Method for producing wear-resisting steel plate

A production method and technology for wear-resistant steel plates, which are applied in the field of iron and steel smelting, can solve the problems of reducing the impact toughness of materials, low plasticity and toughness of steel plates, and easy cracking of cast slabs. The effect of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The production method of NM360 wear-resistant steel plate.

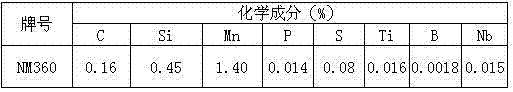

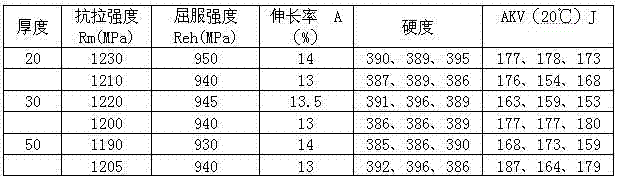

[0022] The composition mass percentage of steel is shown in Table 1.

[0023] Table 1 Performance of chemical composition control of NM360 wear-resistant steel plate

[0024]

[0025] The key production process and main parameters are:

[0026] Rolling:

[0027] Heating system: after the 300mm slab is rolled off the assembly line, the furnace is hot-loaded; the heating temperature is 1180-1220°C, and the time in the furnace is 300min. Rolling process: The stage rolling temperature is 1050°C and the final rolling temperature is 953°C. Rough rolling guarantees that the reduction rate of the last three consecutive passes is greater than 15%. The thickness control of the intermediate slab is controlled according to 3.5h after the slab is widened. The initial rolling temperature of the stage is 912°C, the final rolling temperature is controlled at 820°C, and the cumulative reduction rate ...

Embodiment 2

[0033] Embodiment 2: The production method of NM400 wear-resistant steel plate.

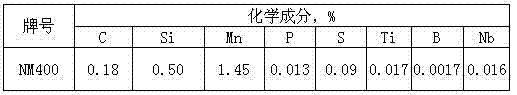

[0034] The composition mass percentage of steel is shown in Table 3.

[0035] Table 3 Performance of chemical composition control of NM400 wear-resistant steel plate

[0036]

[0037] The key process steps and main parameters are:

[0038] Rolling:

[0039] Heating system: after the 300mm slab is rolled off the assembly line, the furnace is hot-loaded; the heating temperature is 1180-1220°C, and the time in the furnace is 300min.

[0040] Rolling process: The stage rolling temperature is 1060°C and the final rolling temperature is 960°C. Rough rolling guarantees that the reduction rate of the last three consecutive passes is greater than 15%. The thickness control of the intermediate slab is controlled according to 3.5h after the slab is widened. The initial rolling temperature of the stage is 900°C, the final rolling temperature is controlled at 810°C, and the cumulative reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com