Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about How to "Prevent decarbonization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold drawing welded tube manufacture process for high-accuracy hydraulic oil cylinder

InactiveCN102527767AReduce processing difficultyImprove deburring speedEngineeringEddy-current testing

The invention discloses a cold drawing welded tube manufacture process for a high-accuracy hydraulic oil cylinder, which sequentially comprises the following steps of longitudinal shearing, roll bending molding, high frequency welding, welding joint treatment, online eddy current testing, sizing cutting, normalization, pinching, surface treatment, cold drawing, annealing, straightening, defect detection and cutting for measurement. The method is quick in processing molding, high in production volume, free of damage on surfaces in cold drawing and high in manufacture accuracy. After cold drawing, bearing capacity of a welded tube is improved by about 60%, and the welded tube is high in tensile strength and good in elongation rate. Follow-up gold processing amount is reduced, utilization rate of steel materials is improved, and manufacture cost is reduced. The cold drawing welded tube can be directly applied to manufacture of high-accuracy hydraulic oil cylinders.

Owner:MARCEGAGLIA CHINA

Automobile transmission gear heat treatment method

ActiveCN104894506AAvoid early crackingAlleviate the problem of bulky carbidesSolid state diffusion coatingFatigue IntensityHigh carbon

The invention discloses an automobile transmission gear heat treatment method. The method includes the steps of carburization, carbonitriding, quenching, cleaning, low temperature tempering and air cooling. The carburization technique is combined with the carbonitriding technique, abrasion resistance, fatigue strength and corrosive resistance are improved by a layer of highly hard nitride layer obtained on the carburized layer on the surface of a gear, and comprehensive performance of a product is good; meanwhile, the problems of massive carbide appearing under the high carbon potential state and network carbide appearing in the cooling process are avoided, and early-age cracking of the surface of the gear is avoided; moreover, by the method, the technological process is simplified, heating and cooling links and discharge links are reduced, carburization deformation and quenching deformation are reduced, generation of black structures is reduced as well, and anti-fatigue performance is guaranteed; finally, by the method, production cycle is shortened greatly, energy consumption is lowered, and production efficiency is improved highly.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Natural mineral-based high-temperature anti-oxidation decarbonization coating

InactiveCN102786822AGood dispersionImprove high temperature resistanceCoatingsPhysical chemistrySlurry

Owner:NANJING UNIV OF INFORMATION SCI & TECH

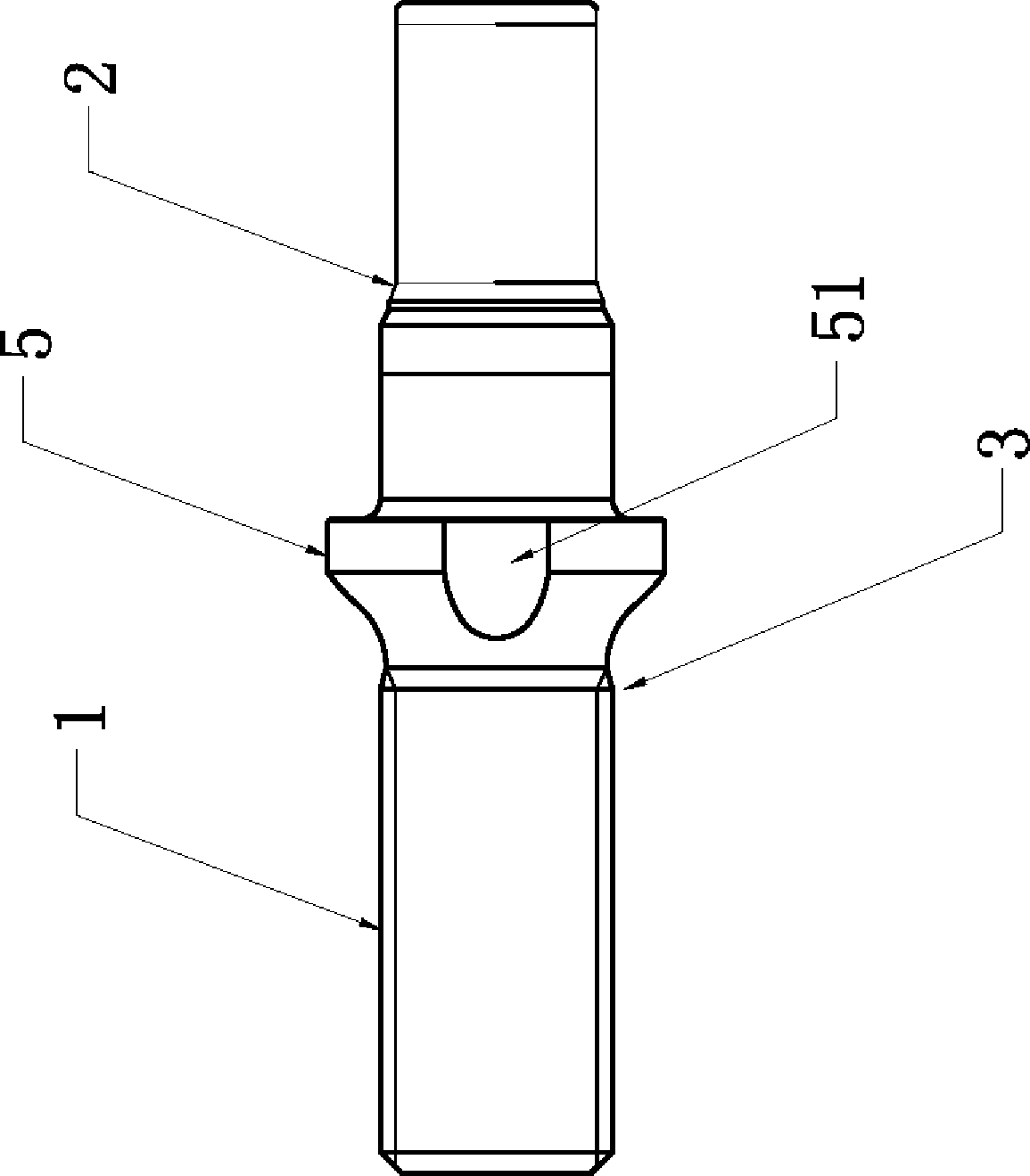

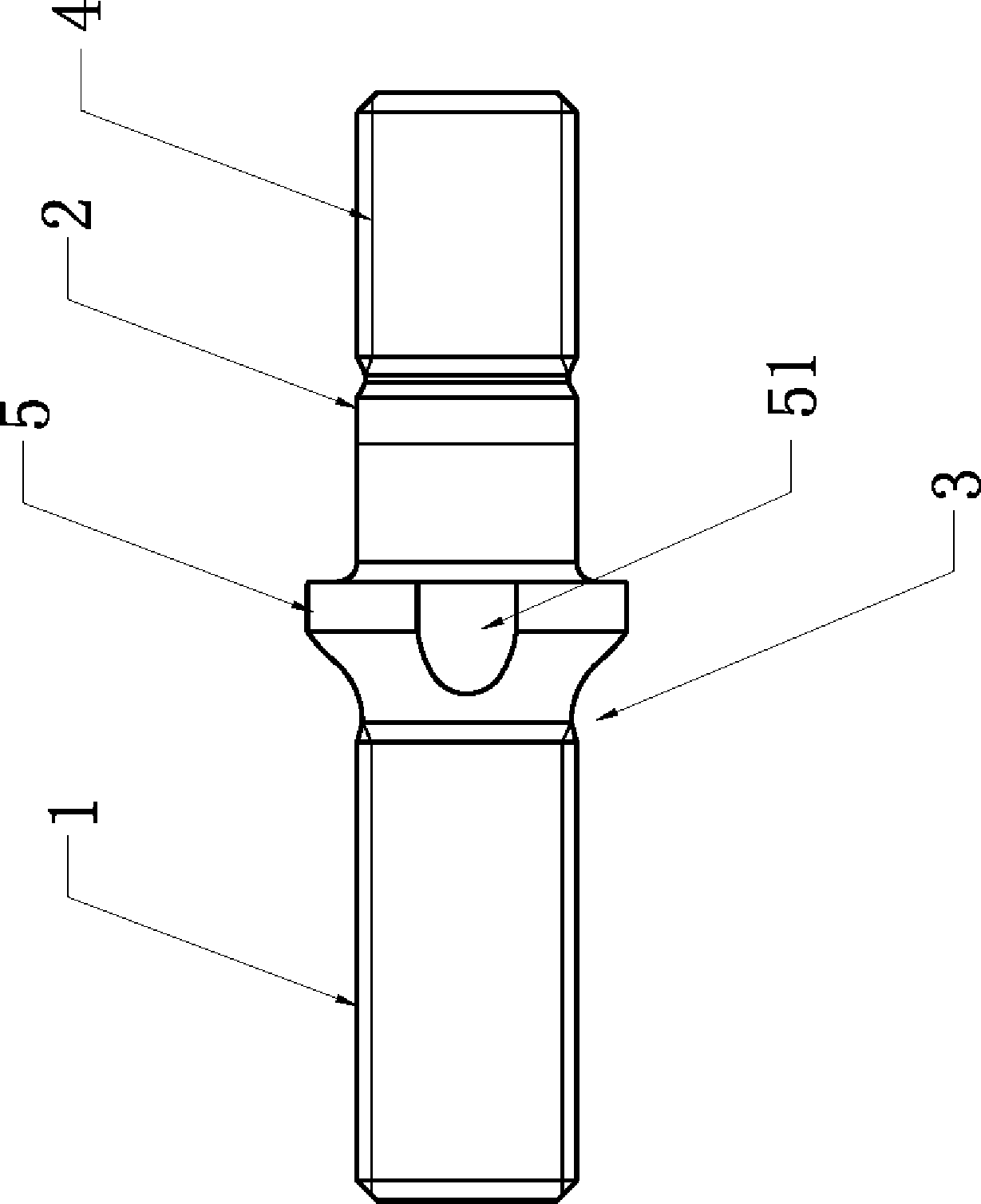

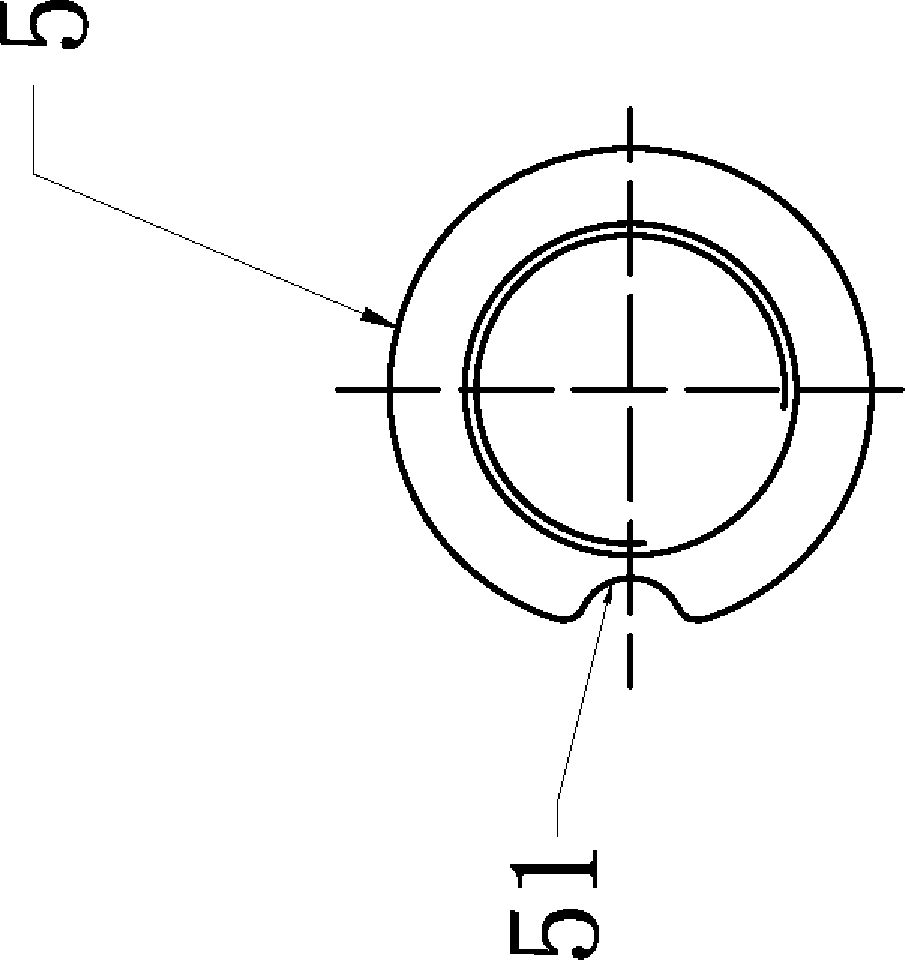

One-step forging and molding method of steering knuckle of heavy-duty car

ActiveCN102500741APrevent decarbonizationGuaranteed accuracyRailway componentsVehicle componentsKnuckleMachining process

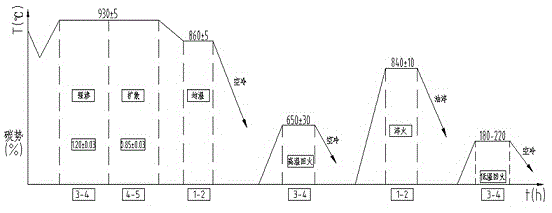

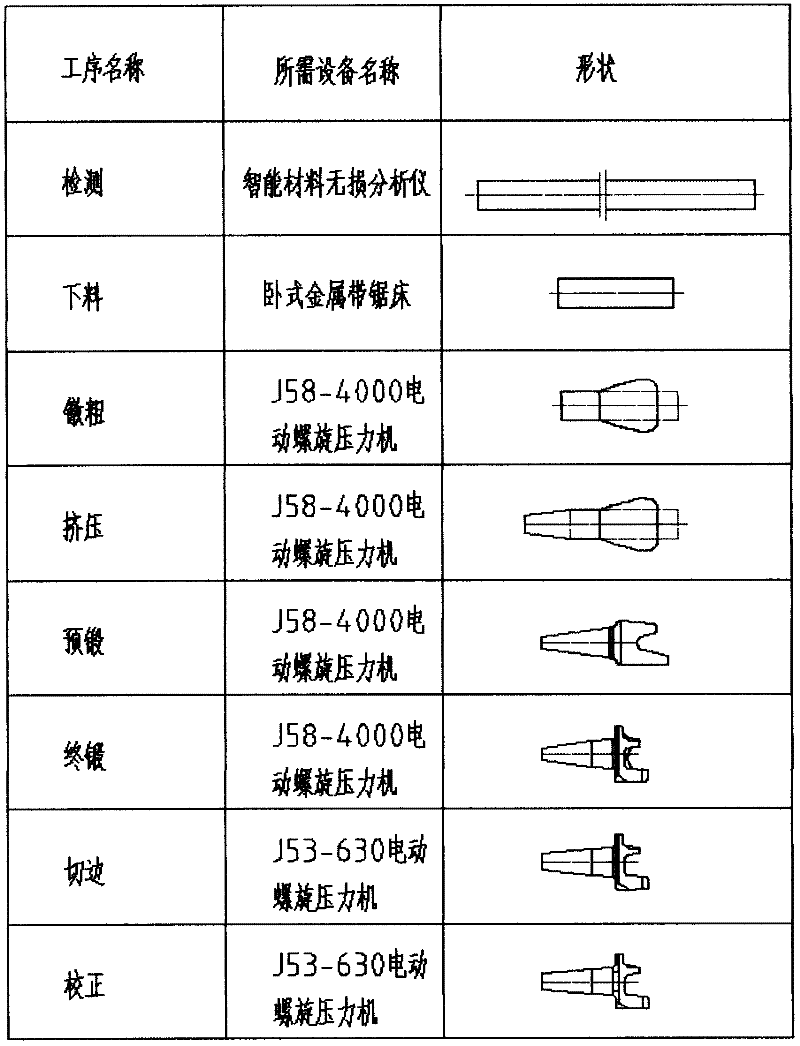

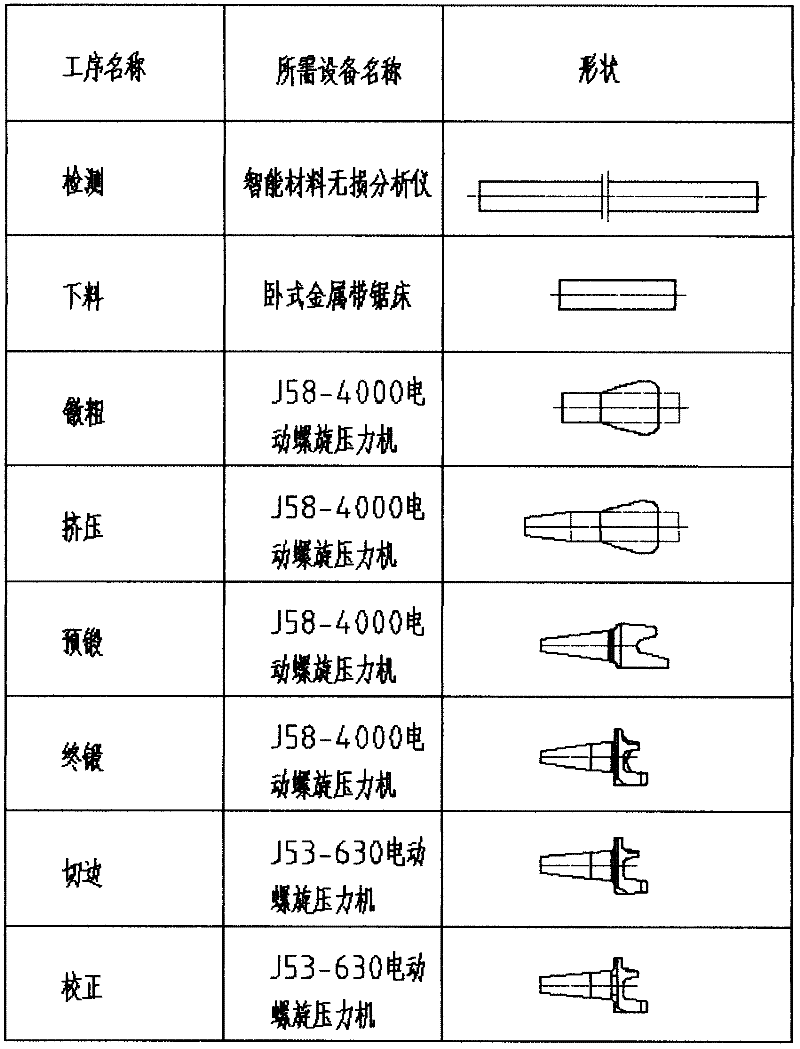

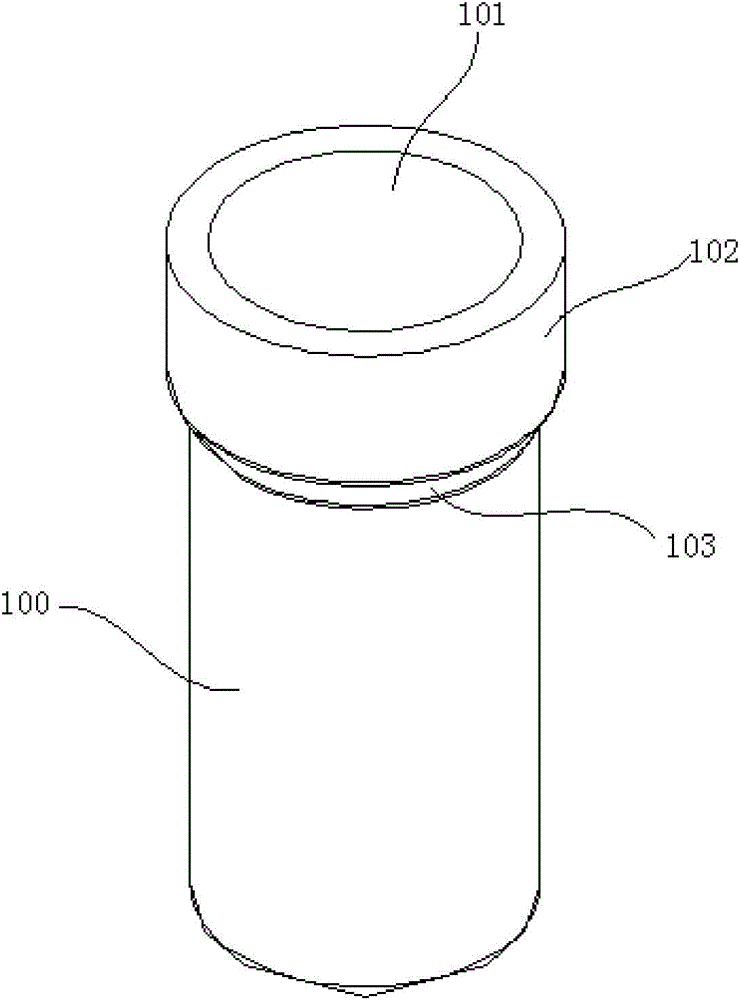

The invention provides a one-step forging and molding method of a steering knuckle of a heavy-duty car. The technical scheme provided by the invention is as follows: a warm forging process is adopted and the method successively comprises the following steps of: checking, baiting (a sawing machine), heating, roughly forging, extruding, pre-forging, carrying out finish forging, cutting edges and correcting, wherein in the heating step, a forging temperature rises in a range of 1100-1200 DEG C through heating and the temperature environment of the finish forging is in a range of 750-850 DEG C. Preferably, the forging temperature of the heating section is 1180 DEG C. Preferably, the finish forging temperature is 800 DEG C. The one-step forging and molding method provided by the invention has the beneficial effects that: in a machining process, the method is energy-saving, fast in temperature-rising speed and high in automation degree; and in a forging process: the method has the advantages of fewer forging equipment, reduced investment, high automation degree, high efficiency, and capabilities of reducing the temperature reduction when a work piece runs in an equipment room, and ensuring the temperature of the finish forging, namely ensuring the machining precision of the work piece; and the production efficiency is high.

Owner:SHAANXI AOBANG FORGING

Heat treatment method for diesel engine cam

InactiveCN101476029AReduce distortionReach hardnessSolid state diffusion coatingFurnace typesMechanical equipmentCam

The invention discloses a diesel engine cam thermal treatment method comprising a carburizing step, a quenching step and a tempering step.After the carburizing step, a pit cooling method is adopted for reducing the deformation of the cam because of the heat treatment process, two times of alkaline bath quenching are adopted for not only reducing thermal stress and deformation, but also having functions of thinning heart crystal grains and eliminating network carbide for satisfying metallography requirement in the first quenching process of the cam, and having a function of assuring to obtain cryptocrystal martensite, residual austenite and partial of granule carbide on the surface for satisfying performance requirements of rigidity, wearing resistance property, contact fatigue degree and the like of the cam surface in the second quenching process of the cam;simultaneously, the cam heart can obtain lath martensite and fine homogeneous ferrite, and the mechanical property of the cam heart can be improved; according to the invention, design requirements of heat rigidity, wearing resistance property, fatigue strength, mechanical property of the cam heart and deflection can all be satisfied, therefore, the manufactured cams can be extensively used in large-scale heavy-duty mechanical equipment.

Owner:CHONGQING YUEJIN MACHINERY

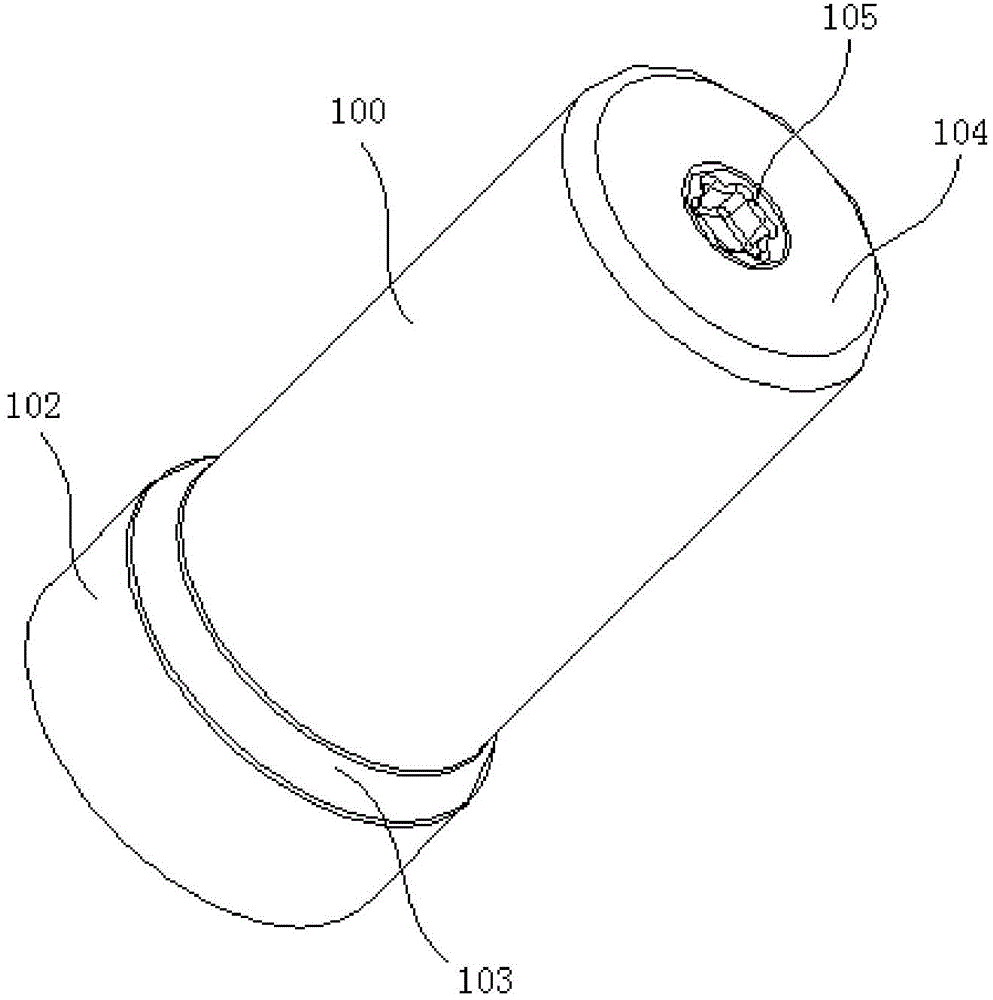

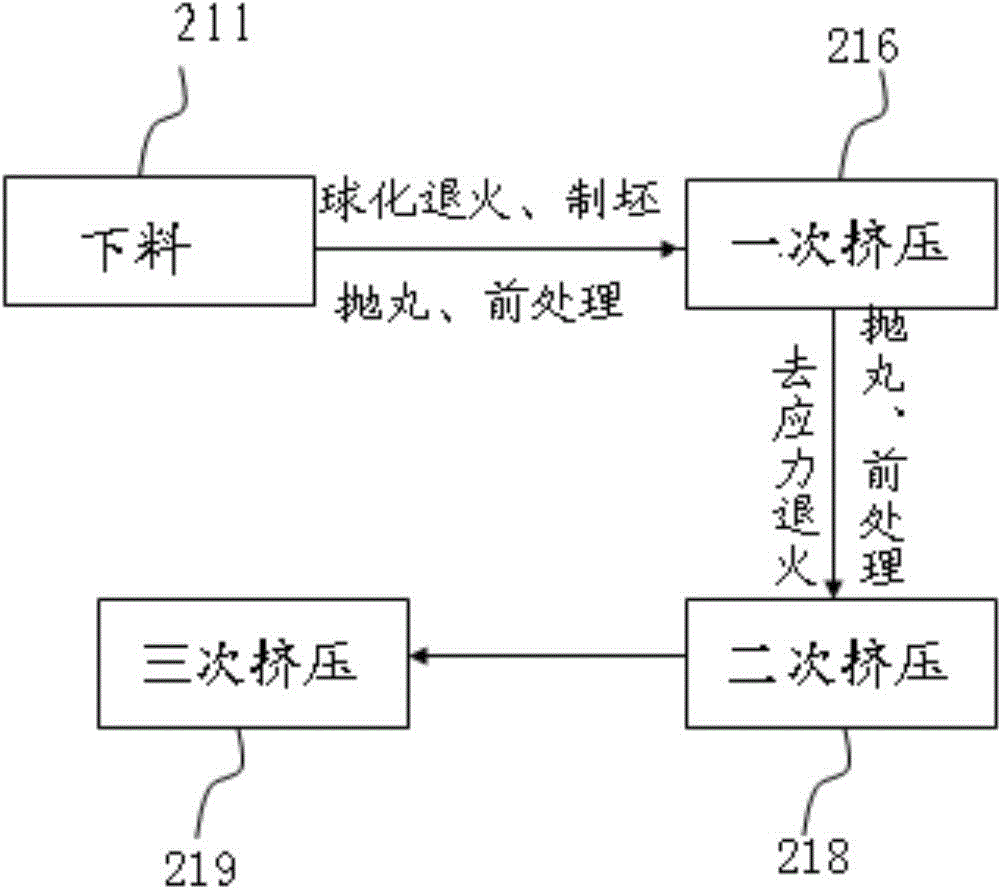

Energy accumulator tank forging forming process and extrusion die

The invention provides an energy accumulator tank forging forming process which comprises the step of carrying out primary extrusion, secondary extrusion and third time of extrusion on a bar stock in sequence to form a goblet blank finished product with one end opened and the other end closed, wherein a step is arranged on the outer wall of the opened end of the goblet blank finished product; a boss is arranged on the inner end face of the closed end; a blind hole is formed in the outer end face of the closed end; the blind hole is opposite to the boss. Compared with the prior art, the energy accumulator tank forging forming process is simple in working procedure and high in material utilization rate, and has the advantages of reducing the production cost, preventing the parts from decarburization, improving the strength of the parts and improving the production efficiency.

Owner:JIANGSU CHUANGYI PRECISION FORGING

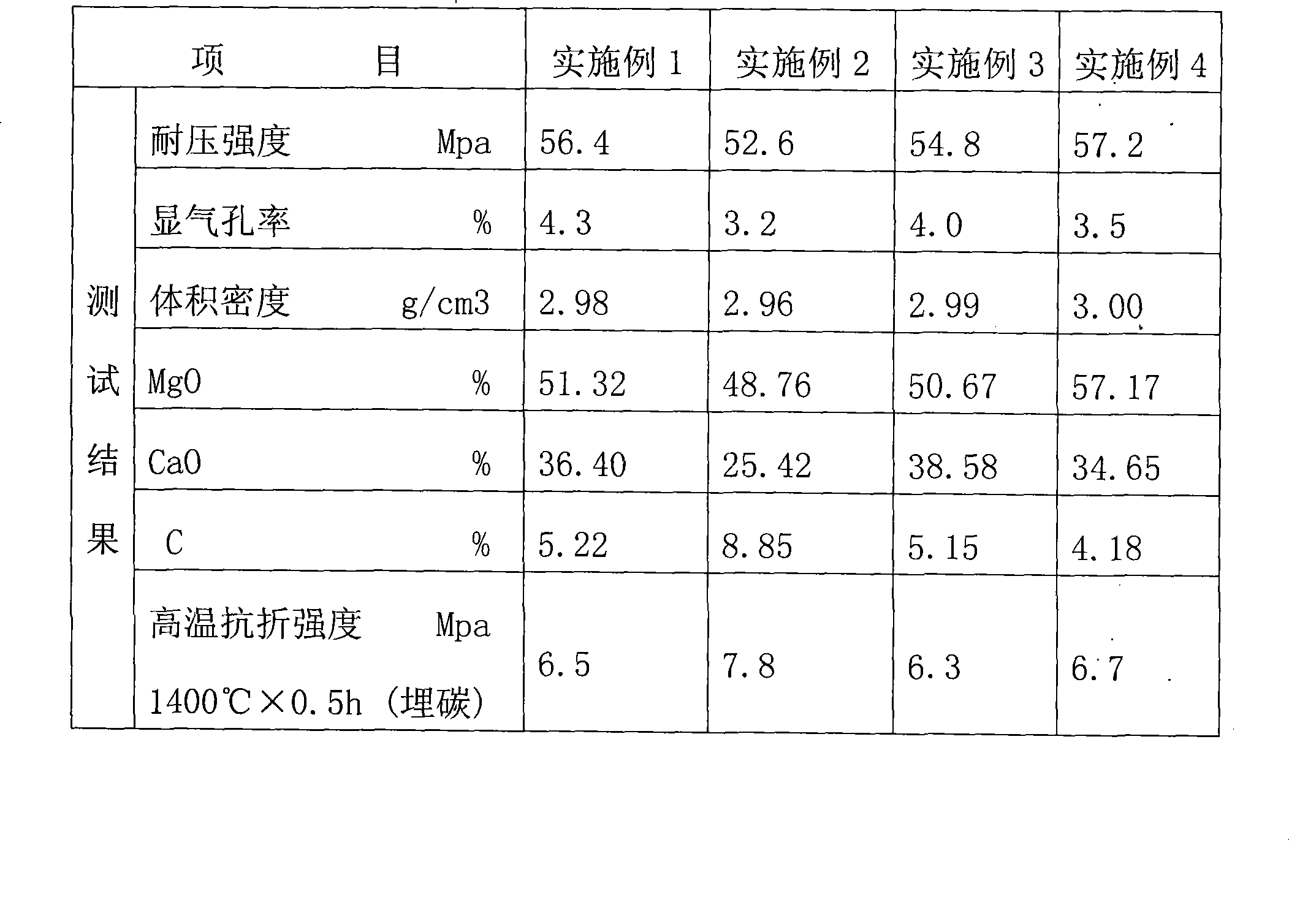

High-calcium magnesia-calcium-carbon brick and manufacturing method thereof

The invention relates to a high-calcium magnesite-dolomite carbon brick and a method for making the same. The invention adopts a technical proposal that the high-calcium magnesite-dolomite carbon brick is made from the following raw materials by weight percentage: 40 to 60 percent of 1 to 5mm calcium magnesite clinker, 5 to 15 percent of less than or equal to 1mm calcium magnesite clinker, 1 to 15 percent of less than or equal to 1mm magnesite clinker, 20 to 30 percent of less than or equal to 0.088mm magnesite powder, 2 to 8 percent of graphite, 0.5 to 3 percent of less than or equal to 0.088mm aluminum powder, 0.5 to 3 percent of less than or equal to 0.088mm silicon powder, 0.5 to 3 percent of less than or equal to 0.088mm silicon carbide powder and 3 to 6 percent of phenolic resin. The method comprises: mixing the raw materials uniformly according to a mixture ratio and pressing the well mixed raw materials into green bricks; keeping the green bricks at 220 DEG C for 4 to 7 hours and drying the green bricks for more than 20 hours totally; and performing hydration-proof treatment to the green bricks after the green bricks are moved out of a drying kiln. The brick is alkaline and can overcome the defects of molten steel pollution and unstable service life.

Owner:DASHIQIAO JINLONG REFRACTORY MATERIAL

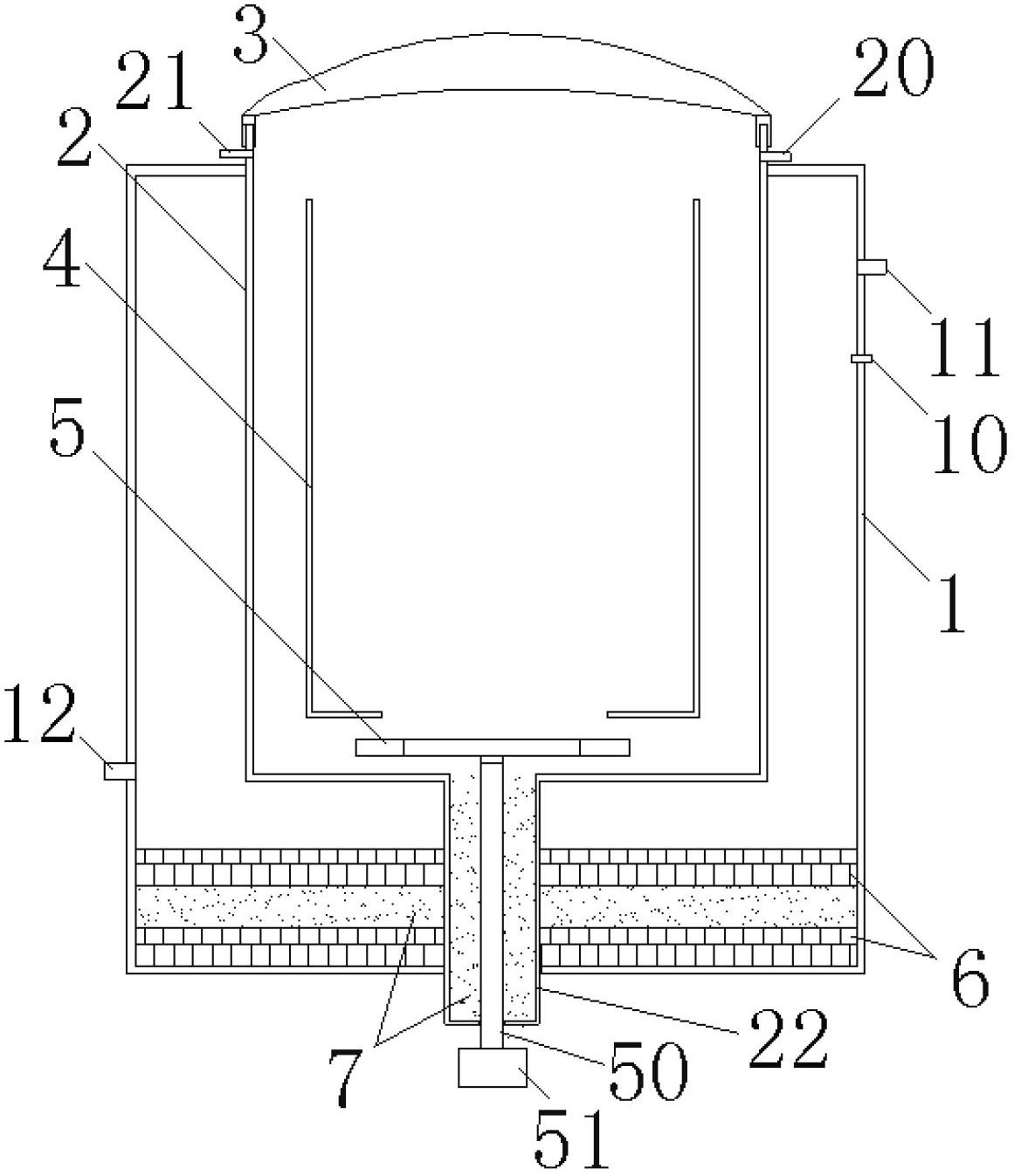

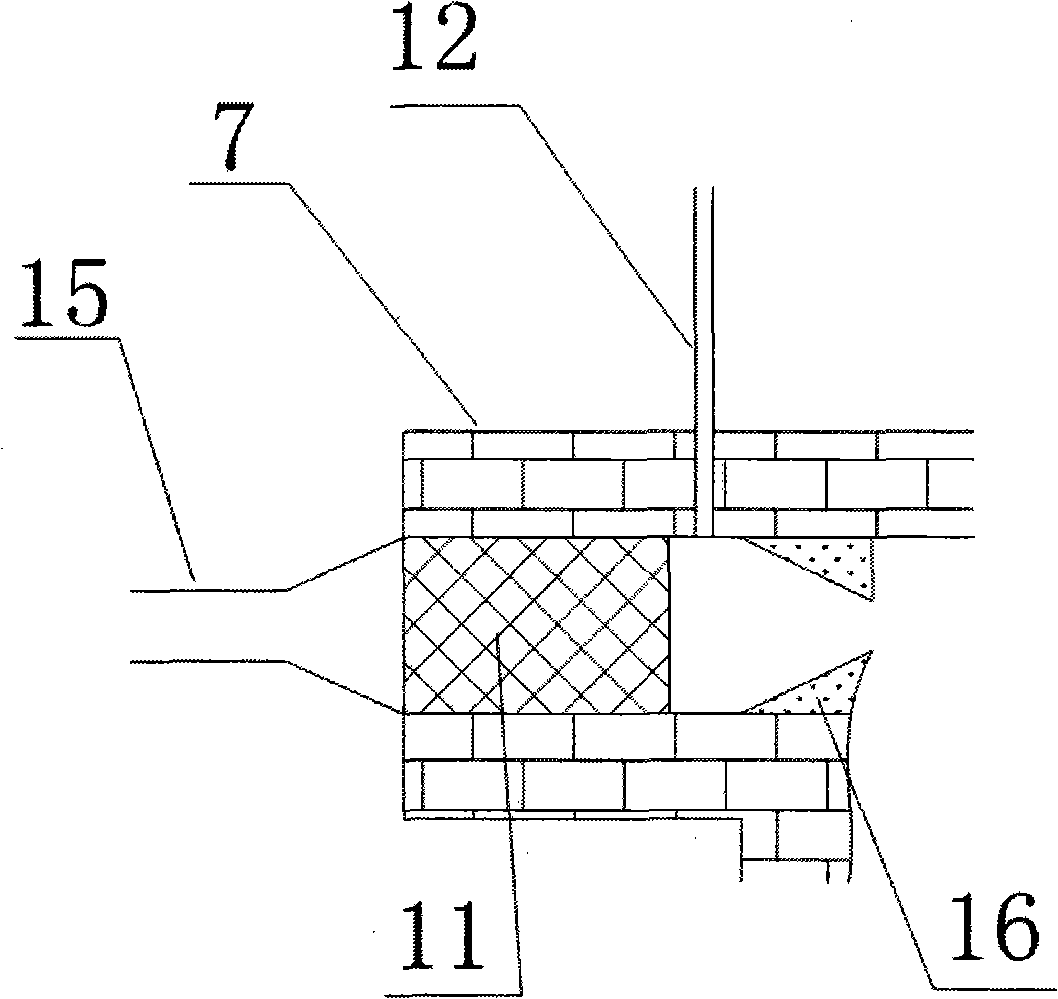

Spheroidizing annealing furnace and annealing process for steel wire

InactiveCN102676762APrevent decarbonizationImprove annealing qualityFurnace typesHeat treatment furnacesDecarburizationCombustion chamber

The invention discloses a spheroidizing annealing furnace for a steel wire. The spheroidizing annealing furnace comprises a furnace body, an inner cylinder and a furnace cover, wherein a coal gas heating point is arranged on the furnace body; a fan is arranged in the inner cylinder; a motor for driving the fan is arranged below the furnace body; a shaft barrel at the bottom of the inner cylinder extends out of the furnace body; and a rotating shaft for connecting the motor with the fan penetrates through the shaft barrel. In the production process for a long time, heat insulating cotton and refractory bricks are aged; waste gas in a combustion chamber is exhausted out of the furnace body from the outer wall of the shaft barrel without entering the inner cylinder; and the steel wire is positioned in the annealing furnace and methanol gas is introduced into the annealing furnace at high temperature, so that the decarburization of the steel wire is prevented and the annealing quality of the steel wire is improved.

Owner:WUHU JINYU FASTENER

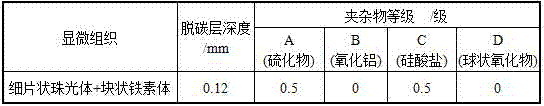

Automobile hub bolt and machining technology thereof

The invention relates to the technical field of machine part machining, in particular to an automobile hub bolt and a machining technology of the automobile hub bolt. The machining technology of the automobile hub bolt comprises the following technology steps of cold heading, heat treatment, tooth rolling, blacking and dehydrogenation. The automobile hub bolt comprises a lock head and a lock pillar, wherein the lock head and the lock pillar are integrally formed. Threads are formed on the outer surface of the lock pillar, and a positioning shaft shoulder is arranged between the lock pillar and the lock head. A notch is formed in the positioning shaft shoulder. According to the automobile hub bolt machining technology, heat treatment is performed at first, and the treatment of tooth rolling is then performed, metal flow lines of the threaded portion of a product and continuity of uniform organizations after the heat treatment can be better protected, and the adverse risks of decarburization, recarburization, cracking and the like of the product can be obviously prevented. The automobile hub bolt is high in strength, good in safety performance of use and capable of effectively reducing safety risks and danger of an automobile.

Owner:EAGLE METALWARE

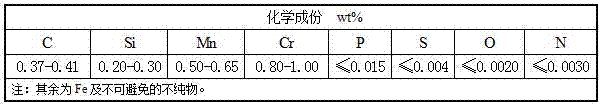

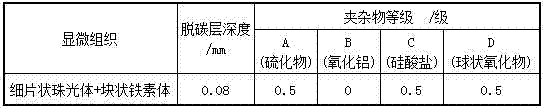

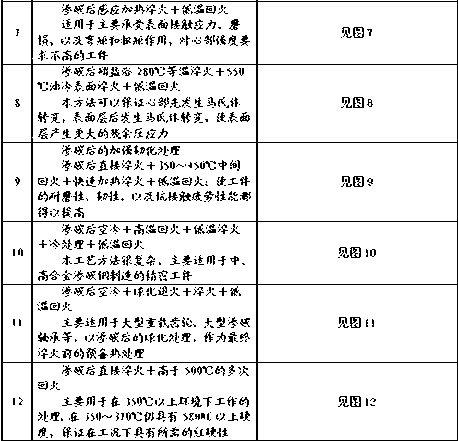

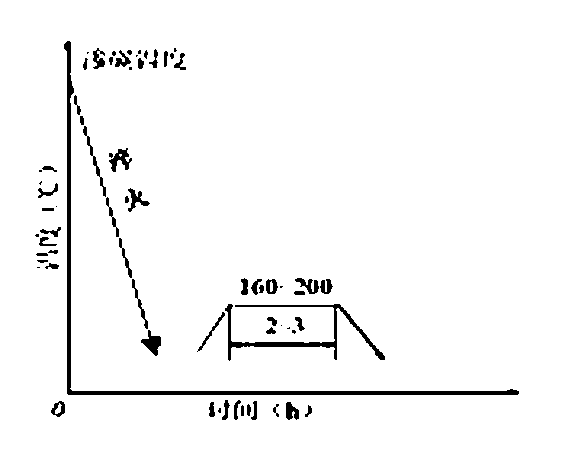

Preparation method of high-quality 40Cr alloy structure straight-bar round steel

ActiveCN106917033AExcellent Surface and Intrinsic QualityExcellent ductility and machinabilityManufacturing convertersDeoxidizationDuctility

The invention discloses a preparation method of high-quality 40Cr alloy structure straight-bar round steel. The preparation method includes the following steps, namely, the step A of molten iron pretreatment and desulfuration, the step B of molten iron smelting, the step C of deoxidization alloying, the step D of molten iron LF furnace refining, the step E of molten iron VD furnace vacuum refining, the step F of molten iron casting, the step G of steel billet heating, the step H of rolling and the step I of steel finishing. The high-quality 40Cr alloy structure straight-bar round steel produced through the method is high in cleanliness and low in inclusion content and content of harmful elements P and S, has high strength, excellent ductility and toughness, excellent impact toughness and excellent upsetting deformation capacity, and can well meet the requirements of the field of high-end machine manufacturing industries.

Owner:WUKUN STEEL

Novel carburizing-constant temperature-quenching process for heavy-duty gears

InactiveCN103132086AReduce oxidative decarburizationReduce consumptionFurnace typesHeat treatment furnacesPhase conversionCooling down

The invention discloses a novel carburizing-constant temperature-quenching process for heavy-duty gears. The process comprises the steps of: (a) after carburizing treatment, cooling down to a temperature range (600-650 DEG C) below Ar1, and carrying out constant temperature for a period of time until the temperature of workpieces is equalized; (b) heating up to quenching temperature, and quenching after carrying out heat insulation for a period of time according to the requirements of the process; and (c) carrying out low-temperature tempering. According to the process, after the carburizing stage for the gears is completed, the gears are cooled down to some temperature below the Ar1 through furnace cooling, and the constant-temperature retention is carried out, so that the first-time phase conversion is realized; the gears are directly heated up to the quenching temperature after the temperature of the gears is equalized at the temperature, so that the second-time phase conversion is realized; and the quenching treatment is carried out, so that the third-time phase conversion is realized. Proved by production practices, the process disclosed by the invention has the advantages that the energy source consumption is remarkably reduced, the oxidation and decarburization of the gears are reduced, the distortion amount is reduced, the heat treatment process flow is shortened, and the efficiency of labor productivity is increased.

Owner:上海市机械制造工艺研究所有限公司

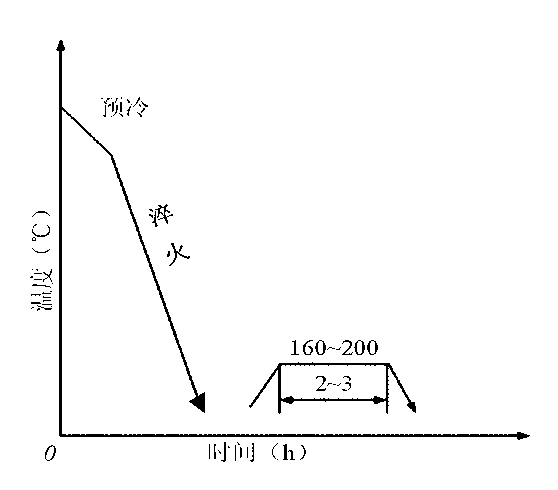

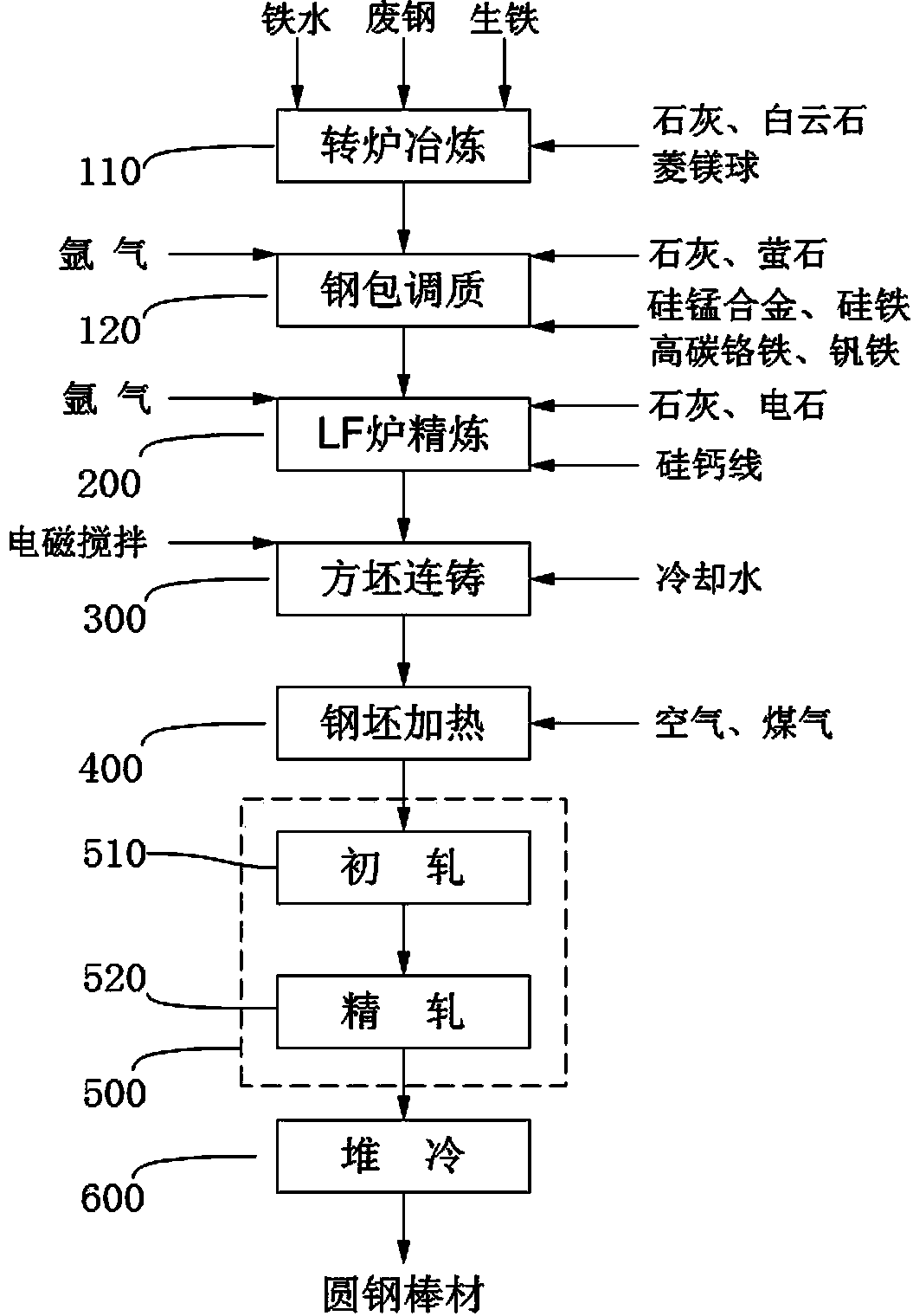

Manufacture method of 50CrVA alloy structural steel type hot rolled round steel bar

ActiveCN103451398AStable qualityReduce manufacturing costManufacturing convertersTruckElectric furnaces

The invention discloses a manufacture method of a 50CrVA alloy structural steel type hot rolled round steel bar. The manufacture method comprises the following steps of: smelting by a converter; refining through an LF furnace; performing continuous casting on a quadrate billet; heating a steel billet; rolling a bar; and cooling in heap, thus obtaining a 50CrVA alloy structural round steel bar ofat phi 60mm, wherein the 50CrVA alloy structural round steel bar ofat phi 60mm has stable quality and outstanding mechanical process performance. According to the manufacture method, the traditional mode of smelting by a large ultra-high-power electric furnace is replaced by the mode of smelting through the converter and refining through the LF furnace during steel-making, so that the manufacture method has the characteristics that the quality is stable, the production cost is low, and little electricity consumption is caused; the processes of smelting by the converter, refining through the LF furnace, fast rolling at a low temperature, and cooling in heap are innovated to produce the 50CrVA alloy structural round steel which has stable quality and outstanding comprehensive performance; the 50CrVA alloy structural round steel can particularly be used as the material for a through shaft and a half shaft of a cargo truck; and compared with the prior art, the manufacture method has the advantages that the production cost can be reduced by more than 50** Yuan per ton of materials, so that the economic benefit is remarkable.

Owner:WUKUN STEEL

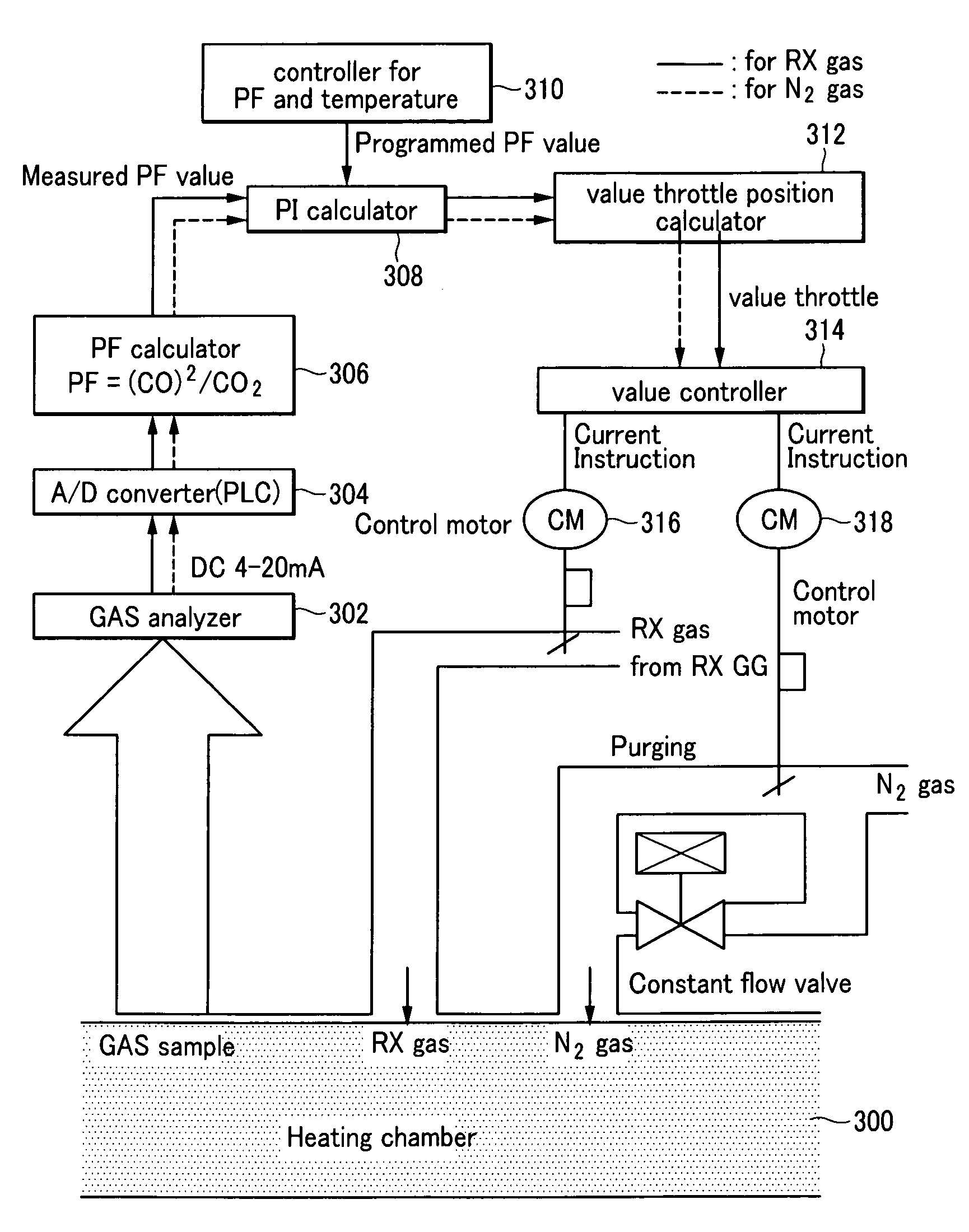

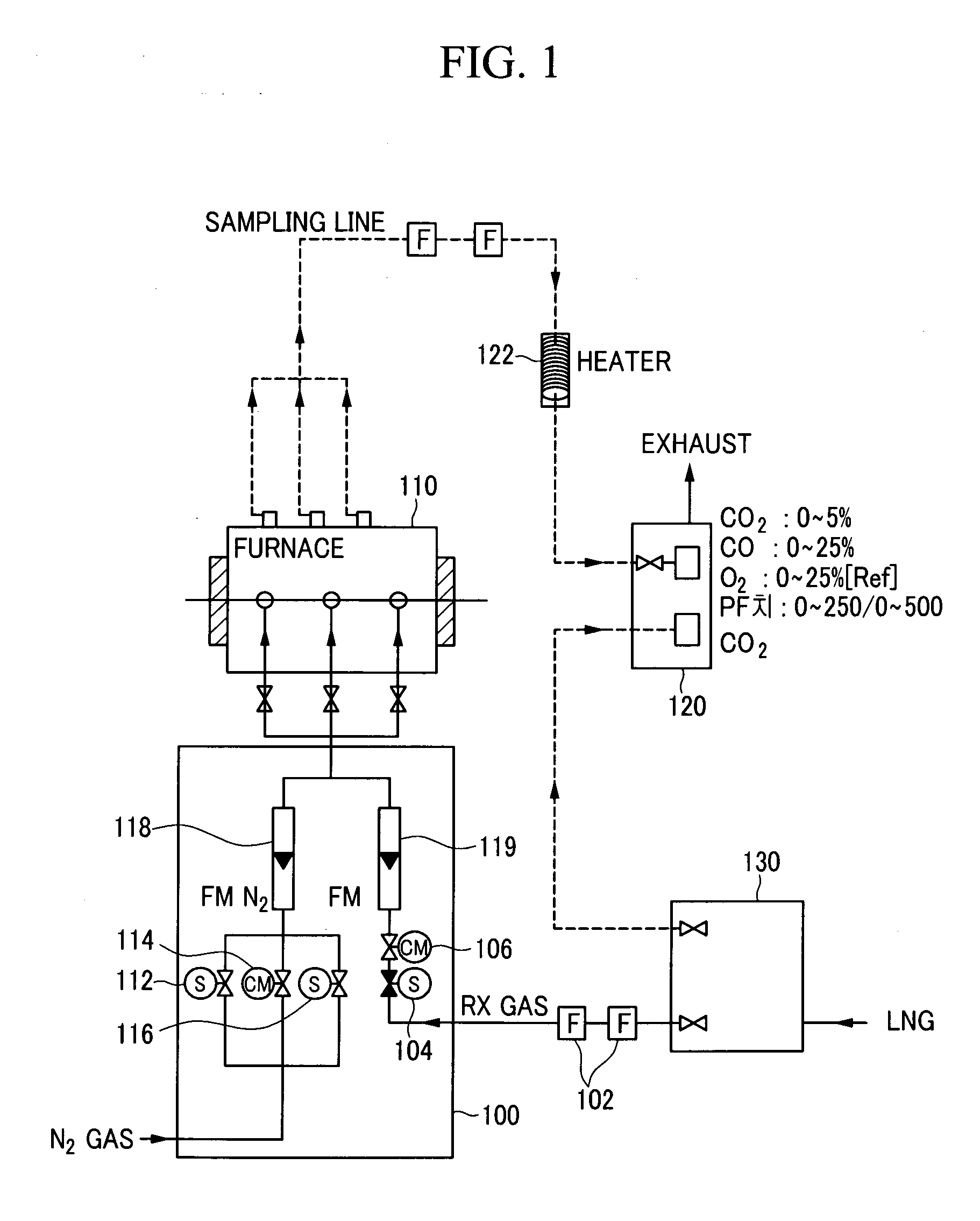

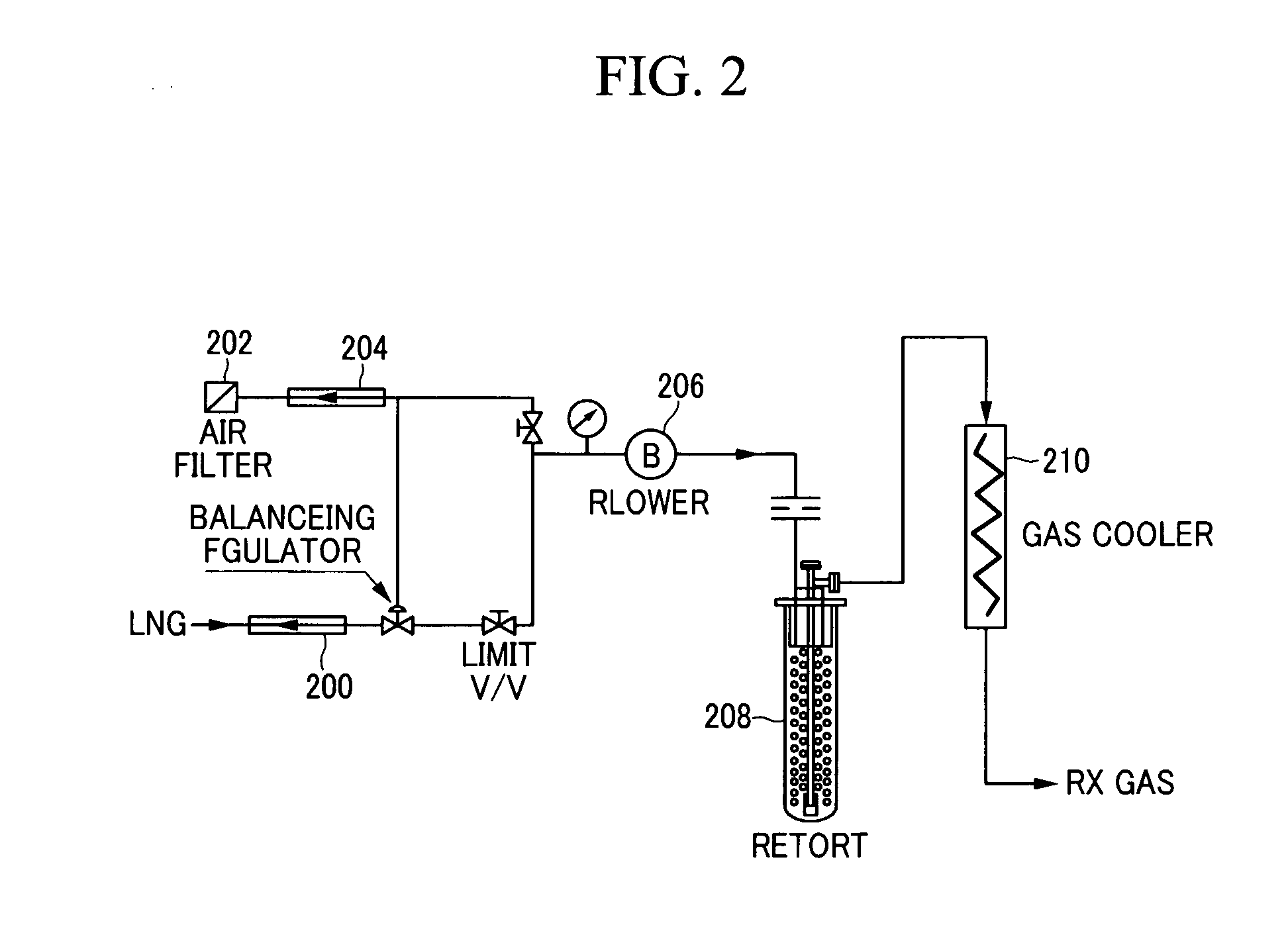

System for controlling atmosphere gas inside furnace

ActiveUS20090253090A1Prevent decarbonizationMaintainance of heating chambersHeat treatment process controlProcess engineeringCarbon steel

A system for controlling atmospheric gas inside a furnace may include a furnace into which an atmospheric gas is charged for thermaltreating carbon steel, a flow control portion that is connected to the furnace for controlling the flow of the atmospheric gas, a gas generator for producing an endothermic gas (Rx gas) and supplying the flow control portion with the endothermic gas, and a gas analyzing control portion for analyzing the atmospheric gas that is supplied through a sampling line that is connected to the furnace and for controlling the flow control portion based on the analyzed data so as to control a flux of the atmospheric gas that is supplied to the furnace. With the system, decarbonization of carbon steel can be prevented or reduced.

Owner:HYUNDAI MOTOR CO LTD

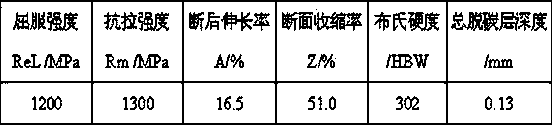

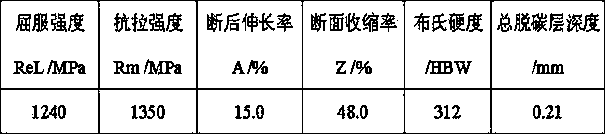

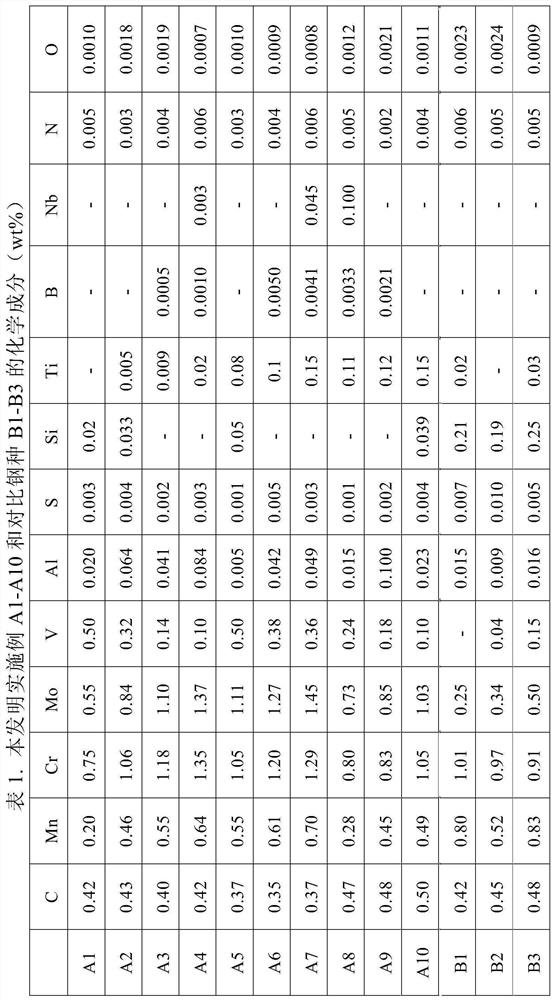

High-strength bolt steel with excellent delayed fracture resistance and preparation method thereof

The invention provides high-strength bolt steel with excellent delayed fracture resistance and a preparation method thereof. The high-strength bolt steel comprises the following components in percentage by weight: 0.35-0.50% of carbon, 0.20-0.70% of manganese, 0.75-1.35% of chromium, 0.55-1.45% of molybdenum, 0.10-0.50% of vanadium, 0.005-0.10% of aluminum, 0-0.005% of sulfur, 0.02-0.05% of silicon, 0.005-0.15% of titanium, 0.0005-0.003% of oxygen, 0.001-0.007% of nitrogen, and the balance iron and other inevitable impurities; the content of titanium is not less than 3.5 times of the content of nitrogen; the sum of the contents of chromium, molybdenum and vanadium is not lower than 1.75%; and the sum of the contents of sulfur, oxygen and nitrogen is not higher than 0.01%. The high-strength bolt steel is high in purity and refined in grains, can be used for manufacturing high-strength bolts with tensile strength not lower than 1400MPa, has a section shrinkage rate not lower than 50%, is excellent in delayed fracture resistance, and can be applied to automobiles and mechanical parts.

Owner:BAOSHAN IRON & STEEL CO LTD

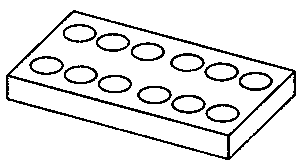

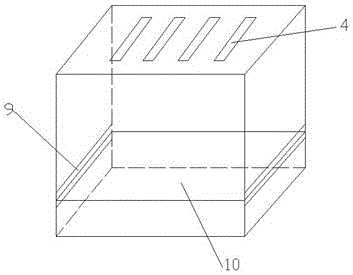

Device and method for microwave high flux preparation of alloy

PendingCN108707731ARealize simultaneous heat treatmentImprove selection efficiencyFurnace typesHeat treatment process controlMicrowave ovenVacuum extraction

The invention relates to a device and method for microwave high flux preparation of alloy, and belongs to the technical field of microwave high flux alloy preparation. The device comprises a microwaveoven body, a microwave generator, high-flux gradient heat treatment array crucibles, a rotary carrying platform, an inert gas inlet and a vacuum extraction opening; the rotary carrying platform is arranged at the bottom of the microwave oven body, and the microwave generator is fixedly arranged at the side wall of the microwave oven body, and communicates with an inner cavity of the microwave oven body through a waveguide tube; the inert gas inlet is formed in the top end of the microwave oven body, and the vacuum extraction opening is externally connected to a vacuum pump; and the front sidewall of the microwave oven body is designed as an openable oven door. In the device provided by the invention, the high flux preparation of alloy of the same type at different gradients and the highflux preparation of different alloys at the same temperature can be achieved by adopting different microwave high-flux crucibles can be achieved.

Owner:KUNMING UNIV OF SCI & TECH

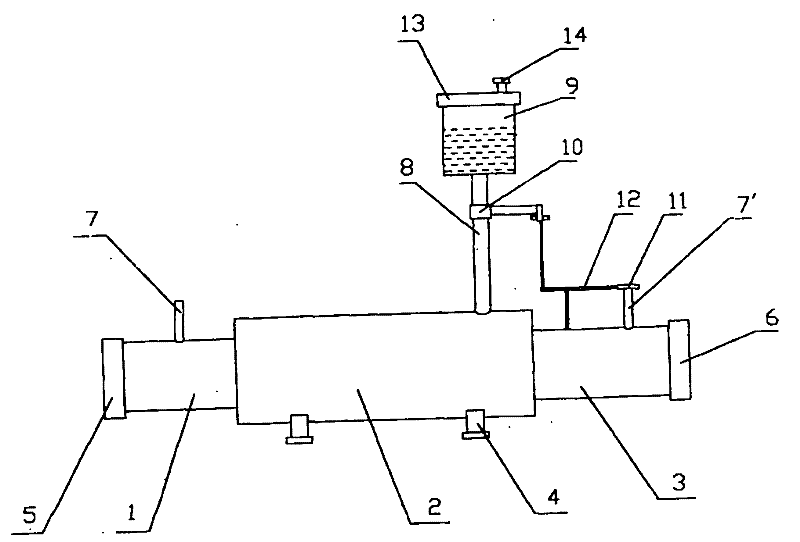

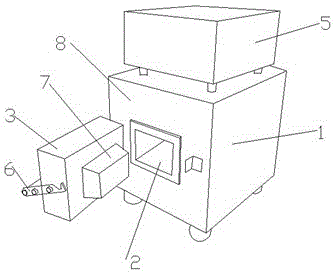

Sintering furnace for powder metallurgy products

InactiveCN102235822ASimple structureEasy to operateFurnace typesGas emission reductionPowder metallurgyLiquid ammonia

Owner:海门市常乐粉末冶金厂

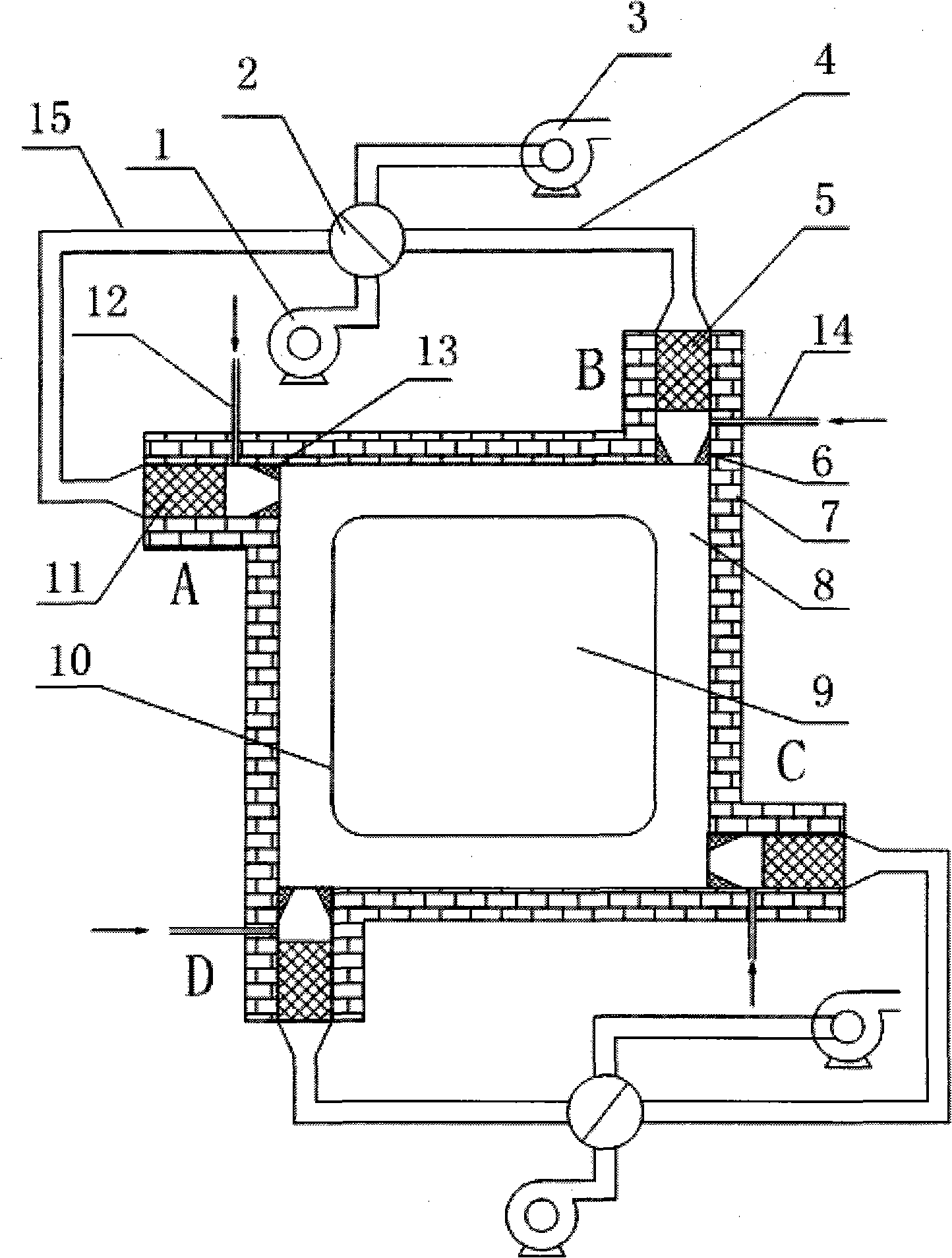

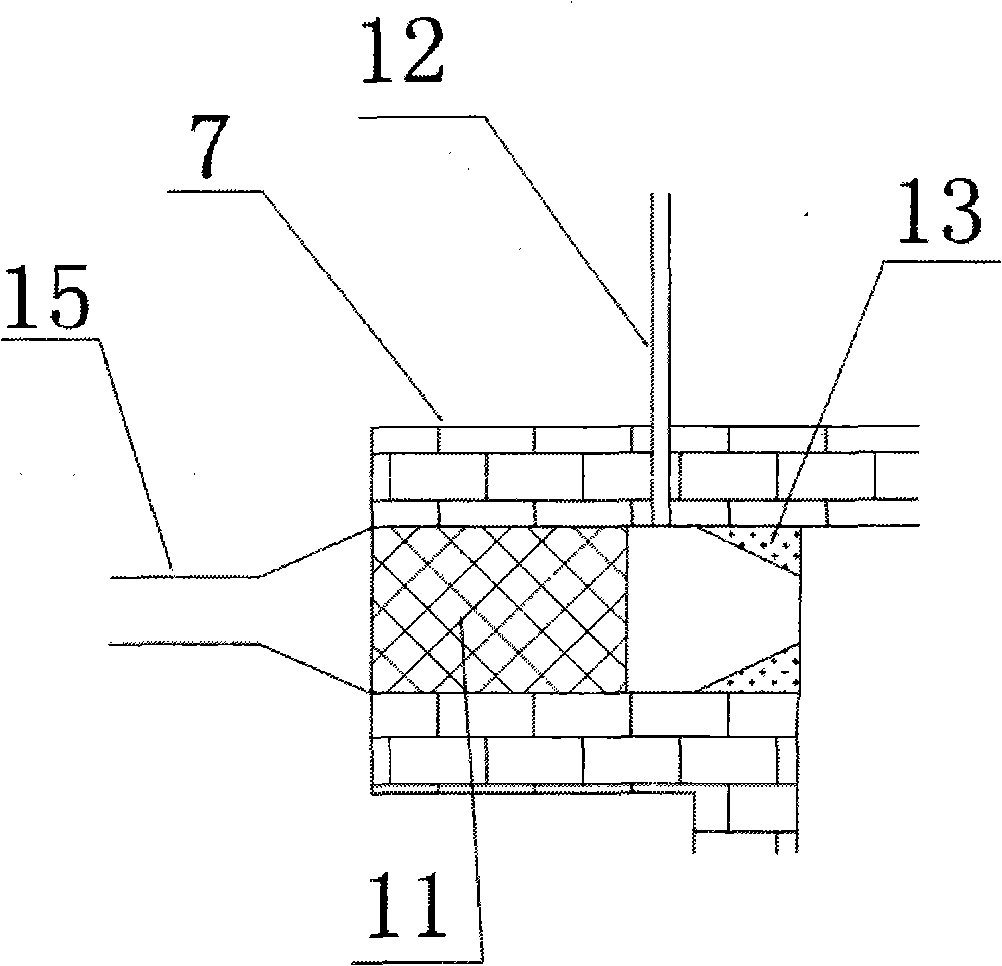

Heat accumulating type heating furnace with smoke backflow

InactiveCN101776392AEmission reductionSave energyCombustion processFurnace typesBrickNitrogen oxides

The invention provides a heat accumulating type heating furnace with smoke backflow, comprising a furnace body, regenerative chambers, a blow-off device, a fume extractor and a reversing device, wherein the furnace body is divided into a furnace cavity and a heating chamber; four corners of the furnace body are provided with four regenerative chambers in which heat accumulators are arranged; the lower course of each regenerative chamber is provided with a fuel nozzle circumscribed with a fuel pipeline; the furnace wall corresponding to the nozzle is provided with a burner block; the furnace cavity is rectangular or round; the regenerative chambers are distributed in four corners of the furnace body; the directions of nozzles are same, i.e. simultaneously clockwise or anticlockwise; the accumulator is spherical or cellular; the burner block can be arch bricks or special-shaped bricks with a guiding function; the furnace cavity and the heating chamber are separated by a refractory material with high thermal coefficient. The invention realizes the purposes of reducing carbon dioxide and nitrogen oxide emission by thermal storage and smoke backflow, separates smoke from workpieces and avoids oxidation and decarburization of workpiece surface.

Owner:UNIV OF SCI & TECH OF CHINA

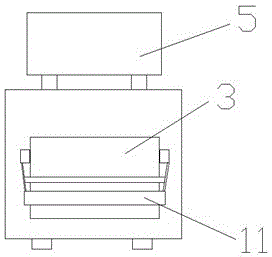

Annealing furnace

InactiveCN106544478APrevent oxidationPrevent decarbonizationFurnace typesHeat treatment bathsThermal insulationHearth

The invention provides an annealing furnace which comprises a furnace shell, a hearth, a furnace door, heating elements, a temperature thermocouple and an intelligent temperature controller. The annealing furnace is characterized in that the furnace door is of a side opening type structure and is arranged on a panel of the furnace shell through multiple sets of hinges, the hearth is closed and is provided with a furnace opening, a protruding block matched with the furnace opening is arranged on the furnace door, and the protruding block tightly presses and is tightly attached to the interior of the furnace opening; a handle is arranged on the furnace door, the position between the furnace shell and the hearth is filled with a thermal insulation layer, and the heating elements surround the four walls of the hearth; a containing support and a rail are arranged inside the annealing furnace, and therefore materials can be continuously pushed into and ejected out of the annealing furnace, the automatic degree is high, and the labor amount is reduced; and the temperature in the hearth is even, the machining efficiency is greatly improved, and the energy resource using rate can be effectively improved.

Owner:丹阳市丹力展览用品有限公司

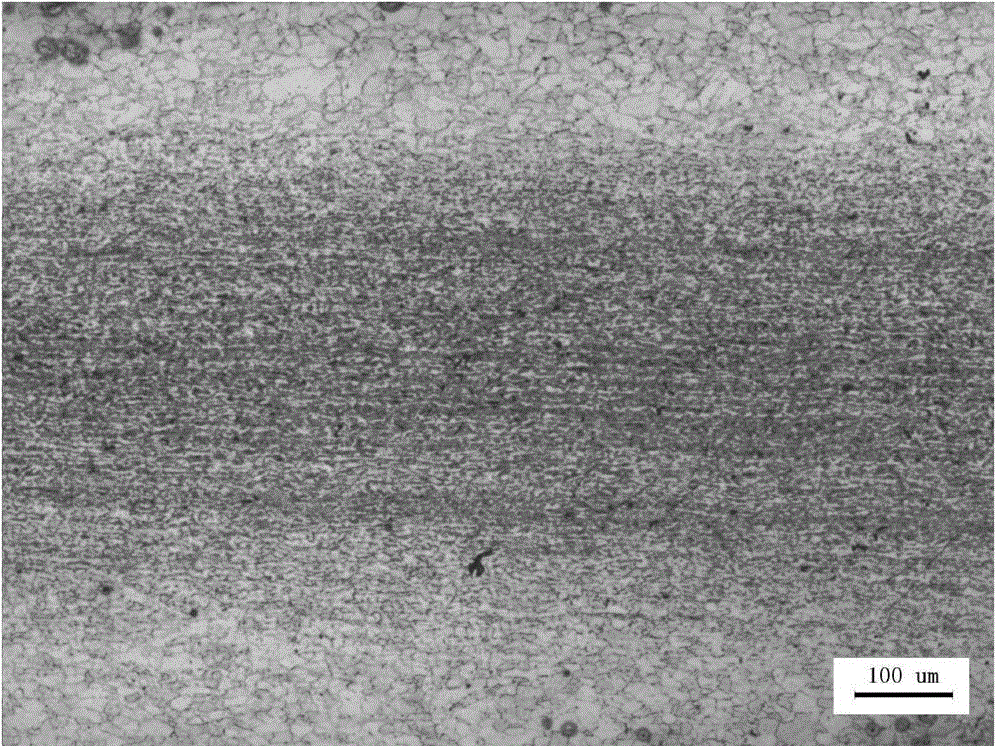

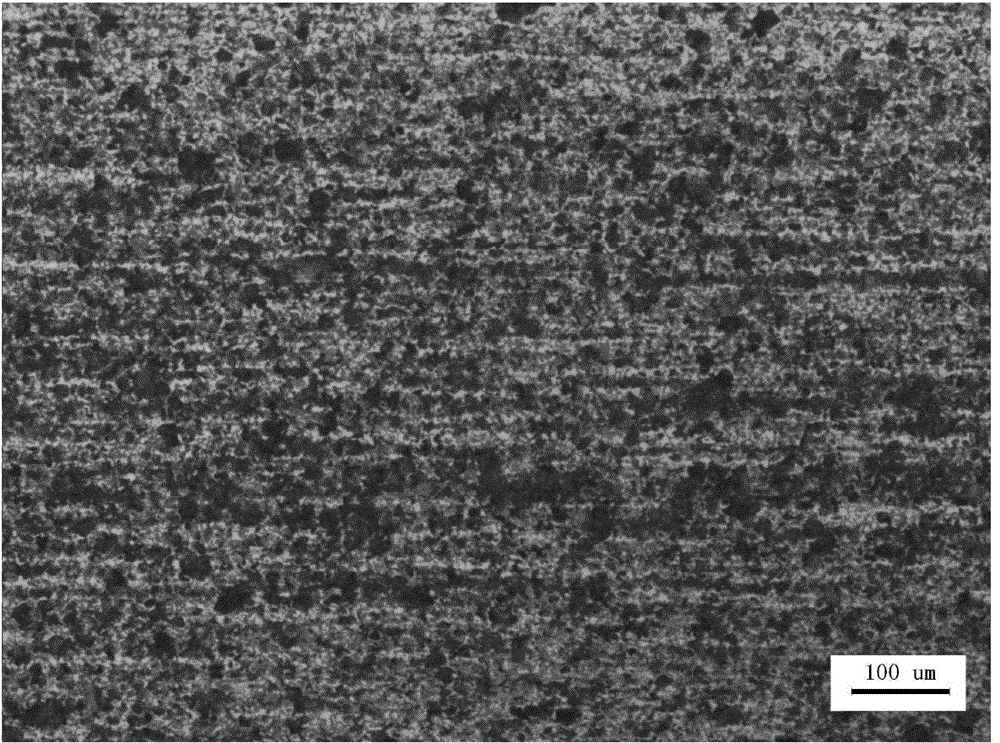

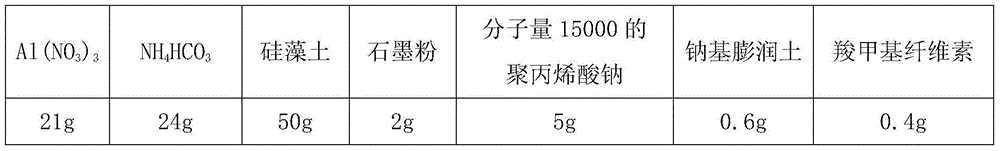

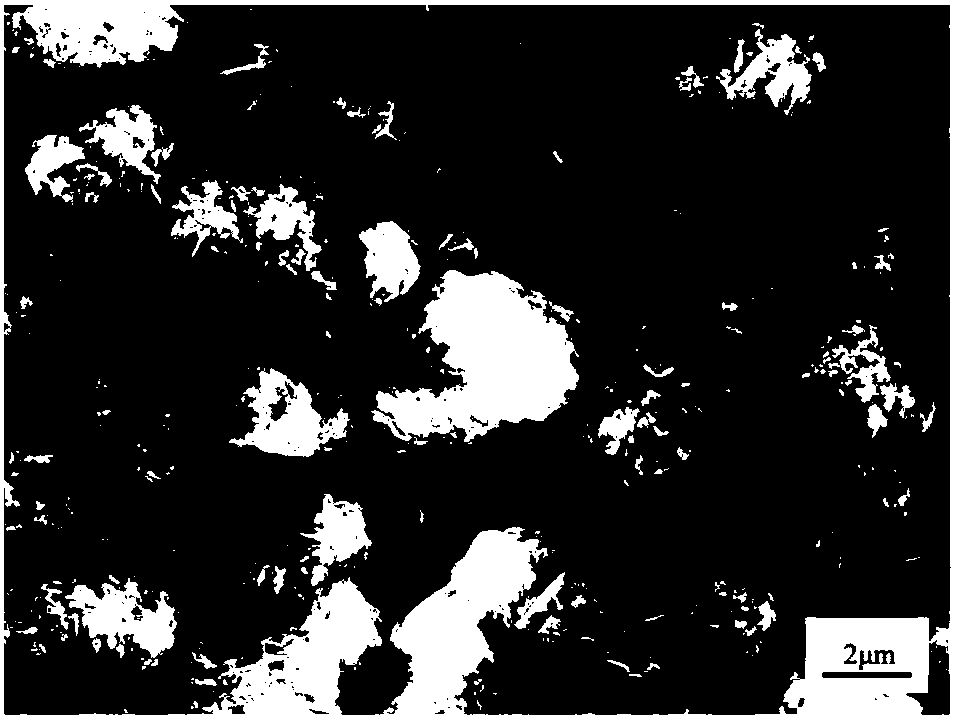

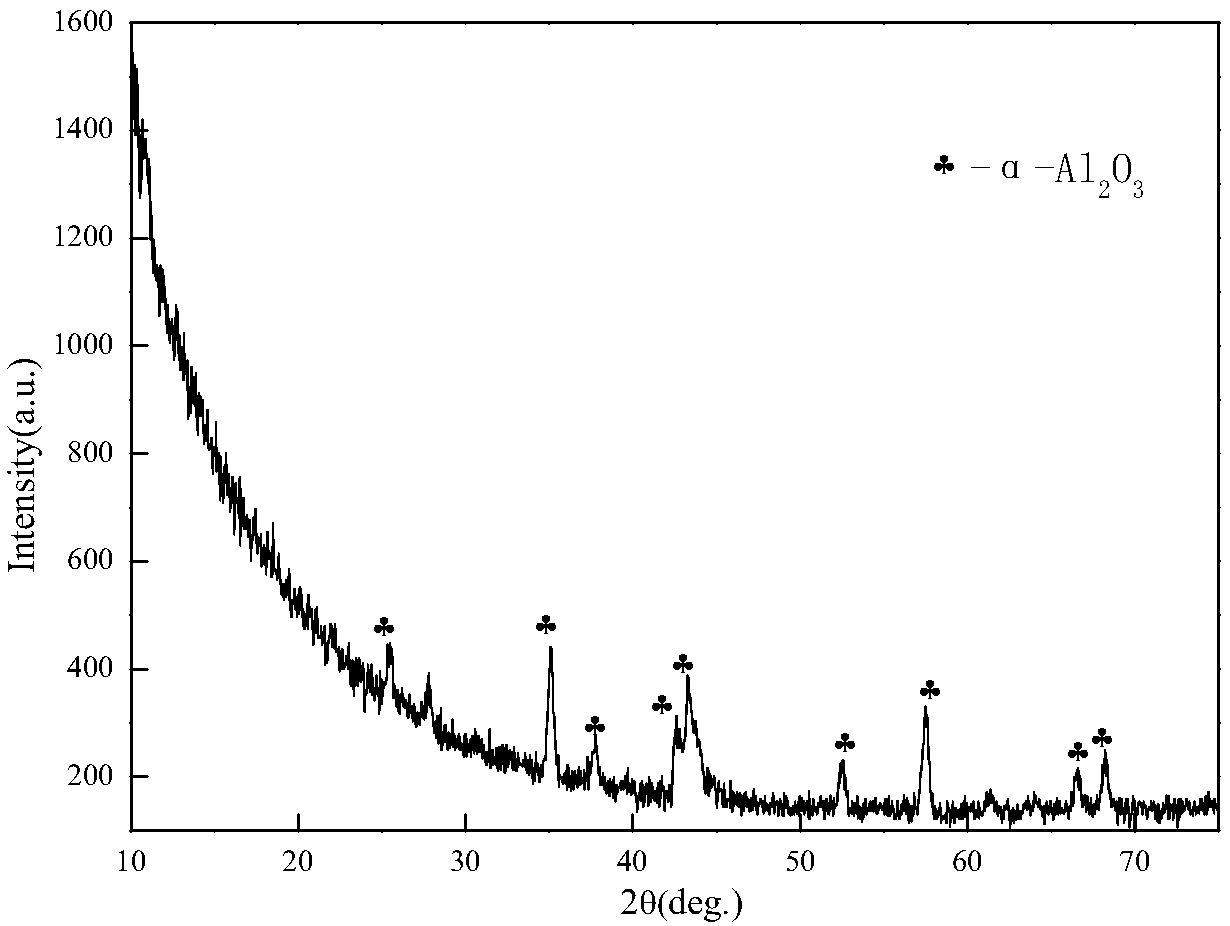

Anti-shedding carbon nano paint and preparation method thereof

InactiveCN105315821AHigh mechanical strengthImprove vitrification abilityPolyether coatingsNano al2o3Slurry

The invention provides an anti-shedding carbon nano paint and a preparation method thereof. The paint is composed of the following components in percentage by weight: 5 to 20 wt% of nano Al2O3, 50 to 80 wt% of diatomite, 2 to 10 wt% of graphite powder, 5 to 20 wt% of binder, 1 to 3 wt% of suspended dispersing agent, and the balance being solvent and impurities. The preparation method comprises the following steps: preparing an Al(NO3)3 water solution and a NH4HCO3 water solution from Al(NO3)3 and NH4HCO3 respectively; adding the Al(NO3)3 water solution into turbid liquid of diatomite and NH4HCO3, filtering and washing generated Al(OH)3 precipitate to obtain a mixture of nano Al(OH)3 and diatomite; heating to dehydrate the mixture to form nano Al2O3; adding a solvent, graphite powder, binder and a suspended dispersing agent into the mixture of nano Al2O3 and diatomite, and evenly mixing to obtain the nano level anti-shedding carbon slurry. The provided paint has the advantages that the size of nano particles is uniform, the size is small, the dispersibility is good, the cost is low, the preparation and painting technologies are simple and feasible, the natural peeling ability is strong, the high temperature oxidation and decarbonization of steel plate can be effectively avoided, and the paint is suitable for precision machining of metal workpiece with complicated shapes.

Owner:ANGANG STEEL CO LTD

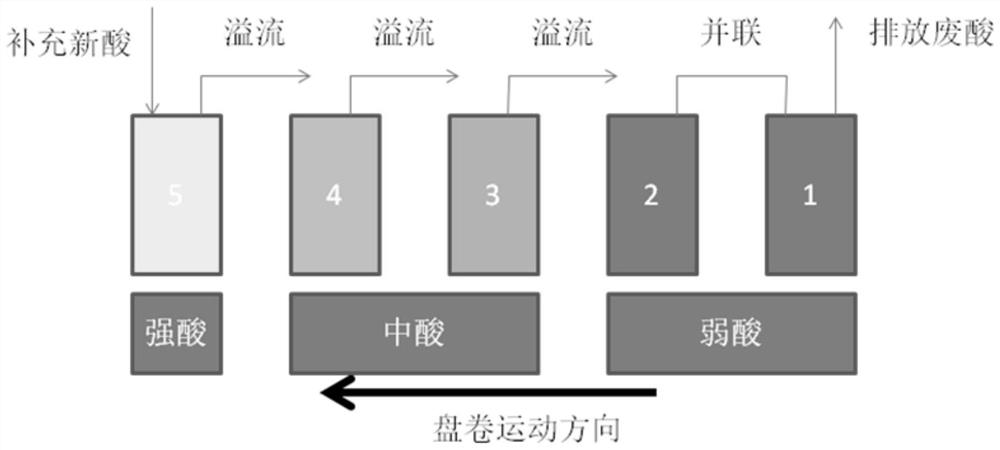

Bearing steel pickling, phosphating and saponifying method

ActiveCN112359362APrevent decarbonizationAchieve quick-drying functionMetallic material coating processesProcess efficiency improvementOXALIC ACID DIHYDRATEWire rod

The invention belongs to the technical field of metallurgy, and particularly relates to a bearing steel pickling, phosphating and saponifying method. The bearing steel pickling, phosphating and saponifying method comprises the steps of pickling, washing, lime treatment, spheroidizing annealing, pickling, rinsing, secondary washing, oxalic acid treatment, phosphating, rinsing, saponifying and drying. Before annealing, a lime pickling process is added, so that oxide scales on the surface of a wire can be washed away, and a quick drying function is achieved; and during spheroidizing annealing, RXgas is added as a protective atmosphere for carburization, so that a stable and reliable furnace atmosphere can be formed, and zero decarburization of a bearing steel wire in a furnace can be achieved. According to bearing steel treated through the pickling, phosphating and saponifying method, decarburization can be controlled to be within 1D%, the pearlite spheroidized structure is at the level2-3, and the bearing steel is suitable for high-speed cold heading machining.

Owner:ZENITH STEEL GROUP CORP +1

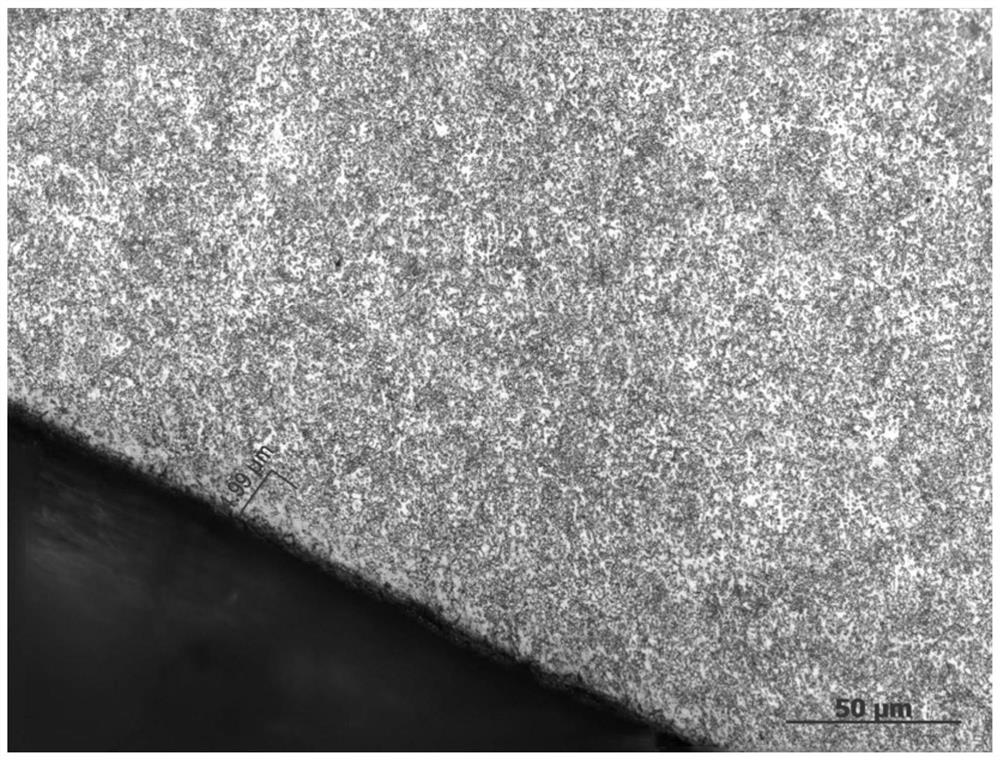

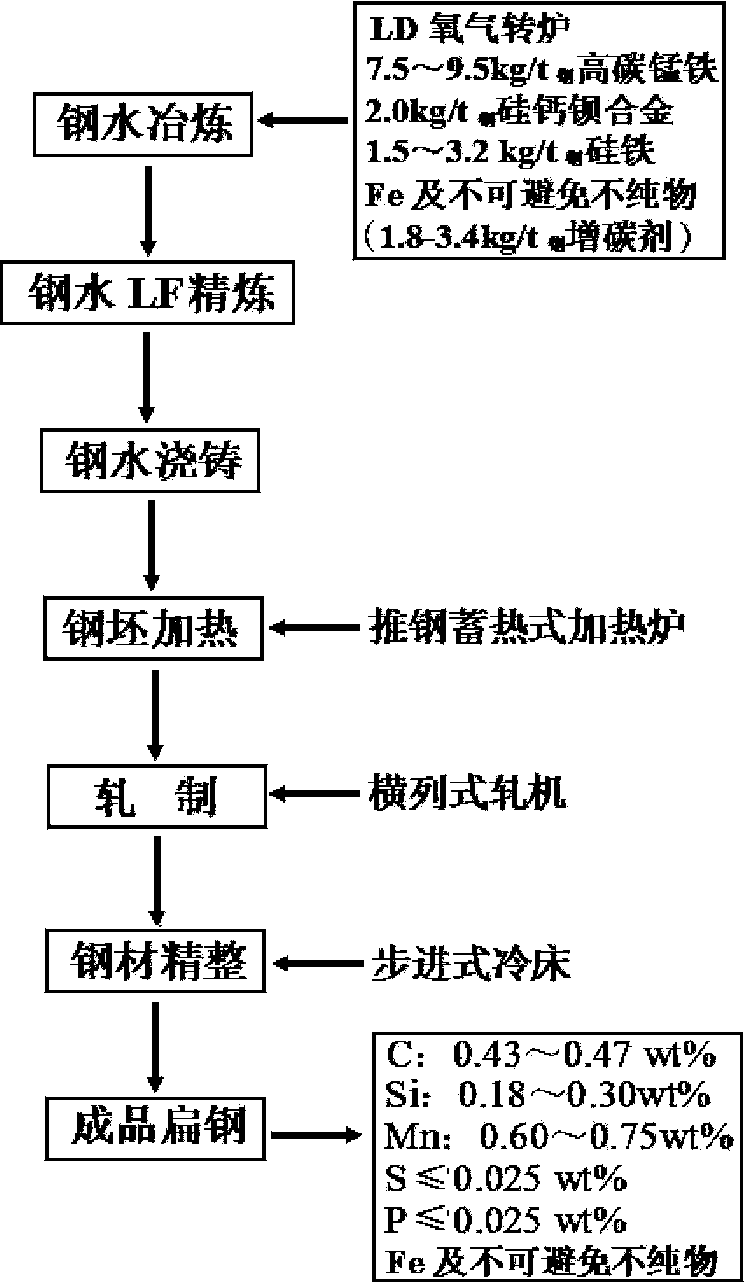

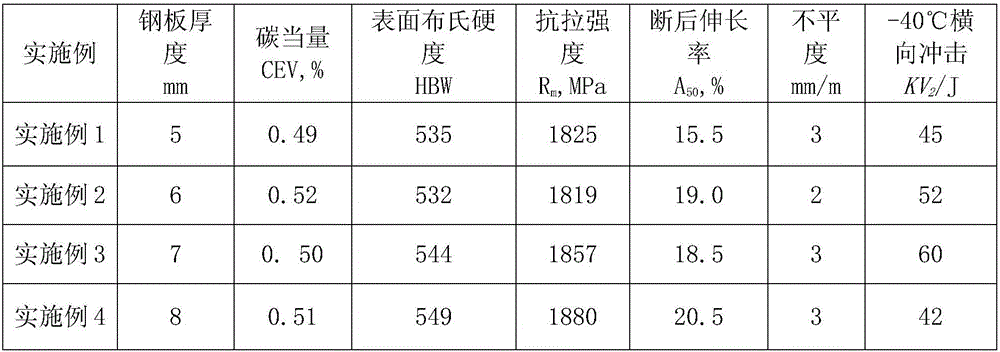

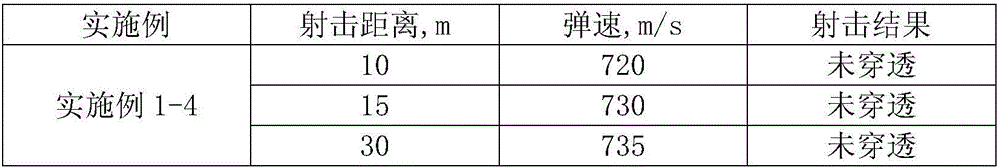

Steel flat for high-performance farm tools and working tools and processing method of steel flat

The invention discloses steel flat for high-performance farm tools and working tools and a processing method of the steel flat. The steel flat is composed of the following components in percentage by weight: 0.43-0.47 wt% of C, 0.18-0.30 wt% of Si, 0.60-0.75 wt% of Mn, not larger than 0.025 wt% of S, not larger than 0.025 wt% of P, and the balance of Fe and inevitable impurities. The steel flat is prepared by the procedures of molten steel smelting and deoxidation alloying, molten steel LF furnace refining, molten steel casting, billet heating, rolling and steel finishing. The 90mm*16mm steel flat for hoe and shovel tools is obtained by the processing method disclosed by the invention, the mechanical processing property of the steel flat is better than that of GB / T699 standard, and the section of the steel flat is rectangular. Compared with 45 steel for hoe and shovel tools produced by a complete continuous-rolled bar rolling mill process, the steel flat disclosed by the invention has the advantages that the rolling cost is reduced by more than 20 Yuan / ton, and the steel flat has the advantages of low production cost, strong process adaptability and controllability, excellent comprehensive product performance and the like, thereby being capable of well meeting the requirements of city greening and farm production development.

Owner:WUKUN STEEL

Armor plate for C-level securicar and preparation method thereof

InactiveCN106148824AGuaranteed mechanical propertiesGuaranteed mechanical properties, i.e. strengthChemical compositionMetallurgy

The invention belongs to the technical field of armor plate production and particularly relates to an armor plate for a C-level securicar and a preparation method thereof. In the armor plate for the C-level securicar, the armor plate smelting chemical composition comprises the following components in percentage by weight: 0.22-0.24% of C, 0.12-0.20% of Si, 1.02-1.20% of Mn, less than or equal to 0.007% of P, less than or equal to 0.003% of S, 0.020-0.030% of Alt, 0.25-0.35% of Cr, 0.10-0.15% of Mo, 0.015-0.025% of Ti, less than or equal to 10ppm of [O], less than equal to 12ppm of [N], less than or equal to 2ppm of [H] and the balance of Fe and unavoidable impurities. The armor plate has excellent bulletproof property, relatively high purity and good shape and facilitates welding.

Owner:SHANDONG IRON & STEEL CO LTD

Preparation method of surface wear-resistant coating for nodular cast iron

ActiveCN107641785AImprove wear resistanceSolve preparation difficultiesSolid state diffusion coatingWear resistantDuctile iron

The invention relates to a preparation method of surface wear-resistant coating for nodular cast iron. The preparation method comprises the following steps: 1, performing aluminizing treatment on a nodular cast iron workpiece, and cooling to obtain an aluminized workpiece, wherein the aluminizing temperature is 780-850 DEG C and heat is preserved for 2-5h at the temperature; 2, performing high-temperature oxidation treatment to the aluminized workpiece obtained in the step 1, wherein the high-temperature oxidation temperature is 900-1000 DEG C and heat is preserved for 2-5h at the temperature.By the preparation method combining the aluminizing treatment and the high-temperature oxidation treatment, the problems that the bonding strength between a wear-resistant layer and a substrate is low and preparation of coating for a workpiece with relatively small volume and having an inner wall is difficult can be solved.

Owner:HEBEI UNIV OF TECH

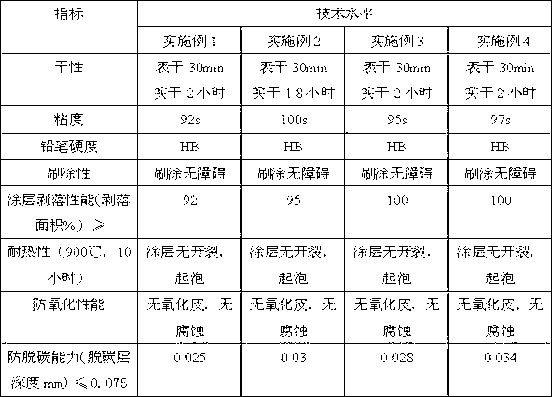

Protective paint for heat treatment of metal

The invention provides protective paint for heat treatment of metal, which is characterized by being prepared from the following raw materials in parts by weight: 2-5 parts of W type ethyl cellulose resin, 5-10 parts of organobentonite paste having an organobentonite content of 20%, 10-15 parts of 11# frit, 10-12 parts of 04# frit, 5-13 parts of M-1 frit, 5-8 parts of industrial grade barium metaborate, 1-6 parts of 400-mesh mica powder, 5-8 parts of industrial grade rubellan iron oxide, 3-11 parts of industrial grade pigment and 20-50 parts of ethanol. In an environment of 900 DEG C, the paint can achieve favorable drying property and excellent physical and chemical properties through secondary film forming of the combined frit; and meanwhile, a coating formed by the paint also has favorable self-releasing property.

Owner:西安经建油漆有限责任公司

Anti-oxidation coating applied to high-temperature steel and preparation method thereof

InactiveCN109294298APrevent decarbonizationReduce oxidation burnAlkali metal silicate coatingsSpray coatingOxidation resistant

The invention discloses an anti-oxidation coating applied to high-temperature steel and a preparation method thereof, and belongs to the technical field of preparation of a high-temperature anti-oxidation coating. Based on the research of heat treatment of steel substrate, an anti-oxidation coating applied to high-temperature steel is developed. The anti-oxidation coating is especially suitable for long-term heat preservation process of carbon steel and silicon steel. The anti-oxidation coating applied to high-temperature steel is characterized in that: the coating comprises the following ingredients (by weight): an inorganic adhesive 30-50, bauxite 10-40, water 50-100, chromium oxide 3-5, magnesia 20-50, feldspar 20-50, industrial aluminum powder 0-10, and an auxiliary agent 1-2. The coating can be applied by the construction process such as spray coating, brush coating, roller coating and the like. The coating is applied on the surface of a workpiece to be heated and undergoes heat treatment with heating of the workpiece, thus effectively preventing high temperature oxidation of the workpiece during the heat treatment process.

Owner:北京隆源纳欣科技有限公司

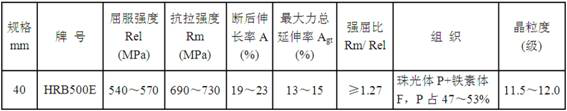

Production method of HRB500E fine-grain high-strength anti-seismic anti-corrosion reinforcing steel bar

InactiveCN112779460ACorrosion resistantImprove corrosion resistanceMetal rolling arrangementsAlloyShock resistance

The invention discloses a production method of an HRB500E fine-grain high-strength anti-seismic anti-corrosion reinforcing steel bar. The method comprises the following steps of converter smelting, deoxidizing alloying, LF refining, square billet continuous casting, steel billet heating, rolling and cooling in sequence to produce the fine-grain high-strength anti-seismic anti-corrosion reinforcing steel bar which is stable in quality, excellent in plasticity and toughness, greater than 1.27 in yield ratio and 11.5-12.0 in ferrite grain size. The Cr, V and Ni composite microalloying process is adopted, converter smelting and LF external refining are matched, the rolling technology for controlling the inner diameter and negative deviation of the reinforcing steel bar at low temperature is adopted, finishing is combined, formation and precipitation of a fine and dispersed microalloy carbon (nitrogen) compound second phase are promoted, the steel strength is improved, meanwhile, the plasticity and toughness are remarkably improved, mechanical connection is further facilitated, reasonable matching of high strength, obdurability, low strain timeliness, shock resistance and corrosion resistance of the reinforcing steel bar is achieved, and the method can be applied to the fields of main stream hydropower station flood discharge tunnel engineering, expressway road and bridge engineering and the like.

Owner:WUKUN STEEL

Mold heat treatment technology preventing cold stamping mold failure

InactiveCN106367565AReduce hardnessLow wear resistanceFurnace typesHeat treatment furnacesStress relievingRoom temperature

The invention discloses a mold heat treatment technology preventing cold stamping mold failure and relates to the field of stamping forming. The mold heat treatment technology comprises the following steps of tempering a cold stamping mold blank at 450-500 DEG C within half an hour after forging to refine grains and relieve stress, performing quenching to rapidly reduce the temperature to 80-120 DEG C within 5-10min after tempering, repeating the steps 5-6, and rapidly reducing to the room temperature within 5-10min after the last tempering, wherein the heat preservation period of the tempering is 70-100min. The technology strictly controls the time and the temperature of the tempering and the quenching, and can improve hardness, abrasive resistance and fatigue resistance of a mold by an incomplete quenching manner; multiple tempering can effectively eliminate residual stress in a quenching process; the toughness of the mold is improved, and early breakage is avoided.

Owner:YAAN FANHUA TOOLING MOLD CO LTD

Hard alloy and process for local laser coating of hard alloy

ActiveCN107760956ATightly boundHigh hardnessTransportation and packagingMetal-working apparatusLaser coatingThermal expansion

The invention discloses a hard alloy and a process for local laser coating of the hard alloy, belonging to the technical field of surface-hardening treatment of metal. The hard alloy comprises, by weight, 20 to 27% of Cr, 10 to 14% of W, 1.5 to 2.5% of C, 21 to 23% of Ni, 1% of Fe, 0.8 to 1% of Si, 1% of B and 1.5% of Re, with the balance being Co. The hard alloy is powdery and has a powder size of 40 to 200 [mu]m. The powdery alloy material used in the invention has good compatibility with a matrix material, the dilution rate of a cladding layer is small, and the thermal expansion coefficients of the two materials are almost same; through pretreatment and post-heat-treatment of a matrix and the cladding layer, temperature gradient is further reduced and internal thermal stress in the cladding layer is decreased, and thus, the phenomena of cracks and shedding of an alloy layer are avoided; therefore, the hard alloy overcomes the problem of infirm bonding between a coated alloy layer and matrix metal in the prior art and has the characteristics of high hardness and good wear resistance.

Owner:佛山铸昊机械设备有限公司

Vacuum furnace quenching process

ActiveCN104178603ACause oxidative damagePrevent decarbonizationQuenching devicesWater solubleQuenching

The invention discloses a vacuum furnace quenching process. The vacuum furnace quenching process comprises the following work procedures: (1) a liquid discharge pump extracts quenching liquid in a quenching pool to a preparation bin; and a vacuum furnace is vacuumized; (2) a heat insulating door is opened; after a workpiece is put in a heating chamber, the heat insulating door is closed; and the workpiece is heated; (3) after the heating of the workpiece is finished, the heat insulating door is opened to take out the workpiece; the heat insulating door is closed; and the workpiece is precooled in a precooling chamber; (4) a liquid returning pump injects the quenching liquid of the preparation bin into the quenching pool; after the quenching liquid reaches a certain volume, the workpiece is descended into the quenching pool for quenching; and (5) after the quenching is finished, a furnace door is opened to take out the workpiece; and if a new production requirement is generated, the first step is returned to for recycling. The vacuum furnace quenching process causes no oxidation damage to the heating chamber, prevents the intergranular oxidation or decarbonization of a heated metal part, and can be intermittently used to achieve the effect of flexible production transfer; and a water soluble quenching medium can be used, so that the vacuum furnace quenching process is suitable for a part with the high requirement on the quenching and cooling speed so as to obtain the higher hardening depth and hardness uniformity.

Owner:东莞市禾盛金属科技有限公司 +2

700MPa-grade thermal forming axle housing steel and preparation method thereof

ActiveCN112195403AImprove impact toughnessAvoid formingRolling resistance optimizationChemical compositionMaterials science

The invention discloses 700MPa-grade thermal forming axle housing steel. The 700MPa-grade thermal forming axle housing steel is prepared from the following chemical components in percentage by mass: 0.17%-0.27% of C, 0.30%-0.50% of Si, 1.2%-1.8% of Mn, less than or equal to 0.02% of P, less than or equal to 0.009% of S, less than or equal to 0.1% of Ti, less than or equal to 0.2% of Cr and the balance of Fe and inevitable impurities, wherein the mass fraction of Si and Mn meets the condition that Si / Mn is more than or equal to 0.23 and less than or equal to 0.27. The invention further discloses a preparation method. The preparation method comprises the steps of adopting the chemical components for smelting, continuous casting, heating, rough rolling, finish rolling, curling and machining treatment with the heating temperature of 1180 DEG C-1220 DEG C and the heating time of 150 min-200 min to obtain the 700MPa-grade thermal forming axle housing steel. The mechanical properties before and after heat treatment are excellent, and a plate obtained after heat treatment is free of obvious microscopic banded structures and has excellent impact toughness.

Owner:SHOUGANG CORPORATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com