Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2044 results about "Stress distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

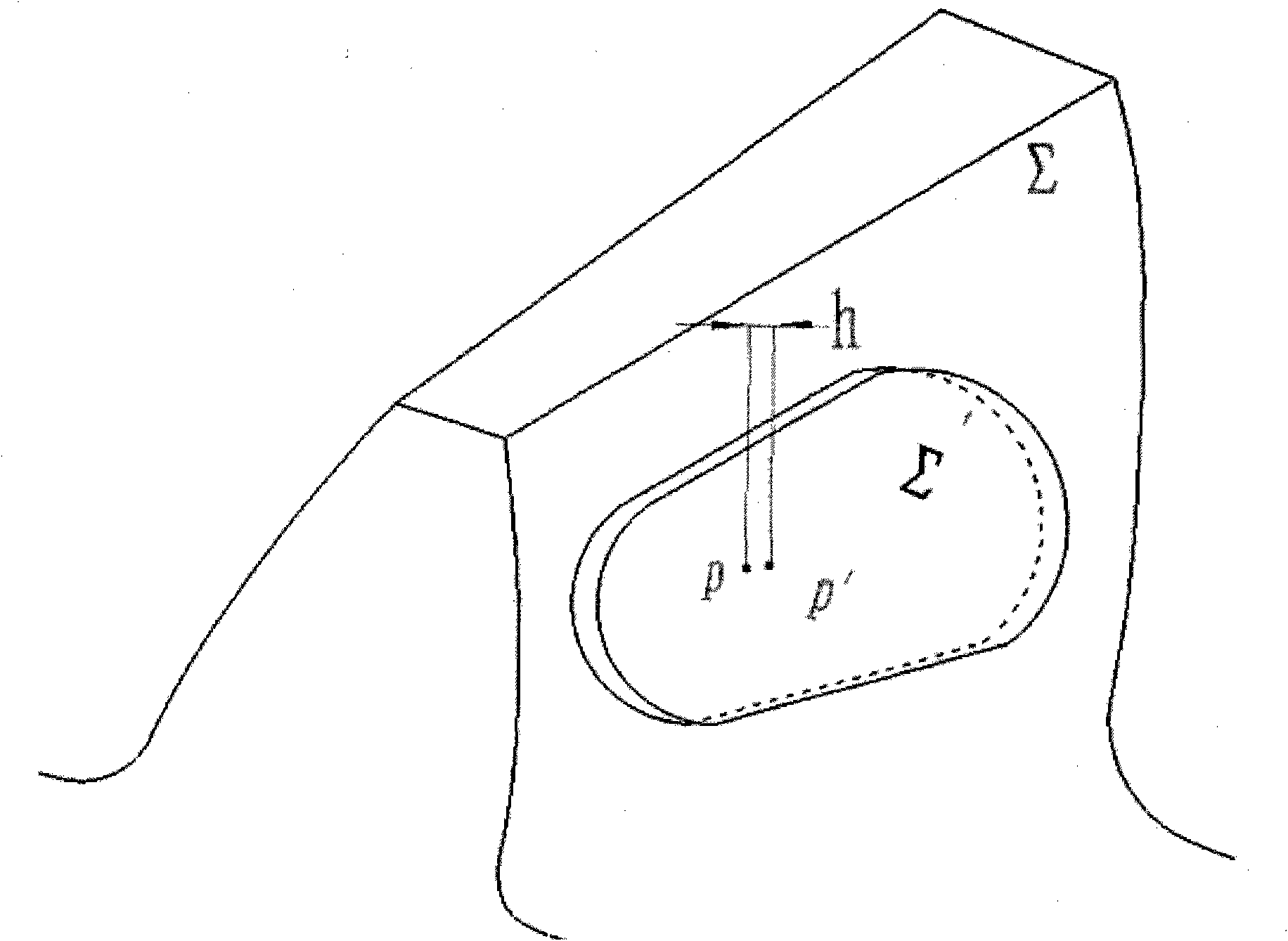

The stress distribution is usually estimated from customer usage data, such as the mileage per year of a passenger car or the load distribution for a beam. The strength distribution, on the other hand, is affected by the material used in the component, the geometric dimensions and the manufacturing process.

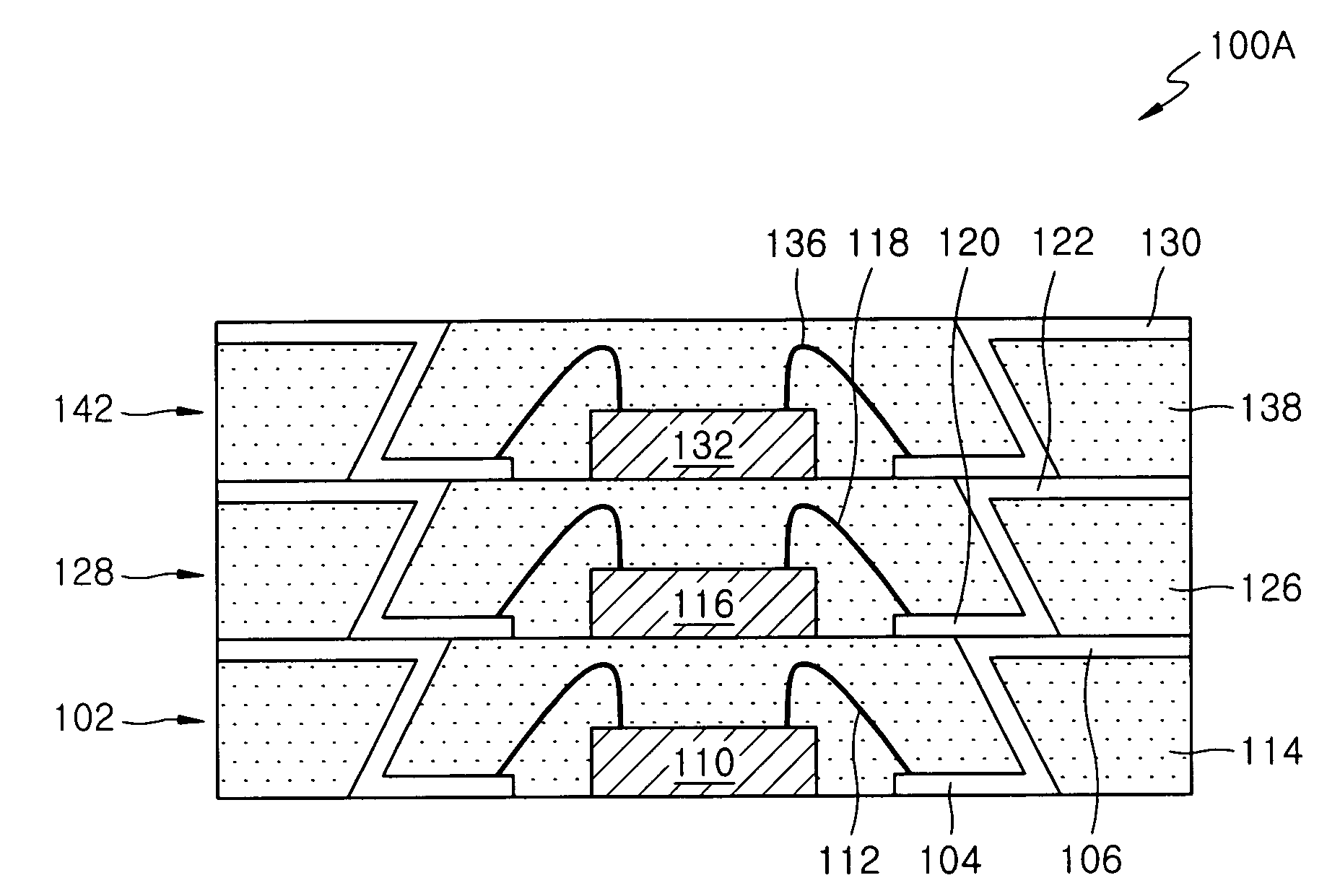

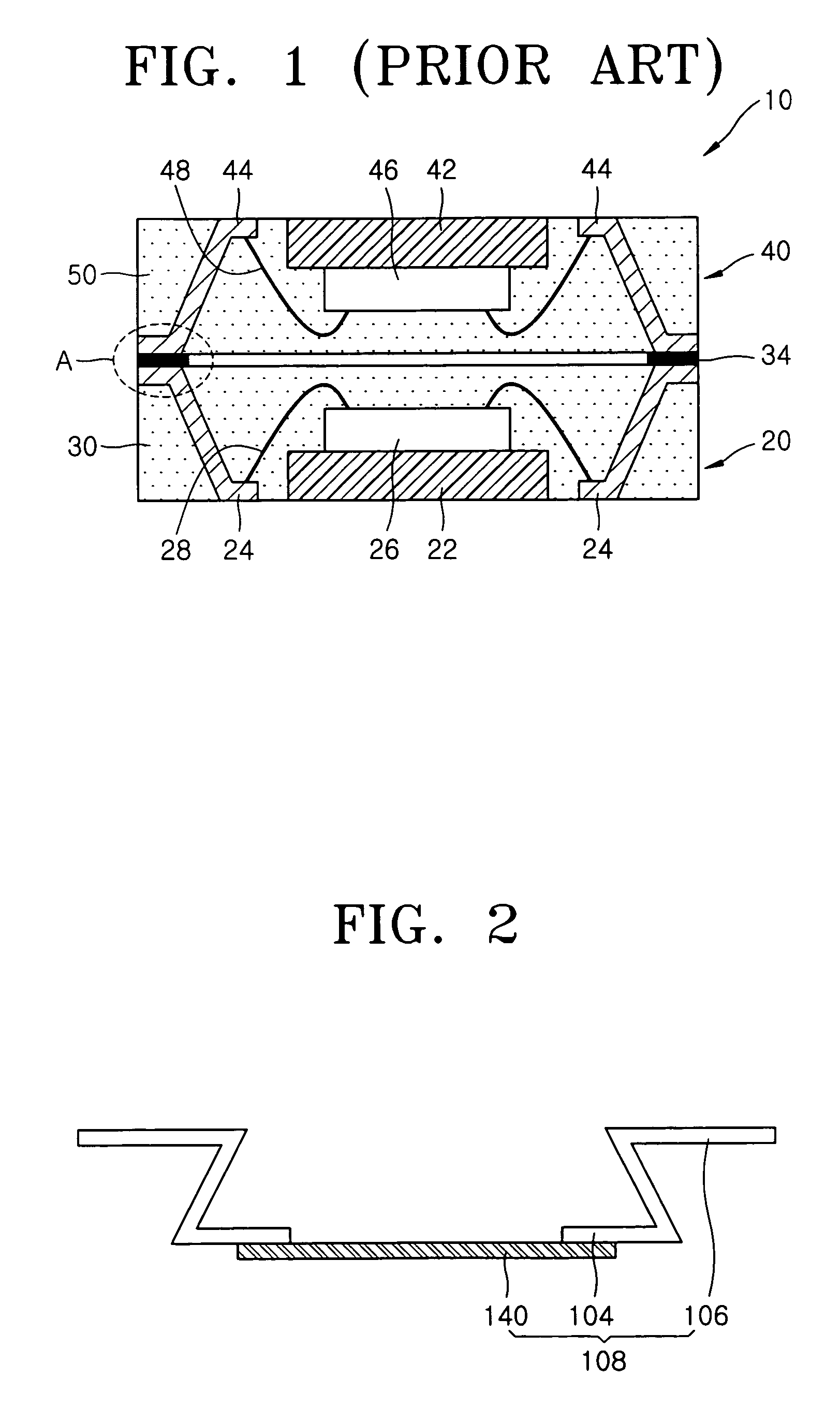

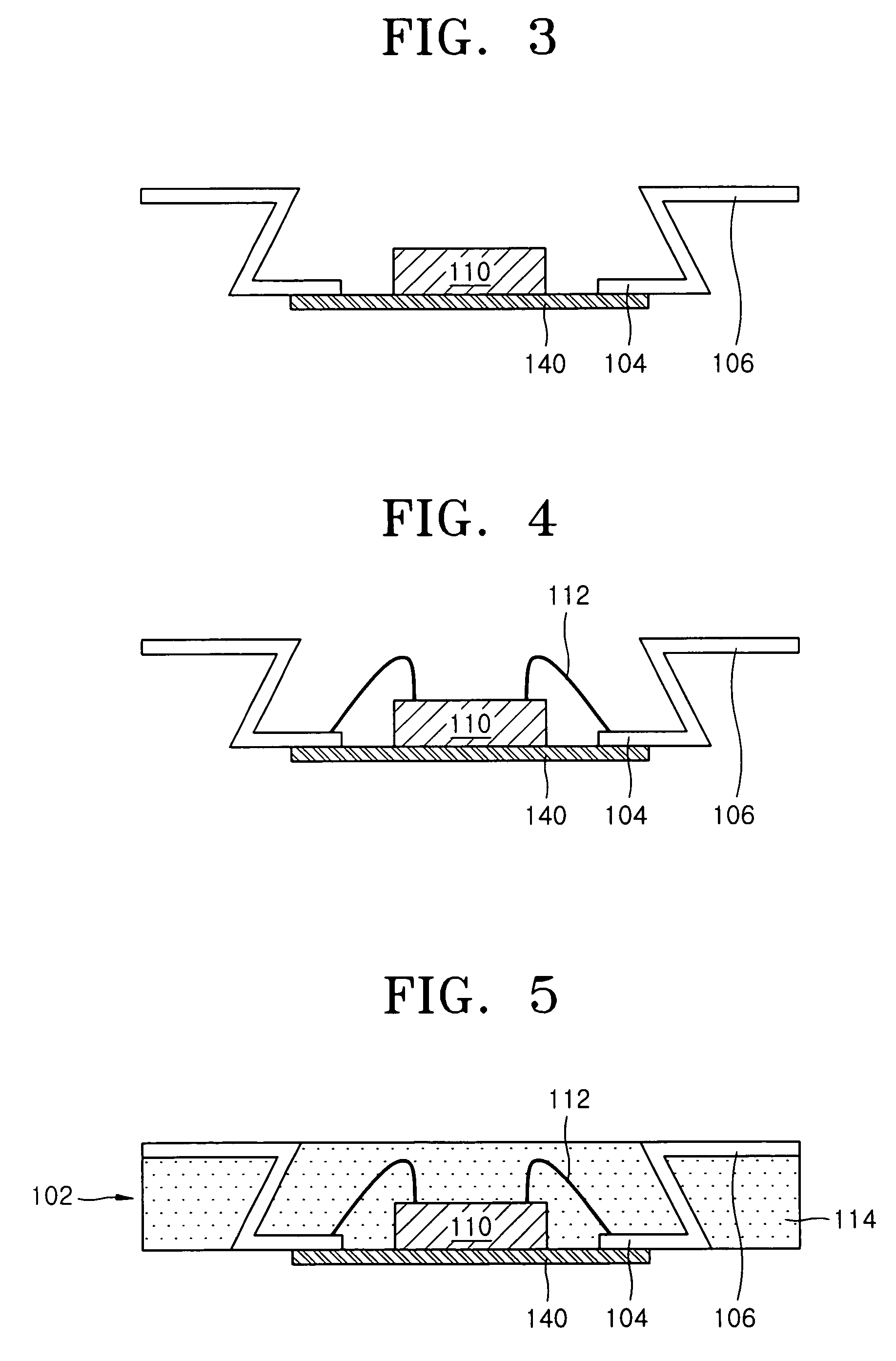

Stack semiconductor package formed by multiple molding and method of manufacturing the same

InactiveUS7476962B2Avoid breakingSemiconductor/solid-state device detailsSolid-state devicesStress concentrationStress distribution

Owner:SAMSUNG ELECTRONICS CO LTD

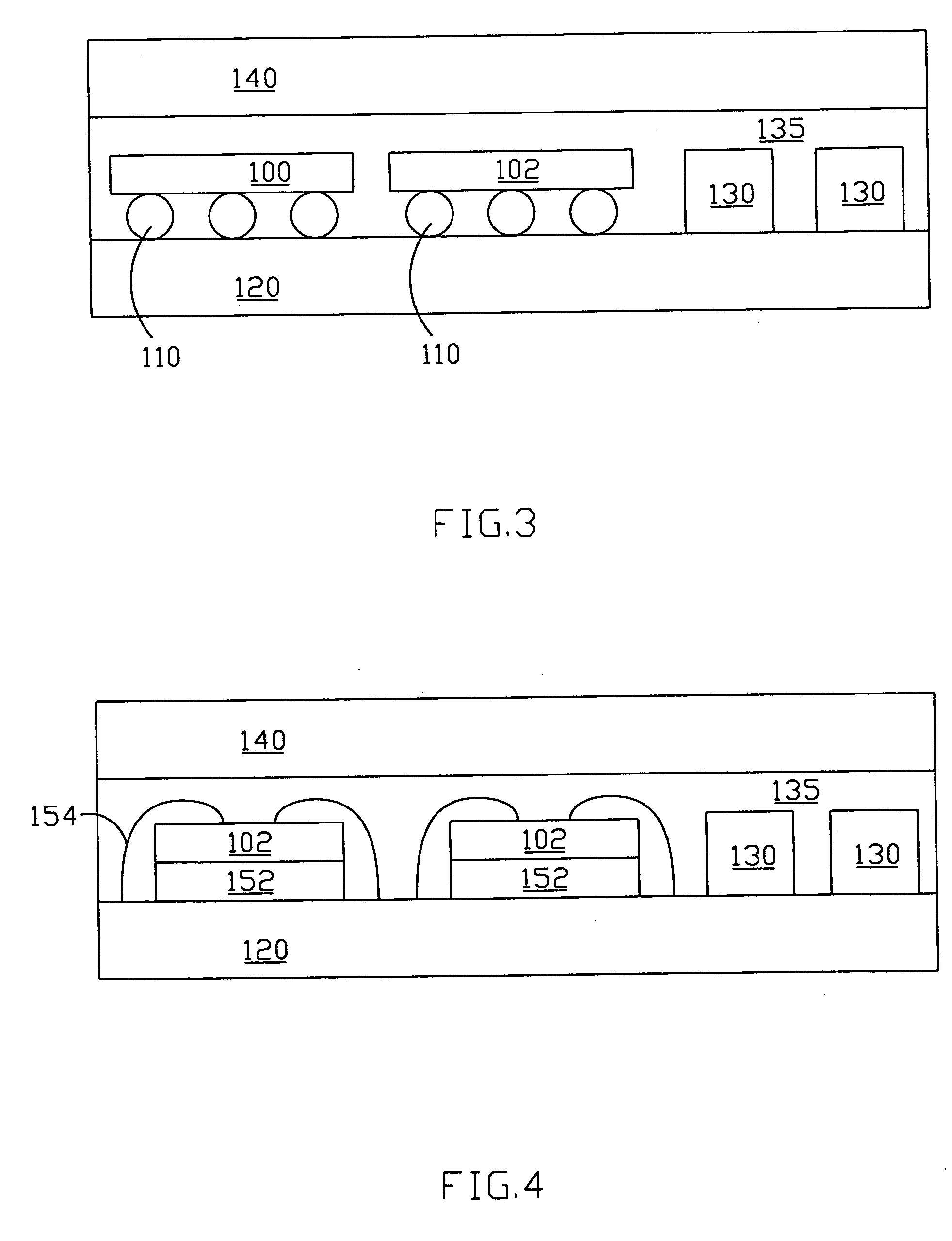

Integrated circuit package with a balanced-part structure

InactiveUS7176559B2Reduce warpageIncrease yield and stabilitySemiconductor/solid-state device detailsSolid-state devicesStress distributionEngineering

An integrated circuit package includes a balanced-part structure. The condition of thermal stress of chips connected on a substrate decides the amount, locations, weights, and the material of at least a balanced-part fastened on a substrate. The balanced-part is fastened on the substrate to balance stress distribution before an adhering heat sinks process and a packaging molding compound process. The balanced-part also decreases thermal stress affection and avoid warpage defects of the integrated circuit packages.

Owner:VIA TECH INC

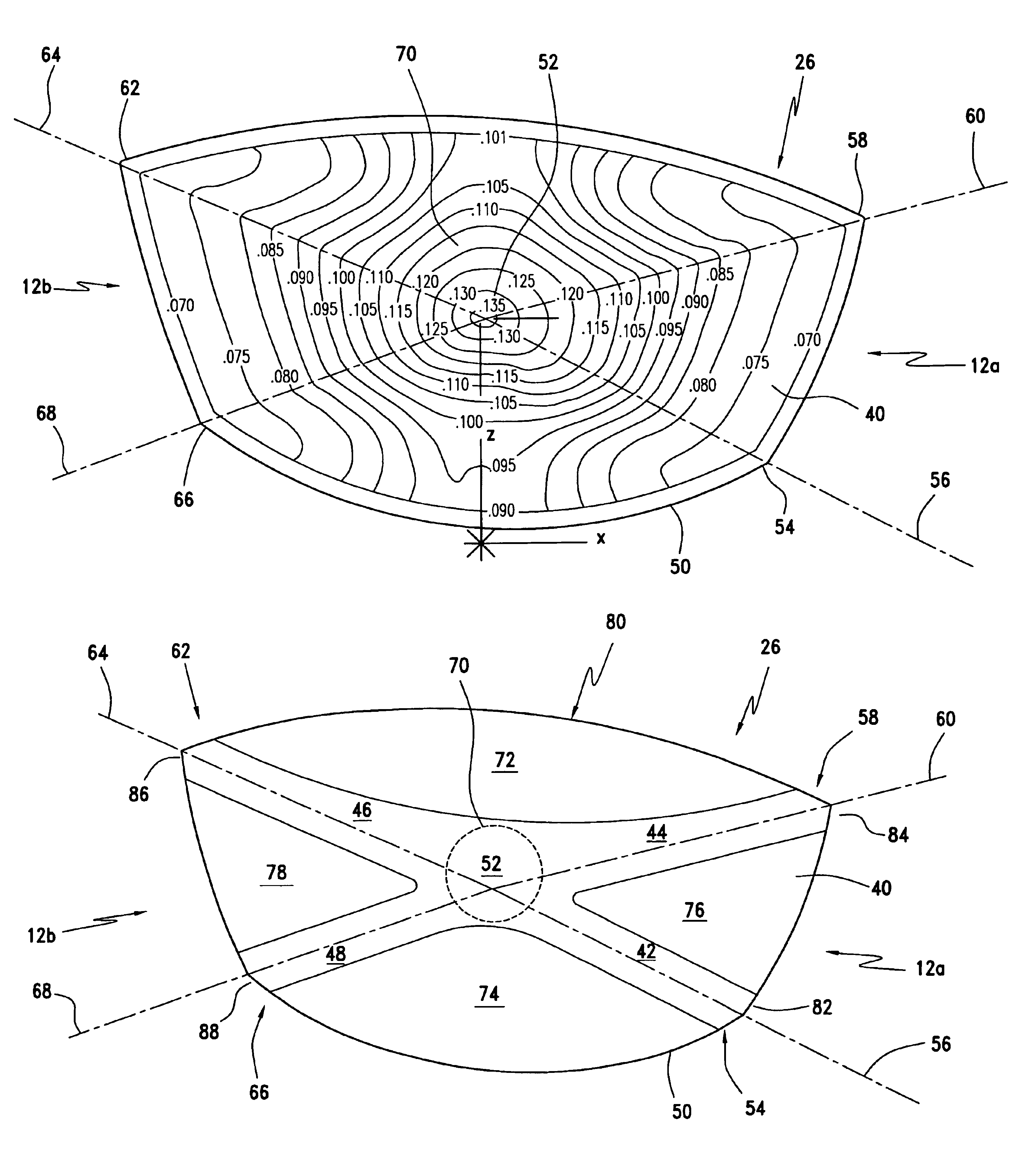

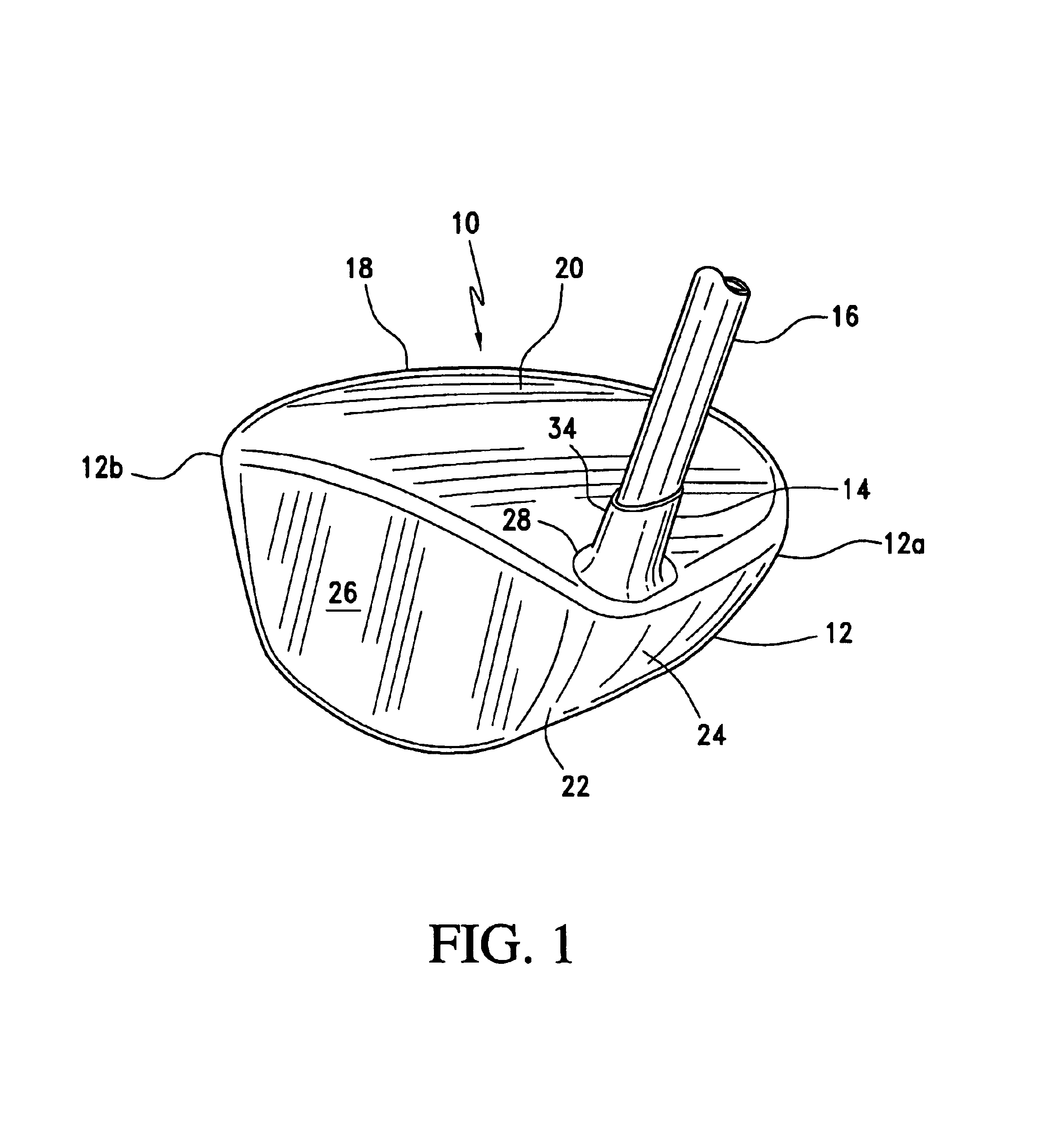

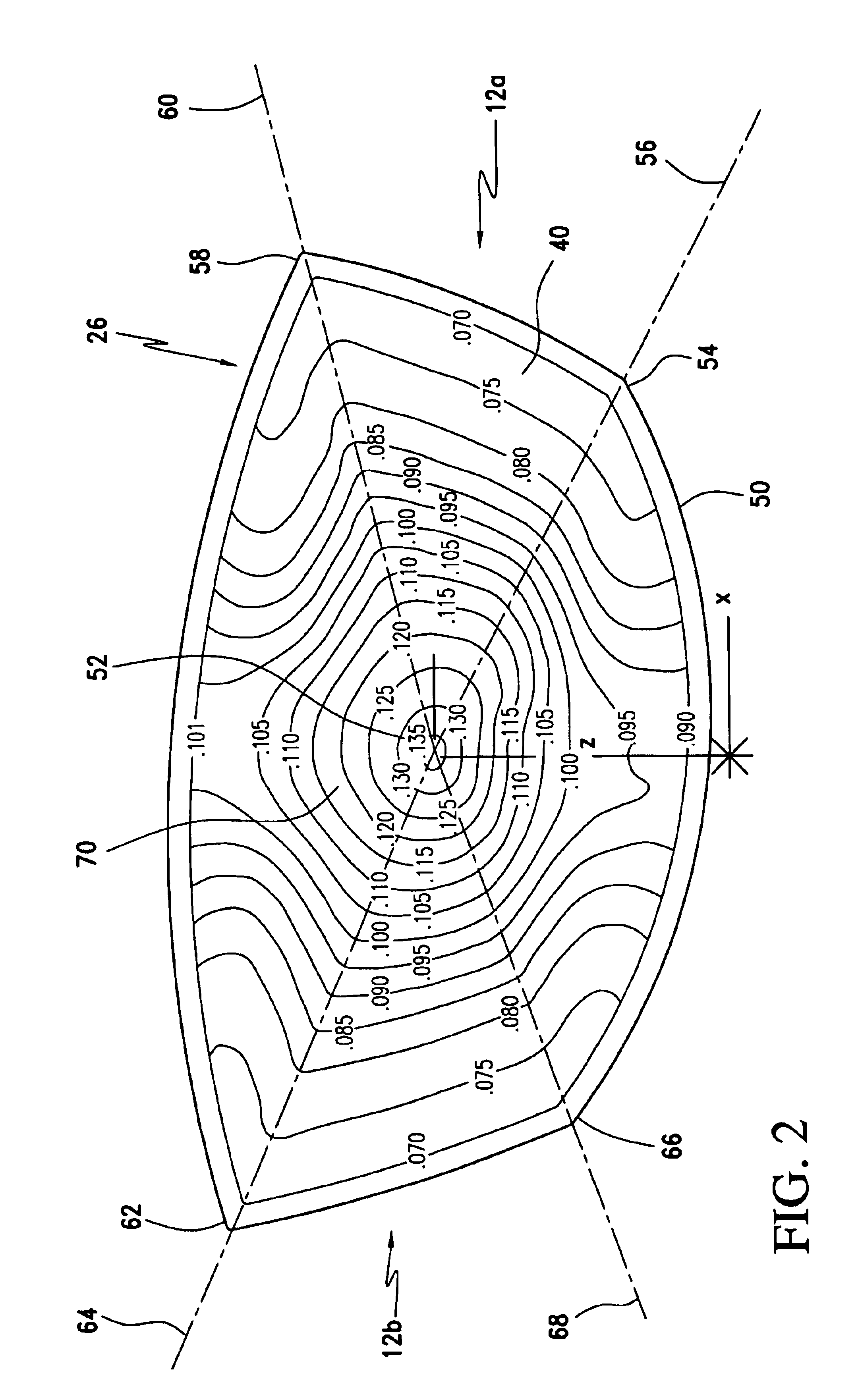

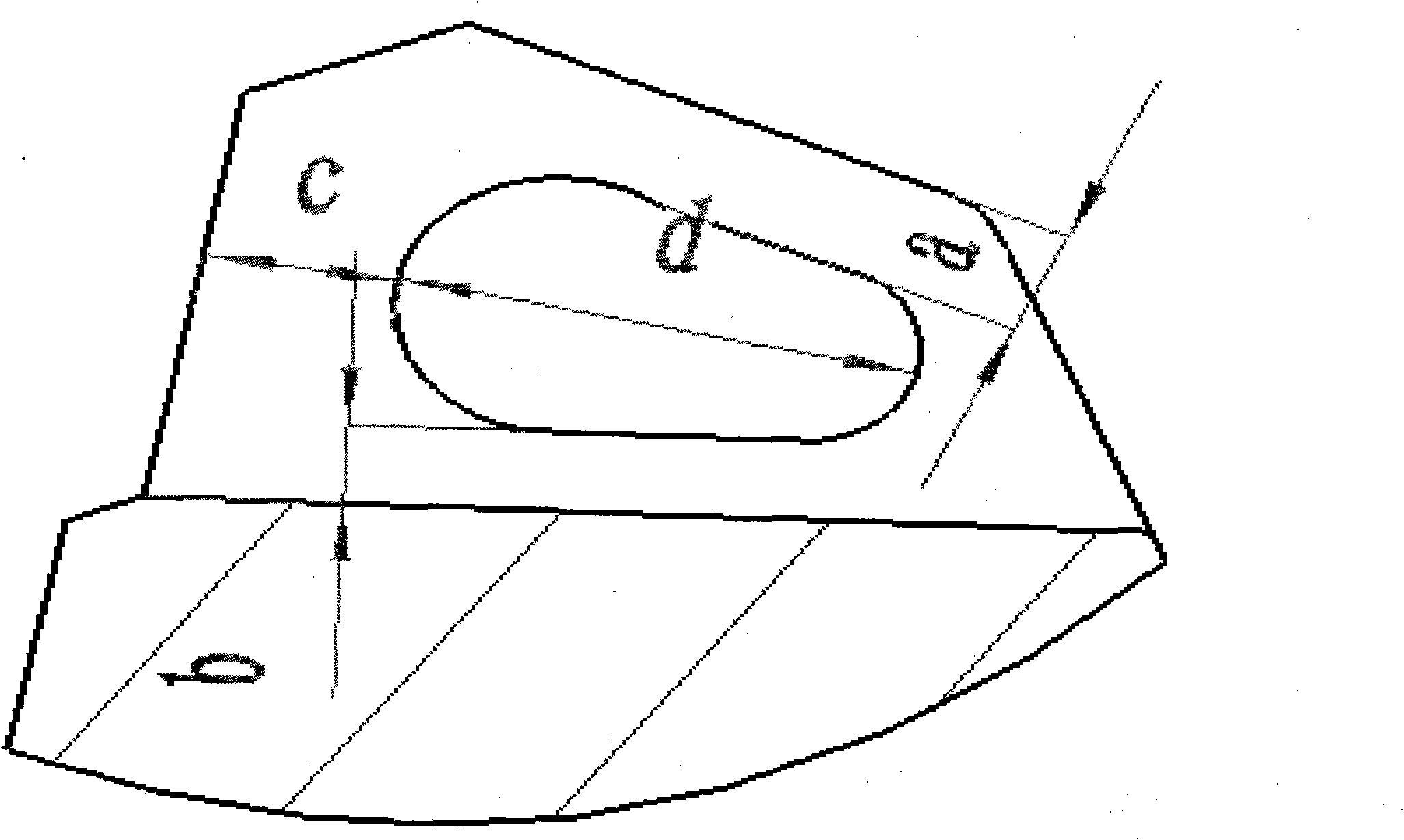

Golf club with diagonally reinforced contoured front wall

InactiveUS6926618B2Convenient lengthEfficient transferGolf clubsRacket sportsStress distributionFour quadrants

A golf club head composed of a forged metal material has a striking surface that is supported by diagonal stiffening regions that extend from a central region of the face toward the heel-sole quadrant, heel-crown quadrant, toe-crown quadrant, and toe-sole quadrants of the face. The diagonal stiffening regions are smoothly contoured to blend into the back surface of the face so as to avoid any stress concentrations. By extending the stiffening regions diagonally from the center of the club face to the four quadrants, a more uniform stress distribution can be obtained and therefore more uniform performance. Additionally, since the diagonal stiffening regions are greater in length than vertical or horizontal stiffening region could be made, the center of the face can deflect a greater amount without exceeding the yield strength of the material and, therefore, there is a more efficient transfer of energy from the club head to the ball.

Owner:KARSTEN MFG CORP

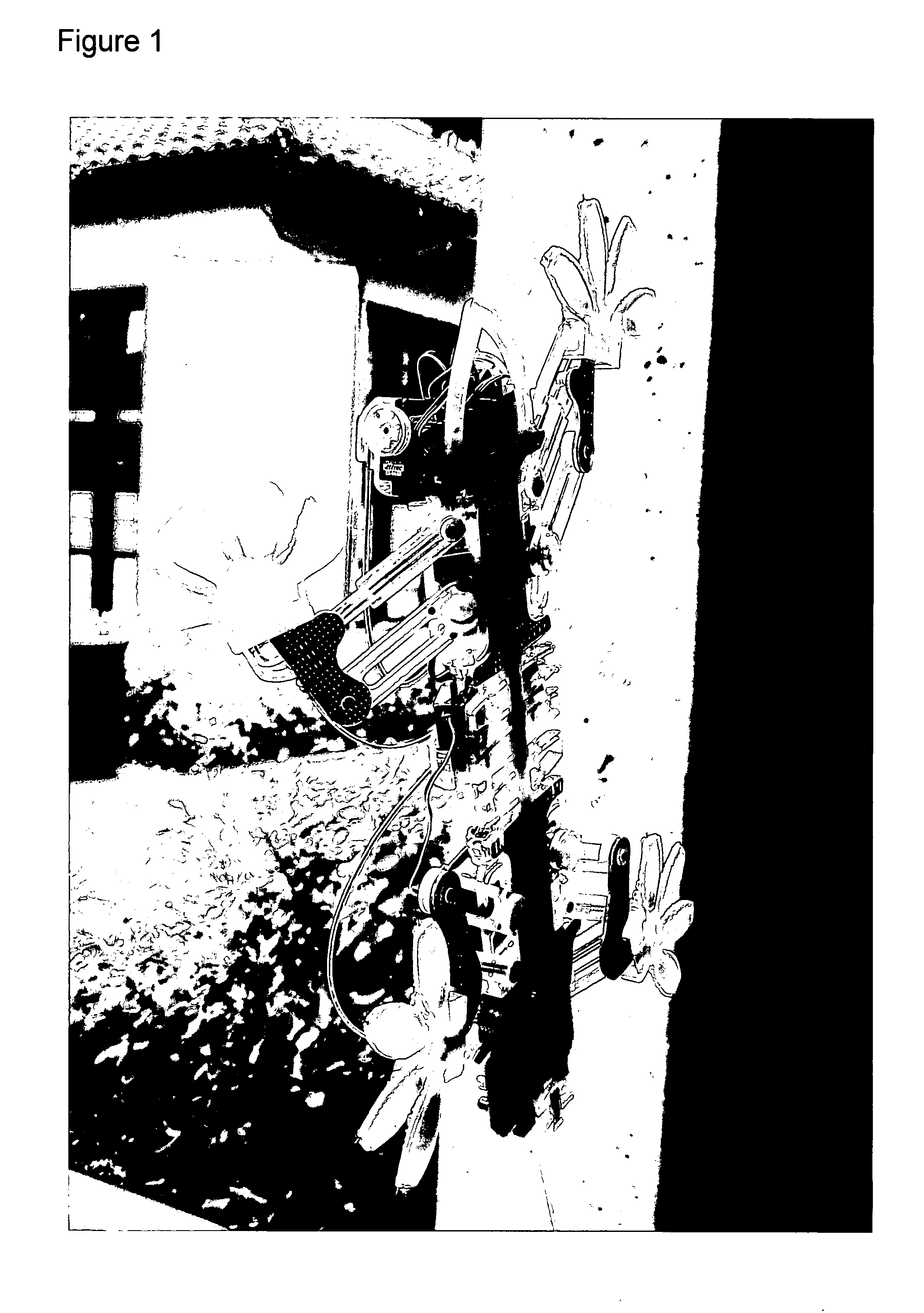

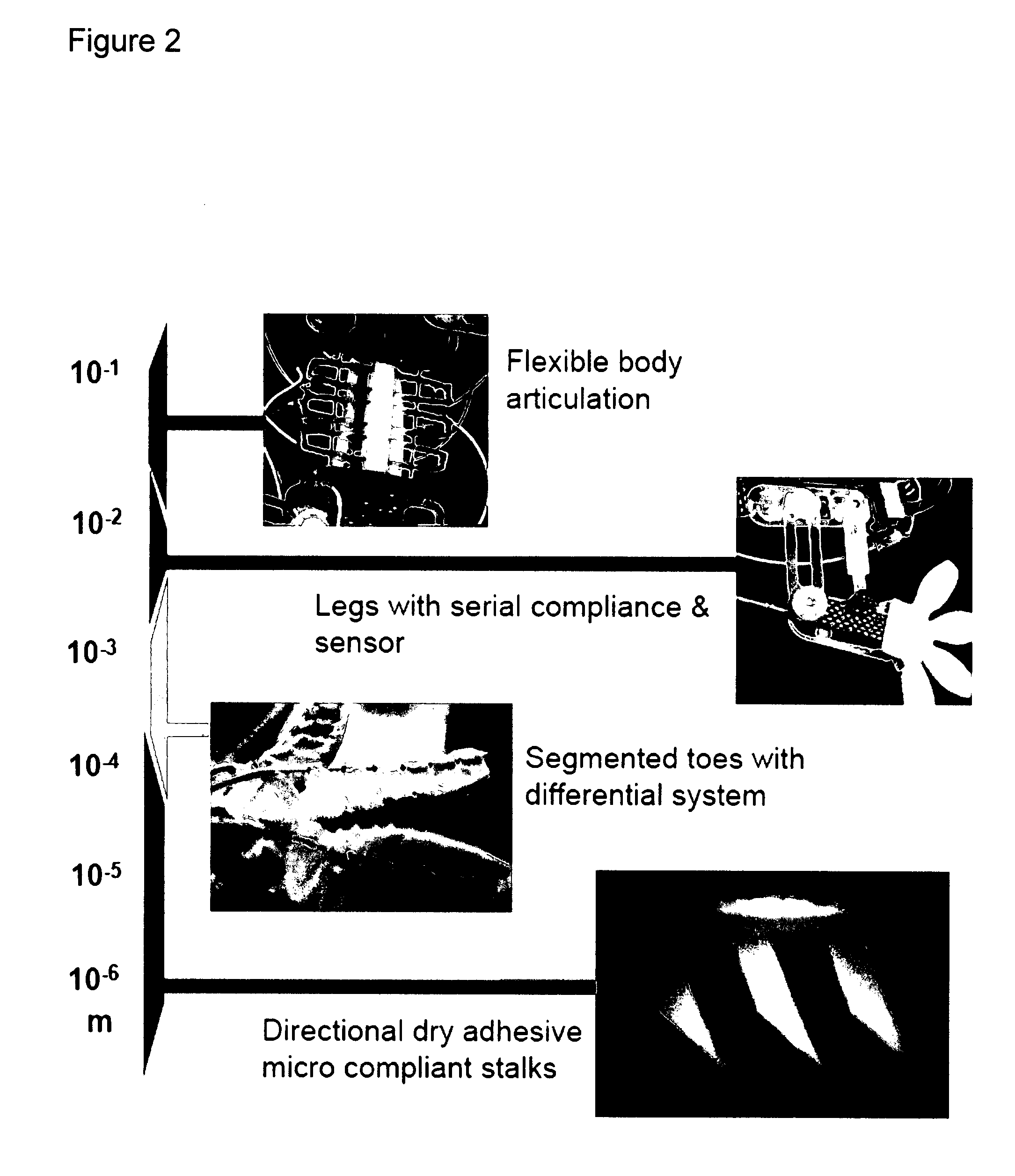

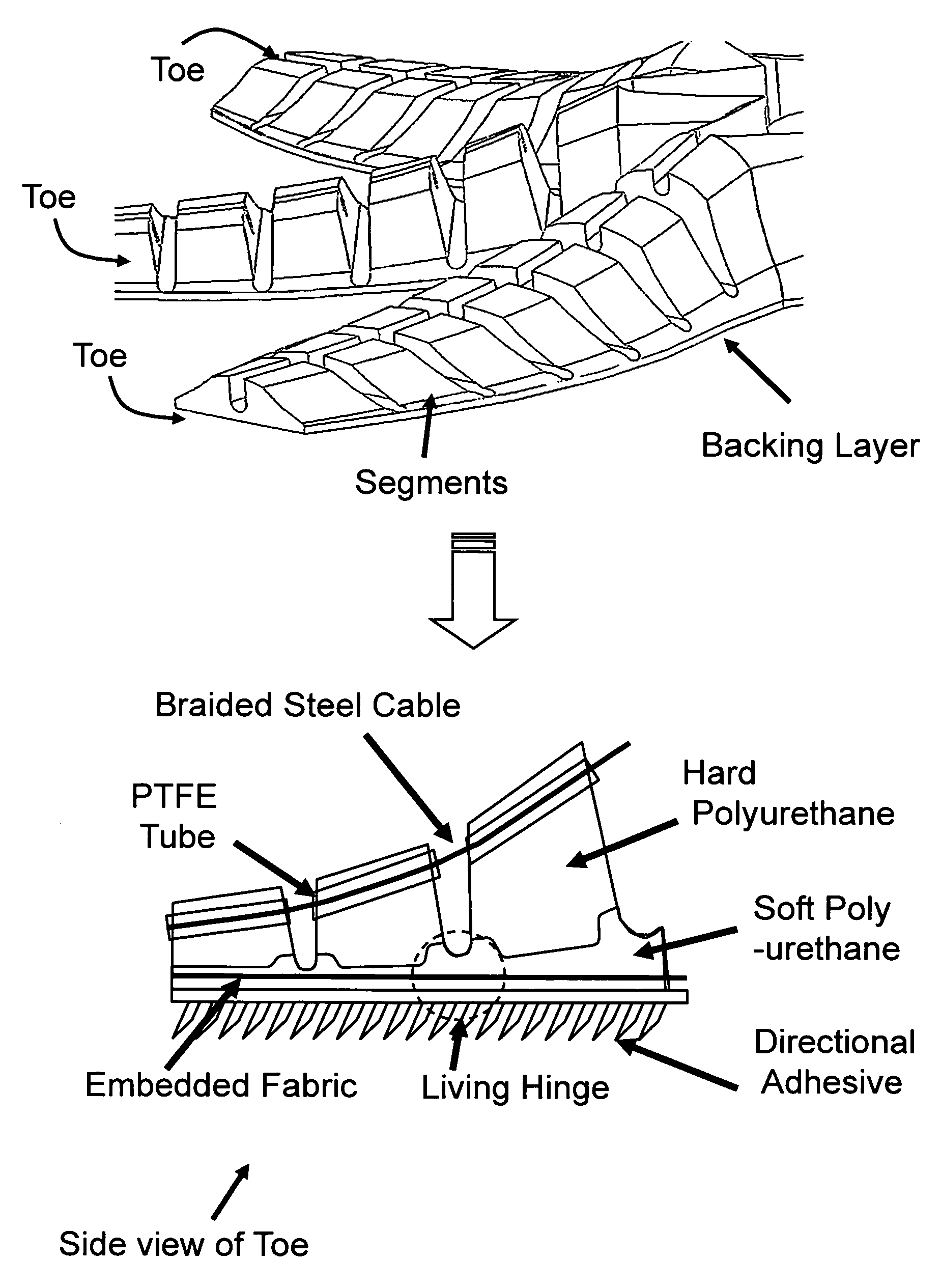

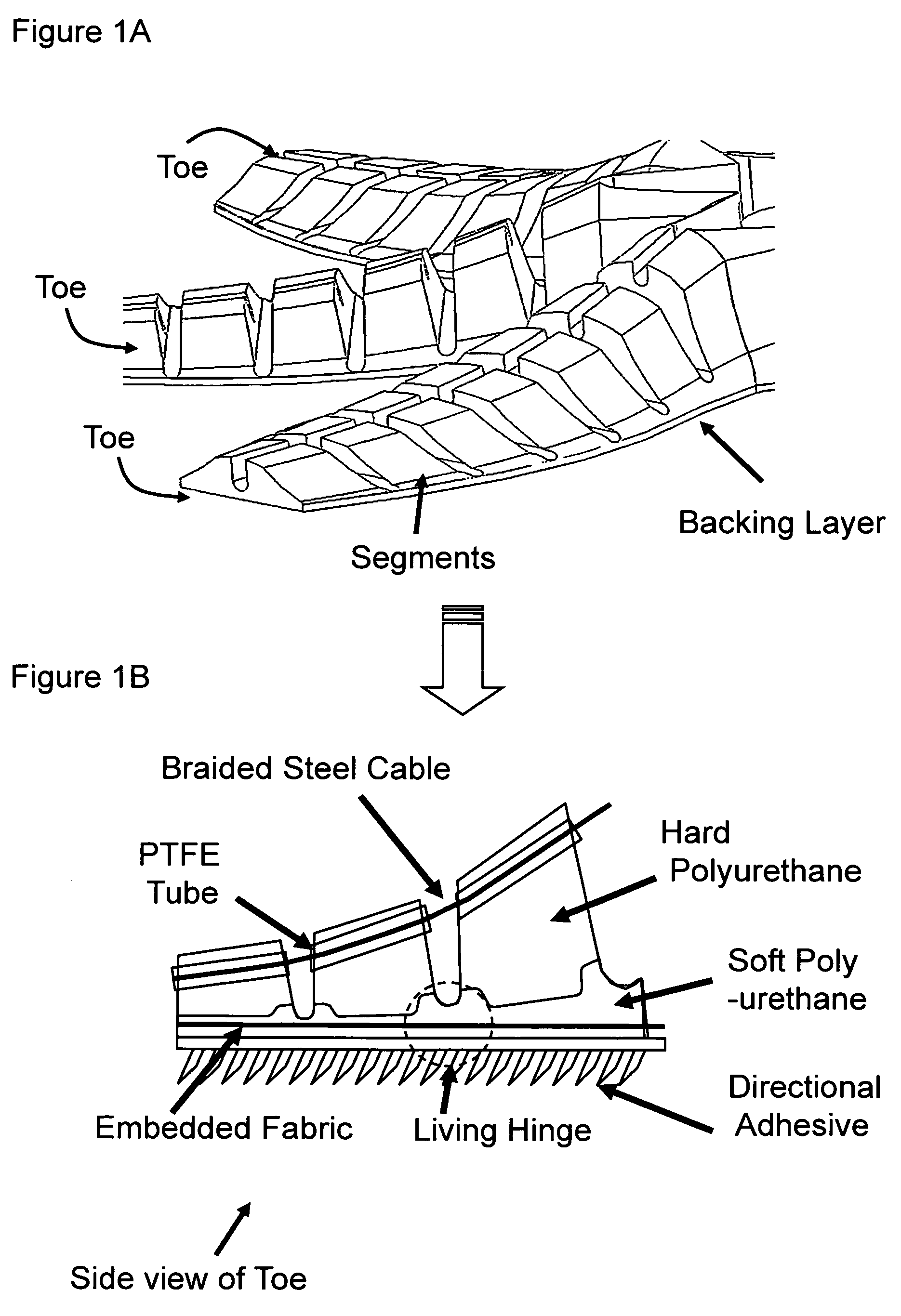

Climbing with dry adhesives

ActiveUS20070289786A1Facilitate disengagementSolve the lack of adhesionLifting devicesVehiclesStress distributionMicrometer

A bio-inspired device is provided designed to scale smooth vertical surfaces using anisotropic frictional materials. The device draws its inspiration from geckos and other climbing lizards and employs similar compliance and force control strategies to climb (or hang onto) smooth vertical surfaces including glass, tile and plastic panels. Foremost among the design features embodied in the device are multiple levels of compliance, at length scales ranging from centimeters to micrometers, to allow the device to conform to surfaces and maintain large real areas of contact so that adhesive forces can support it. Structures within the feet ensure even stress distributions over each toe and facilitate engagement and disengagement of the adhesive materials. A force control strategy works in conjunction with the anisotropic adhesive materials to obtain sufficient levels of friction and adhesion for climbing with low attachment and detachment forces.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

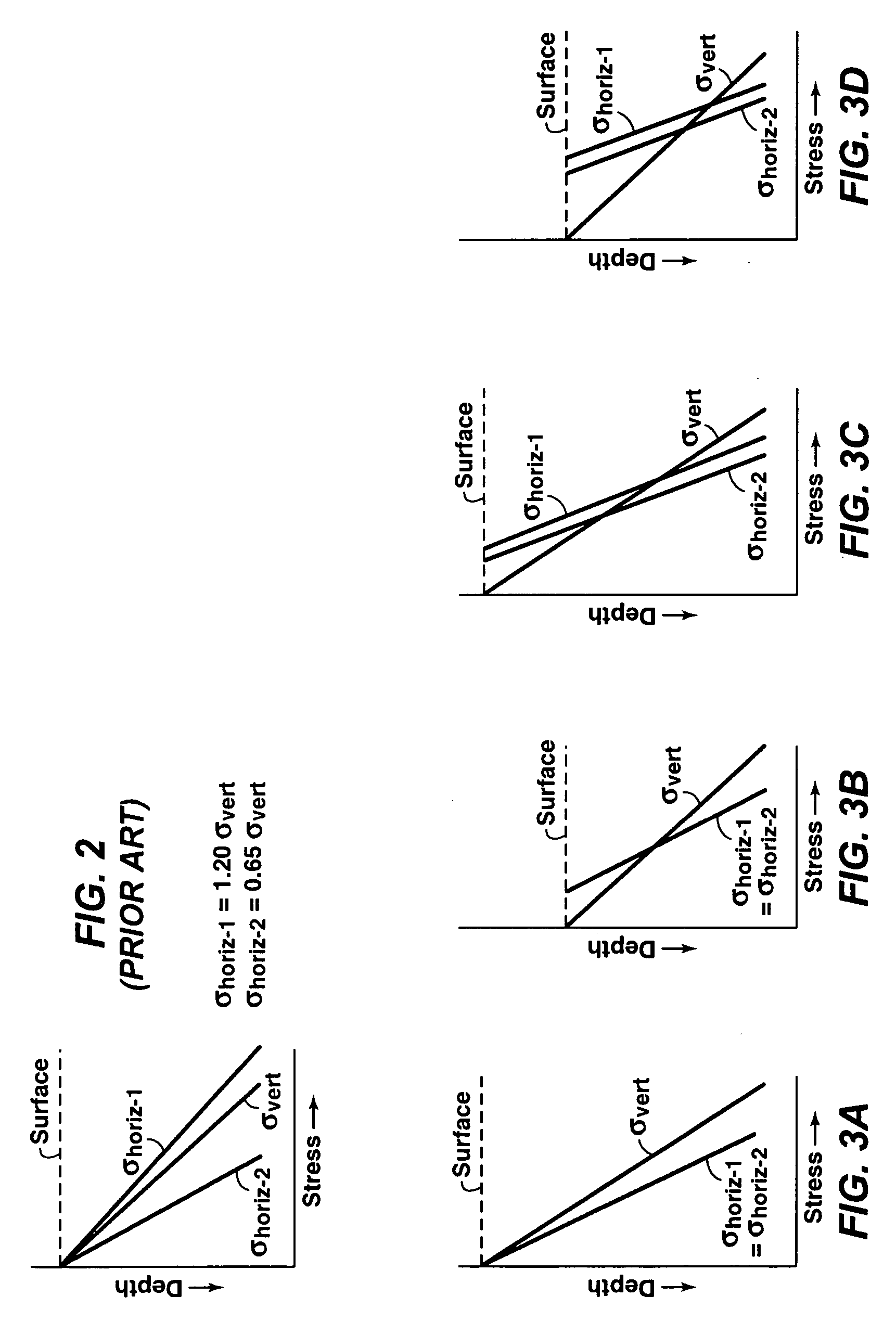

Method for calibrating a model of in-situ formation stress distribution

InactiveUS20060100837A1Borehole/well accessoriesAnalogue processes for specific applicationsPresent dayStress measurement

A method for producing a substantially calibrated numerical model, which can be used for calculating a stress on any point in a formation, accounts for a formation's geologic history using at least one virtual formation condition to effectively “create” the present-day, virgin stress distribution that correlates, within acceptable deviation limits, to actual field stress measurement data obtained for the formation. A virtual formation condition may describe an elastic rock property (e.g., Poisson ratio, Young's modulus), a plastic rock property (e.g., friction angle, cohesion) and / or a geologic process (e.g., tectonics, erosion) considered pertinent to developing a stratigraphic model suitable for performing the desired stress analysis of the formation.

Owner:EXXONMOBIL UPSTREAM RES CO

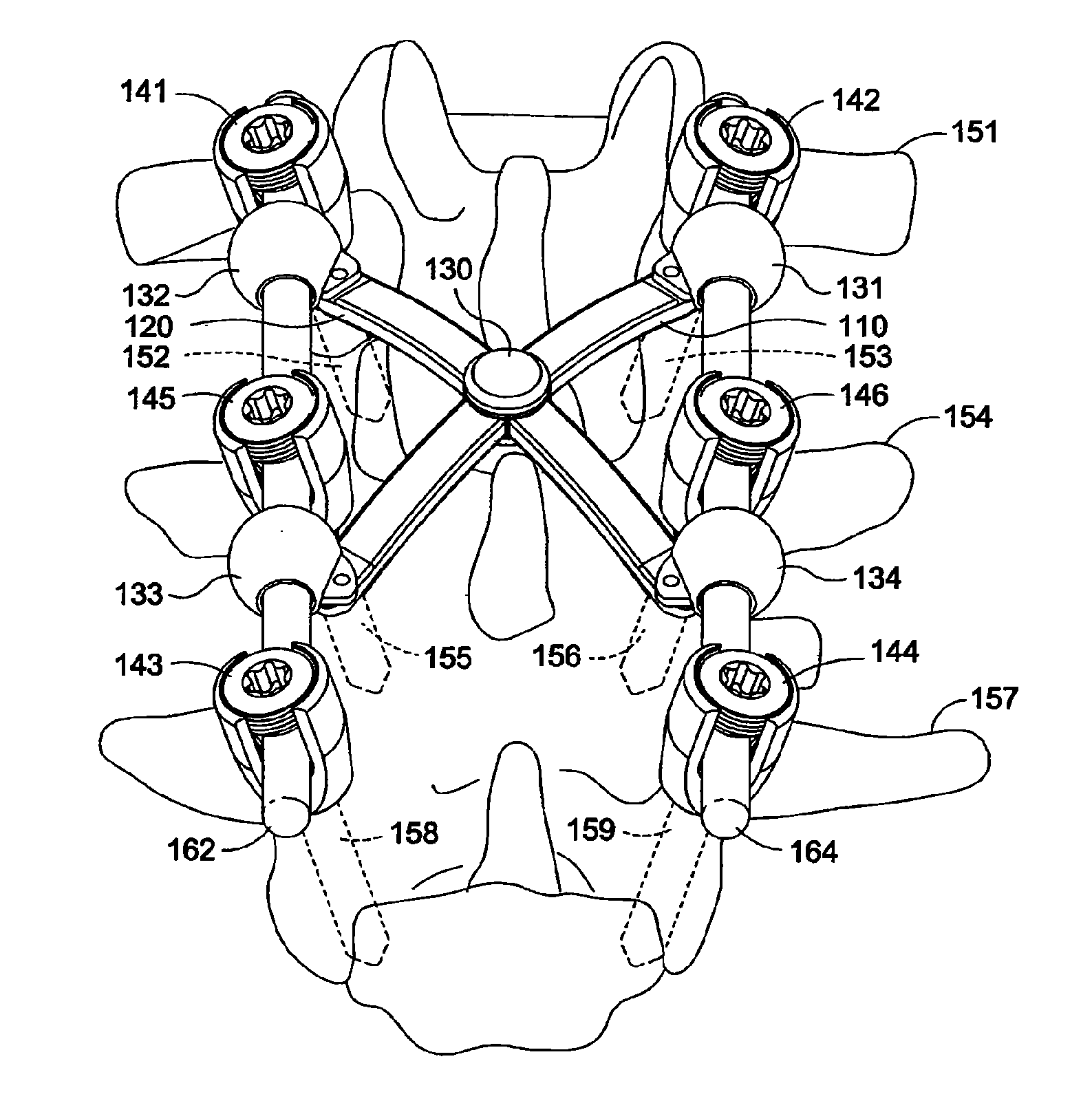

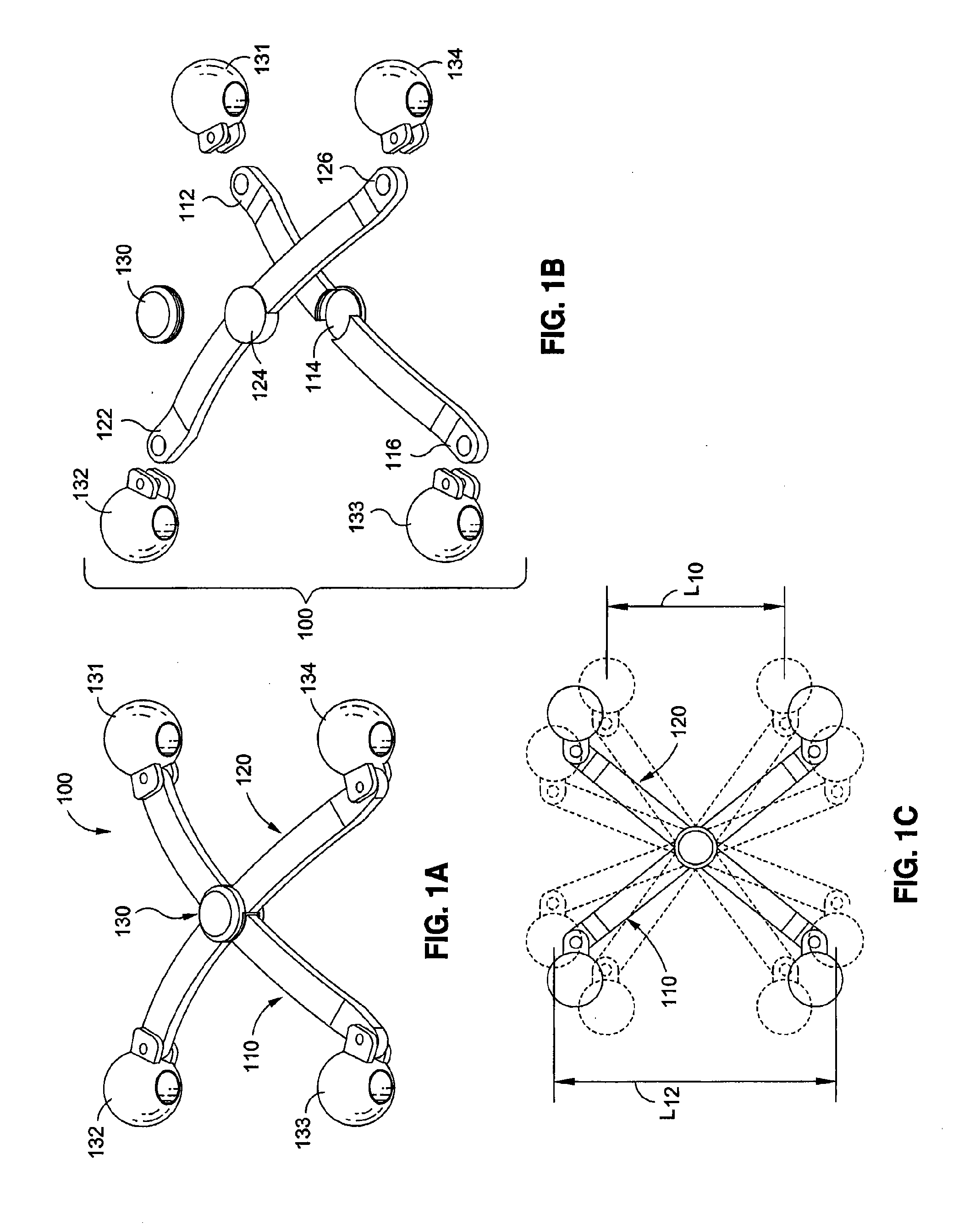

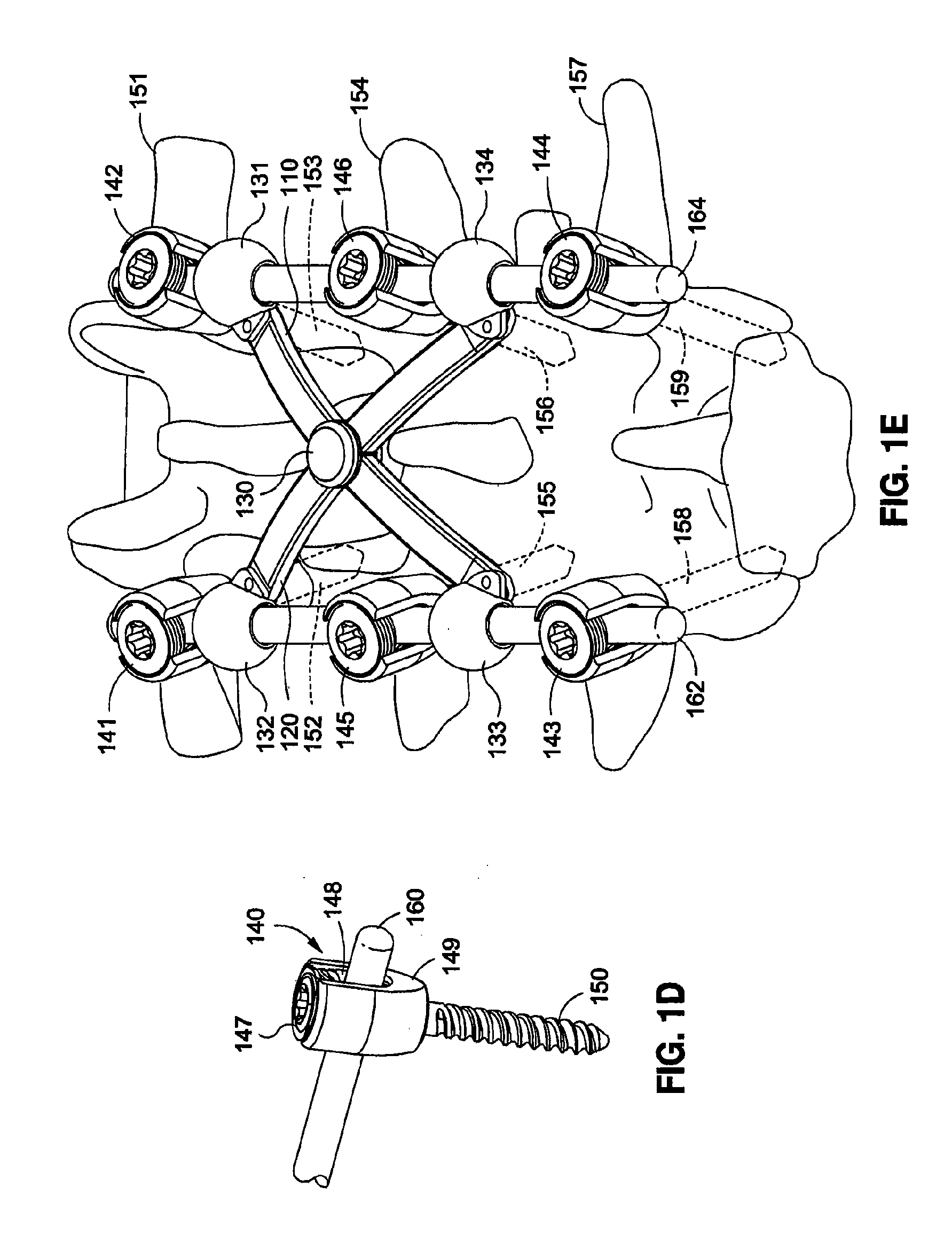

Cross connectors

InactiveUS20120095512A1Limited rangeRestricts lateral movementInternal osteosythesisJoint implantsStress concentrationStress distribution

The present invention may provide various improvements over conventional cross connectors. For example, the present invention may provide various types of Real-X cross connectors, which may have an arch shape X-bridge that curves above the spinal bone segments of the patient. As such, the Real-X cross connectors may be more adaptive to the patient's spinal provide and provide better protect for the patient's the spinal bone segments. Moreover, the Real-X cross connectors may incorporate a complementary pivot joint configuration for smoothening the stress distribution and reducing the stress concentration around the center of the arch shape X-bridge. Advantageously, the complementary pivot joint configuration may enhance the rigidity and stability of the Real-X cross connectors.

Owner:SPINOFIX

Light-emitting device and method of manufacturing the same

InactiveUS20050082546A1Improve light extraction efficiencyLaser detailsSolid-state devicesStress distributionLight emitting device

Provided is a light-emitting device and a method of manufacturing the same. The light-emitting device includes a substrate having at least one protruded portion with a curved surface in which a consistent defect density and uniform stress distribution can be obtained even when the growth of the semiconductor crystal layer and the forming of the light-emitting device are completed. In addition, the light-emitting device has a high the light extraction efficiency for extracting light generated at an electroluminescense layer externally.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Climbing with dry adhesives

ActiveUS7762362B2Facilitate engagement and disengagementSolve the lack of adhesionVehiclesStress distributionMicrometer

A bio-inspired device is provided designed to scale smooth vertical surfaces using anisotropic frictional materials. The device draws its inspiration from geckos and other climbing lizards and employs similar compliance and force control strategies to climb (or hang onto) smooth vertical surfaces including glass, tile and plastic panels. Foremost among the design features embodied in the device are multiple levels of compliance, at length scales ranging from centimeters to micrometers, to allow the device to conform to surfaces and maintain large real areas of contact so that adhesive forces can support it. Structures within the feet ensure even stress distributions over each toe and facilitate engagement and disengagement of the adhesive materials. A force control strategy works in conjunction with the anisotropic adhesive materials to obtain sufficient levels of friction and adhesion for climbing with low attachment and detachment forces.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

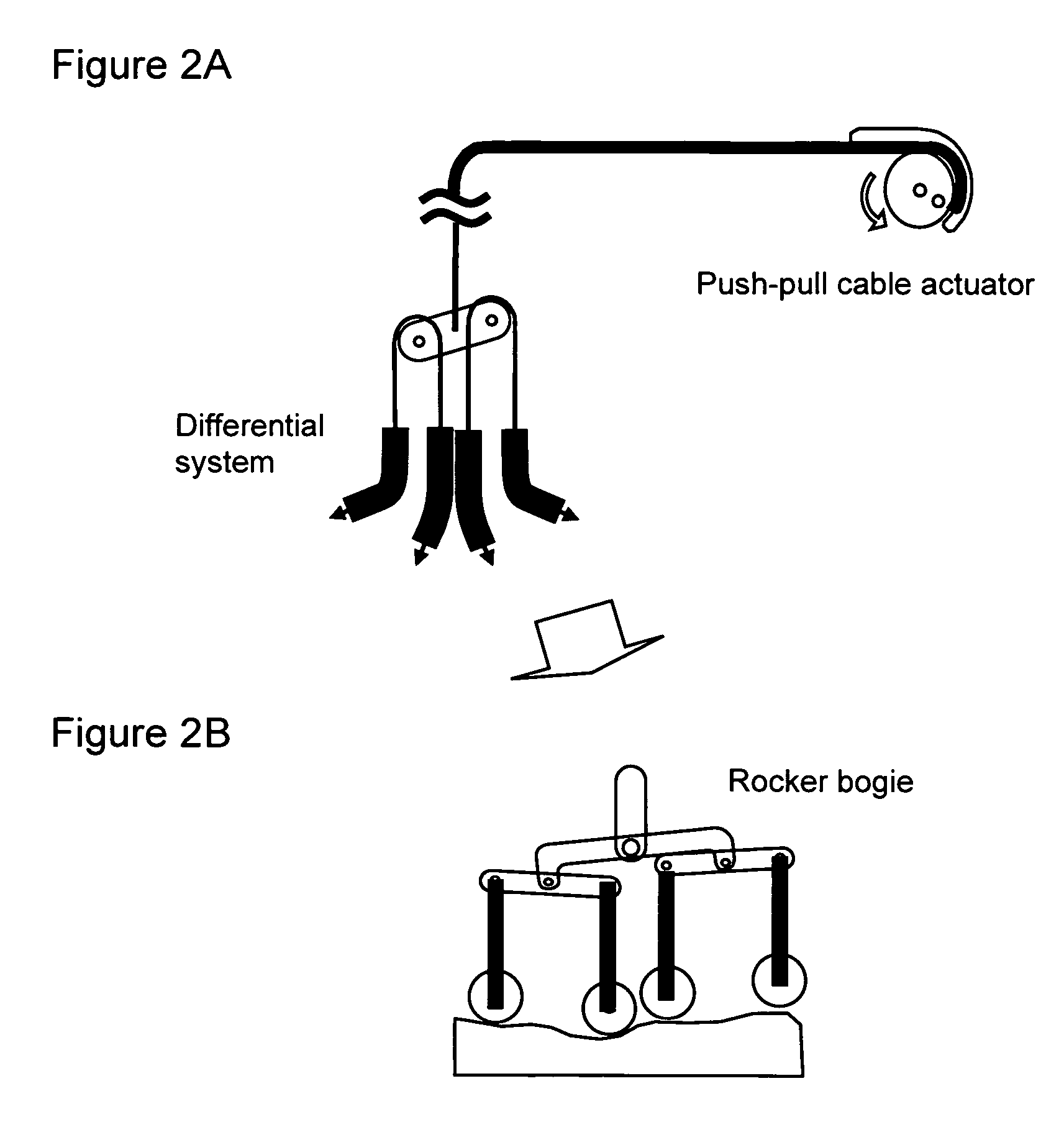

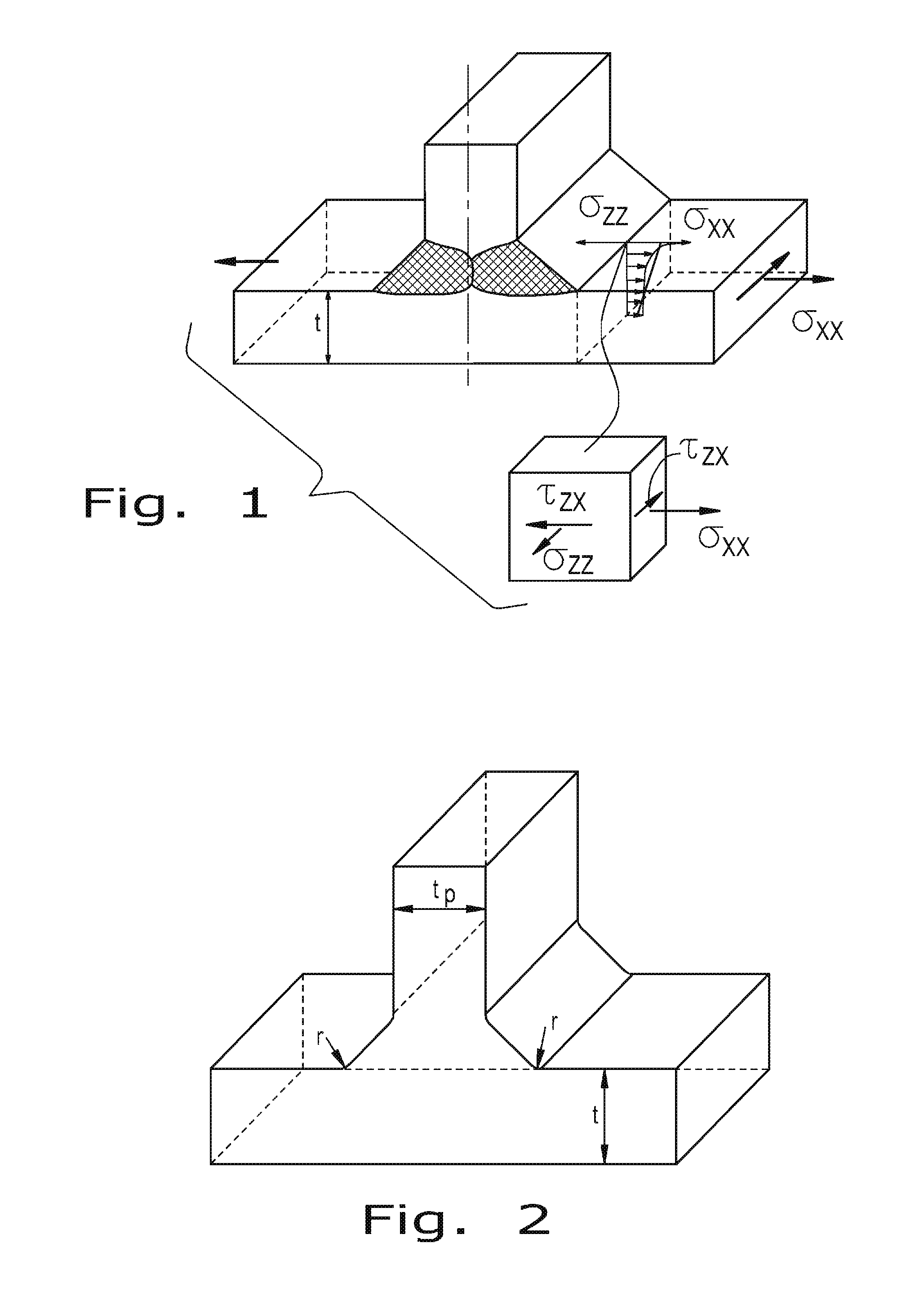

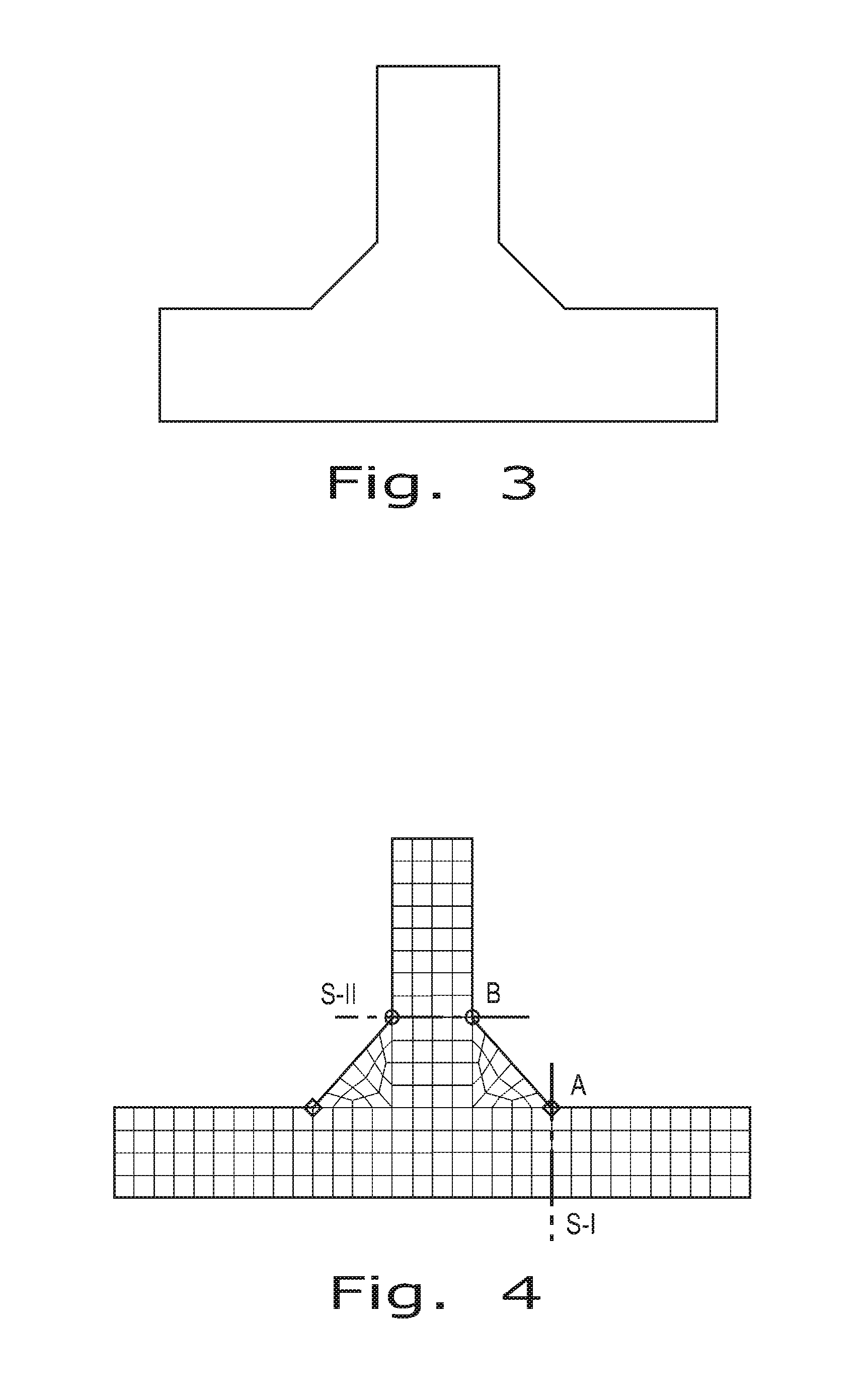

Method for the prediction of fatigue life for welded structures

InactiveUS20120259593A1Design optimisation/simulationComplex mathematical operationsStress distributionCoarse mesh

A method of determining the fatigue life of a welded structure, including the steps of: creating a 3D coarse mesh model of the welded structure to be analyzed; analyzing the coarse mesh model using an FEA model to generate FEA data; identifying a critical stress location on the coarse mesh model having a through thickness stress distribution, based on the FEA data; post processing the FEA data in the middle portion of the through thickness stress distribution while excluding the through thickness stress distribution near the edges of the identified critical stress location to determine a peak stress; and determining a fatigue life of the welded structure at the identified critical stress location, dependent on the determined peak stress.

Owner:DEERE & CO

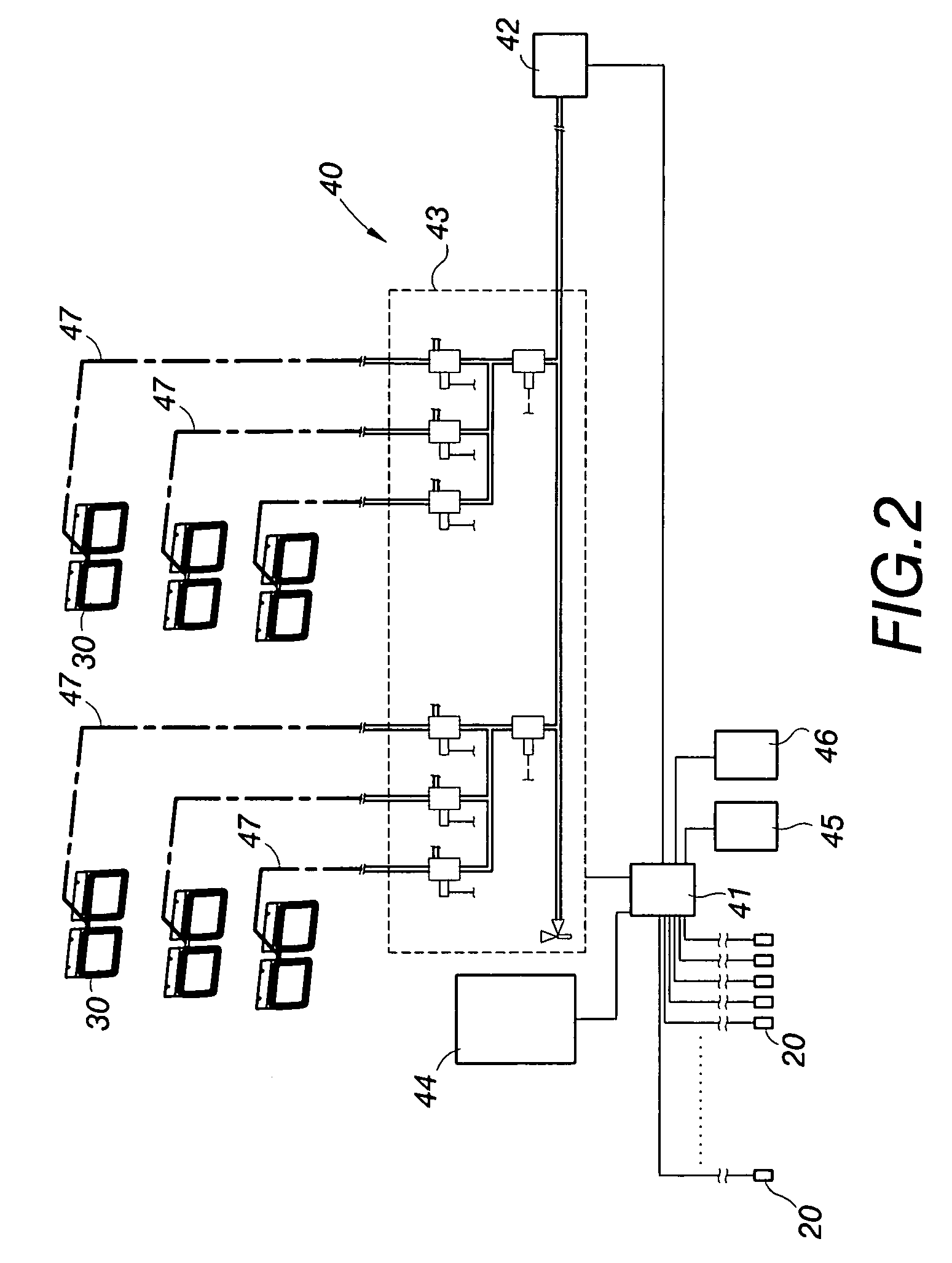

Seat adjusting method and system thereof

InactiveUS20100289302A1Achieve ventilation effectIncrease contact areaVehicle seatsFlow control using electric meansStress distributionEngineering

The present invention discloses a seat adjusting method and a seat adjusting system capable of actively adjusting a user's sitting posture and comfort according to the body weight of different users. Stress sensors are provided for detecting a stress distribution situation of a seat support surface. Airbags are buried into the support surface for actively changing the level of the support surface in order to increase a contact area between the support surface and the user, and the stress distribution situation can be matched with an expected ratio to provide the best ergonomic support effect to users.

Owner:NITRING ENGERPRISE

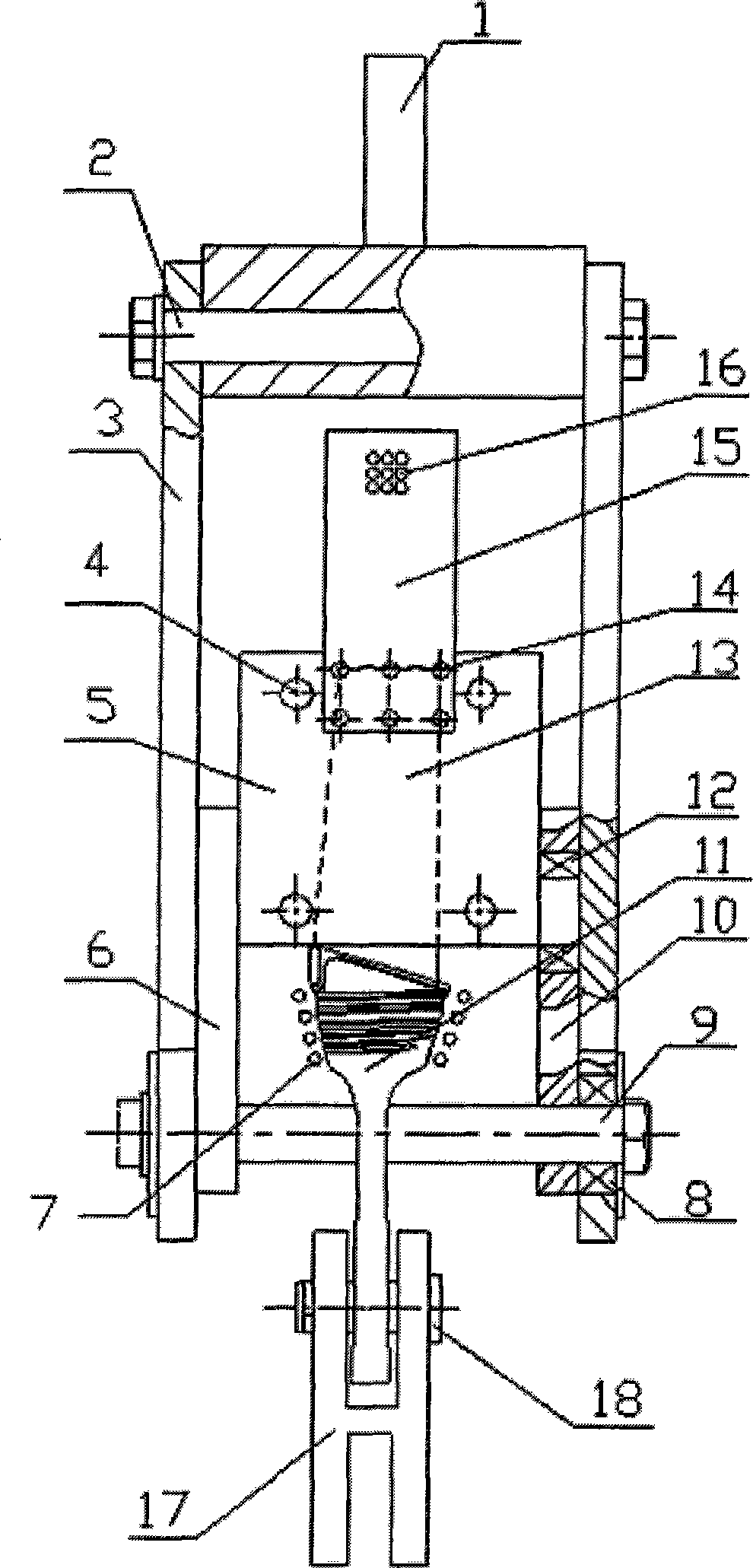

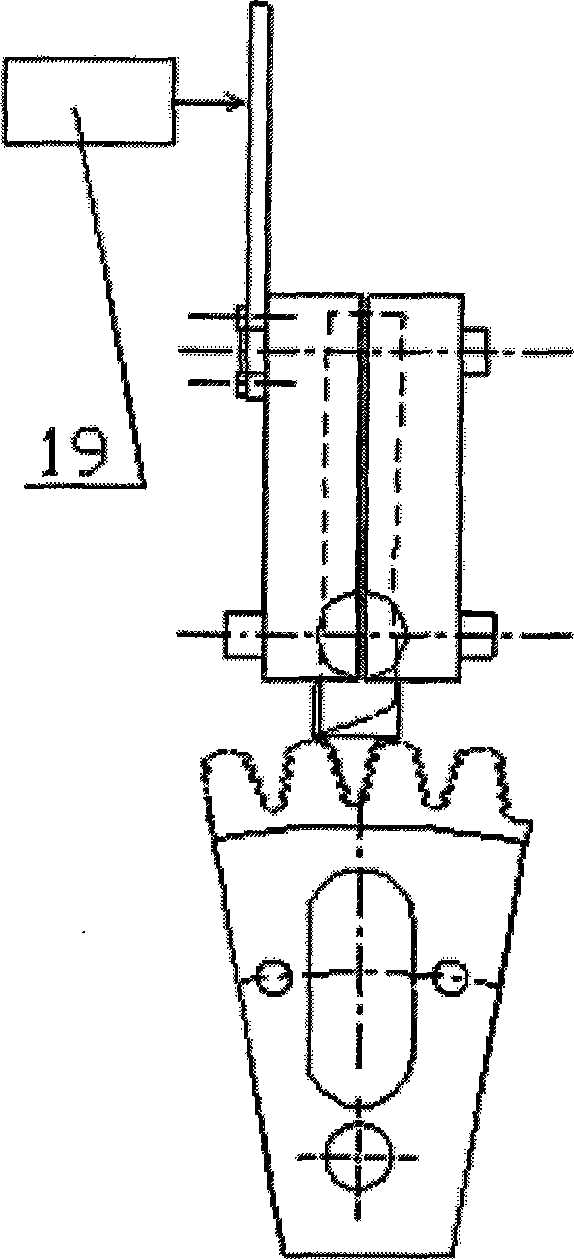

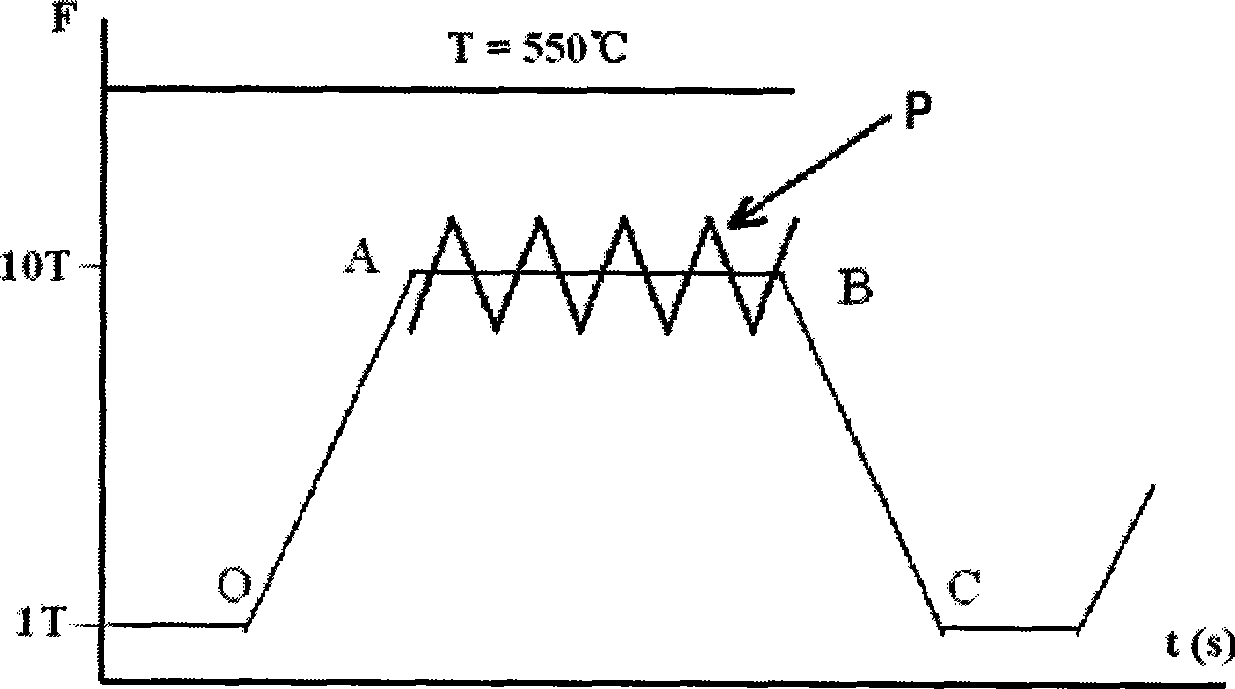

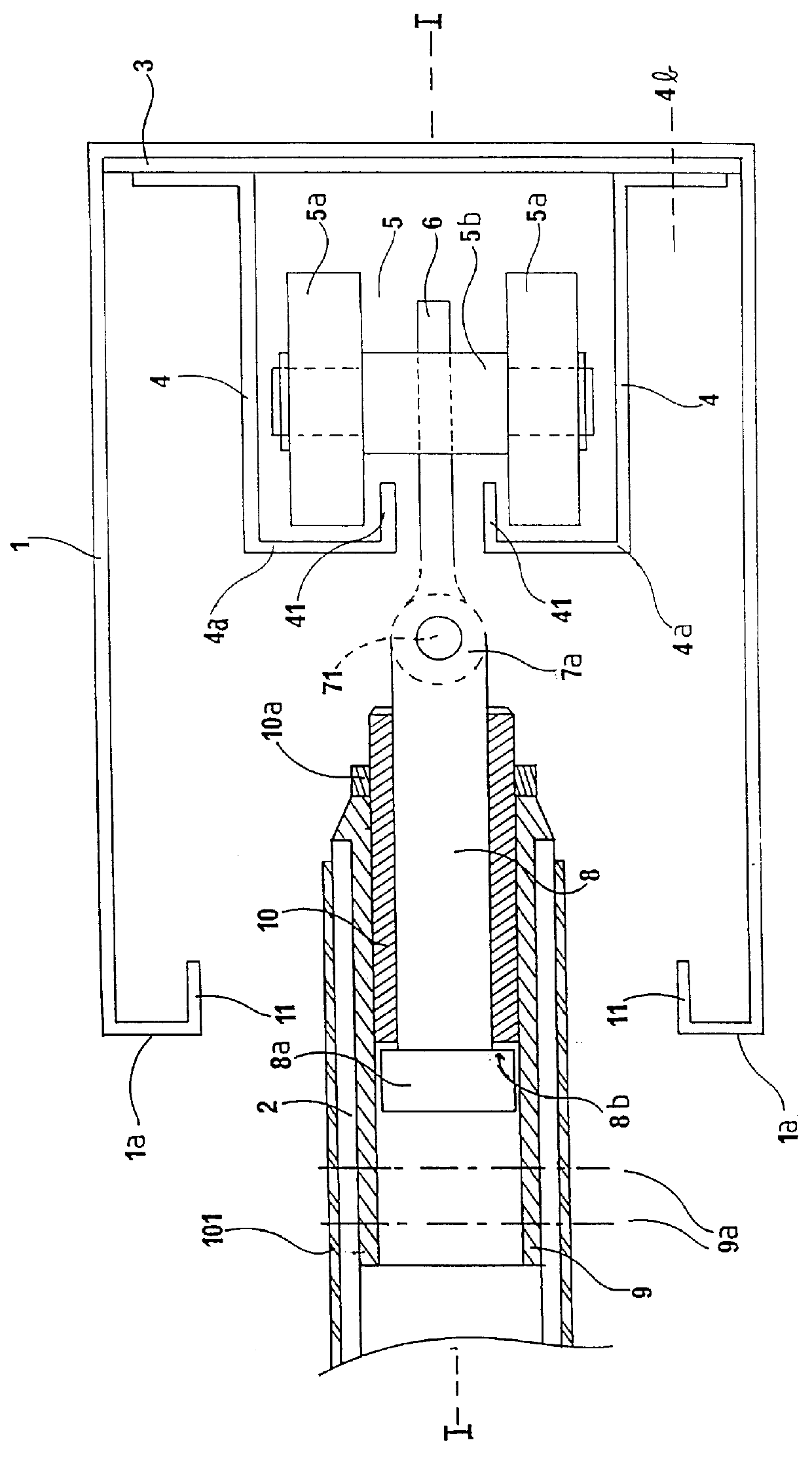

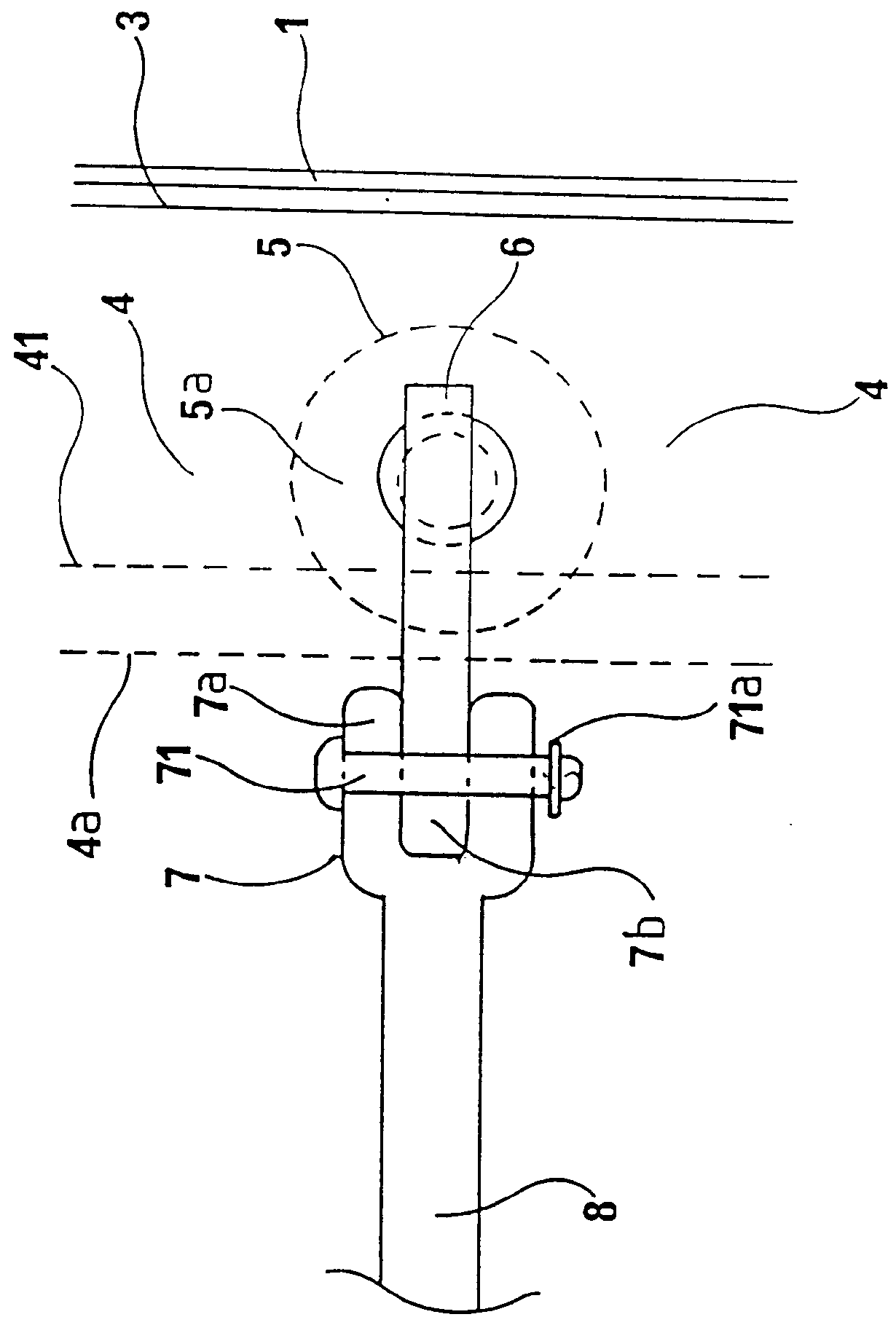

High temperature composite fatigue loading method and apparatus for turbine disc/blade joggled joint

InactiveCN101464240AResolve mutual interferenceReduce resistanceMaterial strength using repeated/pulsating forcesStress distributionFatigue loading

A turbine disc / blade tenon connection high-temperature combined fatigue loading device comprises a low cycle load stress application mechanism, a force transmission pin, a force transmission main tension plate, a force transmission crown plate, a force transmission round bar, a blade clamp, a rolling bearing, a hold-down bolt, a high cycle transmission plate, a high-frequency heating cycle, and a vibration generator, wherein, the low cycle load stress application mechanism is connected with the force transmission main tension plate through the force transmission pin; the force transmission main tension plate is connected with the force transmission round bar through the rolling bearing; the lower end of the force transmission crown plate is sleeved on the force transmission round bar, and the upper end is connected with the load bearing dummy club of the blade clamp through the rolling bearing; the blade clamp is connected with the blade of a turbine through the hold-down bolt; the turbine disc is connected with the low cycle load stress application mechanism through the force transmission pin; the high cycle transmission plate is connected with the blade clamp through the hold-down bolt; and the vibration generator is positioned on one side above a high cycle load transmission plate. The loading method is characterized in that the force application point of low cycle loads is moved backwards, thereby enabling small high cycle loads to be smoothly transferred to the tenon connection position, ensuring the stress distribution along the tenon tooth is reasonable, and preventing combined loads from interfering with each other.

Owner:BEIHANG UNIV

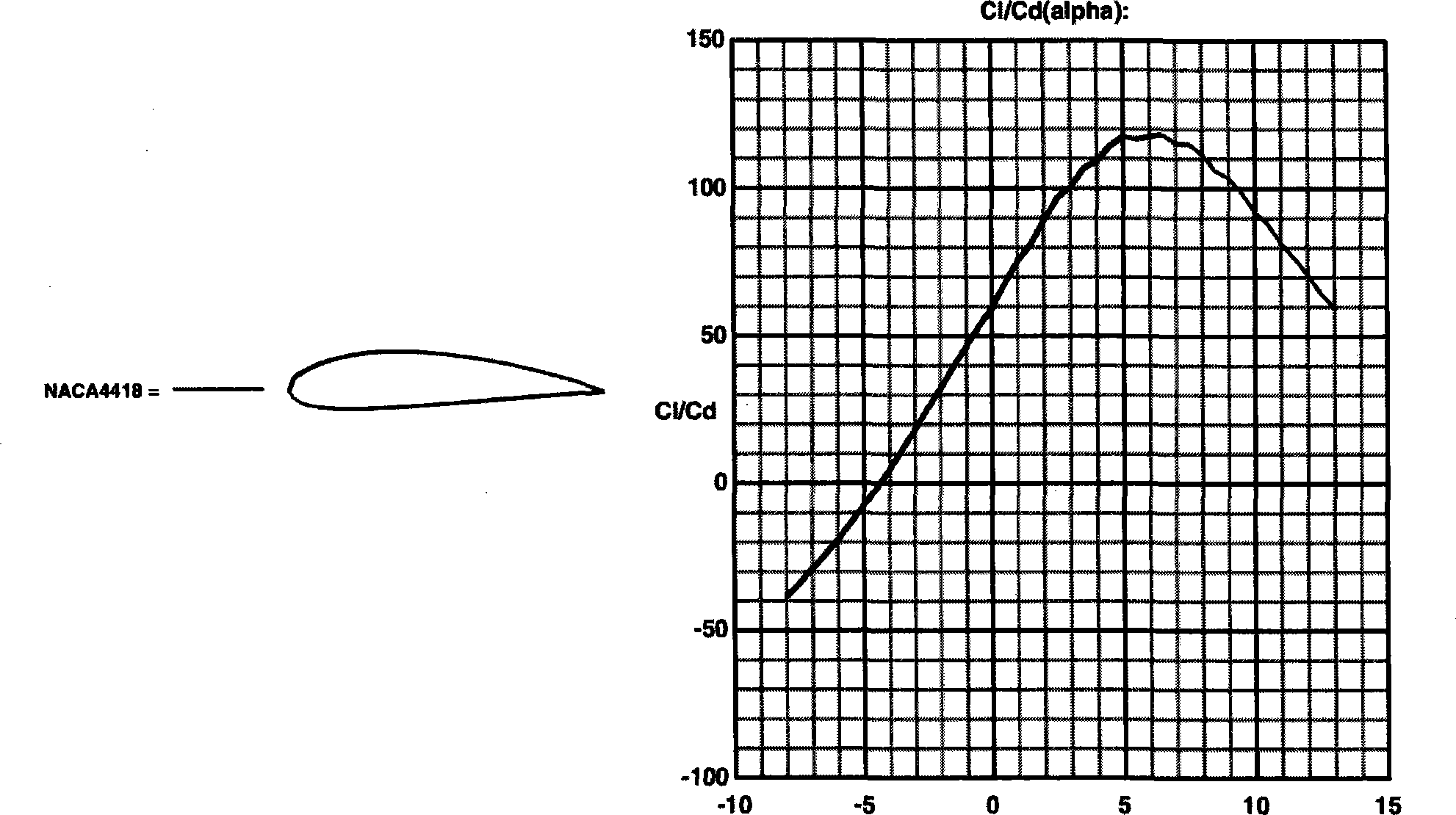

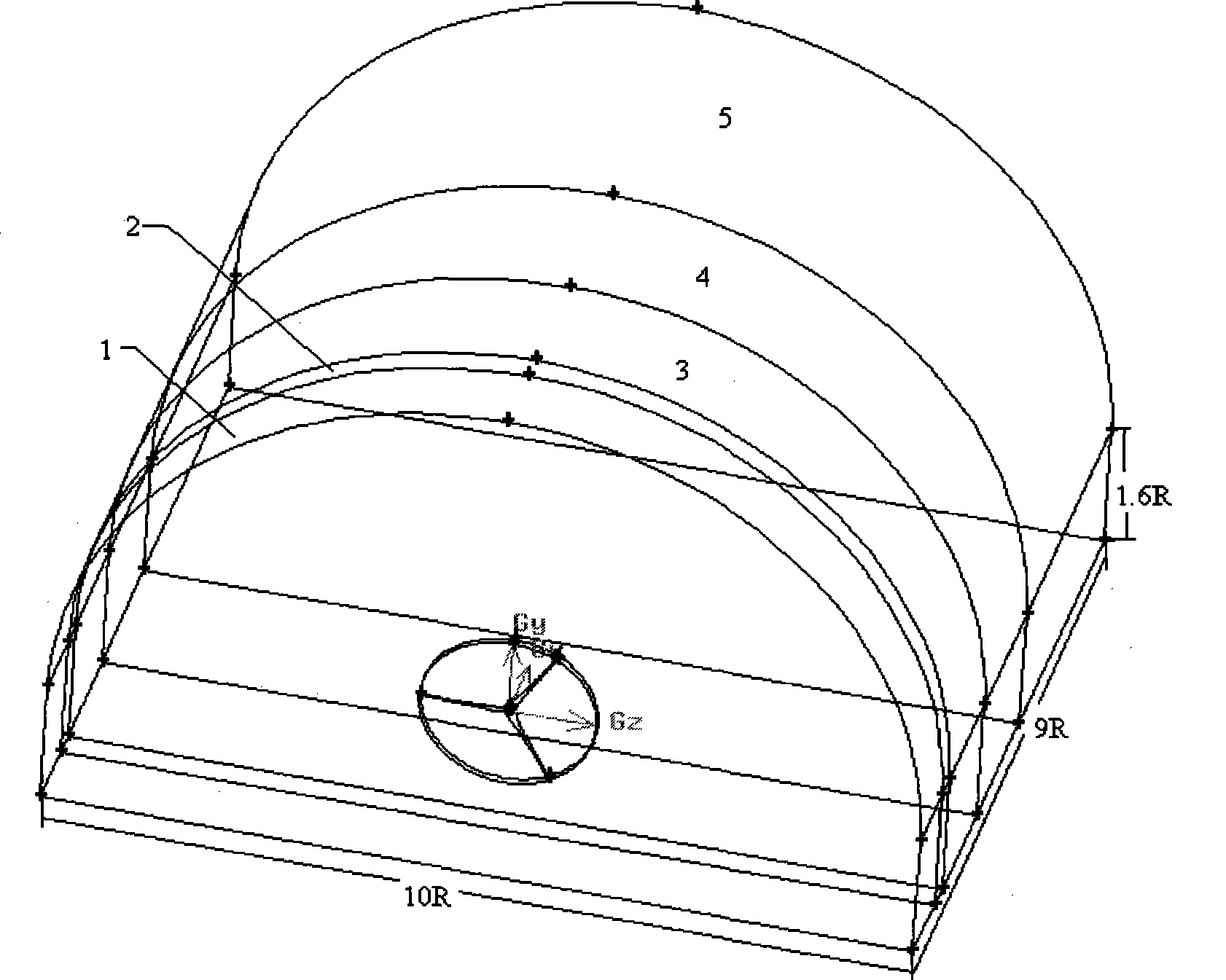

Method for analyzing fluid dynamics and structural mechanics of wind generator blades

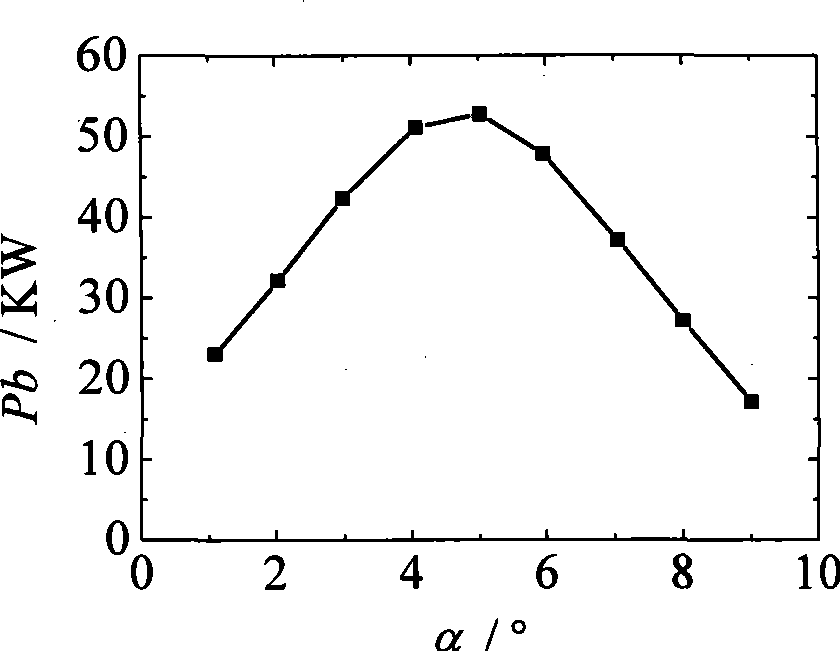

InactiveCN101532906AReduce windward angleReduce the required powerMachine part testingAerodynamic testingEngineeringEntity model

The invention discloses a method for analyzing fluid dynamics and structural mechanics of wind generator blades, which comprises the following steps: combining CFD and CAE methods, determining each parameter of an impeller model by adopting the momentum blade element theory, designing an entity model of the blade, establishing a three-dimensional model of a windmill blade, a hub and a peripheral wind site based on a Gambit software platform, meshing the model by adopting a partial structuring method, setting a proper boundary condition, calculating the performance of a finite element based on a Fluent software platform, extracting the blade torsion and calculating the blade power and the blade efficiency, establishing a blade structural model based on an ansys software platform and meshing the blade structural model, applying load and restraint condition to the blade structural model, analyzing the mode of the blade structure, performing equal torque treatment for pressure distribution acquired by the Fluent software platform, applying pressure surface load to the ansys software platform, calculating the structural mechanics characteristics of the wind generator blades, and extracting blade deformation and stress distribution characteristics.

Owner:SOUTHEAST UNIV +1

Goods-handling door comprising a wind-resistant flexible curtain

InactiveUS6035918AEasy to replaceExact strengthScreensExtensible doors/windowsStress distributionEngineering

A fast-opening and fast-closing goods-handling door for allowing vehicles to pass therethrough includes a foldable or rollable flexible curtain, the edges of which are guided in respective slideways, and which are retained therein by means of retaining carriages guided by rails received in the slideways. The carriages are not able to leave the rails. The goods-handling door is further characterized in that it includes a coupling device for coupling the curtain to the carriages, and at least one stress-distribution device for distributing the stresses exerted on the edges of the curtain by the carriages when the door is subjected to detrimental forces.

Owner:NERGECO

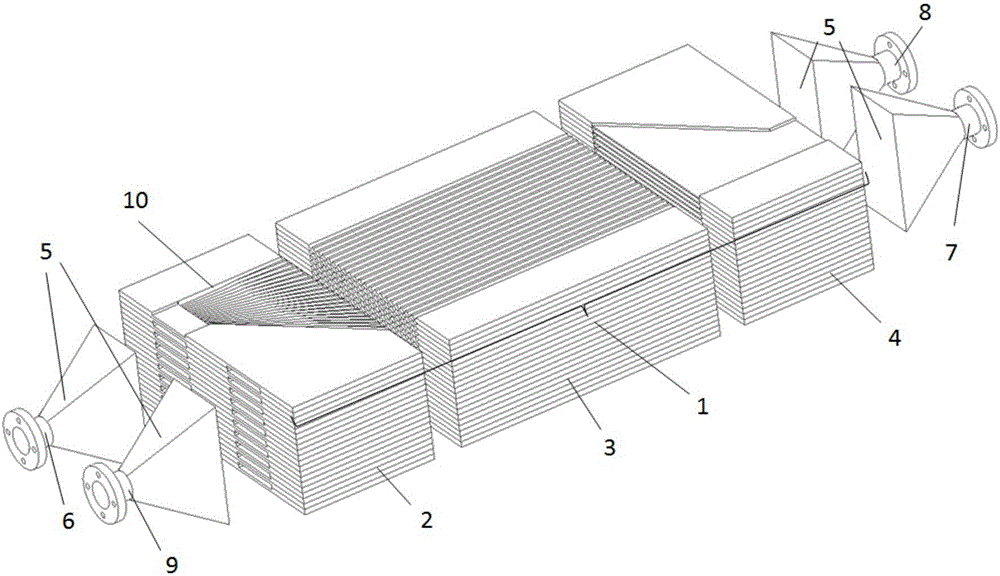

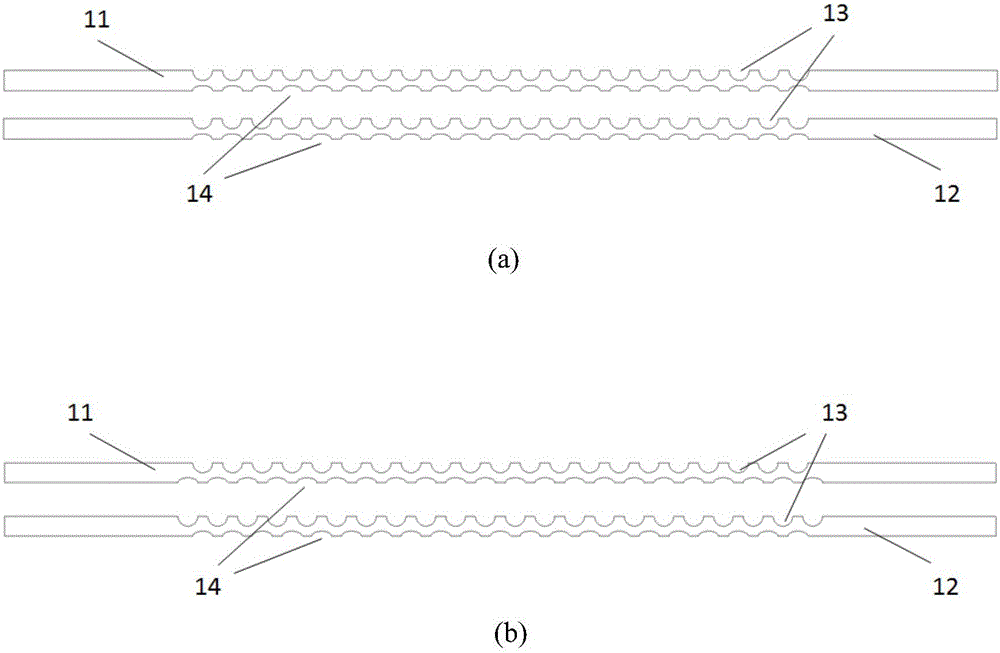

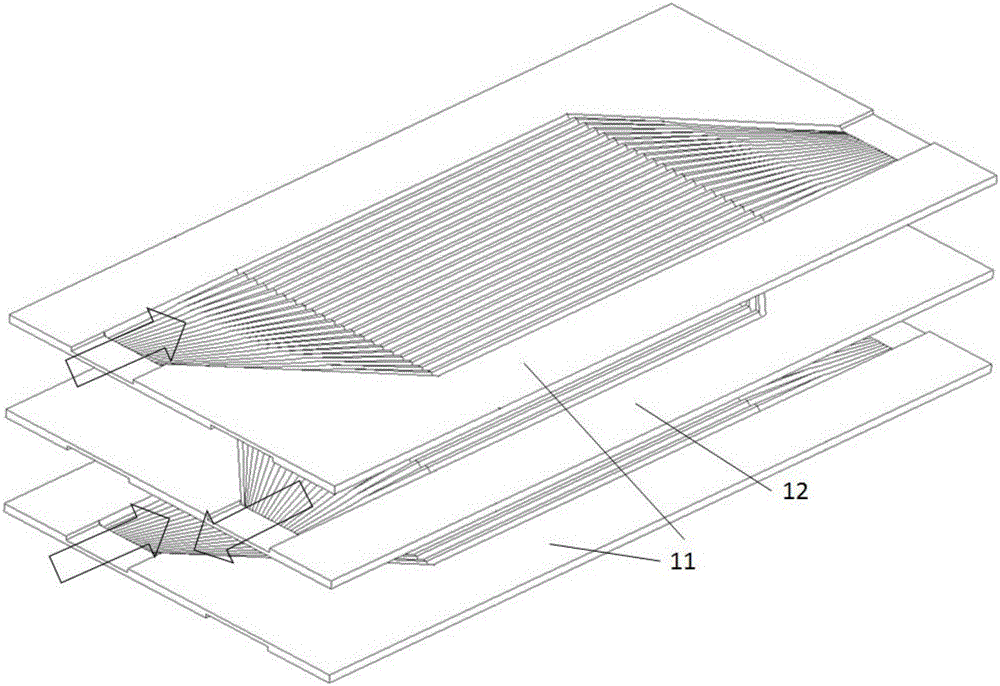

Double-side etching high-temperature and high-pressure printed circuit board heat exchanger

InactiveCN105043144AReduce thermal stressAvoid plastic deformationLaminated elementsStationary plate conduit assembliesStress distributionStress concentration

The invention relates to a double-side etching high-temperature and high-pressure printed circuit board heat exchanger. The double-side etching high-temperature and high-pressure printed circuit board heat exchanger is composed of a heat exchanging core, a flow equalizing section, a hot fluid inlet and outlet port and a cold fluid inlet and outlet port. The core is divided into an inlet section, a core heat exchanging section and an outlet section. According to the heat exchanger, runners are machined in the double sides of heat exchanging plates with a certain thickness in a photochemistry manner, a laser etching manner, a machining manner and the like. The first heat exchanging plate and the second heat exchanging plate are arranged in a spaced manner. A fusion type channel novel structure is adopted in an inlet distribution section, and fluid in the heat exchanger can be easily distributed more evenly. The heat exchanging efficiency of the heat exchanger can be improved, the thermal stress damage at an existing channel sharp corner is effectively avoided, the circulation section area of the heat exchanger is increased, and the compactness of the heat exchanger is improved; thermal stress distribution at the sharp corner is improved, plastic deformation caused by stress concentration is avoided, and the even distribution of fluid in the heat exchanger is improved; and the safety performance of the heat exchanger is improved, and the service life of the heat exchanger is prolonged.

Owner:XI AN JIAOTONG UNIV

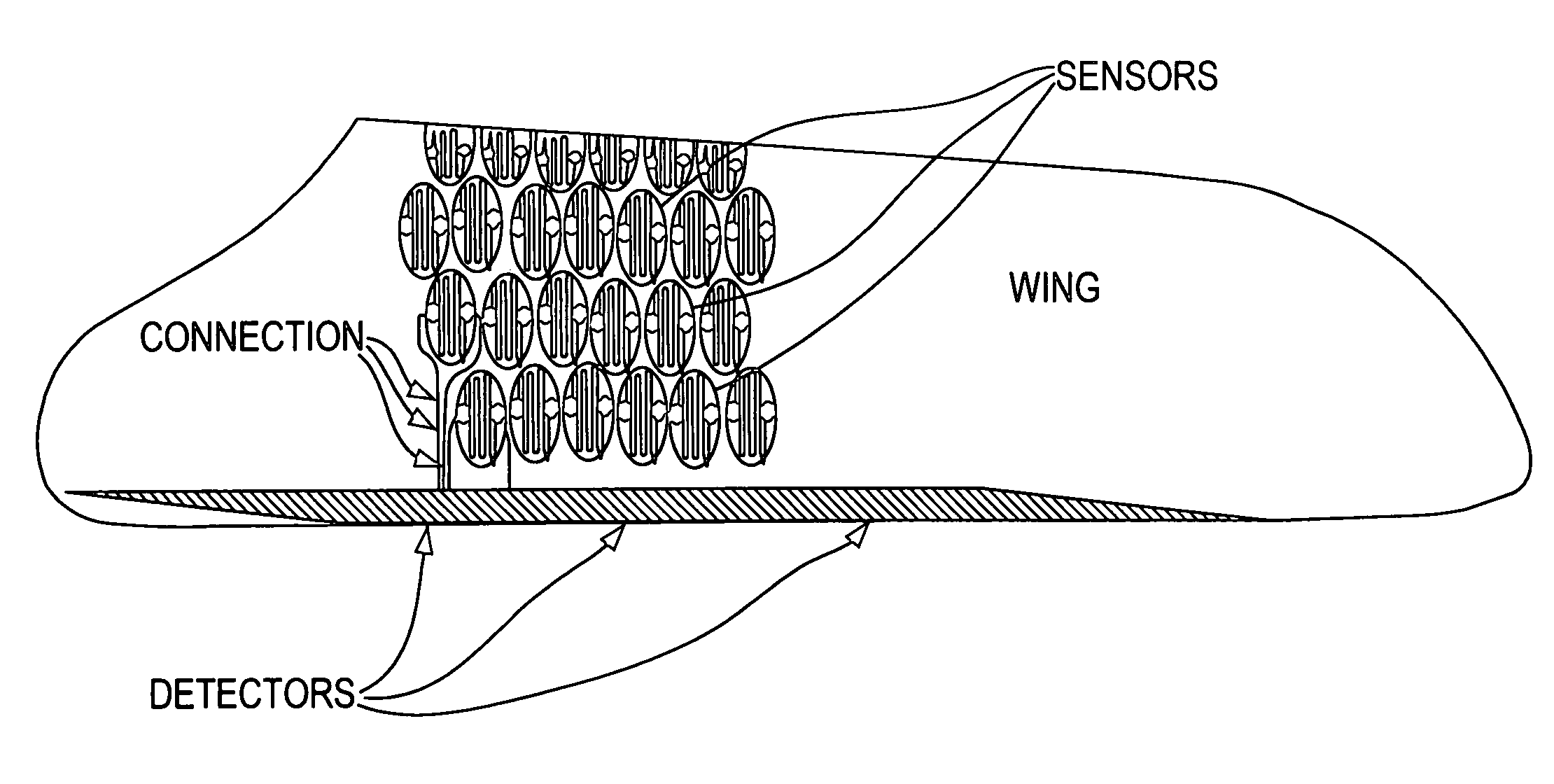

Method and apparatus for strain-stress sensors and smart skin for aircraft and space vehicles

InactiveUS6986287B1Wide rangeChange pressureForce measurementUsing electrical meansFine structureStress sensor

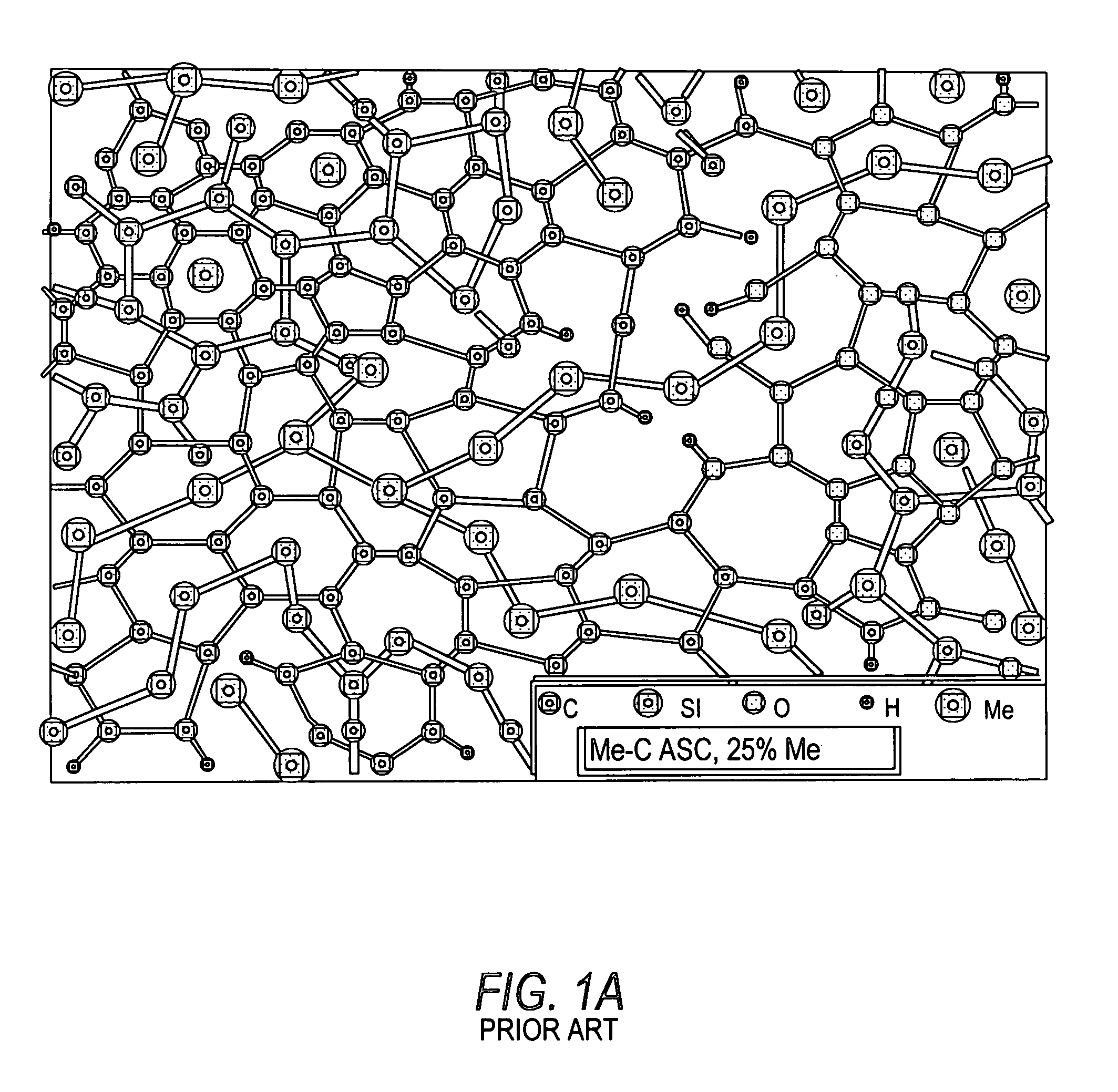

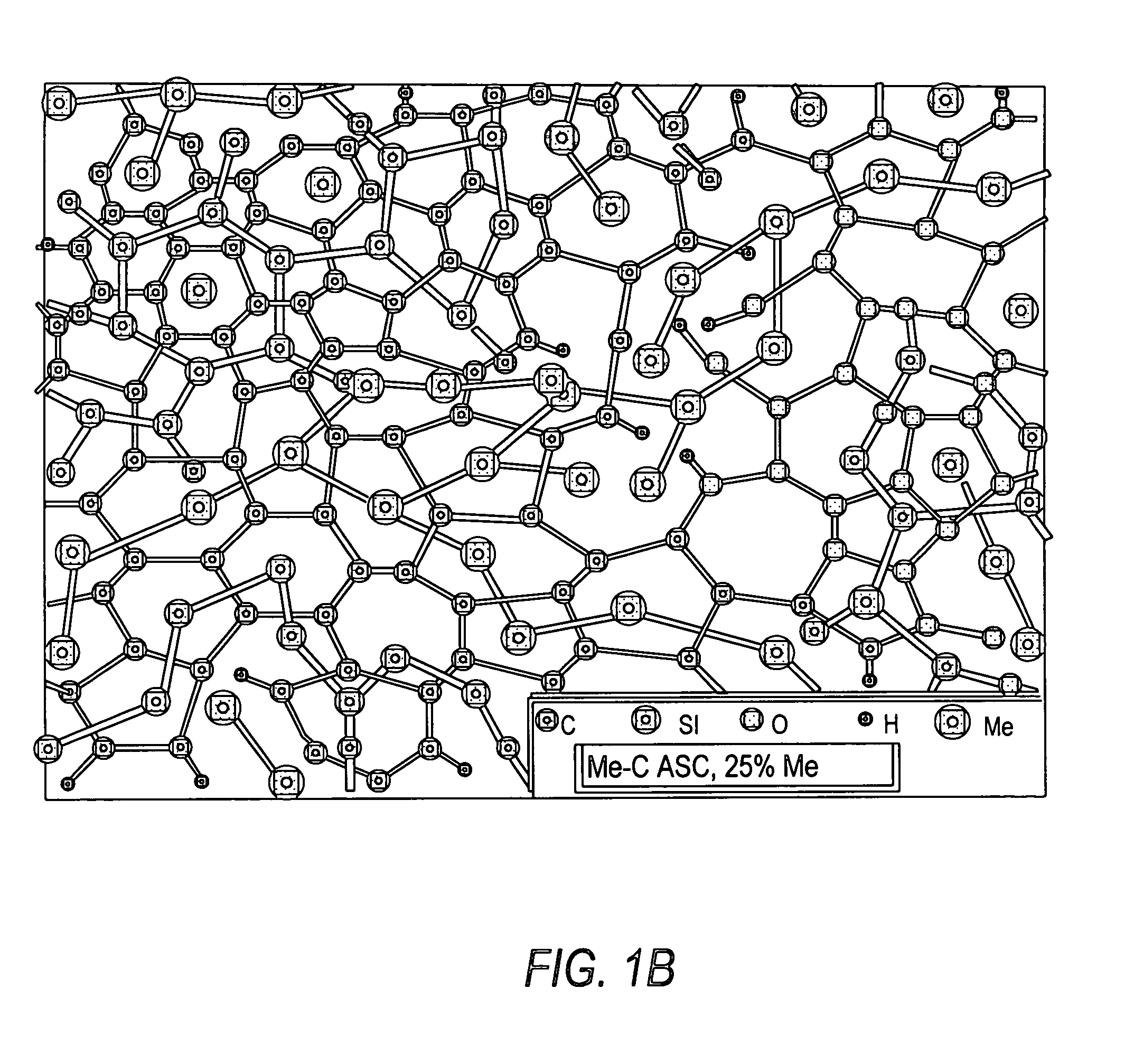

A new family of multifunctional smart coatings based on of stabilized diamond-like metal-carbon atomic scale composites and diamond-like atomic-scale composite (DL ASC) materials. Based on a unique combination of the coating fine structure, properties of the coating / substrate interface, and the mechanical and electrical properties of the coating, the disclosed smart coatings would integrate various high resolution sensors and interconnections, and the sensor would diagnose dangerous stress distribution in the coated subject with no distortion in real time, while these diamond-like coatings would simultaneously provide environmental protection of the coated surface and improve its aerodynamic quality.

Owner:NANODYNAMICS INC

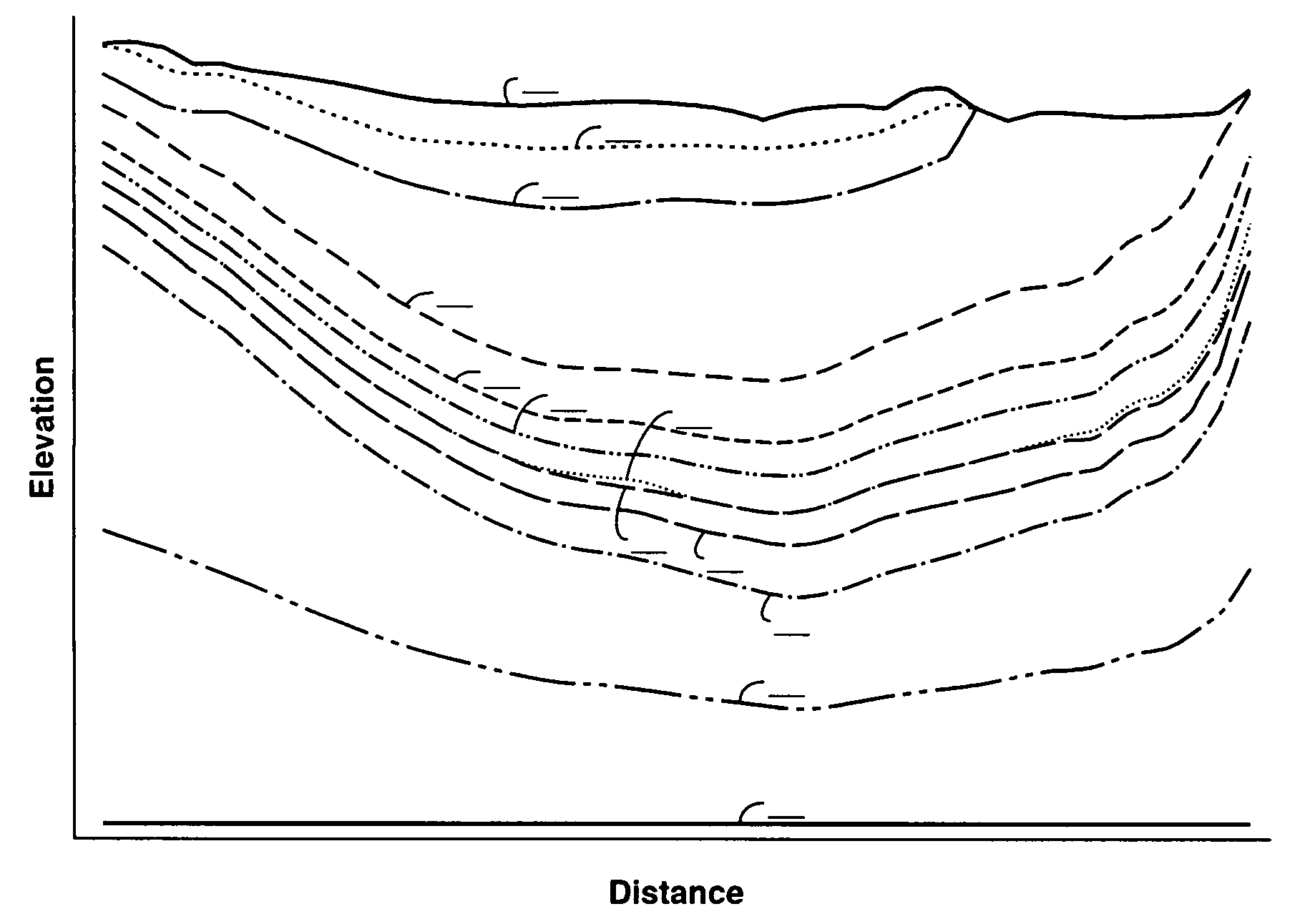

Time-lapse seismic survey of a reservoir region

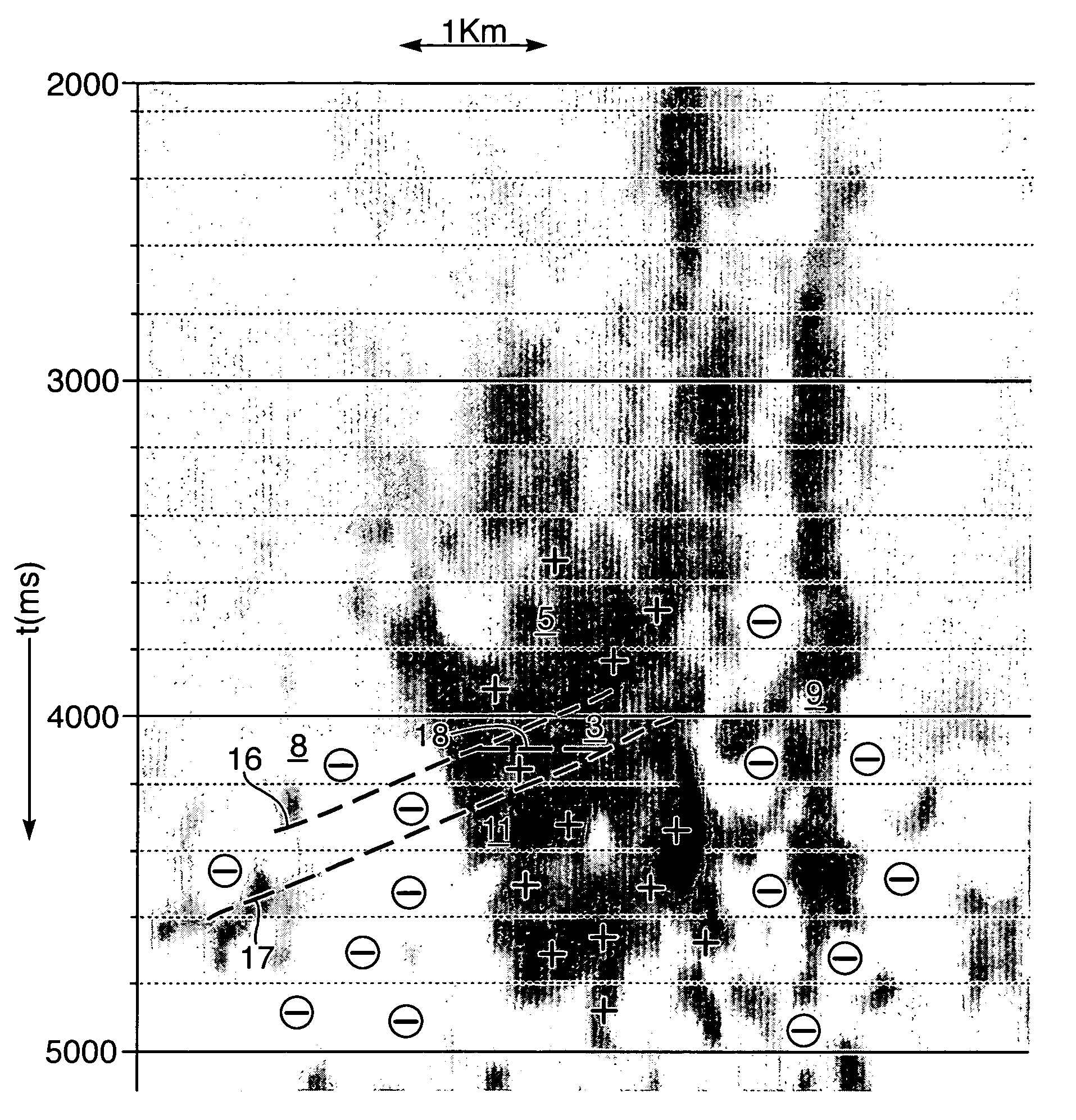

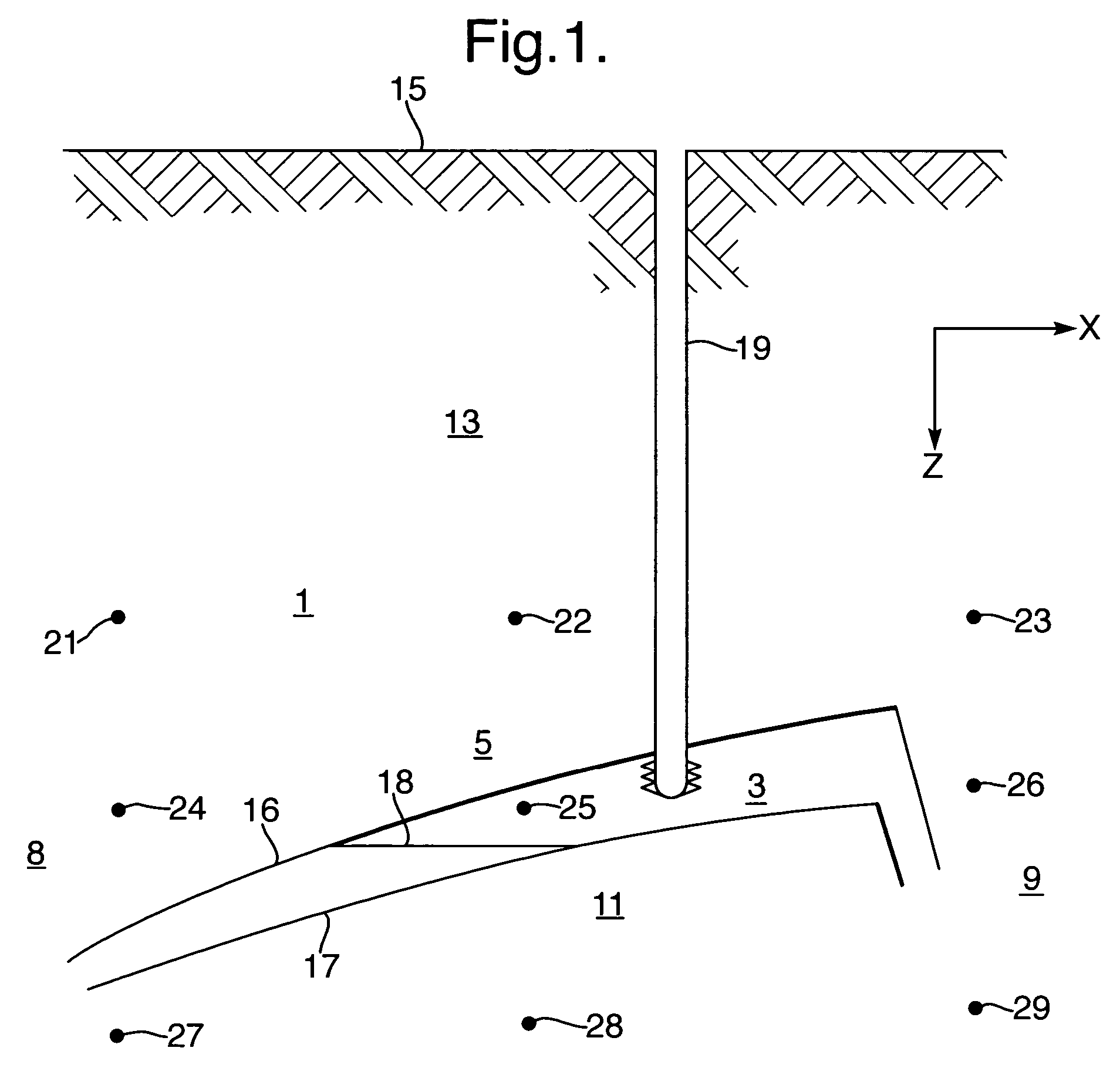

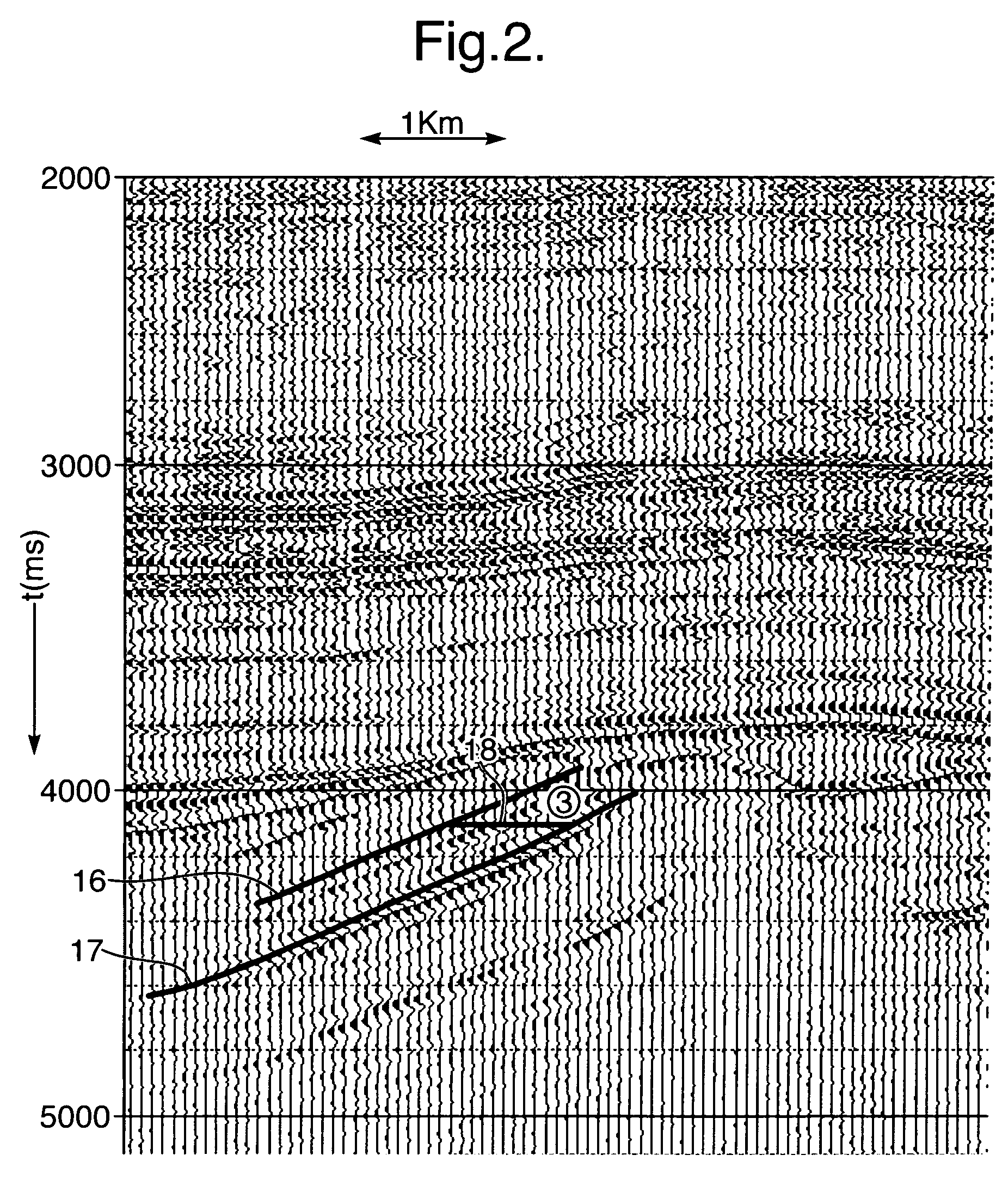

ActiveUS20050149267A1Good estimateGood agreementSeismic signal processingSpecial data processing applicationsStress distributionSeismic survey

A method of investigating a reservoir region in a subsurface formation by a time-lapse seismic survey, which subsurface formation comprises a further formation region adjacent to the reservoir region, which method comprises the steps of obtaining data from a time-lapse seismic survey including seismic data of the subsurface formation at a first point in time and a later point in time, processing the seismic data to obtain a seismic representation of change in a predetermined seismic parameter in the further formation region, which seismic parameter is dependent on stress; interpreting the seismic representation of change in the seismic parameter in the further formation region for an indication of changes of stress distribution in the further formation region; and deriving a property of the reservoir region using the indication of change of stress distribution in the further formation region.

Owner:SHELL USA INC

Method for Prevention and Control of Rockburst by Man-made Spatial Defects

InactiveCN102296958AReduce intensityPlay a role in isolationUnderground miningSurface miningStress distributionHead-hitting

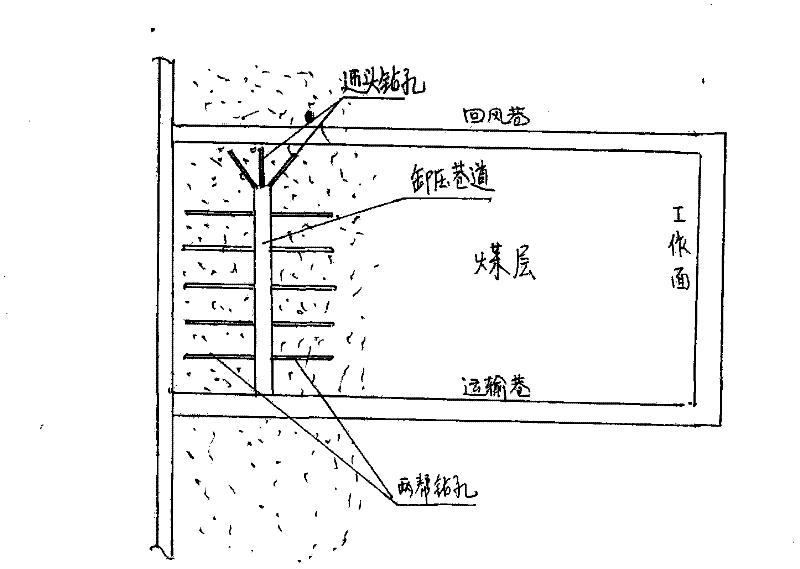

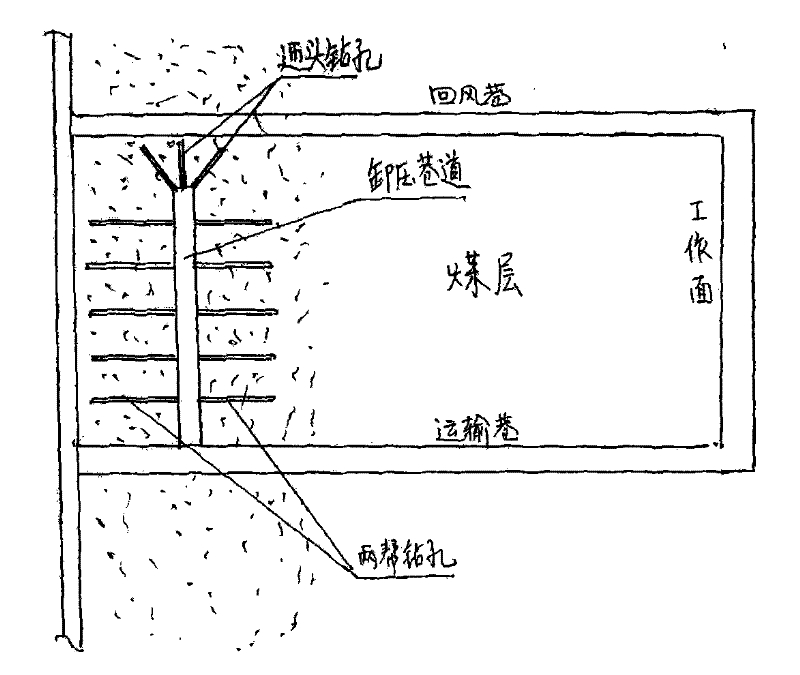

The invention discloses a method for preventing and controlling rockburst by an artificial space defect body. Firstly, one or more pressure relief roadways are excavated in the high stress dangerous area of rockburst, and three boreholes are drilled in the head of the pressure relief roadway. The boreholes are drilled along the centerline of the roadway, and the holes on both sides are drilled obliquely forward at an angle of 30° based on the centerline of the roadway, so that the coal seam can be relieved by deep hole blasting; Drilling, and finally blasting from the head of the roadway to the back of the roadway. The invention changes the stress distribution by creating a large defect space in the high-stress coal body, the stress is far away from the roadway, the coal body around the roadway is destroyed, the energy is greatly released, and the risk of impact is fundamentally reduced.

Owner:SHANDONG UNIV OF SCI & TECH

Time-lapse seismic survey of a reservoir region

ActiveUS7242637B2Seismic signal processingSpecial data processing applicationsStress distributionSeismic survey

A method of investigating a reservoir region in a subsurface formation by a time-lapse seismic survey. The subsurface formation comprises a further formation region adjacent to the reservoir region. Data are obtained from a time-lapse seismic survey and includes seismic data of the subsurface formation at a first point in time and a later point in time. The seismic data is processed to obtain a seismic representation of change in a predetermined seismic parameter in the further formation region, whereby the seismic parameter is dependent on stress. The seismic representation of change in the seismic parameter in the further formation region is interpreted for an indication of changes of stress distribution in the further formation region, and a property of the reservoir region is derived using the indication of change of stress distribution in the further formation region.

Owner:SHELL USA INC

Involute straight tooth cone gear trimming method

InactiveCN101937211AExtend your lifeCompensation for deformationProgramme controlComputer controlNumerical controlStress distribution

The invention provides a technical scheme, in particular an involute straight tooth cone gear trimming method. The method comprises the following steps of: determining a tooth trimming position, a trimming quantity and a tooth profile quantity; solving for a spherical space involute Decare coordinate equation; generating a spherical involute in three-dimensional modeling software, forming a spherical involute plane through curve filling, and realizing straight tooth cone gear solid modeling on the basis of the spherical involute; forming a tooth trimming profile on the central cross section of the gear, and isometrically stretching the profile to the tooth surface to realize tooth isometric trimming; carrying out tooth top arc trimming on the tooth profile; and converting a trimming gear model into a digital control code imported into a digital control machine tool to realize the processing of the trimming cone gear. The invention better controls the stress distribution of the gear through controlling the position and the trimming quantity of the isometric trimming so as to compensate the deformation of the gear and reduces the sensitivity of a cone gear pair to errors and load changes as well as improves the transmission precision of the cone gear pair, reduces the vibration and the noise and prolongs the service life of the gear.

Owner:UNIV OF JINAN

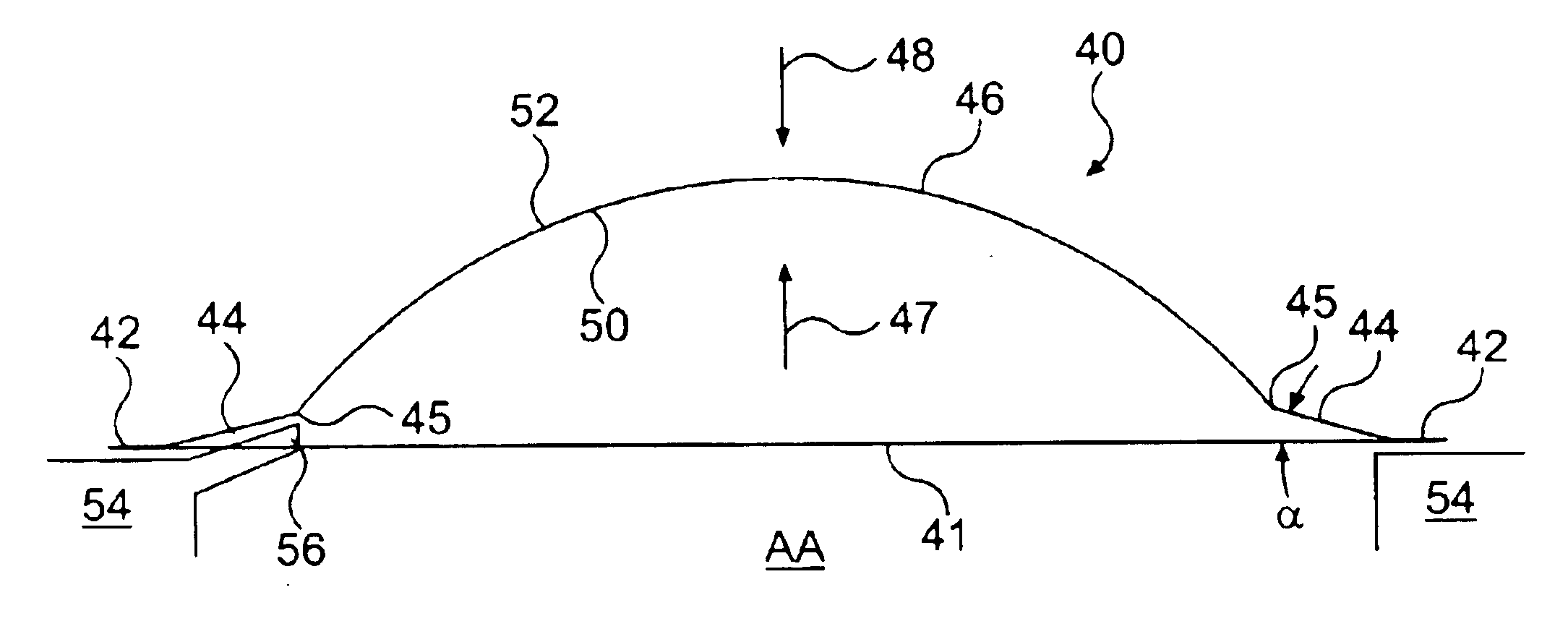

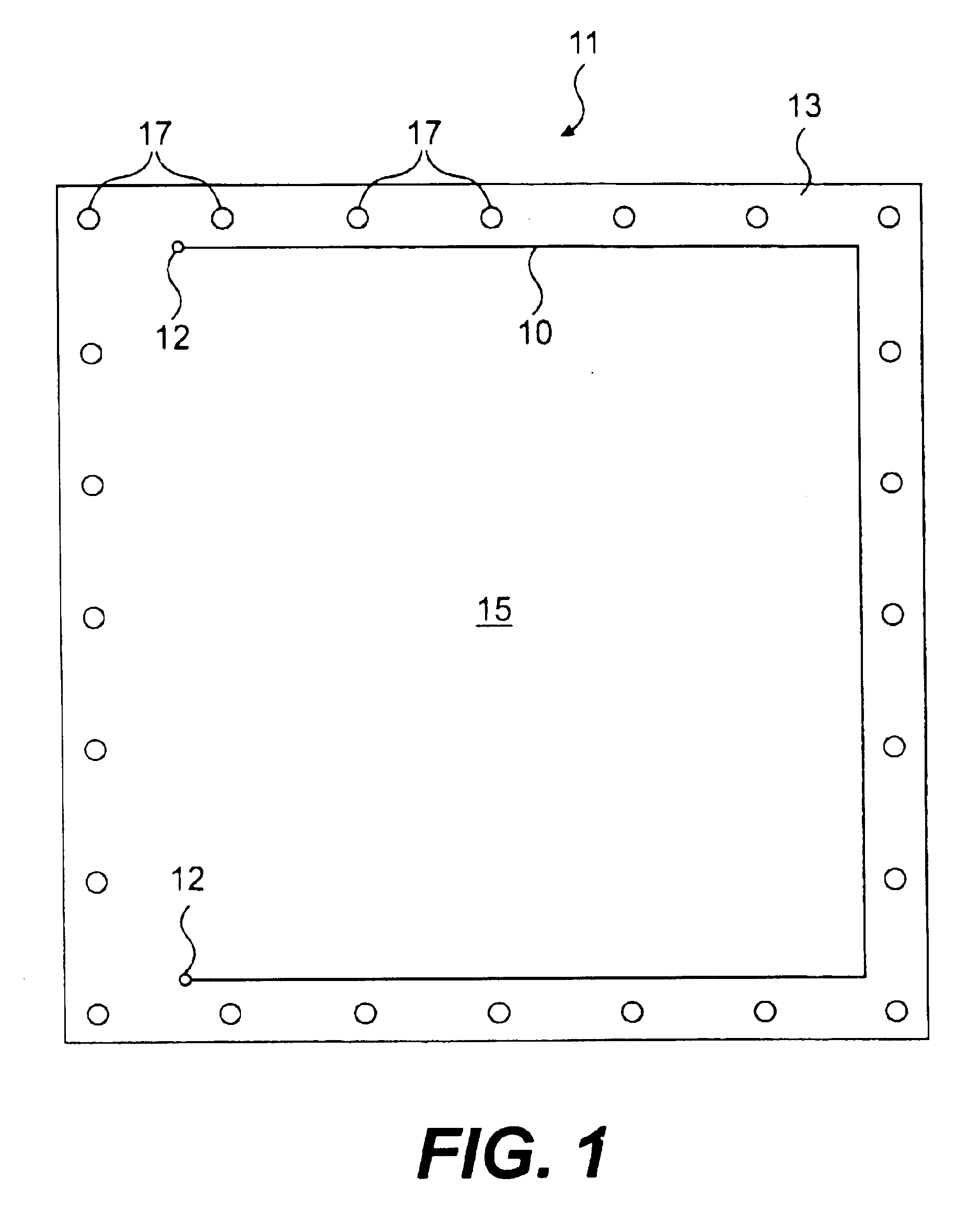

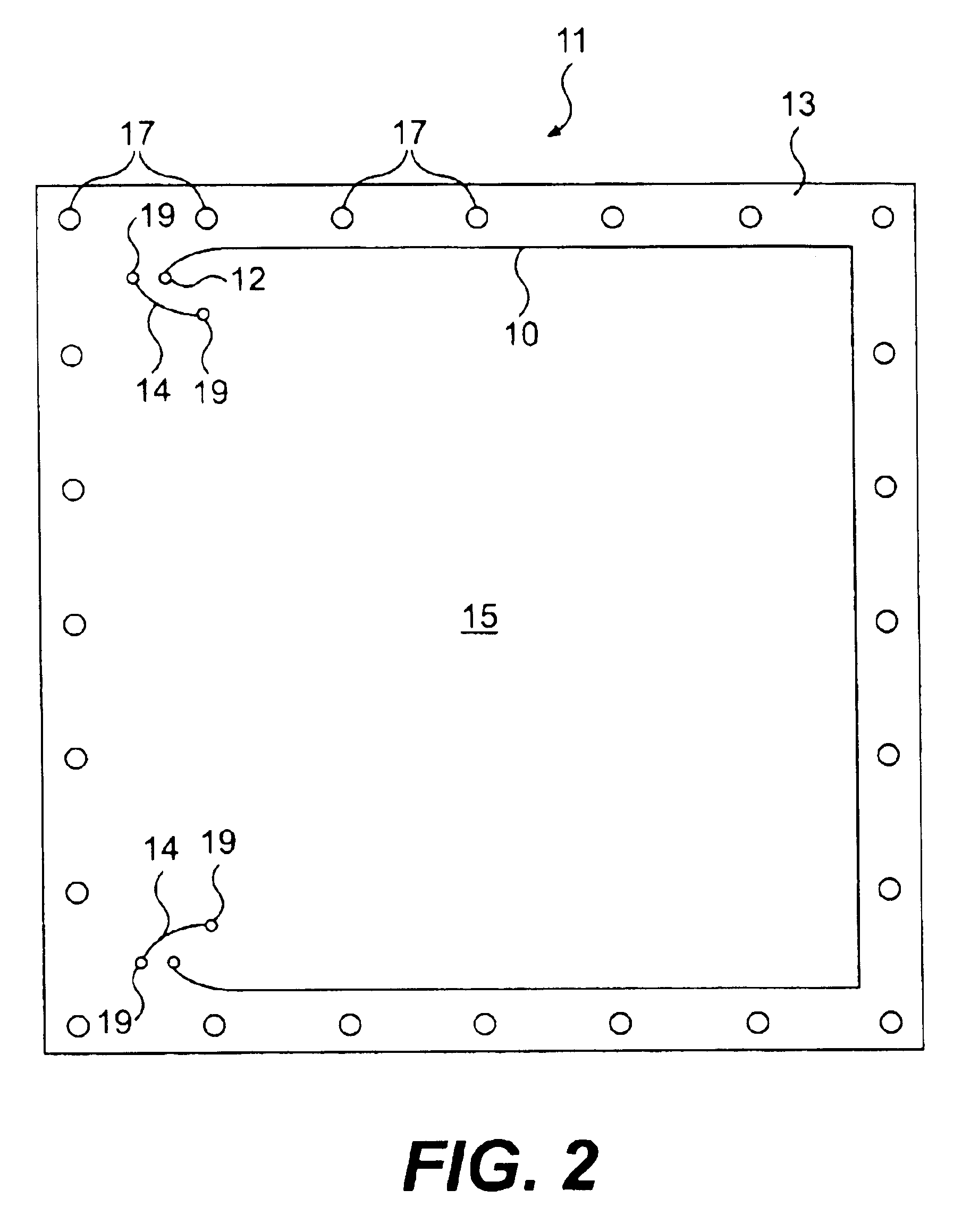

Pressure relief device assemblies

The present invention is directed to pressure relief devices and to corresponding pressure relief assemblies that have improved vacuum resistance, improved fragmentation resistance, and / or improved burst control while maintaining low mass. The pressure relief device includes a substantially flat flange section and a domed section. The domed section may include a transitional line that defines a change in the shape of the domed section. The pressure relief device may also include a bracket for securing or aligning a domed section to a flange section. The pressure relief device may further include a stress distribution feature that is disposed transversely to a line of weakness in the domed section. The pressure relief assembly may include a fastener having a wire that is configured to break and release the pressure relief device when subject to a predetermined tensile load.

Owner:BS&B SAFETY SYST LTD

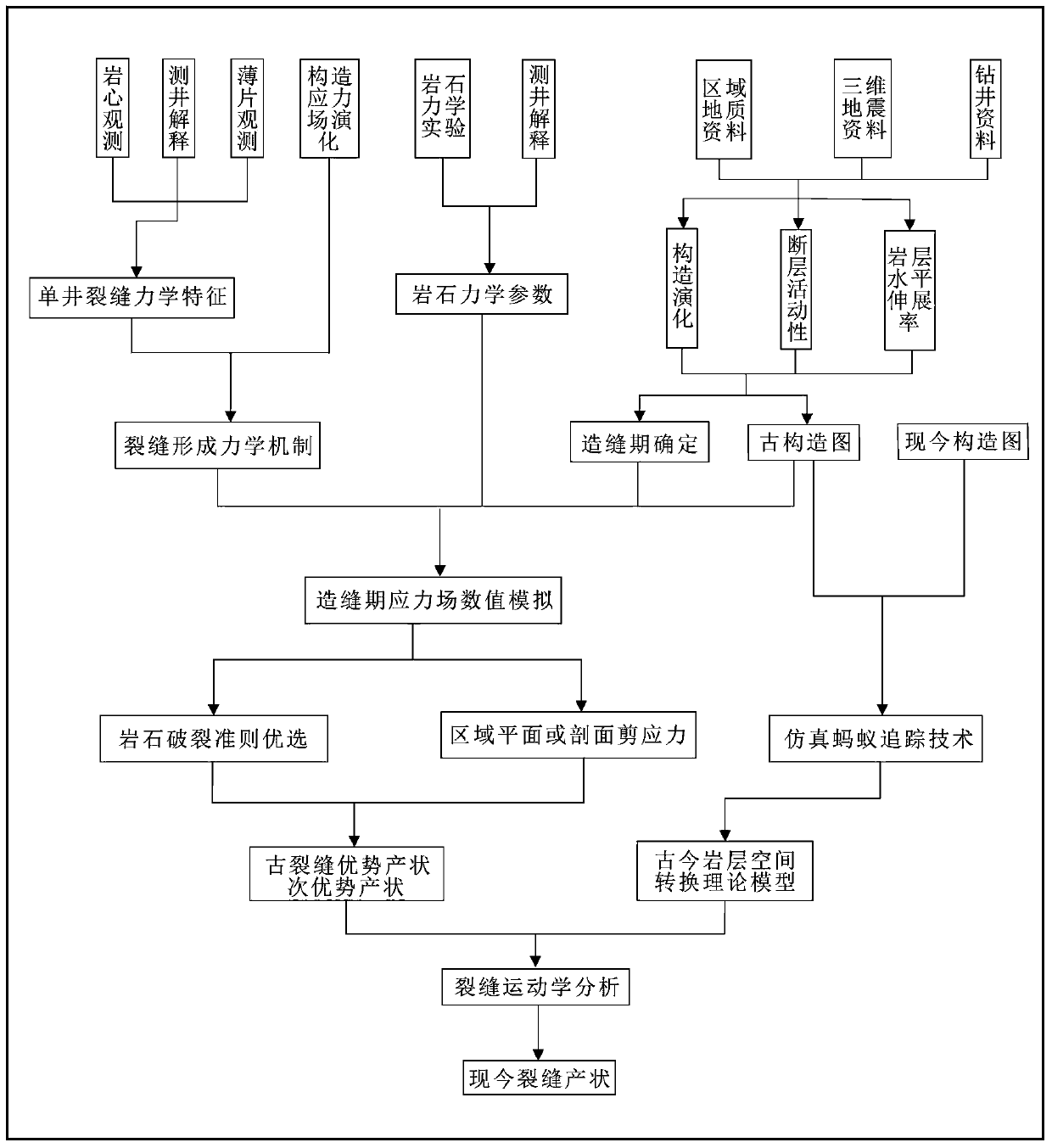

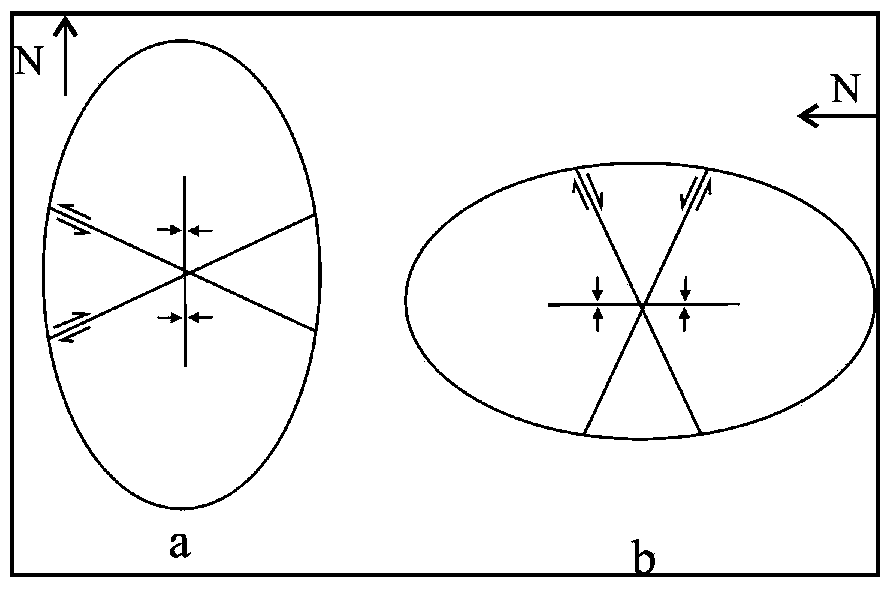

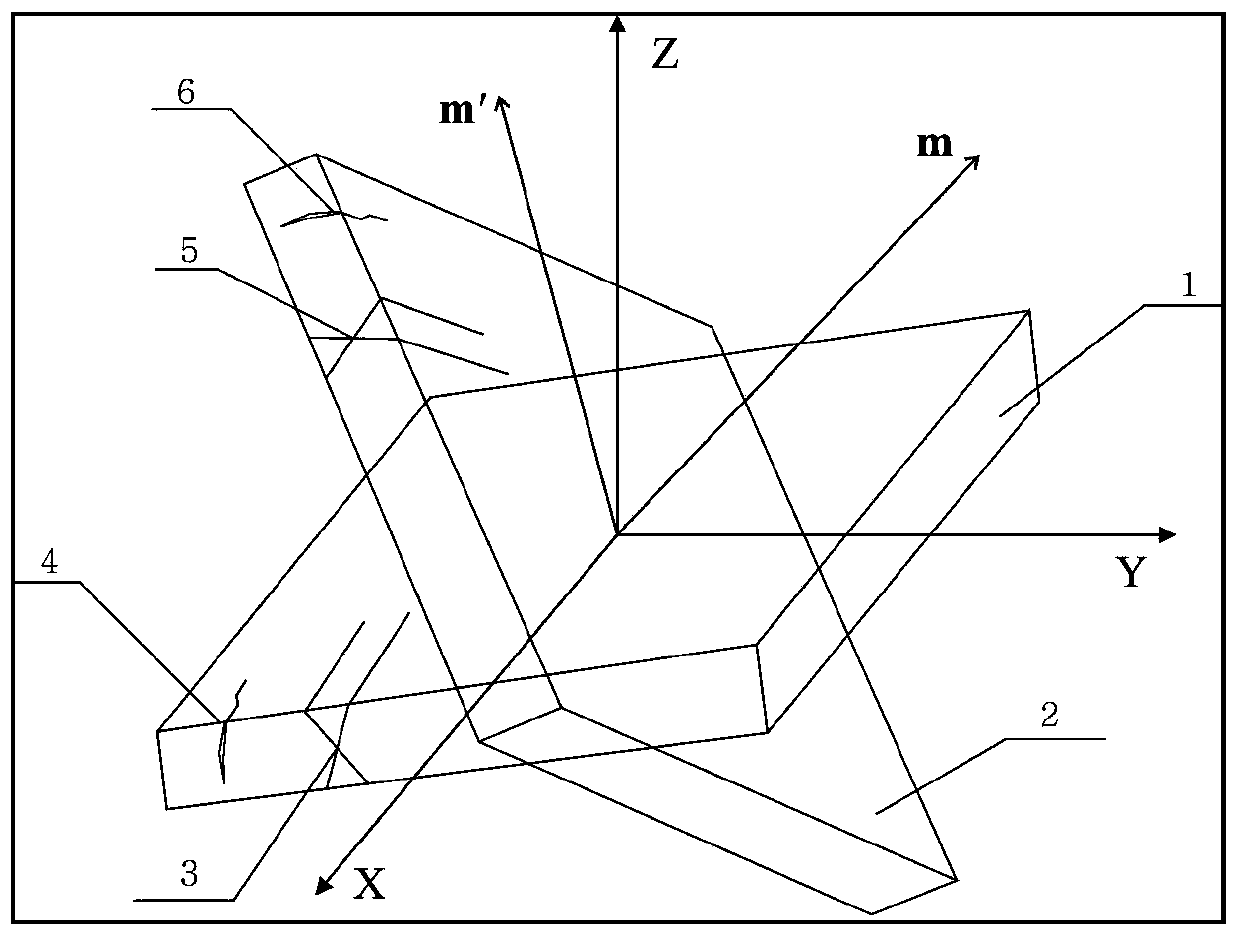

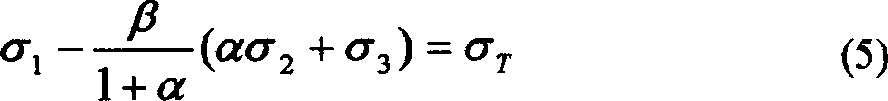

Quantitative forecasting method of tectonic fissure occurrence

InactiveCN104200039AEasy to openHigh porositySpecial data processing applicationsPredictive methodsMechanical property

The invention relates to the field of oil-gas field exploration and development, particularly to a quantitative forecasting method of tectonic fissure occurrence. The quantitative forecasting method includes firstly determining a fissure mechanical property and rock mechanics parameters in a research area and restoring a paleotectonic map; secondly performing a numerical simulation of a paleostress field; thirdly selecting an appropriate rock failure principle according to the simulated paleostress field and the fissure mechanical property, and forecasting the best occurrence and the second-best occurrence of paleofissures on the basis of plane shearing strength distribution or profile shearing strength distribution of the stress field in the research area; coupling spatial positions of the paleorock stratum and the current rock stratum based on the simulated ant tracing technique, and then establishing a spatial switching theoretical model of the paleorock stratum and the current rock stratum; performing the quantitative analysis of fissure kinematics characteristics, and forecasting the occurrence of the current fissures according to that of the paleofissures.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

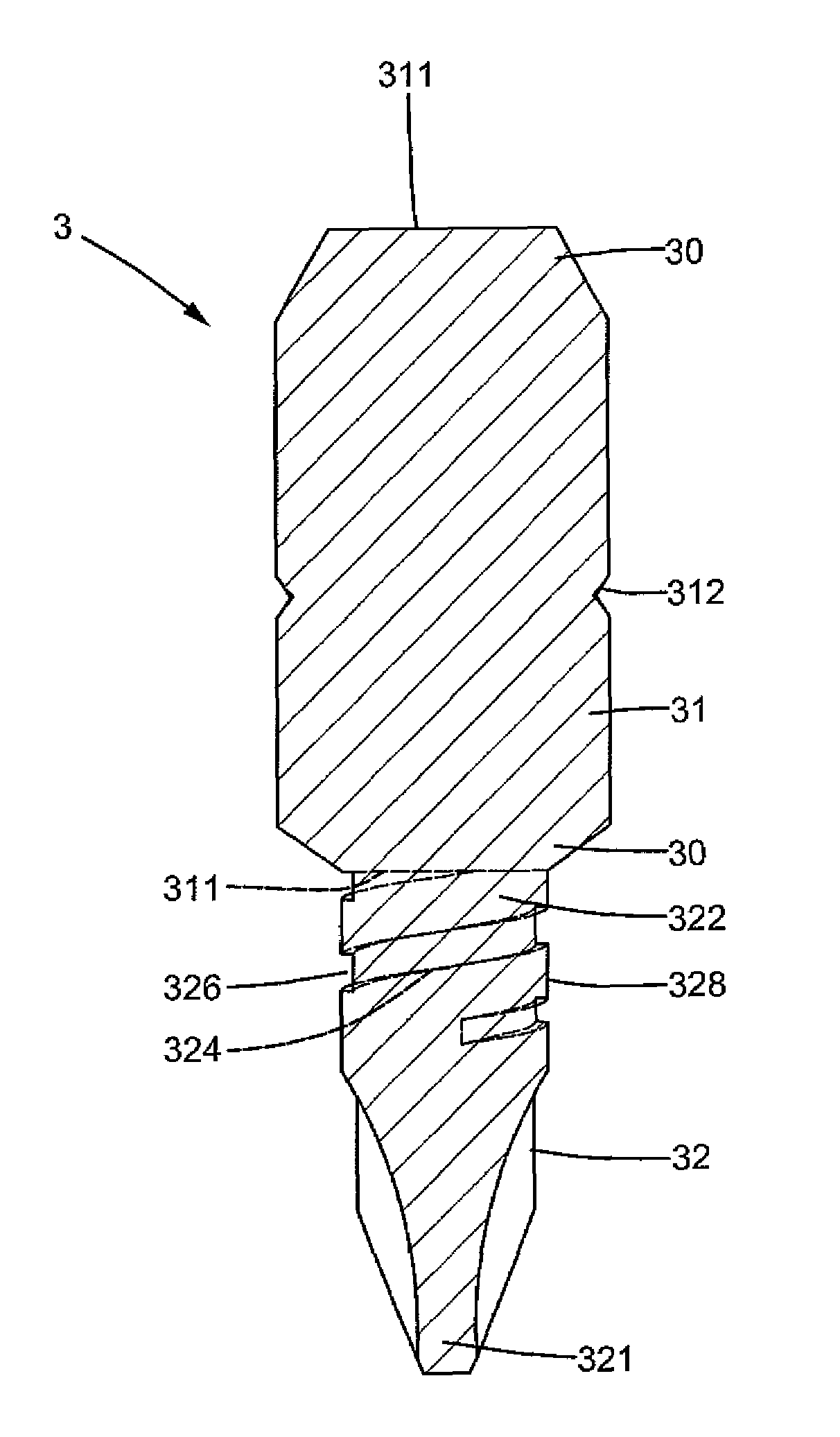

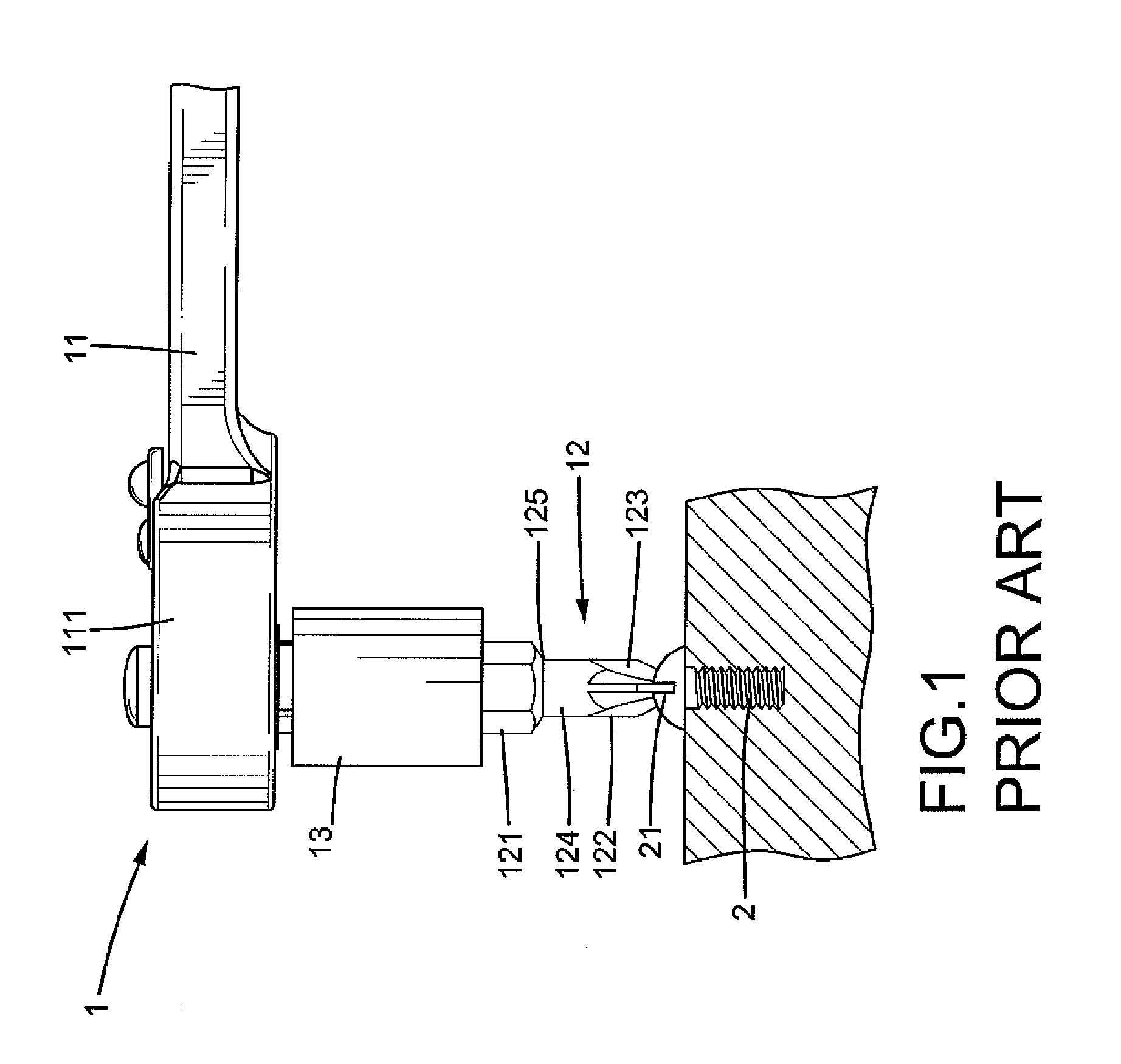

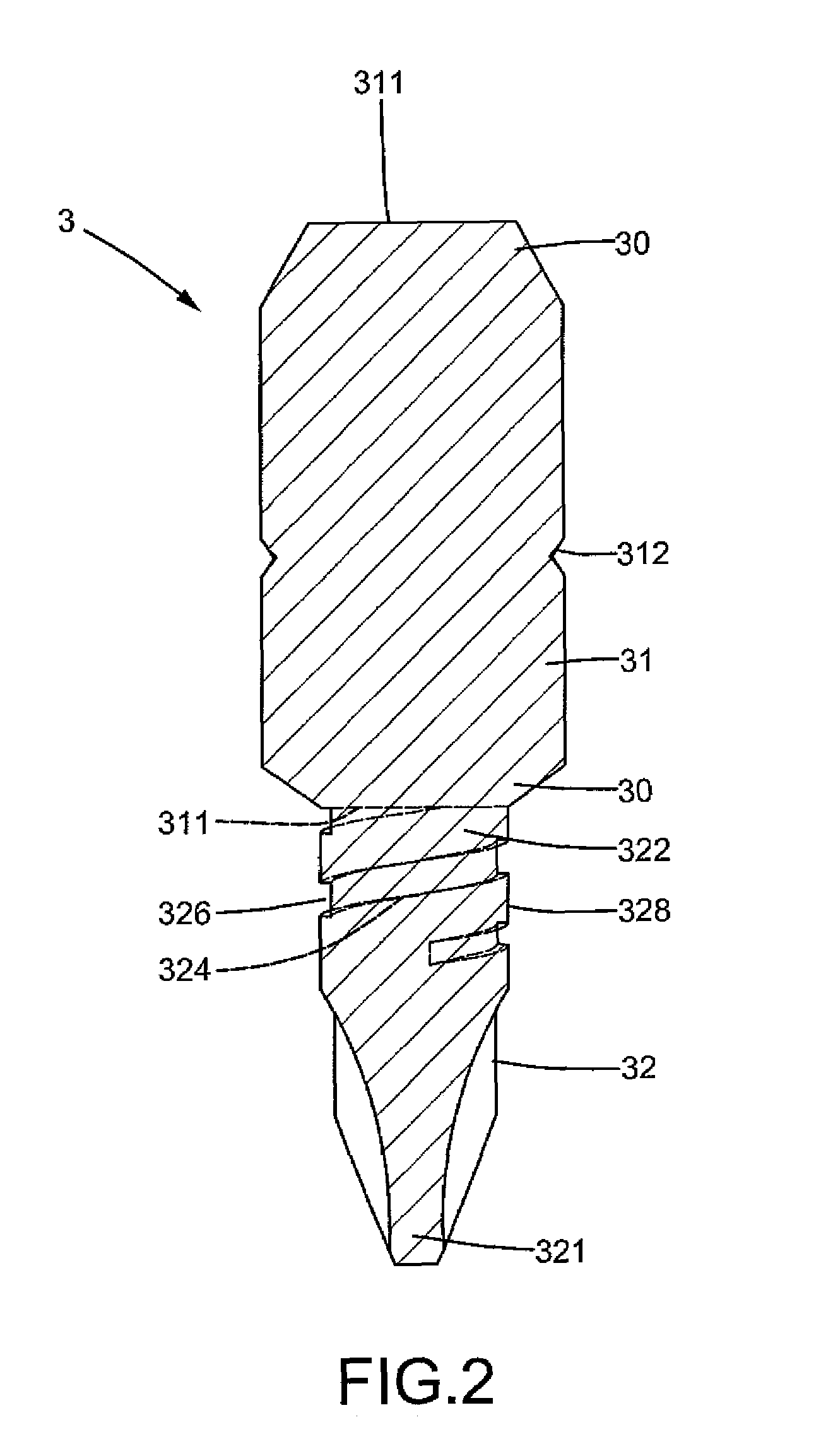

Screwdriver bit

A screwdriver bit includes a shank for coupling with a tool for rotating the shank. An engaging portion extends from one of two ends of the shank and includes an insertion section for coupling with a fastener. A reduced, threaded section is formed between one of the ends of the shank and the insertion section of the engaging portion. The reduced, threaded section includes an outer diameter smaller than that of the ends of the shank and an outer threading. The outer threading of the reduced, threaded section provides uniform stress distribution during torque transmission.

Owner:COMPASS

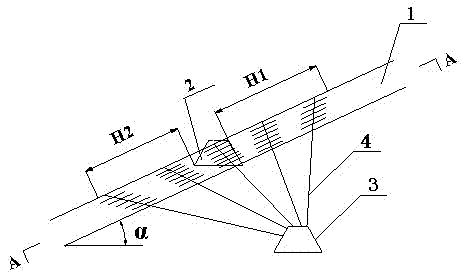

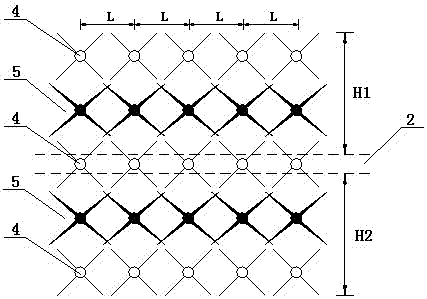

Method for performing through-going seam cutting, pressure relief, permeability enhancement and quick tunneling on soft and high-outburst coal seam

InactiveCN102900460AIncrease the speed of excavationIncrease extraction concentrationGas removalStress distributionType fracture

The invention discloses a method for performing through-going seam cutting, pressure relief, permeability enhancement and quick tunneling on a soft and high-outburst coal seam, and in particular is applied to quick tunneling in a coal seam which is high in outburst danger and a laneway is difficult to support in a coal mine. The method comprises the following steps of: forming a network type fractured net by high-pressure jet flow seam cutting, pressure relief and permeability enhancement technologies, and enhancing an effect of extracting strip-type coal seam gas on a coal laneway subjected to through-going drilling and pre-extraction; and forming a network type filling region by pressing and injecting filling materials, so that the strength and stress distribution of a coal body are improved, the coal laneway is easy to maintain in the tunneling process, a phenomenon that the gas rushes out of a tunneled laneway is avoided, gas accidents are eliminated in the tunneling process, and an aim of safely and quickly tunneling the laneway is fulfilled.

Owner:CHINA UNIV OF MINING & TECH

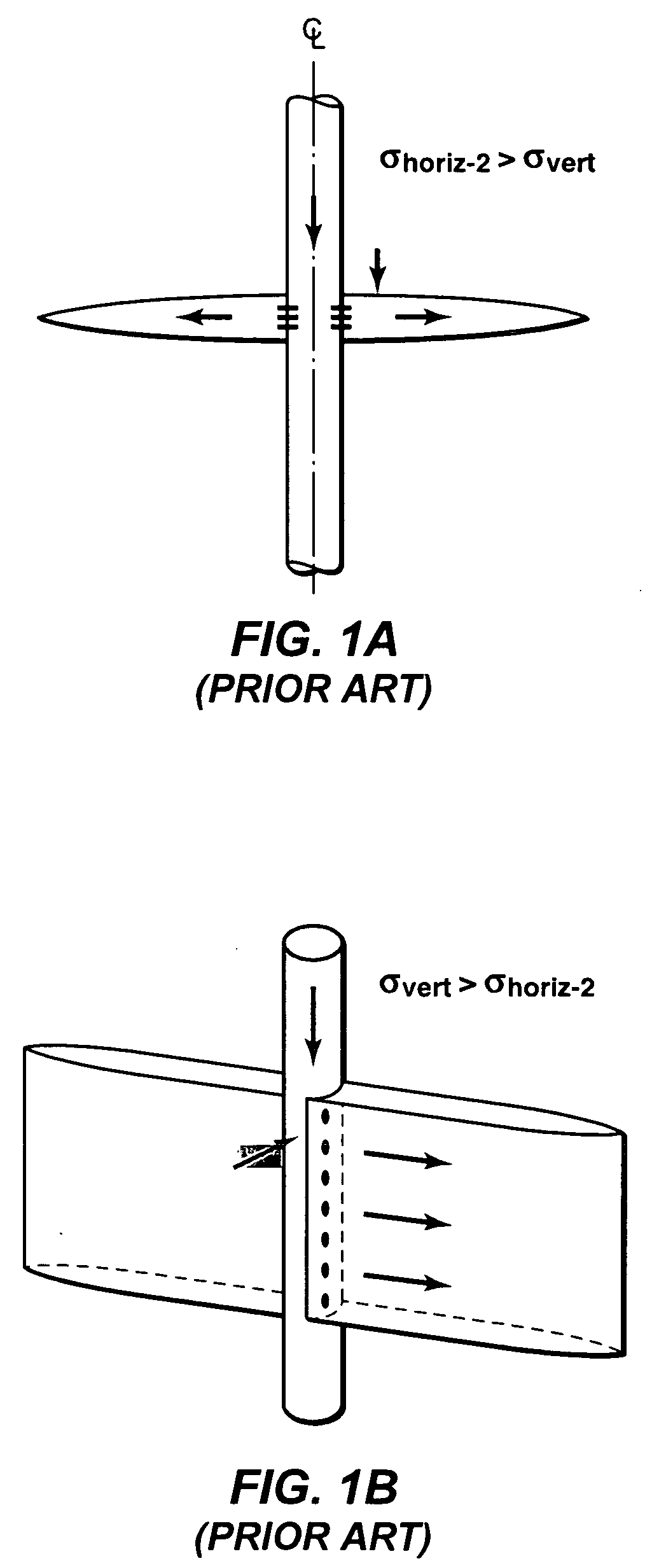

Hydraulic Fracturing Proppants

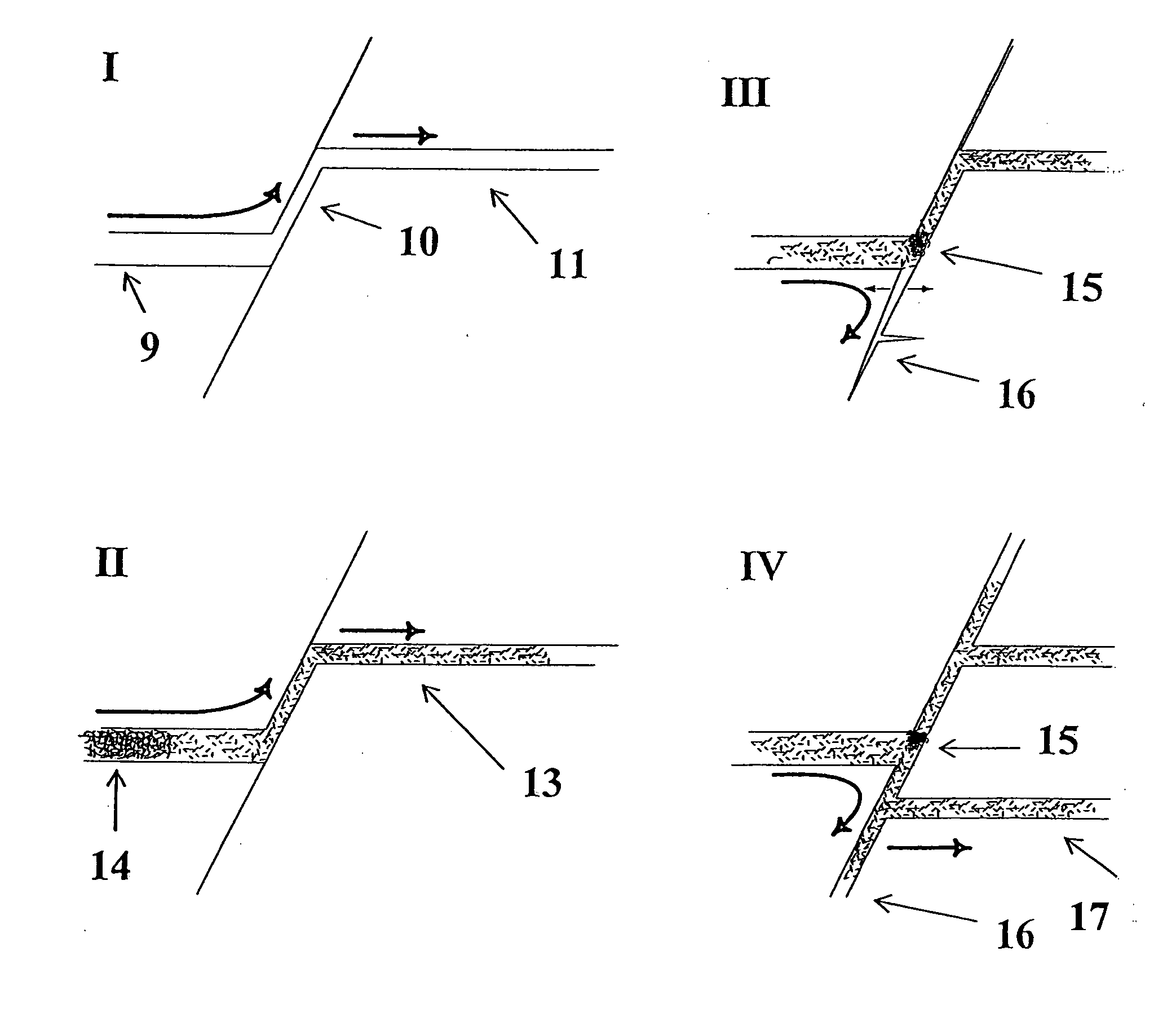

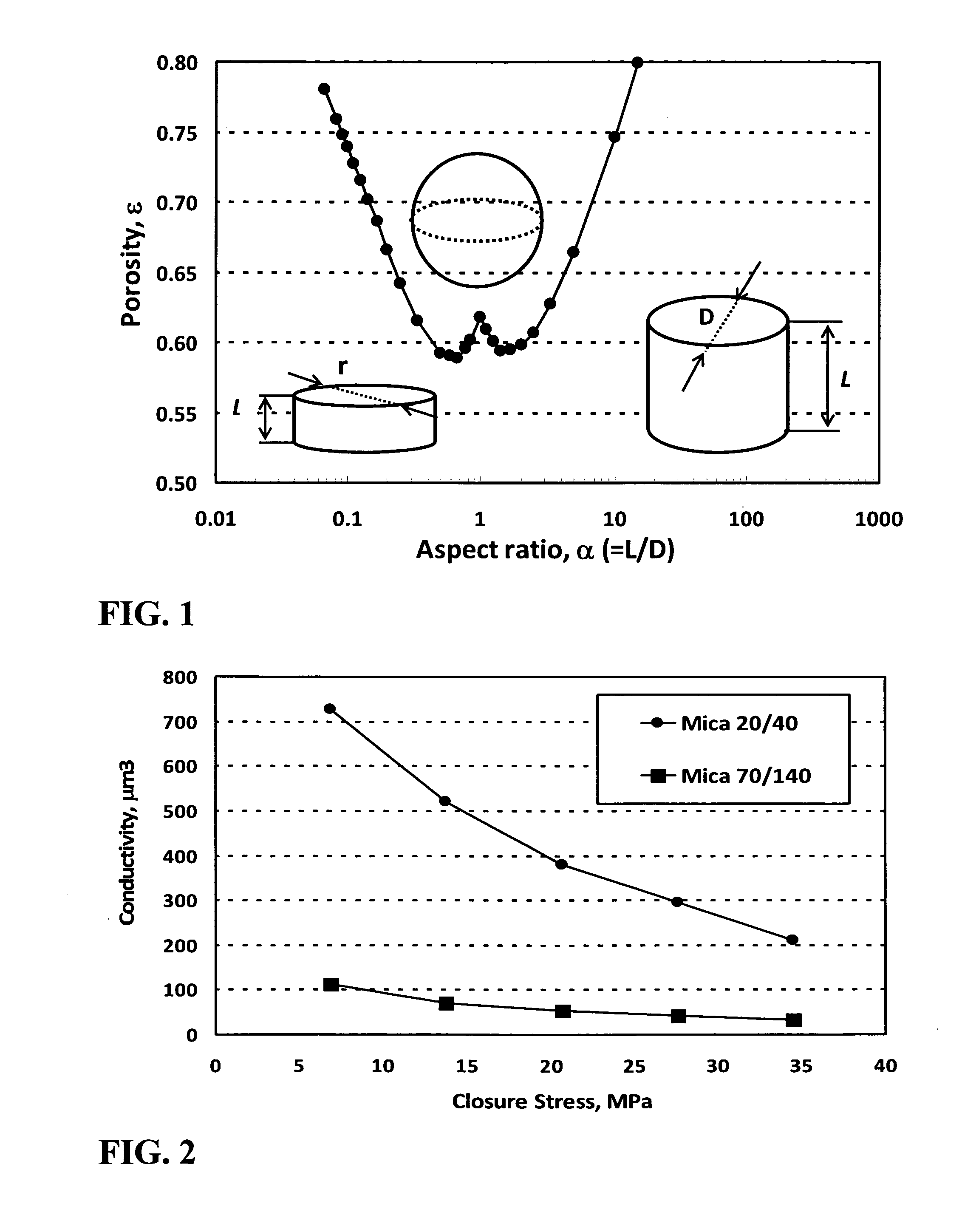

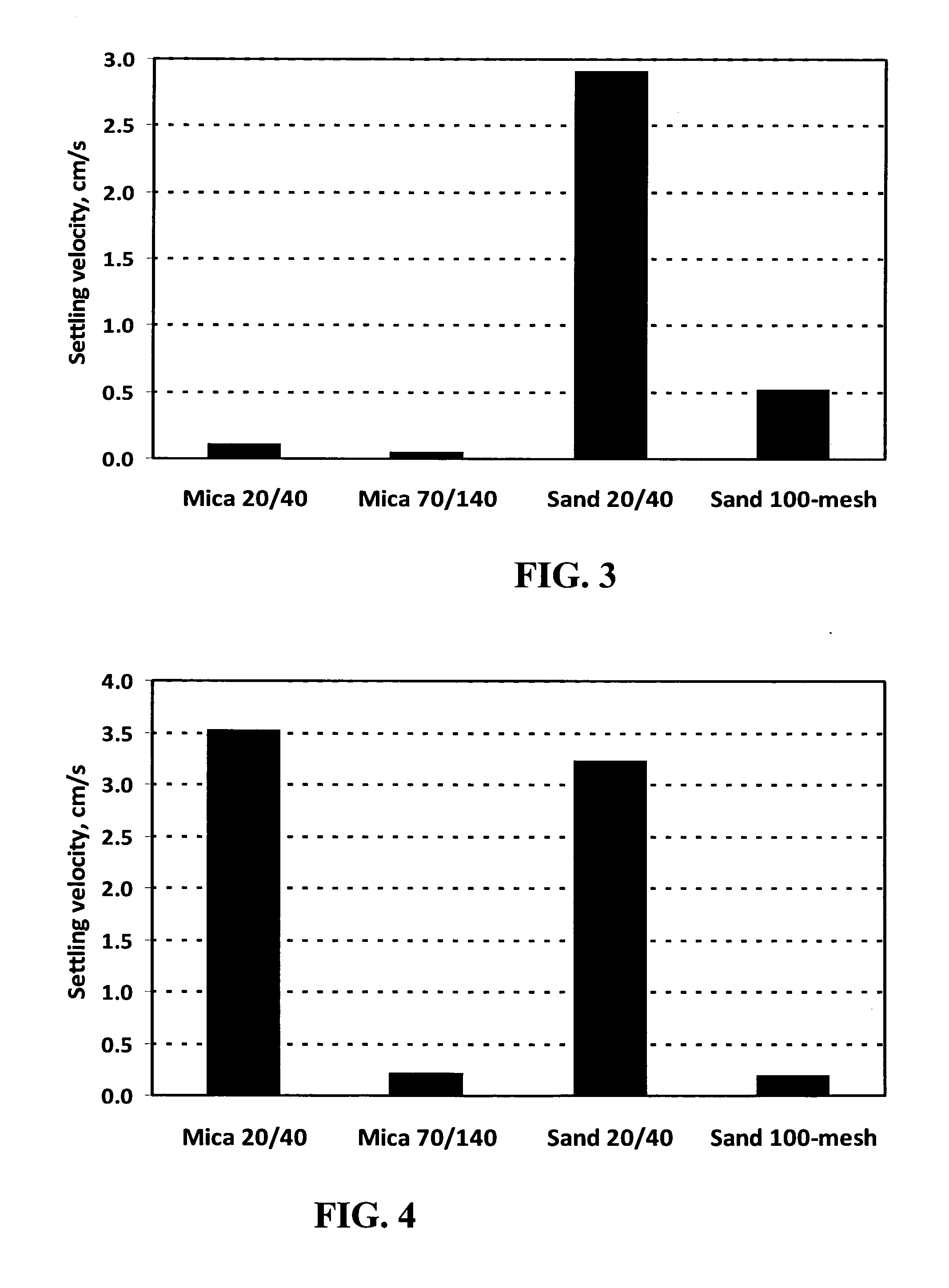

ActiveUS20110180259A1Increase contact areaImprove stress distributionFluid removalDrilling compositionStress distributionEmbedment

A method is given for treating a wellbore in a subterranean formation by hydraulic fracturing, slickwater fracturing, gravel packing, and the like, by using plate-like materials as some or all of the proppant or gravel. The plate-like materials are particularly useful in complex fracture systems, for example in shales. They may be used as from about 20 to about 100% of the proppant. Relative to conventional proppants, plate-like proppants demonstrate (a) enhanced crush resistance of the proppant due to better stress distribution among proppant particles, (b) diminished proppant embedment into formation fracture faces due to the greater contact surface area of proppant particles with the formation, (c) better proppant transport due to lower proppant settling rates, (d) deeper penetration into branched and fine fracture networks, and (e) enhanced proppant flowback control. Preferred plate-like proppants are layered rocks and minerals; most preferred is mica.

Owner:SCHLUMBERGER TECH CORP

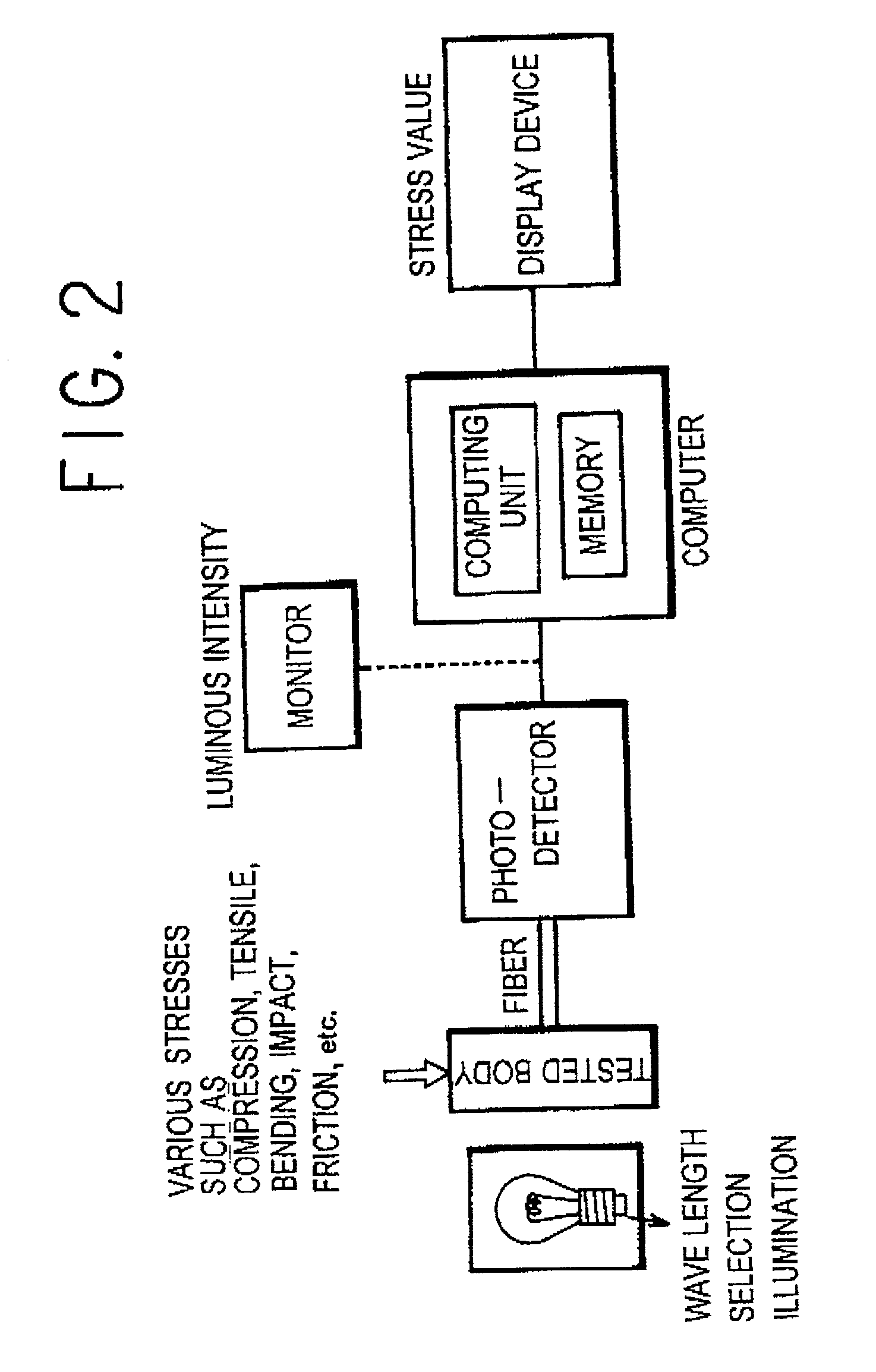

Method of and a system for measuring a stress or a stress distribution, using a stress luminescent material

InactiveUS20010017059A1Improve distributionEasy to measureForce measurement by measuring optical property variationUsing optical meansStress distributionElectricity

This invention is to provide a method and a system which, by making use of a stress luminescent material, renders it possible to directly observe a stress distribution on the base of a real time without electrical contacts, and to easily measure a stress or a stress distribution and a stress image. Essentially, the invention comprises the steps of adding a stress to a tested body containing a stress luminescent material whose light emission is proportional to the stress, making visually observable a stress distribution over the tested body in accordance with a luminous intensity of the stress luminescent material contained in the tested body, measuring the luminous intensity of the luminescent material of the tested body, comparing the measured value of the luminous intensity with certain correlation data indicating a relationship between the luminous intensity of the stress luminescent material and a stress, thereby obtaining a stress value or a stress distribution over the tested body.

Owner:NAT INST OF ADVANCED IND SCI & TECH

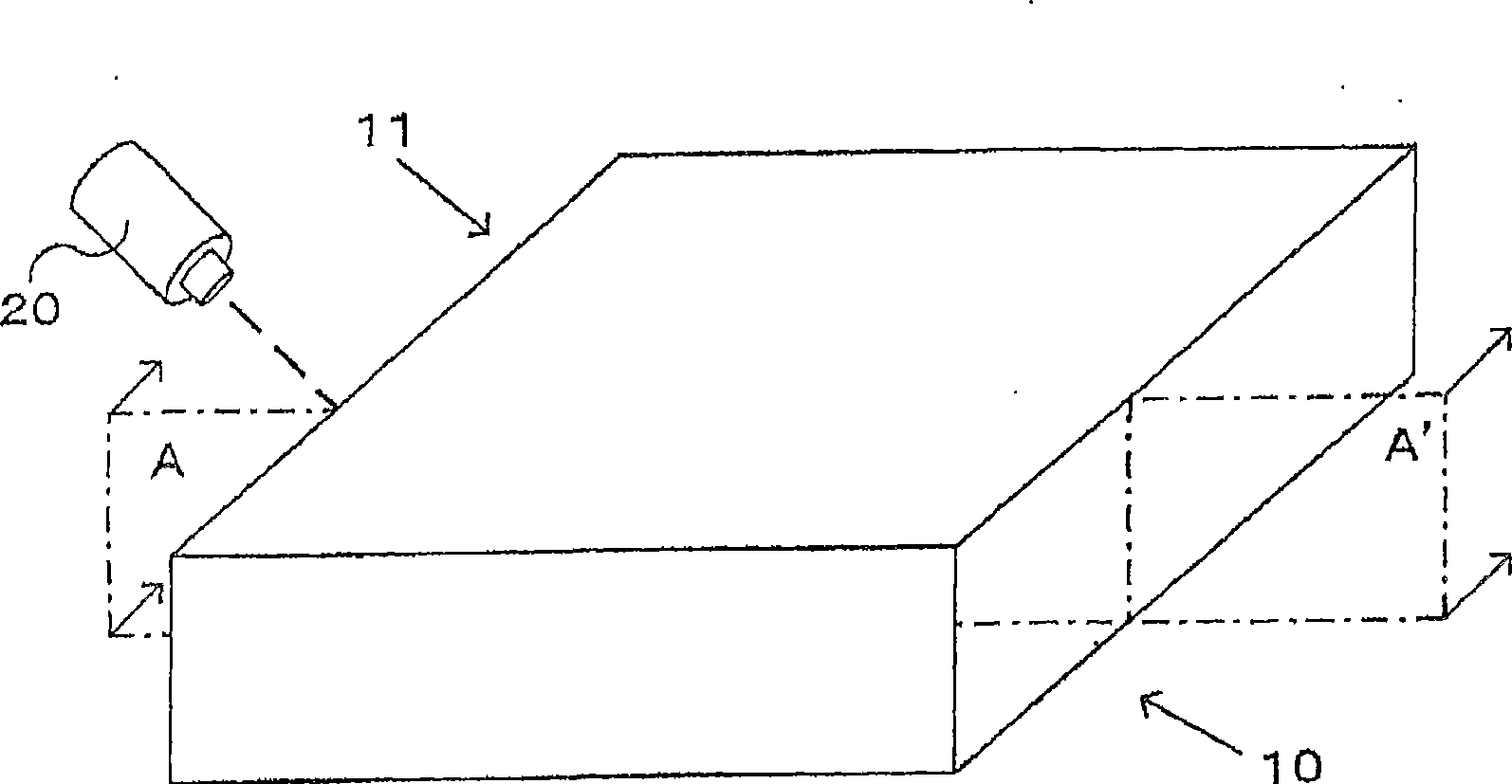

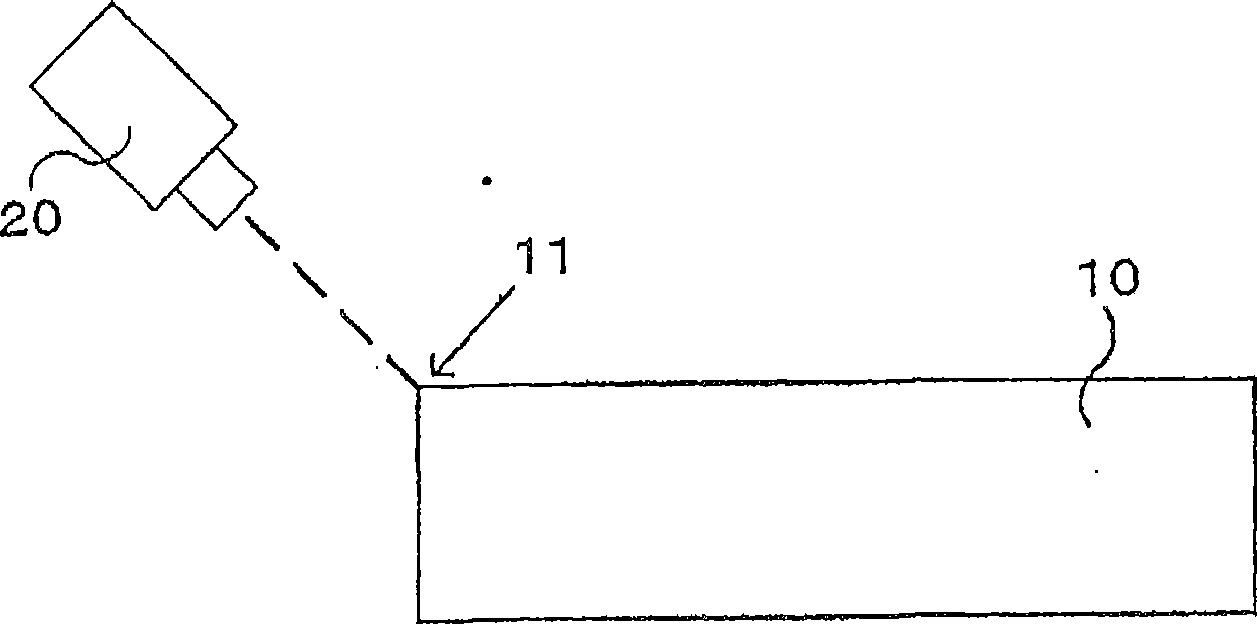

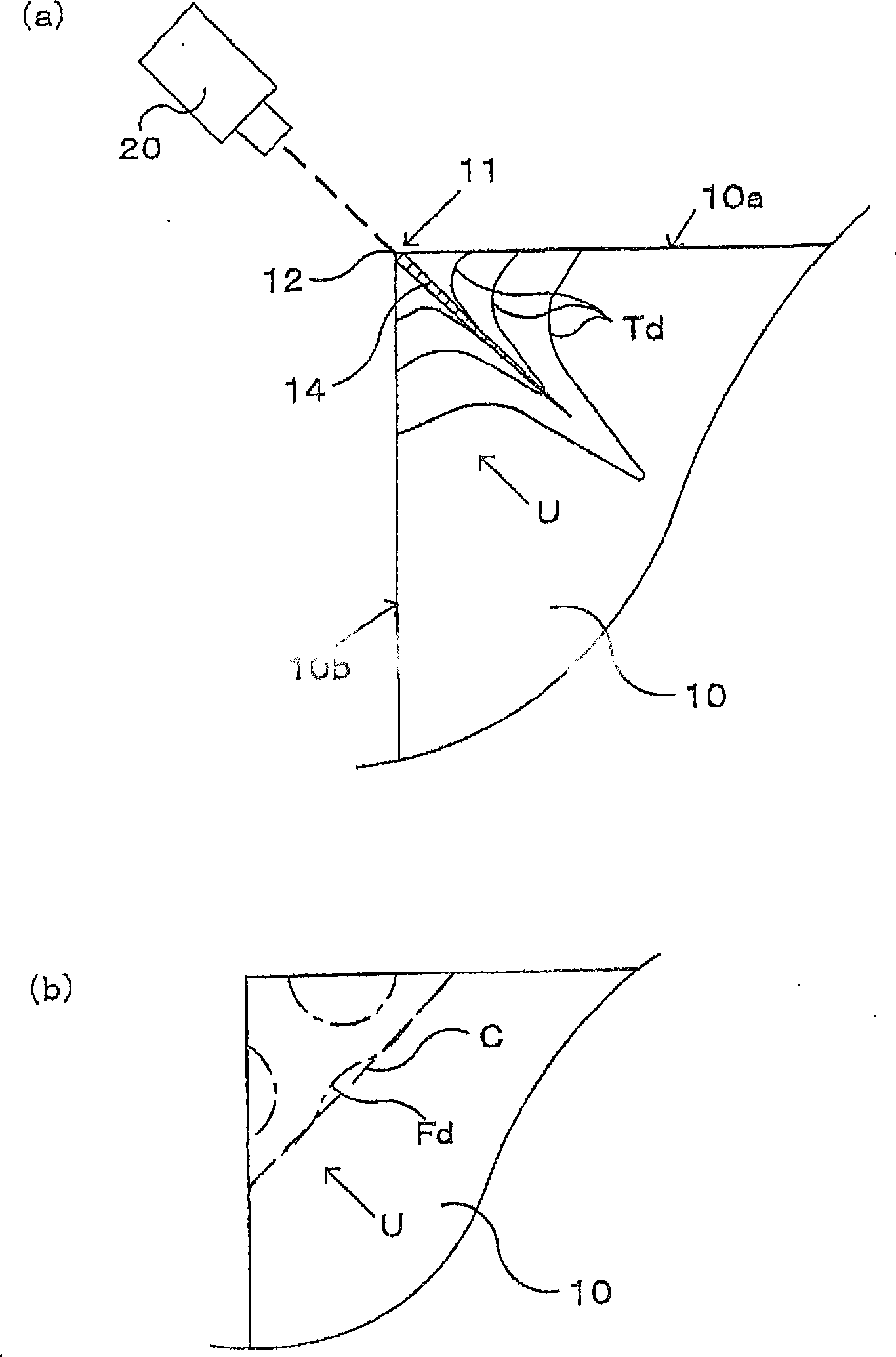

Chamfering method for brittle substrate

InactiveCN101386466AStretch Direction AdjustmentAdjust shapeFine working devicesGlass severing apparatusStress distributionWavelength

The invention provides a chamfering method for brittle material substrate, which can form small depression for chamfering processing surface. A thermal stress distribution field which can control cracks in the substrate is formed by using a laser source with absorptivity of 0.05 to 0.95 relative to the substrate (10), irradiating laser near a edge line (11), forming temperature distribution in the substrate through a laser absorption region (14) from the edge line to inner part of the substrate, extending the cracks through thermal stress distribution in the substrate generated by the temperature distribution, and adjusting extension direction of the cracks.

Owner:MITSUBOSHI DIAMOND IND CO LTD

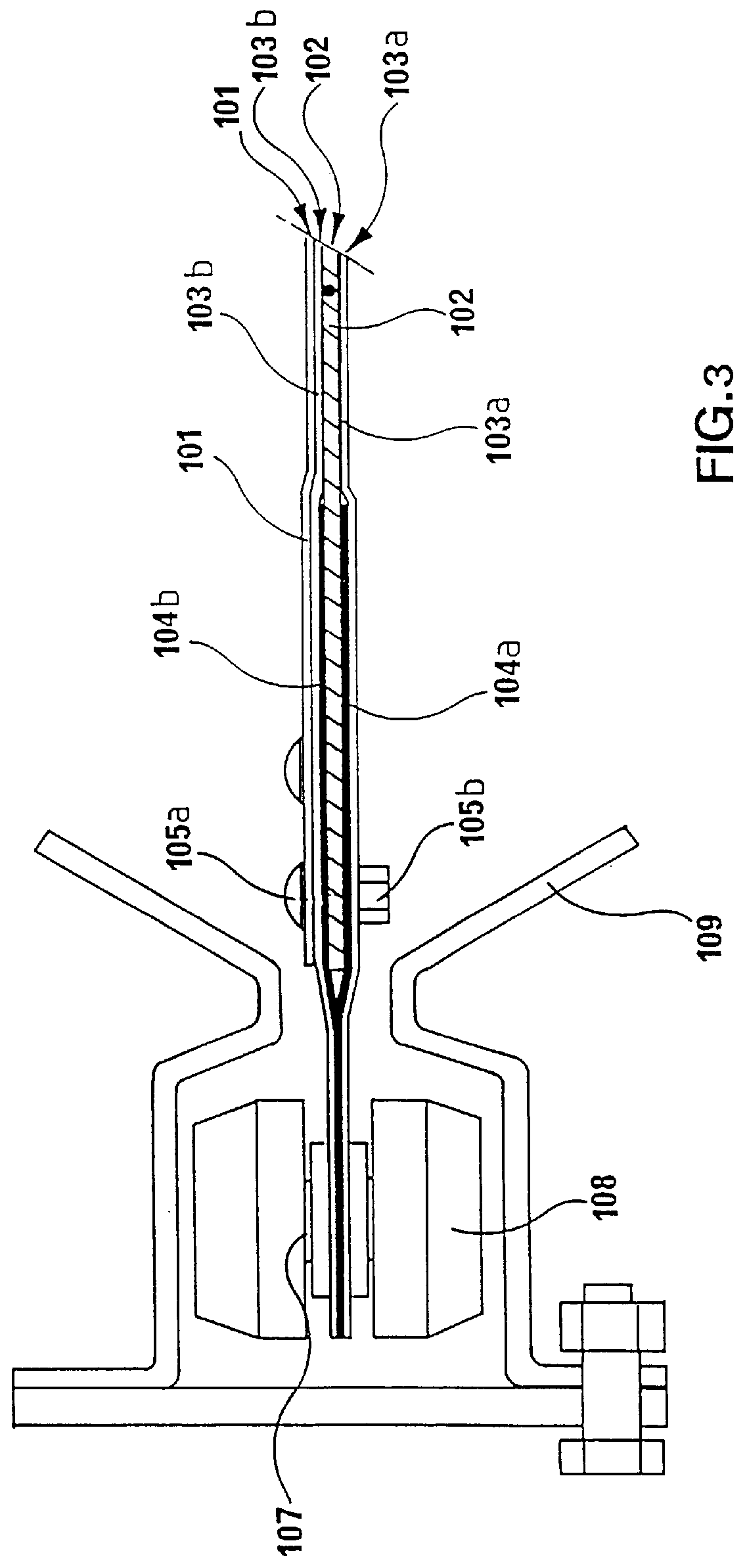

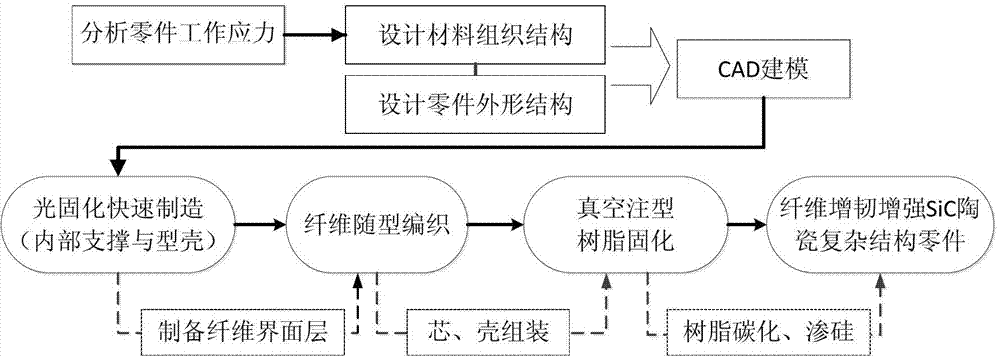

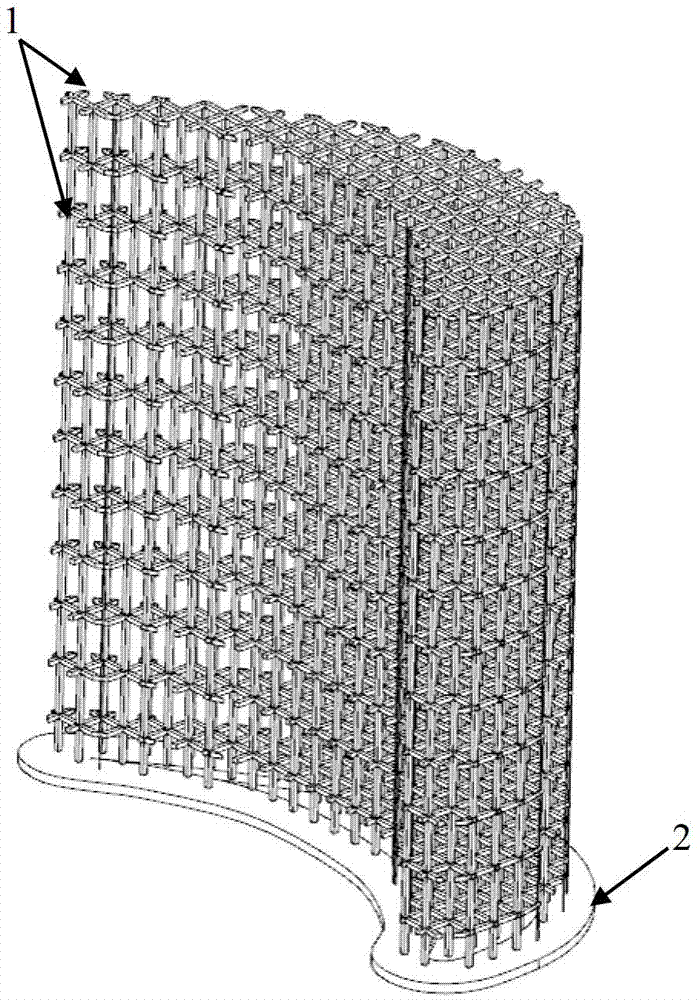

Preparation method of SiCf/SiC ceramic matrix composite turbine blades

InactiveCN103113123AMeet preparation requirementsImprove silicon corrosion resistanceYarnStress distribution

The invention discloses a preparation method of SiCf / SiC ceramic matrix composite turbine blades, which is characterized in that through analyzing the stress distribution of a blade in an application state, based on this point, a performance-controllable SiCf / SiC ceramic matrix composite turbine blade is manufactured through the designing and adopting of processes such as rapid forming, high-performance continuous yarn braiding, gel-casting, reactive sintering, and the like. According to the method, parts such as blades and the like are manufactured by using heterogeneous materials, the contradiction between the uniformity and nonuniform loaded structure of materials is solved, and the performances of materials can be set flexibly according to the bearing needs of manufactured parts; and prepared SiCf / SiC ceramic matrix composite turbine blades have the characteristics of near-net forming variable-cross-section complex structure, controllable material performance, flexible machining, short production cycle, low cost, and the like, and can be applied to the development and manufacturing of high-temperature-resistant complex structured parts for aerospace and the like.

Owner:XI AN JIAOTONG UNIV

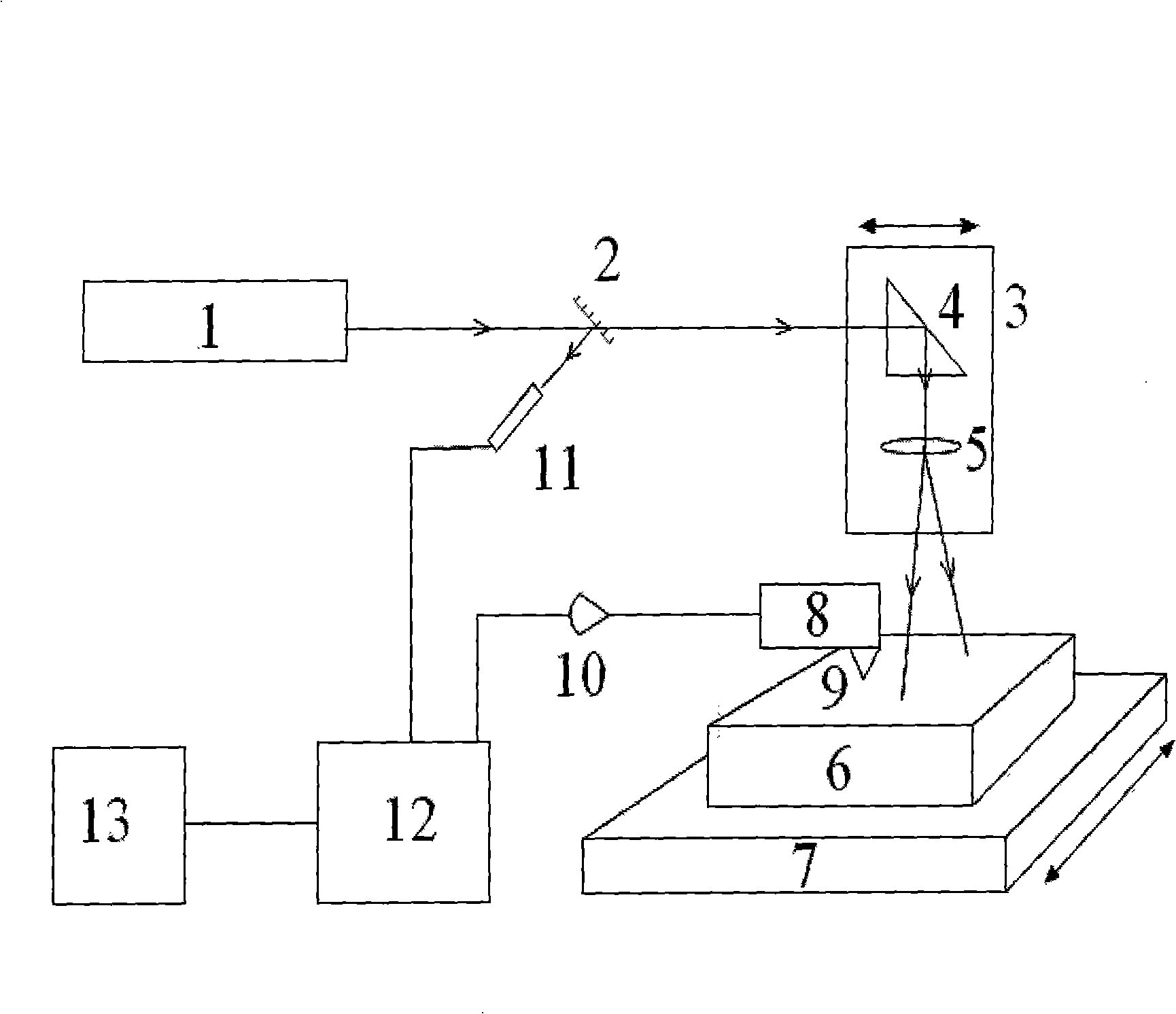

Laser sonic surface wave stress test system

InactiveCN101281172AFast 2D scanningHigh detection sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationMetallic materials

The invention discloses a laser acoustic surface wave stress test system, which is mainly comprises an ultrasound surface wave excitation part composed of a short-pulse laser, a spectroscope, a triple prism and a cylindrical convex lens, and an ultrasound surface wave detection part composed of a PVDF piezoelectric film and a high-frequency pre-amplifier. The invention uses the short-pulse laser to generate a high-frequency ultrasound surface wave on the surface of the samples to be tested, a stress value is obtained according to the principle of acoustic elasticity, the PVDF piezoelectric film is served as the receiver of the ultrasound surface wave, fast two-dimensional scanning is realized on the surface of the samples in the way that the PVDF piezoelectric film is fixed, the excitation source and the samples to be tested are in two-dimensional translation motion, the obtained ultrasound surface wave signals are transmitted to an electronic computer, and the measurement of the stress distribution on the surface and the sun-surface of the samples is realized through fast computing and processing by programming according to the principle of acoustic elasticity. The system has the advantages of simple structure and low cost, which can be widely used in the stress distribution measurement on the surface and the sun-surface of metal materials.

Owner:NANJING UNIV OF SCI & TECH

Method for testing tensile strength of fragile material

InactiveCN1621803AMaterial strength using tensile/compressive forcesSpecial data processing applicationsStress distributionDiameter ratio

The present invention is platform Brazil sample test method of measuring the tensile strength of fragile material. By means of 3D elastic mechanical number analysis, the stress distribution regulation of the fragile material in different height / diameter ratio and different Poisson's ratio conditions may be obtained. Proper fragile material strength theory is selected and the cracking initiating from the end surface center line of the sample is stipulated as the effective damage, so as to obtain tensile strength calculation formulas for the test under different height / diameter ratio and different Poisson's ratio conditions. Based on the tensile strength calculation formulas, the material tensile strength based on the strength theory may be obtained through measuring the sample sizes, Poisson's ratio, damage load and compression strength.

Owner:喻勇

Steel frame stress reduction connection

The present invention provides for improvement of ductility and strength performance of connections in structural steel buildings made typically with rolled structural shapes, specifically in bolted and / or welded beam-to-column connections with welded flanges, by greatly reducing the very significant uneven stress distribution found in the conventionally designed connection at the column / beam weld, through use of slots in column and / or beam webs with or without continuity plates in the area of the column between the column flanges, as well as, optionally, extended shear plate connections with additional columns of bolts for the purpose of reducing the stress concentration factor in the center of the flange welds. Moreover, the slots in beam web adjacent to the beam flanges allow the beam web and flange to buckle independently thereby eliminating the degrading of the beam strength caused by lateral-torsional bucking.

Owner:SEISMIC STRUCTURAL DESIGN ASSOCS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com