Inhomogeneous hard alloy and preparation method thereof

A cemented carbide, non-uniform technology, applied in the field of cemented carbide and its preparation, can solve the problems that the toughness and strength of cemented carbide cannot be achieved, and the improvement of stacking porosity is not obvious enough, so as to achieve good toughness and strength, stacking The obvious effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

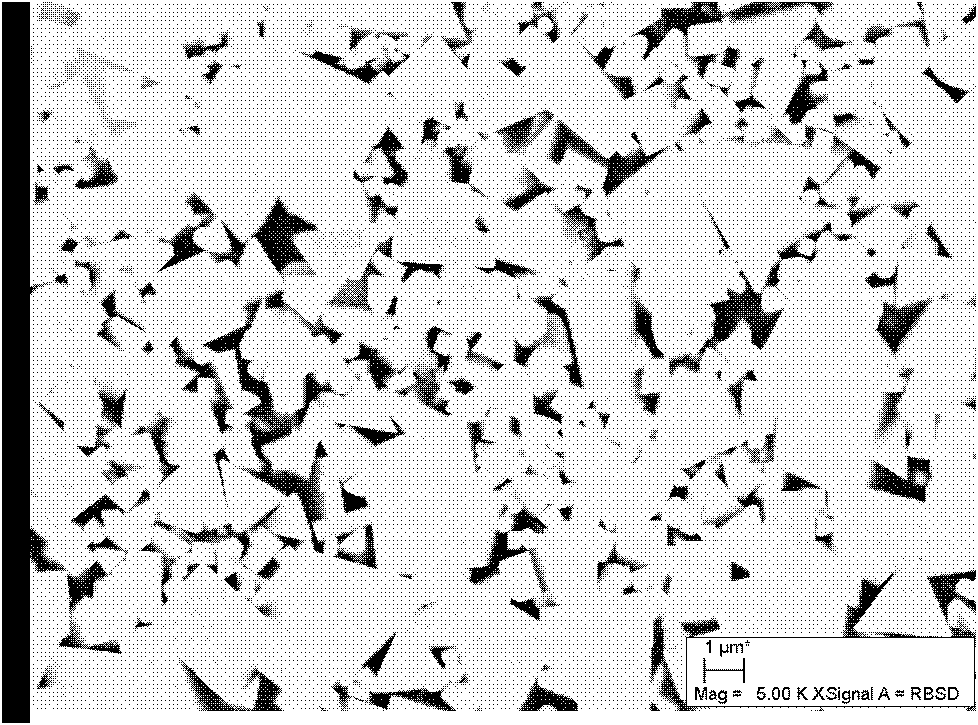

[0028] a kind of like figure 1 The heterogeneous cemented carbide of the present invention shown, the heterogeneous cemented carbide is mainly composed of tungsten carbide, and contains Co phase and cubic carbide phase (also can contain orthogonal carbide phase), the heterogeneous hard alloy The grain distribution of tungsten carbide (WC) in the alloy has a bimodal structure, one of which is 0.7 μm and the other is 2.0 μm.

[0029] The heterogeneous cemented carbide of the present embodiment is prepared according to the following steps:

[0030] (1) Ingredients: select Co powder, TaNbC (6 / 4) and WC powder as raw materials, and the mass percentage of each raw material is

[0031] Co powder 9wt%

[0032] TaNbC 0.8wt% and

[0033] WC powder balance;

[0034] WC powder includes coarse and fine WC powder with two different particle sizes, the average particle size of coarse WC powder is 10.4 μm, and the average particle size of fine WC powder is 0.29 μm; the mass ratio of coars...

Embodiment 2

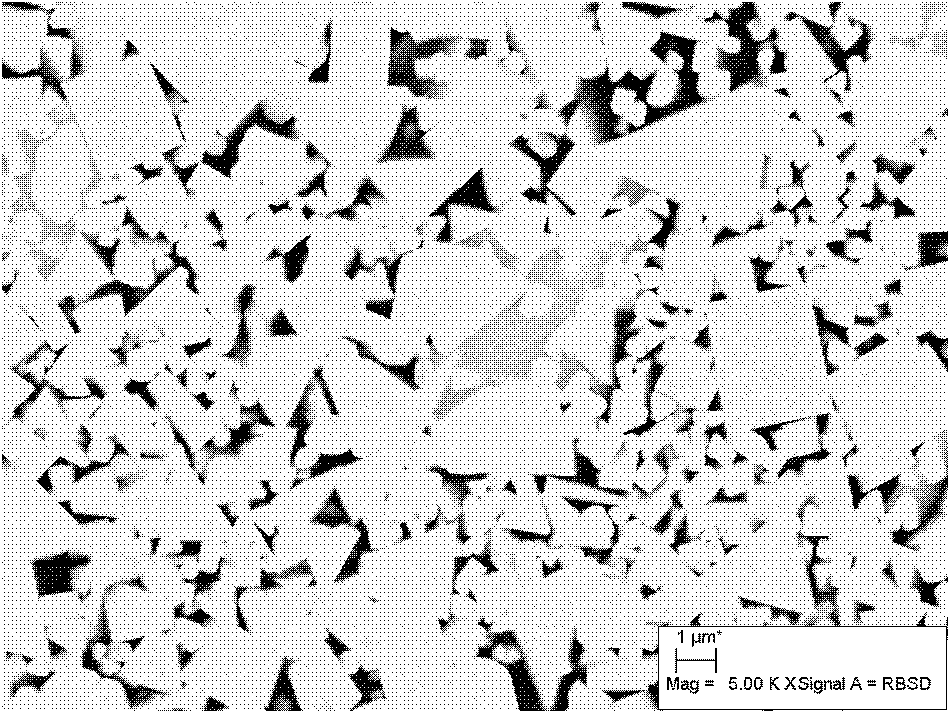

[0039] a kind of like figure 2 The heterogeneous cemented carbide of the present invention shown, the heterogeneous cemented carbide is mainly composed of tungsten carbide, and contains Co phase and cubic carbide phase (also can contain orthogonal carbide phase), the heterogeneous hard alloy The WC grain distribution in the alloy has a bimodal structure, one of which is 0.6 μm and the other is 2.1 μm.

[0040] The heterogeneous cemented carbide of the present embodiment is prepared according to the following steps:

[0041] (1) Ingredients: select Co powder, TaNbC (6 / 4) and WC powder as raw materials, and the mass percentage of each raw material is

[0042] Co powder 9wt%

[0043] TaNbC 0.8wt% and

[0044] WC powder balance;

[0045] WC powder includes coarse and fine WC powder with two different particle sizes, the average particle size of coarse WC powder is 10.4 μm, and the average particle size of fine WC powder is 0.29 μm; the mass ratio of coarse WC powder and fine ...

Embodiment 3

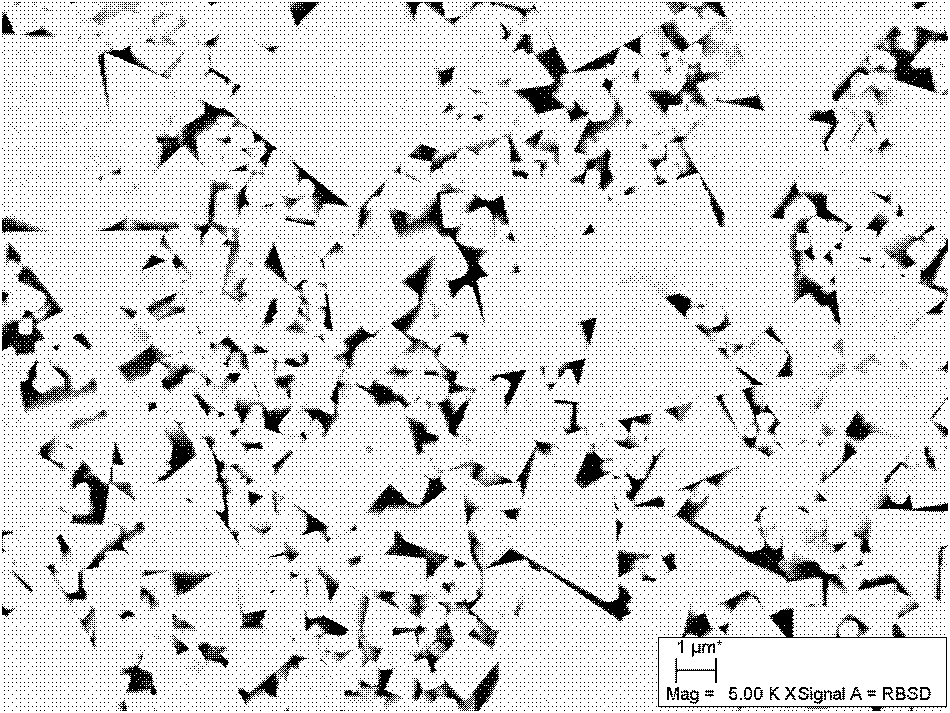

[0050] a kind of like image 3The heterogeneous cemented carbide of the present invention shown, the heterogeneous cemented carbide is mainly composed of tungsten carbide, and contains Co phase and cubic carbide phase (also can contain orthogonal carbide phase), the heterogeneous hard alloy The WC grain distribution in the alloy has a bimodal structure, one of which is 0.6 μm and the other is 2.2 μm.

[0051] The heterogeneous cemented carbide of the present embodiment is prepared according to the following steps:

[0052] (1) Ingredients: select Co powder, TaNbC (6 / 4) and WC powder as raw materials, and the mass percentage of each raw material is

[0053] Co powder 9wt%

[0054] TaNbC 0.8wt% and

[0055] WC powder balance;

[0056] WC powder includes coarse and fine WC powder with two different particle sizes, the average particle size of coarse WC powder is 10.4 μm, and the average particle size of fine WC powder is 0.29 μm; the mass ratio of coarse WC powder and fine WC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com