Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1915 results about "Heat effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

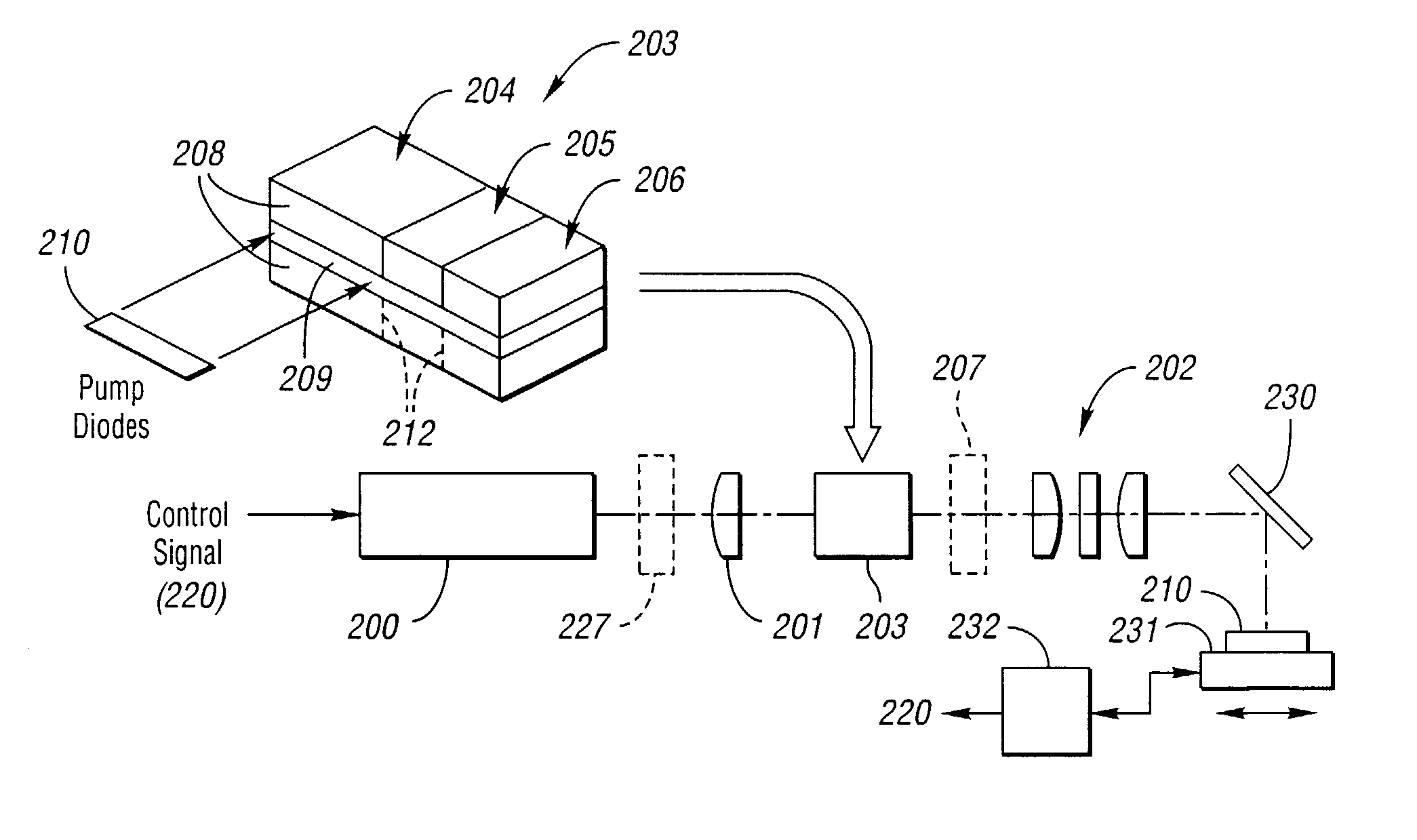

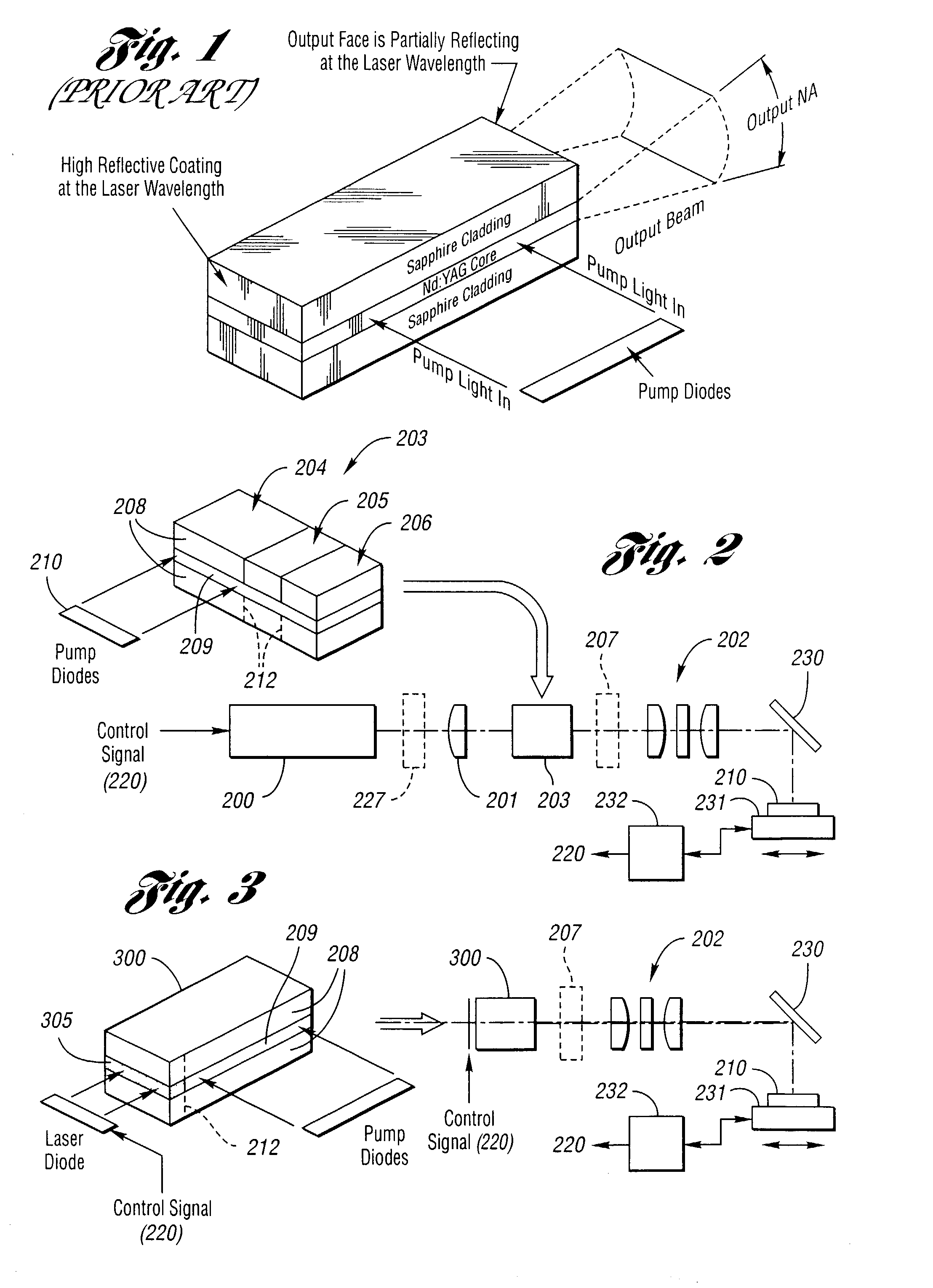

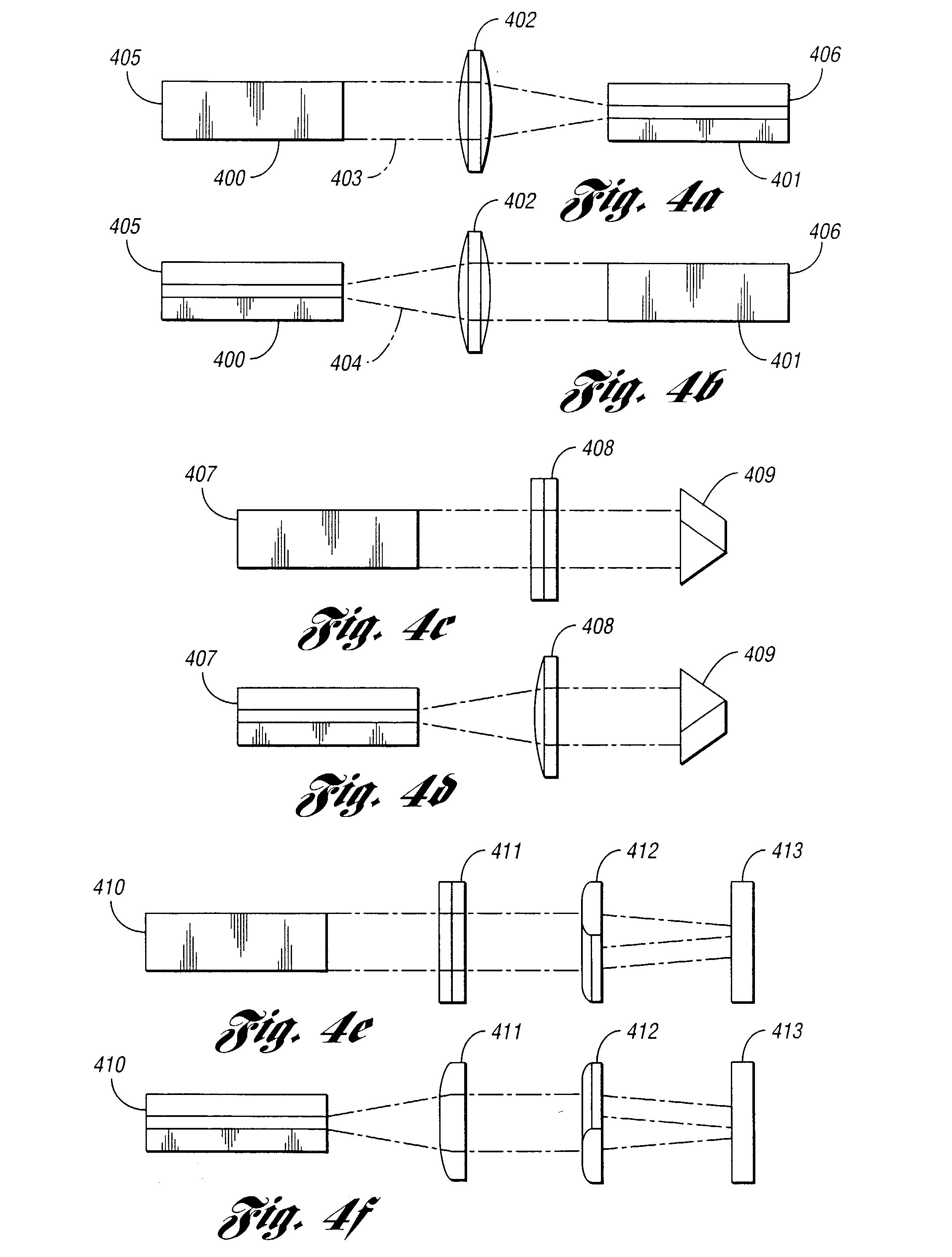

Waveguide architecture, waveguide devices for laser processing and beam control, and laser processing applications

InactiveUS20030161375A1Optical resonator shape and constructionActive medium shape and constructionEngineeringWaveguide

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:GSI LUMONICS LTD

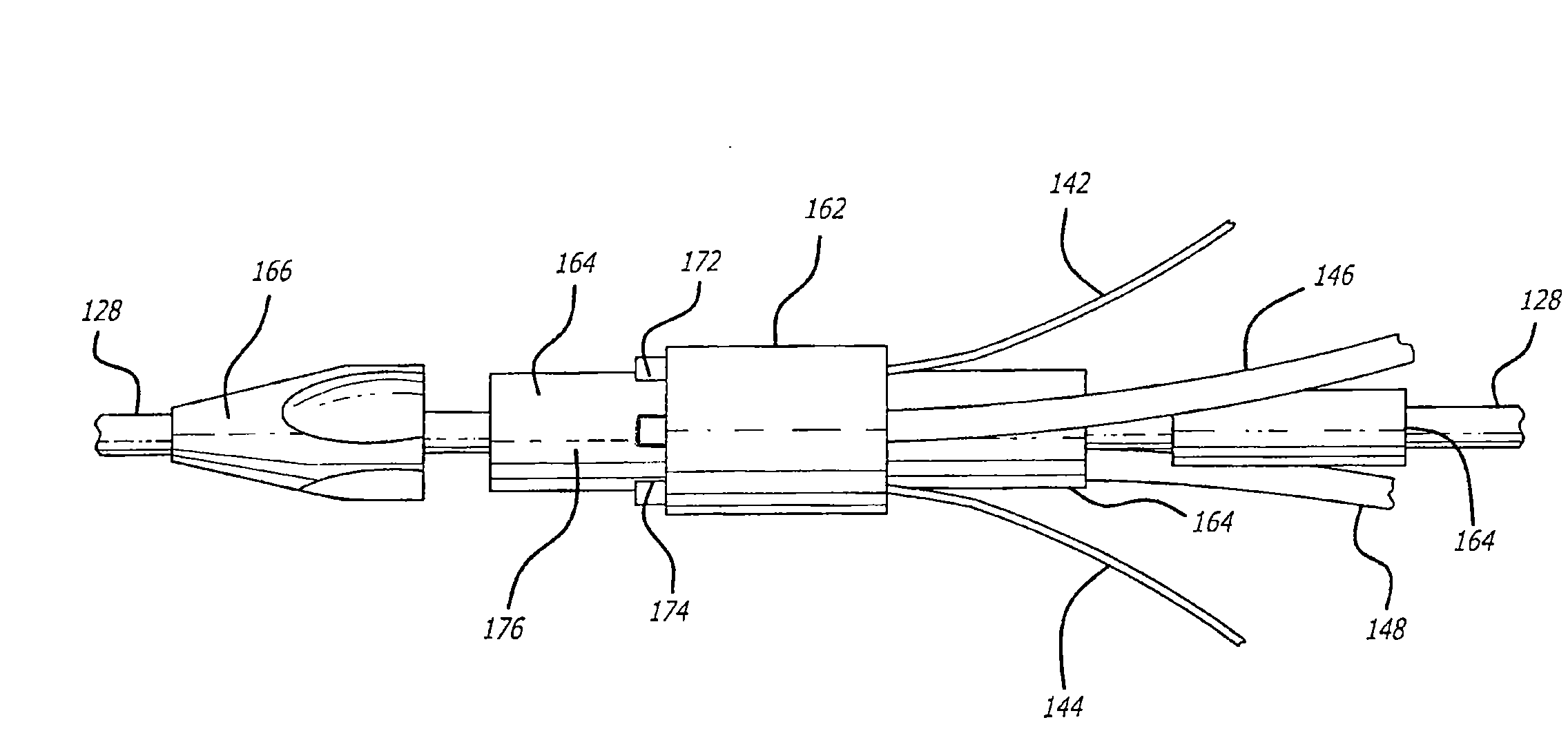

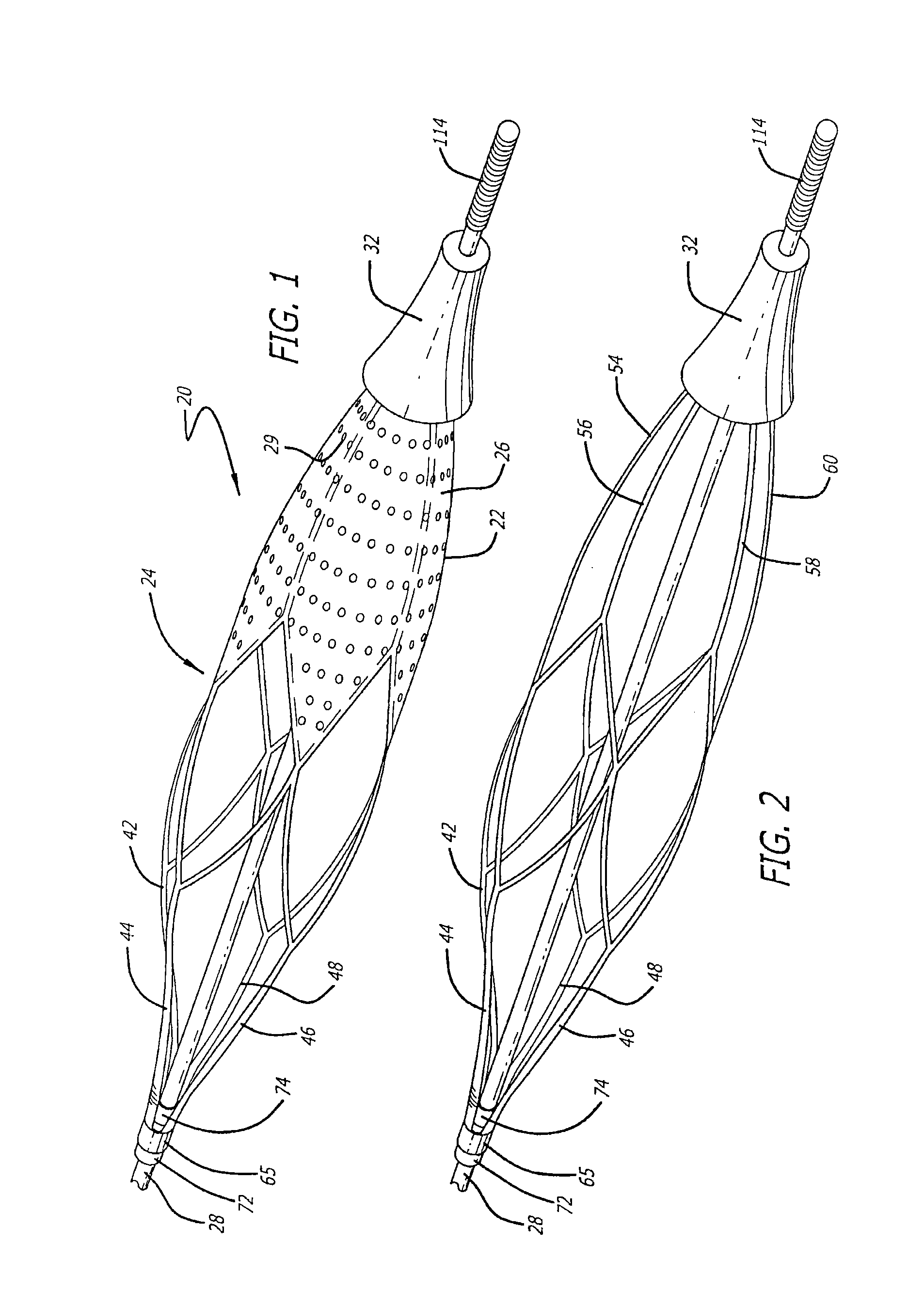

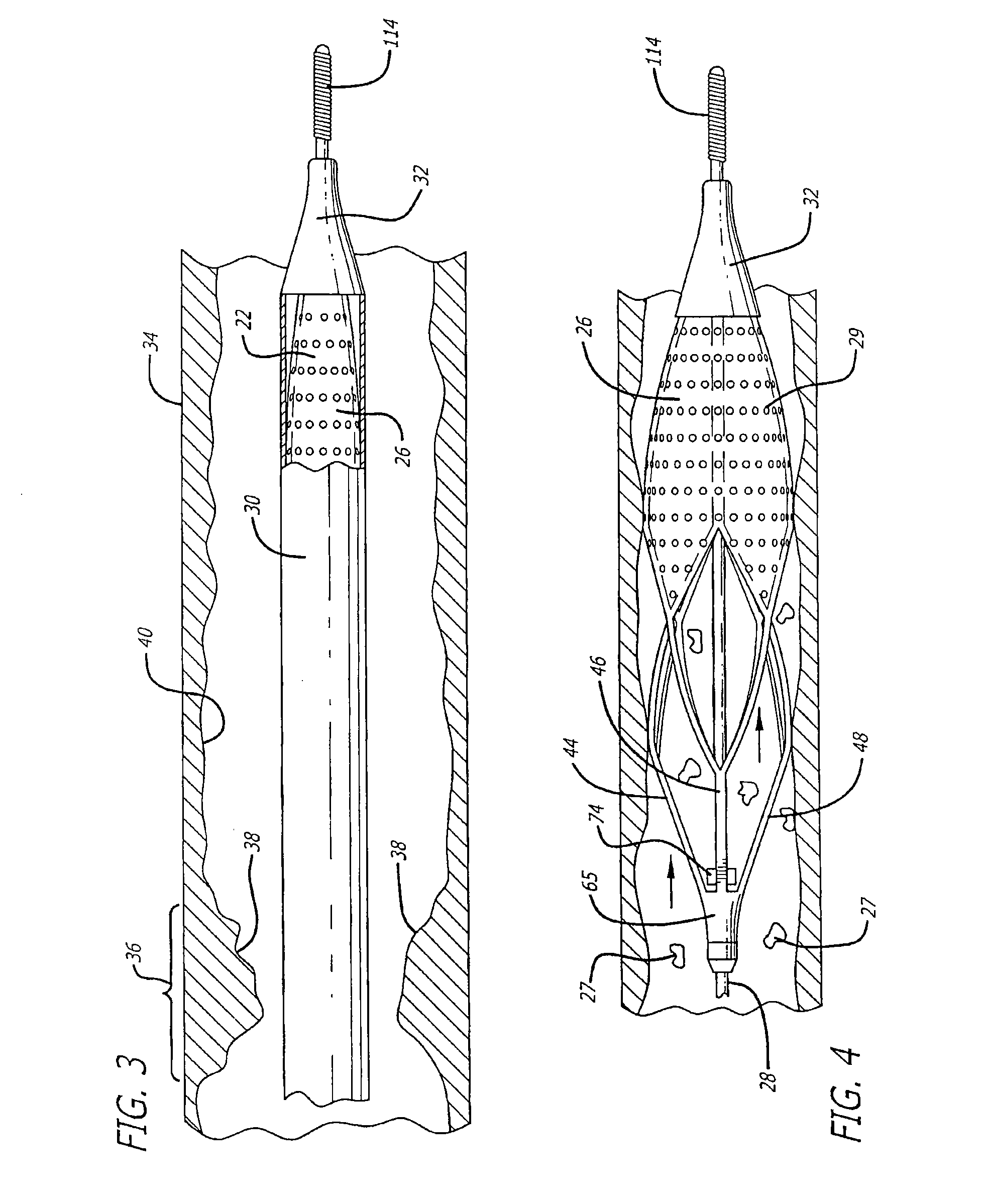

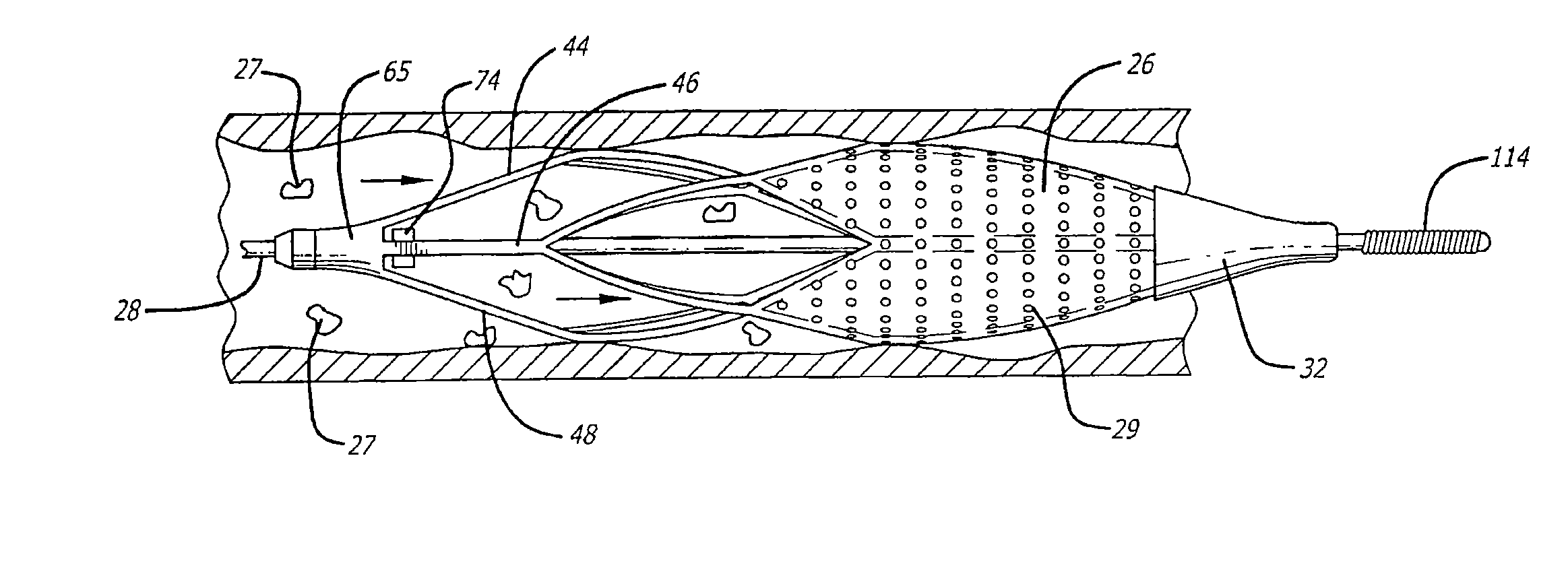

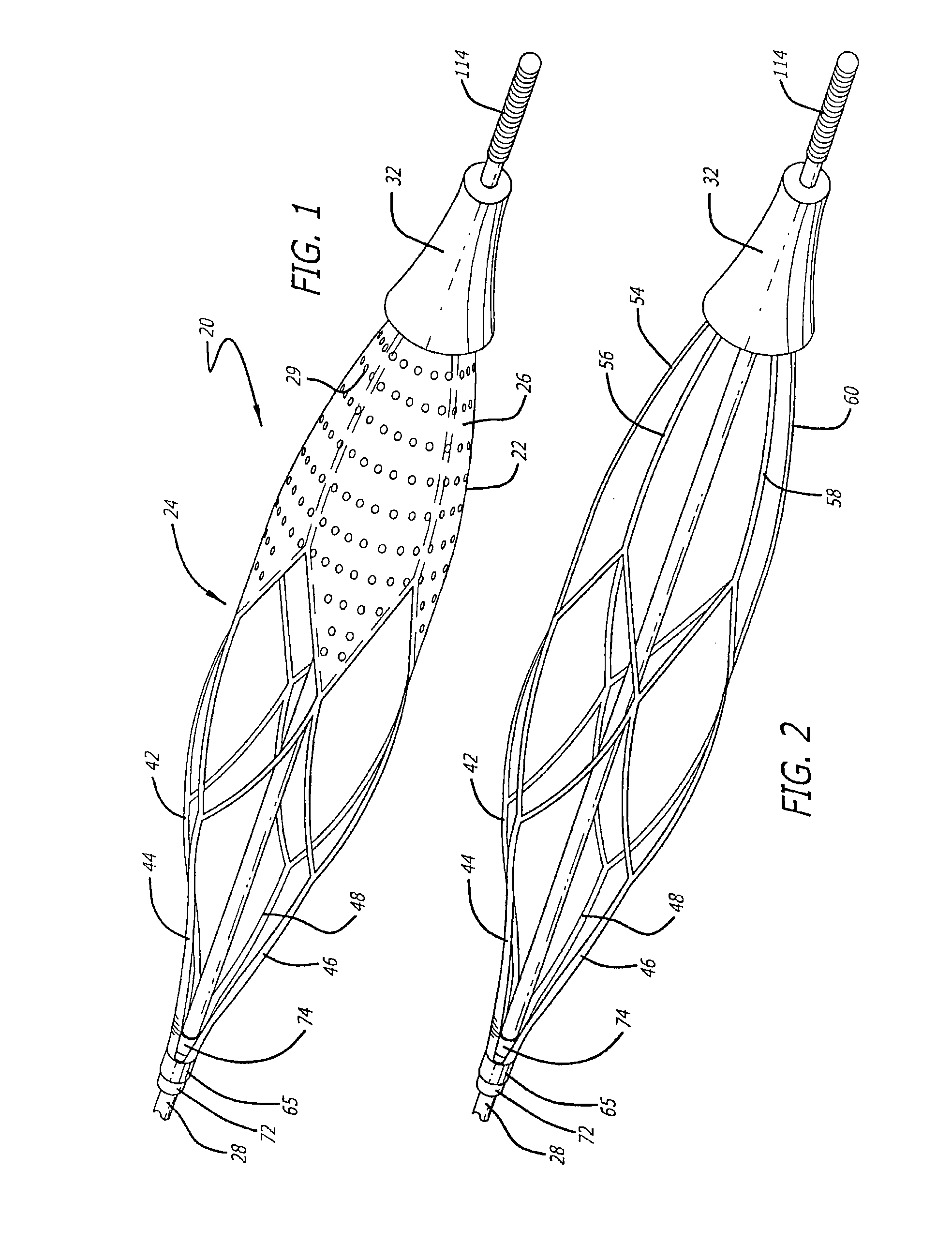

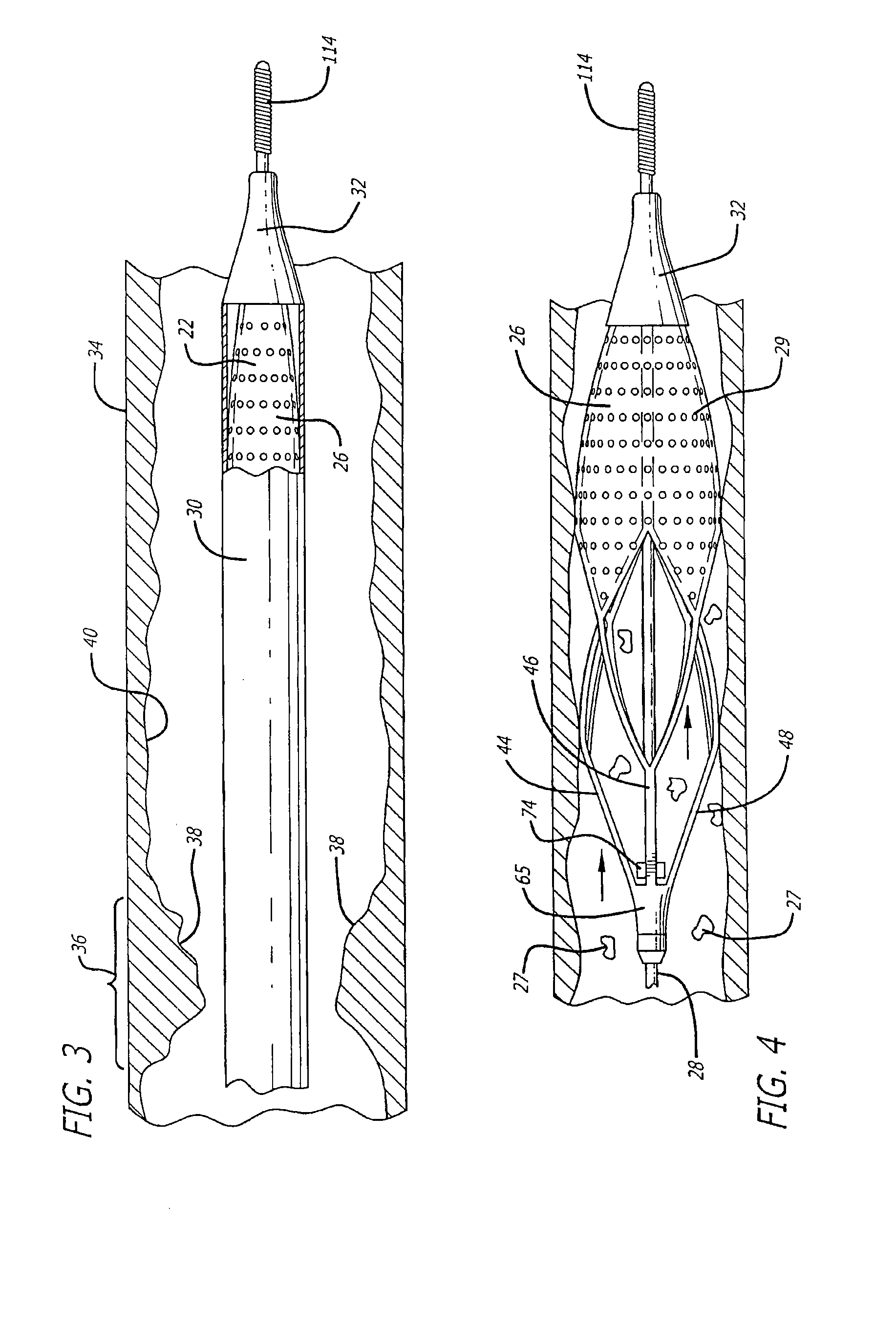

Cage and Sleeve Assembly for a Filtering Device

InactiveUS20080167679A1Efficient preparationSmall diameterMetal-working apparatusDilatorsHeat-affected zoneEngineering

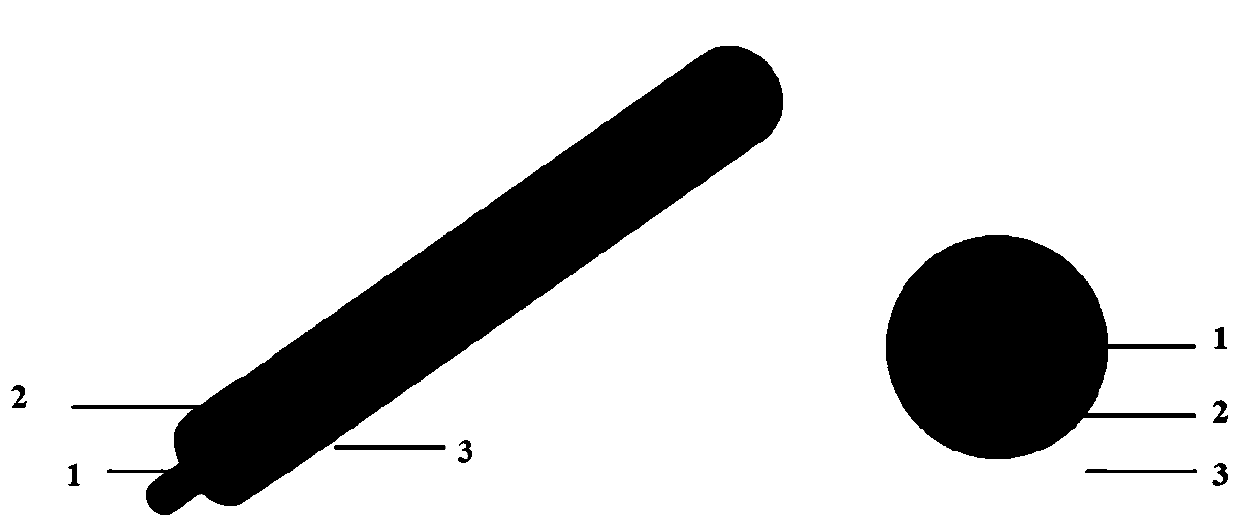

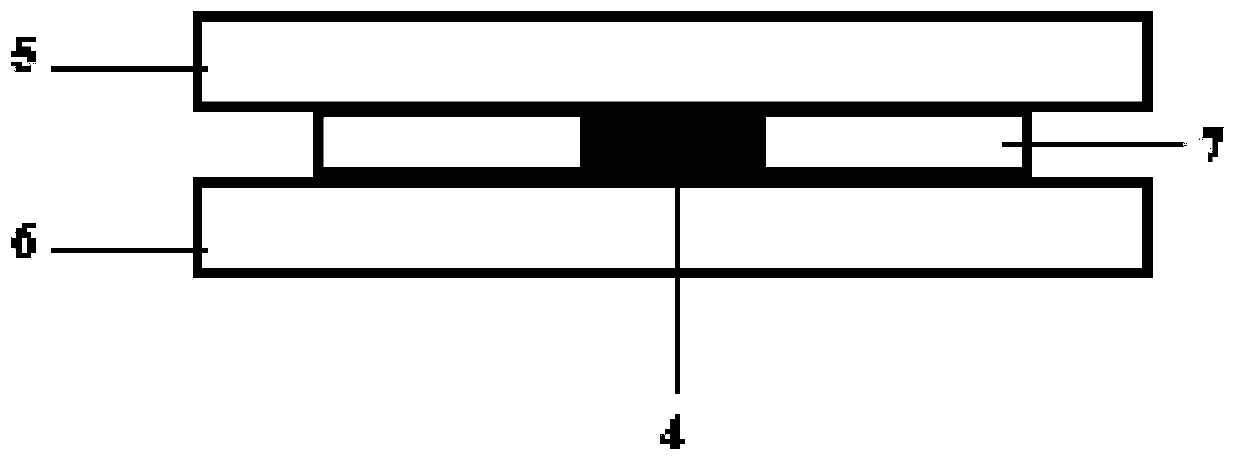

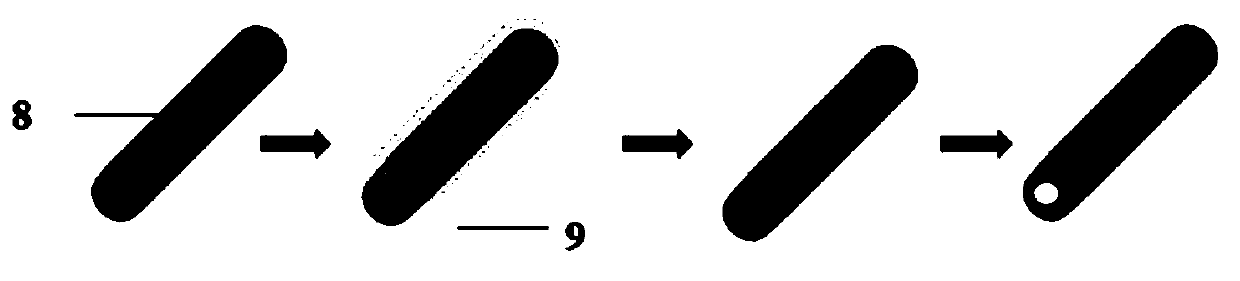

A cage and sleeve assembly for an embolic filtering device used to filter embolic particles from a body vessel has a strut assembly that is movable between an unexpanded position and an expanded position. Struts having strut ends at the respective ends form a cage. The strut ends are initially made from linear elastic nitinol, and a series of spot or laser or other types of welds then secure the strut ends in the sleeve assembly. In one approach, the ends of the strut ends are welded to form a tube. In another approach, the strut ends are welded onto a sleeve. The strut ends may optionally have ends that are partial cylinders, and the partial cylinders are welded onto a cylindrical sleeve. Effects from the welding, such as changing linear elastic nitinol to superelastic nitinol, are contained within a heat-effected zone, and do not extend into areas of the structure that typically bend during use.

Owner:ABBOTT CARDIOVASCULAR

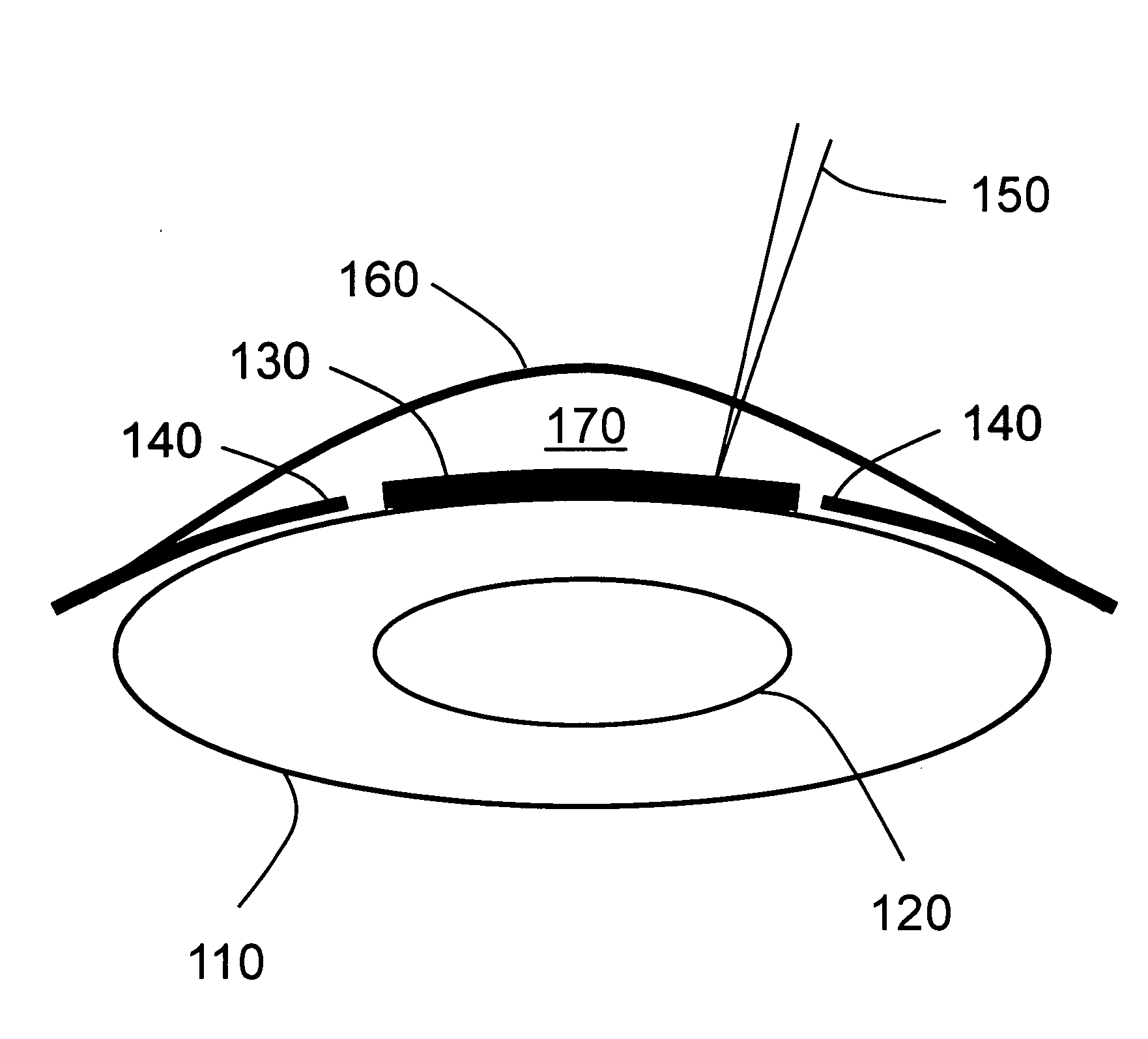

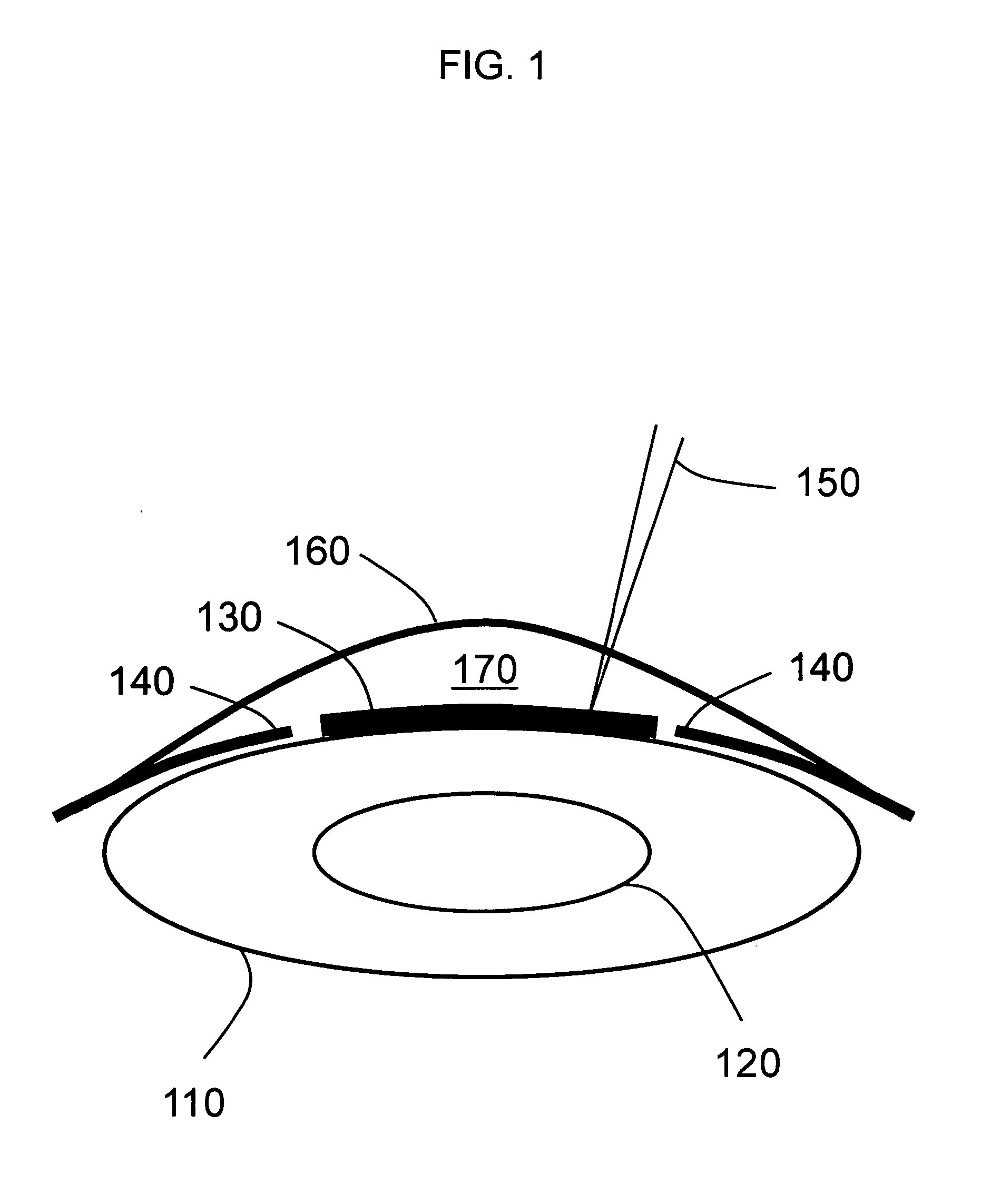

Laser-assisted thermal separation of tissue

A laser-assisted method for fully or partially separating tissue such as collagen-containing tissue is provided. In one embodiment, the method pertains to a capsolurorhexis whereby the laser-assisted method is applied to the lens capsule. A light-absorbing agent is added into or onto the tissue. A light beam with a wavelength capable of being absorbed by the light absorbing agent is then directed at the tissue to cause a thermal effect at the tissue following a predetermined closed curve with the goal to avoid irregularity or potential tears in the resulting rim of the tissue.

Owner:EXCEL LENS INC

Bleaching device using electro-optical and chemical means namely in the medical and dental field

A complete bleaching unit is made up of an electrochemical system, finding its application in particular in the dental and medical fields, allowing, thanks to the creation of an electrophoretic field, a strong, fast penetration and directing the bleaching agents, their removal under the same conditions together with the molecules responsible for coloration and an effective and controlled penetration of the stabilizing agents for the apatite crystal, basic component of the tooth, such as fluorine. Also thanks to its light-based optical system, the invention provides that the activation of the photosensitive bleaching products by decreasing the heat effect while increasing the photonic effect thanks to a selection of wavelength in the range of 400-500 nm and, finally, thanks to an electro-optical unit, the control of the evolution of coloration by objective spectrocolorimetry-based methods.

Owner:DURET

Laser selective cutting by impulsive heat deposition in the IR wavelength range for direct-drive ablation

ActiveUS20060195072A1Material efficiencyImprove efficiencySurgical instrument detailsLight therapyHeat depositionThermal expansion

The present invention provides a method of laser processing of materials, specifically laser induced ablation processes for laser removal of material particularly important in medical and dental applications in which the laser removal of material should be done in such a way as to not damage any of the surrounding soft or hard biomaterial. The ablation process is achieved by impulsive heat deposition (IHD) by direct and specific excitation of short lived vibrations or phonons of the material in such a way as to not generate highly reactive and damaging ions through multiphoton absorption. The heat deposition and ensuing ablation process under prescribed time and wavelength conditions for laser irradiation is achieved faster than heat transfer to surrounding tissue by either acoustic or thermal expansion or thermal diffusion that otherwise would lead to excess heat related damage. The result is that all the deposited laser energy is optimally channelled into the ablation process in which the inertially confined stresses from both photomechanical expansion forces and thermally driven phase transitions and associated volume changes constructively interfere to drive the most efficient ablation process possible with minimal damage to surrounding areas by either ionizing radiation or heat effects. By choosing a specific range of wavelengths, spatial and temporal shaping of infrared laser pulses, the energy can be optimally deposited in a manner that further increases the efficiency of the ablation process with respect to minimizing collateral damage.

Owner:LIGHT MATTER INTERACTION

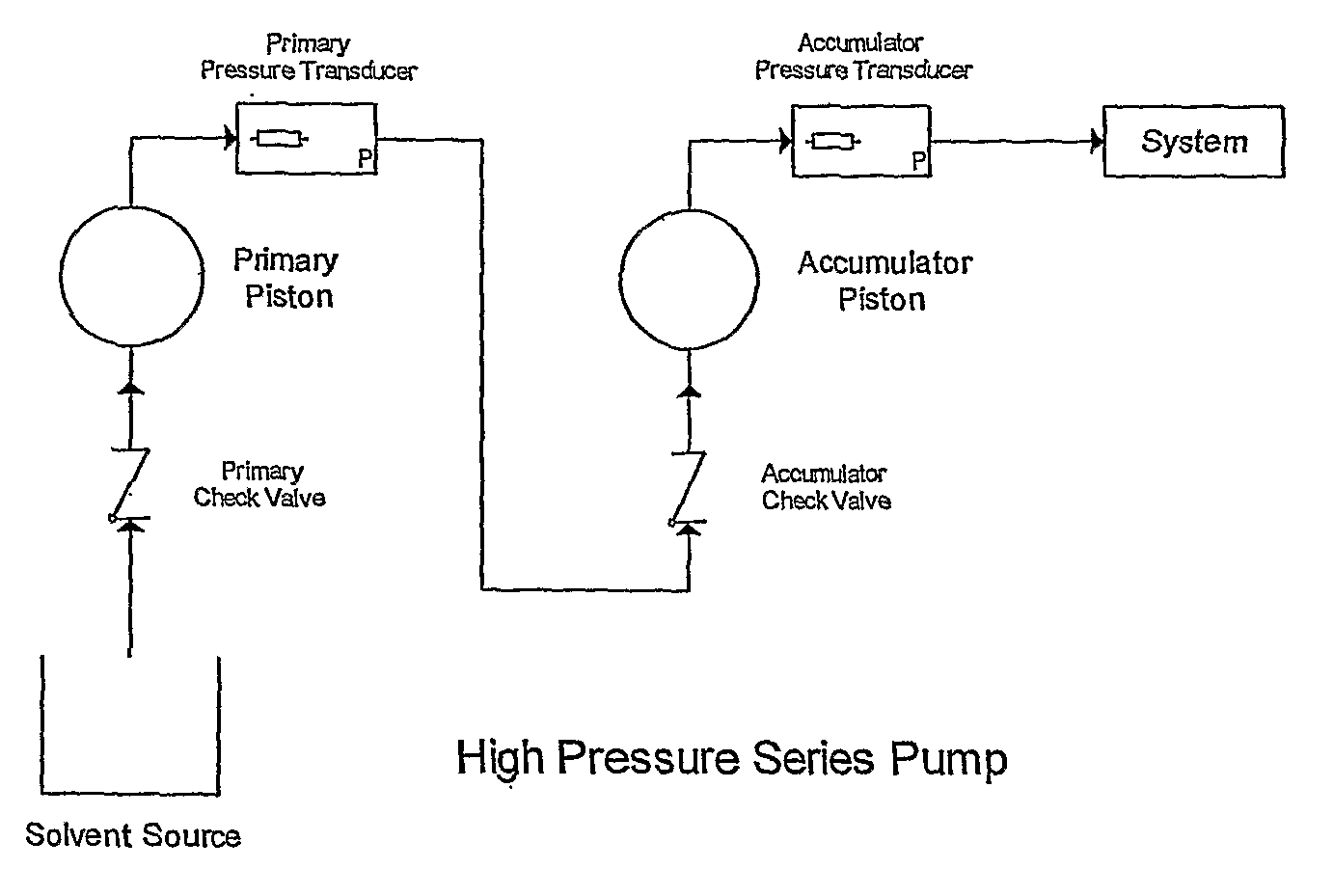

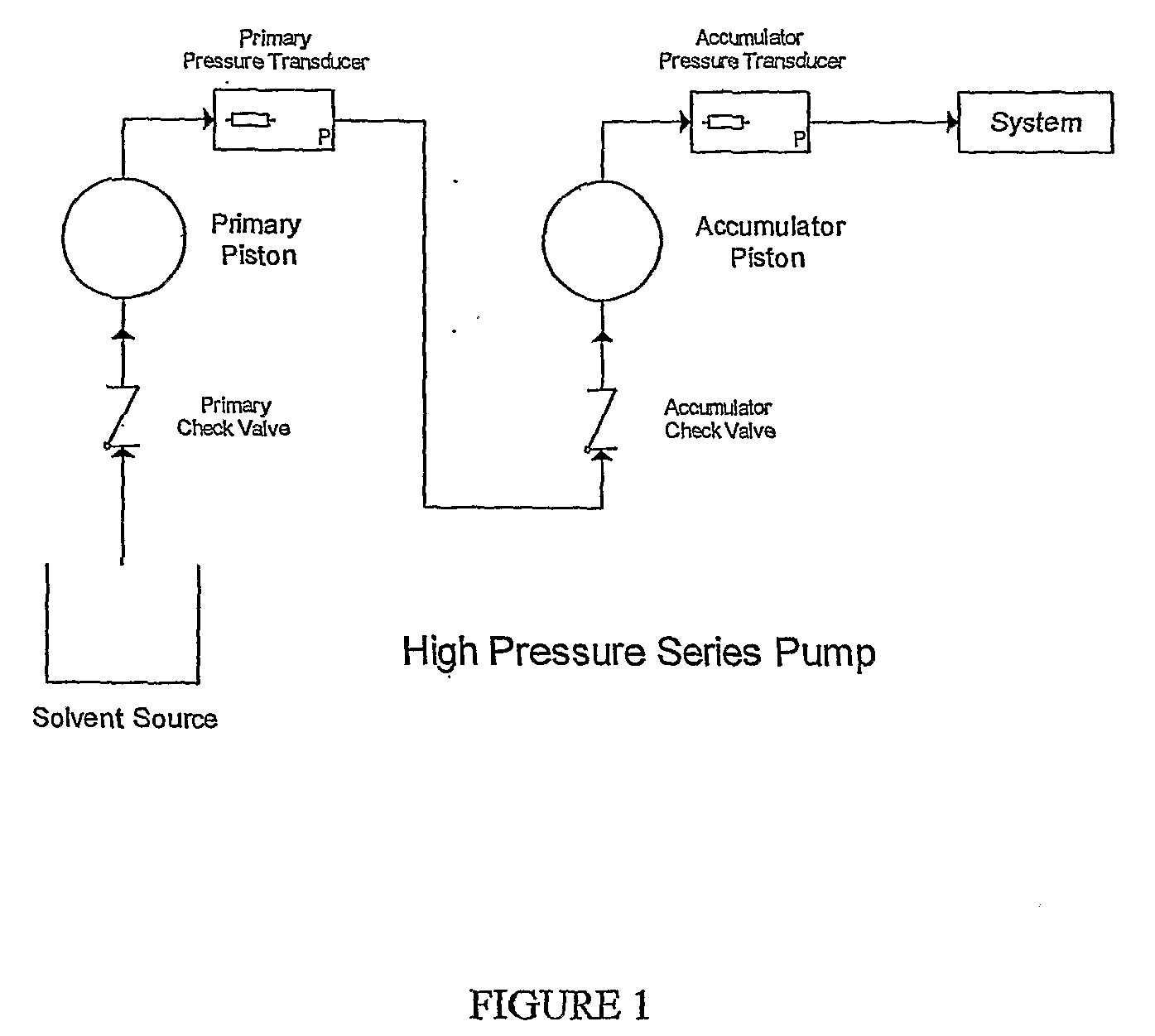

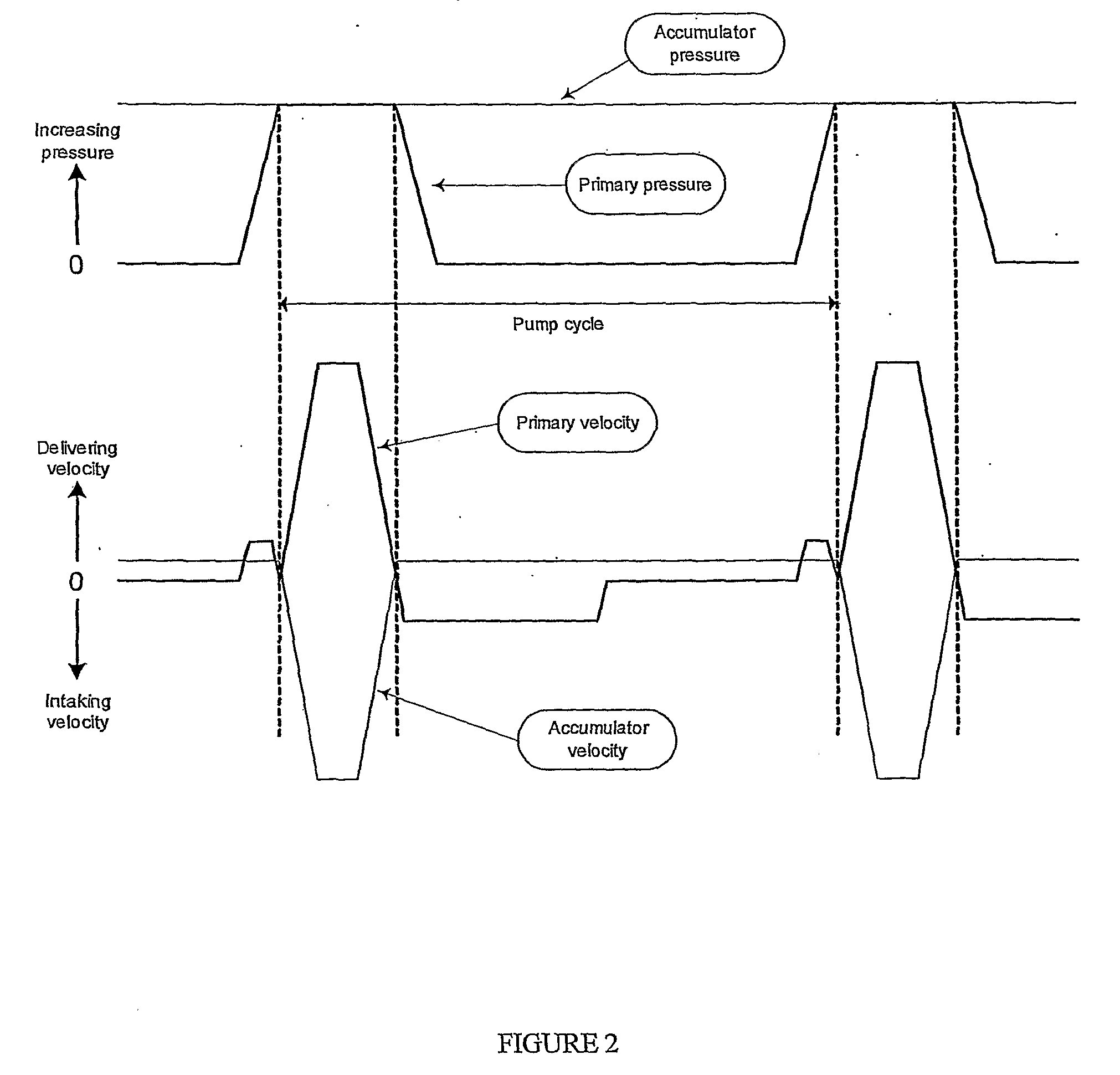

High Pressure Pump Control

ActiveUS20080206067A1Prevent composition errorReduce errorsFluid parameterComponent separationSystem pressureEngineering

A feedback control loop for a high pressure pump modifies the accumulator velocity and pressure during solvent transfer. The accumulator velocity is adjusted to maintain the system pressure equal to the expected pressure to thereby eliminate the effect of the flow deficit created by a thermal effect.

Owner:WATERS TECH CORP

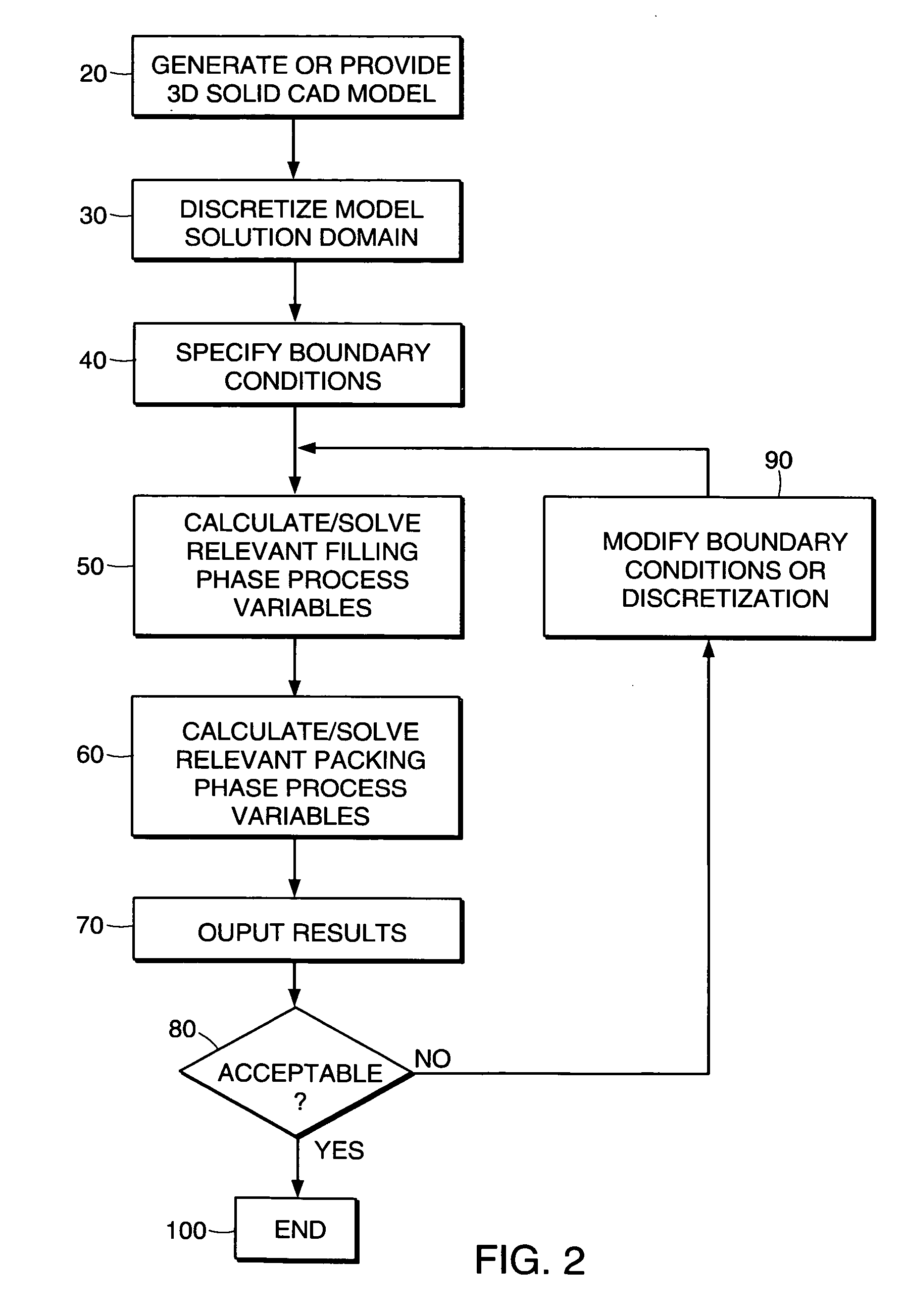

Method and apparatus for modeling injection of a fluid in a mold cavity

InactiveUS20050114104A1Accurate valueAccurately determineComputation using non-denominational number representationDesign optimisation/simulationThermoplasticMolten state

The invention relates to a method and apparatus for analyzing fluid flow while considering heat transfer effects and, in particular, a phase change from a molten state to a solid state. In particular, the method and apparatus may be applied to the analysis of an injection molding process for producing a molded polymer component from a thermoplastic or a thermosetting polymer. In one embodiment, the method may be used to determine pressure required to fill a mold cavity and pressure gradients introduced during filling and packing of the cavity of an injection mold. The results of these analyses may be used to determine the number and location of gates, to determine the best material for the component, and to optimize the process conditions used in the molding process.

Owner:MOLDFLOW IRELAND LTD

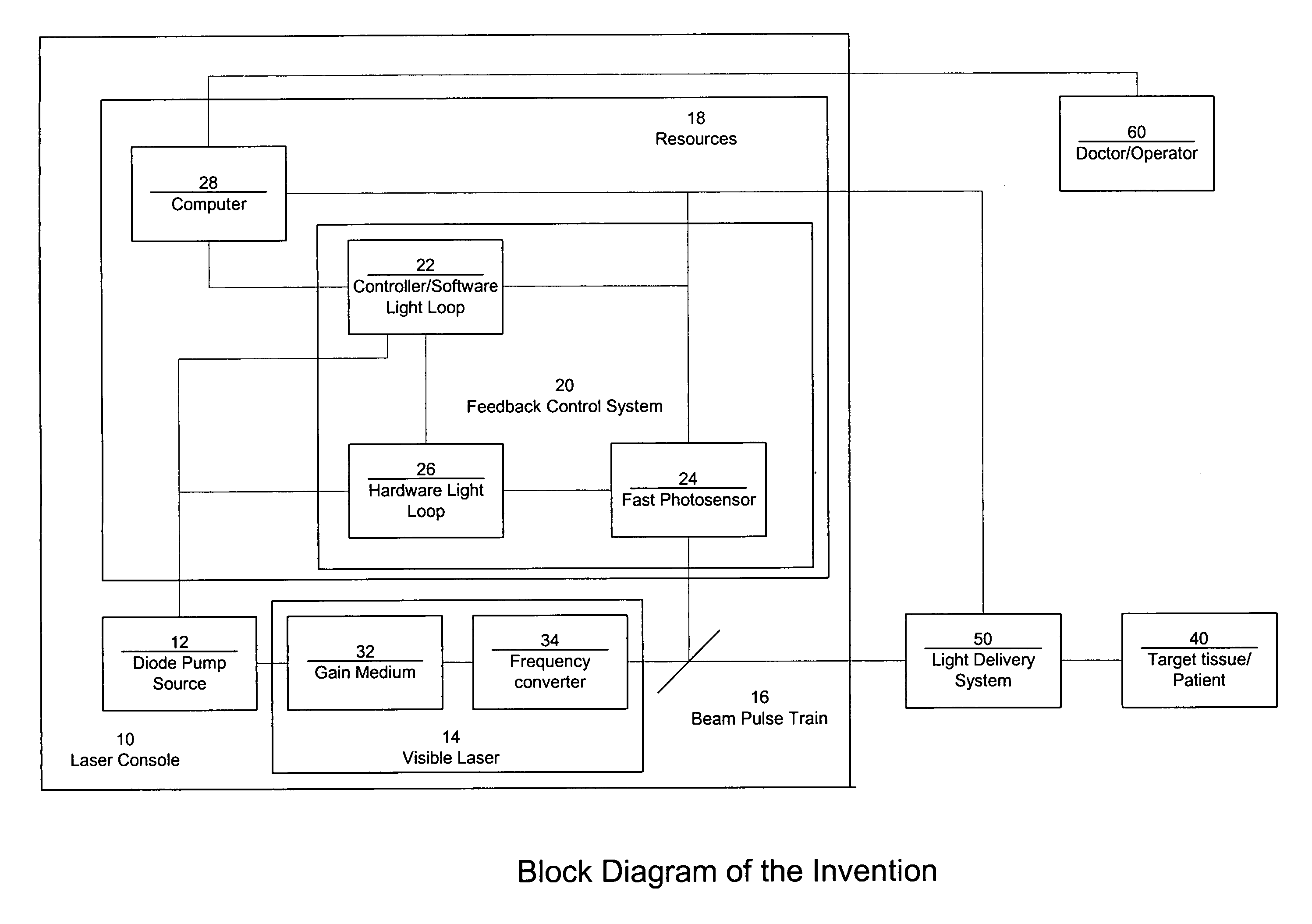

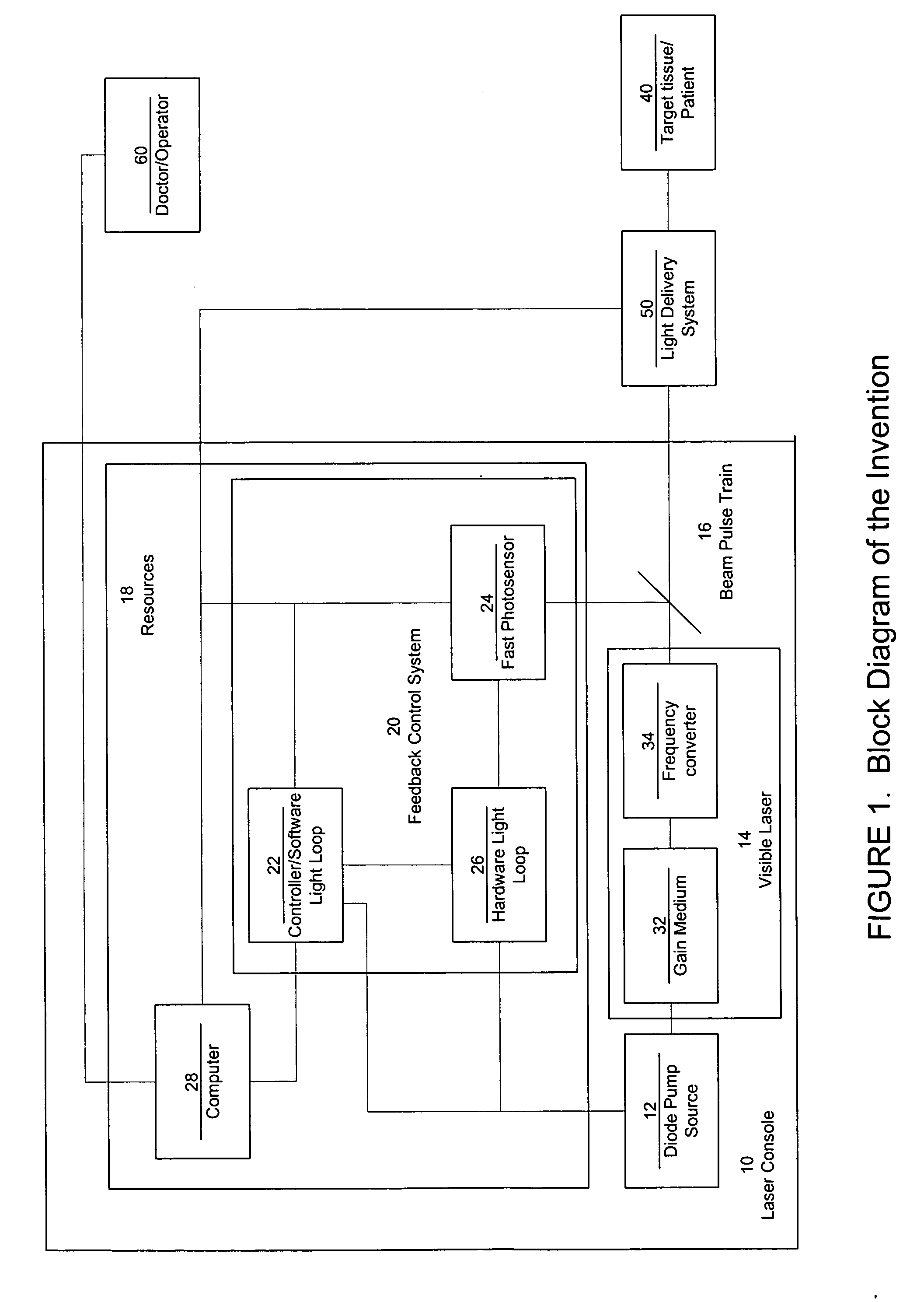

Laser system with short pulse characteristics and its methods of use

ActiveUS20060187978A1Reduce thermal effectsShort and controlled pulse width trainsLaser surgeryLaser detailsPulse characteristicsRetinal damage

A laser system that includes a diode pump source. A frequency doubled solid state visible laser is pumped by the diode pump source and produces a pulsed laser output with a train of pulses. Resources provide instructions for the creation of the pulsed output, with on and off times that provide for substantial confinement of thermal effects at a target site. This laser system results in tissue specific photoactivation (or TSP) without photocoagulation damage to any of the adjacent tissues and without causing full thickness retinal damage and the associated vision loss.

Owner:IRIDEX CORP

Cage and sleeve assembly for a filtering device

InactiveUS20100049240A1Efficient preparationSmall diameterDilatorsExcision instrumentsHeat-affected zoneEngineering

A cage and sleeve assembly for an embolic filtering device used to filter embolic particles from a body vessel has a strut assembly that is movable between an unexpanded position and an expanded position. Struts having strut ends at the respective ends form a cage. The strut ends are initially made from linear elastic nitinol, and a series of spot or laser or other types of welds then secure the strut ends in the sleeve assembly. In one approach, the ends of the strut ends are welded to form a tube. In another approach, the strut ends are welded onto a sleeve. The strut ends may optionally have ends that are partial cylinders, and the partial cylinders are welded onto a cylindrical sleeve. Effects from the welding, such as changing linear elastic nitinol to superelastic nitinol, are contained within a heat-effected zone, and do not extend into areas of the structure that typically bend during use.

Owner:ABBOTT CARDIOVASCULAR

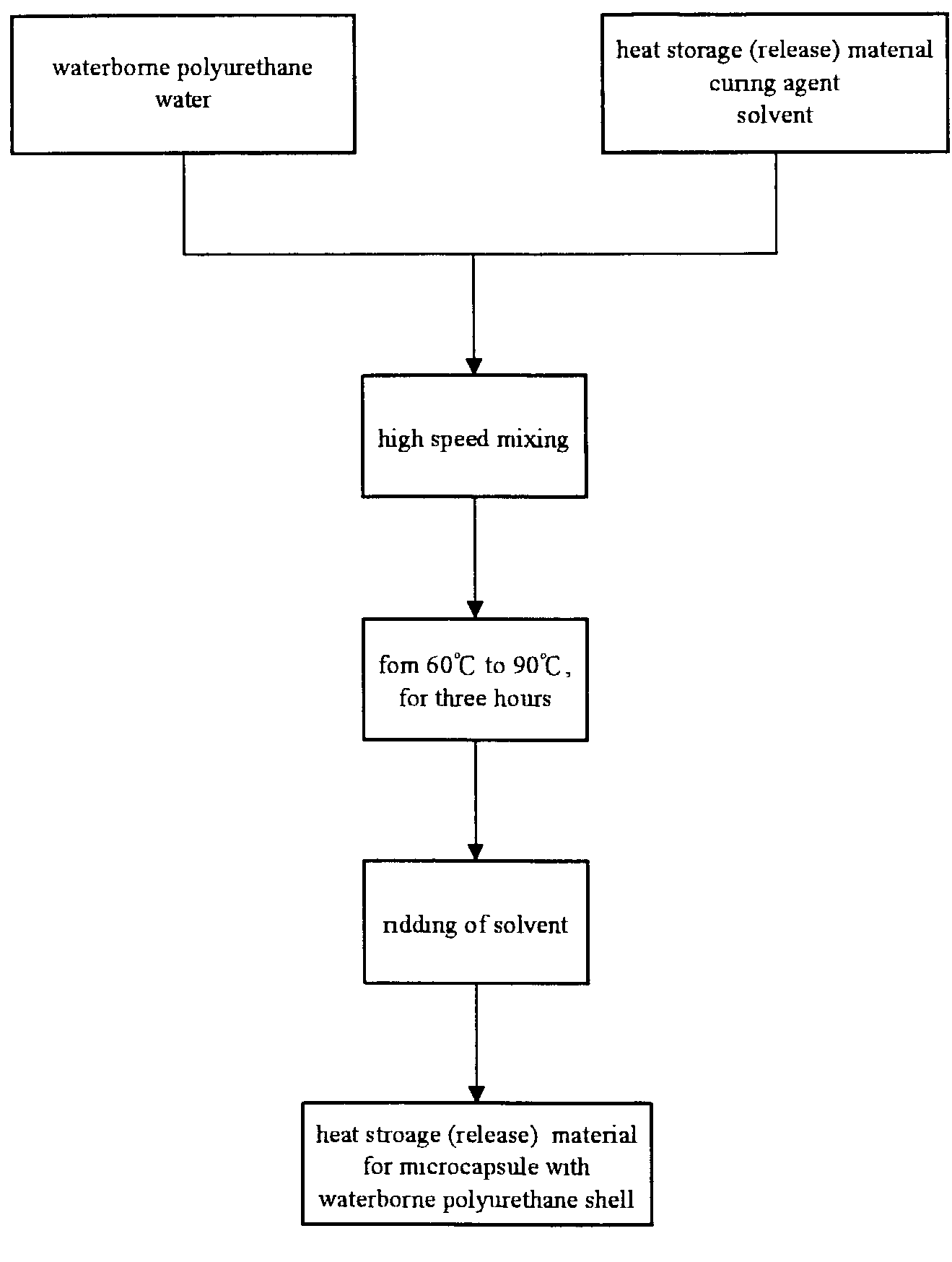

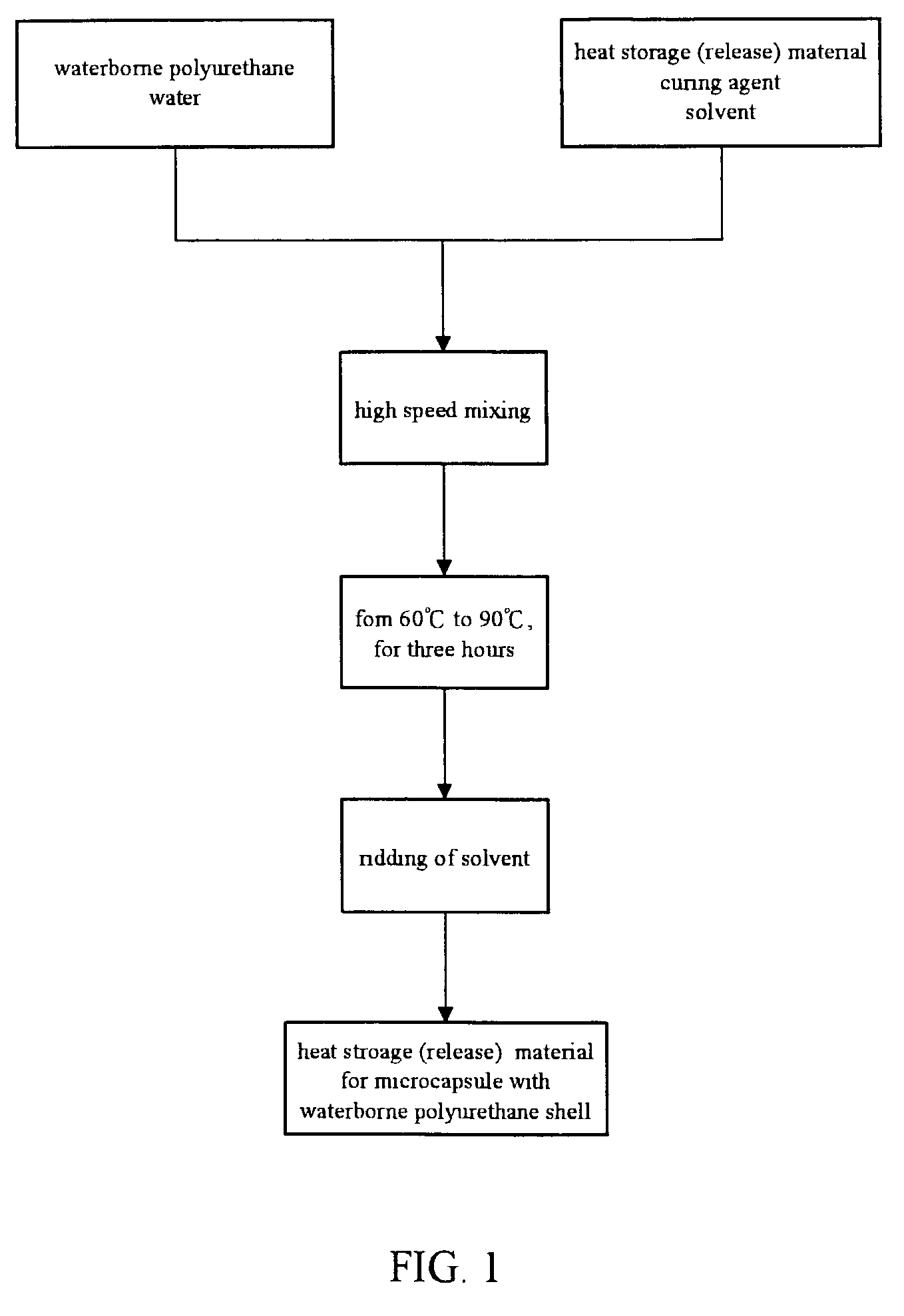

Method and compound fabric with latent heat effect

InactiveUS20040029472A1Heating effectNo fragile microcapsulesHeat storage plantsFibre treatmentLatent heatPolymerization

The present invention provides a method and compound fabric for latent heat effect which means a compound fabric capable of undergoing heat storage (release) material for microcapsules with waterborne polyurethane shell which use interfacial condensation polymerization by waterborne polyurethane thereof, such as alkyl alkyrate (alkyric acid alkyl ester) for temperature in the range of 0° C. to 80° C. The fabric is selected from the group of consisting of woven, non-woven and structure of woven, and the present invention provides method to coat waterborne polyurethane shell microcapsules of heat storage (release) material for compound fabric

Owner:CHINA TEXTILE INST

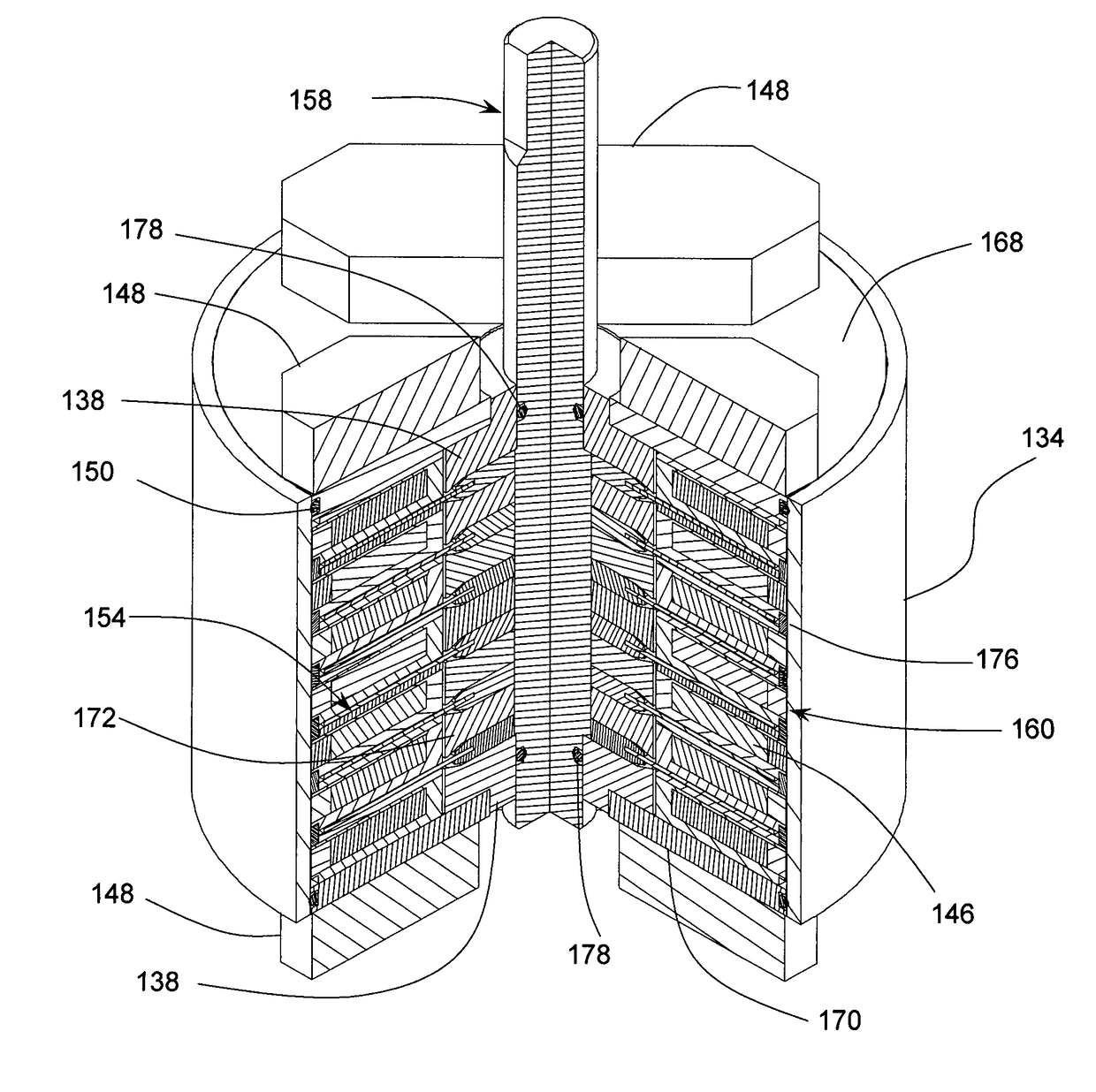

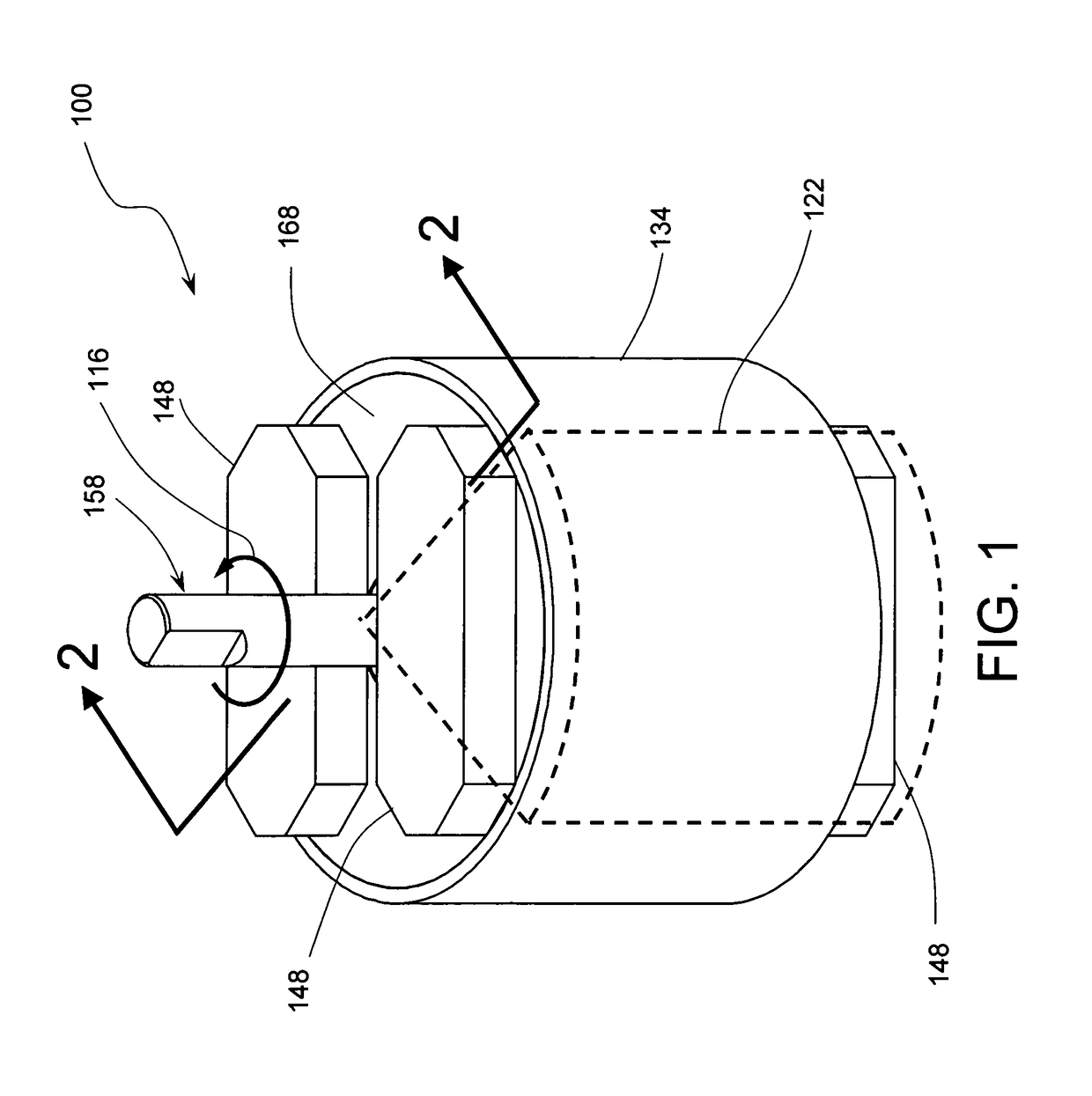

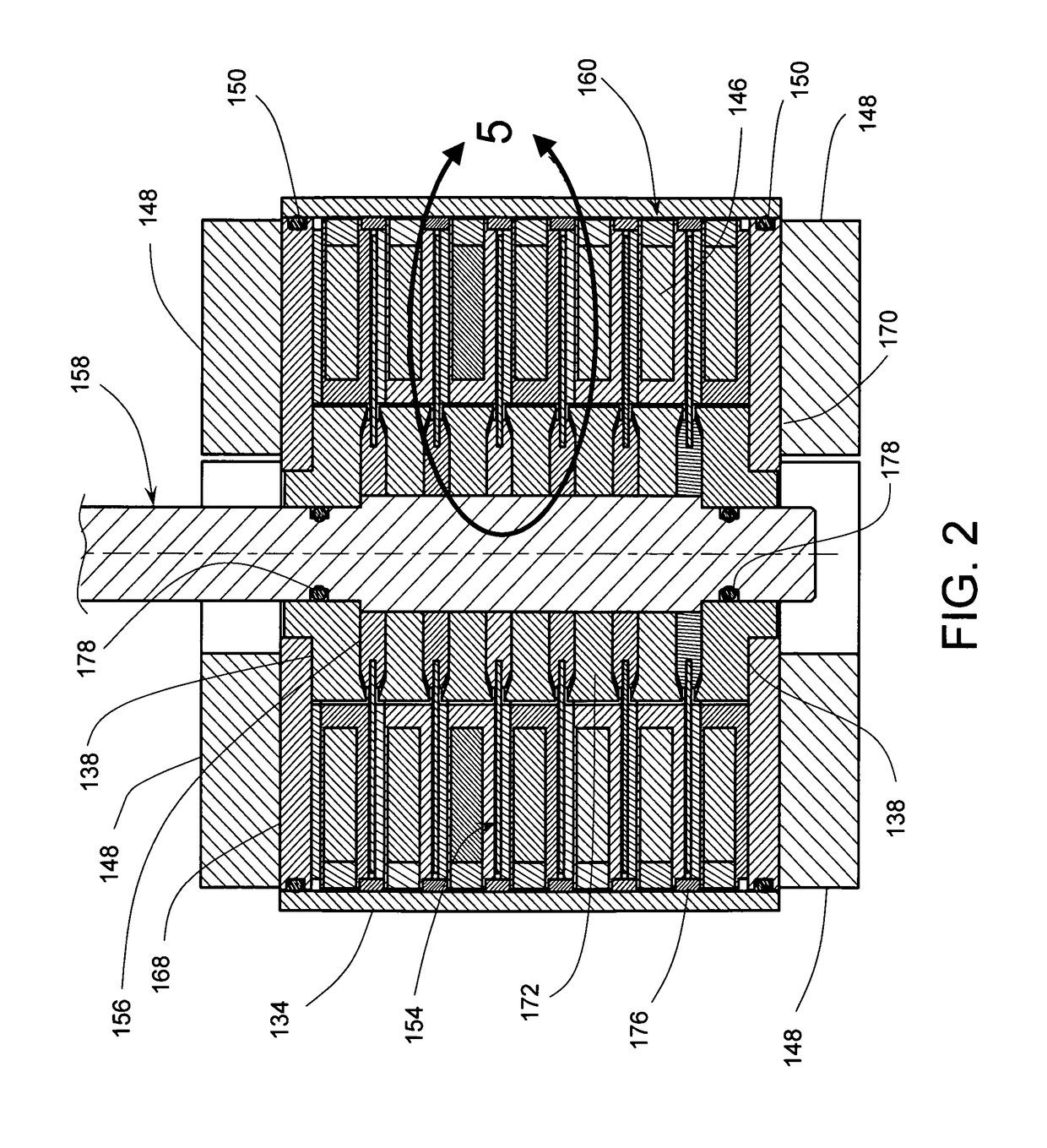

Magnetocaloric refrigerator

InactiveUS9702594B2Improve rendering capabilitiesImprove conductivityEnergy efficient heating/coolingMachines using electric/magnetic effectsIceboxEngineering

Owner:AIP MANAGEMENT LLC

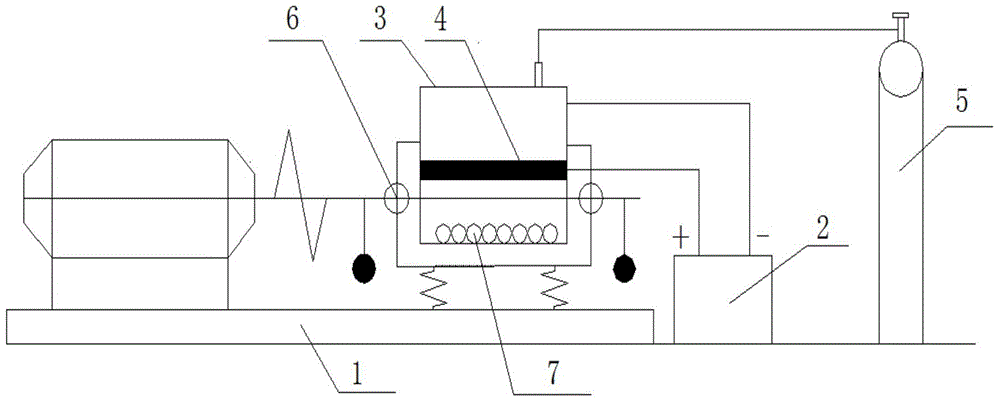

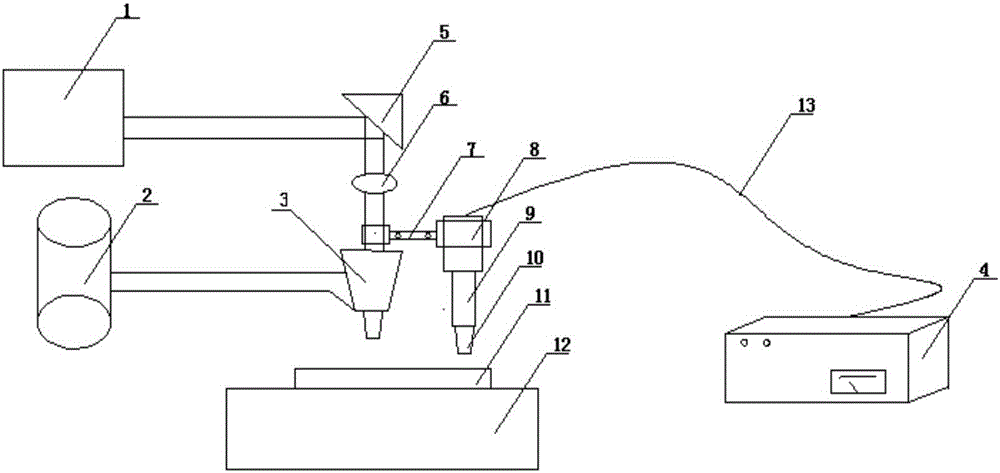

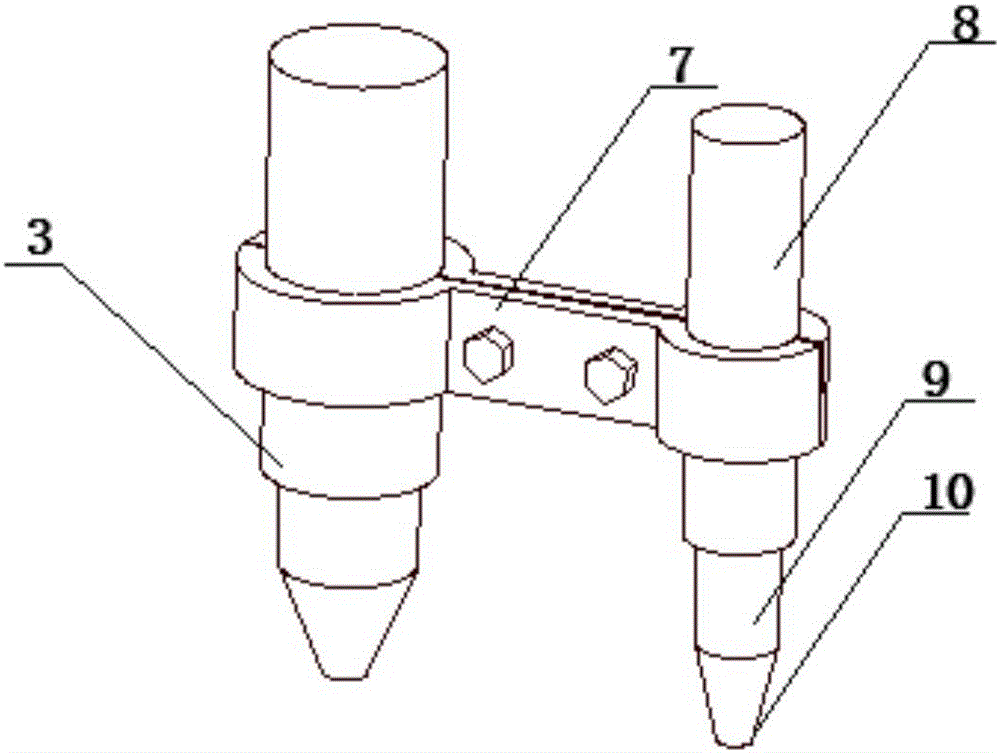

Application method of cold field plasma discharge assisted high energy ball milled powder and plasma assisted high energy ball milling device

The invention provides an application method of cold field plasma discharge assisted high energy ball milled powder and a plasma assisted high energy ball milling device using the cold field plasma discharge assisted high energy ball milling method. The method comprises the following steps: utilizing dielectric barrier discharge to generate plasmas, introducing a dielectric barrier discharge electrode bar into a high-speed vibrating ball-milling tank, on one hand, requiring a solid insulating medium on the outer layer of the electrode bar to simultaneously bear high-voltage discharge and mechanical shock failure of the grinding ball, and on the other hand, requiring the high-speed vibrating ball milling device to uniformly process the powder. The method is based on the ordinary ball milling technology; the processing efficiency and the effect of the ball mill can be greatly improved by the following steps: under a non-heat-balance discharge condition of the pressure that the discharge space pressure is set to be about 102-106 Pa, introducing the discharge plasmas to input another effective energy to the processed powder, promoting the powder to be processed to be subjected to combined action of the mechanical stress effect and the heat effect of the external electric field, and further accelerating refining of the powder and promoting the alloying progress.

Owner:SOUTH CHINA UNIV OF TECH

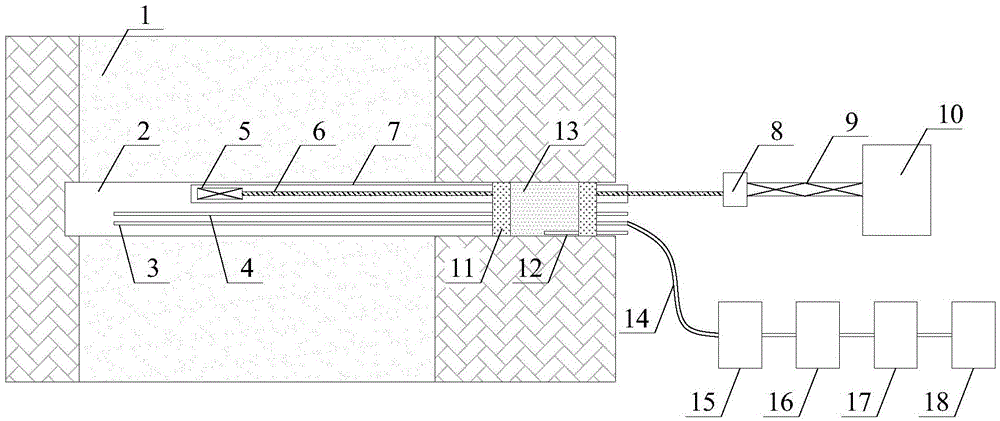

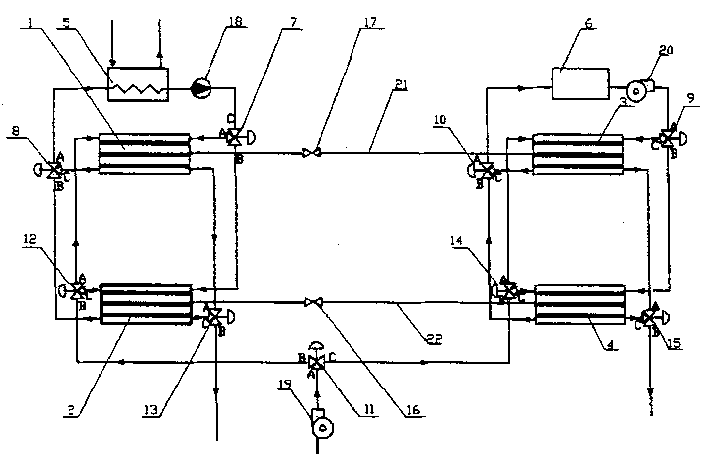

Microwave-assisted extraction and hydrofracture cooperative coal seam anti-reflection method

ActiveCN105484720ADredging holes and fissuresIncrease contact areaFluid removalGas removalPorosityDesorption

The invention provides a microwave-assisted extraction and hydrofracture cooperative coal seam anti-reflection method and belongs to the technical field related to coal mine down-hole hydraulic fracturing. The method includes the steps that a microwave antenna is connected to the innermost end of a coaxial waveguide tube and sent into a fracturing drill hole, the outer most end of the coaxial waveguide tube is connected with a waveguide tube converter, the waveguide tube converter is connected with a rectangular waveguide tube, and the rectangular waveguide tube is connected with a microwave generator; organic solvent and high pressure water are mixed, hydrofracture is conducted on the drill hole through a fracturing tube, meanwhile, the microwave generator is turned on, radiation drilling is conducted through the microwave antenna, fracturing is conducted, a seepage is provided for the solvent, the organic solvent dissolves small organic molecules in coal so that a chambering effect is generated, and methane desorption is promoted through the heat effect of microwaves. According to the method, hydrofracture, solvent extraction and microwave radiation are combined, the porosity and permeability of the coal seam are greatly improved, methane desorption is promoted, and thus the methane extraction effect is greatly improved.

Owner:CHINA UNIV OF MINING & TECH +1

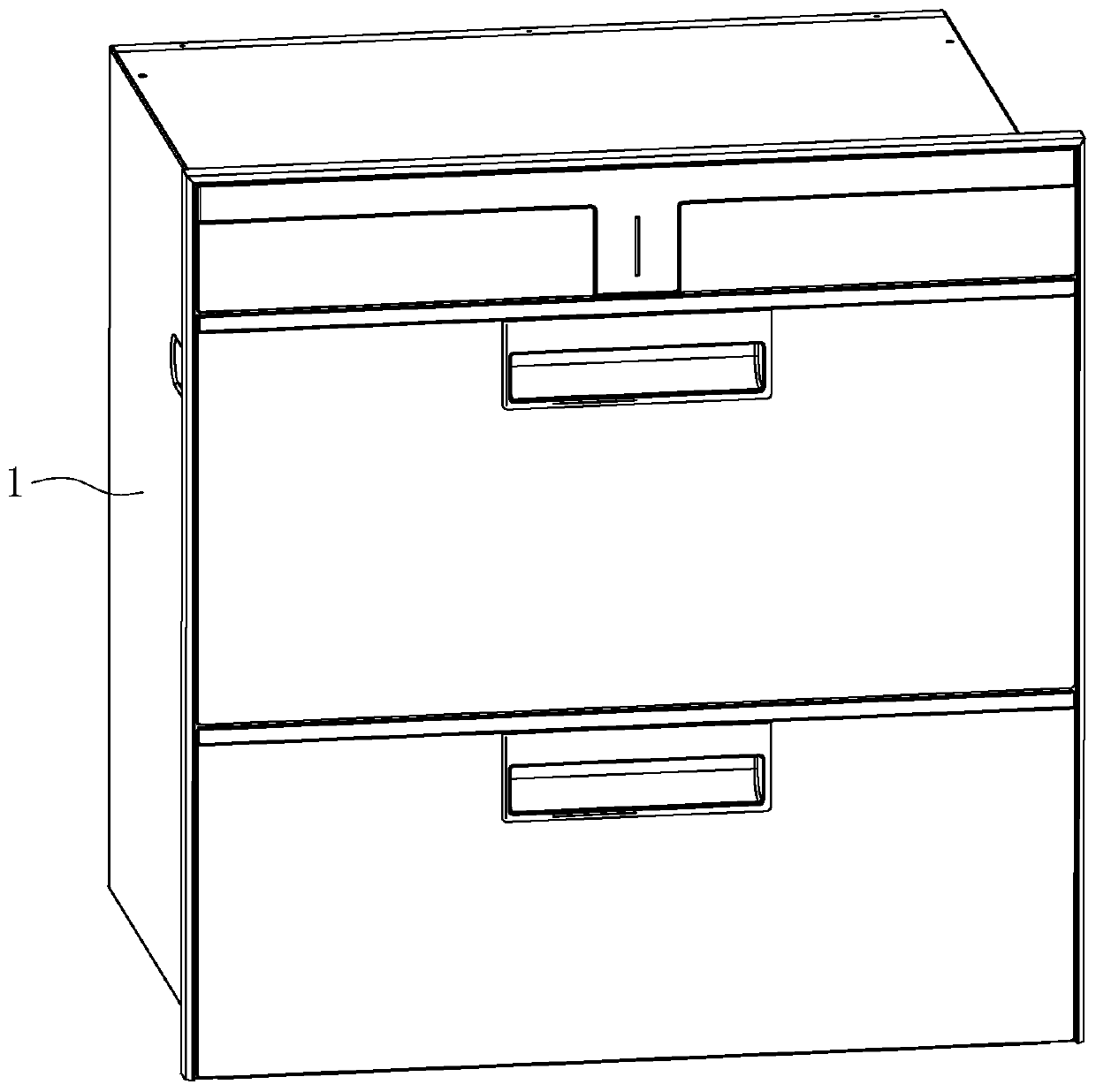

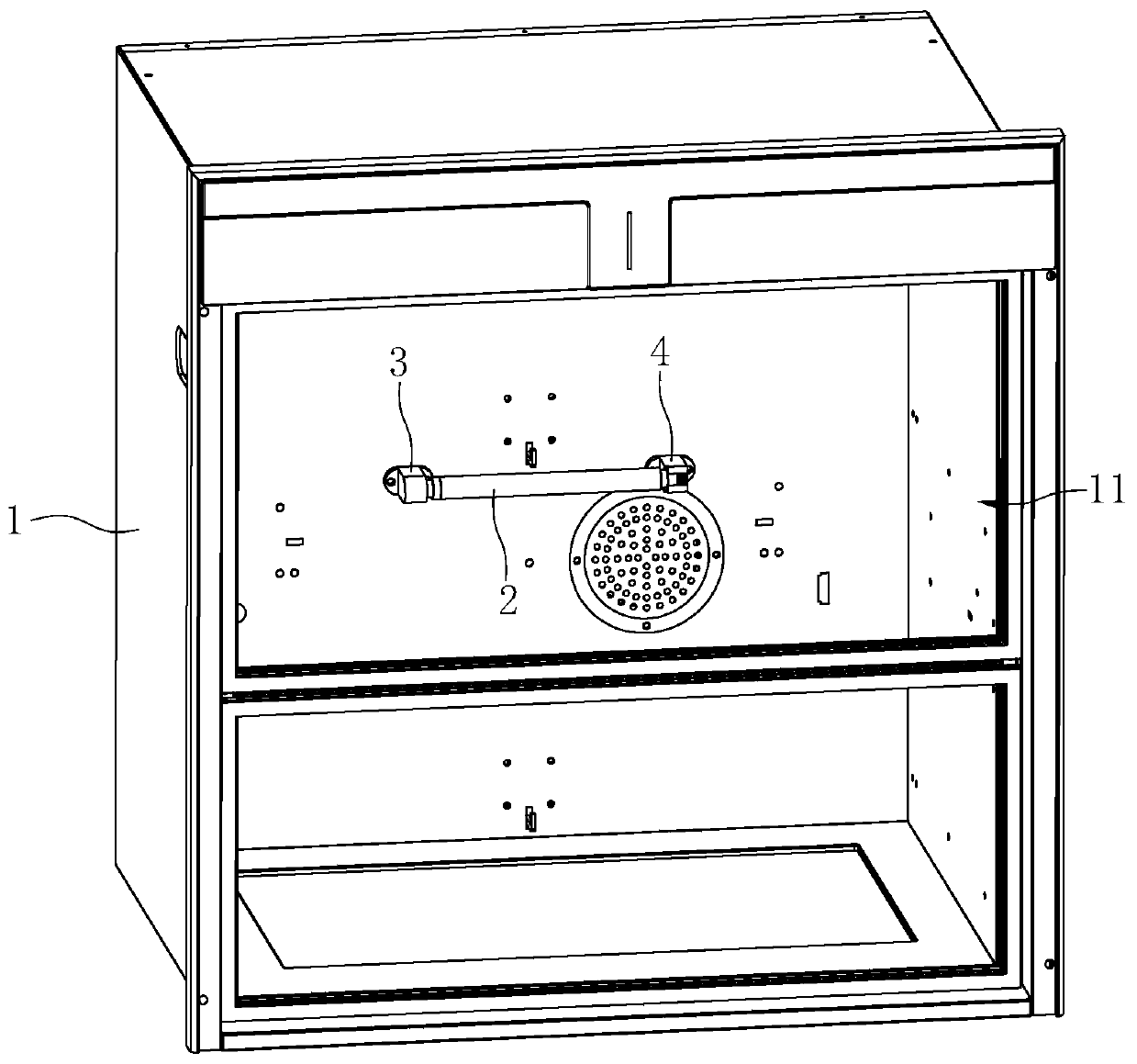

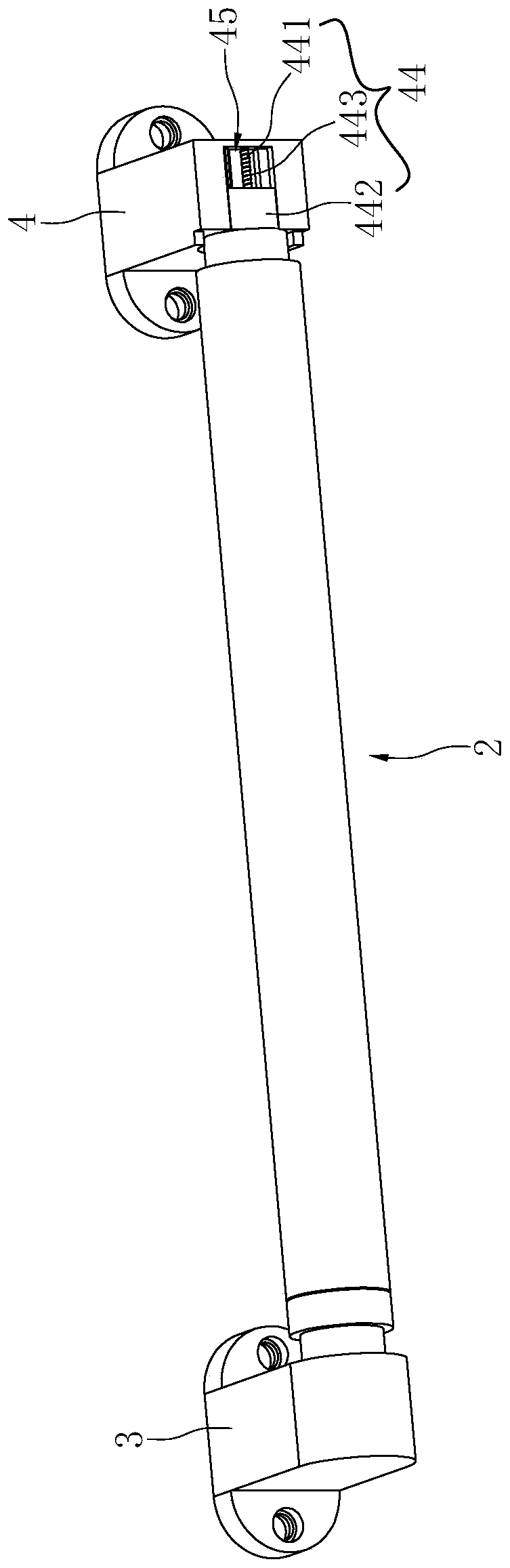

Disinfection cabinet and disinfection method applying same

ActiveCN111388692AImprove disinfection efficiencyGood effectLavatory sanitoryRadiationEngineeringFlashlight

The invention discloses a disinfection cabinet. The disinfection cabinet comprises a cabinet body (1) with a disinfection cavity (11), and is characterized in that a disinfection device which can generate pulse flashlight of which the wavelength is 200-1100nm is arranged in the disinfection cavity (11). The invention further discloses a disinfection method applying the disinfection cabinet. Compared with the prior art, the disinfection cabinet has the advantages that the disinfection device capable of generating the pulse flashlight of which the wavelength is 200-1100nm is arranged in the disinfection cabinet, and the photochemical reaction, the flashlight heat effect and the pulse effect of an ultraviolet band in the pulse flashlight are utilized to disinfect the disinfection cavity, andthus, the disinfection efficiency is high and the effect is good.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

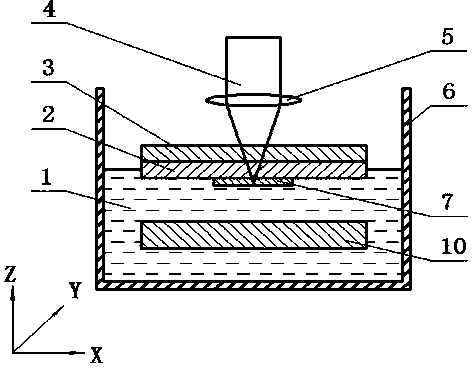

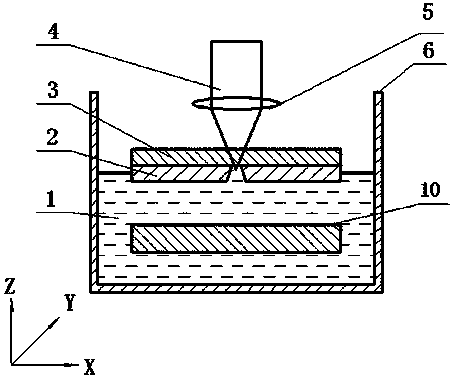

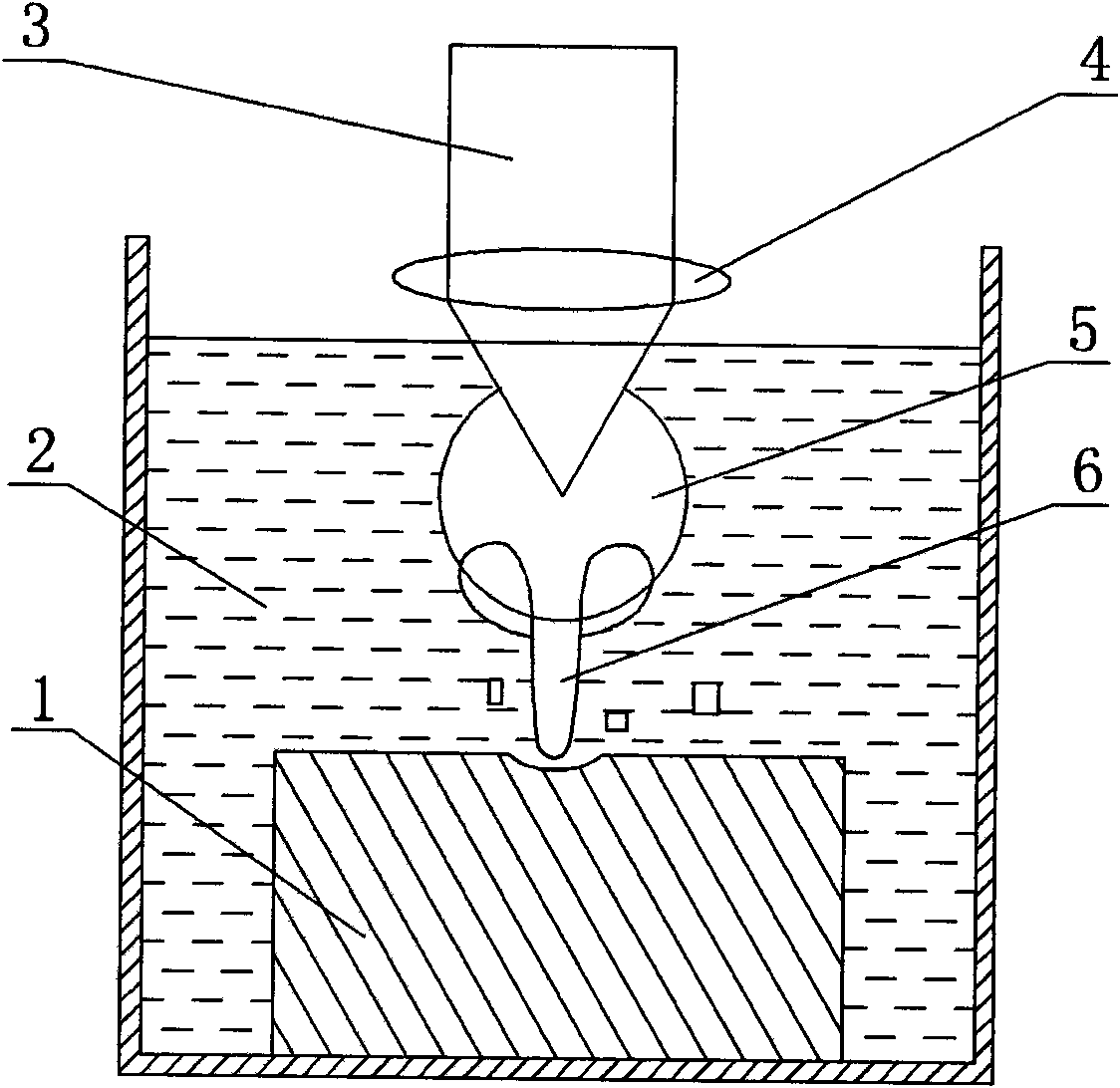

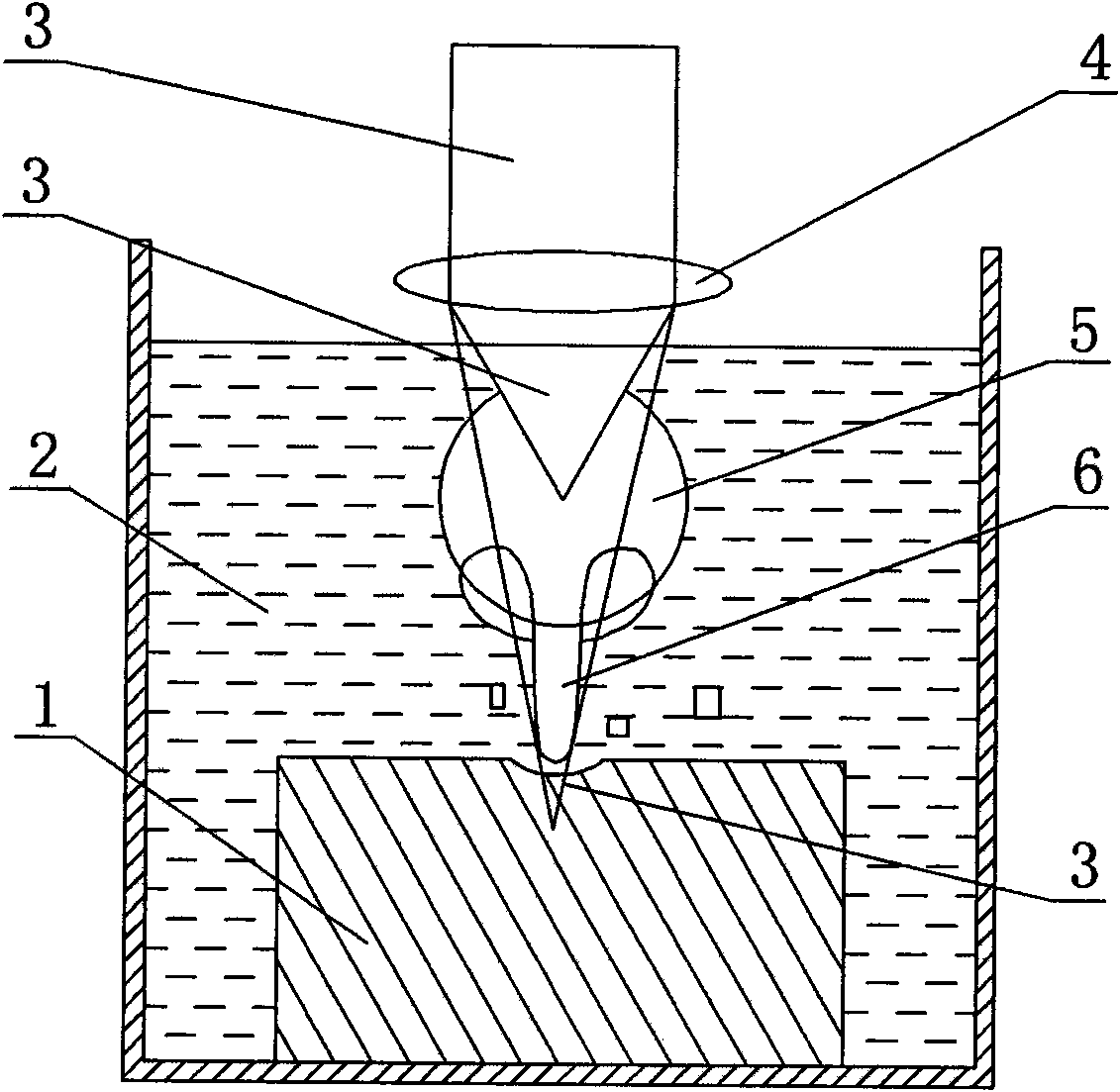

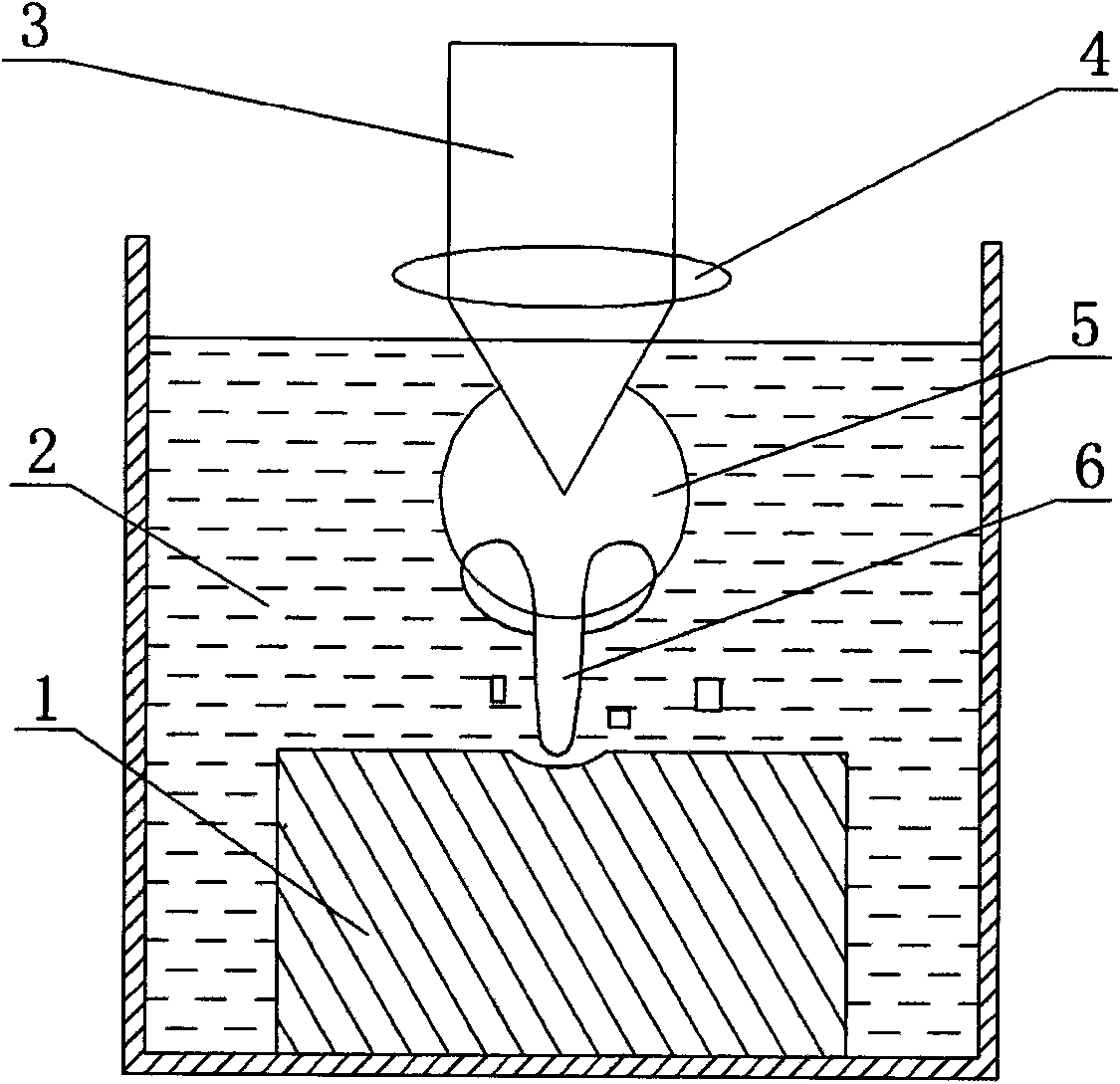

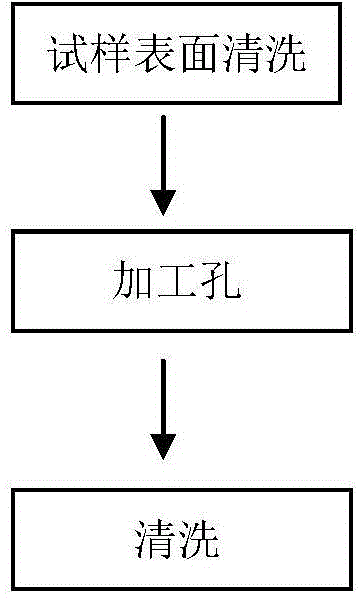

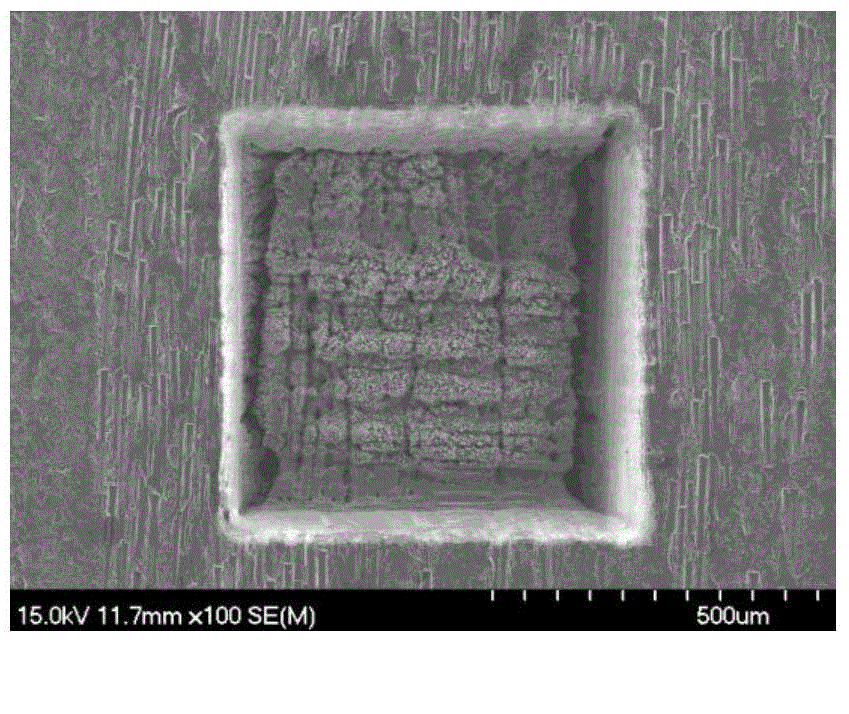

Machining device and machining method for enhancing sapphire laser back wet etching rate

ActiveCN103418912AEnhanced laser etch rateRealize the microstructureLaser beam welding apparatusSemiconductor devicesMicro structureLaser etching

The invention relates to a machining device and a machining method for enhancing a sapphire laser back wet etching rate. The machining device comprises a protection device, a laser beam, a lens assembly, a container and a limit layer, operating fluid is filled in a hollow cavity formed in the container, a workpiece is placed on the surface of the operating fluid and contacts with the operating fluid, the protection device is mounted at the top of the workpiece, the limit layer is mounted below the workpiece, and the laser beam irradiates the back of the workpiece through the lens assembly. The machining device has a high material removing rate under the condition of ensuring fine surface machining quality of sapphires. According to the machining method, chippings are easily taken away by the fluid, the heat effect of laser ablation is small, a regelation layer in a machining area is omitted, machining quality is fine, a laser-induced cavitation effect leads to a micro-jet enhancement effect, the laser etching rate of transparent materials such as the sapphires is enhanced, and micro-structures and shape cutting of material surfaces can be realized. The machining method is simple to operate, convenient, practical and high in machining speed.

Owner:GUANGDONG UNIV OF TECH

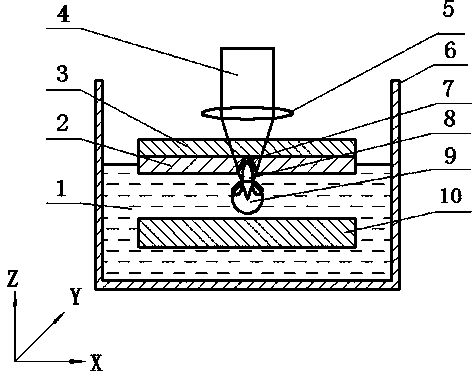

Method for performing microprocessing by utilizing laser cavitation micro jet flow

InactiveCN102248308AAvoid heat damageNo redepositionLaser beam welding apparatusShock waveLaser etching

The invention discloses a method for performing microprocessing by utilizing laser cavitation micro jet flow. The method comprises the following steps of: 1) placing a workpiece to be processed into liquid; 2) focusing laser beams in liquid near the workpiece through a lens group and generating cavitation effect at the focal point; 3) triggering high-speed microjet flow pointing to the workpiece by the cavitation effect and generating high-strength micro shock wave; 4) impacting the high-speed micro jet flow to the surface of the workpiece to form extremely high pressure intensity to damage a material on the surface of the workpiece and removing the material on the surface of the workpiece under the synergism of the high-speed microjet flow and micro shock wave; and 5) processing a fine surface structure on the workpiece under the action of continuous laser pulse and longitudinal or transverse feed of a laser head. Compared with the laser etching technique in the prior art, the method has the advantages of avoiding thermal damage of the workpiece due to low heat effect, not generating phenomenon of depositing processing splash again in the processing process, achieving higher processing precision and contributing to improving processing efficiency.

Owner:GUANGDONG UNIV OF TECH

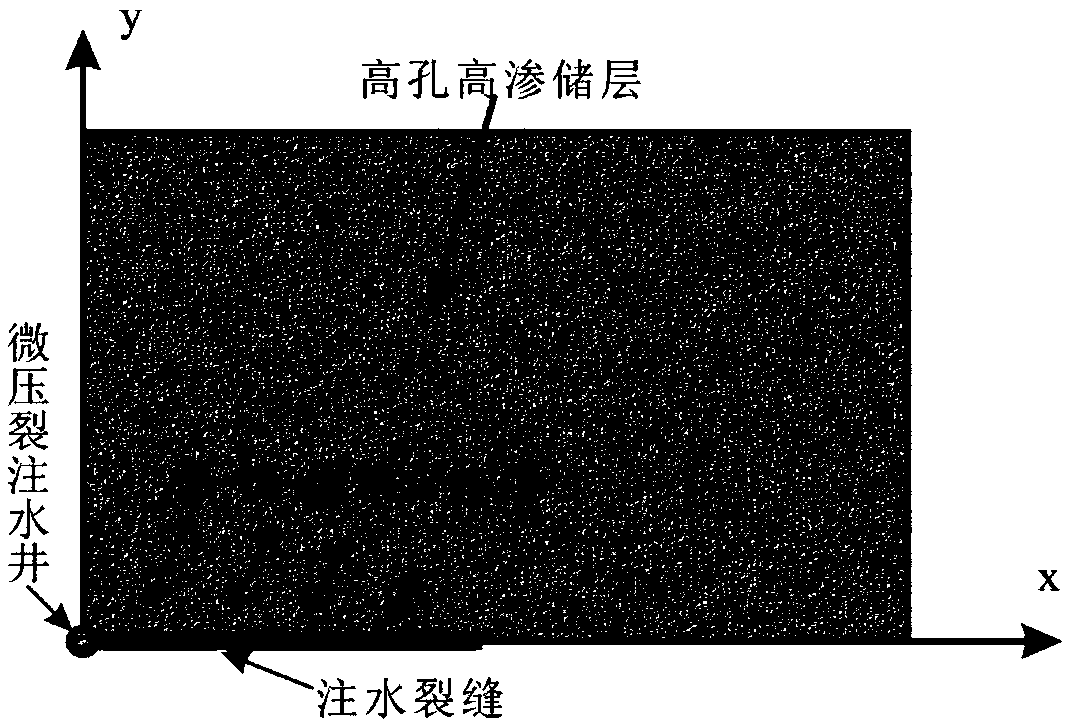

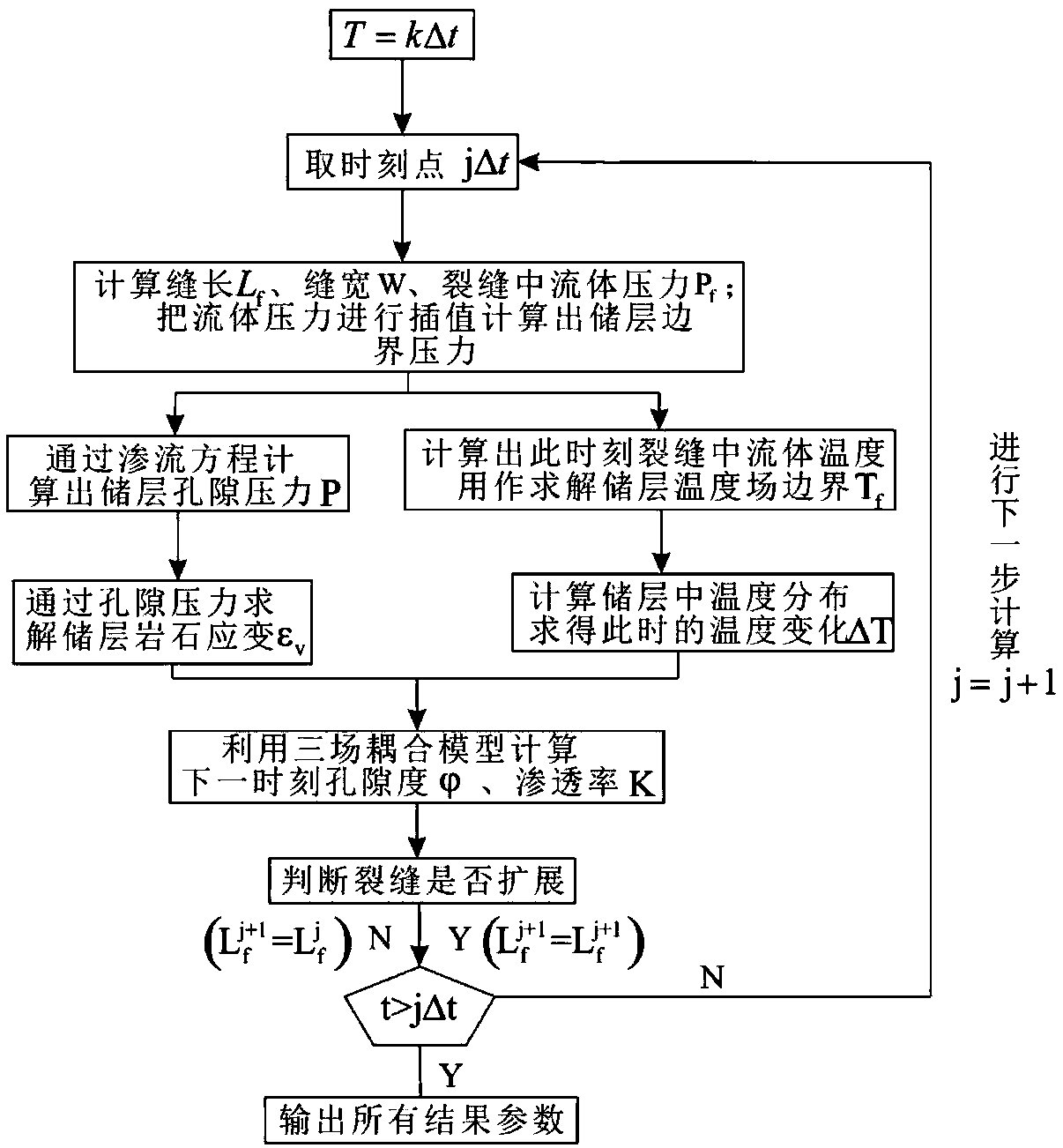

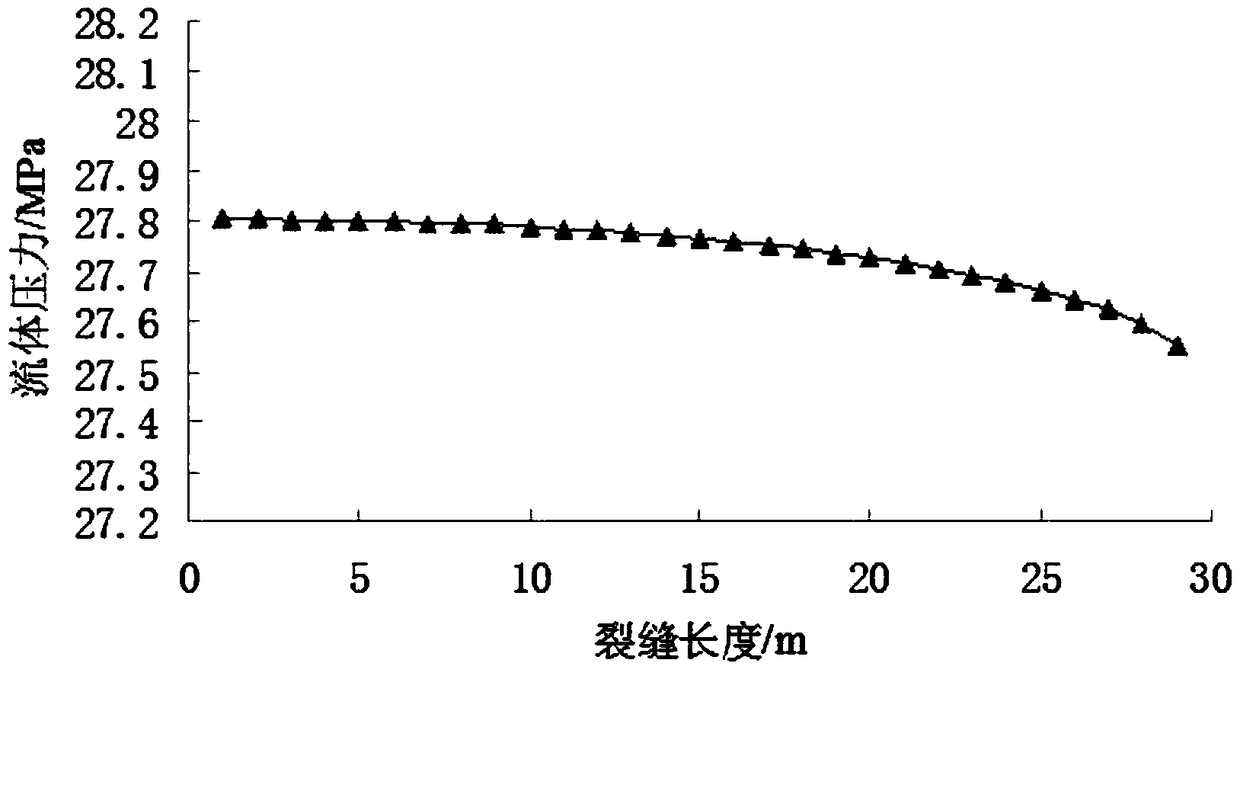

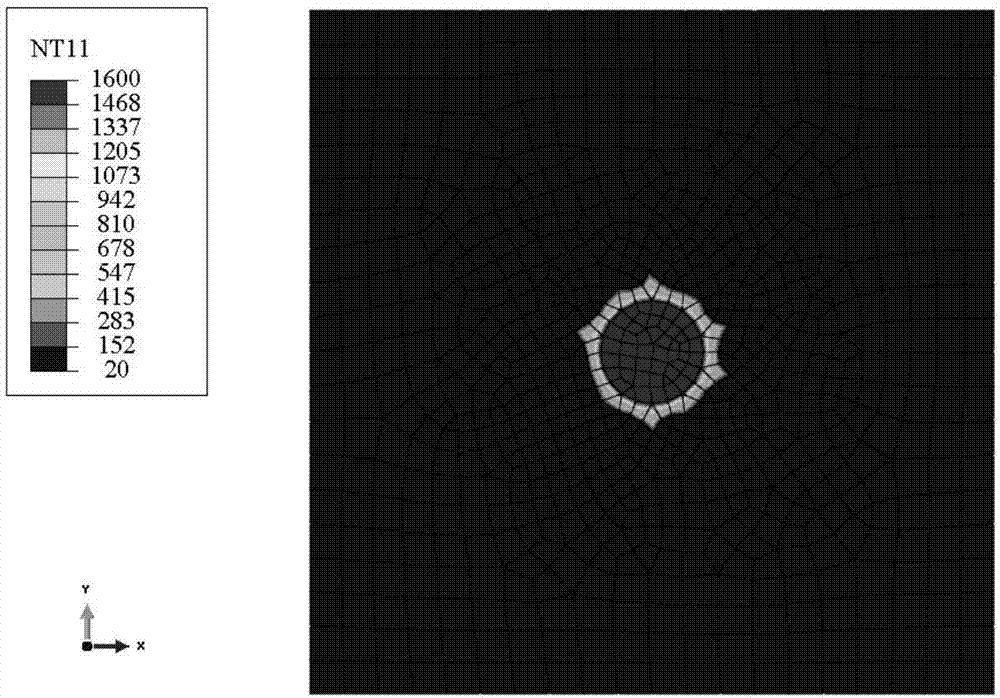

Method for simulating offshore oilfield micro fracturing injection increase crack propagation on basis of fluid-solid-heat coupling theory

ActiveCN108830020AInjection speed is smallReliable Analytical Research MethodsDesign optimisation/simulationSpecial data processing applicationsPorosityFiltration

The invention discloses a method for simulating offshore oilfield micro fracturing injection increase crack propagation on the basis of fluid-solid-heat coupling theory. The method comprises the following steps that geological characteristic parameters are obtained on the basis of offshore micro fracturing well geological data; a hydraulic crack propagation model is built, and fluid pressure and filter loss in a crack are obtained; on the basis of a reservoir matrix model, dynamically changing pore pressure in a reservoir is worked out; on the basis of elastic mechanics and permeation fluid mechanics, a pore elastic deformation relation between fluid and rock is built, that is to say, a fluid-solid coupling model is built, and by means of the calculated pore pressure, rock strain caused bythe fluid can be obtained; a heat effect relation between the temperature and the rock is built, a strain, porosity, permeability and temperature fluid-solid-heat coupling model is built, the permeability and porosity after coupling change are obtained, the pore pressure after three-field coupling change is obtained, the changed pore pressure reacts on a Darcy filtration model, and the crack extension dynamic of the next moment is obtained. According to construction and geological parameters, the dynamic extension situation of the hydraulic crack and real-time change situation of the reservoir parameters in the offshore micro fracturing well long-term injection increase process can be predicted according to the construction and geological parameters.

Owner:SOUTHWEST PETROLEUM UNIV

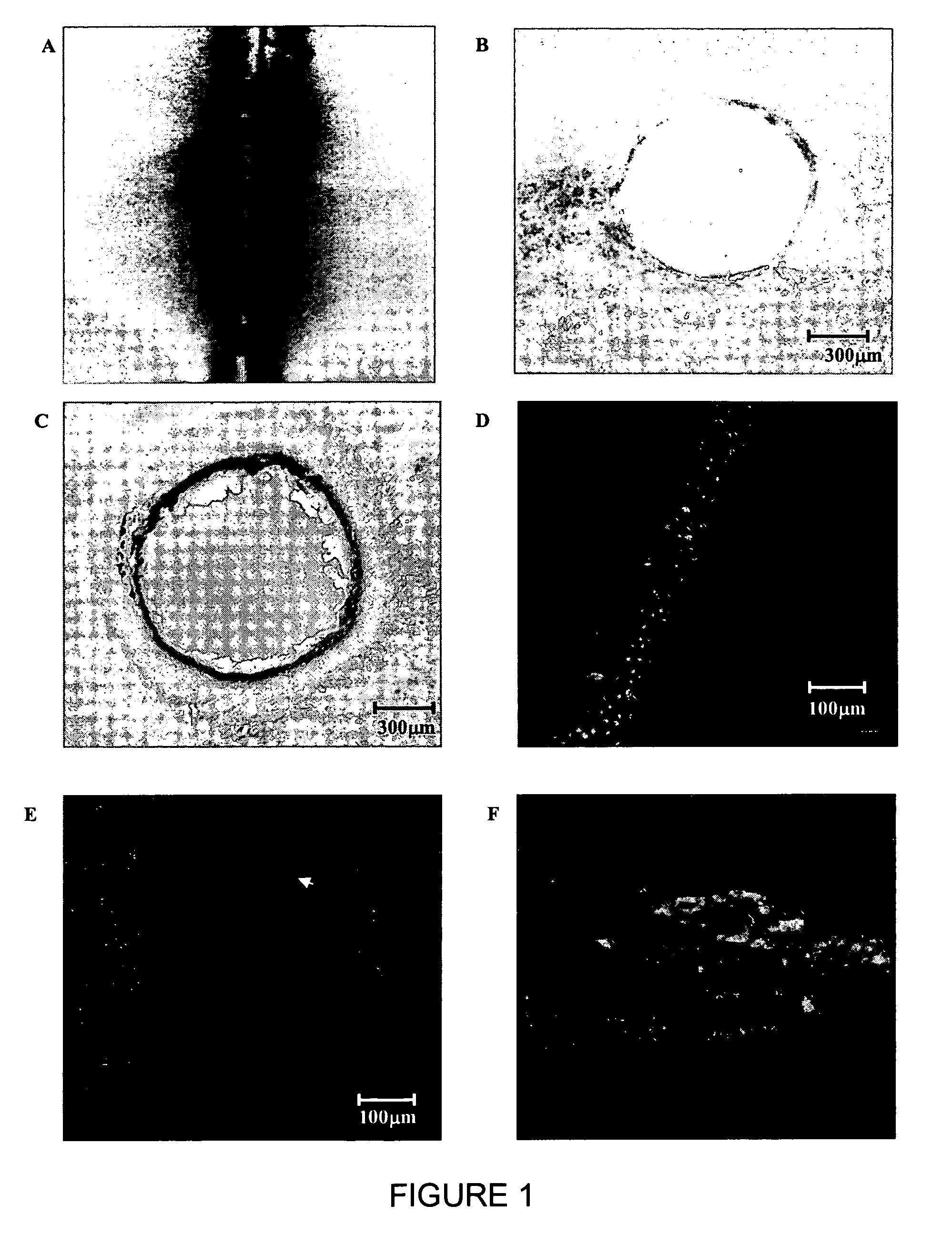

Laser selective cutting by impulsive heat deposition in the IR wavelength range for direct-drive ablation

ActiveUS8029501B2Material efficiencyImprove efficiencySurgical instrument detailsLight therapyThermal dilatationHeat deposition

The present invention provides a method of laser processing of materials, specifically laser induced ablation processes for laser removal of material particularly important in medical and dental applications in which the laser removal of material should be done in such a way as to not damage any of the surrounding soft or hard biomaterial. The ablation process is achieved by impulsive heat deposition (IHD) by direct and specific excitation of short lived vibrations or phonons of the material in such a way as to not generate highly reactive and damaging ions through multiphoton absorption. The heat deposition and ensuing ablation process under prescribed time and wavelength conditions for laser irradiation is achieved faster than heat transfer to surrounding tissue by either acoustic or thermal expansion or thermal diffusion that otherwise would lead to excess heat related damage. The result is that all the deposited laser energy is optimally channelled into the ablation process in which the inertially confined stresses from both photomechanical expansion forces and thermally driven phase transitions and associated volume changes constructively interfere to drive the most efficient ablation process possible with minimal damage to surrounding areas by either ionizing radiation or heat effects. By choosing a specific range of wavelengths, spatial and temporal shaping of infrared laser pulses, the energy can be optimally deposited in a manner that further increases the efficiency of the ablation process with respect to minimizing collateral damage.

Owner:LIGHT MATTER INTERACTION INC

Method and device for preparing crack-free cladding layer through ultrasonic vibration-assisted laser cladding

InactiveCN106350817AIncrease temperatureIncrease stressMetallic material coating processesStress distributionCavitation

The invention discloses a method and a device for preparing a crack-free cladding layer through ultrasonic vibration-assisted laser cladding. Ultrasonic vibration aging is directly introduced into a molten pool micro-area, a direct cavitation effect, a mechanical effect and a heat effect of an ultrasonic wave are utilized for promoting the uniformity of a cladding layer stress field and the refining of grain tissues, and the generation of cracks is inhibited from the root; the ultrasonic wave can be directly acted on a molten pool, a promoting effect on temperature and stress distribution uniformity is higher than an overall vibration effect of a workpiece far away from the molten pool, and the three effects of the ultrasonic wave have a better stirring effect than that of an electromagnetic stirring elimination method, so that the new method has essential difference relative to previous methods, and has better superiority. By repeated experiments, an effect of refining the grain tissues can be achieved so as to prepare the crack-free cladding layer with a favorable surface appearance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

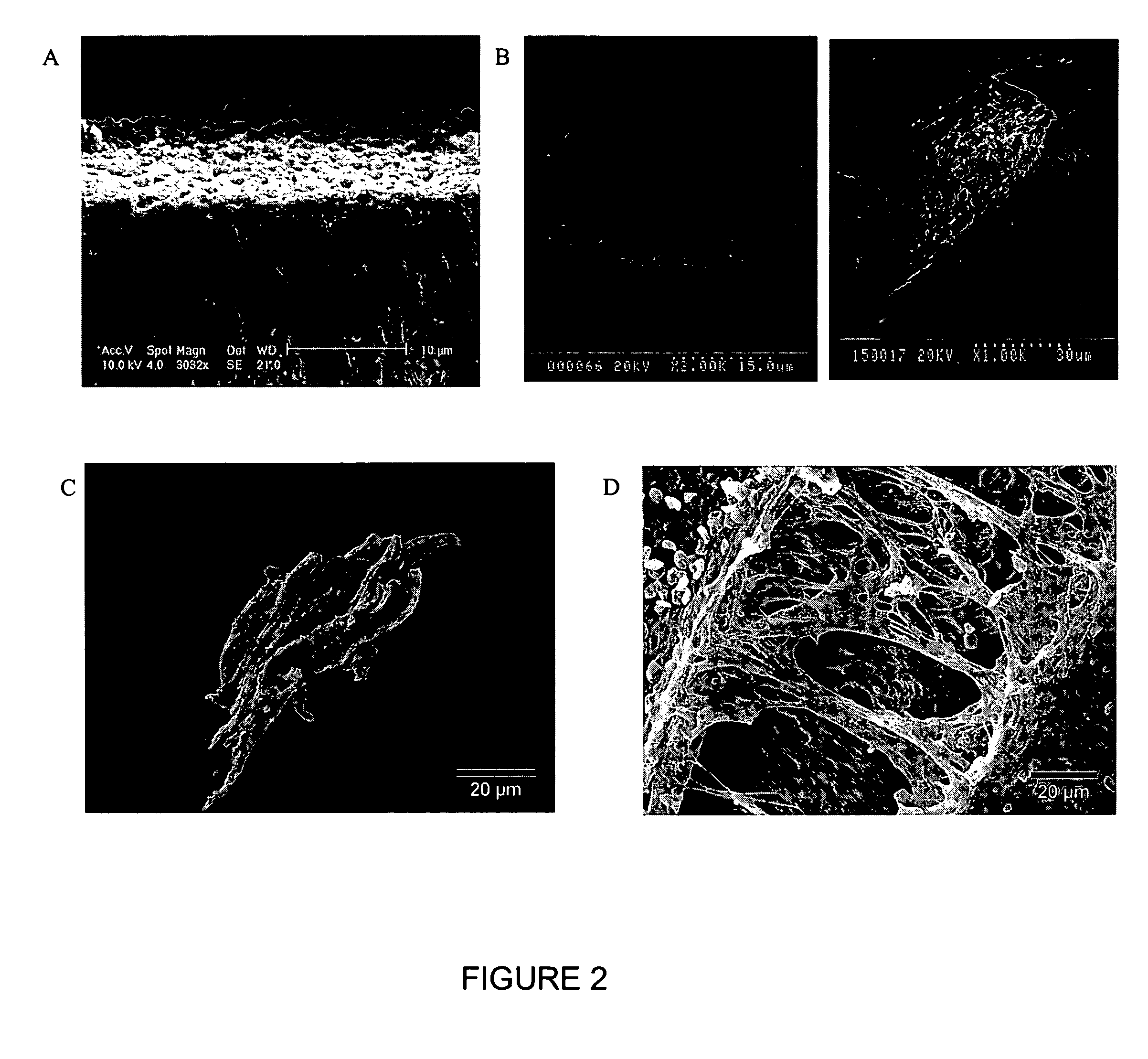

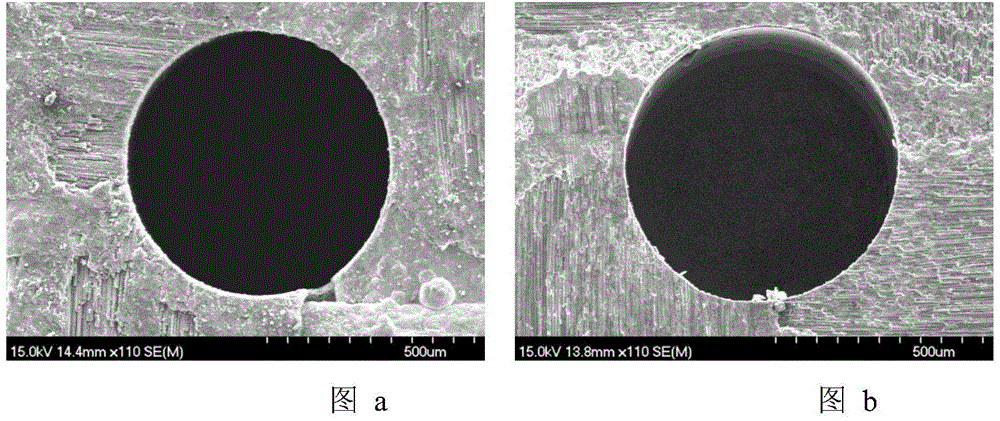

Method for machining micro holes in ceramic matrix composite through femtosecond lasers

ActiveCN104607808AHigh peak powerShort pulse widthWelding/soldering/cutting articlesLaser beam welding apparatusWavelengthLayer removal

The invention relates to a method for machining micro holes in a ceramic matrix composite through femtosecond lasers. According to the method, the silicon carbide ceramic matrix composite sample is placed on a working table and machined layer by layer in a spiral line mode through the femtosecond lasers or machined in a linear scanning mode, wherein the thickness of the sample is smaller than 3 mm; in the micro-machining process, the wave length of femtosecond laser machining ranges from 400 nm-1500 nm, the pulse width ranges from 80 fs to 500 fs, the output power of the lasers is determined according to the requirements of micro-machining and ranges from 20 mW to 20 W, and the repetition frequency of the lasers is determined according to the requirements of micro-machining and ranges from 50 K to 25 MHz; the sample is machined in a layer-by-layer removal mode, wherein the rotation speed of a machining head is 2400 rev / s. In the machining process, the method has the advantages that machining damage is small, and because material around the damage region is still in a cold state after machining, the heat effect is small; machining precision is high, energy of the femtosecond lasers is in Gaussian distribution, absorption and action of the energy in the machining process are limited within the size of which the focus center is quite small, and the machining dimension is expressed from a micro form to a sub-micro form.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Vehicle air-condition with two-stage metal hydride

InactiveCN1482017AContinuous temperature adjustmentAir-treating devicesVehicle heating/cooling devicesAtmospheric airSolenoid valve

The two-stage metal hydride automobile air conditioner refrigerates via the heat effect of reversible reaction between metal hydride and hydrogen. Waste heat of tail gas as high temperature heat source and peripheral atmosphere as medium temperature heat source are utilized to drive the refrigerating circulation of metal hydride, and two pairs of metal hydride reactors are adopted for alternate refrigeration to continuous regulation of temperature inside the automobile. The air conditioner system includes mainly high and low temperature metal hydride reactors, heat exchanger, solenoid valve, water pump, blower, etc. Inside both the high temperature and the low temperature reactors, are arranged fine pipes with filled metal hydride and hydrogen penetrating film in the middle section of pipes and hydrogen collecting general pipe. The air conditioner has no corrosion, no wear, less motion parts, high vibration resistance, no damage to atmosphere ozone layer and other advantages.

Owner:SHANGHAI JIAO TONG UNIV

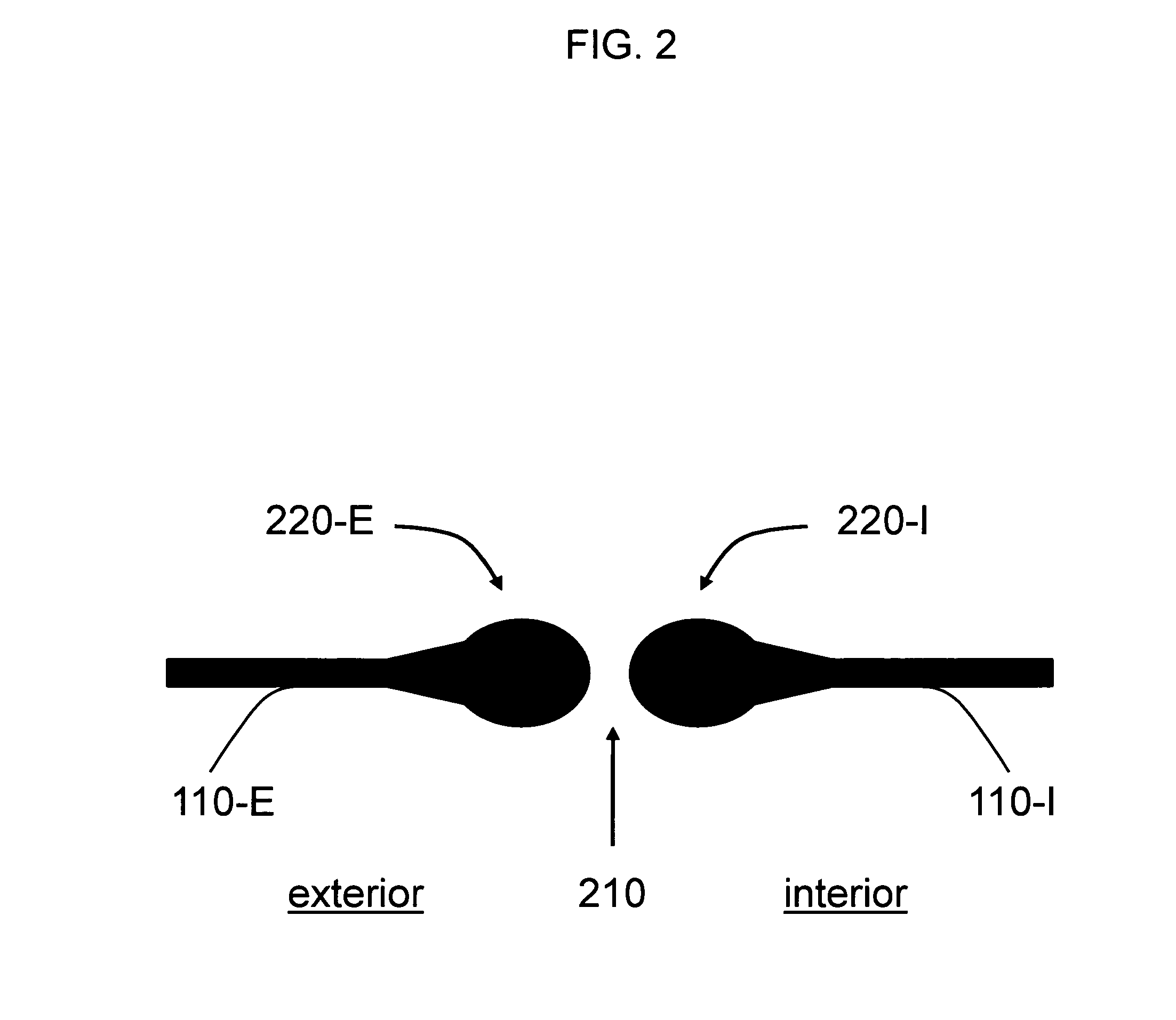

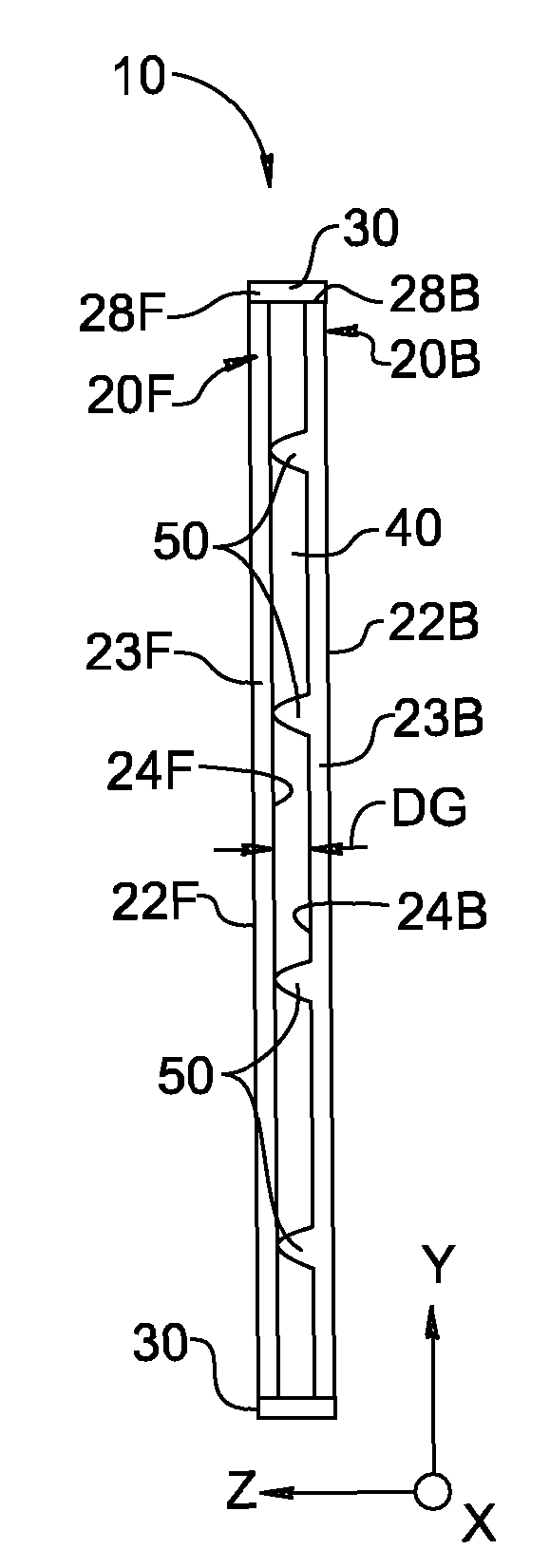

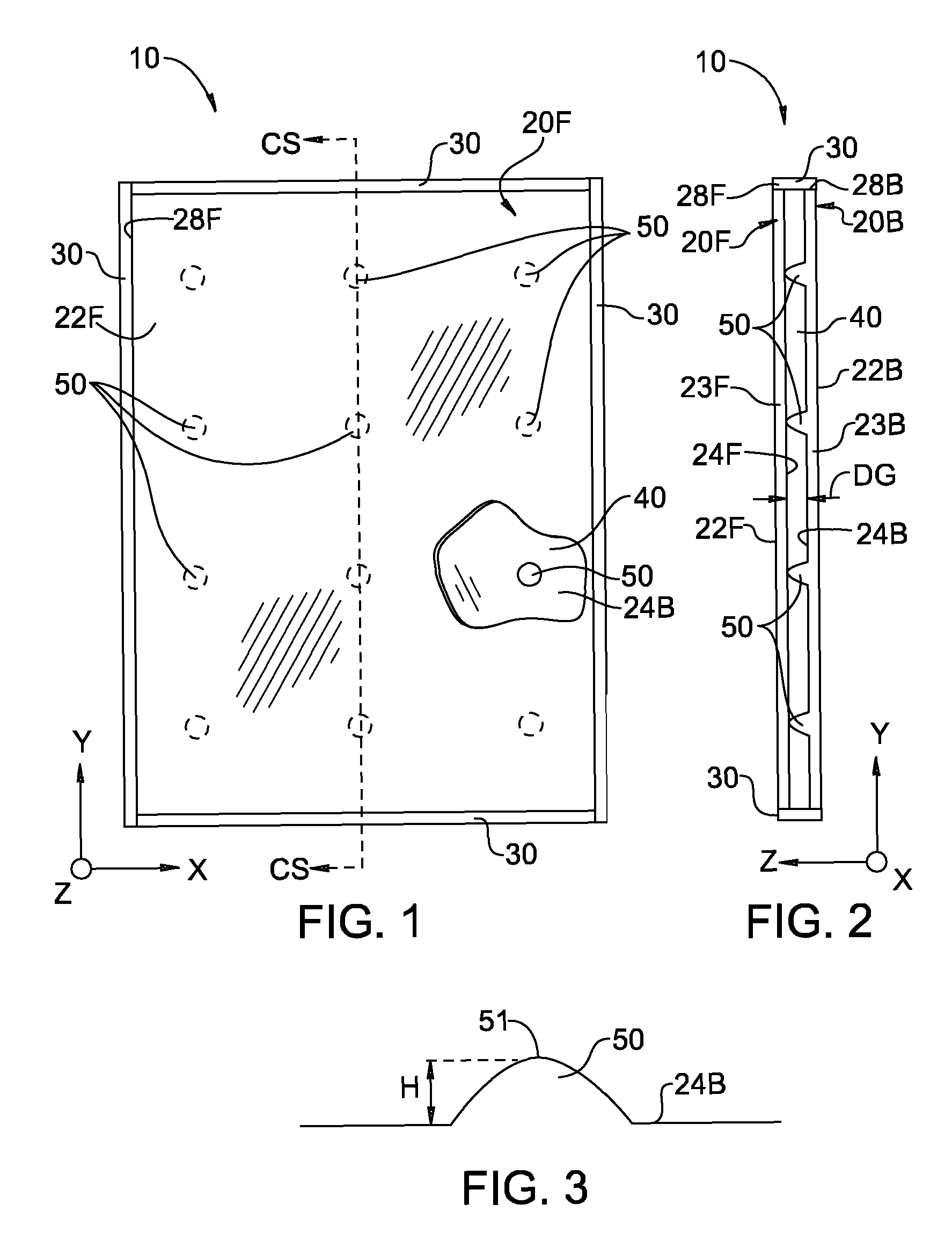

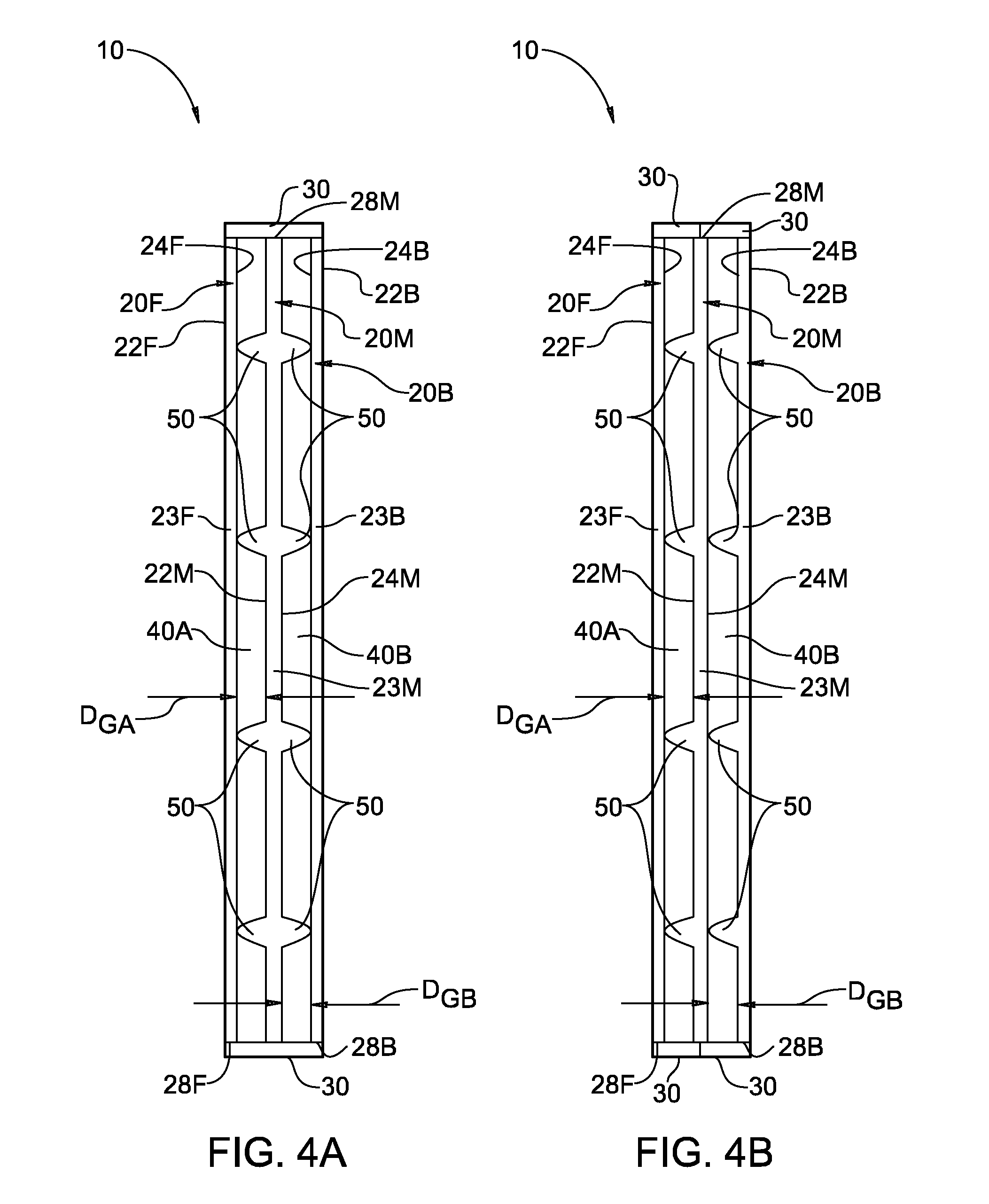

Vacuum-insulated glass windows with glass-bump spacers

Vacuum-insulated glass (VIG) windows (10) that employ glass-bump spacers (50) and two or more glass panes (20) are disclosed. The glass-bump spacers are formed in the surface (24) of one of the glass panes (20) and consist of the glass material from the body portion (23) of the glass pane. Thus, the glass-bump spacers are integrally formed in the glass pane, as opposed to being discrete spacer elements that need to be added and fixed to the glass pane. Methods of forming VIG windows are also disclosed. The methods include forming the glass-bump spacers by irradiating a glass pane with a focused beam (112F) from a laser (110). Heating effects in the glass cause the glass to locally expand, thereby forming a glass-bump spacer. The process is repeated at different locations in the glass pane to form an array of glass-bump spacers. A second glass pane is brought into contact with the glass-bump spacers, and the edges (28F, 28B) sealed. The resulting sealed interior region (40) is then evacuated to a vacuum pressure of less than one atmosphere.

Owner:CORNING INC

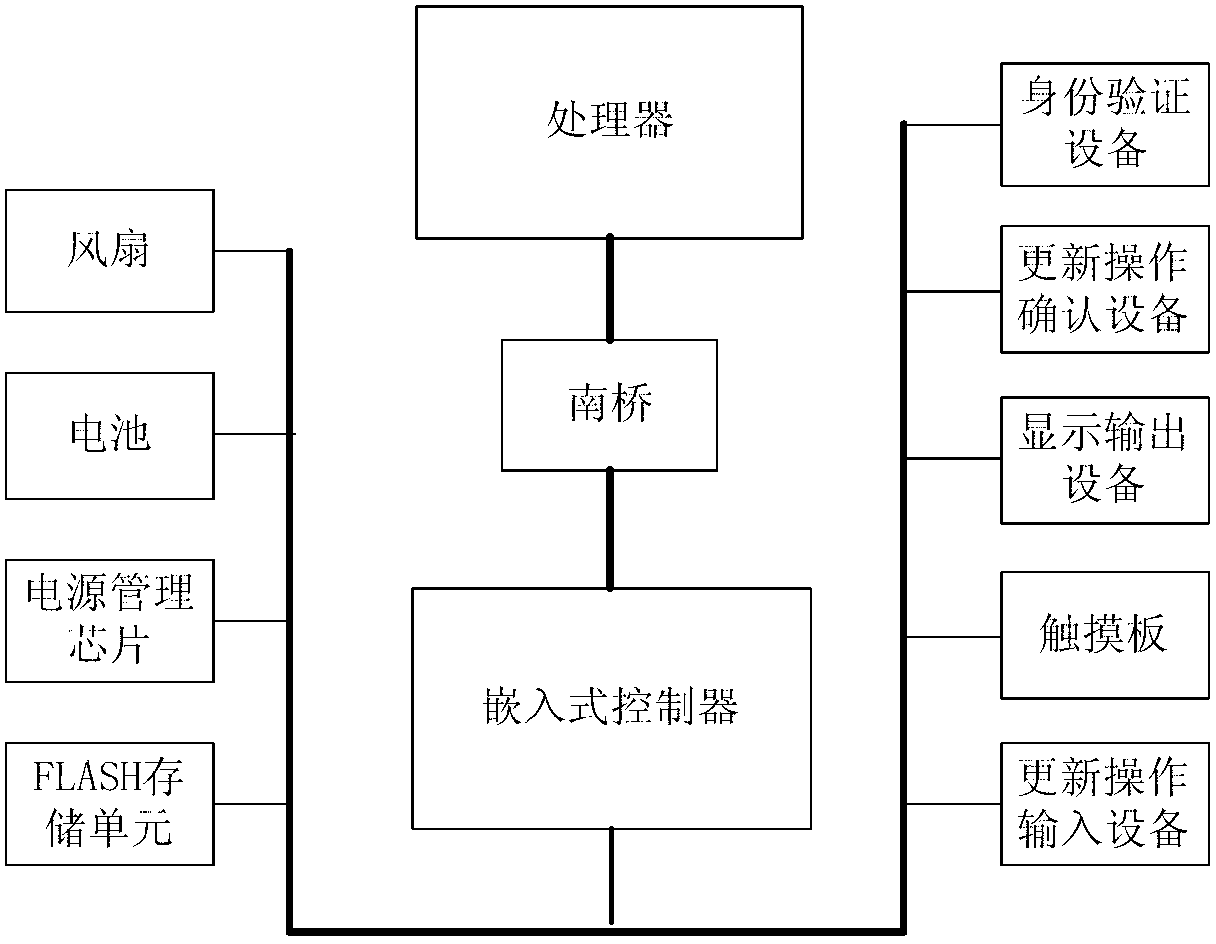

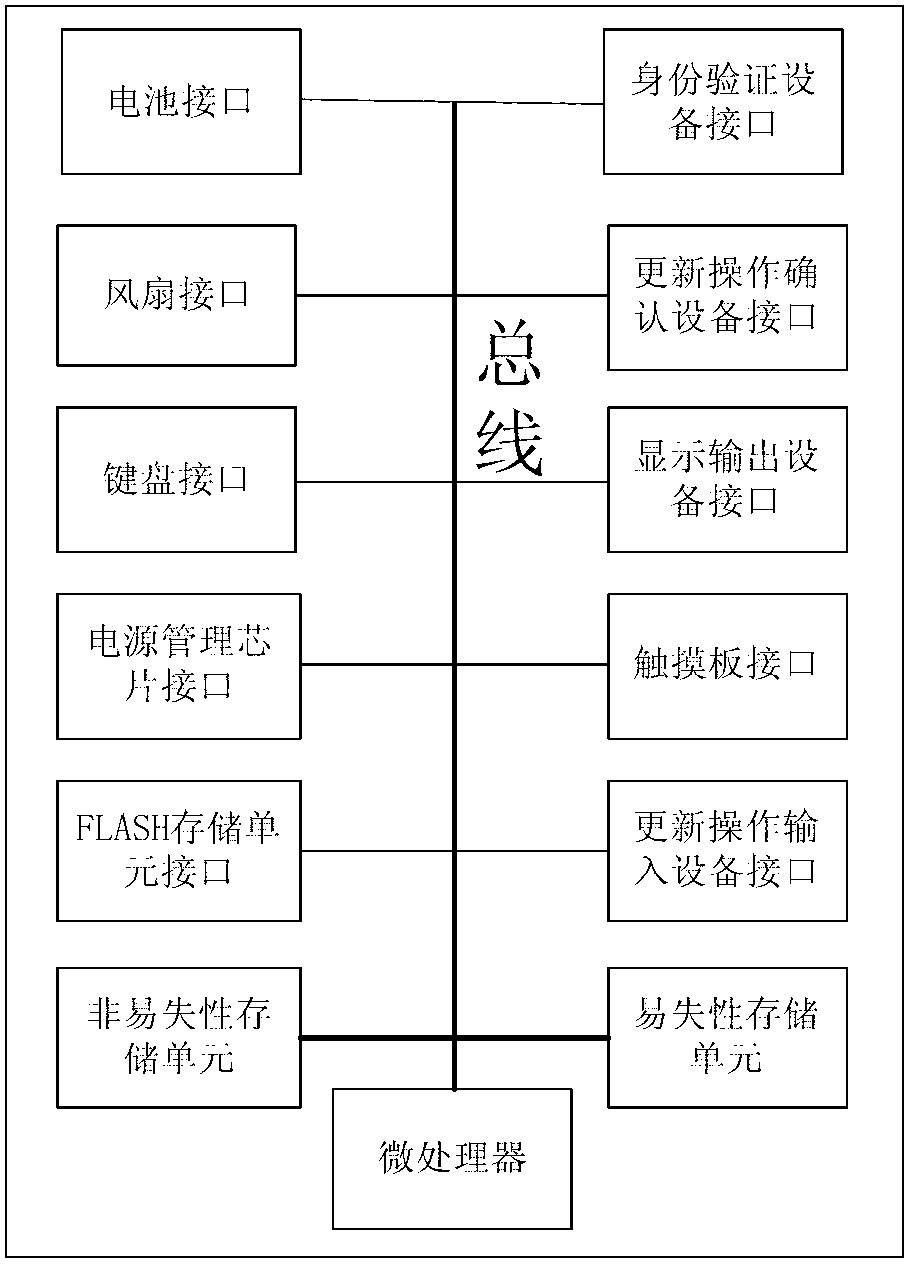

Embedded control system for computers and updating method of embedded control system

The invention discloses an embedded control system for computers and an updating method of the embedded control system and relates to the field of information safety. An EC (embedded controller) is independent from a tablet computer CPU (central processing unit) and generally used for controlling equipment starting time sequence and controlling power switches of various devices and can realize system power management, component power management, CPU power management, component and CPU power effect management, battery management and heat effect management and the like. In order to simplify design and save cost, existing tablet computers directly update hardware of the EC through upper software, but upgrading operation is not subject to validity inspection and upgrading data are not subject to credible inspection in most EC upgrading processes, so incorrect or illegal EC hardware upgrading can change functions of the EC and threatens safety of the tablet computers. After modification, a safe and credible operation method for updating hardware of the embedded controller is implemented in the hardware environment of the embedded controller updating system, and safety and reliability of the hardware of the embedded controller are guaranteed.

Owner:CHINA INFORMATION TECH SECURITY EVALUATION CENT

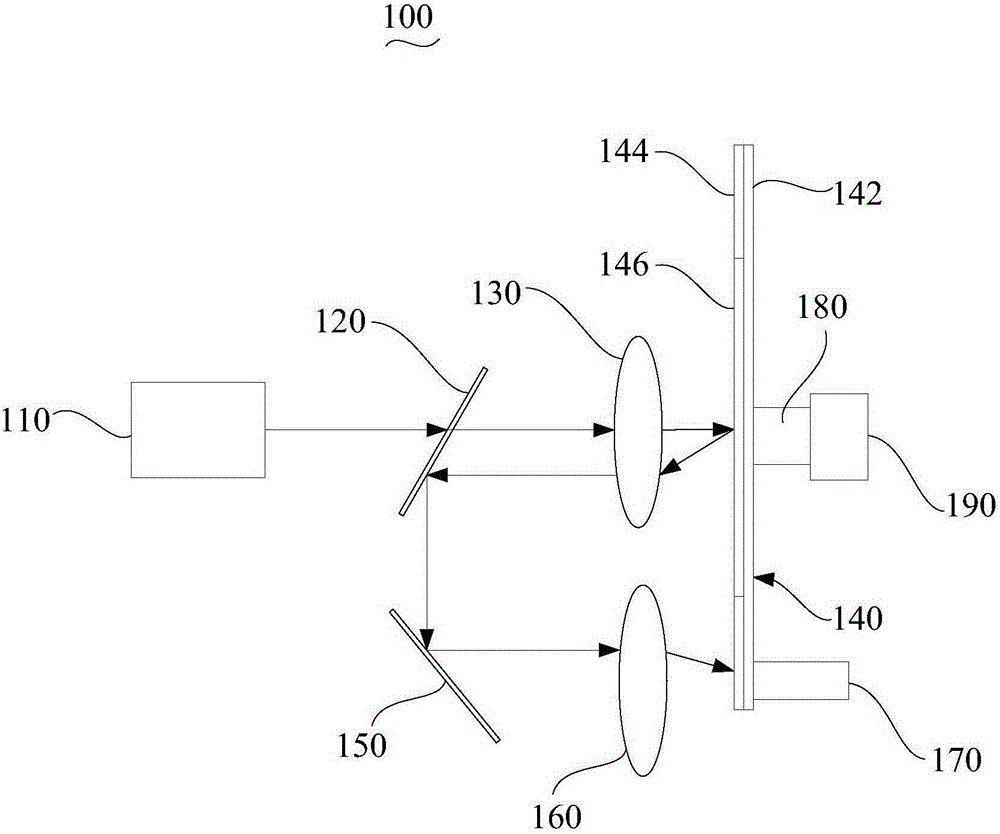

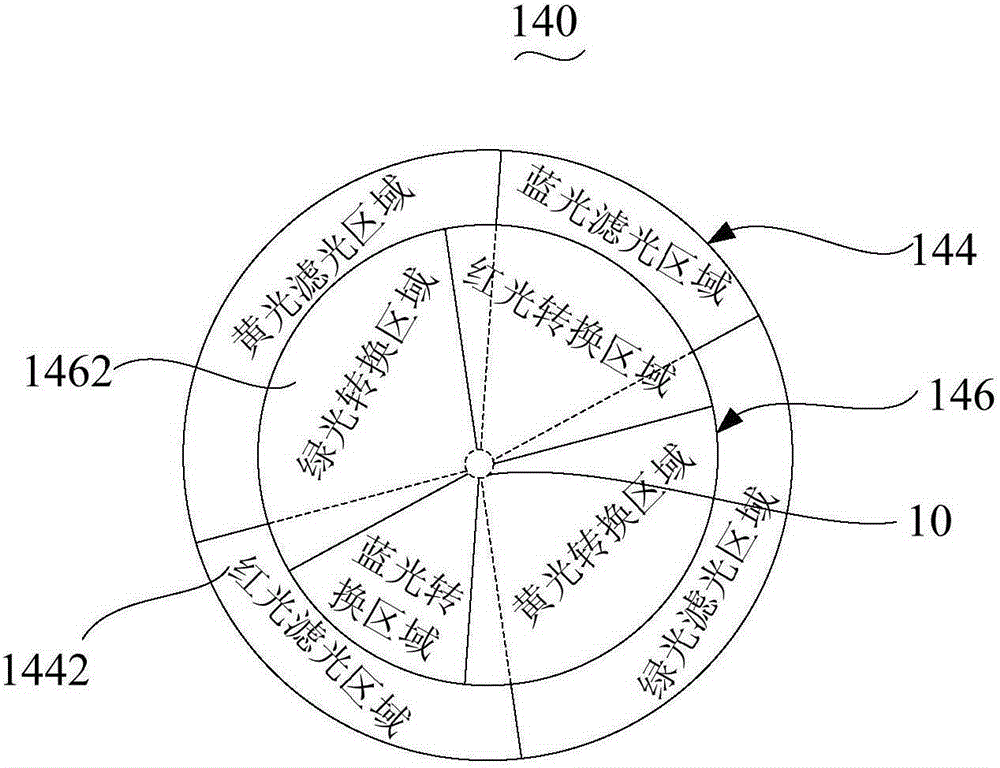

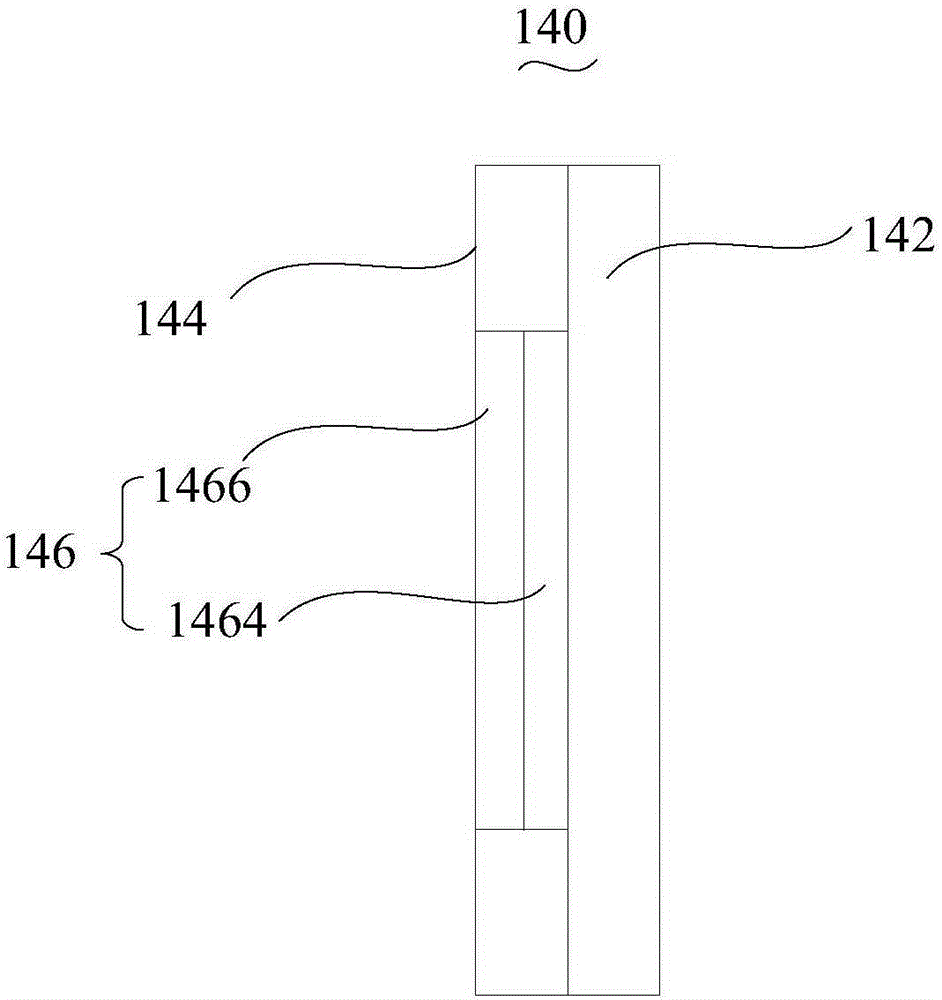

Light source system and application thereof

ActiveCN105353578AIncrease brightnessImprove cooling effectProjectorsOptical elementsFluorescenceProjection system

The invention relates to a light source system and application thereof. The light source system comprises a laser, an interference filter, a first condenser lens, a light conversion device, a reflector, a second condenser lens, a dodging member, a radiating member and an actuator. The light conversion device comprises a transparent substrate, a wavelength conversion layer and a filter layer; the transparent substrate is rotatable; the filter layer is laminated on the transparent substrate and the filter layer is set around the edge of the transparent substrate for a round to form an annular structure; the wavelength conversion layer is laminated on the transparent substrate and the wavelength conversion layer is set in the middle of the transparent substrate; the radiating member is fixedly connected with the transparent substrate at the side far from the wavelength conversion layer; the actuator and the radiating member are fixedly connected; and the actuator can drive the transparent substrate to rotate through the radiating member. The projection system has the advantages of good heat radiation performance, therefore, the heat effect of the light conversion device in the fluorescence transition process can be improved, and the brightness of the light source system can be raised.

Owner:杨阳

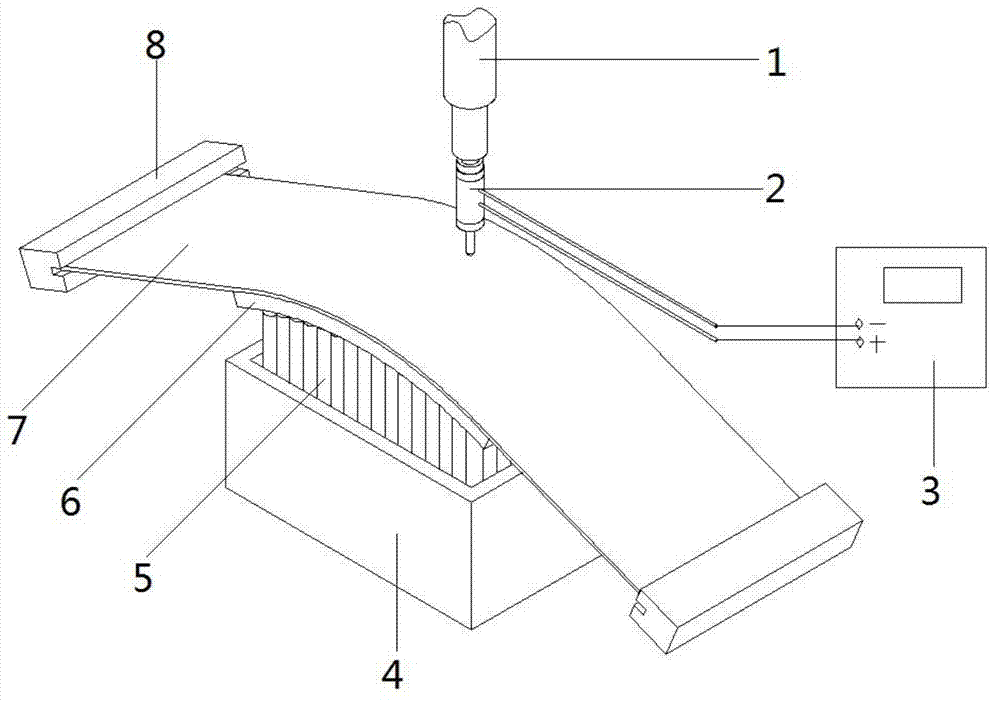

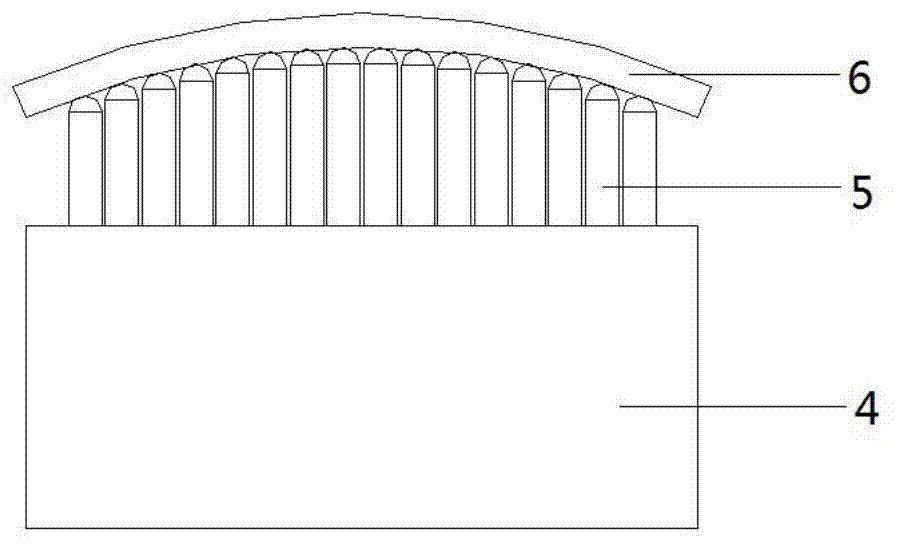

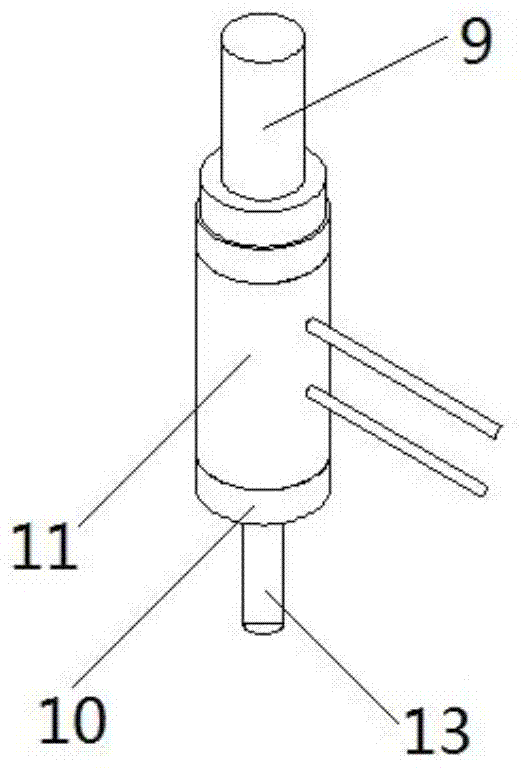

Flexible stretch-forming device and method for carrying out stretch-forming on plate by utilizing same

InactiveCN103480713AReduce deformation resistanceHigh forming precisionShaping toolsIndustrial machineIndustrial manipulator

The invention discloses a flexible stretch-forming device and a method for carrying out stretch-forming on a plate by utilizing the flexible stretch-forming device and solves the technical problem that the stretch-forming accuracy of a flexible stretch-forming device for the molded surface of a reconfigurable unidirectional continuous die is low. The technical scheme includes that the flexible stretch-forming device comprises an industrial manipulator, a heating forming head, a power supply, a multipoint die, a nail post and a polyurethane elastic cushion. The nail post is mounted on the base of the multipoint die, the polyurethane elastic cushion is positioned above the nail post, the lower surface of the polyurethane elastic cushion is attached to the discrete surface formed by the nail head of the nail post, the plate is positioned above the polyurethane elastic cushion, the lower surface of the plate is attached to the upper surface of the polyurethane elastic cushion, the heating forming head is positioned above the plate, and the spherical head surface of the heating forming head is contacted with the upper surface of the plate. According to the flexible stretch-forming device and the method for carrying out stretch-forming on the plate by utilizing the flexible stretch-forming device, the electromagnetic induction heating forming head is adopted to locally heat the plate in the stretch-forming process, the local heat effect of the region can reduce the deformation resistance of the plate, the plasticity is improved, the resilience value is reduced, and the forming accuracy of the plate is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

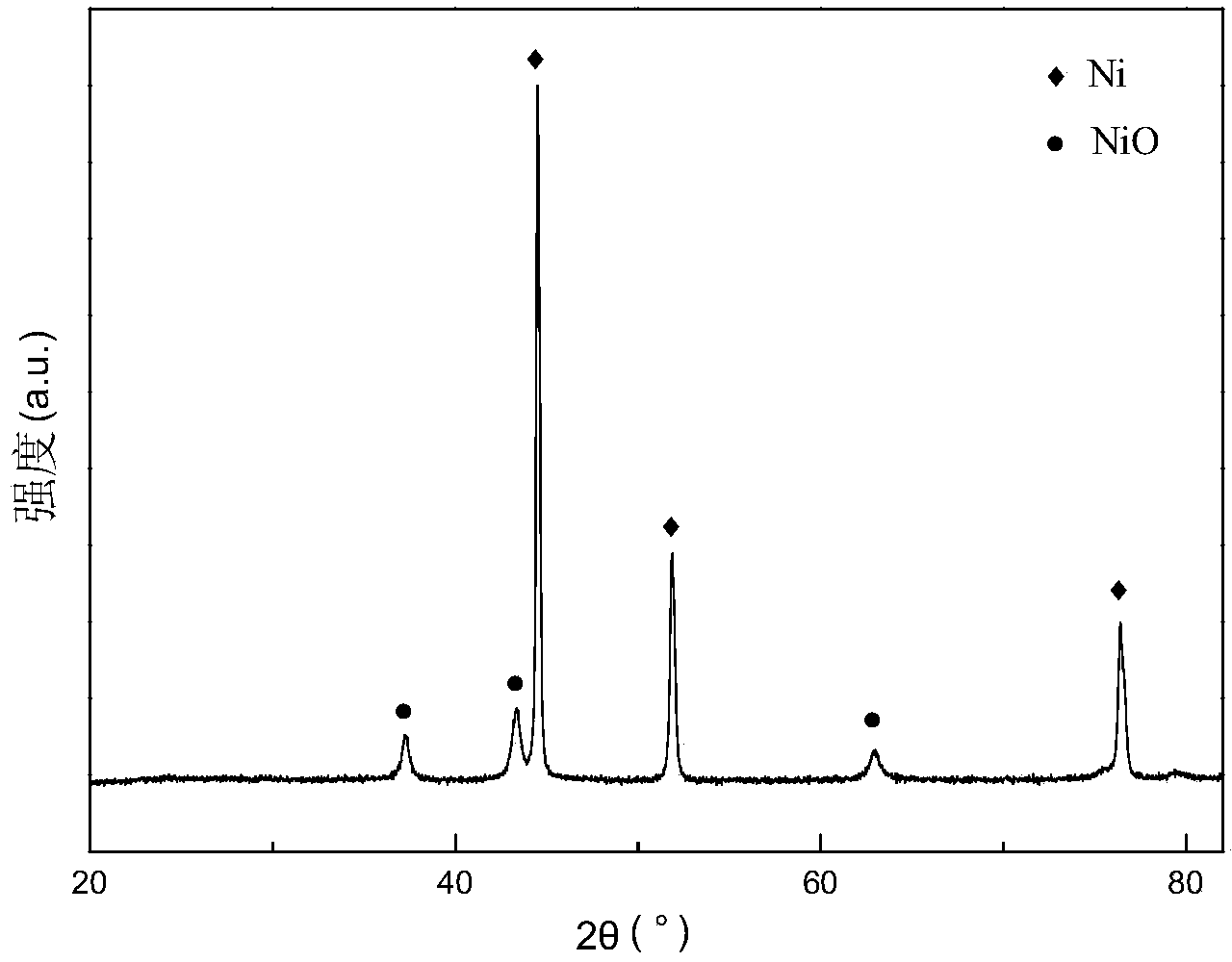

Metal-phase carrier loaded catalyst as well as preparation method and application

ActiveCN103752315AStable structureOptimal Control StructureHydrogenProductsChemical industryActive component

The invention relates to a metal-phase carrier loaded catalyst as well as a preparation method and application of catalyst in preparation of methane and methane synthesized gas reaction by catalyzing carbon oxide or (and) carbon dioxide. The metal-phase carrier loaded catalyst comprises active component metal oxide which is loaded on a metal-phase carrier and auxiliary metal oxide, the general formula of the metal-phase carrier loaded catalyst is as follows: xM1O-yM2O / ZT, wherein M1O represents the active component metal oxide, M2O represents the auxiliary metal oxide, ZT represents the metal-phase carrier, x represents the mass percent of the active component metal oxide in the catalyst, and y represents the mass percent of the auxiliary metal oxide in the catalyst. The catalyst has the advantages of high activity, high stability, excellent heat conduction property, high permeability, convenience in use, long service life, simplicity in preparation and the like, the heat effect difficulty in strong heat discharging / suction reaction in the chemical industry field can be effectively solved, and the catalyst can be used in the methanation process and the methane-producing synthesized gas reaction.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +1

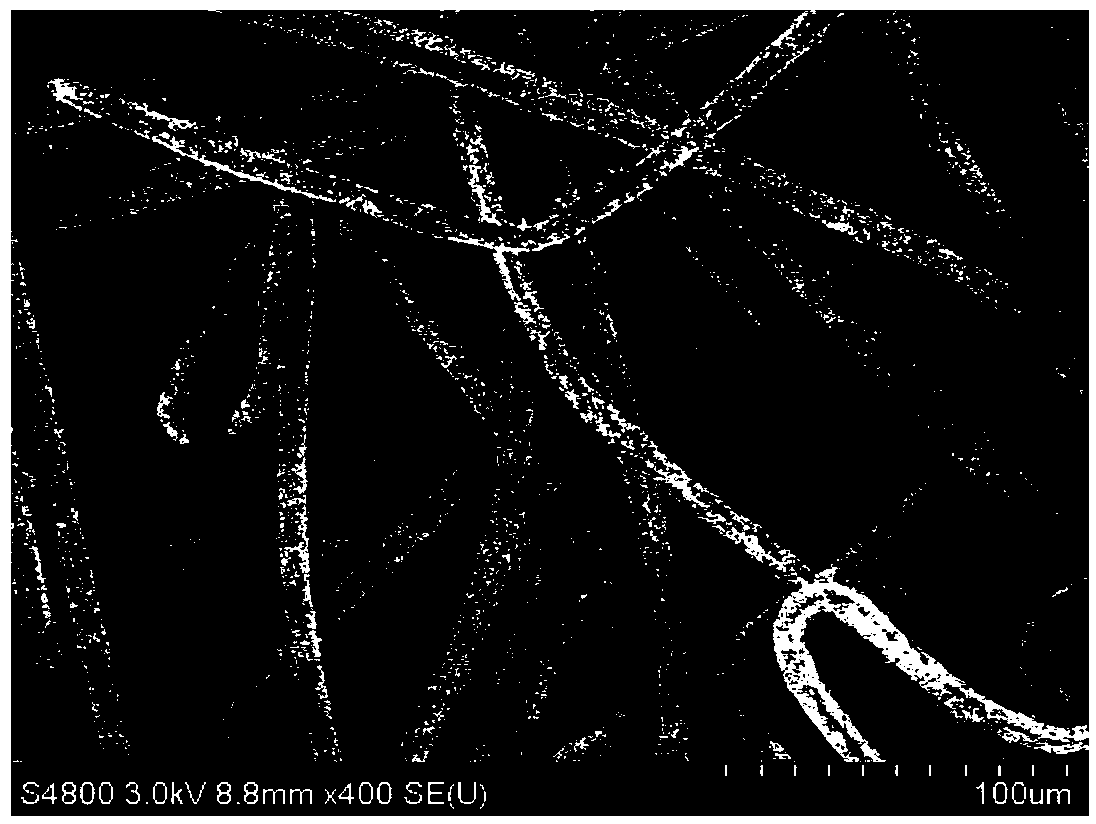

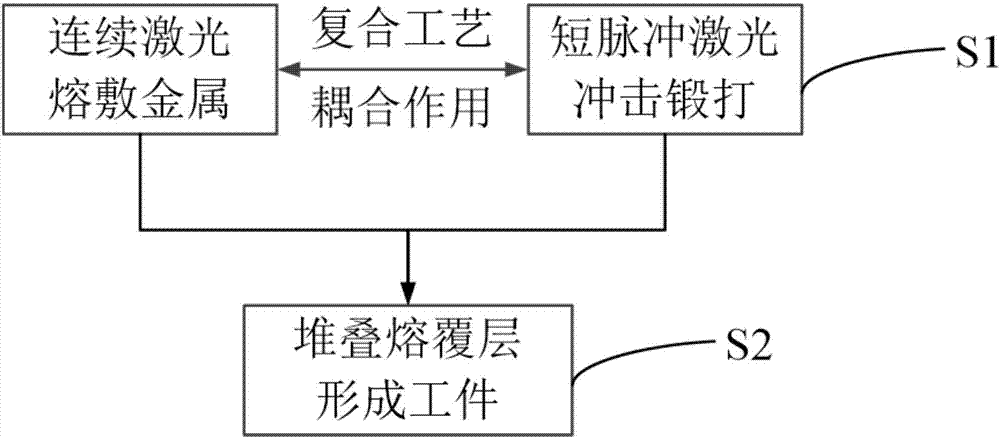

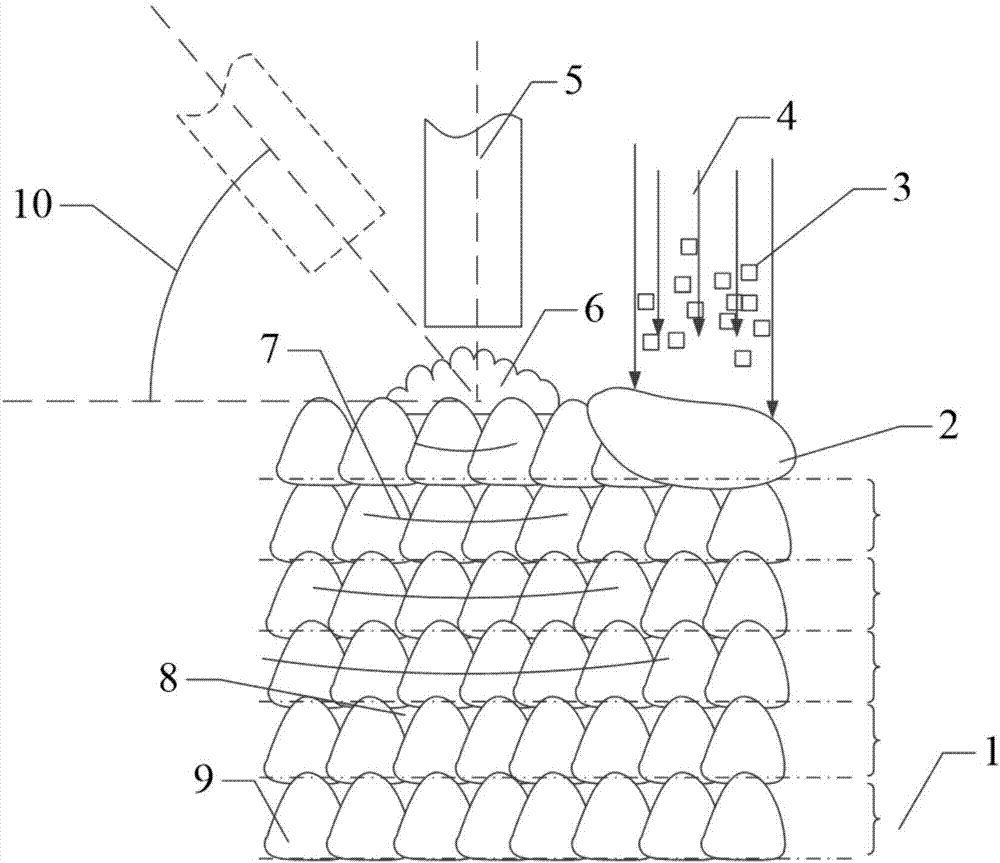

Method for additive manufacturing through depositing, forming, impacting, forging and compositing through double laser beams

InactiveCN107475709AWith laser pulse energyWith laser pulse widthAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsLaser beams

Owner:GUANGDONG UNIV OF TECH

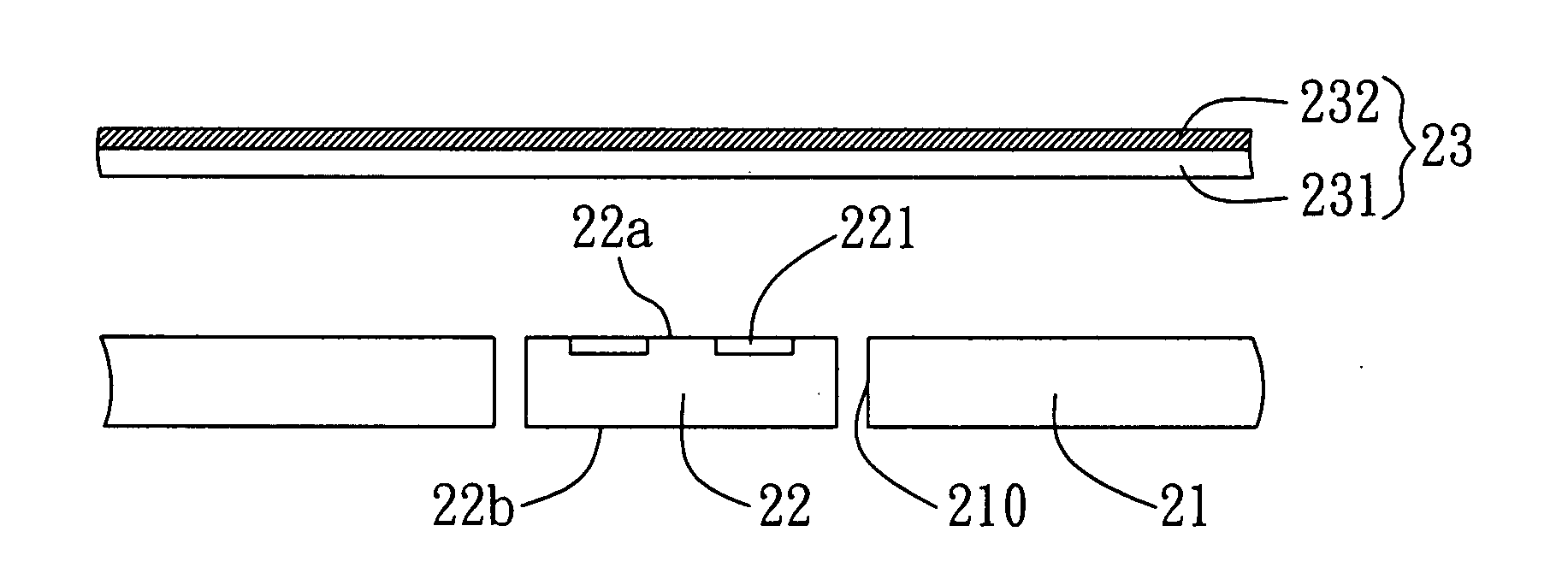

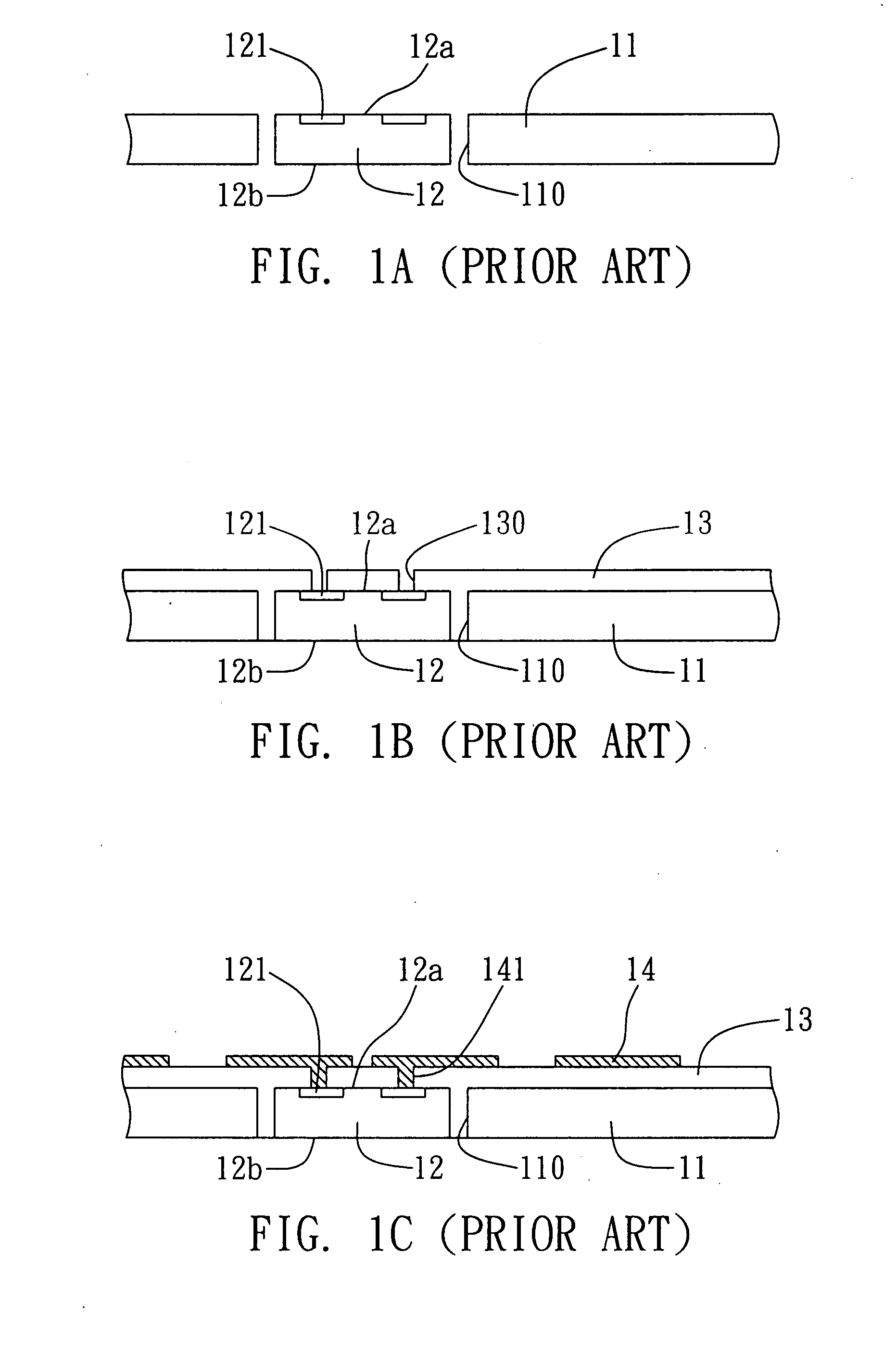

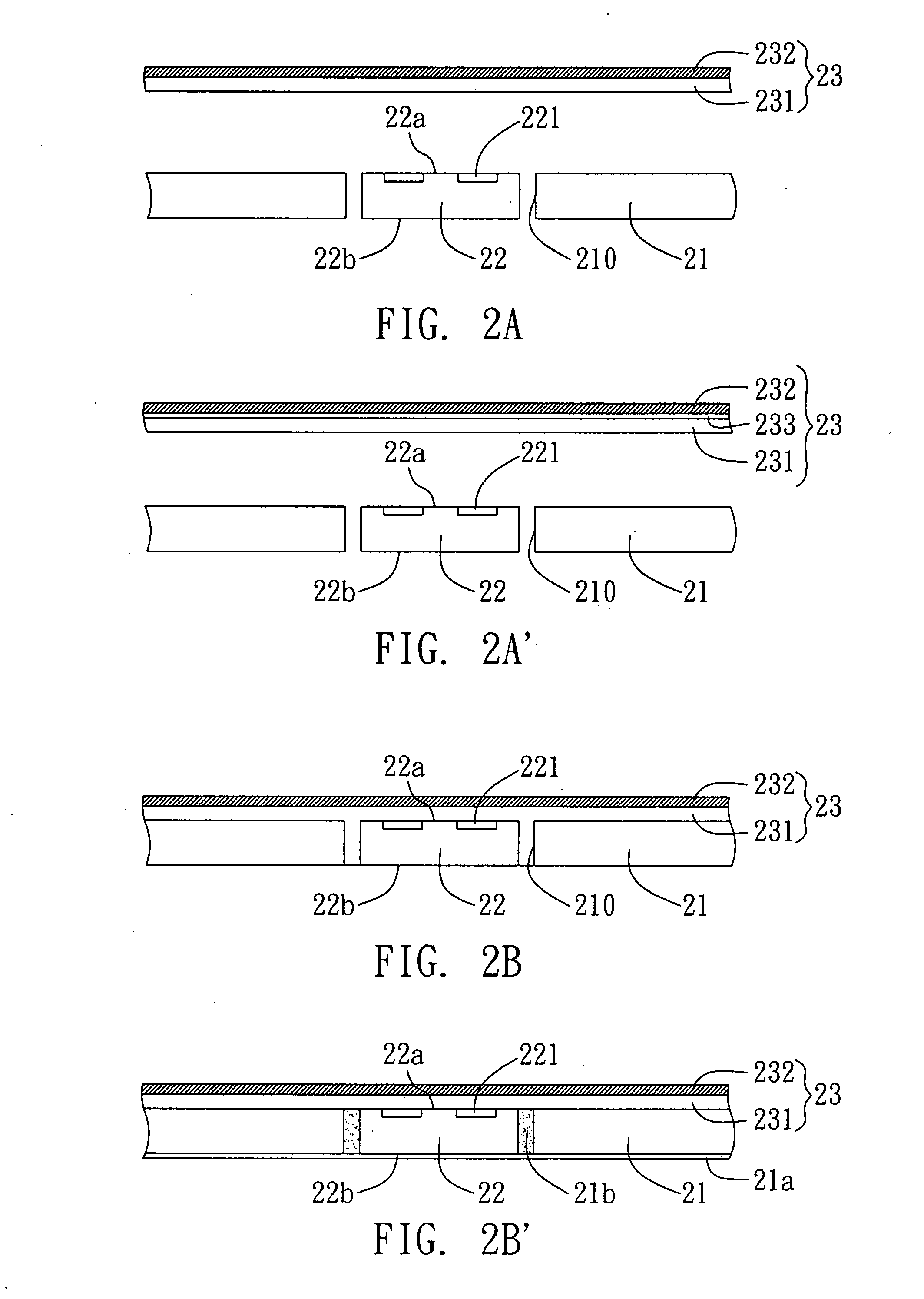

Circuit board structure with embedded semiconductor chip and method for fabricating the same

InactiveUS20080067666A1High bonding strengthReduce problemsSemiconductor/solid-state device detailsPrinted circuit aspectsThin metalSemiconductor chip

A circuit board structure having an embedded semiconductor chip and a method for fabricating the same are disclosed. The circuit board structure includes: a carrier board formed with at least one through hole; a semiconductor chip received in the through hole of the carrier board, the semiconductor chip having an active surface and a non-active surface, wherein the active surface is provided with a plurality of electrode pads; a dielectric layer formed on surfaces of the carrier board and the semiconductor chip and formed with a plurality of openings for exposing the electrode pads of the semiconductor chip; and a composite circuit layer formed on the dielectric layer, including a thinned metal layer, conductive layer, and electroplated metal layer, and electrically connected to the electrode pads by conductive structures formed in the openings of the dielectric layer. Strong bonding provided by the composite circuit layer formed on the dielectric layer thus desirably reduces the warpage problem resulted from thermal effect.

Owner:PHOENIX PRECISION TECH CORP

Electrochromic fiber and preparation method and application thereof

ActiveCN110205688AWide range of choicesPerfect structural designFilament/thread formingWoven fabricsFiberColor changes

The invention belongs to the field of functional fibers and particularly relates to an electrochromic fiber and a preparation method and application thereof. The electrochromic fiber comprises a composite material in a three-layer structure which comprises a coating layer, a middle layer and a core layer sequentially from outside to inside, wherein the coating layer is a protective layer, the middle layer is an electrochromic layer, and the core layer is a conductive layer. The conductive layer is made of a conductive layer material with an electrothermal effect; the electrochromic layer is prepared according to a thermal softening wire-drawing method, and a preformed rod of the electrochromic layer comprises a hole structure; the conductive layer material penetrates a hole of the preformed rod, and the conductive layer serving as the core layer is prepared in the electrochromic layer while the electrochromic layer is obtained according to the thermal softening wire-drawing method. Inuse of the electrochromic fiber, the conductive layer material emits heat under an electrified condition, and the electrochromic layer material of the middle layer gives play to a color changing function under the thermal action of the conductive layer.

Owner:武汉新润兴材料科技有限公司

Microwave-assisted supercritical carbon dioxide cyclic fracturing system and microwave-assisted supercritical carbon dioxide cyclic fracturing method

ActiveCN106285604AImprove diffusion abilityImprove adsorption capacityFluid removalGas removalPorosityDesorption

The invention relates to a microwave-assisted supercritical carbon dioxide cyclic fracturing system and a microwave-assisted supercritical carbon dioxide cyclic fracturing method. The microwave-assisted supercritical carbon dioxide cyclic fracturing system comprises a liquid carbon dioxide tank, a heater, a boosting pump, a fracturing pipe, a return pipe, a three-phase separator, an air compressor and a cooler which form a loop to achieve supercritical carbon dioxide cyclic fracturing, and a fracture network is formed in a coal seam. According to the microwave-assisted supercritical carbon dioxide cyclic fracturing method, the coal seam and carbon dioxide are subjected to microwave heating to ensure that the carbon dioxide is in the supercritical state for a long time, and heat effect of microwave heating is capable of fracturing coal masses, dredging pores and promoting gas desorption. The microwave-assisted supercritical carbon dioxide cyclic fracturing system and the microwave-assisted supercritical carbon dioxide cyclic fracturing method have the advantages that the supercritical carbon dioxide high in diffusivity is capable of going deep into coal mass pores and fractures quite easily as well as dispelling gas; operation costs are reduced effectively and the construction technology is simplified effectively through cyclic fracturing; microwave radiation is combined with supercritical carbon dioxide cyclic fracturing to increase porosity and permeability of the coal seam greatly and promote gas desorption, so that gas extraction effects are improved substantially, and the system and the method are highly practical in the field.

Owner:CHINA UNIV OF MINING & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com