Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2263 results about "Round bar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

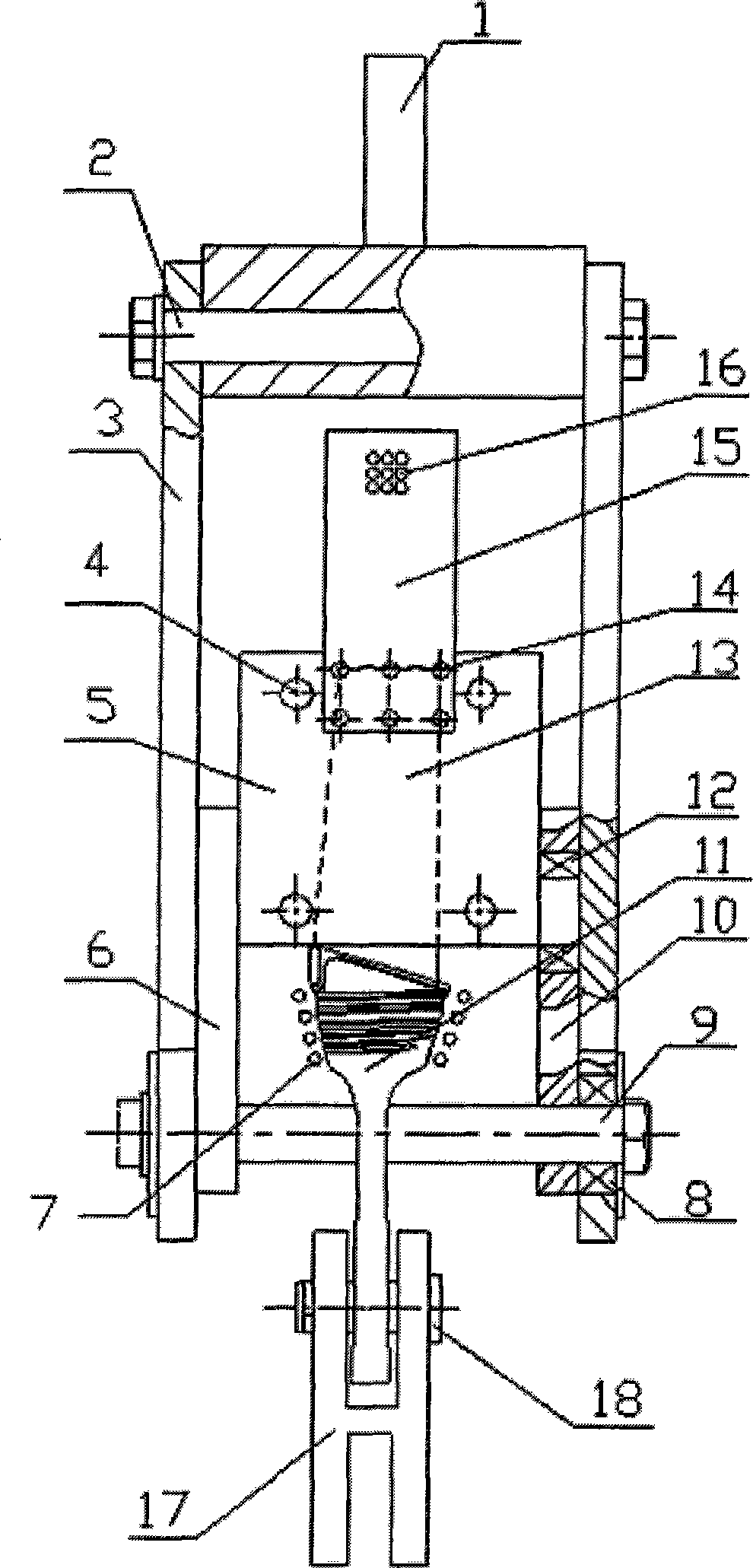

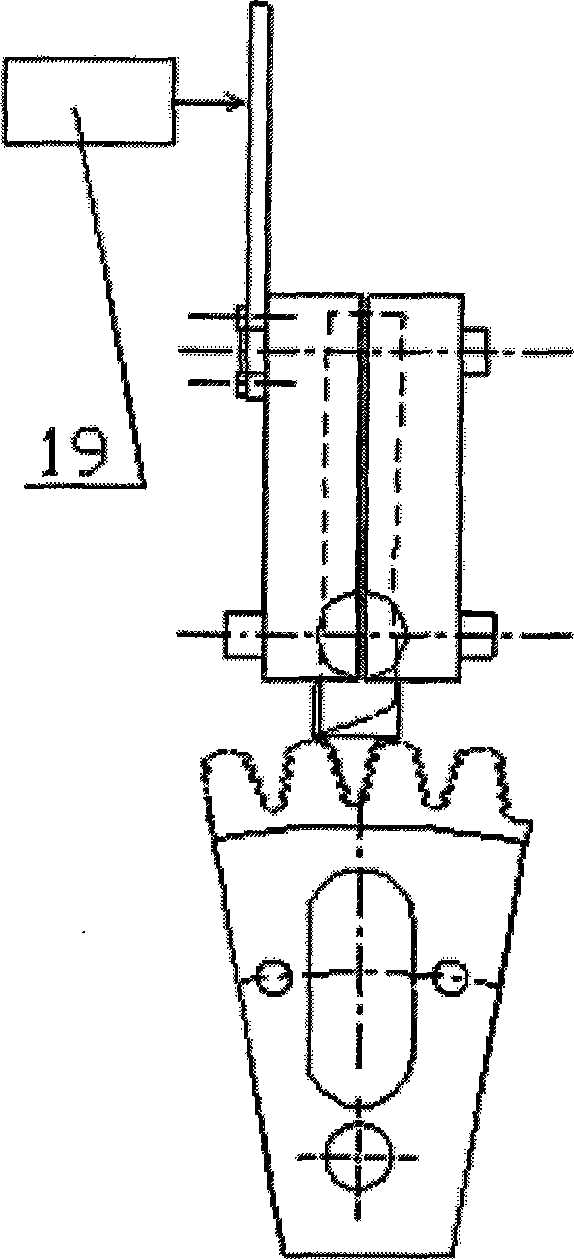

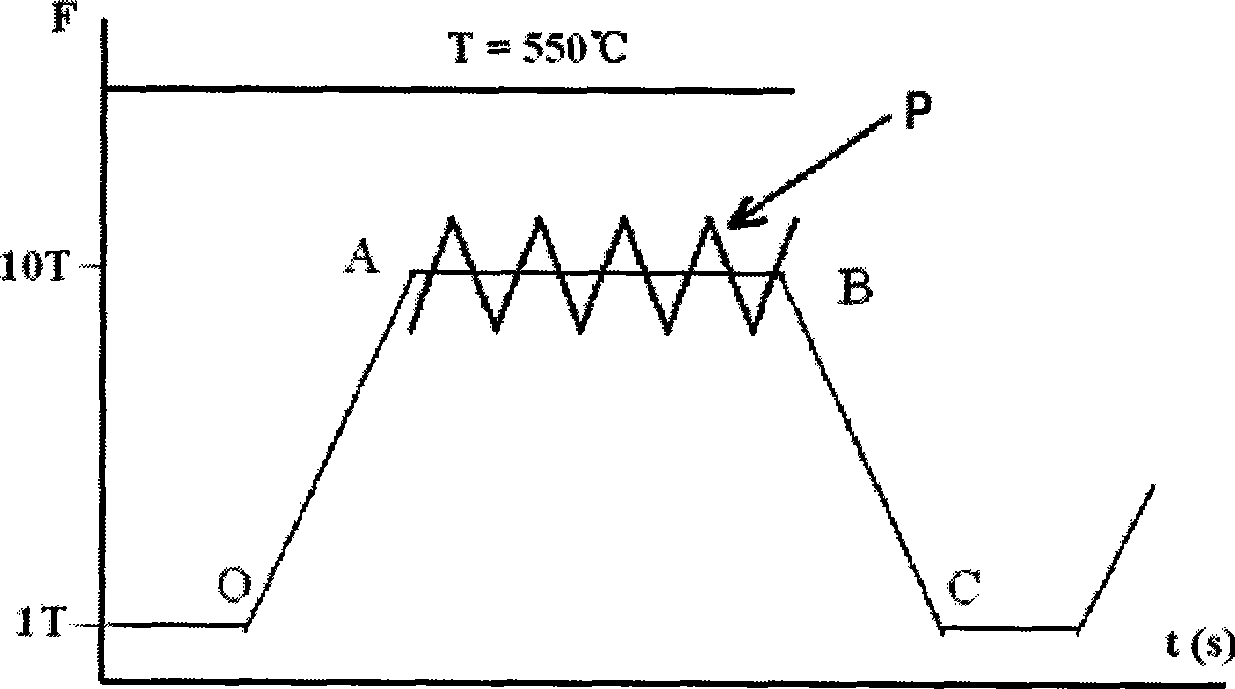

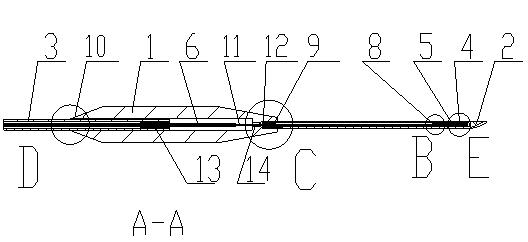

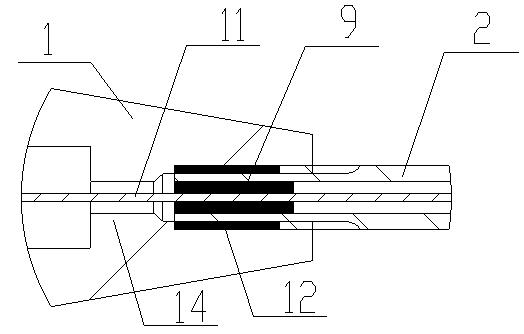

High temperature composite fatigue loading method and apparatus for turbine disc/blade joggled joint

InactiveCN101464240AResolve mutual interferenceReduce resistanceMaterial strength using repeated/pulsating forcesStress distributionFatigue loading

A turbine disc / blade tenon connection high-temperature combined fatigue loading device comprises a low cycle load stress application mechanism, a force transmission pin, a force transmission main tension plate, a force transmission crown plate, a force transmission round bar, a blade clamp, a rolling bearing, a hold-down bolt, a high cycle transmission plate, a high-frequency heating cycle, and a vibration generator, wherein, the low cycle load stress application mechanism is connected with the force transmission main tension plate through the force transmission pin; the force transmission main tension plate is connected with the force transmission round bar through the rolling bearing; the lower end of the force transmission crown plate is sleeved on the force transmission round bar, and the upper end is connected with the load bearing dummy club of the blade clamp through the rolling bearing; the blade clamp is connected with the blade of a turbine through the hold-down bolt; the turbine disc is connected with the low cycle load stress application mechanism through the force transmission pin; the high cycle transmission plate is connected with the blade clamp through the hold-down bolt; and the vibration generator is positioned on one side above a high cycle load transmission plate. The loading method is characterized in that the force application point of low cycle loads is moved backwards, thereby enabling small high cycle loads to be smoothly transferred to the tenon connection position, ensuring the stress distribution along the tenon tooth is reasonable, and preventing combined loads from interfering with each other.

Owner:BEIHANG UNIV

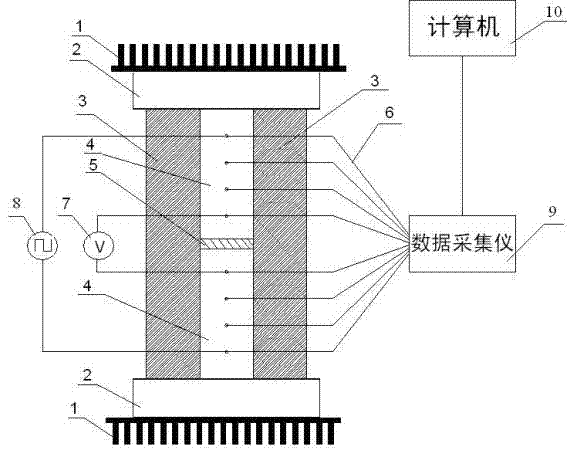

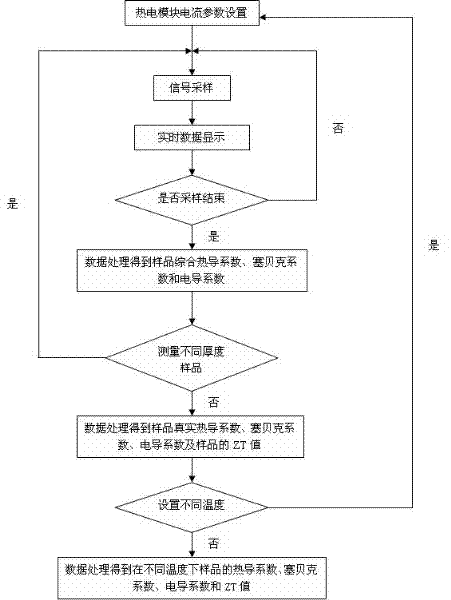

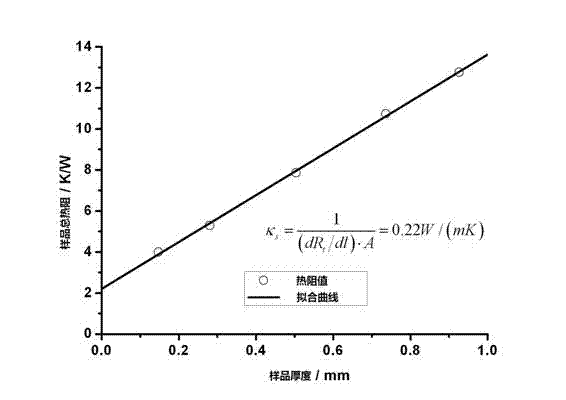

A kind of measuring device and method of thin film thermoelectric performance parameters

InactiveCN102297877AHigh temperature control accuracySave resourcesResistance/reactance/impedenceMaterial heat developmentThermoelectric materialsMeasurement device

The invention provides a device and a method for measuring thermoelectric parameters of a film. The measuring device, which has a symmetric structure, comprises a radiating fin, a thermoelectric module, a heat insulation material, metal round rods, a thermocouple wire, a voltmeter, a power supply, a data acquisition instrument and a computer. The measuring method provided by the invention comprises the following steps of: clamping a film to be measured between two upper and lower metal round rods which are completely same while the area of the film sample is the same as the cross-sectional area of the metal round rods, controlling the ambient temperature of the measuring device and the heat flow of the film sample by the use of the thermoelectric module, detecting and recording each performance parameter of the film thermoelectric material at real time by the use of the data acquisition instrument. The invention has the following advantages: the performance of the film thermoelectric material at different temperatures can be measured, that is to say, the same device can be utilized to simultaneously measure the thermal conductivity coefficient, Seebeck coefficient and conductance coefficient of the film thermoelectric material so as to calculate ZT values of the film thermoelectric material at different temperatures. According to the invention, the measuring device has a simple principle, is convenient to operate, is small in size, has many test functions and has high measuring precision.

Owner:SHANGHAI UNIV

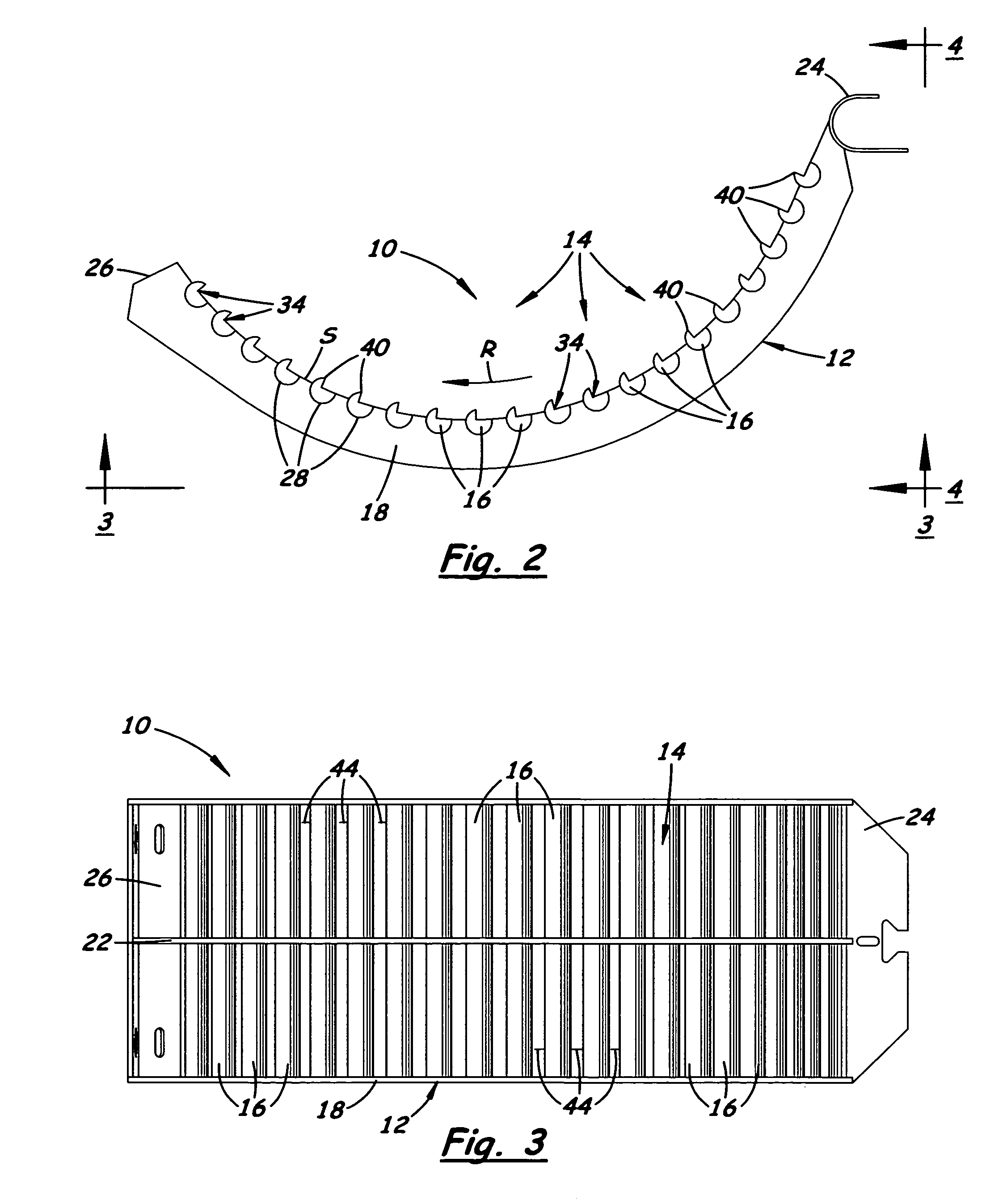

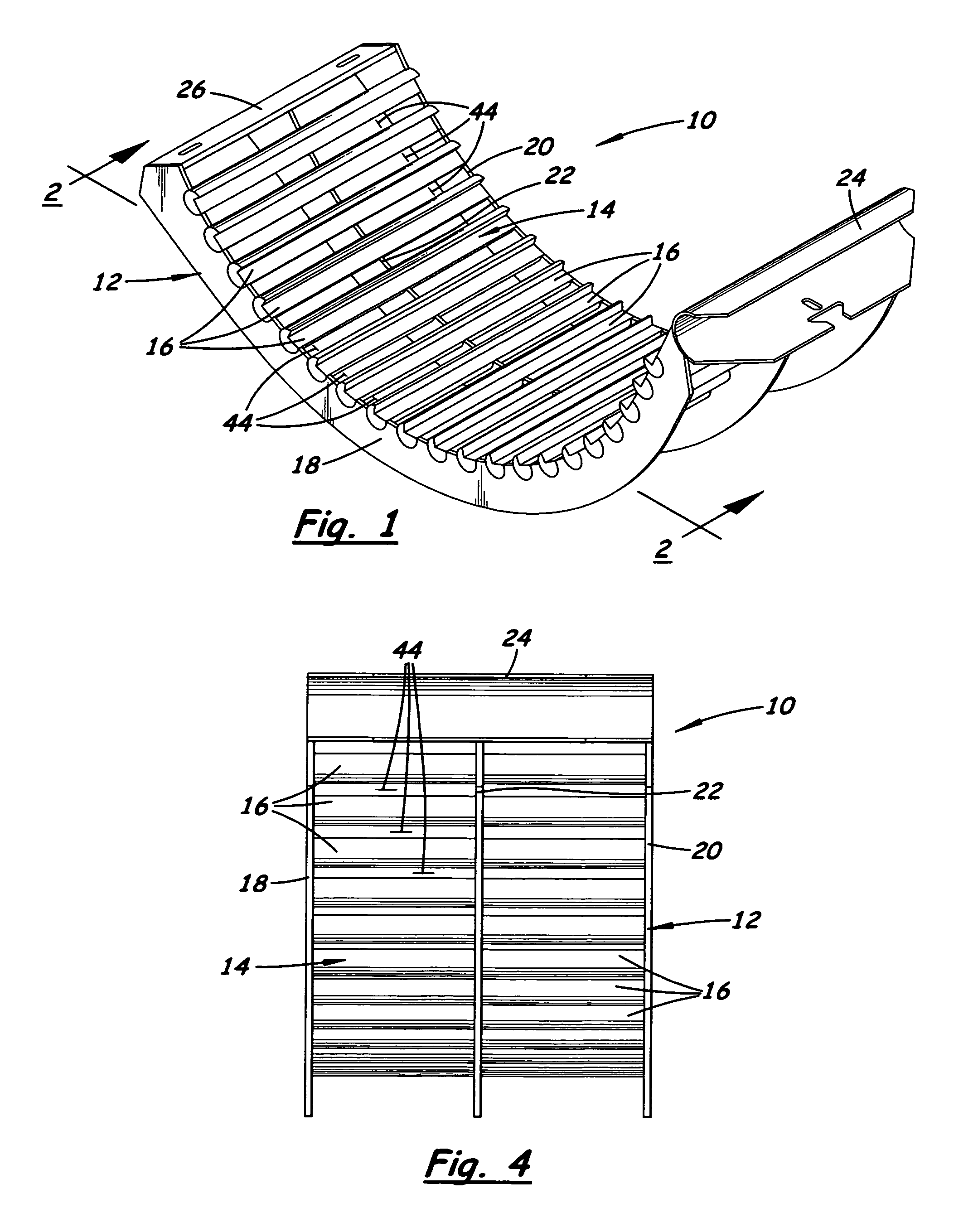

Concave with an array of longitudinally notched spaced apart threshing elements

A concave includes a frame and an array of threshing elements supported by the frame, the threshing elements being spaced apart and extending generally parallel to one another. The threshing elements are configured in the form of round bars each having formed on an upper portion thereof disposed adjacent to an upper portion of the frame a longitudinally-extending notch respectively defining an aggressive threshing edge. The spaced apart relationship and round configuration of the threshing elements reduce plugging of the concave. The threshing edges facing in a direction opposite to the direction of crop material flow restrict crop material flow and thereby enable more effective threshing.

Owner:CSM CORP

Rolling method of low-banded structure gear steel

ActiveCN103194580AImprove fatigue lifeReduce manufacturing costRoll mill control devicesMetal rolling arrangementsOperabilityHigh pressure water

The invention discloses a rolling method of low-banded structure gear steel. The method comprises the following steps of: (1) heating a steel blank within a three-section type heating furnace; (2) carrying out dephosphorization on the heated steel blank by high-pressure water, and sequentially carrying out rough rolling, intermediate rolling, water cooling, and finish rolling; (3) water-cooling and air-cooling the finish-rolled steel blank sequentially; and (4) slowly cooling the cooled round bar steel to be lower than 200DEG C after shearing. Due to the use of the rolling method, the production technology difficulty that the level of the high-end hardenability carburized gear steel banded structure is hard to lower due to the conventional rolling technology can be overcome, so that that the level of the banded structure of the gear steel is lowered to be lower than 1.0 grade from 3.0 grade of the conventional rolling technology, and therefore, the aim of prolonging the fatigue life of the gear can be achieved. The rolling method further has the characteristics of being simple in technical route, low in production cost, high in operability and the like.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

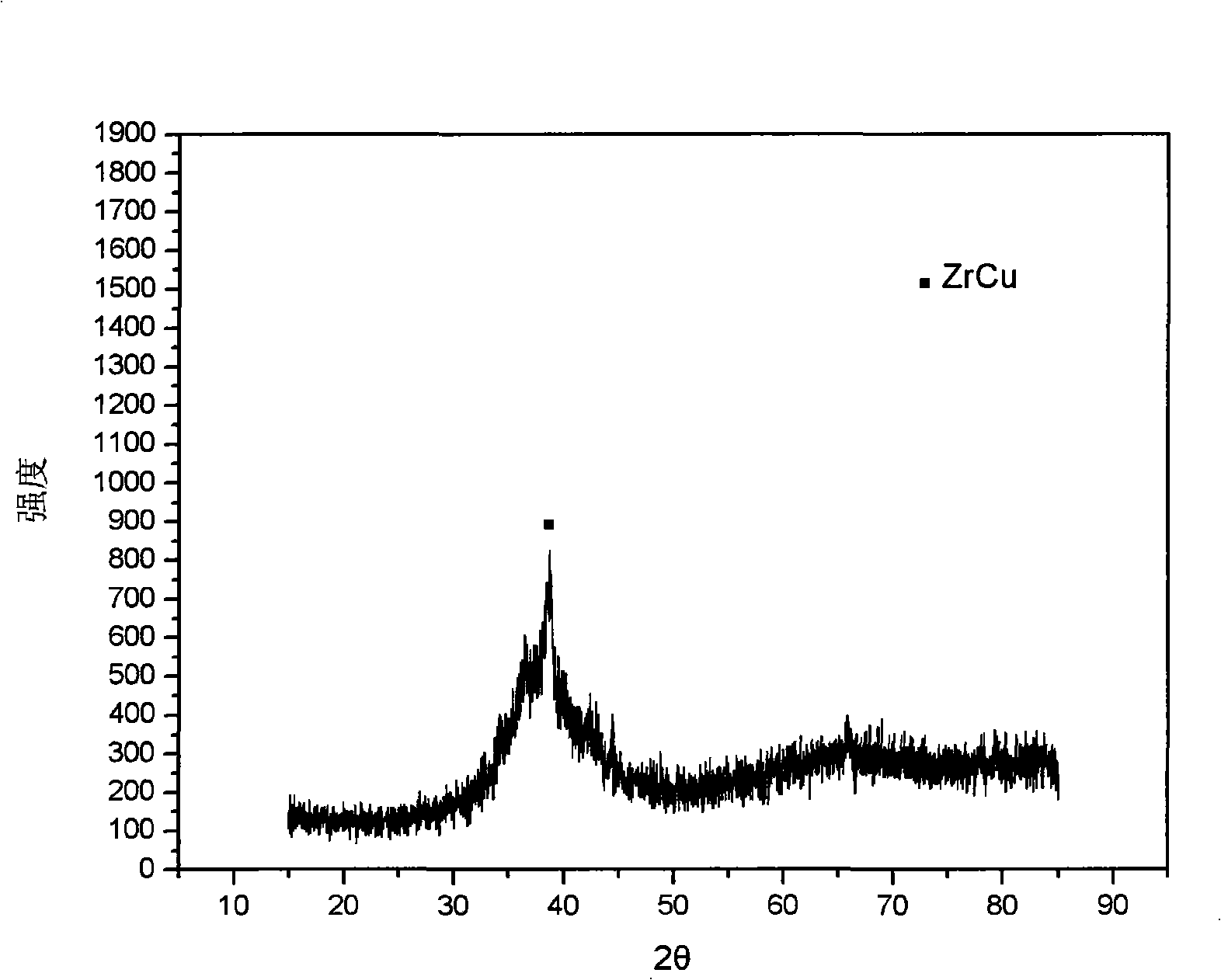

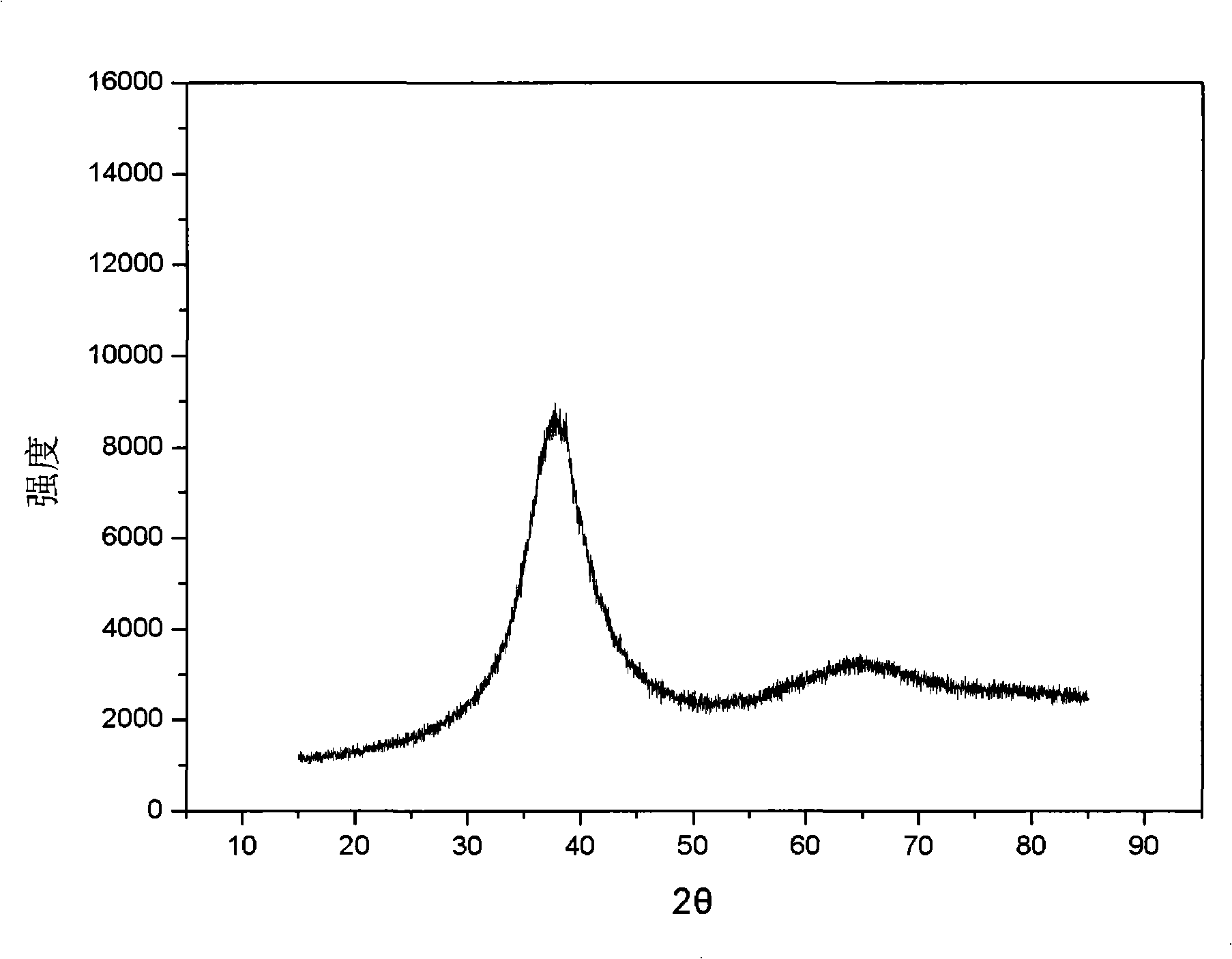

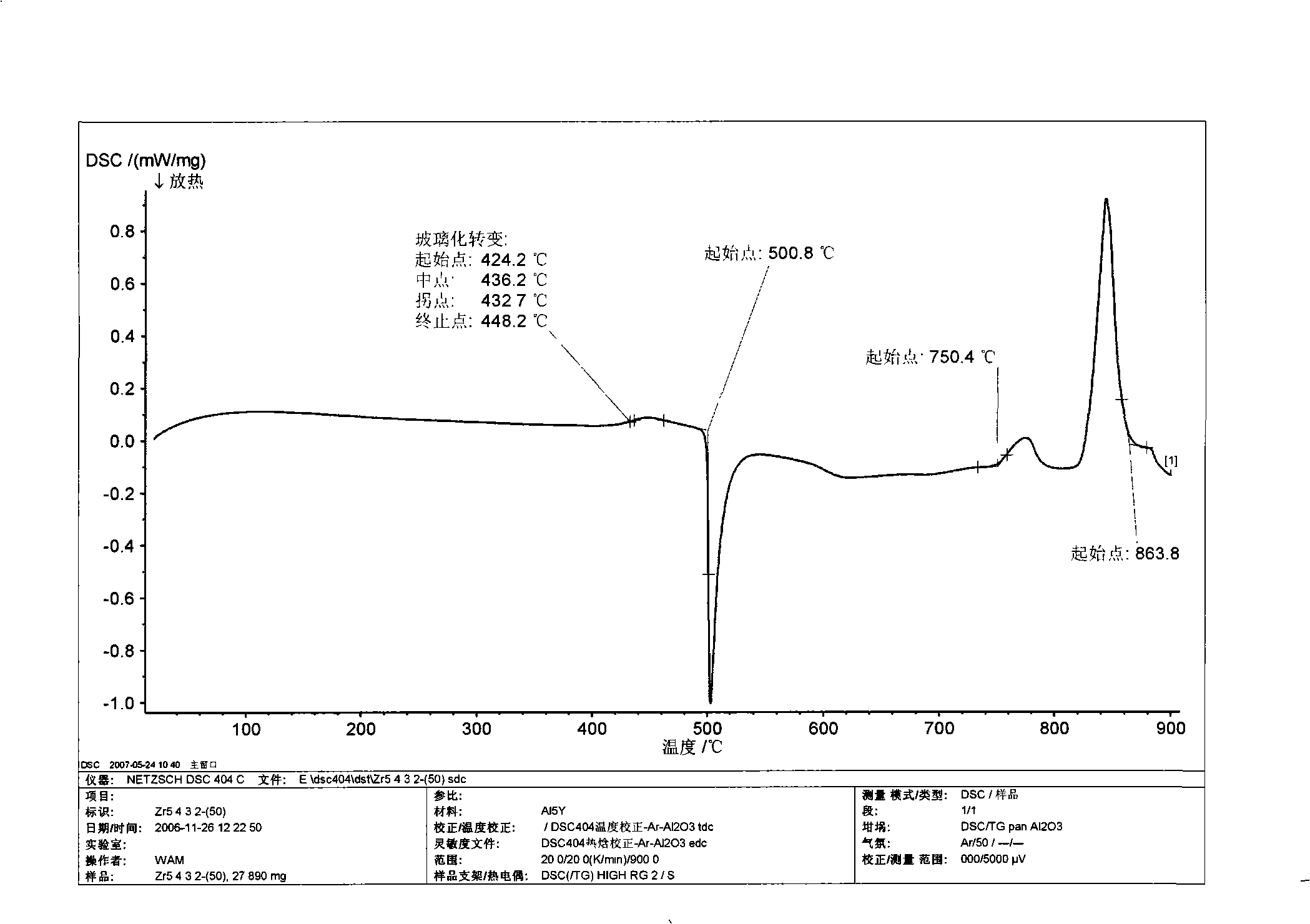

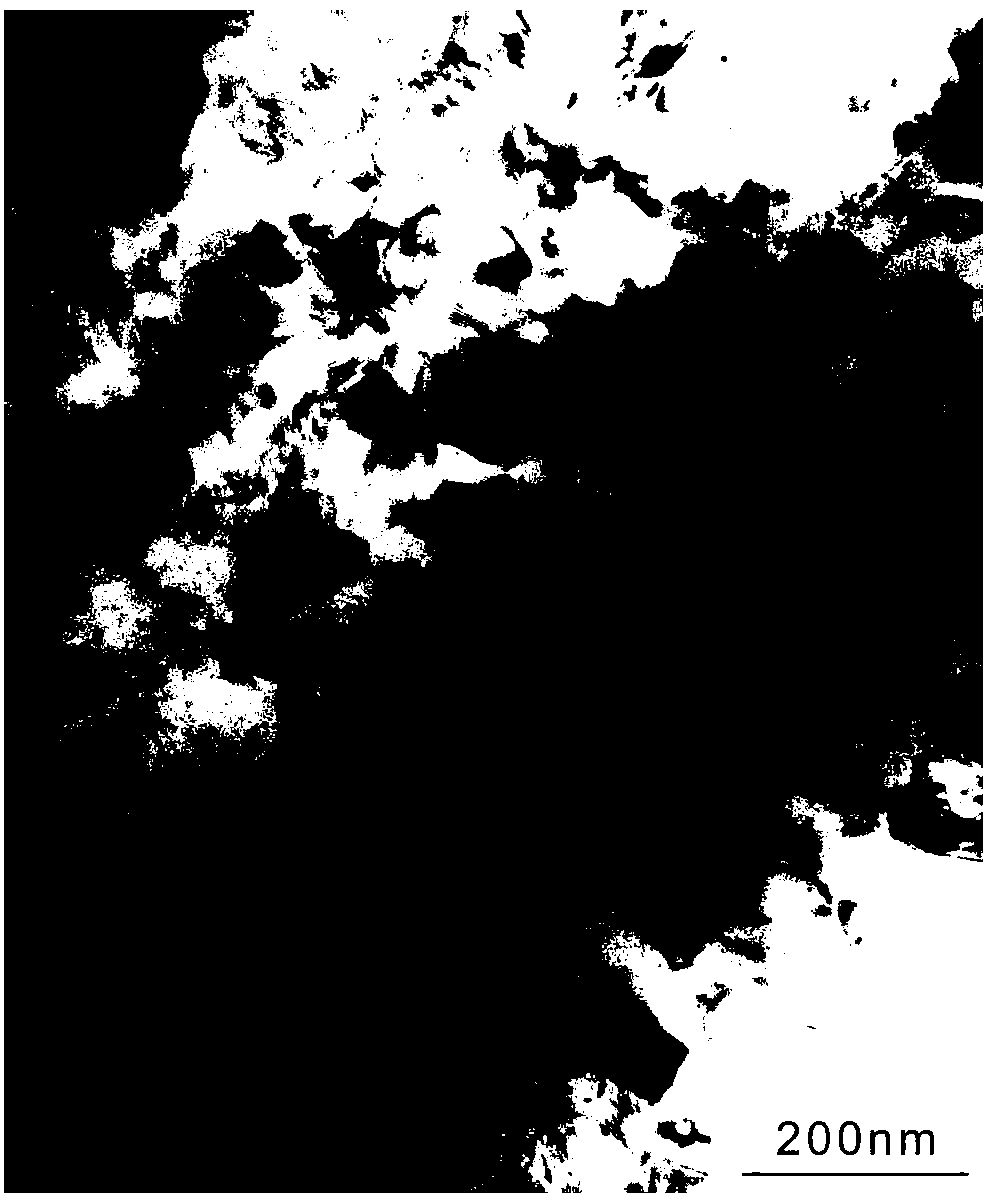

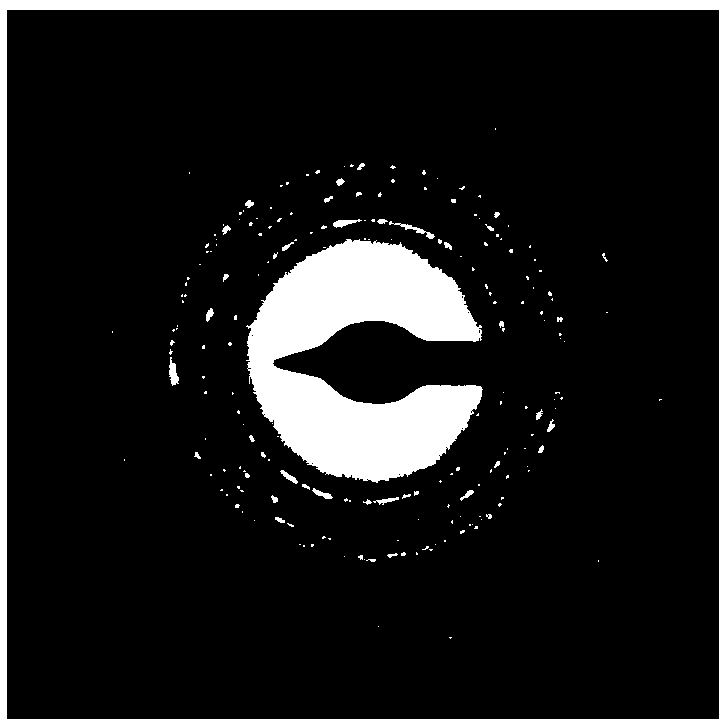

Zr-Cu-Ni-Al-Ag alloy with higher amorphous forming ability and production method thereof

The invention relates to a preparation technology of a block zirconium-base amorphous alloy, in particular to a Zr-Cu-Ni-Al-Ag alloy with higher glass-forming ability and a preparation method thereof, and the characteristic thermodynamics parameter and the mechanical property of the alloy are characterized and tested at the same time. The alloy system is the Zr-Cu-Ni-Al-Ag alloy, which has the component ranges (by atom percentage) that Zr is 41 to 63, Cu is 18 to 46, Al is 4 to 15, Ni is 1.5 to 12.5, and Ag is 1.5 to 26. Based on a Zr-Cu-Ni-Al quaternary alloy, the forming ability of the amorphous alloy is increased through inhibiting the precipitation of a crystalline state phase. The preparation technology adopts an electric arc melting method to prepare a master alloy ingot, then adopts a copper mold casting method to prepare amorphous alloy rods with different diameters, and the alloy in the system can easily prepare amorphous round bars, the diameter of which can reach 2cm. Due to stronger amorphous forming ability and good mechanical property, the alloy has good application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

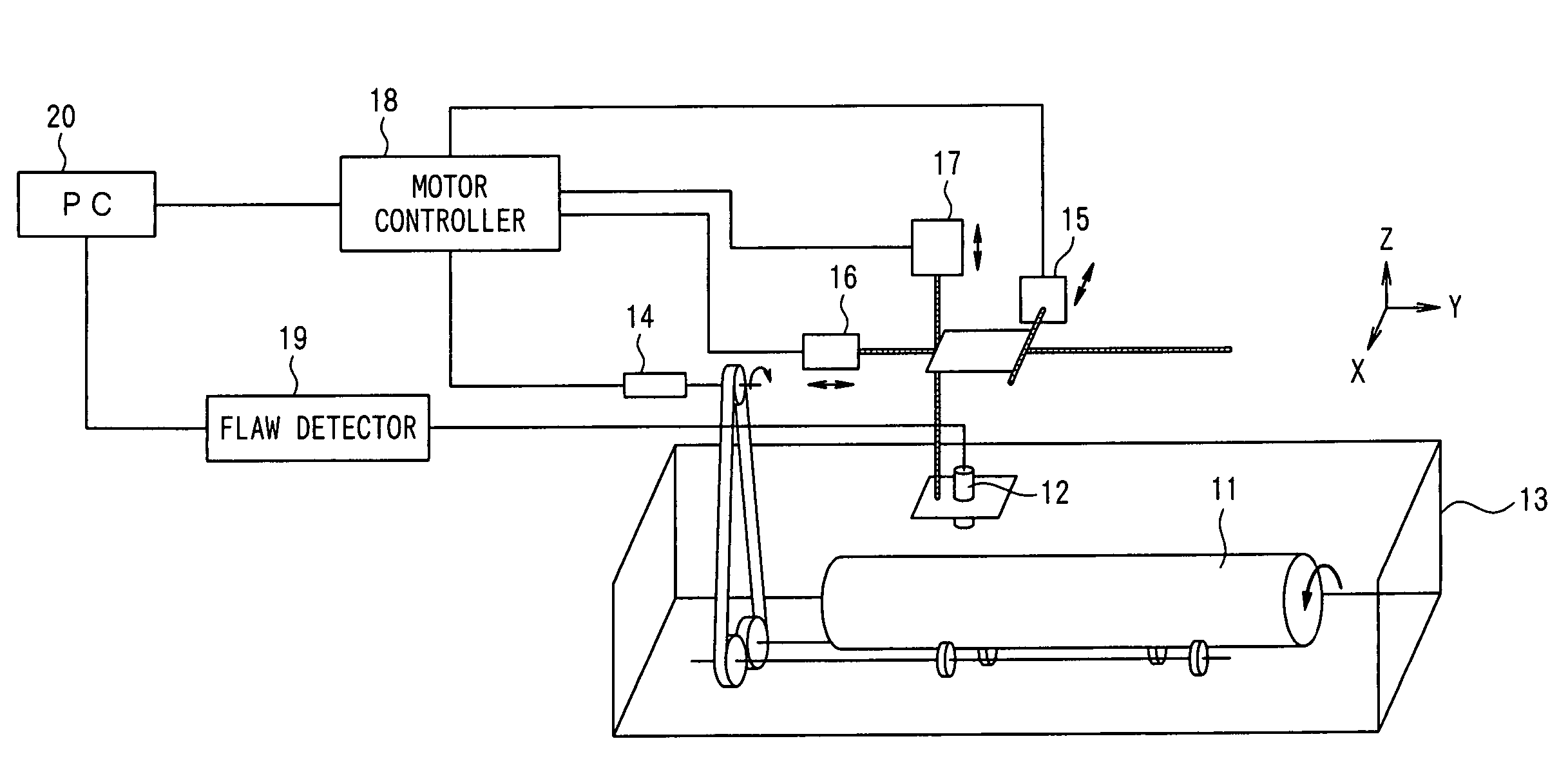

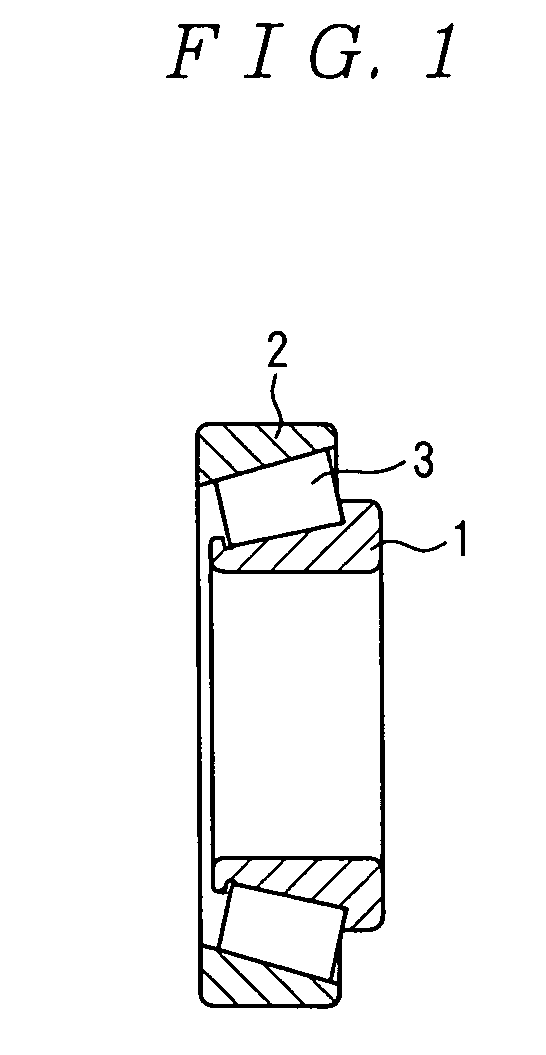

Bearing steel,method for evaluating large-sized inclusions in the steel and rolling bearing

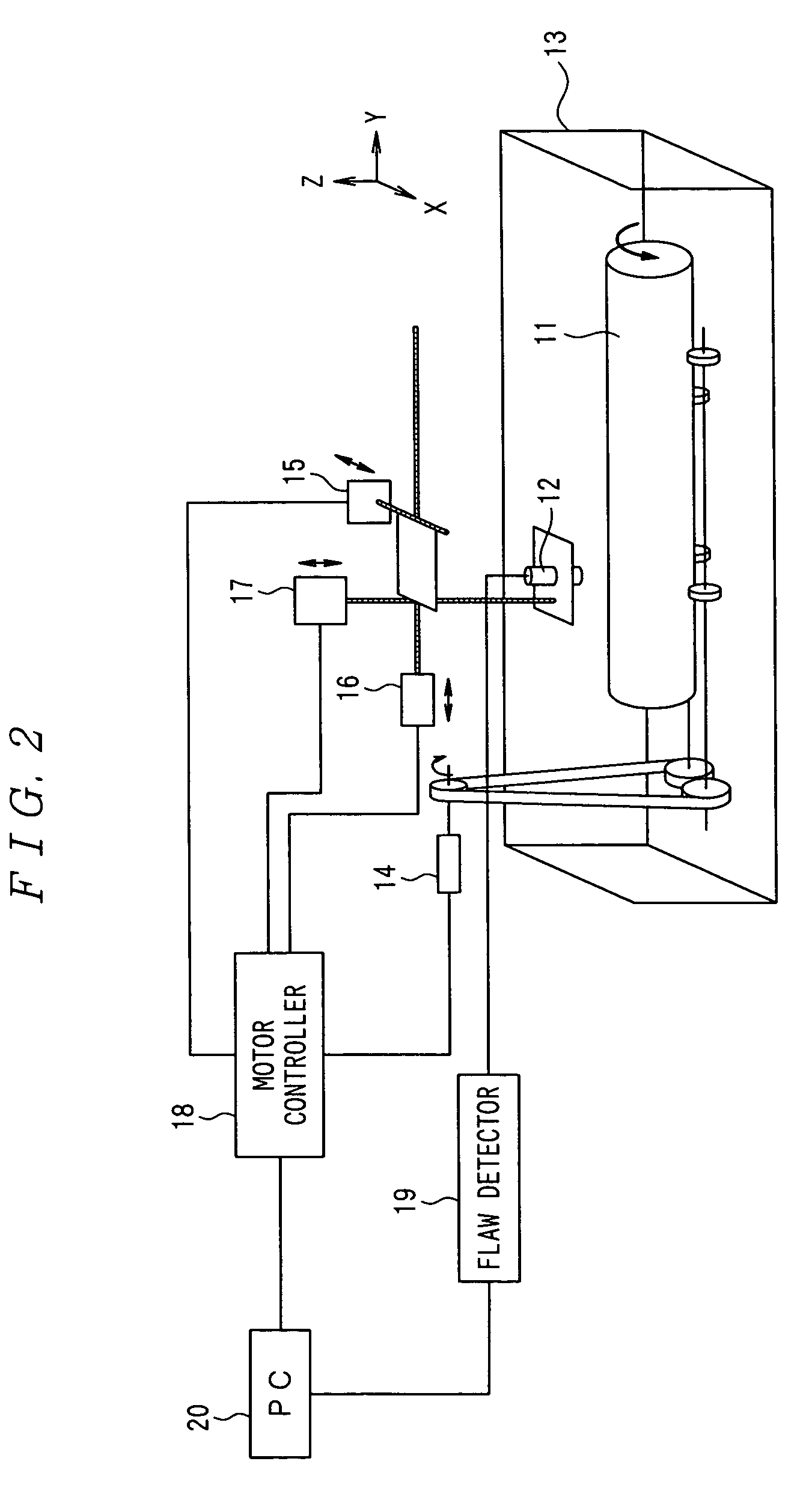

InactiveUS20060048576A1Low costDetection intensity is worsenedVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesMetallurgyRolling-element bearing

A first object is to provide a method for evaluating large-sized inclusions in a bearing steel. The method enables quantitative evaluation of large-sized inclusions even if the steel has a high degree of cleanliness. Further, a second object is to provide an appropriate bearing steel evaluated by the method for evaluating large-sized inclusions. Further, a third object is to provide a rolling bearing capable of eliminating short life products and cracked products and providing longer lifetime for entire bearings. In order to achieve the first object, a round bar formed of a bearing steel to be evaluated and an ultrasonic probe are placed in an ultrasonic transmission medium, and the size and number of large-sized inclusions that are present in the flaw detection volume are measured to estimate the existence probability of large-sized inclusions in the bearing steel to be evaluated. The second object is achieved by specifying large-sized inclusions that are present in the bearing steel in accordance with the method for evaluating large-sized inclusions. Further, to achieve the third object, a rolling bearing is manufactured from a seamless steel tube, as material, having a diameter of 180 mm or less and a wall thickness of 25 mm or less, and ensured that it does not include a defect having a length of 1 mm of more at its material stage.

Owner:NSK LTD

High-strength, high-toughness, weldable and deformable rare earth magnesium alloy

A high-strength, high-toughness, weldable and deformable rare earth magnesium alloy comprised of 0.7˜1.7% of Ym, 5.5˜6.4% of Zn, 0.45˜0.8% of Zr, 0.02% or less of the total amount of impurity elements of Si, Fe, Cu and Ni, and the remainder of Mg, based on the total weight of the alloy. During smelting, Y, Ho, Er, Gd and Zr are added in a manner of Mg—Y-rich, Mg—Zr intermediate alloys into a magnesium melt; Zn is added in a manner of pure Zn, and at 690˜720° C., a round bar was cast by a semi-continuous casting or a water cooled mould, then an extrusion molding was performed at 380˜410° C. after cutting. Before the extrusion, the alloy is treated by the solid-solution treatment at 480˜510° C. for 2˜3 hours, however, the alloy can also be extrusion molded directly without the solid-solution treatment. After the extrusion molding, this alloy has a strength of 340 MPa or more and a percentage elongation of 14% or more at room temperature and is a high-strength, high-toughness, weldable and deformable rare earth magnesium alloy.

Owner:BAISHAN CITY TIANAN MAGNESIUM RESOURCES CO LTD

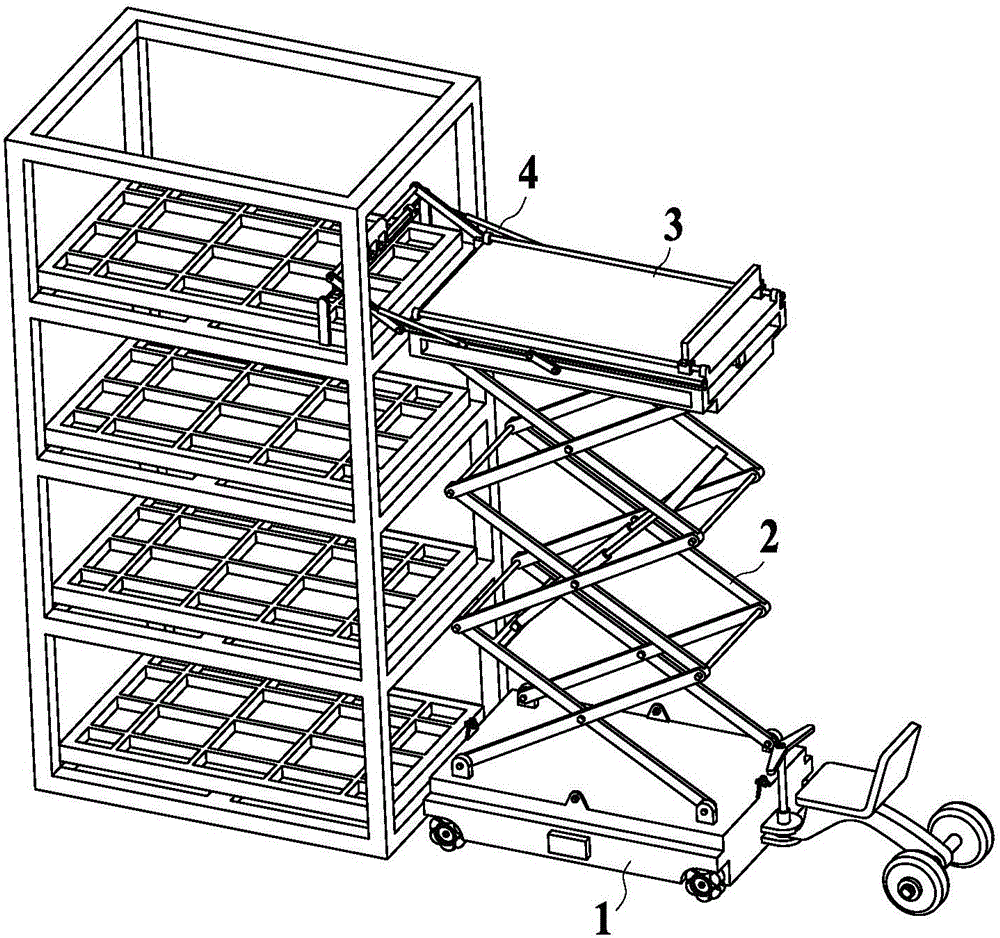

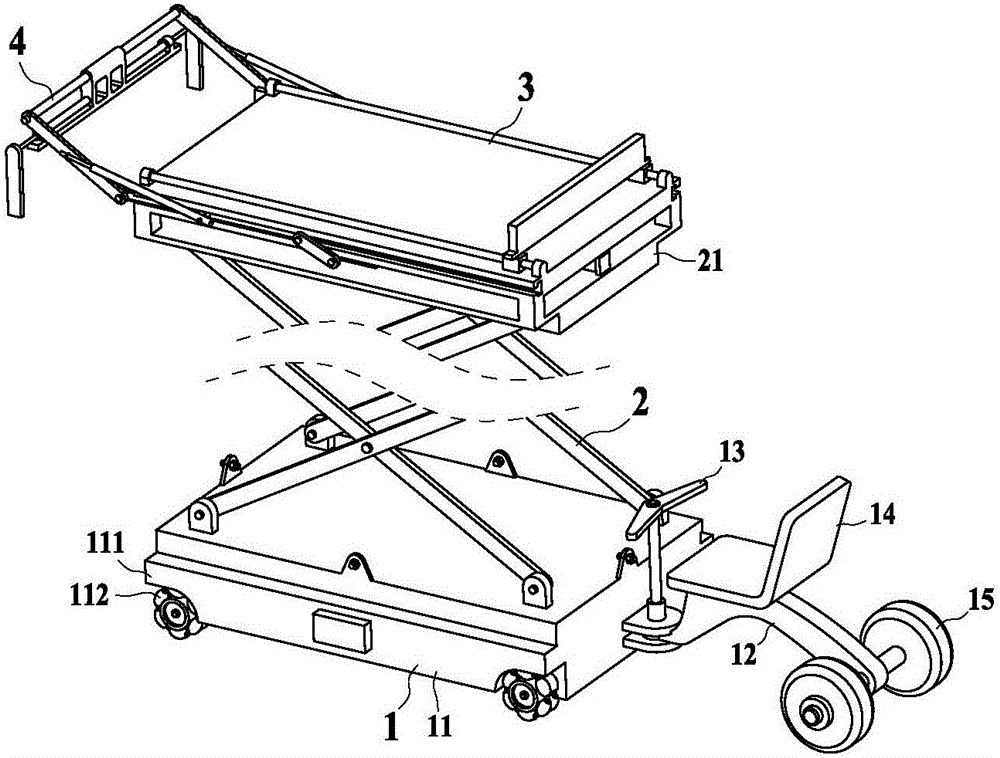

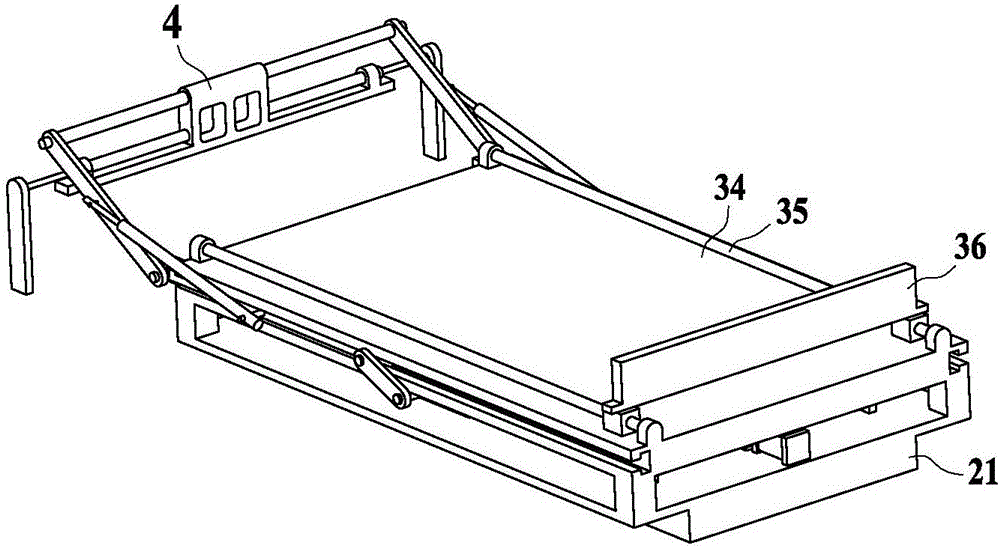

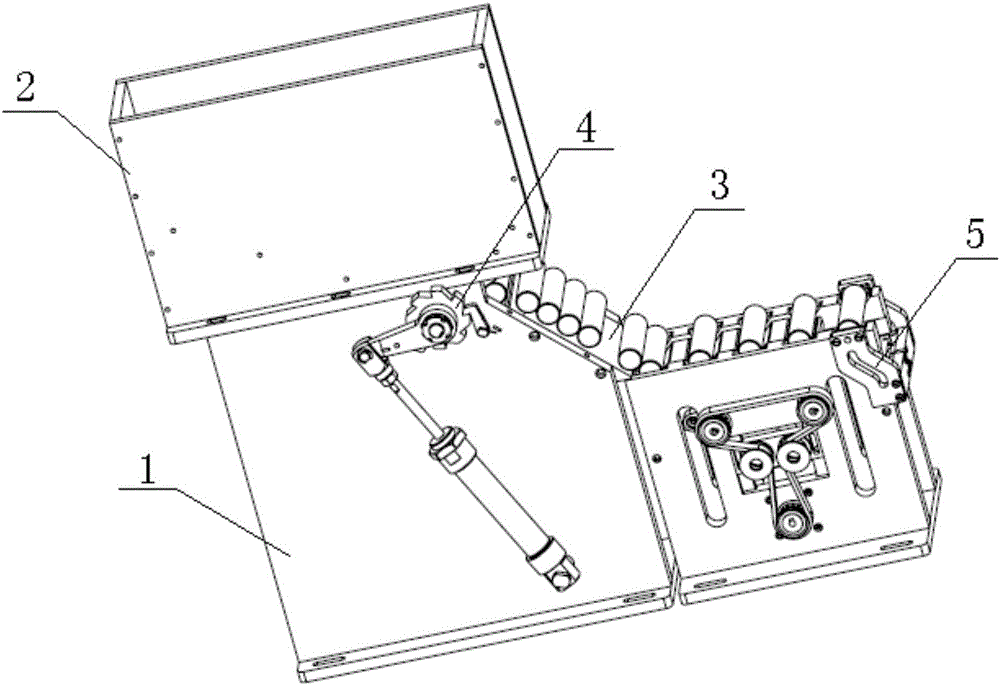

Scissors type plastic uptake mold taking and putting device

ActiveCN105712243AImprove walking flexibilityRealize automatic removalConveyorsLifting framesDrive wheelSteering wheel

The invention relates to the field plastic uptake equipment, in particular to a scissors type plastic uptake mold taking and putting device. The device comprises a running unit, a lifting mechanism, a function platform and a mold taking mechanism. The lifting mechanism is arranged on the running unit. The function platform is installed at the upper end of the lifting mechanism. The mold taking mechanism is installed on the function platform. The running unit comprises a driving unit, a running stand, a steering wheel, a seat and big driven wheels. The lifting mechanism is a conventional scissors type mechanism. The function platform comprises a translational screw, a rotating motor, a movable plate, a supporting table, rodless push cylinders and a push plate. The mold taking mechanism comprises a fixing round bar, a pair of adjusting units, a connecting rod, a supporting frame and a pair of clamping devices. The scissors type plastic uptake mold taking and putting device can automatically store a mold, manual mold conveying is not needed in the whole process, the labor intensity of workers is relieved, time and effort are saved, the production efficiency is improved, and the economic benefits are increased.

Owner:ANQING LIXIANG IND & TRADE

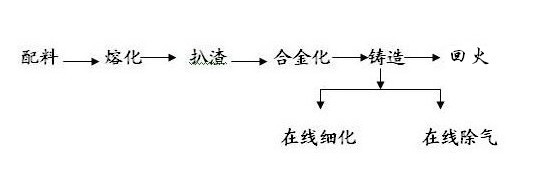

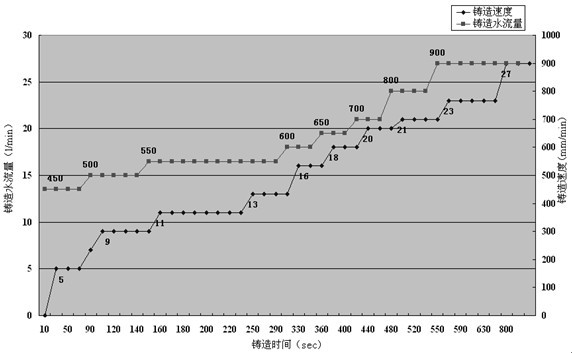

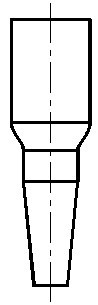

Hot-top casting process of 7075 aluminium alloy round rod with diameter of phi582 mm

ActiveCN102328065AImprove bottom plasticityReasonable control of impurity contentRound bar7075 aluminium alloy

The invention discloses a hot-top casting process for casting a large-diameter hard aluminium alloy round rod by using a wiping disc. The process comprises the following steps of: a, batching; b, melting; and c, casting, wherein the casting step is a key process. The process protected by the invention is a casting process of a largest-diameter hard aluminium alloy which is put into operation in the country currently. Namely, the process comprises: hot-top casting equipment is used; the wiping disc is configured at the same time; step type casting process parameters are adopted; the suspension height of the wiping disc and the three casting process parameters are searched; and finally, the best casting process of the 7075 aluminium alloy round rod with a diameter of phi582 mm is established. According to the process disclosed by the invention, the crack tendency in the process of casting the large-diameter hard aluminium alloy can be greatly reduced without the bottoming process; the cast round bar has good grain size, thin coarse grain layer and good surface quality; and the turning quantity on the cast rod before extruding is reduced, therefore, the production cost is reduced, and the yield is increased.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

Precision die forging and shaping technical method for automobile steering knuckle rough type parts

InactiveCN102672096ALow forming speedNo crack phenomenonRailway componentsMetal-working apparatusEngineeringMaterial distribution

The invention provides a precision die forging and shaping technical method for automobile steering knuckle rough type parts. The precision die forging and shaping technical method mainly comprises the process steps of blanking, heating, extruding and drawing out a rod part, pre-forging, upsetting, performing material distribution and performing multi-way precision die forging and shaping and is specifically as follows: blanking through a cutting device, and heating to the temperature of 1080 DEG C-1180 DEG C in a medium-frequency induction furnace; placing a round bar which is well heated into a female die of an extruding and drawing-out die to form a stock comprising a cylindrical surface and a steering knuckle rough rod part; placing the stock after upsetting and material distribution into a multi-way die forging die, firstly enabling an upper male die and an upper die seat in the vertical direction to move downwards, and closing the upper male die and a lower female die for forging; and then using male dies on the symmetrical left side and right side in the horizontal direction to perform extrusion precision forging and shaping. According to the method provided by the invention, as the die forging is performed on a multi-way die forging hydraulic machine, the shaping speed is much lower than that of die forging on a hammer, thus the occurrence of the phenomenon of forming cracks on the surface due to strong speed sensitivity caused by too-high speed can be avoided; and the contact friction resistance between a forged piece and the surface of a die cavity during the processes of die forging, shaping and ejection of the forced piece can be greatly reduced, the surface quality of the forged piece is further improved, and the utilization rate of the material of the forged piece is improved.

Owner:CHONGQING UNIV OF TECH

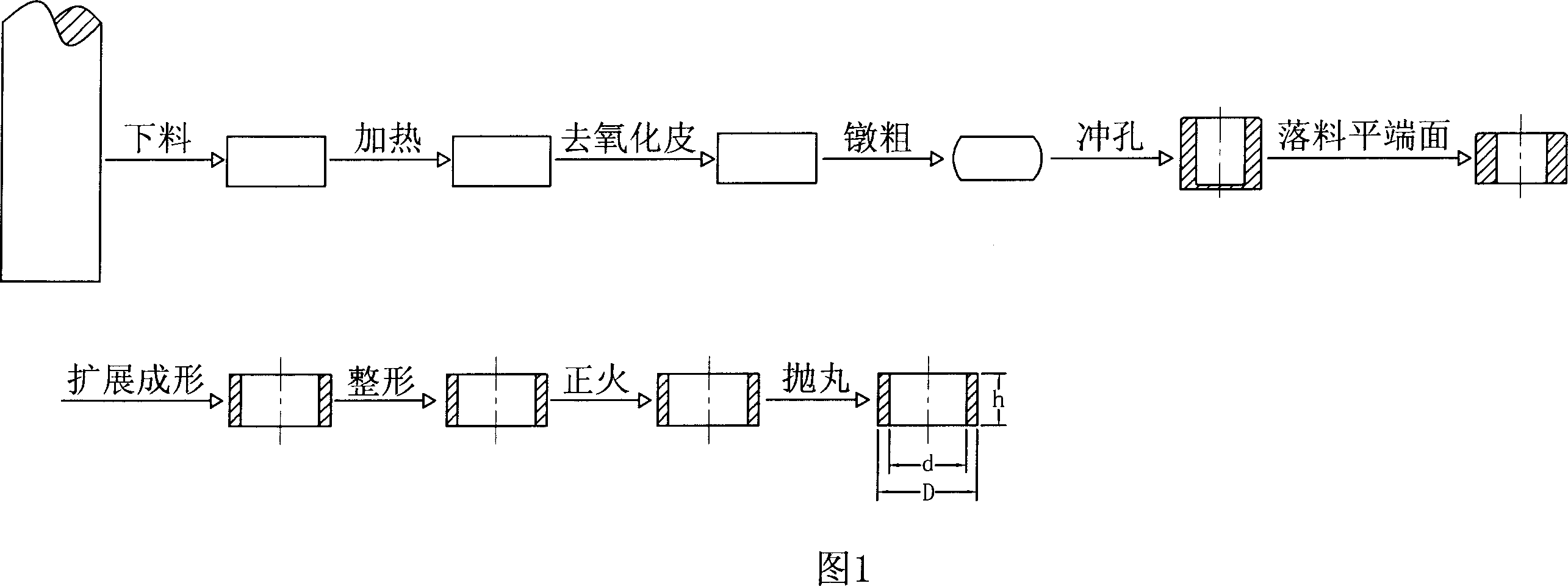

Gear ring blank for automobile synchronizer and method for processing same

InactiveCN1963260AHigh geometric accuracyReduce hole expansion ratioPortable liftingFurnace typesPunchingEngineering

The processing method for a round bar blank into a synchronizer geared ring blank for vehicles are like this: feeding, heating, descaling, metal gathering, punching, discharging end face, extending molding and trimming to make the round bar into a geared ring blank with 50-78 mm diameter, 10-15 wall thickness, 45-60 mm in height. By applying rolling ring processing technique in the process, it greatly reduces the manufacturing cost, improves precision, bettering the heat treatment performance of finished parts, reducing subsequent processing quantity, with improved productivity and lengthened durability of the finished geared ring. After several times road test, compared with traditional manufacturing method, this synchronizer can lengthen durability by 30%, reduce cost 15%, and improve productivity 10%.

Owner:CHONGQING CHANGFENG PRECISE BLANK

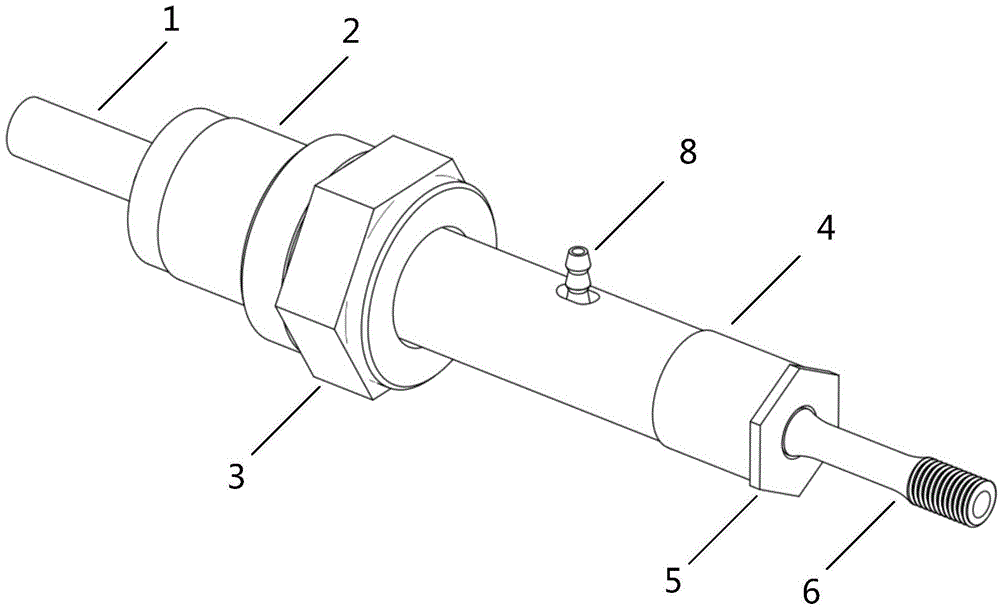

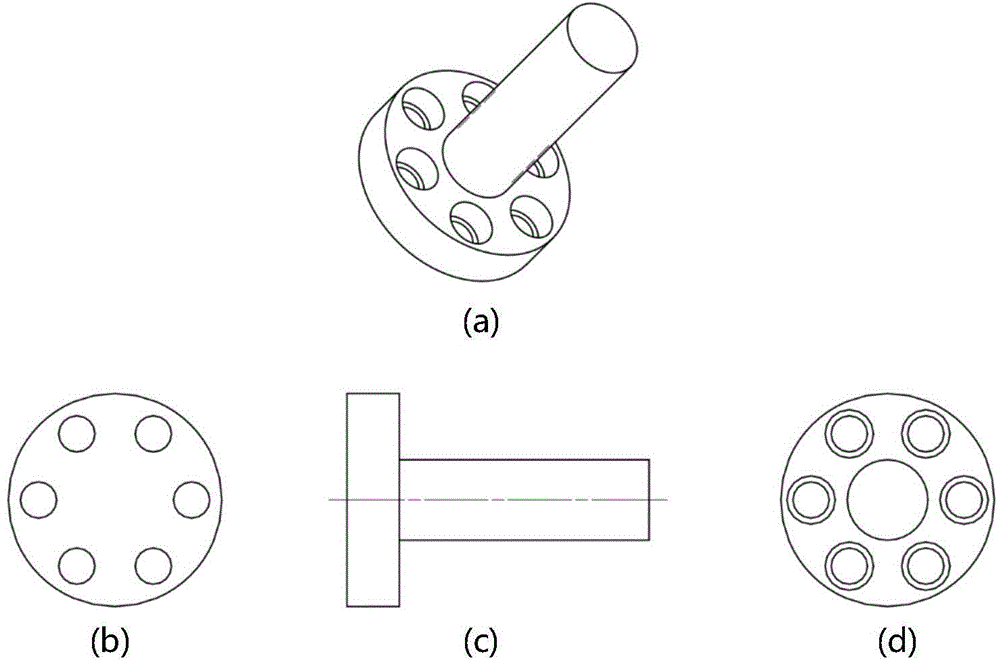

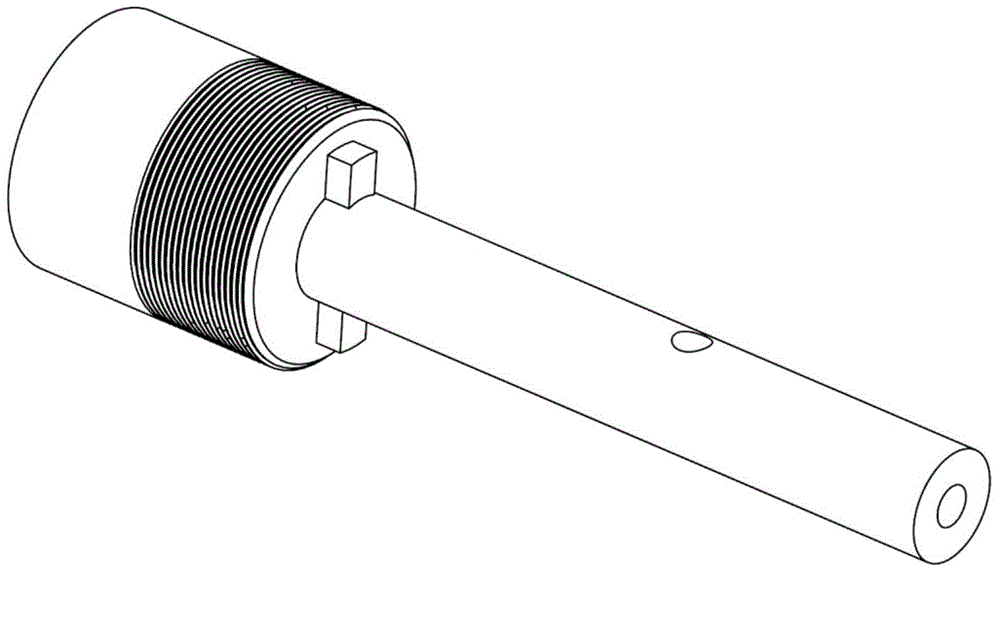

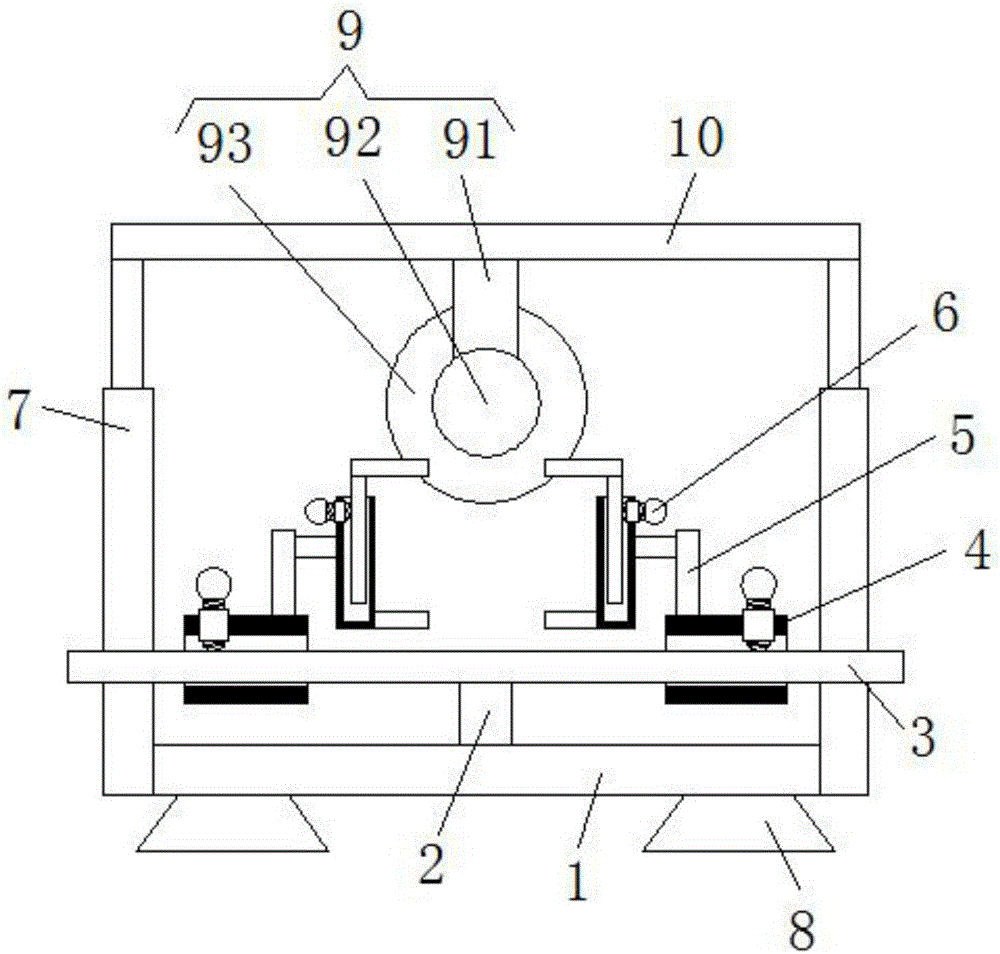

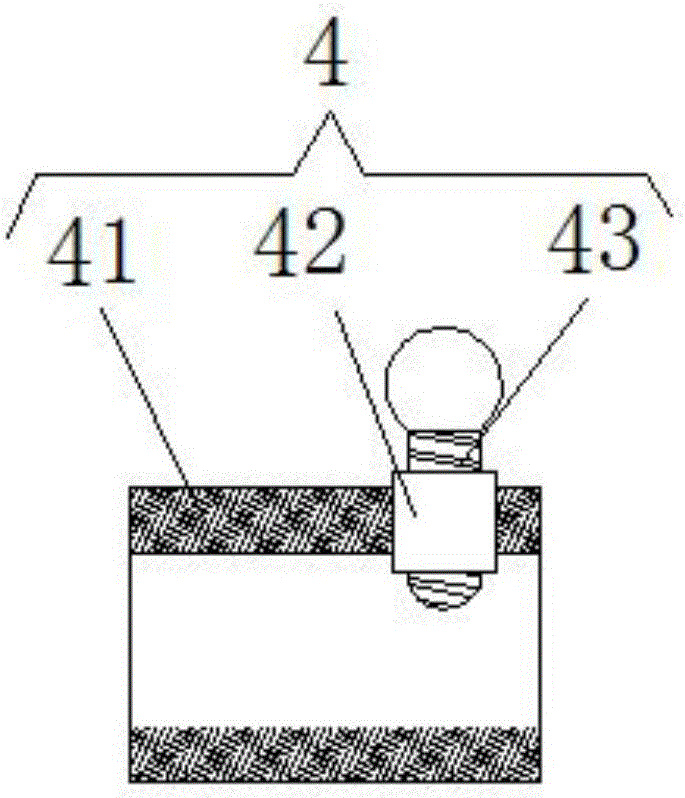

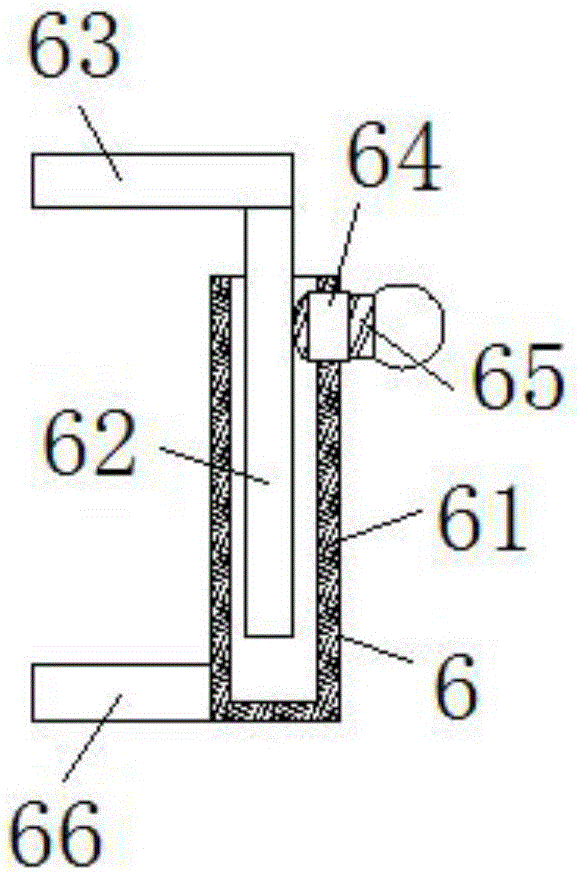

High-temperature push-pull fatigue test clamp for hollow round rod test piece

The invention discloses a high-temperature push-pull fatigue test clamp for a hollow round rod test piece, wherein the hollow round rod test piece is cooled by an air flow inside during a high-temperature test, so that a required temperature gradient on the inner and outer wall surfaces of the hollow round rod test piece during the high-temperature test is realized; a hydraulic chuck of a fatigue machine clamps a light rod end of a joint and is connected with a connecting rod through a countersunk bolt; the connecting rod and a sleeve are fastened by virtue of a nut; the test piece is fastened into a test piece cover and the two are fastened into the sleeve together and are ejected by the hollow rod end of the connecting rod to eliminate the thread pitch; the cooling air flow from a compressor passes through the joint of a cooler, passes through the sleeve through a relatively large hole and enters into the inner cavity of the connecting rod so as to further enter into the hollow round rod test piece to enter into the test piece downward and to be discharged through a lower clamp. The clamp disclosed by the invention can be used for stably clamping the hollow round rod test pieces of various dimensions and uniaxial elongation and elongation / compression fatigue of the test piece under a high temperature condition is realized.

Owner:廊坊智驰动力科技有限公司

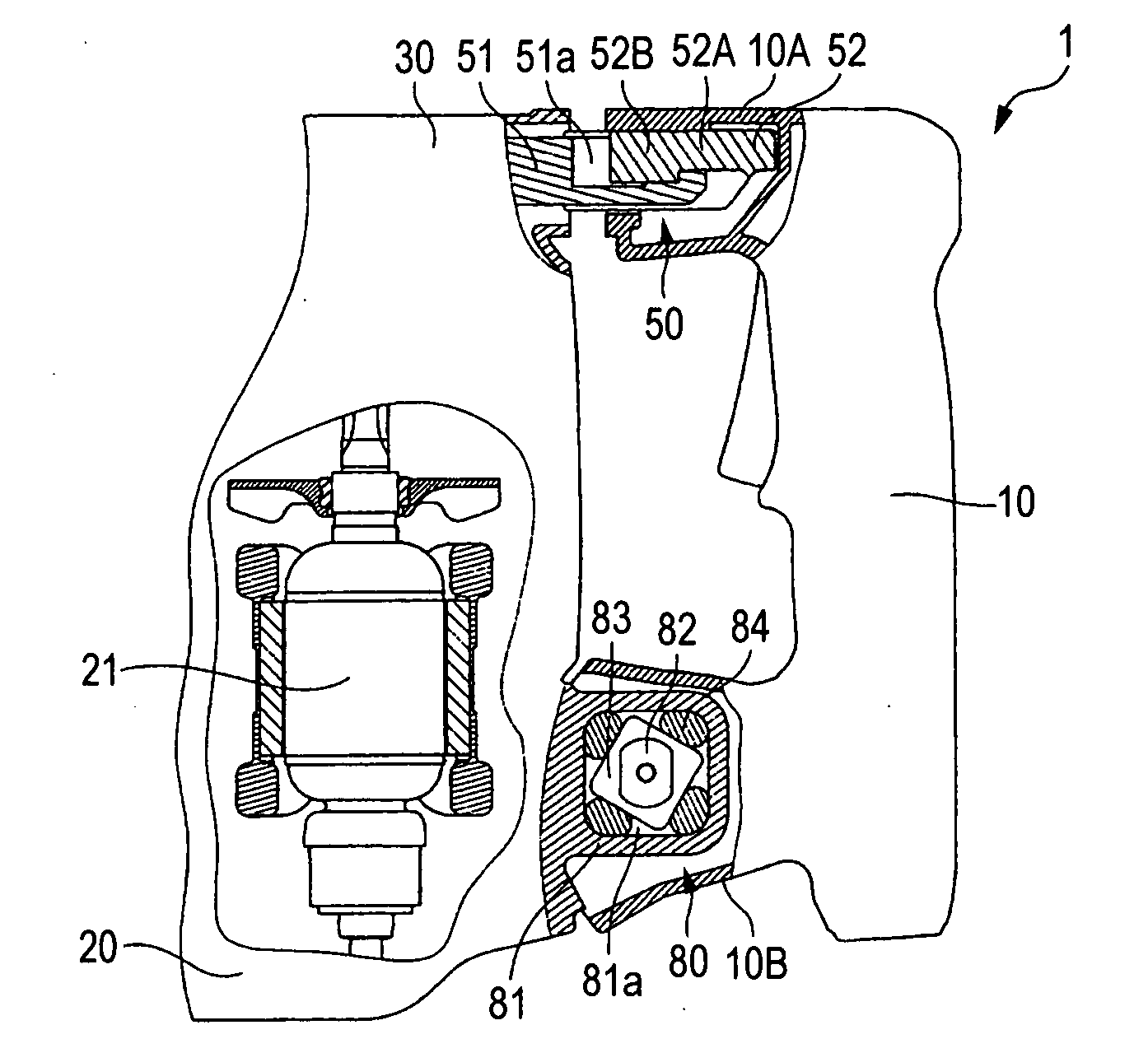

Power tool

ActiveUS20070289762A1Avoid volatilityImprove workabilitySpringsPortable percussive toolsRolling resistancePower tool

Owner:HITACHI KOKI CO LTD

Steel tube cutter

InactiveCN106270724AImprove practicalityAdjustable distanceShearing machinesShearing machine accessoriesArchitectural engineeringRound bar

The invention discloses a steel tube cutter. The steel tube cutter comprises a baseplate, wherein a support bar is fixedly connected to the upper surface of the baseplate; the top end of support bar is fixedly connected with a round bar; two sliding devices are connected to the surface of the round bar in a sleeving manner; the upper surfaces of the two sliding devices are fixedly connected with the side surfaces of two fixing devices through two connecting devices respectively; electric telescopic bars are fixedly connected to the side surface of the baseplate; the tops of the electric telescopic bars are fixedly connected with a cross bar; the lower surface of the cross bar is fixedly connected with a cutting device; each sliding device comprises a round sleeve; the upper surface of each round sleeve is connected with a first threaded cap in a clamping manner. According to the steel tube cutter, slide bars and the two sliding devices work together to adjust the distance between the two fixing devices; as the fixing devices are arranged, the distances between two first clamp bars and two second clamp bars can be adjusted, accordingly, the steel tube cutter can cut steel tubes with different diameters, and the practicability of the steel tube cutter is improved.

Owner:俞彩红

Monocrystal silicon-rod butting technique

InactiveCN101664970AImprove work efficiencyEasy to cutFine working devicesPolishing compositions with abrasivesAdhesiveEngineering

The invention relates to a monocrystal silicon-rod butt technique, comprising the following steps: selecting a round monocrystal silicon rod of which the length is 220-500 mm and the diameter is 153-160 mm, and vertically sticking the silicon rod to crystal support of a butting machine with adhesive; putting the crystal support of the butting machine and the round monocrystal silicon rod on a magnetizing workbench, numbering and recording, and magnetizing to fix the crystal support and the round monocrystal silicon rod; calibrating the positioning table, setting the cutting parameters, and starting the butting machine to carry out the sand-bearing cutting; degumming the cut semifinished product, removing the side skin and separating the crystal support; and inspecting whether the semifinished product is qualified or not. The technique has favorable cutting effect and greatly increases the qualification rate and improves the working efficiency of the machine; and after the space of theguide wheels is corrected, even if the sand during the cutting is not enough, the technique can ensure the whole dimension within the range of the tolerance value.

Owner:无锡尚品太阳能电力科技有限公司

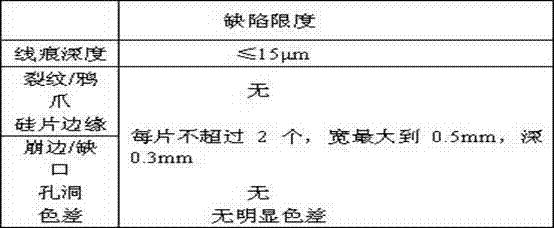

Solar-grade silicon wafer being cut by diamond wire and cutting method thereof

InactiveCN102390094AFast cutting speedSave silicon resourcesFine working devicesDiamond cuttingMicrometer

The invention discloses a solar-grade silicon wafer being cut by a diamond wire and a cutting method thereof. A mono-crystalline silicon square rod is cut by a diamond wire. The cutting method comprises the following steps that: the mono-crystalline silicon square rod which is formed by squaring, grinding and sharpening a mono-crystalline silicon circular rod, the mono-crystalline silicon square rod is fixed on a resin strip through an adhesive bar, the resin strip is fixed on an adhesive plate, then the adhesive plate and the mono-crystalline silicon square rod are collectively placed into a working cabin to be preheated, cutting liquid is circulated in the working cabin to work, then the diamond cutting is performed, the cut mono-crystalline silicon wafer is inversely arranged on a degumming device to degum, and the mono-crystalline silicon wafer is washed by ultrasonic and then is centrifugally dehydrated. Due to the adoption of the cutting method, the photoelectric conversion efficiency and the cutting efficiency of the mono-crystalline silicon wafer can be improved, a silicon wafer with the thickness of 140 to 200 micrometers can be produced, the qualification rate of the product can reach more than 98 percent; and silicon powder is recyclable, so valuable silicon resource can be saved, and the environment-friendly production can be really realized during the production process.

Owner:江西金葵能源科技有限公司

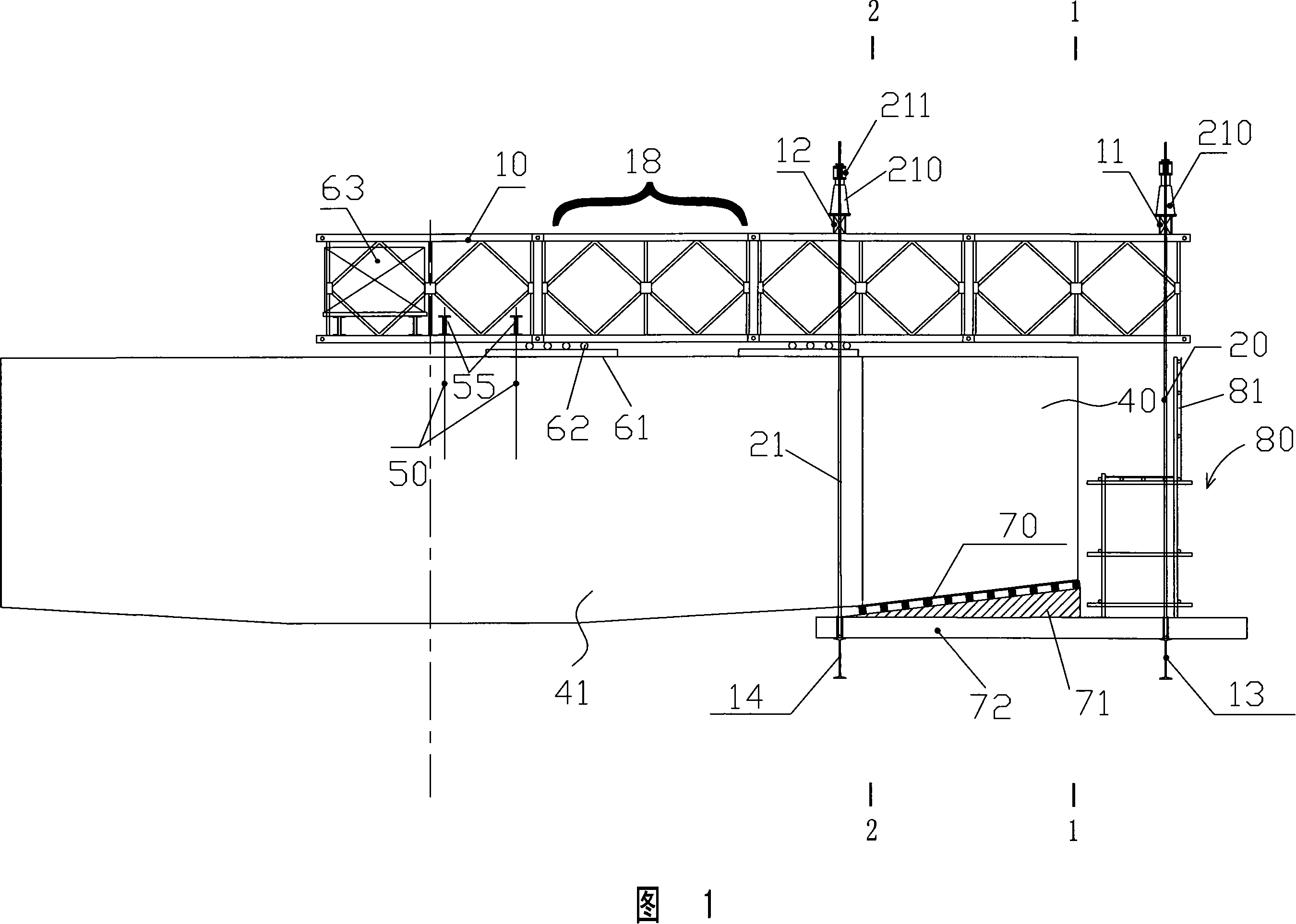

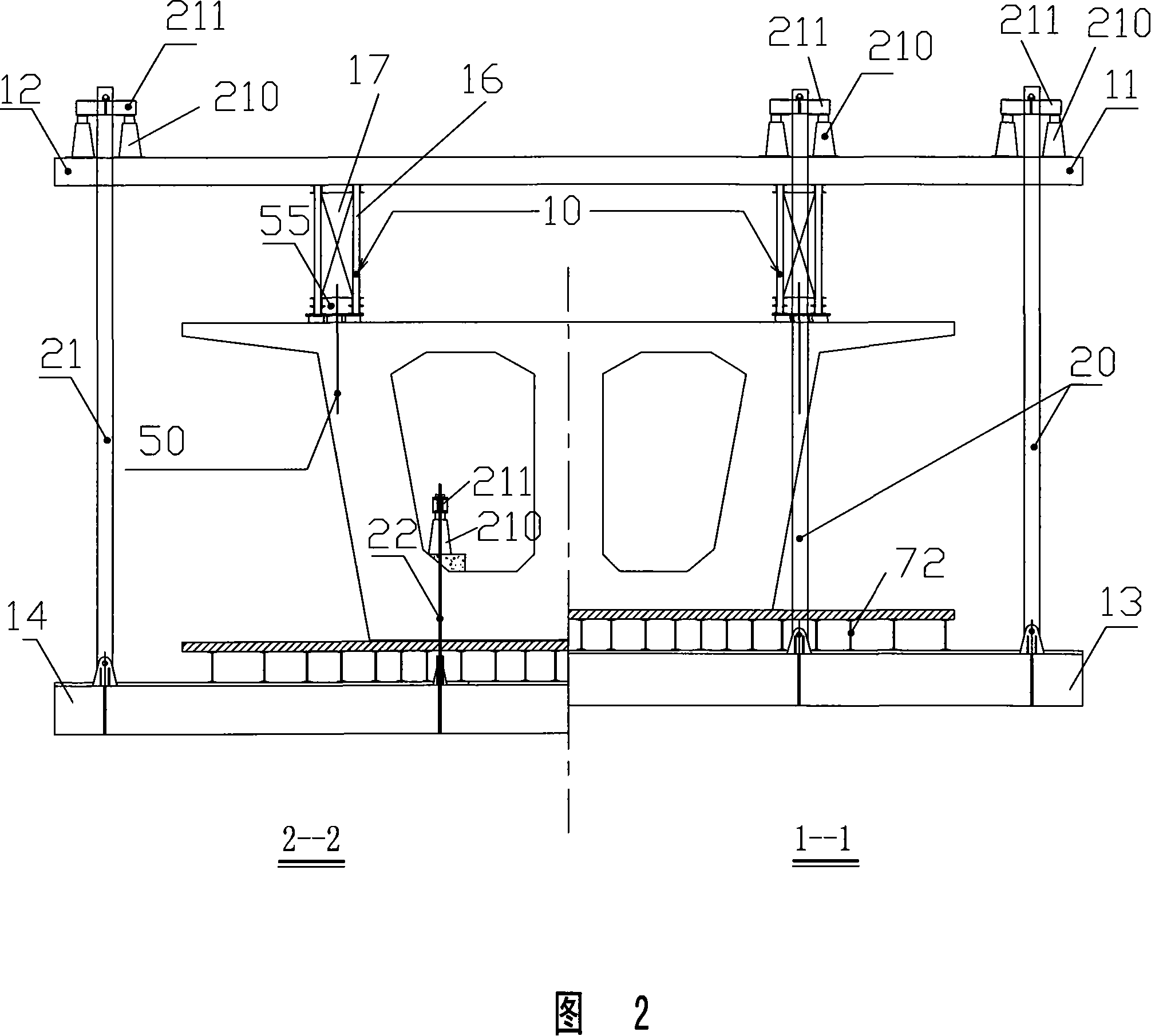

Beret truss type hanging basket and assembling method thereof

InactiveCN101148861ASpeed up preparationReduce manufacturing costBridge erection/assemblyEngineeringHanging basket

Owner:HONGRUN CONSTR GROUP STOCK

Longitudinally notched threshing element for an agricultural combine threshing concave

Owner:CSM CORP

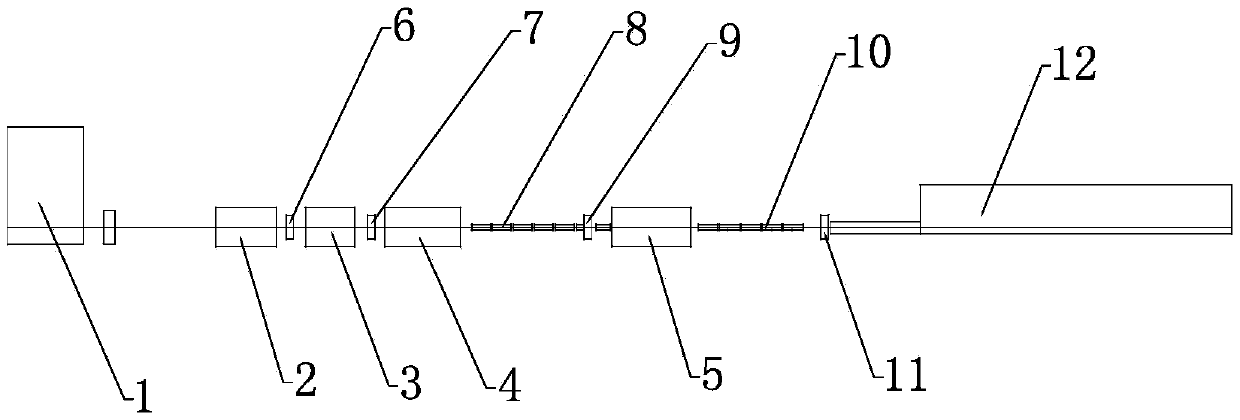

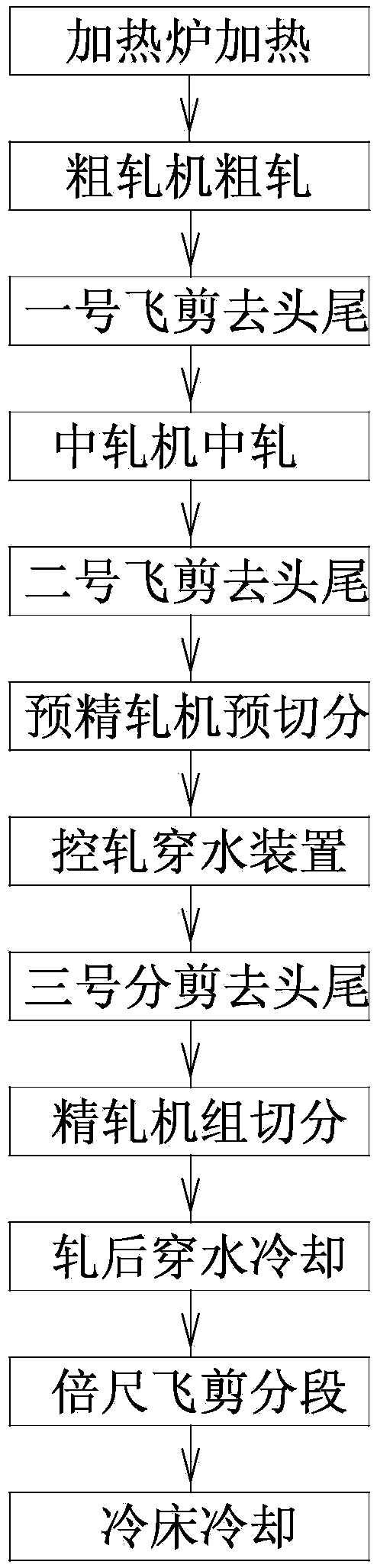

Low-temperature control rolling and splitting process method and device for ribbed steel bars

ActiveCN105290106AReduce the amount addedNot easy to collapseTemperature control deviceWork cooling devicesSocial benefitsEconomic benefits

The invention discloses a low-temperature control rolling and splitting process method for ribbed steel bars. The method comprises the steps of (1), heating square billets to 960-1000 DEG C; (2), conveying the square billets to a rough rolling unit for rolling and rolling the square billets to form round bars; (3), after a first flying shear shears the heads and the tails of the round bars, conveying the round bars to an intermediate rolling unit to form rectangular bars; (4), after a second flying shear shears the heads and the tails of the rectangular bars, conveying the rectangular bars to a finish rolling unit for pre-splitting and rolling the rectangular bars to form rolled pieces shape like dog bones; (5), conveying the rolled pieces to a control rolling and through water cooling device for through water cooling; (6), after a third flying shear shears the heads and the tails of the rolled pieces, rolling the rolled pieces in the finish rolling unit to form a plurality of the independent ribbed steel bars; (7), conveying the ribbed steel bars to a post-rolling control cooling and through water cooling device for cooling; (8) conveying the ribbed steel bars to a multi-length flying shear for multi-length sectioning and then conveying the sectioned steel bars to a cooling bed. According to the invention, the production efficiency is greatly improved, and the economic benefits and social benefits are great because the rolling energy consumption is greatly lowered, the addition amount of alloy is greatly lowered and mine exploitation is greatly reduced.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

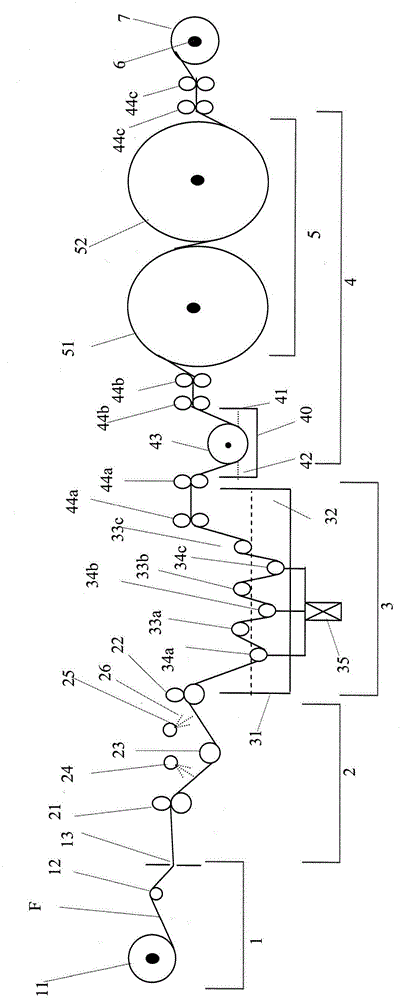

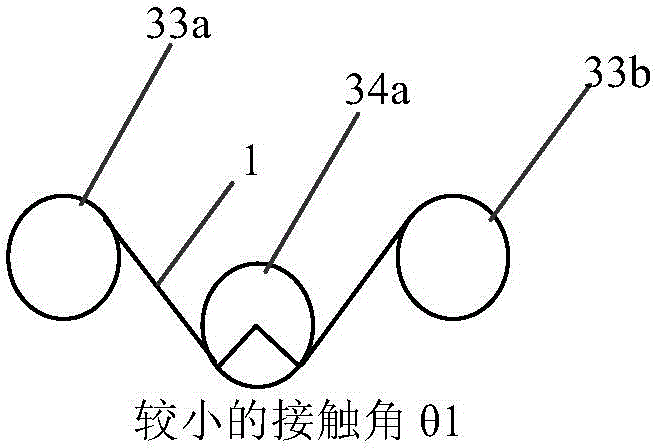

Processing equipment and method for continuous fiber tows

The invention relates to processing equipment and method for continuous fiber tows. The processing equipment comprises a desizing unit, an unfolding and dispersing unit and a sizing unit, wherein the desizing unit uses a fluid washing mode to enable fiber tows to desize, the unfolding and dispersing unit comprises round bars, tension braking rollers and a tension brake which are alternatively arranged, the round bars and the tension braking rollers are used for controlling the contact angles between the fiber tows and the adjacent round bars, the tension brake is connected to each tension braking roller and then used for regulating the tension generated when the tension braking rollers rotate, and the sizing unit is used for conducting re-sizing and drying on the fiber tows. The method for the continuous fiber tows is achieved through the above equipment, the fiber tows after being processed have lowered and uniform fiber distribution density and stable and consistent fiber tow widths, and therefore the fiber tows together with heat plastic plastics can directly be made into heat plastic composite materials or various types of composite material products.

Owner:FORMOSA TAFFETA CO LTD

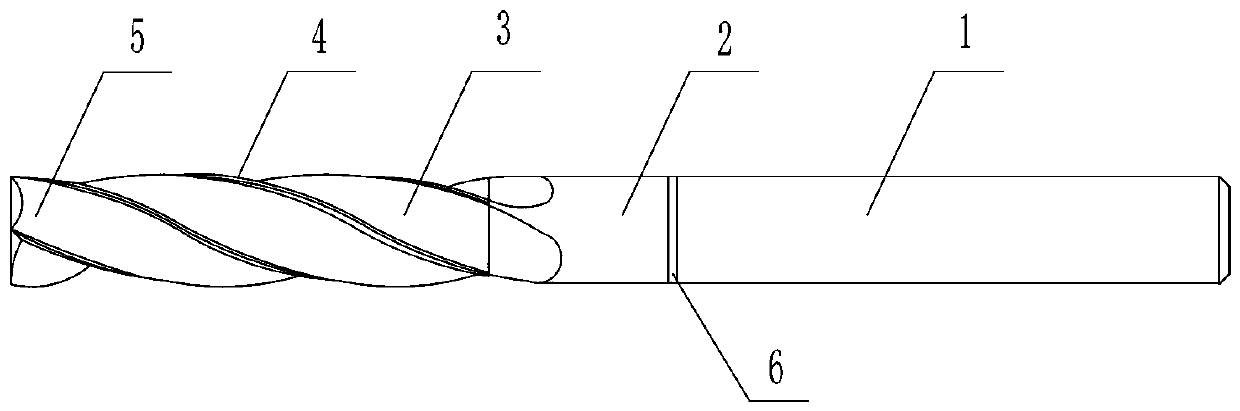

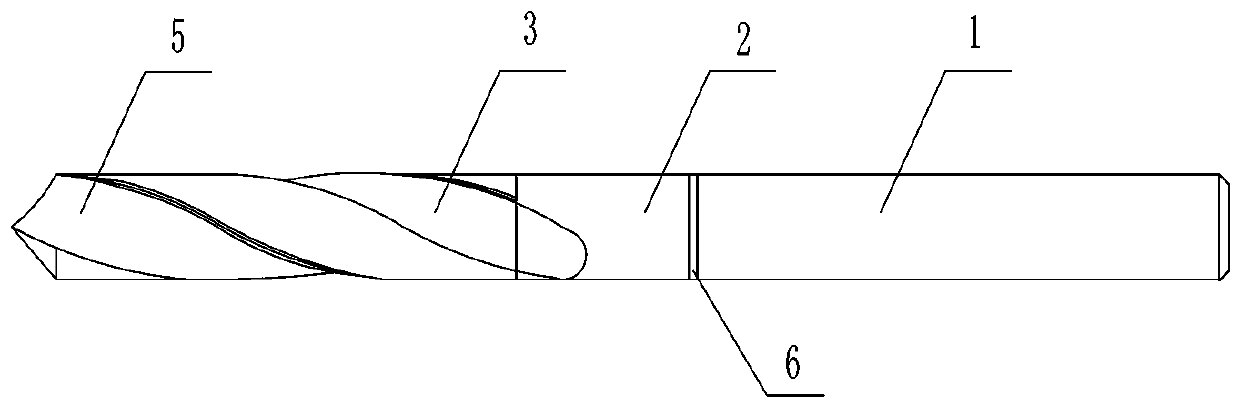

Integrated PCBN round rod-shaped cutting tool and manufacturing method thereof

ActiveCN107738077AExtended service lifeSignificant progressMilling cuttersWorkpiecesTool bitAlloy substrate

The invention provides an integrated PCBN round rod-shaped cutting tool. The integrated PCBN round rod-shaped cutting tool comprises a hard alloy handle and an integrated PCBN round rod-shaped tool bit. The integrated PCBN round rod-shaped tool bit comprises a hard alloy substrate layer and a PCBN layer arranged on one side of the hard alloy substrate layer. A chip groove is formed in the integrated PCBN round rod-shaped tool bit and extends to the middle of the integrated PCBN round rod-shaped tool bit from the PCBN layer. The invention further provides a manufacturing method of the integrated PCBN round rod-shaped cutting tool. The manufacturing method of the integrated PCBN round rod-shaped cutting tool comprises the steps of preparation of a PCBN composite round bar blank, preparationof the integrated PCBN round rod-shaped tool bit and welding formation. By adoption of the manufacturing method, the integrated PCBN round rod-shaped cutting tool of a complex structure can be manufactured, the application range of the PCBN tool is widened, and the service life of the tool is prolonged.

Owner:FUNIK ULTRAHARD MATERIAL

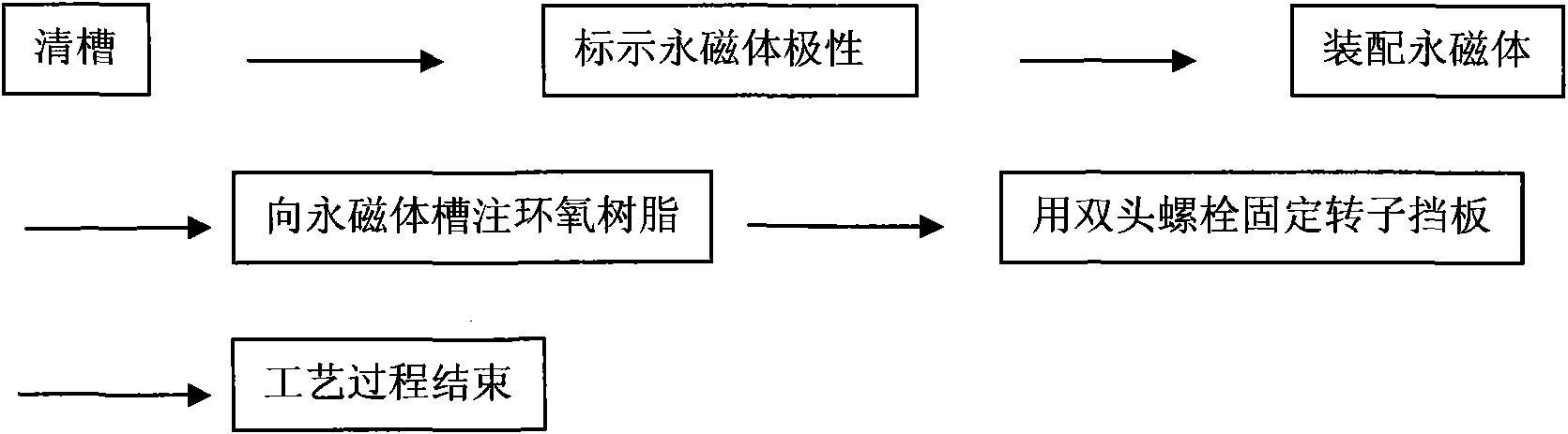

Key manufacturing technology of built-in type permanent magnet synchronous electric motor rotor

ActiveCN101656448AImprove lamination qualityGuaranteed flatnessManufacturing stator/rotor bodiesManufacturing technologyPermanent magnet synchronous motor

The invention relates to a key manufacturing technology of a built-in type permanent magnet synchronous electric motor rotor. An iron core overlying technology comprises the following steps: fixing adummy shaft, and sleeving the dummy shaft into a rotor baffle plate; sleeving arranged rotor sheets into the dummy shaft; inserting two stud bolts, and screwing nuts; then sequentially sleeving rotorsheets into the dummy shaft; installing the rotor baffle plate at the other side of the overlayed rotor sheet, and then fixing the rotor baffle plate; and overlying and firming the rotor sheets on a press machine. A permanent magnet assembling technology comprises the following steps: cleaning a permanent magnet groove, i.e. adding a groove cleaning technology, wherein a groove cleaning tool is asquare lead block, and the permanent magnet groove reaches a permanent magnet groove assembly requirement after being cleaned; marking the polarity of each permanent magnet; placing the permanent magnets into the permanent magnet groove of the rotor; pushing the permanent magnets to the bottom of the permanent magnet groove by a non-magnetic rigid round bar till the permanent magnet groove is filled with the permanent magnets; and pouring epoxy resin glue into the permanent magnet groove. The invention has simple and practical technology process and higher primary qualification rate of products and shortens the production period of the products.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP

A FeGa-RE magnetic-driven flexible materials and its making technology

InactiveCN101086912AHigh magnetostrictive performanceEfficient use ofInorganic material magnetismMagnetostrictive material selectionBridgman methodAdditive ingredient

The invention relates to a FeGa-RE magnetostrictive material and manufacturing technique. The characteristics of magnetostrictive material are that: the ingredient of material consists of Fe, Ga and RE, the content of Ga is 10-40at%, the content of RE is 0.01-20at%, the content of additional intermingle is: C=200-600ppm,N=200-600ppm,O=200-700ppm,other is Fe, the optimal value of Ga is 12-28at%, FeGa-RE magnetostrictive material, the ingredient of material adds one or more kinds of La, Ce, Pr, Nd, Tb, Dy whose content is 0.01-20at%. The manufacturing technique includes the alloy with purified material is cast as the needed round bar, and the alloy bar is crystallized by high temperature gradient flash freezing method and Bridgman method.

Owner:BAOTOU RES INST OF RARE EARTHS

Packing of polycrystalline silicon

ActiveUS20130269295A1Solid materialPackaging under special atmospheric conditionsOptoelectronicsPolycrystalline silicon

A method for packing polycrystalline silicon in the form of fragments or round rods, wherein at least one film in each case is inserted into a cuboidal cardboard box matched to the dimensions of the polycrystalline silicon to be packed, the polycrystalline silicon is introduced into the at least one film, the at least one film of thickness 10 to 1000 μm subsequently being welded and enclosing the polycrystalline silicon, and this at least one film being surrounded by a further film having a reinforcing structure or by a shaping element.

Owner:WACKER CHEM GMBH

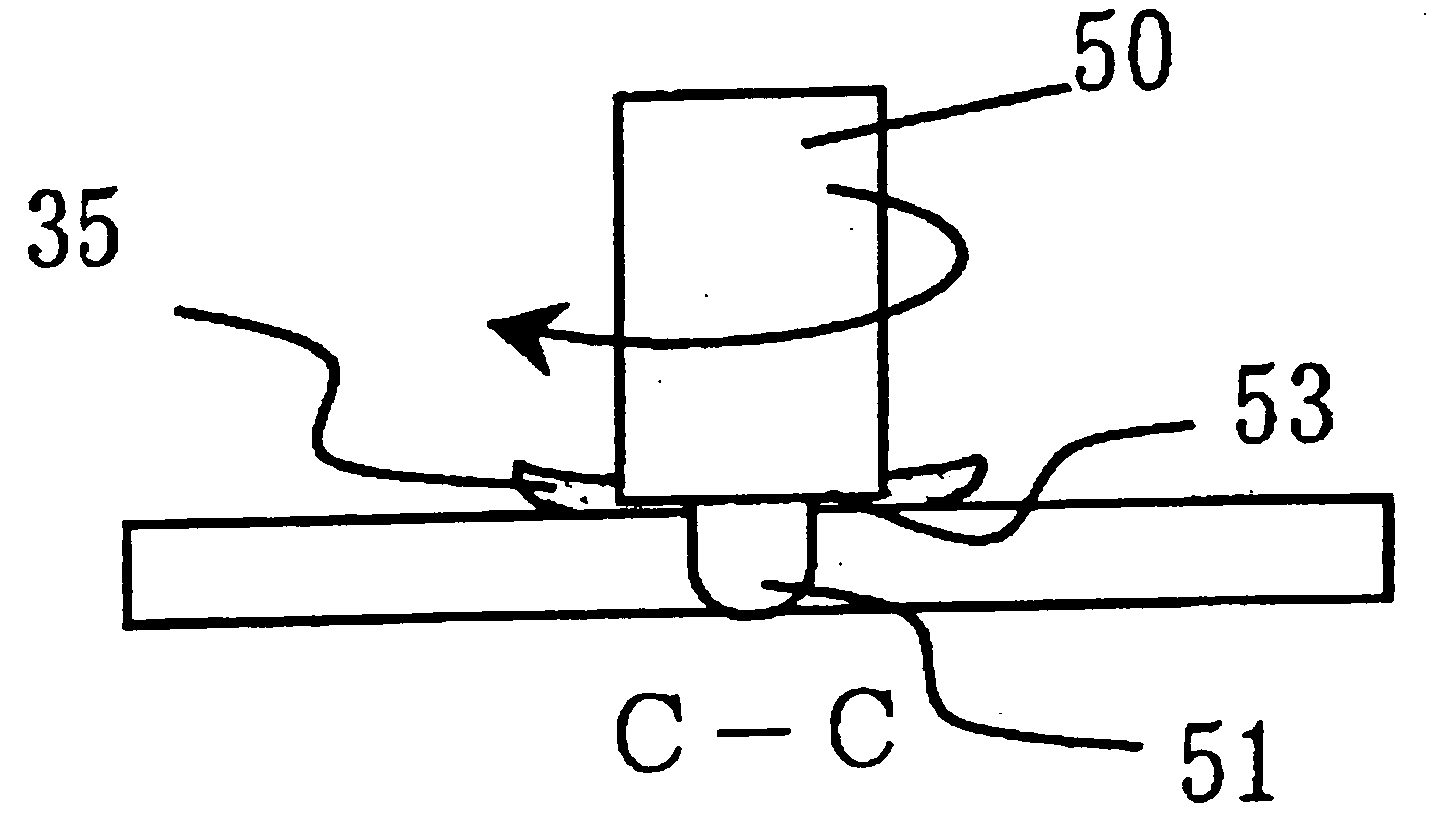

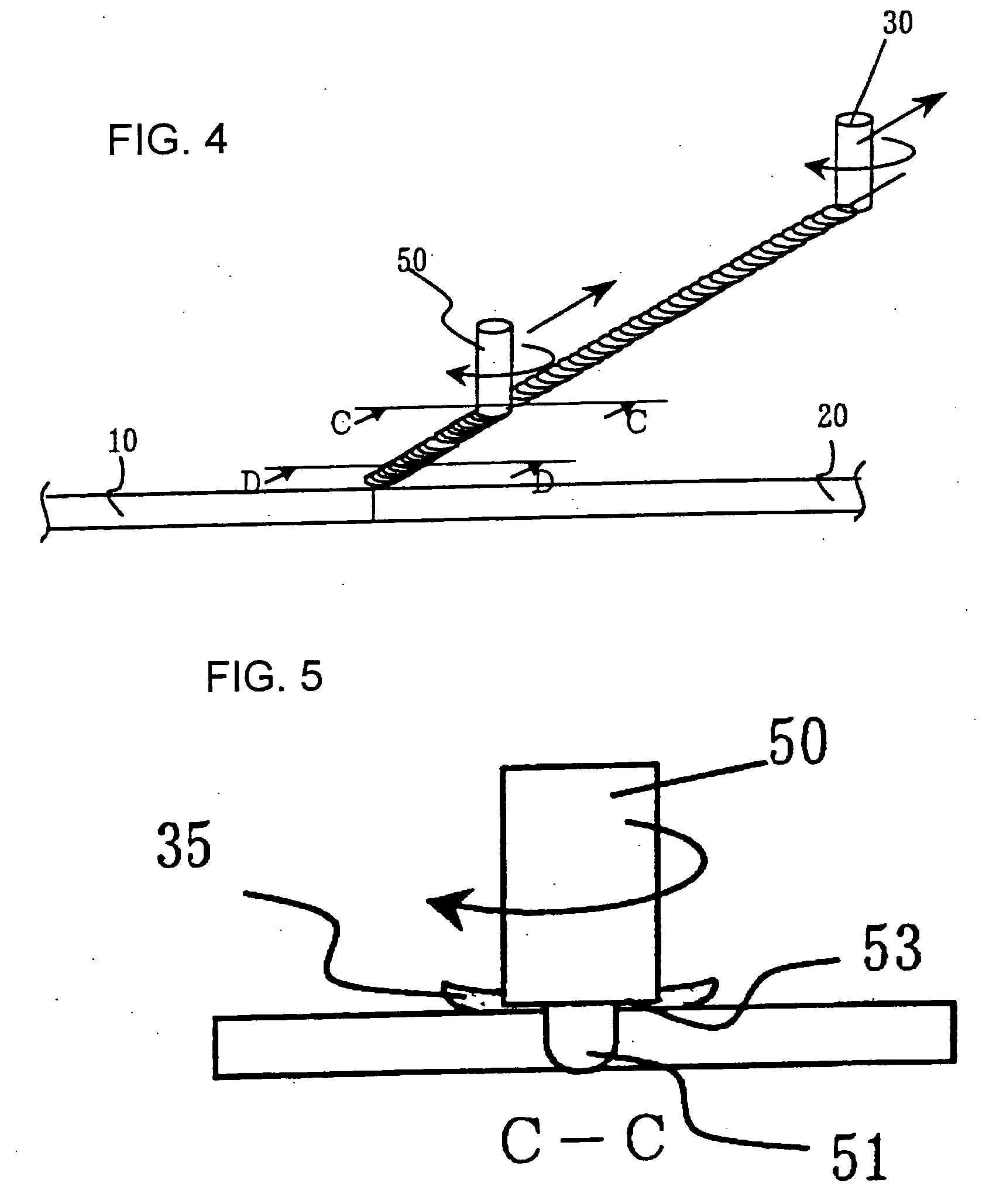

Friction stir welding method

InactiveUS20060169748A1Increase frictionMetal working apparatusTubular articlesFriction weldingRound bar

The invention provides a friction stir welding method with less weld defects upon welding a butted portion between a first member and a second member. A first member 10 is butted against a second member 20, and then a round-bar buildup member 30 is pressed against the upper surface of the butted portion and rotated to weld a buildup bead 35 thereon. The buildup bead corresponds to a projection of the prior art friction stir welding method. Next, a pin 51 of the rotary tool 50 is inserted to the butted portion to perform friction stir welding. According to this method, the buildup bead 35 corresponds to a projection and fills the space formed to the butted portion, so a good weld joint is formed and the generation of defects is suppressed.

Owner:HITACHI LTD

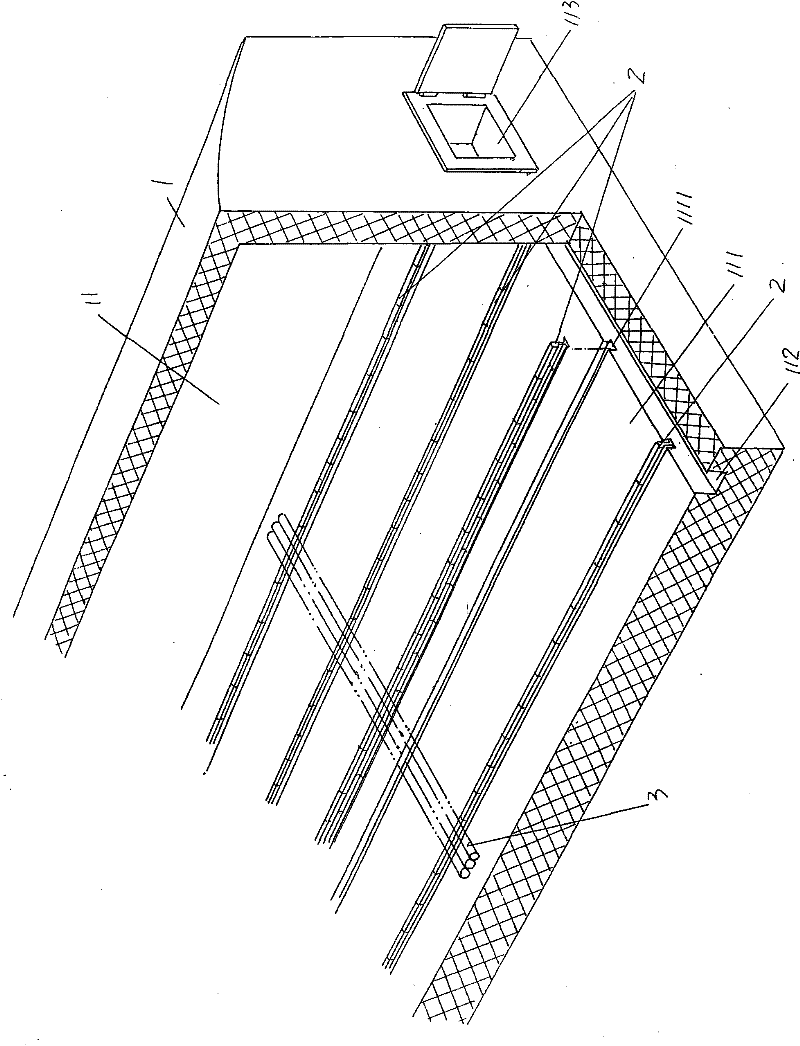

Round bar conveying mechanism

ActiveCN105800337ARealize sequential deliverySimple structureConveyorsLoading/unloadingEngineeringRound bar

The invention relates to the technical field of material transfer, in particular to a round bar conveying mechanism.The round bar conveying mechanism comprises a frame, feed bins arranged in sequence and sequential material conveying mechanisms, wherein the feed bins are arranged at the top end of the frame, material distribution mechanisms are disposed at the outlet end of the feed bins and used for conveying round bars in the feed bins to the sequential material conveying mechanisms, and the outlet end of the sequential material conveying mechanisms is provided with a product detection mechanism.The round bar conveying mechanism has the advantages of simple structure and low manufacturing costs during round bar conveying, which can realize sequential conveying of round bars.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

Large-specification aluminum alloy round bar and casting method thereof

The invention discloses a large-specification aluminum alloy round bar and a casting method thereof. according to the invention, raw materials are blended according to a formula, and are added into a smelting furnace; smelting and deslagging are carried out; the obtained material is delivered into a holding furnace, and on-line degassing and refining are carried out; degassing, deslagging, and purifying are carried out; an aluminum-titanium-boron grain refining agent is added for carrying out grain refinement; the obtained material is cast into an aluminum alloy round bar; and the aluminum alloy round bar is subjected to a homogenization treatment, such that an obtained aluminum alloy round bar can be prevented from cracking, and the tissue of the aluminum alloy round bar is refined. With the method provided by the invention, a diameter of the produced round bar can reach phi1320mm. Also, coring and casting stress of the round bar are eliminated, and product quality is ensured. Mechanical properties of the round bar can satisfy requirements of large structural parts.

Owner:广西南南铝加工有限公司

Fitting structure of guide rail and furnace body of metal round bar heating furnace

InactiveCN102175086AThere will be no crowdingReduce work intensityCharge manipulationEngineeringHeating furnace

The invention relates to a fitting structure of a guide rail and a furnace body of a metal round bar heating furnace, belonging to the technical field of industrial kiln furnaces. The metal round bar heating furnace comprises the furnace body which is provided with a hearth. The fitting structure is characterized in that the hearth bottom wall of the hearth is provided with guide rail grooves at intervals; the guide rail grooves are in parallel with the length direction of the hearth; the guide rail is arranged in each guide rail groove; the guide rail comprises a guide rail seat, a connecting plate and a guiding bar which are mutually integrated into a structure; the guide rail seat is positioned at the bottom part of the connecting plate and is embedded with the guide rail grooves; the guiding bar is positioned at the top part of the connecting plate; the guide rail seat is provided with guide rail seat expansion grooves at intervals; the connecting plate is provided with first connecting plate expansion grooves at intervals; the first connecting plate expansion grooves are communicated with the guide rail seat expansion grooves; the guiding bar is provided with guiding bar expansion grooves at intervals; and the guiding bar expansion grooves and the first connecting plate expansion grooves are formed at intervals. The structure has the advantages that the heating efficiency is improved, energy sources are saved, uniform heating can be ensured, and the working intensity is relieved.

Owner:CHANGSHU FEIFAN METALWORK

Preparation method of nanocrystalline magnesium alloy by continuous and severe plastic deformation

The invention discloses a preparation method of a nanocrystalline magnesium alloy by continuous and severe plastic deformation. The method comprises the following steps of: firstly, smelting a prepared magnesium alloy raw material and casting into a round cast ingot; then, thermally extruding at 340-460 DEG C to a bar with diameter of 9-12mm; cutting the extruded round bar and performing equal channel corner extrusion with 4-8 channels at 200-350 DEG C; and then, cutting the bar into wafer samples which are 0.8-1mm in thickness for twisting at room temperature and high pressure, wherein the pressure is 4-6Gpa and twisting for 2-10 rings. According to the method provided by the invention, conventional thermal extrusion is combined with equal channel corner extrusion and high pressure twisting belonging to a severe plastic deformation process, and the magnesium alloy with the average grain size below 100nm and uniform tissue can be easily prepared, so that the mechanical property of the magnesium alloy is greatly improved, and meanwhile, the method has the characteristics of large size of nanocrystalline magnesium alloy material, simple process, high processing efficiency, less impurities and defects and the like.

Owner:SOUTHEAST UNIV

Fiber Bragg Grating Temperature Sensor and Its Probe

InactiveCN102274006AAccurate heating and temperature controlExtended service lifeThermometers using physical/chemical changesMicrowave therapyFiberMicrowave

The invention relates to a fiber grating temperature sensor which comprises a probe and a demodulating system connected with the probe, wherein the probe comprises a needle head and a handle which are connected together. The fiber grating temperature sensor is characterized in that the needle head is an austenitic stainless steel round bar with a needle point, the center of the bottom surface at one end of the austenitic stainless steel round bar is provided with a blind hole, and the blind hole extends close to the other end of the austenitic stainless steel round bar; and a fiber bragg grating is arranged in the blind hole. The invention is mainly used for manufacturing fiber grating temperature sensors for microwave thermotherapy of bone tumors.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com