Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Improve atomic activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

More than 630 MPa level high strength steel bar and application method thereof in reinforced concrete

The invention discloses a more than 630MPa level high strength steel bar comprising the following components: by weight, 0.28%-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80%-1.50% of Cr, 3.00%-4.00% of nickel, 0.40%-0.60% of molybdenum, 0-0.015% of P, 0-0.015% of sulfur, 0-2.0ppm of hydrogen, 0.10%-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements and the balance of Fe; the invention also designs an application method of the more than 630MPa level high strength steel bar in reinforced concrete; and the more than 630MPa level high strength steel bar has the advantages of high strength, steel saving, no pollution, good hardenability, low tendency to crack and low relaxation degree.

Owner:江苏森林建筑新材料股份有限公司

Production method for thermal treatment prestressed steel strand

The invention discloses a production method for a thermal treatment prestressed steel strand. According to the production method for the thermal treatment prestressed steel strand, AISI4340MOD steel is selected as raw materials and theAISI4340MOD steel comprises the following componentsby mass percent, 0.3 to 0.32 % of carbon, 0.18 to 0.36 % of silicon, 0.50 to 0.70 % of manganese, 0.90 to 1.10 % of chromium, 0.20 to 0.30 % of molybdenum, 0 to 0.02 % of phosphorus, 0 to 0.025 % of sulfur, 0 to 1.8 ppm of hydrogen, 0 to 0.40 % of nickel, 0 to 0.03 % of vanadium, 0 to 0.30 % of copper, 0 to 0.9 % of residual elements and the remaining is ferrum. The production method for the thermal treatment prestressed steel strand has the advantages of improving the strength and hardenability of the steel strand, enabling the steel strand to be not easy to craze, low in looseness, uniform and smooth in surficial galvanization.

Owner:TIANSHUN GROUP

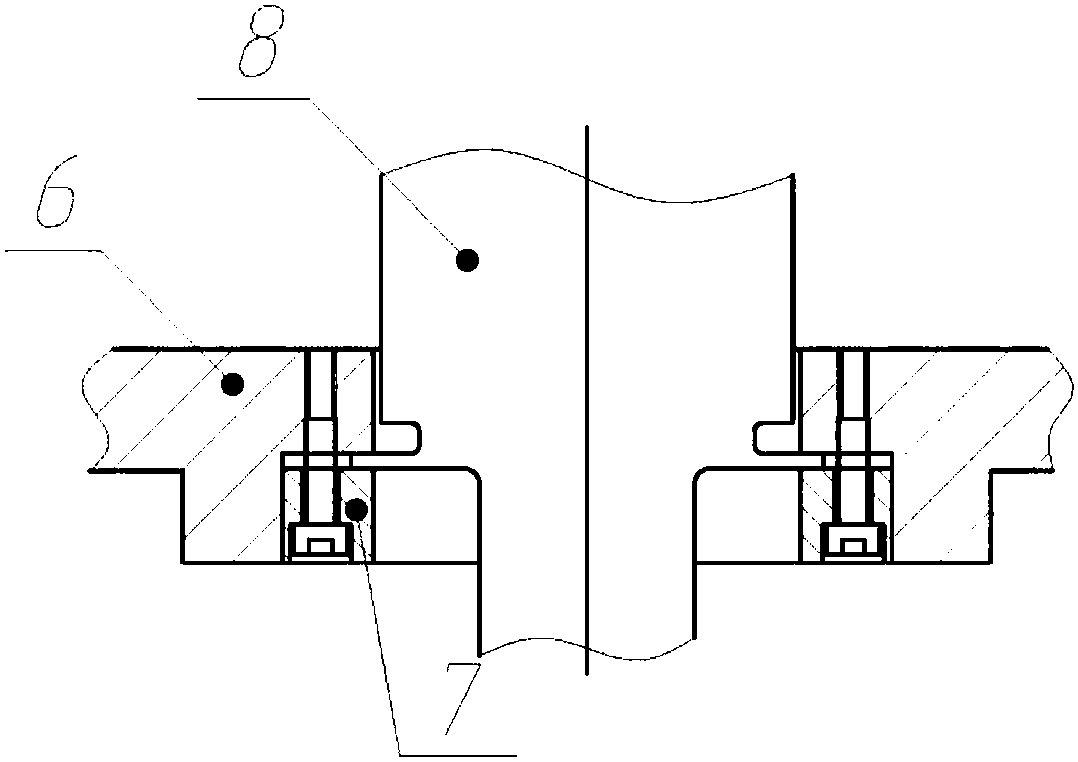

Ultrasonic auxiliary precision forging method and device

InactiveCN108543898AReduce deformation resistanceLow coefficient of contact frictionForging/hammering/pressing machinesUltrasonic vibrationEngineering

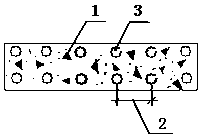

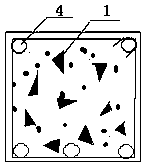

The invention discloses an ultrasonic auxiliary precision forging method and device, and relates to the field of forging. The ultrasonic auxiliary precision forging method and device comprise an upperconcave die, a lower concave die, an upper punch head, a lower punch head, an upper ultrasonic vibration mechanism and a lower ultrasonic vibration mechanism;and an ultrasonic vibration device penetrates through a punch cushion sleeve and a through groove in the middle of a template and is fixedly connected to the punch heads, an variable amplitude rod transmits the amplified ultrasonic vibrationto the punch heads, and the punch heads transmits the vibration to a blank. According to the ultrasonic auxiliary precision forging method and device, the frequency, the amplitude, the vibration modeof the ultrasonic vibration and the shape and the size of the punch heads are changed to suit for precision forging of different products; the method and device have the advantages that the plastic deformation capability of the metal is greatly improved, the metal filling property is improved, the friction force between the blank and the die is reduced, the grain structure is refined, the roughness of the forming surface is reduced, the demolding capability of the forge piece is improved, the applicability is wide, the material utilization rate and the product percent of pass are improved.

Owner:JIANGSU UNIV

High strength steel bar for pre-stressed concrete and production technology thereof

ActiveCN104404380AImproved resistance to hydrogen-induced delayed fractureAvoid inhalationSpinningChemical composition

The invention discloses a high strength steel bar for pre-stressed concrete. The steel bar is composed of the following chemical components in percentage by weight: 0.20 to 0.25% of C, 1.50 to 1.85% of Si, 0.20 to 0.50% of Mn, 0.07 to 0.09% of Cr, 0.30 to 0.35% of Mo, 0.25 to 0.35% of V, 0.05 to 0.08% of Nb, 0.42 to 0.61% of Ti, 0.15 to 0.25% of Ni, 0.25 to 0.40% of Ca, not more than 0.025% of S, not more than 0.025% of P, not more than 0.20% of Cu, 0.15 to 0.30% of composite rare earth, and the balance being Fe. The invention further discloses a production technology of the steel bar. The production technology comprises the following steps: smelting to obtain a steel blank, rolling the steel blank, cooling the rolled steel blank, rolling the steel blank for a second time, carrying out a thermal treatment and a stabilizing treatment, performing a gas nitrogenation treatment, spinning, winding, bundling, and storing the bundles in a warehouse.

Owner:溧阳市万兴特种建材有限公司

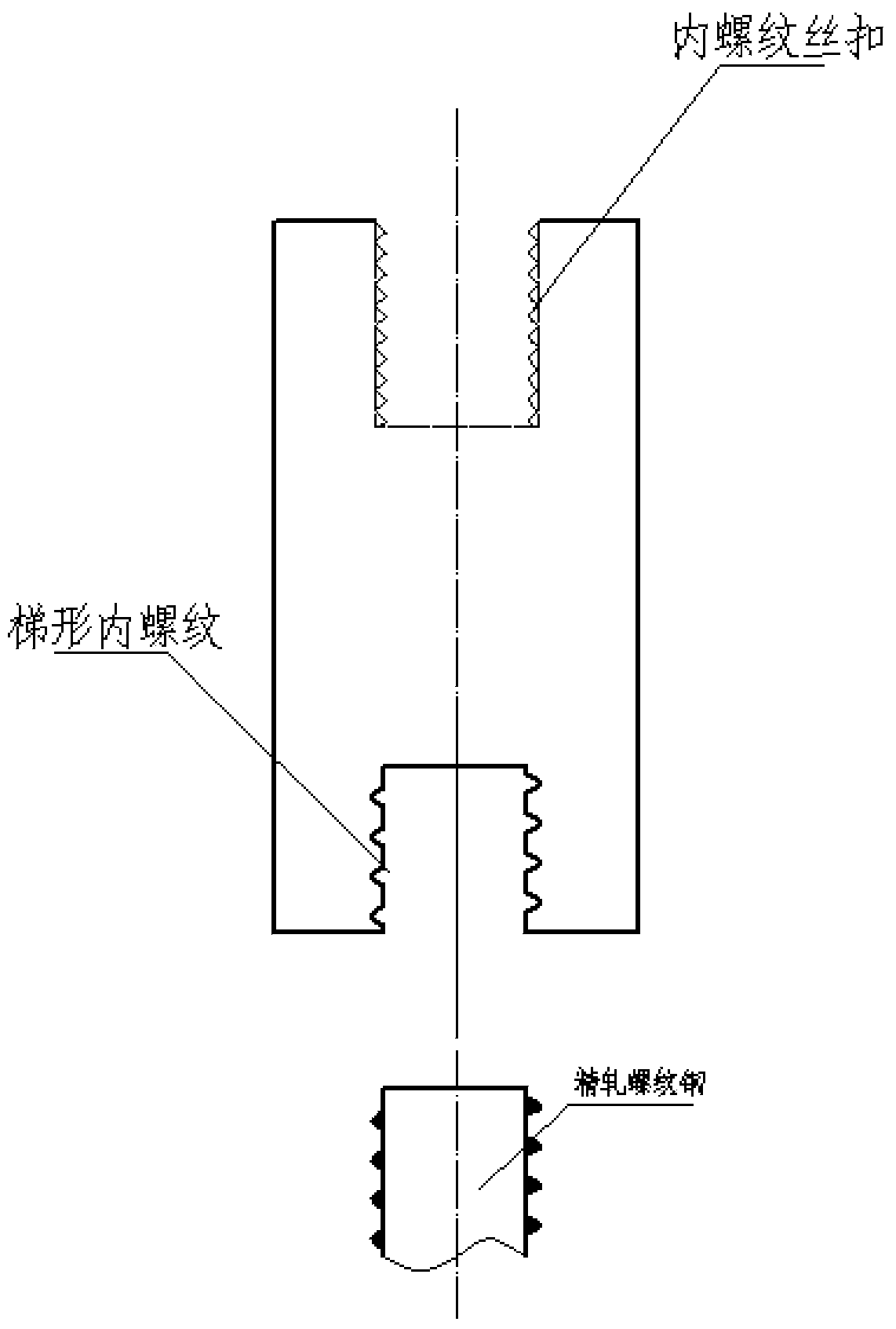

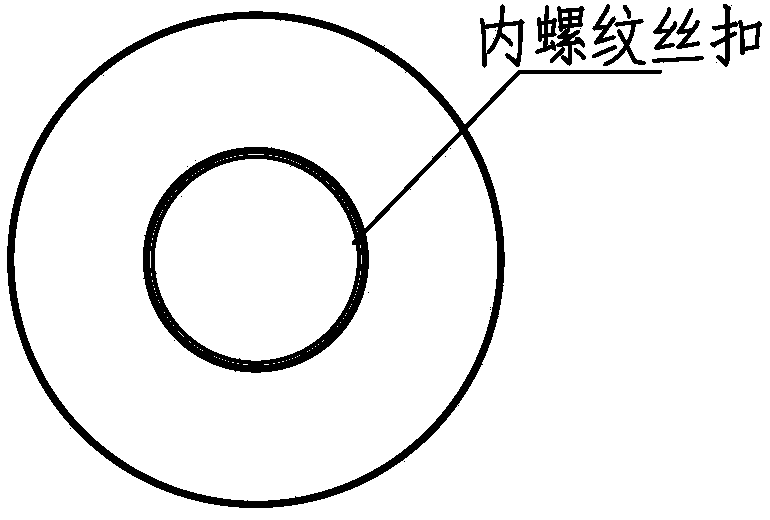

Processing method of above-600MPa-grade high-strength steel bar connection sleeve

ActiveCN103643124AImprove toughnessIncrease elasticityBuilding reinforcementsRebarMechanical engineering

The invention discloses a processing method of an above-600MPa-grade high-strength steel bar connection sleeve. The sleeve selects No.45 round steel as a raw material, and the No.45 round steel comprises 0.38-0.43wt% of C, 0.8-1.1wt% of Cr, 0.75-1.0wt% of Mn, 0.15-0.25wt% of Mo, 0.15-0.3wt% of Si, below 0.035% of S, below 0.035wt% of P, below 0.035wt% of N, and the balance Fe. The designed processing method of the above-600MPa-grade high-strength steel bar connection sleeve substantially improves the tensile strength and the elongation rate, guarantees the external diameter dimension and fineness of a steel tube, and reduces the friction stress between a tap and the inner wall of the sleeve.

Owner:江苏森林建筑新材料股份有限公司

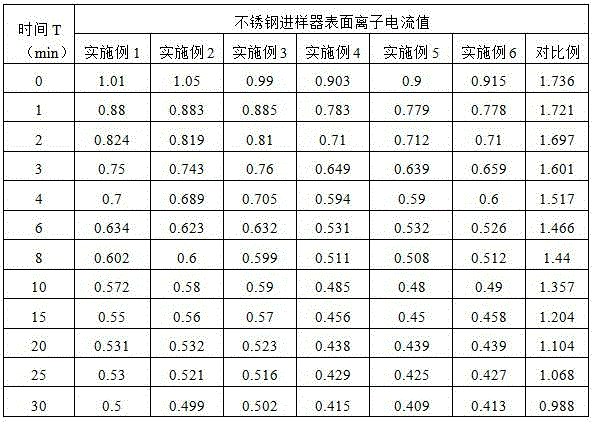

Passivating anticorrosion treatment method for surface of stainless steel sieving plate

InactiveCN107815678AInhibit corrosion reactionImprove corrosion resistanceMetallic material coating processesMetallurgyCorrosion resistant

The invention discloses a passivation and anticorrosion treatment method for the surface of stainless steel sieve plate, which relates to the technical field of stainless steel sieve plate, including: (1) cleaning; (2) vacuum impregnation; (3) surface irradiation treatment; (4) passivation: The surface passivation anticorrosion treatment method of the stainless steel sieve plate of the present invention can not only form a corrosion-resistant passivation film on the surface of the stainless steel sieve plate, but also make the surface of the passivation film smoother, and effectively improve the contact angle of the surface of the passivation film , thereby significantly improving the fouling resistance of the passivation film surface.

Owner:安徽屹翔滤材有限公司

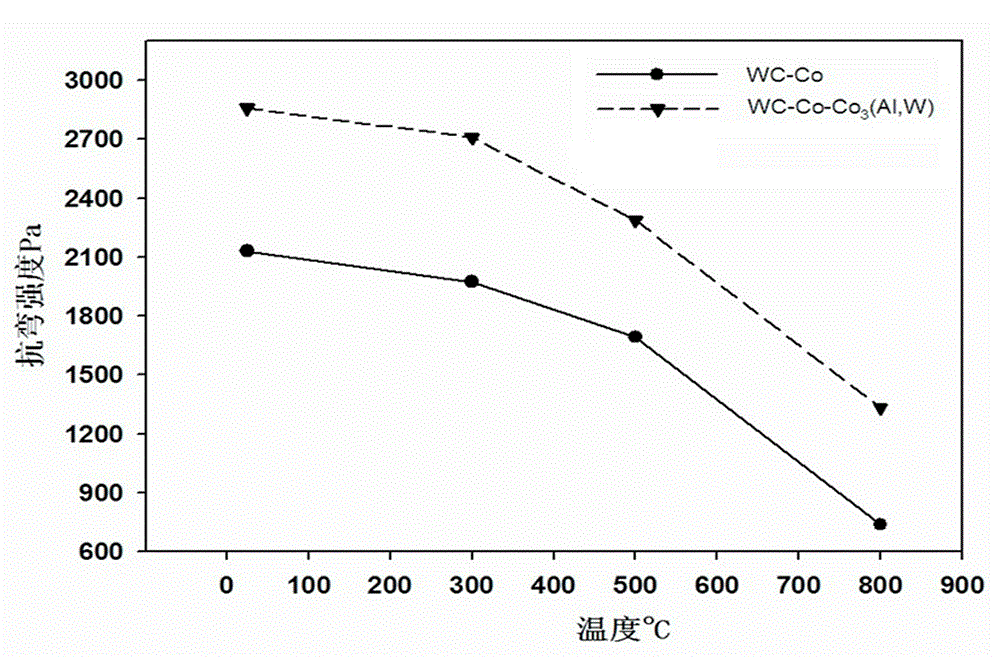

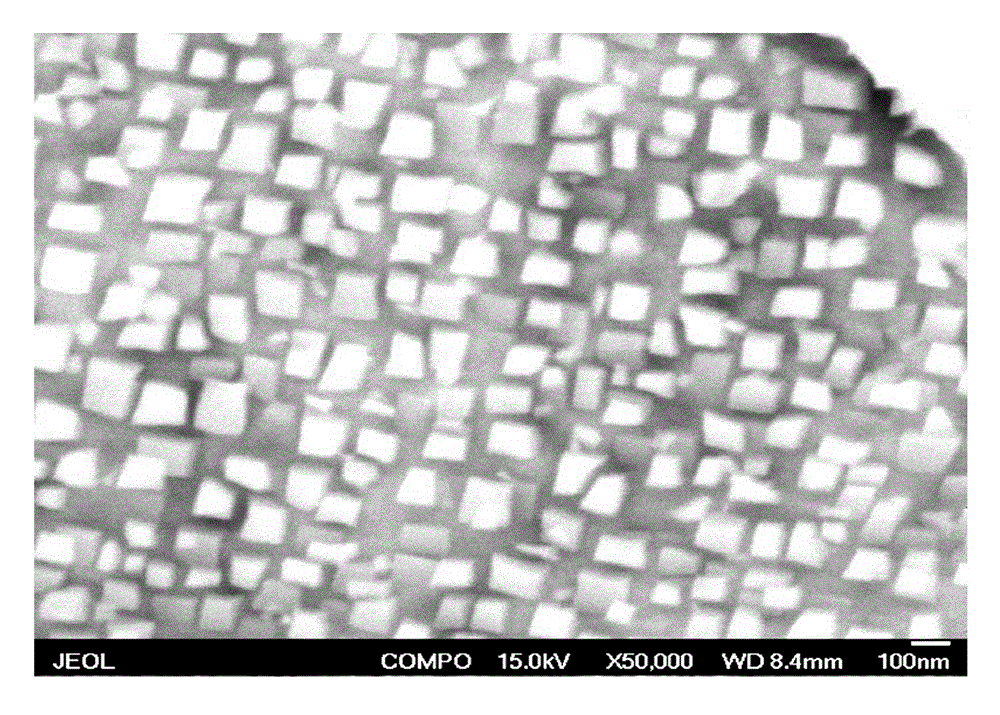

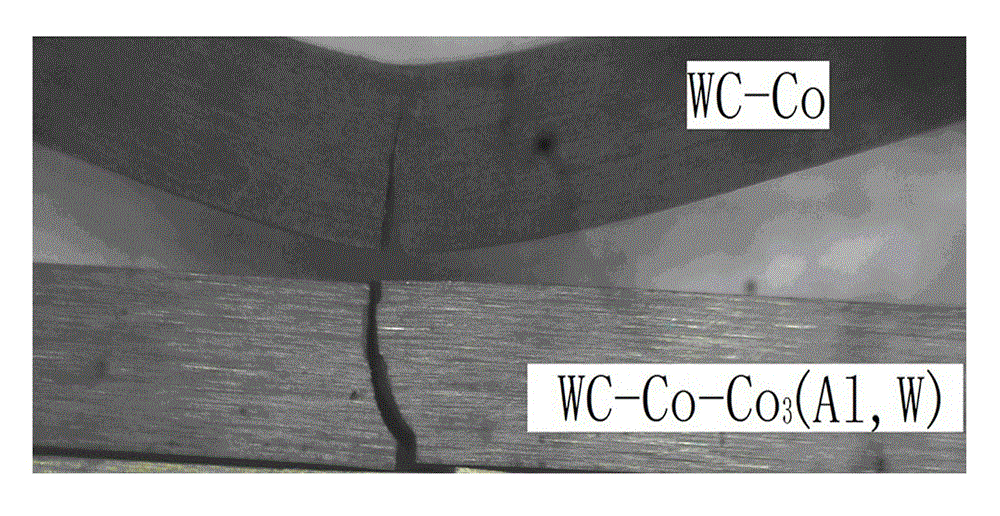

High-heat-resistance high-strength hard alloy and preparation method thereof

ActiveCN103602871AAvoid adverse effects of oxygen contentImprove atomic activityCO bindingRaw material

The invention discloses a high-heat-resistance high-strength hard alloy using WC as a hard phase and Co3(Al,W) reinforced Co as a binding phase, wherein the mass percent of the binding phase Co-Co3(Al,W) is 6-30%. The preparation method comprises the following steps: preparing 0.09-1.43 wt% of Co-Al intermetallic compound powder, 0.27-3.39 wt% of eta-phase powder, 66.41-93.76 wt% of WC and the balance of Co powder, and mixing by wet milling; carrying out spray drying; pressing; carrying out liquid-phase sintering at 1350-1500 DEG C; quickly cooling from final sintering temperature to 700-900 DEG C at the rate of at least 10 DEG C / minute; keeping the temperature for 10 hours to perform aging treatment; and slowly cooling to room temperature to obtain the Co3(Al,W) phase reinforced Co binding phase hard alloy. The Co-Al intermetallic compound is added as the Al source, and the eta-phase is used as the W source, thereby avoiding the adverse effect on the oxygen content in the raw materials; the decomposed Al and W in the liquid-phase sintering process have high atom activity, and form a gamma'(Co3(Al,W)) phase with the liquid-phase Co; and the method has the advantages of complete reaction, high distribution uniformity, obviously higher high-temperature rigidity and high-temperature strength, simple technique and controllable composition.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

High-strength hot-rolled reinforcement bar of 830 MPa level, and production technology thereof

ActiveCN103484780AAvoid excessive corrosion rate and hardnessStrong hysteresis fracture resistanceRebarDuctility

The invention relates to a reinforcement bar and a production technology thereof, in particular to a high-strength hot-rolled reinforcement bar of the 830 MPa level, and a production technology of the reinforcement bar. The reinforcement bar comprises the following chemical components by weight: 0.38 to 0.43% of C, 0.7 to 0.9% of Cr, 0.6 to 0.8% of Mn, 0.15 to 0.25% of Mo, 0.2 to 0.3% of Si, 1.6 to 2% of Ni, 0.035% of S, 0.035% of P, 0.035% of N and the balance of Fe. The shear strength of the reinforcement bar can reach 830 MPa; the reinforcement bar has the advantages of high strength, good ductility, high lagging and fracture resistance, economy of steel material, underrelaxation, easiness in welding, high upset performance and the like, can enable carbide to dissolve fully and diffuse uniformly, and avoids that intercrystalline corrosion and pitting exceeding are caused due to intercrystalline separation of carbide.

Owner:江苏森林建筑新材料股份有限公司

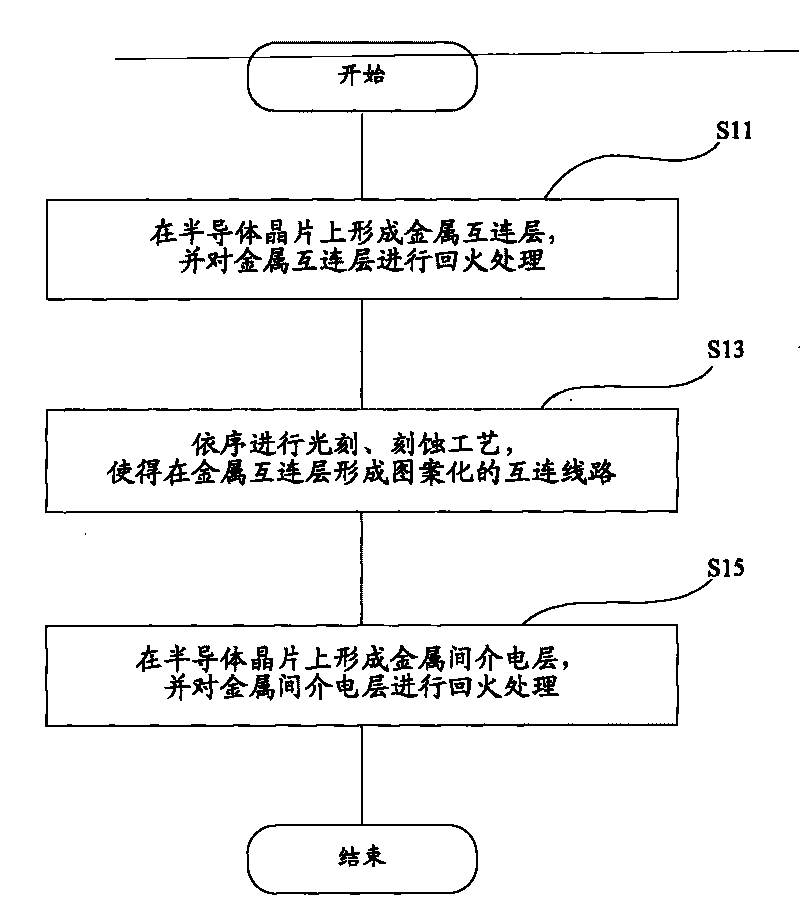

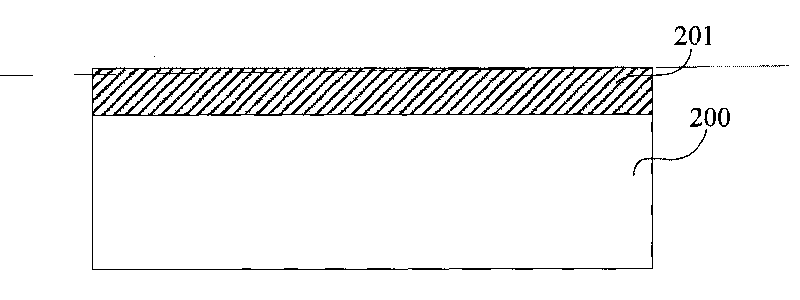

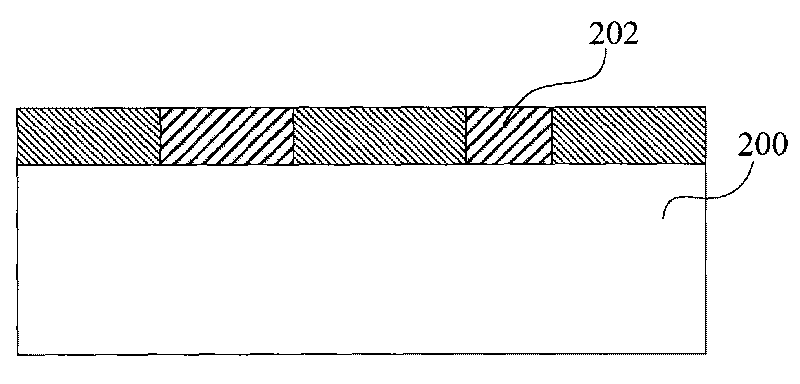

Method for manufacturing semiconductor chip with low warpage

ActiveCN101728316AImprove atomic activityReduce warpageSemiconductor/solid-state device manufacturingSemiconductor chipDielectric layer

The invention discloses a method for manufacturing a semiconductor chip with low warpage. The semiconductor chip is provided with a semiconductor device; a process for manufacturing an inter-metal dielectric layer and a metal interconnecting layer comprises at least once tempering step, so the movability of atoms of the inter-metal dielectric layer and the metal interconnecting layer is improved, the tractility of the two is increased, the stress of the two is correspondingly reduced, and the semiconductor chip has the advantage of low warpage.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Chromium-molybdenum low-alloy zinc-plating steel strand manufacturing method

ActiveCN103639231AImprove toughnessIncrease elasticityFurnace typesHeat treatment furnacesManganeseChromium

The present invention discloses a chromium-molybdenum low-alloy zinc-plating steel strand manufacturing method, wherein the chromium-nickel-molybdenum alloy structure steel comprises, by mass, 0.28-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80-1.50% of chromium, 3.00-4.00% of nickel, 0.40-0.60% of molybdenum, 0-0.015%of phosphorus, 0-0.015% of sulfur, 0-2.0 ppm of hydrogen, 0.10-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements, and the balance of Fe. According to the chromium-molybdenum low-alloy zinc-plating steel strand manufacturing method designed by the present invention, the prepared chromium-molybdenum low-alloy zinc-plating steel strand has characteristics of high strength, good hardenability good, cracking resistance, low relaxation degree, and smooth and uniform surface zinc plating.

Owner:TIANSHUN GROUP

Method for enhancing surface anti-fouling performance of stainless steel product

ActiveCN103147087AImprove anti-pollution performanceImprove atomic activityPreparing sample for investigationSS - Stainless steelPickling

The invention belongs to the field of surface treatment of stainless steel, and particularly relates to a method for enhancing surface anti-fouling performance of a stainless steel product, which comprises the following steps: (1) cleaning the stainless steel product; (2) heating the cleaned stainless steel product to 80-200 DEG C, keeping the temperature for more than 10 minutes, and cooling to room temperature; (3) cleaning with acid to passivate the stainless steel product; and (4) cleaning the stainless steel product subjected to acid cleaning passivation with water, and drying. Heating or repeated heating on the stainless steel product is added before acid cleaning passivation, so that invisible pollutants in holes of the surface of the stainless steel product can be removed easily, thereby enhancing the surface anti-fouling performance of the stainless steel product.

Owner:李鹏 +1

Chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method

ActiveCN103643146AImprove toughnessIncrease elasticityFurnace typesHeat treatment furnacesPre stressManganese

The present invention discloses a chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method, wherein the chromium-nickel-molybdenum alloy structure steel is adopted as a billet material and comprises, by mass, 0.28-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80-1.50% of chromium, 3.00-4.00% of nickel, 0.40-0.60% of molybdenum, 0-0.015%of phosphorus, 0-0.015% of sulfur, 0-2.0 ppm of hydrogen, 0.10-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements, and the balance of Fe. According to the chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method designed by the present invention, strength and toughness of the steel wire can be substantially increased, a corrosion resistance degree of the steel wire can be enhanced, and a service life can be prolonged.

Owner:TIANSHUN GROUP

Processing process of wear-resisting anti-impact type pile foundation steel protective barrel

InactiveCN104328346ASave scrap rate of consumablesQuality improvementSolid state diffusion coatingProcess efficiency improvementHardenabilityMachining process

The invention discloses a processing process of a wear-resisting anti-impact type pile foundation steel protective barrel. 0.16-0.22% of Mn, 0.85-1.0% of Cr and 0.16-0.22% of Mo are added, so that the atomic activities of the elements C and N are improved, air mass formed by each atom can form strong interaction with dislocation to generate a yield platform, and relatively great stress is needed to be provided by the outside to start the dislocation, and therefore, the tensile strength is guaranteed to reach 675 / Mpa, the percentage elongation after fracture is guaranteed to reach 18.20%, the end-surface shrinking percentage is guaranteed to reach 38%, the yield point elongation is guaranteed to reach 44.4J and the yield point elongation is guaranteed to reach 850 / Mpa. The processing process of the wear-resisting anti-impact type pile foundation steel protective barrel disclosed by the invention can be used for improving the hardness and the wear resistance of the pile foundation steel protective barrel, and has the advantages of high strength, no pollution, good hardenability, less possibility in cracking and low degree of relaxation.

Owner:TIANSHUN GROUP

High-strength hot-rolled reinforcement bar of 730 MPa level, and production technology thereof

ActiveCN103484775AImprove atomic activityStrong interactionHeat treatment process controlRebarDuctility

The invention relates to a reinforcement bar and a production technology thereof, in particular to a high-strength hot-rolled reinforcement bar of the 730 MPa level, and a production technology of the reinforcement bar. The reinforcement bar comprises the following chemical components by weight: 0.48 to 0.53% of C, 0.8 to 1.1% of Cr, 0.75 to 1.0% of Mn, 0.15 to 0.25% of Mo, 0.15 to 0.3% of Si, 0.035% of S, 0.035% of P, 0.035% of N and the balance of Fe. The shear strength of the reinforcement bar can reach 730 Mpa; the reinforcement bar has the advantages of high strength, good ductility, high lagging and fracture resistance, economy of steel material, underrelaxation, easiness in welding, high upset performance and the like, can enable carbide to dissolve fully and diffuse uniformly, and avoids that intercrystalline corrosion and pitting exceeding are caused due to intercrystalline separation of carbide.

Owner:江苏森林建筑新材料股份有限公司

Midair multipoint vertical steel bar connecting joint and construction method thereof

The invention discloses a midair multipoint vertical steel bar connecting joint which is made of number 45 round steel. The round steel comprises the chemical components, by weight, 0.38-0.43% of C, 0.8-1.1% of Cr, 0.75-1.0% of Mn, 0.15-0.25% of Mo, 0.15-0.3% of Si, 0.035% of S, 0.035% of P, 0.035% of N, and the balance Fe. The invention further discloses a construction method of the midair multipoint vertical steel bar connecting joint. The midair multipoint vertical steel bar connecting joint and the construction method thereof are simple and practical, simple in construction and capable of greatly improving the strength, the toughness and the tension stress of the steel bar connecting joint.

Owner:TIANSHUN GROUP

High-reliability air switch cabinet

InactiveCN108866430AImprove cooling effectReduce pollutionFoundry mouldsSubstation/switching arrangement casingsRare earthEngineering

The invention discloses a high-reliability air switch cabinet which comprises a cabinet body, a switch chamber, a meter chamber, a mechanism chamber and a cable chamber. The switch chamber, the meterchamber, the mechanism chamber and the cable chamber are arranged in the cabinet body. The cabinet body is prepared from, by mass, 0.18-0.3% of C, 0.6-0.9% of Si, 1.3-1.9% of Mn, 3-6% of Zn, 1-1.5% ofMo, 1-1.2% of Ti, 0.02-0.03% of N, 7-9% of Cr, 0.03-0.06% of Nb, 0.10-0.20% of V, 0.7-0.9% of Mg, 0.001-0.0015% of B, 0.1-0.3% of Cu, 0.1-0.3% of W, 0.025-0.030% of P, 0.010-0.015% of S, 0.1-0.3% ofrare earth elements and the balance Fe and inevitable impurities. The high-reliability air switch cabinet is simple and compact in structure, good in corrosion resistance, high in reliability and longin service life.

Owner:荣马电器有限公司

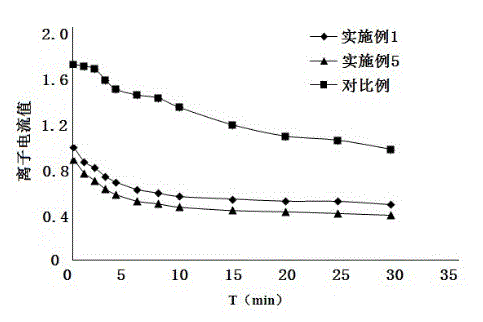

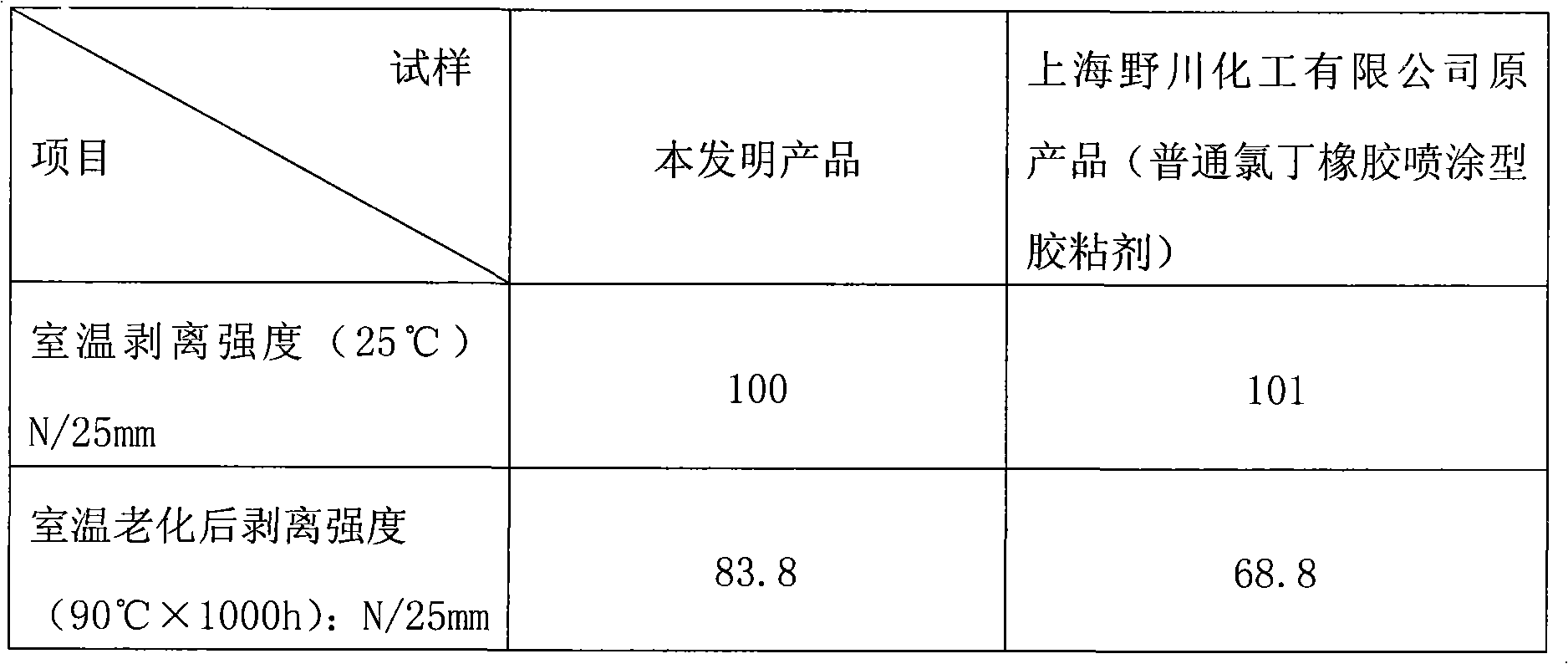

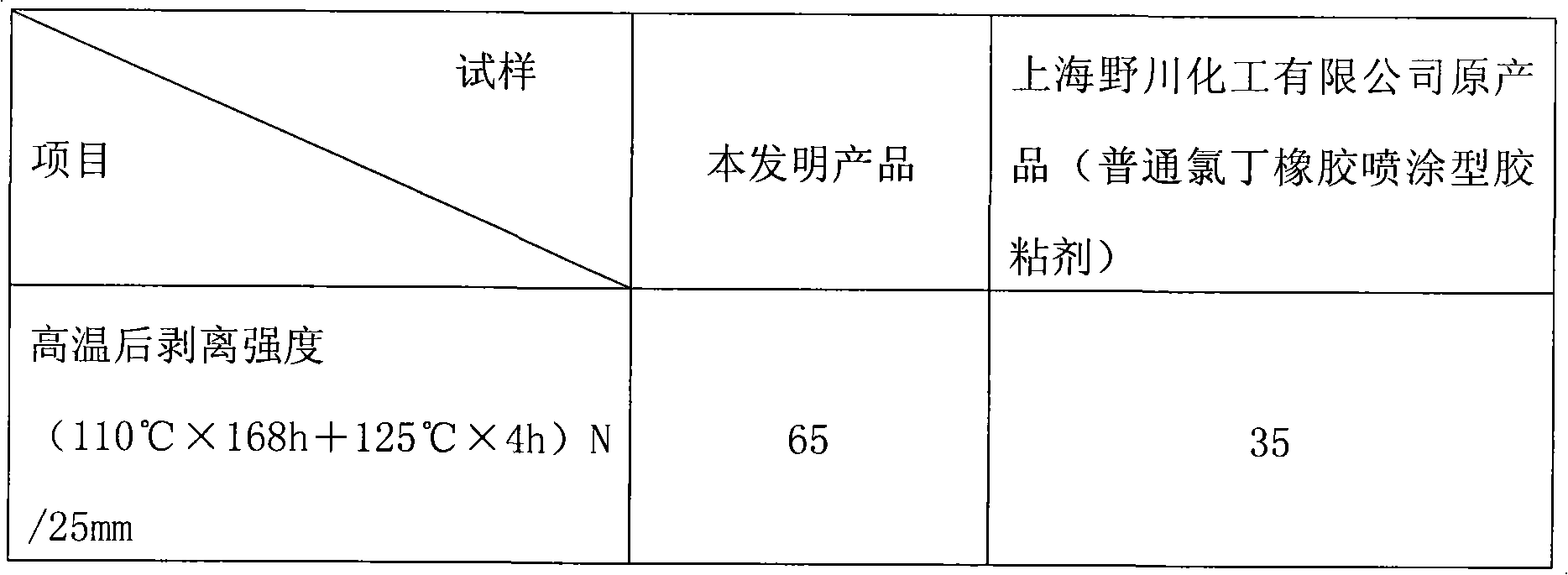

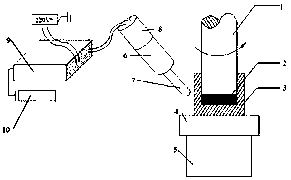

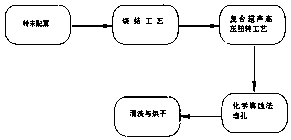

Nano zinc oxide modifying chloroprene rubber spraying type adhesive and preparation method thereof

InactiveCN101260281AImprove atomic activityEasy to crackNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesCalcium silicateAdhesive

The invention provides a formula for nanometer zinc oxide modified neoprene rubber spray coating adhesive. The formula consists of TA-85 neoprene rubber, nanometer zinc oxide, magnesia, magnesia 150, age inhibitor BHT, calcium silicate, liquid resin, FRJ-551 alkyl phenolic resin, methylbenzene, cyclohexane, n-hexane, acetone and water. The invention also provides a preparation method for the nanometer zinc oxide modified neoprene rubber spray coating adhesive. The heat resistance of the nanometer zinc oxide modified neoprene rubber spray coating adhesive provided by the invention can be improved by 20 to 86 percent than the ordinary neoprene rubber spray coating adhesive.

Owner:SHANGHAI YECHUAN CHEM

Manufacturing method of high-yield non-bonding prestress steel bar

ActiveCN103639650ASpread evenlyAvoid excessive intergranular corrosion and pitting corrosionDuctilityManufacturing engineering

The invention discloses a manufacturing method of a high-yield non-bonding prestress steel bar. The steel bar has the advantages of bringing convenience to manual construction, being low in cost, high in strength, good in ductility and high in delayed fracture and saving steel, has ideal insulation effects, and can reduce environment pollution. According to the manufacturing method, steel structure anticorrosive paint is adopted, good mechanical performance and excellent anti-corrosion performance are achieved, stability for weather, oil water mixtures and the like is good, various colors can be mixed according to needs, the steel bar can have good visual effects after the steel anticorrosive paint is used, attractiveness and elegance in decoration are achieved, and cost can also be saved due to the fact that the paint has long anti-corrosion time.

Owner:TIANSHUN GROUP

Method for preparing porous titanium-base composite material through composite ultrasonic vibration high-pressure twisting

ActiveCN108237225AHigh porosityImprove performanceTissue regenerationProsthesisUltrasonic vibrationHigh pressure

The invention relates to a method for preparing a porous titanium-base composite material through composite ultrasonic vibration high-pressure twisting, in particular to a method for preparing a nano-scale reproducible anti-bacterial medical porous titanium-base composite skeleton material through combination of a high-pressure twisting method and an ultrasonic vibration method. Through proper adjustment on the rotation speed, the downward pressing force, the twisting pressing time and the twisting pressing frequency of a pressing head and the vibration frequency and amplitude of ultrasonic vibration, the blocky nano-scale reproducible anti-bacterial medical porous titanium-base composite skeleton material uniform in grain refinement degree can be prepared.

Owner:SHANDONG JIANZHU UNIV

High-strength hot-rolled reinforcement bar of 830 MPa level, and production technology thereof

The invention relates to a steel bar and its production process, which is a 830MPa grade high-strength hot-rolled steel bar and its production process. The chemical composition in weight percentage is: C: 0.38-0.43%, Cr: 0.7-0.9%, Mn: 0.6- 0.8%, Mo: 0.15-0.25%, Si: 0.2-0.3%, Ni: 1.6-2%, S: <0.035%, P: <0.035%, N: <0.035%, and the balance is Fe. The steel bar yield strength of the present invention can reach 830MPa, has the advantages of high strength, good ductility, strong hysteresis fracture resistance, steel saving, low relaxation, easy welding, good upsetting performance, etc., and can fully dissolve carbides and evenly diffuse, It avoids the precipitation of carbides between grains and causes excessive intergranular corrosion and pitting corrosion.

Owner:江苏森林建筑新材料股份有限公司

Wear-resisting valve and heat treatment technology thereof

InactiveCN107893190AImprove atomic activityHigh hardnessFurnace typesValve housingsRare-earth elementWear resistance

The invention discloses a wear-resisting valve. The wear-resisting valve comprises the following components which include, by mass, 0.18-0.3% of C, 0.6-1.1% of Si, 1.0-1.9% of Mn, 0.05-0.2% of Cr, 0.01-0.05% of Nb, 0.1-0.3% of Mo, 0.03-0.05% of Cu, 0.15-0.17% of Ti, 0.01-0.03% of V, 0.1-0.2% of rare earth elements, and the balance Fe and trace impurities, and the sum of all the components is 100%.The rare earth elements comprise, by mass, 5-7% of Pr, 10-13% of Sm, 2-4% of Ce, 10-13% of Lu, 15-18% of Eu and the balance La. The invention further designs a heat treatment technology of the wear-resisting valve. The technology is simple and easy to implement, the cost is low, and the valve obtained after heat treatment is excellent in performance and has good wear resistance.

Owner:朱建海

High-wear-resistance refrigeration device and reinforcing process thereof

InactiveCN108007036AImprove atomic activityHigh hardnessDomestic refrigeratorsAnti-corrosive paintsWear resistantEngineering

The invention discloses a high-wear-resistance refrigeration device and a reinforcing process thereof. The high-wear-resistance refrigeration device comprises a box body, a door body, a drying filterand a heater; and the door body is movably connected to the box body, a refrigeration chamber is arranged in the box body, the drying filter is arranged on the box body, and the heater is used for heating the drying filter. According to the high-wear-resistance refrigeration device, the structure is simple and compact, the wear-resistant effect is good, the reinforcing process is simple and easy to conduct, the reinforced refrigeration device has higher wear resistance, and the service life of the refrigeration device is prolonged.

Owner:博维恩冷冻科技(苏州)有限公司

Wear-resistant anti-corrosion parallel bars for sports and forming technology of such parallel bars

InactiveCN109128014AApplicable castingReduce heat transferAnodisationFoundry mouldsMetallurgyEngineering

The invention discloses wear-resistant anti-corrosion parallel bars for sports. The wear-resistant anti-corrosion parallel bars for sports comprise transverse bars, vertical posts and bases, wherein the vertical posts are arranged on the lower sides of the transverse bars and used for supporting the transverse bars, the bases are arranged at the bottom ends of the vertical posts and used for fixing the vertical posts, and the transverse bars, the vertical posts and the bases are made of a same material. The material comprises, by mass, Mg, Mn, Zn, C, Cu, Si, Cr, Ti, S, P, Fe, inert filler, thebalance Al and inevitable impurities. The invention further provides a forming technology of the wear-resistant anti-corrosion parallel bars for sports. The forming technology is simple and easy to implement. The prepared parallel bars are highly resistant to heat, good in size stability, long in service life and low in cost.

Owner:江苏天泽教育咨询有限公司

AISI4340 prestress steel bar manufacturing method

The present invention discloses a AISI4340 prestress steel bar manufacturing method, wherein a AISI4340MOD steel is adopted as a billet material, the billet material is subjected to smelting and finish rolling to obtain a prestress steel bar forging stock with the required size, the prestress steel bar forging stock is sequentially subjected to a hydrogen diffusion heat treatment, rough processing, water cooling quenching and air cooling quenching, a polyethylene corrosion resistance coating is coated on the outer surface of the steel bar forging stock, and a polyethylene heat shrink sleeve is arranged outside the polyethylene corrosion resistance coating. According to the AISI4340 prestress steel bar manufacturing method designed by the present invention, the obtained AISI4340 prestress steel bar has characteristics of high strength, good ductility, strong delayed fracture resistance, steel saving, low relaxation, easy welding, good upsetting property and the like, and further has effects of substantially enhanced corrosion resistance sealing property, and effectively improved mechanical strength.

Owner:TIANSHUN GROUP

600 MPa-grade-and-above high strength steel bars and reinforced concrete application method thereof

ActiveCN103643147AImprove wear resistanceIncrease resistanceConstruction materialGirdersReinforced concreteRebar

The present invention discloses 600 MPa-grade-and-above high strength steel bars and a reinforced concrete application method thereof. According to the present invention, 0.4-0.65% by weight of Mn, 0.6-0.7% by weight of Cr, 0.15-0.3% by weight of Mo, 0.5-0.65% by weight of Ni, and 0.25-0.4% by weight of V are added to the steel bar component so as to improve strength, toughness, corrosion resistance, wear resistance and impact resistance of the steel bar, make the steel bar be compact, improve hardenability of the steel, and improve atom activities of the elements such as C and N, such that deformation and cracking can be reduced; and the application method of the diameter 6 mm and diameter 22 mm 600 MPa-grade-and-above high strength steel bars in the reinforced concrete has advantages of steel bar consumption reduction, carrying capacity increase, and crack extension resistance.

Owner:江苏森林建筑新材料股份有限公司

A method for manufacturing chromium-molybdenum low-alloy prestressed aluminum-clad steel wire

ActiveCN103643146BImprove toughnessIncrease elasticityFurnace typesHeat treatment furnacesChromium nickelManganese

The present invention discloses a chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method, wherein the chromium-nickel-molybdenum alloy structure steel is adopted as a billet material and comprises, by mass, 0.28-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80-1.50% of chromium, 3.00-4.00% of nickel, 0.40-0.60% of molybdenum, 0-0.015%of phosphorus, 0-0.015% of sulfur, 0-2.0 ppm of hydrogen, 0.10-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements, and the balance of Fe. According to the chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method designed by the present invention, strength and toughness of the steel wire can be substantially increased, a corrosion resistance degree of the steel wire can be enhanced, and a service life can be prolonged.

Owner:TIANSHUN GROUP

Method for preparing pre-stressed steel strand through instantaneous quenching modification

ActiveCN105839434ASimple preparation stepsNot easy to dislocationFurnace typesTextile cablesDislocationQuenching

The invention discloses a method for preparing a pre-stressed steel strand through instantaneous quenching modification and belongs to the technical field of pre-stressed steel strand preparation. Fe, C, Si and other matter are mixed and smelted into steel, the steel is precisely rolled into a rolled steel wire, the rolled steel wire is washed and dried and then twisted into a steel rope, preheating, secondary heat preservation calcining and secondary lead bath cooling are conducted, the material is cooled in an ice-water mixture, ethyl acetate washing and drying are conducted, and the pre-stressed steel strand is prepared. The method has the advantages that the preparation steps are simple, the atomic activity of carbon of the obtained product is higher than that of other products by 23.2% or above, and dislocation is unlikely to happen; the material performance stability is good, the hydrogen content in the steel rope is lower than 1.23 ppm, and cracks are unlikely to be generated.

Owner:天津信丰达预应力钢绞线有限公司

Corrosion-resistant air cooler and reinforcing process thereof

InactiveCN107988559AImprove atomic activityHigh strengthAnti-corrosive paintsPolyurea/polyurethane coatingsRare-earth elementEngineering

The invention discloses a corrosion-resistant air cooler. The corrosion-resistant air cooler is characterized in that the corrosion-resistant air cooler comprises an air cooler shell, a draught fan, arefrigerant circulation system and a control module. The draught fan and the refrigerant circulation system are arranged in the air cooler shell. The control module is used for controlling the draught fan and the refrigerant circulation system. The air cooler shell comprises, by mass percentage, 8-10% of Al, 1-3% of Mn, 0.18-0.3% of C, 0.05-0.1% of Cr, 0.01-0.05% of Nb, 0.01-0.03% of Cu, 2-5% ofSr, 0.0002-0.005% of Nb, 0.005-0.008% of N, 0.0002-0.005% of S, 0.5-0.8% of Zn, 1.5-1.8% of Si, 3-5% of Ca, 0.5-0.8% of Ti, 0.3-0.5% of Ni, 0.002-0.004% of B, 0.1-0.4% of V, 0.5-0.8% of a rare earth element and the balance Fe. The invention further designs a reinforcing process of the corrosion-resistant air cooler. The air cooler is simple and compact in structure and good in corrosion resistingeffect; the service life of the air cooler is prolonged; and the cost is lowered.

Owner:博维恩冷冻科技(苏州)有限公司

A steel bar for high-strength prestressed concrete and its production process

ActiveCN104404380BImproved resistance to hydrogen-induced delayed fractureAvoid inhalationChemical compositionRare earth

The invention discloses a steel bar for high-strength prestressed concrete, the chemical composition of which is: C: 0.20-0.25%, Si: 1.50-1.85%, Mn: 0.20-0.50%, Cr: 0.07-0.09%, Mo: 0.30‑0.35%, V: 0.25‑0.35%, Nb: 0.05‑0.08%, Ti: 0.42‑0.61%, Ni: 0.15‑0.25%, Ca: 0.25‑0.40%, S≤0.025%, P≤0.025 %, Cu≤0.20%, compound rare earth: 0.15-0.30%, and the balance is Fe; the present invention also designs a production process of steel rods for high-strength prestressed concrete as follows: smelting to obtain steel billet-rolling-cooling treatment-the first Secondary rolling - heat treatment and stabilization treatment - gas nitriding treatment - spinning and coiling - bundling and storage.

Owner:溧阳市万兴特种建材有限公司

A spherical plate processing tooling

ActiveCN106282808BGuaranteed smoothnessGuaranteed ferrite contentFurnace typesAnti-corrosive paintsEngineeringMachine tool

The invention discloses a machining tool for a spherical plate. The tool comprises an upper mold and a lower mold, wherein the lower mold comprises a lower columnar structure defined through welding connection of sides of at least three lower rib plates and a seat plate arranged at the bottom of the lower columnar structure; a machining concave end surface is arranged at the top of the lower columnar structure, and the curve of the machining concave end surface is consistent with the radian of a curved surface of the to-be-machined spherical plate; the upper mold comprises an upper columnar structure defined through welding connection of sides of at least three upper rib plates and a top plate arranged at the top of the upper columnar structure; and a machining convex end surface is arranged at the lower end of the upper columnar structure and is matched with the machining concave end surface in radian. The smooth degree of the appearance of the plate can be guaranteed with the tool, assembly, electric welding and polishing in following processes can be reduced, the manufacturing period of the spherical plate can be shortened, and the manufacturing cost of the spherical plate can be saved.

Owner:JIANGSU DAJIN HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com