Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Shorten heat treatment cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

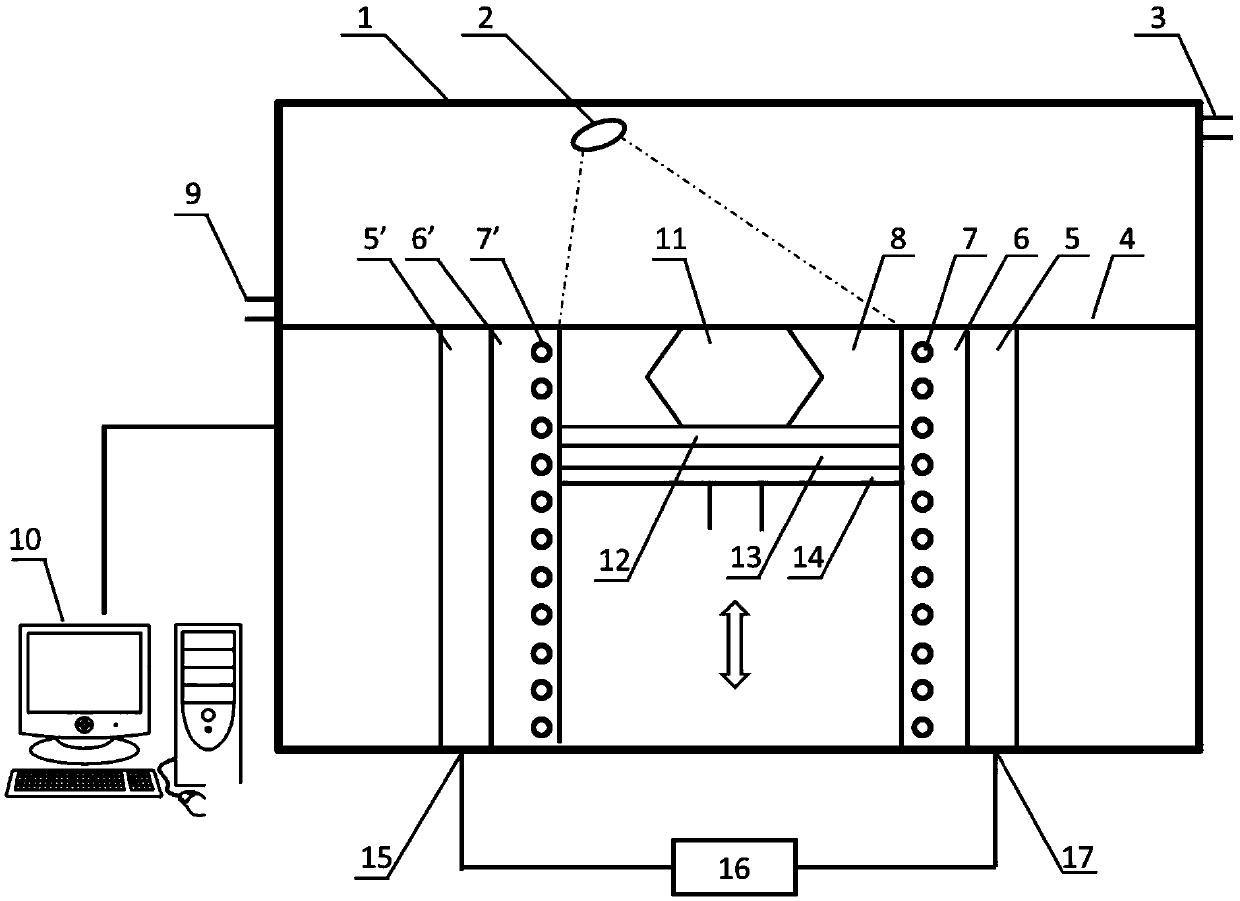

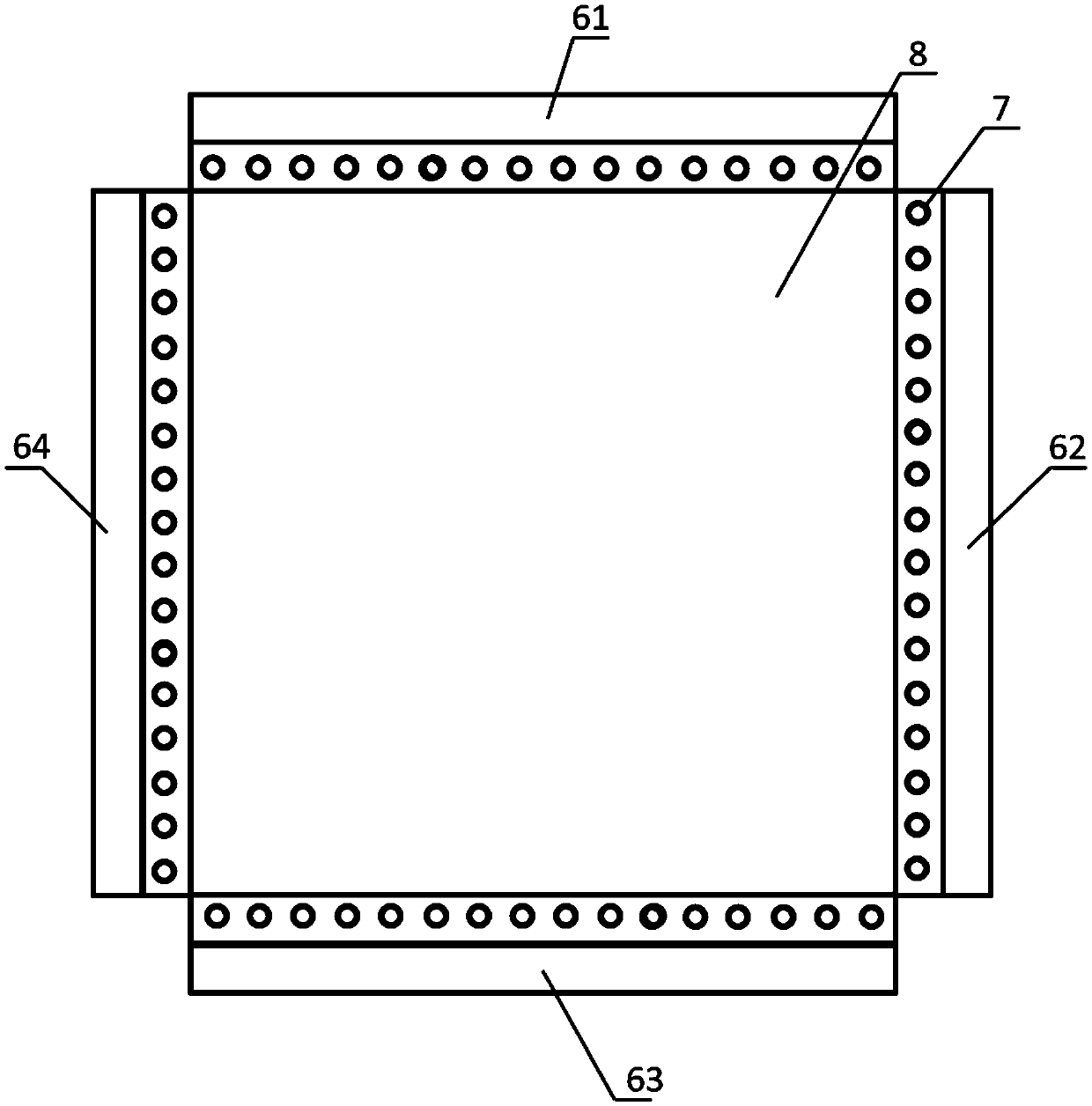

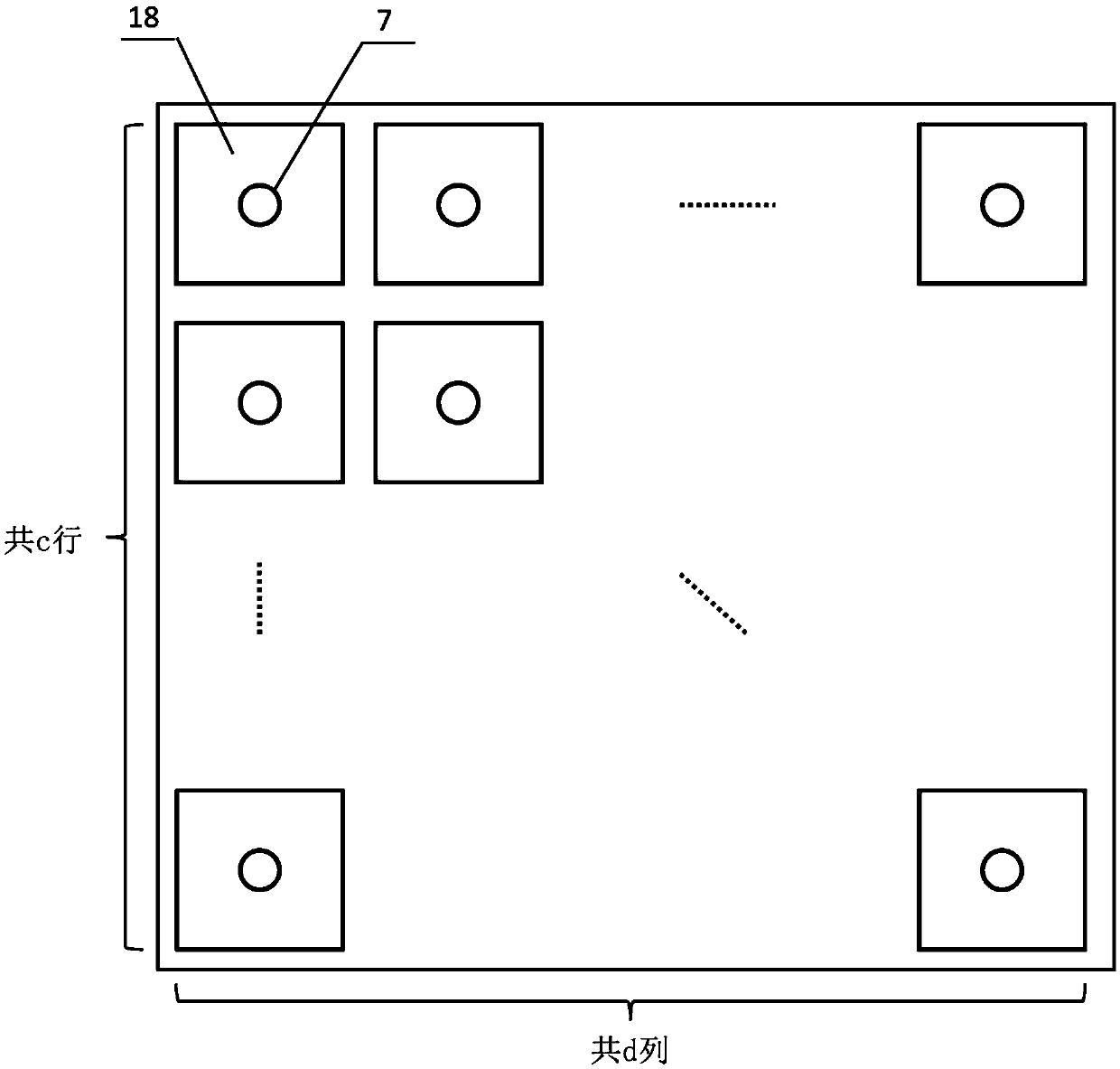

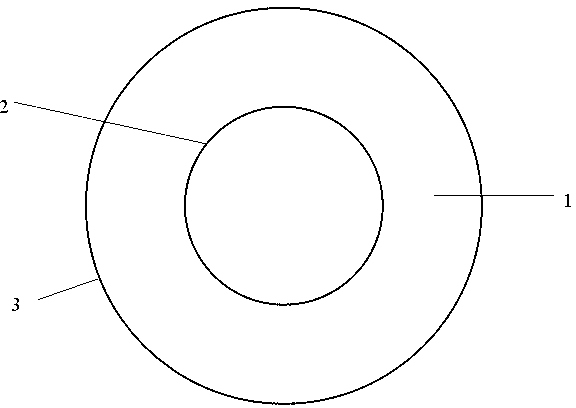

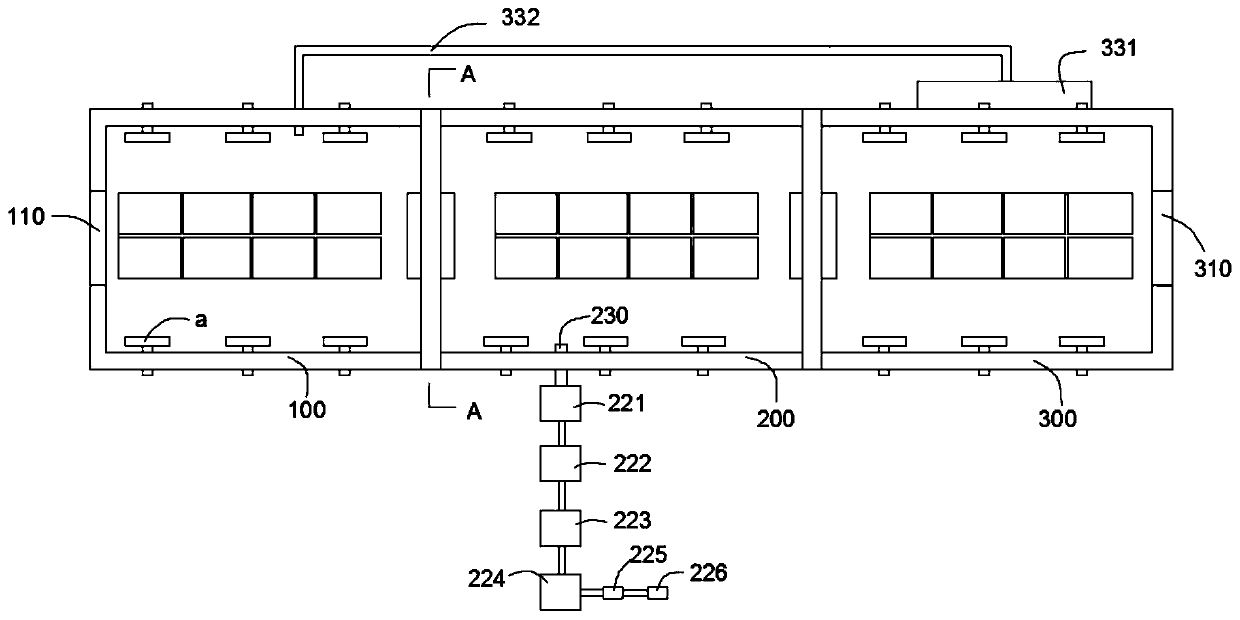

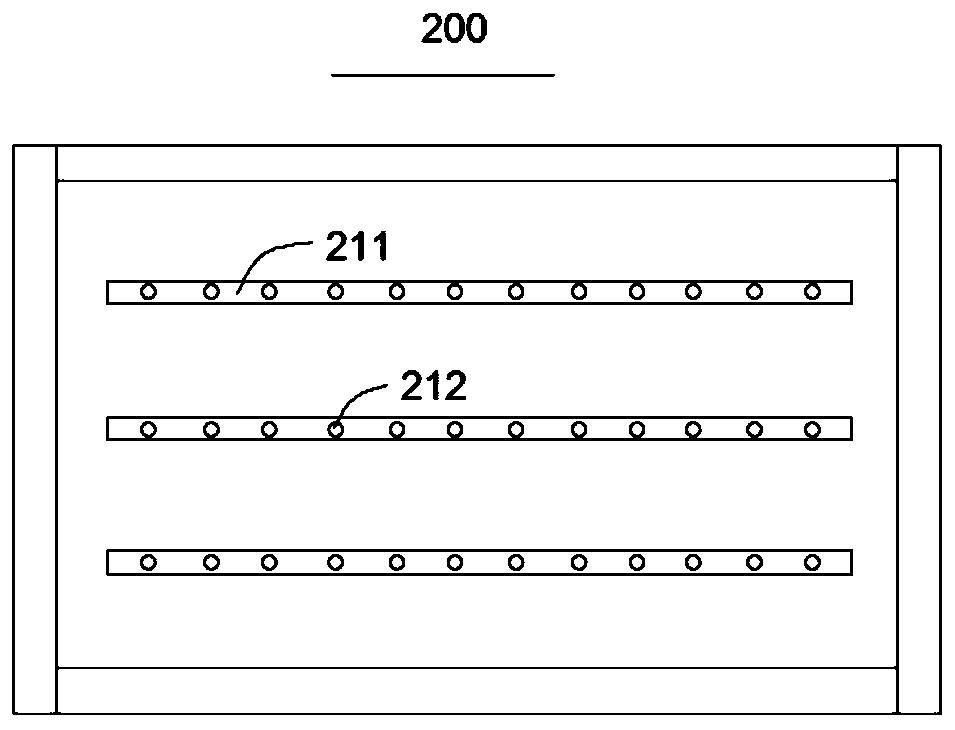

Active temperature field regulating and controlling system for manufacturing high-energy beam reinforced material and control method for active temperature field regulating and controlling system

ActiveCN105499569AShorten heat treatment cycleEnergy savingAdditive manufacturing apparatusIncreasing energy efficiencyHeating systemHolding time

The invention discloses an active gradient temperature field regulating and controlling system and a control method thereof. The system is composed of a temperature field monitoring system, a heating system and a control system, wherein the temperature field monitoring system is used for measuring temperature field information on an XOY plane and at the periphery of a forming region and feeding the temperature field information back to the control system after quantitatively processing the temperature field information; and the heating system is used for independently regulating subregions of a temperature field at the bottom and periphery of a forming tank in real time according to a command of the control system so as to keep the temperature field of the whole machining region constant in the machining process, keep a processed region and an unprocessed region in a reasonable temperature gradient and avoid structural member warping, deforming and cracking caused by thermal stresses. The system can also be used for directly carrying out stress relief annealing on a formed structural member or directly carrying out stress relief on the formed structural member while machining, so that the problems of warping, deforming, cracking and the like easily caused in the forming process are effectively solved, not only is the time shortened, but also energy sources are saved, meanwhile, the holding time of equipment can be effectively shortened, and the utilization ratio of the equipment can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH

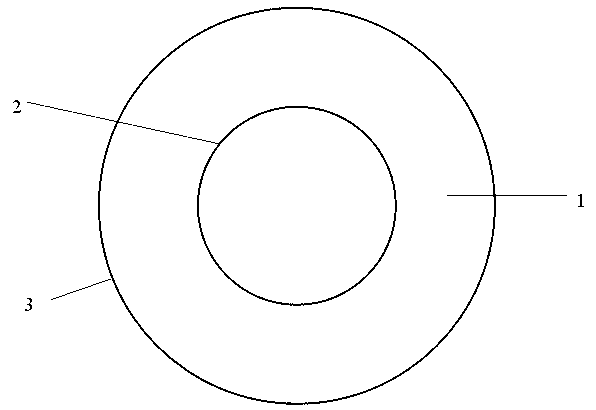

Wear, corrosion and rust resistant metal pipeline

ActiveCN103290306AEvenly distributedHigh hardnessCorrosion preventionPipe protection against corrosion/incrustationTemperingSolid solution strengthening

The invention relates to a wear, corrosion and rust resistant metal pipeline. The metal pipeline is manufactured by manufacturing a wear-resistant pipeline body through centrifugal casting, carrying out the processes of quenching, high-temperature tempering, solid solution strengthening thermal treatment and double tempering and dispersion hardening thermal treatment, then electrostatically spraying a rust-resistant coating on the outer wall of the pipeline, and finally air-spraying a corrosion-resistant coating on the inner wall of the pipeline. The metal pipeline has higher hardness and wear resistance, and the corrosion-resistant coating of the metal pipeline has excellent water resistance, antifouling effect and high temperature resistance.

Owner:NANTONG LITAI CHEM EQUIP

Abrasion resistant cast tube with high temperature oxidation resistant anticorrosive coating

ActiveCN103277629AEvenly distributedHigh hardnessAnti-corrosive paintsRigid pipesTemperingNanocomposite coating

The invention relates to an abrasion resistant cast tube with a high temperature oxidation resistant anticorrosive coating. An abrasion resistant cast tube body is produced through centrifugal casting and is subjected to quenching, high-temperature tempering, solution strengthening thermal treatment and twice tempering dispersion hardening thermal treatment, then a rustproof coating is coated on the outer wall of the tube through electrostatic spraying, finally a water glass nanometer composite coating prepared through testing is sprayed on the inner wall of the tube, and a high temperature oxidation resistant anticorrosive coating film inner layer is obtained after high temperature curing and cooling. The obtained metal tube has high hardness and abrasion resistance, and the anticorrosive coating of the metal tube has excellent waterproof performance, antifouling effect and high temperature resistance.

Owner:江阴德耐特重工科技有限公司

Aluminum alloy automobile wheel hub composite reinforcement technology

InactiveCN102925763AGood castabilityImprove mechanical propertiesCrystalliteMechanical properties of carbon nanotubes

The invention discloses an aluminum alloy automobile wheel hub composite reinforcement technology. Trace elements (comprising Mg, Ti, B, RE and the like) are added on the basis of original alloy components to carry out a reasonable component optimization, and effective purification, crystal grain refinement, deterioration treatment and finished product heat treatment are carried out in the melting process to simultaneously guarantee the good casting performance and the better mechanical performances of the alloy. The tensile strength, the yield strength and the elongation rate of aluminum alloy wheel hub products produced through utilizing the technology reach 262MPa, 179MPa and 9% respectively, and exceed strength performance standards in the Chinese wheel hub industry, so the technology has the advantages of certain practical production meaning, heat treatment period shortening, and substantial saving of the production cost.

Owner:赵凯志

Wear-resisting material used for brake disc of high-speed train and preparation method for wear-resisting material

The invention relates to a wear-resisting material used for a brake disc of a high-speed train and a preparation method for the wear-resisting material. The wear-resisting material consists of the following raw material components in percentage by mass: 0.14-0.22% of C, 0.40-0.65% of Si, 0.80-1.20% of Mn, 2.40-2.90% of Ni, 2.30-3.00% of Cr, 0.90-1.30% of Mo, 0.40-0.80% of V, 0-0.30% of Nb, 0-0.30% of Ti, less than or equal to 0.015% of P, less than or equal to 0.010% of S and the balance of Fe. The invention further discloses the preparation method for the wear-resisting material, and the preparation method comprises the following steps: (A) designing chemical components of alloy steel; (B) adopting a medium-frequency electric furnace to smelt; and (C) carrying out thermal treatment on an as-cast sample. The thermal treatment process comprises the steps of preserving the heat for 1-2 hours at a temperature being 900-1000 DEG C, carrying out water quenching, preserving the heat for 1.5-2.5 hours at a temperature being 550-650 DEG C, and cooling in air. A thermally-treated structure is tempered sorbite which has hardness HRC being 42-45, a friction coefficient stabilized to 0.34-0.38, very good wear resistance, low production cost and good casting performance.

Owner:NANJING INST OF TECH

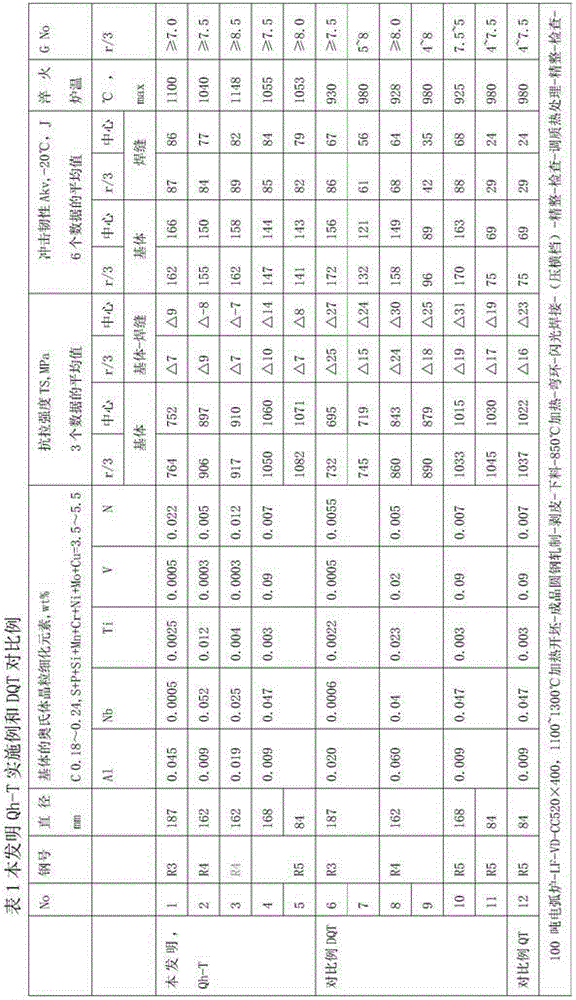

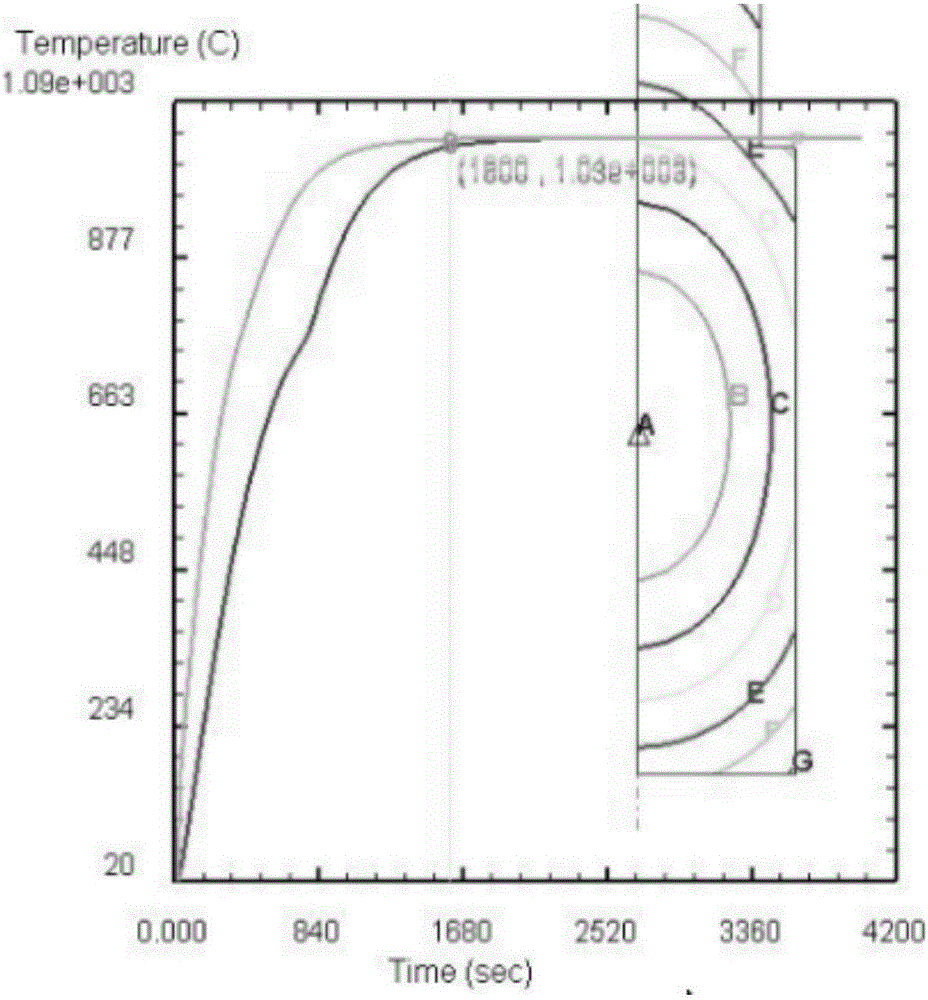

Offshore mooring chain steel and thermal treatment method for mooring chain

The invention discloses offshore mooring chain steel and a thermal treatment method for a mooring chain made of the offshore mooring chain steel. Austenitic grain refining elements in the offshore mooring chain steel comprise 0.006 to 0.024 percent of N by weight, and Al, Nb, Ti and V are precisely cooperated for use. The diameter of the offshore mooring chain is 70 to 210 mm, and a high-temperature quenching-tempering continuous thermal treatment process is adopted; and the furnace temperature of a quenching furnace is greater than 930 DEG C, the highest allowable furnace temperature is 1,150 DEG C, and tempering temperature is 590 to 690 DEG C. According to the offshore mooring chain steel, the potential of an alloy element is developed, the production period is substantially shortened, ideal tissue, substructure and performance can be obtained, and the equipment investment is reduced, so as to pursue the optimal cost performance.

Owner:殷匠

Fabrication method of anti-corrosive and wear-resistant pipeline for delivering minerals

ActiveCN103276282AEvenly distributedHigh hardnessCorrosion preventionPipe protection against corrosion/incrustationTemperingNanocomposite coating

The invention relates to a fabrication method of an anti-corrosive and wear-resistant pipeline for delivering minerals. The method comprises the steps that a wear-resistant pipeline body is fabricated by centrifugal casting; quenching, high temperature tempering, solid solution strengthening heat treatment and a double tempering dispersion hardening heat treatment technology are performed; an outer wall of the pipeline is coated with a water glass nano composite coating subjected to test configuration; high temperature solidifying and then cooling are performed; a high-temperature-resistant, oxidized and anti-corrosive filming inner layer is obtained; and finally an inner wall of the pipeline is coated with a wear-resistant coating. The fabricated metal pipeline has higher hardness and wear-resistant property; the anti-corrosive outer coating of the pipeline has excellent water resistance, anti-fouling effect and high-temperature-resistant property; and the anti-corrosive inner coating of the pipeline has excellent wear-resistant property.

Owner:JIANGSU JINSHENGYUAN SPECIAL VALVE

Preparation method of wear-resistant cast pipe with high-temperature oxidation resistant corrosion-resistant layer

ActiveCN103290336AEvenly distributedHigh hardnessFurnace typesAnti-corrosive paintsTemperingOxidation resistant

The invention relates to a preparation method of a wear-resistant cast pipe with a high-temperature oxidation resistant corrosion-resistant layer. The preparation method is characterized by manufacturing a wear-resistant pipeline body through centrifugal casting, carrying out the processes of quenching, high-temperature tempering, solid solution strengthening thermal treatment and double tempering and dispersion hardening thermal treatment, then electrostatically spraying a rust-resistant coating on the outer wall of the pipeline, finally coating a water glass nano-composite coating prepared through tests on the inner wall of the pipeline, and carrying out cooling after high-temperature curing, thus obtaining a high-temperature oxidation resistant corrosion-resistant film-coated inner layer. The prepared metal pipeline has higher hardness and wear resistance, and the corrosion-resistant coating of the metal pipeline has excellent water resistance, antifouling effect and high temperature resistance.

Owner:JIANGSU JINSHENGYUAN SPECIAL VALVE

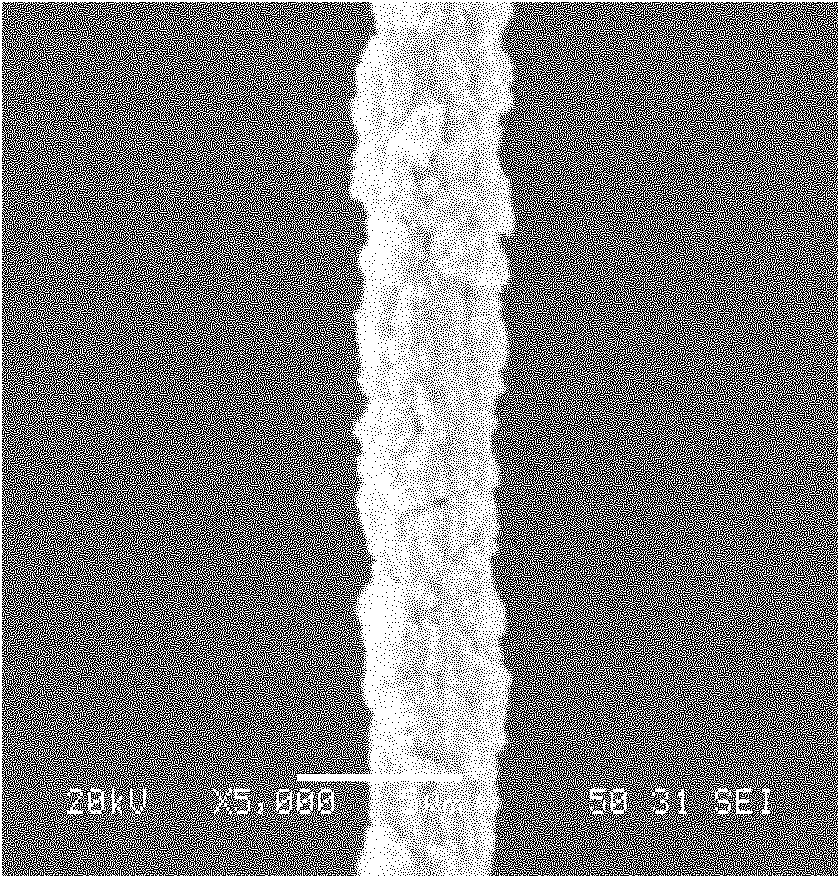

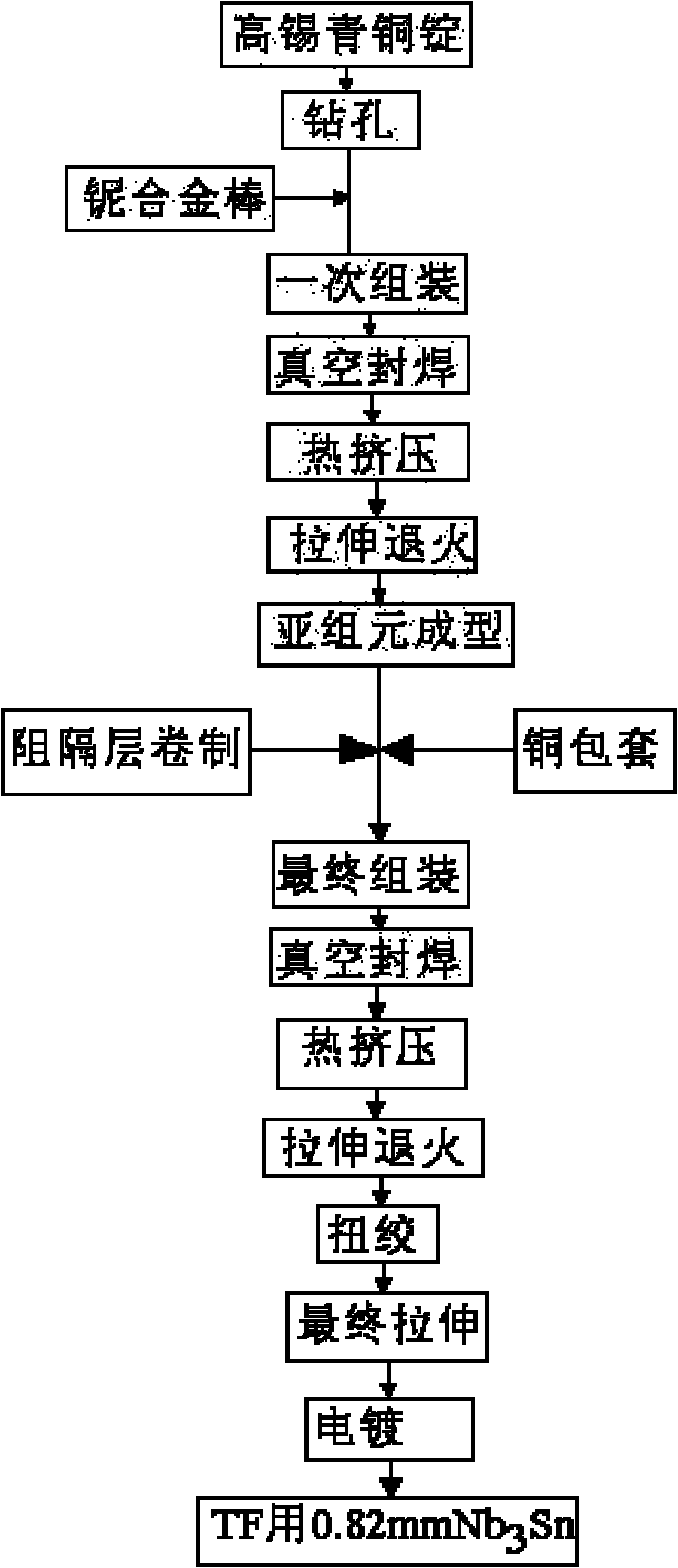

Process for preparing bronze Nb3Sn superconducting wire material

ActiveCN102082009AReduce bondingReduce the effect of current carrying capacitySuperconductors/hyperconductorsSuperconductor devicesNitrogenIngot

The invention discloses a process for preparing a bronze Nb3Sn superconducting wire material. The process comprises the following steps of: drilling a hole on a high tin bronze ingot, assembling the drilled ingot with a niobium alloy rod, soldering and sealing under vacuum, and performing hot extrusion to obtain a rod blank a which serves as a tensile blank; filling the tensile blank in an annealing furnace to perform first annealing; charging a furnace chamber of the annealing furnace with high-purity argon or nitrogen; heating the furnace chamber to the temperature of between 420 and 480 DEG C at the rate of 4 to 8 DEG C / minute; preserving the heat for 30 to 90 minutes; performing forced cooling by circulating the argon or the nitrogen; discharging when the material is cooled to the temperature of between 50 and 100 DEG C; repeatedly processing the material; performing a subcomponent molding process to obtain a hexagonal subcomponent; assembling, soldering and sealing under vacuum and performing the hot extrusion to obtain a rod blank b; and performing second annealing, twisting, performing final stretching and electroplating to obtain the Nb3Sn superconducting wire material. By the process for preparing the bronze Nb3Sn superconducting wire material, the surface of an Nb alloy is improved, and the performance of a strand wire is improved.

Owner:西部超导材料科技股份有限公司

Heat treatment technology for low-temperature high impact toughness medium-thickness steel plate

InactiveCN101892373AShorten heat treatment cycleNo high temperature phase transition stressFurnace typesHeat treatment furnacesSheet steelEnergy consumption

The invention discloses heat treatment technology for a low-temperature high impact toughness medium-thickness steel plate. The heat treatment technology comprises the following steps of: putting the steel plate into a furnace and heating, wherein the heating temperature is 50 to 100 DEG C lower than the Al temperature; keeping the temperature for 40 to 80 minutes; and discharging and performing air cooling to obtain the low-temperature high-toughness medium-thickness steel plate. The heat treatment technology can effectively solve the problems of plate warp, high heat treatment energy consumption, high maintenance cost of heat treatment equipment, low production efficiency and the like due to high heating temperature when normalizing heat treatment is performed on a TMCP steel plate, and also can obtain the low-temperature high-toughness steel plate at the temperature of 40 DEG C below zero.

Owner:NANJING IRON & STEEL CO LTD +1

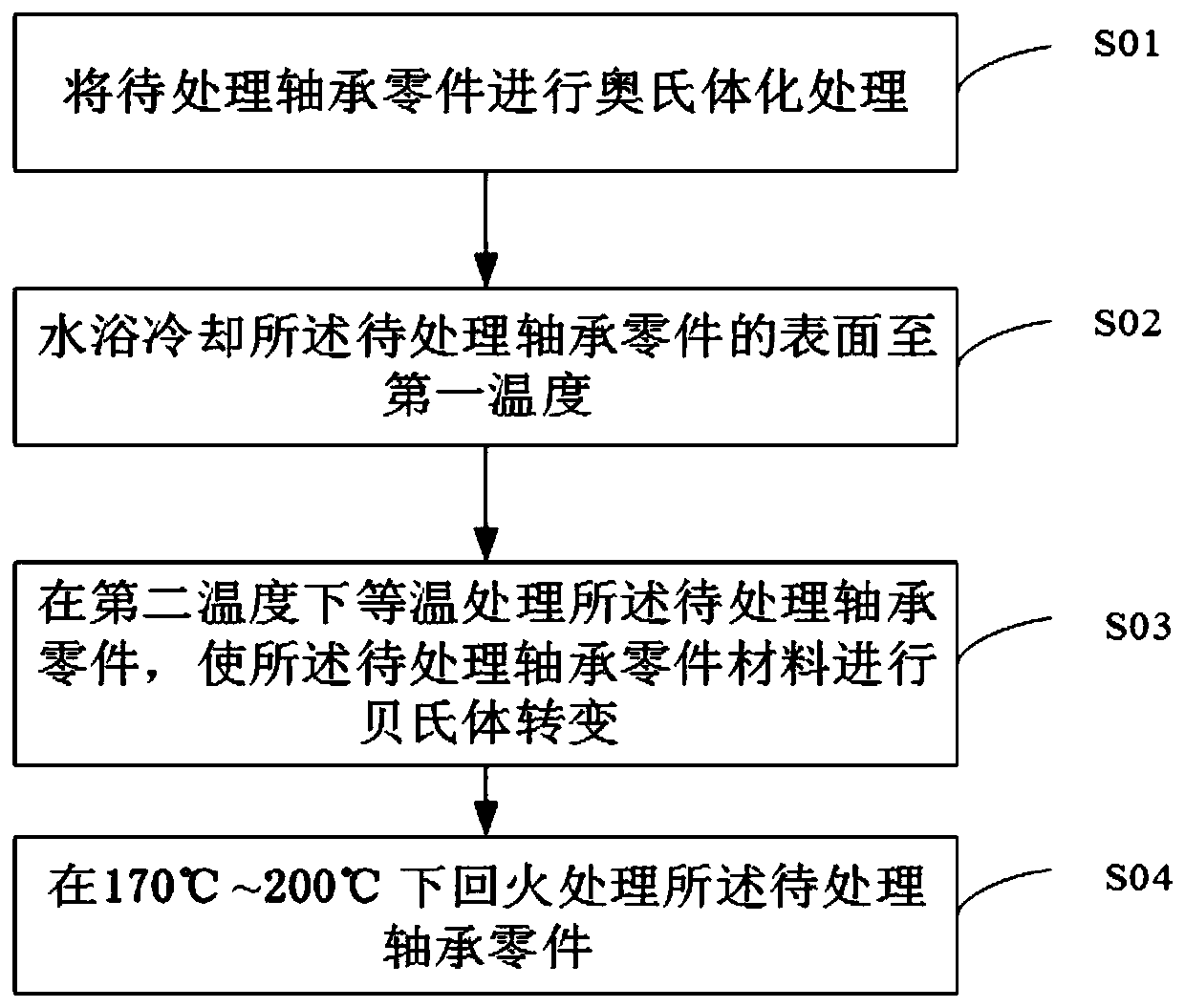

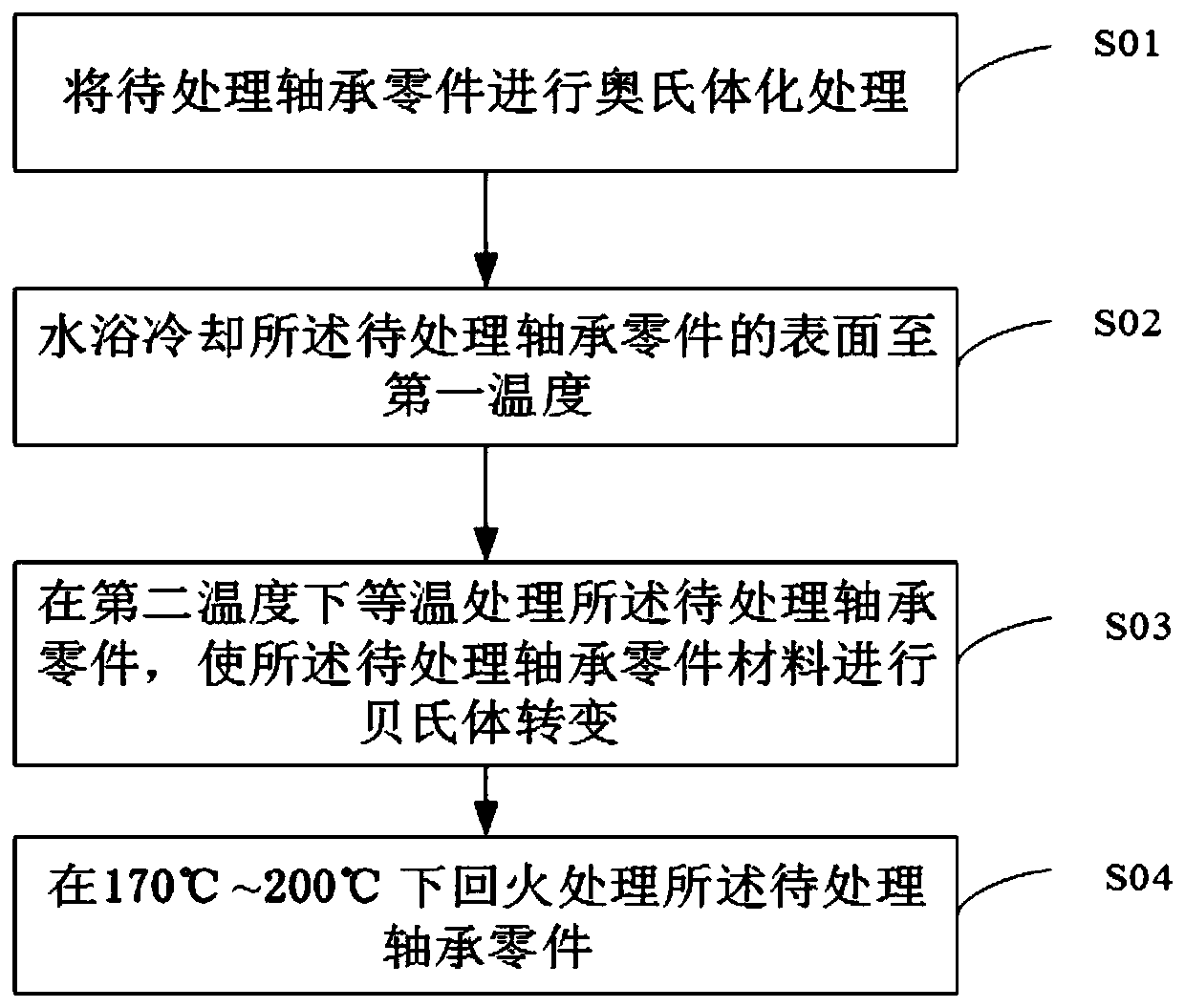

Thermal treatment method of nano-bainite bearing and bearing manufactured by adopting thermal treatment method

ActiveCN110042217AAvoid pollutionAvoid the salt bath methodFurnace typesQuenching agentsThermal treatmentMetallurgy

Owner:YANSHAN UNIV

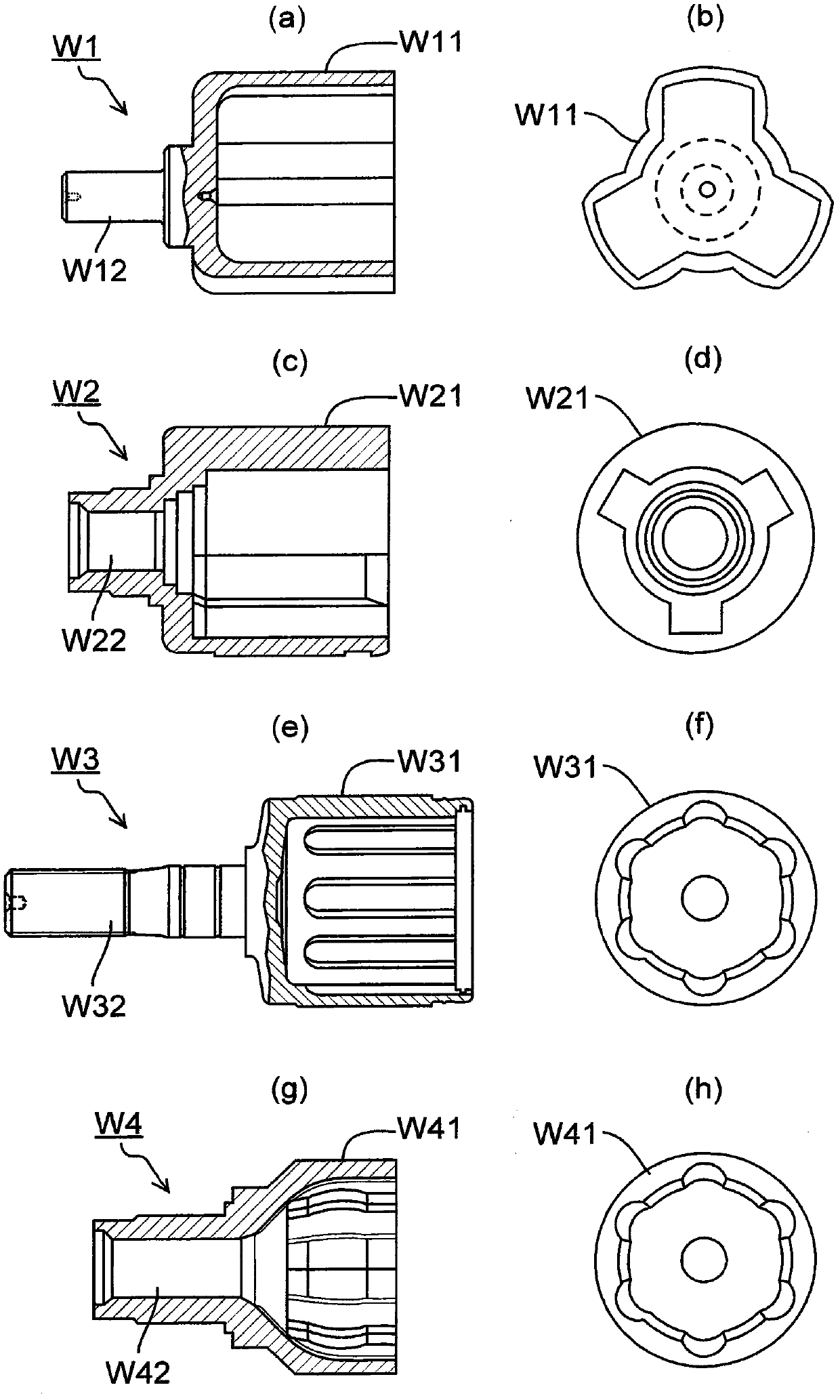

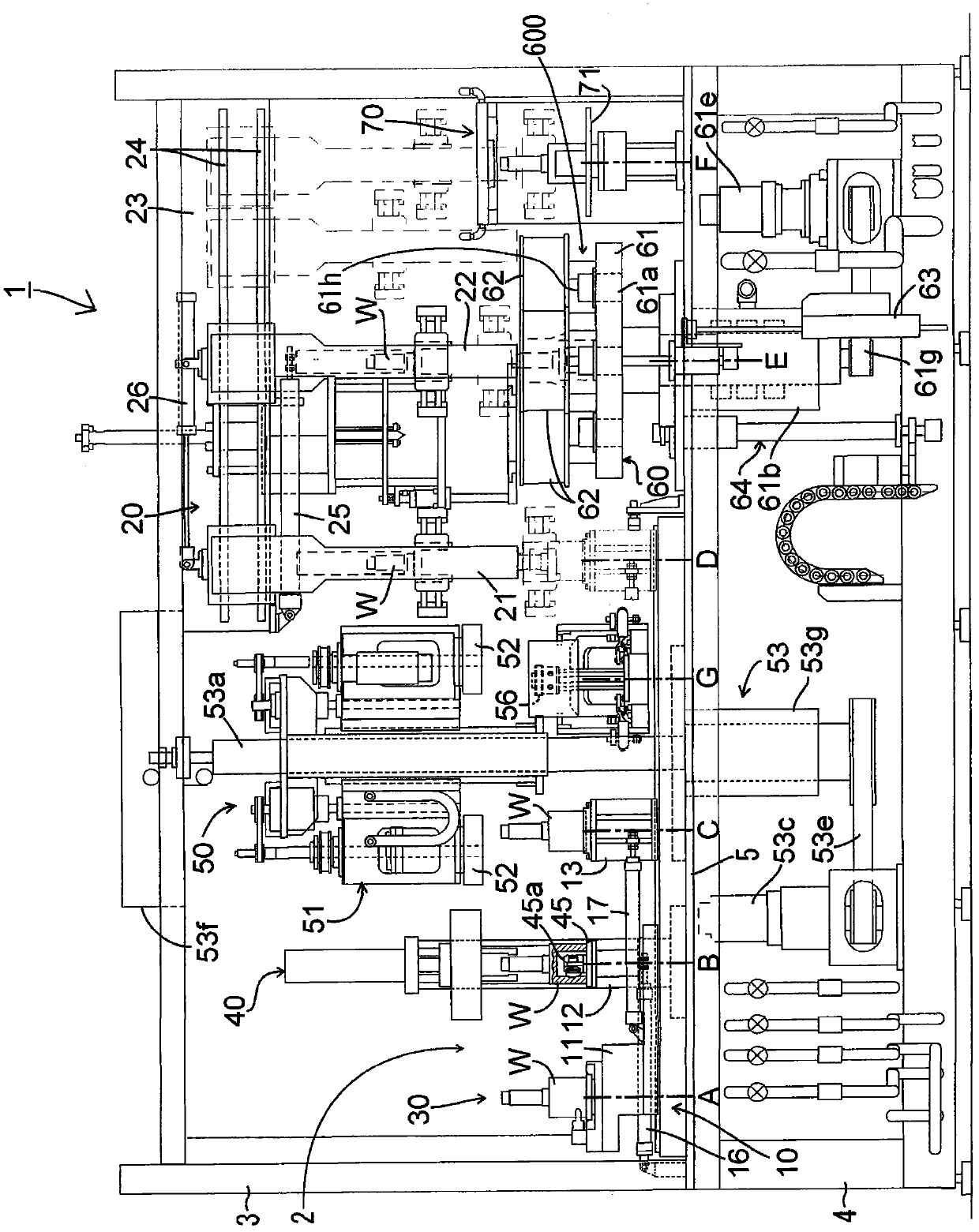

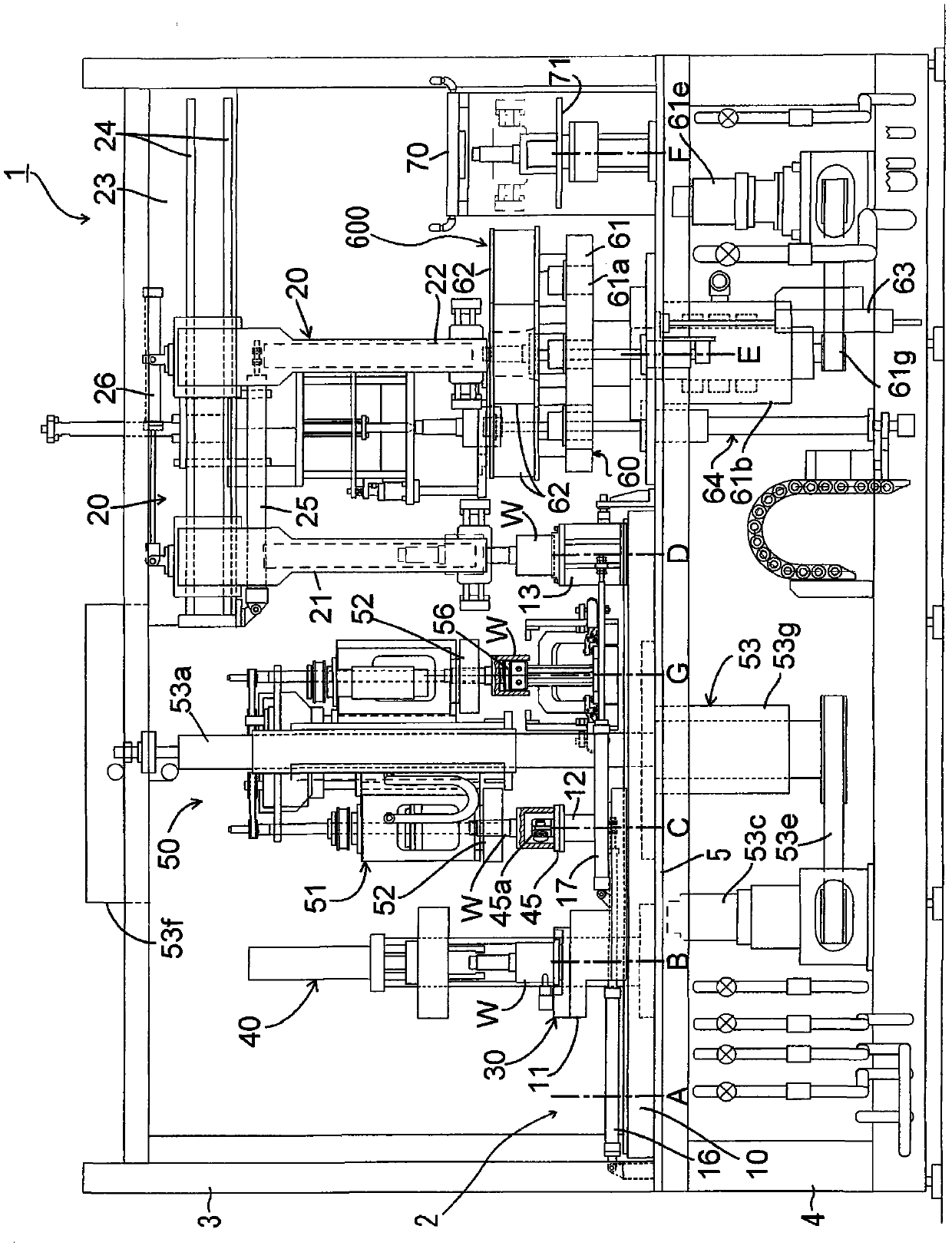

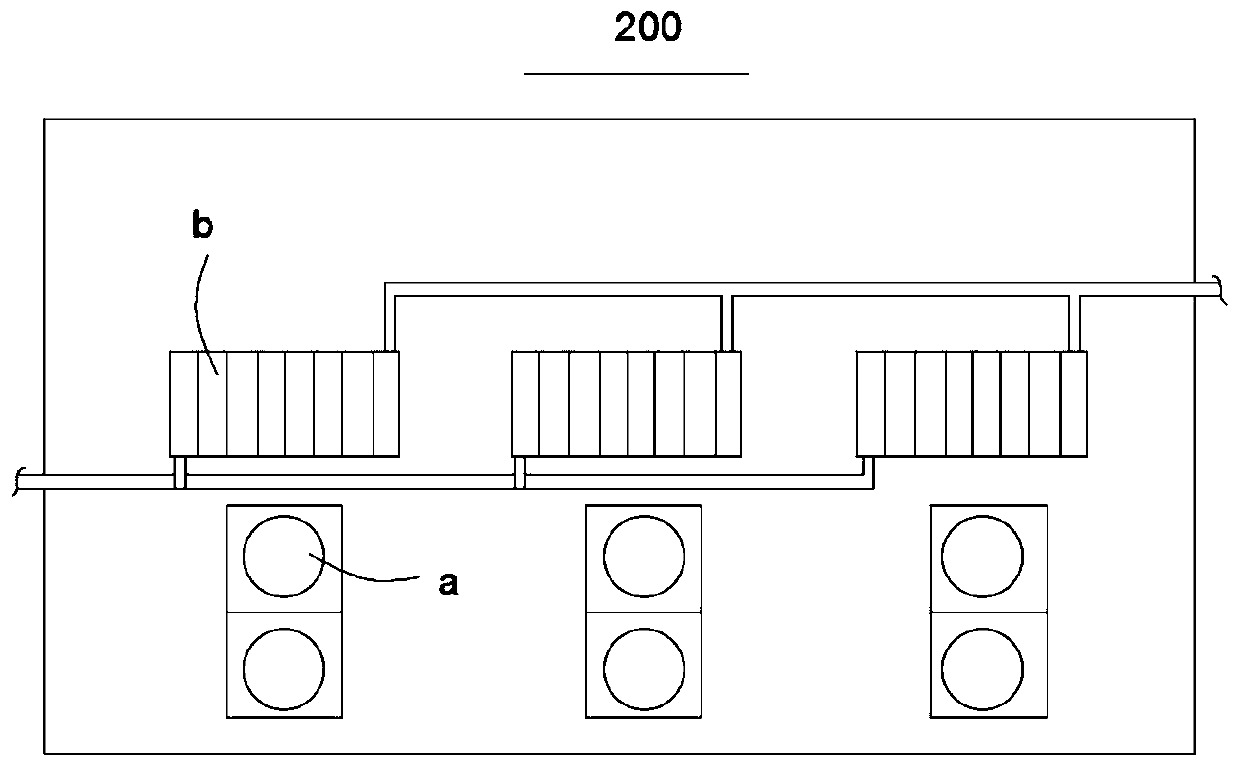

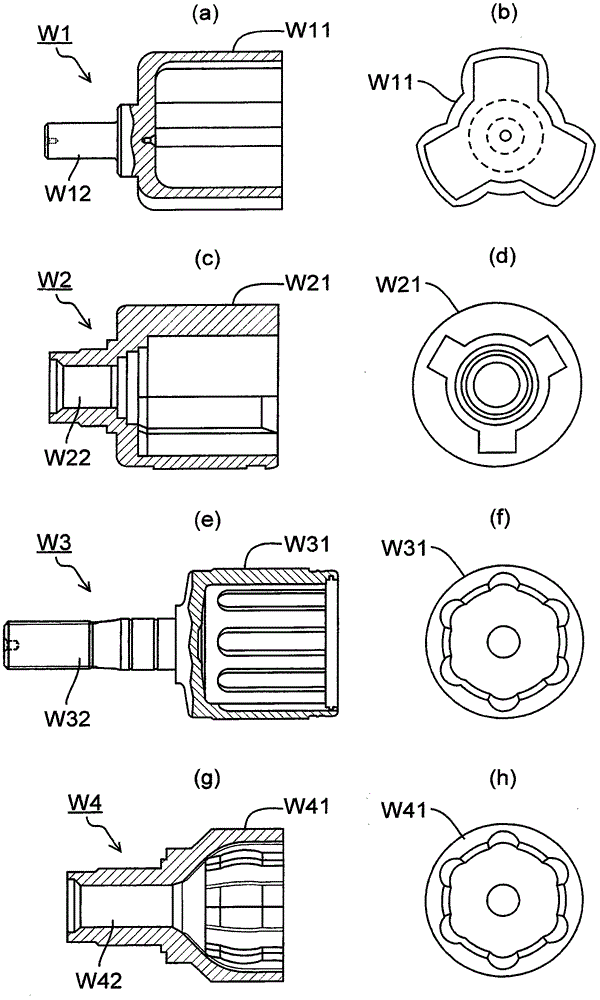

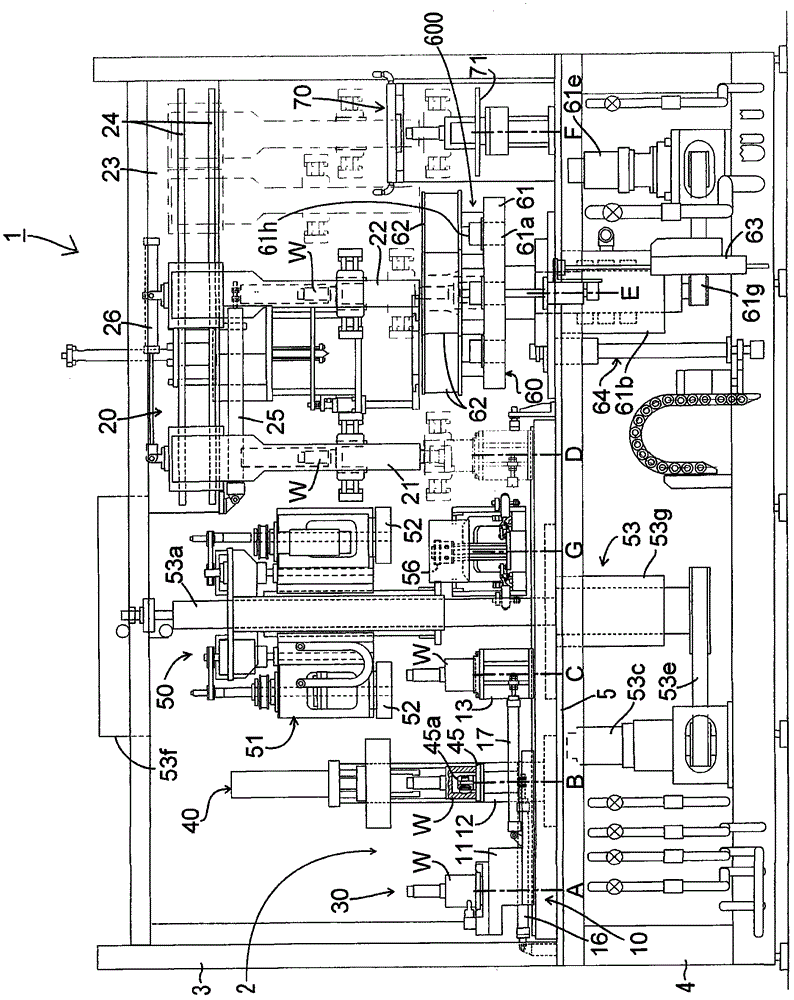

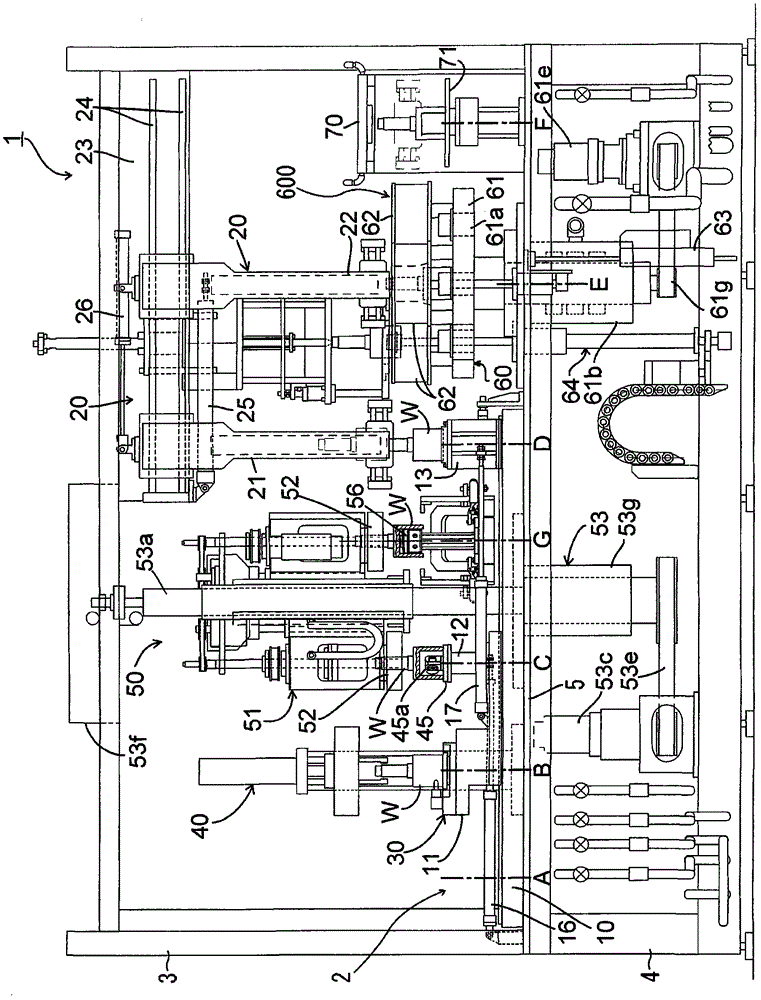

Heat processing apparatus for workpiece

ActiveCN102345004AProduction compactRapid productionIncreasing energy efficiencyFurnace typesProduction lineMaterials science

The invention provides a heat processing apparatus used for the heat treatment of a workpiece, wherein the rod shaft part of the upper portion of a workpiece or the cup-shaped body of the lower portion of the workpiece is subjected to heat treatment by the heat processing apparatus. The heat processing apparatus comprises a temporary phase determination mechanism, a formal phase determination mechanism, a workpiece lower portion heat treatment part and a workpiece upper portion heat treatment part. The heat processing apparatus also comprises one ore more than two of the following members: a desk type conveying mechanism and a suspension bracket type conveying mechanism used for confirming the position of a workpiece or a centering abutting member; a processing component symmetrically equipped with rotary clamping mechanisms with respect to a rotary shaft; a heat treatment head for fixing a fixed base at a predetermined position and connected with a workpiece cooling water pathway; a heating coil for connecting a powered terminal and a power supply terminal and connected with the workpiece cooling water pathway; a workpiece upper portion heating unit for fixing the heating coil of the rod shaft part and the heating coil of the cylinder shaft part at different layers; a rotary cooling device for cooling a workpiece during rotation; and a locking construction for preventing the driving of a heat treatment production line when the locking of an open-close door is unlocked.

Owner:NETUREN CO LTD

Manufacturing method of metal abrasion-proof anti-corrosion anti-rust pipeline

ActiveCN103305774AEvenly distributedHigh hardnessFurnace typesAnti-corrosive paintsTemperingSolid solution strengthening

The invention relates to a manufacturing method of a metal abrasion-proof anti-corrosion anti-rust pipeline. The manufacturing method comprises the following steps of: manufacturing an abrasion-proof pipeline body through centrifugal casting, carrying out quenching, high-temperature tempering, solid-solution strengthening heat treatment and double tempering dispersion hardening heat treatment on the abrasion-proof pipeline body; then coating an anti-rust coating through electrostatic spraying on the outer wall of the pipeline; and finally coating an anti-corrosion coating through air spraying on the inner wall of the pipeline. The metal pipeline disclosed by the invention has the advantages of higher rigidity and abrasion resistant property; and the anti-corrosion coating has the advantages of excellent water resistance and antifouling effect and high temperature resistant property.

Owner:JIANGSU JINSHENGYUAN SPECIAL VALVE

Anti-corrosion, high-temperature-resisting and wear-resisting cast pipe

ActiveCN103267176AEvenly distributedHigh hardnessAlkali metal silicate coatingsCorrosion preventionTemperingNanocomposite coating

The invention relates to an anti-corrosion, high-temperature-resisting and wear-resisting cast pipe. A wear-resisting pipeline body is manufactured by means of centrifugal casting; after the steps of quenching, high-temperature tempering, solid solution strengthening heat treatment and two times of tempering dispersion hardening heat treatment, the inner wall of the pipeline body is coated with a water glass nanometer composite coating configured by a test; and then, the coating is cooled after being cured at a high temperature, so that a high-temperature-oxidation resisting anti-corrosion coating inner layer is obtained. The manufactured metal pipeline has high hardness and high wear-resisting performance. The anti-corrosion coating has excellent water-resisting performance, an excellent antifouling effect and good high-temperature-resisting performance.

Owner:WENZHOU FUCHENG CONSTR ENG CO LTD

Abrasion-resistant metal pipeline with internal anti-corrosion coating

InactiveCN103540862AAchieve resistance reductionEvenly distributedFurnace typesAnti-corrosive paintsHardnessSolid solution strengthening

The invention relates to an abrasion-resistant metal pipeline with an internal anti-corrosion coating. An abrasion-resistant pipeline body is manufactured through centrifugal casting, and is also subjected to quenching, high-temperature tempering, solid solution strengthening thermal treatment as well as twice tempering dispersion hardening thermal treatment technology, and finally, an anti-corrosion coating is coated on the inner wall of the pipeline through air spraying. The metal pipeline has high hardness and abrasion-resistant performance; the anti-corrosion coating has excellent waterproofness, antifouling effect as well as high-temperature-resistant performance.

Owner:徐梁冰

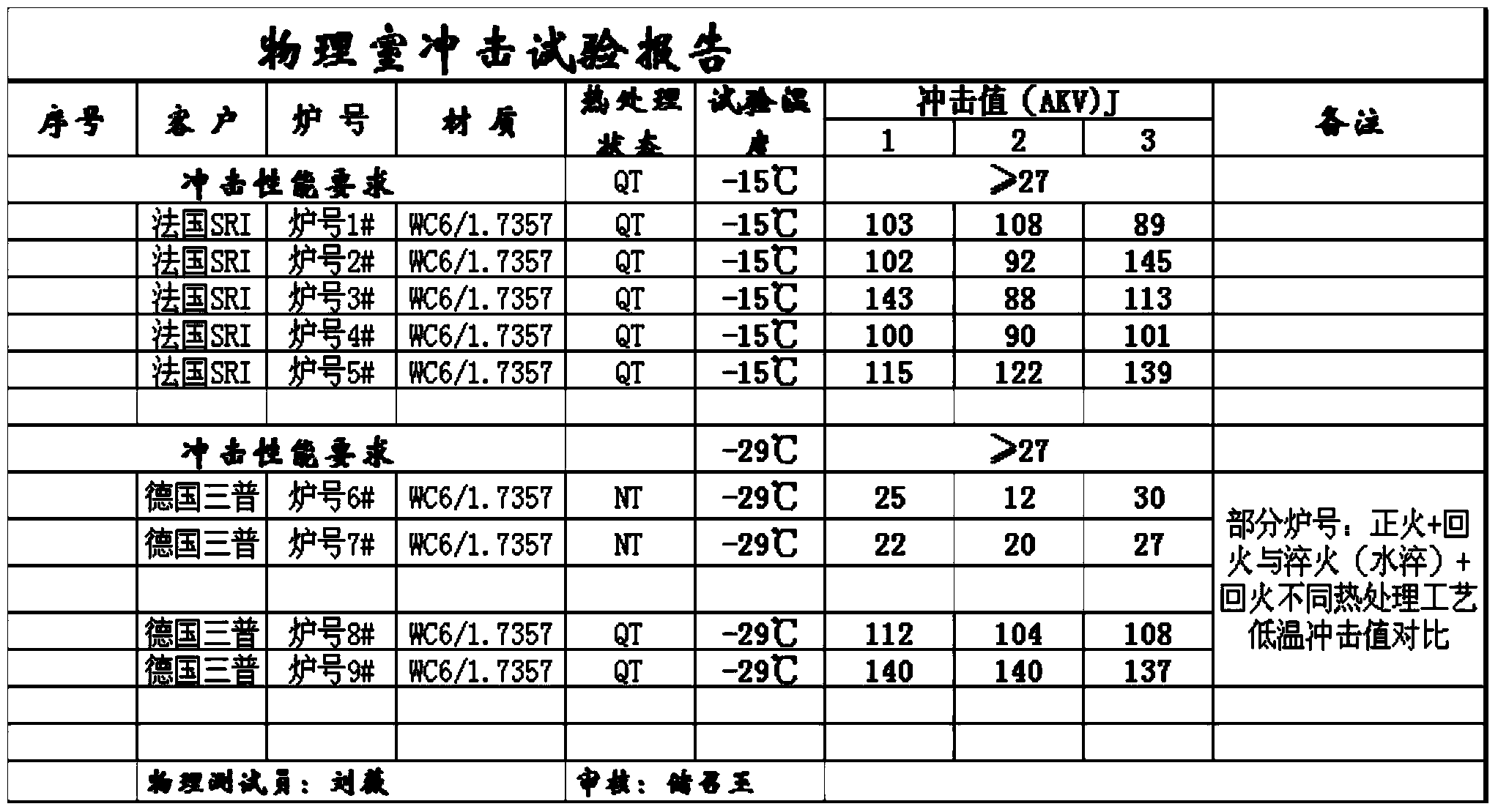

Heat treatment method for improving low-temperature toughness of WC6-1.7357 material

The invention discloses a heat treatment method for improving the low-temperature toughness of a WC6-1.7357 material. The method comprises the following steps of placing a casting and a test block in a heat treatment furnace, gradually raising the temperature of the heat treatment furnace at speed which is controlled to be less than or equal to 120 DEG C per hour, stopping raising the temperature when the temperature of the heat treatment furnace reaches 940+ / -10 DEG C, and keeping the temperature of the heat treatment furnace within the range of 940+ / -10 DEG C; after the casting and the test block are naturally cooled to 860+ / -10 DEG C along with the heat treatment furnace after heat preservation, preserving heat for 0.5 hour, taking the casting and the test block out of the heat treatment furnace, and placing the casting and the test block in a still pool for cooling, wherein the temperature of water is ranged from 30 to 55 DEG C; placing the casting and the test block in the heat treatment furnace again for treatment within 2 hours after the steps are finished, gradually raising the temperature of the heat treatment furnace at speed which is controlled to be less than or equal to 100 DEG C per hour, preserving the heat when the temperature of the heat treatment furnace reaches 720+ / -10 DEG C, and removing the casting and the test block out of the heat treatment furnace for air cooling.

Owner:HUSN CASTING ANHUI YINGLIU GROUP

Roll processing method suitable for improving forging penetration and shortening heat treatment period

The invention relates to a roll processing method suitable for improving forging penetration and shortening a heat treatment period. The method successively comprises the steps of selecting a steel ingot for blanking; forging the steel ingot to form a roll blank; carrying out heat treatment normalizing on the roll blank; roughly turning the roll blank; and carrying out semifinishing on the roll blank. A forging method and a heat treatment method in a production process are improved so that a manufactured roller is good in outer surface quality, low in inclusion content, fine in spheroidized organization grain and low in carbide level, a hardness after heat treatment is lower than a standard requirement, a user requirement is satisfied, about 40% of furnace hour is saved, energy consumptionis reduced, and cost is saved.

Owner:常州常超模具有限公司

Aldehyde reduction heat treating process and continuous energy-saving aldehyde reduction heat treating kiln

InactiveCN111438781AReduce formaldehyde contentShort heat treatment cycleWood treatment detailsThermal wood treatmentThermodynamicsProcess engineering

The invention relates to the technical field of aldehyde reduction of plates, and discloses an aldehyde reduction heat treating process which comprises the following steps: putting an artificial plateinto an aldehyde reduction heat treating kiln for heat treating; putting the artificial plate subjected to the heat treating into a health maintenance balance chamber for health maintenance, whereinthe heat treating mode adopts a preheating-heating-constant temperature multistage aldehyde reduction mode, the constant temperature is 110-130 DEG C, the constant temperature time is 1-4 hours, the preheating temperature is 50-80 DEG C, and the preheating time is 0.5-6 hours. The continuous energy-saving formaldehyde-reducing heat treating kiln comprises a preheating kiln section, a formaldehyde-reducing kiln section and a balance kiln section which are connected in sequence, a feeding port is formed in the preheating kiln section, and a discharging port is formed in the balance kiln section;the formaldehyde reduction kiln section is provided with a heat supply assembly, and an airflow conveying assembly is arranged between the balance kiln section and the preheating kiln section and used for conveying airflow of the balance kiln section to the preheating kiln section. By the adoption of the technology, the aldehyde reduction effect can be effectively achieved, meanwhile, the aldehyde reduction treating period is short, and the production efficiency is improved.

Owner:成都市美康三杉木业有限公司

Thermal treatment method for casting waste heat of high-speed steel roller

The invention discloses a thermal treatment method for casting waste heat of a high-speed steel roller, comprising the following steps of: S1: unpacking, after centrifugal casting is completed, the high-speed steel roller is crystallized, solidified and cooled in a casting mold, and then the roller is unpacked according to the unpacking time calculated by a formula; the formula is Time = unpackingcoefficient * diameter of the roller casting, unit: time - h, diameter - dm; S2: quenching, the high-speed steel roller resistance furnace is evenly heated for a period of time, the temperature is rapidly increased, then the temperature is kept; and then the furnace is cooled by air; S3: tempering. According to the invention, the unpacking time is calculated by the formula obtained through a large number of tests; compared with the traditional cold unpacking roller, the energy saving in the thermal treatment link can be more than 50%, the thermal treatment cycle and the manufacturing cost ofthe roller are shortened, the roller obtained through treatment has high hardness, fine crystal grains, no carbide aggregation and growth phenomenon, excellent performance; and the energy and time consumption in the thermal treatment link are greatly reduced.

Owner:江苏凯达重工股份有限公司

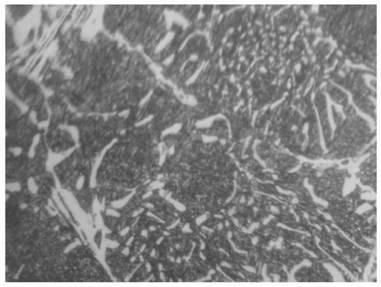

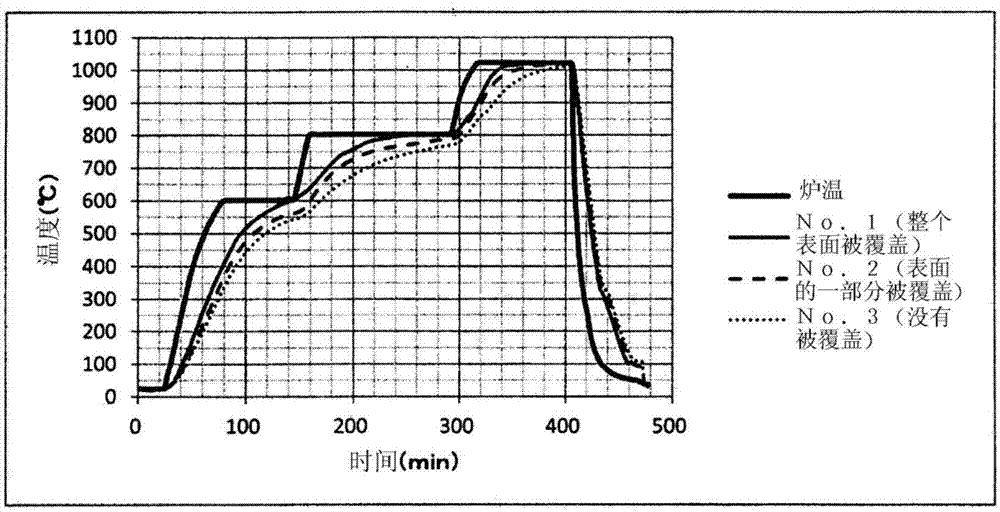

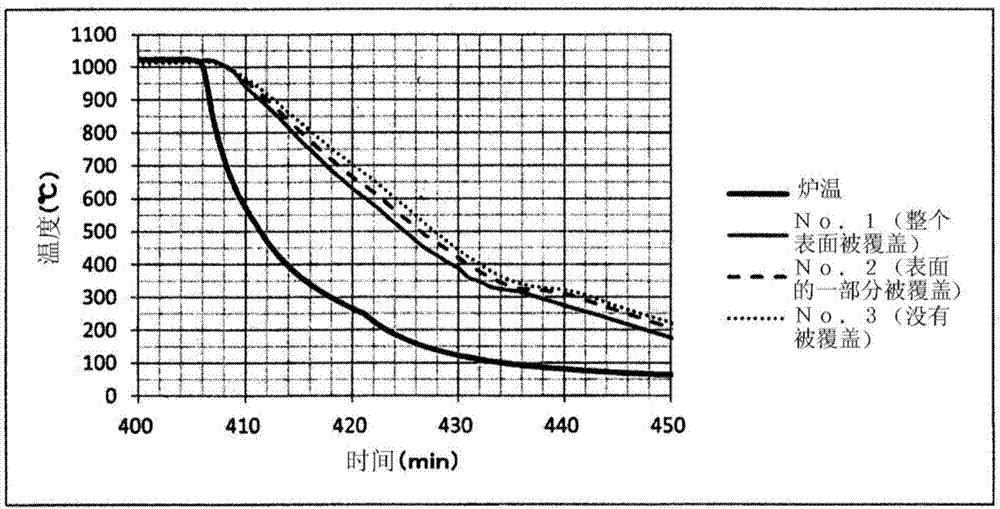

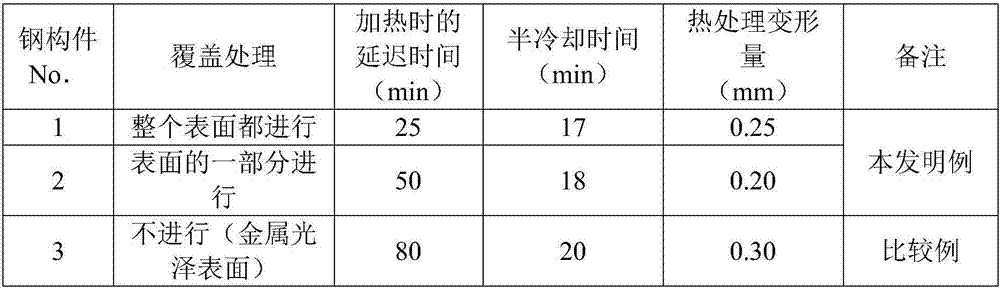

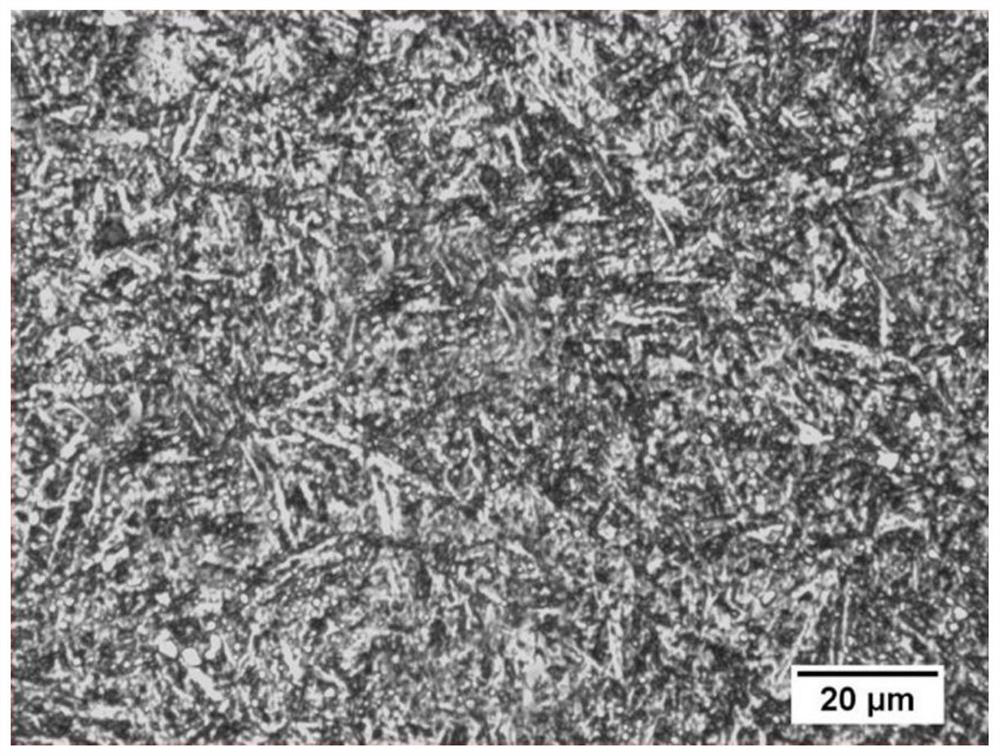

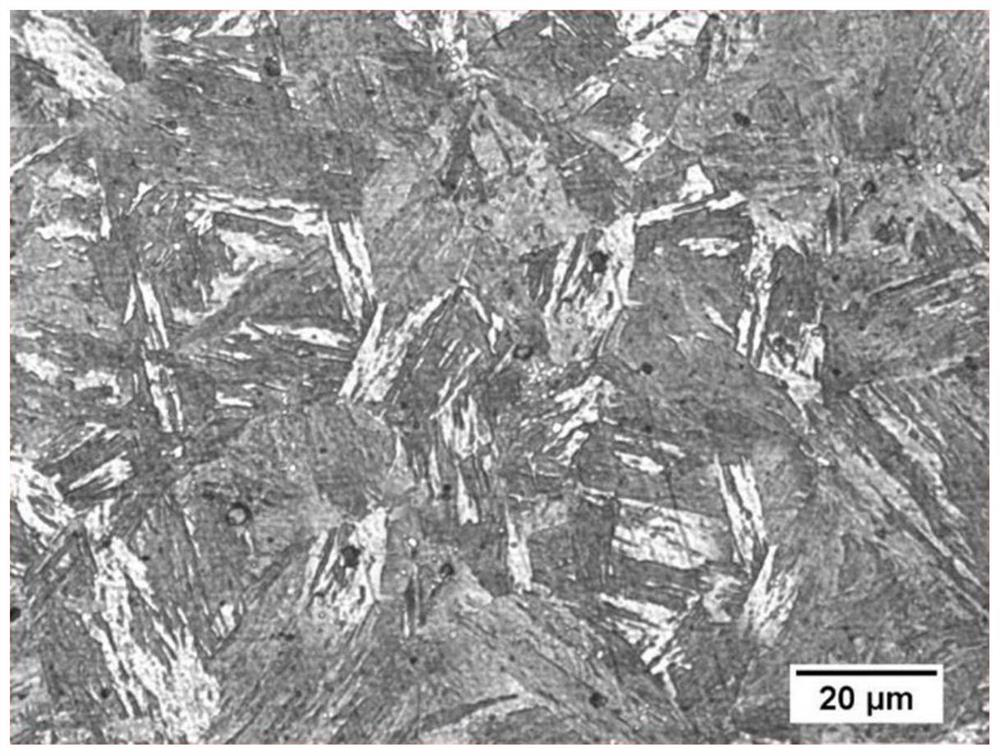

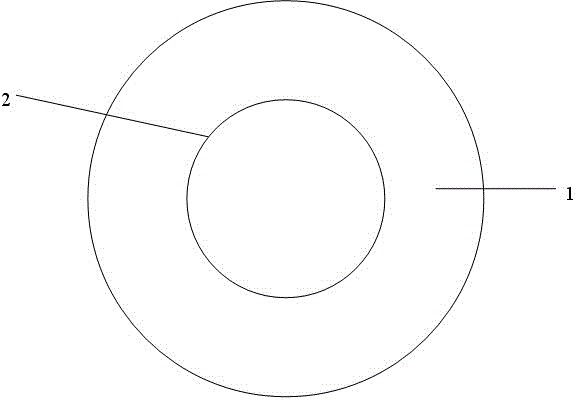

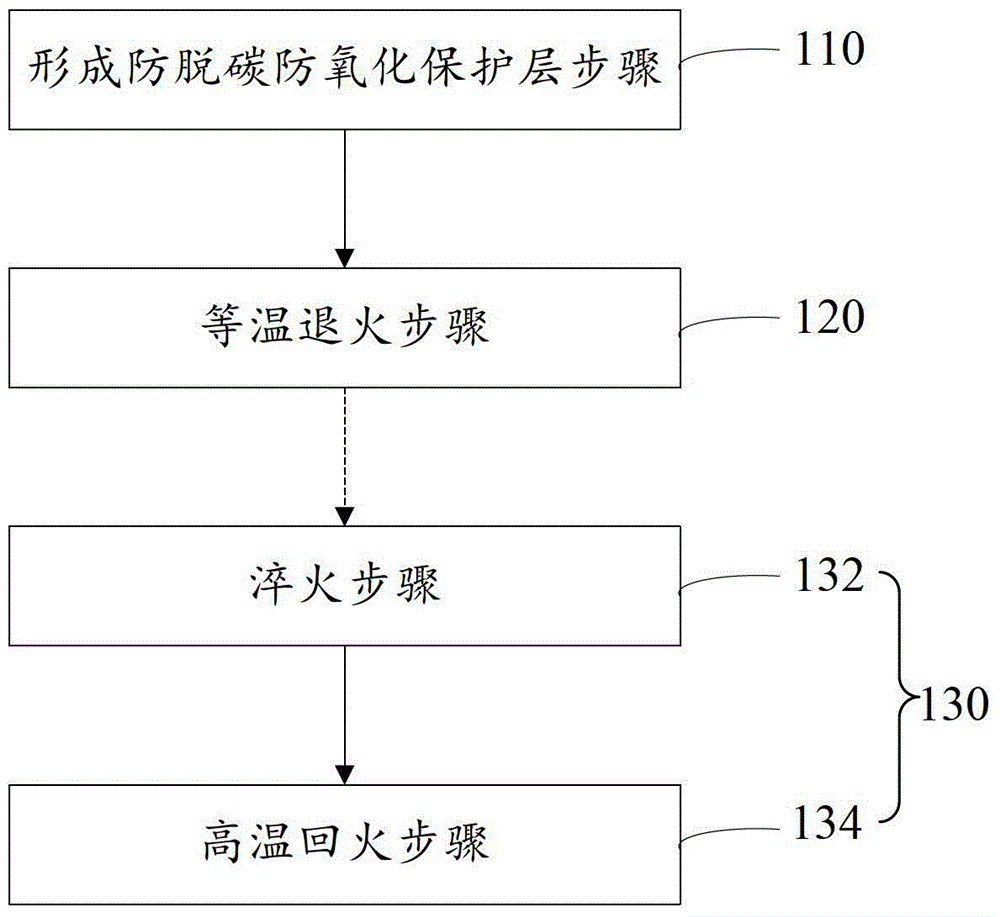

Hardening method of steel member

ActiveCN106987686AReduce uneven heatingShorten heating timeFurnace typesHeat treatment furnacesGraphiteHeating furnace

The invention provides a hardening method of a steel member in which a heat cycle time required for a sequence of hardening process can be shortened and heat treatment deformation after hardening is small. Provided is a hardening method of a steel member in which coating treatment in which one part or the whole of a surface of a steel member before being heated to a hardening temperature is coated with graphite, then the steel member after the coating treatment is heated to a hardening temperature in a heating furnace having an exothermic body, and cooled. In heating to the hardening temperature, at least one time in the heating is preferably performed in a vacuum or a decompressed atmosphere. The coating treatment can be performed with a carburization inhibitor or a decarbonization inhibitor which is coated on a surface of the steel member.

Owner:HITACHI METALS LTD

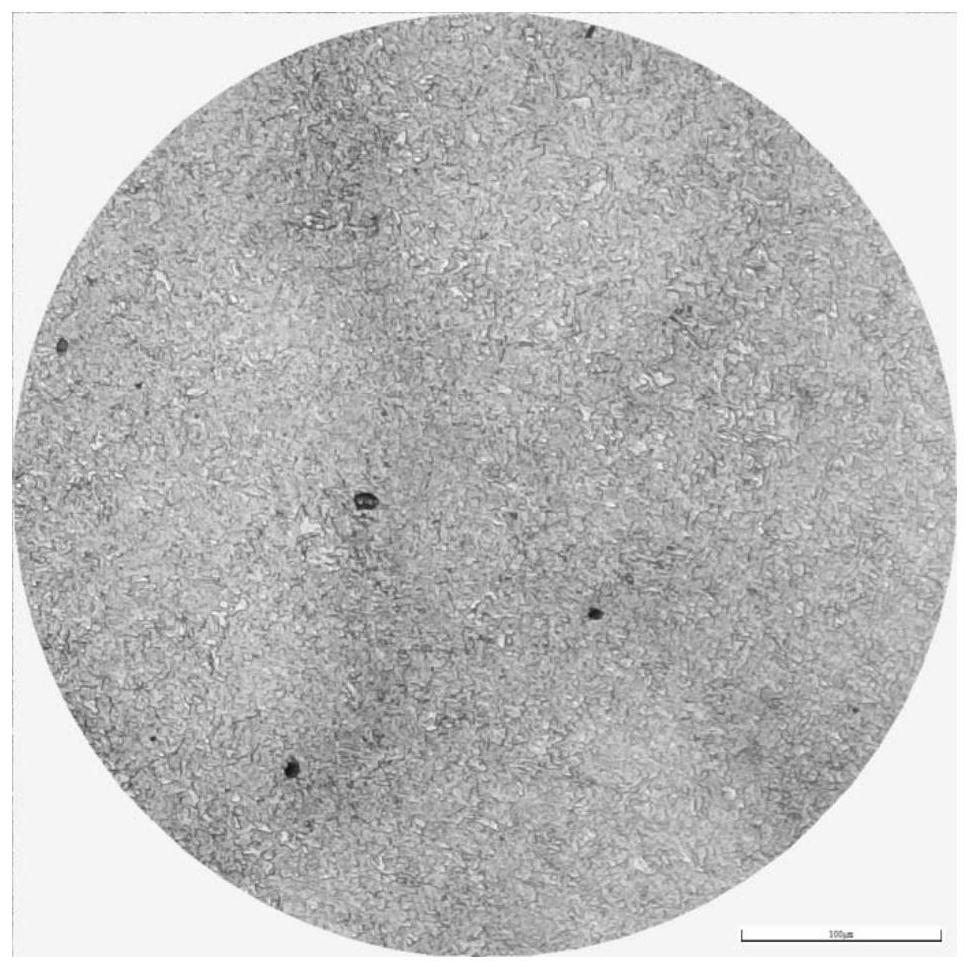

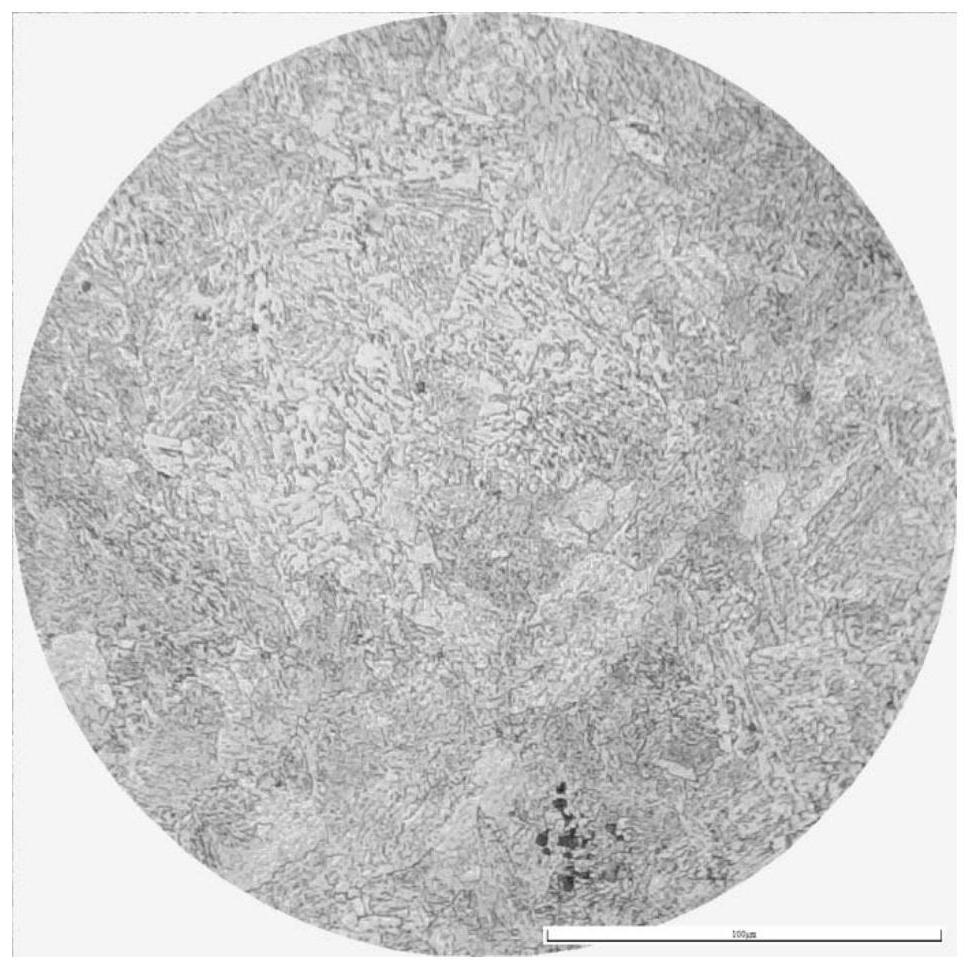

A method for ultra-refinement of martensitic structure of steel for die-casting mold

ActiveCN109576465BReduce design costNo production process changes requiredQuenching agentsTemperingDie casting

The invention relates to a martensite tissue ultra-refining method of steel for a die-casting die. The method comprises the steps that (1) an ultra-refined forging is subjected to vacuum heat treatment and heat preservation, then is subjected to gas quenching, so that the temperature of the surface of the forging is reduced to 255-275 DEG C, the forging is kept at the temperature for 105-130 s, and thus the temperature difference between the surface and the core part of the forging is controlled to be 50-80 DEG C; (2) heat preservation is carried out under the protection atmosphere condition of 360-400 DEG C; (3) heat preservation is carried out at the temperature of 550-600 DEG C, and then the forging is subjected to oil quenching to room temperature; and (4) 1-3 times of de-stress tempering treatments are carried out till the hardness meets the requirements. The method is simple, easy to operate, and is particularly suitable for large-specification die steel; and the heat treatment period is shortened, the impact toughness is improved by 12%-20% under the conventional die casting requirement hardness condition, the service life of the die-casting die can be prolonged, and the hardness requirement of the high-performance die-casting die steel for aluminum alloy automobile part die-casting is met.

Owner:GUANGDONG HONGTAI NANTONG PRECISION TECH CO LTD +1

Method for producing charred wood by heat treatment

InactiveCN101069972BGuaranteed drying qualityShorten the timeWood treatment detailsWood charring/burningUltimate tensile strengthStrength loss

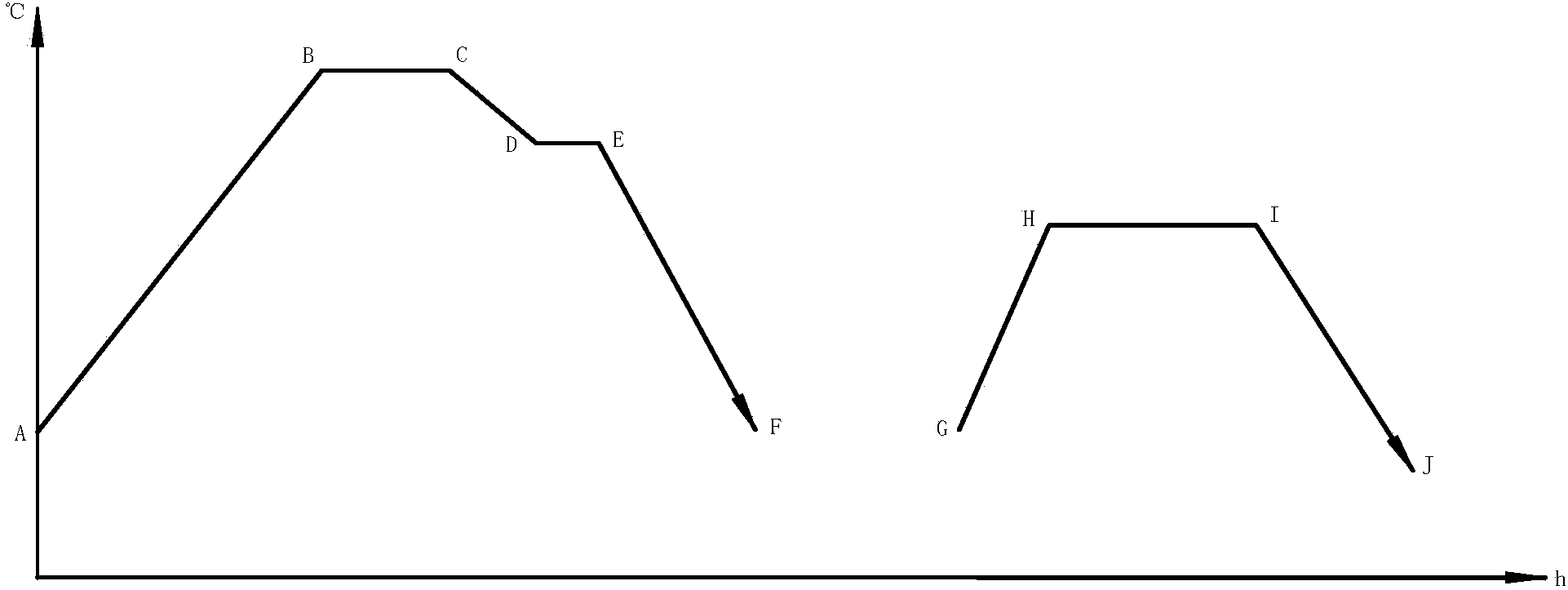

The invention relates to a preparation method of heat-treatment charred wood. It aims at providing the charred wood with short treatment cycle, small wood strength loss, industrialized and high maneuverability. It contains stages of preparing, preheating, heating, insulation and cooling. In the heating stage, heat the medium in the stove to 95-105 C degree with the speed of 10-18 C degree / h. Then, heat the materials to 120-130 C degree with the speed of 3-8 / C degree h for high temperature drying and reduce the inner moisture content of the woods to nearly 0. Finally, heat them to 185-220 C degree with the speed of 12-20 C degree / h. The intermittent steam-jet method is adopted to complete steam-jet treatment during the heating.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Preparation method for wear resistant metal pipeline with internal anticorrosive coating

InactiveCN103276281BEvenly distributedHigh hardnessCorrosion preventionPipe protection against corrosion/incrustationTemperingWear resistant

Owner:江苏中纤管道设备有限公司

An anti-corrosion, high temperature and wear-resistant cast pipe

ActiveCN103267176BEvenly distributedHigh hardnessAlkali metal silicate coatingsCorrosion preventionTemperingNanocomposite coating

The invention relates to an anti-corrosion, high-temperature-resisting and wear-resisting cast pipe. A wear-resisting pipeline body is manufactured by means of centrifugal casting; after the steps of quenching, high-temperature tempering, solid solution strengthening heat treatment and two times of tempering dispersion hardening heat treatment, the inner wall of the pipeline body is coated with a water glass nanometer composite coating configured by a test; and then, the coating is cooled after being cured at a high temperature, so that a high-temperature-oxidation resisting anti-corrosion coating inner layer is obtained. The manufactured metal pipeline has high hardness and high wear-resisting performance. The anti-corrosion coating has excellent water-resisting performance, an excellent antifouling effect and good high-temperature-resisting performance.

Owner:WENZHOU FUCHENG CONSTR ENG CO LTD

Calcined processing method for high strength alloy steel

The invention belongs to the technical field of high strength alloy steel processing, in particular to a calcined processing method for a high strength alloy steel. The calcined processing method comprises the steps that a nanoscale zinc coating is electrodeposited on the surface of the alloy steel, and heating treatment is carried out in a step beam heating furnace. Compared with the prior art, the calcined processing method for the high strength alloy steel has the following advantages that a zinc coating is deposited on the surface of the alloy steel, and the heating treatment is carried out under the protective atmosphere, so that the obtained zinc coating is compact in crystallization, oxidation is avoided, and at the same time decarburization is effectively prevented; the step beam heating furnace and a muffle furnace are used for tempering, so that the process of the heat treatment is simplified, the period of the heat treatment is shortened, and the comprehensive mechanical property of the high strength alloy steel is improved.

Owner:马鞍山市鑫龙特钢有限公司

Manufacturing method of metal abrasion-proof anti-corrosion anti-rust pipeline

ActiveCN103305774BEvenly distributedHigh hardnessFurnace typesAnti-corrosive paintsTemperingSolid solution strengthening

The invention relates to a manufacturing method of a metal abrasion-proof anti-corrosion anti-rust pipeline. The manufacturing method comprises the following steps of: manufacturing an abrasion-proof pipeline body through centrifugal casting, carrying out quenching, high-temperature tempering, solid-solution strengthening heat treatment and double tempering dispersion hardening heat treatment on the abrasion-proof pipeline body; then coating an anti-rust coating through electrostatic spraying on the outer wall of the pipeline; and finally coating an anti-corrosion coating through air spraying on the inner wall of the pipeline. The metal pipeline disclosed by the invention has the advantages of higher rigidity and abrasion resistant property; and the anti-corrosion coating has the advantages of excellent water resistance and antifouling effect and high temperature resistant property.

Owner:JIANGSU JINSHENGYUAN SPECIAL VALVE

Post-forging heat treatment method of alloy steel

The invention relates to a heat treatment method of alloy steel after forging. The method comprises the steps of forming a decarburization-preventing and oxidation-resistant protective layer on a surface of an alloy steel workpiece; and then carrying out isothermal annealing on a to-be-treated alloy steel workpiece with the decarburization-preventing and oxidation-resistant protective layer. The heat treatment method of the alloy steel after forging can effectively prevent the surface of the to-be-treated alloy steel workpiece from decarburization and oxidation and shorten a heating period, thereby being beneficial to improve comprehensive mechanical performance of the to-be-treated alloy steel workpiece.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Heat treatment method of 35CrMo steel casting

The invention discloses a heat treatment method of a 35CrMo steel casting. The heat treatment method comprises the following steps that a, the 35CrMo steel casting is heated to 930-950 DEG C, and heatpreservation is carried out; b, the 35CrMo steel casting is discharged out of the furnace, air cooling is adopted, the 35CrMo steel casting is cooled till the temperature of the 35CrMo steel castingis reduced to 200 DEG C or below, and then the 35CrMo steel casting is naturally cooled to the room temperature in an air cooling mode; and c, the cooled 35CrMo steel casting is heated and tempered to720 DEG C, and air cooling is carried out after heat preservation; When the process is adopted for heat treatment, on the basis that the heat treatment process is reduced and the heat treatment period is shortened, the mechanical property of the obtained 35CrMo steel casting meets the standard requirement, the production cost is reduced, and the production period is shortened.

Owner:NINGBO JINHUI PRECISION CASTING

Heat processing apparatus for workpiece

ActiveCN102345004BProduction compactRapid productionFurnace typesIncreasing energy efficiencyProduction lineMaterials science

The invention provides a heat processing apparatus used for the heat treatment of a workpiece, wherein the rod shaft part of the upper portion of a workpiece or the cup-shaped body of the lower portion of the workpiece is subjected to heat treatment by the heat processing apparatus. The heat processing apparatus comprises a temporary phase determination mechanism, a formal phase determination mechanism, a workpiece lower portion heat treatment part and a workpiece upper portion heat treatment part. The heat processing apparatus also comprises one ore more than two of the following members: a desk type conveying mechanism and a suspension bracket type conveying mechanism used for confirming the position of a workpiece or a centering abutting member; a processing component symmetrically equipped with rotary clamping mechanisms with respect to a rotary shaft; a heat treatment head for fixing a fixed base at a predetermined position and connected with a workpiece cooling water pathway; a heating coil for connecting a powered terminal and a power supply terminal and connected with the workpiece cooling water pathway; a workpiece upper portion heating unit for fixing the heating coil of the rod shaft part and the heating coil of the cylinder shaft part at different layers; a rotary cooling device for cooling a workpiece during rotation; and a locking construction for preventing the driving of a heat treatment production line when the locking of an open-close door is unlocked.

Owner:NETUREN CO LTD

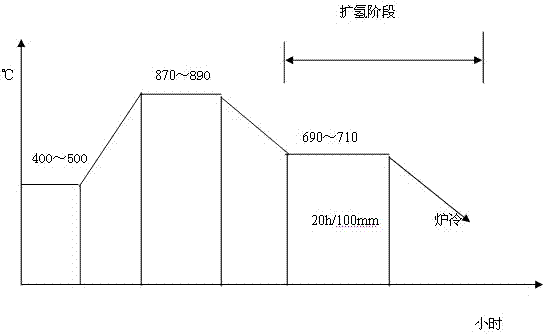

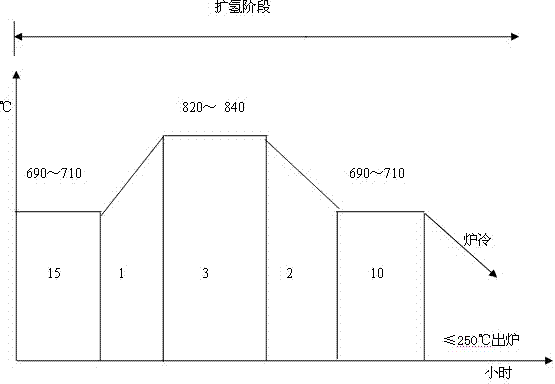

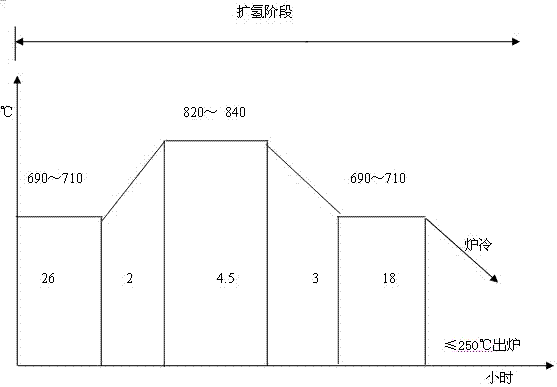

Rapid hydrogen diffusion treatment method for nitrogen alloying anti-corrosion die steel

ActiveCN102787227BIncrease production capacityShortened hydrogen expansion time after forgingDiffusionSolubility

The invention relates to an as-forged rapid hydrogen diffusion treatment method for a nitrogen alloying anti-corrosion die steel, which comprises the following steps of: after forging the nitrogen alloying anti-corrosion die steel, heating to the temperature of 690 to 710 DEG C and carrying out heat preservation according to the heat preservation time of 5 to 6 hours per 100mm of the nitrogen alloying anti-corrosion die steel; heating to 820 to 840 DEG C in an austenite region in 1 to 2 hours and carrying out heat preservation; cooling to the temperature of 690 to 710 DEG C in 2 to 3 hours and carrying out heat preservation according to the heat preservation time of 3 to 4 hours per 100mm of the nitrogen alloying anti-corrosion die steel; and then cooling to the temperature of below 250 DEG C. According to the invention, by a method of circularly heating up and down near a phase transformation point, the tissues of the nitrogen alloying anti-corrosion die steel are transformed repeatedly from austenite to pearlite and the diffusion of hydrogen in the steel is quickened by utilizing the change of the solubility of the hydrogen in different tissues, so that the as-forged hydrogen diffusion treatment time of the nitrogen alloying anti-corrosion die steel is shortened.

Owner:HUBEI SHANGDA MODEL MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com