Steel for 635 MPa level high-strength hot-rolled steel bar

A steel bar and high-strength technology, which is applied in the field of hot-rolled ribbed steel bars for concrete, can solve problems such as difficulties, excessively dense construction of steel bars at beam-column joints, and fat beams and columns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

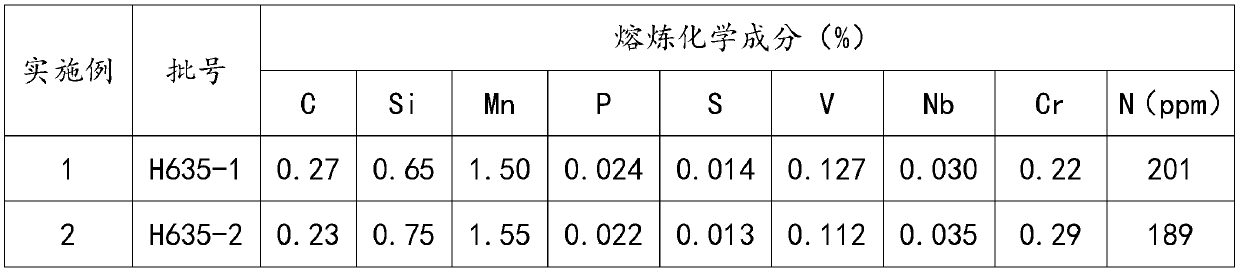

Embodiment 1

[0034] Another technical problem to be solved by the present invention is to provide a method for processing steel for 635MPa grade high-strength hot-rolled steel bars, comprising the following steps:

[0035] 1) Various raw material components required for steelmaking C: 0.27%, Si: 0.65%, Mn: 1.50%, P: 0.024%, S: 0.014%, Nb: 0.030%, V: 0.127%, Cr: 0.22%, N: 201ppm and the balance of Fe are put into the converter for smelting work. Under the smelting of the converter for a certain period of time and temperature, the content of the end point of the converter is C0.09%, which can effectively avoid the peroxidation of molten steel, P0.010%, S ≤0.012%, and block the slag to tap, reduce the internal return of P and S in the molten steel, and the tapping temperature is 1710°C;

[0036] 2) Pour the molten steel smelted in step 1) into the ladle and blow in argon. The ladle uses argon flow rate of 111L / min to blow argon for 5 minutes, fully mix the argon and molten steel, and then let...

Embodiment 2

[0044] Another technical problem to be solved by the present invention is to provide a method for processing steel for 635MPa grade high-strength hot-rolled steel bars, comprising the following steps:

[0045] 1) Various raw material components required for steelmaking C: 0.23%, Si: 0.75%, Mn: 1.55%, P: 0.022%, S: 0.013%, Nb: 0.035%, V: 0.112%, Cr: 0.29%, N: 189ppm and the balance of Fe are put into the converter for smelting work. Under the smelting of the converter for a certain period of time and temperature, the content of the end point of the converter is C0.08%, which can effectively avoid the peroxidation of molten steel, P0.009%, S0 .013%, and stop slag tapping, reduce the internal reversion of P and S of molten steel;

[0046] 2) Pour the molten steel smelted in step 1) into the ladle and blow in argon. The ladle is blown with argon at a flow rate of 101L / min argon for 6 minutes, and the argon and molten steel are fully mixed and stirred, and then the molten steel is ...

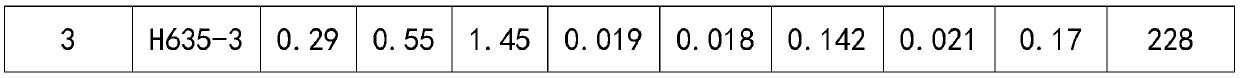

Embodiment 3

[0054] Another technical problem to be solved by the present invention is to provide a method for processing steel for 635MPa grade high-strength hot-rolled steel bars, comprising the following steps:

[0055] 1) Various raw material components required for steelmaking C: 0.29%, Si: 0.55%, Mn: 1.45%, P: 0.019%, S: 0.018%, Nb: 0.021%, V: 0.142%, Cr: 0.17%, N: 228ppm and the balance of Fe are put into the converter for smelting work. Under the smelting of the converter for a certain period of time and temperature, the content of the end point of the converter is C0.07%, which can effectively avoid the peroxidation of molten steel, P0.007%, S0 .013%, and stop slag tapping, reduce the internal reversion of P and S of molten steel;

[0056] 2) Pour the molten steel smelted in step 1) into the ladle and blow in argon. The ladle uses 91L / min argon gas flow rate to blow argon for 7 minutes, fully mix the argon and molten steel, and then let the molten steel stand for a while. , to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com