Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Good strength and toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

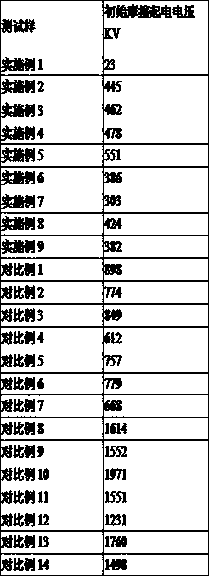

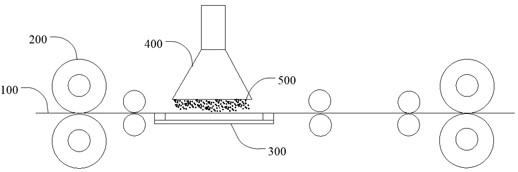

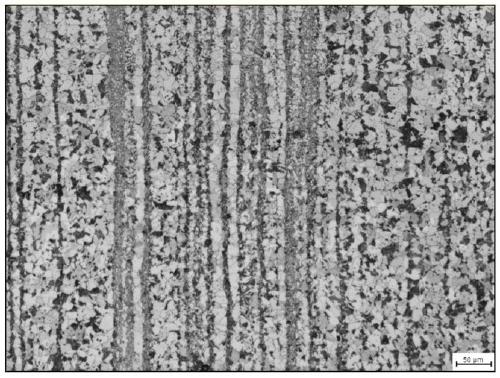

Inhomogeneous hard alloy and preparation method thereof

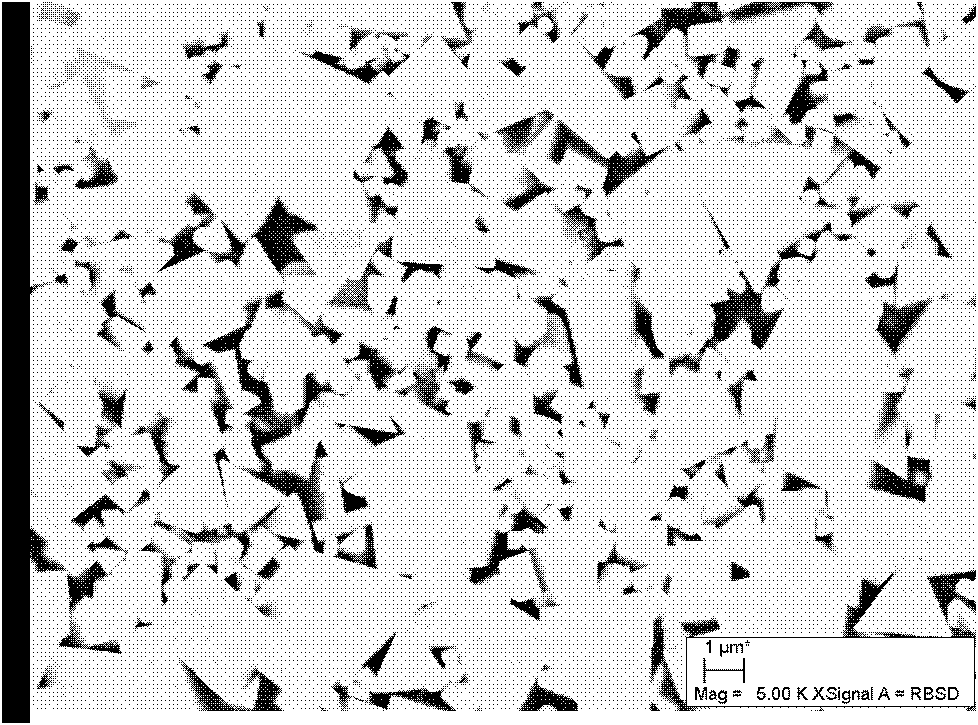

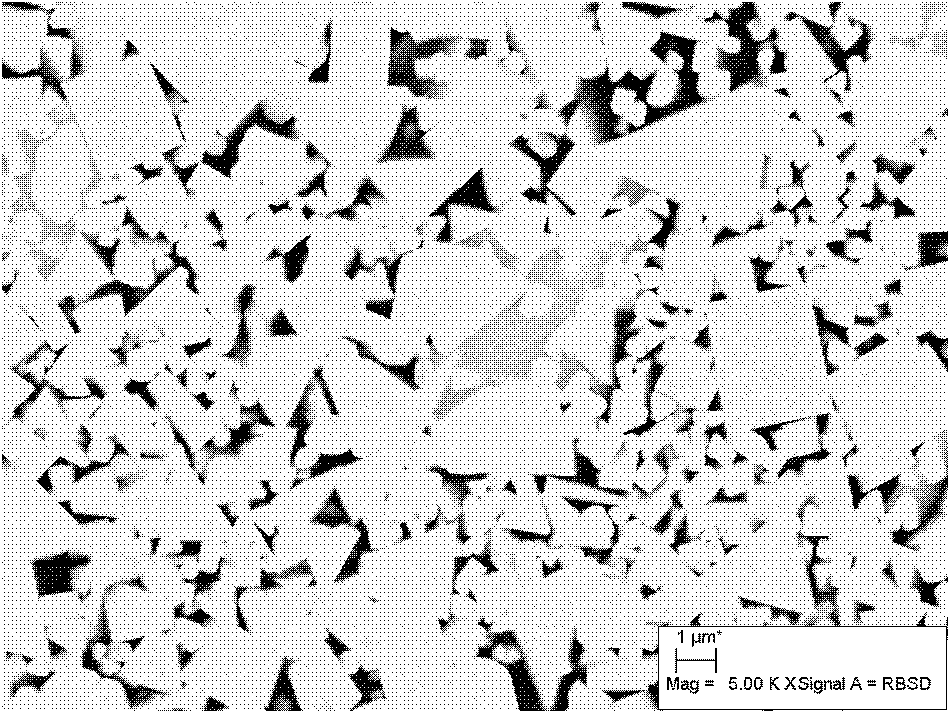

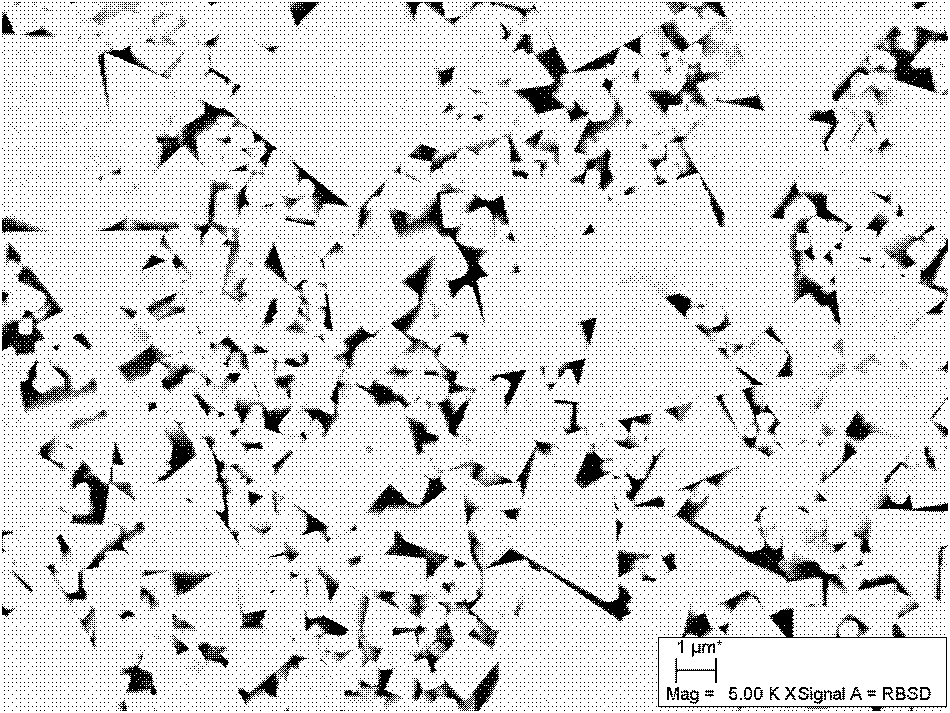

ActiveCN101845579AThe bulk porosity is obviousGood strength and toughnessCemented carbideCrystallite

The invention relates to tungsten carbide based hard alloy and a preparation method thereof and particularly discloses inhomogeneous hard alloy. The grain distribution of the tungsten carbide used as a main component in the inhomogeneous hard alloy has a double-peak structure, wherein one peak is between 0.3mu m and 0.9mu m, and the other peal is between 1.2mu m and 3.5mu n. The preparation method comprises the following steps of: selecting cobalt powder, carbides and tungsten carbide powder in a certain proportion as raw materials, wherein the tungsten carbide powder has two different granularities of being 2-12mu m and smaller than 1mu m, the mass ratio of the coarse tungsten carbide powder to the fine tungsten carbide powder is (0.5-2.0):1, and the carbides are one or more of cubic carbides and orthogonal carbides; then uniformly mixing the prepared raw materials; carrying out ball milling, drying, granulating and pressing; and finally, carrying out vacuum high-temperature sintering to obtain the inhomogeneous hard alloy. The inhomogeneous hard alloy has higher hardness, toughness and strength, simple preparation process and low cost.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

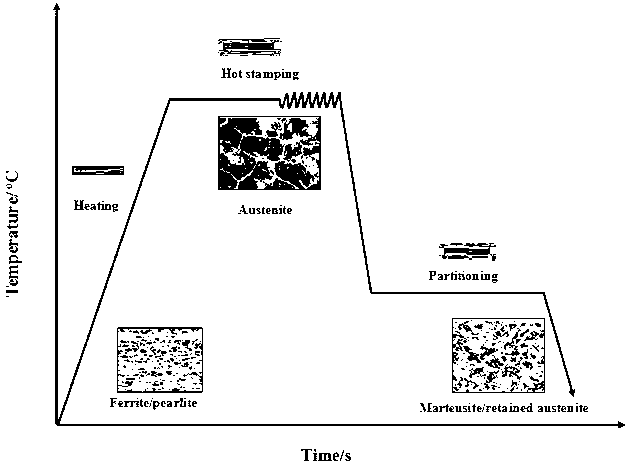

Vehicle high strength and toughness hot-forming steel plate and preparation method thereof

The invention belongs to the technical field of high strength vehicle steels, and provides a vehicle high strength and toughness hot-forming steel plate. In the prior art, a hot forming steel plate has high strength and insufficient toughness after forming. A purpose of the present invention is to overcome the disadvantage in the prior art. Main components of the vehicle high strength and toughness hot-forming steel plate comprise: 0.1-0.5 wt% of C, 0.5-1.5 wt% of Si, 1.2-2.4 wt% of Mn, 0.01-0.05 wt% of Ti, 0.001-0.005 wt% of B, les than or equal to 0.01 wt% of S, less than or equal to 0.01 wt% of P, and the balance of Fe. The preparation method comprises: heating the steel plate steel comprising the components at a speed of 20-100 DEG C / s to achieve an austenization temperature, carrying out constant temperature maintaining for a certain time, and carrying out hot rolling so as to refine austenite grains; quenching at a speed of 50-120 DEG C / s to achieve a temperature of 50-370 DEG C to obtain partial supersaturated martensite and residual austenite with no martensite phase change; carrying out an isothermal treatment for 5-600 s at a tempering temperature of 200-500 DEG C, such that carbon is stably distributed from the martensite to the residual austenite so as to stabilize the austenite; and quenching to a room temperature to obtain a complex phase structure of the refined martensite and the residual austenite. The preparation method has characteristics of simple preparation process, easy operation and low cost, and is suitable for industrial promotion, wherein the prepared high strength and toughness complex phase steel has superior performances.

Owner:ZHONGBEI UNIV

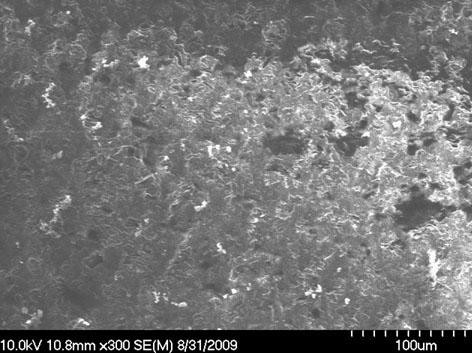

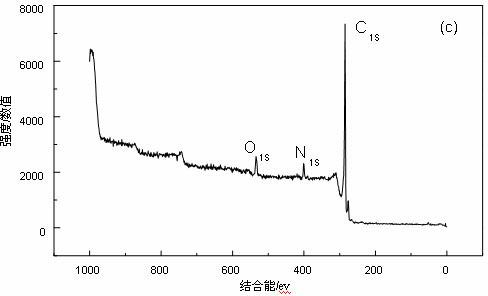

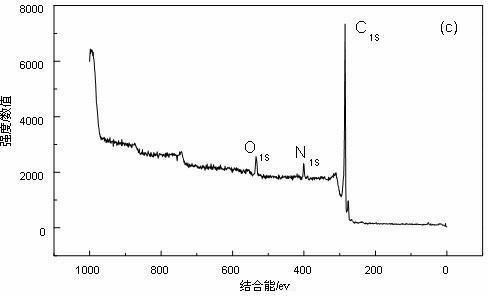

Preparation method of glass fiber/carbon nanotube/epoxy resin multi-dimensional hybrid composite material

InactiveCN102276795AIncreased interlaminar shear strengthImprove interface strengthResin matrixCarbon nanotube

The invention relates to a preparation method of a glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material. The preparation method provided by the invention comprises the following steps of: treating glass fiber with a silane coupling agent; carrying out surface carboxylation and chlorination on carbon nanotubes, then introducing diamine or polyamine to the carbon nanotubes, and modifying the carbon nanotubes connected with an amino group by a polybasic anhydride compound to prepare the carbon nanotubes carrying an anhydride group; dispersing the treated carbon nanotubes in an epoxy resin matrix by ultrasonic oscillation and high-speed stirring, and curing with an organic anhydride curing agent; and compounding the obtained carbon-nanotube-containing epoxy resin polymer used as a matrix with the coupling-agent-treated glass fiber to form a multi-dimensional hybrid composite material structure linked through covalent bonds. The preparation method provided by the invention has the advantages that: the composite material is convenient to prepare, the dispersion of the carbon nanotubes in epoxy resin is improved, and the strength and toughness of the carbon nanotubes are utilized to toughen epoxy resin and to improve the bonding strength with the base surface of the glass fiber, thereby enhancing the overall performance of the glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material and broadening the applications of the glass fiber, carbon nanotubes and epoxy resin.

Owner:TONGJI UNIV

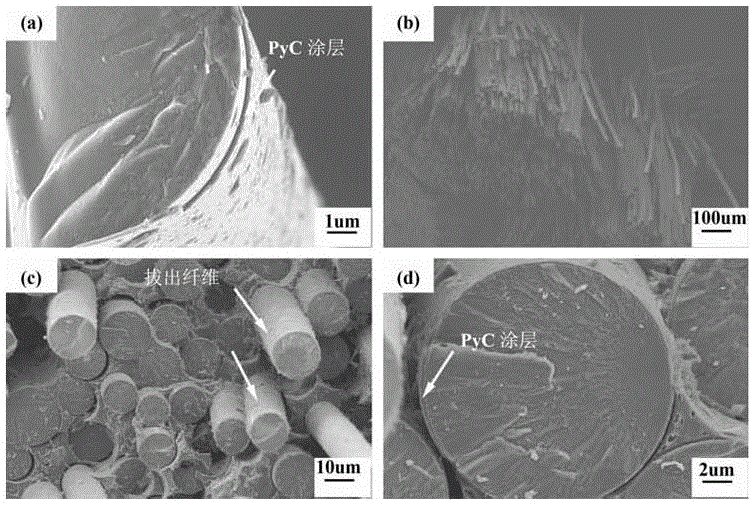

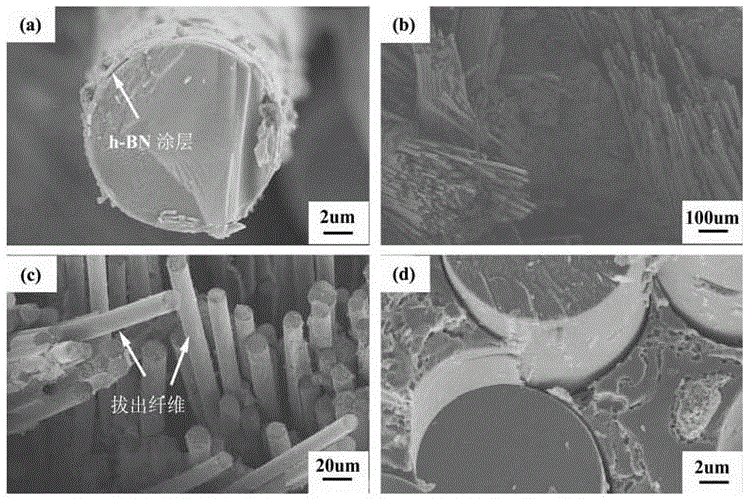

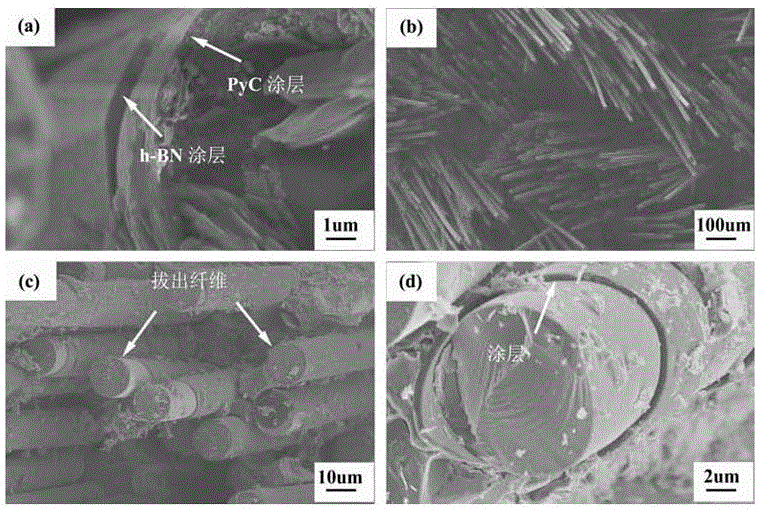

Interface modification method of SiCf/SiC composite material

ActiveCN105152671AImprove bending strengthImprove fracture toughnessSic fiberUltimate tensile strength

Owner:NAT UNIV OF DEFENSE TECH

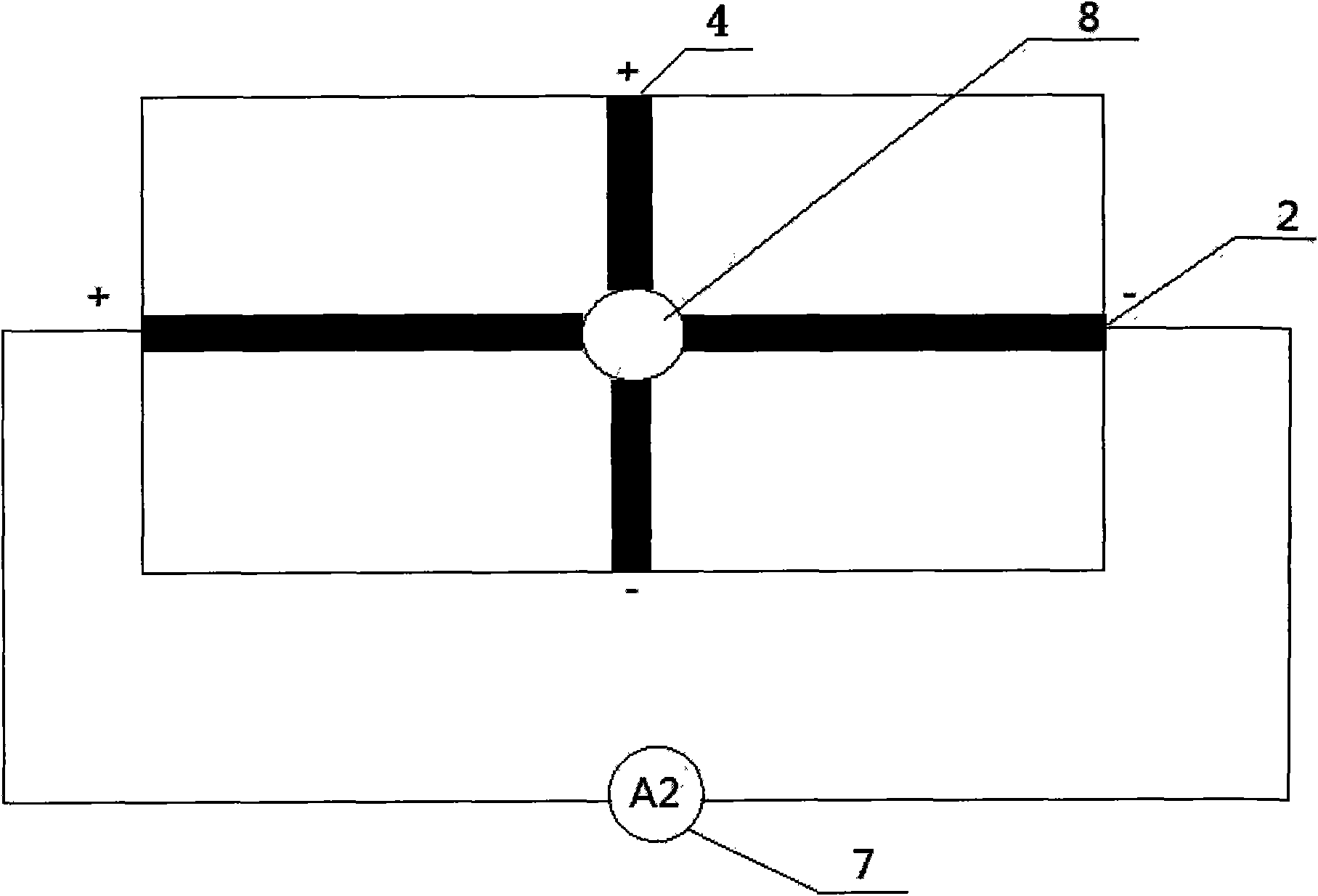

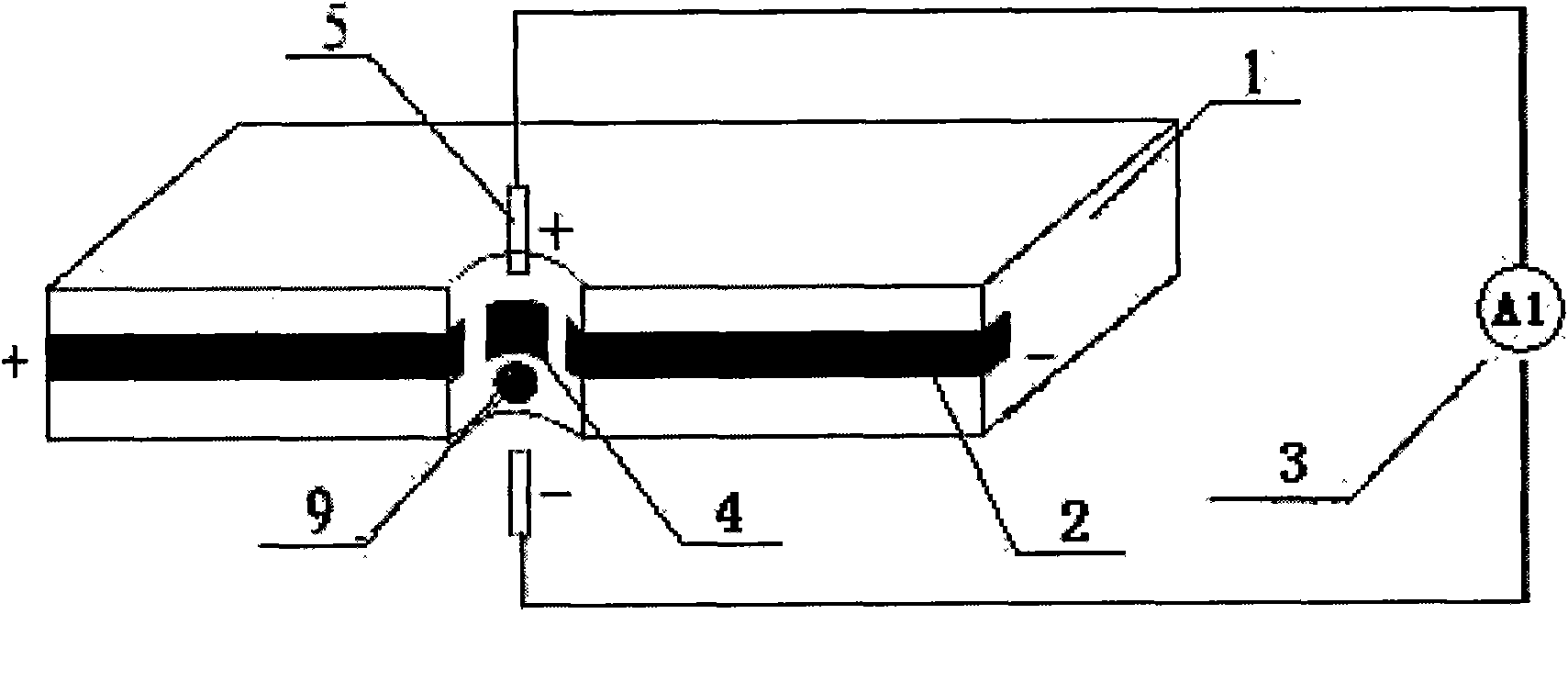

Graphene-based nano-pore monomolecular sensor and medium identification method thereof

InactiveCN102169105AGood strength and toughnessImprove structural stabilityMaterial electrochemical variablesIdentification rateNanopore

The invention discloses a graphene-based nano-pore monomolecular sensor and a medium identification method thereof. In the graphene-based nano-pore monomolecular sensor, conductive single-layer or multi-layer graphene is used as a radial electrode; the graphene electrode is clamped inside an insulation layer, so the structural strength is enhanced; a nano-pore channel is formed on the insulation layer; the cathode and the anode of the radial electrode are located at both ends of the nano-pore channel in the radial direction respectively; and an axial electrode is arranged along the axial direction of the nano-pore channel. During medium identification, both ends of the nano pore are connected with a fluid pool unit, and voltage is exerted between the axial electrode and the radial electrode respectively; and when a medium passes through the nano pore, the medium in the channel is identified by measuring weak change of axial and radial current. The sensor has a simple structure; meanwhile, by comprehensive analysis of the radial current and the axial current, higher sensitivity and identification rate can be obtained; moreover, due to analysis, the pore-passing medium can be detected and the pore-passing state is analyzed according to the tested medium; therefore, the property of the medium can be analyzed.

Owner:SOUTHEAST UNIV

Method for preparing low alloy high wear resistant cast steel plate

The present invention relates to a method for preparing a low alloy high wear resistant cast steel plate. The cast steel plate includes the following components: 0.25-0.35 wt% of C, 0.9-1.6 wt% of Si, 0.3-1.8 wt % of Mn, 0.7-1.0 wt% of Cr, 0.15-0.3 wt% of Mo, 0.05-0.35 wt% of Ti, 0.01-0.05 wt% of Nb, 0.05-0.25 wt% of V, 0.01-0.1 wt% of RE, no more than 0.03 wt% of P and S, and the balance Fe. The components are melted and molded, and then a processed ingot is placed therein for heating. When the temperature reaches 1050-1070 DEG C, the heat preservation lasts. After the completion of heat preservation, the ingot is placed into a 240-245 DEG C salt bath furnace for heat preservation. The ingot is finally cooled by the air. The casting and heat treatment process of the present invention is relatively simple, easily controlled, and low in cost, and the produced material has good strength and toughness.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

Low-alloy high-wear-resistance cast steel

InactiveCN103060705AGood strength and toughnessSimple ingredientsProcess efficiency improvementAlloyHigh wear resistance

The invention relates to a low-alloy high-wear-resistance cast steel which comprises the following components: 0.25-0.35wt.% of C, 0.9-1.6wt.% of Si, 0.3-1.8wt.% of Mn, 0.7-1.0wt.% of Cr, 0.15-0.3wt.% of Mo, 0.05-0.35wt.% of Ti, 0.01-0.05wt.% of Nb, 0.05-0.25wt.% of V, 0.01-0.1wt.% of RE, at most 0.03wt.% of P and S, and the balance of Fe and inevitable impurities. The invention has the advantages of simple preparation process and favorable toughness compatibility.

Owner:张芝莲

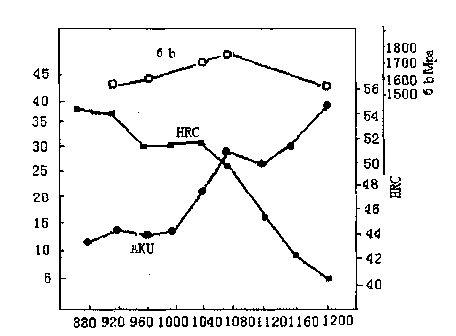

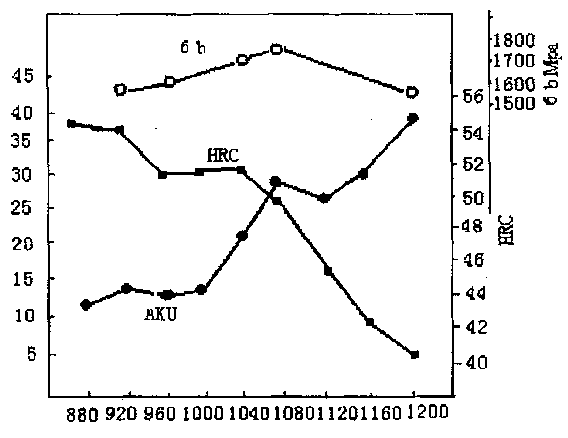

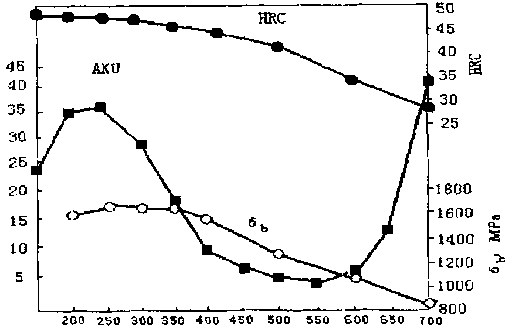

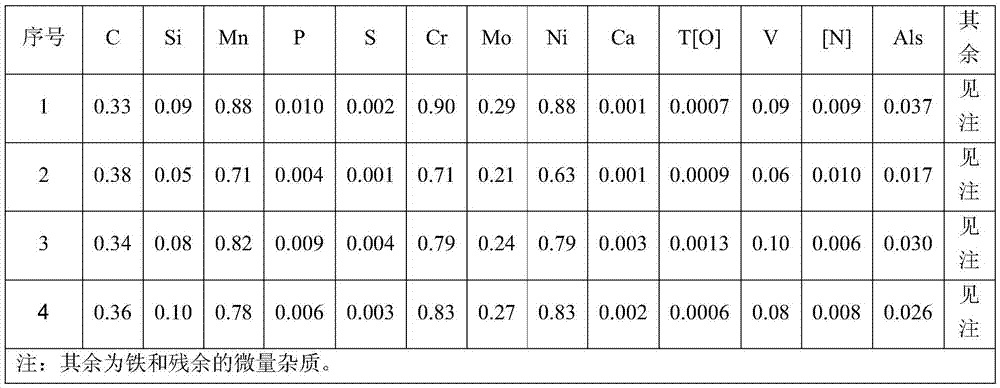

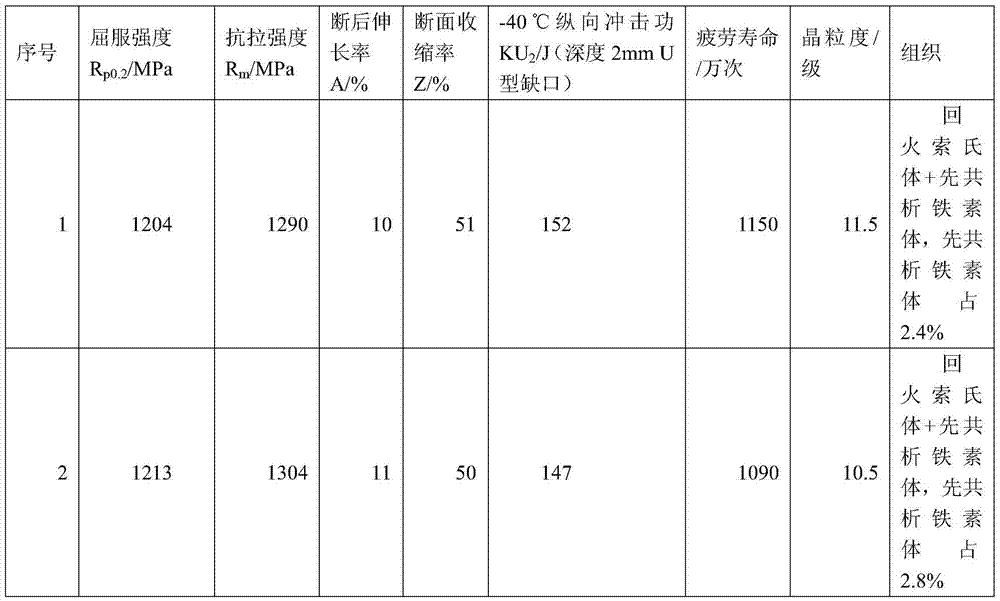

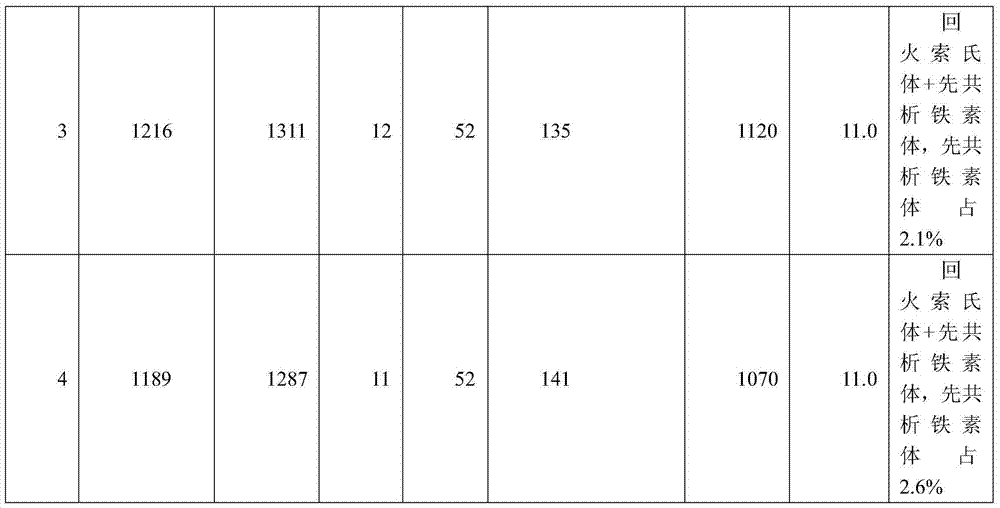

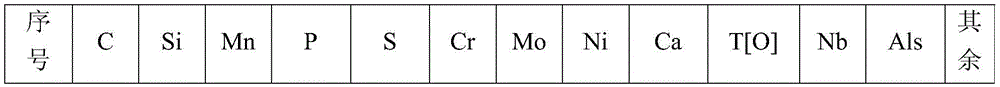

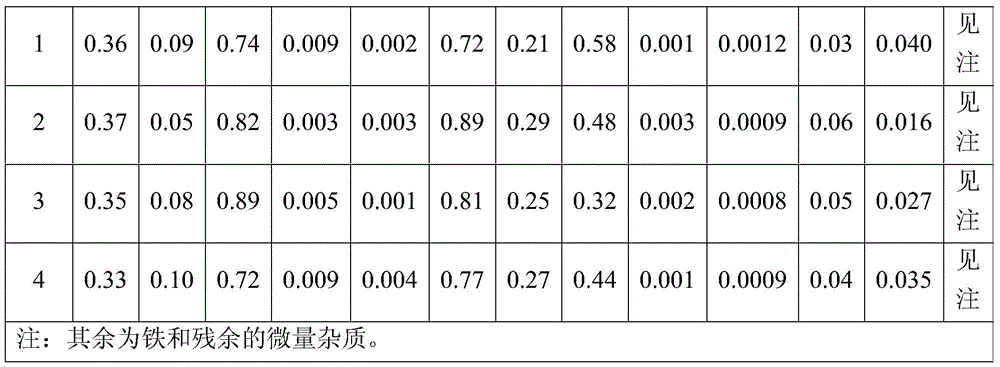

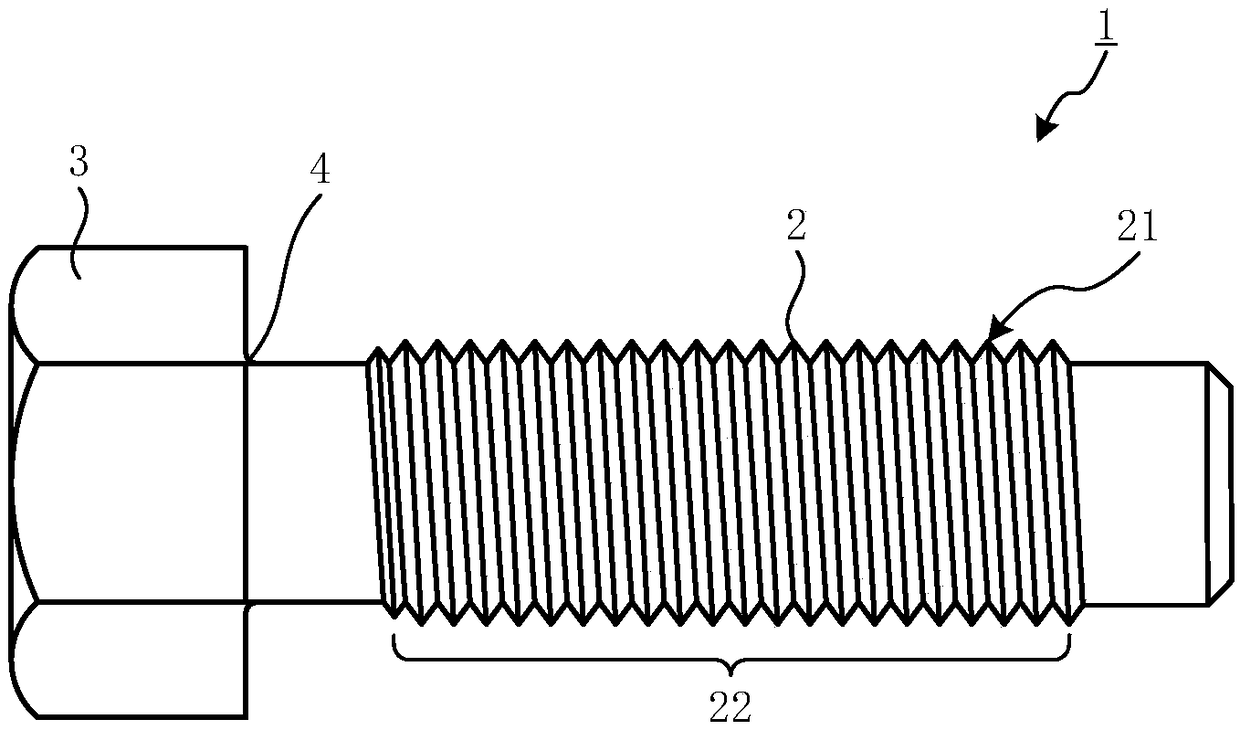

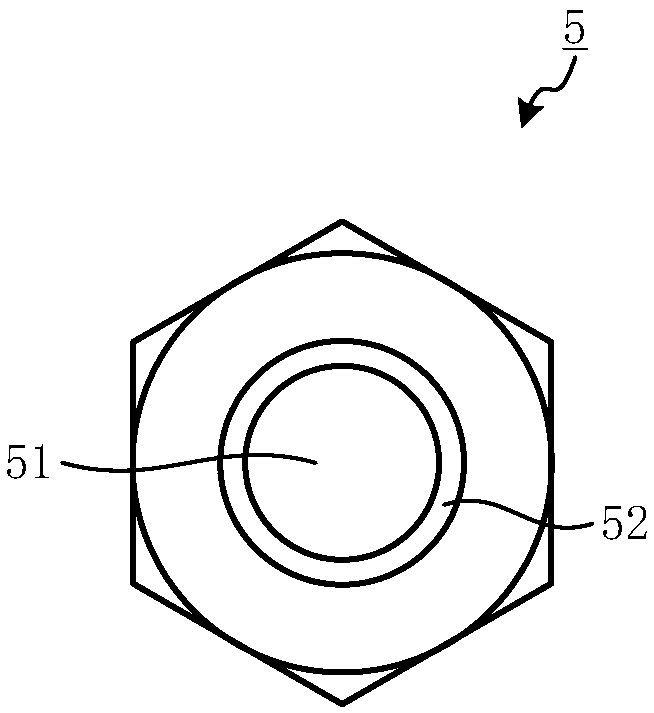

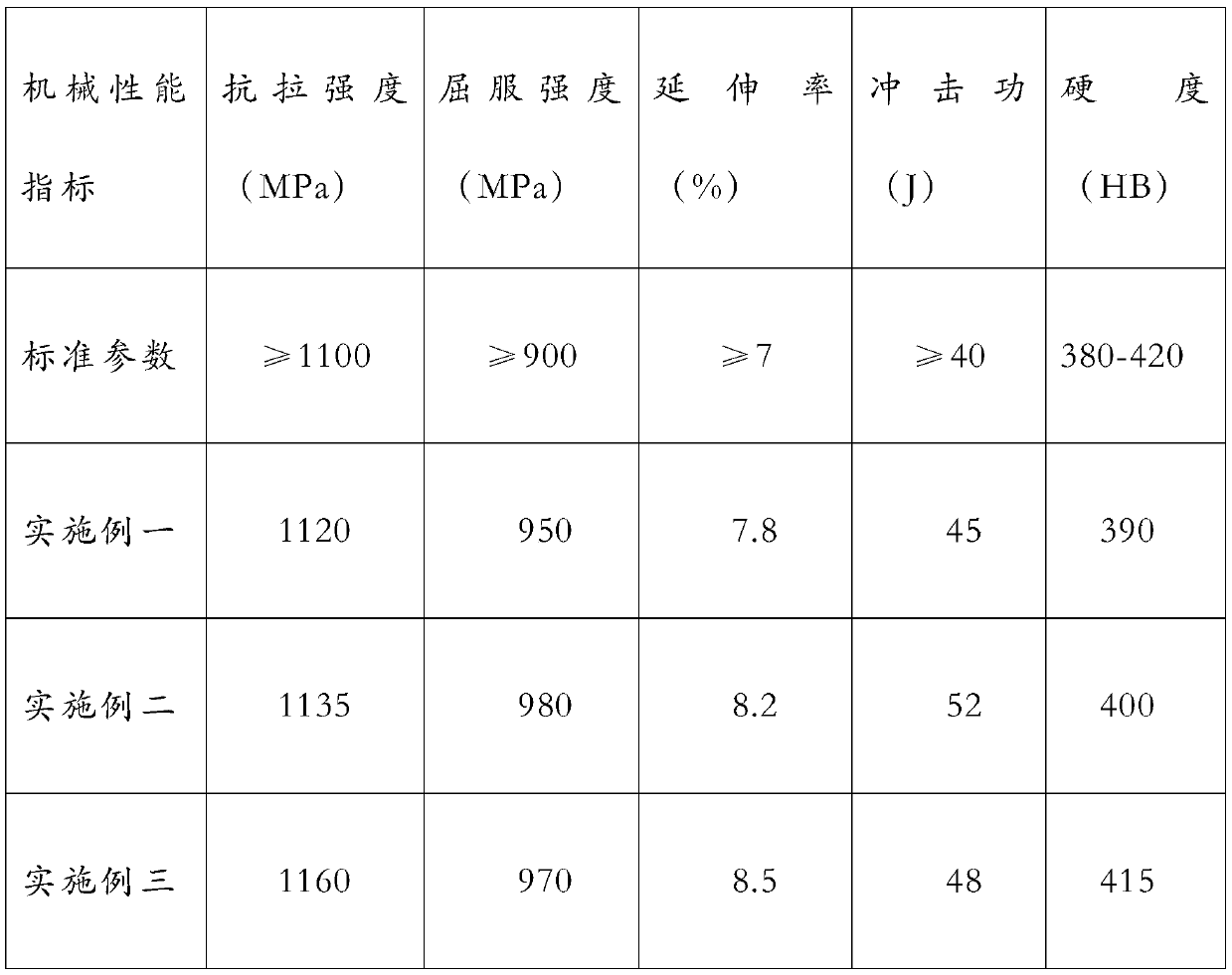

Vanadium-containing 12.9-grade steel for fastener applied to rail transit mobile equipment and thermal treatment process of vanadium-containing 12.9-grade steel

ActiveCN105441788AInhibition of fatigue crack growthImprove fatigue resistanceTemperature control deviceAustenite grainMicrometer

The invention provides a vanadium-containing 12.9-grade steel for a fastener applied to rail transit mobile equipment. The steel mainly comprises the following chemical elements in percentage by mass: 0.33% to 0.38% of C, 0.05% to 0.10% of Si, 0.70% to 0.90% of Mn, 0.70% to 0.90% of Cr, 0.60% to 0.90% of Ni, 0.20% to 0.30% of Mo, 0.015% to 0.045% of Als, 0.06% to 0.10% of V, 0.006% to 0.010% of [N], smaller than or equal to 0.010% of P, smaller than or equal to 0.005% of S and smaller than or equal to 0.0015% of T[O]. The thermally-treated steel is larger than 10.0 grades in austenitic grain size; the structure of the thermally-treated steel is a small amount of small proeutectoid ferrite dispersed on a tempered sorbite base body, wherein the amount of the proeutectoid ferrite is smaller than or equal to 3%, and the size of the proeutectoid ferrite is smaller than or equal to 5 micrometers.

Owner:MAANSHAN IRON & STEEL CO LTD

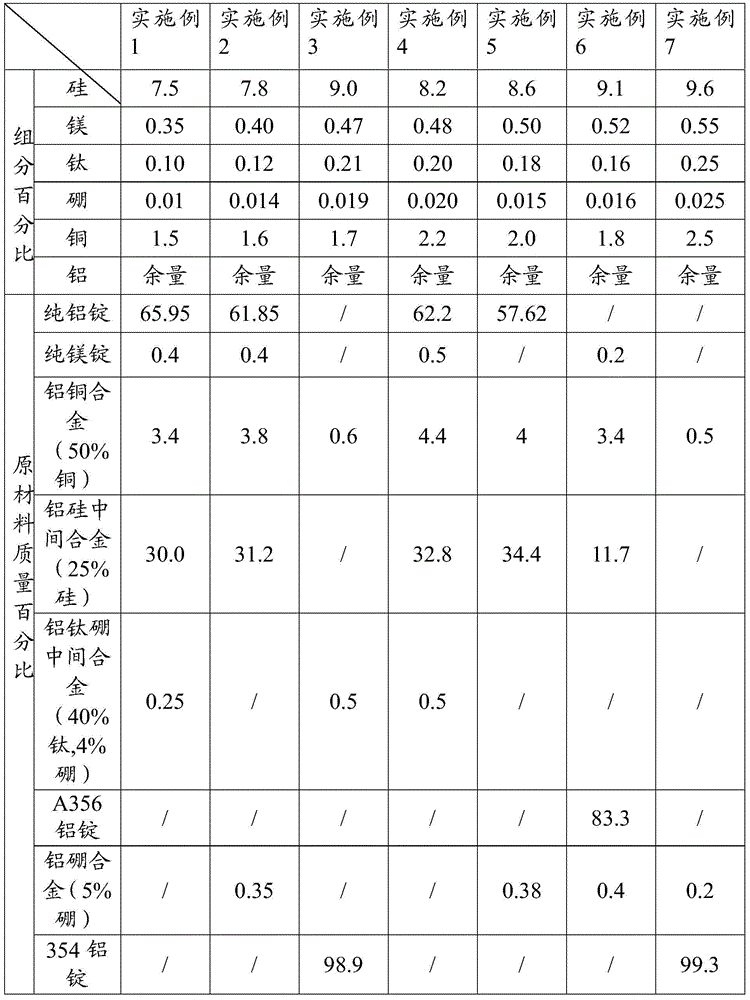

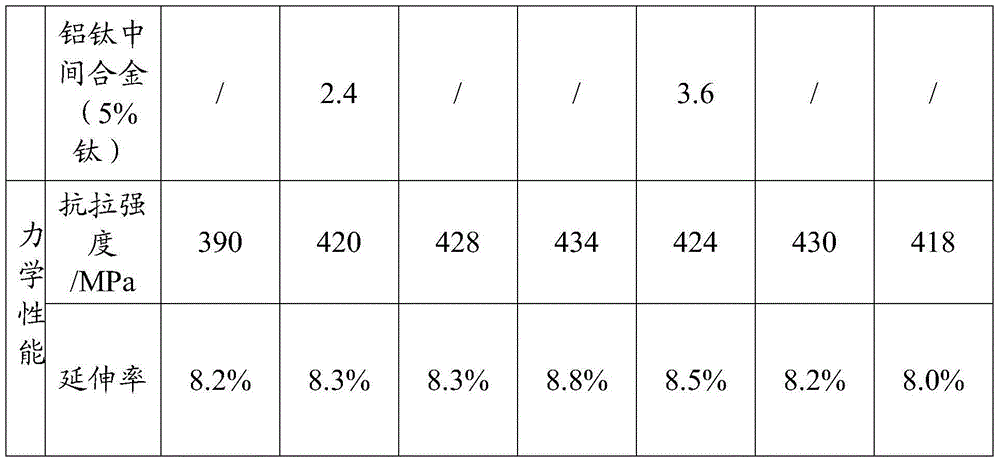

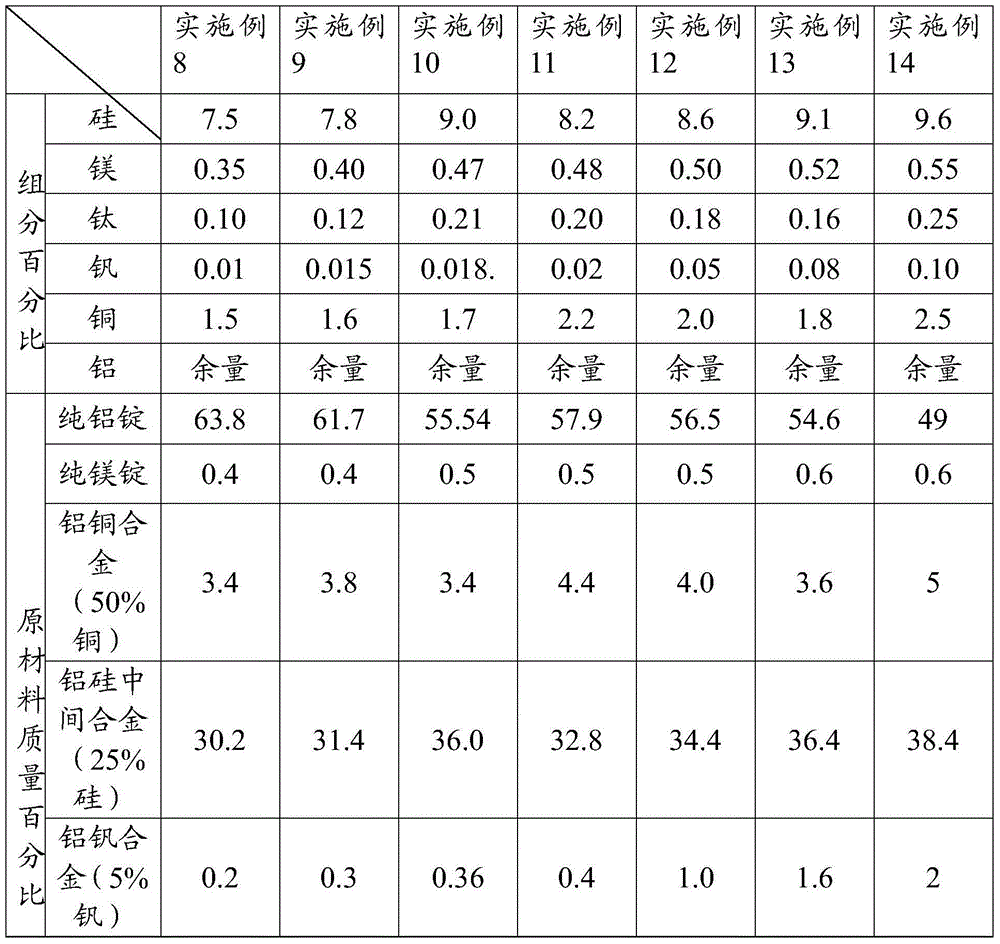

Aluminum silicate composition alloy and production method therof

An Al-Si alloy and manufacturing method thereof, the Al-Si alloy has the following components by mass percentage: 7.5%-10.2% Si, 0.35%-0.60% Mg, 0.10%-0.25% Ti, 0.010%-0.025% B, 1.5%-2.5% Cu, and the balance being Al, or has the following components by mass percentage: 7.5%-10.2% Si, 0.35%-0.60% Mg, 0.10%-0.25% Ti, 0.10%-0.20% V, 1.5%-2.5% Cu, and the balance being Al. Smelting to obtain the Al alloy liquid having the above components, obtaining parts by extrusion casting, and then conducting solution solidifying and aging.

Owner:ZTE KANGXUN TELECOM COMPANY

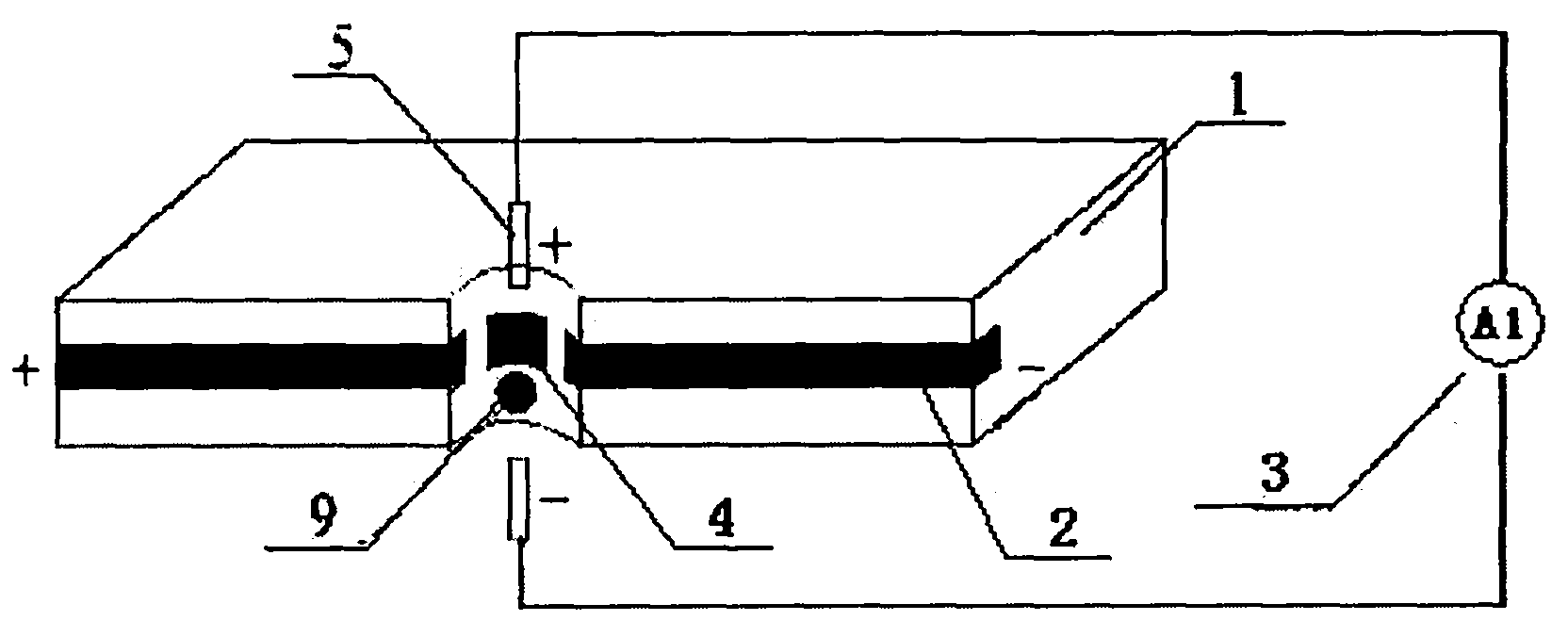

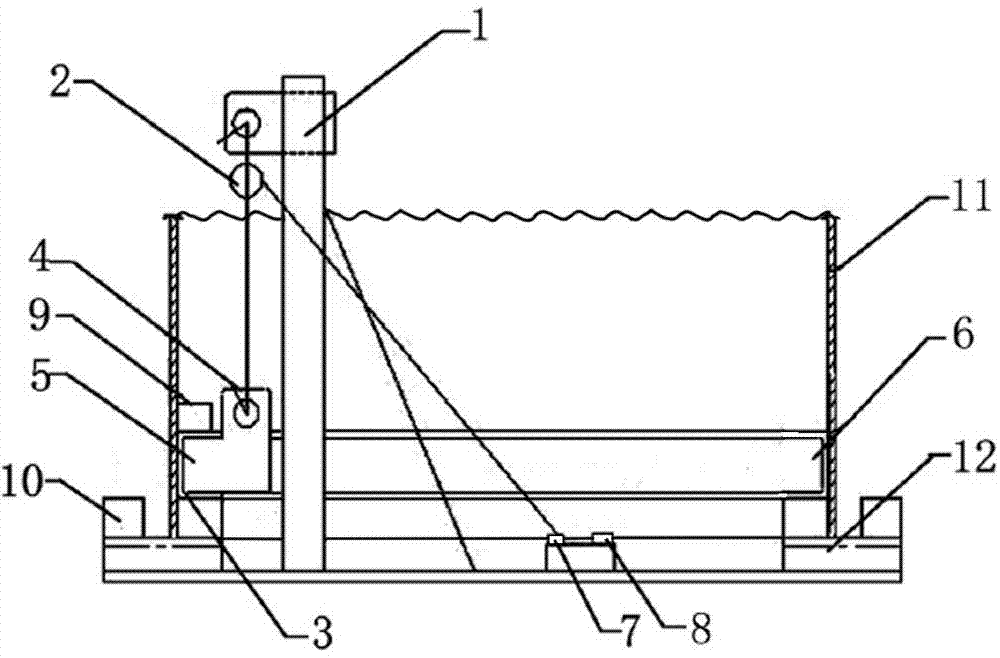

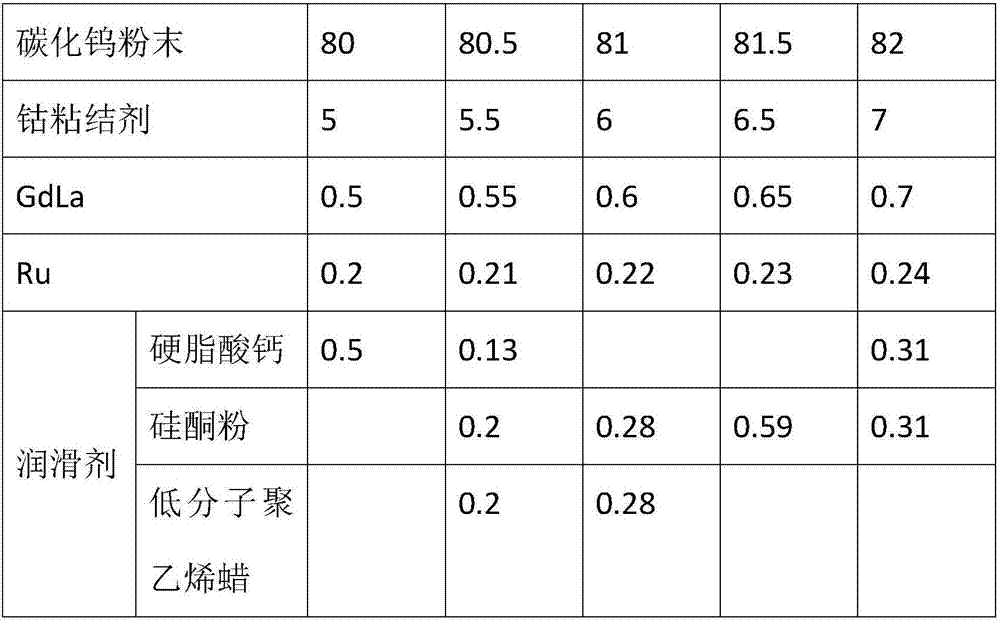

Tank body assembling electric lifting system by flip chip method and hoisting method thereof

InactiveCN102815609AGood strength and toughnessAvoid wear and scratchesLoad-engaging elementsLift systemExpansion joint

The invention provides a tank body assembling electric lifting system by a flip chip method, wherein the tank body assembling electric lifting system by the flip chip method comprises a plurality of electric lifting devices distributed uniformly in the inner side of a cylinder body and an expansion ring fixed on the inner wall of the cylinder body; the expansion ring is an enclosed circular ring with a concave clamping groove; each electric lifting device comprises a rack and an electric inverted chain hanged on the rack; and the electric inverted chain is connected with an expansion ring hanging fixture which is provided with a clamping body adaptive to the concave clamping groove on the expansion ring. The invention provides the lifting system and the hoisting method, and also discloses a lifting method of the tank body assembling by the flip chip method. The lifting system and the hoisting method provided by the invention not only overcomes the defect that the cylinder body rotates automatically during the lifting process and leads to inaccurate positioning, but also electric control is adopted for the full-distance lifting, the lifting system and the hoisting method are simple and feasible, not only relieves the labor intensity, but also lowers the assembling cost, improves the working efficiency, and increases the operation convenience and quickness and safety.

Owner:河北二十冶建设有限公司

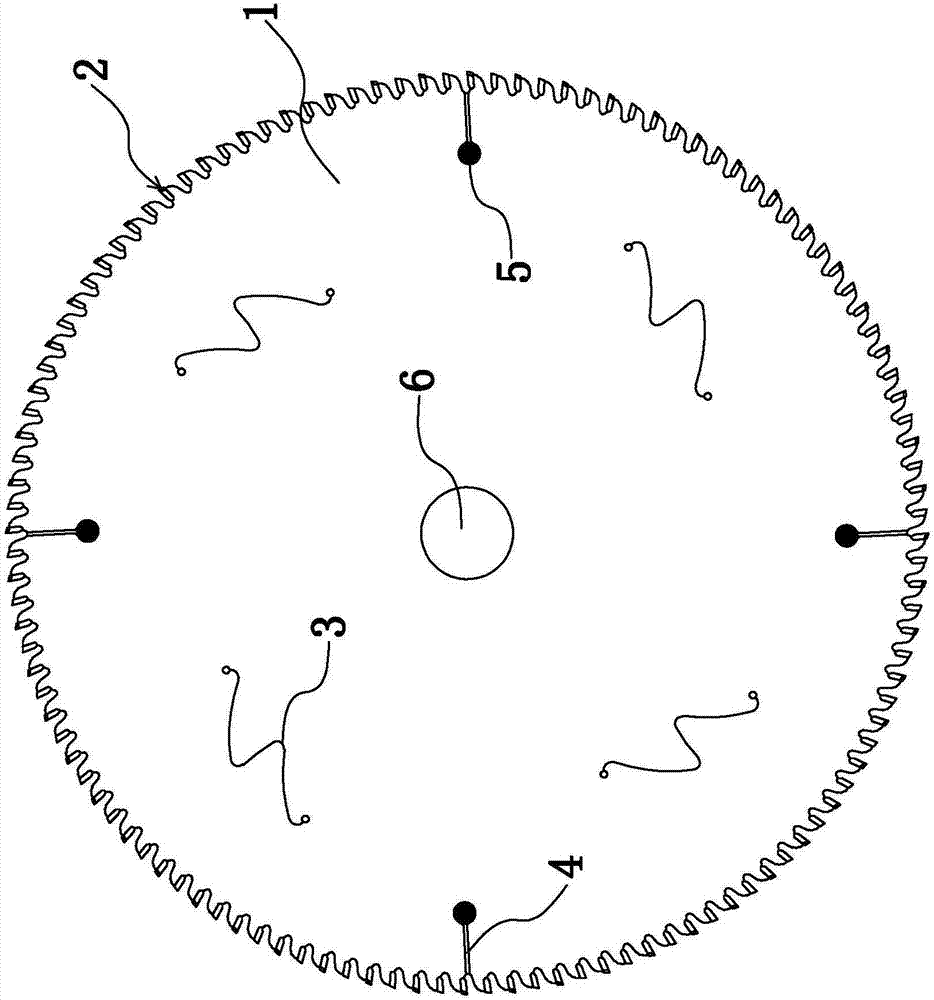

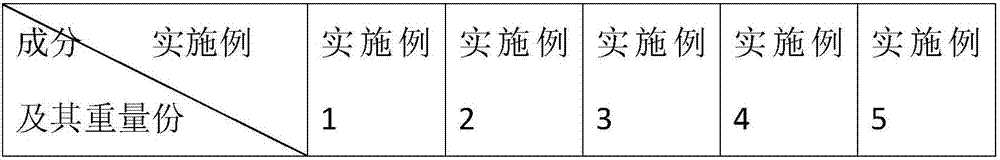

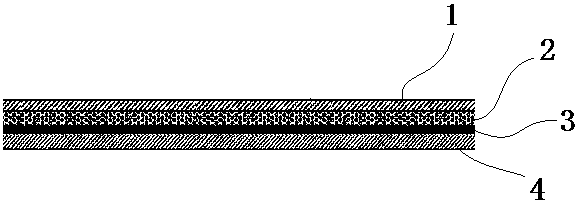

Hard alloy circular saw web

InactiveCN107263737AHigh hardnessGood strength and toughnessMetal sawing toolsCircular sawsCemented carbideTungsten carbide

The invention relates to a hard alloy circular saw web, in particular to an FWF type hard alloy circular saw web, and belongs to the field of hard alloy materials. The FWF type hard alloy circular saw web is made of hard alloy material; and the hard alloy material comprises a hard alloy base and a coating and is prepared from the following components in parts by weight: 75-80 parts of tungsten carbide powder, 5-10 parts of a cobalt binder, 0.5-1 part of GdLa, 0.2-0.3 part of Ru and 0.5-0.8 part of a lubricant. The FWF type hard alloy circular saw web is made of the hard alloy material to ensure that the hard alloy circular saw web has high cutting performance and is high in cutting strength, excellent in tenacity and long in service life.

Owner:宁波妙力斯五金工具有限公司

High-temperature steam-resistant and ageing resistant modified fluororubber cable material

InactiveCN103554795AImprove performanceGood strength and toughnessInsulated cablesInsulated conductorsCarbon blackMagnesium

The invention relates to a cable material, and specifically relates to a high-temperature steam-resistant and ageing resistant modified fluororubber cable material. The cable material comprises the following raw materials in parts by weight: 30-35 parts of fluororubber, 15-18 parts of low density polyethylene, 3-4 parts of zinc oxide, 3-4 parts of 2, 5-dimethyl-2, 5-bi(tert-butyl peroxide) hexane, 2-3 parts of triallyl isocyanurate, 18-20 parts of SG-3 polyvinyl chloride, 10-13 parts of natural rubber, 12-15 parts of calcium carbonate powder, 3-4 parts of magnesium oxide, 1-2 parts of ferrocene, 2-3 parts of isocyanate, 5-8 parts of epoxidized soybean oil, 2-3 parts of isobutyl acrylate, 1-2 parts of sulphur, 30-34 parts of N339 carbon black, 24-28 parts of nano diatomite powder, 7-9 parts of linseed alkyd resin, 1-2 parts of an anti-aging agent NBC (Nickelous N,N-dibutyldithiocarbamate) and 4-5 parts of an assistant. The cable material combines the advantages of fluororubber, natural rubber, low density polyethylene, SG-3 polyvinyl chloride and the like, and enhances the performance of a conventional fluororubber cable material, so that the high-temperature steam-resistant and ageing resistant modified fluororubber cable material has good strength and toughness and excellent high-temperature steam corrosion resistance and ageing-resisting function, can be applicable to special using environmental conditions and has a broad market application prospect.

Owner:安徽文峰电子科技集团有限公司

Preparation method of 17-4PH stainless steel base

PendingCN111607734AControl of delta-ferrite contentIncrease the degree of solid solutionSS - Stainless steelAlloy

The invention belongs to the field of base manufacturing and heat treatment and specifically relates to a preparation method of a 17-4PH stainless steel base. The preparation method of the 17-4PH stainless steel base mainly comprises the following step of manufacturing the 17-PH base by using a component design, smelting, casting, multiple forging and solution and aging combined treatment mode. According to the technical scheme of the preparation method of the 17-4PH stainless steel base, the content of delta-ferrite in the base can be preferably controlled; multiple forging is conducive to the formation of a high density dislocation wall in the base; the alloy micro-structure refining effect is obvious; phenomena of surface crack and hot shortness in the forging process are avoided; and the strength of the 17-4PH base is enhanced. Meanwhile, a convenient and rapid 17-4PH base preparation process is provided, the preparation efficiency is enhanced, the corrosion resistance performanceunder a complicated environment is met while the strength and the tenacity are guaranteed, the use performance of the 17-4PH base is comprehensively improved, demands of industrial production can be preferably satisfied, and scale production is realized.

Owner:SHANDONG JIANZHU UNIV

High-efficiency and environmental-protection agricultural mulching film

InactiveCN105131383ASimple preparation processGood strength and toughnessPlant protective coveringsPolyvinyl alcoholTitanium oxide

A high-efficiency and environmental-protection agricultural mulching film is prepared from the following raw materials in parts by weight: 35-55 parts of polyethylene, 1.2-1.5 parts of an ultraviolet light absorber, 20-27 parts of a PBM biodegradable material, 1.2-2.4 parts of a fog-reduction agent, 12-16 parts of thermoplastic starch, 1-3 parts of polyvinyl chloride, 3-4 parts of polymethyl ethylene carbonate, 2-5 parts of nanoscale titanium dioxide, 3-6 parts of polyvinyl alcohol, 4-7 parts of pullulan, 20-26 parts of a PBM biodegradable material, 4-6 parts of p-methyl xylene, 10-13 parts of an environmental-protection catalyst, 22-32 parts of kaolin, and 8-13 parts of a solvation agent. The high-efficiency and environmental-protection agricultural mulching film has the beneficial effects that the high-efficiency and environmental-protection agricultural mulching film has the advantages of simple preparation process, good toughness, high strength, and good environmental protection, and cannot cause damage to soil.

Owner:QINGDAO KELIKE INFORMATION TECH

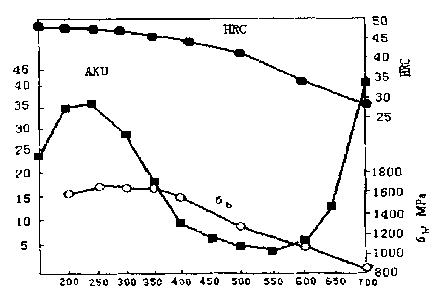

Vanadium-contained 10.9-level steel for fastener for rail transit mobile equipment and heat treatment technology of steel

ActiveCN105543654AInhibition of fatigue crack growthImprove fatigue resistanceAustenite grainMicrometer

The invention provides vanadium-contained 10.9-level steel for a fastener for rail transit mobile equipment. The steel mainly comprises following chemical elements including, by mass percentage, 0.33% to 0.38% of C, 0.05% to 0.10% of Si, 0.70% to 0.90% of Mn, 0.70% to 0.90% of Cr, 0.30% to 0.60% of Ni, 0.20% to 0.30% of Mo, 0.015% to 0.045% of Als, 0.03% to 0.06% of Nb, not larger than 0.010% of P, not larger than 0.005% of S and not larger than 0.0015% of T[O]. The autstenitic grain size of steel obtained after heat treatment of the fastener is larger than 10.0 level, and according to the structure of the steel obtained after heat treatment of the fastener, a small amount of small pro-eutectoid ferrite is dispersed and distributed on a tempered sorbite base body, wherein, the amount of the pro-eutectoid ferrite is smaller than or equal to 5%, and the size of the pro-eutectoid ferrite is smaller than or equal to 5 micrometers. The longitudinal mechanical property of the fastener obtained after heat treatment can meet the standard requirement.

Owner:MAANSHAN IRON & STEEL CO LTD

High-toughness decomposable environment-friendly plastic packaging bag

InactiveCN107778606AGood strength and toughnessGood optical performanceBio-packagingBagsWaxPolyamide

The invention discloses a high-toughness decomposable environment-friendly plastic packaging bag. The high-toughness decomposable environment-friendly plastic packaging bag is prepared from the following raw materials in parts by weight: 40-65 parts of polyolefin plastic, 35-45 parts of corn straw fibers, 5-8 parts of chitosan, 8-10 parts of fresh folium mori, 4-6 parts of kudzu stems and leaves,45-65 parts of polyhydroxybutyrate, 22-35 parts of polyvinyl butyral, 13-20 parts of polyethylene, 6-11 parts of lignin, 5-12 parts of cotton and linen fibers, 6-11 parts of montmorillonite, 1-3 partsof a stabilizer, 2-4 parts of a coupling agent, 1-5 parts of a plasticizer and 0.1-0.2 part of polyamide wax micropowder. The compound plastic packaging bag disclosed by the invention has good strength and toughness, and meanwhile, is good in optical performance and easy for oxydative degradation.

Owner:桐城市强峰包装有限公司

Blue MOFs/cast nylon nanometer composite material as well as preparation method and application thereof

The invention discloses a blue MOFs / cast nylon nanometer composite material as well as a preparation method and application thereof. The preparation method comprises the following steps: adding blue MOF and an aprotic polar solvent into a kettle A contained with caprolactam monomers, heating to the temperature of 70-85 DEG C, stirring for 0.5-2 hours, vacuumizing for 15-60 minutes, heating to the temperature of 130-140 DEG C, and adding an initiator for carrying out a vacuum reaction for 15-30 minutes; heating a kettle B filled with caprolactam monomers, heating to a dissolved state, vacuumizing, totally melting the monomers, adding a catalyst, heating to the temperature of 130-140 DEG C, and vacuumizing for 10-15 minutes; and finally, mixing the kettle A and the kettle B, pouring into a mold of 150-170 DEG C for performing polymerization molding, maintaining the temperature of 10-60 minutes, and demolding. By utilizing the color of blue MOFs and the frame structure, the blue MOFs and nylon matrix have a physical penetrating network combination. The material has the effects of improving the dimensional stability of the product, reducing the shrinkage ratio and reducing degree of crystallinity and melting point of the nylon.

Owner:HUNAN UNIV OF TECH

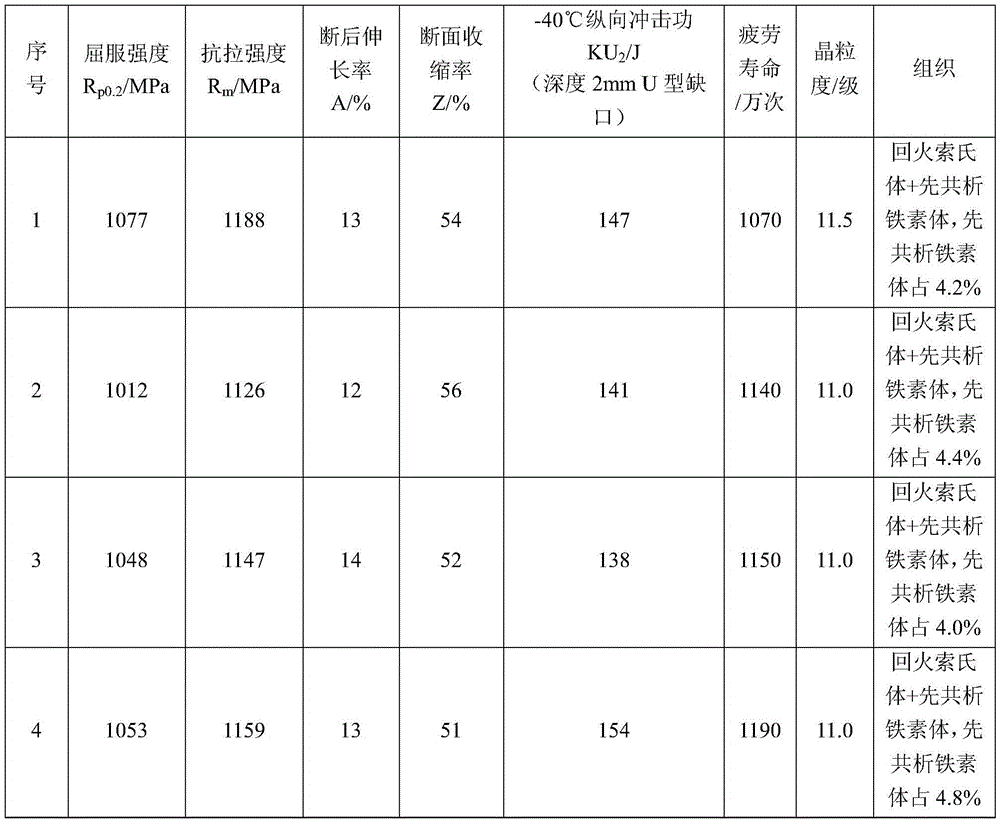

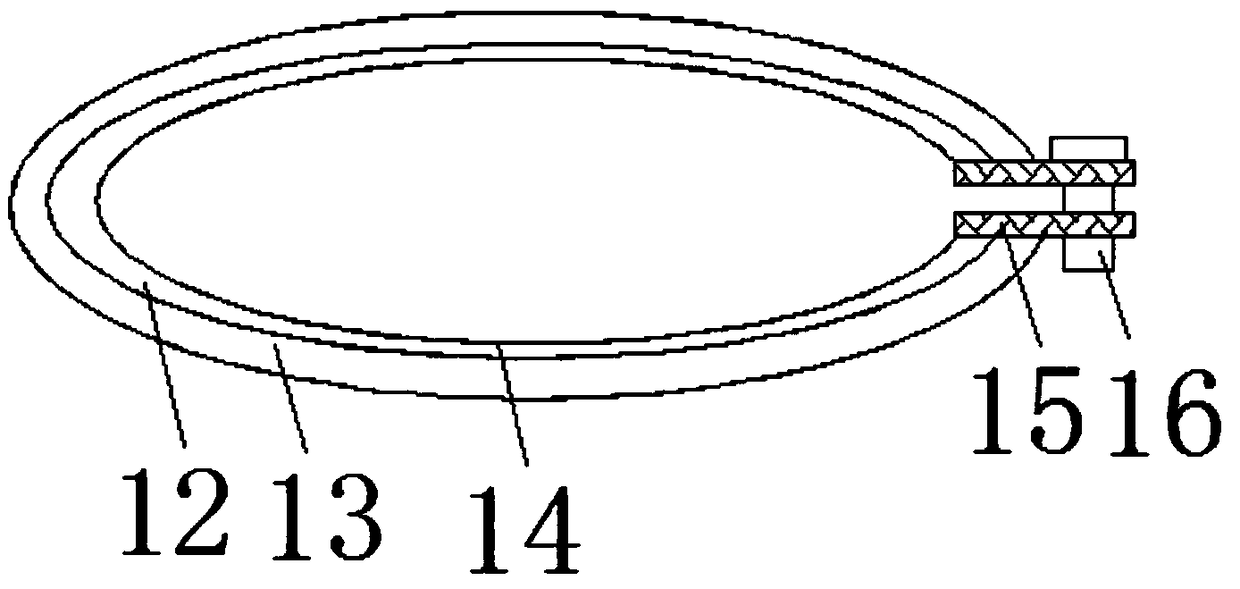

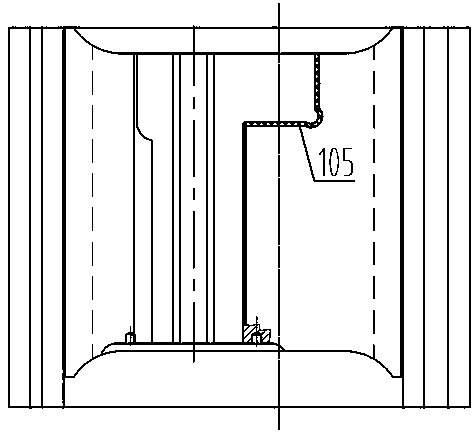

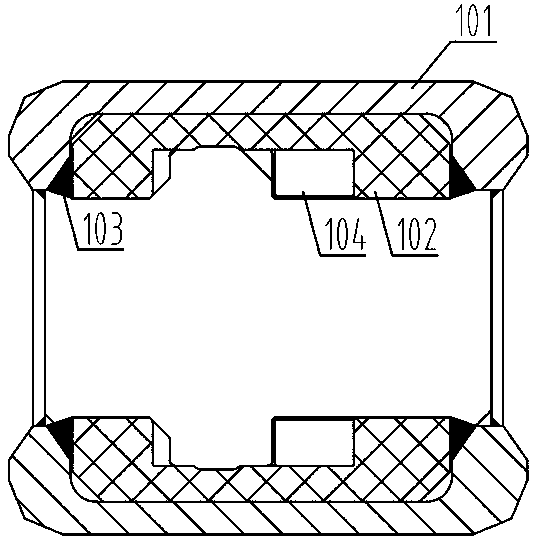

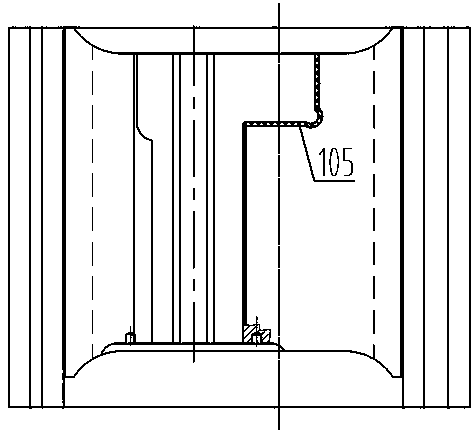

Filter bag structure of dust collector

InactiveCN108744769AWill not cause blockageGood strength and toughnessDispersed particle filtrationEngineeringDust collector

The invention discloses a filter bag structure of a dust collector. The filter bag structure of the dust collector comprises a base; one end of the base is connected with a fixing head; an air-vent port is formed in the center of the fixing head; a bag cage is fixed at the bottom of the air-vent port; the periphery of the bag cage is connected with a filter bag main body; a filter bag head is integrally formed at one end of the filter bag main body; a rubber band is embedded inside the filter bag head; the rubber band is arranged in an annular groove in a sleeving manner; the annular groove isformed in the periphery of the fixing head; the outer side of the filter bag head is clamped and connected with a hoop; the inner side of the hoop is fixed with a clamping block corresponding to theannular groove; and the inner wall of the clamping block is fitted with a rubber pad; according to the invention, through the arranged hoop and a stainless steel clamping ring, the filter bag head andthe fixing head are fixed by the cooperation of the hoop and the annular groove, and the bottom end of the filter bag main body is matched and connected with the bag cage through the stainless steelclamping ring, so that the installation verticality of the filter bag is well ensured, the shaking and wear of the filter bag are effectively reduced, and the service life of the filter bag is prolonged.

Owner:芜湖鑫霖森椽环保科技有限公司

High-strength TBM center cutter box and preparation method

ActiveCN111119915AAvoid Weld CrackingAvoid large welding deformationFurnace typesTunnelsTemperingStructural engineering

The invention provides a high-strength TBM center cutter box and a preparation method. The center cutter box comprises an outer cutter box and an inner cutter box, wherein the outer cutter box is madeof a structural steel material; the inner cutter box is made of a low-carbon medium-alloy structural steel material; and the inner cutter box and the outer cutter box are combined through welding. The center cutter box provided by the invention has the beneficial effects that the inner cutter box is treated with tempering and hardening, connection is realized in a firm of welding of the inner andouter cutter boxes, the inner and outer cutter boxes are formed by a forging technology, and the inner cutter box is made of low-carbon medium-alloy structural steel, so welding stress centralization, cracking and deformation of the inner and outer cutter boxes are reduced; through surface hardening of the inner cutter box, strength and fatigue performance of bearing parts can be enhanced; and through de-stress annealing of the inner and outer cutter boxes, distribution of residual stress during forging formation and welding stress centralization points of the inner and outer cutter boxes canbe reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

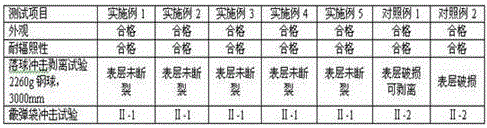

Method for preparing protective film for glass

InactiveCN106590407AGood strength and toughnessImprove impact resistancePolyester coatingsPolycarbonate coatingsSilicone resinChemistry

The invention discloses a method for preparing a protective film for glass and belongs to the technical field of high-polymer materials. The method comprises the following steps: (1) preparing modified silicone resin; (2) preparing nano filler; and (3) uniformly mixing the modified silicone resin, the nano filler, an ethylene-vinyl acetate copolymer, propylene oxide, boron fibers, a silane coupling agent, poly(butyl acrylate) and deionized water, spraying the mixture to the surface of the glass by the thickness of 0.05mm to 0.2mm, and carrying out curing, thereby preparing the protective film for the glass. According to the method for preparing the protective film for the glass, disclosed by the invention, the protective film for the glass is obtained by means of modifying the silicone resin and meanwhile carrying out modifying by using the nano filler; and by using the relatively excellent strength and toughness of the protective film for the glass, the impact resistance of a glass material can be effectively improved, and the injury to human bodies caused by glass breaking is avoided, so that the protective film is an ideal protective film which is relatively low in cost and relatively convenient in use.

Owner:杨永洪

Silane modified silicon carbide fiber and preparation method thereof

The invention discloses silane modified silicon carbide fiber which comprises, by weight, 120-140 parts of silicon carbide fiber, 1-3 parts of silane coupling agent kh550, 2-4 parts of 2, 2-dimethylolpropionic acid, 30-40 parts of ethyl orthosilicate, 3-5 parts of polyamide wax micropowder, 1-2 parts of glycidol, 2-3 parts of barium stearate, 16-20 parts of methyl methacrylate, 0.07-0.1 part of catalyst, 5-8 parts of polytef and 0.8-1 part of triethylamine. A finished product composite material obtained by the silane modified silicon carbide fiber has high strength and toughness, high mechanical stability and excellent comprehensive performance.

Owner:宁波众兴新材料科技有限公司

High-flowability modified plastic particle preparation process

InactiveCN108623971AGood liquidityGood strength and toughnessSodium carboxymethylcelluloseASA-polymer

The invention relates to the technical field of plastic particle preparation, in particular to a high-flowability modified plastic particle preparation process which includes the steps: proportioning:weighing raw materials including, by weight, 50-60 parts of ASA (acrylonitrile styrene acrylate) rubber powder, 1-3 parts of antistatic agents, 1-1.5 parts of anti-aging agents, 1.3-1.7 parts of releasing agents, 1.5-2 parts of toughening agents, 1-1.3 parts of glass fibers, 1-1.7 parts of silicone powder, 1.5-1.8 parts of sodium carboxymethylcellulose and 1.3-1.6 parts of talcum powder; preliminary homogenization, plasticizing, extrusion, water cooling, air drying, screening, cleaning, process routing inspection, homogenization, final inspection, packing and storage. Plastic particles are excellent in flowability, strength and toughness, the flowing performance of colloid raw materials in plastic preparation is ensured, the probability of bubble generation is reduced, and filling of fluids inside a mold is facilitated.

Owner:WUHU CHUANGKE NEW MATERIAL TECH CO LTD

Wear-resistant cast steel and preparation method thereof

InactiveCN110373614AGood strength and toughnessGood wear resistanceIntermediate frequencyPre treatment

The invention discloses a wear-resistant cast steel and a preparation method thereof, and belongs to the technical field of casting. The method comprises the steps of feeding raw materials into an intermediate-frequency induction furnace for smelting under the temperature of 1620-1650 DEG C; maintaining for 5-10min; casting the smelted raw materials into a ladle; adding 0.1-0.3% of aluminum alloyfrom the bottom of the ladle; decreasing the temperature of a mixture to be subjected to ladle casting to be 1580-1600 DEG C; casting and forming to obtain a cast; preprocessing the cast under the temperature of 800-900 DEG C; maintaining the temperature for 4-6h; then cooling by air; quenching the cast, and heating until the temperature reaches 900-1000 DEG C; maintaining the temperature for 4-6h; then quenching by oil; annealing under the temperature of 350 DEG C; maintaining the temperature for 6-8h; and cooling by air until room temperature is reached, thus obtaining the wear-resistant cast steel. The cast steel prepared by the method is outstanding in toughness and wear resistance, and low in cost.

Owner:山东能源重装集团乾泰精密机械有限公司

High-toughness resin optical filter and preparation method thereof

InactiveCN111505755AImprove absorptionHigh light transmittanceOptical filtersRadiation-absorbing paintsInfraredTransmittance

The invention discloses a high-toughness resin optical filter and a preparation method thereof. The optical filter comprises a substrate, and a modified dispersion resin layer is arranged on the outerside of the base plate; a restoration coating is disposed outside the modified dispersion resin layer; and a coating layer is disposed inside the substrate. According to the present invention, the preparation method is simple, and the prepared optical filter has characteristics of good light transmittance, high infrared ray absorption degree, good strength, good toughness, uniform particle distribution, wear resistance, scratch resistance and corrosion resistance, and can be popularized.

Owner:苏州京浜光电科技股份有限公司

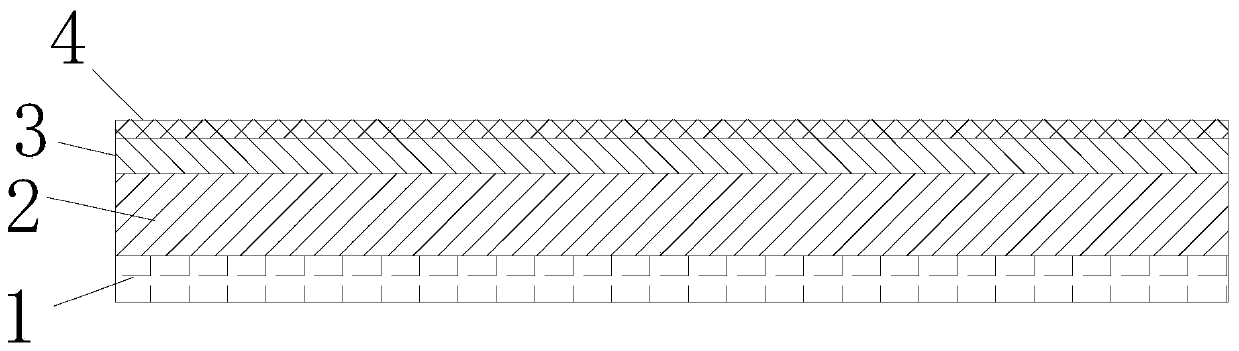

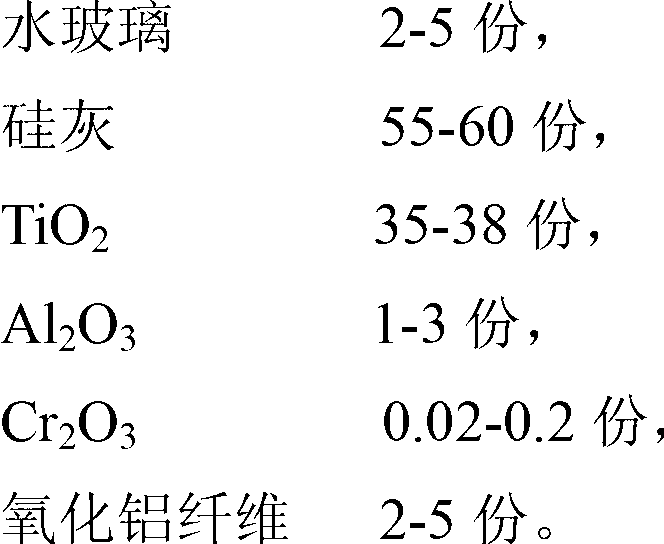

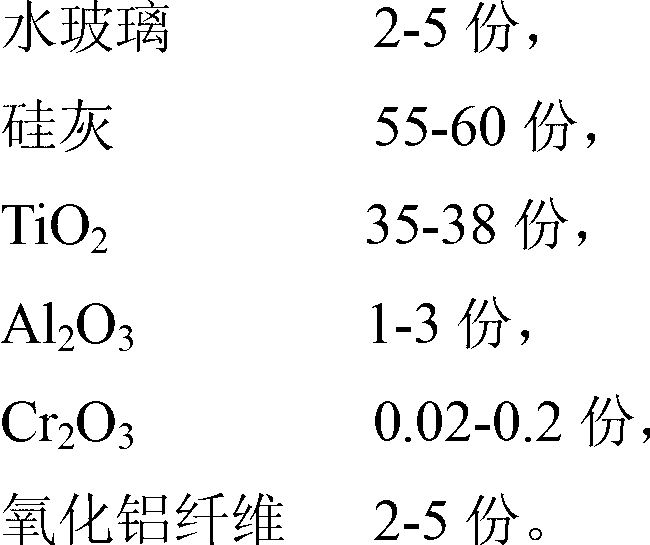

High-temperature nanometer microporous heat transfer board and preparation method thereof

The invention relates to a high-temperature nanometer microporous heat transfer board and a preparation method thereof. The heat transfer board is formed by coating glass fiber cloth or aluminium foil on the outer surface of SiO2 aerogel, wherein the SiO2 aerogel is composed of the following components of, by weight, 2-5 parts of water glass, 55-60 parts of silica fume, 35-38 parts of TiO2, 1-3 parts of Al2O3, 0.02-0.2 parts of Cr2O and 2-5 parts of alumina fiber. With the high-temperature nanometer microporous heat transfer board provided by the invention, mechanical strength of the material can be further increased while a usage temperature and a temperature-resistance grade of the material are guaranteed, by the improvement and adjustment of a conventional SiO2 aerogel formula, and particularly by the design of coating the glass fiber cloth or the aluminium foil on the outer surface of a product. The high-temperature nanometer microporous heat transfer board is convenient for transportation and mechanical process, and provides wider usage environment for the material.

Owner:上海伊索热能技术股份有限公司

Antistatic clothing

InactiveCN108567182AGood strength and toughnessImprove antistatic performanceFibre typesProtective garmentPolyesterPolymer science

The invention discloses antistatic clothing. The antistatic clothing sequentially comprises an antistatic polyester fabric, a flame retardant layer, a waterproof breathable film and an antibacterial layer from outside to inside sequentially, wherein the waterproof breathable film adopts a TPU waterproof breathable film; the flame retardant layer is flame retardant cloth; the antibacterial layer isprepared from antibacterial fabric. The clothing has good antistatic effect, the antistatic polyester fabric used on the surface has excellent strength and toughness, the antistatic property of the clothing can be greatly improved after modification and compounding, and the flame retardant layer, the waterproof breathable film and the antibacterial layer are further arranged on the inner layer ofthe antistatic clothing, so that flame retardancy, breathability, waterproofness and antibacterial property are integrated.

Owner:邳州易萨新型材料有限公司

Fiber-toughened molded composite material, preparation method thereof and degradable meal box

The invention discloses a fiber-toughened molded composite material, a preparation method thereof and a degradable meal box. The preparation method of the fiber-toughened molded composite material comprises the following steps of: S100, respectively preparing first resin powder, second resin powder, third resin powder, aramid fibers and glass fibers; S200, spraying the heated and pressurized first resin powder to the surfaces of the moving aramid fibers to obtain modified aramid fibers; S300, spraying heated and pressurized second resin powder to the surface of the moving glass fiber to obtain modified glass fiber; S400, jointly feeding the modified aramid fibers and the modified glass fibers into doubling and twisting equipment to be blended and woven so as to obtain toughened fibers; and S500, guiding toughening fibers into a mold, filling the third resin powder into the mold, and heating and pressurizing the materials in the mold to obtain the formed composite material. The molded composite material provided by the preparation method of the fiber-toughened molded composite material is higher in mechanical strength and better in stability.

Owner:宁波昌亚新材料科技股份有限公司

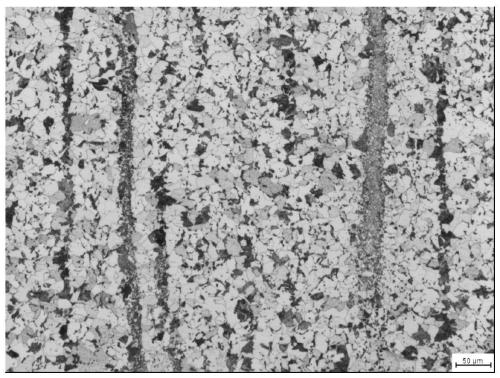

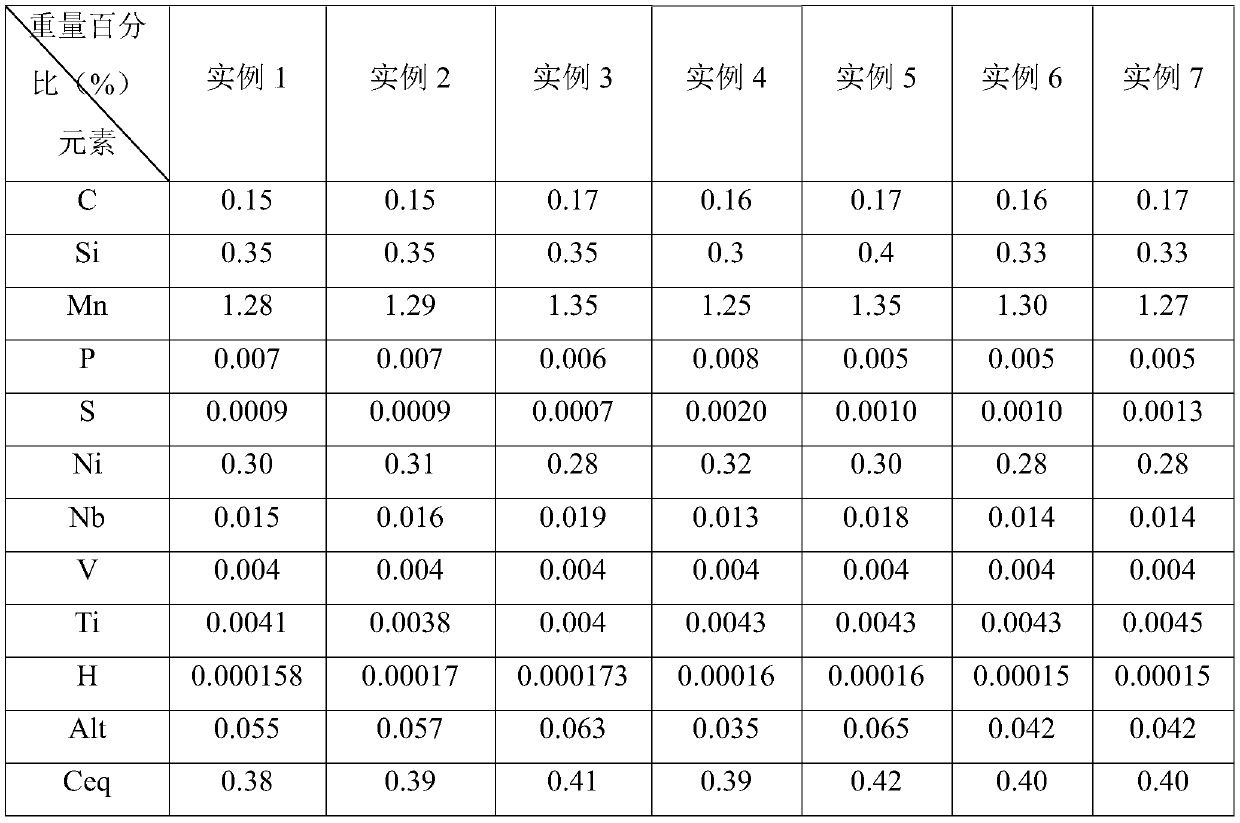

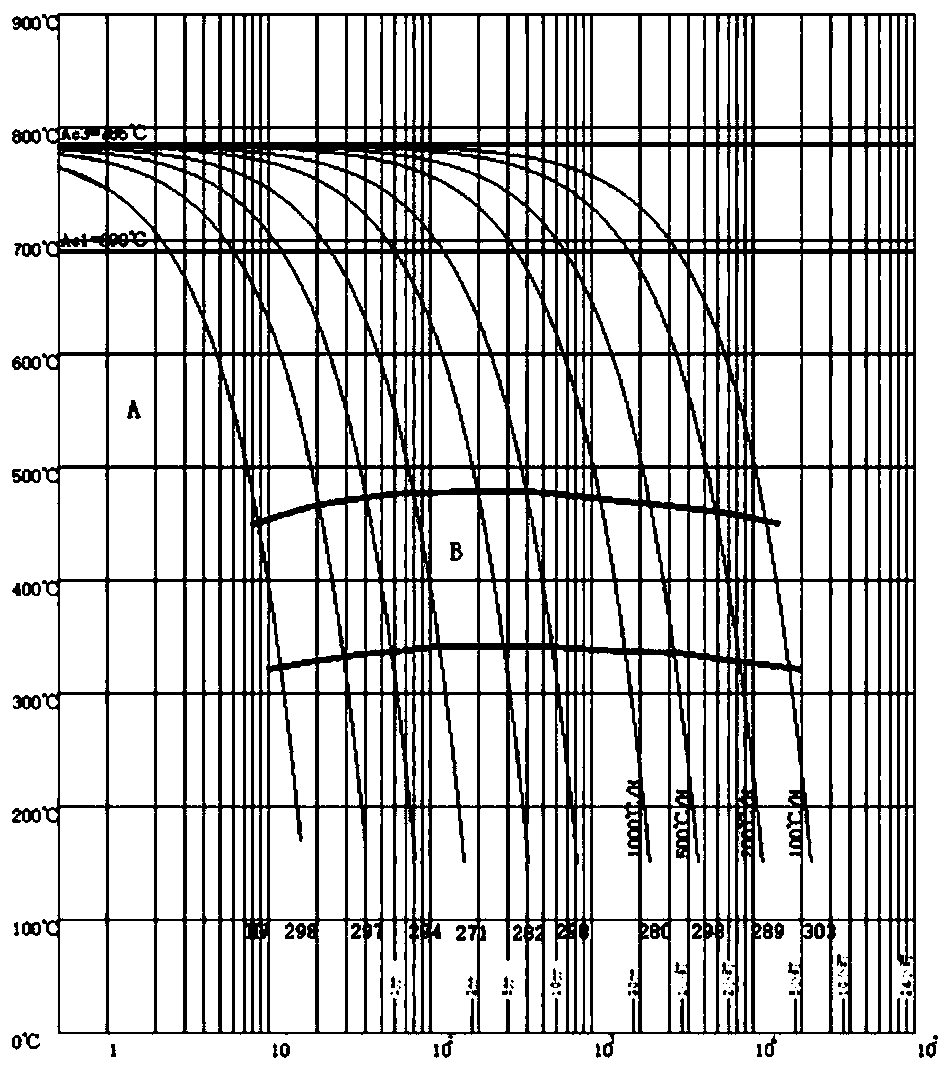

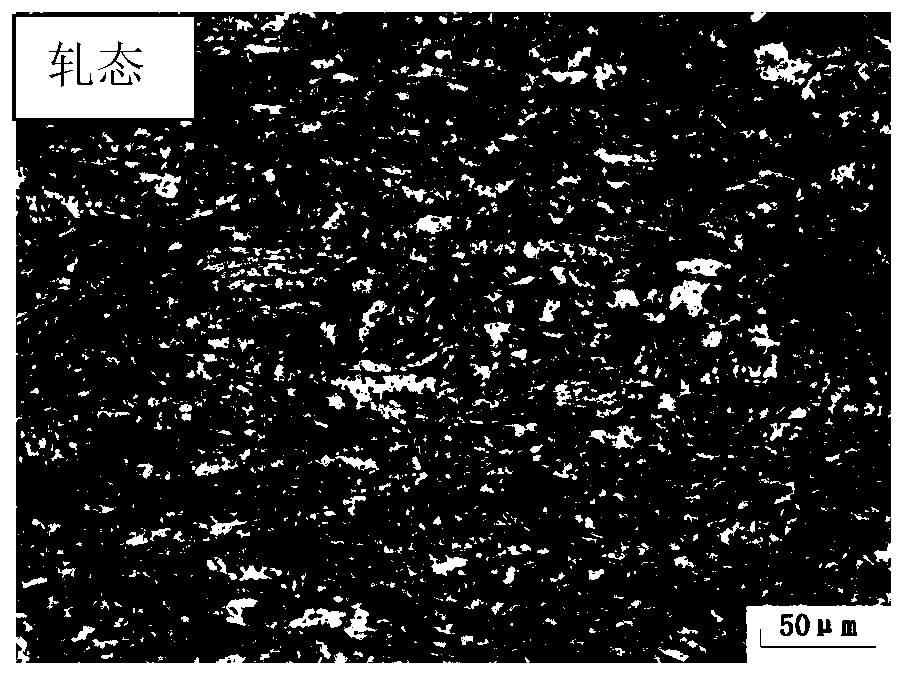

High-die-welded low-temperature container steel plate with medium thickness and high toughness and production method thereof

ActiveCN111270142AGood strength and toughnessReducing Shock Composition Design ComplexitySteel platesWeldability

The invention discloses a high-die-welded low-temperature container steel plate with medium thickness and high toughness and a production method thereof, and belongs to the field of steel making. Thesteel plate is prepared from, by weight percentage, 0.15-0.17% of C, 0.30-0.40% of Si, 1.25-1.35% of Mn, 0-0.008% of P, 0-0.002% of S, 0.28-0.32% of Ni, 0.013-0.019% of Nb, 0.035-0.065% of Alt, 0-0.42% of C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15, and the balance Fe and inevitable impurities. The steel plate can achieve the performance that the tensile strength at the 1 / 4 thickness and 1 / 2 thickness is largerthan or equal to 550 MPa, besides, the transverse impact work Akv at minus 45 DEG C and the 1 / 4 thickness and 1 / 2 thickness is larger than or equal to 100 J, and the toughness is high. According to the production method, on the basis of the ASMESA-516 / SA-516 standard and the reasonable alloying component design, casting blanks are adopted for producing high-die-welded low-temperature container steel with medium thickness and high toughness, and the technological difficulty that the impact property and weldability of the produced low-temperature high-strength container steel at the 1 / 2 thickness are unstable under the technical requirements of high die welding for steel plates with medium thickness in project application is successfully overcome.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Copper-containing ultra-low carbon bainite steel and preparation method thereof

The invention relates to copper-containing ultra-low carbon bainite steel and a preparation method thereof, and belongs to the technical field of metal materials. The problems that an existing copper-containing ultra-low carbon bainite steel production window is narrow, the surface core difference of a wide and thick plate is large, and the performance fluctuation is large are solved. The copper-containing ultra-low carbon bainite steel comprises, by mass, 0.01%-0.03% of C, 0.8%-1.5% of Mn, 1.5%-2.0% of Mo, 0.03%-0.07% of Nb, 3.0%-4.0% of Ni, 0.4%-0.6% of Cr, 0.0010%-0.0018% of B, 1.4%-1.6% ofCu and the balance iron and inevitable impurities. The ultra-low carbon bainite steel is good in production adaptability and stable in tissue performance.

Owner:CENT IRON & STEEL RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com