Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1510results about "Guiding/positioning/aligning arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

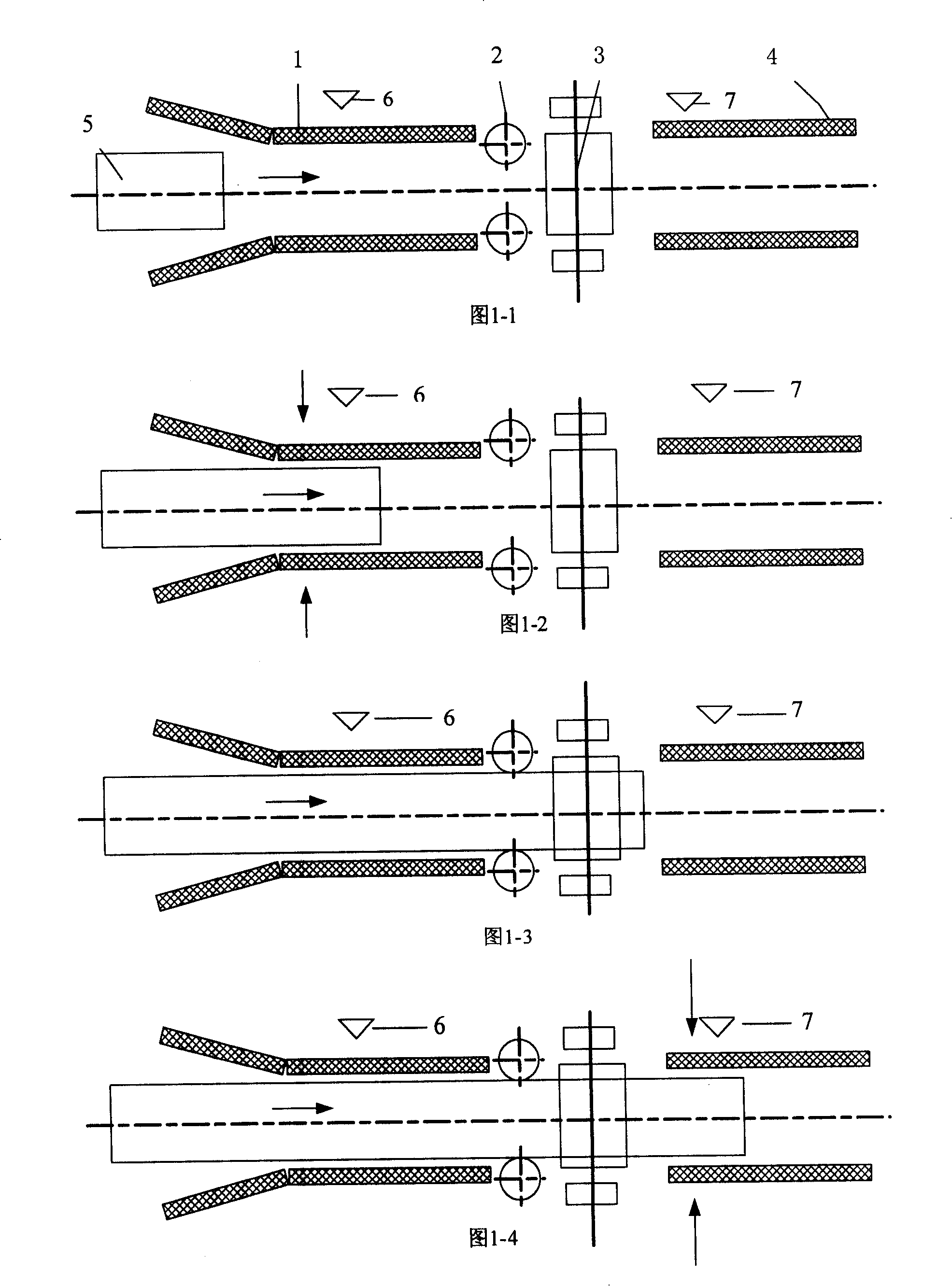

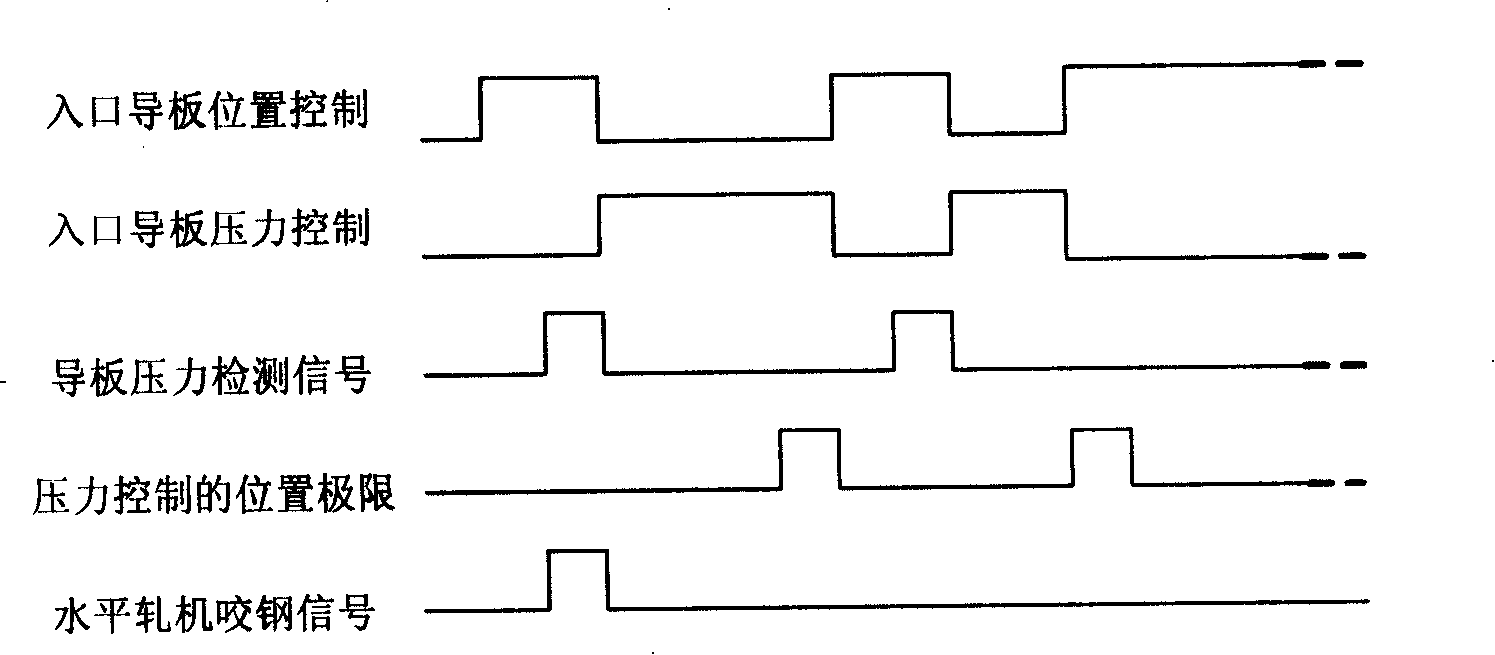

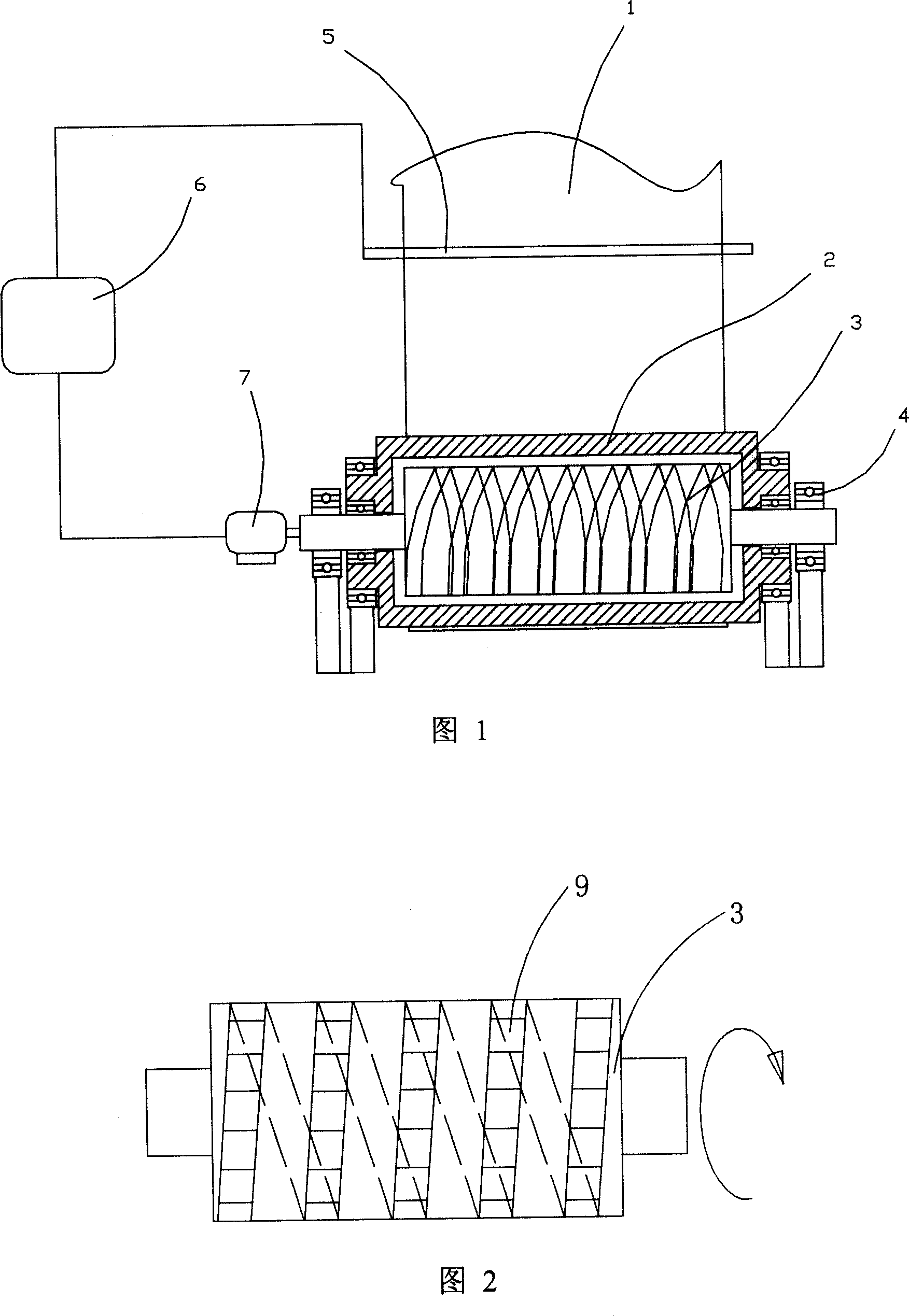

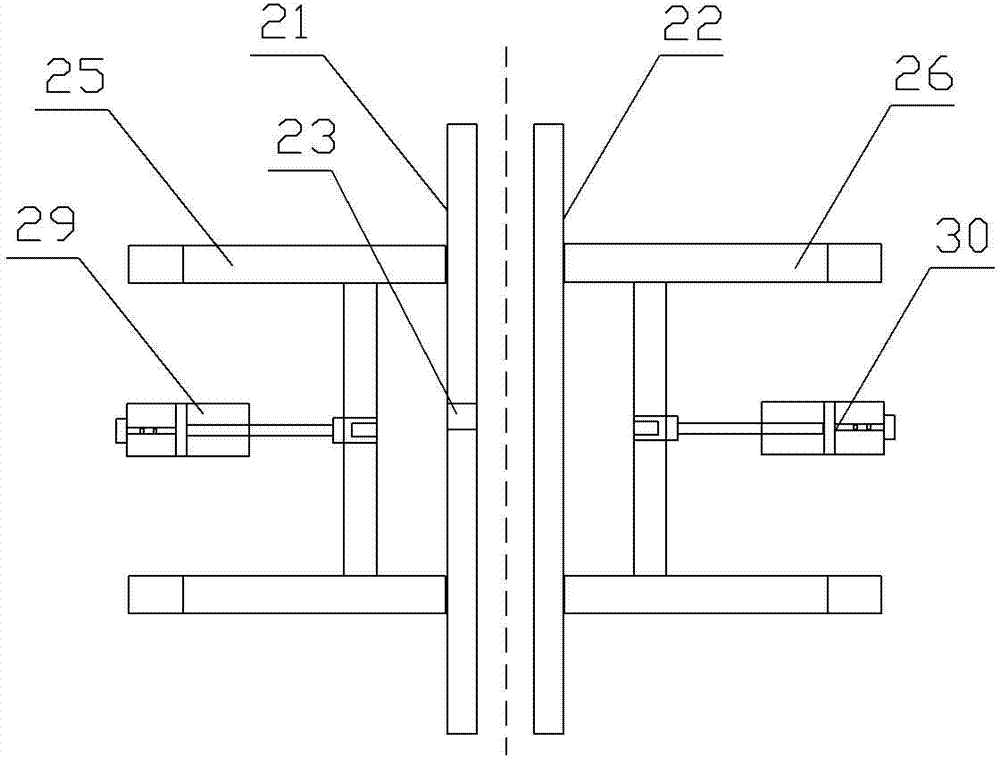

Controlling method of rough rolling breakdown bar camber

ActiveCN101224471APlay a guiding roleLow added valueGuiding/positioning/aligning arrangementsTension/compression control deviceAdditional valuesPosition control

The invention relate to a control technique of the rolling process of a rolling steel. The invention discloses a control method of a rough rolling intermediate billet camber. The control method combines a position control with a pressure control; in a multi-pass rolling of the positive-pass and reverse-pass of a roughing mill, the camber generation of the intermediate billet is restricted. The control method of the invention can reduce the additional value of the openness of a side guide plate, leads the flexible deformation of the intermediate billet between the inlet and the outlet of the roughing mill in the horizontal direction to be restricted by the side guide plate, reduces the camber of the intermediate billet, and prevents the severe abrasion which is caused by the long-term contact of the side guide plate and the intermediate billet.

Owner:BAOSHAN IRON & STEEL CO LTD

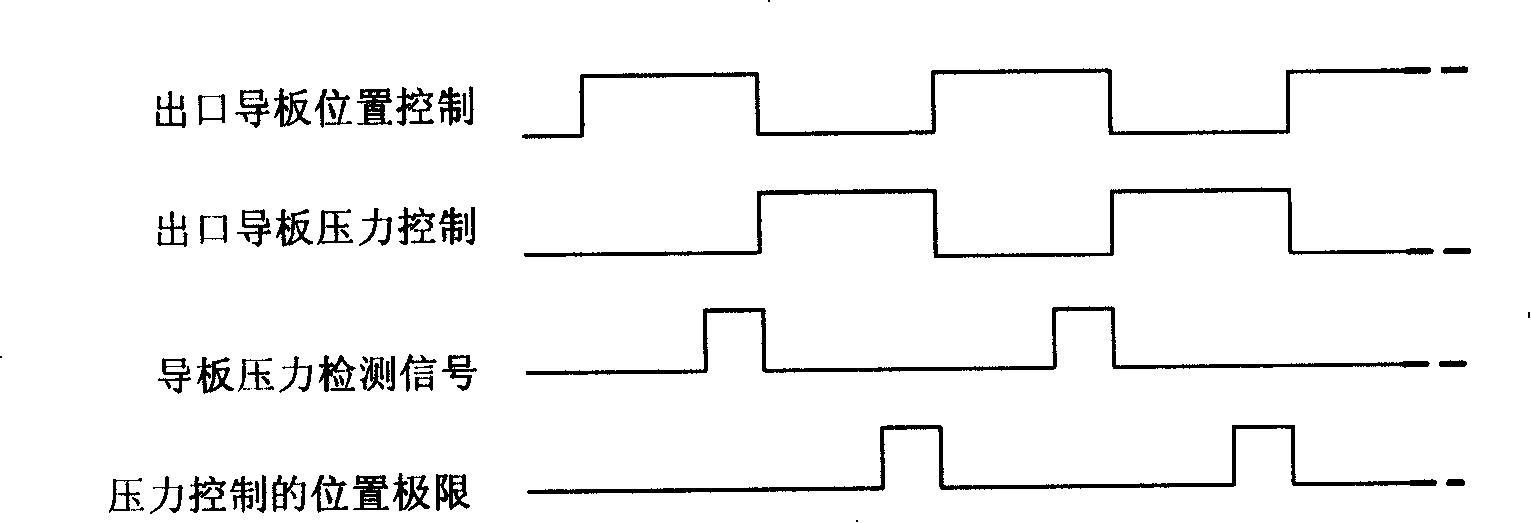

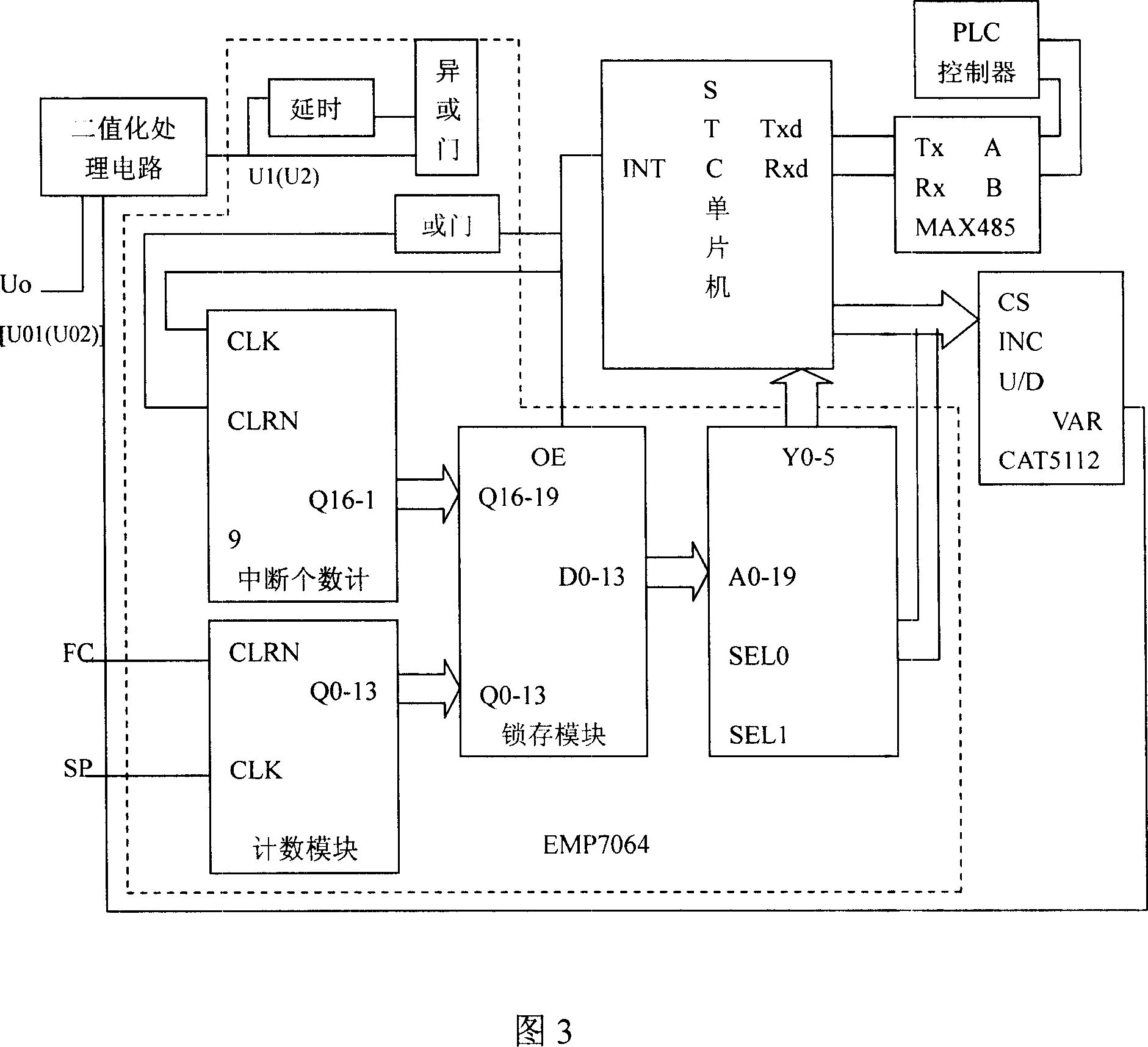

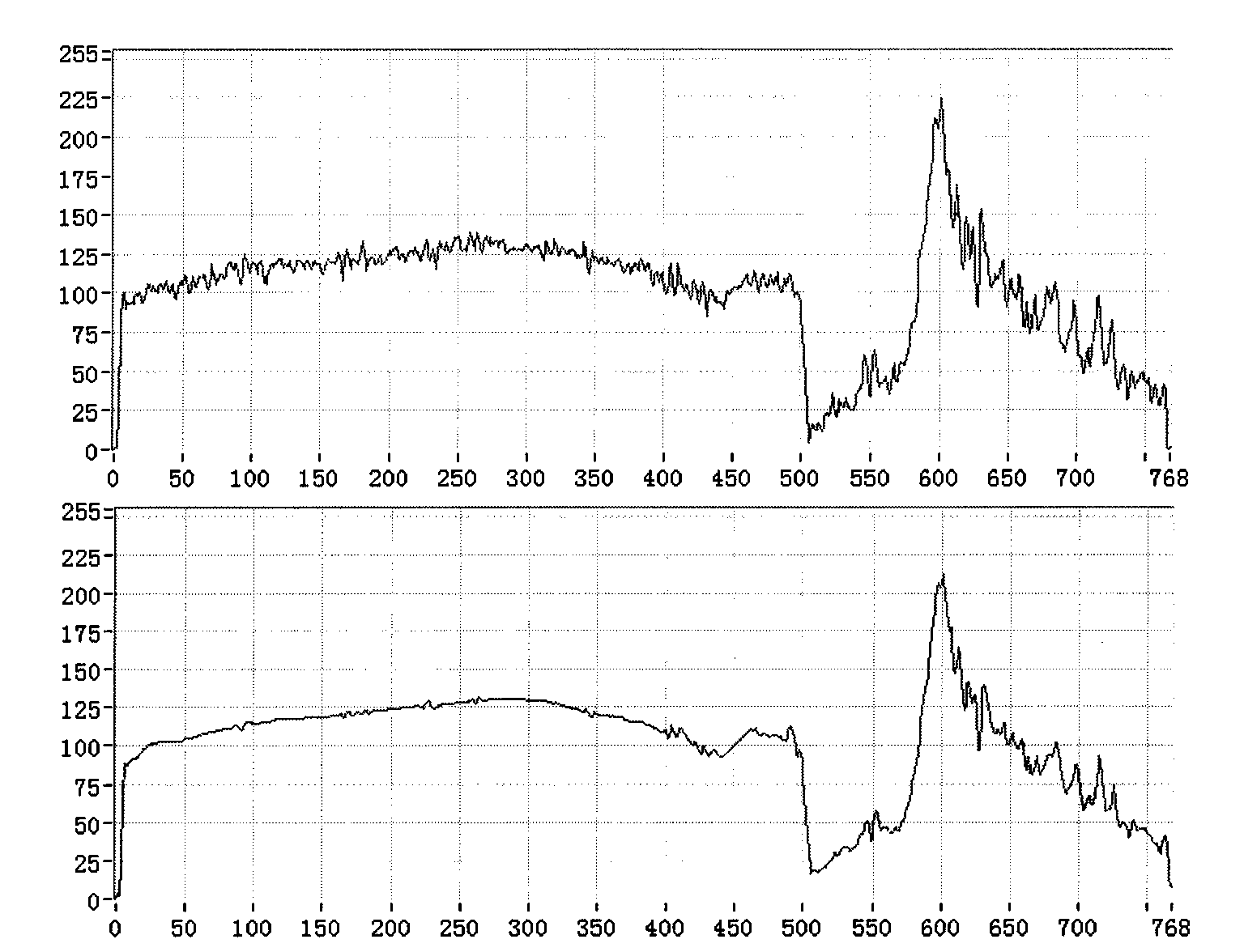

CCD based strip automatic centering CPC detecting system and detecting method

InactiveCN101013023AImprove detection accuracyWide detection rangeGuiding/positioning/aligning arrangementsUsing optical meansDriver circuitLength wave

The invention discloses a CCD-strip-based automatic aiming CPC photoelectric detection system, including the detection sensor and the light source, and the light source using rectangular array of 700~900nm wavelength infrared light-emitting diodes, and the detection sensor including optical lens, narrowband filters, linear array CCD and laser alignment, also including CCD driver circuit and detection processor. The detection method of the system uses the fixed installation positive exposure, and the light of the light source through the both sides of the detected strip, and respectively received by the left and right detection sensors, and when the detected strip moving left and right, the photosensitive pixels of the linear array CCD generates the strip edge location-related changes, and outputs the corresponding strip edge location signal, and respectively sends into the left and right detection processor and CPC controller for subtraction calculation, to determine whether the location of the strip departs from the center line of the machine, and the departure distance. The system has the features of high accuracy detection, board detection range, fast response speed, good stability, and anti-disturbance ability.

Owner:XIAN UNIV OF TECH

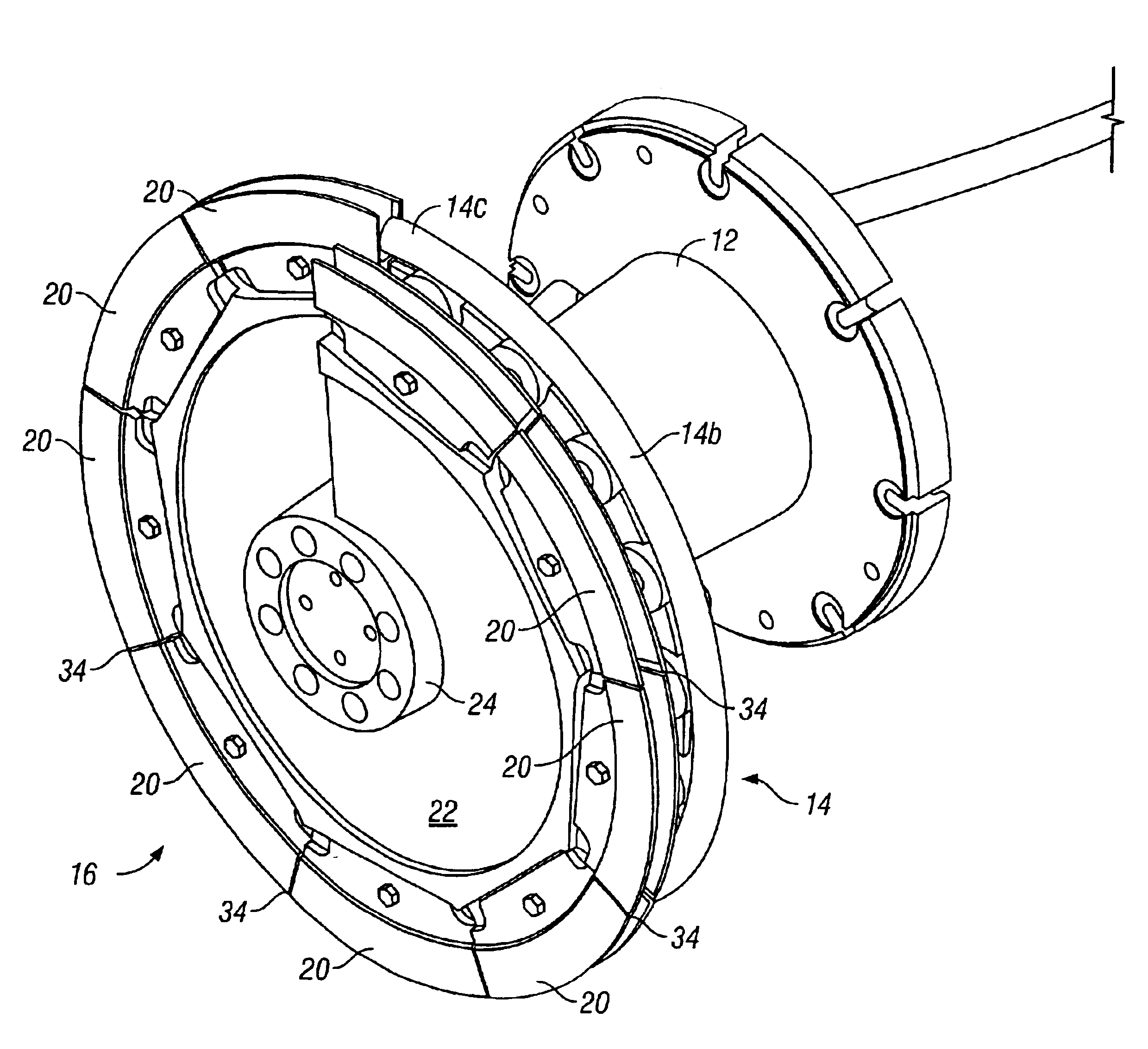

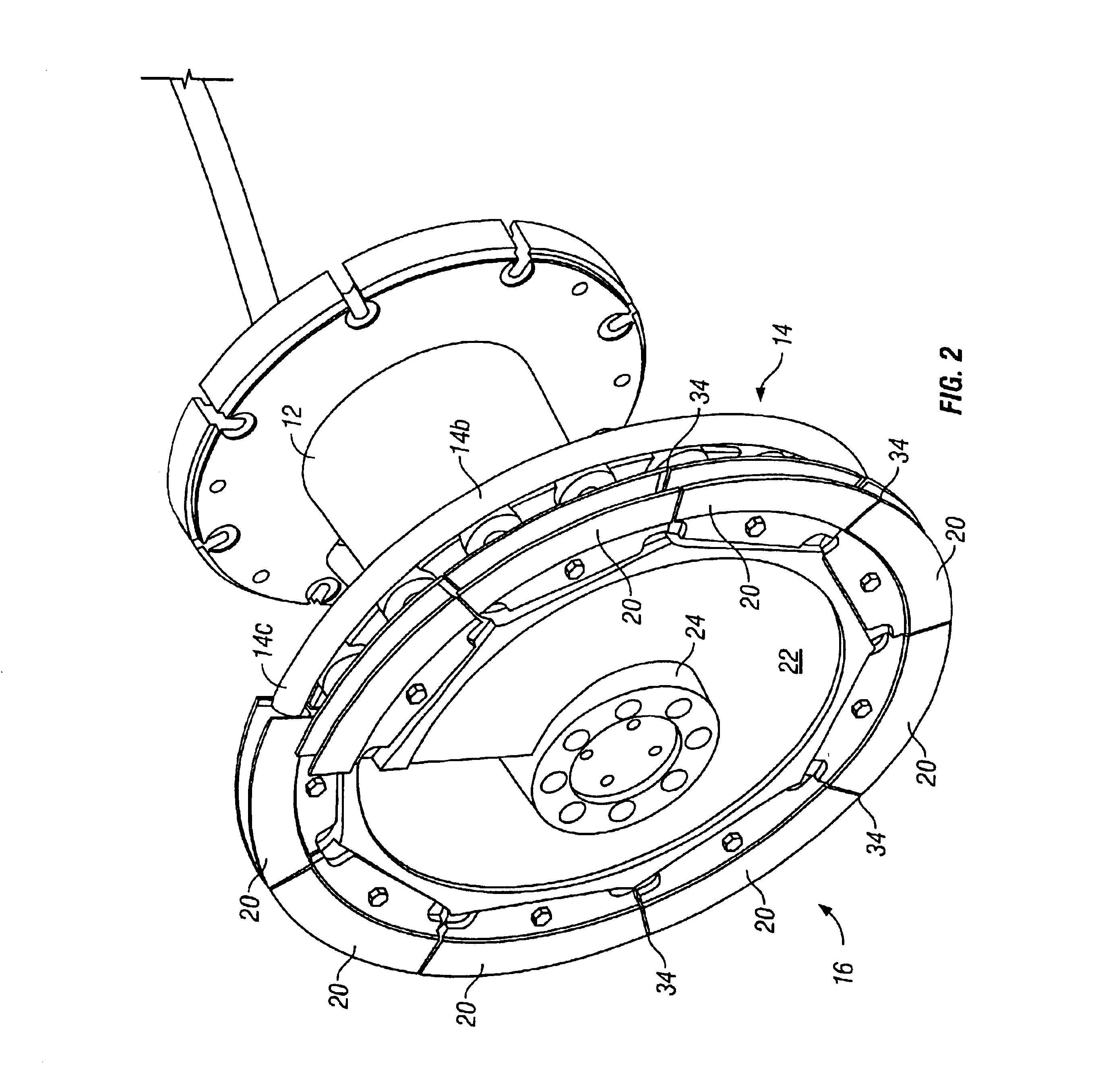

Segmented ring guide for rolling mill laying head

InactiveUS6769641B2Guiding/positioning/aligning arrangementsWork manipulationEngineeringRolling mill

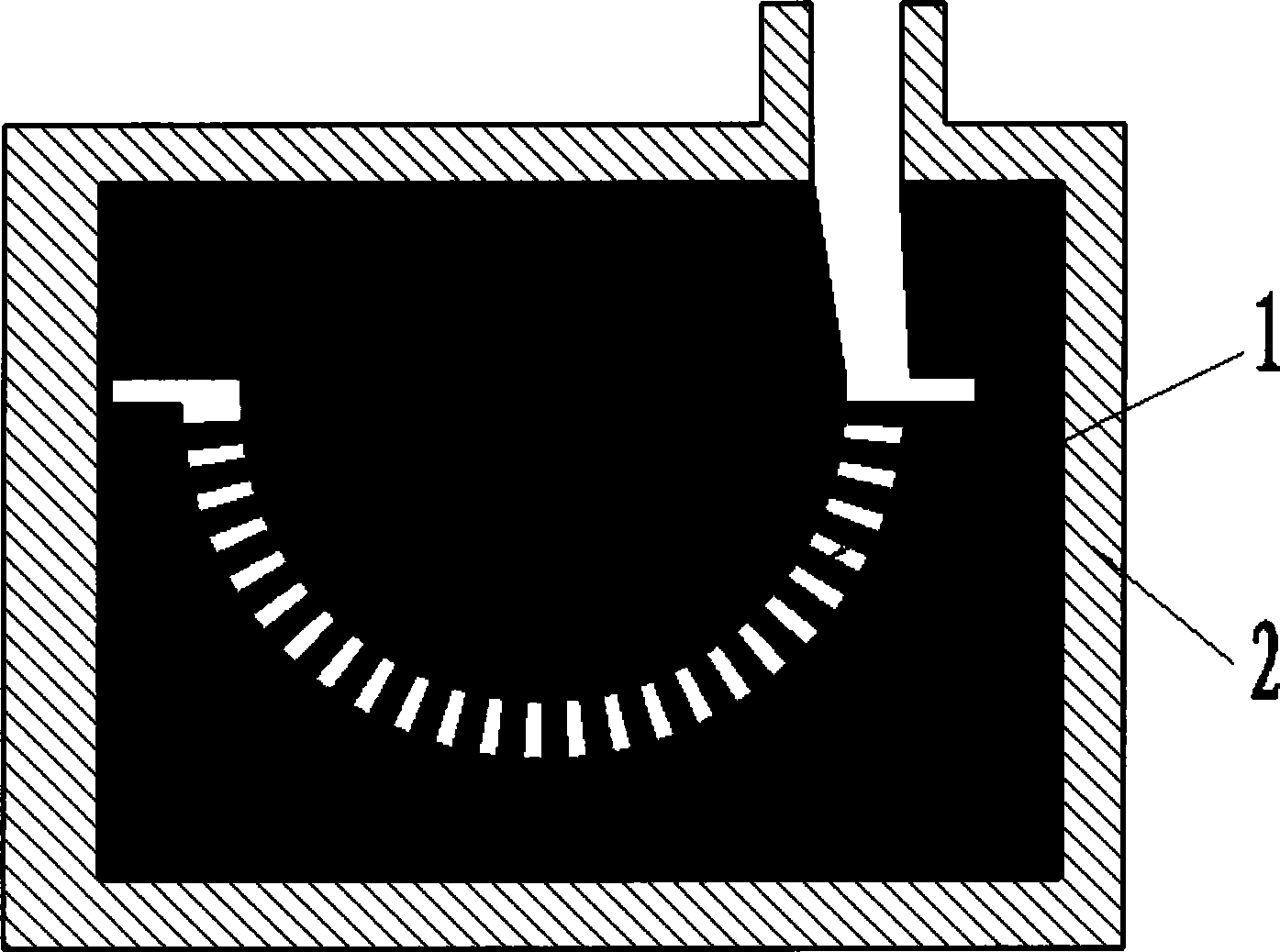

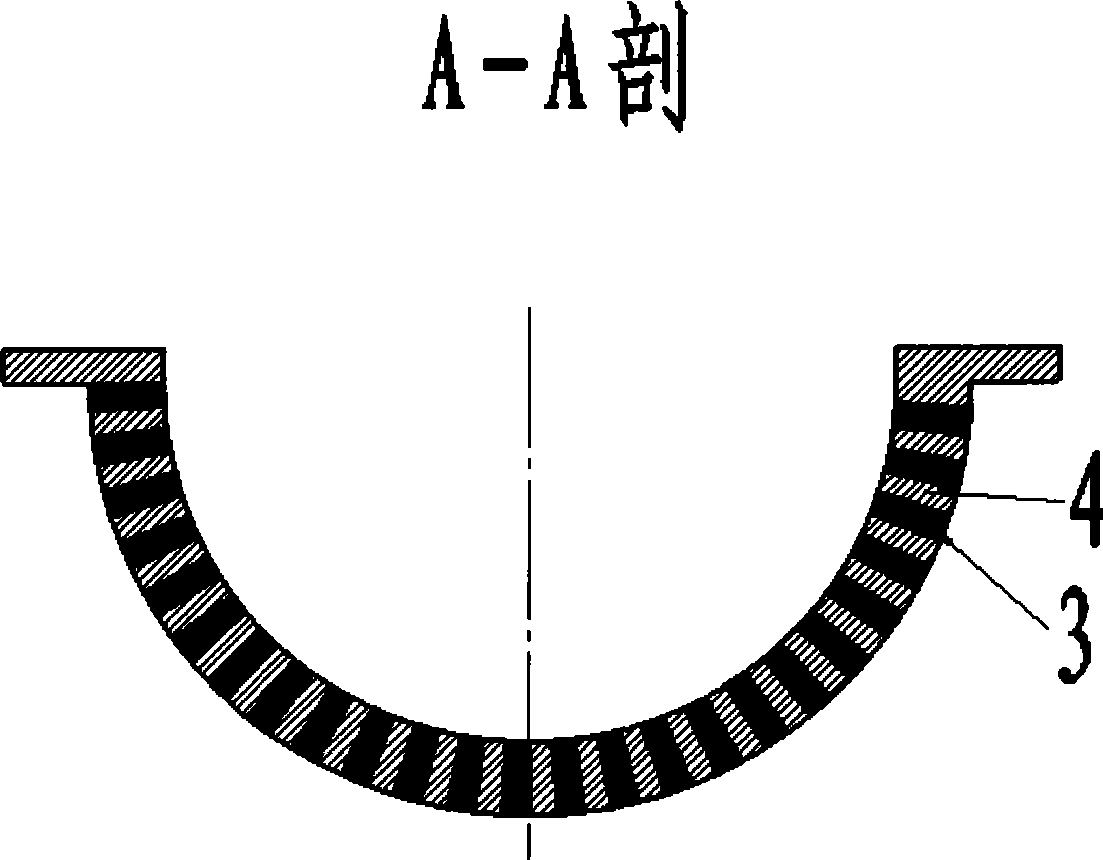

A laying has a quill rotatable about an axis, and a pipe carried on the quill. The pipe has an entry end arranged to receive a product, and an intermediate portion defining a curved guide path leading from the entry and to a delivery end spaced radially from the quill axis and from which the product is discharged as a helical series of rings. A guide defines a helical extension of the guide path, and comprises a helical support plate projecting outwardly from the quill. A plurality of channel-shaped guide sections supported end to end on the support plate. The guide sections form a segmented radially outwardly facing helical trough surrounded by a cylindrical shroud that cooperates with the guide sections to definee radially and axially confined helical extension of the guide path.

Owner:PRIMETALS TECH USA

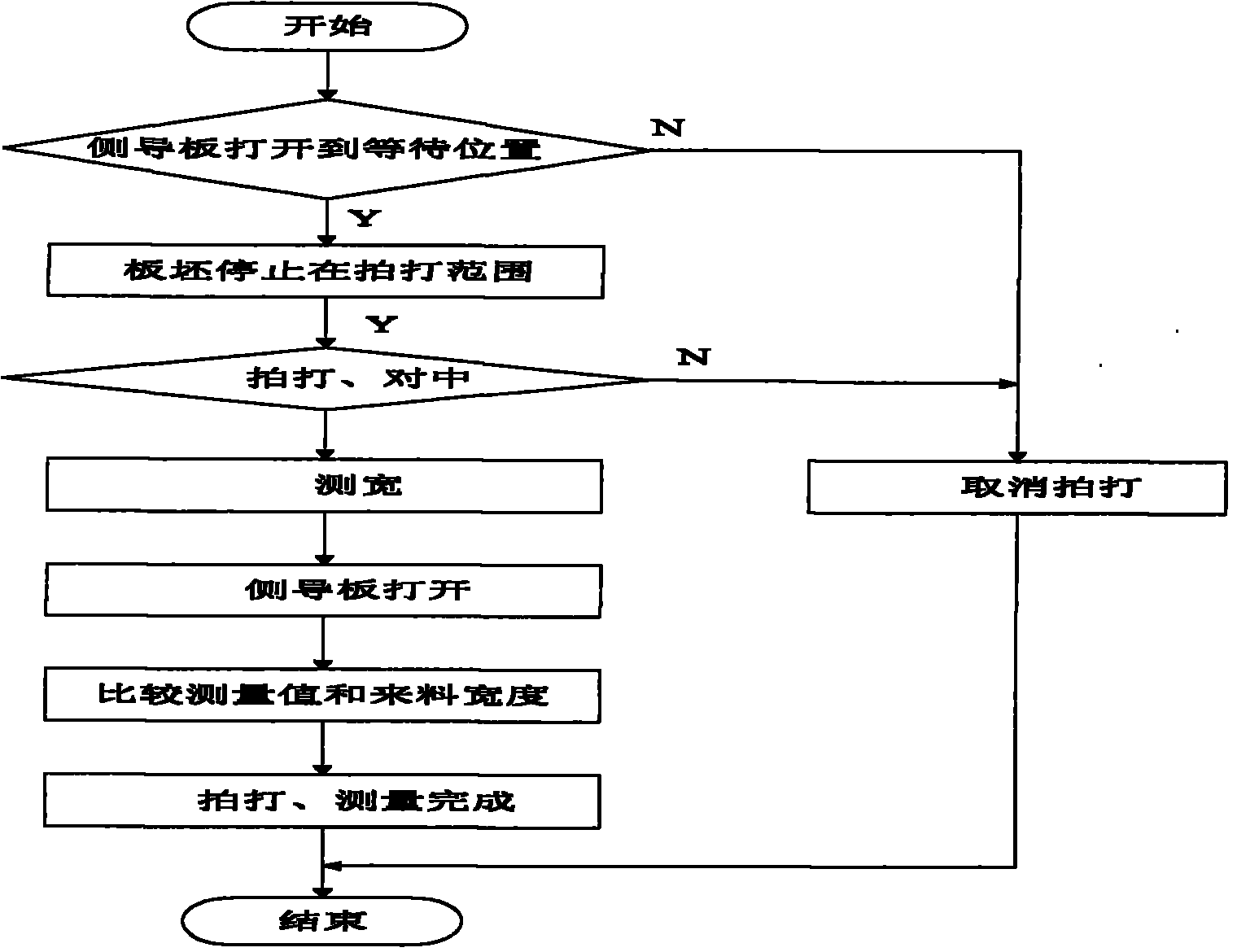

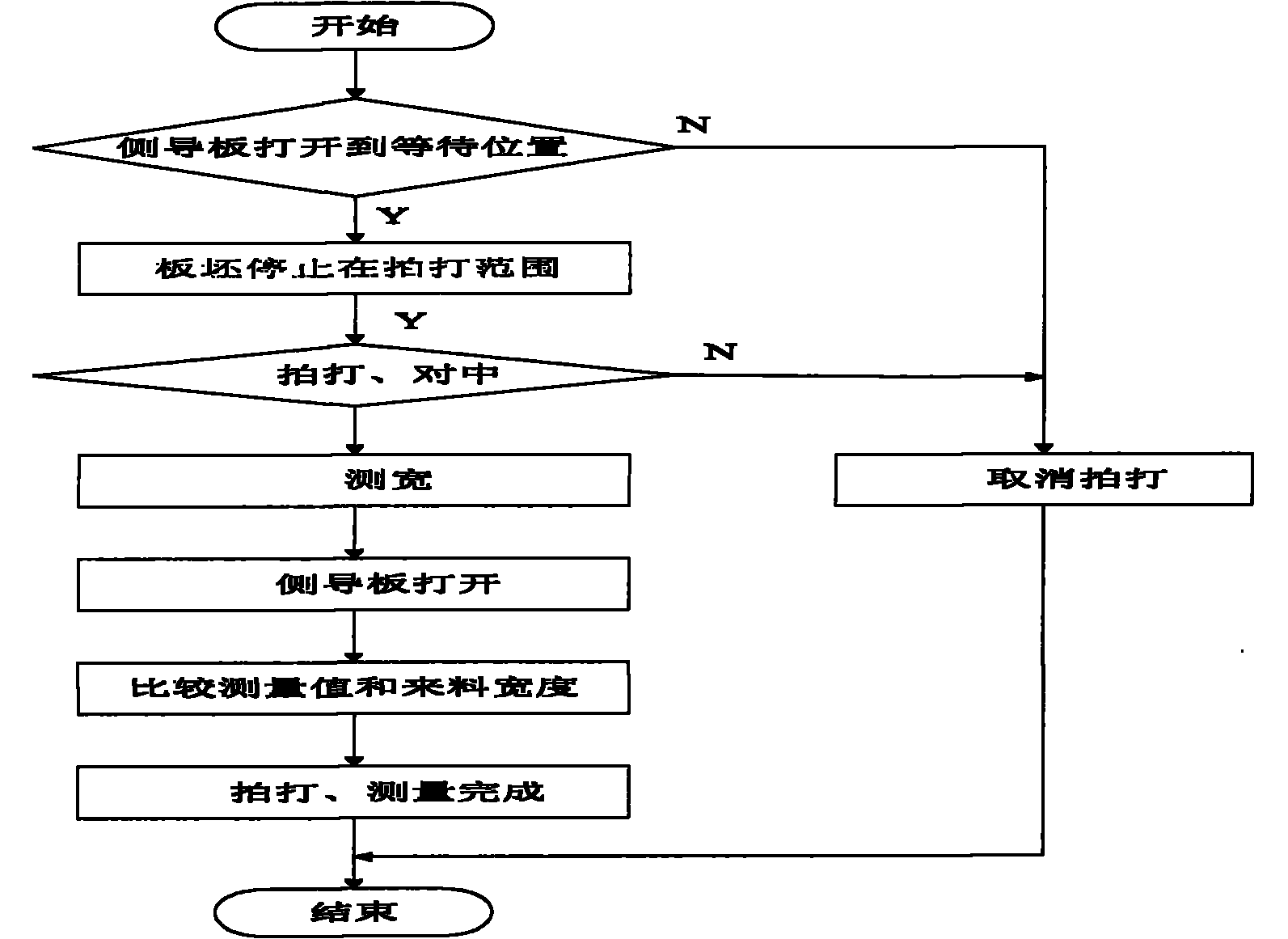

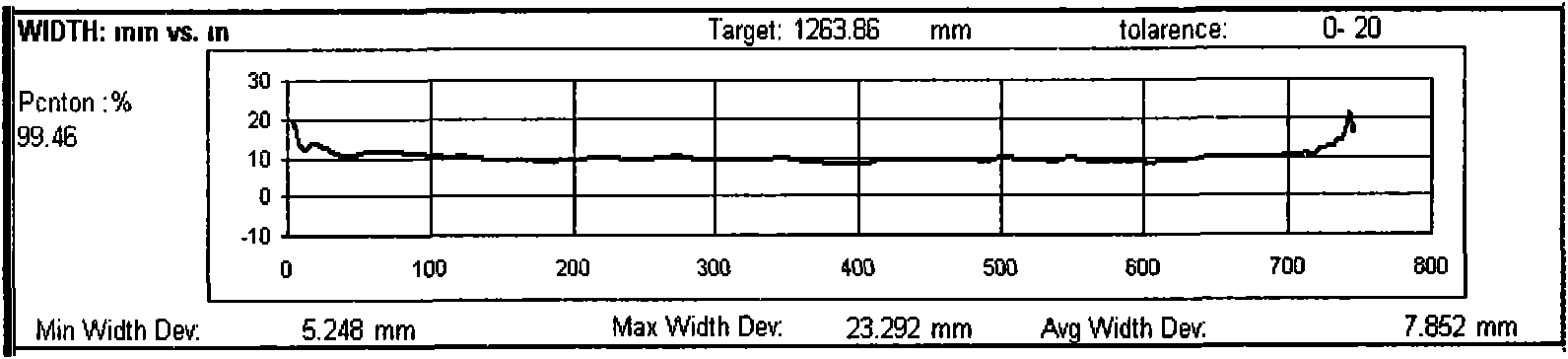

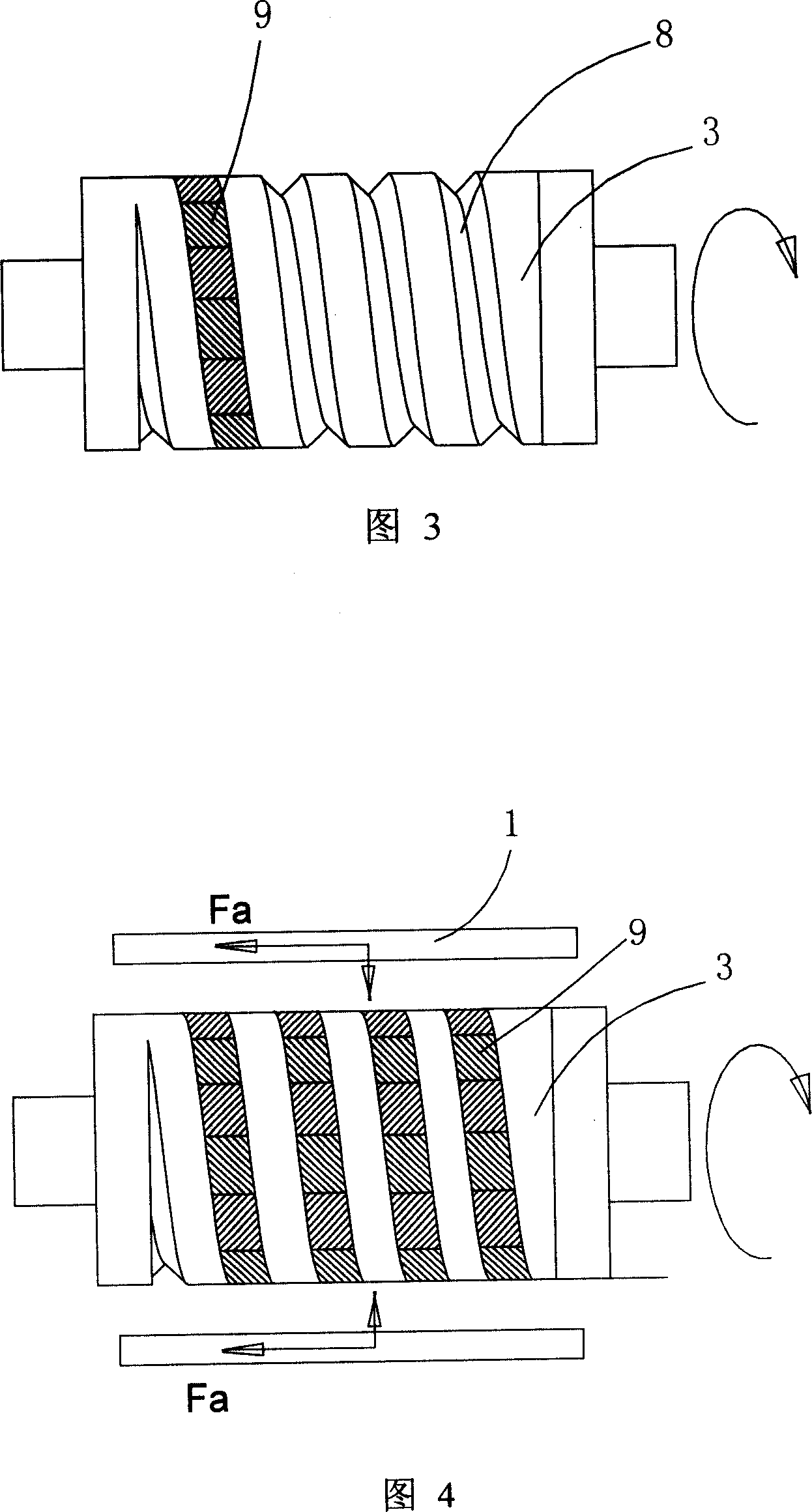

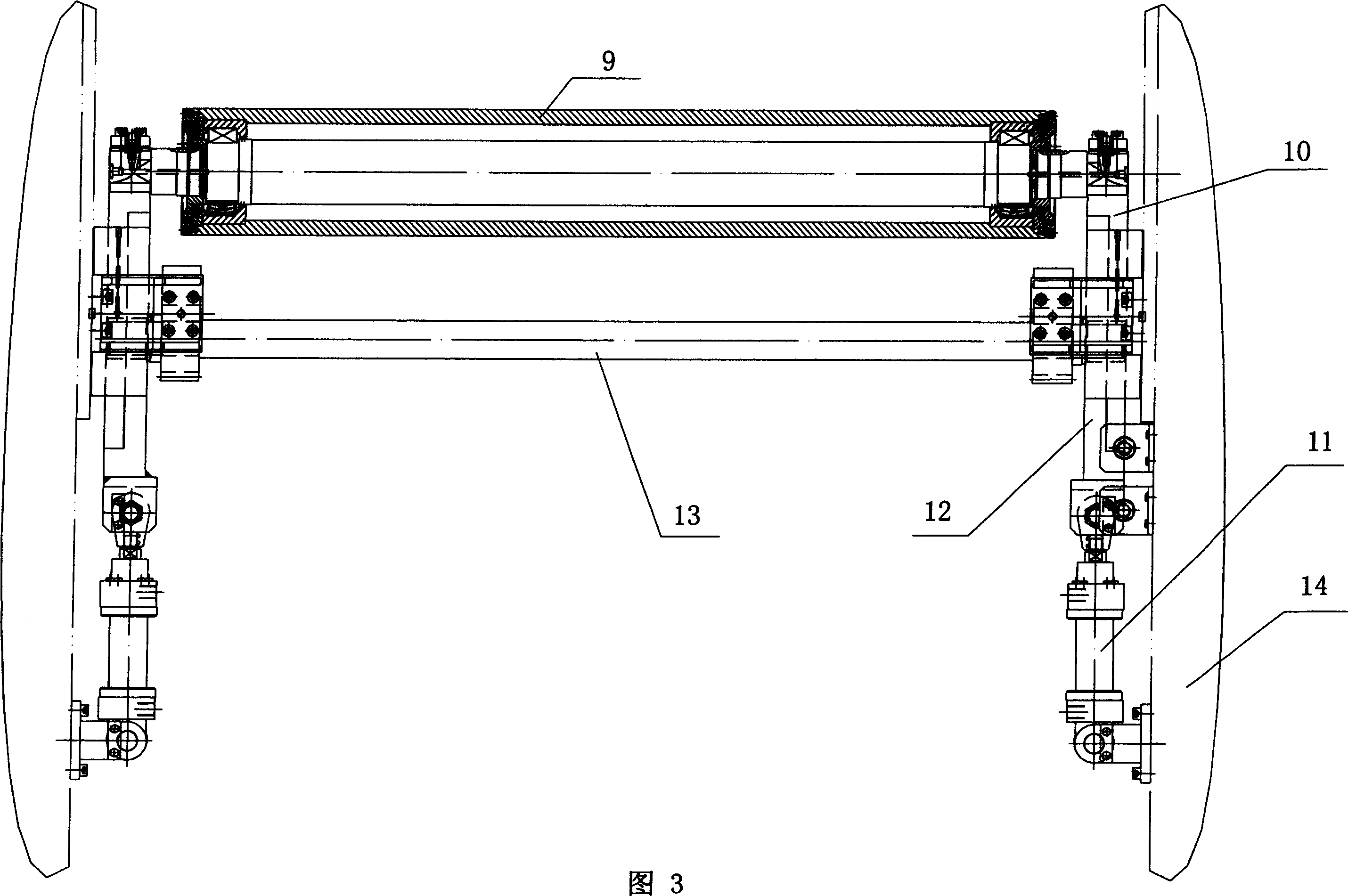

Method suitable for width measurement and centering of rough rolling slab in hot rolling mill

InactiveCN101811140AAccurately measure the actual widthAvoid misuseGuiding/positioning/aligning arrangementsRoll mill control devicesContact pressureEngineering

The invention relates to a method suitable for width measurement and centering of a rough rolling slab in a hot rolling mill, which belongs to the technical filed of steeling rolling computer control. The method mainly comprises the following steps of: 1, controlling a left guide plate and a right guide plate to arrive holding positions; 2, controlling the left guide plate and the right guide plate to move towards the direction of a rolling central line synchronously until contacting and patting a blank plate; 3, when the contact pressures of the left guide plate and the right guide plate, and the blank plate reach a predetermined value; recording the distance between the left guide plate and the right guide plate and the blank plate; 4, taking the recorded distance value as an actual width measurement value of the blank plate which is used for performing on-line control on rolling parts including a vertical roller; and 5, controlling the left guide plate and the right guide plate to return to guide positions. By adopting the method of the invention, original side plates which only have a guiding effect can play a role in patting the blank plate and ensuring the blank plate to be centered, and can be used as a detection device for measuring the actual width of the blank plate accurately, so that an error action caused by data error is avoided and the performance of equipment is remarkably enhanced without adding equipment investment hardly.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

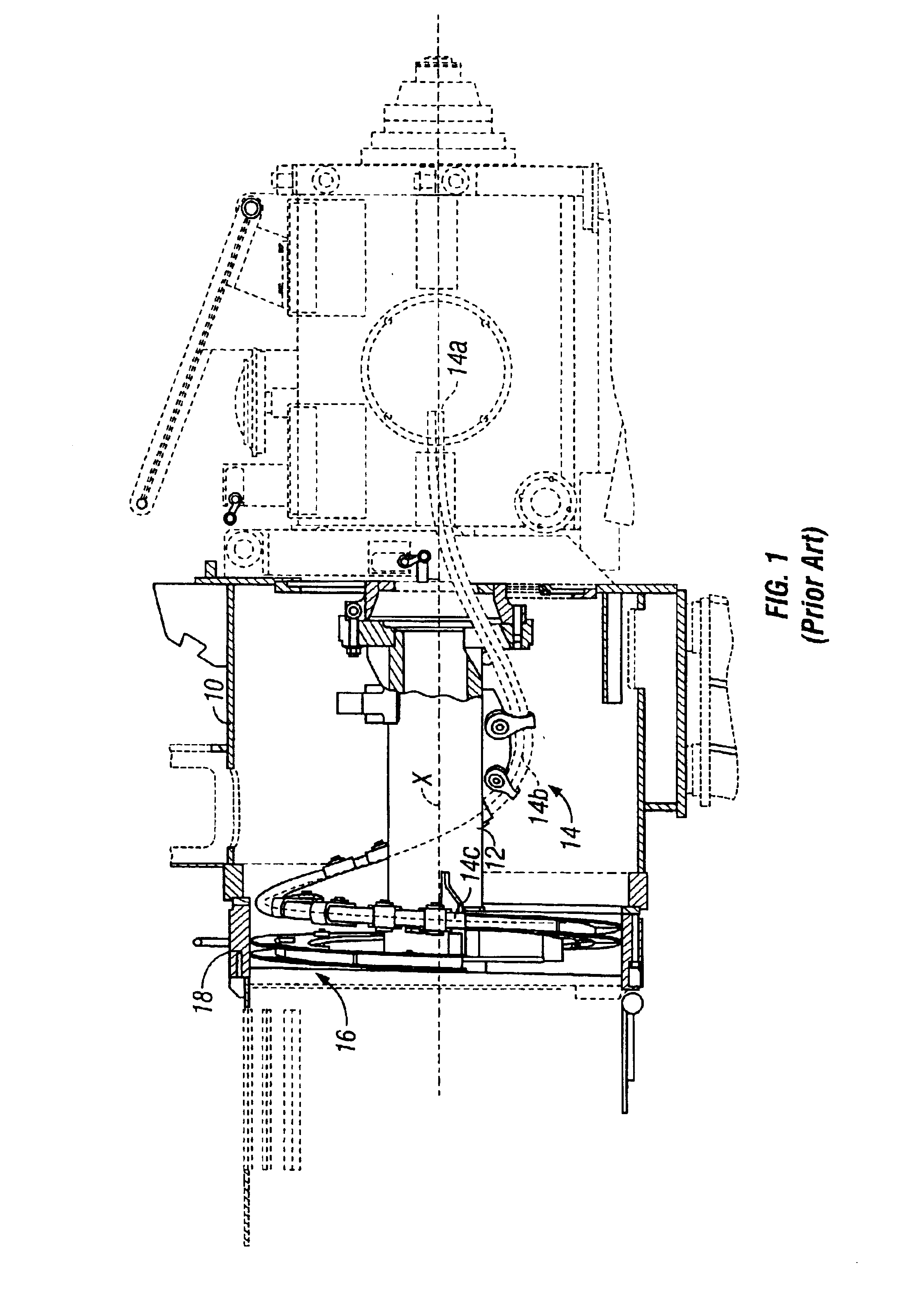

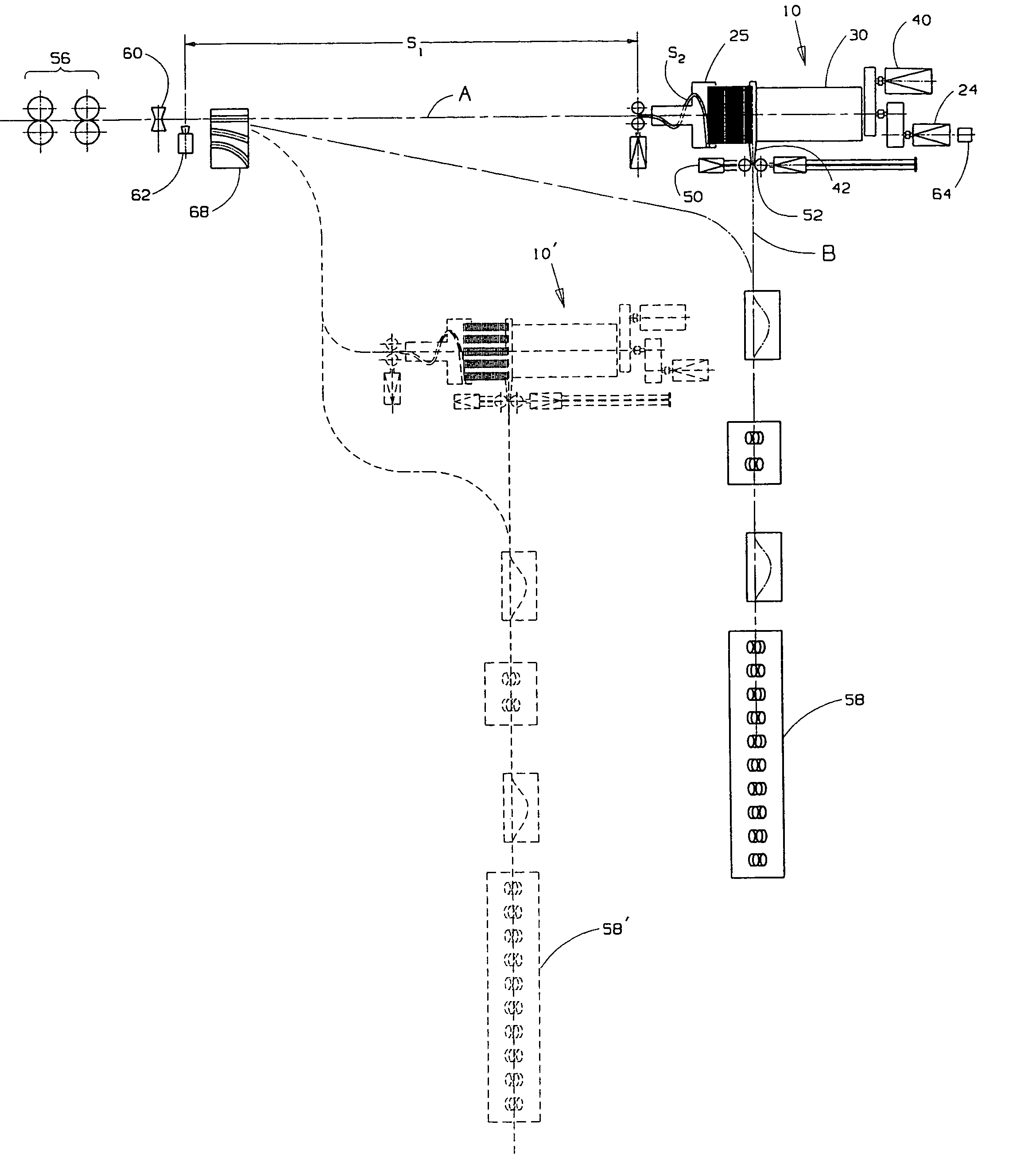

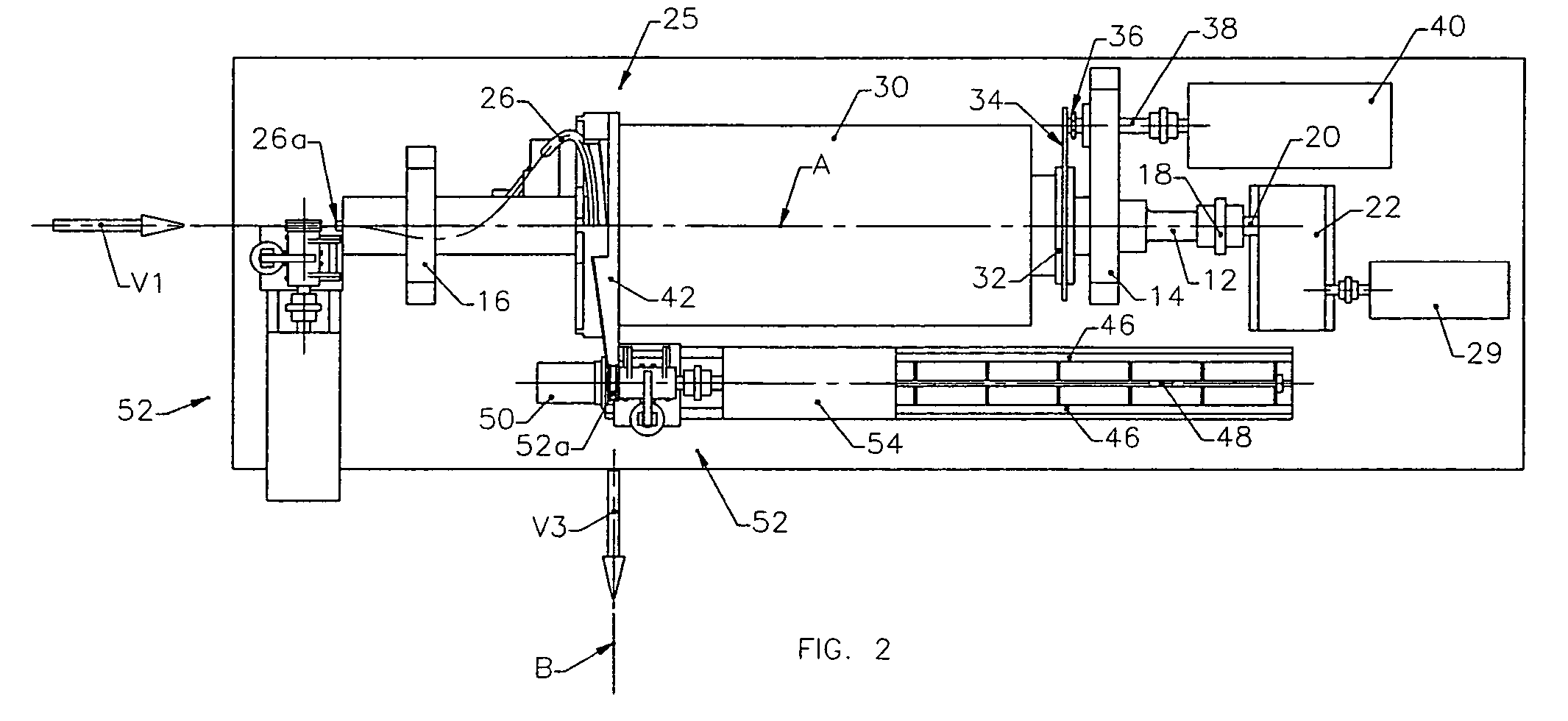

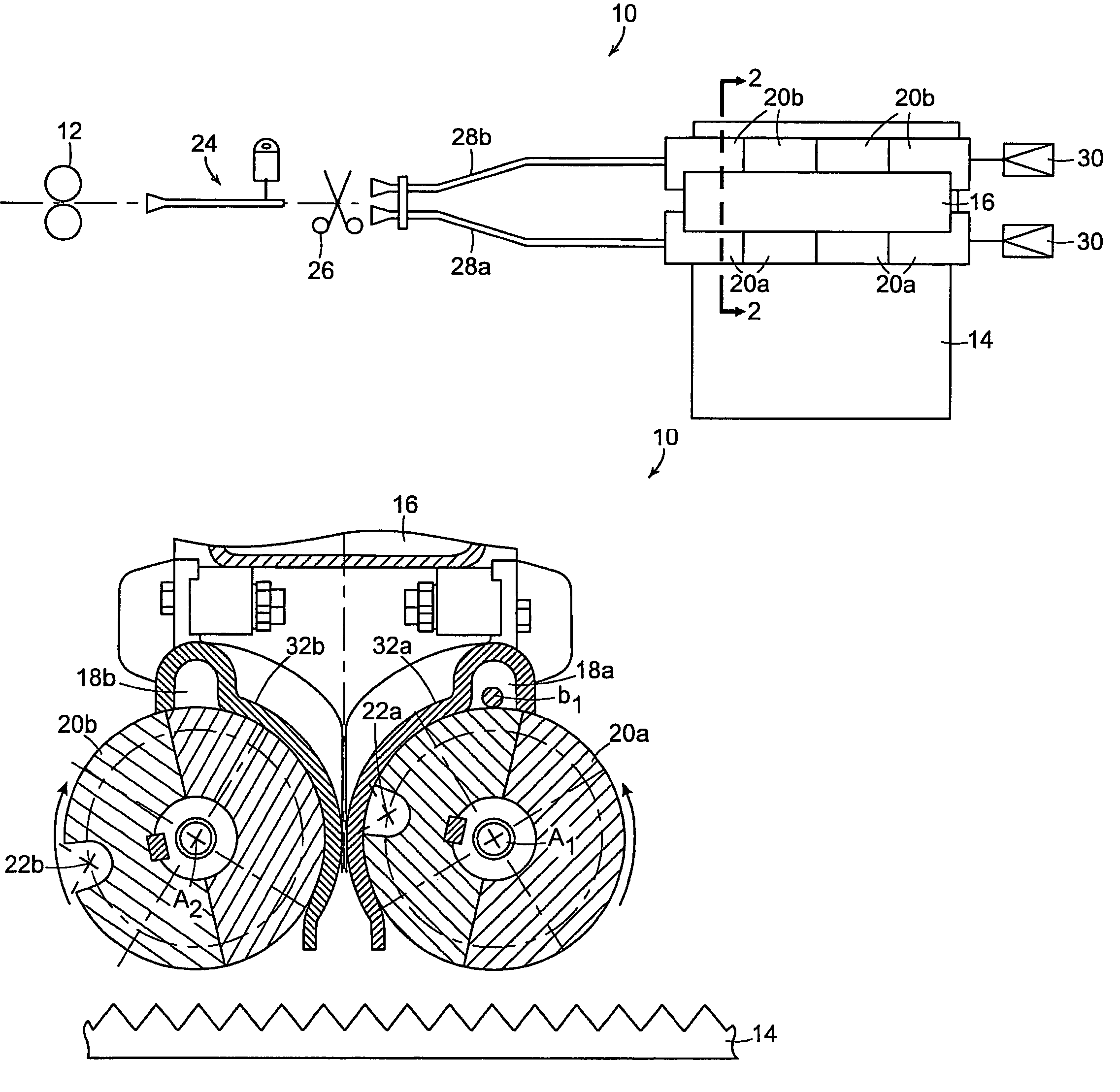

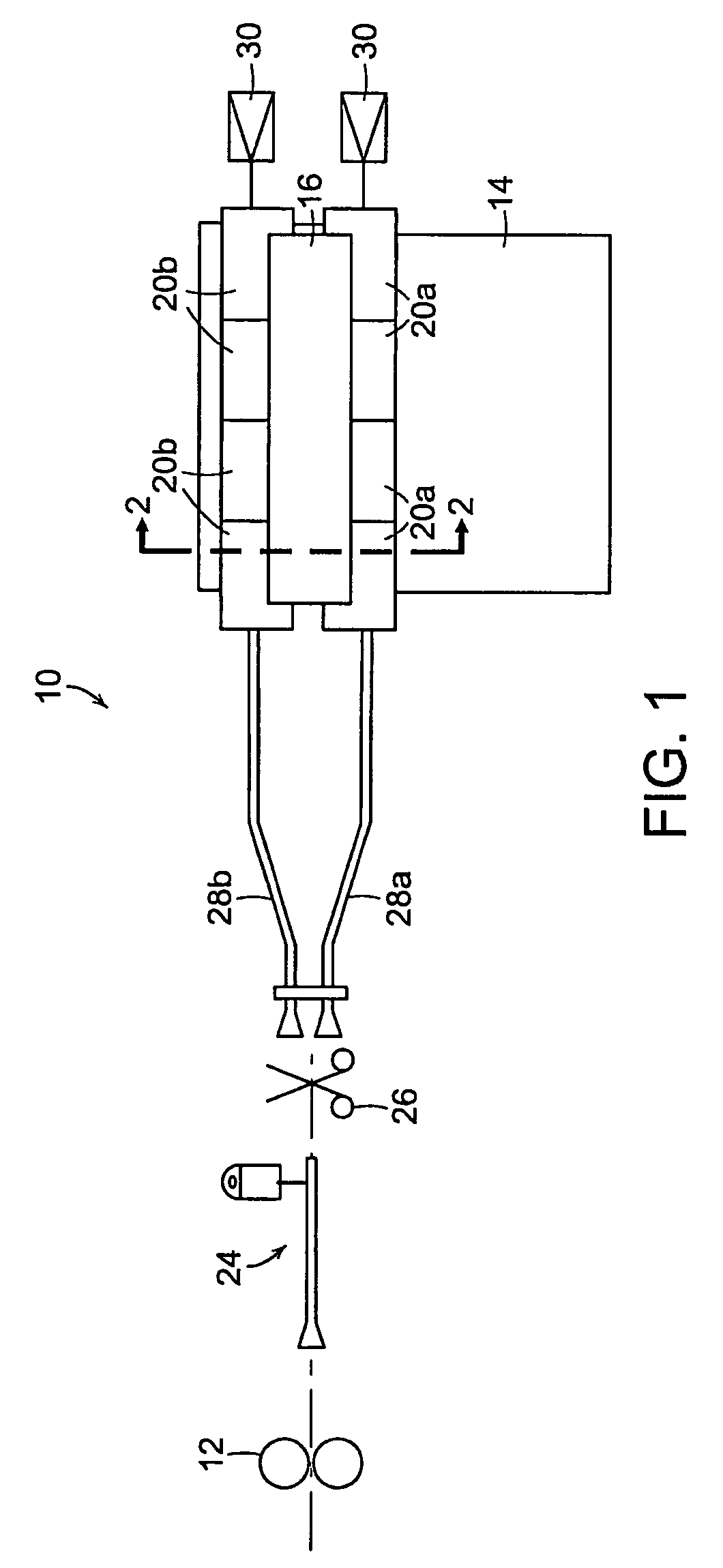

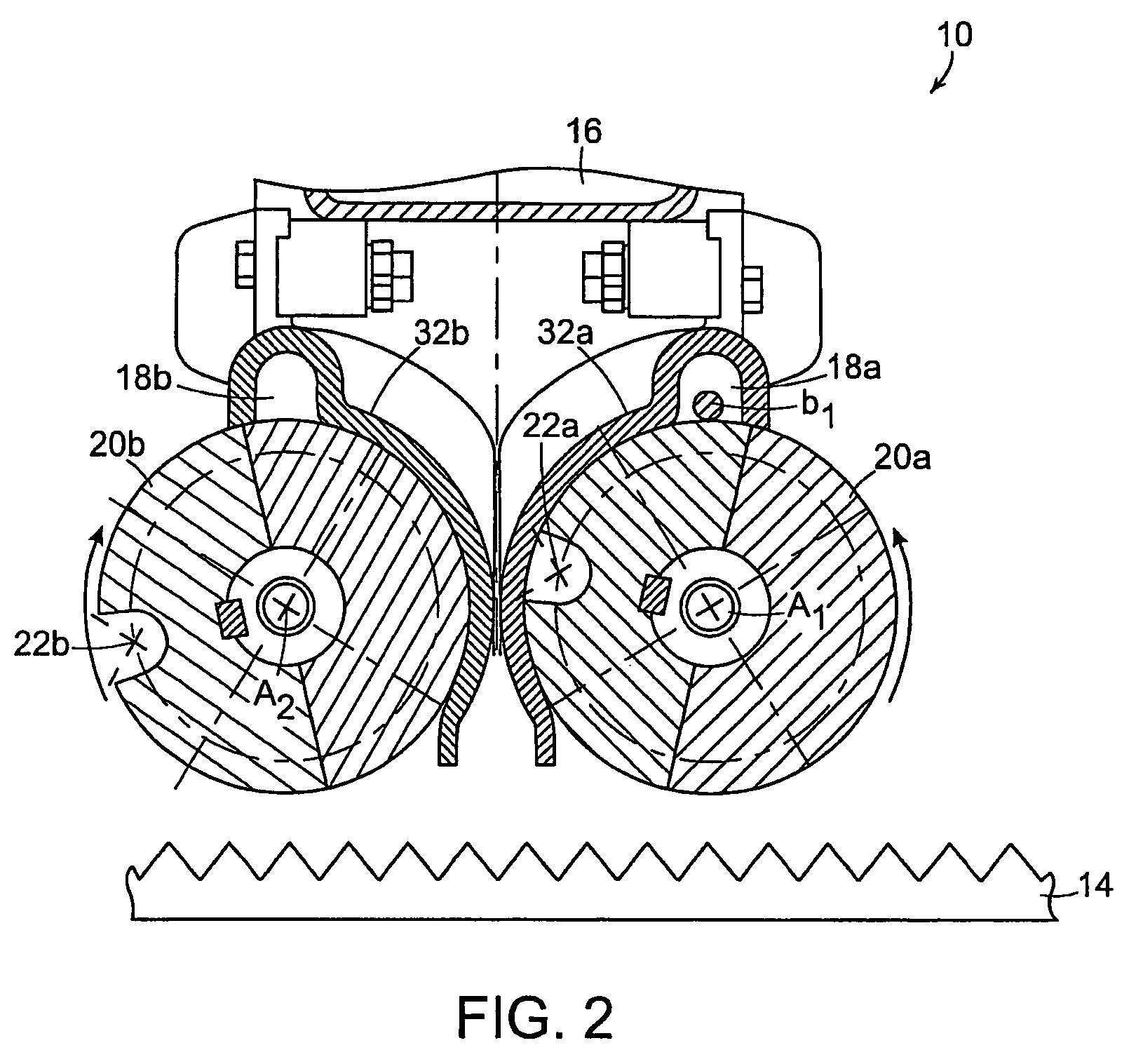

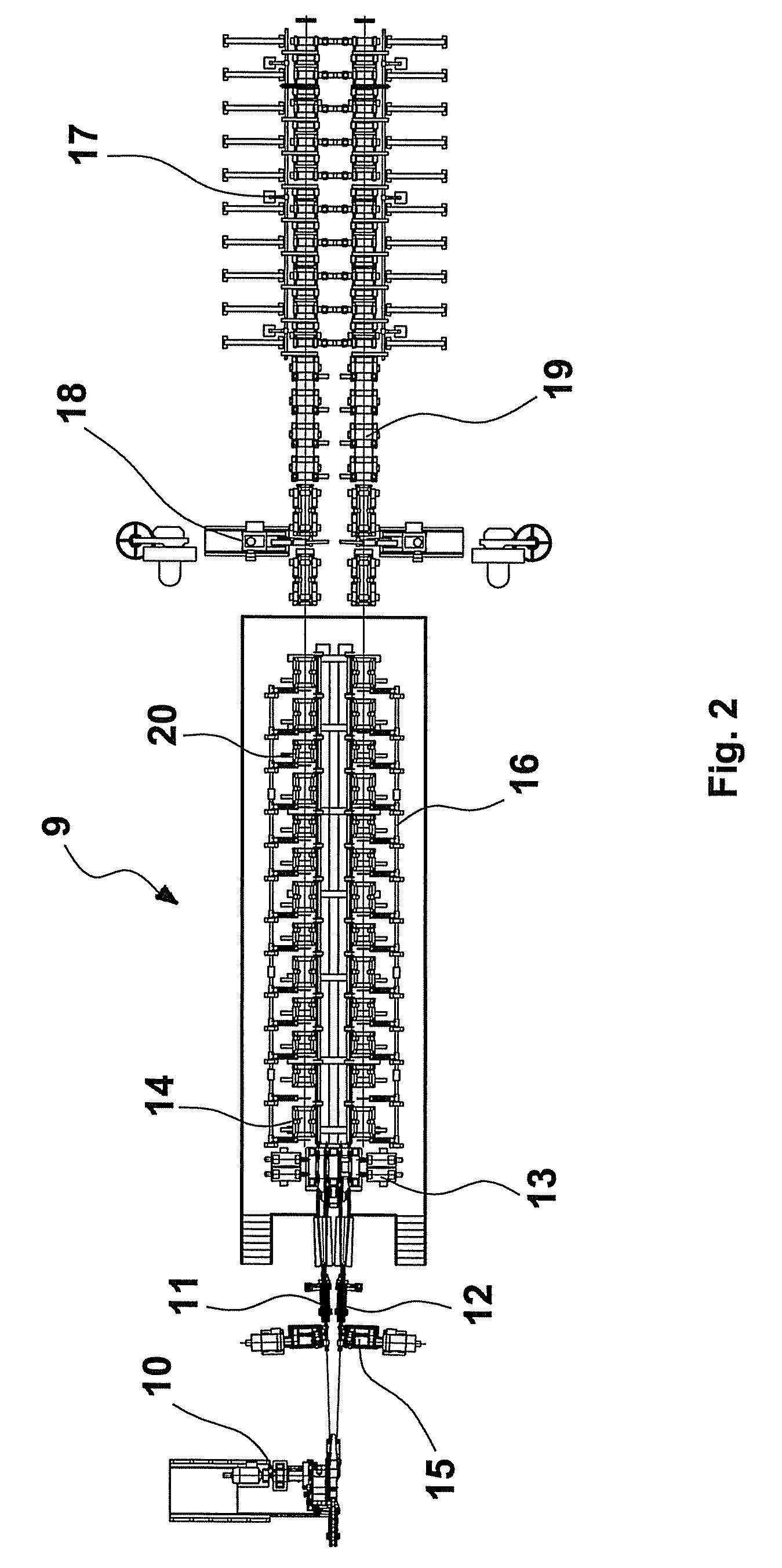

Method and apparatus for decelerating and temporarily accumulating a hot rolled product

InactiveUS7021103B2Guiding/positioning/aligning arrangementsFilament handlingEngineeringMechanical engineering

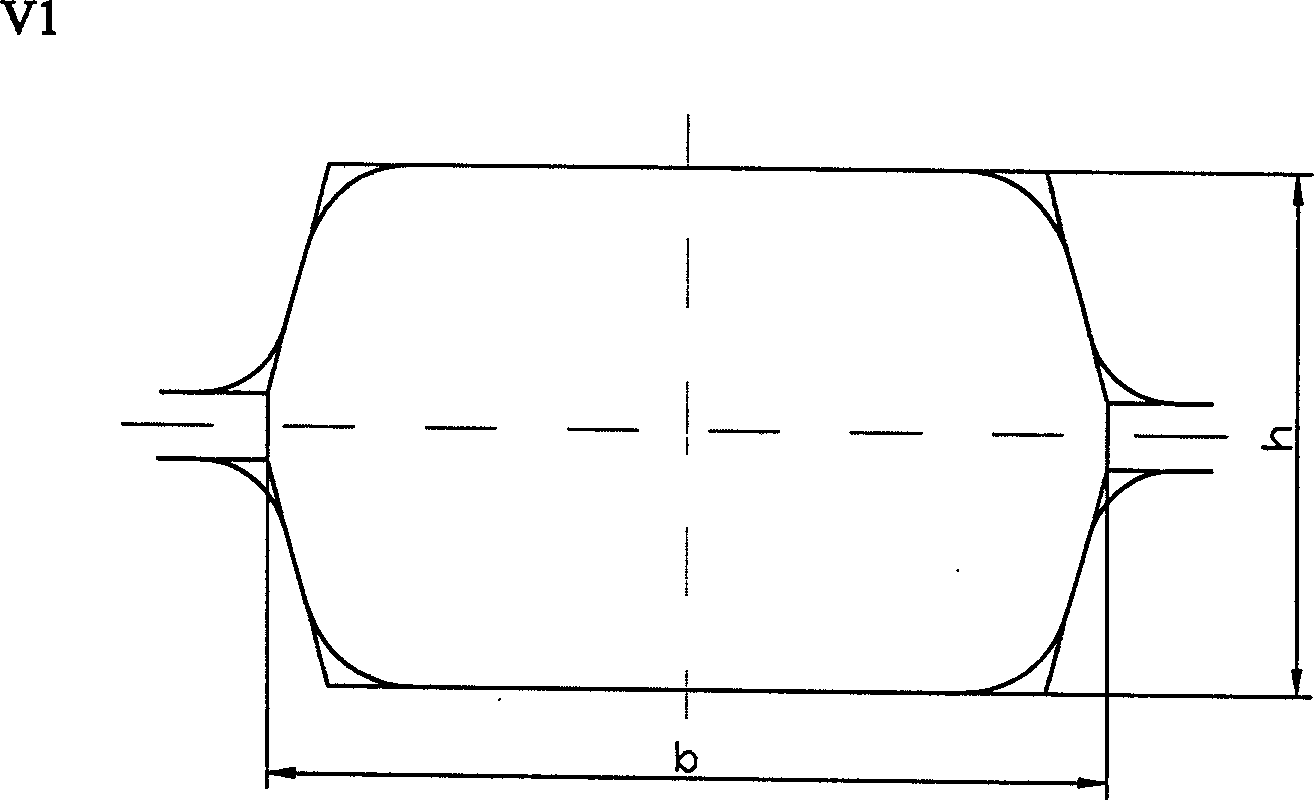

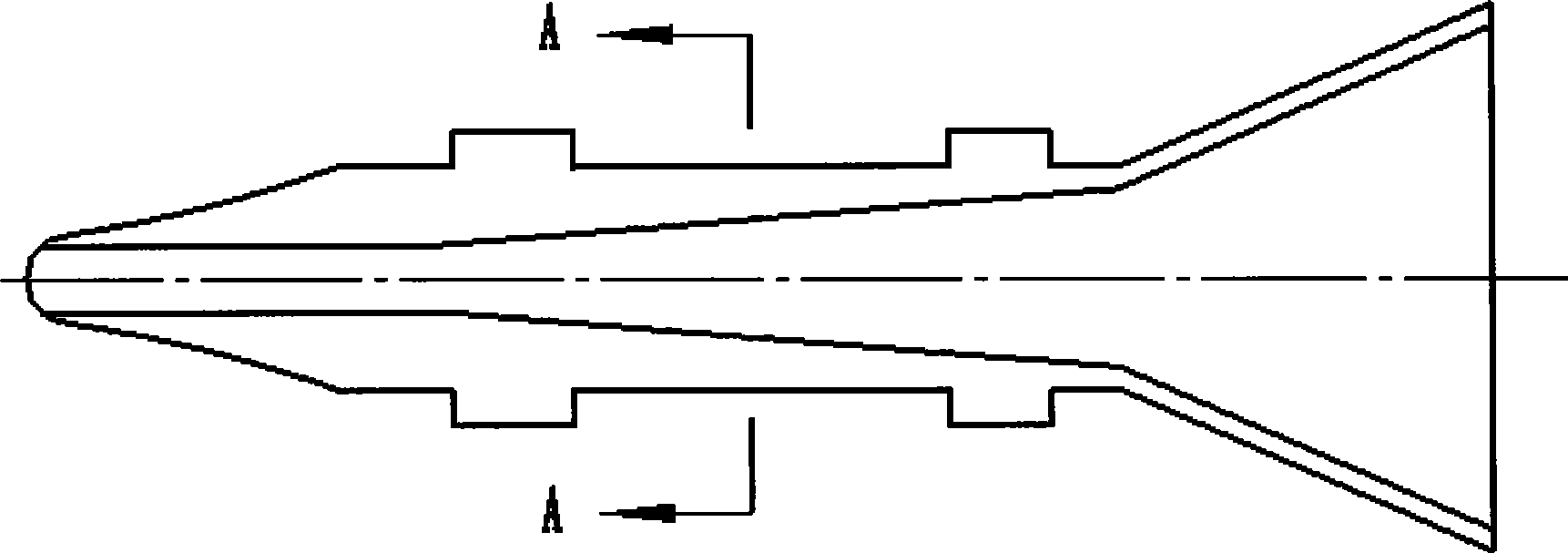

A method and apparatus is disclosed for decelerating and temporarily accumulating a hot rolled product moving longitudinally along a receiving axis at a first velocity V1. The product is directed through a curved guide having an entry end aligned with the receiving axis to receive the product, and an exit end spaced radially from the receiving axis and oriented to deliver the product in an exit direction transverse to the receiving axis. The curved guide is rotated about the receiving axis in a direction opposite to the exit direction of the product and at a speed at which the guide exit end has a velocity V2, thereby decelerating the product being delivered from the guide exit end to a reduced velocity V3 equal to V1−V2. The curvature of the guide and the orientation of its exit end is such as to form the delivered product into a helix deposited and temporarily accumulated on a cylindrical drum. The drum is rotated in a direction opposite to the direction of rotation of the curved guide to thereby unwind the product from the drum.

Owner:PRIMETALS TECH USA

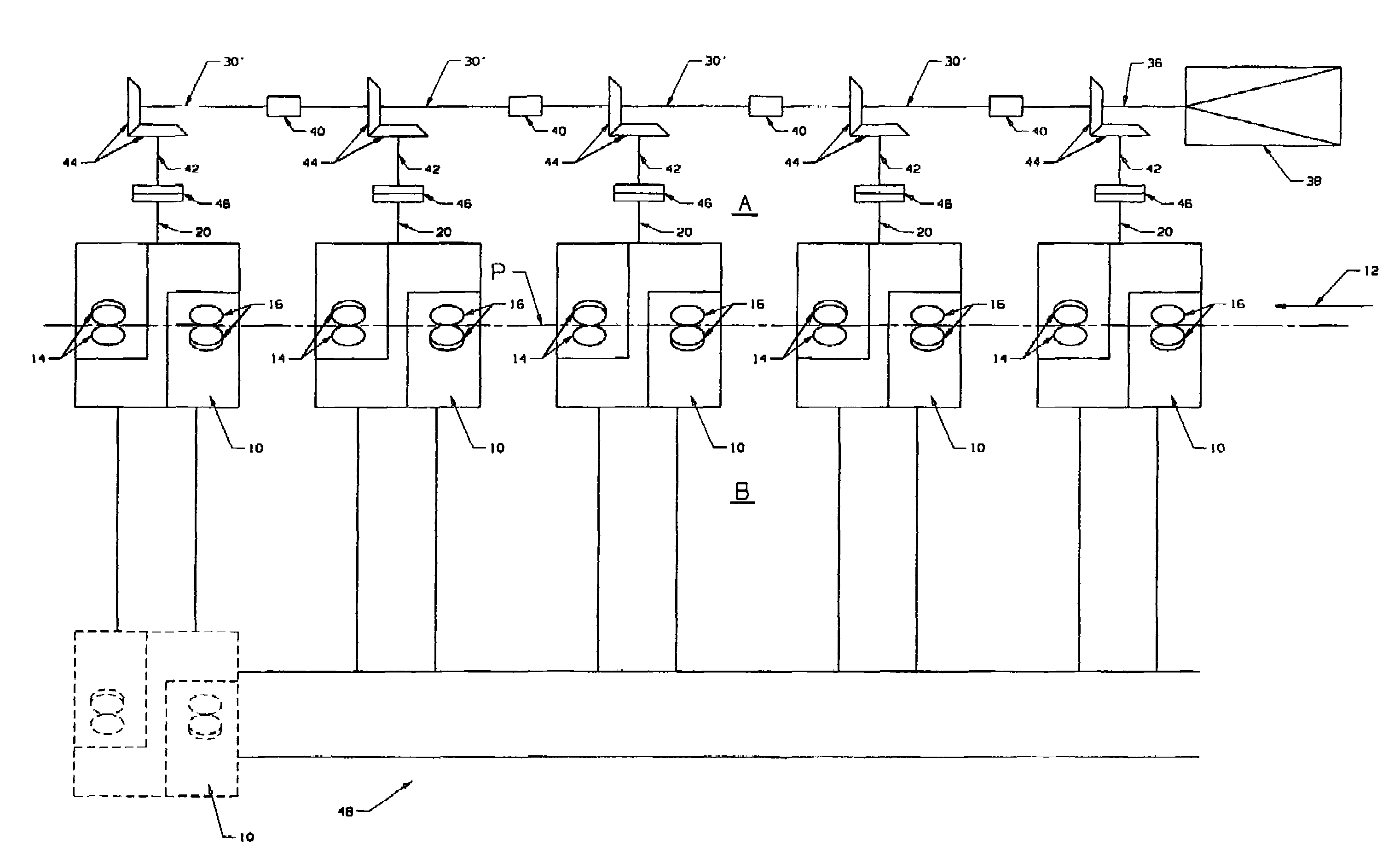

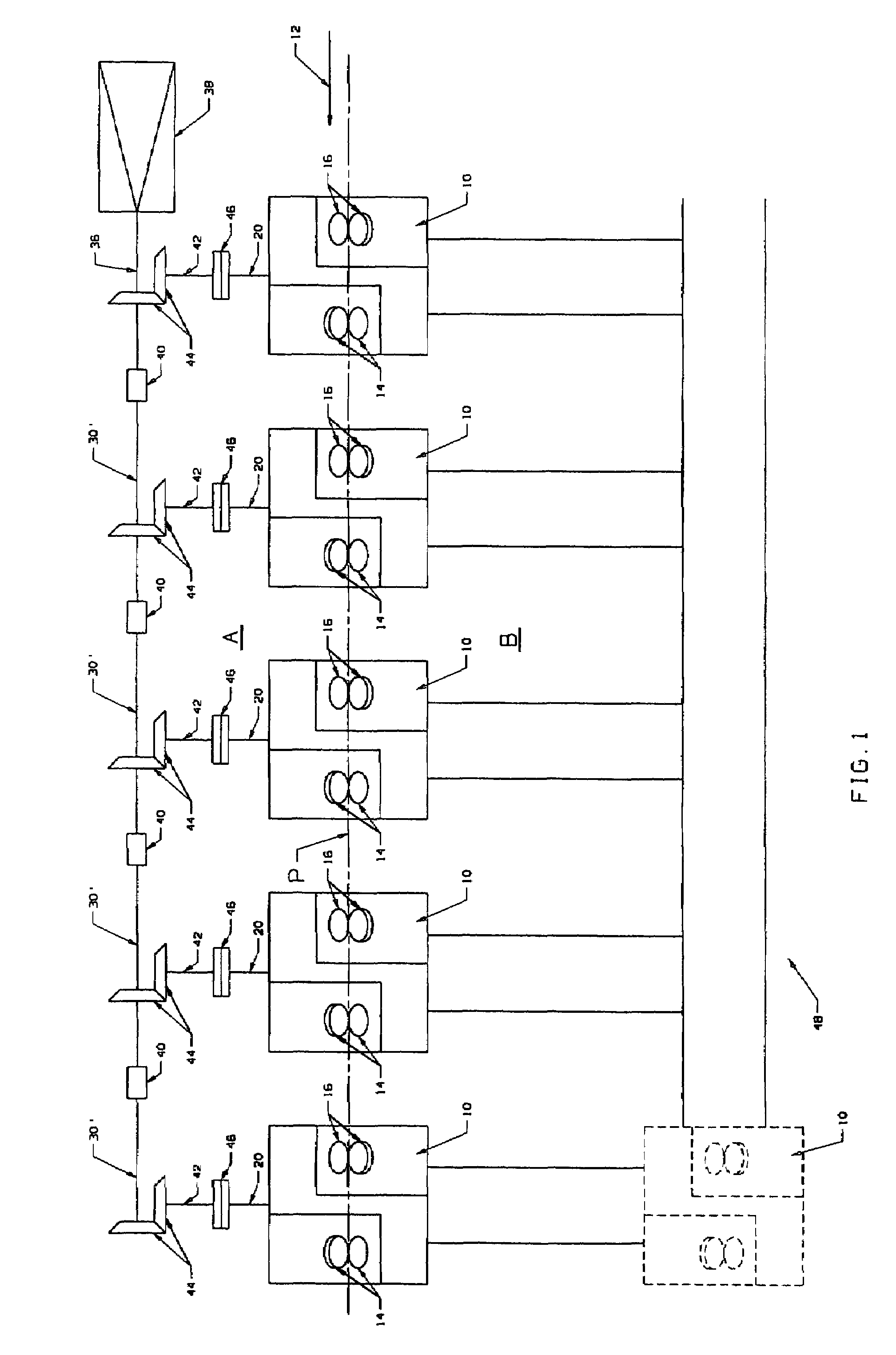

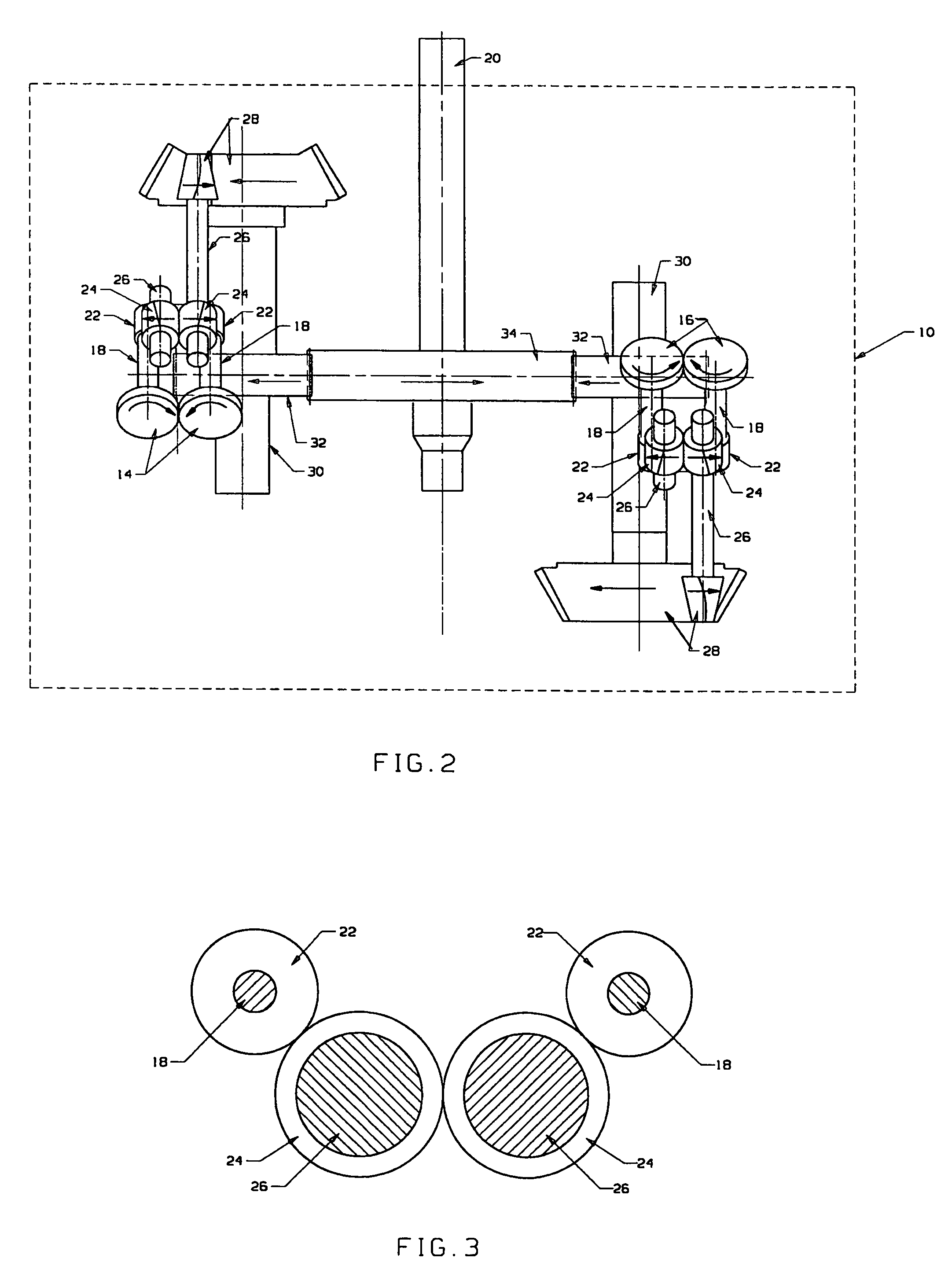

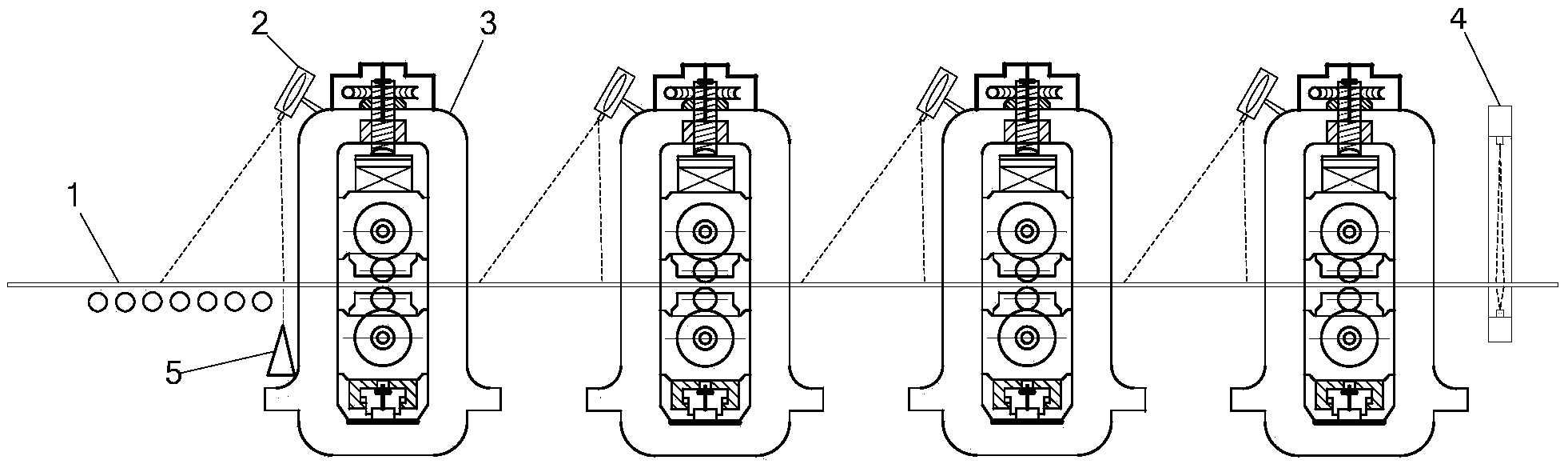

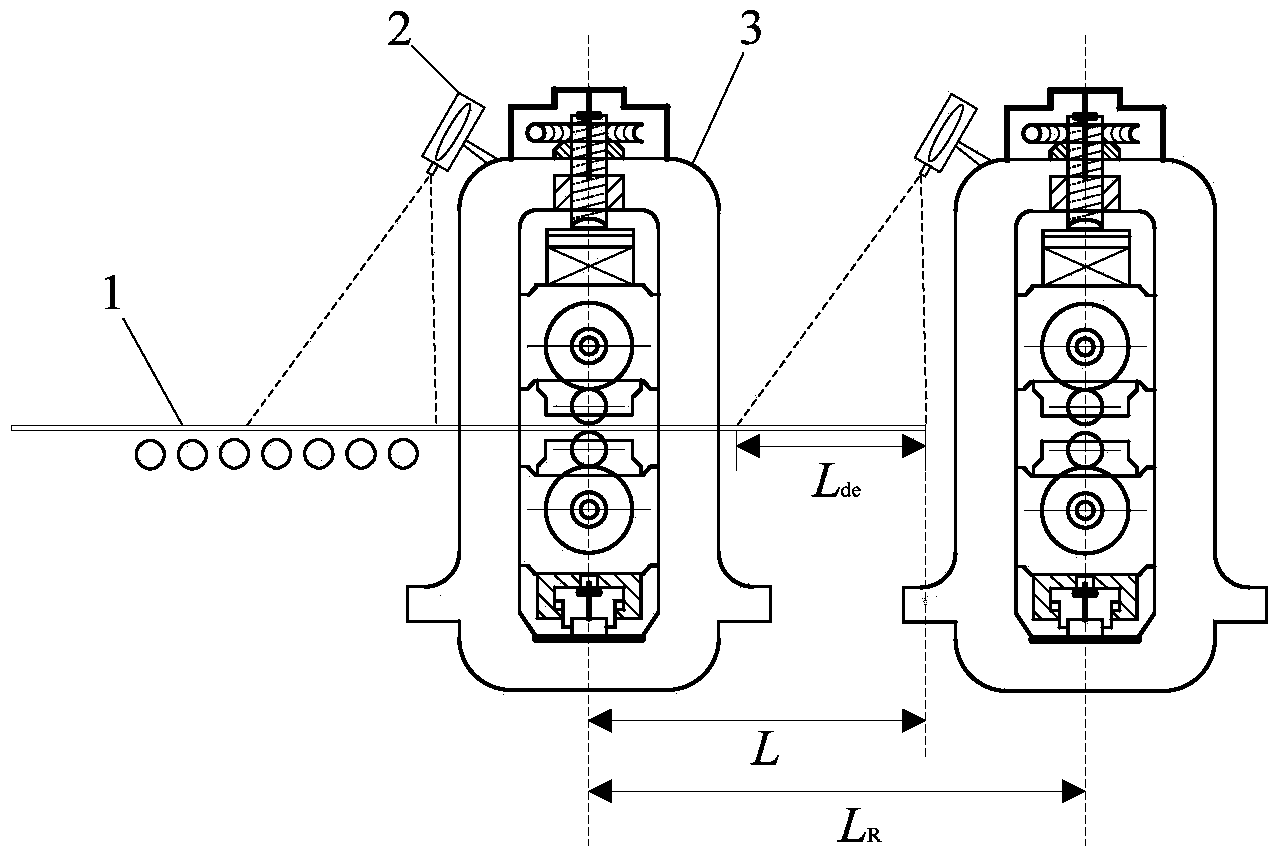

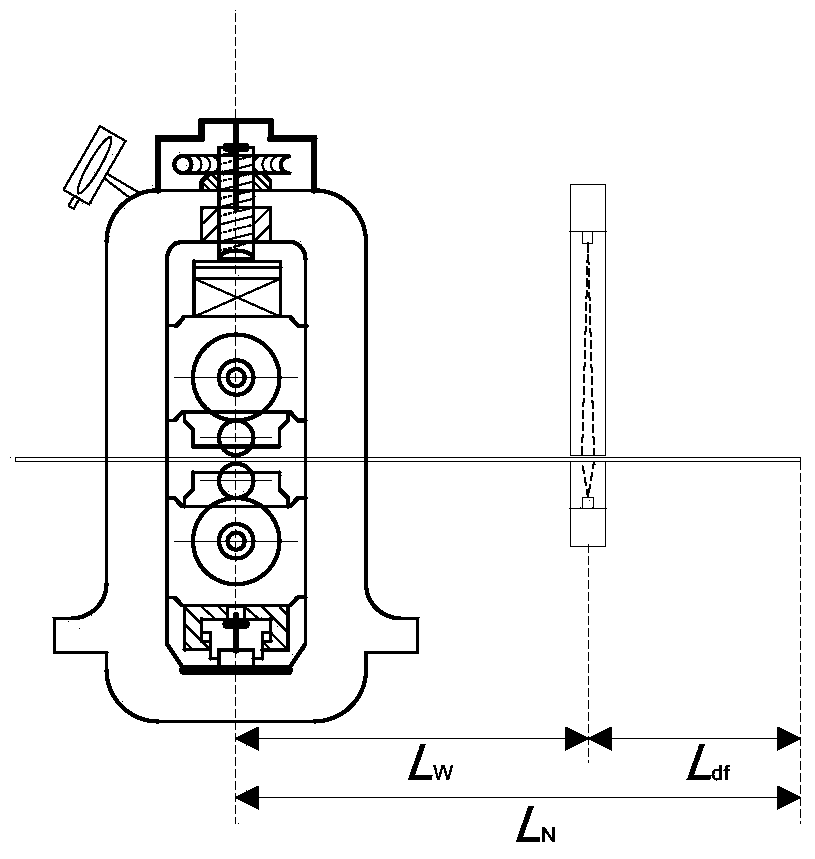

Modular rolling mill

InactiveUS7191629B1Metal rolling stand detailsGuiding/positioning/aligning arrangementsLine shaftWork roll

A modular rolling mill comprises a plurality of separate rolling units arranged along a mill pass line. Each rolling unit includes at least two pairs of work rolls defining oval and round roll passes and carried on roll shafts that are staggered 90° with respect to each other. The rolling units contain intermediate drive trains configured to connect the roll shafts to parallel input shafts projecting to a first side of the pass line from the respective rolling units. A single driven line shaft is parallel to and on the first side of the pass line. Output shafts are mechanically coupled to the line shaft by bevel gear sets. The output shafts project laterally from the line shaft towards the pass line and are connected by separable couplings to the input shafts of the rolling units.

Owner:PRIMETALS TECH USA

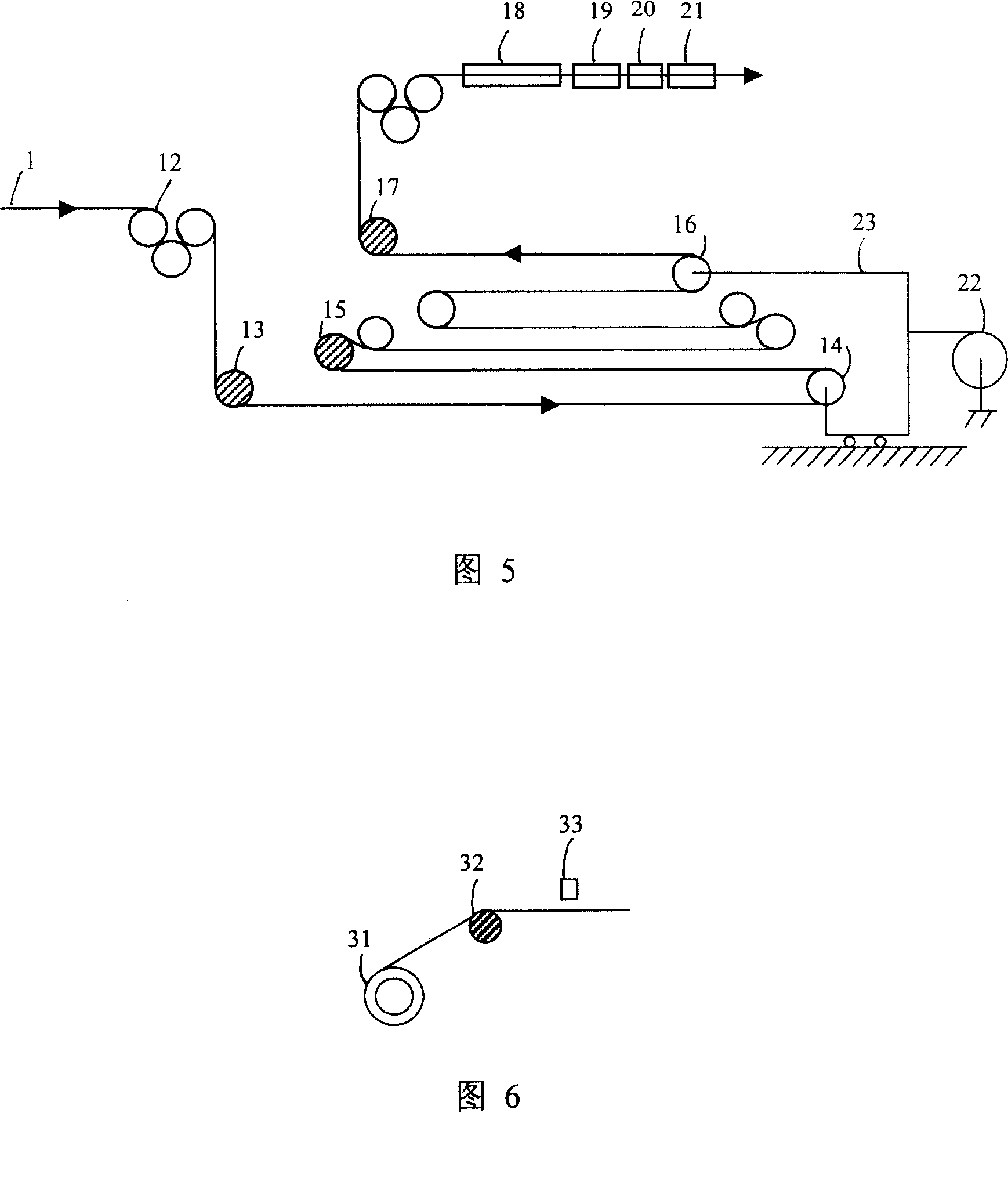

Method and device for rectifying deviation of steel band

InactiveCN101003065AChange the guiding forceSimple structureGuiding/positioning/aligning arrangementsWebs handlingAutomatic controlEngineering

Owner:BAOSHAN IRON & STEEL CO LTD

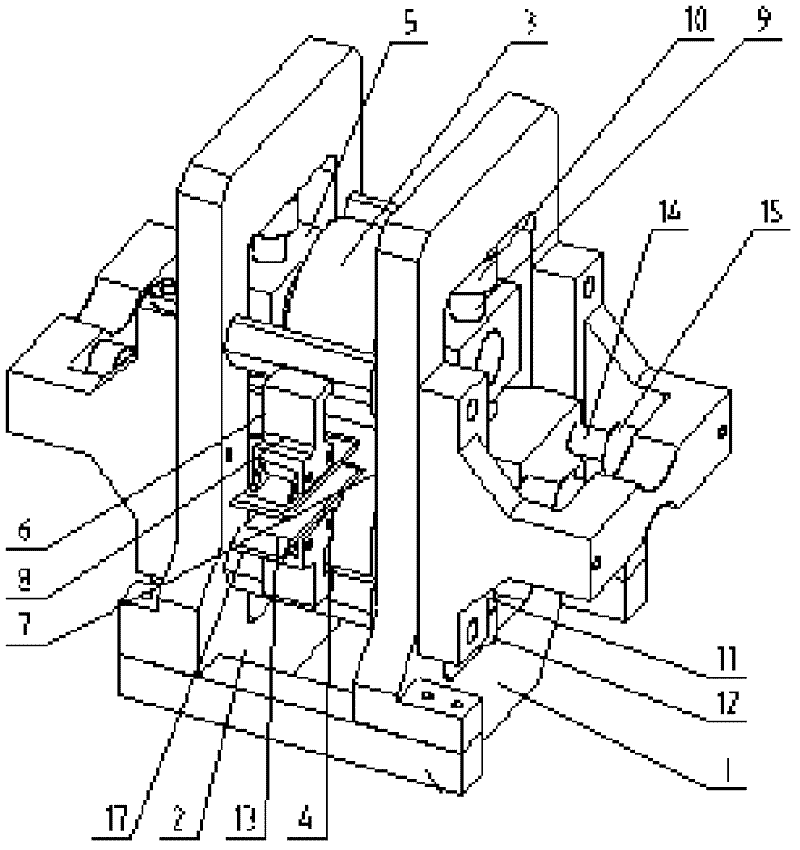

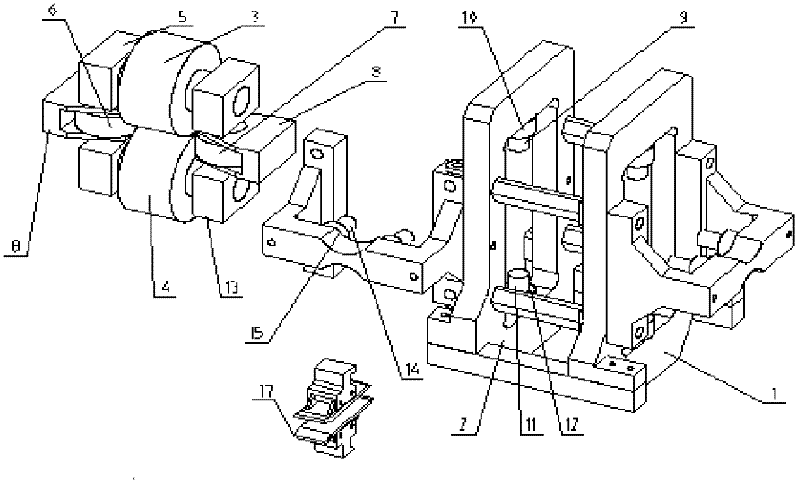

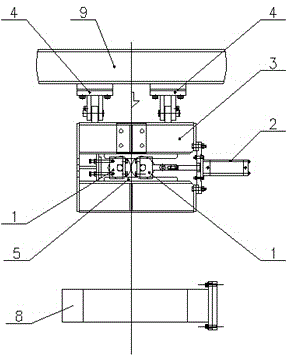

Compact chuck type universal mill

InactiveCN102363156AIncrease stiffnessHigh control precisionMetal rolling stand detailsGuiding/positioning/aligning arrangementsLateral compressionEngineering

The invention provides a compact chuck type universal mill, which comprises stands, a roll system and a guide and guard device, wherein the roll system comprises horizontal rolls, bearing seats, vertical rolls and vertical roll boxes, wherein a press-down device is arranged between the stands and the upper horizontal bearing seat; a press-up device is arranged between the stands and the lower horizontal roll bearing seat; a lateral compression device is arranged between the operating side vertical roll box and the operating side stand; and the operating side stand can move. High-accuracy large-sized section steel can be produced by using a closed stand and a fully hydraulic press-down device. The operating side stand is made to be movable; and when the roll system is replaced, only the operating side stand is required to be moved away to completely expose the roll system, the roll changing is realized so that the roll changing time is saved, the operating efficiency of the mill is increased, and the universal mill can be conveniently converted into a two-roll mill for use. The size of a window of the stands is reduced, so that the size of the entire mill is reduced and the weight of equipment is reduced; and the guide and guard device is integrated with the roll system, reversible rolling is realized.

Owner:中重科技(天津)股份有限公司

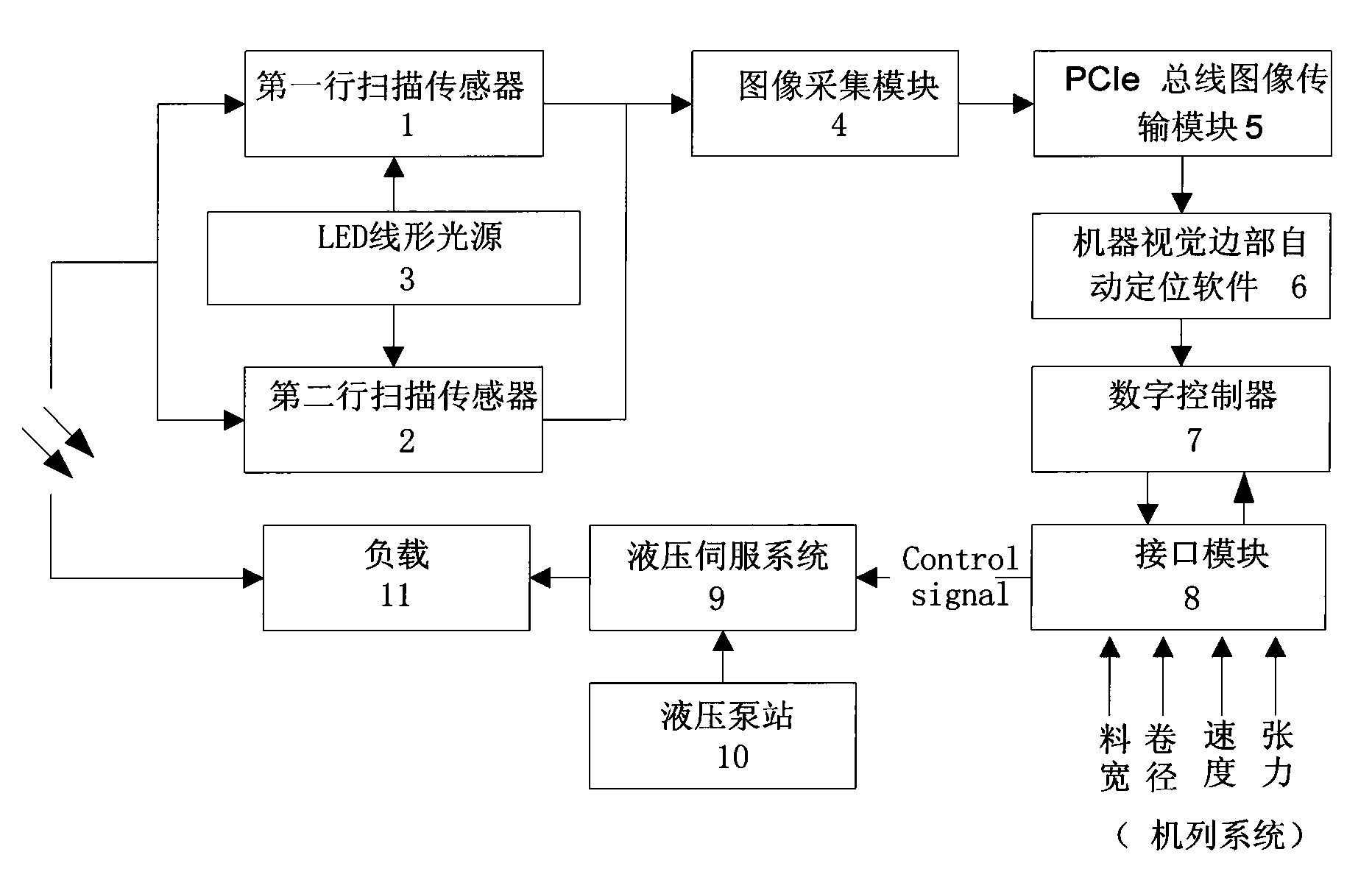

Design method based on machine vision inspection centring control device

ActiveCN101596556AFlexible hardware configurationReduce volumeGuiding/positioning/aligning arrangementsUsing optical meansVIT signalsMoving speed

The invention relates to a design method based on a machine vision inspection centring control device; a line scanning sensor senses wide long banding surfaces, and the result is output to an image acquisition module; LED linear light source generates convergent linear light which is irradiated on the object to be inspected, and surface condition is sent to the line scanning sensor; the image acquisition module carries out bottom layer treatment conversion on input signals of the line scanning sensor; a PCIe bus image transmission module provides point-to-point independent bandwidth bus channels for two routes of data of the image acquisition module; a machine vision margin automatically positioning software carries out positioning tracking on belting margin and calculates belt material centre deviation value; a digital controller determines parameters of the digital controller according to signals introduced by an interface module, and control signals are output to the interface module; the interface module inputs the signals of a system to the digital controller, and the result is output to a hydraulic servo system; the hydraulic servo system adjusts load moving speed according to the control signals output by the interface module; and a power unit supplies stressor.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

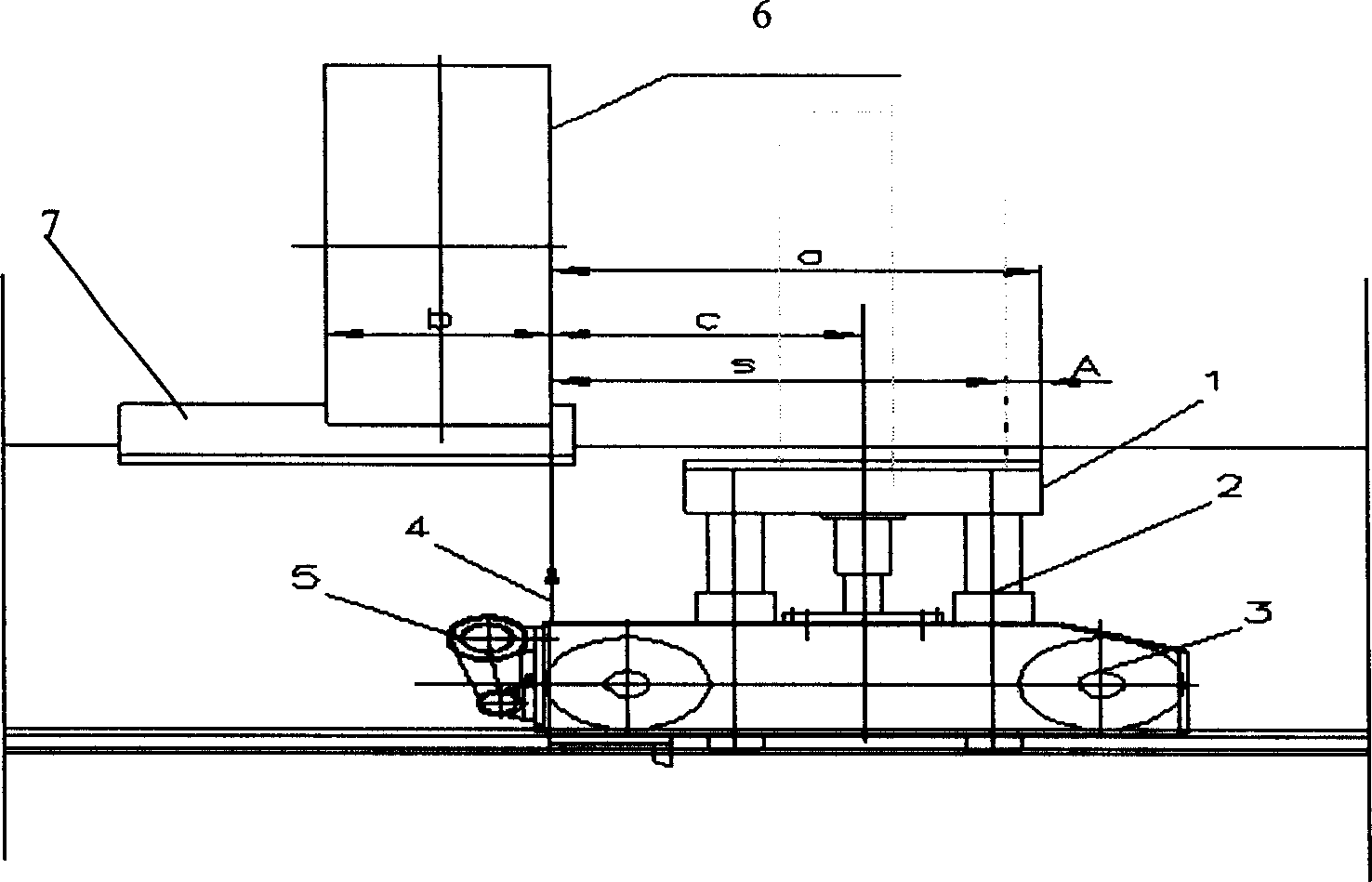

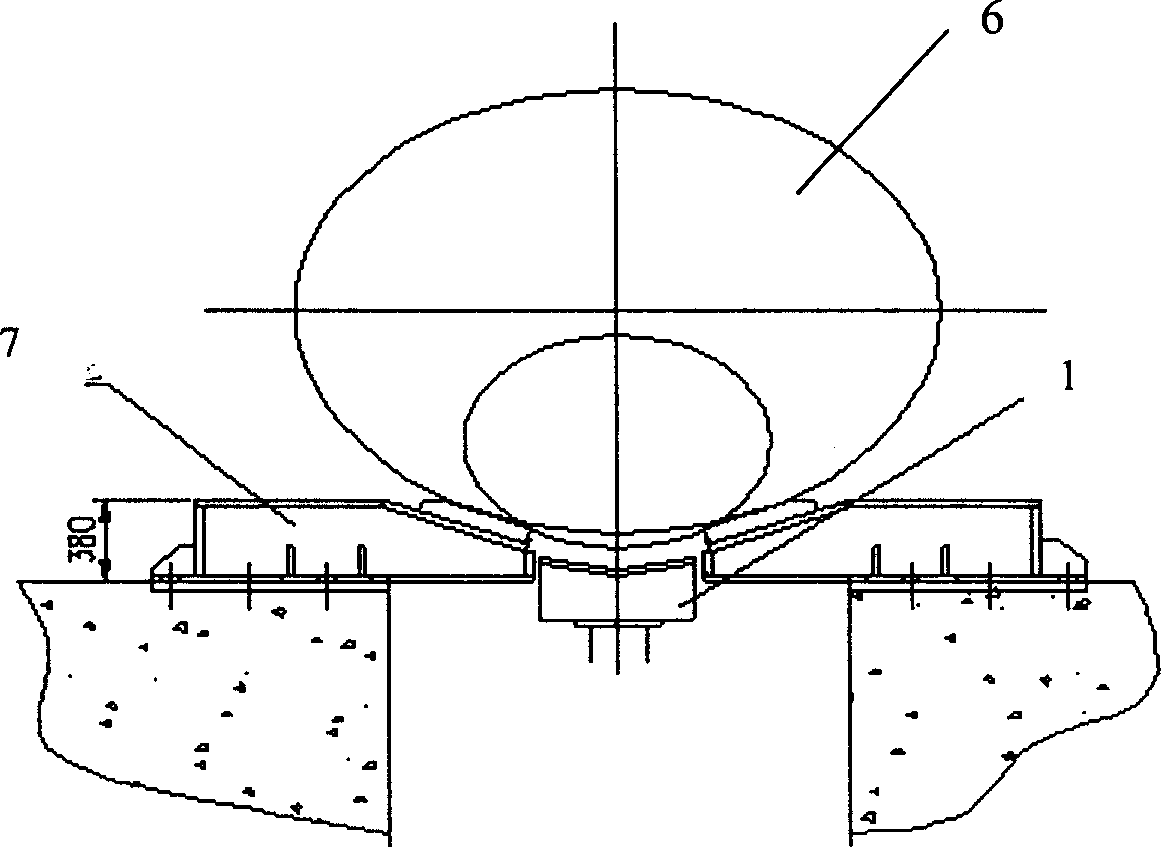

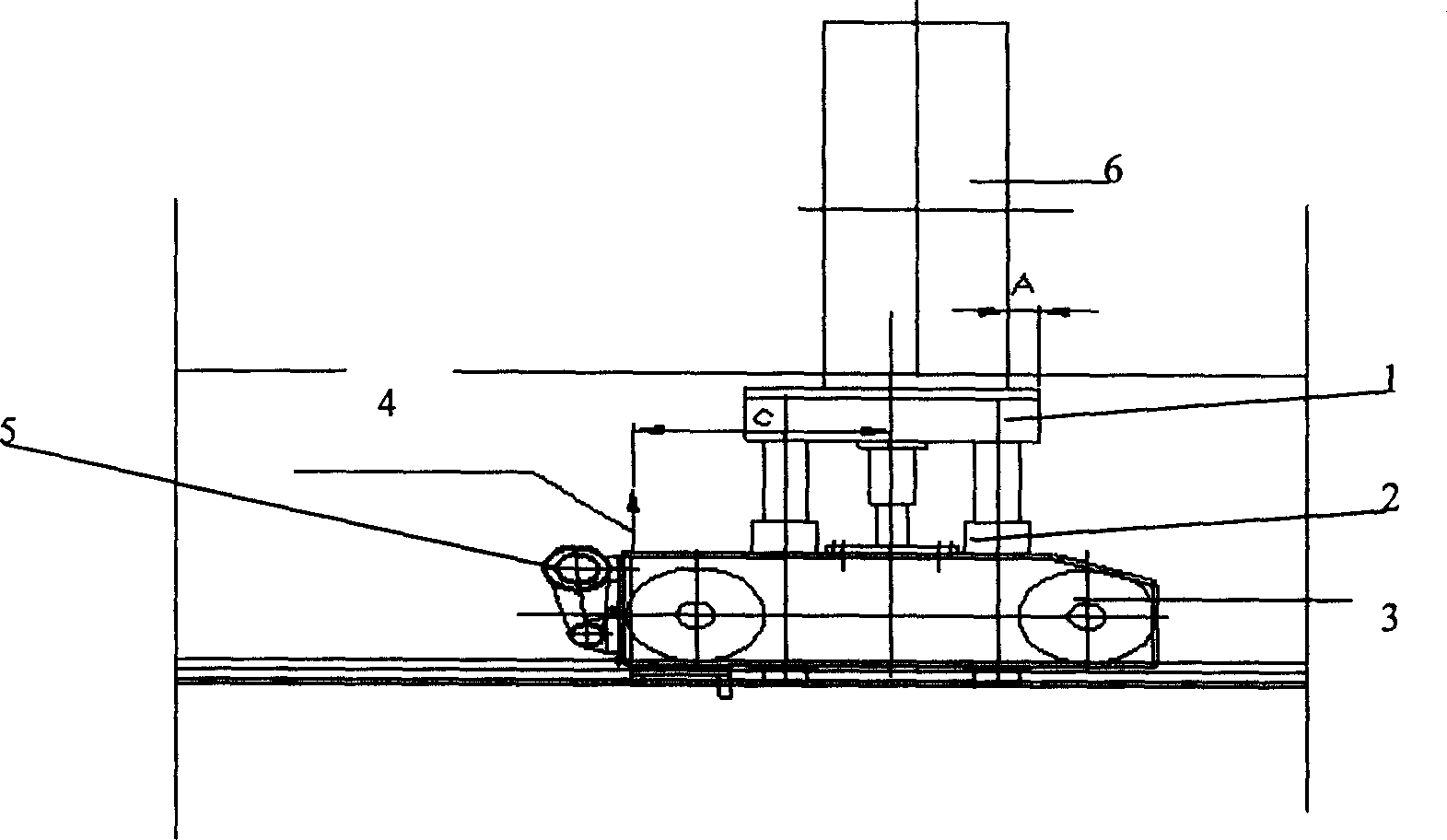

Automatic coil bearer locating apparatus and method

InactiveCN1857811APrecise deliveryAccurate parkingGuiding/positioning/aligning arrangementsConveyor partsBogieProduction line

The present invention relates to auxiliary iron and steel producing apparatus technology, and is especially automatic coil bearer locating apparatus and method for steel rolling production line and post-treatment line. The apparatus includes bearing seat, elevating mechanism, running mechanism, steel coil position detecting element, apparatus stroke detecting and locating control system. The present invention makes it possible to locate steel coil bogie or other conveying toll relatively to the coil accurately. The present invention is simple, smart and reliable.

Owner:BAOSTEEL ENG & TECH GRP

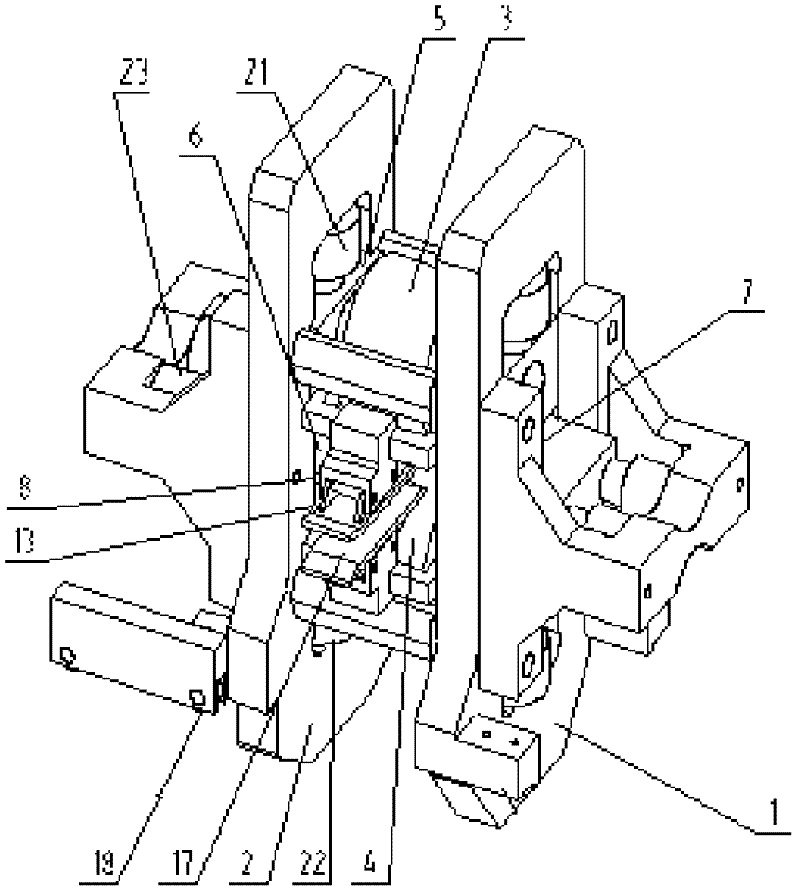

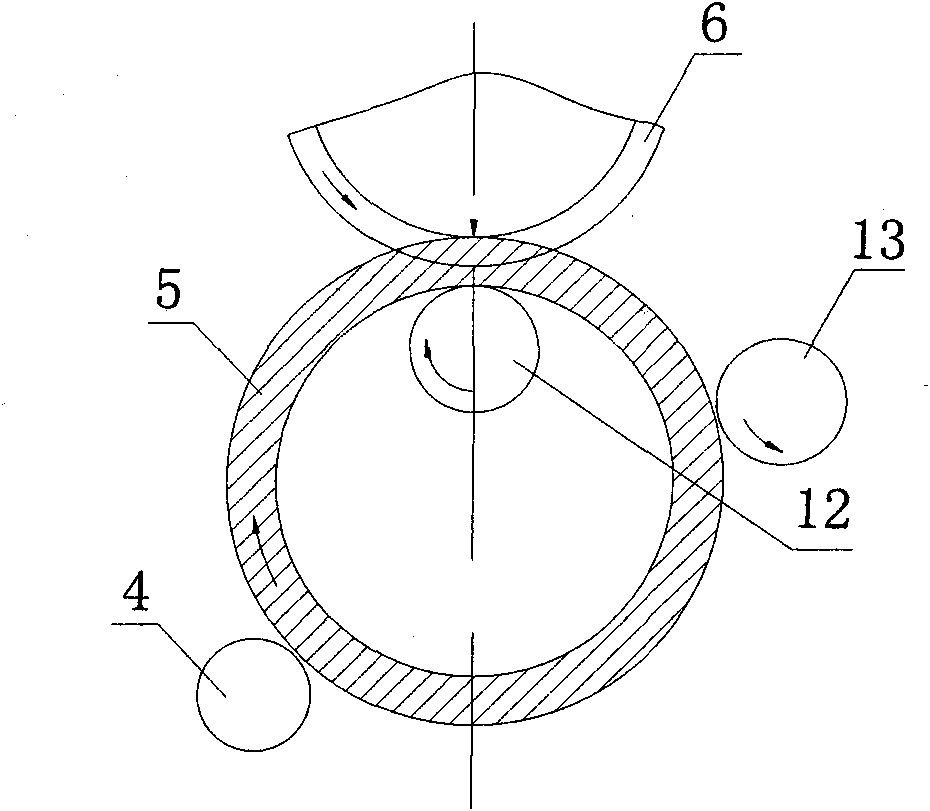

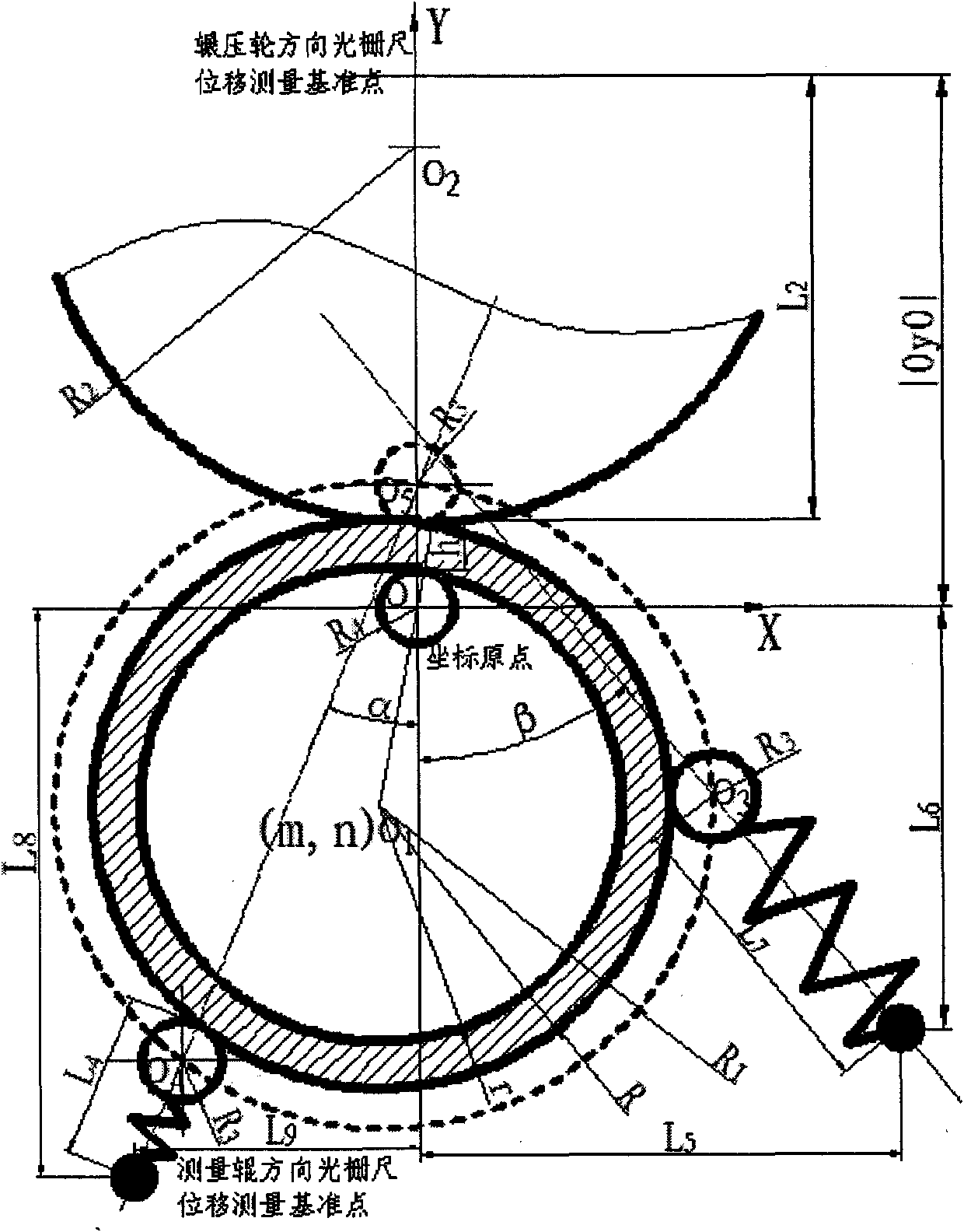

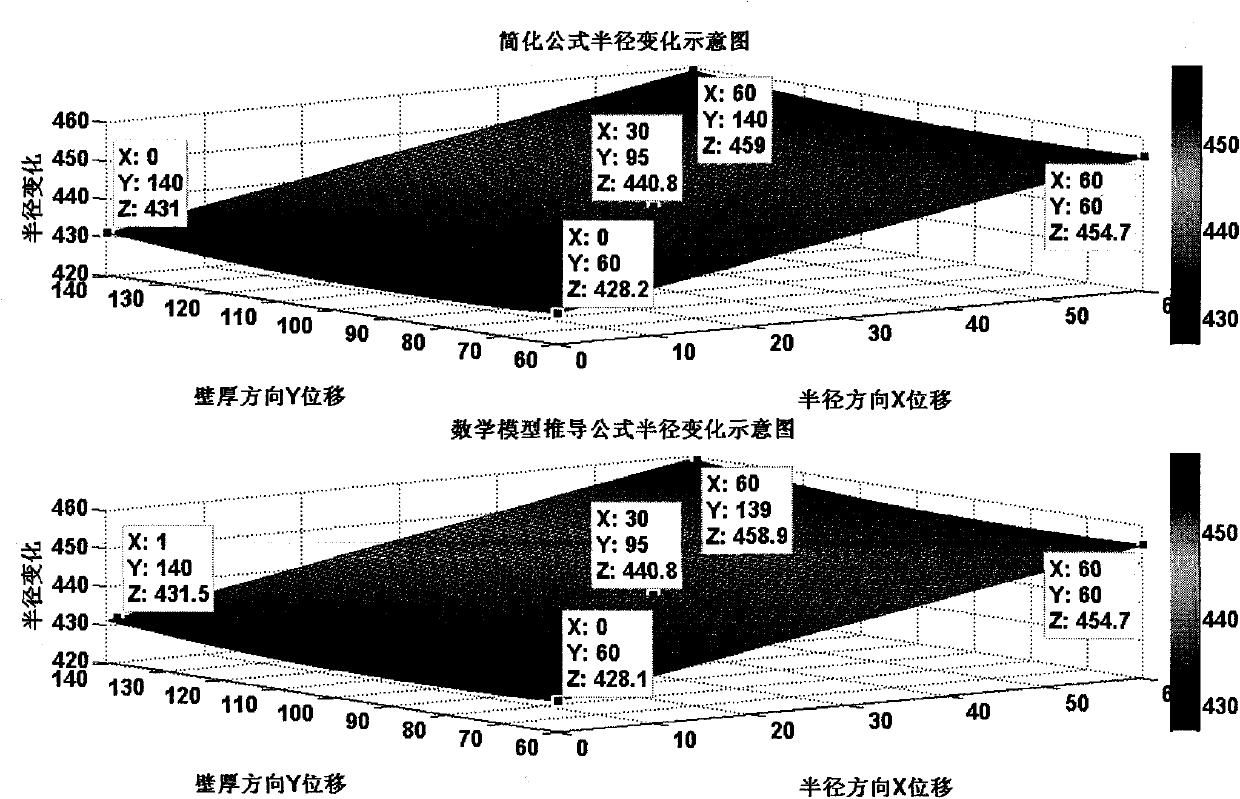

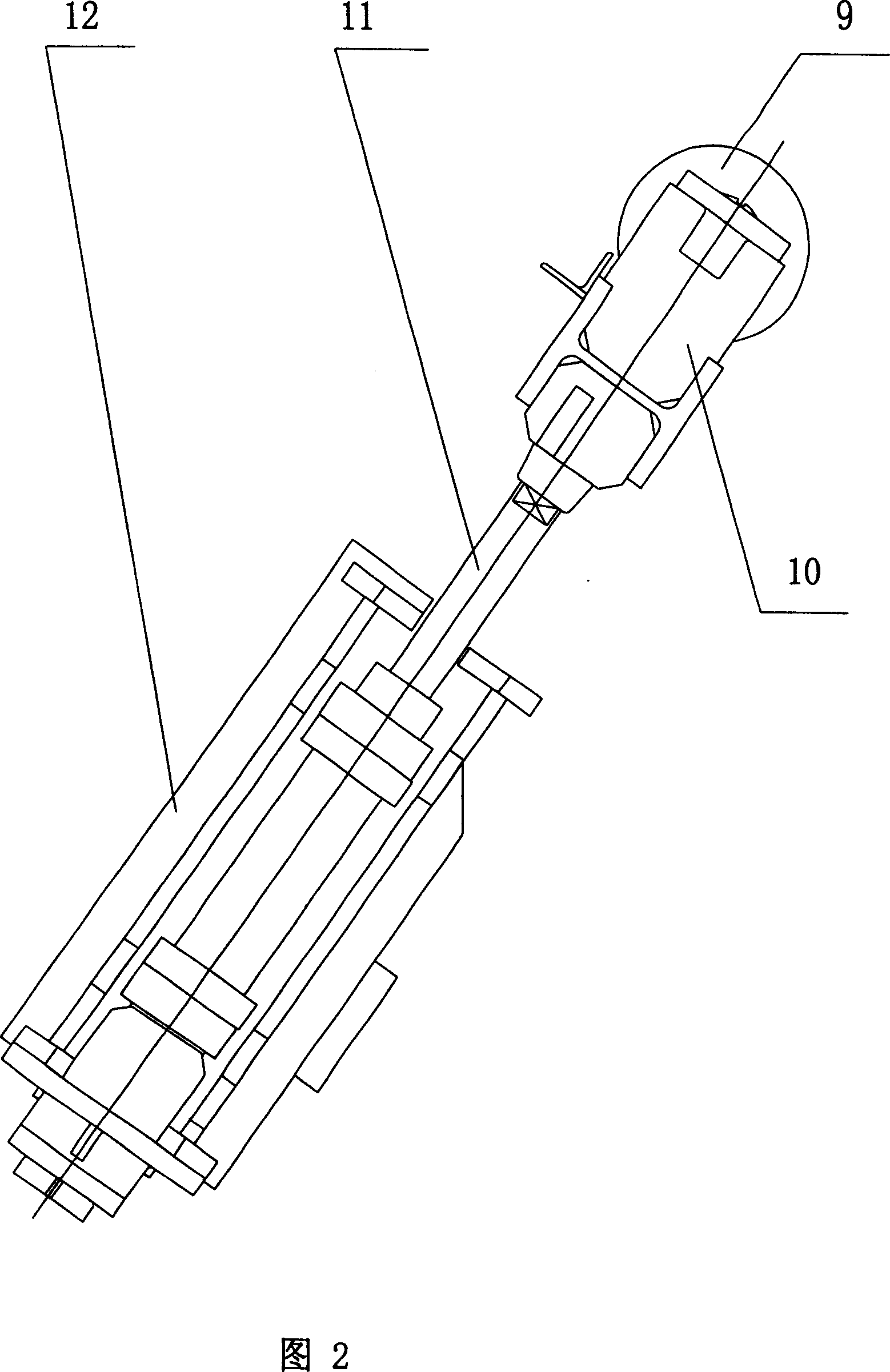

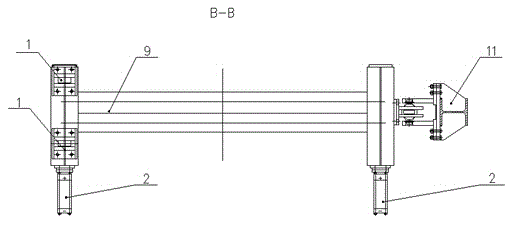

Vertical ring rolling mill capable of realizing on-line measurement control

ActiveCN101791670AReal-time measurement of displacementReal-time measurement of outer diameterGuiding/positioning/aligning arrangementsMeasuring devicesRejection rateMachining

The invention relates to a vertical ring rolling mill. The vertical ring rolling mill capable of realizing on-line measurement control comprises a rack, a rolling wheel mechanism, a measuring roll mechanism, a guide roll mechanism, a core roll mechanism and an unloading device. The vertical ring rolling mill is characterized by also comprising an on-line measurement control device; the on-line measurement control device comprises a displacement sensor group, a first displacement measurement sensor is arranged on a first elastic follow-up device of the measuring roll mechanism, and a second displacement measurement sensor is arranged on a slide block of the rolling wheel mechanism; and the measuring roll mechanism comprises the first elastic follow-up device, a measuring roll, a first push rod, a first bearing, a first shaft and a first bracket, wherein the measuring roll is fixed on the first shaft by the first bearing, the first shaft is fixed on the first bracket, the first bracket is fixed on the first push rod, and the first push rod is arranged on the first elastic follow-up device. The vertical ring rolling mill provides a condition for realizing on-line measurement control of outside diameter sizes of ring blanks, and has the advantages of manpower and material economization, high part molding precision, small post machining amount, low rejection rate and the like.

Owner:WUHAN UNIV OF TECH

A high-boron cast alloy guide and its heat treatment method

InactiveCN101549360AGood resistance to shock and heatReduce carbon contentGuiding/positioning/aligning arrangementsQuenching agentsChemical compositionAlloy

A high-boron cast alloy guide and its heat treatment method pertain to the technical field of steel rolling. The chemical composition of the guide provided by the present invention (mass fraction, %): C 0.25-0.45, Cr 12.0-15.0, B 1.0-2.5, Mo 0.5-0.8, Mn 1.8-2.5, Al 0.10-0.30, Re 0.08-0.20, Mg 0.04-0.08, V 0.05-0.10, N 0.01-0.03, Ti 0.10-0.20, Nb 0.10-0.20, 0.25<=Ti+Nb<=0.35, Si<1.0, S<0.05, P<0.05, and Fe as the rest. Through smelting, casting, oil quenching, tempering and other steps, the present invention prepares a high-boron cast alloy guide with high hardness and strength, desirable tenacity and wear resistance, and low cost.

Owner:BEIJING UNIV OF TECH

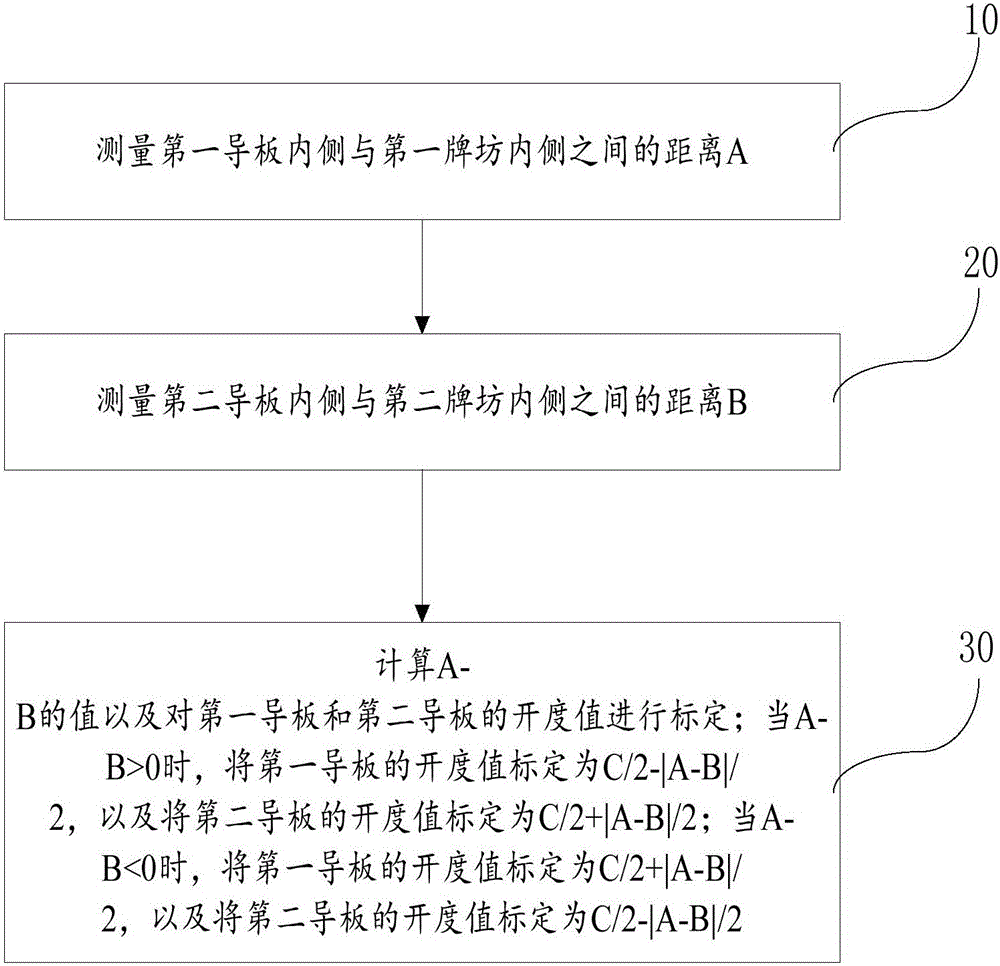

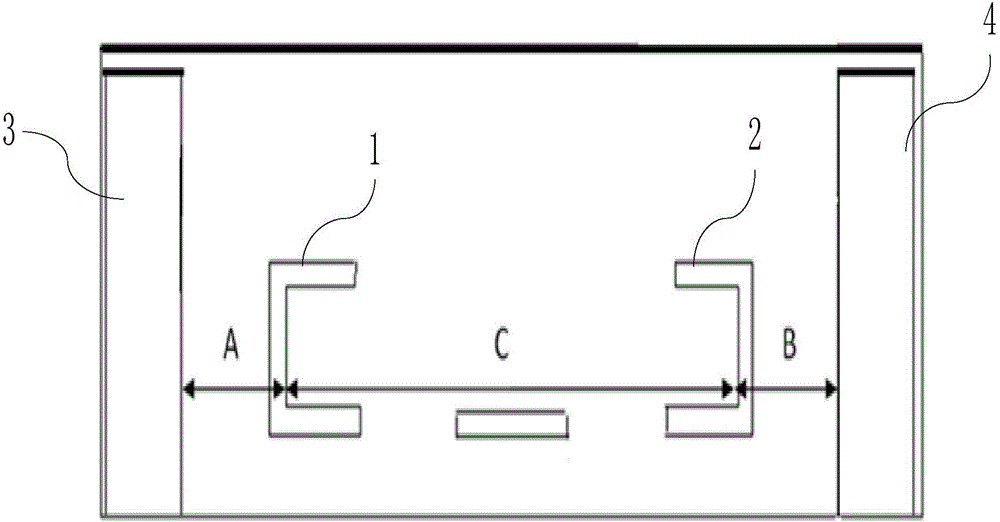

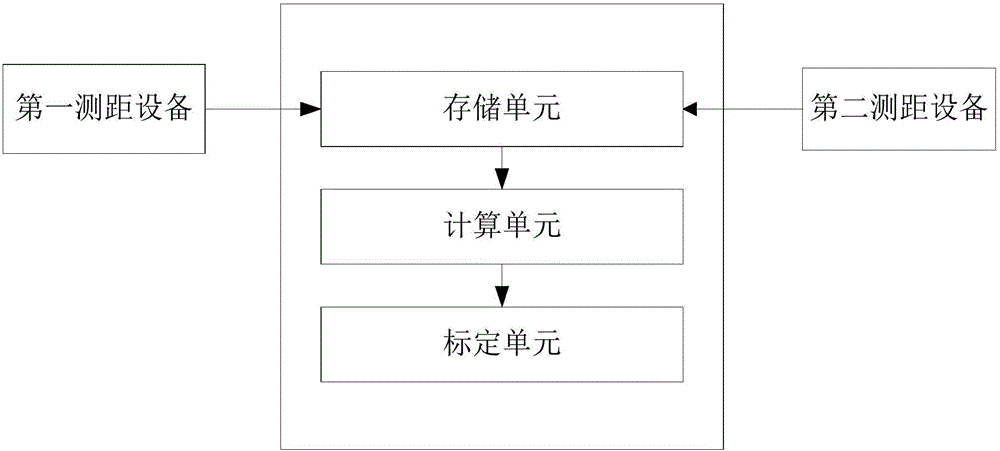

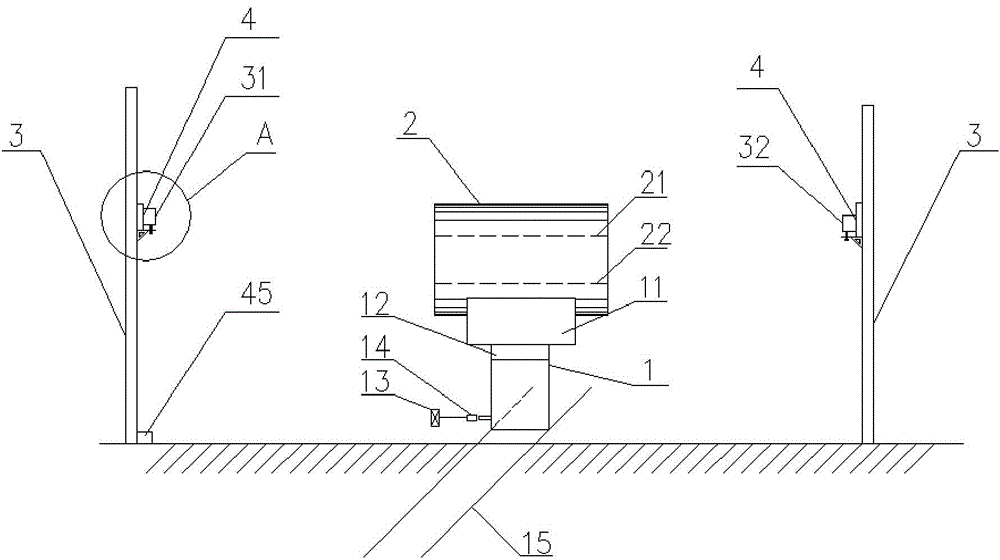

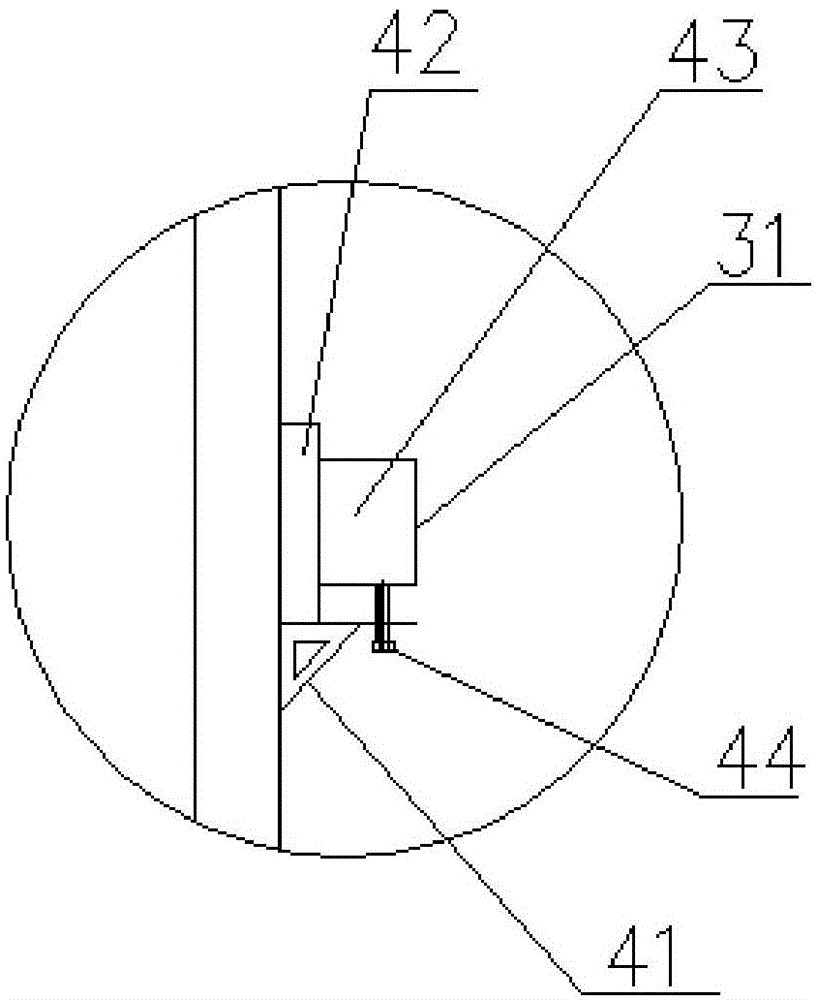

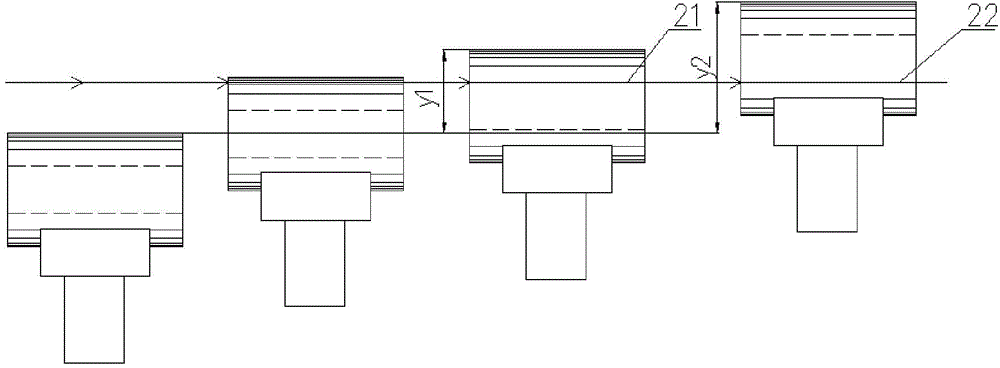

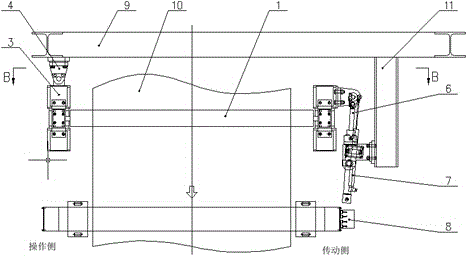

Calibration method and device of centering precision of side guide plates of finishing mill

ActiveCN105057369AImprove stabilityMeet on-site production requirementsGuiding/positioning/aligning arrangementsMeasuring devicesEngineeringDistance measuring equipment

The invention relates to the technical field of hot milling, particularly to a calibration method and device of the centering precision of side guide plates of a finishing mill. The method comprises the following steps: measuring a distance A between the inner side of a first guide plate and the inner side of a first memorial arch; measuring a distance B between the inner side of a second guide plate and the inner side of a second memorial arch; calculating the value of A-B; and calibrating the opening value for the first guide plate, and the opening value for the second guide plate. The device comprises first distance measuring equipment, second distance measuring equipment and treating equipment, wherein the first distance measuring equipment is connected with the treating equipment; the second distance measuring equipment is connected with the treating equipment; the treating equipment is used for calculating the value of A- B, and calibrating the opening value for the first guide plate, and the opening value for the second guide plate. Through the adoption of the calibration method and device of the centering precision of the side guide plates of the finishing mill, provided by the invention, the accurate calibration of the first guide plate and the accurate calibration of the second guide plate are realized, so that the actual centering precision of the side guide plates meets site production requirements, and the stability of strip threading in finishing milling and tail throwing in finishing milling is improved; therefore, milling accidents are avoided.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Steel coil height centering device and method thereof

ActiveCN104475463ANot easy to interfereAmple operating spaceGuiding/positioning/aligning arrangementsMetal working apparatusLight beamHeight difference

The invention discloses a steel coil height centering device and a method thereof. The device is applied to height centering of a steel coil and the core shaft of an uncoiling machine during coiling, and comprises a coiling trolley; a saddle for mounting a steel coil, a lifting device for adjusting the height of the steel coil, a lifting encoder for recording the height of the steel coil lifted by the lifting device and a limiter for limiting a mechanical zero point are arranged on the coil trolley; upright columns are arranged on the two sides of the moving rail of the coiling trolley; a positioning light source for emitting a concentrated light beam is arranged on the upright column on one side, while a light receiving device for receiving the light emitted by the positioning light source is arranged on the upright column on the other side; the positioning light source and the light receiving device are located at the same height and the connecting line of the positioning light source and the light receiving device is perpendicular to the moving rail. The steel coil height centering method of the device is applied to centering in the axial direction of the steel coil, and the height difference between the upper edge and the lower edge of the inner diameter can be directly measured to determine the center of the steel coil. The steel coil height centering device is high in centering accuracy, stable and reliable and simple and convenient to operate.

Owner:武汉钢铁有限公司

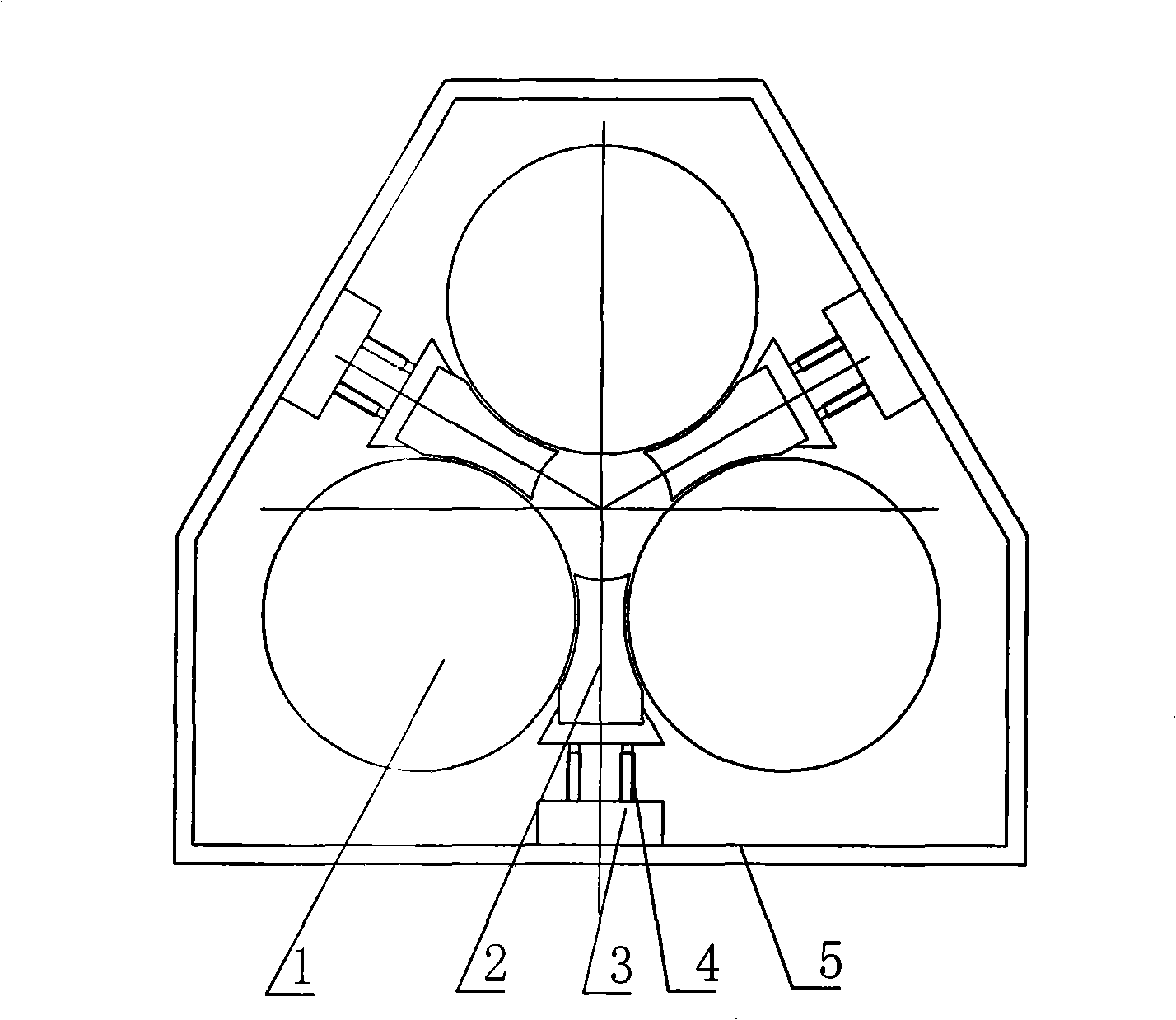

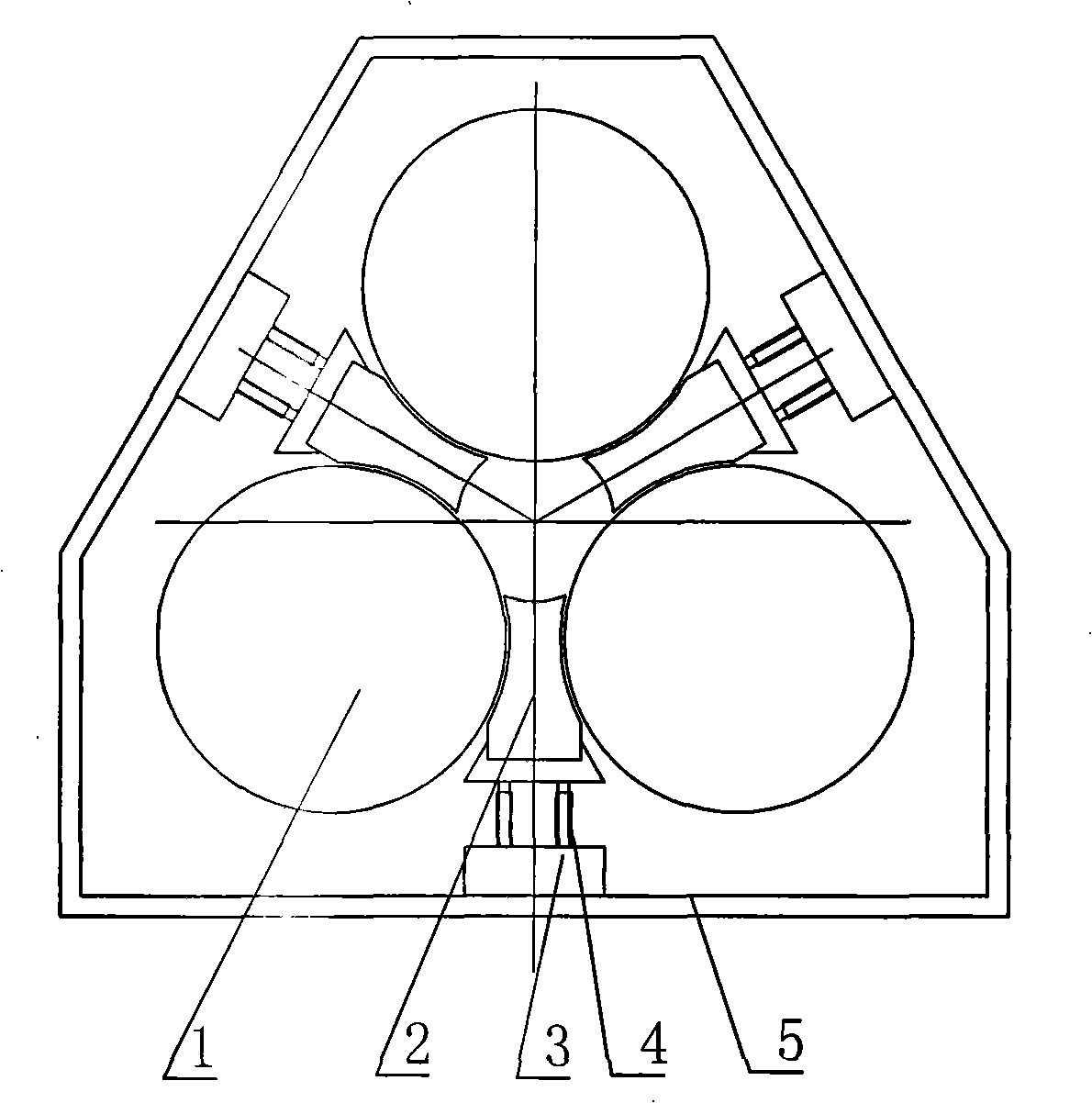

Novel technique for producing large-sized seamless steel pipe

InactiveCN101352728AExtended service lifeQuality improvementGuiding/positioning/aligning arrangementsWork treatment devicesHeating furnaceOrbit

The invention discloses a new production process of a large seamless steel pipe. The process comprises the following steps: pipe billets are preheated to the temperature of 1050-1290 DEG C by a heating furnace, and delivered to a three-roll skew rolling piercing mill for piercing by a skew roll table conveying mechanism to finish diameter expansion and wall reduction rolling, the maximal ratio of diameter to wall D / S is over 32, and hollow billets are produced; the hollow billets are delivered to a three-roll skew rolling elongating finishing mill by a shift oblique orbit conveying mechanism to finish diameter expansion and wall reduction rolling or diameter reduction and wall reduction rolling, and the pierced billets are rolled, straightened, cropped end, cut to length, defect are detected, and the finished products are obtained after passing inspections. The new production process also perfects and improves the conventional three-roll skew rolling seamless steel pipe process, solves the problems of not rolling thin walls and great extension in the three-roll skew rolling process, the diameter expansion and wall reduction rolling can be carried out, and the diameter reduction and wall reduction rolling can be carried out. The new production process is especially suitable for rolling large and oversized seamless steel pipes (Phi is 500-2000mm), the ratio of single reduced diameter and expanded diameter is more than 30%, the reduced wall diameter is more than 70%, and the reduced wall thickness is 5-7 times of that of a longitudinal pipe rolling mill.

Owner:沈阳东方钢铁有限公司

Composite SiC and its making process

InactiveCN1931462AGuaranteed toughnessGuaranteed StrengthMolten spray coatingShaft and bearingsHardnessHigh wear resistance

The present invention is composite SiC guide roller and its making process, and features that the composite SiC guide roller has a steel base body and a surface composite material layer of material comprising SiC 5-40 %, C 0.2-0.6 %, Cr 0-3.0 %, Mo 0-2.0 %, Mn 0-2.0 %, other metal and non-metal elements not more than 5 %, and Fe for the rest. The composite material is coated to the surface of the steel base body with powder, wire or rod of the composite material and through hot spraying, hot spray welding or laser depositing and combined with the steel base body. The composite SiC guide roller of the present invention has high hardness, high wear resistance, low brittleness, capacity of being heat -treated, machinability, low cost, high performance / cost rate and other advantages.

Owner:HEFEI UNIV OF TECH

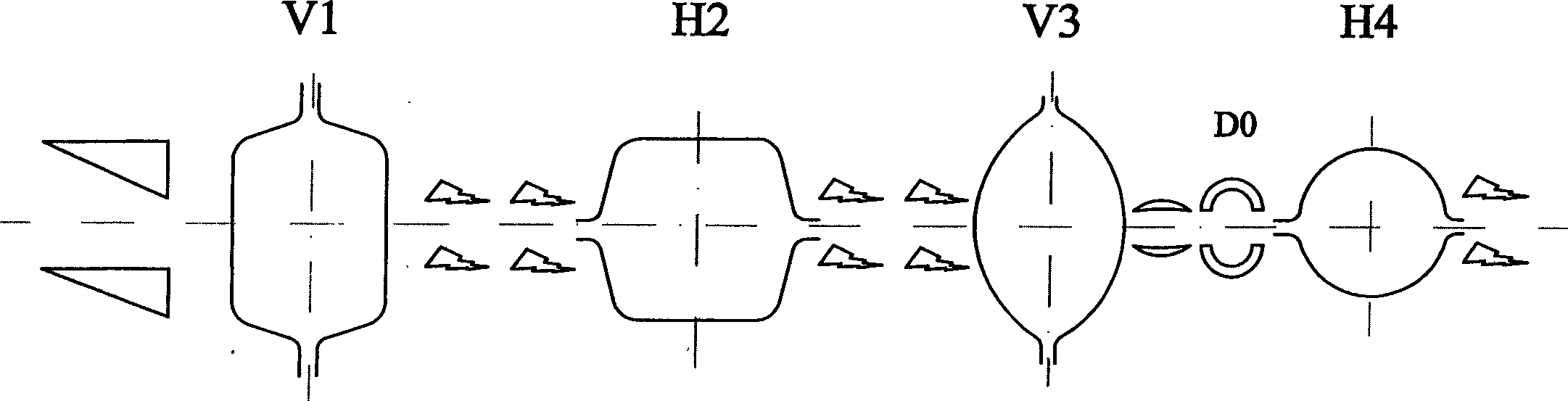

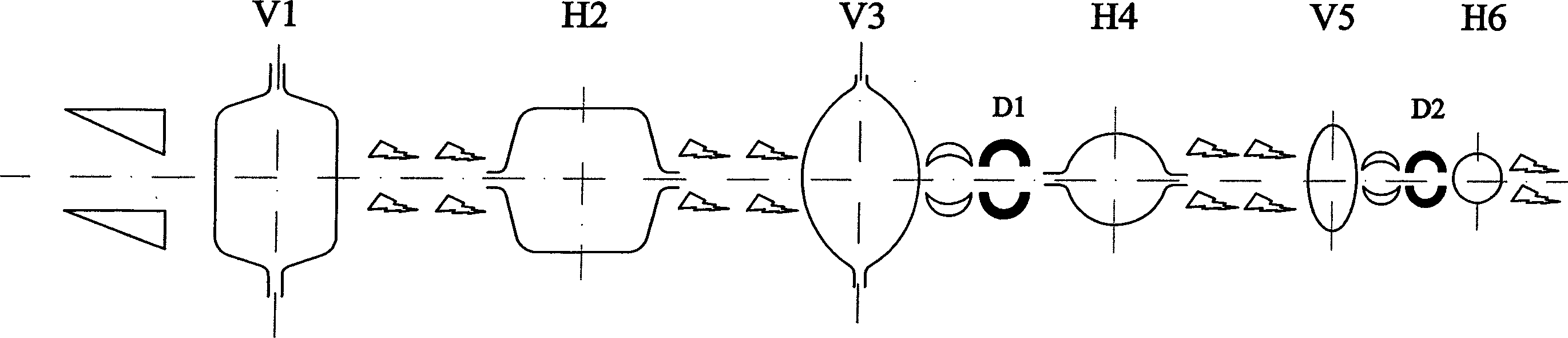

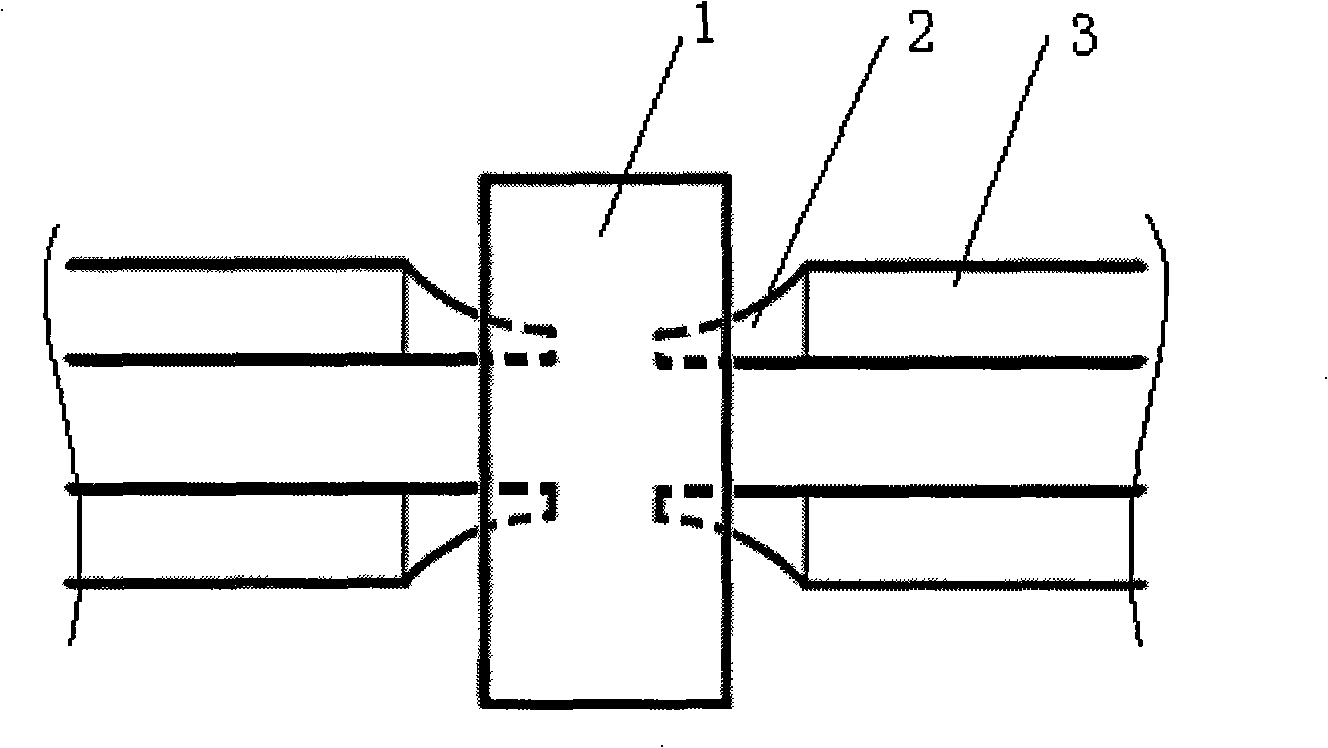

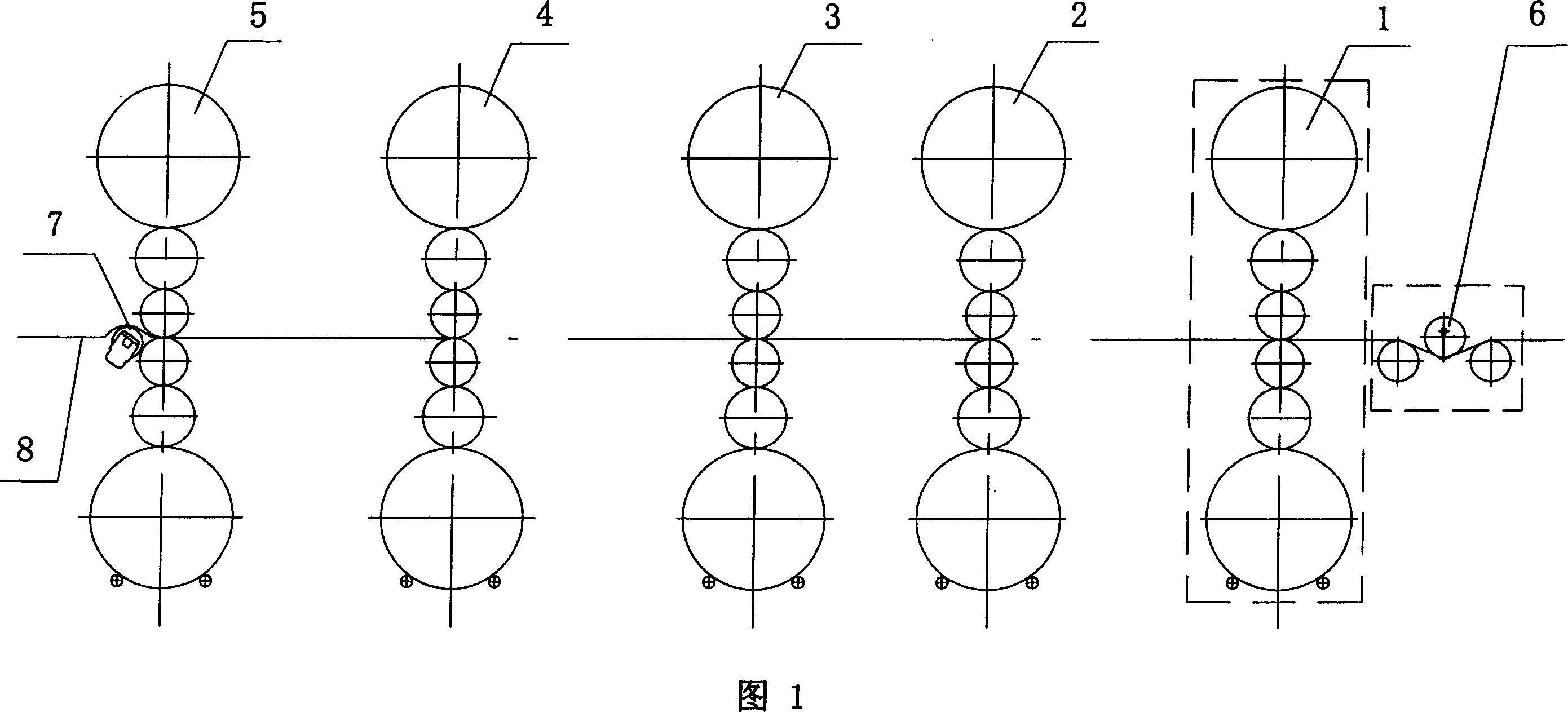

Small-norm steel rod continuous rolling method and its guide and guards

InactiveCN1640567AGood size controlEasy to makeGuiding/positioning/aligning arrangementsMetal rolling arrangementsEngineeringContinuous rolling

The present invention relates to a light-size round steel continuous-rolling method. It adopts a box-square-oval-round-oval-round system and makes the blank undergo the process of continuous rolling treatment by means of alternative six stands of vertical mills and horizontal mills so as to obtain the finished product, and before intermediate round pass stand and round former stand an inlet guide wheel is set.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing composite wear-resistant foreplate

InactiveCN101412095AInhibited DiffusionReduce the temperatureGuiding/positioning/aligning arrangementsWear resistantHardness

The invention discloses a method for preparing a composite antiwear guide plate, which comprises the following steps: alloy dust core bars are bound into bundles and arranged in a guide plate casting mould cavity, and the volume of the alloy dust core bars accounts for 20 to 60 percent of the total volume of the guide plate; molten matrix metal is cast into the guide plate casting mould cavity, the alloy dust core bars are melted and dissolved under the heat effect of the matrix metal, a great number of alloy elements and the molten matrix metal generate metallurgical combination reaction so as to generate a highly dispersed alloy structure on the original position; and finally the alloy structure is cooled and solidified, and the bar-shaped hard phase is metallurgically and transitionally combined into a whole with the matrix metal, thereby preparing the composite guide plate which takes the high-strength and high-ductility metal as the matrix and contains a certain number of metallurgically combined bar-shaped hard points. The composite anti-wear guide plate has high strength and high ductility of the matrix metal and high hardness and high wear resistance of the hard phase, can simultaneously bear high pressure and strong wear, and has the characteristics of long service life, low price, simple preparation and so on.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

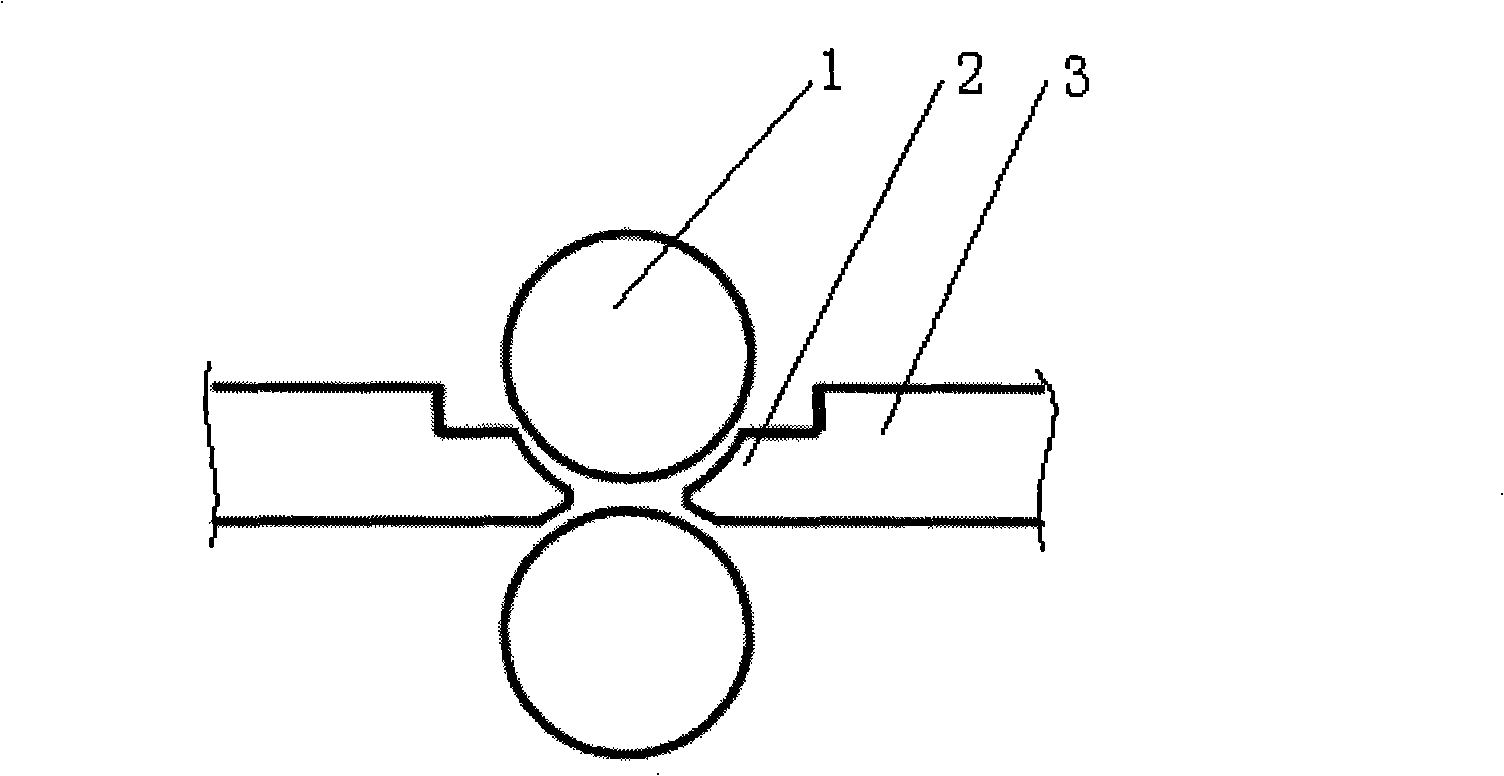

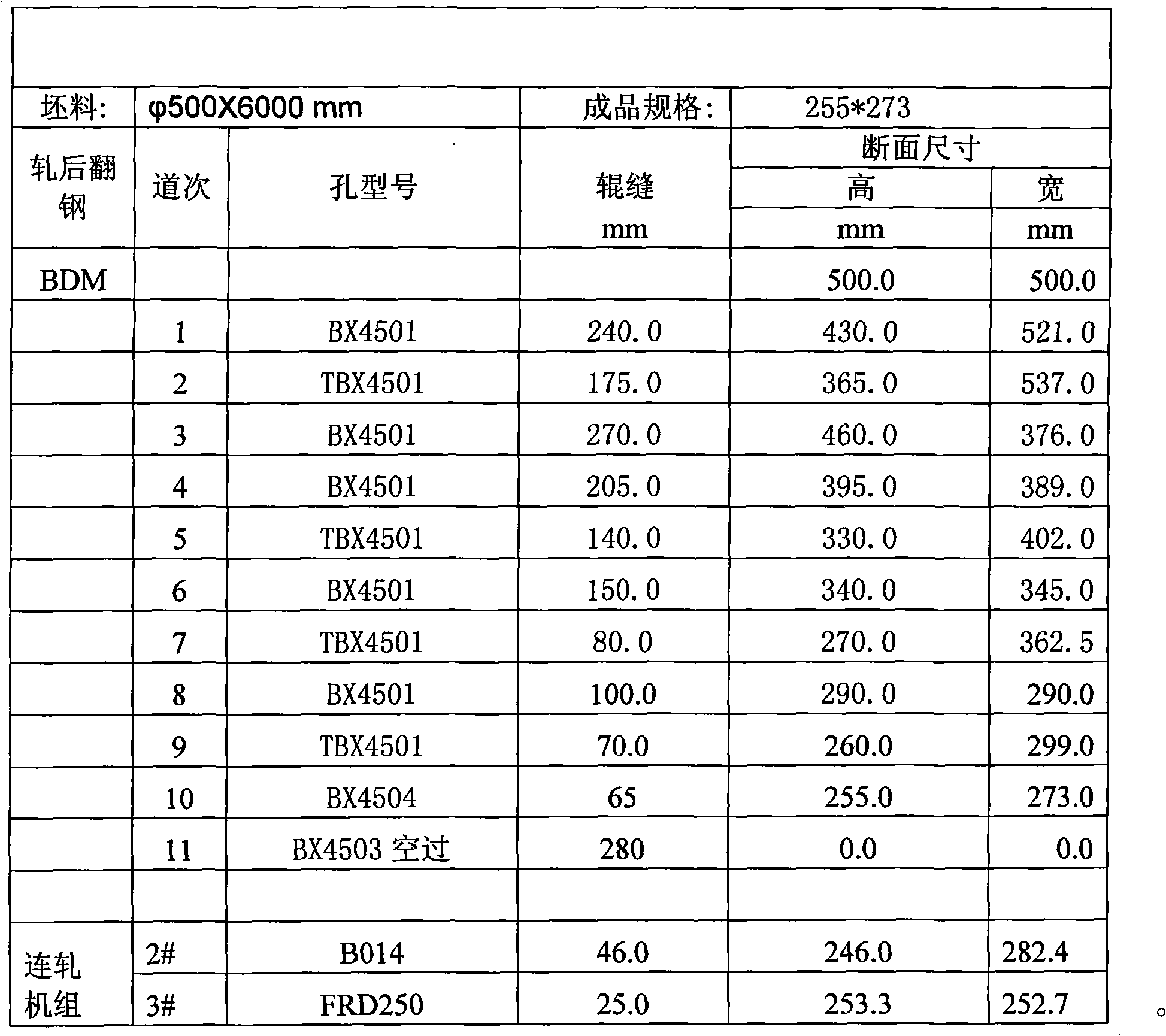

Rolling method of large size round steel

InactiveCN101306431AOvercoming the defects of easy-to-fall steelPour steel avoidGuiding/positioning/aligning arrangementsRoll mill control devicesStrip millEllipse

The invention discloses a method for rolling large-sized round steel, which comprises the following steps: clamping the round casting blank by a manipulator and a foreplate with which the manipulator is provided; loading the casting blank in a roughing mill and turning the casting blank over every 1-3 passes of rolling for 7-11 reduction passes; then, loading the steel billet in a continuous mill and rolling for 2-6 reduction passes; wherein the pass schedule of the roughing mill is a box-box pass type; the pass schedule of the continuous mill is an ellipse-round-ellipse-round pass type; the continuous mill has an arrangement form alternating between horizontal and vertical arrangements; and the continuous mill allows a rectangular billet with the height smaller than 260mm and the width smaller than 280mm to enter. The method has saving passes and few rolling passes without tapping during the rolling process, therefore, the method has the advantages of high rolling efficiency, low rolling cost and saving energy, and more prominently, the quality of finished round steel is good.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

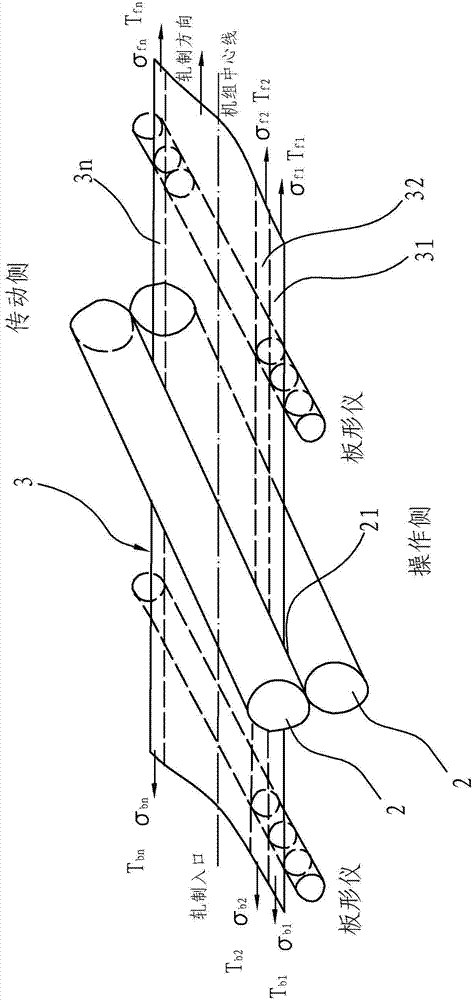

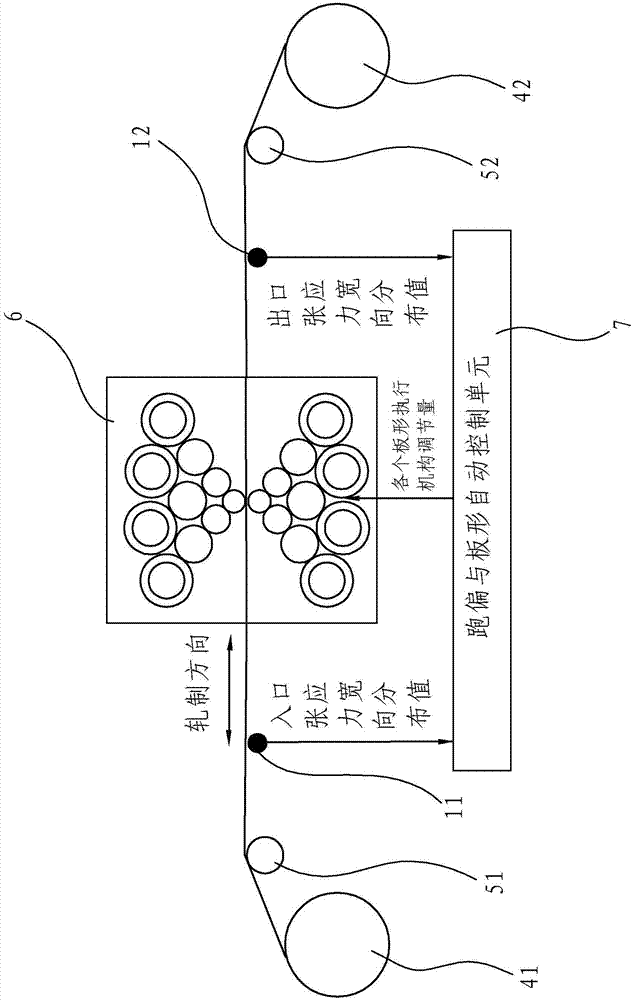

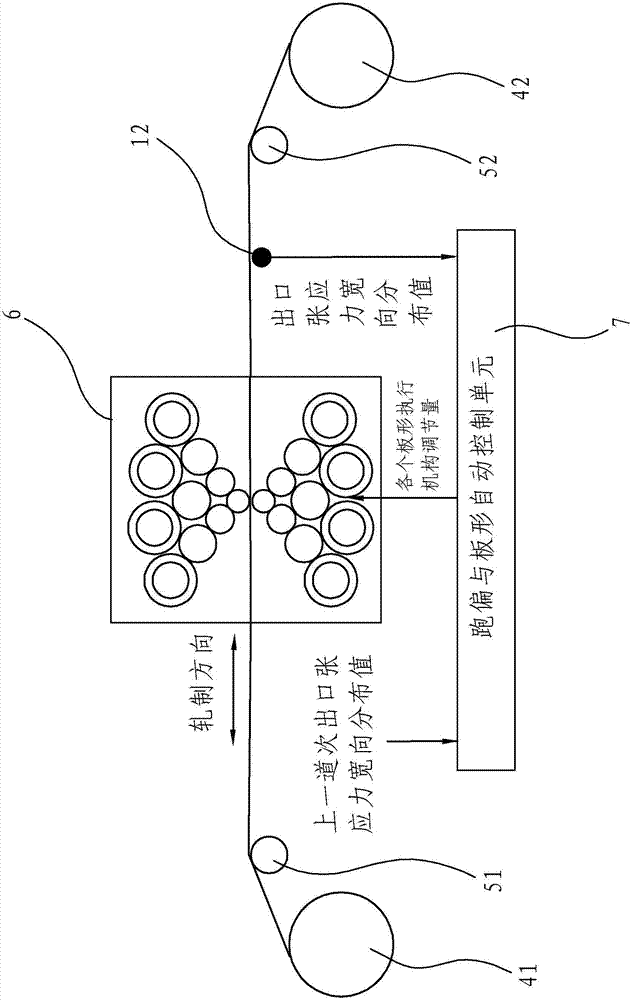

Cold stripe mill deviation and shape automatic control method

ActiveCN104275352AReduce the incidence of deviationImprove product qualityGuiding/positioning/aligning arrangementsProfile control deviceAutomatic controlShape control

The invention discloses a cold stripe mill deviation and shape automatic control method. Stripe shape meters are arranged at the inlet and outlet of a cold mill, the shape of stripe material can be detected before and after cold milling, the shape of the milled stripe material and the deviation amount are adopted as a comprehensive control target, the mill shape adjusting mechanism is adjusted automatically, the deviation between the shape of the milled stripe material and the target shape and the stripe material deviation amount are minimized comprehensively, owing to the real-time detection of the stripe shape meters, real-time calculation of a deviation and stripe shape automatic control unit, adjusting amount of a stripe shape control and output executing mechanism, the deviation occurrence rate in the stripe material cold milling process is decreased effectively, and the unit production capacity is improved; meanwhile, compared with the traditional manual controlling and adjusting manner, the stripe shape control accuracy is guaranteed, and the stripe product quality is improved.

Owner:NINGBO BAOXIN STAINLESS STEEL

Method for preventing hot rolling stainless steel band from rolling cuts and device thereof

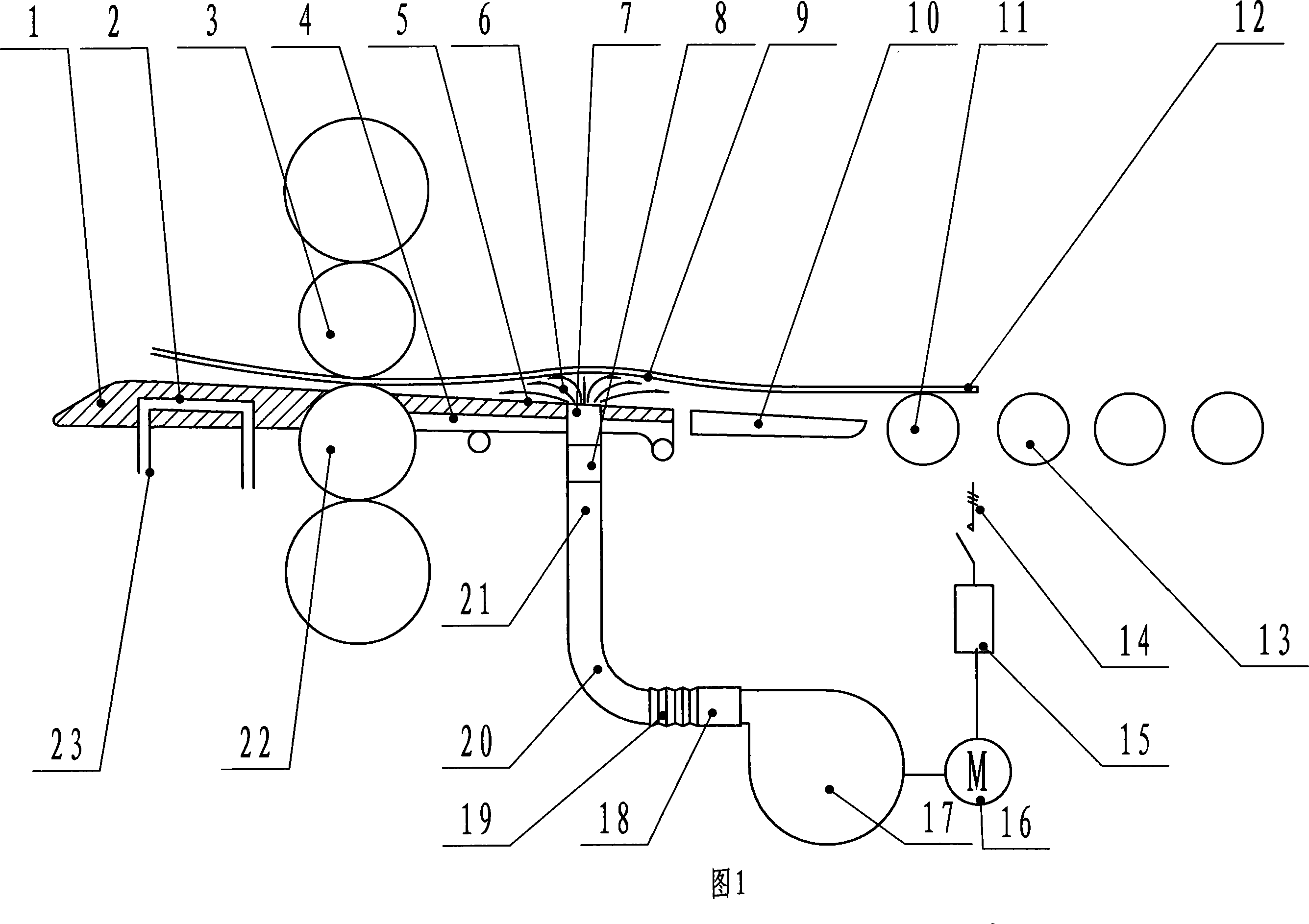

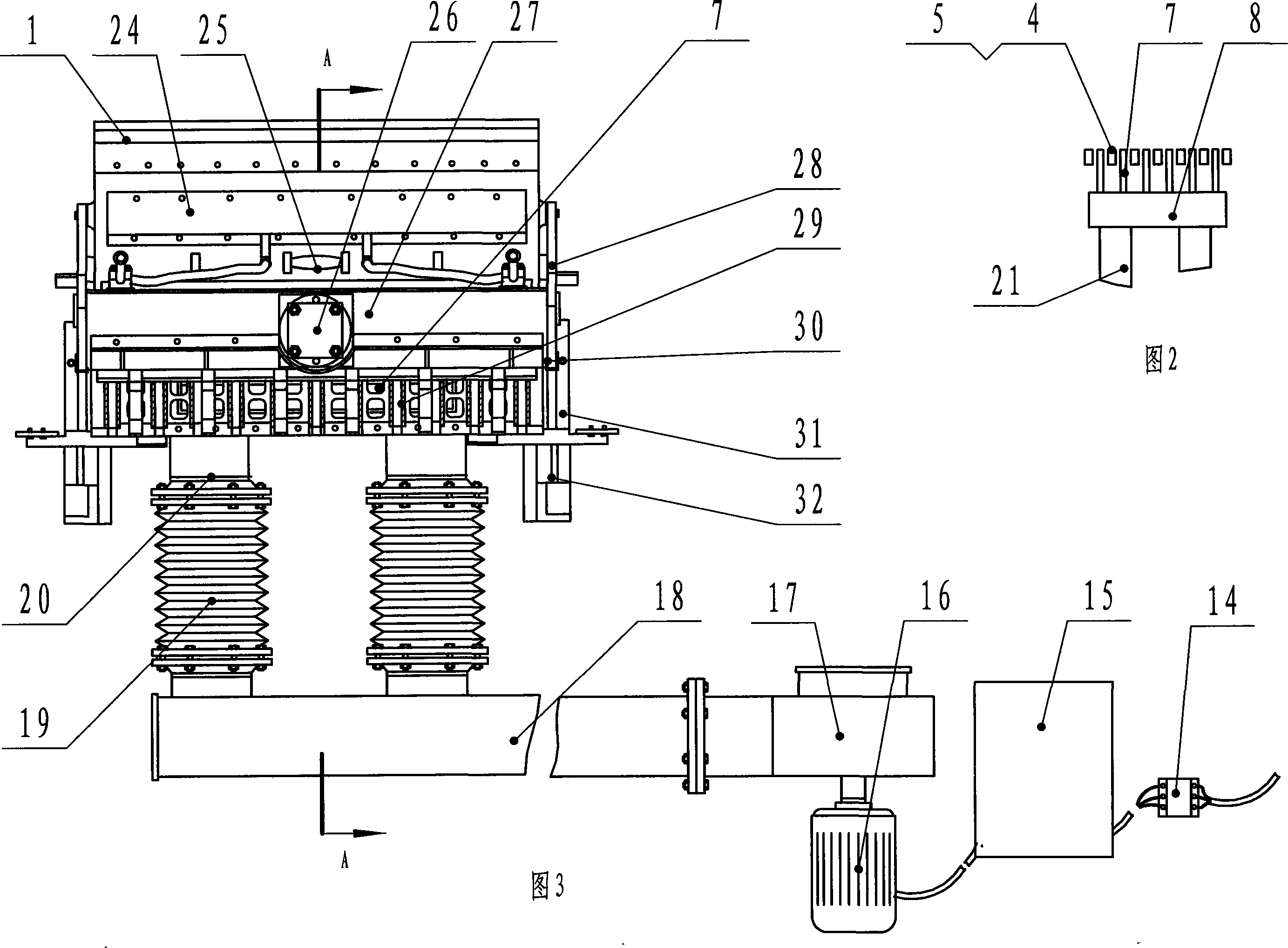

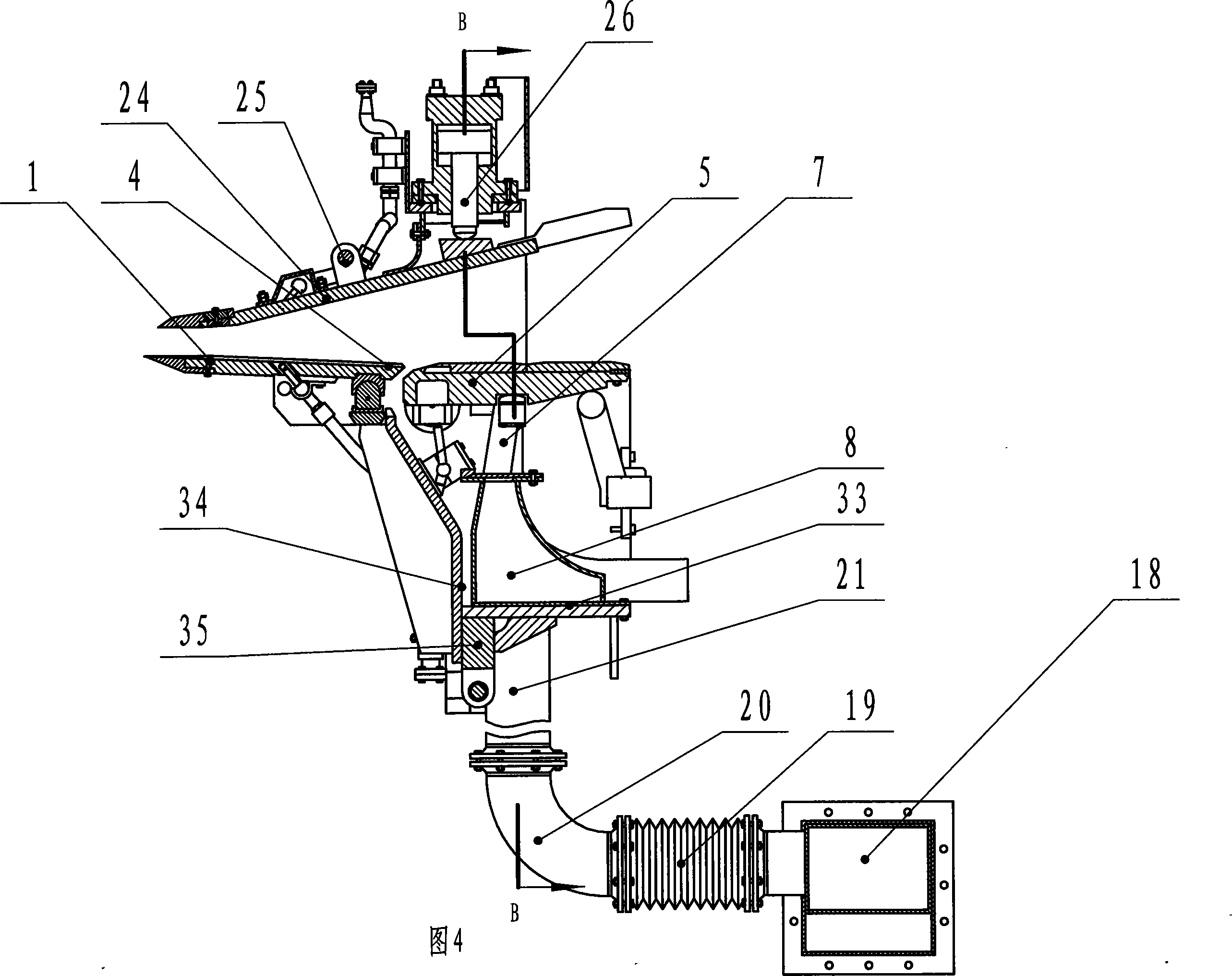

InactiveCN101185944AAvoid scratchesAvoid influenceGuiding/positioning/aligning arrangementsWork treatment devicesArchitectural engineeringStrip steel

The invention relates to a method and a device used for preventing the rolling scratch of the hot rolling stainless steel belt. The method is that when in rolling, the compressed air is blown out from a row of nozzles arranged by the lightening vertical hole of the outlet guide decking of the last hot finisher, the extrusive airflow forms an air cushion which blows and floats the band steel, thereby causing the lower surface of the band steel to be separated from the nonmetal decking fixed on the outlet guide decking. The device comprises an outlet guide beam arranged on an outlet guide frame of the last hot finisher, wherein, the outlet guide beam is provided with a transverse air pipe, and the transverse air pipe is provided with a plurality of vertical nozzles, the air outlet ends of the nozzles stretch into the lightening vertical hole of a vertical grid frame of a lower guide plate body of the outlet guide decking; the lower part of the transverse air pipe is fixed with a vertical air pipe, and the lower end of the vertical air pipe is fixed with a bending pipe, the bending pipe is connected with a corrugated pipe, the corrugated pipe is connected with a fixed pipe, and the fixed pipe is connected with a blower. The method and the device used for preventing the rolling scratch of the hot rolling stainless steel belt thoroughly stop the scratch of the lower surface of the band steel by the guide plate.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

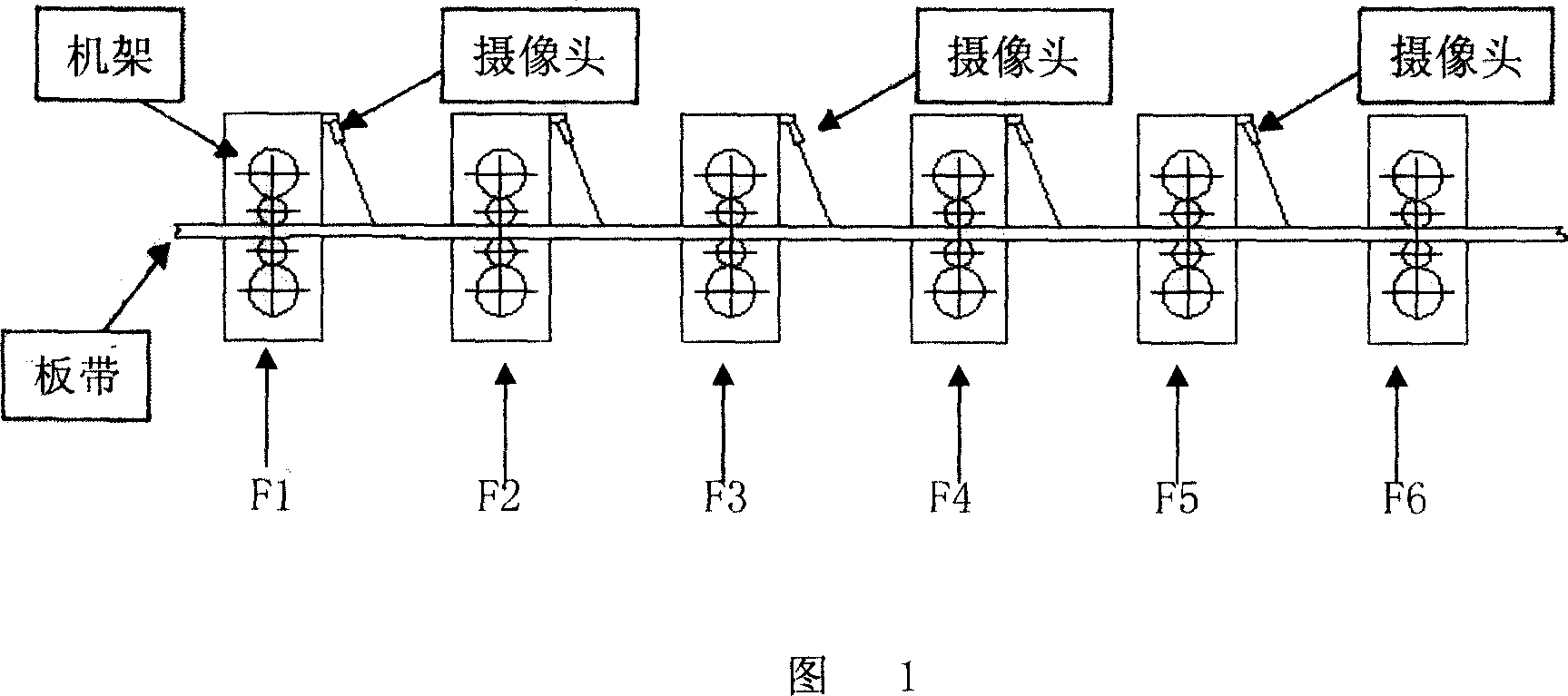

Rolling process of hot rolled steel sheet

InactiveCN1974040AServe as a modelRare end control deviceGuiding/positioning/aligning arrangementsSheet steelDisplay device

The present invention discloses the rolling process of hot rolled steel sheet. In the operation of the rolling process, video cameras are installed in the frame and display terminal is set in the rolling operation desk. During rolling, deviation trend of the rolled band is obtained through observing the positions of the band head, middle and tail in the frame and deviation rectifying operation is performed according to the deviation trend of the rolled band. The method can decrease the thickness of rolled band and raise the quality of the rolled product.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Method for preventing vibration of steel bar under high-speed rolling station of ultra-thin plate

ActiveCN1962103AReduce driveGood effectGuiding/positioning/aligning arrangementsRolling equipment maintainenceHydraulic cylinderStrip steel

The invention relates to a method for the vibration of band steel in high-speed rolling process, wherein said method is characterized in that: the first frame inlet of cold rolling machine is arranged with three-roller stabilizer which comprise left low roller, right low roller and upper middle roller; the upper middle roller is above the left and right low rollers, and above the rolling line; the left and right low rollers are under the rolling line; the band steel is through between the upper middle roller and left low roller and right low roller, the upper middle roller is lifted by hydraulic cylinder; when in normal rolling, the upper middle roller compresses the band steel; the last frame outlet of machine has single-roller vibration resistor; when in normal rolling, the vibration-resistant roller extends out driven by the hydraulic cylinder, to tension the bane steel.

Owner:WISDRI ENG & RES INC LTD

Rolling mill product handling system

ActiveUS7219521B1Guiding/positioning/aligning arrangementsWork manipulationHandling systemRotating drum

A product handling system comprises a support structure defining a pair of stationary inverted first channels with downwardly facing open sides. At least one cylindrical drum is interposed between each of the first channels and an underlying receiver. The drums are rotatable about their axes, with their surfaces arranged to close the open sides of the respective first channels. The drum surfaces are interrupted by second channels, with the first and second channels and the drum axes being arranged in a parallel relationship. Successive product lengths are alternately delivered longitudinally into one and then the other of the first channels. The drums are rotated about their axes resulting in the thus delivered product lengths being sequentially: (i) temporarily retained in the first channels by the rotating drum surfaces; (ii) deposited from the first channels into the second channels when the second channels rotate into radial alignment and communication with the first channels and (iii) downwardly deposited from the second channels to the receiver when the second channels rotate to discharge positions over the underlying receiver.

Owner:PRIMETALS TECH USA

Method for strip head correction in continuous rolling strip threading process

ActiveCN104307892ATimely detection of skewed phenomenaAvoid threading failureRoll force/gap control deviceGuiding/positioning/aligning arrangementsFailure causesMechanical engineering

The invention discloses a method for strip head correction in the continuous rolling strip threading process and relates to the technical field of metal pressure processing. The method comprises a step (A) of setting sampling time points of strip heads reaching each detection position; a step (B) of judging and calculating the strip head deflection degree and the deflection direction by performing imaging collection and processing on edge curves on the two sides of the strip heads when the strip heads reach the detection position of a current to-be-rolled machine frame in the strip threading process; a step (C) of performing on-line adjustment on roll gap differences of the double sides of a currently rolled machine frame; a step (D) of presetting roll gap differences of the double sides of a follow-up machine frame; a step (E) of repeating the step (C) and the step (D) until a profile gaugemeter detects the strip heads, and performing on-line adjustment on roll gap differences of the double sides of a finished product machine frame through the profile curves of two side edges of the strip heads detected by the multichannel profile gaugemeter. According to the method, the deflection of the heads in continuous rolling strip threading process of the strips can be timely found and adjusted so as to avoid yield reduction or strip threading failure caused by the deflection.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

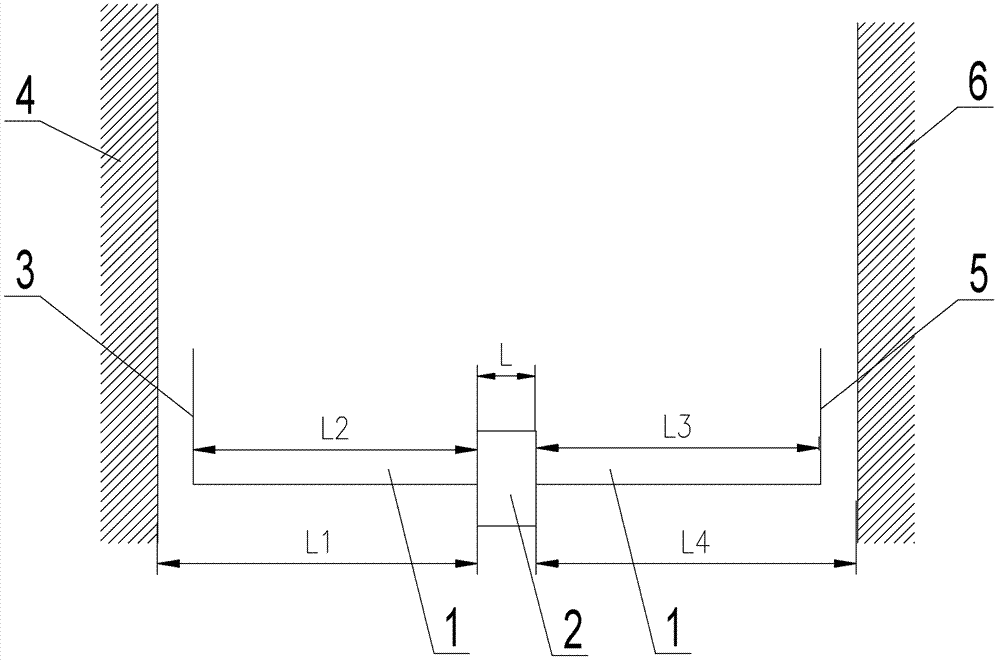

Method for calibrating center line of guide ruler

ActiveCN103191924AAvoid wear and tearReduce defective productsRolling equipment maintainenceGuiding/positioning/aligning arrangementsWaxEngineering

The invention relates to the field of hot rolled strip guide ruler centering, in particular to a method for calibrating the center line of a guide ruler. The method is characterized in that after maintenance is finished every time or strip steel with the thickness of 18 mm is rolled every time, the deviation of a transmission side and an operation side of the guide ruler is corrected in time to ensure the centering of the guide ruler. The method comprises the following specific operation steps: (1) measuring the width L of an extension strip at the middle part of the guide ruler, the distance L2 between the edge of the transmission side to a guiding plate on the transmission side of the extension strip, the distance L1 between the edge of the transmission side of the extension strip and an archway on the transmission side, the distance L3 between the edge of the operation side of the extension strip and the guiding plate on the operation side, and the distance L4 between the edge of the operation side of the extension strip and the archway on the operation side; (2) determining the deviation of the center of the extension strip; and (3) calibrating the center of the guide rule. Compared with the prior art, the method has the benefits that through in time correction of the deviation of the transmission side and the operation side of the guide rule after maintenance is finished every time or strip steel with the thickness of 18 mm is rolled every time, the wear and wax hanging phenomena of one side of the guide ruler, which is resulted from deviation of the guide ruler, are avoided.

Owner:ANGANG STEEL CO LTD

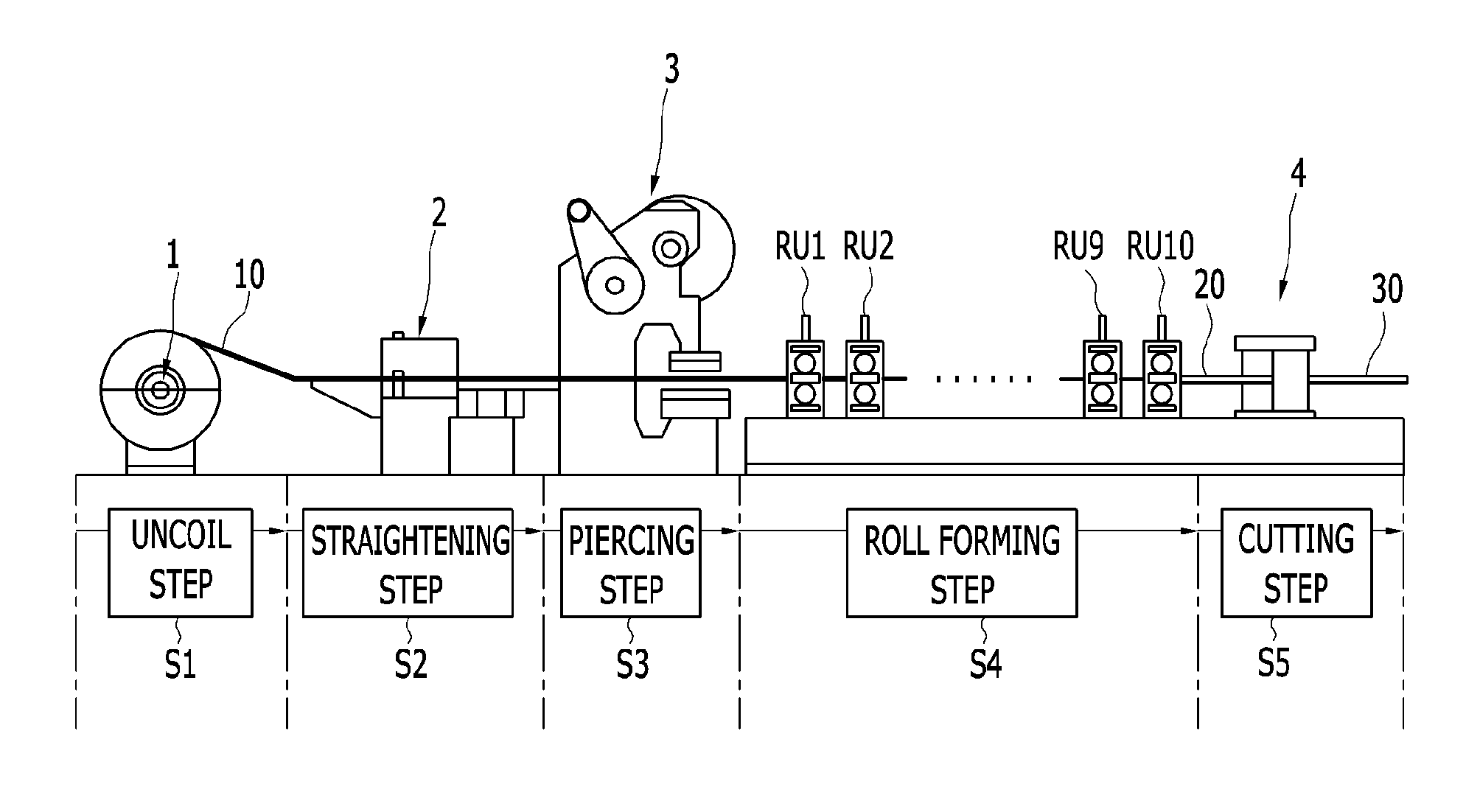

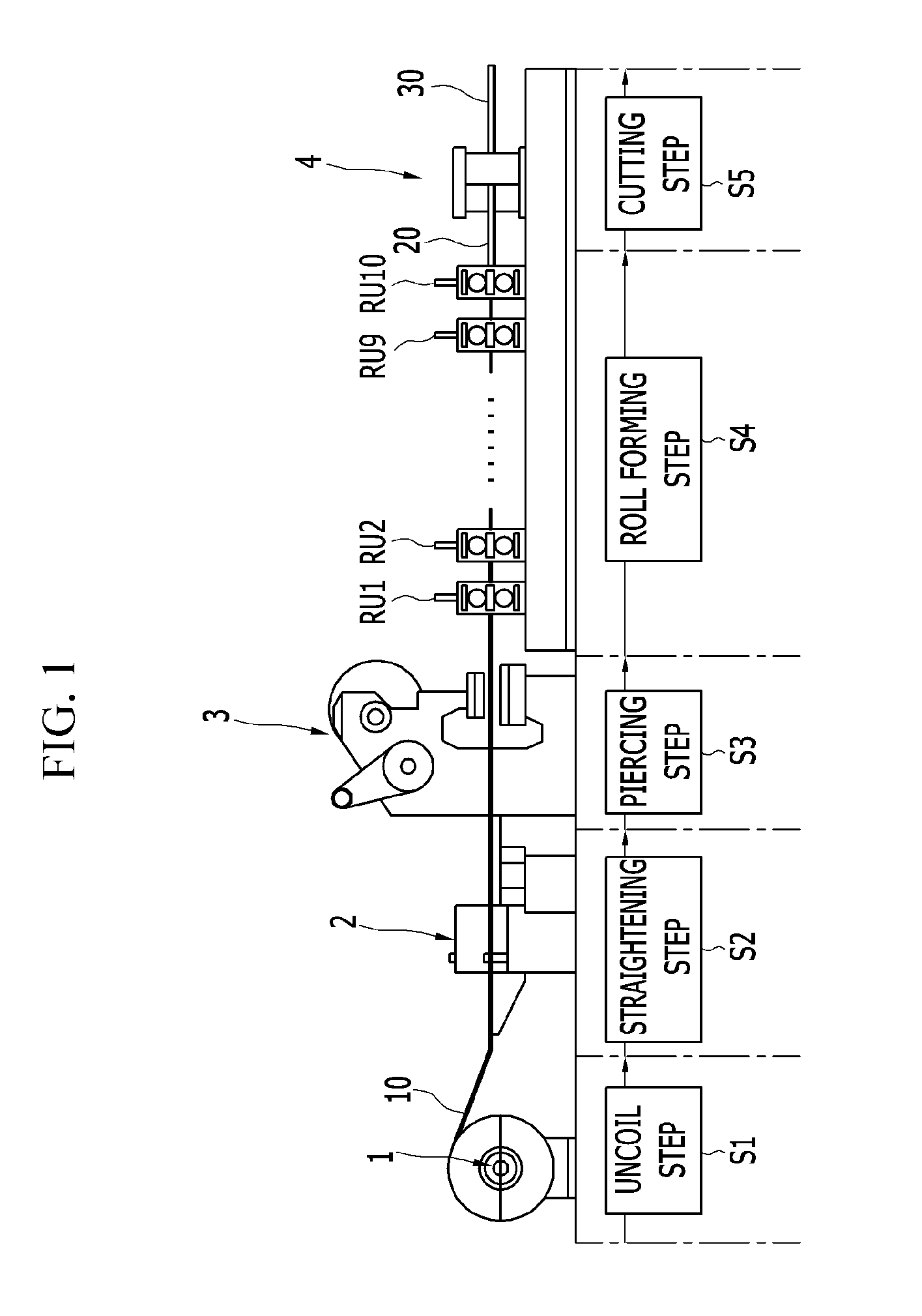

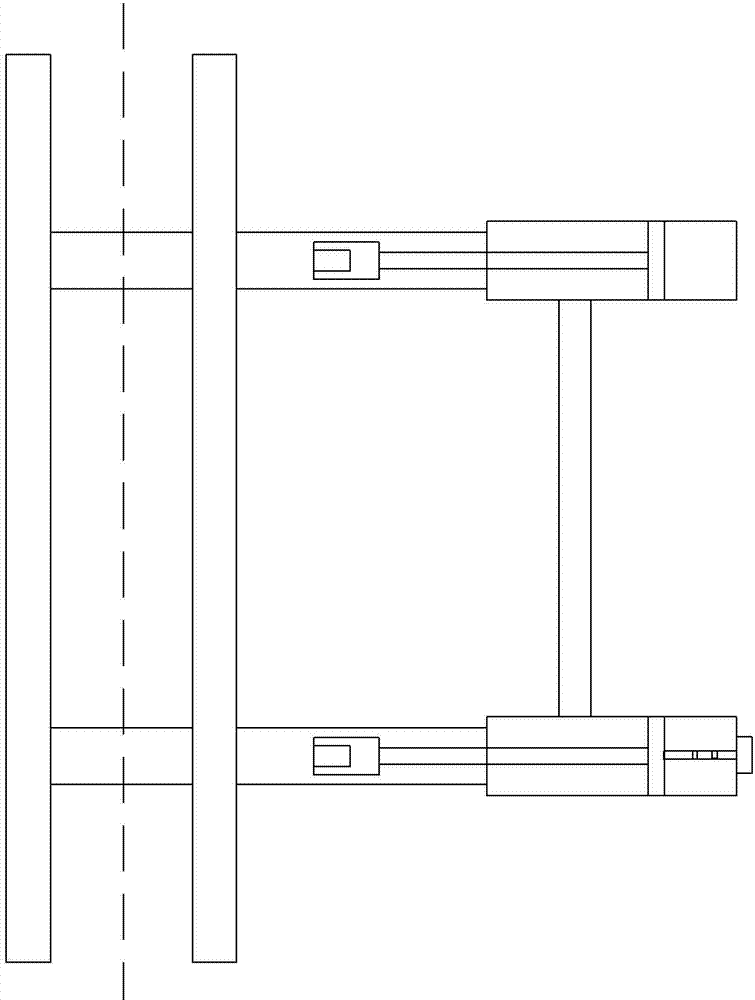

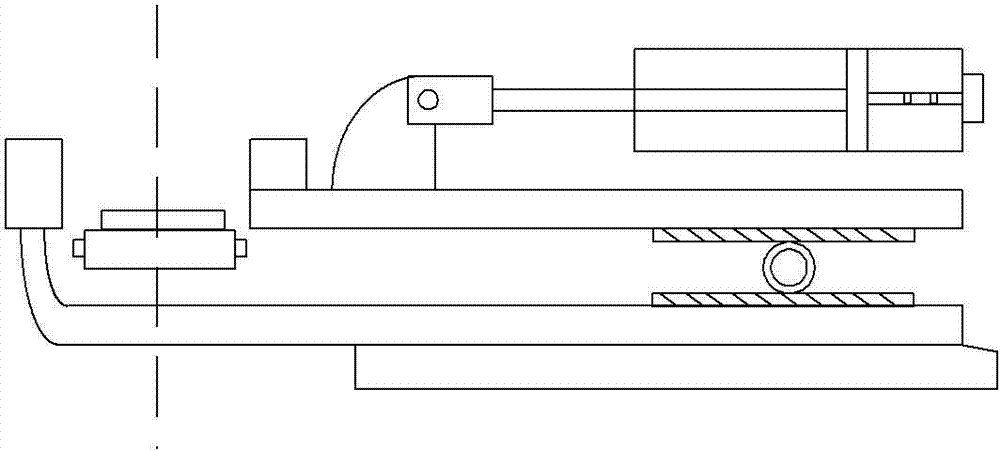

Flexible roll forming device, blank guide device, blank feeding device, and flexible roll forming system having the same

Disclosed is a flexible roll forming device including: bases respectively disposed on opposite sides with respect to a process direction center line in a left / right direction, each having an opening formed in an upper side thereof connected to an inside thereof, and rails configured thereon on opposite sides of the opening in a lateral direction of the process; forward / backward moving means having a slide plate provided to be movable along the rails on the base; turning means rotatably provided to the slide plate; and roll forming means provided on the turning means to include upper and lower forming rolls for subjecting a material fed thereto to flexible roll forming by using the upper and lower forming rolls while varying positions in the lateral direction of processing with the forward / backward moving means, and angles from a process direction with the turning means.

Owner:SUNG WOO HITECH

Metal sheet machining centering device and metal sheet machining centering method

ActiveCN103240284AAvoid pinching the sheetReasonable structureGuiding/positioning/aligning arrangementsHydraulic cylinderThin metal

The invention discloses a metal sheet machining centering device and a metal sheet machining centering method. The metal sheet machining centering device comprises two side guide plates, pressure relays, a metal detector, a laser tachometer and the like. The two side guide plates are symmetrical with each other along a straight center line and are parallelly opposite to each other, the pressure relays are arranged on the side guide plates, each side guide plate is fixedly mounted at one end of a movable support, each movable support is connected with a hydraulic cylinder with a displacement sensor, the displacement sensor of each hydraulic cylinder is electrically connected with a controller, and the metal detector is used for detecting the length of a metal sheet. The metal sheet machining centering method includes a step of enabling the two side guide plates to work simultaneously to respectively push and center the metal sheet and a step of enabling the two side guide plates to individually work to respectively push and center the metal sheet according to the thickness and the length of the metal sheet. Compared with the prior art, the metal sheet machining centering device and the metal sheet machining centering method have the advantage that the problem that metal sheets with low deformation resistance or thin metal sheets cannot be centered by an existing centering device is solved.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

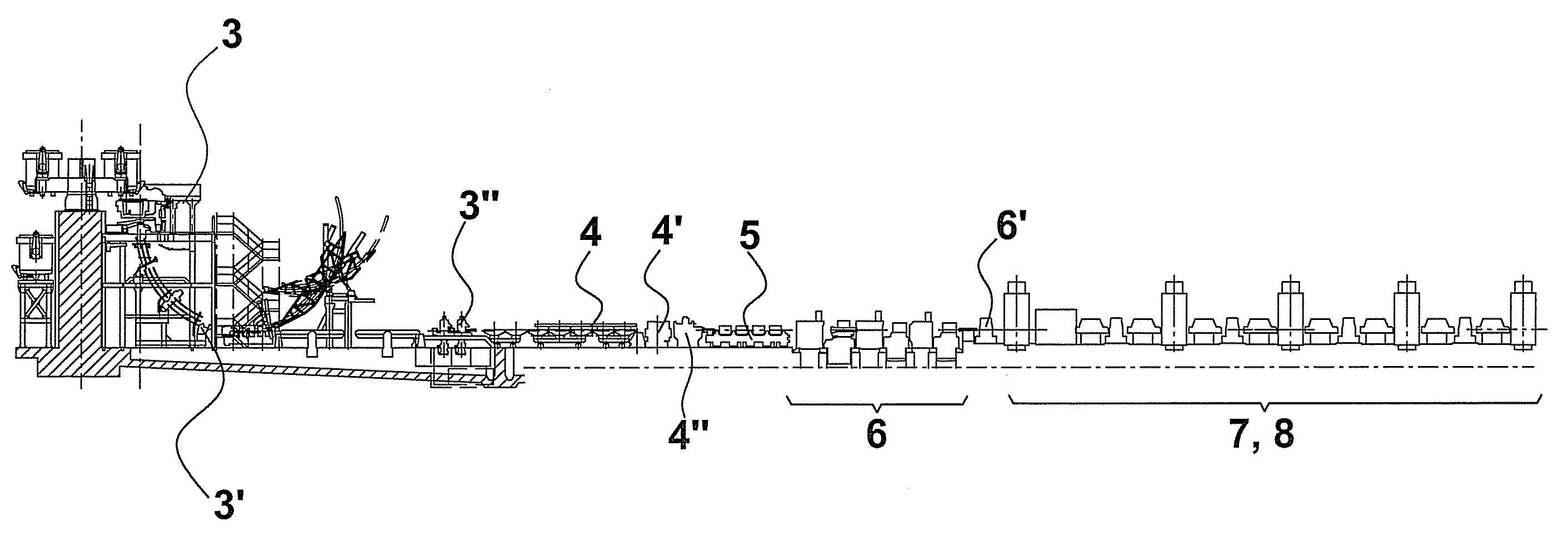

Compact Plant for Continuous Production of Bars and/or Profiles

ActiveUS20080196236A1Low investment costShorten production timeMetal rolling stand detailsGuiding/positioning/aligning arrangementsTO-18Rebar

Compact plant for making steel bars and profiles with which, starting from the scrap, it is possible to obtain the finished product, for example bars with commercial length from 6 to 18 meters, pre-packed, packaged and ready for sale, with all the stations placed in line and operating continuously. All the stations are arranged in reduced spaces, thereby reducing both investment costs and plant management costs, and decreasing production times. Advantageously, the plant of the invention incorporates an extremely compact bar packaging apparatus which, through an innovative arrangement and innovative operating method of the components thereof, allows a further reduction in length.

Owner:DANIELI & C OFF MEC SPA

Vertical pinch correction device

ActiveCN104150161ASimple structureSmall footprintConveyorsGuiding/positioning/aligning arrangementsHydraulic cylinderDrive shaft

The invention relates to a vertical pinch correction device. The vertical pinch correction device comprises a frame, a supporting base, a support, a rack, two pinch rollers, a hydraulic cylinder and a detector, wherein the supporting base and the support are arranged at the two ends of the frame respectively, one end of the rack is pivoted to the supporting base, a guide rail is arranged on the rack, the two pinch rollers are both installed on the guide rail and used for clamping strip steel, the hydraulic cylinder is fixed to the support, a linear displacement sensor is arranged on the hydraulic cylinder, a driving shaft of the hydraulic cylinder is connected to the other end of the rack, the hydraulic cylinder is used for driving the rack to rotate around the supporting base, the detector is arranged under the rack, the detector is connected to a correction hydraulic unit, and the hydraulic unit is connected with the hydraulic cylinder. The vertical pinch correction device is simple in structure, small in occupied area, light in weight, easy to operate and maintain and obvious in correction effect.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com