Midair multipoint vertical steel bar connecting joint and construction method thereof

A technology for connecting nodes and steel bars, which is applied in the direction of connecting components, threaded fasteners, nuts, etc., can solve the problem that the straightening performance of steel bars cannot meet the requirements of pre-embedded components, and the upper and lower steel bars cannot be connected by butt joints. House structural safety and earthquake resistance and other issues, to avoid excessive pitting corrosion, simple and practical construction methods, and solve the problem of multi-point docking in the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

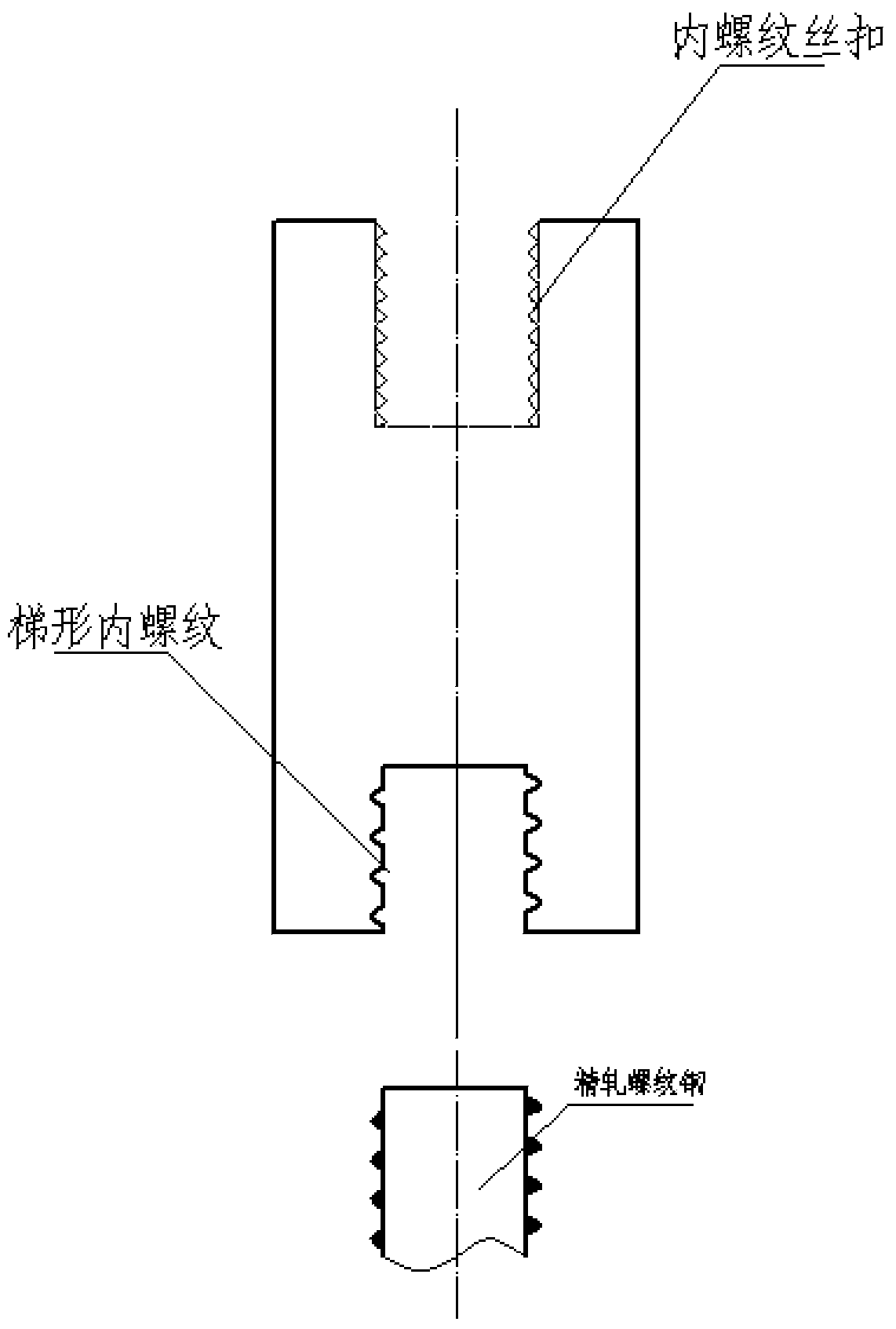

[0033] Such as figure 1 As shown, the multi-point vertical steel bar connection node in the air provided by this embodiment, the raw material of the steel bar connection node is No. 45 round steel, and the chemical composition of the round steel is C: 0.38%, Cr: 1.1%, Mn: 0.75%, Mo: 0.25%, Si: 0.21%, S: 0.025%, P: 0.03%, N: 0.025%, the balance is Fe;

[0034] The manufacturing process of multi-point vertical steel connection nodes in the air is as follows:

[0035] Step (1): Send the above raw materials into the heating furnace to heat up to 1160°C, and draw them into steel rods of required size;

[0036] Step (2): The steel bar heated in step (1) is rapidly cooled to 610°C through the first online cooling process, and then quenched with water or quenching liquid in the quenching device for 11-13 seconds. Then it is heated to 600°C and tempered in a tempering furnace, and after straightening treatment, it is cooled to room temperature through the second cooling process;

[...

Embodiment 2

[0042] This embodiment provides a multi-point vertical steel bar connection node in the air. The raw material of the steel bar connection node is No. 45 round steel, and the chemical composition of the round steel is C: 0.43%, Cr: 0.9%, Mn: 0.85%, Mo: 0.2%, Si: 0.3%, S: 0.013%, P: 0.015%, N: 0.012%, and the balance is Fe;

[0043] The manufacturing process of multi-point vertical steel connection nodes in the air is as follows:

[0044] Step (1): Send the above-mentioned raw materials into the heating furnace to heat up to 1180°C, and draw them into steel rods of the required size;

[0045] Step (2): The steel bar heated in step (1) is rapidly cooled to 630°C through the online first cooling process, and then quenched with water or quenching liquid in the quenching device for 11-13 seconds. Then it is heated to 660°C and tempered in a tempering furnace, and after straightening treatment, it is cooled to room temperature through the second cooling process;

[0046] Step (3): ...

Embodiment 3

[0051] This embodiment provides a construction method for multi-point vertical steel bar connection nodes in the air, and the specific processing is as follows:

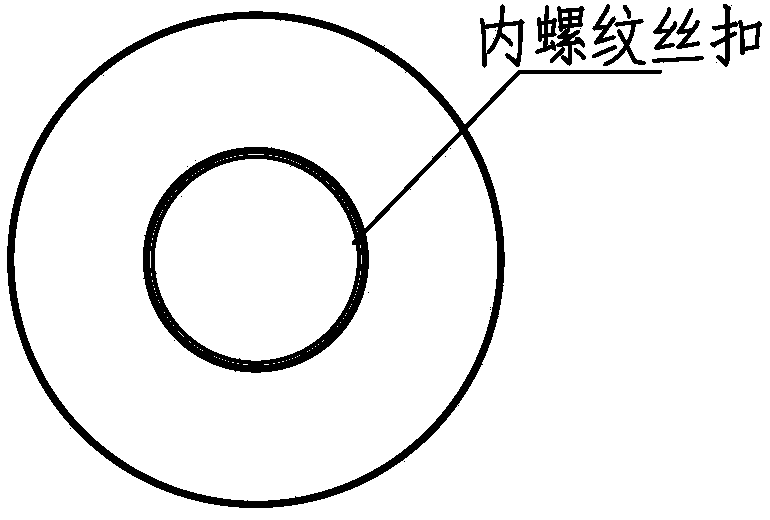

[0052] Before construction, the outer surface of the butt end of the pre-embedded steel bar is processed into a threaded mechanical connection thread structure, and the threaded mechanical connection thread matches the internal thread mechanical connection thread in the groove at one end of the connection node. During assembly:

[0053] First, align the butt end of the pre-embedded steel bar with the groove at the end of the connection node, and securely cooperate with the threaded mechanical connection screw to ensure that the angle of the connection node and the pre-embedded steel bar are even;

[0054] Then, select the required length of finished rolled rebar with a trapezoidal thread at an angle of 82-84 degrees and press it into the groove along the direction perpendicular to the groove on the other end face of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com