Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2350results about How to "Improve hardenability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

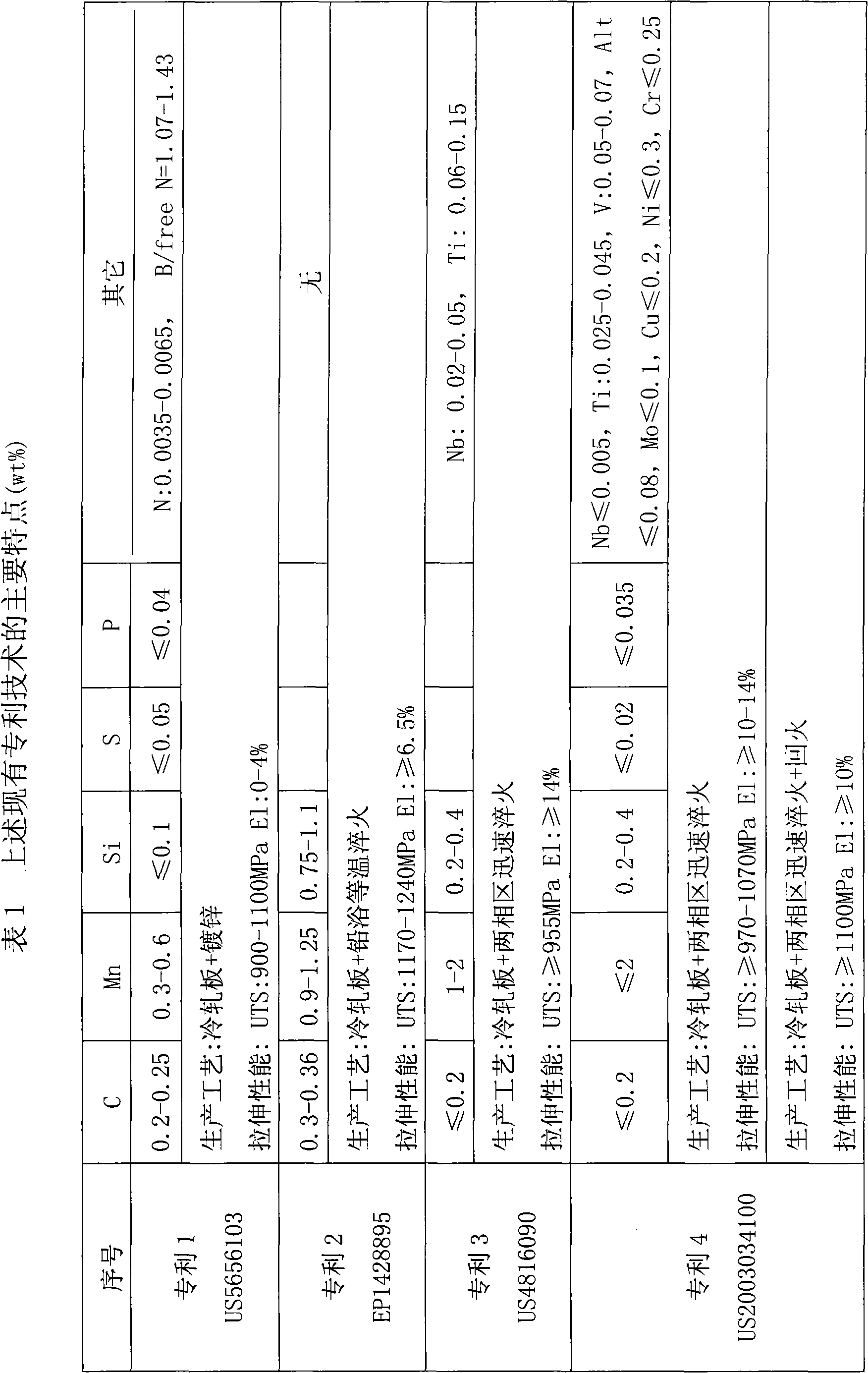

Steel plate for stamping and quenching and thermoforming method of steel plate

ActiveCN102031456ASimple compositionPlay the effect of weight reduction and energy savingHot stampingSimple component

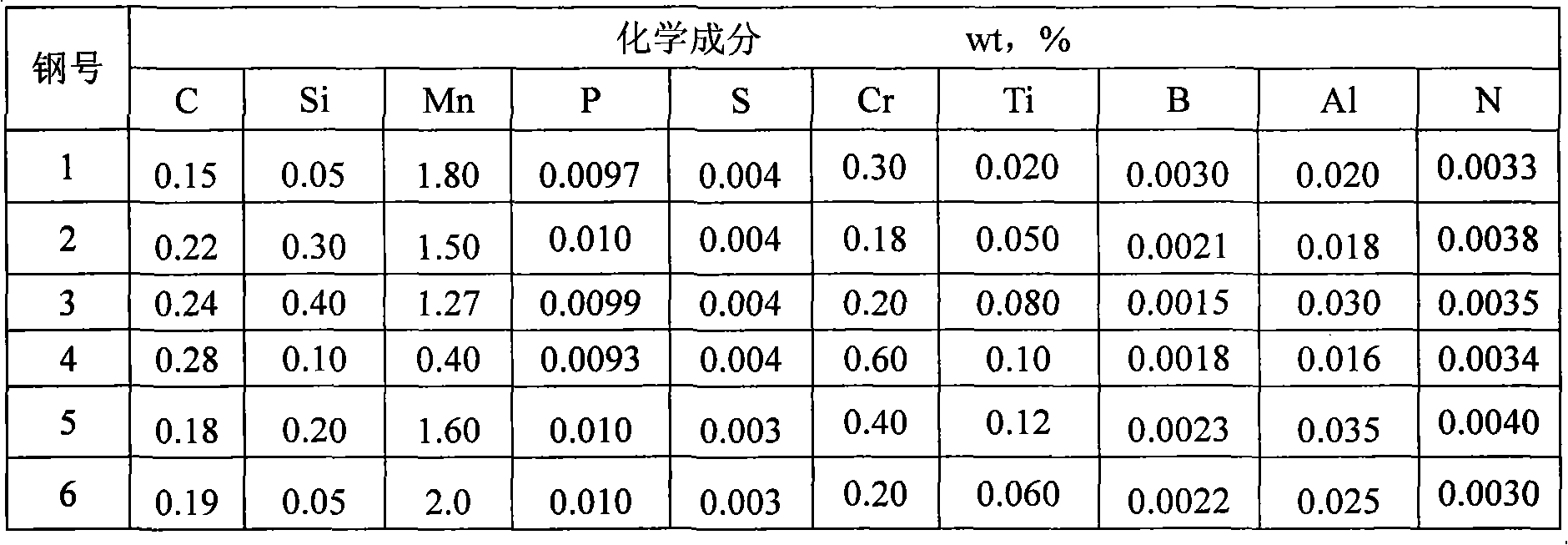

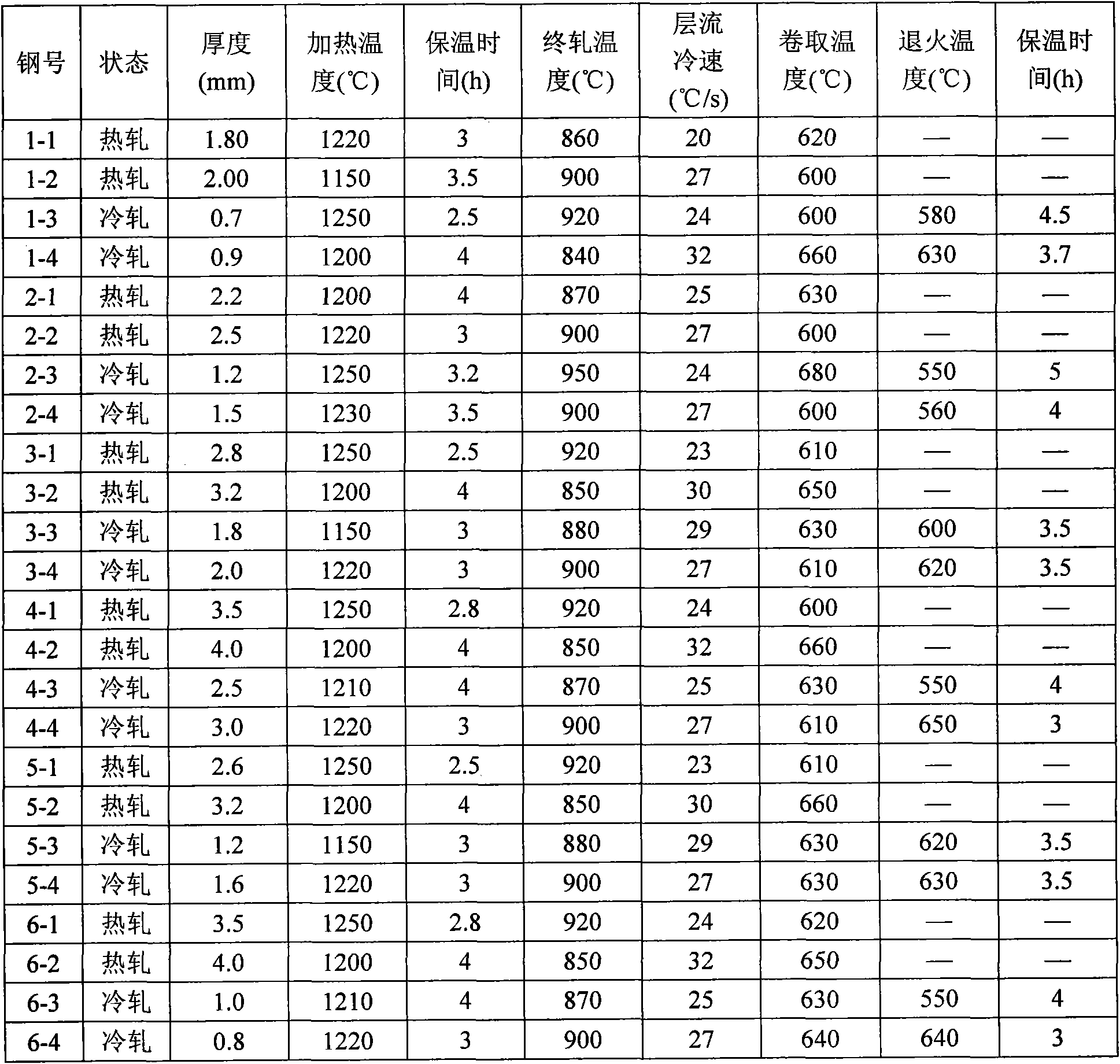

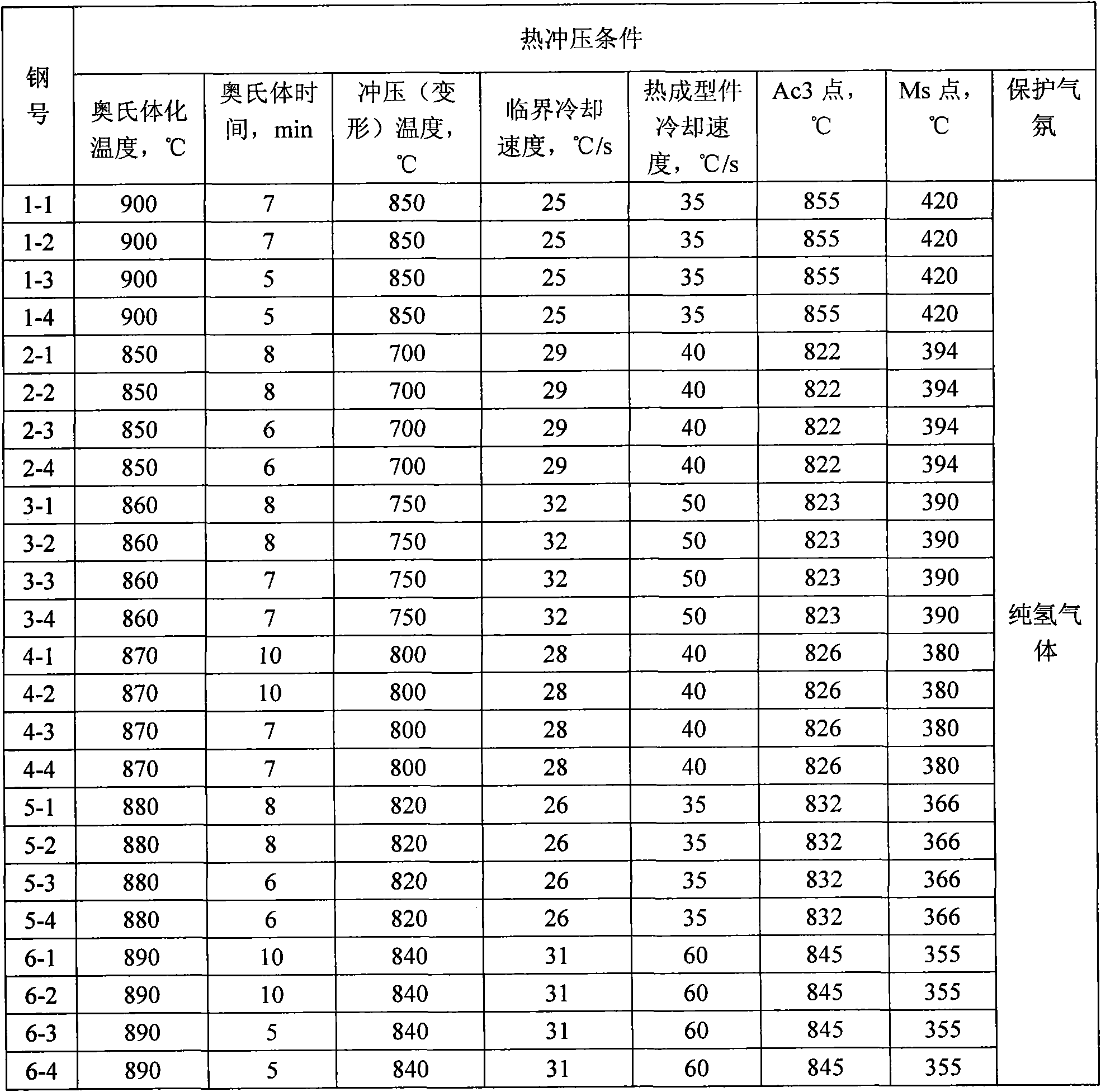

The invention discloses a steel plate for stamping and quenching and a thermoforming method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.28% of C, less than 0.40% of Si, 0.4-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.016-0.040% of Al, 0.15-0.8% of Cr, 0.015-0.12% of Ti, 0.0001-0.005% of B, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The thermoforming method comprises the following steps: blanking by shearing the steel plate, and heating at Ac3 to (Ac3+80) DEG C to carry out austenization; after insulating for 5-10 minutes in the heating furnace, immediately transferring the steel plate to a metal mold the inside of which is cooled by introducing water, and stamping at the high temperature of 650-850 DEG C; cooling the formed workpiece in the closed mold, and cooling the mold by water circulation in the mold, wherein the cooling rate is greater than the critical cooling rate when austenite forms martensite, and the temperature of the workpiece leaving the hot stamping production line is below 150 DEG C; and carrying out air-cooling to room temperature. The steel plate has the advantages of simple component system and favorable hardenability; and the substrate tissues, which are ferrite and pearlite, are processed by hot stamping andquenching to obtain the all martensitic structure. The tensile strength of the steel plate can be higher than 1300 N / mm<2>.

Owner:ANGANG STEEL CO LTD

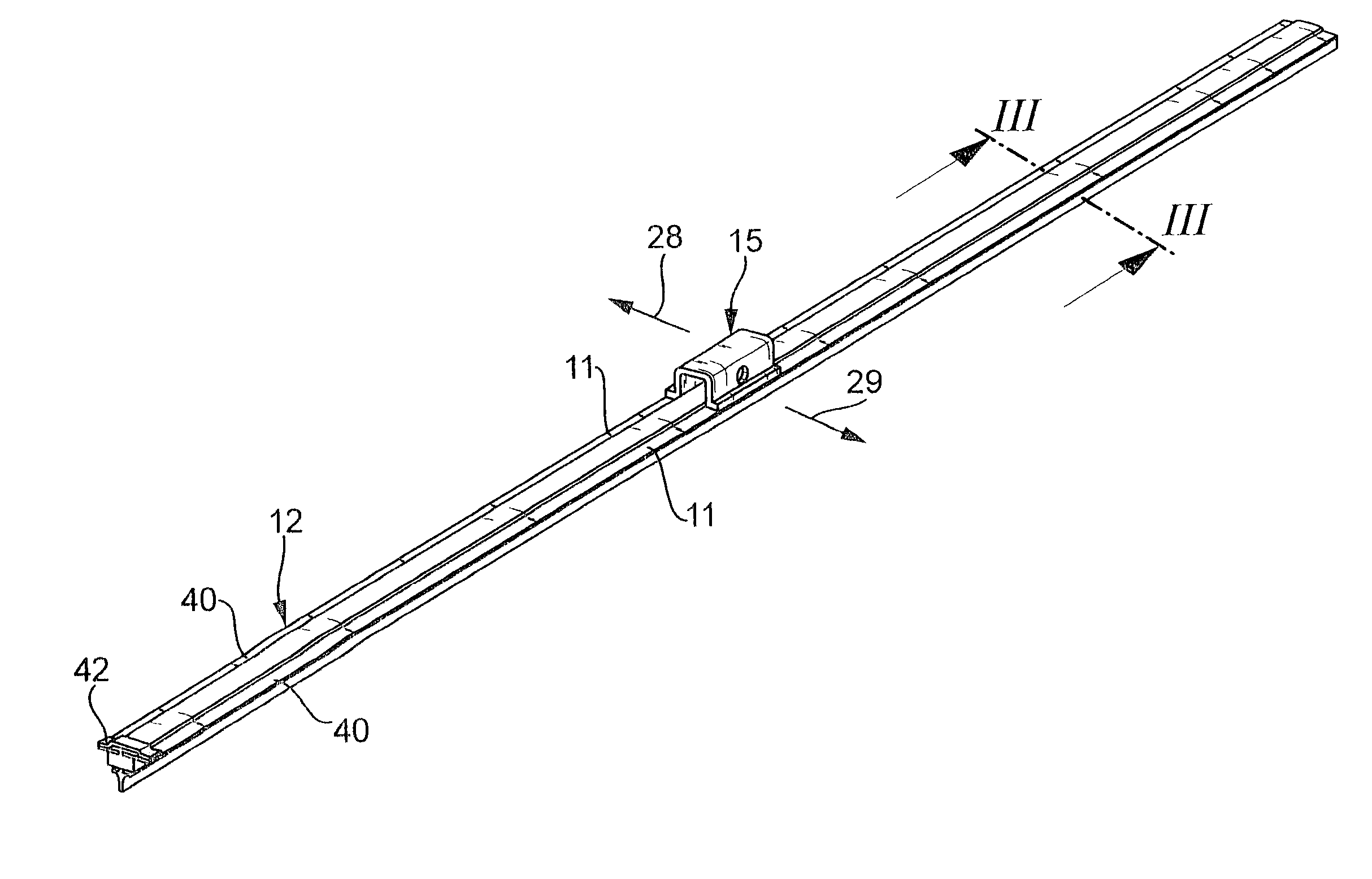

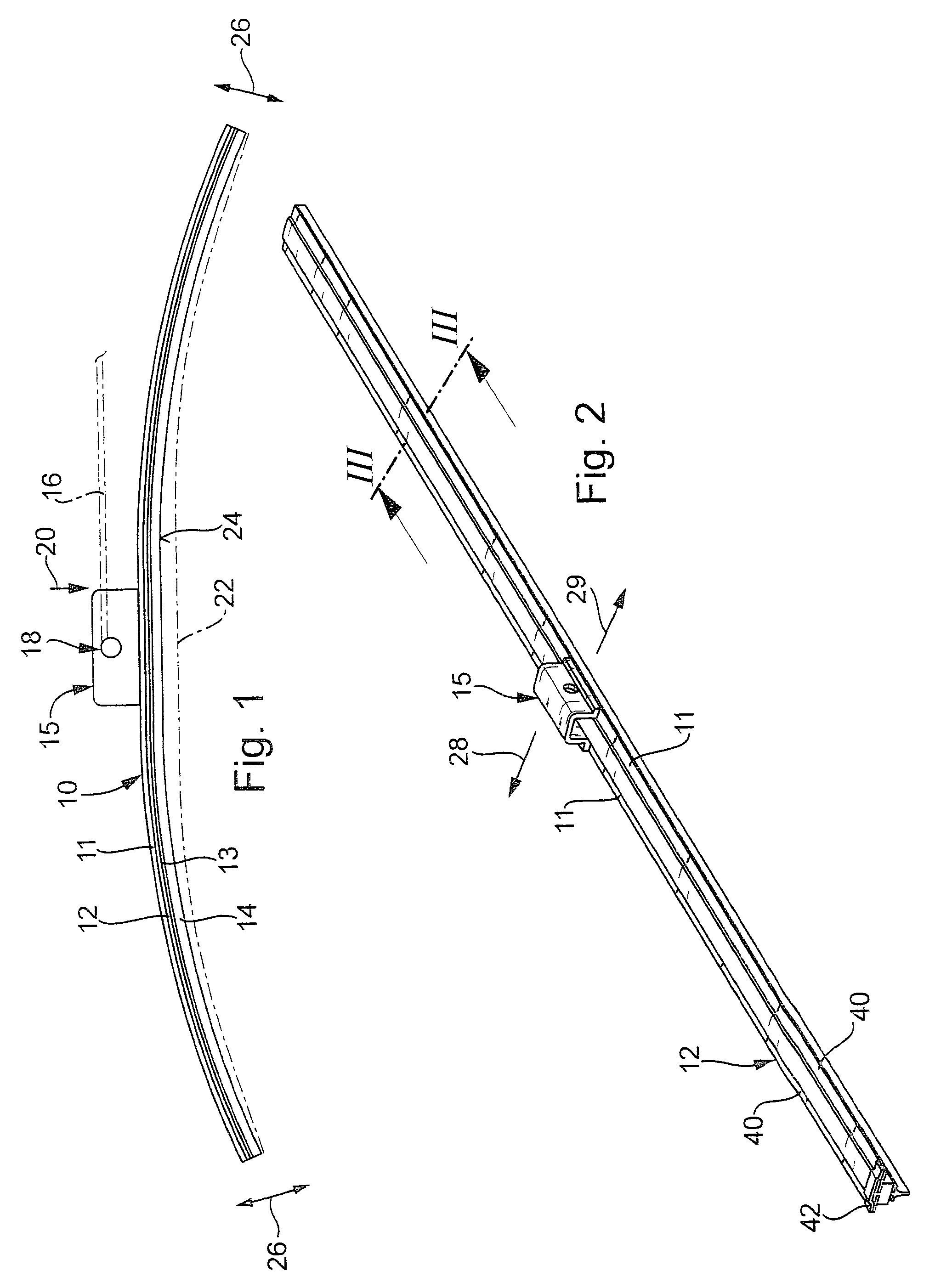

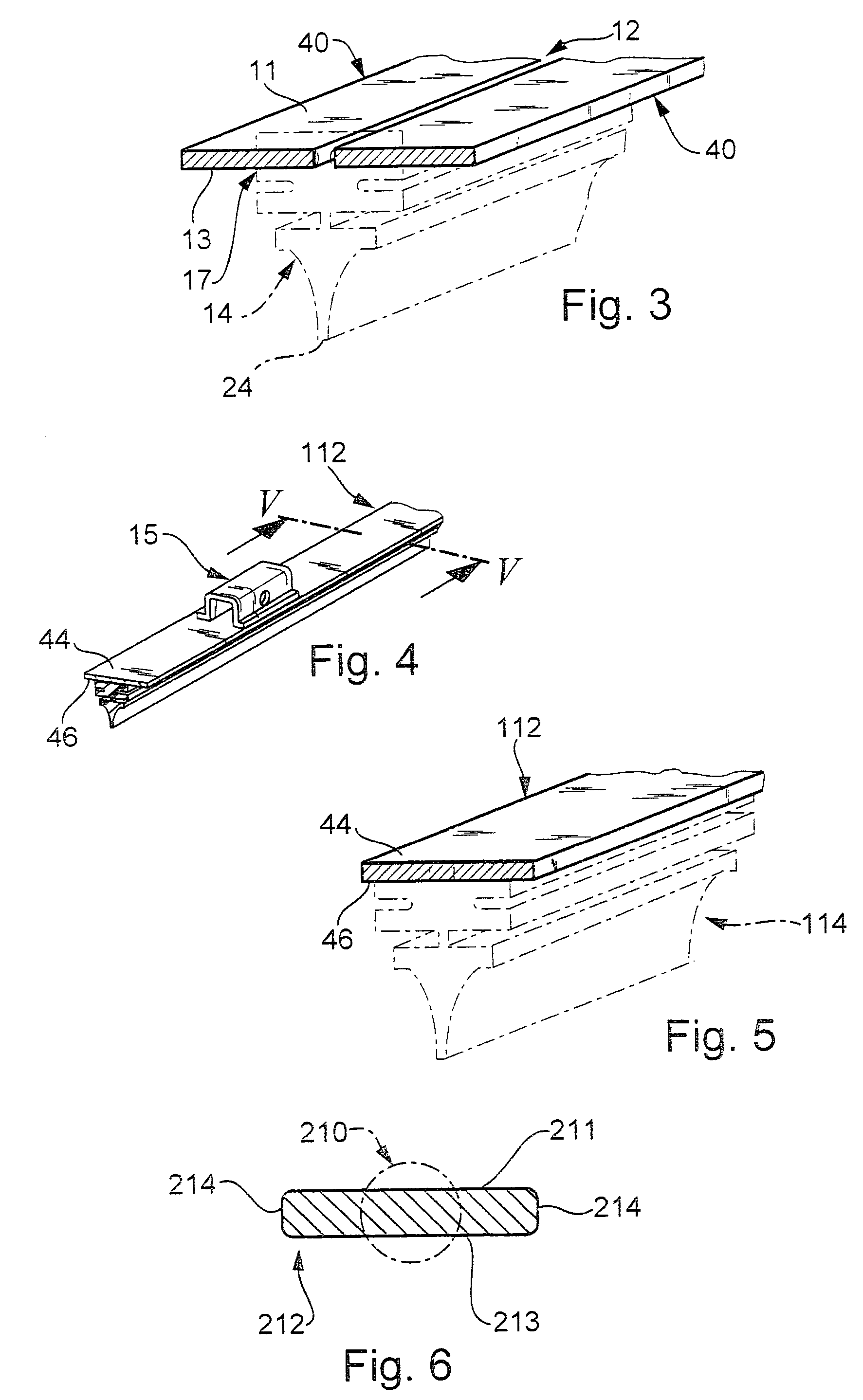

Wiper blade for cleaning glass panes, especially of motor vehicles, and method for the production of said wiper blade

InactiveUS20040025280A1Reduce adverse effectsImprove hardenabilityWindow cleanersVehicle cleaningMobile vehicleSulfur

A wiper blade is proposed for cleaning windows, especially of motor vehicles, is proposed, which is provided with an elongated, rubber-elastic wiper strip that can be placed against the window, which wiper strip is disposed on the lower band face (13), oriented toward the window, of a bandlike-elongated support element (12) made from a spring-elastic steel, on whose other, upper band face (11) facing away from the middle, particularly in the middle portion of the support element, a device (15) for connecting the wiper blade to the free end, urged toward the window, of a driven wiper arm (16) guided on the motor vehicle is welded. It has proved particularly advantageous, in view of the demands made of the support element, if the support element is made from an alloyed quenched and tempered steel, which has the following alloy components: carbon (C), 0.18% to 0.36%; silicon (Si), 0.40% to 0.50 %; manganese (Mn), 1.10 % to 1.80%; phosphorus (P), 0.015% to 0.035%; and sulfur (S), 0.035% to 0.04%.

Owner:ROBERT BOSCH GMBH

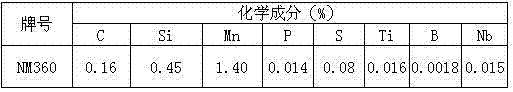

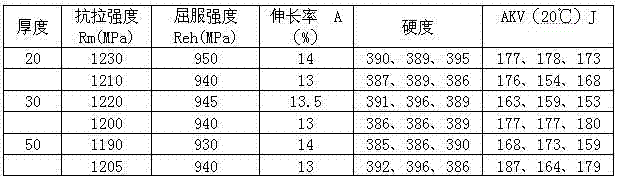

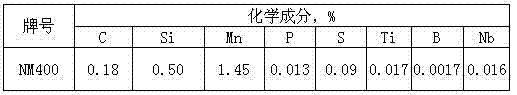

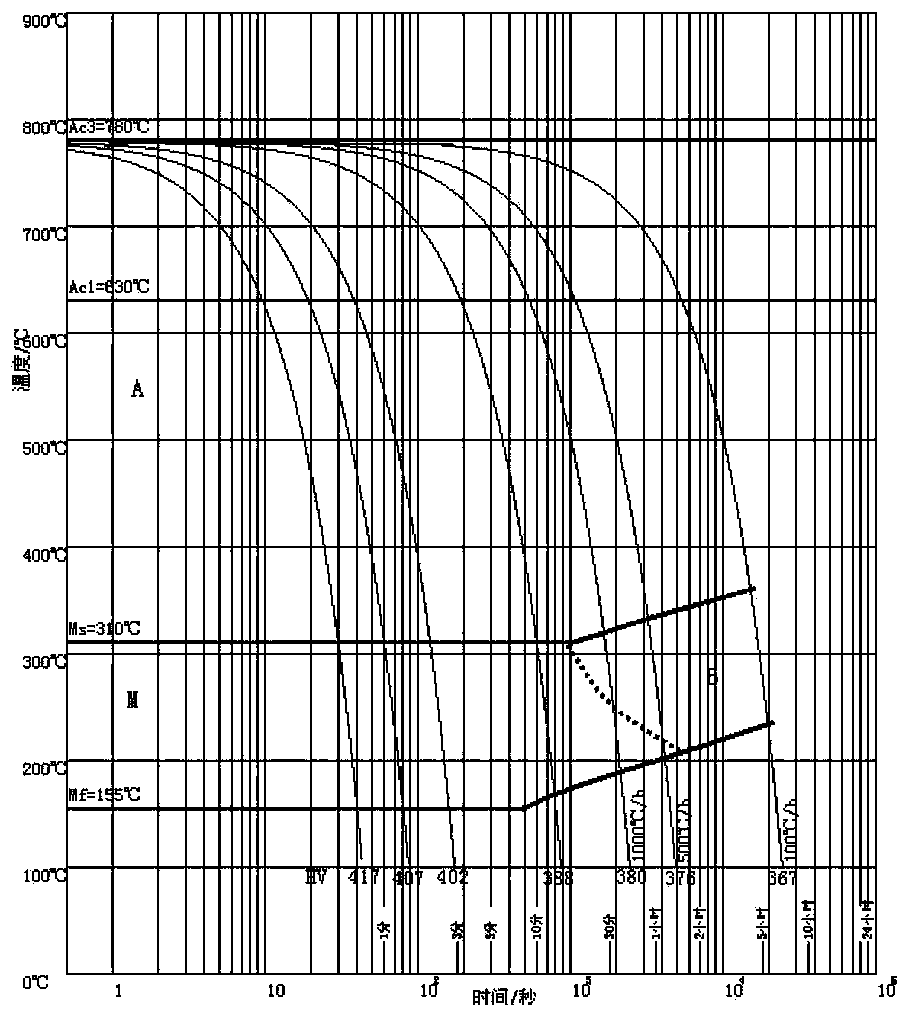

Method for producing wear-resisting steel plate

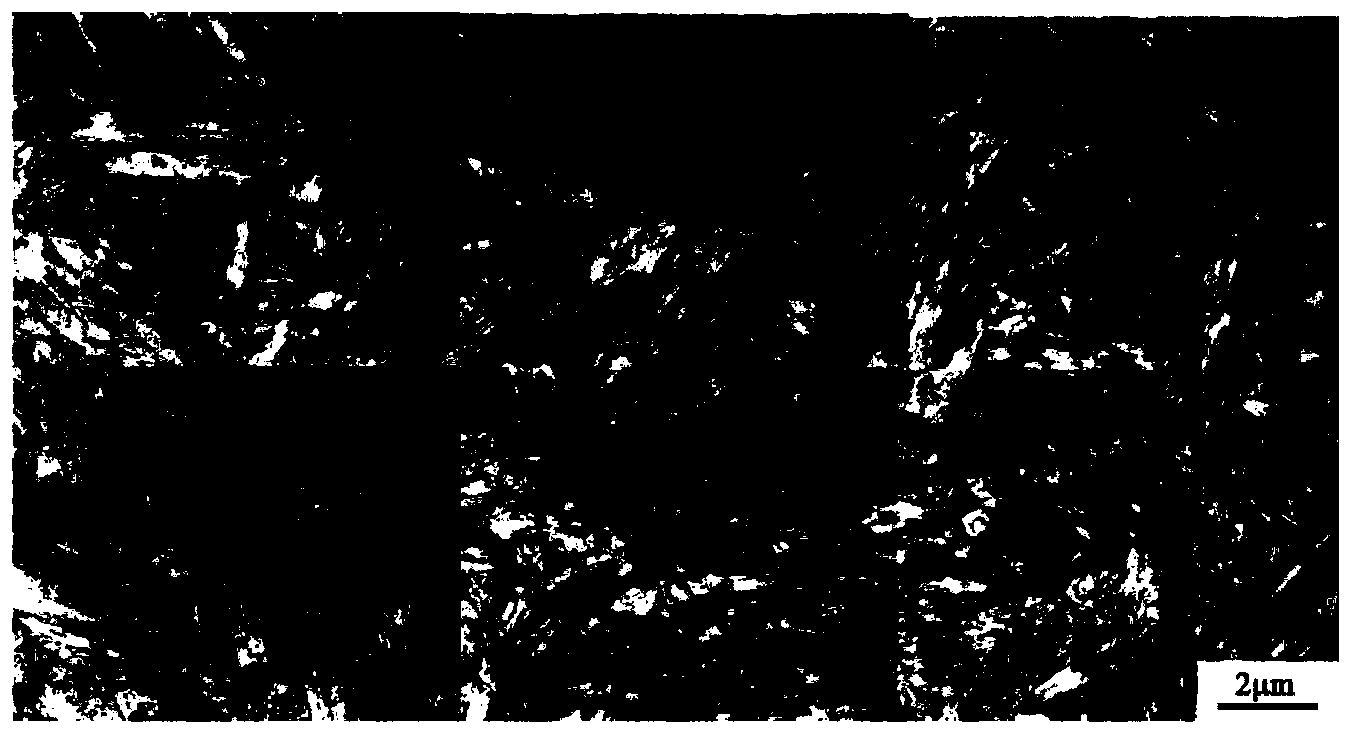

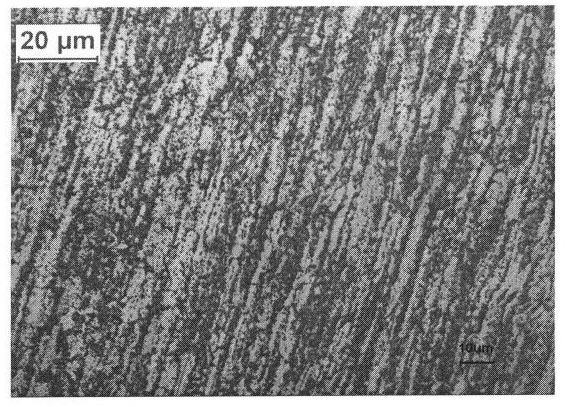

The invention relates to a method for producing a wear-resisting steel plate. Steel comprises the following chemical ingredients in percentage by mass: 0.15 to 0.20 percent of C, 0.4 to 0.7 percent of Si, 0.7 to 1.50 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.010 percent of S, 0.020 to 0.10 percent of Ti, 0.0005 to 0.0020 percent of B, 0.010 to 0.020 percent of Nb and the balance of Fe and inevitable impurities. A production process for the steel comprises the following steps of: desulfurizing by molten iron, smelting by a converter, refining, casting continuously, rolling and performing quenching-carbon partition (Q-P) treatment. In the ingredients of the wear-resisting steel, a C-Si-Mn-Nb-Ti ingredient system and the Nb and Ti micro alloy treatment are adopted, the hardenability of the steel is improved by adding B, an appropriate heat treatment process is adopted to ensure that the steel plate has high plasticity and toughness, and the impact energy of the steel plate is improved by over one time; and the heat treatment is performed by a Q-P process, lath martensite and lath retained austenite (between 5 and 10 percent) are formed and 50 to100 nanometers of carbide complex tissue is precipitated, so that the tissue is fine and uniform, and the tenacity of the steel plate is high.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

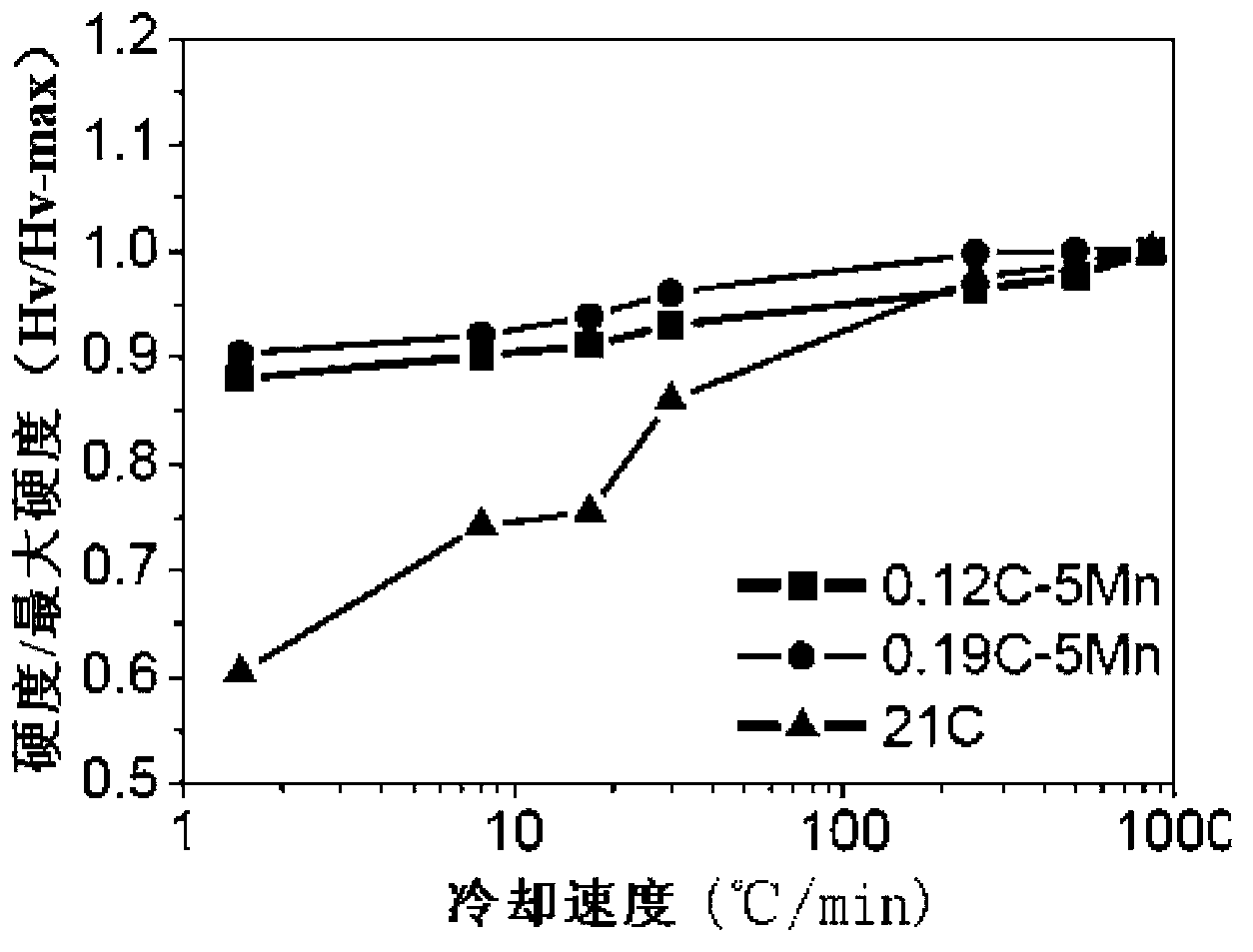

Martensite series wear-resistant steel and preparation method thereof

The invention relates to martensite series wear-resistant steel and a preparation method thereof, belonging to the technical field of wear-resistant steel. The steel comprises the following chemical components: 0.05-0.51wt% of C, 2.0-10wt% of Mn, 0-1.5wt% of Al, 0-1.5wt% of Si, 0-1.5wt% of Cr, 0-1.5wt% of Cu, 0-1.5wt% of Ni and the balance of Fe and inevitable impurities, wherein the Mn / C ratio is not less than 9. Based on this, the following one or more composite elements can be optionally added: 0.02-0.50wt% of Mo, 0.02-0.50wt% of V, 0.02-0.50wt% of Nb, 0.01-0.5wt% of Ti, 0.02-0.50wt% of B and 0.02-0.50wt% of RE. The wear-resistant steel provided by the invention is easy to produce, low in cost and high in performance. The invention is applicable to the technical field of wear-resistant materials for mines, energy, transportation, agricultural machinery, engineering machinery and other industries.

Owner:CENT IRON & STEEL RES INST

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

Ultrahigh-strength structural steel board for ocean engineering and production method thereof

The invention relates to an ultrahigh-strength structural steel board for ocean engineering and a production method thereof, belonging to the technical field of ultrahigh-strength steel. A board blank comprises the following components: 0.05-0.13% of C, 0.1-0.4% of Si, 0.7-1.7% of Mn, 0.01-0.04% of Alt, 0.02-0.05% of Nb, 0-0.05% of V, 0.008-0.02% of Ti, 0-0.6% of Cr, 0.2-0.4% of Mo, 0.15-0.8% of Ni, 0-0.5% of Cu, 0-0.0011% of B, less than 0.01% of P, less than 0.005% of S, less than 0.0010% of O, less than 0.005% of N, less than 0.00015% of H, and the balance of Fe and inevitable impurities, wherein Nb+V+Ti is not more than 0.12%. Aiming at different thickness standards, different chemical component as well as rolling and heat treatment process parameters are adopted. The production process comprises the steps of molten iron desulfurization, converter top and bottom blowing, vacuum treatment, continuous casting, controlled rolling and controlled cooling, quenching and tempering. The steel board has the advantages that: the production cost is lower, and the comprehensive mechanical properties can meet the requirements of the steel for the ocean engineering for various mechanical properties.

Owner:SHOUGANG CORPORATION +1

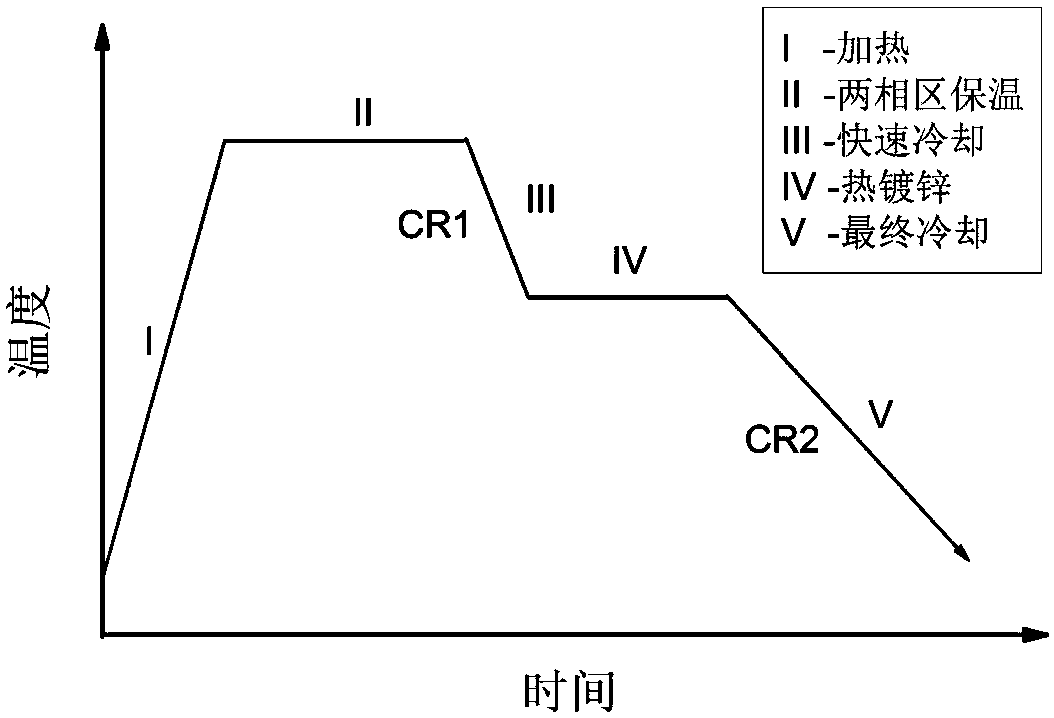

Cold-rolled galvanized duplex steel and manufacturing method thereof

ActiveCN102021482APlatability EliminationHigh strengthHot-dipping/immersion processesManufacturing convertersHigh rateOxygen

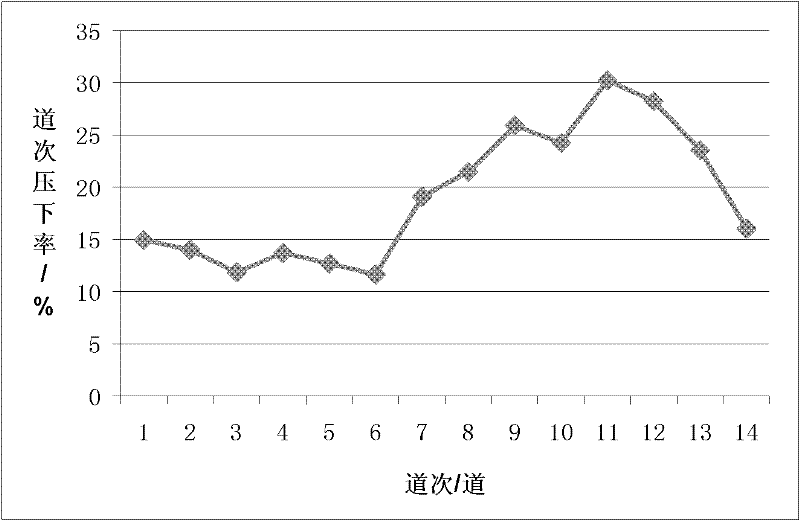

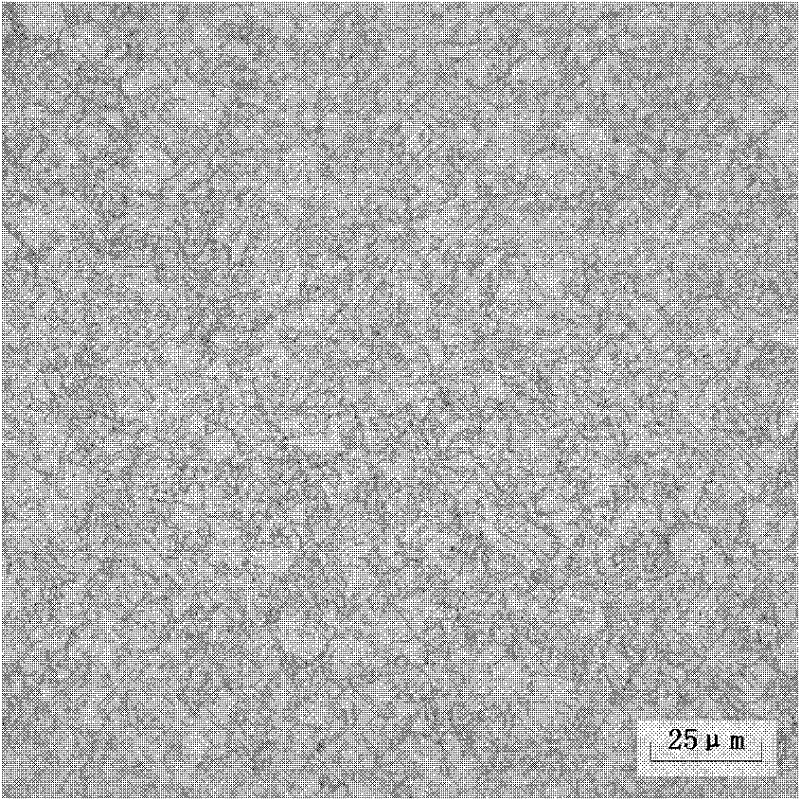

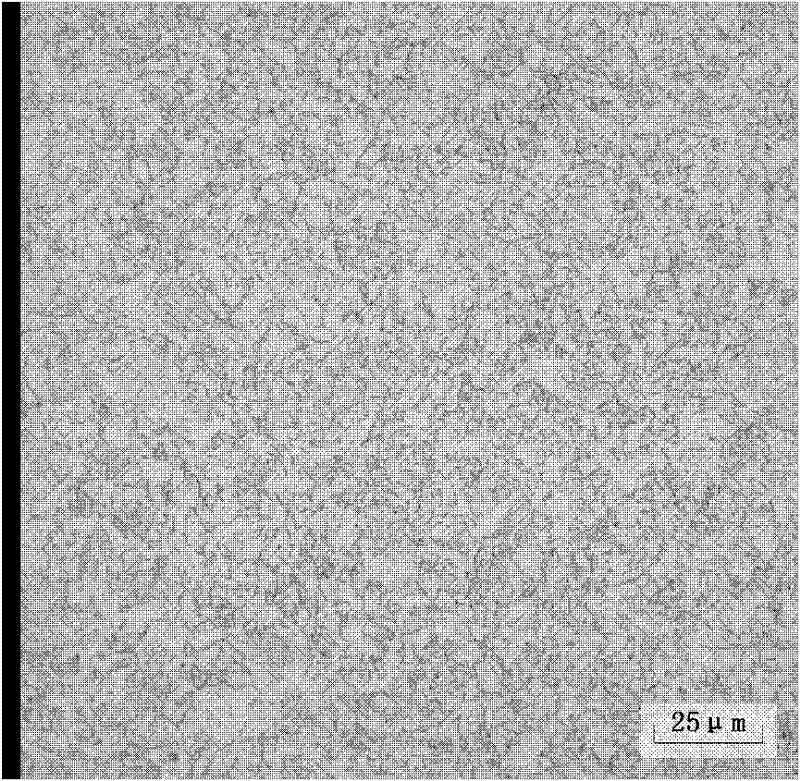

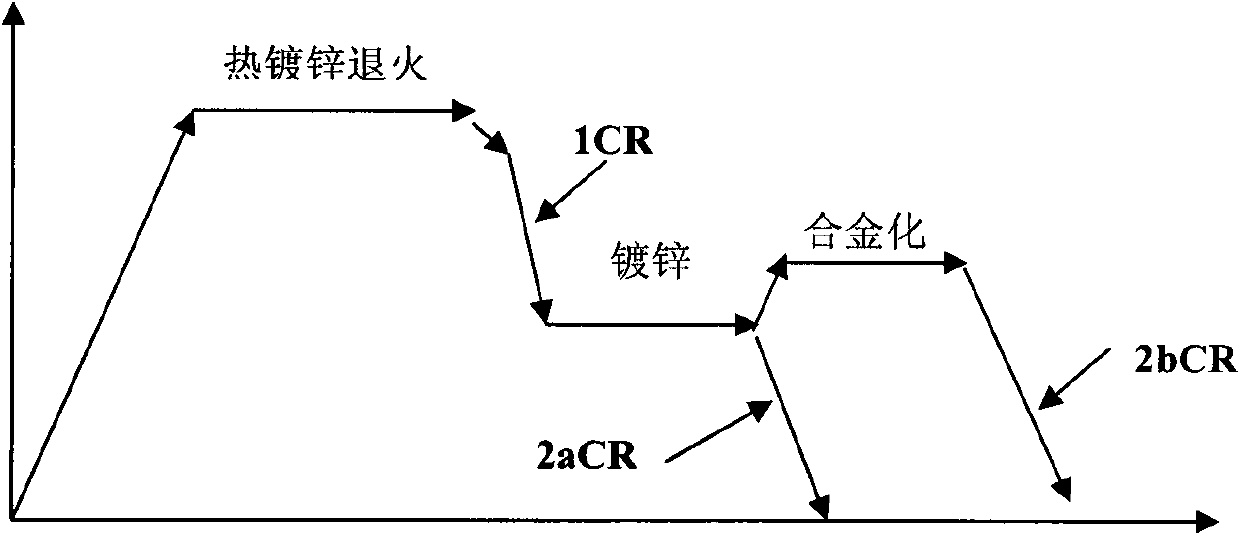

The invention relates to a cold-rolled galvanized duplex steel, wherein the substrate thereof comprises the following components by weight percentage: 0.08 to 0.18 wt.% of C, 0.50 to 1.50 wt.% of Si, 1.50 to 2.5 wt.% of Mn, 0.10 to 1.0 wt.% of Cr, 0.02 to 0.5 wt.% of Mo, 0.005 to 0.05 wt.% of Nb, 0.005 to 0.05 wt.% of Ti, 0.002 to 0.05 wt.% of T.Al, less than or equal to 0.02 wt.% of P, less thanor equal to 0.01 wt.% of S and less than or equal to 0.006 wt.% of N, and the balance of Fe. The manufacturing method thereof comprises the steps of: smelting in an oxygen top-blown convertor, refining in a heating steel ladle, continuously casting into a slab, and then conventionally hot rolling, pickling tandem rolling, galvanizing and annealing, wherein the critical annealing temperature is between 760 and 840 DEG C; the annealing is finished in the two-phase area of ferrite and austenite; 1CR section cooling has a cooling speed of 1 to 40 DEG C / S from the annealing temperature to the zincpool, putting the substrate into the zinc pool having a temperature of 450 to 465 DEG C so as to galvanize; and 2a CR section cooling has a cooling speed more than 3 DEG C / S. The steel of the invention has the advantages of high tensile strength, low yield ratio, capable of being press formed, excellent matching between strength and toughness, high rate of initially work-hardening and being free from yield extending.

Owner:BAOSHAN IRON & STEEL CO LTD

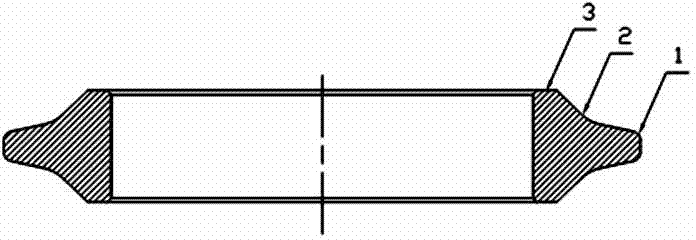

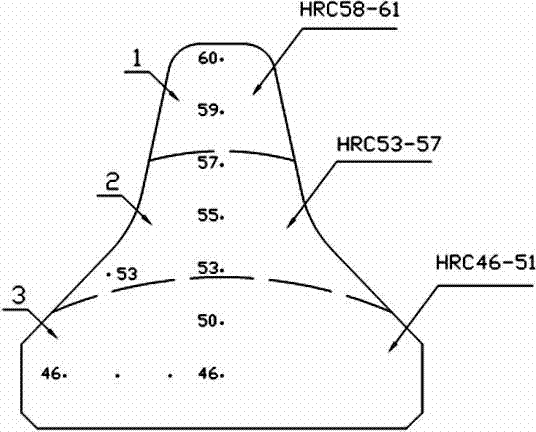

Disk-shaped roller cutter ring and manufacture method thereof

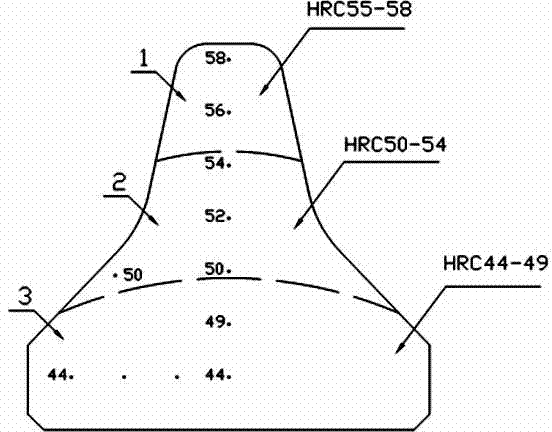

ActiveCN102517502AGuaranteed hardenabilityImprove toughnessFurnace typesHeat treatment furnacesMedium frequencyHardness

The invention discloses a disk-shaped roller cutter ring with high hardness, good toughness and excellent comprehensive performance. The disk-shaped roller cutter ring comprises the following ingredients of: 0.46-0.56% of C, 0.80-1.20% of Si, 0.20-0.65% of Mn, 5.00-5.80% of Cr, 1.15%-1.55% of Mo, 0.85-1.40% of V and the balance Fe and impurities, wherein the content of P is no more than 0.02%, and the content of S is no more than 0.01%; and the overall hardness of the cutter ring is HRC55-61 (Rockwell Hardness C55-61), or the hardness is of graded distribution, i.e. the hardness of a working edge area is HRC55-61, the hardness of a transition surface area is HRC50-57, and the hardness of a step assembly surface area and an inner ring is HRC44-51. A preparation method of the disk-shaped roller cutter ring comprises the following steps of: smelting the raw materials in an electric furnace; carrying out electroslag remelting; preforging; carrying out die forging; carrying out slow cooling; annealing; carrying out rough machining to obtain a disk-shaped roller cutter ring rough blank; carrying out high-temperature vacuum hardening and two-time high-temperature tempering on the cutter ring rough blank; carrying out low-temperature destressing treatment; carrying out fine finishing to obtain the cutter ring with the overall hardness of HRC55-61, wherein the cutter ring with the overall hardness of HRC55-61 is applicable to the tunneling of a hard rock formation by a shield tunneling machine; or carrying out medium-frequency induction tempering treatment prior to the low-temperature destressing treatment to obtain the cutter ring with graded-distribution hardness, wherein the cutter ring with the graded-distribution hardness is applicable to the tunneling of a rock formation with an upper soft part and a lower hard part.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

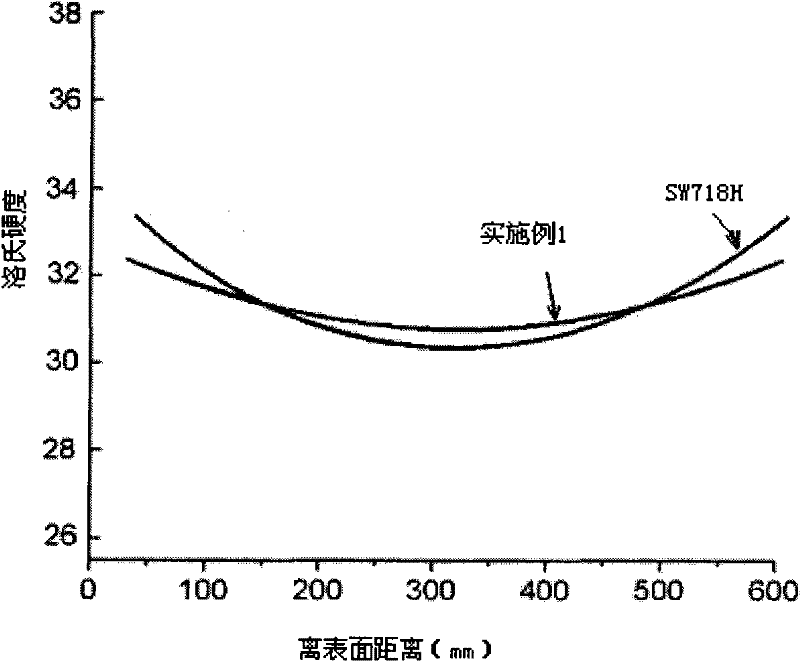

Super-thick non-hardening plastic mold steel and method for manufacturing the same

ActiveCN101096743ARealize non-temperedEliminate quenching and temperingHeat treatment process controlHardnessImpurity

The invention discloses a hyper-thick non-modified plastic die steel, which comprises the following parts: 0.20-0.32% C , 0.20-0.80% Si , 1.80-2.50% Mn, 0.80-1.50% Cr, 0.20-0.60% Mo, 0.08-0.20% V, 0.0010-0.0030% B, 0.02-0.06% Ti , not more than 0.035% P, not more than 0.035% S, ferric and inevitable impurity, wherein the structure condition is bainite. The invention ensures the hardness HRC30-36 of bainite structure and pre-hardening plastic die steel, which controls the cooling speed after forging with thickness over 300mm.

Owner:宝武特种冶金有限公司

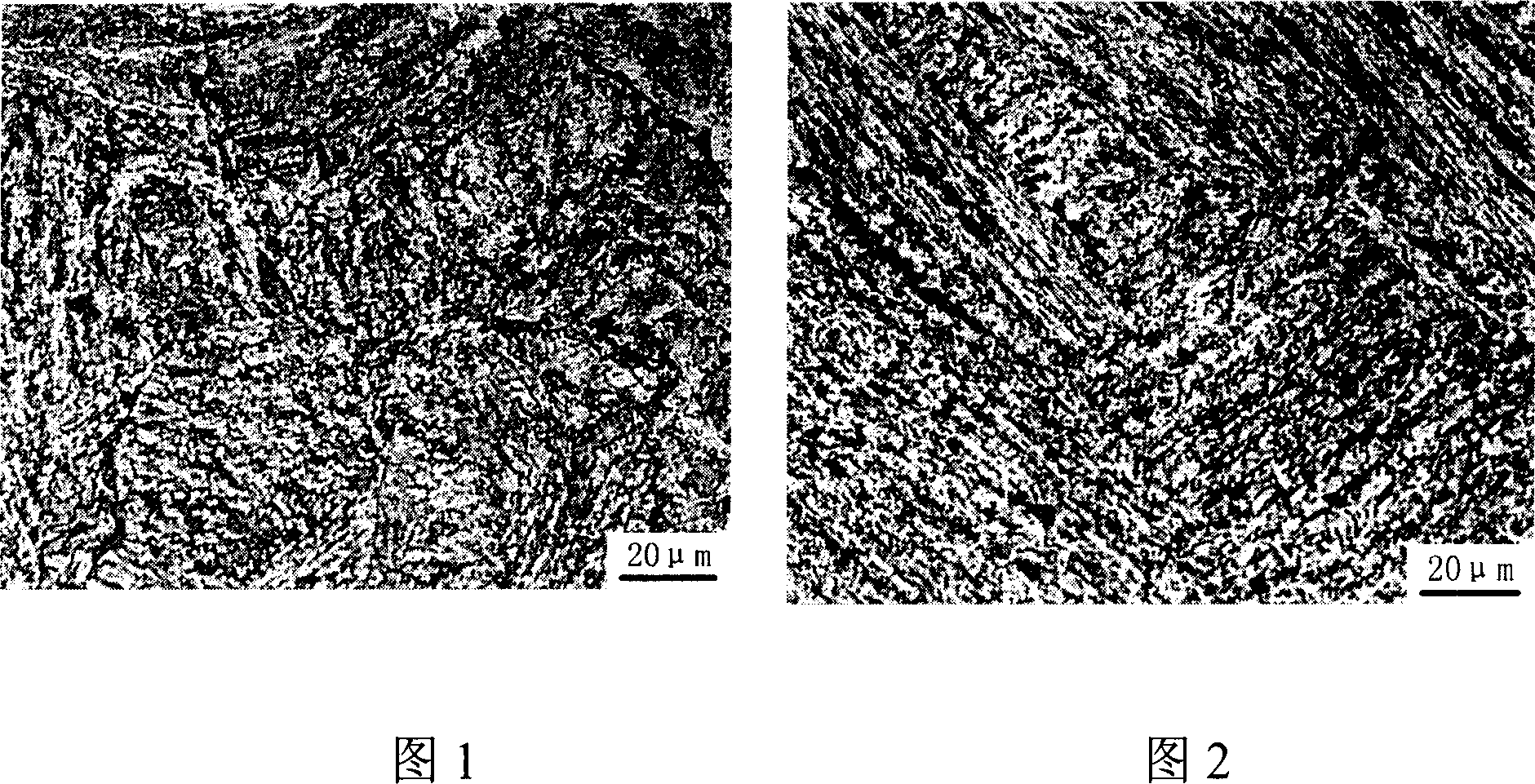

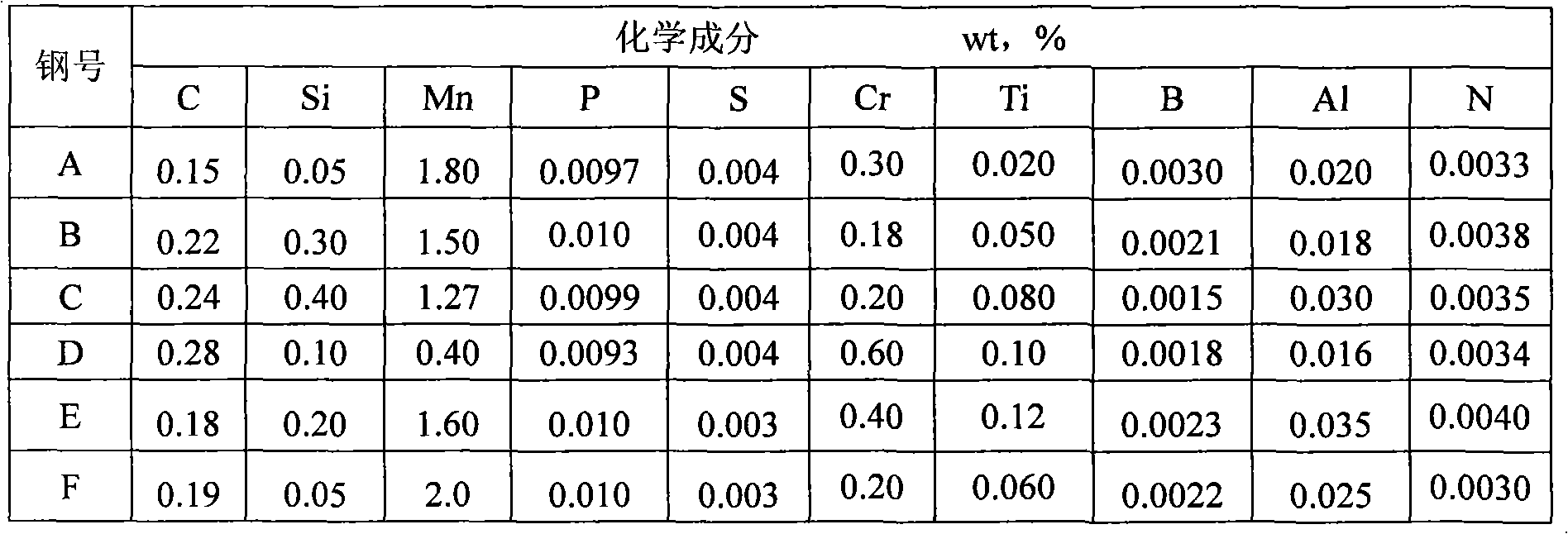

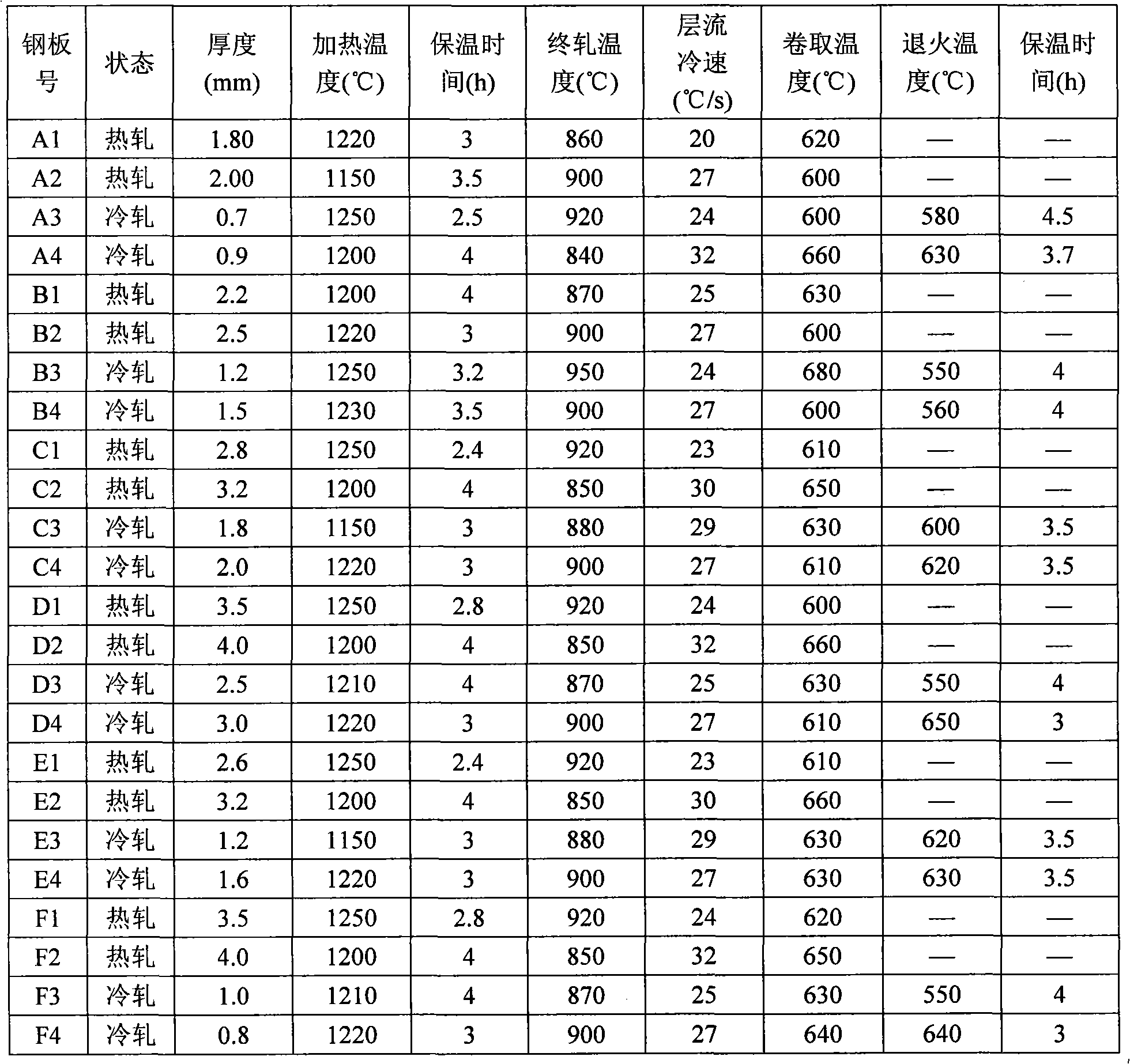

Steel plate for stamping and quenching and manufacturing method thereof

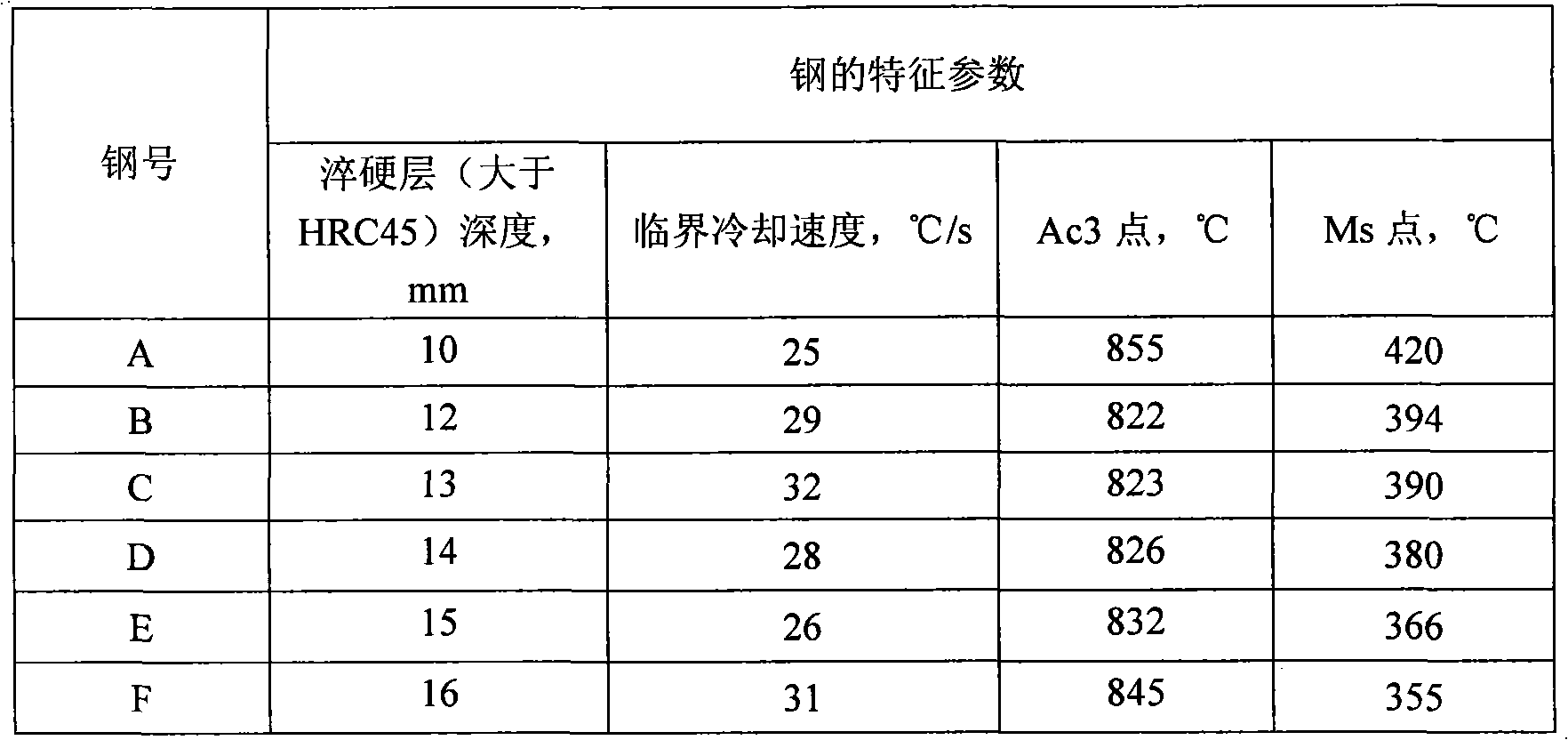

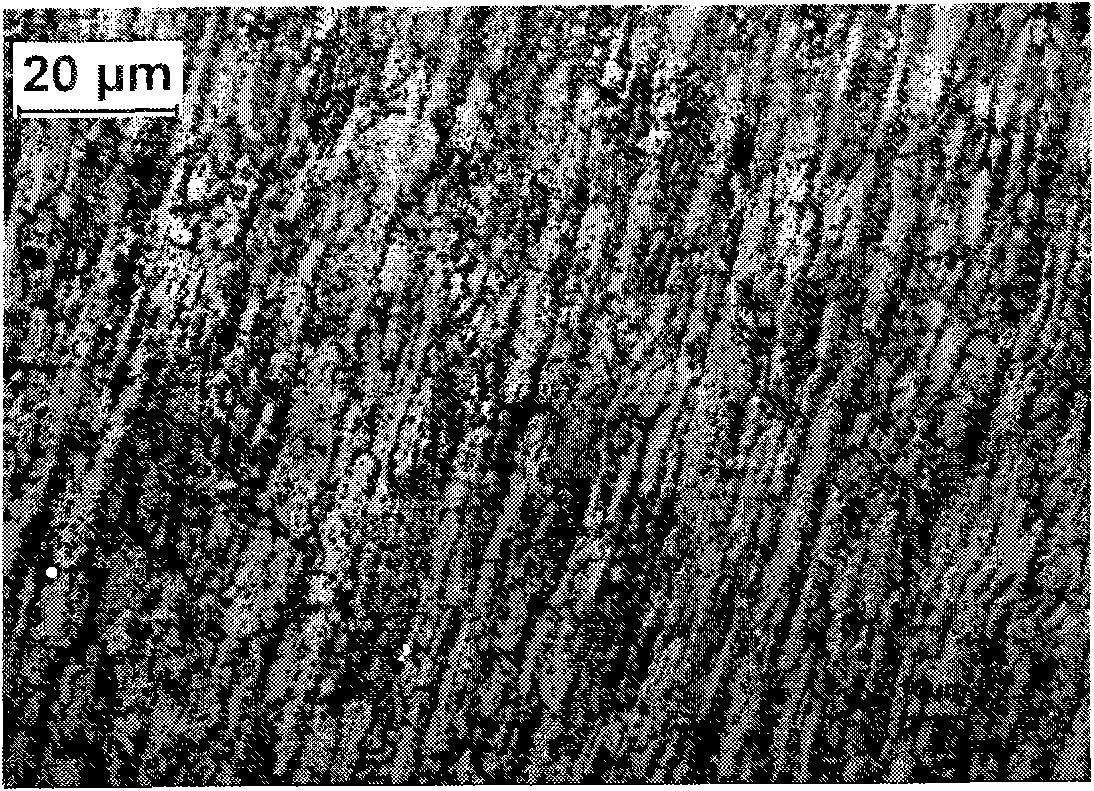

The invention discloses a steel plate for stamping and quenching and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by mass: 0.14 to 0.28 percent of C, less than 0.40 percent of Si, 0.4 to 2.0 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.004 percent of S, 0.016 to 0.040 percent of Al, 0.15 to 0.8 percent of Cr, 0.015 to 0.12 percent of Ti, 0.001 to 0.005 percent of B, less than or equal to 0.005 percent of N, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the following steps of: heating a blank to 1,150 to 1,250 DEG C, preserving heat for 2.5 to 4 hours and performing rough rolling, and then performing finish rolling under multichannel pressure and at the final rolling temperature of between 830 and 950 DEG C, performing laminar cooling, and cooling to the rolling temperature at the cooling speed of more than 10 DEG C / s and the rolling temperature of between 600 and 680 DEG C. The cold-rolled steel plate is obtained by the following steps of: performing cold rolling on a hot rolled steel strip, annealing through a pure hydrogen gas cover furnace, and oiling and packaging. The annealing temperature is 550 to 650 DEG C and the heat preserving time is 3 to 5 hours. The steel has a simple component design and high hardenability. The depth of a hardening layer of more than HRC45 is 10 to 16mm. The steel plate consists of ferrite and pearlite. After thermal stamping and quenching, an all-martensite structure can be obtained. The tensile strength is above 1,300N / mm<2>.

Owner:ANGANG STEEL CO LTD

High strength strapping steel with tensile strength over 1,100 MPa and manufacturing method thereof

The invention discloses high strength strapping steel with tensile strength over 1,100 MPa and a manufacturing method thereof. The high strength strapping steel comprises the following components in percentage by weight: 0.25 to 0.35 percent of C, 1.0 to 2.0 percent of Mn, less than or equal to 0.45 percent of Si, less than or equal to 0.04 percent of S, less than or equal to 0.04 percent of P, and the balance of Fe and inevitable impurities. The manufacturing method comprises a steel smelting process, hot rolling process, cold rolling process and ferrite-austenite two-phase region quick quenching and annealing heat treatment process for smelting pure steel while controlling the state of impurities. The method can realize the excellent combination of strength and plasticity, realizes the clean production of the high-strength strapping steel which has a tensile strength over 1,100MPa and an elongation over 10 percent, and has the advantages of easy-to-implement production operation, high production efficiency, low production cost, light environmental pollution. Thus, the method has a good application prospect.

Owner:BAOSHAN IRON & STEEL CO LTD

High-hardness hypereutectic high chromium, manganese, molybdenum and tungsten alloy wear resistant steel material and use thereof

The invention discloses a high-hardness hypereutectic high Cr-Mn-Mo-tungsten alloy abrasion-resistant steel and iron material which adopts multivariant alloying and has the advantages of good hardenability, high hardness, better abrasion-resistance and wear resistance, and the like compared with the prior high-chromium cast iron especially the addition of C, Cr, Mn, Mo and tungsten, thereby enlarging the application range of materials. The invention is suitable for preparing wearing and corrosive wearing parts, in particular to parts used for impacting corrosive wearing working conditions.

Owner:JINAN UNIVERSITY

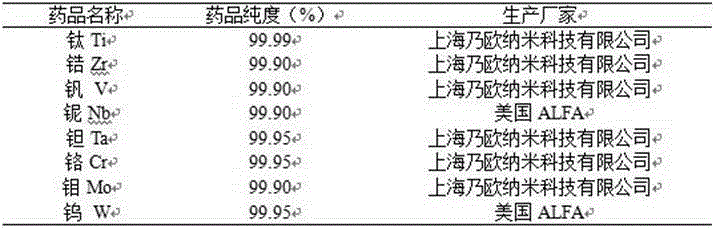

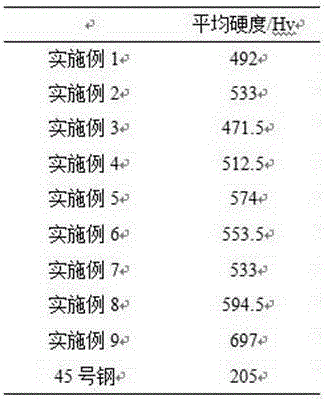

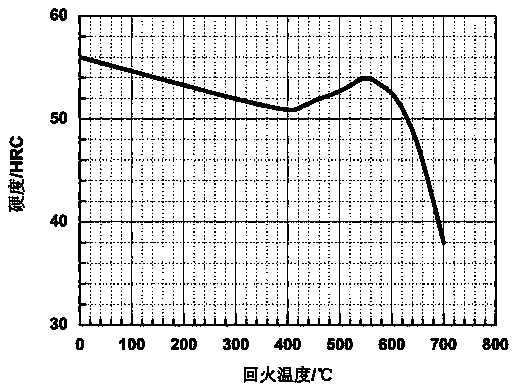

High-entropy alloy powder for laser cladding and preparation method of cladding layer

InactiveCN106086580AHigh bonding strengthEasy to diluteMetallic material coating processesHigh entropy alloysHardness

The invention discloses high-entropy alloy powder for laser cladding and a preparation method of a cladding layer. The high-entropy alloy powder comprises Ti, Zr, V, Nb, Ta and Mo. In addition, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo and W, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo, W and Cr and the preparation method of the cladding layer of the high-entropy alloy powder for laser cladding are provided. The high-entropy alloy powder mainly comprises two characteristics, namely, the high-entropy effect and the cocktail effect, each kind of powder exerts respective advantages, and therefore the cladding layer with high hardness, high corrosion resistance, excellent tempering softening resisting performance and excellent structure performance is obtained. Metallurgical bonding is formed by an alloy layer and a matrix through laser cladding; the bonding strength of the cladding layer and the matrix is greatly improved, and the heating speed is high; metal of the cladding layer is not prone to being diluted by the matrix; little heat deformation is generated; and therefore the part rejection rate is low.

Owner:KUNMING UNIV OF SCI & TECH

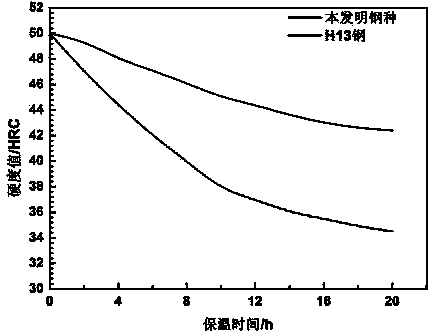

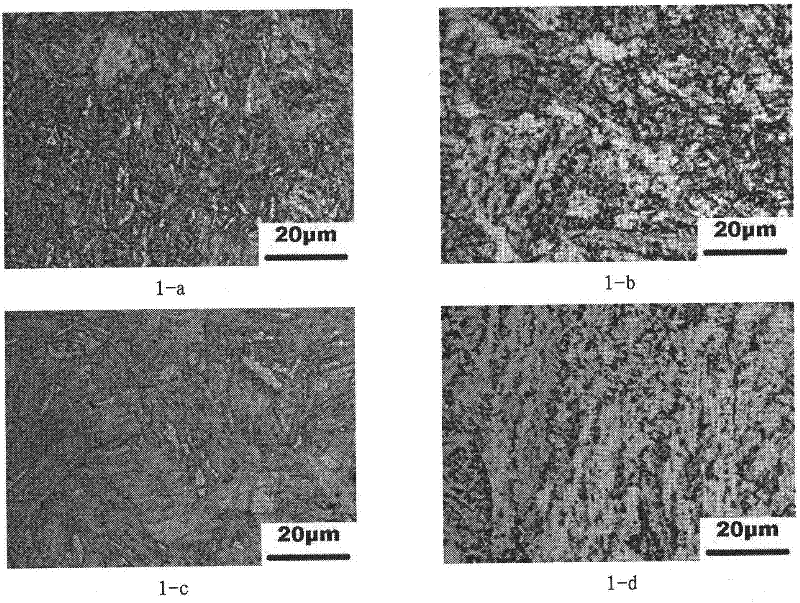

Large-section high-performance hot work die steel for die casting and preparation technology thereof

The invention relates to large-section high-performance hot work die steel for die casting and a preparation technology thereof and belongs to the technical field of an alloy steel preparation technology. The steel is characterized in that main alloy elements in alloy chemical components comprise, by weight, 0.35-0.65% of C, 0.30-1.00% of Si, 0.30-1.00% of Mn, 3.50-5.50% of Cr, 2.00-3.00% of Mo, 0.40-0.80% of V, P being less than or equal to 0.02%, S being less than or equal to 0.01%, 1.00-2.00% of Ni, Nb being greater than or equal to 0.15%, and the balance Fe. The preparation process of the hot work die steel comprises the following steps: burdening, smelting, casting and electroslag remelting; heat treatment by high-temperature heat diffusion, hot working by multi-directional forging and controlled cooling after forging; refining and heat treatment of proeutectoid carbide and isothermal annealing treatment; and heat treatment by quenching and tempering, namely austenitizing by heating to 950-1100 DEG C, oil cooling or mist cooling, and tempering at 540-630 DEG C for two to three times. The hot work die steel provided by the invention has advantages of high hardenability, high thermal stability, high toughness and good resistance to thermal fatigue.

Owner:RUGAO HONGMAO HEAVY FORGING

Flying shear blade and preparation method thereof

InactiveCN101144140AImprove wear resistanceImprove hardenabilityHeat treatment process controlShearing toolsQuenchingImpurity

The present invention discloses a flying shear blade. The component has the weight percentage that C is 0.40-0.70, Si is 0.50-1.20, Mn is 0.20-0.50, Cr is 4.00-6.00, Mo is 0.50-2.00, V is 0.30-1.50, P is less than or equal to 0.02, S is less than or equal to 0.02, and Fe and inevitable impurity are the residual. The present invention provides a manufacture method of electric furnace smelting, and ingot casting; hydrogen removing and annealing treatment, and forging; preliminary heat treatment, rough machining, quenching and tempering heat treatment (primary quenching and high temperature tempering), semi finishing, ultimate heat treatment (secondary quenching, primary low temperature tempering, and secondary low temperature tempering), and fine finishing. By effectively controlling the material texture and the morphology, the quantity, the size and the distribution of carbonide, the quenching temperature and the tempering temperature of the quenching and tempering heat treatment, and the quenching temperature and the tempering temperature of the ultimate heat treatment are controlled, the texture crystal grains are more refined, the carbonide is distributed in a dispersed way, and simultaneously, the thermal stability and the retentivity are remarkably enhanced, thereby being advantageous for improving the operational performance of the blade.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Ultrahigh-strength atmospheric-corrosion resistant steel

The invention discloses a hyperstrength atmospheric corrosion-tolerant steel, which comprises the following parts: 0.01-0.07% C, 0.25-0.50% Si, 1.60-2.00% Mn, not more than 0.018% P, not more than 0.008% S, 0.20-0.50% Cu, 0.40-0.75% Cr, 0.25-0.60% Ni, 0.03-0.08% Nb, 0.10-0.40% Mo, not more than 0.02 Ti, not more than 0.035% Als, not more than 0.003% B and Fe and impurity.

Owner:武钢集团有限公司

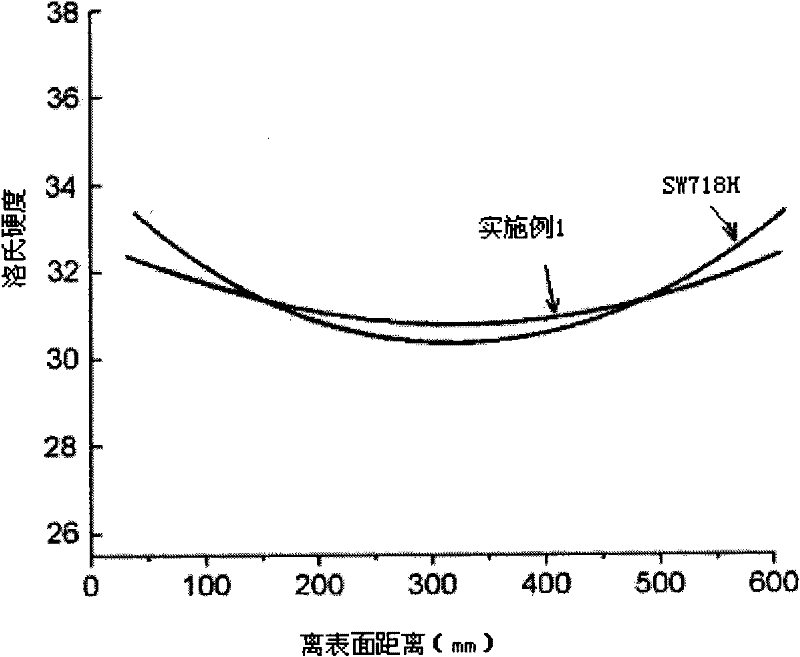

A kind of plastic mold steel and its manufacturing method

The invention discloses a plastic mold steel which comprises the following chemical components in percentage by weight: 0.25-0.29% of C, 1.30-1.50% of Mn, 0.40-0.60% of Si, 1.20-1.50% of Cr, 0.40-0.50% of Mo, 0.02-0.05% of Nb, less than or equal to 0.15% of Ni, less than or equal to 0.15% of Cu, less than or equal to 0.020% of P, less than or equal to 0.015% of S, less than or equal to 0.012% of N and the balance of iron and inevitable impurities. In the manufacture method of the plastic mold steel, a quenching and tempering heat treatment process is not used, and direct air cooling after forging is carried out, thus prehardened plastic mold steel with thickness above 600 mm and uniform hardness from core to surface is manufactured. According to the plastic mold steel disclosed by the invention, the limit that the existing non-quenched and tempered mold steel has thickness smaller than 400 mm is overcome, and the requirements of mold industries on low-cost high-quality large-sized prehardened plastic mold steel are reached.

Owner:宝武特种冶金有限公司

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041AImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium, 0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

1000 MPa low-carbon hot-galvanized dual-phase steel and preparation method thereof

ActiveCN105950998AGood mechanical propertiesGood formabilityHot-dipping/immersion processesMechanical propertyImpurity

The invention belongs to the technical field of steel for high-strength automobiles and particularly relates to 1000 MPa low-carbon hot-galvanized dual-phase steel and a preparation method thereof. The 1000 MPa low-carbon hot-galvanized dual-phase steel comprises, by weight, 0.05-0.10% of C, 0.20-0.60% of Si, 1.40-1.90% of Mn, 0.20-0.70% of Cr, 0.20-0.50% of Mo, 0.02-0.06% of Al, 0.020-0.050% of Ti, 0.010-0.040% of Nb, 0.0010-0.0030% of B, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.006% of N, and the balance Fe and inevitable impurities. The 1000 MPa low-carbon hot-galvanized dual-phase steel has the high forming property and high welding property and the excellent galvanizing property and mechanical property. The 1000 MPa low-carbon hot-galvanized dual-phase steel is 630-700 MPa in yield strength, 1010-1050 MPa in tensile strength and 11-14% in elongation.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Ultrahigh strength abrasion resistant steel and method of preparing the same

InactiveCN101250673AHigh yield strengthImprove impact toughnessTemperature control deviceFurnace typesChemical compositionWear resistant

The invention discloses a superhigh intensity wear-resistant steel and the manufacturing method, which belongs to the manufacturing field of low alloying steels, according to percentage by weight, the chemical components of the steel are that C 0.10-0.17%, Si 0.25-0.50%, Mn 1.20-1.50%, P<=0.018%, S<=0.008%, Cr 0.20-0.05%, Ni0.25-0.50%, Mo 0.10-0.40%, Als 0.02-0.06%, B<=0.005%, RE<=150g / t, and the allowance is Fe and unavoidable impurities, and the content of carbon is Ceq(%)<=0.60, Ceq(5)=C+Mn / 6+(Mo+Cr+V) / 5+(Ni+Cu) / 15. The specific method for producing the steel comprises the following steps: smelting ultra-pure steel, desulfurizing molten iron, compounding and converting the top and the bottom of a converter, doing vacuum treatment, feeding rare earth (RE) silk through a crystallizer, casting into bar plates, heating the bar plates, roughing, planishing, air cooling or feeding middle pressure, water cooling, quenching and tempering steel plates. V does not contain in the chemical components of the steel, inner stress of steel is low, steel welding property is improved, and steel has excellent abrasion resistance and ultra-high strength and toughness properties, which is beneficial for popularization and application.

Owner:武钢集团有限公司

Disk shearing blade and method for manufacturing the same

ActiveCN101177765AImprove wear resistanceHigh strengthShearing machinesFurnace typesHigh intensityWear resistance

A disc scissors blade and its manufacturing method, the composition weight percentage of the material of the disc scissors blade is: C: 0.40-0.70%, Si: 0.50-1.2%, Mn: 0.20-0.50%, Ni: 1.00-1.50% %, Cr: 4.00-6.00%, Mo: 0.50-2.00%, V: 0.30-1.50%, Nb: 0.10-0.80%, P≤0.02%, S≤0.02%. The method introduces an electroslag remelting process into a common manufacturing method of disc shears, and increases the temperature of quenching and tempering heat treatment and final heat treatment. The disc scissors have good wear resistance and deformation resistance, and are suitable for slitting or trimming hot-rolled high-strength thick steel plates. In addition, the disc shear blade of the present invention also has a good use effect on disc shears in other similar working conditions, and can also be applied to disc shears for stripping or edge trimming of cold-rolled strip steel, and also has a promotional effect on non-ferrous metal disc shears. value and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Aluminum alloy of excellent machinability and manufacturing method thereof

An aluminum alloy containing Si: 1.5-12% (mass % here and hereinafter), Mg: 0.5-6% and, optionally, at least one of Mn: 0.5-2%, Cu: 0.15-3% and Cr: 0.04-0.35% and, further, containing Ti: 0.01-0.1% and the balance of Al and inevitable impurities, in which the average grain size of crystallized grains of Si system compounds is from 2 to 20 mu m and an area ratio thereof is from 2 to 12%. The alloy is melted to obtain a cast ingot having DAS (Dendrite Arm Spacing) of 10 to 50 mu m, which is then put to a soaking treatment at 450 to 520 DEG C. and then to extrusion molding. The aluminum alloy has excellent machinability with no addition of low melting metals.

Owner:KOBE STEEL LTD

High-performance bridge weathering steel containing Mo and preparation method thereof

The invention belongs to the field of manufacture of low-alloy steel, in particular to high-performance bridge weathering steel containing Mo and a preparation method thereof. The invention provides bridge weathering steel containing Mo with the high performance, which comprises the following chemical components by mass percent: 0.02-0.05 percent of C, 0.20-0.30 percent of Si, 1.0-1.50 percent of Mn, at most 0.02 percent of P, at most 0.010 percent of S, 0.20-0.40 percent of Cu, 0.40-0.60 percent of Cr, 0.20-0.40 percent of Ni, 0.1-0.30 percent of Mo, 0.04-0.07 percent of Nb, 0.005-0.015 percent of Ti, at most 0.02 percent of Al and the balance of Fe and inevitable impurities. The high-performance bridge weathering steel containing Mo adopts two stages of rolling. The rough rolling and bloom rolling temperature of the first stage is 1050-1070 DEG C, the precision rolling and bloom rolling temperature of the second stage is 900-950 DEG C, and the finish rolling temperature is 800-850 DEG C. The high-performance bridge weathering steel containing Mo disclosed by the invention has good mechanical property, welding performance and atmospheric-corrosion resistance performance. The high-performance bridge weathering steel containing Mo adopts an Ultra-low carbon design, and the production cost is low.

Owner:NORTHEASTERN UNIV LIAONING +1

High strength boron-containing cold heading steel for fastener and preparation process thereof

The invention relates to high strength boron-containing cold heading steel for a fastener and a production method thereof. The cold heading steel comprises the following components in percentage by weight: 0.15-0.35% of C, less than 0.10% of Si, 0.50-1.20% of Mn, 0.08-0.50% of Cr, less than 0.035% of P, less than 0.035% of S, 0.005-0.080% of Al, 0.005-0.100% of Ti, 0.0005-0.0050% of B, and the balance of iron and impurities. The preparation process comprises the following steps of: firstly, preparing a continuous casting according to the compositions of the boron-bearing cold heading steel; secondly, sequentially heating, roughly rolling, intermediately rolling, finely rolling, and cooling the continuous casting; and finally, packaging the continuous casting in whole rolls and cooling naturally to form the finished product. The high strength boron-bearing cold heading steel for the fastener has low steel grade strength and hardness, good plasticity and excellent quenching degree, can simplify the fastener manufacture process, save the energy source and reduce the pollution. The strength of the produced large fastener is above the level 8.8. In addition, the preparation process of the high strength boron-bearing cold heading steel for the fastener has simple preparation process, easy implementation and low cost.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Alloy cast steel for high speed train brake disc, heat treatment method thereof and high speed train brake disc manufactured by the alloy cast steel

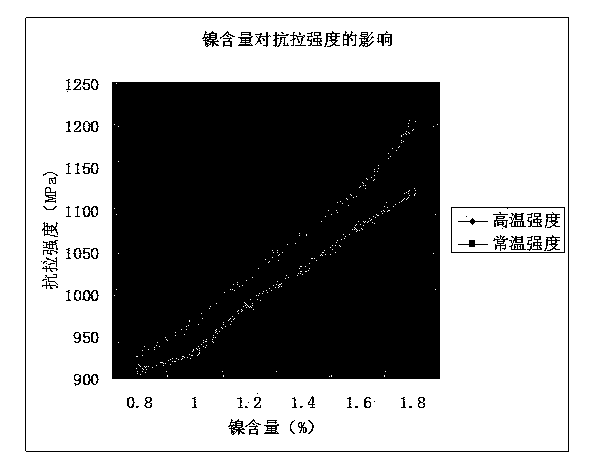

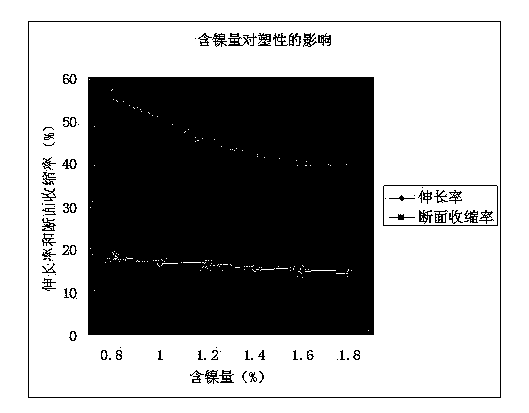

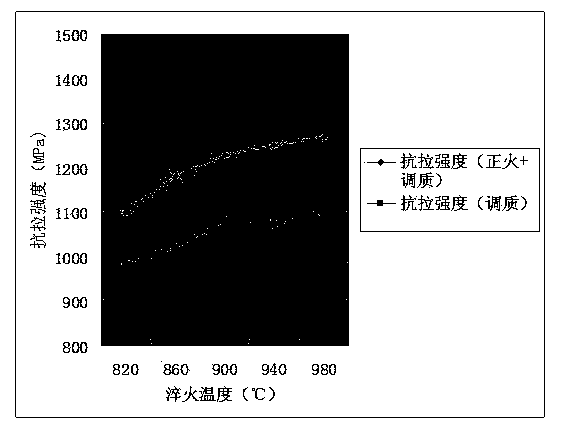

The invention discloses an alloy cast steel for a high speed train brake disc, a heat treatment method thereof and a high speed train brake disc manufactured by the alloy cast steel. The alloy cast steel is composed of the following components in percentage by weight: 0.18-0.26% of carbon, 0.16-0.50% of silicon, 0.55-1.40% of manganese, not larger than 0.03% of phosphorus, not larger than 0.03% of sulfur, 0.90-2.00% of chromium, 0.71-1.80% of nickel, 0.65-1.20% of molybdenum, 0.20-0.35% of vanadium, not larger than 0.30% of other components, smaller than 0.1% of tungsten and the balance of ferrum; and the heat treatment method comprises two steps of normalizing and tempering. The alloy cast steel disclosed by the invention has the beneficial effects that such alloy elements as manganese, nickel, chromium, molybdenum, vanadium, and the like, and such main components in the cast steel material as carbon, silicon and the like are reasonably mixed and are effectively thermally treated to refine the crystalline grain and improve the hardenability and heat resistant properties of the alloy cast steel material, and the normal temperature strength and the high temperature strength are greatly improved, so that the alloy cast steel material has excellent comprehensive mechanical properties. A brake disc manufactured by the alloy cast steel can meet the application requirements of high speed trains.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

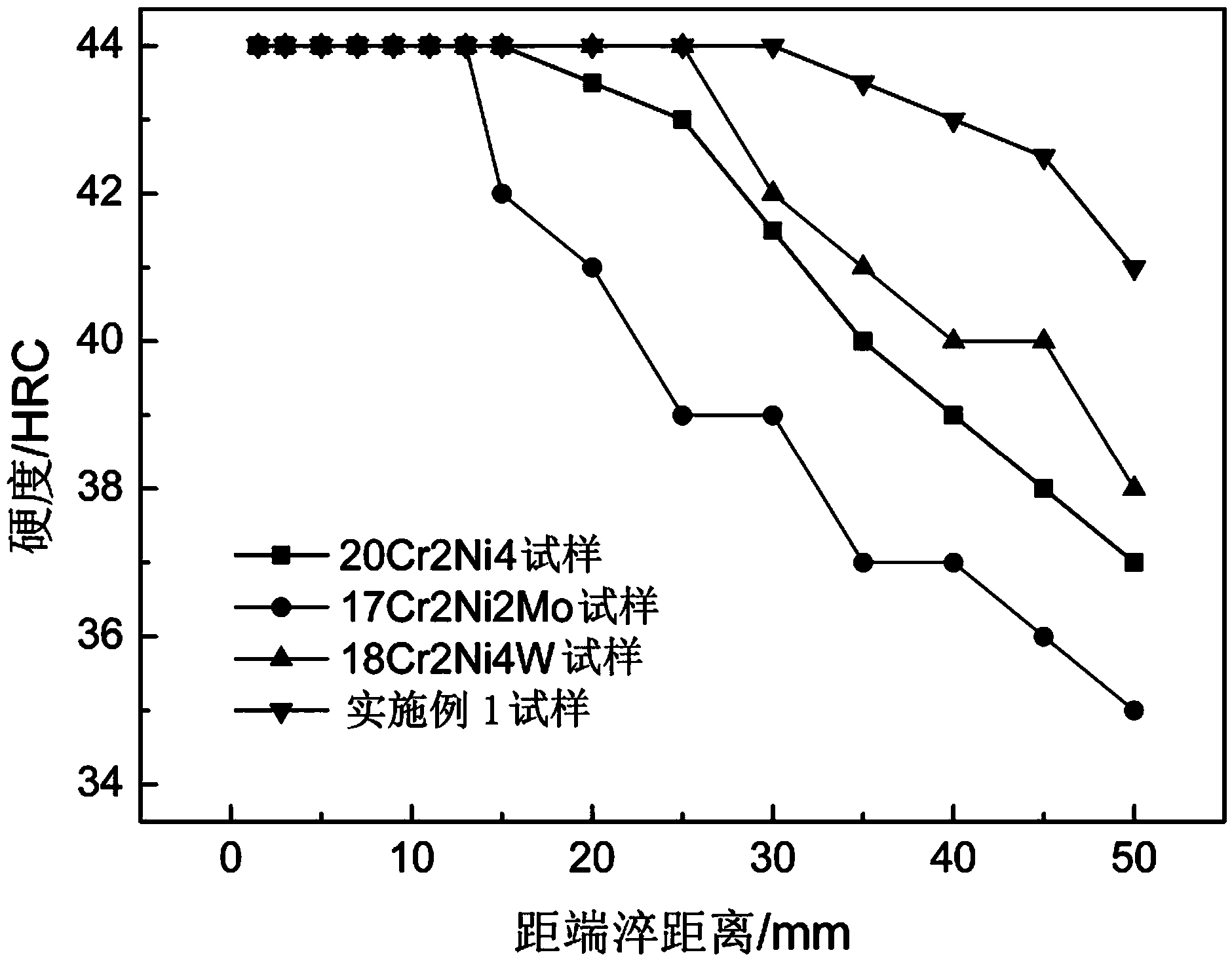

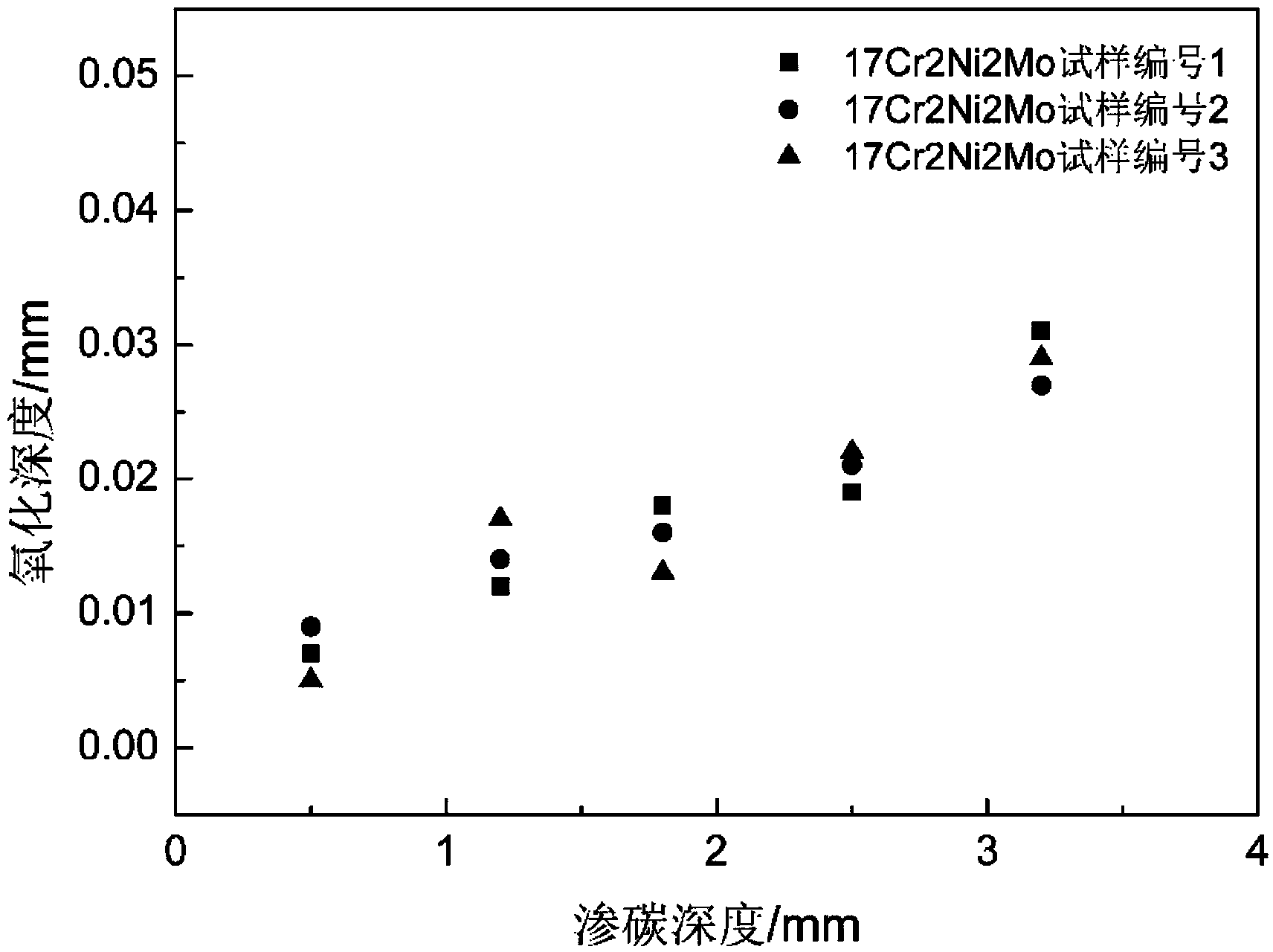

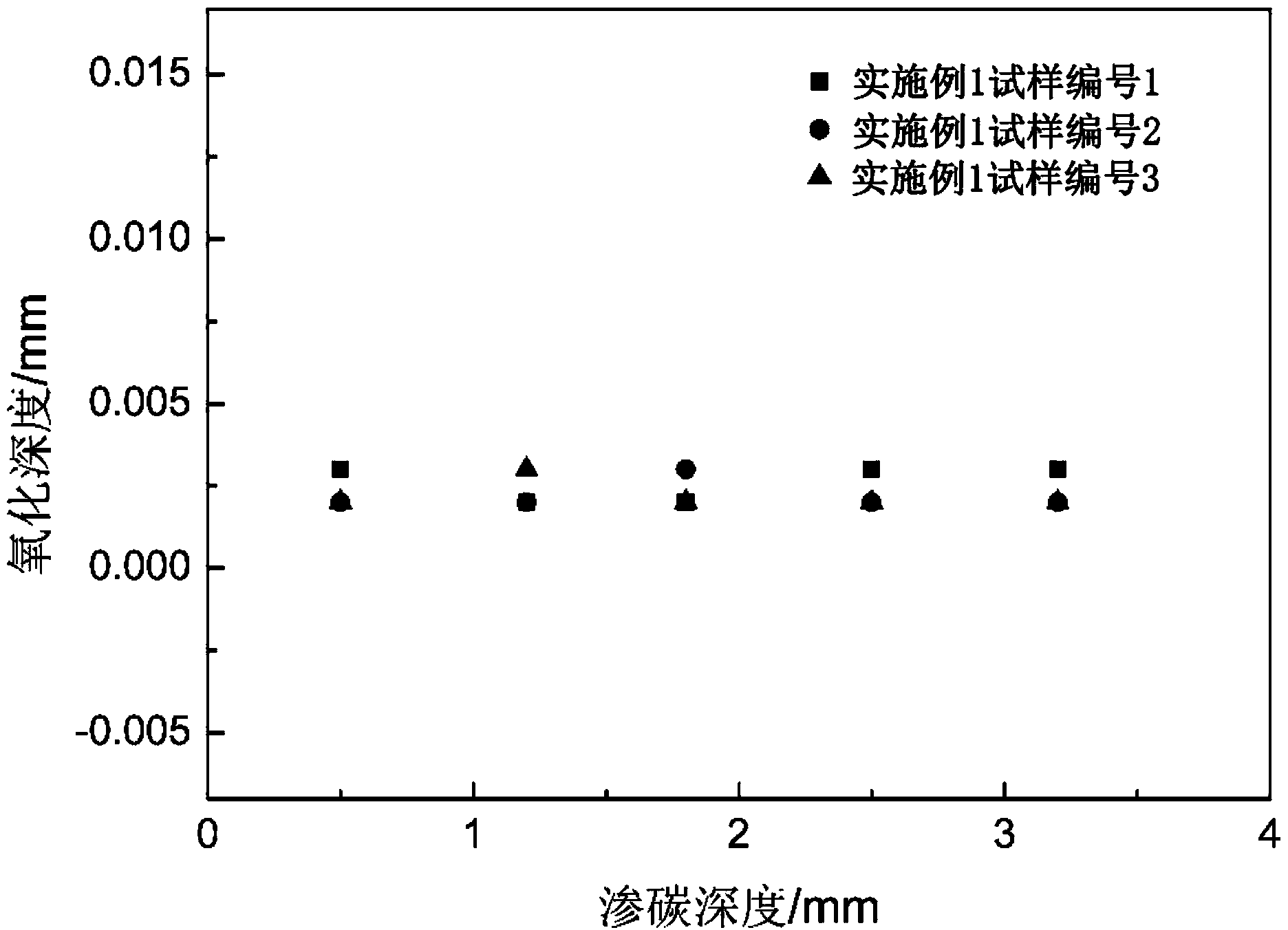

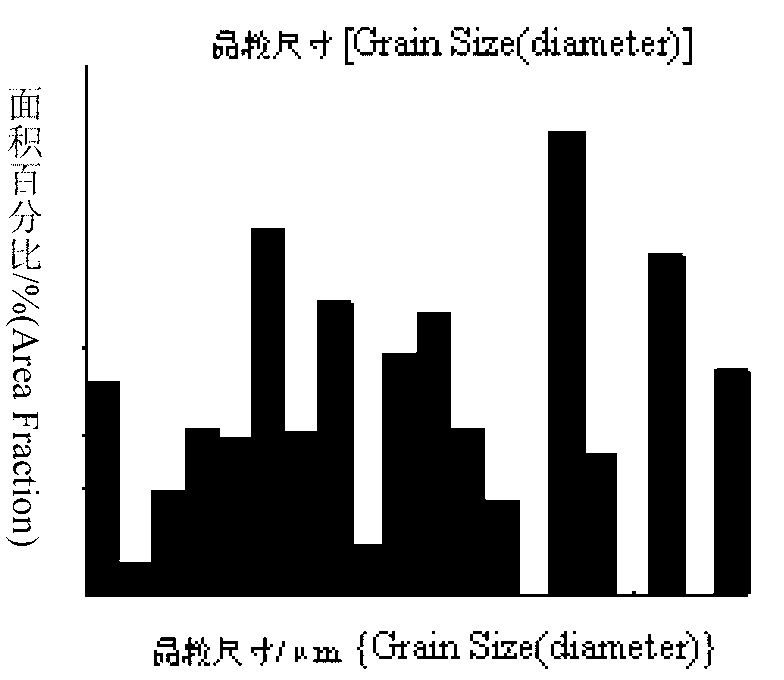

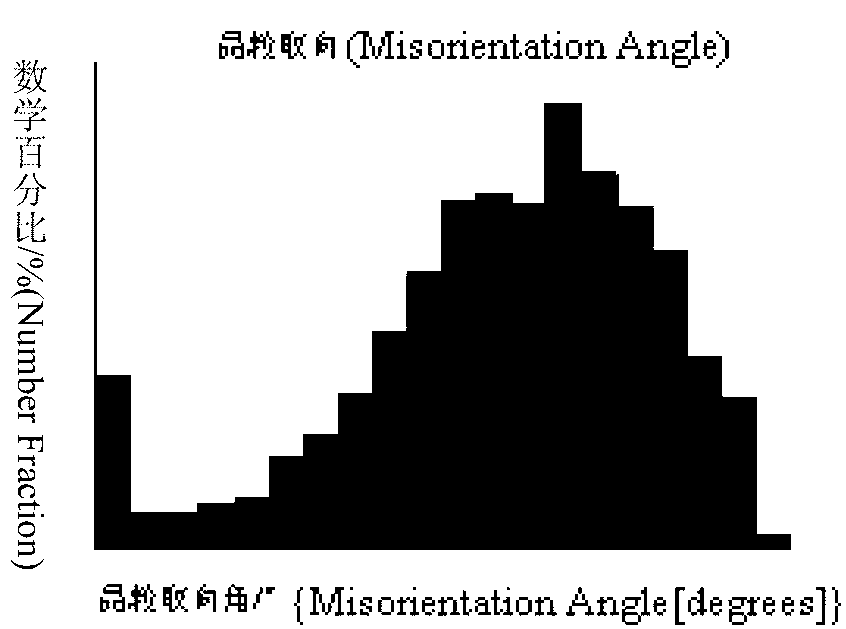

Carburizing alloy steel, and preparation method and application thereof

The invention relates to carburizing alloy steel, and a preparation method thereof. The alloy of the carburizing alloy steel comprises, by mass, 0.15%-0.25% of C, less than or equal to 0.30% of Si, 0.30%-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-1.50% of Cr, 2.80%-3.80% of Ni, 0.30%-1.00% of Mo, 0.01%-0.08% of Al, at least one selected from 0.05%-0.15% of V and 0.025-0.10% of Nb, and the balance being Fe and inevitable impurities. A mass percentage of V, Nb and Al meets an equation of V+Nb+Al <= 0.30%. The carburizing alloy steel provided by the invention has good anti-fatigue performance, excellent comprehensive properties, good hardenability, high yield ratio, extremely small internal oxidation and the characteristic of resisting grain growth at a high temperature, and is suitable for manufacturing heavy-duty gears.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

High crack-arresting toughness steel plate with yield strength of 500MPa and production method thereof

ActiveCN102994874APromote productionIncrease the lengthHeat treatment process controlReduction rateChemical composition

The invention provides a high crack-arresting toughness steel plate with yield strength of 500MPa and a production method thereof. The chemical components of steel comprises the following components in percentage by weight: 0.04-0.08% of C, 0.10-0.5% of Si, 0.8-1.6% of Mn, not more than 0.02% of P, not more than 0.01% of S, 0.03-0.065% of Al, not more than 0.005% of N, 0.005-0.05% of Nb, 0.005-0.03% of Ti, 0.0005-0.003% of B, not more than 0.004% of Ca, and the balance of Fe and avoidless impurities. The preparation method comprises the steps of roughing in an austenite re-crystalline region in a first stage, wherein the rolling temperature is 1000-1130 DEG C, the total reduction rate in the re-crystalline region is greater than or equal to 50%; cooling a rolled steel plate quickly to 580-530 DEG C at a rate of 10 DEG C / s; rolling in a non-re-crystalline region in a second stage when the temperature of the surface of the steel plate is 720-770 DEG C, wherein the accumulated deformation is greater than or equal to 50%, the finish rolling temperature is 700-740 DEG C; and water-cooling after rolling, wherein the cooling rate is 5-15 DEG C / s, and the final cooling temperature is 460-560 DEG C. The high crack-arresting toughness steel plate provided by the invention has the characteristics of high strength, high toughness, inhibition of crack formation and expansion and the like, and meets the performance requirements of special part members of large container ships.

Owner:ANGANG STEEL CO LTD

High-strength-and-toughness low alloy wear resistant steel and manufacturing method thereof

The invention relates to high-strength-and-toughness low alloy wear resistant steel and a manufacturing method thereof, belonging to the technical filed of metallurgy. The high-strength-and-toughness low alloy wear resistant steel comprises the following components by weight percent: 0.15-0.20% of C, 0.1-0.5% of Si, 1.2-1.6% of Mn, less than or equal to 0.015% of P, less than or equal of 0.005% S, 0.02-0.04% of Al, 0.016-0.022% of Ti, 0.16-0.20% of Cr, 0.16-0.22% of Mo, 0.001-0.0015% of B and the balance of Fe, and simultaneously the carbon equivalent Ceq (%) is less than or equal to 0.55. The manufacturing method comprises the following steps: smelting molten steel and pouring into a slab, and carrying out rough rolling after heating and heat insulation; and then carrying out complete quenching treatment, or sub-temperature quenching treatment, or carrying out the complete quenching treatment and then carrying out the sub-temperature quenching treatment, and adopting low temperature tempering to eliminate stress after the quenching. The method of the invention ensures higher hardness, simultaneously can obviously improve the impact toughness of steel plates, increase the impact resistance of the steel plates, and prolong the service life of mechanical equipment, and can obtain wear resistant steel plates with different strength and toughness grades by using the steel with same components and different quenching processing methods.

Owner:NORTHEASTERN UNIV +1

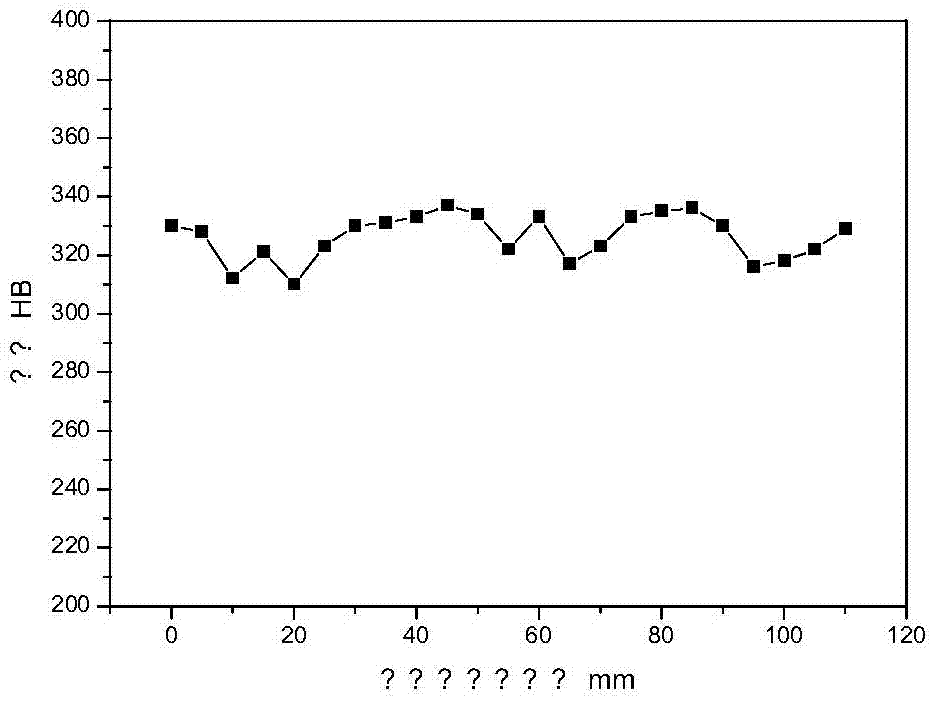

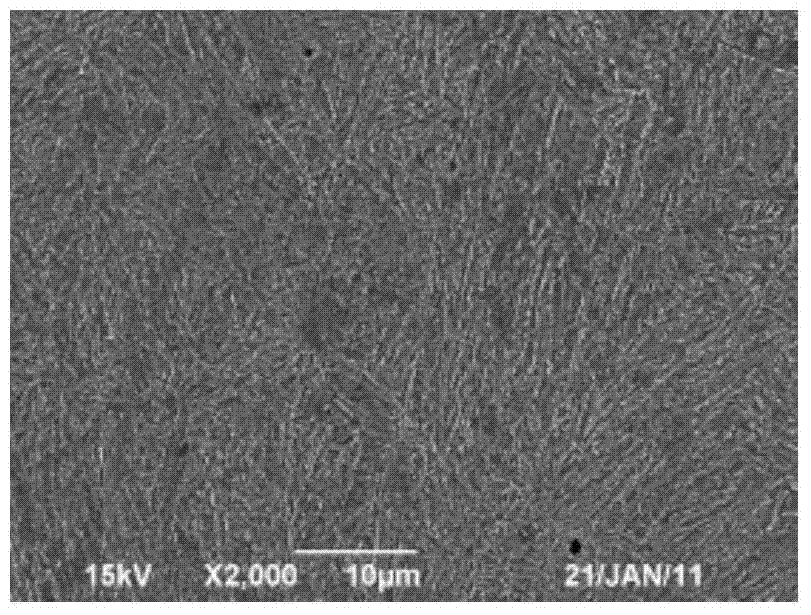

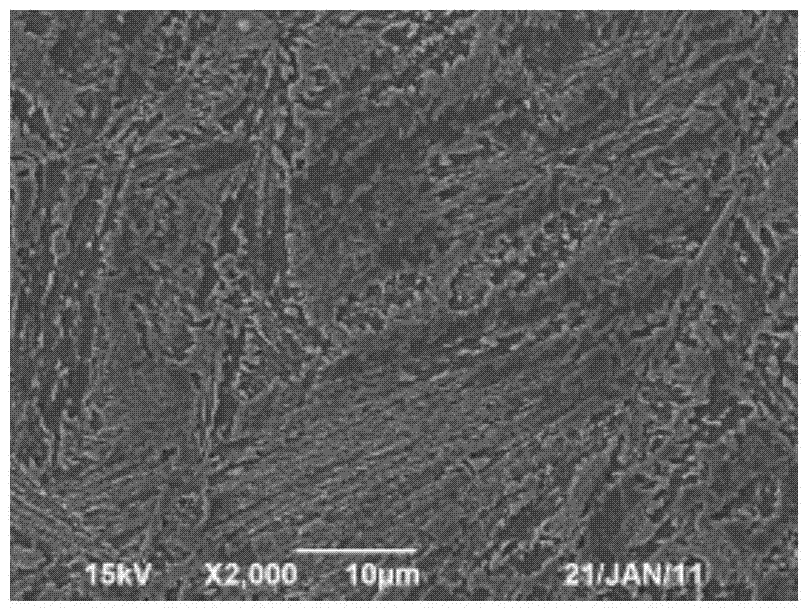

Economical non-quenched and non-tempered micro-alloyed plastic die steel plate and making method thereof

The invention discloses an economical non-quenched and non-tempered micro-alloyed plastic die steel plate and a making method thereof. The economical non-quenched and non-tempered micro-alloyed plastic die steel plate comprises 0.32-0.40wt% of C, 0.20-0.50wt% of Si, 1.00-1.50wt% of Mn, 1.20-1.70wt% of Cr, 0.20wt% or less of Mo, 0.0025wt% or less of B, 0.03wt% or less of Ti, 0.03wt% or less of Nb, and the balance Fe. The making method comprises the following steps: carrying out converter smelting, LF+RH refining and continuous slab casting; heating the obtained slab at 1200-1230DEG C, carrying out precision rolling at 900-950DEG C, and carrying out finishing rolling at 870-920DEG C; carrying out controlled cooling after the steel plate rolling; and tempering the steel plate obtained after the controlled rolling and controlled cooling at 550-600DEG C to obtain the finished pre-hardened plastic die steel plate having a bainite structure. The yield strength, the normal temperature impact toughness and the cross section hardness of the steel plate are above 800MPa, above 20J and 310-350HB respectively. The making method is suitable for the production of pre-hardened plastic die steel plates with the specification of below 120mm from 320mm continuous casting blanks.

Owner:NANJING IRON & STEEL CO LTD +1

Cast steel for bearing parts in mechanical lifting system and its making process

The present invention relates to one kind of cast steel for bearing parts in mechanical lifting system and its making process. The cast steel of Cr-Ni-Mo line consists of C 0.15-0.30 wt%, Mn 0.60-1.10 wt%, Si 0.3-0.8 wt%, Ni 0.4-1.1 wt%, Cr 0.4-1.1 wt%, Mo 0.15-0.40 wt%, S less than 0.025 wt%, P less than 0.025 wt%, and residual elements including Cu, W and V less than 0.60 wt%. The making process of the cast steel includes the following technological steps: making steel in MF furnace or electric arc furnace; casting in sand mold with equivalent circular kiel test rod; normalizing, quenching and tempering of both cast part and test rod in the same furnace; and non-destructive detection of the cast part.

Owner:河南石油勘探局南阳石油机械厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com