Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "High flex ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel for high strength shock-proof hot-rolled steel bar

This invention relates to a aseismatic heat rolled steel bar with high strength, which belongs to alloy steel, especially to the heat rolled steel bar, the steel bar is composed by the following elements: 0.07-0.16úÑCíó1.2-2.0úÑSiíó1.5-2.0úÑMníó íœ0.4úÑCríó0.02-0.14úÑVú¼the rest is Fe and impurity. The universal steel-making device uses the universal technology; it smelts steel according to the said component range and produces heat rolled steel bar or rod with highe strength and better aseismatic charater. Wherein the yield strengthen ªÊs(p0.2)í¦550MPaú¼the yield proportion ªÊb / ªÊs(p0.2)í¦1.45. And the high strength and high yield proportion of the steel bar can enforce the aseismatic charater of the building.

Owner:MAANSHAN IRON & STEEL CO LTD

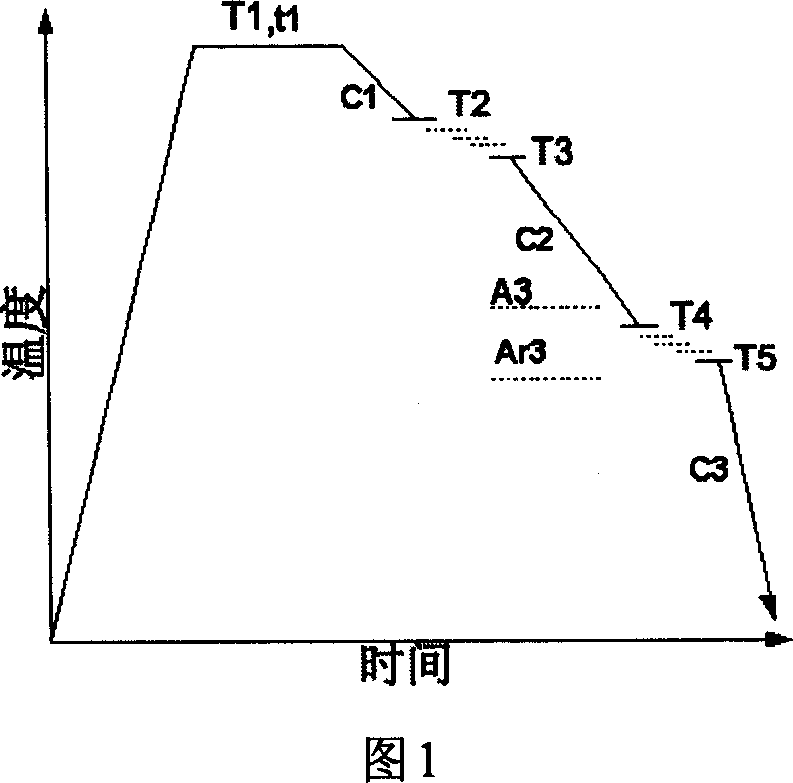

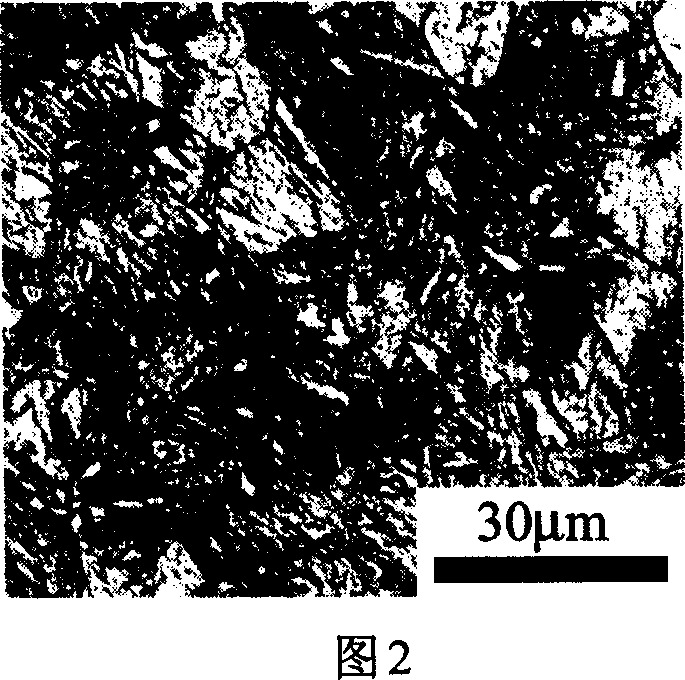

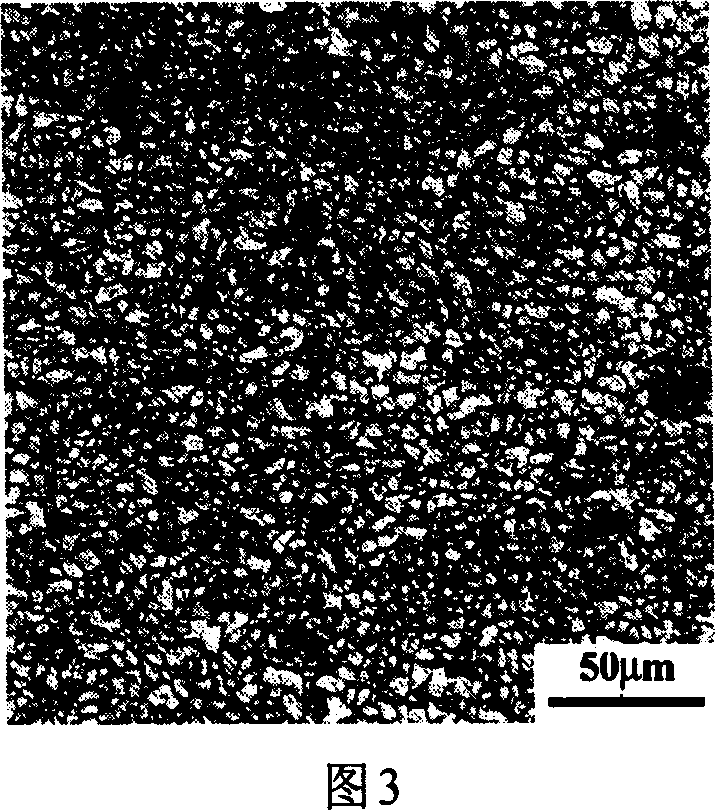

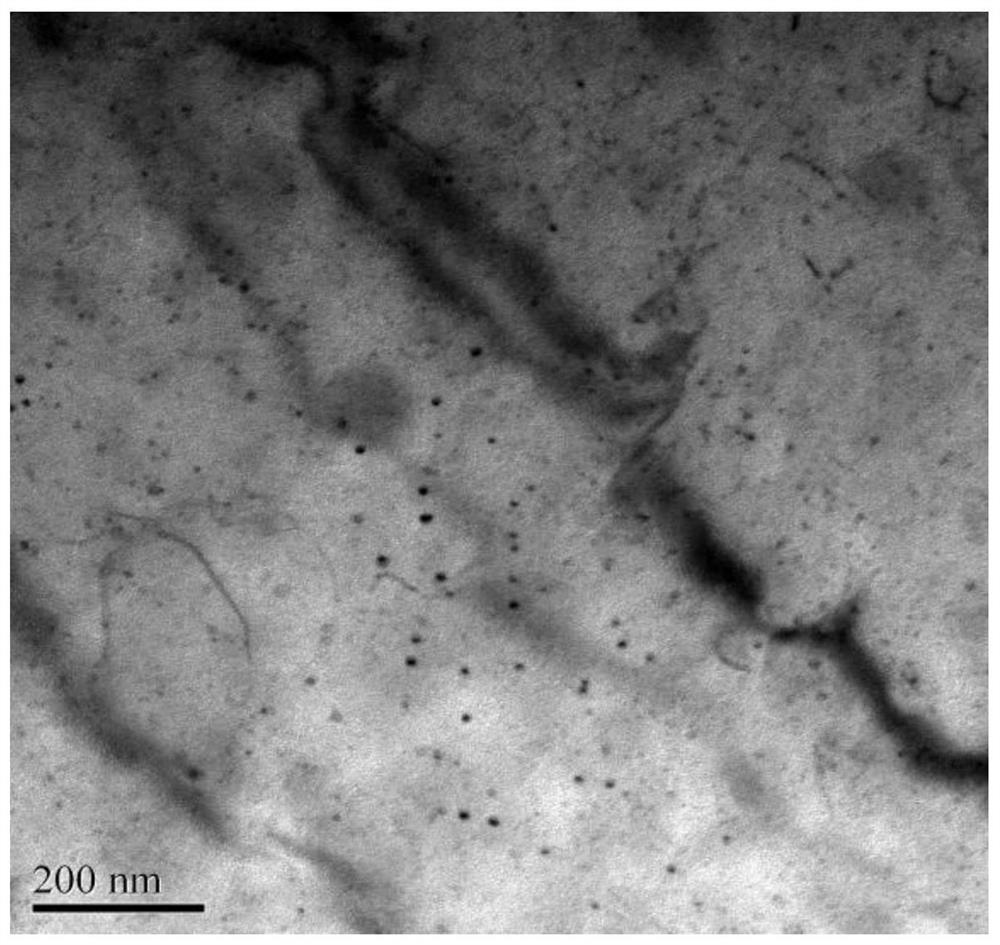

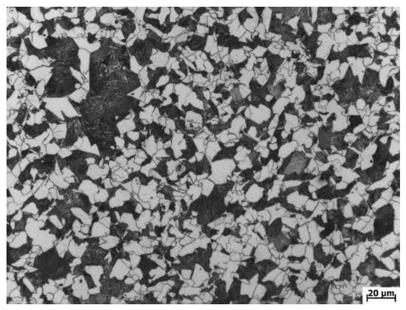

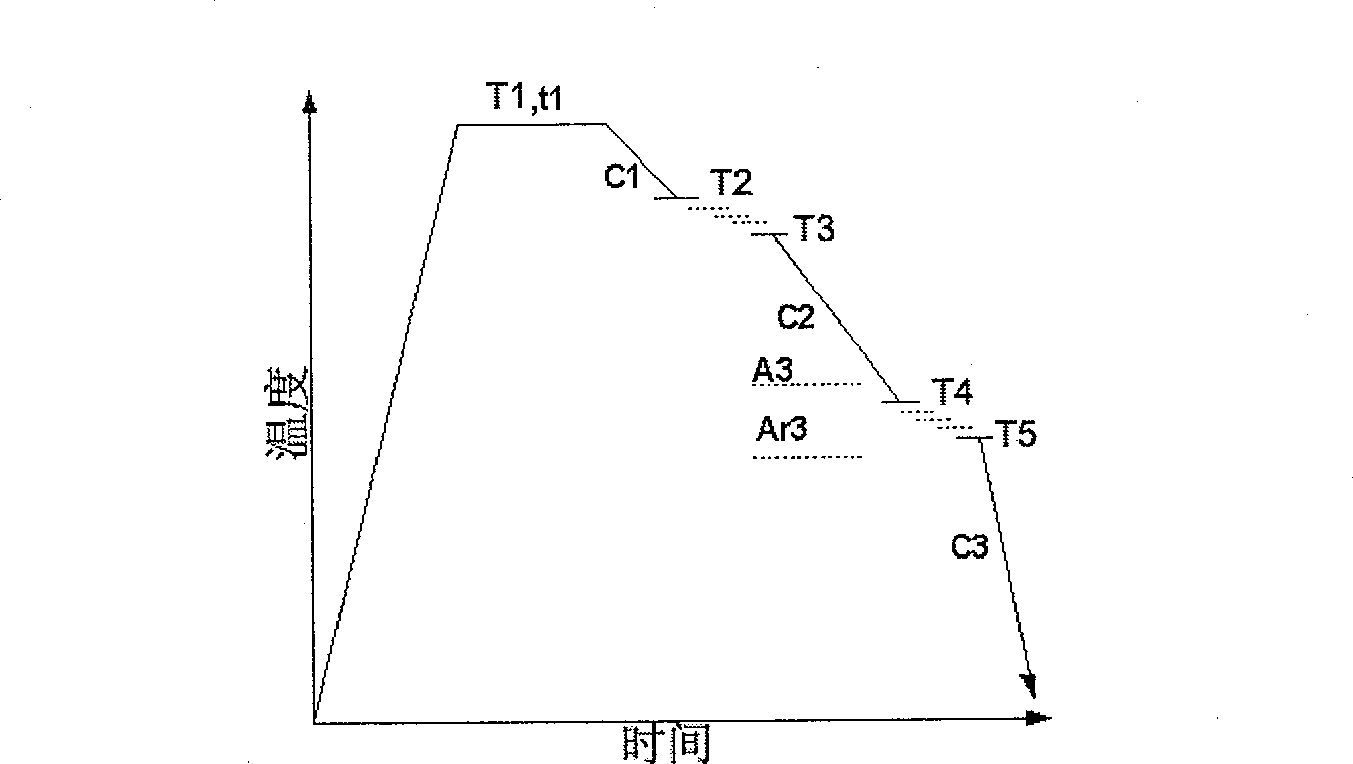

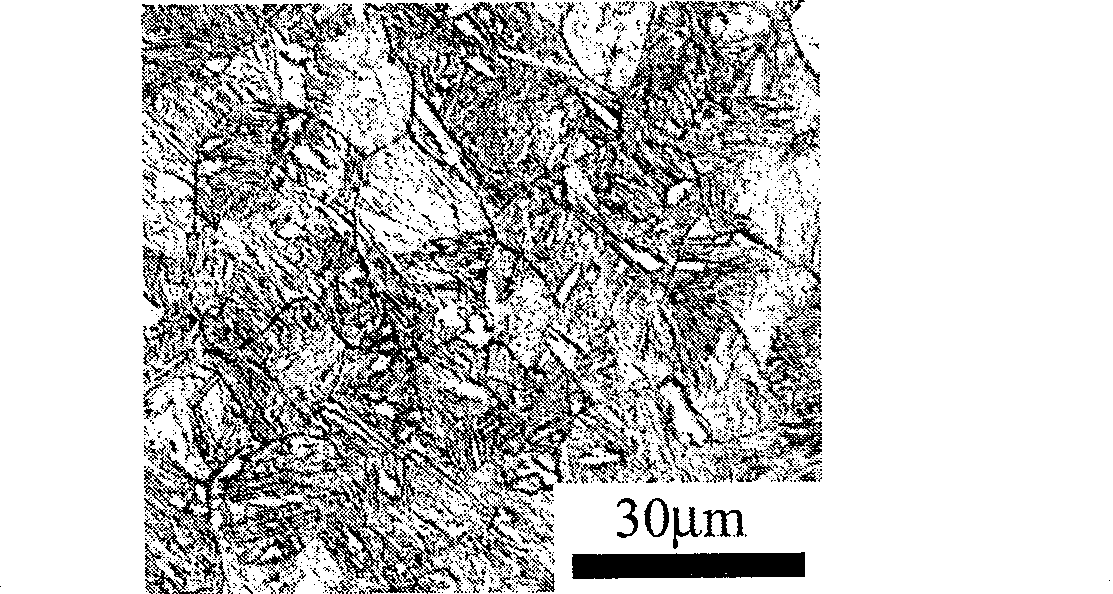

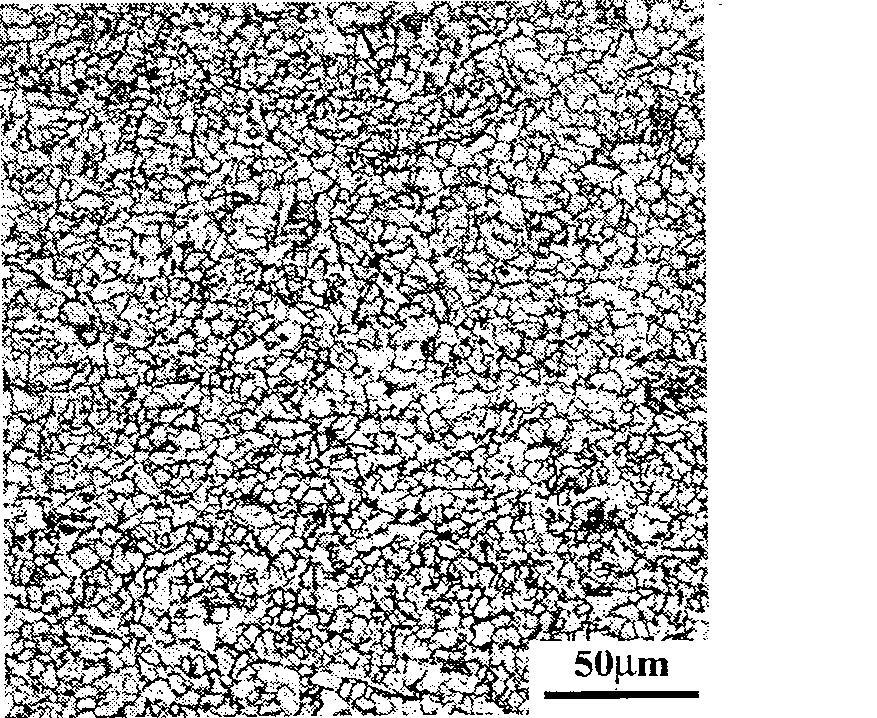

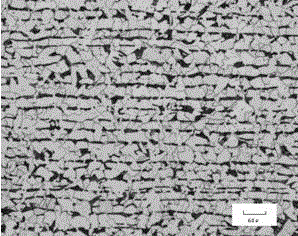

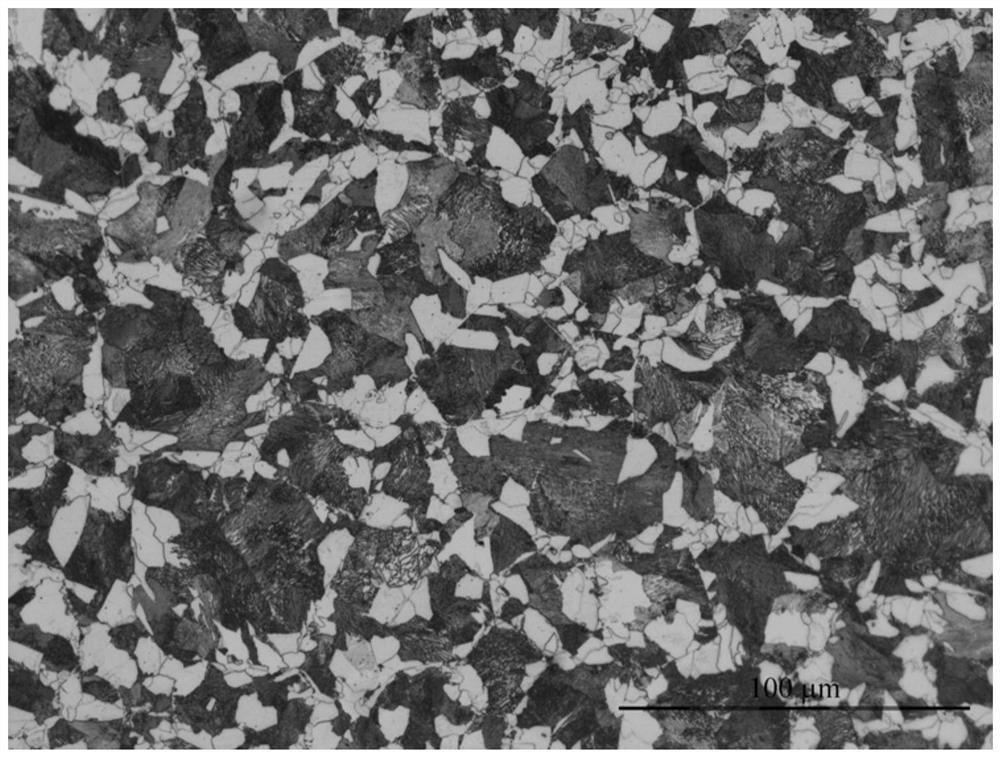

Method of preparing high-strength thin-crystal two-phase steel

InactiveCN101054621AHigh flex ratioImprove work hardening abilityHeat treatment process controlManganeseRoom temperature

The invention relates to a method for producing the fine grained dual phase steel, especially by low carbon(manganese) steel. The method comprises making the common low carbon(manganese) steel austenization, obtaining small austenitic organism after multi-pass deformation of recrystallized zone, over-cooling to a certain temperature in the temperature range of A3-Ar3 by proper cooling speed to apply multi-pass deformation with a strain rate between 0.1s-1 to 30s-1, getting 80-90% ferrite transforming mass by controlling each pass dependent variable, then quickly cooling or quenching to the room temperature. The average dimension of isometric ferrite grain in fine grained dual phase organism is less than 5 mum. The Martensite island integration number is 10-15% and the average dimension is less than 3 mum. The method is more controllable and is easy to apply on the conventional hot mill.

Owner:UNIV OF SCI & TECH BEIJING

HRB600E reinforcement steel bar and production method thereof

The invention discloses a HRB600E reinforcement steel bar and a production method thereof. The reinforcement steel bar consists of the following elements in percentage by weight: 0.20-0.28 percent of C, 1.30-1.60 percent of Mn, 0.30-0.80 percent of Si, 0.80-0.12 percent of V, less than or equal to 0.020 percent of S, less than or equal to 0.030 percent of P, 0.05-0.40 percent of Cr and the balance of Fe and inevitable impurities. The production method comprises a smelting procedure, a continuous casing procedure and a steel rolling procedure. In the smelting procedure, molten steel in a ladle is alloyed, so that the molten steel contains 0.08-0.12 percent by weight of V and 0.05-0.40 percent by weight of Cr. The vanadium content of the reinforcement steel bar is reduced by about 30-40 percent than the vanadium content of a reinforcement steel bar with the same level of yield strength, and the reinforcement steel bar has the advantages of high yield strength, high tensile strength, high yielding-to-tensile ratio, high specific elongation and the like.

Owner:LAIWU IRON & STEEL GRP

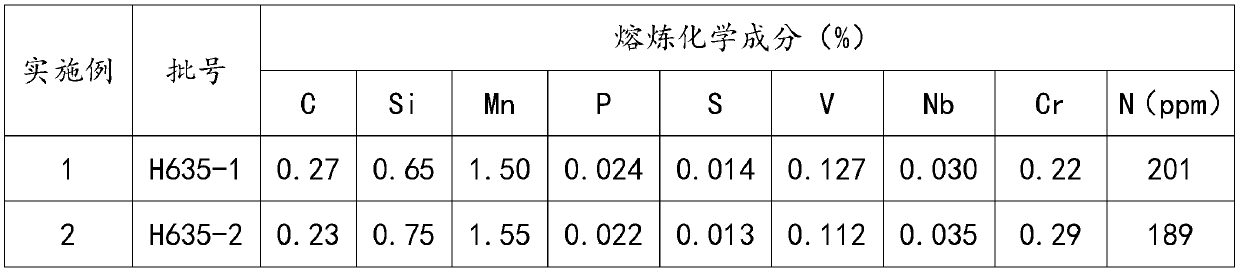

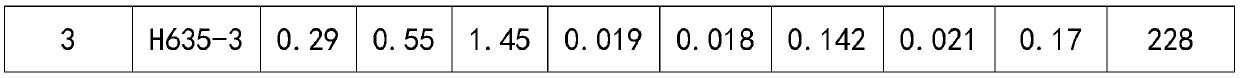

Steel for 635 MPa level high-strength hot-rolled steel bar

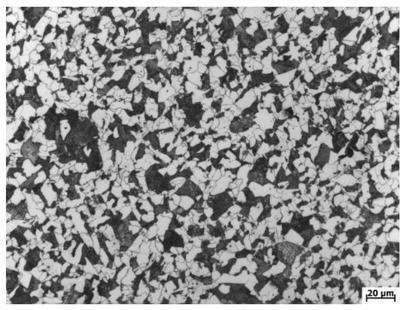

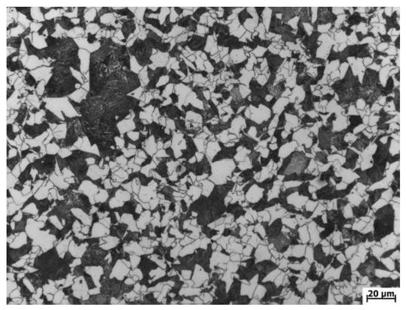

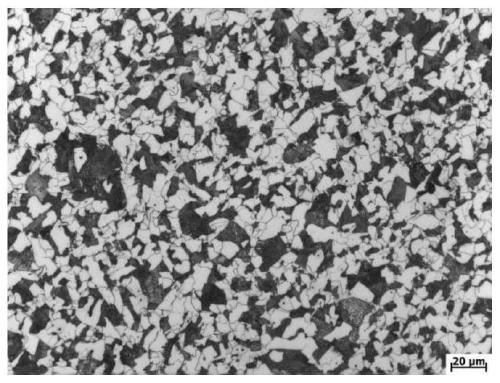

The invention relates to the technical field of hot-rolled ribbed steel bars, and discloses steel for a 635 MPa level high-strength hot-rolled steel bar. The steel is prepared from, by weight, 0.22-0.30% of C, 0.50-0.80% of Si, 1.40-1.60% of Mn, not larger than 0.025% of P, not larger than 0.025% of S, 0.015-0.035% of Nb, 0.105-0.145% of V, 0.15-0.35% of Cr, 0.018-0.025% of N and the balance Fe. According to the steel for the 635 MPa level high-strength hot-rolled steel bar and a machining method thereof, by adopting C, C is a cheap element, the strength of the steel can be remarkably improved, the extension performance of the steel can be lowered, meanwhile, the cold brittleness and aging sensitivity of the steel are improved, the integrated ingredients are reasonable, the comprehensive performance of the whole steel is improved, the stability of the steel performance is enhanced, the overall performance of the steel on the aspects of yield strength, tensile strength, the high yield ratio, the percentage elongation after fracture, the total elongation percentage under the maximum force and the like is good, meanwhile, the steel metallographic structure is ferrite+pearlite, the granularity is 11.5, the good fatigue resistance is achieved, the steel is suitable for large-scale industrial production, and benefits are remarkable.

Owner:安徽吾兴新材料有限公司

Steel for 650MPa-level high-strength explosion-proof fireproof steel bars and heat engine rolling technology of steel

InactiveCN109881118AHigh strengthHigh flex ratioTemperature control deviceMetal rolling arrangementsExtensibilityRebar

The invention relates to the technical field of hot-rolled ribbed steel bars for concrete, and discloses steel for 650MPa-level high-strength explosion-proof fireproof steel bars and a heat engine rolling technology of the steel. The steel comprises the following raw materials in percentage by weight of 0.20-0.30% of C, 0.40-0.80% of Si, 1.20-1.60% of Mn, 0.02-0.05% of Nb, 0.05-0.15% of V, 0.15-0.75% of Cr, 0.20-0.60% of Mo, 0.04-0.06% of Ti, lower than or equal to 0.030% of P, lower than or equal to 0.030% of S and 0.02-0.04% of Fe. According to the steel for 650MPa-level high-strength explosion-proof fireproof steel bars and the heat engine rolling technology of the steel disclosed by the invention, tissue can be refined, low-temperature toughness can be improved, favorable mechanical property can be obtained, and fatigue strength can be improved; the steel has better surface quality; and the comprehensive strengthening means of steel and iron materials including solid solution, deposition and fine-grain strengthening of microalloy elements and fine-grain strengthening of TMCP and the like are comprehensively utilized, so that under the premise that the plasticity of the materialis maintained, the 650MPa-level steel bars which are excellent in comprehensive property are produced, the yield strength is greater than or equal to 650MPa, the tensile strength is greater than or equal to 800MPa, the extensibility after breaking is greater than or equal to 14%, and the total elongation percentage under maximum force is greater than or equal to 7.5%.

Owner:安徽吾兴新材料有限公司

High-strength hot-rolled reinforcement bar of 830 MPa level, and production technology thereof

ActiveCN103484780AAvoid excessive corrosion rate and hardnessStrong hysteresis fracture resistanceRebarDuctility

The invention relates to a reinforcement bar and a production technology thereof, in particular to a high-strength hot-rolled reinforcement bar of the 830 MPa level, and a production technology of the reinforcement bar. The reinforcement bar comprises the following chemical components by weight: 0.38 to 0.43% of C, 0.7 to 0.9% of Cr, 0.6 to 0.8% of Mn, 0.15 to 0.25% of Mo, 0.2 to 0.3% of Si, 1.6 to 2% of Ni, 0.035% of S, 0.035% of P, 0.035% of N and the balance of Fe. The shear strength of the reinforcement bar can reach 830 MPa; the reinforcement bar has the advantages of high strength, good ductility, high lagging and fracture resistance, economy of steel material, underrelaxation, easiness in welding, high upset performance and the like, can enable carbide to dissolve fully and diffuse uniformly, and avoids that intercrystalline corrosion and pitting exceeding are caused due to intercrystalline separation of carbide.

Owner:江苏森林建筑新材料股份有限公司

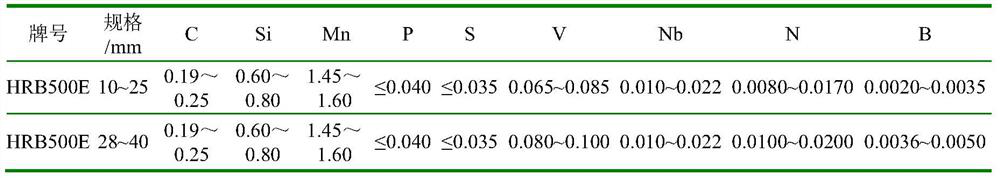

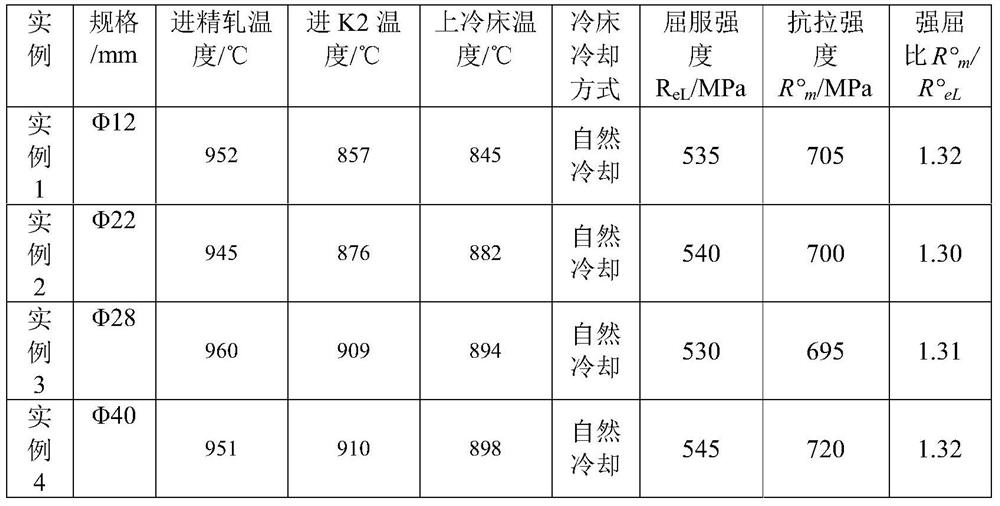

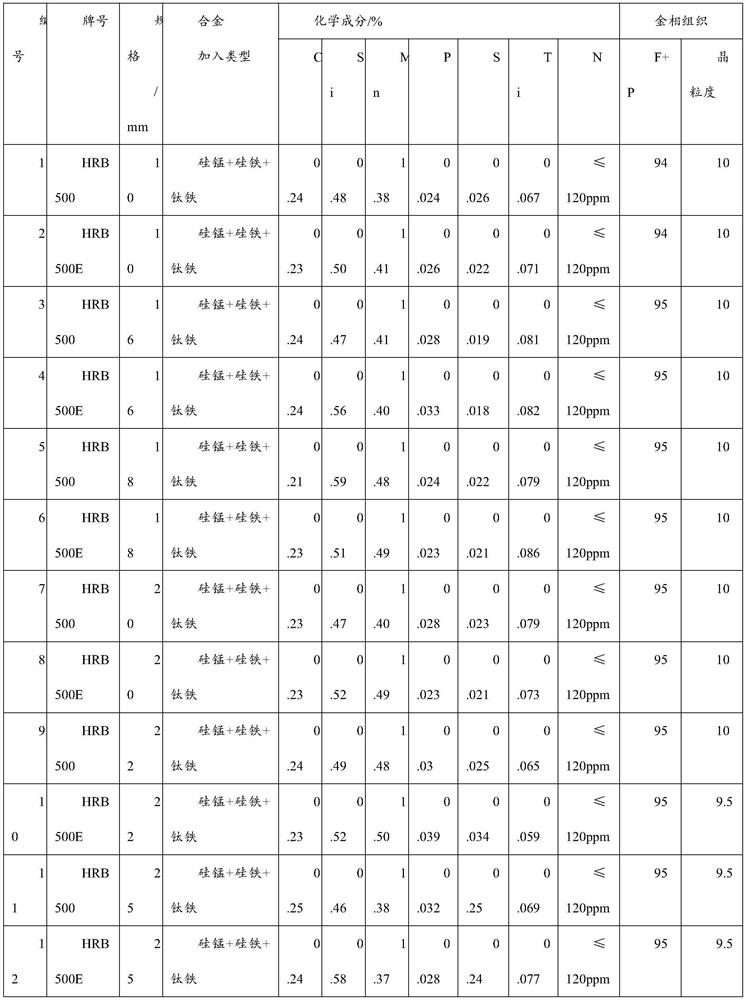

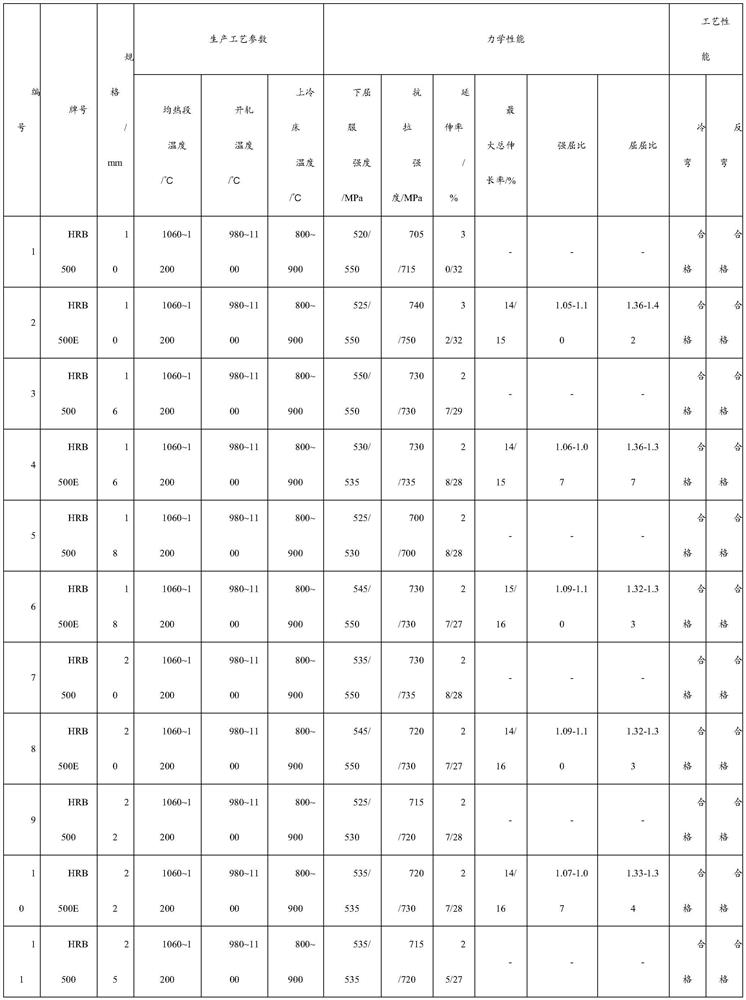

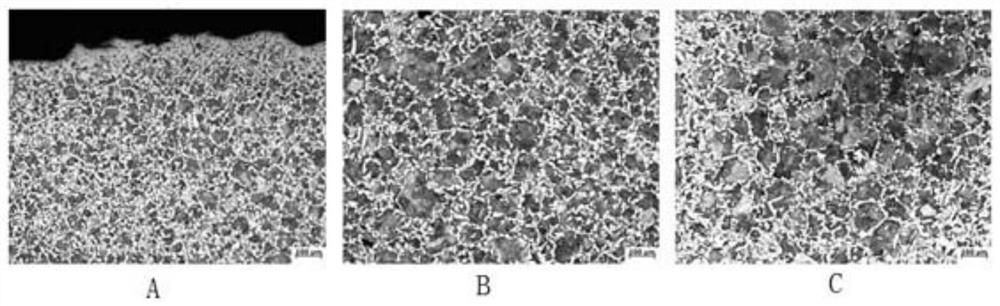

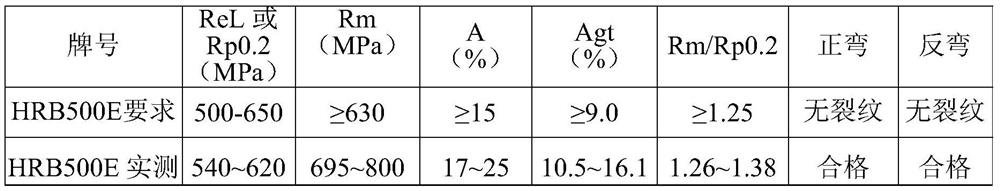

HRB500E ordinary-speed hot-rolled ribbed steel bar with tensile-to-yield ratio greater than 1.28 and production method thereof

ActiveCN113441545AHigh flex ratioProcess efficiency improvementWork heating devicesMolten steelRebar

The invention provides an HRB500E ordinary-speed hot-rolled ribbed steel bar with a tensile-to-yield ratio greater than 1.28 and a production method thereof. The production method of the HRB500E ordinary-speed hot-rolled ribbed steel bar with the tensile-to-yield ratio greater than 1.28 comprises the following process stages which are sequentially conducted: blast furnace molten iron smelting, molten iron desulfurization pretreatment, converter molten steel smelting, LF refining, square billet continuous casting and hot continuous rolling. The HRB500E ordinary-speed hot-rolled ribbed steel bar is prepared from the following components in percentage by weight: 0.19 to 0.25 percent of C, 0.60 to 0.80 percent of Si, 1.45 to 1.60 percent of Mn, less than or equal to 0.040 percent of P, less than or equal to 0.035 percent of S, 0.065 to 0.10 percent of V, 0.010 to 0.022 percent of Nb, 0.008 to 0.020 percent of N, and 0.0020 to 0.0050 percent of B. The specification of the ordinary-speed hot-rolled ribbed steel bar is 10 mm to 40 mm. The cooling bed cooling mode is natural cooling. The HRB500E ordinary-speed hot-rolled ribbed steel bar with the tensile-to-yield ratio greater than 1.28 and the production method of the HRB500E ordinary-speed hot-rolled ribbed steel bar with the tensile-to-yield ratio greater than 1.28 are adopted.

Owner:广西柳钢华创科技研发有限公司 +1

635MPa-grade high-strength anti-seismic steel bar and preparation method thereof

The invention belongs to the technical field of hot-rolled ribbed steel bars for reinforced concrete structures, and particularly relates to a 635MPa-grade high-strength anti-seismic steel bar and a preparation method thereof. Steel in a steel bar comprises the following chemical components in percentage by weight: 0.24-0.29 percent of C, 0.70-0.80 percent of Si, 1.50-1.60 percent of Mn, less thanor equal to 0.035 percent of P, less than or equal to 0.035 percent of S, 0.100-0.160 percent of V, 0.010-0.030 percent of Nb and the balance of Fe and inevitable impurity elements. The 635MPa-gradehigh-strength anti-seismic steel bar with high strength and high plasticity is produced by adopting a high-C, Si and Mn component design and a V and Nb combined microalloying manner under the condition of existing process equipment of a production plant and combining steelmaking and steel rolling processes, is stable in performance and good in comprehensive mechanical property, and has yield strength greater than or equal to 635MPa, tensile strength greater than or equal to 795MPa, percentage elongation after fracture greater than or equal to 15%, total elongation under maximal force greater than or equal to 9.0%, the strength-to-yield ratio greater than or equal to 1.25 and the yield-to-yield ratiogreater than or equal to 1.30, good anti-seismic performance is achieved, and the requirements of high-rise and large-span anti-seismic structures are met.

Owner:安徽吾兴新材料有限公司

High-strength hot-rolled reinforcement bar of 830 MPa level, and production technology thereof

The invention relates to a steel bar and its production process, which is a 830MPa grade high-strength hot-rolled steel bar and its production process. The chemical composition in weight percentage is: C: 0.38-0.43%, Cr: 0.7-0.9%, Mn: 0.6- 0.8%, Mo: 0.15-0.25%, Si: 0.2-0.3%, Ni: 1.6-2%, S: <0.035%, P: <0.035%, N: <0.035%, and the balance is Fe. The steel bar yield strength of the present invention can reach 830MPa, has the advantages of high strength, good ductility, strong hysteresis fracture resistance, steel saving, low relaxation, easy welding, good upsetting performance, etc., and can fully dissolve carbides and evenly diffuse, It avoids the precipitation of carbides between grains and causes excessive intergranular corrosion and pitting corrosion.

Owner:江苏森林建筑新材料股份有限公司

Earthquake-resistant steel bar

The invention discloses an earthquake-resistant steel bar. The earthquake-resistant steel bar is characterized by being prepared from, by weight percent, 0.21%-0.24% of C, 0.45%-0.55% of Si, 1.45%-1.55% of Mn, 0.018%-0.032% of Nb, not larger than 0.045% of P, not larger than 0.045% of S and the balance Fe and impurity elements. According to the earthquake-resistant steel bar, under the condition of guaranteeing that the need of the mechanical property is met, different element composition proportions are adopted according to different diameter specifications, the niobium content is reduced, and therefore the use level of niobium and iron is reduced, the production cost is reduced, and economic benefits are improved.

Owner:YUNNAN DESHENG STEEL CO LTD

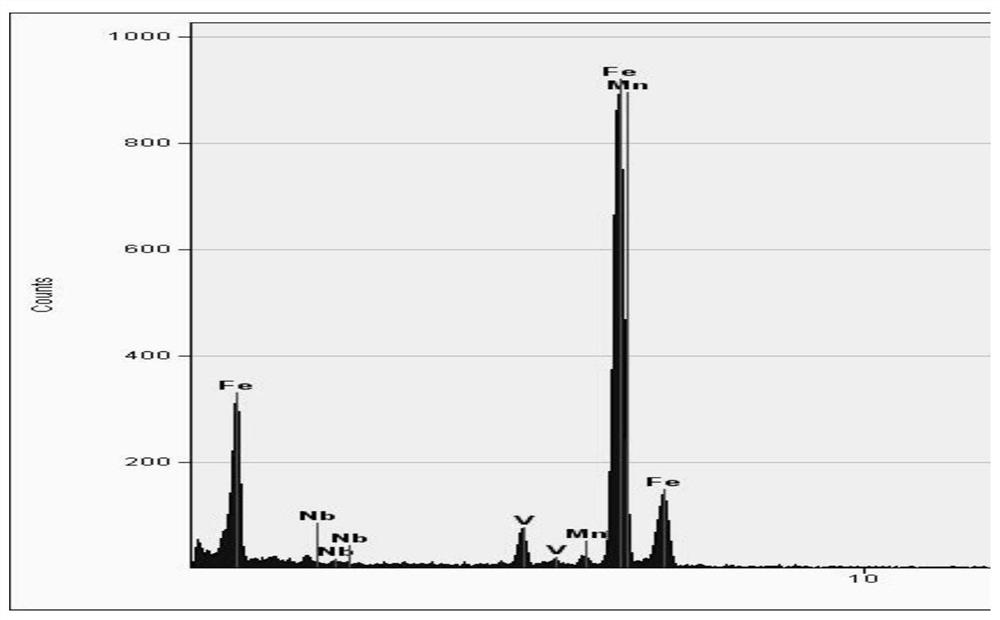

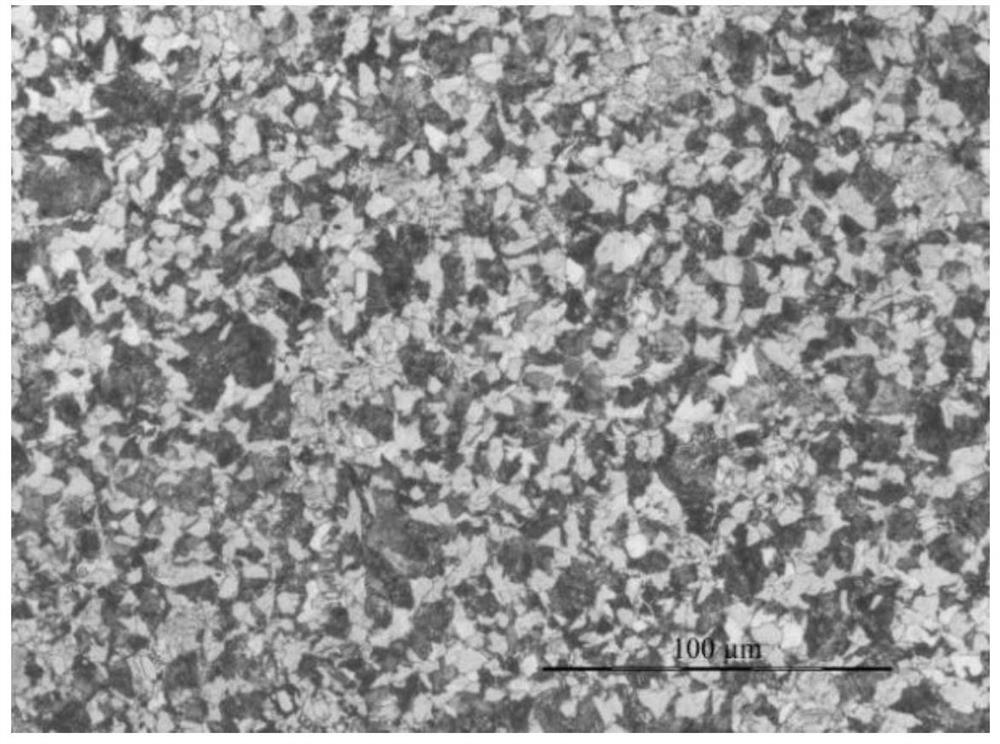

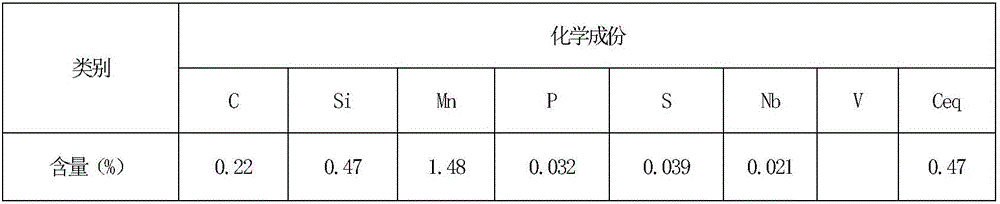

Hot-rolled steel bar

The invention discloses a hot-rolled steel bar. The hot-rolled steel bar is characterized by comprising, by weight, 0.20-0.24% of C, 0.44-0.55% of Si, 1.48-1.55% of Mn, 0.020-0.032% of Nb, P, S and the balance Fe and impurity elements, wherein the weight percentage of P is smaller than or equal to 0.040%, and the weight percentage of S is smaller than or equal to 0.040%. The diameter specification of the hot-rolled steel bar is 16-32mm. The hot-rolled steel bar has advantages that by adjustment of microalloy contents of the hot-rolled steel bar, safety and earthquake resistance of building structures can be met, mechanical properties, welding properties and anti-seismic properties can reach standards, the steel bar is high in strength, steel materials can be saved, construction cost is reduced, structural strength is improved, and safety storage quantity is increased.

Owner:YUNNAN DESHENG STEEL CO LTD

High-N composite reinforced 500MPa-grade and 600MPa-grade steel bar, smelting method and production method

InactiveCN111334719AMake full use of the strengthening effectHigh flex ratioManufacturing convertersFerroniobiumSmelting process

The invention provides a high-N composite reinforced 500MPa-grade and 600MPa-grade steel bar, a smelting method and a production method. Smelting is conducted by adopting a smelting process, in the converter smelting tapping process, according to the amount of 2.5-4.0 kg per ton of steel, high-nitrogen ferrovanadium alloy FeV30N14 with N being 14%-16% in content, V being 29%-31% in content and thebalance Fe and inevitable impurities is added, according to the amount of 0.2-0.25 kg per ton of steel, ferroniobium with Nb being 63.0%-65% in content by weight percentage is added, so that the V / Nratio of molten steel is controlled to be 3.49-3.83. According to the high-N composite reinforced 500MPa-grade and 600MPa-grade steel bar, the smelting method and the production method, vanadium nitrogen and ferroniobium in the prior art are replaced with the high-nitrogen ferrovanadium alloy (FeV30N14) and the ferroniobium, so that the nitrogen content in the steel just reaches a theoretical value, the V (N, C) precipitation strengthening effect is fully exerted, and the purposes of saving vanadium and reducing the cost are achieved.

Owner:JIANGSU YONGGANG GROUP CO LTD

Anti-seismic reinforcing steel bar and preparation method thereof

The invention relates to the technical field of ferrous metallurgy, in particular to an anti-seismic reinforcing steel bar and a preparation method thereof.The anti-seismic reinforcing steel bar comprises, by weight, 0.20%-0.25% of C, 0.65%-0.80% of Si, 1.35%-1.60% of Mn, 0.090%-0.110% of V, 0.20%-0.30% of Cr, larger than or equal to 0.0180% of N, smaller than or equal to 0.035% of P, smaller than or equal to 0.035% of S, smaller than or equal to 0.55% of Ceq and the balance Fe and inevitable impurities. The beneficial influence of the specification effect of the small-specification HRB600E anti-seismic steel bar on the strength performance is fully considered, the C content is properly reduced and controlled to be 0.20%-0.25%, Ceq is smaller than or equal to 0.55%, the requirements for the C content and the carbon equivalent of the 500 MPa-grade steel bar in the GB / T 1499.2-2018 standard are met, the continuous casting rejudgment of the 500 MPa-grade steel bar can be achieved on a production organization, the production efficiency is not affected, the production organization is facilitated, and waste judgment loss is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

High-strength hot-rolled profile and temperature control and cooling process thereof

InactiveCN111575583AHigh flex ratioHigh strengthTemperature control deviceMetal rolling arrangementsTemperature controlChemical composition

The present invention provides a high-strength hot-rolled profile. The high-strength hot-rolled profile comprises the following chemical compositions of: 0.14-0.25% of C, 1.40-1.80% of Mn, 0. 40-0.60%of Si, 0.075-0.095% of V, less than or equal to 0.045% of P / S, 0.0215-0.025% of N, 0.015-0.020% of Nb, and the balance Fe and inevitable impurities. The V / N ratio of the chemical composition of the hot-rolled profile is 3.49-3.83. The hot-rolled profile also comprises chemical components B and Cr, the chemical composition of B being 0.0015-0.005%, and the chemical composition of Cr is 0.6-0.7%. According to the invention, the chemical compositions and rolling processes are adjusted on the basis of a common profile, and the comprehensive performance of the profile is improved.

Owner:江苏联峰实业有限公司

Economical 500MPa-grade steel bar and preparation method thereof

The invention discloses an economical 500MPa-grade steel bar and a preparation method thereof. The economical 500MPa-grade steel bar comprises 0.20-0.25 wt% of C, less than or equal to 1.60 wt% of Mn,less than or equal to 0.80% of Si, less than or equal to 0.045% of P, less than or equal to 0.045% of S, more than or equal to 0.05% of Ti and the balance iron and inevitable impurity elements. The key Si content of the preparation method is achieved by silicomanganese and ferrosilicon alloy, and ferrotitanium is added in the tapping process; and compared with an existing 500 MPa-grade traditional vanadium and niobium hot rolling process, the alloy consumption is low, no precious metal element is contained, economical efficiency is achieved, and the cost can be reduced.

Owner:ZHANGJIAGANG RONGSHENG SPECIAL STEEL CO LTD +1

Method of preparing high-strength thin-crystal two-phase steel

InactiveCN100500880CHigh flex ratioImprove work hardening abilityHeat treatment process controlManganeseRoom temperature

The invention relates to a method for preparing fine-grain dual-phase steel, in particular to preparing fine-grain dual-phase steel from low-carbon (manganese) steel. This method austenitizes ordinary low-carbon (manganese) steel, obtains a fine austenite structure through multi-pass deformation in the recrystallization zone, and supercools to a certain temperature range from A3 to Ar3 at an appropriate cooling rate. The temperature is subjected to multi-pass deformation, and the strain rate is between 0.1s-1 and 30s-1. By controlling the strain of each pass, 80% to 90% of the ferrite transformation value is obtained, and then rapidly cooled or quenched to room temperature. The average size of equiaxed ferrite grains in the fine-grained dual-phase structure obtained by the above process is less than 5 microns, the volume fraction of evenly distributed martensite islands is 10% to 15%, and the average size is less than 3 microns. The process is more controllable, the structure is more uniform, and it is easy to realize on the traditional hot rolling mill.

Owner:UNIV OF SCI & TECH BEIJING

A kind of hot-rolled h-shaped steel for buckling restraint support and its production process

ActiveCN112301285BNarrow yield strength rangeHigh flex ratioTemperature control deviceMetal rolling arrangementsChemical compositionUltimate tensile strength

The invention discloses a hot-rolled H-shaped steel for buckling restraint support and its production process. The chemical composition of the H-shaped steel in the invention is calculated by mass percentage, including C: 0.09-0.12%, Si: 0.19-0.22%, and Mn: 0.57-0. 0.60%, P: ≤0.015%, S: ≤0.015%, V: 0.020~0.035%, N: ≤0.0080%, the rest is Fe and unavoidable impurity elements; the production process of the H-shaped steel includes: blast furnace molten iron →Molten iron pretreatment→converter smelting→argon blowing station→LF refining→full protection casting of shaped blanks→H-beam rolling; the invention has narrow yield strength range, large strength-to-yield ratio, good extensibility and low production cost.

Owner:MAANSHAN IRON & STEEL CO LTD

Common hot-rolled steel plate with high strength and yield ratio and manufacturing method thereof

ActiveCN103469056BHigh tensile strengthLower yield strengthManufacturing convertersProcess efficiency improvementUltimate tensile strengthCarbon steel

The invention discloses a high-tensile-to-yield-ratio common hot rolled steel plate and a making method thereof. The high-tensile-to-yielding-ratio common hot rolled steel plate comprises, by mass, 0.12-0.22% of C, 0.12-0.30% of Si, 0.30-0.90% of Mn, 0.025% or less of P, 0.025% or less of S, 0.0010-0.0020% of B, and the balance Fe and residual elements. The making method of the high-tensile-to-yielding-ratio common hot rolled steel plate comprises the steps of converter smelting, LF furnace refining, continuous casting, plate blank heating, rolling, controlled cooling and finishing. The making method of the high-tensile-to-yielding-ratio common hot rolled steel plate has a low production cost, changes very small chemical components of a common hot rolled steel plate and almost changes no microscopic structure of the common hot rolled steel plate. The addition of the boron element is very small, so the influence on the processing making cost of the common hot rolled steel plate is very small. The addition of 10-20ppm of the boron element to low carbon steel increases the tensile strength of steel by 5-15MPa and decreases the yield strength by 30-50MPa, so the tensile-to-yield ratio of the steel is substantially improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

630 MPa-grade high-strength hot-rolled reinforced bar and production process thereof

Owner:江苏森林建筑新材料股份有限公司

A hot-rolled ribbed steel bar with a strength-to-yield ratio ≥ 1.25 and its production method

A hot-rolled ribbed steel bar having a strength-to-yield ratio of 1.25 or more comprises 0.17-0.25wt% of C, 0.4-0.8wt% of Si, 1.2-1.5wt% of Mn, 0.045wt% or less of P, 0.045wt% or less of S, 0.05-0.08wt% of V, 0.006-0.018wt% of N, and the balance of Fe and impurity elements, and has a specification diameter of 12-40mm. A production method of the hot-rolled ribbed steel bar comprises the following steps: desulfurizing molten iron; carrying out top-bottom blowing of a converter; carrying out component fine-adjustment at an argon station, and blowing in nitrogen; refining an LF furnace, and blowing nitrogen into the LF furnace; continuously casting; carrying out stacking cooling; heating casted blanks; carrying out rough rolling and finish rolling; and naturally cooling to room temperature. Nitrogen is blown to realize greatly reduced cost, greatly reduced vanadium alloy consumption, increased V (C,N) amount and dispersity with the increase of the content of N in steel, substantial reinforcement effect and stable mechanical performances on the premise that mechanical performances comprising a hot-rolled yield strength of above 530MPa, a strength-to-yield ratio of 1.25-1.30, an A value of 18% or more and an Agt value of 10 or more are guaranteed.

Owner:武汉钢铁有限公司

Hot-rolled H-shaped steel for buckling restrained brace and production process

ActiveCN112301285ANarrow yield strength rangeHigh flex ratioTemperature control deviceMetal rolling arrangementsBuckling-restrained braceUltimate tensile strength

The invention discloses hot-rolled H-shaped steel for a buckling restrained brace and a production process. The hot-rolled H-shaped steel for the buckling restrained brace comprises, by mass, 0.09-0.12% of C, 0.19-0.22% of Si, 0.57-0.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.020-0.035% of V, less than or equal to 0.0080% of N, and the balance Fe and inevitable impurity elements. The production process of the H-shaped steel comprises the steps of blast furnace molten iron treatment, molten iron pretreatment, converter smelting, argon blowing station treatment, LF refining, special-shaped blank full-protection casting and H-shaped steel rolling. The hot-rolled H-shaped steel is narrow in yield strength range, large in yield ratio, good in extensibility and low in production cost.

Owner:MAANSHAN IRON & STEEL CO LTD

High-strength hot-rolled reinforcement bar of 730 MPa level, and production technology thereof

ActiveCN103484775BImprove atomic activityStrong interactionHeat treatment process controlChemical compositionCarbide

The invention relates to a steel bar and its production process, which is a 730MPa grade high-strength hot-rolled steel bar and its production process. The chemical composition in weight percentage is: C: 0.48-0.53%, Cr: 0.8-1.1%, Mn: 0.75- 1.0%, Mo: 0.15-0.25%, Si: 0.15-0.3%, S: <0.035%, P: <0.035%, N: <0.035%, and the balance is Fe. The steel bar yield strength of the present invention can reach 730Mpa, has the advantages of high strength, good ductility, strong hysteresis fracture resistance, steel saving, low relaxation, easy welding, good upsetting performance, etc., and can fully dissolve carbides and evenly diffuse, It avoids the precipitation of carbides between grains and causes excessive intergranular corrosion and pitting corrosion.

Owner:江苏森林建筑新材料股份有限公司

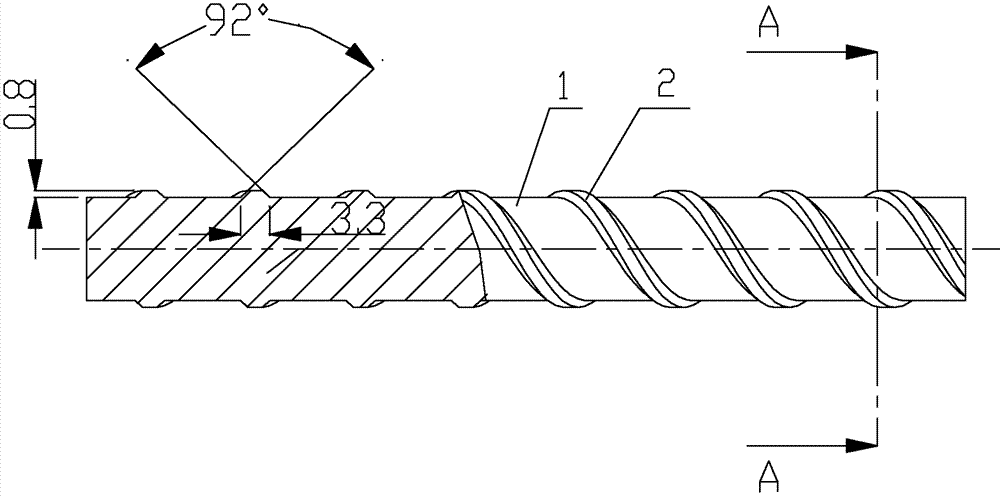

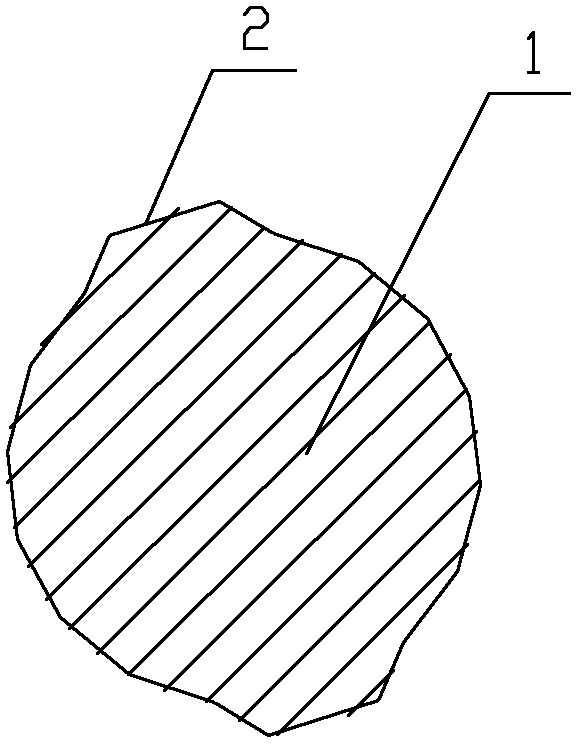

High-strength reinforcing steel bar with spiral fins and processing method of high-strength reinforcing steel bar

The invention relates to a reinforcing steel bar and a processing method thereof, in particular to a high-strength reinforcing steel bar with spiral fins and a processing method of the high-strength reinforcing steel bar. The high-strength reinforcing steel bar consists of following components including, in weight percentage, from 0.25 to 0.4% of C, from 0.1 to 0.2% of Si, from 0.3 to 0.45% of Mn, from 0.04 to 0.05% of Nb, from 0.08 to 0.09% of Cr, from 0.01 to 0.04% of V, from 0.002 to 0.003% of B, from 0.001 to 0.003% of Mo, from 0.015 to 0.03 of Al, from 0.002 to 0.003% of S, from 0.008 to0.009% of Ti, from 0.004 to 0.005% of Ni, from 3 to 5% of composite rear earth and the balance Fe. The processing method includes using a roll to roll a reinforcing steel bar into a reinforcing steelbar with the continuous spiral fins on the surface in a hot state; feeding the reinforcing steel bar with the continuous spiral fins on the surface after hot rolling into a heating furnace and heating the reinforcing steel bar to the temperature of 880-990 DEG C; then fast cooling the reinforcing steel bar to the temperature of 650-680 DEG C by an online cooling device via compressed air or vaporous quenching liquid; quenching in a quenching device by water or quenching liquid for 15-25 seconds; and tempering after heating the reinforcing steel bar to the temperature of 500-550 DEG C via a tempering heating furnace. The high-strength reinforcing steel bar with the spiral fins has a good anchoring property, fine ductility and a high yielding-to-tensile ratio.

Owner:TIANSHUN GROUP +2

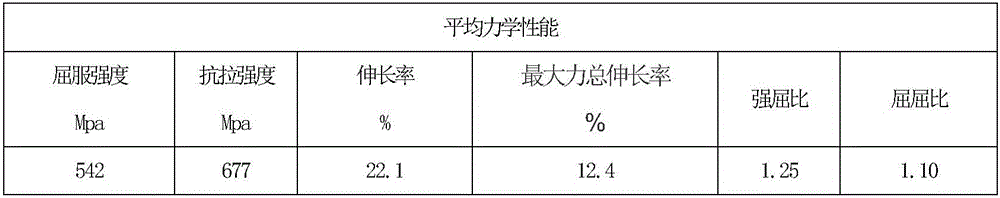

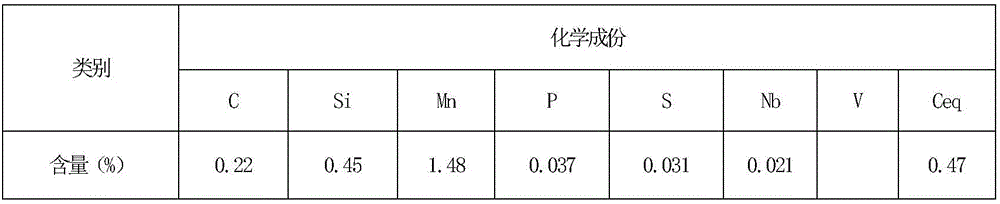

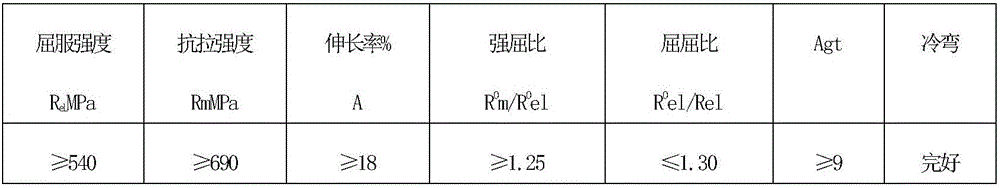

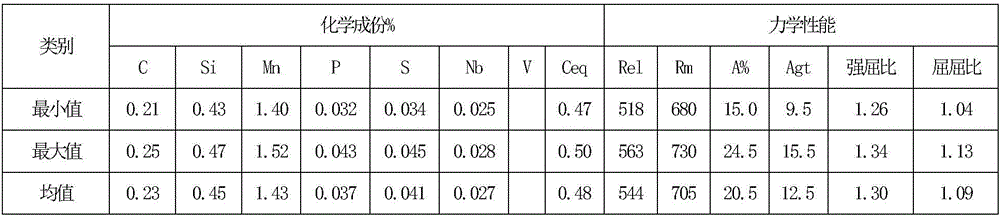

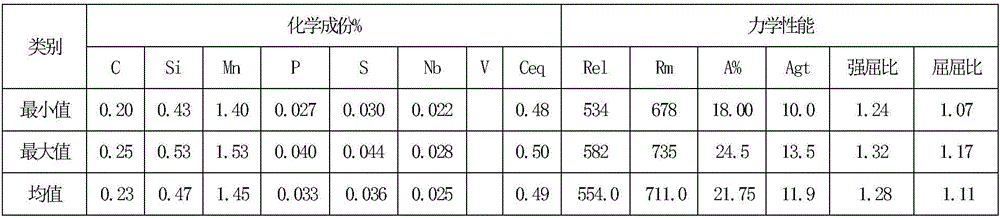

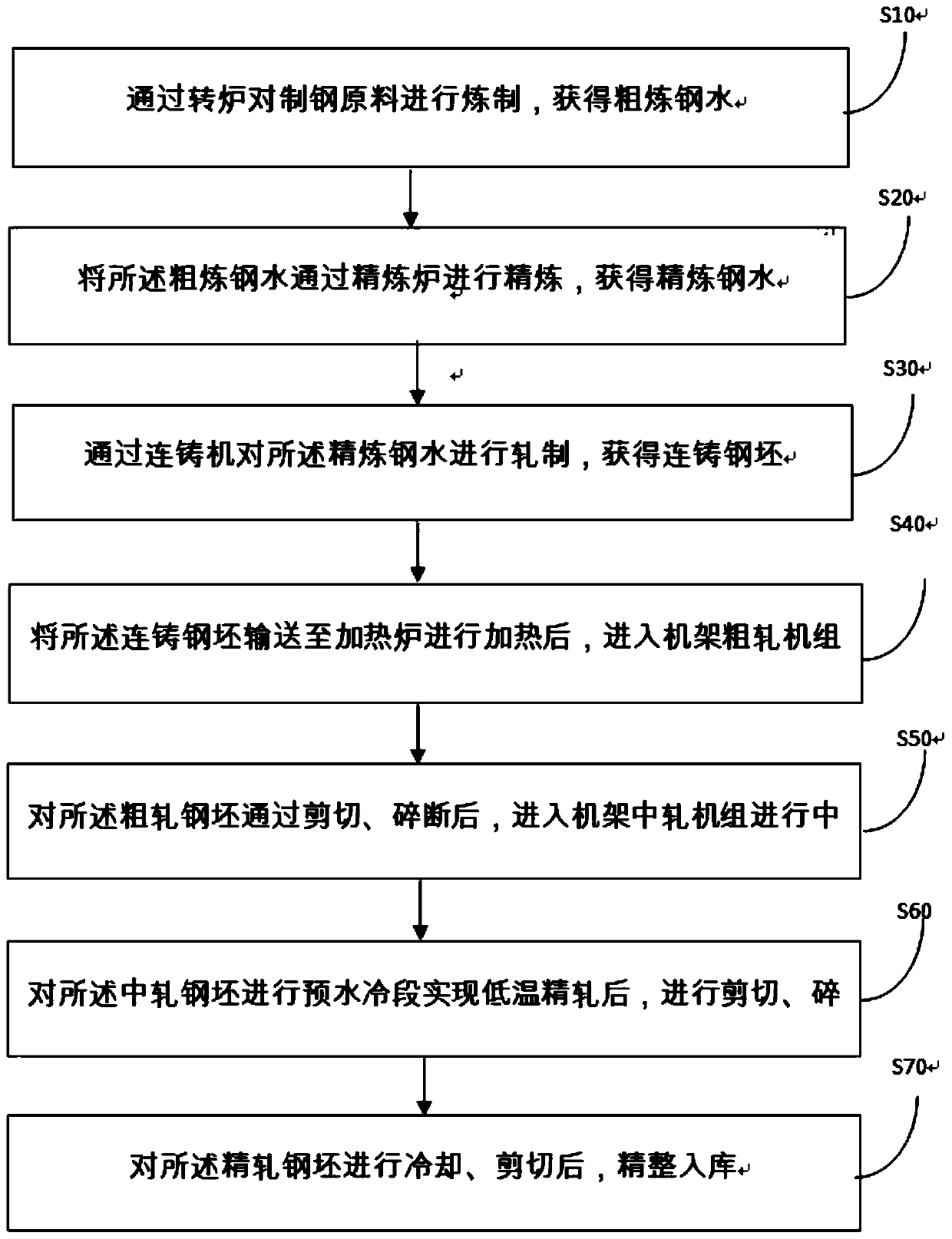

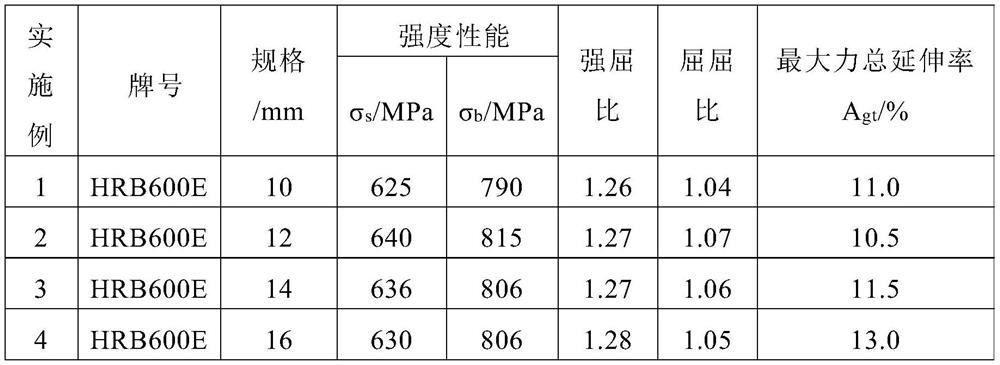

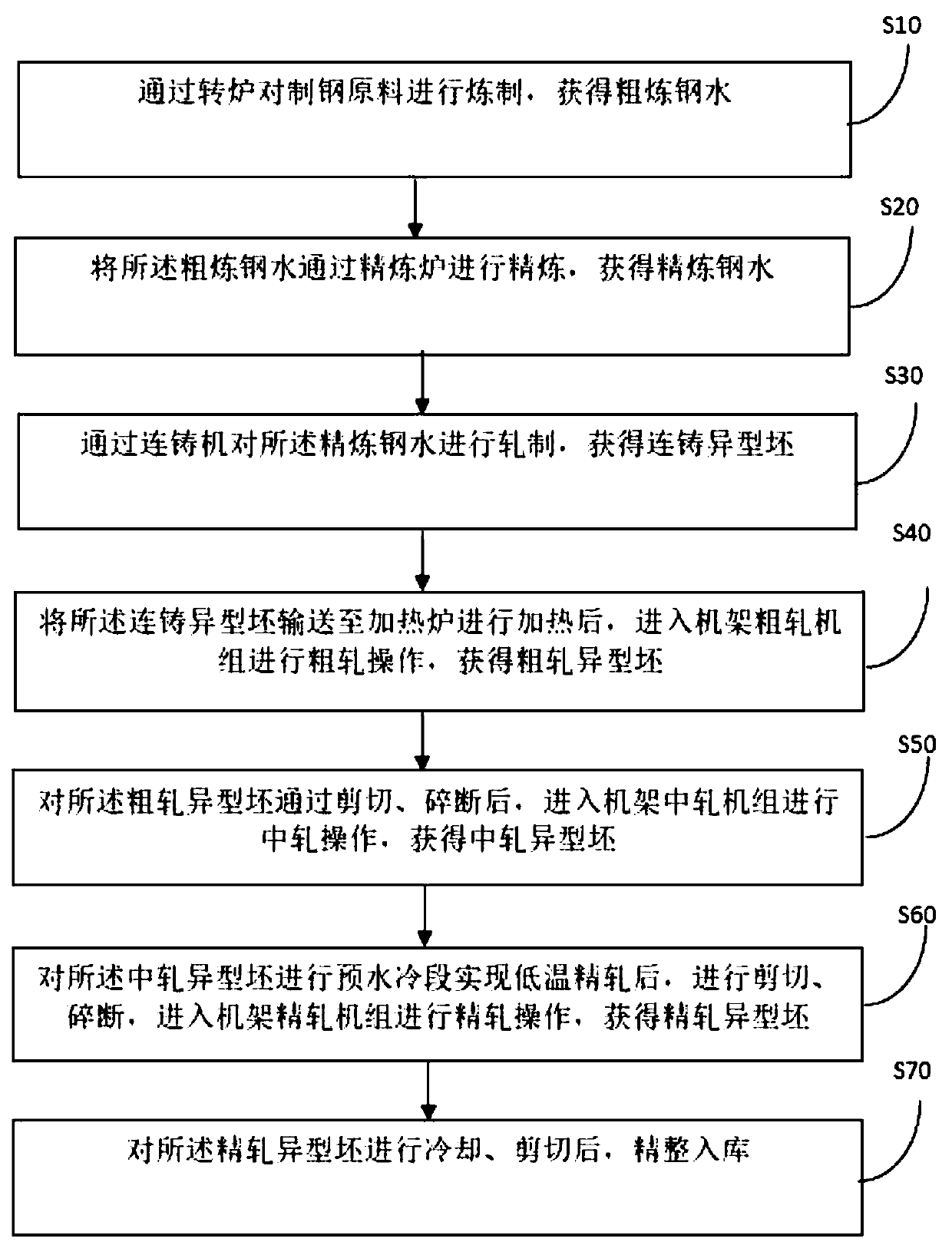

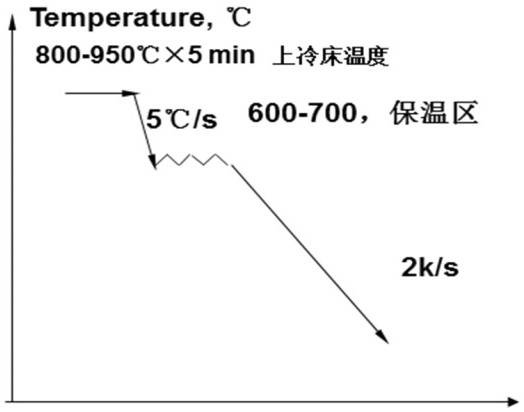

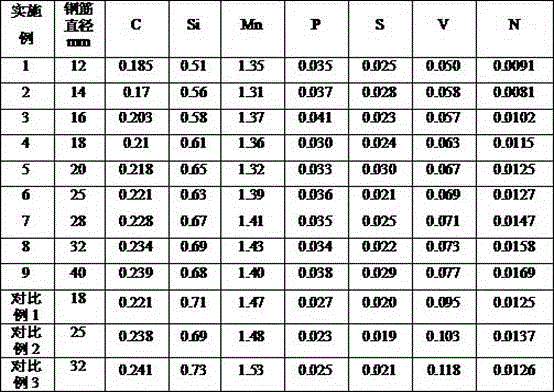

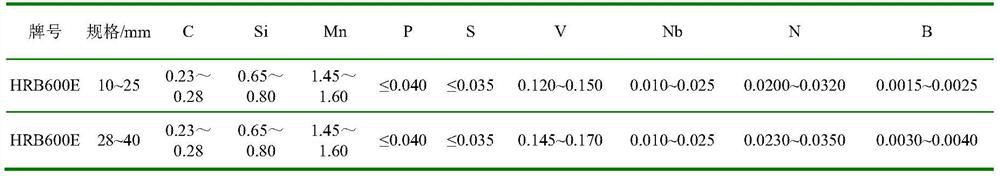

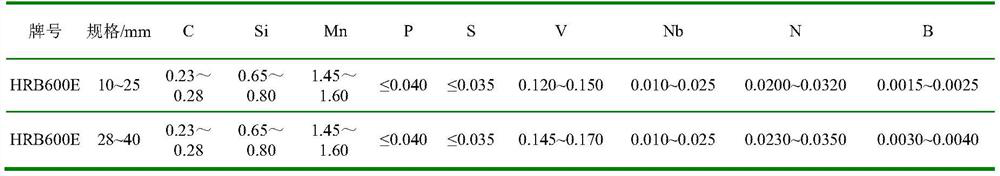

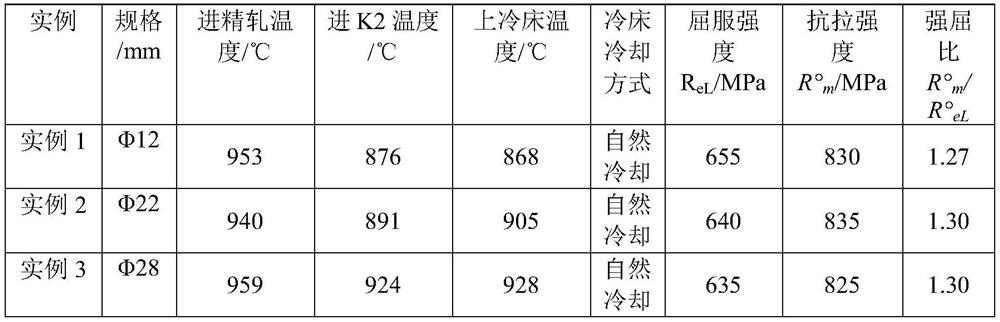

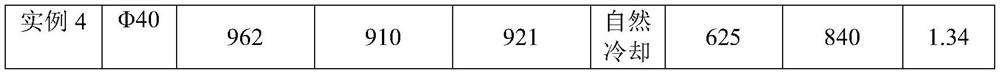

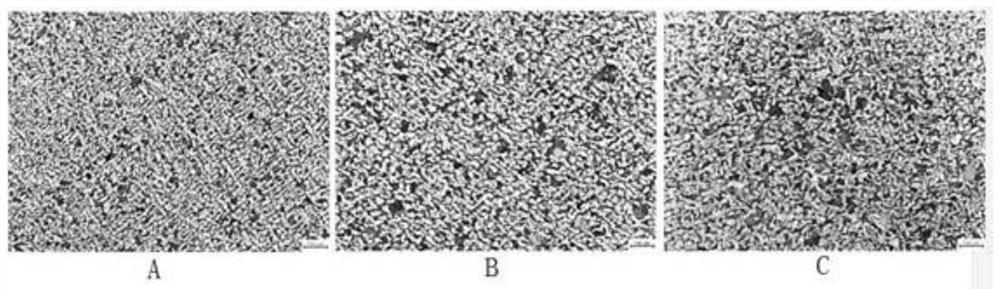

HRB600E general-speed hot-rolled ribbed steel bar with a strength-to-yield ratio greater than 1.26 and its production method

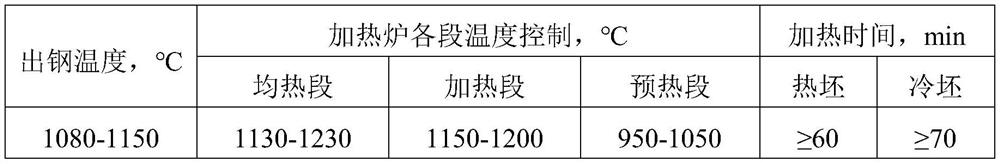

The invention provides a HRB600E normal-speed hot-rolled ribbed steel bar with a yield ratio greater than 1.26 and a production method thereof. The production method of the HRB600E normal-speed hot-rolled ribbed steel bar with a yield ratio greater than 1.26 comprises the following steps: Process stage: blast furnace hot metal smelting, hot metal desulfurization pretreatment, converter molten steel smelting, LF refining, billet continuous casting, hot continuous rolling, cut-to-length cutting and inspection; the temperature control in hot continuous rolling is: control the casting slab heating temperature to 1150-1200°C, billet heating time 60-90 minutes, rolling start temperature 1020-1080°C. Normal speed hot-rolled ribbed steel bar adopts the above-mentioned production method.

Owner:广西柳钢华创科技研发有限公司 +1

HRB500E anti-seismic rebar rolling method

InactiveCN104668284AAvoid over-refinementAvoid surface crackingTemperature control deviceMetal rolling arrangementsFree coolingReducing atmosphere

The invention discloses a HRB500E anti-seismic rebar rolling method. The method includes a heating process, a rolling process and a cooling process. In the heating process, the temperature of a raw material before being fed into a heating furnace is lower than 500 DEG C, a raw material heating temperature ranges from 1200 DEG C to 1250 DEG C, the time of the material in the furnace is 70-100 minutes, and the heating furnace adopts a reducing atmosphere. The cooling process adopts a natural cooling manner. By the HRB500E anti-seismic rebar rolling method, weakening of intercrystalline binding force and excessive thinning of crystalline grains can be effectively avoided, dislocation density is reduced, and increase of yield-tensile ratio and avoidance of surface cracks are realized. The HRB500E anti-seismic rebar rolling method has the advantages of technical simplicity, excellent mechanical property, high product yield and the like, product production cost can be effectively reduced, and product quality is improved.

Owner:HEBEI IRON AND STEEL

A kind of nb, v composite 700mpa grade high-strength anti-seismic reinforcement steel and its production method

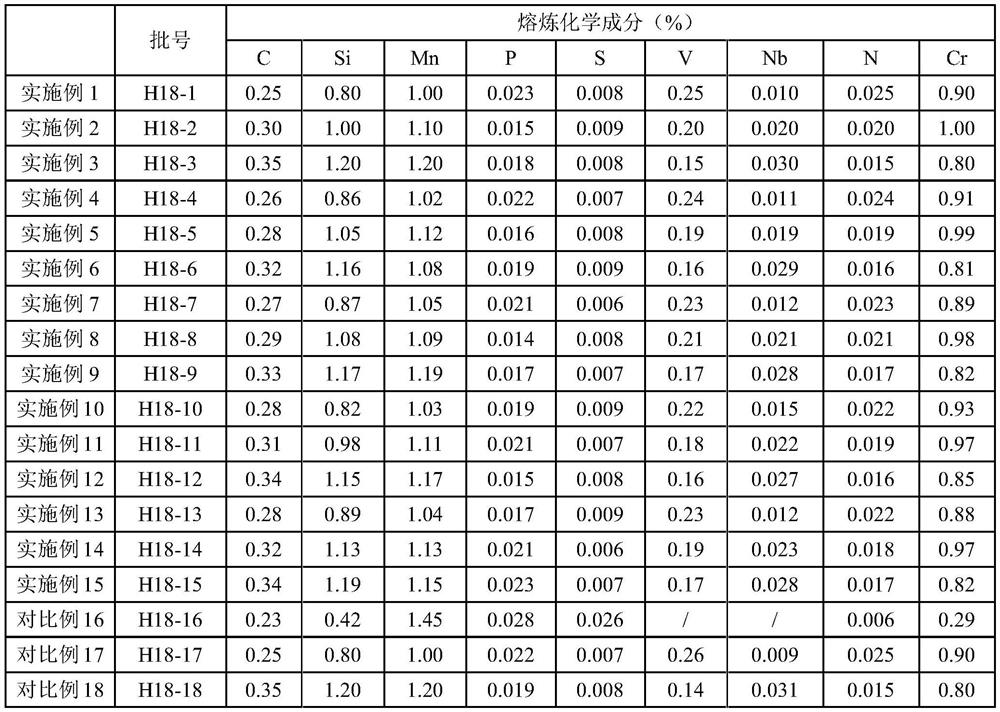

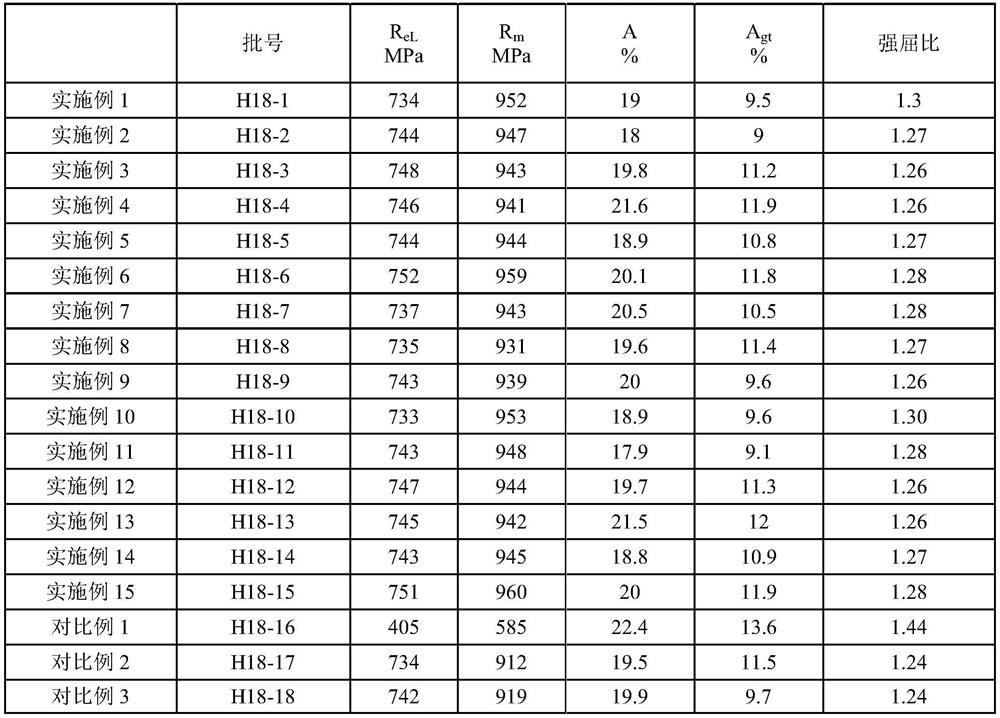

The invention discloses a Nb, V composite 700MPa-grade high-strength anti-seismic reinforcement steel and a production method thereof, which belong to the technical field of hot-rolled ribbed reinforcement. Its chemical composition and mass percentage content include C: 0.25-0.35%, Si: 0.80-1.20%, Mn: 1.00-1.20%, V: 0.15-0.25%, Nb: 0.010-0.030%, Cr: 0.80-1.00% , N: 0.015~0.025%, P: ≤0.025%, S: ≤0.010%, the rest are Fe and unavoidable impurity elements; Nb, V composite microalloying, converter steelmaking (or electric arc furnace), continuous rod Rolling in steel rolling mills, under the existing technology and equipment level of steel enterprises, realizes large-scale industrial production of 700MPa high-strength seismic steel bars to meet the needs of high-rise and long-span concrete building structures in my country.

Owner:MAANSHAN IRON & STEEL CO LTD

Steel for high strength shock-proof hot-rolled steel bar

This invention relates to a aseismatic heat rolled steel bar with high strength, which belongs to alloy steel, especially to the heat rolled steel bar, the steel bar is composed by the following elements: 0.07-0.16%C, 1.2-2.0%Si, 1.5-2.0%Mn, <=0.4%Cr, 0.02-0.14%V, the rest is Fe and impurity. The universal steel-making device uses the universal technology; it smelts steel according to the said component range and produces heat rolled steel bar or rod with highe strength and better aseismatic charater. Wherein the yield strengthen sigmas(p0.2)>=550MPa, the yield proportion sigmab / sigmas(p0.2)>=1.45. And the high strength and high yield proportion of the steel bar can enforce the aseismatic charater of the building.

Owner:MAANSHAN IRON & STEEL CO LTD

HRB600E ordinary-speed hot-rolled ribbed steel bar with tensile-to-yield ratio greater than 1.26

Owner:GUANGXI LIUGANG HUACHUANG TECH R & D CO LTD +1

A kind of 500mpa level large-scale straight bar rebar and its preparation method

ActiveCN111979486BIncrease air cooling timeIncrease temperatureTemperature control deviceFurnace typesFurnace temperatureChemical composition

The invention discloses a 500Mpa large-scale straight threaded steel and a preparation method thereof. The chemical composition of the threaded steel contains: C: 0.22-0.25%, Si: 0.40-0.60%, Mn: 1.35-1.60% in mass percentage , P≤0.045%, S≤0.045%, V: 0.100~0.120%, N: 0.010%~0.020%, the rest is Fe and unavoidable impurities; the preparation methods include converter smelting, argon blowing and stirring, continuous casting, heating, Phosphorus removal and rolling; in the heating process, the furnace temperature in the preheating section is controlled to be 500~900°C, the furnace temperature in the heating section is 1100~1180°C, the furnace temperature in the soaking section is 1130~1180°C, and the heating time is 80~150min; In the rolling process, the rolling start temperature is 1000~1100°C, and the rolling speed decreases with the increase of the diameter of the straight rebar. The present invention eliminates or compresses the reticular ferrite in the finished straight rebar through proper heating temperature and rolling process to a very small range in the core, significantly improves the microstructure of 500MPa large-scale straight rebar, and ensures Its strength and bending properties meet the requirements.

Owner:NANJING IRON & STEEL CO LTD

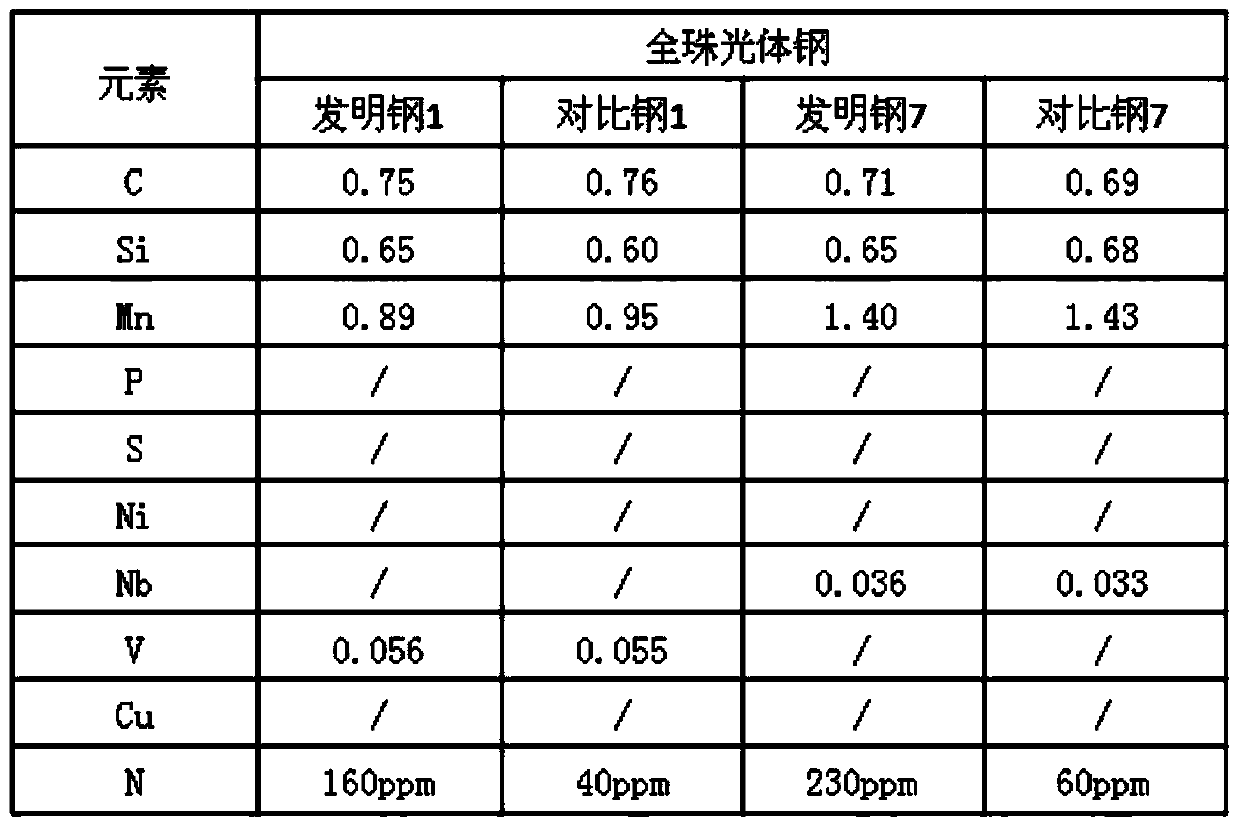

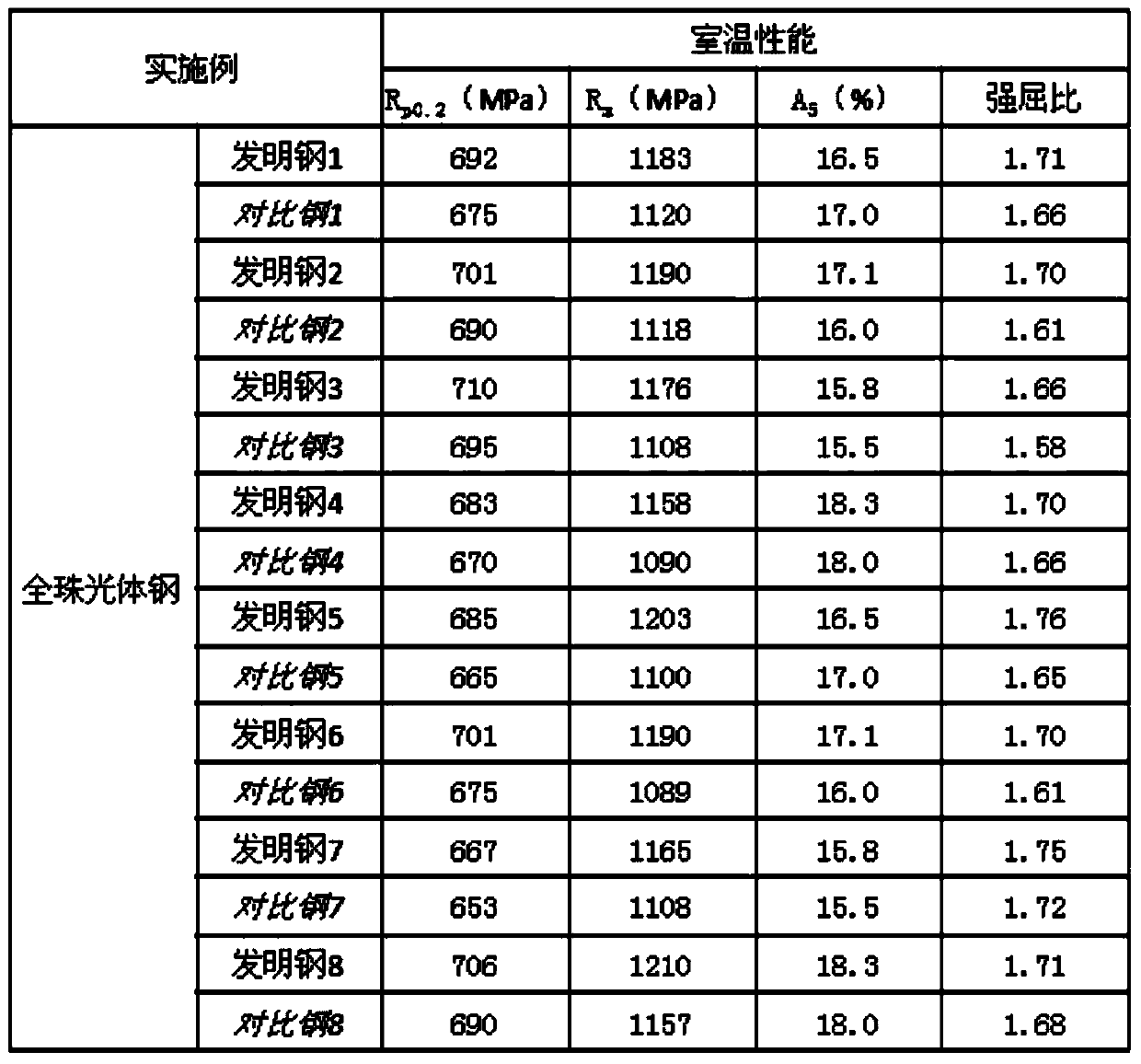

High-nitrogen pearlitic steel

The invention discloses a high-nitrogen pearlitic steel, and belongs to the technical field of metal materials. The high-nitrogen pearlitic steel comprises the following components in percentage by weight: 0.60-0.80% of C, 0.3-0.8% of Si, 0.80-1.40% of Mn, P not higher than 0.045%, S not higher than 0.035%, N not higher than 300 ppm and not lower than 120 ppm, and the balance of Fe and impurity elements, wherein such alloy elements as Nb, V, Cr, Ni and Cu can be properly added according to the comprehensive performance requirement of the steel. The high-nitrogen pearlitic steel has the following advantages: various technical measures for denitrification in the steel making process are avoided; pearlite in the steel is strengthened by using cheap nitrogen; the tensile strength of the steel is improved; the process is simple; and the cost is low.

Owner:CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com