Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Adjust aperture size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and application of polycaprolactone/natural polymer composite porous scaffold

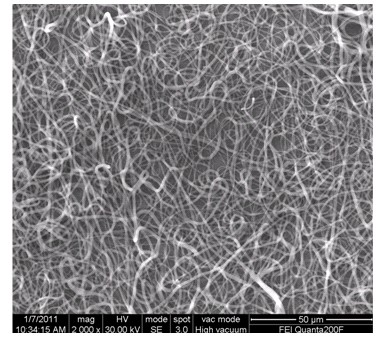

InactiveCN102277737AImprove hydrophilicityEasy to spreadLayered productsFibre typesFiberPolymer science

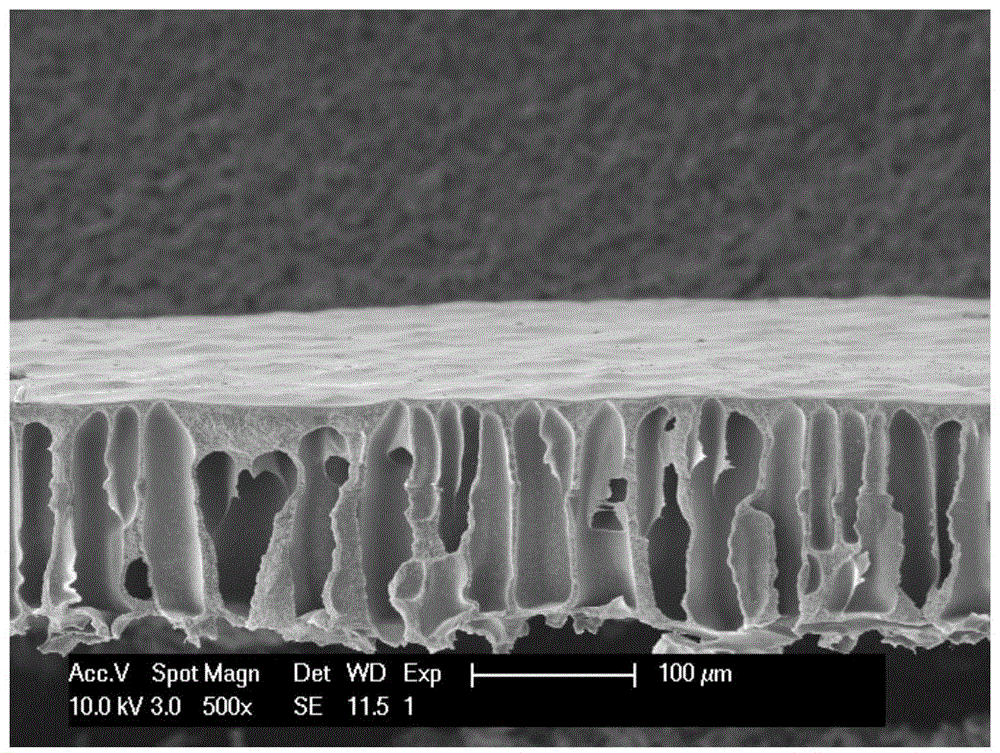

Preparation method and application of polycaprolactone / natural polymer composite porous scaffold, method: including preparation of polycaprolactone electrospun nanofiber membrane; (1) placing polycaprolactone electrospun nanofiber membrane in alkaline solution reaction, soaking and rinsing in deionized water; (2) putting the fiber membrane obtained in (1) into DMTMM or natural polymer solution of DTMMM to react, immersing and rinsing in deionized water, and then immersing in natural polymer for room temperature reaction, to remove Ionized water soaking and rinsing; (3) Evenly coating and casting the mixed solution of natural polymer materials on the fiber membrane obtained in (2), freeze-drying, and extracting the solvent; (4) Applying the double-layer scaffold obtained in (3) After soaking in the cross-linking room temperature reaction, soaking in deionized water, rinsing, and freeze-drying. The porous scaffold prepared by the invention is stable, has suitable pore diameter, good biocompatibility and fast degradation rate, and can be used for skin and clinical tissue and organ defect repair, reconstruction or wound dressing.

Owner:NANCHANG UNIV

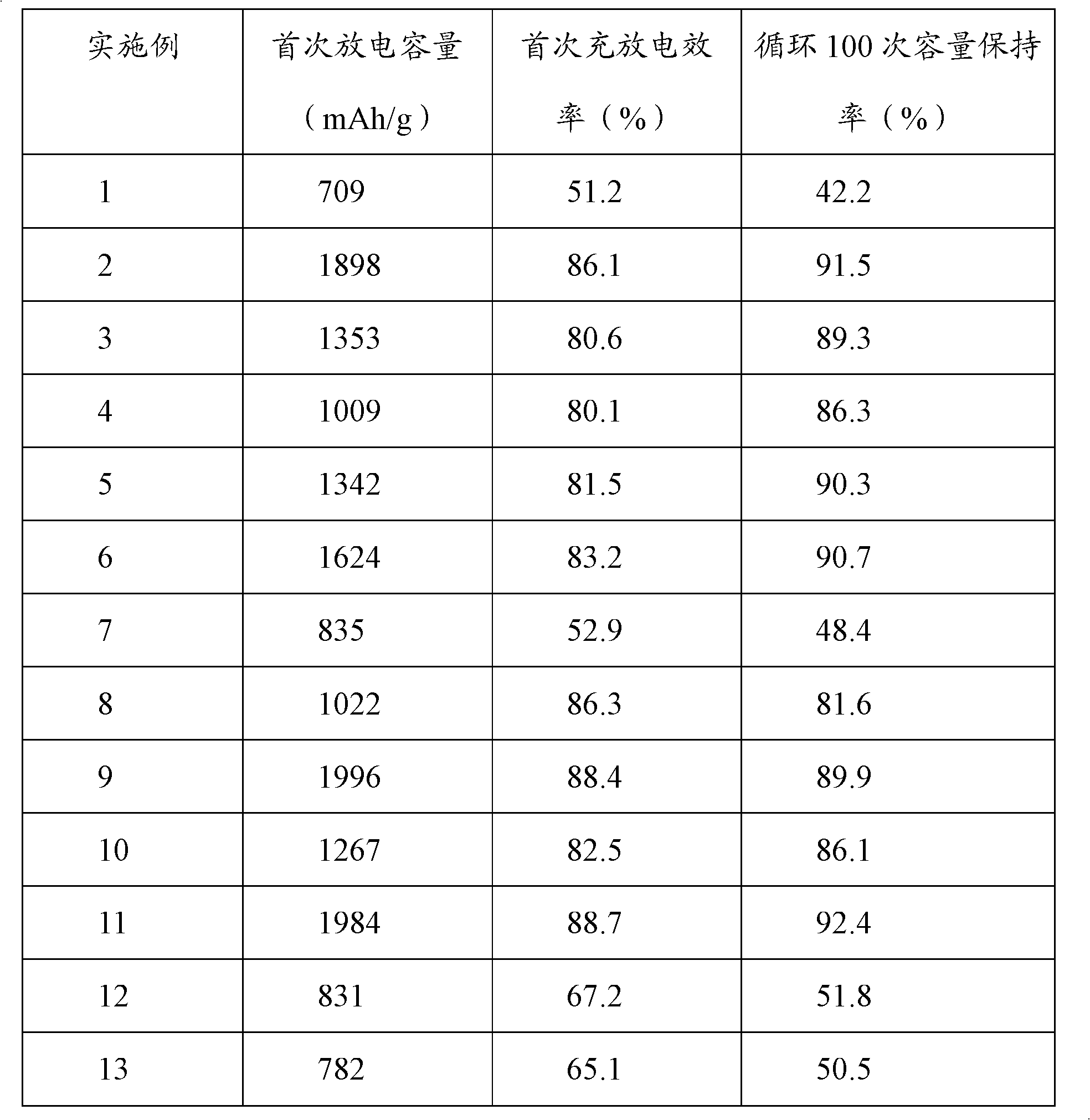

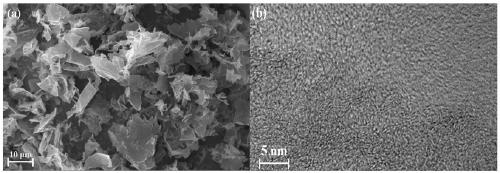

Silicon-based cathode composite material for lithium ion battery and preparation method thereof

ActiveCN102324501ARelief of mechanical stressEliminate volume effectCell electrodesSodium-ion batteryLithium-ion battery

The invention discloses a silicon-based cathode composite material for a lithium ion battery and a preparation method thereof. The cathode composite material is a Si / CuOx / C composite material (0<=x<=1) with a porous structure. Silicon with a porous structure is used as a base, and CuOx particles are inserted in the pores, and carbons with different forms are distributed on a surface and pore walls of the silicon-based material. The preparation method of the cathode composite material comprises steps that silicon material realizes pore-forming through an in situ catalytic reaction between silicon and halogenated hydrocarbon, and reaction condition parameters are regulated to control pore size, distribution and amount of porosity of the silicon material; a post-modification technology is employed to carry out modifications on the surface and the pore walls of the porous silicon, so as to obtain the Si / CuOx / C composite material with a porous structure. The porous silicon-based cathode composite material has low production costs, simple process and no pollution, and is suitable for industrialized production; besides the porous silicon-based cathode composite material has high charge and discharge capacity, small initial irreversible capacity and good cycle performance.

Owner:河北中芯凤华科技发展有限公司

Production method for high-energy ratio super capacitance electrode material

ActiveCN101369492AAdjust aperture sizeRegulatory distributionElectrolytic capacitorsHybrid/EDL manufactureCapacitanceCarbon black

The invention relates to a method for manufacturing super capacitor electrode materials with high energy ratio, belonging to energy material technology and related field. The invention uses mechanical chemical treatment means to prepare porous carbon / electric conduction agent / polytetrafluoroethylene composite electrode materials. The prepared materials can evenly compound porous carbon / carbon black / polytetrafluoroethylene to form composite electrode materials composed of nanoes, thereby adjusting pore size of the porous carbon and improving utilization efficiency of the carbon pore; when preparing the super capacitor electrode using the materials, because the carbon black and the polytetrafluoroethylene are evenly dispersed in the porous carbon base by the mechanical chemical treatment, the size and the distribution of the pore diameter of the carbon pore are changed, so that the electrode has higher unit capacity, on the other hand, the carbon framework can also provide a good electric conduction channel for the carbon black corpuscules dispersed therein, equivalent internal resistance of the capacitor is reduced, so the capacitor has higher power and energy density.

Owner:安徽国研新能电芯技术有限公司

Amphiphilic polymer brush carbon nanotube/PVDF (polyvinylidene fluoride) nanofiltration membrane and preparation method thereof

ActiveCN107051215AAchieve functionalizationImprove performanceMembranesWater/sewage treatment bu osmosis/dialysisChemical reactionClick chemistry

The invention belongs to the field of preparation of nanofiltration membranes, and particularly relates to a click-chemistry-synthesized amphiphilic polymer brush carbon nanotube / PVDF (polyvinylidene fluoride) nanofiltration membrane and a preparation method thereof. The method comprises the following steps: synthesizing a novel macromolecule initiator capable of performing click chemistry reaction and initiating azido reaction, grafting the clickable macromolecule initiator onto the surface of the single-wall carbon nanotubes by click chemistry reaction, selecting an appropriate hydrophilic modifier monomer, and preparing amphiphilic polymer brush carbon nanotubes; carrying out blending, extrusion and casting on the click-chemistry-synthesized amphiphilic polymer brush carbon nanotubes and PVDF according to a certain proportion, wherein a biaxial orientation technique is adjusted to control the biaxial orientation temperature and speed and adjust the pore size of the microporous membrane; and compounding and coating a nano-pore-size ultrathin thin layer on the obtained microporous membrane, thereby obtaining the amphiphilic polymer brush carbon nanotube / PVDF nanofiltration membrane.

Owner:CHANGZHOU UNIV

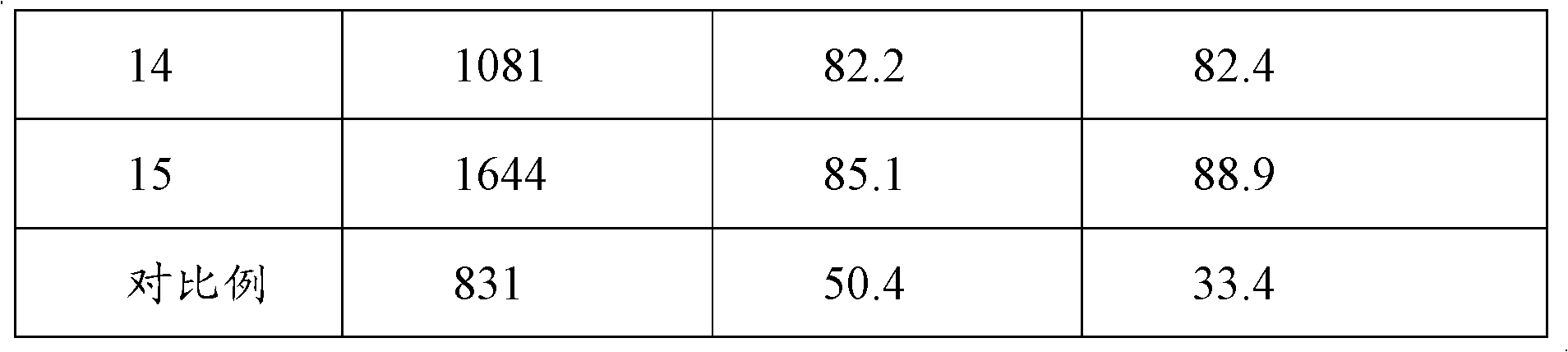

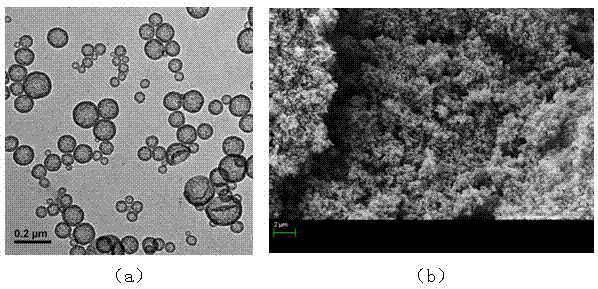

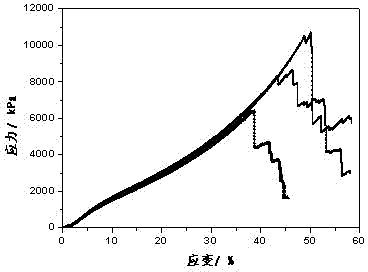

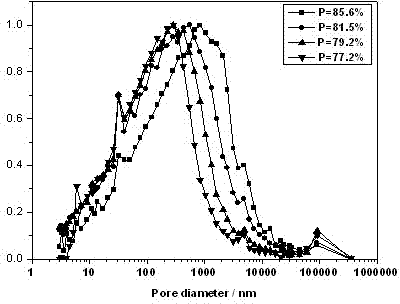

Method for preparing super thermal isolation polymer materials from polymer nanometer hollow capsules

ActiveCN102504326AEasily adjust porosityEasily adjust aperture sizeMicroballoon preparationMicrocapsule preparationThermal isolationCross-link

The invention discloses a method for preparing super thermal isolation polymer materials from polymer nanometer hollow capsules. According to the method, firstly, hydrophilic and oleophilic macromolecular reversible addition fragmentation chain transfer reagents are used for preparing polymer nanometer capsules, then, inter-capsule cross linking agents are prepared, finally, the inter-capsule cross linking agents and the polymer nanometer capsule emulsion are mixed according to a mass ratio of capsule to inter-capsule cross linking agents of 2.5:1 to 0.8:1, the pH is regulated to be 3.0 to 6.8, the reaction lasts 30 minutes to 24 hours at the temperature being 60 to 90 DEG C, the emulsion is gelatinized, then, core paraffin wax in the nanometer capsules is replaced through tetrahydrofuran, and polymer nanometer porous materials are obtained through vacuum drying. The method has the advantages that the preparation process is simple, and the porosity and the pore size can be regulated through changing the solid content of the nanometer capsule emulsion, the consumption of etherified melamine formaldehyde resin and the self porosity of the nanometer hollow capsules. In addition, compared with the traditional thermal isolation materials, the porous materials have high mechanical strength.

Owner:ZHEJIANG UNIV

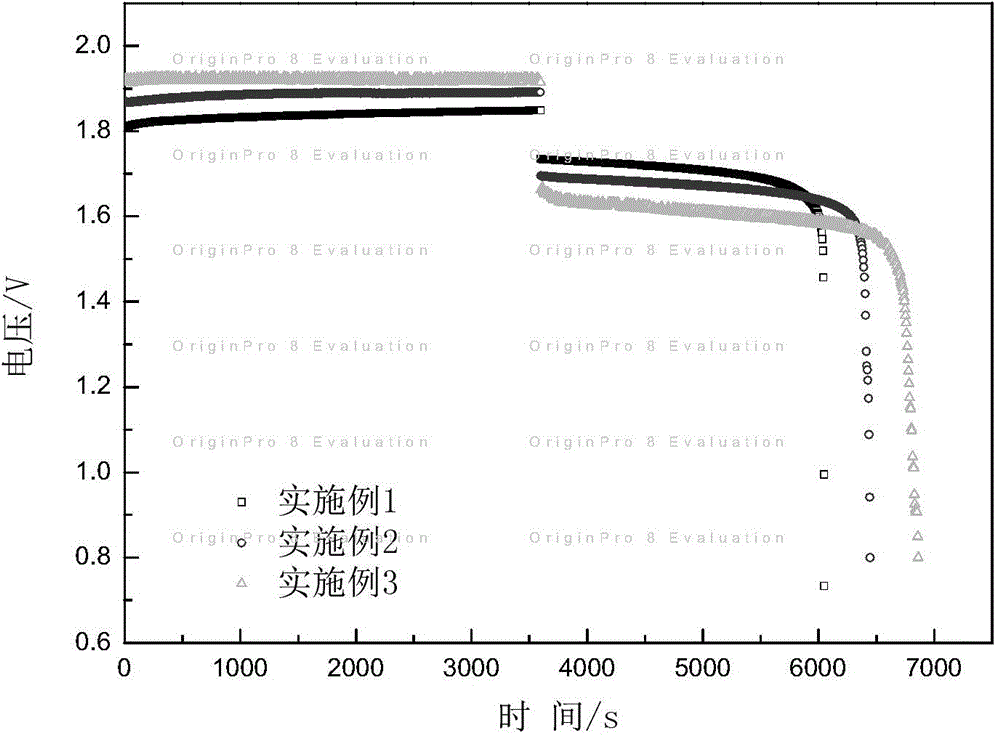

Application of porous separating membrane in zinc-bromine flow battery

InactiveCN105742549AAperture controllableAchieve separationRegenerative fuel cellsCell component detailsPorosityCellulose acetate

The invention discloses an application of a porous separating membrane in a zinc-bromine flow battery. The porous separating membrane is prepared from more than one or two of polysulfone, polyketone, polyimide, polybenzimidazole, polyvinylidene fluoride, polyvinyl pyridine, polyacrylonitrile, polypropylene, polyethylene, polybutadiene or cellulose acetate; the aperture sizes in the porous separating membrane are 0.05-20nm; and the porosity is 20%-60%. The prepared membrane material can effectively achieve separation of different zinc ions and keep the ion selectivity of the membrane. Furthermore, the membrane material can achieve ion transport without introducing an ion exchange group; and the selection range of the flow battery membrane material is expanded.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Staged porous charcoal, and preparing method and applications thereof

ActiveCN108996486AOvercome removal difficultiesFew preparation stepsGeneral water supply conservationCarbon preparation/purificationMass ratioCarbonization

The invention discloses staged porous charcoal, and a preparing method and applications thereof, and belongs to the field of material preparation and application. One or two of potassium citrate or sodium citrate, adopted as a raw material A, and one or more than two of calcium citrate, iron citrate or zinc citrate, adopted as a raw material B, are fully mixed; a template agent and an activating agent are generated through high-temperature carbonization and self-activation so that addition of extra template agents and activating agents is not needed; and the staged porous charcoal having a micropore-mesopore-macropore structure having three types of pores is prepared through one step, omitting a step of secondary activation. The preparing method is simple, short in period, low in cost andenvironmentally friendly. Through adjusting the mass ratio of the raw materials, the pore sizes and distribution of micropores, mesopores, and macropores in the staged porous charcoal can be adjusted.The prepared staged porous charcoal is wide in pore diameter distribution, high in pore capacity and high in specific surface area, and has a certain graphene structure. A solid microextraction probeprepared by utilizing the staged porous charcoal can achieve trace detection of organic pollutants in water environments.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

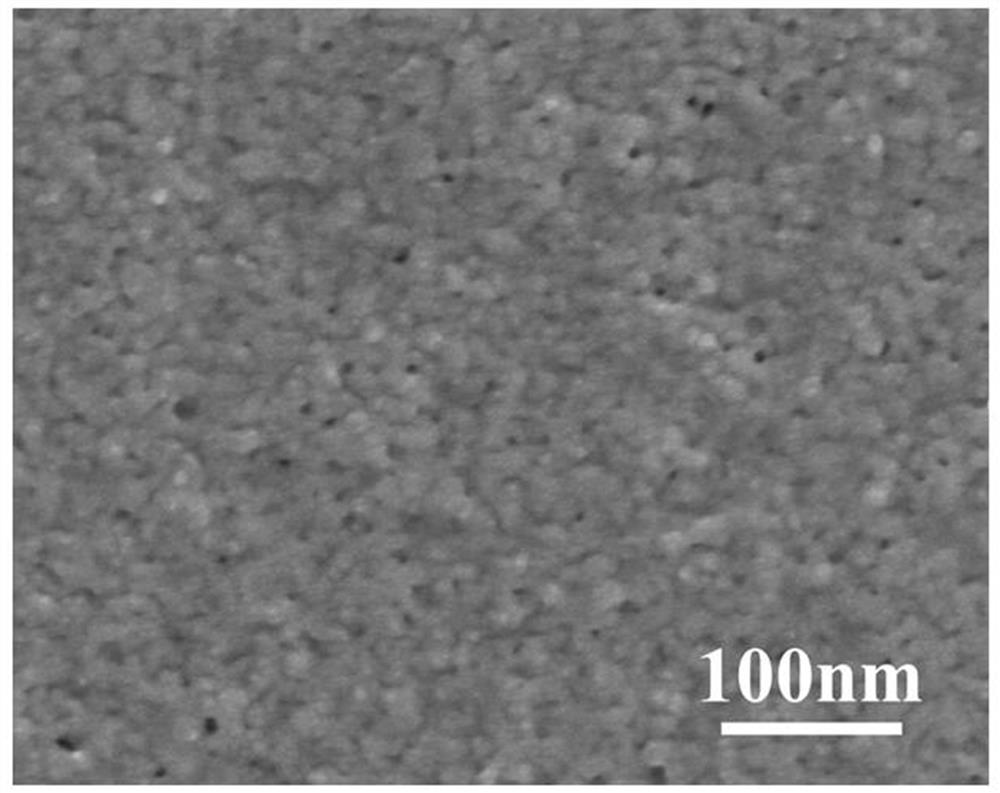

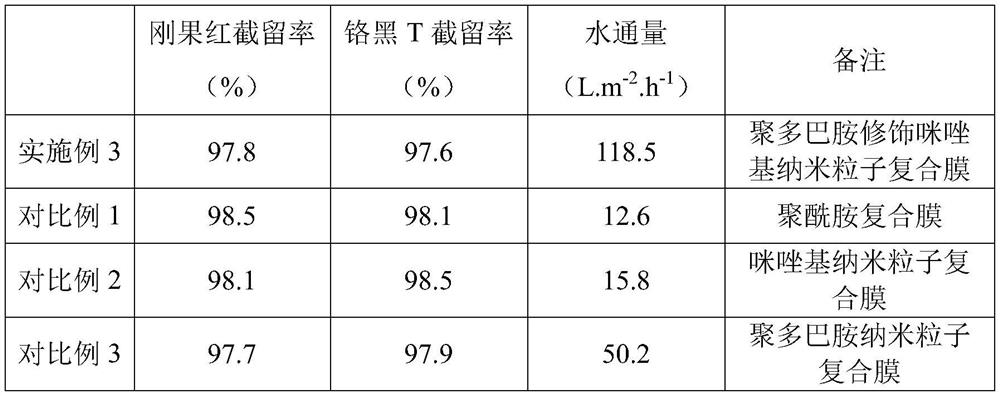

Preparation method of polydopamine modified imidazolyl nano particle composite nanofiltration membrane

ActiveCN111921387AParticle size adjustableGood water dispersibilityWater contaminantsUltrafiltrationAlkaline waterNanofiltration

The invention discloses a preparation method of a polydopamine modified imidazolyl nano particle composite nanofiltration membrane. The preparation method comprises the following steps: taking aromatic polyamine monomer molecules, an aldehyde compound and a dicarbonyl compound as reaction raw materials, carrying out polycondensation in an acidic aqueous solution to form imidazolyl nano particles,adding dopamine into an alkaline aqueous dispersion of the imidazolyl nano particles, carrying out oxidative polymerization to obtain polydopamine-modified imidazolyl nano particles, and finally, preparing the composite nanofiltration membrane on a porous ultrafiltration membrane by virtue of a surface coating-interface crosslinking method. The prepared polydopamine modified imidazolyl nano particle composite nanofiltration membrane has high permeation selectivity and strong anti-pollution stability, and has a good industrial application prospect.

Owner:ZHEJIANG UNIV OF TECH

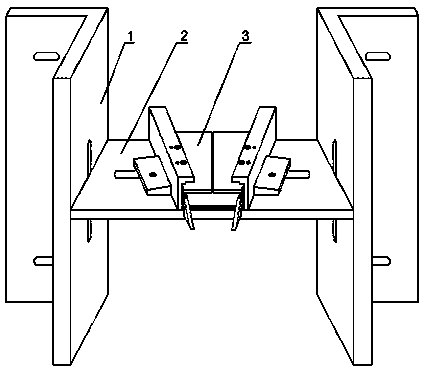

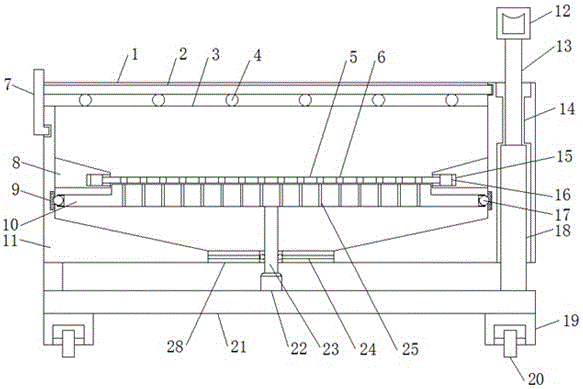

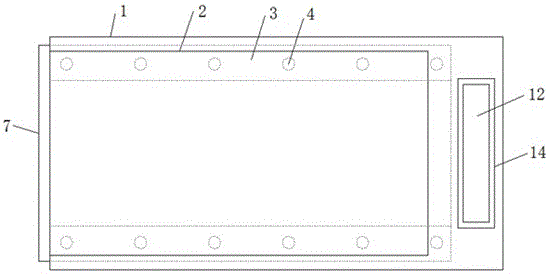

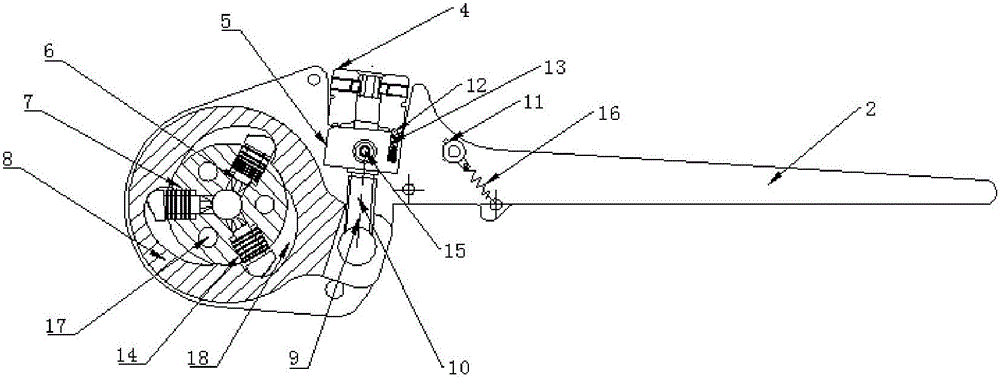

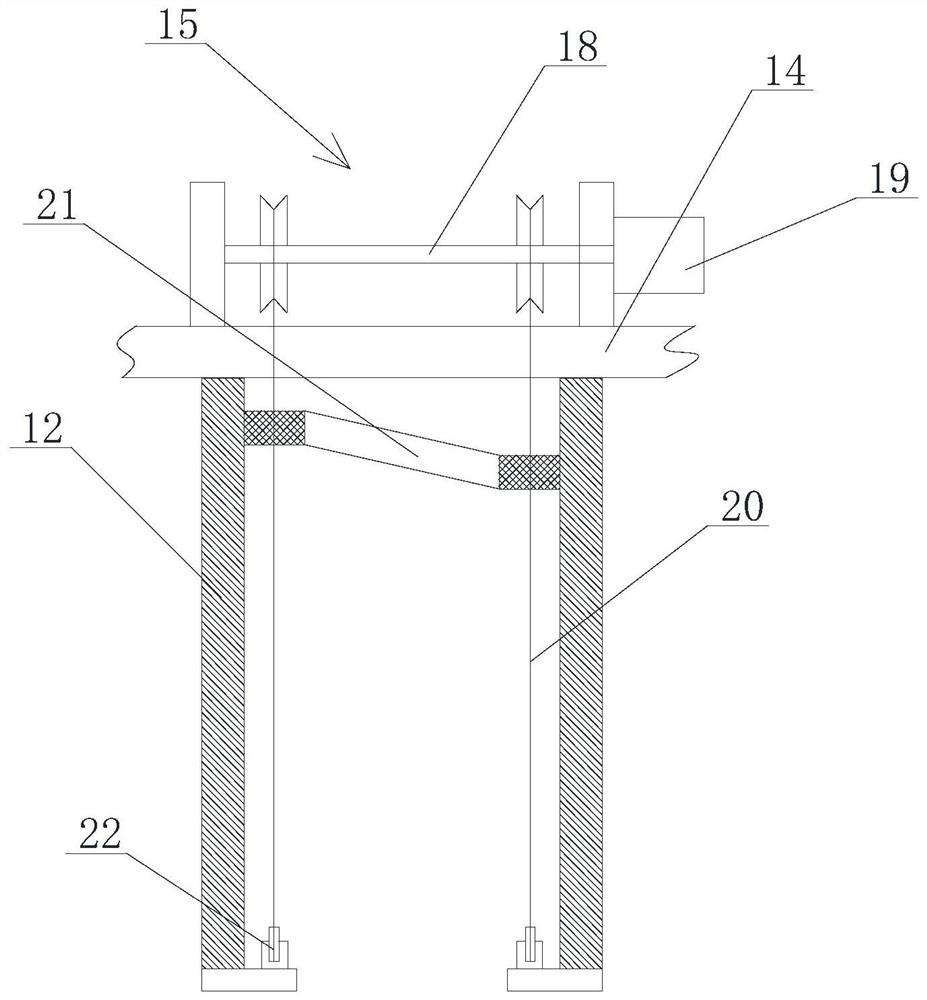

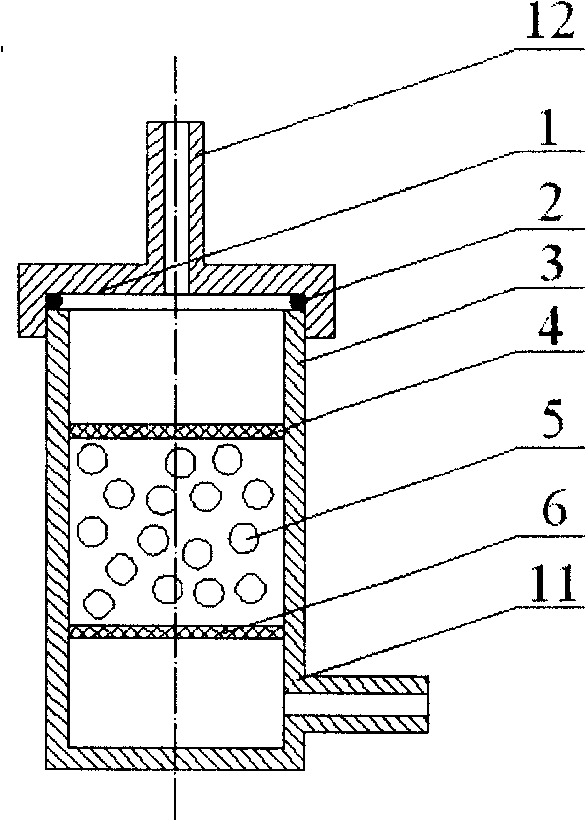

Guide and guard device for rolling of profile steel with special-shaped section

InactiveCN104368608ASimple structureEasy to maintainGuiding/positioning/aligning arrangementsEngineeringFixed Slide

Owner:WUHAN UNIV OF SCI & TECH

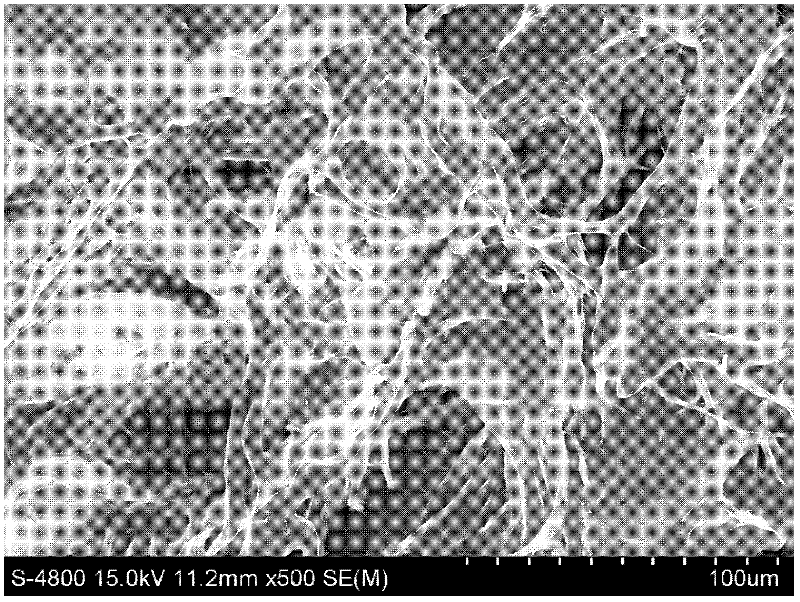

Preparation method for sponge material with adsorption, separation, filtering and purification function

InactiveCN107987310AEasy to prepareLow costWater contaminantsTreatment involving filtrationCross-linkWater filter

The invention provides a preparation method for a sponge material with an adsorption, separation, filtering and purification function for chemical substances including organic dyes, heavy metal ions and the like in water. The preparation method comprises the following steps: (1) accurately weighting polyvinyl alcohol, and dissolving the polyvinyl alcohol into deionized water at a certain mass ratio, and evenly stirring; (2) adding graphene oxide, a foaming agent, a cross-linking agent and a catalyst into polyvinyl alcohol solution, and stirring for certain time after one reagent is added to evenly disperse the reagent; (3) transferring a precursor into a die, and heating and solidifying for forming; (4) cleaning a formed compound sponge with water for multiple times, and drying to obtain the dried sponge material. The preparation method has the advantages of simple process, low cost and wide applicable range. The obtained sponge material is porous, hydrophilic and resistant to solvent,has a high adsorption rate and high removal efficiency for the organic dyes and heavy metal ions, and does not need additional energy consumption, and the sponge material can be desorbed, cleaned andutilized after pollutants are adsorbed and is suitable for industrial wastewater processing and household water filters.

Owner:TIANJIN POLYTECHNIC UNIV

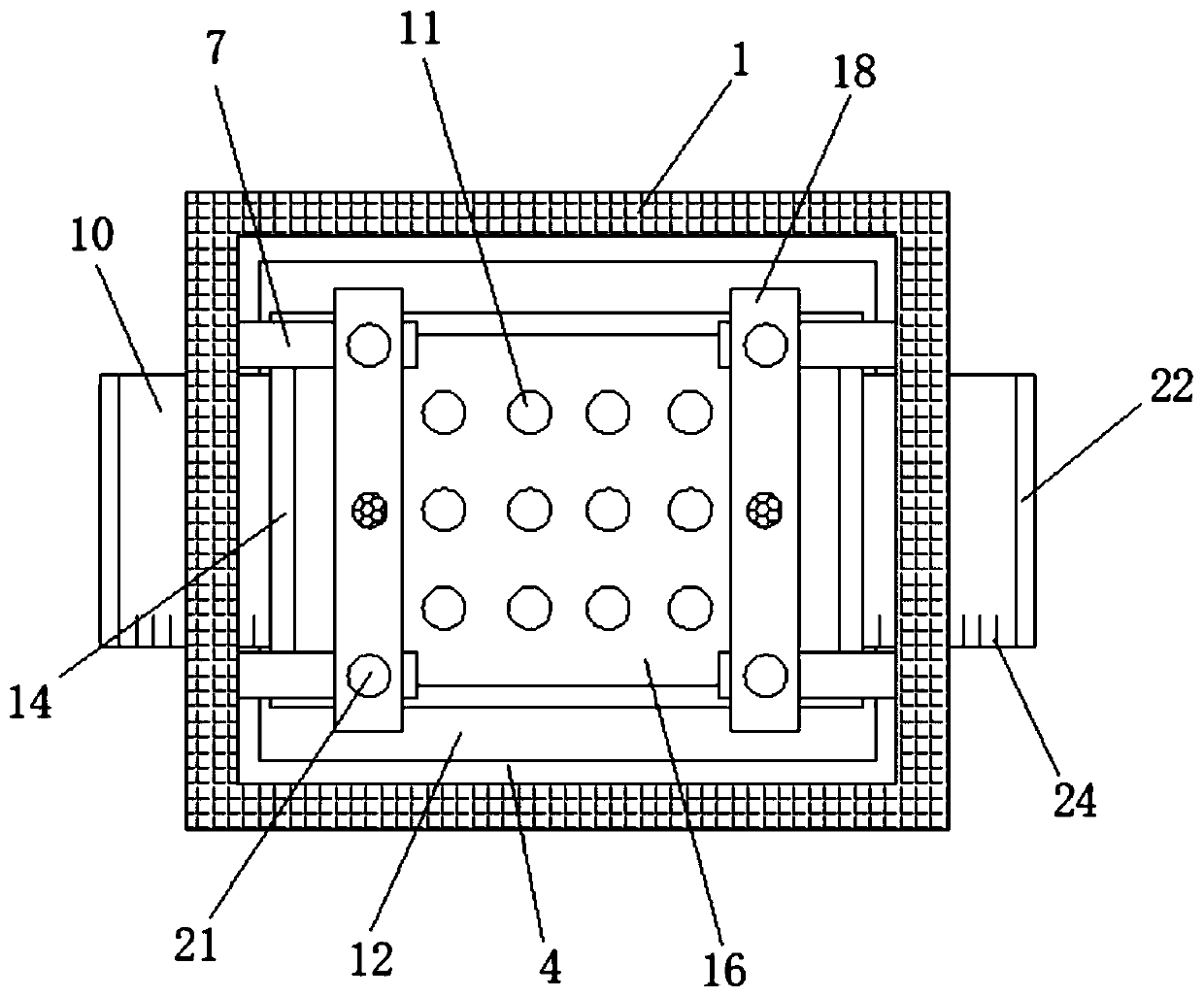

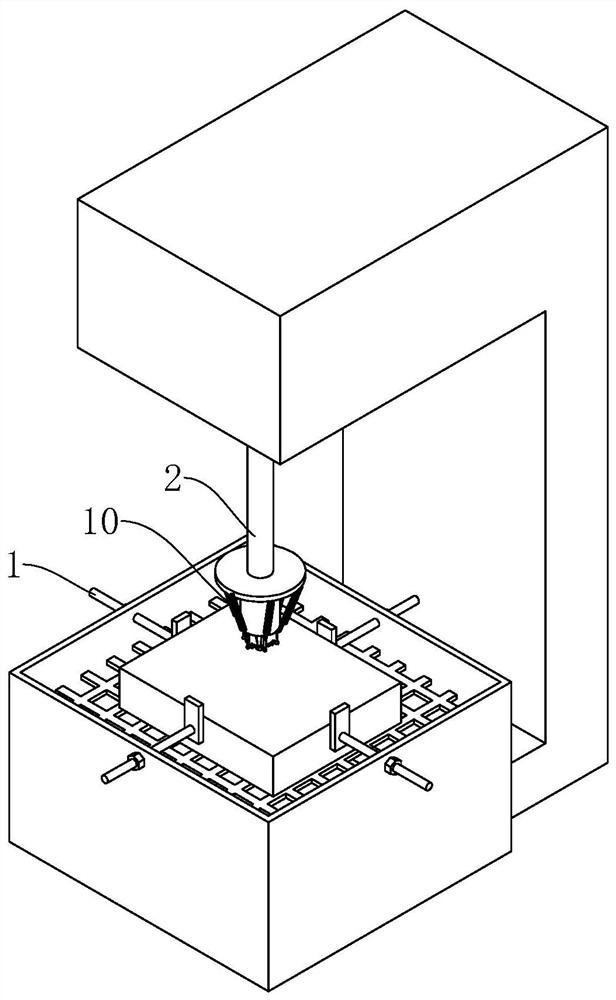

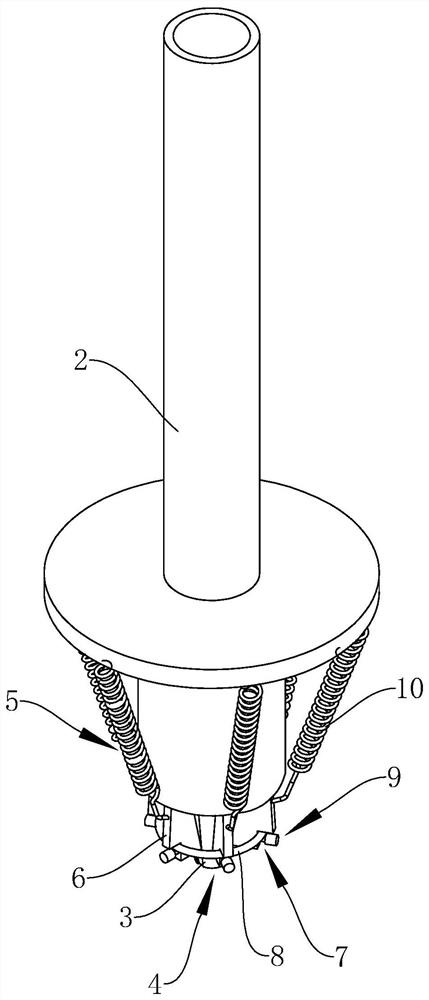

Powder recovering and treating device applied to metal powder spraying

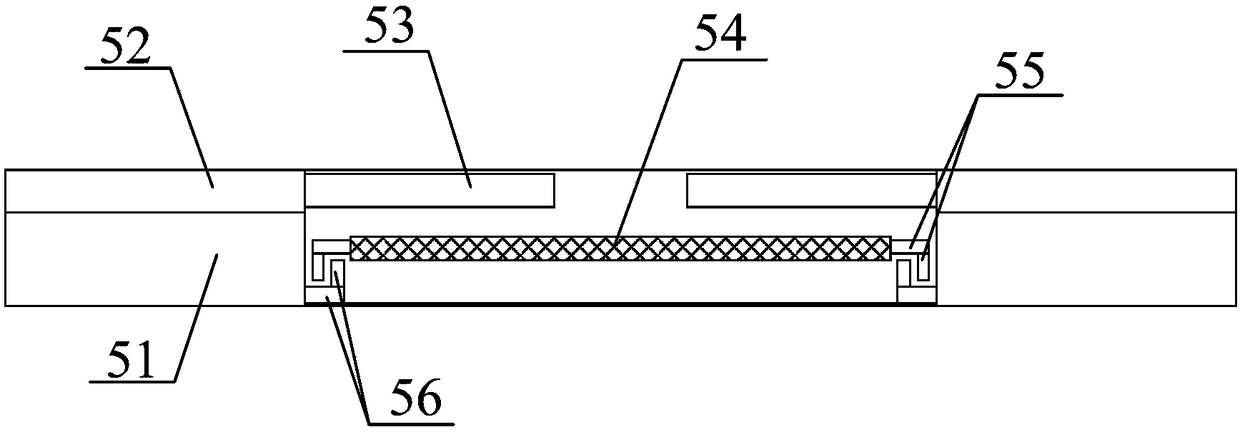

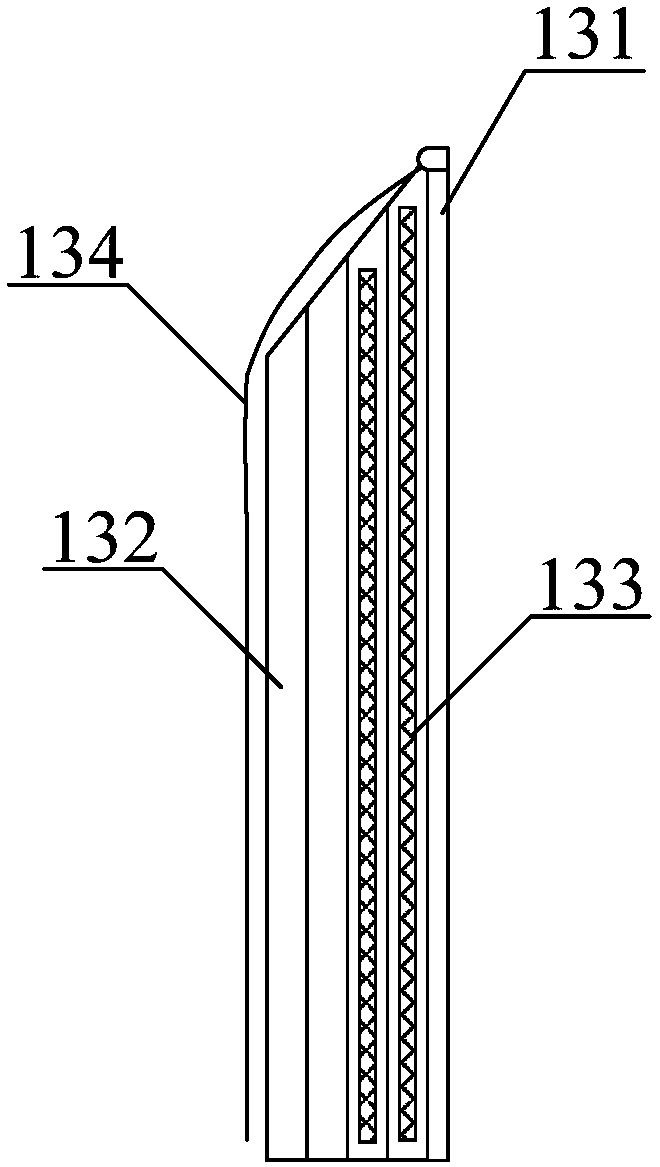

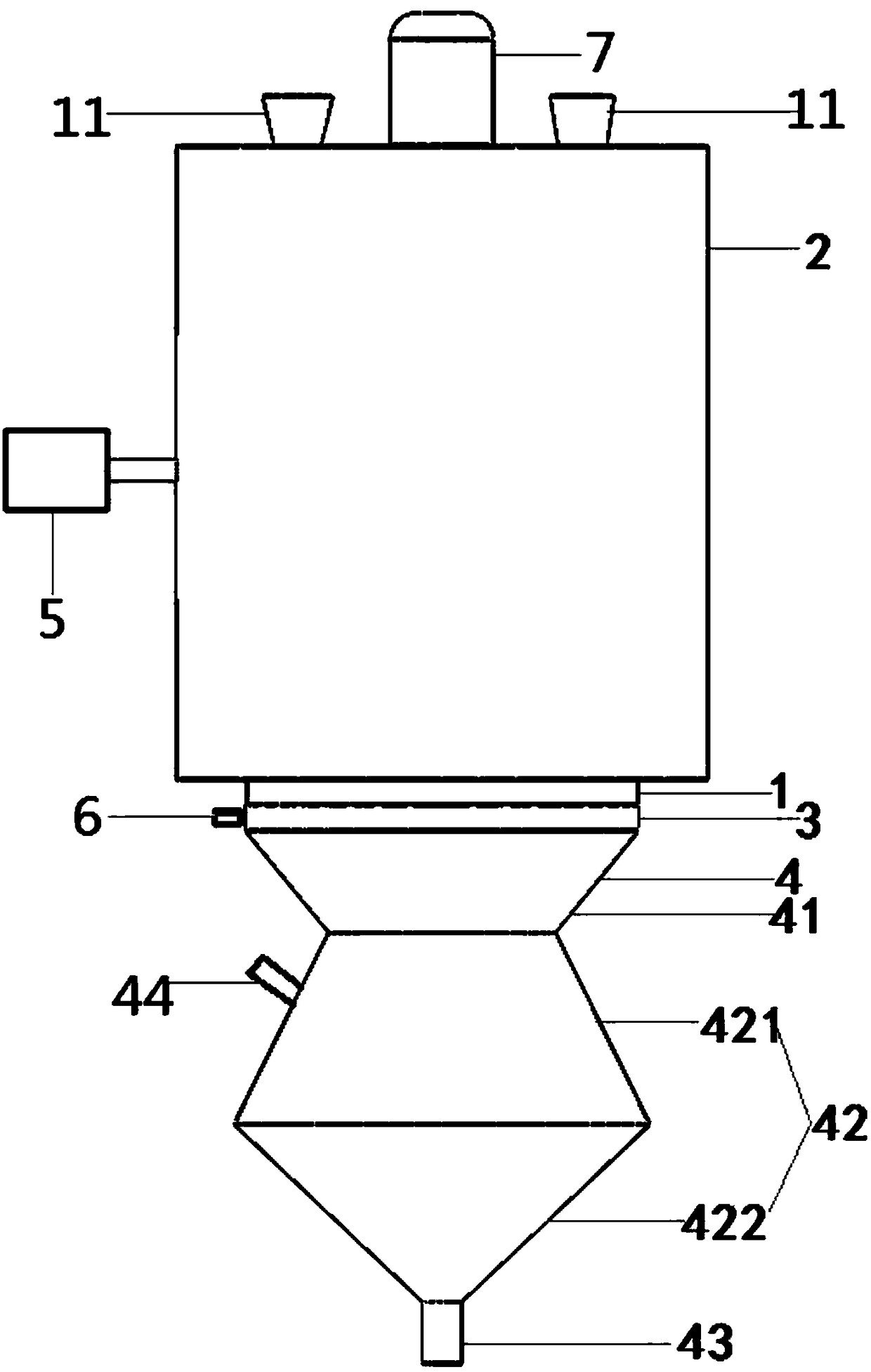

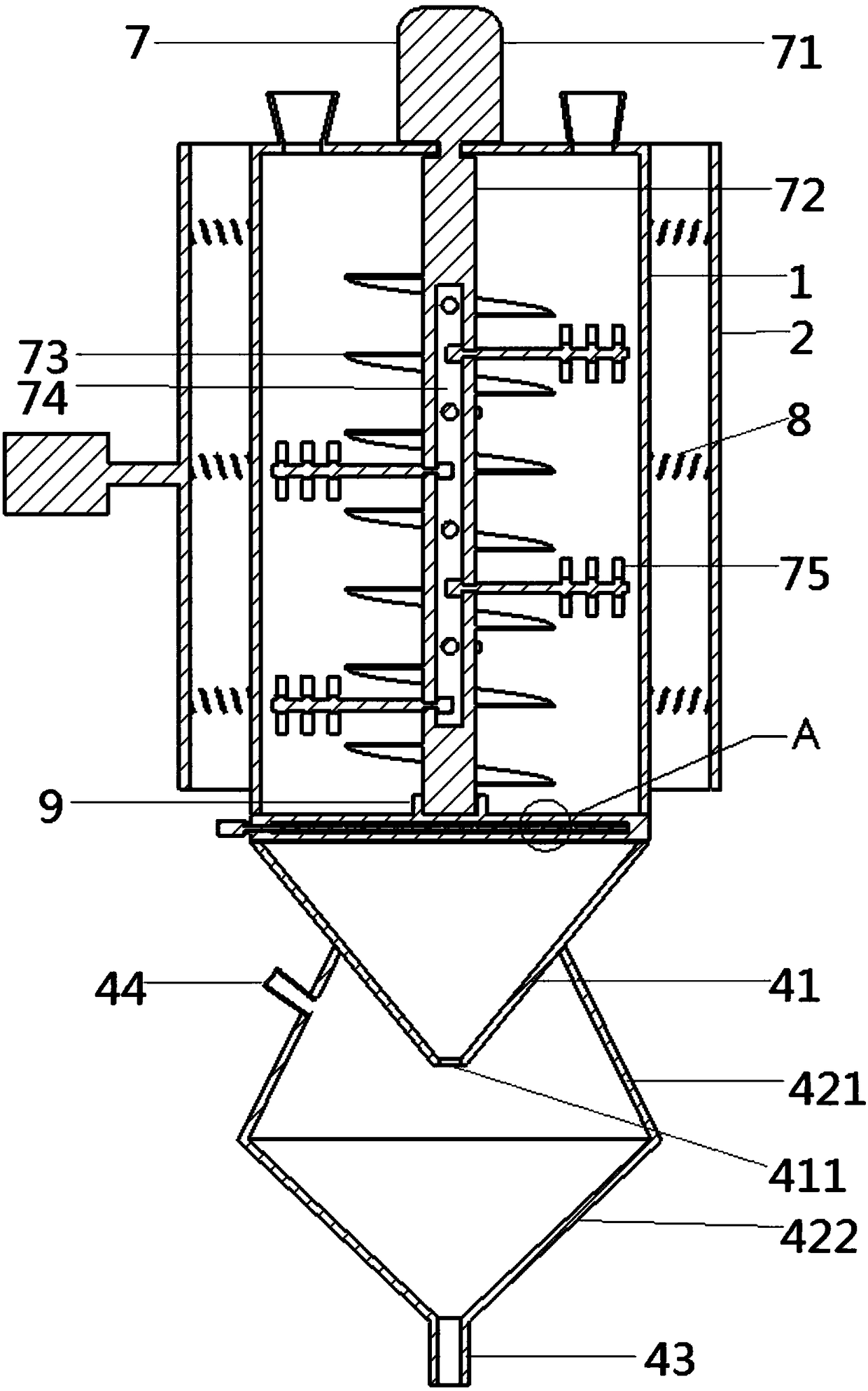

ActiveCN106622810ASolve problems that are difficult to reuseEasy to openSpraying apparatusBiochemical engineeringMetal powder

The invention discloses a powder recovering and treating device applied to metal powder spraying. The powder recovering and treating device comprises a device body which is of a cavity structure. An opening is formed in one side of the top end of the device body. The two sides of the opening communicate with first sliding grooves correspondingly. A baffle is arranged in the opening. Two sets of first rolling balls arranged linearly are arranged at the bottom end of the baffle. A clamping plate is arranged on one side, away from the device body, of the baffle. Fixing blocks are arranged on the inner walls of the two sides of the device body correspondingly. Clamping grooves are formed in the sides, close to each other, of the two fixing blocks correspondingly. A screen plate arranged horizontally is arranged between the clamping grooves. Multiple first screen holes are formed in the screen plate. A micro vibrator is arranged in each clamping groove. An adjusting plate is further arranged in the device body. The adjusting plate is provided with second screen holes. The bottom end of the adjusting plate is connected with a rotating rod. The powder recovering and treating device is reasonable in design layout, avoids waste of raw materials, is convenient to move and can be used on many sites. Meanwhile, powder recovering quality and treating efficiency are improved, and the comfort level of users is improved.

Owner:滁州市友邦涂装有限公司

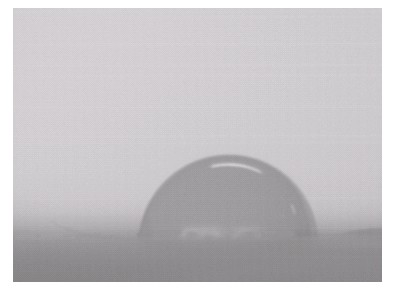

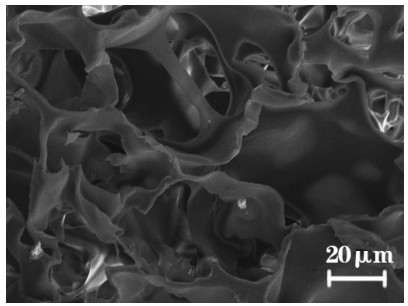

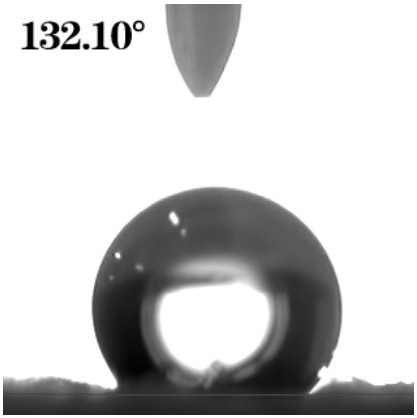

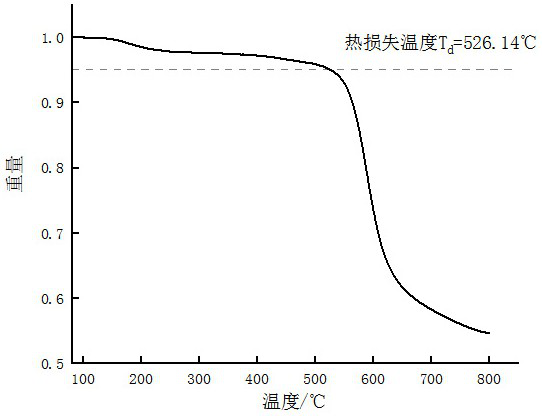

Inorganic/organic mutually doped hydrophobic polyimide aerogel and preparation method thereof

The invention discloses a preparation method and performance test of a low-density hydrophobic polyimide aerogel material with a green and convenient preparation process. A water-soluble polyamide acid precursor is synthesized from a diamine monomer and a dianhydride monomer. Wet gel is continuously prepared by using the polyamide acid precursor, and further the hydrophobic polyimide aerogel is prepared by adopting processes such as freeze drying and thermal amidation. The aerogel prepared by the invention has the characteristics of hydrophobicity, suitability for various molding and pouring processes, simple preparation process, great reduction of organic matter volatilization in the preparation process and the like. The interior of the material is porous, the density is less than 0.1 g / cm<3>, the water contact angle on the surface of the aerogel can reach 120 degrees or more, and the aerogel has good thermal performance. The material has a large application space in the fields of heat insulation, catalysis, organic matter adsorption, air filtration and the like.

Owner:FUZHOU UNIV

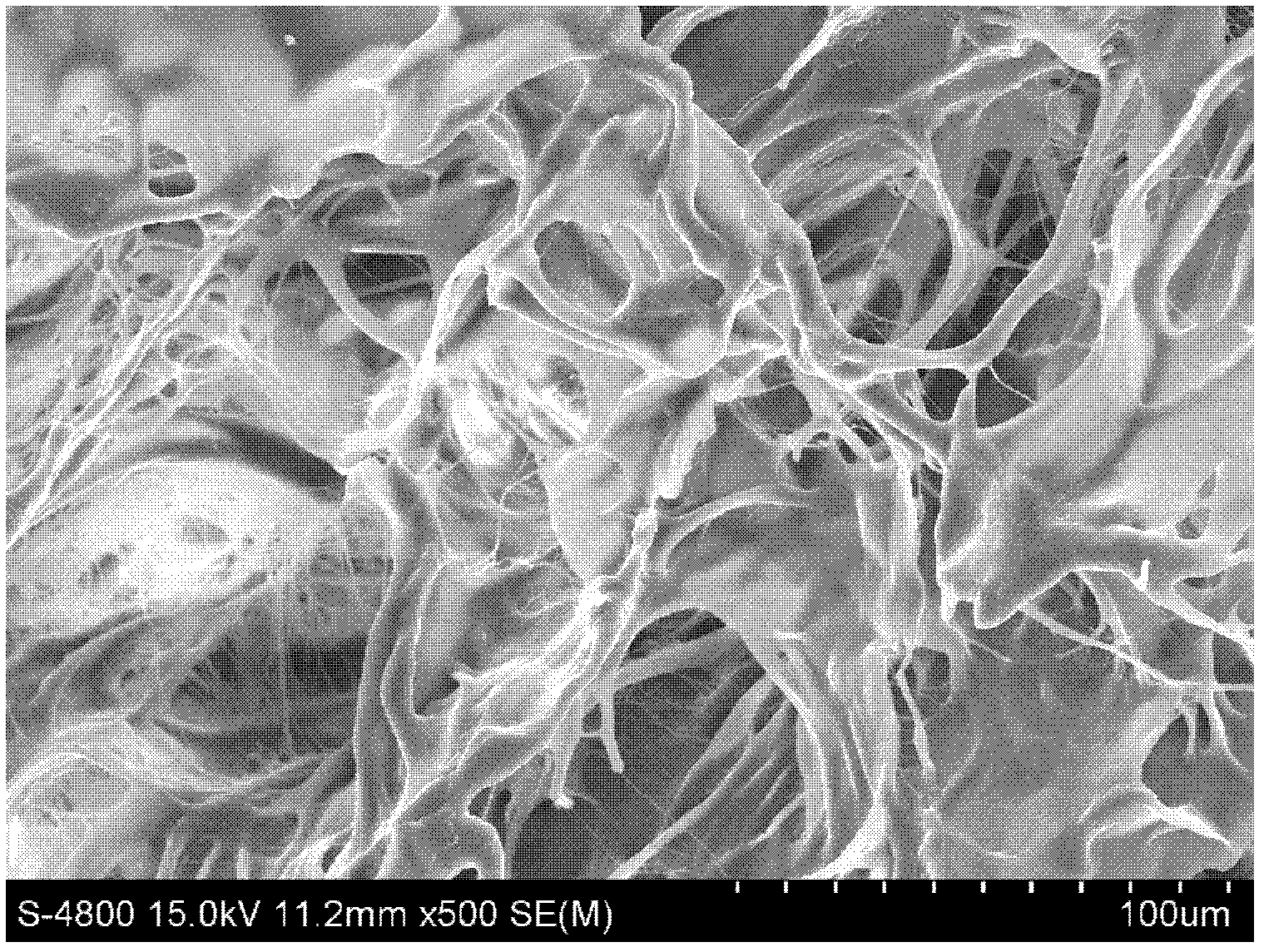

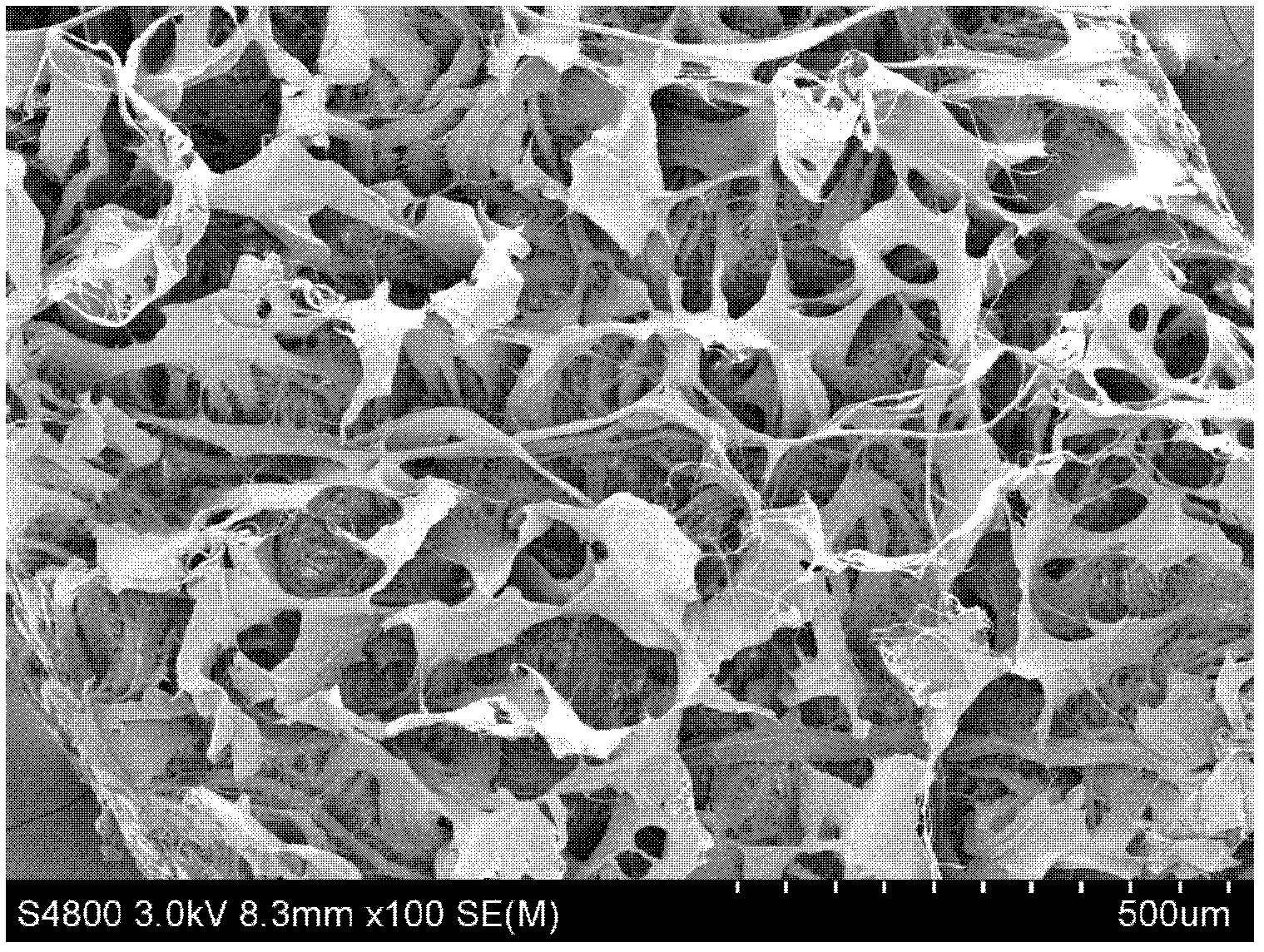

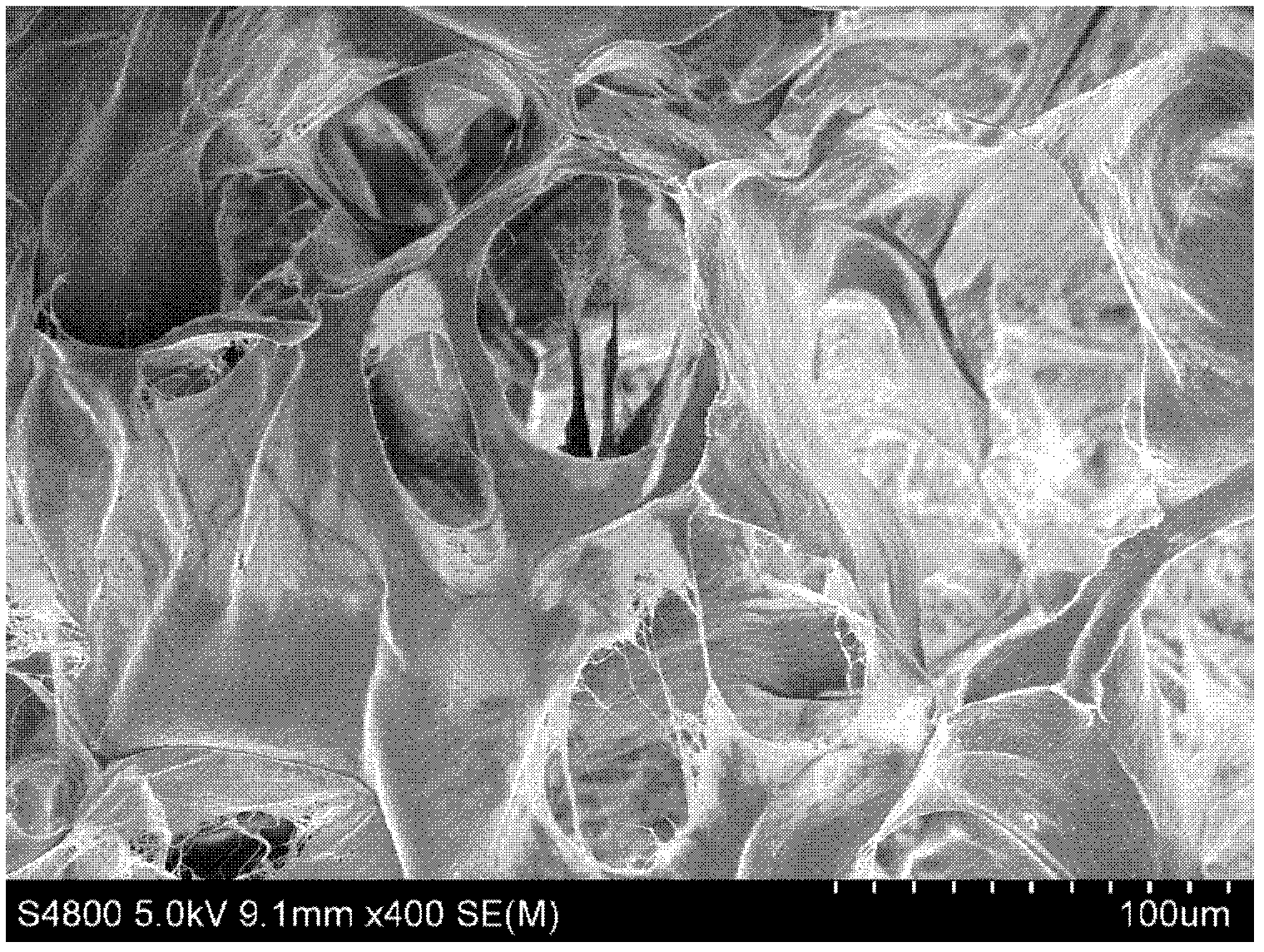

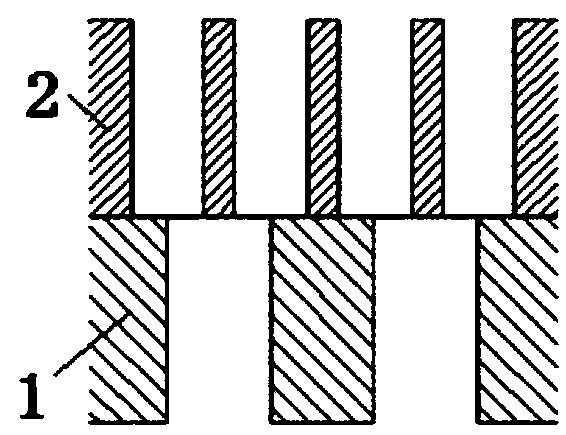

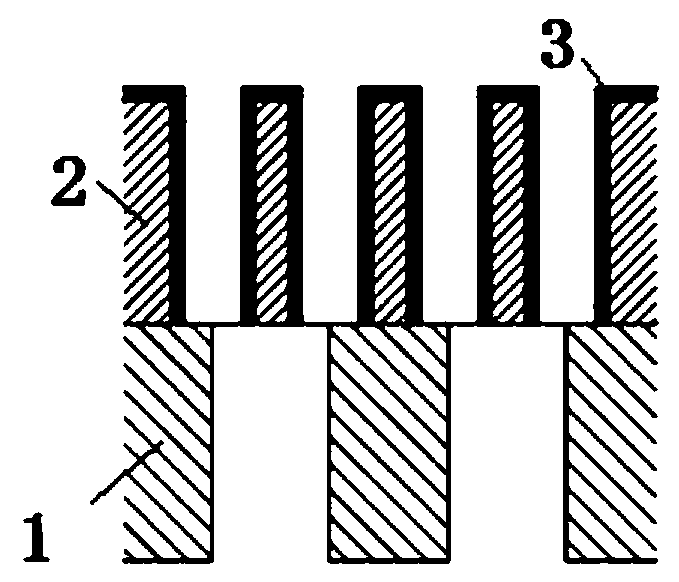

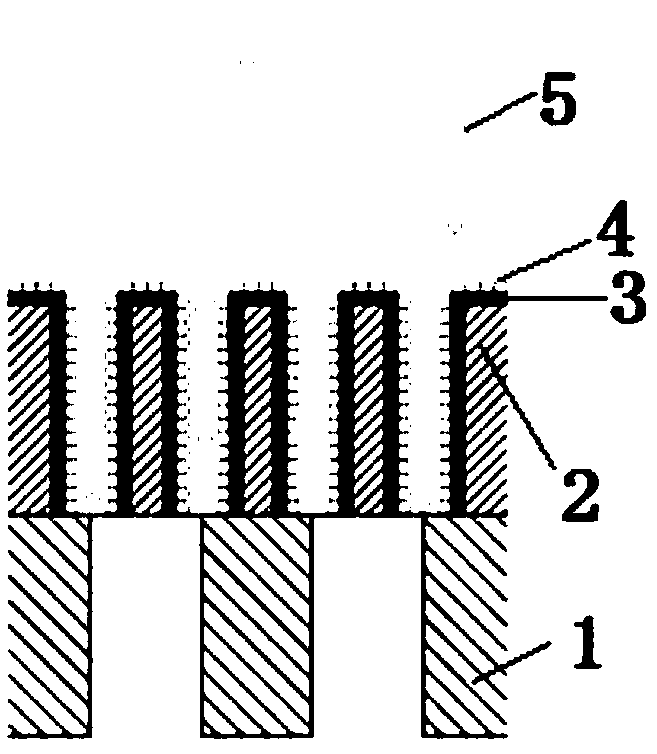

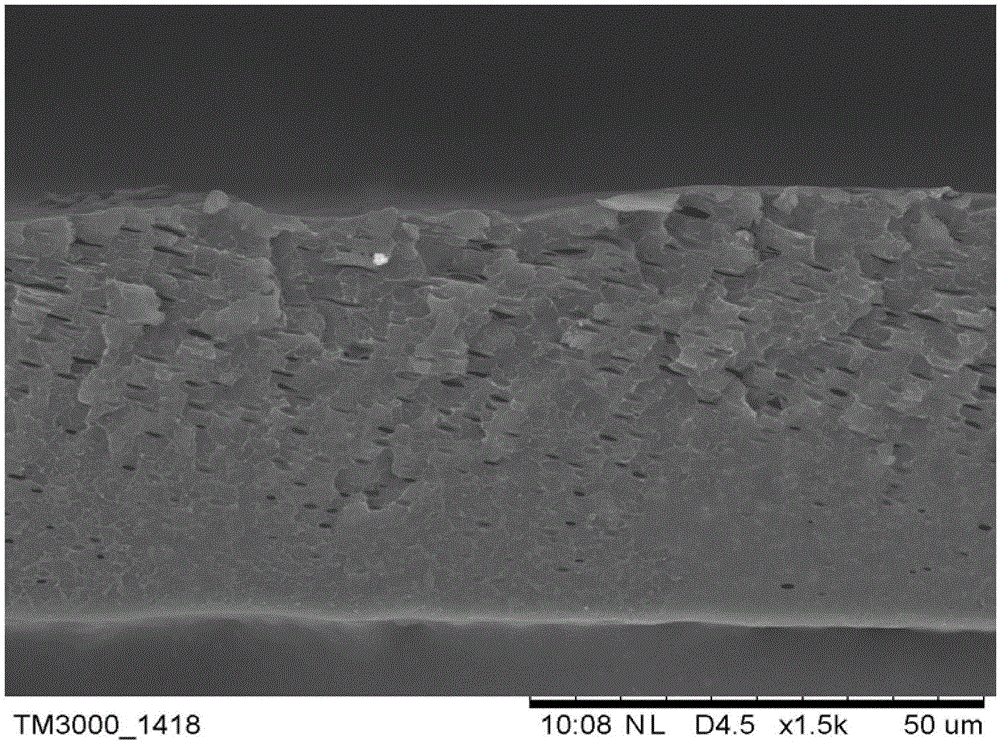

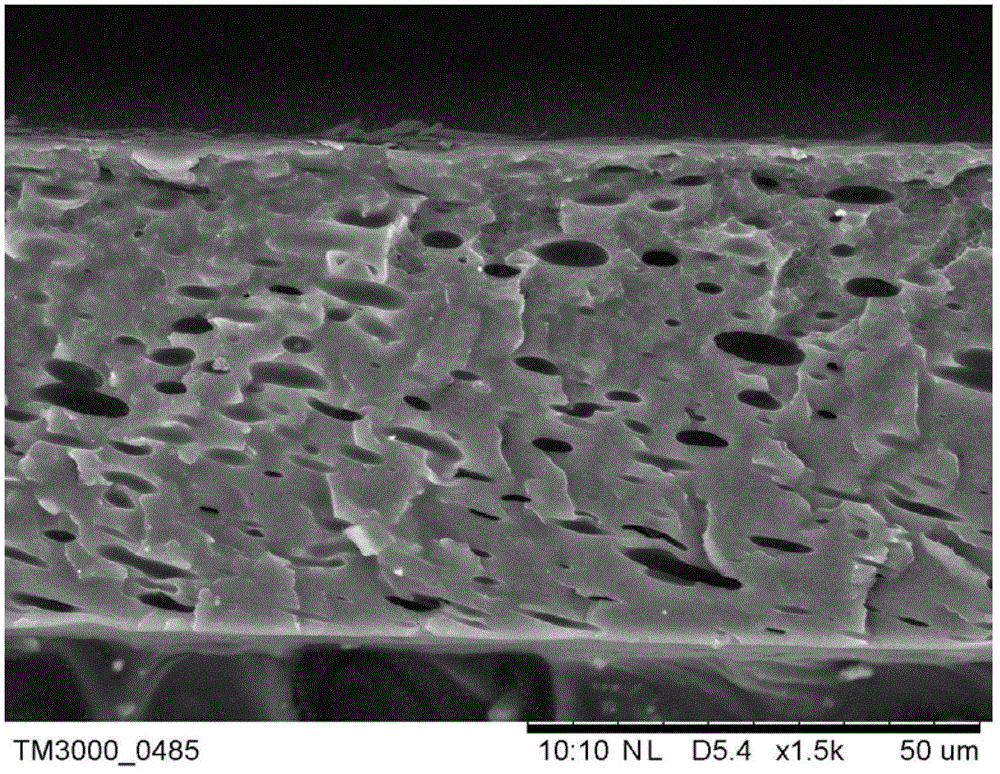

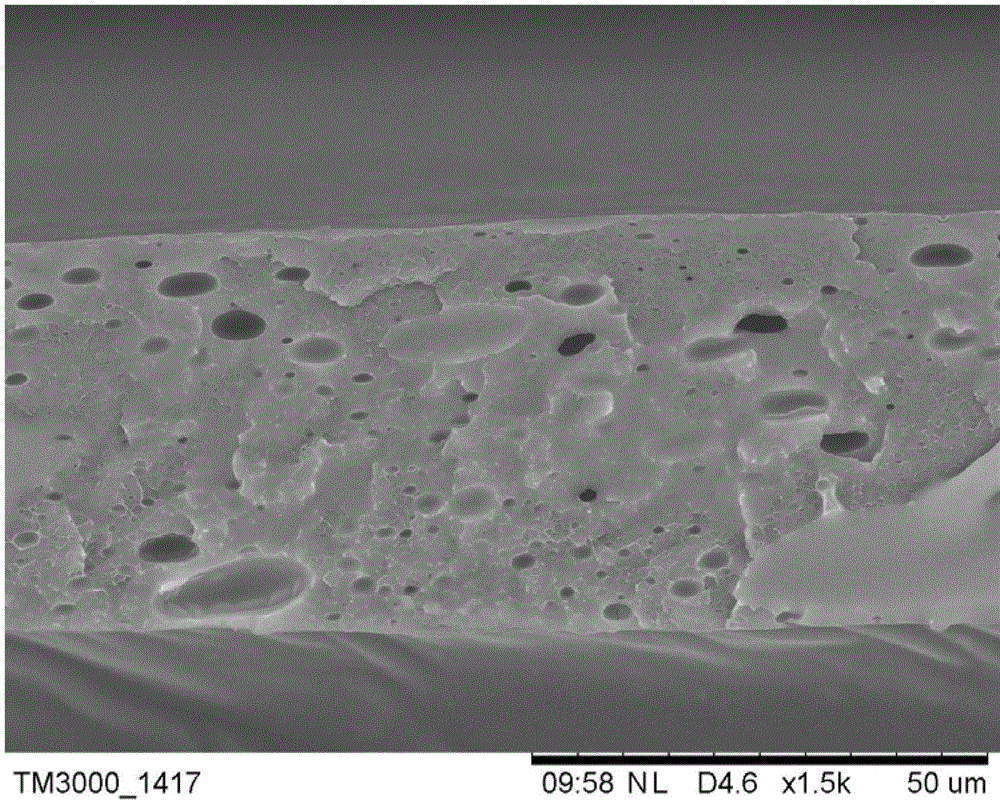

A method for adjusting pores of porcine acellular dermal matrix for tissue engineering

InactiveCN102258807AAdjust aperture sizeEffective adjustment of aperture sizeProsthesisZeta potentialSodium polyaspartate

The invention discloses a porcine acellular dermal matrix (PADM) pore adjusting method for tissue engineering, which is implemented by adding anion biomacromolecules or cation biomacromolecules into a sufficiently wetted PADM water solution and regulating the electrokinetic potential (zeta potential) of collagen, wherein the anion biomacromolecules are sodium polyaspartate, the cation biomacromolecules are water-soluble chitosan, and the weight ratio of the biomacromolecules to the PADM is 1:5-1:25. The method disclosed by the invention effectively adjusts the pore size of the PADM, and adjusts the structure pattern of the collagen beam; and the obtained PADM has the natural structure of collagen, which predicts that the material can have wide application prospects in repair medicine.

Owner:SHANDONG UNIV

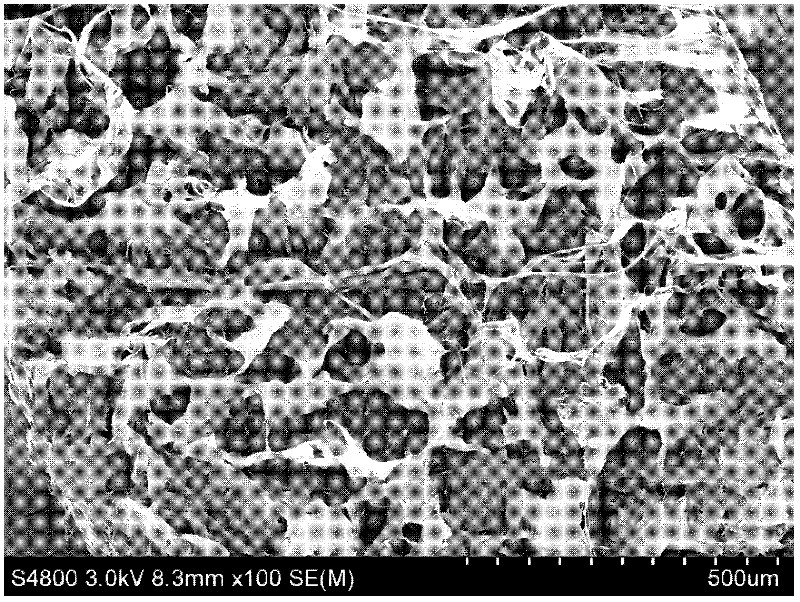

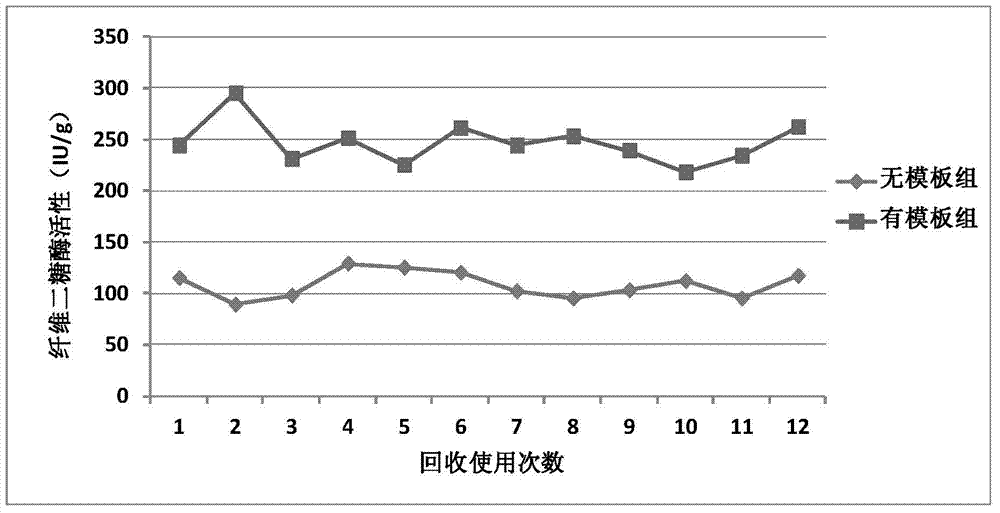

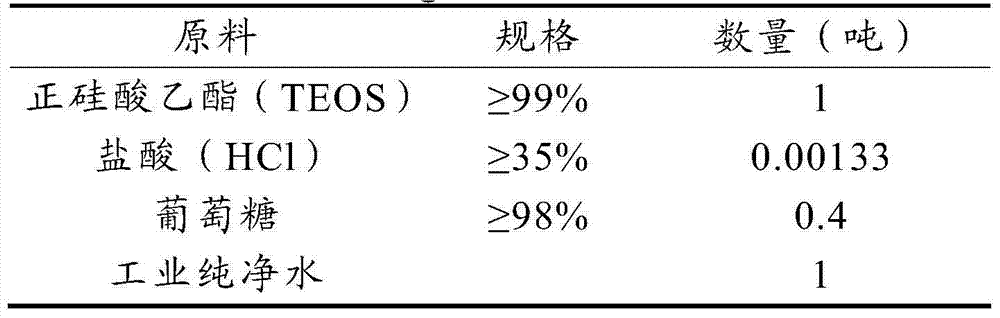

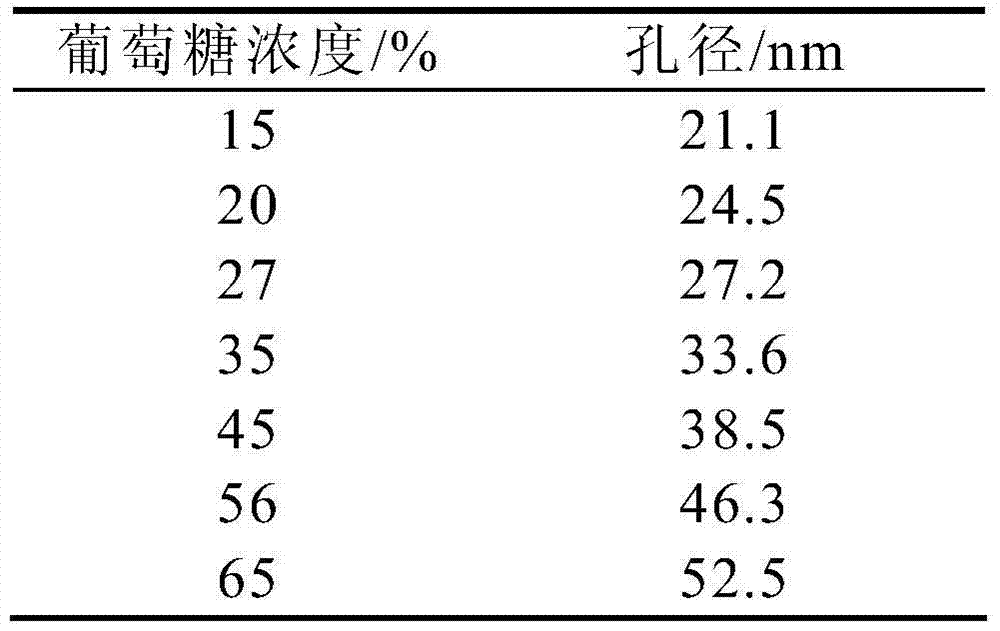

Preparation method of mesoporous material

InactiveCN103691372AEasy to makeMild production reaction conditionsSilicaOn/in organic carrierChemistryBioactive substance

The invention relates to the field of materials and discloses a preparation method of a mesoporous material. The preparation method comprises the following steps: adding an acid or alkali solution into a precursor in a stirring state, performing hydrolysis to obtain a transparent solution, cooling the transparent solution and recycling ethyl alcohol; adding a template solution into the transparent solution in a stirring state, and adjusting the pH value of the mixed solution to be neutral by an acid or alkali solution for gelatinizing; smashing wet glue obtained by the gelatinizing; removing the template through water washing; carrying out suction filtration on the mixed solution after water washing to obtain white gel; and drying the gel, smashing, and sieving, thus obtaining the mesoporous material. According to the preparation method of the mesoporous material provided by the invention, an immobilized enzyme can be obtained by adding bioactive substances including enzymes into a reaction system in the preparation process. The experiment shows that the enzyme activity of the immobilized enzyme of the mesoporous material nearly keeps unchanged after the immobilized enzyme is repeatedly used.

Owner:廖文强

Porcine acellular dermal matrix (PADM) pore adjusting method for tissue engineering

InactiveCN102258807BAdjust aperture sizeEffective adjustment of aperture sizeProsthesisZeta potentialWater soluble chitosan

The invention discloses a porcine acellular dermal matrix (PADM) pore adjusting method for tissue engineering, which is implemented by adding anion biomacromolecules or cation biomacromolecules into a sufficiently wetted PADM water solution and regulating the electrokinetic potential (zeta potential) of collagen, wherein the anion biomacromolecules are sodium polyaspartate, the cation biomacromolecules are water-soluble chitosan, and the weight ratio of the biomacromolecules to the PADM is 1:5-1:25. The method disclosed by the invention effectively adjusts the pore size of the PADM, and adjusts the structure pattern of the collagen beam; and the obtained PADM has the natural structure of collagen, which predicts that the material can have wide application prospects in repair medicine.

Owner:SHANDONG UNIV

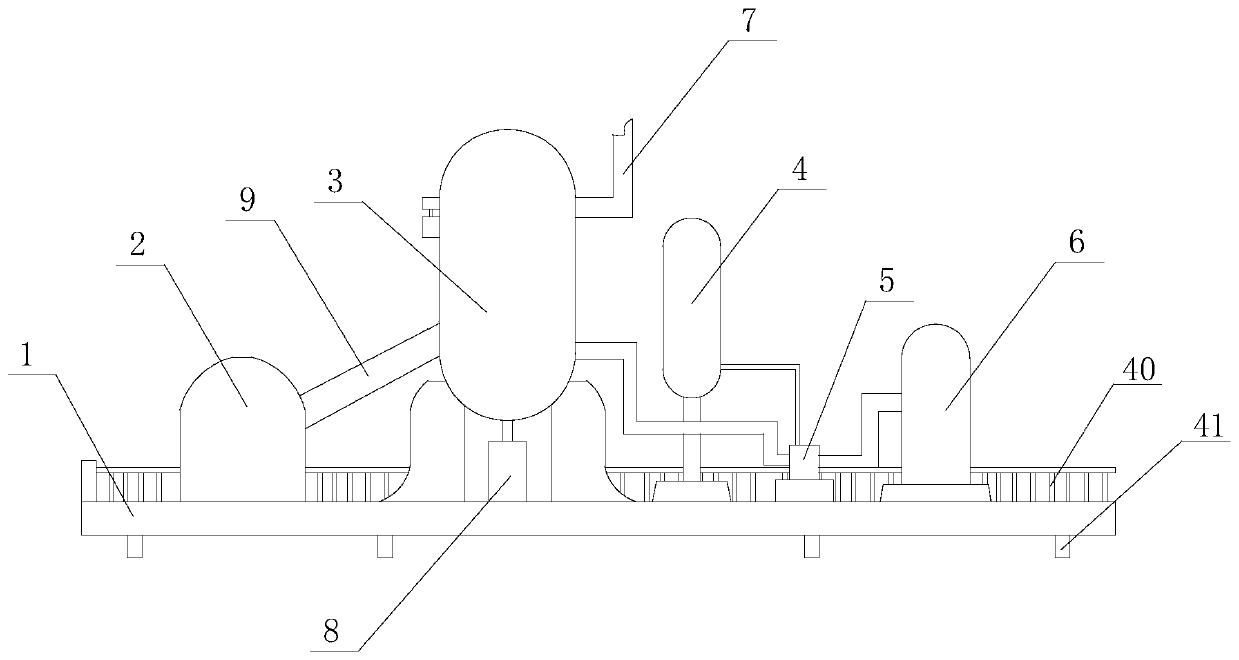

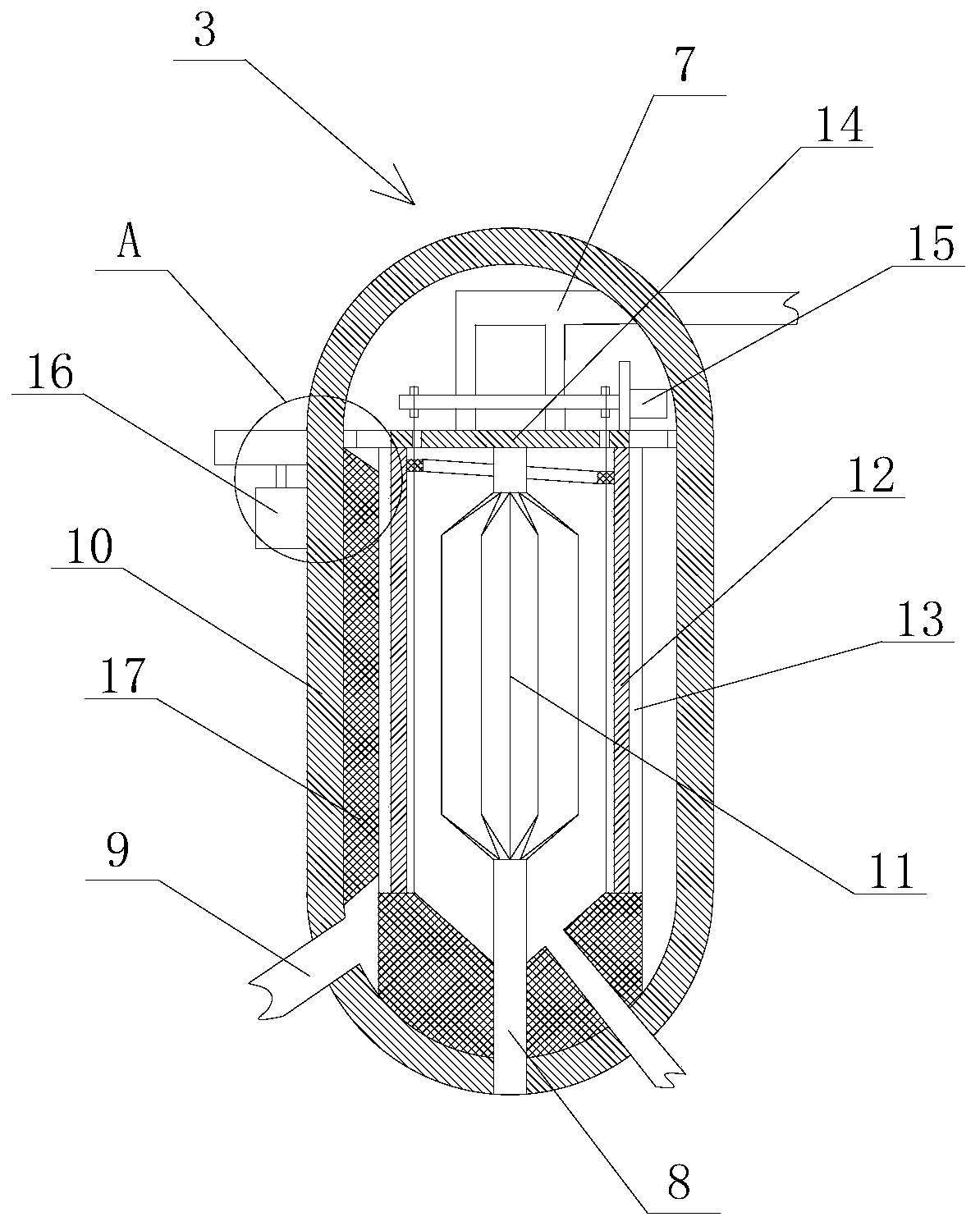

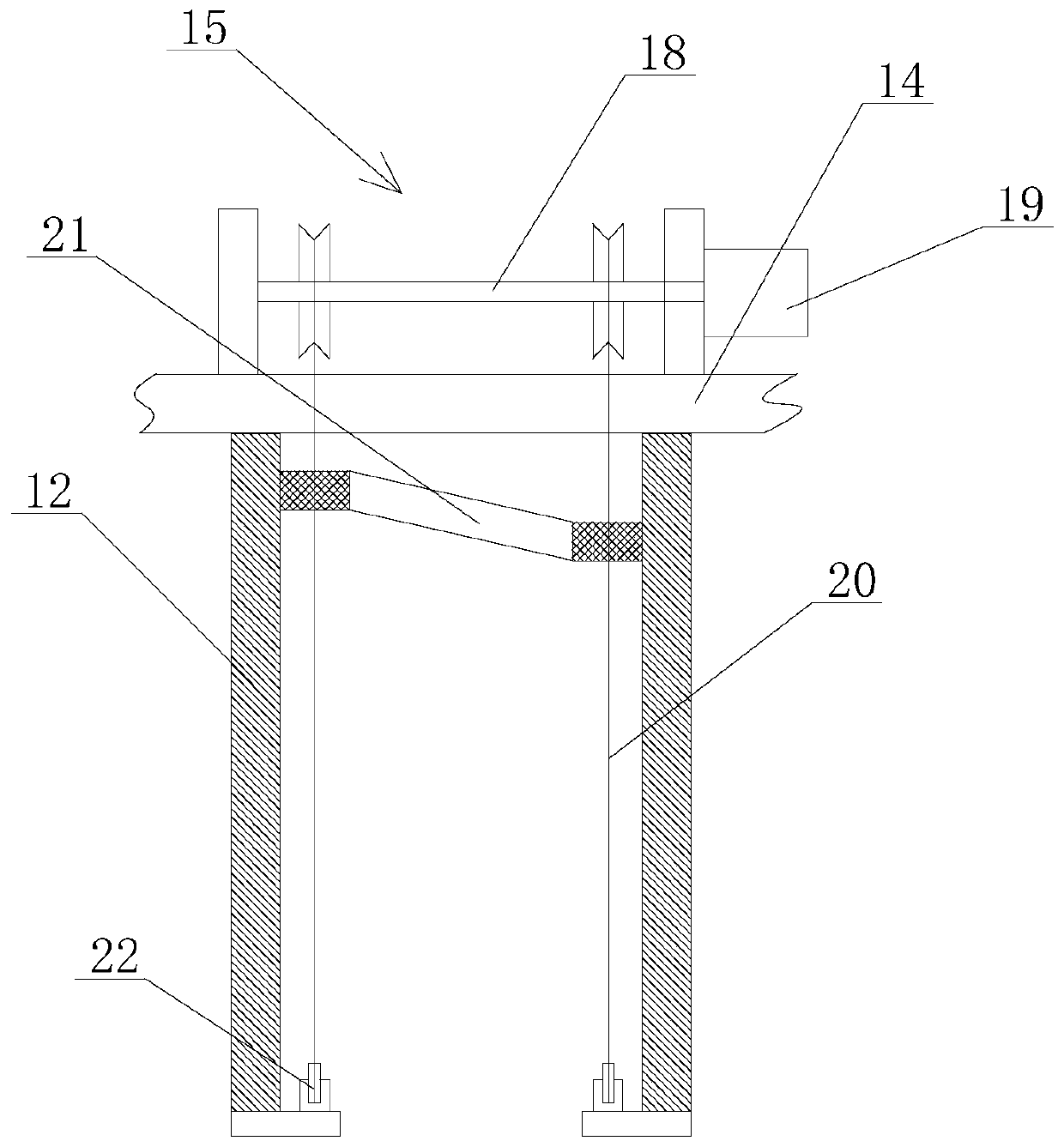

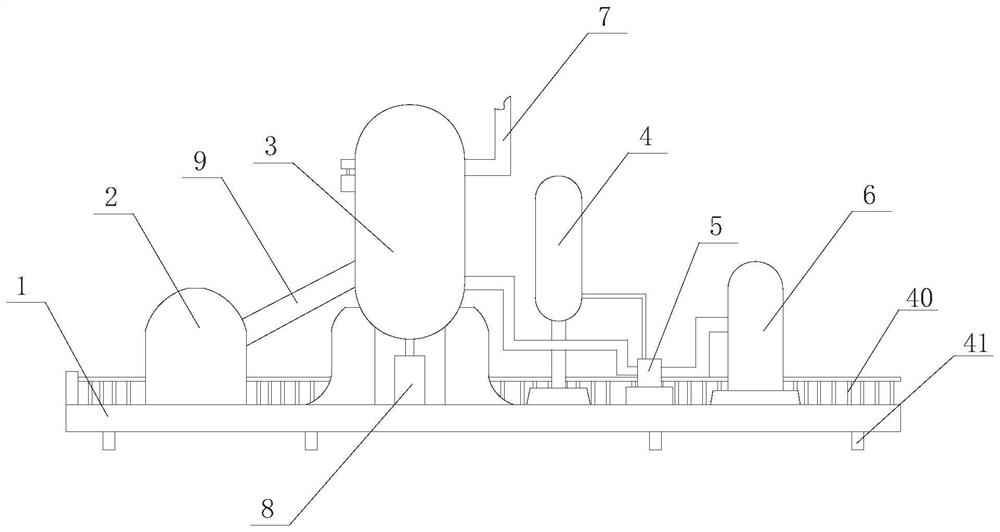

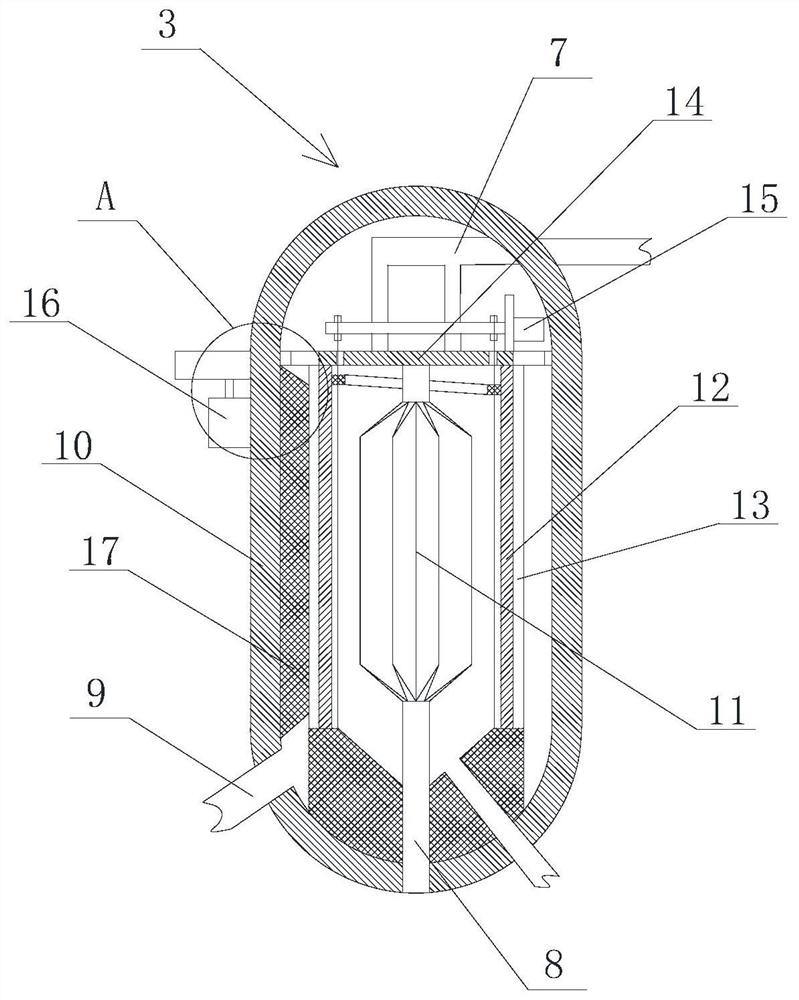

Centrifugal device for producing modified polyamide resin

The invention discloses a centrifugal device for producing modified polyamide resin. The centrifugal device comprises a machine base, wherein a first material storage bin, a centrifugal device body, an air storage tank, a feeding device and a second storage bin are sequentially and fixedly connected to the top of the machine base from left to right; a discharging pipe is fixedly connected to the upper side of the centrifugal device body, and a first motor is rotationally connected to the bottom of the centrifugal device body; and a discharging device is arranged between the first storage bin and the centrifugal device, and the left end and the right end of the discharging device are fixedly connected with the right side of the first storage bin and the lower side of the centrifugal devicebody respectively. The centrifugal device has the advantages that the aperture size of a filter screen can be adjusted, and the filter screen can be easily blocked by separated objects; and the direction of a rotational flow solution is not changed by arranging a spiral cleaning ring, and an adhesive in a first filter screen is not required to be cleaned by the method.

Owner:ANQING HONGTAI NEW MATERIAL

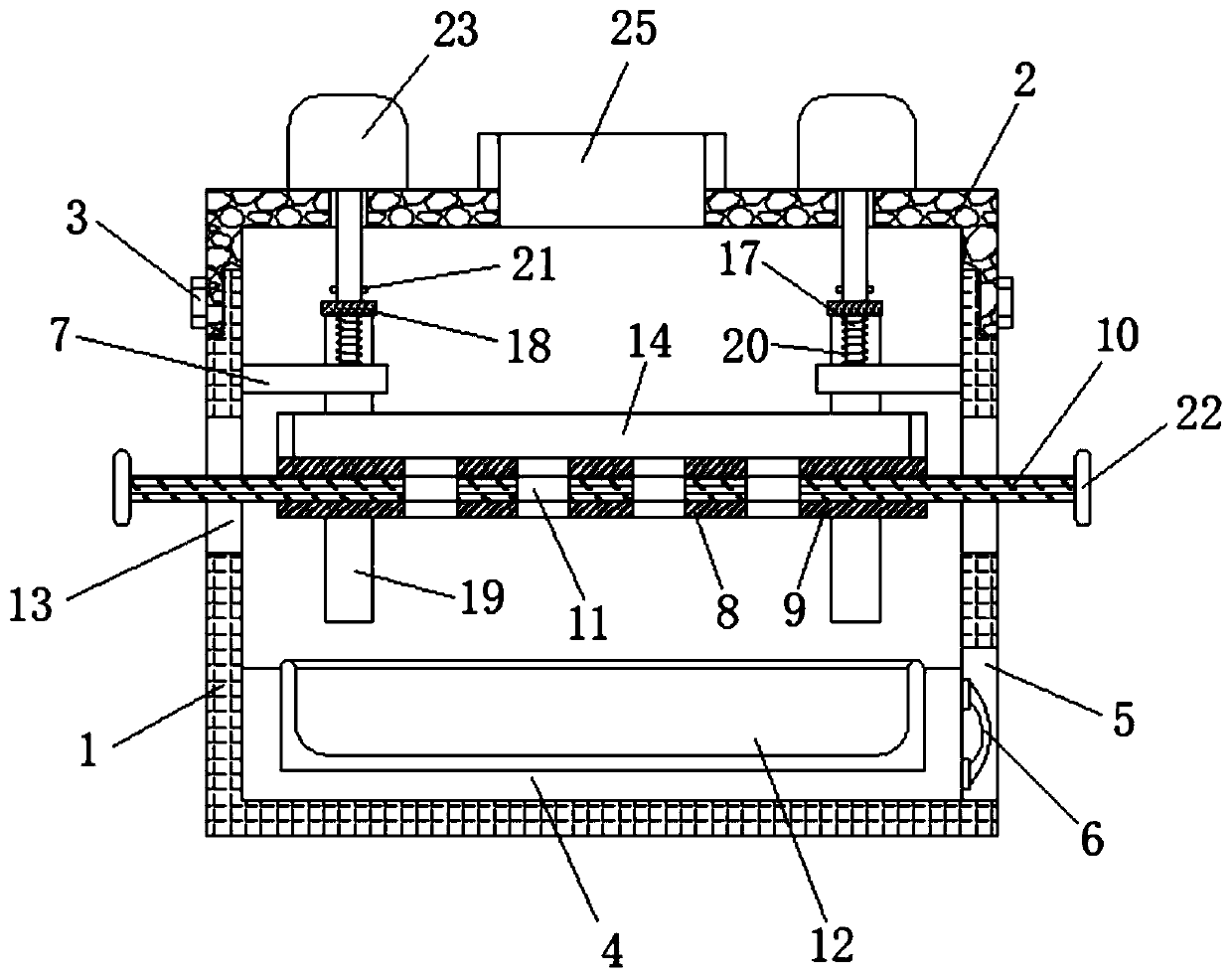

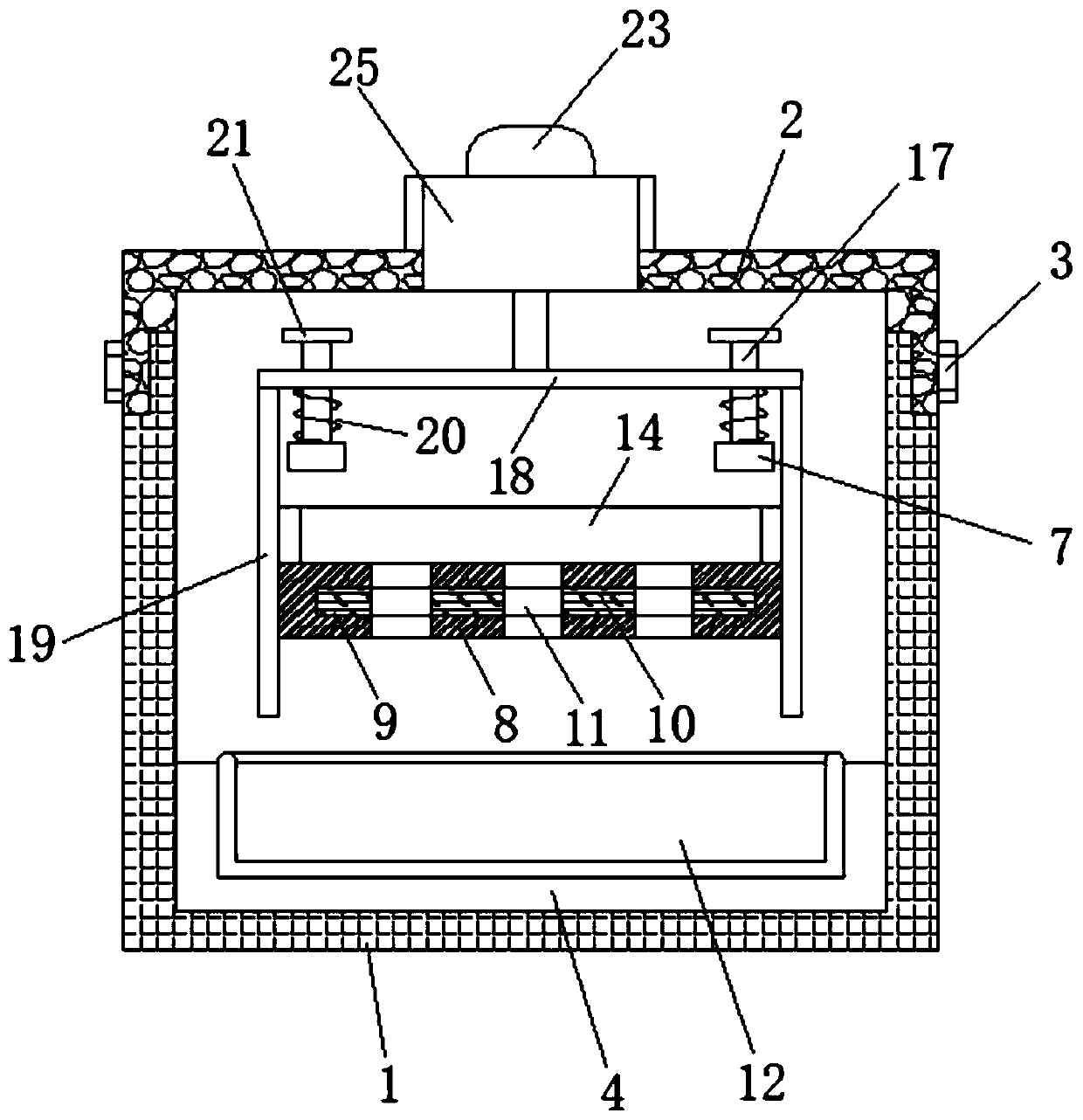

Sieving device with adjustable sieving holes for green plum processing

The invention relates to the technical field of green plum processing, in particular to a sieving device with adjustable sieving holes for green plum processing. The sieving device comprises a shell,wherein the shell is of a cuboid structure, and the upper side is open; the top end of the shell is connected with an upper cover in a clamping manner, and the shell is fixedly connected with the upper cover through bolts; the bottom end of the interior of the shell is provided with a containing mechanism; four symmetrically distributed supporting rods are arranged above the containing mechanism and inside the shell; a sieving plate is fixedly arranged on the supporting rods through a vibrating mechanism; a square frame matched with the sieving plate in size is fixedly welded to the top surface of the sieving plate; and the inner wall enclosed by the sieving plate and the square frame is fixedly provided with a buffering mechanism. By adjusting the position between a sliding plate and thesieving plate, the aperture of the through holes can be adjusted, the purpose of adjusting the aperture of the sieving holes is achieved, the problem that a plurality of sieving devices with sieving holes with different apertures are needed due to the fact that apertures are difficult to adjust in the prior art is solved, the resource consumption is reduced, the practicability of the sieving device with the adjustable sieving holes is improved, and the sieving device with the adjustable sieving holes is suitable for popularization.

Owner:LIAONING LIAODA FOOD CO LTD

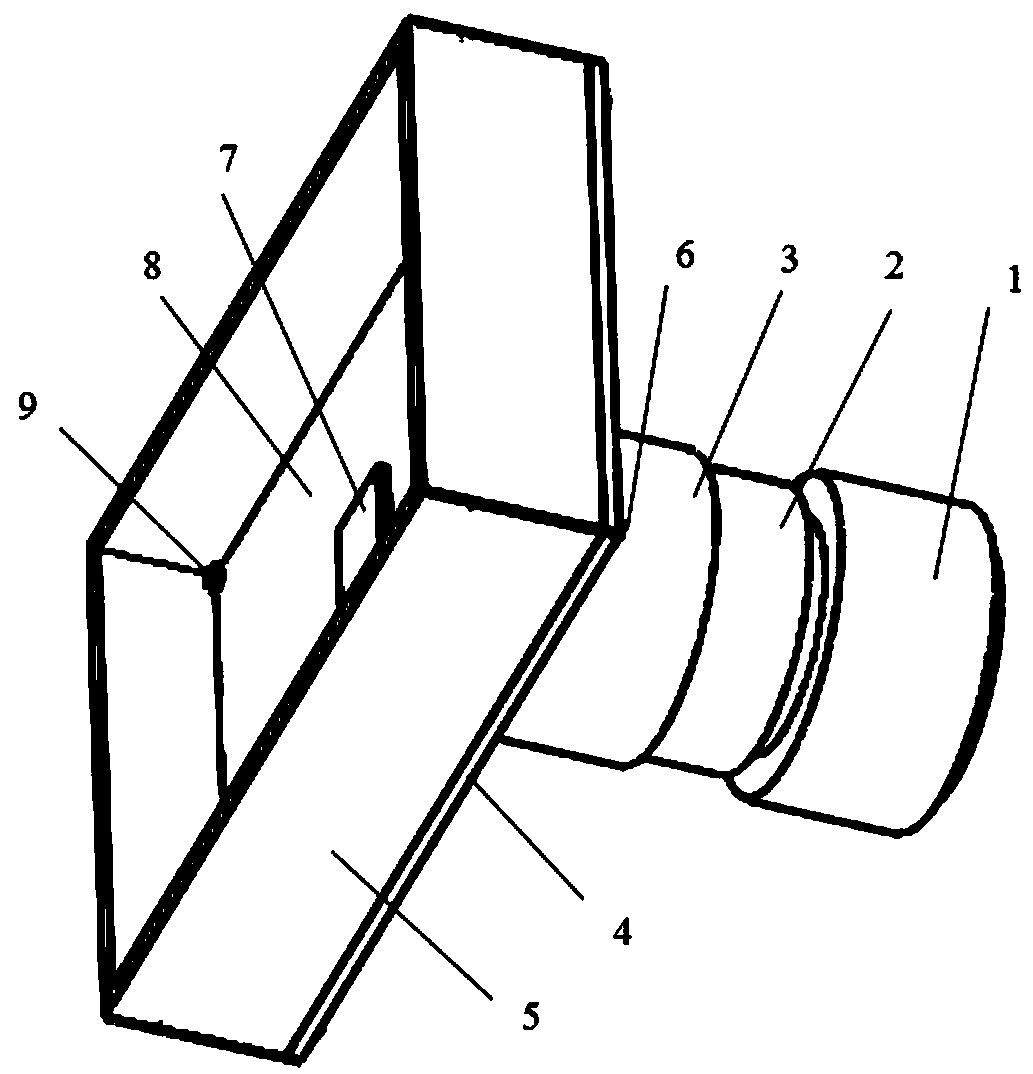

Lens focusing and aperture adjusting imaging device

PendingCN108802959AAdjust aperture sizeSimple structureMountingsCamera diaphragmsCamera lensEngineering

The invention relates to a lens focusing and aperture adjusting imaging device. The device comprises an optical lens, an adjustment component, a focusing sleeve, a fixing plate, a metal box, a drivingcircuit board and an imaging detector. The adjustment component is provided with a boss structure and is used for rotatably fastening and connecting with the groove structure of the optical lens. Theinternal thread of the focusing sleeve is cooperated with the external thread of an aperture adjusting component so as to carry out adjusting and focusing. The fixing plate and the metal box are connected through four bolts so as to be used for fixing the focusing sleeve. The driving circuit board is used for driving the imaging detector. Compared with the prior art, by using the device of the invention, the aperture size of the optical lens can be adjusted, and lens focusing can be realized; and the structure is simple, dismounting is convenient, manufacturing cost is low and the device is stable and reliable.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Organic composite porous ceramic material and preparation method thereof

ActiveCN111620678AEasy to prepareLow costReversible hydrogen uptakeCeramicwarePore distributionAdhesive

The invention discloses an organic composite porous ceramic material and a preparation method thereof, and relates to the technical field of porous ceramic processing. The organic composite porous ceramic material disclosed by the invention is composed of silicon dioxide, diatomite, aluminum powder and modified cellulose. The preparation method comprises the following steps: uniformly mixing the components, grinding the mixture into mixed powder, adding a water-soluble adhesive and water into the mixed powder, uniformly mixing, carrying out freeze drying to obtain a porous ceramic precursor, and carrying out high-temperature sintering on the porous ceramic precursor. The organic composite porous ceramic material provided by the invention has very high porosity and uniform pore distribution, and the pore size and shape can be controlled. The organic composite porous ceramic material can also be used for storing hydrogen, has the characteristics of high hydrogen storage capacity, simplehydrogen absorption and desorption operation, high-temperature and high-pressure resistance and the like, is good in cycling stability and can be repeatedly used for multiple times, and the prepared product is high in strength and not easy to deform.

Owner:贵州群华九九特种陶瓷科技有限公司

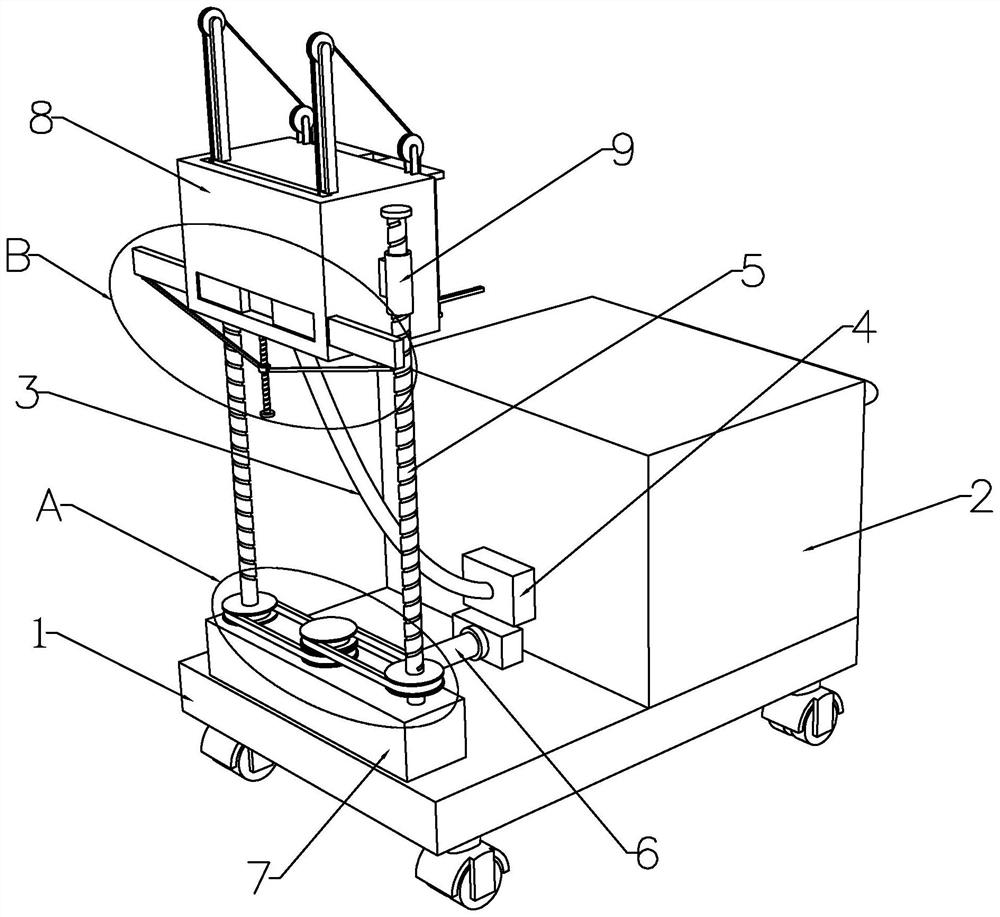

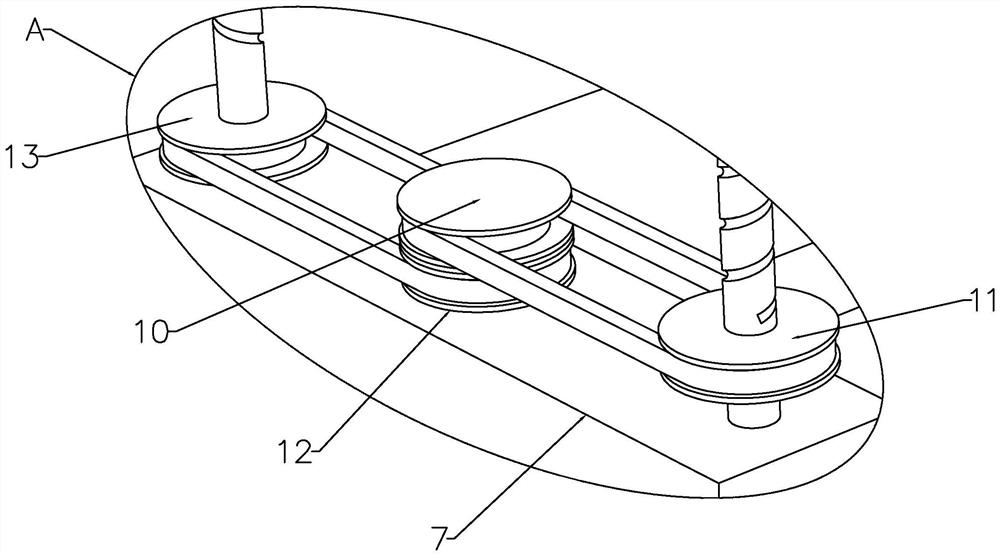

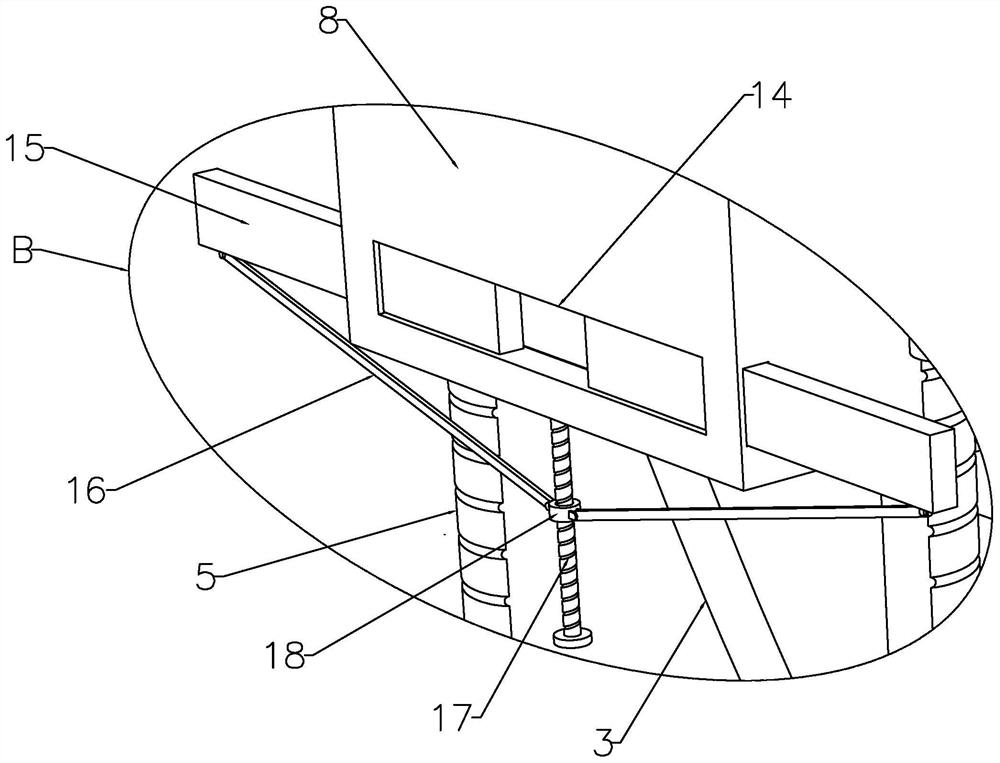

Concrete building surface defect repairing device and repairing method thereof

The invention discloses a concrete building surface defect repairing device and a repairing method thereof, relates to the field of concrete building surface defect repairing, and aims to solve the problems that existing concrete building wall surface repairing operation cannot achieve automatic treatment, so that the repairing efficiency is low, and certain danger exists during repairing operation. According to the technical scheme, the device comprises a movable vehicle body, a raw material box is fixedly installed on one side of the top end of the movable vehicle body, a first electric telescopic rod is fixedly installed on the other side, facing the movable vehicle body, of the raw material box, and a movable base is fixedly connected to the end of the first electric telescopic rod; and the movable base is slidably mounted at the top end of the movable vehicle body. The concrete surface defect repairing device can replace manpower to conduct repairing operation on defects of different sizes on the concrete surface, the repairing efficiency of the concrete surface defects is improved, and meanwhile the danger of repairing the concrete surface defects can be reduced.

Owner:安徽联赢环境建设有限公司

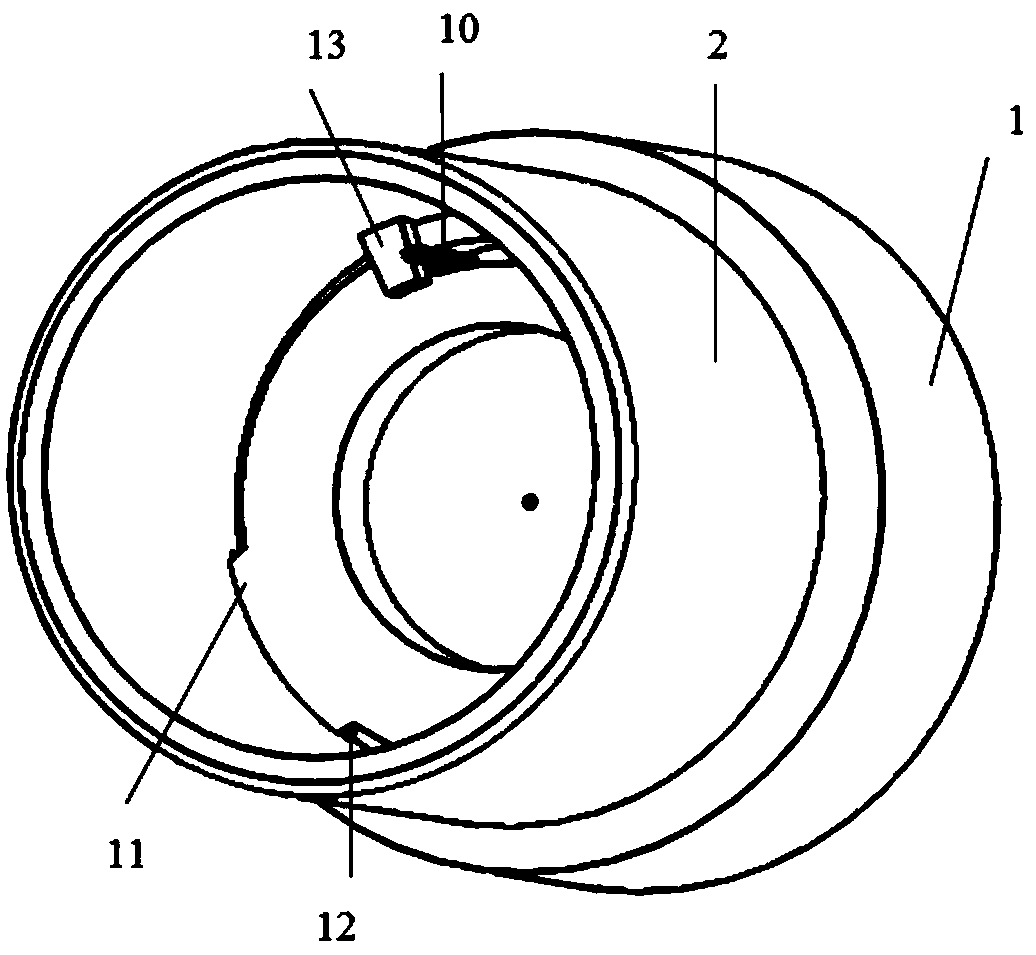

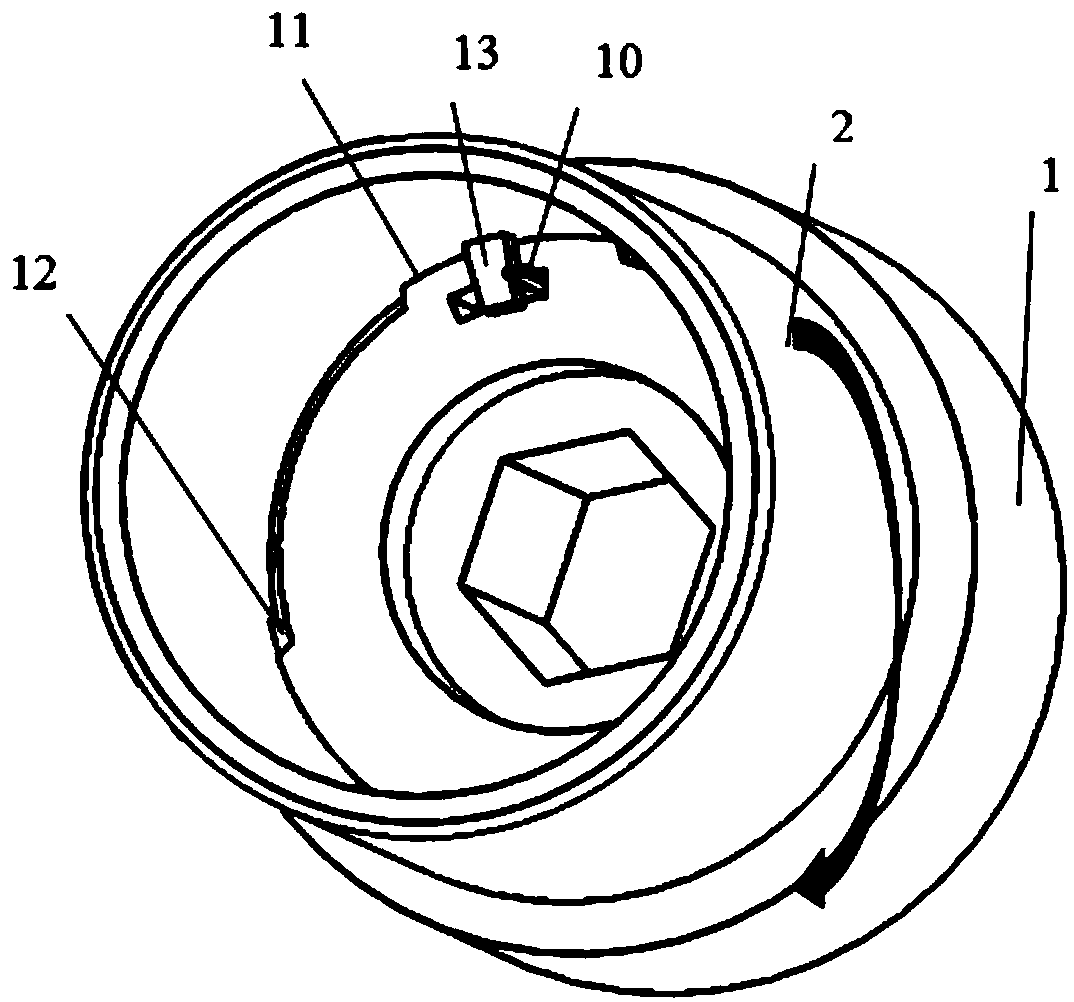

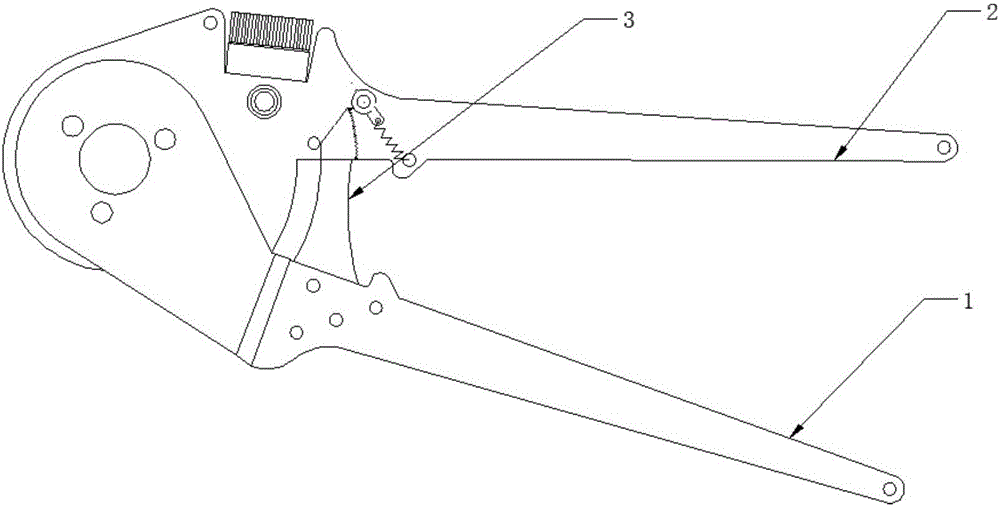

Three-claw-centering wire-pressing pliers

InactiveCN106410558AConvenience and simplicitySave materialConnection formation by deformationMaterial consumptionEngineering

The invention discloses a pair of three-claw-centering wire-pressing pliers. The three-claw-centering wire-pressing pliers comprise a plier opening, an accurate adjusting mechanism and handles; the three-claw-centering wire-pressing pliers are characterized in that the plier opening comprises an outer sleeve, an inner sleeve and crimping heads, wherein the outer sleeve is a fixed sleeve connected with an upper handle; the inner sleeve is a movable sleeve which is positioned in the center of the outer sleeve and connected with a lower handle; inner arcs which are deviated from the center are formed in positions of three equally-divided parts of 120 degrees on the inner side of the outer sleeve; three movement inner cavities are formed between the three inner arcs and the outer side wall of the inner sleeve; three column holes and three side holes are formed in the inner sleeve in a crossing manner; crimping heads sleeved with compressed springs are arranged in the three side holes respectively; the tail parts of the crimping heads prop against the corresponding inner arcs of the movement inner cavities; therefore, when the lower handle is kneaded upwardly to drive the inner sleeve to rotate, the tail parts of the crimping heads can be driven to move, in a manner of being tightly clung to the inner arcs; and meanwhile, the heads of the crimping heads can realize the wire-pressing function through extension in a central wire-pressing hole. By adoption of the three-claw-centering wire-pressing pliers, three-claw centering and guarantee of non-eccentricity in the wire-pressing process can be accurately accomplished under the conditions of lower cost and low material consumption.

Owner:HEFEI UNIV OF TECH

Oil-water separation composite filter material and preparation method thereof

PendingCN109289251AHigh strengthImprove filtering effectFatty/oily/floating substances removal devicesNon-miscible liquid separationMicro structureSurface modification

The invention relates to an oil-water separation composite filter material and a preparation method thereof. The oil-water separation composite filter material comprises a base filter material and a supporting material, wherein the base filter material is arranged above the supporting material; a low surface energy adhesive material is arranged above the base filter material; and a nano micro-particle thin film is adhered to the surface of the low surface energy adhesive material. The base filter material is a metal filter screen, filter cloth or filter paper; the micro-hole diameter range ofis 5-300 Mum; the supporting material is a stainless steel supporting structure, and the hole diameter range is 0.5-10 mm; the diameter of the nano micro-particles is 200 nm-2 Mum. The nano micro-particles are adhered to the surface of the base filter material in the form of dispersion and natural sedimentation, so that the change of the surface micro-structure of the low surface energy coating layer and the surface modification treatment are realized; and the liquid-liquid two-phase separation material has the advantages of high strength, controllable surface wettability, long service life and the like.

Owner:北京揽山环境科技股份有限公司

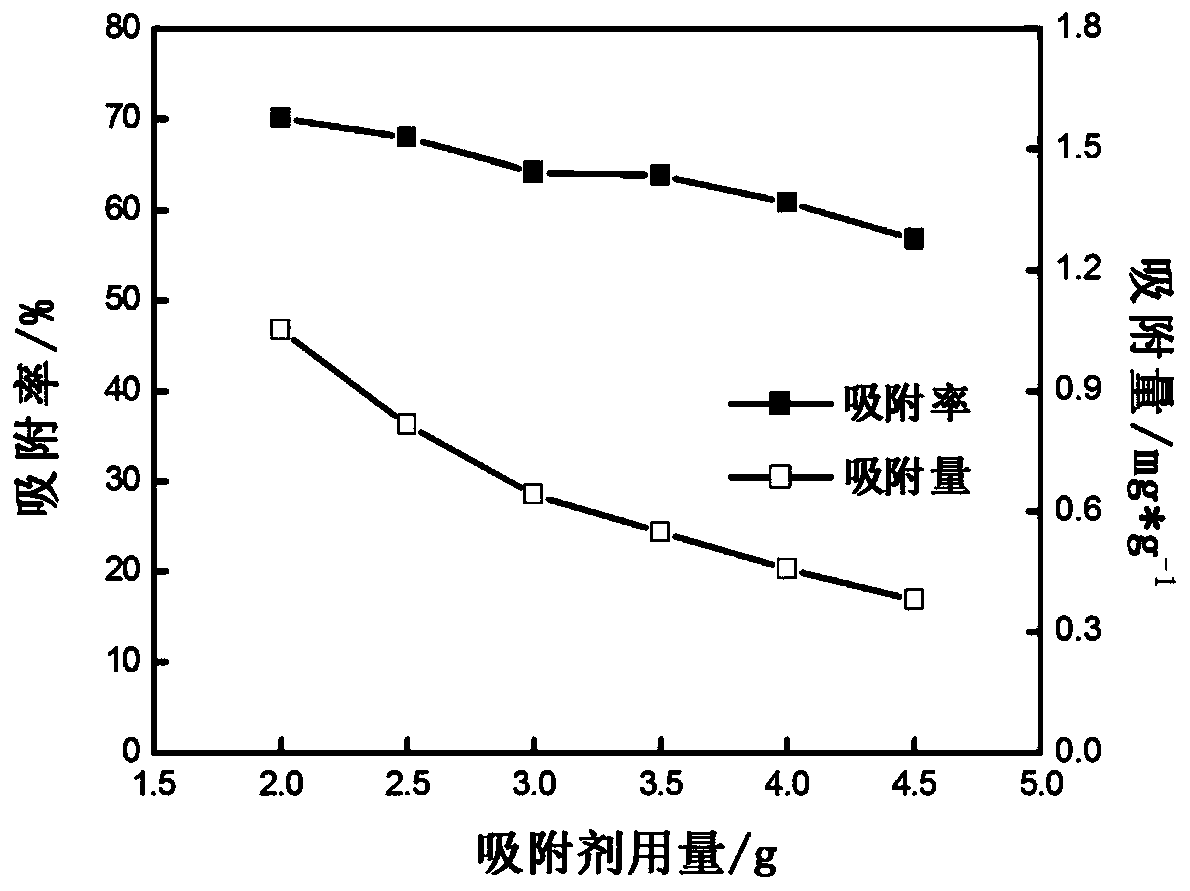

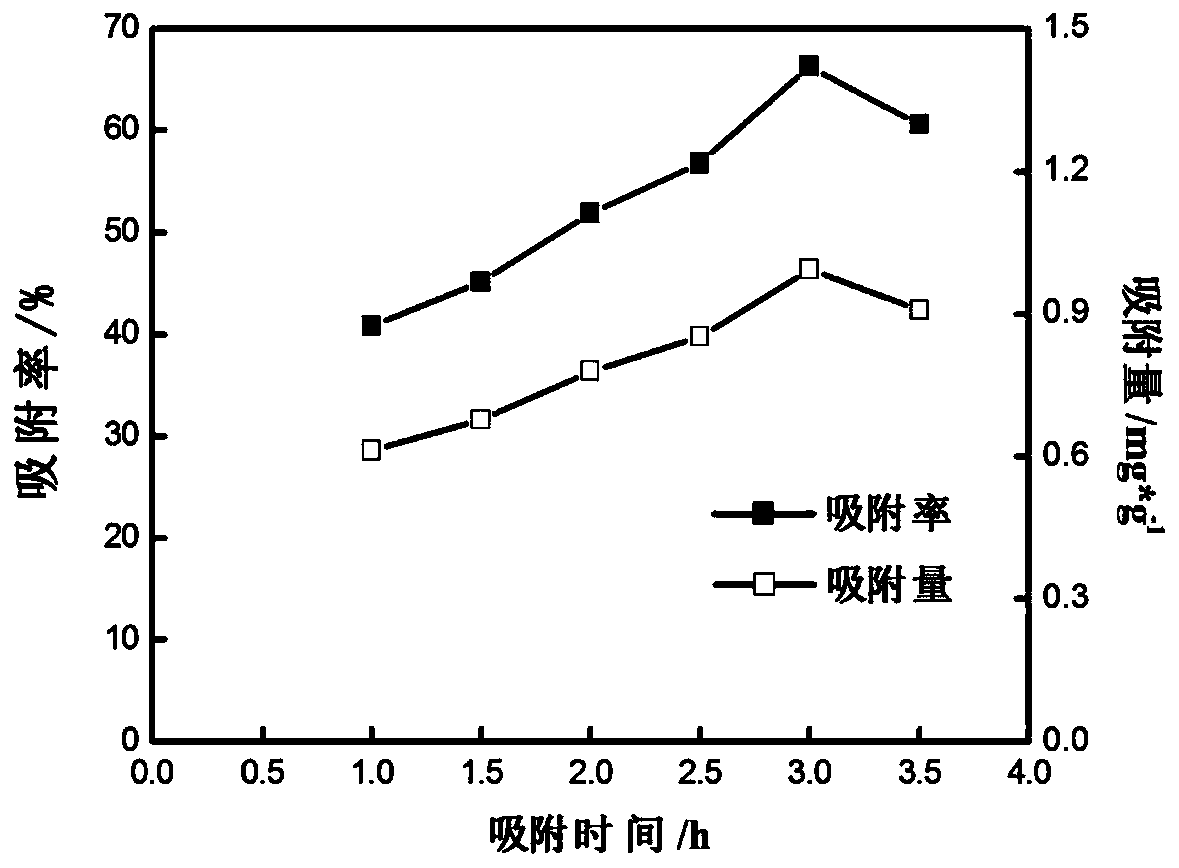

Preparation method of modified volcanic slag filter material and its application

InactiveCN110548476ALow costImprove adsorption efficiencyOther chemical processesWater contaminantsSlagChloride

The invention discloses a preparation method of a modified volcanic slag filter material and its application, belonging to the technical field of water treatment. The preparation method comprises thefollowing steps of: screening and pretreating volcanic slag, taking ferric chloride as a modifier, soaking the pretreated volcanic slag in a modification solution, drying after a certain time, calcining in a muffle furnace, and completing modification through multiple operations. The modified volcanic slag filter material prepared by the invention has larger specific surface area and developed pore structure, the method of the invention does not generate secondary pollution problems, and the volcanic slag is cheap and easy to obtain, the modification method and the adsorption process are simple to operate, the treatment effect is good, the treatment cost is greatly saved, and the method can be widely applied to the field of water treatment industry.

Owner:CHANGCHUN UNIV OF TECH

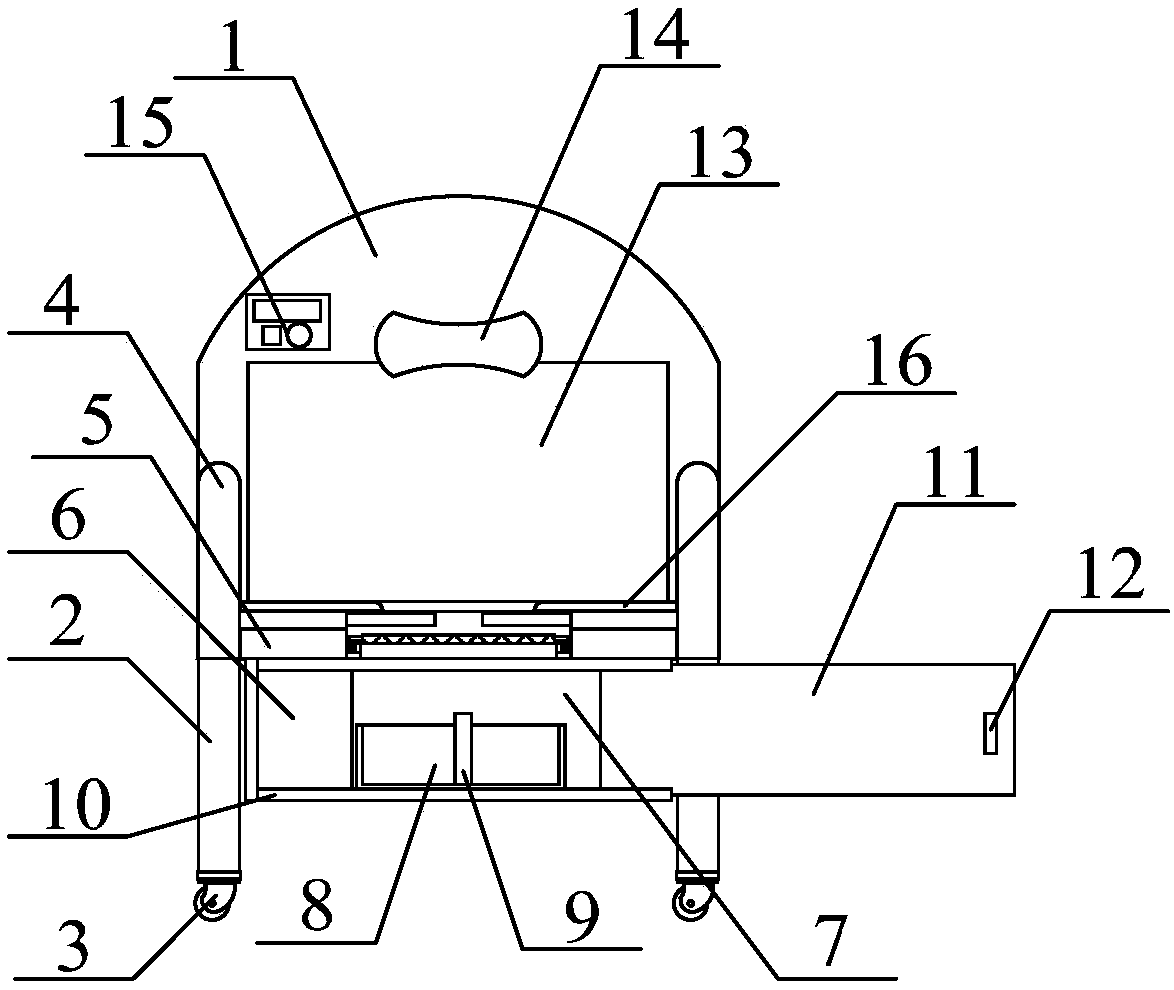

Intelligent gynecology hot-smoking treatment instrument

InactiveCN108464929APlay a protective effectPrevent jumpingDevices for heating/cooling reflex pointsSmoking treatmentMassage

The invention provides an intelligent gynecology hot-smoking treatment instrument. The intelligent gynecology hot-smoking treatment instrument comprises a backrest, supporting legs, universal bottom wheels, handrails, a tool storage box, a storage frame, a wormwood storage box, a wormwood column, sliding rails, a baffle, a handle, an adjustable cushion structure, a pillow, a timing alarm device and a detachable massage cushion structure, wherein the backrest is installed on the upper side of the back portion of an adjustable protective partition plate structure through a bolt. According to theintelligent gynecology hot-smoking treatment instrument, a semiconductor heating plate is embedded into the inner side bottoms of side seat cushions and electrically connected with a storage batteryin series, and the physical therapy effect on the freshly-merged haunch can be conveniently achieved; an anti-dust partition net is installed at the upper portions of L-shaped cushion frames through L-shaped connecting frames, the protection effect on wormwood in the wormwood storage box can be conveniently achieved, and waste wormwood residues are thus prevented from jumping the body of a patient; adjustable cushion plates are inserted into the inner sides of protection inserting frames at the outer ends respectively, and the hole diameter in a seat plate can be conveniently adjusted as required.

Owner:中科伊诺(北京)国际医学研究院有限公司

Mixing and stirring device for food processing and using method of mixing and stirring device

ActiveCN108525781AAchieve mixing and stirring operationsSmash thoroughlySievingScreeningEngineeringFood processing

The invention discloses a mixing and stirring device for food processing and a using method of the mixing and stirring device. The mixing and stirring device for food processing comprises a mixing andbeating box, a supporting barrel, a transverse supporting spring, a mixing and beating mechanism and a screening plate, wherein the mixing and beating box is arranged in the supporting barrel and issuspended through the transverse supporting spring; the mixing portion and the beating portion of the mixing and beating mechanism are arranged in the mixing and beating box; the mixing portion of themixing and beating mechanism can convey lump materials of the mixing and beating box to a high end from a low end; the beating portion of the mixing and beating mechanism can smash the lump materialsof the mixing and beating box; the screening plate is provided with an aperture adjusting mechanism capable of adjusting apertures; and a dustproof receiving device is arranged under the screening plate. The mixing and stirring device for food processing is simple in structure and convenient to operate, different materials can be mixed when the lump materials are smashed, the lump materials are smashed and mixed thoroughly, and the efficiency is high.

Owner:上海老盛昌配送有限公司

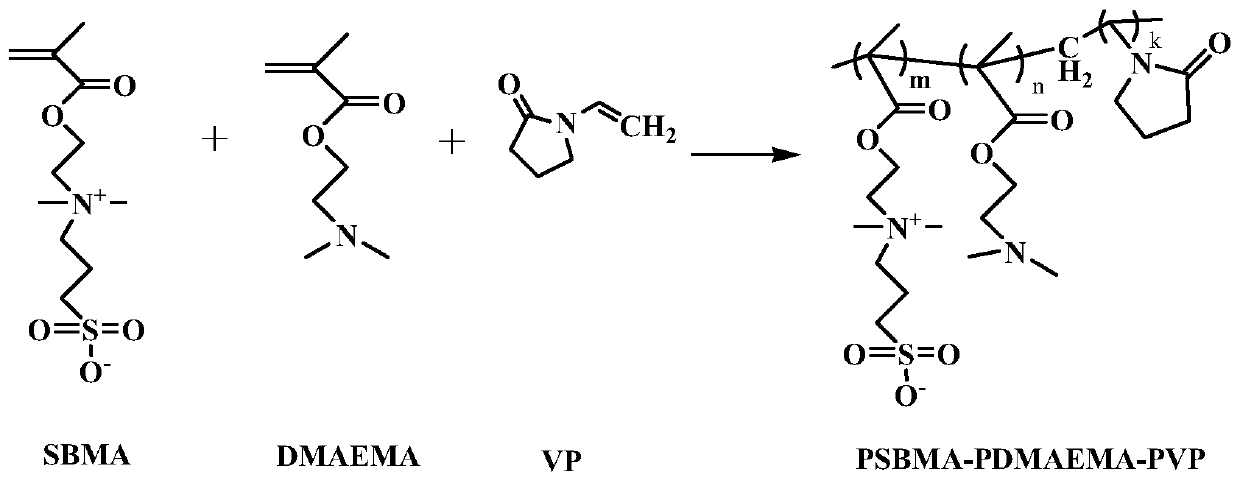

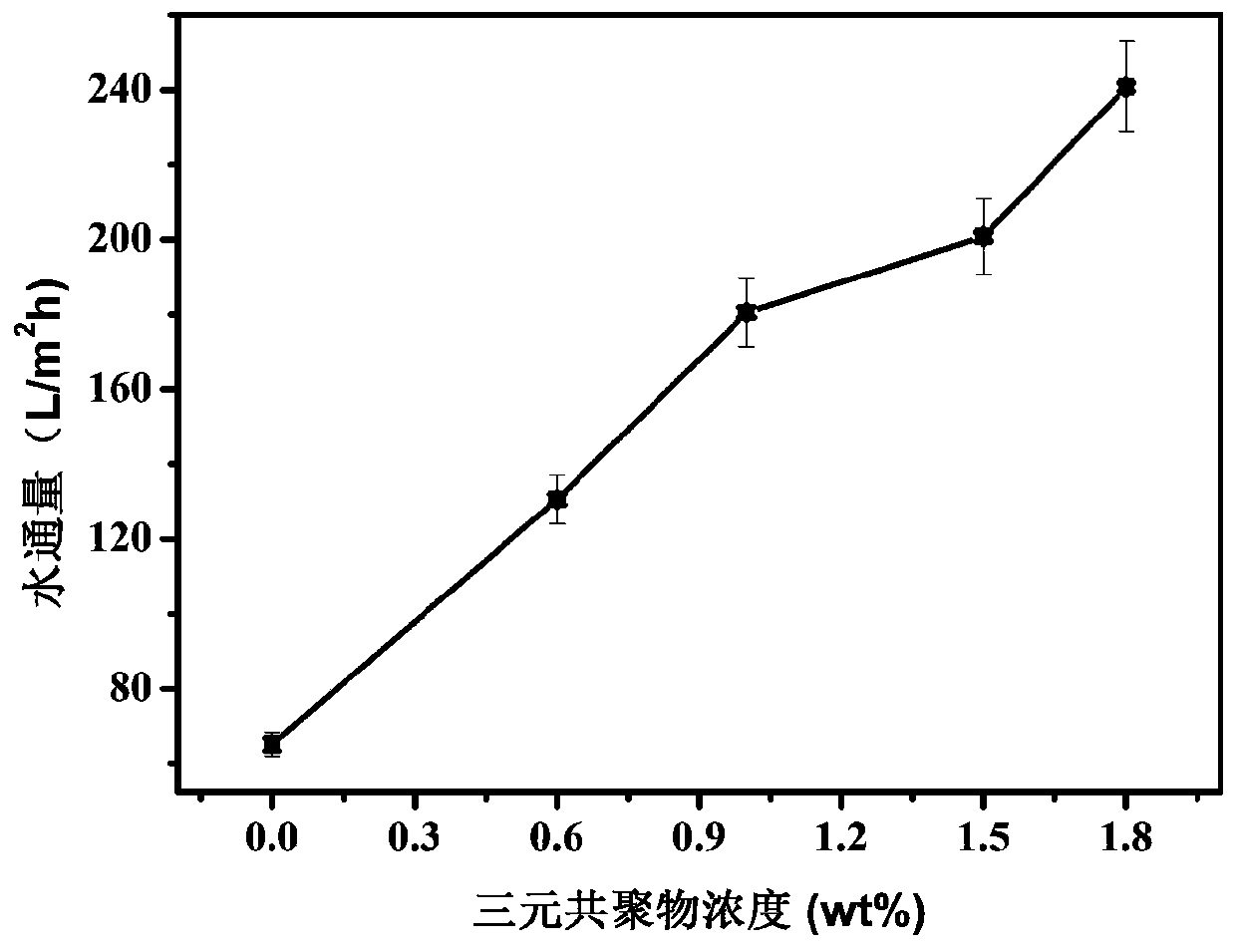

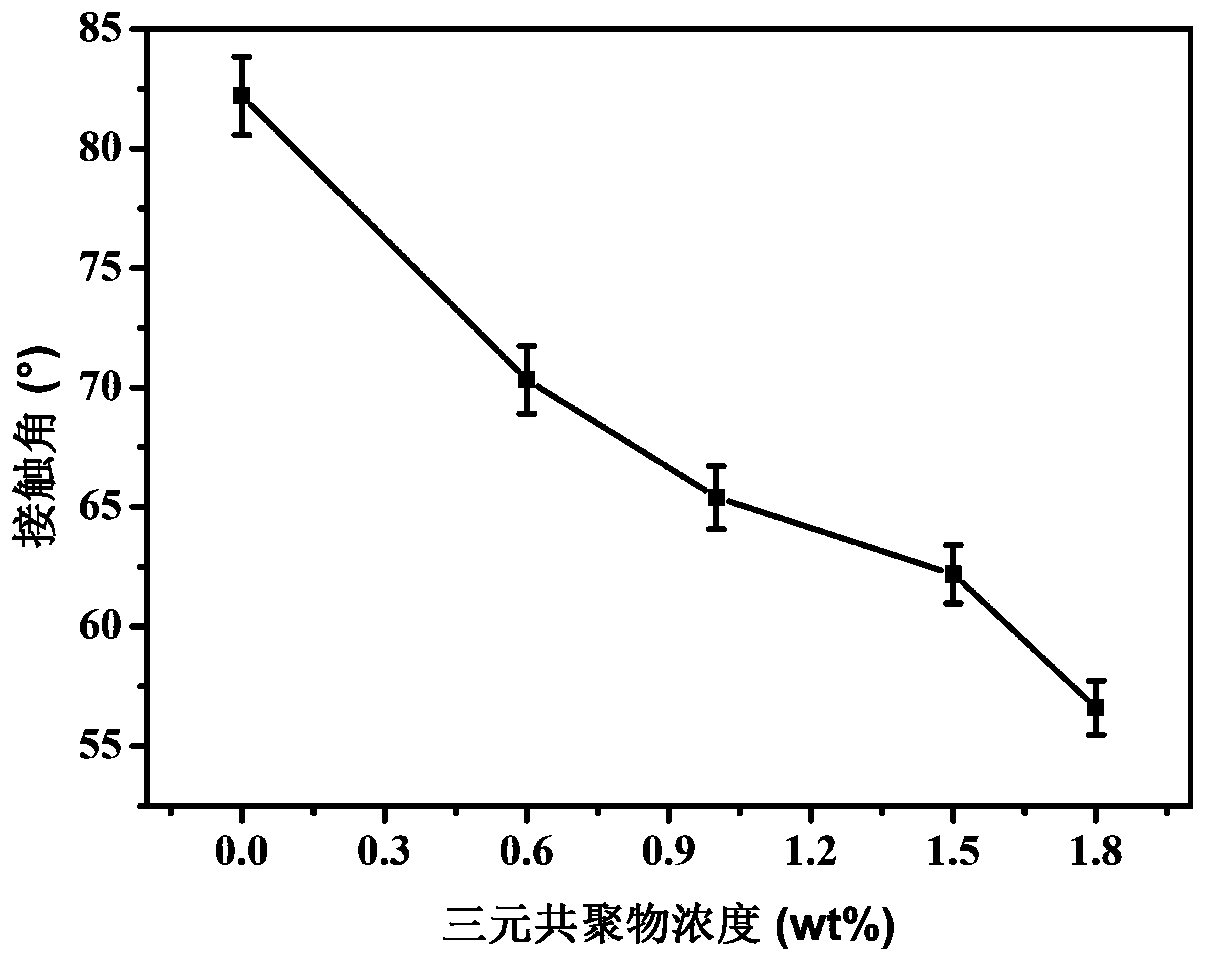

Amphiphilic terpolymer modified ultra-filtration membrane preparation method

ActiveCN110681264APromote mutual solubilityAvoiding Phase Separation DifficultiesUltrafiltrationMethacrylatePolymer science

The invention discloses an amphiphilic terpolymer modified ultra-filtration membrane preparation method, and belongs to the technical field of membrane separation. The specific scheme comprises: 1, copolymerizing dimethylaminoethyl methacrylate, methacryloylethylsulfobetaine and vinyl pyrrolidone through a reversible addition-chain fragmentation transfer polymerization method to prepare a structure-controllable amphiphilic terpolymer; and 2, blending the terpolymer and polyaryletherketone to obtain a membrane casting solution, and preparing the ultra-filtration membrane through a non-solvent induced phase inversion method. According to the invention, in the membrane casting solution of the organic solvent, the polarity of the hydrophobic chain segment in the amphiphilic polymer is similarto the polarity of polyaryletherketone, so that the intermiscibility is improved; in the water phase, the hydrophilic chain segments in the amphiphilic polymer are enriched on the surface of the membrane, so that the antifouling effect is achieved; the pore size and the hydrophilicity of the ultra-filtration membrane are effectively regulated by adjusting the contents and the structures of the membrane forming substance and the modified additive in the membrane casting solution; and the method is simple to operate and has important application prospect.

Owner:HARBIN INST OF TECH AT WEIHAI

Preparation method of polymer micro-filtration membrane

ActiveCN103191656BAdjust aperture sizePore Density AdjustmentSemi-permeable membranesPolymer scienceFiltration membrane

The invention provides a preparation method of a polymer micro-filtration membrane. The preparation method comprises the following steps of: carrying out polymerization reaction on a sulfonic acid monomer containing double bonds in an organic solvent containing poly(phthalazinone ether sulfone ketone) under the action of an initiator to obtain a first reaction mixture; then heating to generate a crosslinking reaction to obtain a second reaction mixture; and finally carrying out film forming treatment to obtain the polymer micro-filtration membrane, wherein the poly(phthalazinone ether sulfone ketone) containing phthalazinone. According to the preparation method provided by the invention, the aperture size and the hole density of the polymer micro-filtration membrane can be simply and effectively adjusted by changing the proportions of raw material components in the reaction on the basis of pore-forming through interaction among polymer molecule chains; and meanwhile, reagents used in the preparation process are common reagents and are low in cost and easy for implementation of reaction conditions, and a pore-forming method is convenient and fast.

Owner:UNIV OF SCI & TECH OF CHINA

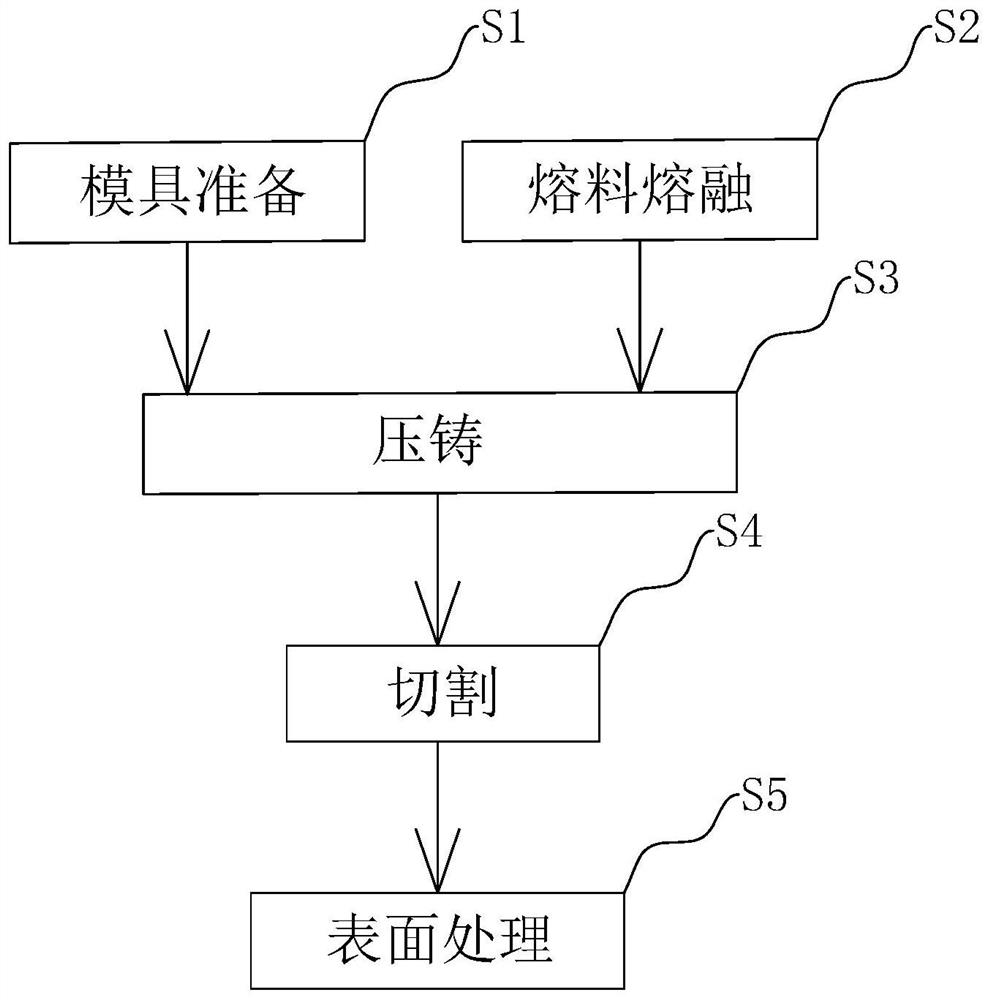

Die casting machining process and cutting system

ActiveCN113369455AImprove cutting accuracyStable temperatureBlast gunsAbrasive blasting machinesSand blastingDie casting

The invention relates to a die casting machining process and cutting system, and relates to the field of die casting production. The die casting machining process comprises the following steps of: a die preparation procedure, specifically, a die is preheated, and a release agent is sprayed; a melt melting procedure, specifically, the solid metal is melted to obtain liquid metal; a die-casting procedure, specifically, the liquid metal is injected into a die for die-casting forming to obtain a die casting; a cutting procedure, specifically, water cutting is performed on the die casting by using high-pressure water flow to obtain a part; and surface treatment, specifically, powder spraying, paint baking, oil spraying, oxidation, sand blasting, electroplating and the like are carried out on the part to improve the mechanical strength of the part. The invention has the effect of improving the die casting cutting precision.

Owner:上海恩耀机电有限公司

A centrifugal device for the production of modified polyamide resin

The invention discloses a centrifugal device for modified polyamide resin production, which includes a machine base, and the top of the machine base is fixedly connected with a first storage bin, a centrifugal device, an air storage tank, a feeding device and a second feeding device in order from left to right. Two storage bins; the upper side of the centrifugal device is fixedly connected with a feeding pipe, and the bottom of the centrifugal device is rotatably connected with a first motor; a discharge device is arranged between the first storage bin and the centrifugal device. The left and right ends of the discharge device are respectively fixedly connected with the right side of the first storage bin and the lower side of the centrifugal device. The advantage of the present invention is that the pore size of the filter screen can be adjusted, and it is easy to be blocked by the separator; the present invention does not change the direction of the swirl solution by setting the spiral cleaning ring, and does not need to stop the present invention to remove the sticky material inside the first filter screen. Knot.

Owner:ANQING HONGTAI NEW MATERIAL

Method of organizing polymer porous support material for engineering and its preparation device

InactiveCN100431622CUnique pore structureEasy to prepareCoatingsProsthesisPolymer scienceFreeze-drying

A porous polymer scaffold material for tissue engineering is prepared through putting the ice particles in a mould, negative-pressure osmosis of pre-cooled polymer solution into the gaps between ice particles, freezing to become a prefabricated block, freeze drying for removing solvent and vacuum drying for removing ice particles.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com