High-temperature nanometer microporous heat transfer board and preparation method thereof

A heat transfer plate and nanotechnology, applied in the field of high-temperature nano-micro heat transfer plate and its preparation, can solve the problems of easy fracture and pulverization in cutting, easy damage in transportation, and reduction of SiO, and achieve good strength and toughness, and are easy to use and transport Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation method of high-temperature nano-micro heat transfer plate

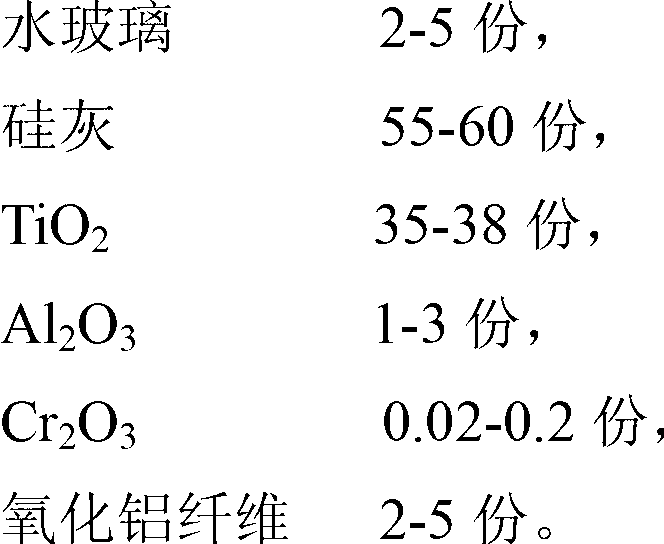

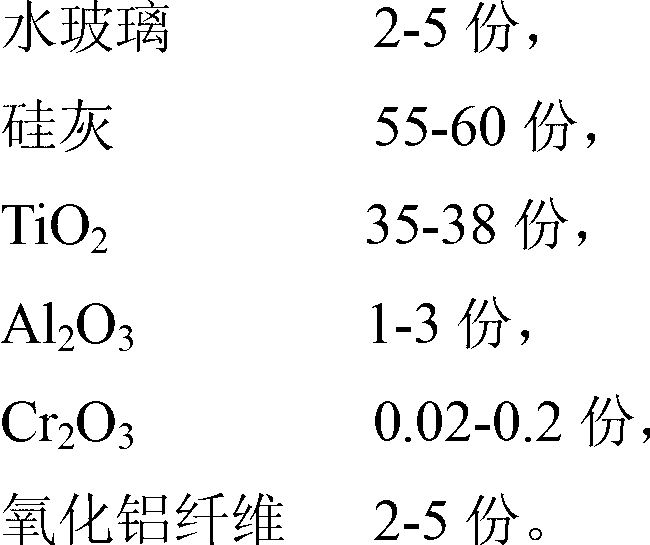

[0021] 1) SiO2 2 Preparation of airgel: Weigh 40g of water glass and place it in a beaker, add 500g of water to dilute and disperse it evenly, then weigh 460g of silica fume, TiO 2 300g, Al 2 o 3 24g, Cr 2 o 3 1.6g was added to the diluted water glass solution and stirred evenly, then weighed 40g of alumina fiber into the mixture and stirred for 3-5min to ensure that the alumina fiber was evenly dispersed in the mixture, and added 0.2 g catalyst ethylene glycol, control the gel time to 60min, and use hydrochloric acid to adjust the pH value of the mixture to 10, and the mixture becomes gel after fully stirring;

[0022] 2) Preparation of high-temperature nano-micro heat transfer plate: seal the container holding the gel, and place it in an environment with a temperature of 45°C for 4 hours. After standing still, stir the gel evenly and inject it into the mold, and vibrate the gel injected ...

Embodiment 2

[0026] (1) Preparation method of high-temperature nano-micro heat transfer plate

[0027] 1) SiO2 2 Preparation of airgel: Weigh 30g of water glass and place it in a beaker, add 500g of water to dilute and disperse it evenly, weigh 480g of silica fume, TiO 2 300g, Al 2 o 3 20g, Cr 2 o 3 Add 1.8g into the diluted water glass solution and stir evenly, then weigh 50g of alumina fiber and put it into the mixture and stir for 3-5min to ensure that the alumina fiber is evenly dispersed in the mixture, add 0.25g of catalyst to the above container Ethylene glycol, control the gel time to 45min, and use hydrochloric acid to adjust the pH value of the mixture to 11, and the mixture becomes gel after fully stirring;

[0028]2) Preparation of high-temperature nano-micro heat transfer plate: seal the container holding the gel, and place it in an environment with a temperature of 25°C for 5 hours. After standing still, stir the gel evenly and inject it into the mold, and vibrate the g...

Embodiment 3

[0032] (1) Preparation method of high-temperature nano-micro heat transfer plate

[0033] 1) SiO2 2 Preparation of airgel: Weigh 30g of water glass and place it in a beaker, add 500g of water to dilute and disperse it evenly, weigh 500g of silica fume, TiO 2 250g, Al 2 o 3 22g, Cr 2 o 3 Add 1.5g into the container of the diluted water glass solution and stir evenly, then weigh 40g of alumina fibers into the mixture and stir for 3-5min to ensure that the alumina fibers are evenly dispersed in the mixture, add 0.1g catalyst sulfuric acid, control the gel time to 45min, and use hydrochloric acid to adjust the pH value of the mixture to 11, and the mixture becomes gel after fully stirring;

[0034] 2) Preparation of high-temperature nano-micro heat transfer plate: seal the container holding the gel, and place it in an environment with a temperature of 50°C for 4 hours. After standing still, stir the gel evenly and inject it into the mold, and vibrate the gel injected into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum operating temperature | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com