Preparation method and application of polycaprolactone/natural polymer composite porous scaffold

A technology of natural macromolecules and polycaprolactone is applied in the field of preparation of medical porous stents, which can solve the problems of unsatisfactory histocompatibility and cell affinity, and achieve the effect of being beneficial to spreading and improving hydrophilicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this embodiment, NaOH is selected to treat the modified polycaprolactone electrospun nanofiber membrane, type gelatin, and coat the gelatin solution. The crosslinking agent is a mixture of EDC / NHS for crosslinking. The specific steps are as follows:

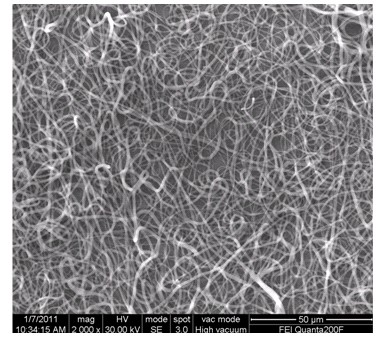

[0051] The first step, the preparation of polycaprolactone electrospun nanofiber membrane: Dissolve PCL in methanol / chloroform mixed solvent with a volume ratio of 1 / 1 to prepare an electrospinning solution with a concentration of 12 wt%, and fill the solution with In the feeding device of the electrospinning equipment, the feeding rate of the solution is set to 20 l / min, the acceptance distance is 8 cm, and the electrostatic voltage is 15 kV, the biodegradable ultrafine electrospun nanofiber membrane can be obtained (attached figure 1 ).

[0052] In the second step, the surface of polycaprolactone electrospun nanofiber membrane is modified by alkali treatment: the polycaprolactone electrospun nanofiber membrane is pla...

Embodiment 2

[0057] In this embodiment, the KOH-treated modified polycaprolactone electrospun nanofiber membrane is selected, the mixed solution of water-soluble chitosan, coated gelatin and chitosan is input, and the cross-linking agent is a mixture of EDC / NHS. Specific steps are as follows:

[0058] The first step, the preparation of polycaprolactone electrospun nanofiber membrane: dissolve PCL in DMF / chloroform with a volume ratio of 3 / 2 to prepare an electrospinning solution with a concentration of 18 wt%, and put the solution into the electrospinning In the feeding device of silk equipment, set the feeding rate of the solution to 20 l / min, the acceptance distance is 8 cm, and the electrostatic voltage is 15 kV, the biodegradable ultrafine electrospun nanofiber membrane can be obtained.

[0059] In the second step, the polycaprolactone electrospun nanofiber membrane is subjected to surface alkali treatment modification: the polycaprolactone electrospun nanofiber membrane is placed ...

Embodiment 3

[0064] In this embodiment, NaOH is selected to treat the modified polycaprolactone electrospun nanofiber membrane, gelatin is added, gelatin and sodium alginate mixed solution are coated, and the dehydrating agent is selected from a mixture of EDC / NHS for crosslinking. The specific steps are as follows:

[0065] The first step, the preparation of polycaprolactone electrospun nanofiber membrane: Dissolve PCL in methanol / chloroform mixed solvent with a volume ratio of 1 / 1 to prepare an electrospinning solution with a concentration of 15 wt%, and fill the solution with In the feeding device of the electrospinning equipment, the feeding rate of the solution is set to 20 l / min, the acceptance distance is 8 cm, and the electrostatic voltage is 15 kV, the biodegradable ultrafine electrospun nanofiber membrane can be obtained.

[0066] In the second step, the polycaprolactone electrospun nanofiber membrane is modified by surface alkali treatment: the polycaprolactone electrospun nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com