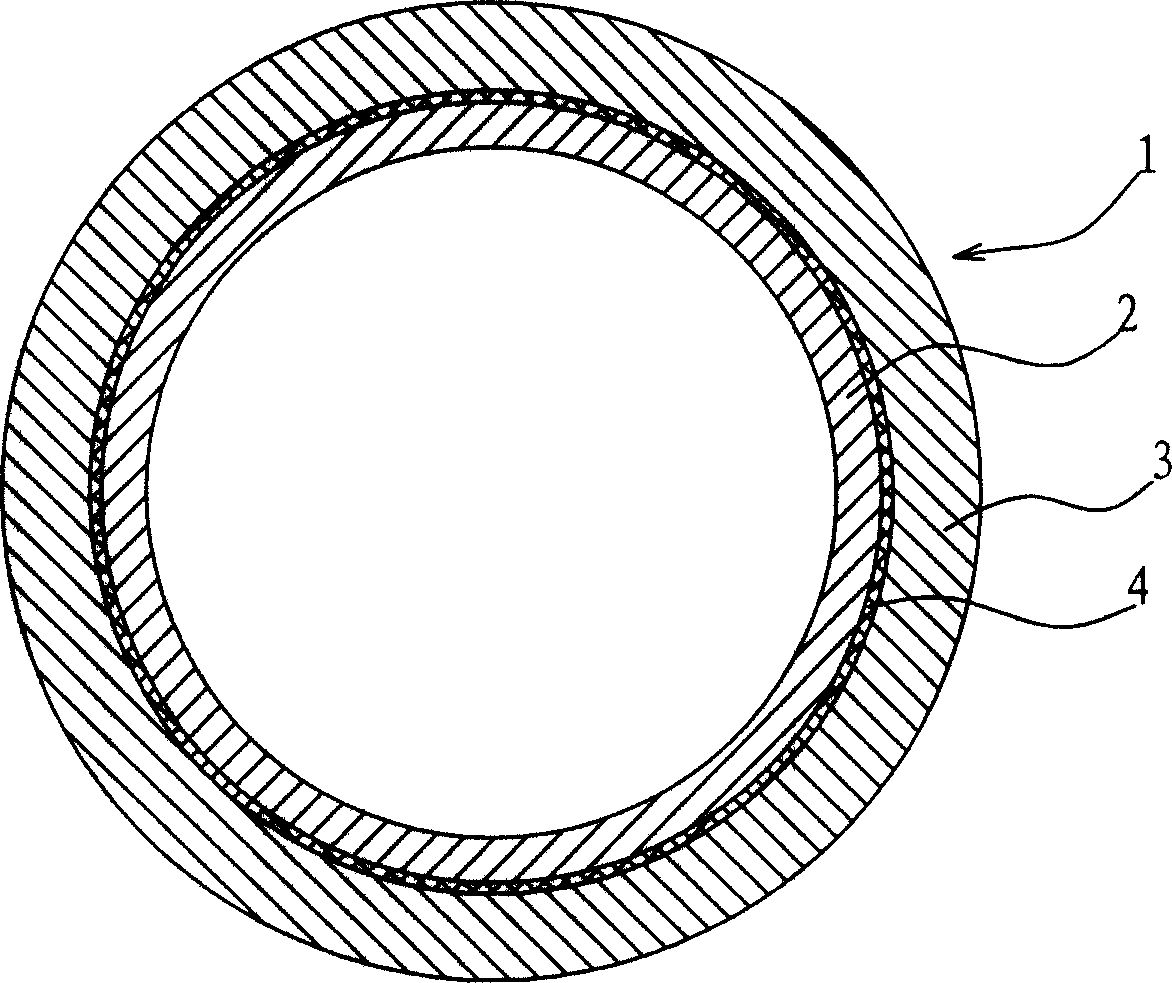

Method for manufacturing copper aluminium composite tubing and copper aluminium tubing produced thereby

The invention relates to a copper-aluminum compound tube material and relative producing method, belonging to the technique of metallic compound tube material production. Said invention comprises a copper inner layer and an aluminum outer layer. It is characterized in that: at the connection of copper and aluminum layers, said inner and outer layers are dispersed to each other to form a connecting layer to combine them. The producing method comprises; using planet rolling tube has single-rail sectional contraction rate on the compound tube is 50-95%; the outlet rolling speed is 5-30m / min; and the single-rail rolling is processed when the temperature of distortion section reaches 200-600Deg. C. The inventive method can combine two layers, with fewer processes, high efficiency, large batch and lower cost. And the product has better mechanical and thermal exchange properties, without defects in following process. It can be used to replace copper and alloy tube, to reduce producing cost.

Owner:JIANGSU XINGRONG HI TECH

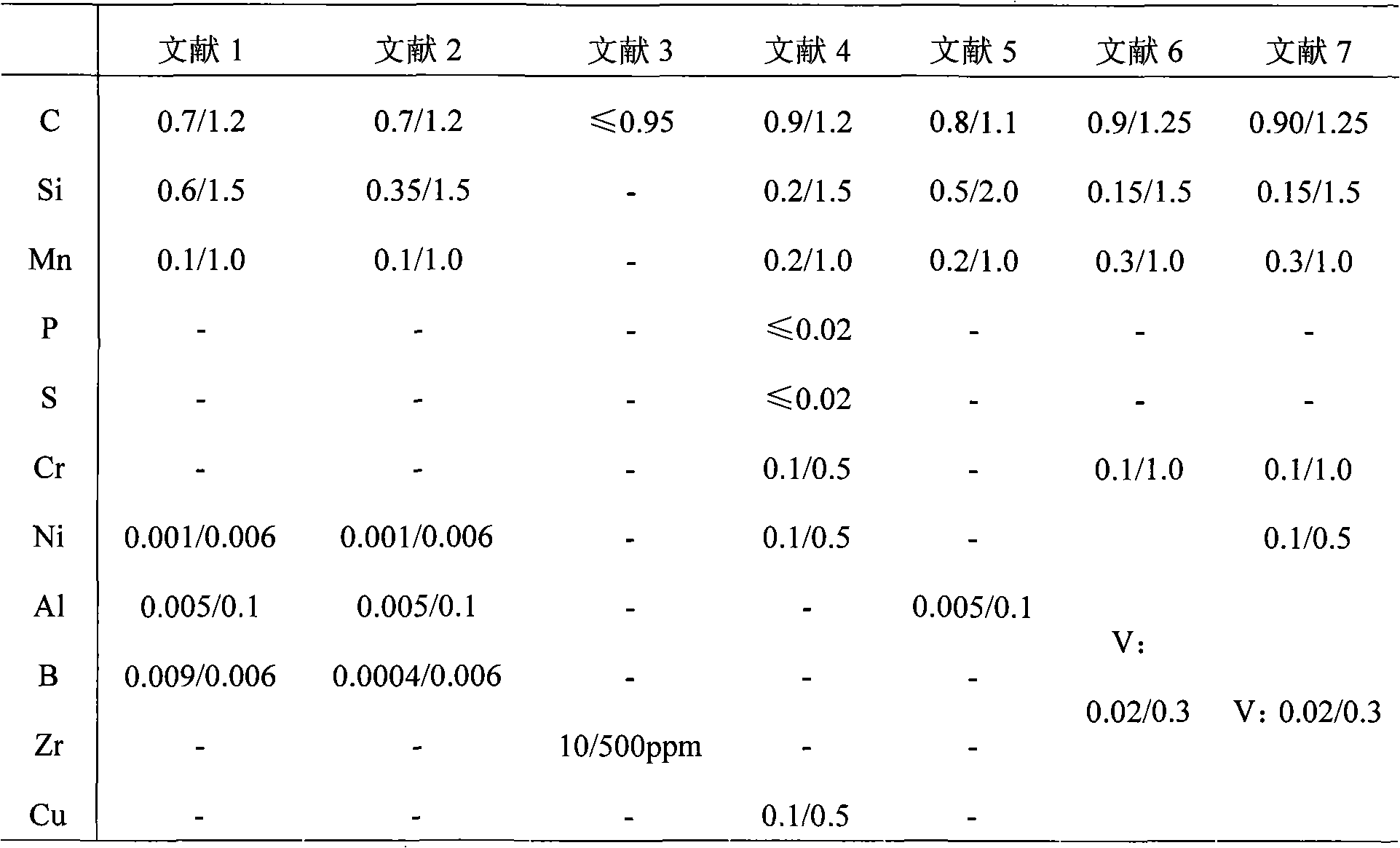

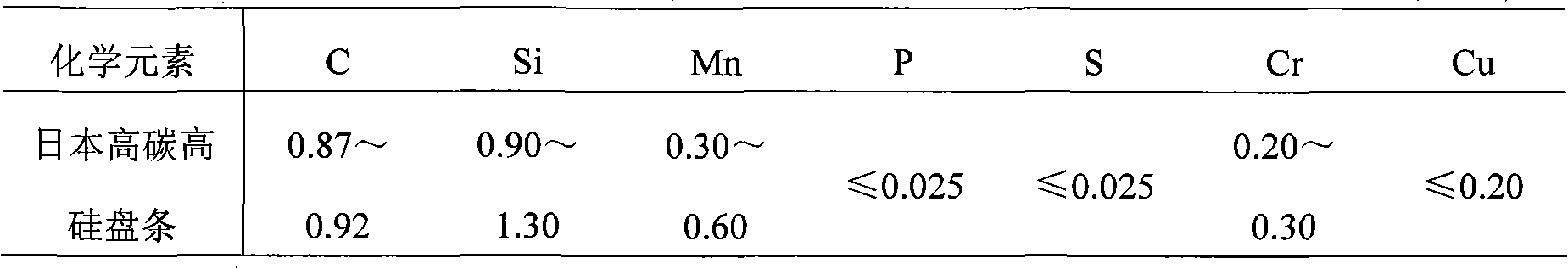

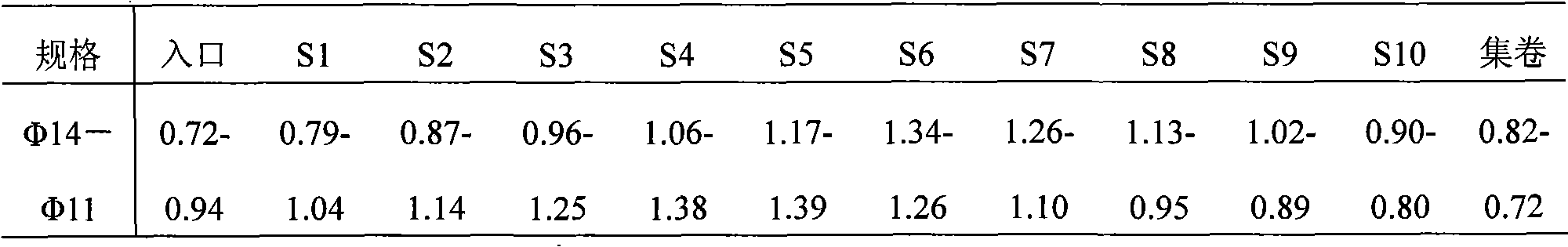

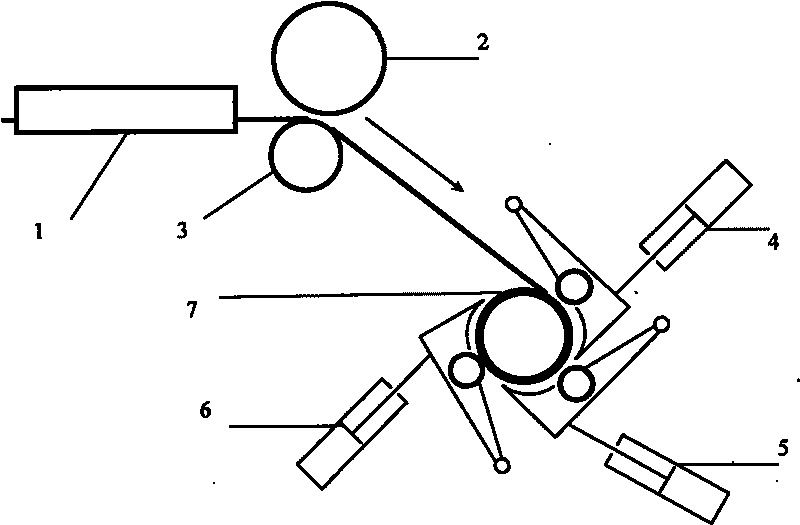

Wire rod for producting1770Mpa bridge cable galvanized steel wire and method for manufacturing same

ActiveCN101311288AHigh Dynamic Load Fatigue TestImprove toughnessRoll mill control devicesHeat treatment process controlWire rodToughness

The invention provides a wire rod for a galvanized steel wire of a 1770MPa bridge stay cable comprising the following chemical elements (by wt percentage): C, 0.85 to 0.9; Si, 0.12 to 0.32; Mn, 0.6 to 0.9; P, less than or equal to 0.025; S, less than or equal to 0.025; Cr, 0.1 to 0.25; V, less than or equal to 0.06; Cu, less than or equal to 0.1; the rest, inevitable impurity elements. The invention also provides a manufacturing method of the wire rod. The wire rod provided by the invention has the tensile strength Rm of 1300 to 1400 MPa, the elongation after fracture A which is more than or equal to 8 percent, and the contraction of area Z which is more than or equal to 30 percent (after aging, the contraction of area is more than or equal to 35 percent). The galvanized steel wire made of the wire rod can completely meet the technical requirements of the galvanized steel wire of the 1770MPa bridge stay cable, such as fatigue tests of high dynamic load (more than or equal to two million cycle-index), high toughness and high torsion (more than or equal to eleven times), etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Mn-containing creep-resisting rolled zinc alloy belt material and preparation method thereof

InactiveCN101906555AOutstanding advantagesHighlight positive effectsRoll mill control devicesMetal rolling arrangementsRare-earth elementManganese

The invention relates to a Mn-containing creep-resisting rolled zinc alloy belt material. The material comprises the following components in percentage by weight: 0.5 to 3.0 percent of copper, 0.01 to 2.0 percent of manganese, 0.05 to 0.3 percent of titanium and the balance of zinc and less than 0.05 percent of impurities. An alloy component can also contain the following component in percentage by mass: 0.01 to 0.5 percent of X, wherein the X is at least one of aluminum and rare earth elements (Ce+La). A method for preparing the material comprises the following steps of: smelting by a protective covering method and adding alloy elements in the forms of pure zinc, Zn-Cu, Zn-Ti, Cu-Mn, pure aluminum and Ce+La composite rare earth, wherein a smelting temperature is between 650 and 740 DEG C; pouring at the temperature of between 420 and 480 DEG C; uniformly annealing cast ingots at the temperature of between 350 and 380 DEG C for 6 to 10 hours; performing hot rolling for multiple times at the temperature of between 220 and 280 DEG C, wherein total deformation is between 60 and 95 percent; performing cold rolling, wherein the total deformation is between 50 and 80 percent; and after rolling, annealing at the temperature of between 180 and 200 DEG C for 2 to 3 hours. The alloy of the invention has high creep resistance, hot processing performance and mechanical property and is suitable for the fields of building decoration, transportation, instruments, meters and the like.

Owner:CENT SOUTH UNIV

Weather-resistant hot rolled narrow steel strip and method for manufacturing same

InactiveCN101135030AReduce controlLow costRoll mill control devicesMetal rolling arrangementsChemical compositionContinuous rolling

The present invention relates to one kind of weather resistant hot roller narrow steel strip for welded structure and its production process. The steel strip has the chemical composition comprising C 0.07-0.12 wt%, Si 0.25-0.50 wt%, Mn 0.30-0.50 wt%, P 0.07-0.15 wt%, S less than 0.035 wt%, Cu 0.25-0.40 wt%, Cr 0.30-1.2 wt%, Ni 0.10-0.50 wt%, and Fe and inevitable impurity for the rest. It is produced through smelting in a top blown converter, LF refining, continuously casting steel strip billet and hot rolling in a continuous rolling mill train. It has high purity, excellent corrosion resistance, excellent welding performance and homogeneous mechanical performance. It may be applied in making square welded tube or other accessories for container.

Owner:LAIWU IRON & STEEL GRP

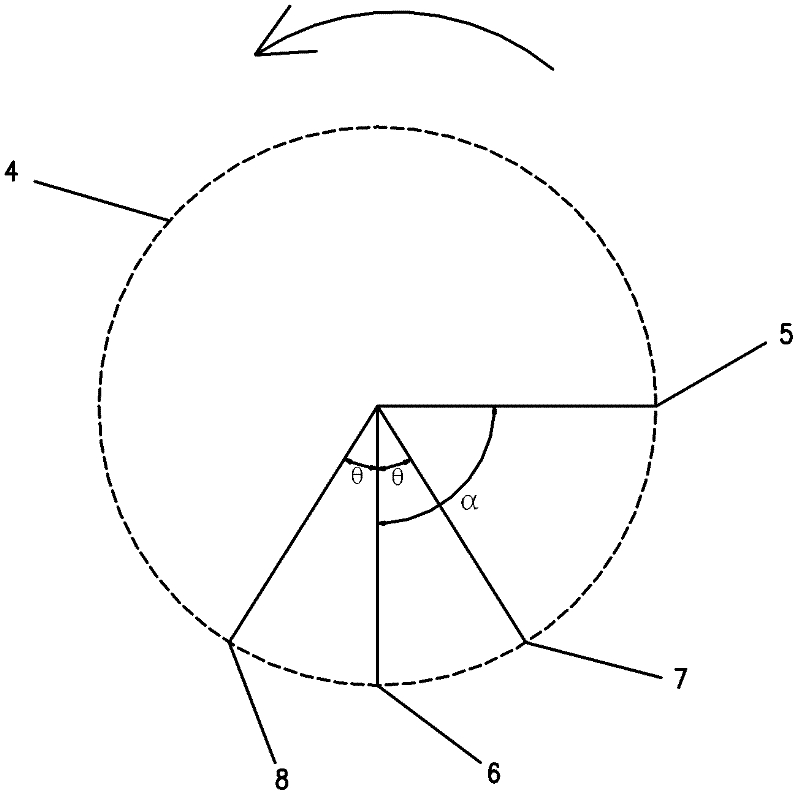

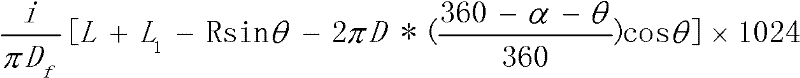

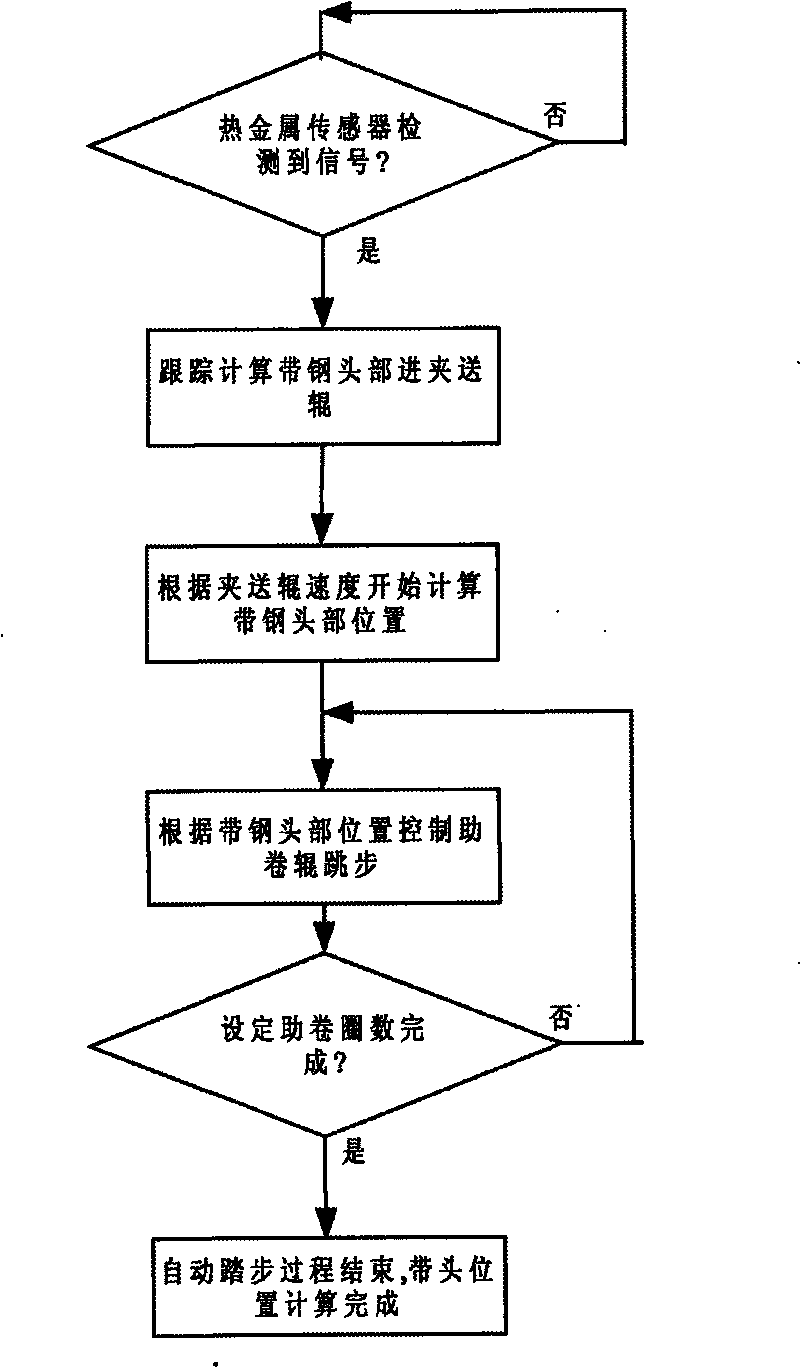

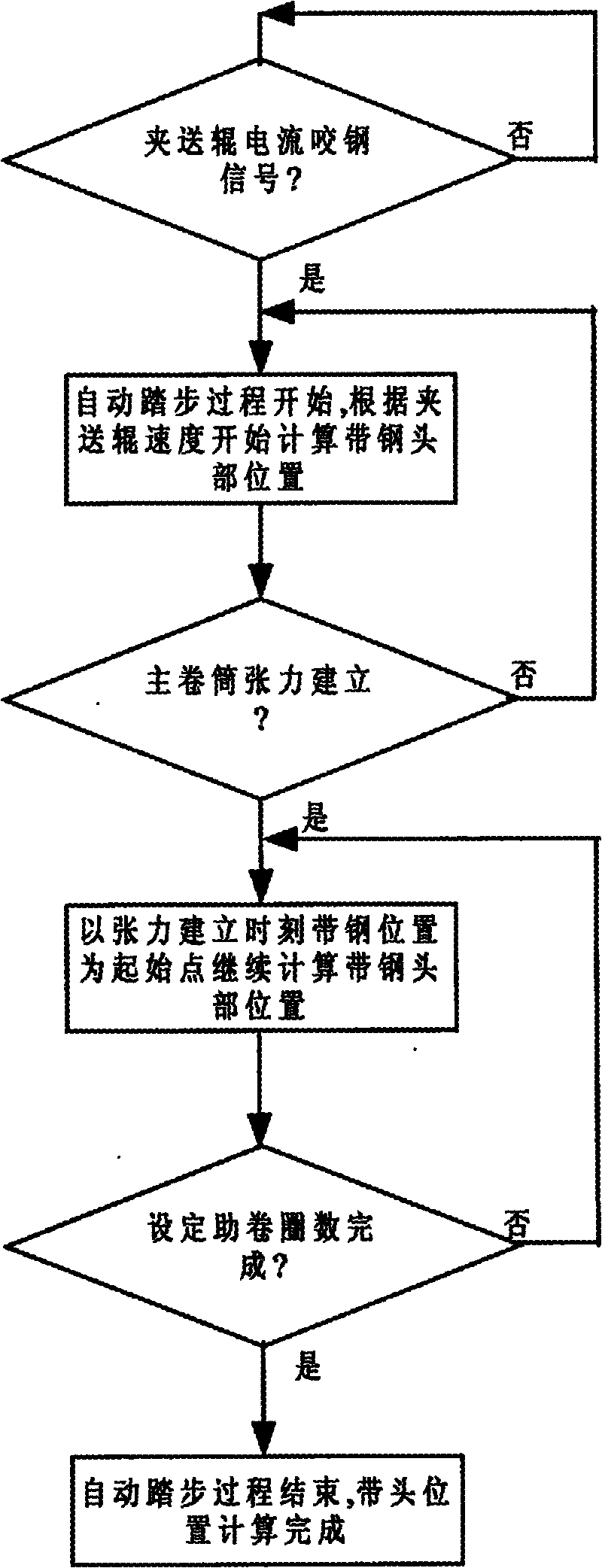

Method for calculating and locating strip steel head of automatic stepping system of hot continuous rolling coiling machine

InactiveCN101722196AOvercome the shortcomings of being susceptible to various interferences on siteHigh degree of automationRoll mill control devicesMeasuring devicesHead positionEngineering

The embodiment of the invention provides a method for calculating and locating the strip steel head of an automatic stepping system of a hot continuous rolling coiling machine, comprising the following steps of: detecting whether the strip steel enters a pinch roll, wherein when the strip steel is detected to enter the pinch roll, the automatic stepping process begins, the head position of the strip steel is calculated according to the speed of a lower pinch roll; detecting the tension of a main drum, if the tension of the main drum is not established, the head position of the strip steel is continuously calculated according to the speed of a lower pinch roll, if the tension of the main drum is established, the head position of the strip steel is continuously calculated by using the momentary position of the strip steel head at the main drum at the tension establishing moment as a start point; detecting whether the set wrapping number of turns is finished, if the set wrapping number of turns is not finished, the head position of the strip steel is continuously calculated by using the head position of the strip steel at the tension establishing moment as a start point; if the set wrapping number of turns is finished, the automatic stepping process stops and the calculation for the head position of the strip steel is finished. The invention can effectively overcome the defects that an on-site hot metal detector and an optoelectronic detecting element are subject to various on-site interferences.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Aluminum alloy foil material for brazing type heat exchanger and production process

InactiveCN101220430AIncrease contentHigh tensile strengthRoll mill control devicesMetal rolling arrangementsSocial benefitsPlate heat exchanger

The invention relates to an aluminum alloy foil material used in a brazing heat exchanger and a manufacturing method of the materials; wherein, indicated by weight percentage, the components of the material comprise0.50 to 1.00 of Si, less than or equal to 0.60 of Fe, 0.05 to 0.10 of Cu, 1.00 to 1.60 of Mn, less than or equal to 0.05 of Mg, 1.60 to 2.20 of Zn, 0.10 to 0.20 of Zr, 0.01 to 0.05 of Ti and unavoidable impurities and the allowance is Al; the materials are made through the manufacturing steps of melting, standing furnace refinement, grain refinement, online degassing, filtration, continuous cast rolling, cold rolling and finishing rolling. The aluminum alloy foil of the invention has the thinner thickness of 0.05mm; the tensile strength is more than 250N / mm<2>, which improves the brazing property; at the same time, the invention is simple in technique and saves the production cost by more than at least 50 percent compared with the method of hot rolling, and therefore, the aluminum alloy foil of the invention has better economic and social benefits.

Owner:河南顺源宇祥铝业科技有限公司

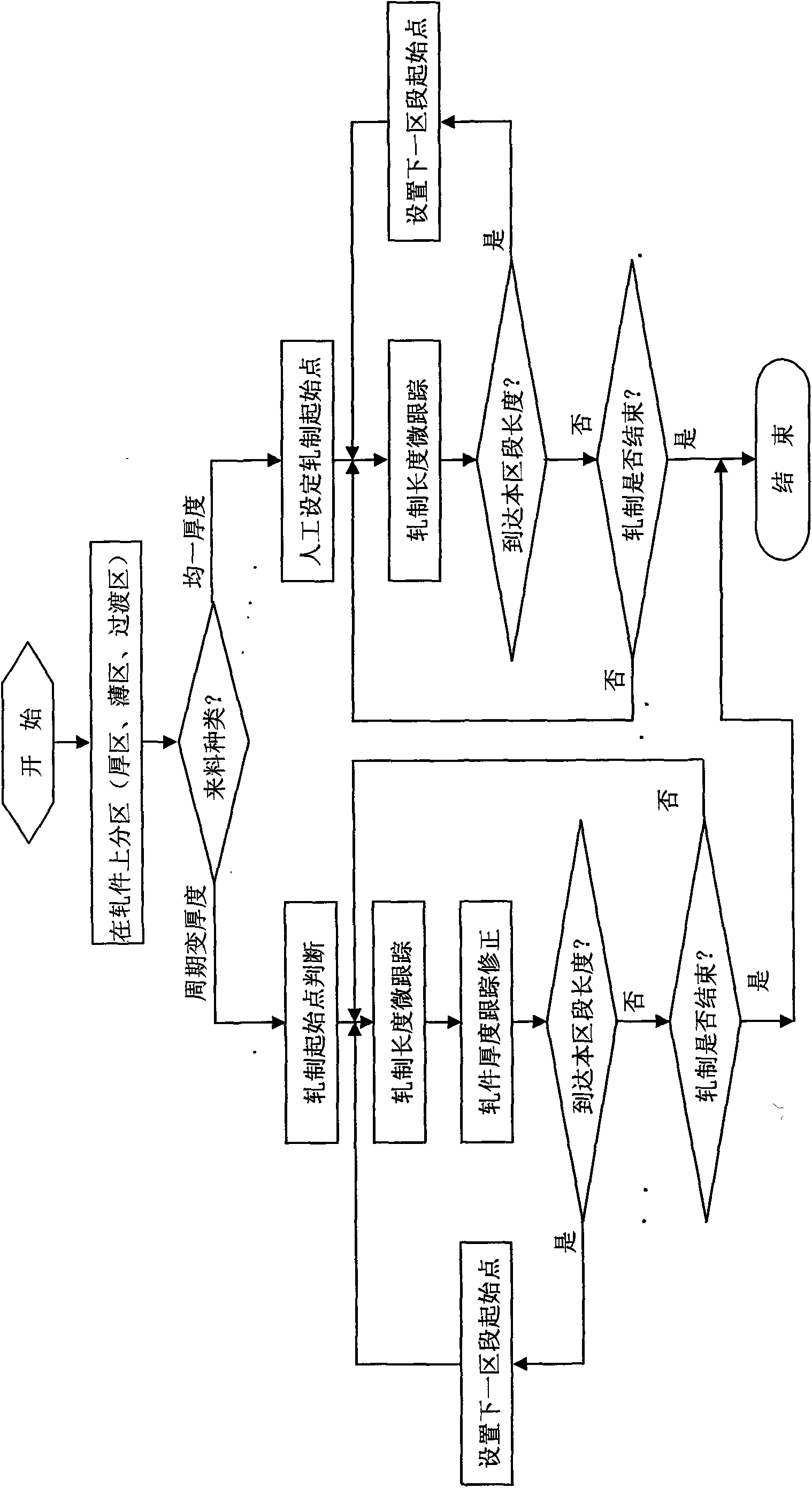

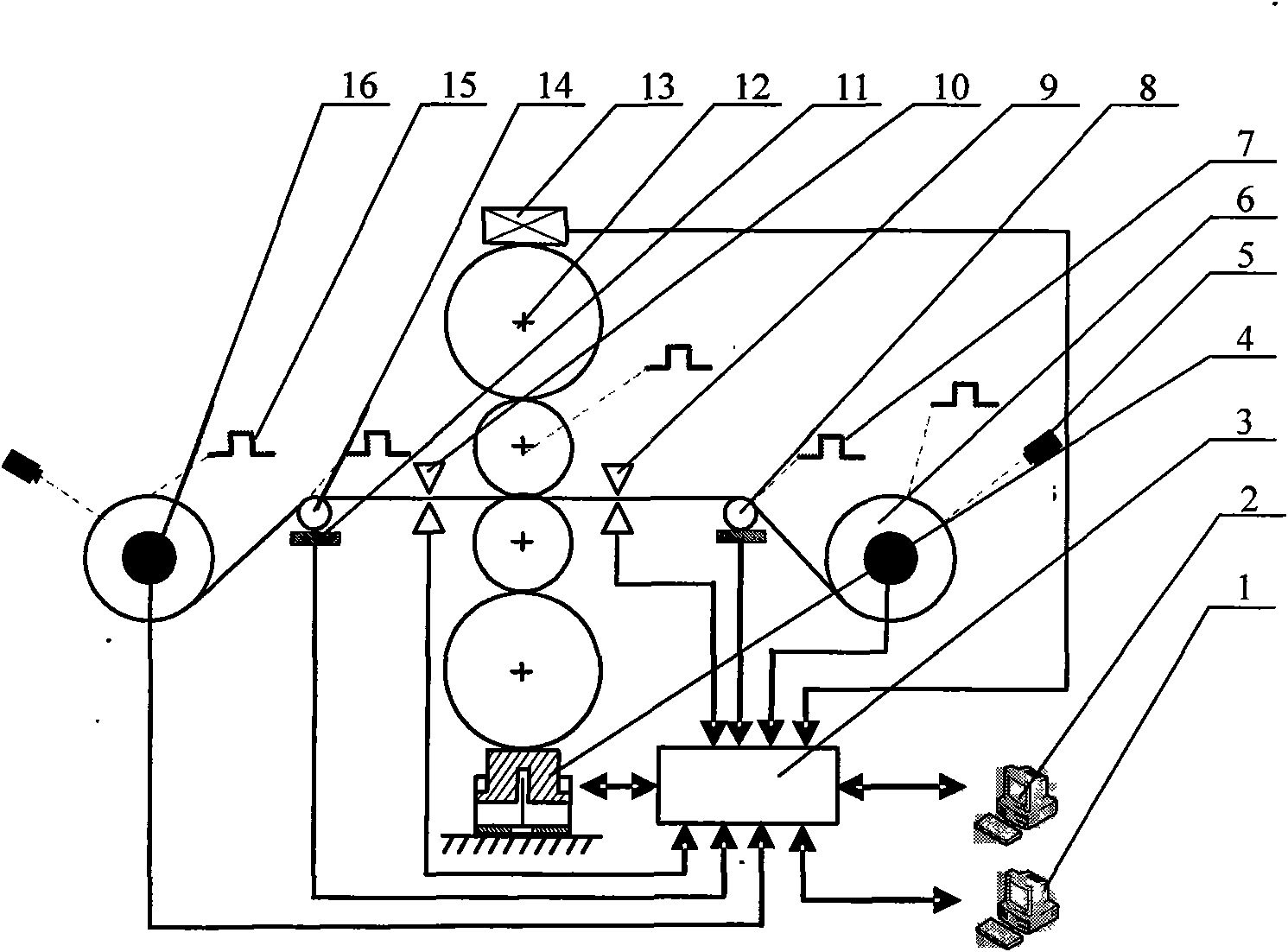

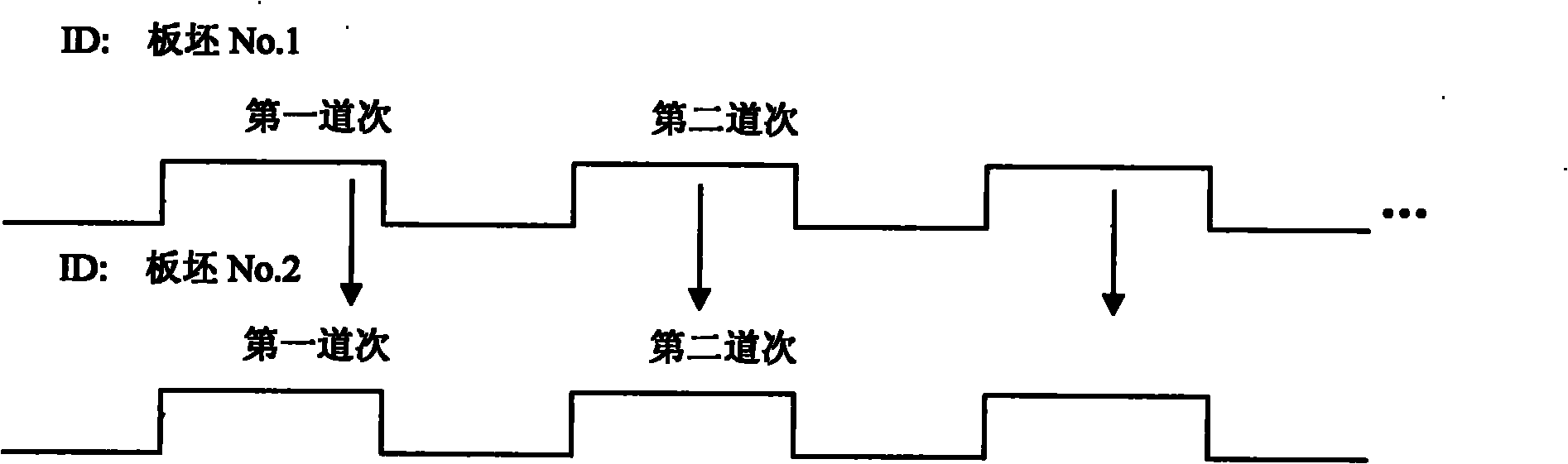

Micro-tracking method and system of rolled pieces in the process of rolling periodic variable-thickness strips

ActiveCN101602065AMeet the accuracy requirements for position trackingMeet the precision requirementsRoll mill control devicesProgramme control in sequence/logic controllersComputer control systemHydraulic cylinder

A micro-tracking method and a system of rolled pieces in the process of rolling periodic variable-thickness strips belong to the technical field of rolling. The method comprises the following steps: dividing thickness zones, thinness zones and transition zones on the rolled pieces of the periodic variable-thickness strips, setting whether the incoming materials are uniform-thickness rolled pieces or periodic variable-thickness rolled pieces, determining the starting point of rolling, micro-tracking the rolling length in the process of rolling and carrying out tracking correction on the periodic variable-thickness rolled pieces. The system comprises a rolling mill; coiling machines are arranged at both sides of the rolling mill respectively; length-measuring rollers are arranged between the coiling machines and the rolling mill; thickness gauges are arranged at both sides of the rolling mill respectively; coil diameter gauges are arranged on the coiling machines; a rolling force sensor and a hydraulic cylinder are arranged on the rolling mill; tensiometers are arranged below the length-measuring rollers and pulse coders are arranged on the length-measuring rollers; the thickness gauge, the coil diameter gauge, the rolling force sensor, a displacement sensor of the hydraulic cylinder, the tensiometer and the pulse coder are respectively connected with a computer control system.

Owner:SHENYANG DONGBAO HAIXING METAL MATERIAL TECH

Precise machining method for capillary tube for biodegradable magnesium alloy intravascular stent

ActiveCN103394545ASmall sizeImprove surface qualityRoll mill control devicesMetal rolling arrangementsStress reliefIntravascular stent

The invention discloses a precise machining method for a capillary tube for a biodegradable magnesium alloy intravascular stent. The method comprises the following steps of: step 1, performing stress relief annealing and machining on a magnesium alloy extrusion bar to obtain a tube blank; step 2, extruding the tube blank to obtain a seamless extrusion tube blank, and performing stress relief annealing; step 3, performing multi-pass rolling and annealing on the annealed seamless extrusion tube blank to obtain a thin tube blank; and step 4, performing multi-pass drawing and annealing on the thin tube blank to obtain the capillary tube for the biodegradable magnesium alloy intravascular stent. The capillary tube produced by the method disclosed by the invention is accurate in dimension (a wall thickness error is not greater than 5%), can be more than 1 metre long, is high in surface quality, uniform in matrix structure, excellent in mechanical property, low in machining cost and high in machining efficiency, and can be subjected to industrialized batch production.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

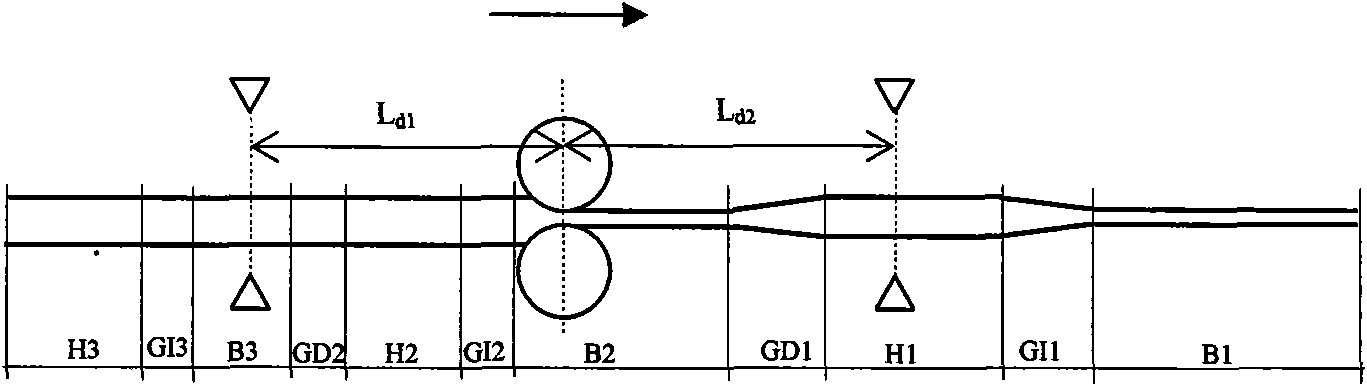

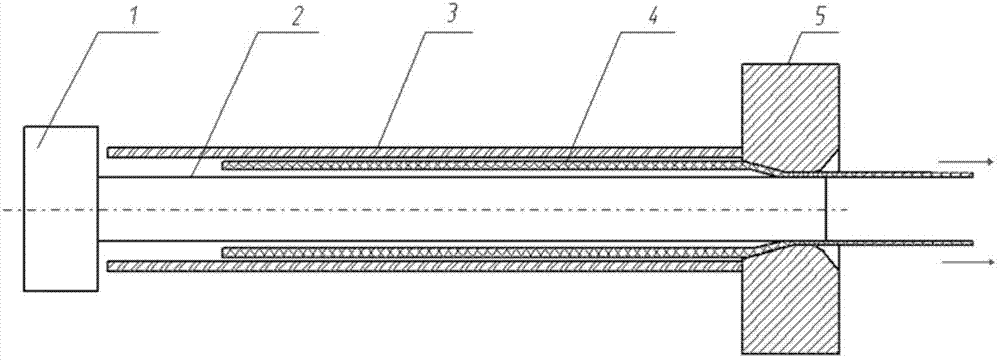

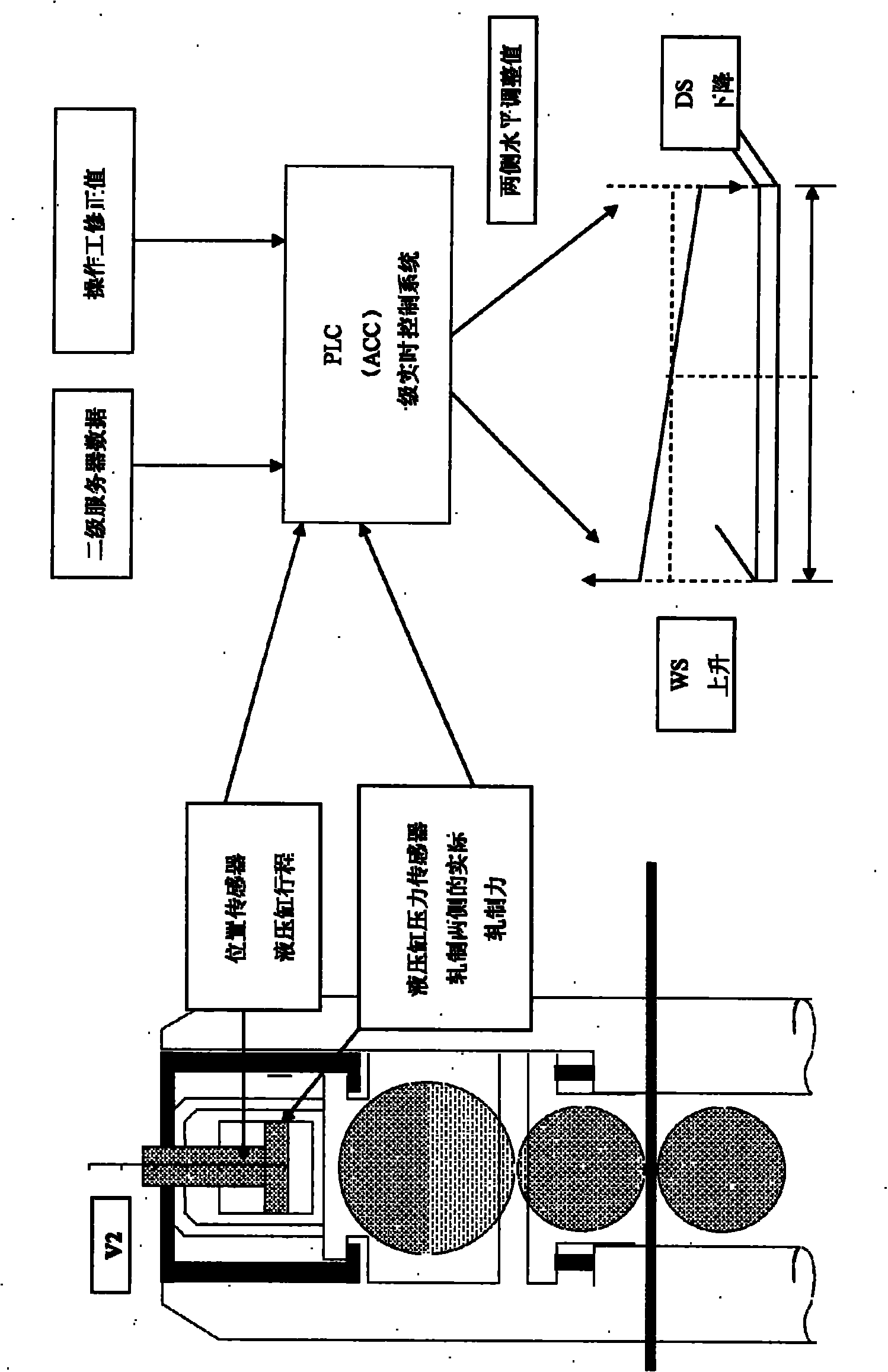

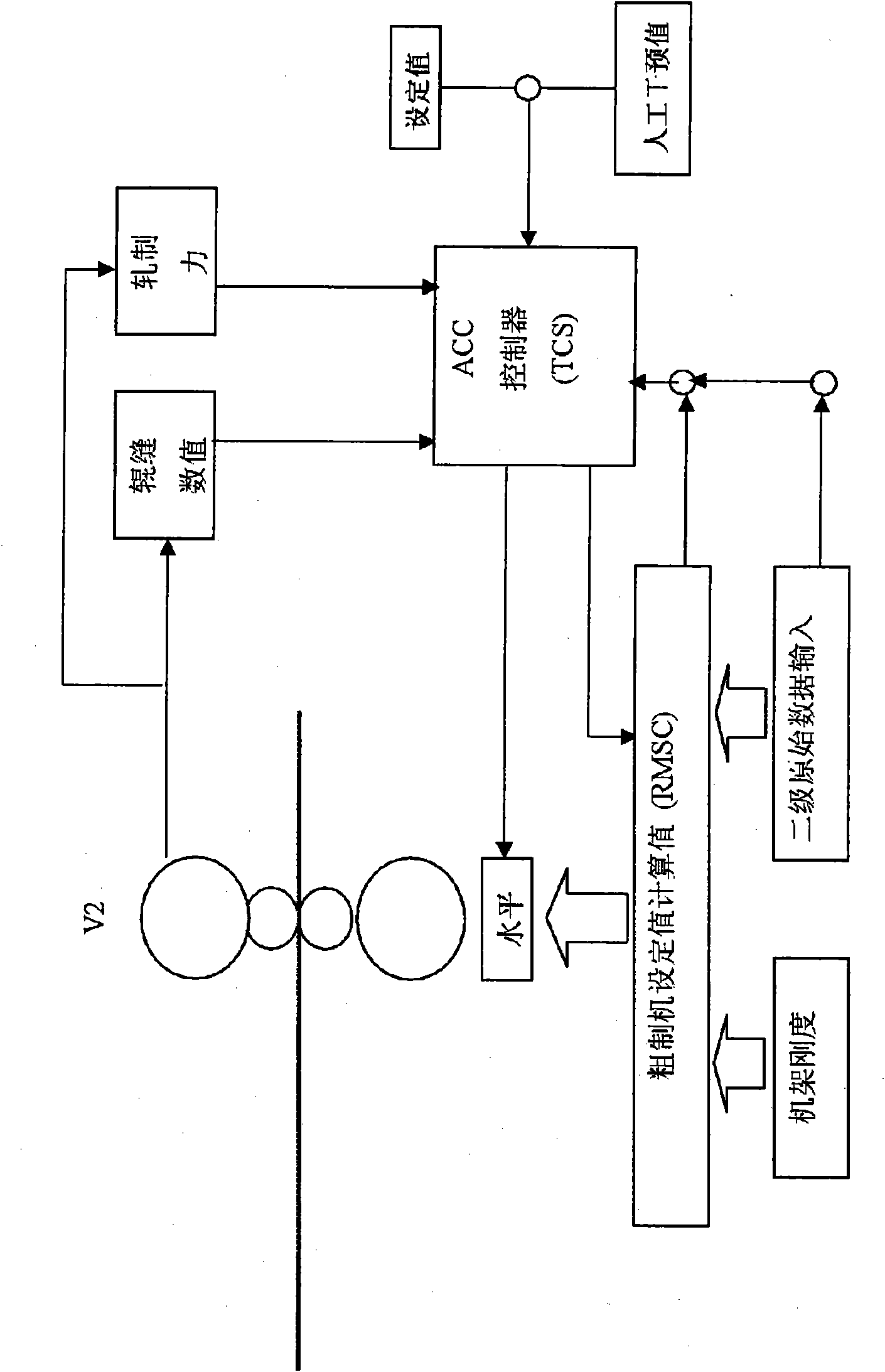

Automatic control method for camber and wedge of hot rolled strip roughing mill

ActiveCN101934292AOptimal control methodEasy to implementRoll mill control devicesMetal rolling arrangementsAutomatic controlStrip mill

The invention provides an automatic control method for a camber and a wedge of a hot rolled strip roughing mill, which is realized by adding an auxiliary control module in a hot rolled strip roughing mill control system. The automatic control method takes the actual values of rolling forces on two sides of an in-situ roughing mill, the actual calculated values of a gap between rolls and bounce parameters on two sides of a rack as inputs to be accurately calculated, and finally realizes the correction to the camber and the wedge through regulating the gap between rolls on one side or two sides of the rolling mill. By applying the control method, the extremely accurate control over the camber and the wedge can be realized without adding a camber shape detection device with blanks, and the control effect of the control method can be further assured if the camber shape detection device is equipped in situ.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

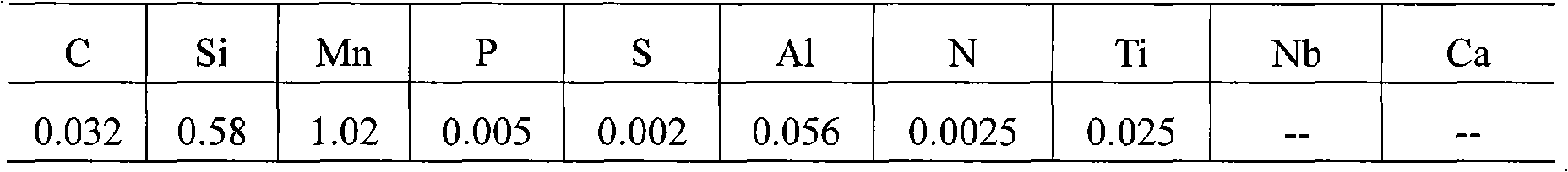

Hot rolling high reaming steel plate having 440MPa grade of tensile strength and manufacturing method thereof

InactiveCN101353757AExcellent hole expandabilityGood formabilityRoll mill control devicesMetal rolling arrangementsChemical compositionSheet steel

The invention provides a hot-rolled high reaming steel sheet with tensile strength of 440MPa, comprising the following chemical composition (weight percent): C: 0.01 to 0.06 percent, Si: 0 to 0.6 percent, Mn: 0.8 to 1.3 percent, P: less than or equal to 0.035 percent, S: less than or equal to 0.010 percent, Al: 0.025 to 0.060 percent, N: less than or equal to 0.0060 percent, Nb: 0 to 0.25 percent, and the rest are Fe and inevitable impurities. The invention also provides a preparation method of the hot-rolled high reaming steel sheet, and the method does not need heat treatment, can reduce the cost, and needs no complicated control of cooling technology after hot rolling, which is convenient for production. The steel sheet provided by the invention has good reaming performance, moldability and cold processing performance, and is mainly used for the molding and processing of parts with complicated shapes for automobile chassis.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com