Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8188results about "Fibre types" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for hydrophilizing materials using hydrophilic polymeric materials with discrete charges

A method of rendering materials having hard and soft surfaces hydrophilic or more hydrophilic is disclosed. The method involves hydrophilizing such materials by applying a high energy treatment and charged particles and / or one or more hydrophilic polymeric materials with discrete charges to such materials.

Owner:THE PROCTER & GAMBLE COMPANY

Curable aqueous composition and use as fiberglass nonwoven binder

This invention relates to a formaldehyde-free curable aqueous composition containing a polyacid, a polyol and a phosphorous-containing accelerator. The composition may be used as a binder for heat resistant nonwovens such as nonwovens composed of fiberglass.

Owner:ROHM & HAAS CO

Absorbent article and process for preparing an absorbent article

InactiveUS6417425B1Reduce the amount of waterLower performance requirementsFibre typesPretreated surfacesFiberPolymer science

Absorbent articles and processes for making absorbent articles are provided. The process includes spraying onto a fibrous web a blend containing superabsorbent polymer particles, superabsorbent forming monomer, initiator and water, and subjecting the web to polymerization conditions. The resulting web is useful as an absorbent article particularly in disposable hygiene products.

Owner:BASF CORP

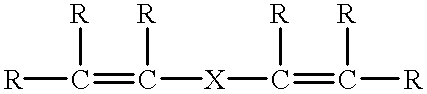

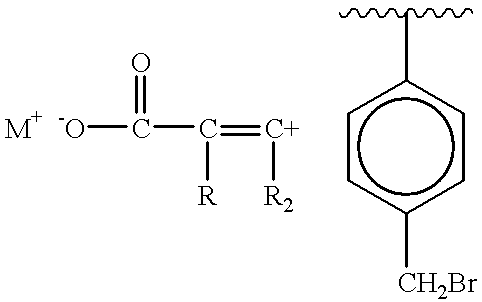

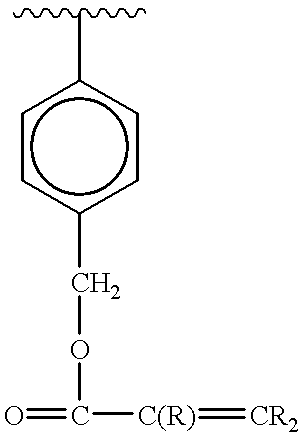

Antimicrobial and antistatic polymers and methods of using such polymers on various substrates

The present invention relates to a substrate having antimicrobial and / or antistatic properties. Such properties are imparted by applying a coating or film formed from a cationically-charged polymer composition. The polymer composition includes a noncationic ethylenically unsaturated monomer, an ethylenically unsaturated monomer capable of providing a cationic charge to the polymer composition, and a steric stabilization component incorporated into the cationically-charged polymer composition. The present invention also relates to a polymeric material comprising a base polymer blended with the above cationically-charged polymer composition.

Owner:MALLARD CREEK POLYMERS

Hydrophilic polymer treatment of an activated polymeric material and use thereof

InactiveUS6830782B2Simple materialImprove nucleationRadiation applicationsFibre typesFiberMicroorganism

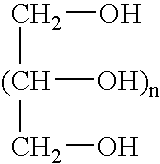

A method of modifying a polymeric material which comprises the steps of activation-treatment and a hydrophilic polymer-treatment, or comprises the steps of activation-treatment, a hydrophilic polymer-treatment, and monomer grafting in this order, or comprises the step of a solvent-treatment followed by these steps. Thus, the polymeric material, e.g., polyolefin, is improved in hydrophilicity, adhesion, etc. without lowering the practical strength thereof. The polymeric material thus improved in adhesion and other properties can be used in many applications where water absorption and adhesion are required, such as an absorption material, e.g., a wiping / cleansing material, a water retention material, a material for microorganism culture media, a separator for batteries (or cells), a synthetic paper, a filter medium, a textile product for clothing, a medical / sanitary / cosmetic supply, and reinforcing fibers for composite materials.

Owner:KB INT

Activated organic coatings on a fiber substrate

InactiveUS6517906B1Easy and less-expensive to manufactureImprove versatilityOther chemical processesFibre typesFiberDecomposition

A composite contains substrate fibers, and an activated organic coating, on the substrate fibers. The activated organic coating is formed at a low temperature, making possible the use of substrate fibers have a softening or decomposition temperature of at most 500° C.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

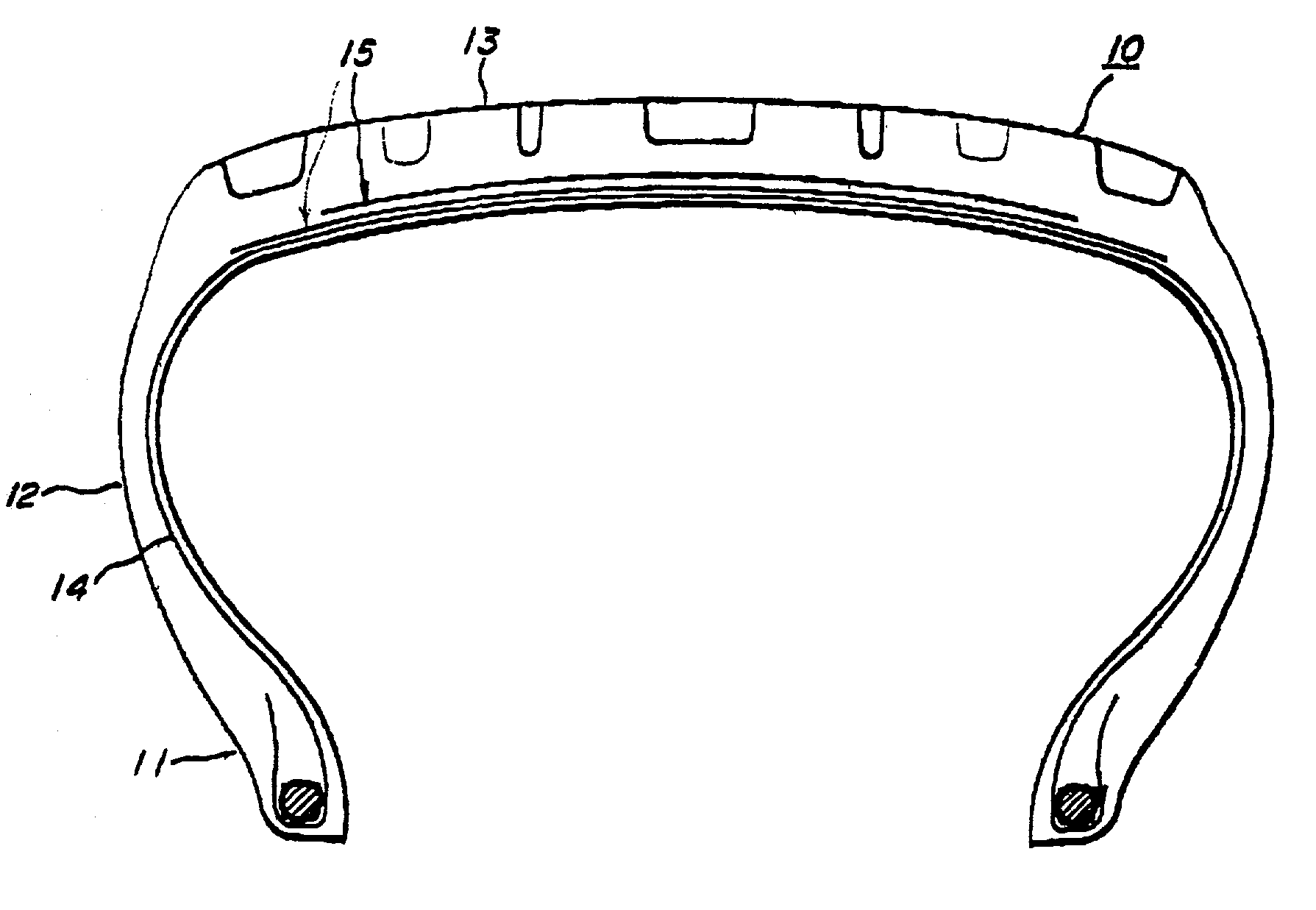

Tire reinforced by an elongate composite element of the monofilament type, and such element

A tire, in particular an elastomeric pneumatic tire, reinforced by lengths of a monofilament elongate composite element of long glass fibers impregnated in a thermoset resin having a glass transition temperature Tg greater than 130° C., in which the fibers are all parallel to each other, the elongate composite element having, under a bending stress an elastic deformation in compression of at least 2%, in flexion a breaking stress in compression greater than the breaking stress in extension.

Owner:CONCEPTION & DEV MICHELIN SA

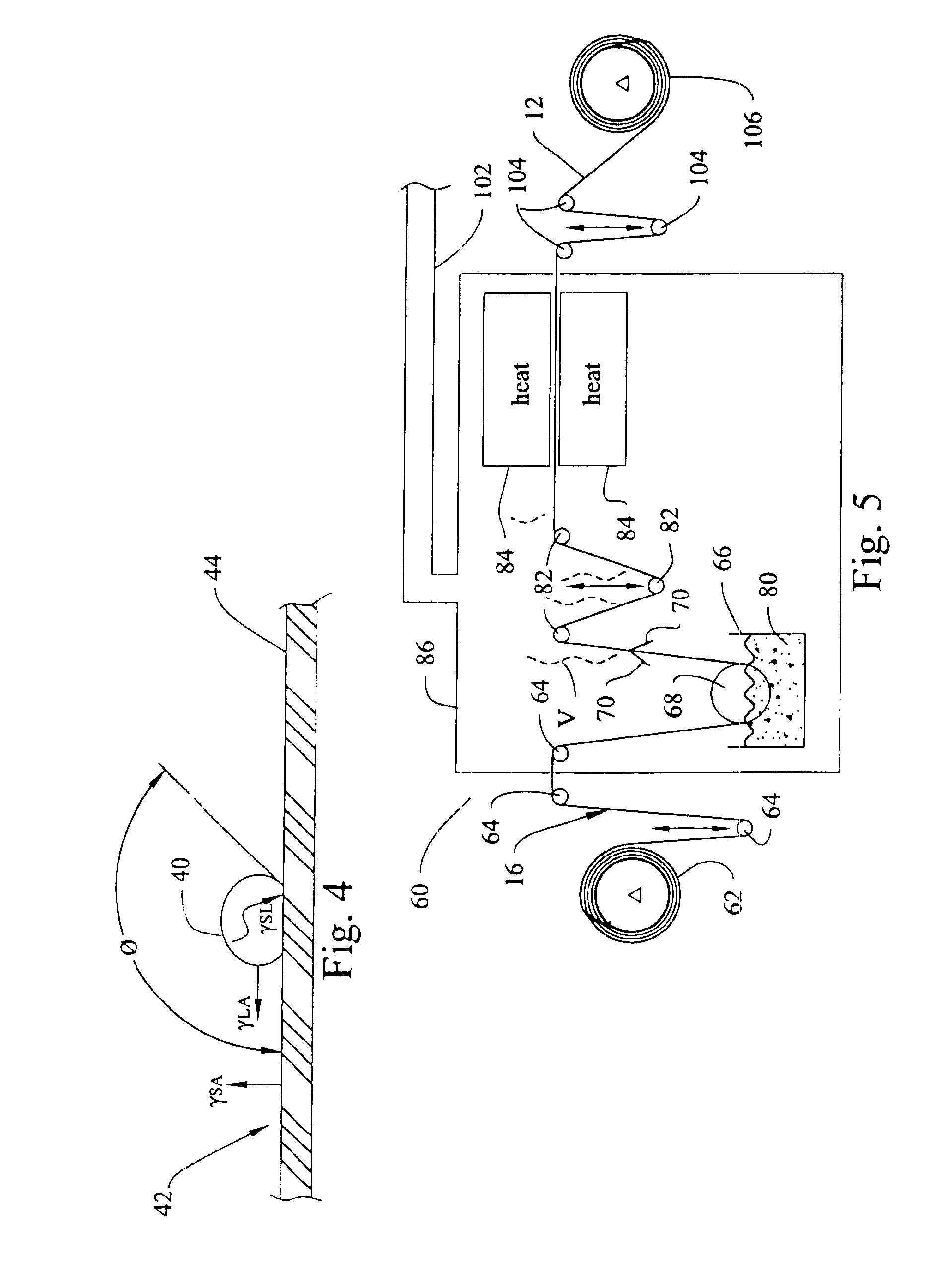

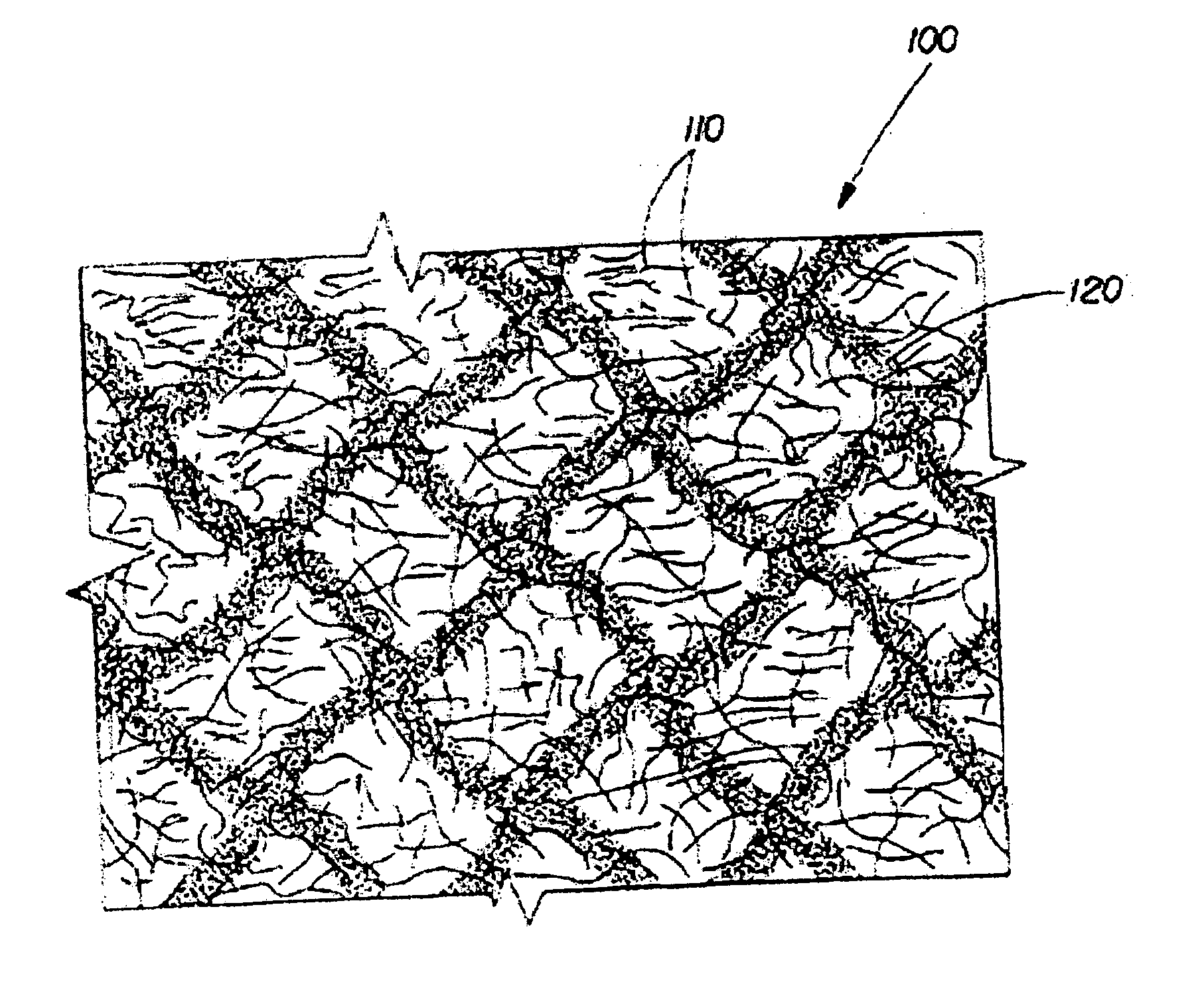

Method for forming a fibrous structure comprising synthetic fibers and hydrophilizing agents

InactiveUS20070232178A1Natural cellulose pulp/paperWater-repelling agents additionEngineeringFiber structure

Owner:THE PROCTER & GAMBLE COMPANY

Hydrophilic nonwovens with low retention capacity comprising cross-linked hydrophilic polymers

InactiveUS20050215965A1Reduce the amount requiredFibre typesBaby linensCross-linkHydrophilic polymers

The present invention relates to hydrophilic synthetic nonwoven webs. At least a region of 1 cm by 1 cm comprised by the web of the invention comprises cross-linked hydrophilic polymers and has a retention capacity of less than 100 g of aqueous liquid per m2 of the nonwoven fibrous web. Moreover, the invention relates to a method for making such nonwoven webs. Furthermore, the invention also relates to absorbent articles comprising the nonwoven webs comprising cross-linked hydrophilic polymers.

Owner:THE PROCTER & GAMBLE COMPANY

Porous membrane structure and method

A method of treating a membrane comprises the steps of providing a membrane with surfaces that define a plurality of pores extending through the membrane. Providing a dispersion of oleophobic fluoropolymer solids. Stabilizing the dispersion with a stabilizing agent. Diluting the dispersion with a wetting agent. Wetting surfaces which define the pores in the membrane with the diluted and stabilized dispersion. Removing the wetting agent and the stabilizing agent from the membrane. Coalescing the oleophobic fluoropolymer solids of the dispersion on surfaces that define pores in the membrane. A composite membrane comprises a porous membrane having a plurality of interconnecting pores extending through the membrane and made from a material which tends to absorb oils and certain contaminating surfactants. A coating is disposed on surfaces of the nodes and fibrils defining the interconnecting passages in the membrane. The coating comprises oleophobic fluoropolymer solids coalesced on surfaces of the nodes and fibrils to provide oil and surfactant resistance to the composite membrane without completely blocking pores in the membrane. The composite membrane is gas permeable, liquid penetration resistant and capable of moisture vapor transmission at a rate of at least 70,000 gr / m2 day.

Owner:BHA ALTAIR

Nonwoven fibrous structure comprising synthetic fibers and hydrophilizing agent

Owner:THE PROCTER & GAMBLE COMPANY

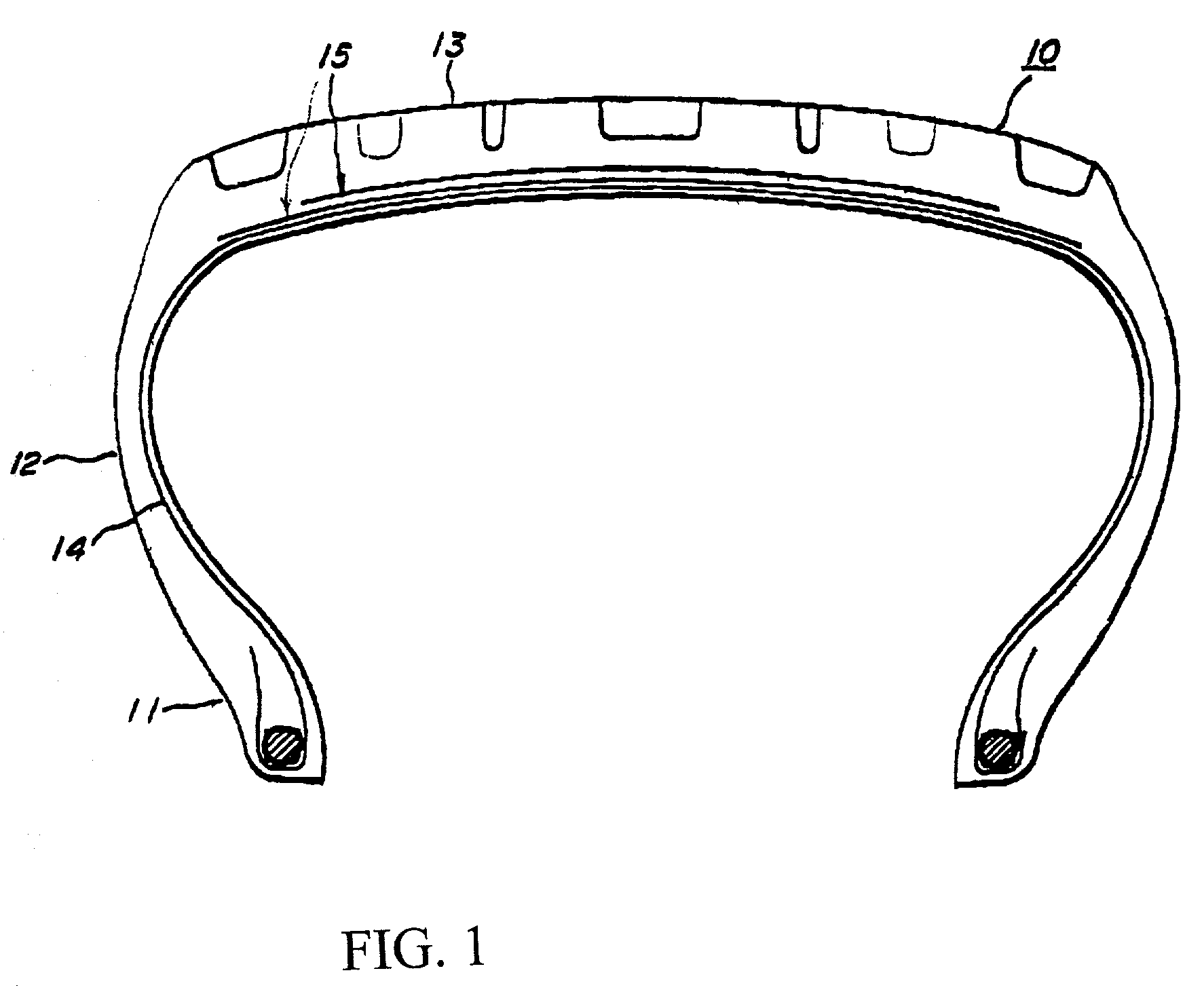

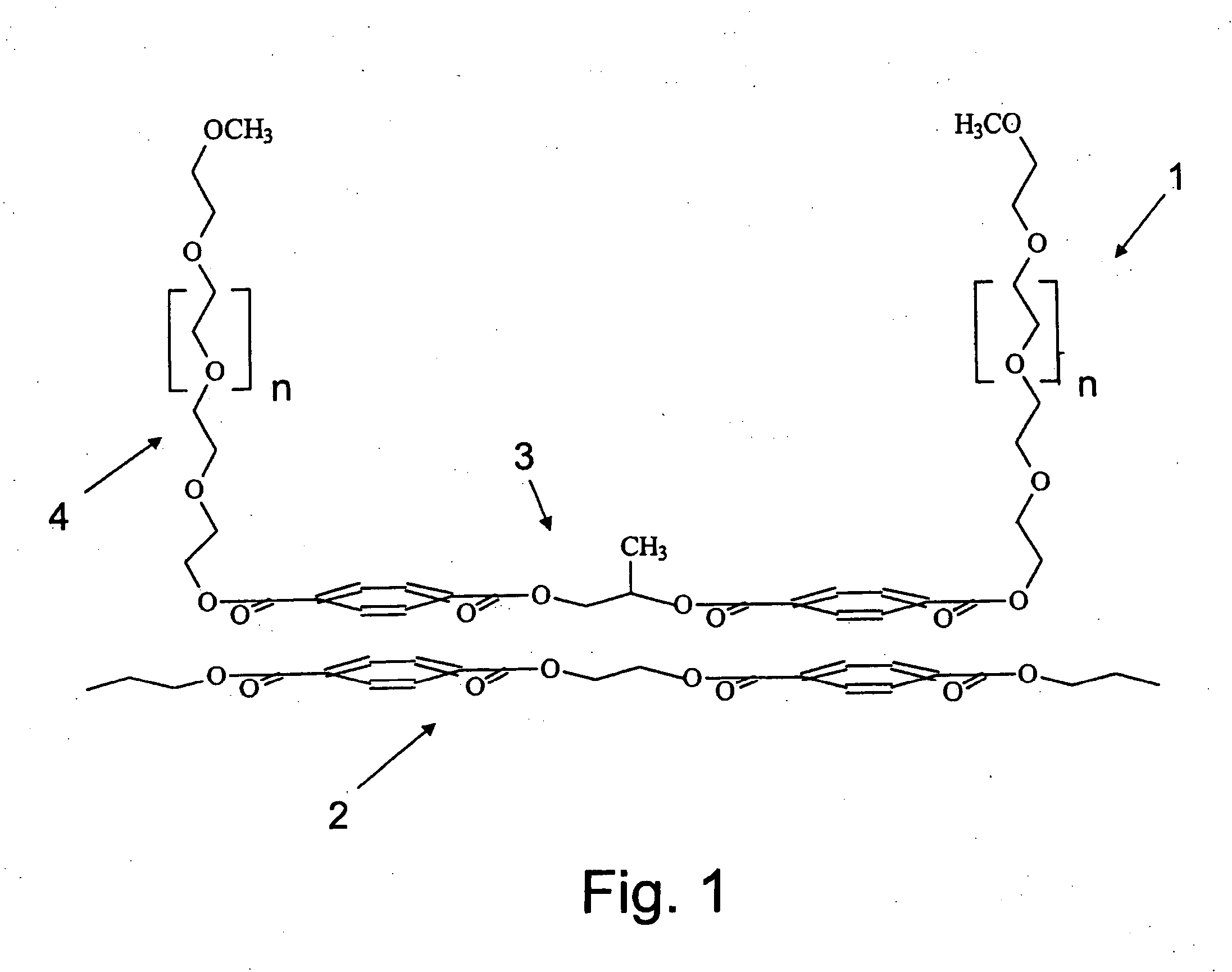

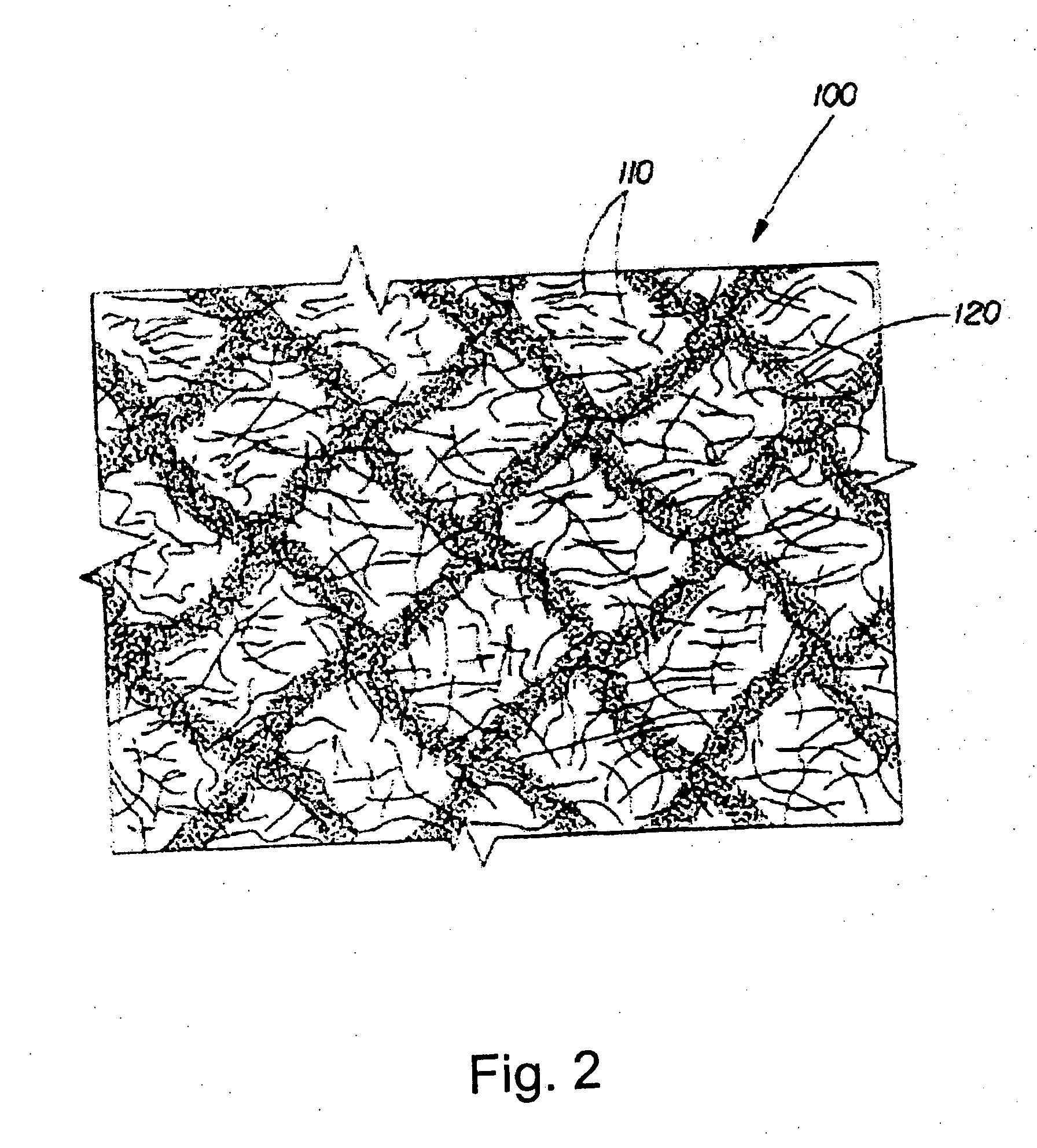

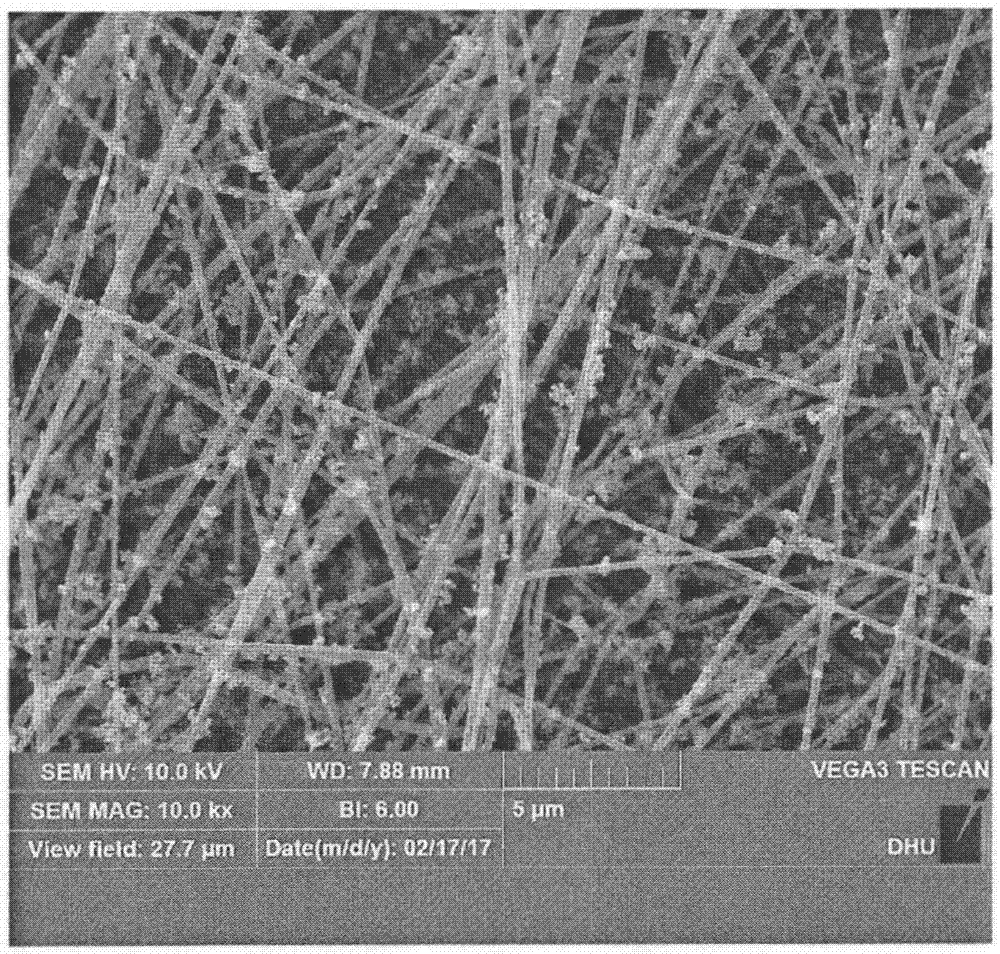

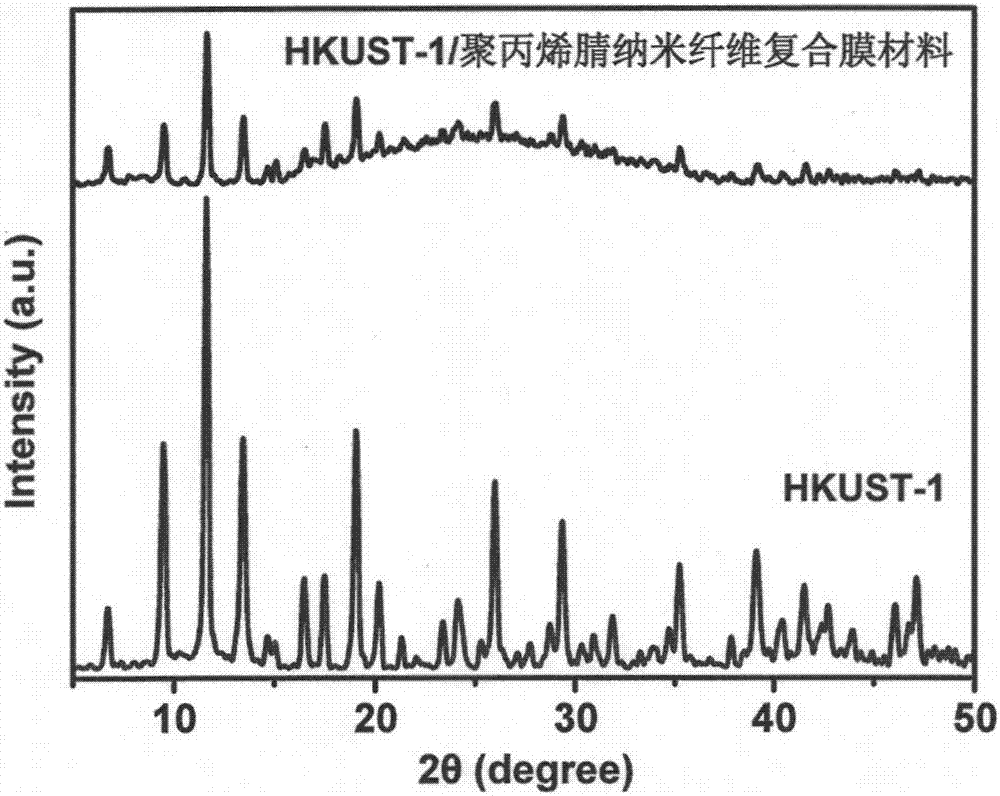

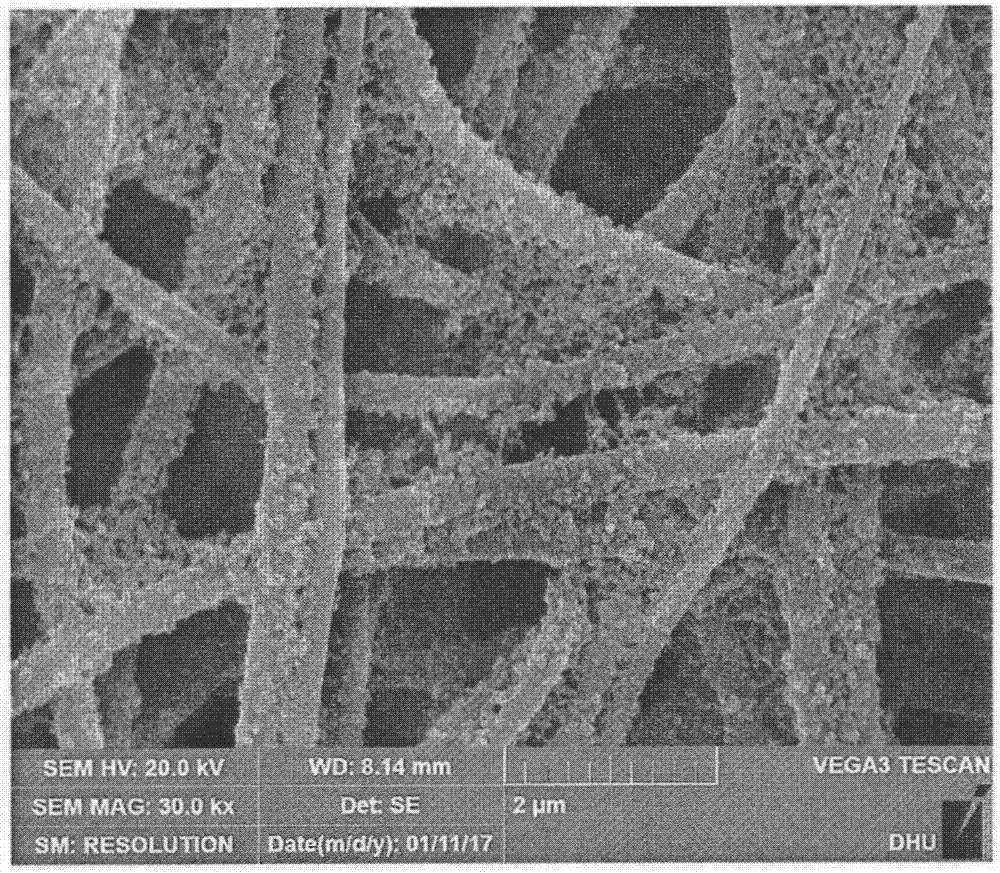

Metal organic framework/polymer nanofiber composite membrane material and preparation method thereof

InactiveCN107022899AUniform, stable and dense growthStable growthFibre typesNon-woven fabricsMetal-organic frameworkFiber

The invention provides a metal organic framework / polymer nanofiber composite membrane material and a preparation method thereof. The metal organic framework / polymer nanofiber composite membrane material is characterized by being prepared from a polymer nanofiber membrane; a metal organic framework layer grows on the surfaces of nanofibers in the polymer nanofiber membrane. The preparation method is characterized by comprising the steps of firstly preparing the polymer nanofiber membrane, hydrolyzing the polymer nanofiber membrane, and putting the hydrolyzed polymer nanofiber membrane into a precursor solution of a metal organic framework to enable the metal organic framework to grow on the polymer nanofiber membrane so as to obtain the metal organic framework / polymer nanofiber composite membrane material. The metal organic framework / polymer nanofiber composite membrane material has great application potential in the fields such as gas adsorption and separation, catalysts, sensors and electrode materials.

Owner:DONGHUA UNIV

TPE composition that exhibits excellent adhesion to textile fibers

InactiveUS6503984B2Increase stiffnessHigh modulusFibre typesOther rubber adhesivesTextile fiberPolyester

A combination of a low flexural modulus and low crystallinity polyolefin and a functionalized polyolefin were found to result in an olefin composition with excellent adhesion to metals and polar polymers (e.g. polyesters, polyamides, etc) especially fibers therefrom. When these two polyolefins were added to a thermoplastic vulcanizate (e.g. used to partially or fully replace the semicrystalline polyolefin of a thermoplastic vulcanizate), the thermoplastic vulcanizate was found to have the necessary adhesion to form fiber reinforced thermoplastic vulcanizate.

Owner:EXXONMOBIL CHEM PAT INC

Fiberglass non-woven catalyst

The present invention relates to novel catalysts for use with a fiberglass non-woven binder. The catalyst can be a Lewis acid, an organic acid salt, a free-radical generator, or a mixture thereof. The catalyst provides stronger bonding, increased crosslinking density, reduced curing times, and reduced curing temperatures. Fiberglass mats made with polymer binder compositions containing the catalyst exhibit both flexibility and elasticity, allowing the mats to be compressed for storage, yet return to original thickness once the compressive forces are removed. Formaldehyde-free wood composites, such as plywood and fiberboard, may also be produced with polymer binder compositions containing the catalyst.

Owner:SIEMENS AG +1

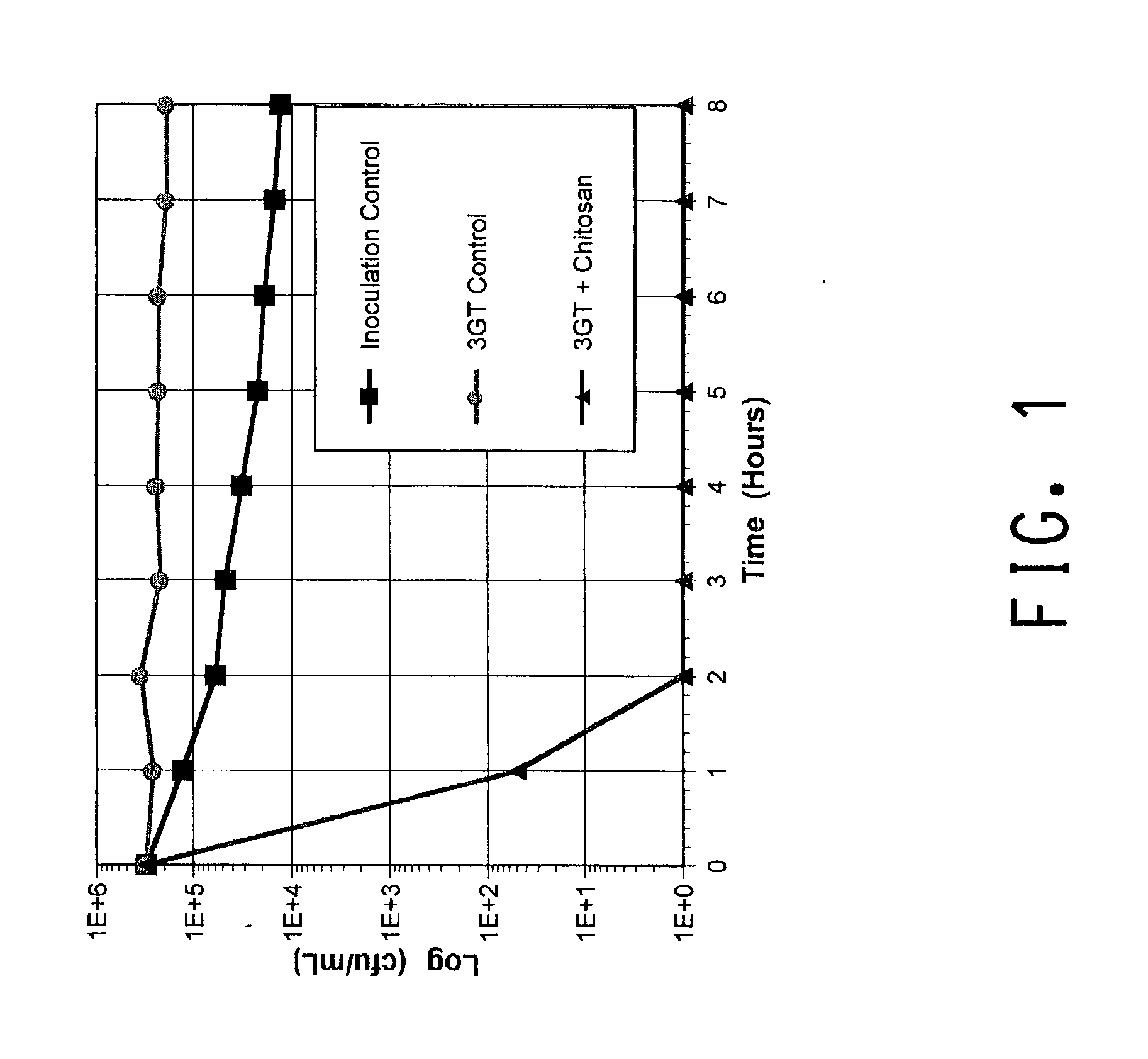

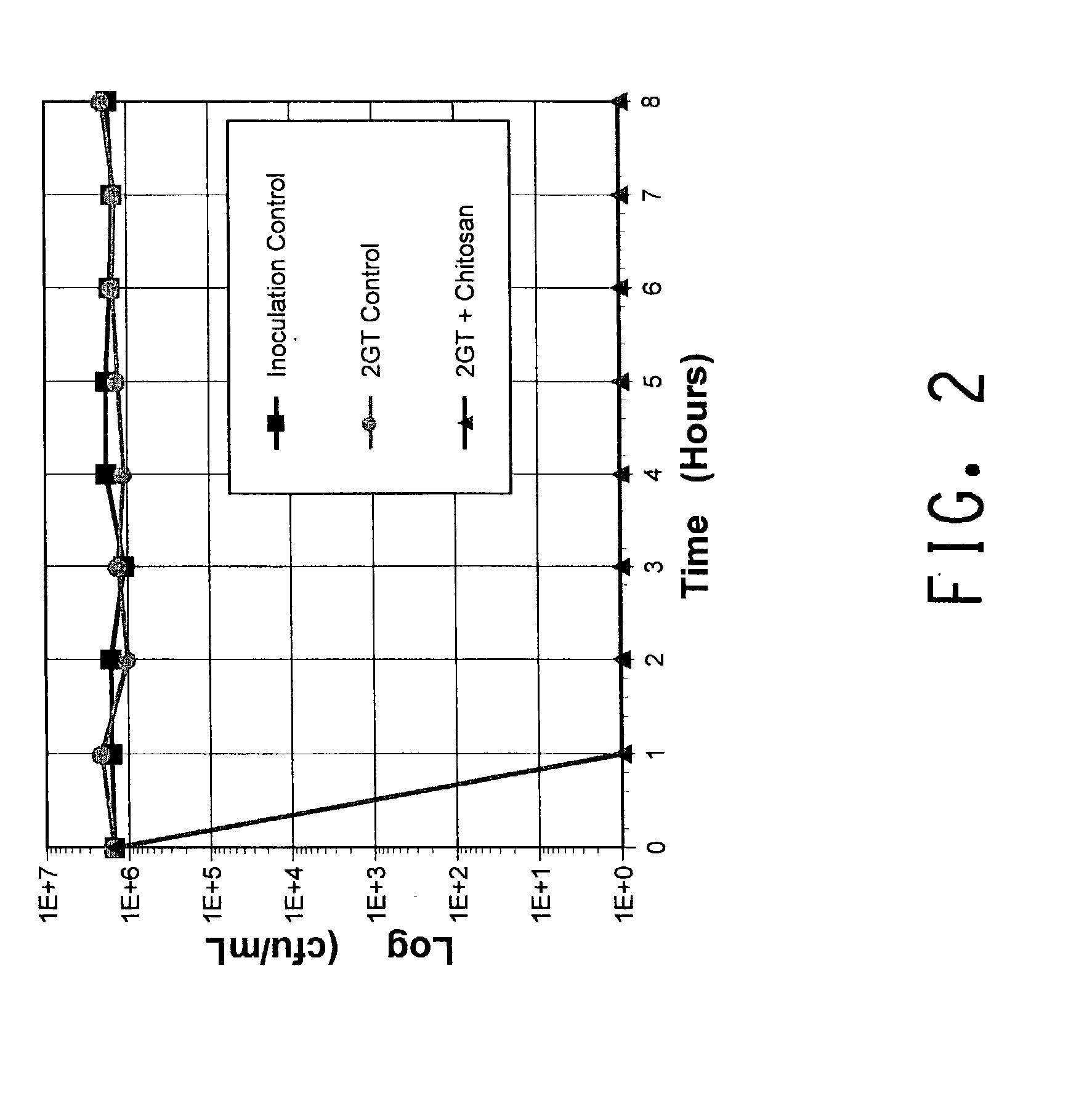

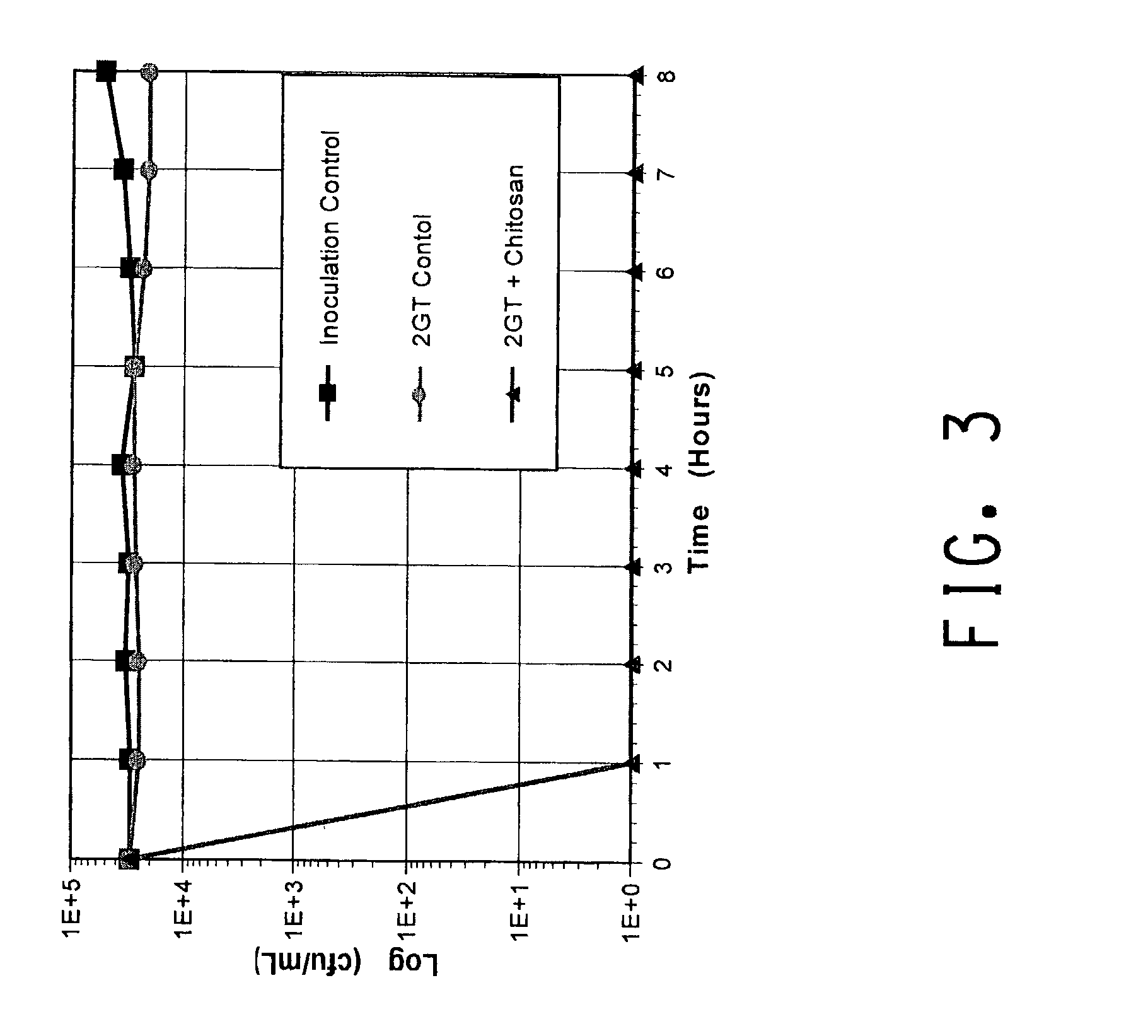

Antimicrobial polyester-containing articles and process for their preparation

This invention relates to antimicrobial polyester-containing articles and methodology for the preparation of antimicrobial polyester-containing articles utilizing chitosan and chitosan-metal complexes as the antimicrobial agent.

Owner:EI DU PONT DE NEMOURS & CO

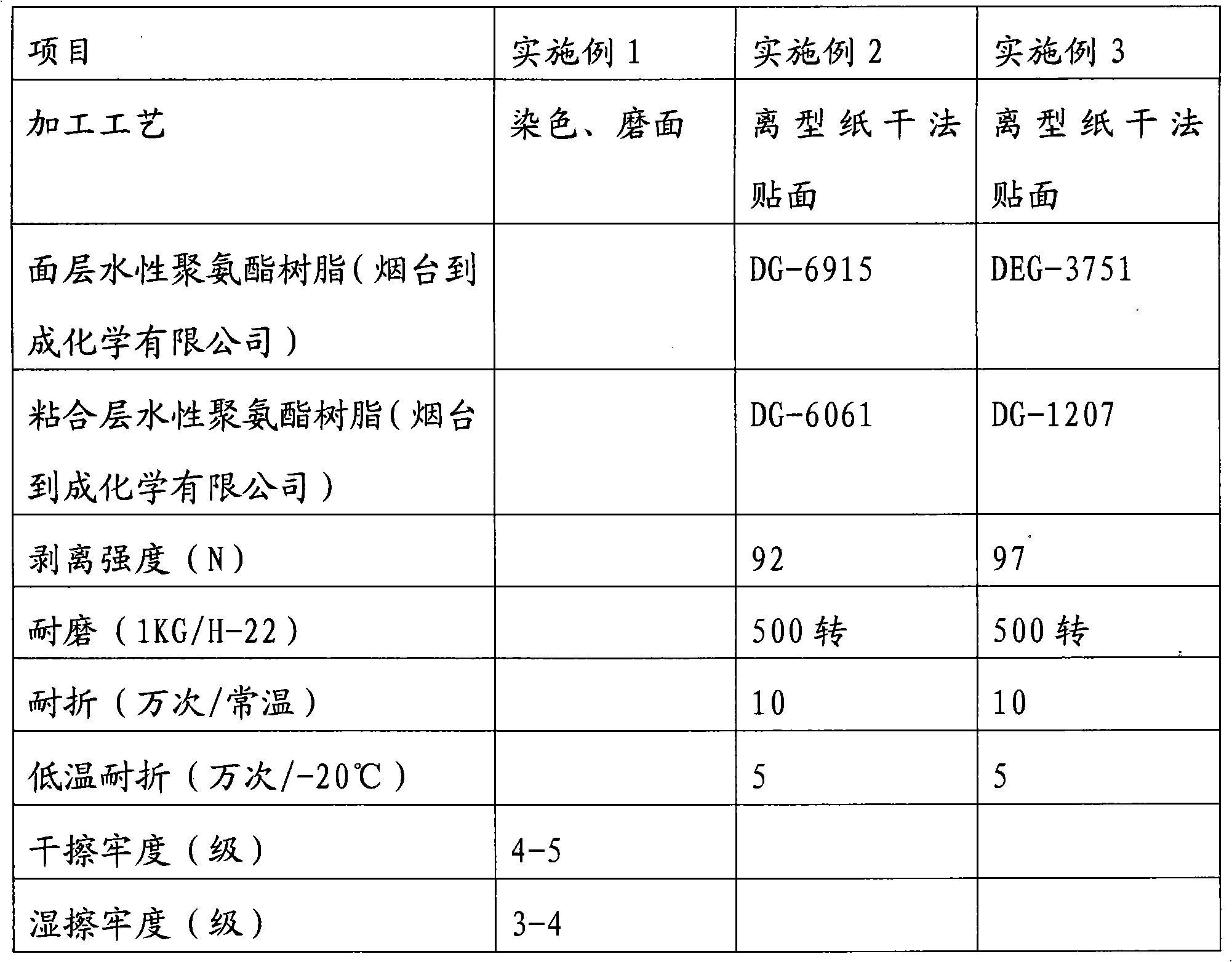

Aqueous polyurethane superfine fiber synthetic leather and preparation method thereof

The invention relates to aqueous polyurethane superfine fiber synthetic leather and a preparation method thereof. The preparation method comprises the following steps of: firstly, adding the following components according to parts by weight, i.e. 2-5 parts of foaming agents, 50-200 parts of water, 2-3 parts of foam stabilizers and 0-3 parts of waterborne colorants, into 100 parts of aqueous anionic polyurethane dipping sizing agents, and stirring the components and the sizing agents uniformly at high speed by using a blender so as to prepare a sizing agent; secondly, dipping non-woven fabricsin the sizing agent, scrapping the surface of the fabrics and keeping partial cells; thirdly, solidifying aqueous polyurethane on the dipped non-woven fabrics through aqueous coagulating liquid so asto form cells; fourthly, carrying out water scrubbing after aqueous polyurethane resin is completely solidified, and drying the aqueous polyurethane resin by an infrared drying oven so as to obtain base cloth; fifthly, treating the dried base cloth through an alkali reducing process; sixthly, treating the base cloth treated through the alkali reducing process through an postprocessing process; and seventhly, preparing the obtained base cloth into the synthetic leather. The aqueous polyurethane superfine fiber synthetic leather is prepared by the method.

Owner:HUADA CHEM GRP CO LTD

Preparation method and application of polycaprolactone/natural polymer composite porous scaffold

InactiveCN102277737AImprove hydrophilicityEasy to spreadLayered productsFibre typesFiberPolymer science

Preparation method and application of polycaprolactone / natural polymer composite porous scaffold, method: including preparation of polycaprolactone electrospun nanofiber membrane; (1) placing polycaprolactone electrospun nanofiber membrane in alkaline solution reaction, soaking and rinsing in deionized water; (2) putting the fiber membrane obtained in (1) into DMTMM or natural polymer solution of DTMMM to react, immersing and rinsing in deionized water, and then immersing in natural polymer for room temperature reaction, to remove Ionized water soaking and rinsing; (3) Evenly coating and casting the mixed solution of natural polymer materials on the fiber membrane obtained in (2), freeze-drying, and extracting the solvent; (4) Applying the double-layer scaffold obtained in (3) After soaking in the cross-linking room temperature reaction, soaking in deionized water, rinsing, and freeze-drying. The porous scaffold prepared by the invention is stable, has suitable pore diameter, good biocompatibility and fast degradation rate, and can be used for skin and clinical tissue and organ defect repair, reconstruction or wound dressing.

Owner:NANCHANG UNIV

Polyolefin fibers and method for the production thereof

InactiveUS6811716B1Poor propertyPoor processabilityOther chemical processesFibre typesFiberPolyolefin

A method for producing hydrophobic polyolefin-containing fibers or filaments, in particular cardable staple fibers, using spin finishes applied after spinning and stretching, that comprise at least one water-insoluble ester of a mono-, di-, tri- or tetrahydric alcohol with a molecular weight not exceeding 500 and a branched or straight chain fatty acid with between 12 and 30 carbon atoms, e.g. a water-insoluble ester of ethylene or propylene glycol, glycerol, neopentyl glycol, trimethylolethane or trimethylolpropane and at least one saturated or unsaturated fatty acid residue having 12-24 carbons atoms, an anionic or nonionic antistatic agent preferably being applied after crimping; fibers produced by the method; and nonwovens produced from such fibers.

Owner:FIBERVISIONS LP

Terylene coral fleece blanket fabrics and processing method thereof

The invention relates to terylene coral fleece blanket fabrics and a processing method thereof, which belongs to the technical field of terylene fiber products and comprises voile weave and ground weave, the raw material used by the voile weave is DTY terylene filament in 133dtex / 192f, 111dtex / 192f or 111dtex / 144f, and the raw material used by the ground weave is FDY terylene filament of 75dtex / 24f, wherein the mass percentage of the DTY terylene filament occupied in the fabrics is 60-70 percent, and the mass percentage of the FDY terylene filament occupied in the fabrics is 30-40 percent. The invention can lead villus of the fabrics to be straight so as to have excellent lodging resistance and warmth retention property, and can obtain 150-250g / m<2> of gram weight of thread count and be suitable to fabricate household wares such as bathrobe, sleepwear, sheet, and the like. The method can ensure the advantages of the terylene coral fleece blanket fabrics, and can lead the terylene coral fleece blanket fabrics to have better sterilizing, antistatic and anti-allergic effects so as to meet the serviceability.

Owner:CHANGSHU XINXIN WARP & KNITTING

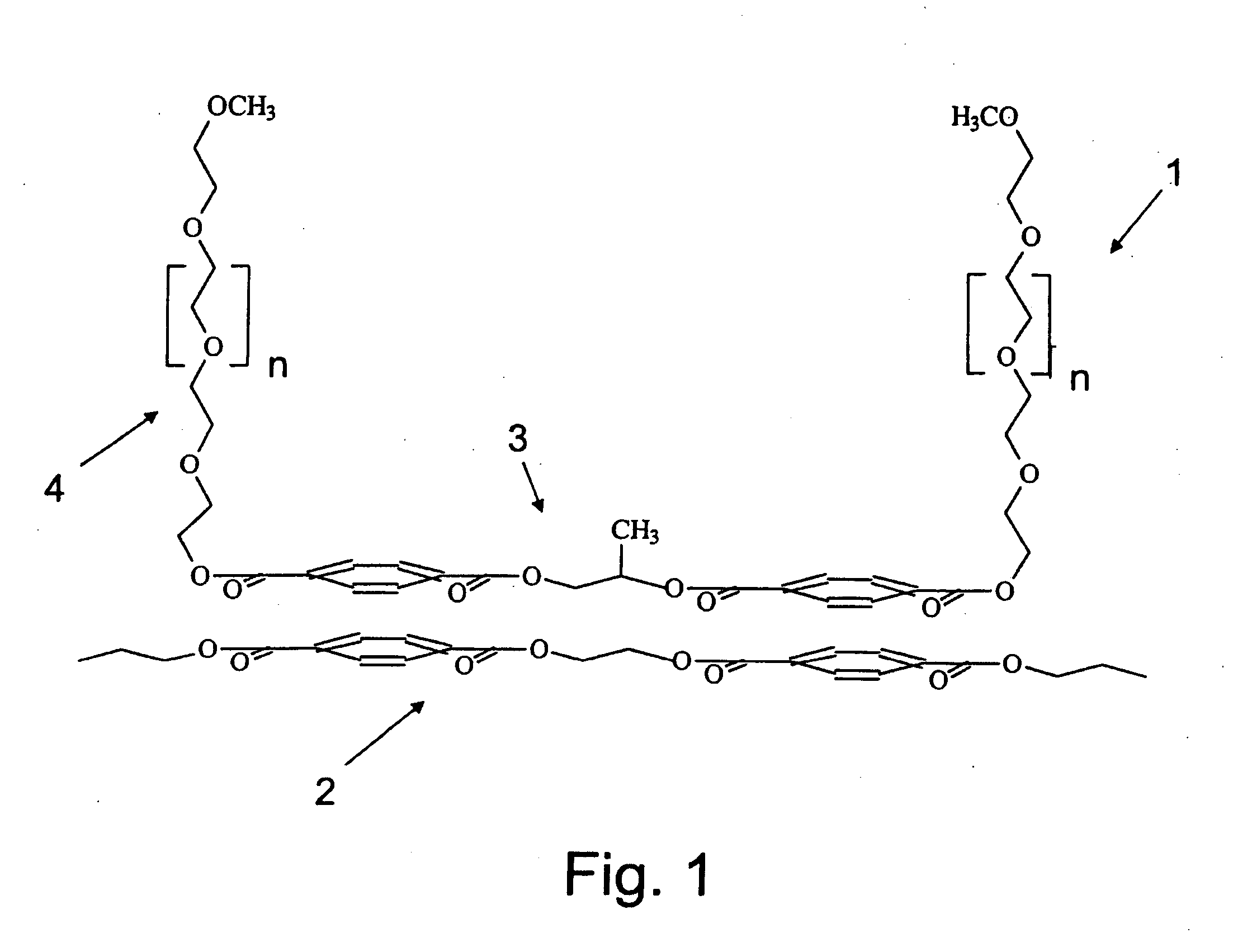

Moisture absorption perspiration-discharging dressing agent and its manufacturing technique and application

ActiveCN101265664AGood moisture absorption and perspirationGood modification effectFibre typesDyeing processFiberPolyester

The invention discloses the formula, the production process and the application of moisture absorbent and sweat conductive comfortable finishing agent which is used for modifying the polyester fiber to enable the polyester fiber to have moisture absorbent and sweat conductive capabilities. The formula of the moisture absorbent and sweat conductive comfortable finishing agent contains: polyethylene glycol, ethylene glycol, polyether and dimethyl terephthalate. The two-step continuous production process is adopted: in the first step of esterifying, polyethylene glycol, ethylene glycol, polyether and dimethyl terephthalate are put into a reaction vessel for esterification under the action of catalysts; and in the second step that the material produced after the esterification is transported to a polymerization kettle for polymerization under the actions of high temperature, vacuum, and catalysts, in order to generate polyester-polyether copolymer with high molecular weight to be 30000-50000, namely, the moisture absorbent and sweat conductive comfortable finishing agent. The moisture absorbent and sweat conductive comfortable finishing agent can be directly used or be used after being mixed with substances such as amino silicone oil and so on, and carry out chemical modification on the polyester fiber.

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

Anti-tack spandex fibers containing antimicrobial agents therein and fabrics made therefrom

InactiveUS6479144B2Easy to processImprove cohesionMonocomponent polyurethanes artificial filamentBiocideYarnFiber

Polyurethane elastomer yams (particularly spandex) containing certain silver-based antimicrobial formulations therein are provided. This invention relates to polyurethane elastomer yams (particularly spandex) containing certain silver-based antimicrobial formulations therein. Such formulations comprise antimicrobial compounds, such as, preferably, triclosan and / or silver-containing ion-exchange resins, such as zirconium phosphate, glass, and / or zeolite compounds. The inventive spandex yarns exhibit excellent antimicrobial qualities as well as surprisingly good anti-tack / frictional characteristics. As a result, antimicrobial spandex yams are provided which exhibit ease in processing, particularly in further knitting, weaving, etc., to produce fabrics therefrom. Such fabrics are also encompassed within this invention.

Owner:MILLIKEN & CO

Electroconductive woven and non-woven fabric and method of manufacturing thereof

ActiveUS20070054577A1Improve adhesionUniform and stableNanotechPhysical treatmentEngineeringBiological activation

The invention relates to an electroconductive textile material and method of preparation thereof. The method consists mainly of two stages: 1) special pretreatment of the fabric substrate for activation and making it suitable for subsequent application and strong attachment of a conductive coating with the use of a layer-by-layer technique (LBL); 2) subsequent application and strong attachment of a conductive coating by means of a layer-by-layer technique. The first stage may be carried out thermally, thermochemically, by treating in hot solutions, or plasma-chemically by plasma treatment. The pre-treatment may be performed, e.g., for swelling and / or for the formation of unsaturated chemical bonds or uncompensated charges in the fabric material. The pretreatment is needed to ensure more efficient penetration of chemical components into the fabric structure during subsequent LBL applications of treatment solutions that contain nano-particles and that determine the density of the molecular layer. The types and amounts of the nano-particles determine their charge density (solution pH is very important for charge density) in the sublayer. Such a pretreatment increases bonds of the applied layers with the substrate material.

Owner:EEONYX CORP

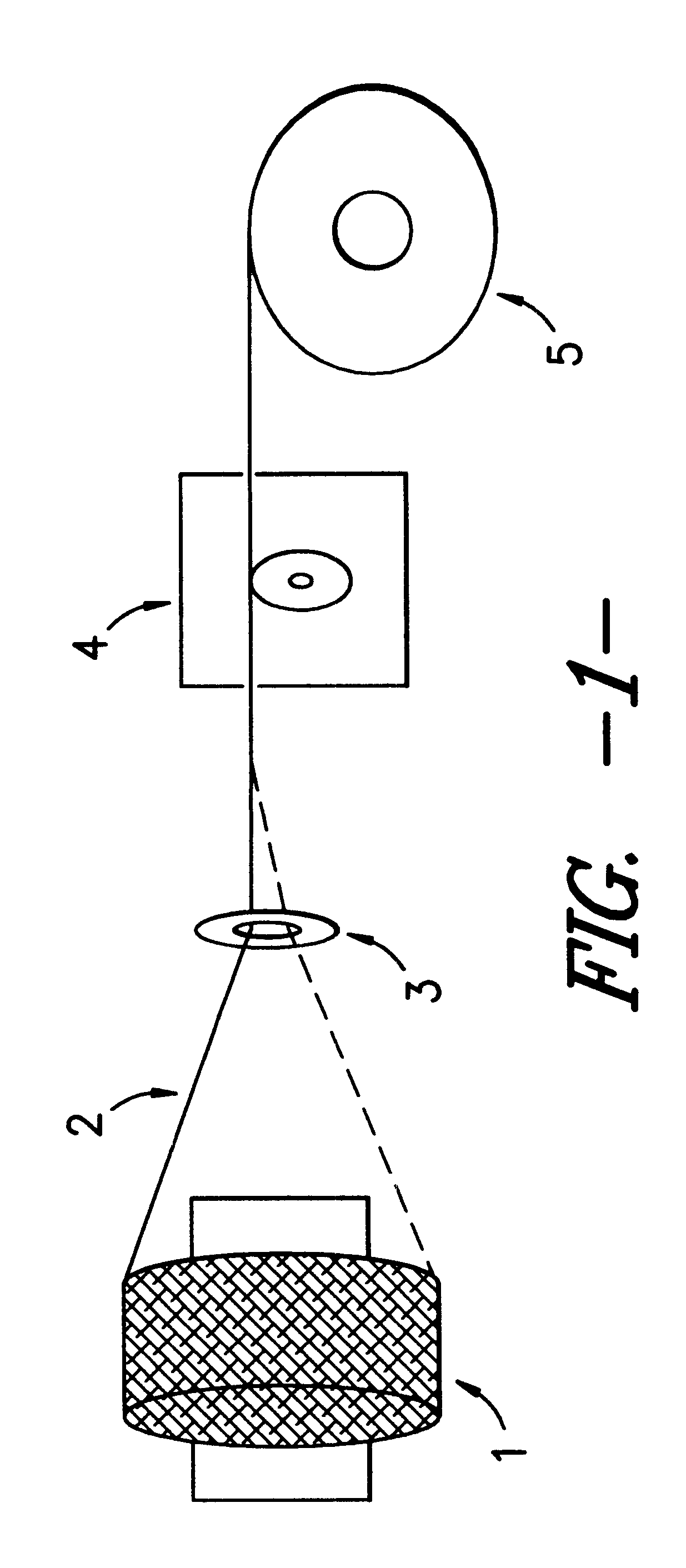

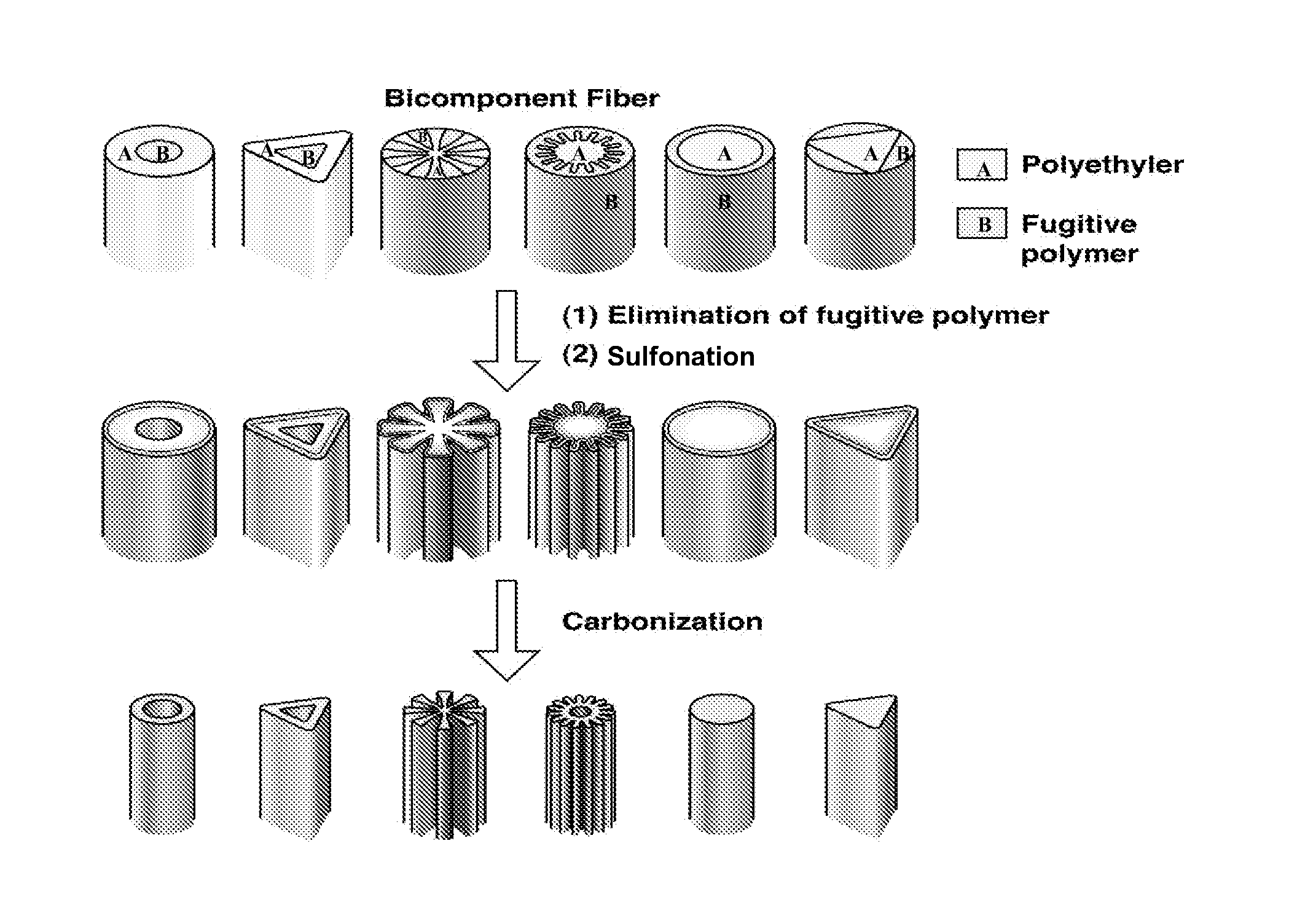

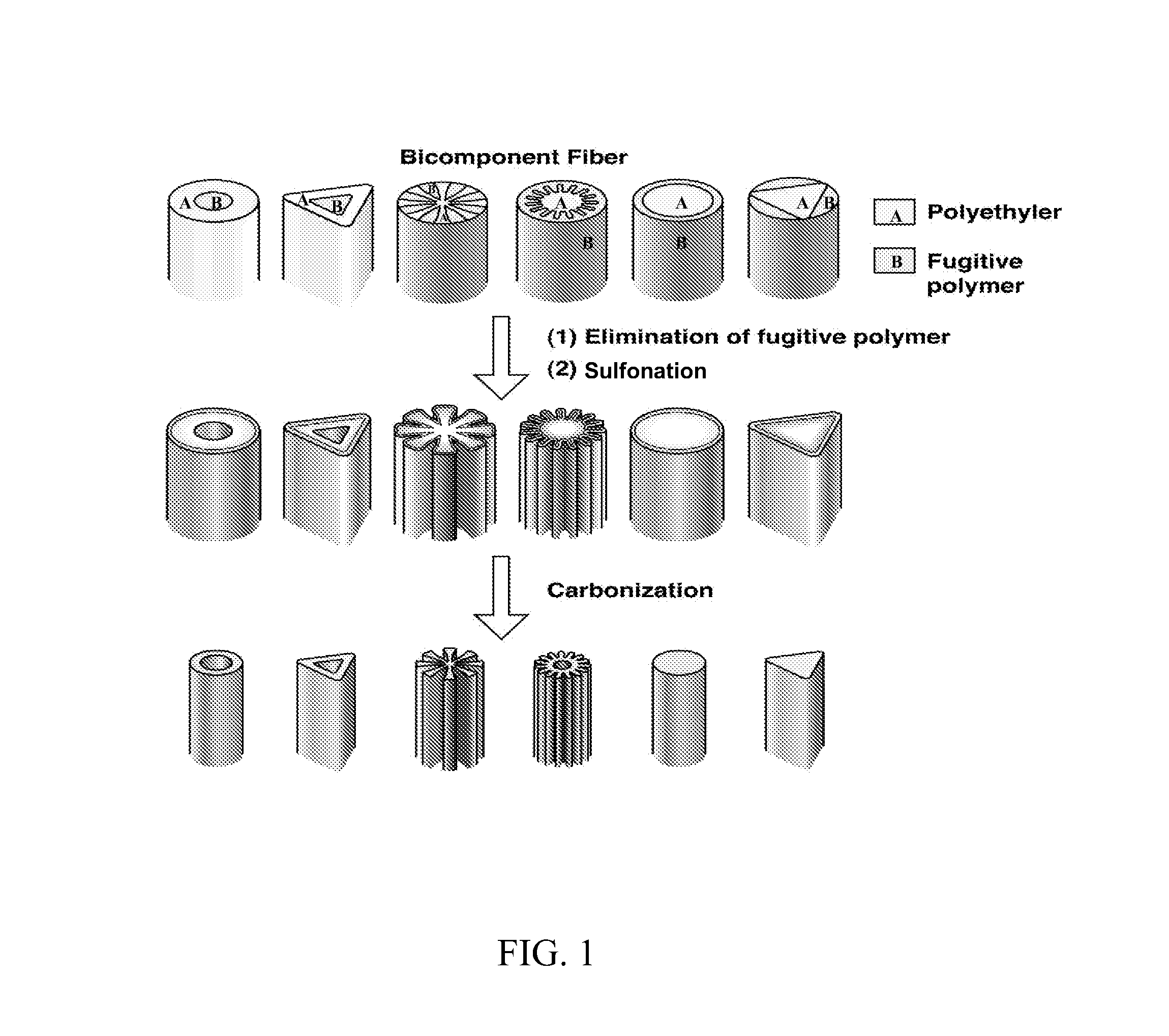

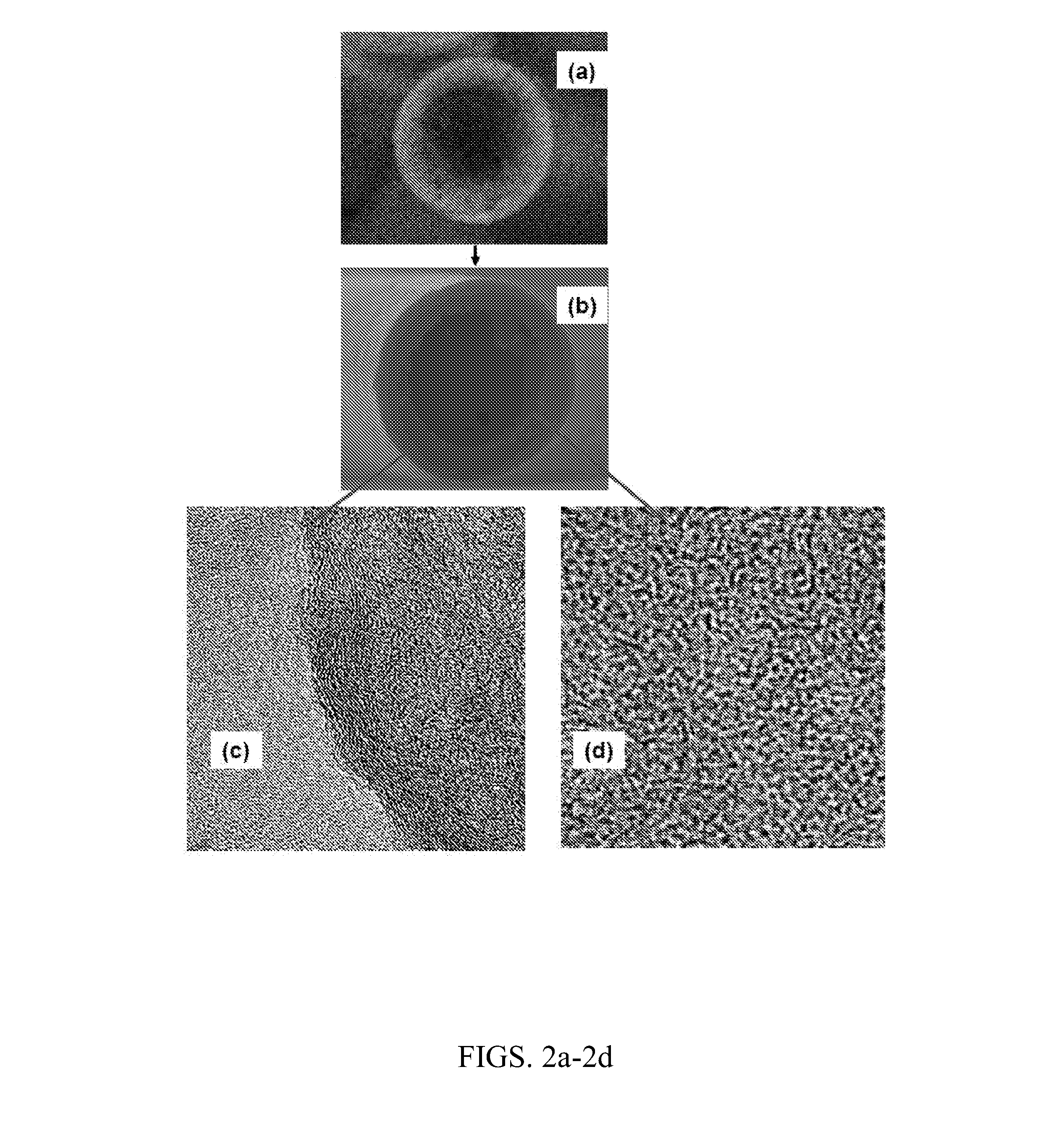

Method for the preparation of carbon fiber from polyolefin fiber precursor, and carbon fibers made thereby

Methods for the preparation of carbon fiber from polyolefin fiber precursor, wherein the polyolefin fiber precursor is partially sulfonated and then carbonized to produce carbon fiber. Methods for producing hollow carbon fibers, wherein the hollow core is circular- or complex-shaped, are also described. Methods for producing carbon fibers possessing a circular- or complex-shaped outer surface, which may be solid or hollow, are also described.

Owner:UT BATTELLE LLC

Method for improving creep resistant performance of ultra-high molecular weight polyethylene fiber

ActiveCN102493168AHigh surfaceIncrease internal cross-link pointsPhysical treatmentFibre typesFiberPolymer science

The invention relates to a method for improving the creep resistant performance of an ultra-high molecular weight polyethylene fiber; and the method is characterized by jointly triggering crosslinking by using a photosensitizer and a thermal initiating agent, thereby crosslinking points of the surface and interior of the ultra-high molecular weight polyethylene fiber are increased, the crosslinking efficiency of a cross-linking agent is improved, the relative slippage among molecules of the ultra-high molecular weight polyethylene fiber is effectively impeded and the creep resistant performance of the fiber is increased.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Antibacterial non-woven fabric and preparation method thereof

ActiveCN103161071ADoes not affect softnessGood antibacterial effectFibre typesPolymer scienceEmulsion

The invention provides an antibacterial non-woven fabric and a preparation method thereof. Both the upper surface and the lower surface of the antibacterial non-woven fabric are provided with antibacterial film-forming agent layers; each antibacterial film-forming agent layer is obtained by thermally curing a polymer film-forming agent; the polymer film-forming agent has the viscosity of 50-20,000cp and the solid content of 5-55 percent; the film-forming agent has the fluid rate of 2-20 percent; and the polymer film-forming agent is prepared from the following raw materials in percentage by mass: 80-94 percent of a high polymer emulsion, 1-10 percent of a bacteriostatic agent and 5-10 percent of an addition agent. The polymer film-forming agent is selectively roller-coated on the non-woven fabric after the non-woven fabric is formed, so that an antibacterial effect of the non-woven fabric is improved, the antibacterial time is prolonged, and the really long-term antibacterial purpose is achieved.

Owner:TIANJIN SINOSH NEW MATERIAL TECH

Antimicrobial and antistatic polymers and methods of using such polymers on various substrates

The present invention relates to a substrate having antimicrobial and / or antistatic properties. Such properties are imparted by applying a coating or film formed from a cationically-charged polymer composition. The polymer composition includes a noncationic ethylenically unsaturated monomer, an ethylenically unsaturated monomer capable of providing a cationic charge to the polymer composition, and a steric stabilization component incorporated into the cationically-charged polymer composition. The present invention also relates to a polymeric material comprising a base polymer blended with the above cationically-charged polymer composition.

Owner:MALLARD CREEK POLYMERS

Electroconductive fibers with carbon nanotubes deposited thereon, electroconductive threads, fiber structure, and process for producing same

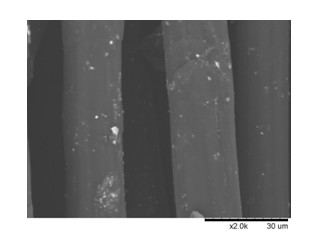

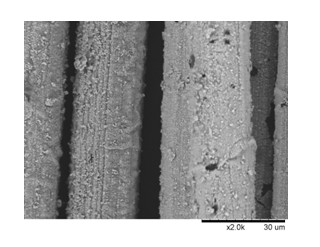

ActiveCN102131980AImprove conductivityGood flexibilityFibre typesUltrasonic/sonic fibre treatmentPolymer scienceMicrometer

Owner:HOKKAIDO UNIVERSITY +1

Preparation method of graphene composite conductive fiber

The invention discloses a preparation method of a graphene composite conductive fiber and relates to the technical field of graphene. The method comprises the following steps: processing a common textile polymer fiber with an organic solvent to remove impurities such as an oiling agent on the fiber surface; dipping the textile polymer fiber into an alkali liquor and an oxidized graphene solution, and enabling the fiber surface to fully contact the oxidized graphene; and dipping the dried fiber with an oxidized graphene coating into a solution containing a reducing agent to obtain the graphene composite conductive fiber. By adopting a simple dip coating method, the obtained composite fiber has mechanical property, high temperature resistance and flexibility performance of a traditional high polymer material and also has good conductivity. The method is easy to operate, environment-friendly and convenient to industrialize.

Owner:宁国市龙晟柔性储能材料科技有限公司

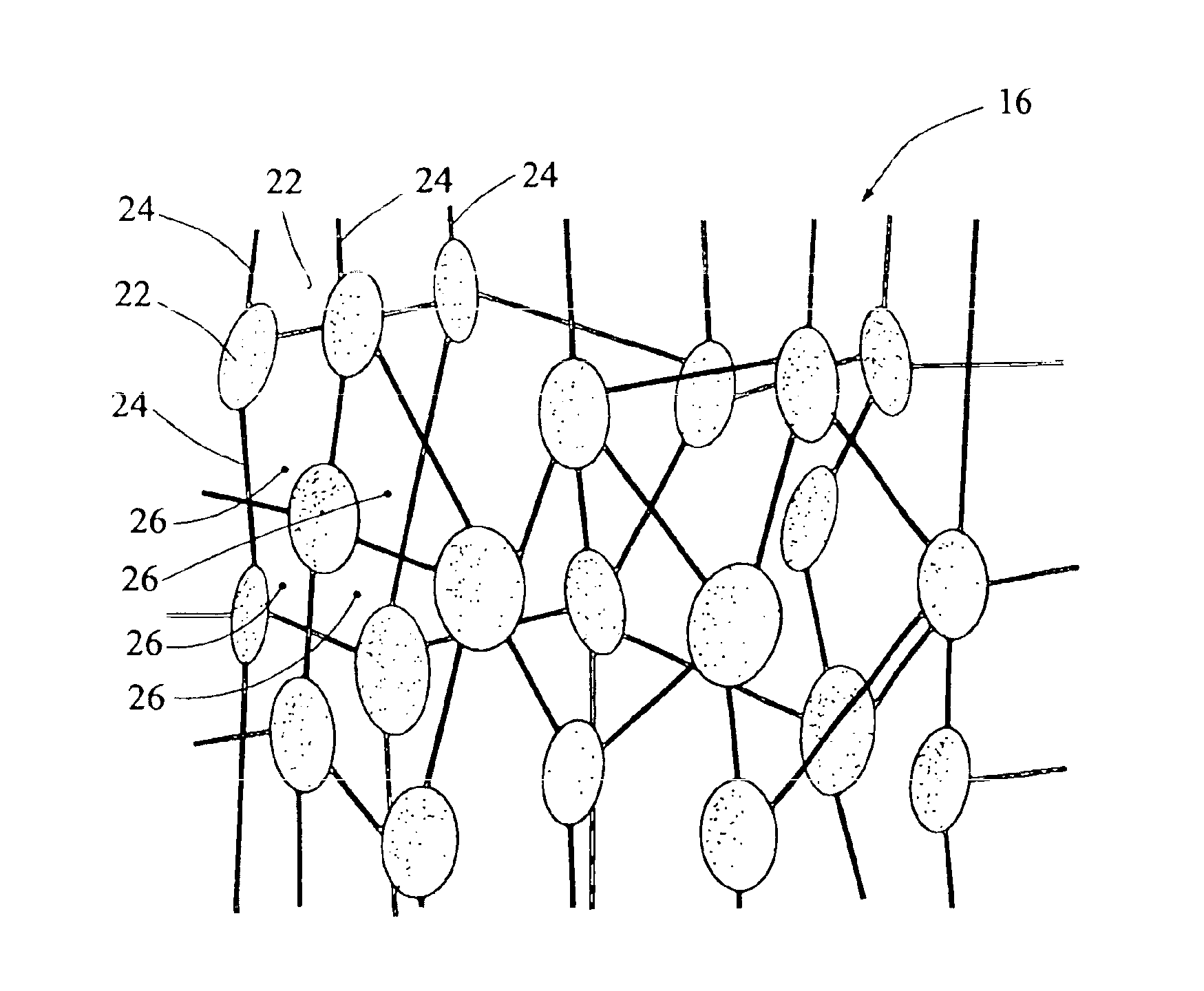

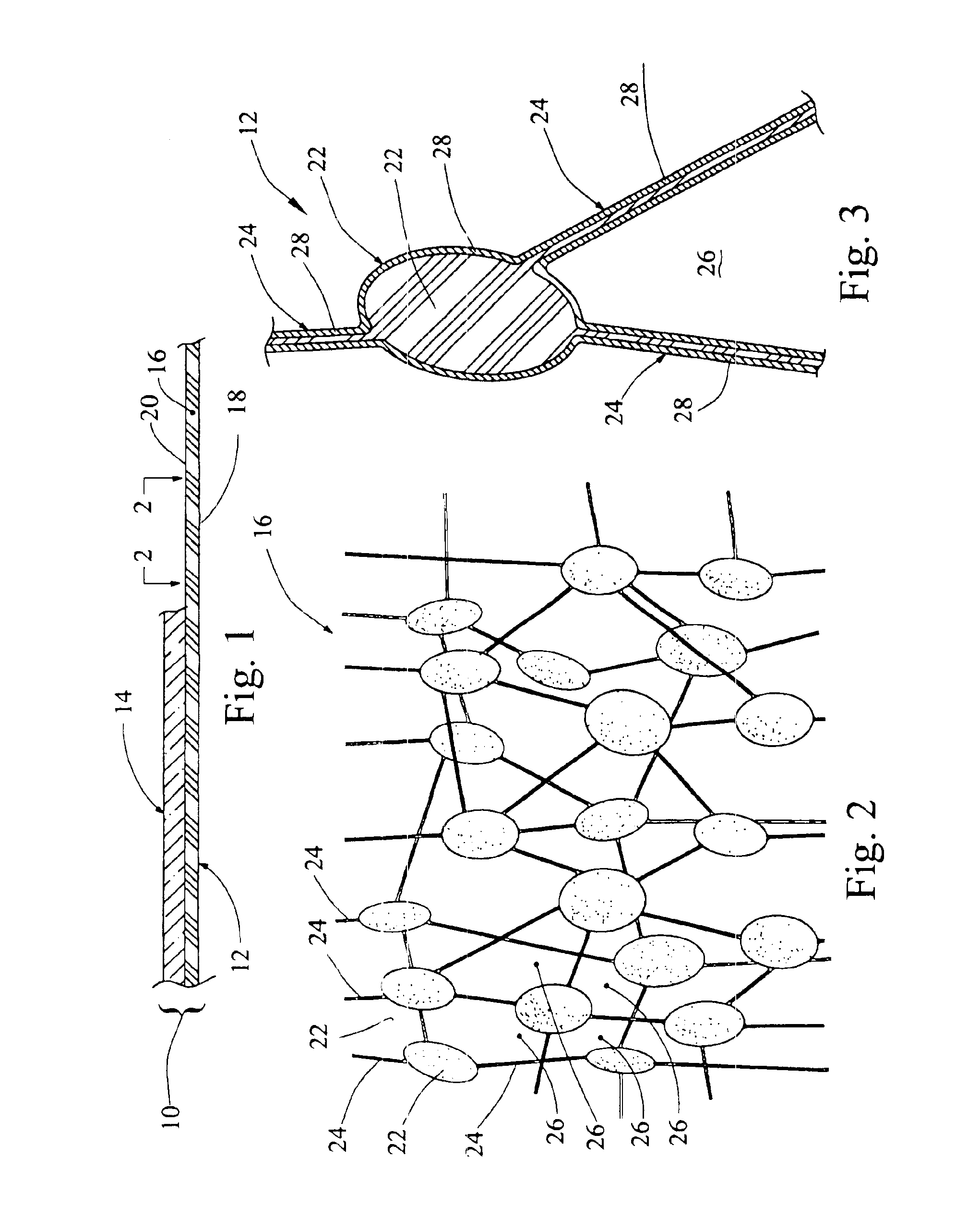

Method of binding binder treated particles to fibers

InactiveUS7018490B2Efficiently and economically attachedReduced particle wastageAdhesive processesNon-fibrous pulp additionParticulatesFiber

A binder is applied to particles which are then combined with fibers to bind the particles to the fibers. The particles have functional sites for forming a hydrogen bond or a coordinate covalent bond. The fibers have hydrogen bonding functional sites. The binder comprises binder molecules, the binder molecules having at least one functional group that is capable of forming a hydrogen bond or a coordinate covalent bond with the particles, and at least one functional group that is capable of forming a hydrogen bond with the fibers. A substantial portion of the particles that are adhered to the fibers may be adhered in particulate form by hydrogen bonds or coordinate covalent bonds to the binder, and the binder in turn may be adhered to the fibers by hydrogen bonds. Fibers containing particles bound by this method are easily densified.

Owner:WEYERHAEUSER CO

Method for preparing conductive ultrahigh molecular weight polyethylene fiber

The invention relates to a method for preparing a conductive ultrahigh molecular weight polyethylene fiber. The conventional method is complicated in process and causes environmental pollution. The method comprises the following steps of: firstly, immersing the ultrahigh molecular weight polyethylene fiber into acetone, ethanol or a tetrahydrofuran solution, performing ultrasonic washing on the fiber and airing; secondly, dissolving a dopamine substance into a buffer solution to prepare an activation solution, placing the ultrahigh molecular weight polyethylene fiber into the activation solution and activating the ultrahigh molecular weight polyethylene fiber under stirring; and finally, immersing the activated ultrahigh molecular weight polyethylene fiber in a plating solution at temperature of 10 to 60 DEG C for 0.5 to 10 hours so as to finish silver plating. By the method, the surface of the ultrahigh molecular weight polyethylene fiber is activated by using dopamine polymer and metallized by using chemical plating, so that the ultrahigh molecular weight polyethylene fiber with extremely high conductivity can be obtained; and the whole process is environment-friendly and pollution-free.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com