Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164results about How to "Fast pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

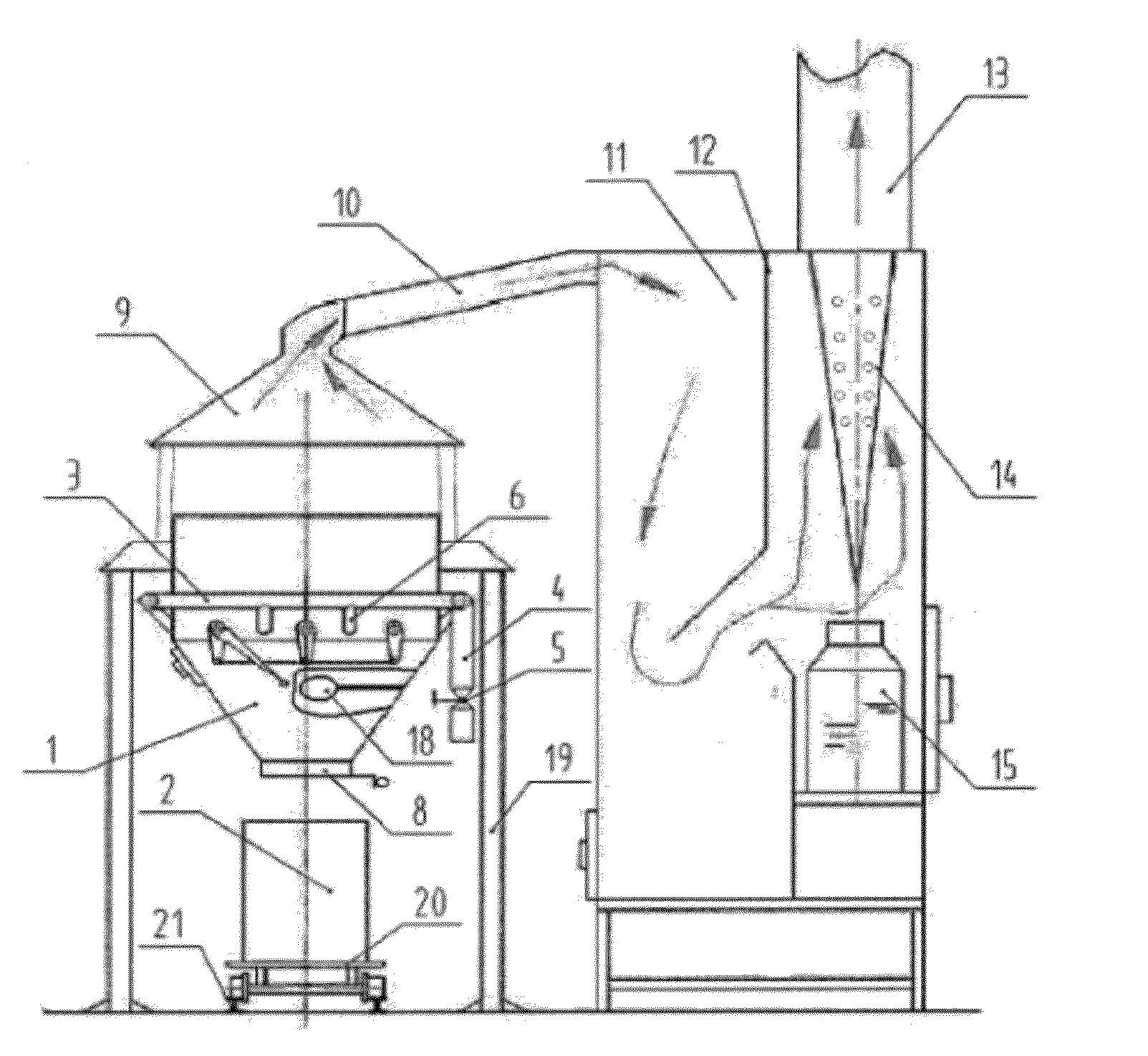

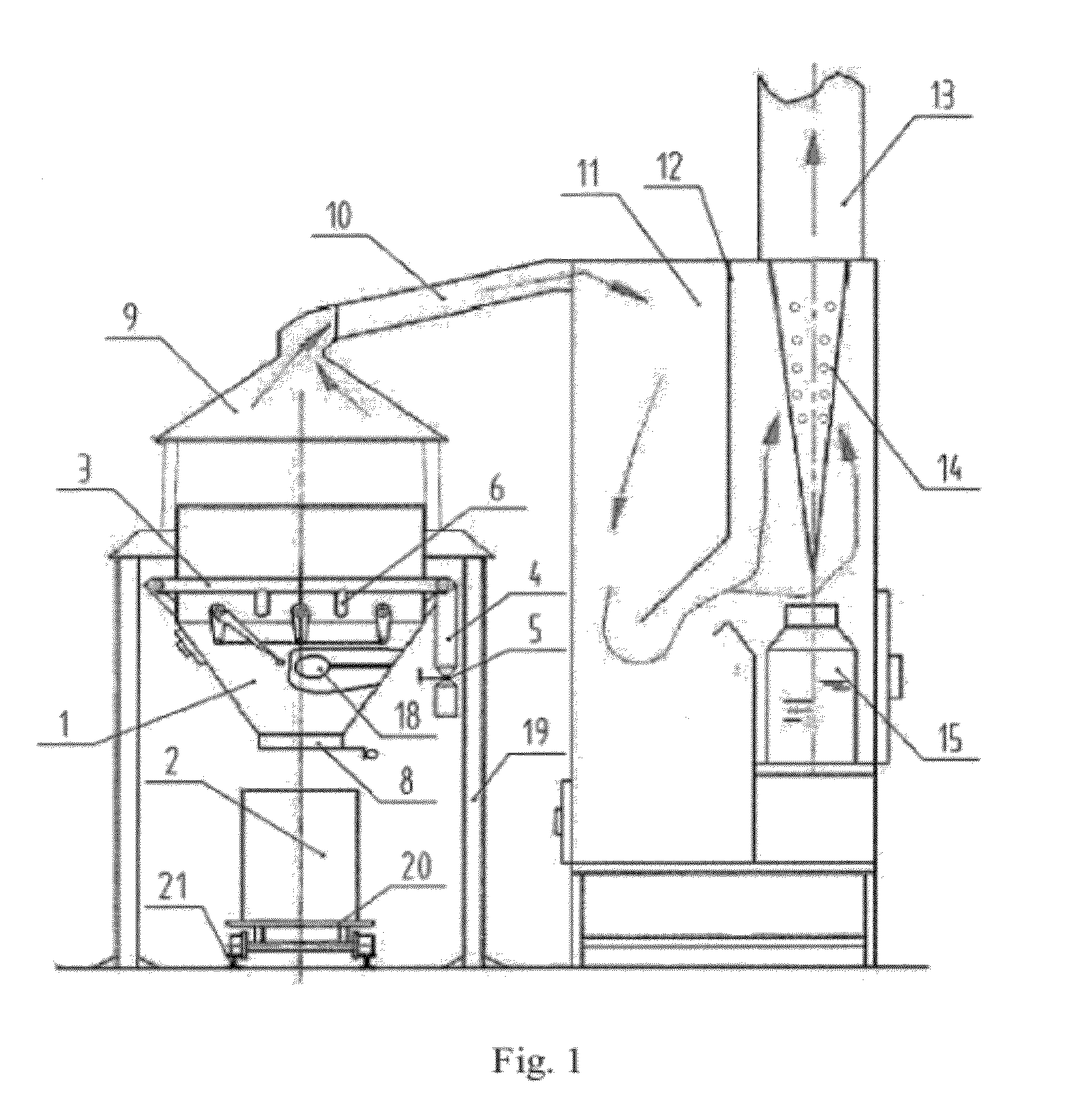

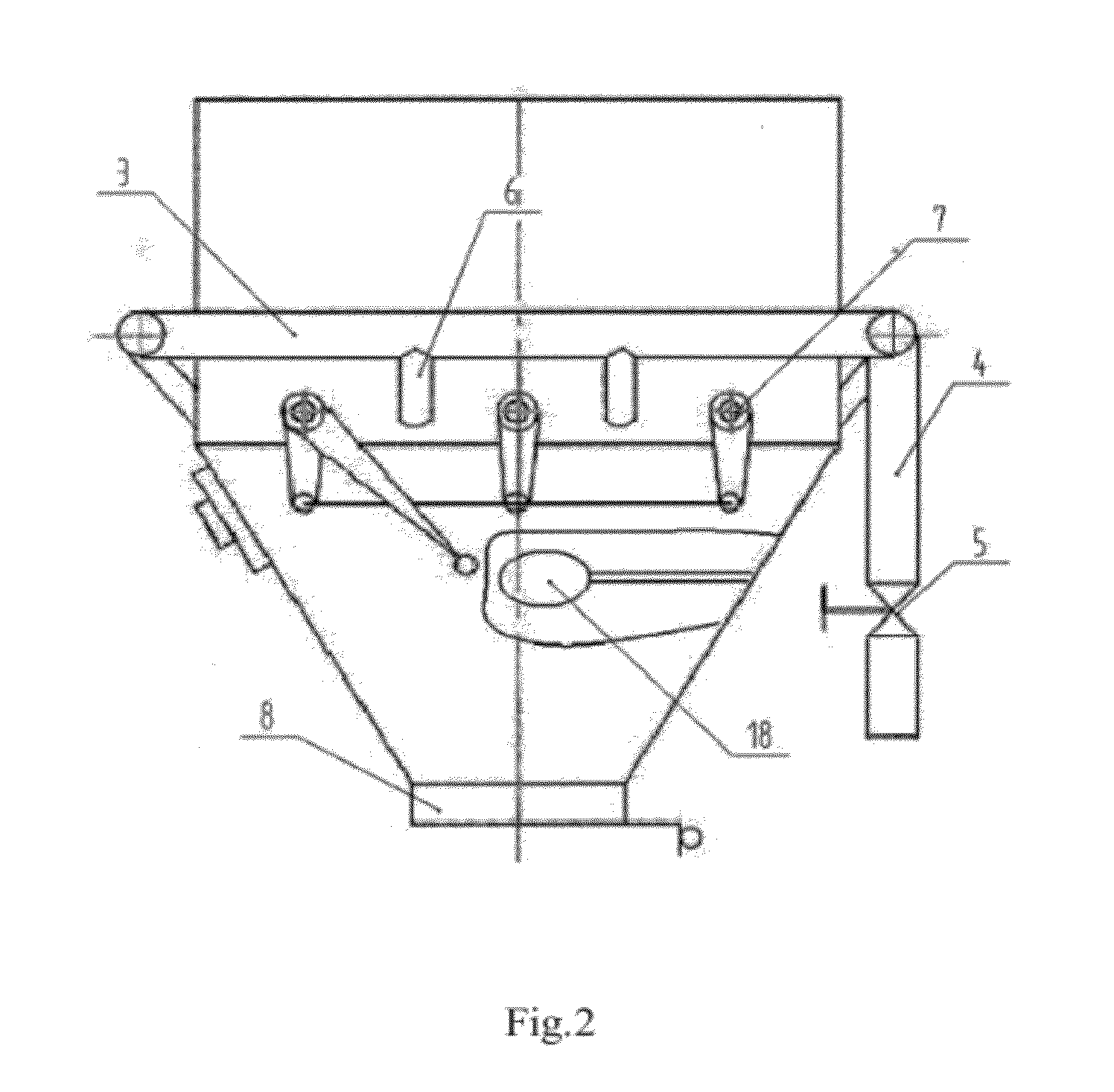

Method and device for carbonification of crop straws

ActiveUS20120305380A1SpeedReduce the temperatureCombustible gas coke oven heatingDirect heating destructive distillationEngineeringOxygen

The present invention is to provide a method for carbonification of crop straws and a device thereof. Pyrolysis process is controlled by regulating the feeding of oxygen during said pyrolysis process, and pyrolysis and carbonification are respectively conducted in separate pyrolysis and carbonification pools, wherein the straws are pyrolyzed in said pyrolysis pool and entered into said carbonification pool to be carbonified. The present invention can quickly raise the temperature of the pyrolysis process, shorten the time of the pyrolysis process, and improve the pyrolysis carbonification efficiency.

Owner:SHANXI SUPPLY & MARKETING COOP

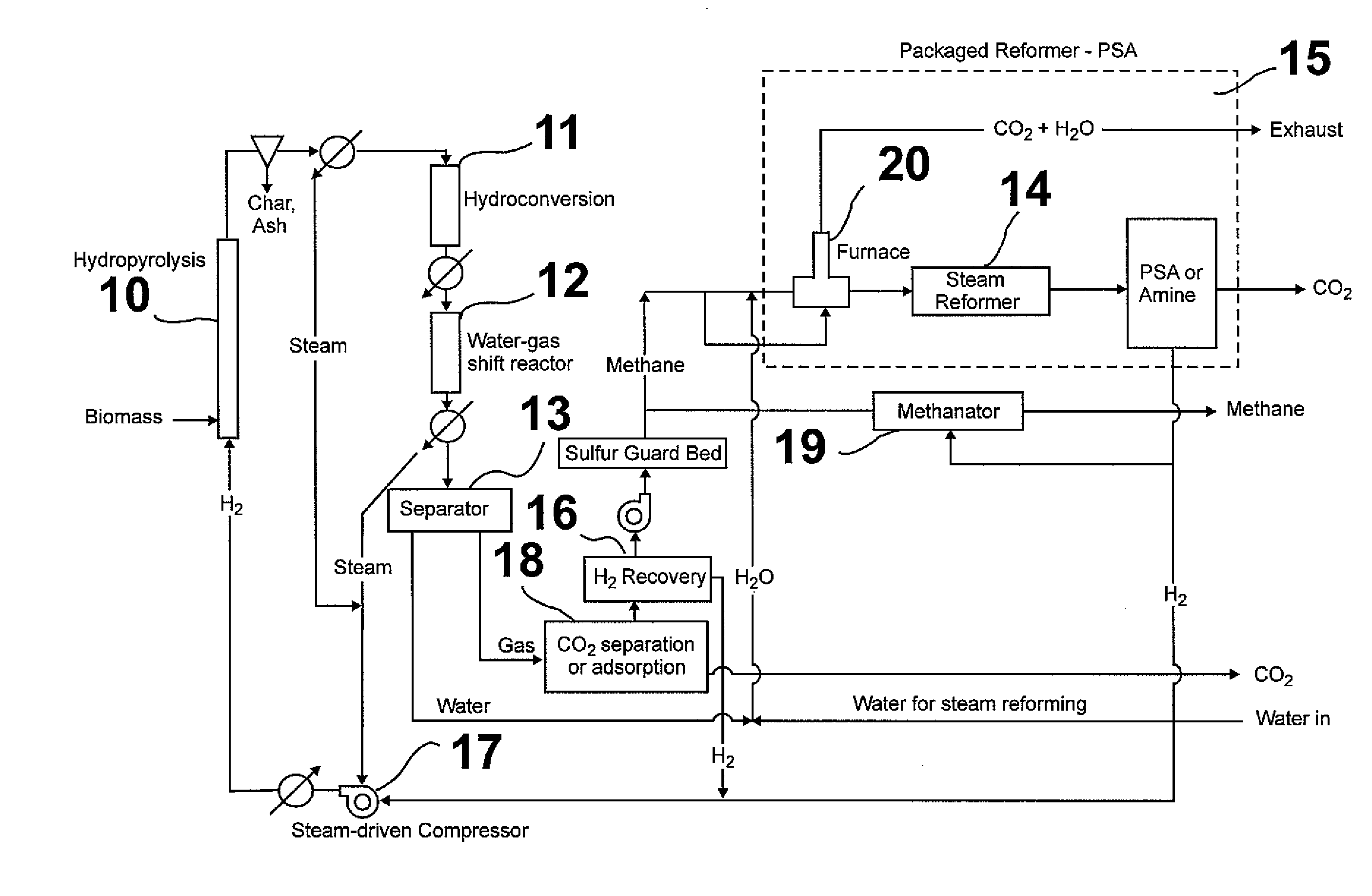

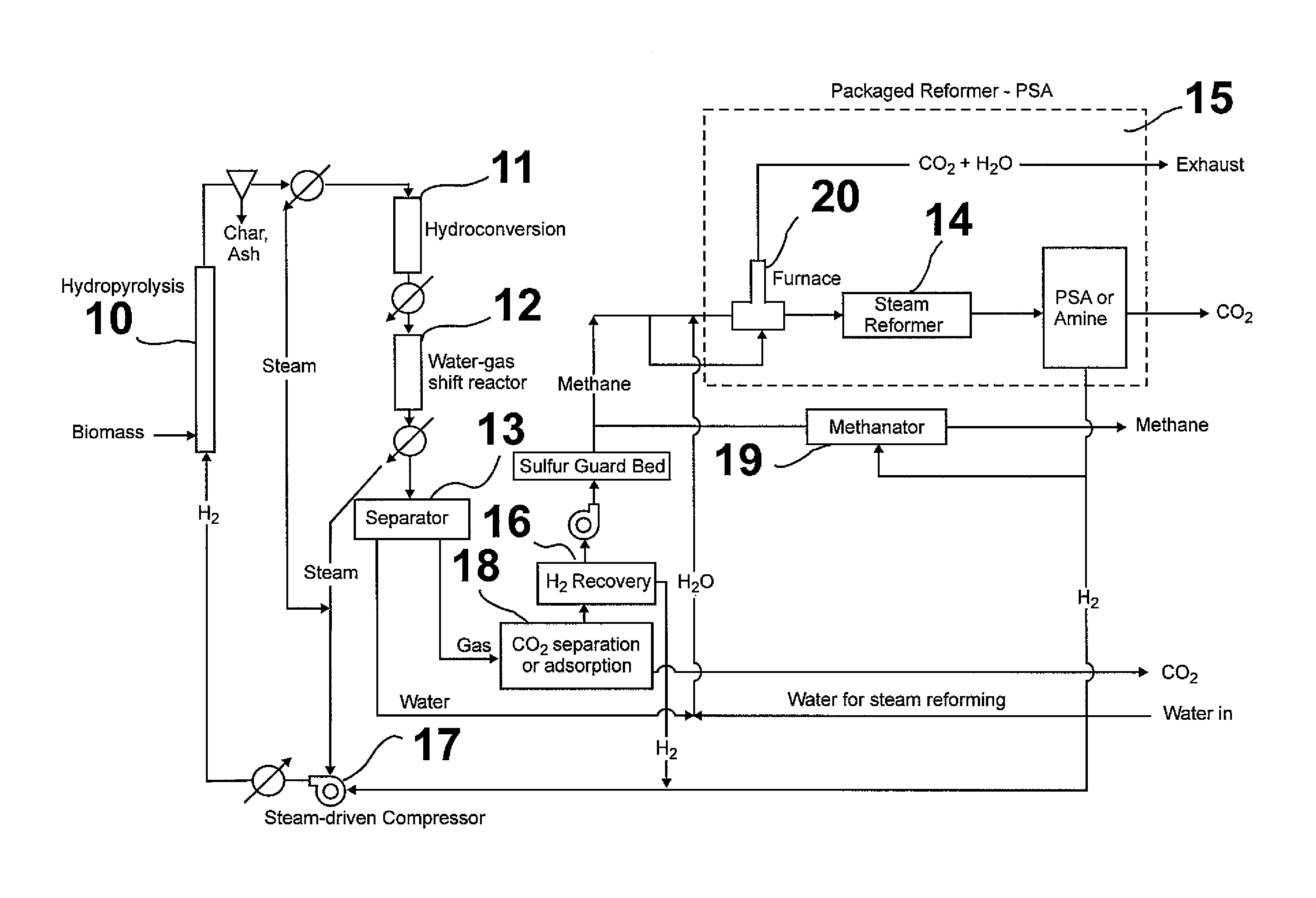

Method for producing methane from biomass

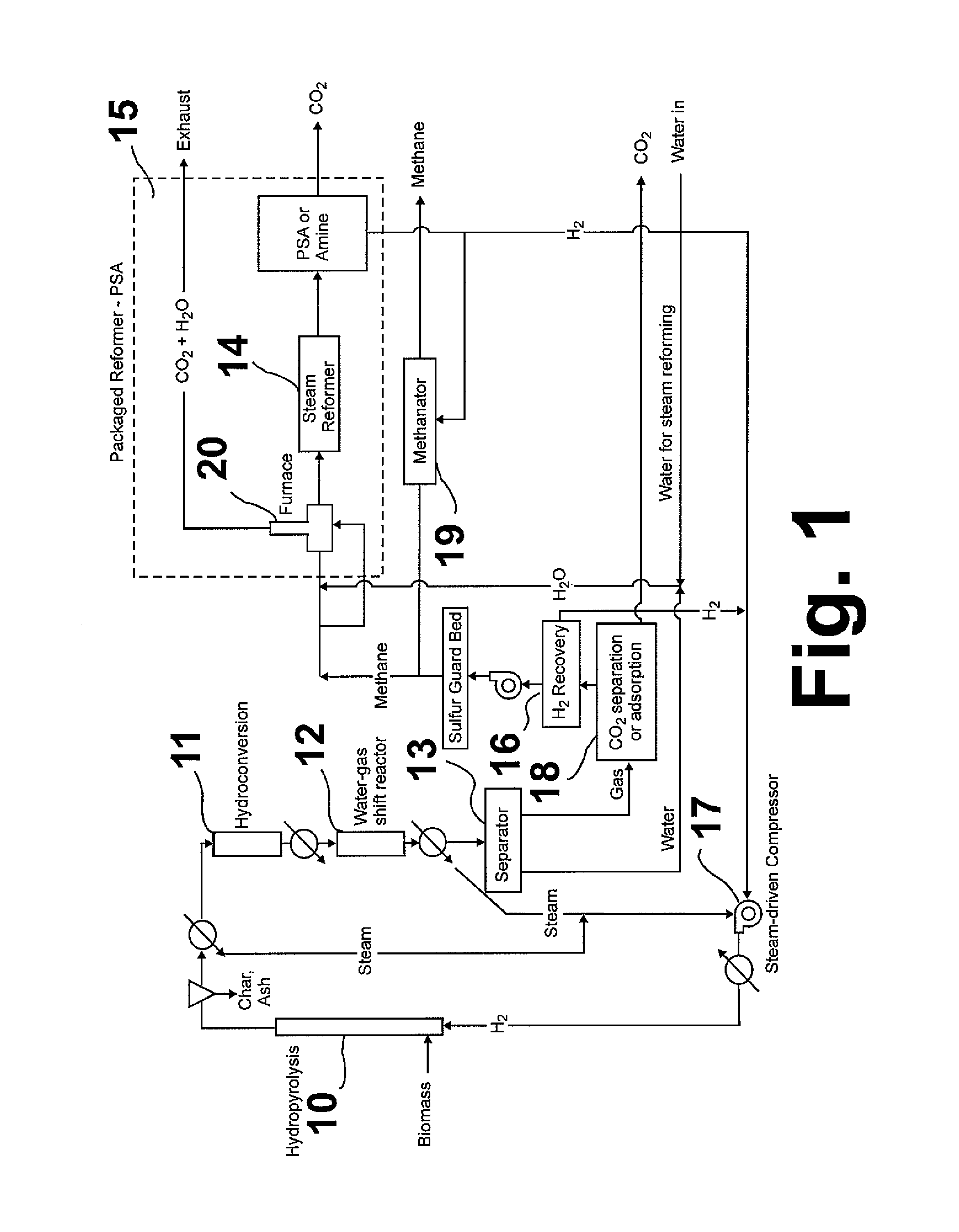

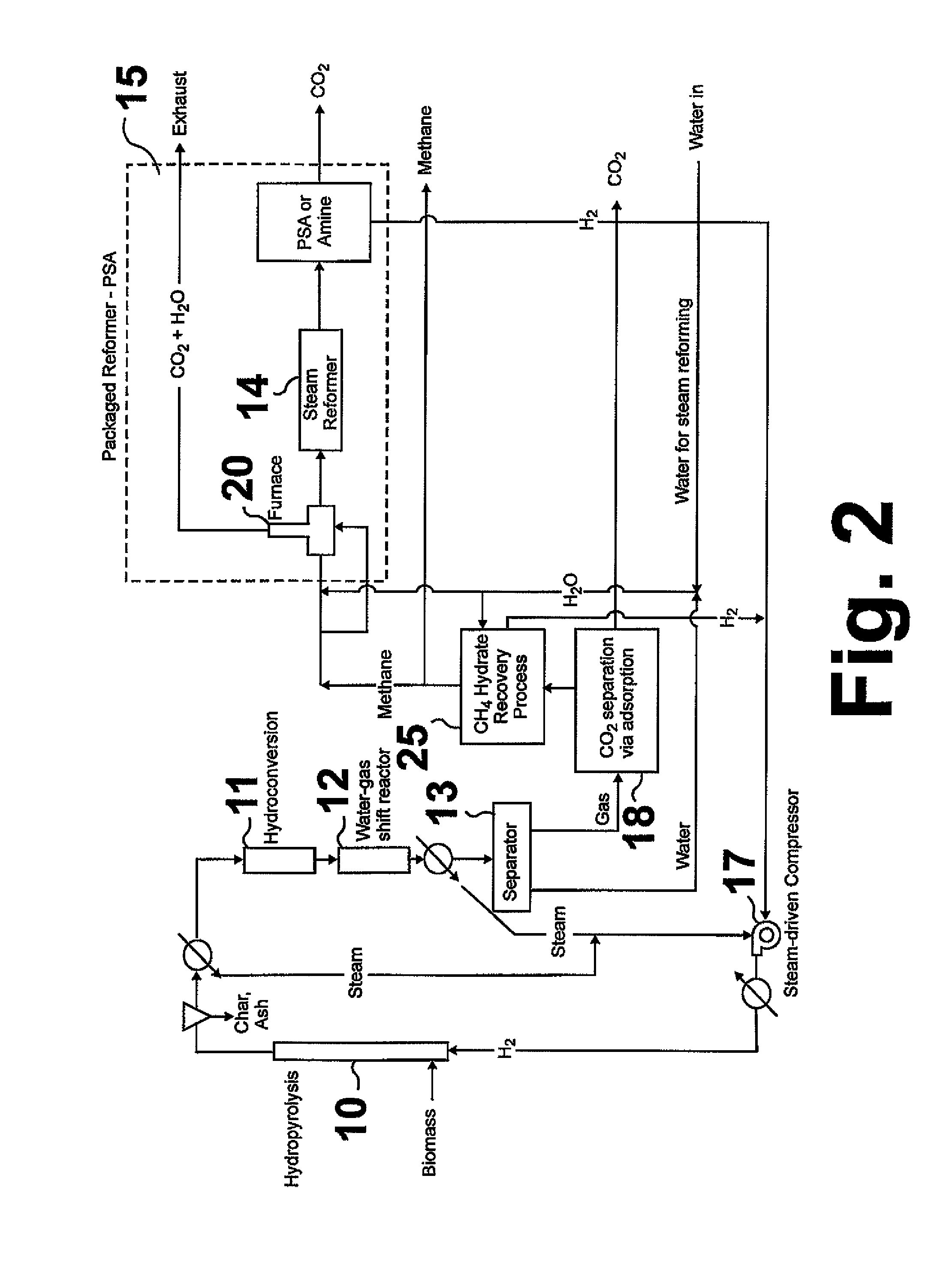

ActiveUS20100251615A1Superior methane yieldFast pyrolysisGasification catalystsDirect heating destructive distillationHydrogenProduct gas

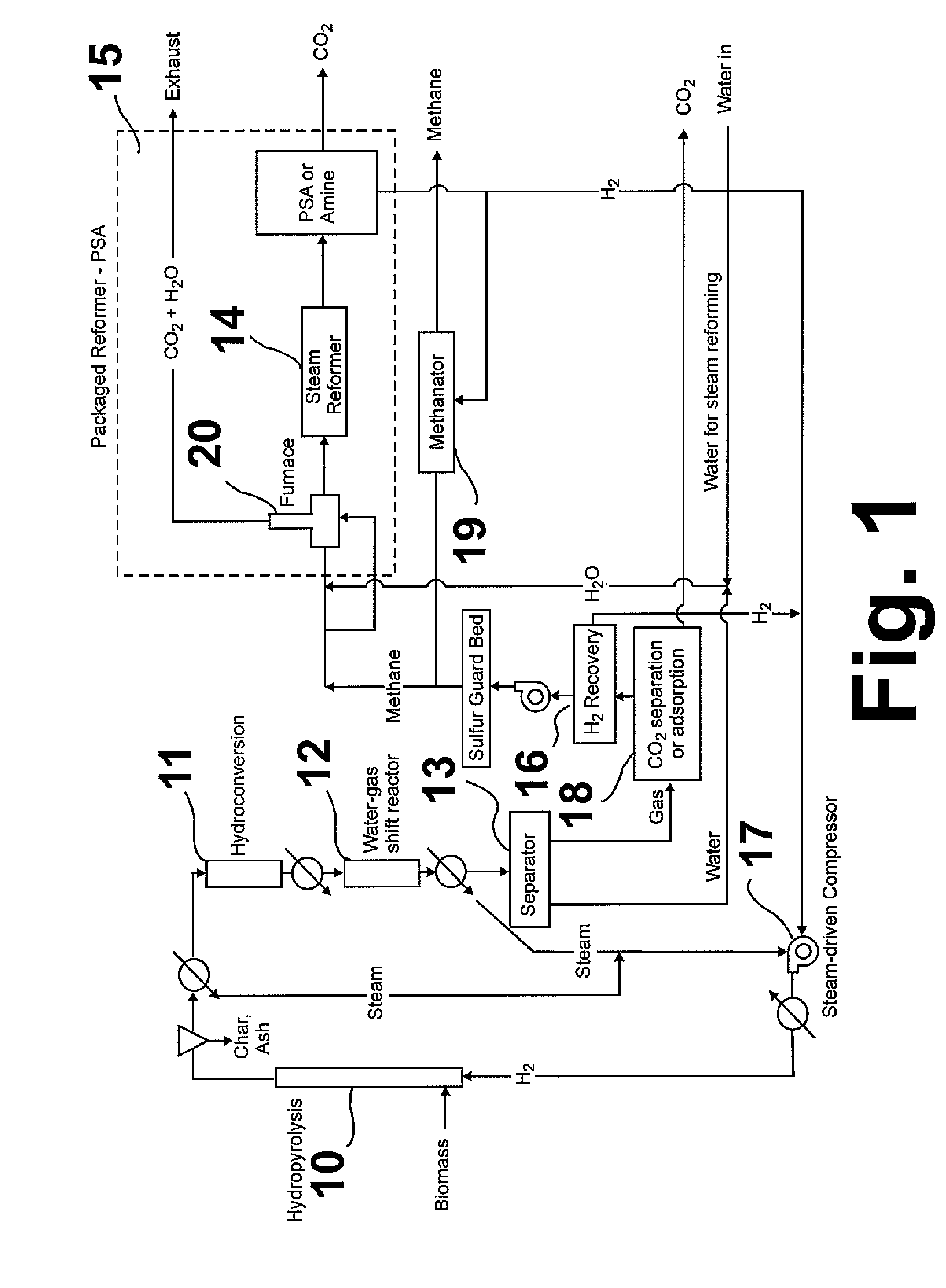

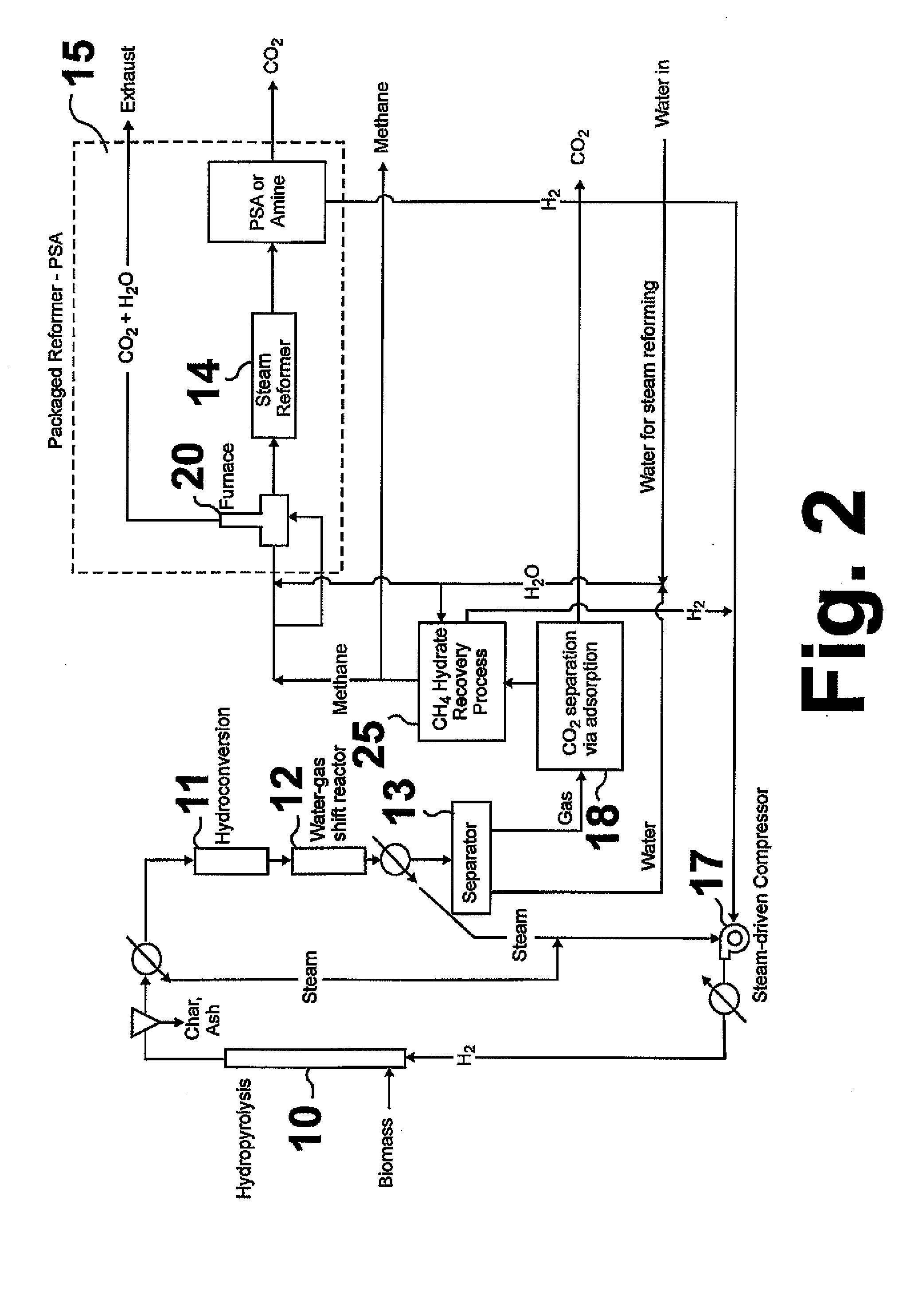

A multi-stage method and apparatus for producing methane from biomass in which the biomass is hydropyrolyzed in a reactor vessel containing molecular hydrogen and a deoxygenating catalyst, the output of which is hydrogenated using a hydroconversion catalyst. The output from the hydroconversion step is provided to a water-gas-shift process providing a mixture of H2O and product gases including CO2, H2, and methane. The mixture components are separated, resulting in a product stream comprising substantially only methane.

Owner:GAS TECH INST

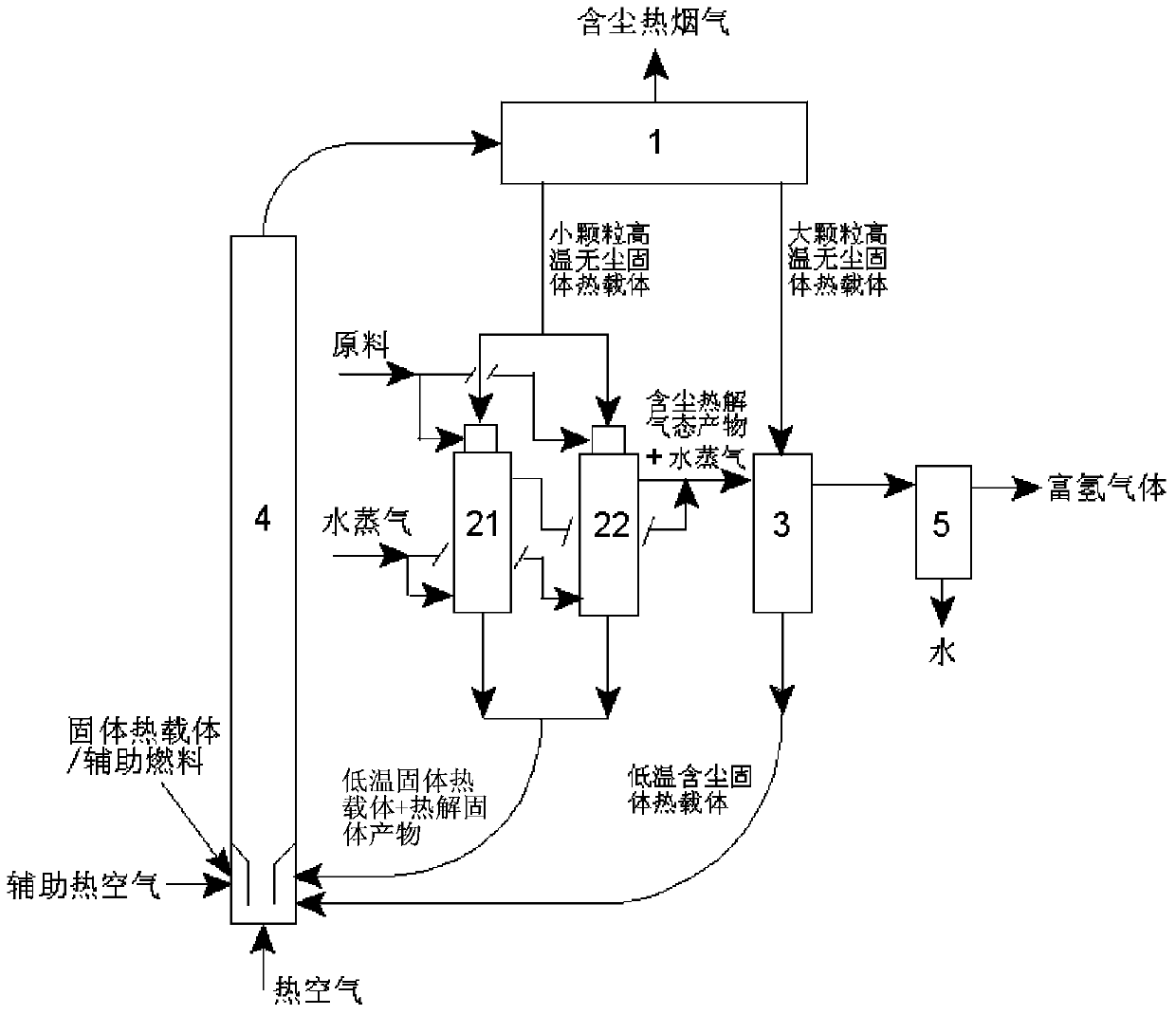

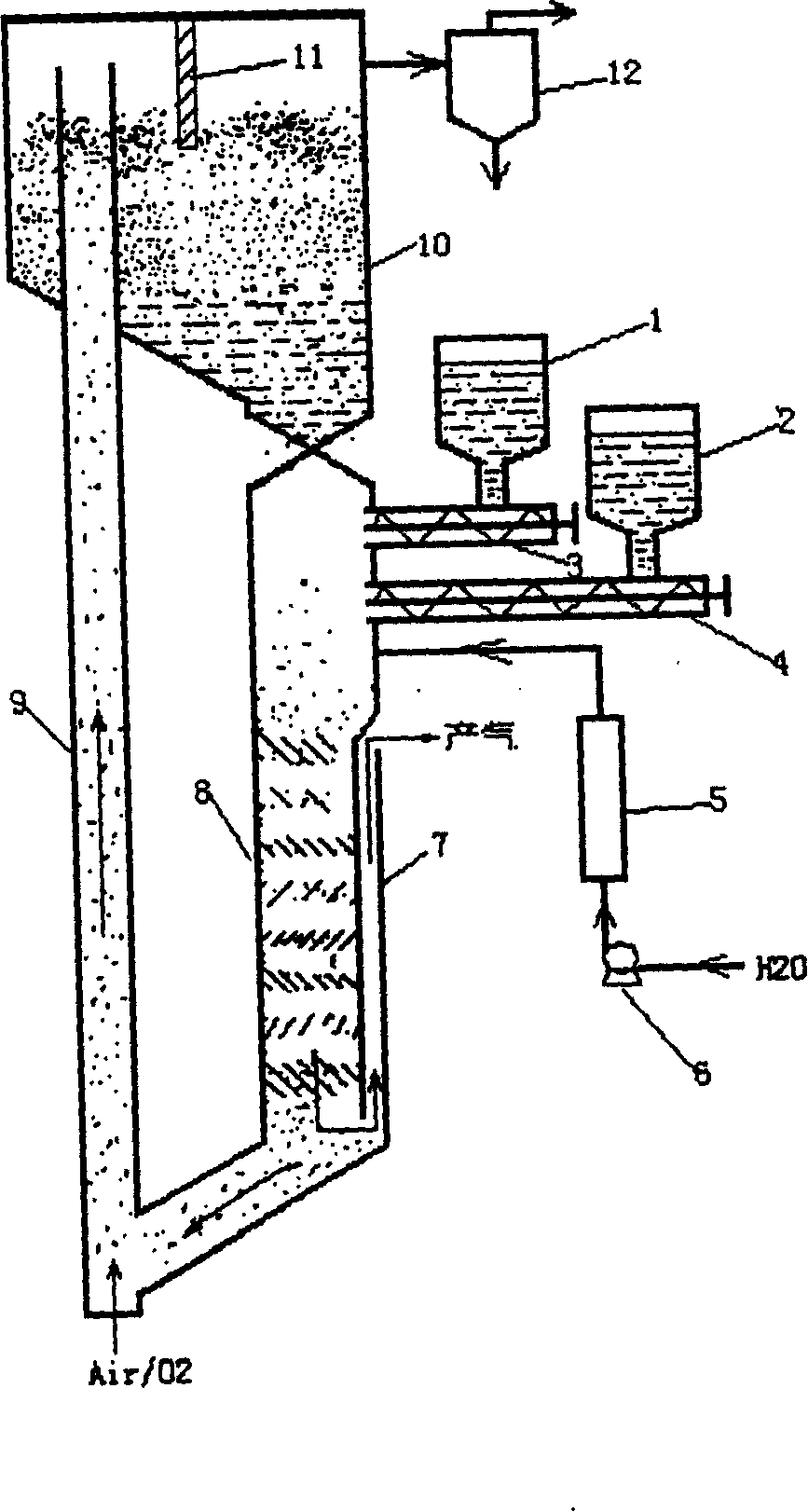

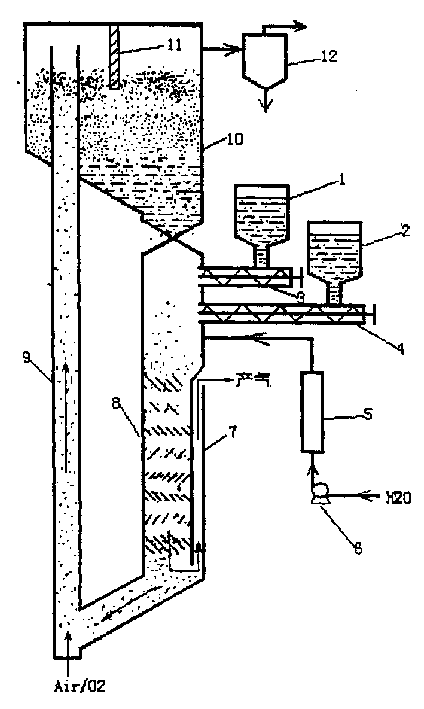

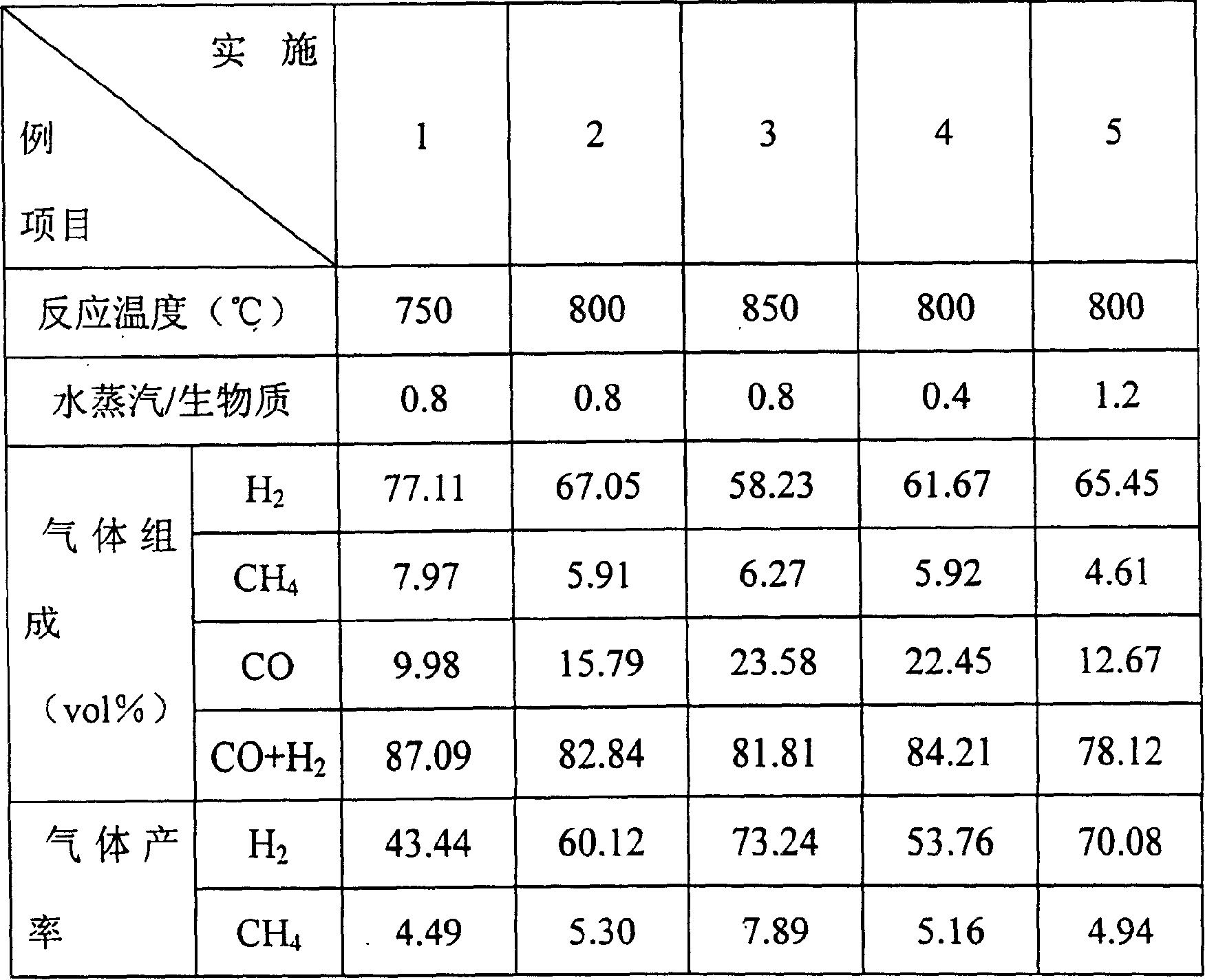

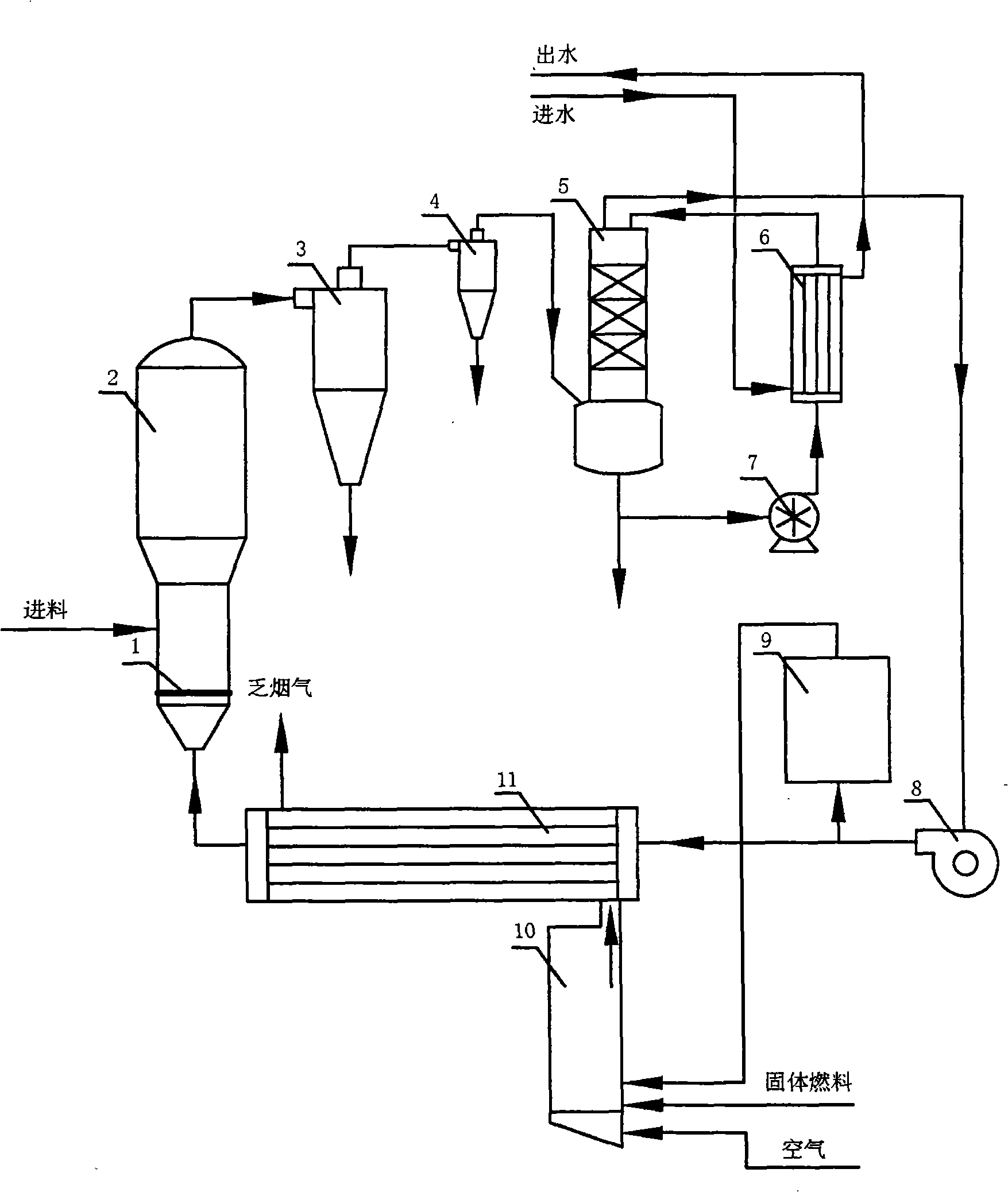

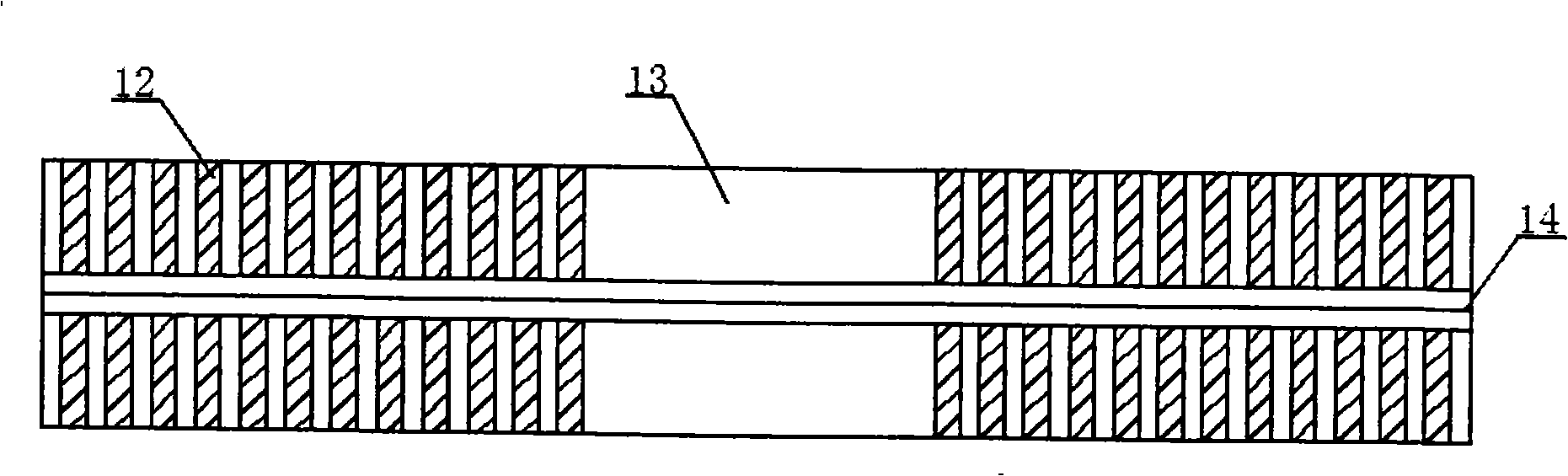

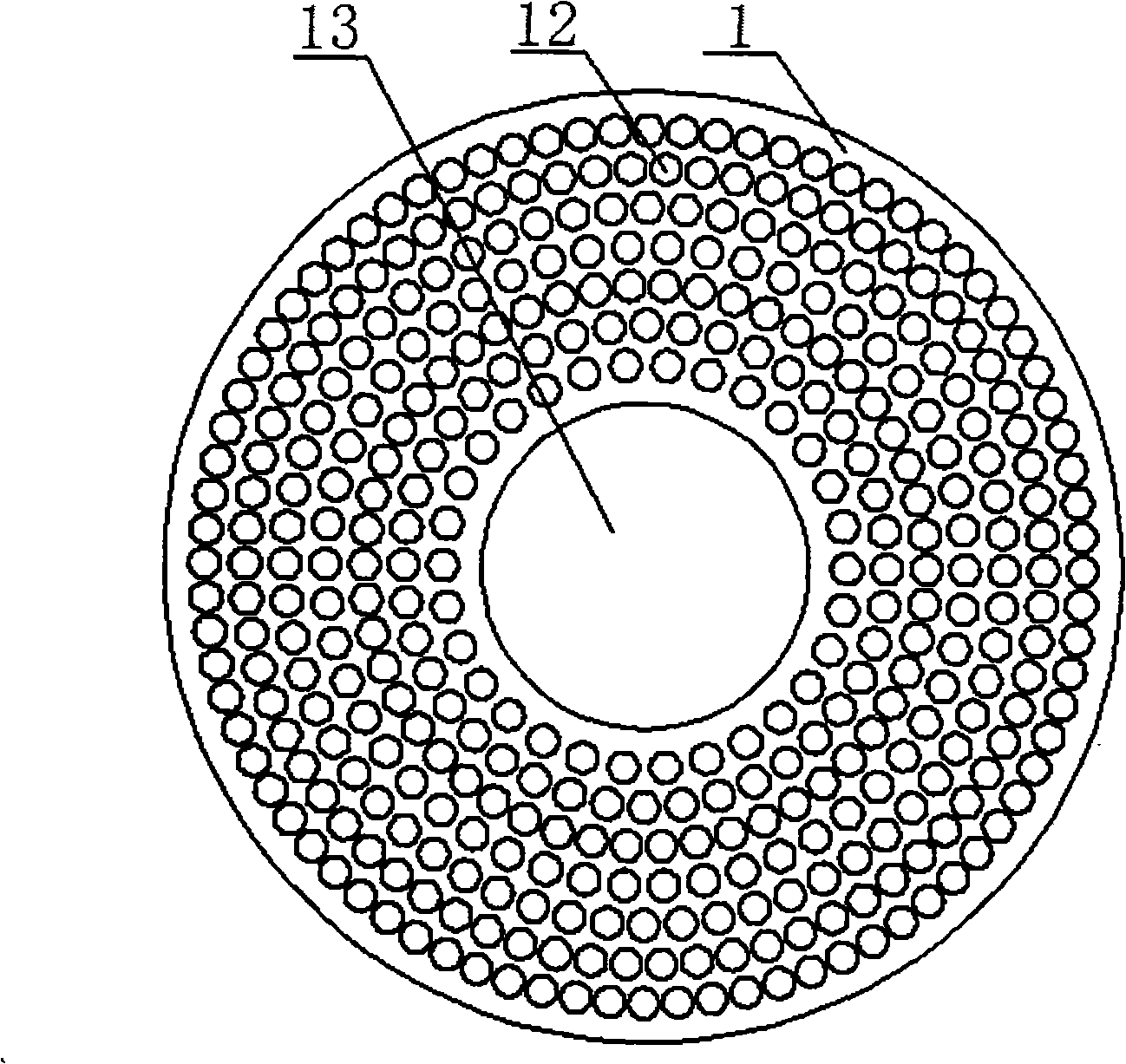

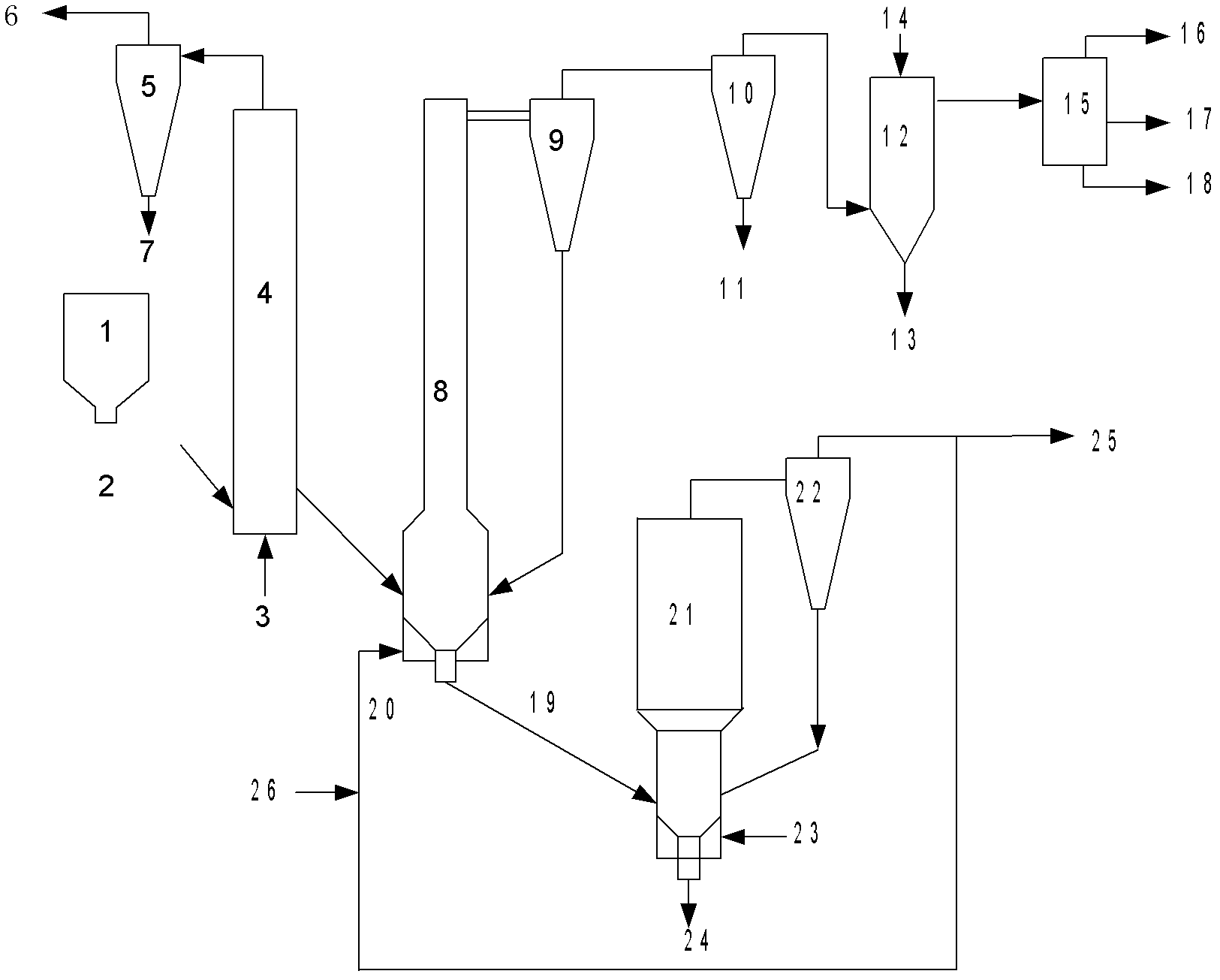

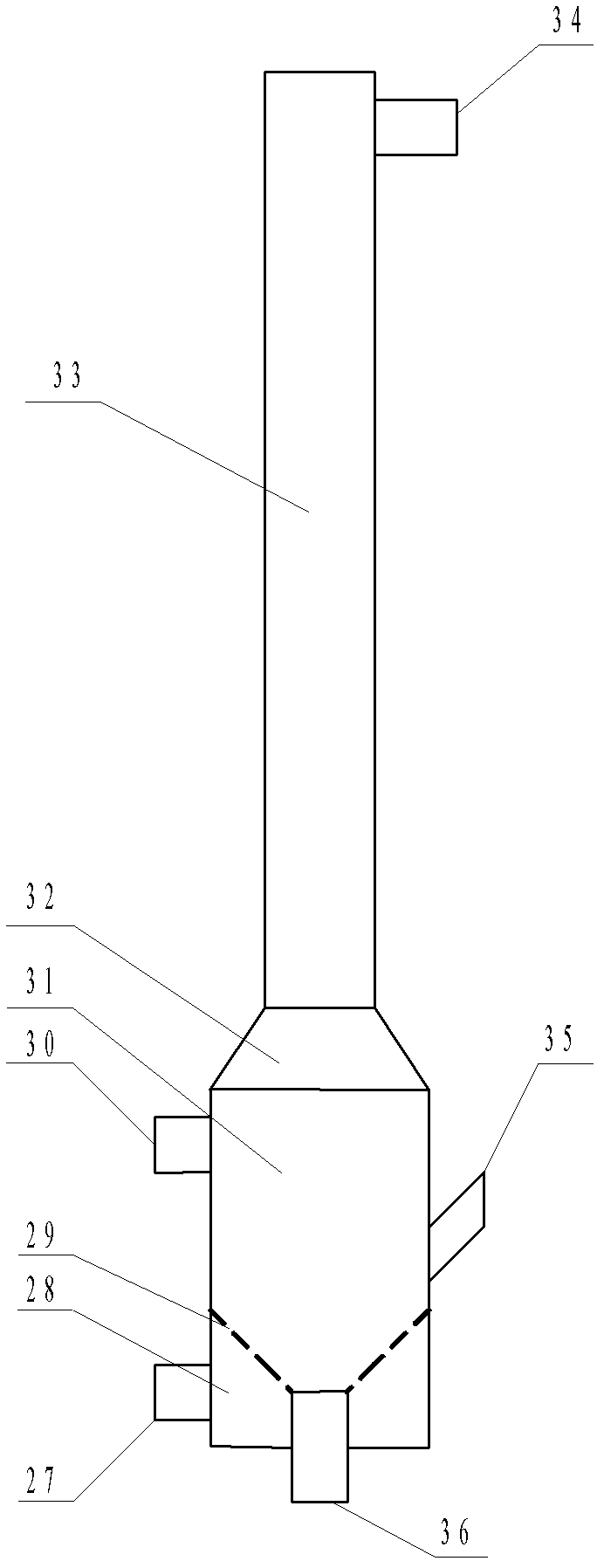

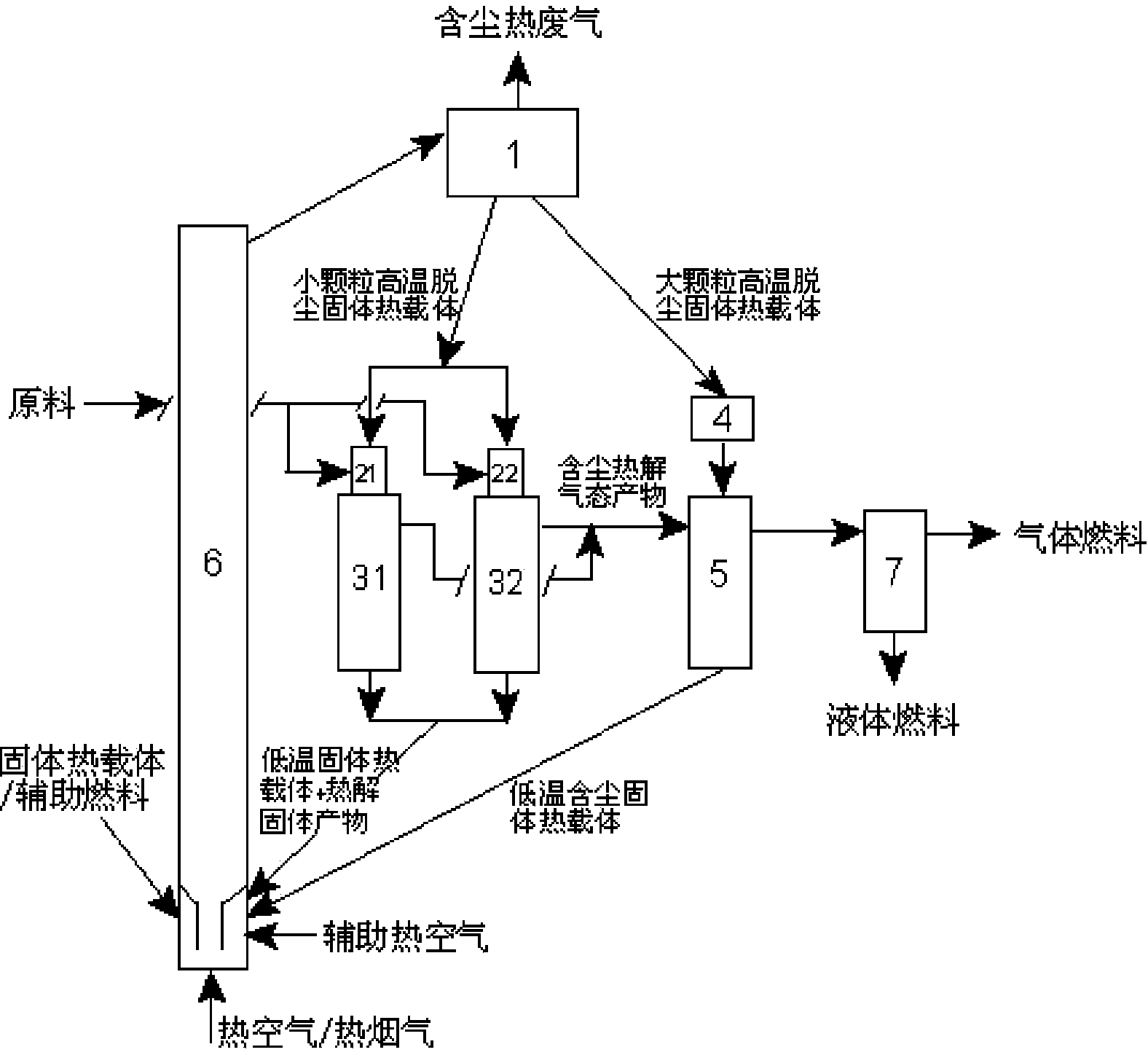

Preparation method for hydrogen-rich gas through steam gasification of solid organic matter

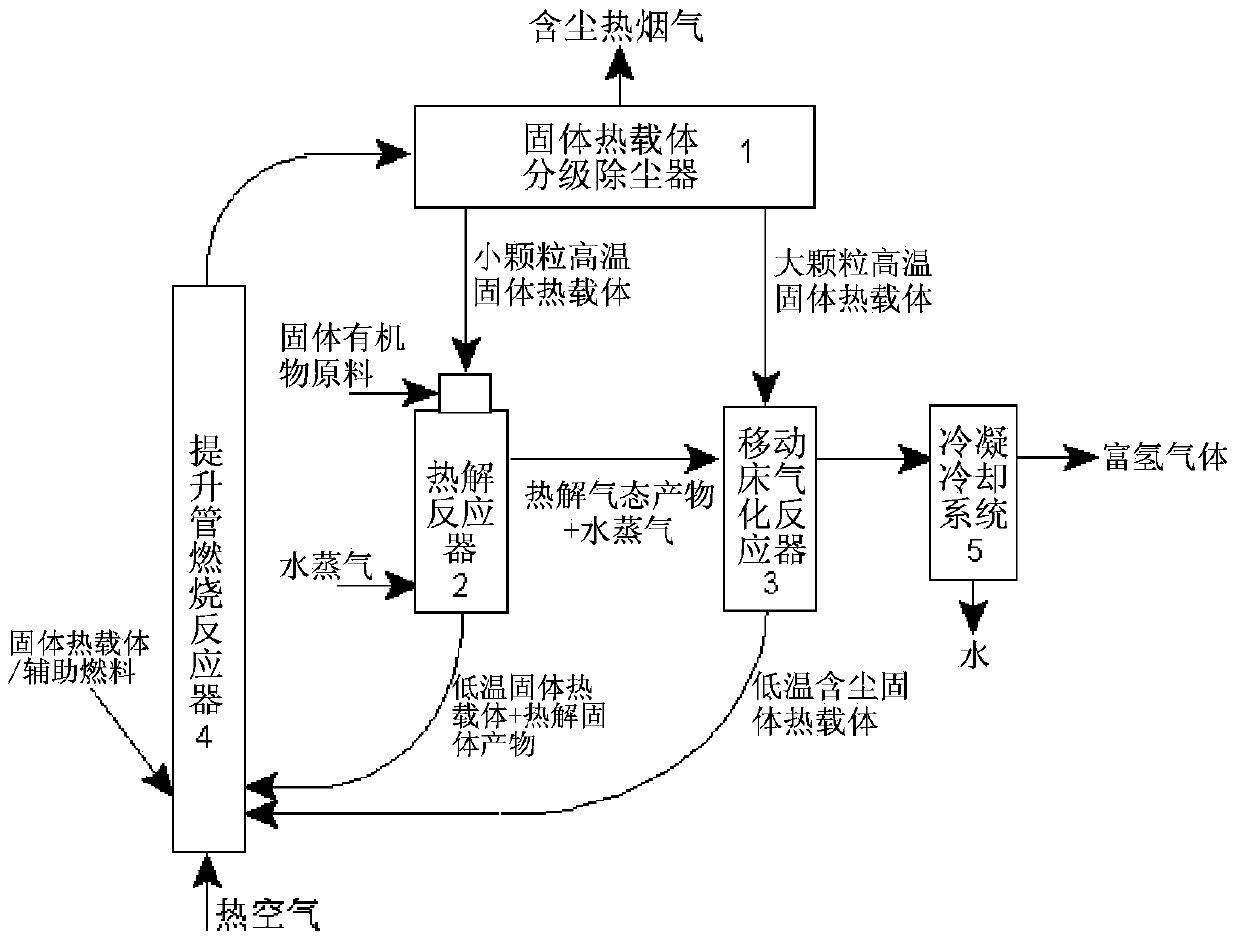

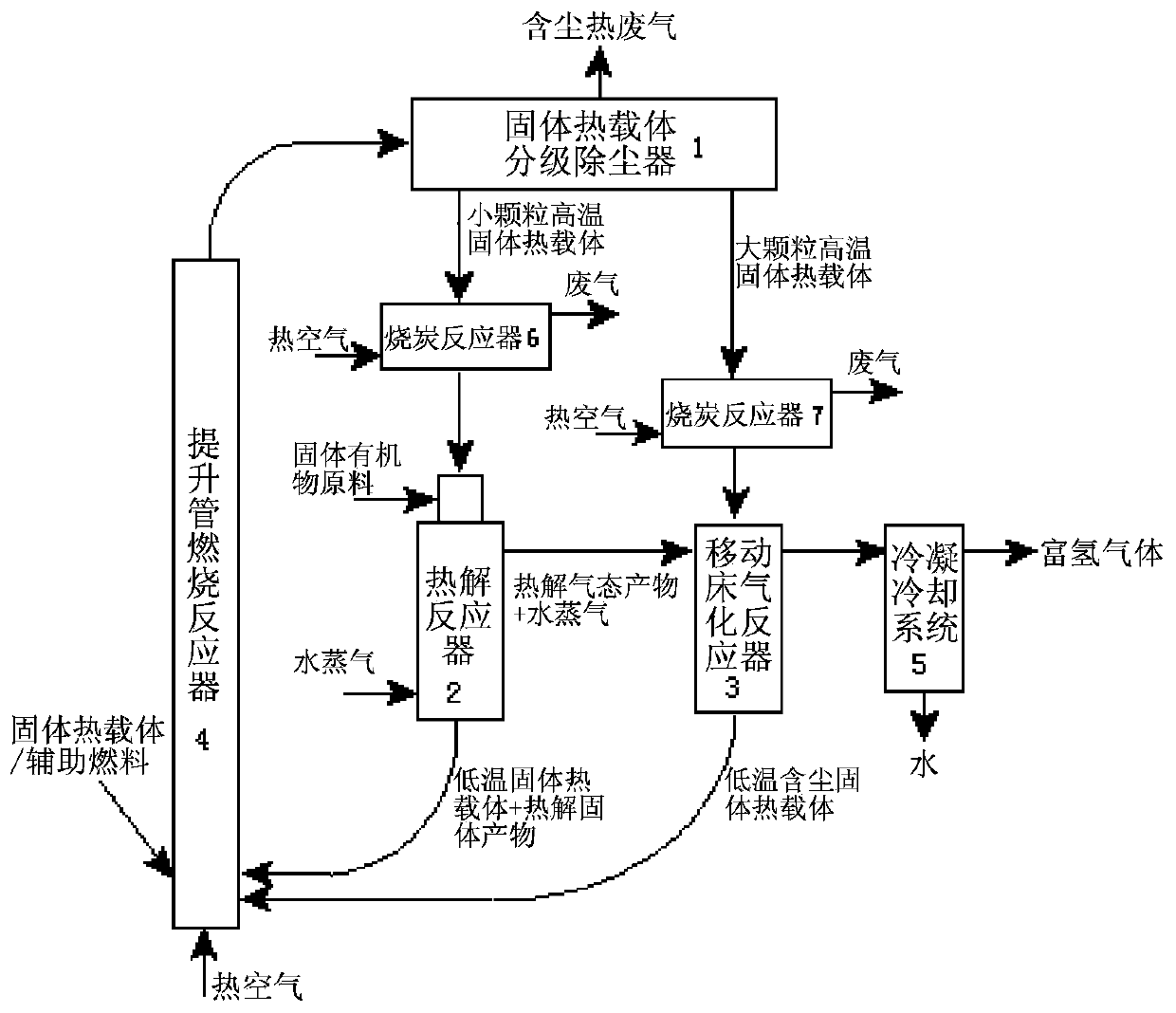

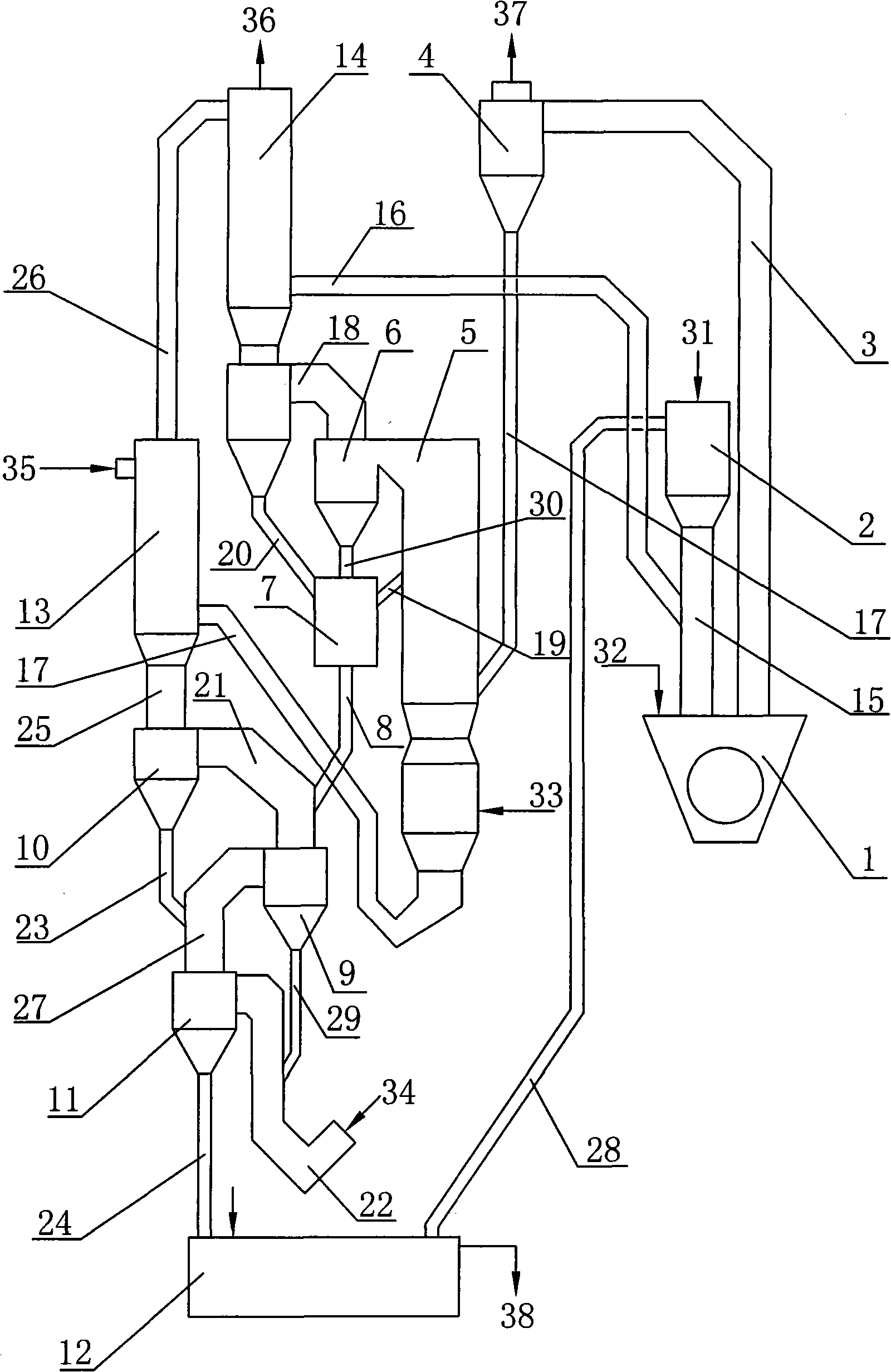

ActiveCN103468322AFast pyrolysisSimple processCombustible gas chemical modificationGasification catalystsWater vaporMoving bed

The invention provides a preparation method for hydrogen-rich gas through steam gasification of a solid organic matter. The method comprises the following steps: heating the raw material--the solid organic matter in a pyrolysis apparatus for pyrolysis; and subjecting a gaseous product produced after pyrolysis and steam to gasification in a moving bed gasification apparatus so as to produce the hydrogen-rich gas. The invention further provides a system for preparing the hydrogen-rich gas from the solid organic matter. The system comprises a solid thermal carrier gradient deduster, the pyrolysis apparatus, the moving bed gasification apparatus and a riser combustion reactor. The method provided by the invention is implemented at normal pressure, has simple process and is applicable to gasification and co-gasification of a variety of organic matters with high content of volatile components, including raw materials with high content of moisture, mineral matters and sulfur.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +1

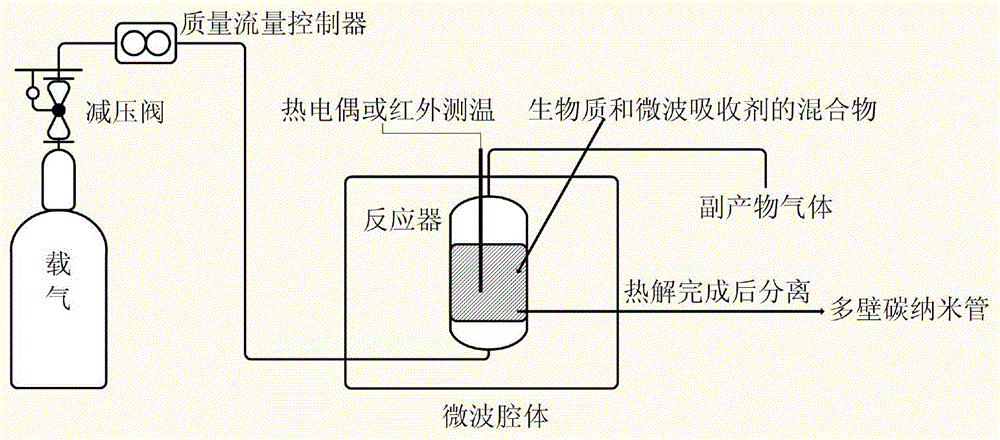

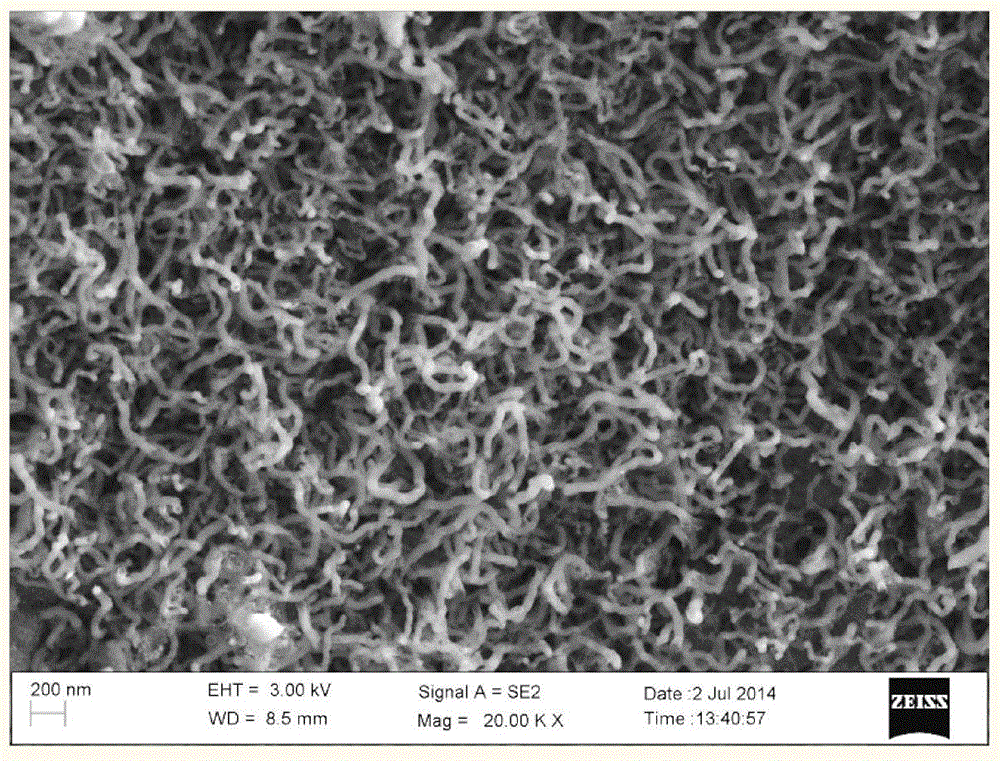

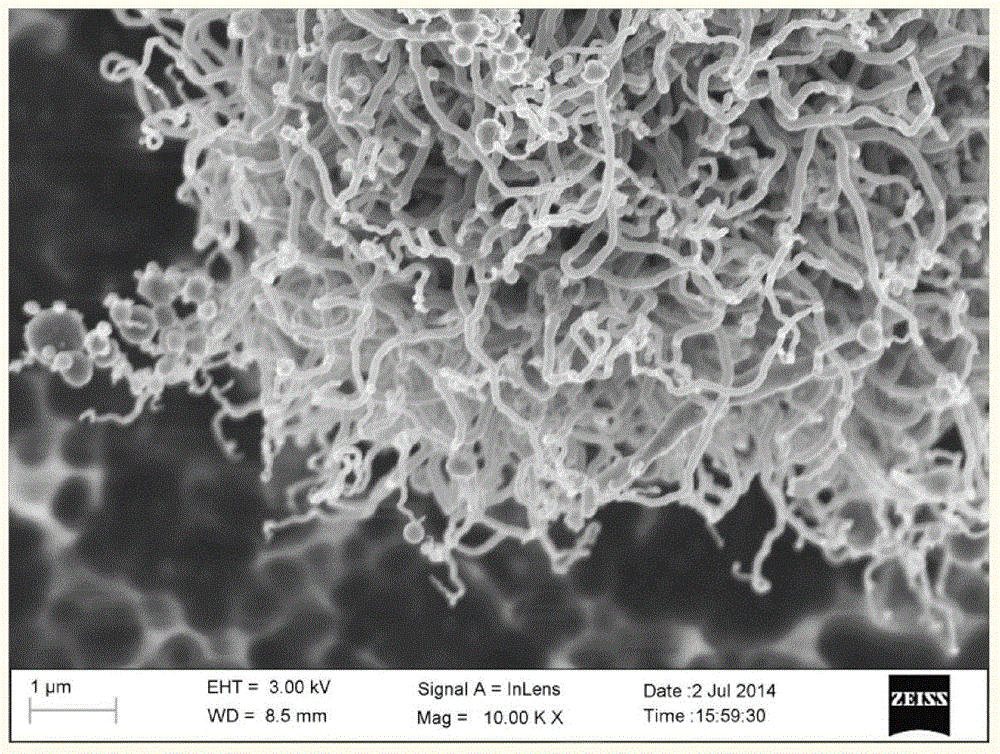

Method for preparing multiwalled carbon nanotube through microwave enhanced fast pyrolysis of biomass and/or carbonaceous organic waste

ActiveCN104787747AFast pyrolysisReduce manufacturing costMaterial nanotechnologyMean diameterMicrowave cavity

The invention discloses a method for preparing a multiwalled carbon nanotube through microwave enhanced fast pyrolysis of biomass and / or carbonaceous organic waste. The method comprises the following steps: biomass, carbonaceous organic waste, a mixture of the biomass and carbonaceous organic waste or a mixture of the biomass and carbonaceous organic waste uniformly mixed with a microwave absorbent is placed in a reaction vessel in a microwave cavity; an inert gas is introduced into the reaction vessel until an oxygen-free environment is formed; the microwave input power is adjusted to be higher than 500w, and the reaction vessel is heated to 400-1,500 DEG C for a pyrolytic reaction; the multiwalled carbon nanotube is obtained after the reaction. The method for preparing the multiwalled carbon nanotube is cheap and easy, the prepared carbon nanotube is curly, has the mean diameter of 3 nm-200 nm, can be applied to the fields of composites, electrode materials, catalyst preparation and the like and has a broad application prospect.

Owner:THE UNIV OF NOTTINGHAM NINGBO CHINA

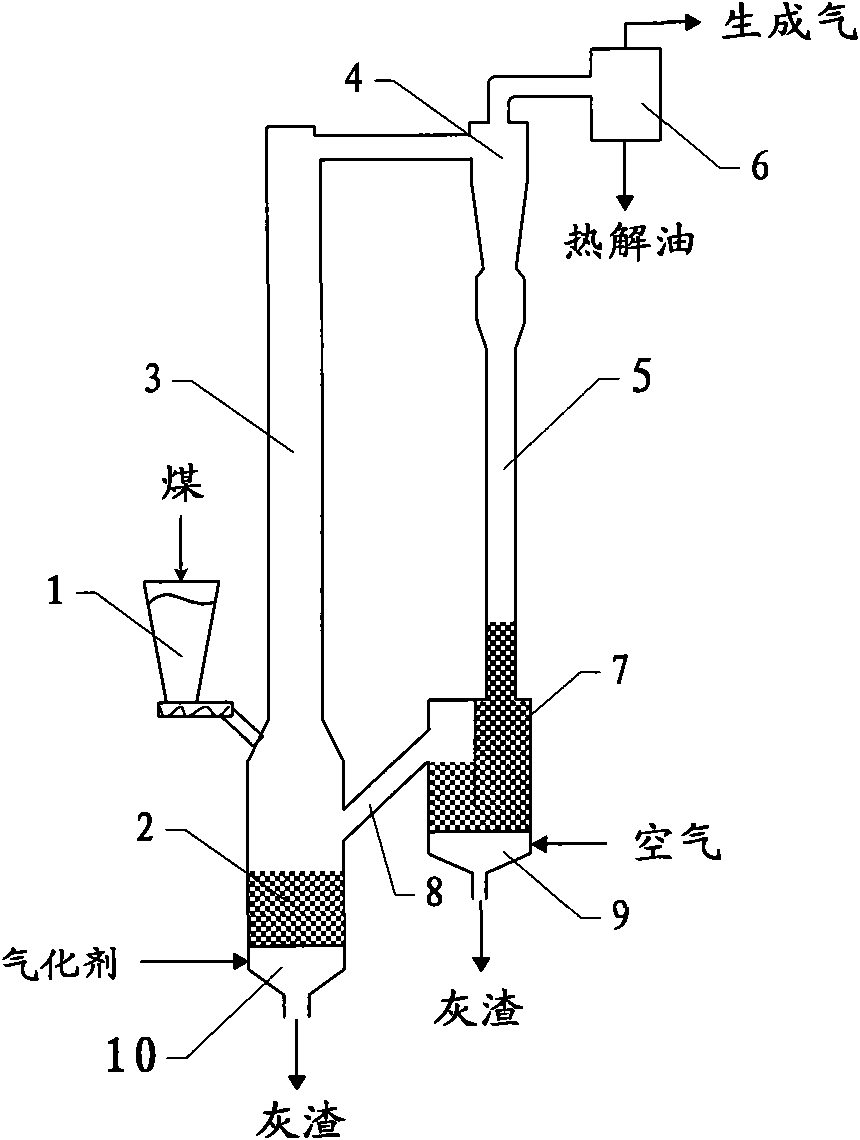

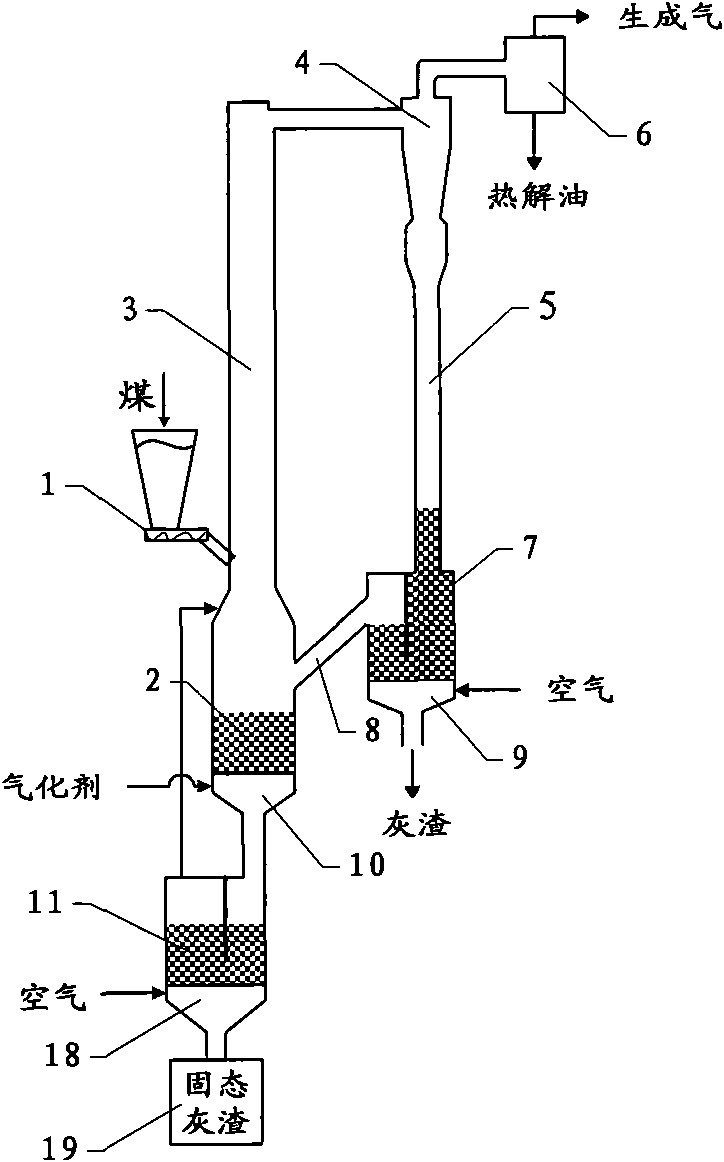

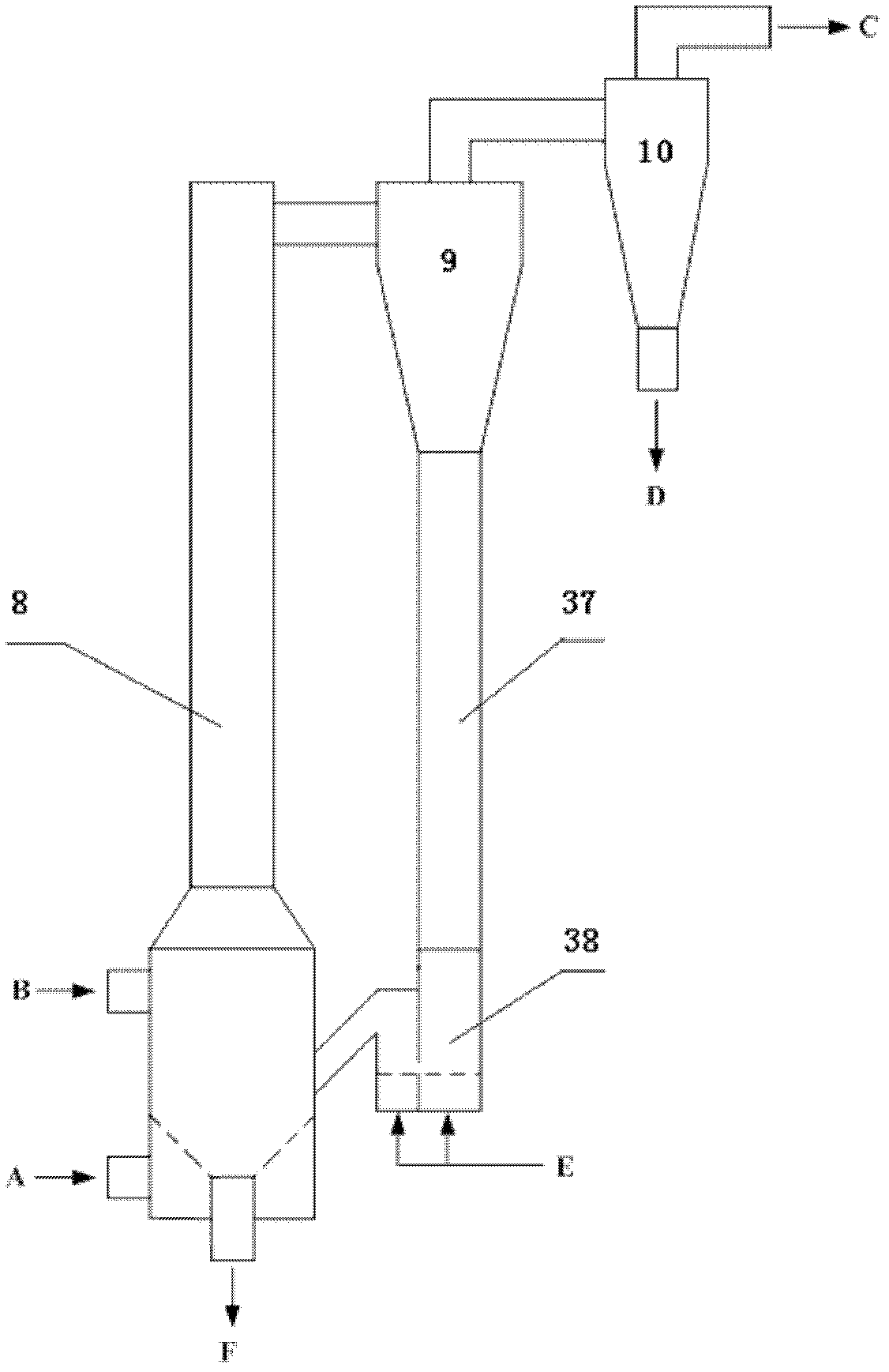

Method and device for utilizing high value through pyrolysis and gasification of coal

ActiveCN101781583ARealize joint productionFast pyrolysisLiquid hydrocarbon mixture productionCombined combustion mitigationOrganic structureFluidized bed

The invention relates to a method and a device for utilizing high value through pyrolysis and gasification of coal. The pyrolysis and gasification processes of the coal are separated in a mode of coupling a dilute phase conveying bed and a dense phase fluidized bed; and the coal is partially or wholly pyrolyzed before gasification, and co-production of pyrolysis gas, gasification generated gas and pyrolysis oil is realized. The dilute phase conveying bed and the dense phase fluidized bed can be coupled in two modes, namely upper-lower coupling and left-right coupling, and are applied to treating the coal in wide particle diameter distribution. High-value organic structures in the coal can be extracted before the gasification of the coal, and the utilization value of the coal is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process of catalyzing and gasifying fresh substance by solid thermophore for preparing hydrogen-rich gas

InactiveCN1482056AFast pyrolysisRapid mixing and heatingDirect heating destructive distillationHydrogen productionHydrogenHeat carrier

The present invention relates to the method of extracting hydrogen from biomass, and is especially the solid heat carrier catalyzing and gasifying method of preparing hydrogen-rich gas from biomass.The method includes mixed heating of solid heat carrier catalyst and biomass, fast thermolysis of biomass, catalytic gasifying and regeneration circulation of solid catalyst grain. The catalyst as solid heat carrier has accumulated heat for gasifying biomass. The technological apparatus consists of mobile bed reactor, material feeder, regenerating riser tube, catalyst storage tank, etc. The present invention makes the hydrogen in biomass converted into hydrogen gas at most, and the continuous switch-less regeneration of catalyst solves the problem of fast deactivation of catalyst. The present invention has low tar content, simple operation and high gas product purity, and is new technological process with great potential.

Owner:DALIAN UNIV OF TECH

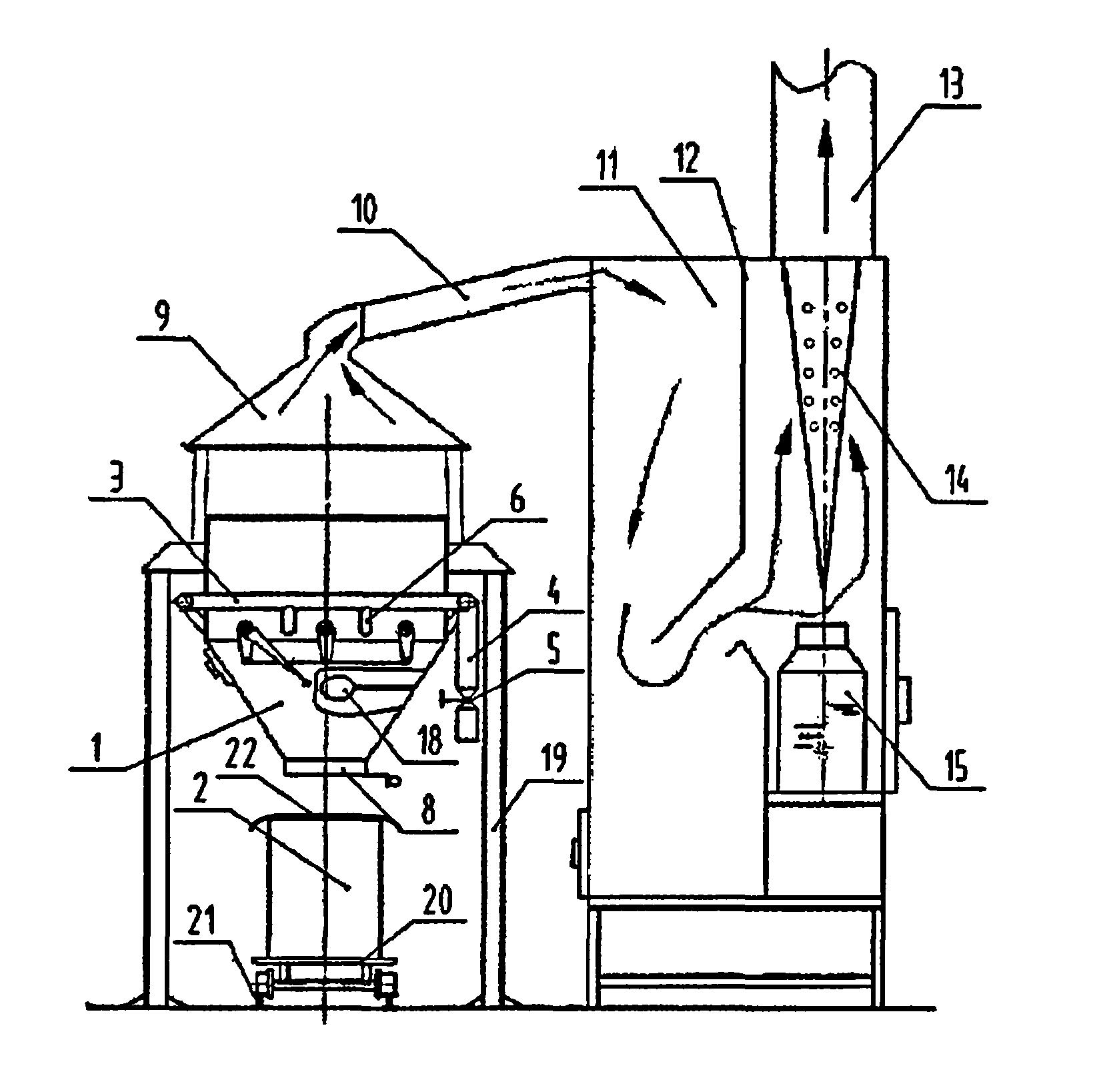

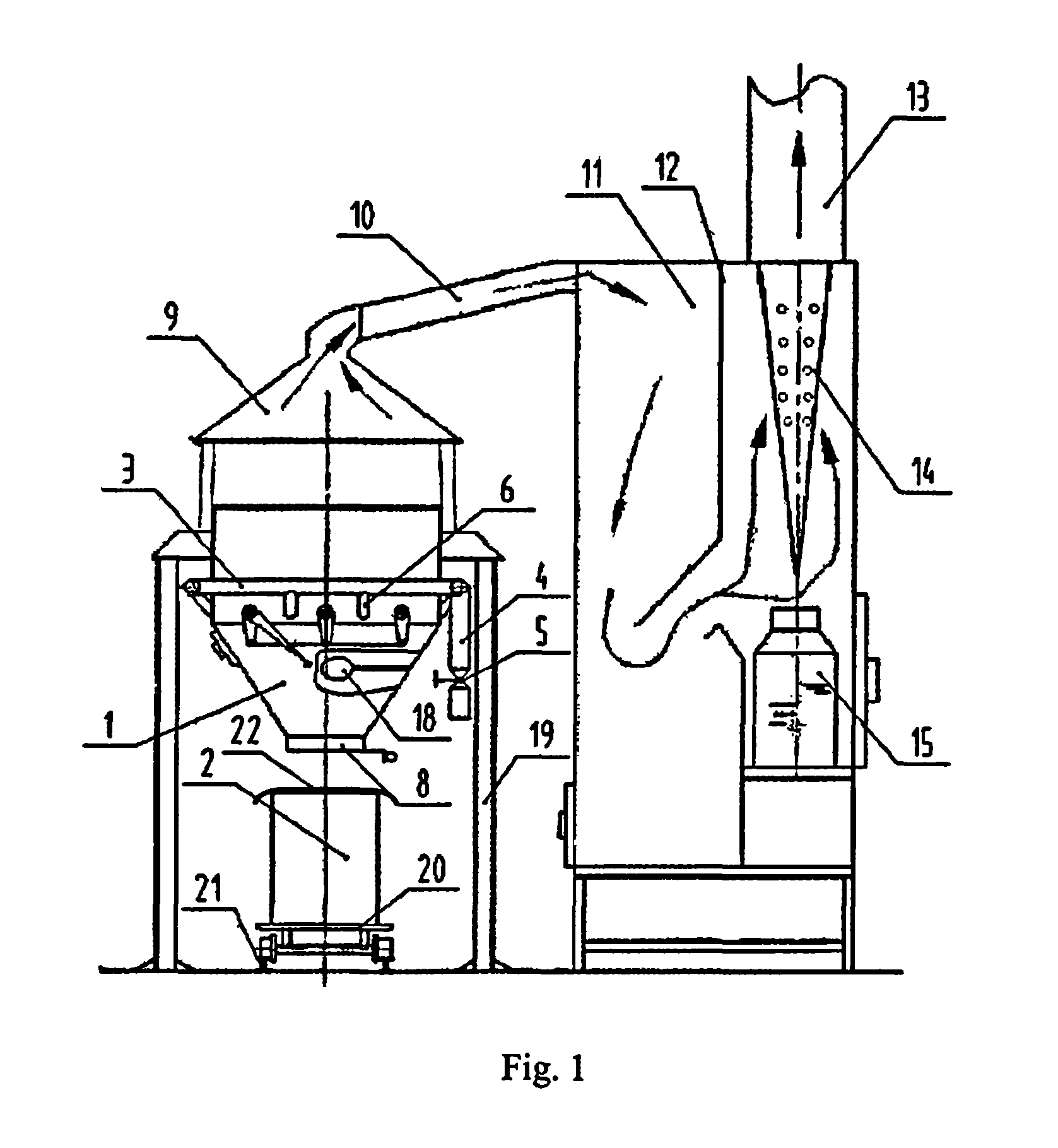

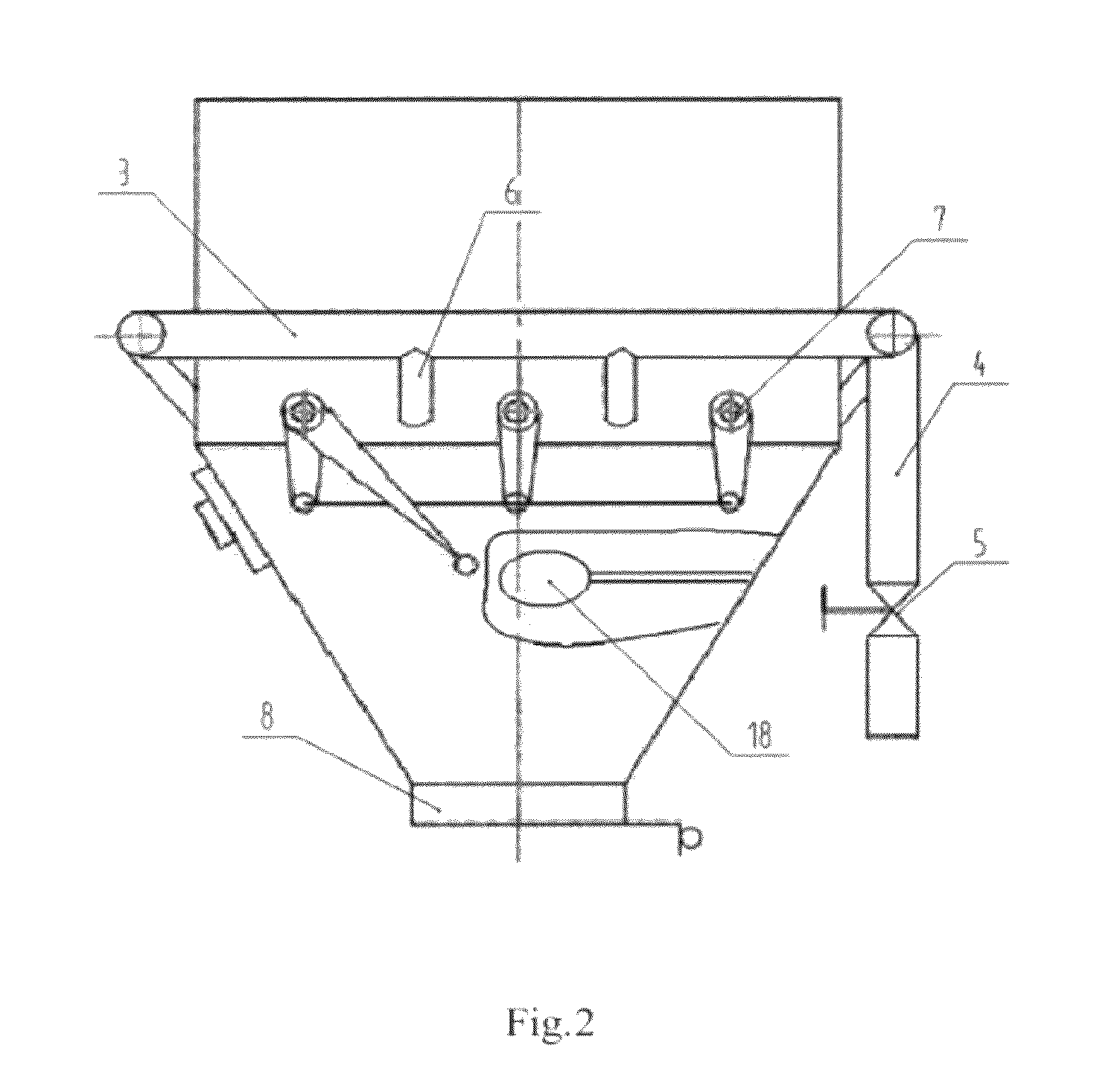

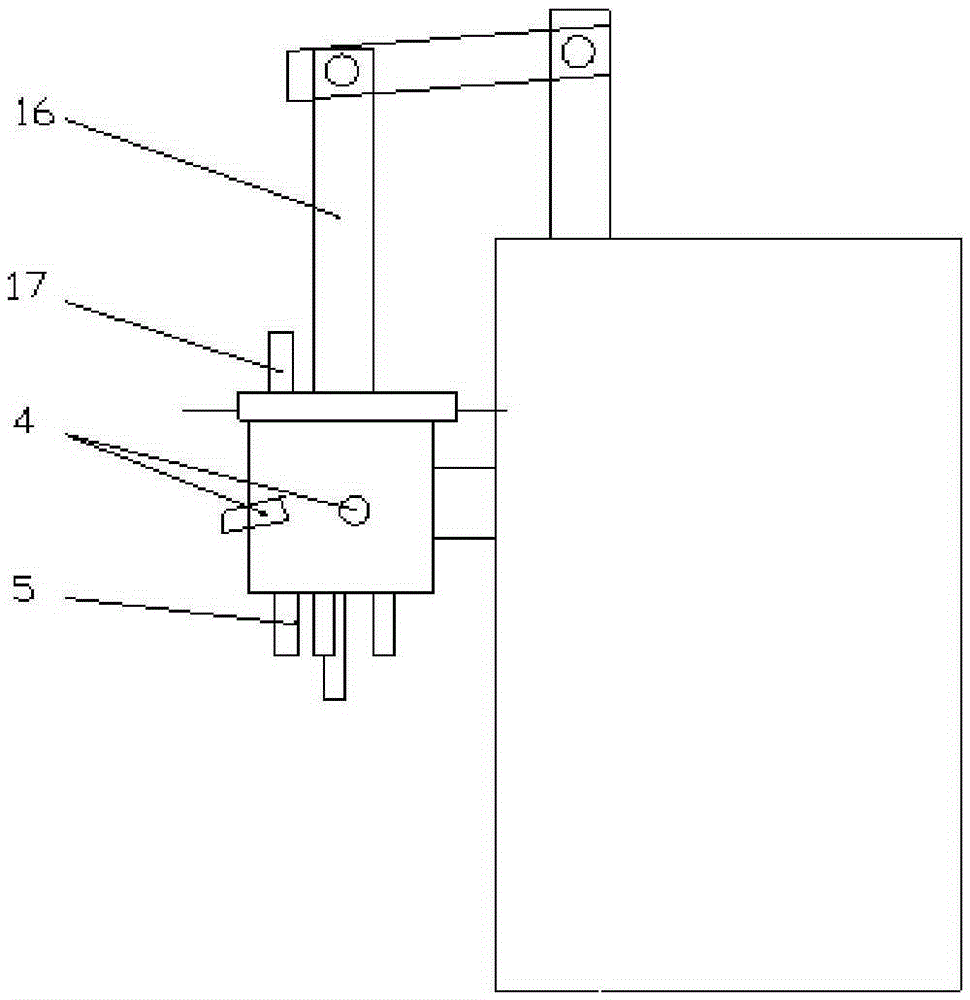

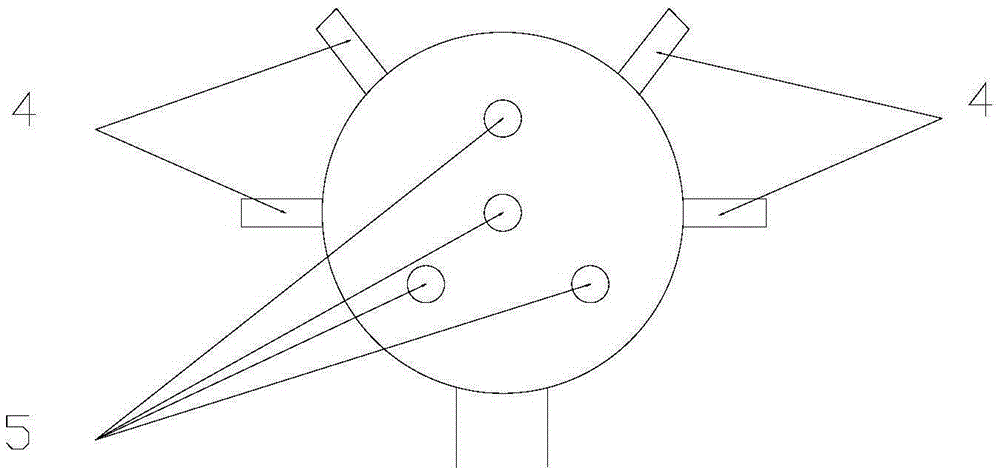

Industrial continuous agricultural and forestry biomass fast pyrogenation oil refining method and device thereof

InactiveCN101525545AAvoid settingSimple structureLiquid hydrocarbon mixture productionProduct gasEngineering

The present invention relates to an industrial continuous agricultural and forestry biomass fast pyrogenation oil refining method and a device thereof. The invention belongs to the technical field of biomass regeneration utilization and changing into energy. The crushed and dried agricultural and forestry biomass material is delivered into a pyrolysis reactor from the base for reacting. The carbon and pyrolysis are generated, wherein the pyrolysis enters a condenser along with the circulating gas. The bio-oil obtained after condensing the pyrolysis gas and incoagulable gas enter a reacting system for being heated by a combustion furnace for recycling. The fast pyrogenation oil refining method and the device of the invention use the incoagulable gas generated in the system as circulating fluidizing agent gas and heat supplying gas for high-efficiently executing the fast pyrogenation, gas-solid separation, condensing oiling of agricultural and forestry biomass and furthermore realizing the excellent circulation in the system. The device of the invention also has the advantages of reasonable structure of reactor, compact mechanism, stable operation of whole device, and suitability for industrial continuous production.

Owner:北京海润川投资咨询有限公司

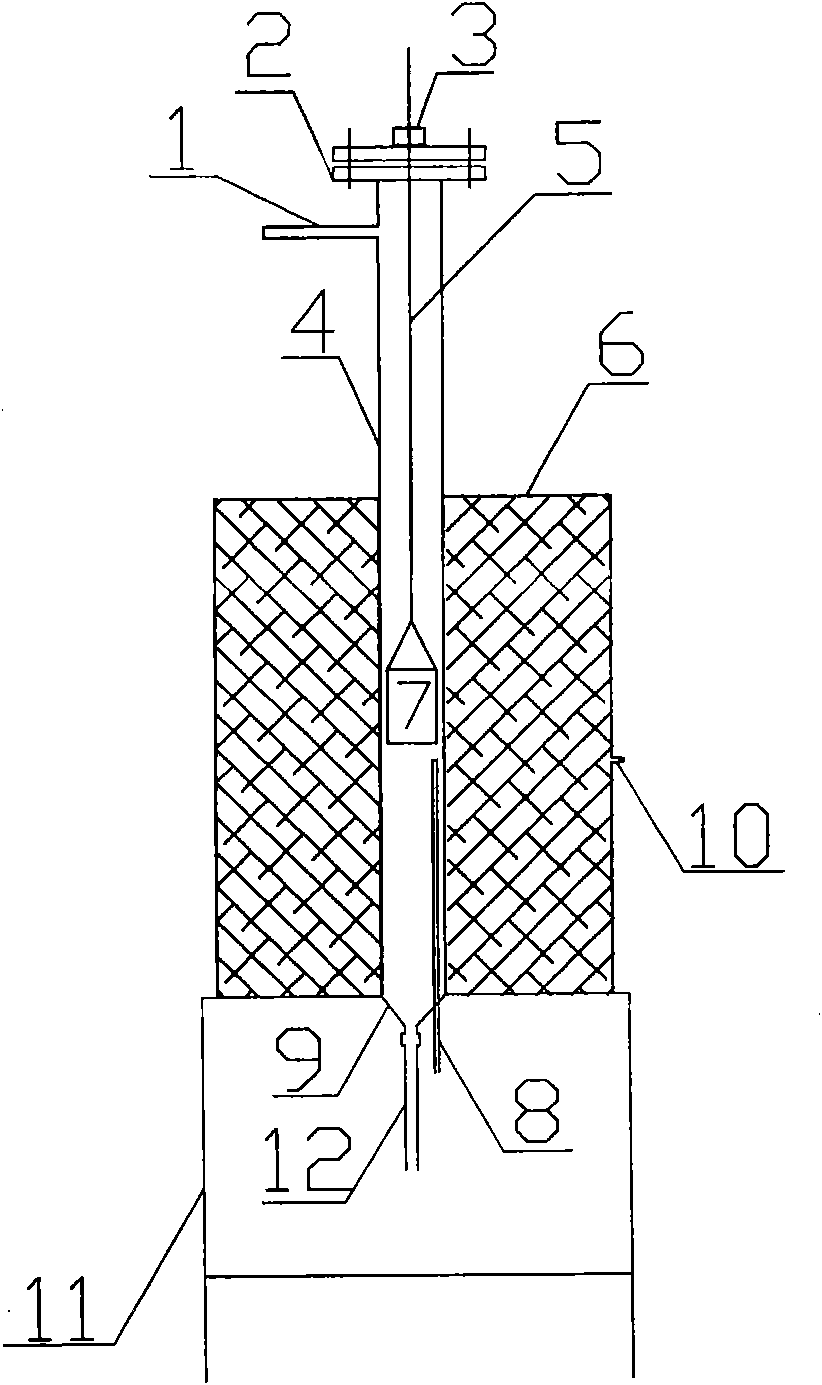

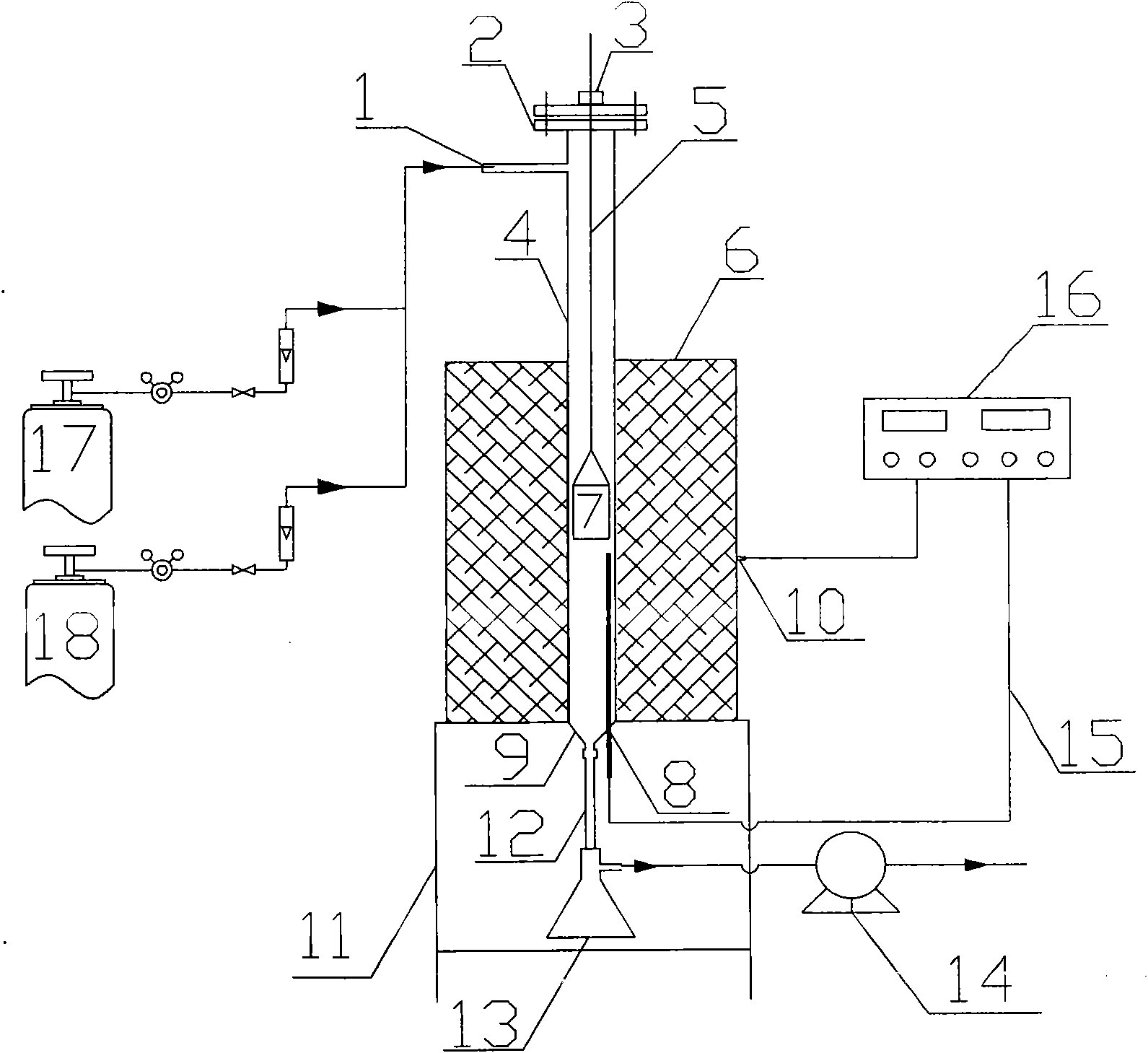

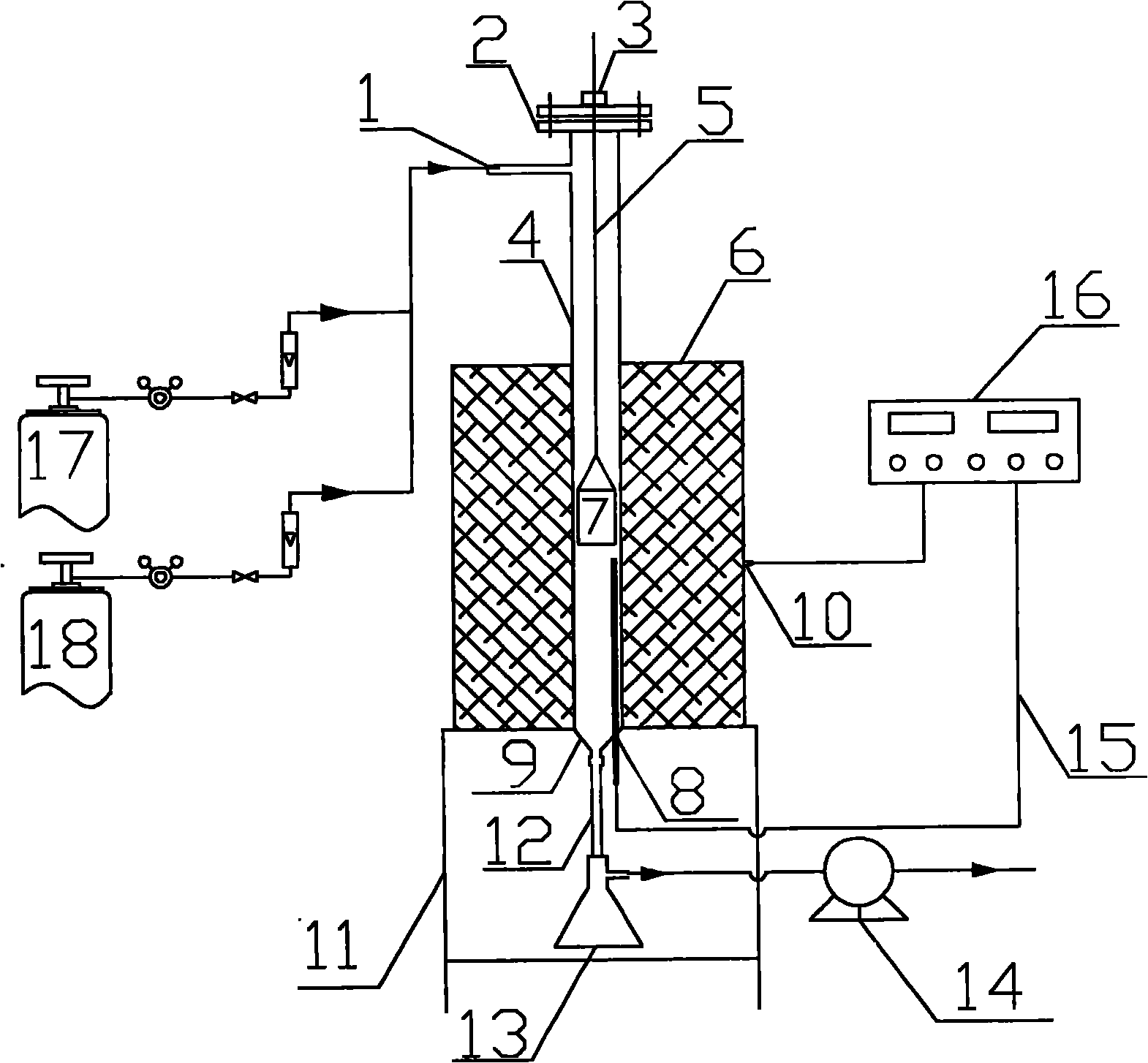

Fast pyrolytic test device and application

InactiveCN101846642AFast pyrolysisGood value for moneyMaterial weighingInvestigating phase/state changeTarEngineering

The invention relates to a fast pyrolytic test device, which consists of a tubular electric heating furnace (6), an object carrying frame (11), a temperature test and control opening (8), a reaction tube (4), an air inlet opening (1) and an oil air outlet opening (9). The invention is characterized in that the air inlet opening (1) is arranged at the upper part of the reaction tube (4), the top of the reaction tube (4) is provided with an adjustable sealing element (3), a stainless steel rod (5) is arranged in the reaction tube (4), the top end of the stainless steel rod (5) is connected with the adjustable sealing element (3), the lower end of the stainless steel rod (5) is connected with a sample hanging basket (7), the middle lower part of the reaction tube (4) is positioned inside the tubular electric heating furnace (6), the bottom of the reaction tube (4) is provided with the temperature test and control opening (8) and the conical oil air outlet opening (9), the conical oil air outlet opening (9) is connected with an oil air outlet tube (12), and the tubular electric heating furnace (6) is positioned on the object carrying frame (11). The invention has the advantages of high performance price ratio, simple and convenient operation, simple structure and low equipment cost, can realize slow temperature rise and fast pyrolysis under the condition of simulated work conditions, can realize fast cooling, and can accurately measure the tar amount generated by the pyrolysis.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

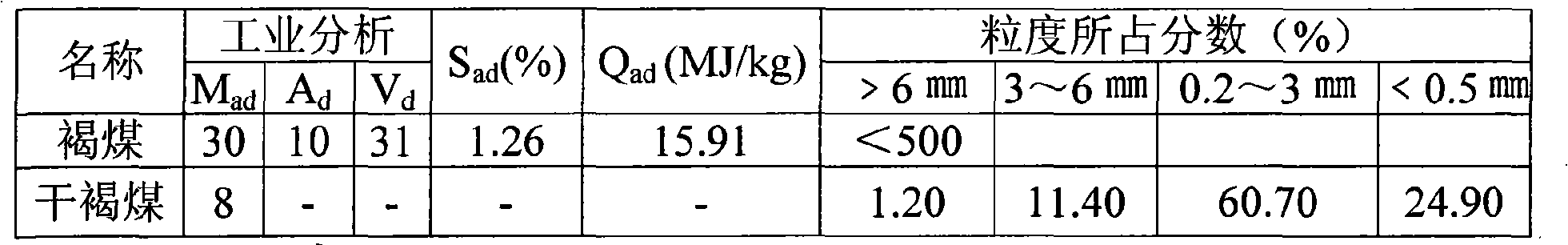

Large-scale brown coal quality-improving process and apparatus

InactiveCN102757833AImprove utilizationComprehensive utilization of product quality improvementSolid fuelsSpecial form destructive distillationBrown coalMicrowave

The invention belongs to the technical field of brown coal quality improving, and relates to a large-scale brown coal quality-improving process and a large-scale brown coal quality-improving apparatus. According to the invention, an interrelated large-scale continuous brown coal quality-improving system is composed of three modules which are a tunnel internal-heat drying module, an external-heating microwave destructive distillation module, and a powdery brown coal molding and drying module. Because of large-amount water discharging, a brown coal block large-capillary framework is collapsed, so that the brown coal is naturally broken into small blocks and powder without mechanical disruption. The small-block brown coal is subjected to destructive distillation under high-temperature hot wind external heating and microwave coupling, until the blocks turn into semi-coke; water-containing coal gas, water-containing coal tar, anhydrous gas, and anhydrous coal tar are respectively obtained by destructive distillation. With a binder of the water-containing coal tar and coal tar pitch (one or a mixture thereof), the powdery brown coal is subjected to kneading and aging; the material is processed into granules by using a vacuum extrusion granulator; and the particles are processed by using a low-temperature microwave drying device, so that high-quality brown coal particles with high strength, low moisture absorption, and high heat value are obtained. The brown coal particles can endure long-distance transportation.

Owner:周灿旭

Method for rapid medium-low temperature dry distillation of coal by using microwave

InactiveCN101440290AFast pyrolysisEffectively adjust the content of valuable componentsSpecial form destructive distillationMicrowaveTar

The invention discloses a method for carbonizing low-temperature coal of low metamorphic coal. The method adopts a microwave generation device as a heating source with the frequency of microwave of between 0.3 and 300 GHz; and the low metamorphic coal is heated to the a temperature of between 300 and 800 DEG C and is subjected to low-temperature carbonization to generate semi-coke, tar and coal gas. The method selects coal with shallow metamorphic degree as a raw material, utilizes a microwave radiation type heating mode to rapidly and selectively heat a coal material, depends on the dielectric property of the coal material to convert microwave energy and produce heat, utilizes the function of microwave activated molecules and achieves the aim of rapidly pyrolyzing the low metamorphic coal, thereby obtaining the semi-coke, tar and the low-temperature carbonization coal gas. The method has rapid coal pyrolyzing speed, can effectively improve the content of valuable compositions in the carbonation coal gas and is favorable for effective and comprehensive reclaiming of the coal gas.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

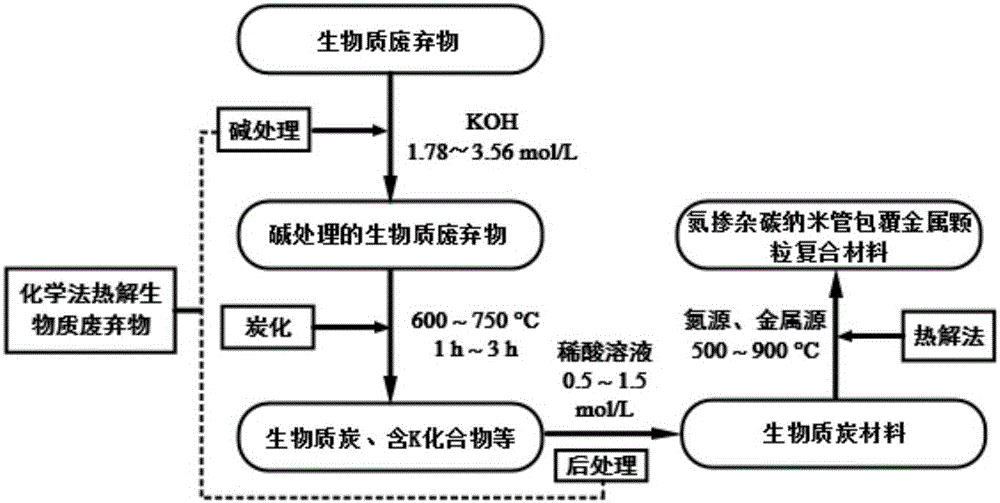

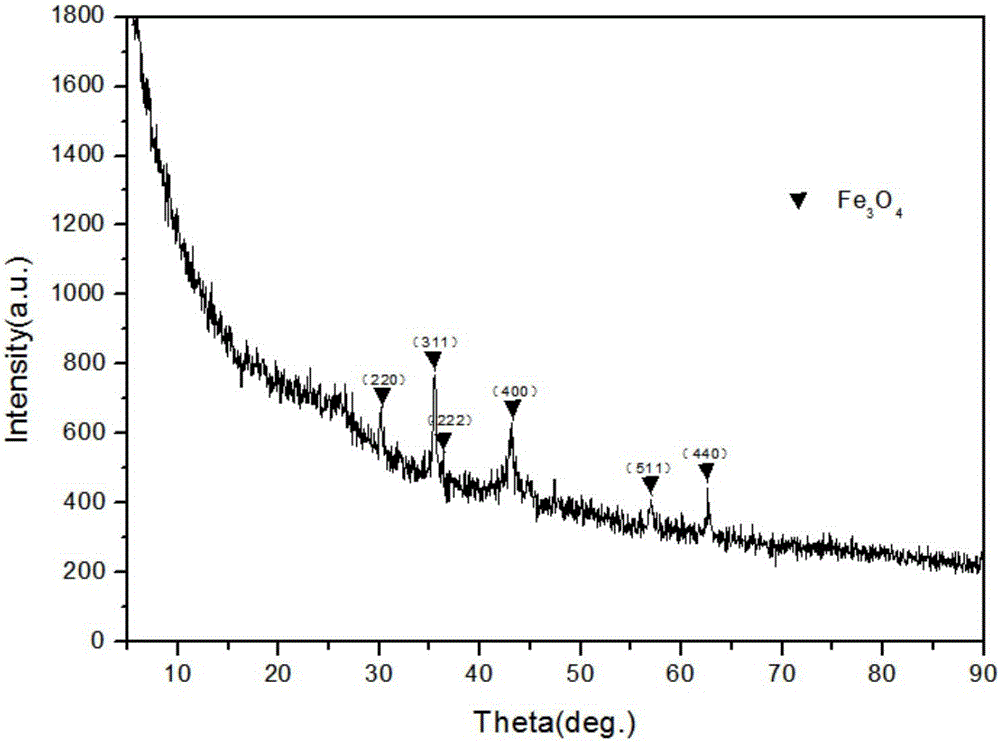

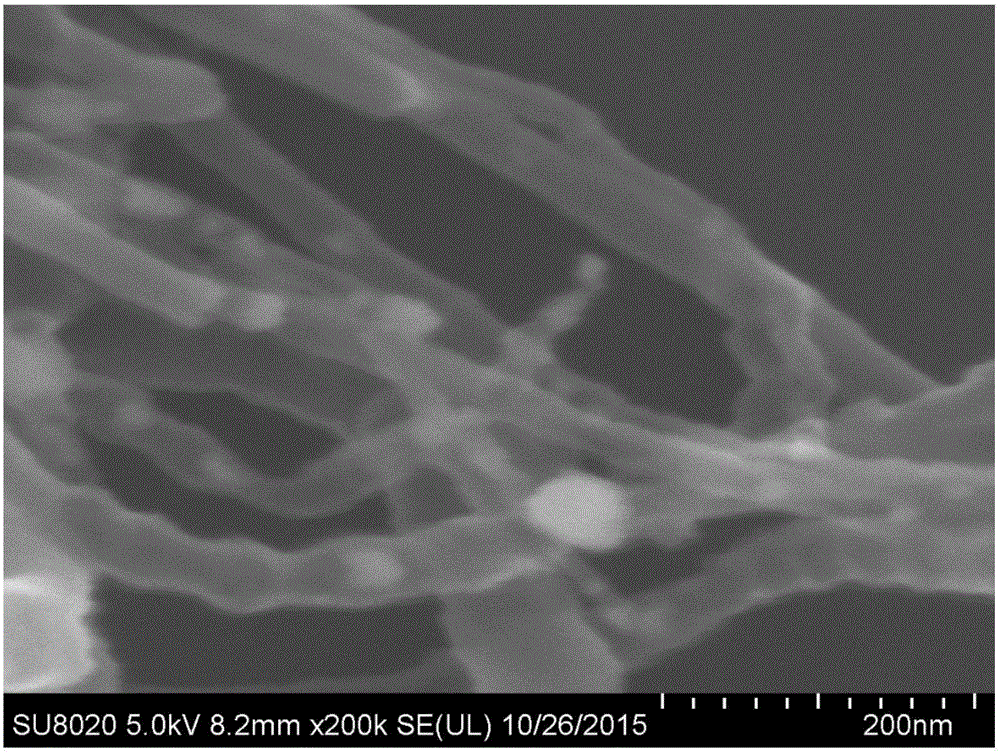

Method for using biomass waste for preparing nitrogen-doped carbon nanotube coated metal particle composite material

ActiveCN105772708AGood dispersionImprove stabilityTransportation and packagingMetal-working apparatusCarbon layerDispersity

The invention discloses a method for using biomass waste for preparing a nitrogen-doped carbon nanotube coated metal particle composite material. The method includes the following steps that firstly, the biomass waste and KOH are evenly mixed in deionized water, an obtained heterogeneous mixture is carbonized under the protection of inert gas, and biomass charcoal is obtained; and then, the biomass charcoal, a nitrogenous nonmetallic compound and water-soluble divalent metal salt are evenly mixed in methyl alcohol, the obtained heterogeneous mixture is subjected to pyrolysis under the protection of the inert gas, and therefore a target product is obtained. By the adoption of the method, a two-step pyrolysis technology is adopted for achieving growth of carbon nanotubes, and dispersion of metal nanoparticles and formation of a cooperative acting mechanism are promoted; the stability of the composite material is reinforced through the structure of carbon nanotube coated metal nanoparticles; the surface activity and dispersity of a carbon layer are improved through in-situ decoration of the nitrogen element; and the contact and active site point number is increased through the formation of a rich pore structure and the high specific surface area.

Owner:安徽皖瑞能源科技有限公司

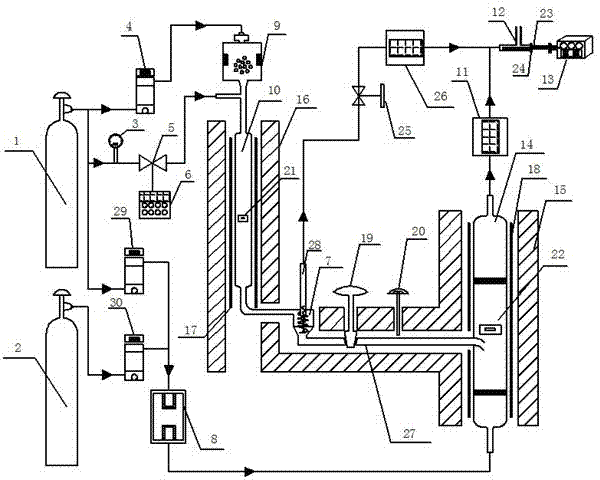

Method for producing methane from biomass

ActiveUS8915981B2High yieldFast pyrolysisGasification catalystsDirect heating destructive distillationHydrogenProduct gas

A multi-stage method and apparatus for producing methane from biomass in which the biomass is hydropyrolyzed in a reactor vessel containing molecular hydrogen and a deoxygenating catalyst, the output of which is hydrogenated using a hydroconversion catalyst. The output from the hydroconversion step is provided to a water-gas-shift process providing a mixture of H2O and product gases including CO2, H2, and methane. The mixture components are separated, resulting in a product stream comprising substantially only methane.

Owner:GAS TECH INST

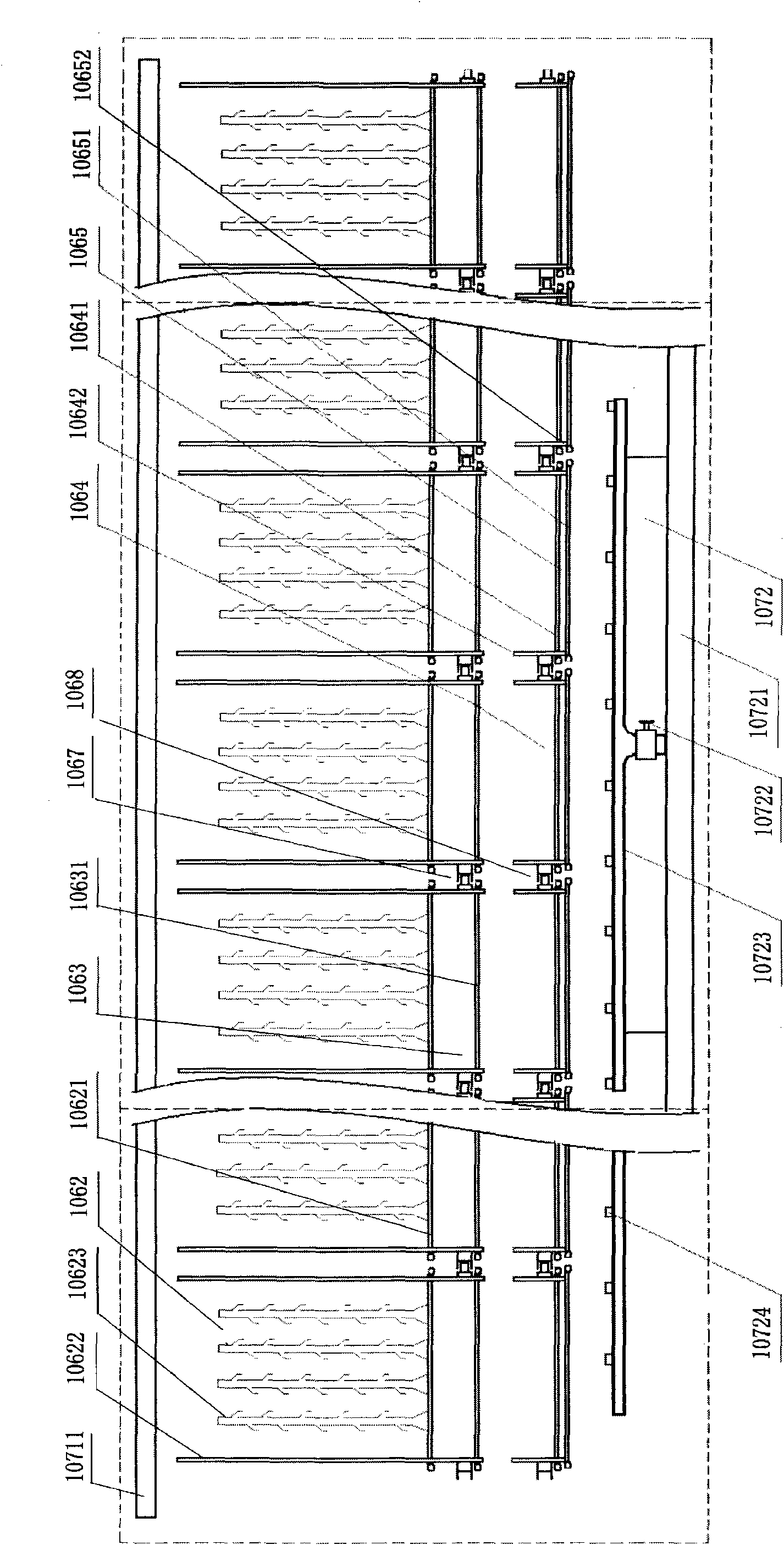

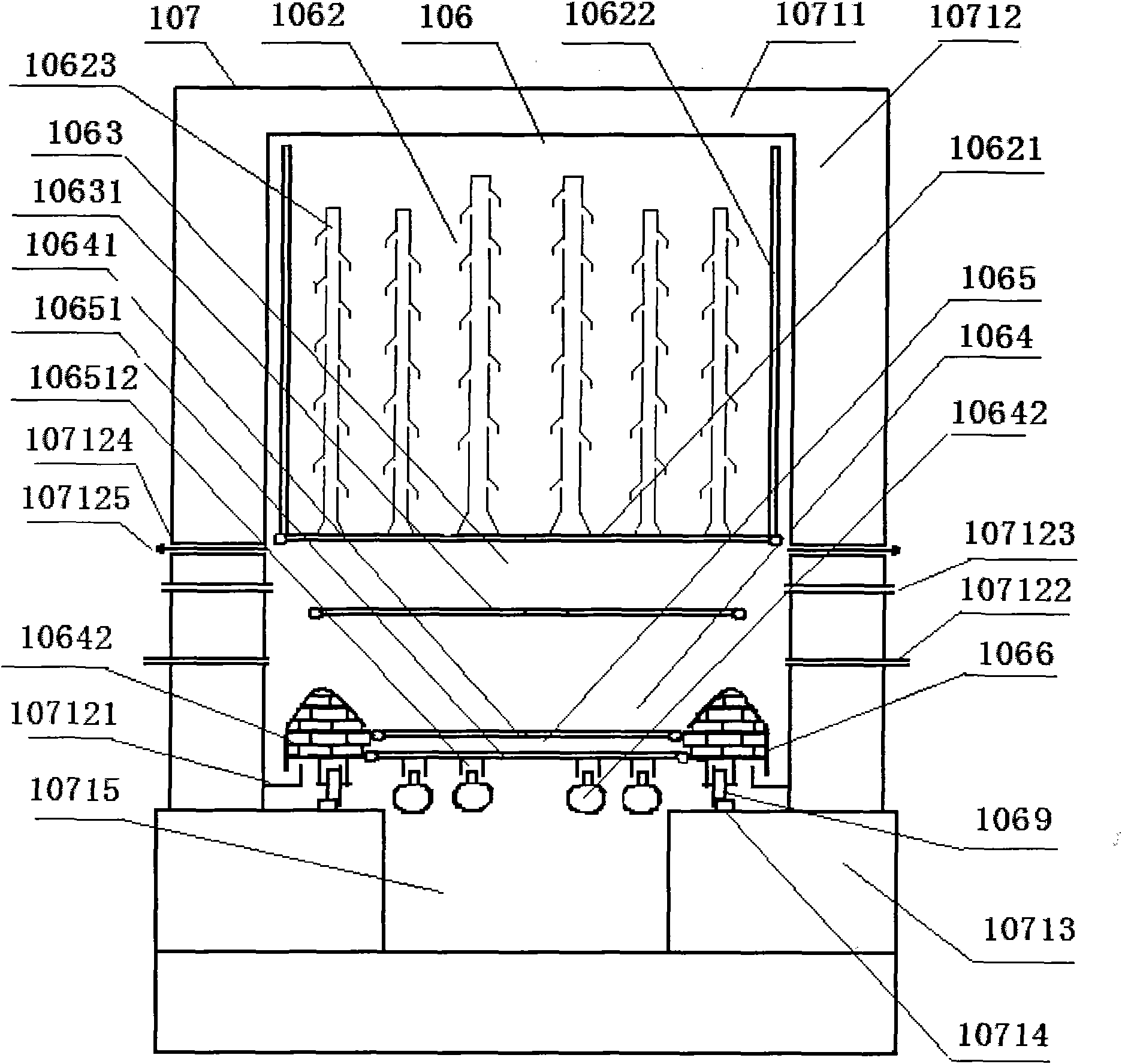

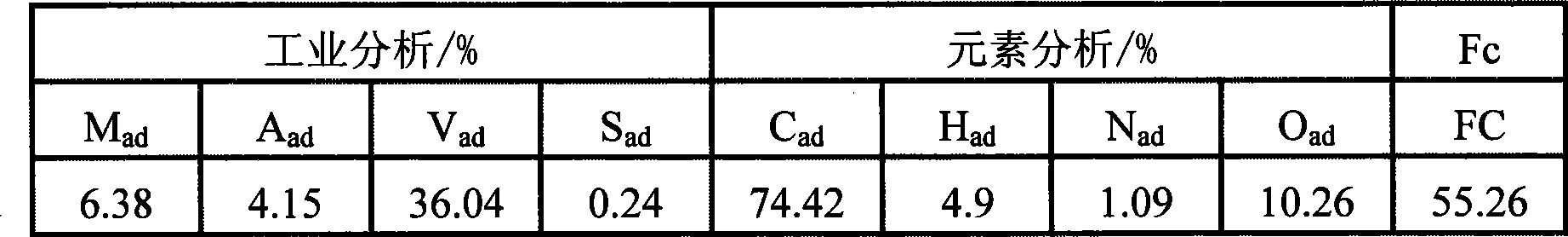

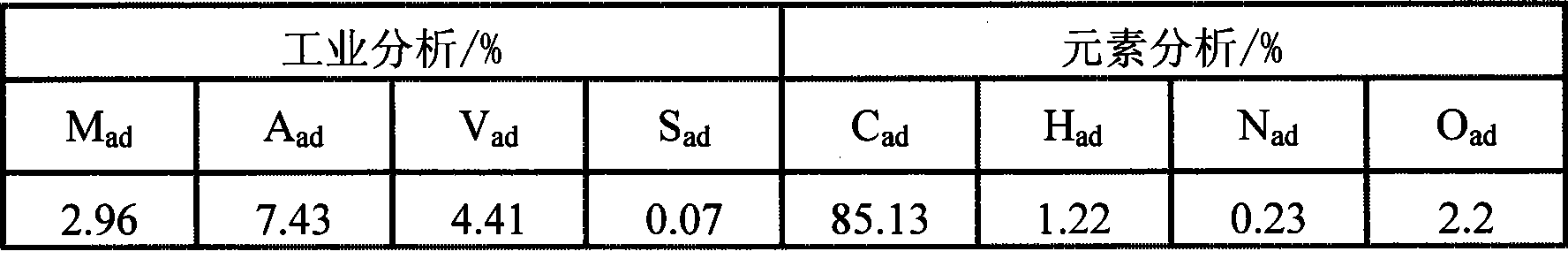

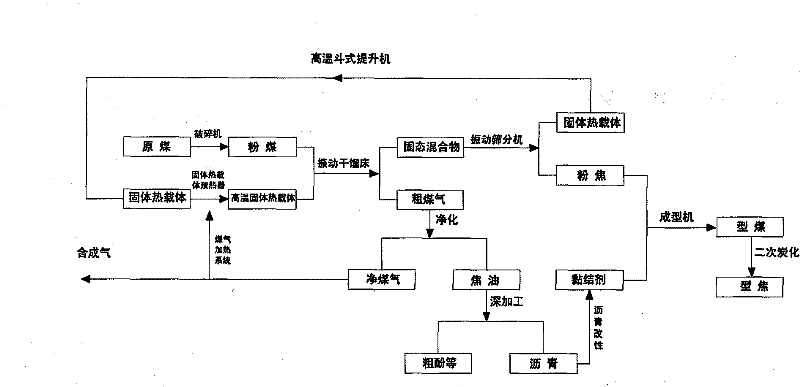

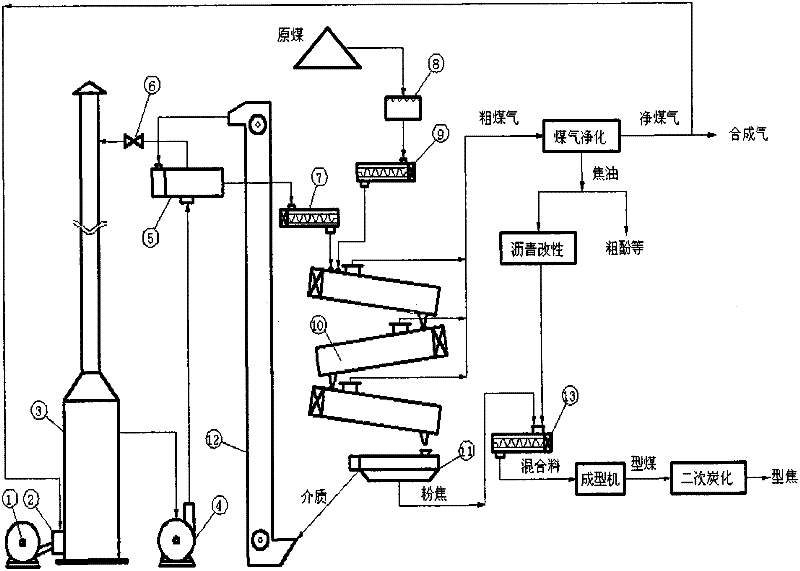

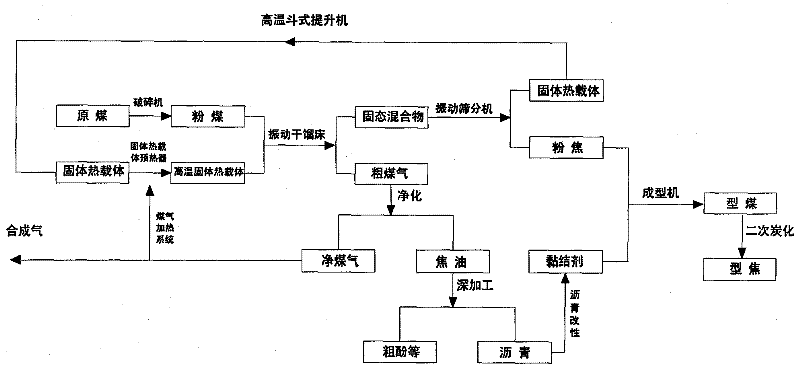

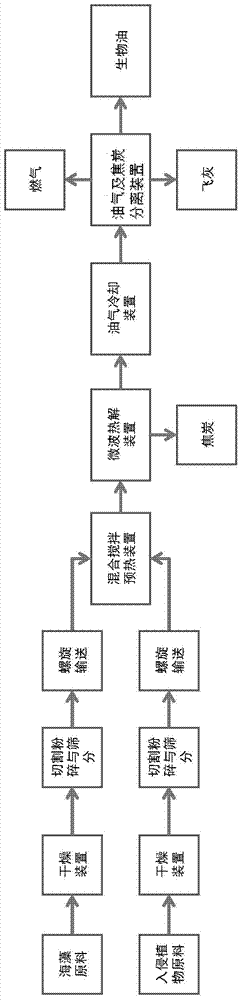

Poly-generation process for pyrolyzing solid thermal carrier via low-rank coal vibration bed

InactiveCN102453489AFast pyrolysisExtended service lifeDirect heating destructive distillationSolid fuelsGeneration processTar

The invention provides a poly-generation process for pyrolyzing a solid thermal carrier via a low-rank coal vibration bed. The process flow is as follows: mixing and retorting coal powder and a high-temperature solid thermal carrier in a vibration carbonization bed; introducing crude gas generated in the retorting process into a gas purification section; carrying out tar deep processing and asphalt modification on the separated tar to prepare crude phenol, an asphalt binder and the like; and carrying out formation and ball pressing on a retorted product powder semi-coke and the asphalt binder as well as other additives, and secondarily carbonizing to prepare a formed coke. In the process provided by the invention, a burning or oxidization phenomenon is not generated during the period of retorting; the product powder semi-coke is low in ash content, high in gas thermal value and high in useful component; the relative motion speed of the solid thermal carrier and the coal powder is small; crude gas does not carry fine coke particles, thereby avoiding adhesion of tar and fine particles on the inner wall of a pipeline and ensuring the long-term operation of a system; and the solid thermal carrier is surrounded by the powder coal, the probabilities of friction and collision between the solid thermal carriers are reduced, and the service life is prolonged. The process provided by the invention is the poly-generation process for pyrolyzing the solid thermal carrier via the low-rank coal vibration bed, and the poly-generation process is practicable in the aspects of technology, materials, cost and the like.

Owner:CHINA UNIV OF MINING & TECH

Fluidized bed low-temperature destructive distillation system and low-temperature destructive distillation method of low-rank coal

InactiveCN103160299AExtended stayHigh solid contentDirect heating destructive distillationSpecial form destructive distillationPartial hydrogenationHydrogen atmosphere

The invention provides a fluidized bed low-temperature destructive distillation system and a low-temperature destructive distillation method of low-rank coal. According to the method, a mixed gas of hot coal gas produced by a gasification furnace and circulation cold coal gas is adopted as a hot carrier and a fluidizing gas of a destructive distillation reaction. A hydrogen atmosphere of coal gas can provide a partial hydrogenation effect, such that obtained tar has the advantages of high light component content, good quality, high thermal efficiency, and high yield. Also, with the method, a two-stage low-temperature destructive distillation reactor is adopted, such that the retention time of solid particles in the reactor is increased, destructive distillation effect is improved, high solid content in the bed can be maintained, and operation stability can be maintained. The invention also provides a low-temperature destructive distillation reactor. The low-temperature destructive distillation reactor is the two-stage low-temperature destructive distillation reactor, such that the retention time of solid particles in the reactor is increased, and destructive distillation effect is improved. With the two-stage low-temperature destructive distillation reactor, high solid content in the bed can be maintained, and operation stability can be maintained.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

Method for carbonization of crop straws

ActiveUS9321966B2Limited production scaleLow efficiencyCombustible gas coke oven heatingDirect heating destructive distillationCarbonizationProcess engineering

The present invention is to provide a method for carbonification of crop straws and a device thereof. Pyrolysis process is controlled by regulating the feeding of oxygen during said pyrolysis process, and pyrolysis and carbonification are respectively conducted in separate pyrolysis and carbonification pools, wherein the straws are pyrolyzed in said pyrolysis pool and entered into said carbonification pool to be carbonified. The present invention can quickly raise the temperature of the pyrolysis process, shorten the time of the pyrolysis process, and improve the pyrolysis carbonification efficiency.

Owner:SHANXI SANTIANYULONG AGRI TECH CO LTD

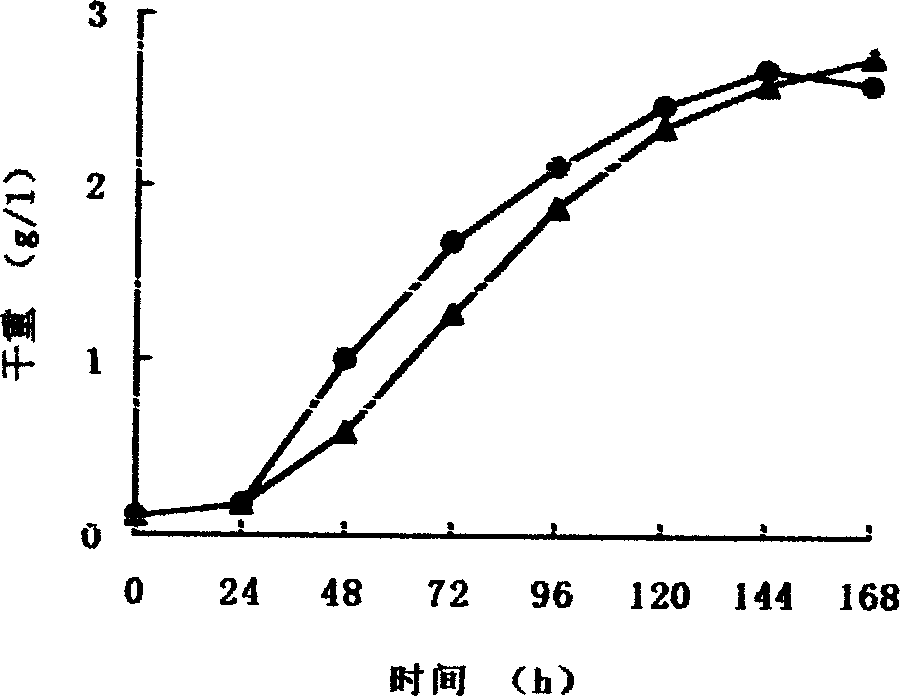

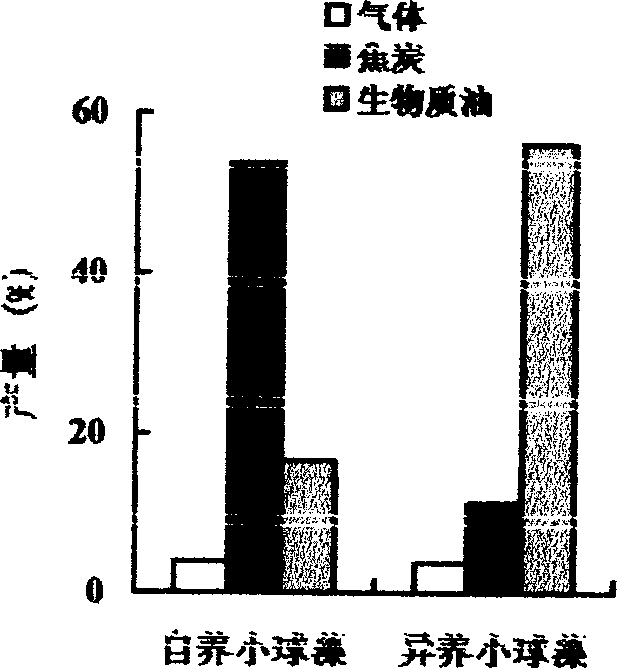

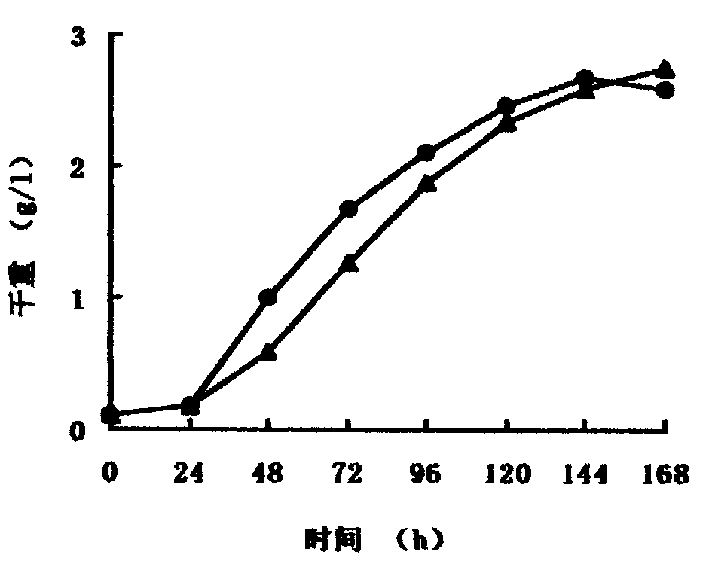

Method for preparing biology diesel oil by using amylum enzymolysis to cultivate heterotrophy alga

InactiveCN1446882AReduce manufacturing costHigh yieldLiquid hydrocarbon mixture productionBio-feedstockBiodieselLower grade

A process for preparing biologic diesel oil from starch includes enzymolyzing low-grade starch to obtain aqueous solution of glucose, preparing culture madium, heterotrophic transfer to obtain heterotrophic chlorella, and fust pyrolysis to obtain biologic diesel oil. Its advantages are high output rate, quality and heat value, and high flowability.

Owner:TSINGHUA UNIV

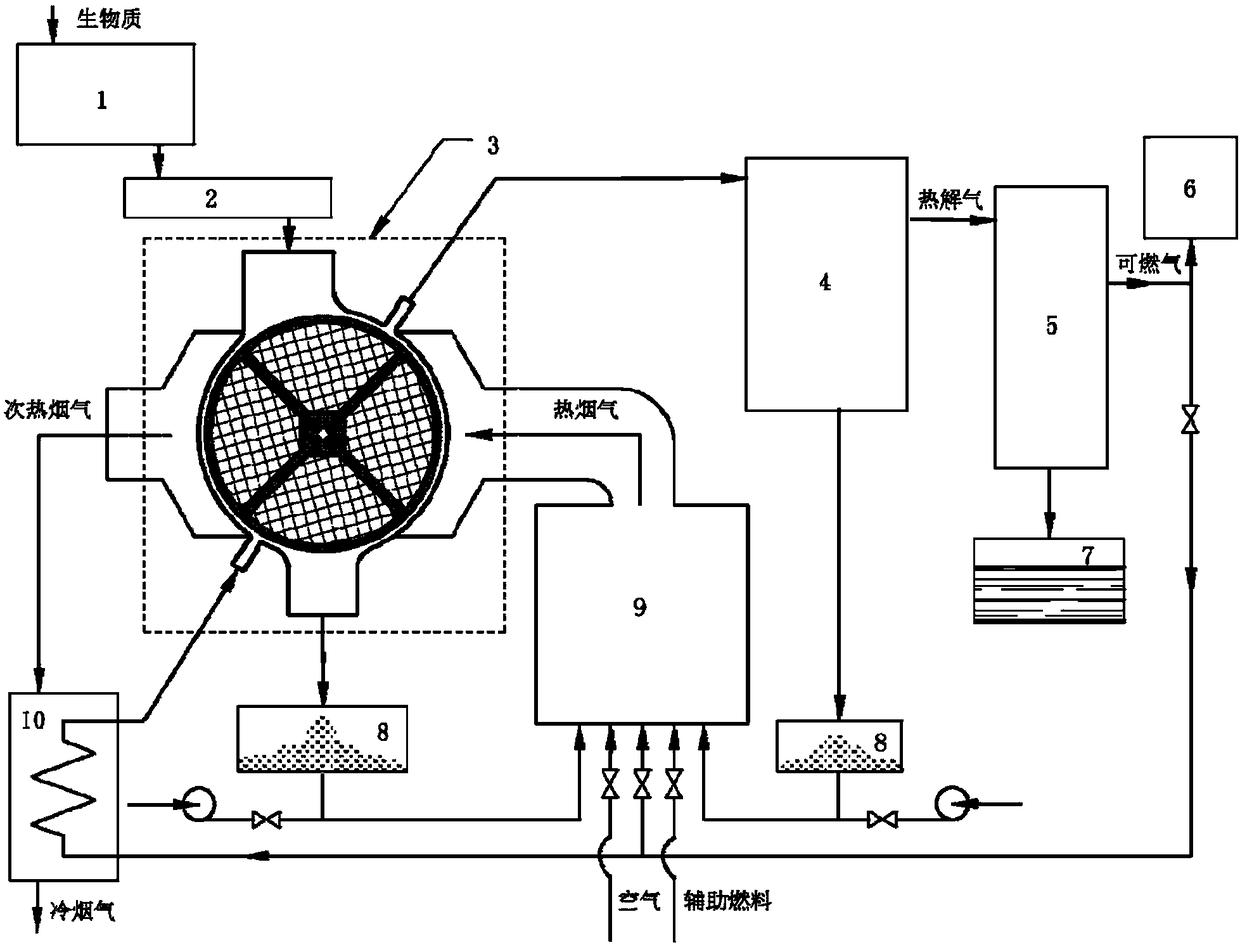

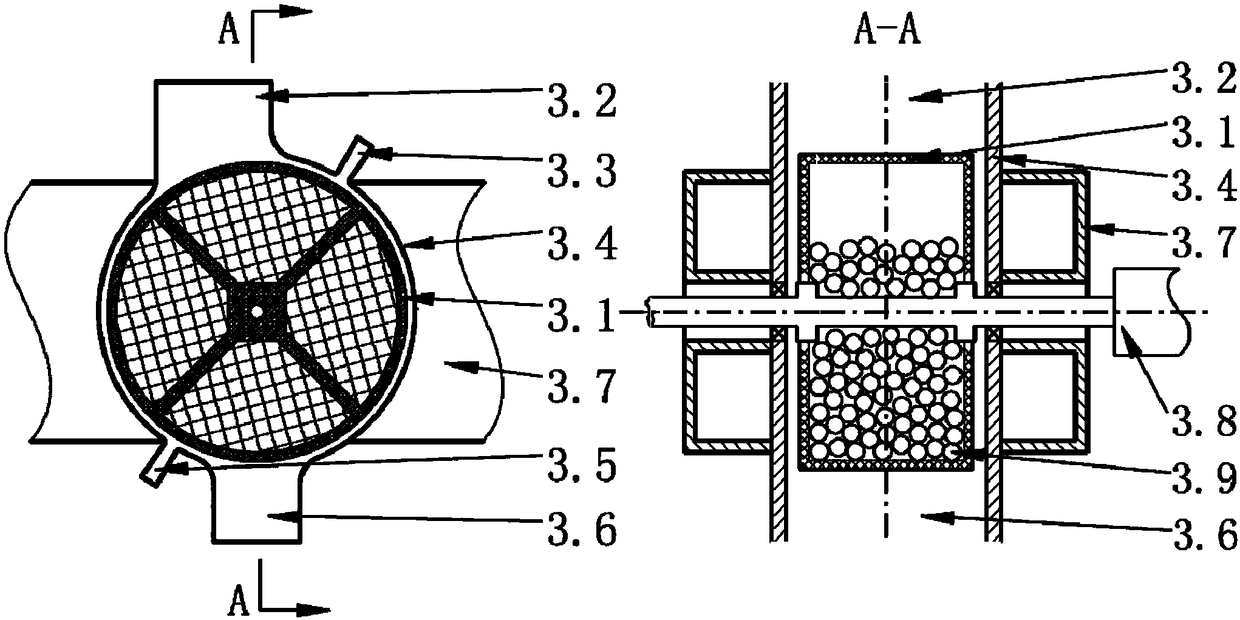

Biomass quick catalytic pyrolysis device and method

ActiveCN108587671AEvenly heatedHeating up fastBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisCombustion system

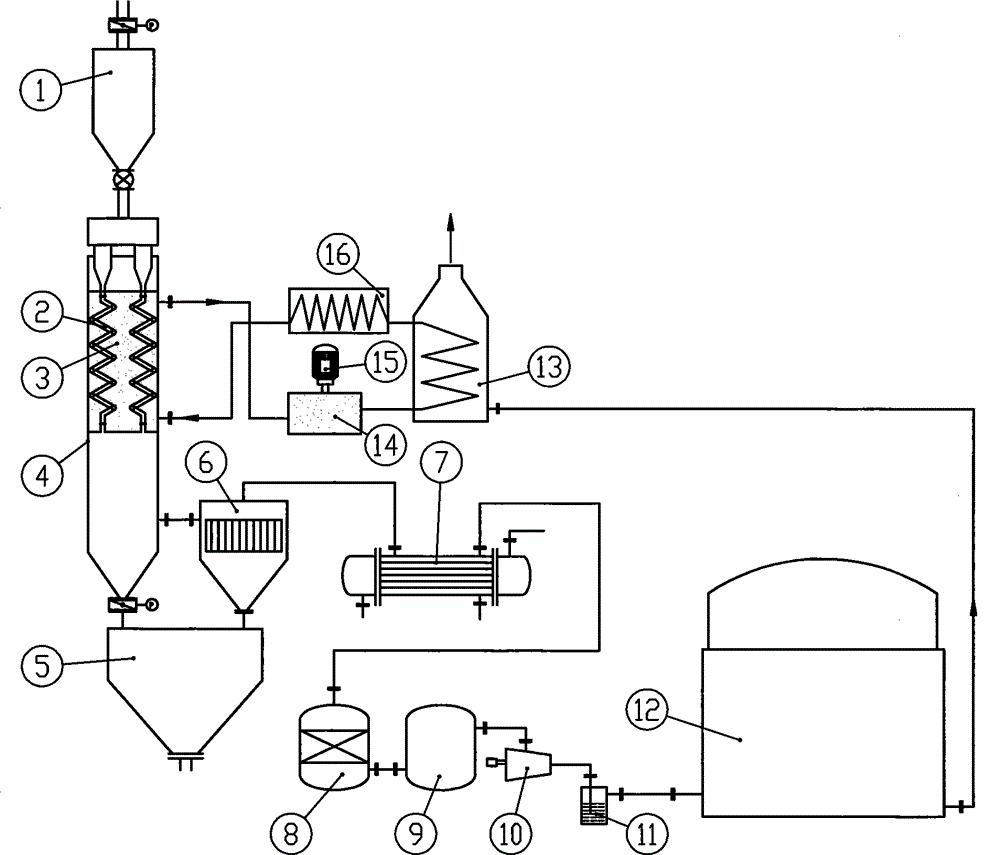

The invention belongs to the technical field of biomass energy utilization, and particularly relates to a biomass quick catalytic pyrolysis device and method. The device comprises a hopper, a feed system, a revolving bed pyrolysis reactor, a gas-solid separation system, a pyrolysis gas condensation system, a flammable gas storage tank, a liquid collecting box, a solid coke collecting box, a burning system and a gas carrying and heat exchanging system, wherein the revolving bed pyrolysis reactor is composed of a revolving bed body, an airtight shell, a heat exchanging flue passage, a drive system, a spherical carrier and the like. After pretreatment, biomass particles enter into the revolving bed body and are subjected to quick catalytic pyrolysis under the effect of a catalyst, and generated pyrolysis gas is subjected to quick condensation to obtain certain bio-oil; non-condensing flammable gas and coke are collected and are used for burning and heat supply to achieve self-heating pyrolysis. The device can prepare high-grade liquid fuel or bio-oil containing rich high value-added chemicals by adjusting reaction working conditions and catalyst types.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for pretreating lignocellulosic biomass

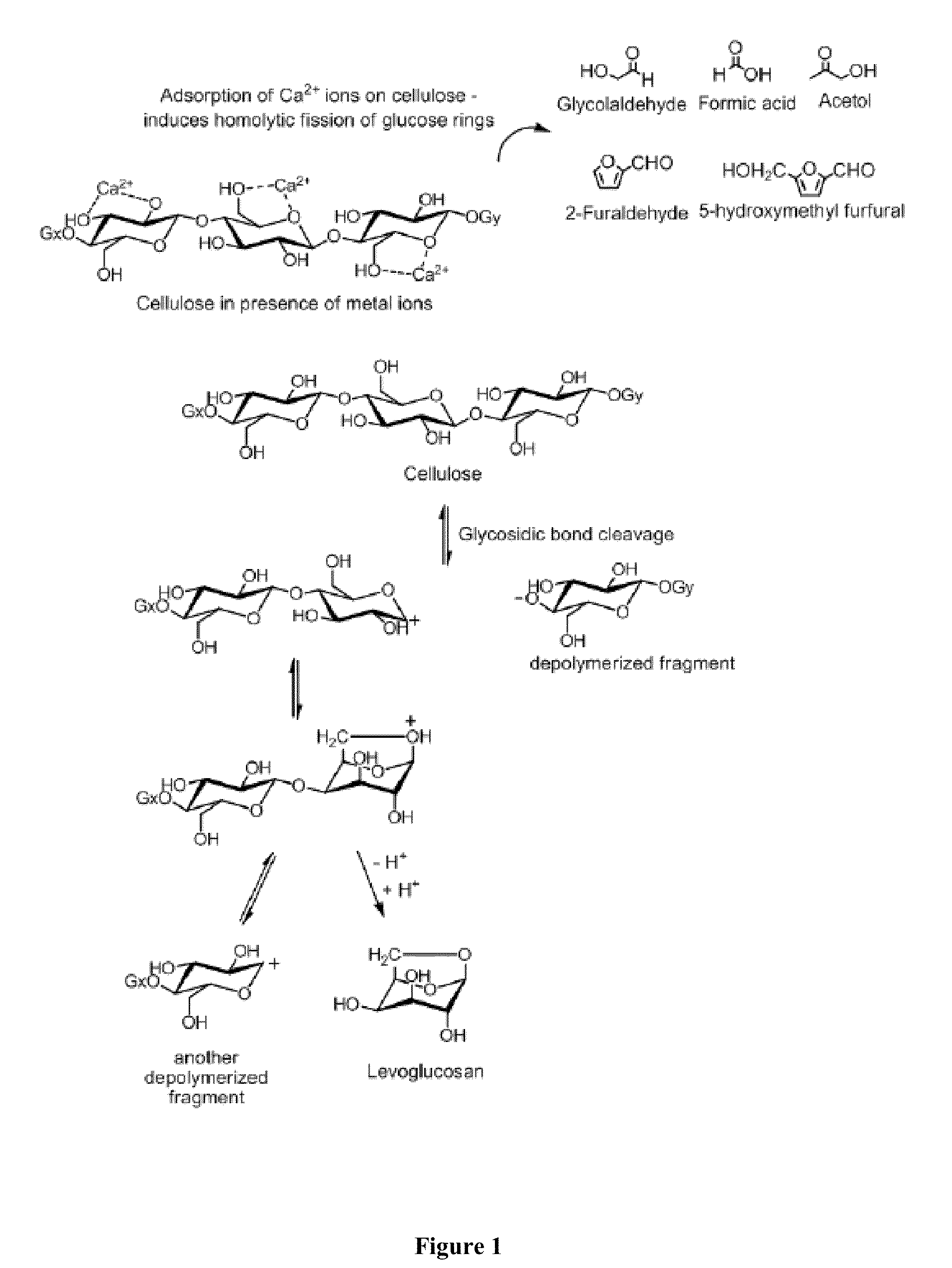

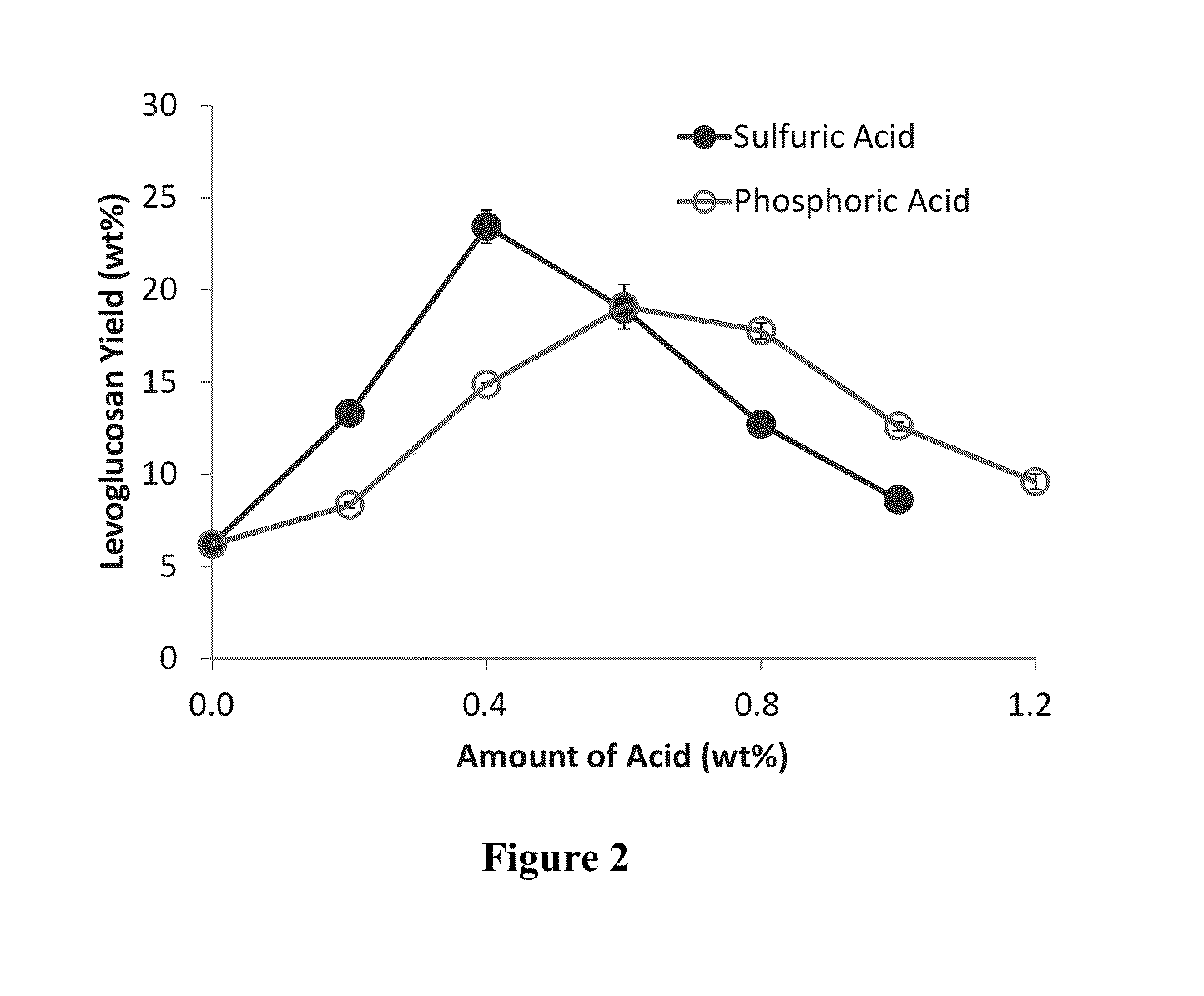

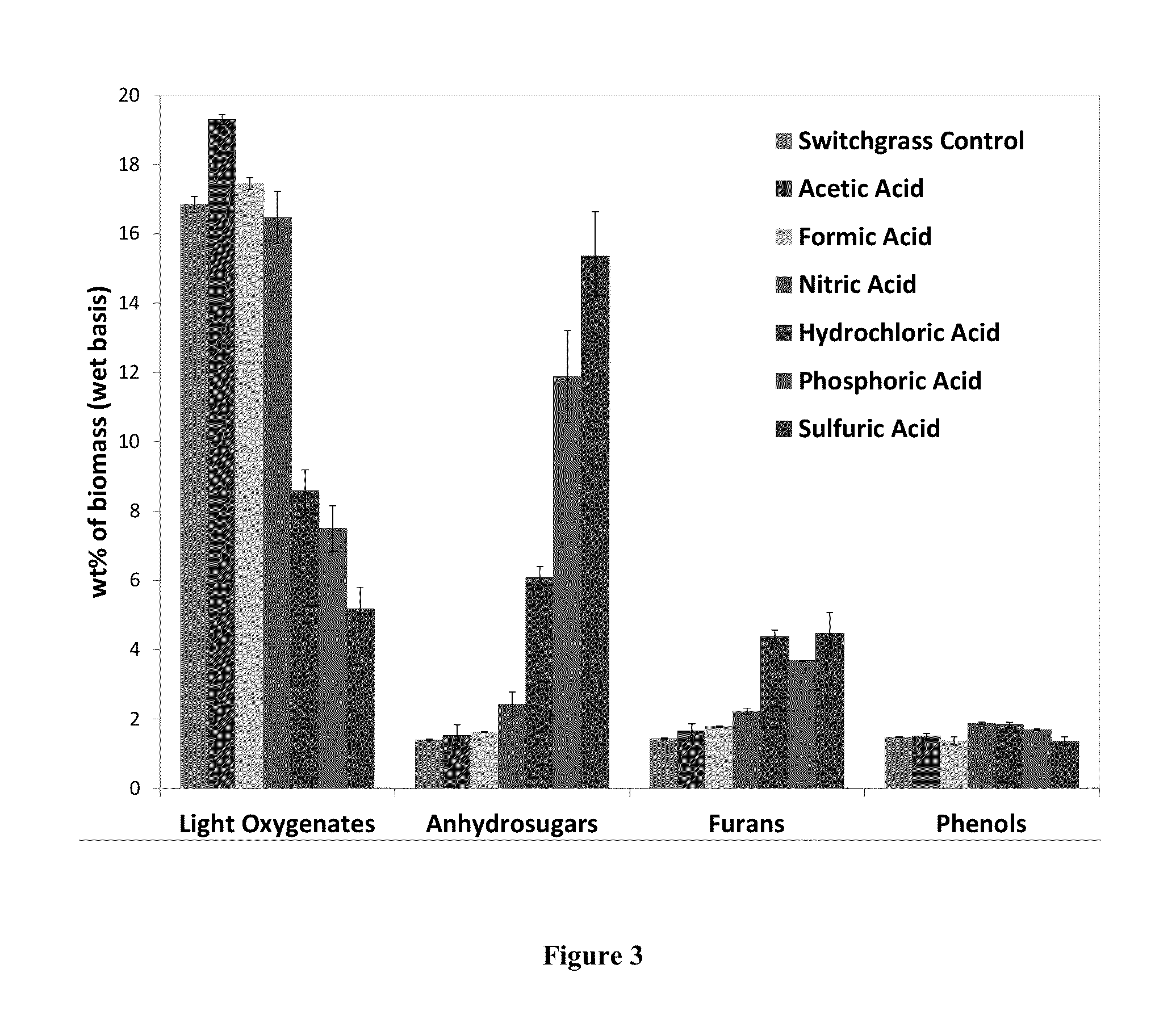

ActiveUS20130340746A1Reduce fragmentationIncrease productionBiofuelsSpecial form destructive distillationCelluloseAlkaline earth metal

The present invention relates to a method for pretreating lignocellulosic biomass containing alkali and / or alkaline earth metal (AAEM). The method comprises providing a lignocellulosic biomass containing AAEM; determining the amount of the AAEM present in the lignocellulosic biomass; identifying, based on said determining, the amount of a mineral acid sufficient to completely convert the AAEM in the lignocellulosic biomass to thermally-stable, catalytically-inert salts; and treating the lignocellulosic biomass with the identified amount of the mineral acid, wherein the treated lignocellulosic biomass contains thermally-stable, catalytically inert AAEM salts.

Owner:IOWA STATE UNIV RES FOUND

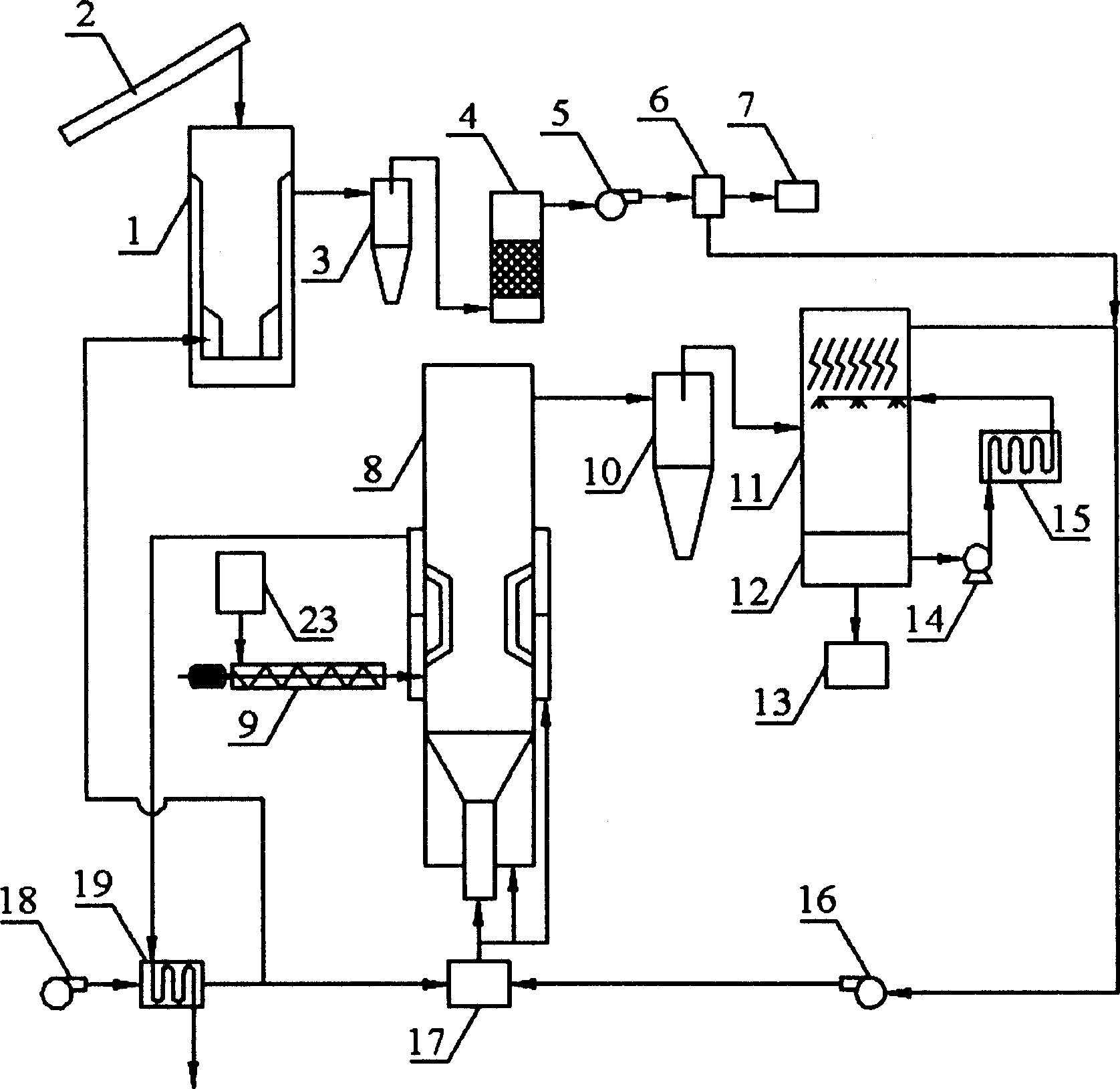

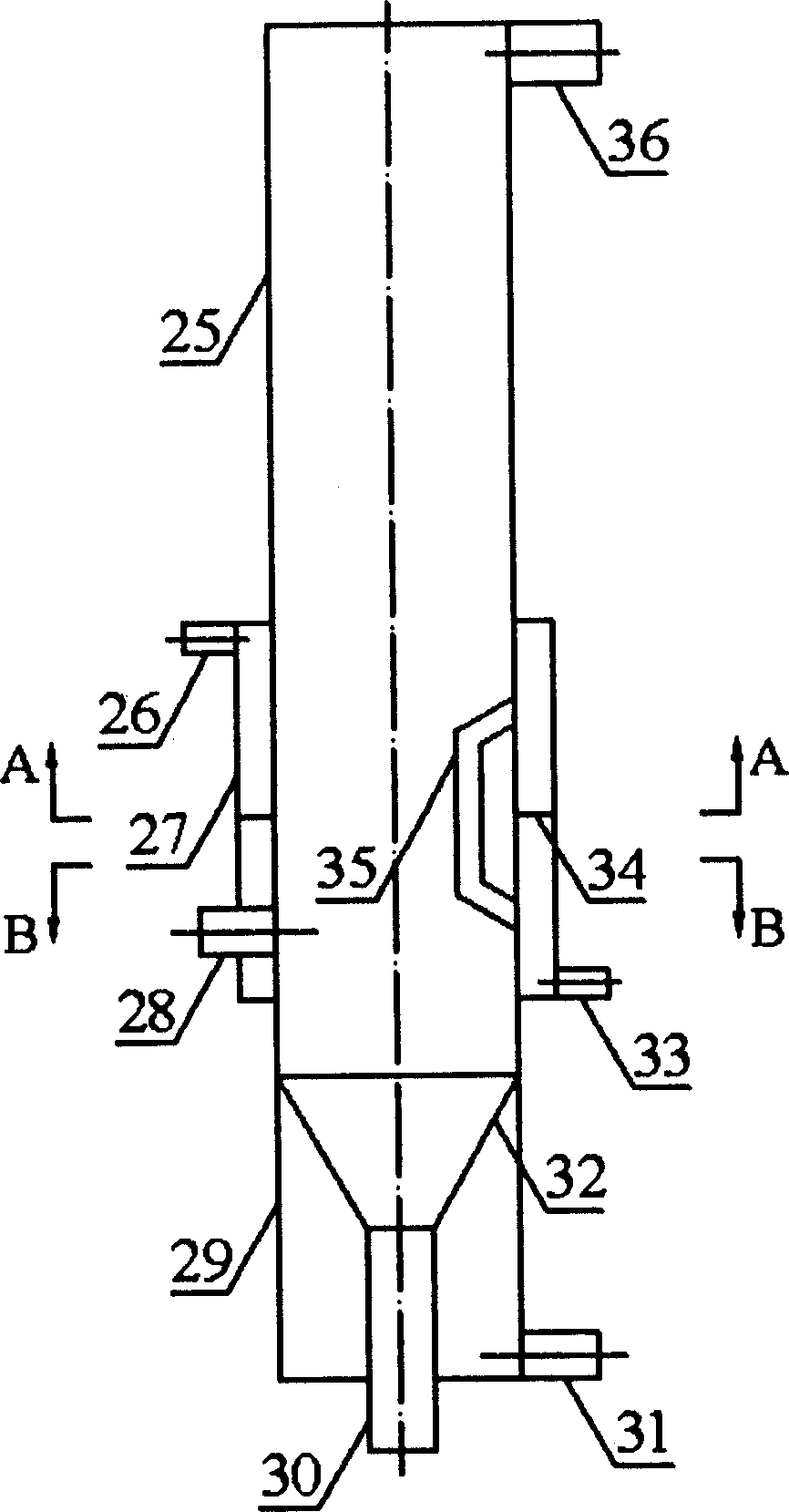

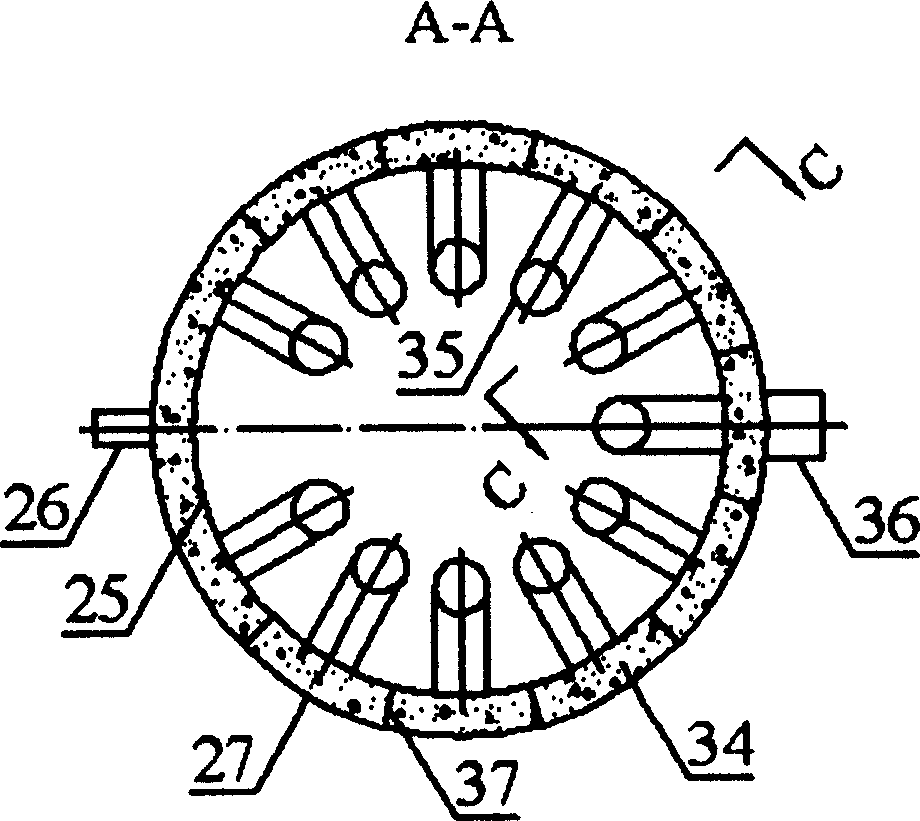

Process for preparing carbocoal, coke tar and coal gas by treating bovey coal by suspending pyrogenation device

ActiveCN101289621ASave spaceIncrease productivityDirect heating destructive distillationHeat carrierGas cooler

The invention relates to a gas heat carrier brown coal suspension pyrolysis device, and adopts the following process: brown coal is fed in a hammer type drier for crushing and drying with the drying temperature lower than 400 DEG C, and then is fed in a suspension pyrolysis oven at 110 to 130 DEG C to generate semicoke and tar gas mixed gas; when separated by a first pyrolysis cyclone separator, the tar gas mixed gas is fed in oil gas cooling gas and is discharged after cooling; semicoke is fed in a detention tank; after pyrolysis reaction and quenching coke through a three-stage quenching coke system, the semicoke is fed in a semicoke cooler and then is fed in a storage yard after cooling; quenching coke gas is fed in an oxygen source heater to cool down oxygen source gas, and then is fed in an oil gas cooler as cooling medium to cool down tar gas mixed gas. Compared with the prior process, the gas heat carrier brown coal suspension pyrolysis device reduces land occupation, investment and labor force, and has uniform thermal transmission, fast speed and high output capacity of tar and coal gas; moreover, the pyrolysis device improves the flammable characteristics of semicoke product and is convenient for safe storage and transportation; in addition, the pyrolysis device has the advantages of lower heat consumption, higher output capacity of semicoke, tar and coal gas and cooling water conservation, etc.

Owner:SHENYANG XINBO IND TECH

Mobile biomass liquefaction system

InactiveCN1803982ASolve problems that require grid powerFast pyrolysisLiquid hydrocarbon mixture productionCooling towerBiomass gasifier

The disclosed mobile biomass liquefaction system comprising: a biomass gasification furnace, a fuel decontamination plant, a fuel generating set, a biomass pyrolysis furnace with heat from the firing of gasified fuel and incondensable gas, a cooling tower, and a pretreatment device. This system realizes complete self-support for energy, can convert the biomass into bio-oil locally for further centralized treatment, and has high operation efficiency for wide application range.

Owner:HUAZHONG UNIV OF SCI & TECH

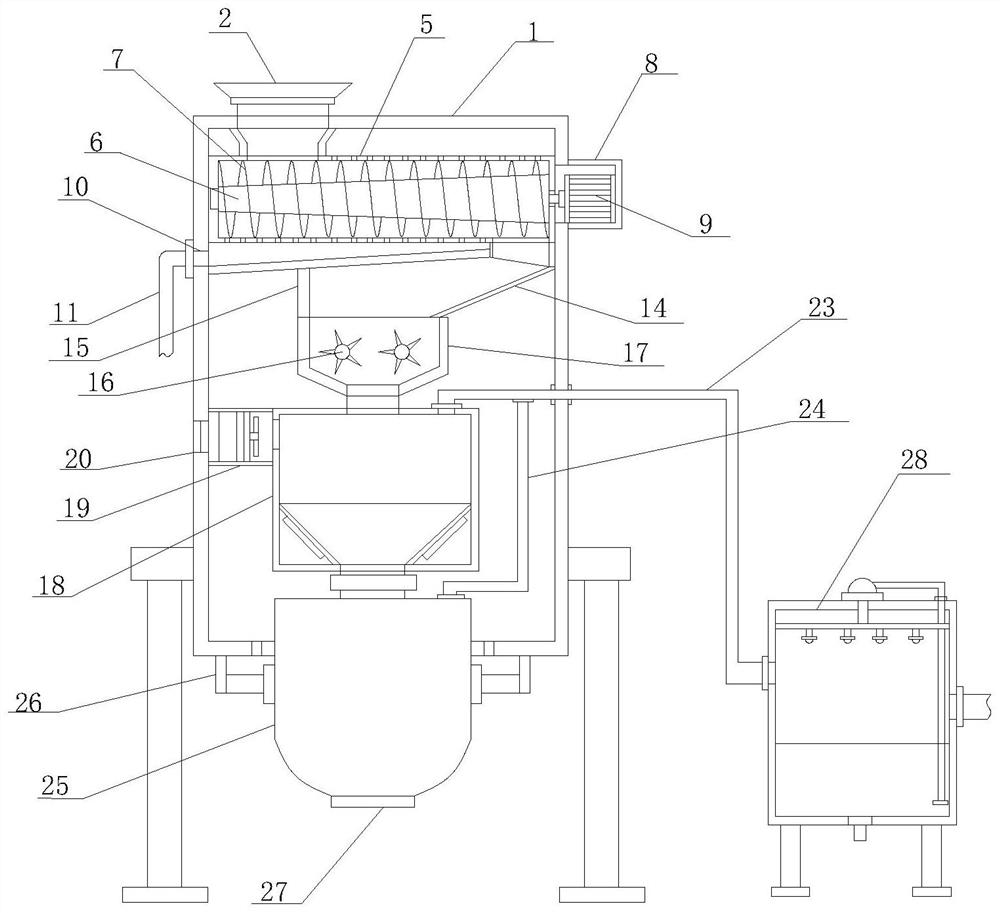

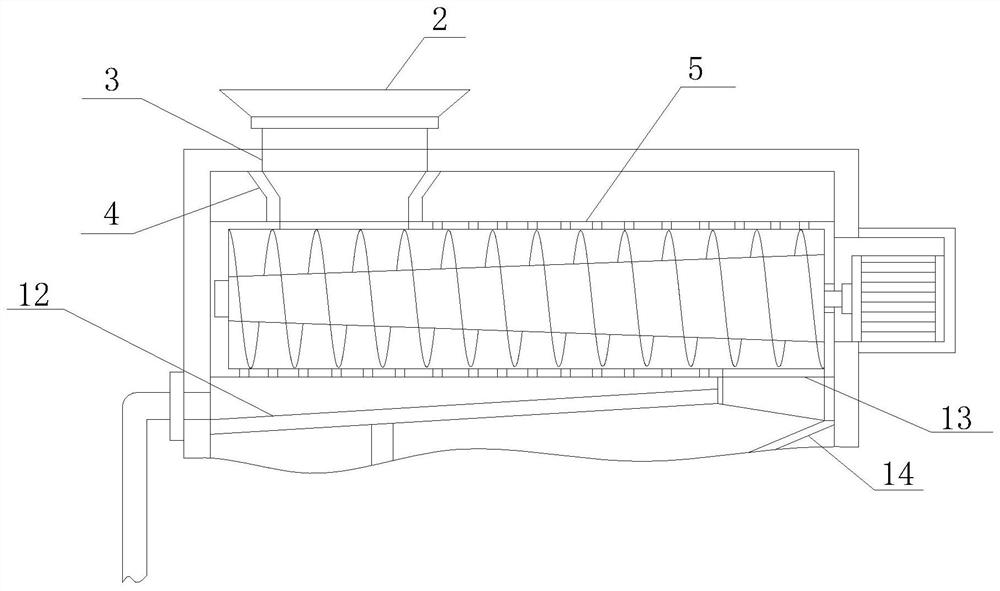

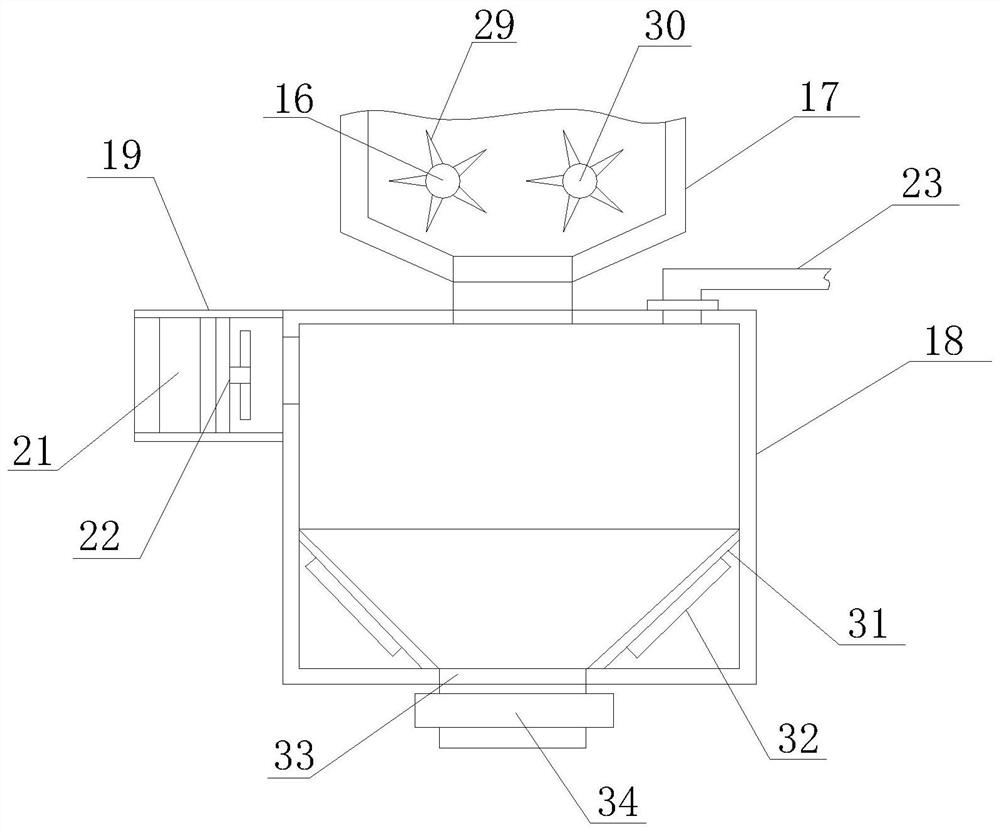

Garbage drying and pyrolyzing method

InactiveCN111853802AReduce moisture contentFast pyrolysisUsing liquid separation agentDrying solid materials without heatElectric machineDust control

The invention discloses a garbage drying and pyrolyzing method. The method comprises the following steps that pyrolytic garbage is poured into a feeding hopper, the garbage enters an extrusion cylinder, a driving motor is started to drive an extrusion rotating shaft to rotate, the garbage moves rightwards under the action of a spiral blade, the garbage is extruded through the inner wall of the extrusion cylinder to discharge water, sewage drips into a sewage tank and is discharged from a sewage outlet, and the garbage enters a crushing box from a first discharging opening; a crushing motor isstarted to drive a first crushing shaft and a second crushing shaft to rotate, crushing blades on the crushing shafts crush the garbage, and the crushed garbage enters a drying box; and a first heating plate, a second heating plate and a fan are started to dry the garbage in the drying box, generated gas enters a dust removal water tank from an exhaust pipe, an electric valve at the bottom of thedrying box is opened, and the dried garbage is discharged into a pyrolyzing furnace. According to the method, the moisture content in the garbage is greatly reduced, the pyrolysis speed of the garbagein the pyrolyzing furnace is increased, residues are reduced, and generated gas does not contain a large amount of incineration particles.

Owner:济南鸿泰华丰机械有限公司

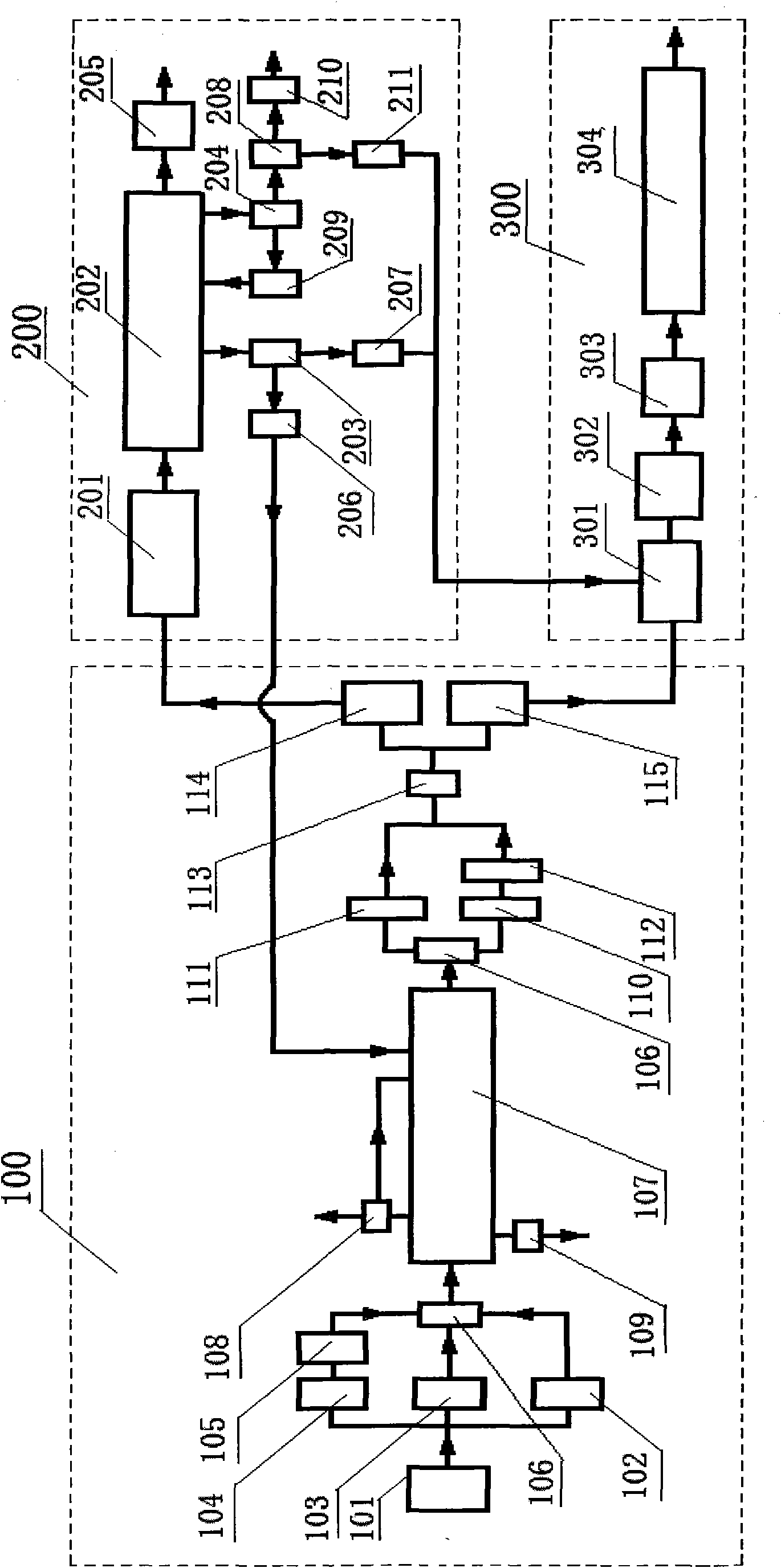

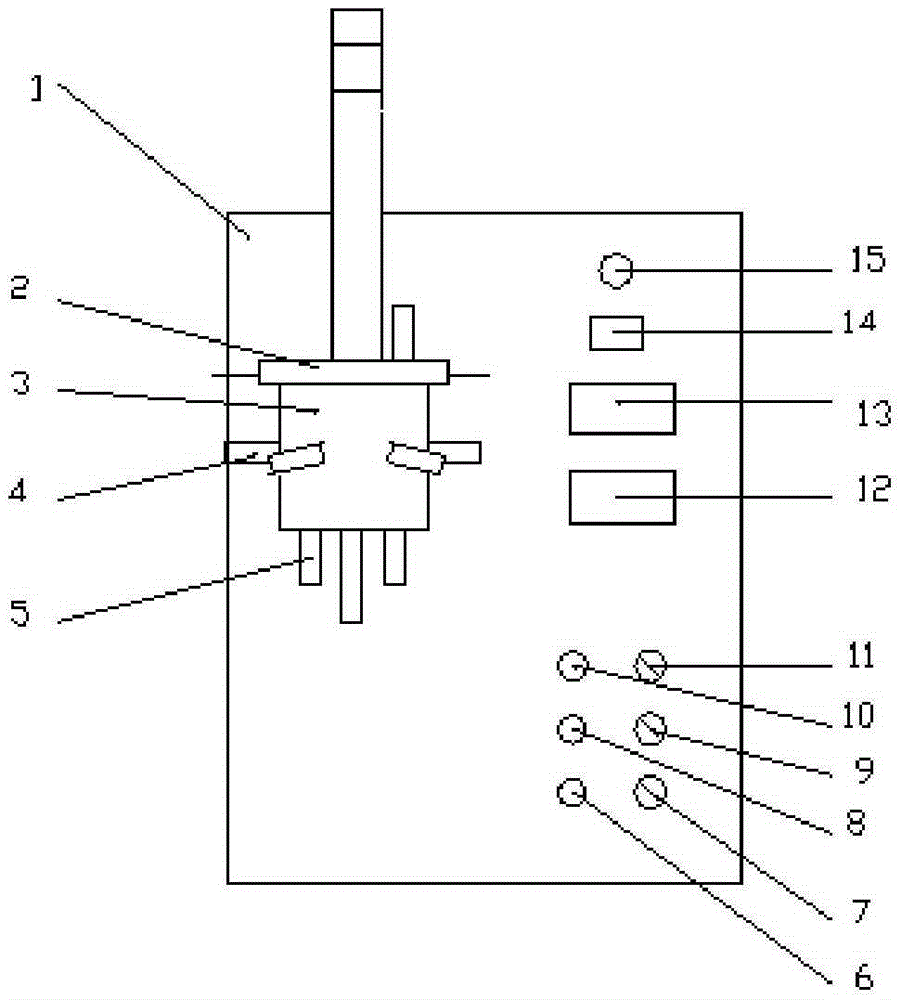

Micro double-bed solid fuel decoupling combustion reaction dynamic analyzer

ActiveCN103543237AAchieve pyrolysisRealize the coke combustion processChemical analysis using combustionAir atmosphereGas detector

The invention provides a micro double-bed solid fuel decoupling combustion reaction dynamic analyzer which comprises a fuel pyrolytic reaction generation device, a residual coke combustion reaction generation device, a double-bed high-temperature coupling device, a gas path device and an analysis test device, wherein solid fuel is firstly pyrolyzed under an inert atmosphere in a micro gas flow bed; then residual cokes enter the micro gas flow bed for combustion test under an air atmosphere; a quick gas detector is used for judging a reaction mechanism by measuring a generation sequence and a generation quantity characteristic of gas components in a fuel pyrolysis process and a coke combustion process, so that reaction dynamic parameters can be calculated. According to the micro double-bed solid fuel decoupling combustion reaction dynamic analyzer, the combustion dynamic parameters of the solid fuel can be tested through direct decoupling combustion through independent and quick switching of the atmospheres and the temperature; the pyrolyzed residual cokes are directly subjected to the combustion test without a cooling process; the temperature rising rates of the gas flow bed and a fluidized bed are high, so that a combustion condition in an actual boiler can be well simulated; the measured reaction dynamic parameters are close to intrinsic reaction dynamic parameters.

Owner:HUAZHONG UNIV OF SCI & TECH

Rapid rice husk pyrolysis apparatus and matching system thereof

ActiveCN105400528AFast pyrolysisAchieve self-sufficiencyBiofuelsSpecial form destructive distillationScrew conveyorPyrolysis

The present invention discloses a rapid rice husk pyrolysis apparatus. According to the rapid rice husk pyrolysis apparatus, the main body of a reactor is a stainless steel housing, the upper portion is tightly provided with an vacuum material feeder through a material inlet on the upper end, the lower portion, a screw conveyor and two pneumatic gate valves maintain the reactor and outside air isolation state through a material outlet, multiple groups of molten salt heaters are vertically and densely arranged inside the reactor, a fuel gas outlet is arranged above the right side of the main body, the external is connected to a vacuum pump, a condenser and a filter, and separated combustible gas enters a combustor to combust so as to heat high temperature molten salt adopted as a thermal carrier, such that the energy self-sufficiency can be achieved. With the apparatus of the present invention, the rapid rice husk pyrolysis at the temperature of 450-650 DEG C under the total pressure of 5-15 kPa can be achieved, the natural nanometer structure of the silica inside the rice husk is not damaged, and the complete oxidation of the subsequent combustion oxidation unit impurity carbon is easily achieved.

Owner:王开辉

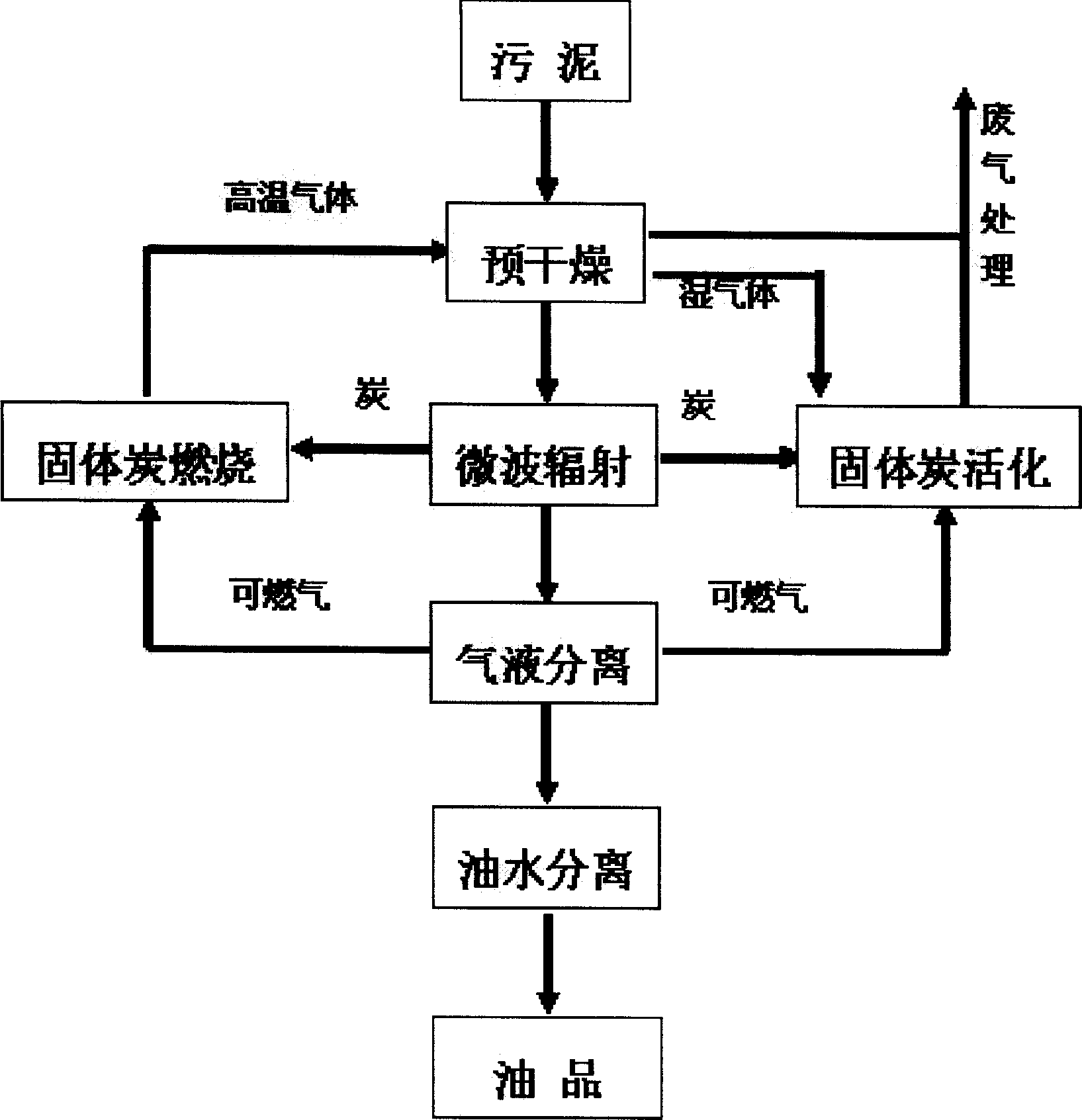

Method for preparing biodiesel from sludge by microwave radiation

The invention relates to a solid wastes sludge processing method, especially relates to microwave radiation sludge making biology diesel oil. The feature is that it directly sends the microwave energy to the sludge to take rapid pyrolysis to gain quality oil constituent that would be used as biology diesel oil. The invention has rapid speed, high efficiency, energy saving, and low cost.

Owner:DALIAN UNIV OF TECH

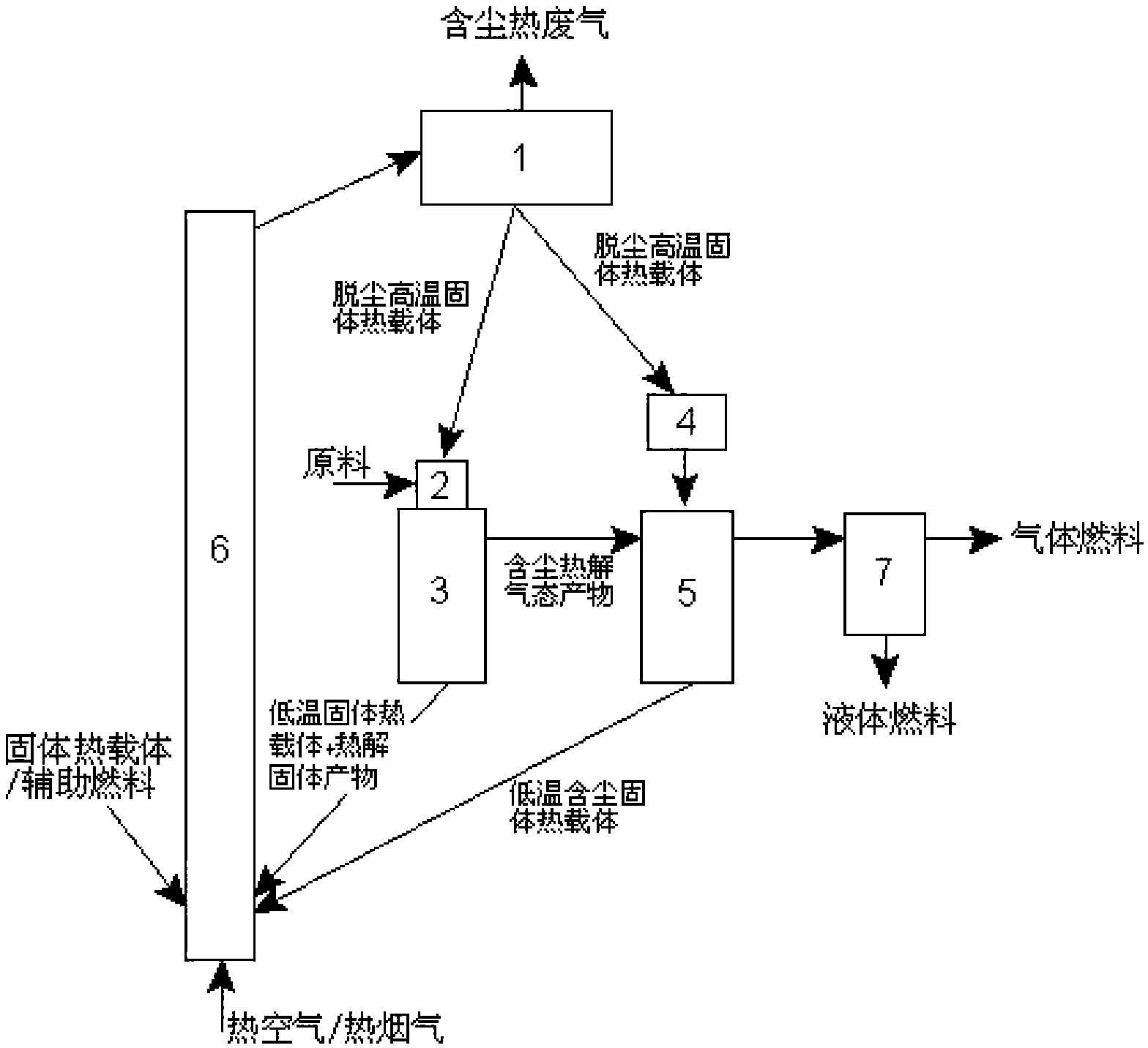

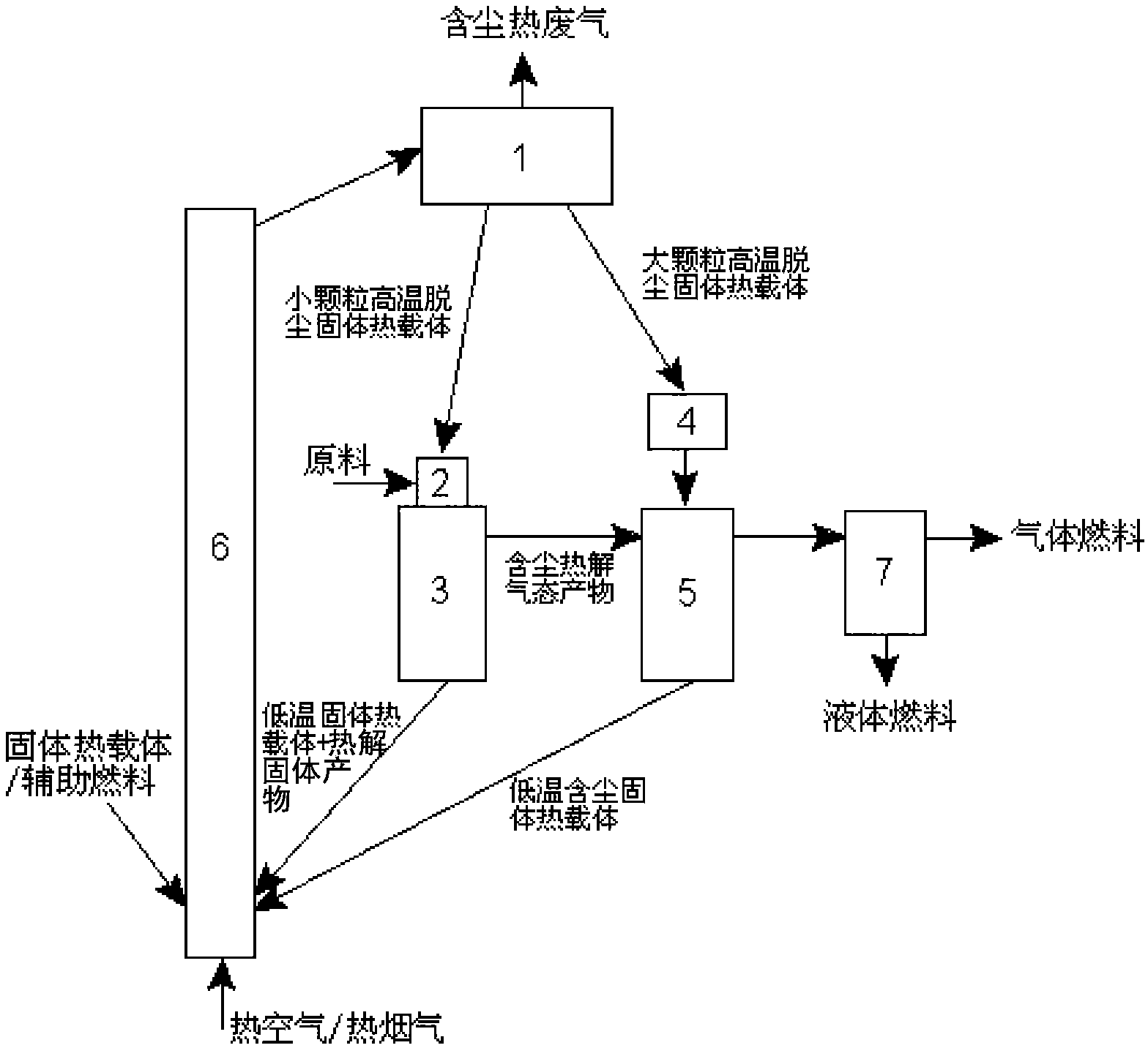

Method for producing liquid fuel by performing fast pyrolysis on solid organic matters

ActiveCN103450914AFast pyrolysisImprove qualityDirect heating destructive distillationBiofuelsCarrier heatingFiltration

The invention provides a method for producing a liquid fuel by heating solid organic matter materials with solid thermal carriers as heating media. The method comprises the steps of heating the solid organic matter materials with a first part of solid thermal carriers as a heating medium to perform pyrolysis on the materials so as to obtain a liquid fuel, and capturing dust in gaseous products produced from pyrolysis by adopting a second part of the solid thermal carriers. The invention also provides a corresponding system. The system comprises a pyrolysis reactor and a movable particle layer filtering and dust cleaning device. Compared with a traditional rapid pyrolysis method based on a solid thermal carrier heating technology, in which solid thermal carriers are taken as a single heating medium, the method provided by the invention is characterized in that circulating solid thermal carrier particles have dual functions, and are taken as the heating media to perform rapid pyrolysis on the solid organic matter materials and also as a filter material for particle layer filtration to capture the dust in the gaseous products subjected to pyrolysis.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +1

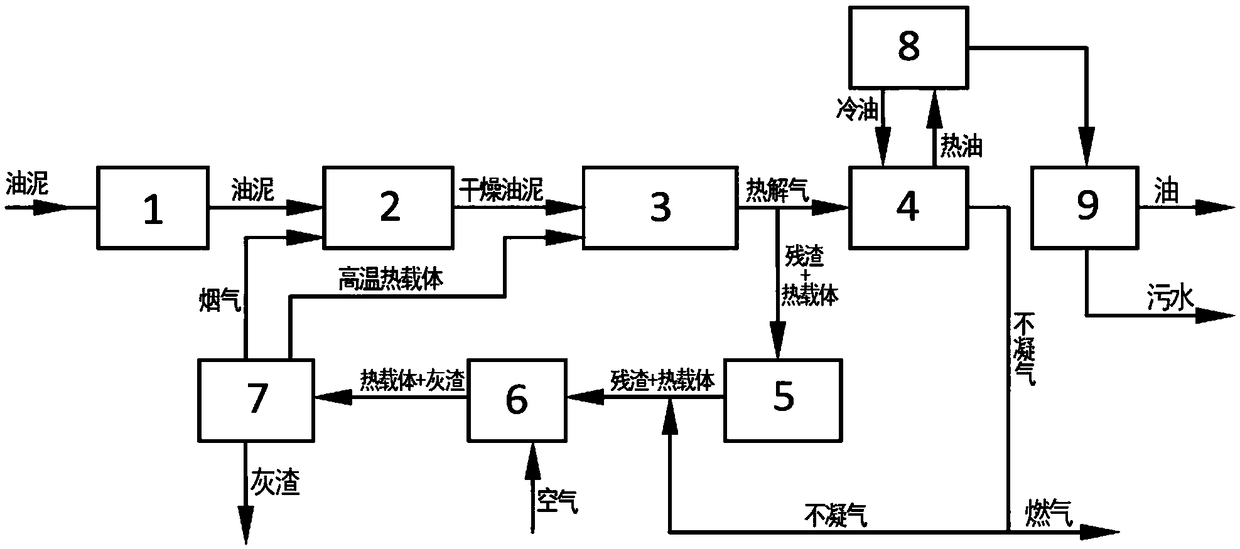

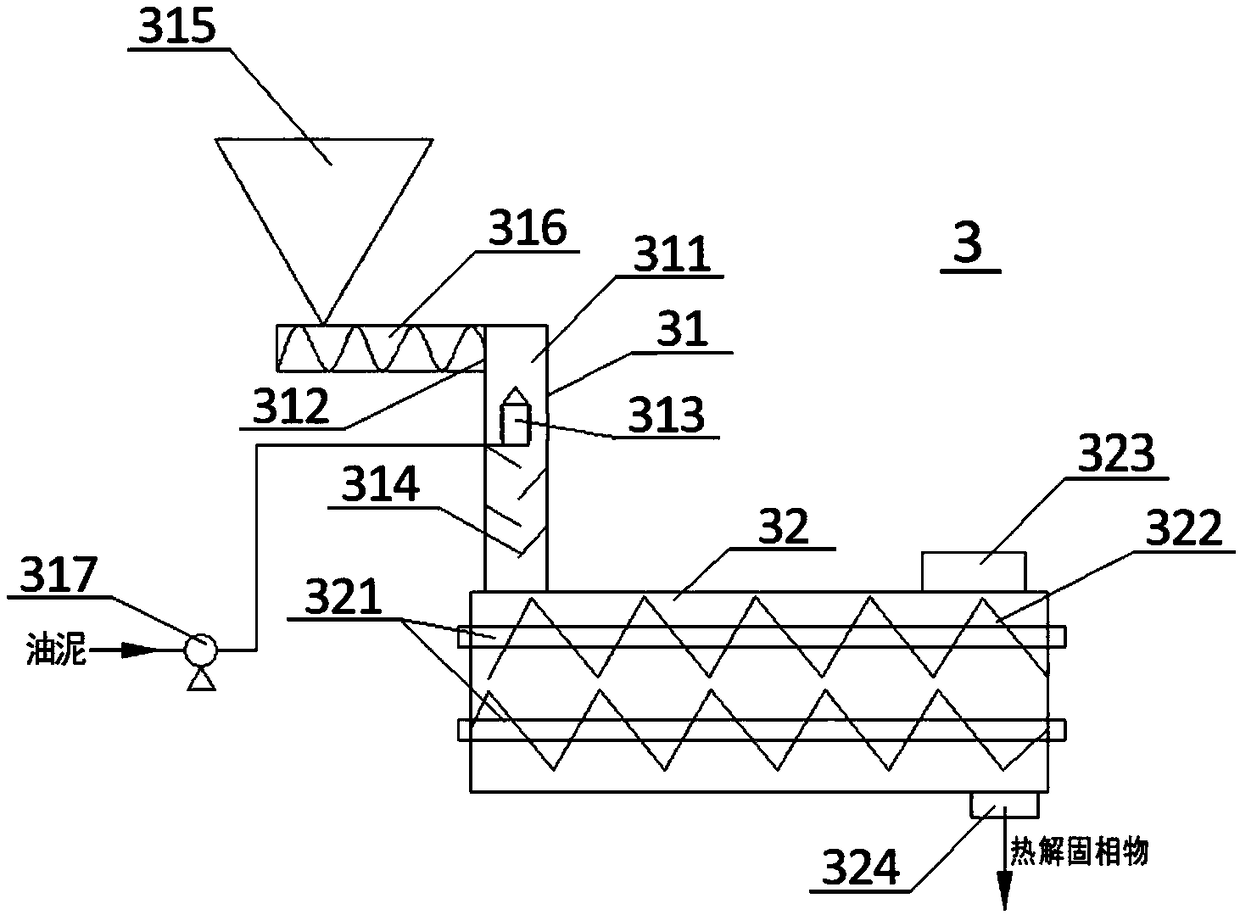

A pyrolysis resource utilization system and method for oily sludge

InactiveCN108947170AFast pyrolysisImprove thermal efficiencySludge treatment by pyrolysisByproduct vaporizationHeat carrierResource utilization

A pyrolysis resource utilization system and method for oily sludge are disclosed. The system includes a mechanical dehydration unit, a flue gas drying unit, a rapid pyrolysis unit, a pyrolysis gas condensation unit, a cooling unit, an oil-water separation unit, a heat carrier lifting unit, a heating unit and a heat carrier separation unit. The oily sludge after mechanical dehydration and drying with flue gas is fed into the rapid pyrolysis unit together with a high-temperature heat carrier; generated pyrolysis gas passes through the pyrolysis gas condensation unit to obtain oil and noncondensable gas a part of which is fed into the heating unit and combusted; residues and the heat carrier after pyrolysis are fed into the heating unit through the heat carrier lifting unit, and then ash residues and the heat carrier are separated through the heat carrier separation unit; the separated high-temperature heat carrier is fed into the rapid pyrolysis unit for repeated use; and generated fluegas is conveyed to a flue gas drying unit for cyclic use. A process of cyclic heating and pyrolysis utilizing a large-particle solid heat carrier is adopted to significantly increase the oil extraction yield, and coking of the rapid pyrolysis unit can be prevented, thus ensuring continuous operation of the unit.

Owner:嘉禾聚能(天津)科技有限公司

Microwave oven device for pyrolysis and pyrolysis method thereof

ActiveCN105276639ASmall volumeReduce the amount of adhesionDomestic stoves or rangesLighting and heating apparatusLower limitMicrowave oven

The invention discloses a microwave oven device for pyrolysis and a pyrolysis method thereof. The microwave oven device comprises a microwave oven body and a reaction cavity formed outside the oven body. A closed end cover is arranged on the top of the reaction cavity. Four side face air inlets are distributed in the circumferential wall of the reaction cavity. Four bottom air inlets are formed in the bottom of the reaction cavity. An electric heating device is arranged on the peripheral wall of the reaction cavity. The reaction cavity is connected with the oven body through a movable connecting rod support. According to the requirement of materials to be pyrolyzed, the number of the side face air inlets or the bottom air inlets is selected, a stop button and a start button are pressed, and after a machine body is operated, the upper limit and lower limit of the temperature and power are set. The reaction time is set according to requirements, and after setting is finished, an electric heating button is pressed to insulate the reaction cavity, and when the actually-measured temperature of a thermocouple reaches 300 DEG C, a microwave button is pressed, and whether the stirring function is started or not is selected according to experiment requirements. After pyrolysis of the materials is finished, a microwave oven is automatically stopped.

Owner:SOUTH CHINA UNIV OF TECH

Method for quickly producing coke through microwave heating

InactiveCN101591549AShorten the production cycleImprove efficiencyCoke ovensCarbonizationEngineering

The invention discloses a method for quickly producing coke through microwave heating, which adopts a microwave generator as a heating heat source, wherein the microwave frequency is between 300 and 300,000 MHz, and the coals for coking are heated to a temperature of between 900 and 1,100 DEG C to perform high temperature carbonization so as to generate the coke, coal tar and coal gas. The coal charges processed by the method can raise the temperature to the temperature range required by the coking in a short time under the action of microwaves, and the volatile components in the coal charges can be sufficiently pyrolyzed to finally generate the coke, the coal tar and the coal gas. The method can be applied to the pyrolytic process of coking coal and the processes of extracting the coal tar and the coal gas through coal pretreatment, preheating coking coal or preparing formed coke and the like in electric power plants, and has the characteristics of short flow, short cycle, high efficiency, stable product quality, and high resource comprehensive utilization rate.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Poly-generation utilization method based on collaborative microwave pyrolysis of seaweeds and aquatic invasive plants

ActiveCN104263390AReduce consumptionReduce supplyBiofuelsLiquid hydrocarbon mixture productionMicrowave pyrolysisCombustible gas

The invention discloses a poly-generation utilization method based on collaborative microwave pyrolysis of seaweeds and aquatic invasive plants. The method comprises the following steps: (1) collecting seaweeds and aquatic invasive plants, drying, cutting or crushing and then sieving; feeding to a microwave pyrolysis device, mixing, stirring and adjusting micro-wave power to evaporate moisture; (2) after the moisture is evaporated, stopping a mixing and stirring device, carrying out microwave high-temperature pyrolysis treatment for 10-20 minutes at 450-600DEG C under the conditions that the microwave irradiation frequency is 2450MHz and the power is 0-750W and continuously adjustable; and (3) cooling mixed oil and gas generated by microwave pyrolysis and then feeding to a separating device, wherein the separating device separates the mixed oil and gas into bio-oil, combustible gas and fly ash, the yield of the bio-oil is 30%-60%; the recovery rate of combustible gas is 10%-20%; the coke yield is 30%-50%, and three-phase poly-generation of the bio-oil, the combustible gas and the fly ash is achieved.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

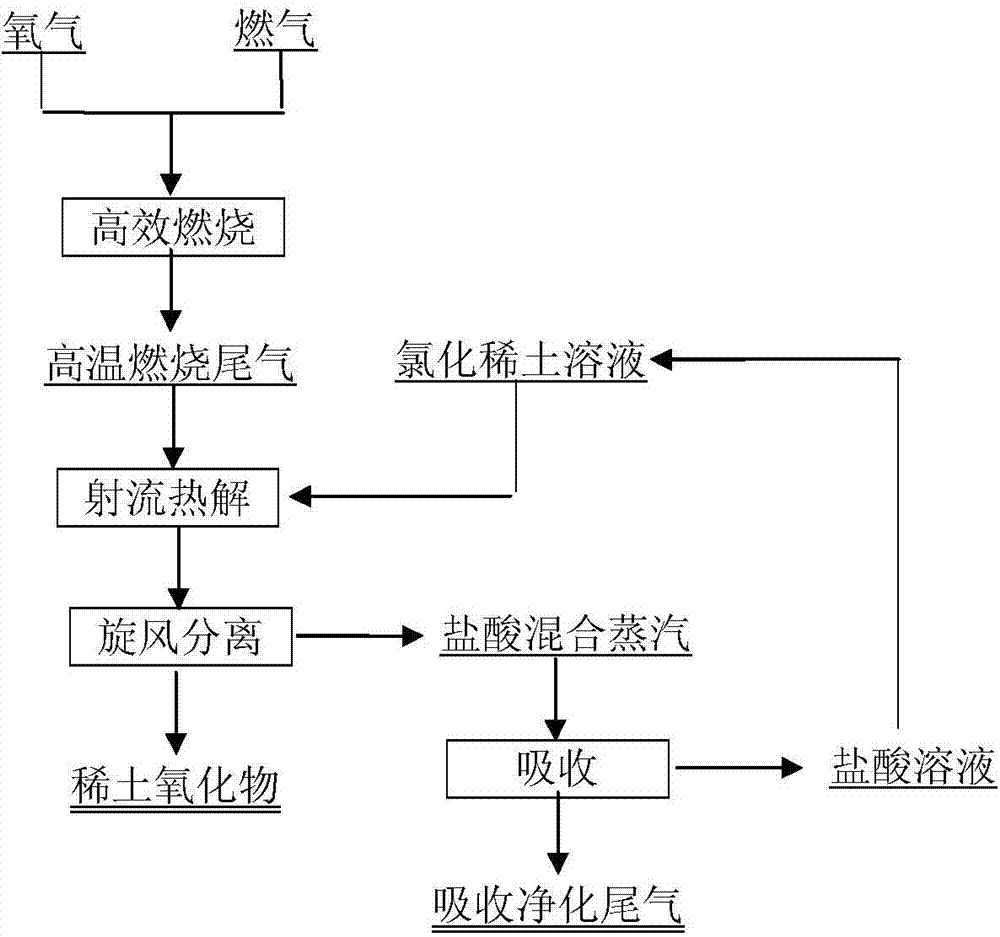

Preparation method for rare earth oxide through jet pyrolysis of rare earth chloride solution

ActiveCN103833064ALarge reaction interfacePyrolysis reaction is sufficientRare earth metal compoundsWorking fluidRare earth

The invention brings forward a preparation method for a rare earth oxide through jetting low-temperature rapid pyrolysis of a rare earth chloride solution. The method comprises the following steps: (1) combusting combustion gas and O2 according to certain flow so as to form high temperature mixed tail gas which is used as a heat source and a working fluid for a pyrolytic reaction; (2) allowing the rare earth chloride solution to enter into a jet device and be heated by the high temperature mixed tail gas so as to realize gasification and form tiny bubbles in dispersed distribution and carrying out the pyrolytic reaction so as to obtain rare earth oxide powder and high temperature pyrolysis tail gas containing HCl gas; and (3) introducing a gas-solid mixture of the rare earth oxide powder and the pyrolysis tail gas obtained after pyrolysis into a cyclone separator, carrying out gas-solid separation so as to obtain the rare earth oxide powder, introducing the pyrolysis tail gas into an absorbing tower for absorption by an absorbent so as to obtain a hydrochloric acid solution and totally discharging residual purified tail gas. The method can substantially reinforce mass transfer and heat transfer efficiency, reduces pyrolysis energy consumption and enables the rare earth chloride solution to be rapidly pyrolyzed; and the obtained rare earth oxide powder has small granularity, uniform particle distribution and high purity.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com