Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

434results about How to "Reasonable ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

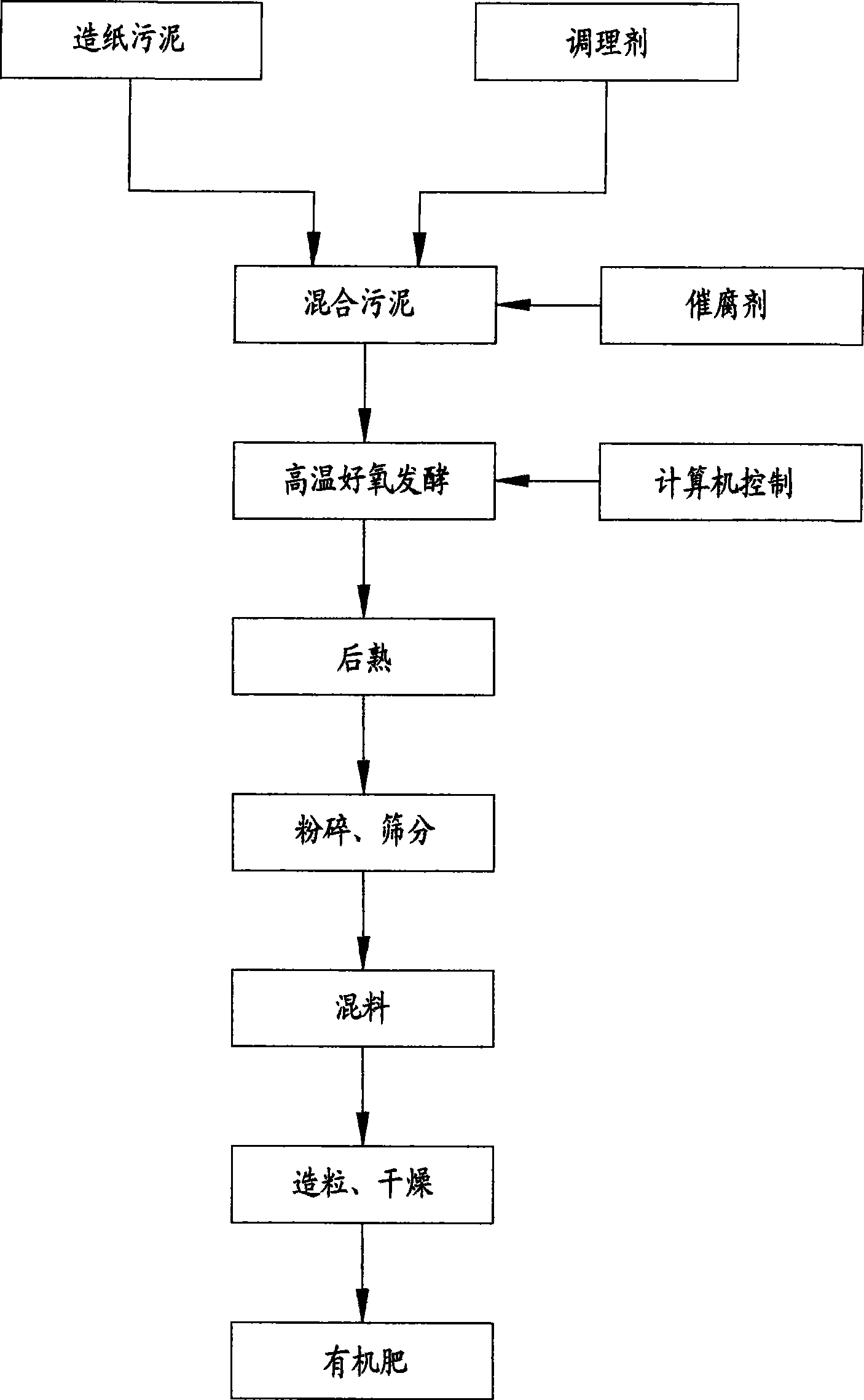

Method for producing fertilizer with papermaking sewage sludge

InactiveCN101429066ARealize comprehensive utilizationSolve processing problemsBio-organic fraction processingOrganic fertiliser preparationSludgePotassium

The invention discloses a method for preparing organic fertilizer from paper-making sludge. The materials such as paper-making sludge, amendment are mixed, subjected to high-temperature aerobic fermentation, post maturation and crushing, screened, and mixed with fertilizer of nitrogen, phosphorus, potassium and the like and medium and micro elements to prepare the organic fertilizer. The method has the advantages of simple process, easy operation, obvious innocuous effect, no environmental pollution and little nutrient loss; and the organic fertilizer prepared by the method is widely applied to industrial crops such as vegetables, fruit trees, Chinese herbal medicines, flowers and field crops such as wheat, corn, paddy rice.

Owner:SHOUGUANG CAILUN ZHONGKE FERTILIZER

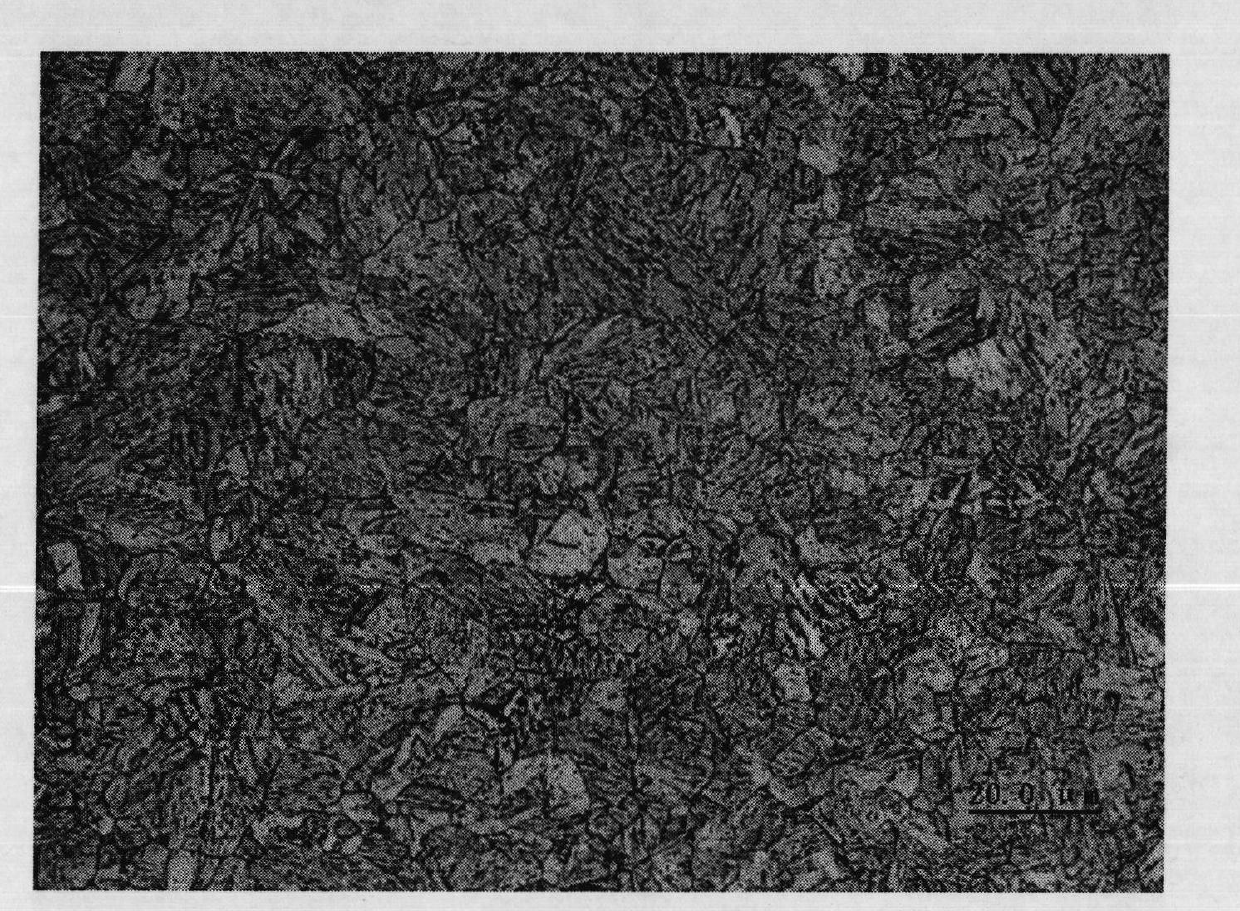

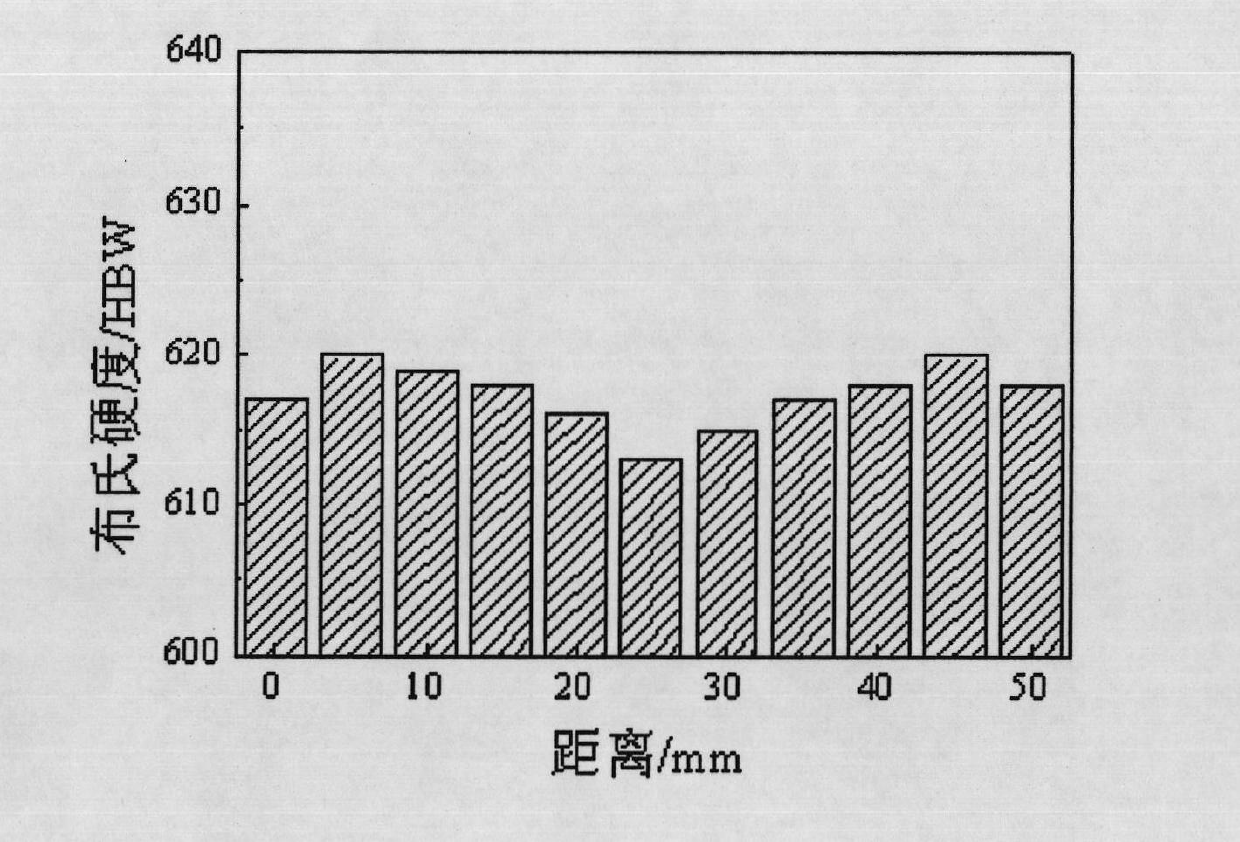

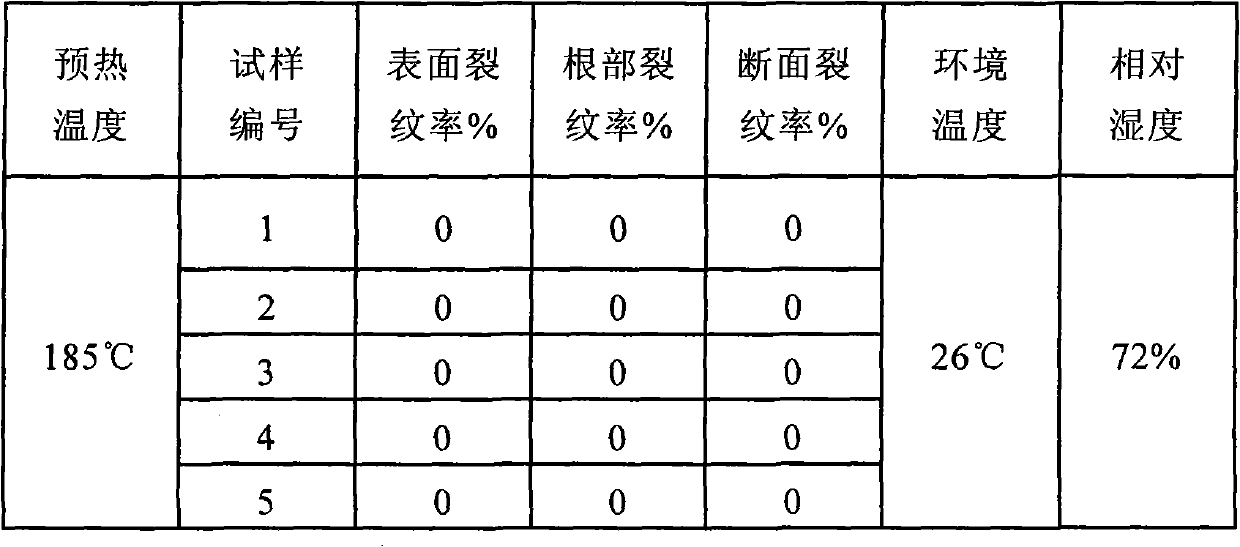

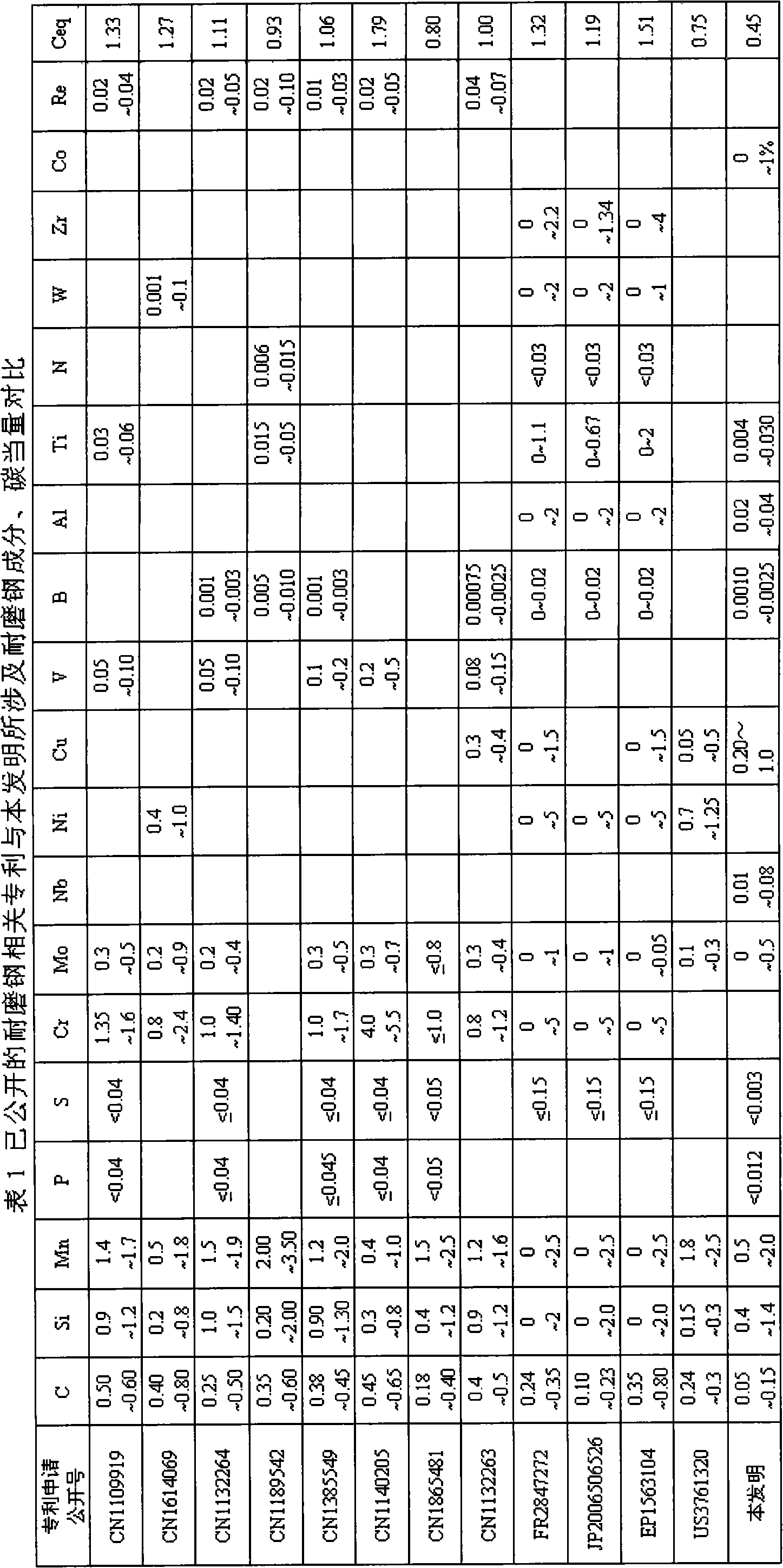

600HB-grade wear resistant steel plate and its manufacturing method

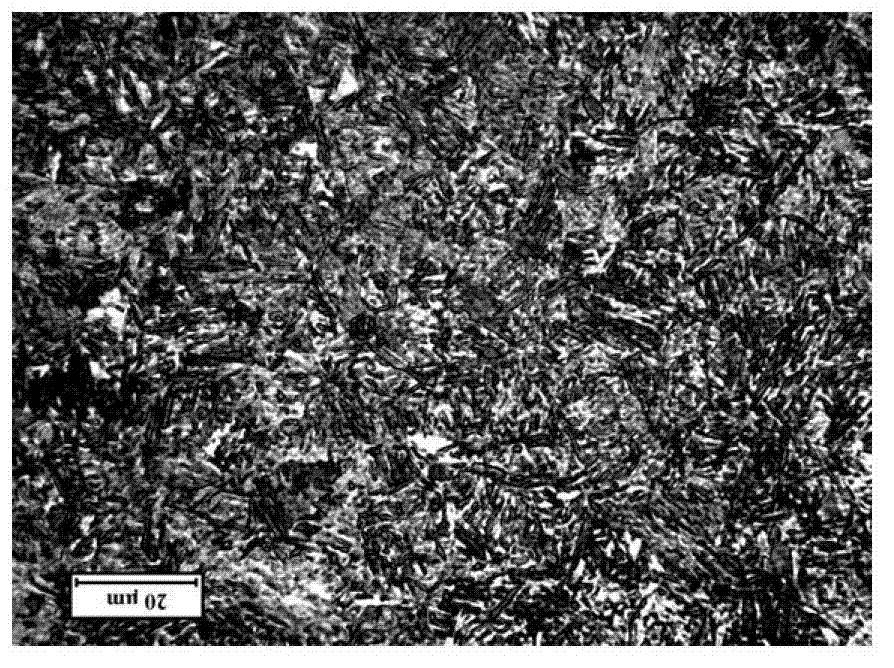

Disclosed is a 600HB-grade wear resistant steel plate, comprising, by weight, 0.41 to 0.50% of C, 0.10 to 0.60% of Si, 0.20 to 1.20% of Mn, no more than 0.050% of P, no more than 0.030% of S, 0.01 to 1.50% of Cr, 0.01 to 1.00% of Mo, 0.01 to 1.50% of Ni, 0.001 to 0.10% of Ti, 0.001 to 0.10% of Al, 0.001 to 0.10% of RE, 0.01 to 1.00% of W, 0.0005 to 0.0040% of B, 0.001 to 0.010% of Ca, the balance Fe and unavoidable impurities. The 600HB-grade wear resistant steel plate provided in the invention has high hardness (no less than 600HB), good toughness and plasticity, high abrasion resistance and excellent processability and weldability; the microstructure is martensite or martensite and retained austenite. Therefore, the 600HB-grade wear resistant steel plate is extremely suitable for being used in high abrasion environment, especially for being used in vehicles or equipment which contact with such materials of high hardness as high strength ores, for example, a bucket, or the compartment of an electric wheel self-discharging truck for mining, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for growing nuisance free selenium-rich rice by using biological technique

InactiveCN101292615ANo pollution in the processFormula refiningSoil lifting machinesPlantingContinuous croppingDisease

The invention relates to a method for planting pollution-free rice rich in selenium by adopting biotechnology, belonging to a planting method of plants; the planting method comprises the steps of land selection, soil preparation, application of the soil activator Medina, variety selection and seed treatment, seedling strengthening by means of dry raising and spaced planting cultivation, timely rice transplanting and reasonable compact planting, adequate fertilization, scientific irrigation, adoption of selenium supplementing and transforming technology, comprehensive prevention and control of diseases and pests, harvesting and threshing, drying and storing. The method of the invention has obvious effect; proved by field production trials, the application of the biologics of the Medina can increase the plant yield by 20 percent to 40 percent and decrease the fertilizer dosage by 25 percent to 50 percent and improve the rate of emergence in saline and alkali waste lands by 40 percent to 80 percent; the method can overcome diseases of continuous cropping effectively, eliminate soil crusting and optimizing greenhouses, etc. so as to preserve the soil properties of land capability.

Owner:濮阳市中原农村实用技术研究所

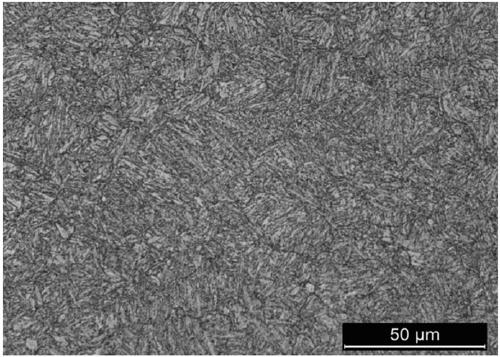

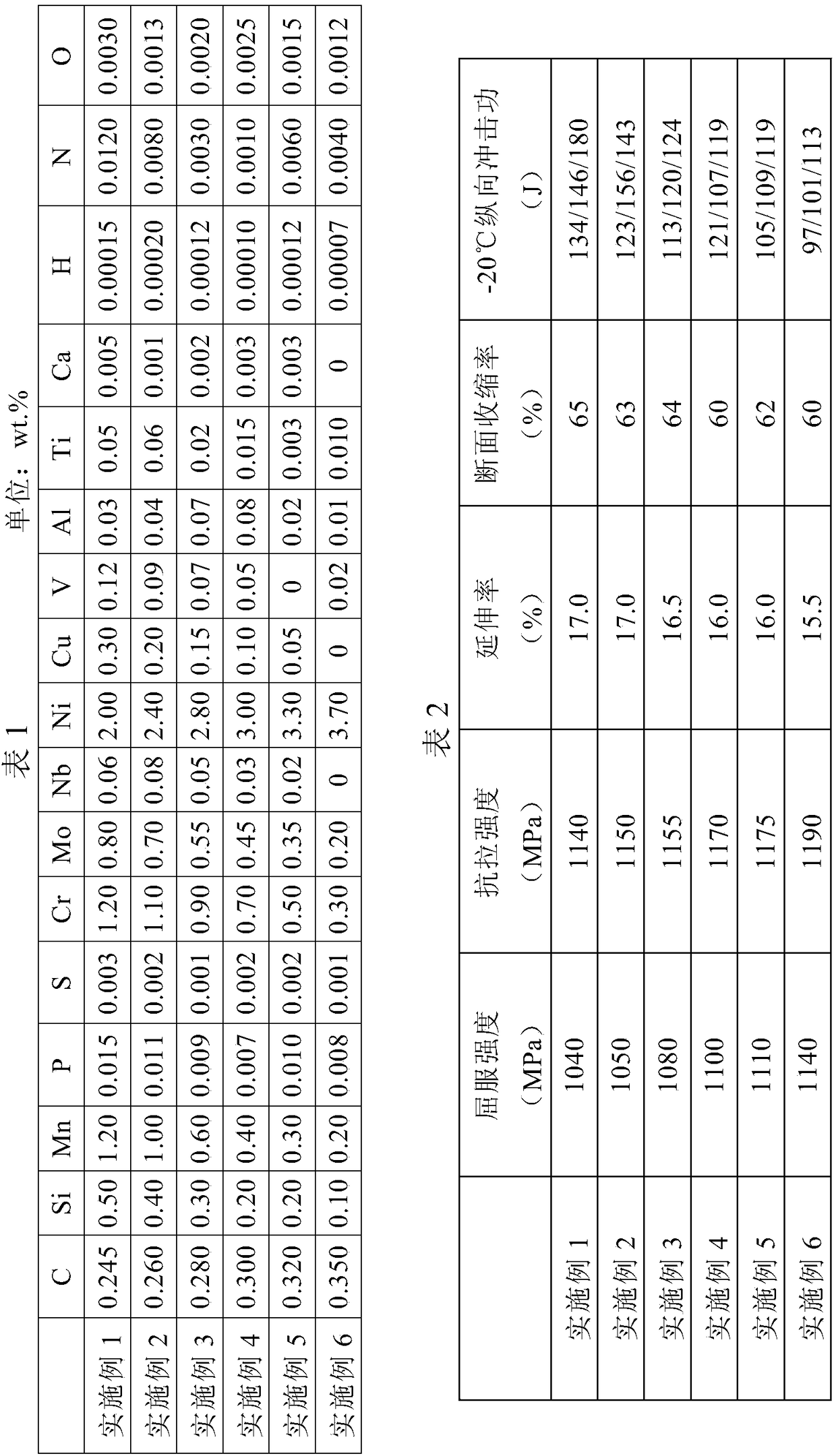

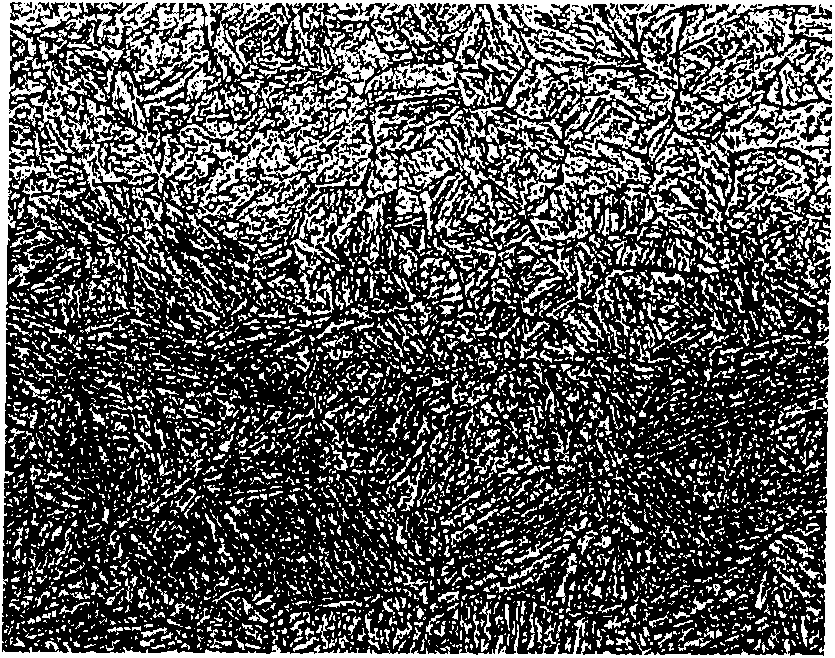

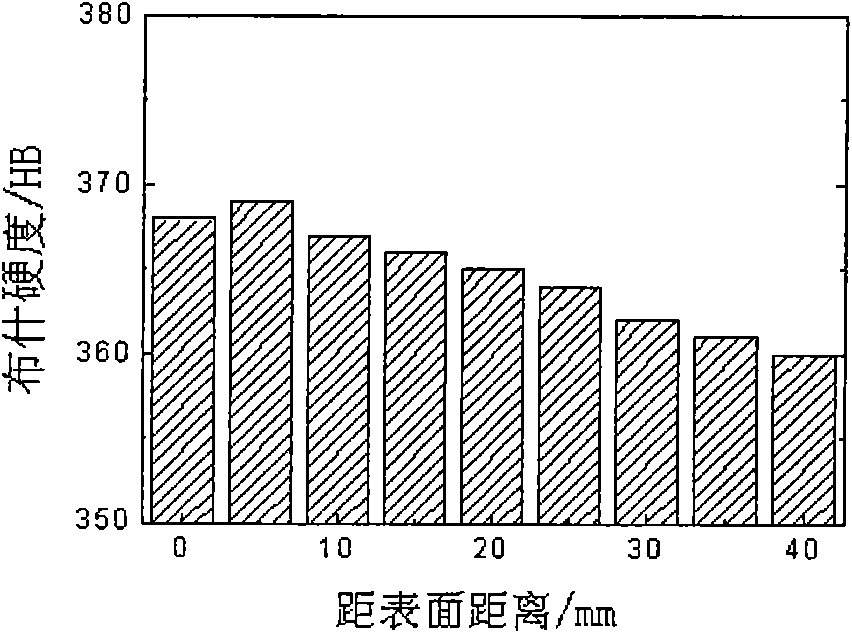

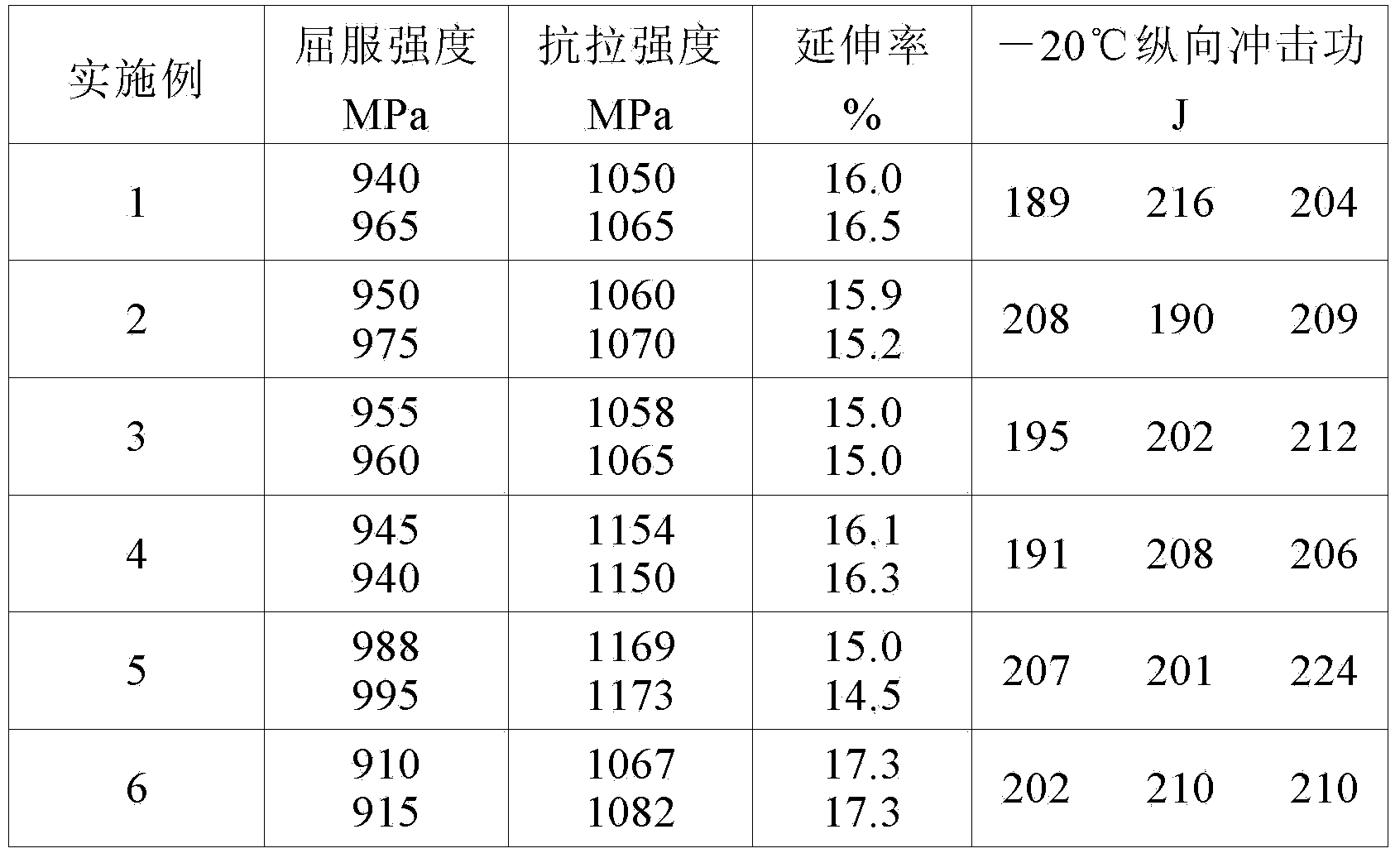

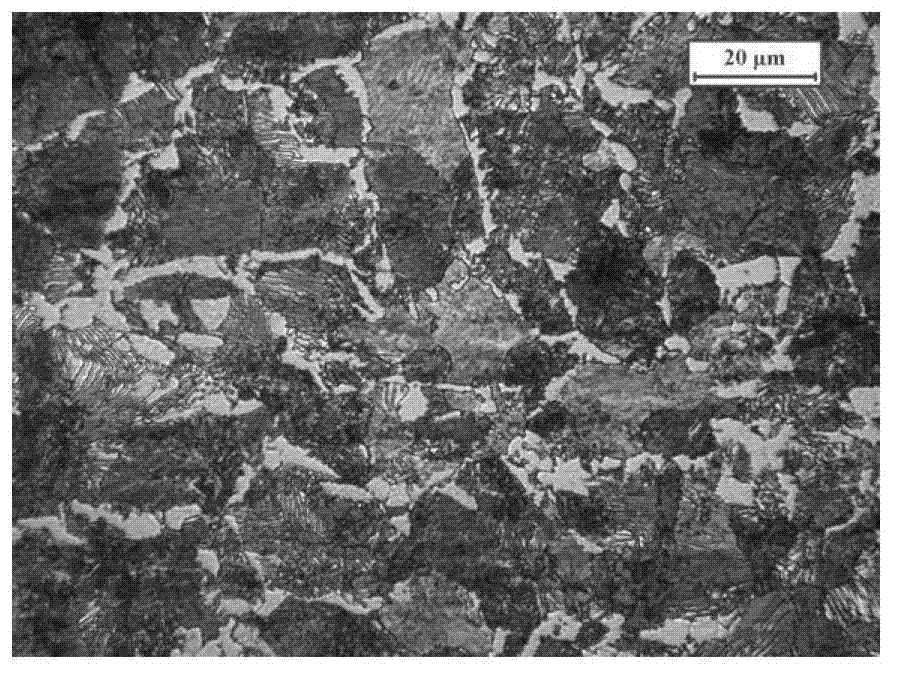

Ultrahigh tough steel with tensile strength of 1100 Mpa and manufacturing method thereof

InactiveCN109136737AImprove low temperature impact toughnessImprove tensile propertiesShrinkage rateUltimate tensile strength

The invention discloses ultrahigh tough steel with tensile strength of 1100 Mpa and a manufacturing method thereof. Chemical components of the tough steel comprises, by weight, 0.245-0.350% of C, 0.10-0.50% of Si, 0.20-1.20% of Mn, P less than or equal to 0.015%, S less than or equal to 0.003%, 0.30-1.20% of Cr, 0.20-0.80% of Mo, 2.00-3.70% of Ni, 0-0.30% of Cu, 0-0.08% of Nb, 0-0.12% of V, 0.01-0.08% of Al, 0.003-0.06% of Ti, Ca less than or equal to 0.005%, H less than or equal to 0.002%, N less than or equal to 0.0120%, O less than or equal to 0.0030%, Fe and inevitable impurities. The preparation method adopts quenching plus tempering heat treatment, and tempered martensites plus tempered bainites and residual austenite tissue are obtained. The yield strength of steel is greater than or equal to 900 Mpa, the tensile strength is greater than or equal to 1100 Mpa, the charpy impact energy Akv (-20 DEG C) is greater than or equal to 70 J, the elongation rate is greater than or equal to 15%, the shrinkage rate of a fracture surface is greater than or equal to 50%, good strength, low-temperature toughness and plasticity are achieved, and the ultrahigh tough steel can be used for manufacturing high-performance ocean platform mooring cables of R6 grade and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

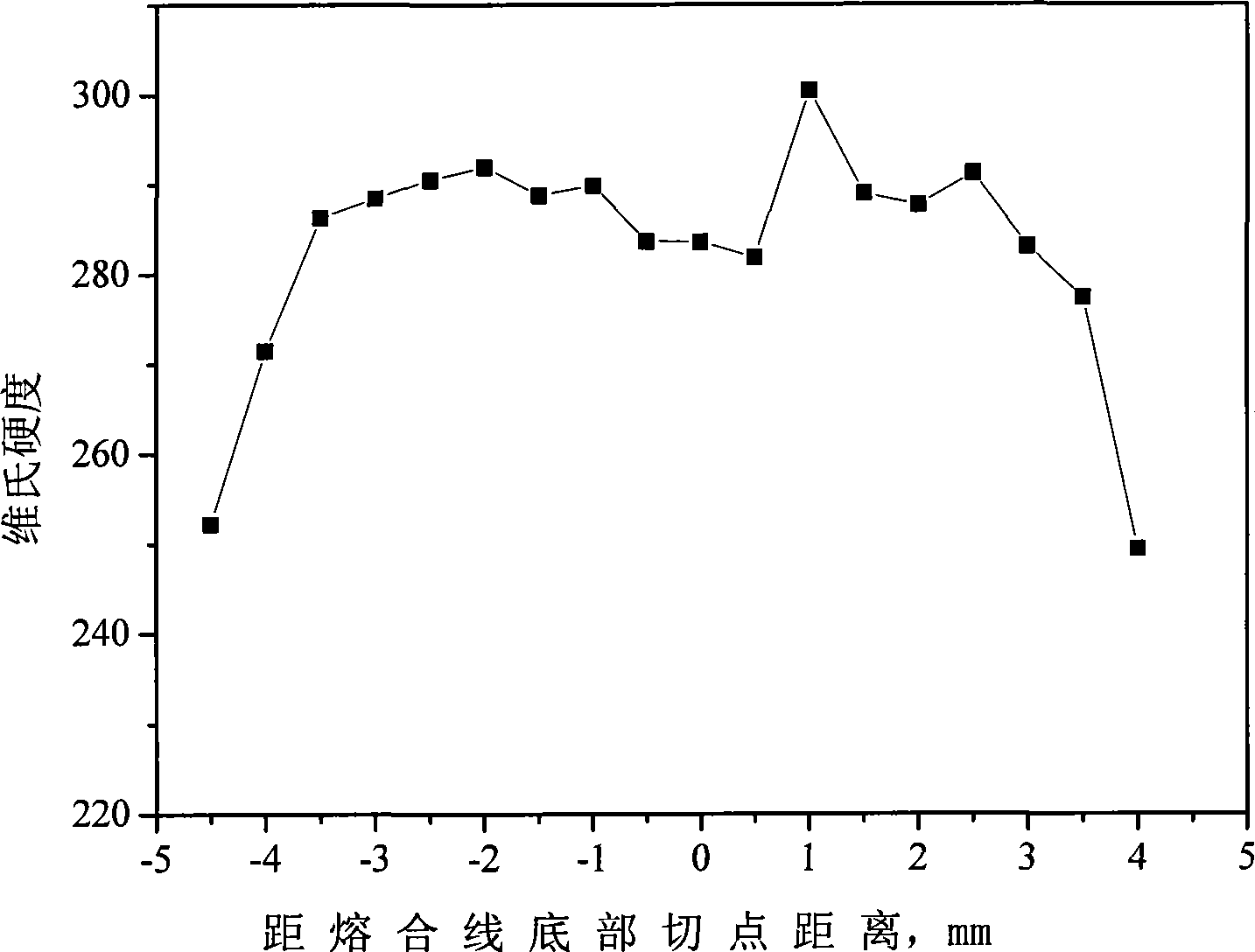

High-flexibility wear-resistant steel plate and manufacturing method thereof

ActiveCN101775539AImprove wear resistanceImprove low temperature toughnessMicro structureForeign matter

The invention provides a high-flexibility wear-resistant steel plate, which is characterized by comprising the following chemical components by weight percent: 0.04 to 0.11 percent of C, 0.10 to 0.50 percent of Si, 0.50 to 1.50 percent of Mn, less than 0.015 percent of P, less than 0.010 percent of S, 0 to 0.60 percent of Cr, 0 to 0.50 percent of Mo, 0 to 0.80 percent of Ni, 0 to 0.050 perent of Nb, 0.005 to 0.0040 percent of B, 0.010 to 0.060 percent of Al and 0.005 to 0.060 percent of Ti, and the surplus is Fe and inevitable foreign matters; and the content of Si, Mn and Cr satisfies that: Si+Mn+Cr is less than or equal to 2.4 percent and more than or equal to 1.30 percent; and the content of Mo, Ni and Nb satisfies that: Mo+Ni+Nb is less than or equal to 1.10 percent more than or equal to 0.10 percent. The hardness of the high-flexibility wear-resistant steel plate is more than 350 HB, the longitudinal impact power is more than 100J at the temperature of minus 40 DEG C, the micro-structure is of bainite or martensite, and the welding performance is excellent. The wear-resistant steel plate has simple and easy production technology and excellent low-temperature flexibility and welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

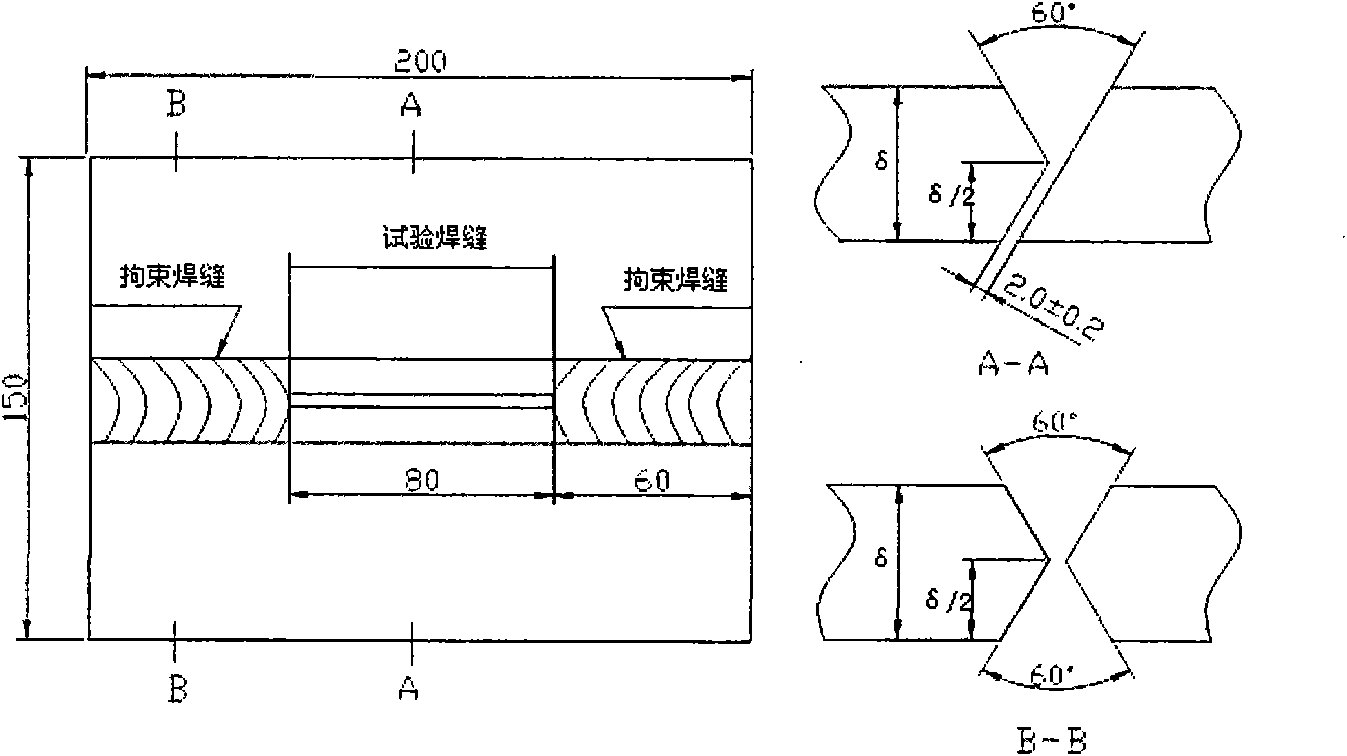

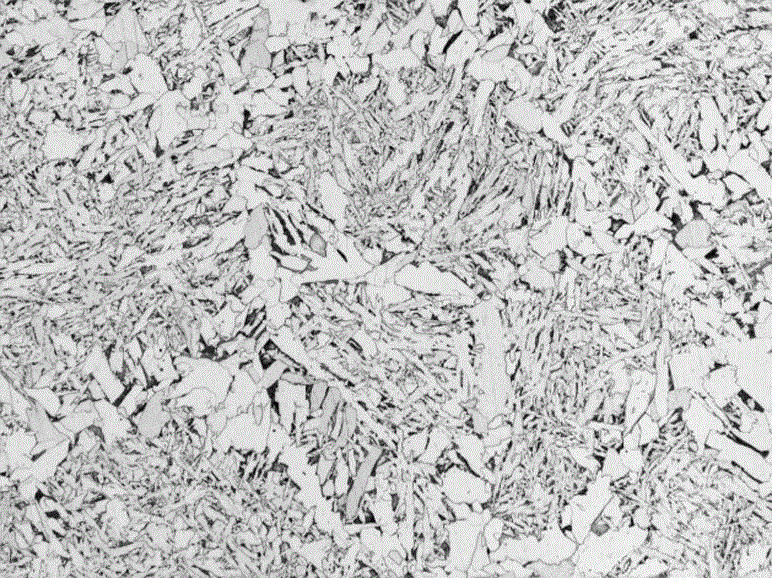

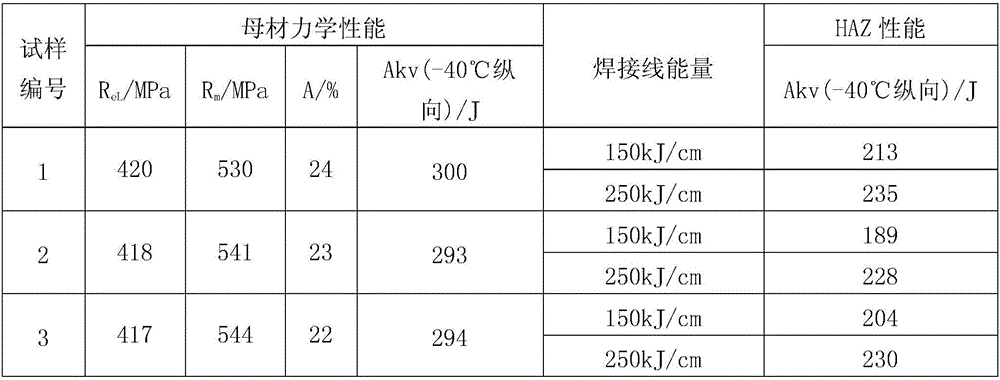

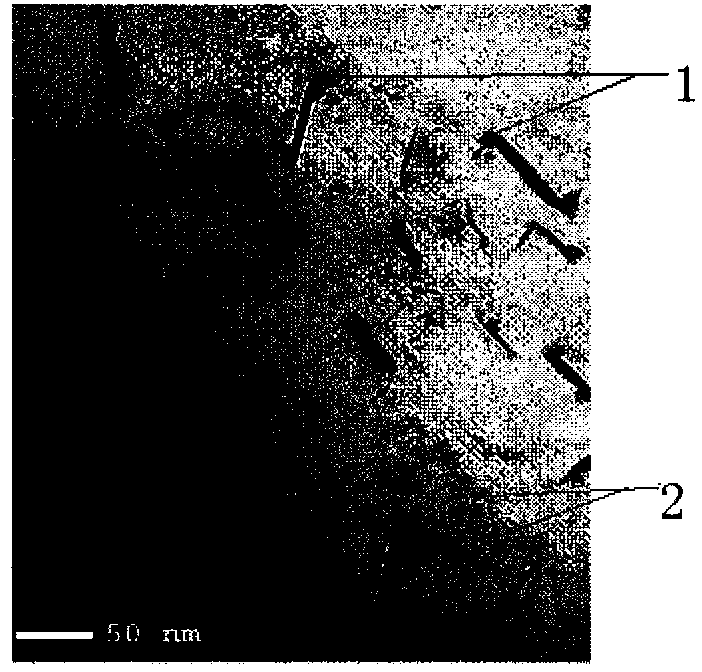

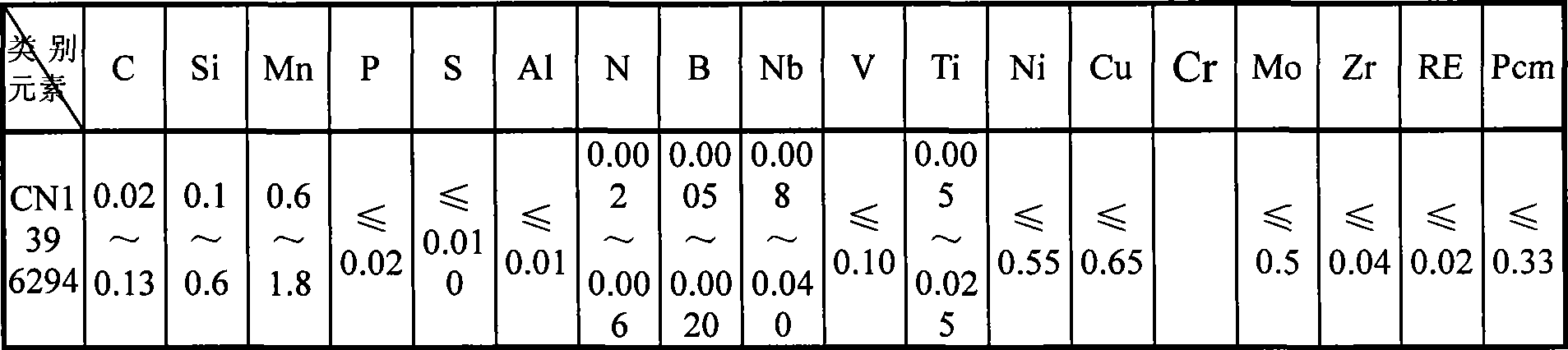

TMCP-state low-cost high-strength ship plate steel for high-heat input welding and manufacturing method of TMCP-state low-cost high-strength ship plate steel

ActiveCN106756543AReasonable ingredientsGood comprehensive mechanical propertiesSteel platesHeat treated

The invention discloses TMCP-state low-cost high-strength ship plate steel for high-heat input welding. The TMCP-state low-cost high-strength ship plate steel comprises the chemical components in percentage by weight: 0.04-0.12% of C, 0.15-0.35% of Si, 1.10-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.0030% of S, 0.030-0.060% of V, 0.005-0.060% of Alt, 0.32-0.41% of Ceq, 0.005-0.030% of Ti, 0.0005-0.0040% of Ca, 0.05-0.40% of Ni and the balance of Fe and unavoidable impurities. The steel plate disclosed by the invention has the yield strength of larger than or equal to 400MPa and the tensile strength of larger than or equal to 510MPa, is suitable for high-strength ship plate steel with welding heat input being within the range of 150-250kJ / cm, the average impact power of HAZ of the steel plate under 40 DEG C is higher than 150J under the high-heat input welding conditions of 150kJ / cm and 250kJ / cm, heat treatment is not needed, and the production cost is low.

Owner:NANJING IRON & STEEL CO LTD

Rare earth-contained heat-resistant magnesium alloy and preparation method thereof

ActiveCN103421999AImprove mechanical propertiesGood mechanical propertiesRare earthUltimate tensile strength

The invention discloses a rare earth-contained heat-resistant magnesium alloy and a preparation method thereof, belongs to the technical field of magnesium alloy preparation. The heat-resistant magnesium alloy disclosed by the invention comprises the following materials by weight: 2 to 8 percent of Sm, 0.5 to 6 percent of Gd, 0.1 to 2 percent of Zn, 0.1 to 1.5 percent of Zr, and Mg and inevitable impurity elements in balancing amount, wherein the total weight of the impurity elements is equal to or smaller than 0.02 percent. By adding ally elements (Sm, Gd and Zn) to replace Y and Nd of WE series alloies, and adjusting corresponding heat treatment processes to ensure that the prepared magnesium alloy has excellent indoor temperature intensity, high-temperature strength and plasticity, the indoor temperature intensity, high-temperature strength and plasticity of the magnesium alloy prepared according to the preparation method are more excellent than those of the conventional WE series commercial magnesium alloies; the preparation method of the magnesium alloy prepared according to the preparation method is lower than that of the conventional WE series commercial magnesium alloies. The process is simple; industrialized application is facilitated.

Owner:CENT SOUTH UNIV

Steel plate with yield strength of 960MPa and manufacturing method thereof

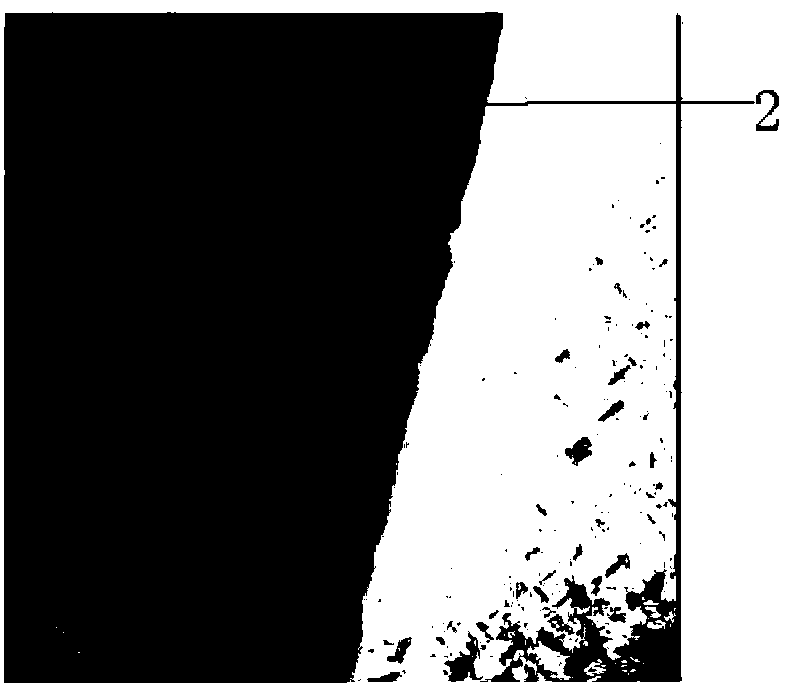

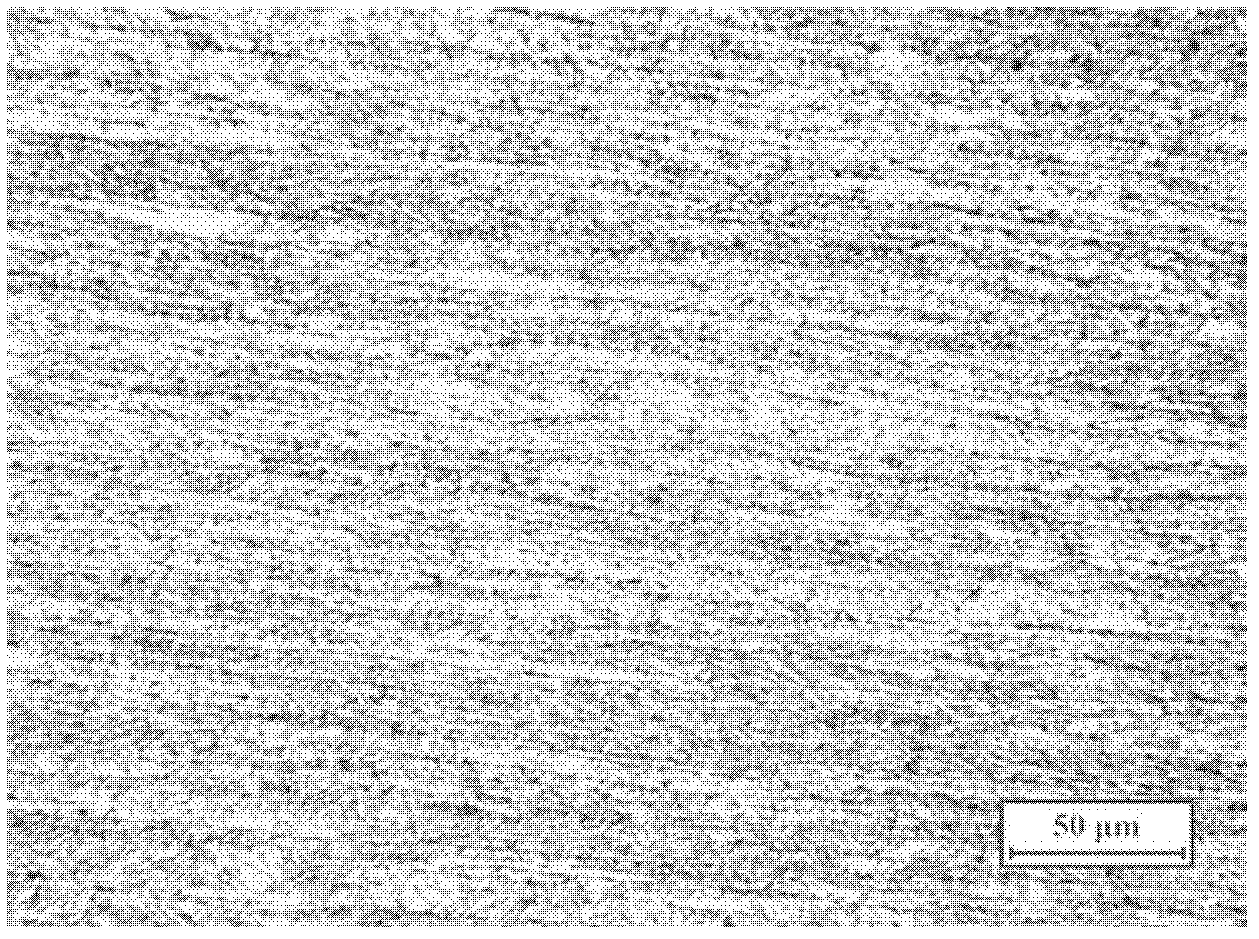

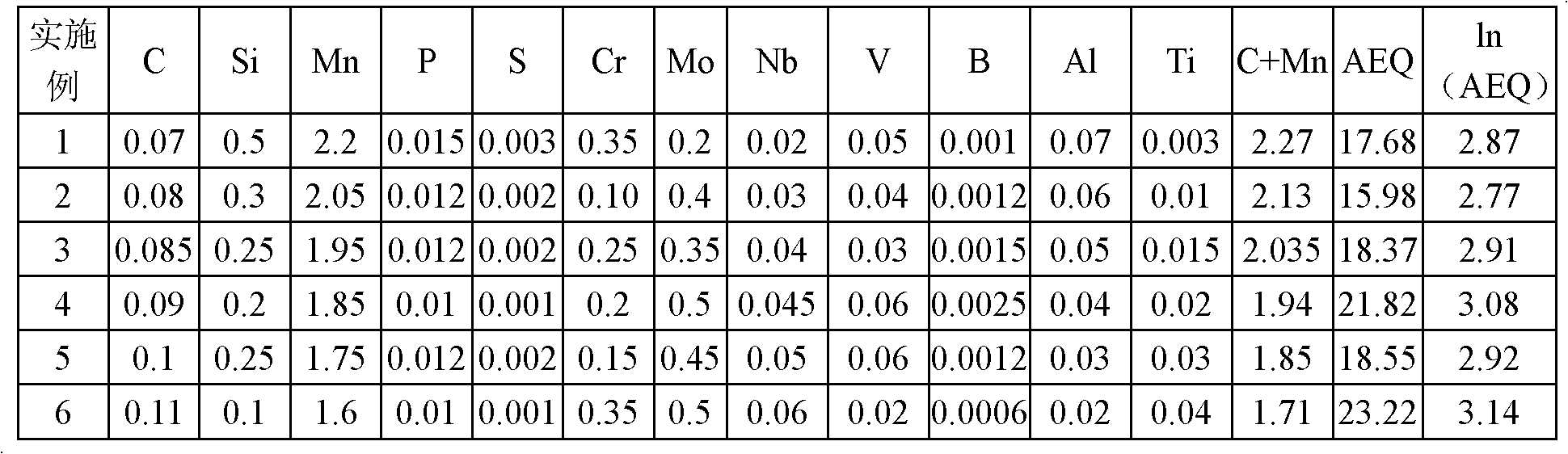

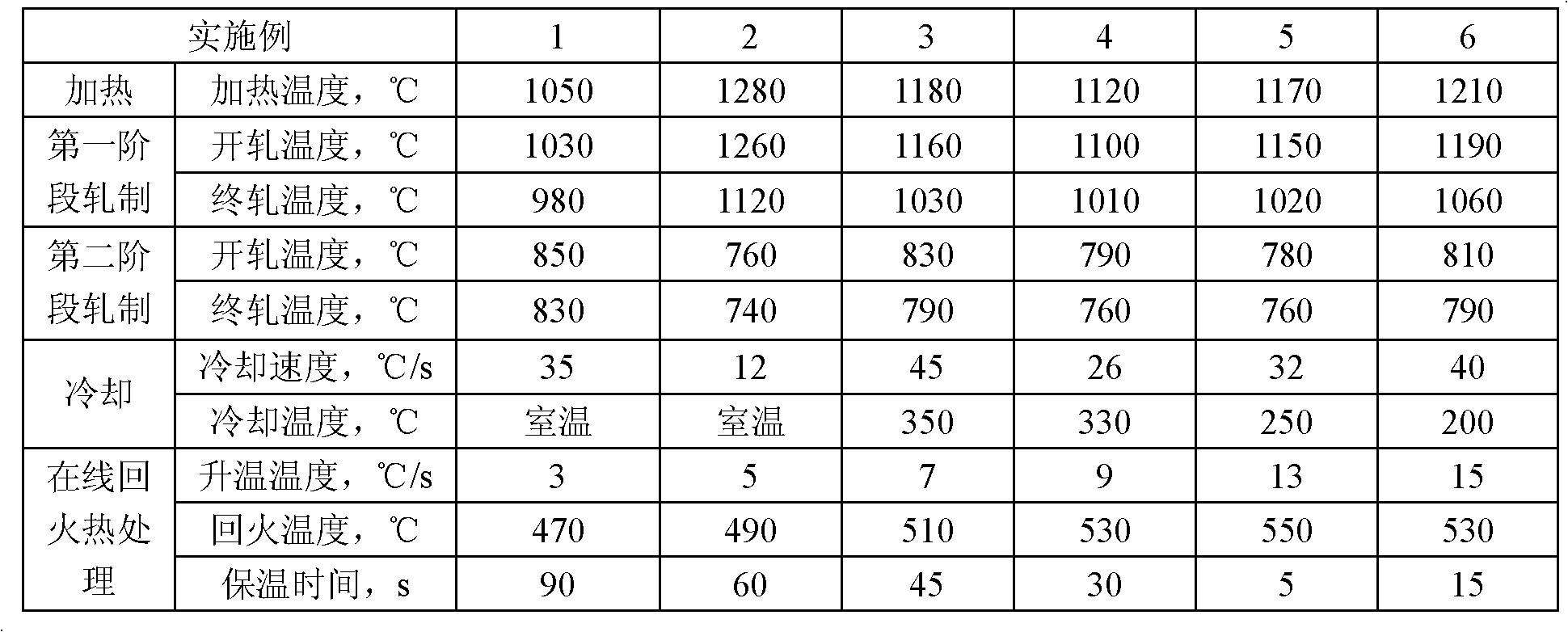

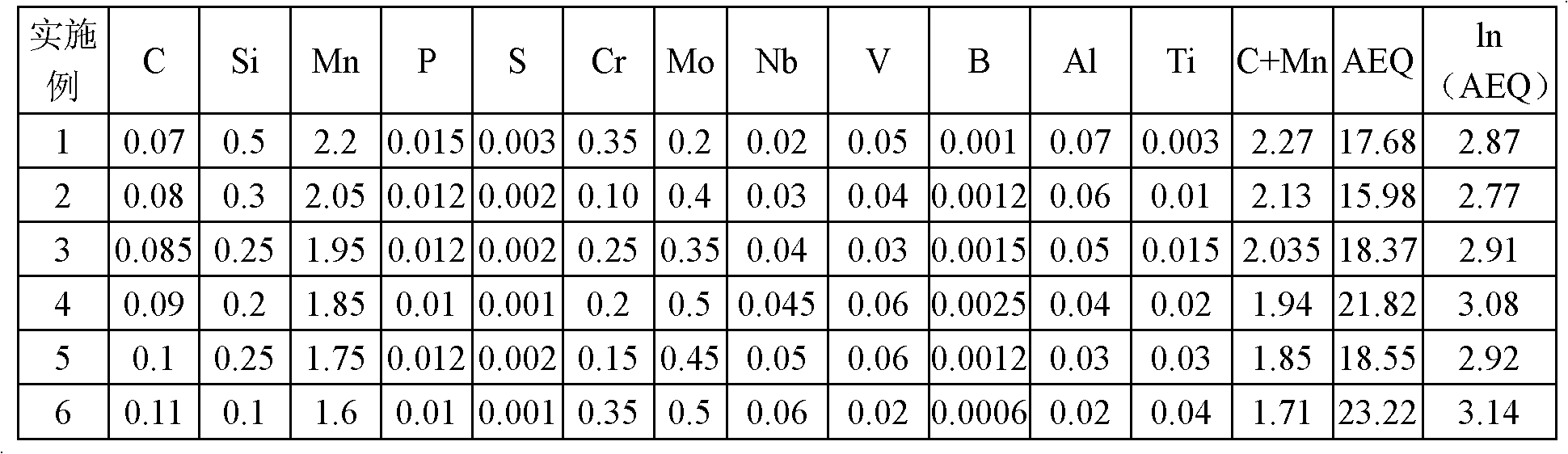

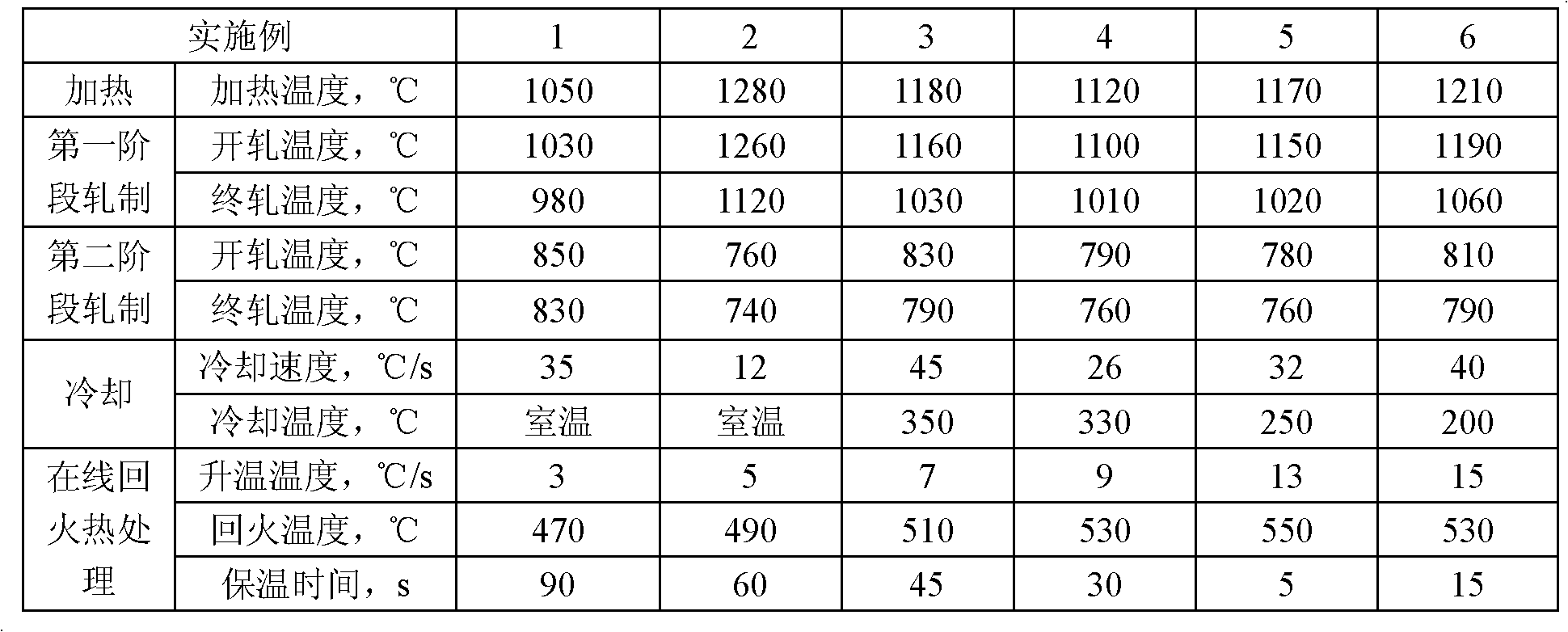

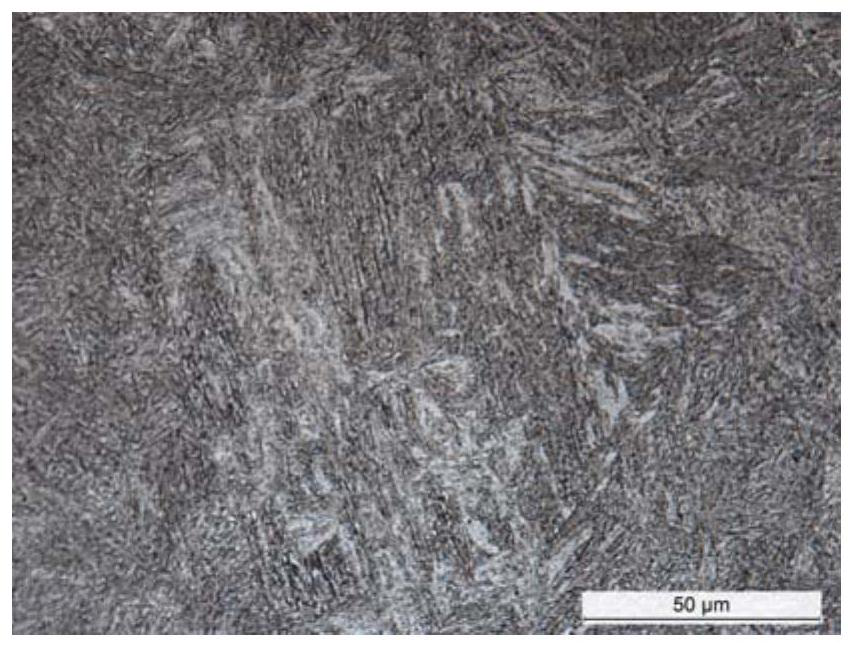

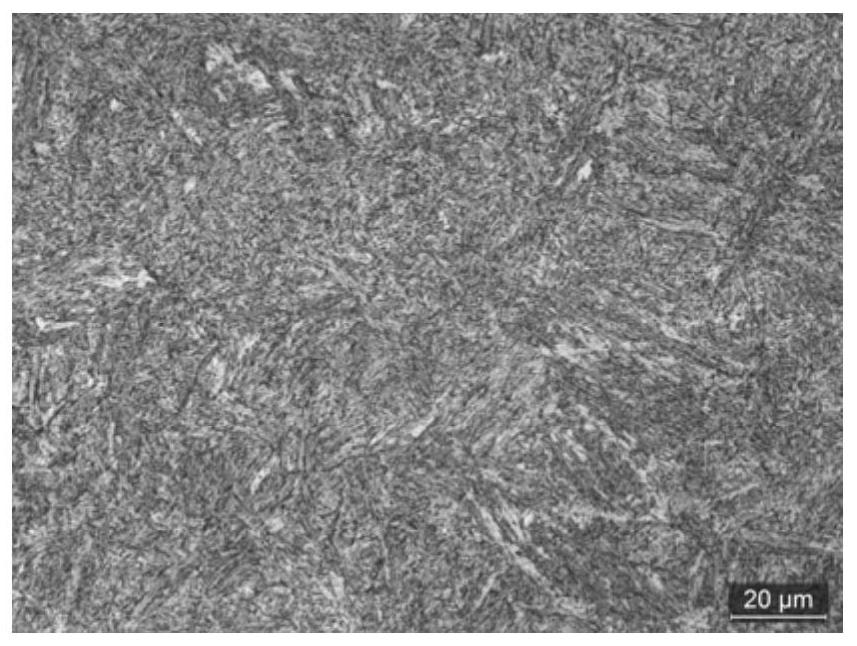

The invention discloses a steel plate with yield strength of 960MPa, which comprises the following chemical components in weight percent: 0.07-0.11 percent of C, 0.10-0.50 percent of Si, 1.60-2.20 percent of Mn, not greater than 0.015 percent of P, not greater than 0.003 percent of S, 0.10-0.35 percent of Cr, 0.20-0.50 percent of Mo, 0.02-0.06 percent of Nb, 0.02-0.06 percent of V, 0.003-0.04 percent of Ti, 0.02-0.07 percent of Al, 0.0006-0.0025 percent of B and the balance of Fe and other inevitable impurities. The steel plate with the yield strength of 960MPa also meets the following relational expressions: C+Mn is not less than 1.853Si+2.078Cr+3.112Mo-1298.532B but is not greater than 5.891Si+4.115Cr+4.797Mo-398.532B, and ln(AEQ) is not less than 2.08 but is not greater than 3.41. The invention also discloses a manufacturing method for the steel plate. The tensile strength of the obtained steel plate is not less than 980MPa, the Charpy impact power Akv (-40 DEG C) is not less than 80J, and the carbon equivalent (CEV) is not greater than 0.58 percent. The steel plate is excellent in welding property.

Owner:BAOSHAN IRON & STEEL CO LTD

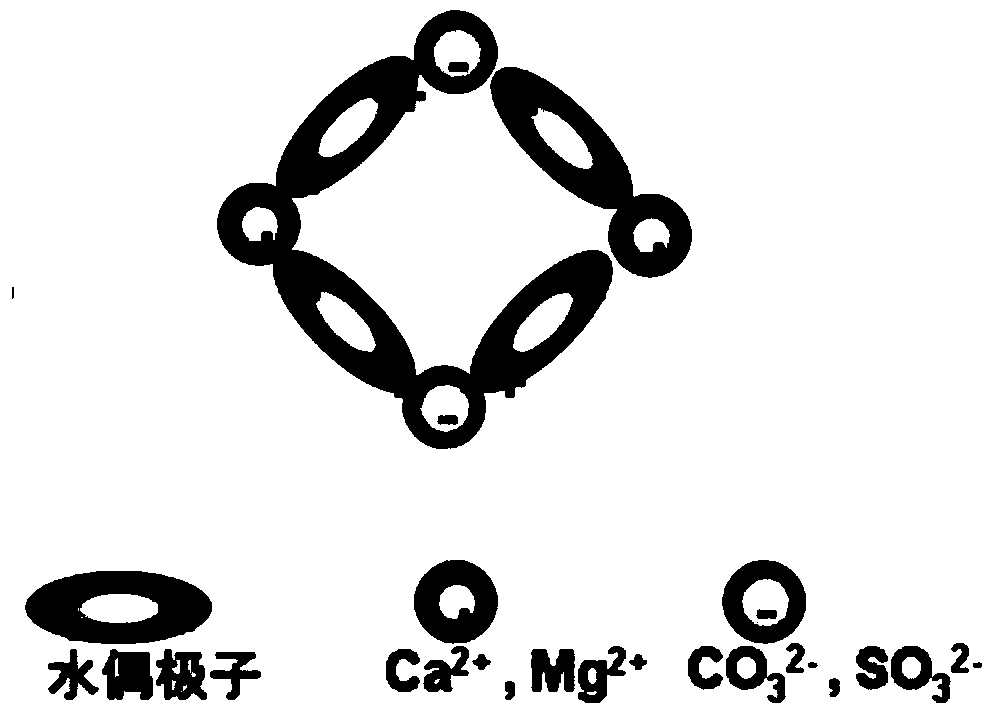

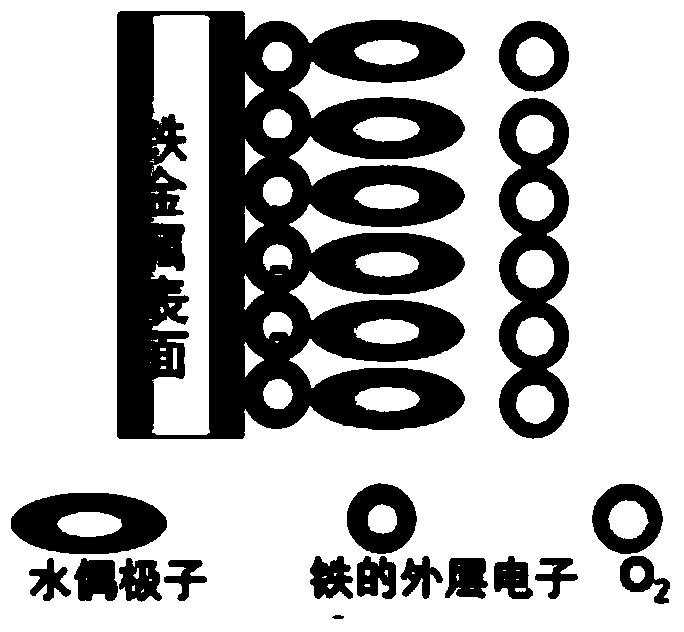

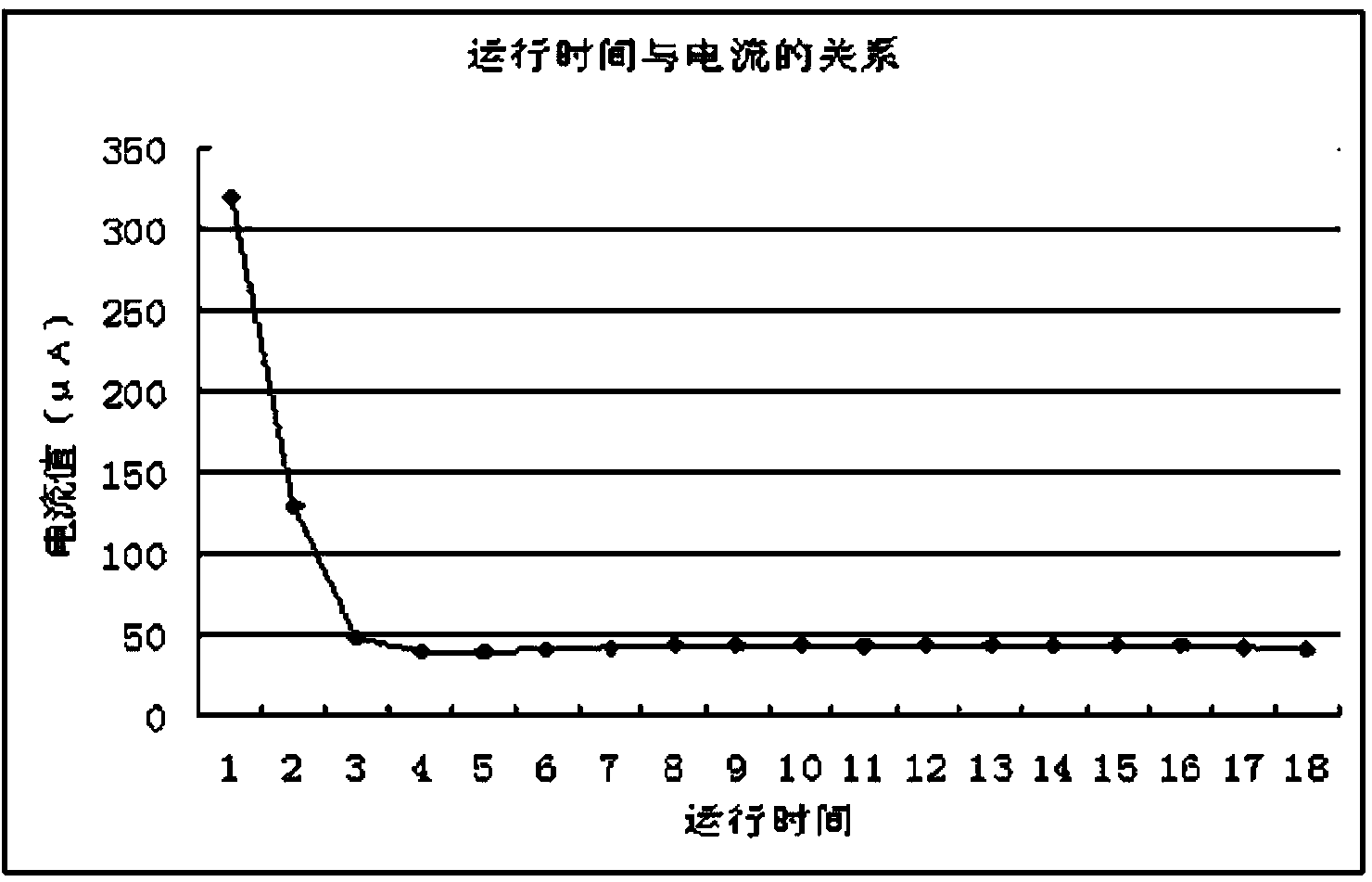

Scale-inhibition copper-based catalyst alloy and preparation method thereof

ActiveCN103805808APrevent scale formationStrong ability to dissolve scaleMetal/metal-oxides/metal-hydroxide catalystsWeak currentElectricity

The invention discloses a scale-inhibition copper-based catalyst alloy and a preparation method thereof. The catalyst alloy comprises the following components in percentage by weight: 40%-70% of Cu, 5%-20% of Ni, 10%-35% of Zn, 5%-30% of Sn, 0.5%-20% of Ag, 0.1%-8% of Fe, 0.01%-2% of Sb and 0.05%-5% of Mn, wherein the components are chemically compounded to form a columnar crystal alloy directionally growing along an S100 crystal axis. The scale-inhibition copper-based catalyst alloy is used for inhibiting the formation of water scale by virtue of an advanced weak-current composite scale-inhibition mechanism on the premise that chemical components of fluid are not changed and has very strong water scale dissolving capacity; the additional maintenance does not need to be carried out in an operation process, the magnetism, the electricity and an additional power supply are not required.

Owner:NANJING CHAOXUSCIENCE&TECH DEV

Low-sugar fruity mint tabletting candy and preparation method thereof

The invention relates to a low-sugar fruity mint tabletting candy, comprising the following components: sorbitol, citric acid, fruit powder, fruit essence, magnesium stearate, raspberry fruit powder, malic acid, refrigerant, mentha arvensis oil and natural menthol, wherein the fruit powder comprises lemon powder, apple powder, grapefruit powder, mango powder, strawberry powder and blueberry powder; the fruit essence comprises lemon essence, rose bud essence, apple essence, mango essence, strawberry essence, brown sugar essence, vanilla essence, passion fruit essence, grapefruit essence, blueberry essence, raspberry essence and vatica astrotricha essence. The low-sugar fruity mint tabletting candy prepared by the method disclosed by the invention is a daily healthy buccal tablet which is good in taste, very low in sugar content, and applicable to mass people, can relieve dental ulcer, clear and nourish a throat and remove fatigue, and has the effects of refreshing breath, relaxing the mind and promoting oral health after being eaten.

Owner:深圳市聚特佳生物科技有限公司

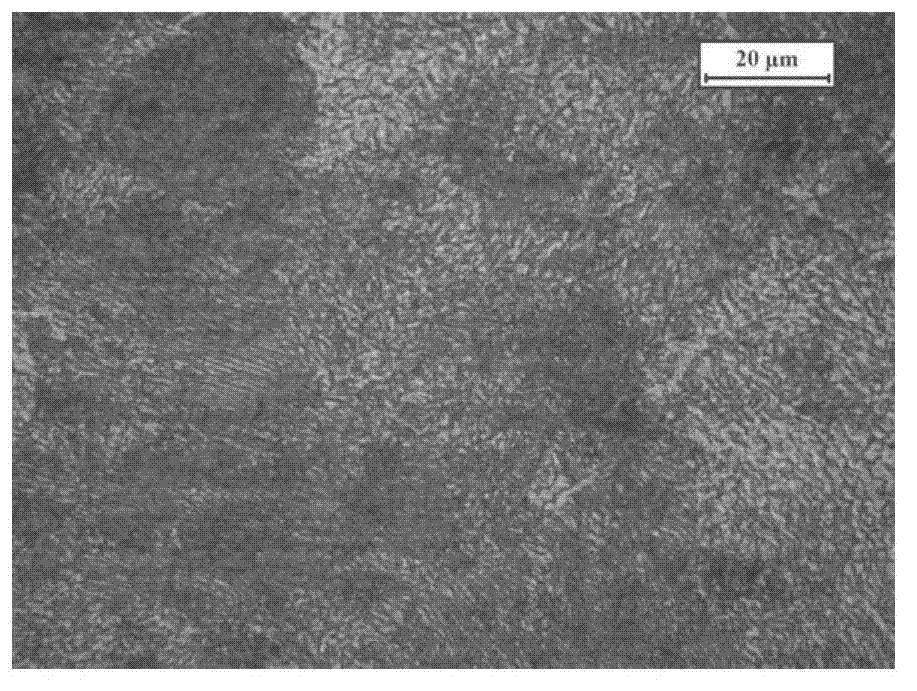

Steel plate with 890MPa-grade yield strength and low welding crack sensitivity and manufacturing method thereof

ActiveCN103898406AReduce C contentLow costFurnace typesHeat treatment furnacesSheet steelUltimate tensile strength

The invention discloses a steel plate with 890MPa-grade yield strength and low welding crack sensitivity and a manufacturing method thereof. The steel plate comprises the following components by weight percent: 0.06-0.13wt.% of C, 0.05-0.70wt.% of Si, 1.20-2.30wt.% of Mn, 0-0.25wt.% of Mo, 0.03-0.11wt.% of Nb, 0.002-0.050wt.% of Ti, 0.02-0.15wt.% of Al, 0-0.0020wt.% of B, no more than 8.5% of 2Si+3Mn+4Mo, and the balance being Fe and inevitable impurities. The tissue of taking a super-fine bainitic lath as a matrix is obtained by adopting a technology of controlling hot mechanical rolling and cooling, so as to improve the strength, the plasticity and the toughness of the steel plate. The yield strength of the steel plate with low welding crack sensitivity is greater than 800MPa, the tensile strength is greater than 900MPa, the charpy impact energy Akv (-20 DEG C) is greater than or equal to 150J, the welding crack sensitivity index Pcm is smaller than or equal to 0.20%, and the welding property is good.

Owner:BAOSHAN IRON & STEEL CO LTD

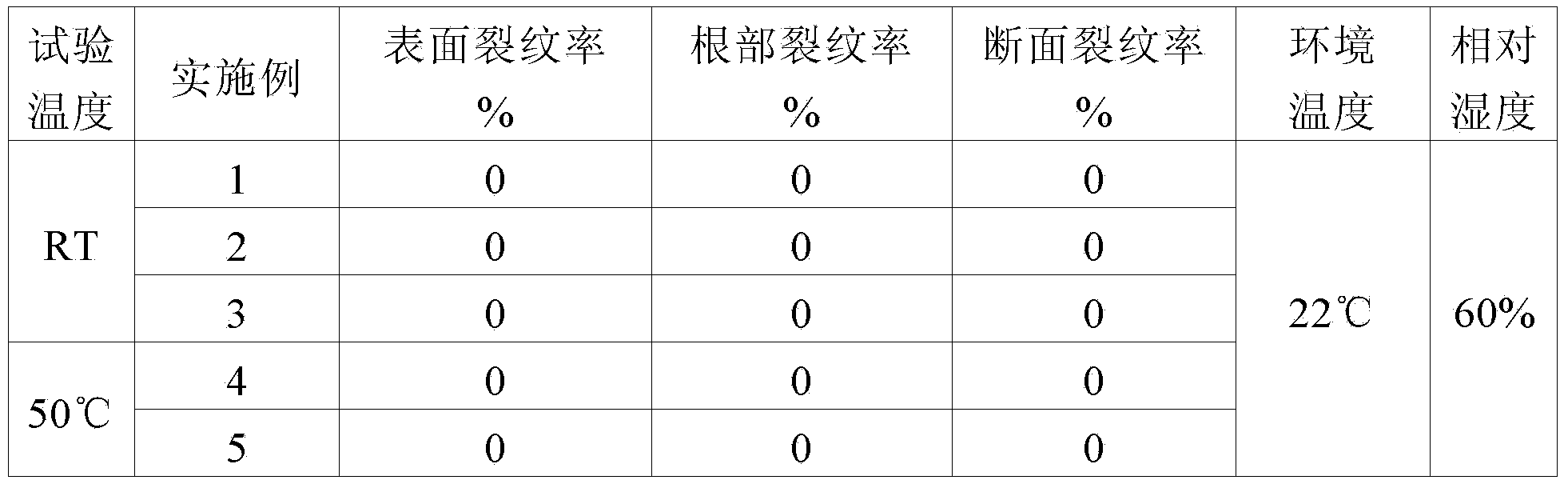

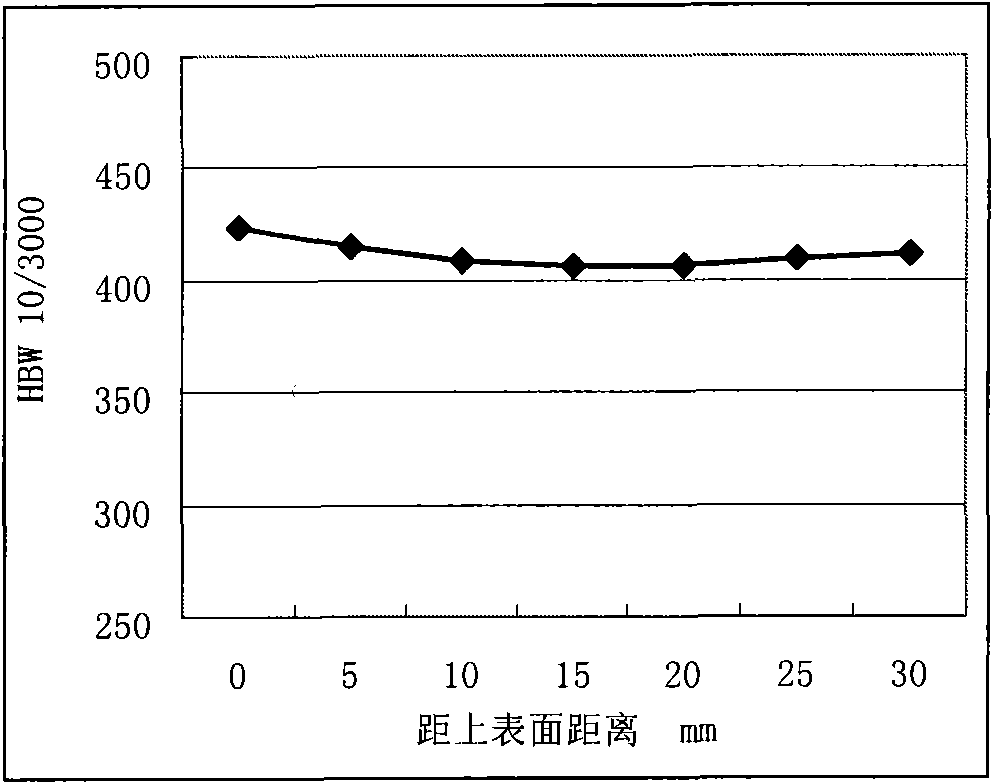

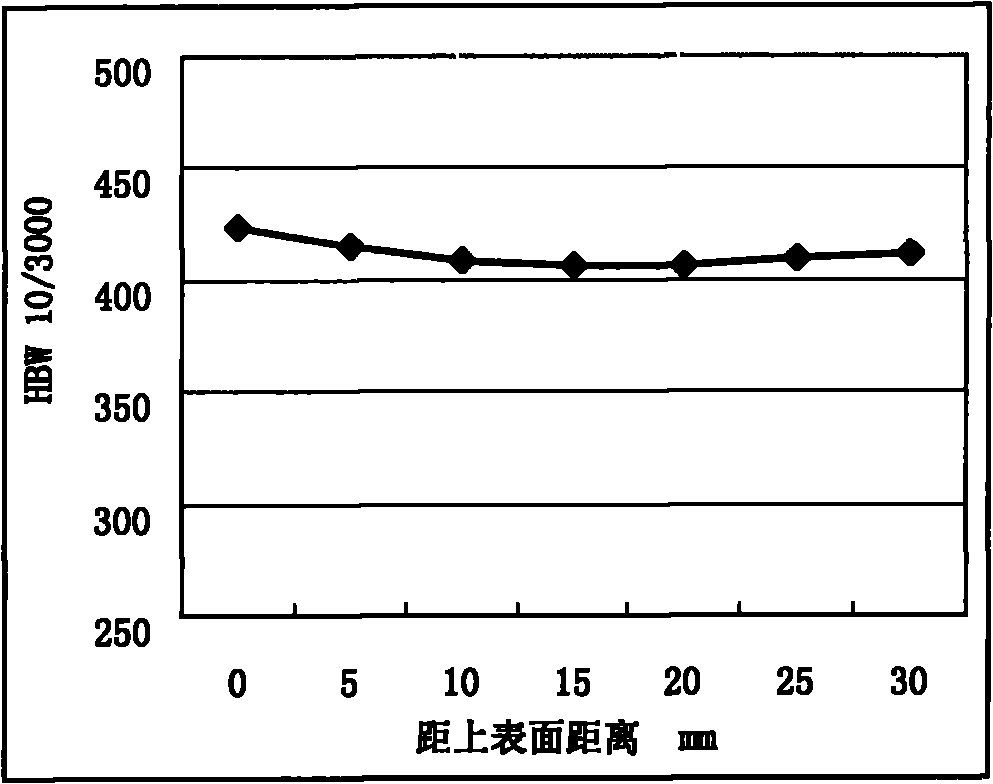

HB400-grade wear-resisting steel plate and production method thereof

The invention discloses an HB400-grade wear-resisting steel plate and a production method thereof. The steel plate comprises the following chemical components in percentage by weight: C 0.05-0.15wt%, Si 0.4-1.4wt%, Mn 0.5-2.0wt%, P <0.012wt%, S <0.003wt%, Mo 0-0.5%, Nb 0.01-0.08%, Cu 0.20-1.0%, Co 0-1.0%, B 0.0010-0.0025wt%, Al 0.02-0.04wt%, Ti 0.004-0.030wt%, and the balance of Fe and inevitable impurities, wherein the content of Mo and Nb needs to satisfy the condition that the Mo+Nb is not less than 0.023C+0.059Ti+1.71B and not more than 2.574C+0.62Mn+10.36Ti +2.11B. The invention reduces production cost by adding some cheap alloy elements; and when the value of carbon equivalent Ceq is not more than 0.45, the HB400-grade wear-resisting steel plate has good welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

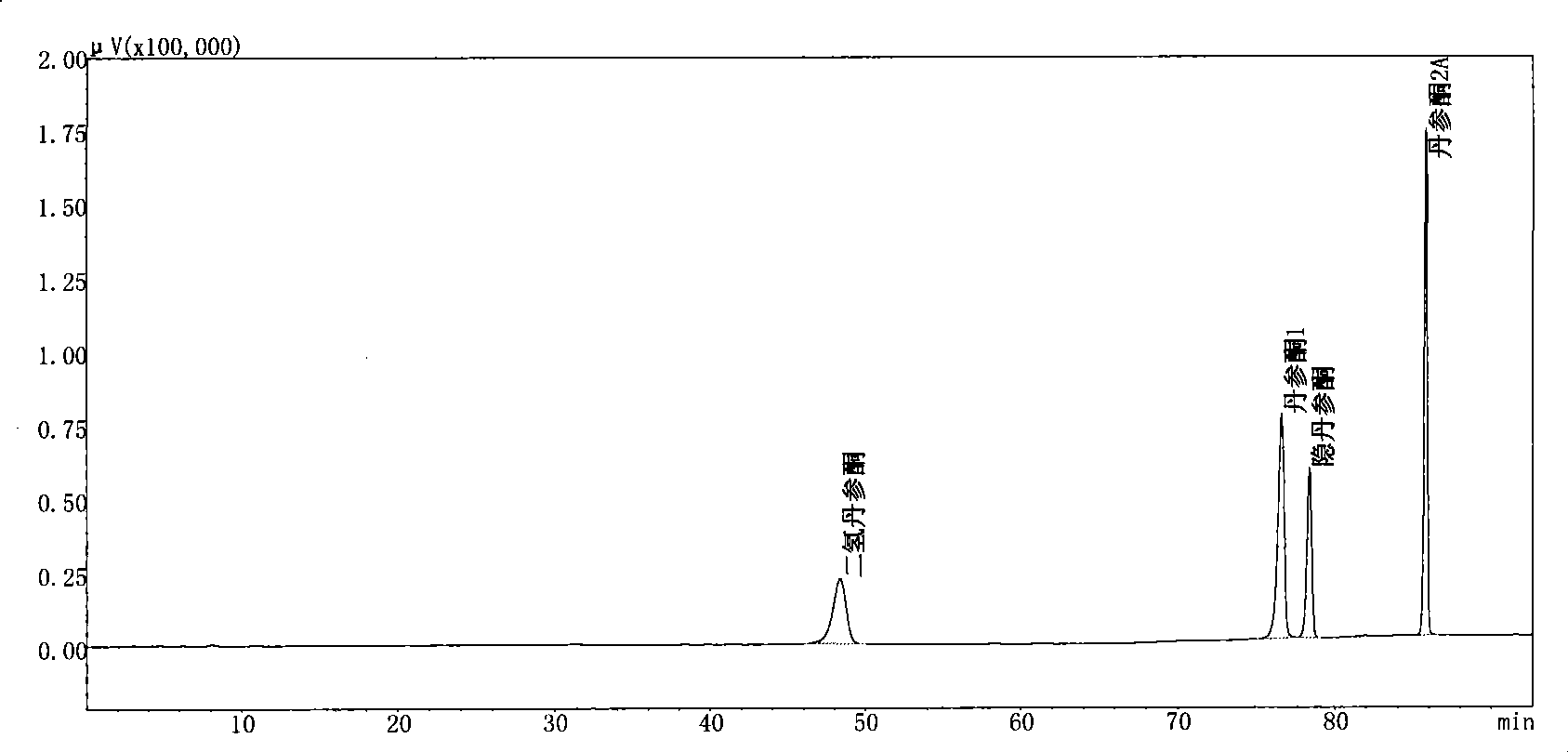

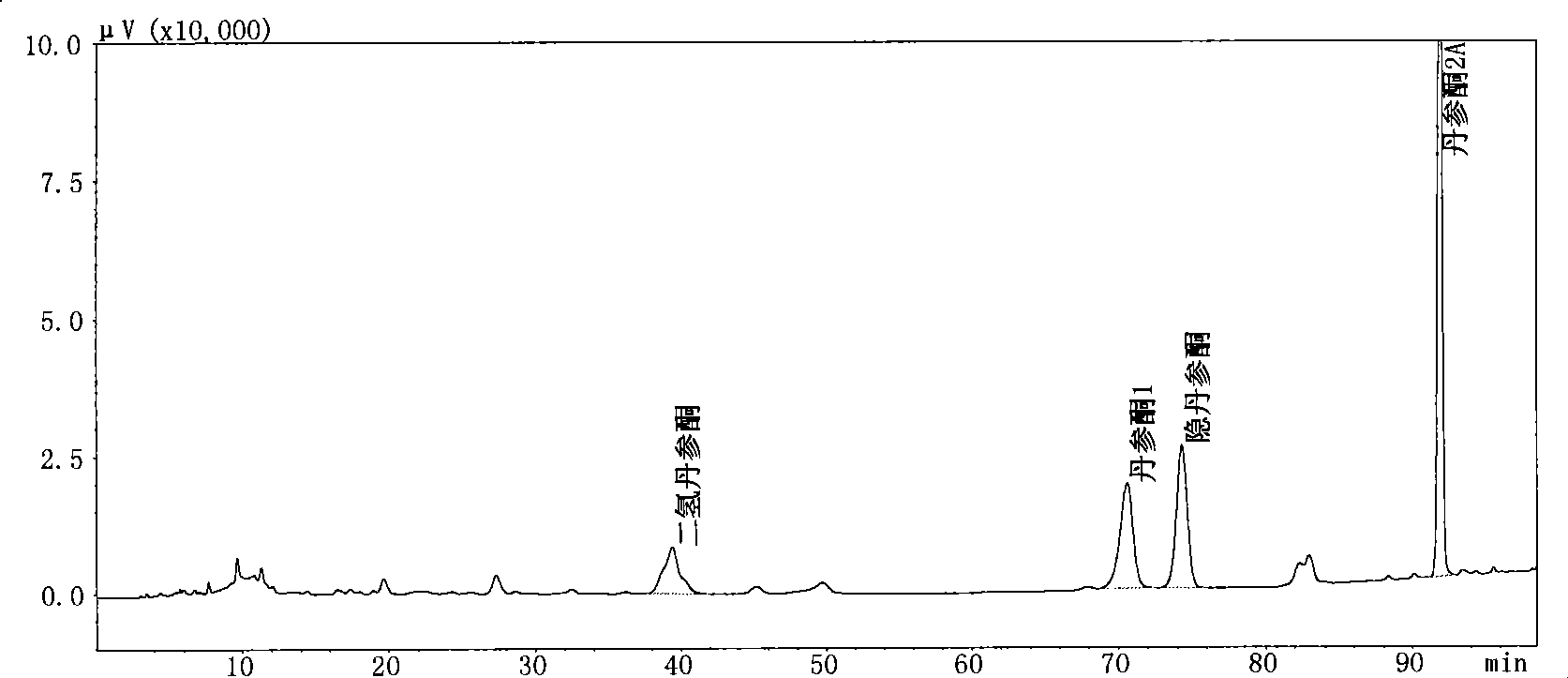

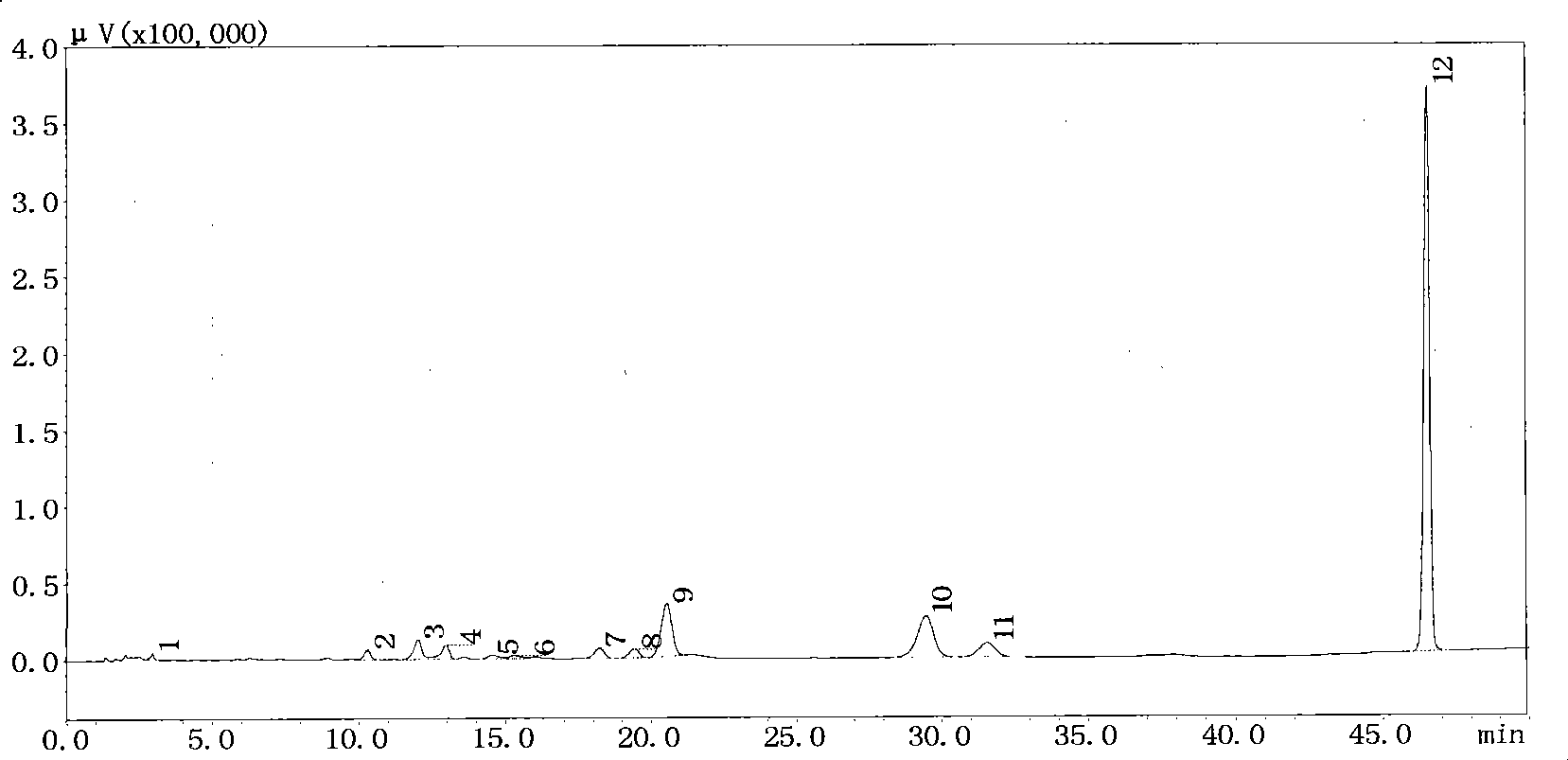

Antibiotic tanshinone extract, preparation method thereof, use and products produced thereby

InactiveCN101411745AHigh purityReasonable proportionAntibacterial agentsOrganic active ingredientsTanshinone IIAAntibiotic Y

The invention relates to an antibacterial tanshinone extract extracted from Salvia spp. roots, a preparation method thereof, application of the antibacterial tanshinone extract and products of the antibacterial tanshinone extract. The extract contains cryptotanshinone, dihydro-tanshinone, tanshinone I and tanshinone IIA, wherein the total weight content of the four compounds is 40 to 99 percent of the total weight content of the extract; the weight content of the cryptotanshinone is 50 to 95 percent of the total weight of the four compounds; the weight content of the dihydro-tanshinone is 5 to 30 percent of the total weight of the four compounds; the weight content of the tanshinone I is 0 to 20 percent of the total weight of the four compounds; and the weight content of the tanshinone IIA is 0 to 40 percent of the total weight of the four compounds. The preparation method comprises the steps of diacolation extraction and purification for two times. The extract is used for preparing antibacterial medicines or other products. The tanshinone extract obtained has high purity, more reasonable proportions of various compositions, and can exert better clinic effect.

Owner:BOTANIC CENTURY BEIJING

Composite albumen powder for improving immune capability

ActiveCN102871019AEnhance immune functionImprove deformation abilityFood preparationWhey proteinDietary fibre

The invention relates to a composite albumen powder for improving immune capability. The composite albumen powder comprises the following components in percentage by weight: 65 to 75 percent of soy isolate protein, 10 to 30 percent of concentrated whey protein, 1 to 10 percent of cherry powder, 1 to 10 percent of synanthrin and 1 to 5 percent of dietary fiber flour. The cherry powder, the synanthrin and the dietary fiber flour are matched with the soy isolate protein and the concentrated whey protein reasonably in scientific amount and are synergic to improve immune capability; and the composite albumen powder is comprehensive in nutrition and easy to absorb.

Owner:WEIHAI BAIHE BIOTECH

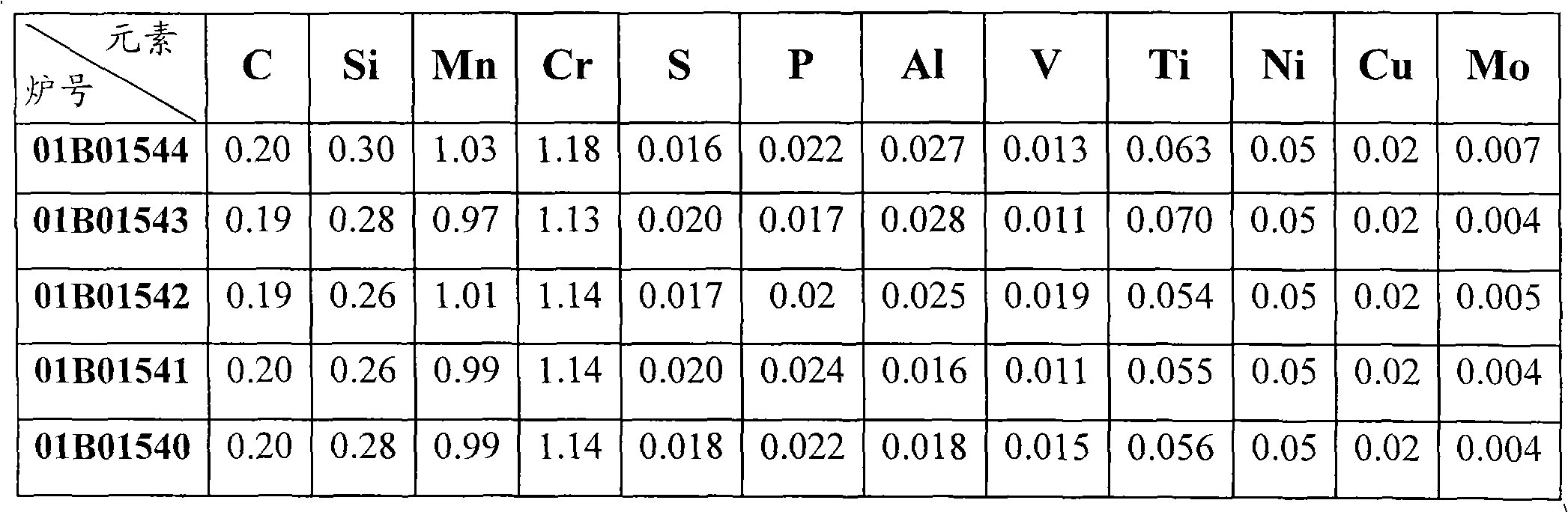

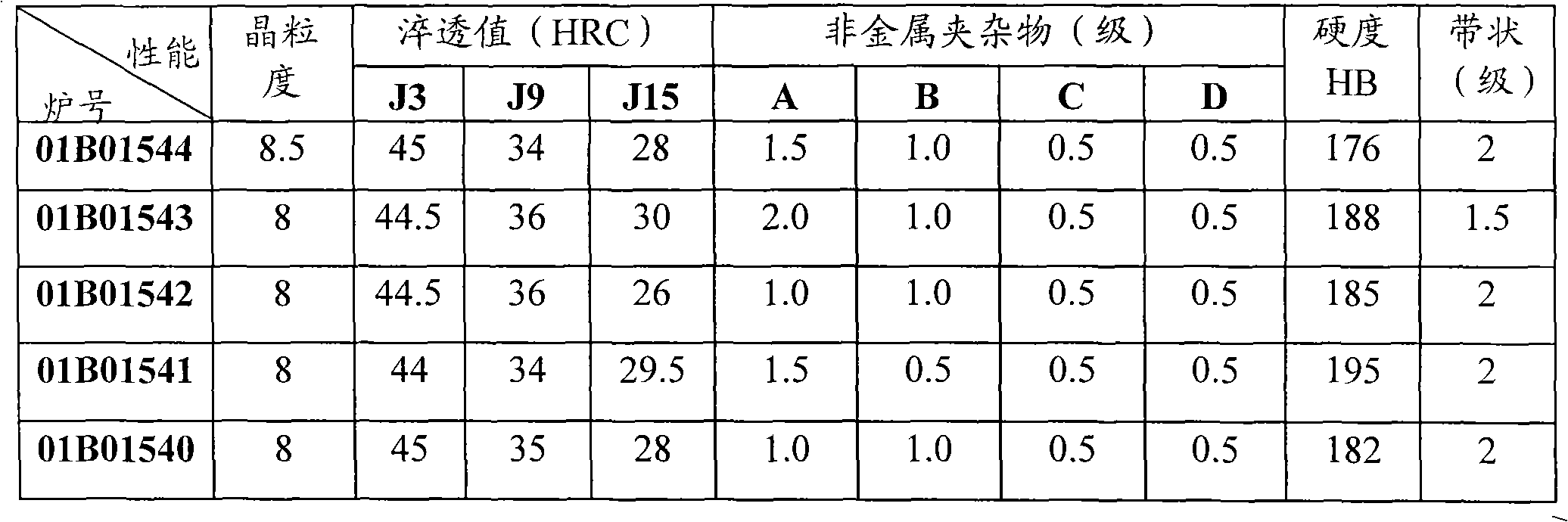

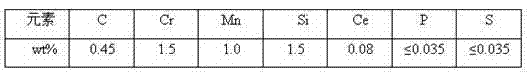

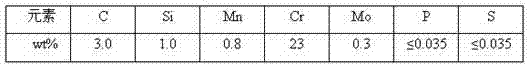

CrMnTi series gear steel and processing technique thereof

The invention discloses a CrMnTi series gear steel, which consists of the following components in percentage by weight: 0.16 to 0.23 percent of C, 0.20 to 0.37 percent of Si, 0.80 to 1.25 percent of Mn, 1.00 to 1.45 percent of Cr, 0.015 to 0.035 percent of S, 0 to 0.035 percent of P, 0.01 to 0.02 percent of V, 0.04 to 0.10 percent of Ti, 0.015 to 0.035 percent of Al, 0 to 0.25 percent of Ni, 0 to0.20 percent of Cu, 0 to 0.04 percent of Mo and the balance of Fe and impurities. The gear steel is processed by a special technique. The gear steel manufactured by using the formula and the processing technique has the characteristics of low cost, simplified process, stable quenching property, high production efficiency, good mechanical property and long service life, and is easy to process.

Owner:CHENGDE JIANLONG SPECIAL STEEL

Low crack sensitivity steel plate with yield strength 500MPa and manufacturing method thereof

ActiveCN101481774ALow raw material costSimplify the manufacturing processFurnace typesHeat treatment furnacesSteel platesMetallurgy

The invention discloses a crack sensitivity steel plate with the yield strength of 500MPa, which is characterized by comprising the following chemical elements in terms of weight percentage: 0.010 to 0.09 percent of C, 0.10 to 0.65 percent of Si, 1.10 to 2.00 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.006 percent of S, 0.020 to 0.090 percent of Nb, 0.02 to 0.06 percent of Al, 0.004 to 0.030 percent of Ti, 0.0005 to 0.0025 percent of B and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: smelting and casting the raw materials into casting blank or steel ingot; 2) heating; 3) rolling; and 4) entering a cooling accelerator, cooling till the temperature of 450 to 560 DEG C, and air cooling after water drainage. The crack sensitivity steel plate has little sensitivity of welded crack, and the welding performance is good when the yield strength is more than 500MPa.

Owner:BAOSHAN IRON & STEEL CO LTD

Easy welding steel plate with yield strength of 550MPa and high toughness and manufacturing method thereof

The invention discloses an easy welding steel plate with yield strength of 550MPa and high toughness and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by weight: 0.05 to 0.08 percent of C, 0.25 to 0.50 percent of Si, 1.65 to 1.90 percent of Mn, 0.03 to 0.07 percent of Nb, 0.03 to 0.07 percent of V, 0.0006 to 0.002 percent of B, 0.01 to 0.04 percent of Al, 0.01 to 0.03 percent of Ti, and the balance of Al and inevitable impurities, wherein the content of Fe accords with the following relation that: Mn is more than or equal to 3.01Si +12.8Nb+6.65V-12.12C and less than or equal to 4.78Si+13.8Nb+12.72V-10.13C. A tissue with a bainite strip serving as a substrate is obtained by a control rolling and control cooling technology. The yield strength of the easy welding thick plate with yield strength is more than 550MPa, the tensile strength is more than 670MPa, the Charpy impact power Akv(-20 DEG C) is more than 150 J, and the sensitivity index Pcm of welding cracks is less than or equal to 0.19 percent. The steel plate has high welding property.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing magnesium slag aerated concrete building block added with cinder

InactiveCN101190834AHigh strengthReduce pollutionSolid waste managementCeramicwareSmelting processEconomic benefits

The invention discloses a magnesium slag aerated concrete block and a preparation method thereof, which takes the raw materials at the weight ratio of: magnesium-reduced slag of 50-87 portions, cement of 5-30 portions, gypsum of 3-10 portions, coal cinder of 5-25 portions and gas former of 0.05-0.15 portions, and then the product is obtained by adding water of 20-60 percent at the weight proportion of all the dry materials. The product is obtained according to the methods as follows: magnesium-reduced slag, coal cinder, cement, gypsum, water and gas former are mixed evenly at certain proportion and then are treated with standing and maintaining, inverting and incising, autoclaving and conserving. The invention adopts the magnesium slag generated from the magnesium-smelting process as the main raw material to produce 4MPa building aerated concrete block to be conducive to the reuse of the waste, thereby the enterprise not only is free from the expense of waste treatment, but also has new economic benefit, thus avoiding the occupation of land.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

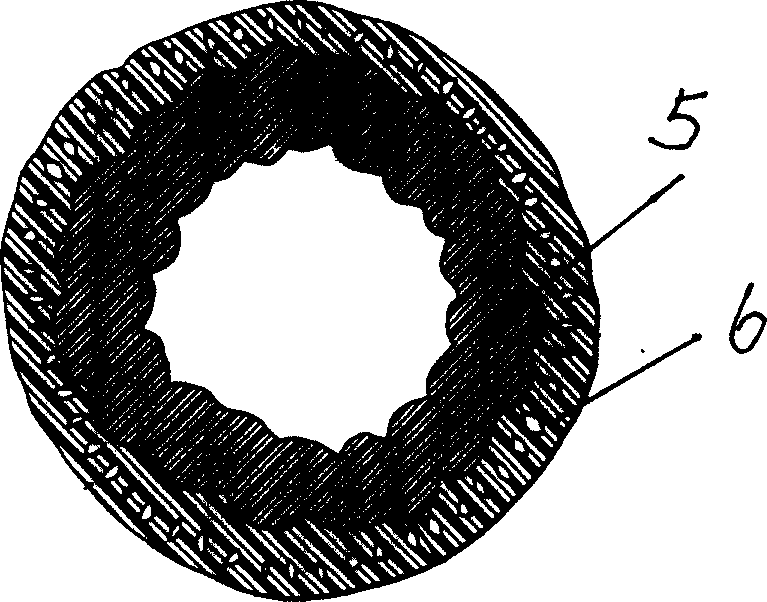

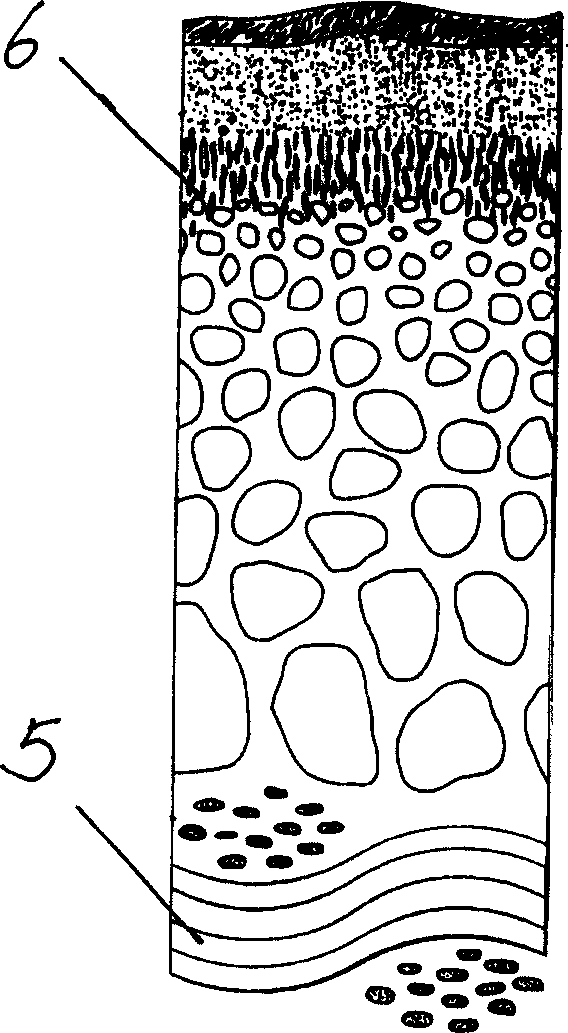

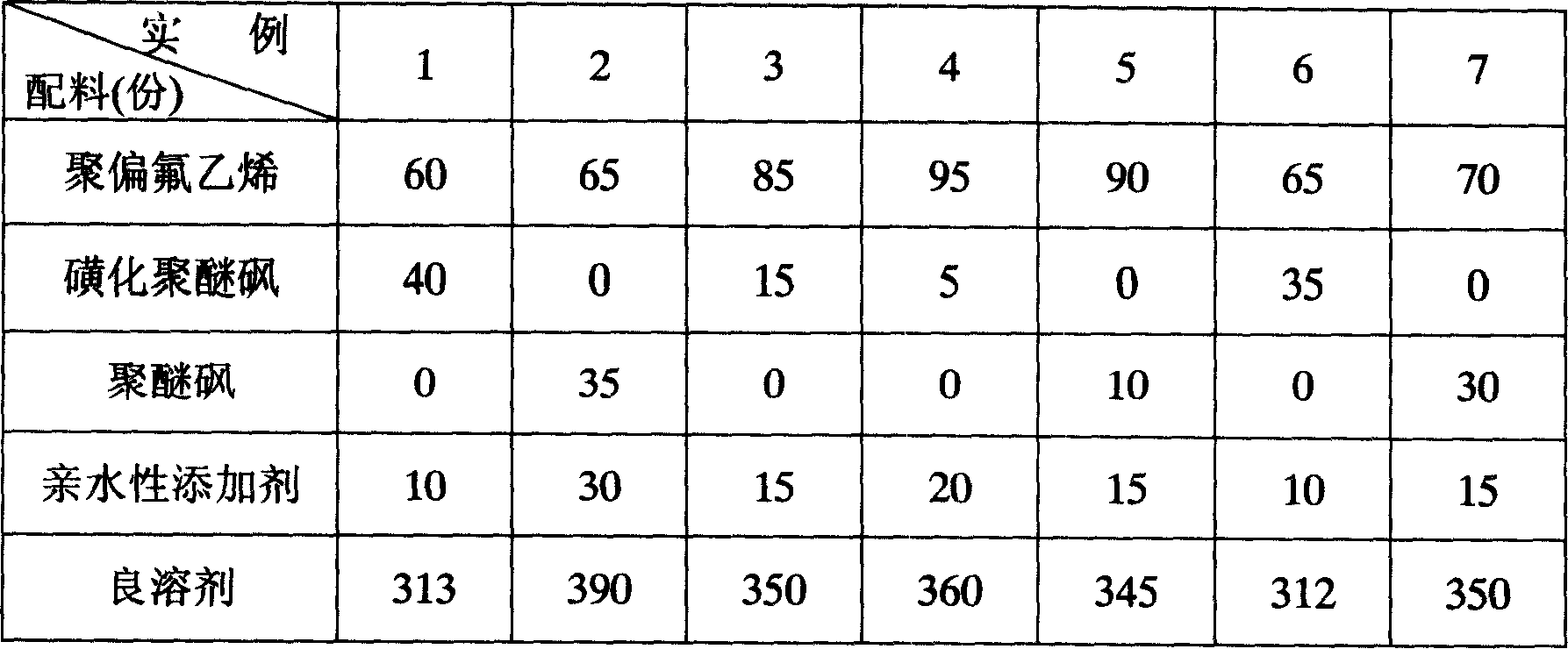

Sintered alpha-alumina/polyviny lidene fluoride blended hollow fiber membrane preparing method and its product

InactiveCN1579602AReasonable ingredientsLarge apertureSemi-permeable membranesPolymer sciencePolyvinylidene difluoride

The invention relates to an approach of producing asymmetry sintering alpha-alumina / polyvinylidene fluoride crossblend hollow fibre membrane. It also relates prescription of private membrane-forming liquor and its production. Use polyvinylidene fluoride as materials; disperse sinteringalpha-alumina in its good solvent to make them react to form mixing liquor; Add hydrophilicity compound which react with the mixing liquor to get membrane-forming liquor with some viscosity; using phase transmitting method to produce hollow fibre membrane. So the invention has merits of rational proportion, simple technics, low requirements to equipment and components complementation. It can manufacture bigger aperture, high permeation flux and asymmetry membranes.

Owner:ZHEJIANG OMEX ENVIRONMENTAL ENG CO LTD

Kit for detecting mosquito borne pathogens and detection method thereof

InactiveCN103911463AStrong specificityHigh sensitivityMicrobiological testing/measurementAgainst vector-borne diseasesEpidemic encephalitisMultiplex polymerase chain reaction

The invention discloses a kit for detecting a plurality of mosquito borne pathogens and a detection method thereof. The plurality of mosquito-borne infectious pathogens are detected by using multiplex polymerase chain reaction (PCR) combined with a liquid chip, and a yellow fever virus (YFV), dengue fever viruses (DV) I-IV type, epidemic encephalitis B (japanese encephalitis) virus (JEV), plasmodium (Plasmodium), (including plasmodium vivax (PV), plasmodium falciparum (PF), plasmodium malariae (PM), plasmodium ovale (PO)), a west nile virus (MNV) and a chikungunya virus (CHIKV) can be detected in parallel one time. The kit has the advantages of being large in flux, high in specificity and sensitivity, stable in result, good in repeatability, simple to operate and fast in detection speed.

Owner:河北国际旅行卫生保健中心

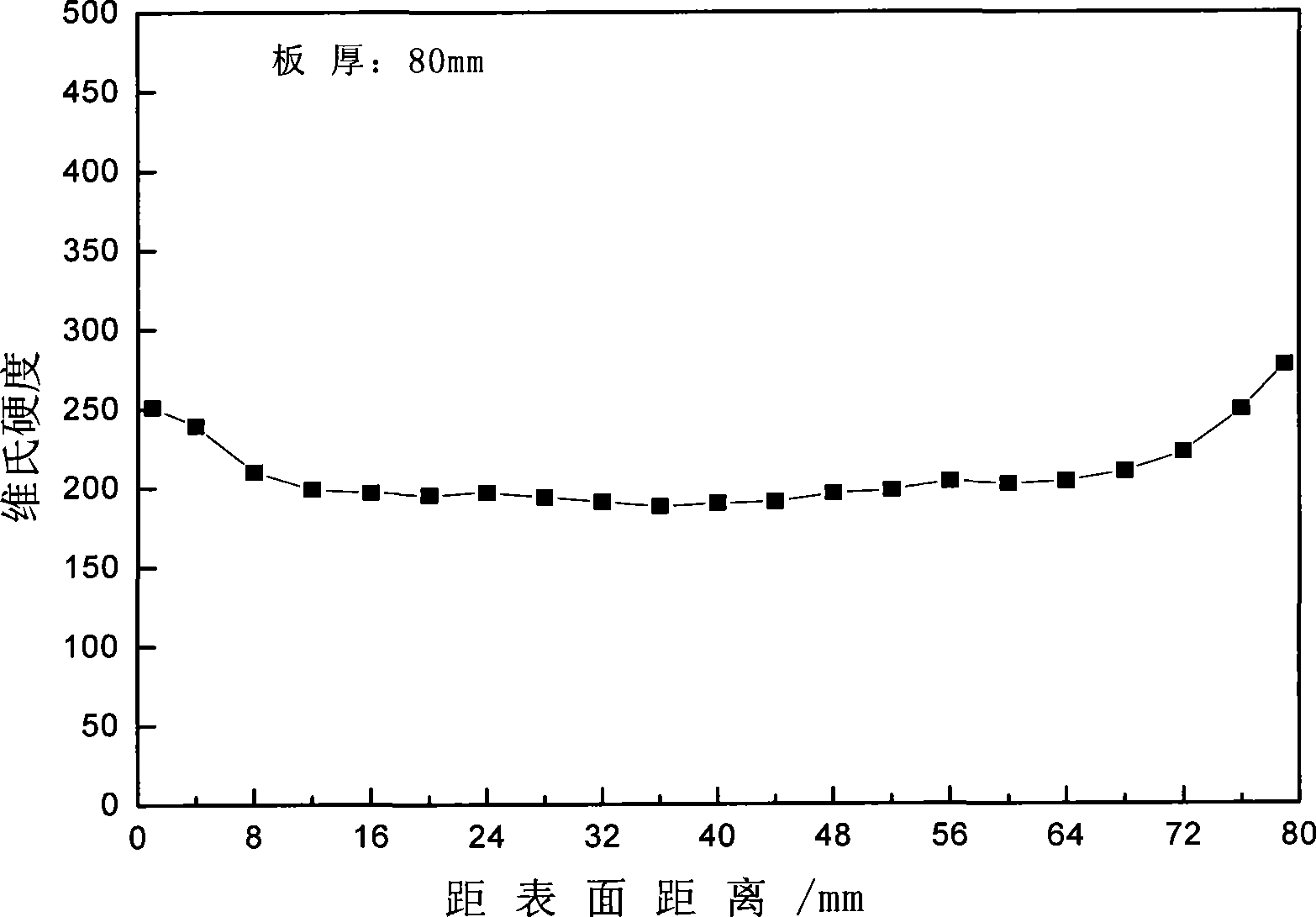

High-hardness wear-resistant steel plate and manufacturing method thereof

ActiveCN103205643AImprove mechanical propertiesImprove wear resistanceFurnace typesHeat treatment furnacesChemical compositionWear resistant

The present invention provides a high-hardness wear-resistant steel plate and a manufacturing method thereof. The high-hardness wear-resistant steel plate comprises the following chemical compositions (wt%) of 0.60-0.75% of C, 0.10-0.40% of Si, 0.60-1.30% of Mn, 0-0.020% of P, 0-0.010% of S, 0.10-0.50% of Cu, 0.10-0.50% of Ni, 0.0030-0.0100% of N, and the balance being Fe and inevitable impurities. The manufacturing method comprises the following steps of smelting, casting, hot rolling, annealing, pipe making, welding, quenching and tempering and other steps. The wear-resistant steel plate obtained by the above compositions and through the above process has high hardness and high wear resistance, with typical Rockwell hardness of HRC 62 to 66, and is suitable for easy-to-wear parts in various mechanical equipments, such as concrete pump delivery pipes.

Owner:BAOSHAN IRON & STEEL CO LTD

Maca teabag and preparation method thereof

The invention relates to a maca teabag and a preparation method thereof. The maca teabag is prepared from the raw materials of 10-15 parts of maca, 5-8 parts of raspberries, 3-6 parts of barley, 2-4 parts of osmanthus fragrans and 1-3 part(s) of Pu-Er ripe tea through the steps of raw material selecting, smashing, screening with a vibrating screen, weighting, component mixing and final subpackage. The maca teabag is reasonable in components and ratio design, and rich in nutrition, and the effects of all components are supplementary to one another; the preparation method is simple and convenient, and the cost is low; the maca teabag is prepared from natural components completely, so that original taste and flavour are kept, the tea soup of the maca teabag is brownish yellow, strong in wheat flavor and flower fragrance, and mellow in taste; the dissolution rate is high, extract is multiple, brewing resistance is achieved, maca teabag is carried and drunk conveniently by people, and a new beverage with the efficacities of tonifying kidney, building body and resisting fatigue is provided.

Owner:HANGZHOU EFUTON TEA

Low-cost Q345R steel plate and production method thereof

The invention discloses a low-cost Q345R steel plate which comprises the following chemical components in percentage by weight: 0.16-0.18% of C, 0.2-0.3% of Si, 1.3-1.5% of Mn, at most 0.02% of P, at most 0.005% of S, 0.0015-0.003% of Ca, 0.017-0.027% of Als, and the balance of iron and impurities. The invention also discloses a production method of the low-cost Q345R steel plate. The low-cost Q345R steel plate can be produced by proper heating, controlled rolling and controlled cooling; and no expensive alloy elements, such as Nb, V, Ti and the like, are added to the steel plate, so the production cost is low.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Steel plate with yield strength of 960MPa and manufacturing method thereof

The invention discloses a steel plate with yield strength of 960MPa, which comprises the following chemical components in weight percent: 0.07-0.11 percent of C, 0.10-0.50 percent of Si, 1.60-2.20 percent of Mn, not greater than 0.015 percent of P, not greater than 0.003 percent of S, 0.10-0.35 percent of Cr, 0.20-0.50 percent of Mo, 0.02-0.06 percent of Nb, 0.02-0.06 percent of V, 0.003-0.04 percent of Ti, 0.02-0.07 percent of Al, 0.0006-0.0025 percent of B and the balance of Fe and other inevitable impurities. The steel plate with the yield strength of 960MPa also meets the following relational expressions: C+Mn is not less than 1.853Si+2.078Cr+3.112Mo-1298.532B but is not greater than 5.891Si+4.115Cr+4.797Mo-398.532B, and ln(AEQ) is not less than 2.08 but is not greater than 3.41. The invention also discloses a manufacturing method for the steel plate. The tensile strength of the obtained steel plate is not less than 980MPa, the Charpy impact power Akv (-40 DEG C) is not less than 80J, and the carbon equivalent (CEV) is not greater than 0.58 percent. The steel plate is excellent in welding property.

Owner:BAOSHAN IRON & STEEL CO LTD

High-toughness mining chain steel and manufacturing method thereof

ActiveCN113322409AEasy to rollReasonable ingredientsFurnace typesForging press detailsTemperingWeather resistance

The invention discloses high-toughness mining chain steel and a manufacturing method thereof. The high-toughness mining chain steel comprises the following components in percentage by weight: 0.20-0.28% of C, 0.01-0.40% of Si, 0.50-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.30-2.00% of Cr, 0.50-2.00% of Ni, 0.10-0.80% of Mo, 0.01-0.30% of Cu, 0.01-0.05% of Al, 0.001-0.10% of Nb, 0.001-0.10% of V, less than or equal to 0.00018% of H, less than or equal to 0.0150% of N, less than or equal to 0.0020% of O and the balance of Fe and inevitable impurities. The manufacturing process comprises the working procedures of smelting, refining, vacuum treatment, casting, heating, forging or rolling, quenching and tempering heat treatment and the like. The chain steel has high strength and good impact toughness, ductility and percentage reduction of area, can resist stress corrosion cracking, has good weather resistance, wear resistance and fatigue resistance, and can be used for engineering machinery, ocean engineering and other occasions needing high-strength and high-toughness steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Formula of preparation liquid for hollow-fibre membrane and products thereof

InactiveCN1593734AMaintain stabilityReasonable ingredientsSemi-permeable membranesPolymer sciencePolyvinyl alcohol

The invention relates to a kind of hollow fiber membrane, especially a hollow fiber membrane formula with mixing hydrophilic poly-biasfluorine ethylene and its products. Raw material of this membrane is the mixture of poly-biasfluorine ethylene and sulfonated poly-ethersulphone or the mixture of bias fluorine polyethylene and poly-ethersulphone. Then the mixture reacts with hydrophilic additive that is polyethylene pyrrolidone or polyvinyl alcohol, then forms the hydrophilic hollow fiber membrane by the way of chemical grafting. Poly-biasfluorine ethylene has nice flexibility and poly-ethersulphone or sulfonated poly-ethersulphone has high intensity, so mixing them can make advantages for them of their abilities. In the result, it can make the resulting hollow fiber membrane have the high water flux and the temperate intensity, can improve hydrophilicity and stability of it, and can make it have longer service life. This membrane can be used extensively in the fields such as Medicine, Sanitation, Foodstuff, Industry and so on.

Owner:ZHEJIANG OMEX ENVIRONMENTAL ENG CO LTD

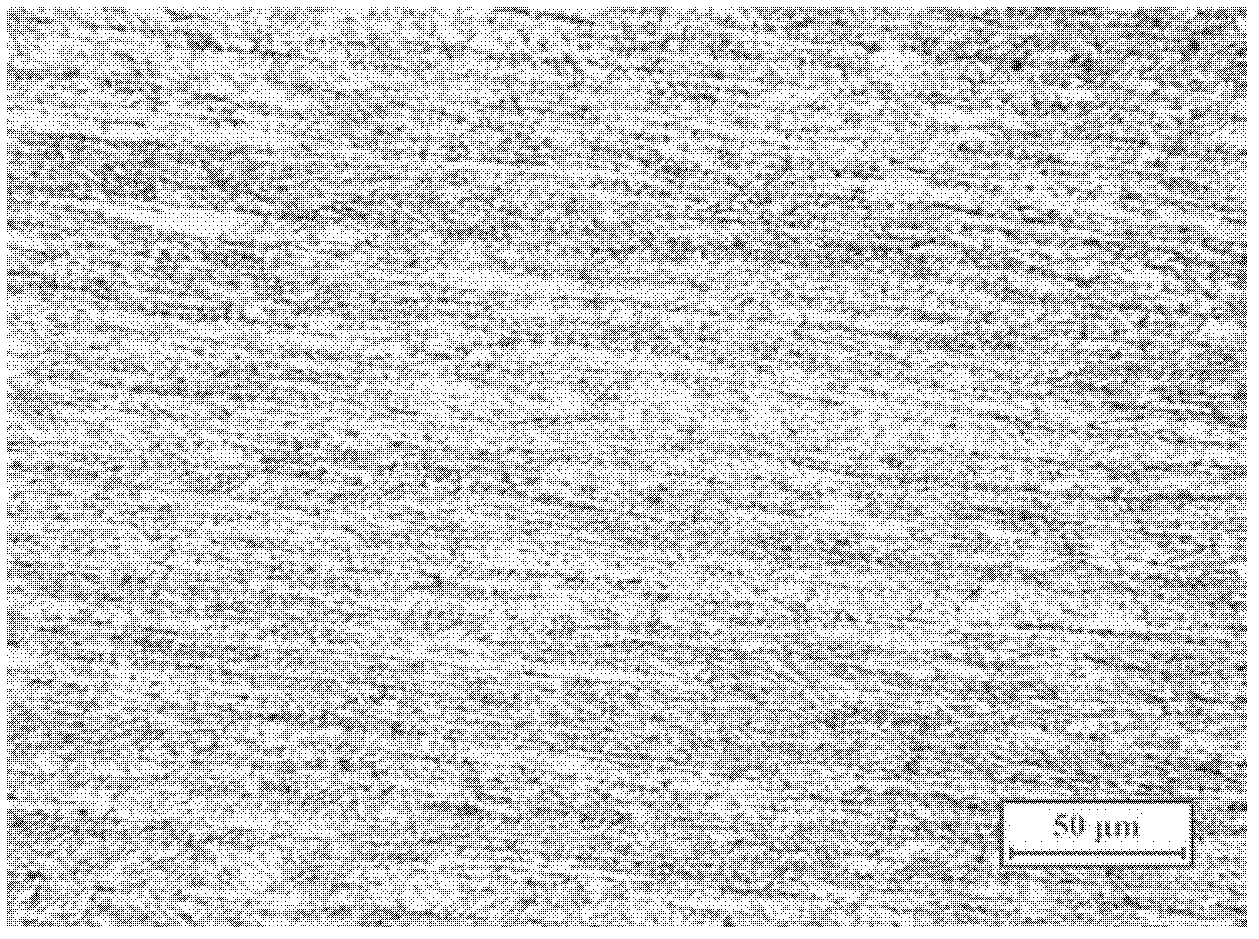

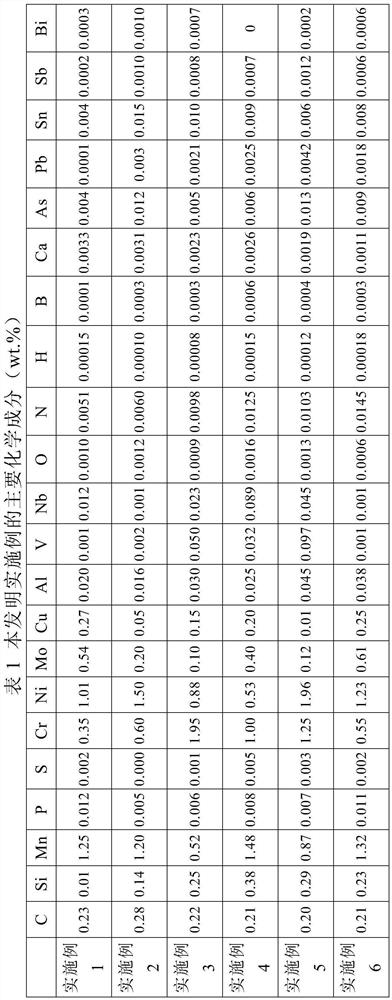

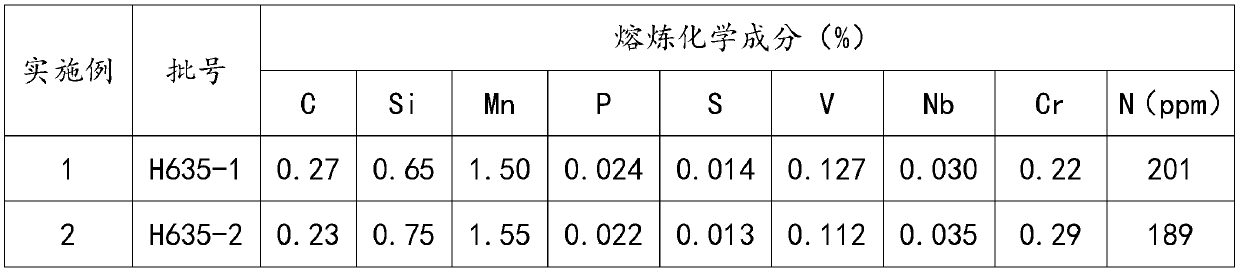

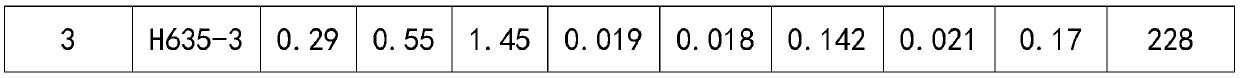

Steel for 635 MPa level high-strength hot-rolled steel bar

The invention relates to the technical field of hot-rolled ribbed steel bars, and discloses steel for a 635 MPa level high-strength hot-rolled steel bar. The steel is prepared from, by weight, 0.22-0.30% of C, 0.50-0.80% of Si, 1.40-1.60% of Mn, not larger than 0.025% of P, not larger than 0.025% of S, 0.015-0.035% of Nb, 0.105-0.145% of V, 0.15-0.35% of Cr, 0.018-0.025% of N and the balance Fe. According to the steel for the 635 MPa level high-strength hot-rolled steel bar and a machining method thereof, by adopting C, C is a cheap element, the strength of the steel can be remarkably improved, the extension performance of the steel can be lowered, meanwhile, the cold brittleness and aging sensitivity of the steel are improved, the integrated ingredients are reasonable, the comprehensive performance of the whole steel is improved, the stability of the steel performance is enhanced, the overall performance of the steel on the aspects of yield strength, tensile strength, the high yield ratio, the percentage elongation after fracture, the total elongation percentage under the maximum force and the like is good, meanwhile, the steel metallographic structure is ferrite+pearlite, the granularity is 11.5, the good fatigue resistance is achieved, the steel is suitable for large-scale industrial production, and benefits are remarkable.

Owner:安徽吾兴新材料有限公司

Functional ball of nano level composite porous ceramic material and its production process

The functional ball is made with the nanometer level composite porous ceramic material comprising tourmaline, Chinese medicinal stone, zeolite, loess, active carbon, organic pore expanding agent and adhesive. Compared with available technology, the present invention has the features of reasonable material compounding, long service life, high air purifying effect, many functions, etc. The functional ball can release negative ion and far infrared ray continuously, adsorb heavy metal ions, purify air, activate body' cell, promote plant growth, and prevent radiation.

Owner:杨振龙 +1

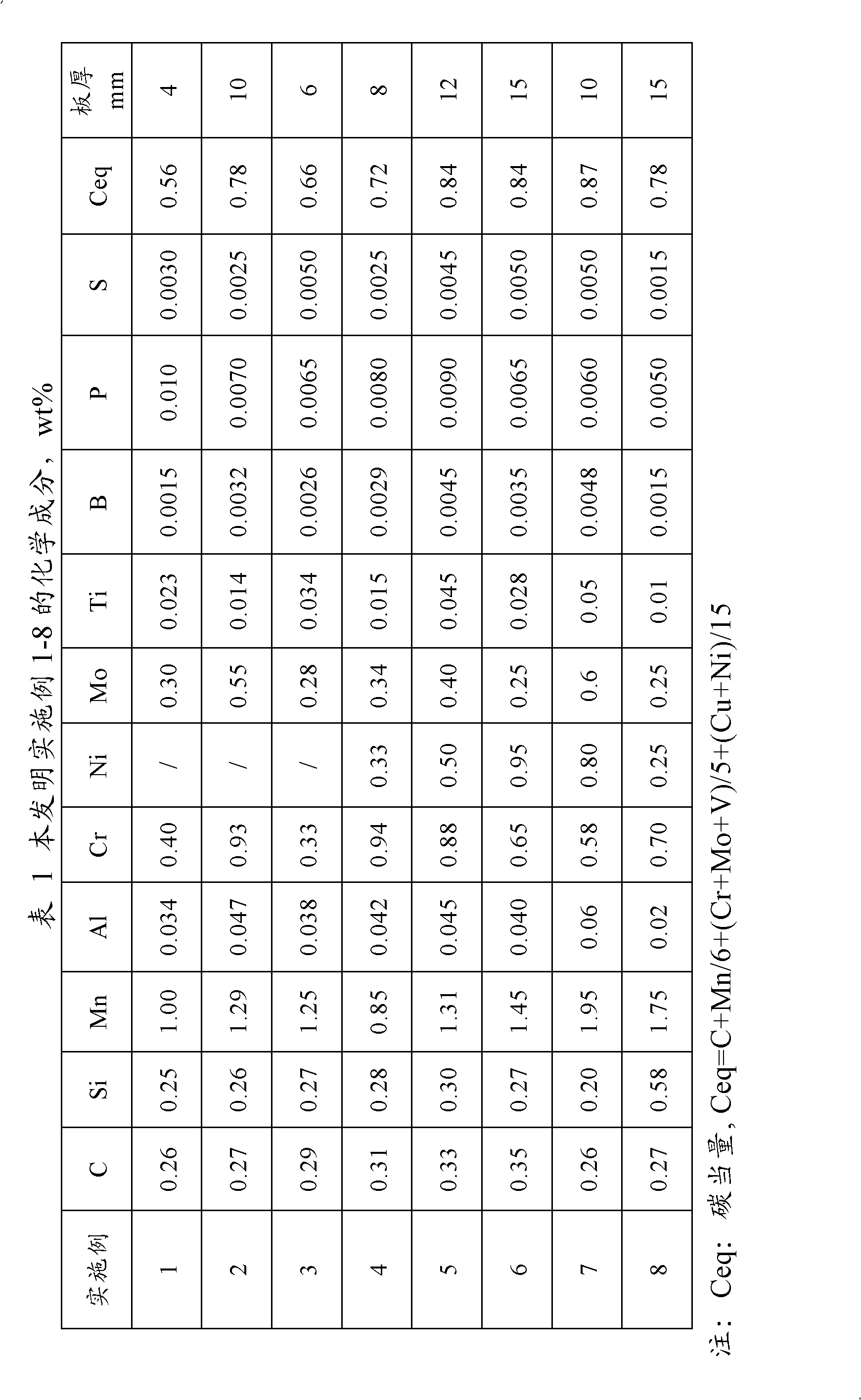

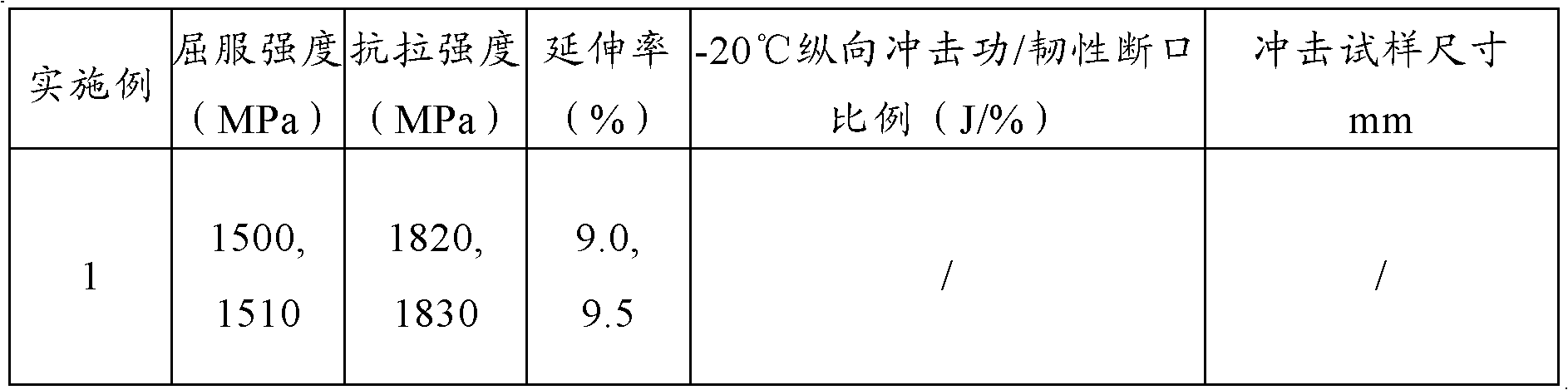

Ultrahigh-strength steel plate and production method thereof

The invention relates to an ultrahigh-strength steel plate, which comprises, by weight percentage, 0.25-0.35% of C, 0.20-0.60% of Si, 0.8-2.0% of Mn, no more than 0.010% of P, no more than 0.005% of S, 0.02-0.06% of Al, 0.30-1.00% of Cr, 0.20-0.60% of Mo, 0.01-0.05% of Ti, 0.001-0.005% of B, no more than 1.0% of Ni, and the balance of Fe and unavoidable impurities. A production method of the ultrahigh-strength steel plate includes: smelting the components, obtaining a blank or ingot by casting; heating the bank or ingot to 1180-1250 DEG C prior to rolling, rolling in the first stage in a recrystallization area, performing multi-pass high reduction rolling with accumulative deformation not less than 80%; rolling in the second stage in a non-recrystallization area, finish rolling temperature being controlled at 870 to 930 DEG C); accelerating to cool the rolled steel plate to below 200 DEG C; and tempering at 200+ / -20 DEG C to obtain the steel plate 4-15mm thick. The yield strength of the steel plate is not less than 1400MPa, the tensile strength of the steel plate is not less than 1800MPa, and Charpy impact power Akv at -20 DEG C is not less than 20J.

Owner:BAOSHAN IRON & STEEL CO LTD

Double-liquid double-metal oil quenching hammer and machining method thereof

ActiveCN103667870ASimple processReasonable ingredientsFurnace typesHeat treatment furnacesFerrosiliconCarbon alloy

The invention discloses a double-liquid double-metal oil quenching hammer and a machining method thereof. The machining method comprises the following steps: matching waste steel, pig iron, ferrochromium, ferromanganese and ferrosilicon as furnace materials according to chemical component content of a hammer head part and a hammer handle part of a product, respectively putting the materials into a sensing furnace to be smelted, casting and shaping, performing thermal treatment so as to obtain the double-liquid double-metal oil quenching hammer. The double-liquid double-metal oil quenching hammer has the advantages of simple process, reasonable material matching and low production cost; as a high-chromium iron material is added into an alterant with ferroboron, ferrotitanium, ferrovanadium and rare earth silicon to cast the hammer head part, a low-carbon alloy steel material is added into an alterant with rare earth lanthanum and cerium, ferrosilicon particles, rare earth magnesium and ferroboron to cast the hammer handle part, and the requirements on hardness and wear-resistance of the hammer part and on hardness, toughness and wear-resistance of the hammer handle part can be met through thermal treatment at one step.

Owner:BEIPIAO JINSHIDA MACHINERY MFR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com