Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3553 results about "Hanging basket" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hanging basket is a suspended container used for growing decorative plants. Typically they are hung from buildings, where garden space is at a premium, and from street furniture for environmental enhancement. They may also be suspended from free standing frames sometimes called hanging basket trees. One type of hanging basket is the inverted planter where plants are grown in an upside down pot and are watered from the top.

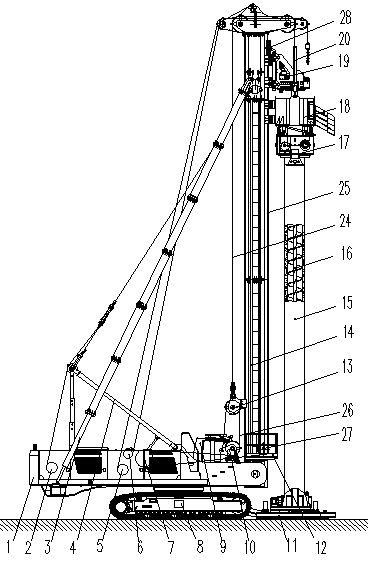

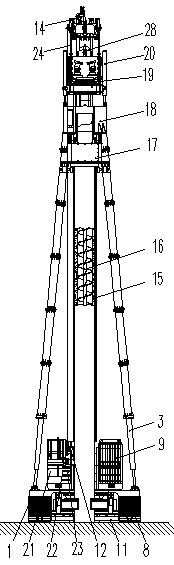

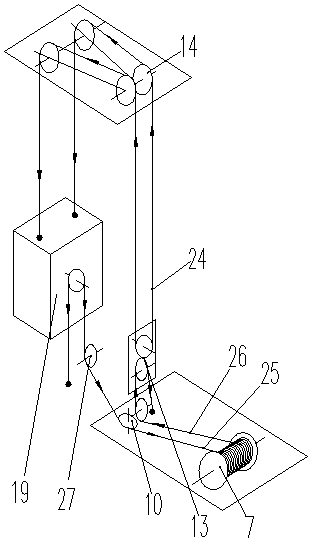

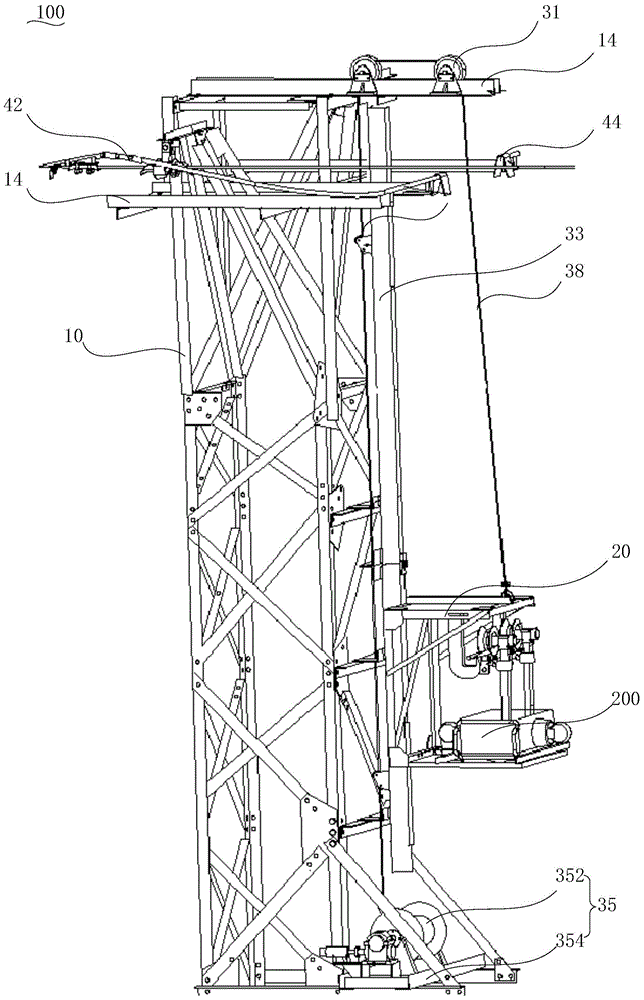

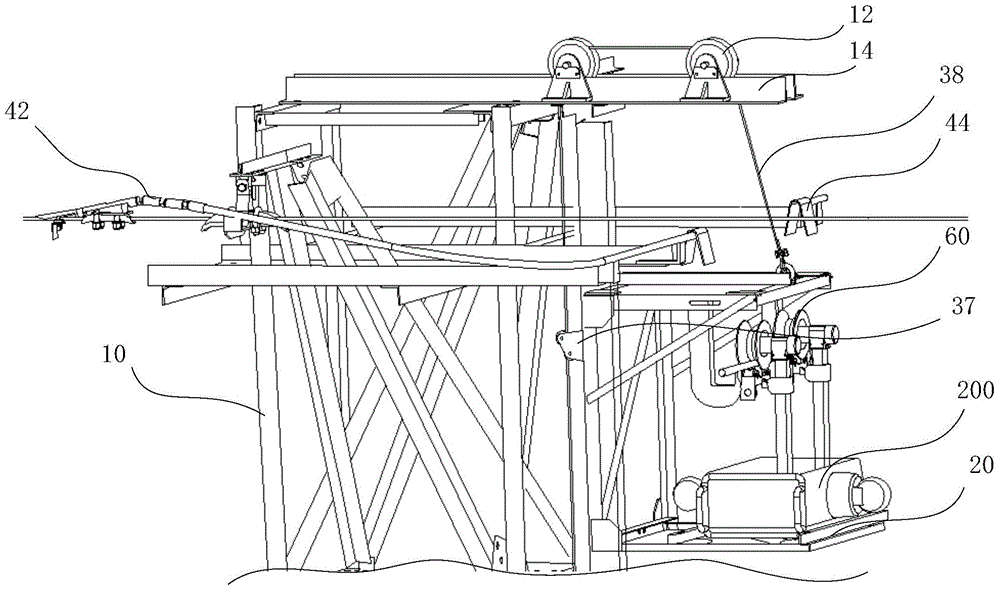

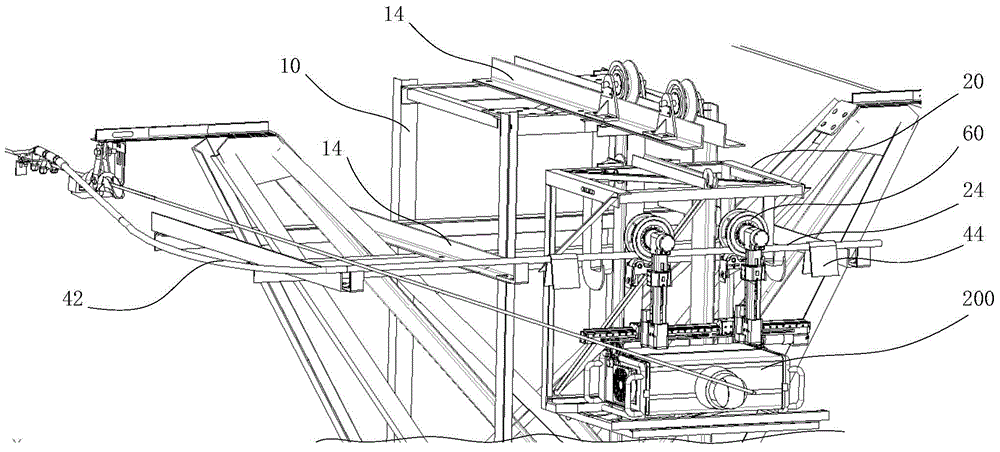

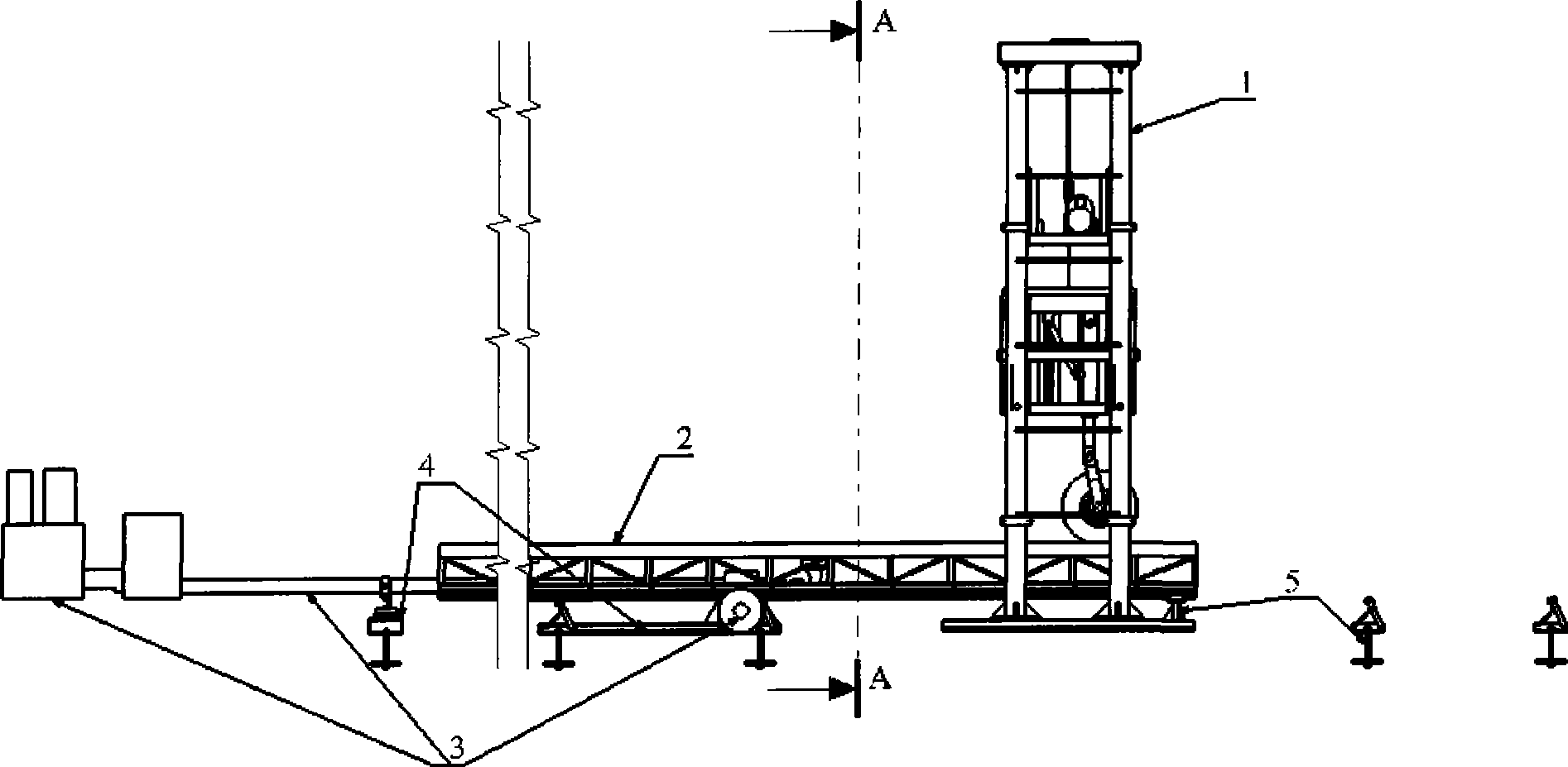

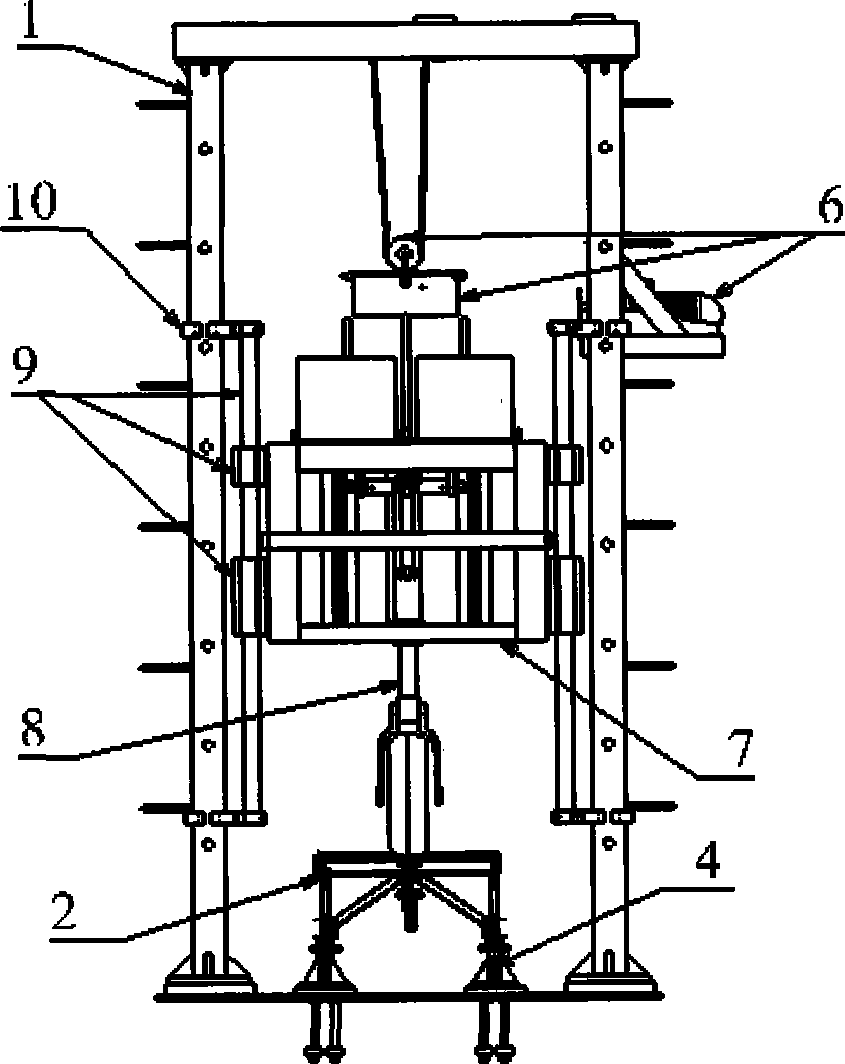

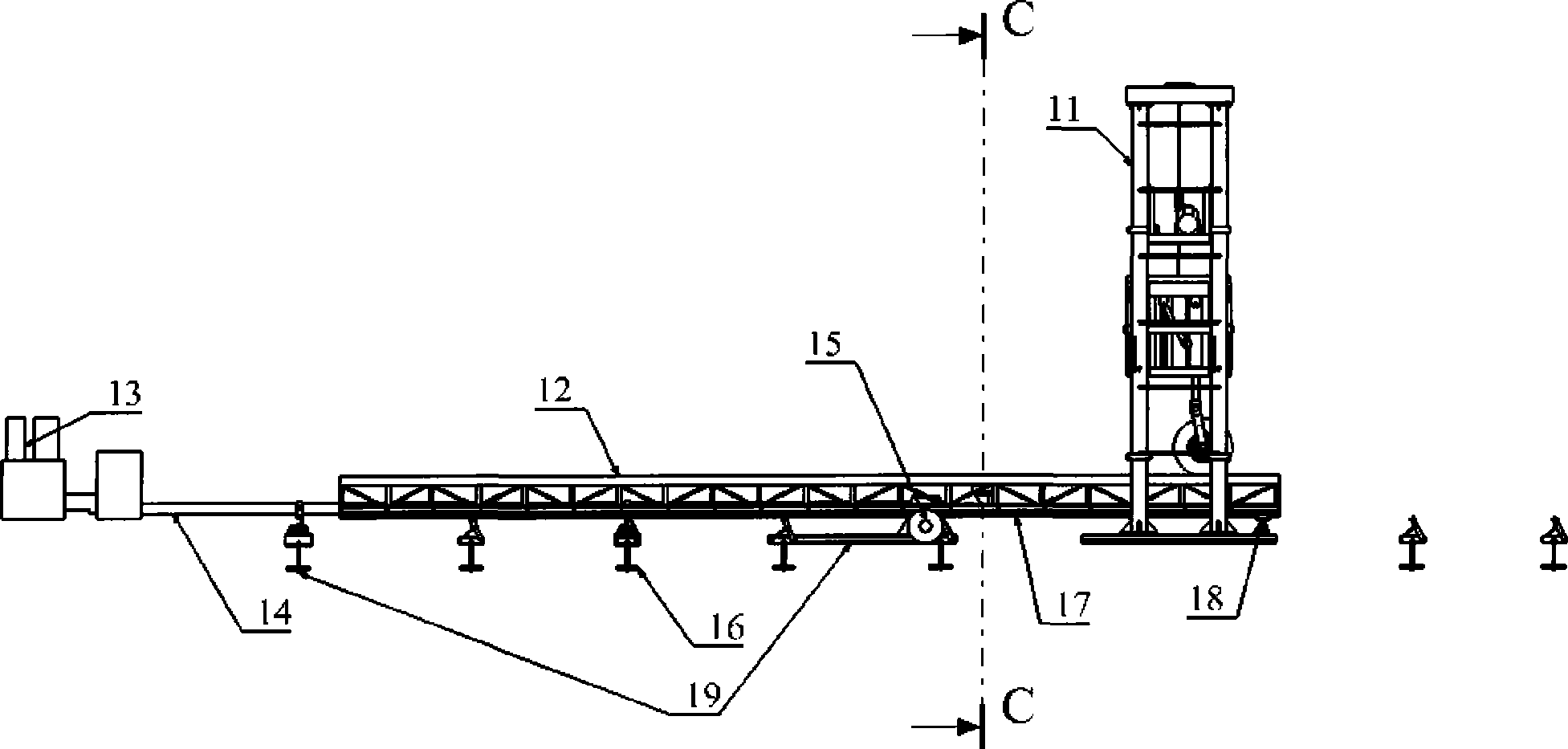

Drilling rig with following pipe pile and construction method for following pipe pile

ActiveCN102561946AImprove stabilityPowerfulBulkheads/pilesDrilling machines and methodsControl systemEngineering

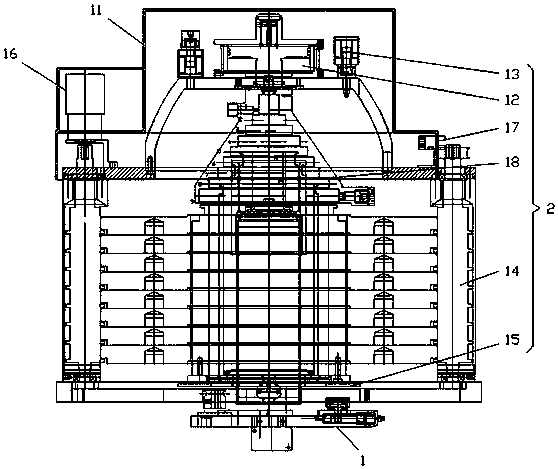

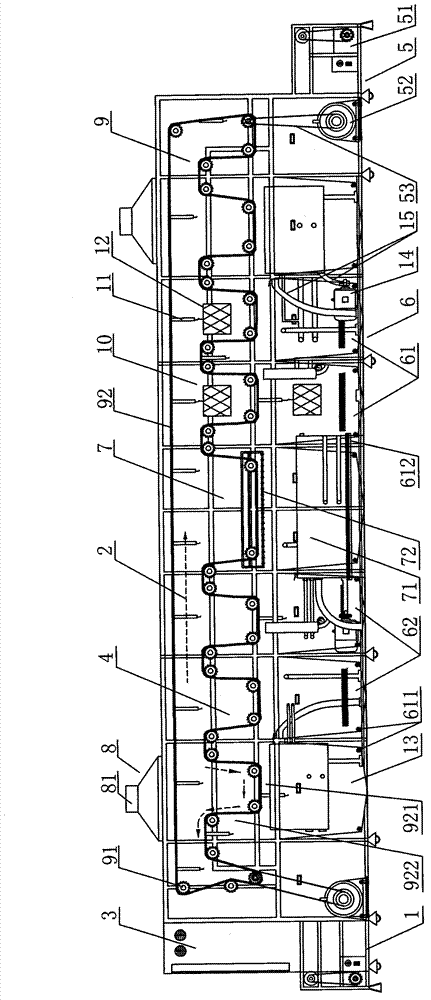

Disclosed are a drilling rig for drilling with a following pipe pile and a construction method for the following pipe pile. The drilling rig is provided with a chassis, a platform, a cab, a power system, a hydraulic system, a control system, upright columns, supporting rods, a vertical winch, a power head, a soil discharge box, a spiral drill stem assembly, a reamer bit, a vibration exciter, an adjusting cylinder, a manned hanging basket, a hanging basket winch, a pressurizing winch, an auxiliary winch and a pile controller, wherein the platform, the cab, the power system, the hydraulic system and the control system are located on the chassis, the upright columns and the supporting rods are mounted on the platform, and the auxiliary winch is used for hoisting heavy objects. The construction method for the following pipe pile comprises following steps: leveling the pile controller after the pile controller is aligned with a pile location and adjusting verticality of upright columns of the drilling rig; mounting a prefabricated pipe pile and a drill and leading the reamer bit to penetrate out of the lower end surface of the prefabricated pipe pile; forwards rotating the power head, leading a reamer wing of the reamer bit to be opened to begin to realize reamer drilling and leading the prefabricated pipe pile to be jacked in afterwards; backwards rotating the power head after a preset depth is achieved, withdrawing the reamer wing of the reamer bit to be closed, lifting out the reamer wing of the reamer bit from the inside of the prefabricated pipe pile and starting the vibration exciter to impact the prefabricated pipe pile; and realizing grouting piling for the sides and the bottom of the pile.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD +1

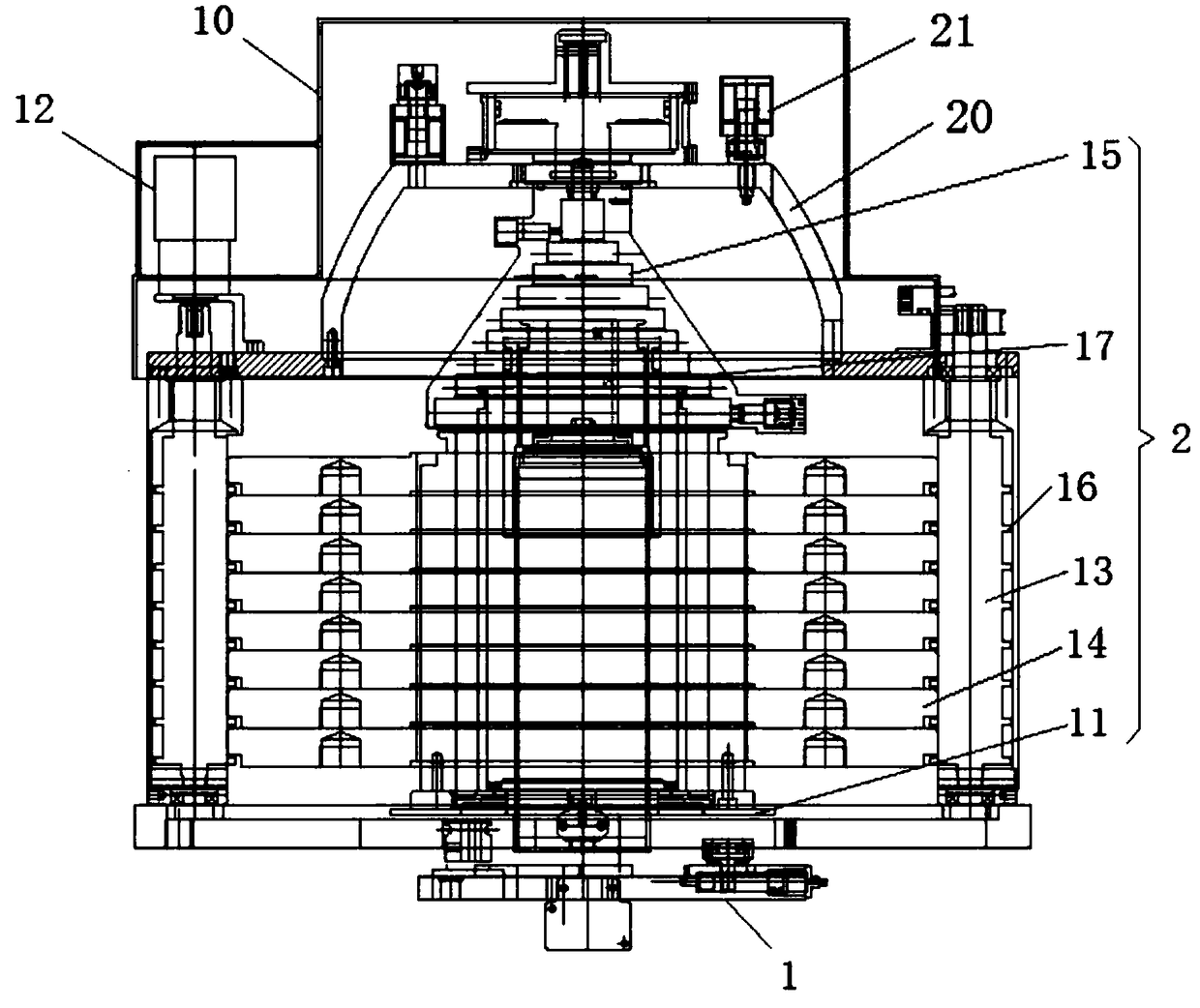

Cryogenic vial storing and fetching device

ActiveCN105857941AAchieve strict controlKeep aliveDomestic cooling apparatusLighting and heating apparatusThermal insulationHanging basket

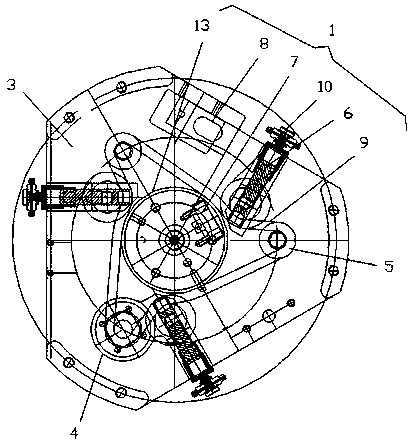

The invention discloses a cryogenic vial storing and fetching device. The cryogenic vial storing and fetching device comprises a frame and a liquid nitrogen cylinder, wherein the liquid nitrogen cylinder is located in the frame; the liquid nitrogen cylinder comprises a cylinder body and a moving mechanism; the cylinder body is provided with a sealed opening; the sealed opening is provided with a first thermal insulation shell; the moving mechanism is arranged in the cylinder body and is used for moving hanging baskets in the liquid nitrogen cylinder to the opening; the cryogenic vial storing and fetching device further comprises a hoisting mechanism, a tray shoveling mechanism and a vial selecting mechanism; the hoisting mechanism is used for hoisting a hanging basket at the opening into the first thermal insulation shell; the tray shoveling mechanism is used for storing or fetching a cryogenic tray from the hanging basket which is hoisted by the hoisting mechanism; and the vial selecting mechanism is used for storing or fetching a cryogenic vial from the cryogenic tray which is fetched by the tray shoveling mechanism. By adopting the cryogenic vial storing and fetching device, the process for selecting a single target cryogenic vial for biological samples is realized; and during the whole selecting process, the cryogenic vials are all in a liquid nitrogen environment, and non-target cryogenic vials are prevented from being exposed at environment temperature, so that the activity of the biological samples is ensured.

Owner:SHANGHAI ORIGINCELL BIOLOGICAL CRYO EQUIP CO LTD

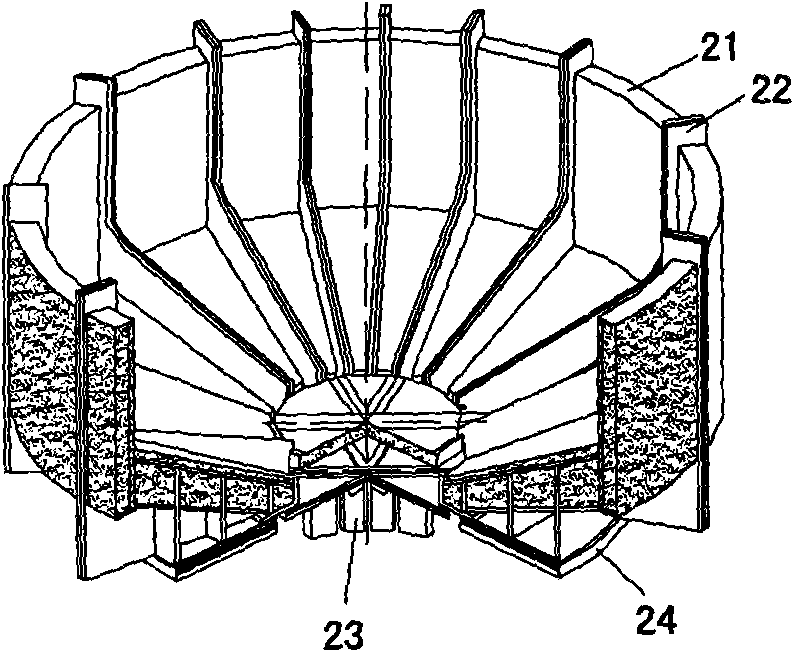

Method for installing reactor core catcher of nuclear power station

ActiveCN102097137ANuclear energy generationEmergency protection arrangementsCore catcherNuclear power

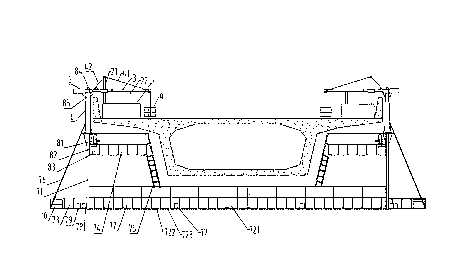

The invention provides a method for reliably installing a reactor core catcher in a narrow reactor vertical shaft, comprising the steps of: (1) installing a forging heat exchange device on a bottom plate of the reactor vertical shaft; (2) installing a hanging basket with fillers; and (3) installing a ventilation system and a lower bottom plate, wherein the step 1 for installing the forging heat exchange device further comprises the steps of: (1a) placing a plurality of forgings of a heat exchange device on the foundation of the reactor vertical shaft in advance, and confirming the actual respective positions of the forgings; (1b) installing a central fixing member and a supporting ribbed plate in the center of the vertical shaft; (1c) installing forgings on two sides of the ribbed plate according to the actual positions, and respectively fixing the forgings on the wall and the bottom plate of the vertical shaft through connecting pieces; and (1d), sequentially installing and welding the supporting ribbed plate and the forgings of the heat exchange device according to certain sequence. Accordingly, the method provided by the invention is favorable for greatly lowering the construction difficult and the construction workload at the same time of ensuring that all the parts of the reactor core capturer are safe and effective.

Owner:CHINA NUCLEAR IND 23 CONSTR

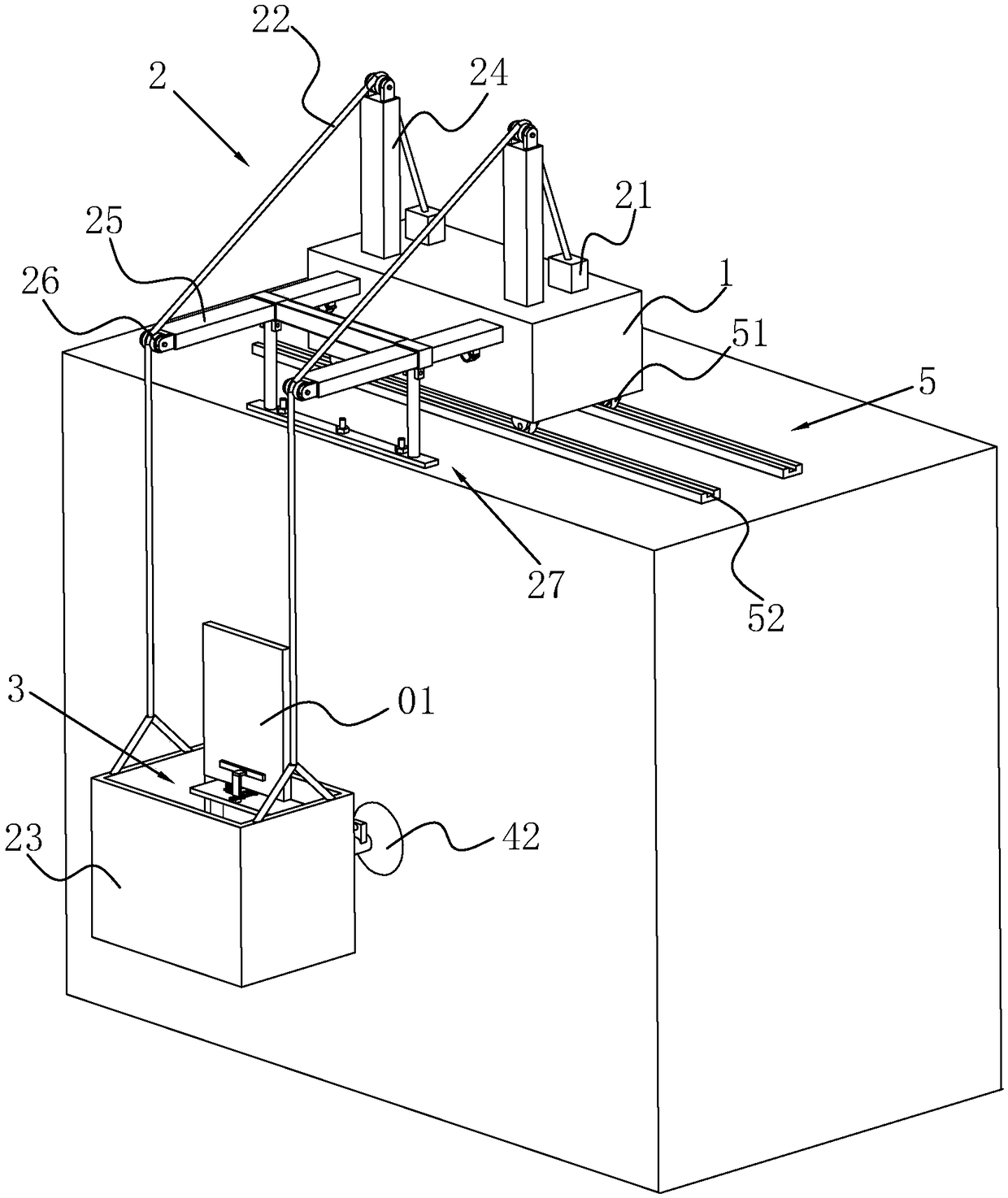

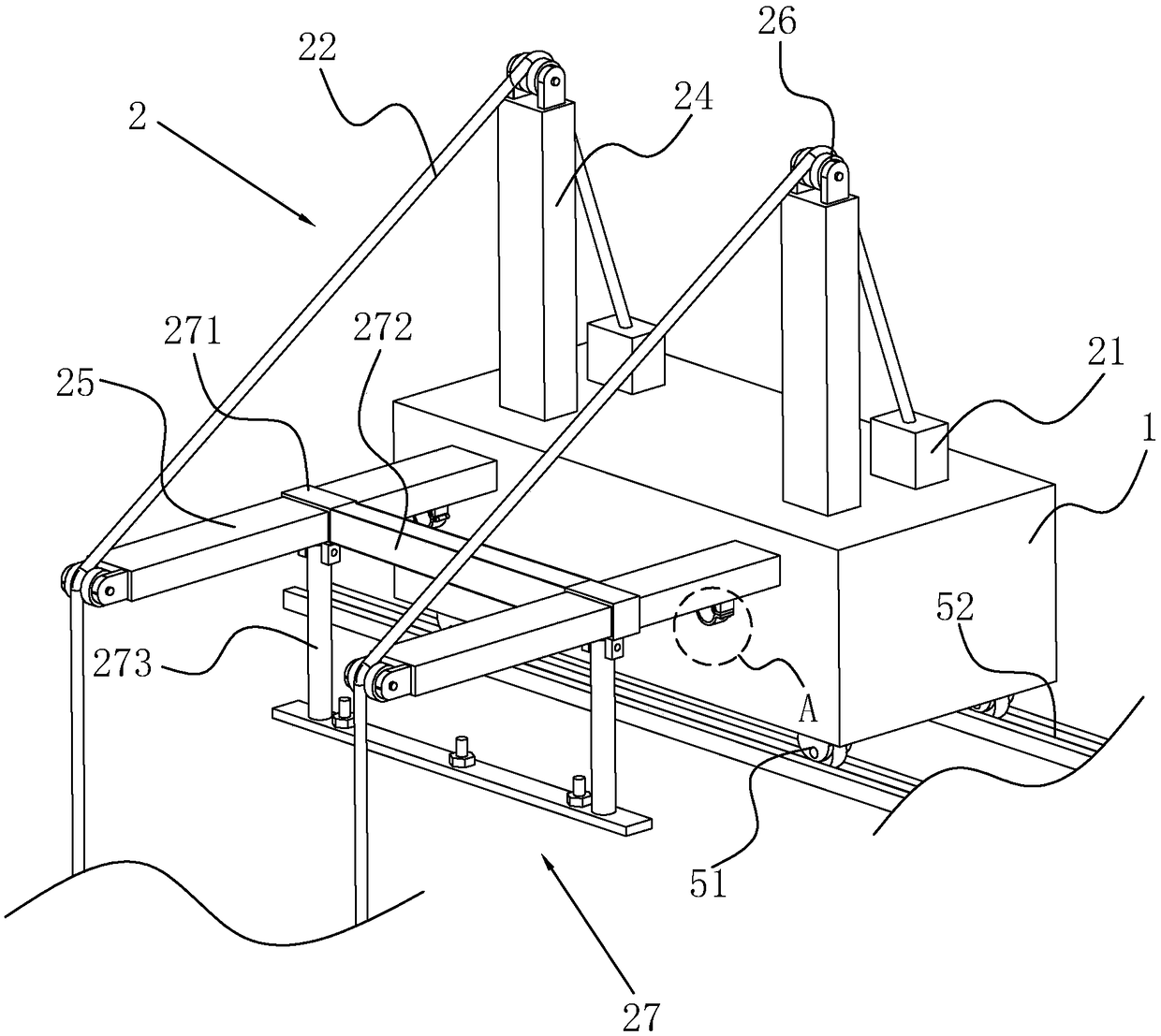

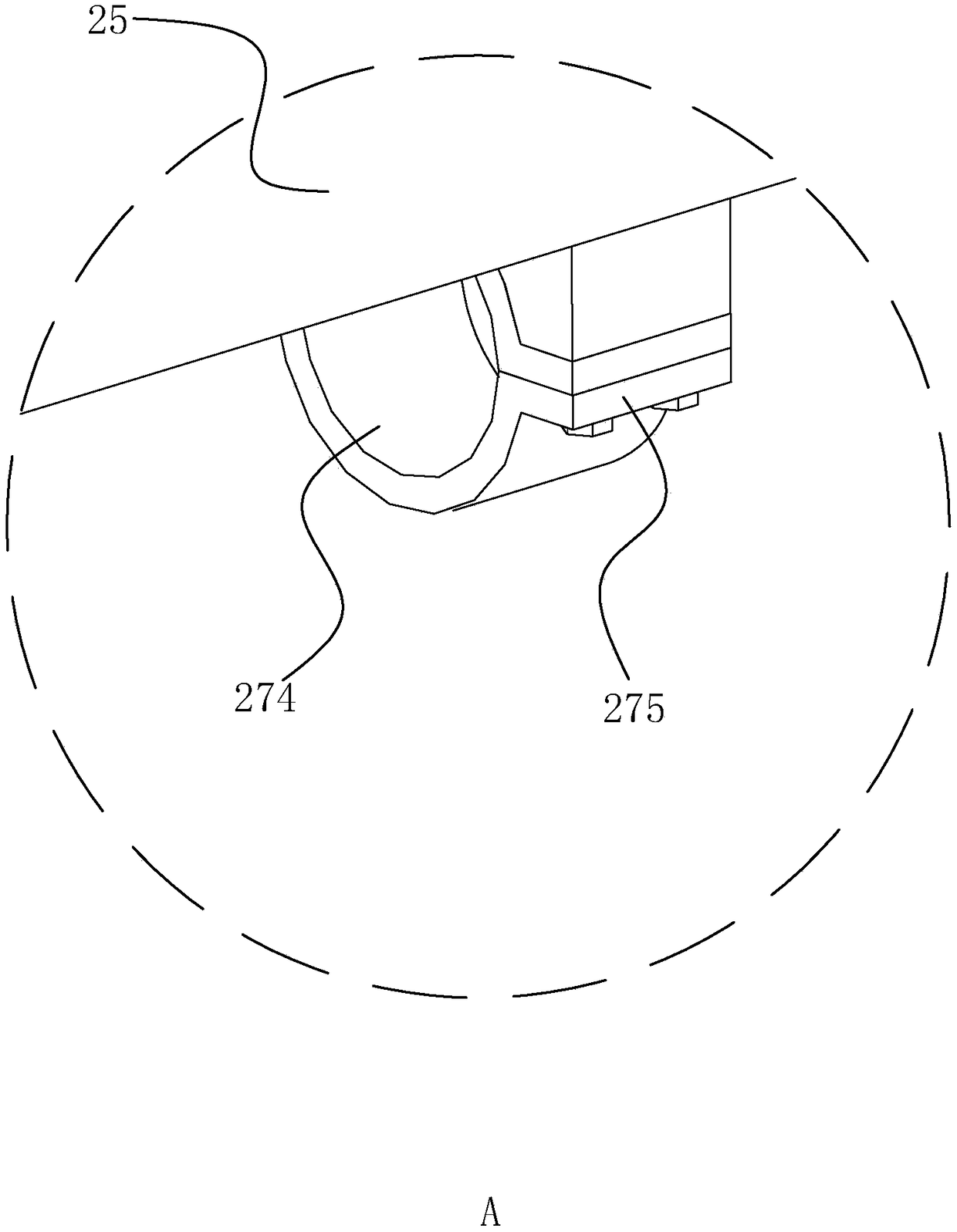

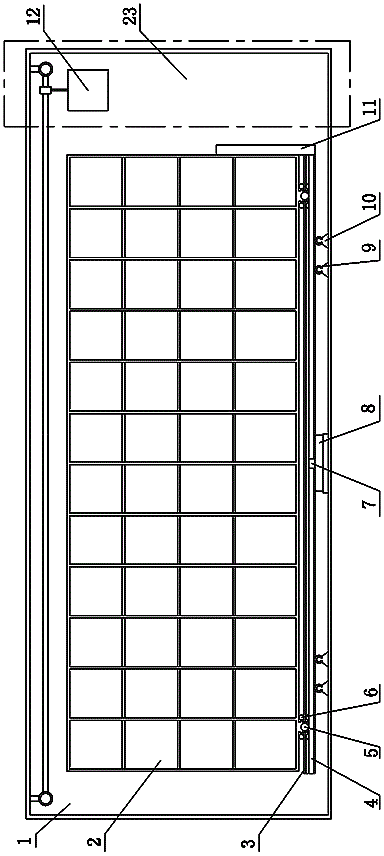

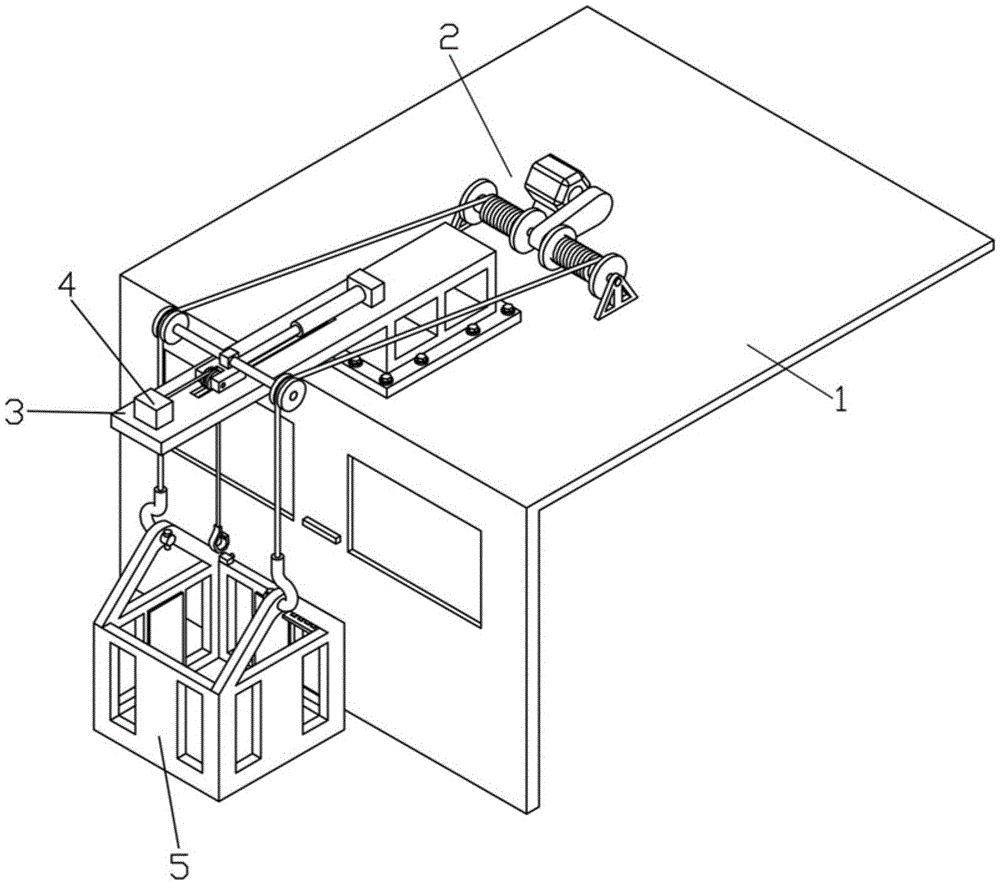

Fabricated architectural decoration stone artificial board curtain wall mounting frame

InactiveCN108952184AImprove conveniencePlay a supporting roleWallsBuilding material handlingEngineeringHanging basket

The invention discloses a fabricated architectural decoration stone artificial board curtain wall mounting frame and relates to the technical field of curtain wall mounting. The problems that in the prior art, the overall weight of a mounting frame is difficult to support by a guide rail attached to a wall, a large quantity of areas around the roof surface are occupied, consequently the strength is low, stability is poor, and curtain wall mounting is inconvenient are solved. The fabricated architectural decoration stone artificial board curtain wall mounting frame is characterized in that thefabricated architectural decoration stone artificial board curtain wall mounting frame comprises a base, a hoisting support facing the outer side of a roof is arranged on the base, and a winch is mounted on one side of the hoisting support; the winch is connected with a hanging basket through a steel rope which is arranged along the hoisting support in a penetrating mode, and the hoisting supportcomprises two spaced supporting rods which are longitudinally arranged on the base, and two spaced cantilevers which are transversely arranged on the base; the distance between the supporting rods isequal to the distance between the cantilevers and equal to the length of the hanging basket, and fixed pulleys are arranged at the ends, away from the base, of the supporting rods as well as the ends,away from the supporting rods, of the cantilevers correspondingly; and the ends, close to the fixed pulleys, of the cantilevers are provided with roof surface steel trusses. The fabricated architectural decoration stone artificial board curtain wall mounting frame has the advantages that the strength is high, the stability is good, and curtain wall mounting is convenient.

Owner:江苏华欣装饰集团有限公司

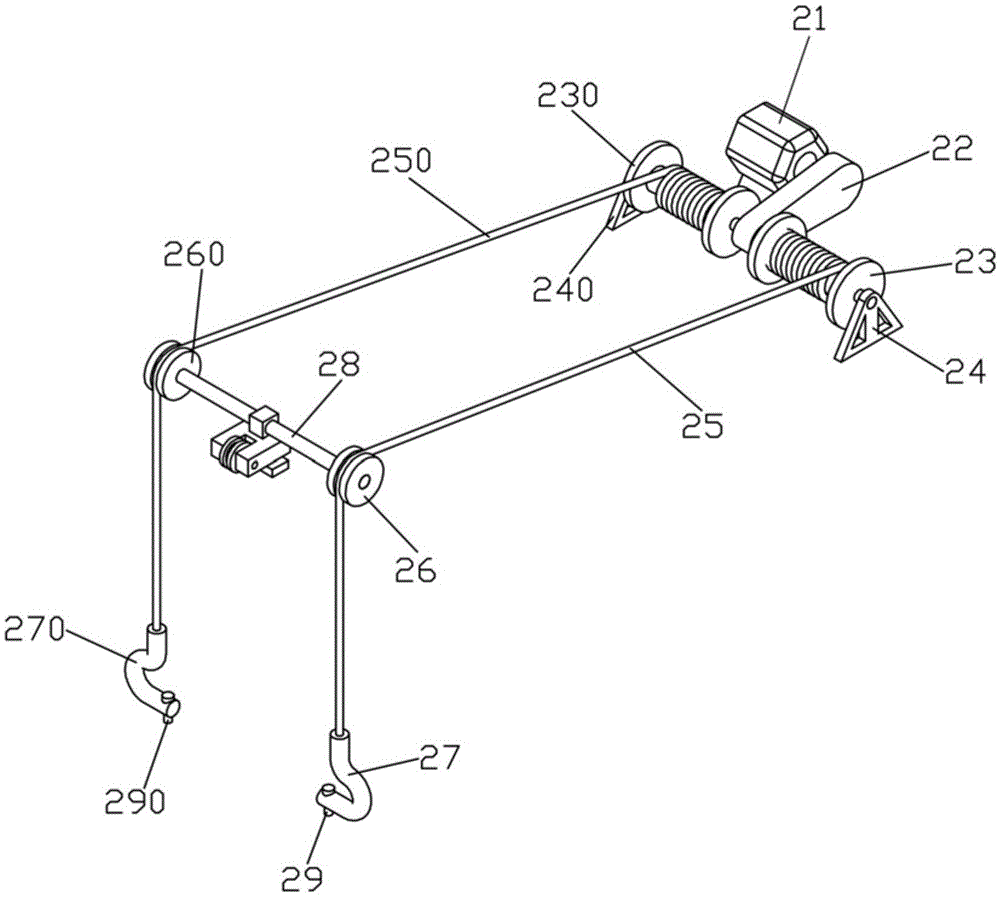

Line inspection robot on-line and off-line device and line inspection robot on-line and off-line system provided with same

The invention relates to a line inspection robot on-line and off-line device and a line inspection robot on-line and off-line system provided with the same. The line inspection robot on-line and off-line device comprises a hanging basket, a lifting device and a guiding device, wherein the hanging basket is used for supporting a line inspection robot and is provided with a hanging basket guide rail, the lifting device is connected with the hanging basket, and the guiding device comprises a guiding guide rail which is provided with a docking port matching with the hanging basket guide rail. The lifting device drives the hanging basket to rise to a position where the guiding guide rail is along a line pole; the hanging basket guide rail is in butt joint with the guiding guide rail; the line inspection robot can move from the hanging basket guide rail to the guiding guide rail, further to an overhead transmission line ground wire through the guiding guide rail, so that the automatic on-line is finished. Or, the line inspection robot moves from the overhead transmission line ground wire to the hanging basket guide rail through the guiding guide rail, so that the automatic off-line is finished. Therefore, operators do not need to climb the line pole for hanging the line inspection robot on the overhead transmission line ground wire or taking down the line inspection robot from the overhead transmission line ground wire, thereby improving the installation efficiency.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Drop test device for movable impact platform

A drop test device for a movable impact platform can be used in the fields of spin-up drop tests of an aircraft landing gear, rolling property tests, tire static property tests and tire dynamic property tests. The drop test device for the movable impact platform comprises a portal frame, a ground fixing mechanism, a retraction jack, a hanging basket, a landing gear, a hanging basket guide mechanism, a clearance regulation mechanism, a movable impact platform, a hydraulic driving system and a ground guide mechanism. The movable impact platform of the invention consists of a truss-frame structure and high-speed guide rails, wherein the high-speed guide rails are connected with the truss-frame structure by blots through guide rail mounting holes. The hydraulic driving system is a high-speed servo proportional hydraulic system and is fixed on the ground through the ground fixing mechanism. The ground guide mechanism is two rows of guide sliding blocks which pass through the portal frame and are arranged parallelly. The movable impact platform is connected with the hydraulic driving system and is placed on the ground guide mechanism. The drop test device for the movable impact platform provided by the invention has the advantages of compact and simple structure and high strength and rigidity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

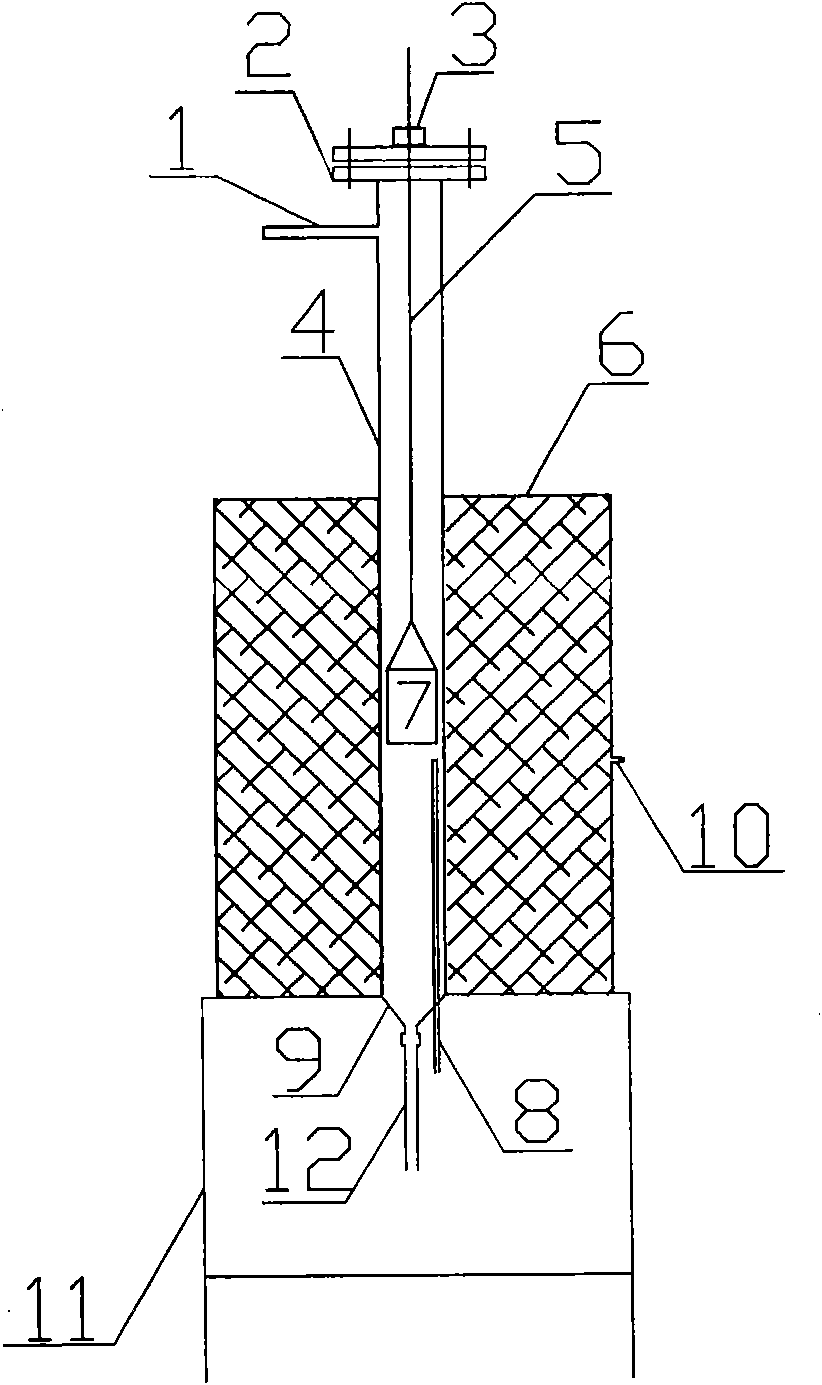

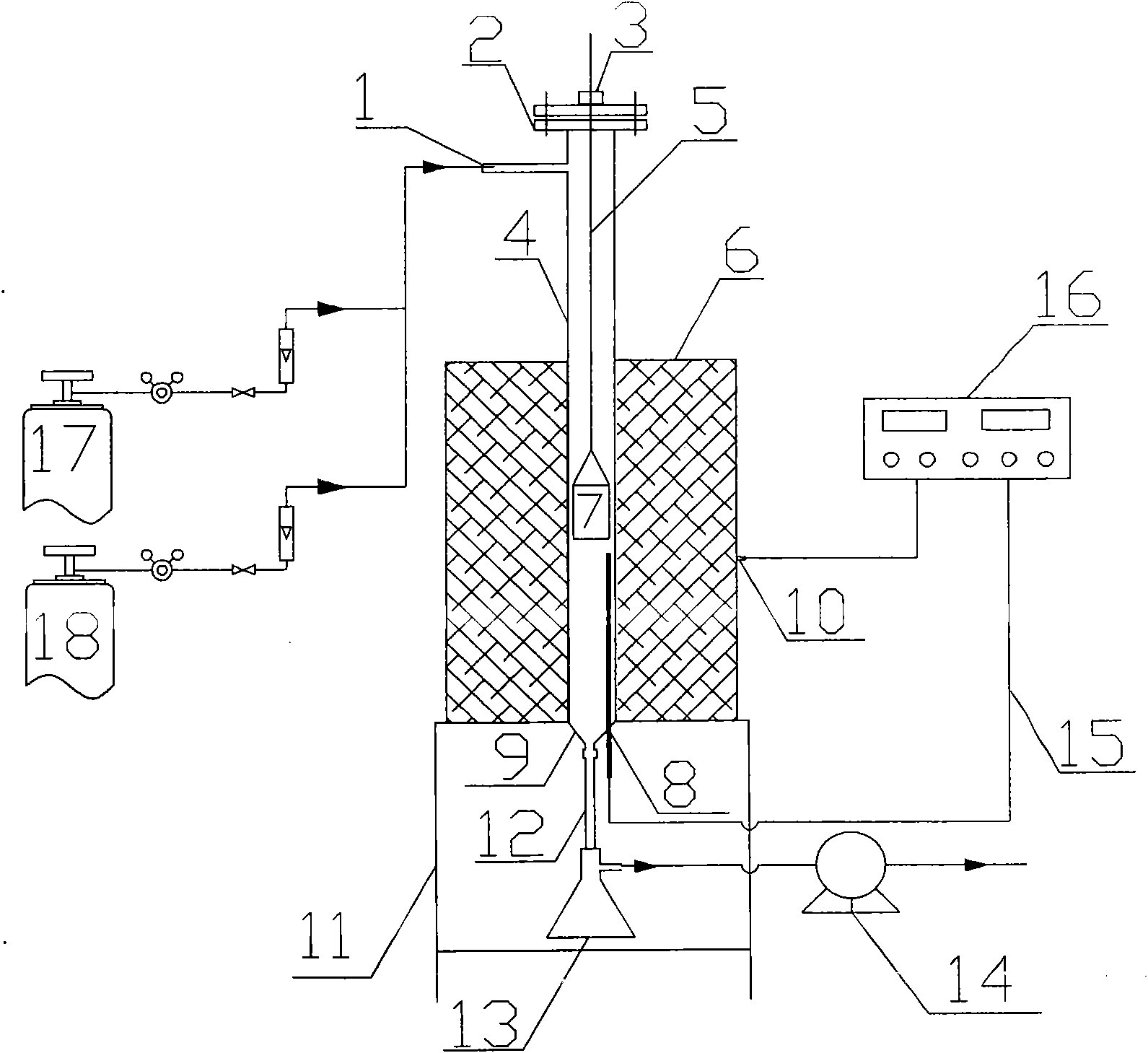

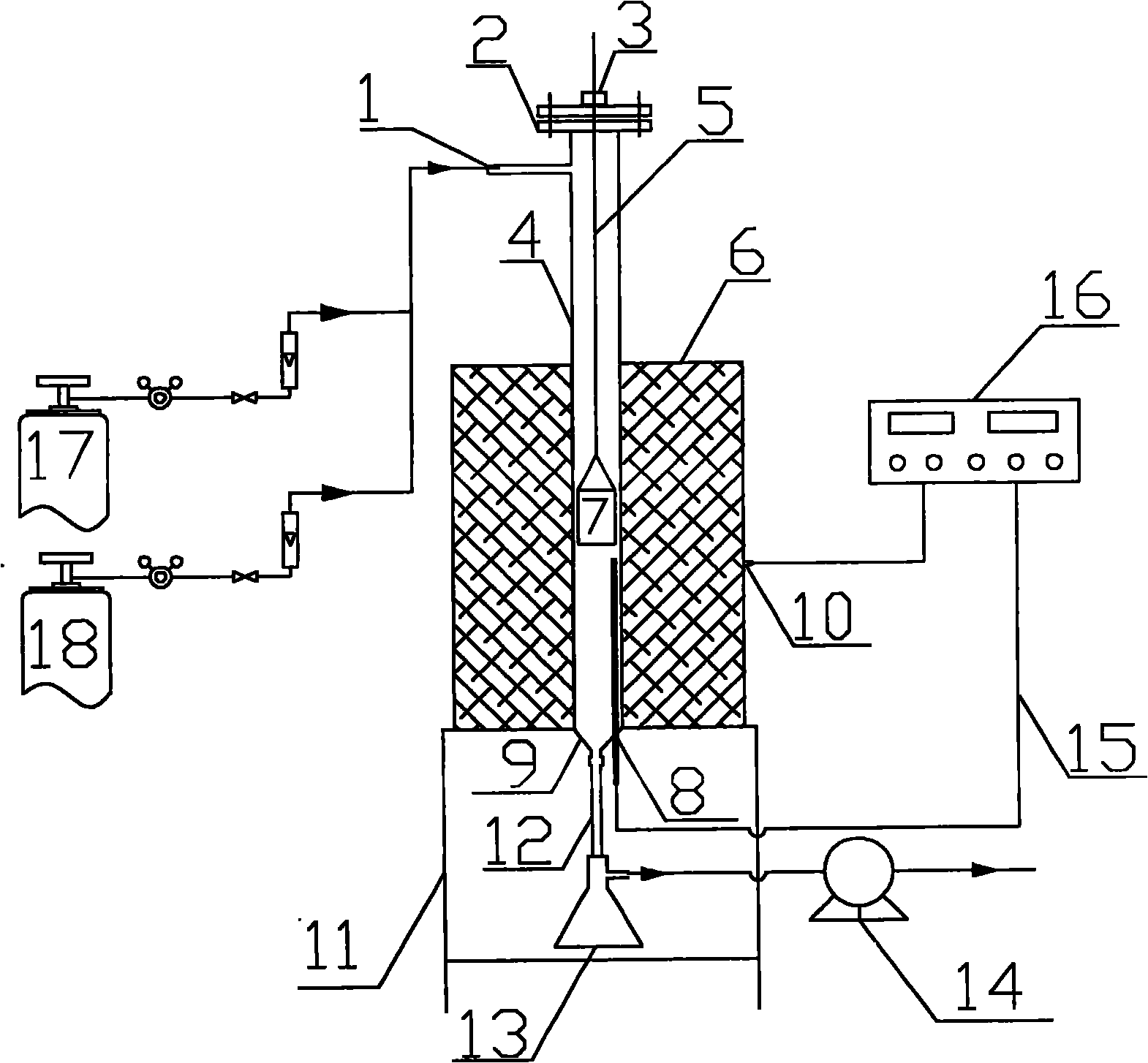

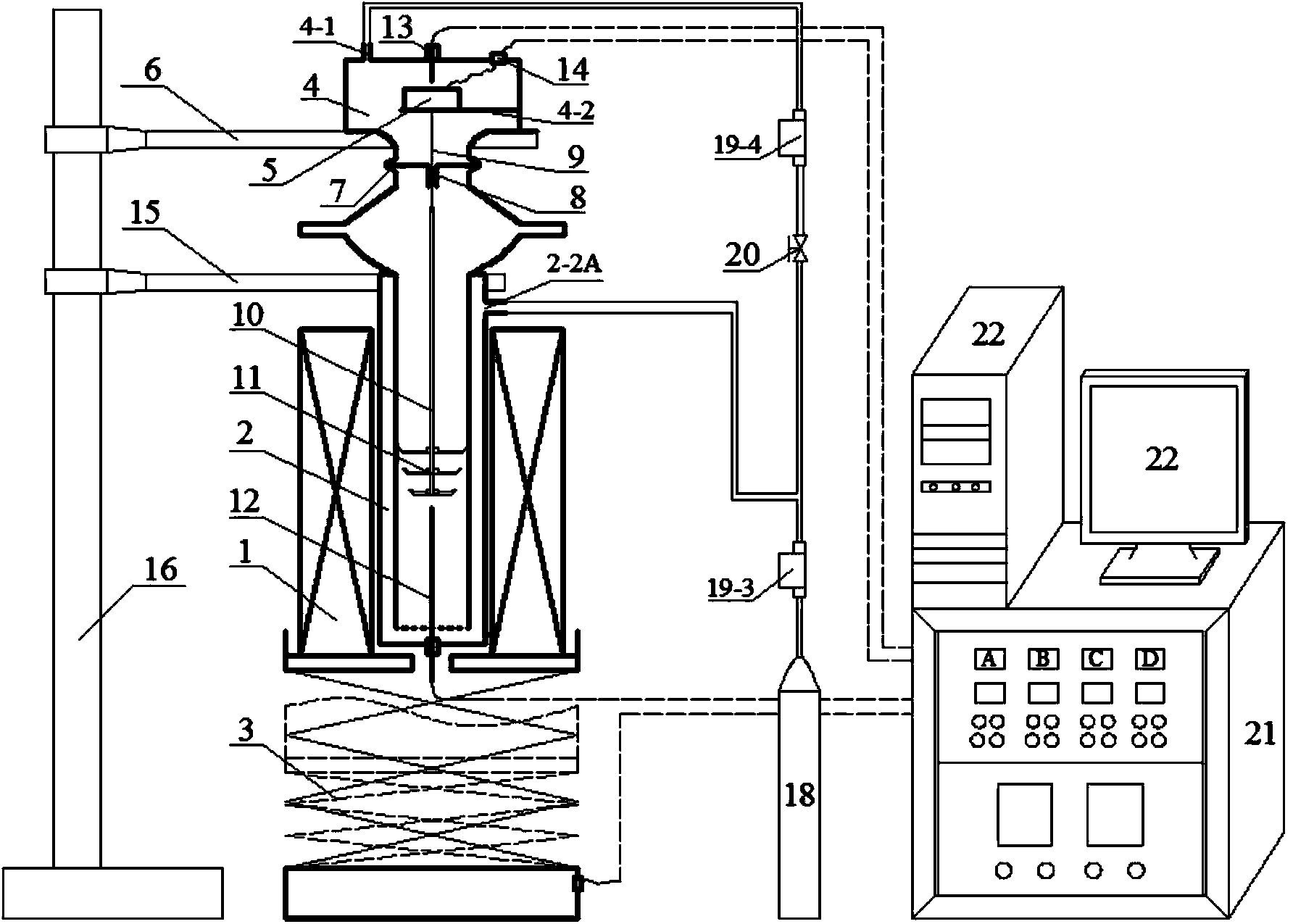

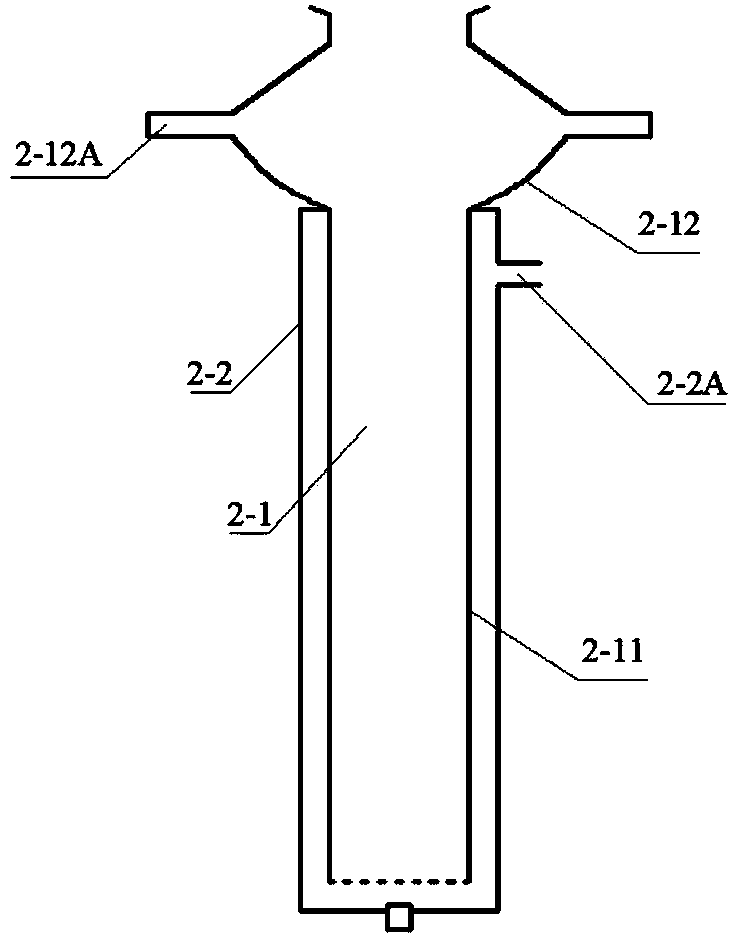

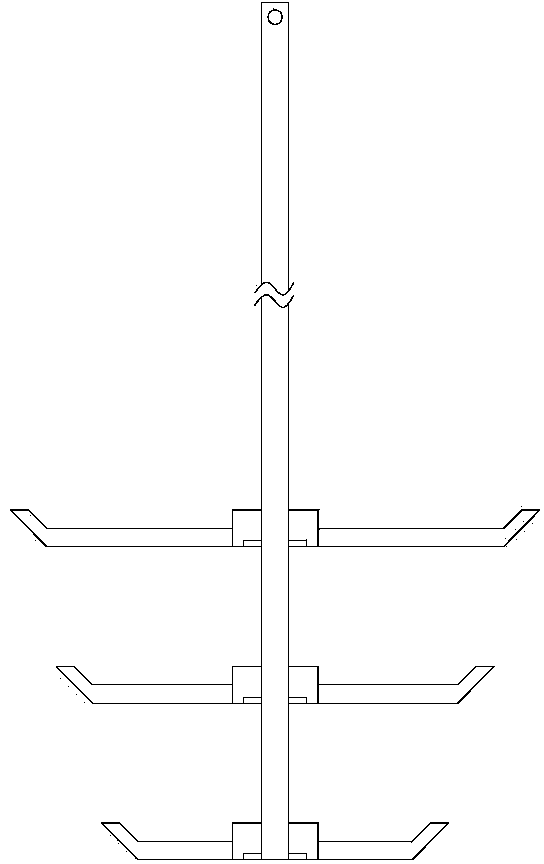

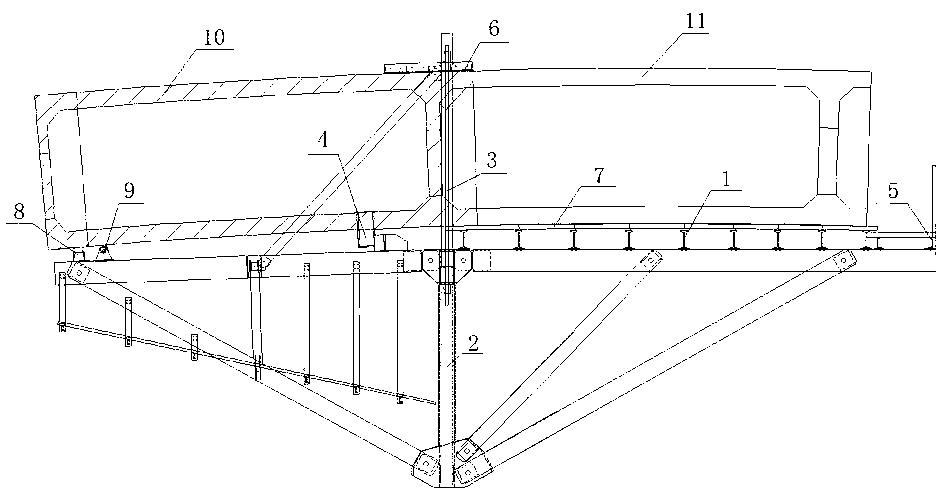

Fast pyrolytic test device and application

InactiveCN101846642AFast pyrolysisGood value for moneyMaterial weighingInvestigating phase/state changeTarEngineering

The invention relates to a fast pyrolytic test device, which consists of a tubular electric heating furnace (6), an object carrying frame (11), a temperature test and control opening (8), a reaction tube (4), an air inlet opening (1) and an oil air outlet opening (9). The invention is characterized in that the air inlet opening (1) is arranged at the upper part of the reaction tube (4), the top of the reaction tube (4) is provided with an adjustable sealing element (3), a stainless steel rod (5) is arranged in the reaction tube (4), the top end of the stainless steel rod (5) is connected with the adjustable sealing element (3), the lower end of the stainless steel rod (5) is connected with a sample hanging basket (7), the middle lower part of the reaction tube (4) is positioned inside the tubular electric heating furnace (6), the bottom of the reaction tube (4) is provided with the temperature test and control opening (8) and the conical oil air outlet opening (9), the conical oil air outlet opening (9) is connected with an oil air outlet tube (12), and the tubular electric heating furnace (6) is positioned on the object carrying frame (11). The invention has the advantages of high performance price ratio, simple and convenient operation, simple structure and low equipment cost, can realize slow temperature rise and fast pyrolysis under the condition of simulated work conditions, can realize fast cooling, and can accurately measure the tar amount generated by the pyrolysis.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

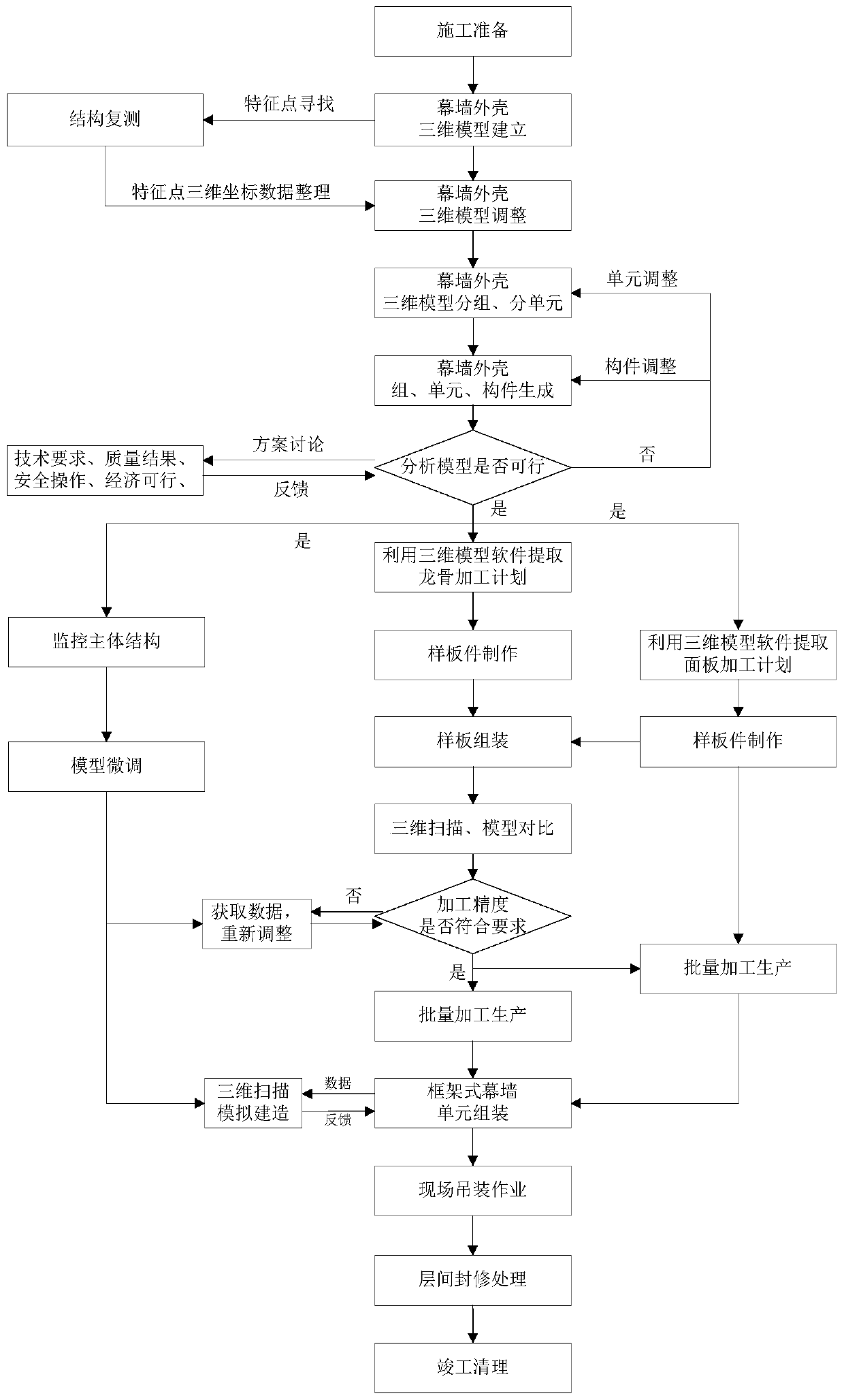

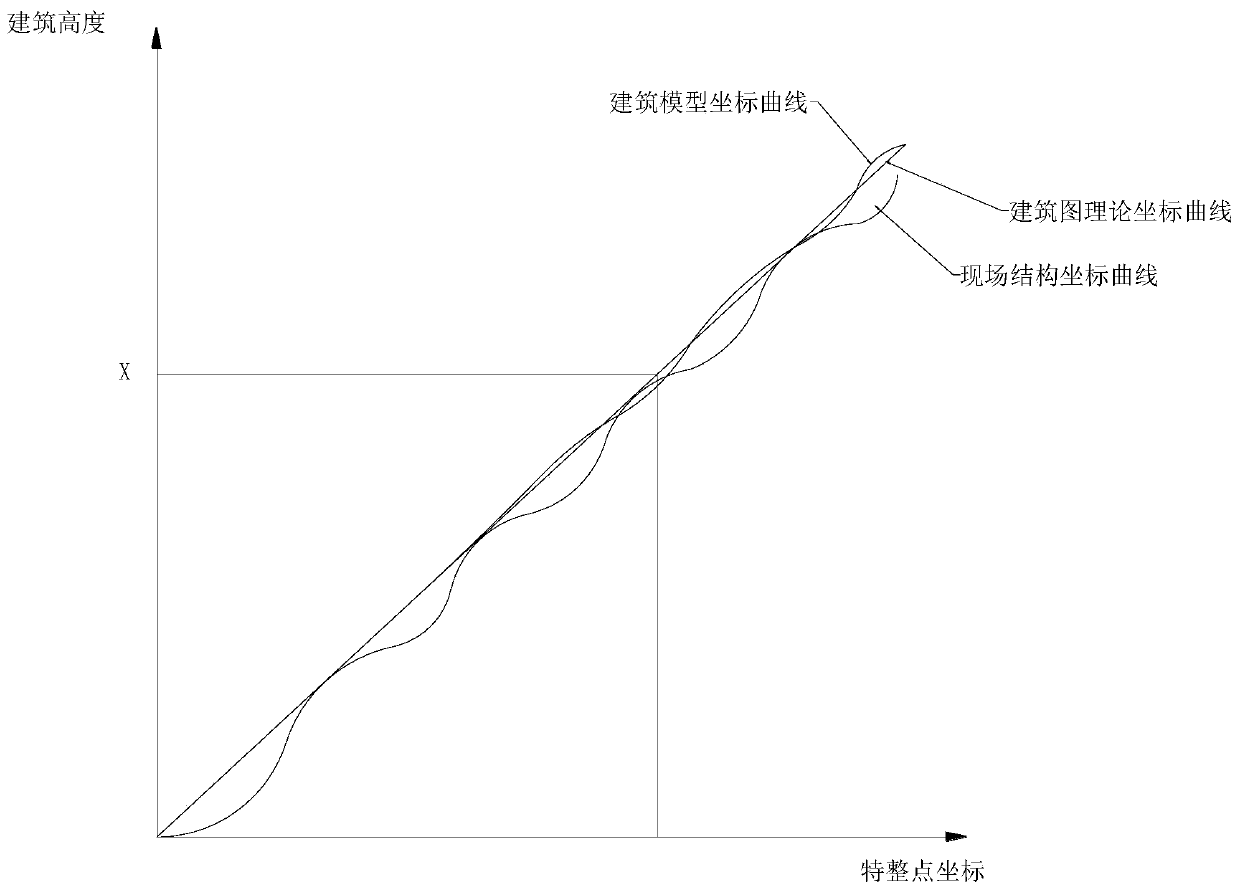

Frame-type curtain wall rapid assembly construction method and system based on BIM

InactiveCN110056106AFast and accurate generationSingle construction workWallsBuilding material handlingThree dimensional measurementHanging basket

The invention discloses a frame-type curtain wall rapid assembly construction method and system based on a BIM, and belongs to the field of curtain wall assembly construction. The to-be-solved technical problems are how to realize rapid assembly construction of a frame-type curtain wall and ensure the installation quality and performance of the curtain wall, according to the technical scheme, theframe-type curtain wall rapid assembly construction method includes the steps that three-dimensional model creation and adjustment of a curtain wall shell, curtain wall unit division, material component splitting and ordering are conducted through a BIM technology and a three-dimensional measurement technology, unit bodies of the frame-type curtain wall are assembled through centralized industrialprocessing, the processing quality of the frame-type curtain wall units is controlled by manufacturing standard parts, standard samples and using a three-dimensional scanning technology, site quick assembly construction of the frame-type curtain wall is completed through an integral hoisting technology, then treatment between layers is completed through a construction hanging basket or an elevating operating vehicle, and finally, rapid assembly construction operation of the frame-type curtain wall is realized. The invention further discloses the frame-type curtain wall rapid assembly construction system based on the BIM.

Owner:CHINA CONSTR EIGHTH ENG DIV

Intelligent express delivery distribution vehicle and use method thereof

ActiveCN105539248AGuaranteed tidyEasy loadingLoad securingItem transportation vehiclesButt jointHanging basket

The invention relates to an intelligent express delivery distribution vehicle which comprises a carriage (1), a goods cabinet, a bottom moving mechanism and a hanging basket moving mechanism (12). The carriage (1) is of a hollow cuboid structure. The bottom moving mechanism is arranged on the bottom face of the inner side of the carriage (1). The goods cabinet is installed on the bottom moving mechanism in a matched manner. A hanging basket stop region (23) is arranged in the portion, on one side of the goods cabinet, of the carriage (1). The hanging basket moving mechanism (12) is installed above the hanging basket stop region (23). A ferry vehicle butt-joint module (16) is further arranged at the bottom of the carriage (1). The bottom moving mechanism comprises a load bearing sliding rail (4), a linear motor (8), transverse moving sliding blocks (9), transverse moving guide rails (10) and a bottom frame (11). The goods cabinet comprises drawer frames, multiple storage drawers (2) and magnetic seats (13) and load bearing idler wheels (5) are installed at the bottoms of the drawer frames. The intelligent express delivery distribution vehicle has the beneficial effects that the intelligence degree is high, loading is convenient, the distribution process is simple, and time and labor are saved.

Owner:SOUTHWEST PETROLEUM UNIV

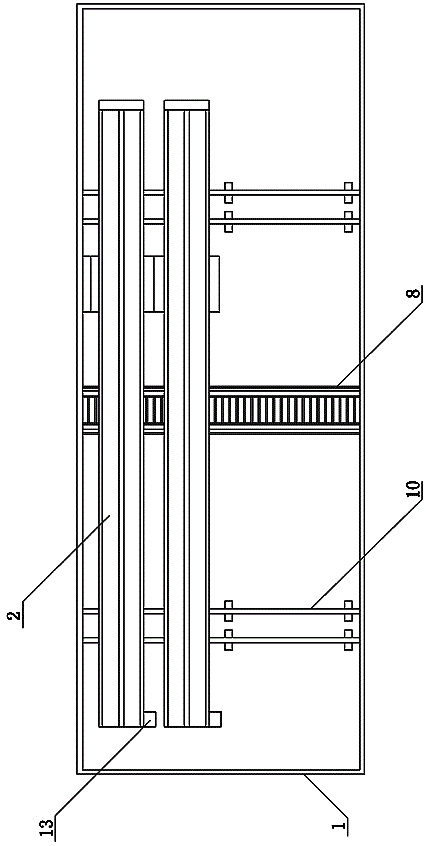

Thermal gravimetrical reactor applied to bulk specimen testing

The invention discloses a thermal gravimetrical reactor applied to bulk specimen testing, belonging to testing equipment for performing thermo gravimetric analysis on specimens and aiming to solve the problems that small-mass and small-sized specimens are required and a sample vessel is unbeneficial to gas-solid reactions in the conventional thermo gravimetric analyzer. Through a high-temperature reactor, reaction gas is preheated fully, so that mass measuring errors caused by temperature change of the reaction atmosphere are avoided; two types of hanging baskets are specific to different specimens respectively, so that the diffusion resistance during the reactions of bulk specimens is reduced effectively, and complete reactions and measuring accuracy are ensured; the height of an electric heating furnace is adjusted through a hydraulic lifting platform, so that samples can be heated at constant temperature under a high-accuracy condition. The thermal gravimetrical reactor can be used for dynamically measuring the mass changes of bulk specimens at various heating rates or under a constant-temperature condition, and is more consistent with the requirements of scientific research production than the conventional thermal gravimetrical analyzer.

Owner:HUAZHONG UNIV OF SCI & TECH

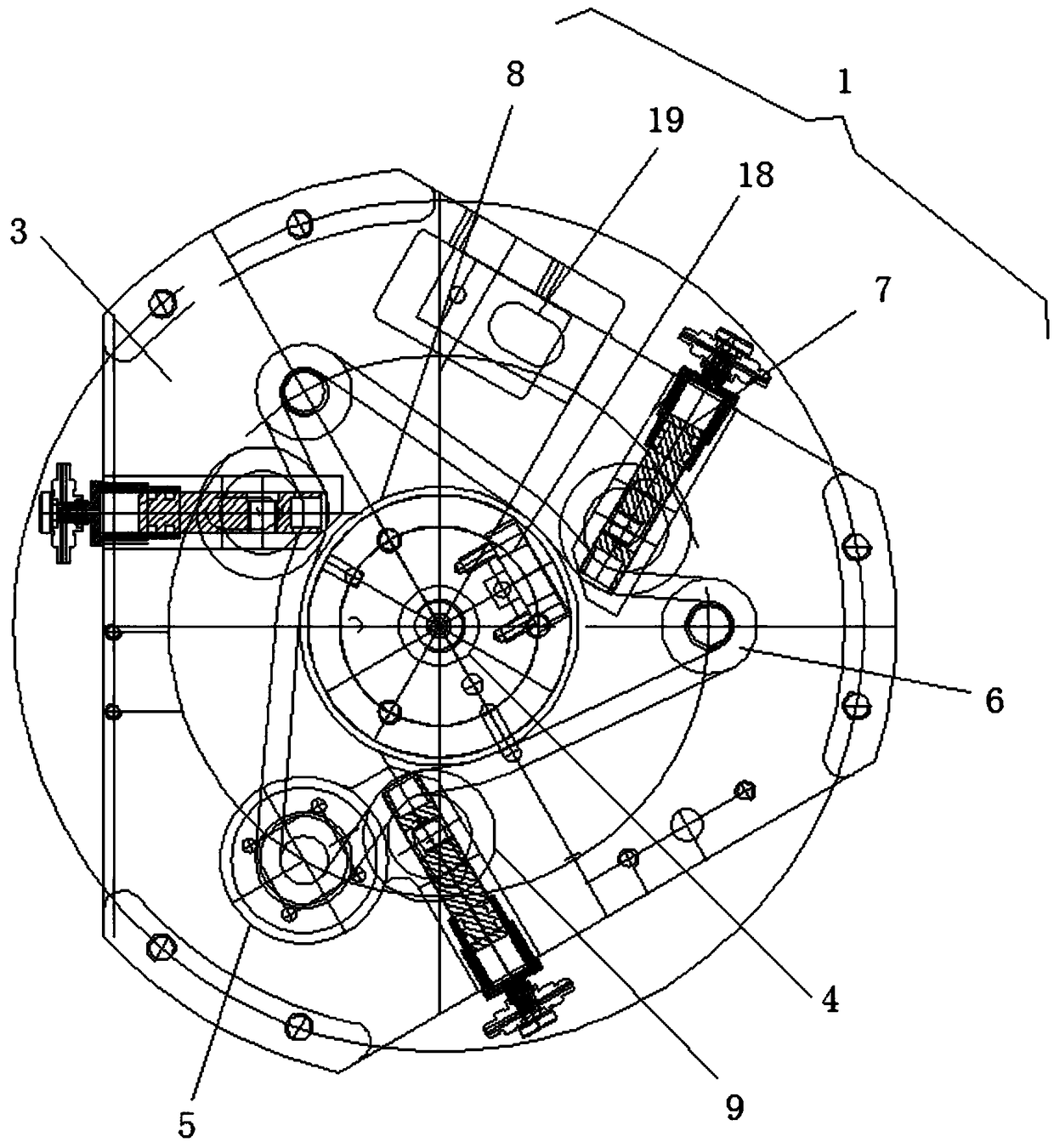

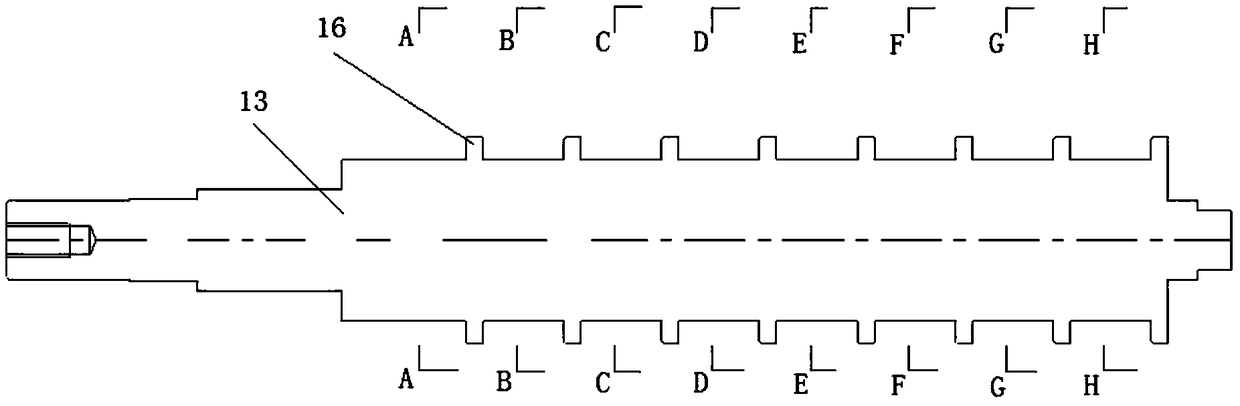

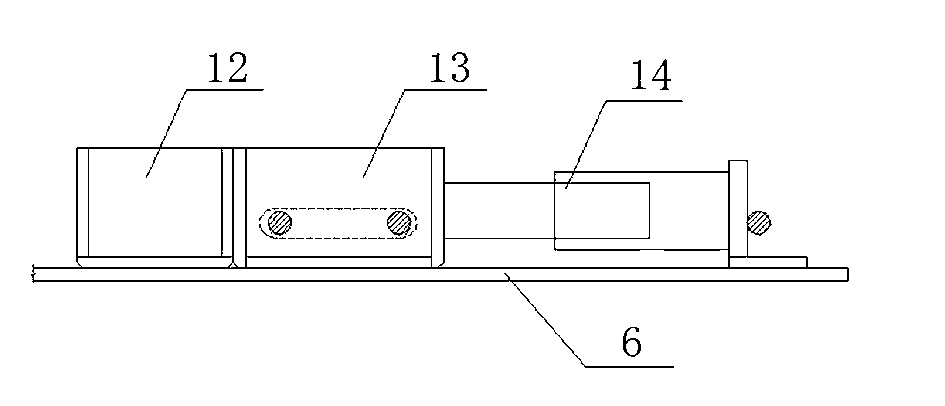

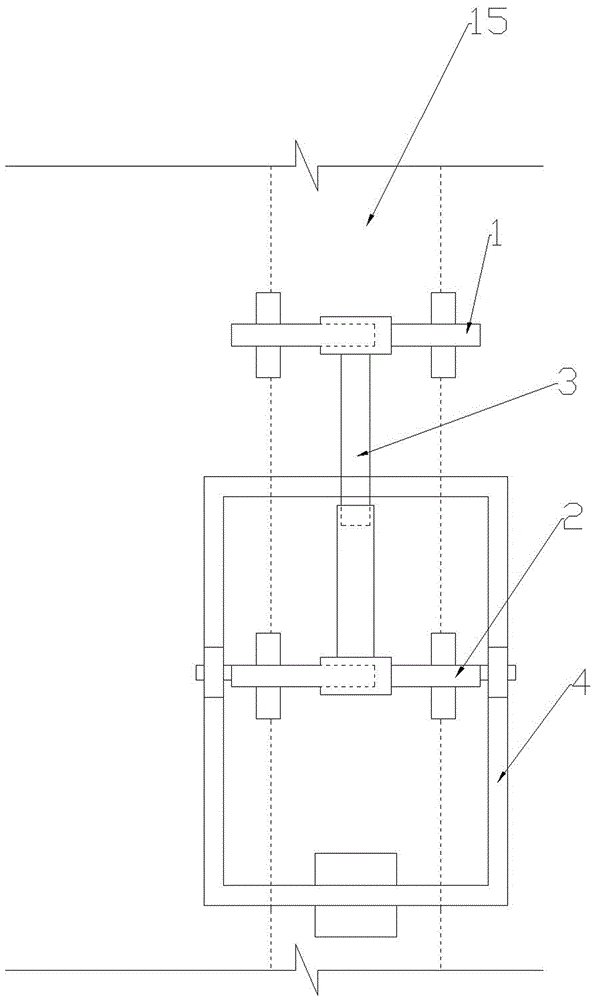

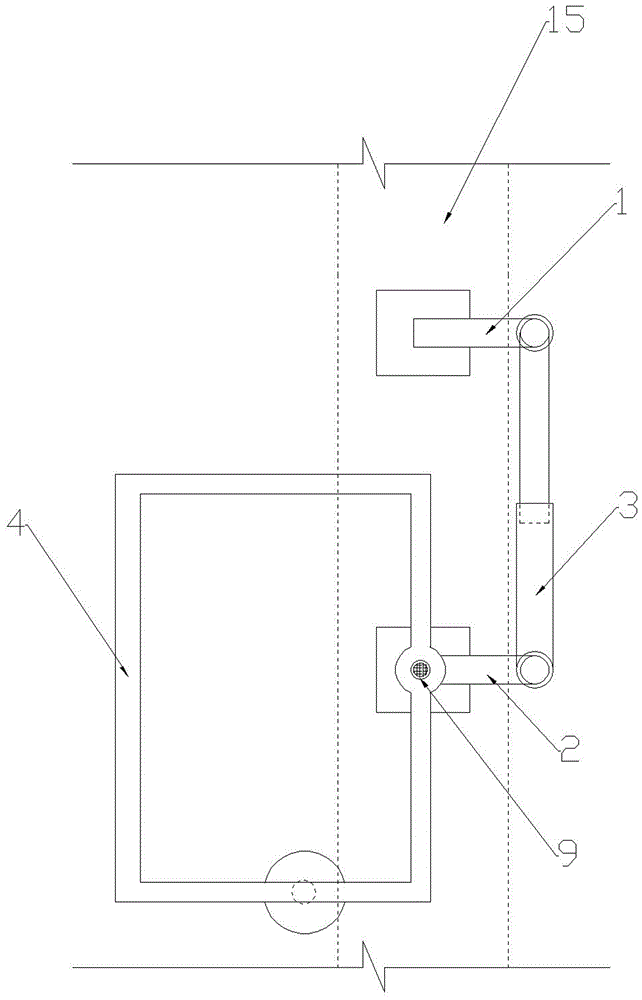

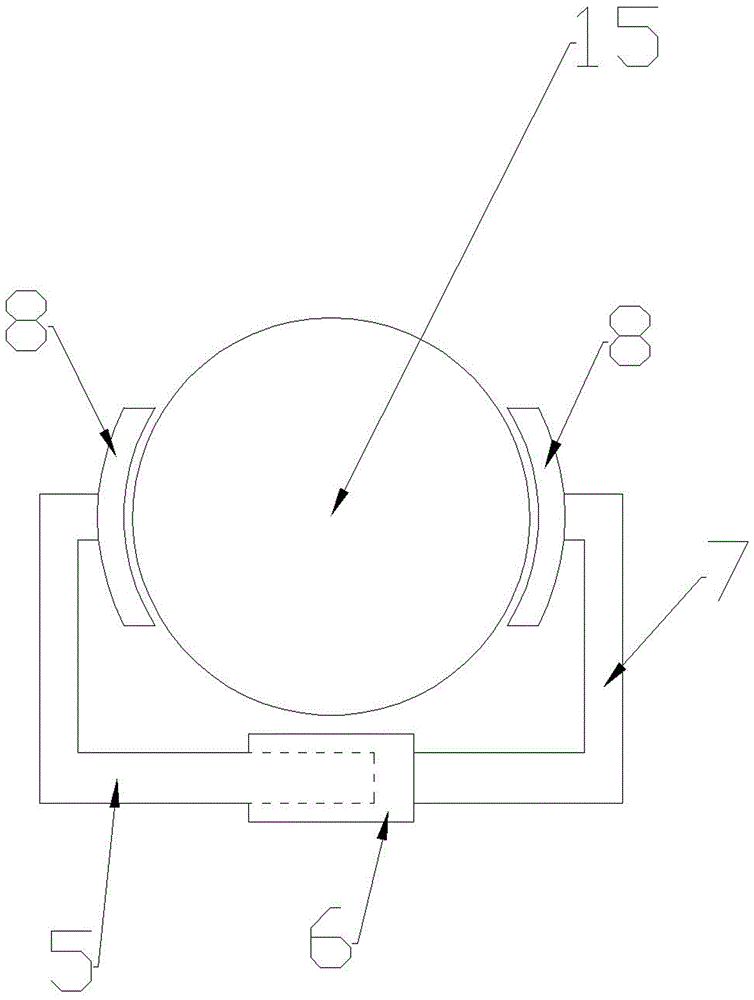

Full-automatic piston type pressure gauge

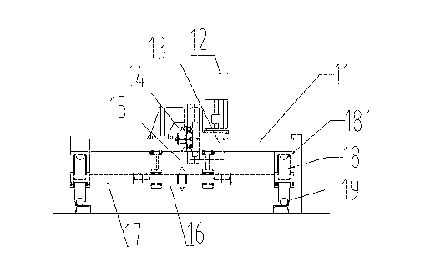

InactiveCN108801533ARealize automatic workHigh precisionFluid pressure measurement using pistonsHanging basketSelection system

The invention discloses a full-automatic piston type pressure meter which comprises a piston rotating system (1) and a weight selection system (2), wherein the piston rotating system is located on atthe bottom of the weight selection system (2); an upper cover shell (10) is arranged at the top of the weight selection system (2); the piston rotating system (1) comprises a base (3), a central shaft(4), a first stepping motor (5), a belt wheel (6) and a tensioning piston (7), wherein the weight selection system (2) comprises an upper cover shell (10), a hanging basket (11), a second stepping motor (12) and a plurality of guide columns (13). The automatic work of the measuring device is achieved through cooperation of electrical components, the error of manual operation is avoided, and the detection efficiency and accuracy are improved.

Owner:上海敏榆实业有限公司

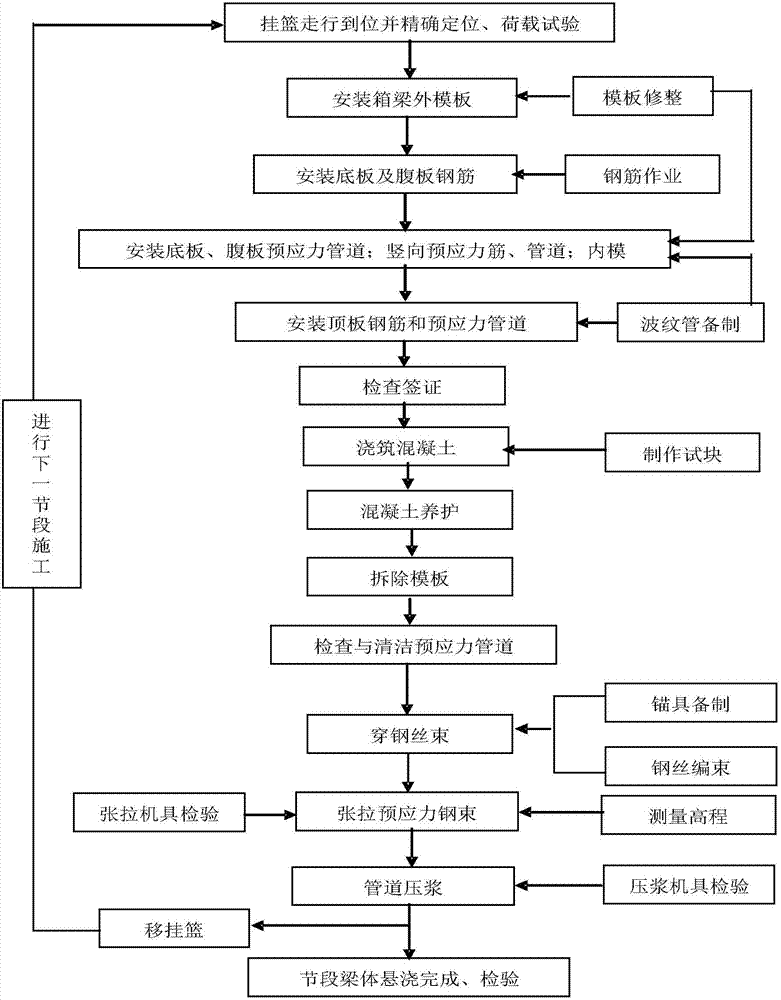

Open web type continuous steel bridge structure and buckling, hanging and pouring method of cantilever

InactiveCN101619562AImprove leaping abilityImprove structural load-bearing efficiencyBridge structural detailsBridge erection/assemblyFull bridgeHanging basket

The invention discloses an open web type continuous steel bridge structure and a buckling, hanging and pouring method of a cantilever. The method comprises the following steps: (1) hollowing a web plate of a root area so as to ensure that a beam body of the root area is separated into an upper chord and a lower chord, and taking a main span diameter as the length of the root web plate; (2) taking the main span diameter as the total height of the root; (3) selecting the height of a solid-web beam, taking the height of a joining point of the upper chord and the lower chord as the length of the solid-web beam and taking the main span diameter as the height of a middle span; (4) taking the length of a hollowing area as the height of the upper chord beam; (5) taking the length of the main span diameter as the height of the lower chord beam, and changing the lower edge of the lower chord and the lower edge of the solid-web beam according to a continuous curve; (6) arranging a hanging basket on the lower chord section of the symmetrical construction in the buckling, hanging and pouring method of the cantilever of the upper chord; and (7) carrying out constructions on each section of the solid-web beam by the cantilever and joining the sections to finish the construction of the whole bridge. The invention has simple method, convenient construction, safety, simple structure, stability and reliability and improves the spanning capacity and the engineering economy of the bridge.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

Beret truss type hanging basket and assembling method thereof

InactiveCN101148861ASpeed up preparationReduce manufacturing costBridge erection/assemblyEngineeringHanging basket

Owner:HONGRUN CONSTR GROUP STOCK

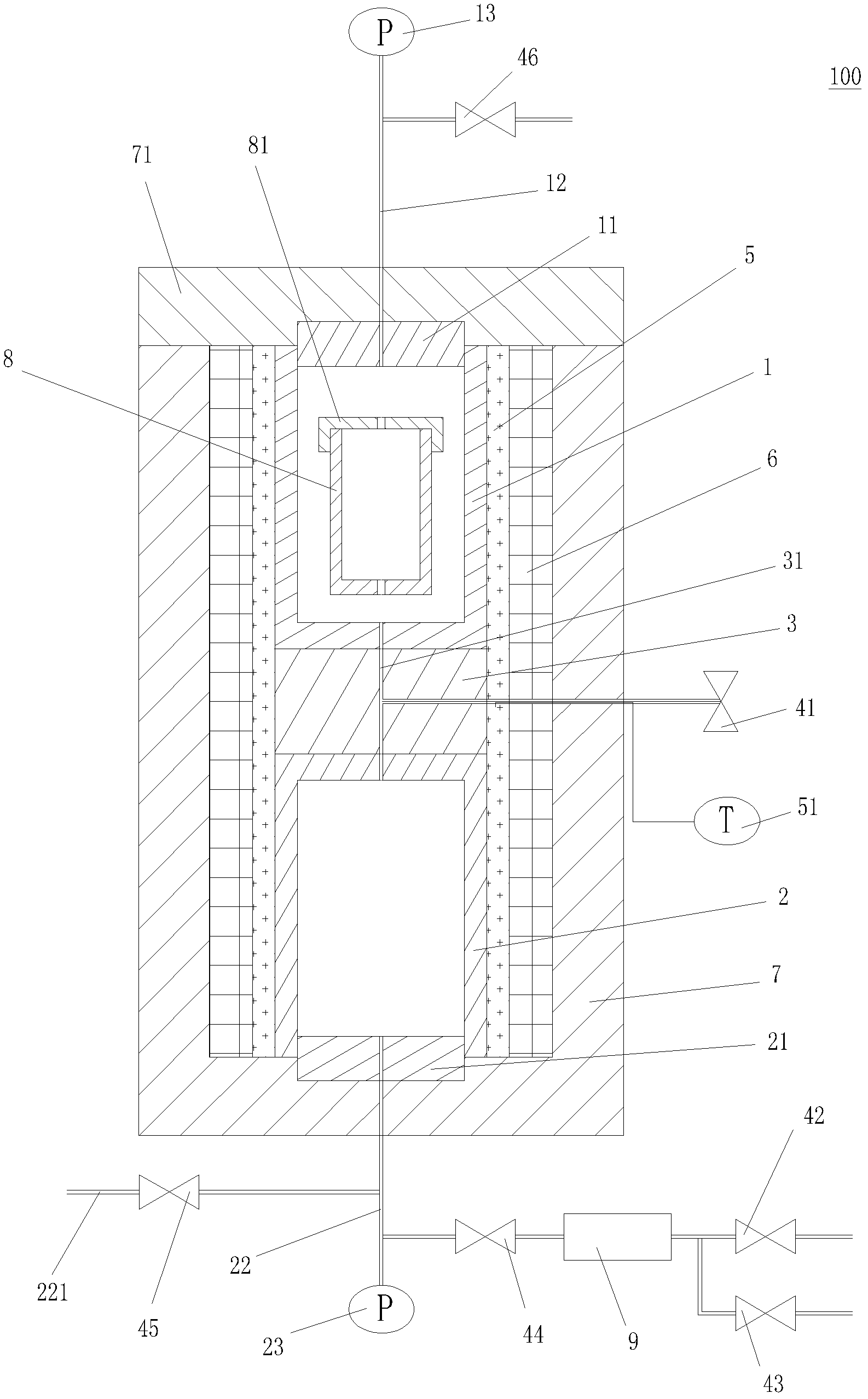

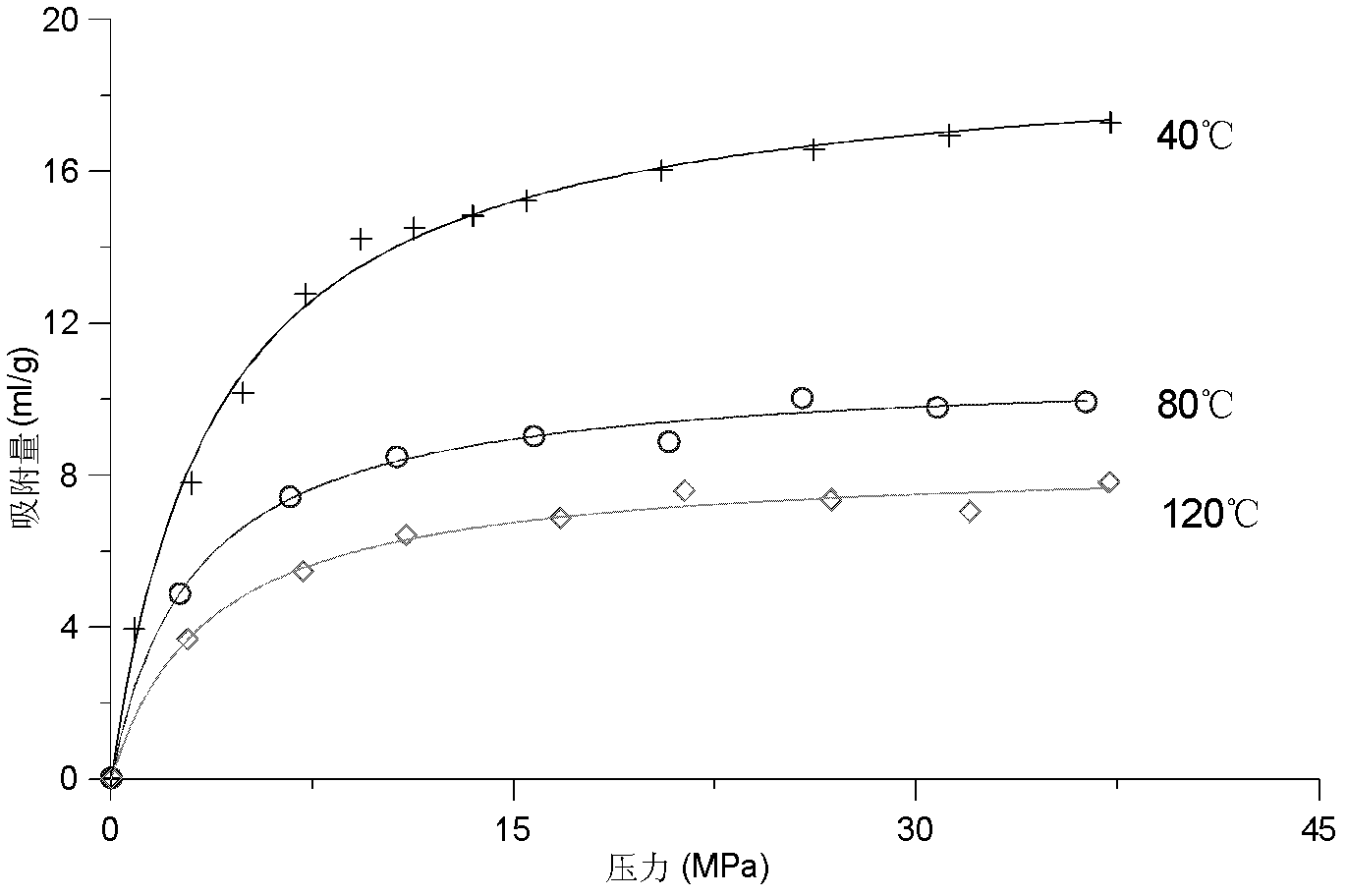

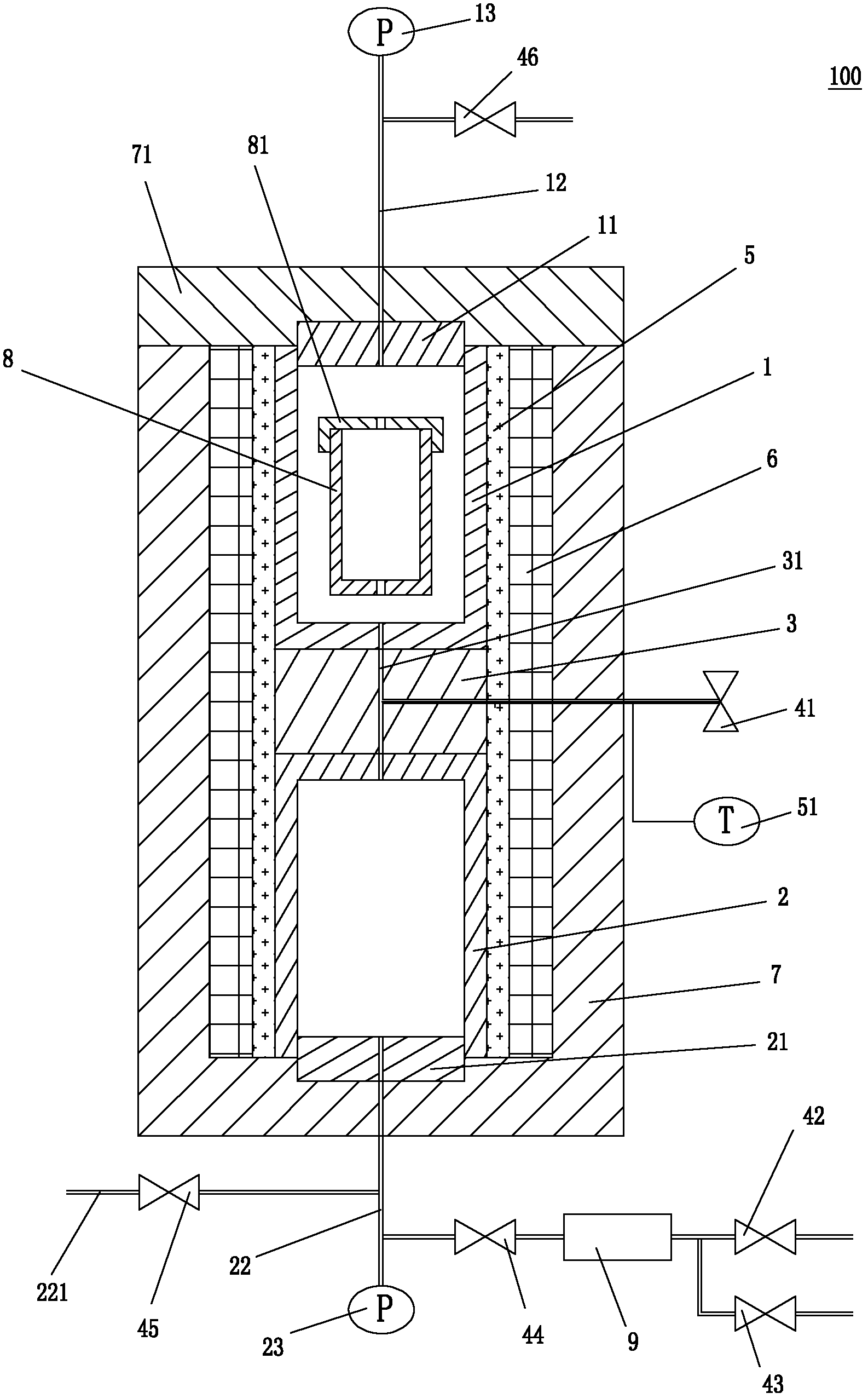

Coal/shale adsorption capacity measuring device

ActiveCN102607991AUniform temperatureEvenly distributedPermeability/surface area analysisTest sampleEngineering

The invention relates to a coal / shale adsorption capacity measuring device, which comprises an adsorption cylinder and a reference cylinder, wherein cylinder bottoms of the two cylinders are respectively fixed on the top surface and the bottom surface of a cylindrical steel block; the adsorption cylinder and the reference cylinder are communicated through a communicating pipe which penetrates through the two cylinder bottoms and the cylindrical steel block; a first control valve is arranged on the communicating pipe; outer side walls of the adsorption cylinder, the reference cylinder and the cylindrical steel block are provided with heating jackets, and heat insulation jackets are arranged at outer sides of the heating jackets; all the combined members, namely the adsorption cylinder, the reference cylinder, the cylindrical steel block, the heating jackets and the heat insulation jackets, are placed in a vacuum heat insulation tank; a sample hanging basket which is filled with a test sample is arranged in the adsorption cylinder; the adsorption cylinder is provided with an exhaust pipe and a first pressure sensor; and the reference cylinder is provided with an air inlet pipe and a second pressure sensor, wherein the air inlet pipe is connected to one end of a gas boosting pump, and the other end of the gas boosting pump is communicated with experiment gas and helium through a second control valve and a third control valve which are communicated in parallel. The coal / shale adsorption capacity measuring device can be used for simulating the process of adsorbing natural gas by coal / shale under actual geological conditions and evaluating the adsorption capacity of the coal / shale.

Owner:PETROCHINA CO LTD

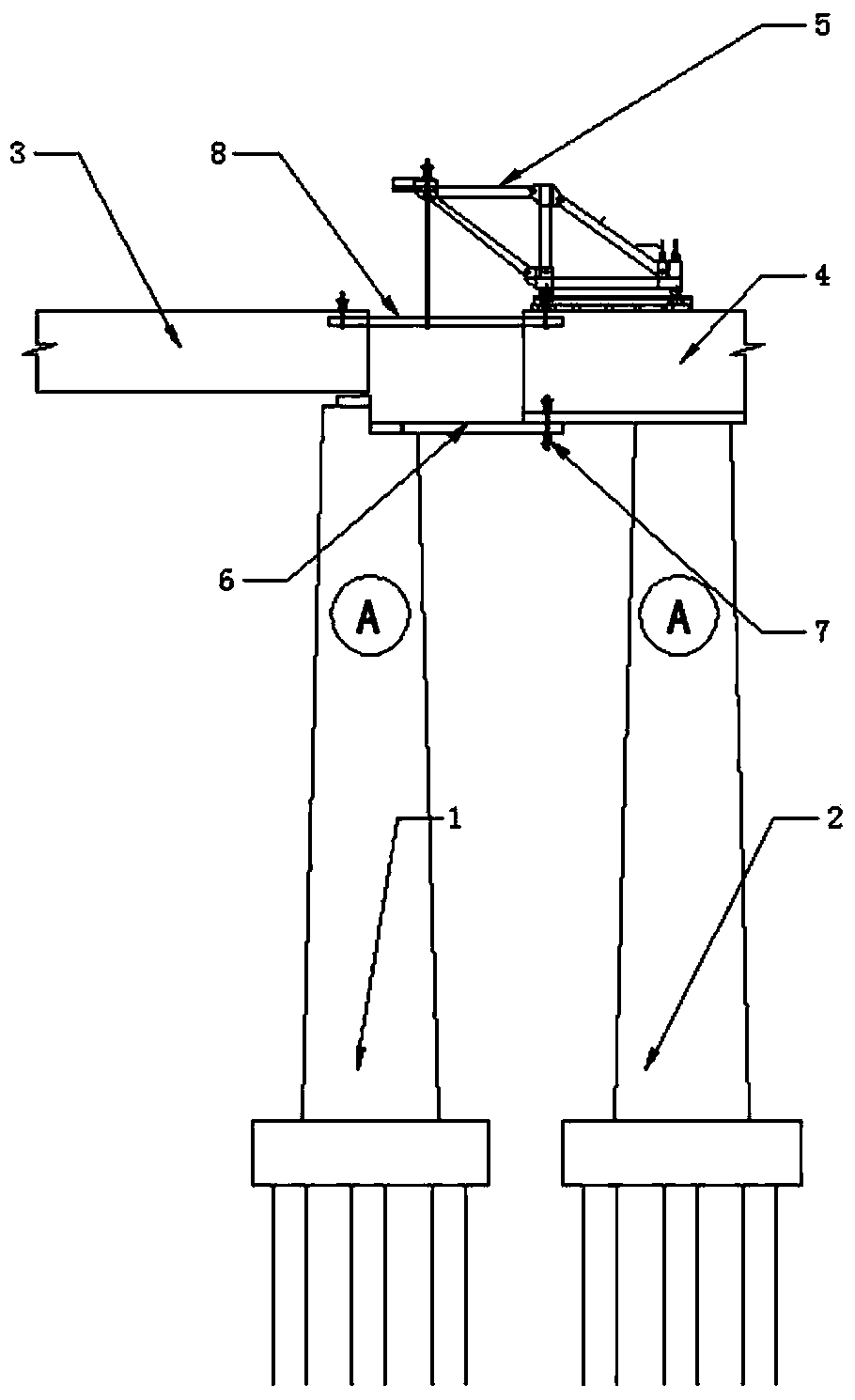

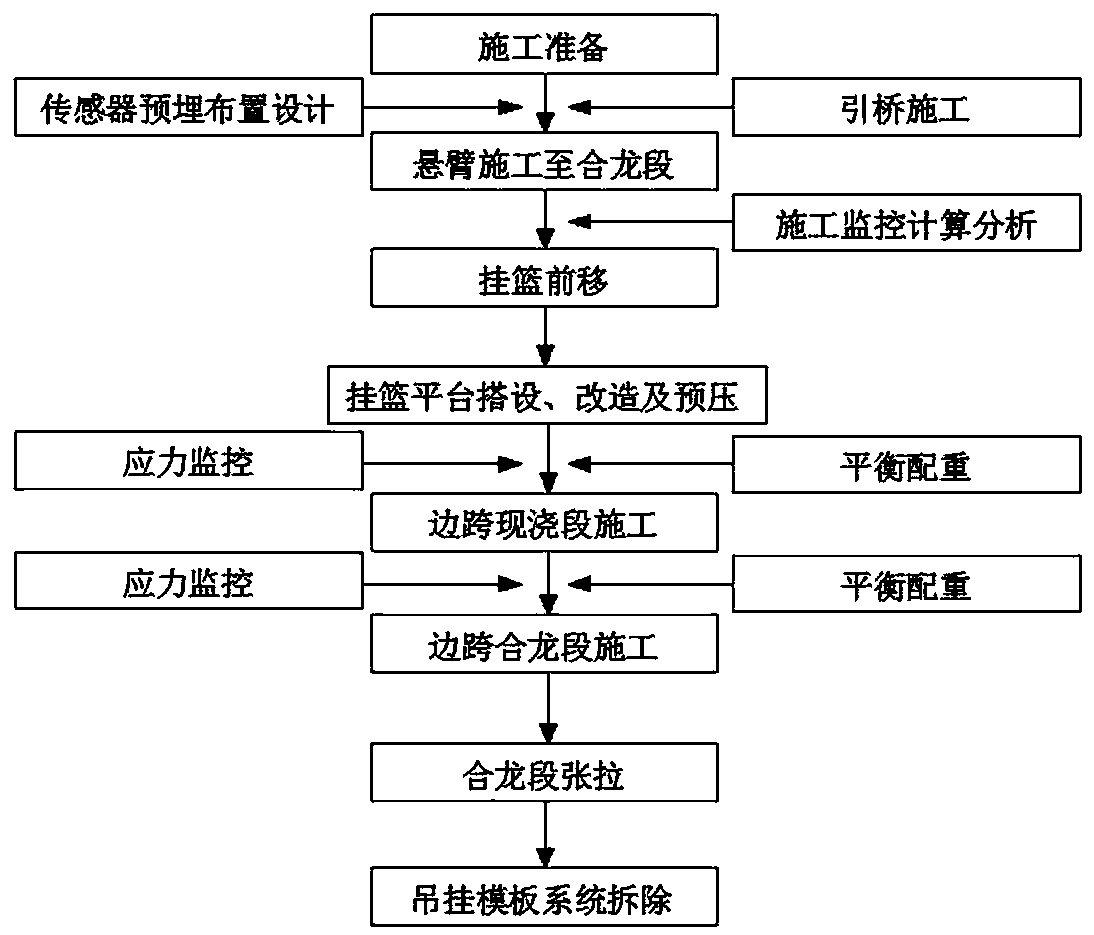

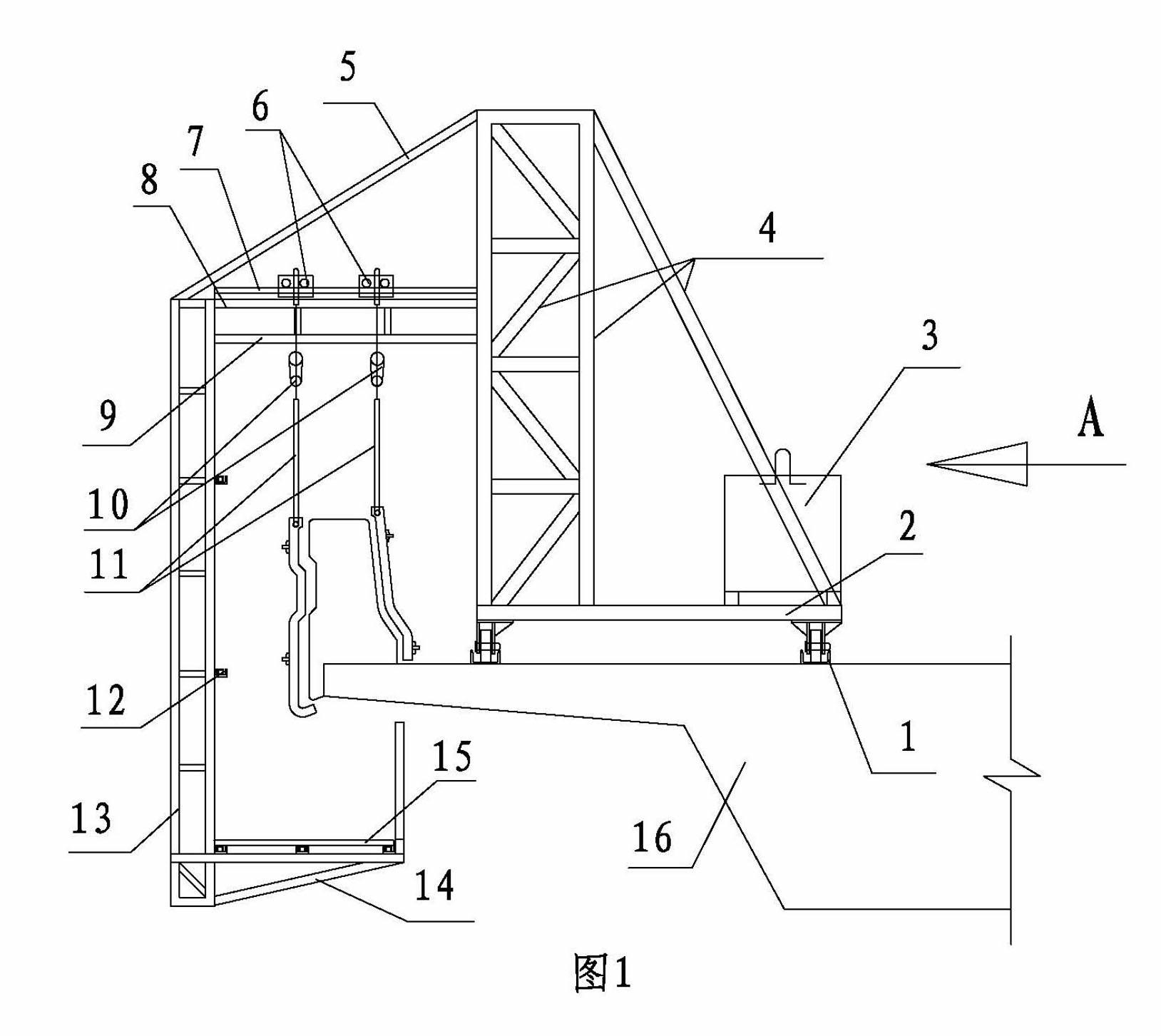

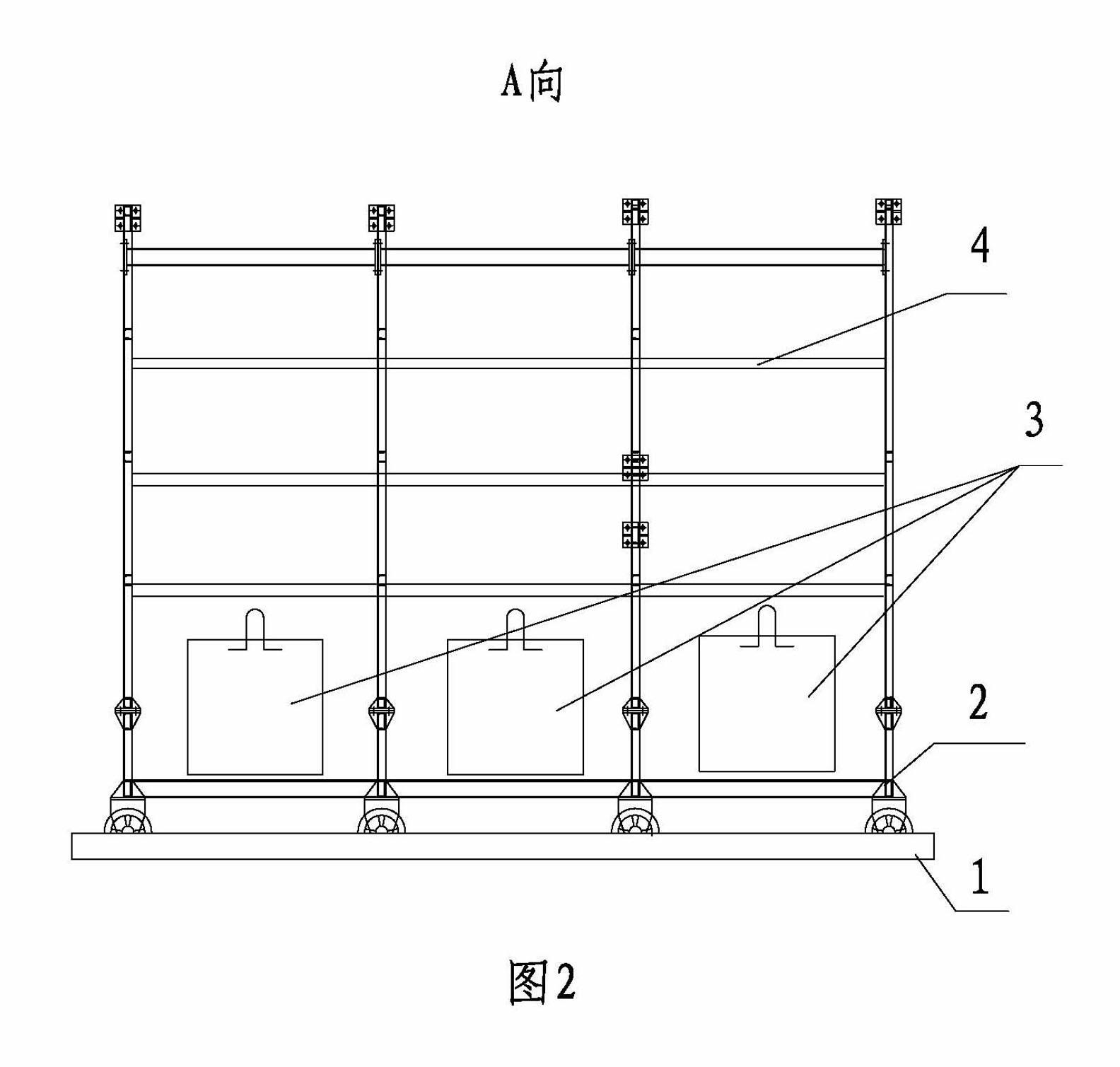

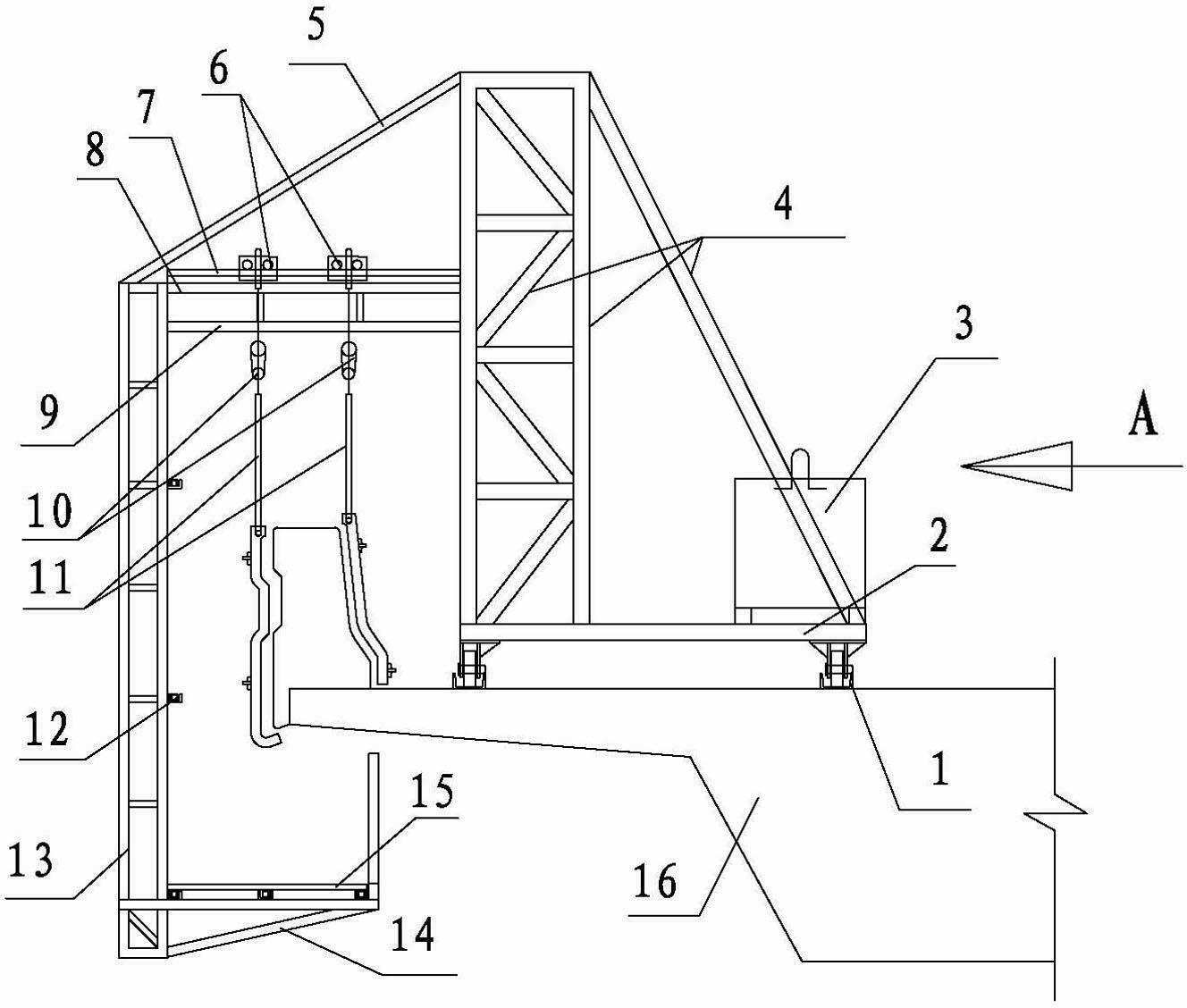

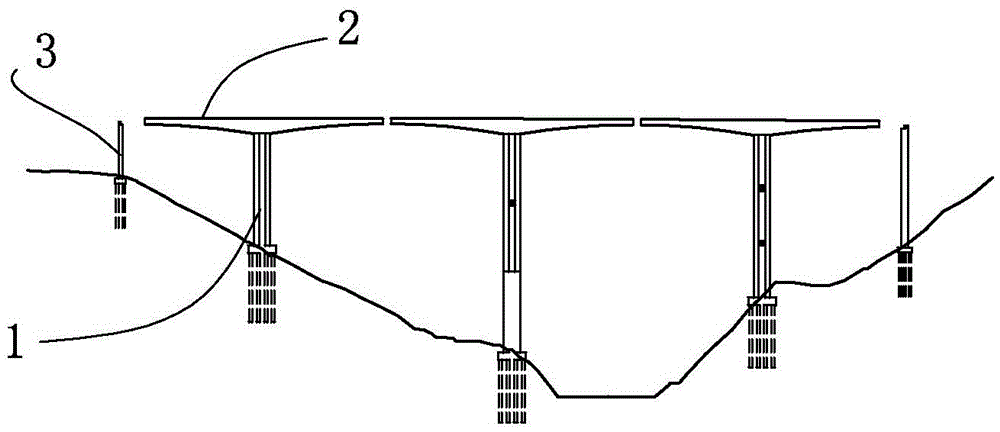

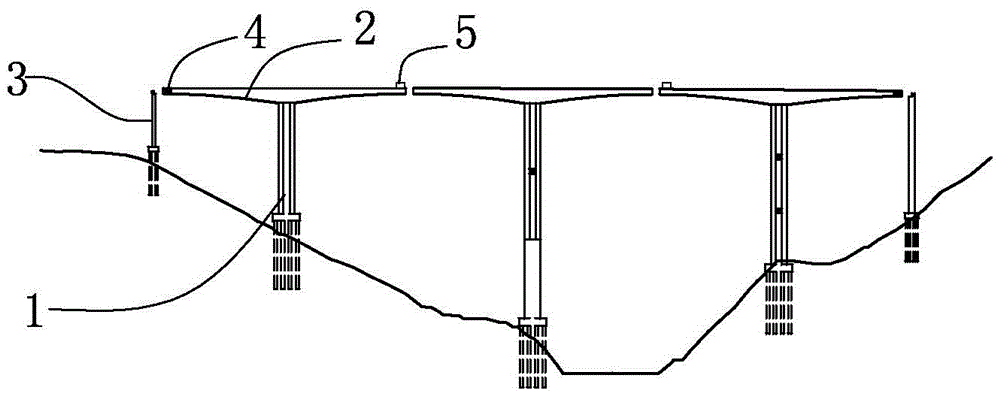

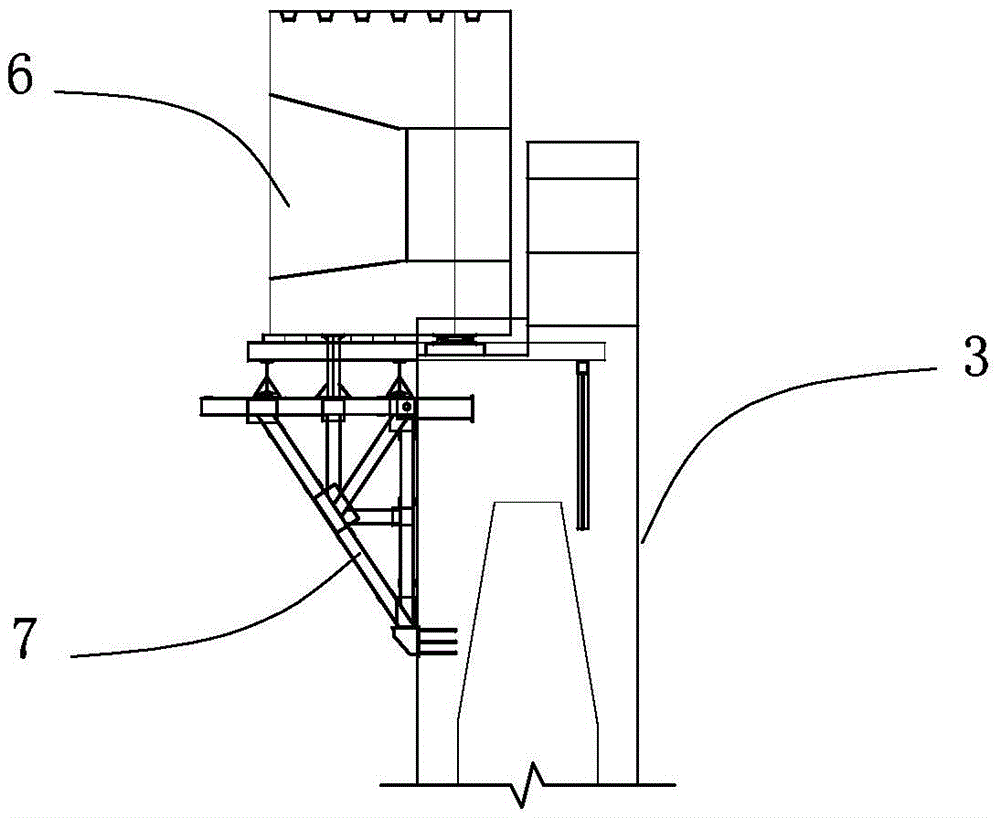

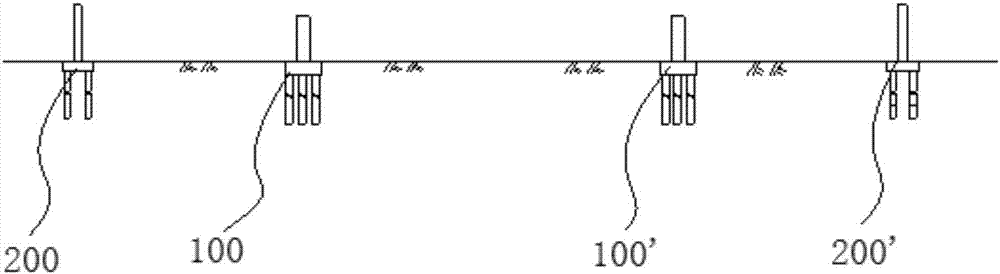

High pier continuous beam side span cast-in-place section and closed section integrated construction system and construction method

PendingCN109944170ASolve the erection problemAvoid constructionBridge erection/assemblyContinuous beamHanging basket

The invention relates to the technical field of building construction, in particular to a high pier continuous beam side span cast-in-place section and closure section integrated construction system and construction method, the construction method comprises the following steps of: construction preparation; construction monitoring calculation analysis; cantilever construction to the closure sectionand bridge approach construction; basket forward movement and basket platform reconstruction; pre-pressing; side span cast-in-place section construction; side span cast-in-place section construction;side span closure section construction; side span closure section tensioning; and lifting platform system dismantling. Compared with a prior method, the method effectively solves the problem of highpier support erection, avoids a large number of support erection construction, adopts the stress of the hanging system of the hanging basket, has simple construction technology, reduces the use amountof materials, reduces the use of large-scale hoisting equipment, has the obvious advantages of cost saving, construction period saving, better technical economy and the like aiming at the work of possibly prior support treatment and the like, avoids the prior construction support erection, avoids the work of a large number of basic treatment and the like, and has obvious construction period saving.

Owner:CHONGQING CONSTR ENG MUNICIPAL TRAFFIC ENG +1

Upper air anti-collision guardrail module transfer hanging bracket and construction method

InactiveCN102493346AQuality improvementFast constructionBridge erection/assemblyArchitectural engineeringBridge deck

Provided are an upper air anti-collision guardrail module transfer hanging bracket and a construction method. The module transfer hanging bracket comprises a sliding rail on a viaduct bridge and a walking car provided with a plurality of counter weights and inner trusses. The plurality of inner girders are longitudinally connected through connecting rods, and each inner girder is connected with an outer girder with a guard railing through an oblique beam, an upper beam and a lower beam. The outer girder is suspended outside a bridge floor, the lower portion of the outer girder is connected with a horizontal frame, and a slide on the upper beam is slidingly connected two slide bodies connected with electric blocks and steel moulding plate hooks. The plurality of outer girders and horizontal frames are connected through footboards to form an anti-collision guardrail module transfer hanging basket which can enable ten (or more than ten) persons to conduct steel moulding plate concrete pouring operation simultaneously, and movement of a steel moulding plate saves time and is convenient and short in time. An operating platform is reasonable in structure, firm and stable, and workers are safe in working high above the ground. The upper air anti-collision guardrail module transfer hanging bracket is connected through bolts, is convenient in assembly and capable of using in a turnover mode, needs to occupy no roads by adopting the upper air anti-collision guardrail module transfer hanging bracket and the construction method, does not influence passing of vehicles under bridges, and has obvious economic benefits.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

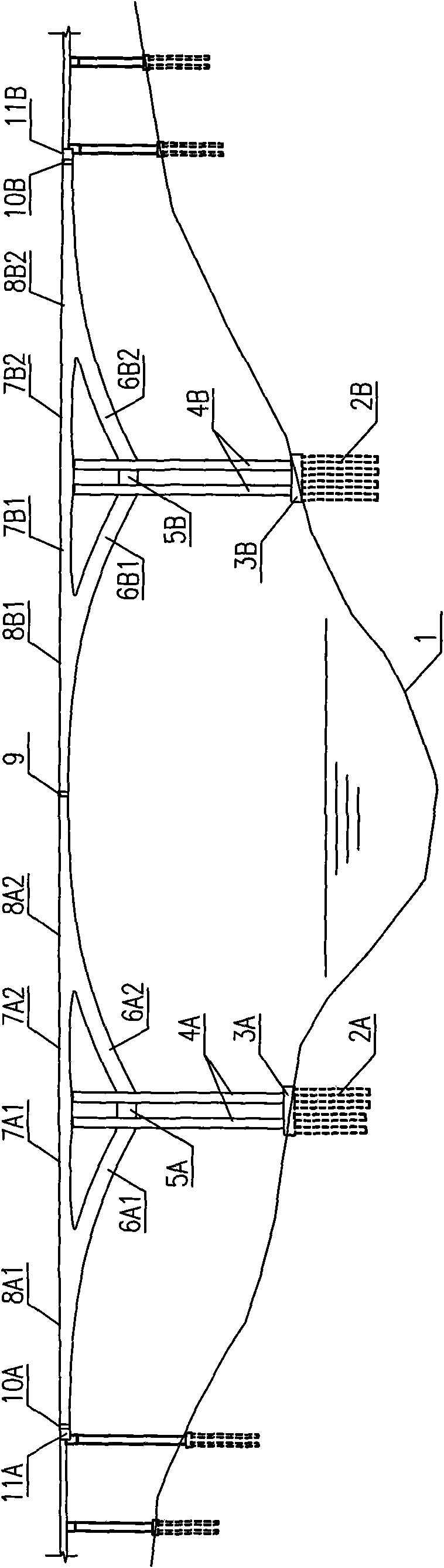

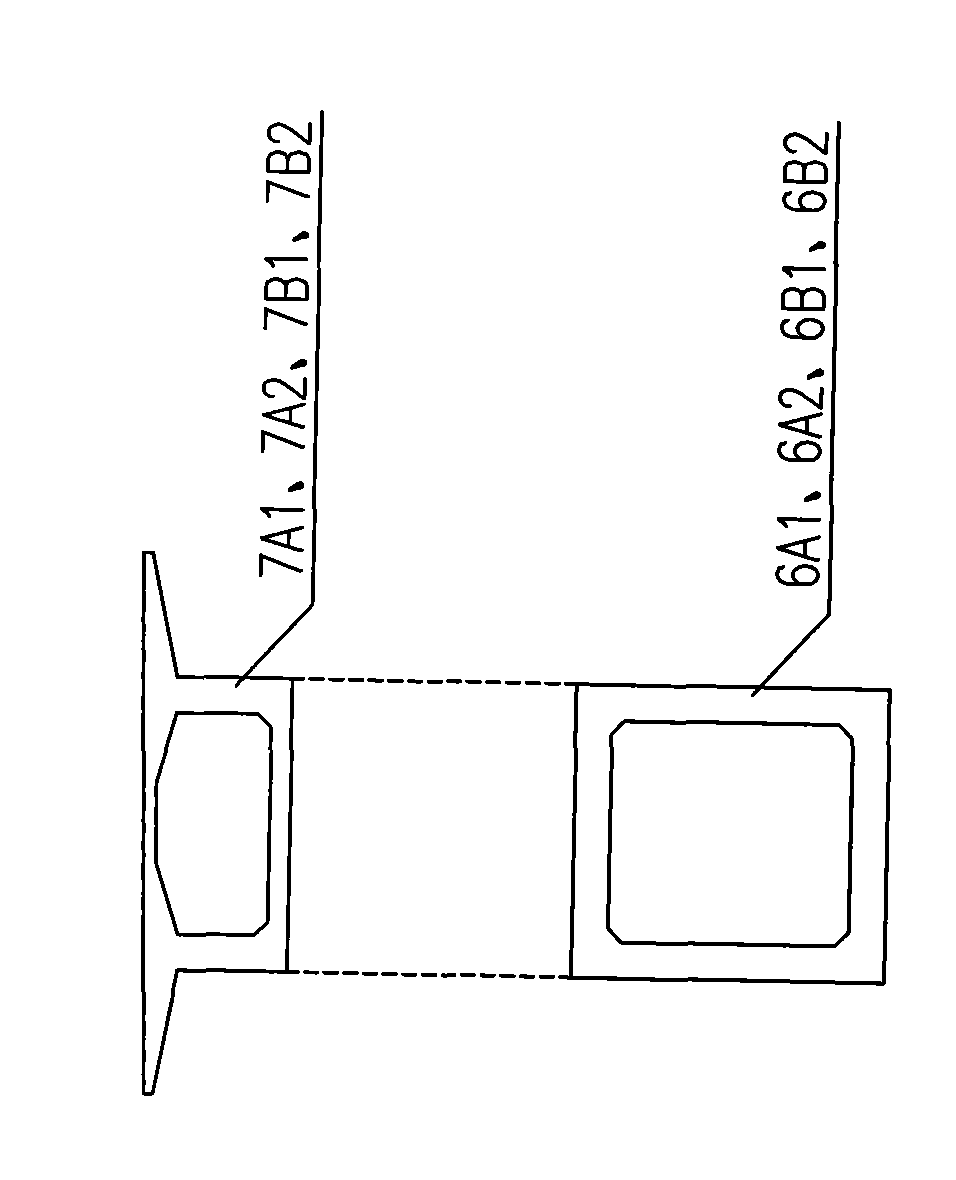

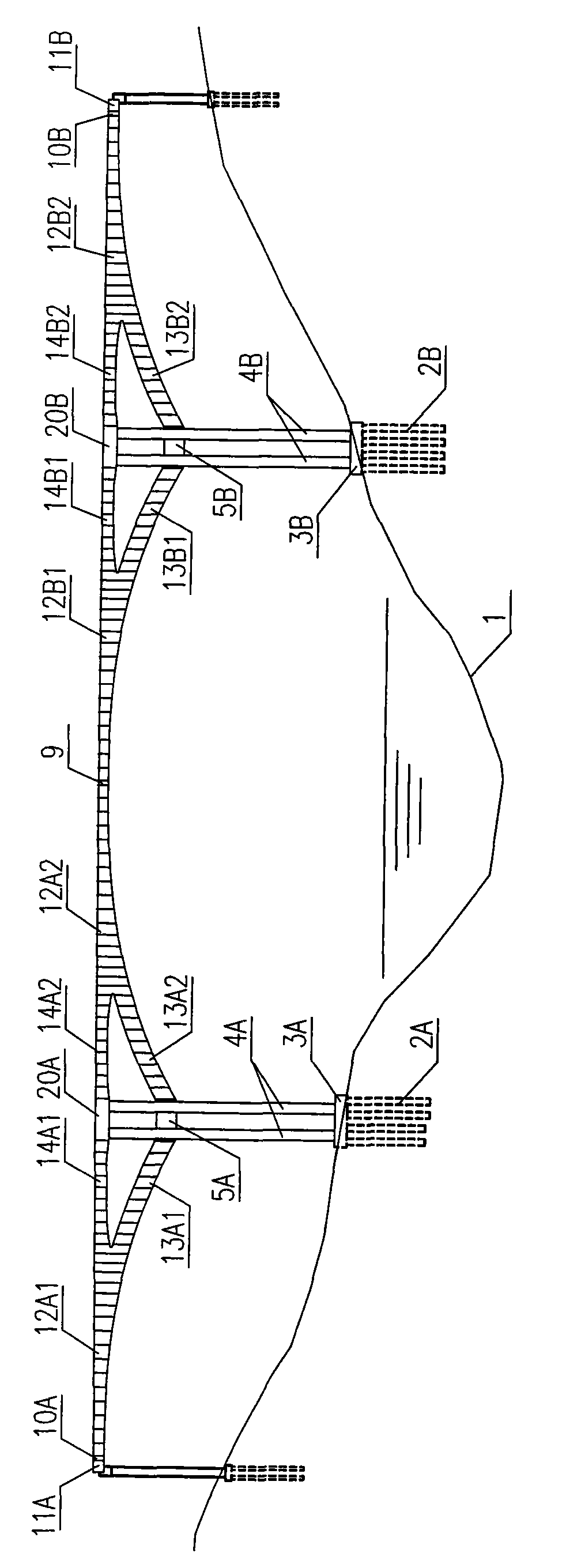

Asymmetrical casting construction method of side span of rigid frame bridge with extra high piers and long span length

InactiveCN105484158AIncrease the lengthShorten the lengthBridge erection/assemblyHanging basketEngineering

The invention provides an asymmetrical casting construction method of a side span of a rigid frame bridge with extra high piers and a long span length. The asymmetrical casting construction method comprises the following steps that after each T-shaped structure of each main pier is symmetrically cast to have largest cantilevered ends in a suspended manner, a hanging basket on one side of the side span of each main pier is continuously moved forward, and an asymmetrical suspended casting segment is cast on the side of the side span in a suspended manner; when the asymmetrical suspended casting segments are constructed, cantilever brackets for 0# block construction of transition piers are directly adopted as side span cast-in-place brackets for constructing side span cast-in-place segments; after the casting of the side span cast-in-place segments is completed, the hanging baskets for constructing the asymmetrical suspended casting segments are put down and moved forward, front cross beams of bottom baskets of the hanging baskets are placed on the side span cast-in-place brackets, rear cross beams of the bottom baskets of the hanging baskets are suspended and hung on baseplates and flange plates of tank beams to be used as side span closing hanging baskets, and the casting construction of side span closing segments is performed; after the side span closing segments meet design requirements, the side span closing hanging baskets are detached, and the side span construction is completed.

Owner:ROAD & BRIDGE INT +1

Fully-automatic piston pressure gauge

InactiveCN108020375ARealize automatic workHigh precisionRapid change measurementSolenoid valveHanging basket

Owner:赵珊珊

Mounting method of bottom width overhaul hanging basket of bridge

InactiveCN103306199APrevents deflection from deflection momentsAvoid leaningBridge structural detailsEngineeringReducer

The invention discloses a mounting method of a bottom width overhaul hanging basket of a bridge. The mounting method comprises the following steps that: a, spare parts of a travelling mechanism and rails are transported onto the bridge by a transporter, b, the spare parts of the travelling mechanism and the rails are assembled on site, c, a working platform is assembled on the ground, and d, a first platform is connected with a second platform, steel wire ropes on pulleys are put on the ground and connected with reels; the two reels are driven by a motor and a speed reducer to take up the steel wire ropes synchronously, when the first platform and the second platform are contacted with cantilevers, the take-up of the steel wire ropes is stopped, and the working platform is connected with the cantilevers. According to the method, the mounting can be relatively convenient without large hoisting equipment, all the spare parts are dismountable to facilitate recycling, the first platform and the second platform ascend and descend synchronously through a lifting mechanism, and the deflection and inclination of a working hanging basket and a lateral hanging basket platform due to a deflection torque are avoided.

Owner:CHONGQING YUNAN ELECTROMECHANICAL MFG

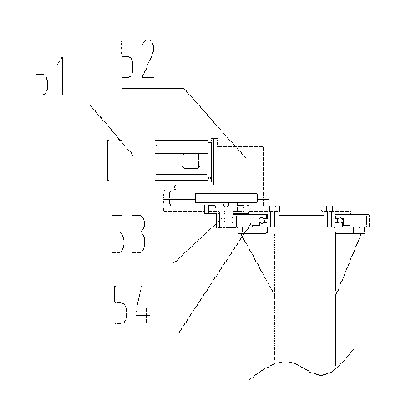

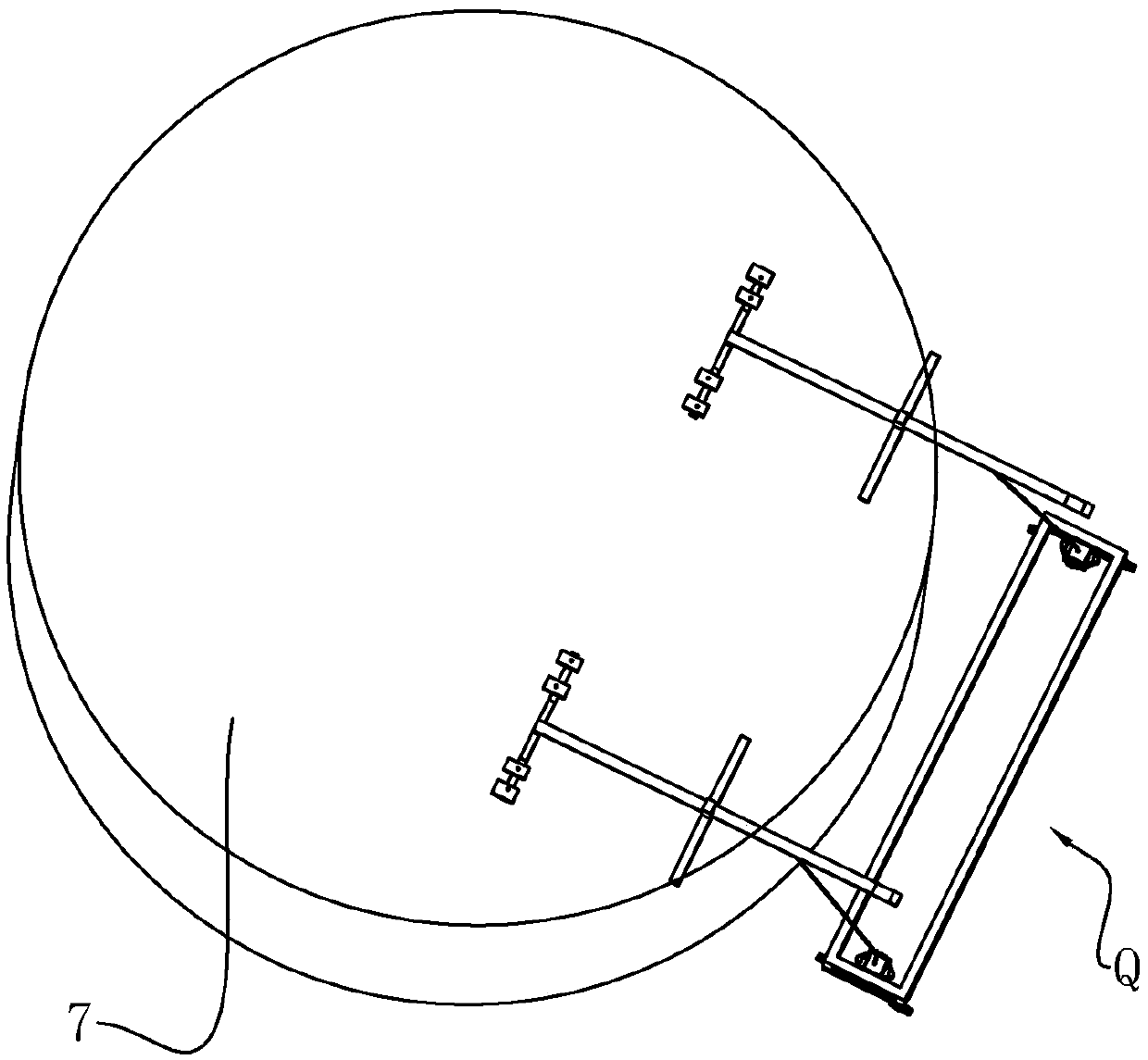

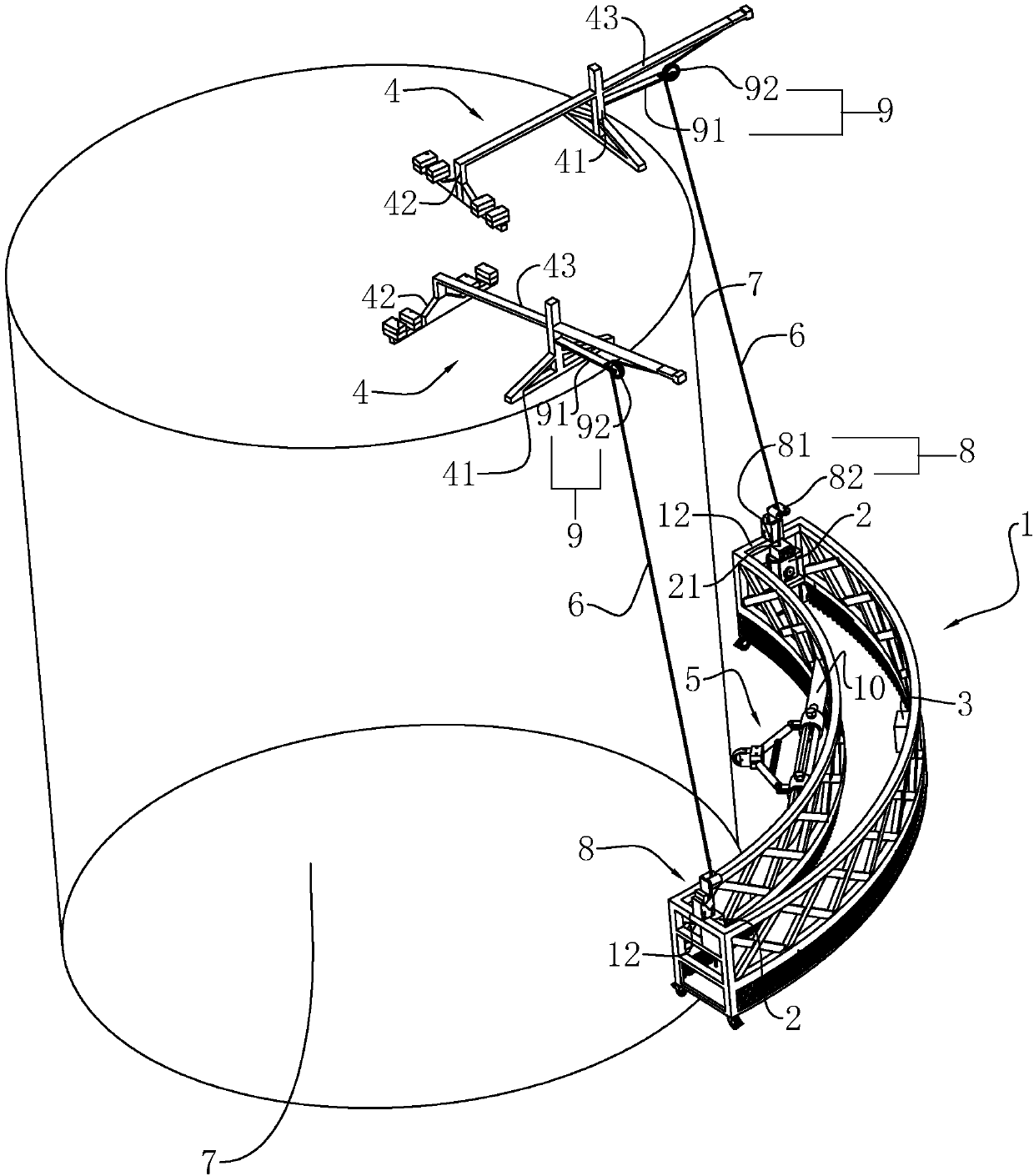

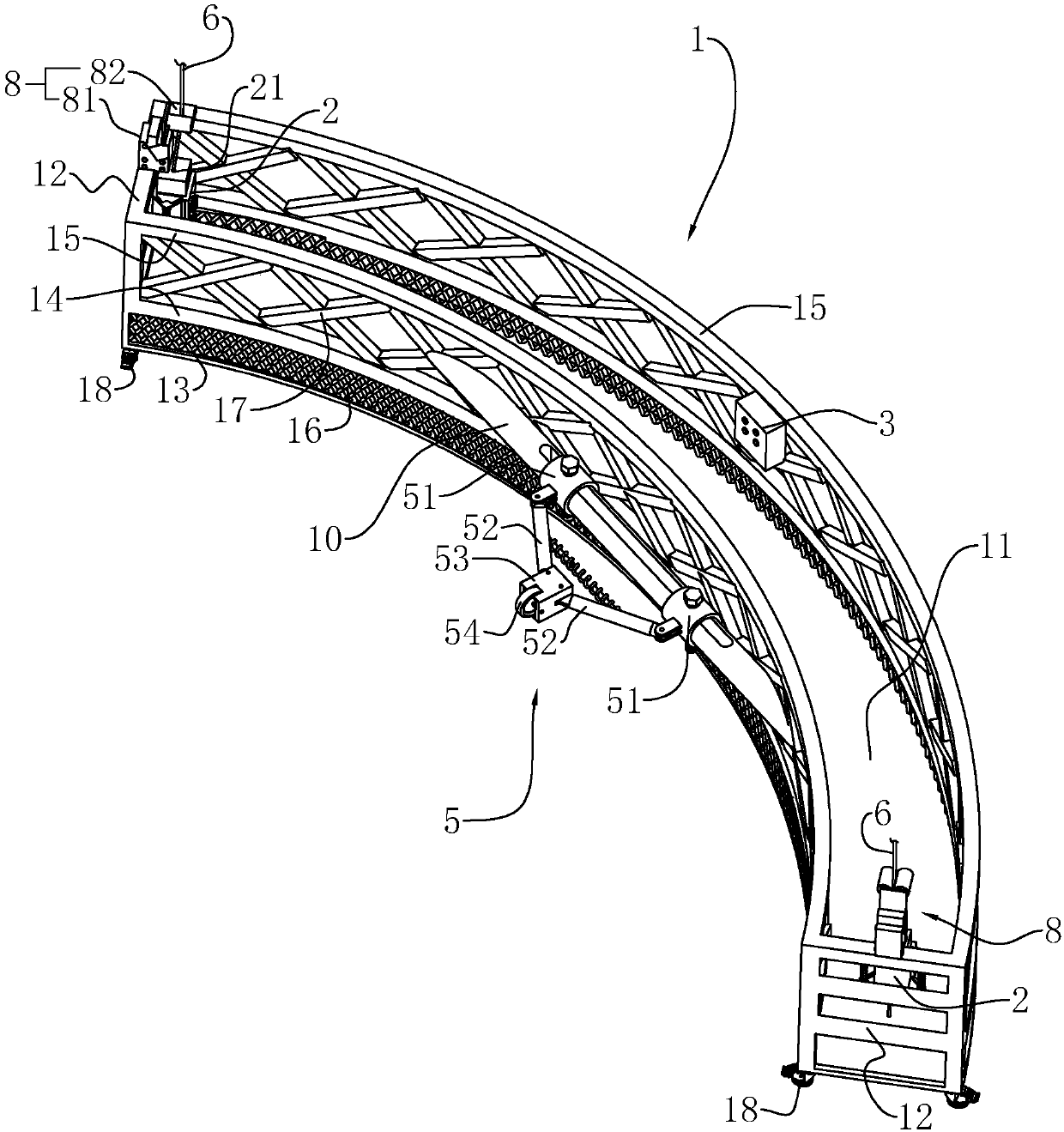

Circular-arc-shaped hanging basket and circular-ring-shaped hanging basket formed by splicing circular-arc-shaped hanging baskets

PendingCN107859315AImprove fitEasy constructionBuilding support scaffoldsHanging basketElectric control

The invention discloses a circular-arc-shaped hanging basket and a circular-ring-shaped hanging basket formed by splicing the circular-arc-shaped hanging baskets. According to main points of the technical scheme, the circular-arc-shaped hanging basket comprises a hanging basket body, two hoisters fixedly connected to the interior of the hanging basket body, an electric control box fixedly connected to the interior of the hanging basket body, a suspending device arranged on the top of a building and used for suspending the hanging basket body and a steel wire rope arranged between the suspending device and the hanging basket body; the upper end of the steel wire rope is connected with the suspending device, and the lower end of the steel wire rope is connected with the hoisters; the hangingbasket body is in a circular-arc-shaped frame shape, and the radian of the hanging basket body is matched with the radian of a circular wall; and the electric control box controls the hoisters to climb upwards along the steel wire rope and drives the hanging basket body to move upwards. The hanging bracket in the circular-arc-shaped frame shape and the circular-ring-shaped hanging basket are adopted to be better attached to the circular wall of the building, and construction of workers in the hanging basket on the circular wall is more convenient and safer.

Owner:北京中易房建筑工程有限公司

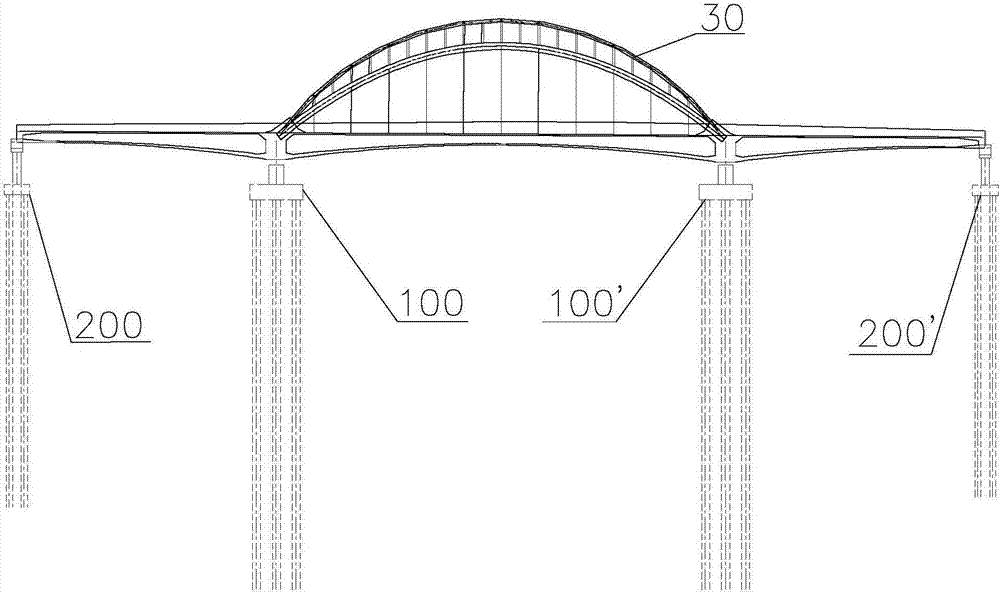

Cantilever construction method for arch rib bridge girder

ActiveCN107119574AReduce security risksGuaranteed simultaneous symmetrical constructionBridge erection/assemblyLinear controlHanging basket

The invention discloses a cantilever construction method for an arch rib bridge girder. The cantilever construction method comprises the following working procedures that firstly, zero box girder sections are constructed; secondly, first box girder sections are constructed; thirdly, second box girder sections to eighth box girder sections are subjected to cantilever casting continuously and symmetrically; fourthly, ninth box girder sections are subjected to cantilever casting symmetrically, and side span cast-in-place section supports are erected; fifthly, tenth box girder sections and side span cast-in-place sections are subjected to cantilever casting symmetrically; sixthly, side span closure sections are constructed; and seventhly, middle span closure sections are constructed. According to the cantilever construction method for the arch rib bridge girder, cantilever casting is constructed through hanging baskets, it can be guaranteed that the left and right sides of the bridge are constructed simultaneously and symmetrically, and a favorable condition is provided for linear control of the bridge; and the construction period can further be effectively shortened, working efficiency is improved, the risk is reduced, and the potential safety hazard of a lower channel in the crossing position is reduced furthest.

Owner:CCCC THIRD HARBOR ENG +2

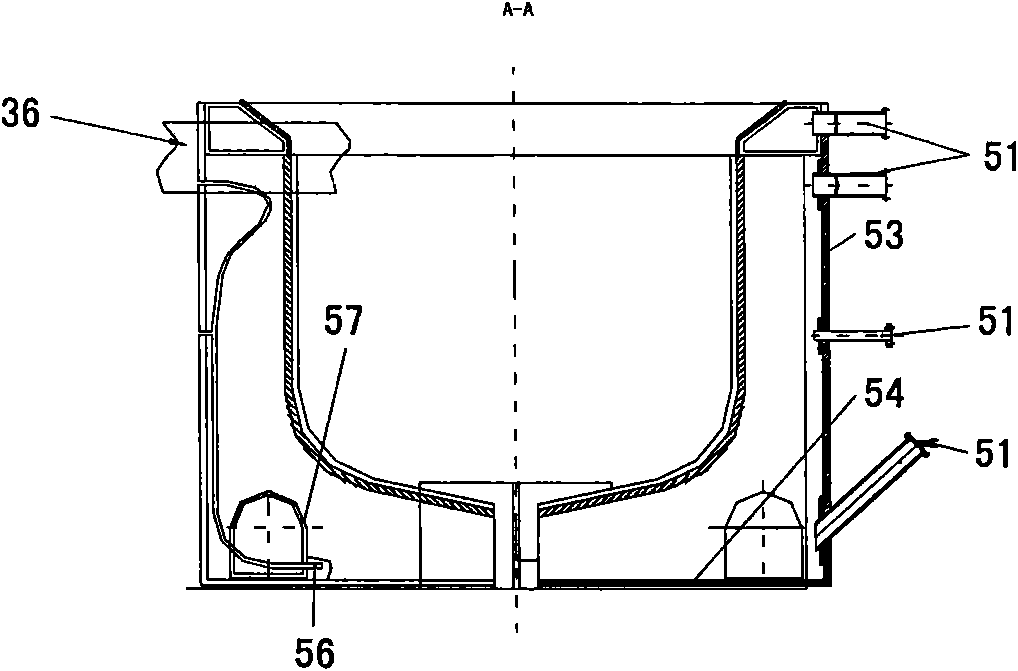

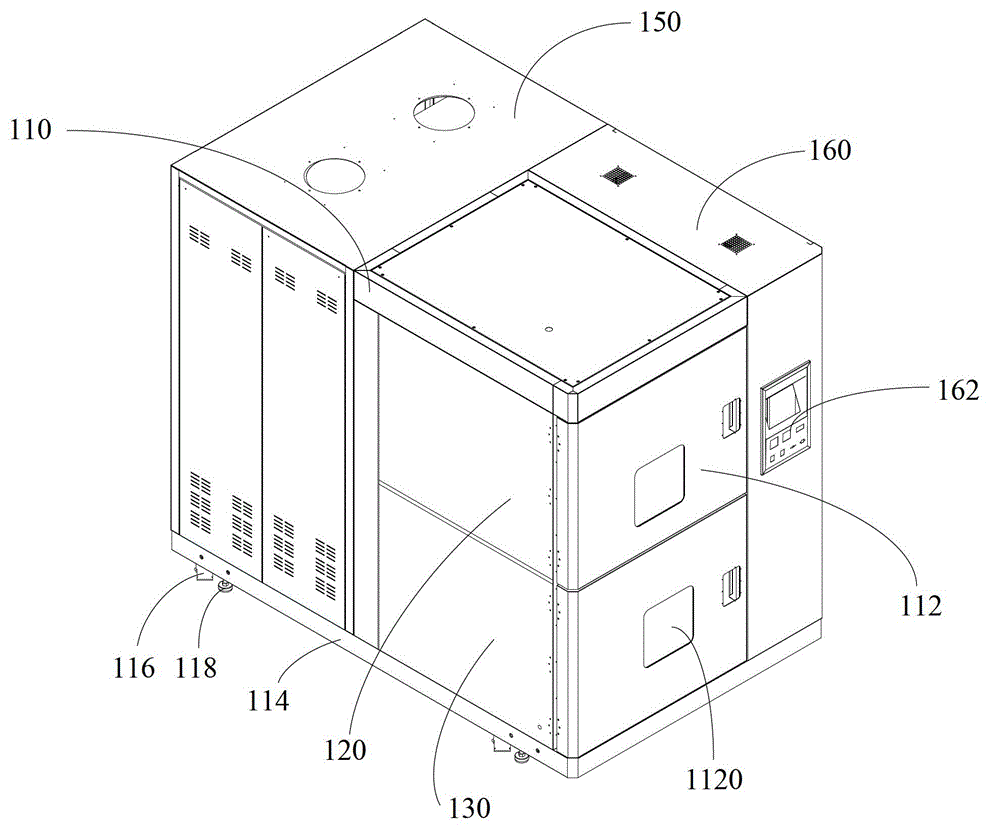

Two-box type impact testing box

The invention discloses a two-box type impact testing box. A hanging basket between a high-temperature box and a low-temperature box is moved to transfer a test sample and a room-temperature box does not need to be arranged, so that the defrosting time can be shortened, the consumption of electric quantity is reduced and the testing cost is saved; inner walls of the high-temperature box and the low-temperature box are respectively provided with a heating device and a refrigerating device; the circulation of air flow is driven by an impeller; the air flow rapidly and circularly flows to realize the effect of rapidly heating the test sample or refrigerating the test sample; an impeller, one heating device, an evaporator, a regenerator and the like are all located on the side wall of the high-temperature box or the low-temperature box; a motor drives the impeller to rotate to drive the air flow to flow in the front and rear direction of the box body; the air flow can rapidly flow and the distribution of the air flow is uniform so as to reduce the formation of frost and realize a long-time defrosting-operation-free circulating continuous test; a driving device for moving the hanging basket is arranged in a refrigerator cabinet rather than in the low-temperature box, so as to avoid influences on the driving device by the low temperature and rapidly move the hanging basket; the safety is high.

Owner:GUANGZHOU CEPREI INSTR & EQUIP

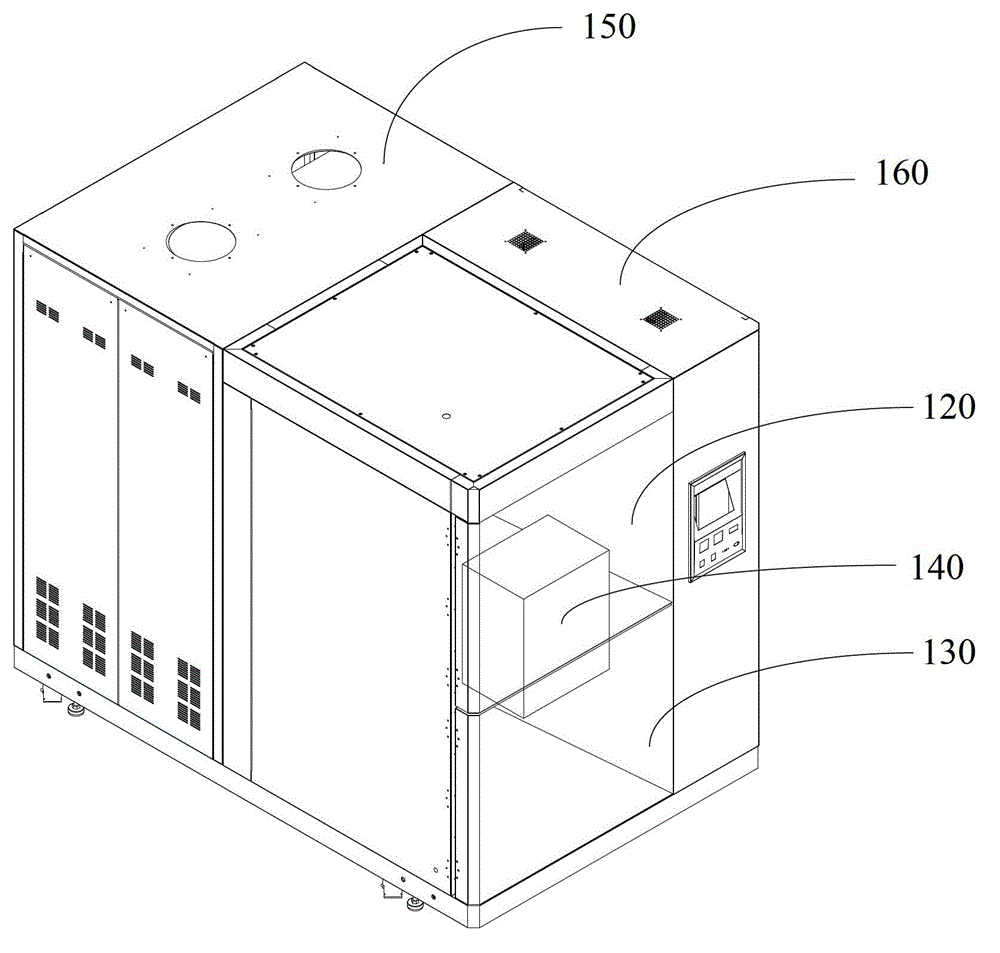

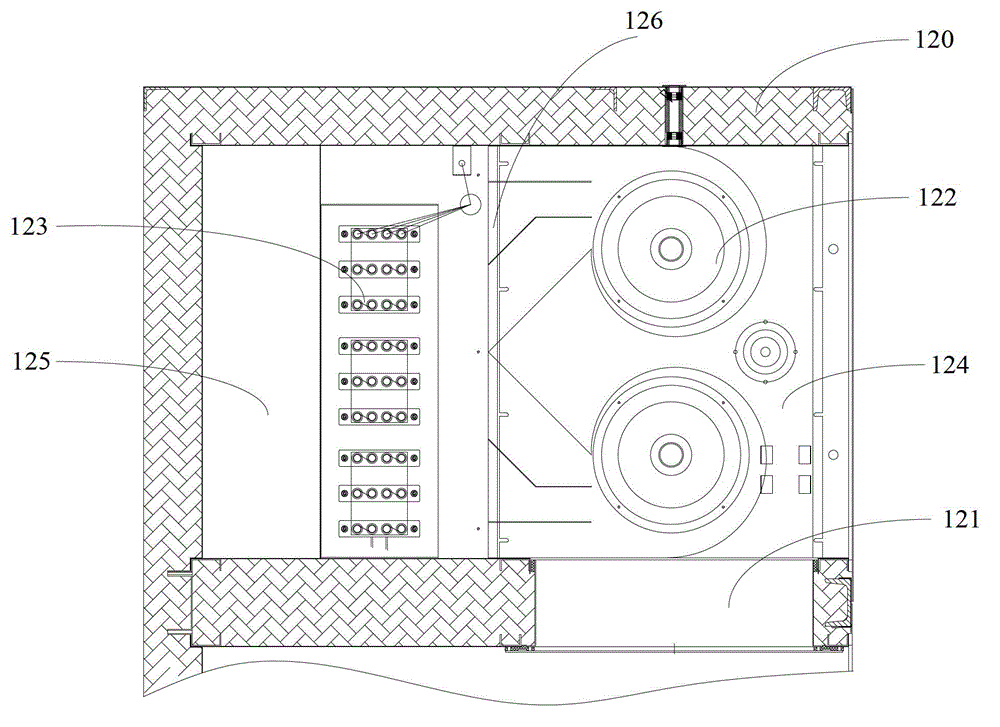

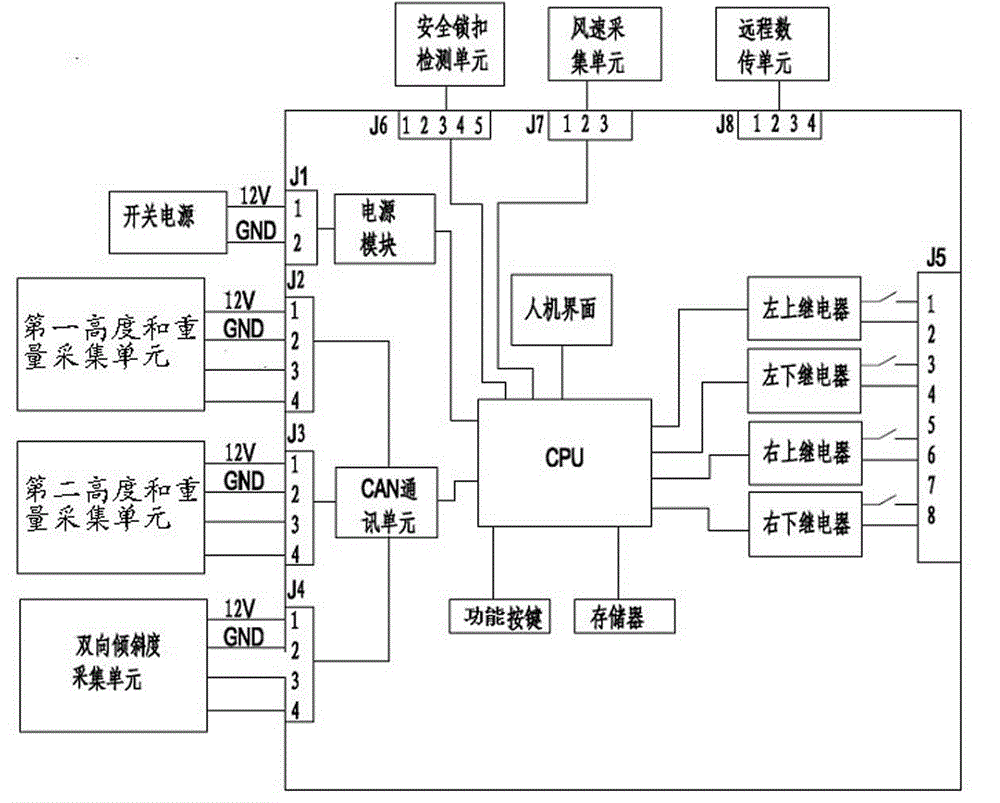

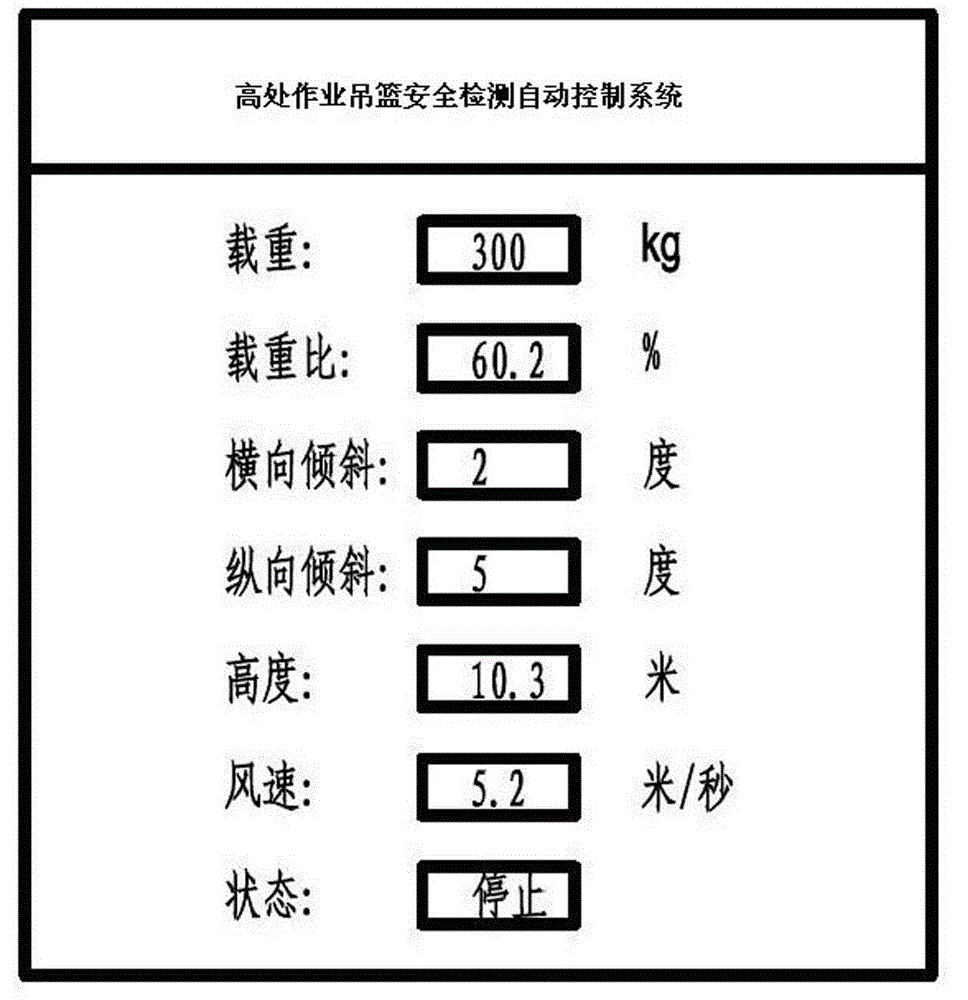

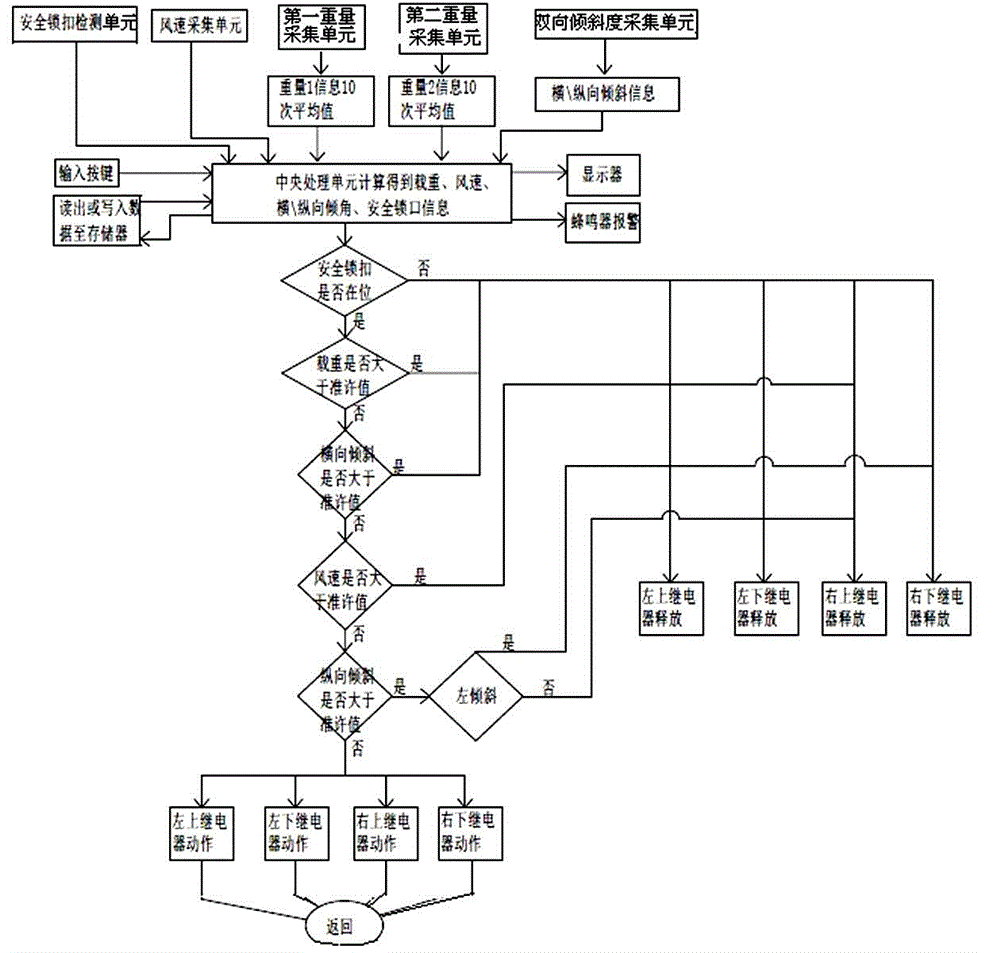

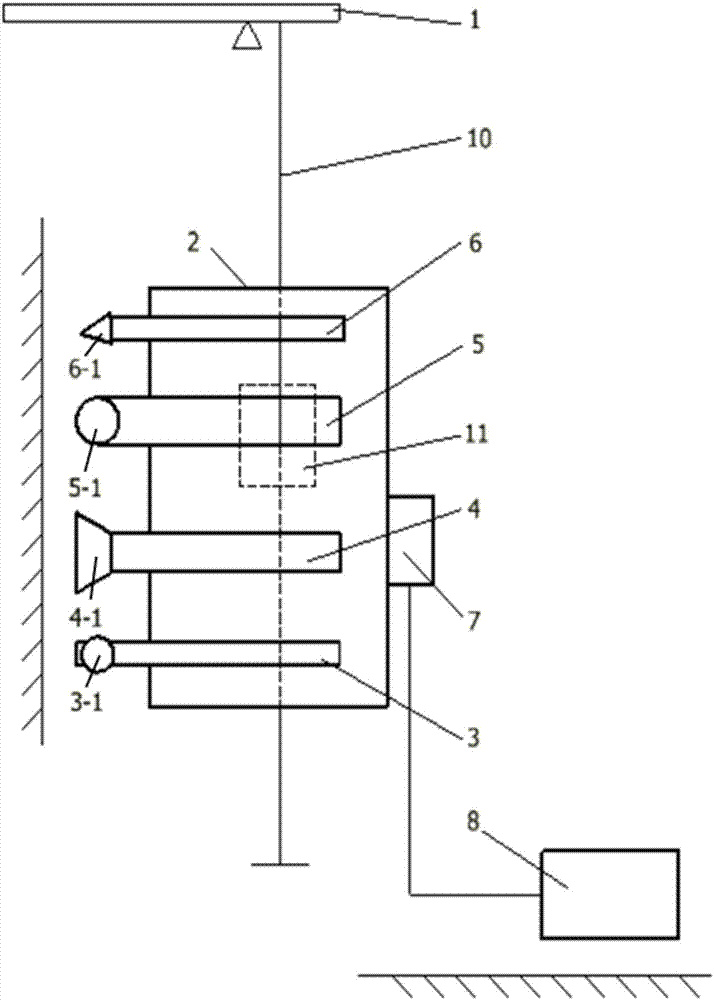

Hanging basket safety detection automatic control system in high-place operation

InactiveCN103332547ARealize detectionRealize all-round protectionTransmission systemsElevatorsAutomatic controlControl system

The invention belongs to the technical field of hanging basket safety protection in high-place operation, and particularly relates to a hanging basket safety detection automatic control system in high-place operation. The hanging basket safety detection automatic control system in high-place operation comprises a hanging basket working information collecting device and a safety controller. The hanging basket working information collecting device is used for collecting the information of the current working state of a hanging basket in real time, and is used for collecting the working height, the load, the longitudinal inclination and the lateral inclination of the hanging basket, the locking state of a safety rope lock catch and the wind speed of a working environment in real time respectively. The safety controller is connected with the hanging basket working information collecting device and is used for judging the current operating state of the hanging basket according to the current working state information of the hanging basket, distinguishing different conditions and giving out a sound and / or light alarm, or controlling and adjusting the hanging basket to work in a preset working parameter range, or cutting off a loop power which enables a dangerous state to continue developing. The hanging basket safety detection automatic control system in high-place operation can achieve comprehensive detection on the working state of the hang basket, can conduct comprehensive safety protection on operation of the hanging basket, can be suitable for detection and protection of various hanging baskets, and is strong in universality.

Owner:CONSTR MECHANIZATION INST CHINESE ACAD OF ARCHITECTURE SCI +2

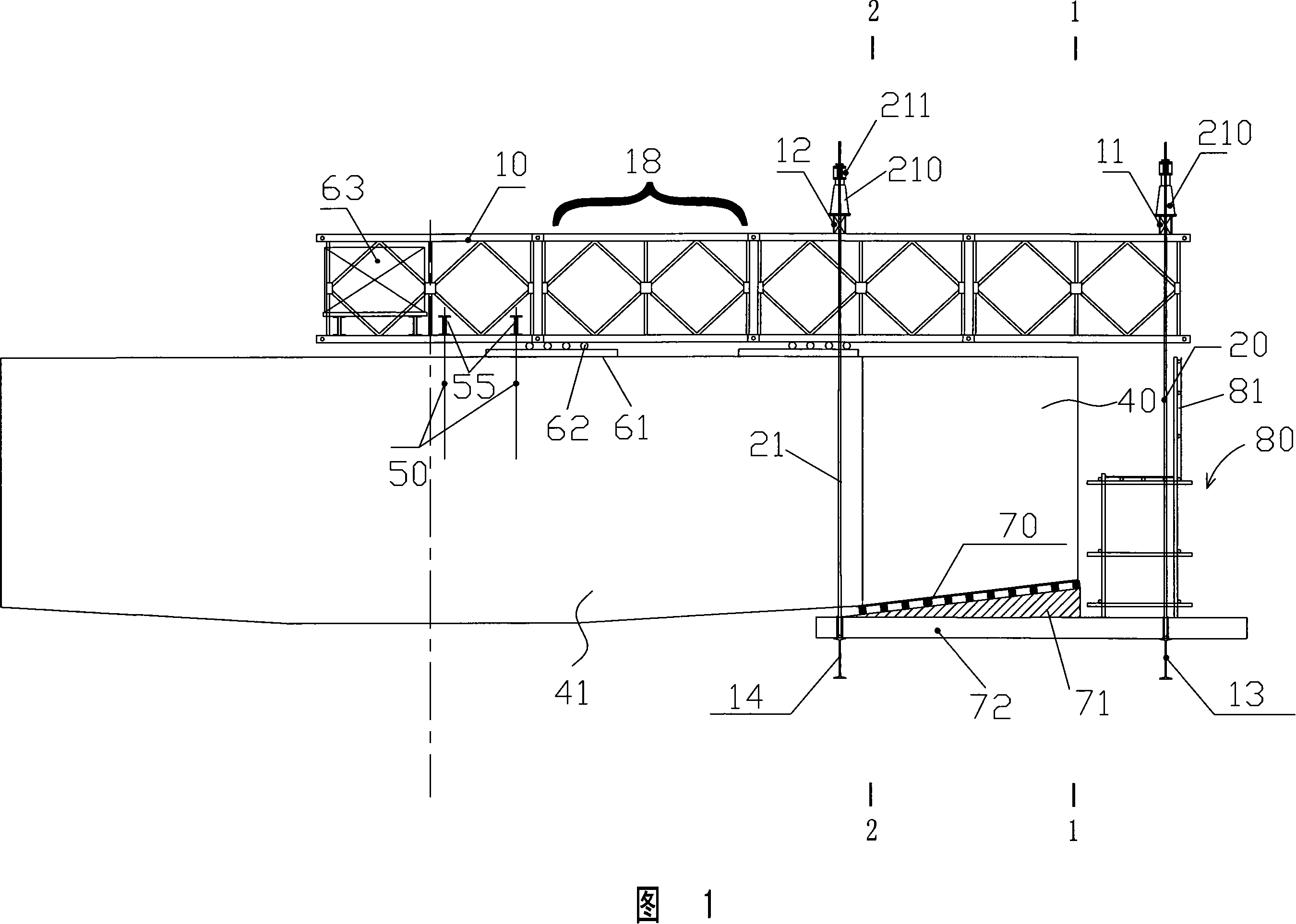

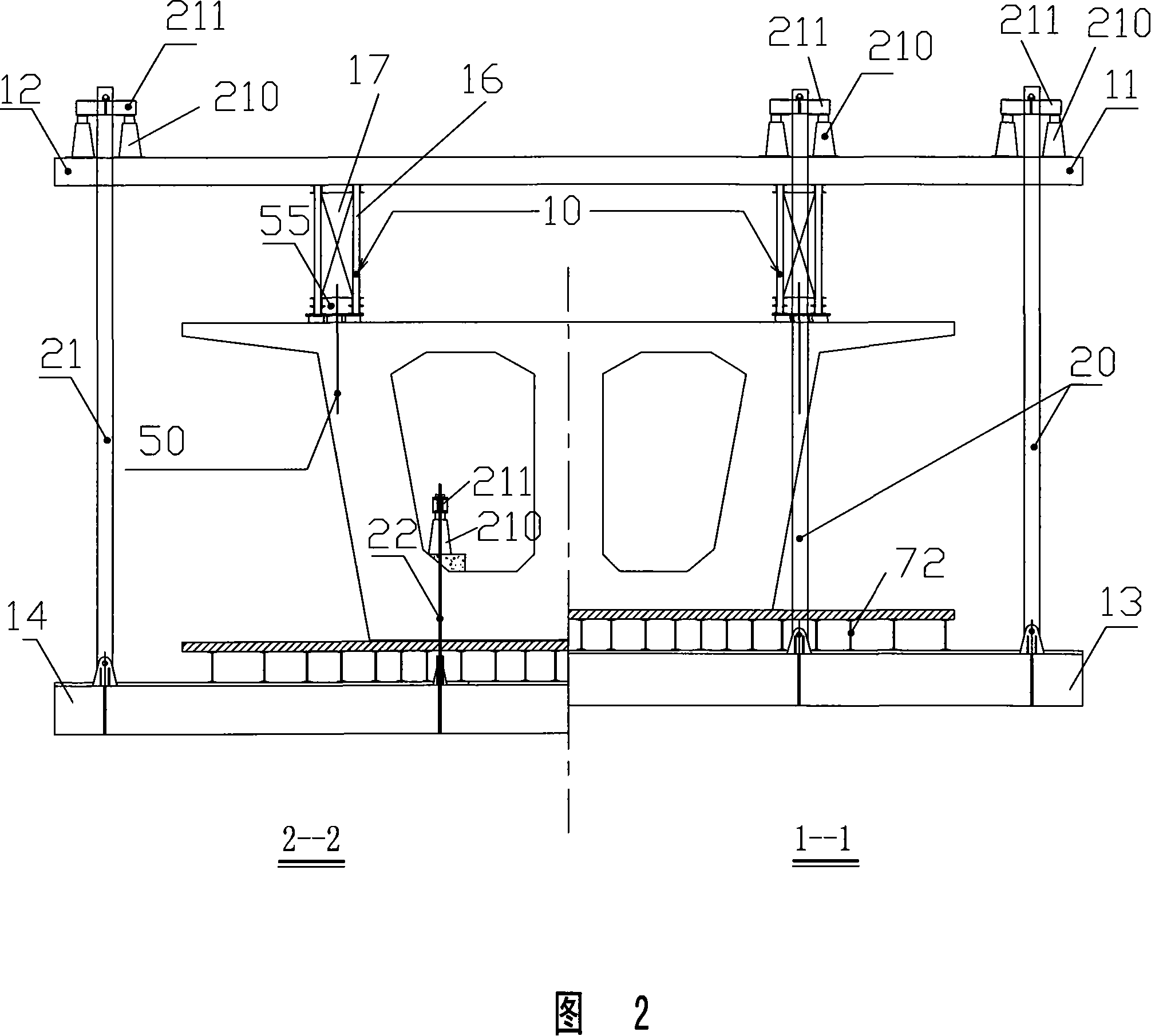

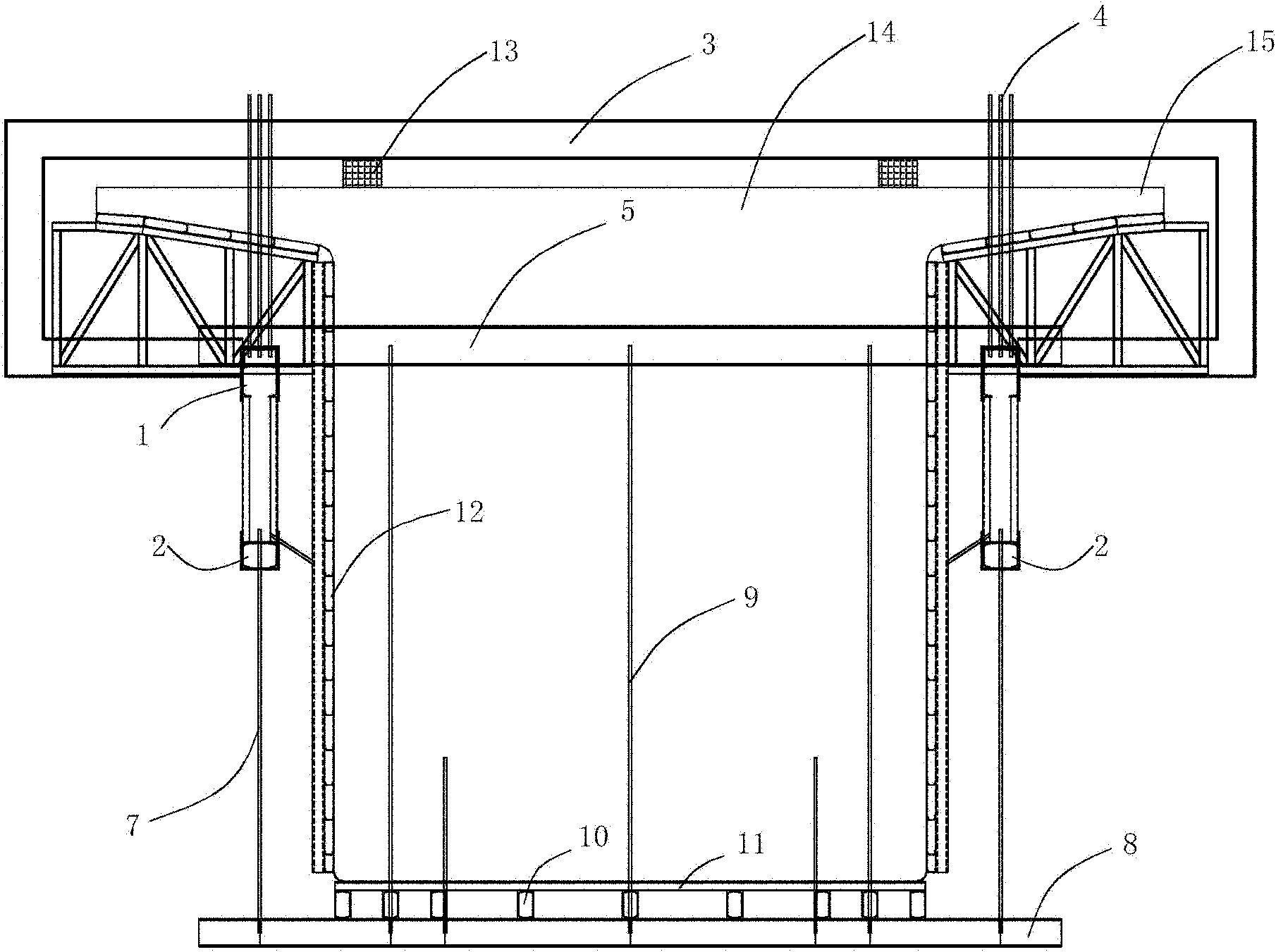

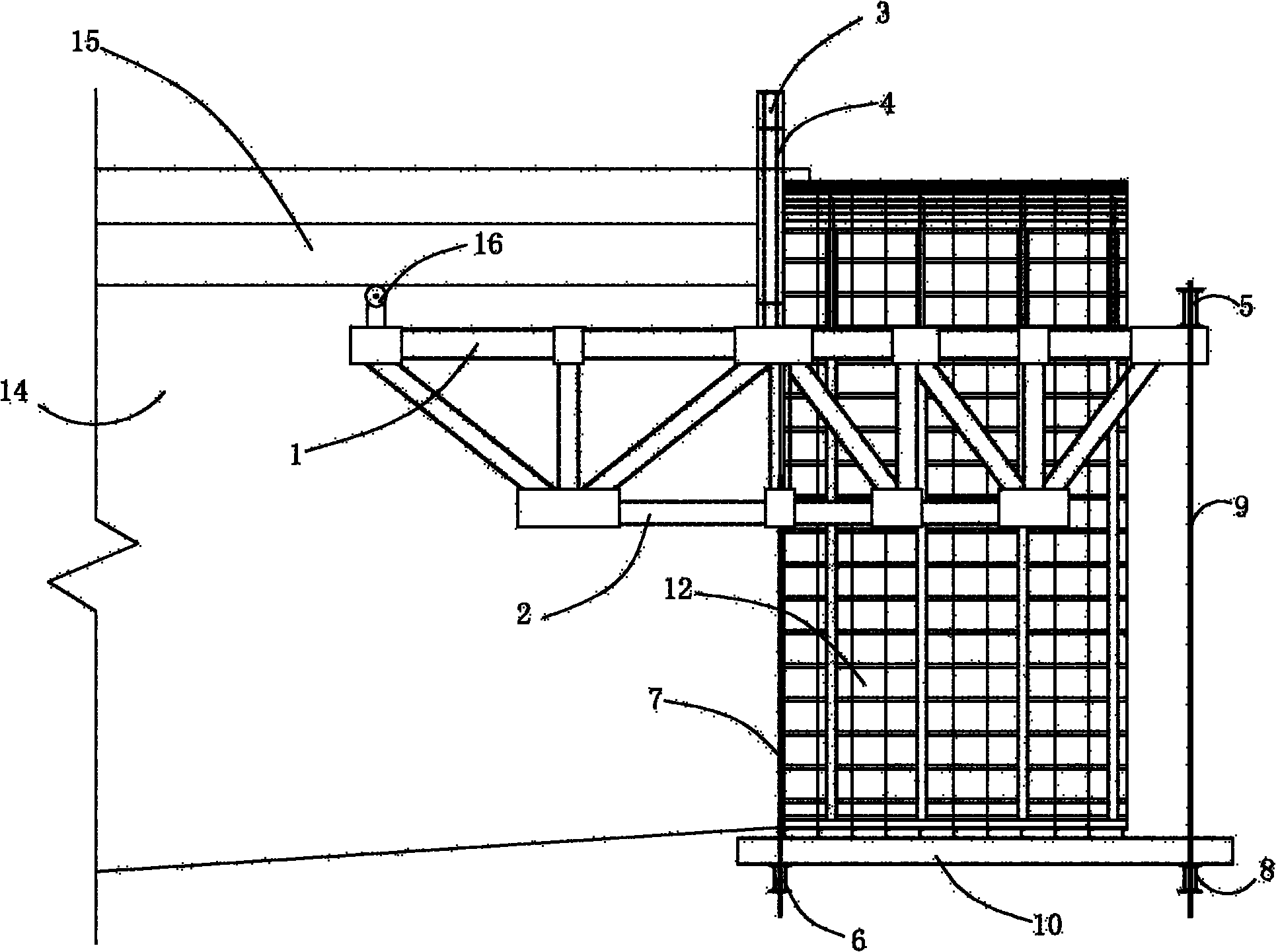

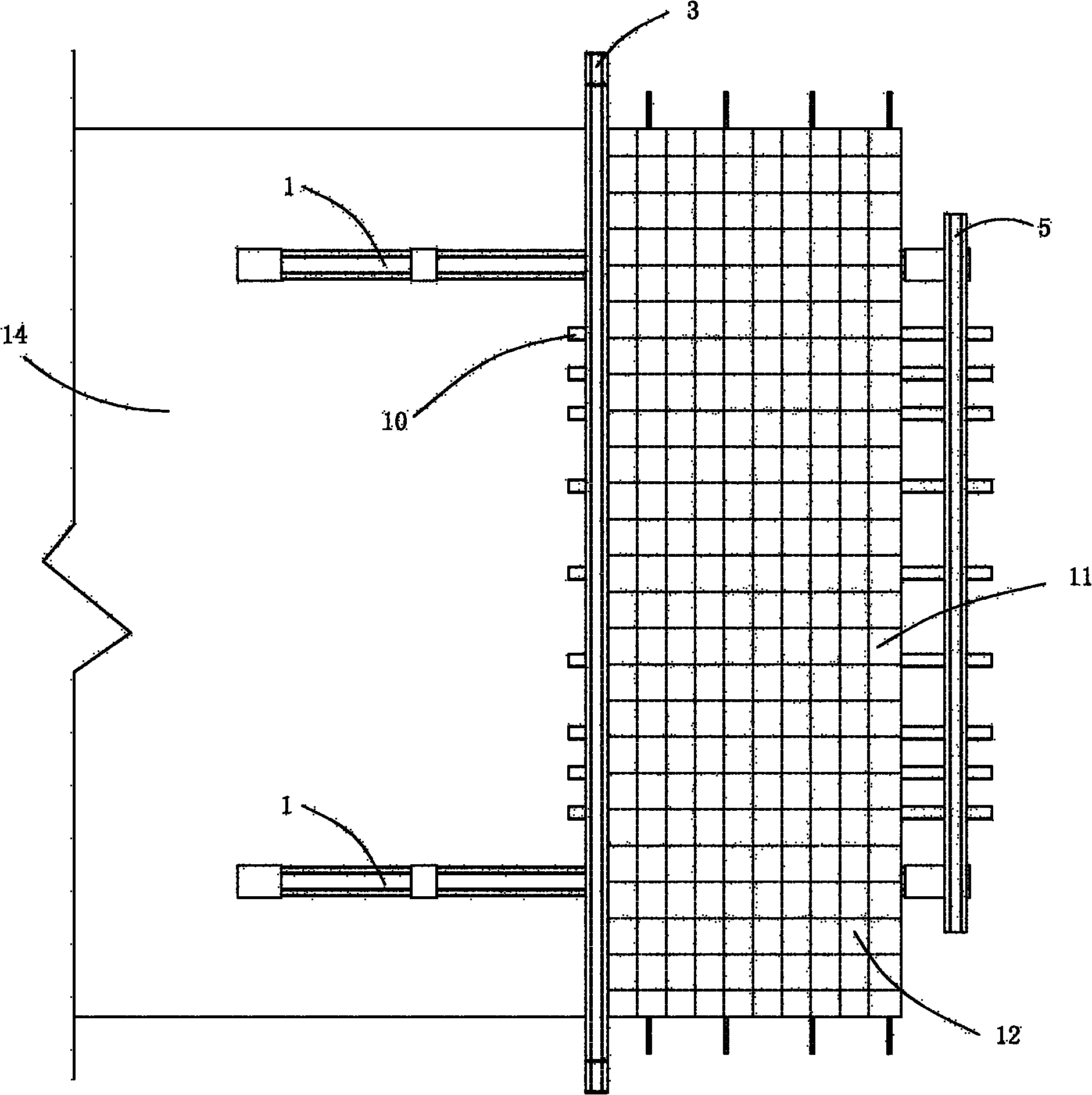

Lower supported hanging basket in bridge construction and application thereof

ActiveCN102094392AShorten the on-site construction periodClear forceBridge erection/assemblyTravel modeArchitectural engineering

The invention discloses a lower supported hanging basket in bridge construction and application thereof. The invention is characterized in that: the lower supported hanging basket is provided with two primary trusses having inverted trapezoidal structures, and an upper chord shoring jack is arranged between the tail of an upper chord and the bottom surface of a box girder edge board; an upper rear suspender is arranged between the middle of the upper chord and an upper rear crossbeam; the front end of the upper chord is connected with an upper front crossbeam; a lower rear suspender is arranged between the middle of a lower chord and a lower rear crossbeam; the upper front crossbeam is connected with a lower front crossbeam through a front suspender; parallelly arranged bottom basket longitudinal beams are fixedly connected between the lower front crossbeam and the lower rear crossbeam; and a hanging basket bottom die is fixedly arranged on the bottom basket longitudinal beams, and hanging basket side dies are positioned on the inner side of the two primary trusses. The hanging basket travelling mode is improved, a bound framework of steel reinforcement can be integrally hoisted into a bottom die platform space and directly subjected to concreting operation, and the construction period is shortened.

Owner:THE FIRST ENG CO LTD OF CTCE GRP

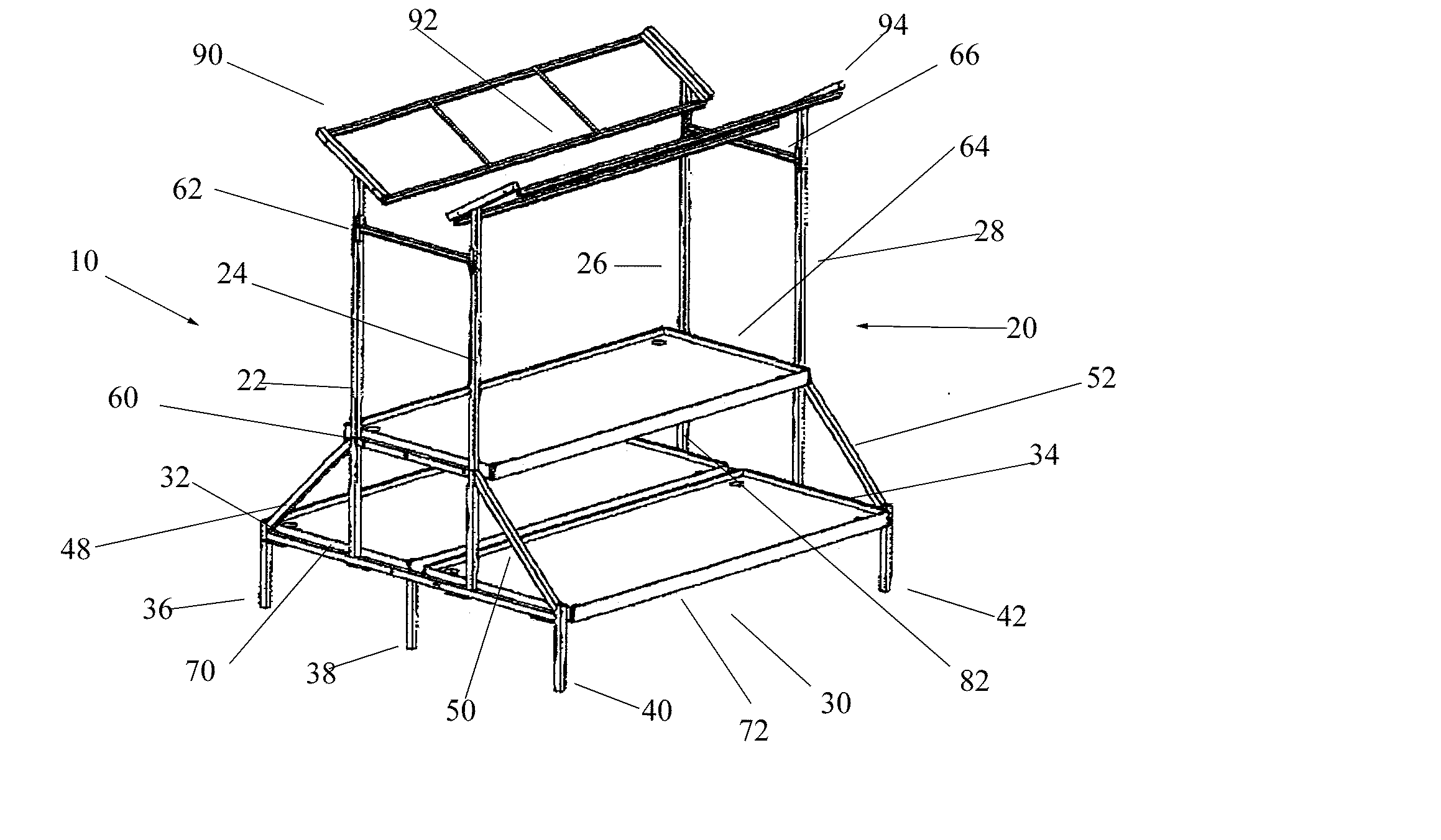

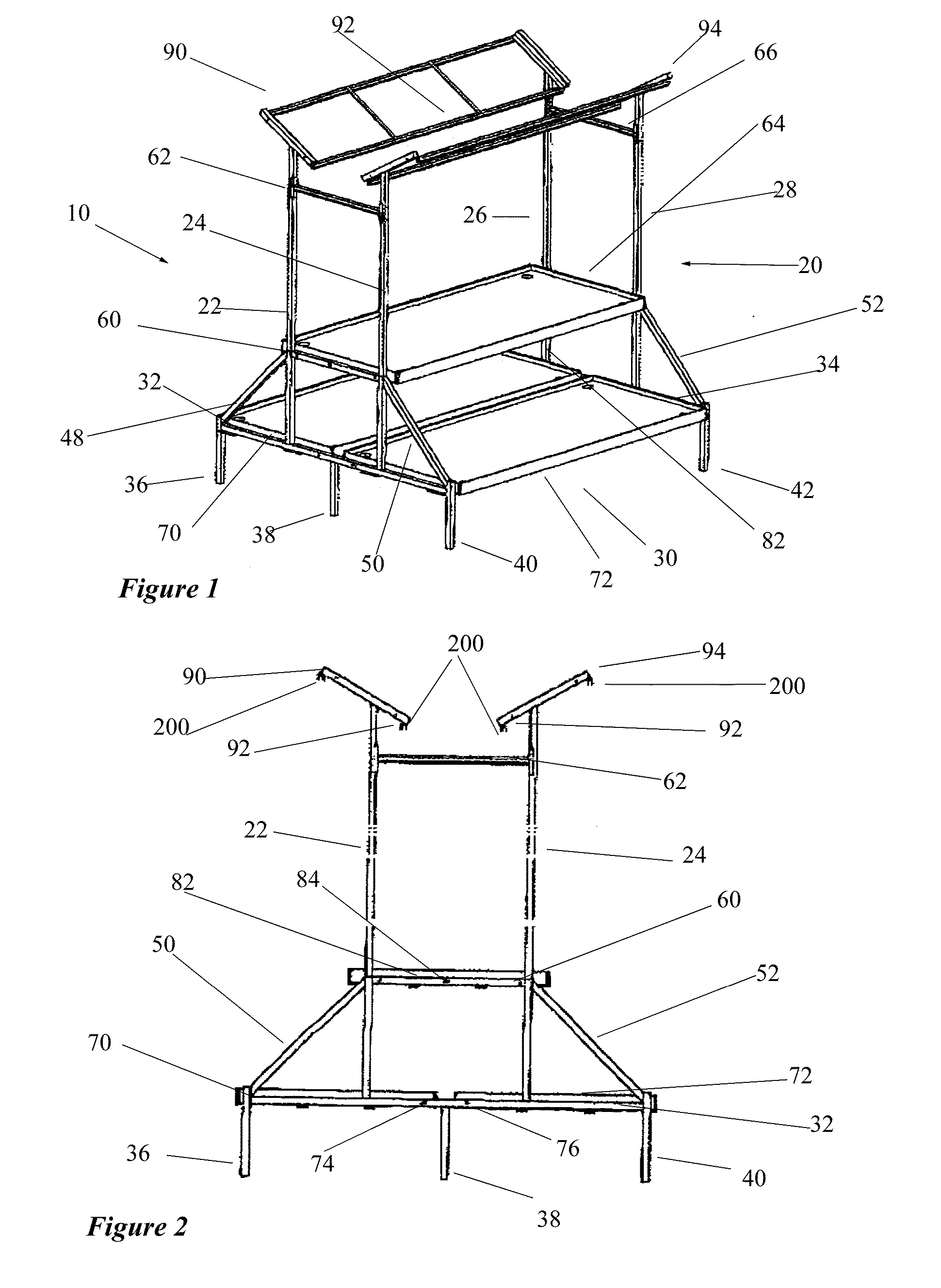

Plant display system

InactiveUS20050039390A1Attractive displaySmooth supplyFlower tablesShow shelvesWater leakageEngineering

A display structure convertible between use as for displaying plants and for storage. The display structure includes at least one display case that is pivotally mounted on said display structure to allow movement between a horizontal display use and a vertical storage use. A support bracket supports hanging baskets as well as holding a misting tube to water plants hanging from said support bracket. The display cases also include corner trim portions to protect the corners of the display case as well as preventing water leakage.

Owner:NEXUS INC

Construction method adopting inverted triangular obliquely-crawling hanging basket

InactiveCN102797227AEasy to assembleImprove stabilityBridge erection/assemblyArchitectural engineeringHanging basket

The invention discloses a construction method adopting an inverted triangular obliquely-crawling hanging basket. The method comprises the following steps: an assembled bottom basket skeleton (1) and part of cross beams of a main truss system (2) are loaded in the bottom surface of a poured box girder (10), and a pull rod (3) and a retaining shearing arm (4) are mounted; a track (6), a basket hanging hook and a traveling system are mounted on a girder surface of the poured box girder (10), the track (6) is mounted, and the traveling system is positioned in the track (6); the triangular main truss system (2) is mounted under the bottom basket skeleton (1); and a template system (7) is mounted and poured; the pull rod (3) and a pivot lifting jack (8) are loosened so as to enable a counterforce wheel (9) to be in contact with the bottom of the poured box girder (10), so that the hanging basket can move forwards along the track (6) to the next construction position. The construction method has the characteristics separated support and bearing systems during construction, simplicity and convenience for assembly, and high traveling stability.

Owner:GUIZHOU ROAD & BRIDGE GRP

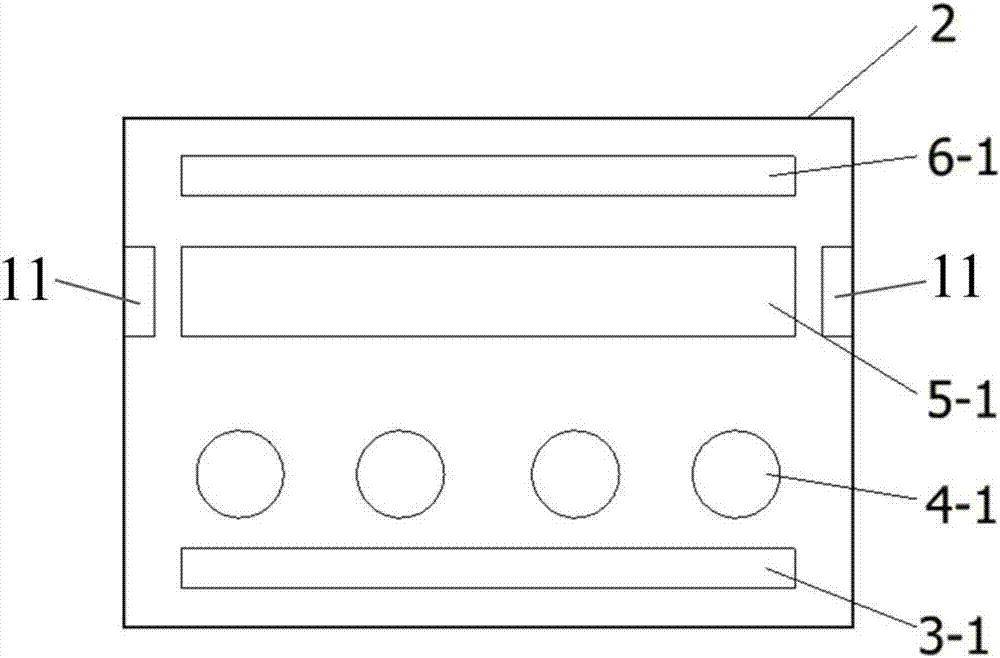

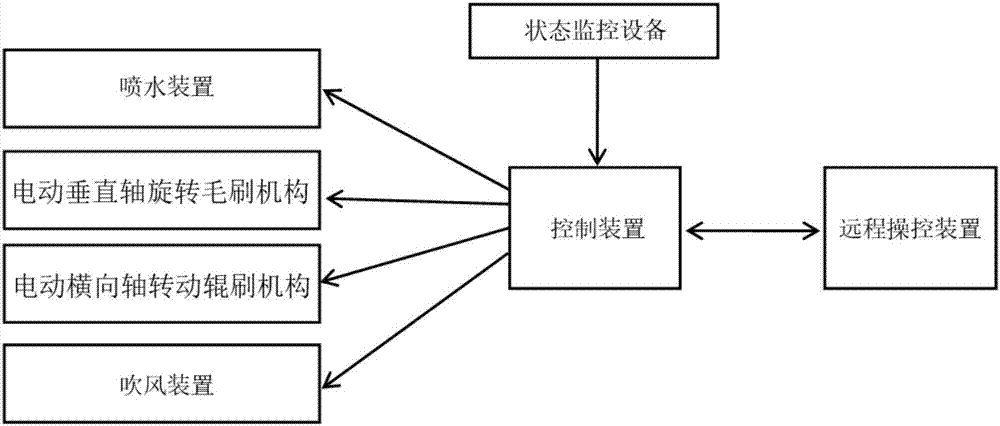

Vertical scrolling type robot system used for curtain cleaning

ActiveCN106974583ASimple structureEasy to operateCarpet cleanersCleaning action controlRobotic systemsHanging basket

The invention discloses a vertical scrolling type robot system used for curtain cleaning. The system comprises a hanging device (1) provided with a hanging basket framework (2) moving up and down, and a water injection nozzle (3-1) of a water injection device, brushes (4-1 and 5-1) of an electric rotary brush mechanism and an air blowing nozzle (6-1) of an air blowing device are sequentially located on the side, opposite to a curtain, of the hanging basket framework from bottom to top; a control device (7) is installed on the hanging basket framework, and separately in electric connection with the water injection device (3), the electric rotary brush mechanism (4) and the air blowing device (6); a remote manipulation device (8) is electrically connected with the control device. The robot system moves downward along the curtain and sequentially passes through the water injection nozzle, the brushes and the air blowing nozzle for cleaning and removal, and the remote manipulation device (8) enables ground operators to remotely control the working state in a wired or wireless mode.

Owner:汤瑞平

Hanging basket device with double-insurance function

ActiveCN105621327ANo impact damageConvenient construction workSafety devices for lifting equipmentsWindow cleanersArchitectural engineeringHanging basket

The invention discloses a hanging basket device with a double-insurance function. The hanging basket device comprises a hanging basket body, a lifting device, a safety belt unit, a sliding mechanism and a supporting frame, wherein the lifting device is connected with the upper end of the hanging basket body, the safety belt unit is used for braking under emergency situations, and the supporting frame is used for fixing and supporting the safety belt unit. The hanging basket body is located on the outer side of a building wall. The lifting device and the supporting frame are fixedly installed on a top cover of a building. The distance between the lifting device and the building wall is larger than the distance between the supporting frame and the building wall. The distance between the hanging basket body and the building wall can be changed under adjusting of the sliding mechanism. The hanging basket device is provided with the safety belt unit capable of braking quickly, and the effect that constructors do not fall off can be ensured as soon as possible; moreover, the hanging basket device is further provided with safety air bags, so that the constructors are prevented from being injured by the impact force of falling under protection of the safety air bags; meanwhile, the hanging basket device is capable of adjusting the distance between the hanging basket body and the wall surface under the action of the sliding mechanism, so that construction operation for the constructors is facilitated, and the construction efficiency is improved.

Owner:甘肃路桥飞宇交通设施有限责任公司

Automatic pole climbing device capable of being applicable to variable cross-section bar and with protection function

The invention relates to an automatic pole climbing device capable of being applicable to a variable cross-section bar and with a protection function. The automatic pole climbing device is mainly used for climbing an electric power electric pole or climbing poles in other fields, is safe and reliable, can carry a larger tool and equipment and can realize automatic pole climbing. The automatic pole climbing device is mainly composed of an upper clamp hydraulic system (1), a lower clamp hydraulic system (2), a lift hydraulic system (3) and a hanging basket (4). A working process of the automatic pole climbing device comprises the following steps: keeping a clamped state of the lower clamp hydraulic system (2), loosening one pair of clamping pieces (8) of the upper clamp hydraulic system (1), then extending a lift piston (11) of the lift hydraulic system (3), then clamping one pair of clamping pieces (8) of the upper clamp hydraulic system (1), then loosening one pair of clamping pieces (8) of the lower clamp hydraulic system (2), retracting the lift piston (11) of the lift hydraulic system (3), upwards moving the lower clamp hydraulic system (2), driving the hanging basket (4) to ascend by the lower clamp hydraulic system (2), and driving the hanging basket (4) to descend when the lower clamp hydraulic system (2) moves downward.

Owner:大航电科(江苏)新能源有限公司

Chain type ultrasonic full-automatic cleaning device for stainless steel tableware

InactiveCN102755145AAvoid collisionImprove cleaning efficiencyTableware washing/rinsing machine detailsProduction lineMegasonic cleaning

The invention discloses a chain type ultrasonic full-automatic cleaning device which comprises a base and further comprises an electrical control part, a convey mechanism, a power mechanism, an ultrasonic cleaning part, a sprinkling part and a drying part which are all arranged on the base; the power mechanism is in transmission connection with the convey mechanism; the convey mechanism comprises an intermittent lifting drive device which can control stainless steel dinnerware to descend to enter or to rise so as to leave the ultrasonic cleaning part and the sprinkling part and can move along a cleaning production line; and a detachable movable loading mechanism is arranged on the intermittent lifting drive device and used for holding to-be-cleaned dinnerware. Due to the adoption of the chain type convey manner, the device is simplified; due to the adoption of the intermittent cleaning manner, the cleaning efficiency and the cleaning quality are greatly improved; the to-be-cleaned dinnerware is loaded in a hanging basket, so that the problem that dead space is difficult to clean is solved, and the dinnerware is prevented from colliding effectively; and due to the adoption of the manner that a hook is directly connected to a chain, the disassembly is convenient, and the work efficiency is effectively improved.

Owner:QINGDAO RUIJIN STAINLESS STEEL PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com