Method for producing hot-rolled ferritic stainless steel strip steel

A technology for stainless steel strips and production methods, applied in the direction of metal rolling, metal rolling, heat treatment equipment, etc., can solve the problems of rough surface of stainless steel products, affecting appearance and use, stamping defects, etc., to meet the requirements of surface finish and reduce production costs , taking into account the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

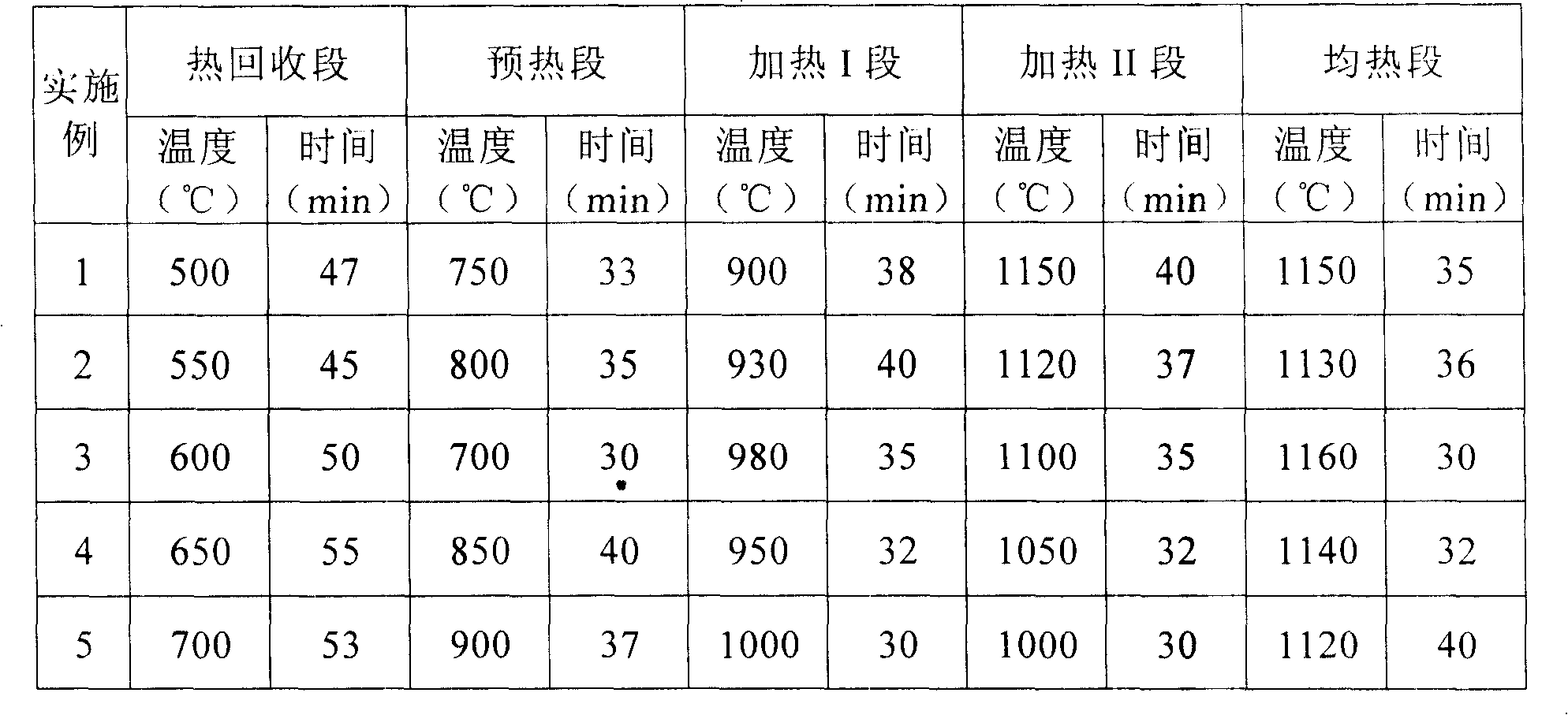

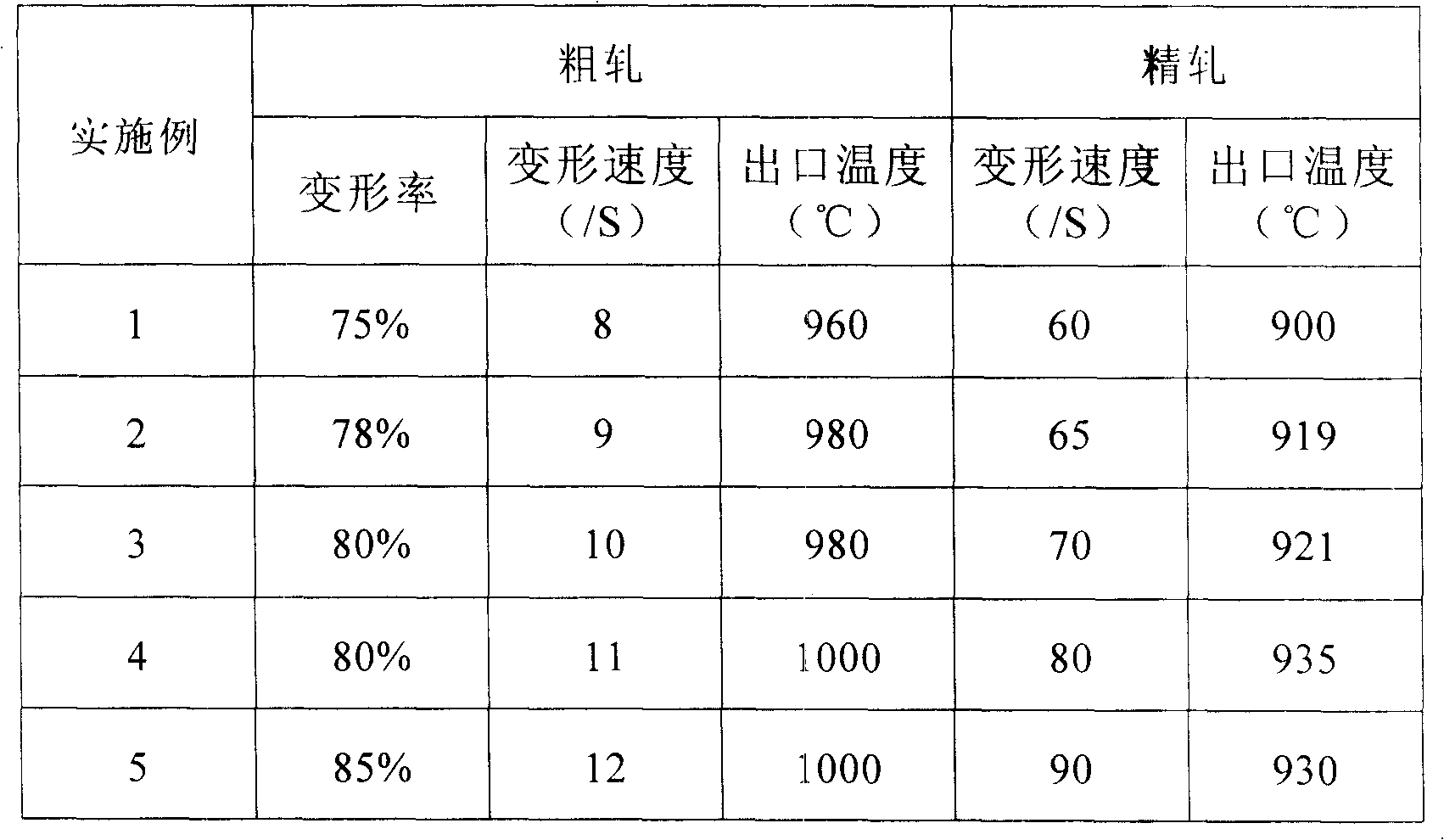

[0027] The embodiment of the present invention takes 410S stainless steel strip as an example, see Table 1, the heating process parameters of hot rolling are shown in Table 2, and the rolling process parameters of hot rolling are shown in Table 3.

[0028] Table 1 Unit: mass percentage

[0029] Example

C

Si

mn

S

P

Cr

Fe

1

0.025

0.95

0.025

0.020

0.031

12.00

margin

2

0.040

0.82

0.030

0.025

0.030

12.30

margin

3

0.030

0.50

0.040

0.023

0.014

12.15

margin

4

0.035

0.18

0.035

0.028

0.034

12.20

margin

5

0.032

0.30

0.028

0.004

0.018

12.50

margin

6

0.026

0.23

0.025

0.004

0.011

12.00

margin

7

0.040

0.21

0.030

0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com