Guide and guard device for rolling of profile steel with special-shaped section

A guide device and cross-section technology, applied in the direction of guiding/positioning/alignment devices, etc., can solve the problems of unusable devices, increased production costs, and lack of versatility, and achieve the effects of convenient fixing, convenient maintenance, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

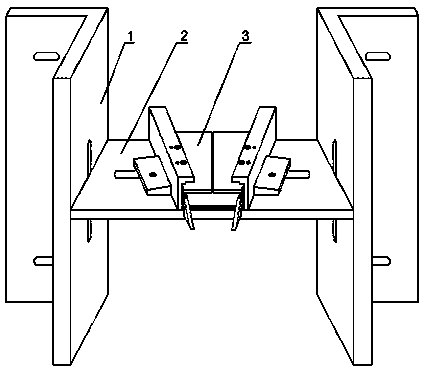

[0036] The utility model relates to a guide device for rolling special-shaped section steel. Such as figure 1 As shown, the guide device is composed of a bracket 1 , a guide support plate 2 and a guide 3 . Both sides of the guide support plate 2 are symmetrically equipped with brackets 1, and a guide 3 is installed at the middle position of the upper plane of the guide support plate 2.

[0037] Such as figure 2 As shown, the shape and structure of the two supports 1 are symmetrical, and the support 1 is a whole composed of two mutually perpendicular flat plates. A vertical strip-shaped adjustment hole 5 is provided along the vertical direction at the middle position of a flat plate, and a horizontal strip-shaped adjustment hole 4 is correspondingly opened along the horizontal direction near the upper and lower sides of the other flat plate.

[0038] Such as image 3 As shown, the shape and structure of the guide support plate 2 are: the middle position of the rectangular ...

Embodiment 2

[0049] The utility model relates to a guide device for rolling special-shaped section steel. Except following technical parameter, all the other are with embodiment 1: the base angle α of right-angled trapezoid 1 =70~74°;

[0050] The length of the vertical strip adjustment hole 5 is 700mm-900mm;

[0051] The depth L of the lower screw hole 17 1 =0.25~0.30L 0 , the outer diameter of the lower screw hole 17 is 1.3 to 1.5 times the width of the lower adjustment guide groove 18;

[0052] The depth L of the two upper screw holes 16 1 =0.25~0.30L 0 , The outer diameters of the two upper screw holes 16 are 1.3 to 1.5 times the width of the upper adjustment guide groove 15.

[0053] Compared with the prior art, this specific embodiment has the following positive effects:

[0054] This specific embodiment is assembled from a bracket 1, a guide support plate 2 and a guide 3, and has a simple structure and convenient maintenance. The vertical strip-shaped adjustment hole 5 opene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Bottom corner | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com